Patents

Literature

171results about How to "Improve elimination" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

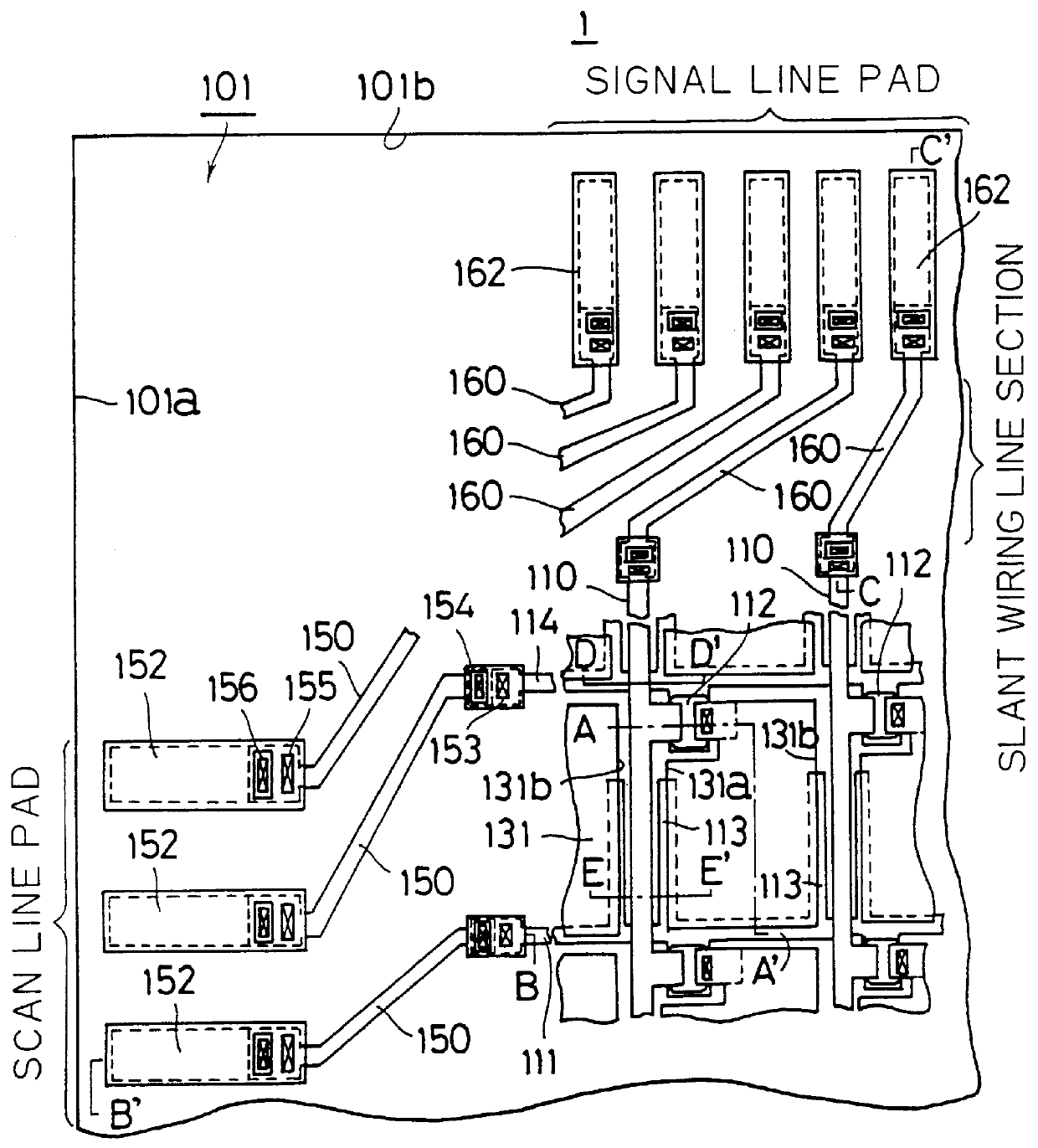

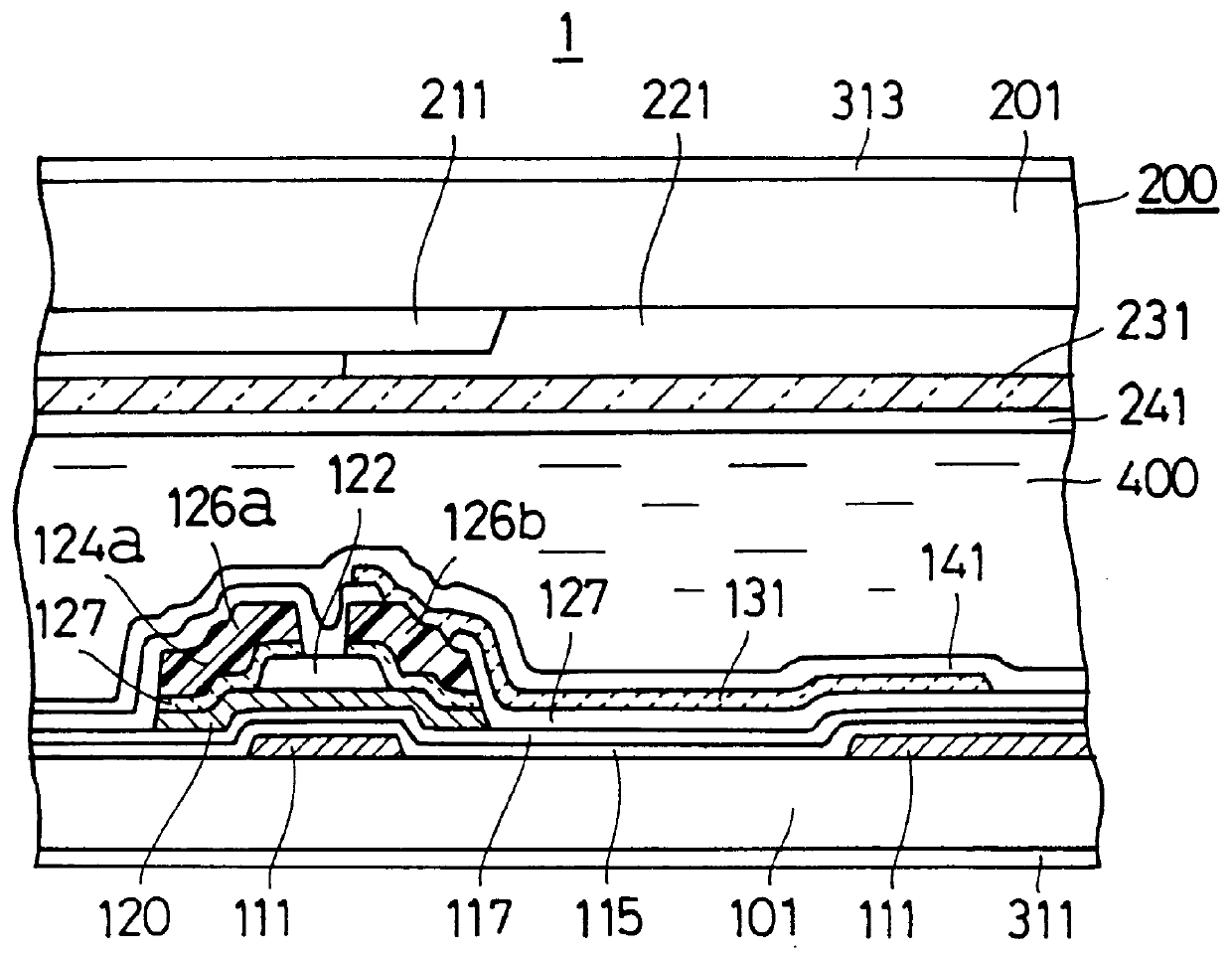

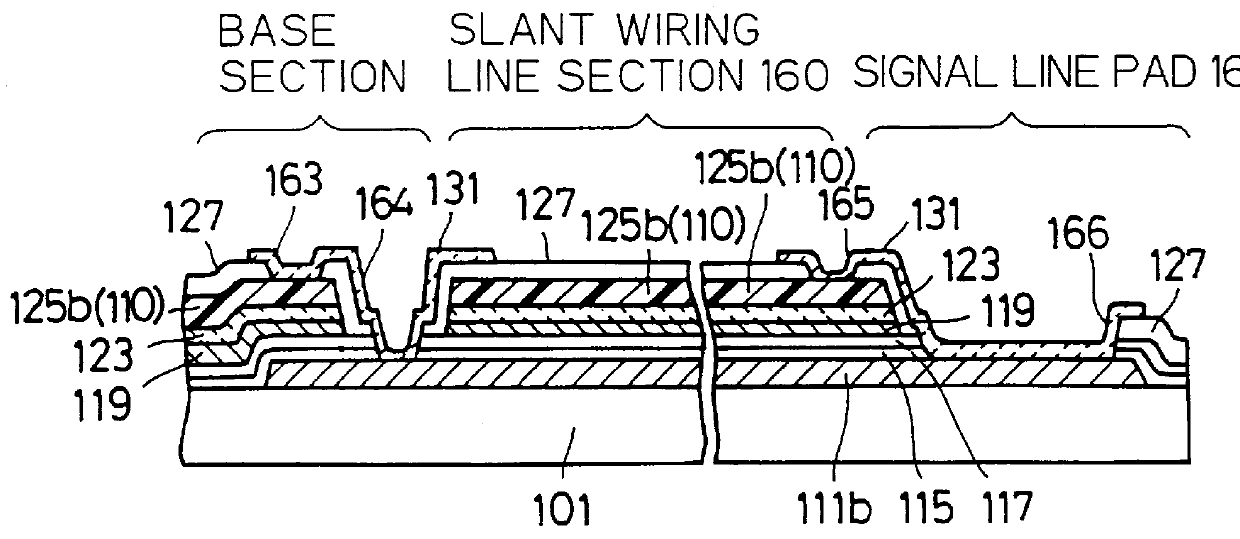

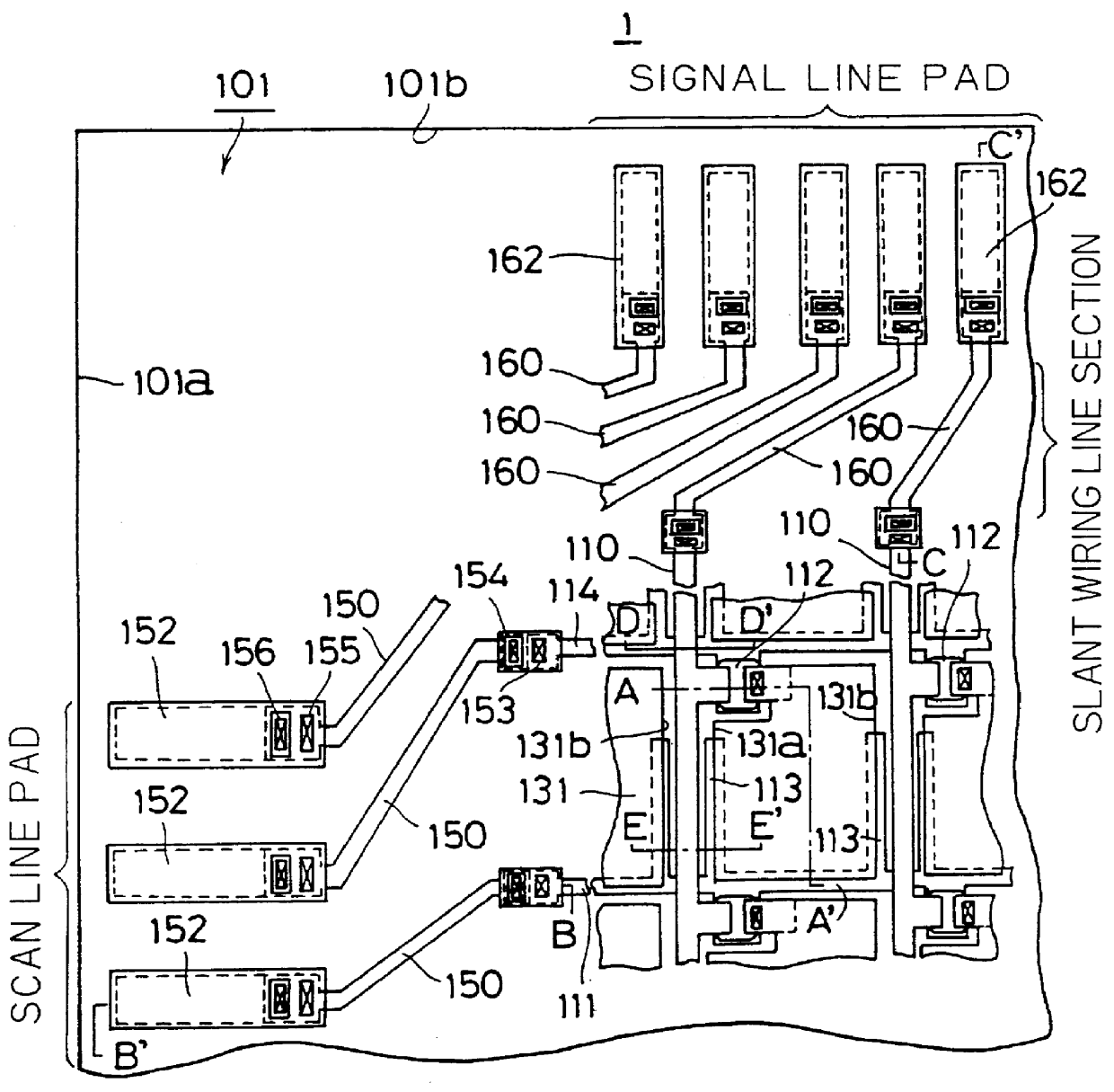

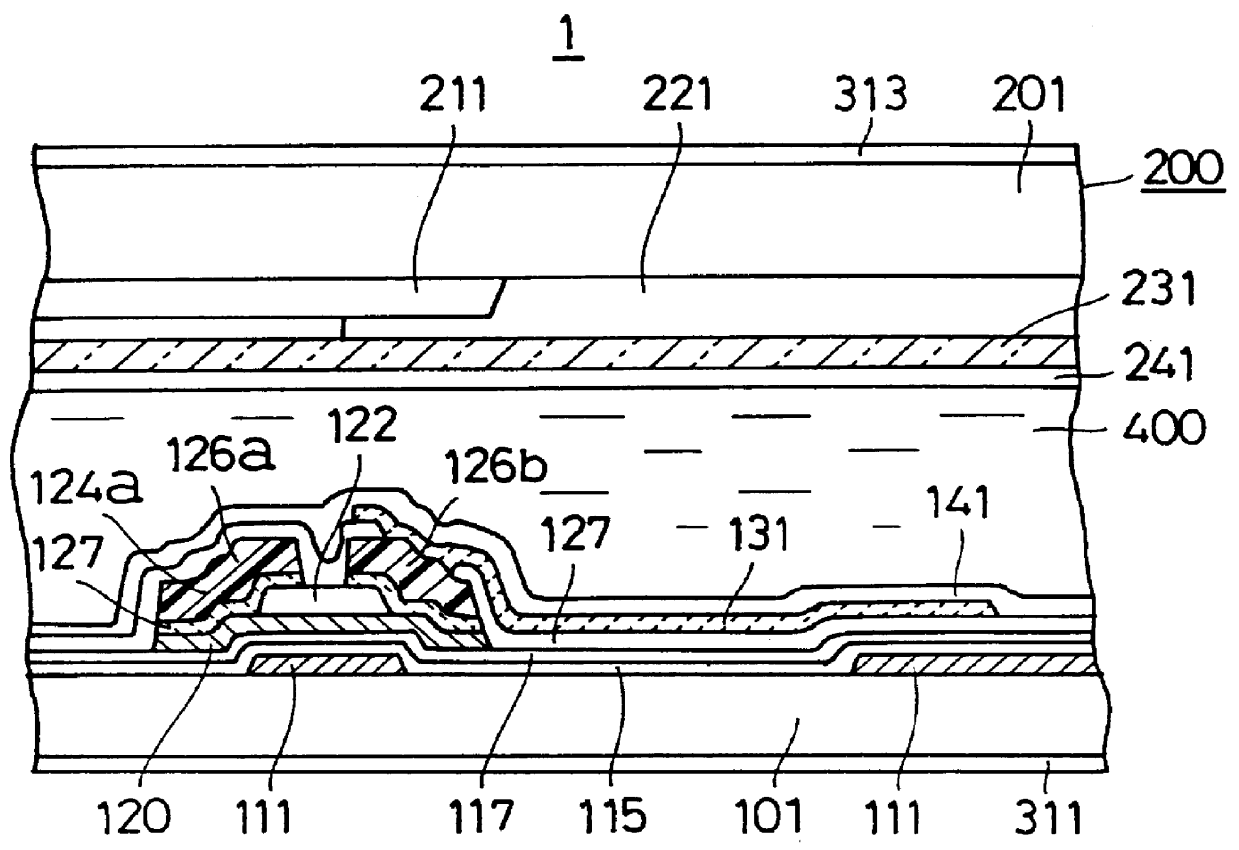

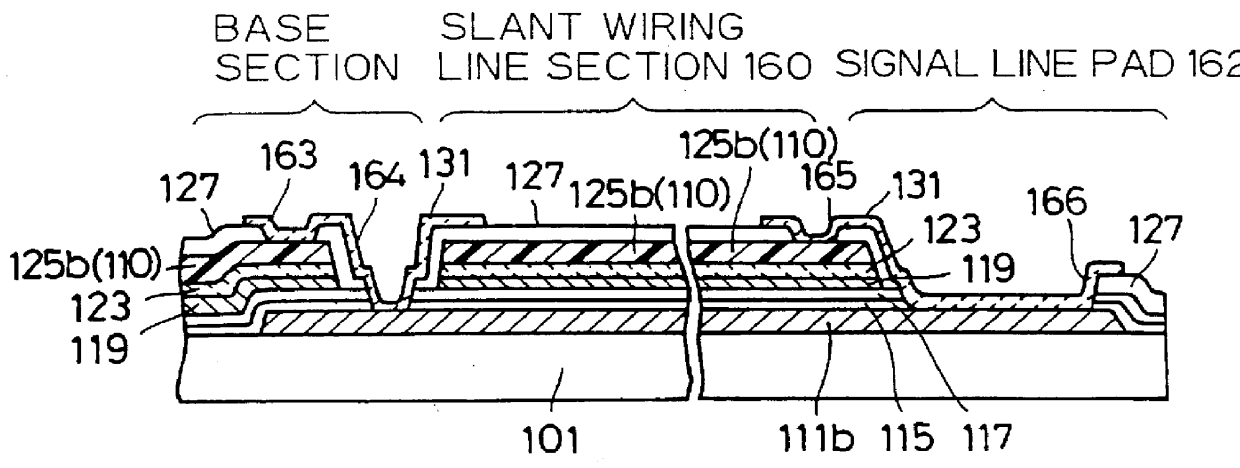

Array substrate comprising semiconductor contact layers having same outline as signal lines

InactiveUS6078366AImprove eliminationReduce the ratioSolid-state devicesSemiconductor/solid-state device manufacturingContact layerAperture ratio

An array substrate includes plural scanning lines (111); a thin film transistor (112) having a first dielectric film (115), (117), a semiconductor film (120) thereon, and a source electrode (126b) electrically coupled to the semiconductor film (120) and a drain electrode (126a); a signal line (110) as taken out of the drain electrode (126a) to extend at substantially right angles to the scanning lines (111); and a pixel electrode (131) electrically connected to the source electrode (126b), wherein the pixel electrode (131) is electrically connected to the source electrode (126b) through a second dielectric film (127) as disposed on at least the signal line (110) while the pixel electrode (131) overlaps an elongate region (113) from its neighboring scanning line (111) through the first and second dielectric films (115), (117), (127). With such an arrangement, an appropriate storage capacitor can be formed by causing the scanning lines and pixel electrode to overlap each other without having to decrease the manufacturing yield while enabling achievement of high aperture ratio.

Owner:JAPAN DISPLAY CENTRAL CO LTD

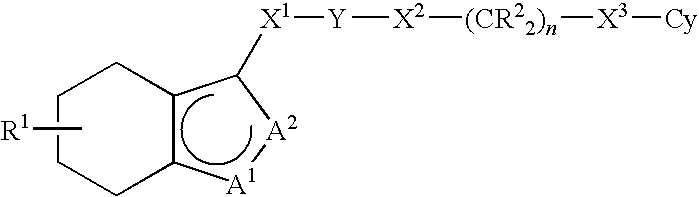

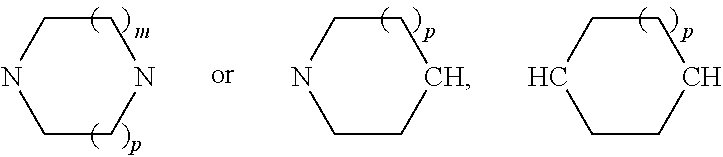

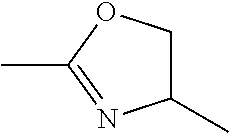

Tetrahydrobenzoisoxazole and tetrahydroindazole derivatives as modulators of the mitotic motor protein

InactiveUS20100022530A1Shorten the progressImprove eliminationBiocideOrganic chemistryMotor proteinStereochemistry

Owner:MERCK PATENT GMBH

Array substrate for display device and manufacturing method thereof

InactiveUS6028652AIncrease opening ratioLower manufacturing yieldSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

An array substrate includes plural scanning lines (111); a thin film transistor (112) having a first dielectric film (115), (117), a semiconductor film (120) thereon, and a source electrode (126b) electrically coupled to the semiconductor film (120) and a drain electrode (126a); a signal line (110) as taken out of the drain electrode (126a) to extend at substantially right angles to the scanning lines (111); and a pixel electrode (131) electrically connected to the source electrode (126b), wherein the pixel electrode (131) is electrically connected to the source electrode (126b) through a second dielectric film (127) as disposed on at least the signal line (110) while the pixel electrode (131) overlaps an elongate region (113) from its neighboring scanning line (111) through the first and second dielectric films (115), (117), (127). With such an arrangement, an appropriate storage capacitor can be formed by causing the scanning lines and pixel electrode to overlap each other without having to decrease the manufacturing yield while enabling achievement of high aperture ratio.

Owner:JAPAN DISPLAY CENT INC

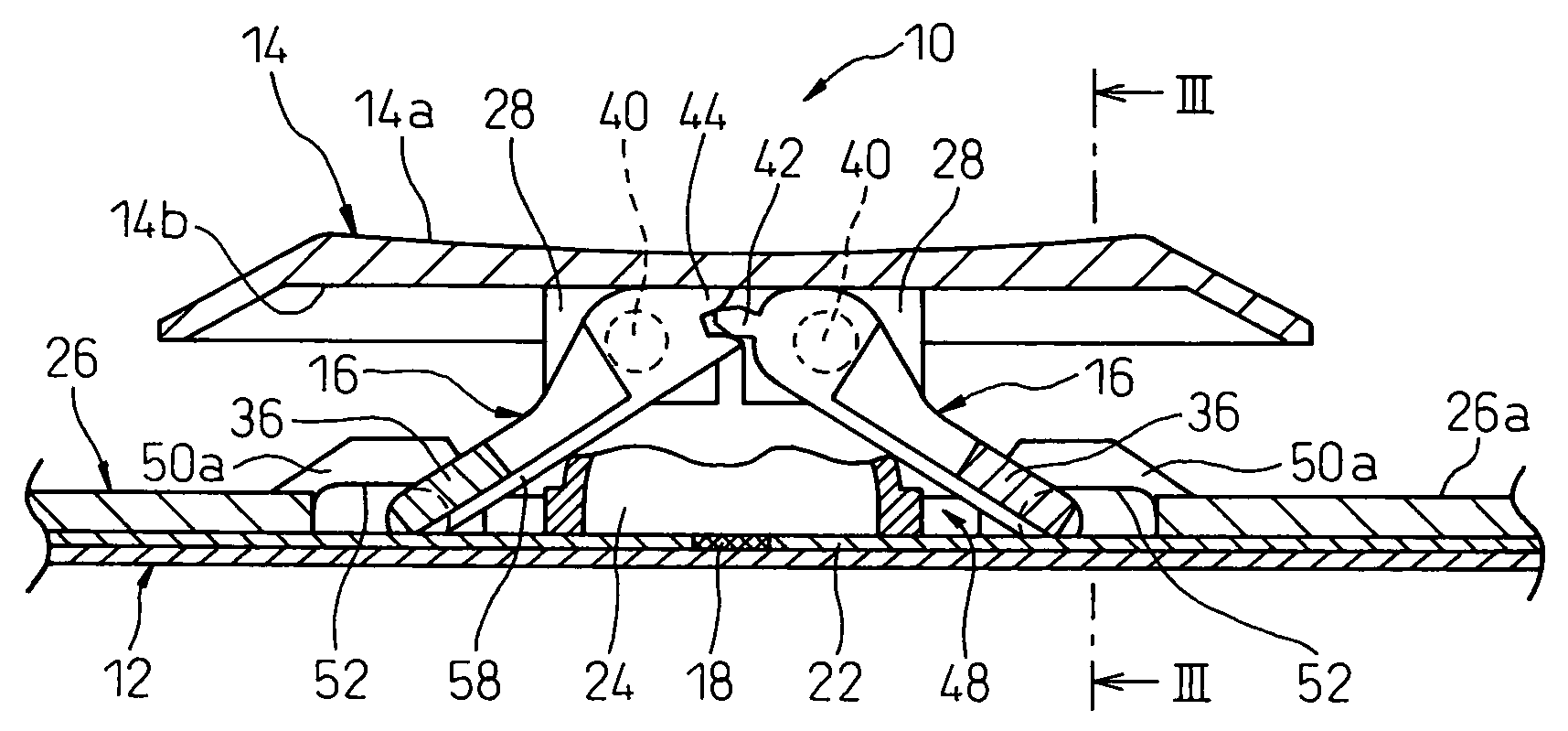

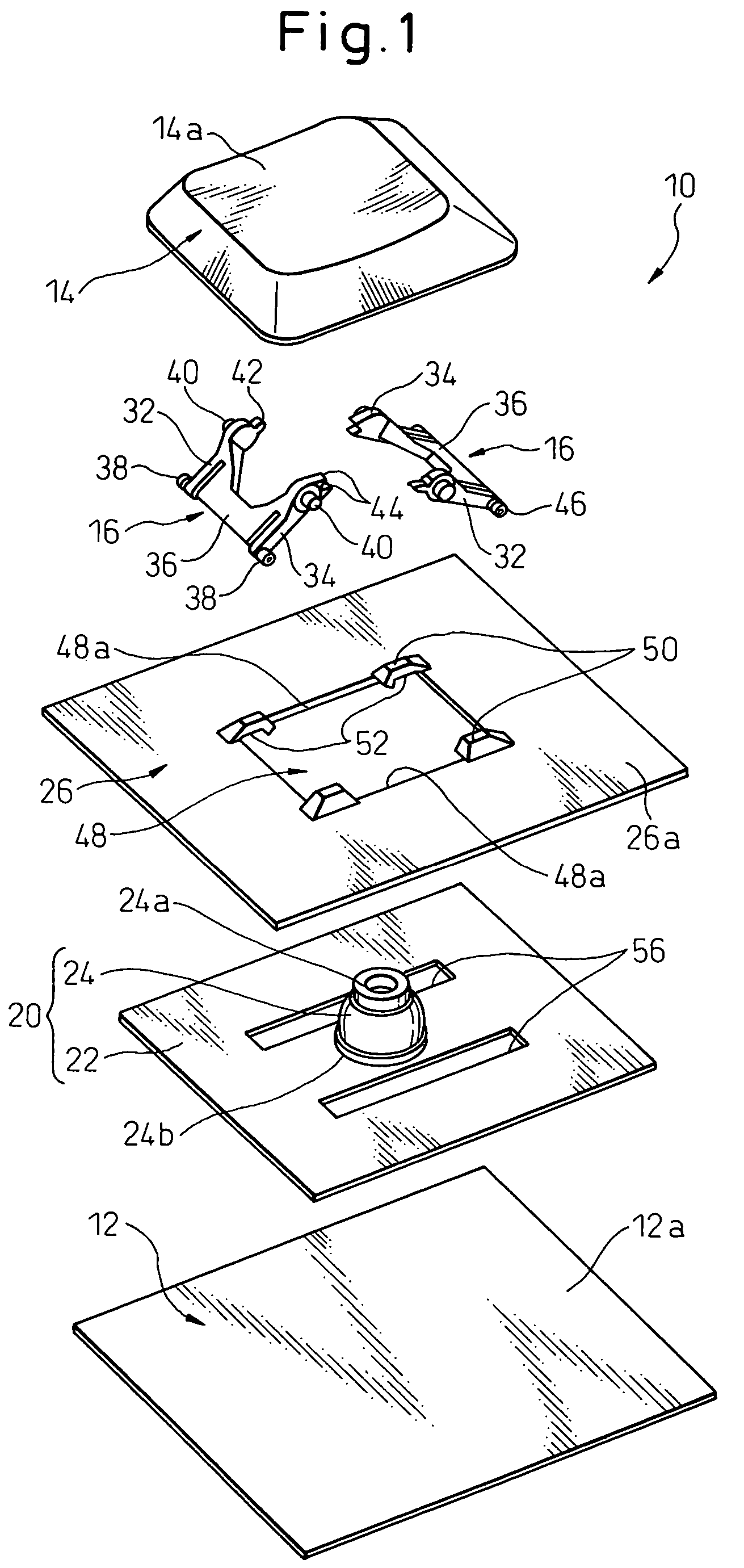

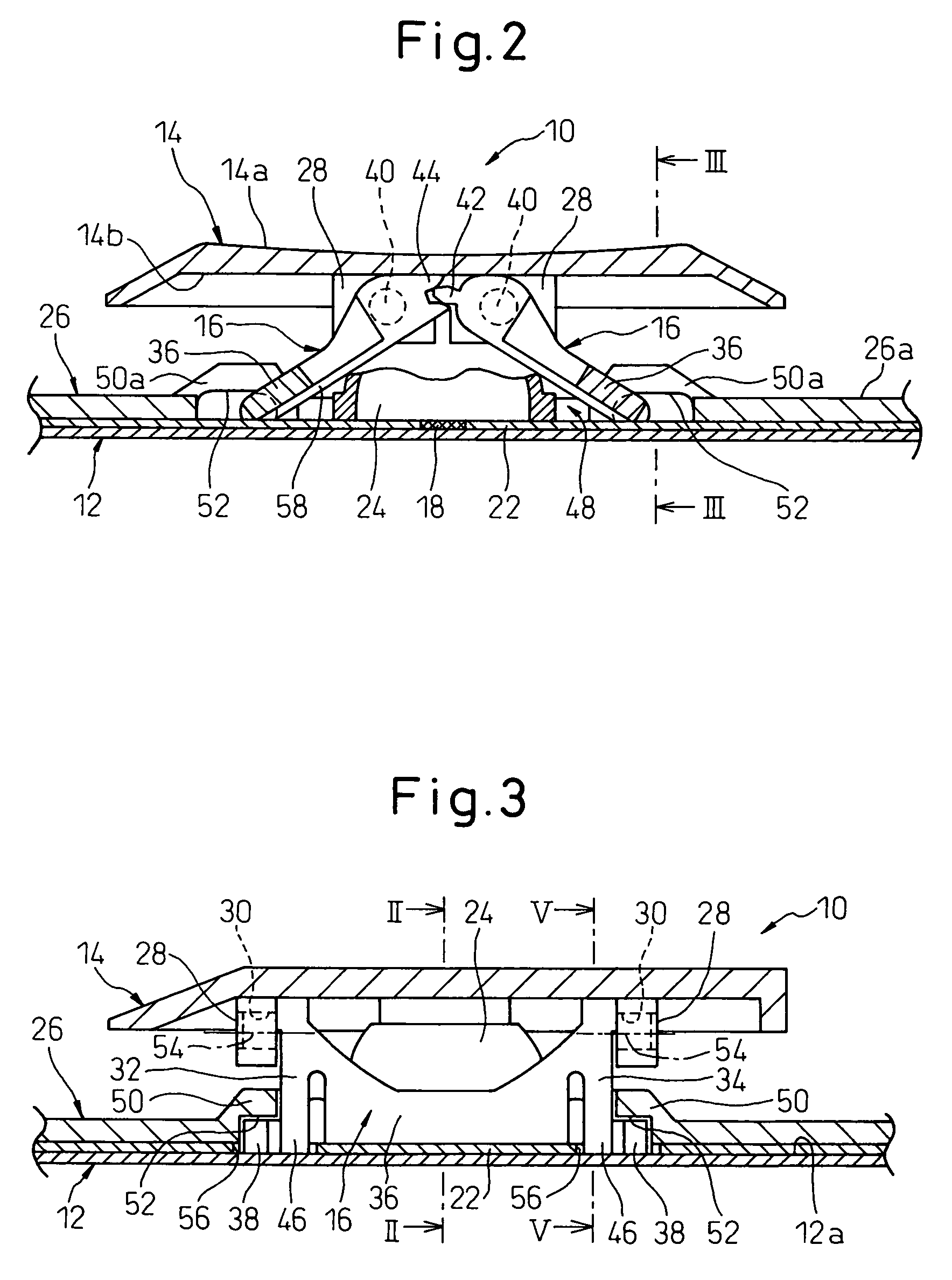

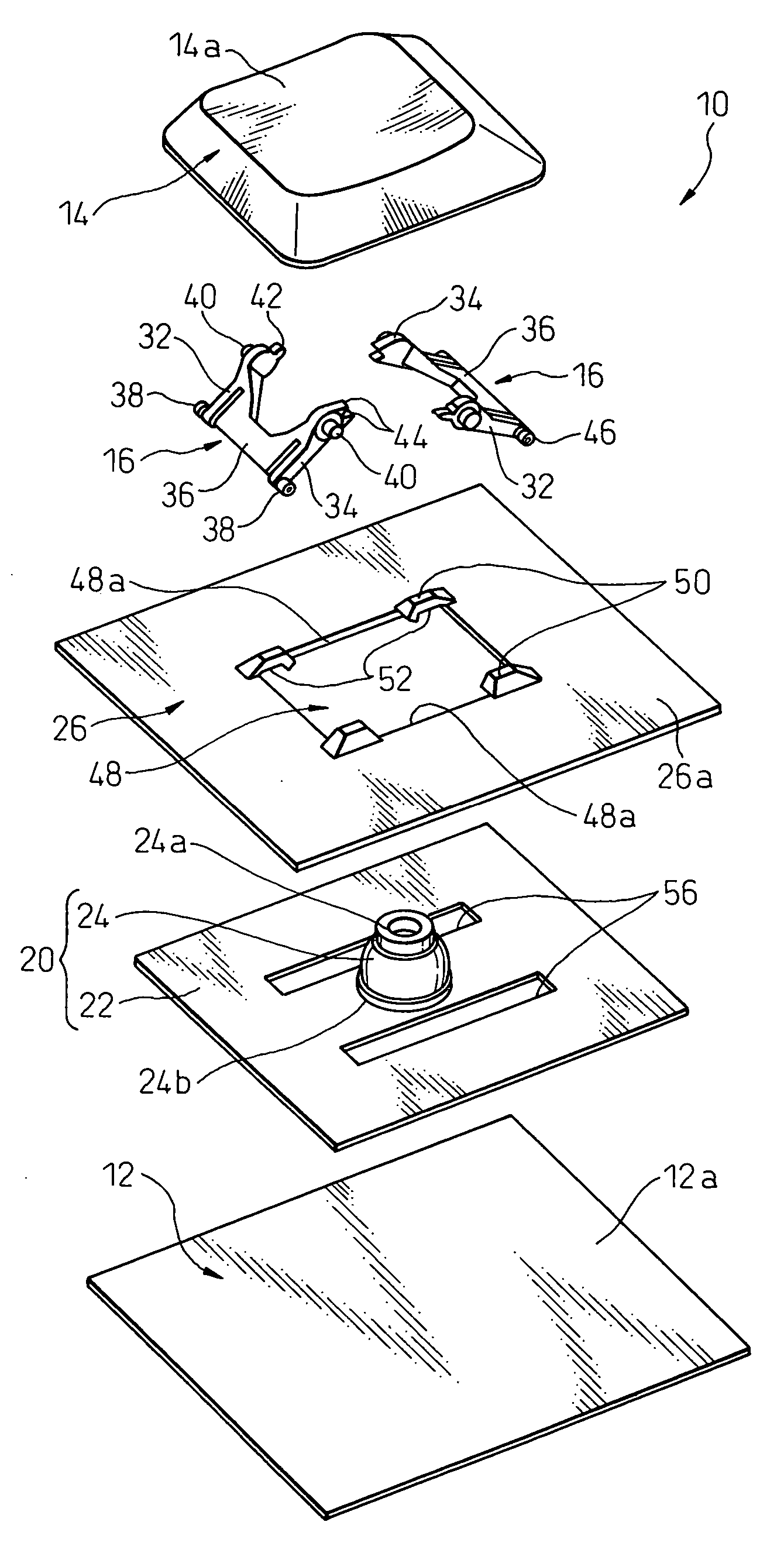

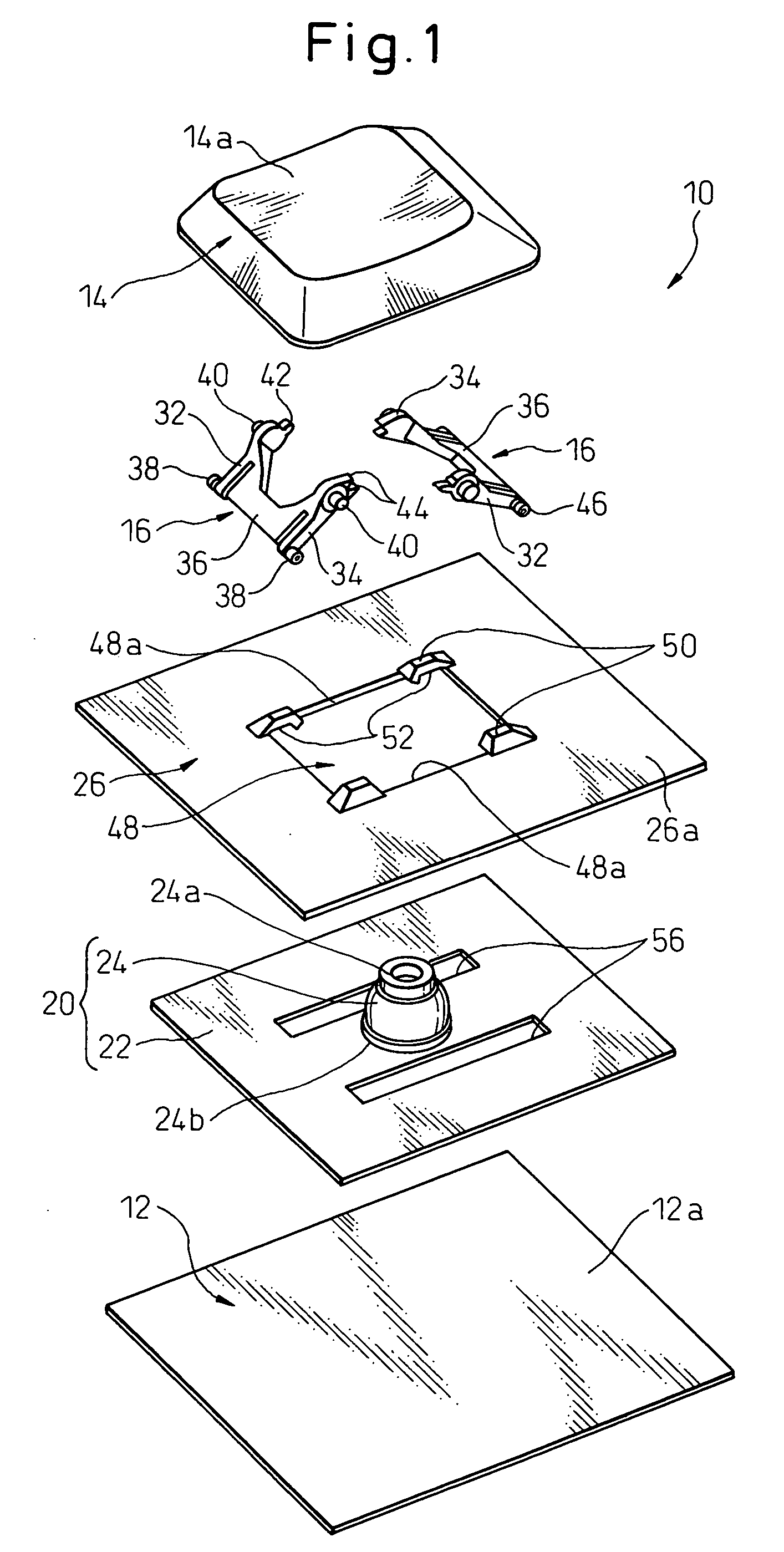

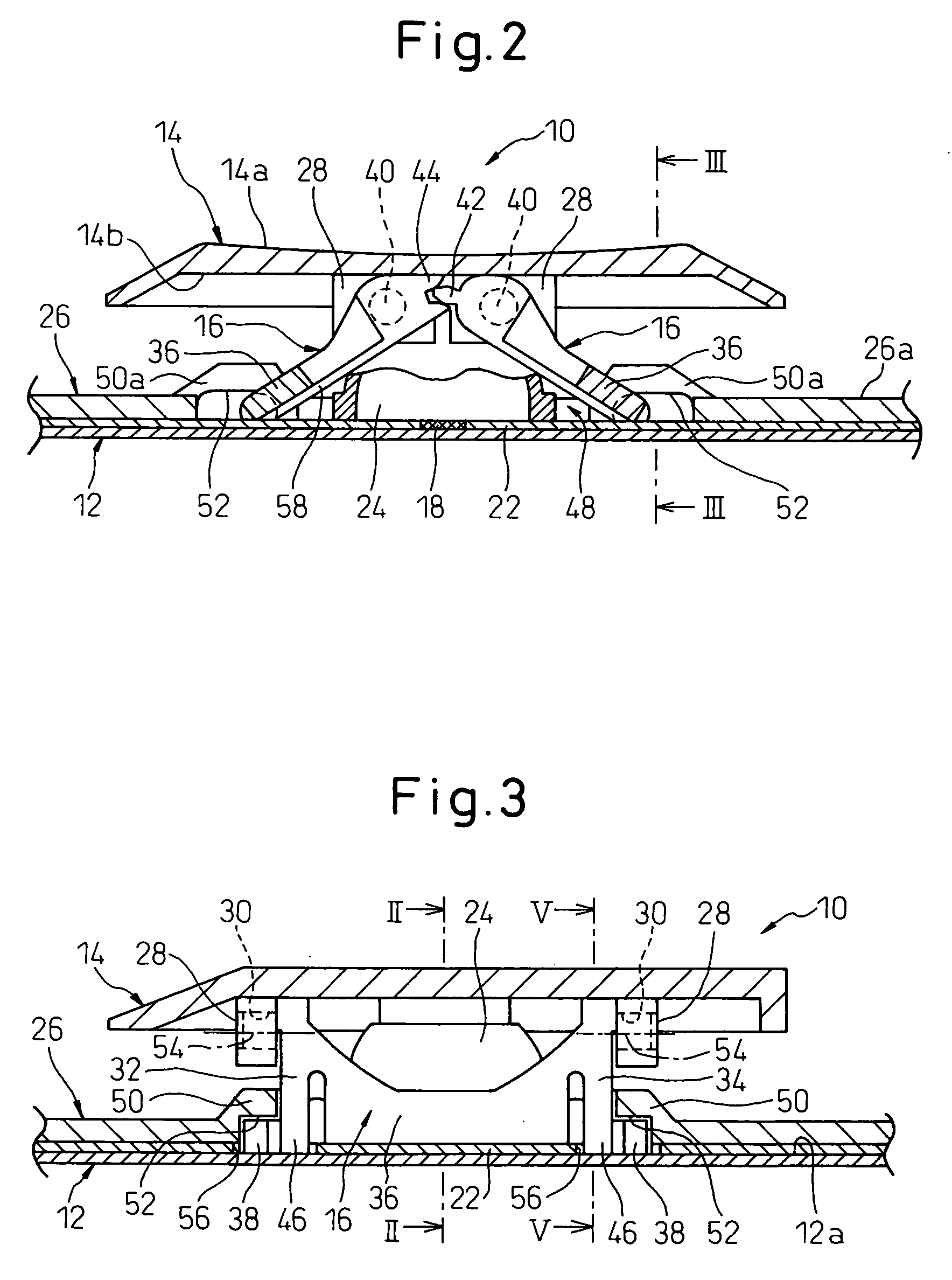

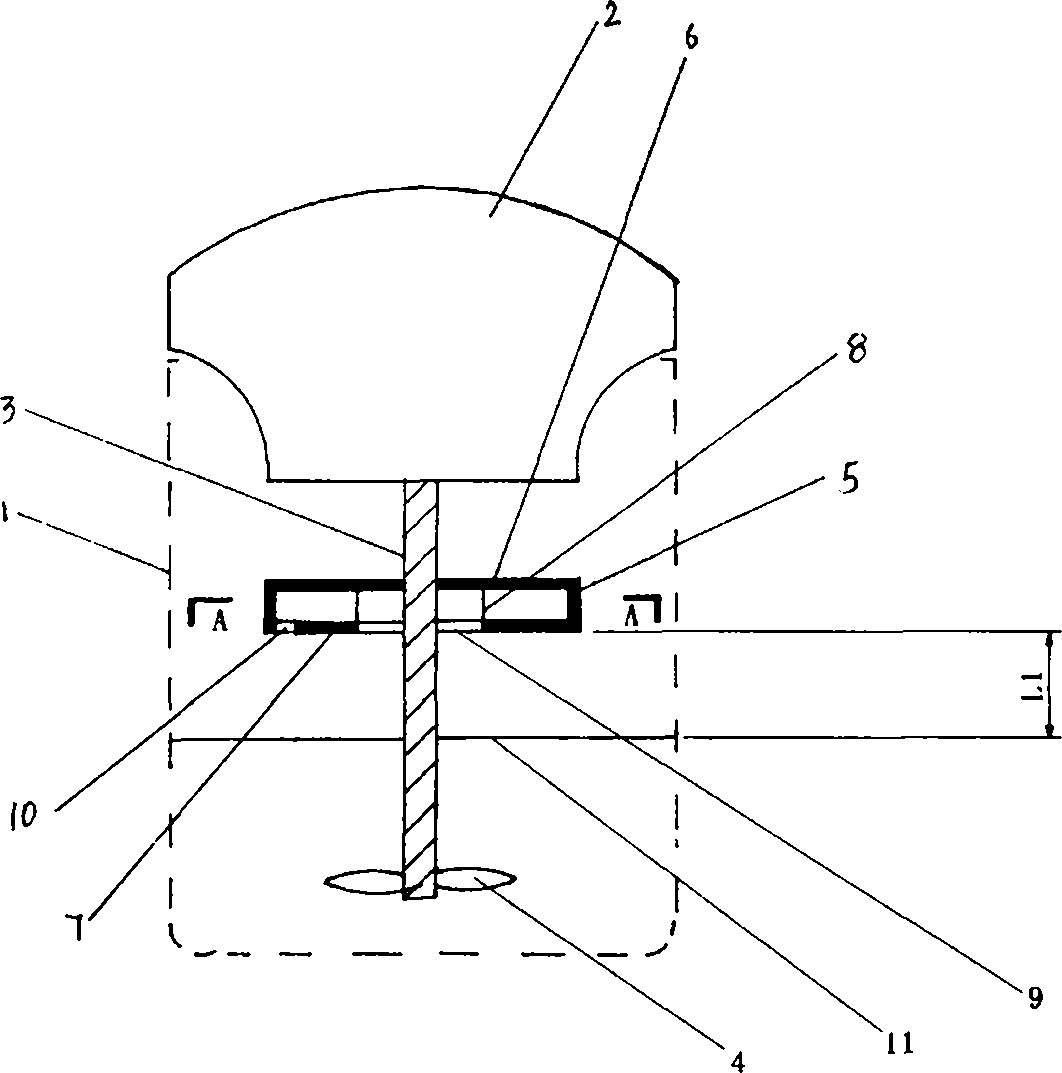

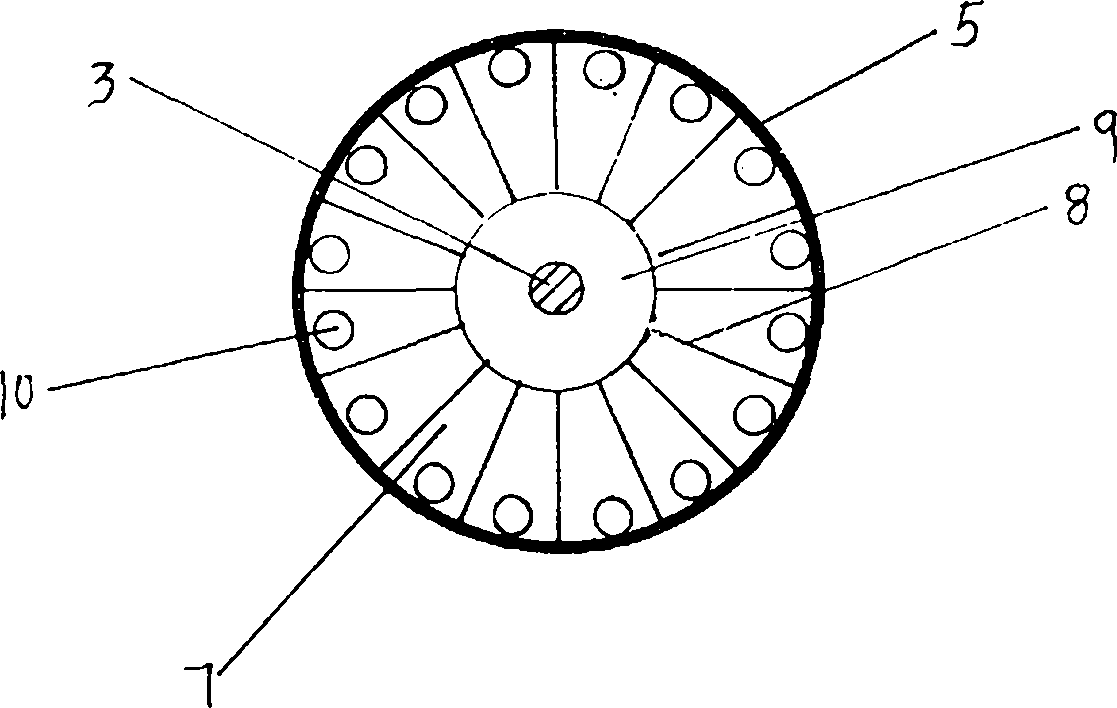

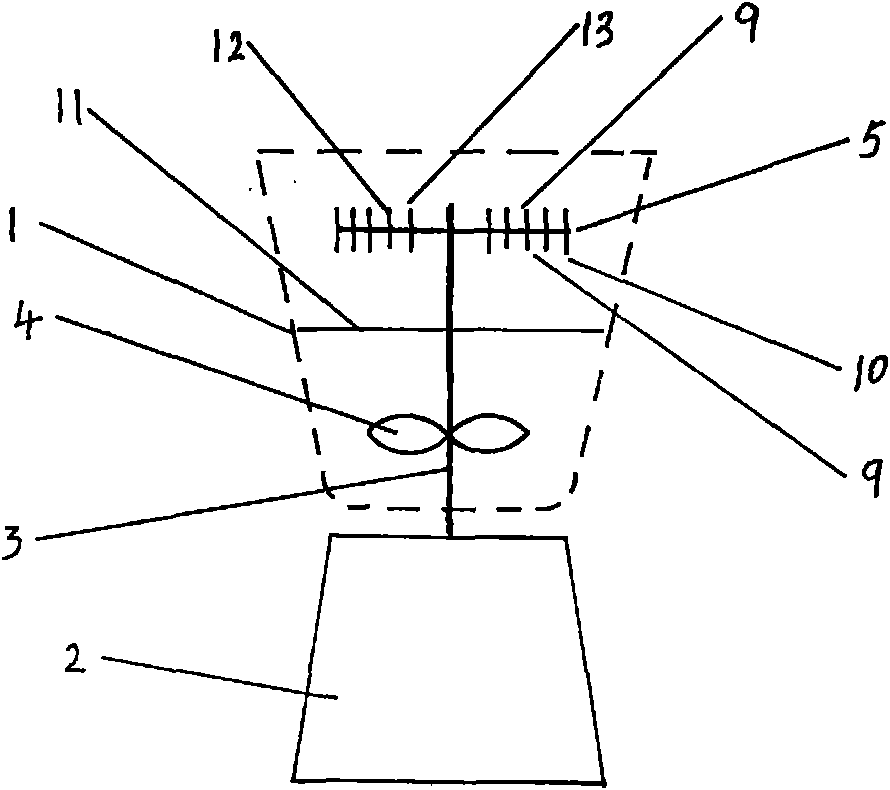

Key switch, keyboard and key-switch assembling jig

ActiveUS7138587B2Increase the itineraryReduced overall height dimensionContact mechanismsContact surface shape/structureMembrane switchKey switch

A key switch used for a keyboard incorporated as an input device in electronic equipment. The key switch includes a support plate; a key top arranged above the support plate; a pair of link members interlocked to each other to support the key top above the support plate and direct the key top in a vertical direction; and a switch mechanism capable of opening and closing a contact section of an electric circuit in accordance with a vertical movement of the key top. The switch mechanism includes a membrane switch sheet carrying the contact section at a position corresponding to the key top and placed on the support plate. Each of the link members includes a sliding part slidably engaged with the support plate. The membrane switch sheet is provided with a through-hole in a region where the sliding part of each link member is engaged with the support plate, the sliding part of the link member being slidably placed on the support plate through the through-hole in the membrane switch sheet.

Owner:FUJITSU COMPONENENT LTD

Key switch, keyboard and key-switch assembling jig

ActiveUS20060000694A1Increase the itineraryReduced overall height dimensionContact mechanismsContact surface shape/structureMembrane switchEngineering

A key switch used for a keyboard incorporated as an input device in electronic equipment. The key switch includes a support plate; a key top arranged above the support plate; a pair of link members interlocked to each other to support the key top above the support plate and direct the key top in a vertical direction; and a switch mechanism capable of opening and closing a contact section of an electric circuit in accordance with a vertical movement of the key top. The switch mechanism includes a membrane switch sheet carrying the contact section at a position corresponding to the key top and placed on the support plate. Each of the link members includes a sliding part slidably engaged with the support plate. The membrane switch sheet is provided with a through-hole in a region where the sliding part of each link member is engaged with the support plate, the sliding part of the link member being slidably placed on the support plate through the through-hole in the membrane switch sheet.

Owner:FUJITSU COMPONENENT LTD

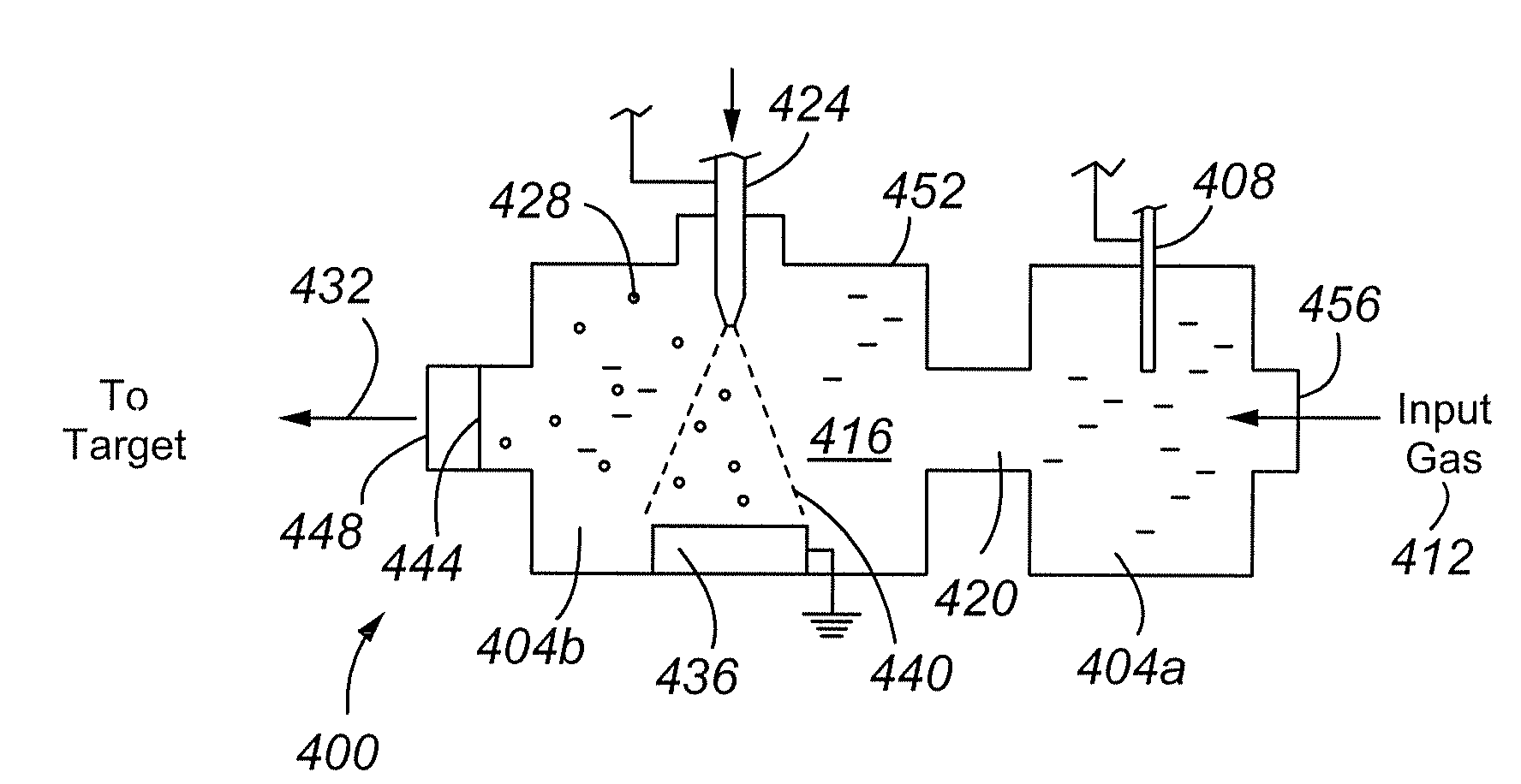

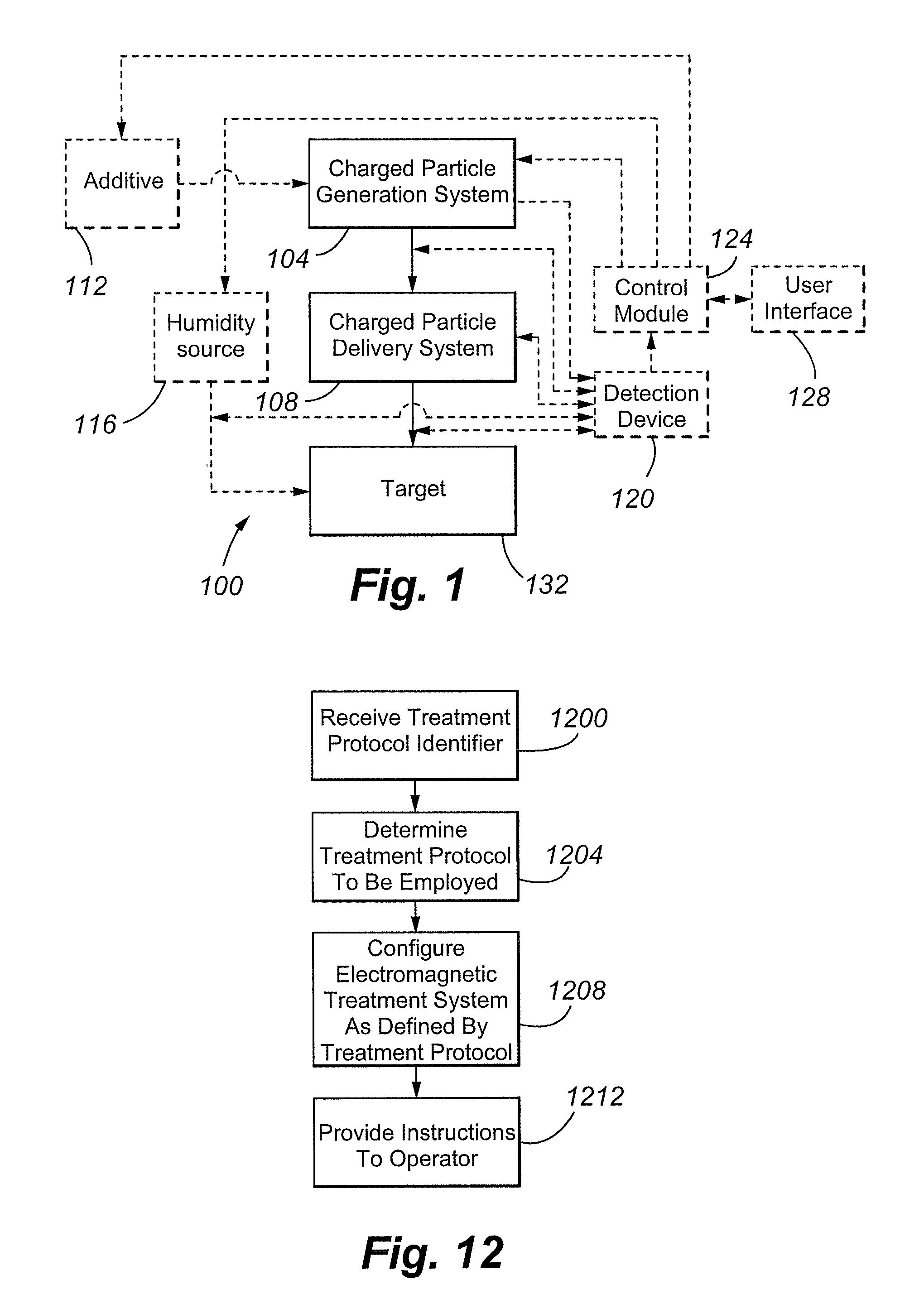

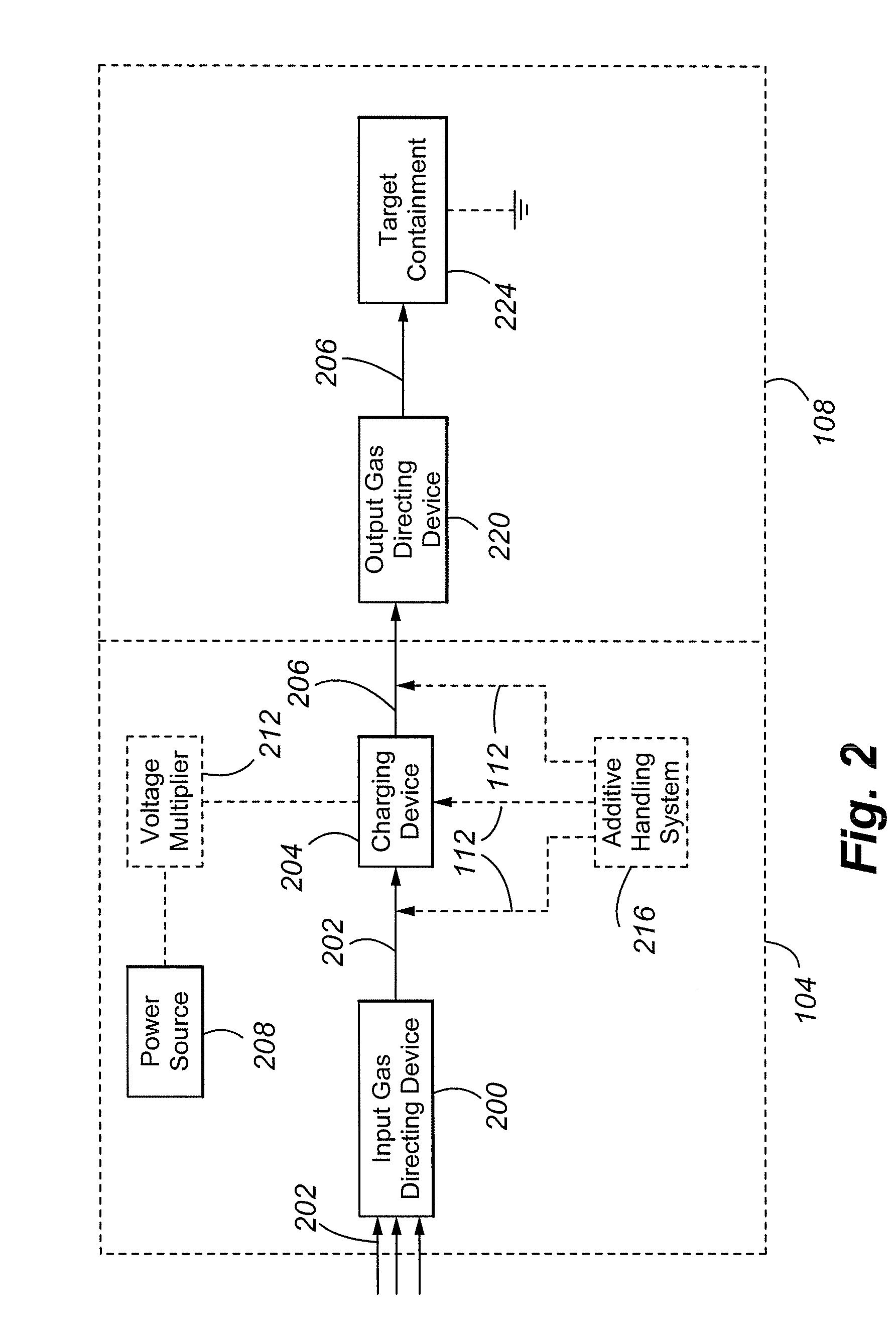

Electrotherapeutic treatment device and method

InactiveUS20090114218A1Improve eliminationGood effectMedical devicesInhalatorsBiological bodyAirflow

The present invention is directed to a treatment method and system that (a) while controlling ozone production, electrically charges a plurality of (i) atomic particles (e.g., diatomic oxygen and water molecules) and / or (ii) electrically charged droplets in an input gas stream to form a charged gas stream and (b) provides the charged gas stream to a living organism to be treated.

Owner:ADA TECH

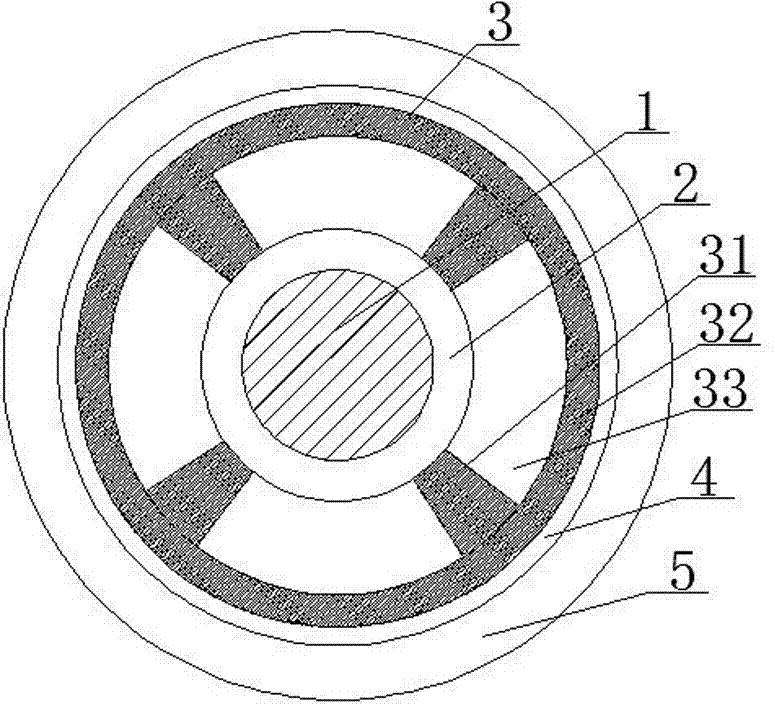

Food processor with high-efficiency defoaming device

The invention relates to a food processor with a high-efficiency defoaming device. A food processor main body comprises a grinding cutter, a motor, a grinding cutter shaft and a barrel body, and the high-efficiency defoaming device is arranged on the food processor; the high-efficiency defoaming device comprises a defoamer main body; the defoamer main body is provided with a foam inlet, an air outlet and a liquid outlet; and at least one of the top of the foam inlet of the defoamer main body, the top of the air outlet, the top of the liquid outlet and the top of the defoamer main body is positioned at 5mm-800mm above the liquid level of foodstuff. According to the food processor, under the situations of heating at any temperature and any heating power and intensely grinding, foams generated when the foodstuff is ground, heated and cooked are rapidly and actively broken, so that grinding or heating cooking operation is continuously and rapidly carried out without intermittent stop, therefore the grinding or cooking time is greatly shortened, and the working efficiency is improved.

Owner:王晓东

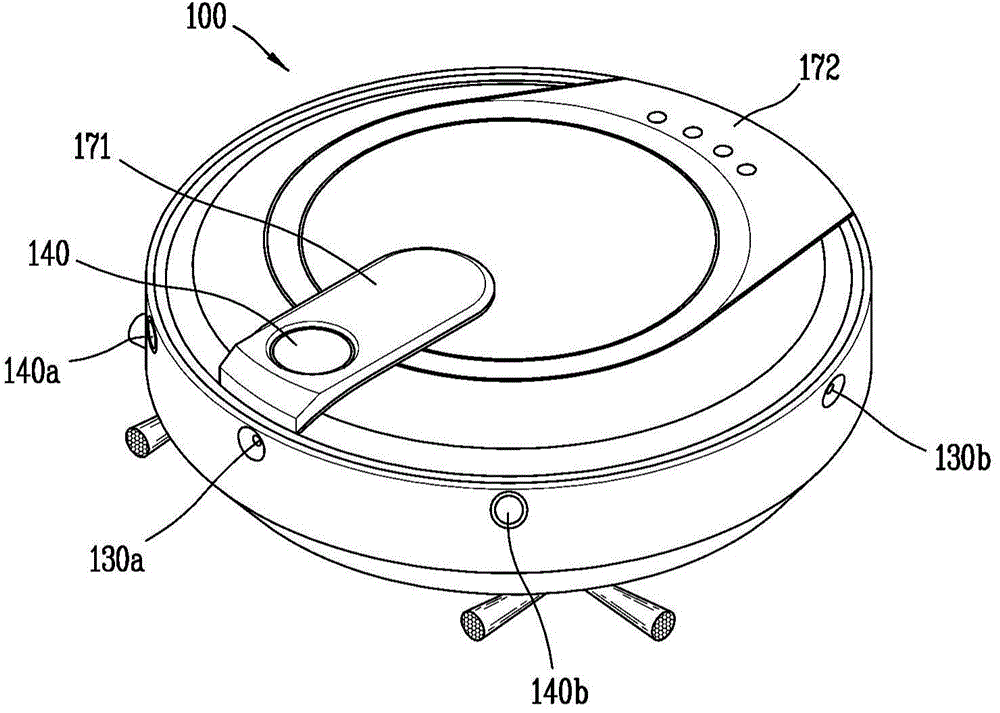

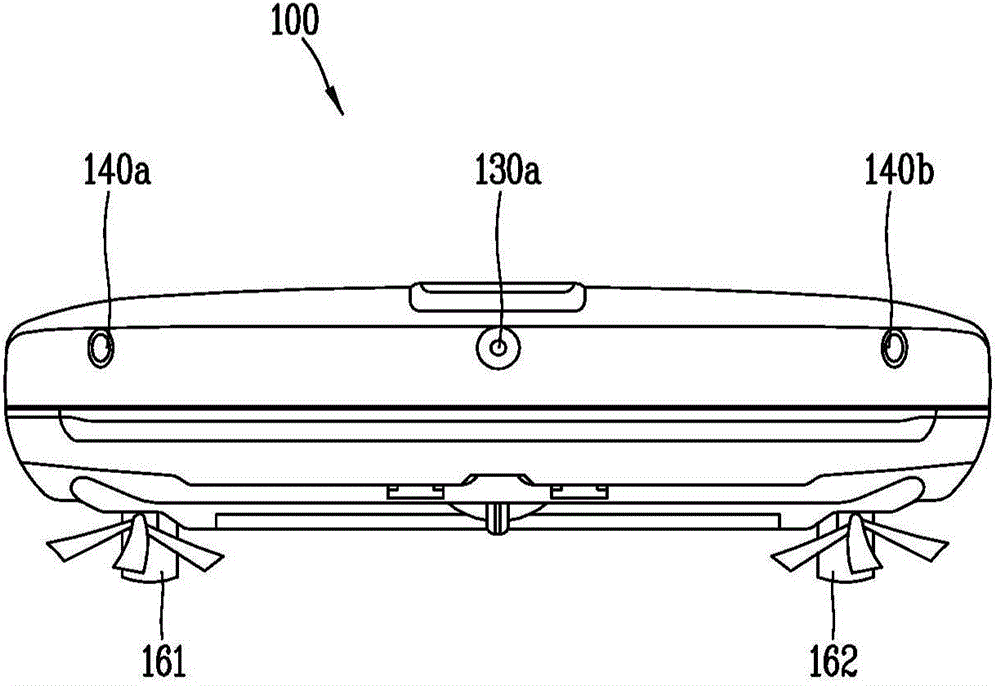

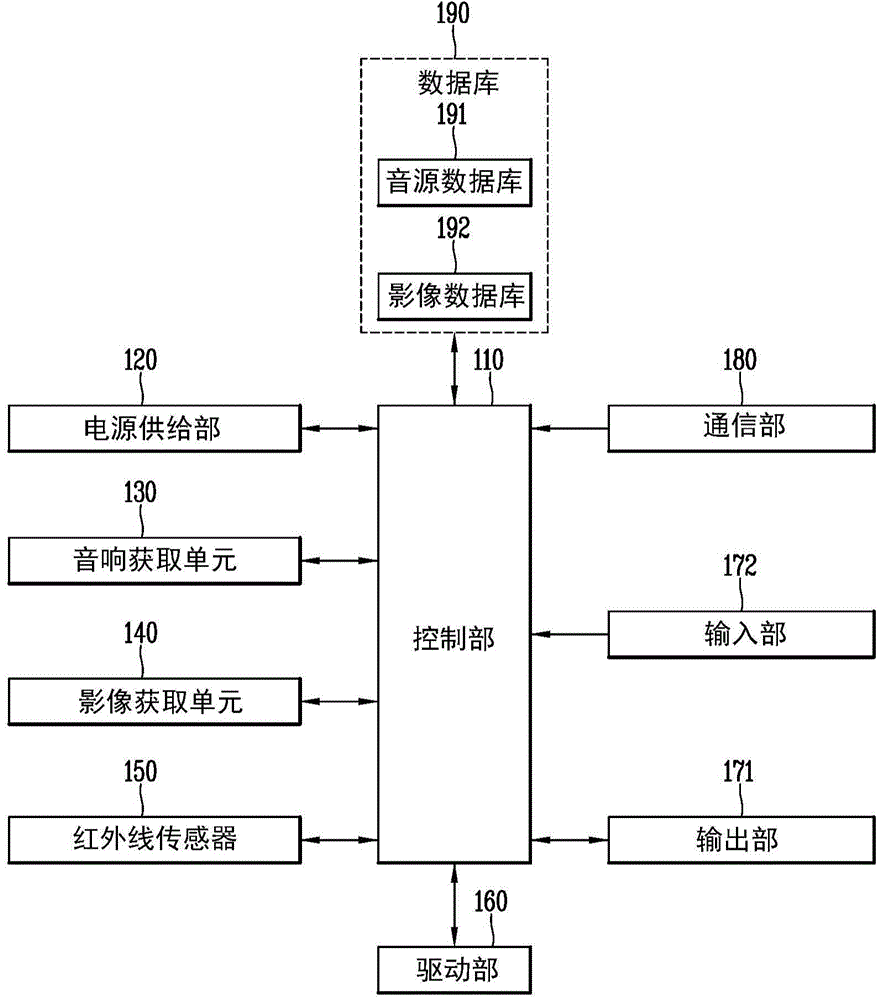

Robot cleaner and method for controlling a robot cleaner

ActiveCN104414590AMinimize power consumptionEfficient communicationProgramme-controlled manipulatorAutomatic obstacle detectionSimulationComputer vision

A robot cleaner 100 having a monitoring function and minimizing power consumption and / or securing communication efficiency and a method of controlling a robot cleaner 100 are provided. The robot cleaner 100 may include at least one sound obtaining device 130; at least one image obtaining device 140; and a controller 110 configured to determine whether a sound obtained through the at least one sound obtaining device 130 is abnormal, sense a direction in which an abnormal sound is generated, and obtain images in the direction in which the abnormal sound is generated. The robot cleaner 100 may automatically recognize a surrounding situation, and when necessary, the robot cleaner 100 may rotate and / or move in a corresponding direction and / or position to obtain images or transmit the obtained images to a remote terminal 200, thereby minimizing power consumption of the robot cleaner 100 with limited power.

Owner:LG ELECTRONICS INC

Composition and method for neck skin firming

InactiveUS20070031367A1Soften sharp edgeSmooth appearanceBiocideCosmetic preparationsWrinkle skinBenzaldehyde

A topical composition and method for its use for reducing sagging or wrinkles in the neck area of human skin. The composition includes safe and effective amounts of a mild topical astringent (such as Camphor) for skin tightening, a topical antispasmodic (such as benzaldehyde or benzyl cinnamate) for skin smoothing, and a topical skin irritant to increase localized skin circulation. The composition can also optionally include palmitoyl oligiopeptides to stimulate production of collagen and elastin in skin, a mushroom or plant leaf ferment extract to increase the cell turnover rate skin, and to increase hydration, skin firmness and elimination of fine facial lines, a cocao ferment extract to inhibit lipid peroxidation, inhibit excess ornithine decarboxylase activity, and stimulate cutaneous blood flow to reduce lines and wrinkles, and a Lactobacillus lysate extract to stimulate collagen production. These ingredients are mixed in a dermatologically acceptable carrier for topical application.

Owner:BROWN VERA +1

Compound for neck skin firming

InactiveUS20060045894A1Soften sharp edgeSmooth appearanceCosmetic preparationsBiocideWrinkle skinAdditive ingredient

A topical compound for reducing sagging or wrinkles in the neck area of human skin. The compound includes safe and effective amounts of a mild topical astringent (such as Camphor) for skin tightening, a topical antispasmodic (such as benzyl cinnamate) for skin smoothing, and a topical skin irritant to increase localized skin circulation. The compound can also optionally include palmitoyl pentapeptide-3 to stimulate production of collagen and elastin in skin, a mushroom ferment extract to increase the cell turnover rate skin, and to increase hydration, skin firmness and elimination of fine facial lines, a cocao ferment extract to inhibit lipid peroxidation, inhibit excess ornithine decarboxylase activity, and stimulate cutaneous blood flow to reduce lines and wrinkles, and a Lactobacillus lysate extract to stimulate collagen production. These ingredients are mixed in a dermatologically acceptable carrier for topical application.

Owner:BROWN VERA +1

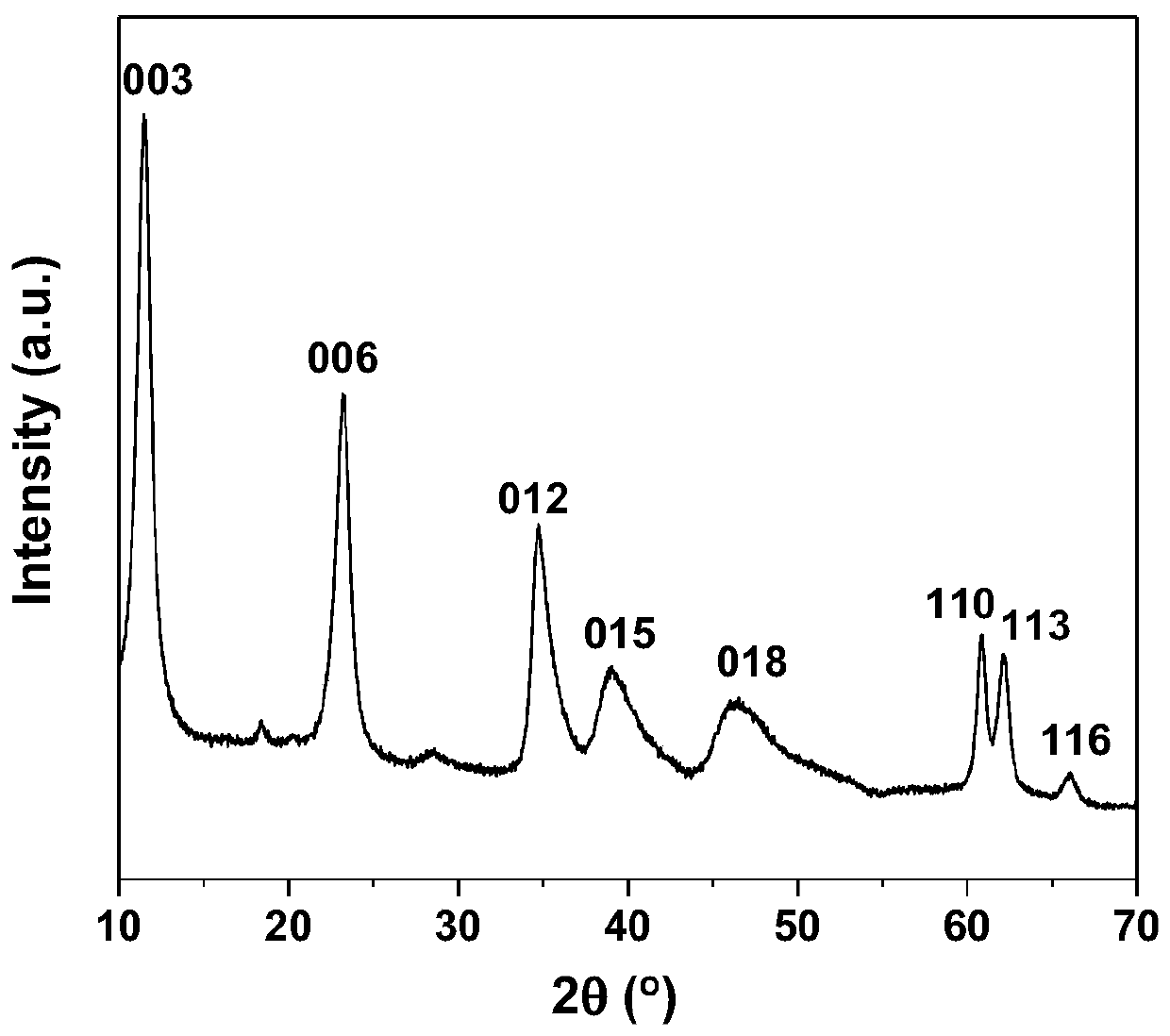

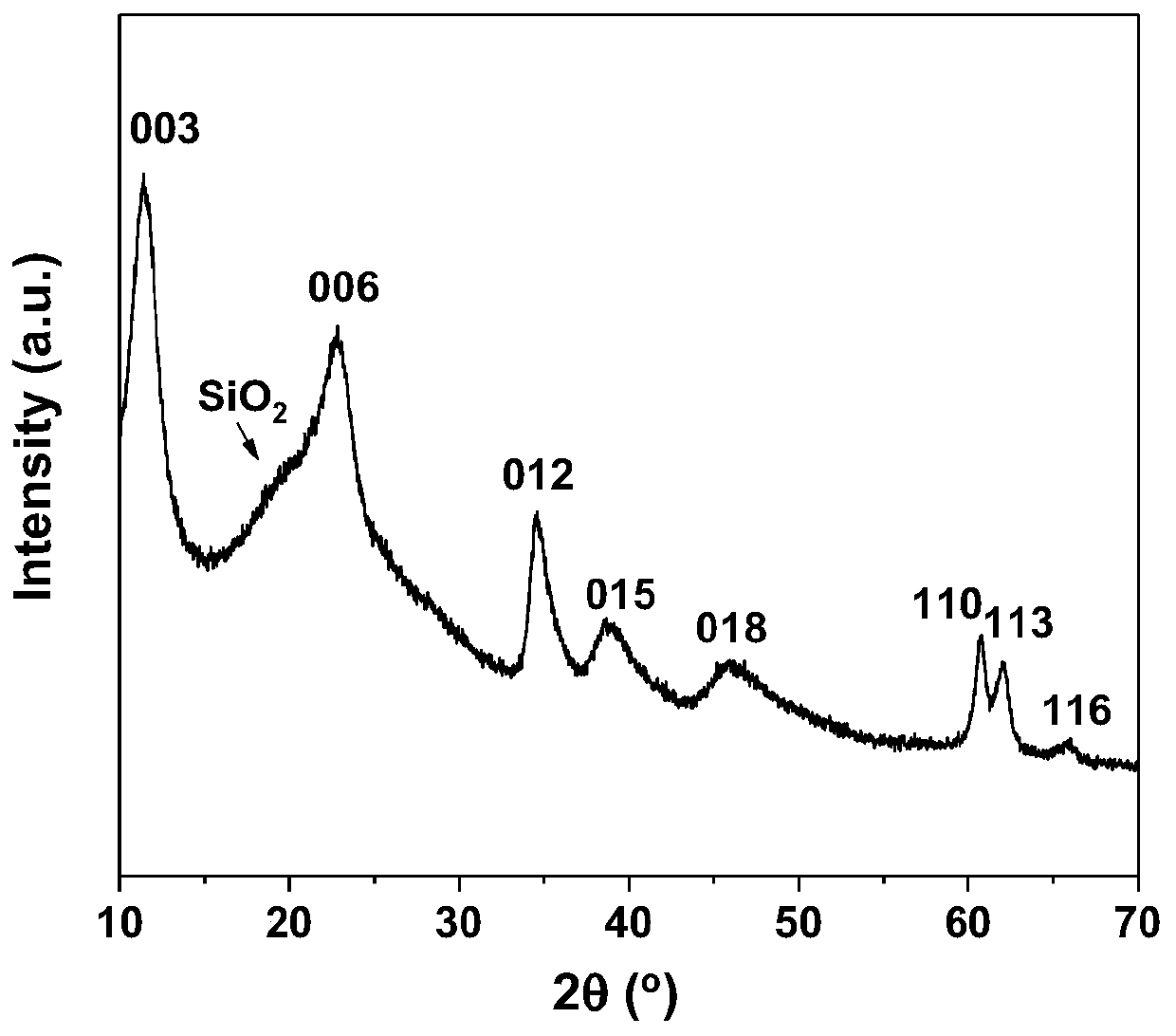

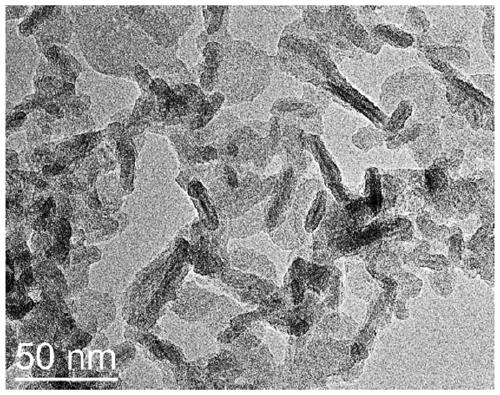

High activity and carbon deposition resistant catalyst for reforming of dry methane gas and preparation method thereof

ActiveCN109967081AAchieve directed assemblyReduce usageHydrogenHydrogen/synthetic gas productionWater-gas shift reactionDehydrogenation

The invention discloses a high activity and carbon deposition resistant catalyst for the reforming of dry methane gas and a preparation method thereof. Specifically, stable sol with a nano laminated structure is prepared through a precipitation method; then a second component is in-situ coated; and after drying, burning, and reduction-activating, the catalyst with a nano laminated coated structureis obtained. The catalyst has high activity in the reforming reactions of dry methane gas, has a strong carbon deposition resistant performance, can continuously play a catalyst role at a temperatureof 400 to 900 DEG C, and is resistant to inactivation. The raw materials are easily available, the technology is simple, and the catalyst can also be applied to reforming of methane water steam, carbon dioxide assisted dehydrogenation of ethane and propane, and water-gas shift reaction.

Owner:DALIAN UNIV OF TECH

Agent for source control of household garbage stench as well as preparation and application methods of agent

InactiveCN105331028AImprove eliminationNo secondary pollutionChemical protectionPolyvinyl alcoholMethyl cellulose

The invention relates to an agent for source control of household garbage stench as well as preparation and application methods of the agent. The preparation method comprises steps as follows: 0.4%-2.0% by mass of polyvinyl alcohol, 1.0%-3.0% by mass of polyvinylpyrrolidone and 0.5%-1.8% by mass of hydroxypropyl methyl cellulose are taken firstly, polyvinyl alcohol is added to water and stirred, an aqueous polyvinyl alcohol solution with the mass concentration of 0.8%-4.0% is prepared and is cooled to the room temperature, an isometric solvent is added and uniformly stirred, finally, polyvinylpyrrolidone and hydroxypropyl methyl cellulose are sequentially added and sufficiently and uniformly mixed, and the stench removing agent is obtained. The agent is sprayed to the surface of household garbage, a film layer is formed rapidly, and the source stench of the household garbage is shielded accordingly, or different effective components are doped for elimination of stench in air. The stench removing agent is simple to prepare, the stench removing principle is novel, the effect is obvious, the secondary pollution is avoided, the requirement for equipment is not high, and the agent can be widely applied to other industrial fields with stench pollution production.

Owner:TONGJI UNIV

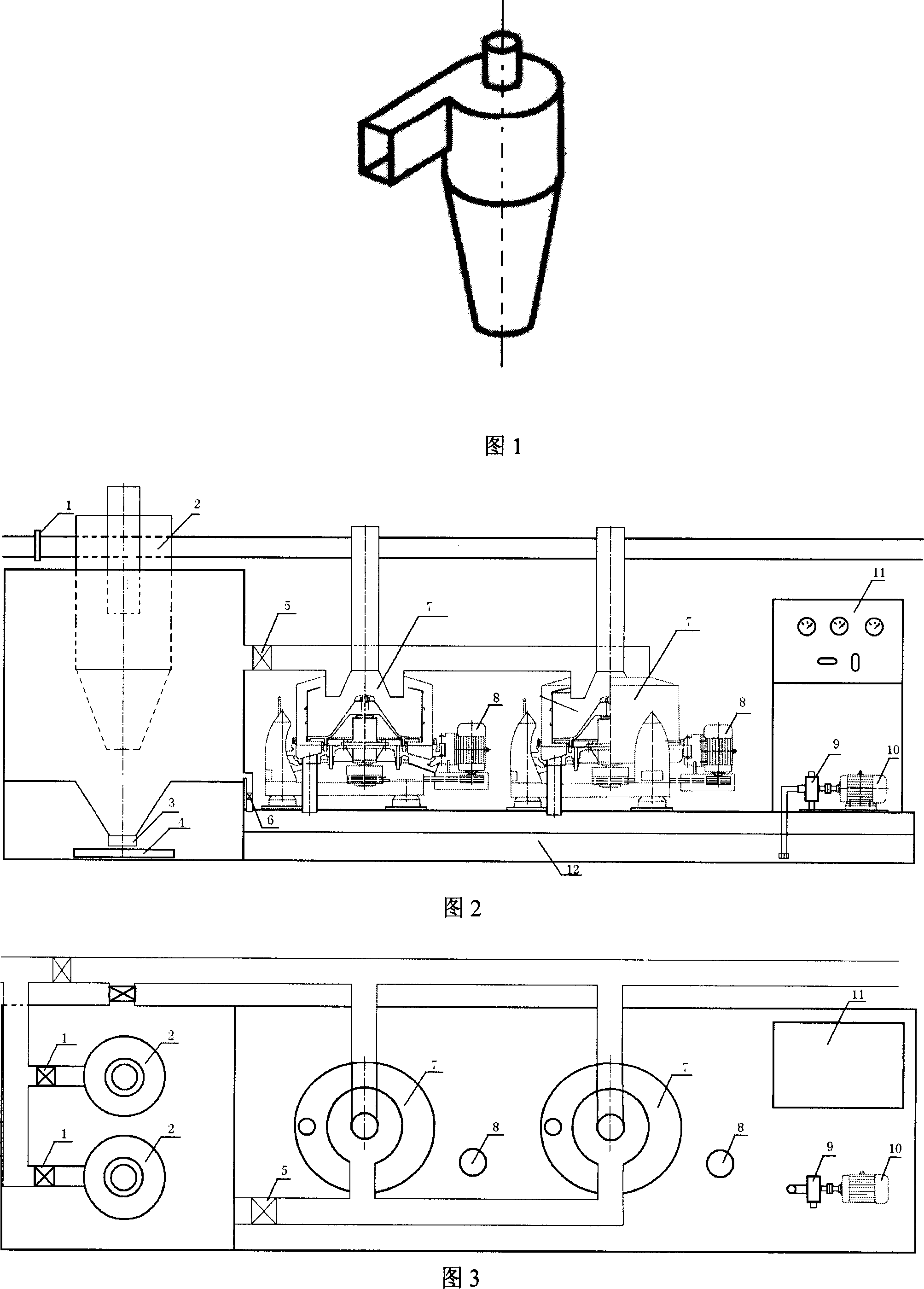

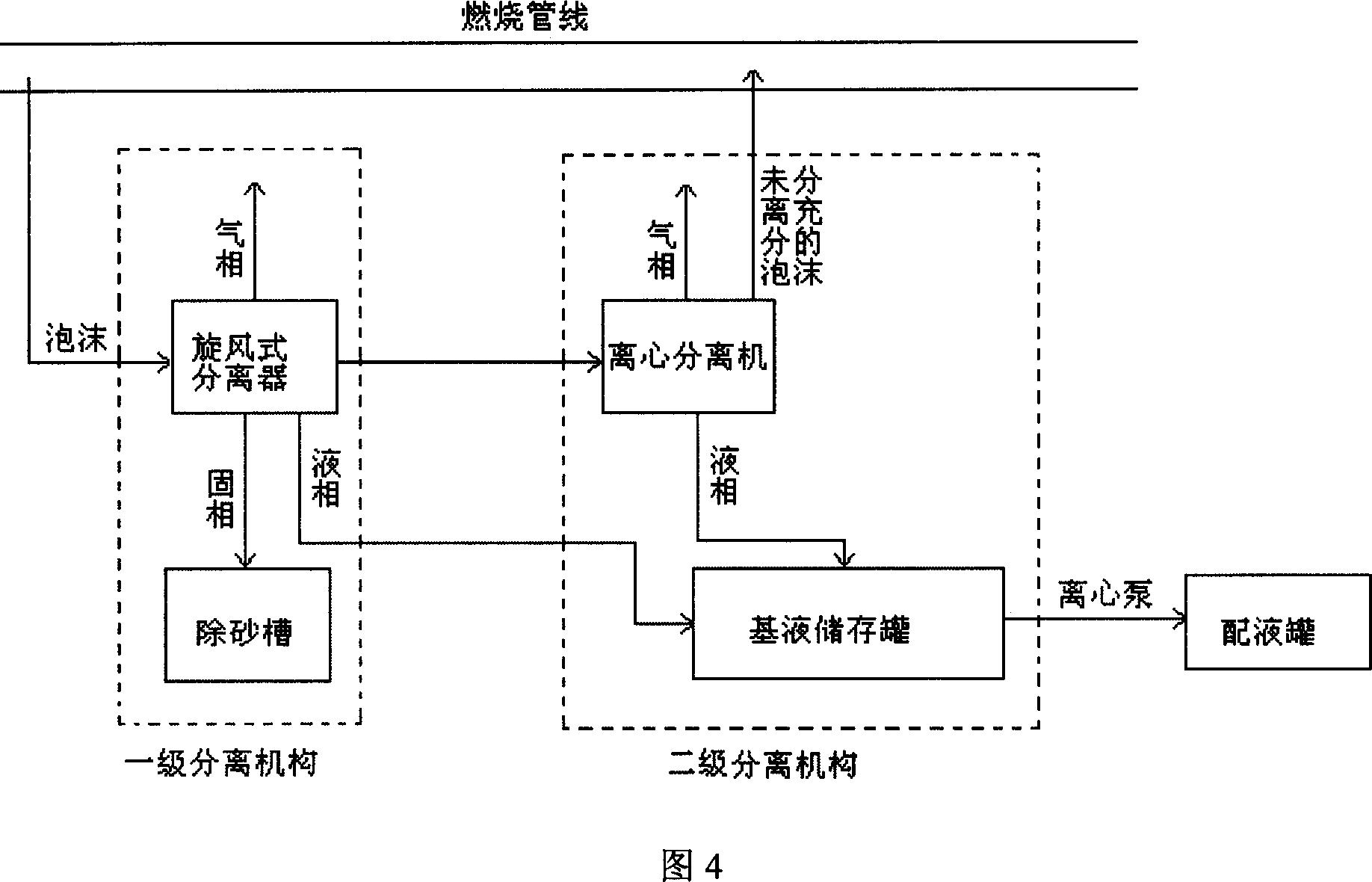

Defoaming method for the foam well drilling

InactiveCN101095990AImprove eliminationSimple methodVortex flow apparatusDrilling compositionCycloneFailure rate

The invention relates to an anti-foaming method in foam drill, belonging to the oil drilling field. In the method solid phase, partial air phase and partial liquid phase can be separated by first-order cyclone separator. Not-separated foam enters into second-order anti-foaming centrifugal machine to separate air phase and liquid phase fully. The method can eliminate foam effectively in foam drilling process so that drilling matrix liquid can be used repeatedly. It is provided with convenient method, small cubage of anti-foaming device, light weight, few assistant equipment, low failure rate, decreased drilling cost and decreased circumstance pollution so on.

Owner:WESTERN DRILLING KELAMAYI DRILLING TECH INST

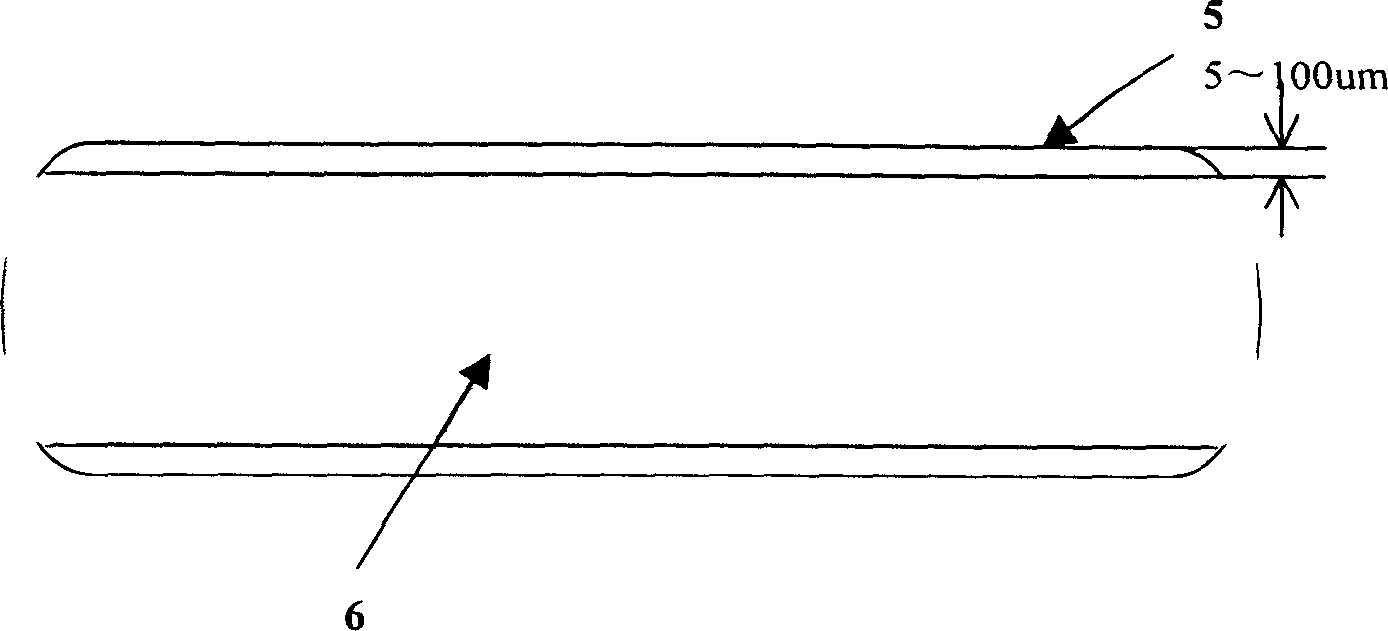

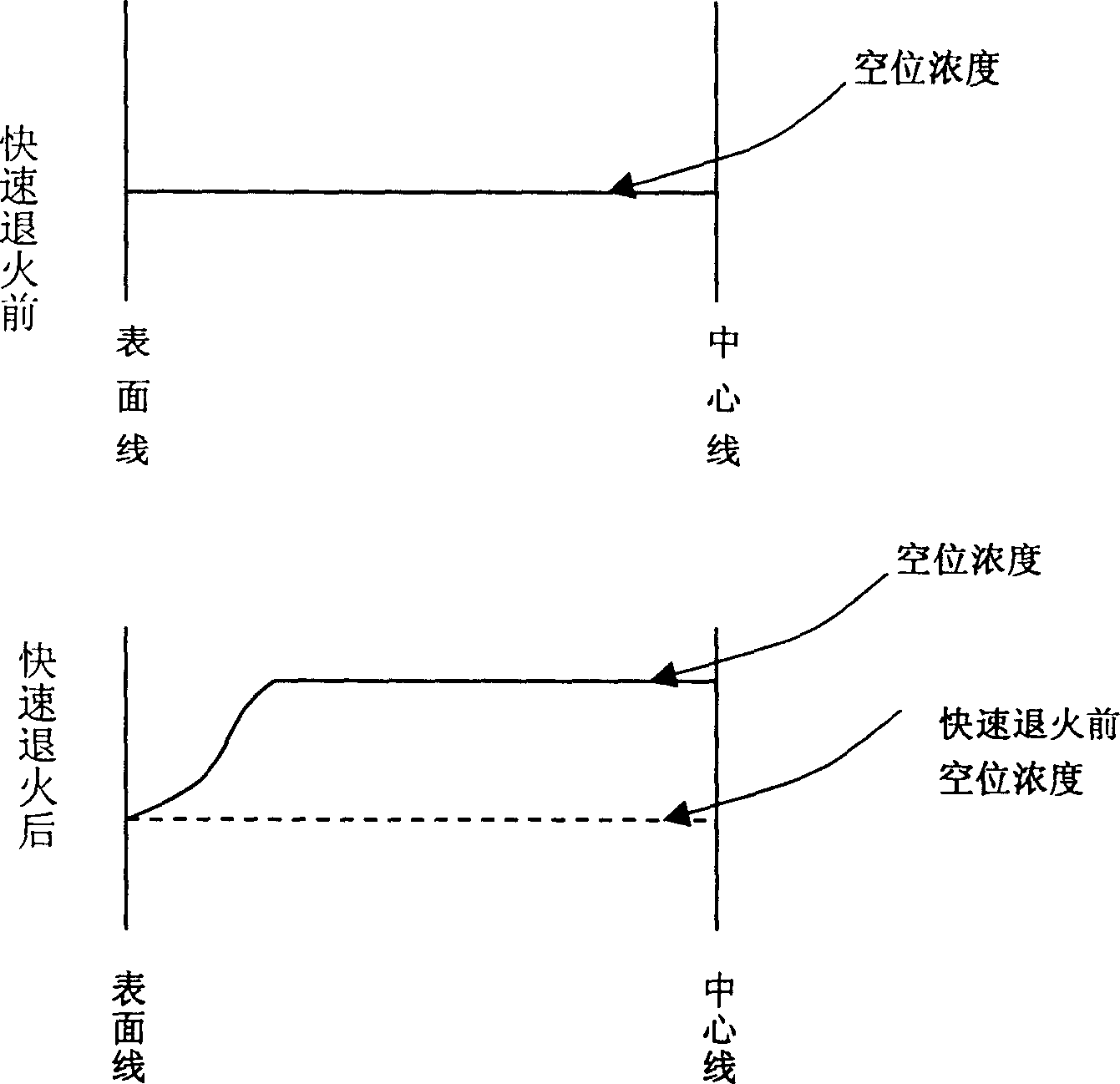

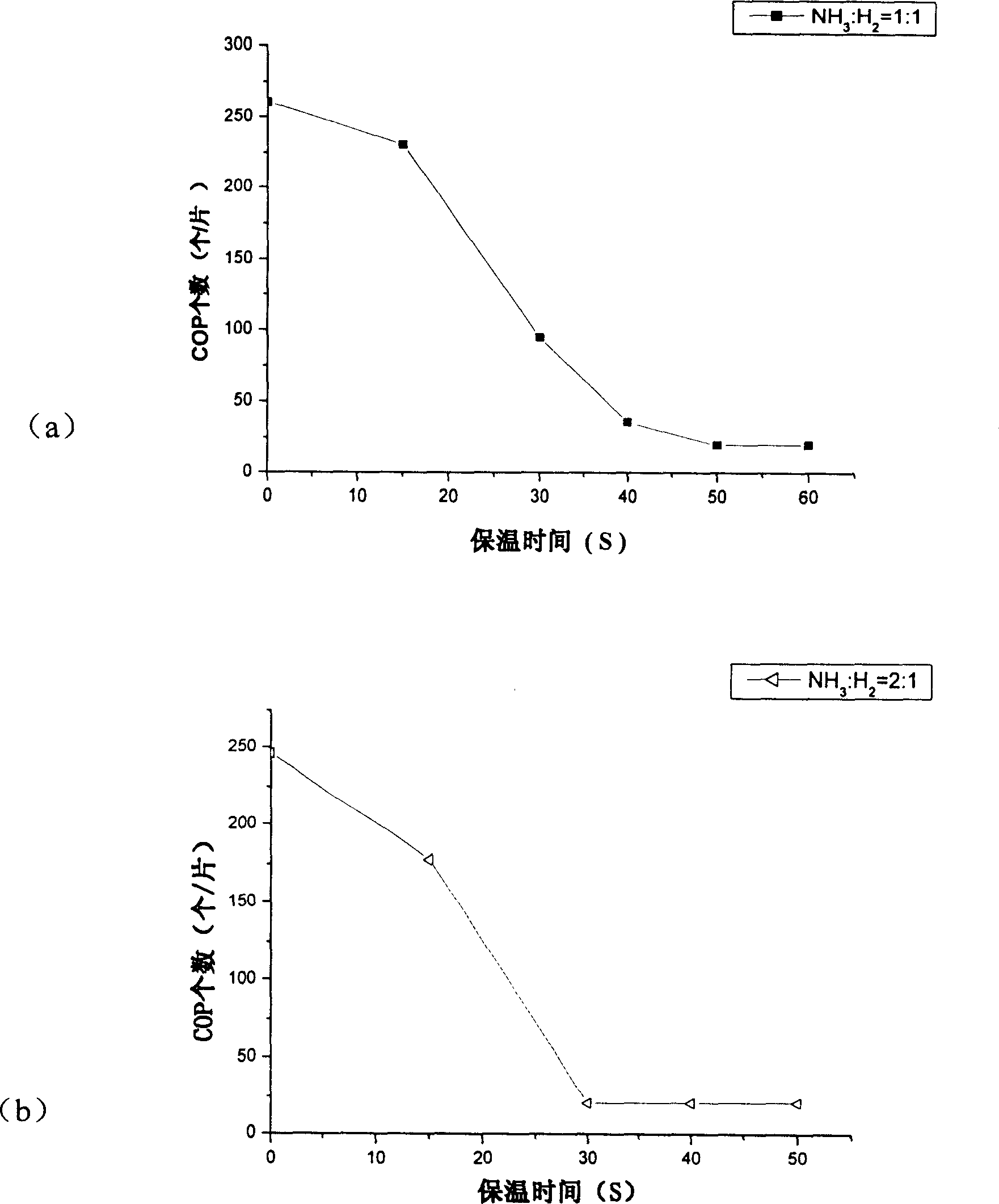

Rapid thermal process for silicon sheet capable of obtaining denuded zone and product thereof

ActiveCN1838388AImprove eliminationMeet the requirements of getteringSemiconductor/solid-state device manufacturingHeat treatedOxygen

This invention relates to a silicon fast heat process technology for obtaining clear area and its product. The method includes: (1) in Ar / NH3 / H2 or N2 / NH3 / H2, heating silicon sheet up to 1150- 1250DEG.,then keeping the temperature of the silicon sheet under 1150-1250DEG., then lowering temperature by 20-100DEG. / S speed to normal temperature; (2)anneal by regular method ; (3) heat processing by regular method to obtain the silicon sheet with clear area. This technology can control the thickness of the clear area between 5-40 mum, under which the technology can improve the oxygen deposition density of the impurity absorbing area and lower COP density of the surface.

Owner:GRINM SEMICONDUCTOR MATERIALS CO LTD

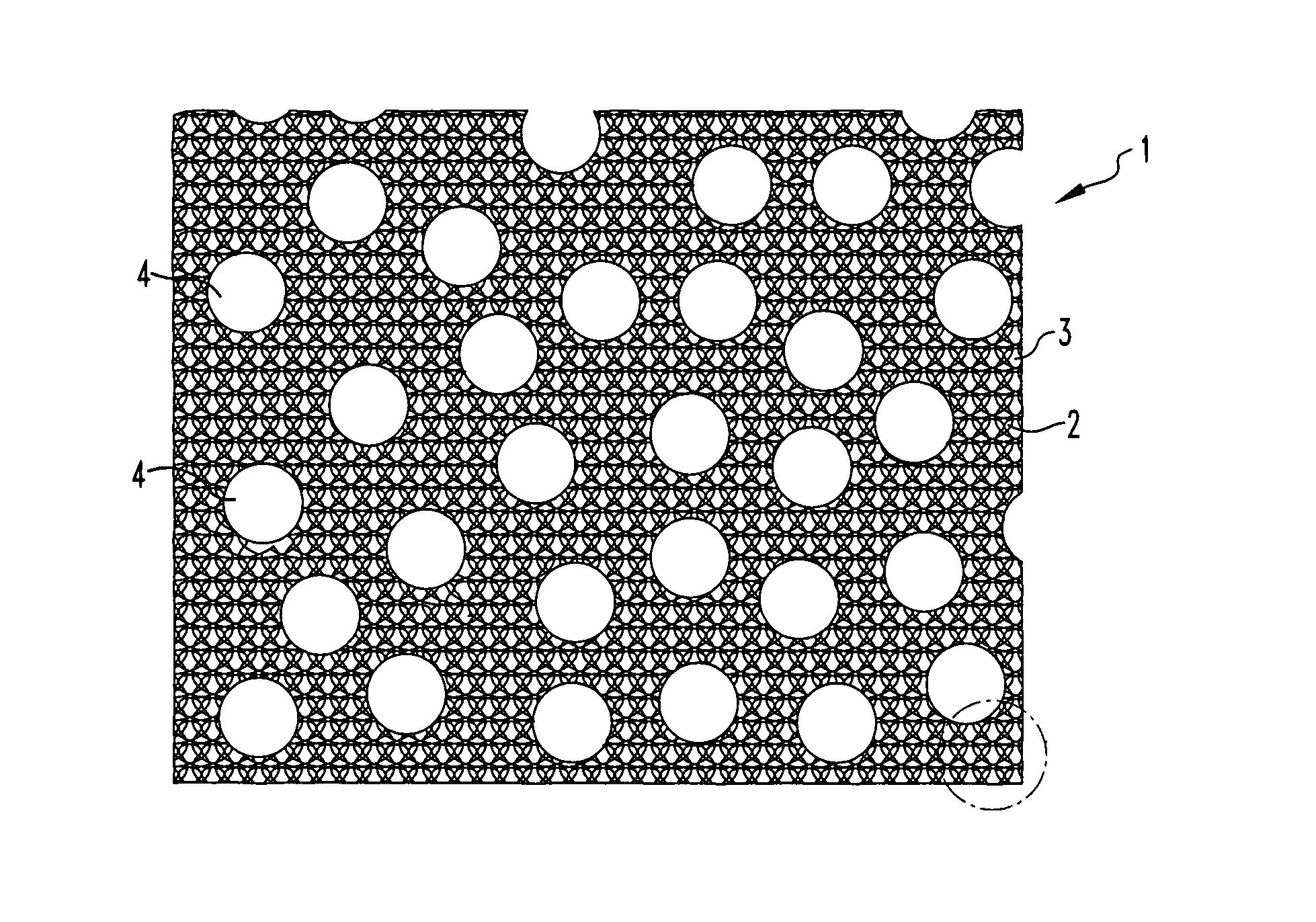

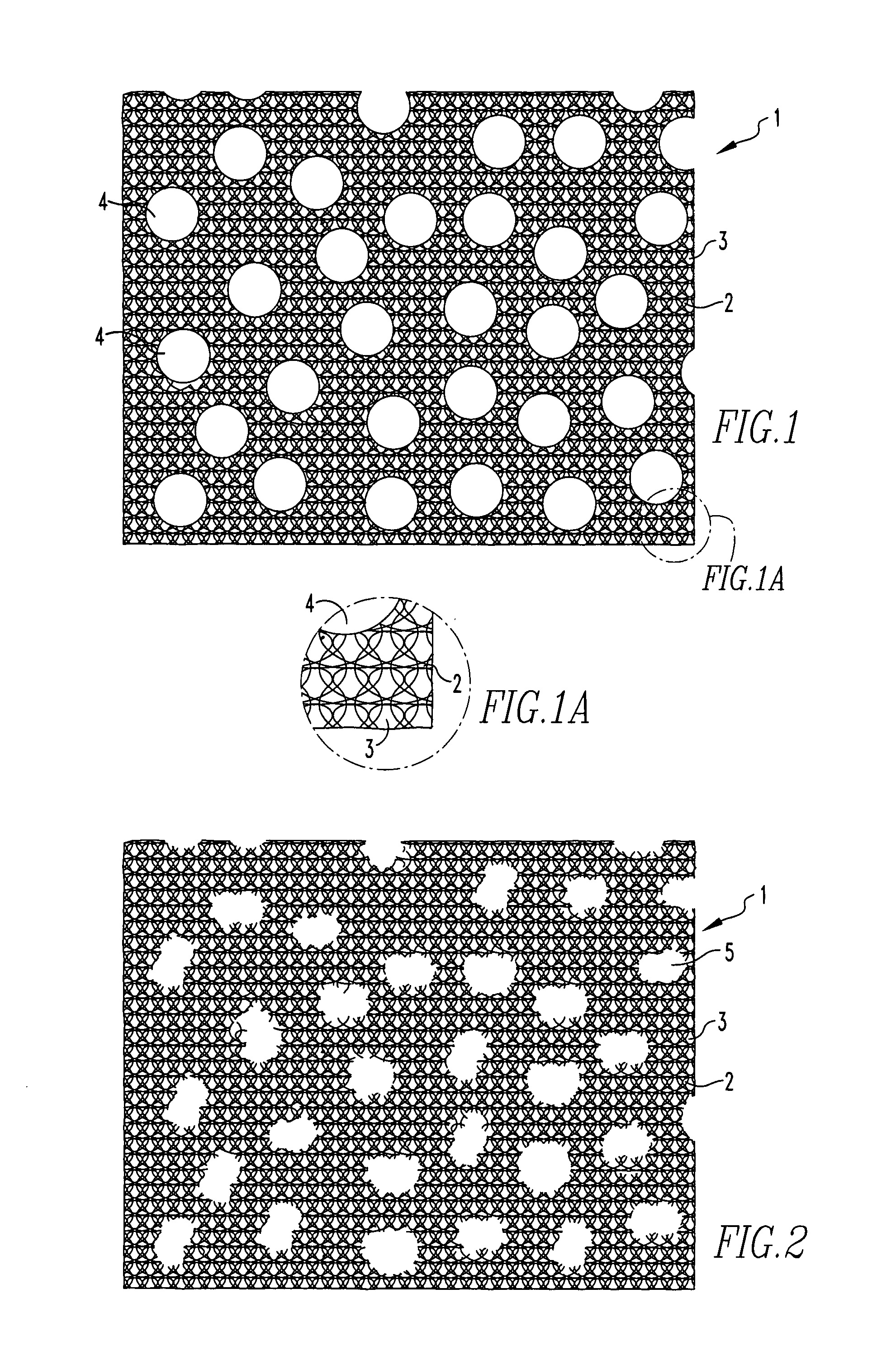

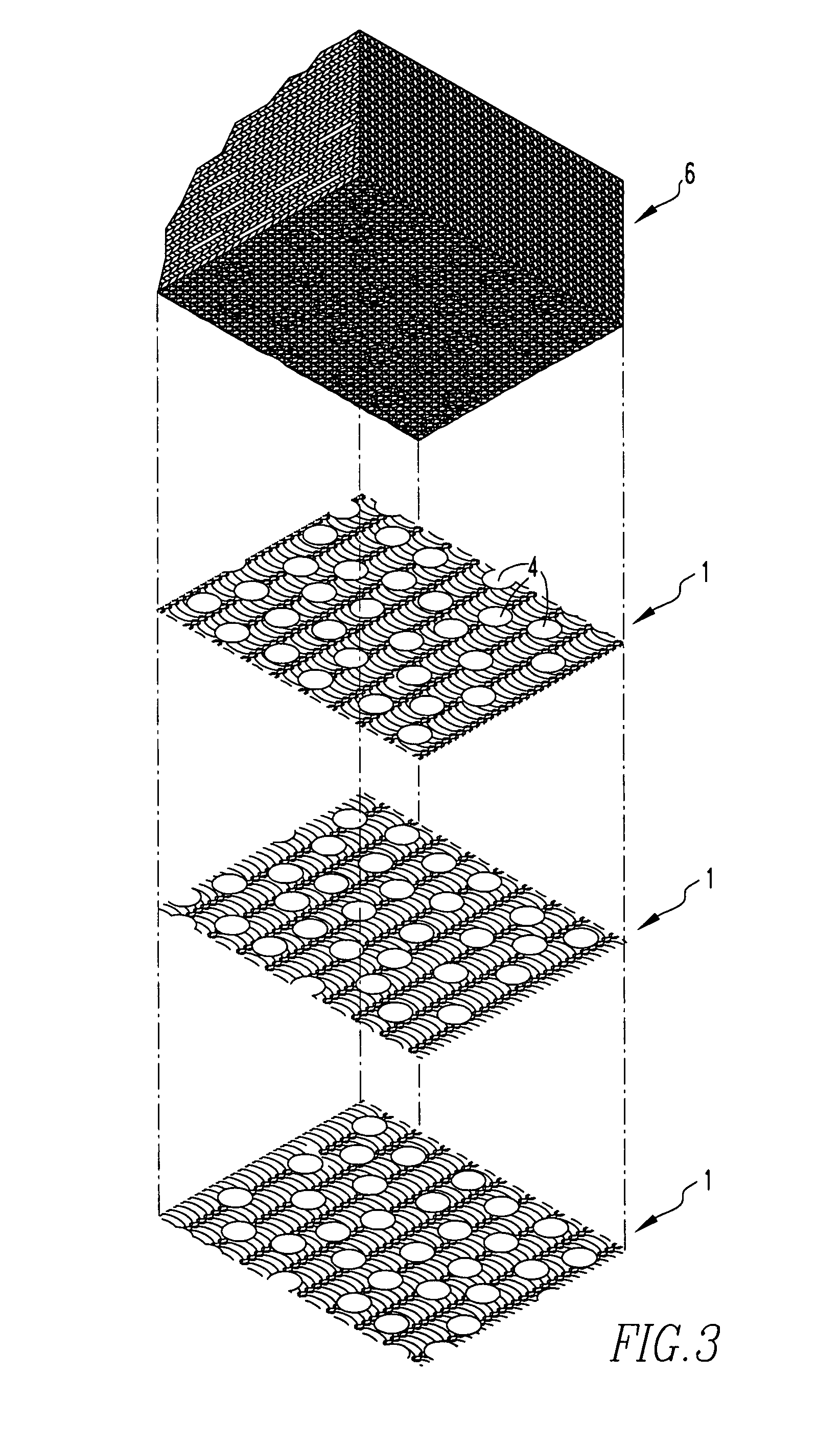

Filamentary pad for improved mist elimination and mass transfer

InactiveUS7291196B1Maximizing gas flowSimple methodCombination devicesButtonsBiomedical engineeringLow resistance

An apparatus and method of making a filamentary pad for improved mist elimination and mass transfer comprising a plurality of layers of mesh, each layer of mesh having a plurality of mesh openings defined therein. A plurality of preferential gas flow openings, each having an area larger than any of the areas of said mesh openings absent said preferential gas flow openings, are defined within at least two layers of mesh. The plurality of layers of mesh are vertically stacked to form the filamentary pad. The preferential gas flow openings provide preferential low-resistance paths for gas flow.

Owner:LERNER BERNARD J

Nano silver-group formaldehyde eradicating-liquid and preparation method thereof

ActiveCN1907546AImprove eliminationNot corrosiveDispersed particle separationDeodrantsEscherichia coliComplexons

The invention relates to a nanometer silver formaldehyde eradicating-liquid, which is formed by triethanolamine, sodium sulfite, complexon, amchlor, amylaceum, water and water-soluble colloidal silver, wherein the average diameter of water-soluble colloidal silver is 1-100nm; said eradicating-liquid can quickly disinfect bacillus coli, etc, and reduce the free formaldehyde density under 0.08mg / m3, while the virus disinfection rate is above 90%. The invention also discloses a relative preparation.

Owner:上海沪正实业有限公司

Pulse current assisted aluminum alloy homogenization heat treatment method

The invention discloses a pulse current assisted aluminum alloy homogenization heat treatment method. The method is characterized in that an alloy workpiece is connected with a current generation device, and the alloy workpiece undergoes heat insulation in a heat treatment furnace; a heat insulation temperature is a routine homogenization heat treatment temperature or is 5-15DEG C lower than the routine homogenization heat treatment temperature; a pulse current is applied to the alloy workpiece when a heat insulation time reaches 30-70% of a total routine alloy homogenization heat time; and after the treatment time of the alloy workpiece reaches the total routine homogenization time, power-off and discharge from the furnace are sequentially carried out. The method respectively considers the phases with different properties in the cast state of an aluminum alloy, and utilizes the Peltier heat effect and parts of joule heat of the interface of a current flowing substrate and an intermetallic compound after the solid solution of low melting point compounds in the cast is full in the homogenization heat treatment process in order to promote the elimination of a sharp interface between a high melting point phase and the aluminum alloy substrate.

Owner:GUIZHOU UNIV

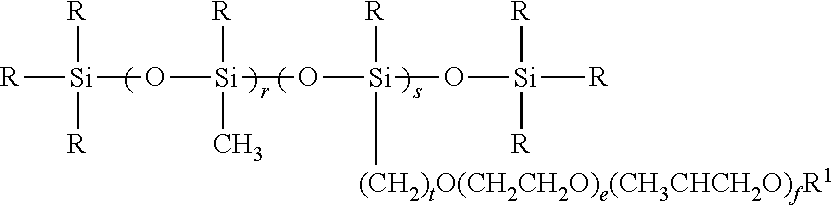

Particle defoamer and process for preparing same

ActiveUS20140142020A1Ensure qualityImprove production stabilityNon-ionic surface-active compoundsOrganic detergent compounding agentsEmulsionPolymer science

A process for preparing a particle defoamer. The particle defoamer of 55%-75% of a carrier, 15%-35% of a silicone emulsion, 3%-10% of a texturing agent and 2%-10% of a solvent, based on the total weight of the particle defoamer; the process for preparing the particle defoamer is: (1)first adding a carrier A1 into a mixer, and then adding thereto a silicone emulsion B1, and stirring uniformly; (2)adding a carrier component A2 to the mixture obtained in (1), and stirring uniformly; (3)adding a silicone emulsion B2 to the mixture obtained in (2), and, after uniformly stirring, adding the solvent thereto and stirring uniformly; and (4)pelleting and drying by baking the mixture obtained in(3), so as to produce the product.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

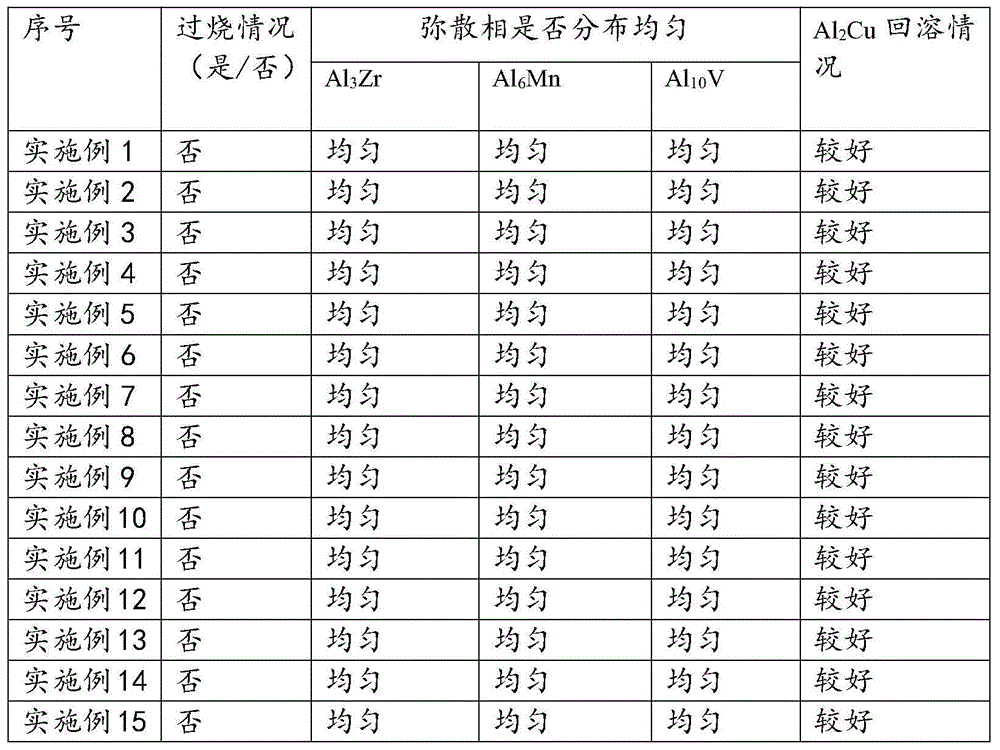

Homogenization thermal-treatment method for ultra-large semi-continuous cast round ingot

The invention discloses a homogenization thermal-treatment method for an ultra-large semi-continuous cast round ingot and relates to the technical field of aluminum alloy processing. The method comprises the following concrete steps: (1) heating the round ingot to the temperature of 180 DEG C at a temperature rising speed below 15 DEG C / h; (2) heating the round ingot to the temperature of 520 to 535 DEG C from the temperature of 180 DEG C at a temperature rising speed of 60-90 DEG C / h, and keeping the temperature for 30h to 80h at the temperature of 520 to 535 DEG C; (3) cooling the round ingot to the temperature of 360 DEG C from the temperature of 520 t0 535 DEG C at a temperature descending speed below 60DEG C / h; (4) cooling the round ingot to the temperature of 130 DEG C from the temperature of 360 DEG C at a temperature descending speed of 80 to 200 DEG C / h; (5) cooling the round ingot to room temperature from the temperature of 130 DEG C. According to the characteristics of the ultra-large semi-continuous cast round ingot, the method disclosed by the invention can be used for fully eliminating dendritic structures and low-melting-point eutectic structures, also enabling the elements such as zirconium, manganese and vanadium to be dispersed and distributed uniformly and guaranteeing the deformation processing structures in the later period and the final comprehensive performances of products.

Owner:广西南南铝加工有限公司

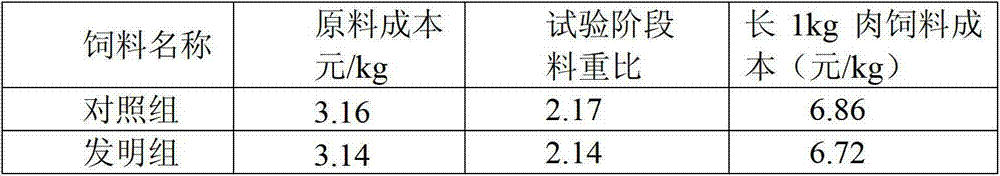

Piglet compound feed composition with fermented rapeseed meal

The invention discloses a piglet compound feed composition with fermented rapeseed meal. The piglet compound feed composition contains the following raw material components in percentage by weight: 40%-60% of corns, 8%-15% of puffed corns, 3%-5% of bran, 1%-3% of freshwater fish meal, 15%-20% of bean pulp, 5%-10% of fermented rapeseed meal, 0.2%-0.5% of dicalcium phosphate, 0.5%-1% of limestone powder, 0.1%-0.3% of 98% lysine, 0.01%-0.03% of methionine, 0.05%-0.1% of choline chloride, 0.2%-0.5% of salt, and 1%-1.5% of premixes. The compound feed disclosed by the invention is based on a normal corn and bean pulp piglet feedstuff formula, and adopts the fermented rapeseed meal to replace equivalent 8% bean pulp to supplement part of artificially synthesized amino acid; and partial bean pulp is replaced by the fermented rapeseed meal, the pig production performance is not affected, and the weight gaining cost of pork pigs is lowered at the same time.

Owner:GUANGDONG EVERGREEN FEED INDAL +3

Flexible cable used for new energy automobile

ActiveCN107039117AImprove eliminationMeet special use requirementsRubber insulatorsInsulated cablesInsulation layerElectrical conductor

The invention discloses a flexible cable used for a new energy automobile. The cable comprises a conductor and an insulation layer used for wrapping the conductor. The outer part of the insulation layer is provided with a cooling layer in a wrapped manner, and at least one cooling medium channel extended along the length direction of the insulation layer is disposed in the cooling layer, and is used to introduce the cooling medium for the cooling and the heat dissipation of the insulation layer. Heat energy radiated by the insulation layer outwardly is effectively, reliably, quickly, and greatly eliminated by the cooling medium, and then the heat energy radiated on the outer part of the cooling layer is reasonable, controllable, and safe, and then the special use requirement of the new energy automobile is satisfied. The flexible cable is in service and operated reliably, safely, and stably in various severe environments, and has advantages of simple structure, convenient forming, small forming difficulty, low forming costs, compact structure, good flexibility, excellent heat dissipation effect, high flame resistant performance, high reliability, good safety performance, and strong practicability.

Owner:TBEA DEYANG CABLE CO LTD

Method for adhesive tape treatment in production of thin film by casting machine

The invention discloses a method for adhesive tape treatment in the production of thin film by a casting machine. On the surface of a steel tape, both the temperature in a viscosity drying tunnel for polyamic acid resin solution and the wind velocity at the outlet of a nozzle are regulated to a best state, the stripping condition of thin film at the steel tape where a front drum operates is detected, the speed of the steel tape is decreased when the adhesive tape width at one or two sides of the steel tape is more than 5.0mm, the speed of the steel tape is increased when the adhesive tape width at one or two sides of the steel tape is not more than 3.0mm, and the speed of the steel tape is decreased or increased when the adhesive tape width at one or two sides of the steel tape is in a range from 3.0 to 5.0mm. The increase or decrease for the speed of the steel tape is conducted in multiple steps, and the amplitude of each adjustment is from 0.1 to 1.5m / min, which is within the normalspeed range of the steel tape. In order to keep the solvent content of a semi-finished thin film unchanged, the temperature of the drying tunnel and / or the wind velocity at the outlet of the nozzle of a plenum chamber is regulated during speed adjustment of the steel tape. The lip opening of a casting die head can also be regulated during speed adjustment of the steel tape to eliminate the adhesive tape, and the increase or decrease for the lip opening of the die head can be conducted in multiple steps as well. The method of the invention can eliminate the adhesive tape rapidly to enable the casting machine to operate normally.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

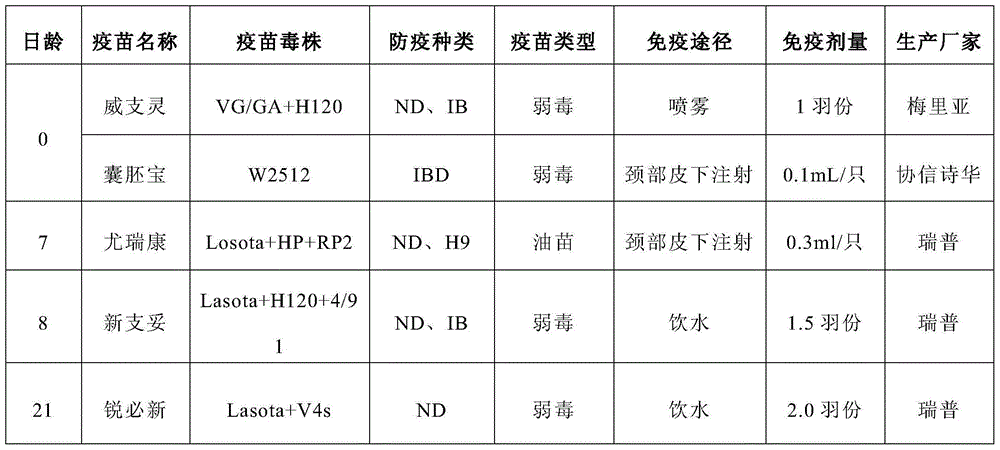

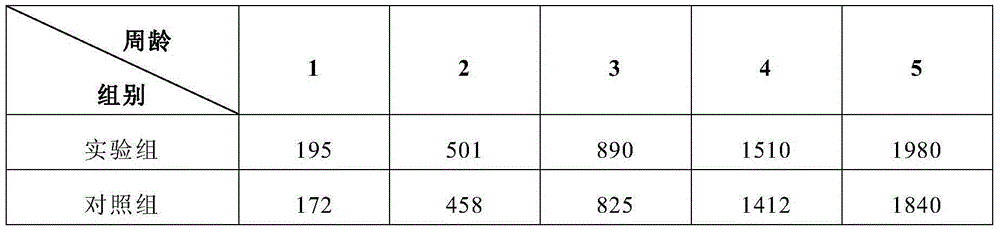

Antibiotic-free broiler chicken feeding method

InactiveCN104521885AImprove disease resistanceImprove survival rateHydroxy compound active ingredientsViral antigen ingredientsDiseaseVaccination

The invention provides a healthy antibiotic-free broiler chicken feeding method. The method mainly comprises the steps of conducting chicken house sterilization and drinking pipeline sterilization before chicken enter a chicken house; conducting vaccination periodically so that broiler chicken can have the immune antibody; adding immune traditional Chinese medicine to drank water to improve the habitus and immunity of the chicken, adding microecologics to drank water to restrain breeding of harmful bacteria and enable intestinal florae to be balanced, and adding respiratory tract traditional Chinese medicine to drank water so that respiratory mucosa recovery can be facilitated, respiratory mucosa inflammation can be avoided and respiratory diseases can be prevented and treated. By the adoption of the method, disease resistance of broiler chicken can be effectively improved, the health of chicken is guaranteed, the ideal feeding effect is realized, the quality of chicken can be improved, antibiotic residues in broiler products are effectively controlled, and feeding cost is effectively reduced.

Owner:HUBEI TONGXING AGRI

Adhesive tape processing method in film production of slobbering machine

ActiveCN102416684AImprove operational efficiencyImprove eliminationCoatingsAir velocityPolyamic acid

The invention discloses an adhesive tape processing method in film production of a slobbering machine. The surface of a steel tape, the viscosity of polyamic acid resin solution, temperature in a drying tunnel and air velocity at a nozzle outlet are all adjusted to the best state; the film stripping condition is detected; if the width of the adhesive tape on one side or two sides of the steel tape is greater than 5.0 mm, the current lip opening of the side or two sides of a die head is reduced; if the width of the adhesive tape on one side or two sides of the steel tape is less than or equal to 3.0 mm, the current lip opening of the side or two sides of the die head is increased; and if the width of the adhesive tape on one side or two sides of the steel tape is 3.0-5.0 mm, the current lip opening of the side or two sides of the die head is reduced or increased. The lip opening is adjusted for multiple times, and the amplitude of each adjustment is 5-12 microns, within an adjustment range of the lip opening. In order to keep the solvent content of a semi-finished product of the film unchanged, the temperature of the drying tunnel and / or the air velocity at the nozzle outlet of a static pressure box are adjusted when the lip opening is adjusted. In the speed adjustment of the steel tape, the moving speed of the steel tape also can be adjusted to eliminate the adhesive tape. Themethod can quickly eliminate the adhesive tape so that the slobbering machine operates normally.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

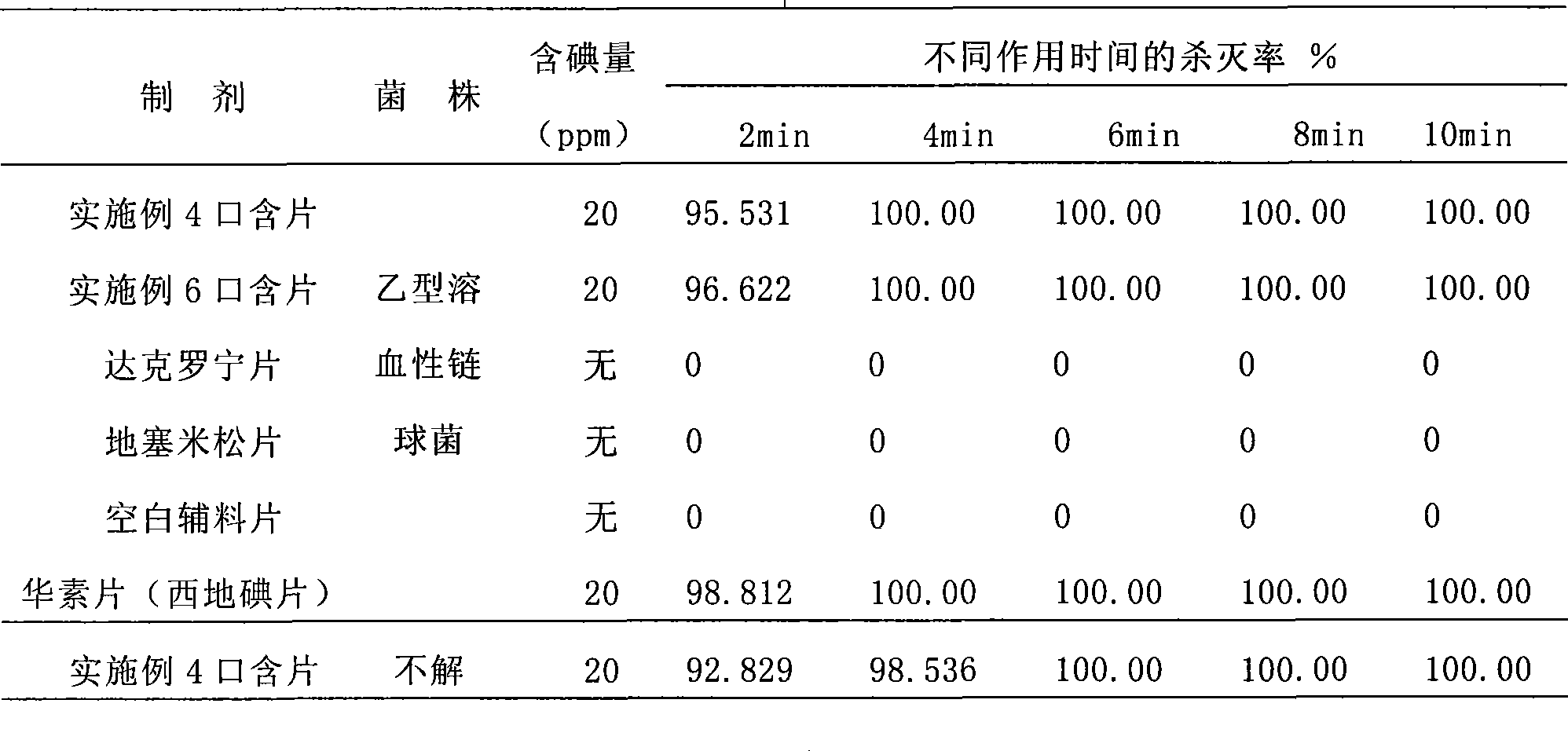

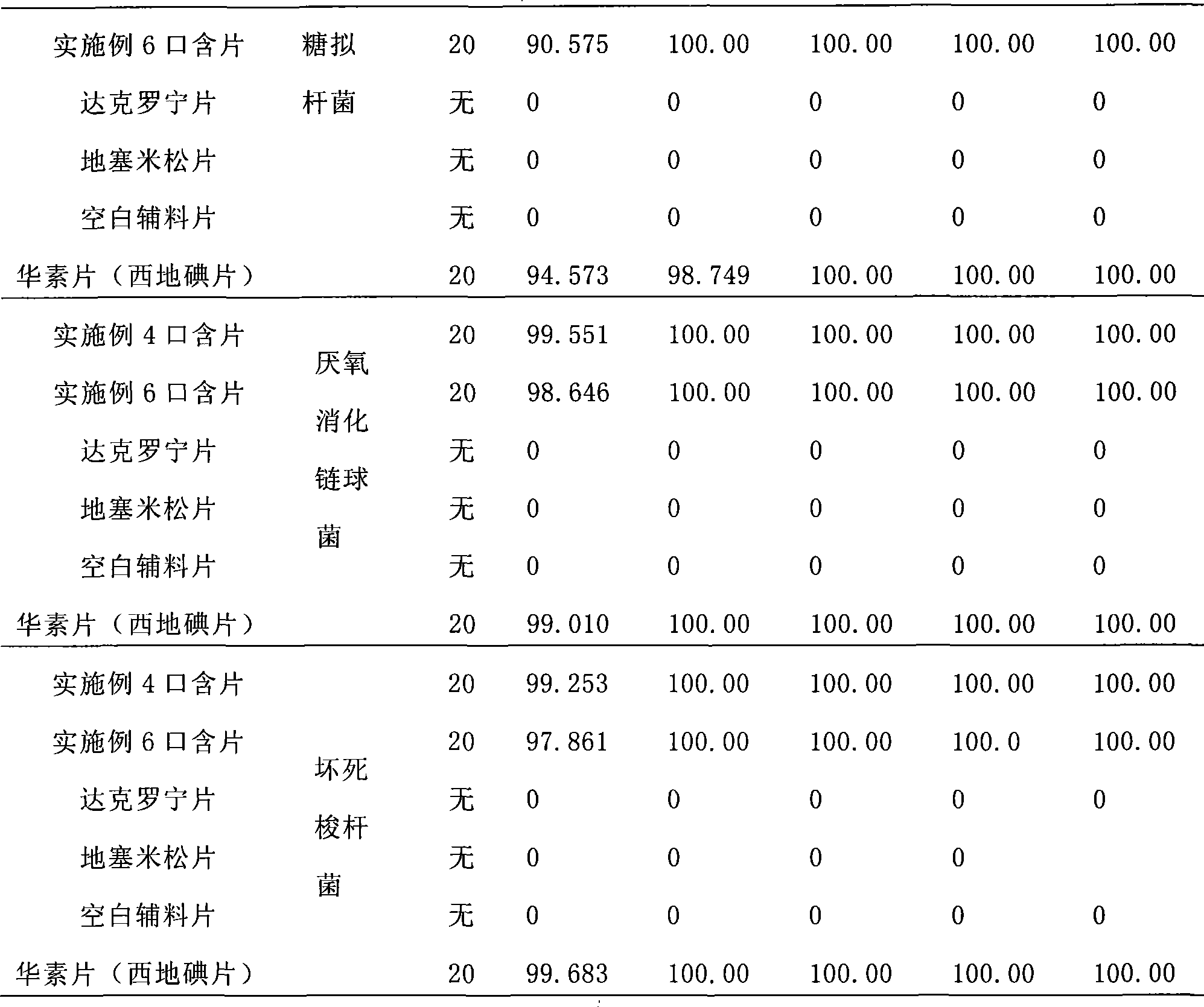

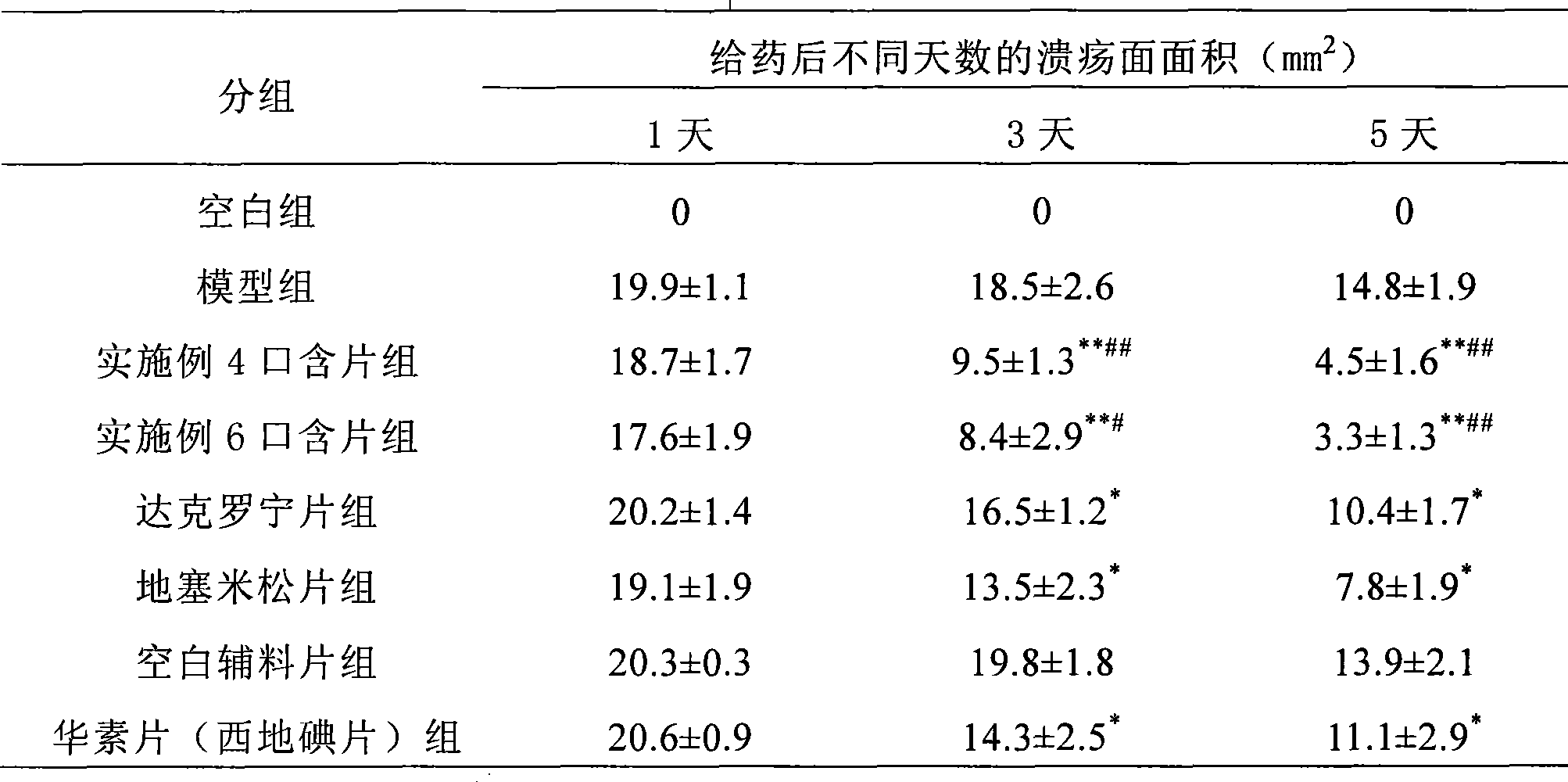

Medicine composition for treating mouth, throat disease and preparation method thereof

ActiveCN101396370AImprove permeabilityEasy to removeAerosol deliveryDigestive systemDiseaseIrritation

The invention relates to a medical combination for remedying oral and throat diseases and belongs to the pharmacy field. A medical combination for remedying the oral and throat diseases consists of active components and medically acceptable auxiliary material. The active components are cydiodine and novocain, and the weight portion ratio of the cydiodine and the novocain is 5-13 to 0.5-2. Or the active components are the cydiodine, the novocain and anti-inflammatory drug, the weight portion ratio of the cydiodine, the novocain and the anti-inflammatory drug is 5-13 to 0.5-2 to 0.1-0.5, and the weight percentage of the active components is 1 percent to 35 percent. The medical combination has the advantages that the invention selects the cydiodine as bactericide which has efficient effect on killing various microorganisms and does not produce drug resistant strain; and the medical combination integrates three effects of sterilizing, resisting inflammation and alleviating pain as a whole and can effectively promote the elimination of the symptoms of the oral and throat diseases and the concrescence of wound surface. The medical combination also is characterized by no irritation on mucosa, simple preparation technology, stable performance and fit for the industrialized production.

Owner:BEIJING HUMANWELL JUNWEI PHARM TECH CO LTD

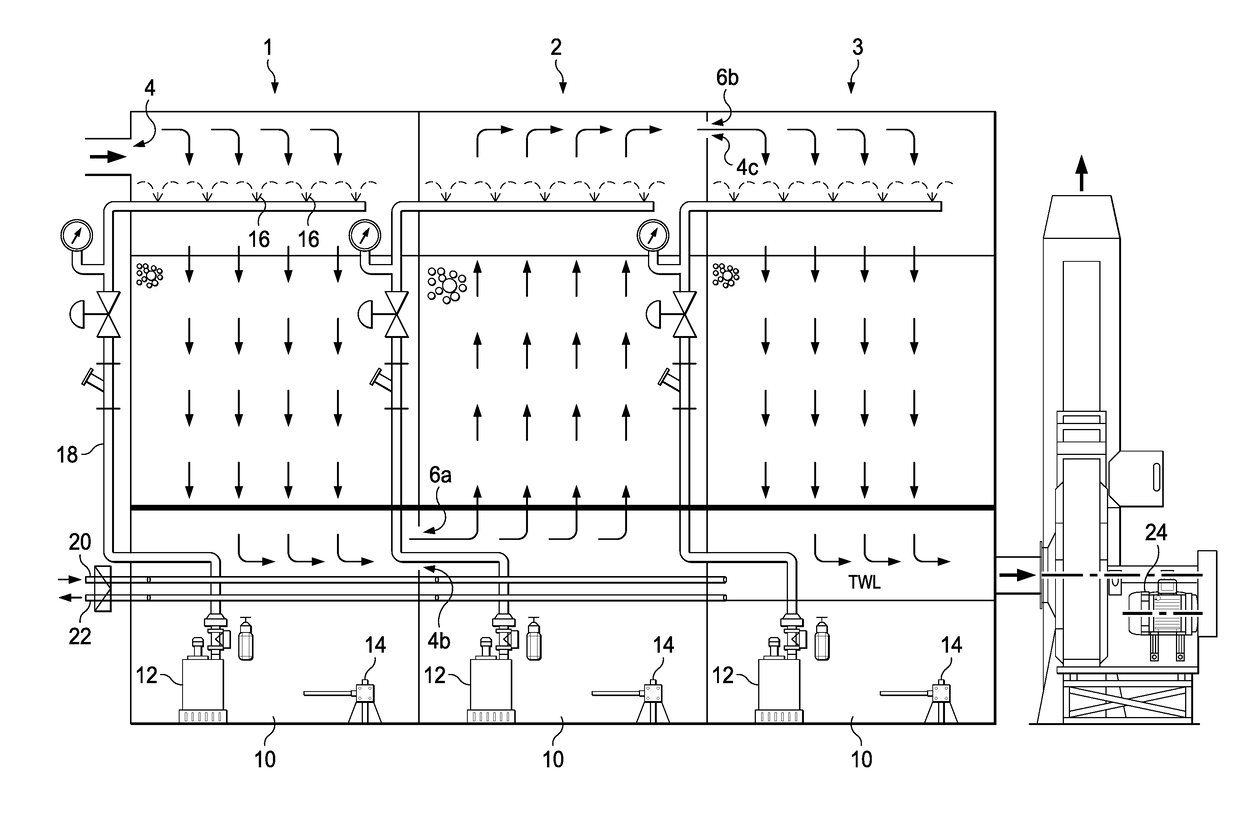

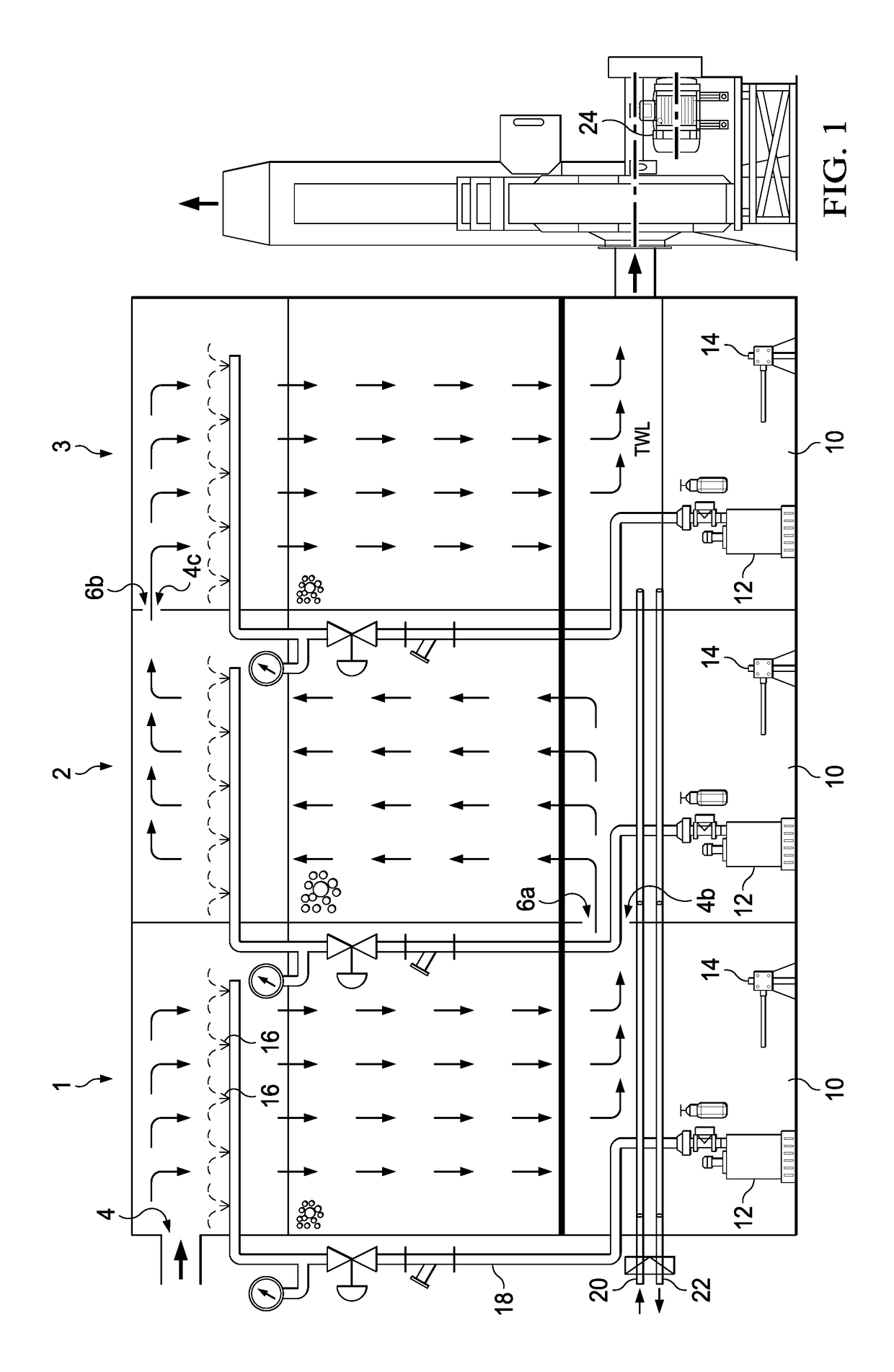

Method and apparatus for cleaning a contaminated air stream

ActiveUS20170173526A1Increases face velocity of airImprove efficiencyGas treatmentGaseous fuelsEngineeringContaminated air

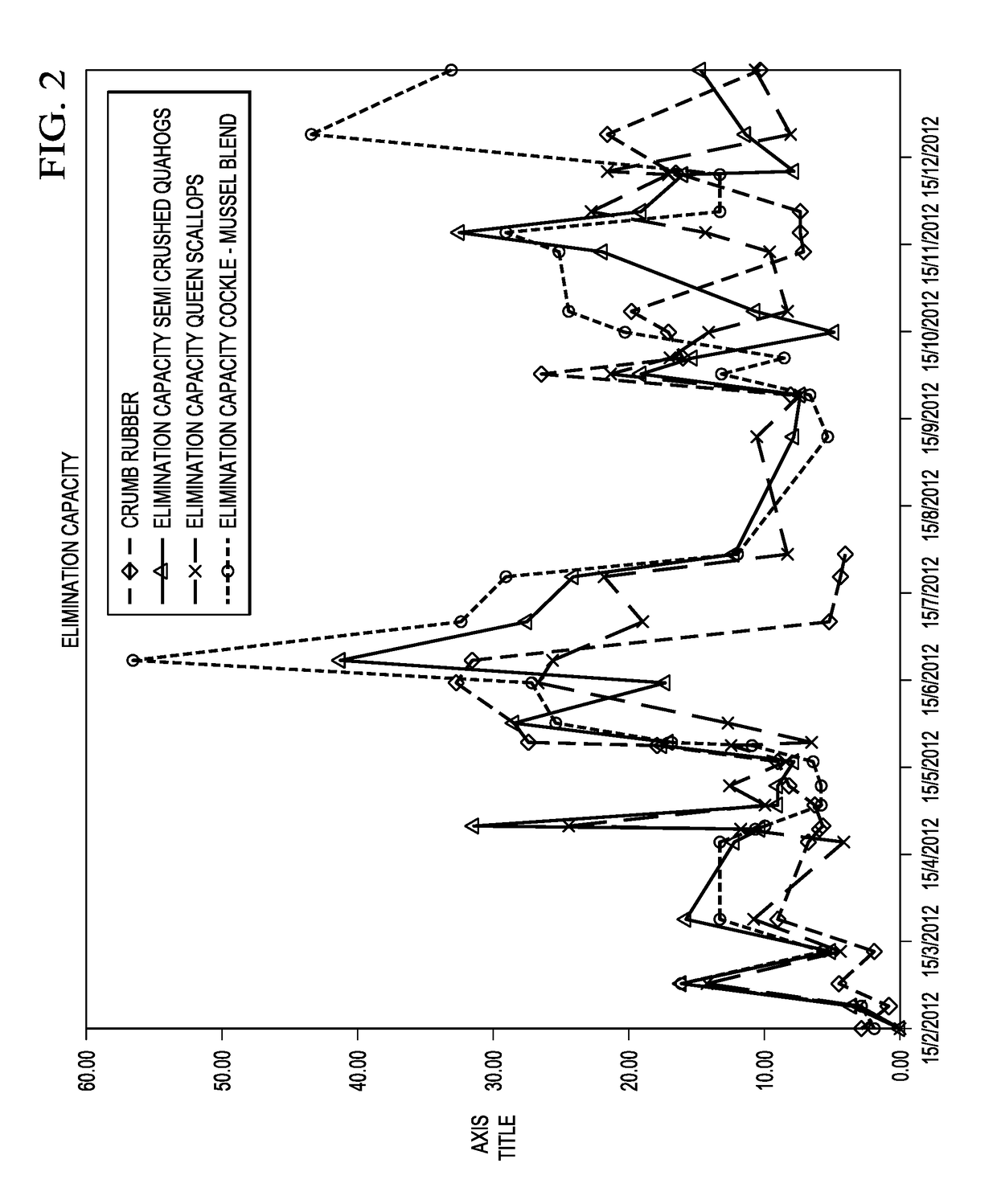

A method and apparatus for cleaning a contaminated air stream, the method comprising the step of passing the contaminated air stream through a multistage cleaning reactor, wherein at least two stages of the multistage cleaning reactor comprise marine shell material.

Owner:ANUA CLEAN AIR INT LTD

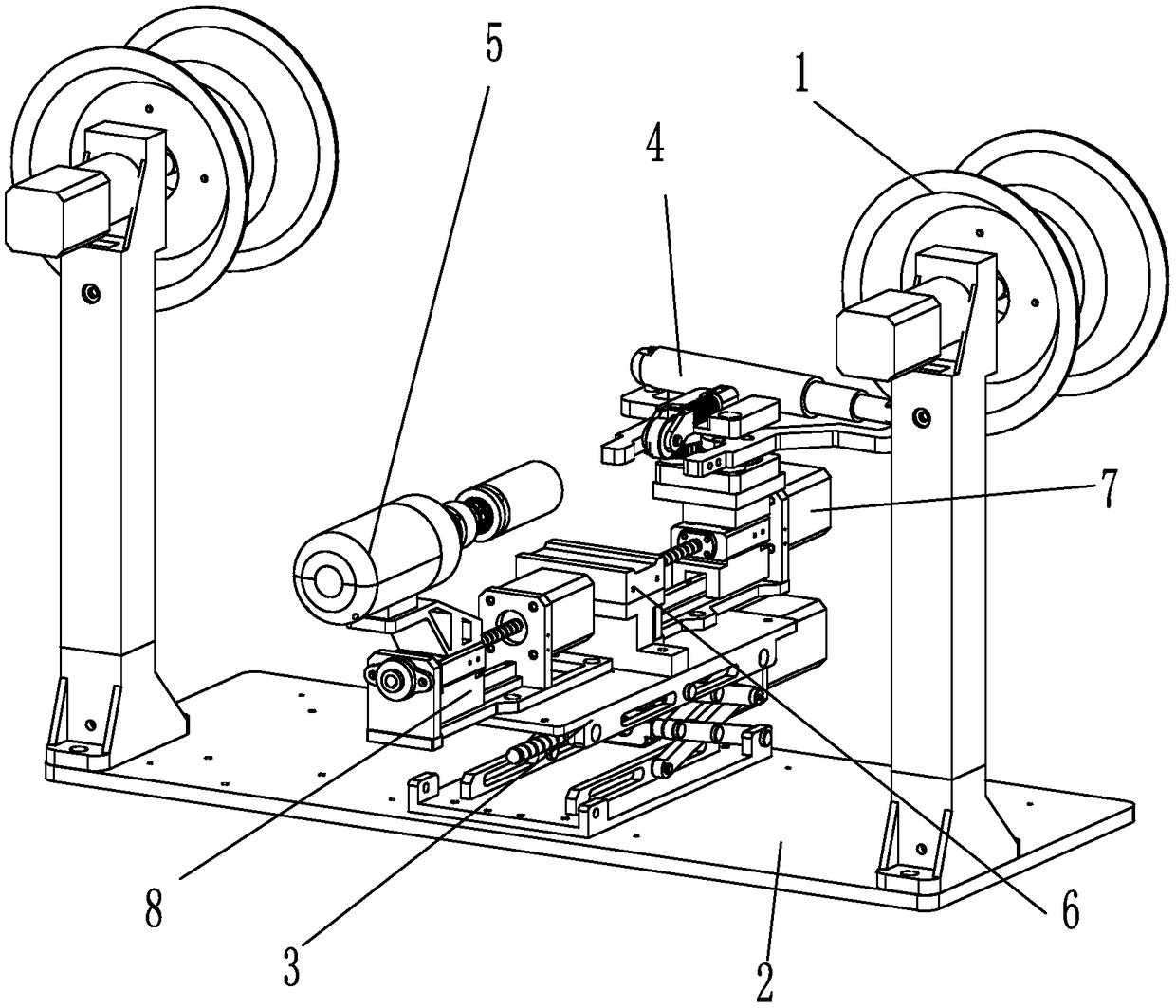

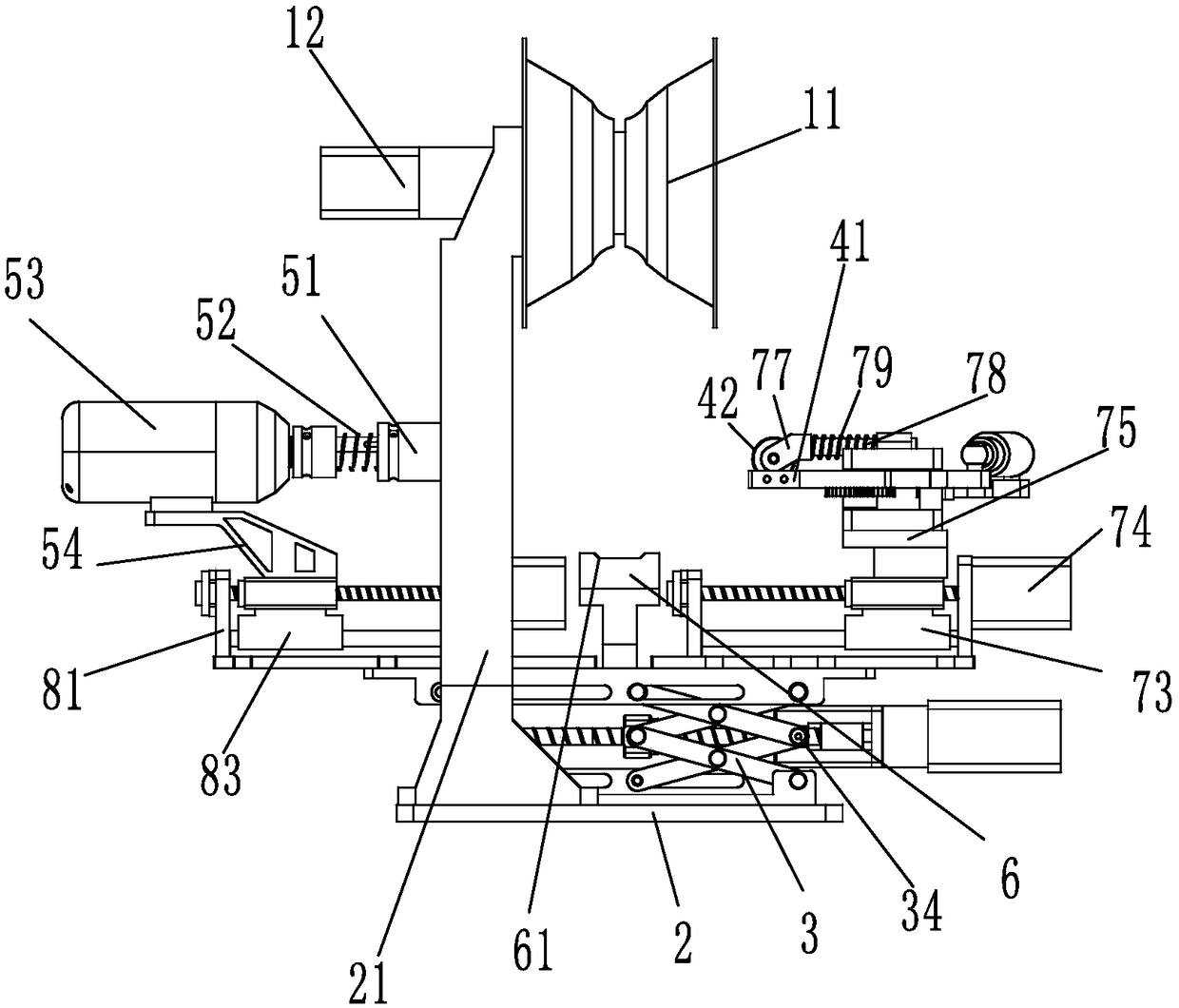

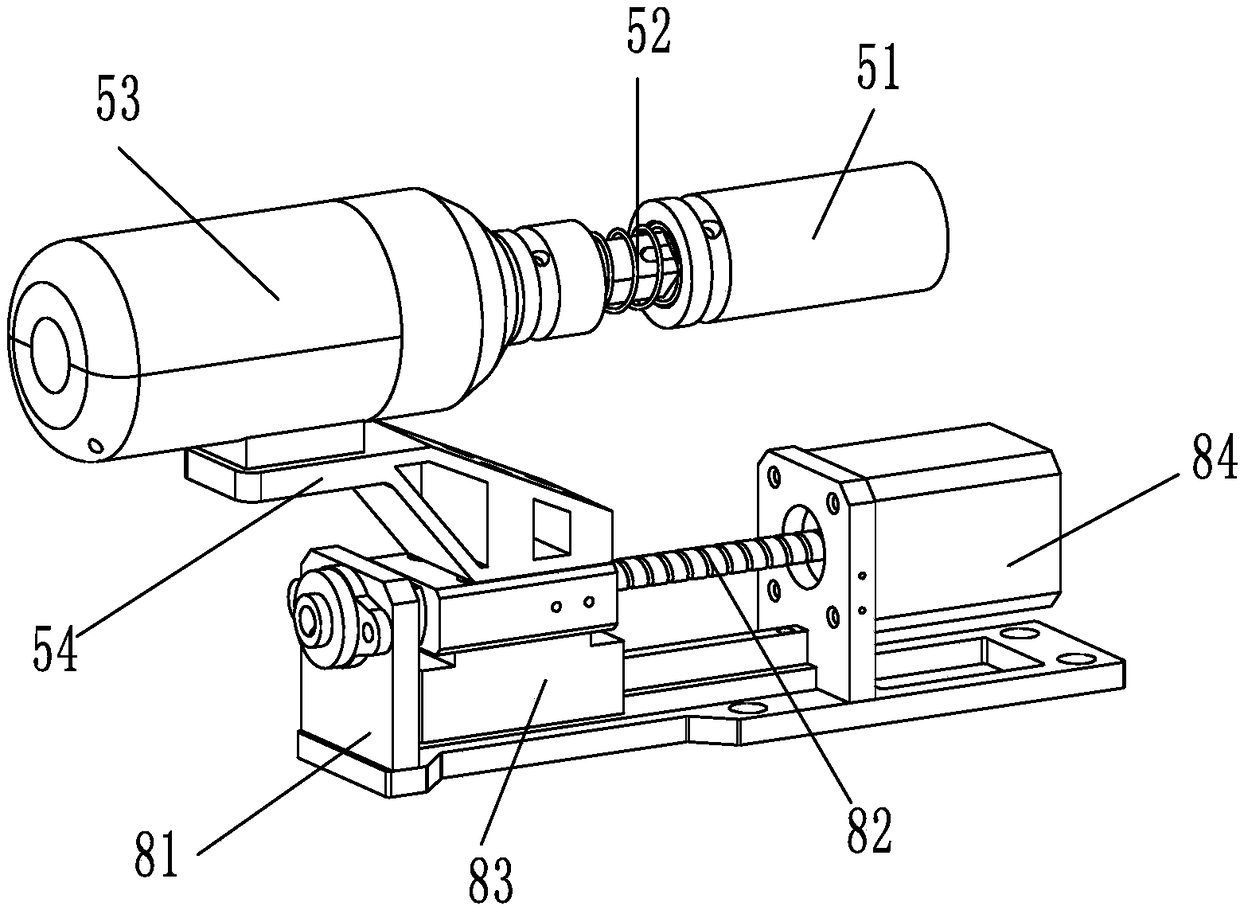

Hinged damper disassembly and assembly device and method

ActiveCN108927644AEasy to operateSmall space requirementMetal working apparatusEngineeringSpace requirements

The invention discloses a hinged damper disassembly and assembly device and a method. The hinged damper disassembly and assembly device comprises a clamping and positioning assembly, a spanner assembly, a base, a walking assembly and a lifting platform assembly, wherein the clamping and positioning assembly comprises two clamping jaws which can extend and retract and are used for clamping and positioning a damper; the spanner assembly comprises a disassembly and assembly sleeve which is used for rotating a bolt of the damper; the walking assembly comprises a walking wheel which is used for driving the device to walk on an overhead line; the lifting platform assembly is located below the clamping and positioning assembly and the spanner assembly and is used for lifting the clamping and positioning assembly and the spanner assembly; and a damper support frame is arranged between the clamping and positioning assembly and the spanner assembly. The hinged damper disassembly and assembly device has the advantages that hot-line working personnel are replaced by an equipotential hot-line working mode so as to realize a disassembly function of a damaged damper and repositioning and installing functions of a dislocated hinged damper, the operation is convenient, the space requirement is low, and the labor intensity and safety risk of operating personnel are reduced.

Owner:沈彦南

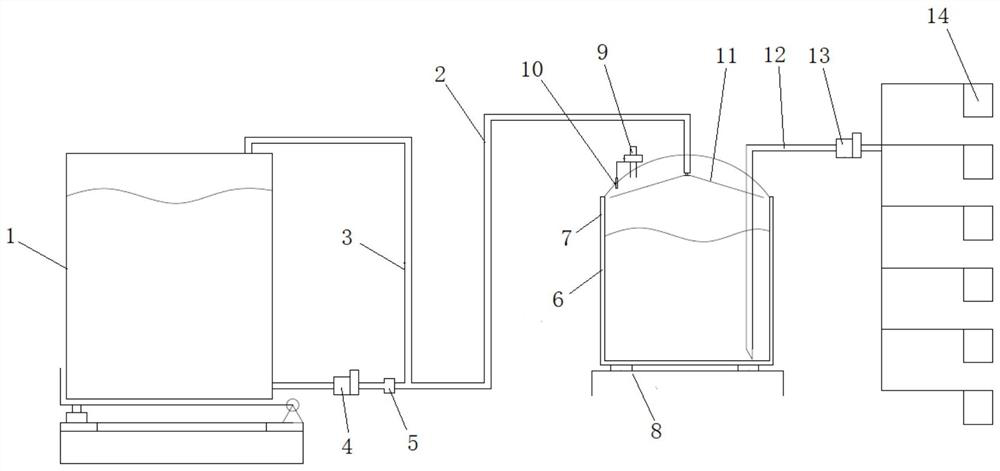

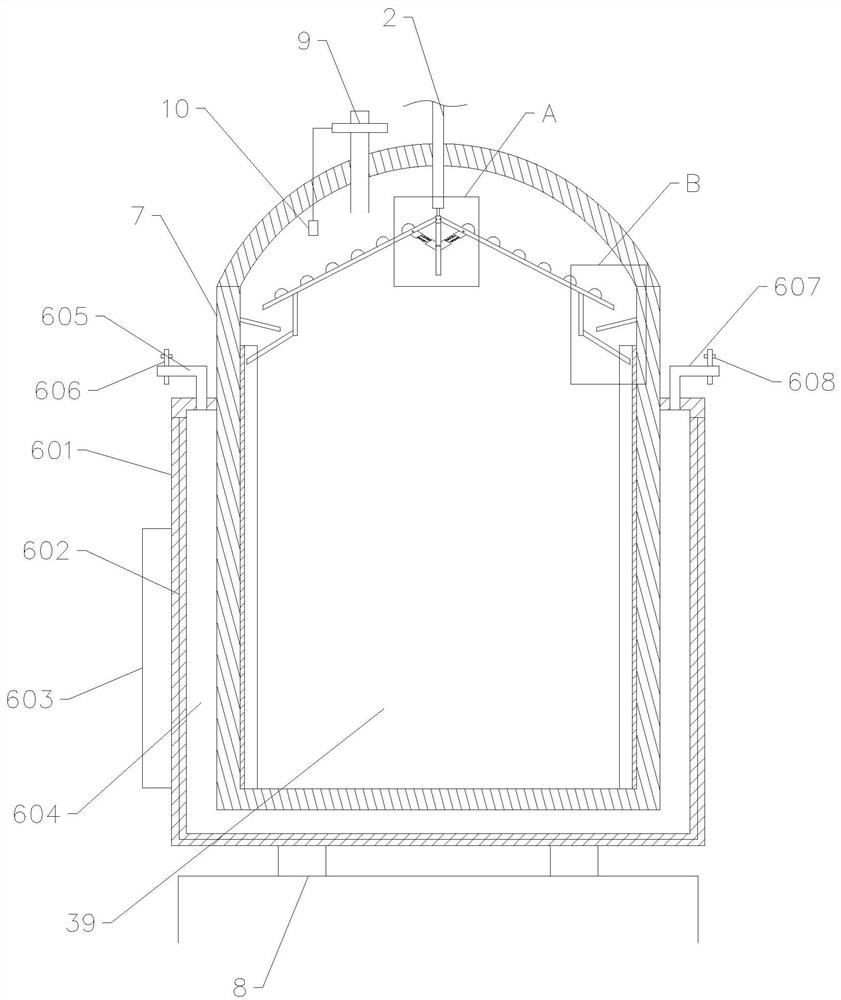

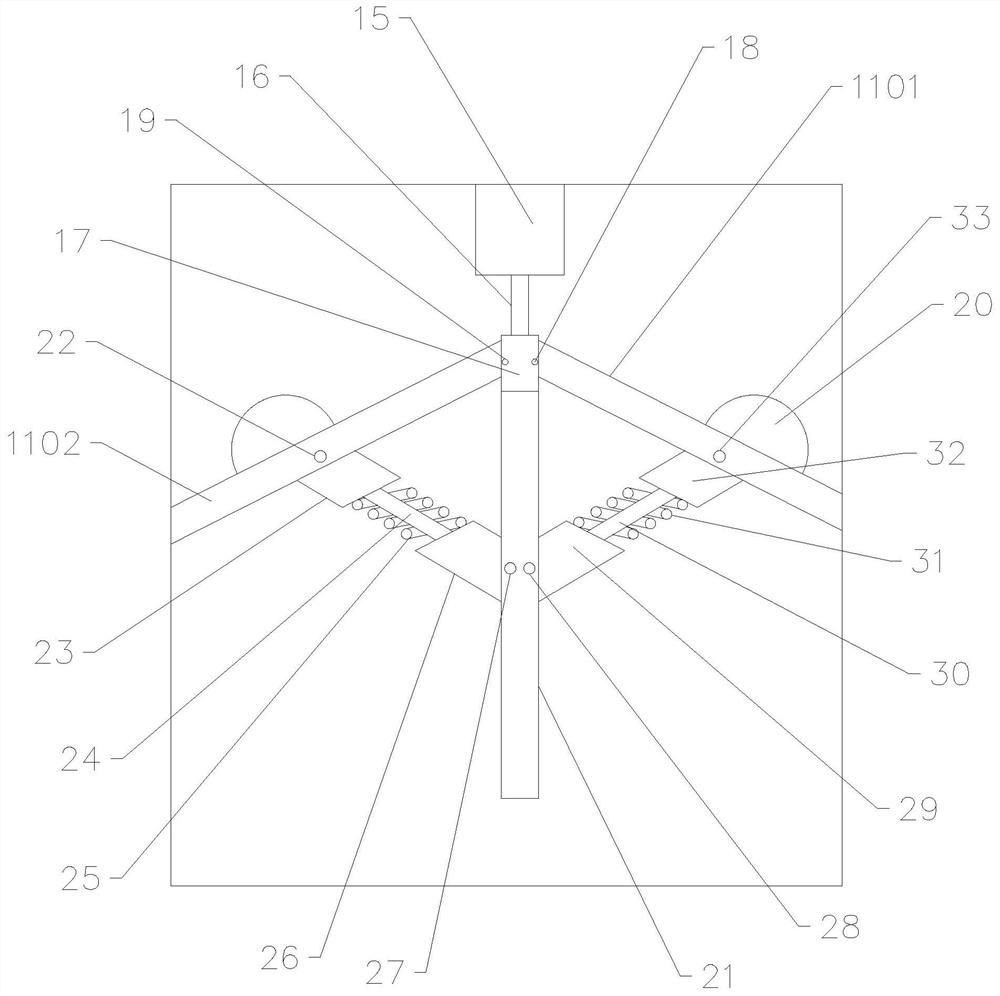

Device and method for eliminating optical fiber cable feeding bubbles

PendingCN111635145ATo promote floatingImprove eliminationFoam dispersion/preventionDiaphragm pumpBuffer tank

The invention relates to a device for eliminating optical fiber cable feeding bubbles. The device is characterize in that a transmission pipe is connected between a ton barrel and a buffer tank; a first diaphragm pump and a bubble detector are arranged on the transmission pipe; a bubble reflux pipe communicated with the ton barrel is connected between the bubble detector and the buffer tank and ispositioned on the transmission pipe; an output pipe is connected between the buffer tank and a feeding tank; a second diaphragm pump is arranged on the output pipe; a weighing table is arranged at the lower end of the buffer tank; a water bath heating barrel is further arranged on the periphery of the buffer tank; a defoaming cavity is formed in the buffer tank; a vacuum pump control device is arranged at the upper end of the buffer tank and located in the defoaming cavity; a pressure detector electrically connected with the vacuum pump control device is further arranged in the defoaming cavity; the transmission pipe is connected with a feeding pipe in the defoaming cavity; and a flow divider is installed on the feeding pipe. The invention also discloses a method for eliminating optical fiber cable feeding bubbles. The invention aims to provide a scheme for reducing optical fiber coating bubbles, improve the percent of pass of optical fibers and reduce waste optical fibers.

Owner:杭州金星通光纤科技有限公司

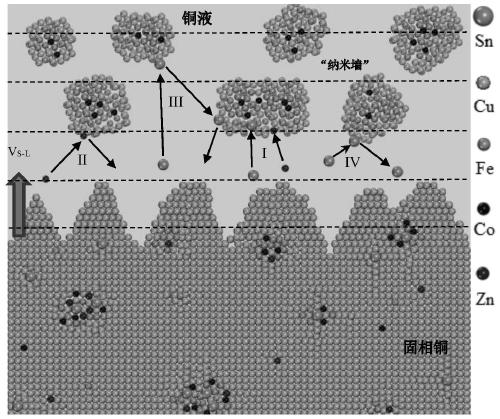

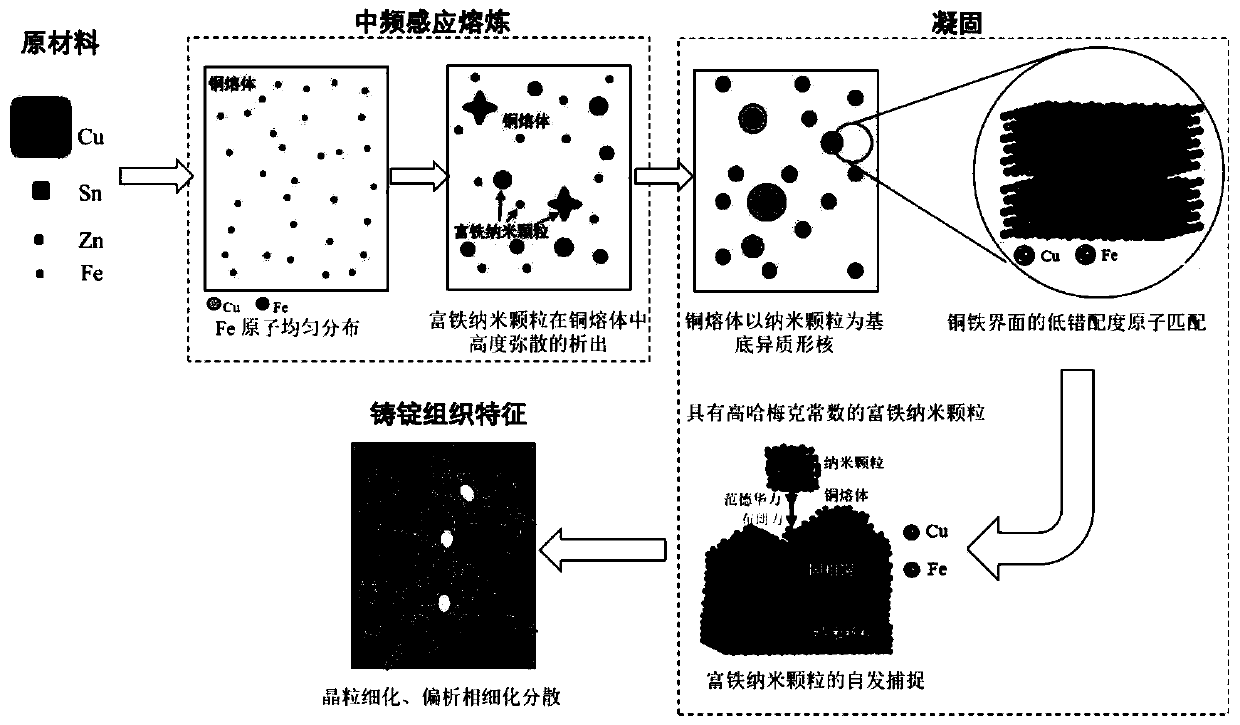

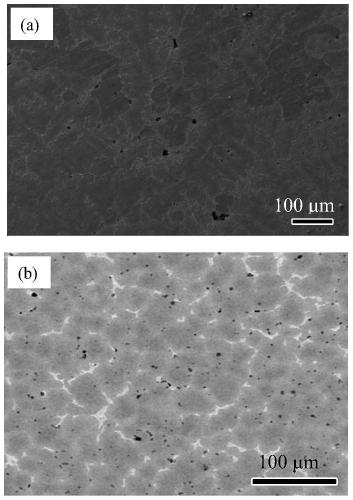

Method for weakening and even eliminating segregation at grain boundary of copper alloy

The invention provides a method for weakening and even eliminating segregation at grain boundary of a copper alloy. The highly dense nano-particles generated in situ in a melt in the casting process are used for reducing or even eliminating the segregation at the grain boundary in the alloy from three aspects, and specifically, solute re-distribution is hindered in the solidification process, meanwhile, a heterogeneous nucleation effect is exerted to refine grains so as to shorten a segregation path and divide the segregation phase, and a diffusion channel is provided for the segregation phasecomposition element during the heat treatment process. According to the method, the micro-alloy element and nano-particles formed by the micro-alloy element are required to be provided with three conditions which comprising that the nano-phase forming elements meet the conditions that separating out in advance in the matrix melt; the crystal lattice mismatch degree of the nano-particles and a matrix is small, a remarkable crystal grain refining effect is generated through the heterogeneous nucleation effect of the nano-particles in the solidification process, and meanwhile, the potential of particle capture is enhanced; and the nano-particles have the Hamaker constants higher than those of the matrix, and the negative van der Waals force is provided for spontaneous capture of the nano-particles; and the process is simple, the cost is low, and mass production can be realized.

Owner:UNIV OF SCI & TECH BEIJING

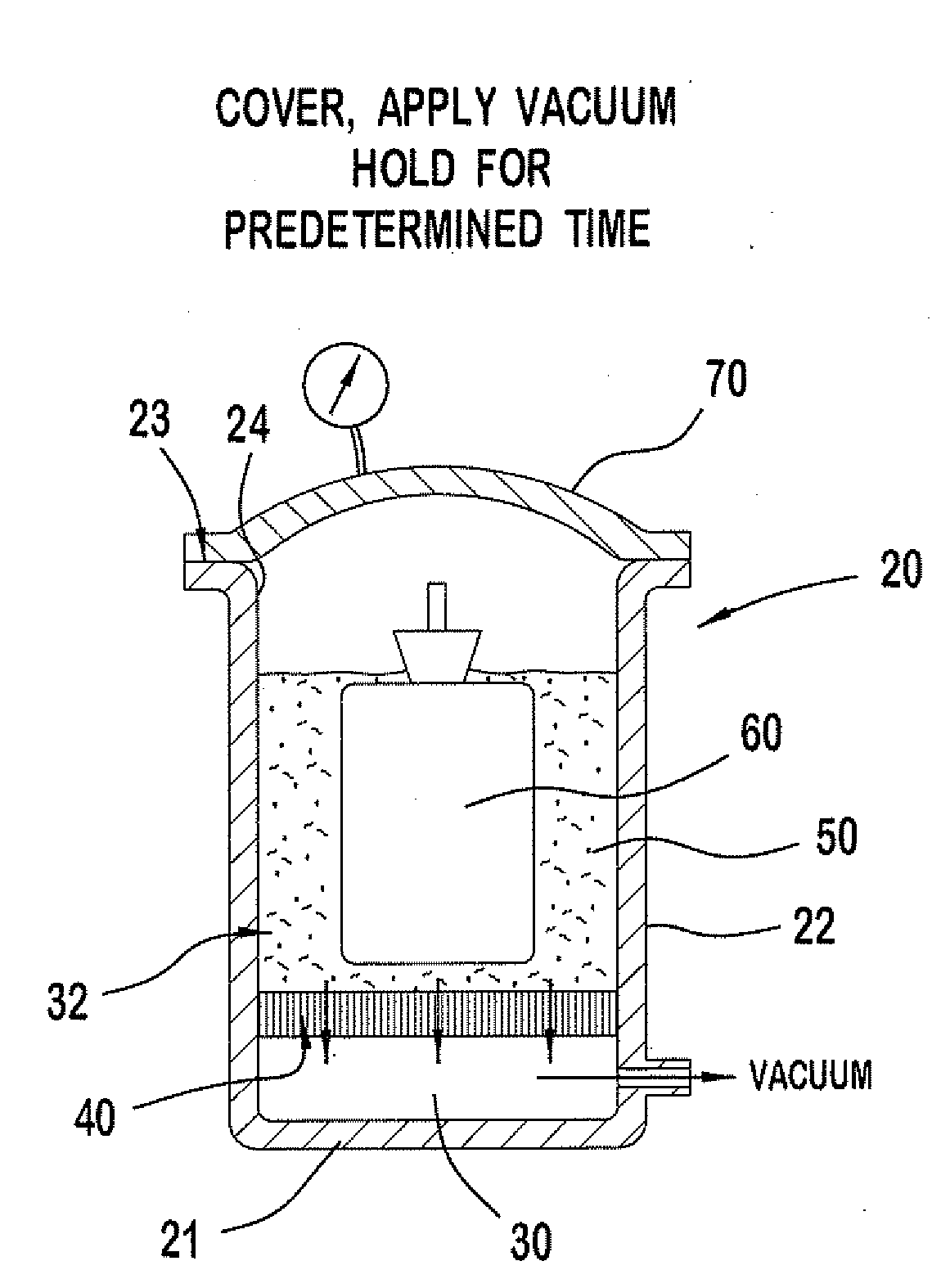

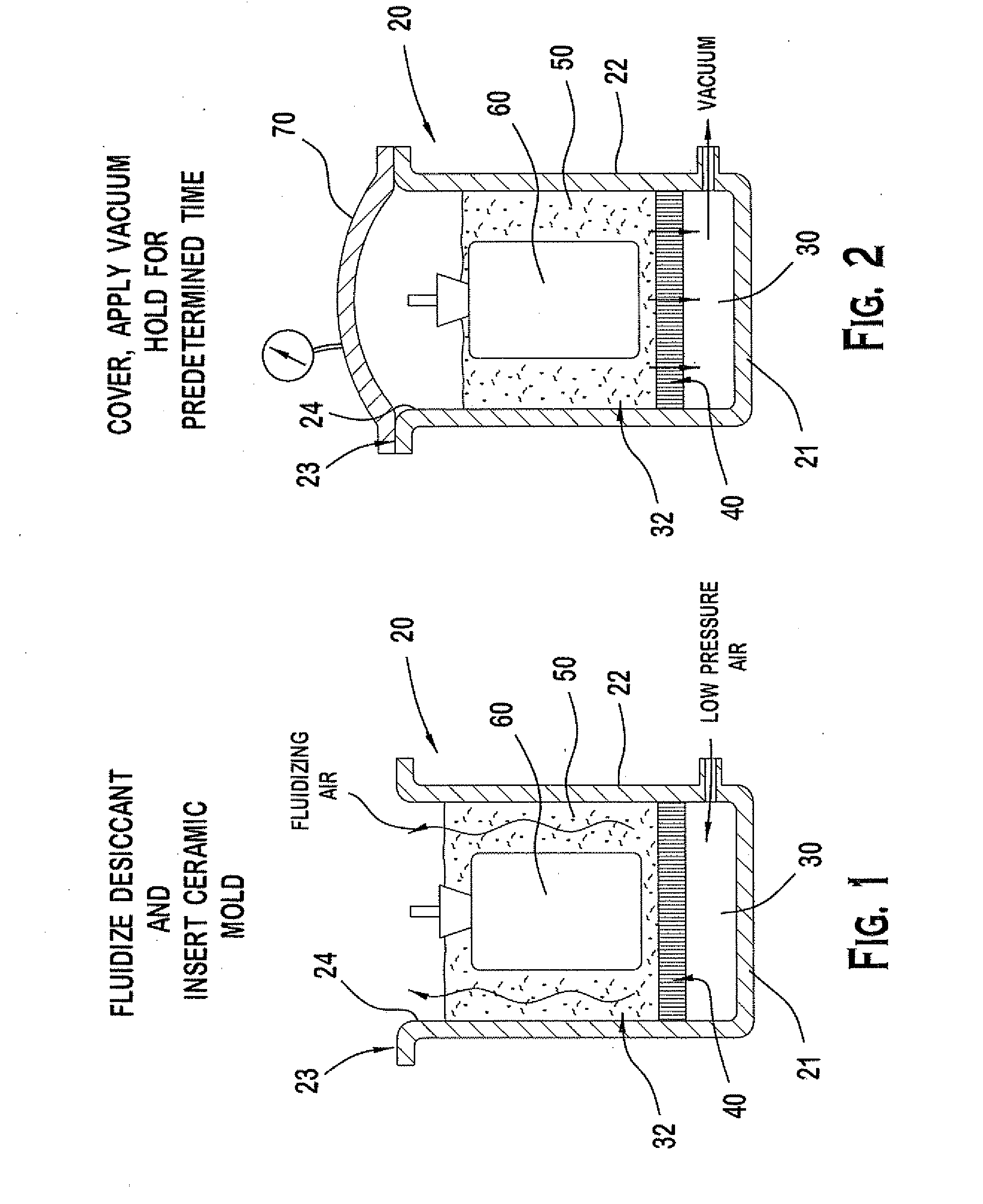

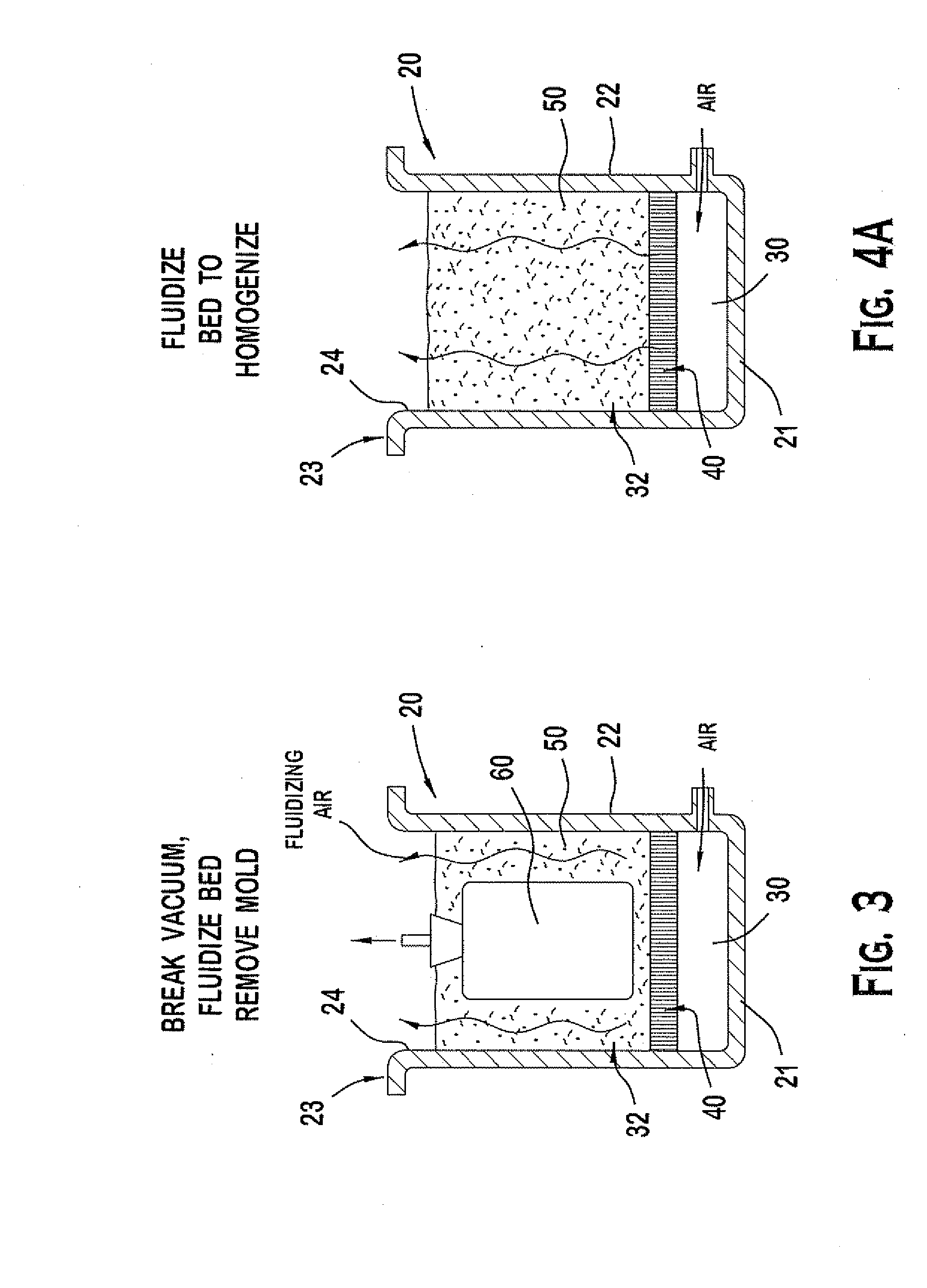

Method and system for drying casting molds

ActiveUS20090071621A1Keep dryReduces mold drying timeFoundry mouldsFoundry coresVacuum pressureDesiccant

Owner:STURM RUGER & CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com