Nanofluid Production Apparatus and Method

a production apparatus and a technology of nanofluid, applied in the direction of cleaning the installation of drawing off water, cleaning using liquids, separation processes, etc., can solve the problems of large size, difficult to use and perform matching, and difficult to put nanofluid to practical use, etc., to reduce the manufacturing cost of nanofluid, simple and inexpensive structure, and easy and fast intra-apparatus cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]Embodiments of the present invention will be described below based on the accompanying drawings.

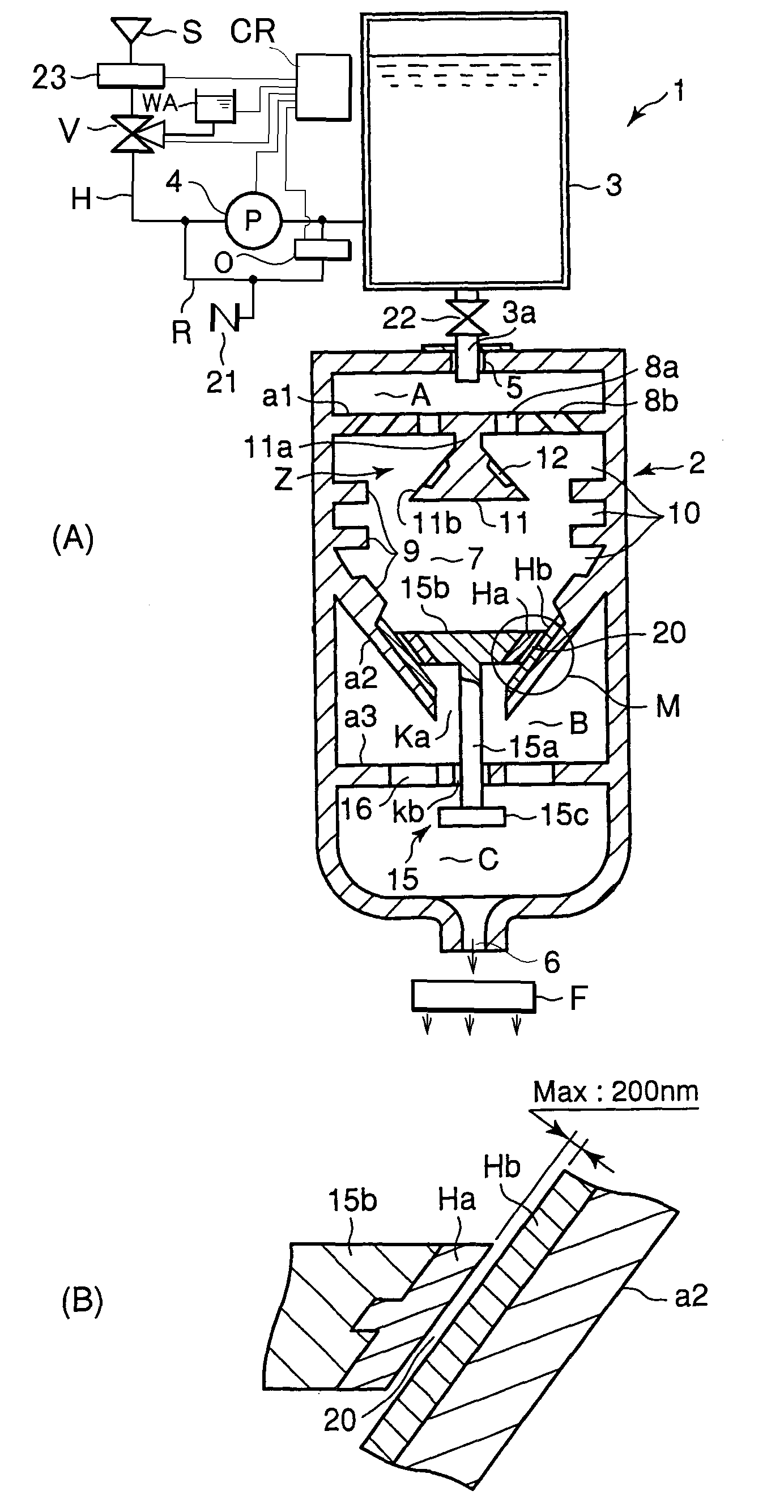

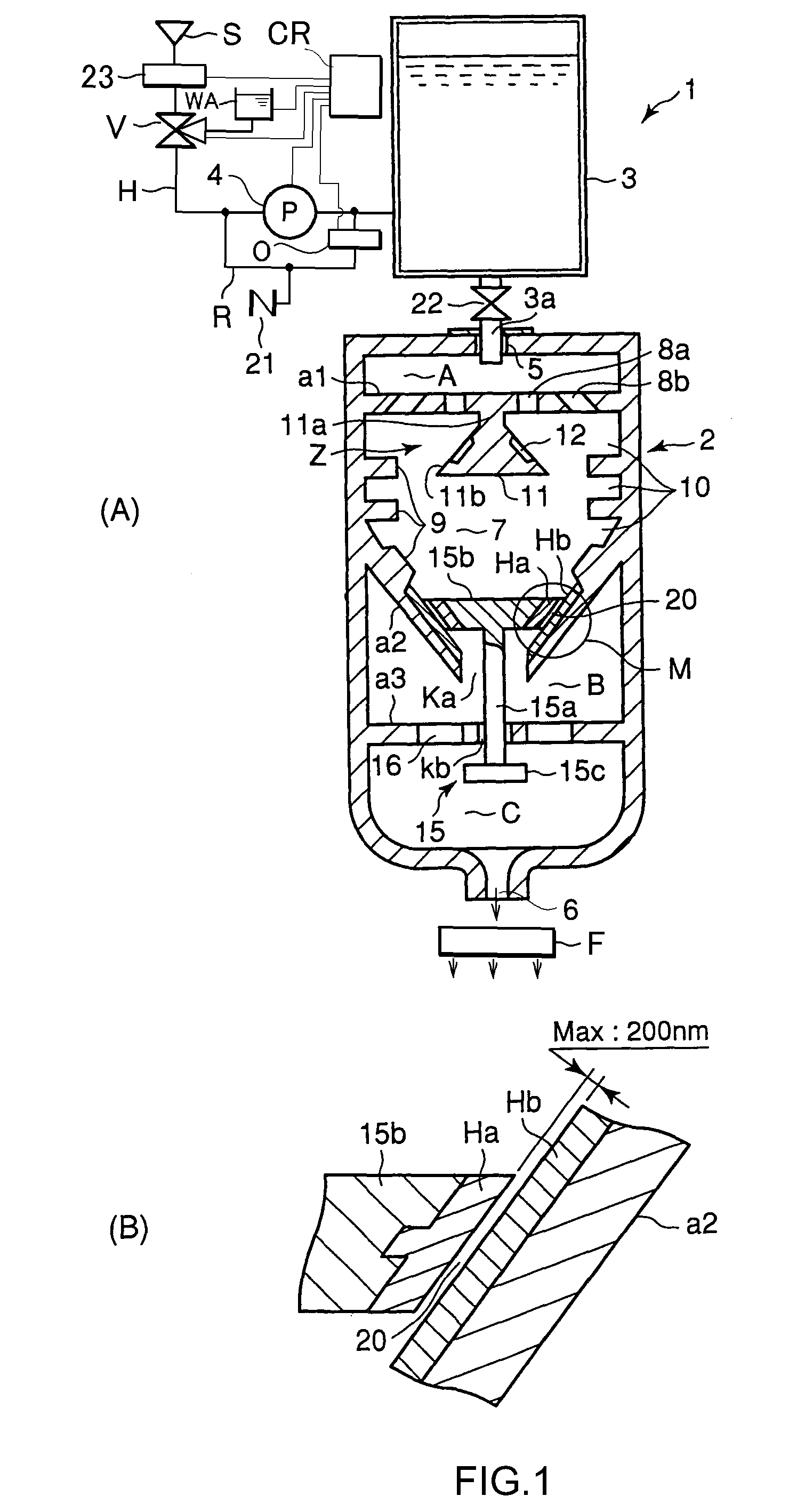

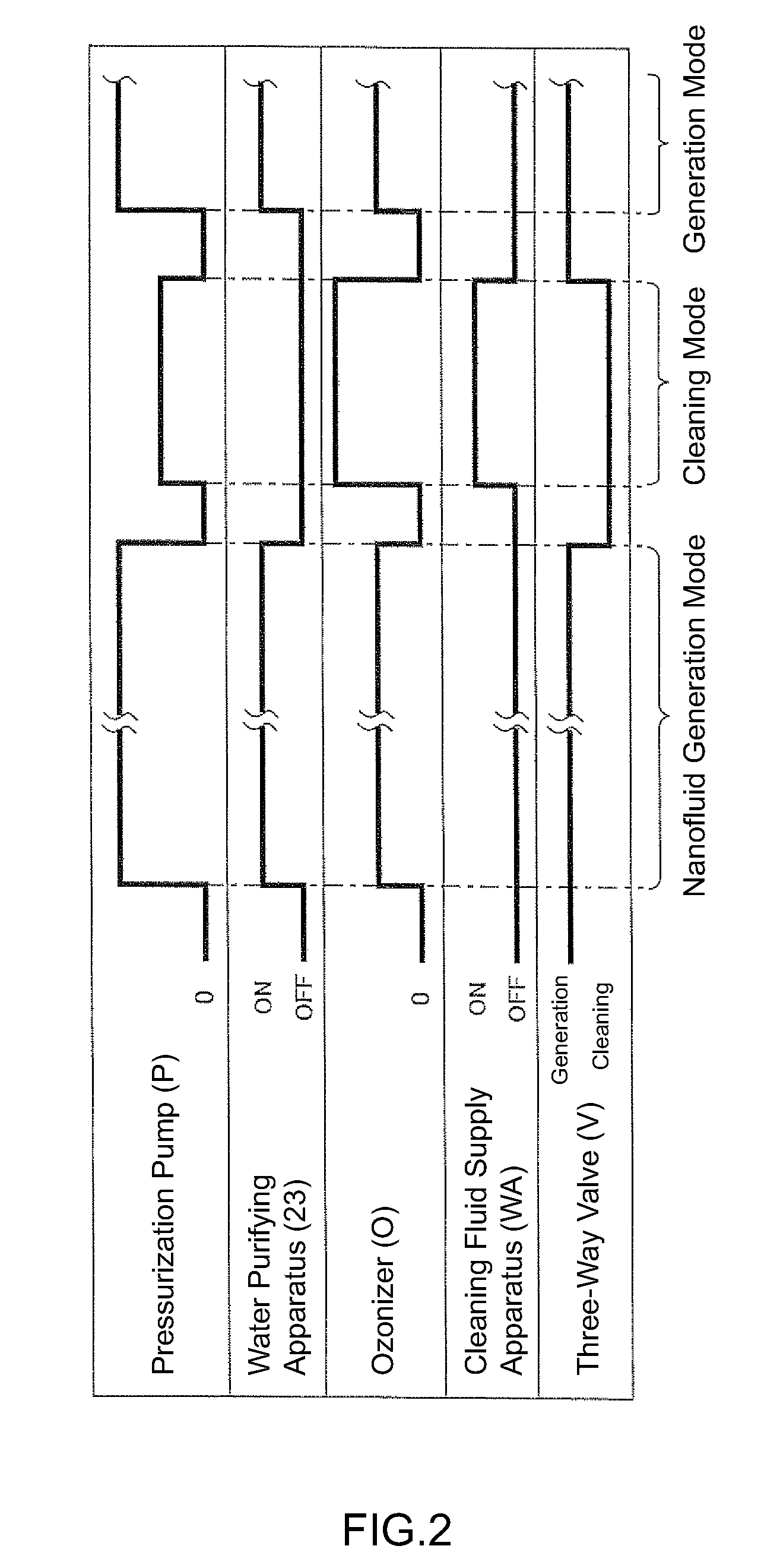

[0036]FIG. 1(A) is a schematic cross-sectional view of a nanofluid generating apparatus 1 according to one embodiment of the present invention; FIG. 1(B) is a fragmentary sectional view showing an enlarged key portion M, which is circled in FIG. 1(A); and FIG. 2 is a timing diagram showing a control flow by a control unit.

[0037]The nanofluid generating apparatus 1 is composed of a generator 2, a holding tank 3, a pressurization pump (pressurization means) 4, a piping H in communication with the generator 2 from a water supply source through the pressurization pump 4 and the holding tank 3, an ozonizer O for generating ozone, a control unit (control section) CR for switching and controlling a nanofluid generation mode and an intra-apparatus cleaning mode, a ozone filter F for collecting ozone, and a cleaning unit WS for cleaning the inside of the apparatus.

[0038]A water purifying app...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com