Food processor with rotary type defoaming device

A technology for eliminating foam devices and food processors, which is applied in the direction of household machinery for filtering food, beverage preparation devices, household appliances, etc., can solve the problems of wasting time and insufficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

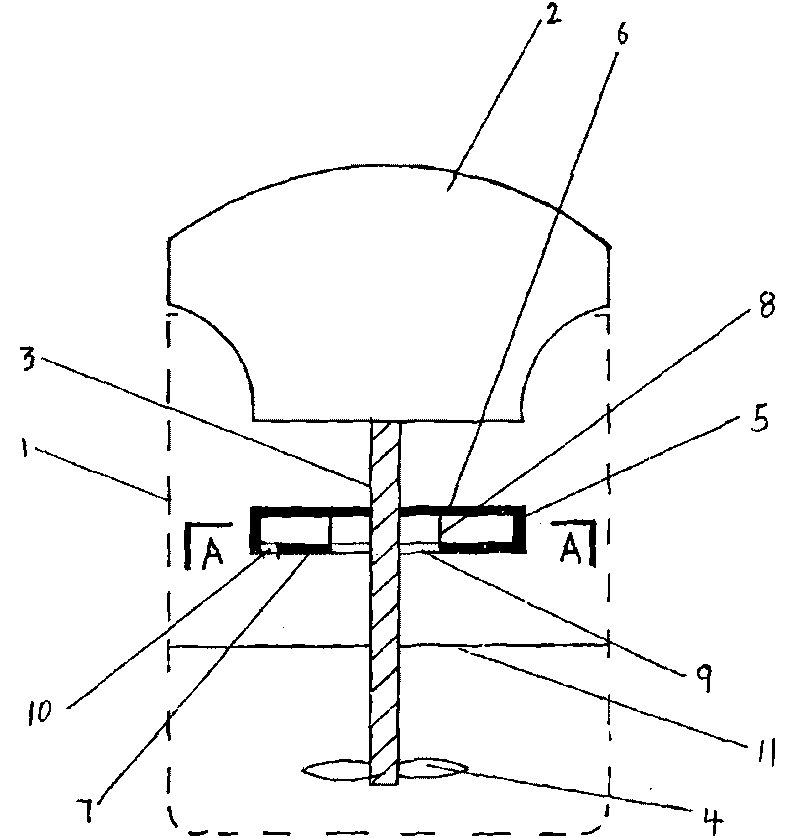

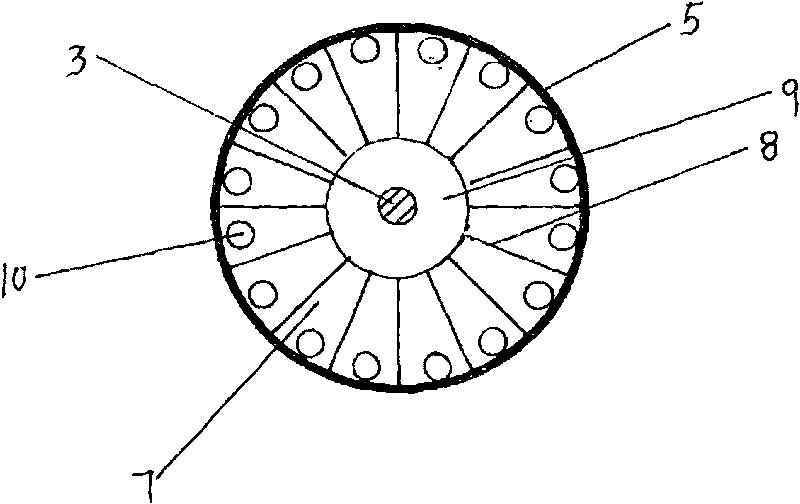

Embodiment 1

[0094] Another advantage of Embodiment 1 is that no matter what the reason or when the foam is generated, as long as the crushing knife shaft 3 is rotating, the foam can be crushed to avoid foam accumulation and overflow from the barrel body 1 .

[0095] The lower cover 7 of the first embodiment may not be provided. The centrifugal impeller type defoamer 5 becomes a semi-open centrifugal impeller, and its defoaming process and principle are still the same, except that the downward flanging of the upper cover 6 edge becomes the drain port 10. Simultaneously, because there is no lower cover 7, so the area covered by the whole lower cover 7 is also all foam inlet 9 (doubling as exhaust port 13 simultaneously).

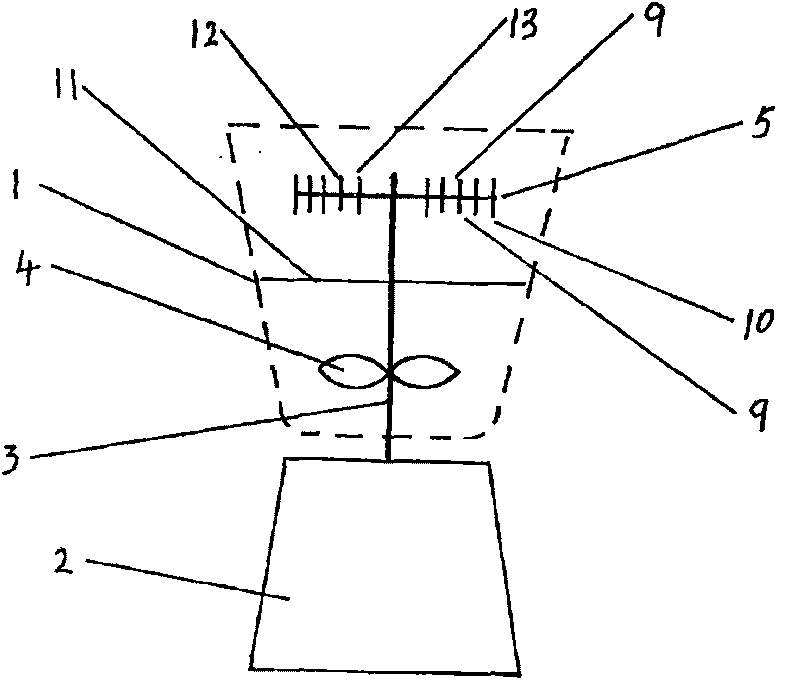

[0096] Such as image 3 As shown, the second embodiment of the present invention is a food processor with a rake type defoamer, and the (crushing cutter) motor is a down type.

[0097] The rotary defoamer 5 in this embodiment is a rake defoamer 5 .

[0098] The barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com