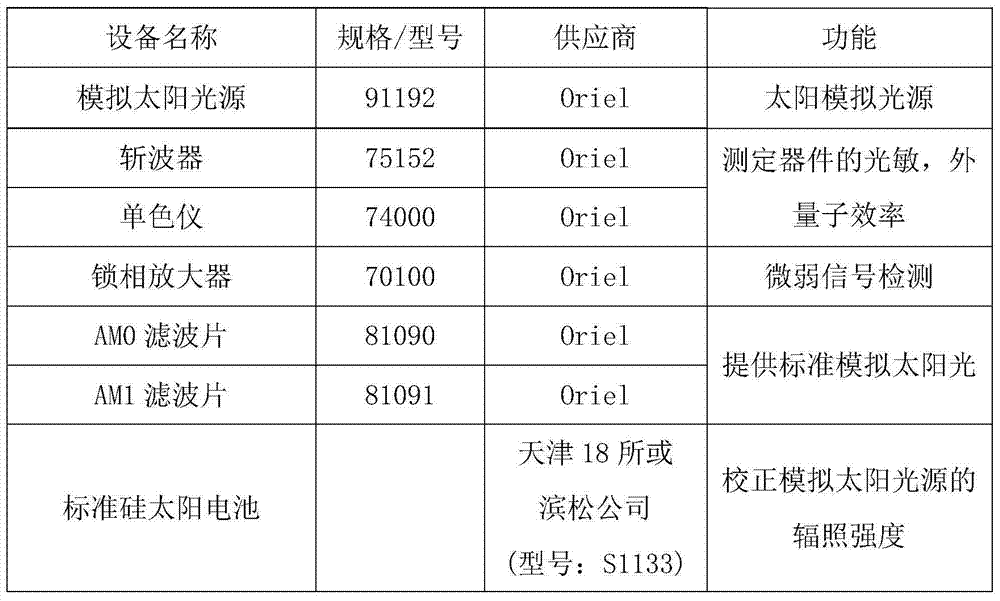

Patents

Literature

86results about How to "Small lattice mismatch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

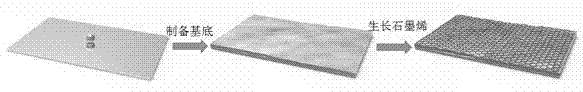

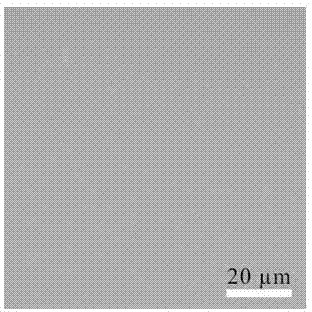

Method for growing single-layer graphene thin film by virtue of low-temperature chemical vapor deposition

The invention discloses a method for growing a single-layer graphene thin film by virtue of low-temperature chemical vapor deposition, and belongs to the technical field of two-dimensional thin film material preparation. The preparation method comprises the following steps: (1) preparing an alloy substrate; (2) performing leveling treatment on the alloy substrate; (3) performing annealing treatment on the alloy substrate under a protective atmosphere; and (4) depositing graphene by using a chemical vapor deposition process, and cooling to room temperature to obtain the alloy substrate with a grown single-layer graphene thin film, wherein conditions of the chemical vapor deposition process are as follows: the temperature is 200-800 DEG C, the time is 5-180min, and a carbon source is a gas phase carbon source, a liquid phase carbon source or a solid phase carbon source. The method disclosed by the invention has the advantages that the method is simple, convenient and fast, also is low in cost, and ensures that uniform and single-layer high-quality graphene can be prepared at relatively low temperature; and the method has universality, is simple and mild in condition, uniform in product distribution and good in repeatability, is suitable for industrial production, and is particularly suitable for controllable preparation of single-layer or few-layer graphene.

Owner:WUHAN UNIV

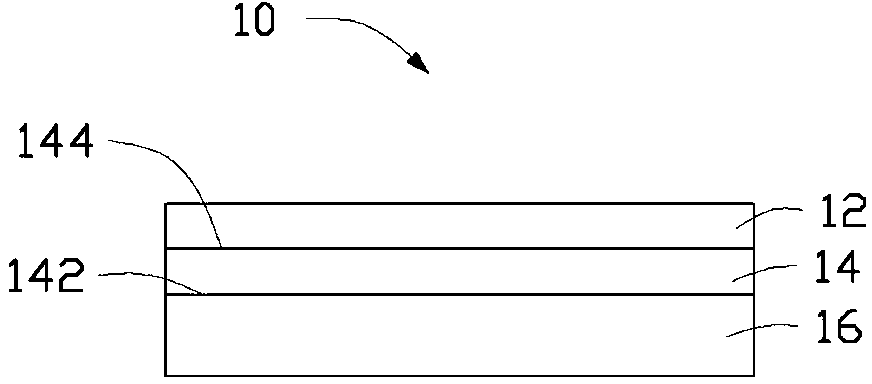

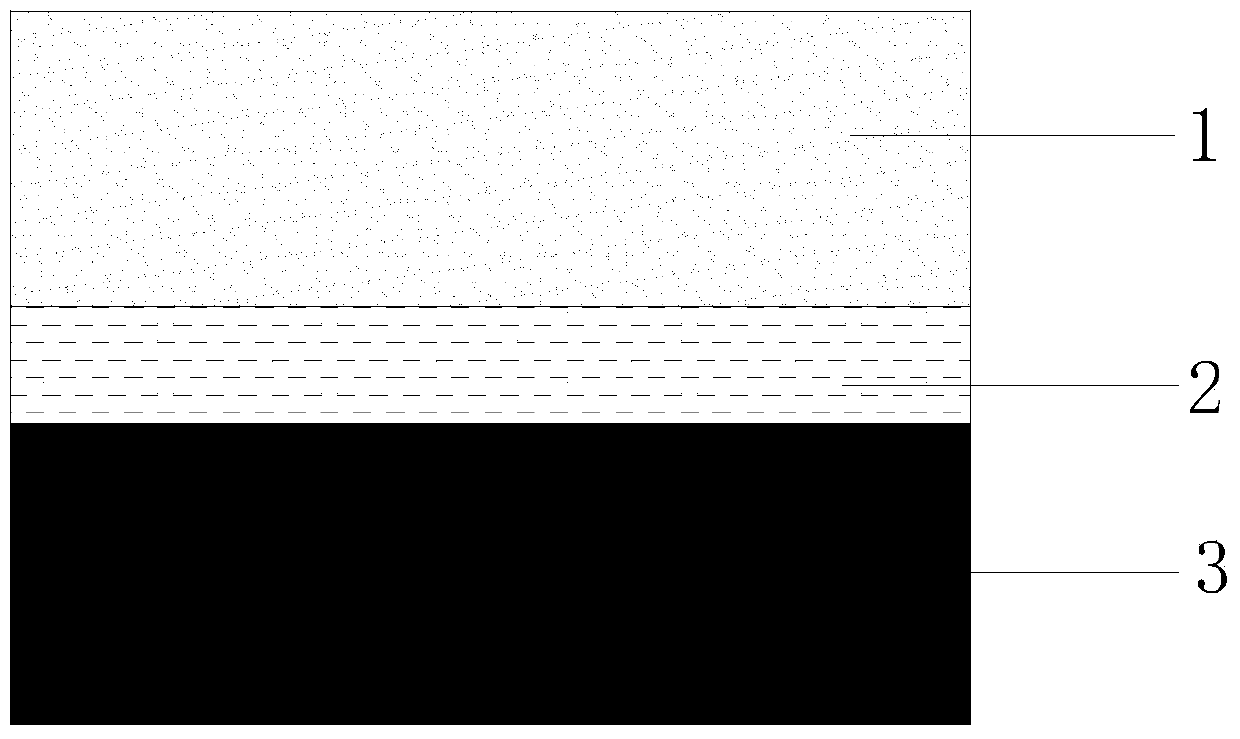

Preparation method of high-temperature superconducting thin film

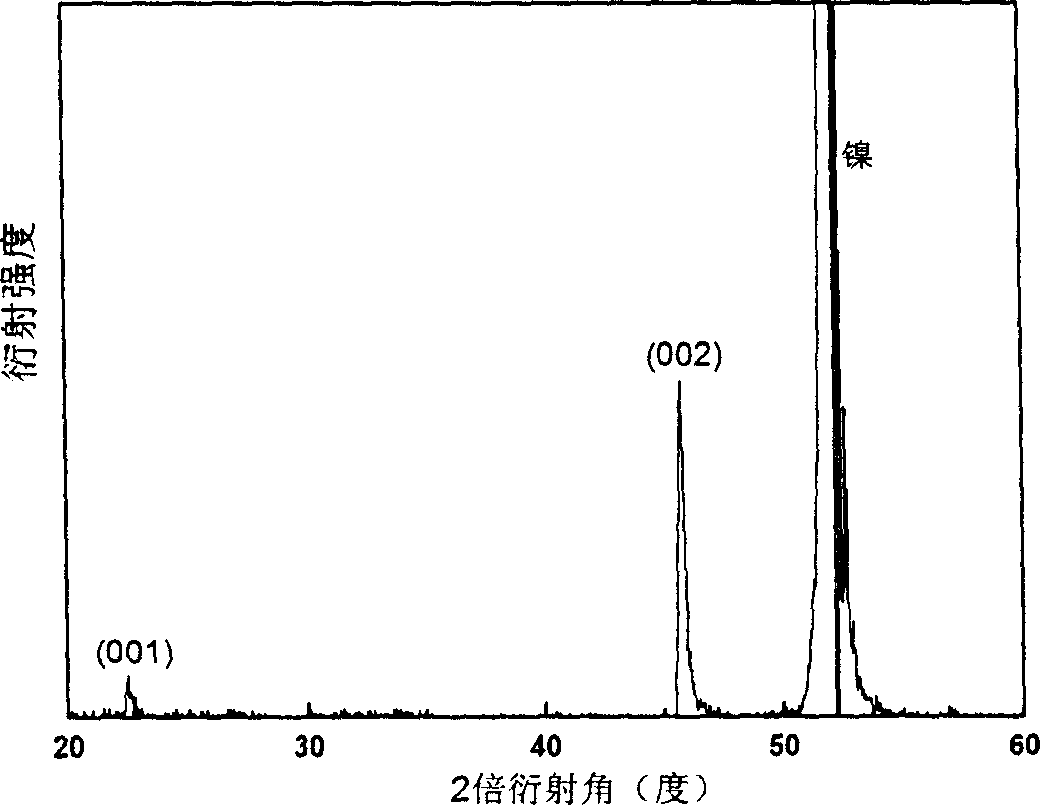

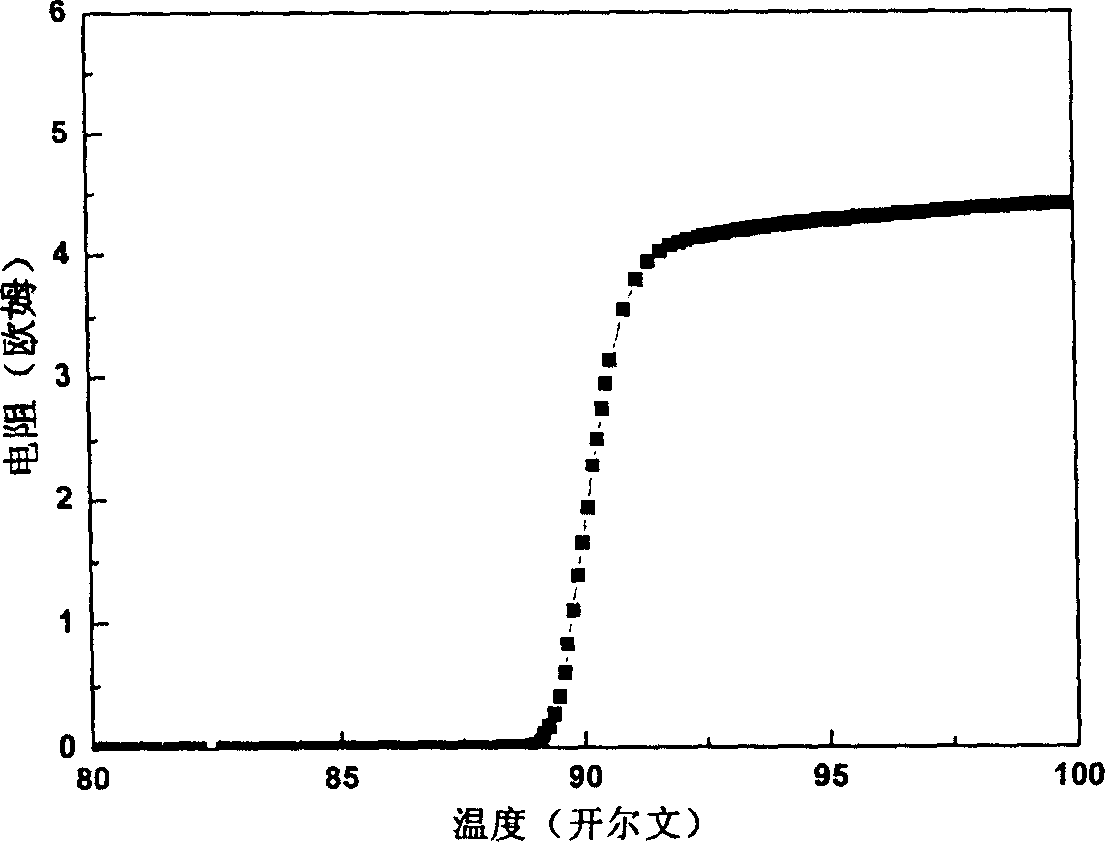

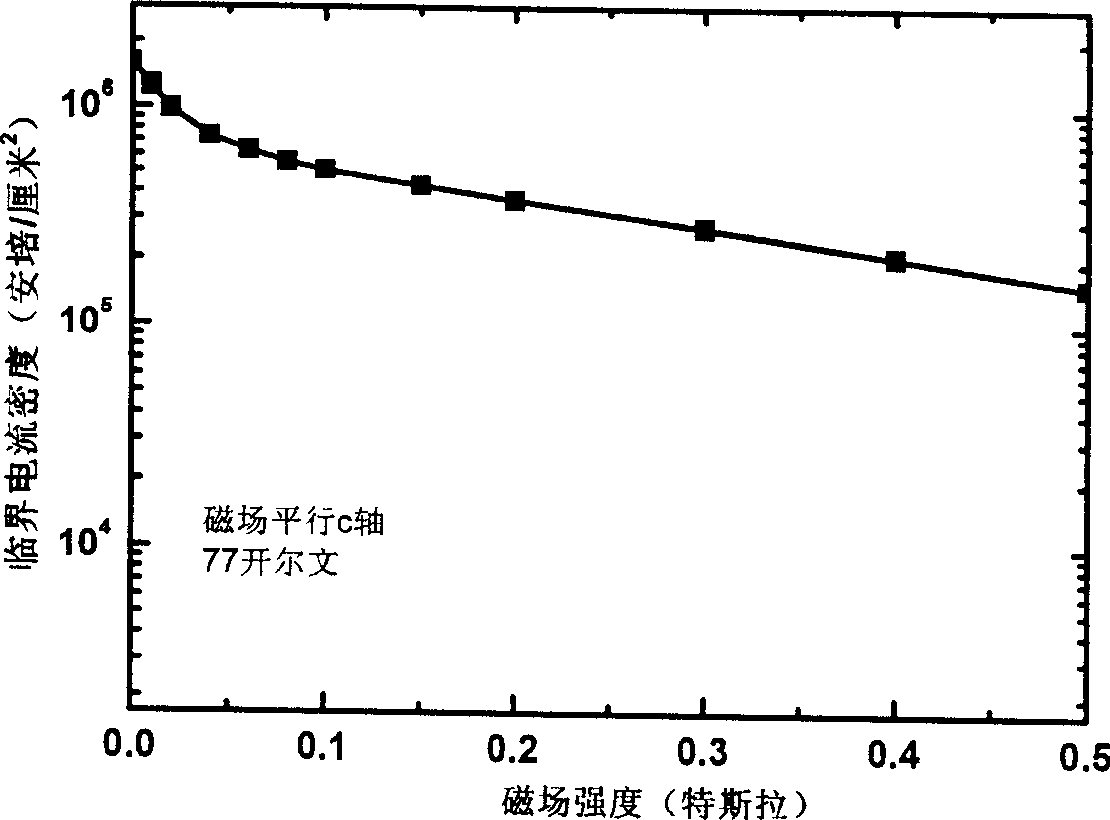

ActiveCN103184513AGuaranteed 2D epitaxial growthAtomic level flatteningPolycrystalline material growthFrom chemically reactive gasesCrystal structureCondensed matter physics

The invention relates to a preparation method of a high-temperature superconducting thin film. The method specifically comprises steps as follows: providing an SrTiO3 substrate and placing the SrTiO3 substrate in a super-high vacuum system, growing an FeSe monocrystal layer on the surface of the SrTiO3 substrate by adopting a molecular beam epitaxy growing technology, and growing a protective layer with a layered crystal structure by adopting the molecular beam epitaxy growing technology and covering the surface of the FeSe monocrystal layer with the protective layer. By means of the method, the high-quality and ultrathin high-temperature superconducting thin film can be prepared, the starting temperature of superconducting transition of the thin film is above 54K, and the critical current density is higher than 106A / cm<2> when the starting temperature of superconducting transition of the thin film is 12K.

Owner:TSINGHUA UNIV +1

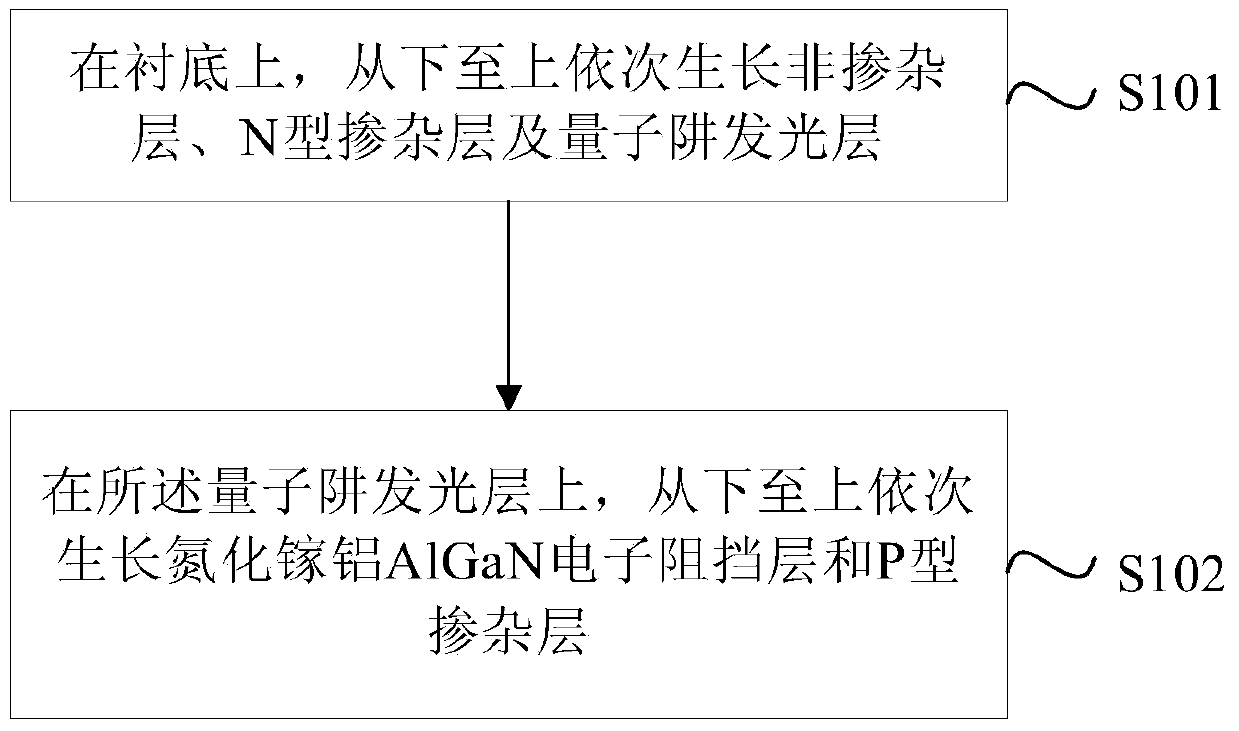

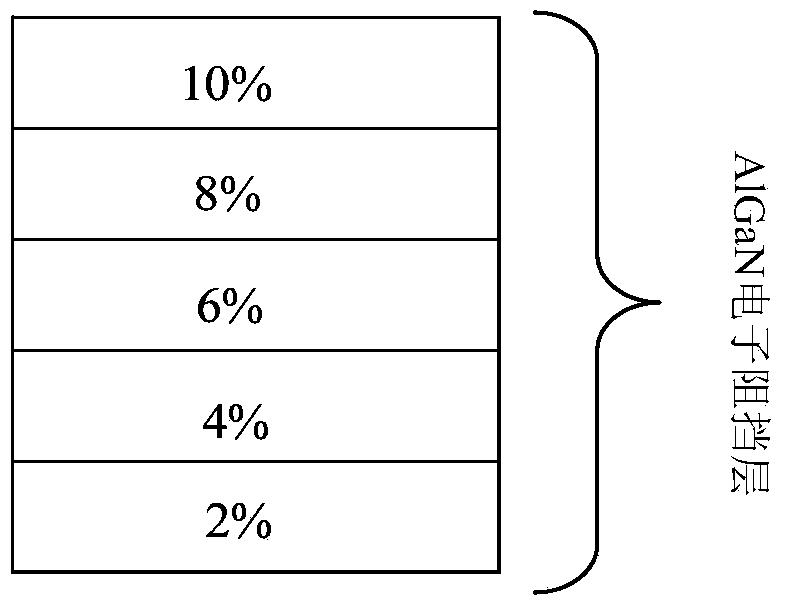

Light emitting diode epitaxy and growing method of light emitting diode electronic barrier layer

InactiveCN104201263AAvoid accessImprove compound efficiencySemiconductor devicesQuantum wellInterface layer

Owner:EPITOP PHOTOELECTRIC TECH

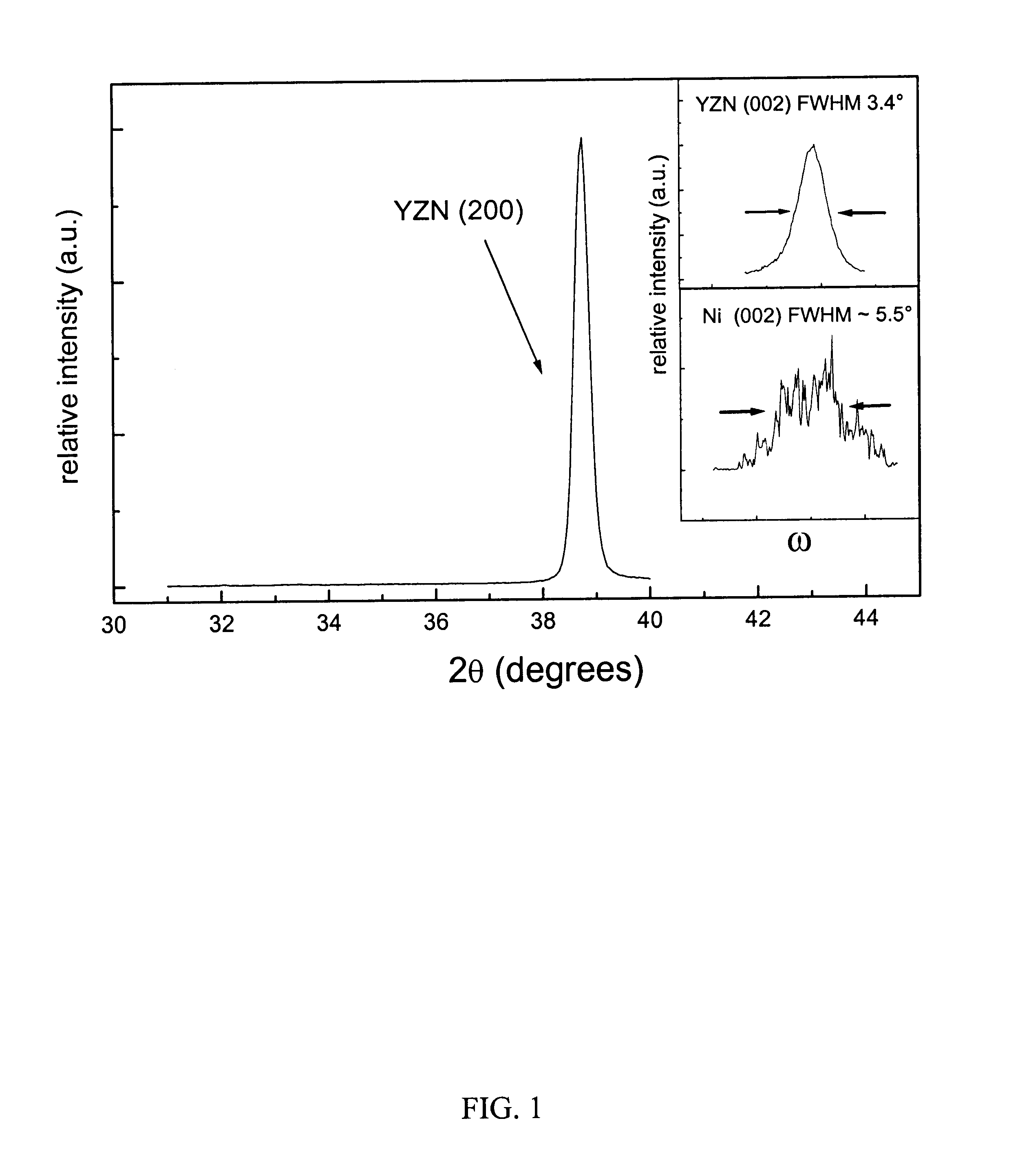

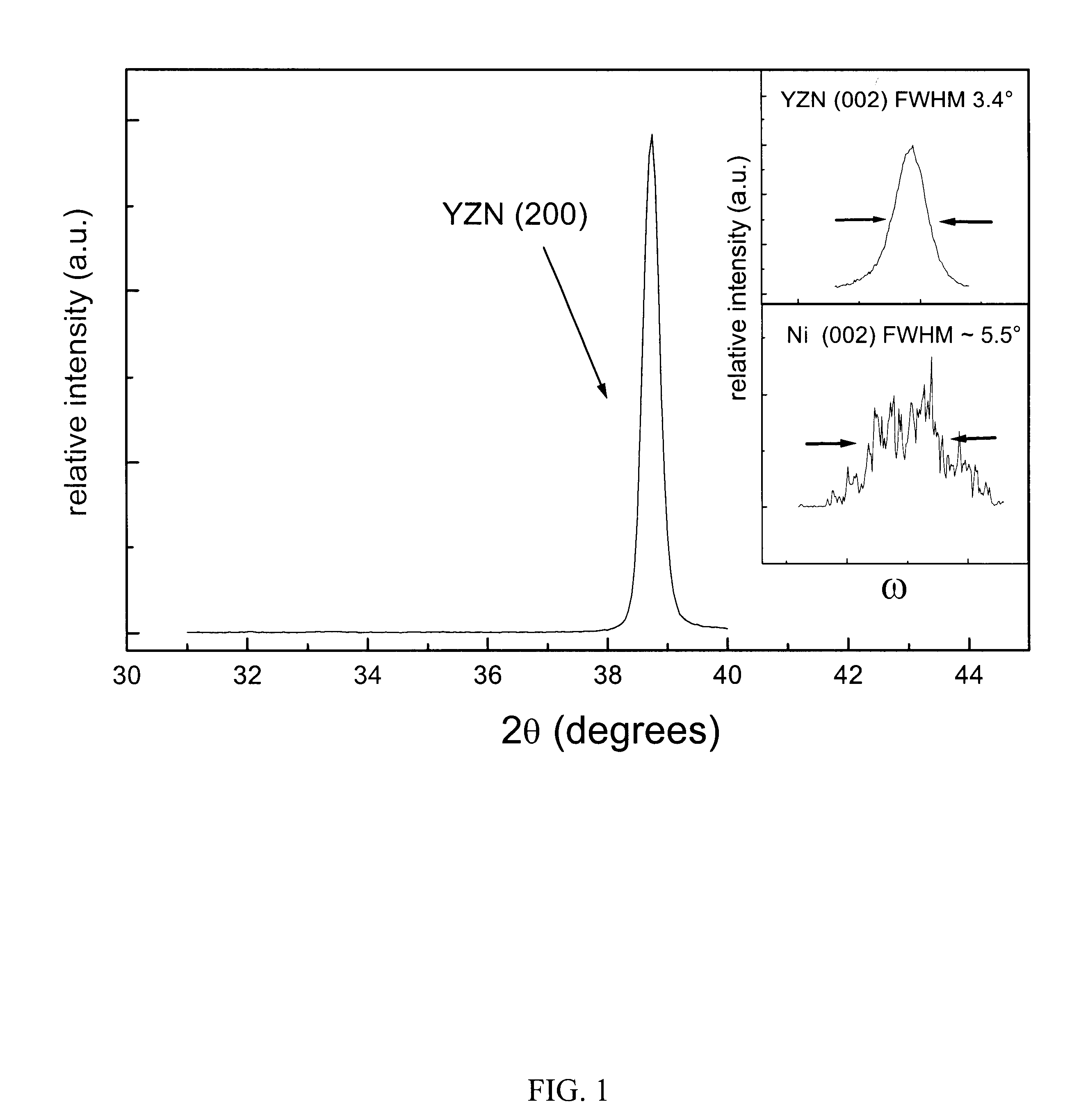

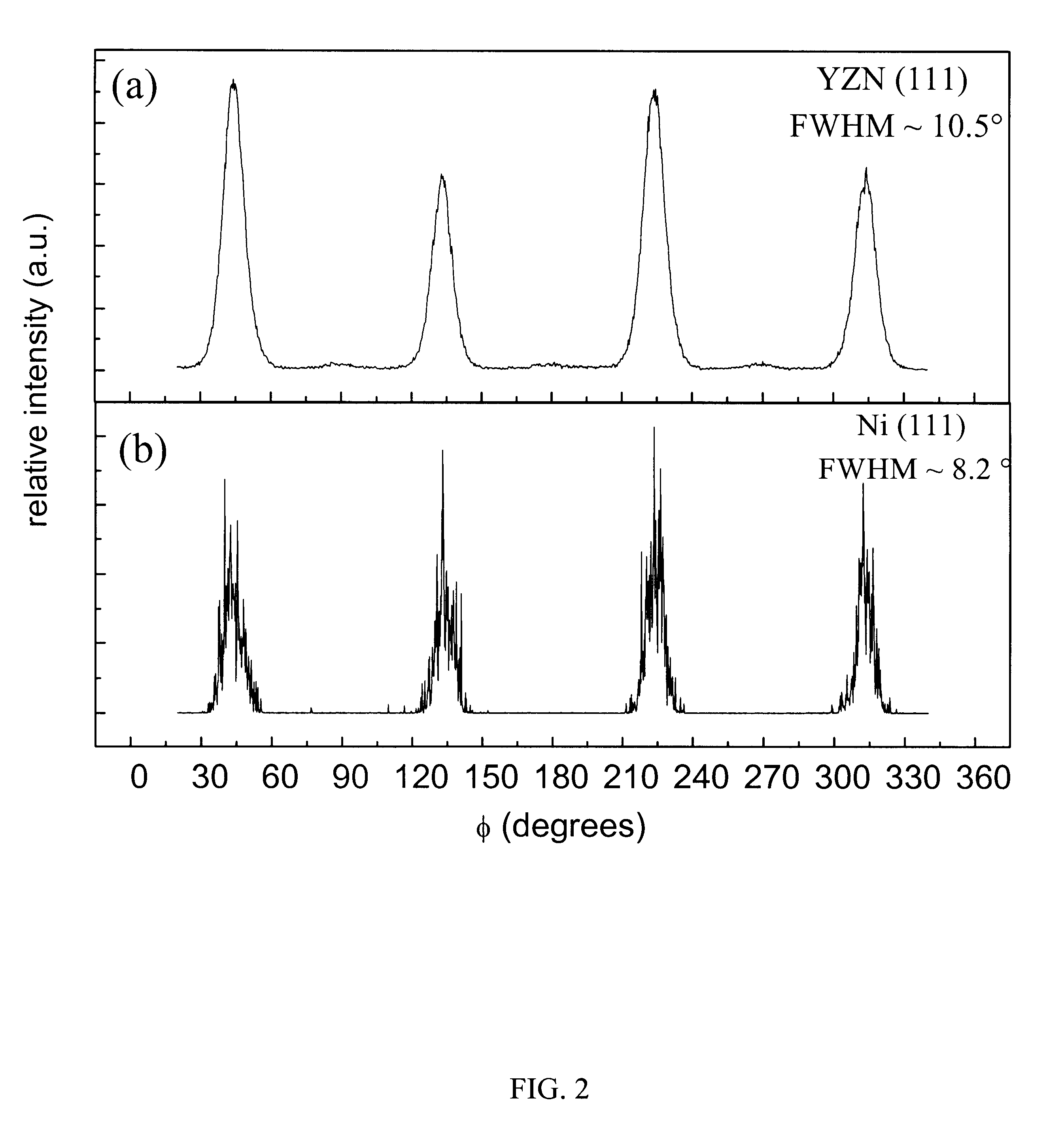

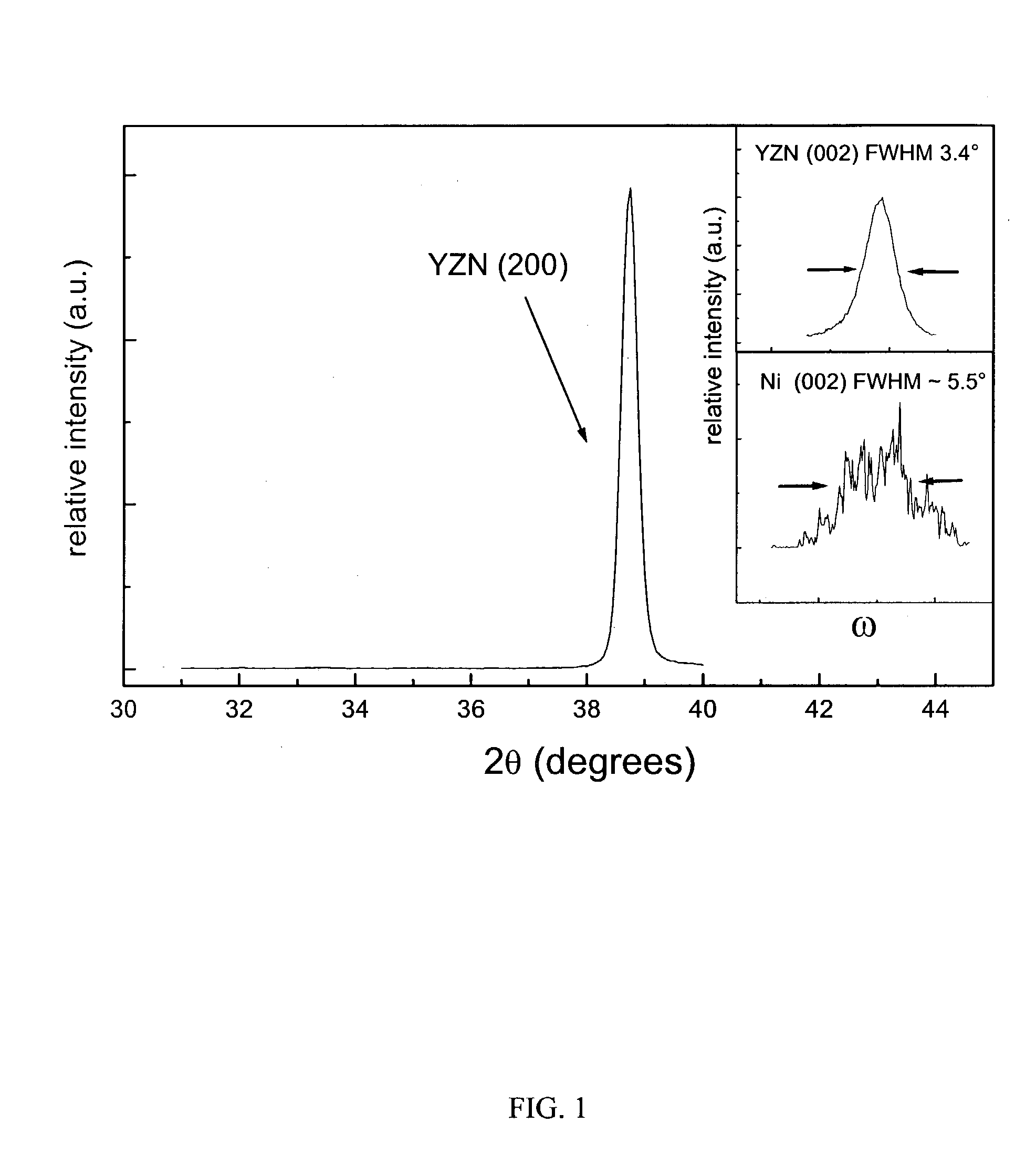

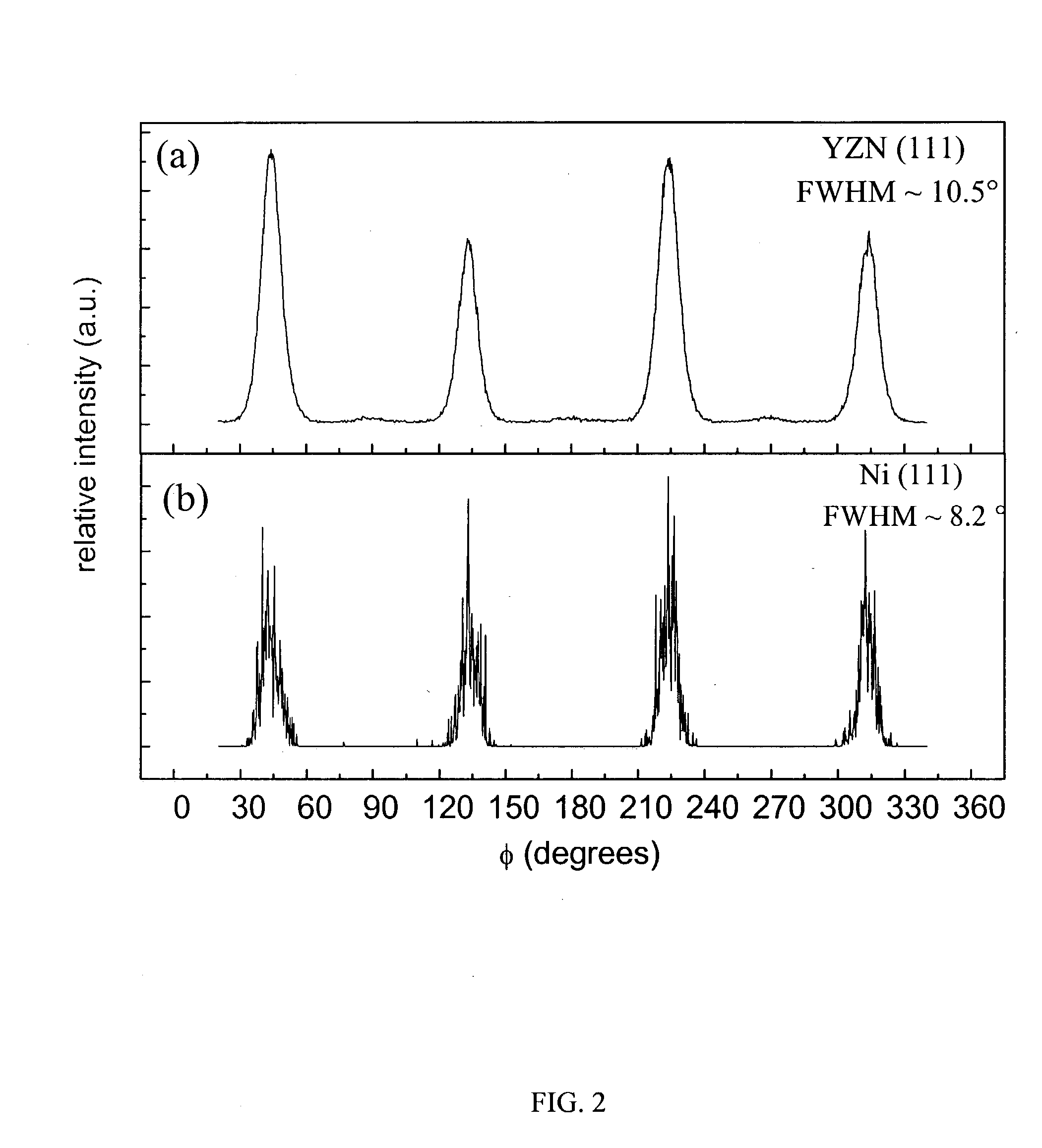

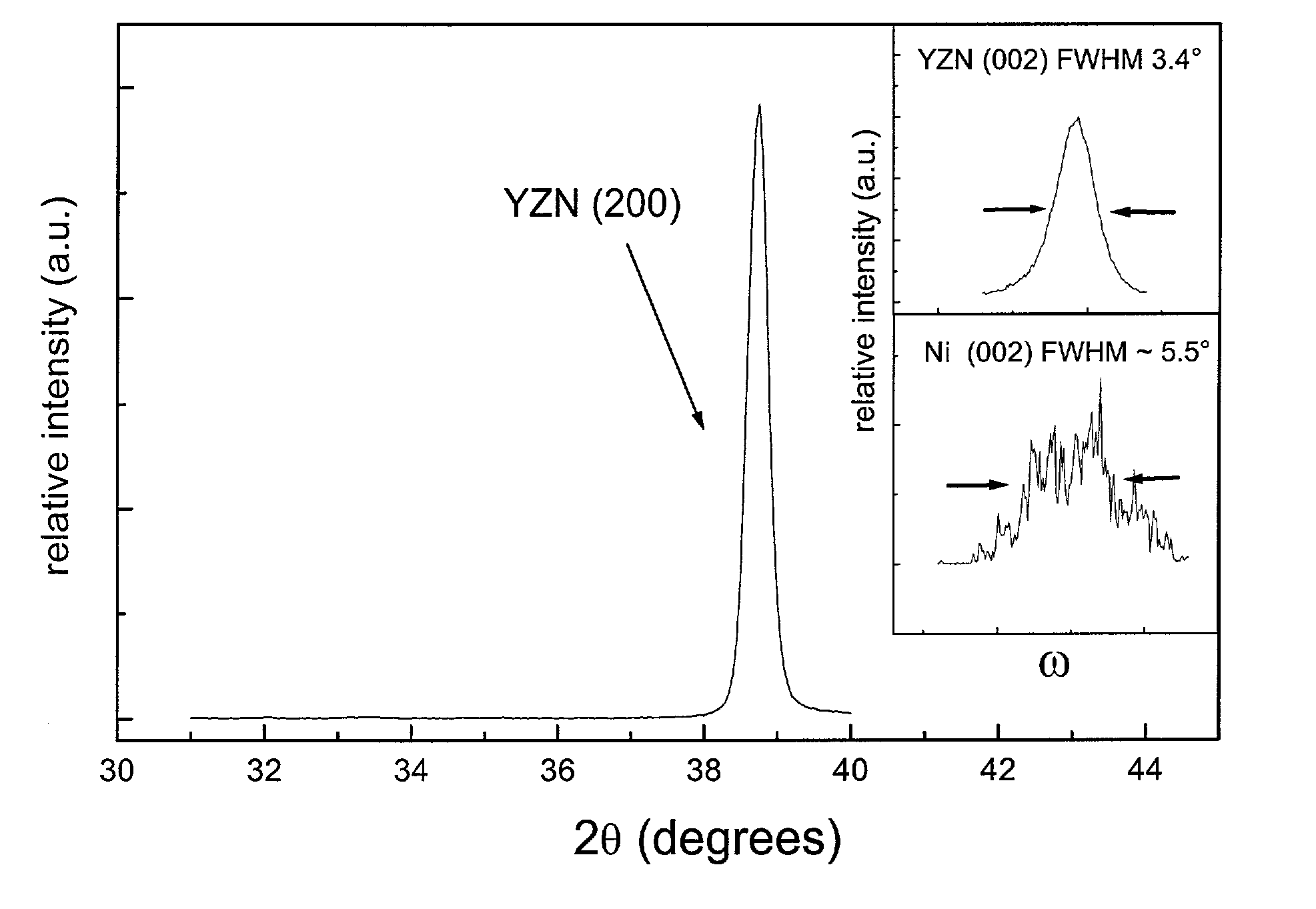

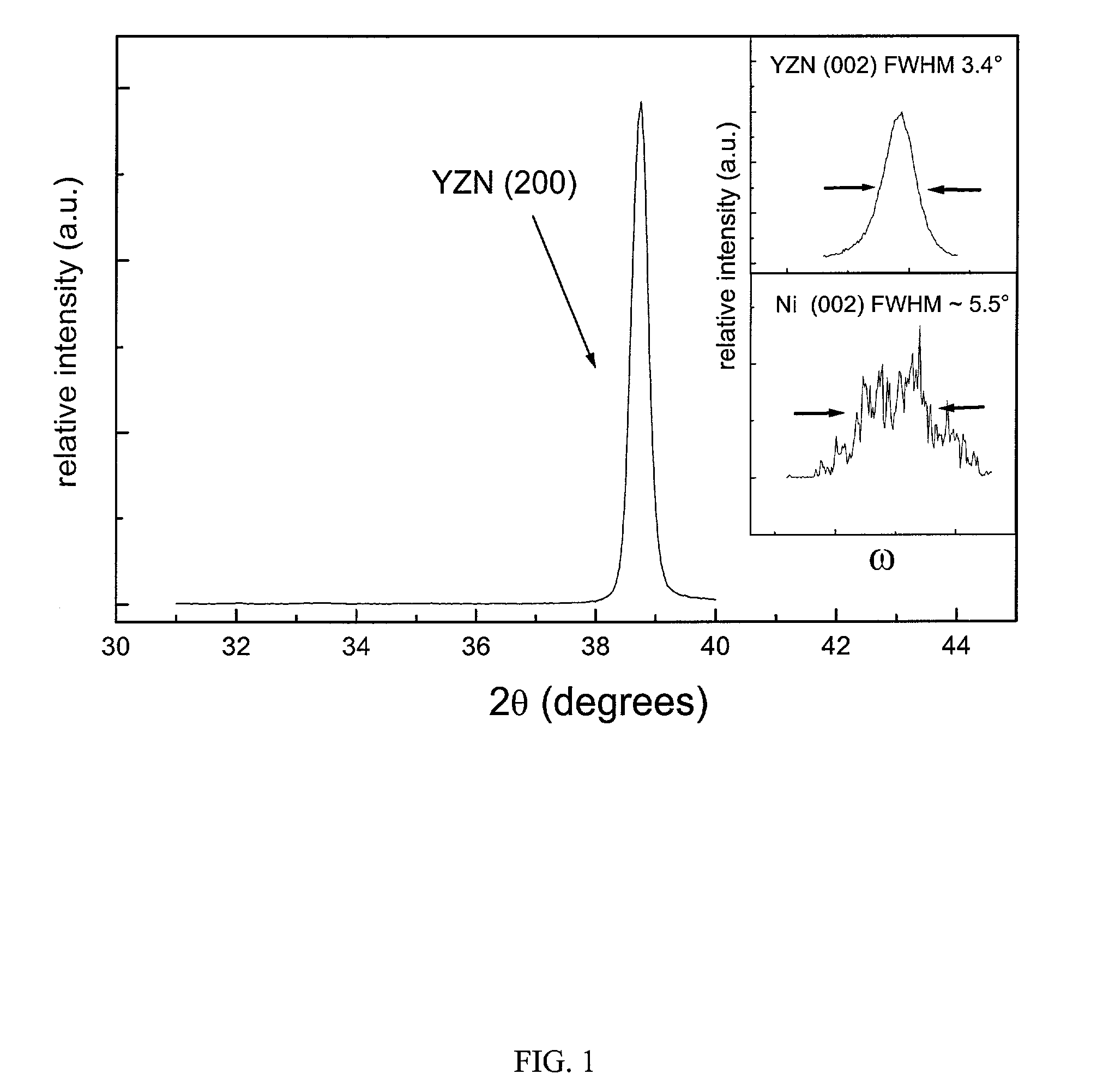

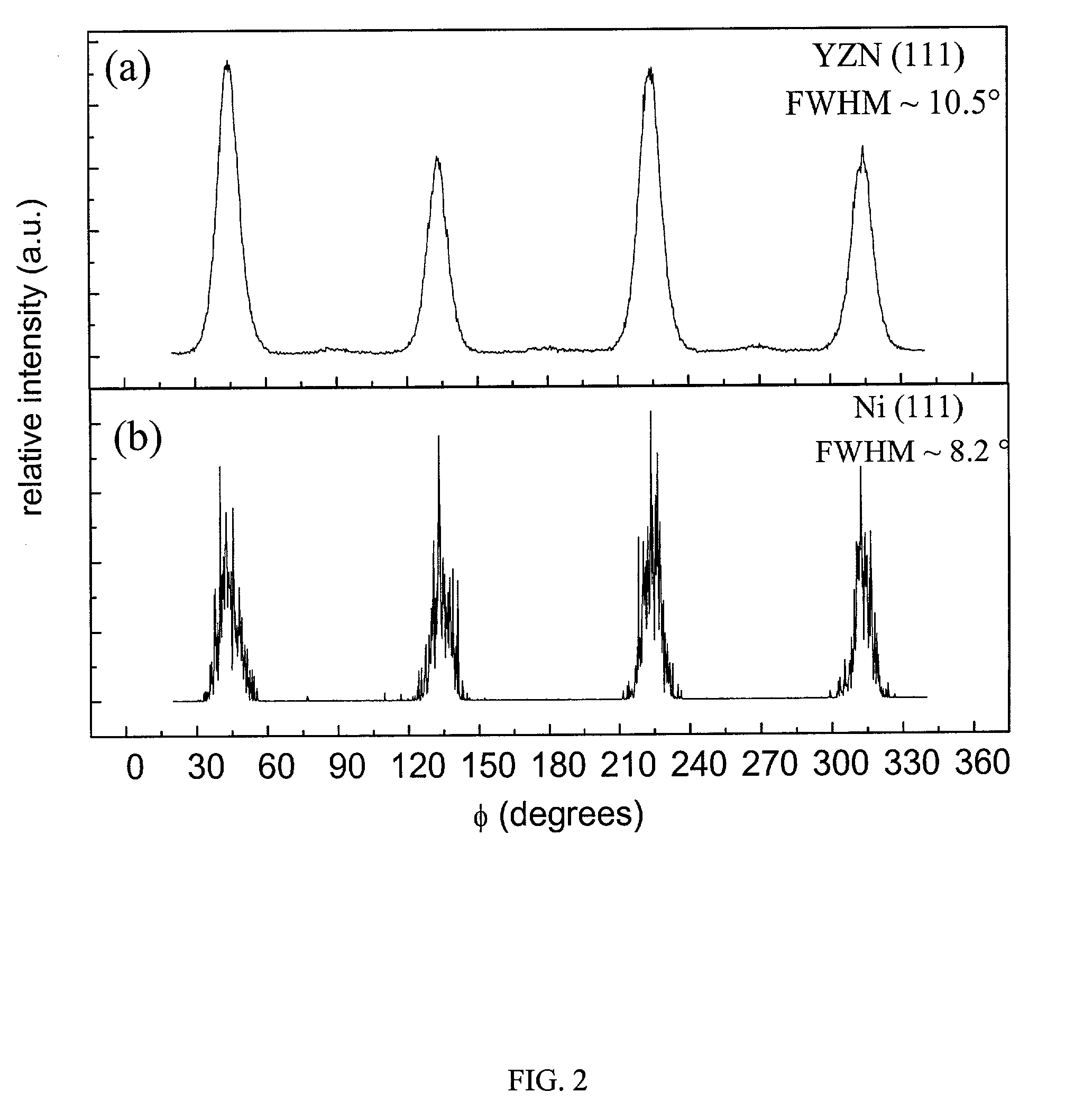

Zirconium nitride and yttrium nitride solid solution composition

InactiveUS6573209B1Small lattice mismatchStraightforward growth processPolycrystalline material growthAfter-treatment detailsYttrium nitrideSolid solution

Owner:APPL THIN FILMS INC

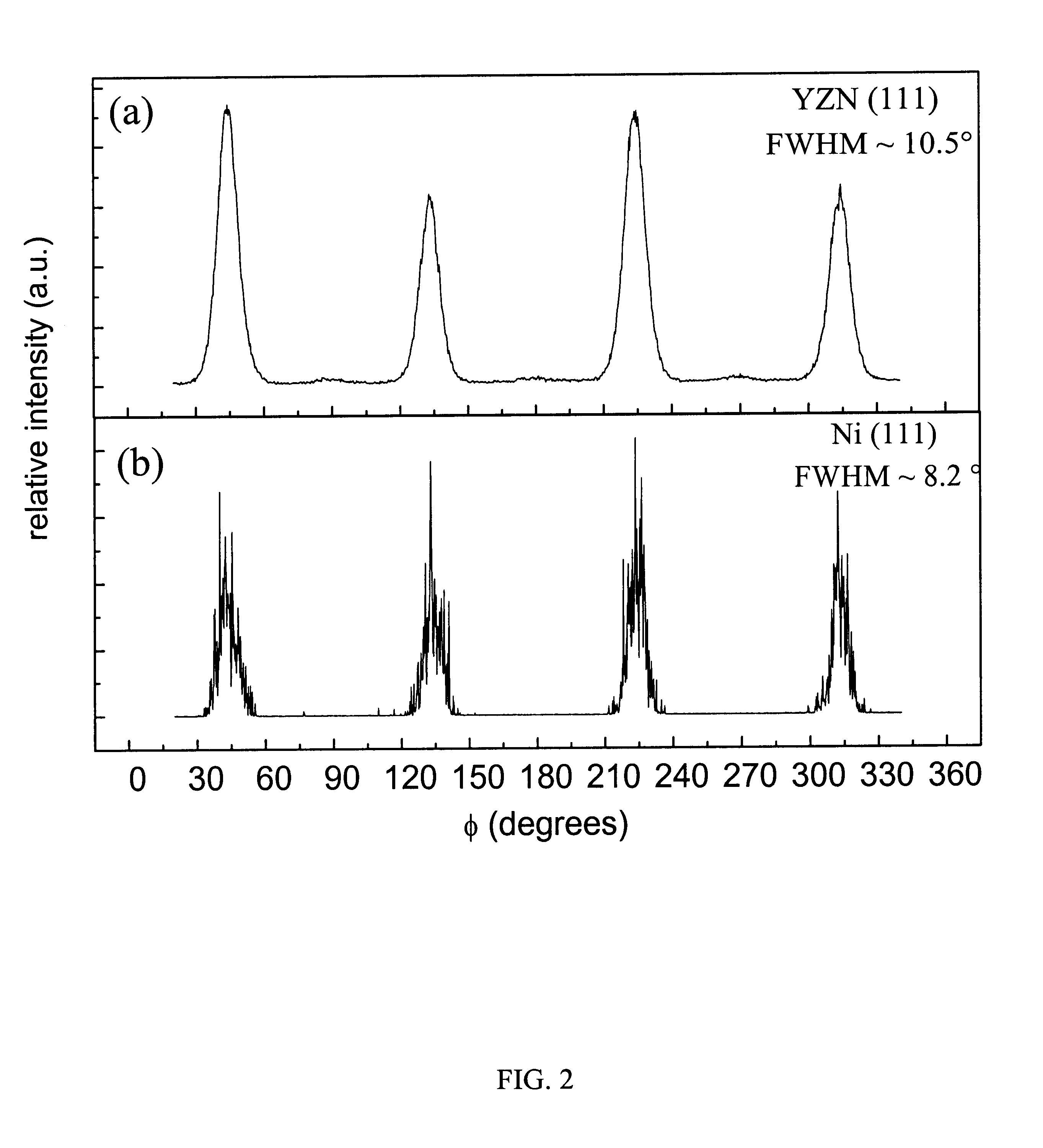

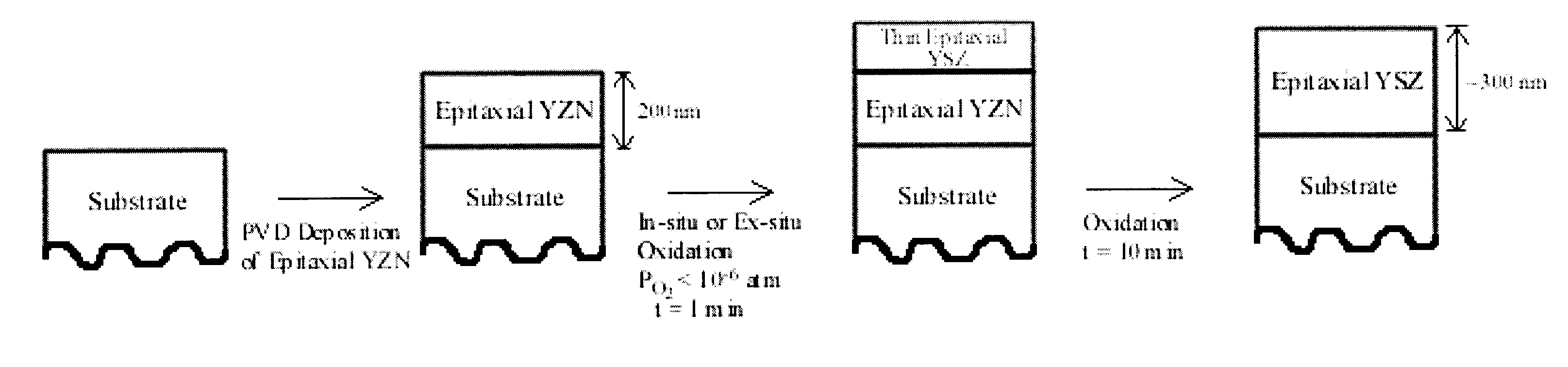

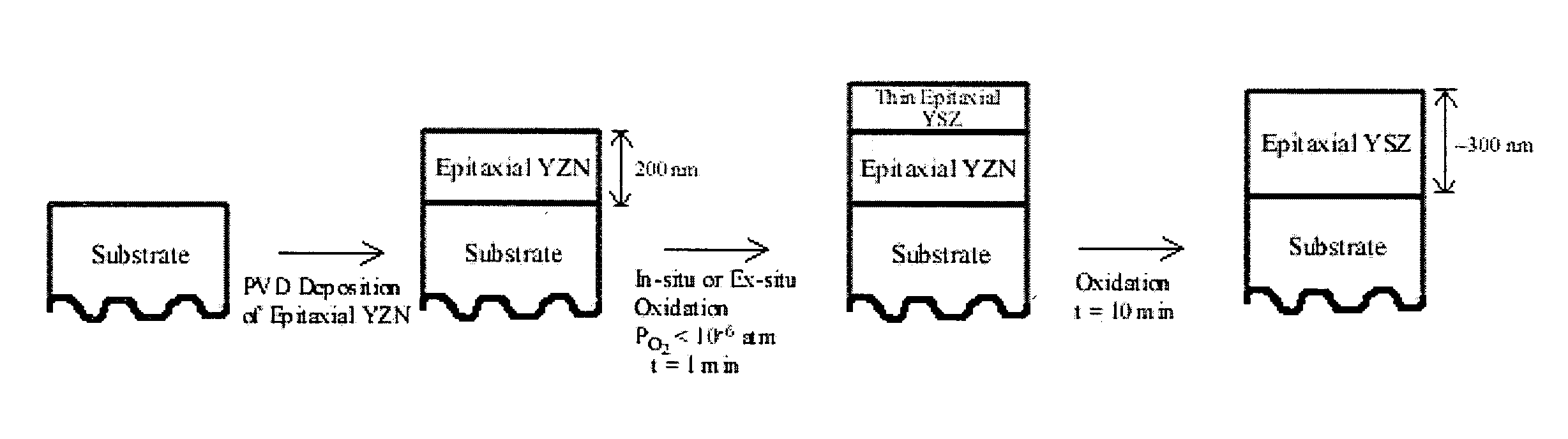

Epitaxial oxide films via nitride conversion

InactiveUS6645639B1Improve the epitaxial quality/in-plane orientationSmall lattice mismatchVacuum evaporation coatingSemiconductor/solid-state device manufacturingNitrideChemistry

Owner:APPL THIN FILMS INC

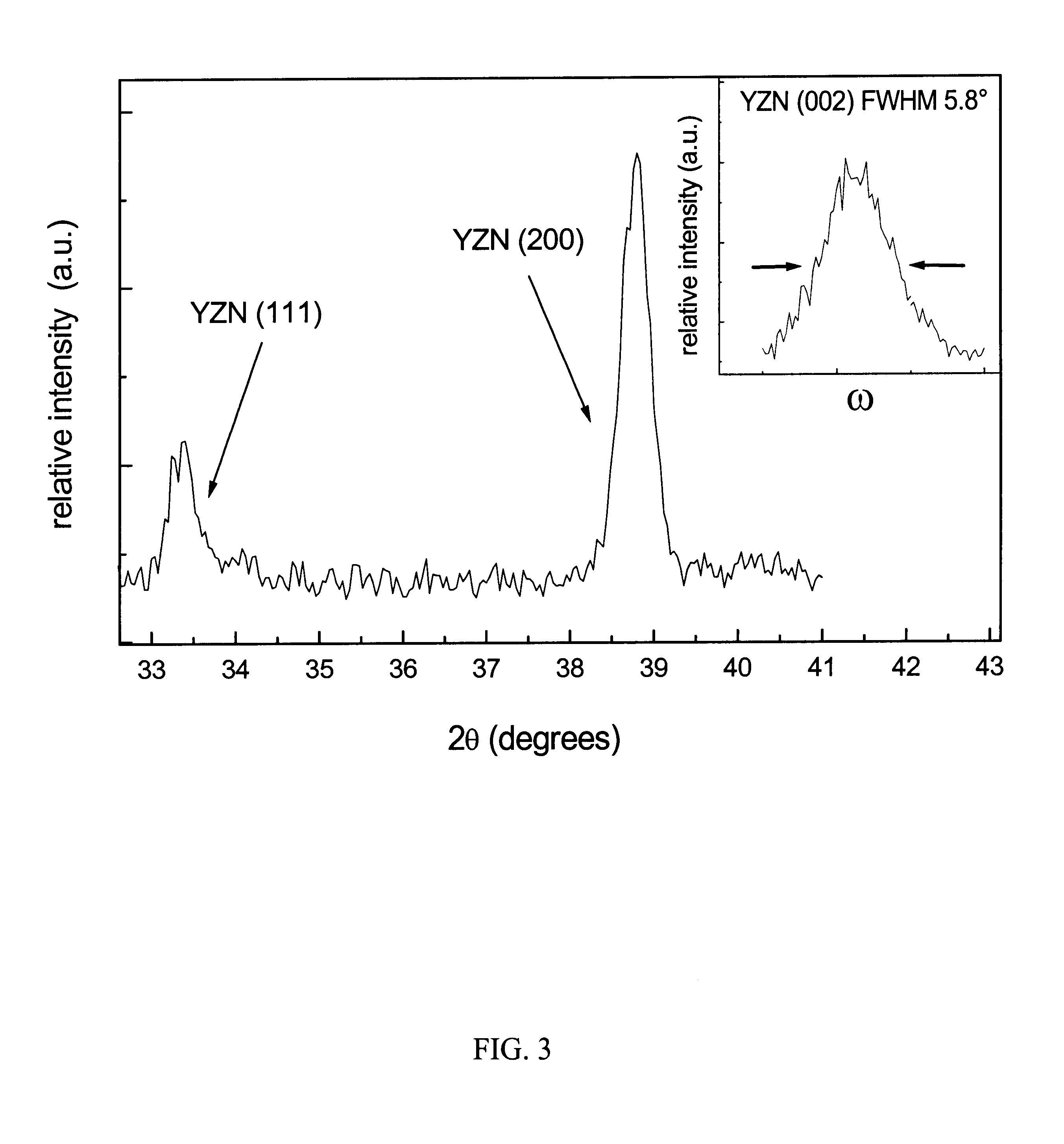

Epitaxial oxide films via nitride conversion

InactiveUS20040096707A1Small lattice mismatchStraightforward growth processPolycrystalline material growthAfter-treatment detailsNitrideChemistry

The present invention relates to oxides on suitable substrates, as converted from nitride precursors.

Owner:APPL THIN FILMS INC

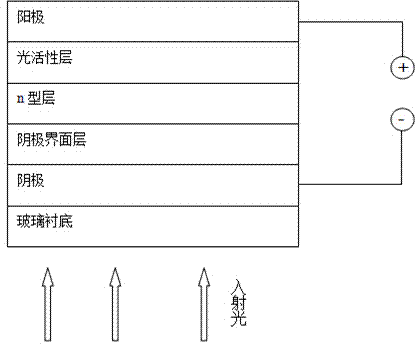

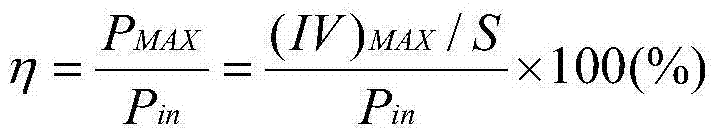

Inverted-structure CdTe nanocrystalline heterojunction high-efficiency solar cell processed by solution method, and preparation method of solar cell

InactiveCN104505423ASmall lattice mismatchImprove performanceMaterial nanotechnologyFinal product manufactureNanometreFill factor

The invention provides an inverted-structure CdTe nanocrystalline heterojunction high-efficiency solar cell processed by a solution method, and a preparation method of the solar cell. The solar cell is formed by sequentially overlapping a glass substrate, a cathode, a cathode interface layer, an n-type layer, a photoactive layer and an anode together from bottom up, wherein the thickness of the photoactive layer is 100-700 nm; the photoactive layer consists of one or more CdTe nanocrystalline layers; and the n-type layer is a CdSe film. According to the invention, energy conversion rate of the CdTe- CdSe full-inorganic nanocrystalline heterojunction solar cell is greatly increased; open-circuit voltage and a fill factor of the solar cell are increased; and the service life of the solar cell is greatly prolonged. The method is simple in preparation technology; the main process can be completed by solution processing in a common fuming cupboard; comparatively low temperature heat treatment is employed and the preparation cost is greatly lowered.

Owner:SOUTH CHINA UNIV OF TECH

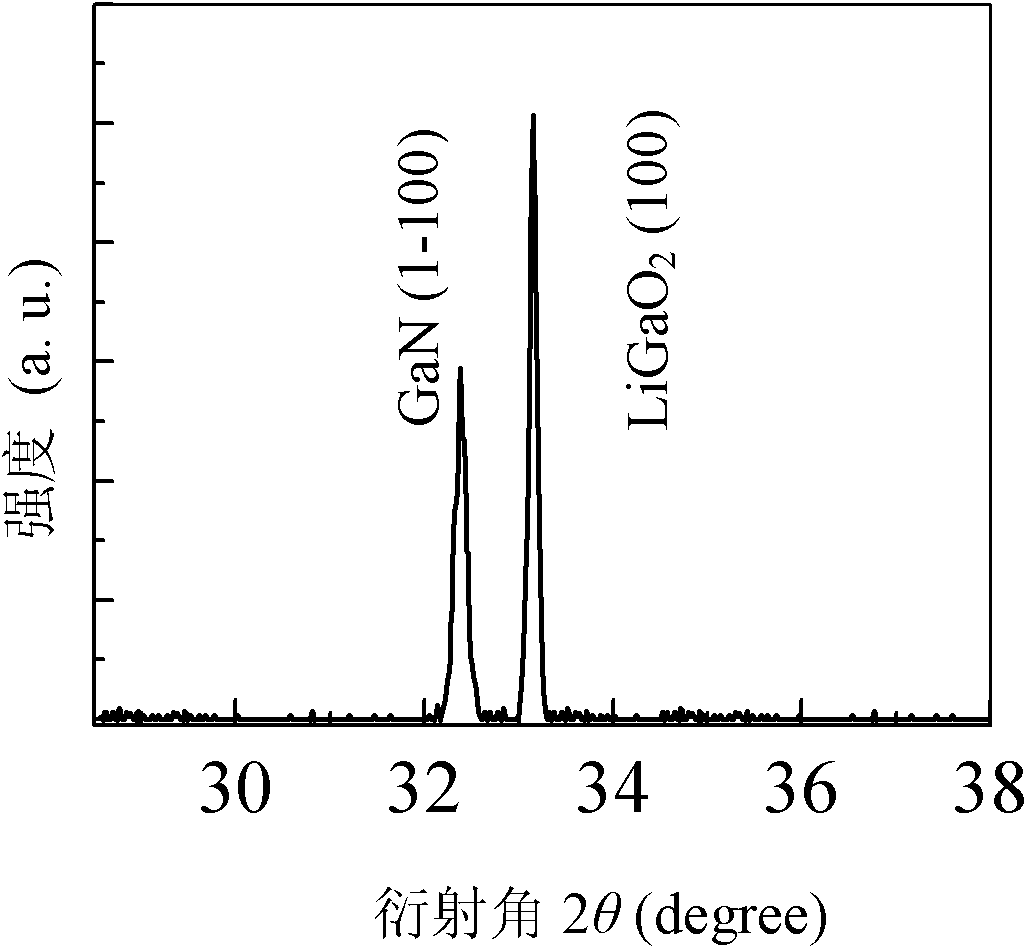

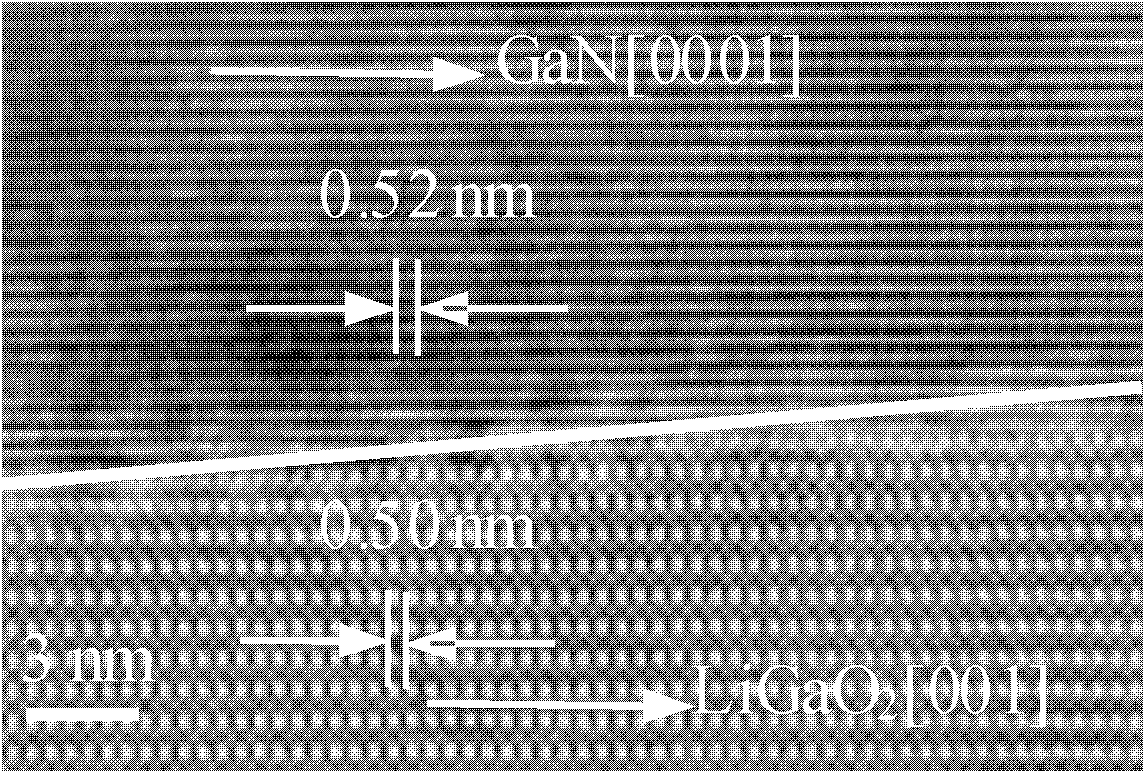

Non-polar GaN thin film grown on LiGaO2 substrate, as well as manufacturing method and application thereof

InactiveCN102544276AImprove luminous efficiencySmall lattice mismatchFinal product manufactureSemiconductor devicesThin membraneMaterials science

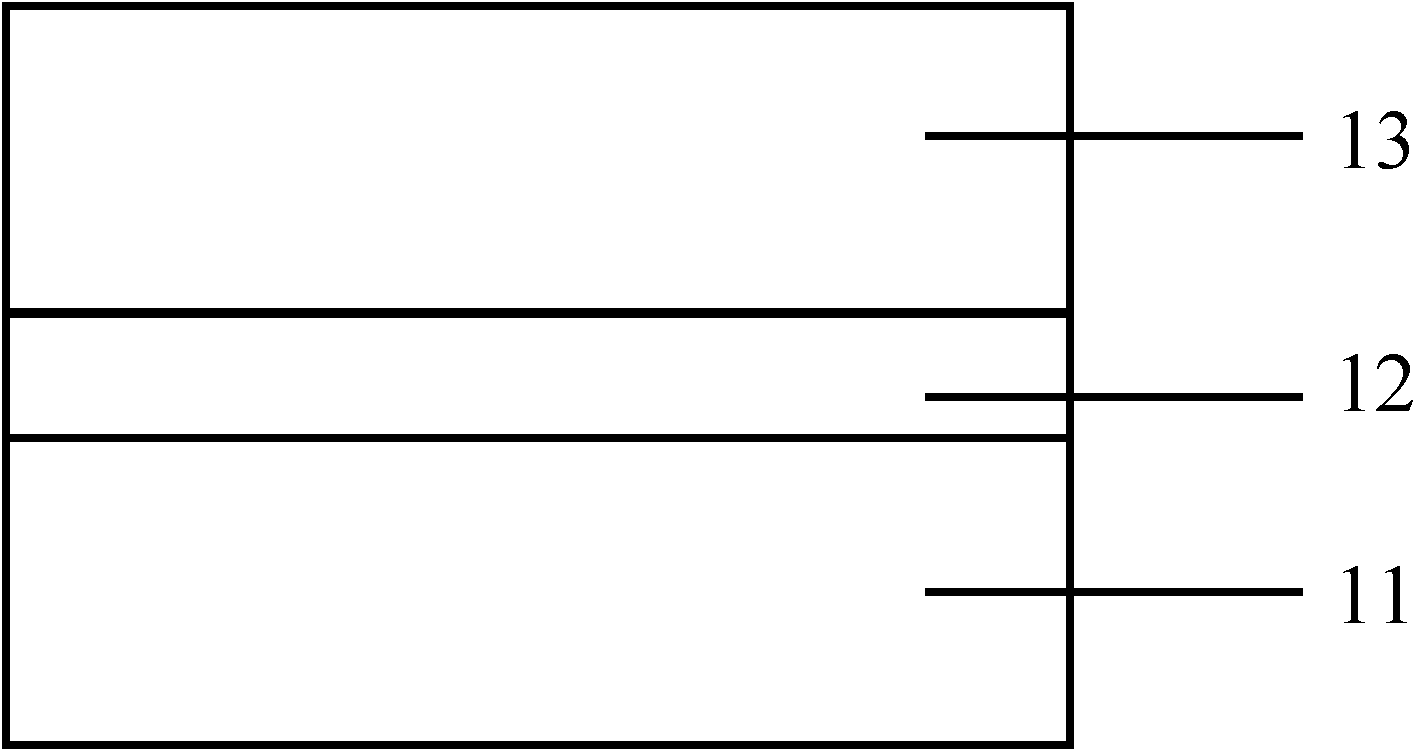

The invention discloses a non-polar GaN thin film grown on a LiGaO2 substrate. The non-polar GaN thin film comprises a non-polar m-surface GaN buffer layer and a non-polar m-surface GaN layer, wherein the non-polar m-surface GaN buffer layer is grown on the LiGaO2 substrate, and the non-polar m-surface GaN layer is grown on the non-polar m-surface GaN buffer layer; the non-polar m-surface GaN buffer layer is a GaN film layer growing when the temperature of the LiGaO2 substrate is 220-350 DEG C; and the non-polar m-surface GaN layer is a GaN film layer growing when the temperature of the LiGaO2 substrate is 600-750 DEG C. The invention further discloses a manufacturing method and an application of the non-polar GaN thin film. Compared with the prior art, the non-polar GaN thin film disclosed by the invention has the advantages of simple growth process and low manufacturing cost; and in addition, the manufactured non-polar GaN thin film has low defect density and good crystallization quality.

Owner:SOUTH CHINA UNIV OF TECH

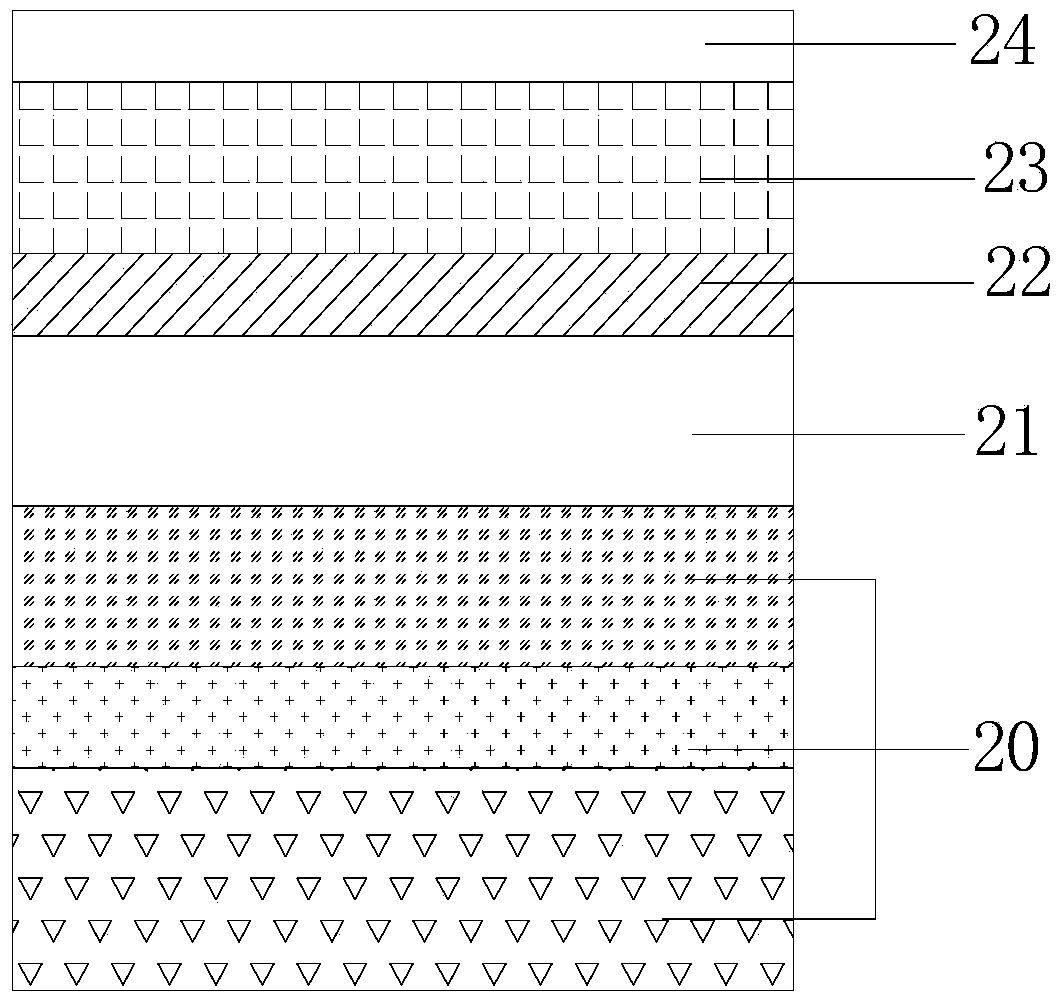

Y-Ba-Cu-O coating conductor with conducting buffer layer and preparing process

InactiveCN1905081ASmall lattice mismatchQuality improvementNon-insulated conductorsSuperconductors/hyperconductorsStrontium titanateElectrical conductor

The invention relates to yttrium barium copper oxygen coating conductor with conduct buffer layer. It includes adulterated strontium titanate conduct buffer layer and YBCO superconducting layer. The former includes niobium strontium titanate SrTi1-xNbxO3, indium strontium titanate SrTi1-xInxO3, or lanthanum strontium titanate Sr1-xLaxTiO3 which x is between 5mol% and 30mol%. Its manufacturing method includes the following steps: using pulsed laser deposition technique to adjust pressure at 1-5Pa in reaction chamber, substrate temperature at 700-800 degree centigrade, conductive film deposition thickness at 30-50nm; pumping out the mixed gas from the reaction chamber; filling 10-2Pa oxygen with 99.99% purity; keeping the temperature not change; making the deposition thickness of the adulterated strontium titanate conductive film at 100-500nm.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

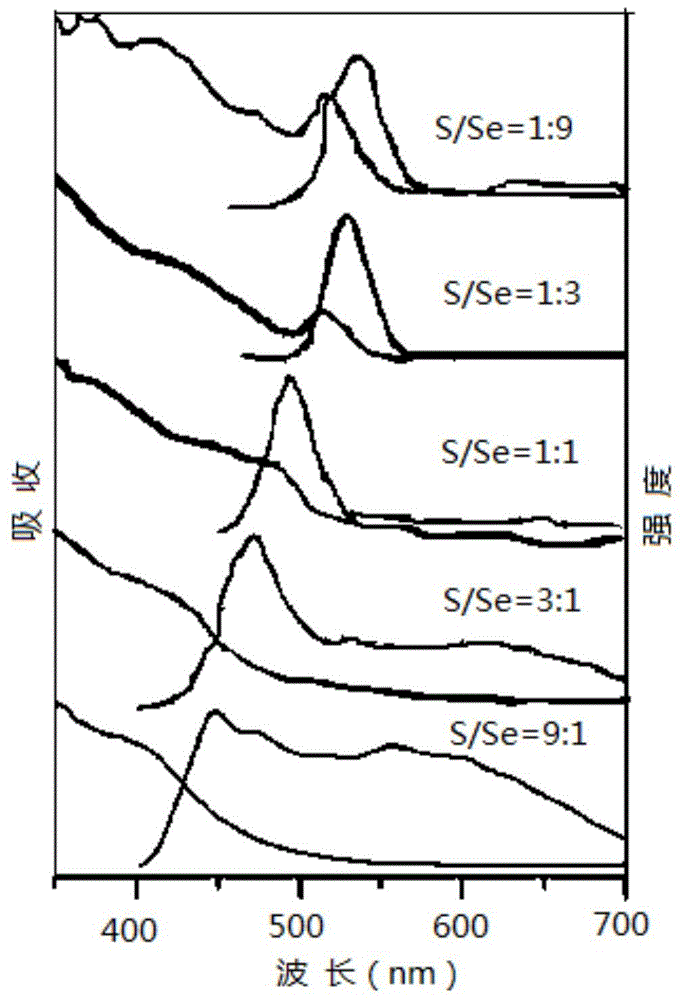

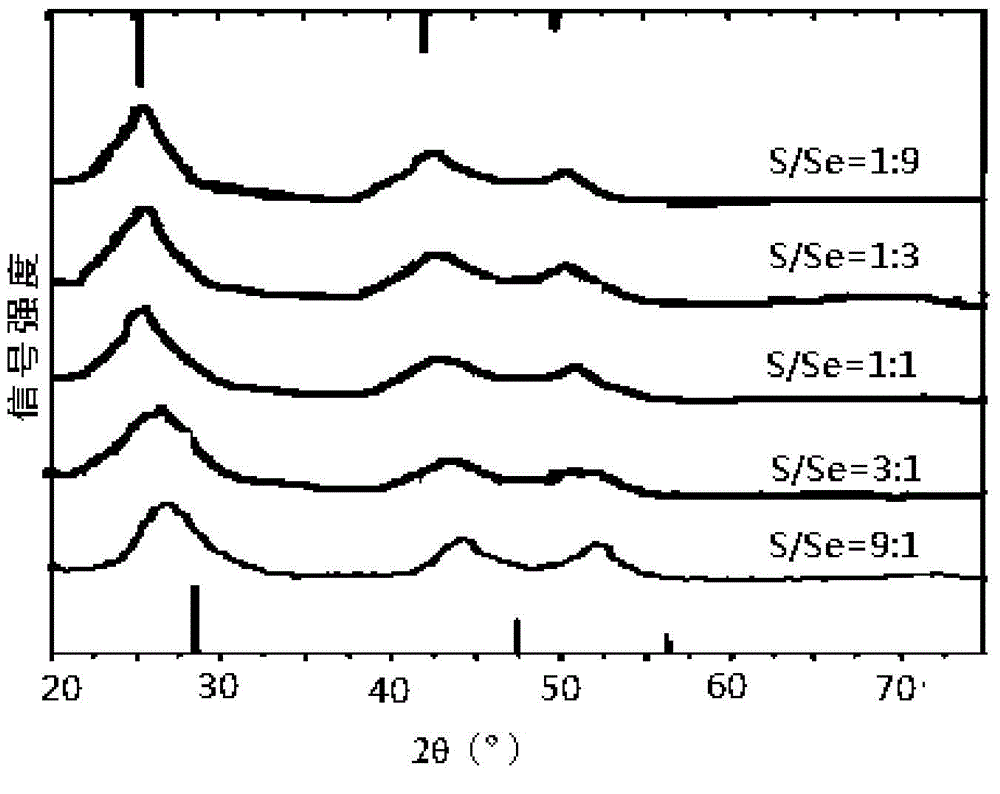

Method for microwave-assisted preparation of CdTeSeS/ZnTe core-shell quantum dot in water

InactiveCN104974742ARich sourcesLower synthesis costLuminescent compositionsQuantum yieldPotassium borohydride

The invention relates to a method for microwave-assisted preparation of a CdTeSeS / ZnTe core-shell quantum dot in water. The method comprises the following steps: 1) preparing a sodium elenosulfate solution; 2) preparing a cadmium chloride solution; 3) adding mercaptopropionic acid into the cadmium chloride solution; 4) adjusting the pH value of the solution; 5) dissolving a sodium tellurite crystal in the solution and simultaneously adding potassium borohydride and the sodium elenosulfate solution; 6) subjecting a mixture obtained in the step 6) to heating reaction in a microwave digestion furnace; 7) carrying out cooling to room temperature and adding isopropanol for purification so as to obtain CdTeSeS quantum dot gel; and 8) preparing a mixed solution of the cadmium chloride solution, the mercaptopropionic acid and the sodium tellurite crystal, dissolving the CdTeSeS quantum dot gel in the mixed solution anew, adding potassium borohydride and successively carrying out heating reaction in the microwave digestion furnace, cooling to room temperature, addition of isopropanol for purification and drying with a lyophilizer so as to obtain solid powder of the CdTeSeS / ZnTe core-shell quantum dot. The method is fast and simple and has easily controllable technological parameters and a low price; and the synthesized quantum dot has uniform particle size distribution, high stability, high fluorescence quantum yield and wide emission spectrum.

Owner:天门市天宝化工科技有限公司

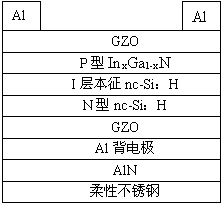

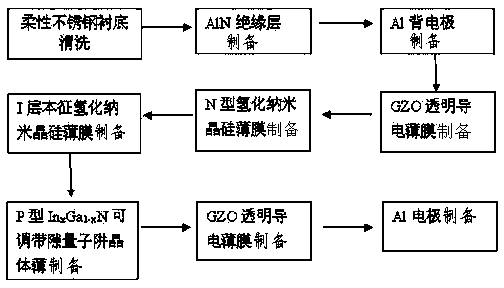

Stainless steel substrate solar battery in adjustable-band-gap quantum well structure and preparation method thereof

ActiveCN103746016AReduce weightImprove conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingInsulation layerSolar battery

The invention belongs to the technical field of flexible solar battery manufacturing, and particularly relates to a stainless steel substrate solar battery in an adjustable-band-gap quantum well structure and a preparation method thereof. The stainless steel substrate solar battery provided by the invention is of the following concrete structure: Al electrode / GZO (gallium zinc oxide) / P type In<x>Ga<1-x>N / I layer intrinsic nc-Si:H / N type nc-Si:H / GZO / Al back electrode / AlN insulation layer / flexible stainless steel substrate. The preparation method of the stainless steel substrate solar battery comprises the steps that firstly, magnetron sputtering is carried out for preparing an AlN insulation layer and an Al back electrode, then, ECR-PEMOCVD is adopted for sequentially depositing a GZO based transparent conducting film, an N type nc-Si:H film, an I layer intrinsic nc-Si:H film, a P type In<x>Ga<1-x>N film and a GZO film, and finally, the metal Al electrode is prepared. The stainless steel substrate solar battery in the adjustable-band-gap quantum well structure has the advantages that the flexibleness is excellent, the weight is light, the carrying is convenient, the industrialization potential and the market space are realized, in addition, the preparation process is simple, and the scale production can be realized.

Owner:SHENYANG INST OF ENG

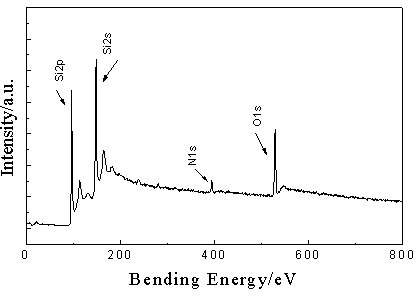

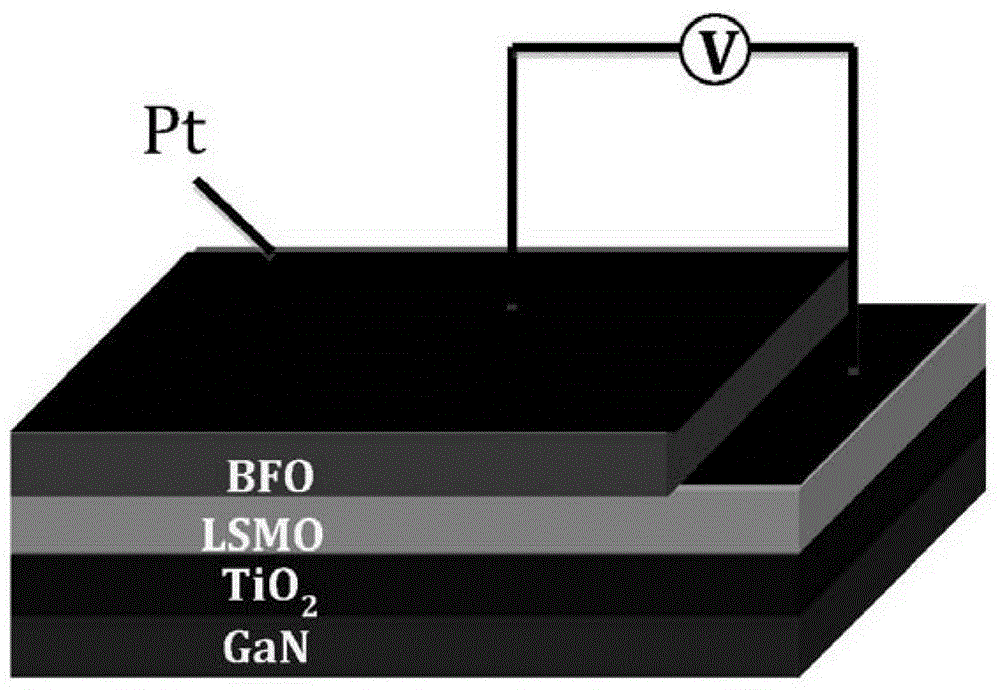

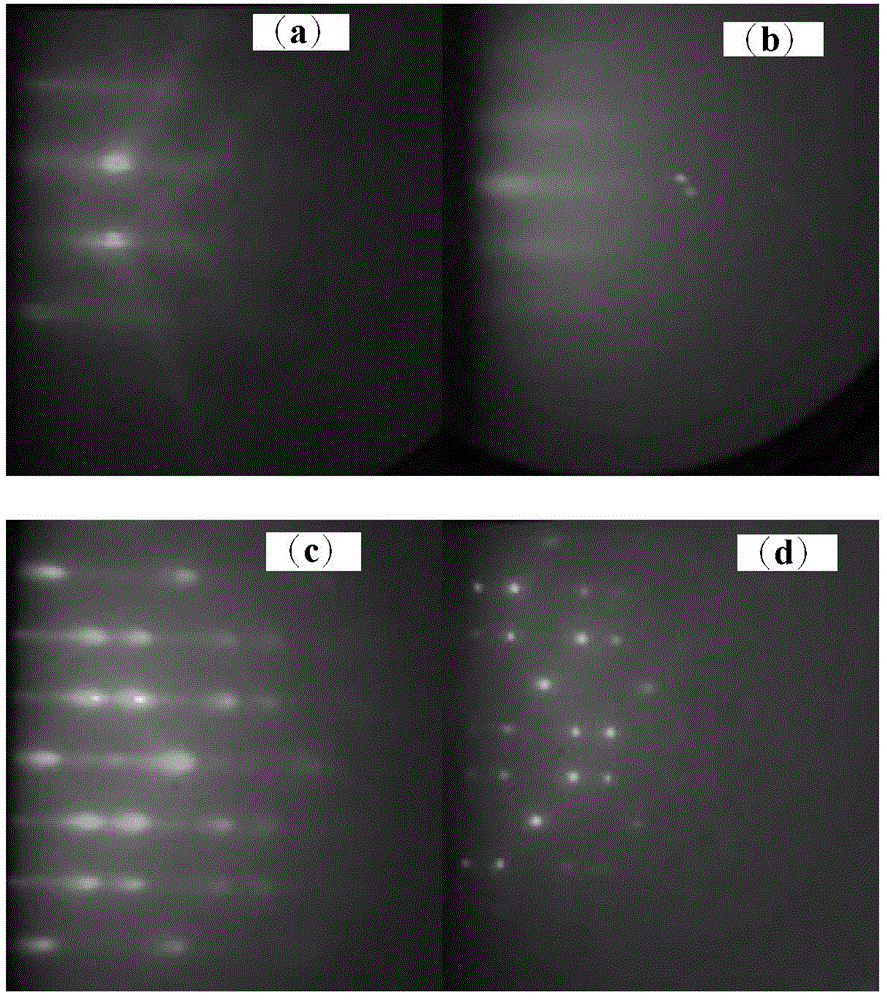

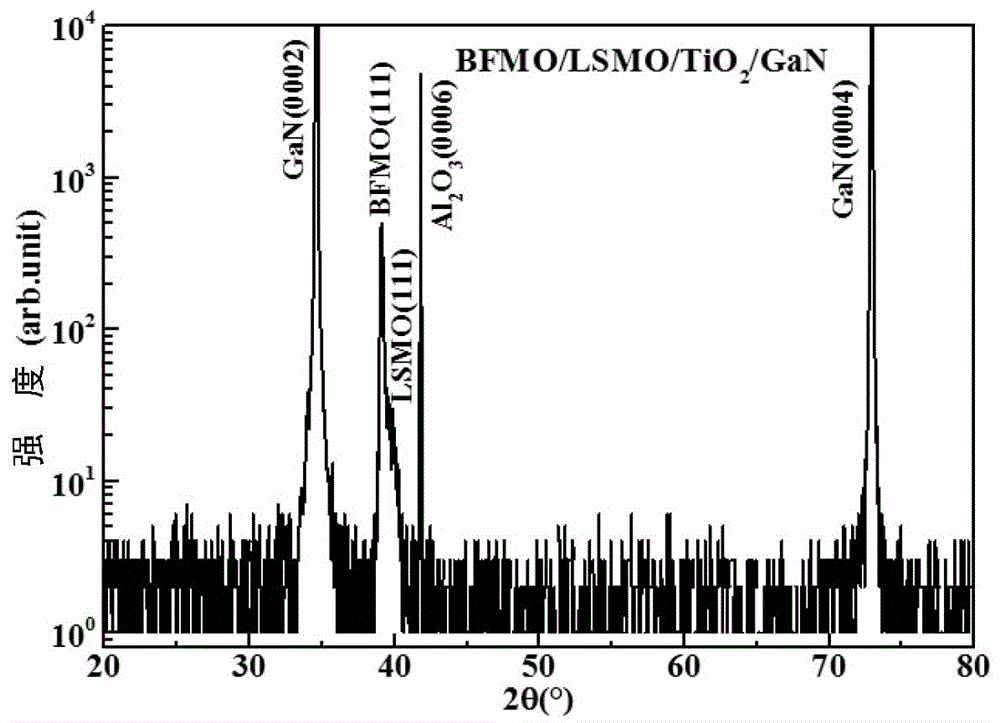

Gallium nitride-based bismuth ferrite ferroelectric thin film and preparation method thereof

InactiveCN106129243ASmall lattice mismatchAchieve epitaxial growthPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostrictive device material selectionCrystallographyFerroelectric thin films

The invention relates to a gallium nitride-based bismuth ferrite ferroelectric thin film and a preparation method thereof. The gallium nitride-based bismuth ferrite ferroelectric thin film comprises a TiO<2> buffer layer, a strontium lanthanum manganate buffer layer and a bismuth ferrite ferroelectric thin film which are formed on a gallium nitride semiconductor thin film substrate in sequence through a pulse laser deposition technology. The gallium nitride-based bismuth ferrite ferroelectric thin film and the preparation method thereof have the following beneficial effects: the LSMO / TiO<2> dual buffer layers are adopted, so that the lattice mismatching degree between bismuth ferrite and gallium nitride is reduced; the epitaxial growth of the bismuth ferrite ferroelectric thin film on the gallium nitride semiconductor thin film is realized; the (111) single-oriented bismuth ferrite thin film is obtained; and the epitaxial integration of the bismuth ferrite ferroelectric thin film and the gallium nitride semiconductor is realized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Epitaxial oxide films via nitride conversion

InactiveUS20030207132A1Good biaxial textureSmall lattice mismatchVacuum evaporation coatingPretreated surfacesChemistryOxide

The present invention relates to oxides on suitable substrates, as converted from nitride precursors.

Owner:APPL THIN FILMS INC

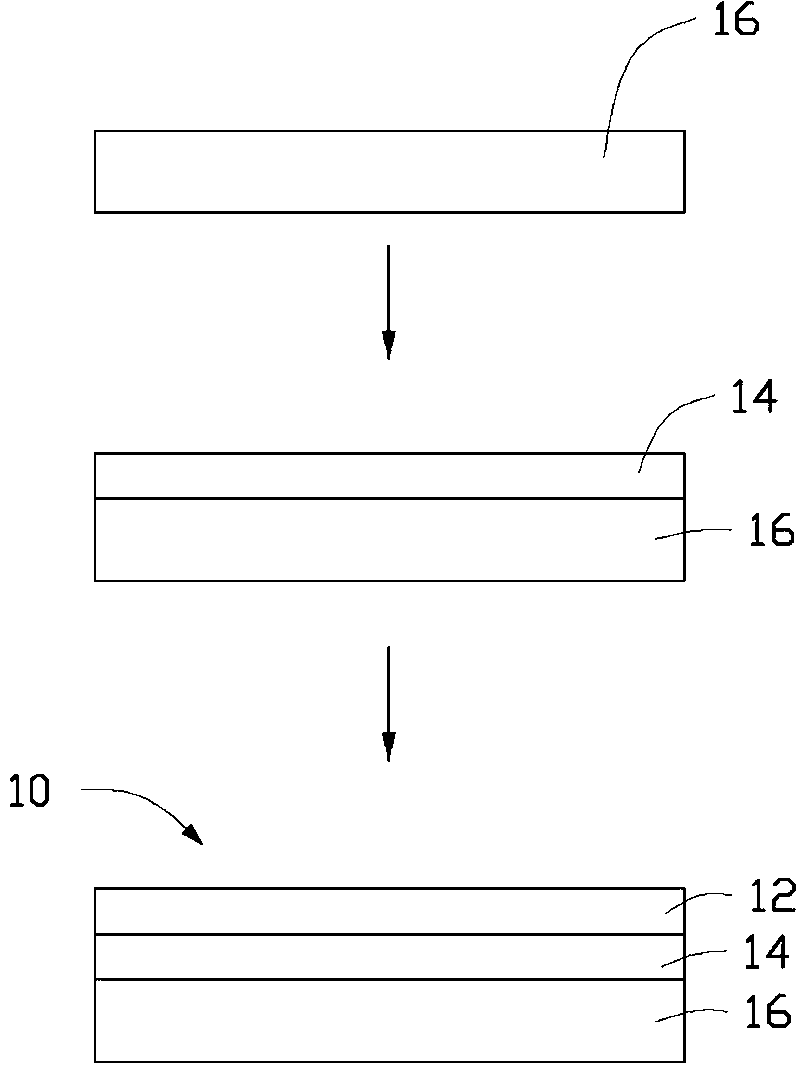

Light-emitting diode epitaxial wafer, manufacturing method thereof, light-emitting diode chip manufacturing method, and substrate recycling method

ActiveCN104810444AAchieve reuseReduce pollutionSolid-state devicesSemiconductor/solid-state device manufacturingQuantum wellLight-emitting diode

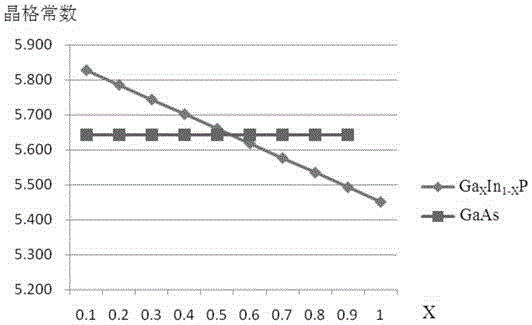

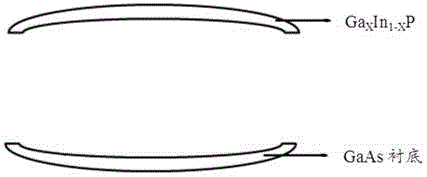

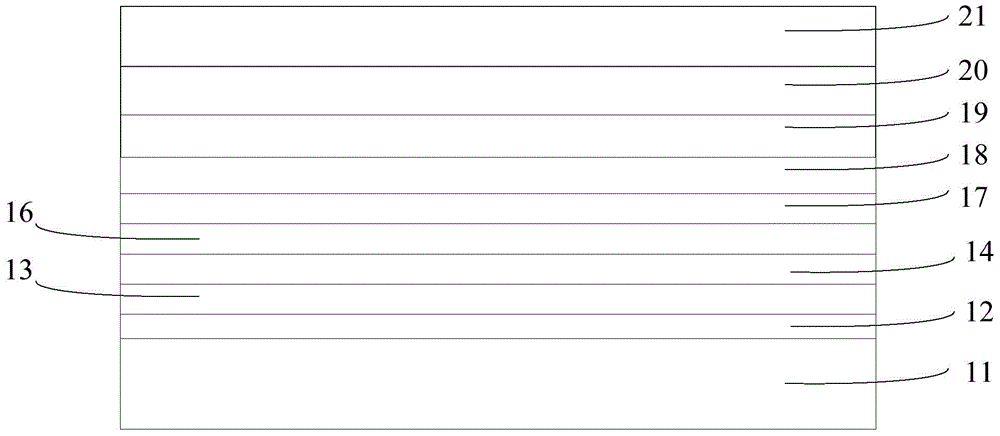

The invention discloses a light-emitting diode epitaxial wafer, a manufacturing method thereof, a light-emitting diode chip manufacturing method, and a substrate recycling method, which belongs to the field of light-emitting diodes. The light-emitting diode epitaxial wafer comprises a GaAs substrate, and a first epitaxial layer growing on the GaAs substrate, wherein the first epitaxial layer comprises an N-type GaAs buffer layer, a first N-type GaXIn1-XP layer, an N-type GaAs layer, an N-type AlAs sacrificial layer, an N-type GaInP etching stop layer, an N-type GaAs ohmic contact layer, an N-type AlInP layer, a quantum well layer and a P-type layer located on the GaAs substrate in sequence, and X is larger than 0.47 but smaller than 0.51. The light-emitting diode epitaxial wafer manufacturing method comprises steps: the GaAs substrate is provided; the first epitaxial layer grows on the GaAs substrate; and the light-emitting diode epitaxial wafer is obtained. According to the embodiment of the invention, the GaAs substrate is stripped from the first epitaxial wafer, the GaAs substrate is not fully damaged, and environmental pollution is reduced; and the stripped GaAs substrate is used for manufacturing the epitaxial wafer again, repeated use of the GaAs substrate is realized, and the cost of the LED epitaxial wafer is greatly reduced.

Owner:HC SEMITEK SUZHOU

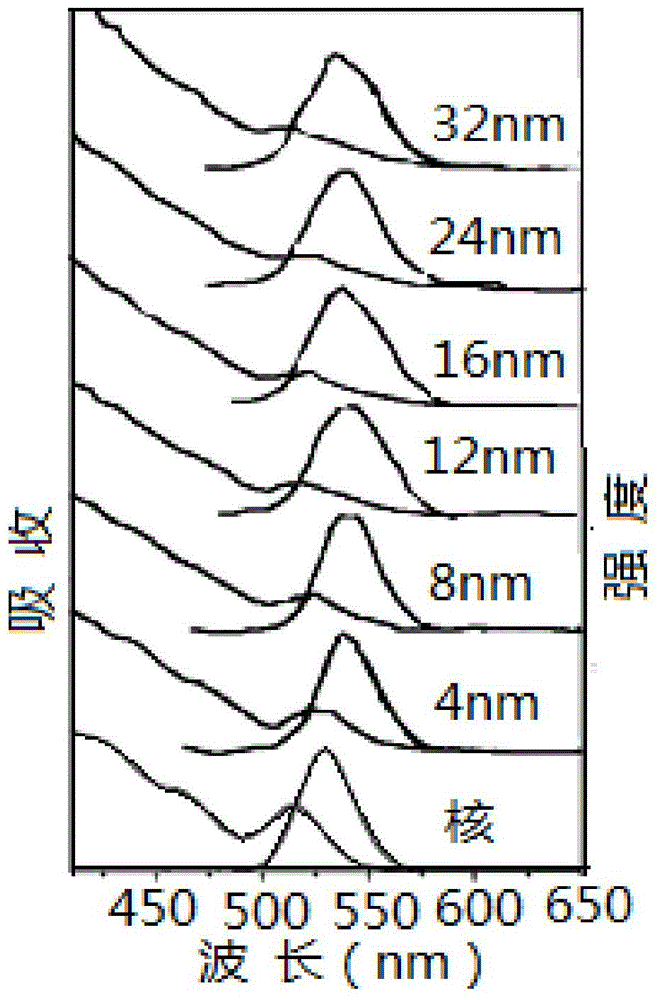

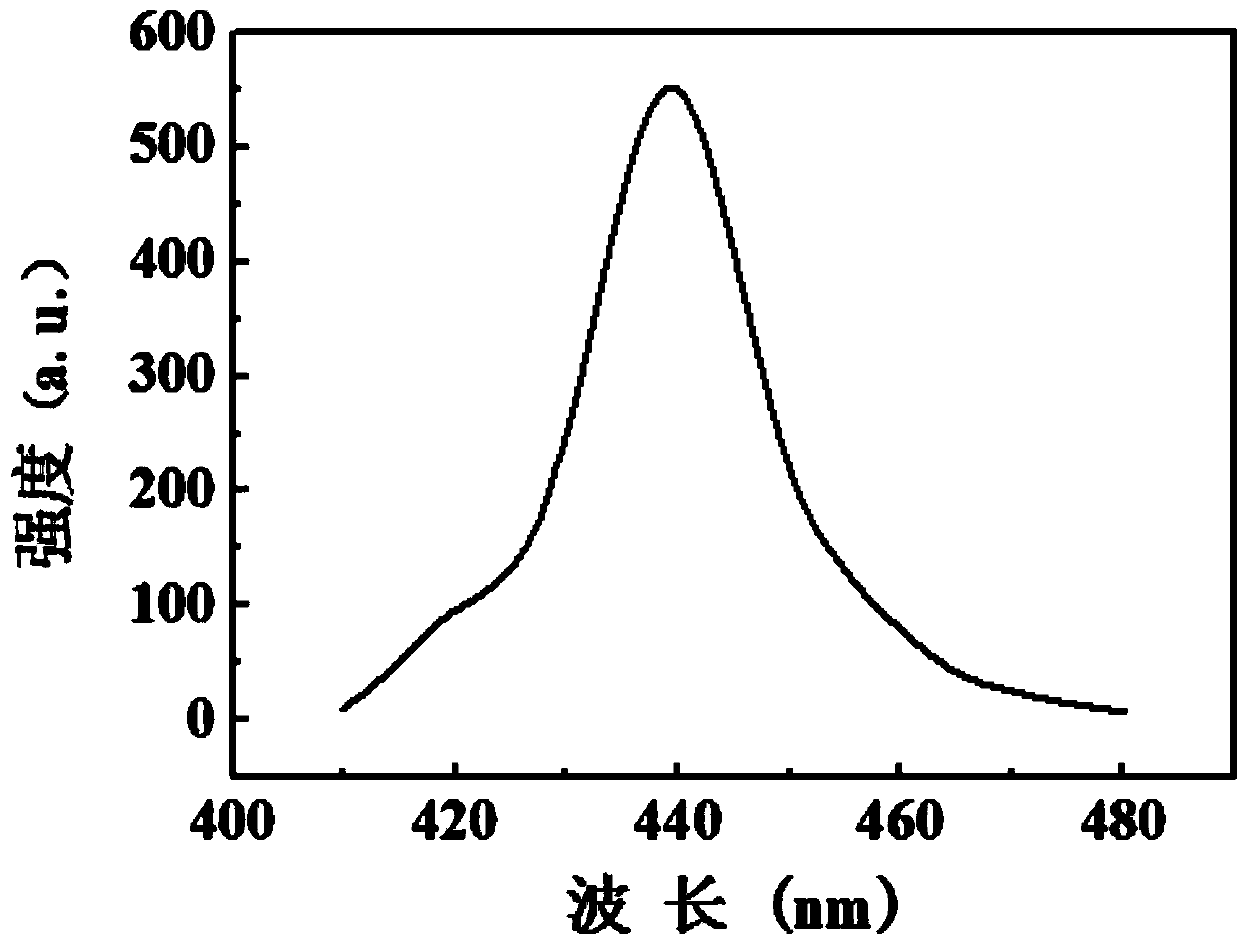

Blue-green light-emitting quantum dot and preparation method thereof

The invention discloses a blue-green light-emitting quantum dot and a preparation method thereof. The blue-green light-emitting quantum dot comprises a ZnnCd1-nSmSe1-m core and a shell coating the ZnnCd1-nSmSe1-m core. In the ZnnCd1-nSmSe1-m core, n is greater than 0 and is less than 1, m is greater than or equal to 0 and less than or equal to 1 and the shell is a ZnS shell, a ZnSe shell or a CdS shell. The blue-green light-emitting quantum dot comprises the ZnnCd1-nX quantum dot as a core and the epitaxial growth ZnS shell, ZnSe shell or CdS shell so that a quantum dot structure is simplified. Through a core-shell structure, a lattice mismatch degree of the core-shell structure is reduced. The blue-green light-emitting quantum dot formed in a wavelength scope of 450-550nm so that the QD-LED maximum brightness of the blue-green light-emitting quantum dot is 4700cd / m<2> or more.

Owner:BYD CO LTD

LED epitaxial wafer growing on Ag substrate and preparing method and application of LED epitaxial wafer

ActiveCN103996764AImprove luminous efficiencyEasy to getSemiconductor/solid-state device manufacturingSemiconductor devicesPhotovoltaic detectorsCrystal orientation

The invention discloses an LED epitaxial wafer growing on an Ag substrate. The LED epitaxial wafer growing on the Ag substrate comprises the Ag substrate, an AlN buffer layer, a U-GaN film layer, an N-GaN film layer, an InGaN / GaN multi-quantum-well layer and a P-GaN film. The AlN buffer layer, the U-GaN film layer, the N-GaN film layer, the InGaN / GaN multi-quantum-well layer and the P-GaN film sequentially grow on the Ag substrate. By the adoption of the low-temperature growth technology, a GaN film grows on the novel metal Ag substrate in an epitaxial mode, so that the LED epitaxial wafer with the high quality is obtained; by the adoption of the metal Ag substrate, the growth technology is simple, the price is low, and the manufacturing cost of a device can be reduced to a great extent; by the selection of the proper crystal orientation, the GaN epitaxial film with the high quality is obtained from the Ag substrate (111) and the efficiency of nitride devices such as a photoelectric detector can be improved to a great extent.

Owner:广州市众拓光电科技有限公司

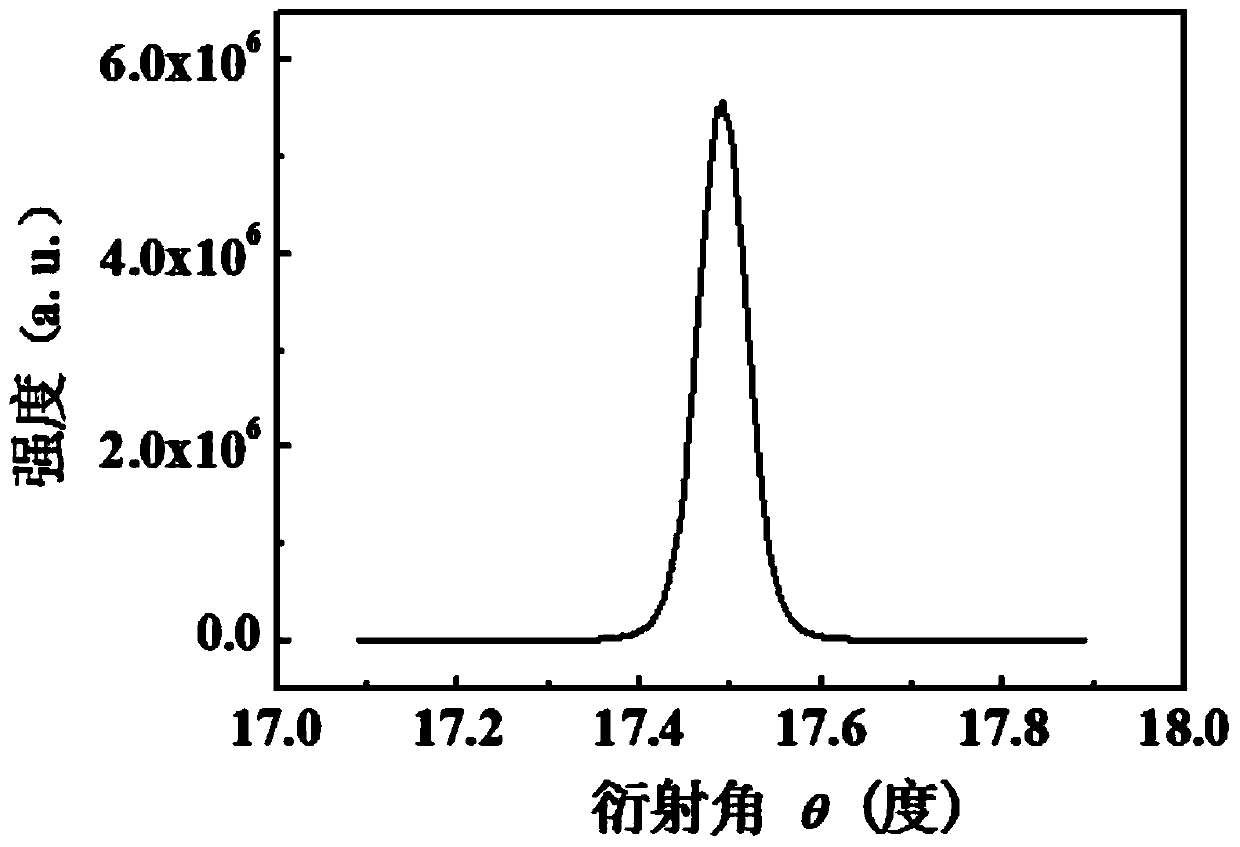

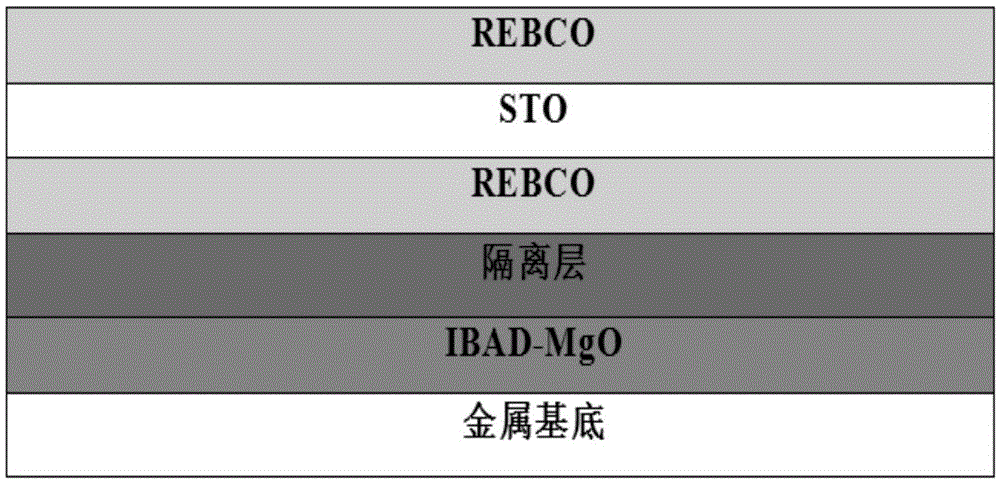

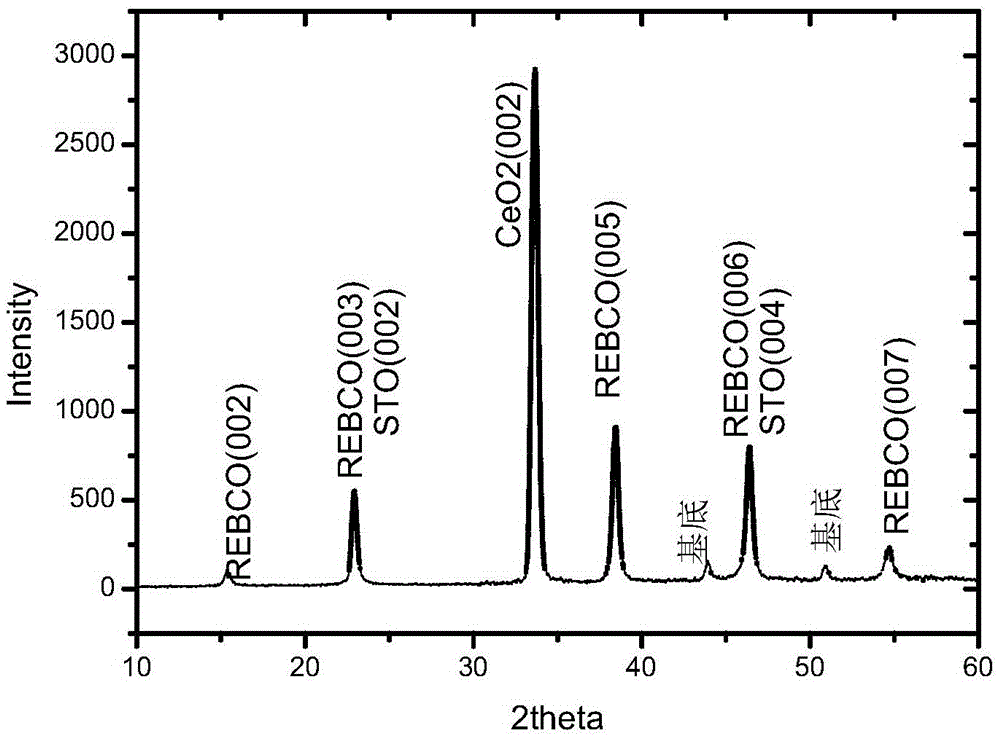

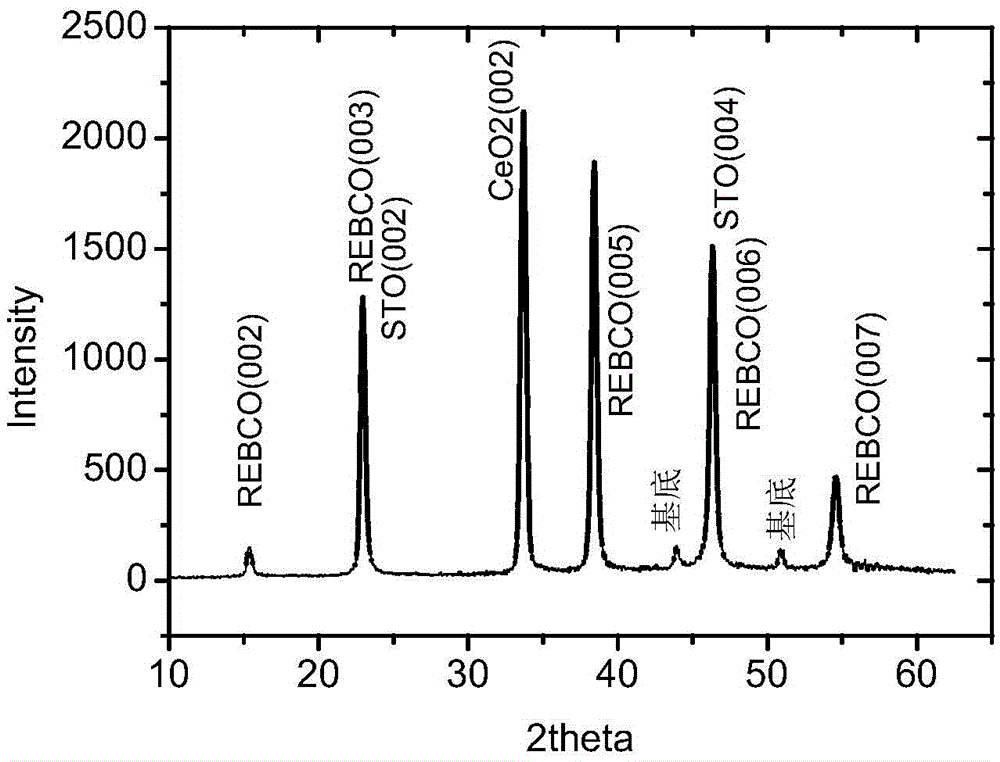

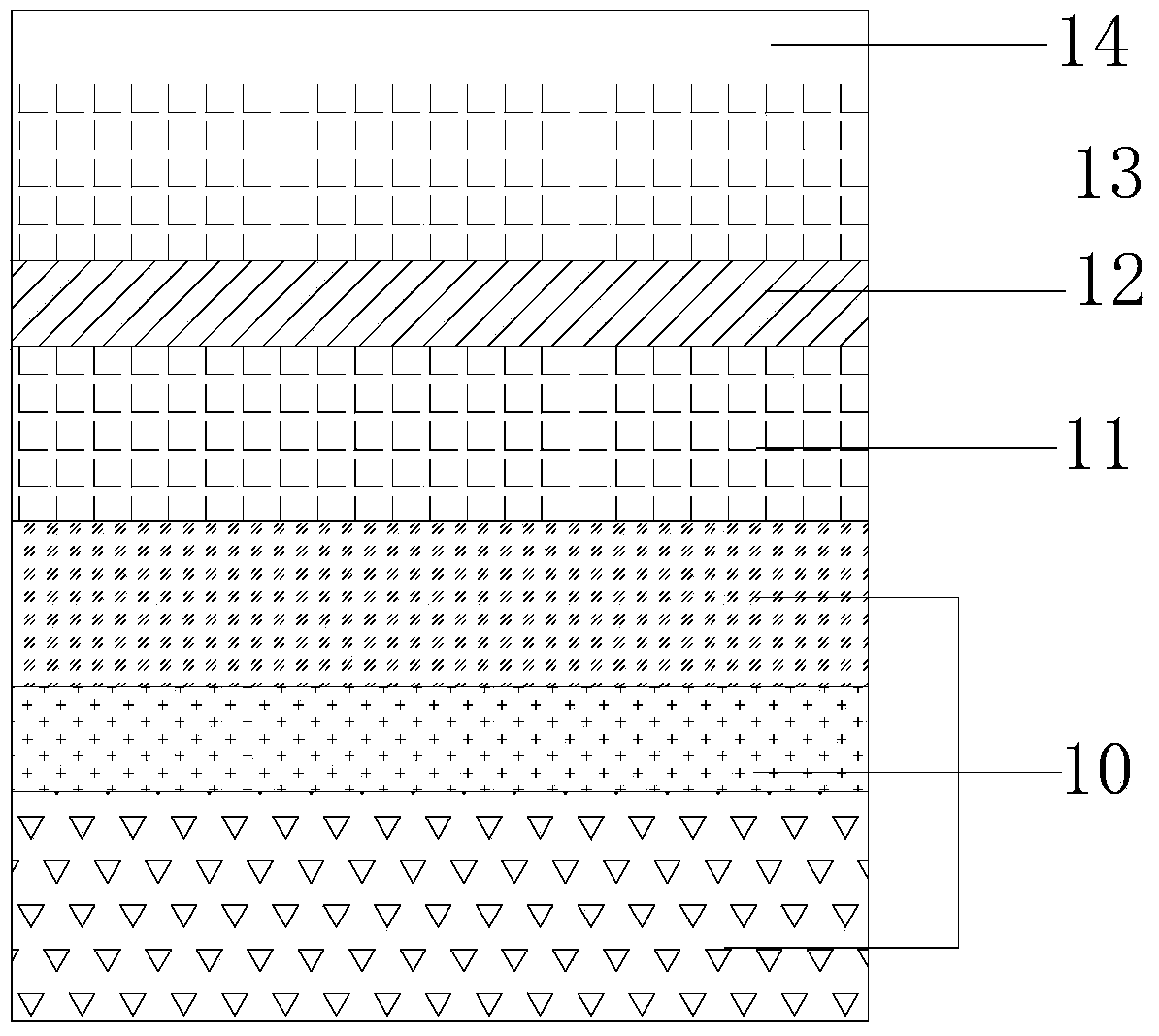

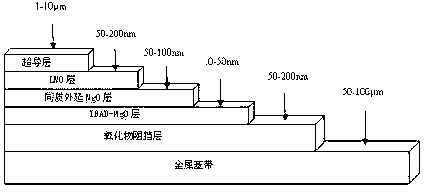

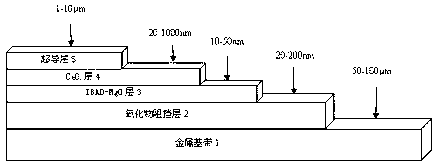

High-performance REBCO multilayer film, application and preparation method for high-performance REBCO multilayer film

ActiveCN105648401AHigh shape stability and repeatabilityIncrease the critical current densityVacuum evaporation coatingSputtering coatingBinding forceElectrical conductor

The invention relates to the technical field of yttrium barium copper oxide coating conductors, in particular to a high-performance REBCO multilayer film, application and a preparation method for the high-performance REBCO multilayer film. The high-performance REBCO multilayer film is composed of a REBCO thin film layer and an STO interlayer. The invention further relates to the application of the high-performance REBCO multilayer film during preparing of a high-temperature superconductive belt material and relates to the preparation method for the high-performance REBCO multilayer film. The preparation method comprises the following steps that an IBAD-MgO base belt plated with an isolated layer is taken, and the high-performance REBCO multilayer film is prepared through a multi-target multi-channel pulse laser method. The prepared high-performance REBCO multilayer film prepared has a pure C-axis orientation, a smooth compact surface and a high critical current density, and the critical current density reaches up to 5 MA / cm<2>. The REBCO multilayer film has high critical current under a self field or a magnetic field, has the high binding force, can meet the application requirements for a superconducting cable and the like and is suitable for industrialization production.

Owner:SHANGHAI JIAO TONG UNIV

Photocatalytic thin film on foam metal-graphene composite substrate and preparation method

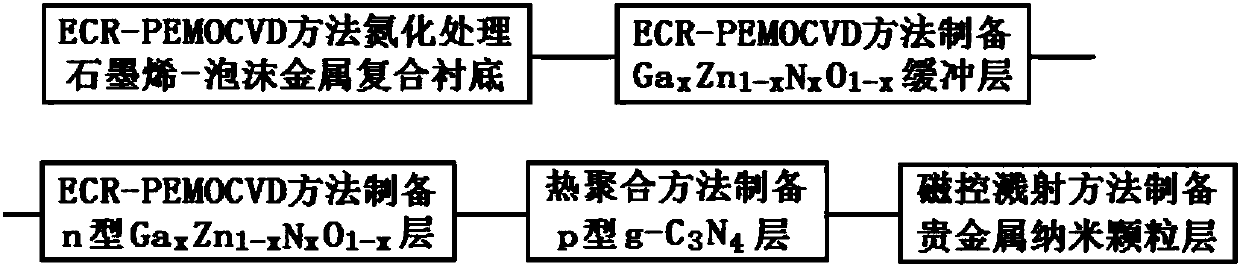

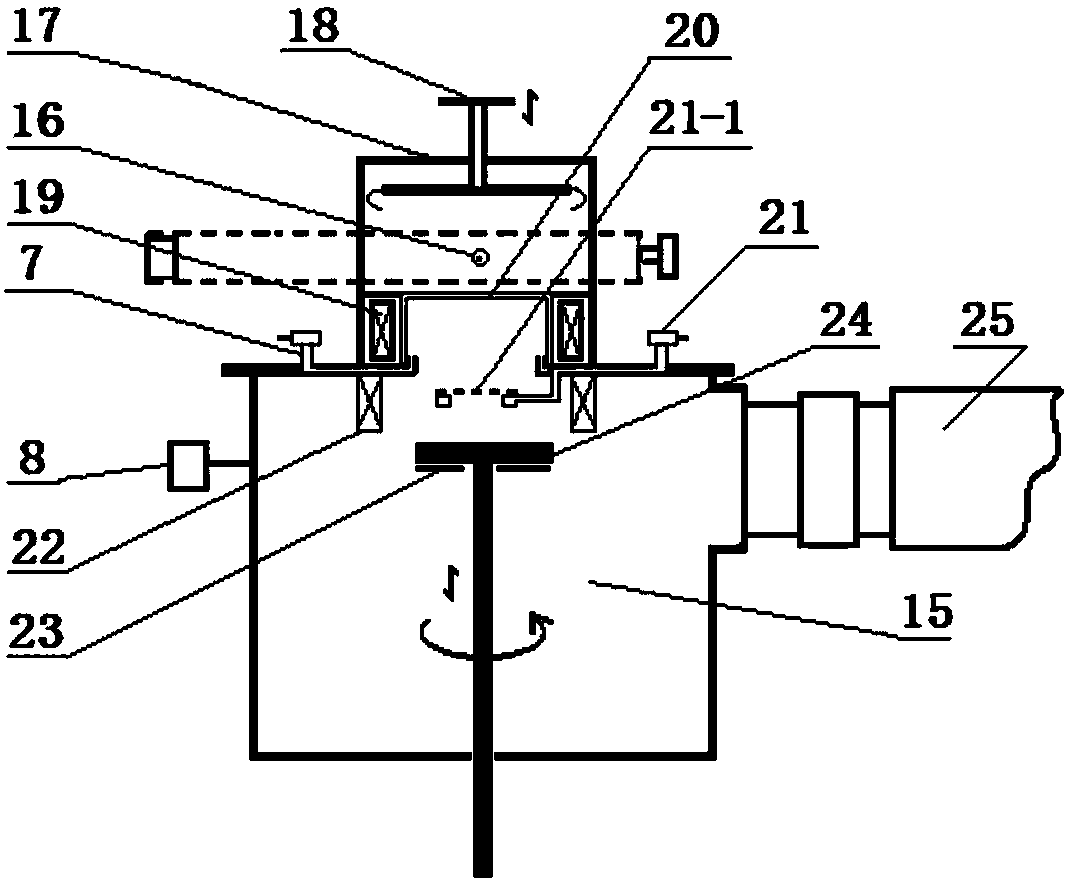

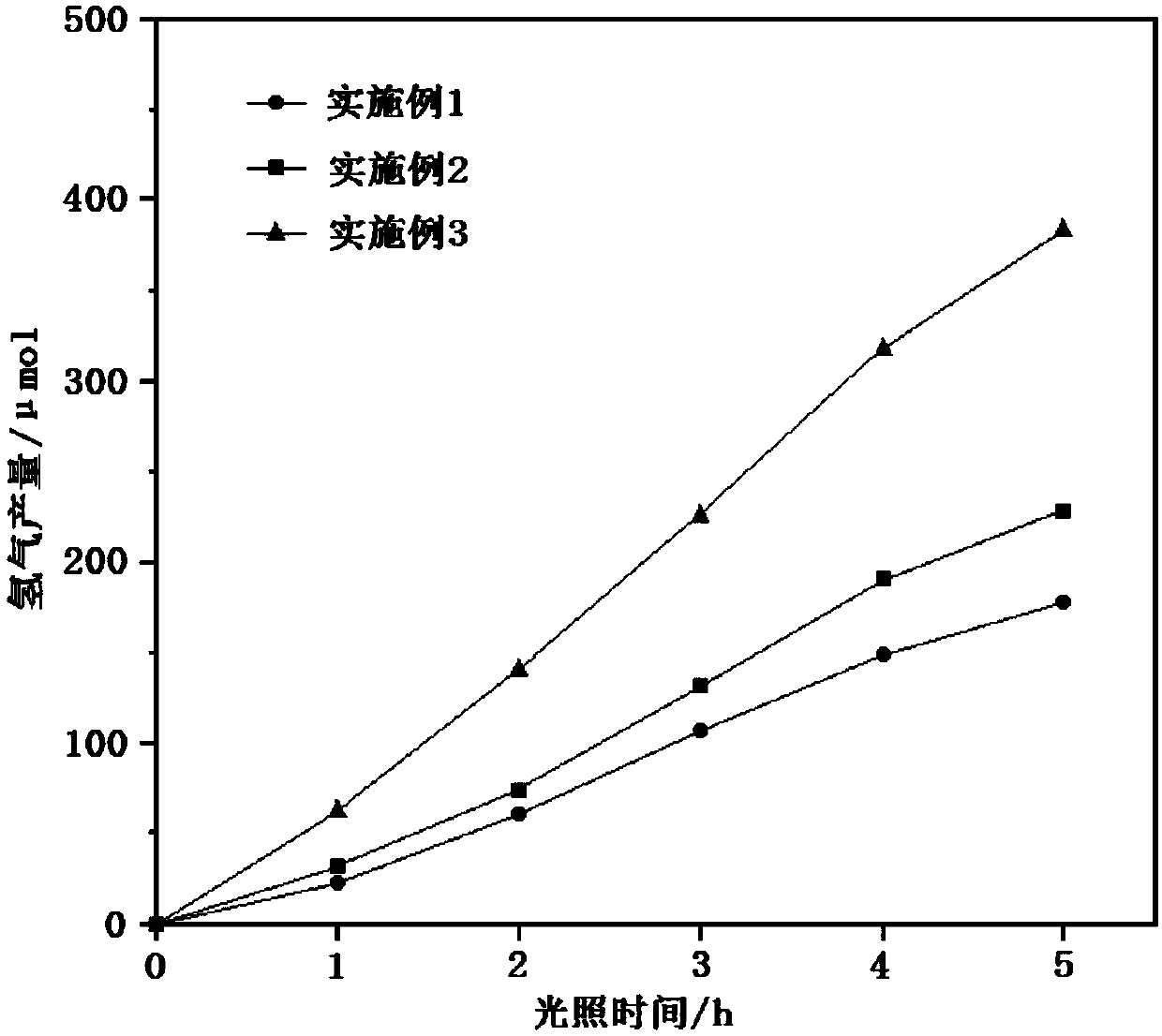

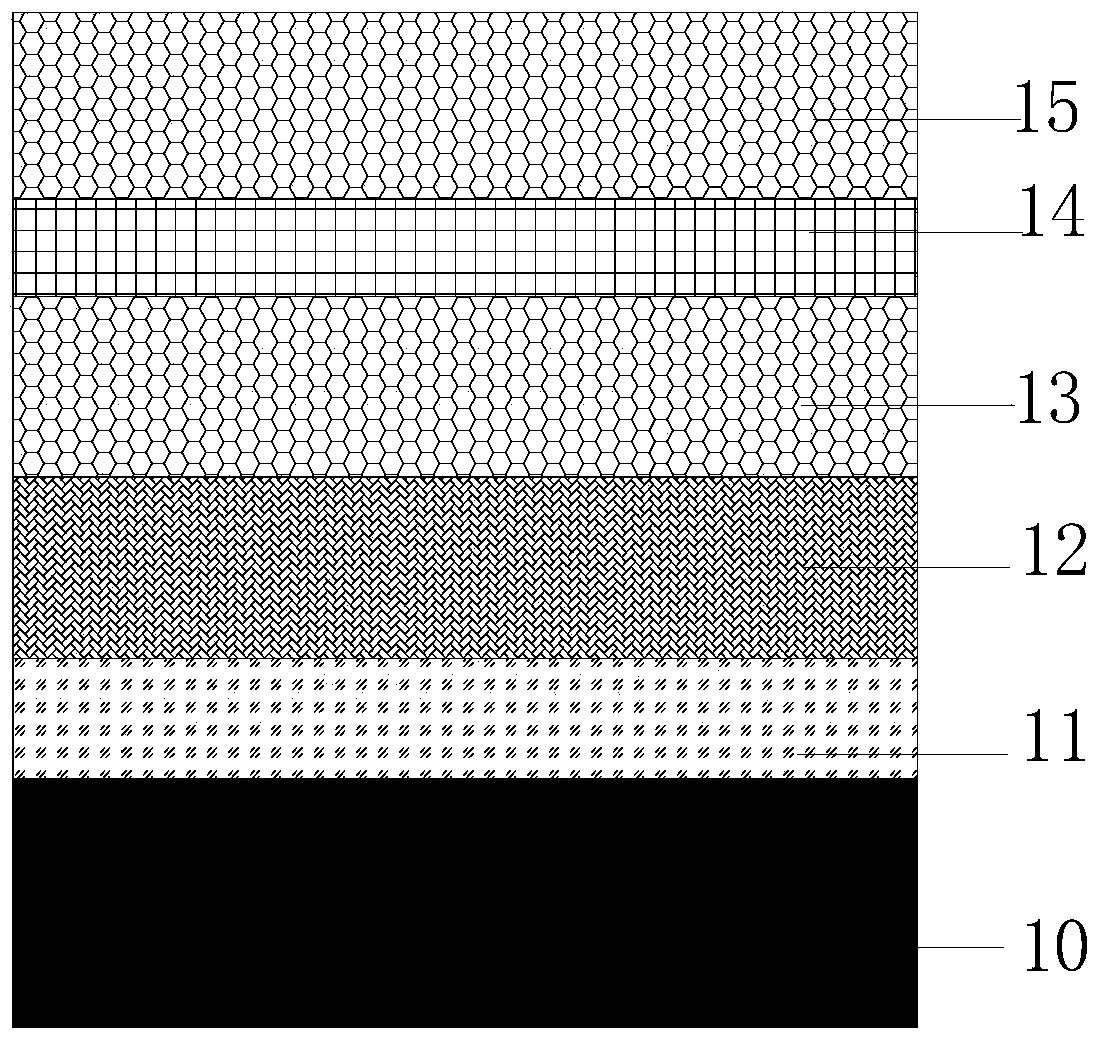

InactiveCN107649165AImprove mechanical propertiesUniform pore structureCatalyst activation/preparationHydrogen productionCvd grapheneNitrogen treatment

The invention belongs to the technical field of photocatalytic thin film manufacturing, and provides a photocatalytic thin film on a foam metal-graphene composite substrate and a preparation method. Concretely, the preparation method comprises the steps of taking a foam metal-graphene composite material as a substrate, firstly using an electron cyclotron resonance-plasma enhancing metal organic matter CVD (chemical vapor deposition) method to successively perform nitrogen treatment of the foam metal-graphene composite substrate, preparation of a GaxZnl-xNxO1-x buffer layer and preparation of an n-type GaxZn1-xNxO1-x layer, then using a thermal polymerization method to prepare a p-type g-C3N4 layer, and finally using a magnetron sputtering method to prepare a precious metal nanometer granular layer. The prepared photocatalytic thin film has a very good visible light photocatalysis effect, can be used for photolyzing water to produce hydrogen, degrading organic pollutant in waste water,removing harmful gas and purifying air, and has a broad application prospect.

Owner:秦永泽

LED epitaxial wafer growing on metal Al substrate and preparing method and application thereof

ActiveCN103996763AQuality improvementImprove internal quantum efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

The invention discloses an LED epitaxial wafer growing on a metal Al substrate. The LED epitaxial wafer comprises the metal Al substrate, an Al2O3 protecting layer growing on the metal Al substrate with a metal Al substrate crystal face (111) as an epitaxial face, a U-GaN thin film layer, an N-GaN thin film layer, an InGaN / GaN multi-quantum-well layer and a p-type GaN thin film. The epitaxy orientation relationship of the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film is GaN (0001) / / Al2O3 (0001) / / Al (111), and the U-GaN thin film layer, the N-GaN thin film layer, the InGaN / GaN multi-quantum-well layer and the p-type GaN thin film grow on the Al2O3 protecting layer from bottom to top. By selecting proper crystal orientation, a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate, and accordingly the light emitting efficiency of an LED is improved.

Owner:广州市众拓光电科技有限公司

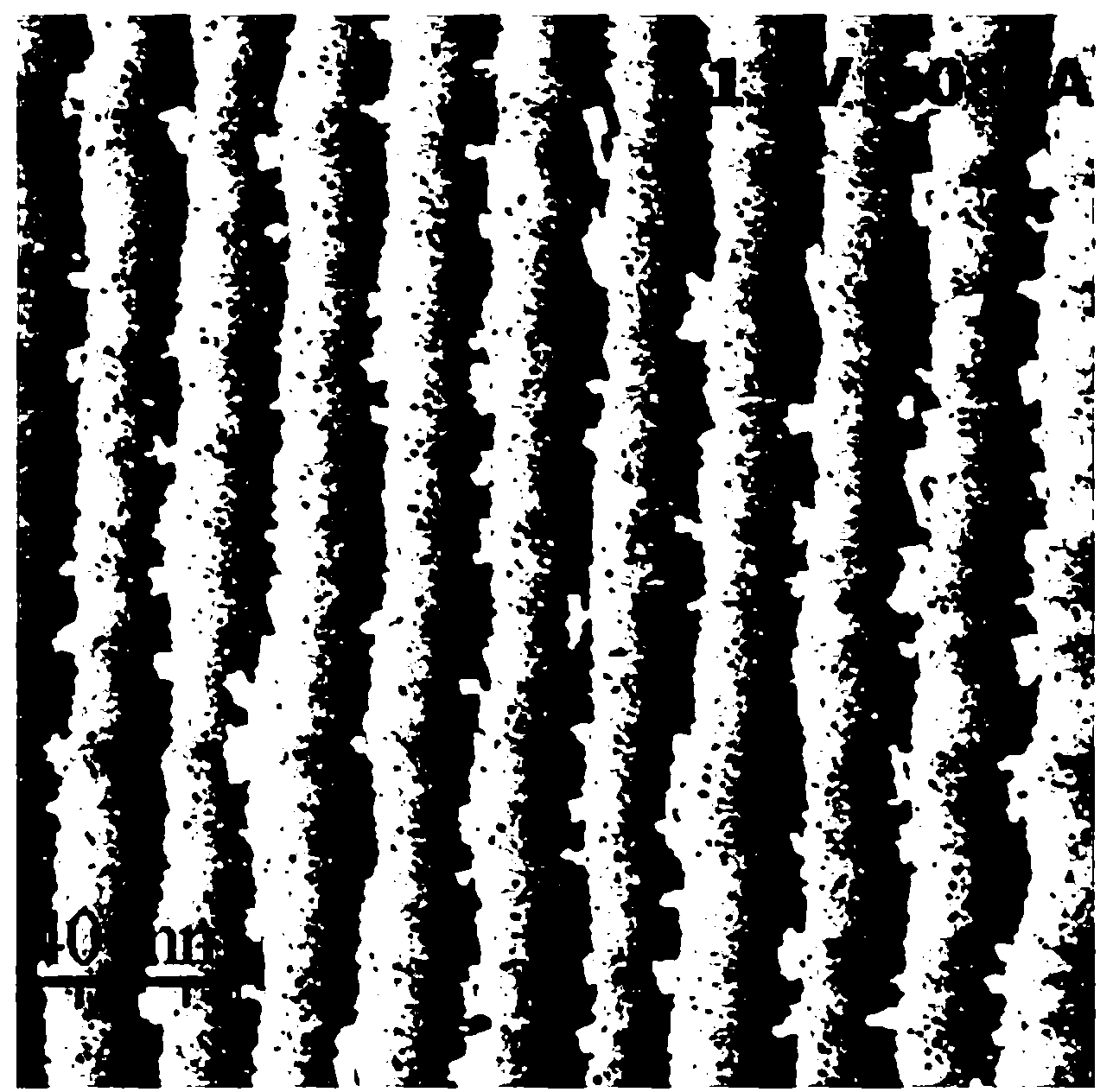

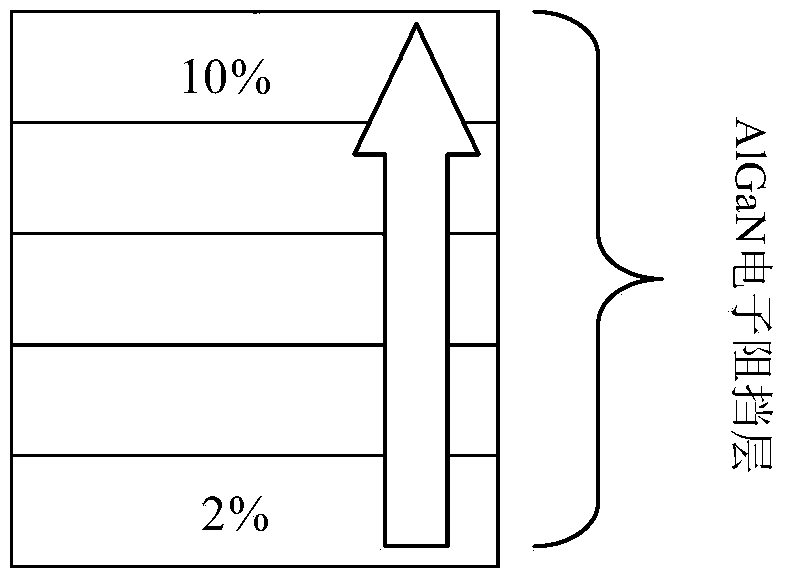

LED epitaxial wafer growth method

ActiveCN109300854AEvenly filledImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsActive layer

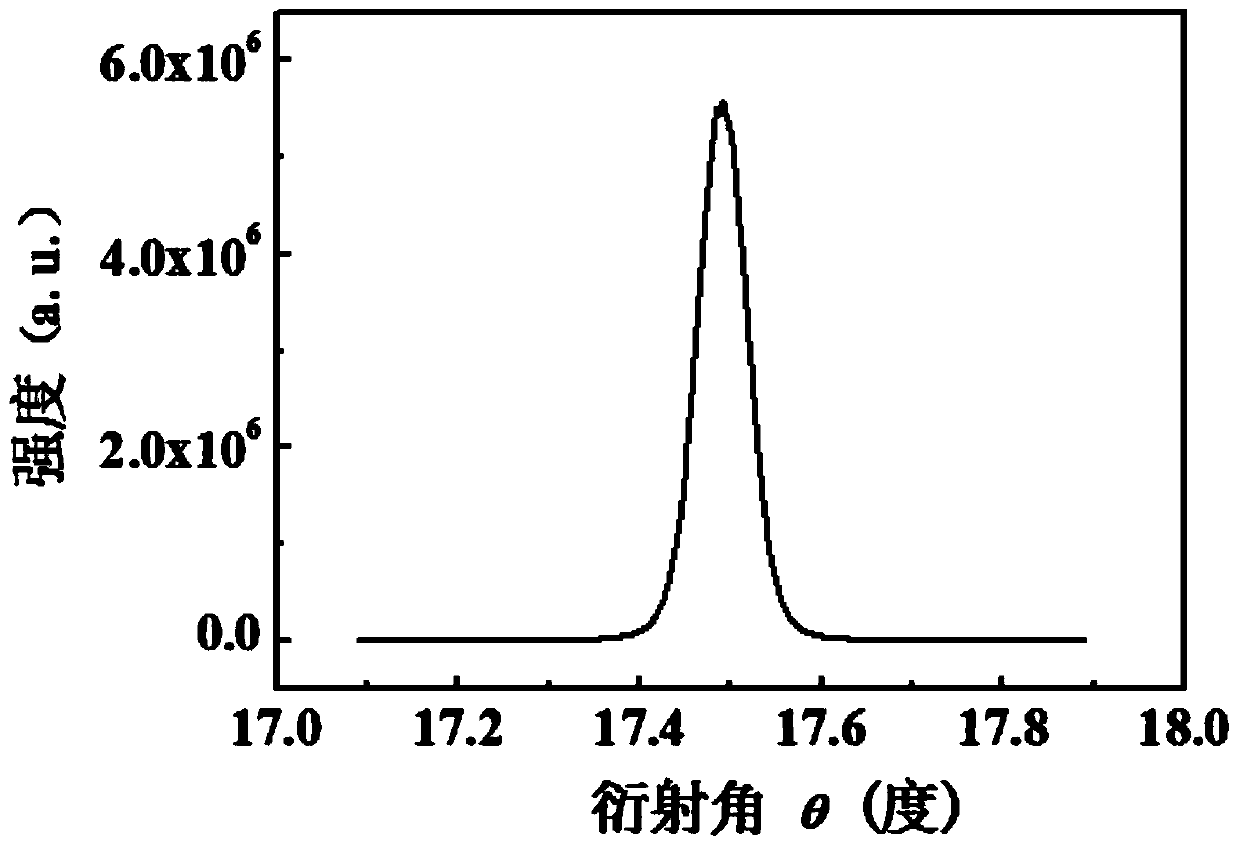

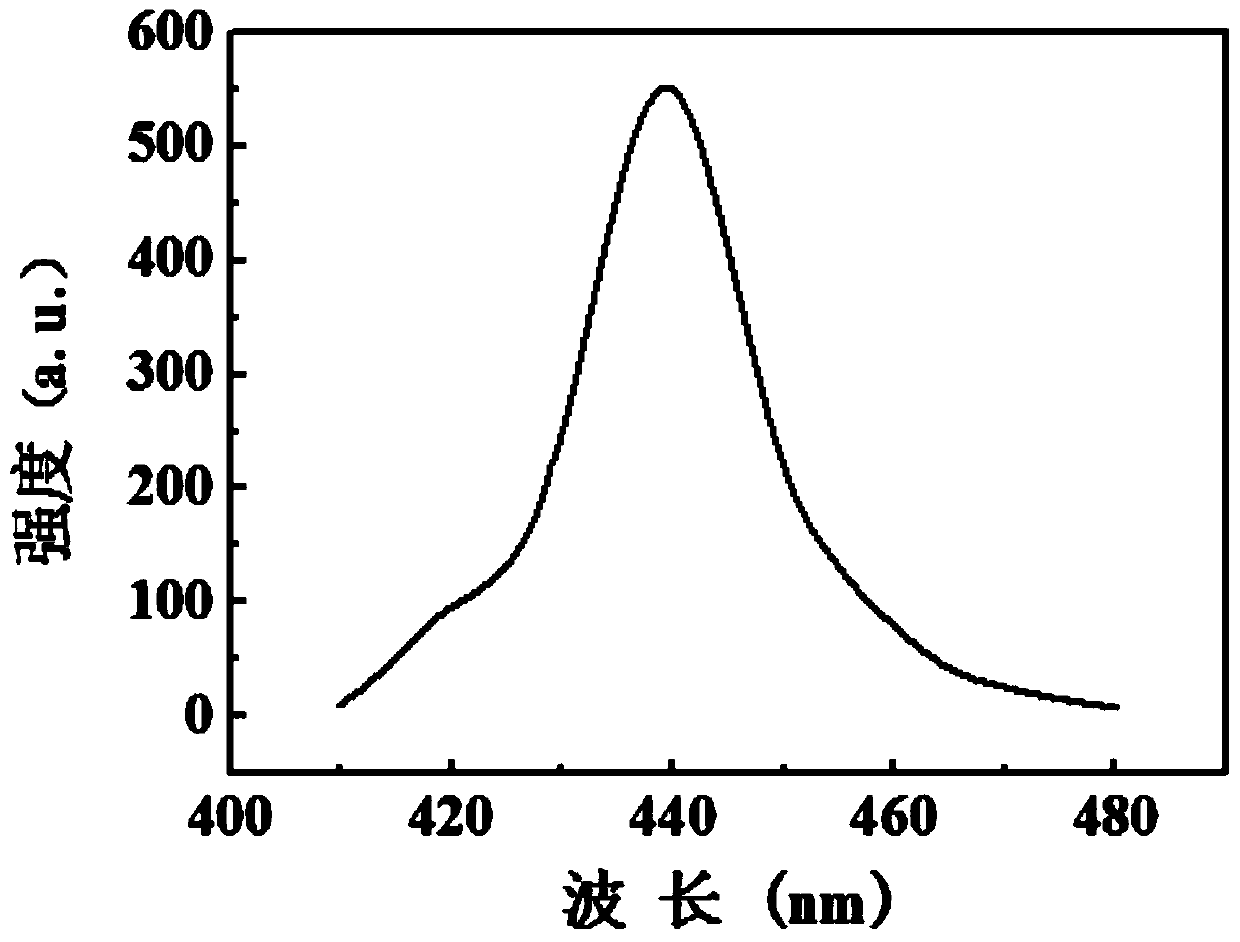

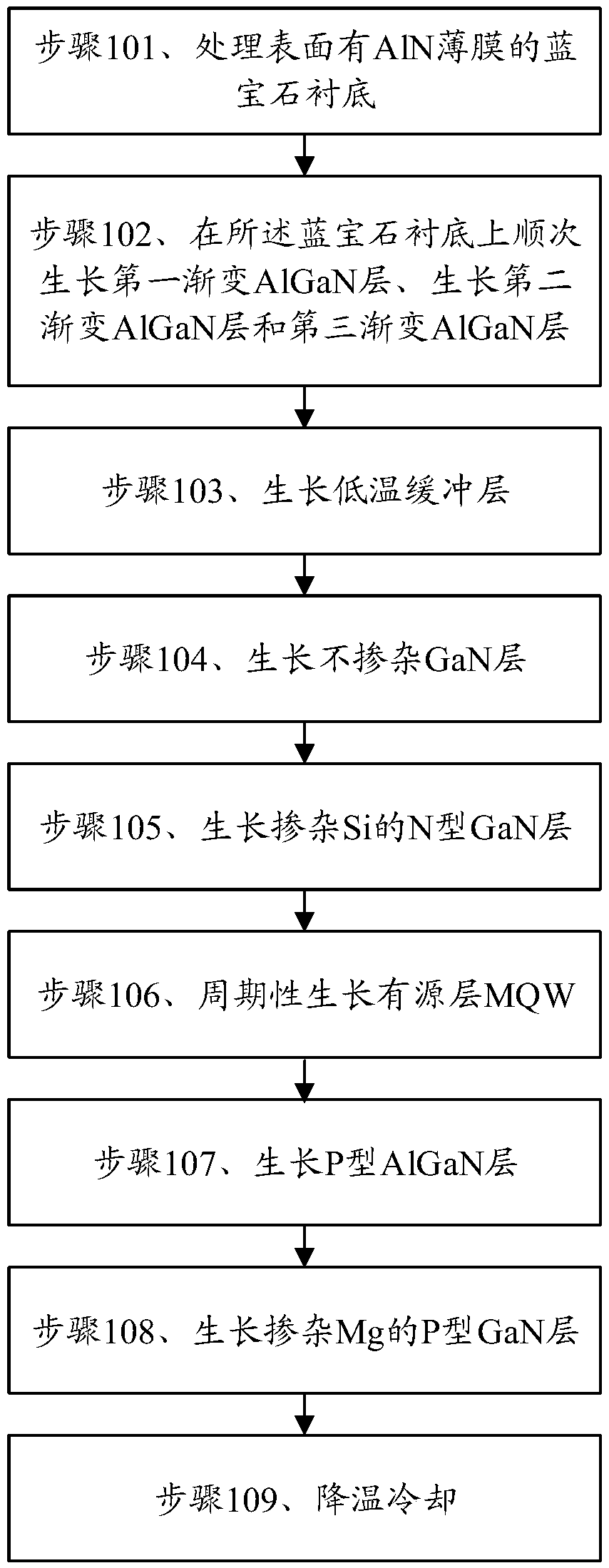

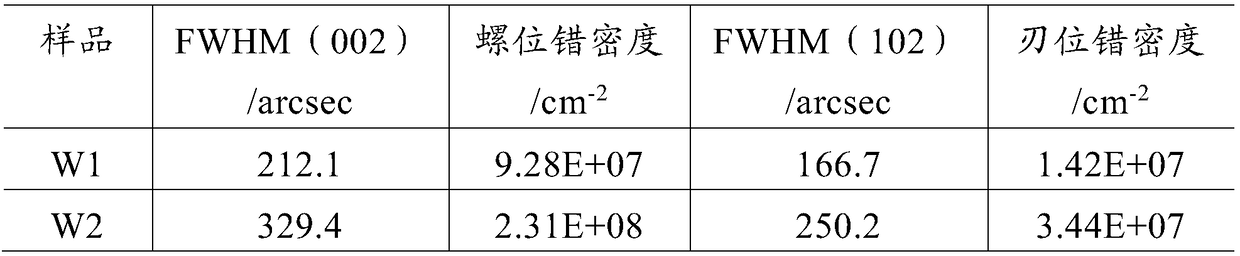

The present invention discloses an LED epitaxial wafer growth method. The method comprises the steps of: arranging a sapphire substrate of an AlN film at a processing surface, growing a first gradualchange AlGaN layer, a second gradual change AlGaN layer and a third gradual change AlGaN layer in order on the sapphire substrate, growing a low-temperature buffer layer, an un-doped GaN layer and a Si-doped N-type GaN layer, periodically growing an active layer MQW, growing a P-type AlGaN layer, growing a Mg-doped P-type GaN layer, and performing cooling. The first gradual change AlGaN layer, thesecond gradual change AlGaN layer and the third gradual change AlGaN layer are grown to reduce the dislocation density, improve the crystalline quality, reduce the warping of an epitaxial wafer, improve the percent of pass of the GaN epitaxial wafer and improve the LED luminous efficiency. The gradual change AlGaN layers are subjected to annealing processing to allow the whole surface of the epitaxial wafer to be smoother, allow the surface hexagonal defects and the hollow pits to be fewer and allow the whole appearance to be better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

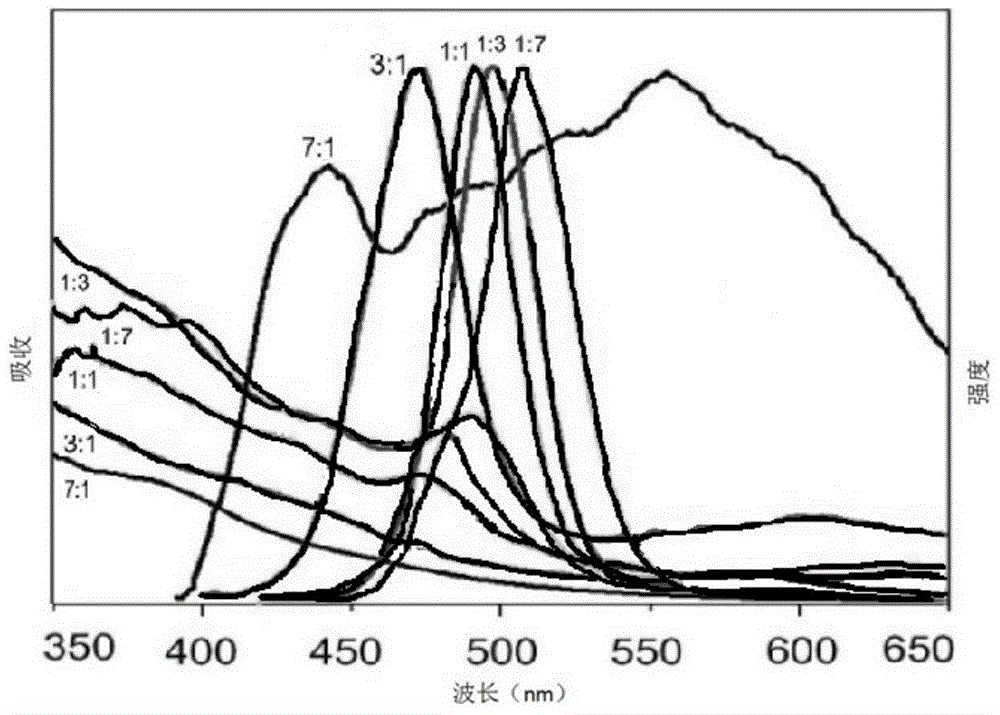

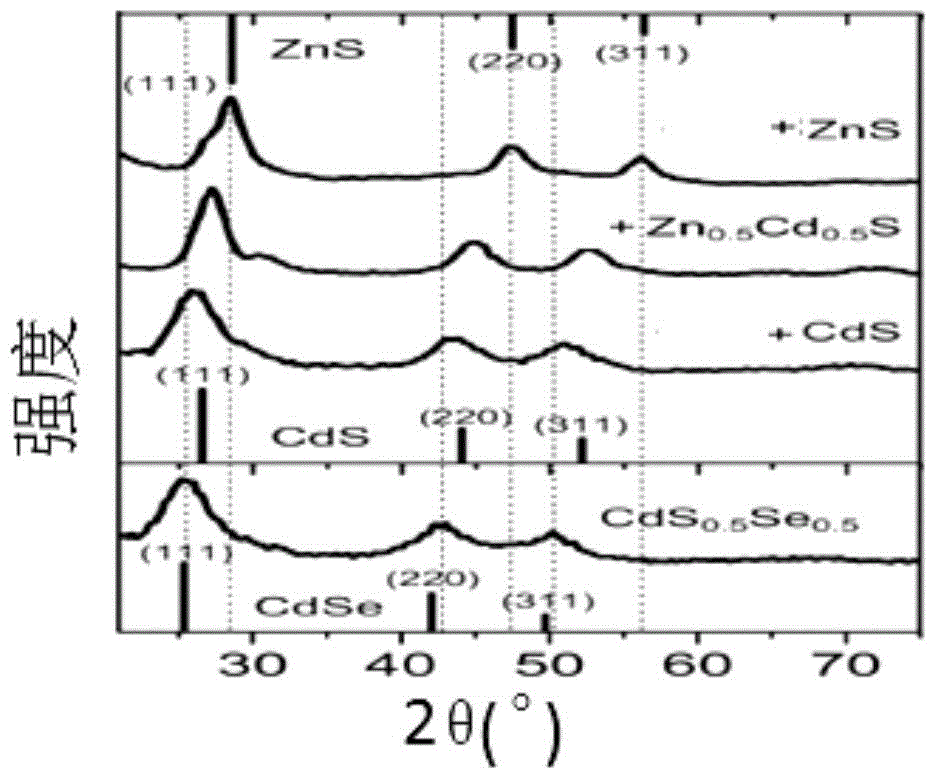

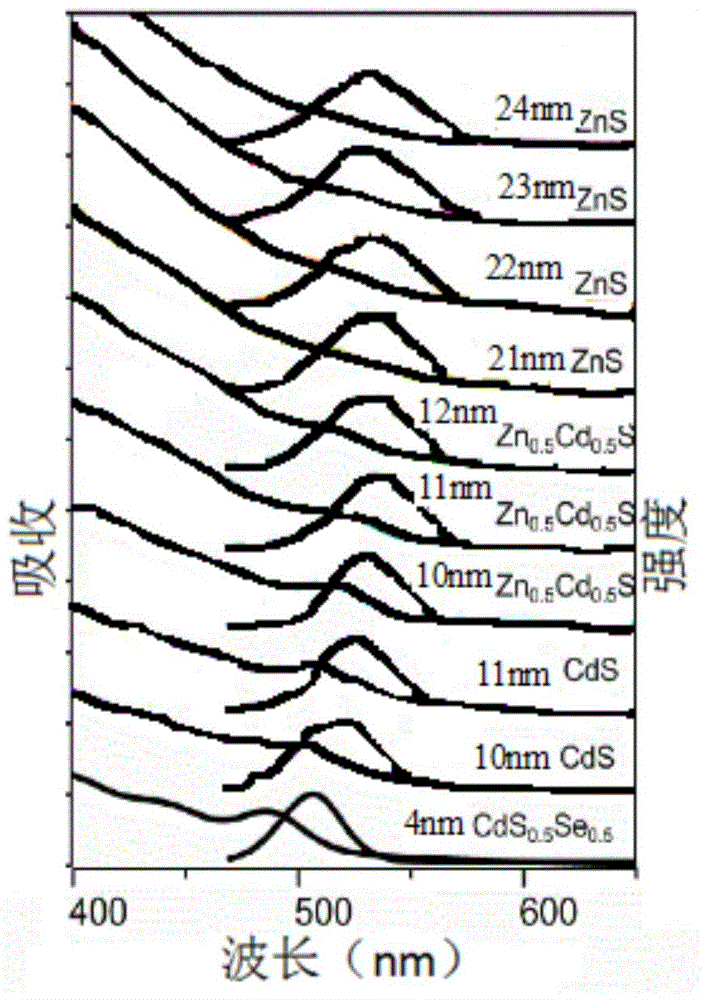

Blue-green luminescent quantum dots and preparation method therefor

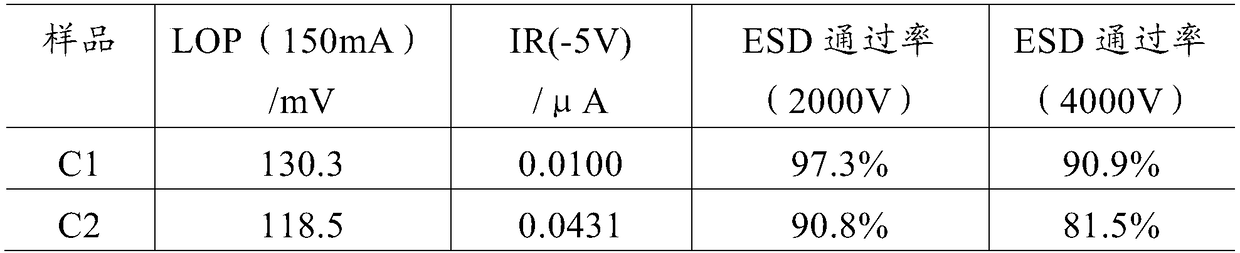

The invention discloses blue-green luminescent quantum dots and a preparation method therefor. Each quantum dot comprises a CdS(n)Se(1-n) core, a CdS buffer layer, a Zn(0.5)Cd(0.5)X buffer layer and a ZnS shell. In the CdS(n)Se(1-n) core, n is greater than 0 and is smaller than 1. The CdS buffer layer coats the outer periphery of the CdS(n)Se(1-n) core, the Zn(0.5)Cd(0.5)X buffer layer coats the outer periphery of the CdS buffer layer, and X is S or Se; and the ZnS shell coats the outer periphery of the Zn(0.5)Cd(0.5)X buffer layer. According to the blue-green luminescent quantum dots, through introducing the CdS buffer layer and the Zn(0.5)Cd(0.5)X buffer layer sequentially, the lattice mismatch degree of a core-shell structure is lowered, and the blue-green luminescent quantum dots in the wavelength range of 450nm to 550nm are formed, so that the maximum brightness of an QD-LED using the blue-green luminescent quantum dots can reach 4,700cd / m<2> or more.

Owner:BYD CO LTD

GaN thin film growing on metal Al substrate and preparing method and application thereof

ActiveCN103996611ASmall lattice mismatchFacilitate depositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic detectorsCrystal orientation

The invention discloses a GaN thin film growing on a metal Al substrate and a preparing method and application thereof. The GaN thin film growing on the metal Al substrate comprises the Al substrate, an Al2O3 protecting layer growing on an epitaxy face which is a face (111) of the Al substrate and a GaN thin film layer growing on the Al2O3 protecting layer in an epitaxial mode. The crystal epitaxial orientation relationship of the Al2O3 protecting layer and the GaN thin film layer is GaN (0001) / / Al2O3 (0001) / / Al (111). Proper crystal orientation is selected, so that a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate and is used for improving nitride device efficiency. The GaN thin film is mainly used as dielectric layer thin films of a sound wave resonator, a logic circuit, a light-emitting diode, an optoelectronic thin film device, a solar cell, a photodiode, a photoelectric detector, a laser device and the like.

Owner:广州市众拓光电科技有限公司

Method for quickly preparing simplified single CeO2 buffering layer on IBAD (Ion Beam Assisted Deposition)-MgO base band by using PLD (Pulsed Laser Deposition) technology

InactiveCN103233205ASimple manufacturing processLow costVacuum evaporation coatingSputtering coatingYttrium barium copper oxideComputational physics

The invention discloses a method for quickly preparing a simplified single CeO2 buffering layer on an IBAD (Ion Beam Assisted Deposition)-MgO base band by using a PLD (Pulsed Laser Deposition) technology. By using the method disclosed by the invention, an excellent crystallographic orientation can be acquired by not using an epitaxial homogeny MgO layer in a structure of a buffering layer with single orientation and high texture degree essential to an epitaxial growth YBCO (Yttrium Barium Copper Oxide) superconducting layer; and the simplification and low cost of a manufacturing process of the buffering layer in a preparation process of a YBCO superconducting band material are realized.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

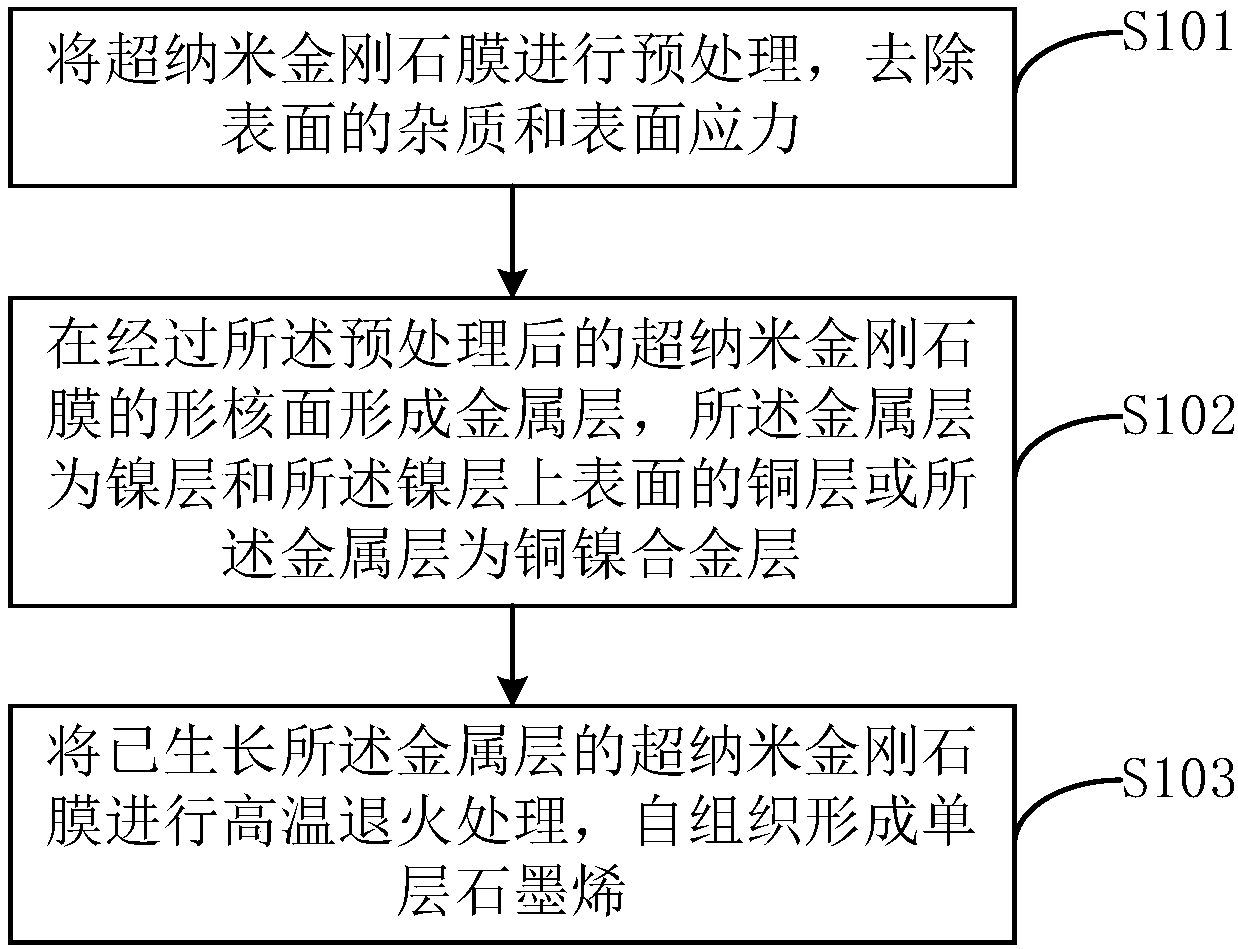

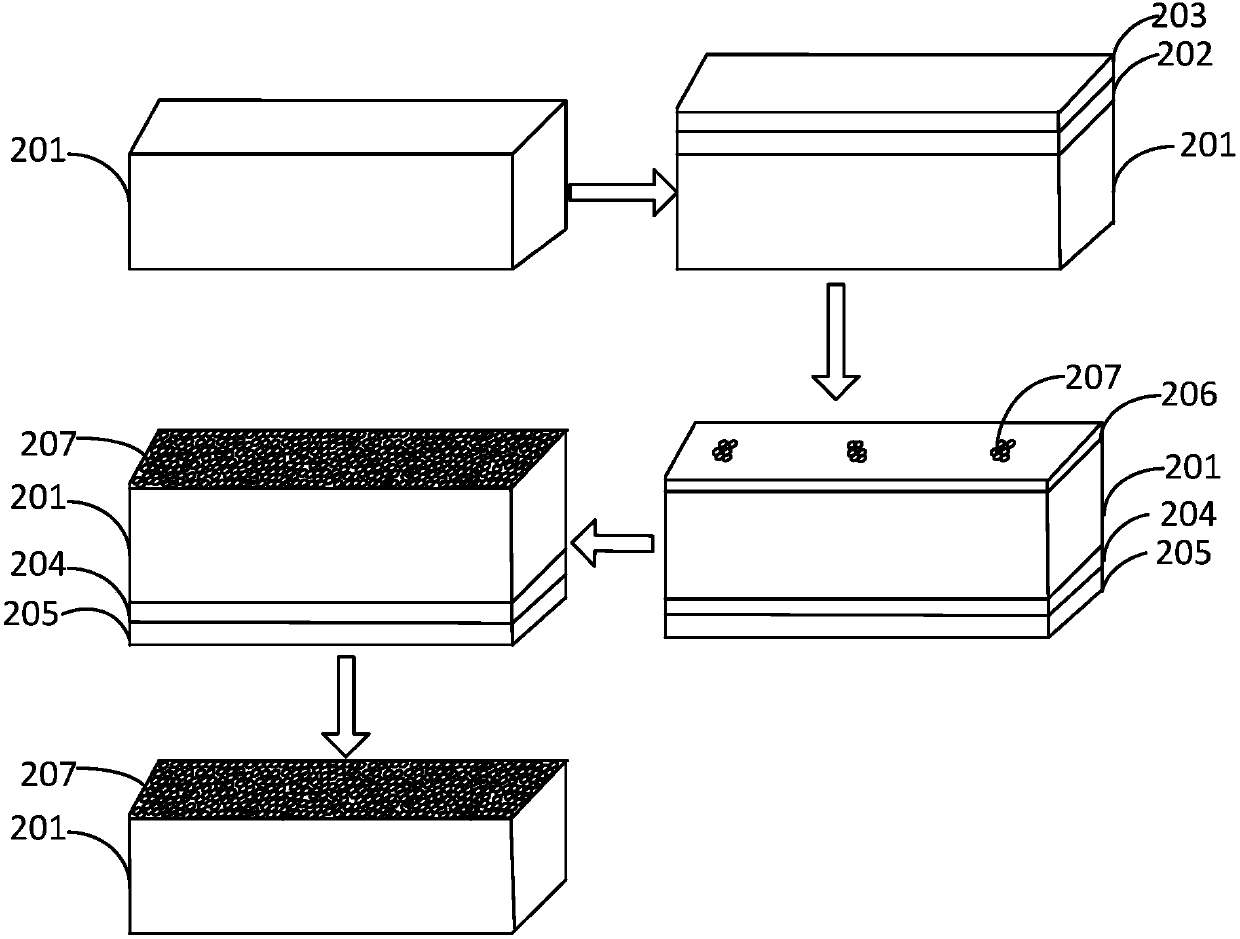

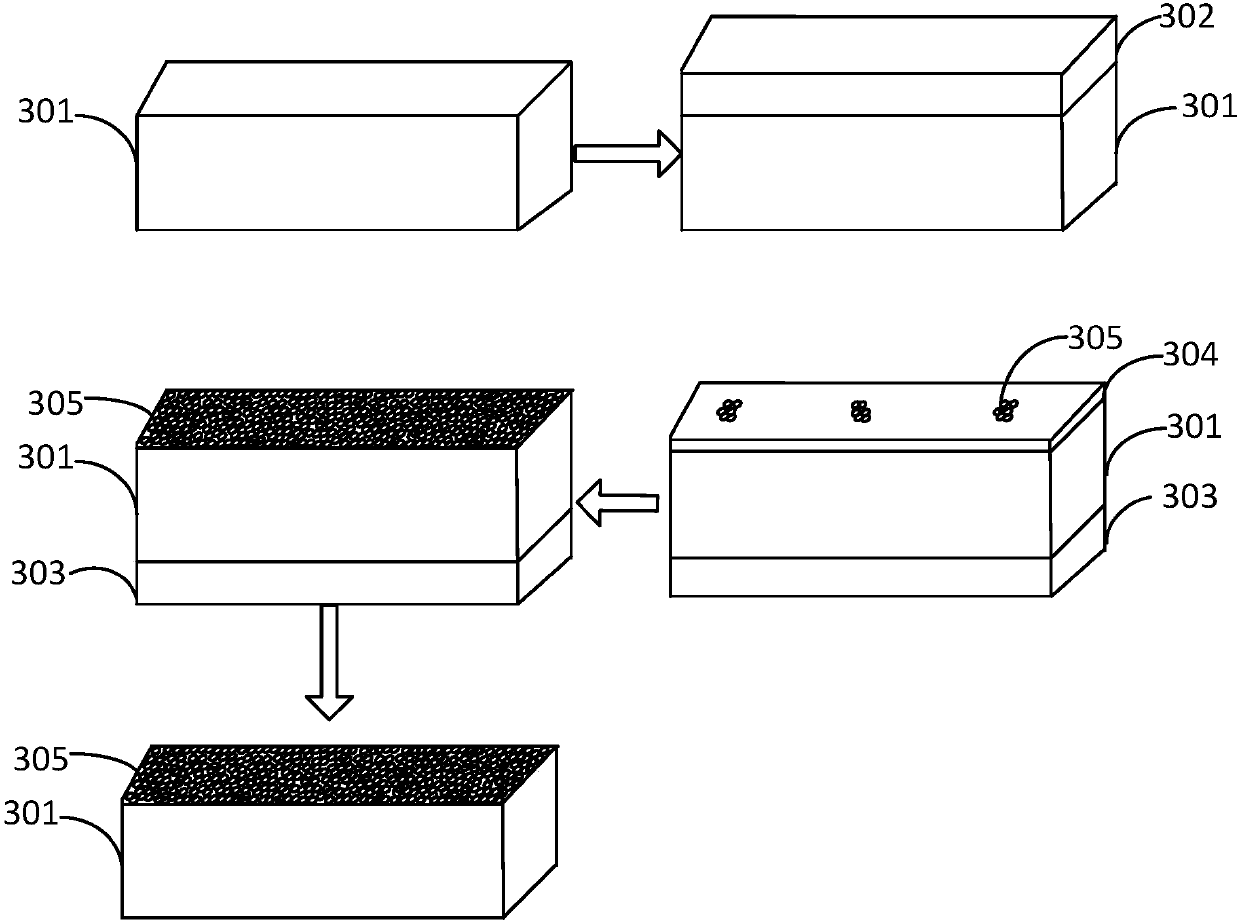

Method for preparing single-layer graphene on surface of ultranano diamond

ActiveCN107902650ALarge Boundary DensityEffective diffusionSingle layer grapheneDiamondLattice mismatchSingle layer graphene

The invention is applicable to the technical field of semiconductor and provides a method for preparing single-layer graphene on the surface of ultranano diamond. The method comprises preprocessing anultranano diamond film to eliminate surface impurities and surface stress; forming a metal layer on the nucleation surface of the preprocessed ultranano diamond film, wherein the metal layer is composed of a nickel layer and a copper layer on the upper surface of the nickel layer or is a copper-nickel alloy layer; performing high-temperature annealing treatment on the ultranano diamond film withthe grown metal layer to self-organize the single-layer graphene. The method for preparing the single-layer graphene on the surface of the ultranano diamond saves a second transfer process by directlygrowing the single-layer graphene on the ultranano diamond film, thereby effectively avoiding introduced impurities and lattice imperfection during second transfer processes; meanwhile, the grown single-layer graphene is small in lattice mismatch and surface change.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

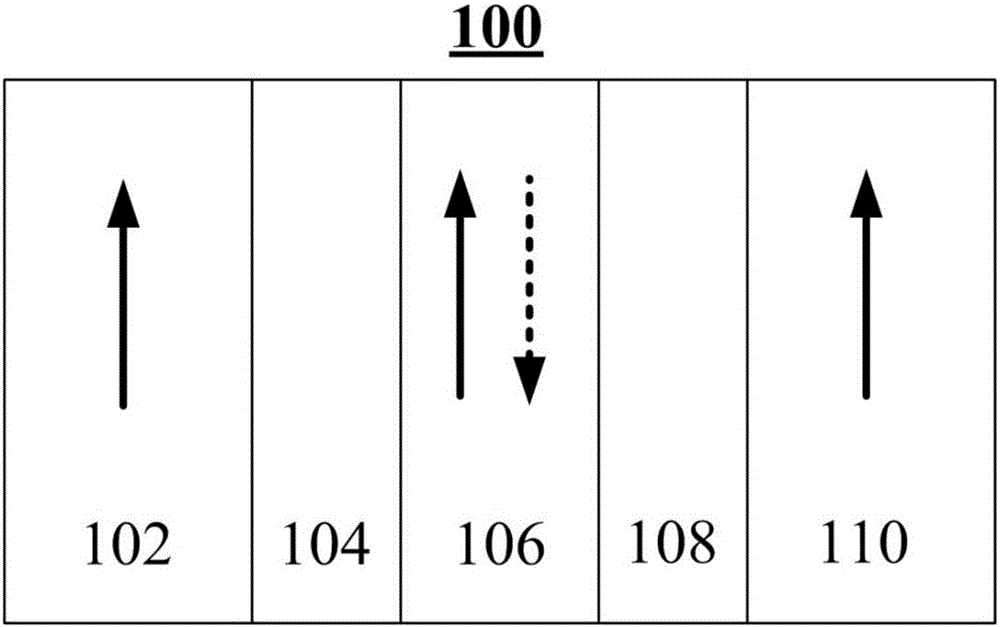

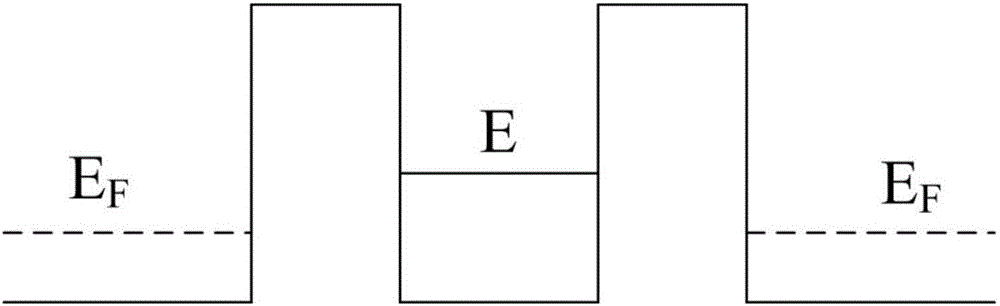

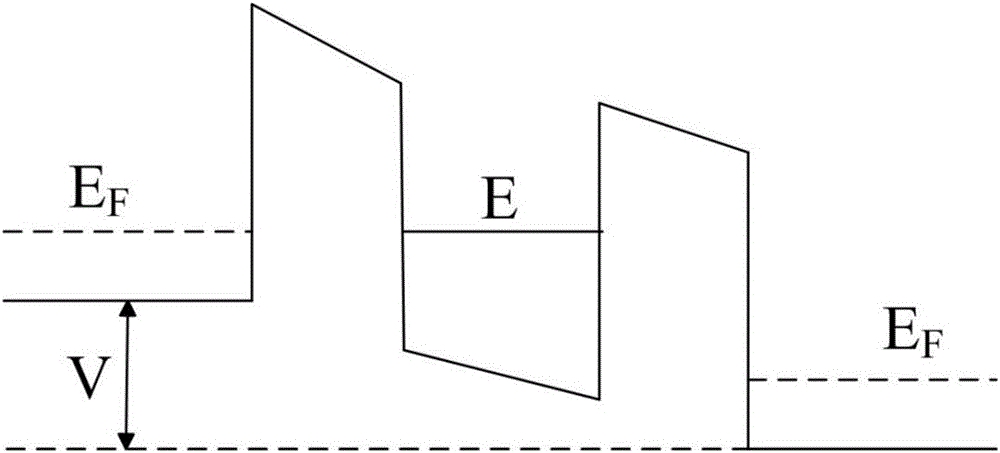

Magnetic tunnel junction with quantum effect, and spin diode and spin transistor comprising magnetic tunnel junction

ActiveCN106328805ASmall lattice mismatchLow bias dependenceMagnetic-field-controlled resistorsGalvano-magnetic device detailsSpinsCrystal structure

The invention relates to a magnetic tunnel junction with a quantum effect, and a spin diode and a spin transistor comprising the magnetic tunnel junction. The magnetic tunnel junction comprises a first reference layer, a first barrier layer, a free layer, and a second barrier layer, wherein the first reference layer is formed by a magnetic conductive material and has a fixed magnetizing direction; the first barrier layer is arranged on the first reference layer and formed by an insulating material; the free layer is arranged on the first barrier layer, and formed by a magnetic conductive material, and the magnetizing direction of the free layer can respond to an outer magnetic field to be freely changed; and the second barrier layer is arranged on the free layer and formed by an insulating material, wherein the insulating materials of the first barrier layer and the second barrier layer both comprise a spinel-like crystal structure.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

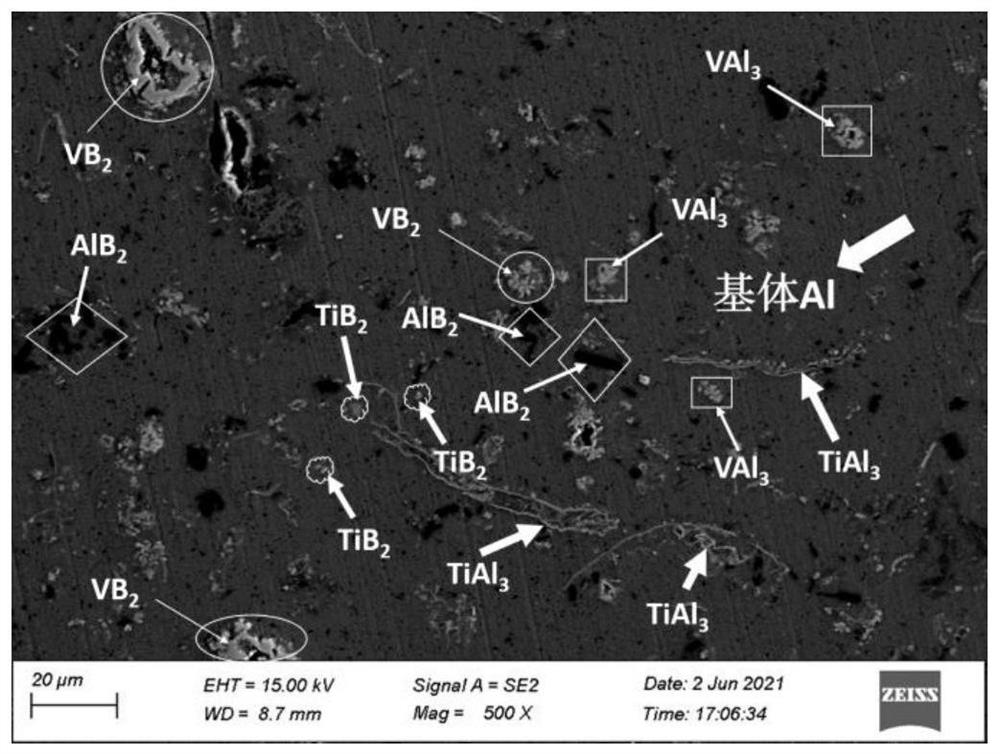

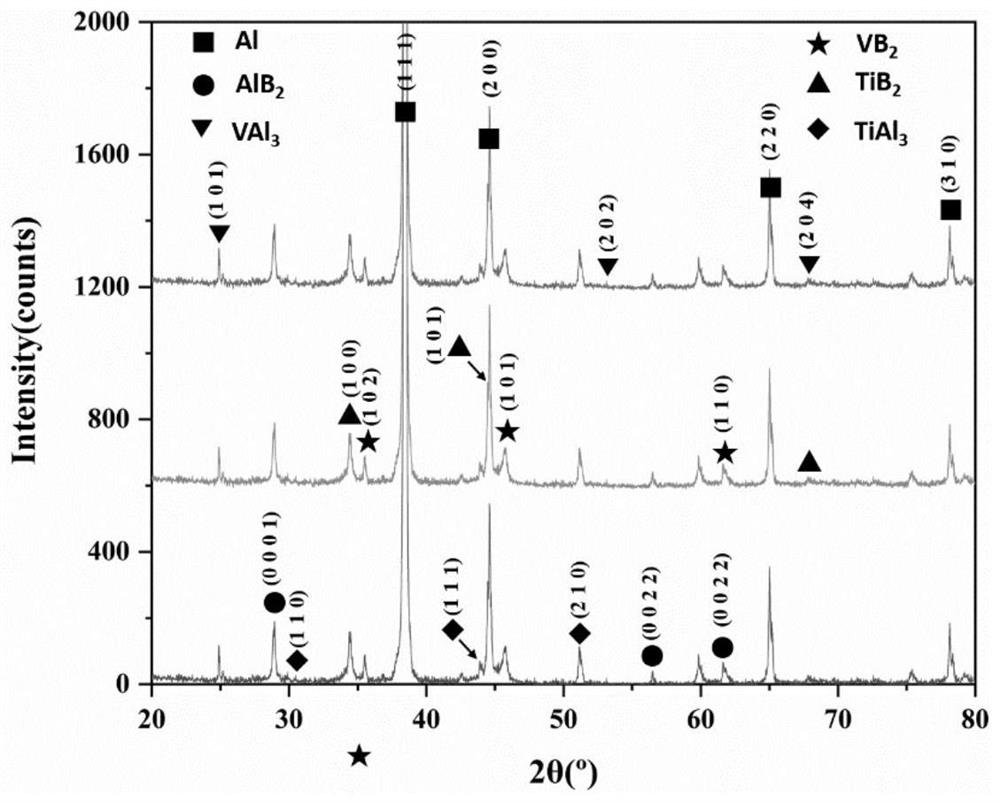

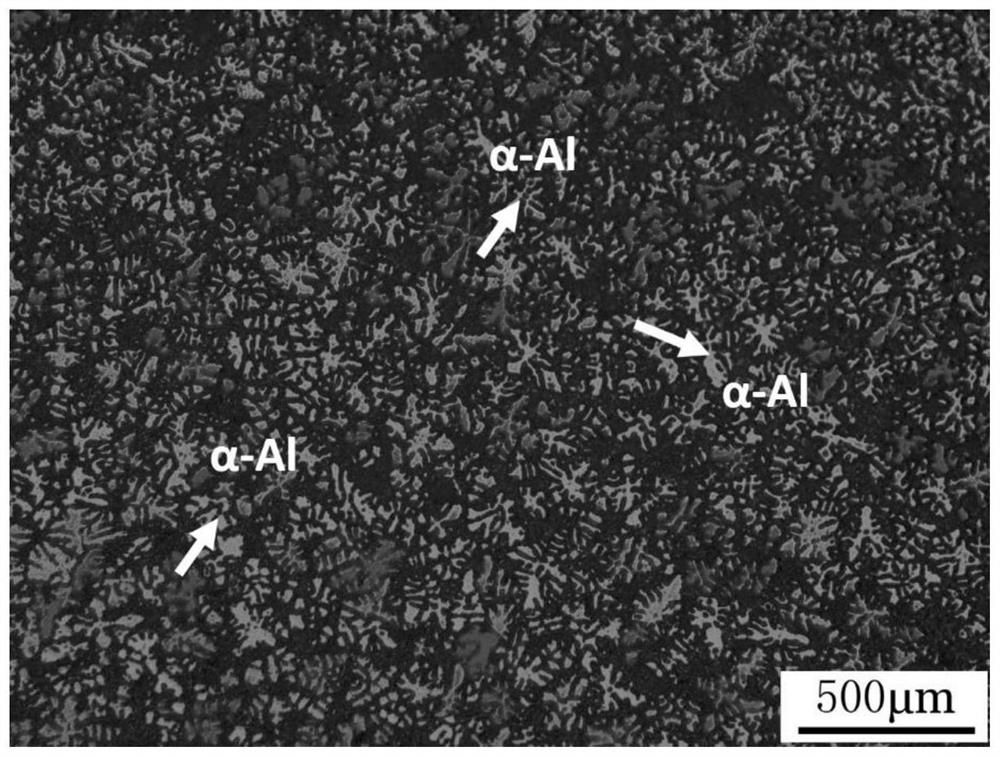

High-performance Al-Ti-V-B alloy refiner and preparation method and application thereof

The invention discloses a high-performance Al-Ti-V-B alloy refiner and a preparation method and application thereof. The Al-Ti-V-B alloy comprises the following chemical elements, by mass, 0.5-3.0 wt% of Ti, 1.0-4.0 wt% of V, 1.0-6.0 wt% of B, less than 0.1 wt% of inevitable impurities and the balance Al, and the Al-Ti-V-B alloy consists of an Al matrix and TiAl3, VAl3, VB2, TB2 and AlB2 phase grains with the size of 1 to 100 micrometers. According to the Al-Ti-V-B refiner prepared by adopting the methods of melting, heating, blending, stirring, pouring and the like, the grain size of alpha-Al in the cast aluminum-silicon alloy can be refined to be below 160 microns; and therefore, the Al-Ti-V-B alloy has a remarkable refining effect on alpha-Al grains in the cast aluminum-silicon alloy, the preparation method is simple and convenient to implement, the cost is relatively low, and the Al-Ti-V-B alloy is suitable for large-scale industrial production.

Owner:JILIN UNIV

Non-polar doped GaN film grown on LiGaO2 substrate and preparation method thereof

ActiveCN103031595AImprove luminous efficiencyIncrease the doping concentrationPolycrystalline material growthFrom chemically reactive gasesChemistryCrystallization

The invention discloses a doped GaN film grown on a LiGaO2 substrate. The doped GaN film comprises the LiGaO2 substrate, a non-polar m-surface GaN buffer layer, a non-polar m-surface GaN epitaxial layer and a non-polar doped GaN film, wherein the non-polar GaN film is a non-polar p-type GaN film or a non-polar n-type GaN film. The invention also discloses a preparation method of the non-polar doped GaN film. Compared with the prior art, the non-polar doped GaN film has the advantages of simple growth process and low preparation cost, and the prepared non-polar doped GaN film is low in defect density, good in crystallization quality and high in electrical property.

Owner:SOUTH CHINA UNIV OF TECH

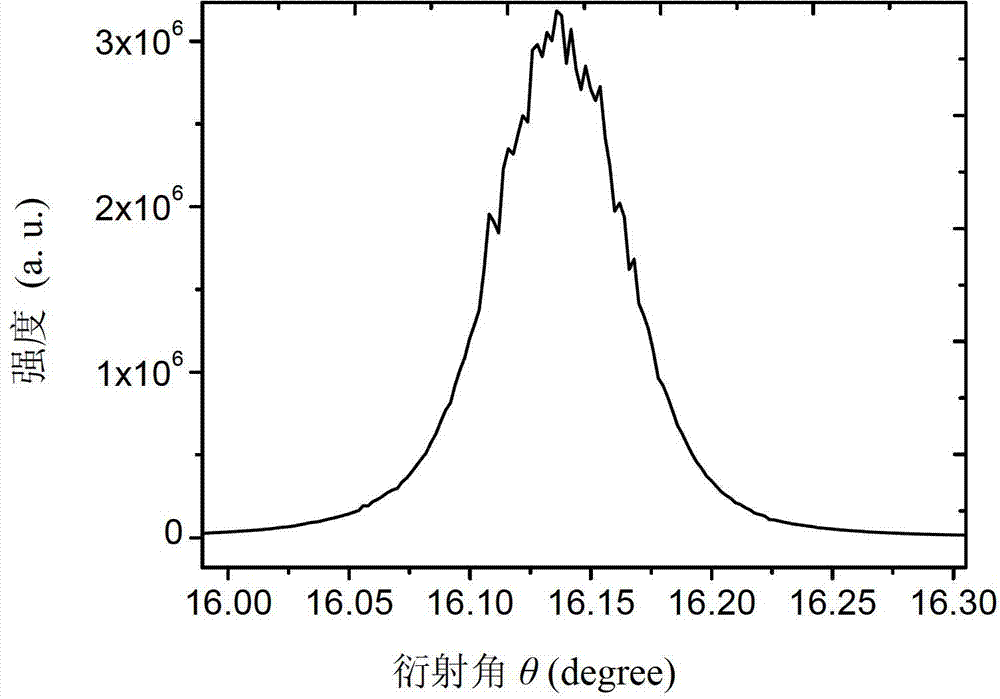

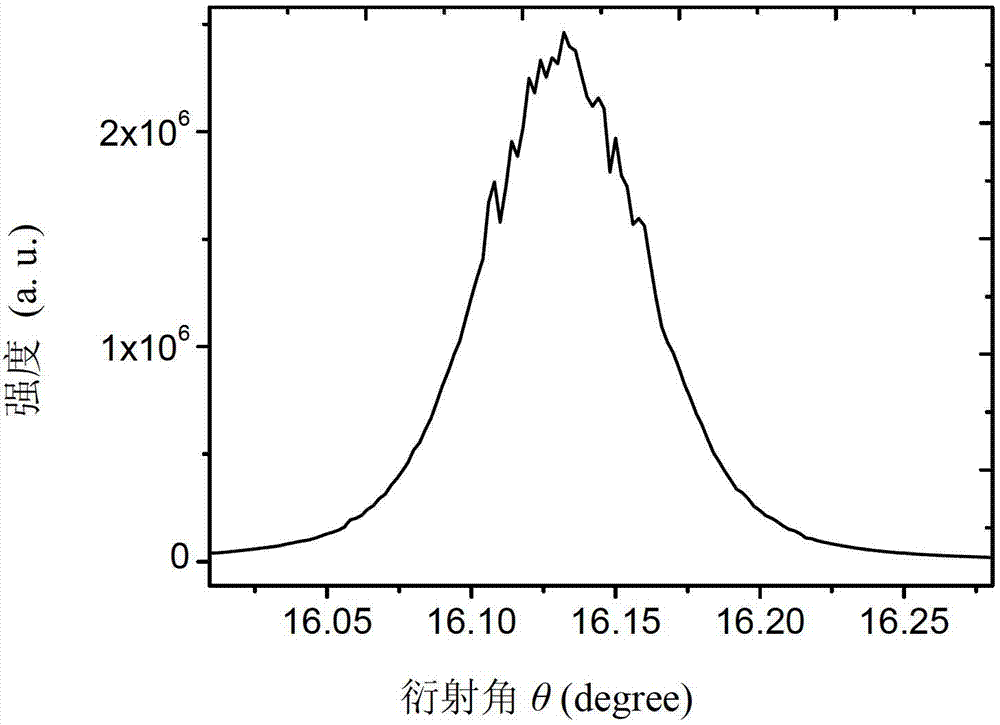

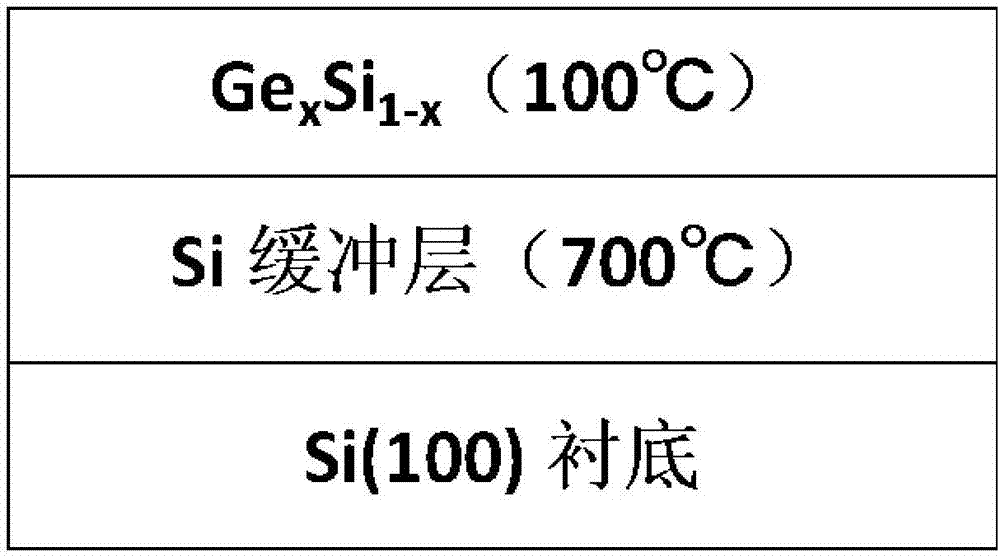

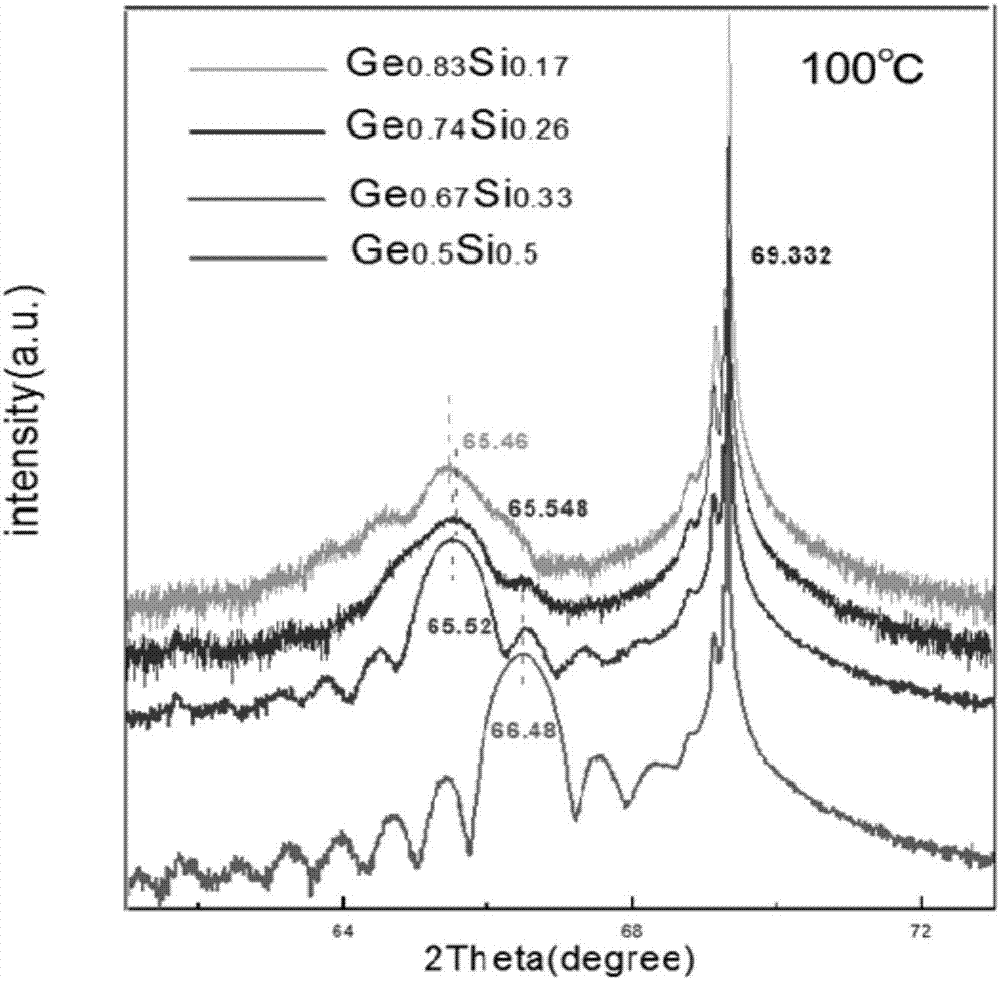

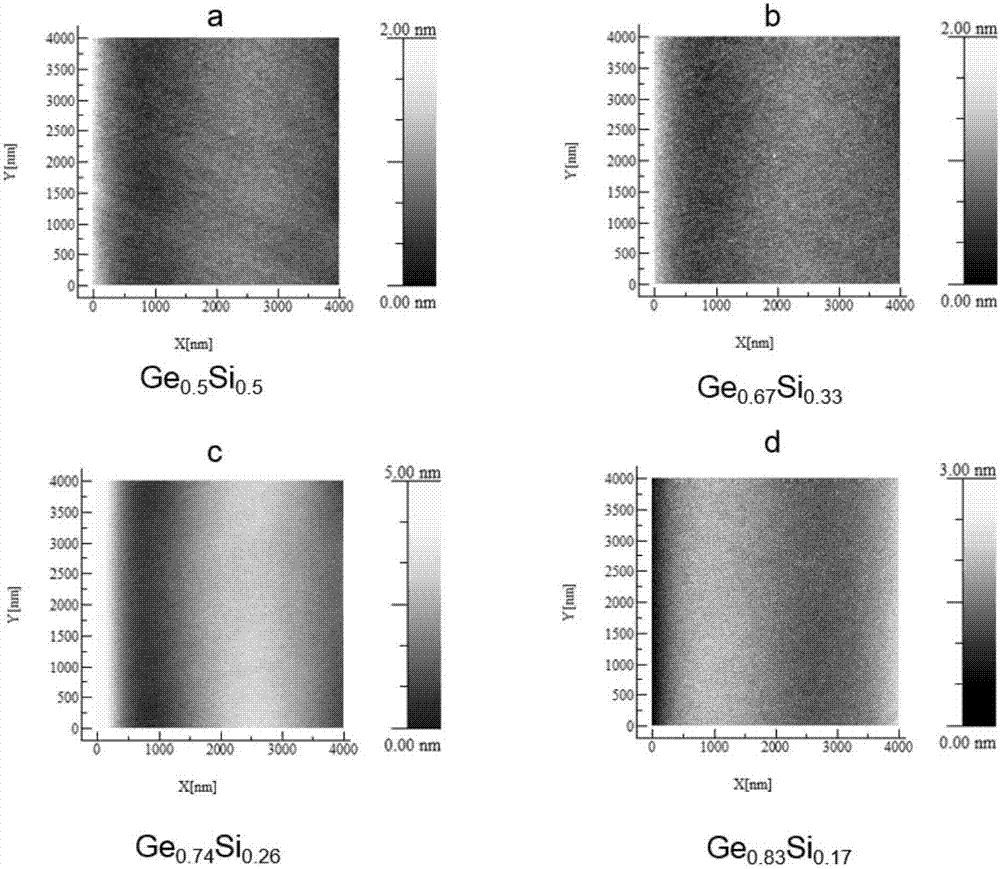

Low-temperature epitaxy preparation method of germanium-silicon film with high germanium content

ActiveCN107316802ASmall lattice mismatchAdjust the content ratio of germanium to siliconSemiconductor/solid-state device manufacturingAlloyLattice constant

The invention discloses a low-temperature epitaxy preparation method of a germanium-silicon film with high germanium content. The low-temperature epitaxy preparation method comprises the following specific steps: (1) providing a silicon substrate with a (100) crystal face; (2) carrying out deoxidation on the silicon substrate at the temperature of 1350 DEG C, wherein the deoxidation lasts for 10 minutes; (3) through a molecular beam epitaxy method, growing a silicon buffer layer with the thickness of 20 to 50 nm on the silicon substrate after deoxidation, wherein the growth temperature is 700 DEG C; and (4) cooling the silicon buffer layer to a growth temperature which is below 300 DEG C, then growing GexSi1-x alloy, and adjusting the content of Ge, namely an x value, by changing the growth rates of Ge and Si. According to the preparation method, the high-quality germanium-silicon (GexSi1-x) film material with adjustable lattice constants can be directly grown on the silicon wafer at low temperature, and the content of germanium at most can reach 83%. The method does not need to adopt a layer-by-layer growth pattern for improving the content of germanium layer by layer, so that the method is simpler in operation and lower in cost.

Owner:NANJING UNIV

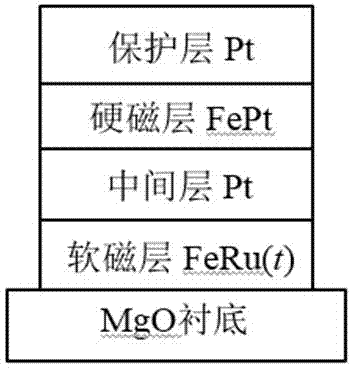

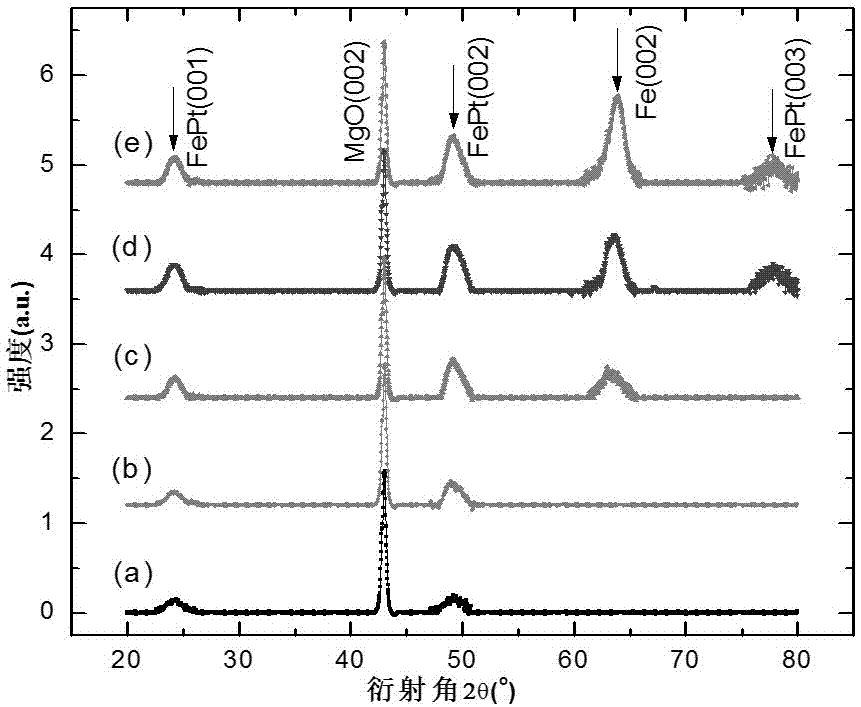

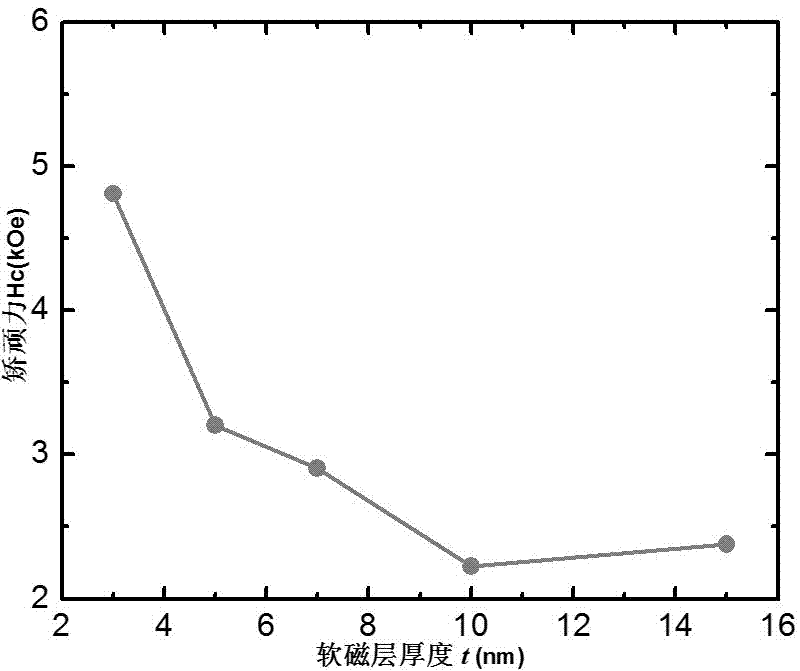

Exchange-coupling composite magnetic recording medium and manufacturing method thereof

InactiveCN107123433AGuaranteed normal growthGuaranteed thermal stabilityVacuum evaporation coatingSputtering coatingComposite filmMagnetic storage

The invention belongs to the technical field of magnetic storage, and particularly relates to an exchange-coupling composite magnetic recording medium and a manufacturing method thereof. The composite magnetic recording medium is a coupling composite film and comprises a soft magnetic layer, a middle layer, a hard magnetic layer and a protective layer sequentially from bottom to top, a substrate adopts a single crystal MgO substrate, the soft magnetic layer is a FeRu layer with a thickness of t, the middle layer is a Pt layer, the hard magnetic layer is L1<0>-FePt, and the protective later is a Pt layer. The problem that in the case of information writing in the traditional ECC structure, the distance between the lower layer and a magnetic head is over large, and the acquired magnetic field is insufficient can be solved. In the structure, the hard magnetic layer is the L1<0>-FePt thin film with the thickness of 5.0 nm and with high order degree, and the coercive force is about 9.0 kOe; through introducing the soft magnetic layer FeRu, when the thickness of the soft magnetic layer is 10.0 nm, the overall coercive force of the composite thin film can be reduced to 2.2 kOe; and when the included angle between an external field and a film surface normal changes between 0 DEG to 60 DEG, the coercive force angle feature curve of the ECC thin film presents good angle containment. Improvement of the performance facilitates writing of the information.

Owner:FUDAN UNIV

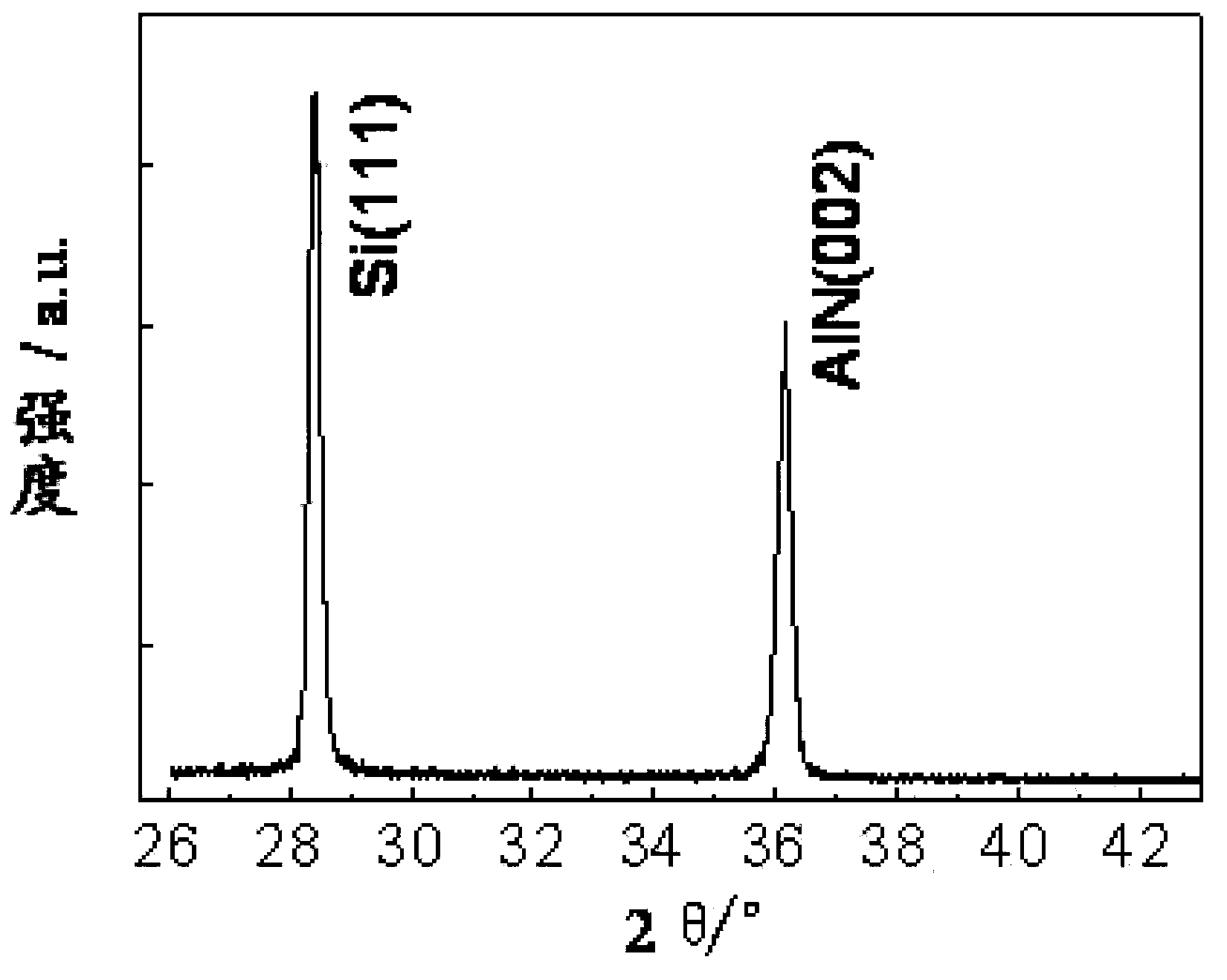

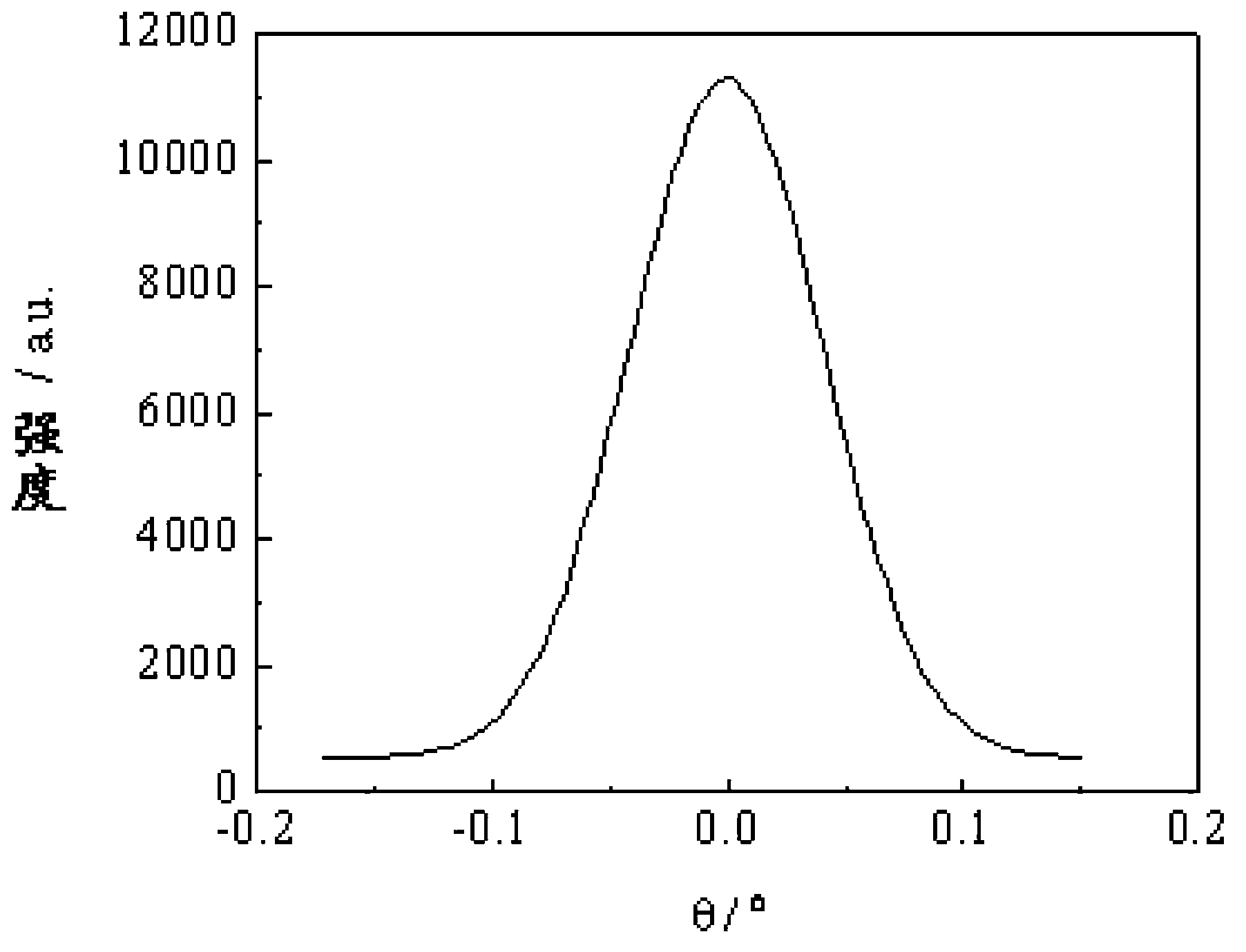

Aluminum nitride film growing on silicon substrate and preparation method and application thereof

ActiveCN103022295BQuality improvementSmall lattice mismatchFinal product manufactureSemiconductor devicesPhotovoltaic detectorsLattice mismatch

The invention discloses an aluminum nitride film growing on a silicon substrate and a preparation method and the application thereof. The aluminum nitride film is obtained by the following preparation method: adopting the silicon substrate, selecting the (111) crystal face of the silicon substrate as crystal orientation, growing an aluminum buffer layer on the (111) crystal face of the silicon and then growing an aluminum nitride film in epitaxial growth mode. The silicon is adopted as the substrate, simultaneously a pulse laser deposition growth method is adopted to grow the aluminum nitride film on the Si (111) substrate, the aluminum nitride film crystal grows in preferred orientation to obtain low lattice mismatch degree between the substrate and the aluminum nitride, quality of the aluminum nitride crystal is greatly improved, and the aluminum nitride film is suitable for being applied to photoelectric detectors and light-emitting diode (LED) devices.

Owner:广州市艾佛光通科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com