LED epitaxial wafer growing on metal Al substrate and preparing method and application thereof

A technology for LED epitaxial wafers and substrates, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of unstable chemical properties of metal Al substrates, difficulty in thin film epitaxy, and affecting the quality of epitaxial thin film growth, etc. Achieve the effect of improving internal quantum efficiency, shortening nucleation time, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

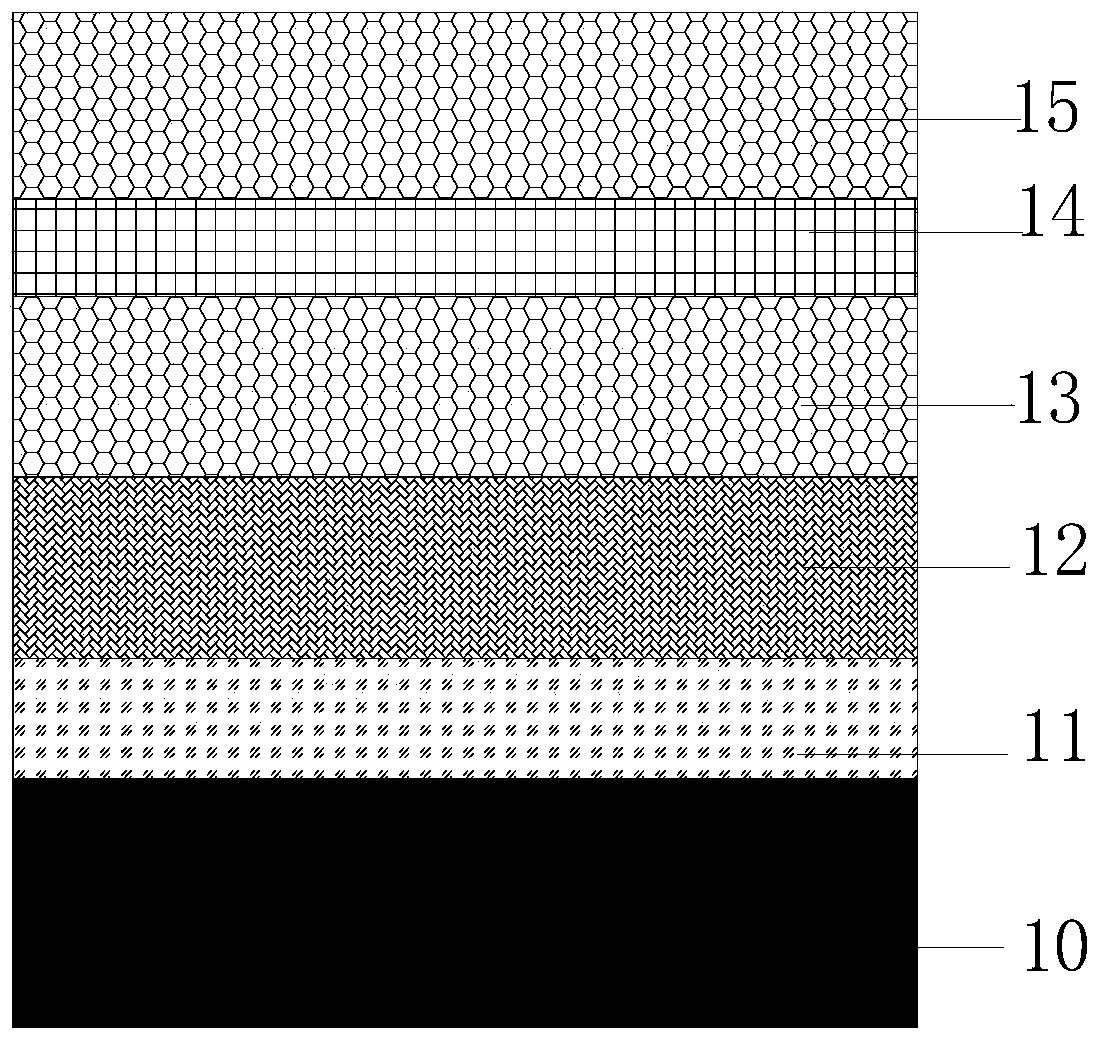

[0051] An LED epitaxial wafer grown on a metal Al substrate, which is prepared by the following method:

[0052] 1) Substrate treatment: select metal Al as the substrate, and polish the surface of the Al substrate with diamond slurry, and observe the surface of the substrate with a microscope when there is no scratch, and then use chemical mechanical polishing to polish the substrate. Then, the cleaned substrate was put into deionized water and ultrasonically cleaned at room temperature for 5 minutes to remove the dirt particles on the surface of the Al substrate, and then washed with hydrochloric acid, acetone, and ethanol in sequence to remove the surface organic matter; after cleaning The substrate was blown dry with dry nitrogen with a purity of 99.9999%; finally, the substrate Al was placed under a pressure of 2×10 -10 In the growth chamber of Torr’s UHV-PLD, bake at 450°C for 1 hour to remove pollutants on the substrate surface, and then air cool to room temperature;

...

Embodiment 2

[0067] An LED epitaxial wafer grown on a metal Al substrate, which is prepared by the following method:

[0068] 1) Substrate treatment: select metal Al as the substrate, and polish the surface of the Al substrate with diamond slurry, and observe the surface of the substrate with a microscope when there is no scratch, and then use chemical mechanical polishing to polish the substrate. Then, the cleaned substrate was put into deionized water and ultrasonically cleaned at room temperature for 5 minutes to remove the dirt particles on the surface of the Al substrate, and then washed with hydrochloric acid, acetone, and ethanol in sequence to remove the surface organic matter; after cleaning The substrate was blown dry with dry nitrogen with a purity of 99.9999% (v%); finally the substrate Al was placed under a pressure of 2×10 -10 In the growth chamber of Torr’s UHV-PLD, bake at a high temperature of 500 ° C for 1 hour to remove pollutants on the substrate surface, and then air c...

Embodiment 3

[0083] An LED epitaxial wafer grown on a metal Al substrate, which is prepared by the following method:

[0084] 1) Substrate treatment: select metal Al as the substrate, and polish the surface of the Al substrate with diamond slurry, and observe the surface of the substrate with a microscope when there is no scratch, and then use chemical mechanical polishing to polish the substrate. Then, the cleaned substrate was put into deionized water and ultrasonically cleaned at room temperature for 5 minutes to remove the dirt particles on the surface of the Al substrate, and then washed with hydrochloric acid, acetone, and ethanol in sequence to remove the surface organic matter; after cleaning The substrate was blown dry with dry nitrogen with a purity of 99.9999%; finally, the substrate Al was placed under a pressure of 2×10 -10 In the growth chamber of Torr’s UHV-PLD, bake at a high temperature of 550 ° C for 1 hour to remove pollutants on the substrate surface, and then air cool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com