Patents

Literature

47results about How to "Reduced nucleation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

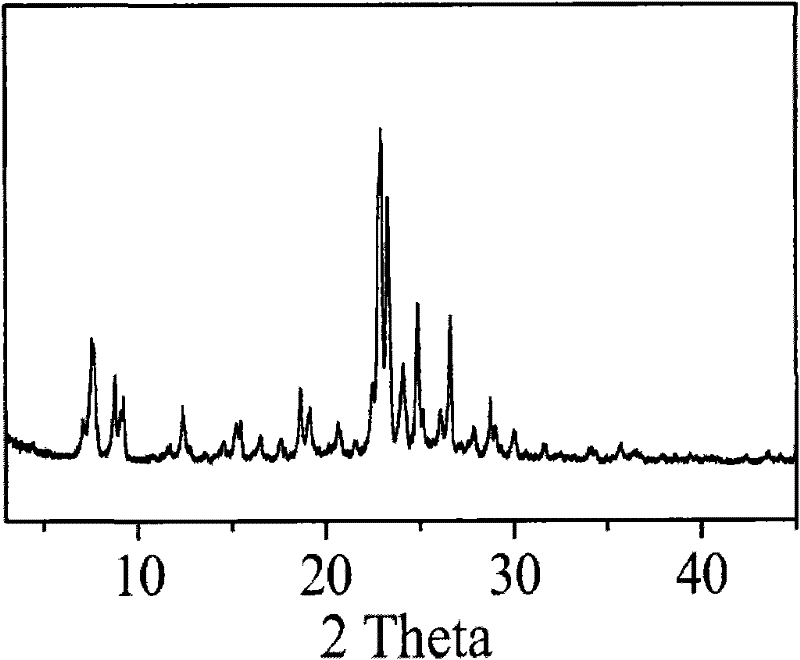

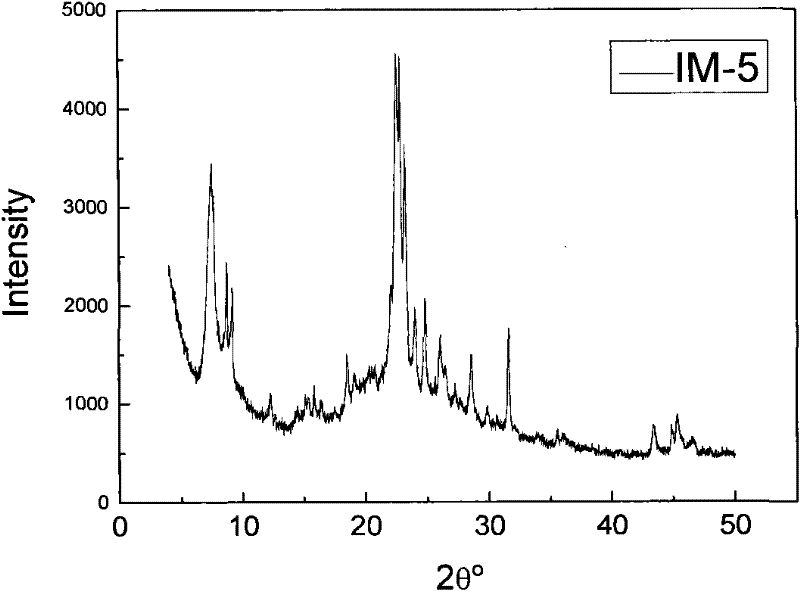

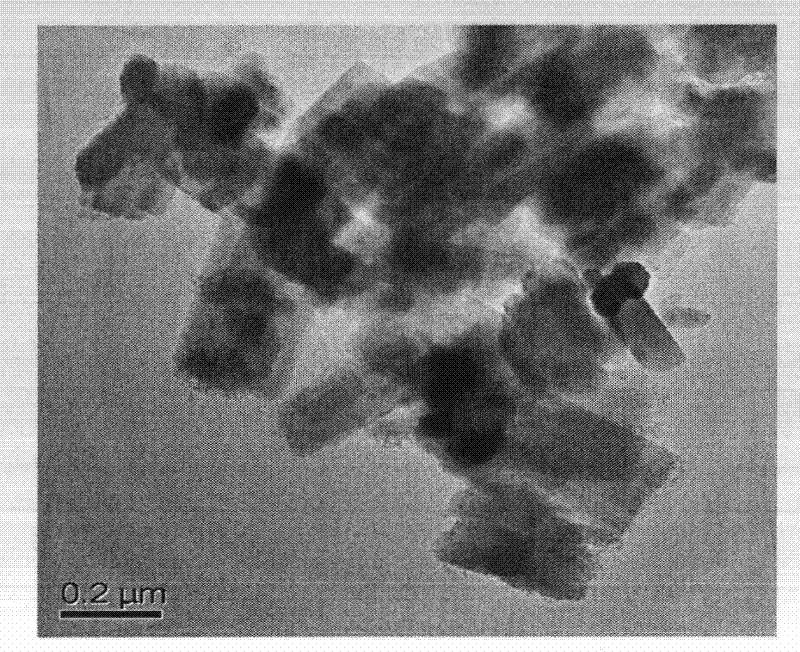

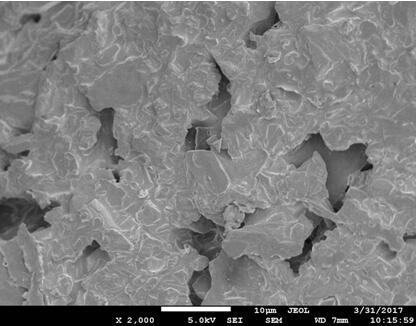

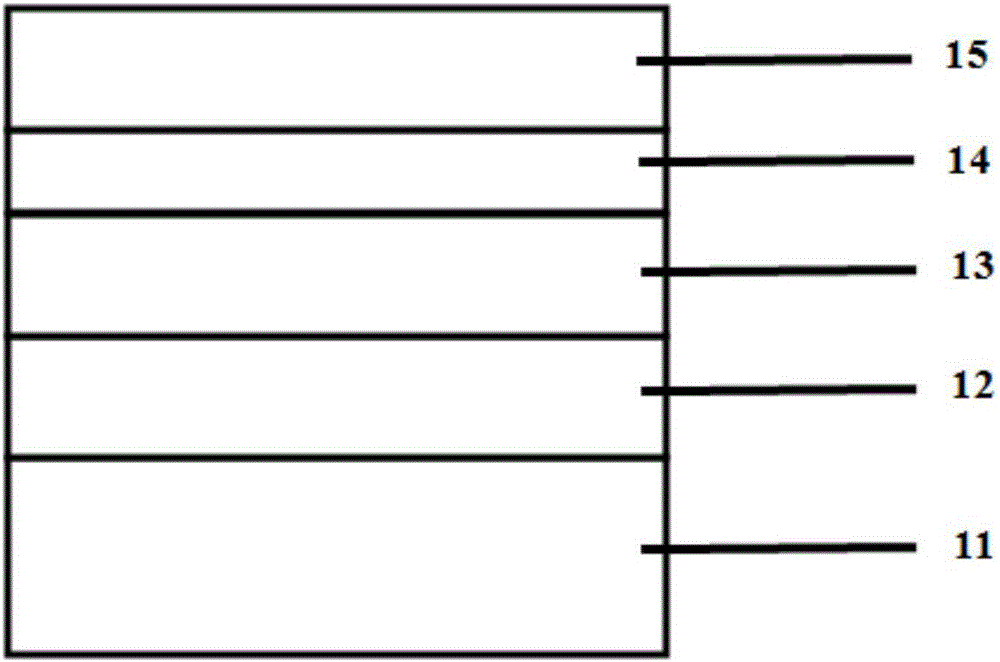

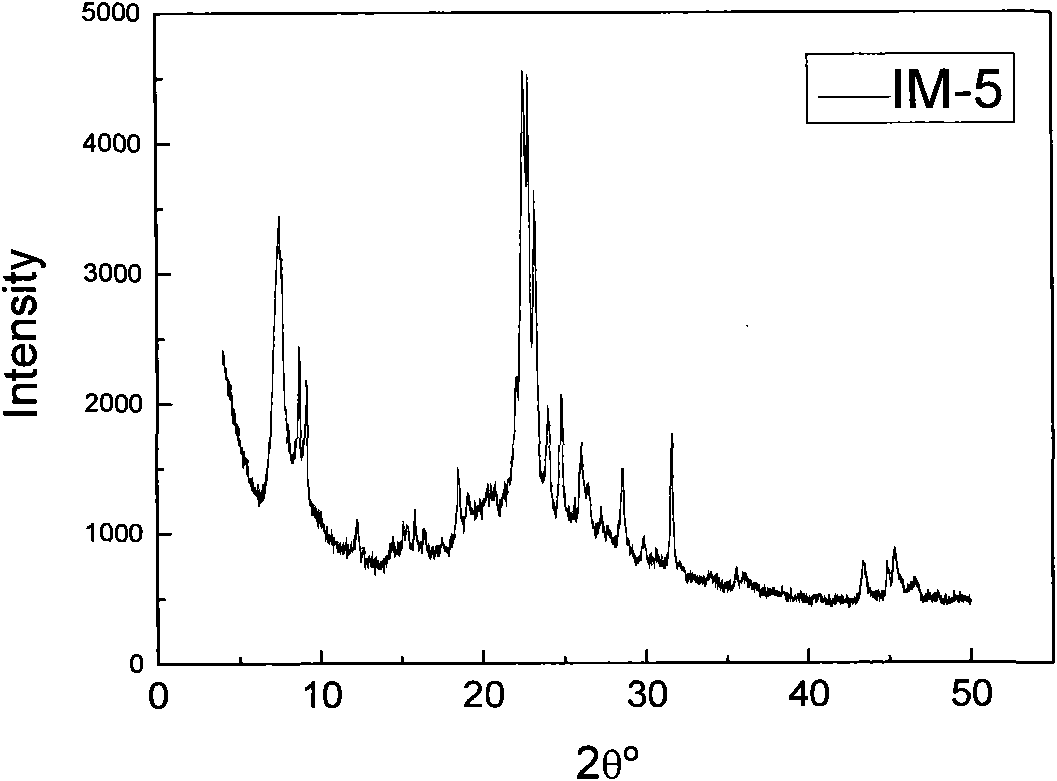

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667AReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesMolecular sieveAlkali metal oxide

The invention provides a method of synthesizing IM-5 molecular sieve by using a composite template. The method comprises the following steps: (1) dissolving an inorganic base, an aluminum source and two templates in deionized water and carrying out uniform mixing so as to prepare a mixed solution; (2) adding a silicon source into the mixed solution obtained in step (1), optionally adding an additive and carrying out uniform mixing so as to prepare colloid or a solid-liquid mixture; (3) transferring the colloid or the solid-liquid mixture obtained in step (2) to a crystallization kettle, carrying out hydrothermal crystallization at a temperature of 120 to 200 DEG C for 1 to 10 d, carrying out cooling after crystallization and rinsing, filtering and drying the obtained mixed liquor so as to obtain raw powder of the IM-5 molecular sieve. A mole ratio of reactants satisfies the equation of SiO2: Al2O3: M2O: R1: R2: H2O = 60: 0.4-6: 6-21: 0.6-18: 0.6-12: 300-1800, wherein M2O is an alkali metal oxide, R1 is a first template, and R2 is a second template. The method provided in the invention widens the range of mixing ratios of raw materials, improves yield of a single kettle and enables time for crystallization to be further shortened and enlarged production to be easier.

Owner:CHINA PETROLEUM & CHEM CORP +1

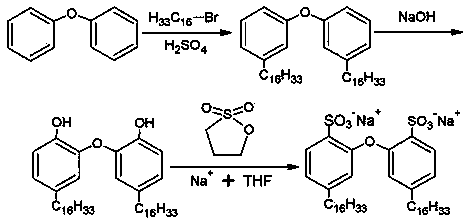

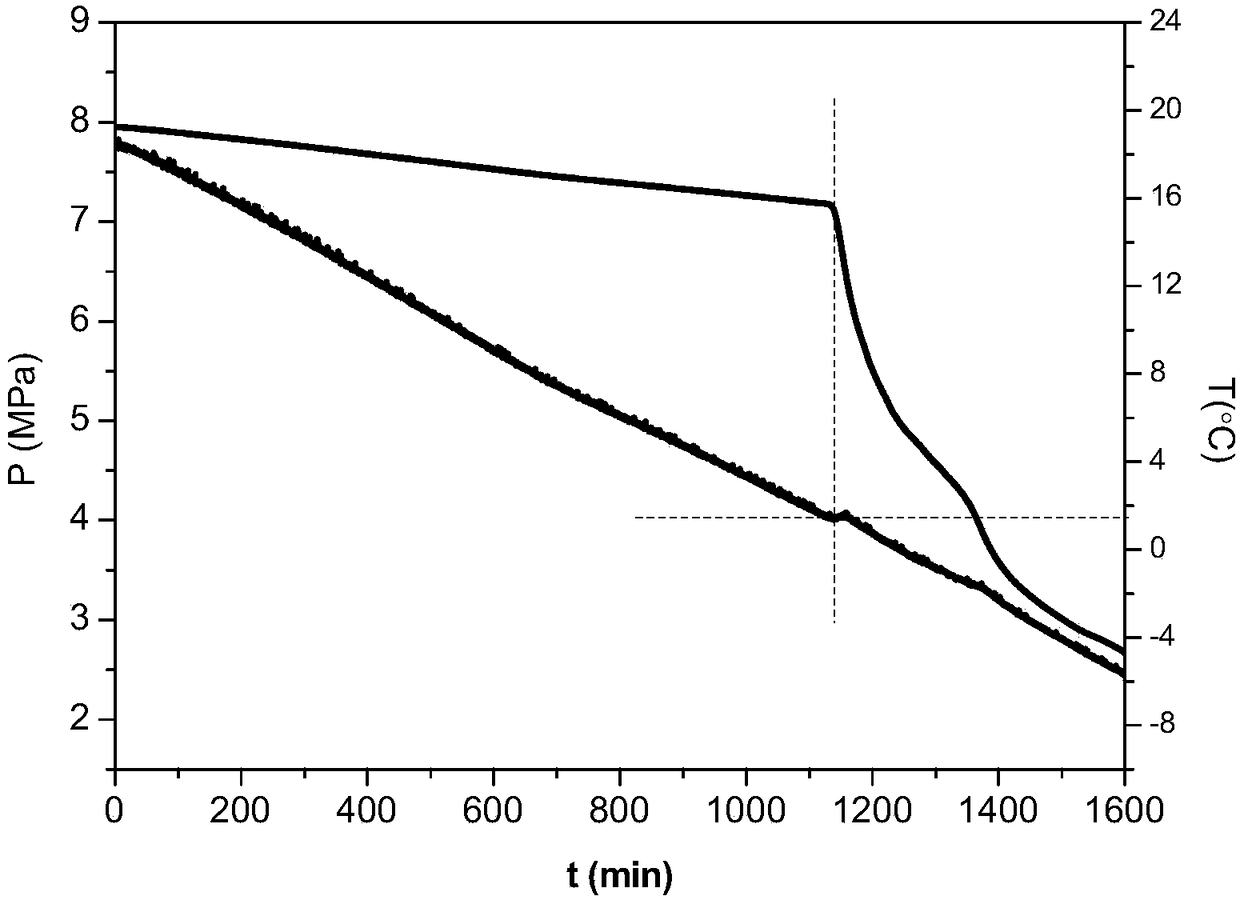

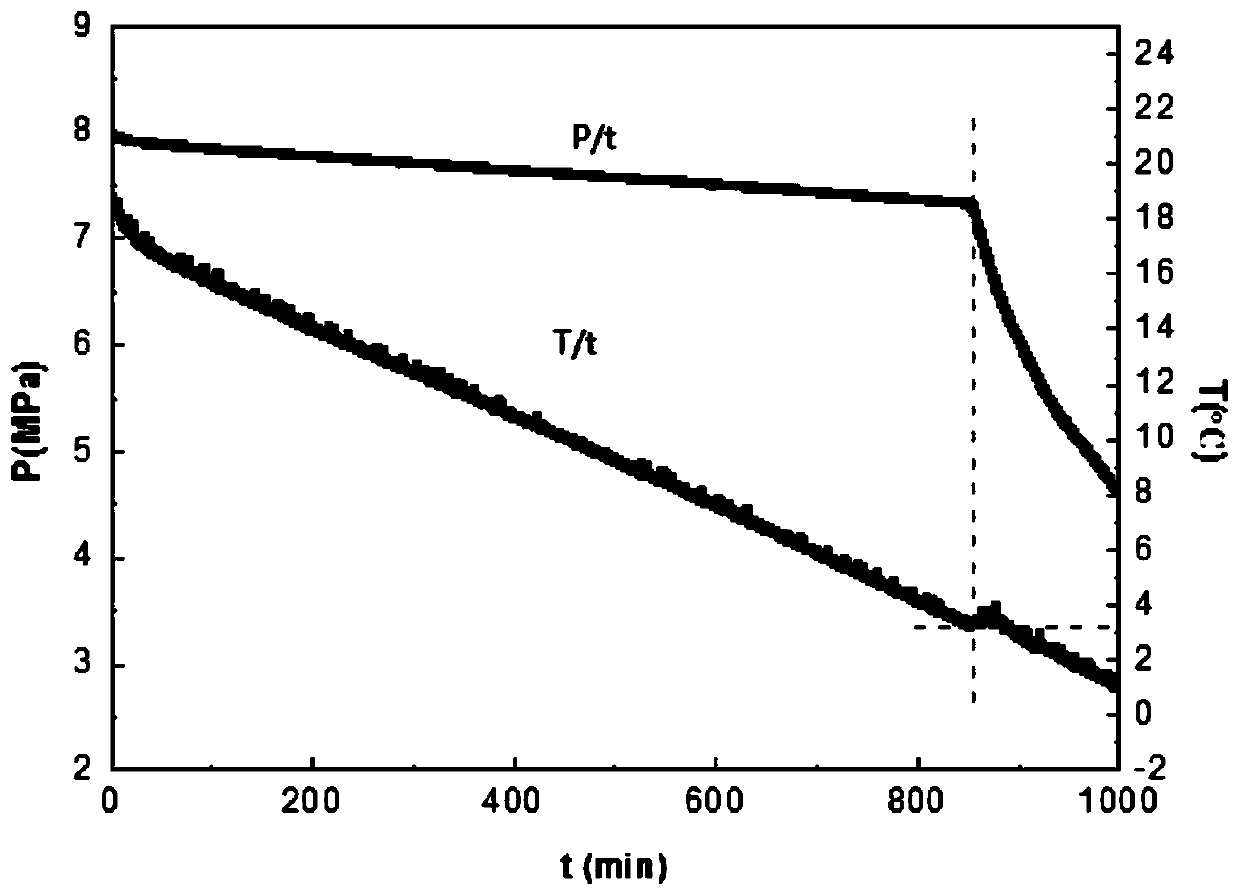

Accelerant for generating gas hydrate

ActiveCN103962078AImprove production efficiencyReduced nucleation timePressurized chemical processGaseous fuelsMass ratioSolid particle

The invention relates to a natural gas hydrate, and particularly to an accelerant for strengthening the generation of a gas hydrate. The accelerant for generating the gas hydrate, provided by the invention, is prepared by compounding of a novel anion gemini surfactant and solid activated carbon particles with a strong heat transmission effect at a certain mass ratio; a liquid mixture is formed after the high-speed mechanical agitation and the ultrasonic dispersion are conducted on the reagent, and the essence is that solid particles with a high heat-conducting property are wrapped in the gemini surfactant, so that nanometer solid particles cannot be agglomerated easily, and the mixing solution with uniformly dispersed solutes is formed, and the mixing solution is free of sediment; the application temperature ranges from 0 DEG C to 10 DEG C, the pressure ranges from 0 MPa to 12 MPa, and the time of hydrate generation induction period ranges from 1 min to 3 min; compared with the pure water system, the generation speed rate of the hydrate is increased by 140%-200%.

Owner:南通东湖国际商务服务有限公司

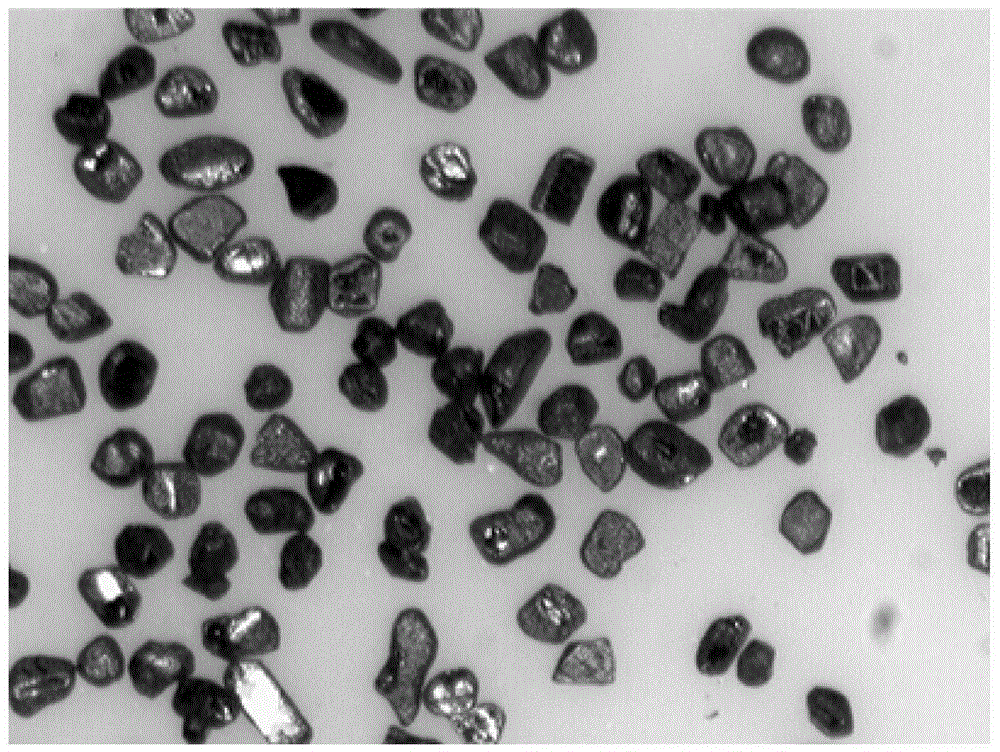

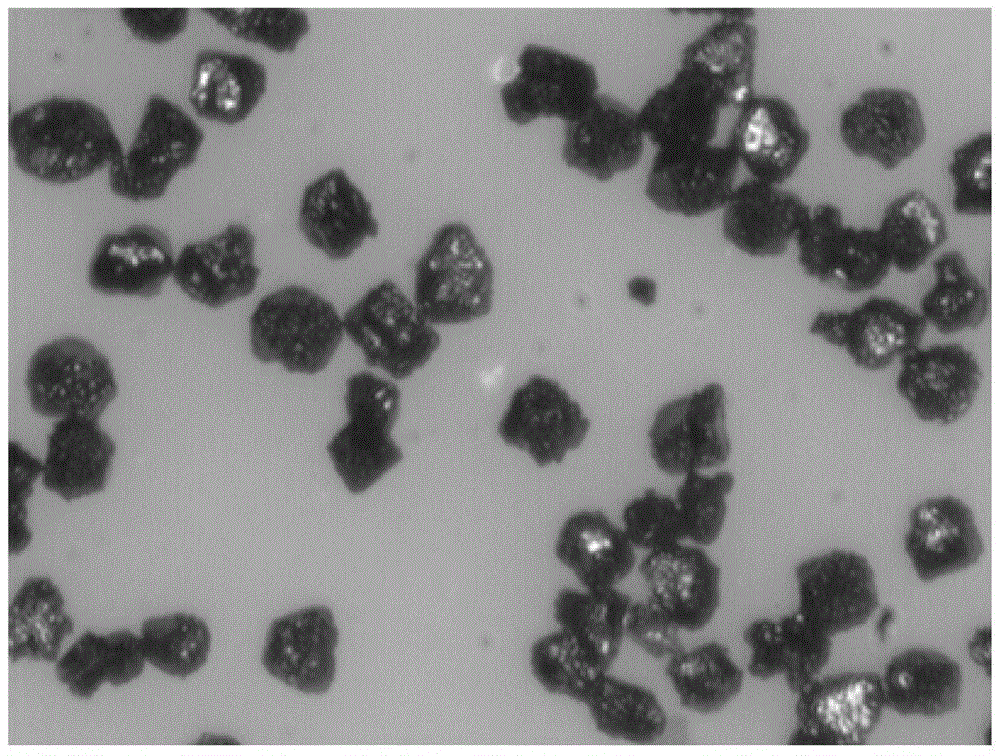

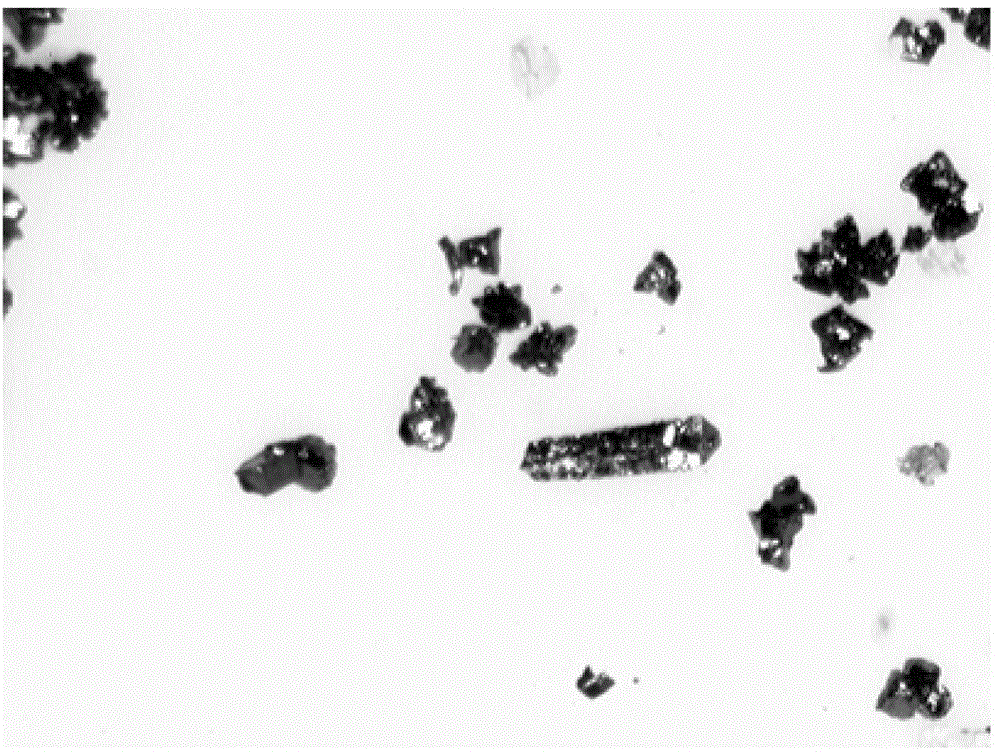

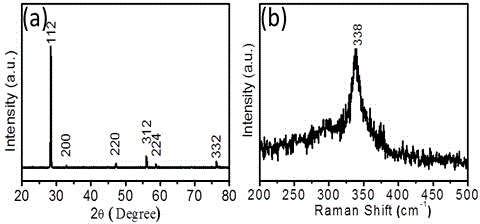

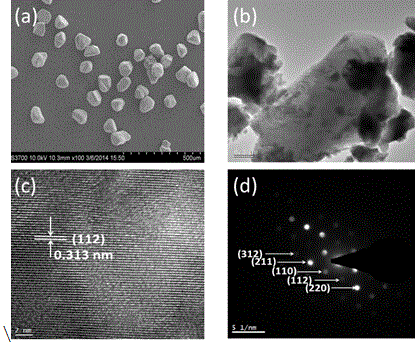

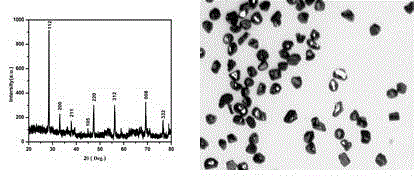

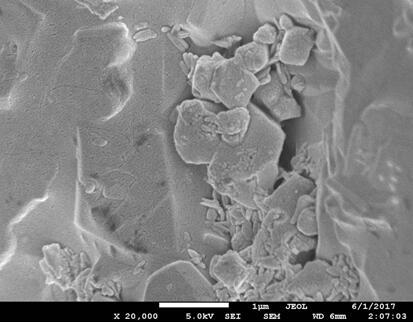

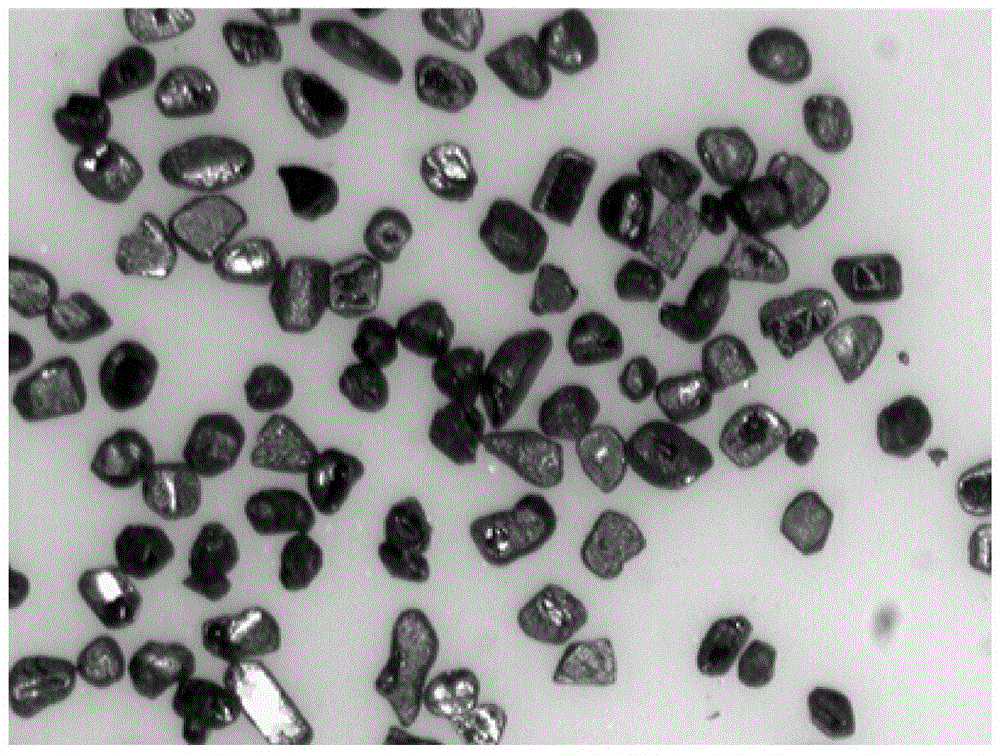

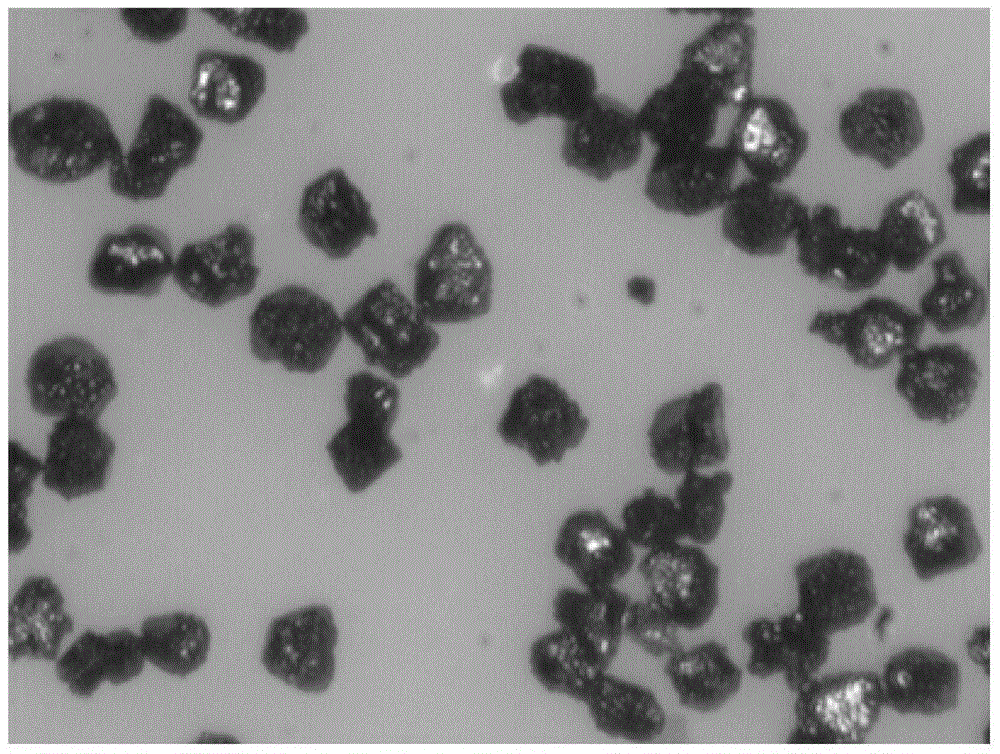

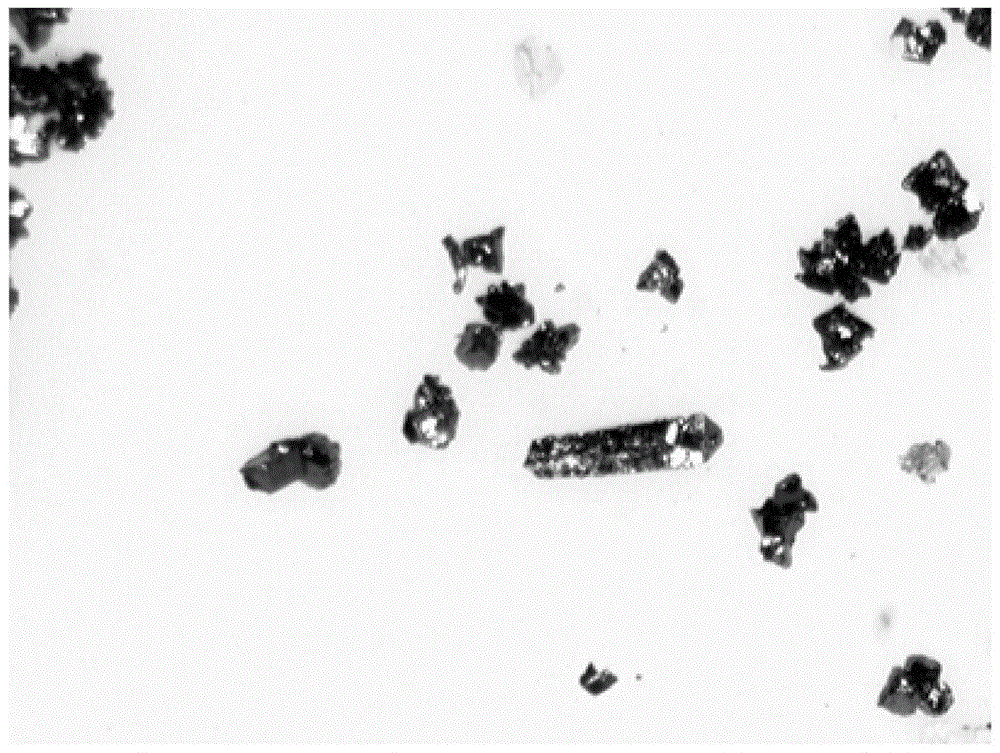

Preparation method for micron-sized spherical CZTSSe monocrystalline particles

ActiveCN104979429AUniform sizeThe size is easy to controlFinal product manufacturePhotovoltaic energy generationPowder mixtureDevice material

The invention relates to the technical field of semiconductor photovoltaic materials and semiconductor devices, and discloses a preparation method for micron-sized spherical CZTSSe monocrystalline particles. Metal simple substance powder, sulfide powder, selenide powder, elemental sulfur powder, elemental selenium powder, flux, Cu2ZnSnS4 nanoparticles and as the like are combined as reaction raw materials, and are ground and mixed according to the designed formula. The powder mixture is vacuum-encapsulated into a quartz reactor; the quartz reactor is kept at the temperature of 750 DEG C to 1000 DEG C for 48-120 hours, and then is quickly cooled to the room temperature; and samples are taken out, cleaned and dried to obtain the CZTSSe monocrystalline particles. The size of the prepared monocrystalline particles can be regulated and controlled by utilizing recrystallization temperature and time, and the components of the particles can be effectively regulated within a certain range through the molar ratio of the elements in a precursor. The prepared monocrystalline particles are uniform and controllable in size, and are better than the monocrystalline particles prepared by the traditional method in performance.

Owner:LINGNAN NORMAL UNIV

Micron-sized spherical copper-zinc-tin-sulfur monocrystal particle preparation method

ActiveCN104952979AThe size is easy to controlImprove performanceFinal product manufactureSemiconductor devicesPhysical chemistrySingle crystal

The invention relates to the technical field of semiconductor photoelectric materials and devices and discloses a micron-sized spherical copper-zinc-tin-sulfur monocrystal particle preparation method. The method includes: grinding and mixing different combinations of metal powder, sulfides, elemental sulfur powder, fluxing agents, copper-zinc-tin-sulfur nano particles and the like according to designed proportions, packaging mixed powder in a quartz reaction vessel in a vacuum manner, keeping the quartz reaction vessel at the temperature of 750-1000 DEG C for 48-120h, and quickly cooling the quartz reaction vessel to the room temperature; taking out a sample, and washing and drying to obtain copper-zinc-tin-sulfur monocrystal particles; the prepared monocrystal particles are adjustable in size by means of recrystallization temperature and time, and ingredients of the particles can be effectively regulated within a certain range through a molar ratio of elements in a precursor. The prepared monocrystal particles are uniform in ingredient and controllable in size so as to be superior to those prepared according to traditional methods.

Owner:LINGNAN NORMAL UNIV

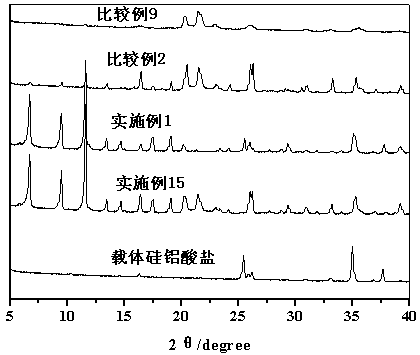

Hybrid material containing metal organic framework material, and preparation method thereof

PendingCN109721737AUniform growthUniform grain sizeOther chemical processesDispersed particle separationMetal-organic frameworkAdsorption separation

The invention relates to a hybrid material containing a metal organic framework material, and a preparation method thereof. The preparation method comprises: (1) carrying out acid treatment on an aluminosilicate carrier, washing to achieve a neutral state, and drying; (2) immersing the carrier in an organic ligand solution, and impregnating; (3) transferring the material into a reactor containinga copper salt solution while supplying a trimesic acid solution, and carrying out stand treatment at a low temperature; and (4) transferring the reactor into a drying oven, drying, taking the mixtureout of the reactor, filtering, washing, and drying to obtain the hybrid material containing the metal organic framework material. According to the present invention, the copper-based metal organic framework material HKUST-1 in the hybrid material grows uniformly, and the hybrid material has high ethylene adsorption capacity and selective ethylene / ethane adsorption separation effect, and further has good mechanical strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

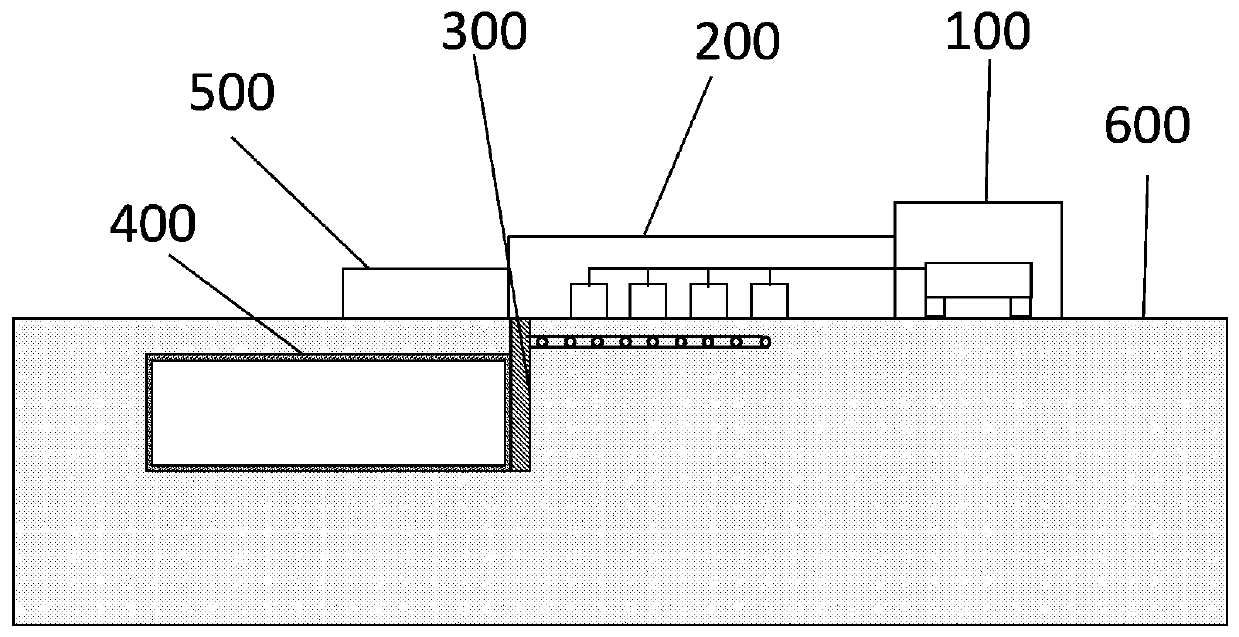

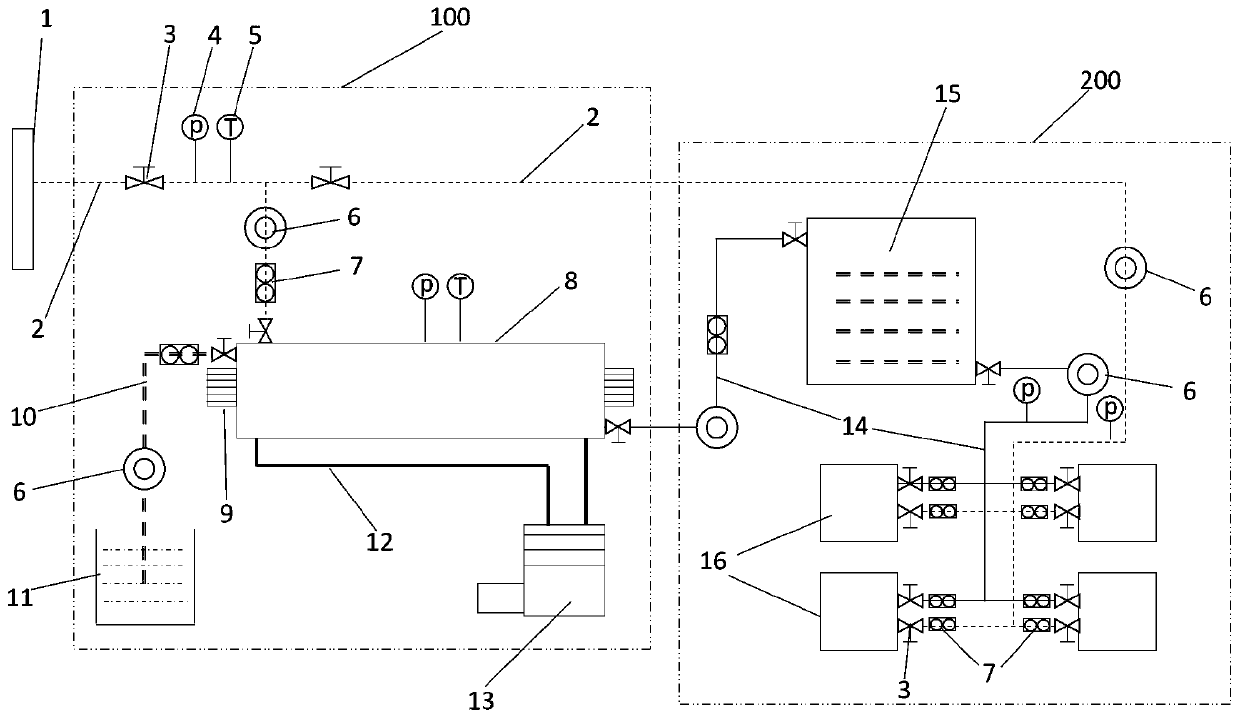

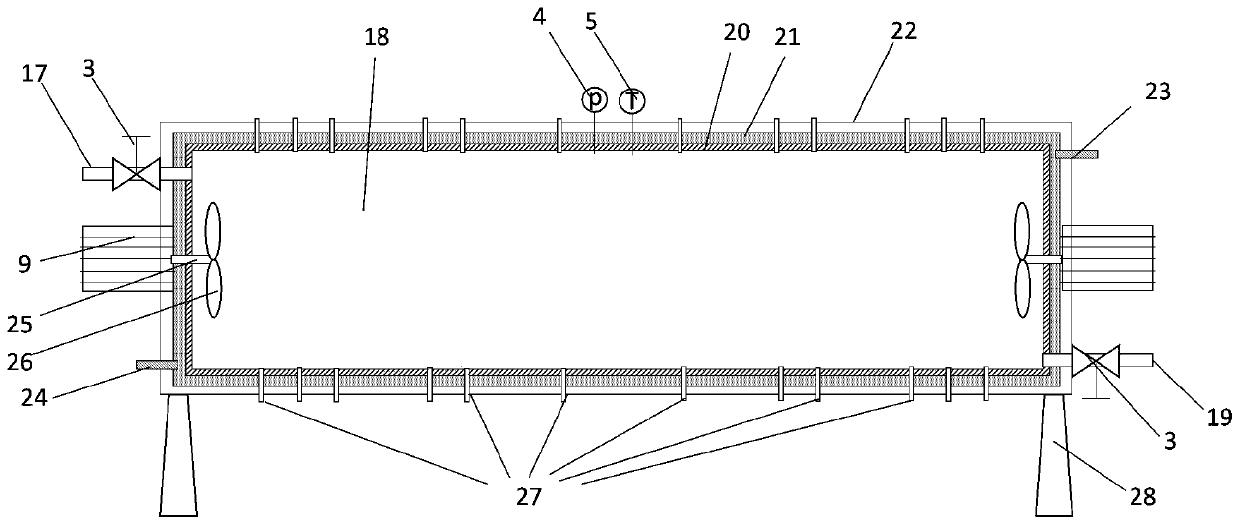

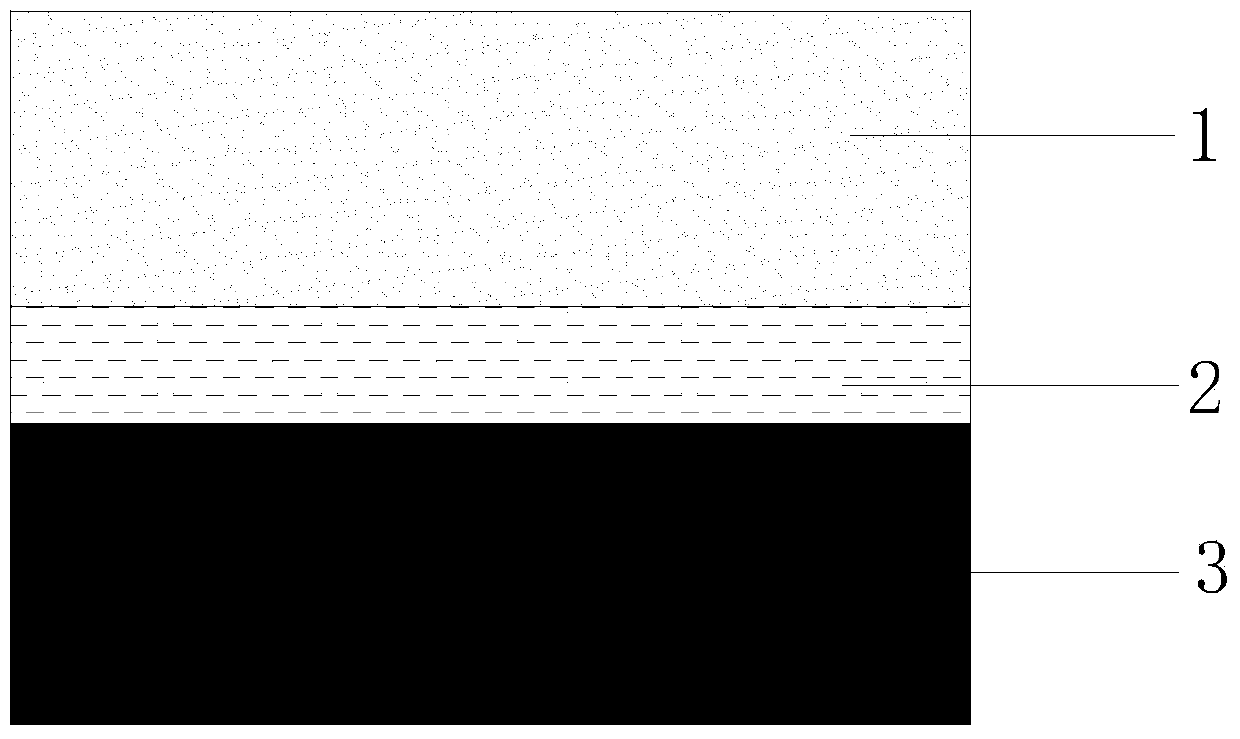

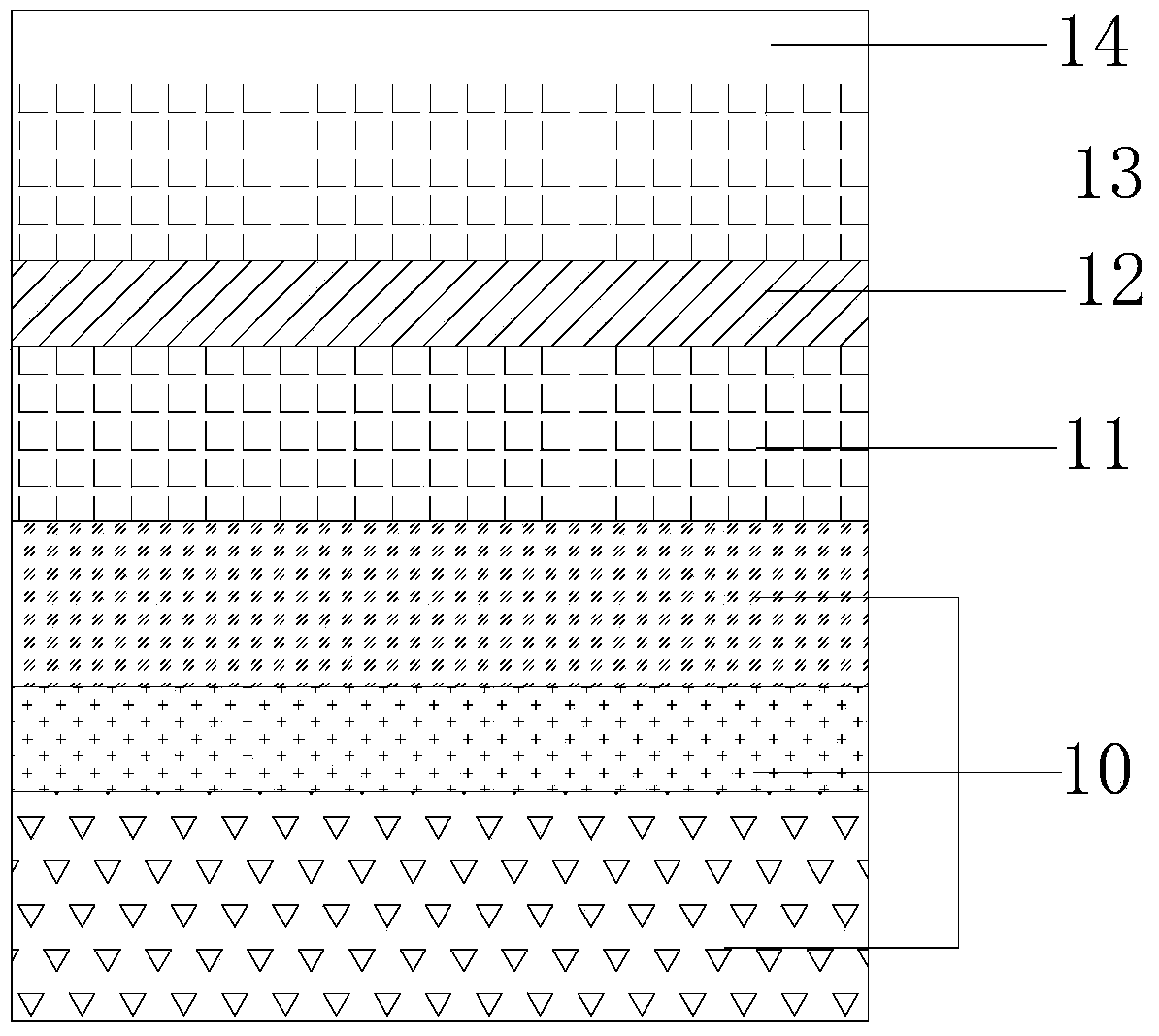

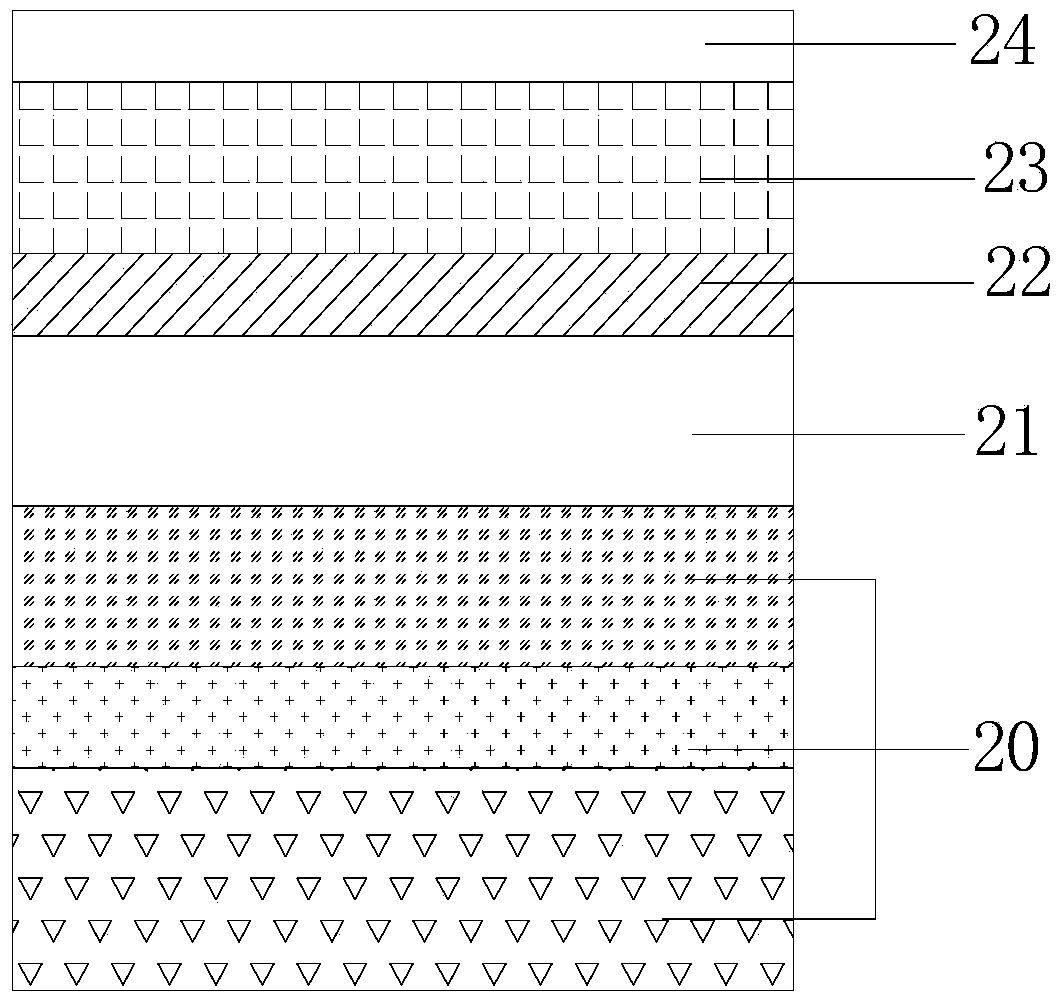

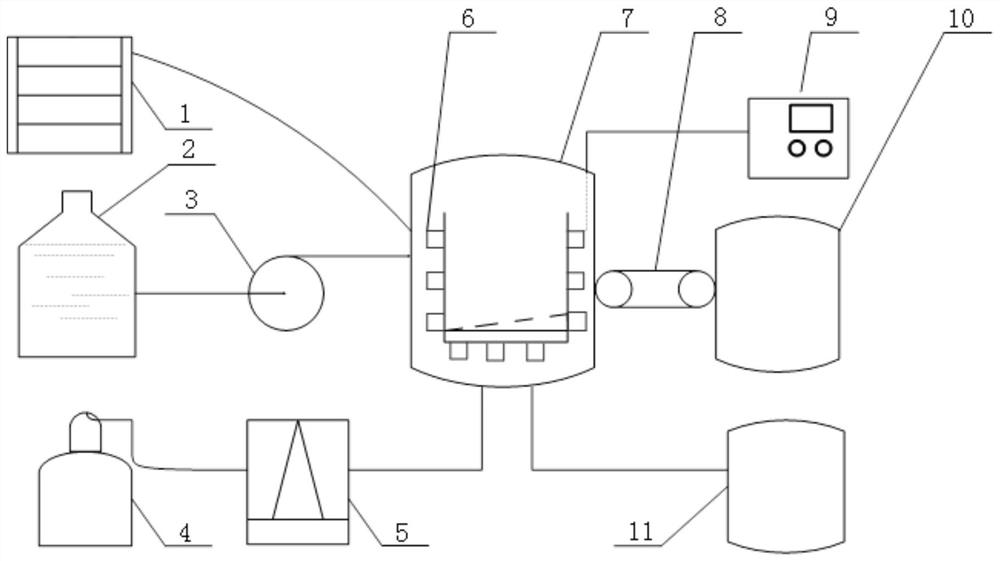

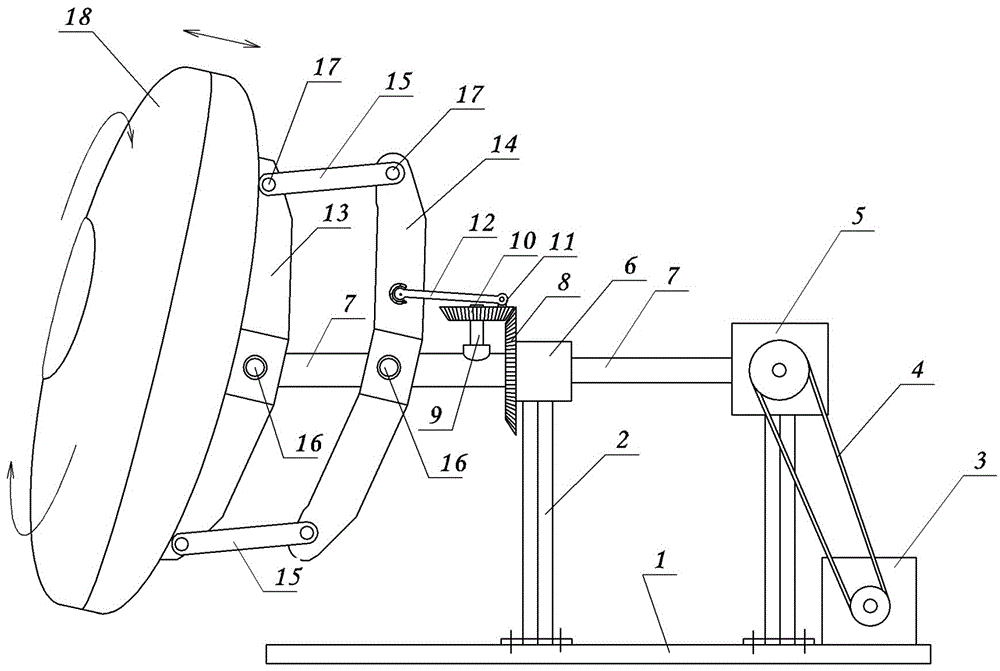

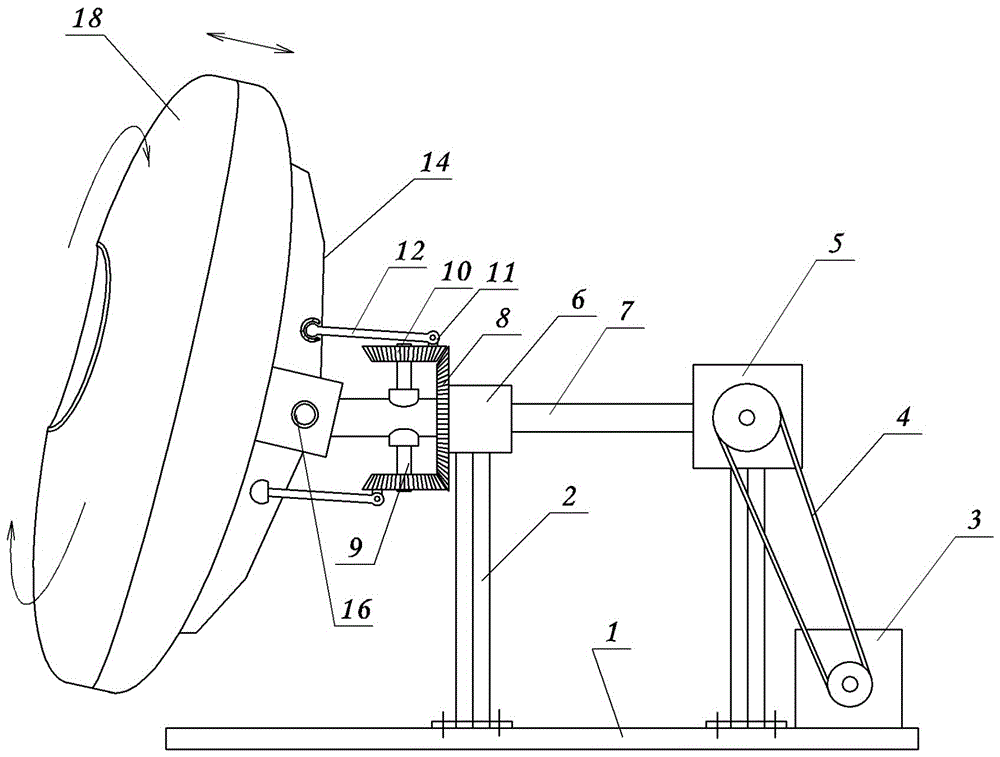

System for storing and transporting natural gas based on hydrate method and use method of system

The invention discloses a system for storing and transporting natural gas based on a hydrate method and a use method of the system, relates to the field of natural gas storage and transportation, andparticularly relates to a system for storing and transporting the natural gas based on the hydrate method and the use method of the system. Specifically the system is a system for carrying out hydratesynthesis, storage and decomposition reutilization on the natural gas by the hydrate method. The system comprises a hydrate slurry synthesis system, a low-temperature hydrate generation system, a transmission system, a hydrate underground low-temperature storage reservoir and a hydrate decomposition system. According to the system, natural gas and configuration water are used for synthesize hydrate slurry through the mode comprising stepped distribution of gas injection ports, pressure-fluctuation-type injection of the natural gas, and forward and reverse vortex-type stirring; and the hydrateslurry and the natural generate a natural gas hydrate through spraying. The preparation method provided by the invention simple, the processes are few, and the problem of blockage in a water circulation loop is solved, so that the natural gas can be stored and transported in a solid form, and the storage and transportation mode is more flexible and convenient.

Owner:DALIAN DONGYOU RUIJIA PETROLEUM TECH CO LTD

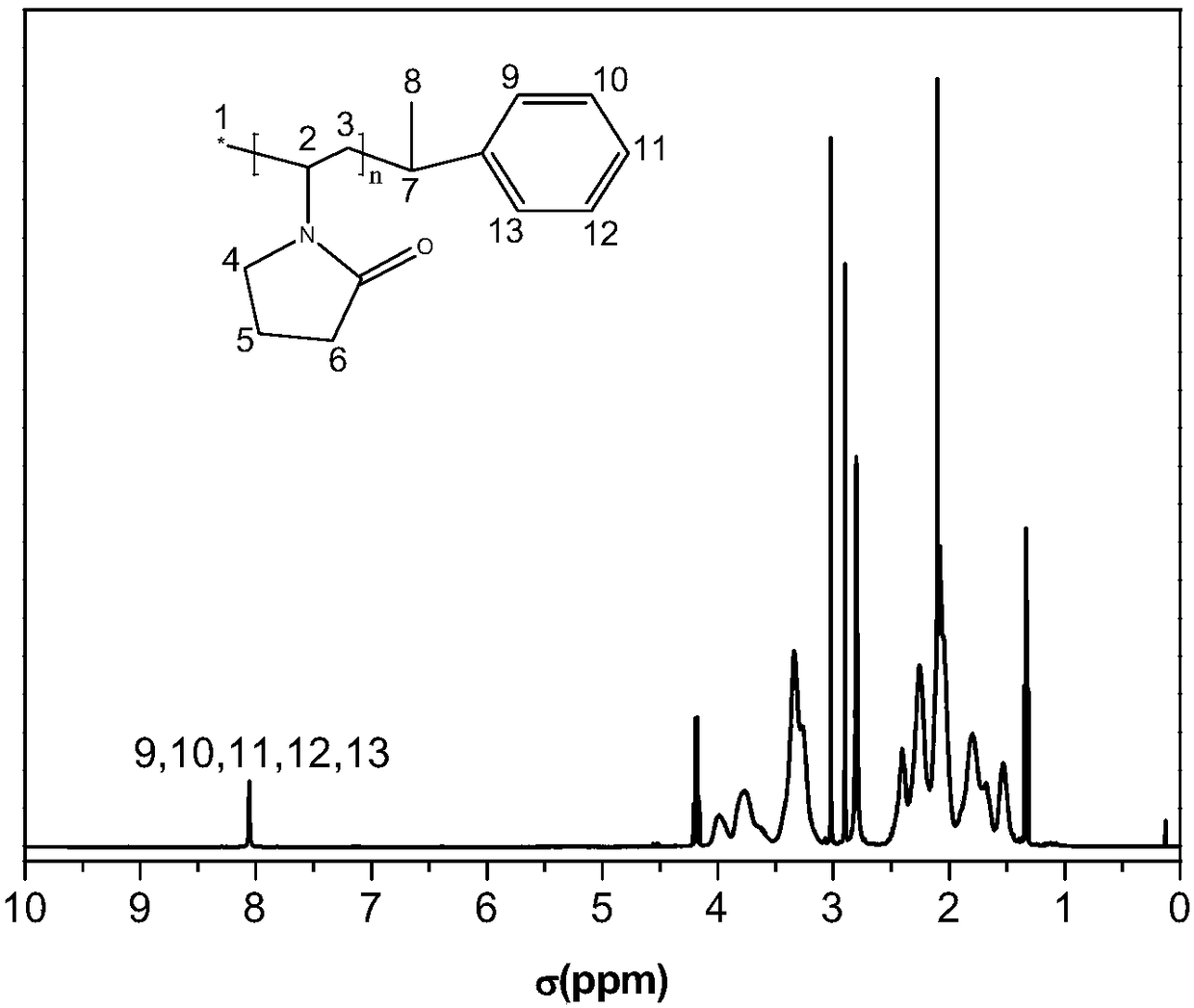

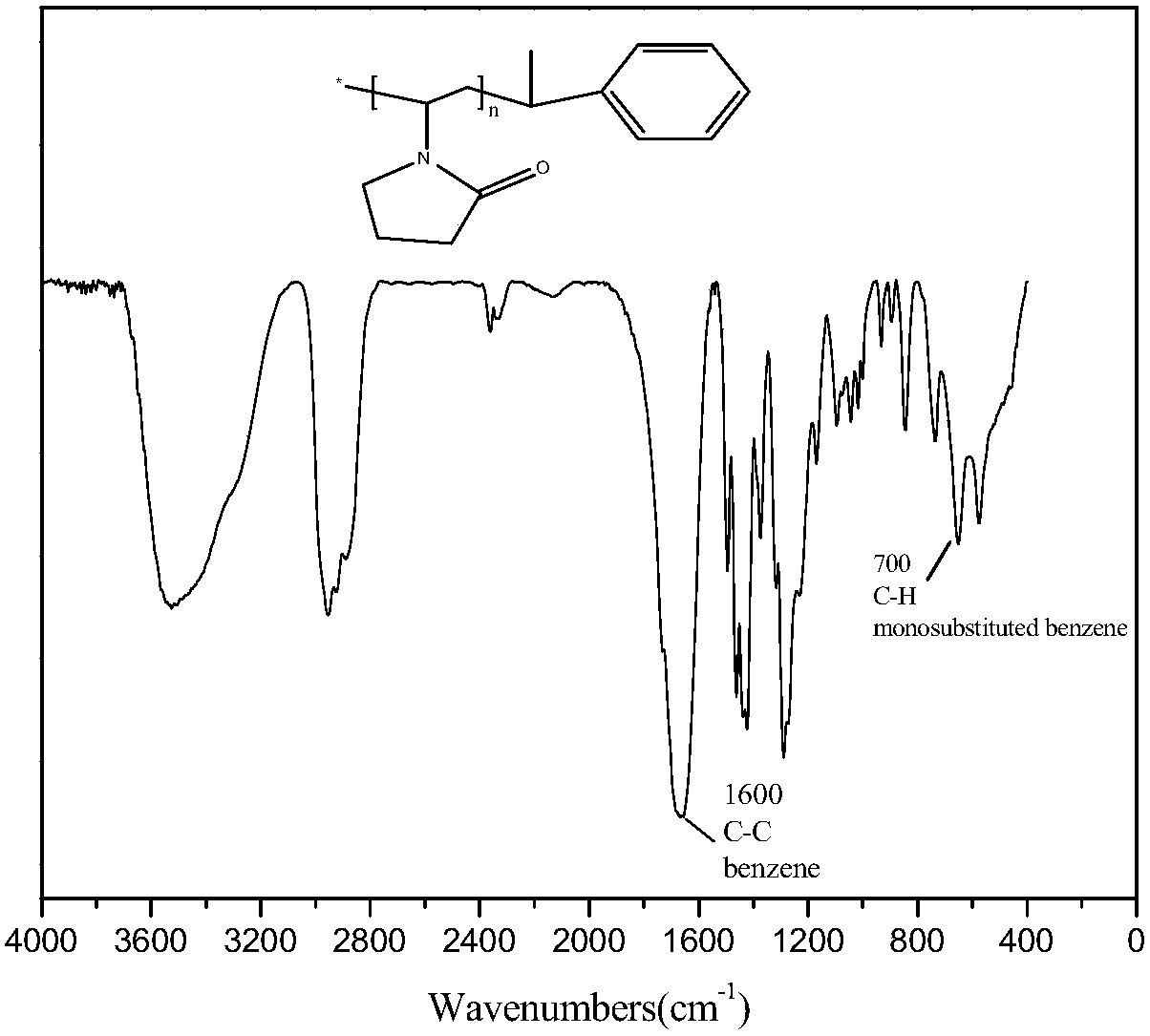

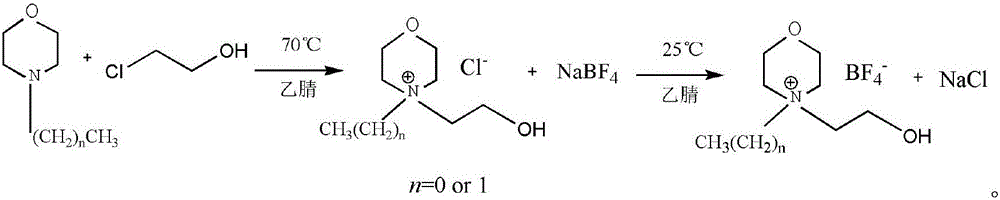

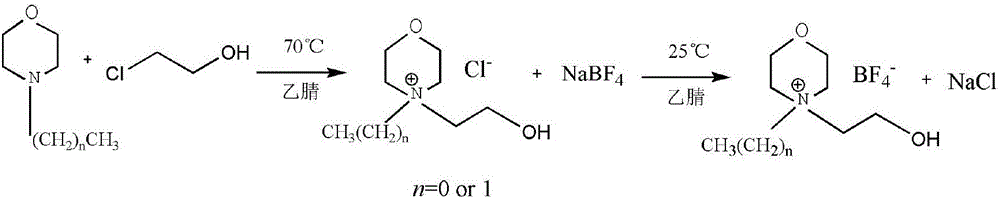

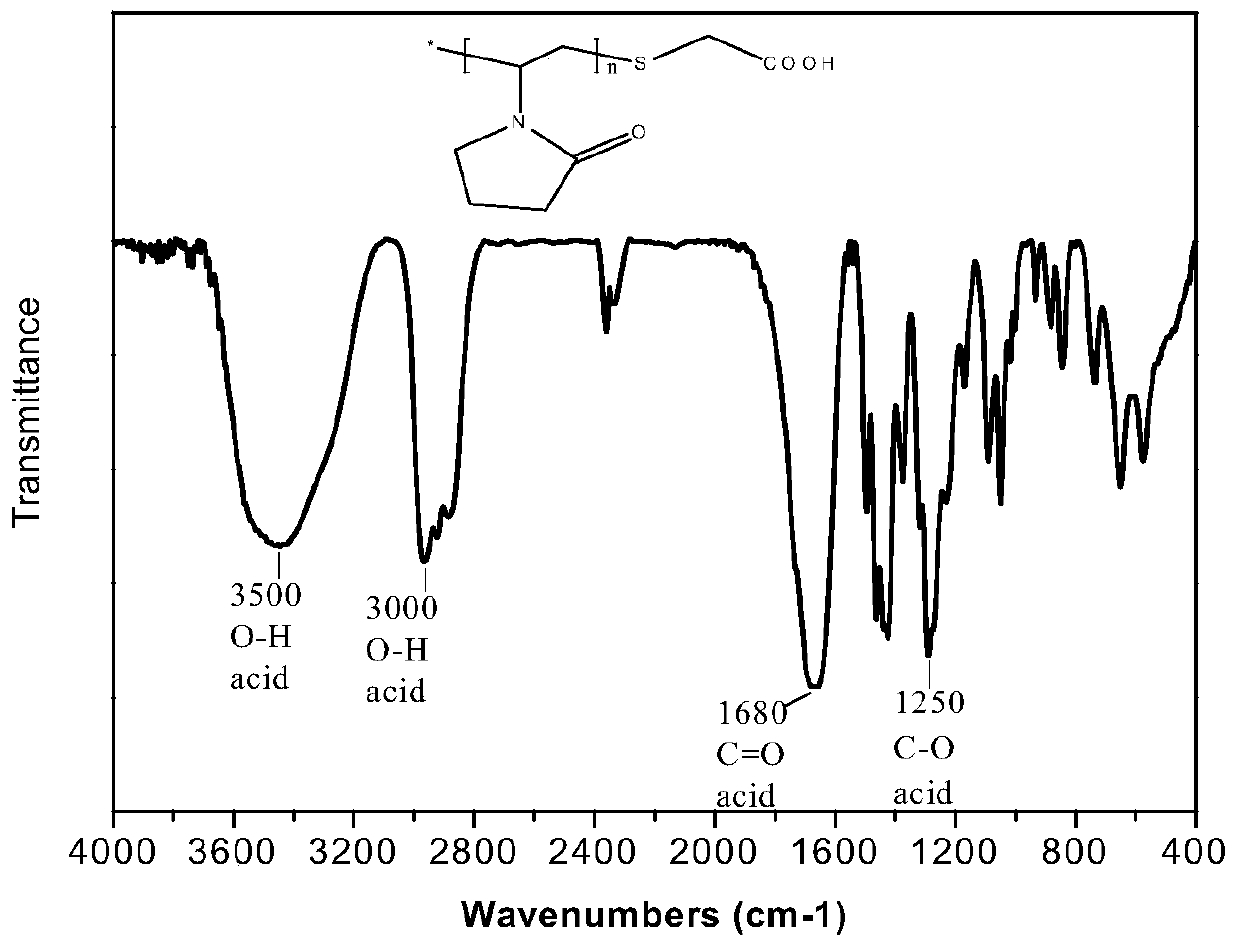

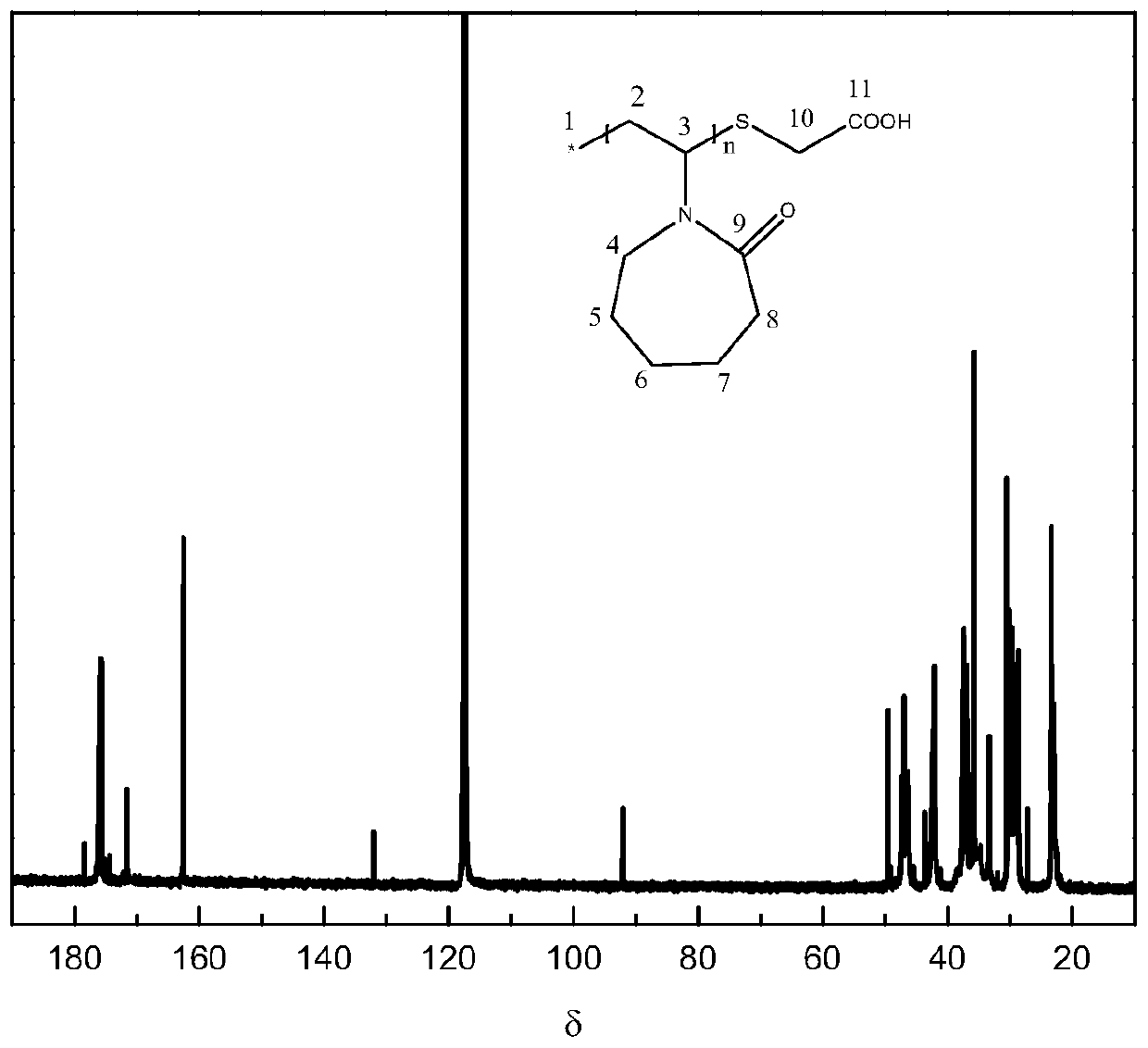

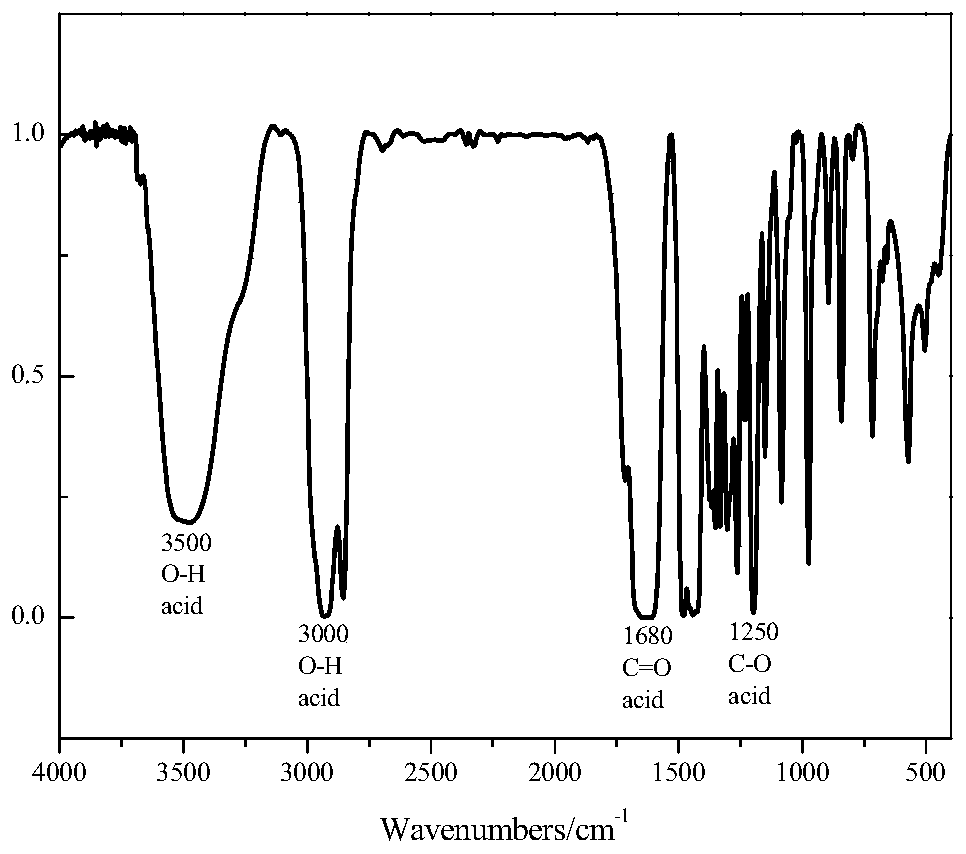

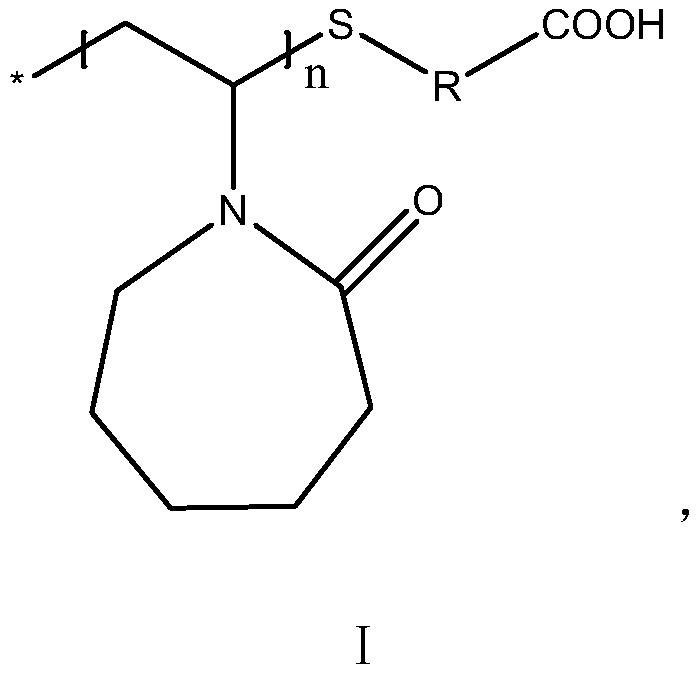

Novel hydrate dynamic inhibitor as well as preparation method and application thereof

The invention discloses a novel hydrate dynamic inhibitor of a structural formula I as shown in the description. The inhibitor is high in inhibition activity, good in inhibition effect, small in amount and low in cost, is capable of effectively prolonging the nucleation time of hydrate and reducing the generation velocity of the hydrate with a low dosage concentration (0.5-2wt%) in a high supercooling degree environment, is applicable to coexistence systems of three phases of oil, gases and water or two phases of oil and water or two phases of gases and water, can be applied to inhibition of generation of hydrate in the oil-gas exploration, processing and conveying process, is not limited by supercooling degrees or application situations, and has wide application prospects.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

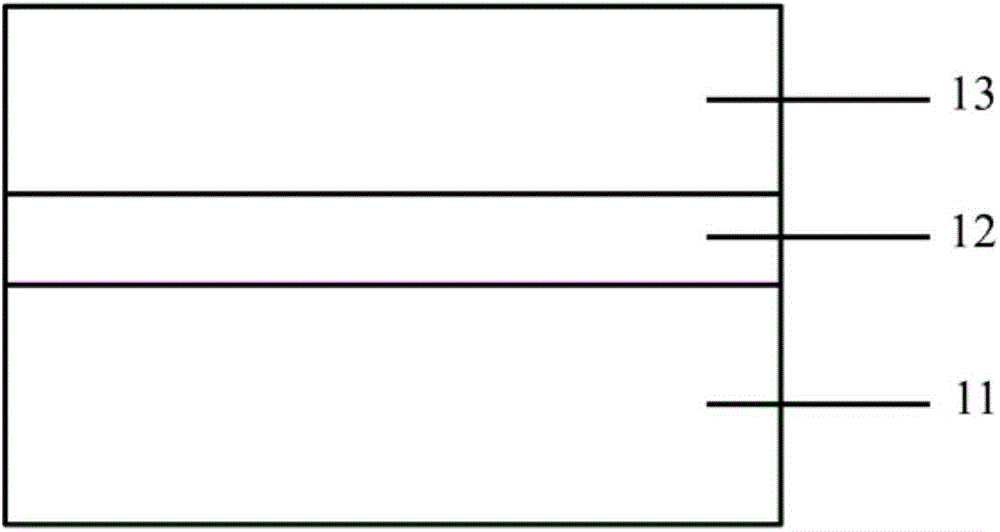

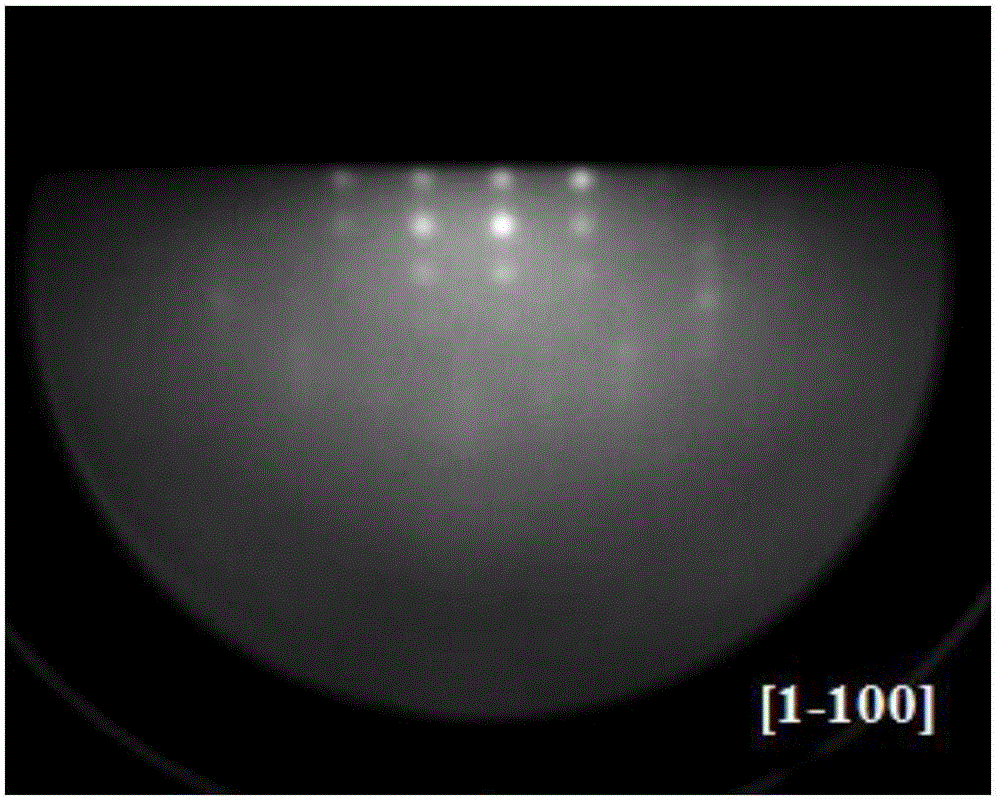

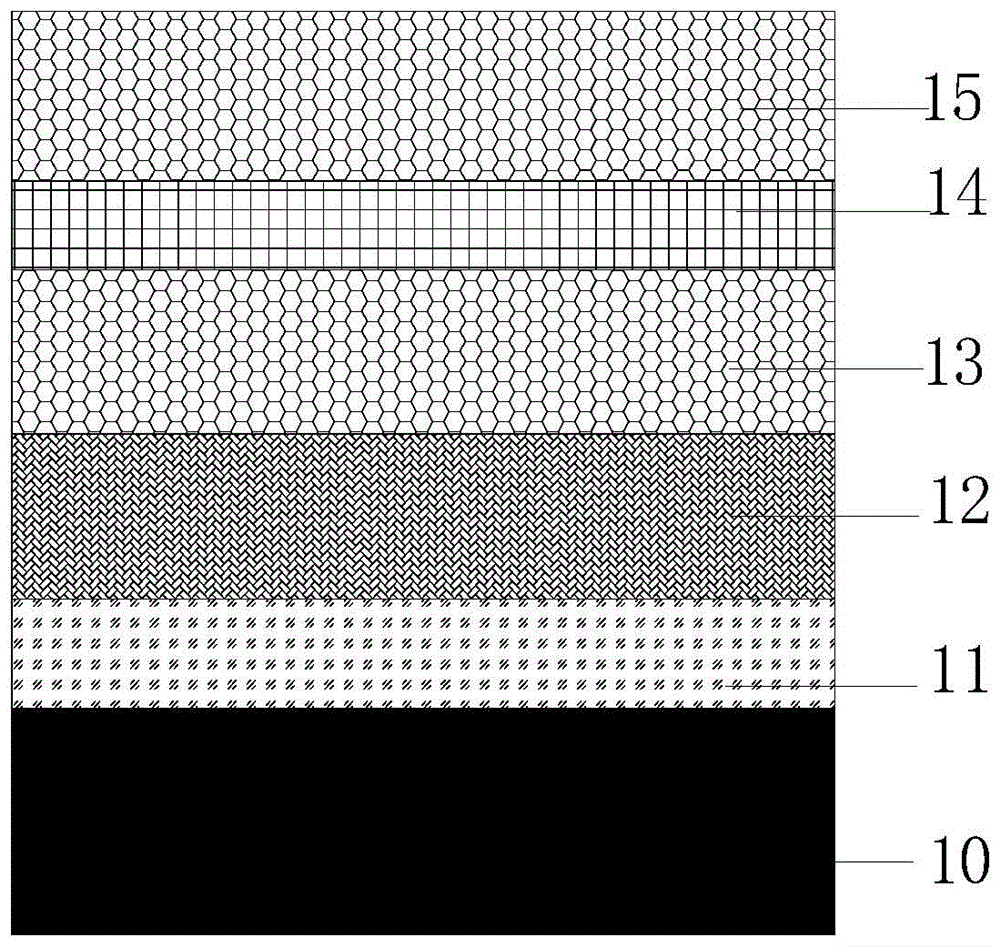

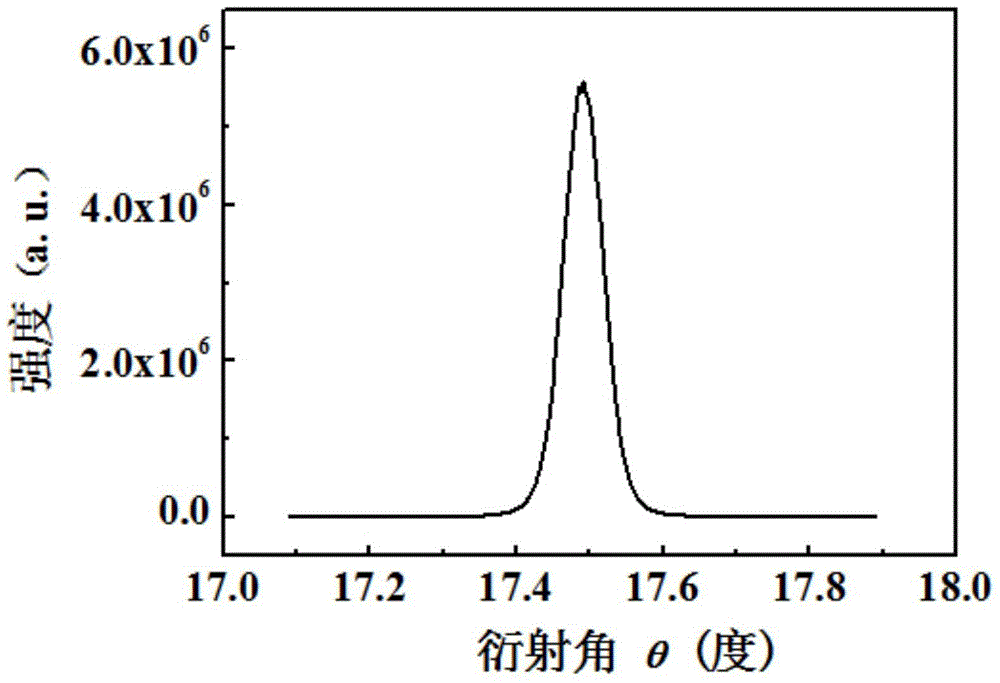

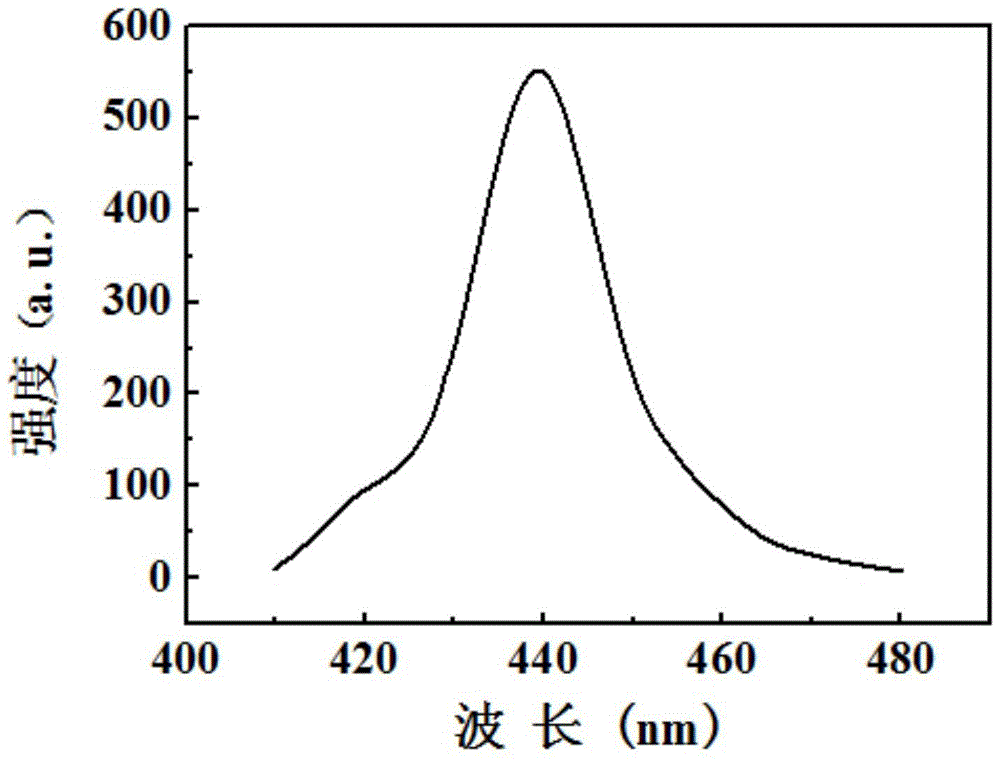

GaN thin film growing on metal Al substrate and preparing method and application thereof

ActiveCN103996611ASmall lattice mismatchFacilitate depositionSemiconductor/solid-state device manufacturingPhotovoltaic energy generationPhotovoltaic detectorsCrystal orientation

The invention discloses a GaN thin film growing on a metal Al substrate and a preparing method and application thereof. The GaN thin film growing on the metal Al substrate comprises the Al substrate, an Al2O3 protecting layer growing on an epitaxy face which is a face (111) of the Al substrate and a GaN thin film layer growing on the Al2O3 protecting layer in an epitaxial mode. The crystal epitaxial orientation relationship of the Al2O3 protecting layer and the GaN thin film layer is GaN (0001) / / Al2O3 (0001) / / Al (111). Proper crystal orientation is selected, so that a high-quality GaN epitaxial thin film is obtained on the Al (111) substrate and is used for improving nitride device efficiency. The GaN thin film is mainly used as dielectric layer thin films of a sound wave resonator, a logic circuit, a light-emitting diode, an optoelectronic thin film device, a solar cell, a photodiode, a photoelectric detector, a laser device and the like.

Owner:广州市众拓光电科技有限公司

Quantum dot and preparation method thereof

InactiveCN110964503AImprove luminous performanceHigh crystallinityMaterial nanotechnologyNanoopticsQuantum dotMetal halides

The invention relates to a quantum dot and a preparation method thereof. The preparation method comprises the following steps: providing a group-III cationic precursor and a ligand, wherein the group-III cationic precursor comprises one or more metal halide precursors, one or more metal acetylacetonate precursors, one or more metal oxide precursors and / or one or more metal hydroxide precursors; dissolving the group-III cationic precursor and the ligand in a solvent, and carrying out heat treatment under a first temperature condition to obtain a mixed solution; and continuously heating the mixed solution to a second temperature, then adding a group-V anionic precursor into the mixed solution, and carrying out a nucleation reaction to obtain a group-III-V quantum dot core solution. The preparation method is stable in technology, simple in process, low in cost and beneficial for later large-scale preparation; and the prepared quantum dot is improved in luminous efficiency, remarkably narrowed in peak width, and more beneficial for the growth of a thick shell layer.

Owner:TCL CORPORATION

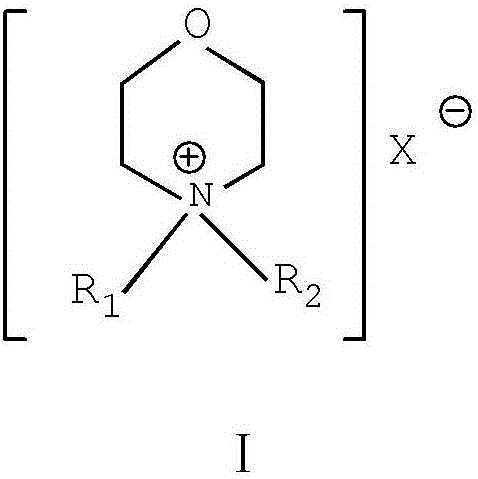

Double-effect composite hydrate inhibitor and preparation method thereof

ActiveCN106753300AReduced nucleation timeInhibit growthOrganic chemistryDrilling compositionTetrafluoroborateMorpholine

The invention discloses a double-effect composite hydrate inhibitor which comprises hydroxylated morpholine ionic liquid, amino acid and water, wherein the structural formula of the hydroxylated morpholine ionic liquid is as shown in the specification. The composite hydrate inhibitor is high in conductivity, biodegradable, free from toxicity, environmentally friendly and efficient in inhibition performance and has double-effect inhibition performance of thermodynamics and dynamics, and hydrate formation can be effectively inhibited under low dosage concentration of 1wt%-5wt%. In the structural formula, R1 is C1-C4 alkyl substituent, R2 is ethoxyl, and X is tetrafluoroborate.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

Variable-frequency ultrasonic-assisted hydrate liquid food concentration device and method

The invention discloses a variable-frequency ultrasonic-assisted hydrate liquid food concentration device and method. The device comprises a concentration processor, a condensation circulating system,a feeding tank, a bubble generator, an ultrasonic probe, an ultrasonic controller, a hydrate crystal tank and a concentrated solution tank, wherein the ultrasonic probe is arranged in the concentration processor; the condensation circulating system, the bubble generator, the ultrasonic controller and the concentrated solution tank are connected with the concentration processor separately; the feeding tank is connected with the concentration processor through a conveying pump; and the hydrate crystal tank is connected with the concentration processor through a conveying pipeline. According tothe method, on the basis of concentrating the liquid food by a gas hydrate method, a variable-intensity ultrasonic and bubble control device is used for concentration, and different ultrasonic treatments are provided in a gas filling stage, a phase change stage and a crystal growth stage respectively. Concentrated juice which is short in phase change treatment time, sterile and capable of maintaining original nutrition, color and flavor of materials to the maximum extent can be obtained.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

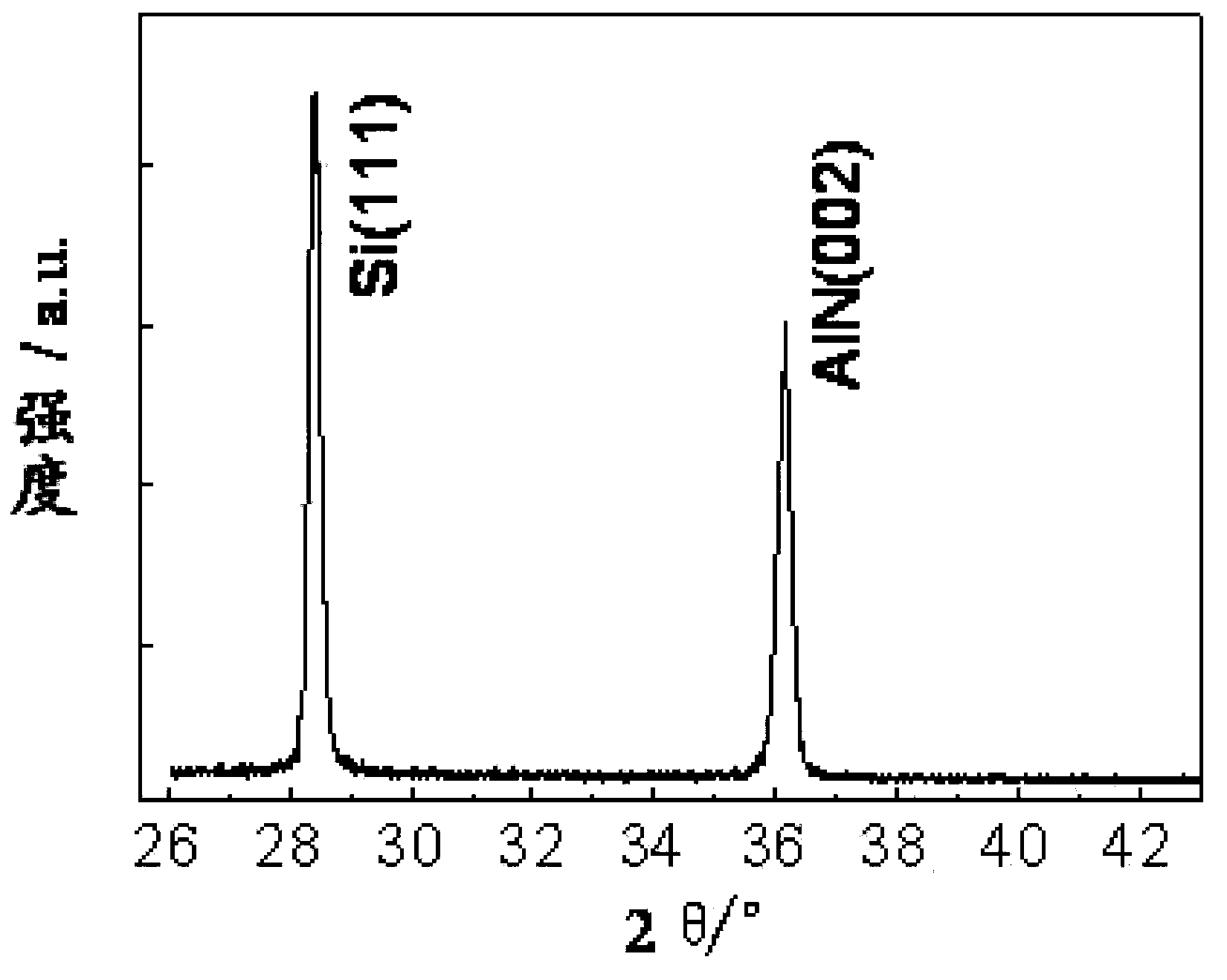

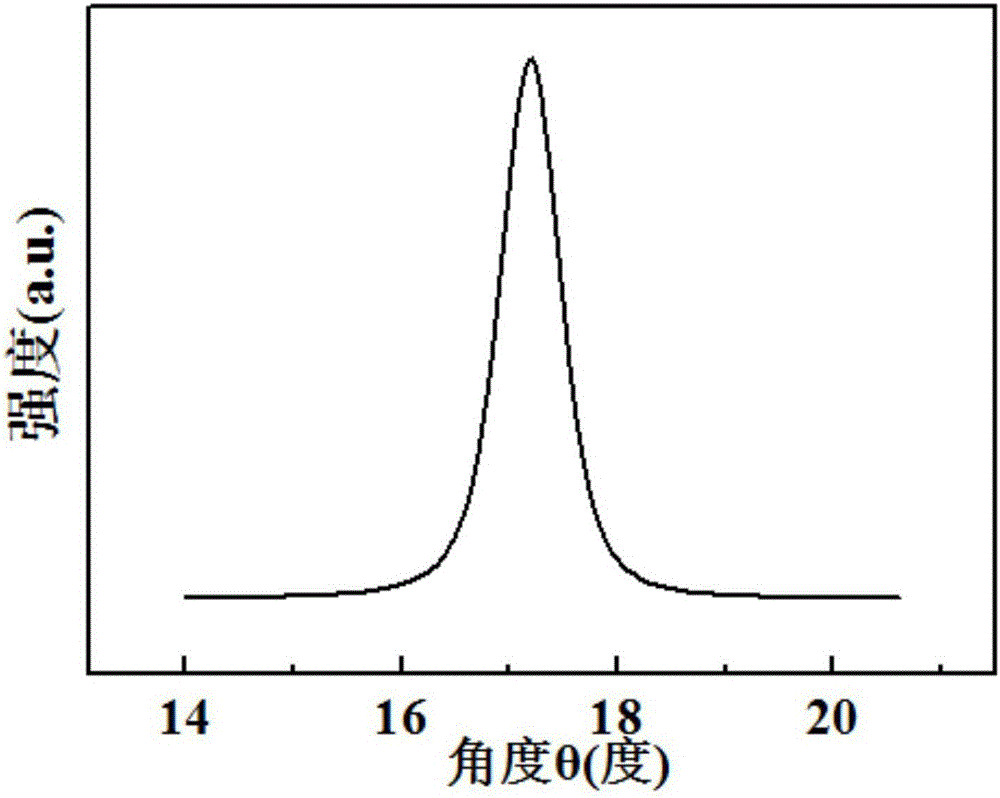

Aluminum nitride film growing on silicon substrate and preparation method and application thereof

ActiveCN103022295BQuality improvementSmall lattice mismatchFinal product manufactureSemiconductor devicesPhotovoltaic detectorsLattice mismatch

The invention discloses an aluminum nitride film growing on a silicon substrate and a preparation method and the application thereof. The aluminum nitride film is obtained by the following preparation method: adopting the silicon substrate, selecting the (111) crystal face of the silicon substrate as crystal orientation, growing an aluminum buffer layer on the (111) crystal face of the silicon and then growing an aluminum nitride film in epitaxial growth mode. The silicon is adopted as the substrate, simultaneously a pulse laser deposition growth method is adopted to grow the aluminum nitride film on the Si (111) substrate, the aluminum nitride film crystal grows in preferred orientation to obtain low lattice mismatch degree between the substrate and the aluminum nitride, quality of the aluminum nitride crystal is greatly improved, and the aluminum nitride film is suitable for being applied to photoelectric detectors and light-emitting diode (LED) devices.

Owner:广州市艾佛光通科技有限公司

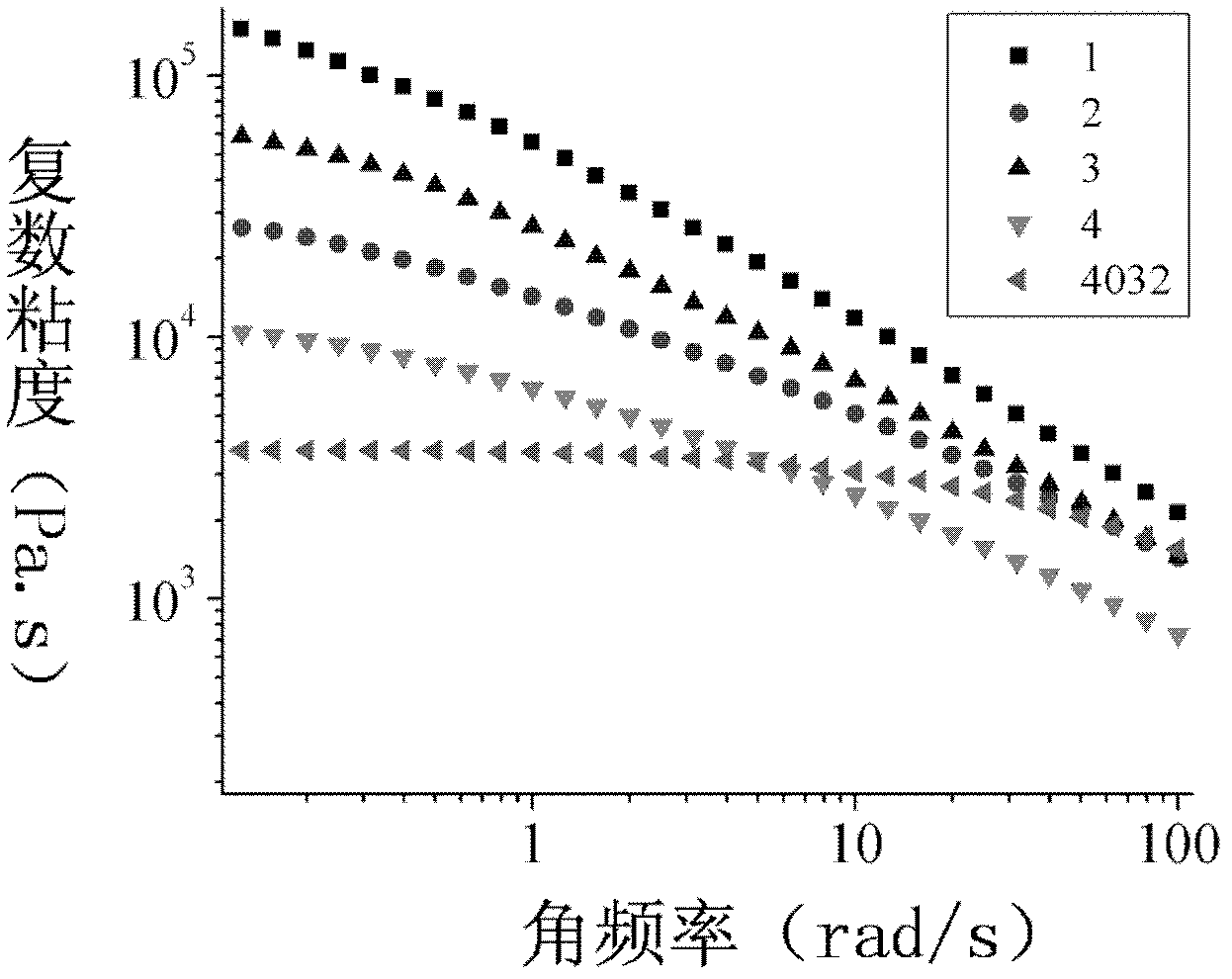

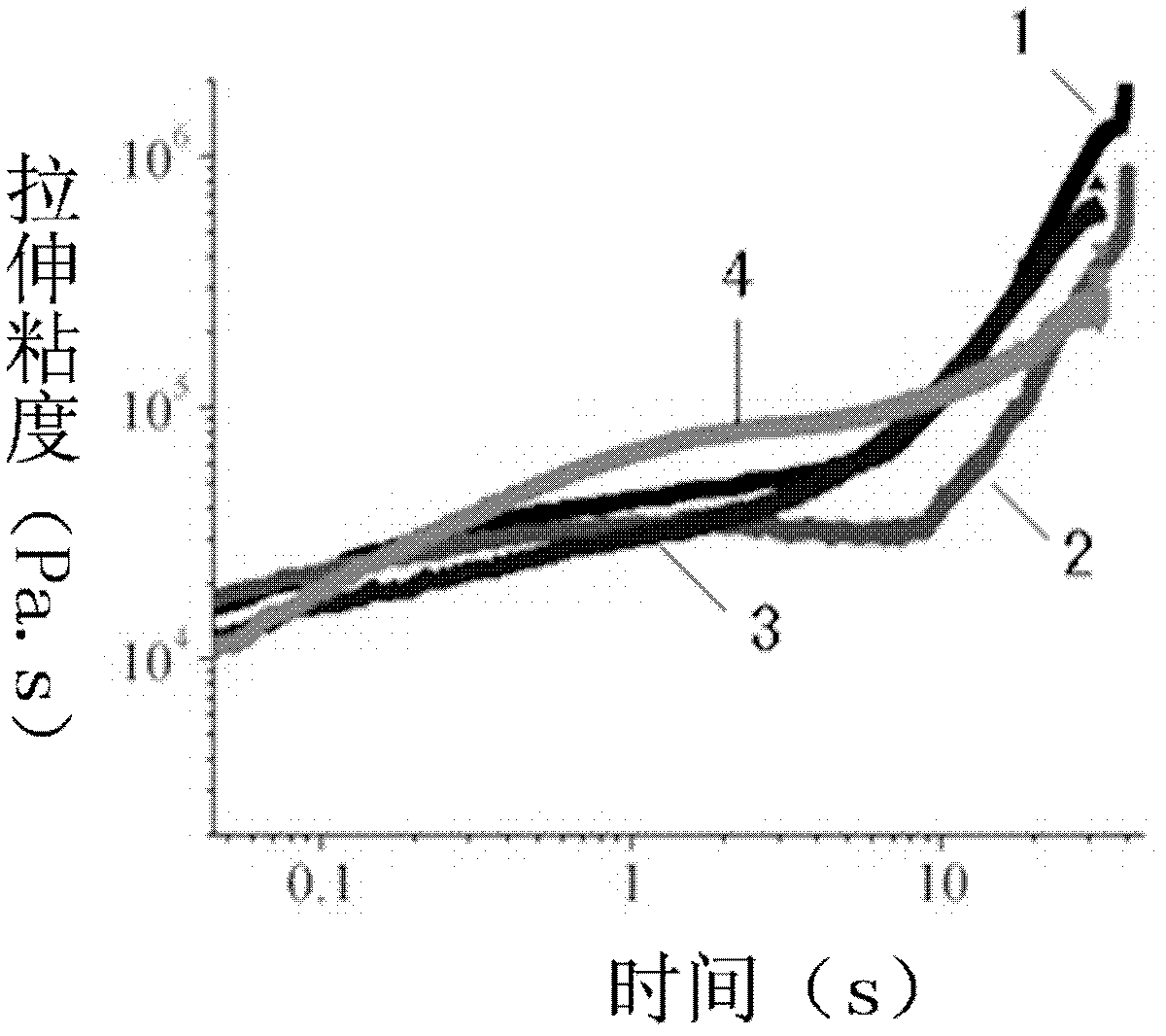

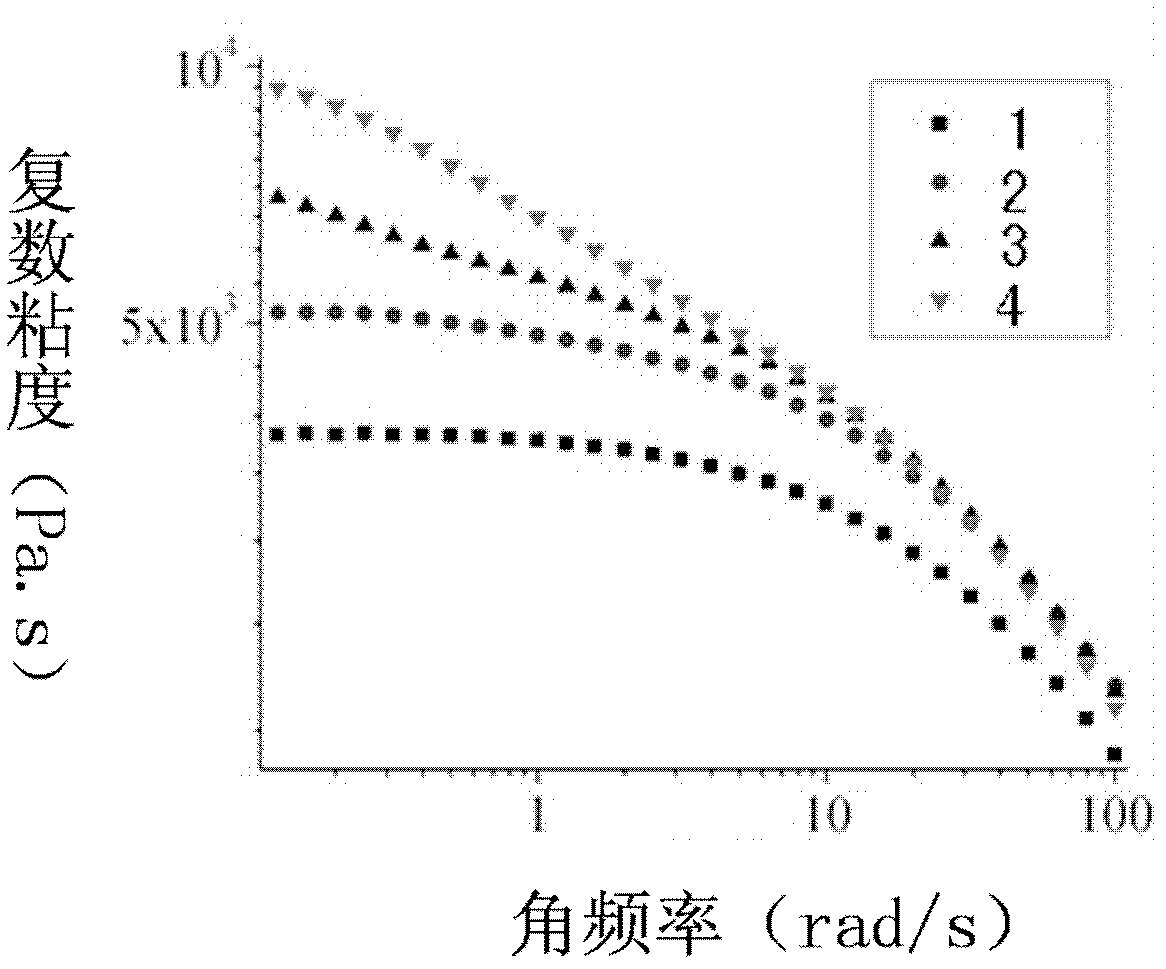

Long-chain branched polylactic resin and preparation method and application thereof

ActiveCN102675577BGood for tangleFacilitate processing and molding such as shape fixation after foamingBlow moldingPolymer science

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

GaN thin film growing on W substrate, as well as preparation method and application thereof

InactiveCN104157755ASmall lattice mismatchImprove luminous efficiencySemiconductor devicesOptoelectronicsDislocation

The invention discloses a GaN thin film growing on a W substrate. The GaN thin film comprises an AlN buffer layer growing on the W substrate and a GaN thin film growing on the AlN buffer layer; the AlN buffer layer is an AlN buffer layer growing at 400-500 GEG C; the GaN thin film is a GaN thin film growing at 700-800 DEG C. The invention further discloses a preparation method and application for the GaN thin film growing on the W substrate. The GaN thin film growing on the W substrate prepared by the method has the advantages of low dislocation density and high crystal quality.

Owner:SOUTH CHINA UNIV OF TECH

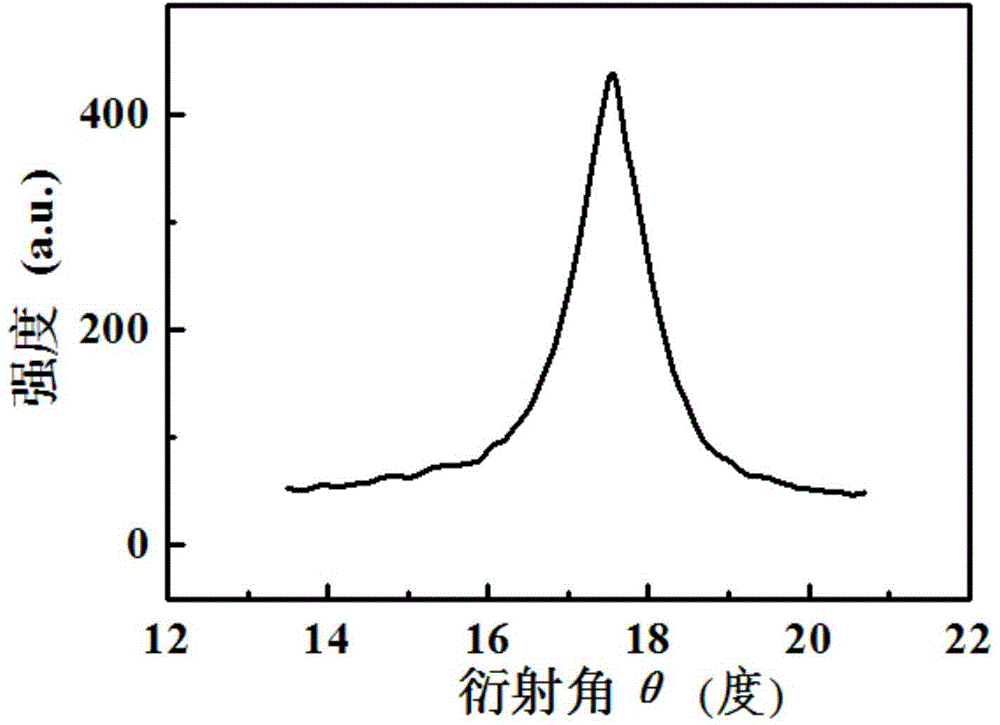

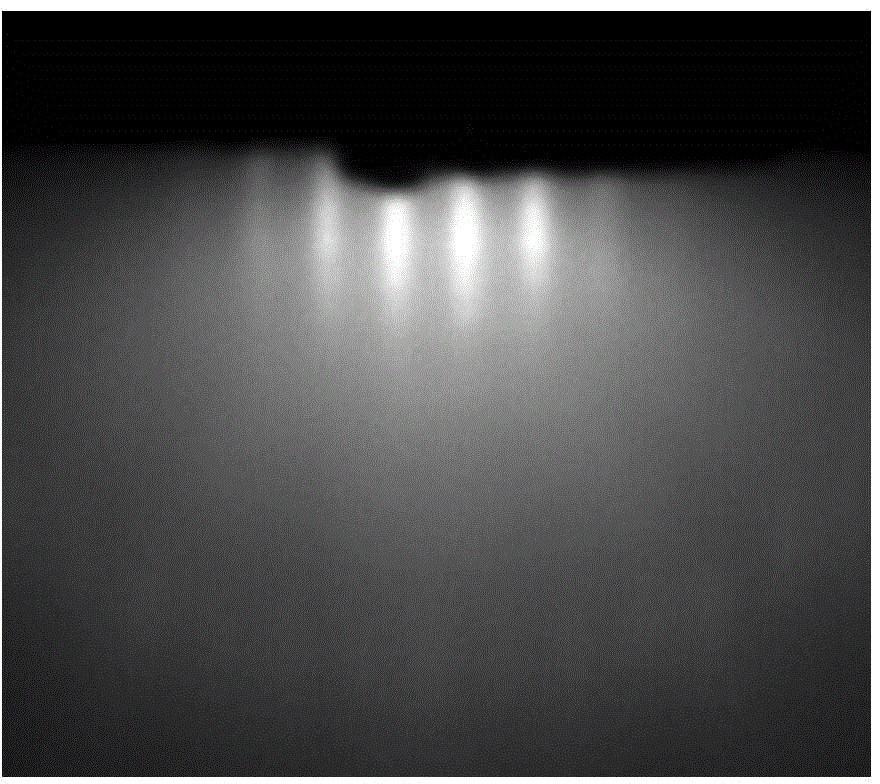

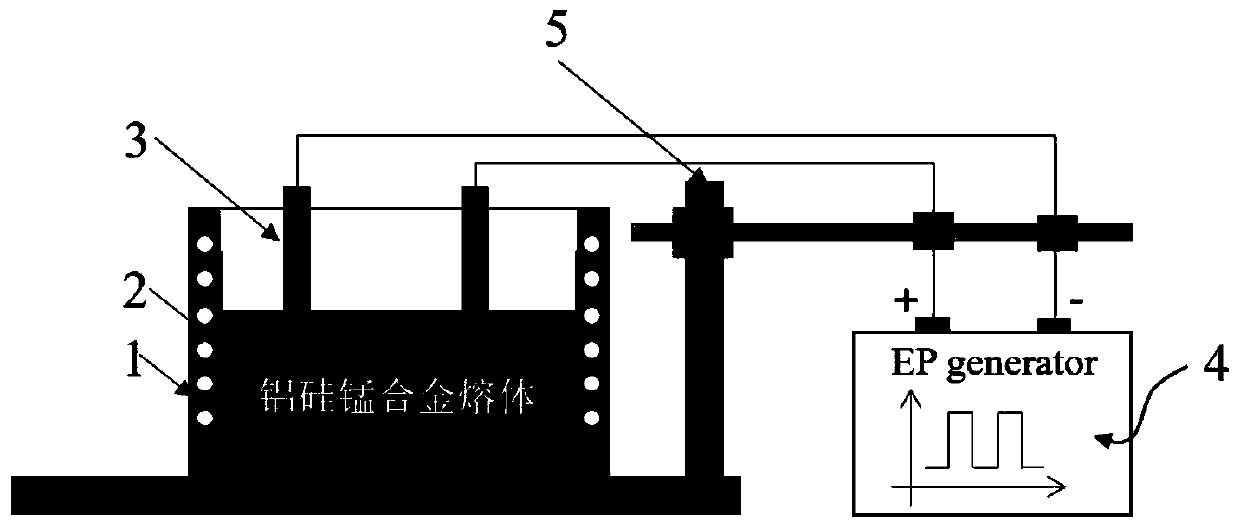

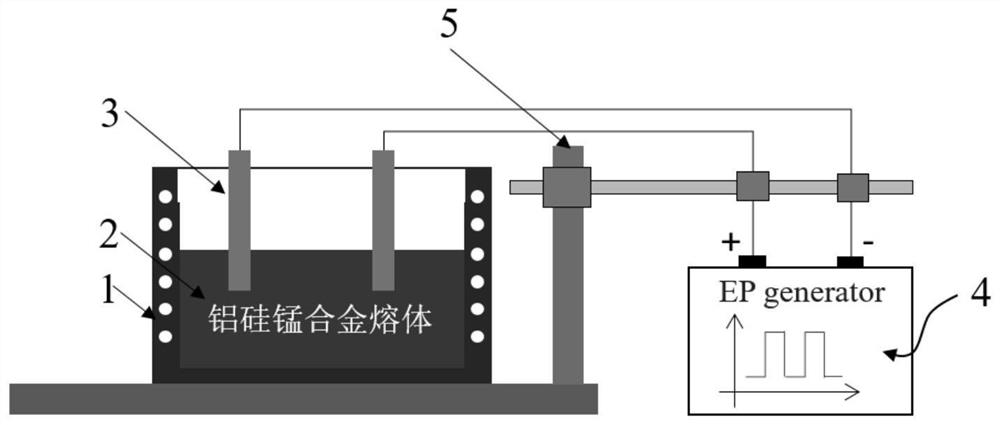

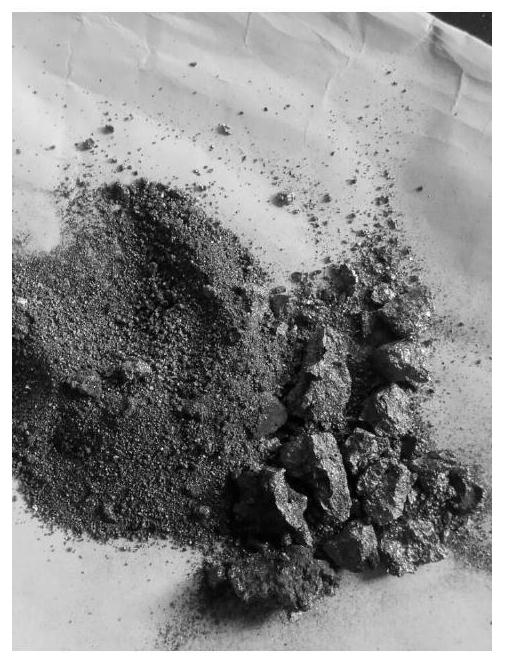

Electrical pulse treatment method for improving chalking resistance of aluminum ferro silicon manganese alloy

The invention discloses an electrical pulse treatment method for improving chalking resistance of an aluminum ferro silicon manganese alloy. The mass percentage of each chemical component in the aluminum ferro silicon manganese alloy is that 49-51% of Mn, 19-21% of Al, 17-20% of Si, 5-14% of Fe and the balance of impurity elements such as carbon. The alloy preparation process comprises the following steps of (1) weighing each raw material according to designed components; (2) adding each raw material to be smelted according to a designed sequence; (3) when all raw materials are melted, switching off an induction furnace power supply; and meanwhile, inserting two pure ferro electrodes connected with an electrical pulse power supply into a high temperature molten pool; and applying high-energy density pulse current to the interior of the molten pool; and (4) after 5-10 minutes of electrical pulse treatment, cooling the molten pool to obtain the aluminum ferro silicon manganese alloy. Theproduct obtained by the electrical pulse treatment method for improving the chalking resistance of the aluminum ferro silicon manganese alloy has the advantages of smaller grain size, compact alloy structure, stable structure, excellent chalking resistance and long alloy storage period. Requirements of a deoxidizing agent for steel making are met.

Owner:CENT SOUTH UNIV

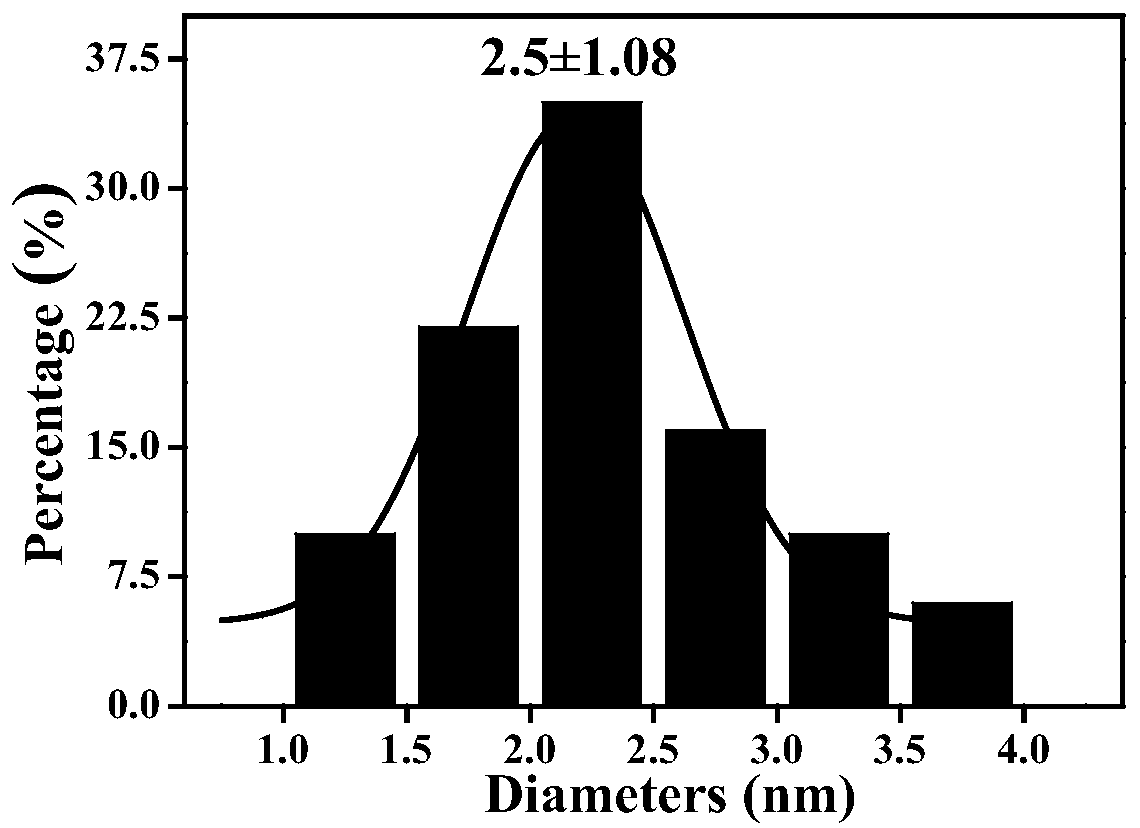

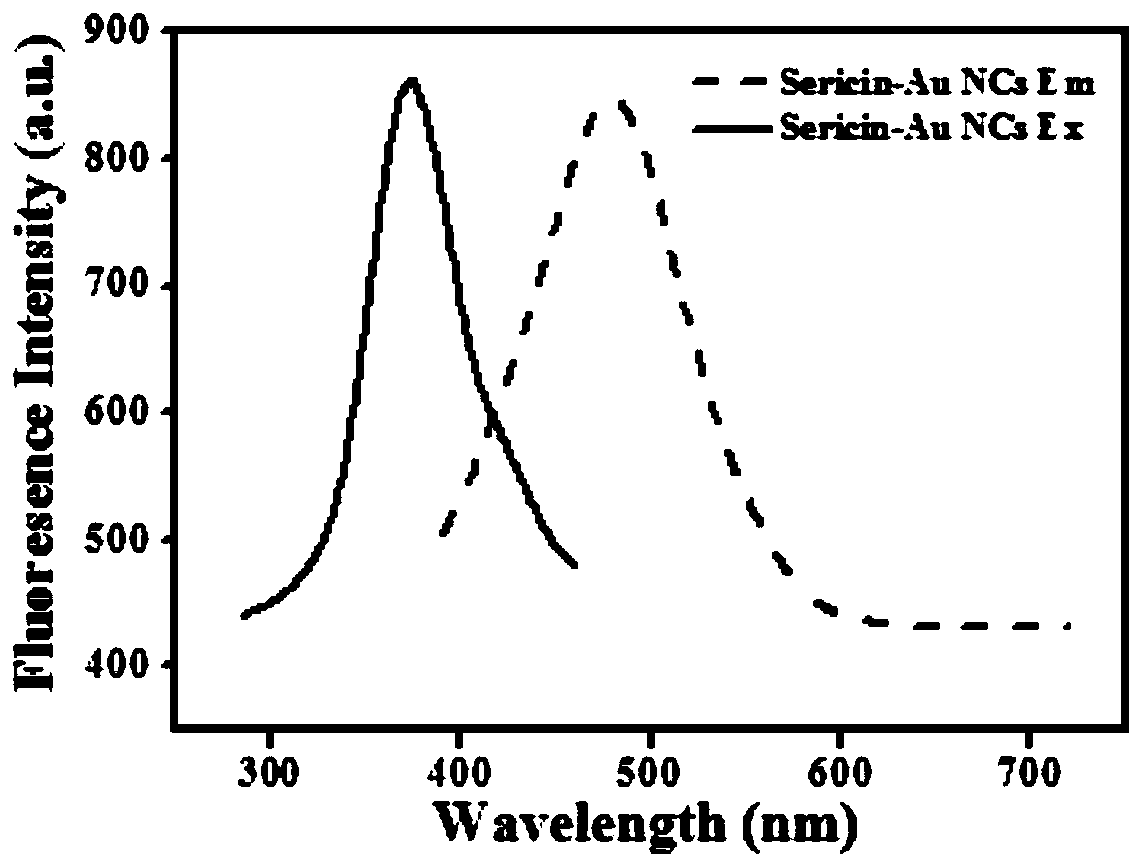

Fluorescent sericin metal nano-cluster and preparation method and application thereof

PendingCN110548865AHigh fluorescence intensityHigh selectivityMaterial nanotechnologyTransportation and packagingIonBiocompatibility Testing

The invention discloses a fluorescent sericin metal nano-cluster and a preparation method and application thereof. The metal nano-cluster synthesized by taking sericin as a template is successfully prepared through a microwave radiation method. The preparation method comprises the following steps that firstly, a sericin aqueous solution is prepared, a HAuCl 4 aqueous solution is added into the sericin aqueous solution, and the mixed solution is uniformly mixed, wherein the mass ratio of the sericin to the HAuCl 4 is 25:1-25:10; and then NaOH is added to adjust the pH value of the mixed solution, and the mixed solution is put in a microwave reactor for reaction, wherein the microwave power is 500-900 W, and the reaction time is 1-20 min. According to the sericin metal nano-cluster preparedby the preparation method, the average particle size is 2.5 nm, the maximum excitation wavelength is 360 nm, the maximum emission wavelength is 480 nm, the stability is high, the biocompatibility is good, the light stability is high, the fluorescence is strong, the sensitivity is high, and the nano-cluster can be used as a probe to detect the content of Fe <3+> ions in a water environment or serumand can be served as a fluorescent probe to be applied to biological imaging research.

Owner:ANHUI NORMAL UNIV

Preparation process of high-strength hydrophobic ceramsite

ActiveCN105110810BTo achieve the purpose of useHigh strengthCeramic materials productionCeramicwareExpanded clay aggregateHigh intensity

The invention discloses a preparation process of ceramsite with high strength and hydrophobicity. The preparation process comprises the steps of raw material preparation, raw material drying, grinding, primary stirring and secondary stirring and auxiliary material adding. The preparation process has the beneficial effects that the grain rolling time is lengthened by firstly nucleating coarse powder and then adding fine powder in the granulation process; the product properties are improved through multiple times of different-temperature firing processes; the aim of waste utilization is achieved; auxiliary materials MnO2 and TiO2 in different ratios are added and are respectively used in the coarse material and the fine material so as to improve the properties of the ceramsite, such as strength; hydrophobic process treatment is also adopted, thus obviously reducing the water absorption of the ceramsite; multiple times of different degrees of firing processes are respectively adopted in the firing process to improve the sintering strength and properties; and the preparation process has the effect of increasing the density, strength and hydrophobicity of the ceramsite and is smooth in spherical grain surfaces and quite good in effects.

Owner:河南祥盛陶粒有限公司

Quantum dot and preparation method thereof

InactiveCN110964505AImprove luminous performanceHigh crystallinityMaterial nanotechnologyNanoopticsChemical physicsPhysical chemistry

The invention belongs to the technical field of nanomaterials, and particularly relates to a quantum dot and a preparation method thereof. The preparation method comprises the following steps: providing a group-III cationic precursor and a ligand, wherein the group-III cationic precursor comprises one or more metal acetylacetonate precursors and one or more metal halide precursors; dissolving theIII-group cationic precursor and the ligand in a solvent, and carrying out heat treatment under a first temperature condition to obtain a mixed solution; and continuously heating the mixed solution toa second temperature, then adding a V-group anionic precursor into the mixed solution, and carrying out a nucleation reaction to obtain a III-V-group quantum dot core solution. The preparation methodis stable in technology, simple in process, low in cost and beneficial for later large-scale preparation; and the prepared quantum dot has higher luminous efficiency and remarkably narrowed peak width.

Owner:TCL CORPORATION

Quantum dots and preparation method thereof

InactiveCN110964507AImprove luminous performanceHigh crystallinityMaterial nanotechnologyNanoopticsQuantum dotMetal halides

The invention belongs to the technical field of nano materials, and particularly relates to quantum dots and a preparation method thereof. The preparation method comprises the following steps: providing a group III cationic precursor and a ligand, wherein the group III cationic precursor comprises one or more metal halide precursors and one or more metal oxide precursors and / or one or more metal hydroxide precursors; dissolving the group III cationic precursor and the ligand in a solvent, and carrying out heating treatment under a first temperature condition to obtain a mixed solution; and continuously heating the mixed solution to a second temperature, then adding a group V anion precursor into the mixed solution, and carrying out a nucleation reaction to obtain a group III-V quantum dotnuclear solution. The preparation method is stable in technology, simple in process, low in cost and beneficial to later-period large-scale preparation, and the prepared quantum dots not only improvethe luminous efficiency, but also are more beneficial to growth of a thick shell layer.

Owner:TCL CORPORATION

Quantum dots and preparation method thereof

InactiveCN110964508AImprove luminous performanceHigh crystallinityMaterial nanotechnologyNanoopticsChemical physicsPhysical chemistry

The invention belongs to the technical field of nano materials, and particularly relates to quantum dots and a preparation method thereof. The preparation method comprises the following steps: providing a group III cationic precursor and a ligand, wherein the group III cationic precursor comprises one or more metal oxide precursors and / or one or more metal hydroxide precursors; dissolving the group III cationic precursor and the ligand in a solvent, and carrying out heating treatment under a first temperature condition to obtain a mixed solution; and continuously heating the mixed solution toa second temperature, then adding a group V anion precursor into the mixed solution, and carrying out a nucleation reaction to obtain a group III-V quantum dot nuclear solution. The preparation methodis stable in technology, simple in process, low in cost and beneficial to later-period large-scale preparation, and the prepared quantum dots are more beneficial to growth of the thick shell layer.

Owner:TCL CORPORATION

Epitaxial growth GaN thin film on metal Al substrate and preparation method of GaN thin film

ActiveCN105742424AReduce defectsReduce dislocation densitySemiconductor/solid-state device manufacturingSemiconductor devicesCrystal orientationOptoelectronics

The invention provides an epitaxial growth GaN thin film on a metal Al substrate. The GaN thin film comprises an Al substrate, an AlN buffer layer, a GaN buffer layer, an amorphous AlN insertion layer and a GaN thin film layer, wherein the AlN buffer layer grows on the epitaxial surface of the Al substrate (111); the GaN buffer layer epitaxially grows on the AlN buffer layer; the amorphous AlN insertion layer grows on the GaN buffer layer; the GaN thin film layer epitaxially grows on the amorphous AlN insertion layer; and the crystal epitaxy orientation relationship between the AlN buffer layer and the GaN thin film layer is that GaN (0001) is parallel to AlN (0001) and parallel to Al (111). The high-quality GaN epitaxial thin film is obtained on the Al substrate (111) through selecting proper crystal orientation; and the efficiency of a nitride device is improved.

Owner:HEYUAN CHOICORE PHOTOELECTRIC TECH CO LTD

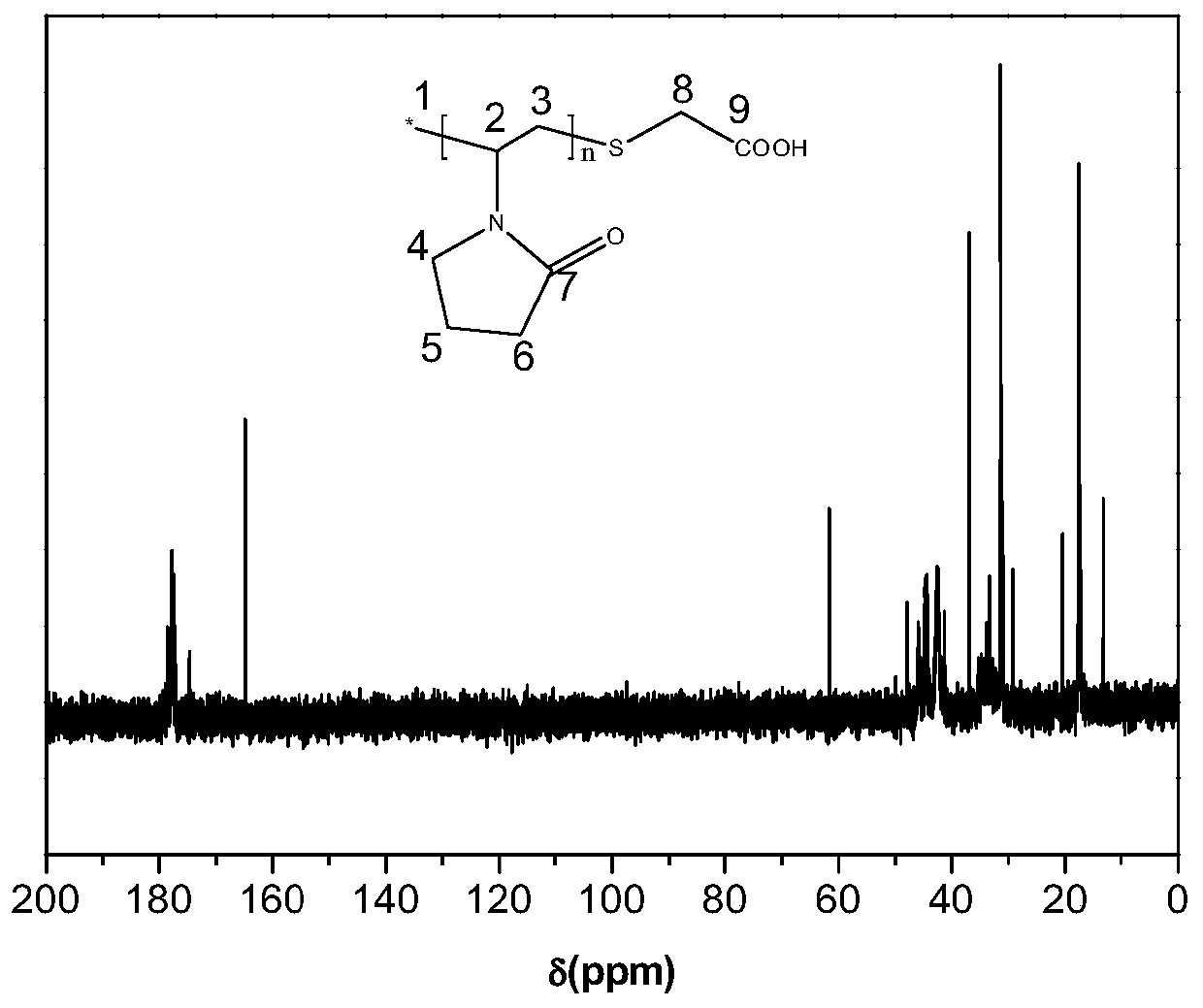

A novel hydrate kinetic inhibitor and its preparation method

ActiveCN107868157BSuppress generationGood water solubilityDrilling compositionSolubilityGeneration rate

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

An electric pulse treatment method for improving the anti-powdering performance of Al-Silicon-Mn-Ferroalloy

The invention discloses an electrical pulse treatment method for improving chalking resistance of an aluminum ferro silicon manganese alloy. The mass percentage of each chemical component in the aluminum ferro silicon manganese alloy is that 49-51% of Mn, 19-21% of Al, 17-20% of Si, 5-14% of Fe and the balance of impurity elements such as carbon. The alloy preparation process comprises the following steps of (1) weighing each raw material according to designed components; (2) adding each raw material to be smelted according to a designed sequence; (3) when all raw materials are melted, switching off an induction furnace power supply; and meanwhile, inserting two pure ferro electrodes connected with an electrical pulse power supply into a high temperature molten pool; and applying high-energy density pulse current to the interior of the molten pool; and (4) after 5-10 minutes of electrical pulse treatment, cooling the molten pool to obtain the aluminum ferro silicon manganese alloy. Theproduct obtained by the electrical pulse treatment method for improving the chalking resistance of the aluminum ferro silicon manganese alloy has the advantages of smaller grain size, compact alloy structure, stable structure, excellent chalking resistance and long alloy storage period. Requirements of a deoxidizing agent for steel making are met.

Owner:CENT SOUTH UNIV

GaN film growing on Zr substrate, preparation method and application

InactiveCN104134726AFacilitate depositionImprove luminous efficiencySemiconductor devicesOptoelectronicsDislocation

The invention discloses a GaN film growing on a Zr substrate. The GaN film sequentially comprises the Zr substrate and a GaN film part from the bottom up, wherein the GaN film part is a GaN film part growing at 500-700 DEG C. The invention further discloses a preparation method and an application of the GaN film growing on the Zr substrate. The GaN film growing on the Zr substrate has the advantages of low dislocation density and good crystal quality; the Zr substrate is easy to obtain and low in price; and the production cost can be lowered.

Owner:SOUTH CHINA UNIV OF TECH

Method of synthesizing IM-5 molecular sieve by using composite template

ActiveCN102452667BReduced nucleation timeShorten crystallization timeCrystalline aluminosilicate zeolitesAlkali metal oxideMixing ratio

Owner:CHINA PETROLEUM & CHEM CORP +1

A Novel Hydrate Kinetic Inhibitor

ActiveCN107868156BSuppress generationGood water solubilityDrilling compositionSolubilityKinetic Inhibitor

Disclosed is a hydrate kinetic inhibitor of a structural formula as represented by formula I. The inhibitor of the present invention has a good water solubility, a high inhibitory activity, a capability of achieving a good inhibitory effect, a small usage amount and a reduced cost; has the advantages of a low dosage, a high efficiency, an extensive applicability, etc.; can be used in an environment of a high degree of undercooling at a low dosage concentration (0.1-10 wt%); can effectively delay the hydrate nucleation time and reduce the hydrate generation rate; is suitable for an oil-gas-water three-phase or oil-water or gas-water two-phase coexistence system; is applied to the inhibition of the generation of hydrates during the exploration, processing and transportation of oil and gas, without subjecting to undercooling and application constraints; and has a broad prospect of application. wherein n = 100-40000, R is *(CH2)m*, and m = 1-5.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

A kind of led epitaxial wafer grown on metal al substrate and its preparation method and application

ActiveCN103996763BSmall lattice mismatchFacilitate depositionSemiconductor devicesQuantum wellCrystal orientation

The invention discloses an LED epitaxial wafer grown on a metal Al substrate, which comprises a metal Al substrate, the (111) crystal plane of the metal Al substrate as the epitaxial plane, and Al grown on the metal Al substrate. 2 o 3 The protective layer, and the crystal epitaxial orientation relationship is GaN(0001) / / Al 2 o 3 (0001) / / Al(111), in Al 2 o 3 U-GaN thin film layer, N-GaN thin film layer, InGaN / GaN multiple quantum well layer, and p-type GaN thin film grown from bottom to top on the protective layer. The invention improves the luminous efficiency of the LED by selecting a suitable crystal orientation and obtaining a high-quality GaN epitaxial thin film on the Al(111) substrate.

Owner:广州市众拓光电科技有限公司

Menthol purification method

PendingCN111004093AEffective size controlEffective control structureOrganic chemistry methodsHydroxy compound separation/purificationMENTHOL CRYSTALSEngineering

The invention belongs to the technical field of menthol purification, and particularly relates to a menthol purification method which comprises the following steps: preparing a composite solution froma composite solvent and a menthol raw material, and assisting ultrasonic treatment in the crystallization process, wherein a plurality of crystallization processes are adopted, so that the purification degree of menthol can be improved. Compared with the prior art, the method has the following advantages that: by reasonably preparing the solvent and cooperating with the effect of an ultrasonic generator, the properties of a crystal growth interface can be affected, the size and structural form of growth elements of crystals can be effectively controlled, then the nucleation time can be shortened, the menthol purity can be improved, the optical rotation can be improved, and it shows that the content of L-menthol is increased, and the quality of menthol crystals is greatly improved.

Owner:安徽恒达药业有限公司

A preparation method of micron-scale spherical copper-zinc-tin-sulfur-selenide single crystal particles

ActiveCN104979429BUniform sizeThe size is easy to controlFinal product manufacturePhotovoltaic energy generationPowder mixtureSingle crystal

The invention relates to the technical field of semiconductor photovoltaic materials and semiconductor devices, and discloses a preparation method for micron-sized spherical CZTSSe monocrystalline particles. Metal simple substance powder, sulfide powder, selenide powder, elemental sulfur powder, elemental selenium powder, flux, Cu2ZnSnS4 nanoparticles and as the like are combined as reaction raw materials, and are ground and mixed according to the designed formula. The powder mixture is vacuum-encapsulated into a quartz reactor; the quartz reactor is kept at the temperature of 750 DEG C to 1000 DEG C for 48-120 hours, and then is quickly cooled to the room temperature; and samples are taken out, cleaned and dried to obtain the CZTSSe monocrystalline particles. The size of the prepared monocrystalline particles can be regulated and controlled by utilizing recrystallization temperature and time, and the components of the particles can be effectively regulated within a certain range through the molar ratio of the elements in a precursor. The prepared monocrystalline particles are uniform and controllable in size, and are better than the monocrystalline particles prepared by the traditional method in performance.

Owner:LINGNAN NORMAL UNIV

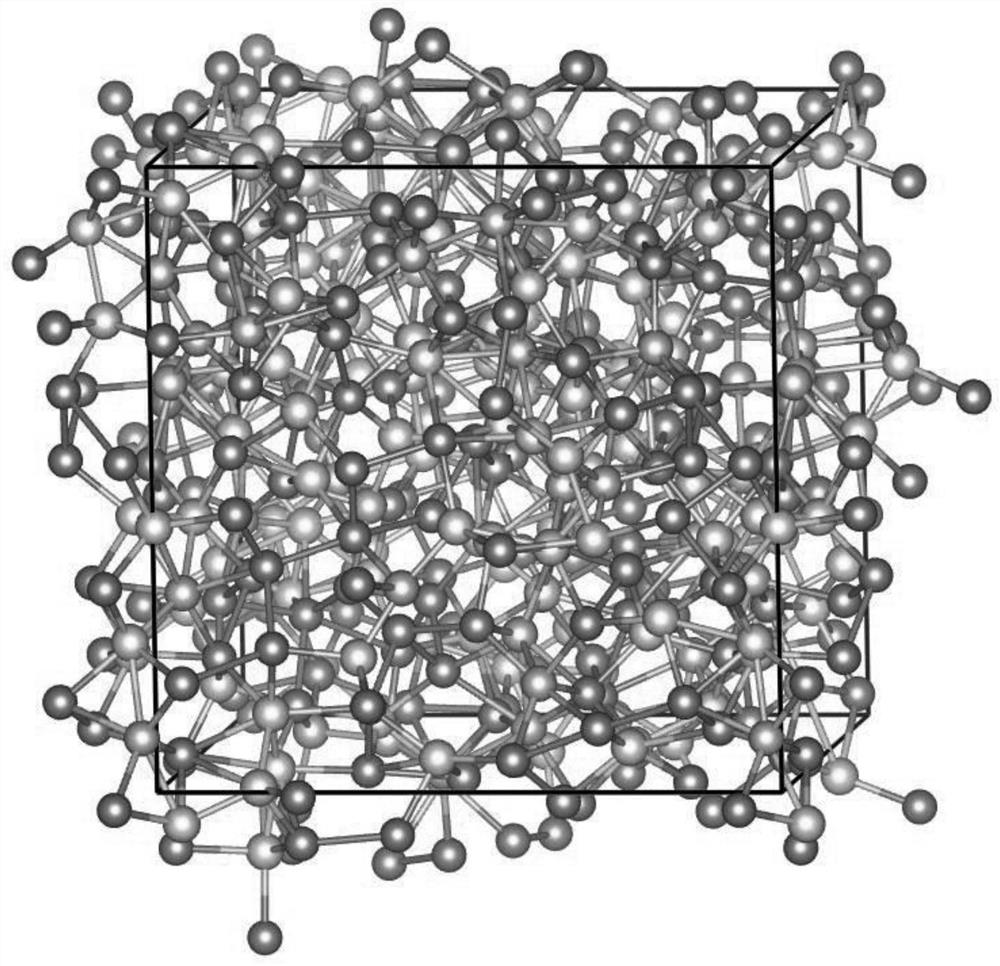

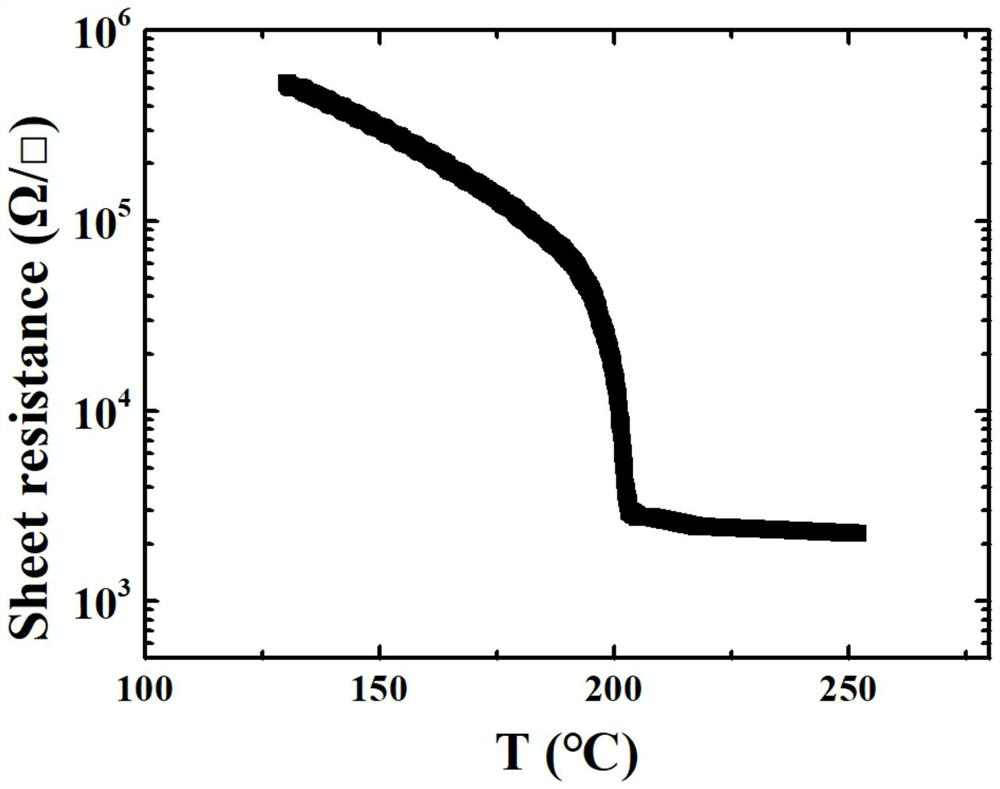

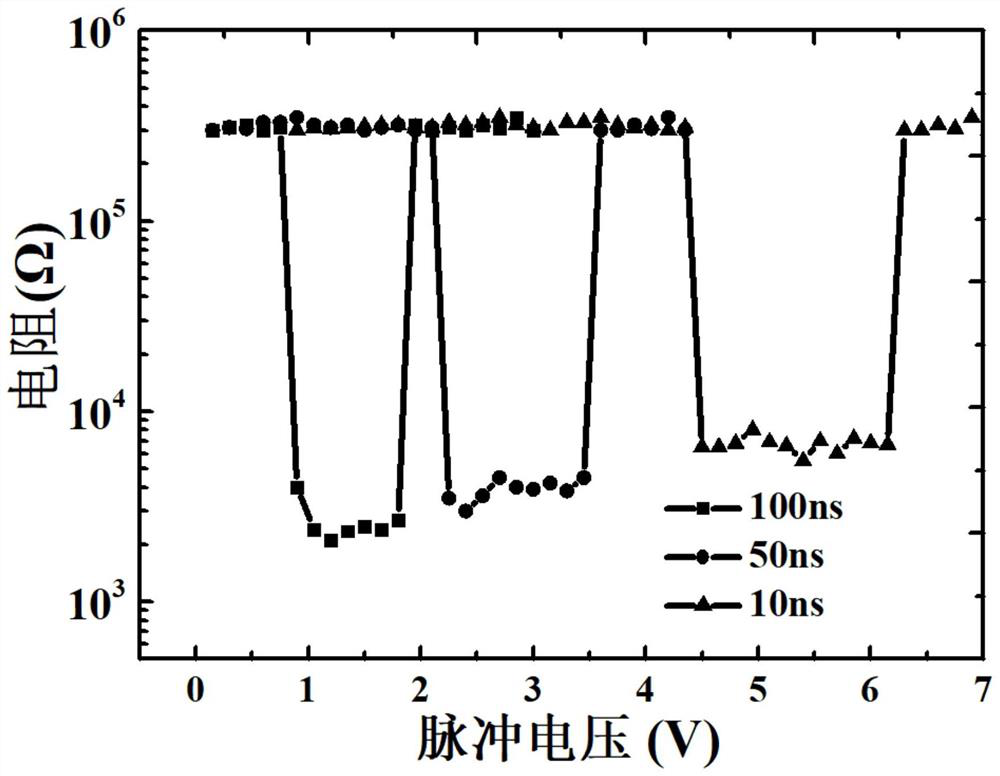

Ti-ga-sb phase change material, phase change memory and preparation method of ti-ga-sb phase change material

ActiveCN110729400BImprove stabilityIncrease the amorphous densityElectrical apparatusPhase-change memoryMetallurgy

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com