Hinged damper disassembly and assembly device and method

An anti-vibration hammer, hinged technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of hidden safety hazards, manual disassembly, power failure, etc., to ensure safety and reliability, convenient operation, space less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

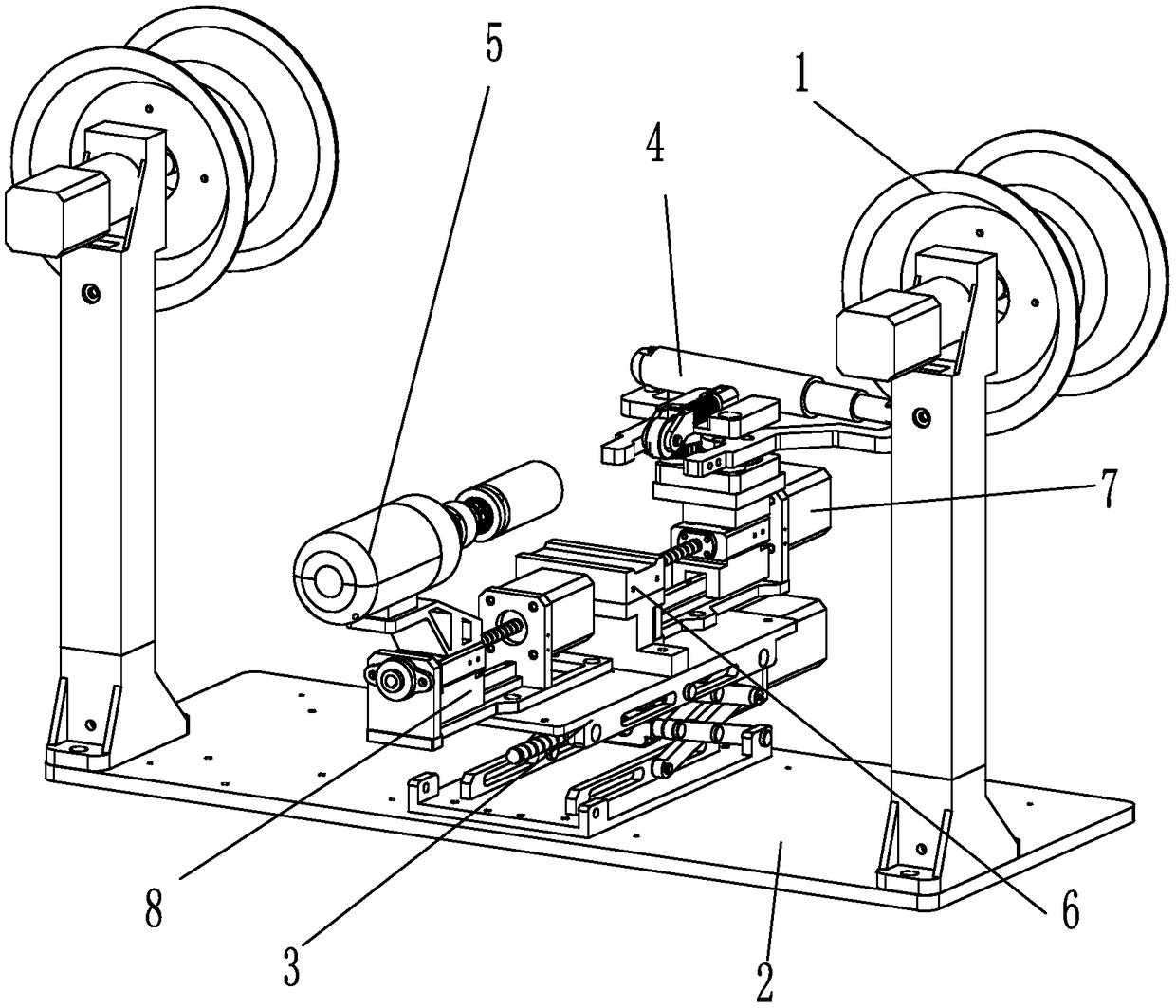

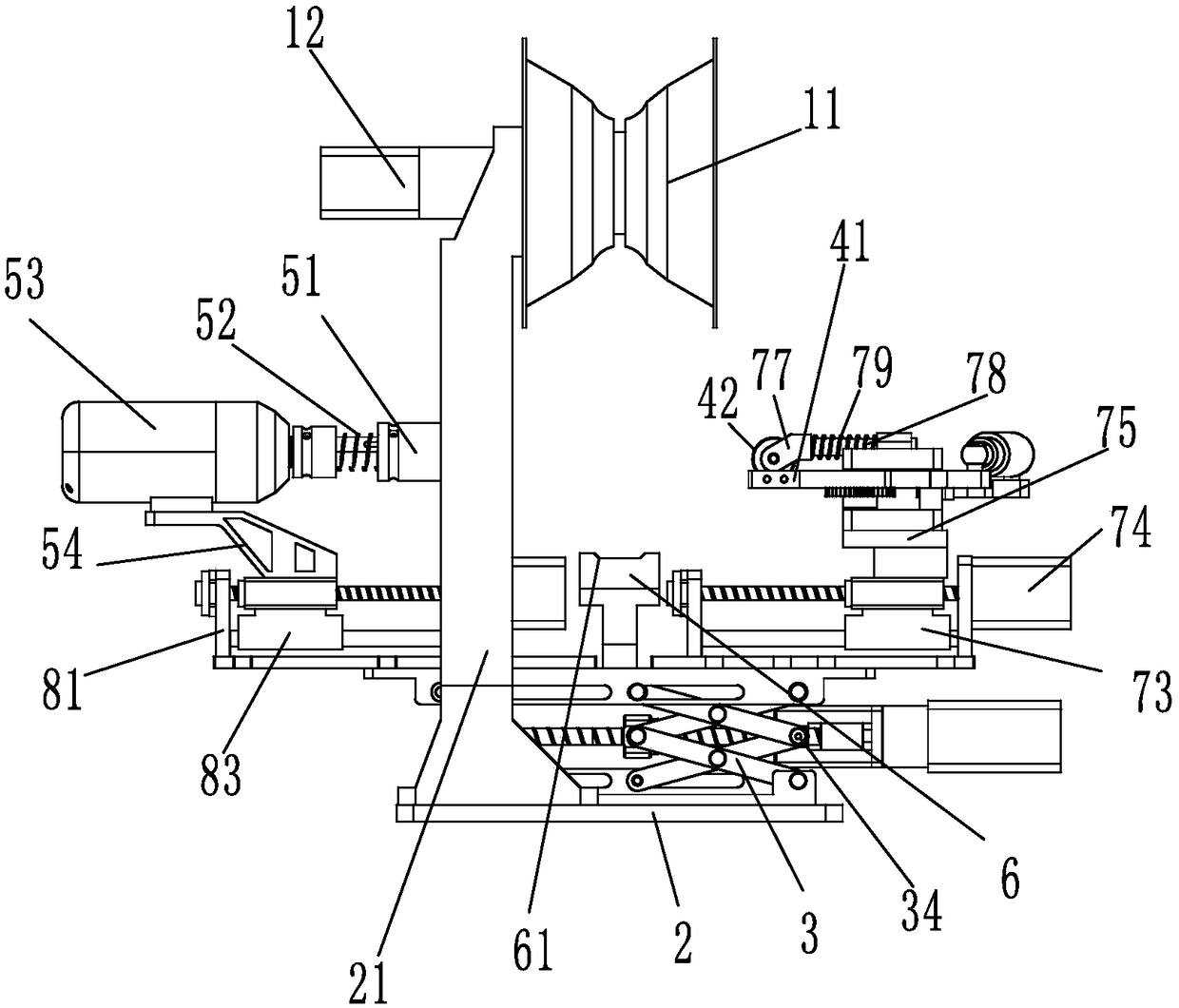

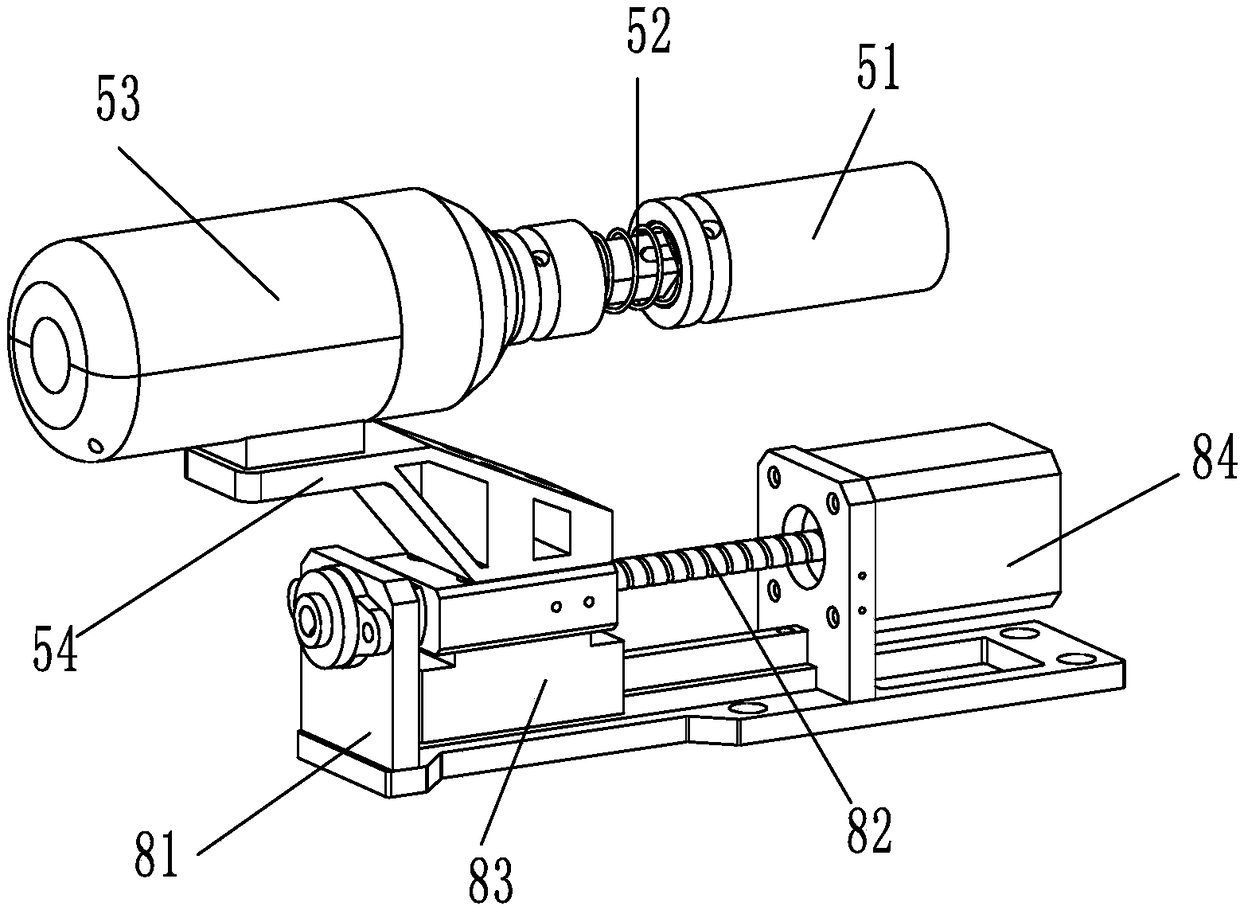

[0034] figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Among them, a hinged anti-vibration hammer disassembly device includes a clamping and positioning assembly 4, a wrench assembly 5, a base 2, a walking assembly 1 and a lifting platform assembly 3, and the walking assembly 1 includes walking wheels 11, which are used to drive the device on an overhead Walking on the line; the peripheral side of the walking wheel 11 is provided with a concave card slot matching the overhead line, so that the walking wheel 11 can be fixed on the overhead line. Walking assembly 1 is provided with two groups, and one side of walking wheel 11 is provided with traveling motor 12, both sides of base 2 are fixed with column 21, and walking assembly 1 is fixed on the column 21, figure 1 The housing of the middle travel motor 12 is fixed on the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com