Electrical pulse treatment method for improving chalking resistance of aluminum ferro silicon manganese alloy

A technology of Al-Si-Mn-Fe and its processing method is applied in the field of improving the structure and properties of alloys, which can solve the problems affecting product performance and life, and achieve the effects of improving the anti-pulverization performance, wide application range and short experimental period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

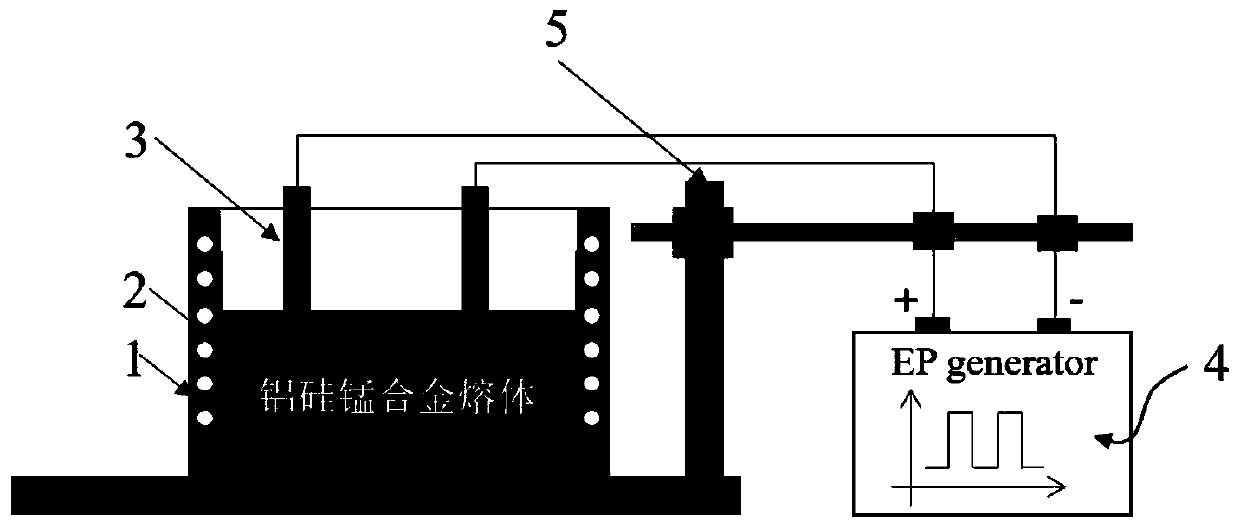

Image

Examples

Embodiment 1

[0053] 1) Raw material preparation: 59.6g of high-purity aluminum pellets, 12.34g of high-purity manganese flakes, 14.3g of high-purity silicon block, 11.42g of high-purity ultra-fine GR iron powder, 200g of silicon-manganese alloy, and the raw materials need to be stored in a drying oven at 80°C Bake for two hours, weigh the mass after cooling.

[0054] 2) Electric pulse equipment parameter setting: Before the experiment, set the electric pulse power supply parameters, set the peak voltage to 20V, the pulse width to 100μs, the pulse frequency to 90Hz, and the pulse action to 10 minutes.

[0055] 3) Electric pulse electrode adjustment: Before the experiment, adjust the position of the electric pulse electrode, insert the electrode into the crucible in the induction furnace, and set the insertion depth to 10cm through the turntable on the electrode fixing / moving frame, and set it on the electrode fixing / moving frame Adjust the distance between the two electrodes with the horizo...

Embodiment 2

[0060] 1) Raw material preparation: 59.6g of high-purity aluminum pellets, 12.34g of high-purity manganese flakes, 14.3g of high-purity silicon block, 11.42g of high-purity ultra-fine GR iron powder, 200g of silicon-manganese alloy, and the raw materials need to be stored in a drying oven at 80°C Bake for two hours, weigh the mass after cooling.

[0061] 2) Electric pulse equipment parameter setting: Before the experiment, set the electric pulse power supply parameters, set the peak voltage to 30V, the pulse width to 100μs, the pulse frequency to 90Hz, and the pulse action to 10 minutes.

[0062] 3) Electric pulse electrode adjustment: Before the experiment, adjust the position of the electric pulse electrode, insert the electrode into the crucible in the induction furnace, and set the insertion depth to 10cm through the turntable on the electrode fixing / moving frame, and set it on the electrode fixing / moving frame Adjust the distance between the two electrodes with the horizo...

Embodiment 3

[0067] Other conditions are the same as in Example 2, except that in step 5), after 10 minutes of electric pulse treatment, the electrodes and crucible are taken out, and the crucible is placed in flowing argon, and cooled at a rate of 100K / s. Al-Si-Mn alloy was obtained. It weighs 297.88g, which is recorded as the original weight.

[0068] The obtained alsilicon-manganese ferroalloy was placed in a drying dish, and the storage condition of the alloy was observed after 45 days. Because the powder is less, the pulverization rate is calculated by weighing the mass of the block (289.96g); 100%-(block mass / original weight)=2.64%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com