Patents

Literature

241 results about "Food handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

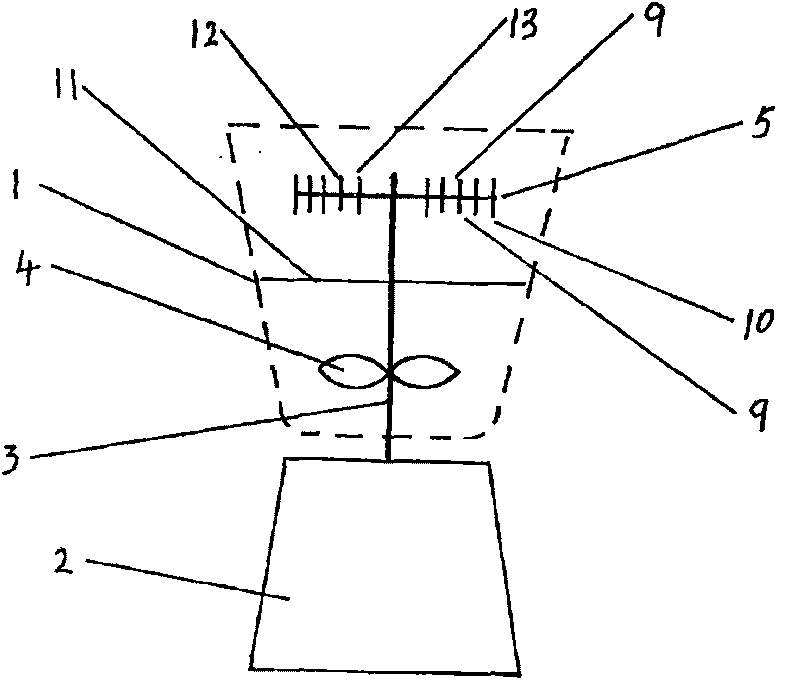

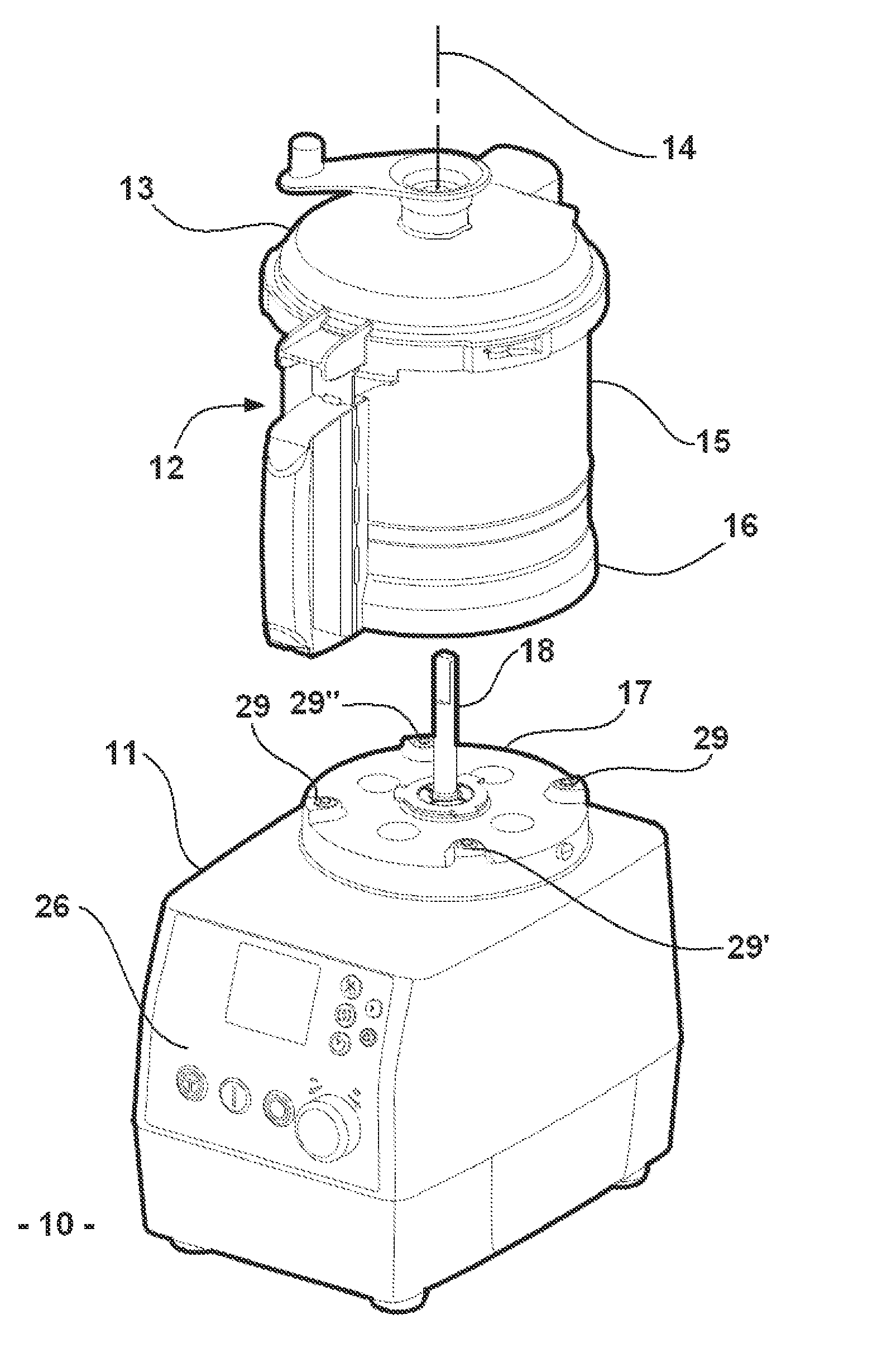

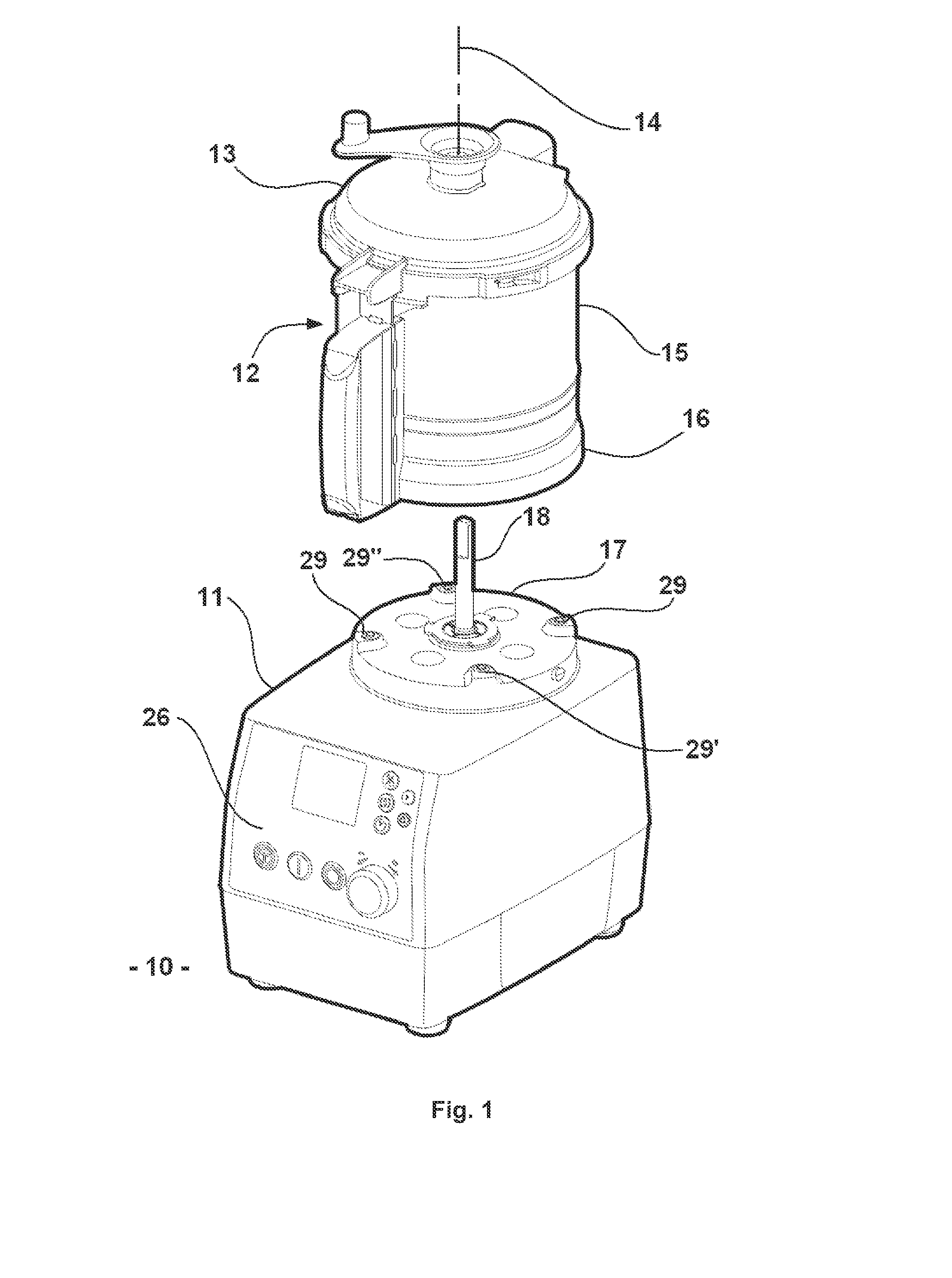

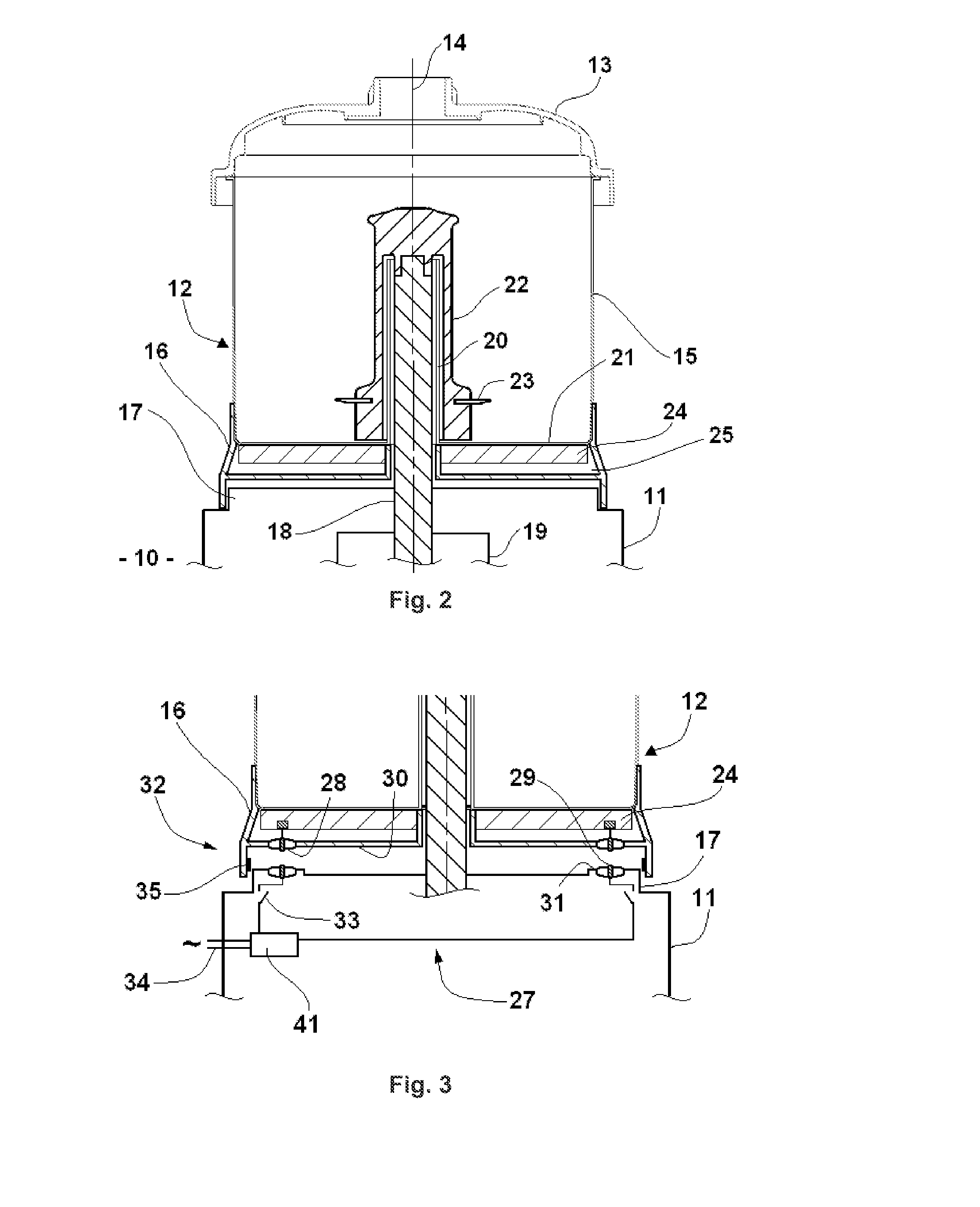

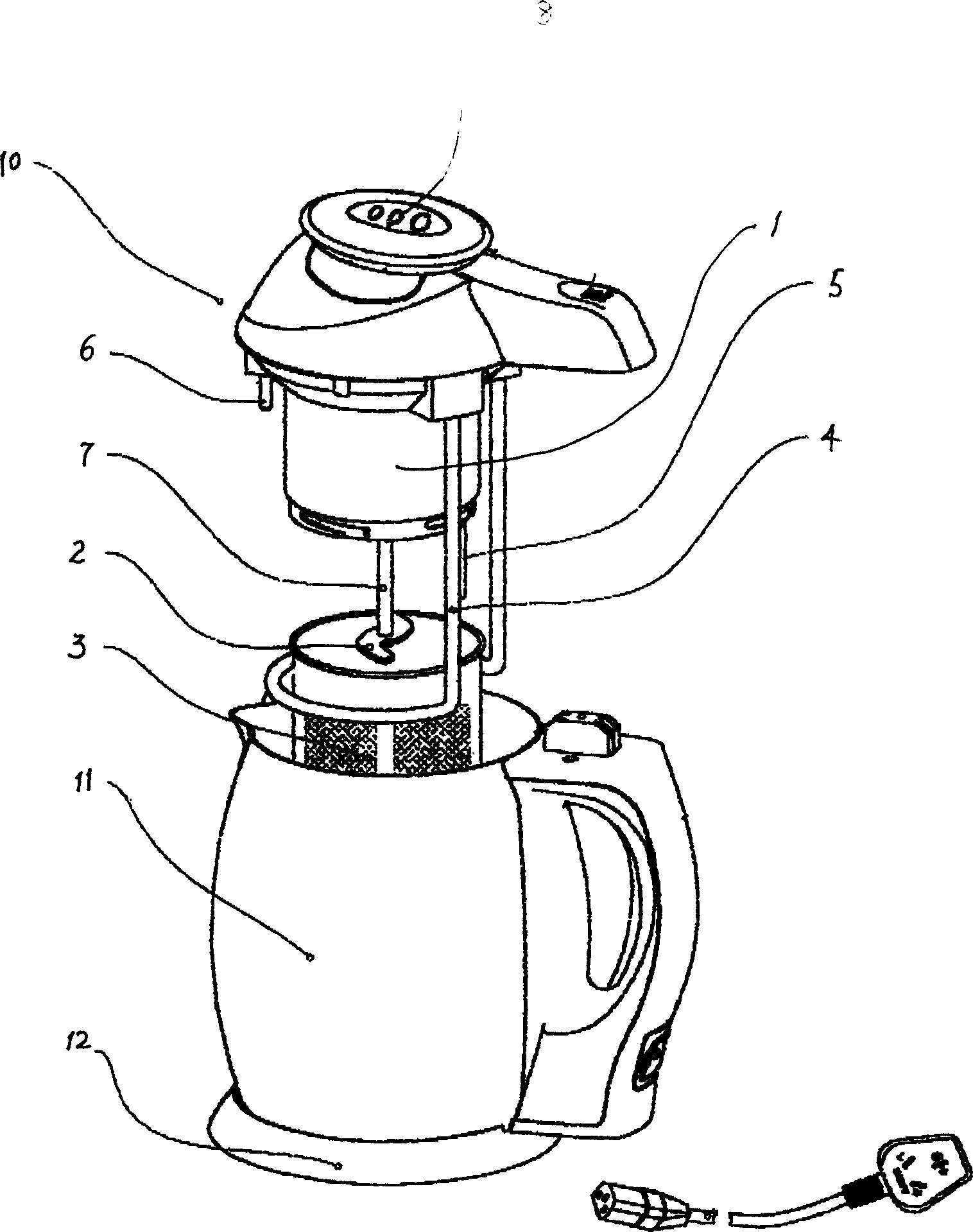

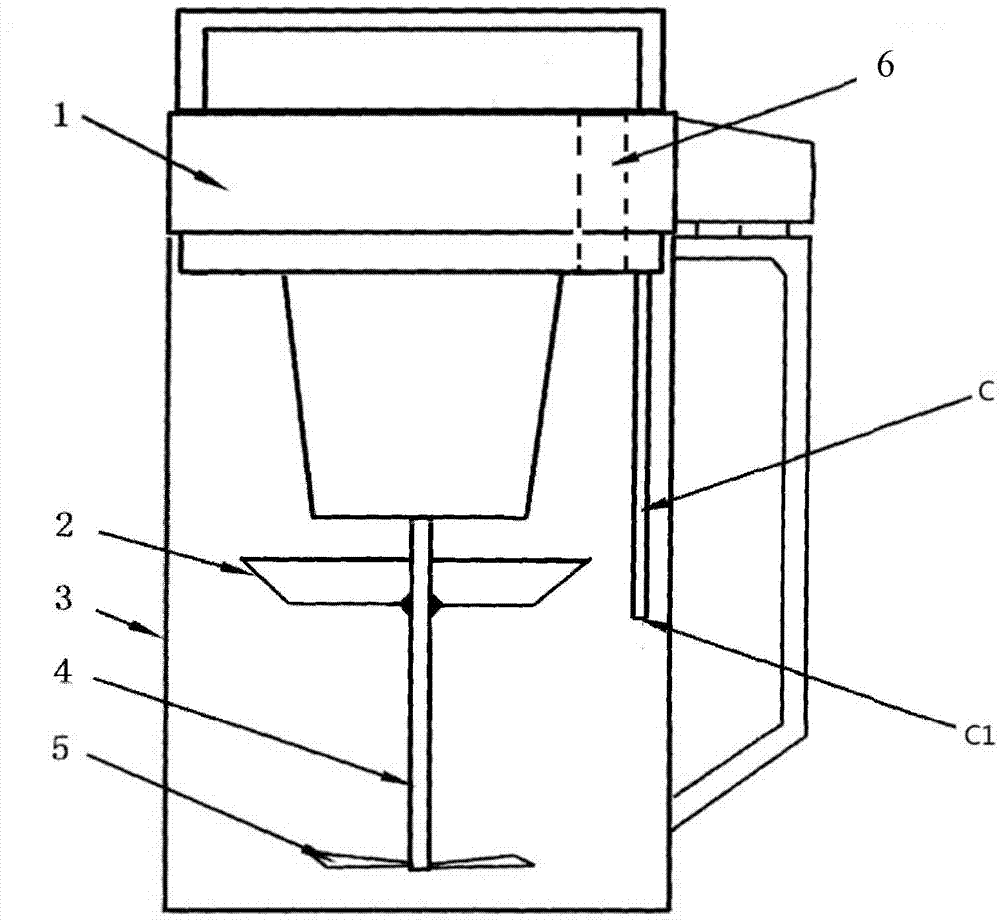

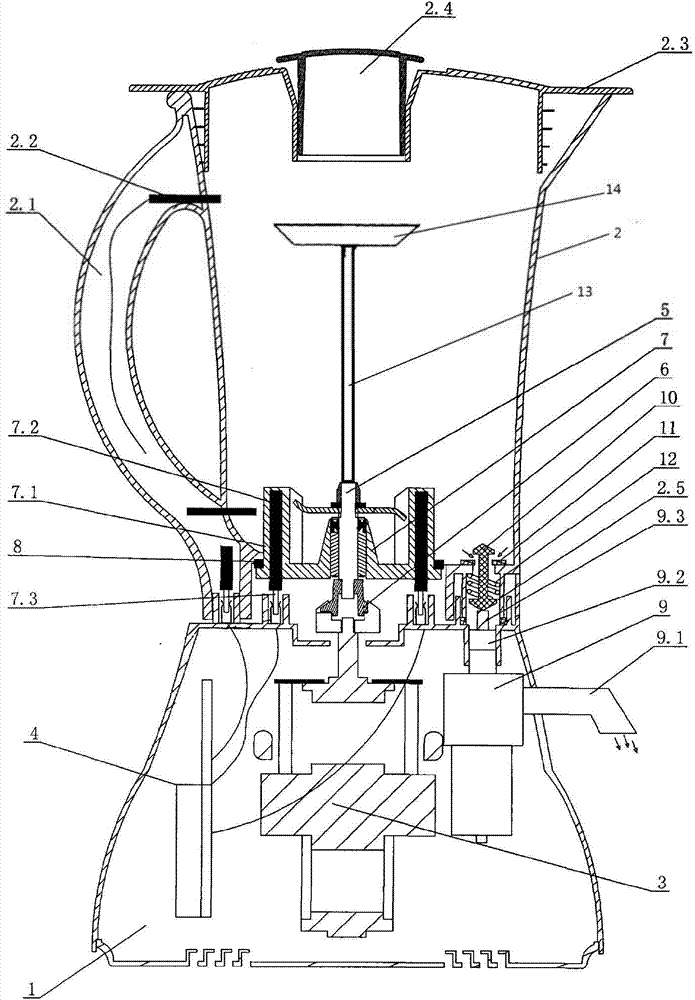

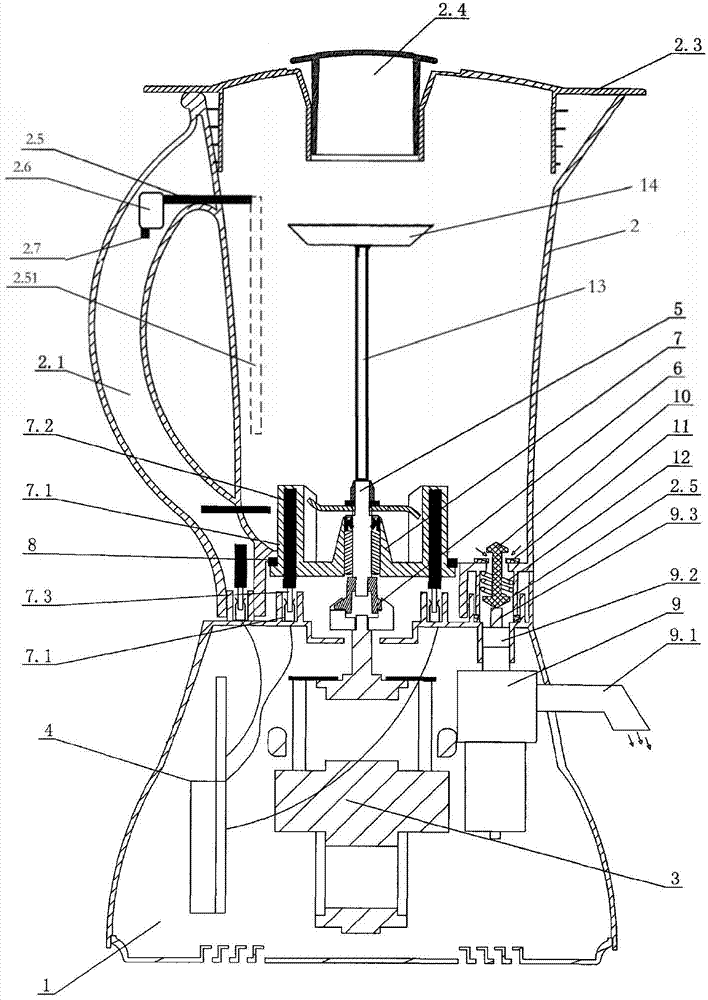

Food processing machine with electric sucking pump and method for vacuumizing to produce foodstuff liquid

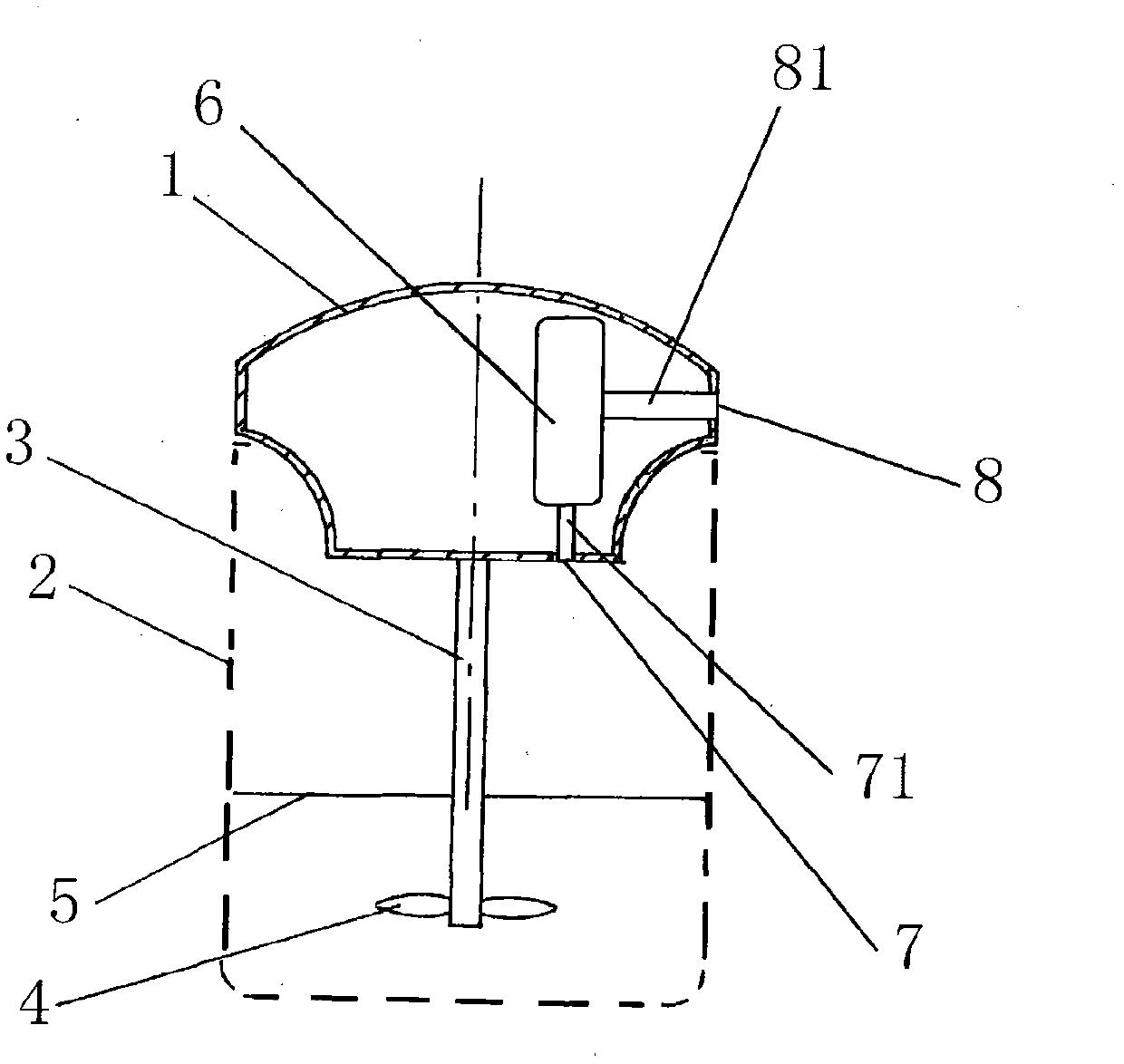

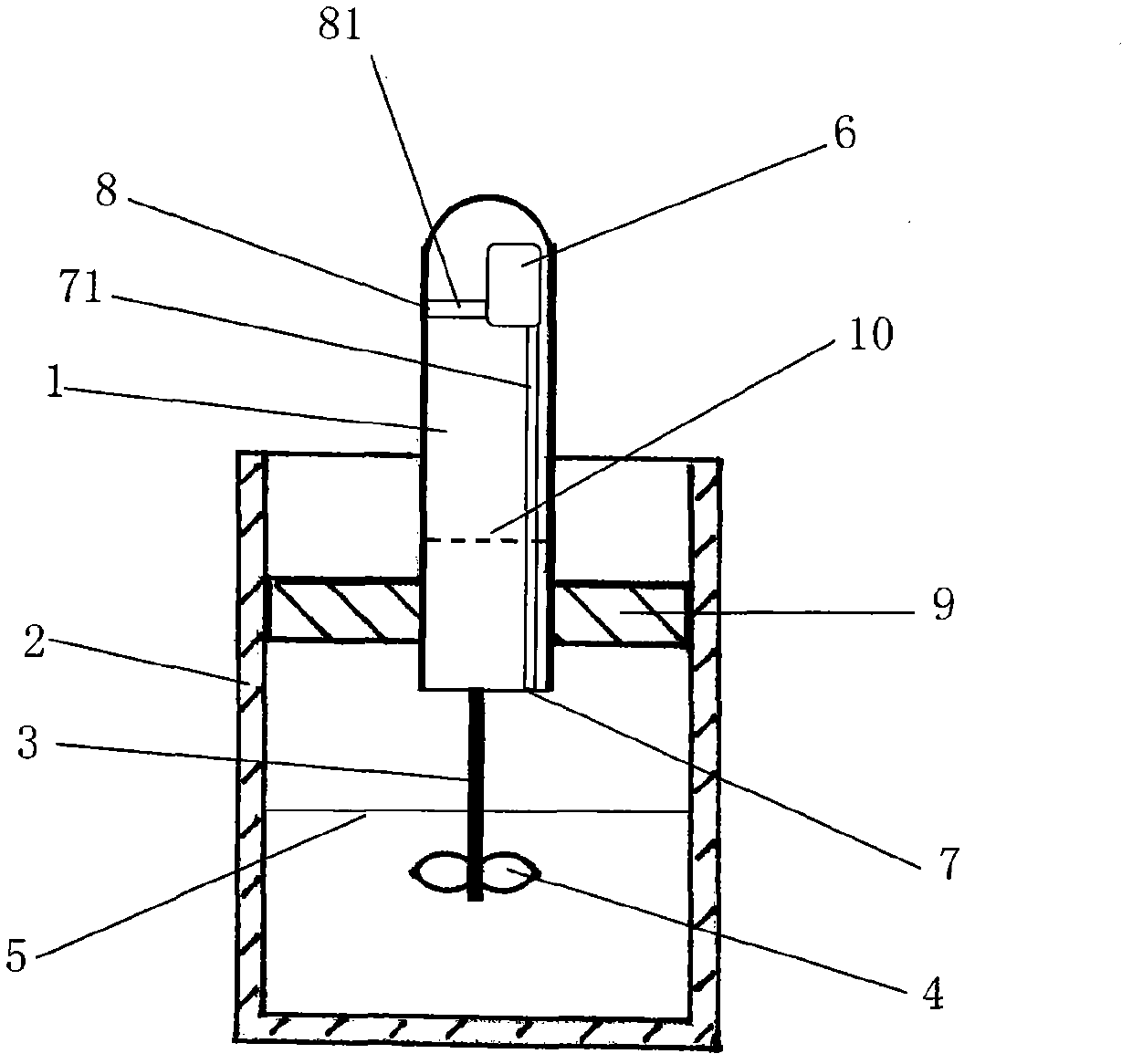

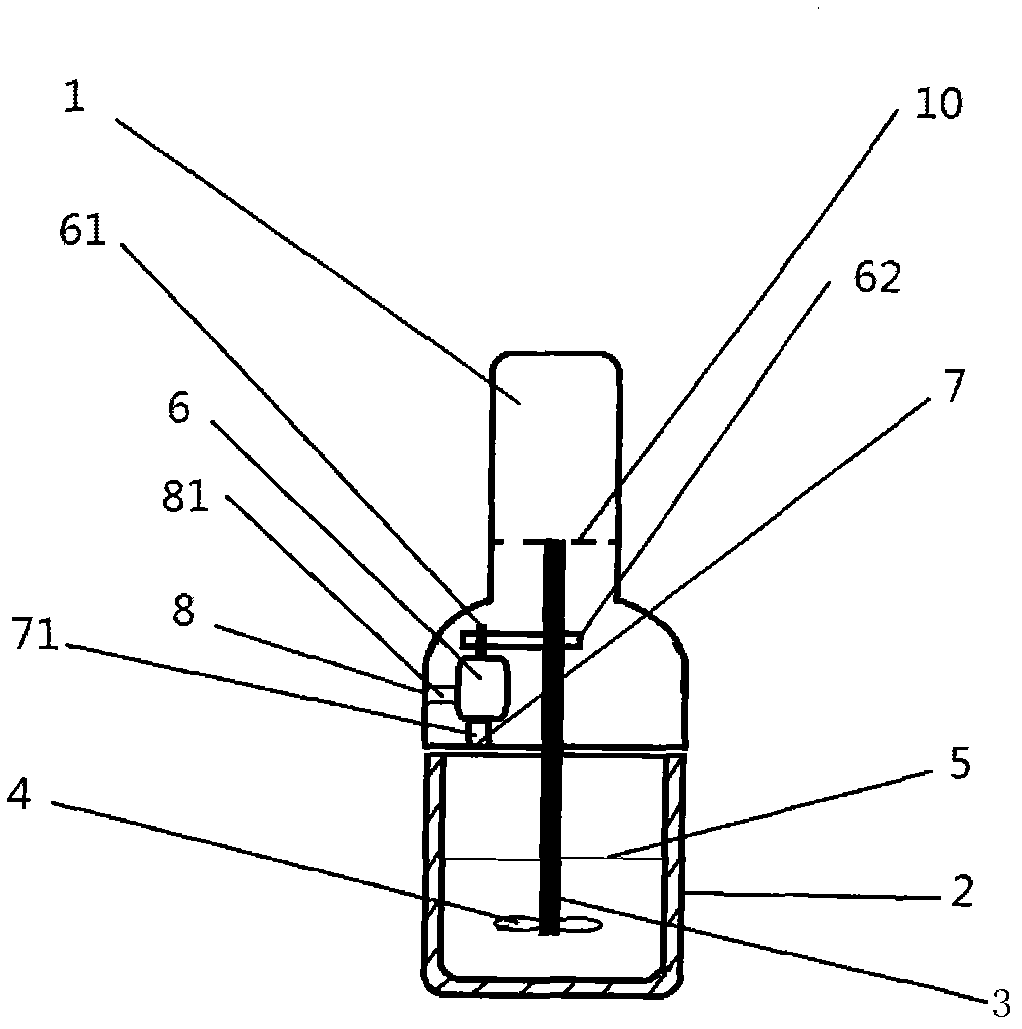

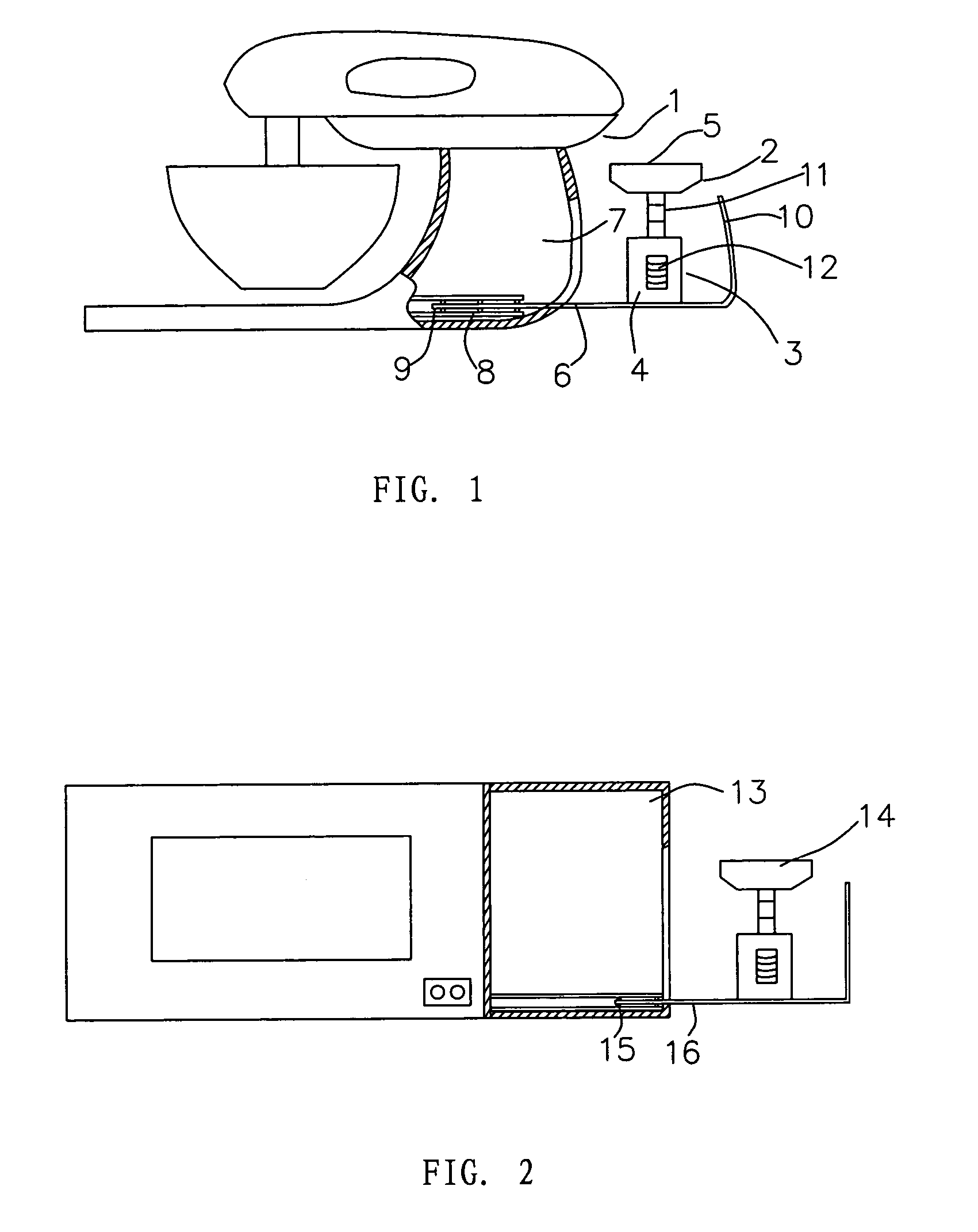

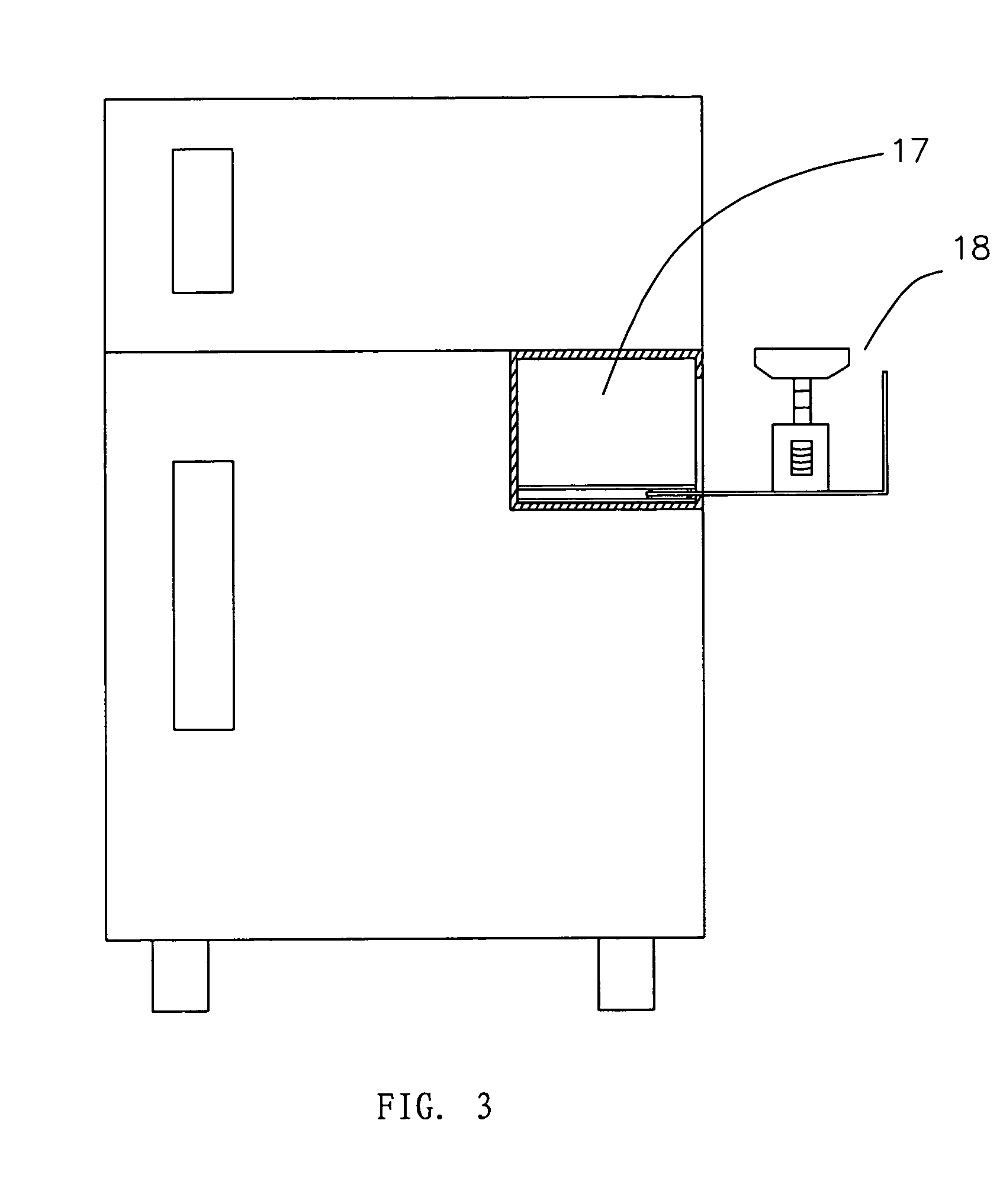

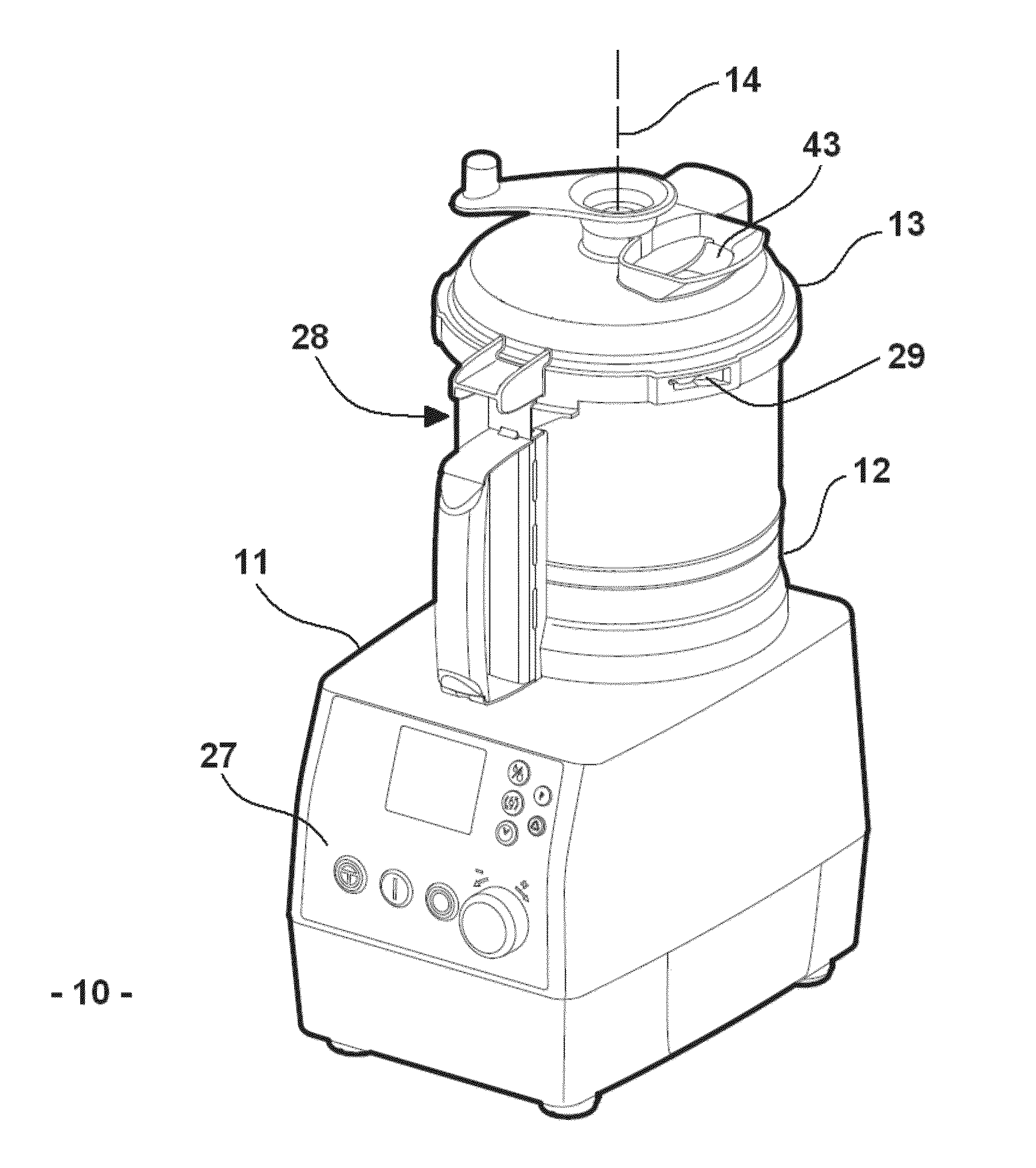

The invention relates to a food processing machine with an electric sucking pump and a method for vacuumizing to produce foodstuff liquid. The food processing machine comprises a crushing cutter device, a machine head or a machine base, a motor, a barrel and a control circuit board, wherein the barrel is provided with a sealing device, has or does not have a heating device. An electric sucking pump is arranged on the machine head, the machine base, the sealing device, the barrel or a barrel handle of the food processing machine, the sucking port of the electric sucking pump is positioned in the barrel and above the foodstuff liquid level, the exhaust port of the electric sucking pump is communicated with the outer part of the barrel; and the electric power source of the electric sucking pump is an independent motor, an electromagnetic vibration device, a piezoelectric ceramic vibration device or the crushing cutter device of the food processing machine. A sealing mode is adopted to seal the barrel of the food processing machine, the electric sucking pump is used to pump air out of the barrel, then crushing and heating are carried out to crush and heat the foodstuff in the barrel of the food processing machine under the vacuum condition, the oxidation of the foodstuff liquid is greatly reduced and avoided for the crushing and heating processes, so the nutritive loss is reduced, and the good taste and appearance color are kept.

Owner:王晓东

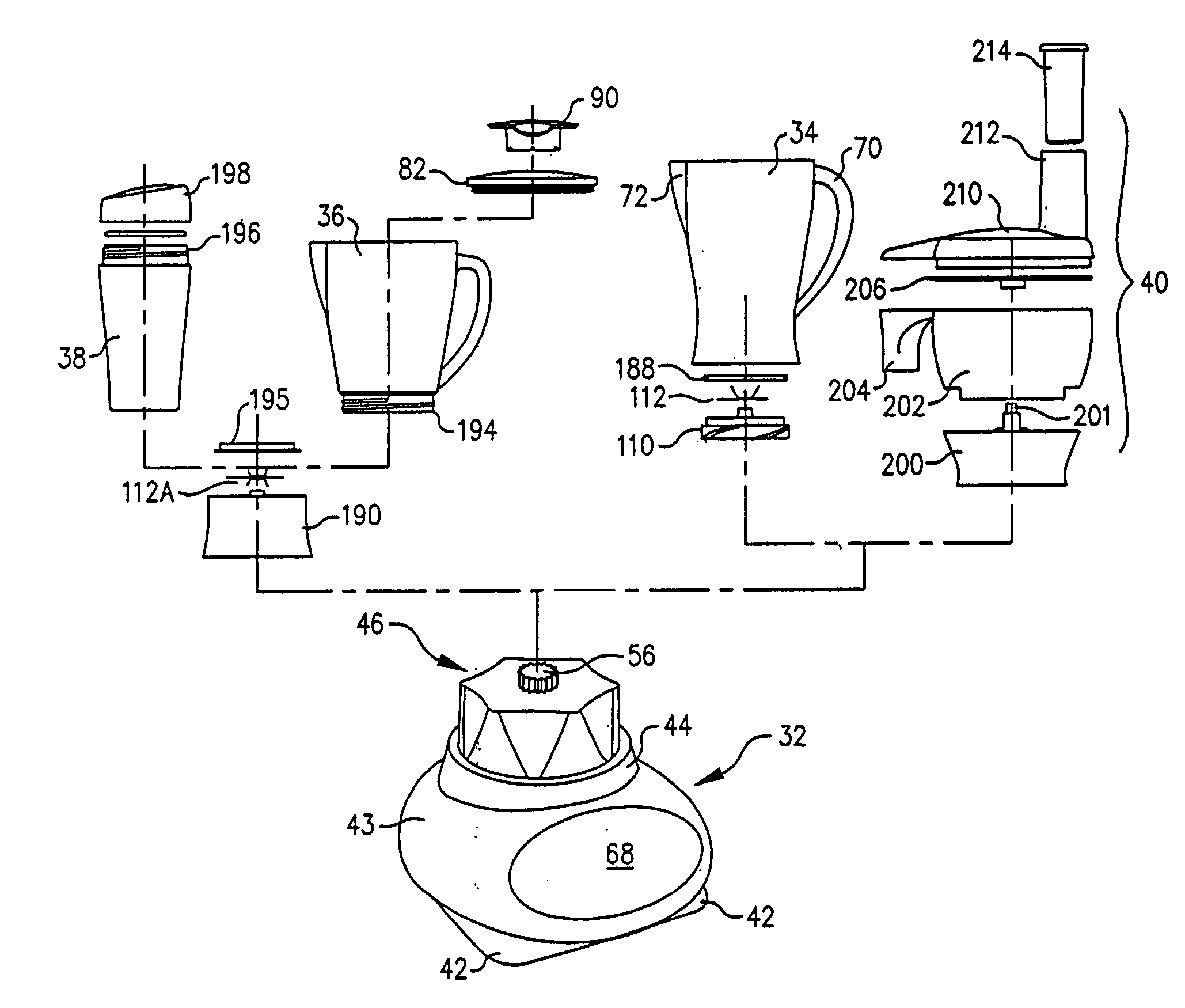

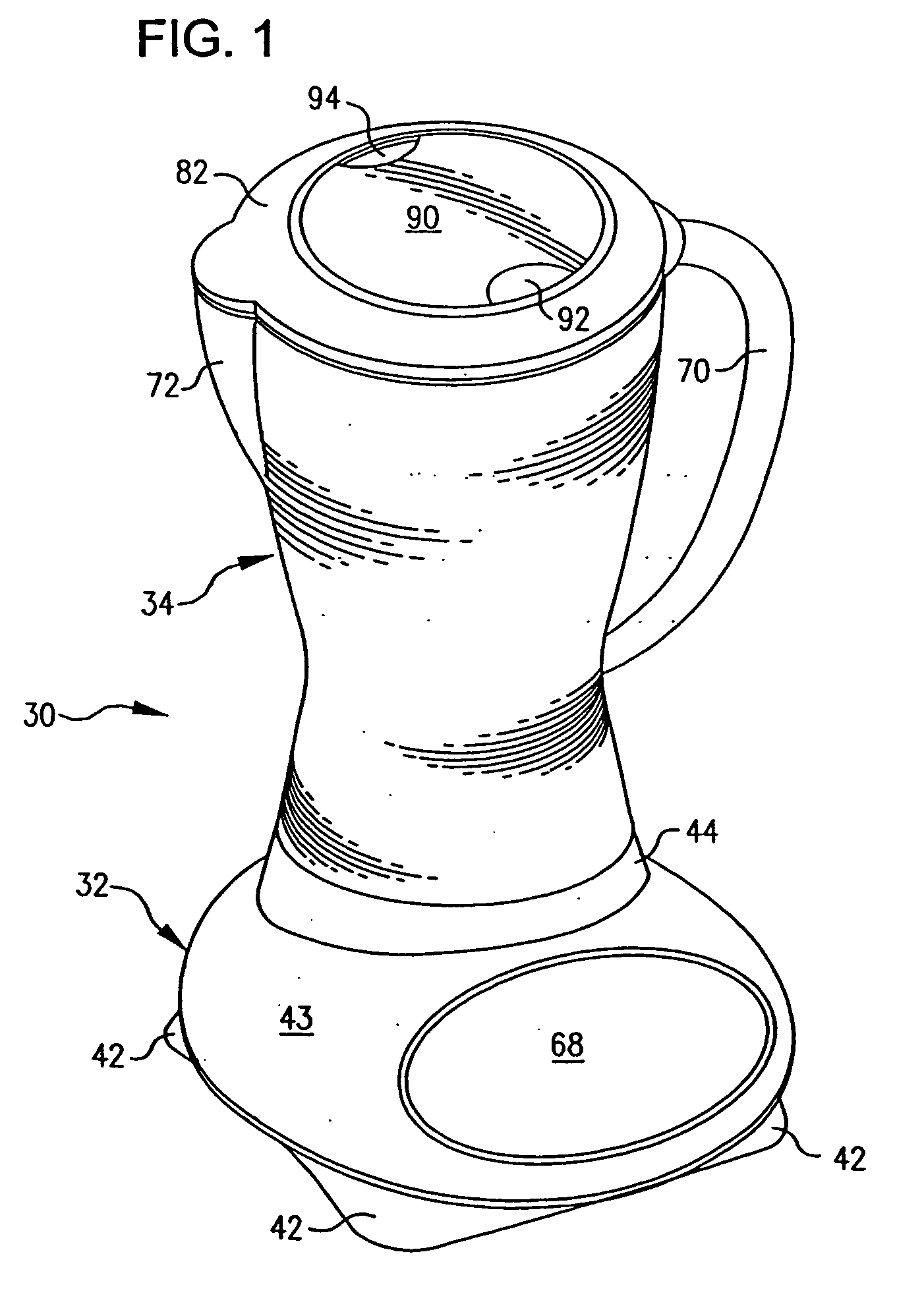

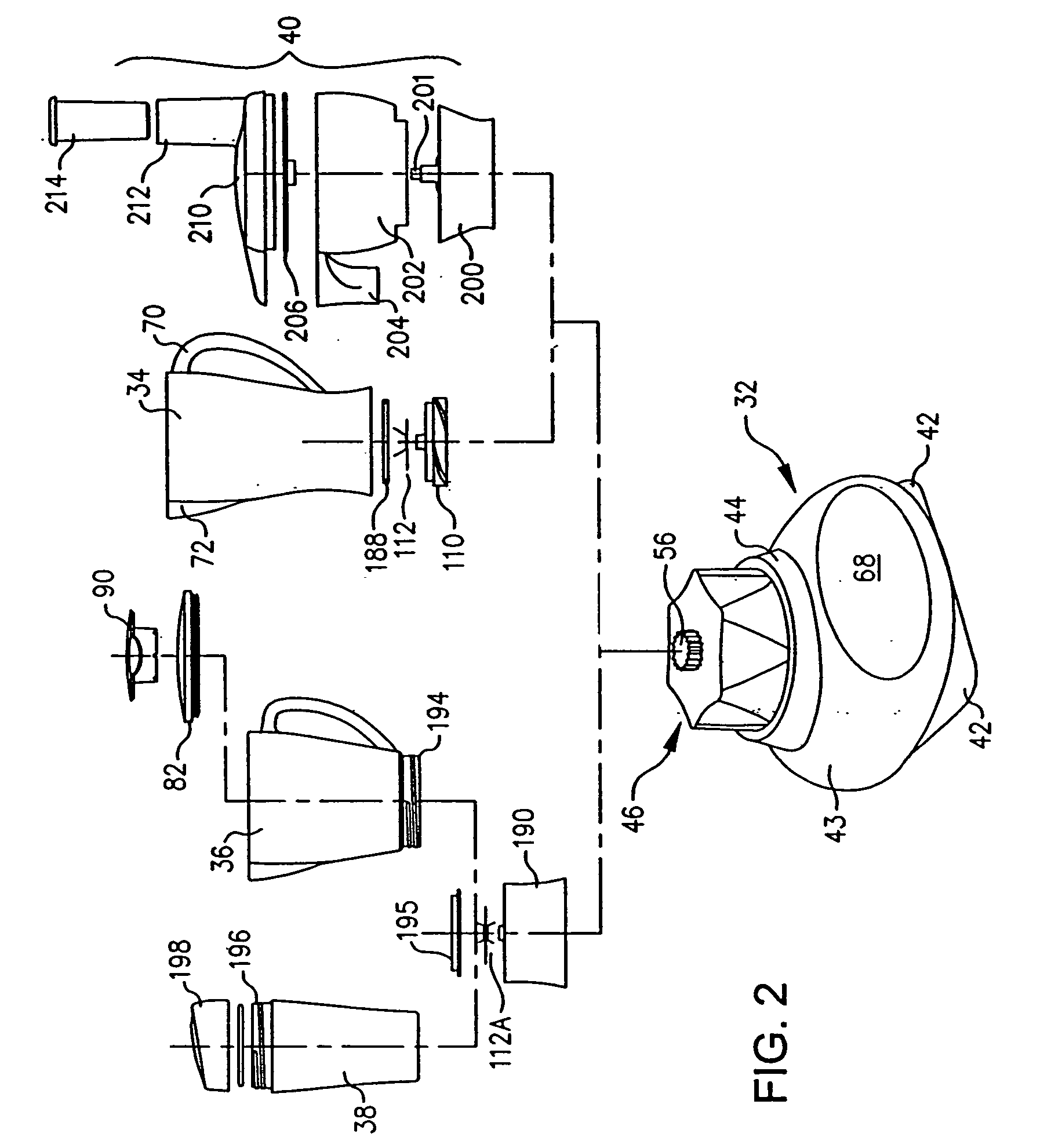

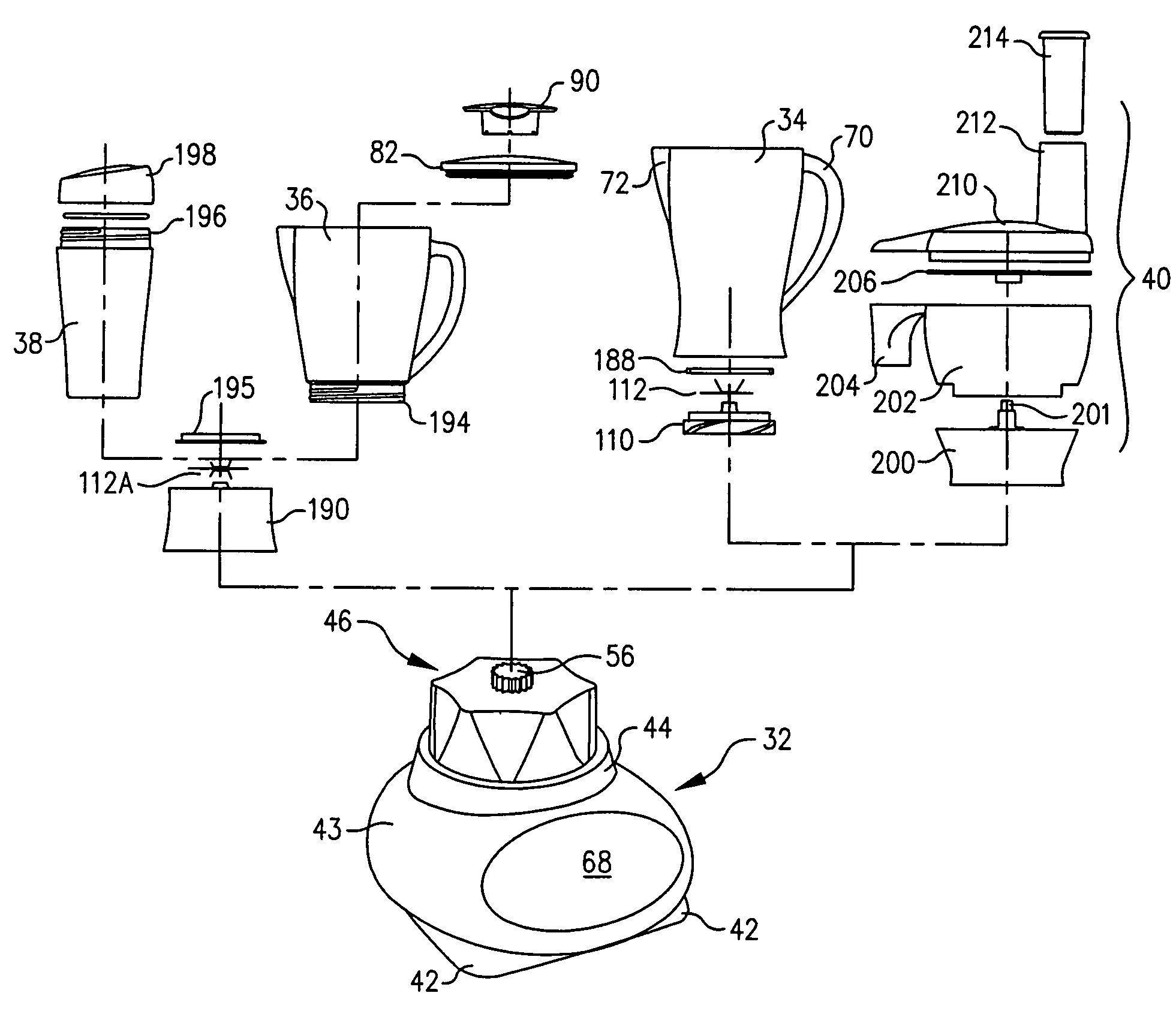

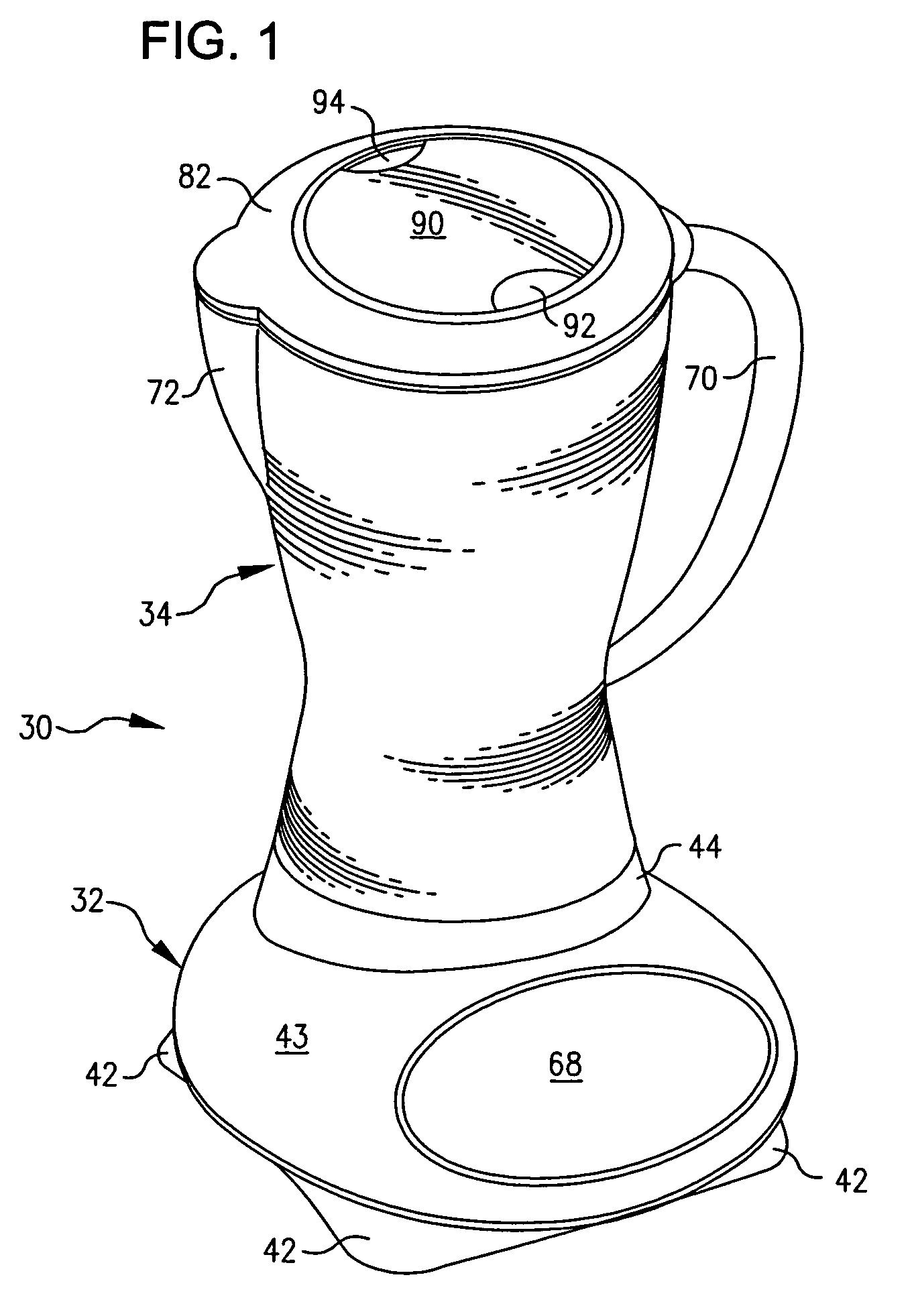

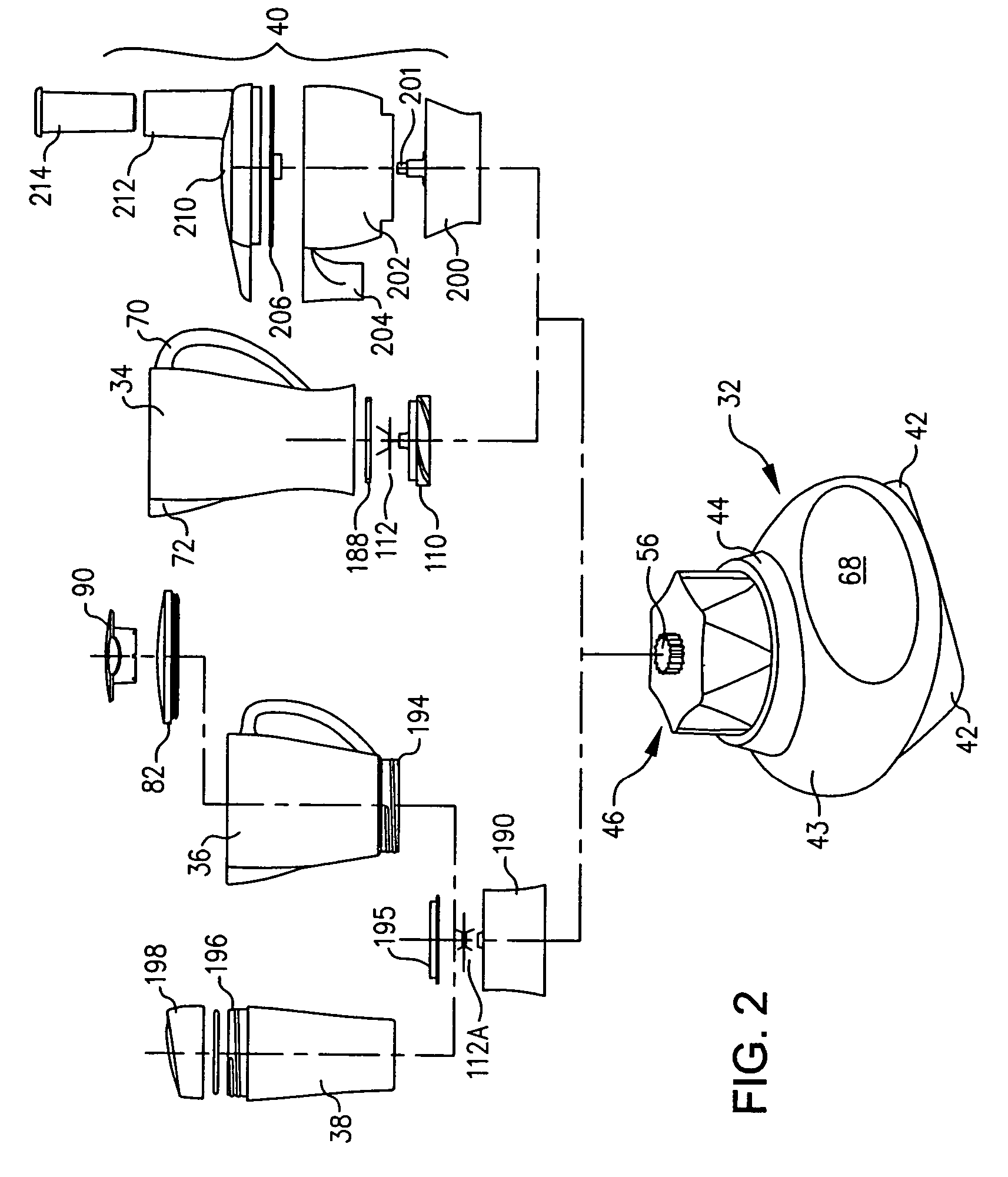

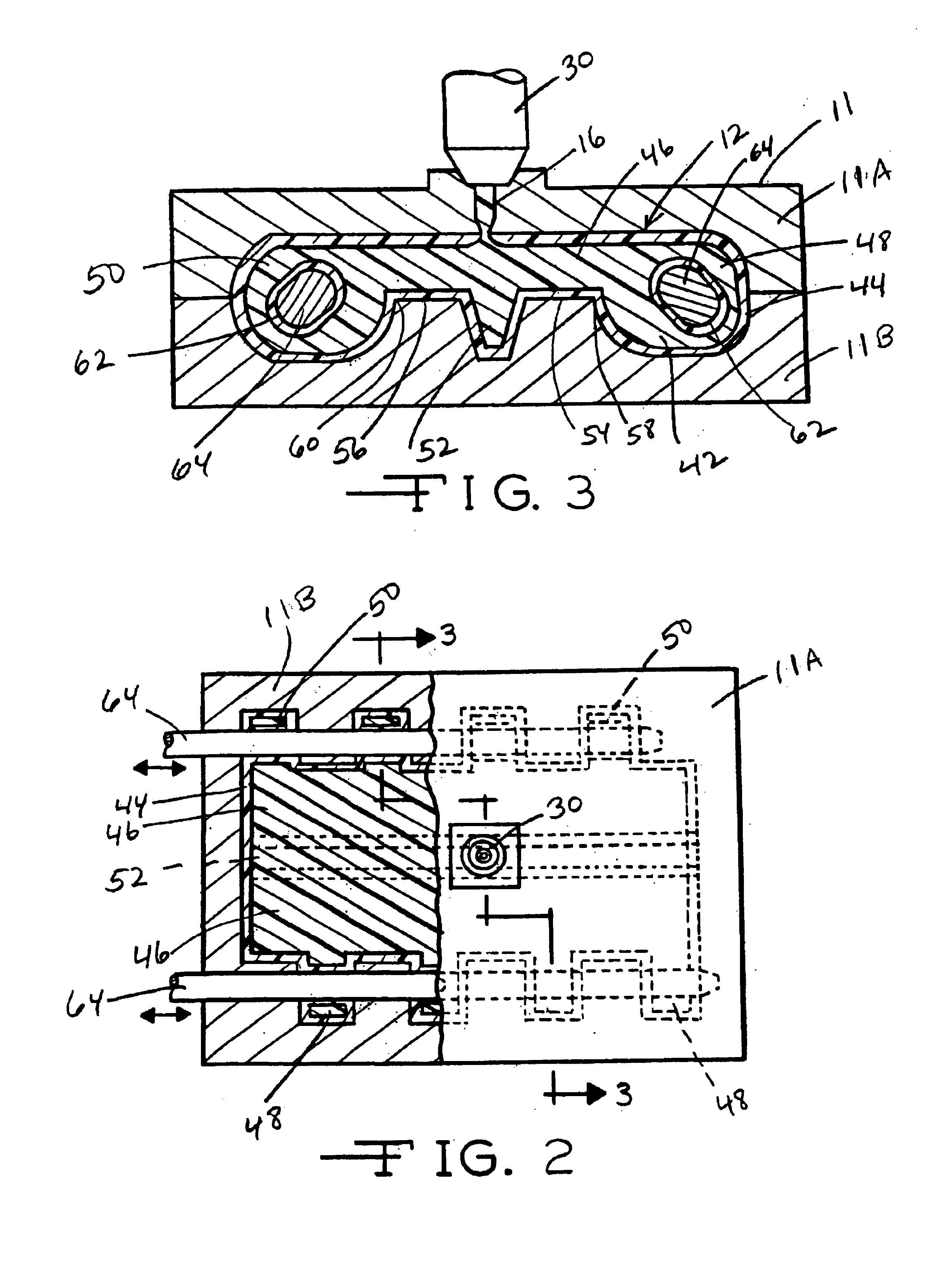

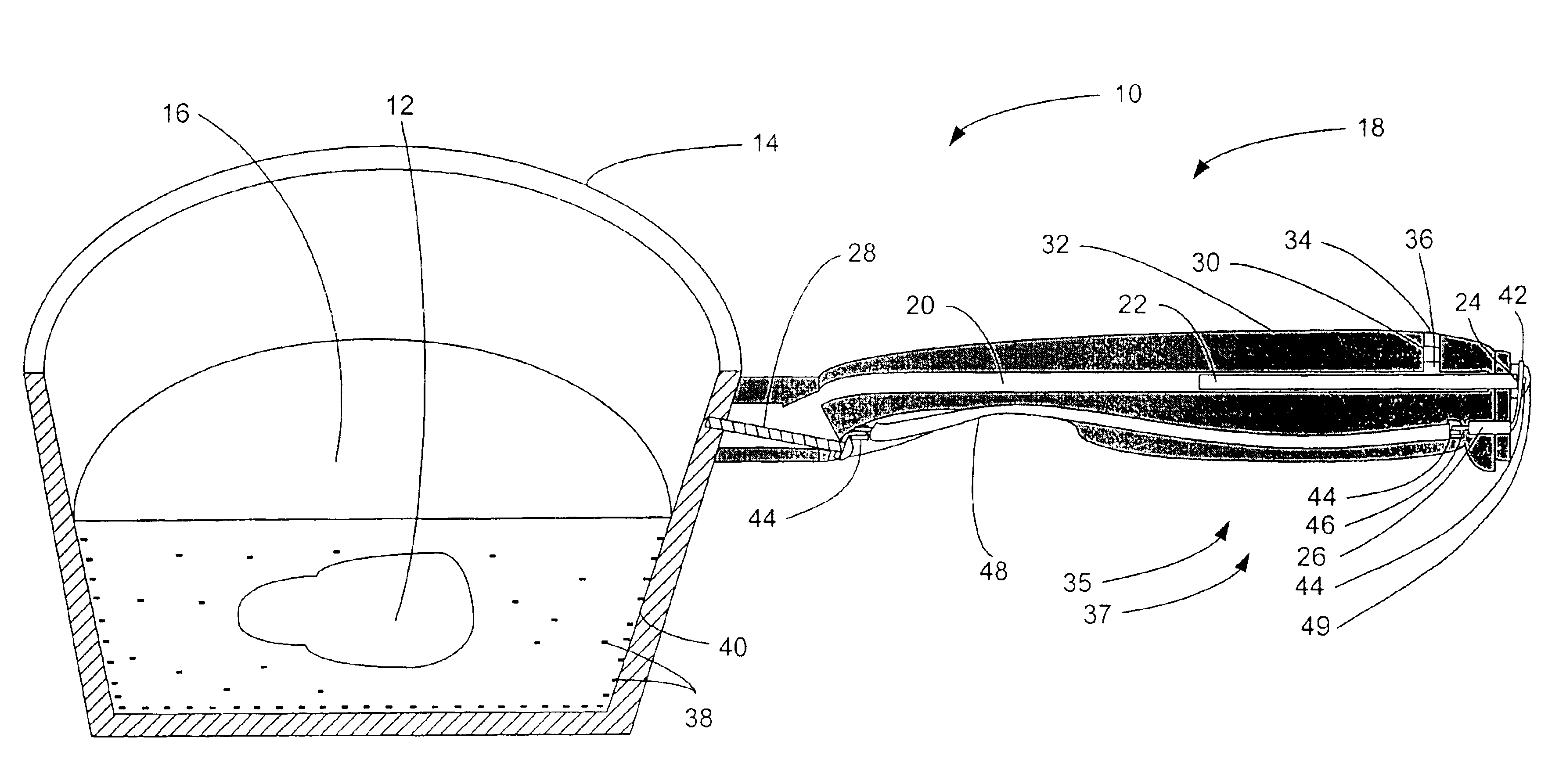

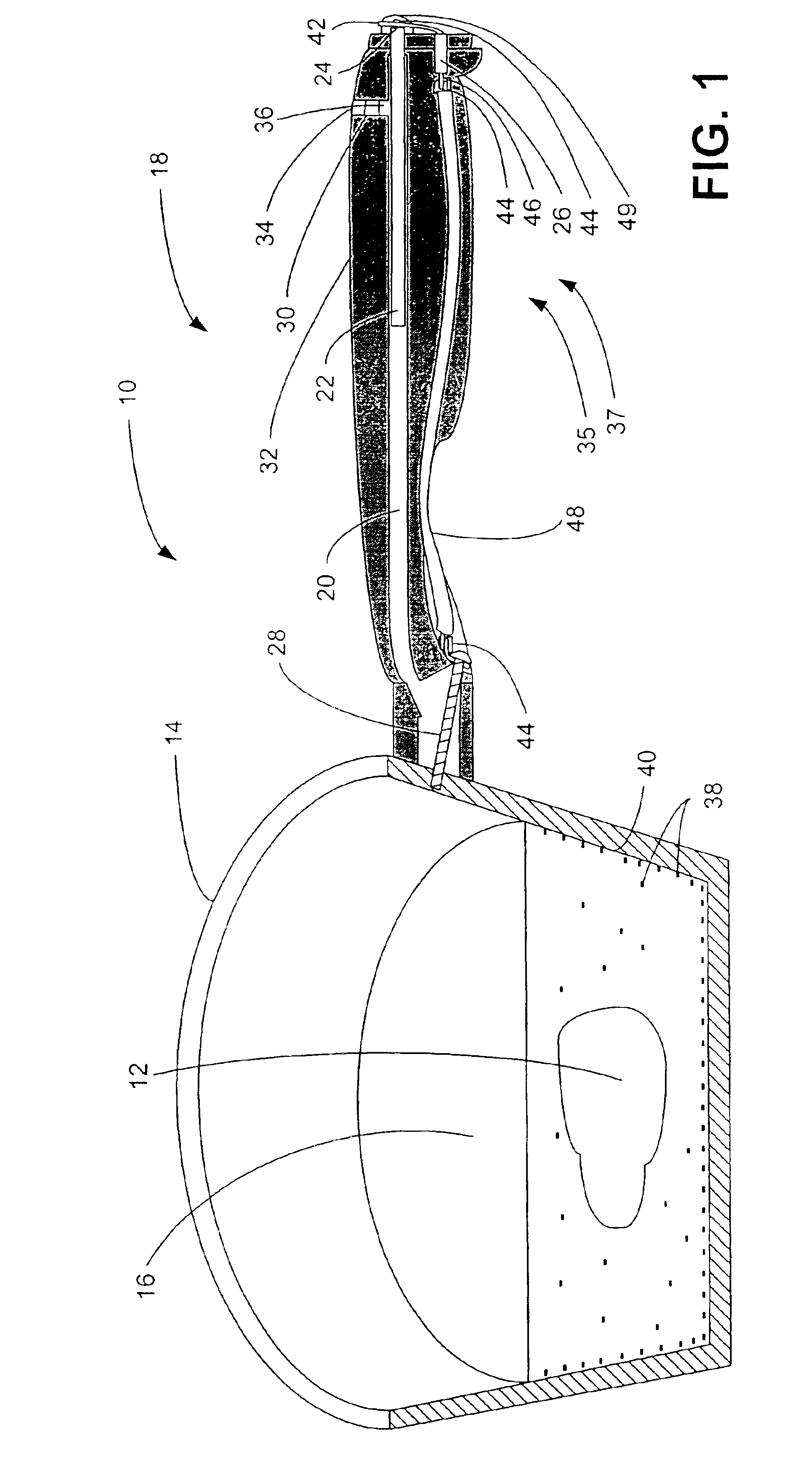

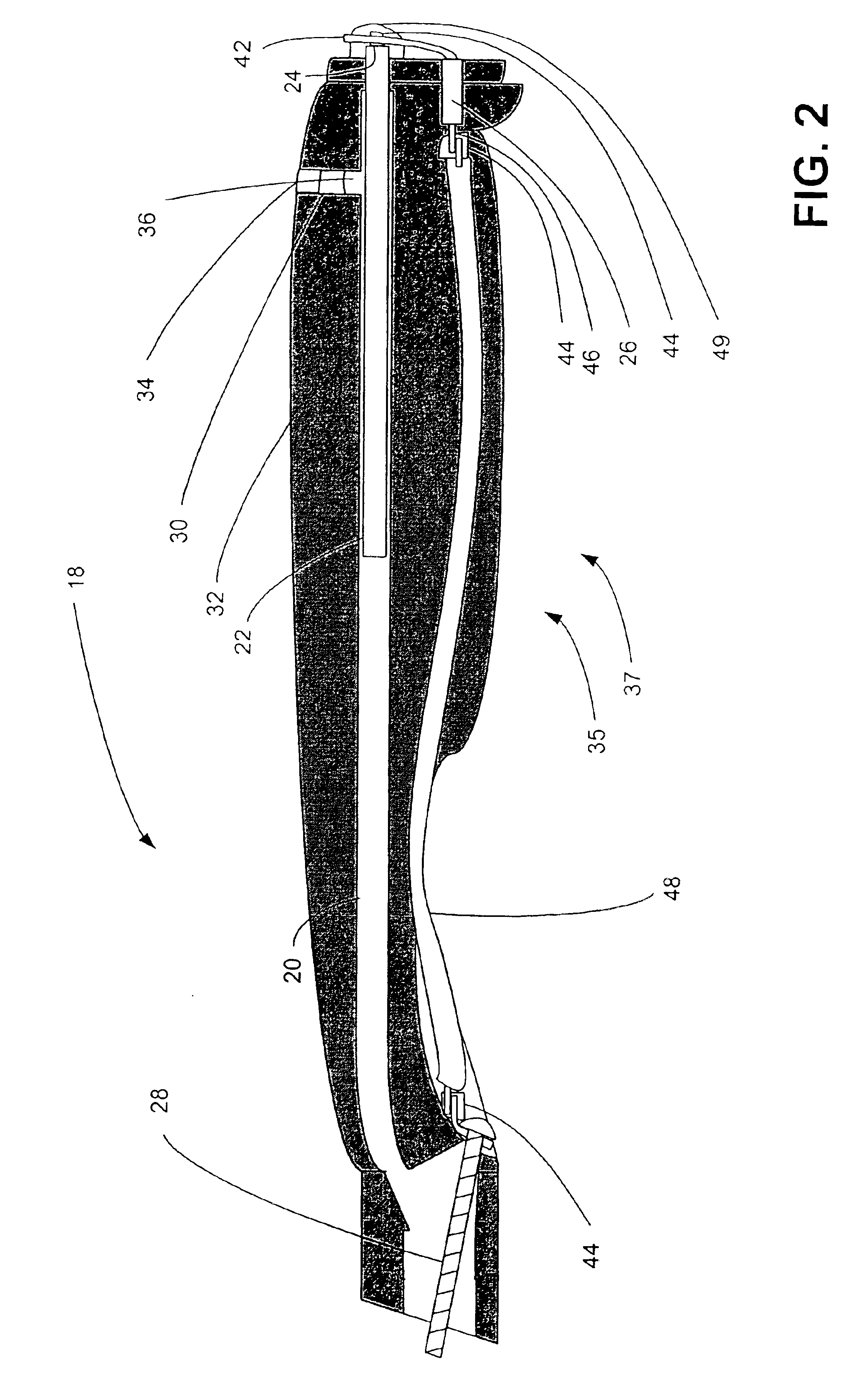

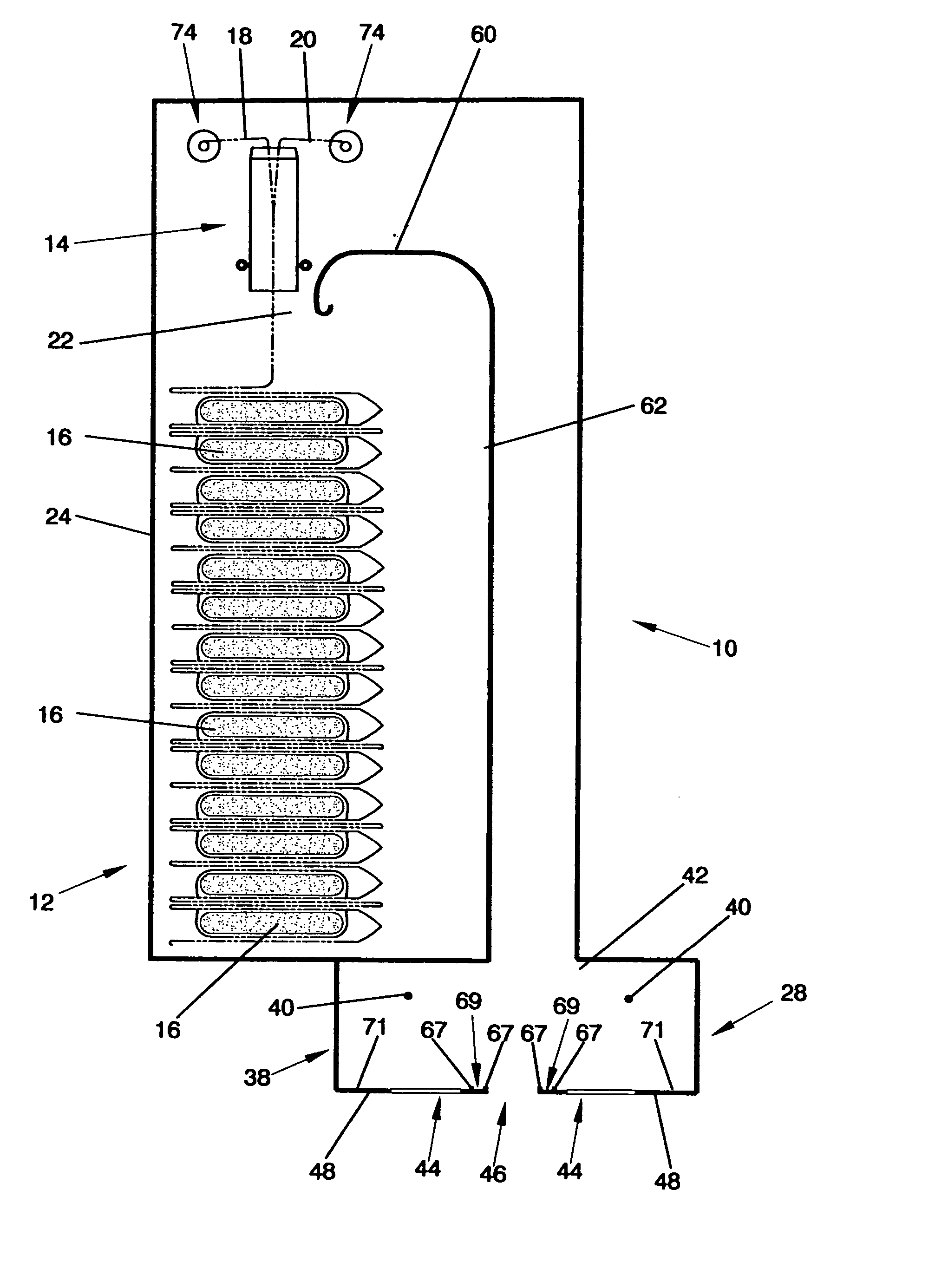

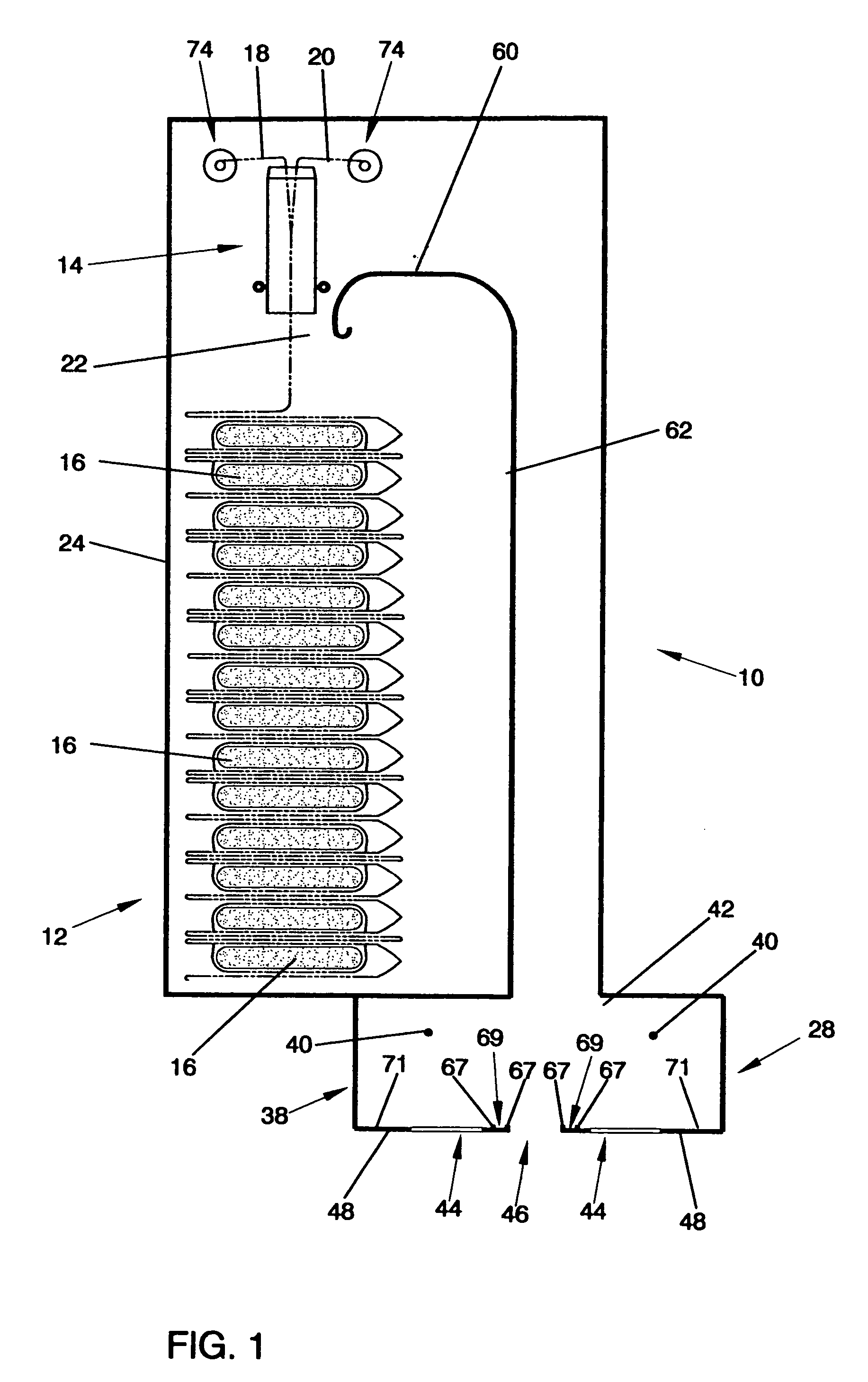

Blender base with food processor capabilities

InactiveUS20050068846A1Avoid vibrationImprove stabilityGas current separationTransportation and packagingMicrocontrollerLiquid-crystal display

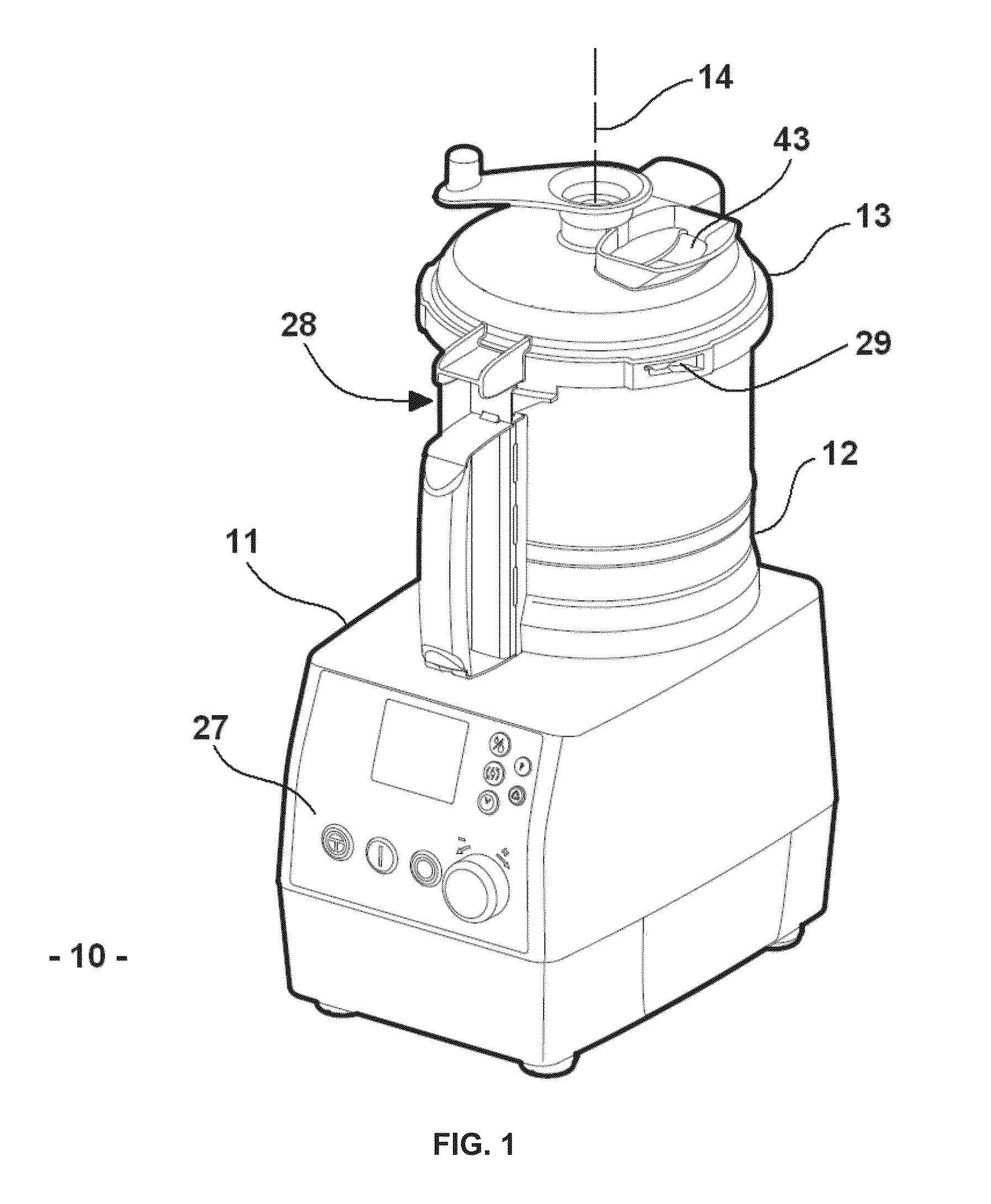

A blender base that may be used with a food processor container, a blender container, and a single use beverage container. The blender container includes a novel blade unit having a food processor-style blade and blender type blades. Programs with preprogrammed motor commands for desired operations are stored in memory and may be selected by a user on a user interface. The user interface may include a liquid crystal display, or function switches and light emitting diodes. Upon selection of a particular pre-defined function, the microcontroller retrieves the appropriate program from the read only memory and specifies the preprogrammed motor commands to accomplish the selected function.

Owner:WULF JOHN DOUGLAS +5

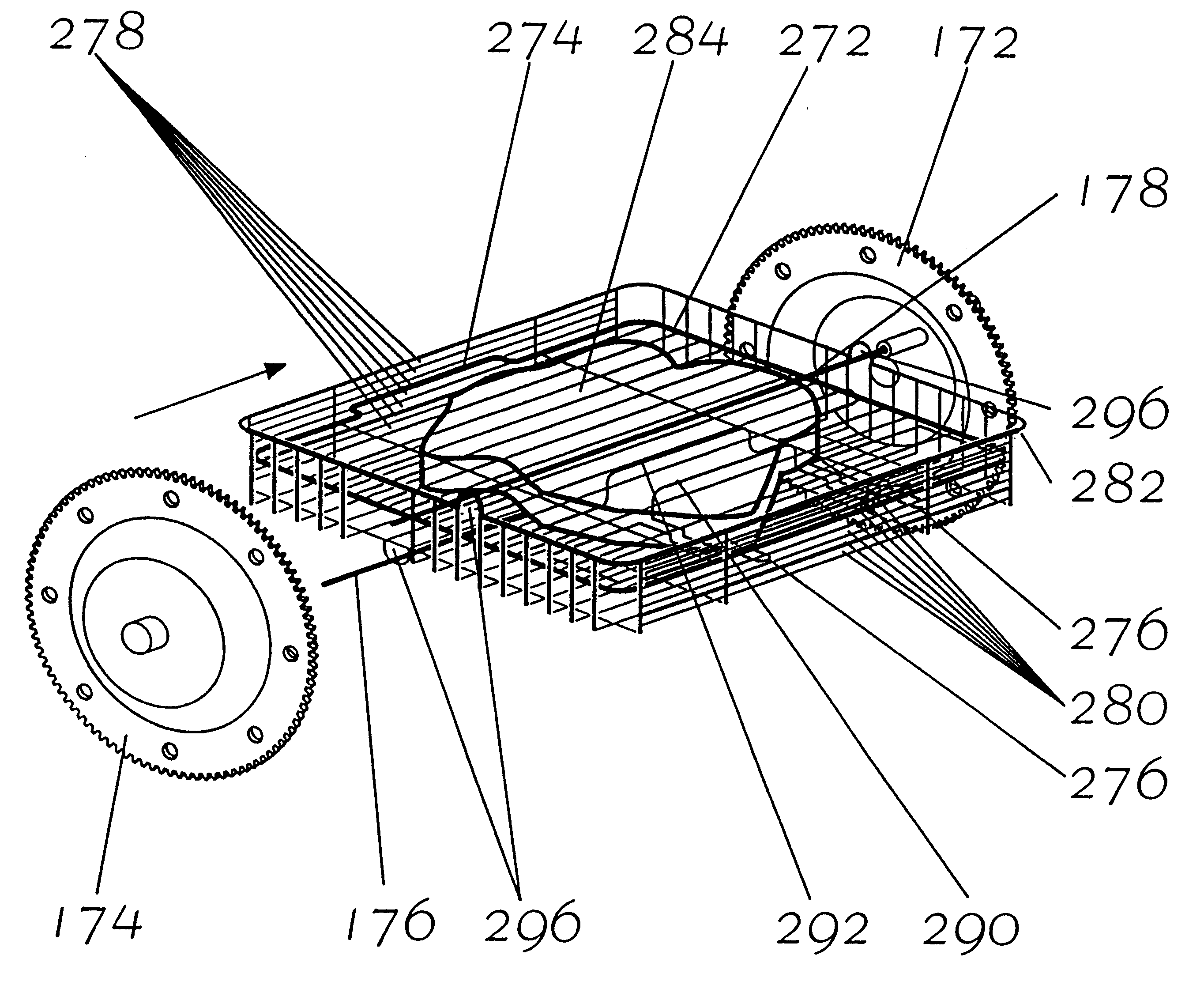

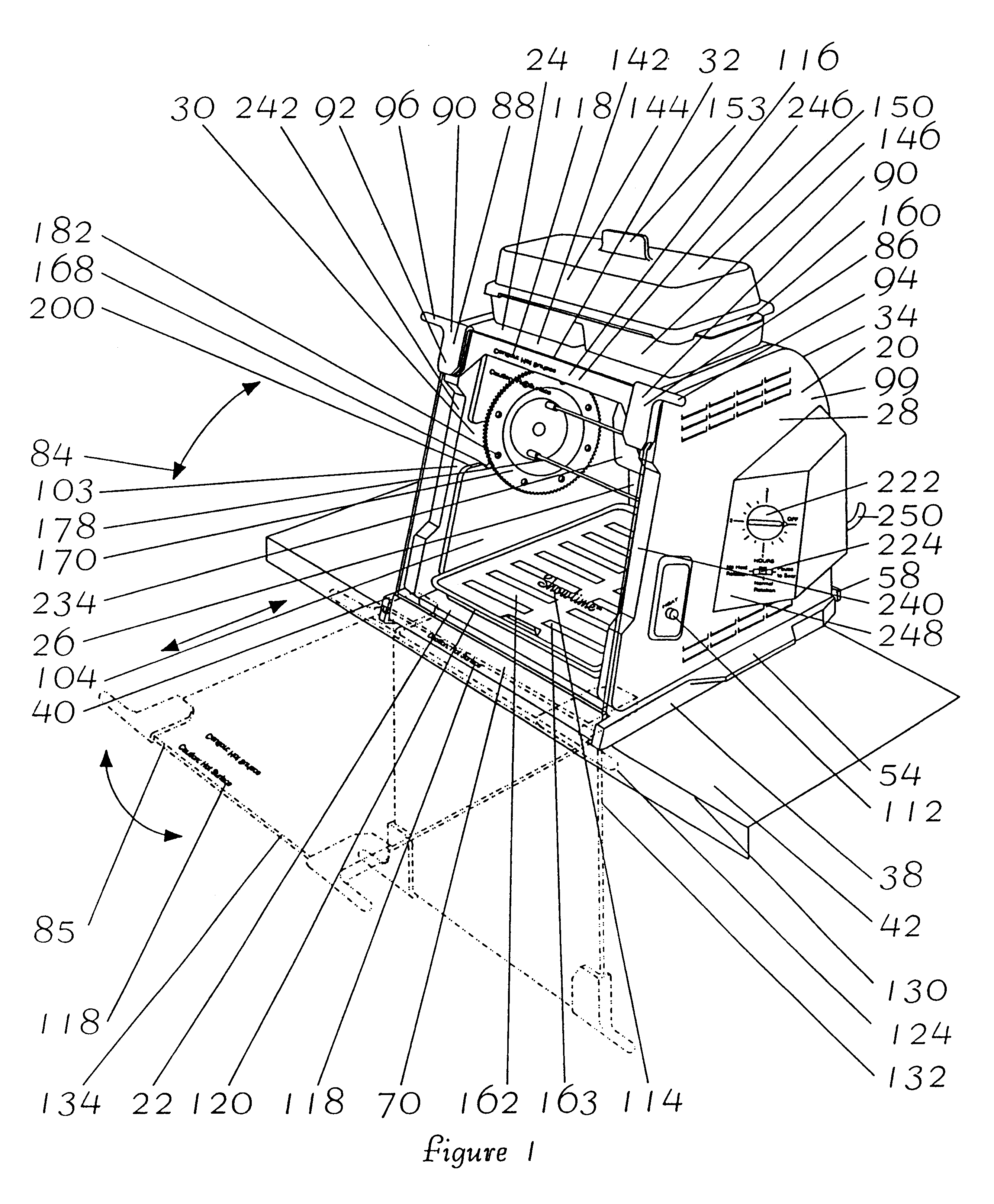

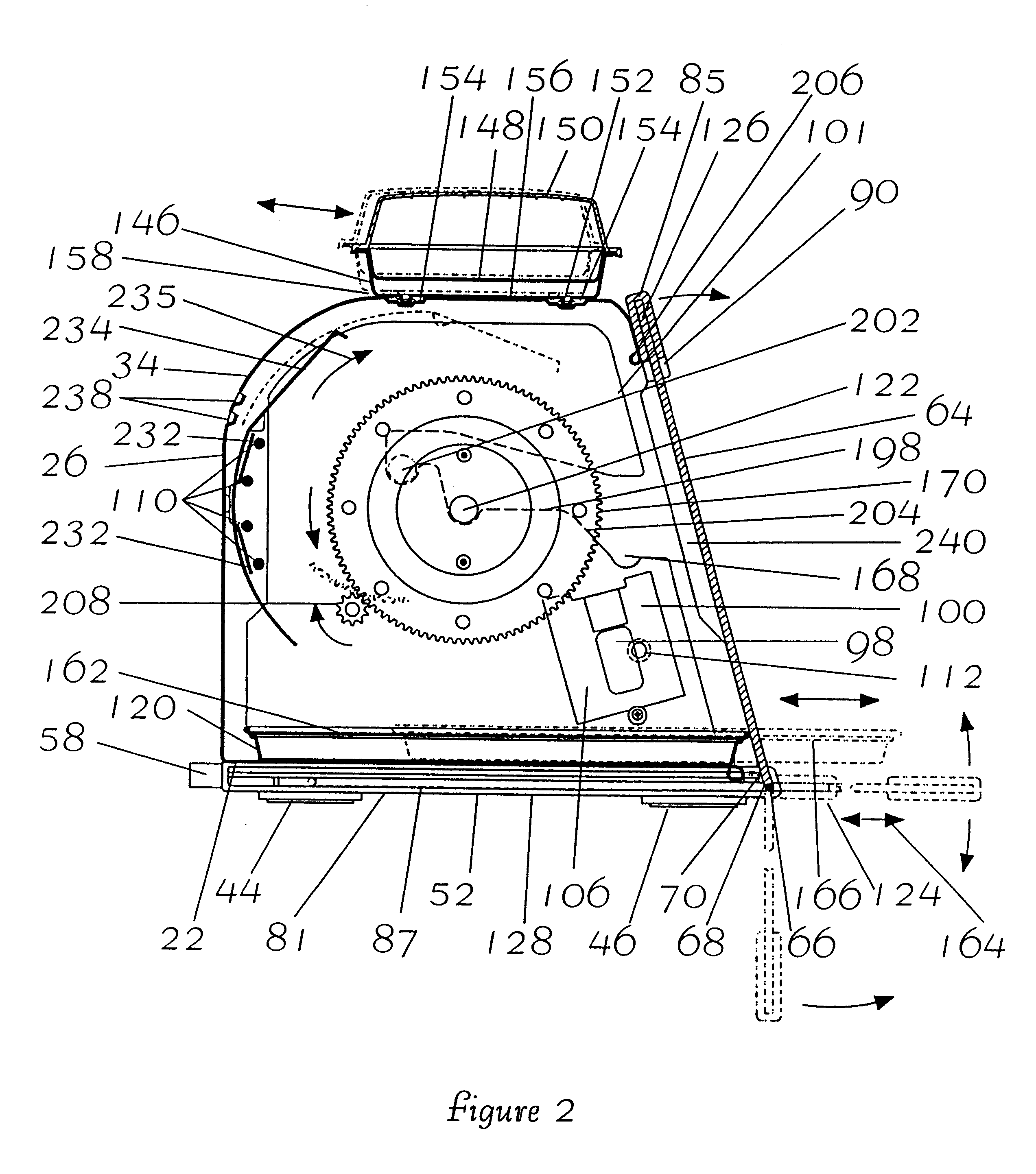

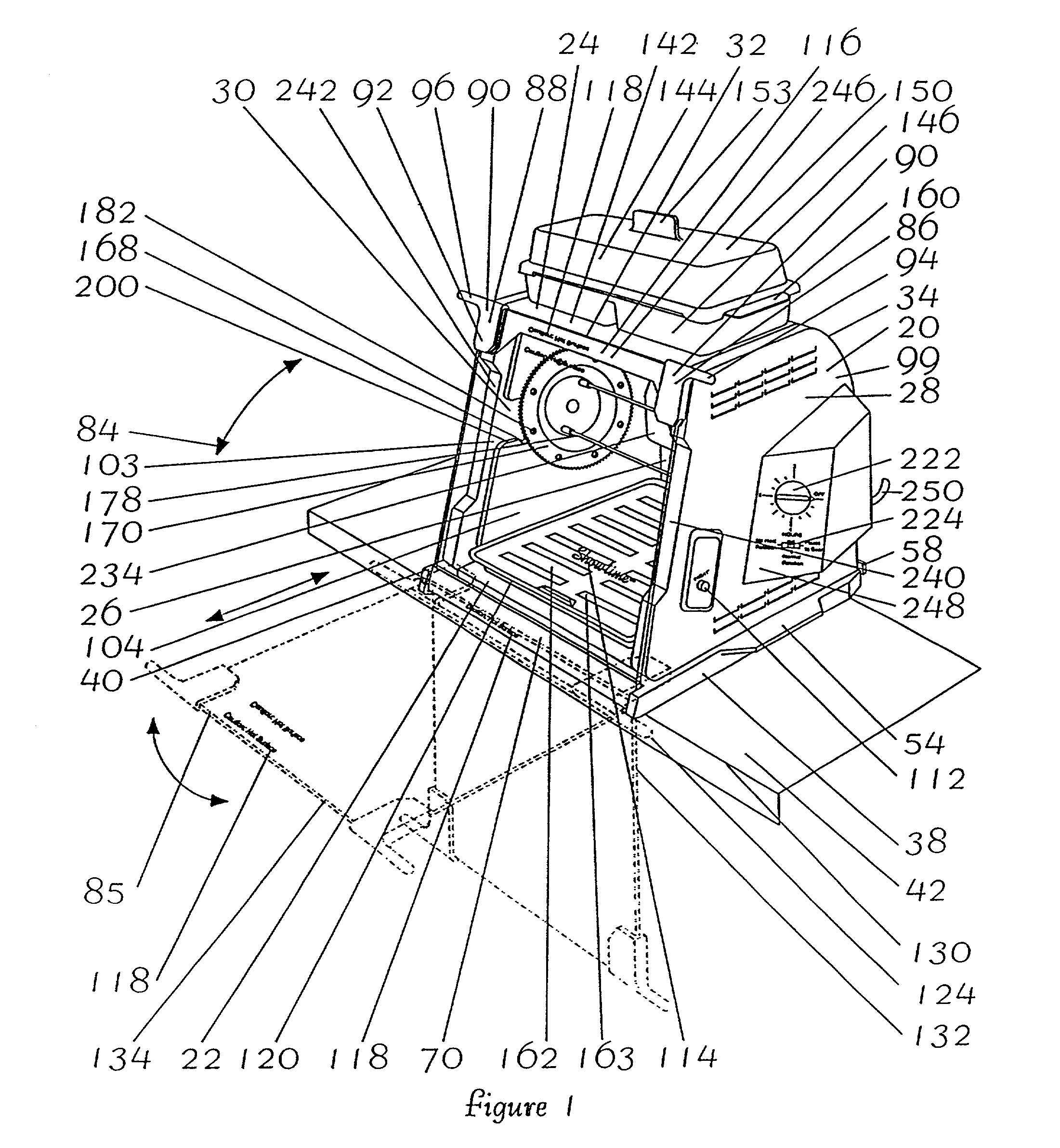

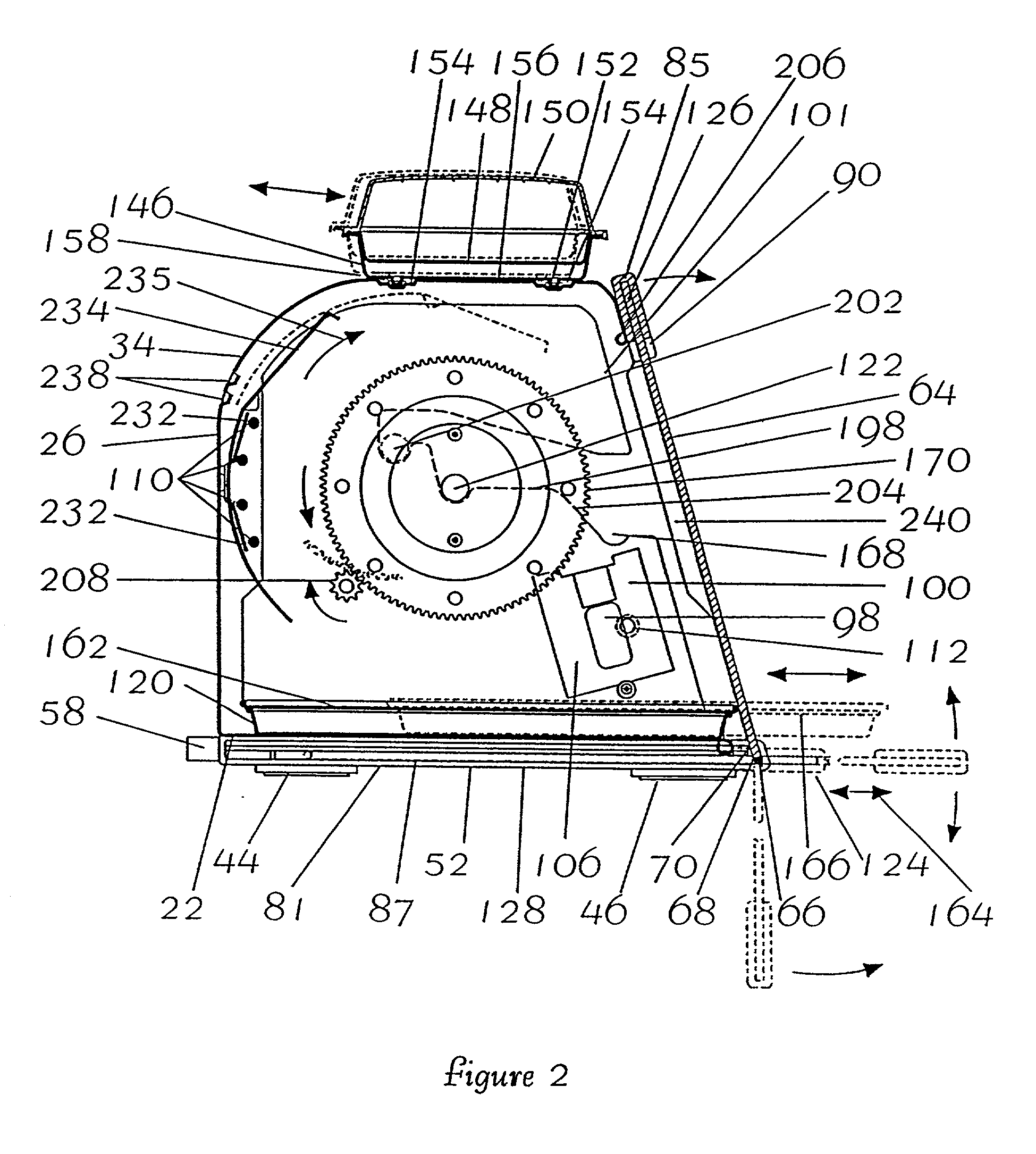

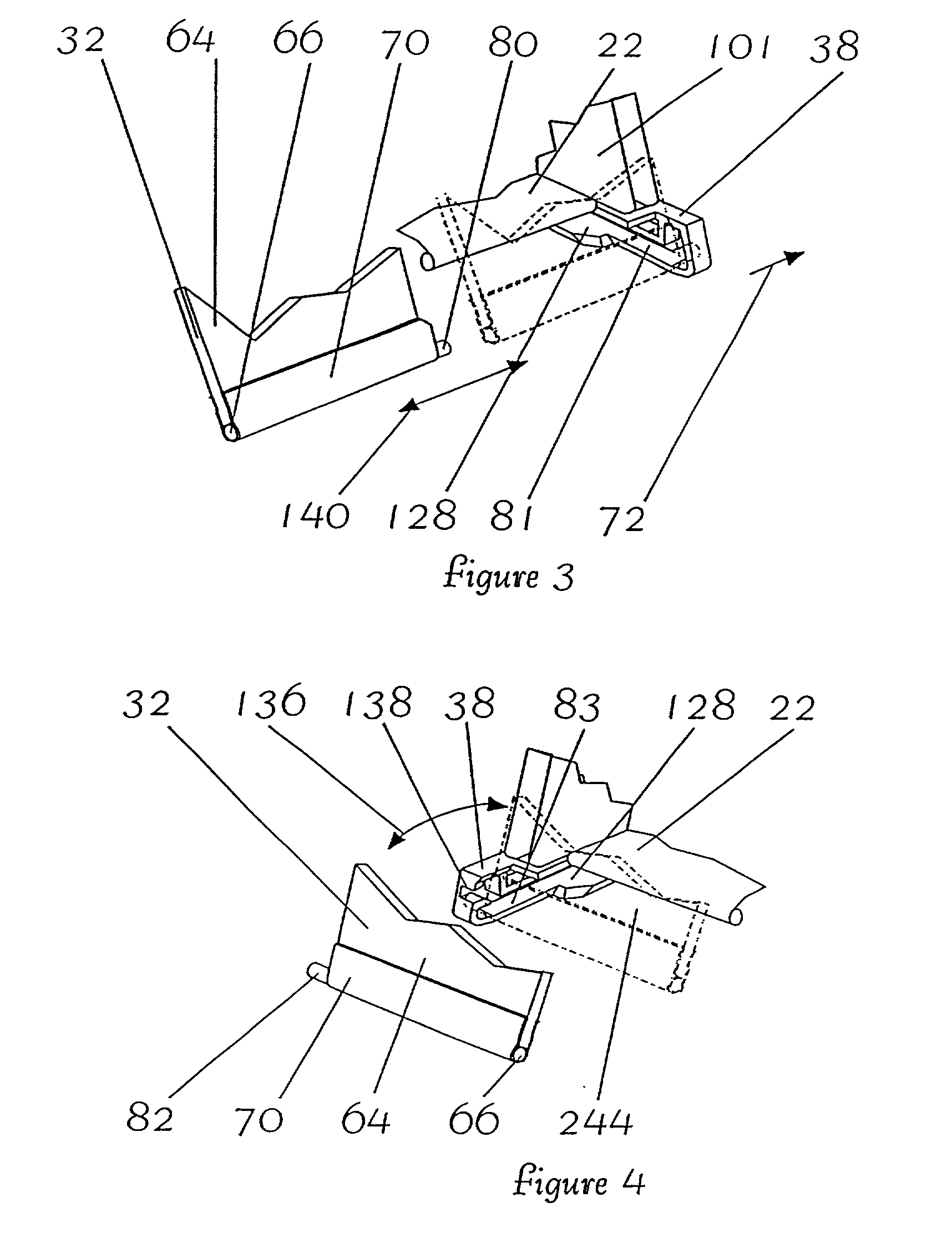

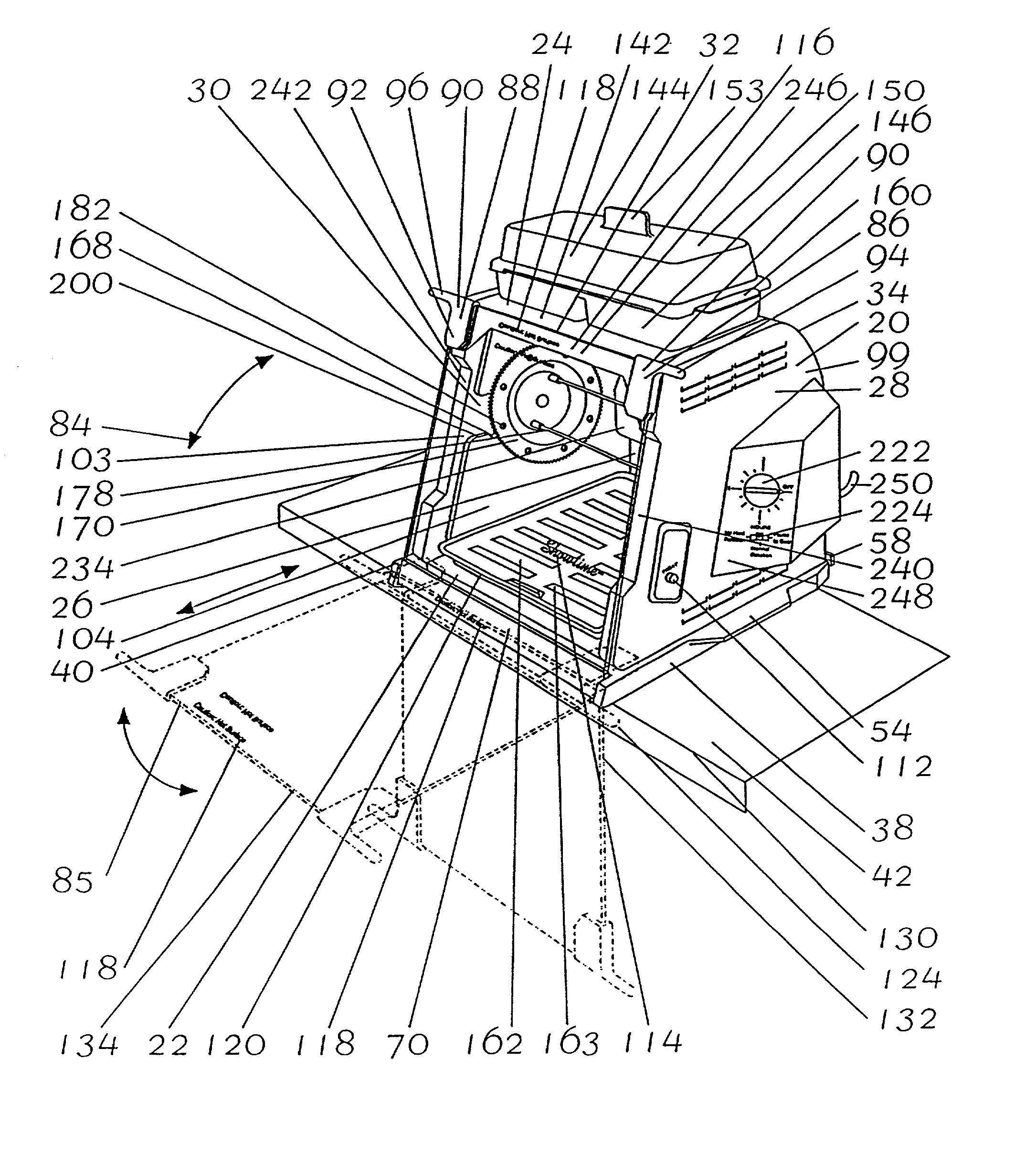

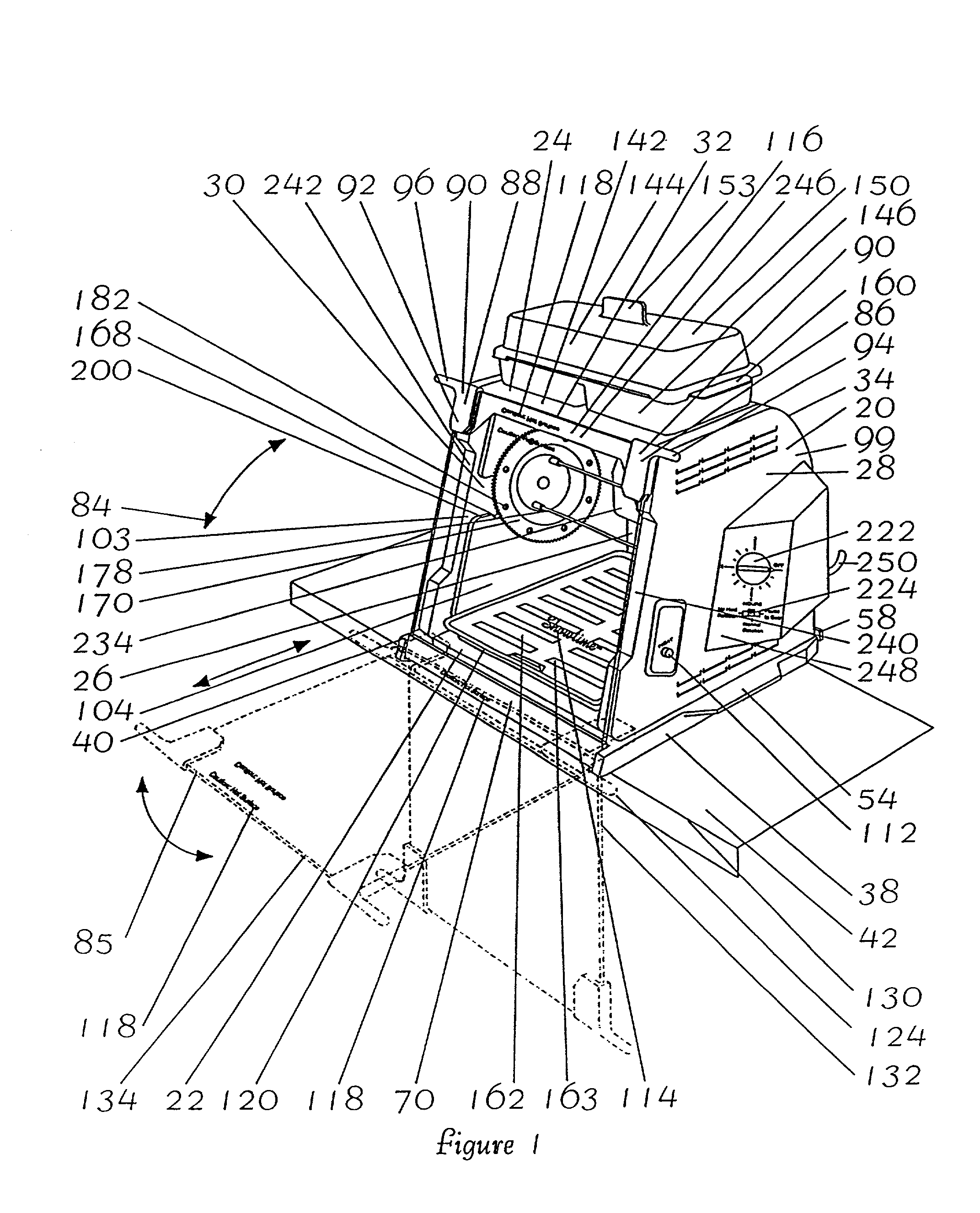

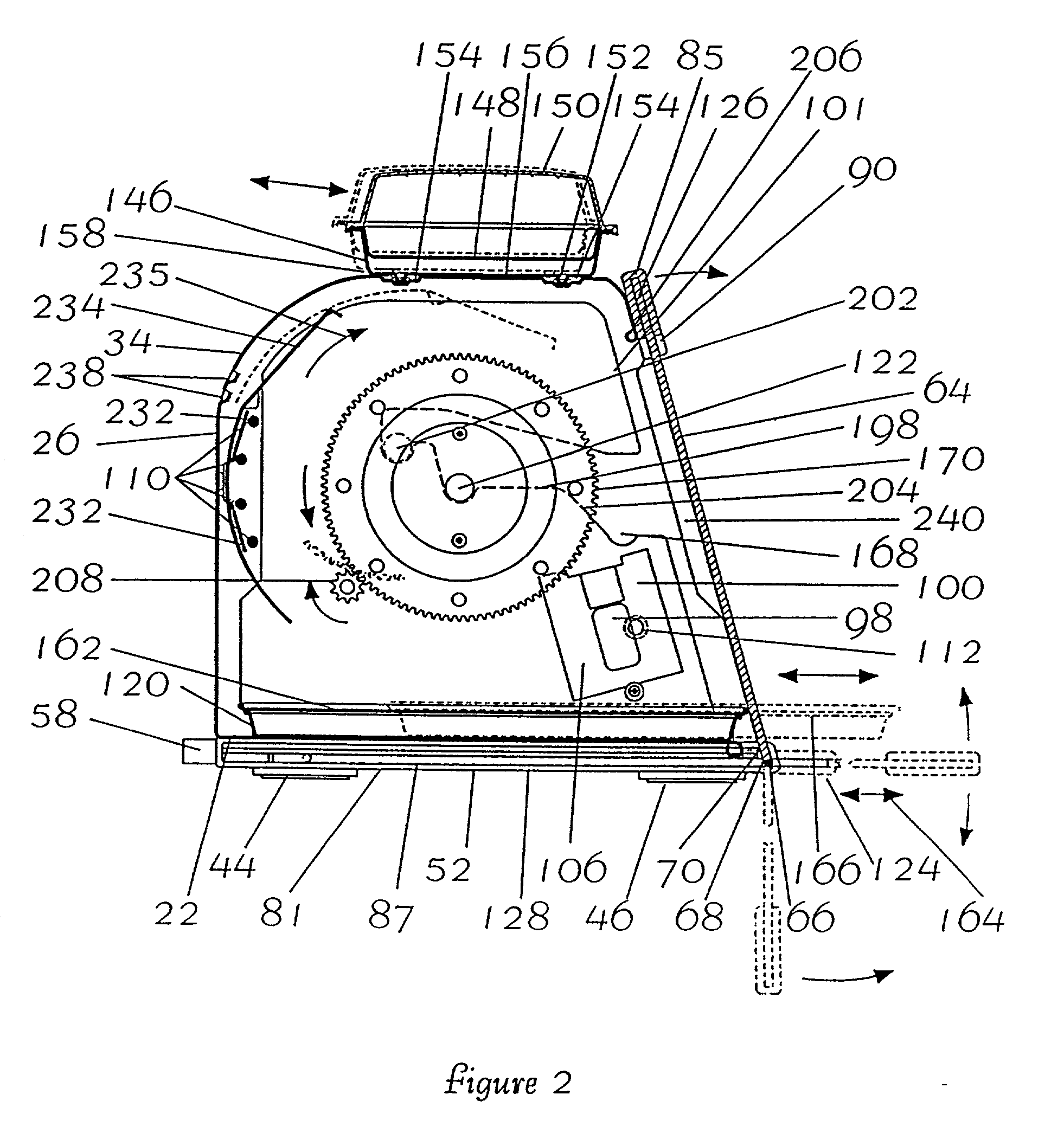

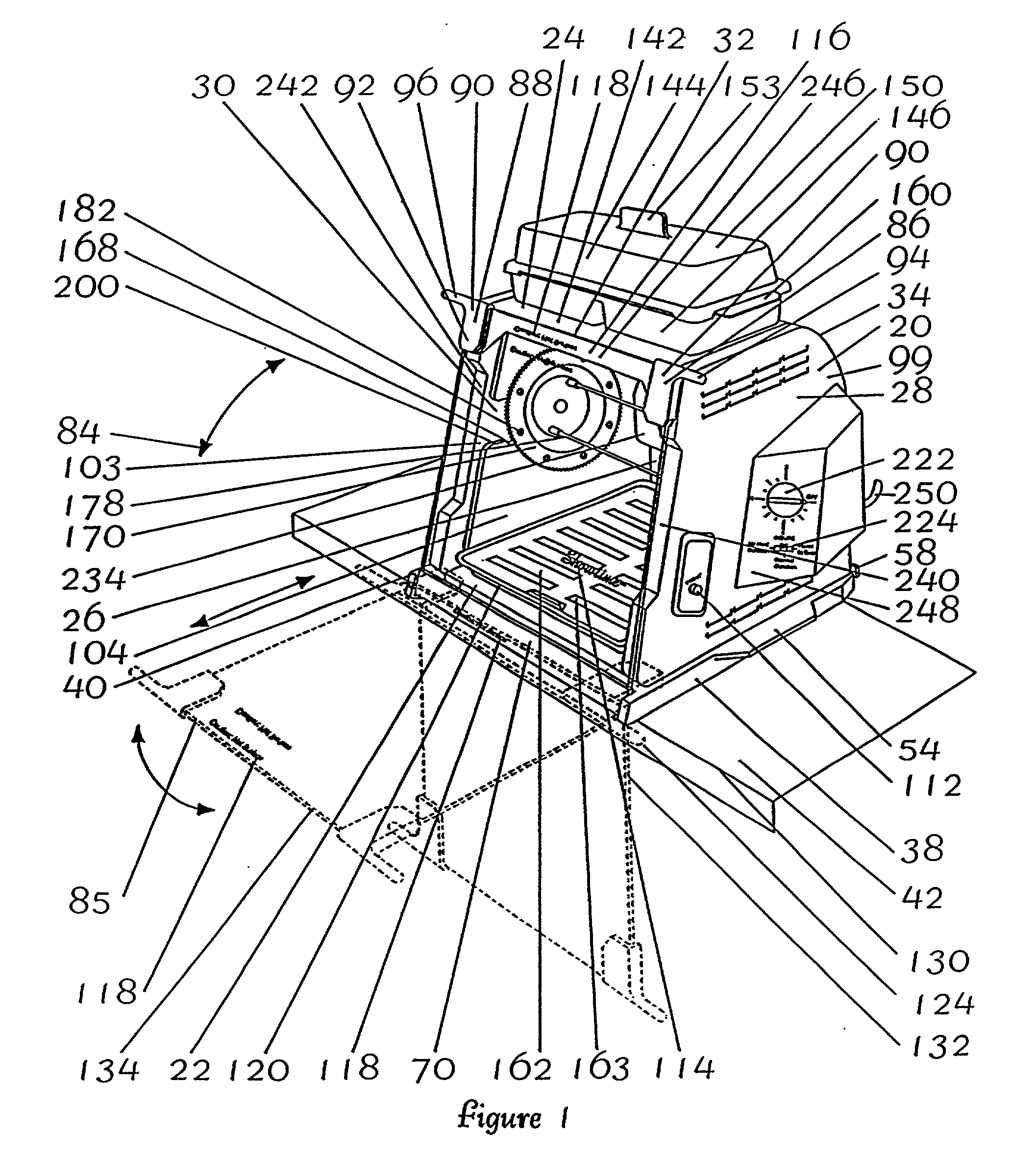

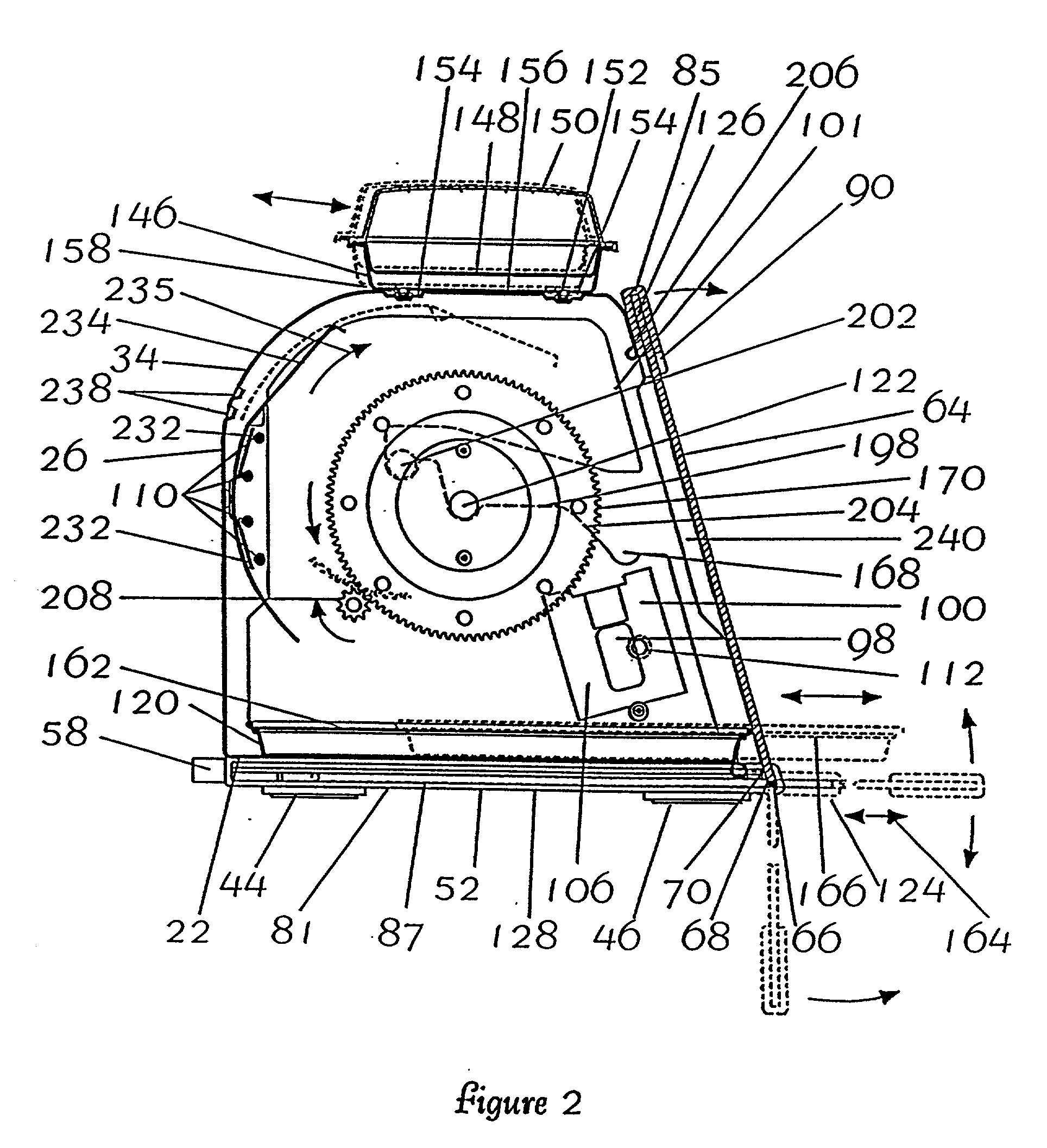

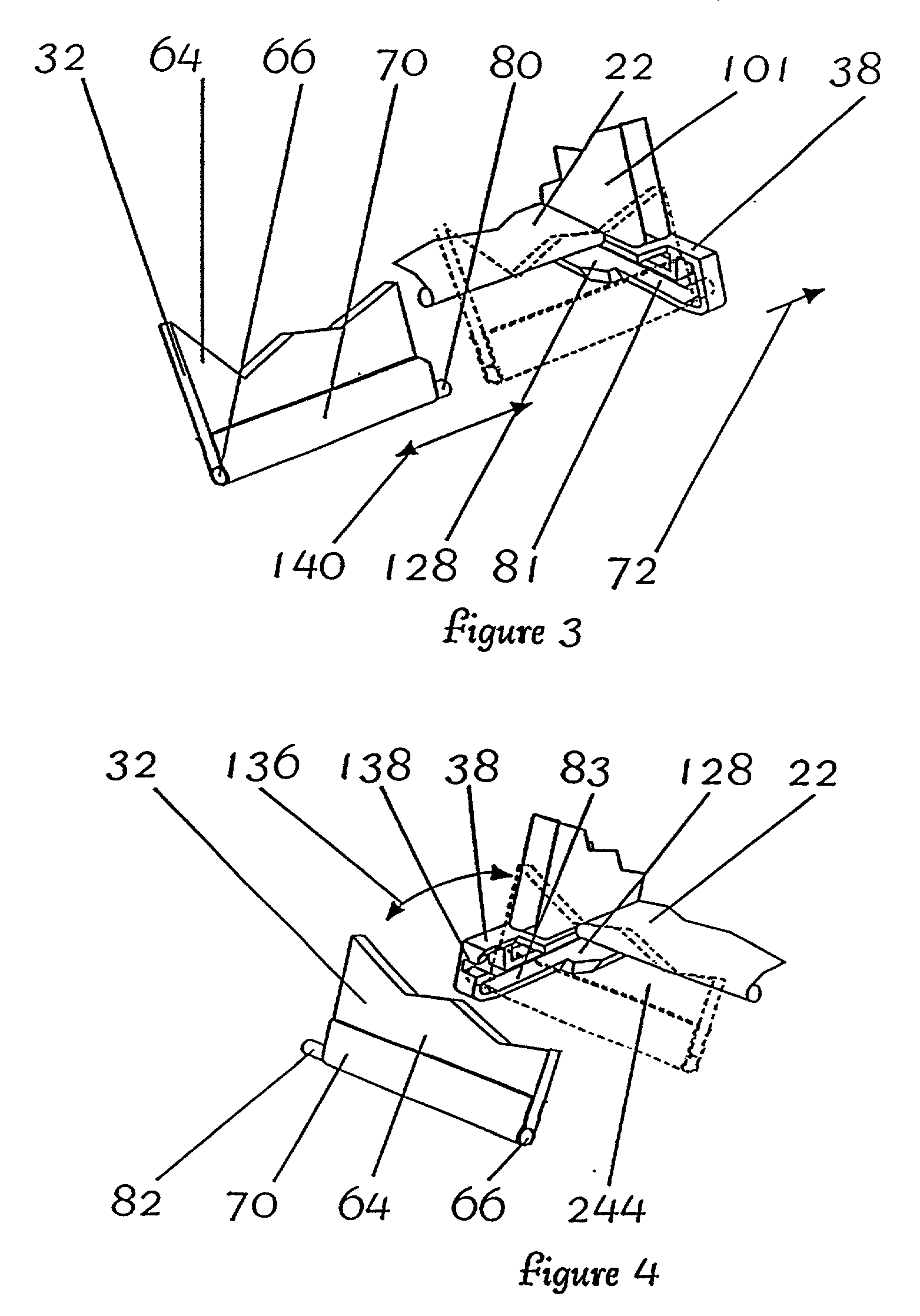

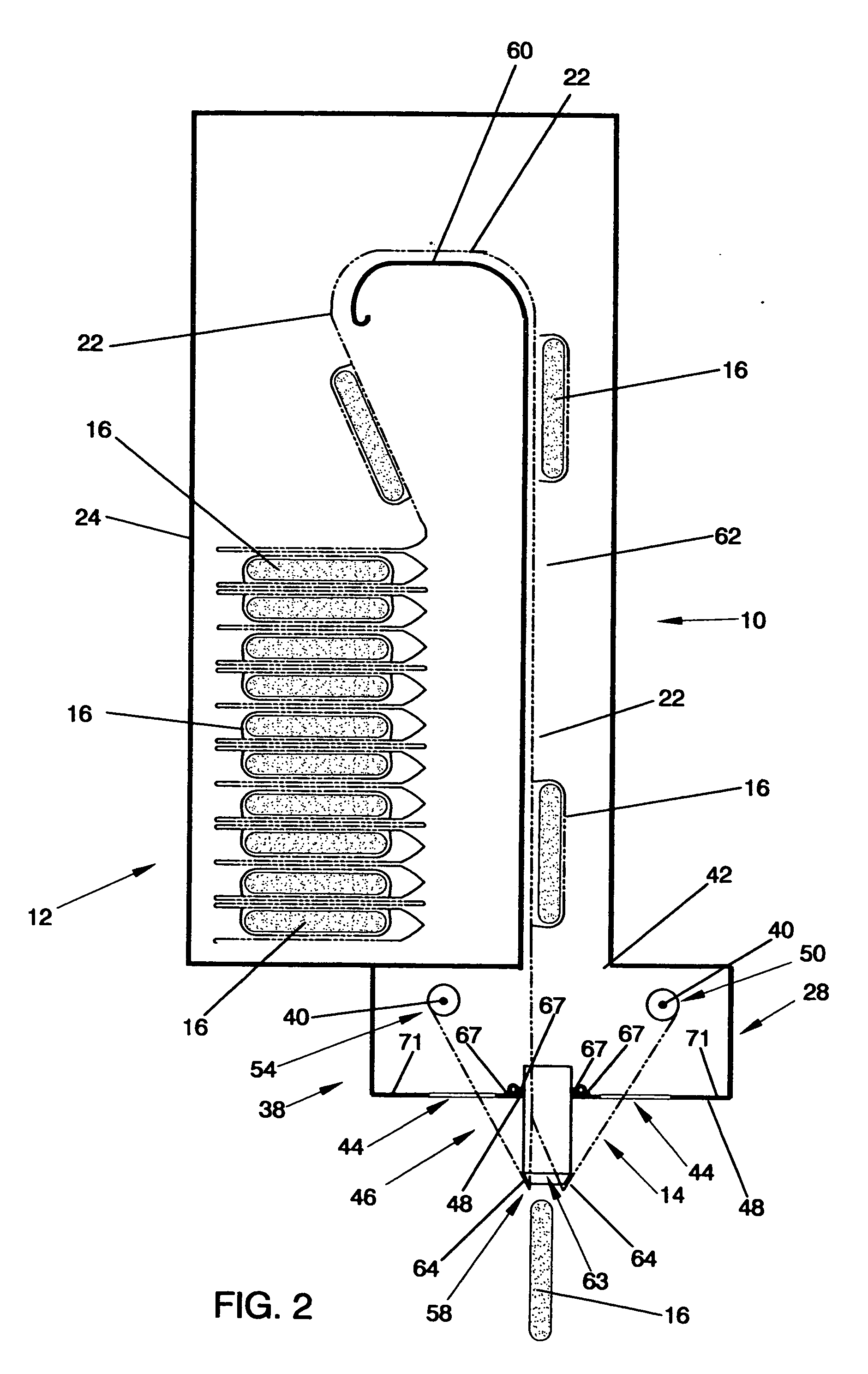

Convenient food supporting vessel for use on a rotisserie cooking spit

InactiveUS6173645B1Prevent slippingEasy to handleCooking-vessel lids/coversMeat processingGear driveGear wheel

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:RONCO HLDG +1

Blender base with food processor capabilities

InactiveUS7520659B2Avoid vibrationImprove stabilityElectric motor controlOther chemical processesMicrocontrollerLiquid-crystal display

Owner:SUNBEAN PROD INC

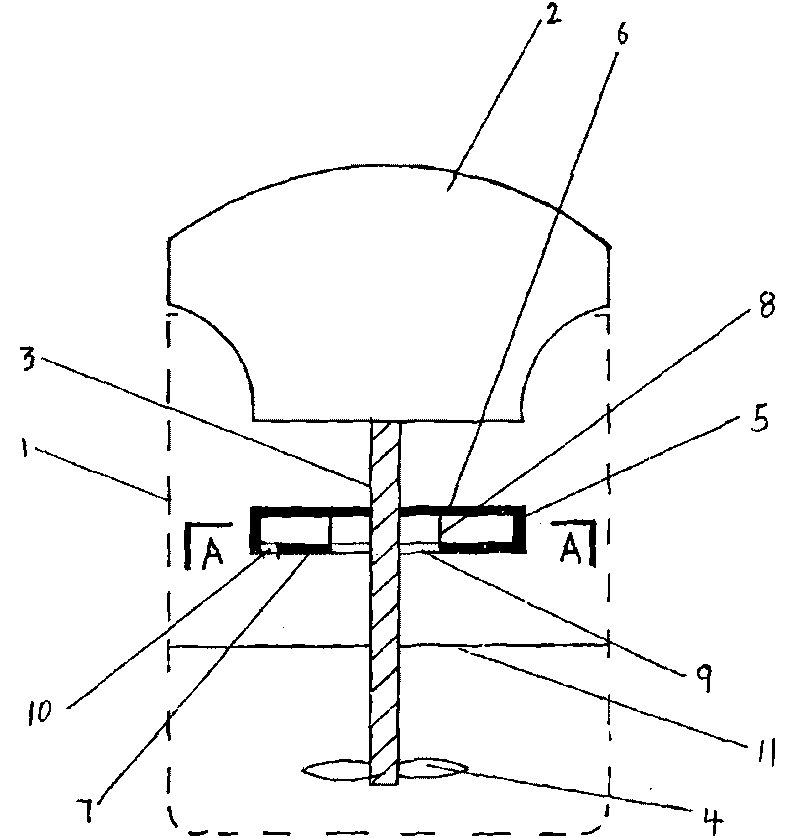

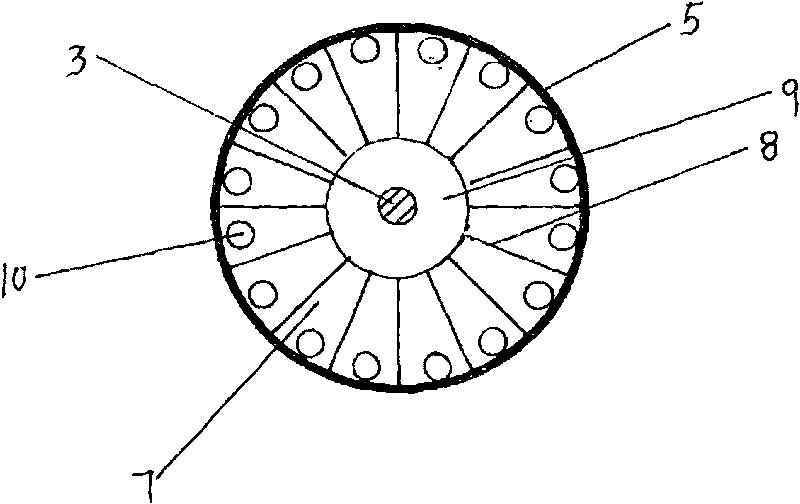

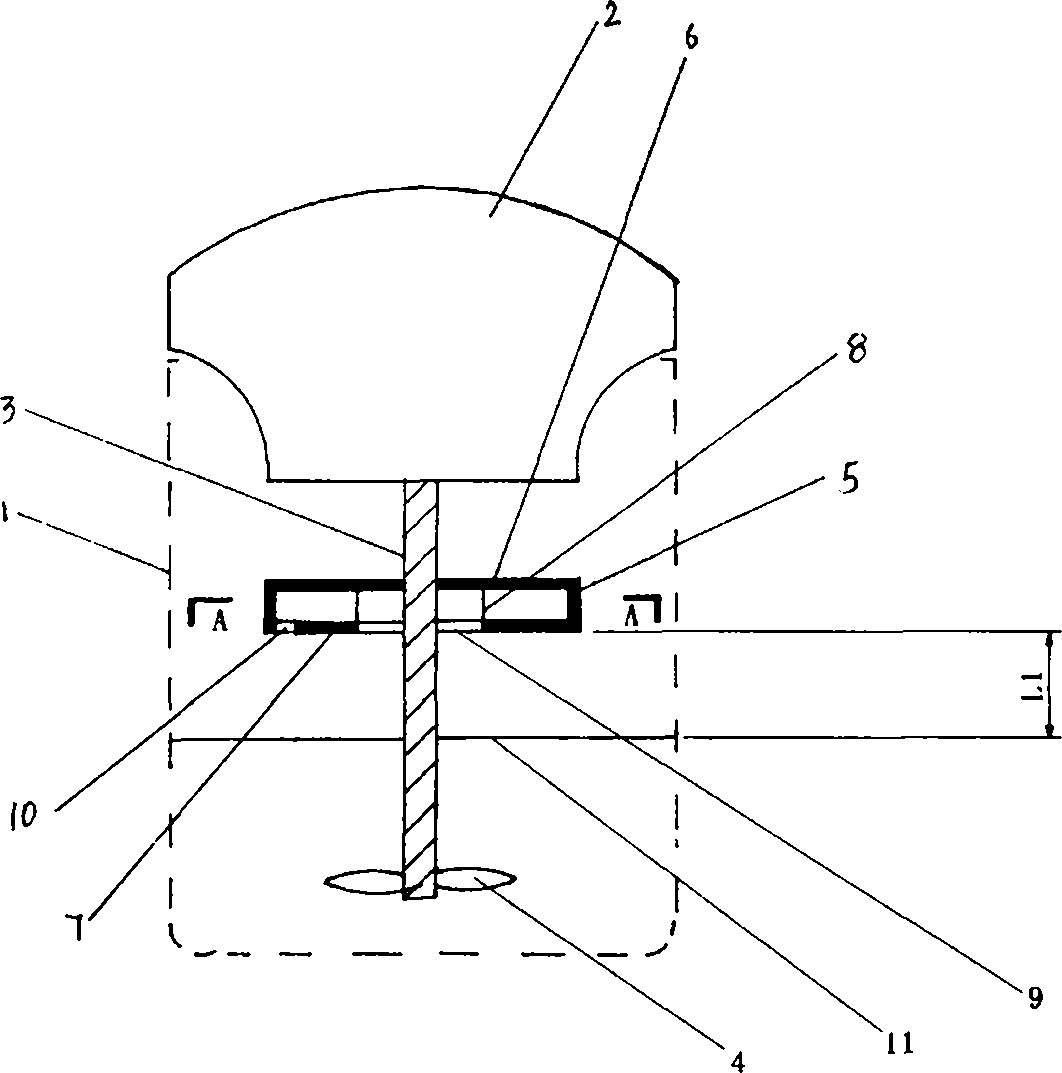

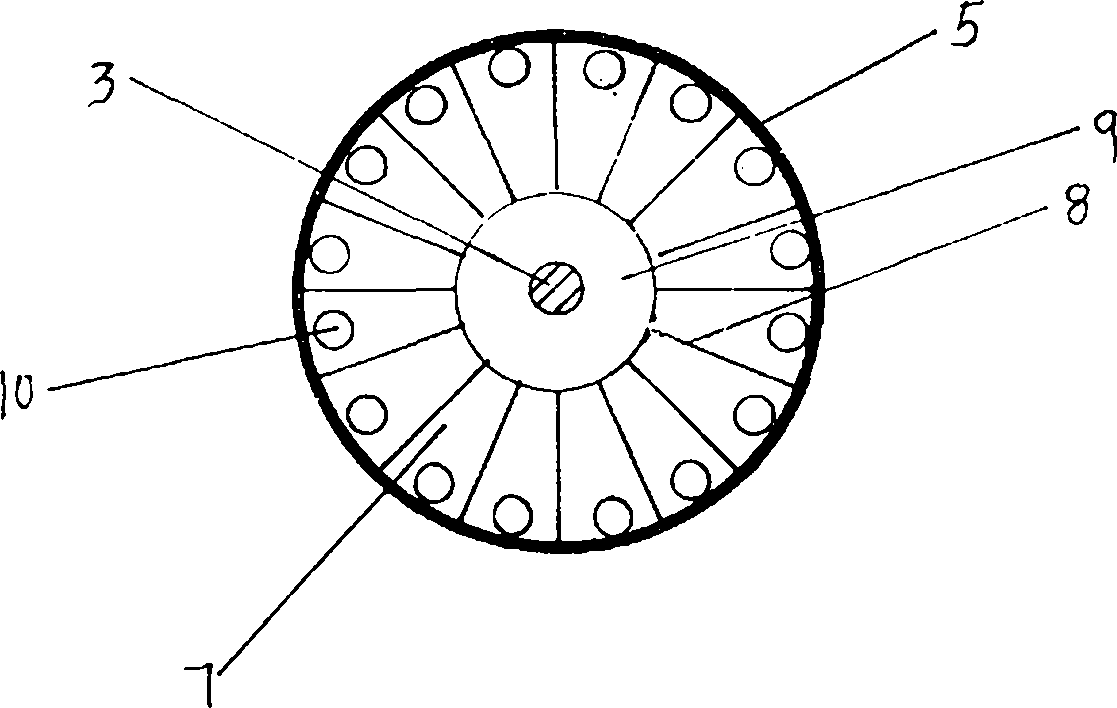

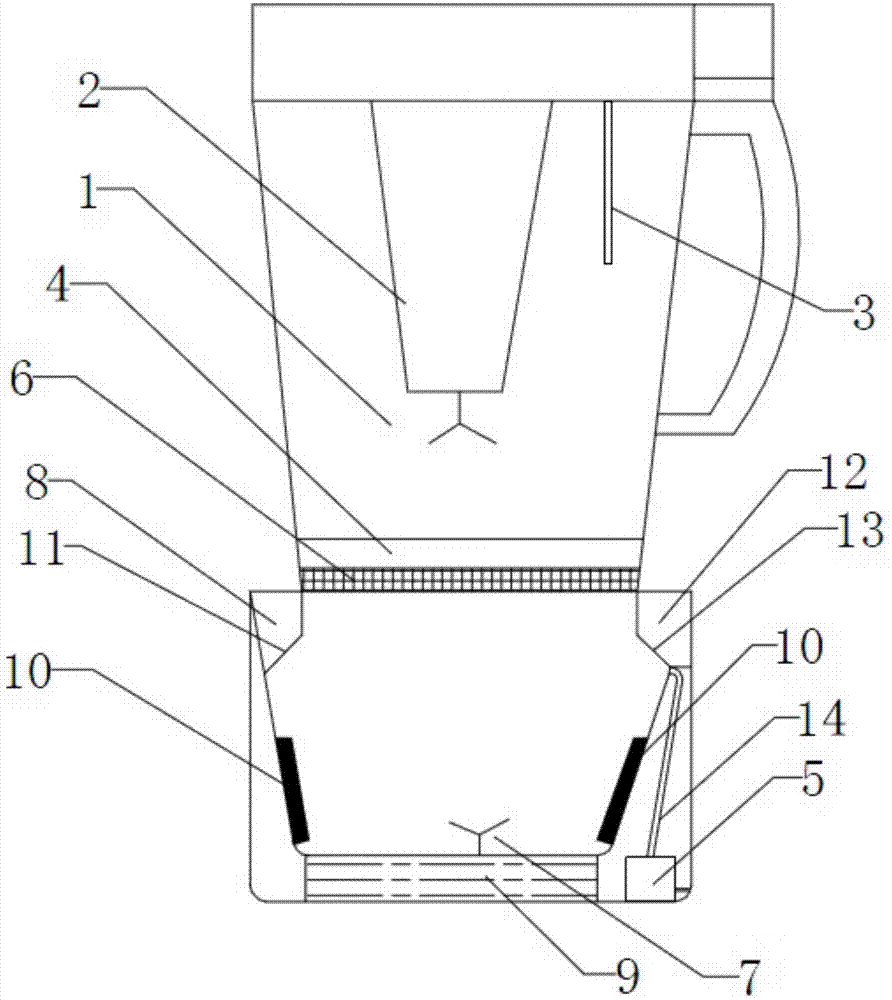

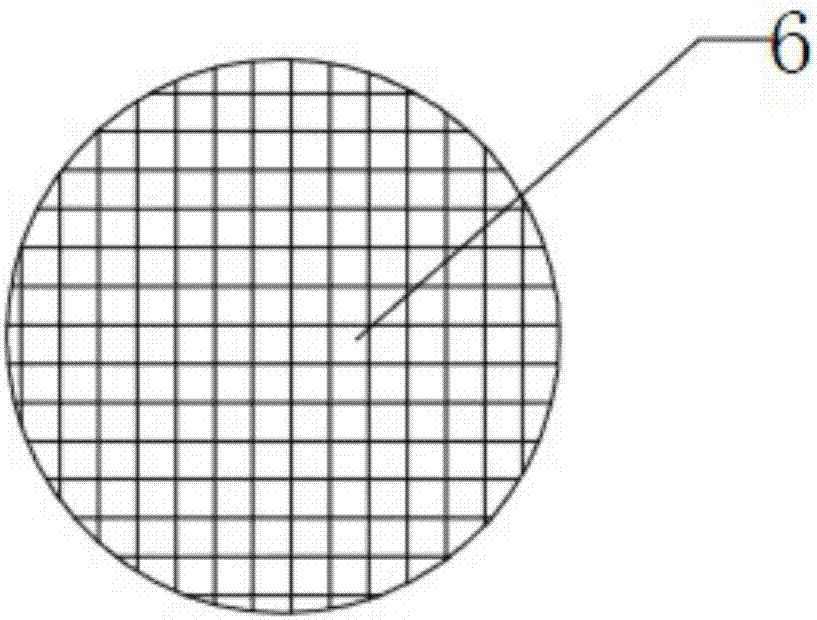

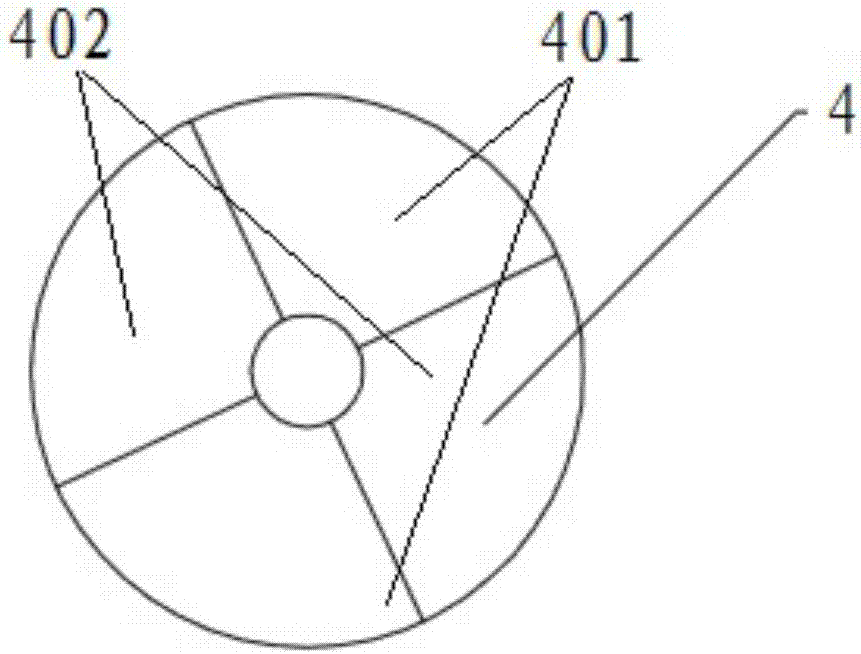

Food processor with rotary type defoaming device

InactiveCN101703365AEliminate generationContinuous heatingBeverage vesselsStrainersSocial benefitsEconomic benefits

The invention relates to a food processor with a rotary type defoaming device. A main body of the food processor comprises a pulverization cutter, a motor, a pulverization knife shaft and a barrel body; a rotary type defoaming device is arranged on the food processor; the rotary type defoaming device comprises a defoamer main body, wherein the rotation center position of the defoamer main body is provided with a shaft center installation hole, or the defoamer main body is provided with a rotating shaft; and the defoamer main body is connected with a power shaft, and the power shaft is the self pulverization knife shaft or other power shafts of the food processor. The invention can actively eliminate foam generated when foods are pulverized, heated and cooked in time, enables the pulverization operation or the heating and cooking operation to be continuously and quickly carried out without intermittent stop, shortens the pulverization or cooking time greatly, enhances the working efficiency, can meet the rhythm of the modern family life and the requirement of quick rhythm of the modern commercial management, enhances the quality of the modern family life and the efficiency of the commercial management obviously and has great economic benefit and social benefit.

Owner:王晓东

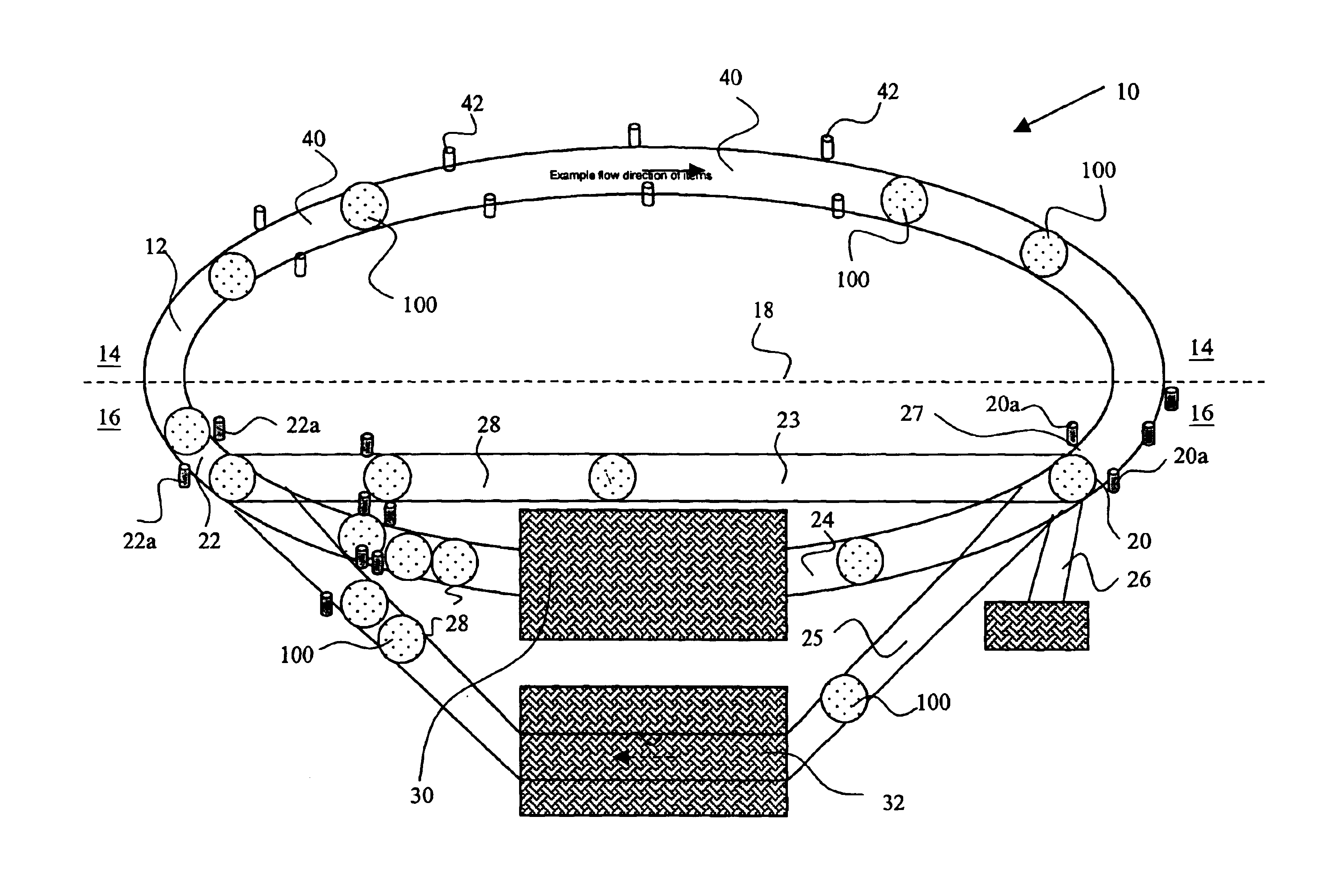

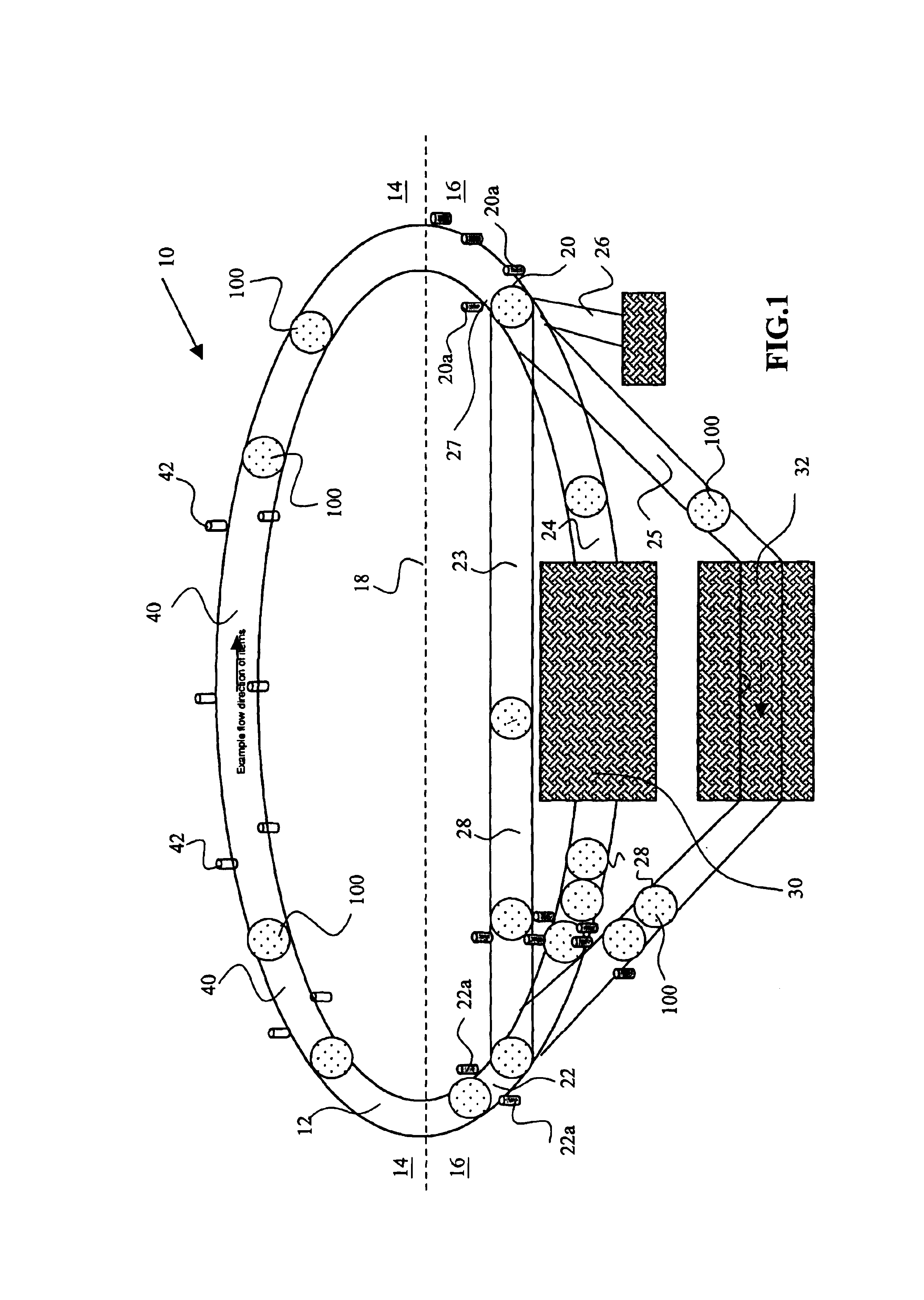

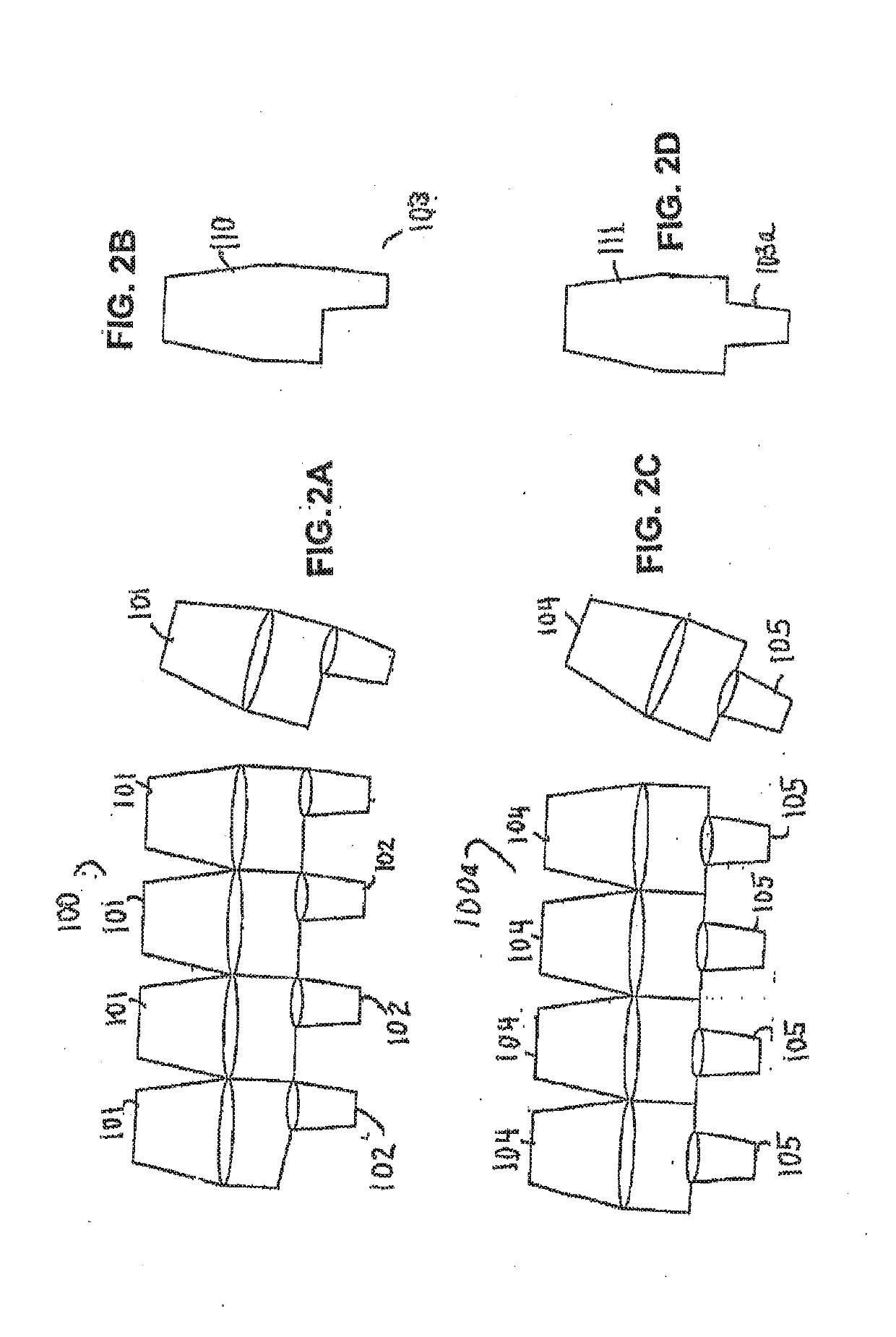

Apparatus, method and system for food management and food inventory

InactiveUS6930296B2Avoid unnecessary workEfficient and effectiveAutomatic control devicesFurnace typesEngineeringFood handling

An automated food handling system for food servings comprising a transfer means for transporting food servings therealong; a plurality of treatment modules coupled in parallel to the transfer means; means for sensing and recognizing the type of food servings being transported on the transfer means; and means for automatically diverting the food serving from the transfer means into one of the treatment modules. The treatment modules may be machines that bring the food servings to the desired temperature. An inventory system is also provided.

Owner:NATURE FOOD HLDG

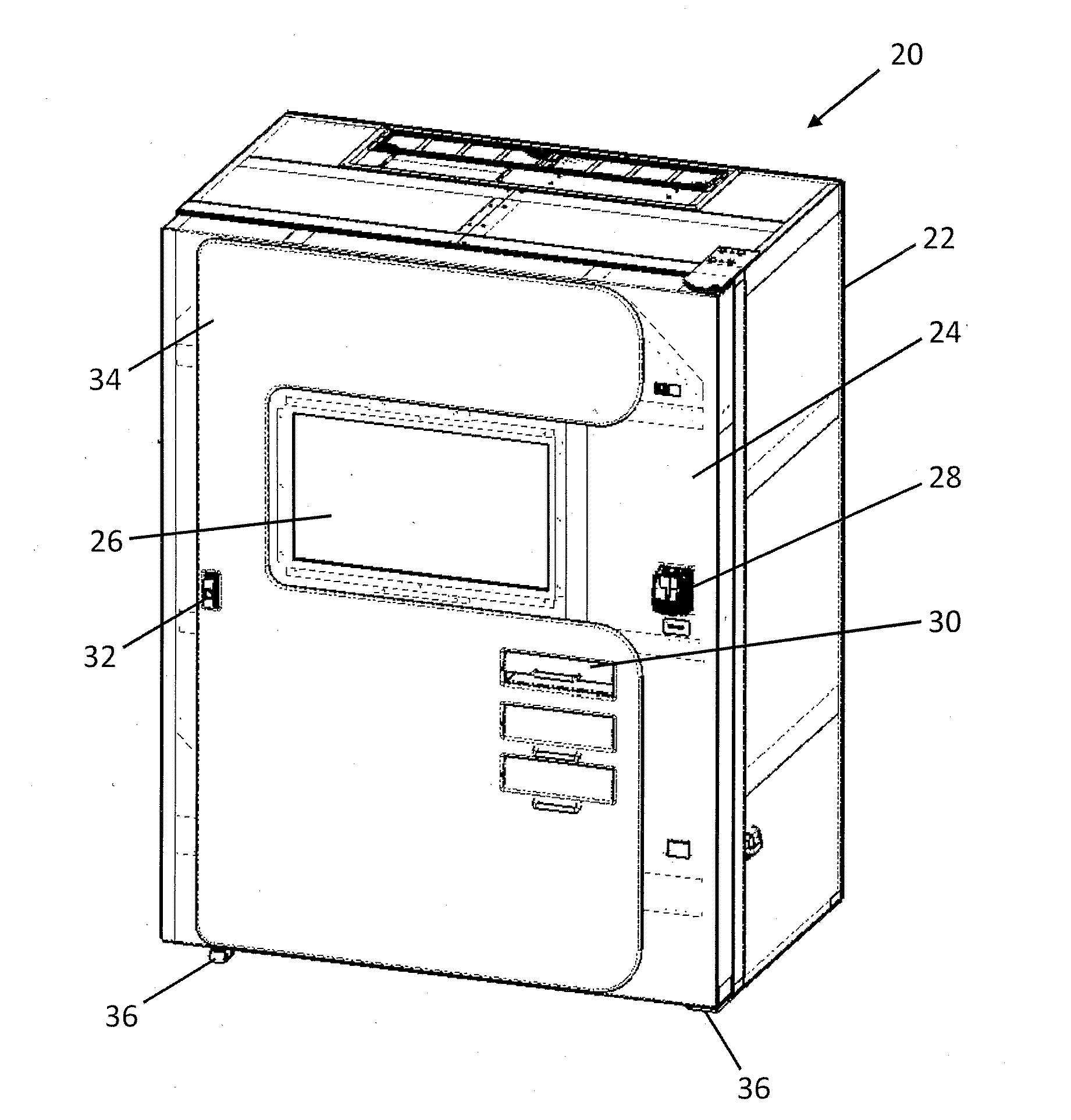

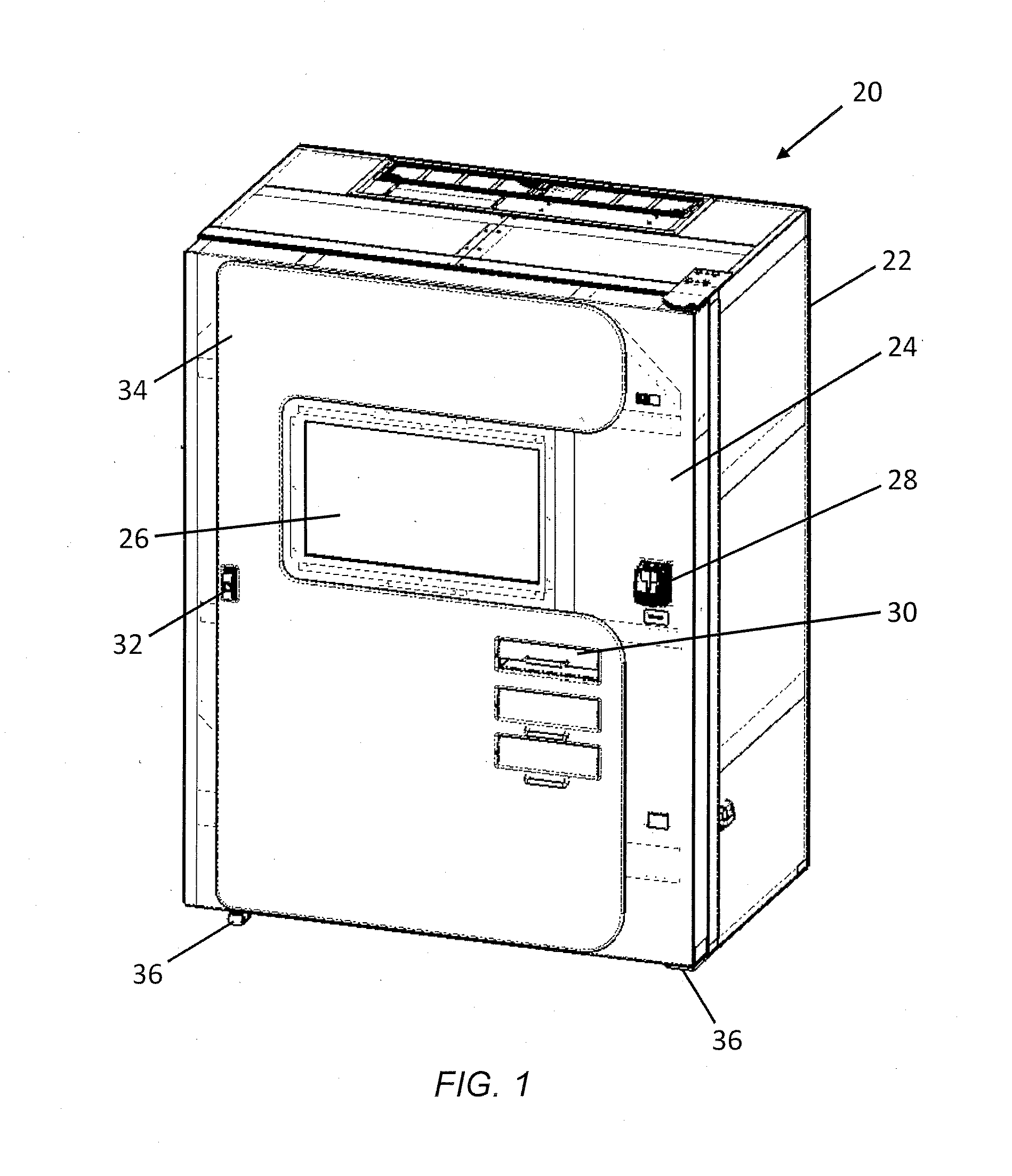

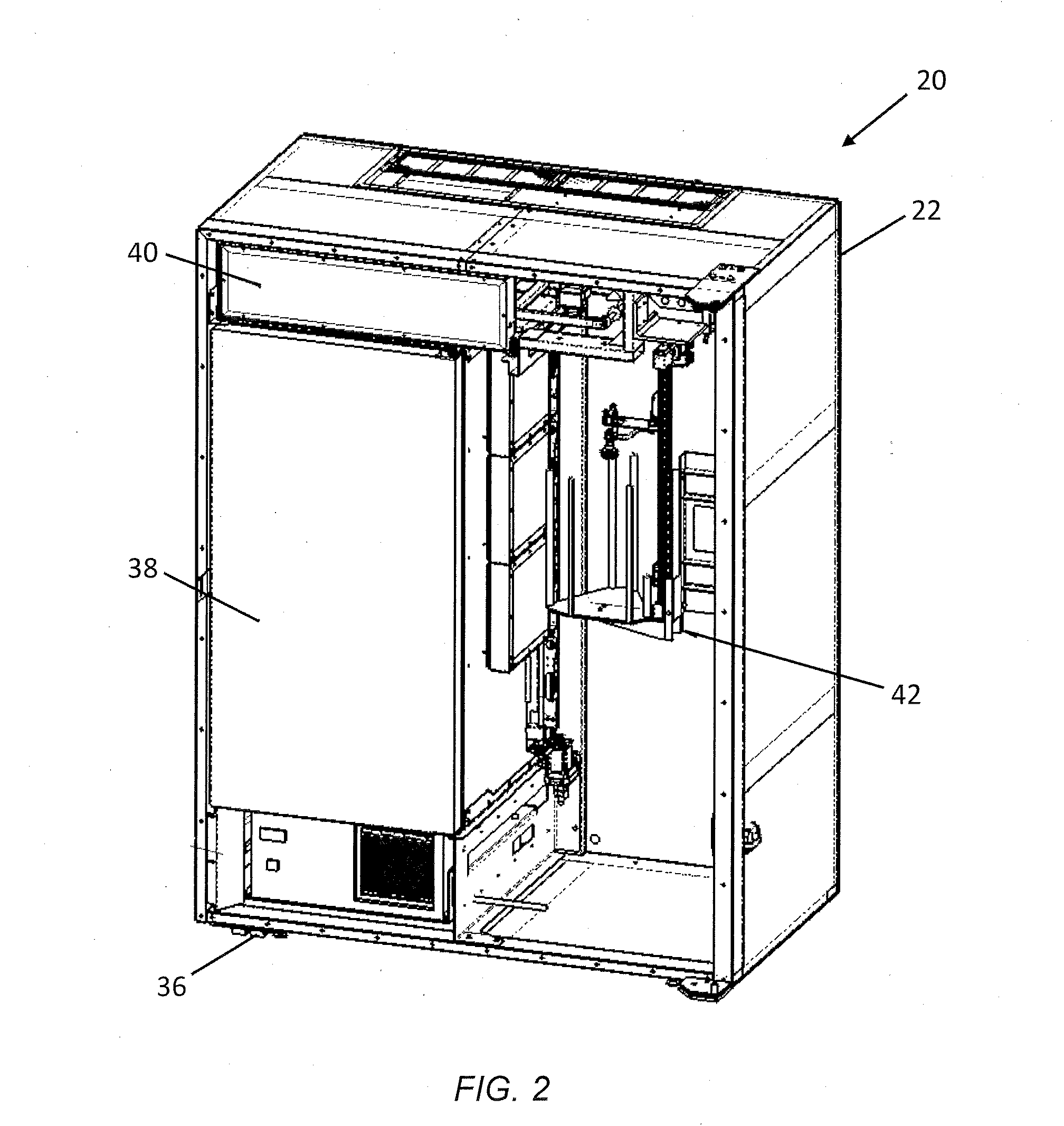

Food vending machine with sanitary food cartridge

A food cartridge assembly adapted for use in a vending machine including a base, a lockable cover, a plurality of food trays housed beneath the cover, and a door covering an opening through the cover for accessing unpackaged food items on the trays, wherein the food cartridge is adapted to be filled off-site with unpackaged food items and loaded into the vending machine without any intermediate food handling.

Owner:LEPRECHAUN CAPITAL INVESTMENTS II LLC

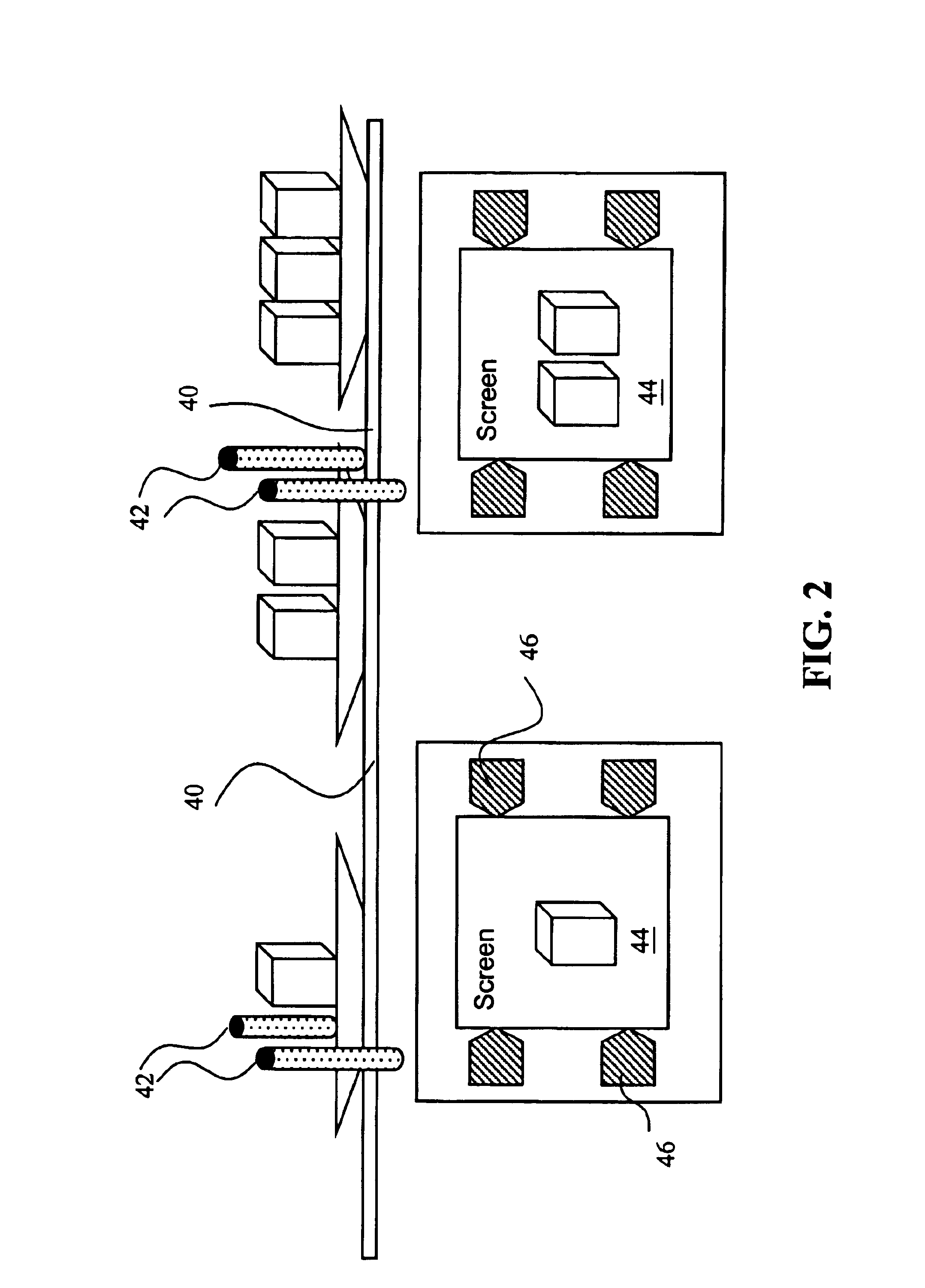

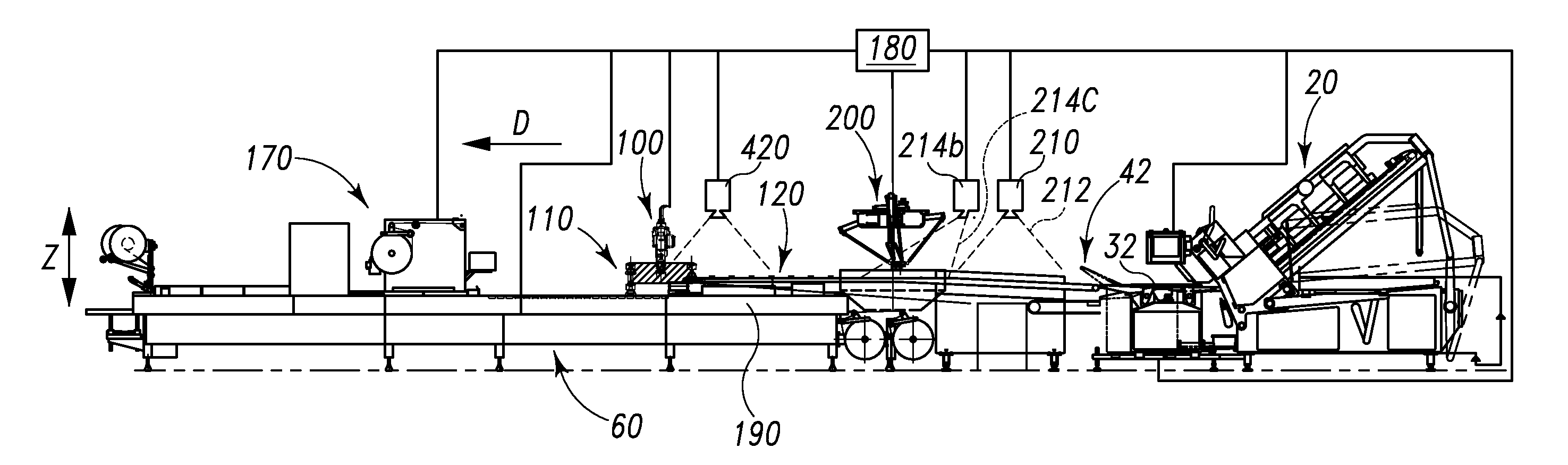

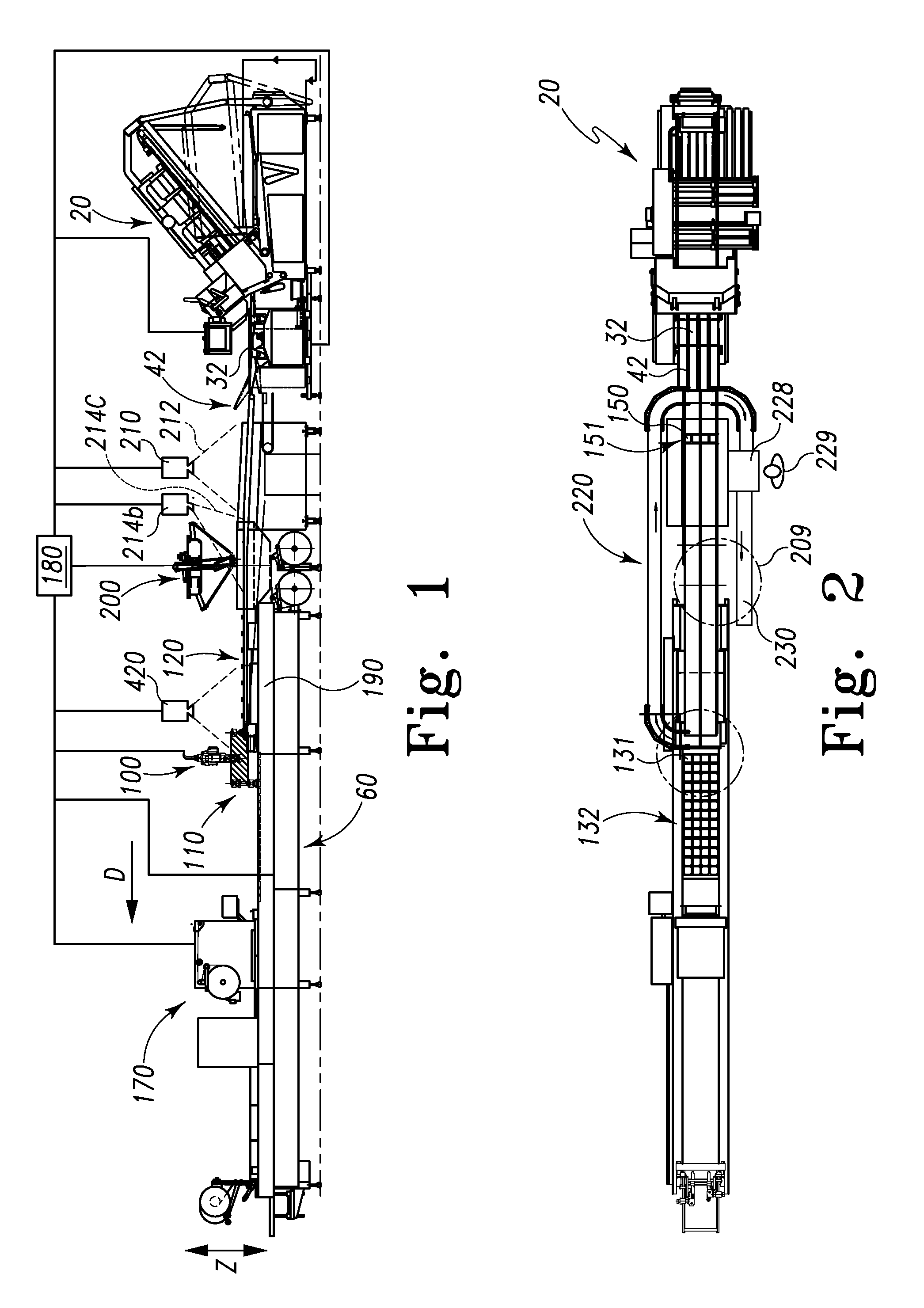

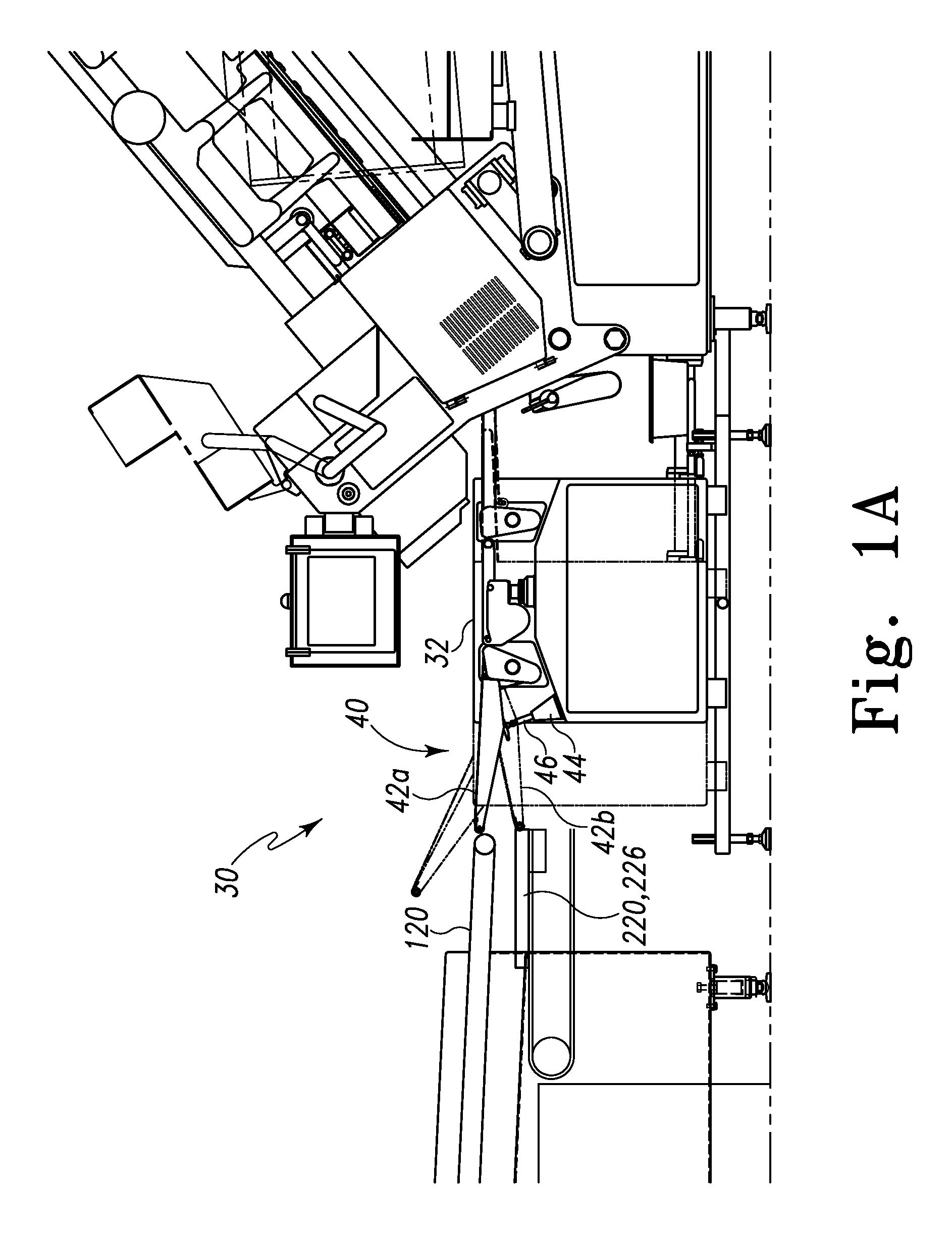

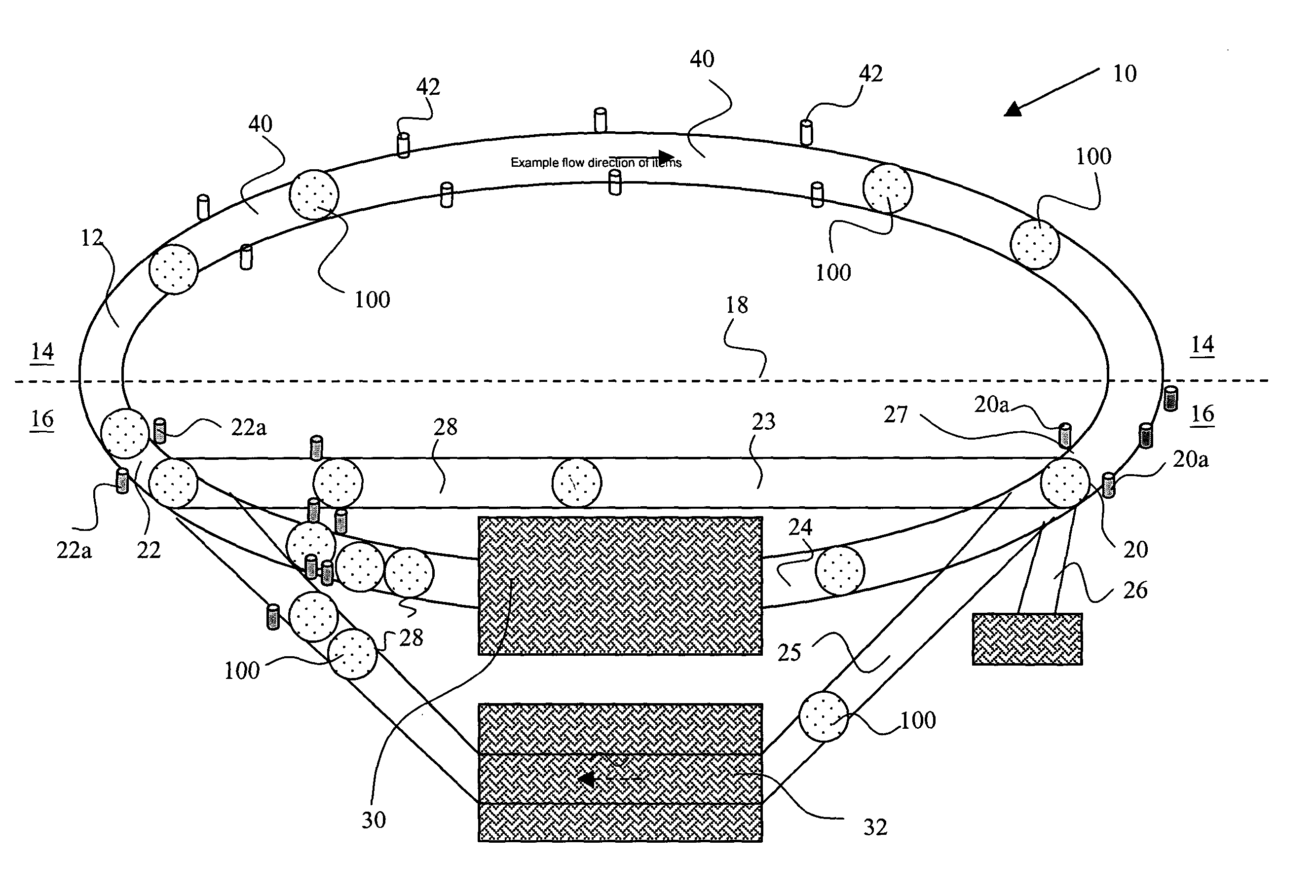

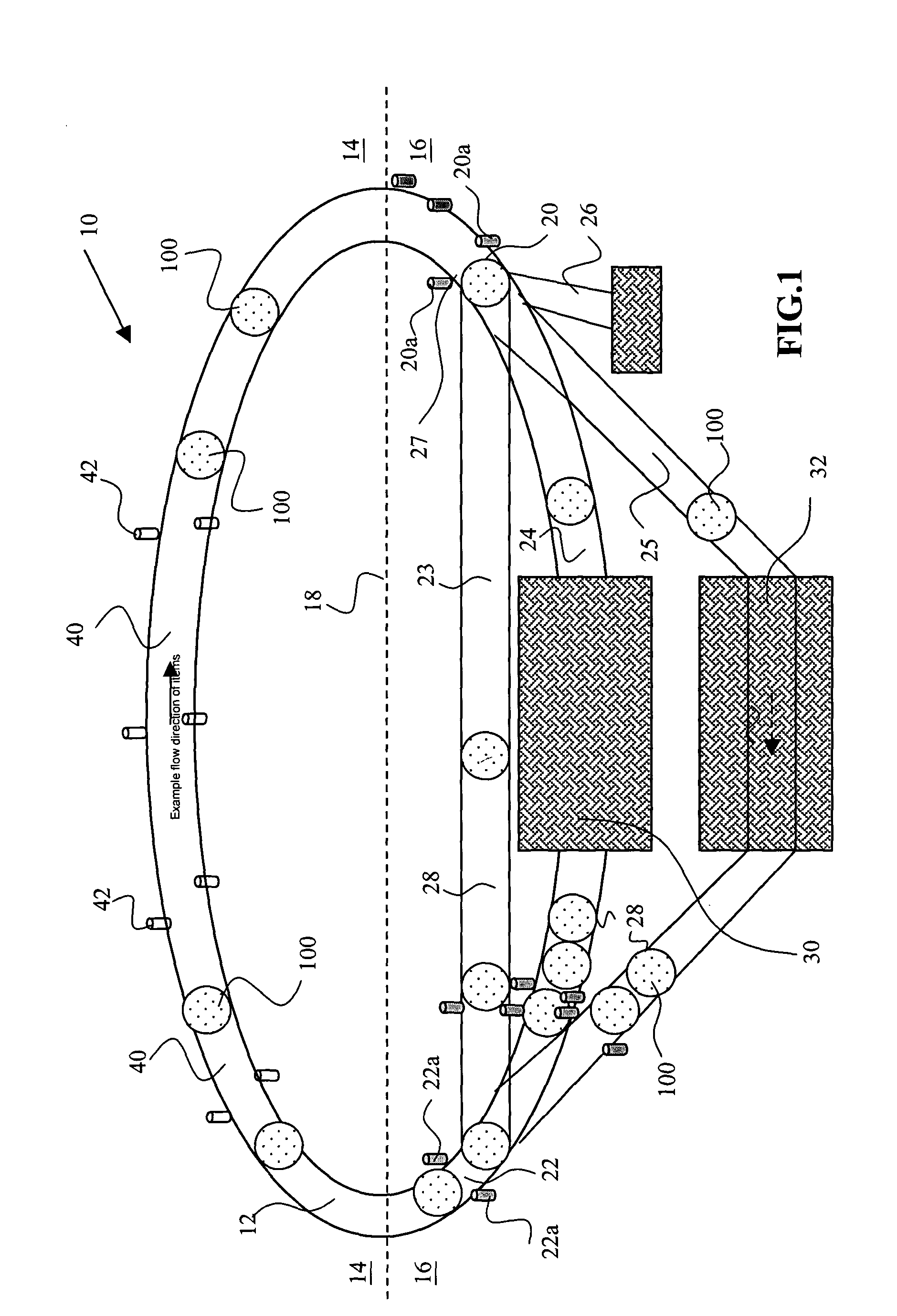

Food Product Vacancy Reduction System

A food handling system having a vacancy reduction system. The vacancy reduction system includes the main conveyor, a food product parking station, a vacancy detector, a robot, and a controller. The vacancy detector is configured to detect a vacant food product position on the main conveyor. The robot has a working range for moving between the parking station and the main conveyor. The controller is signal-connected to the vacancy detector. The controller is configured to receive a signal from the vacancy detector indicating a vacant food product position on the conveyor. The controller is signal-connected to the robot and has control instructions for instructing the robot to move the food product from the food product parking station to the vacant food product position on the main conveyor.

Owner:PROVISUR TECHNOLOGIES INC

Food processor

ActiveUS20130074706A1Good electrical contactEasy to cleanCocoaVessels with intergral heatingElectricityEngineering

Owner:HAMEUR & CIE

Rotisserie oven having a heat shield

InactiveUS20010009128A1Prevent slippingEasy to handleCooking-vessel lids/coversMeat processingGear driveReady to use

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The spit assembly may also be mounted at various distances from the heating element to decrease cooking times. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. The embodiment's design makes efficient use of valuable counter space by recessing back and raising off the countertop its controls. A contained light as well as room light emitted through the inclined glass door illuminate the enclosure's interior to make the rotisserie cooking into a taste tempting show. Two countertop supported sizes for the embodiment are suggested, one for larger families and entertaining, and the other for small families and singles. Cooking times are decreased and manufacture simplified by the embodiment heating element remaining on constantly during the cooking process. Maintenance is minimized by various embodiment parts being removable for cleaning including a cleaning shield located behind the heating element, the glass door, and a drip pan with slotted cover. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:RONCO HLDG +1

Food processor with high-efficiency defoaming device

The invention relates to a food processor with a high-efficiency defoaming device. A food processor main body comprises a grinding cutter, a motor, a grinding cutter shaft and a barrel body, and the high-efficiency defoaming device is arranged on the food processor; the high-efficiency defoaming device comprises a defoamer main body; the defoamer main body is provided with a foam inlet, an air outlet and a liquid outlet; and at least one of the top of the foam inlet of the defoamer main body, the top of the air outlet, the top of the liquid outlet and the top of the defoamer main body is positioned at 5mm-800mm above the liquid level of foodstuff. According to the food processor, under the situations of heating at any temperature and any heating power and intensely grinding, foams generated when the foodstuff is ground, heated and cooked are rapidly and actively broken, so that grinding or heating cooking operation is continuously and rapidly carried out without intermittent stop, therefore the grinding or cooking time is greatly shortened, and the working efficiency is improved.

Owner:王晓东

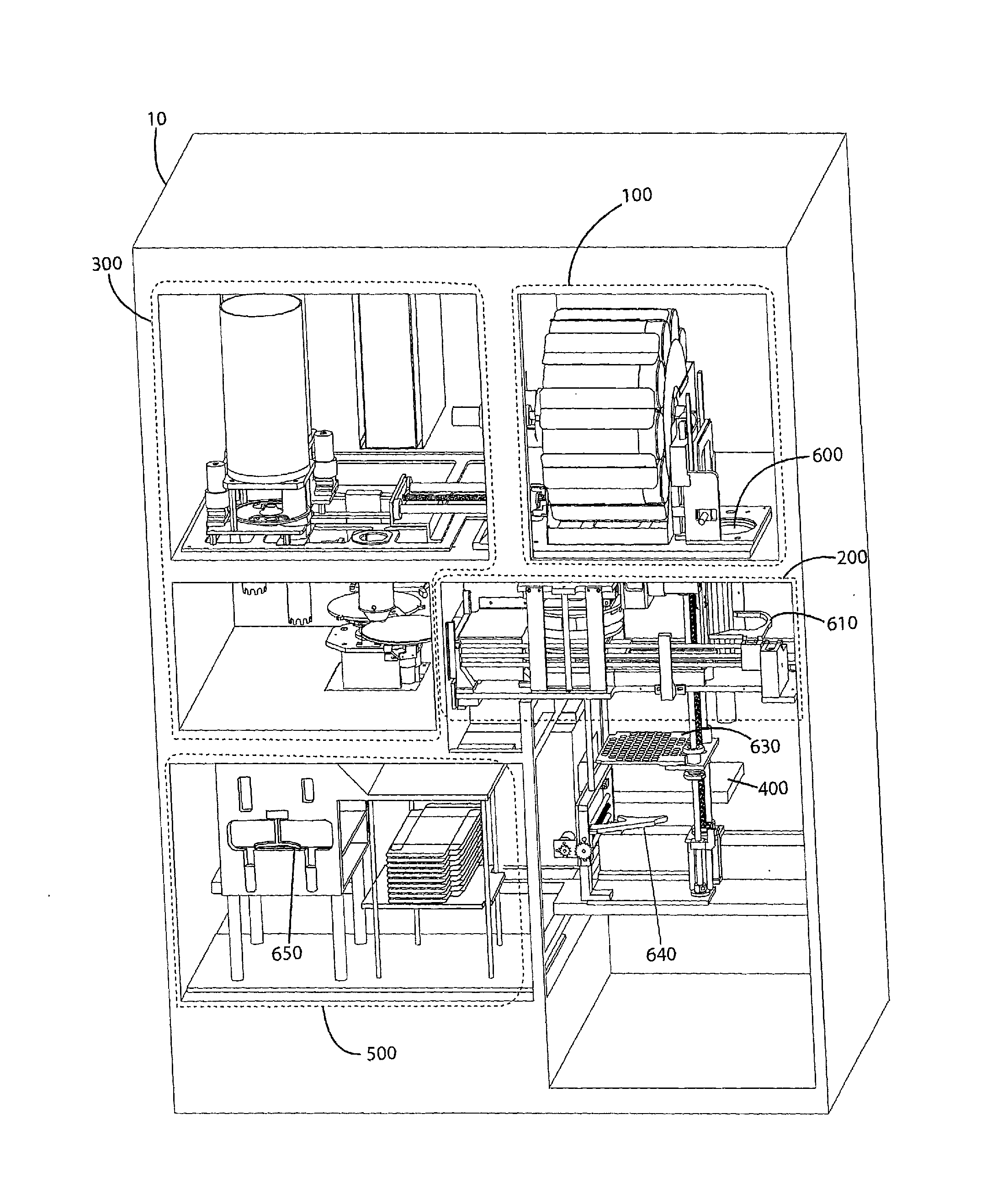

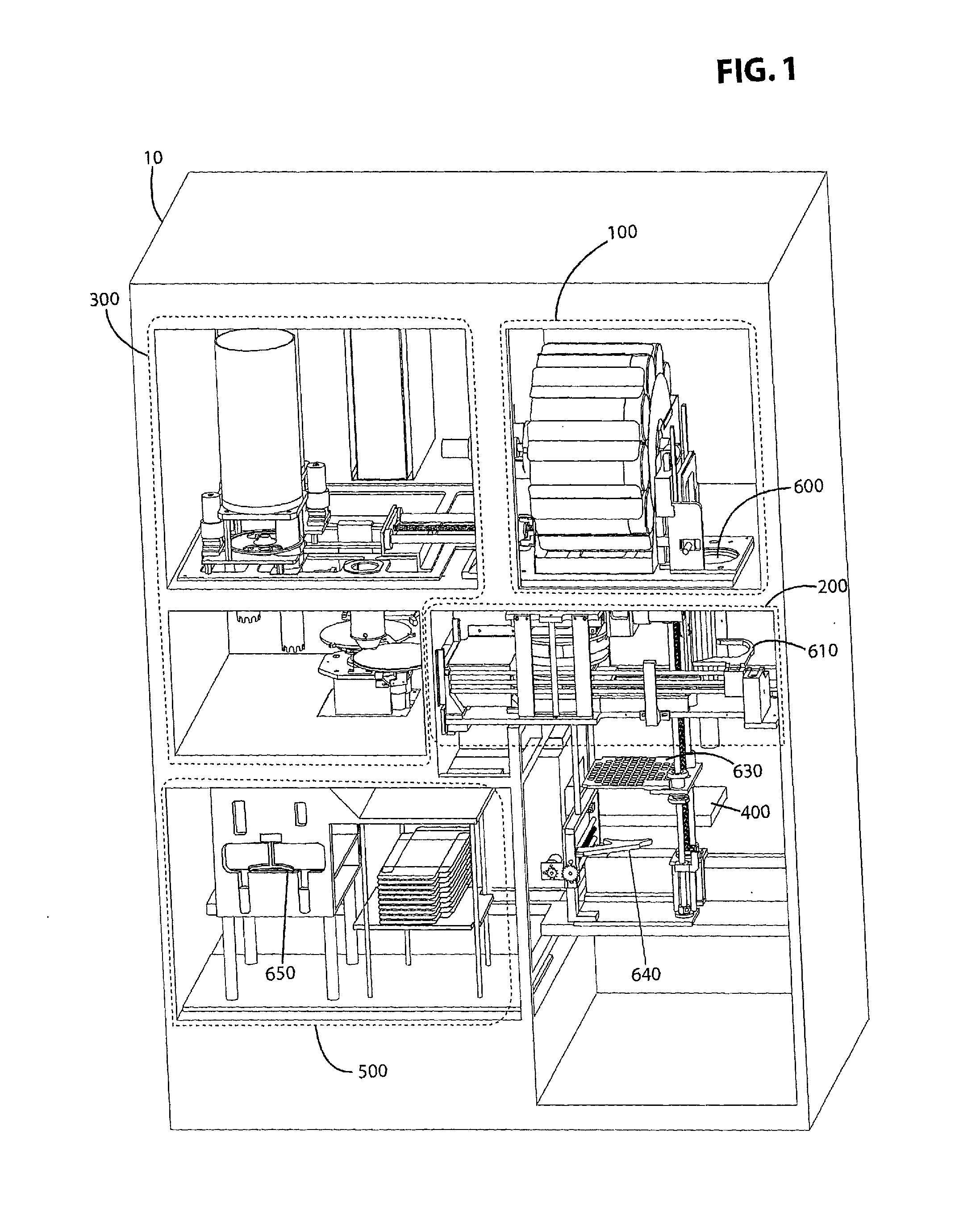

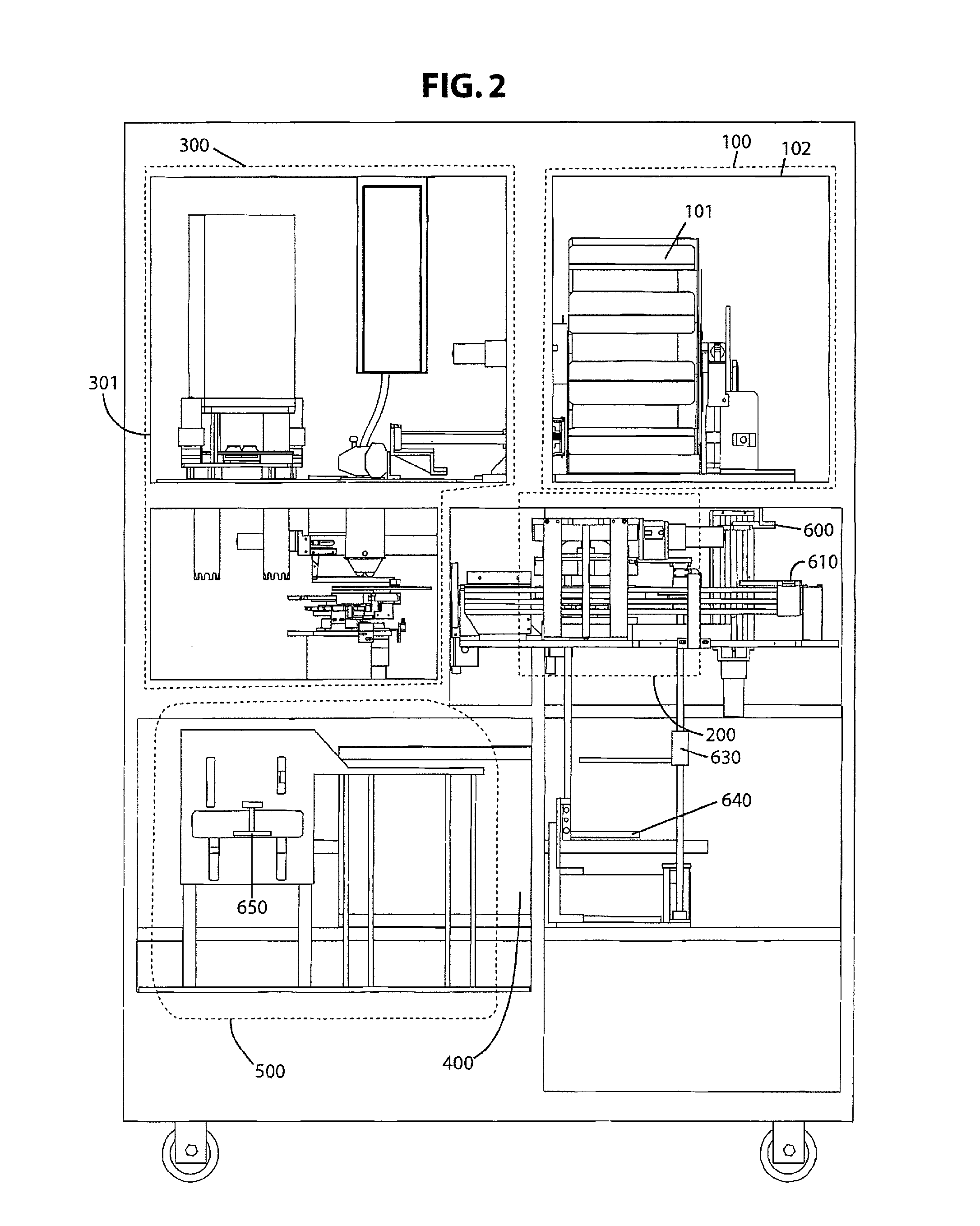

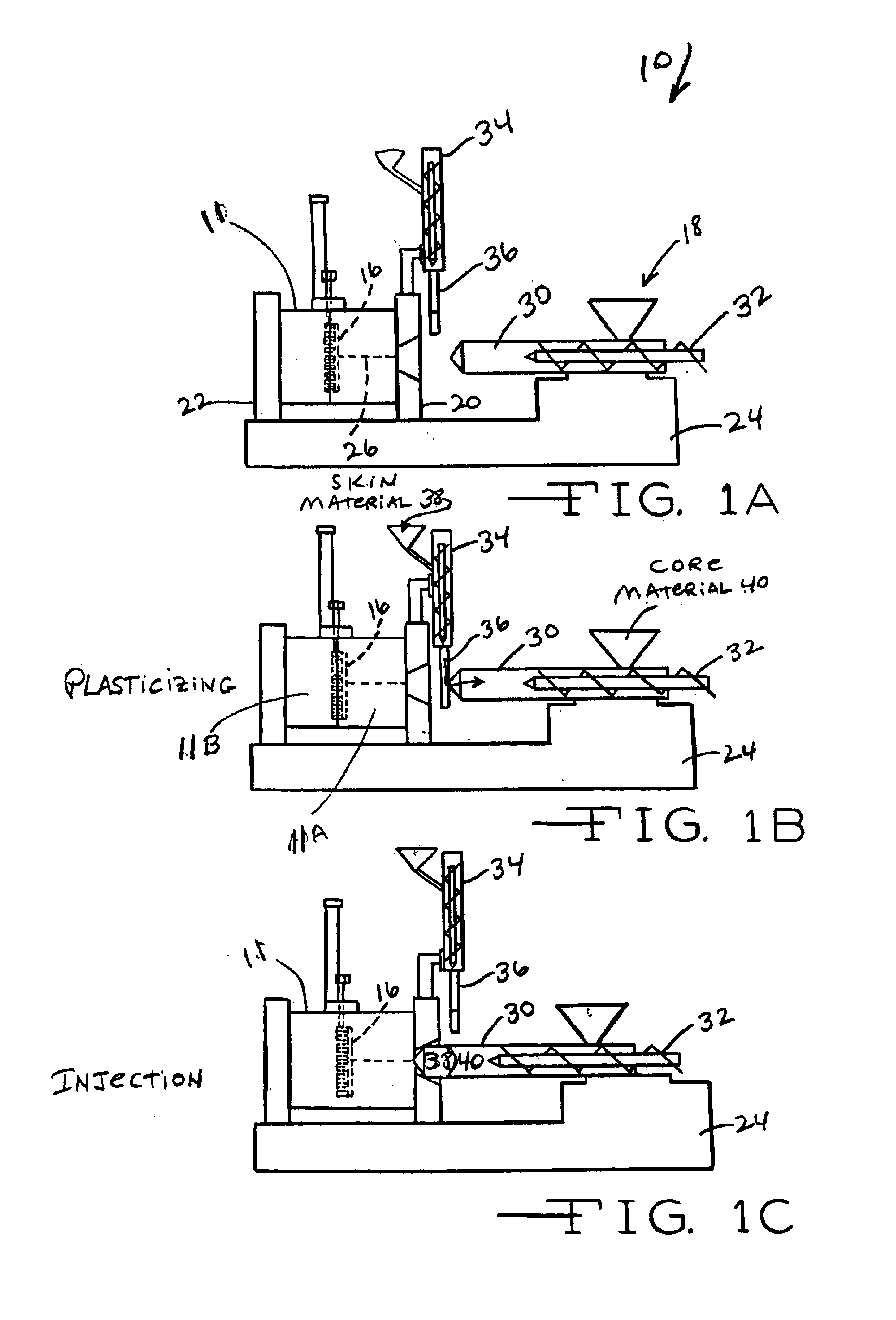

Automated pizza preparation and vending system

An apparatus and method for preparing and cooking pizza using fresh ingredients, the apparatus being in the form of a vending type of machine. By way of a keypad, touchpad, display or other user interface provided on the machine, a user specifies the type of pizza that they want. The machine then proceeds to combine the ingredients needed to create the requested pizza, cooks the pizza, as appropriate, places it in a box, and dispenses the boxed pizza to the user or customer. The dough may be provided in the form of sealed canisters or tubes, which are opened in an automated fashion. Slices of dough may be cut from the dough canisters for each pizza which is to be made. Sauce may be provided in the form of sealed tubes, bags, or containers, whereby a controlled amount of the sauce may be dispensed by way of a controlled dispensing system, such as a pump or similar mechanism. Finally, the cheese may be provided in a bag or other container, whereby a measured amount of cheese may be dispensed and provided on each pizza as it is prepared. The pizza preparation machine may also include a refrigerated section for maintaining ingredients which need to be refrigerated at an appropriate temperature in order to maintain the freshness of such ingredients, as well as to maintain a proper sanitary and food handling environment. The pizza preparation machine may also include an oven section where the pizza is cooked. Additionally, the pizza preparation machine may also include a box formation section where a box may be formed for the pizza to be placed inside the box.

Owner:K & G ENTERPRISES

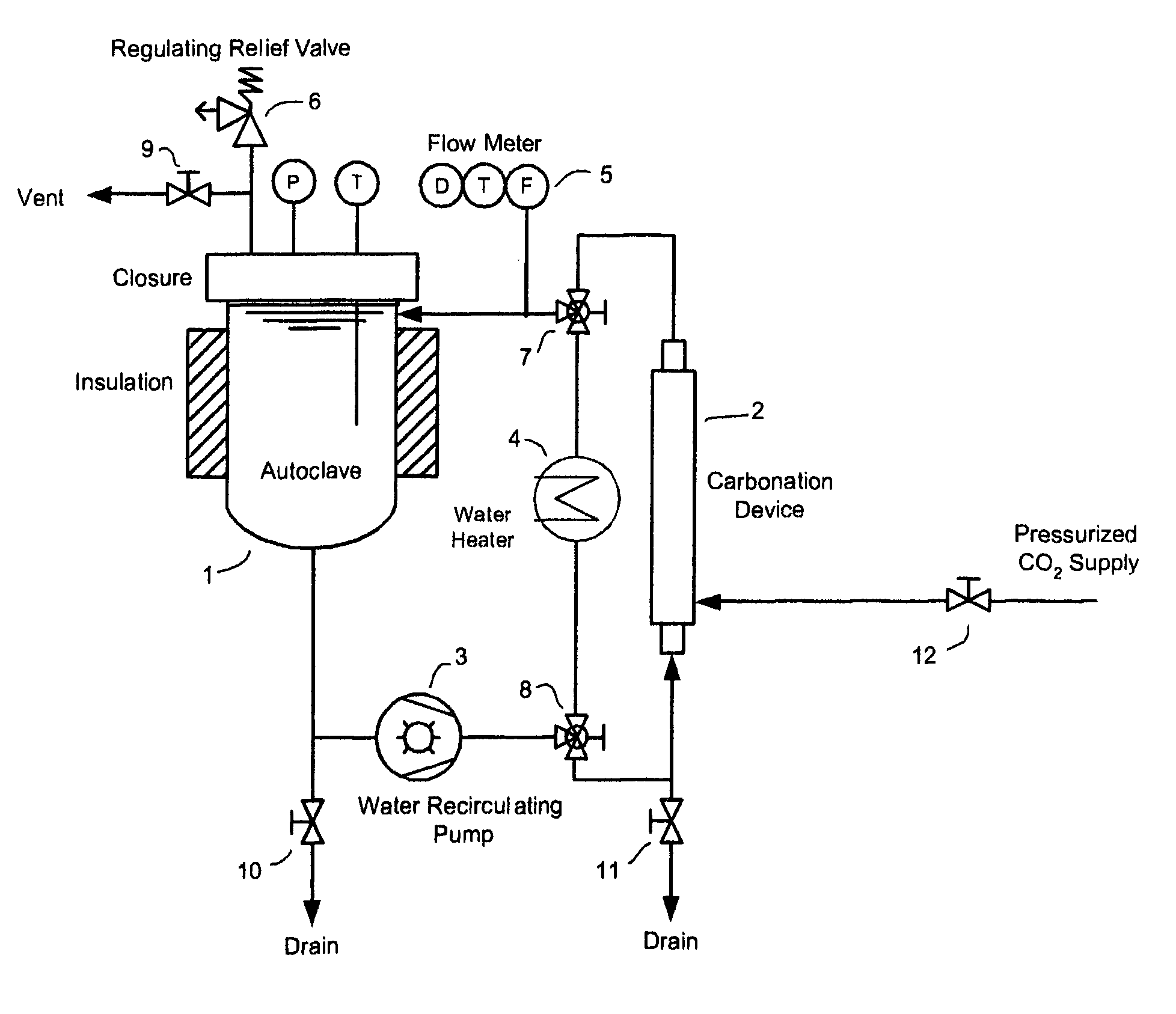

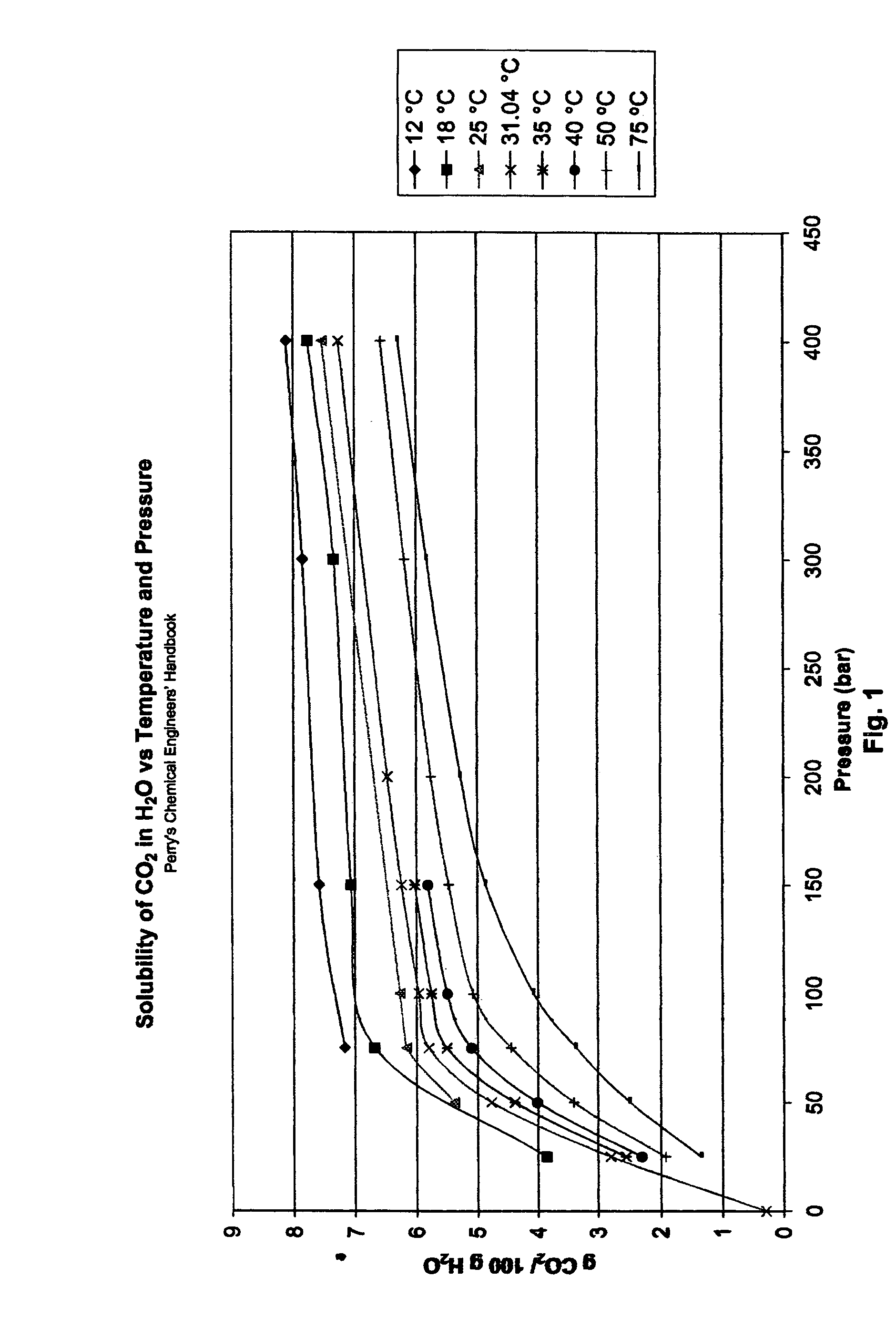

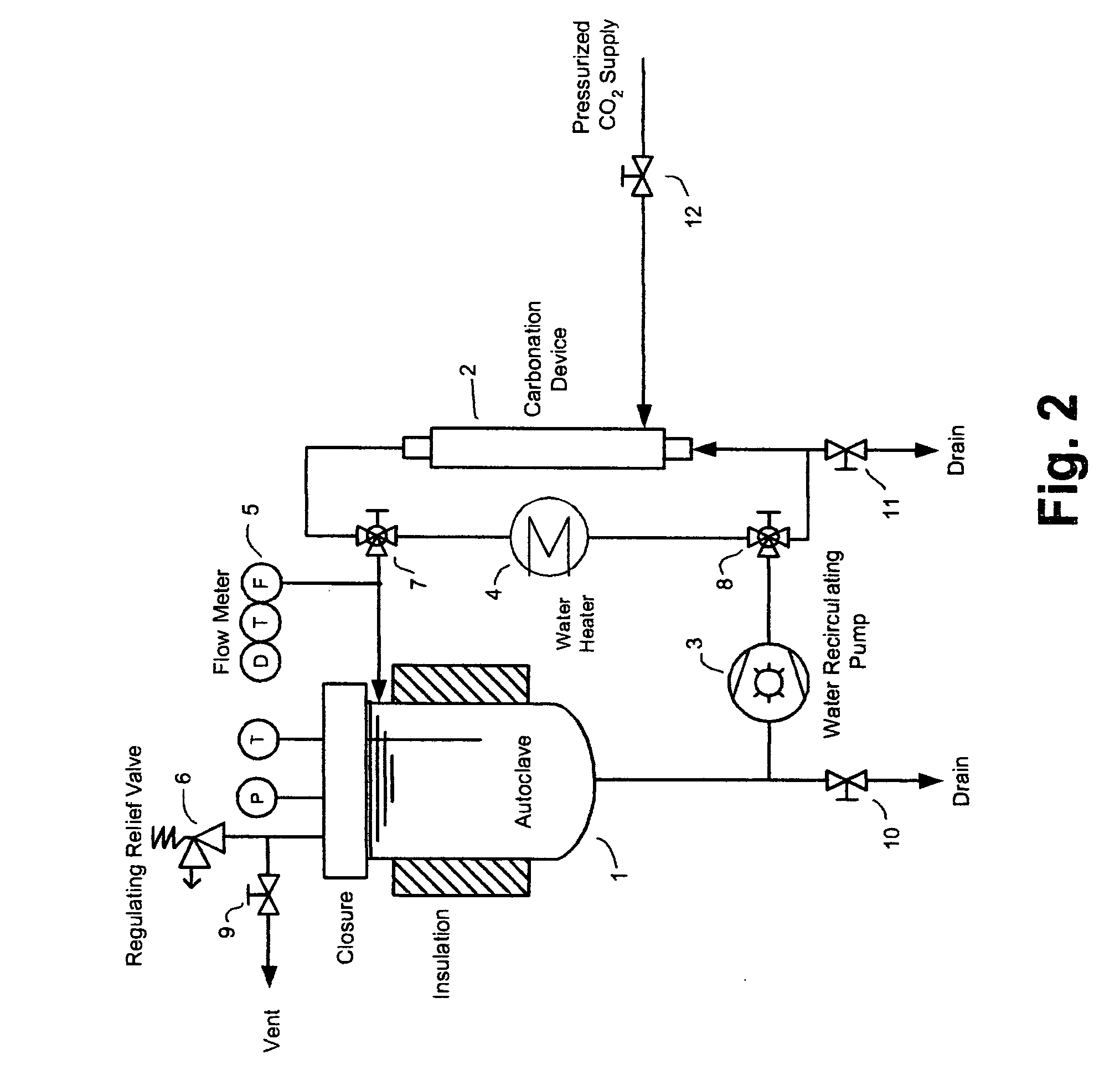

Method for sterilizing articles using carbonated water

A method of sterilizing, disinfecting and / or sanitizing articles such as medical instruments, medical implants, food handling or processing devices, devices used in space exploration, or any other article in which sterility or biological passivity is required. In general terms, the method comprises placing the article in a pressure chamber, filling the chamber with water so as to cause the article to be submerged, sealing the chamber, mixing carbon dioxide in the water, maintaining a greater than atmosphere pressure in the chamber, and controlling the temperature of the water with dissolved carbon dioxide therein.

Owner:SIMS MARC

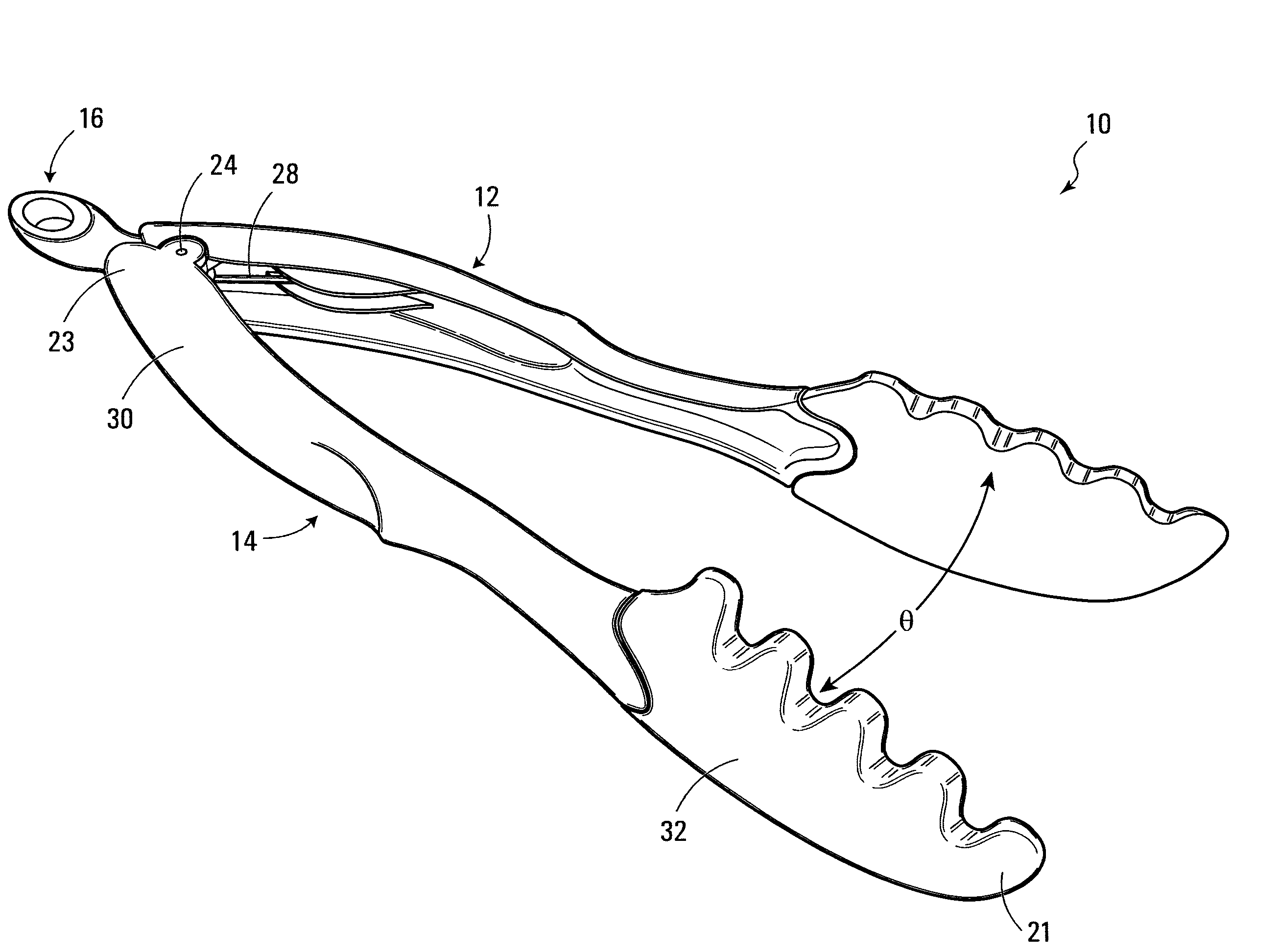

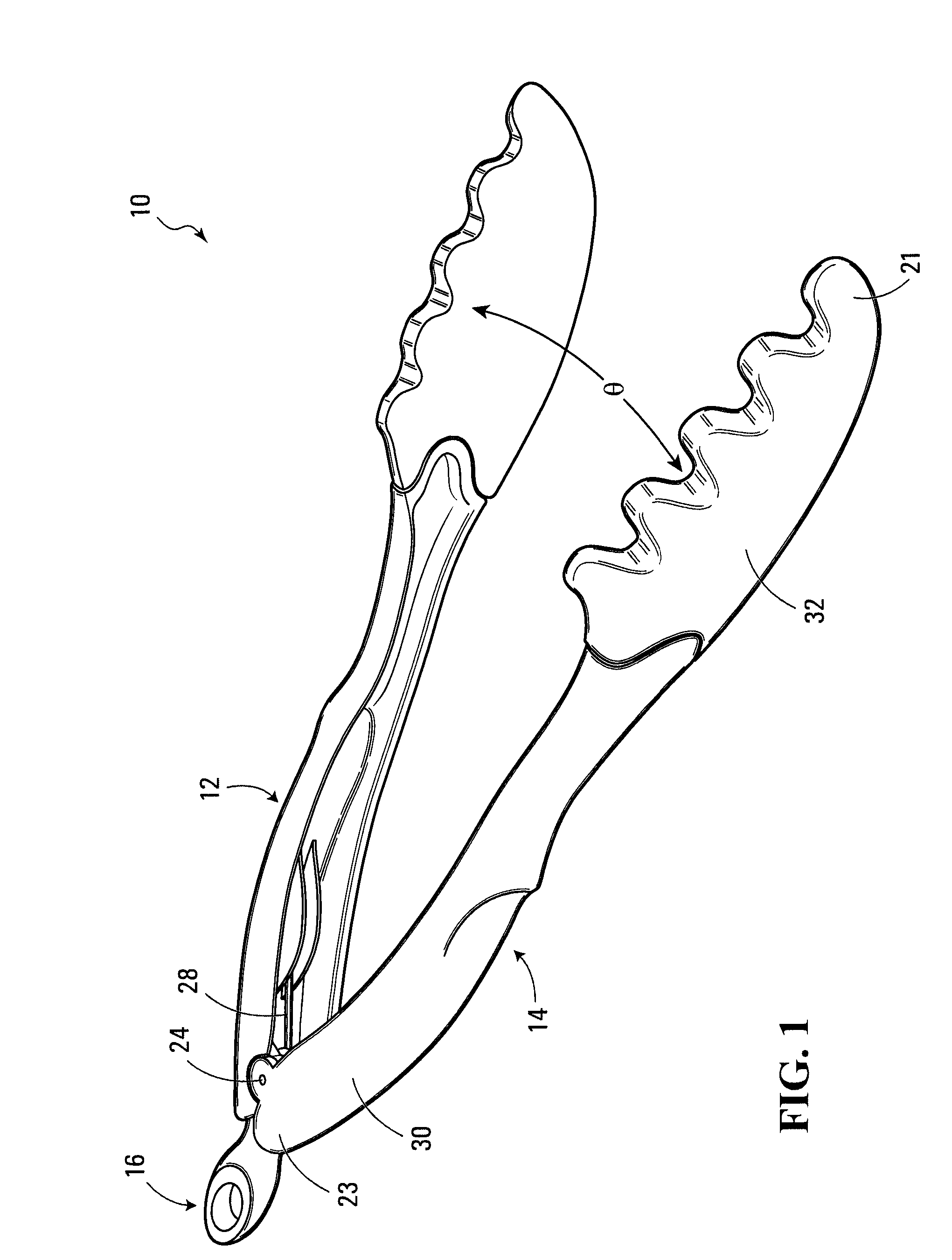

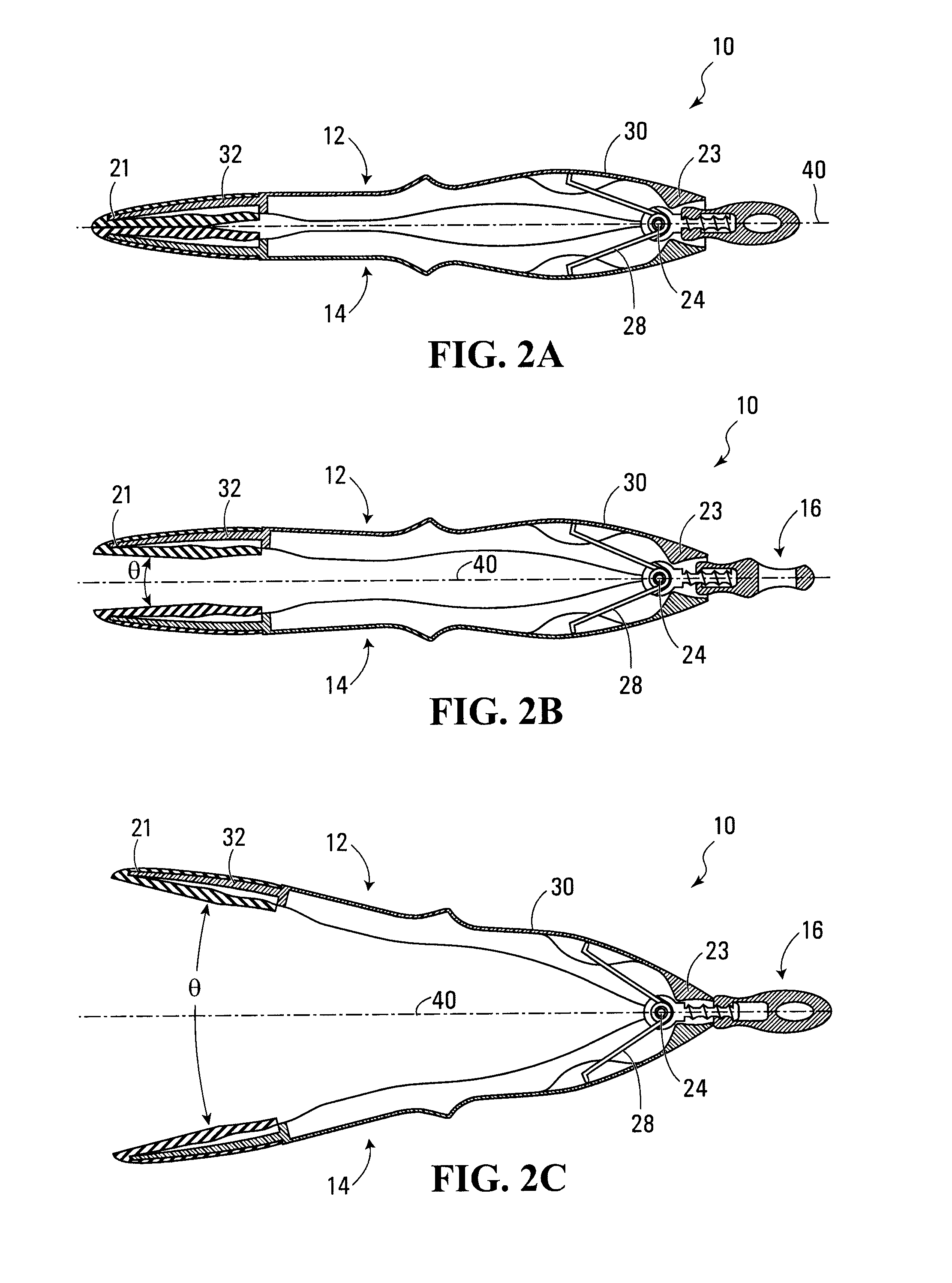

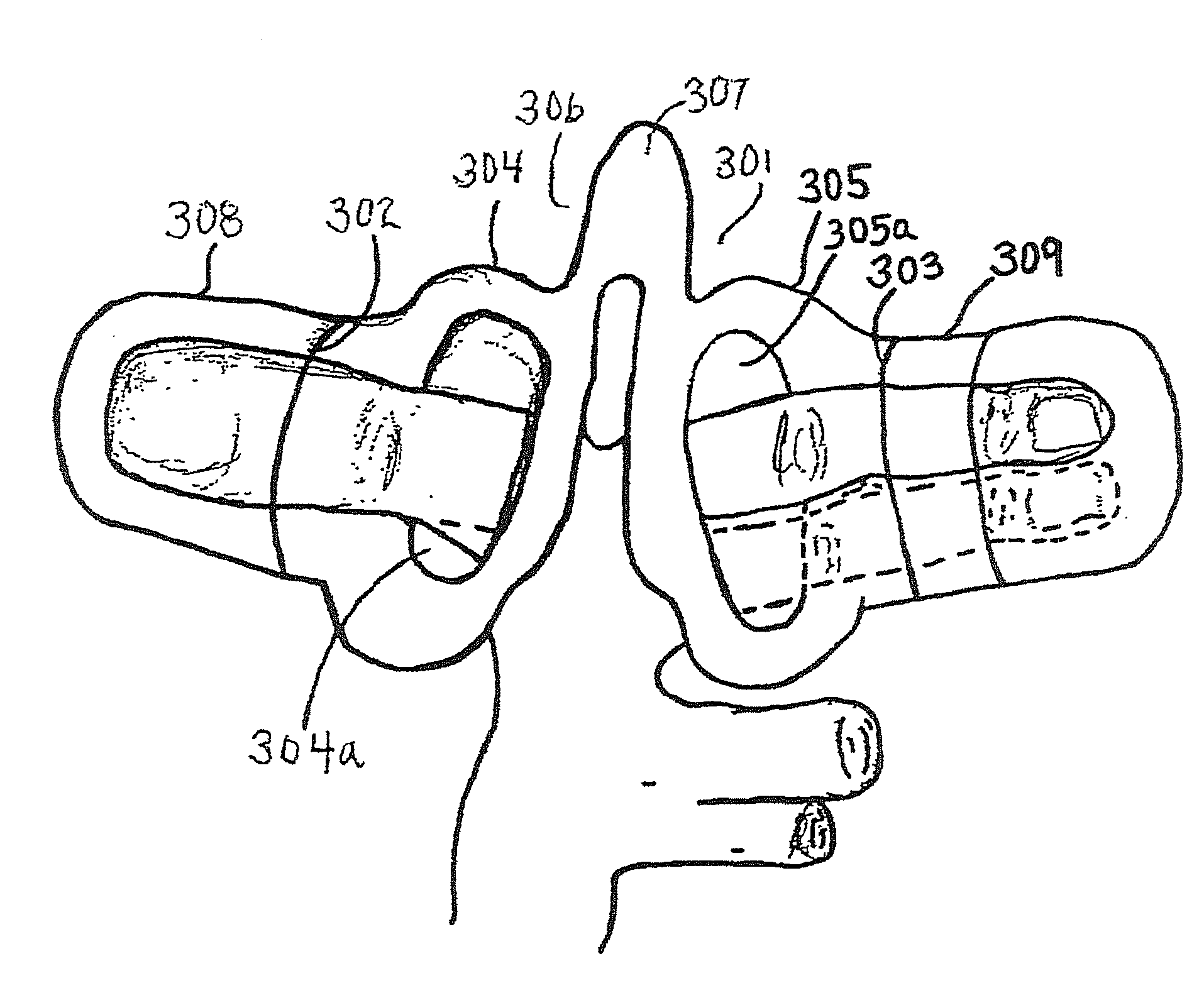

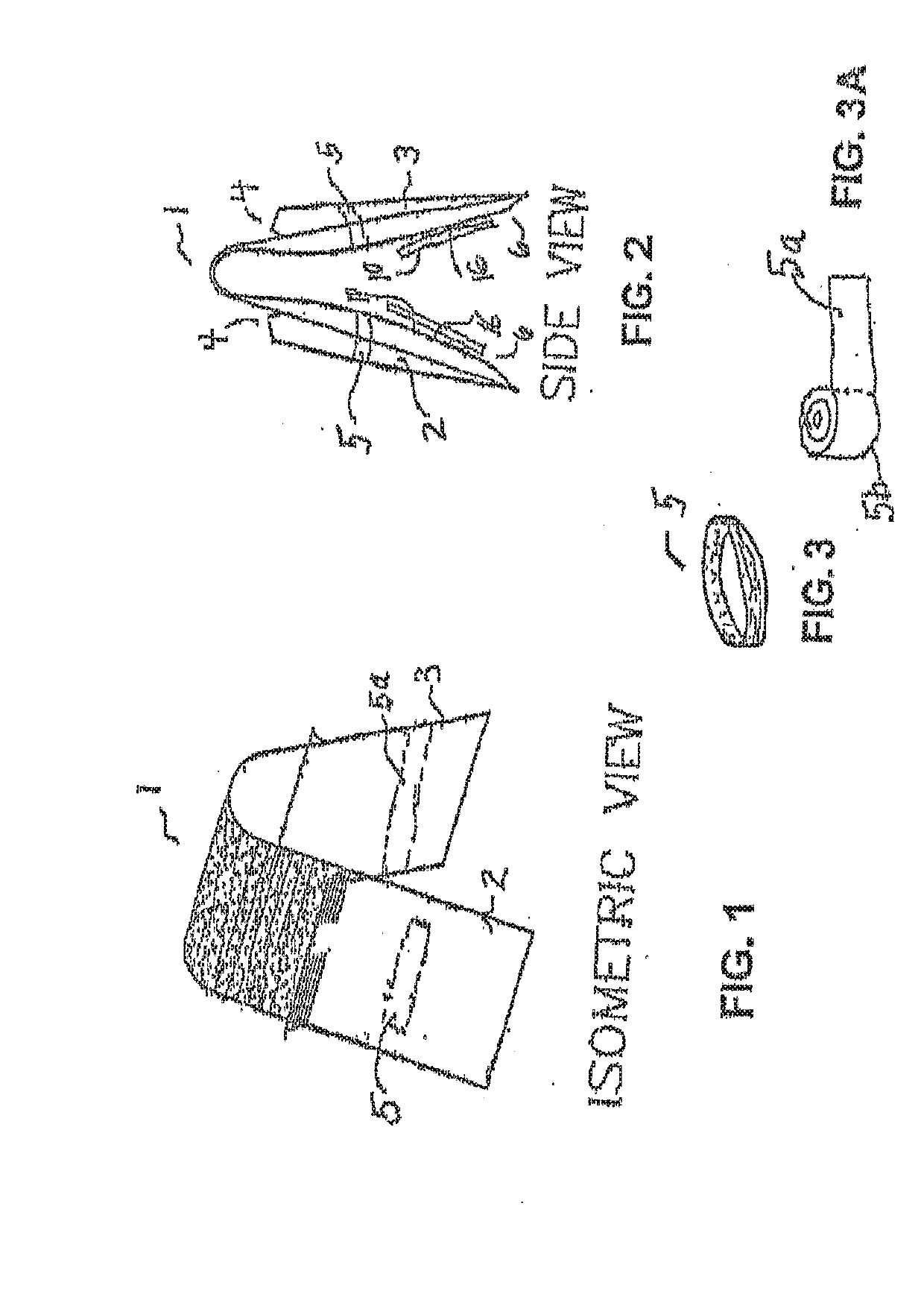

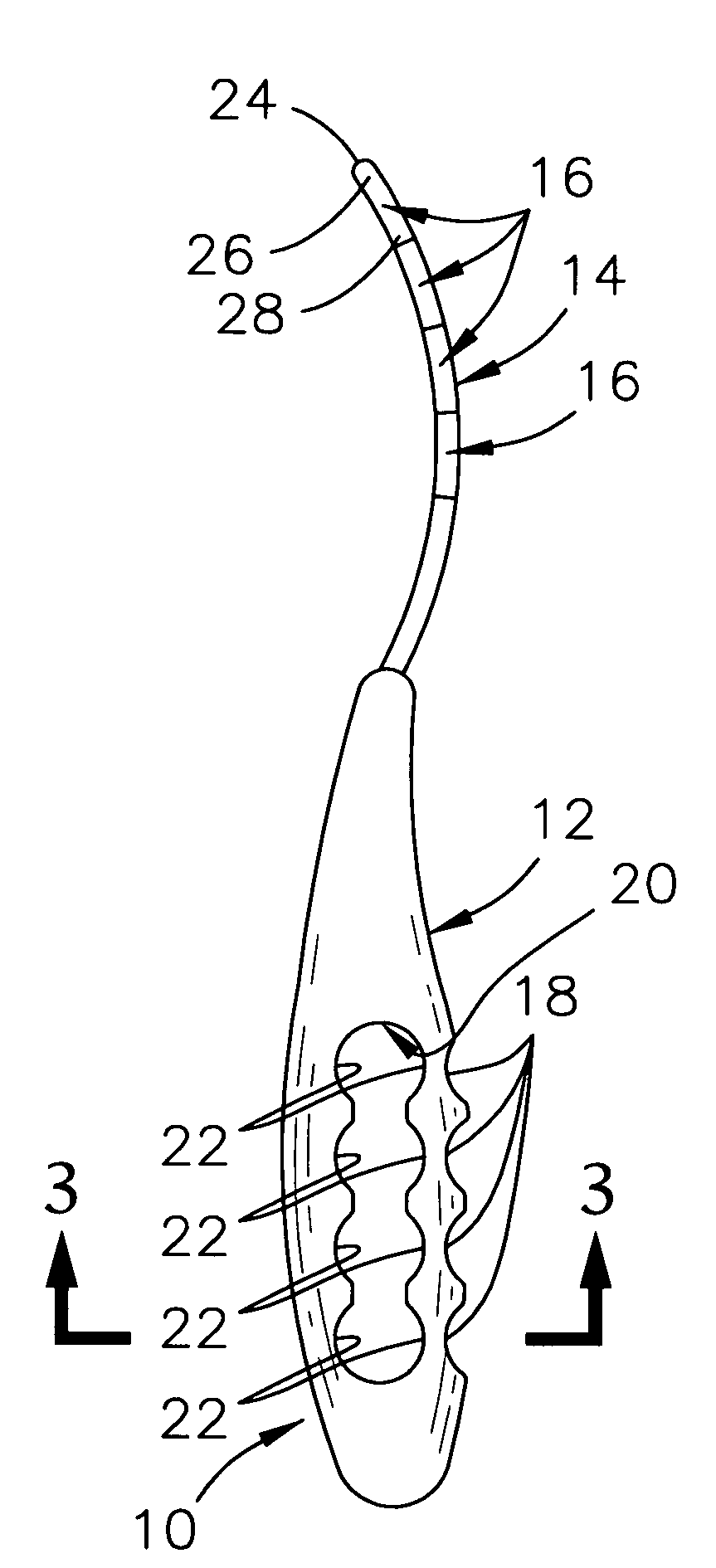

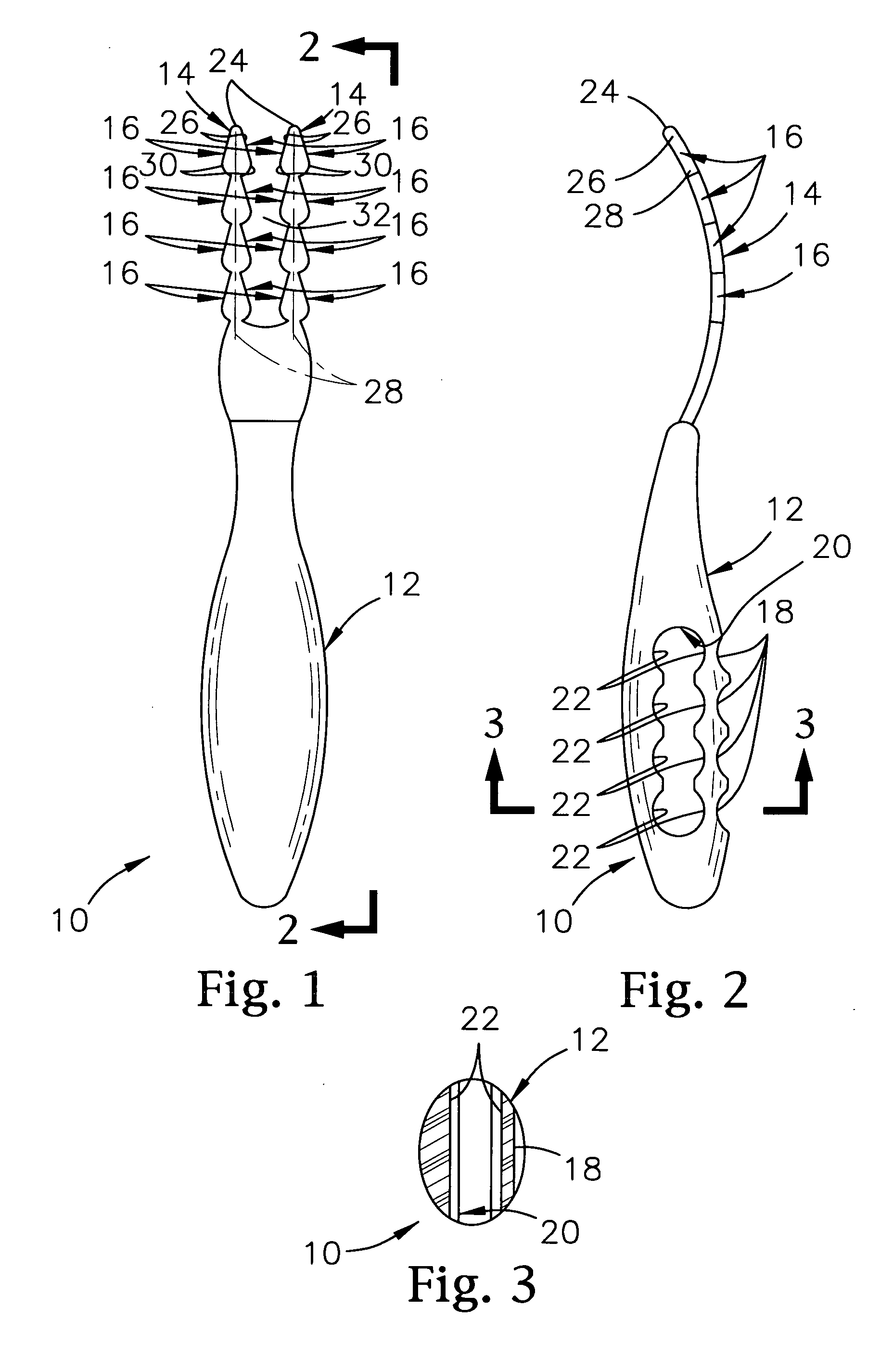

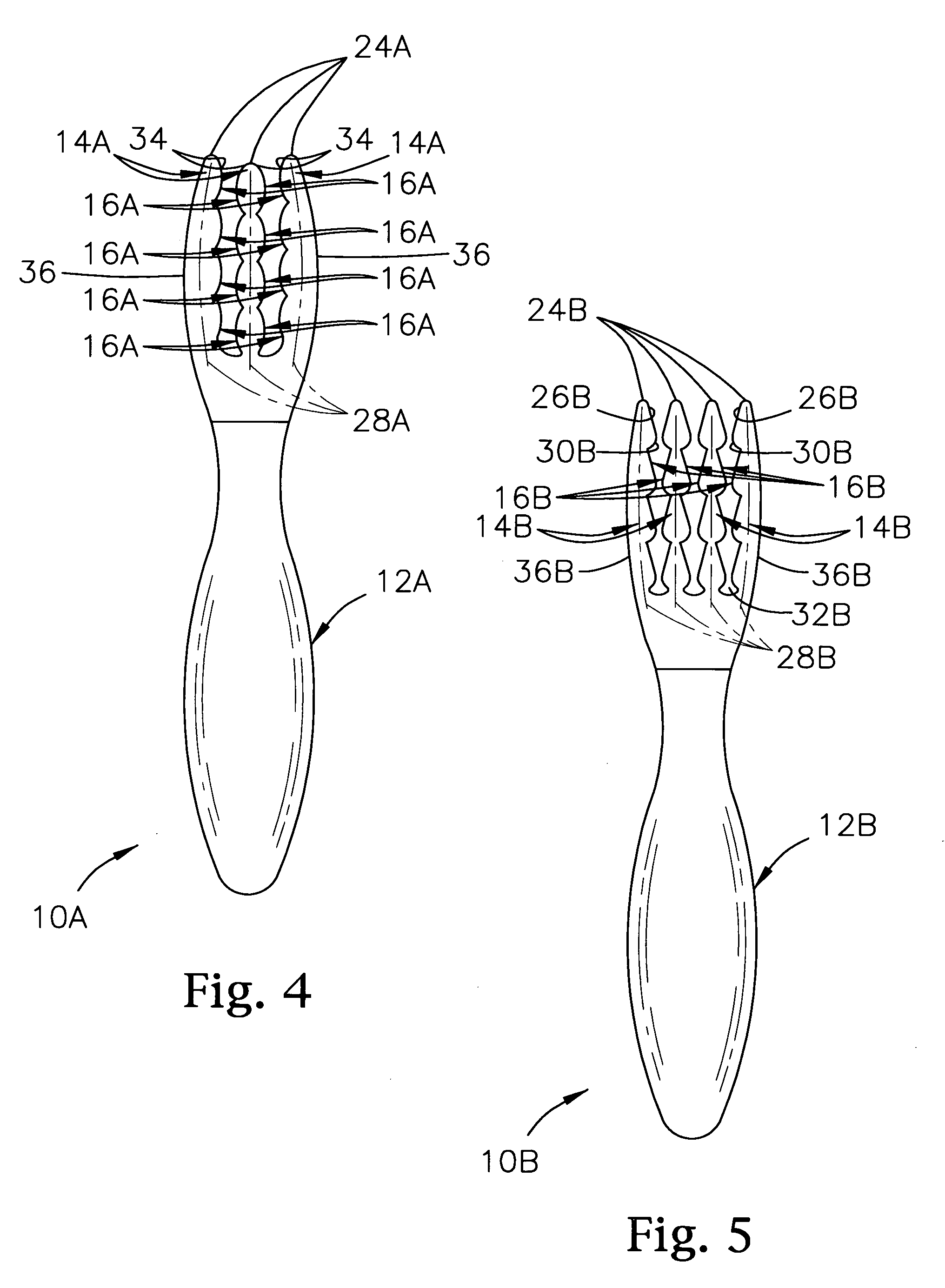

Tongs for Handling Food

InactiveUS20080179903A1Decrease opening angleIncrease opening anglePliersKitchen equipmentHandling foodActuator

Tongs for handling food. The tongs comprise a pair of tong members pivotally connected together and biased away from each other to define an opening angle therebetween. The tongs also comprise an adjustment mechanism for adjusting the opening angle to a desired opening angle in a range of opening angles. The adjustment mechanism may comprise a manually operable actuator rotatable about a longitudinal axis of the tongs for adjusting the opening angle to a desired opening angle in the range of opening angles. Each of the tong members comprises a handle portion and a food-handling portion. The food-handling portion of each of the tong members may have a removable element.

Owner:TRUDEAU 1889

Apparatus, method and system for food management and food inventory

InactiveUS20050051528A1Prevent drying outAvoid unnecessary workAutomatic control devicesFurnace typesEngineeringFood handling

An automated food handling system for food servings comprising a transfer means for transporting food servings therealong; a plurality of treatment modules coupled in parallel to the transfer means; means for sensing and recognizing the type of food servings being transported on the transfer means; and means for automatically diverting the food serving from the transfer means into one of the treatment modules. The treatment modules may be machines that bring the food servings to the desired temperature. An inventory system is also provided.

Owner:NATURE FOOD HLDG

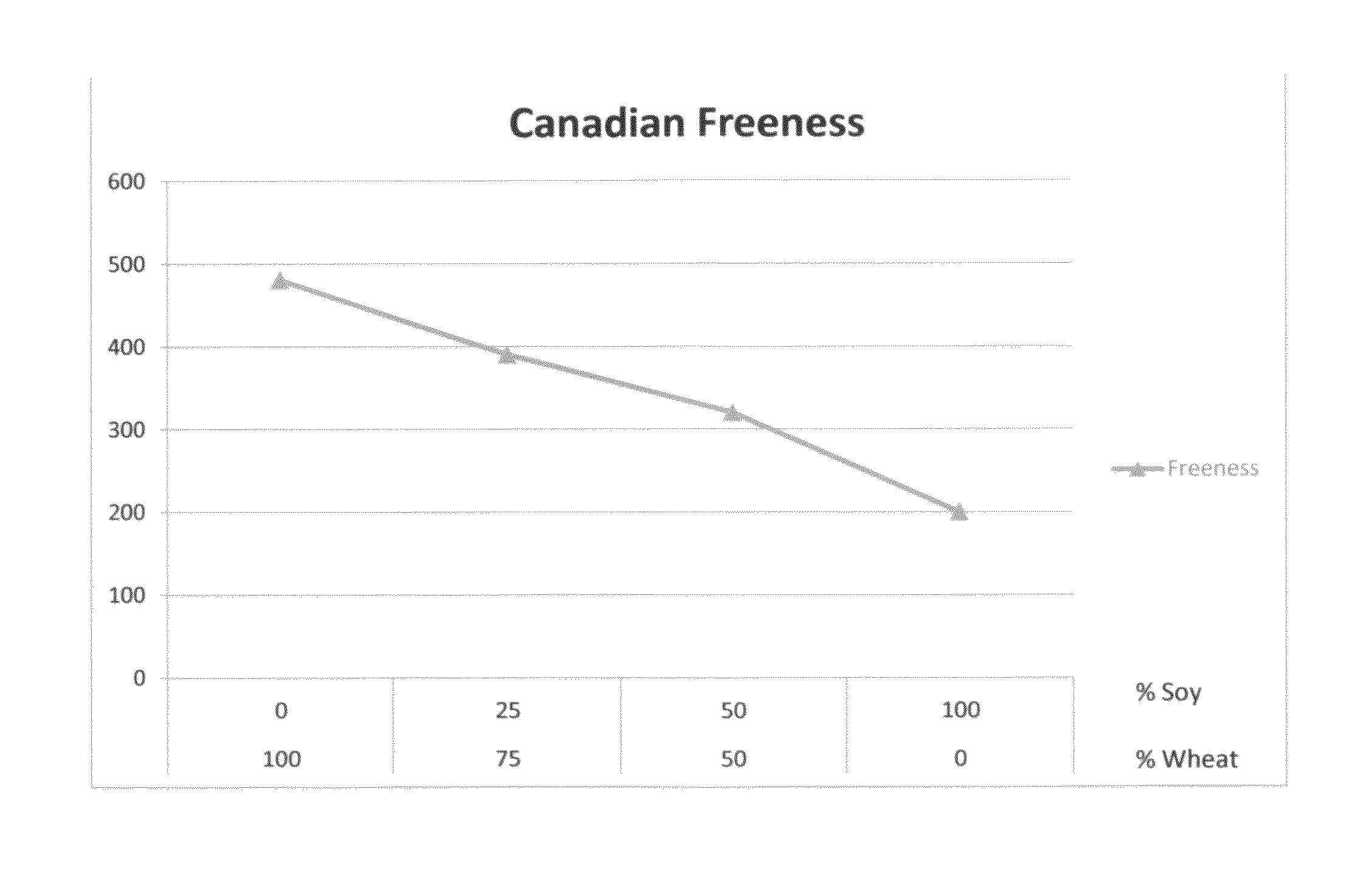

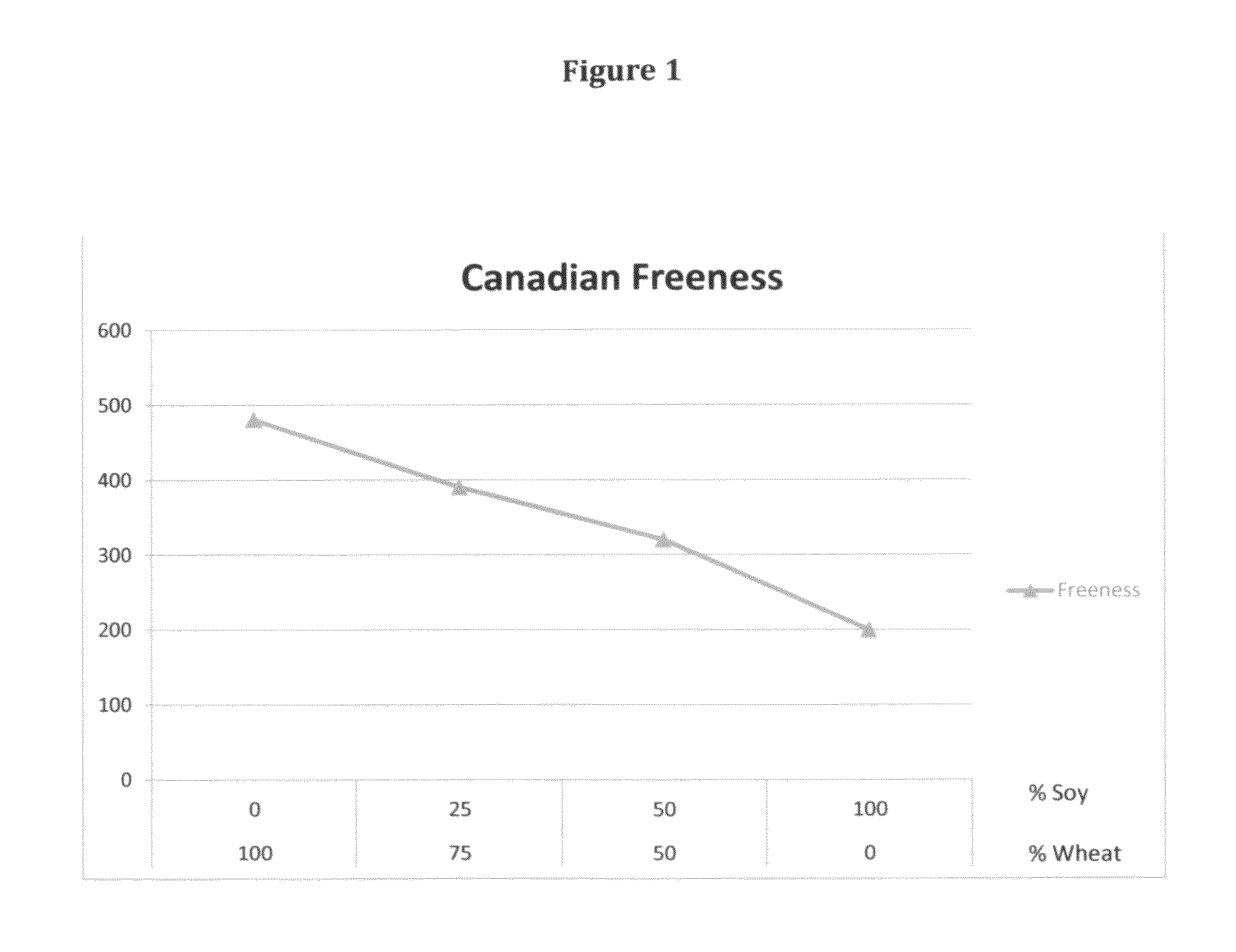

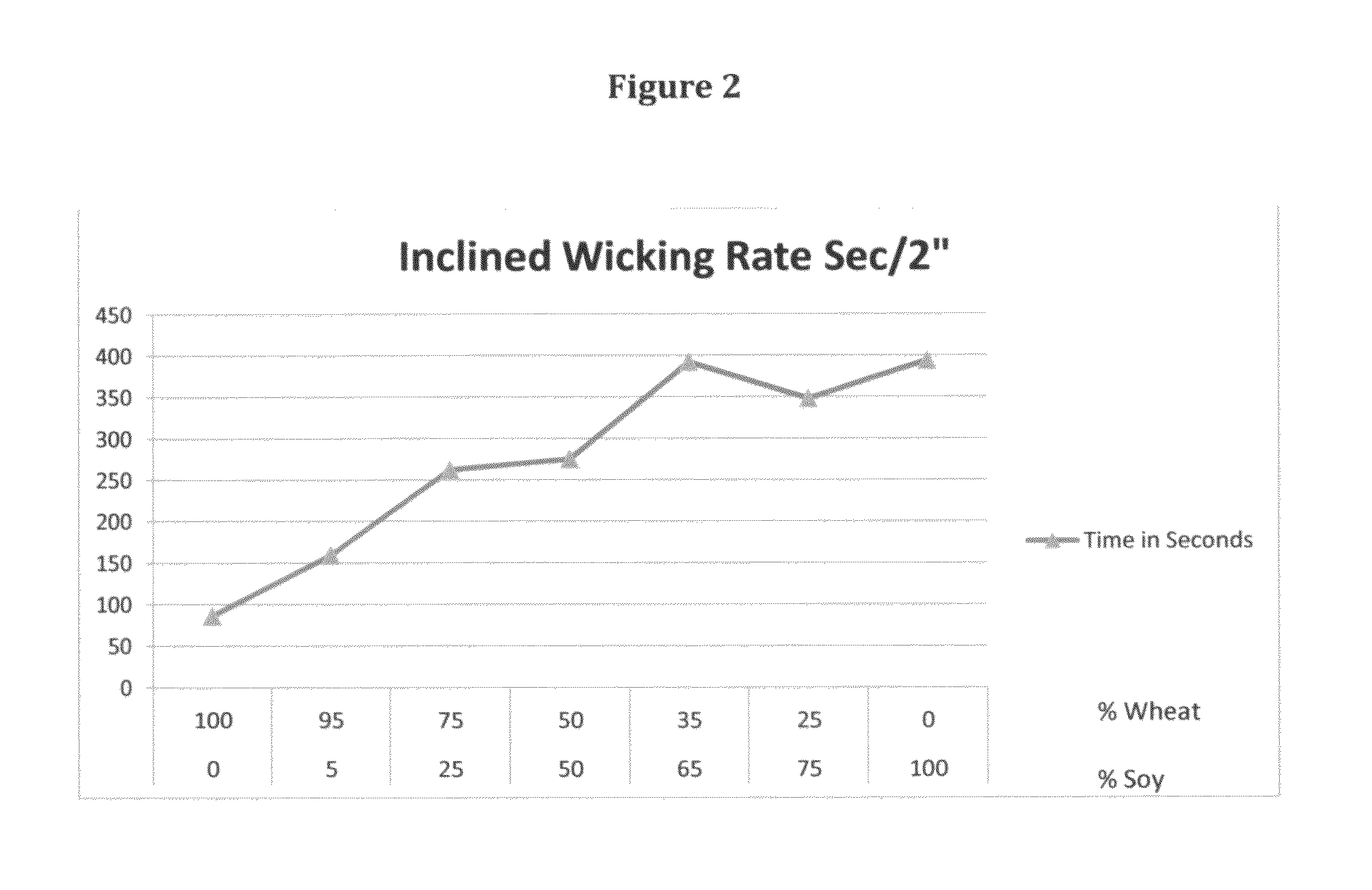

Soy stalk and wheat straw pulp fiber mixtures

InactiveUS8715464B2Reduce roughnessShorten the lengthNon-fibrous pulp additionSpecial paperCardboardFood chain

This invention relates to annual crop straw and stalk fibers having properties suitable for use in paper, paperboard, and related products disposable paper plates, cups, and bowls, molded and thermoformed pulp products, disposable food handling containers, tissue and toweling, and absorbent products such as airlaid roll goods, wipes, diapers and feminine hygiene articles. Annual crop straw or stalk is the waste product from the harvesting of the food including soy, wheat, corn, rice, and oats. The food chain is not impacted by use of these stalks and straw. Currently, most of the straw or stalk is burned, tilled under for soil amendment, or otherwise disposed of. Use of this stalk or straw for paper, paperboard and related products, and absorbent products manufacture including any product made from cellulose fibers represents an opportunity to provide additional income to farmers and a green alternative to wood pulp and therefore conserve trees.

Owner:PURE PULP PROD

Horizontal spit rotisserie cooking device

InactiveUS20020023547A1Easy to mountFacilitated releaseBoiling over preventionMeat processingGear driveEngineering

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The spit assembly may also be mounted at various distances from the heating element to decrease cooking times. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. The embodiment's design makes efficient use of valuable counter space by recessing back and raising off the countertop its controls. A contained light as well as room light emitted through the inclined glass door illuminate the enclosure's interior to make the rotisserie cooking into a taste tempting show. Two countertop supported sizes for the embodiment are suggested, one for larger families and entertaining, and the other for small families and singles. Cooking times are decreased and manufacture simplified by the embodiment heating element remaining on constantly during the cooking process. Maintenance is minimized by various embodiment parts being removable for cleaning including a cleaning shield located behind the heating element, the glass door, and a drip pan with slotted cover. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:BACKUS ALAN L +1

Rotisserie oven including gloves and method of using the gloves

InactiveUS20010022140A1Prevent slippingEasy to handleCooking-vessel lids/coversRoasting apparatusGear driveReady to use

Enclosed rotisserie with added convenience, including a countertop resting box-like enclosure housing a safety rear mounted heating element and a power rotated dual rod spit assembly. The gear driven spit assembly may be easily inserted and removed straight into and out of the enclosure without need for angling or coupling the assembly to a power drive socket. The spit assembly may also be mounted at various distances from the heating element to decrease cooking times. The open front of the enclosure is from time to time covered by an inclined glass panel door which may be opened in various ways to facilitate food insertion into and removal from the enclosure, and which may be easily removed for cleaning or other purposes. The embodiment's design makes efficient use of valuable counter space by recessing back and raising off the countertop its controls. A contained light as well as room light emitted through the inclined glass door illuminate the enclosure's interior to make the rotisserie cooking into a taste tempting show. Two countertop supported sizes for the embodiment are suggested, one for larger families and entertaining, and the other for small families and singles. Cooking times are decreased and manufacture simplified by the embodiment heating element remaining on constantly during the cooking process. Maintenance is minimized by various embodiment parts being removable for cleaning including a cleaning shield located behind the heating element, the glass door, and a drip pan with slotted cover. A variety of foods may be cooked using the spit and accessories that attach to the spit. Such accessories include wire baskets and a rotating stir fryer. Foods may be cooked on top of the embodiment as well using an included warming tray and an inserted steaming tray with cover. Grease-tight rotisserie / barbecue gloves make food handling easier and safer, as can also be said for a spit support platform which supports the spit assembly for food mounting and carving. Self-rotating kabob rods cook kabobs on all sides evenly and allow for increasing rotisserie capacity by increasing the length of rotating rods available for rotisserie food mounting.

Owner:BACKUS ALAN L +1

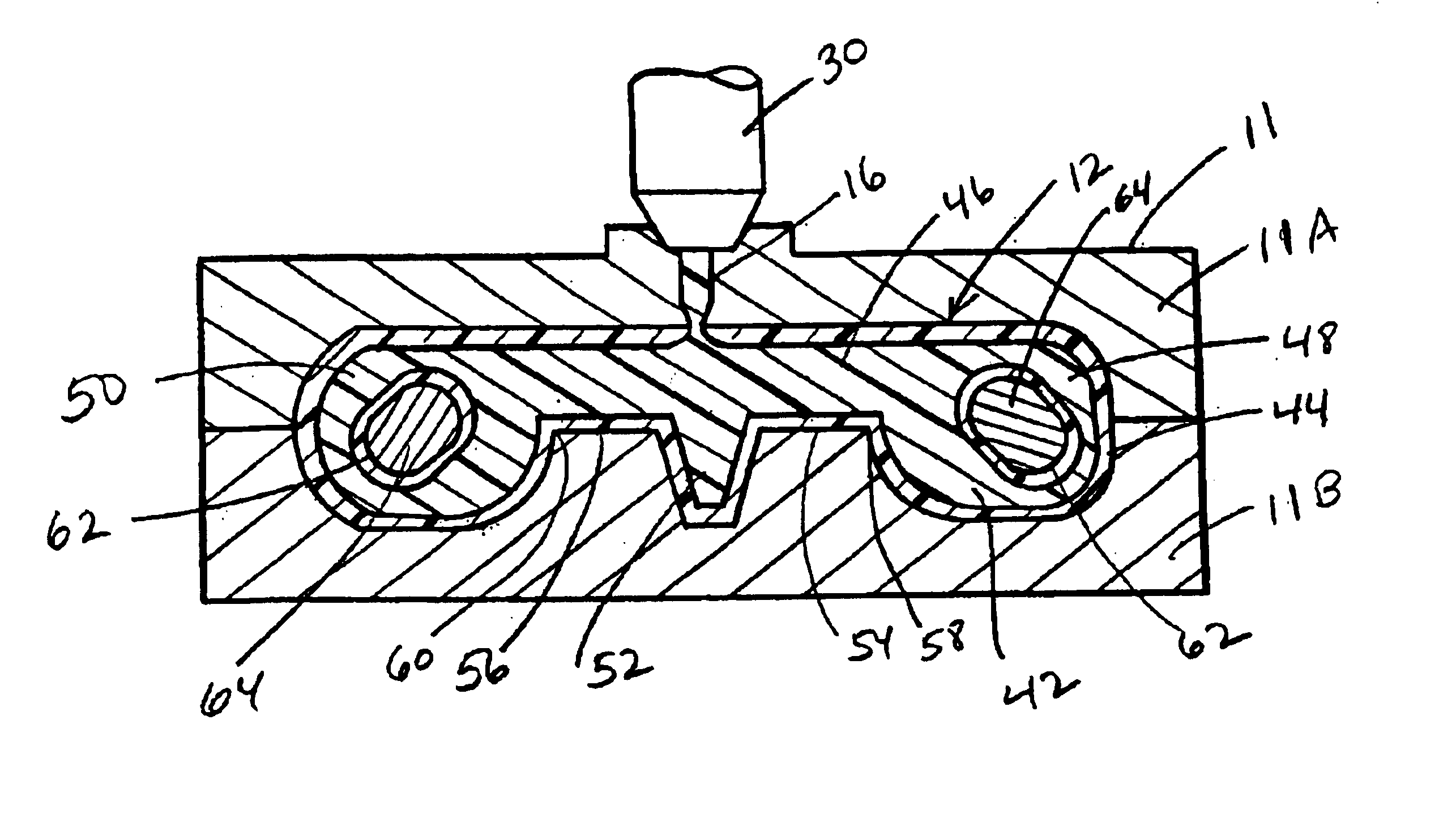

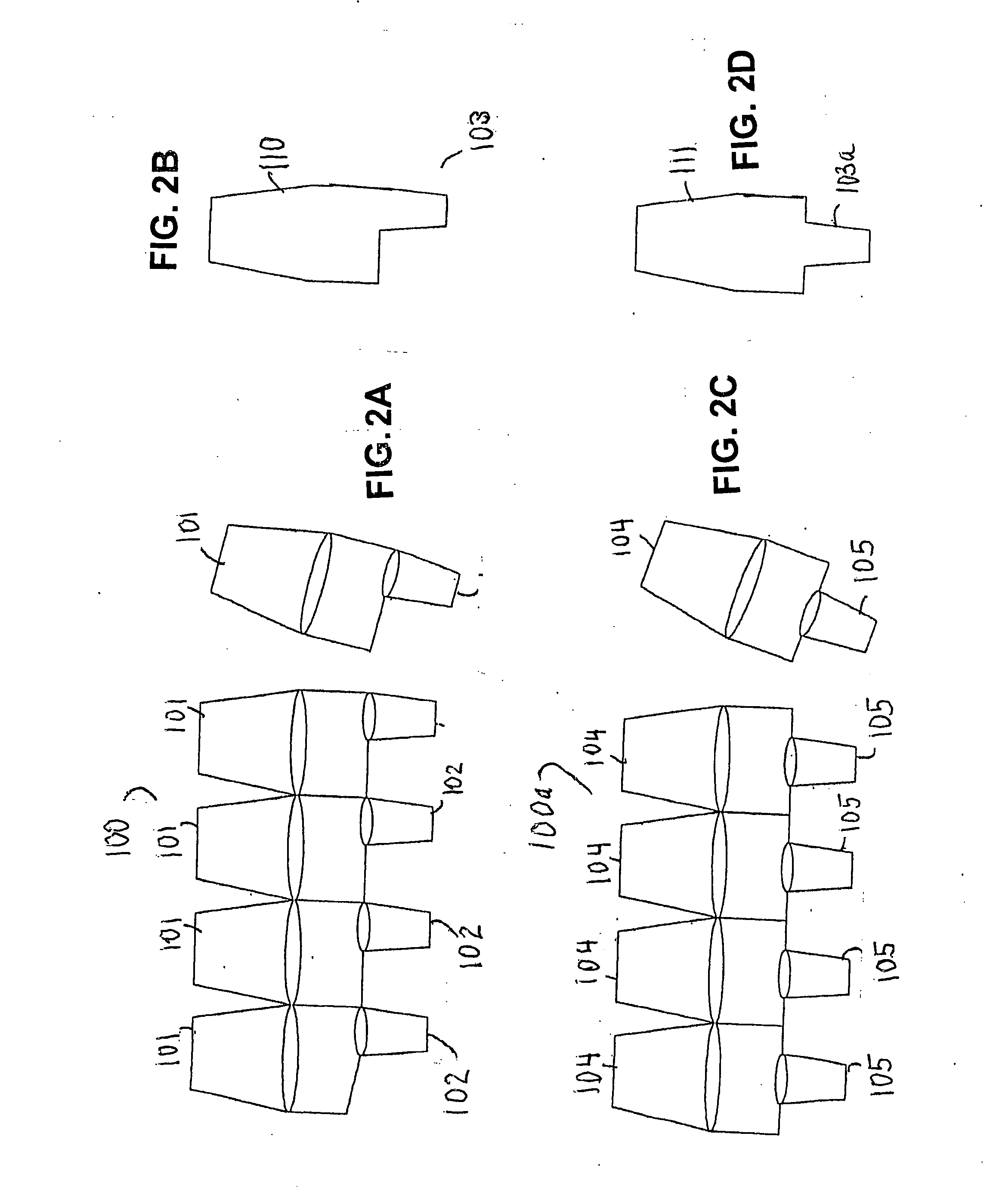

Module for a modular conveyor belt having a sandwich layer construction and method of manufacture

A module for a modular conveyor belt, is described. The module is of a sandwich layer construction having a core polymeric material completely surrounded by a skin polymeric material. The skin material includes an antimicrobial material for inhibiting bacterial growth on the module, and the conveyor belt is particularly useful for conveying and transporting foods including food processing and food handling applications.

Owner:HABASIT AG

Disposable finger tongs for handling a food product

InactiveUS20160157647A1Improve grabbingReduced tearabilityFinger bandagesLifting devicesEngineeringFood contact

A disposal food handling finger tongs have finger pockets for grasping food. The pockets are connected by at least one connecting tab. At least one functional finger / thumb accommodation area is presented and at least one finger / thumb stability is optionally provided. The disposable tongs provide a triple protection to the user by providing soft irregular peripheral edges help prevent paper cuts. Also the central connecting tab between the two jaw pockets can be torn to separate the tongs into two tongs, so that the two food contact sides of the respective pockets can be folded against each other. Third, if both the front and back of pockets are messy, the clean central tab can be torn, and folded over the back and / or front of the messy pockets, thereby keeping the hands, fingers and / or thumb of the user clean during disposal.

Owner:RAMPERSAD KENRICK

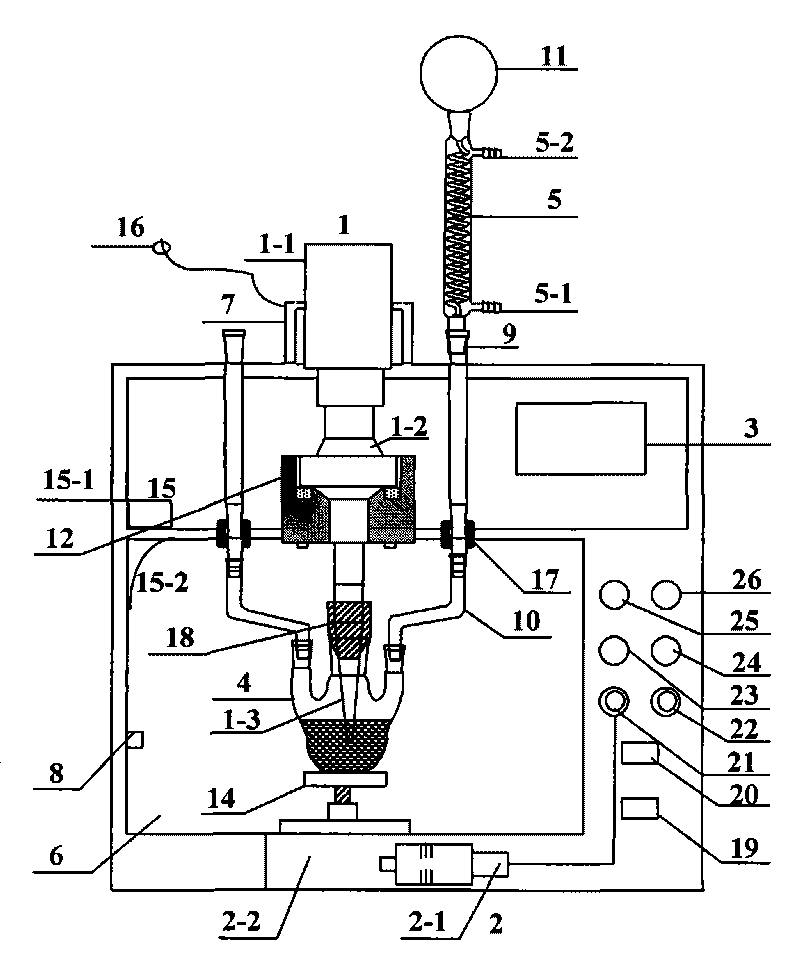

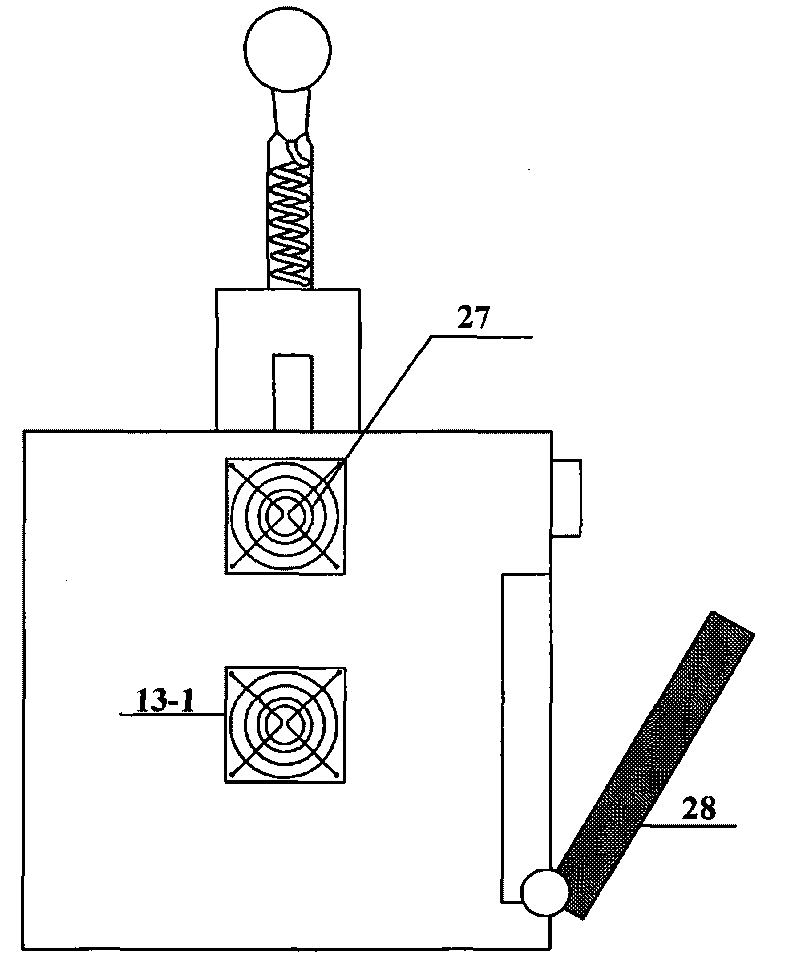

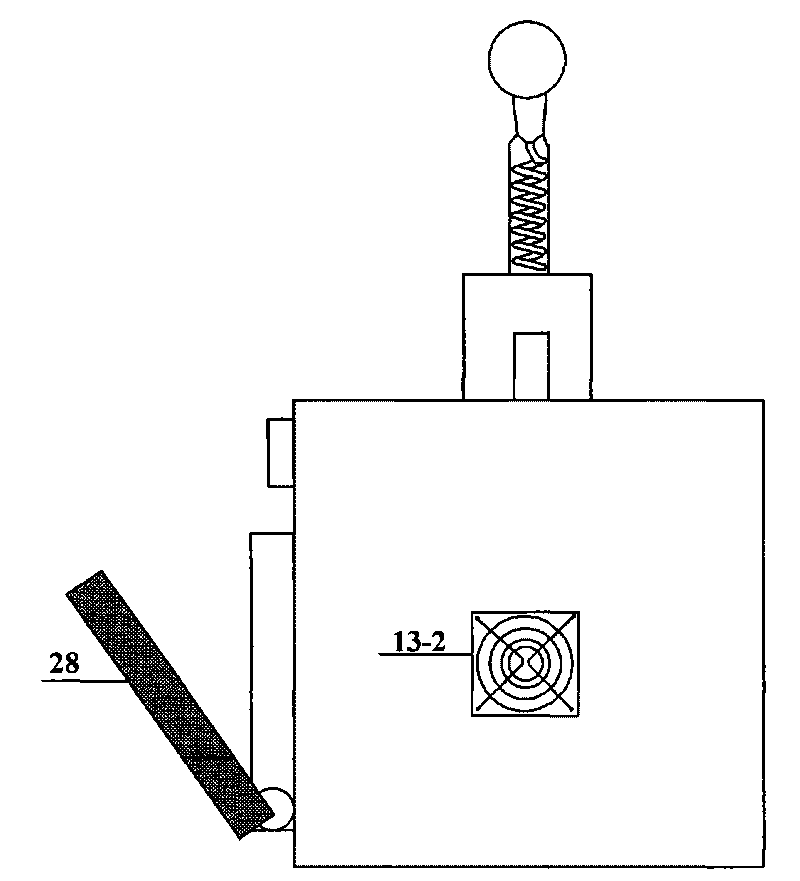

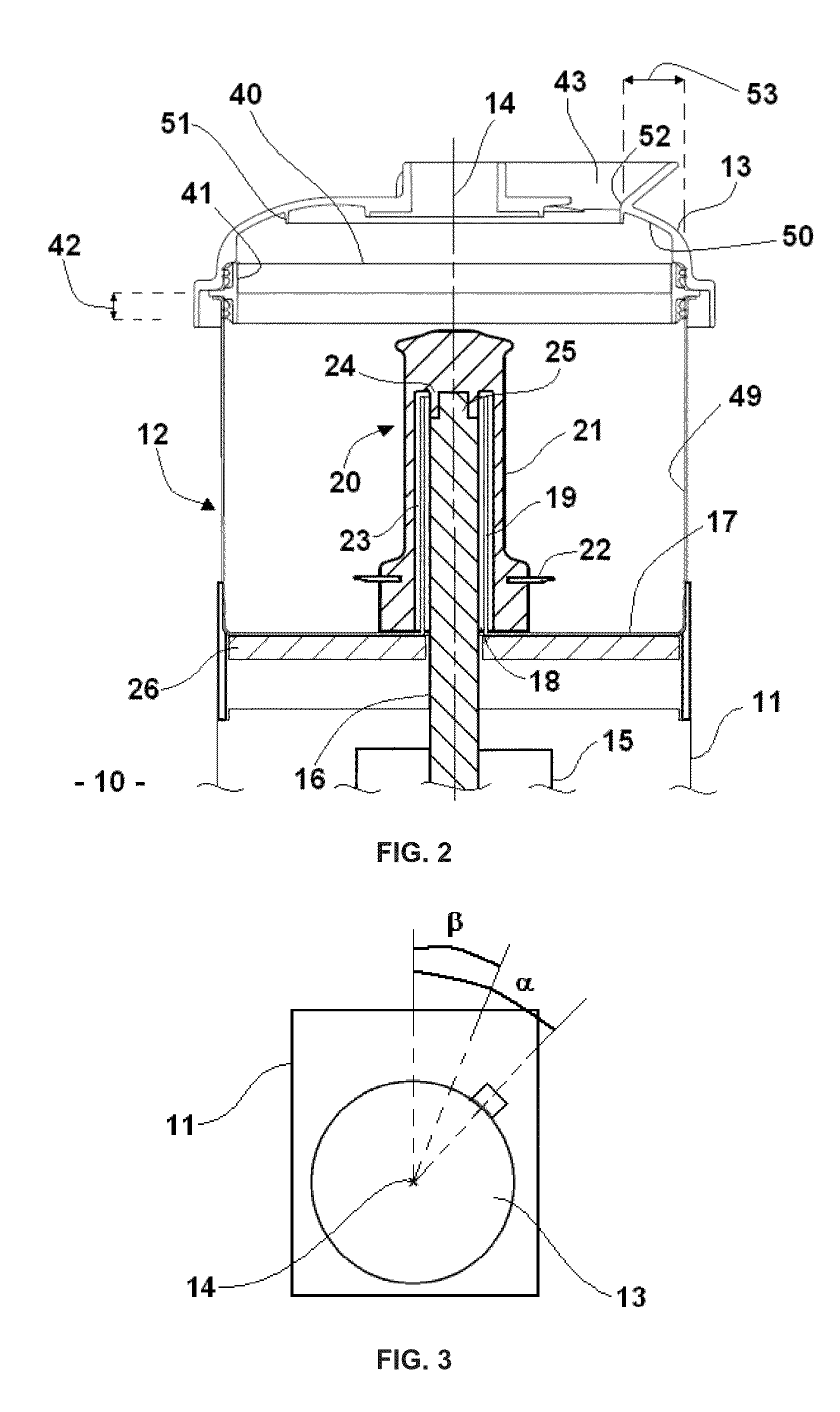

Multifunctional ultrasonic microwave collaborative chemical reactor and method for preparing nano semiconductor chalcogenide by using same

InactiveCN101711970AImprove sealingQuality improvementSulfide/polysulfide preparationEnergy based chemical/physical/physico-chemical processesChemical industryMicrowave shielding

The invention discloses a multifunctional ultrasonic microwave collaborative chemical reactor and a method for preparing a nano semiconductor chalcogenide by using the same. The multifunctional ultrasonic microwave collaborative chemical reactor comprises an ultrasonic generator, a microwave generator, a temperature / time / power display control device, a reaction vessel, a condensing device, a microwave resonator, a microwave shielding device, an air exhausting and air feeding device, and a reaction vessel supporting and lifting device. The chemical reactor has the advantages of uniform vibration, consistent action stressed by all the points in a sample medium, many varieties of selectable extraction solvents, wide range of targets, reduction of the binding force of the targets and sample substrates; accelerated process of the targets from solid phase to solvent phase, large processed sample amount and the like. The chemical reactor can overcome the phenomenon of overheat charring, and can obtain more uniform and better-quality products than single microwave reaction. The chemical reactor has wide application prospect in the fields of chemistry and chemical industry, pharmacy, materials, energy sources, food processing and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

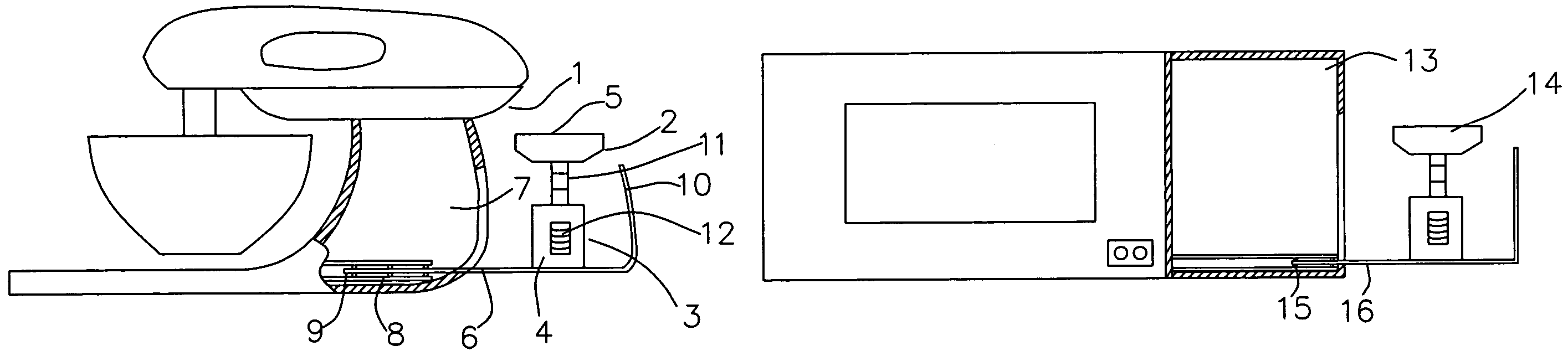

Food treating apparatus with a weighing scale

InactiveUS7598464B2Simple structureLow costAutomatic control devicesDomestic cooling apparatusDisplay deviceEngineering

Owner:DENG ZHIMING

Food processor with a protected lid

ActiveUS20130075505A1Small sizePrevent fallingCooking-vessel lids/coversBalingMechanical engineeringVertical axis

The present invention relates to a mechanical food treatment processor comprising a driving block topped by a bowl. The driving block comprises a motor connected to a rotation driving means. The processor further comprises a food treatment tool with means of coupling with the rotation driving means. The bowl is topped by a lid with an opening / closing system placed on the bowl and operable to rotate about a substantially vertical axis. The lid is provided with a safety device operable to block the opening of the lid when a force, substantially parallel to the axis of rotation, is exerted on the lid. The claimed device is operable to avoid a brutal ejection of the lid and / or emissions of extreme burning steam in the event of an overpressure in the bowl.

Owner:HAMEUR & CIE

Electron source for food treating apparatus and method

Owner:SIMIC GLAVASKI BRANIMIR

Food processor for making sour soybean milk and method for making sour soybean milk

PendingCN107951388AAchieve separationMeet the needs of making yogurt productsBeverage vesselsMilk substitutesBiotechnologyAgricultural science

The invention relates to the technical field of sour soybean milk making, and provides a food processor for making sour soybean milk and a method for making the sour soybean milk according to the foodprocessor. The food processor comprises a soybean milk machine cup body, a machine head assembly of the soybean milk machine and a fermentation container arranged under the soybean milk machine cup body; a filtering mechanism and a water blocking plate are arranged between the soybean milk machine cup body and the fermentation container. A feeding mechanism used for adding sugars and strains to bean products in the fermentation container and a temperature controlling device used for controlling feeding temperature and fermentation temperature are arranged on the fermentation container. According to the food processor for making the sour soybean milk, a function of making the sour soybean milk is added to basic functions of an original soybean milk machine to meet demands of existing markets for making sour soybean milk products; the filtering mechanism is arranged between the soybean milk machine cup body and the fermentation container, so that separation of residues and liquid of thefood processor for making the sour soybean milk is achieved.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Food handling system

A food handling system to store and dispense food products disposed within protective packaging comprises a food storage assembly to retain the food products to be dispensed therefrom and a food dispensing assembly to separate the food products from the protection packaging to dispense the food products.

Owner:ALMBLAD ROBERT +1

Disposable finger tongs for handling a food product

ActiveUS20190142192A1Improve grabbingReduced tearabilityGarment special featuresFinger bandagesFinger-stallEngineering

A disposal food handling finger tongs or hand coverings for grasping food or other objects. The pockets or finger stalls are connected by at least one connecting tab. At least one functional finger / thumb accommodation area is presented and at least one finger / thumb stability is optionally provided. The disposable tongs or hand coverings provide protection to the user by providing freely extending, unbonded, soft irregular peripheral edges help prevent paper cuts. If both the front and back of pockets or hand coverings are messy, optionally the tongs or hand coverings can be torn, and folded over the back and / or front of the messy pockets, thereby keeping the hands, fingers and / or thumb of the user clean during disposal.

Owner:RAMPERSD KENRICK

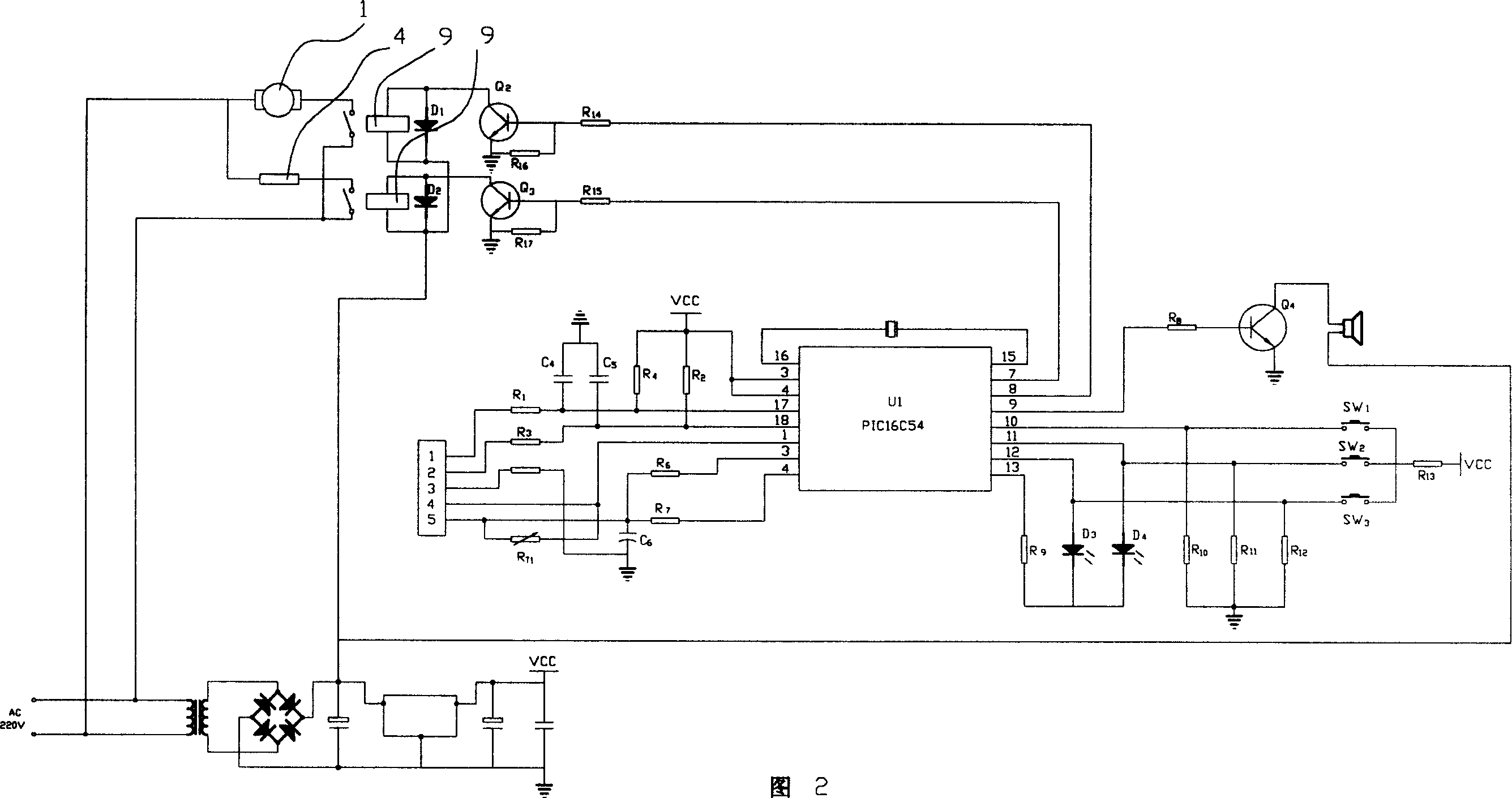

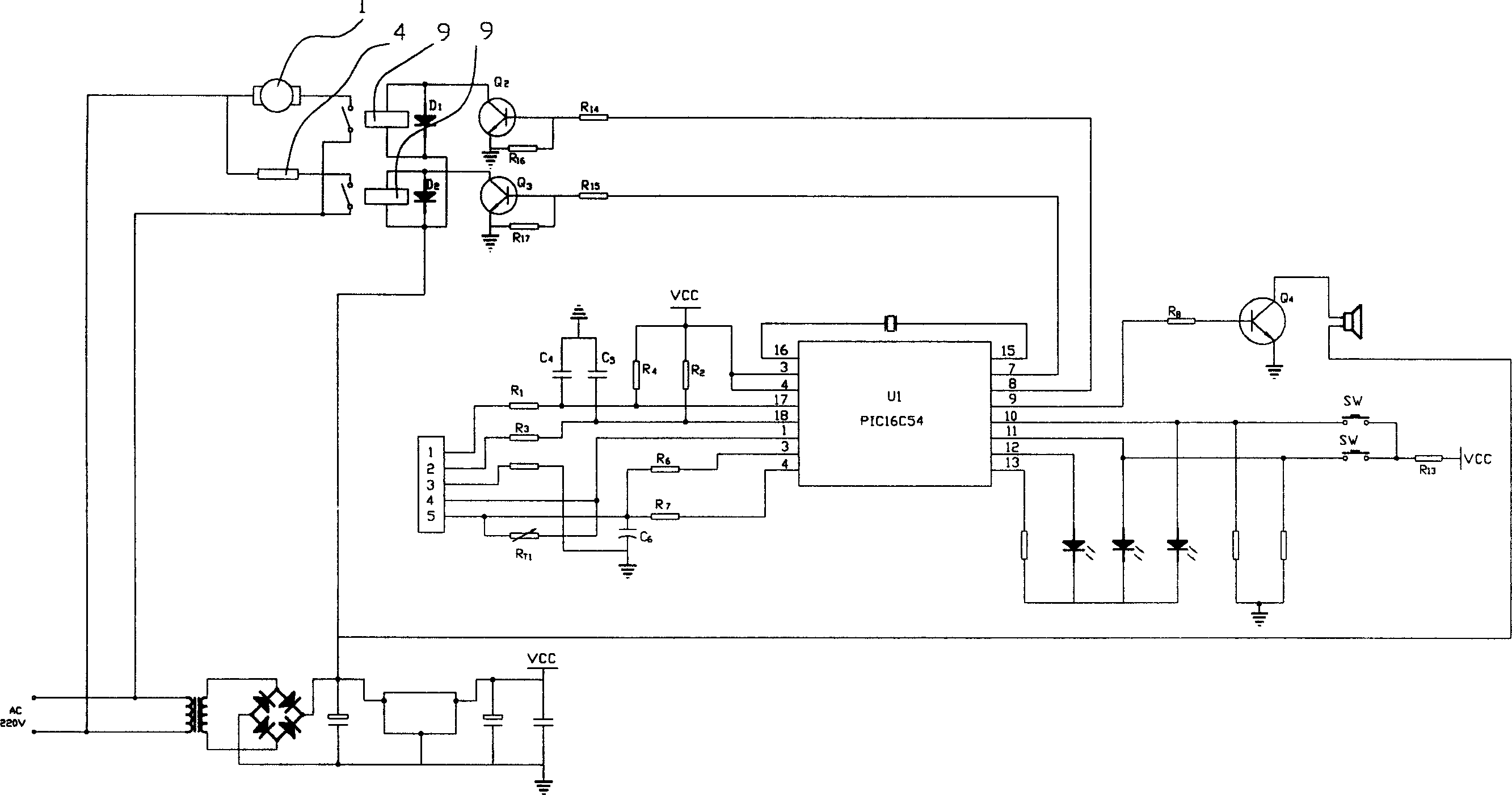

Multifunctional domestic food processing method and apparatus

InactiveCN1507826AAdd application functionsSimple structureKitchen equipmentCyclic processIt equipment

The present invention relates to a multifunctional domestic food treatment method and its equipment. Said method includes three programs of pulverizing, cooking soybean milk and cooking rice paste. Said equipment comprises machine shell body, motor heater, single-chip microprocessor, cup body, signal collecting circuit, actuator circuit, control circuit and switch key, etc. Said invention also can be used for cooking sesame paste and peanut paste, and also provides its application method.

Owner:蔡镜波

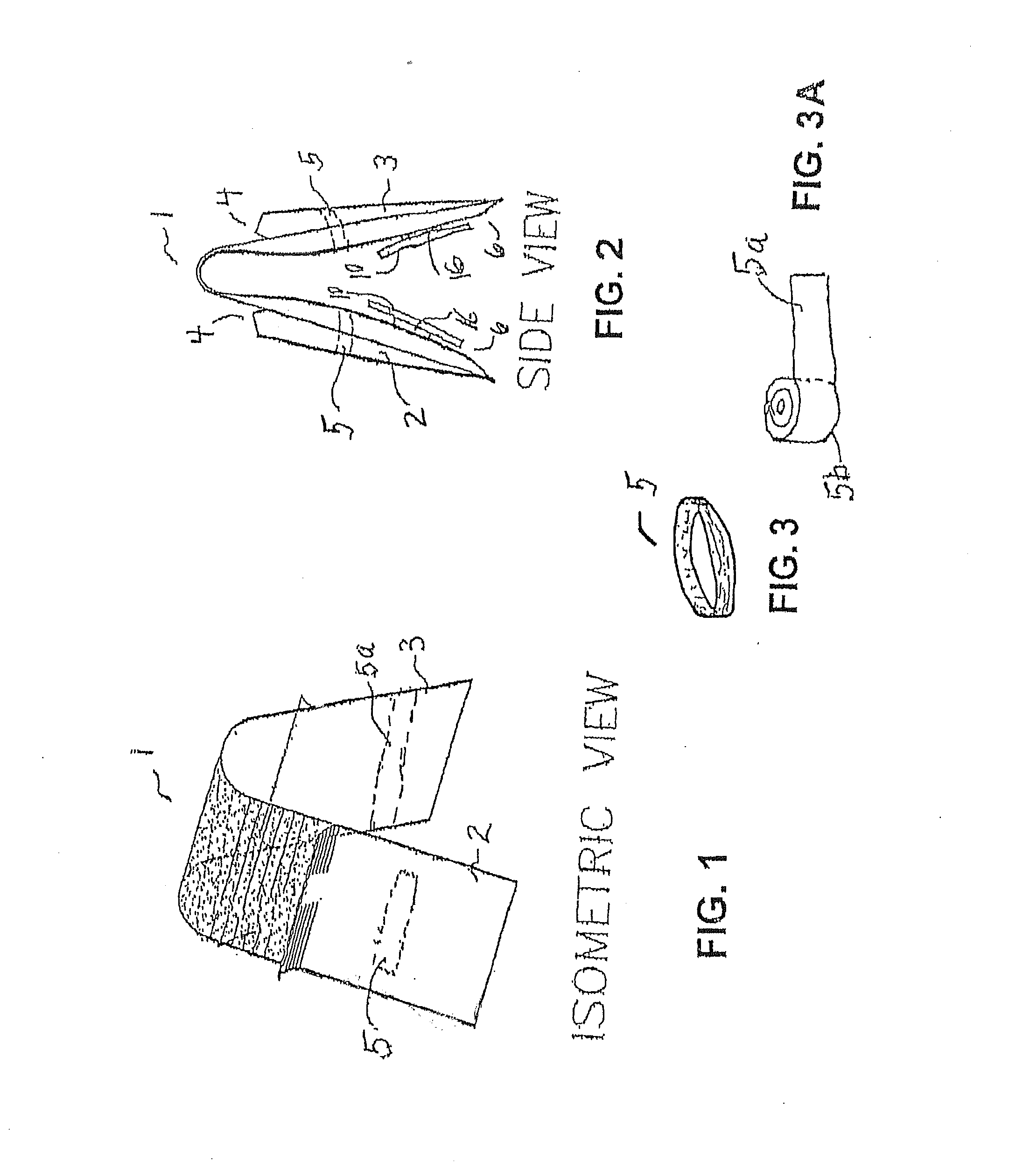

Food handling utensil

A food-handling utensil has tines with opposing sides that are provided with a plurality of smooth projections spaced along the length thereof adapted to engage and retain food impaled by the tines but only marginally inhibit release of the impaled food during handling of the food. Several exemplary embodiments of the utensil are disclosed in the form of a fork having more than two tines and with various forms of the projections, the provision of projections on other sides of the times, adapting the invention to sporks and also providing the handle of the utensil with an ergonomic grip.

Owner:HEBEBRAND SCOTT T

Functional food processing machine for manufacturing sprout-stock foods and manufacturing method of sprout-stock foods

ActiveCN104756844AQuick and easy to manufactureEasy to manufactureKitchen equipmentCultivating equipmentsPlanting seedEngineering

The invention provides a functional food processing machine for manufacturing sprout-stock foods and a manufacturing method of the sprout-stock foods. The machine comprises a crushing knife device, a machine head or a base, a motor, a barrel body, a control circuit board and a heating device; a material storing device is arranged on the machine and positioned in the barrel body or the space of the material storing device is communicated with the space in the barrel body; raw / processed sprout-stocks and raw / processed sprout-stock pulp manufacturing control programs are installed in the control circuit board. According to the functional food processing machine for manufacturing the sprout-stock foods and the manufacturing method of the sprout-stock foods, the plant seeds and water are prepared into raw sprout-stocks through the inherent functions of a machine body, and then the raw sprout-stocks are processed into processed sprout-stocks or not processed; the raw / processed sprout-stock pulp manufacturing method is that the raw / processed sprout-stocks prepared, then the raw / processed sprout-stocks and water are crushed together the crushing knife device driven by the motor to obtain raw / processed sprout-stock pulp; therefore, the automatic manufacturing process from germination of the plant seeds to preparation of sprout-stocks or sprout-stock pulp is achieved.

Owner:王晓东

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com