Patents

Literature

347 results about "Epitaxial thin film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

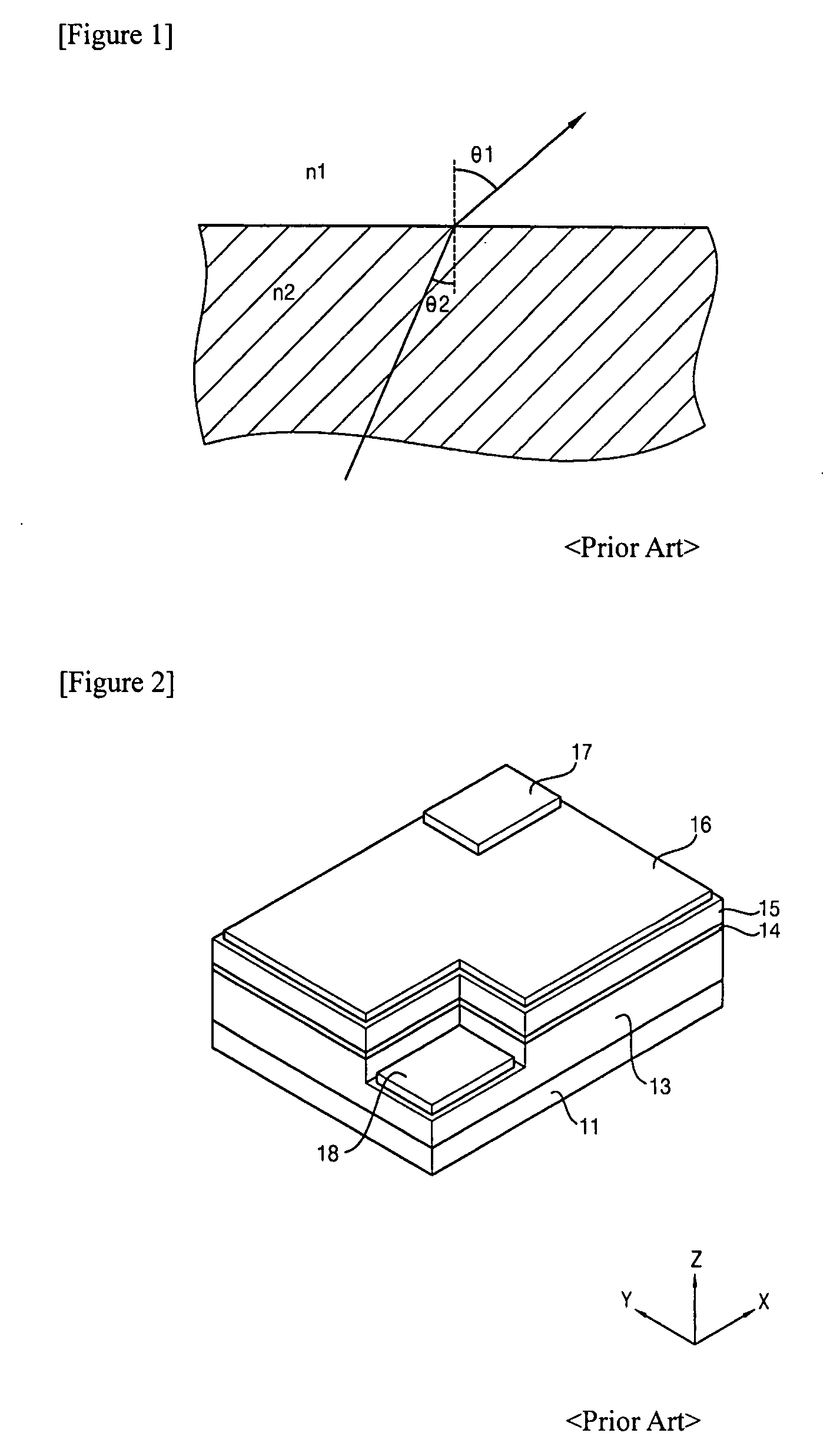

Epitaxy can produce thin films with atomic perfection that rivals that of single crystals as well as metastable phases (such as body-centered cubic Ni on Fe and face-centered cubic Fe on Cu), superlattices, quantum wells, and strained-layer architectures with tunable properties (2).

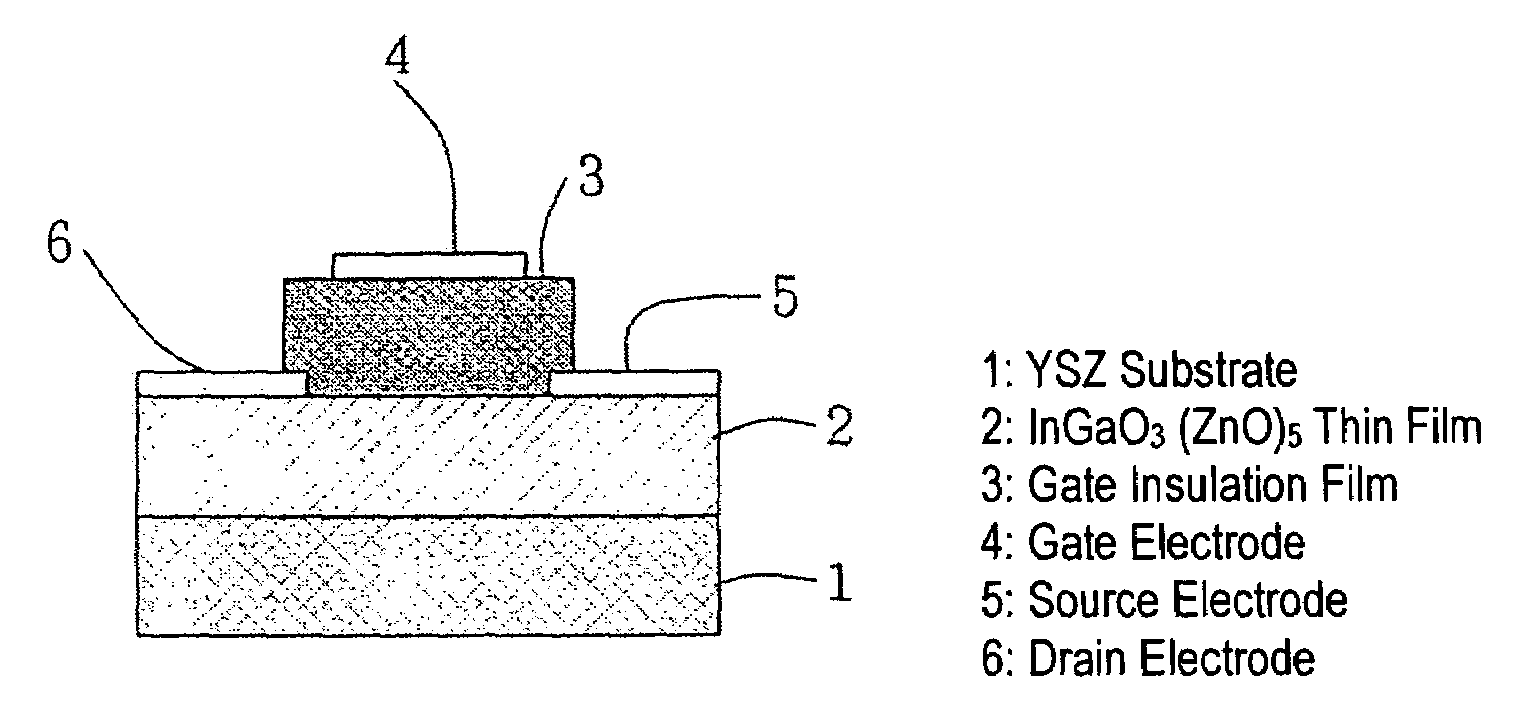

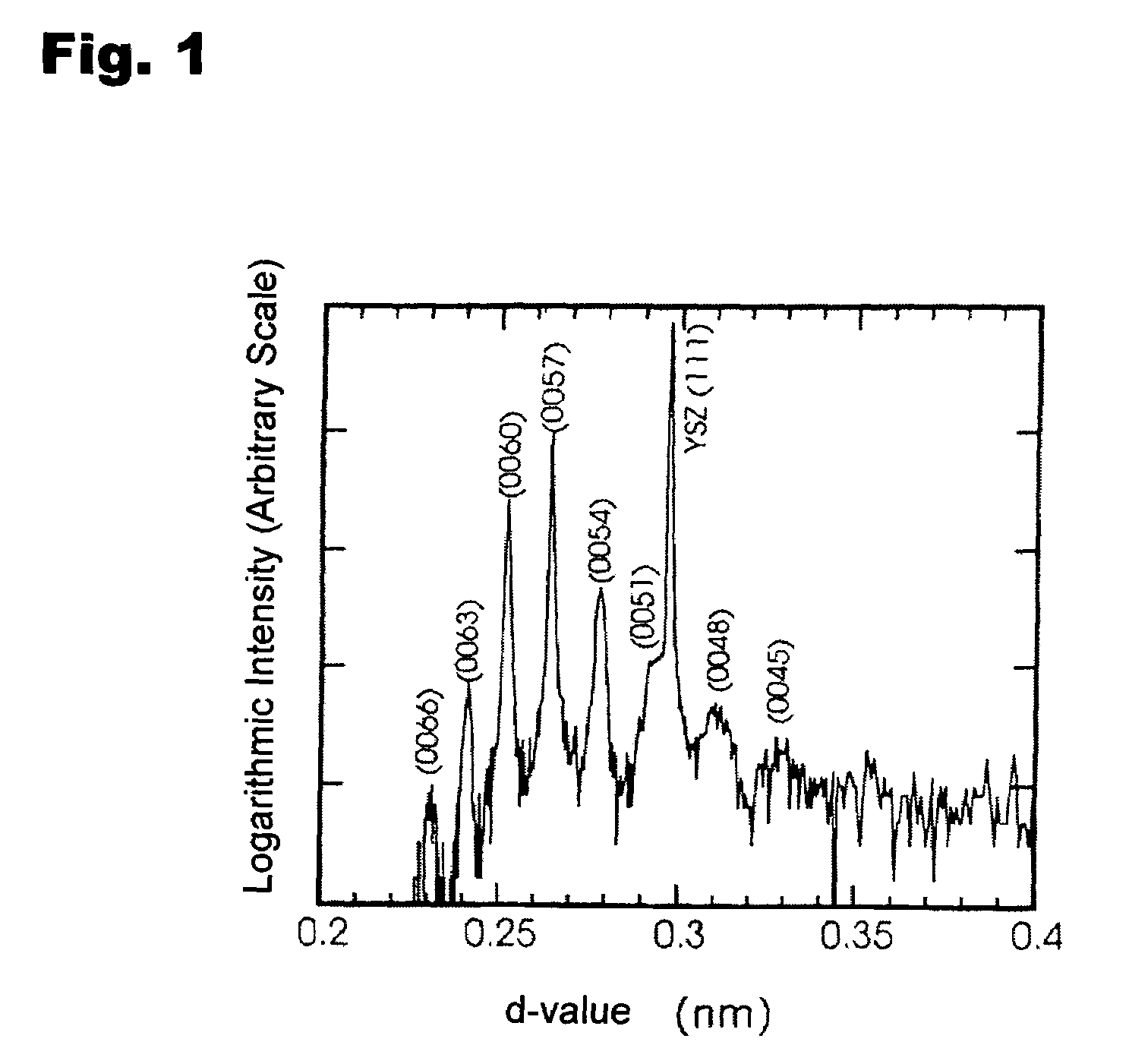

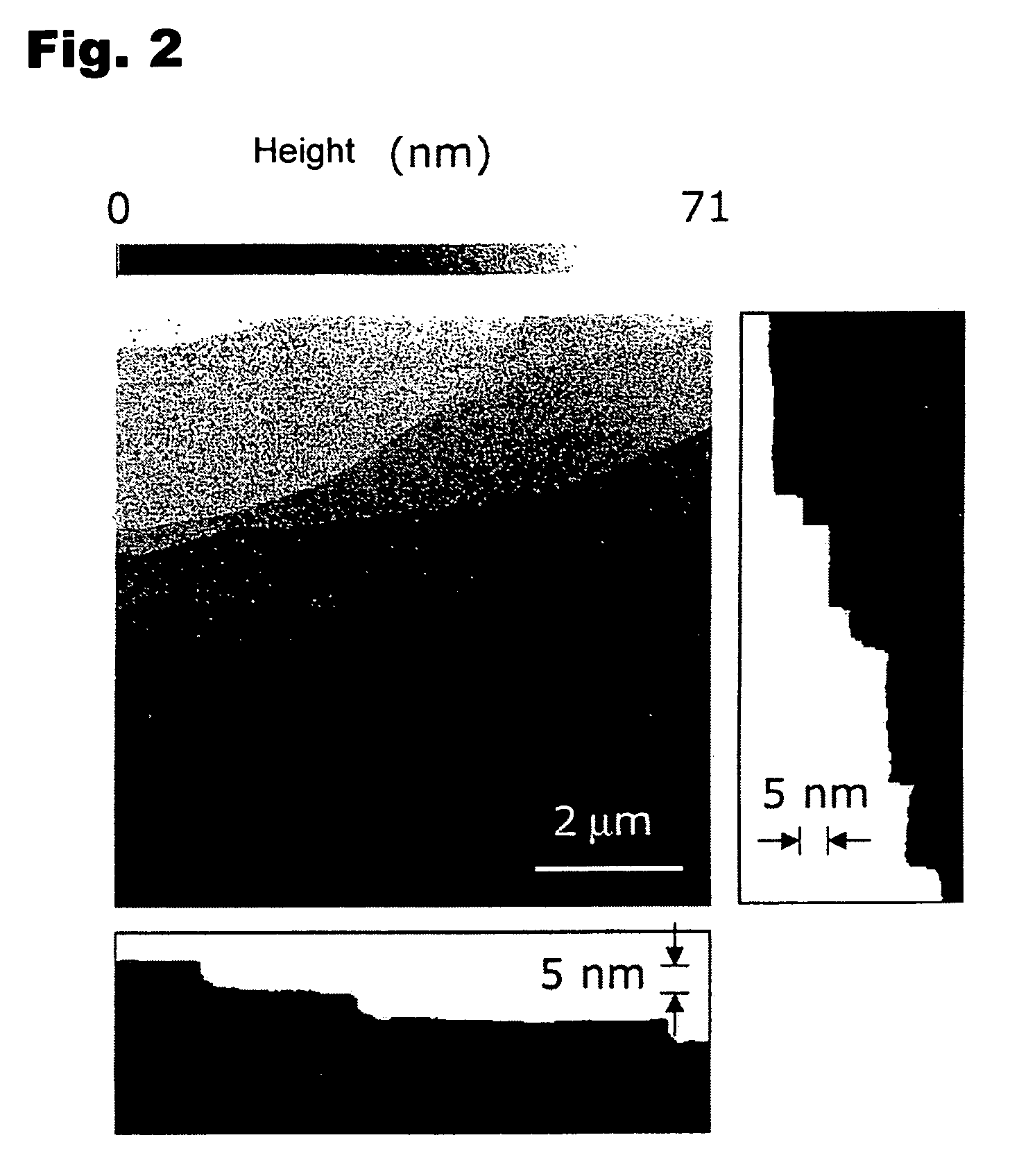

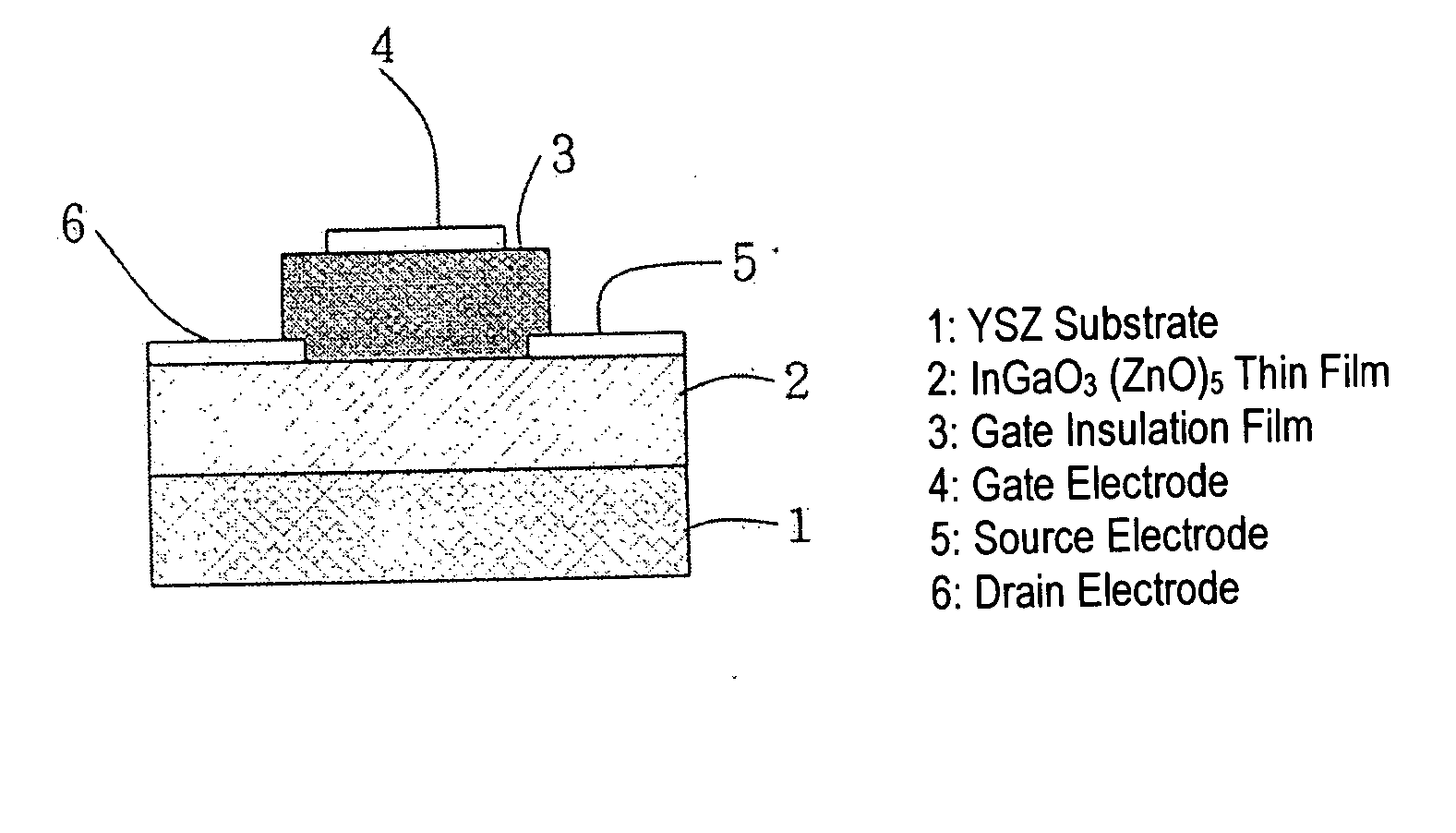

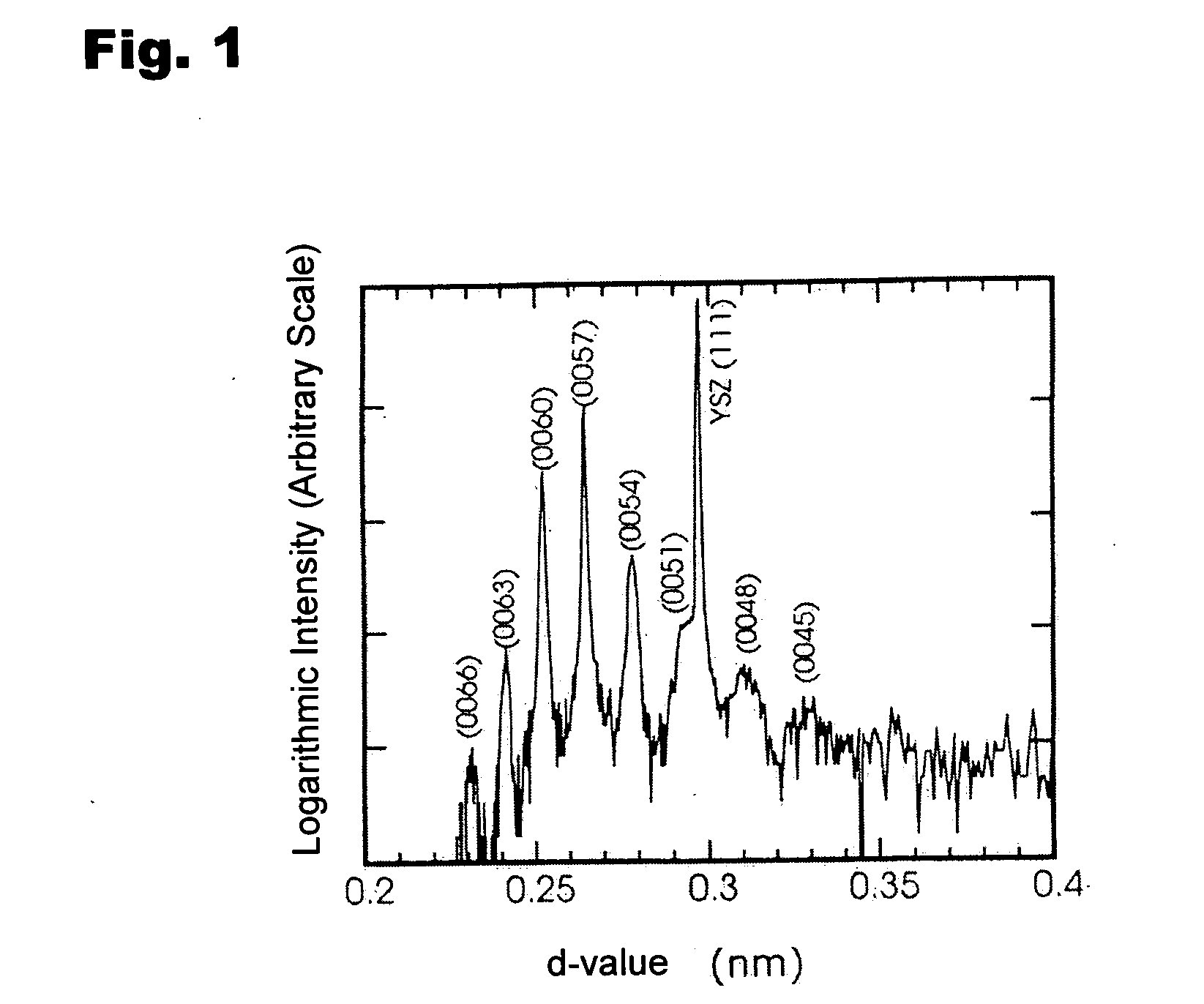

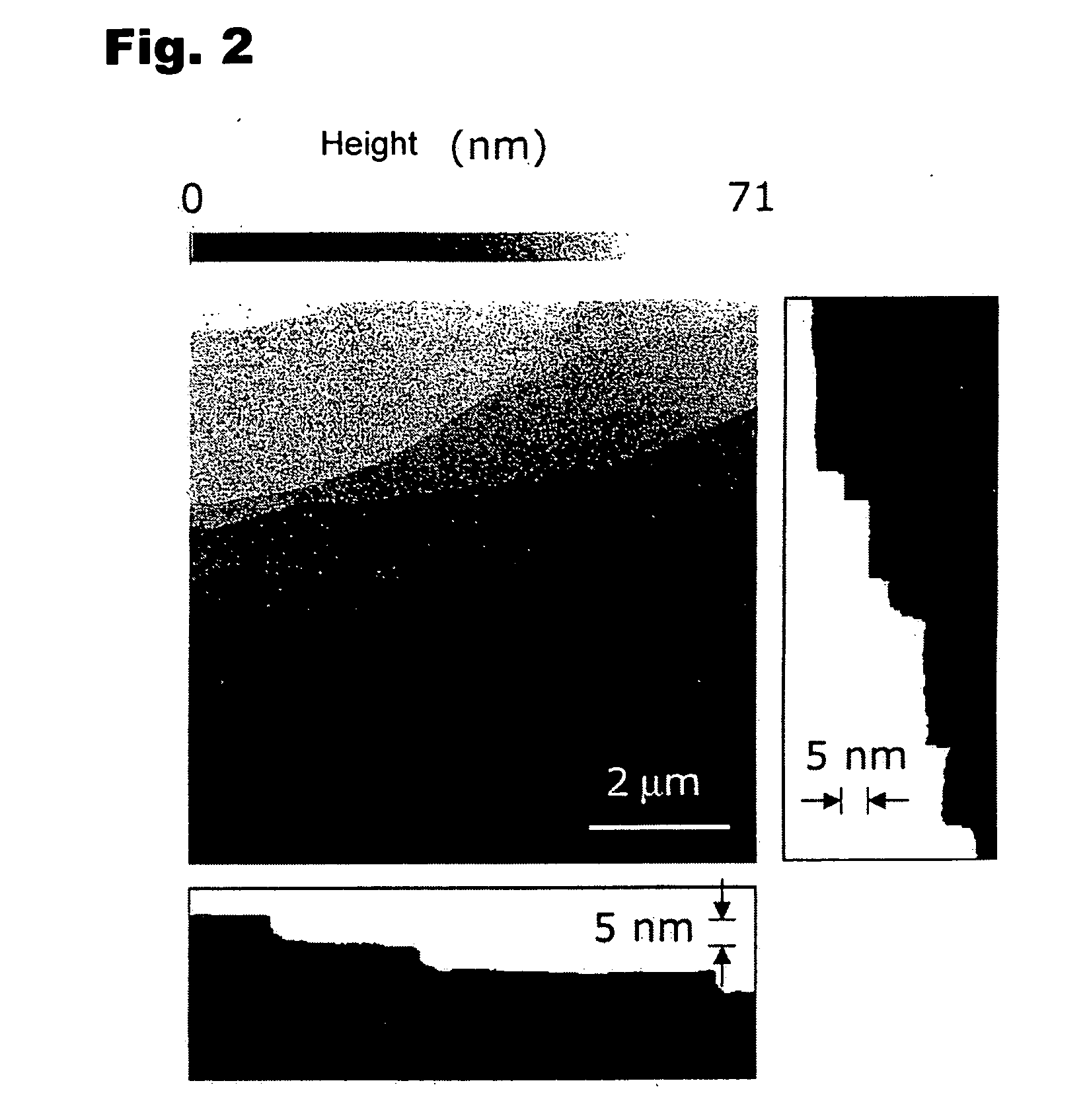

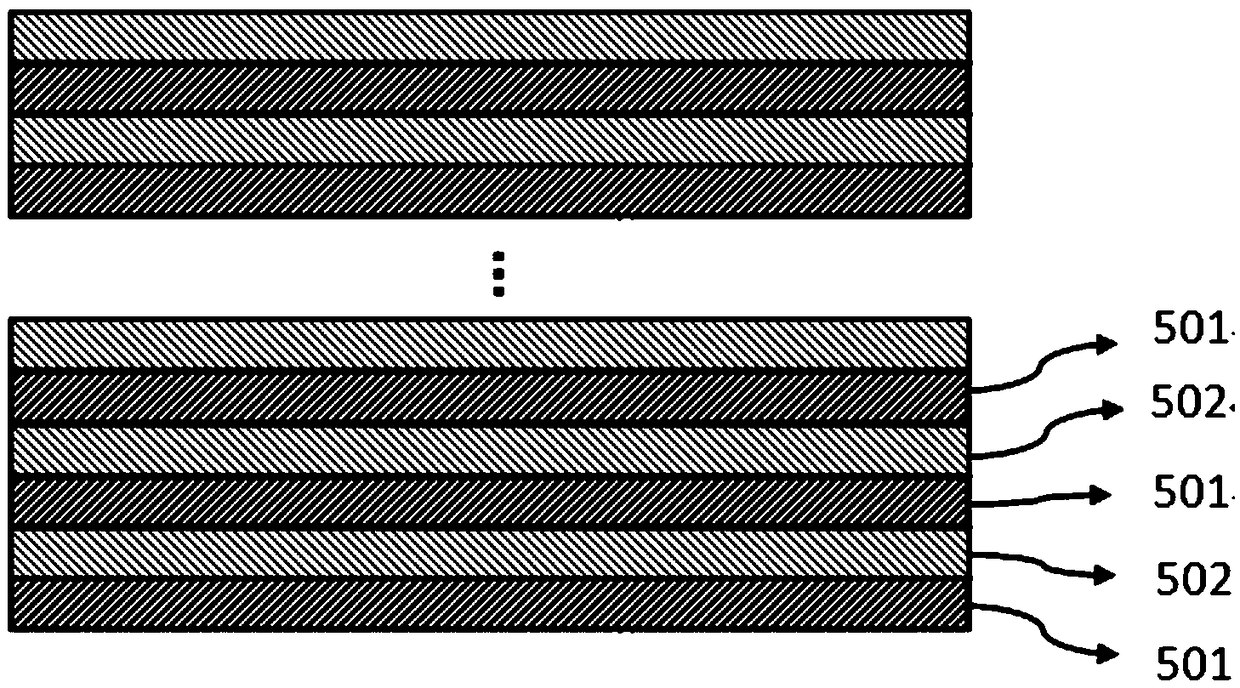

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS7061014B2Easy to controlSimple processTransistorPolycrystalline material growthSingle crystal substrateSingle crystal

Disclosed is a natural-superlattice homologous single-crystal thin film, which includes a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

Natural-superlattice homologous single crystal thin film, method for preparation thereof, and device using said single crystal thin film

InactiveUS20050039670A1Avoid large deviationImprove insulation performanceTransistorPolycrystalline material growthX-raySingle crystal substrate

Disclosed is a natural-superlattice homologous single-crystal thin film, which comprises a complex oxide which is epitaxially grown on either one of a ZnO epitaxial thin film formed on a single-crystal substrate, the single-crystal substrate after disappearance of the ZnO epitaxial thin film and a ZnO single crystal. The complex oxide is expressed by the a formula: M1M2O3 (ZnO)m, wherein M1 is at least one selected from the group consisting of Ga, Fe, Sc, In, Lu, Yb, Tm, Er, Ho and Y, M2 is at least one selected from the group consisting of Mn, Fe, Ga, In and Al, and m is a natural number of 1 or more. A natural-superlattice homologous single-crystal thin film formed by depositing the complex oxide and subjecting the obtained layered film to a thermal anneal treatment can be used in optimal devices, electronic devices and X-ray optical devices.

Owner:HOYA CORP +1

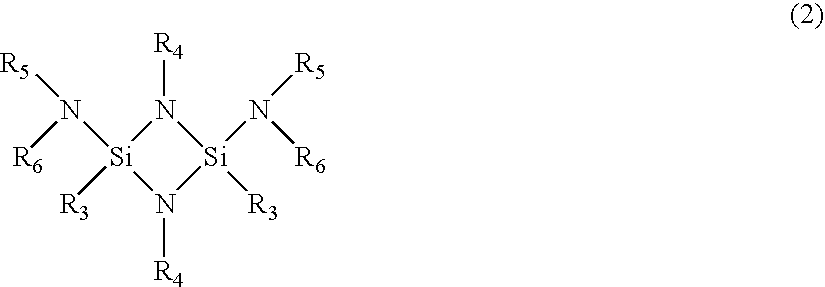

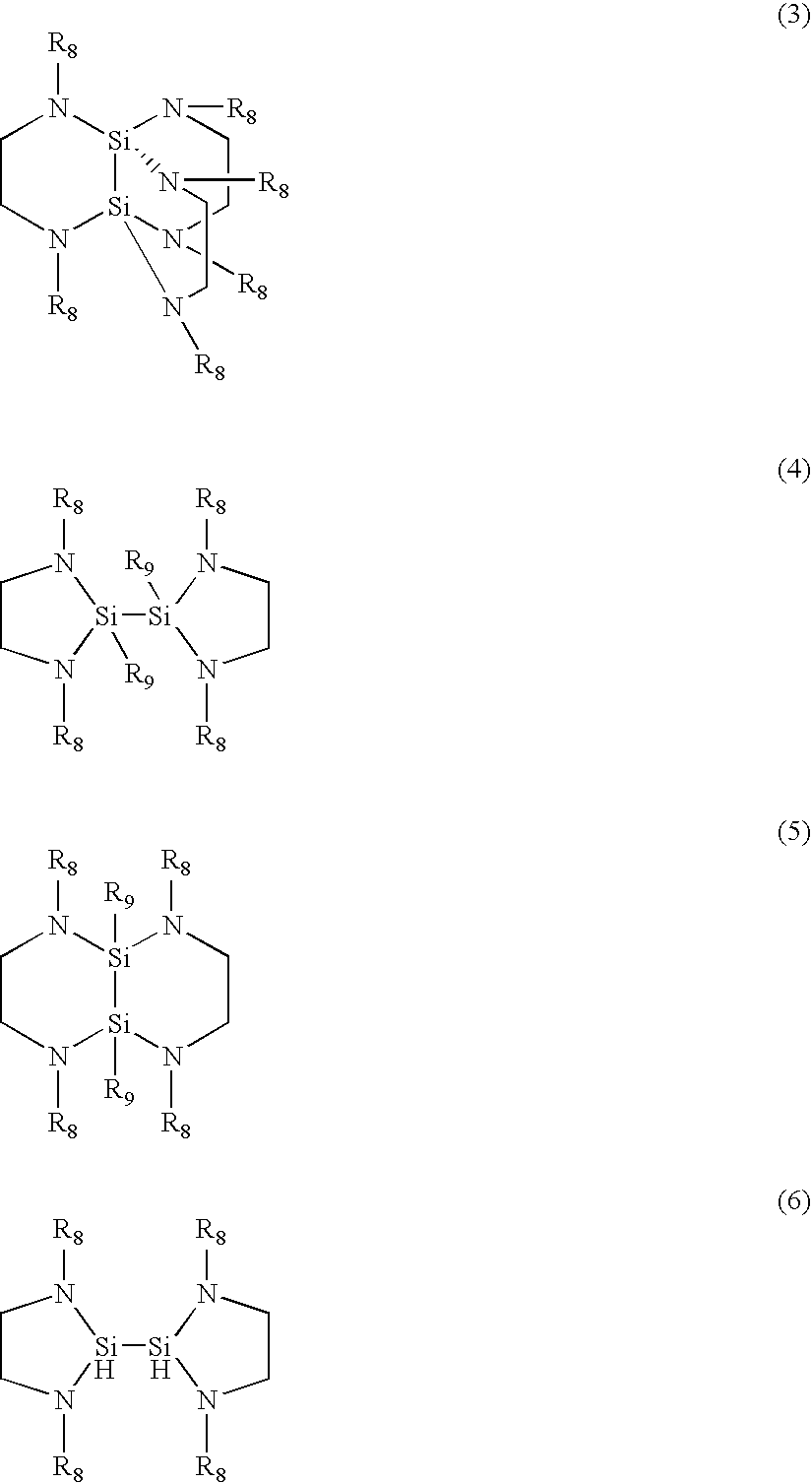

Composition and method for low temperature deposition of silicon-containing films such as films including silicon nitride, silicon dioxide and/or silicon-oxynitride

ActiveUS20040096582A1Silicon organic compoundsPolycrystalline material growthLow temperature depositionGas phase

Silicon precursors for forming silicon-containing films in the manufacture of semiconductor devices, such as low dielectric constant (k) thin films, high k gate silicates, low temperature silicon epitaxial films, and films containing silicon nitride (Si3N4), siliconoxynitride (SiOxNy) and / or silicon dioxide (SiO2). The precursors of the invention are amenable to use in low temperature (e.g., <500° C.) chemical vapor deposition processes, for fabrication of ULSI devices and device structures.

Owner:ENTEGRIS INC

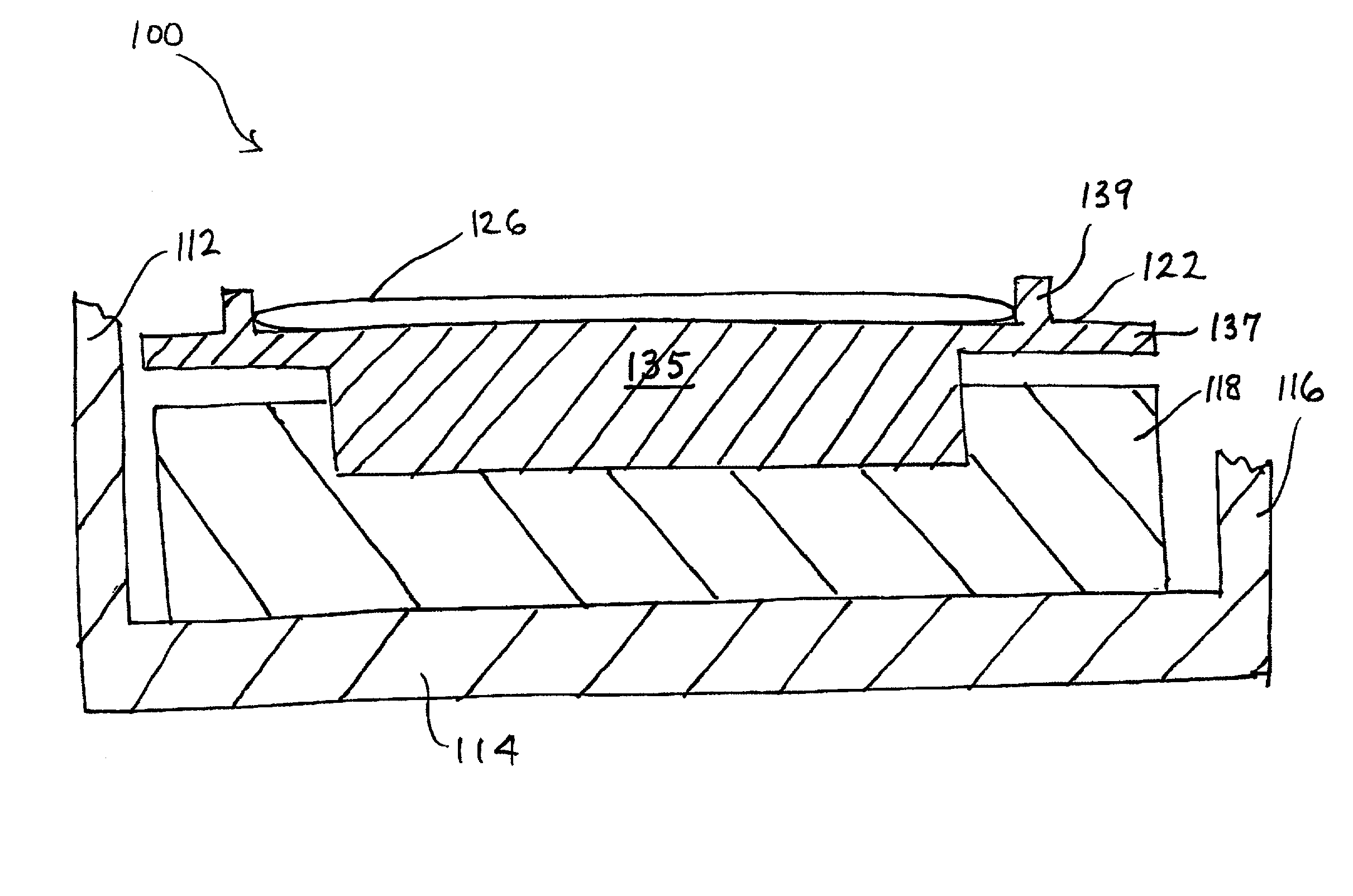

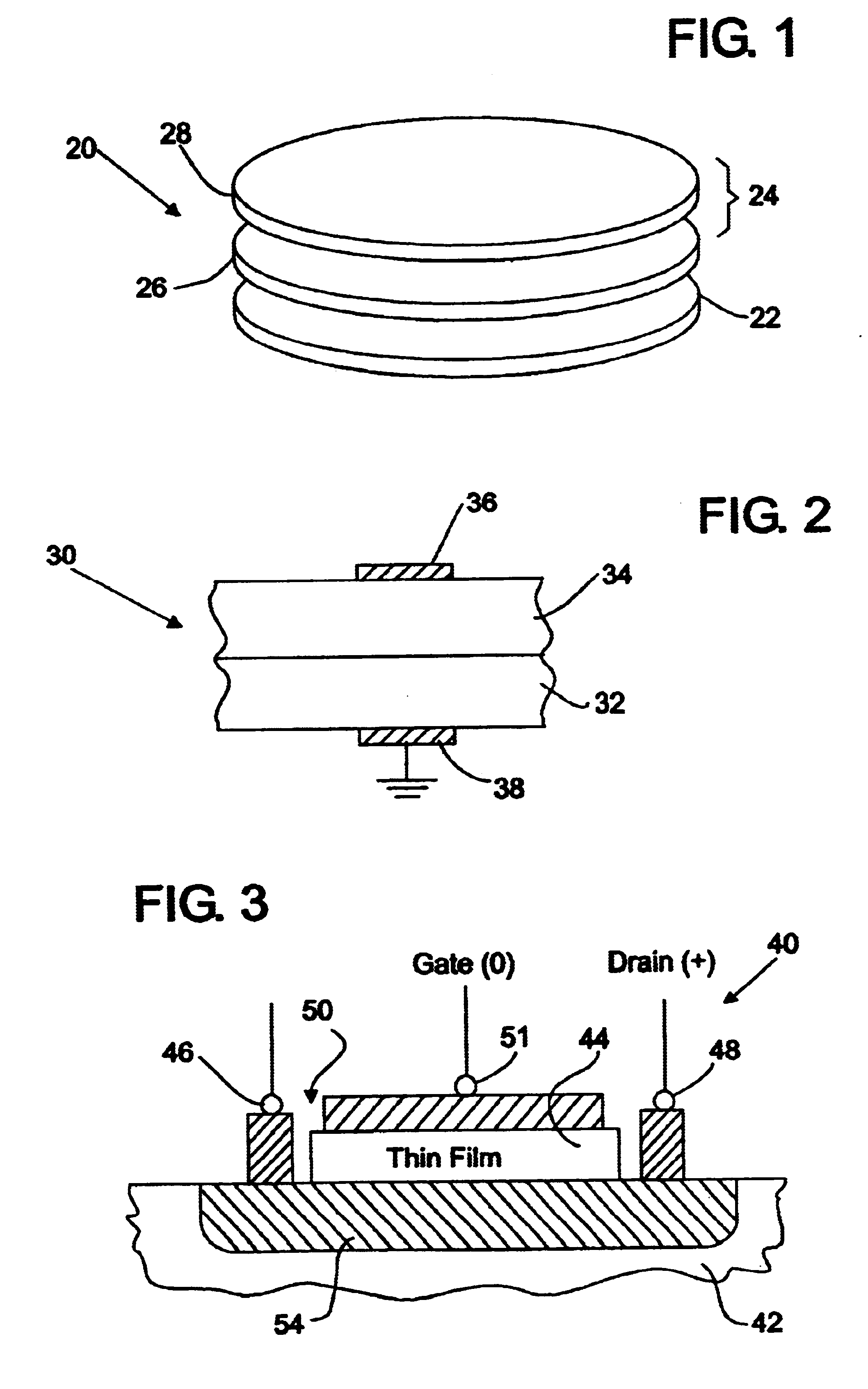

Wafer carrier for semiconductor process tool

InactiveUS20030114016A1Not to create too much space (gap)Not to "pinch" the waferConveyorsSemiconductor/solid-state device manufacturingWaferingEngineering

A wafer carrier enabling a wafer of different size and / or shape to be processed in a process tool configured for processing a wafer of a predetermined size and / or shape, wherein the wafer carrier has such predetermined size and / or shape and includes at least one recess therein having the different size and / or shape. The wafer carrier enables the use in a process tool (e.g., a semiconductor epitaxial thin film deposition reactor such as a single wafer reactor) of differently sized wafers than those for which the process tool is designed.

Owner:INTERNATIONAL RECTIFIER COEP

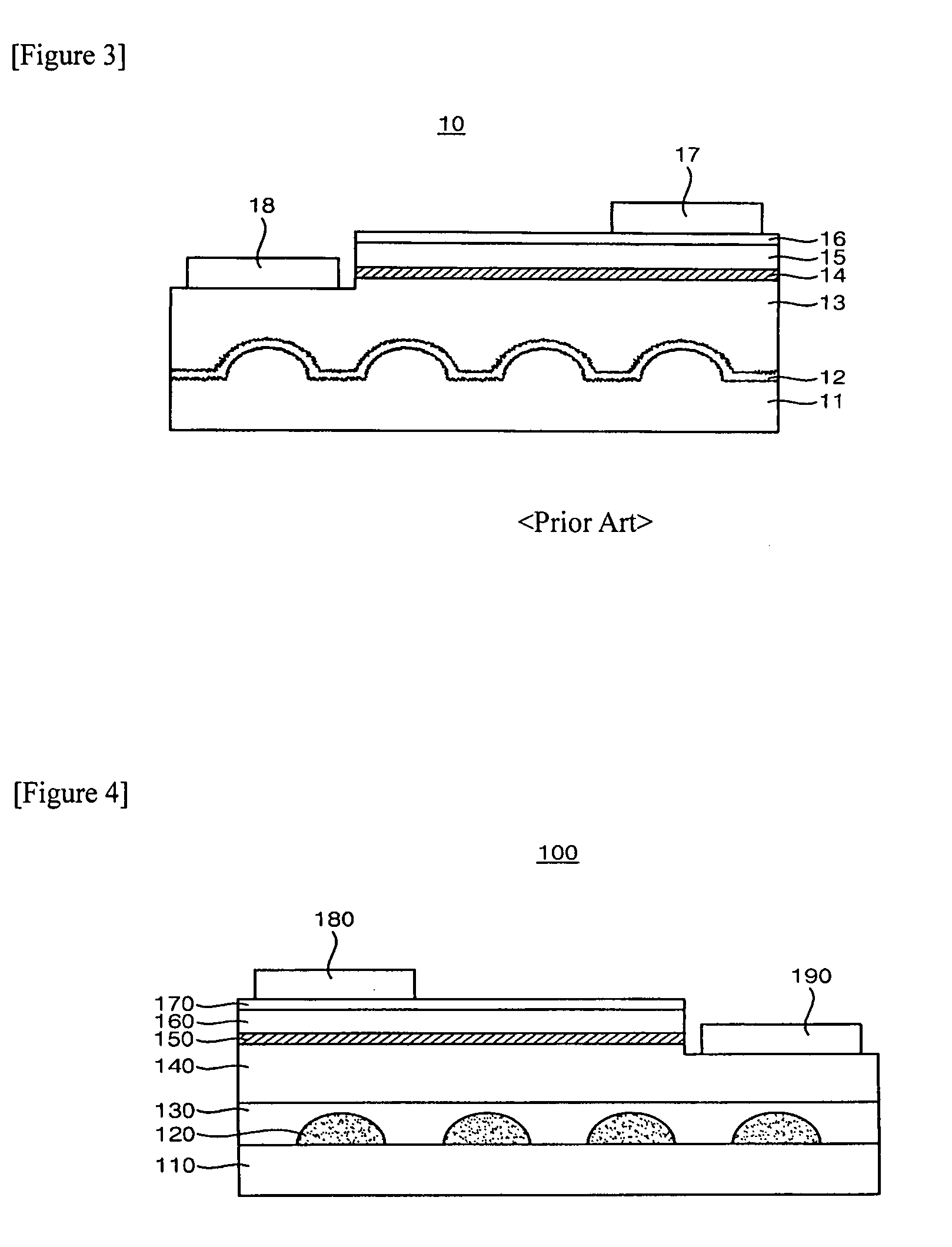

Light emitting element and a manufacturing method thereof

InactiveUS20090057700A1Light extraction efficiency can be improvedQuality improvementBallastwaySemiconductor/solid-state device manufacturingOptoelectronicsDielectric thin films

A light emitting element and a method for manufacturing the same are disclosed. In accordance with the element and the method, the dielectric thin film including the embossed pattern partially covering the sapphire substrate prevents damage of a sapphire substrate that occurs during a texturing of the sapphire substrate and a defect of an epitaxial thin film formed in a subsequent process.

Owner:THELEDS

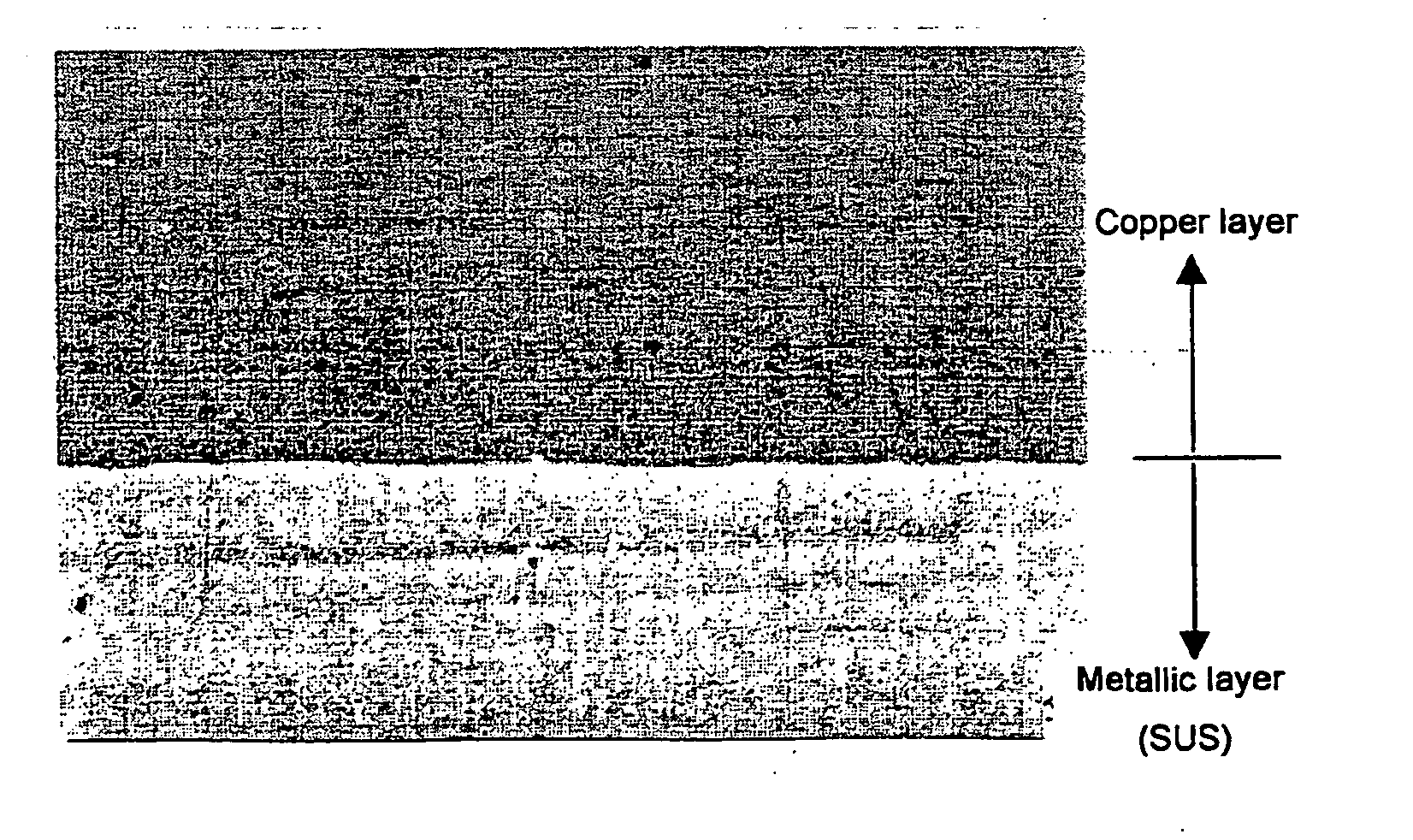

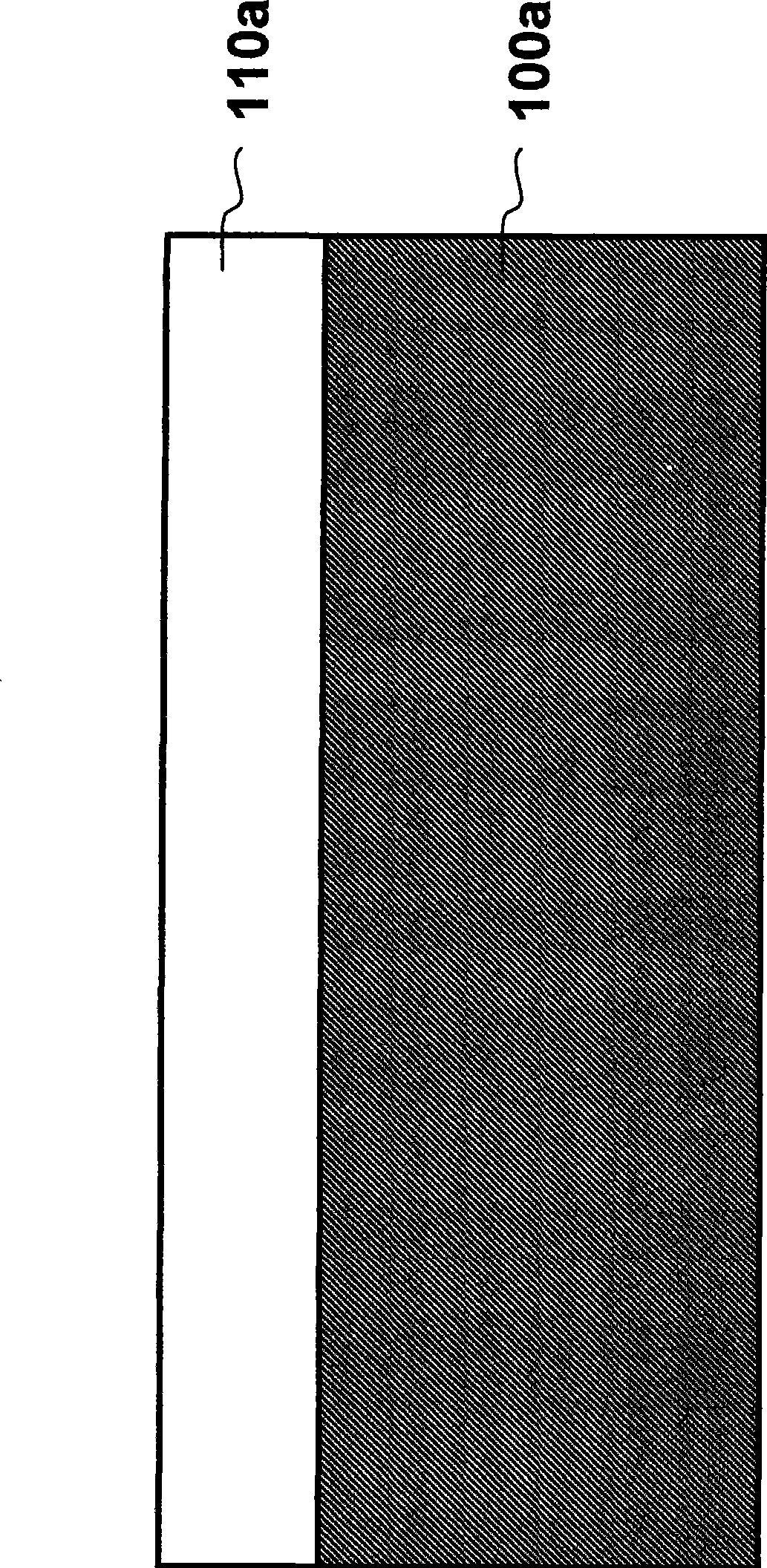

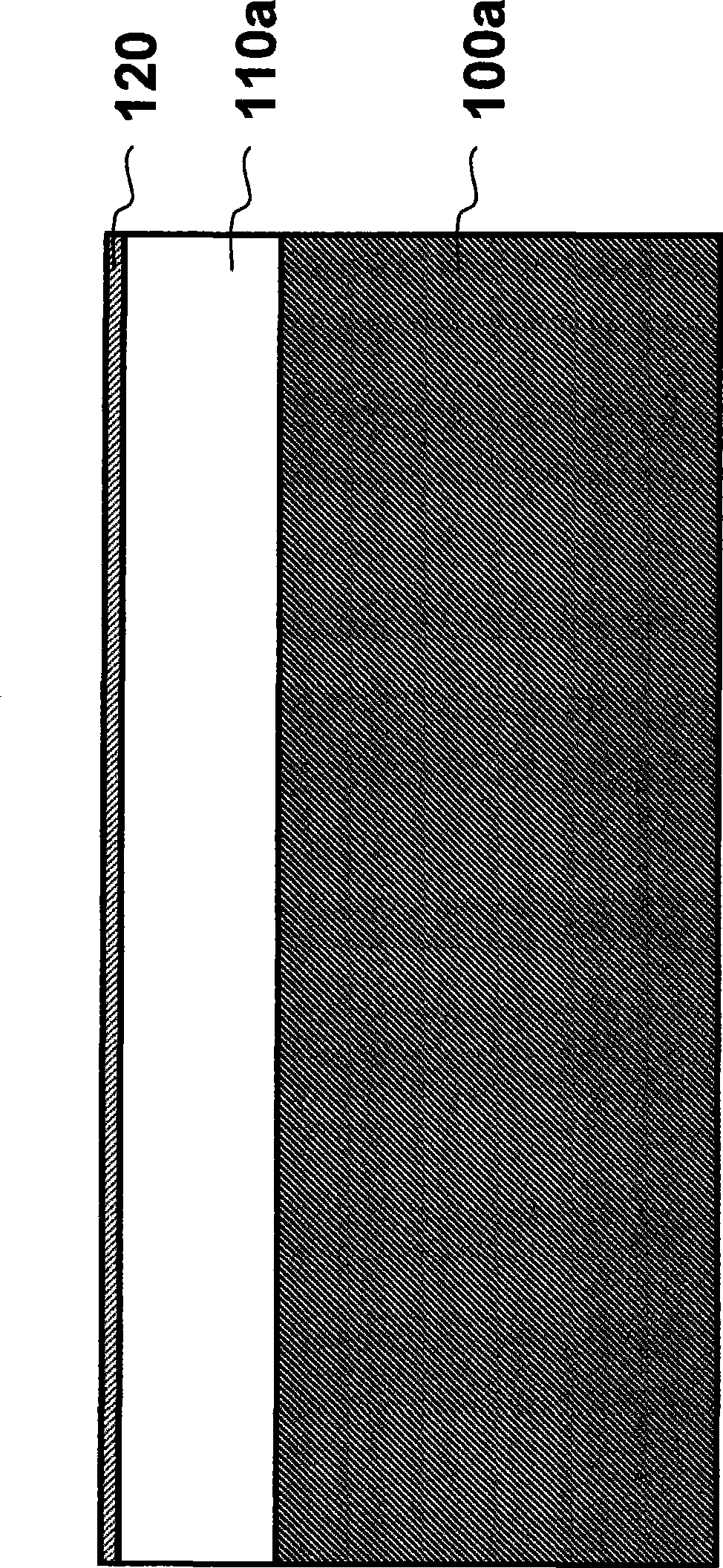

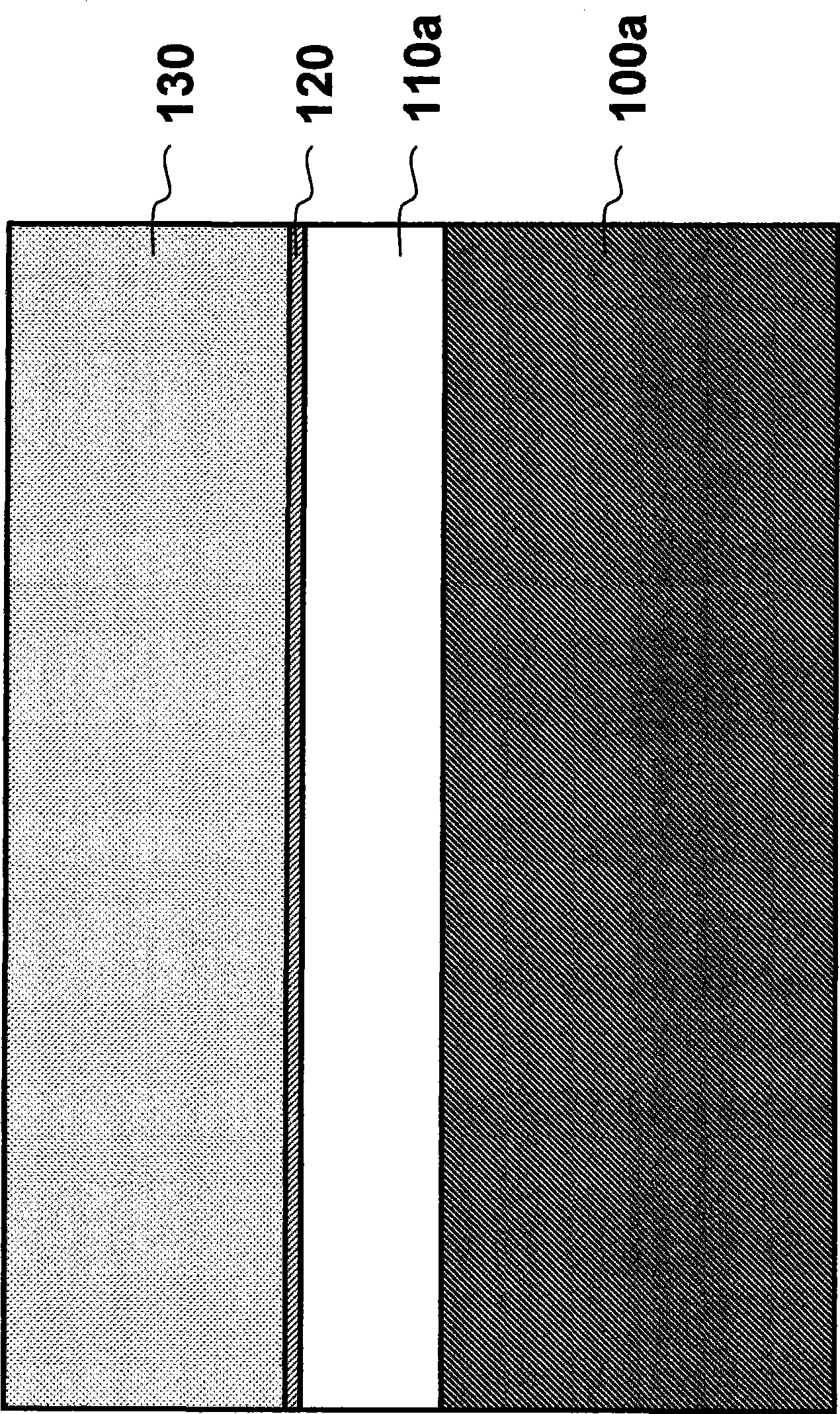

Clad textured metal substrate for forming epitaxial thin film thereon and method for manufacturing the same

ActiveUS20080261072A1Flat surfaceNot easy to produceSurface reaction electrolytic coatingVacuum evaporation coatingIridiumStrontium titanate

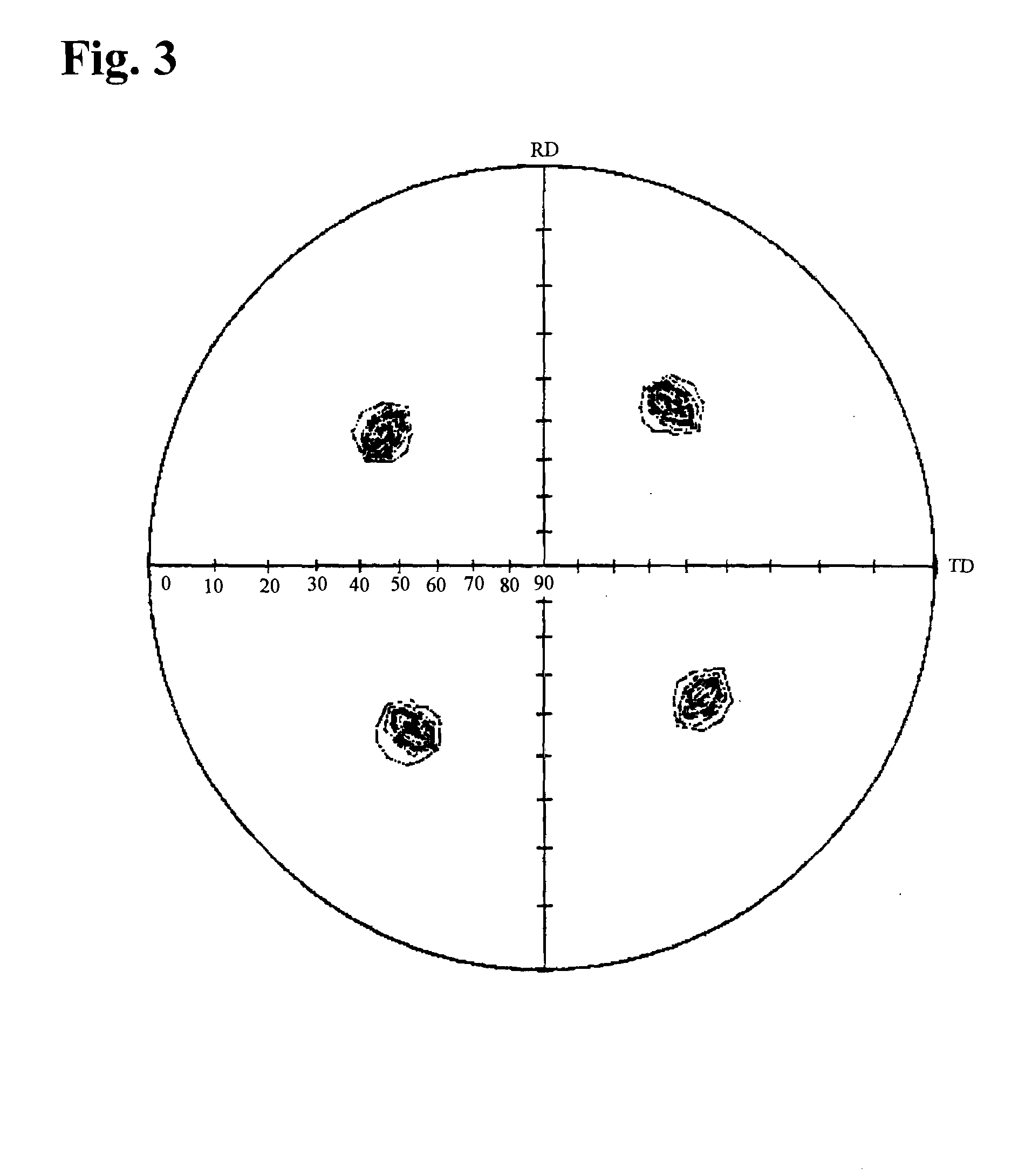

The present invention provides an oriented substrate for forming an epitaxial thin film thereon, which has a more excellent orientation than that of a conventional one and a high strength, and a method for manufacturing the same. The present invention provides a clad textured metal substrate for forming the epitaxial thin film thereon, which includes a metallic layer and a copper layer bonded to at least one face of the above described metallic layer, wherein the above described copper layer has a {100}<001> cube texture in which a deviating angle Δφ of crystal axes satisfies Δφ≦6 degree. The clad textured metal substrate for forming the epitaxial thin film thereon has an intermediate layer on the surface of the copper layer so as to form the epitaxial thin film thereon, wherein the above described intermediate layer preferably includes at least one layer of a material selected from the group consisting of nickel, nickel oxide, zirconium oxide, rare-earth oxide, magnesium oxide, strontium titanate (STO), strontium barium titanate (SBTO), titanium nitride, silver, palladium, gold, iridium, ruthenium, rhodium and platinum.

Owner:TANAKA PRECIOUS METAL IND

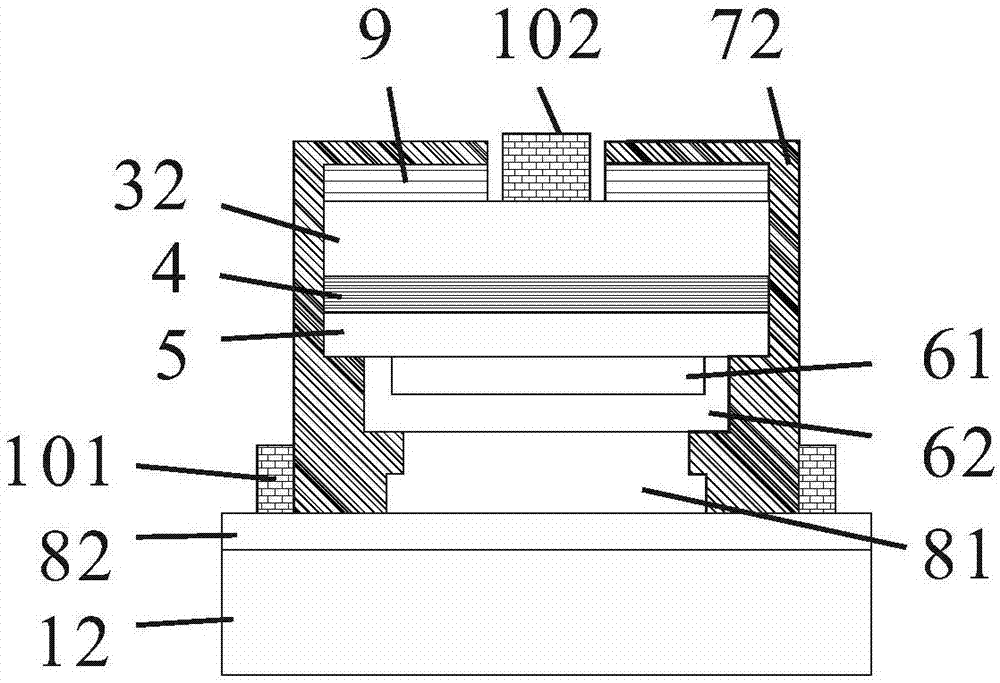

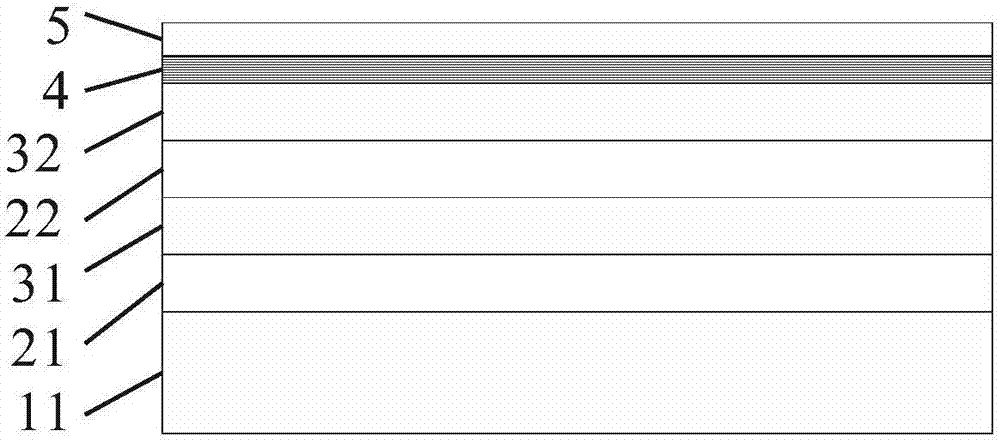

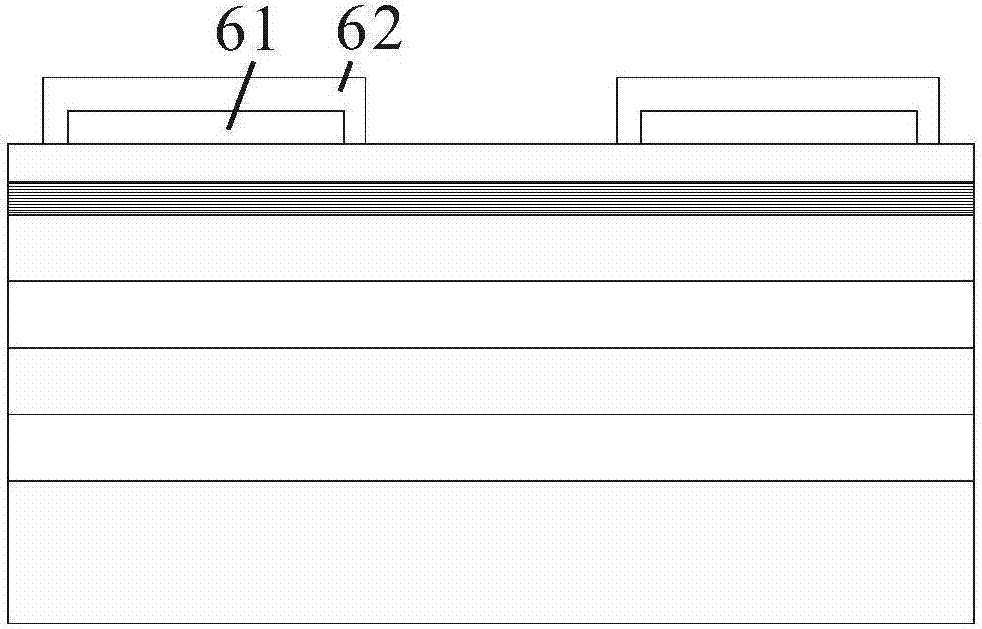

Micro-resonant cavity LED chip with substrate removed through chemical erosion and preparation method thereof

ActiveCN107369746ANo pollutionImprove reflectivityFinal product manufactureSemiconductor devicesResonant cavityQuantum well

The invention discloses a micro-resonant cavity LED chip with a substrate removed through chemical erosion and a preparation method thereof. The LED chip is an inversely installed film structure, and an epitaxial film only contains a p-GaN layer, a quantum well layer and an n-GaN layer. The lower surface of the p-GaN layer is a metallic reflection electrode with high reflectivity, a medium distributed Bragg reflection mirror is arranged on the upper surface of the n-GaN layer, a metallic reflection electrode and a medium DBR form a reflector of a resonant cavity, and the chamber length of the resonant cavity is order of magnitude of the wavelength. According to the preparation method, the substrate of an LED epitaxial wafer is removed through first photoelectric auxiliary chemical erosion and second chemical erosion, and then the LED epitaxial wafer is distributed on a heat conduction substrate through metallic bonding to obtain the micro-resonant cavity LED chip with substrate removed through chemical erosion. No extra material is introduced in the preparation method, pollution of the vacuum cavity of epitaxial growth equipment can be prevented, and the length of the resonant cavity can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

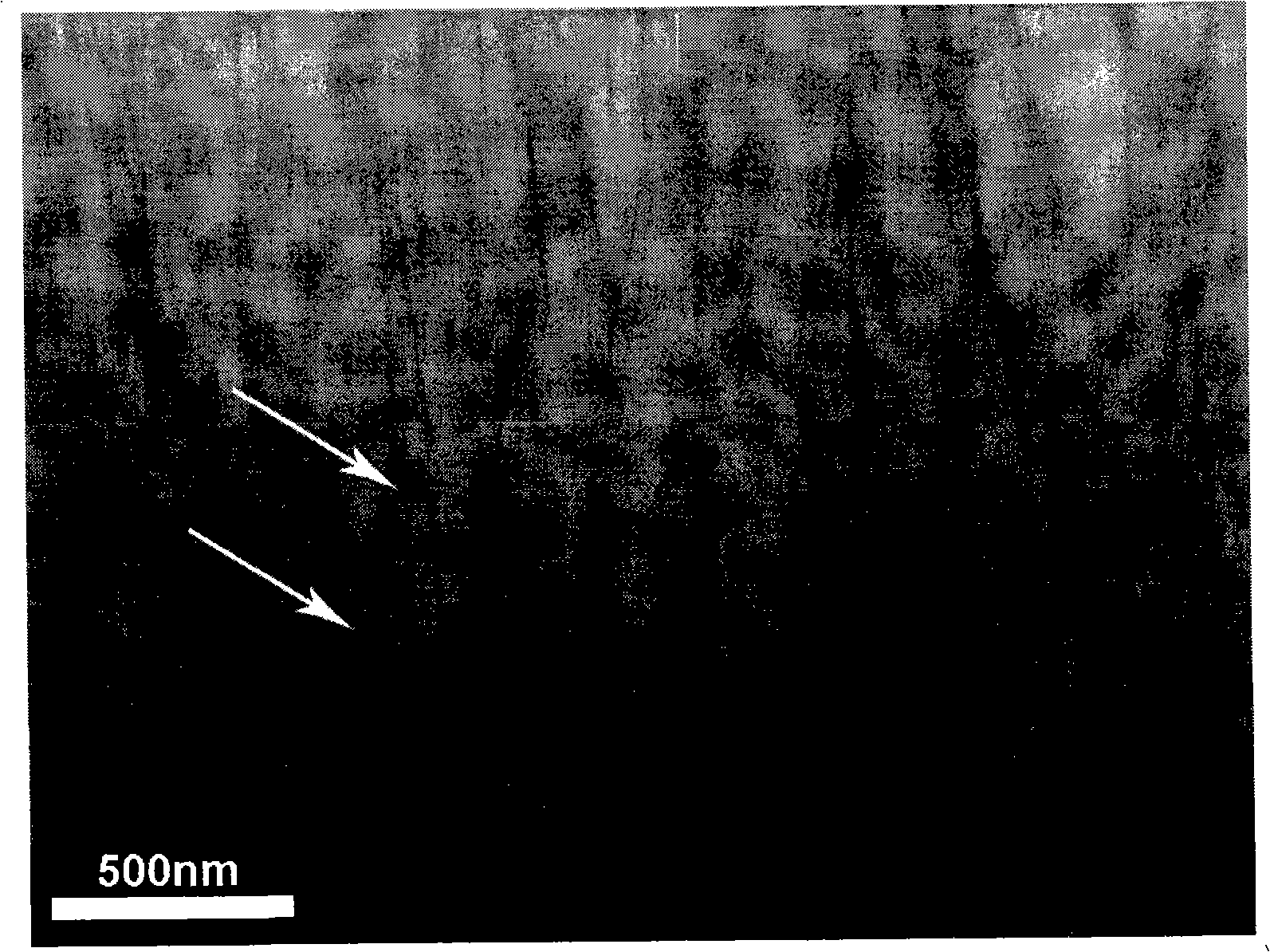

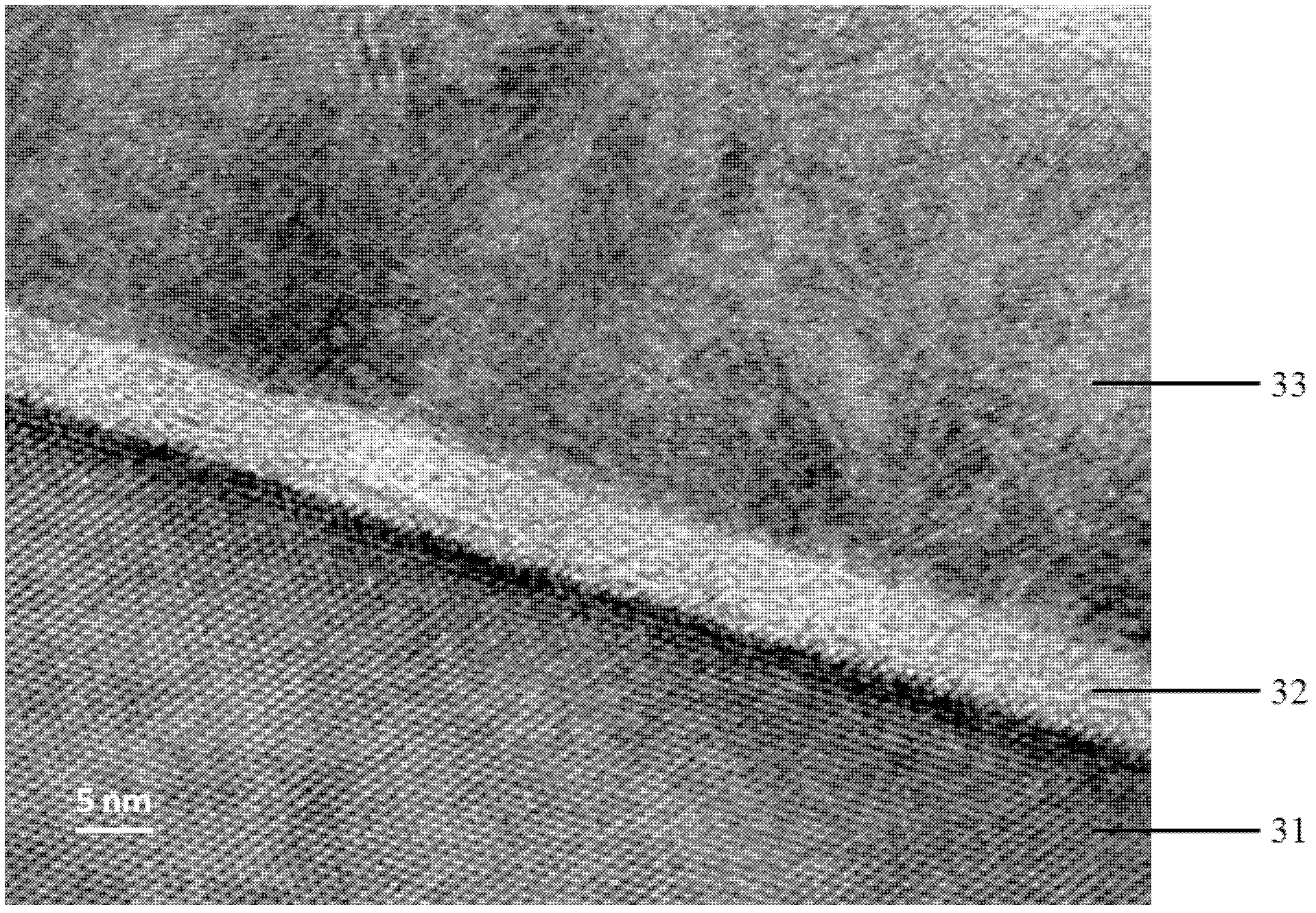

AIN film preparing method

ActiveCN101335200ALow edge dislocation densitySemiconductor/solid-state device manufacturingDislocationChemistry

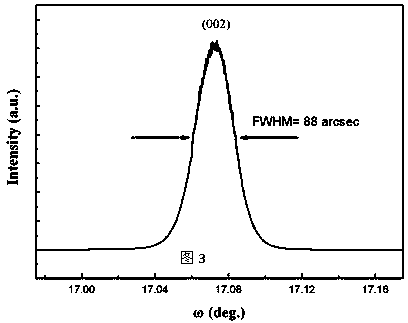

The invention discloses a preparation method of AlN membranes, which is characterized in that: 1.1 Al2O3, SiC or Si are taken as an underlayer which is subjected to nitridation for 10min to 30min in an extending membrane growth chamber at the temperature of 800 DEG C to 850 DEG C; 1.2 an AIN buffer layer of 10nm to 20nm grows at the temperature of 500 DEG C to 765 DEG C; 1.3 an extending layer of AIN grows at the temperature over 780 DEG C; 1.4 during the growth of the extending layer of AIN, an AIN inserting layer of 10nm to 20nm grows at the temperature of 500 DEG C to 765 DEG C, following the growth of each 100nm to 500nm of the extending layer of AIN, a growth interruption to the AIN for 0.5min to 3min is carried out by using growth interruption method, and then the extending layer of AIN continues to grow at the temperature over 780 DEG C; and the processes of growth and interruption are repeated till obtain the required layers. The preparation method has the advantages that the AIN membrane with mirror-like and smooth surface but without cracks can be obtained, the performance parameters, such as the not more than 255-arcsec of full width at half maximum of a rocking curve of X-ray diffraction (002) surface with high resolution, the not more than 290-arcsec of full width at half maximum of a rocking curve of (105) surface, the lower than 5 multiplied by 10<8> cm <-2> of edge dislocation density and the not more than 0.29nm in the range of 4Mum multiplied by 4Mum of the smoothness of the surface, can be obtained.

Owner:常熟紫金知识产权服务有限公司

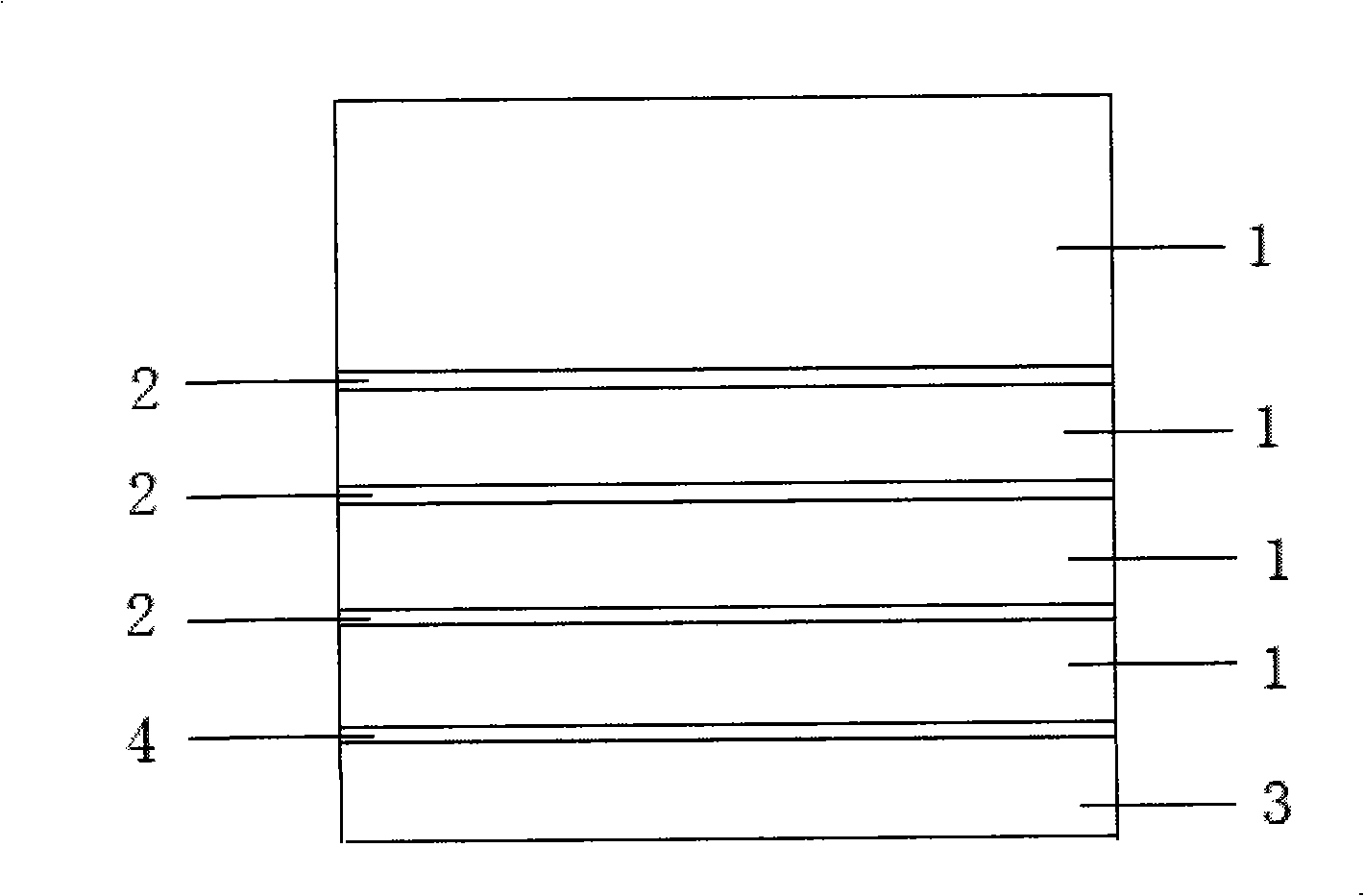

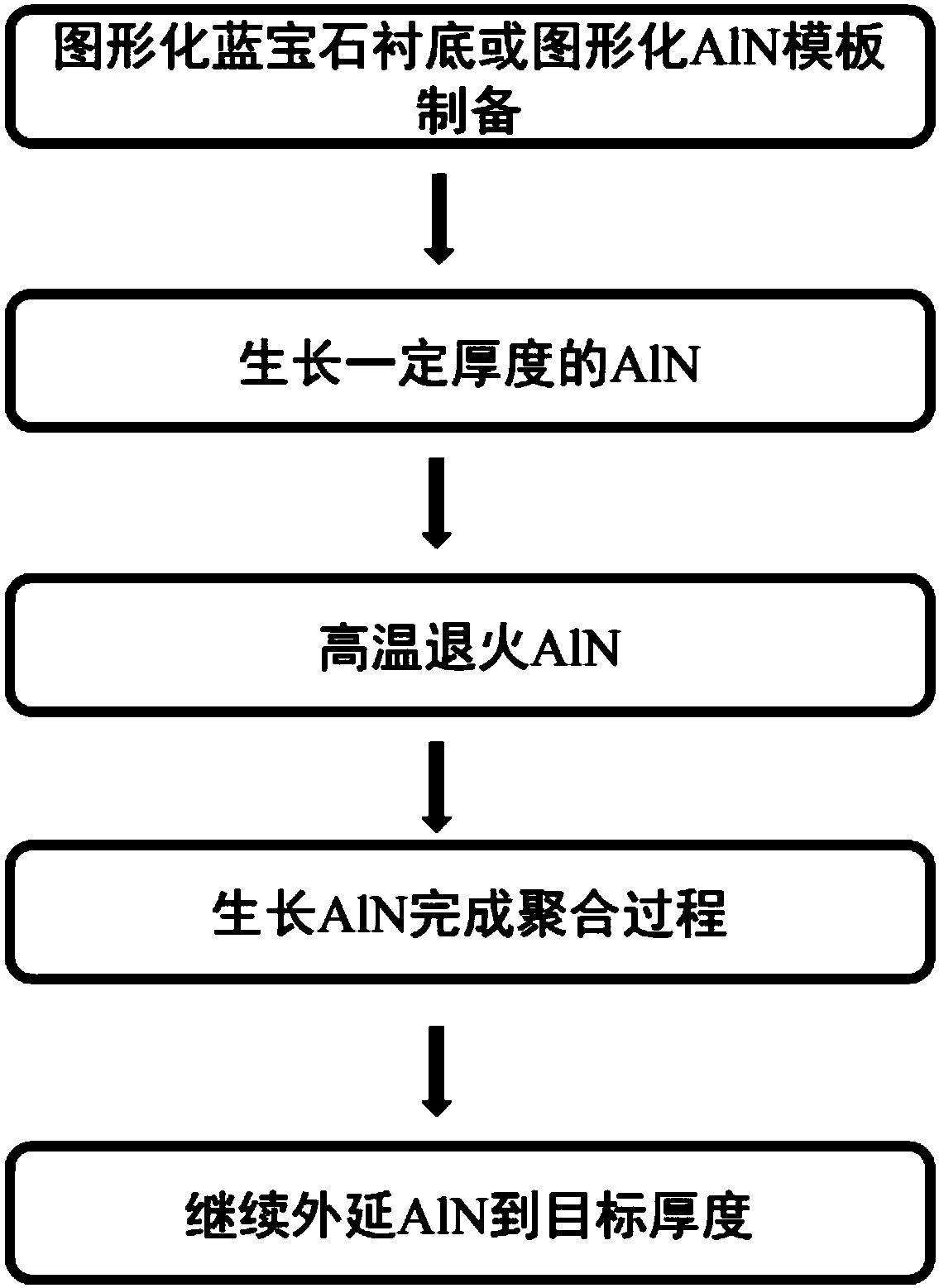

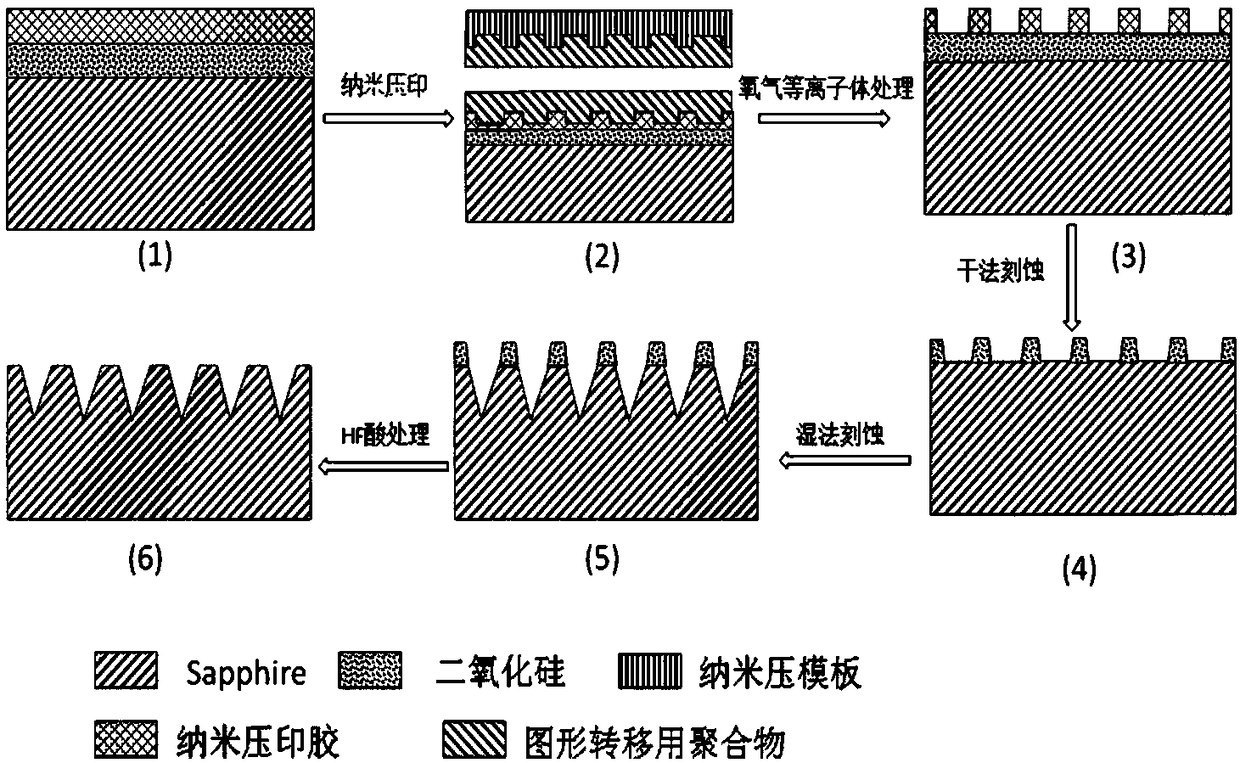

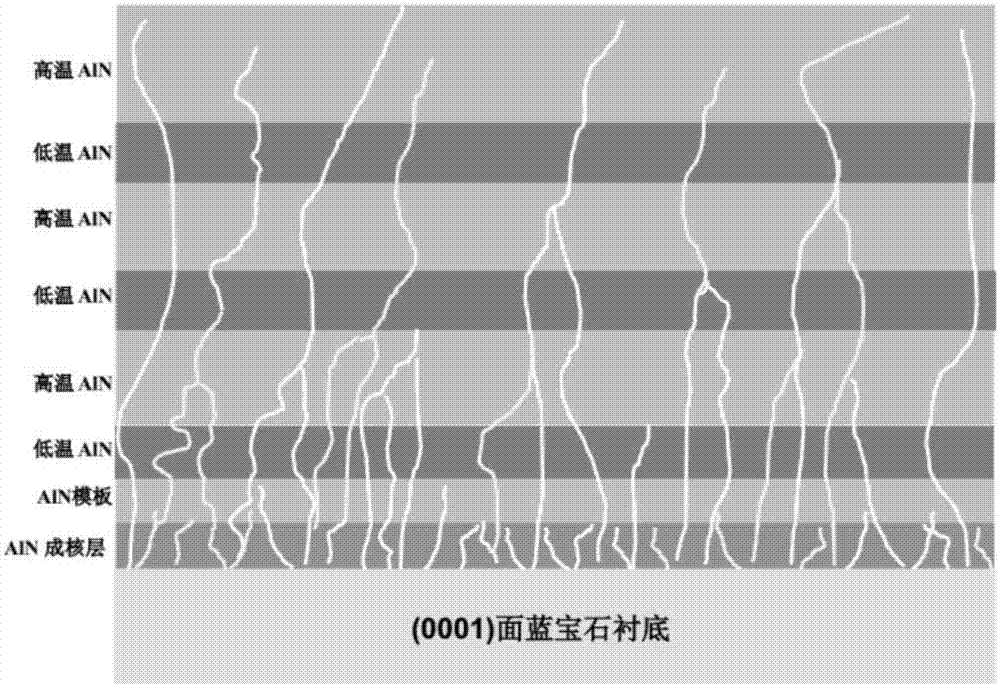

High-quality AlN epitaxial film, preparation method of high-quality AlN epitaxial film and application of high-quality AlN epitaxial film

InactiveCN108155090AReduce dislocation densityEliminate cracksFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsDislocation

The invention relates to a high-quality AlN epitaxial film, a preparation method of the high-quality AlN epitaxial film and the application of the high-quality AlN epitaxial film. According to the invention, the two core links of imaging a sapphire substrate / AlN template and carrying out the high-temperature annealing are combined. The approach of effectively reducing the residual stress is realized through the lateral epitaxy process and the high-temperature annealing process. In this way, an AlN epitaxial film, which is free of cracks, flat in atom level and low in dislocation density, is obtained. As a result, the invention has important significance for realizing the industrial application of AlGaN-based deep ultraviolet high-performance light-emitting and detecting instruments.

Owner:北京中博芯半导体科技有限公司

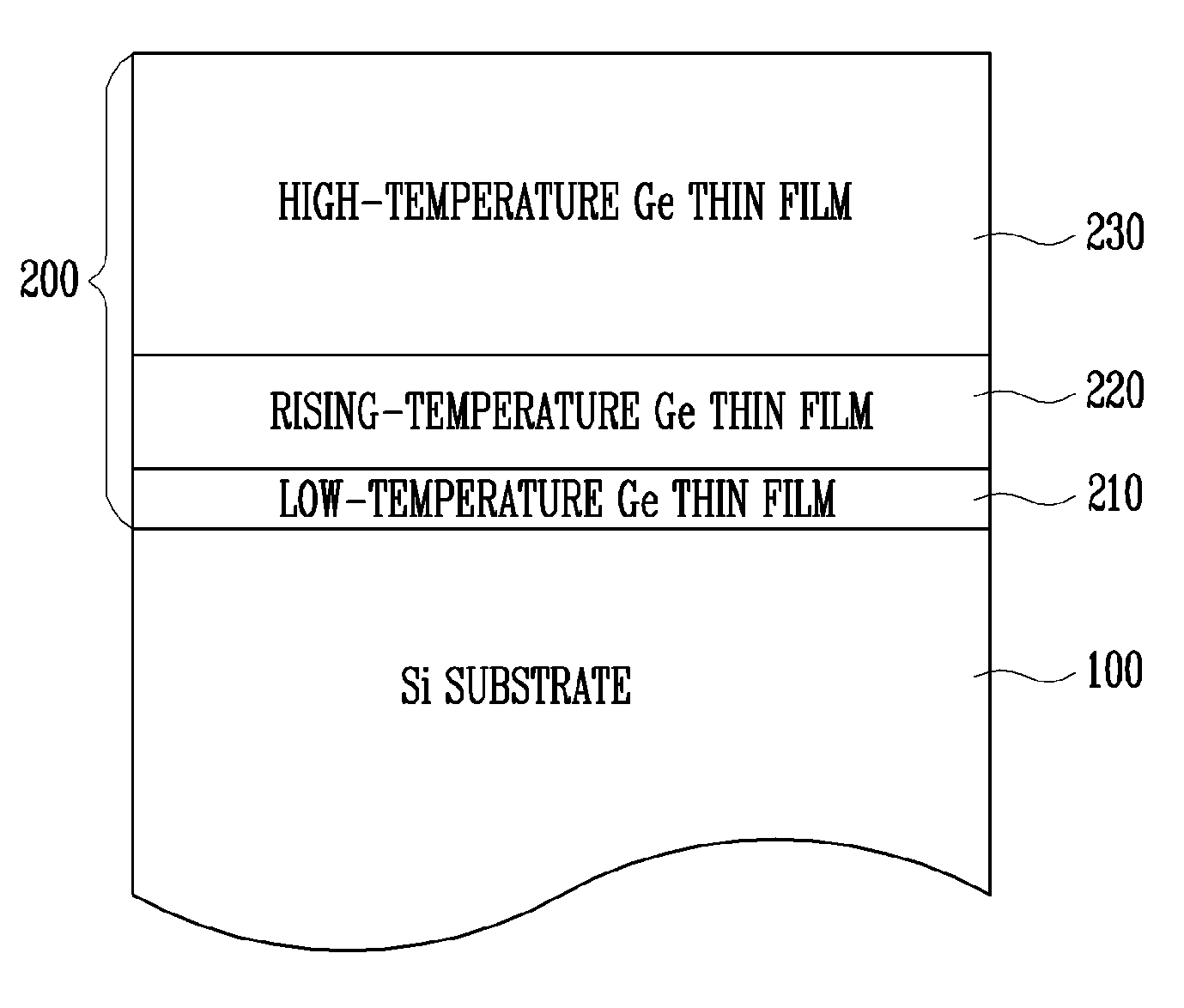

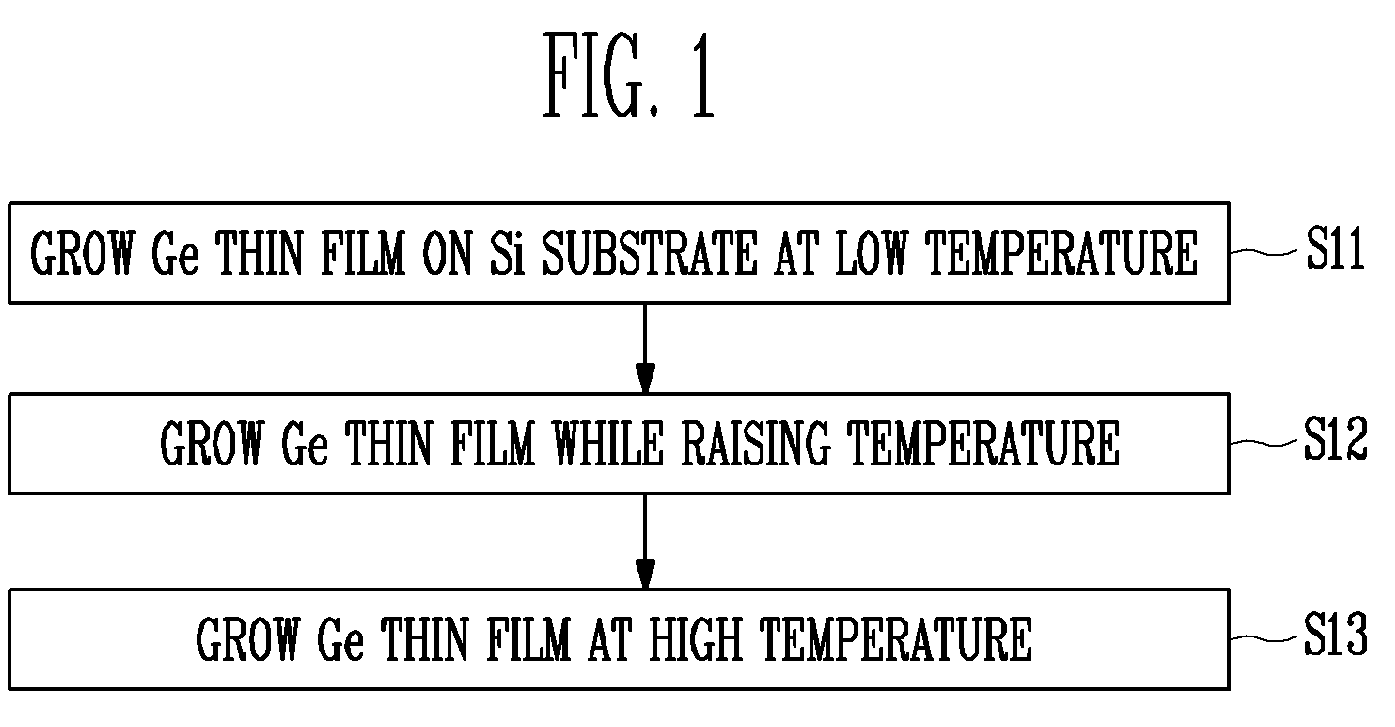

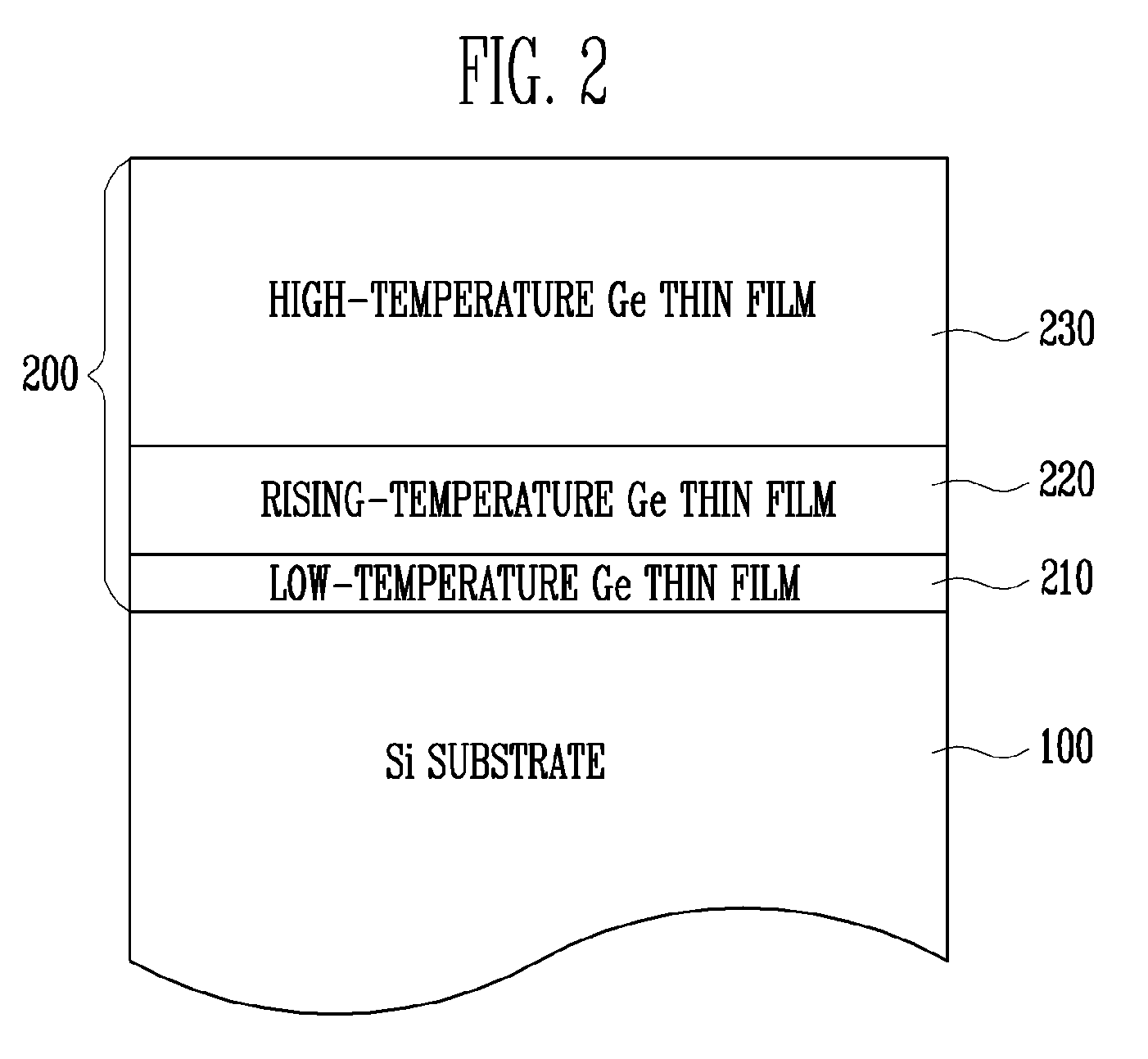

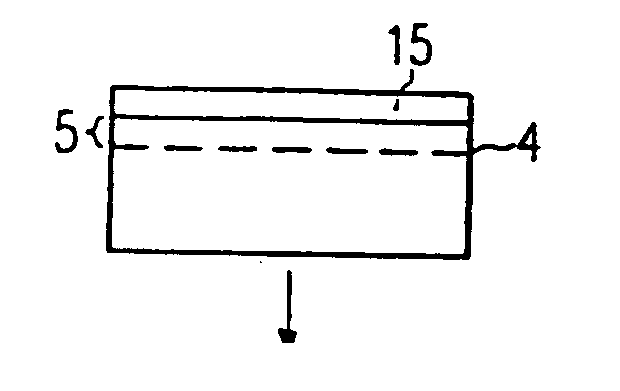

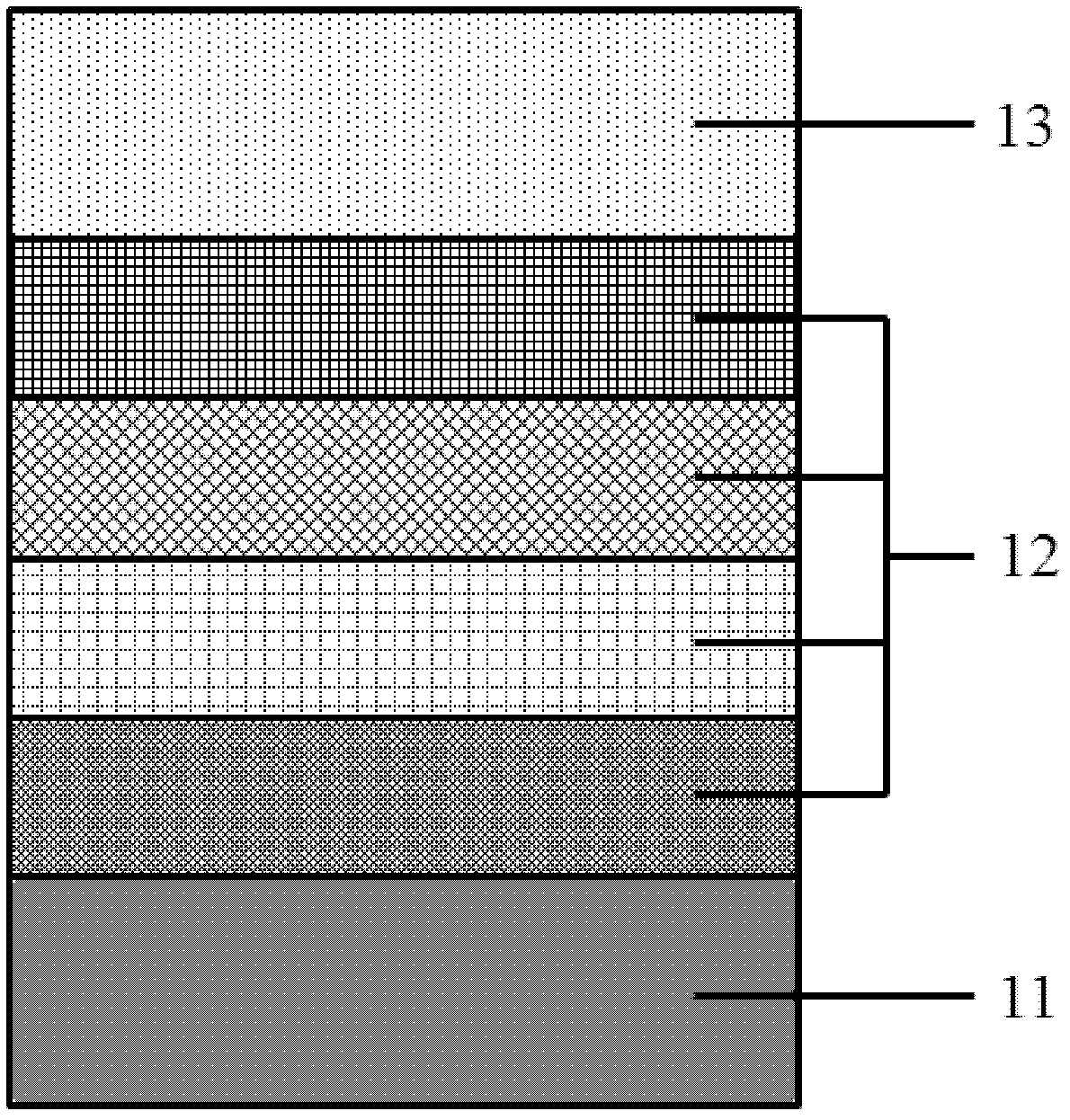

Growth of germanium epitaxial thin film with negative photoconductance characteristics and photodiode using the same

ActiveUS8188512B2Reduce pressureEasy to mass producePolycrystalline material growthSemiconductor/solid-state device manufacturingThree stageReduced pressure chemical vapor deposition

A method of growing a germanium (Ge) epitaxial thin film having negative photoconductance characteristics and a photodiode using the same are provided. The method of growing the germanium (Ge) epitaxial thin film includes growing a germanium (Ge) thin film on a silicon substrate at a low temperature, raising the temperature to grow the germanium (Ge) thin film, and growing the germanium (Ge) thin film at a high temperature, wherein each stage of growth is performed using reduced pressure chemical vapor deposition (RPCVD). The three-stage growth method enables formation of a germanium (Ge) epitaxial thin film characterized by alleviated stress on a substrate, a lowered penetrating dislocation density, and reduced surface roughness.

Owner:ELECTRONICS & TELECOMM RES INST

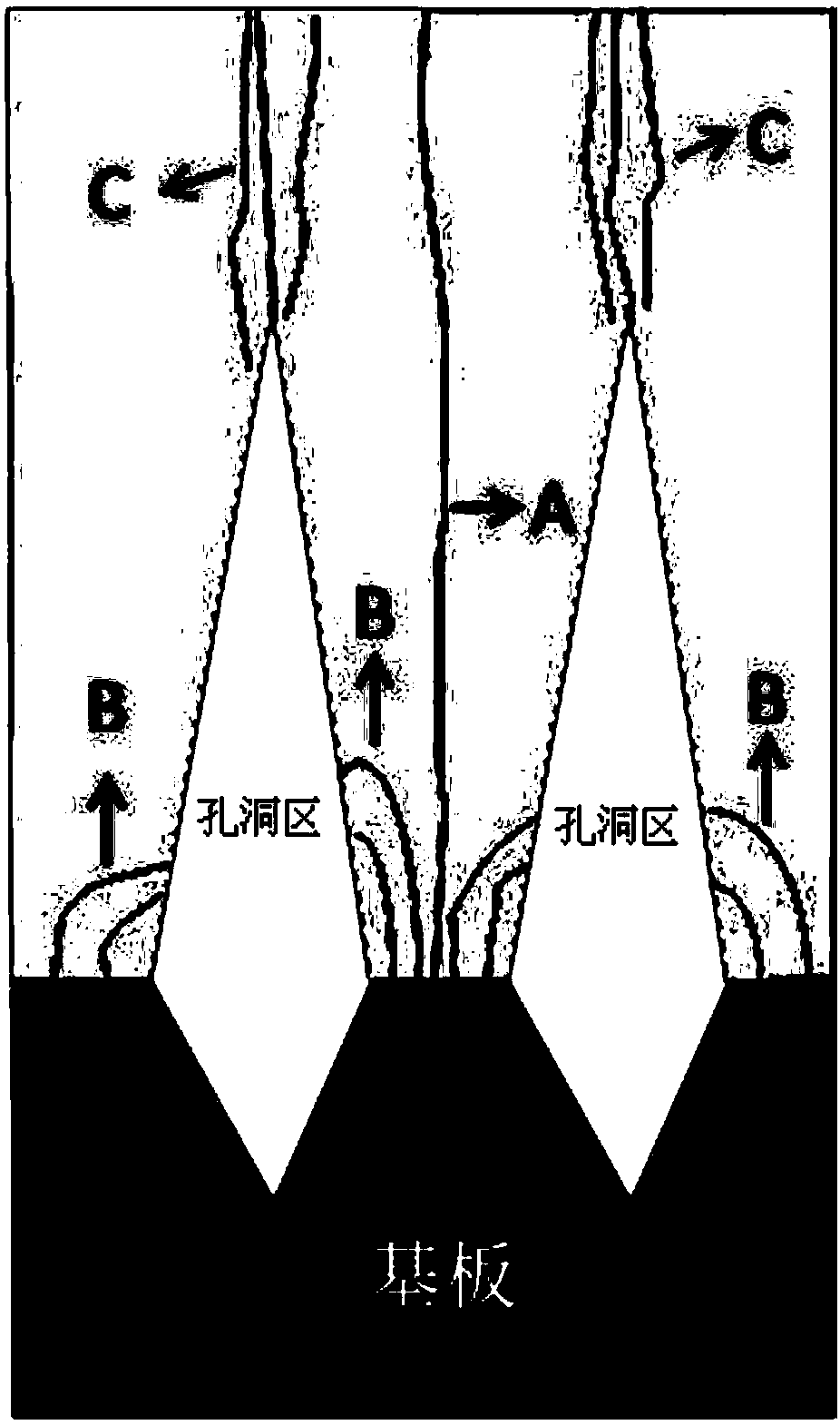

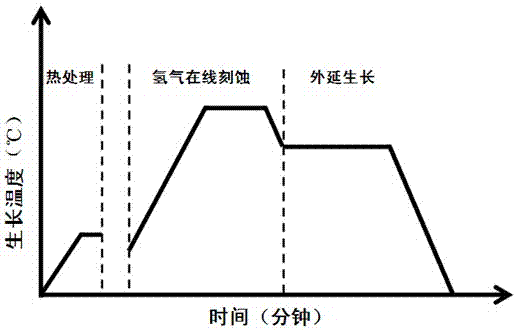

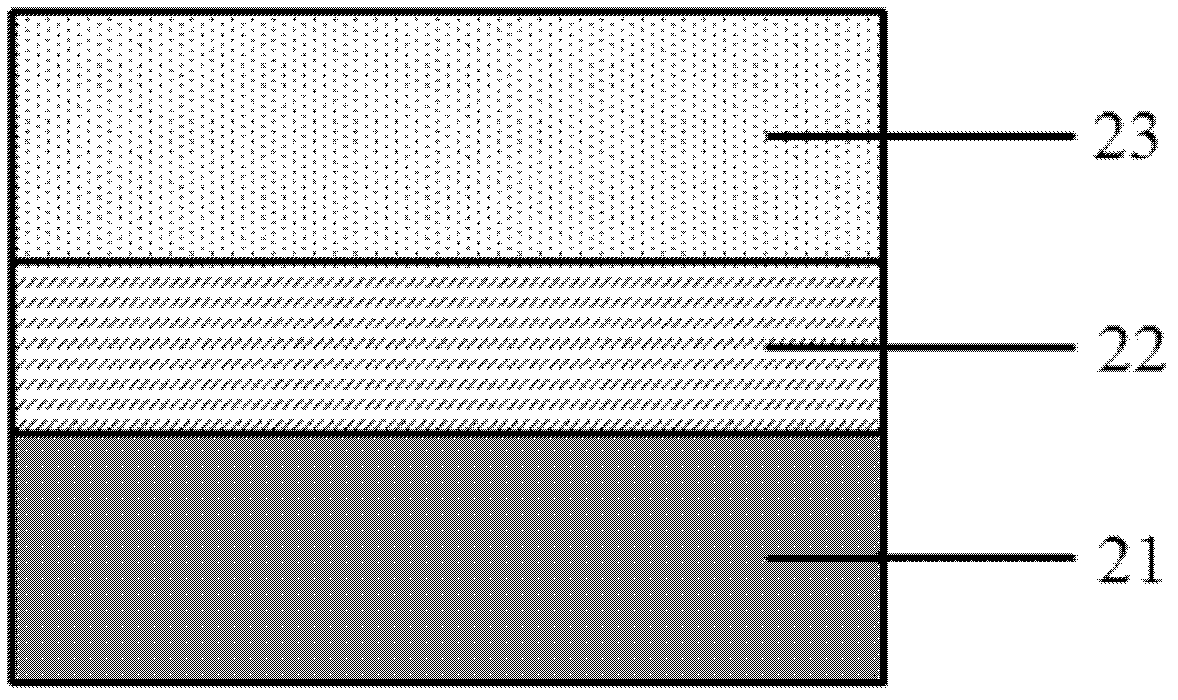

Gallium nitride homoepitaxy method based on in situ etching

ActiveCN103614769AQuality improvementEfficient removalSemiconductor/solid-state device manufacturingFrom chemically reactive gasesMicro structureEffective solution

The invention discloses a gallium nitride homoepitaxy method based on in situ etching. The method comprises the following steps: 1) selecting a gallium nitride substrate and transferring the substrate into an MOCVD system; 2) conducting fast etching on the substrate for a short time; 3) conducting long-time slow etching after the fast etching to form hexagonal pyramid micro structures on the substrate surface; 4) laterally growing to merge the hexagonal pyramid micro structures; and 5) continuing to grow a high-quality GaN epitaxial layer on the merged film. The invention has the following advantages: through the control of components of in situ etching gas, impurities on the surface of the substrate are removed, while the hexagonal pyramid micro structures are formed on the surface of the substrate; and the micro structures are merged in a lateral epitaxial stage, so as to reduce the dislocation density of the epitaxial layer and finally obtain the gallium nitride epitaxial thin film with high quality. Formation of hexagonal pyramid micro structures on the surface of the substrate does not need additional process equipment; the method is economical, simple and practicable; and the epitaxial material has good performance. Therefore, the method provided by the invention is an effective solution for realizing high-quality and low-cost growth of GaN epitaxial thin film.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

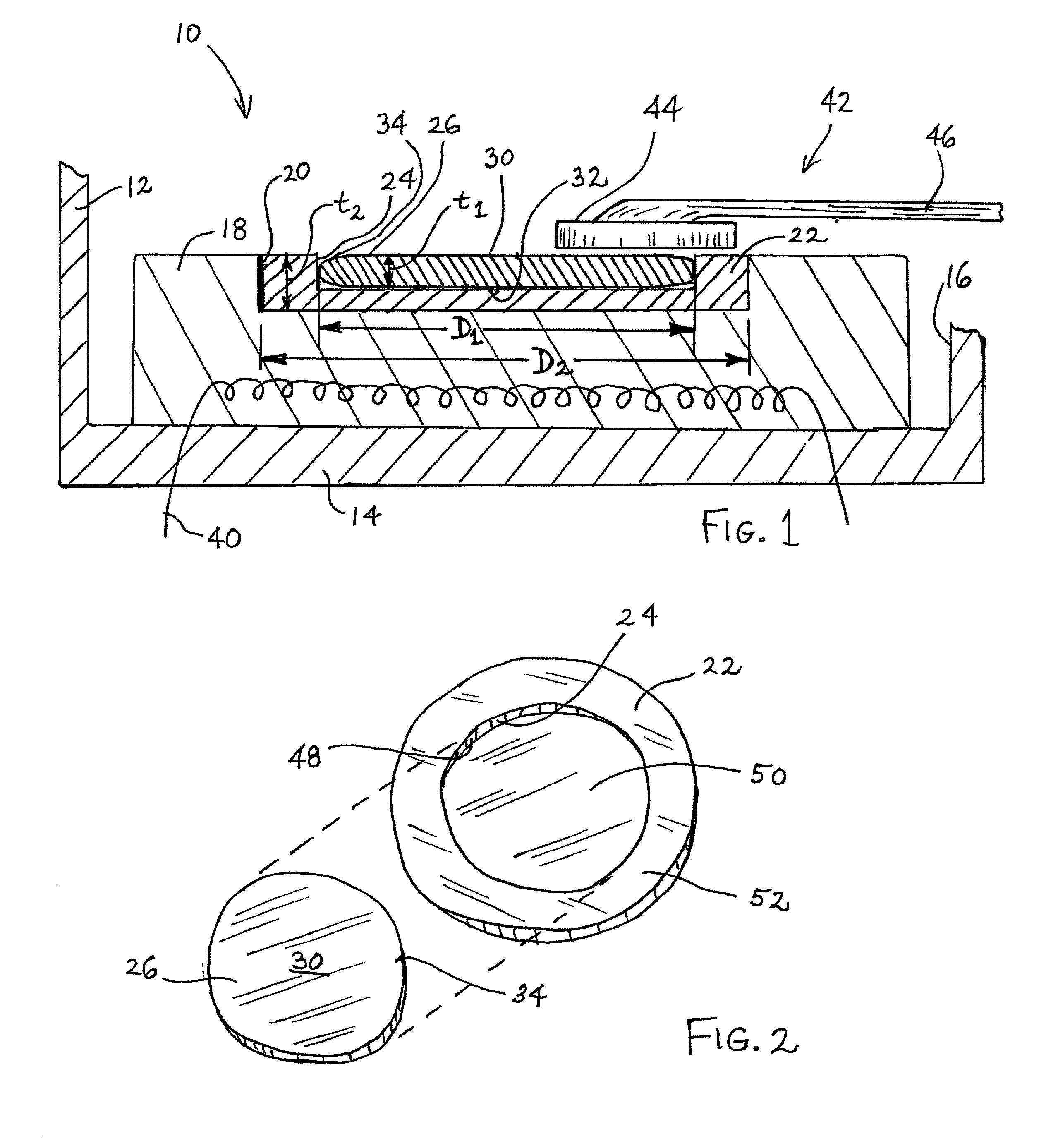

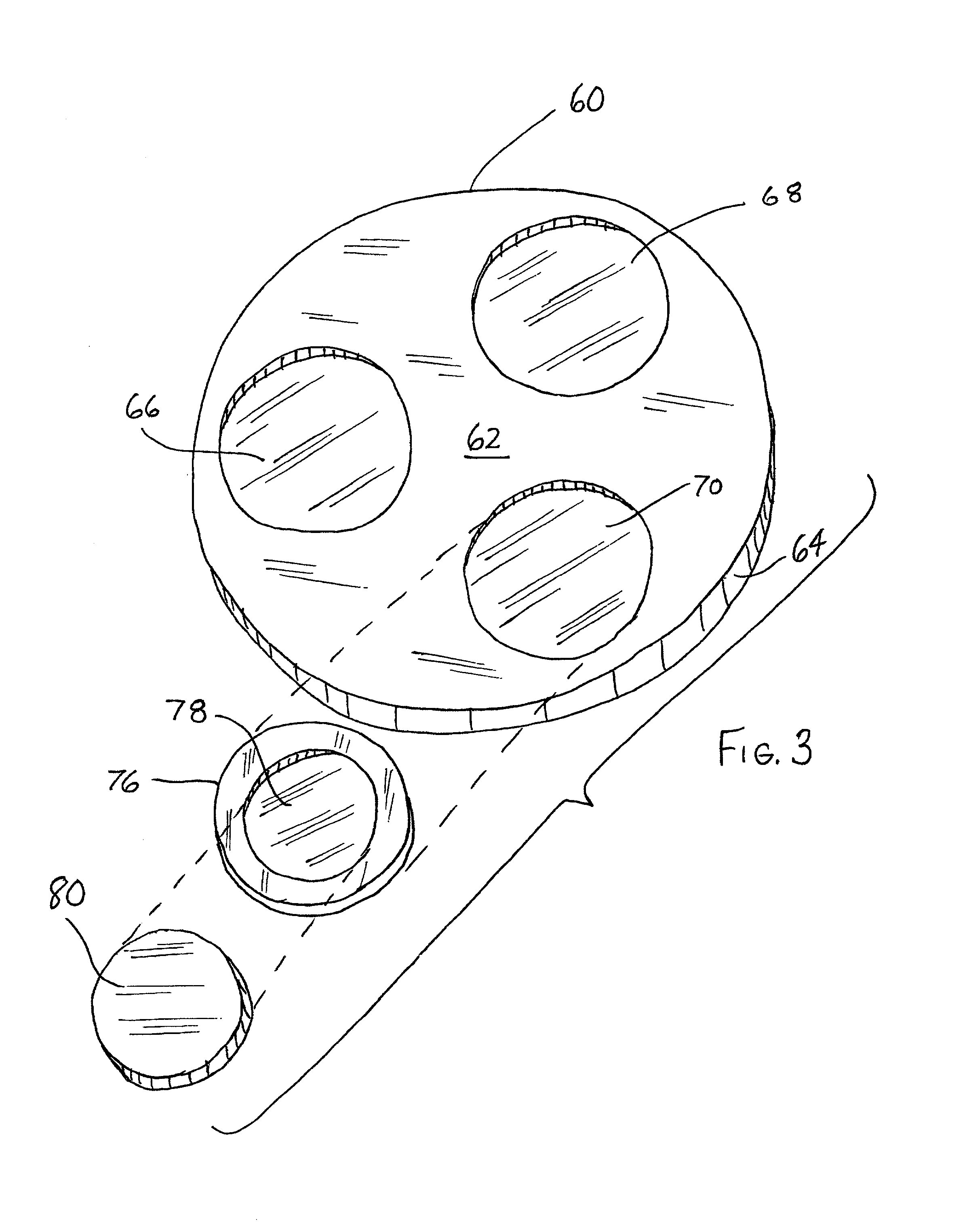

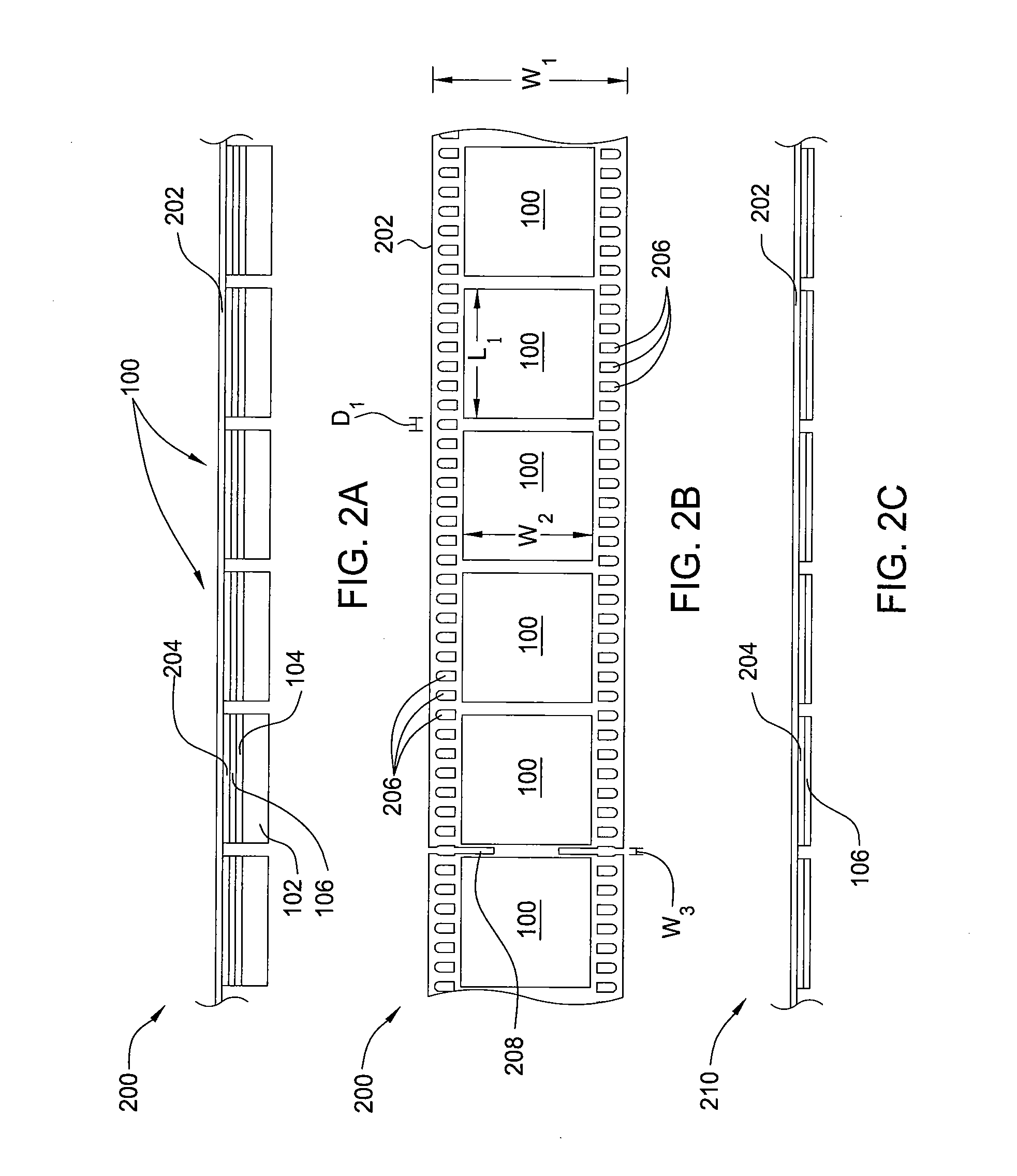

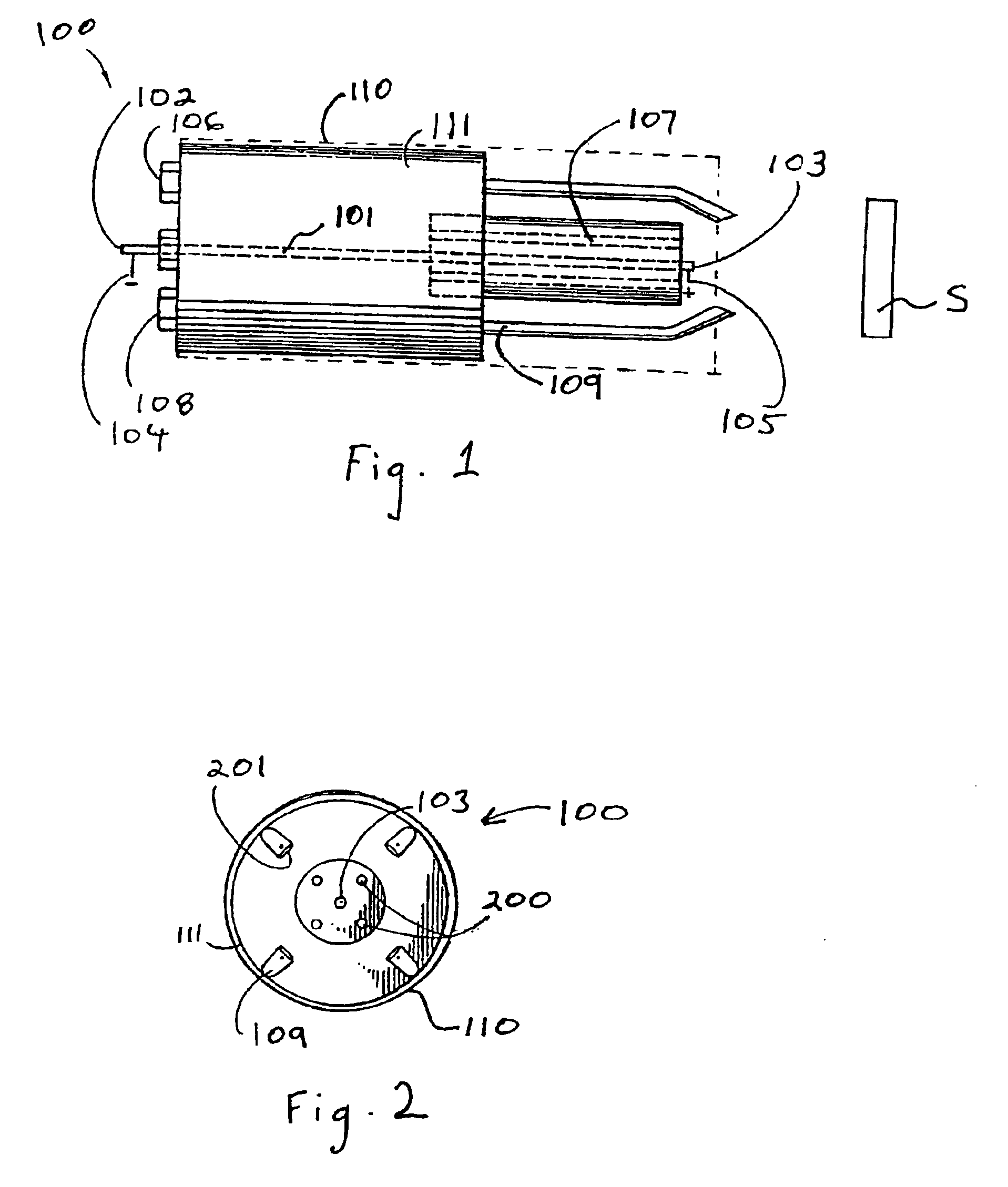

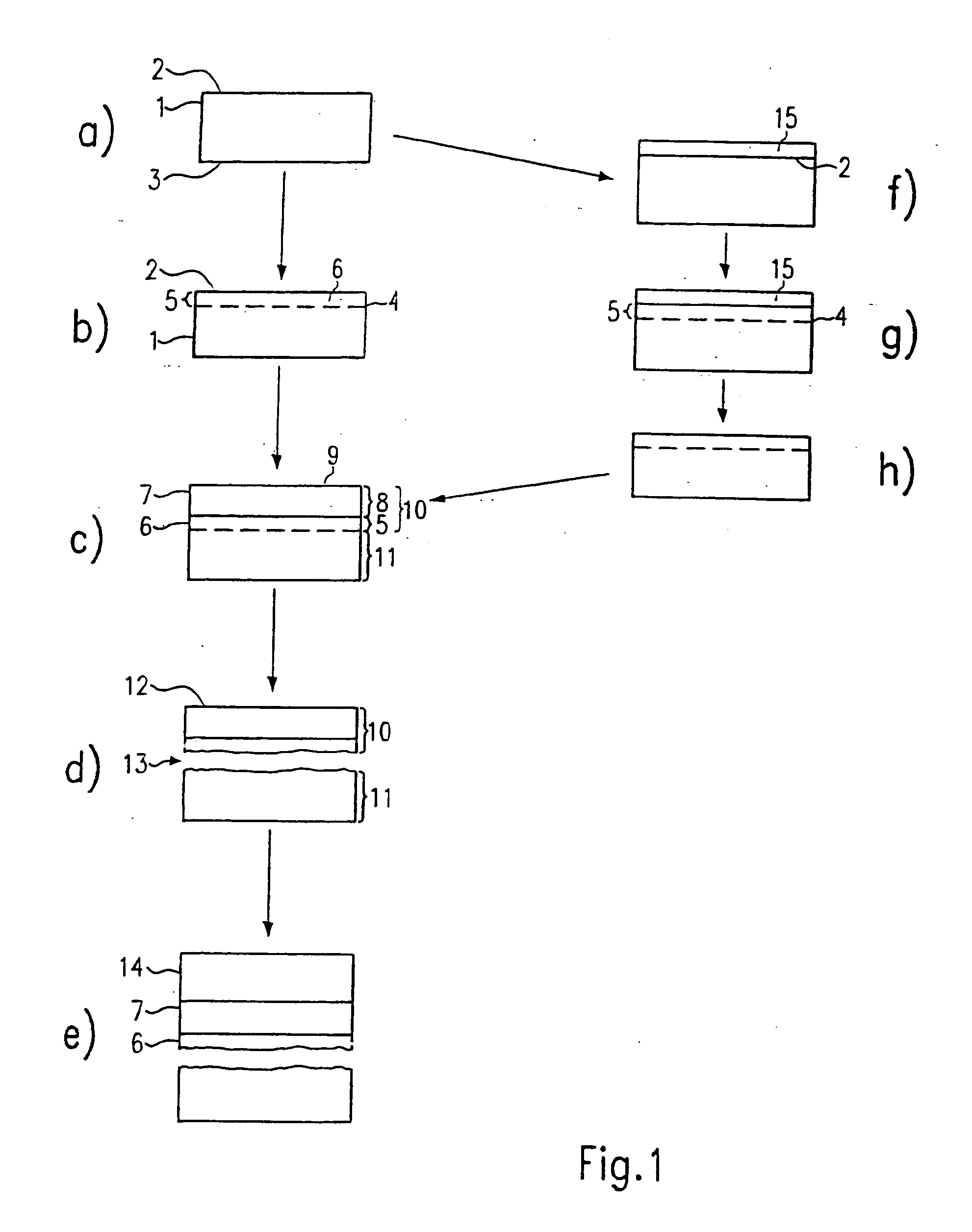

Tape-based epitaxial lift off apparatuses and methods

ActiveUS20100151689A1Solid-state devicesSemiconductor/solid-state device manufacturingWaferingEngineering

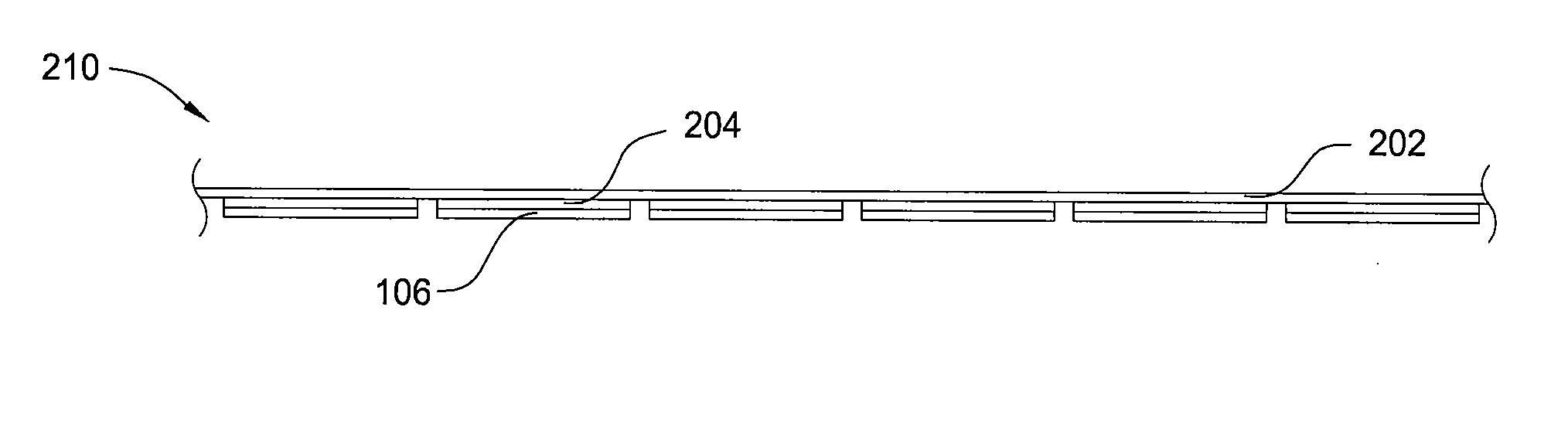

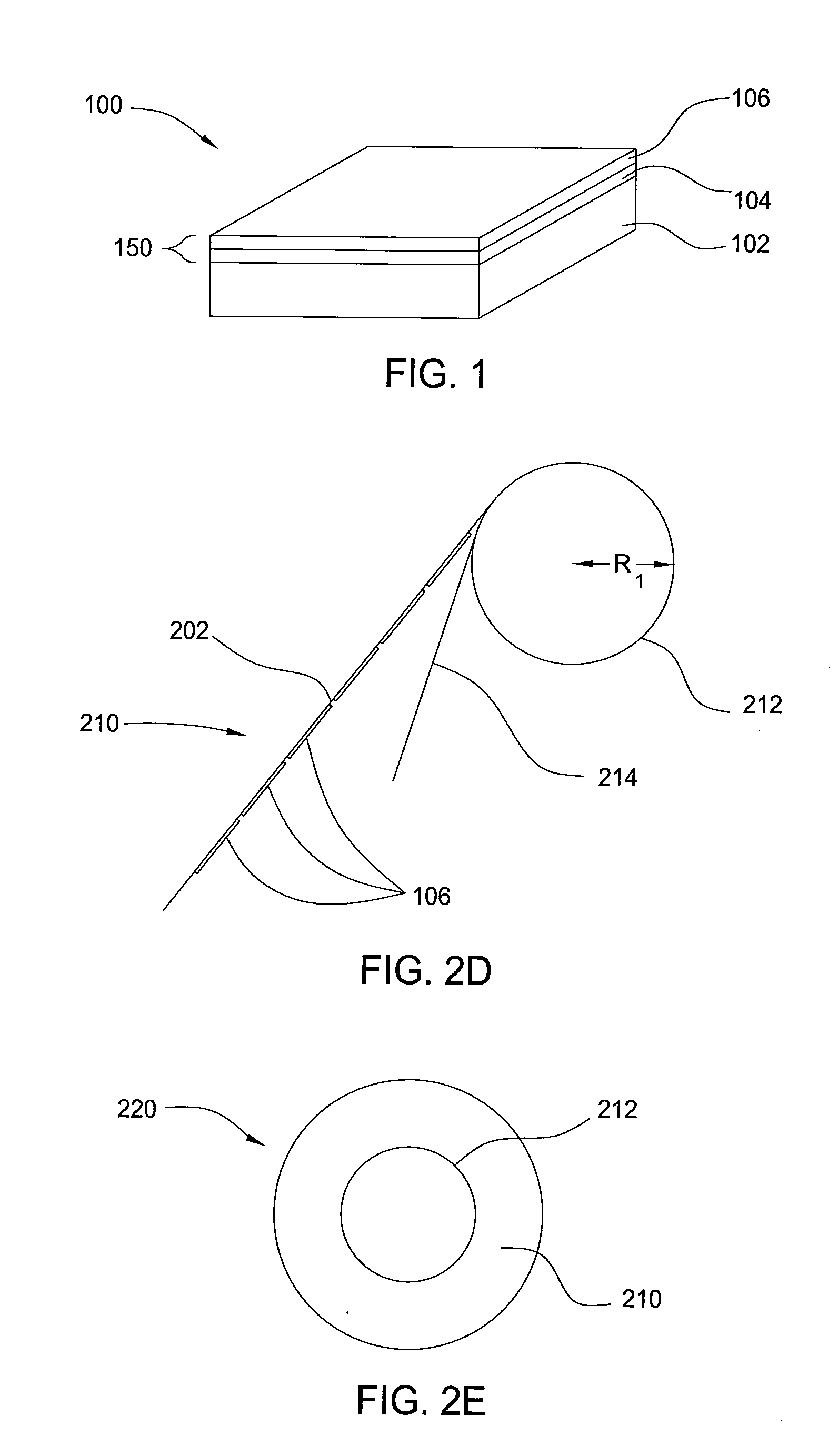

Embodiments of the invention generally relate to apparatuses and methods for producing epitaxial thin films and devices by epitaxial lift off (ELO) processes. In one embodiment, a method for forming thin film devices during an ELO process is provided which includes coupling a plurality of substrates to an elongated support tape, wherein each substrate contains an epitaxial film disposed over a sacrificial layer disposed over a wafer, exposing the substrates to an etchant during an etching process while moving the elongated support tape, and etching the sacrificial layers and peeling the epitaxial films from the wafers while moving the elongated support tape. Embodiments also include several apparatuses, continuous-type as well as a batch-type apparatuses, for forming the epitaxial thin films and devices, including an apparatus for removing the support tape and epitaxial films from the wafers on which the epitaxial films were grown.

Owner:ALTA DEVICES INC

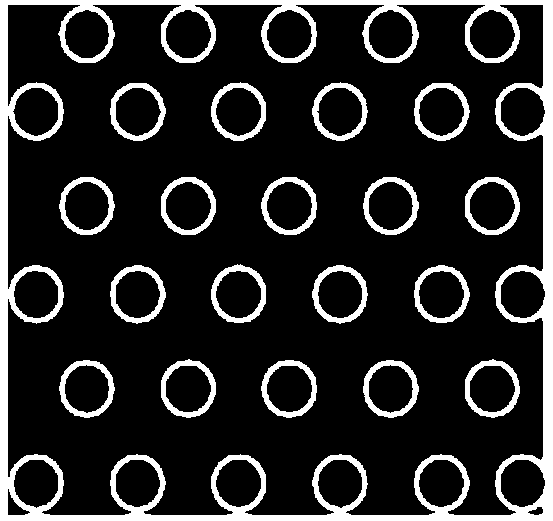

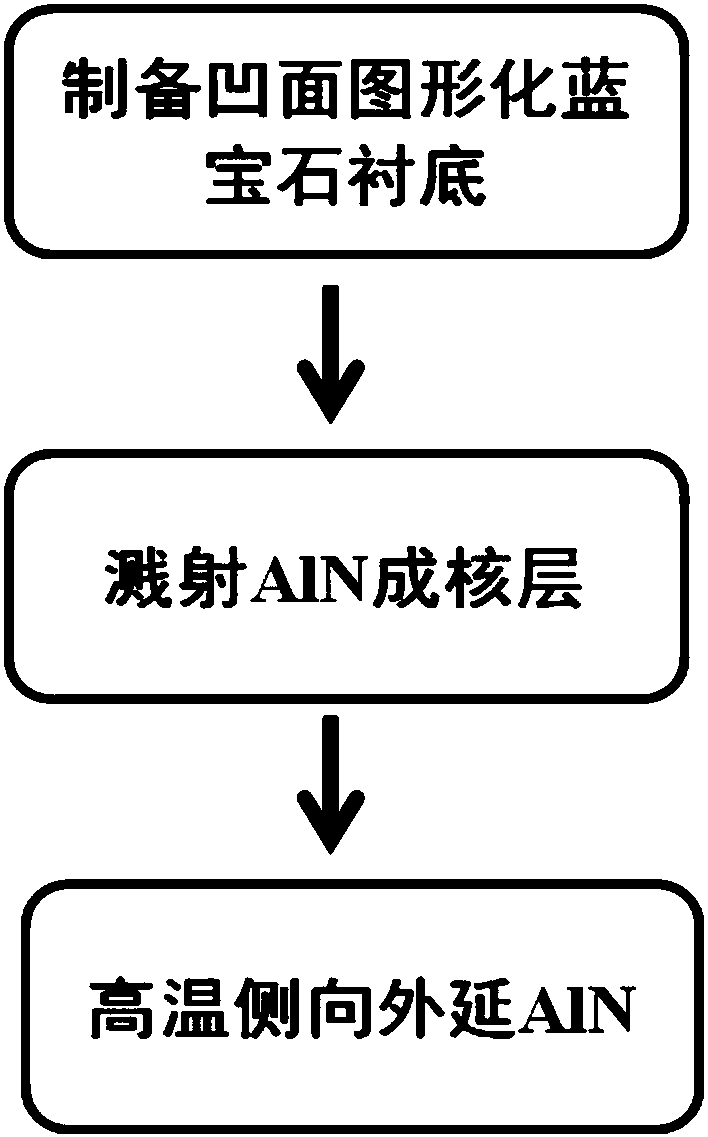

AlN film preparation method based on patterned sapphire substrate and pre-sputtering technology

The invention belongs to the field of III-family nitride semiconductor preparation technology, and relates to preparation of a low-dislocation-density AlN epitaxial film. The method of the invention is combined with two core key links of a patterned sapphire substrate and a pre-sputtering AlN nucleation layer. Based on the two core key links, a lateral epitaxial process is realized through metal organic chemical vapor deposition (MOCVD), thereby obtaining the AlN film with smooth surface and low dislocation density.

Owner:PEKING UNIV

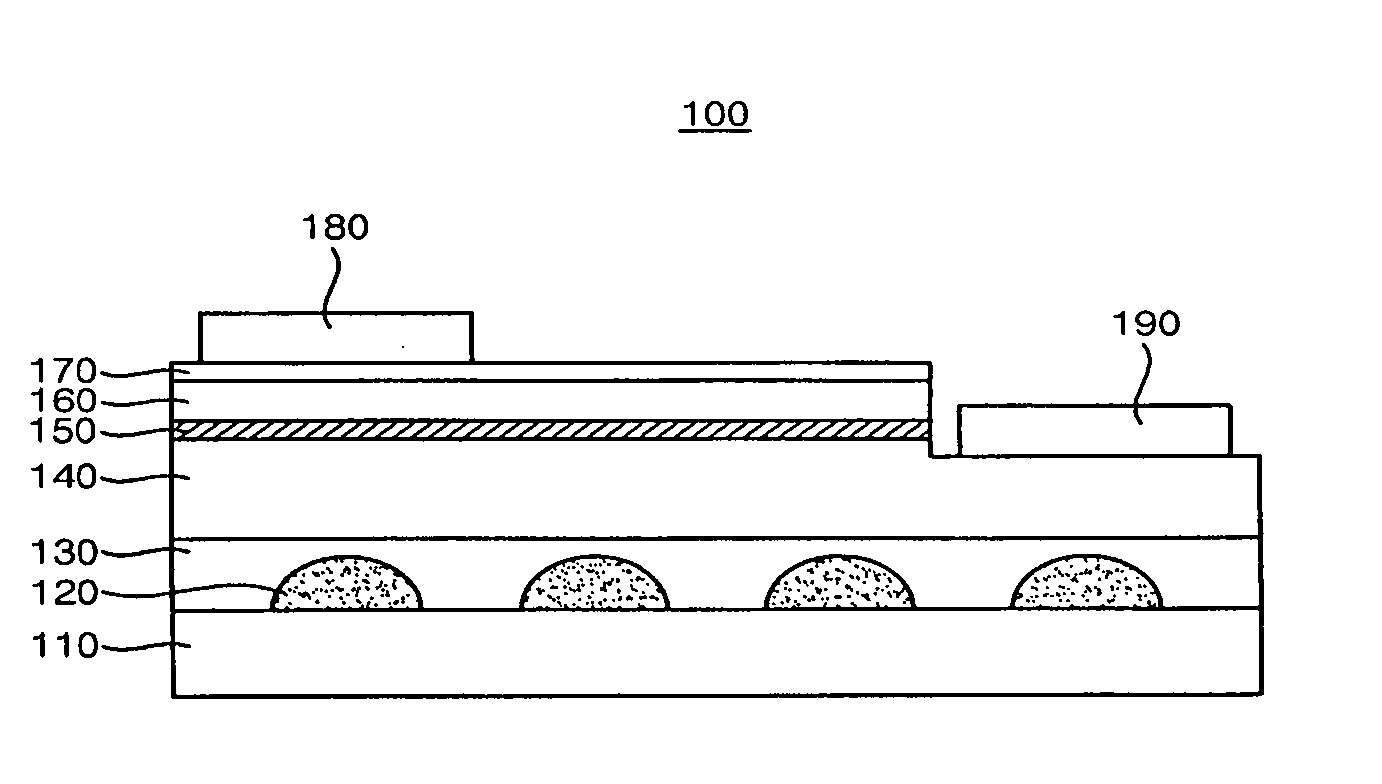

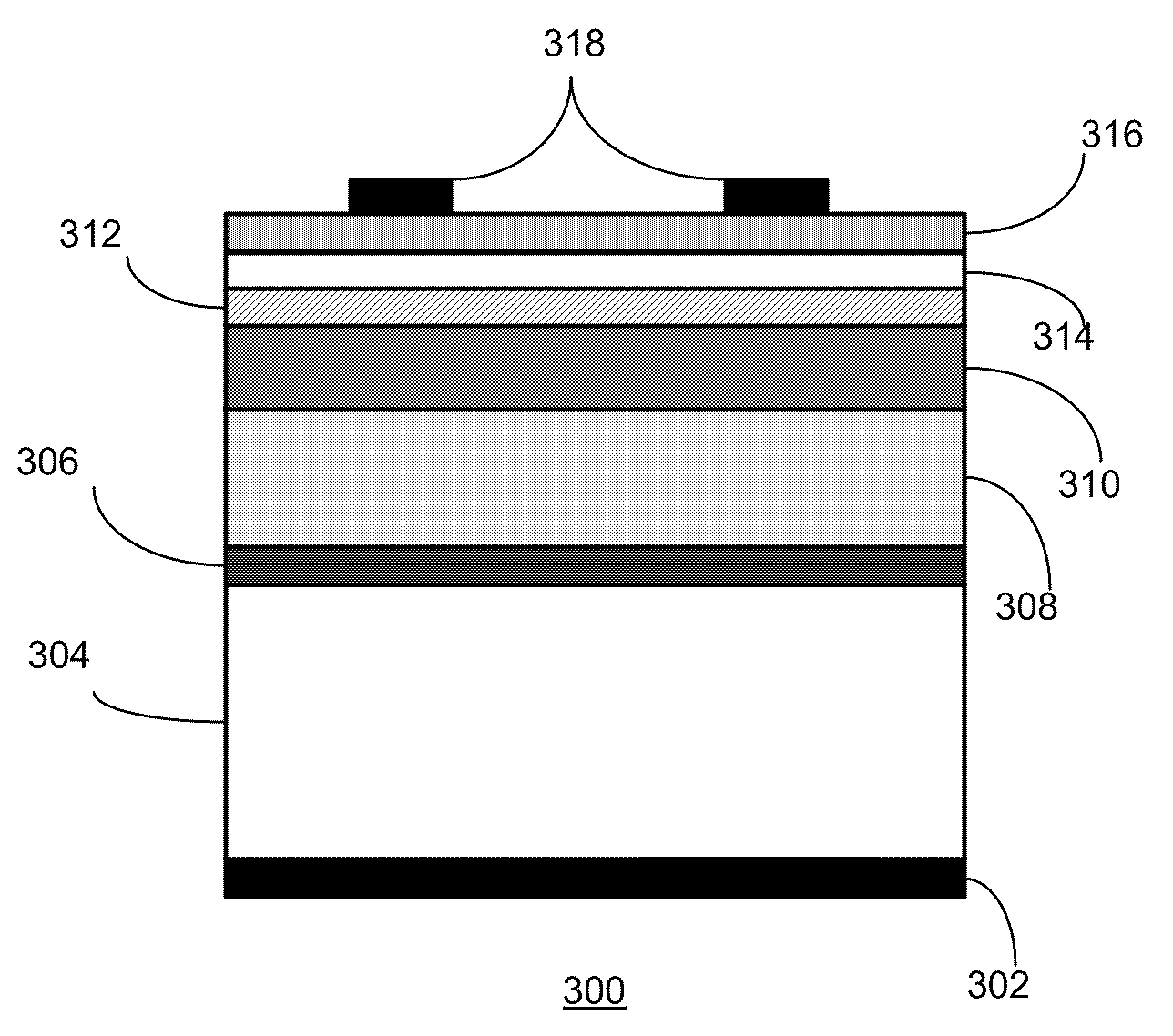

Silicon-based dielectric stack passivation of si-epitaxial thin-film solar cells

ActiveUS20100258168A1Final product manufactureSemiconductor/solid-state device manufacturingOhmic contactDielectric layer

One embodiment of the present invention provides a solar cell. The solar cell includes a metallurgical-grade Si (MG-Si) substrate, a first layer of heavily doped crystalline-Si situated above the MG-Si substrate, a layer of lightly doped crystalline-Si situated above the first heavily doped crystalline-Si layer, a backside ohmic-contact layer situated on the backside of the MG-Si substrate, a second layer of heavily doped crystalline-Si situated above the lightly doped crystalline-Si layer, a first layer of dielectric situated above the second heavily doped crystalline-Si layer, a second layer of dielectric situated above the first dielectric layer, and front electrodes situated above the second dielectric layer.

Owner:SOLARCITY

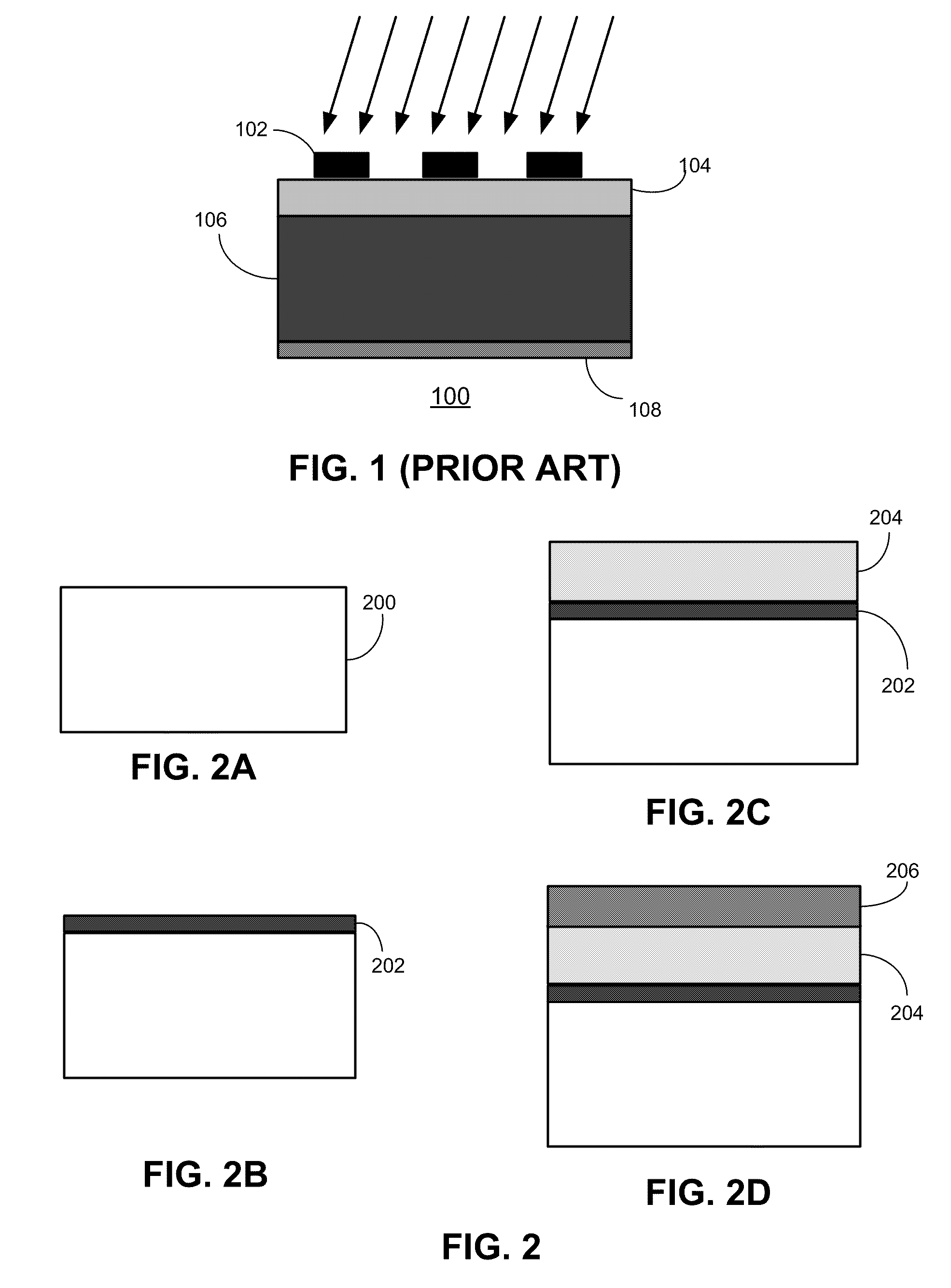

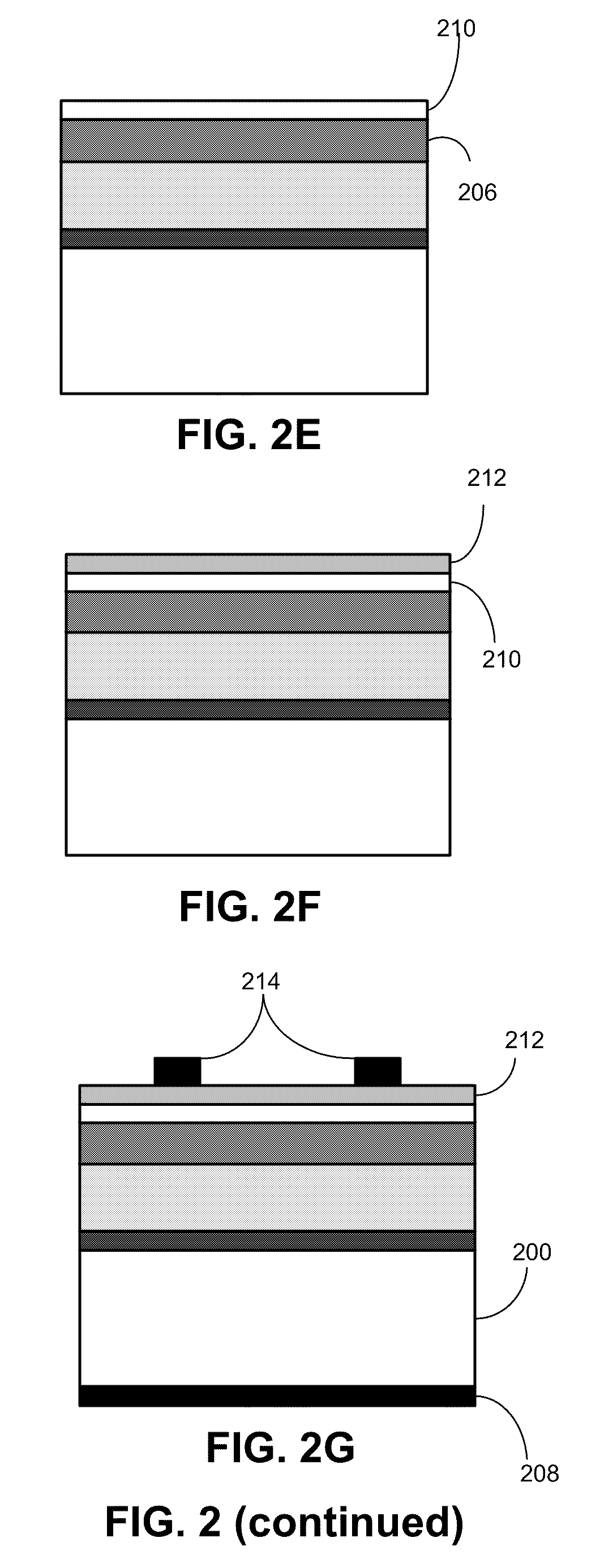

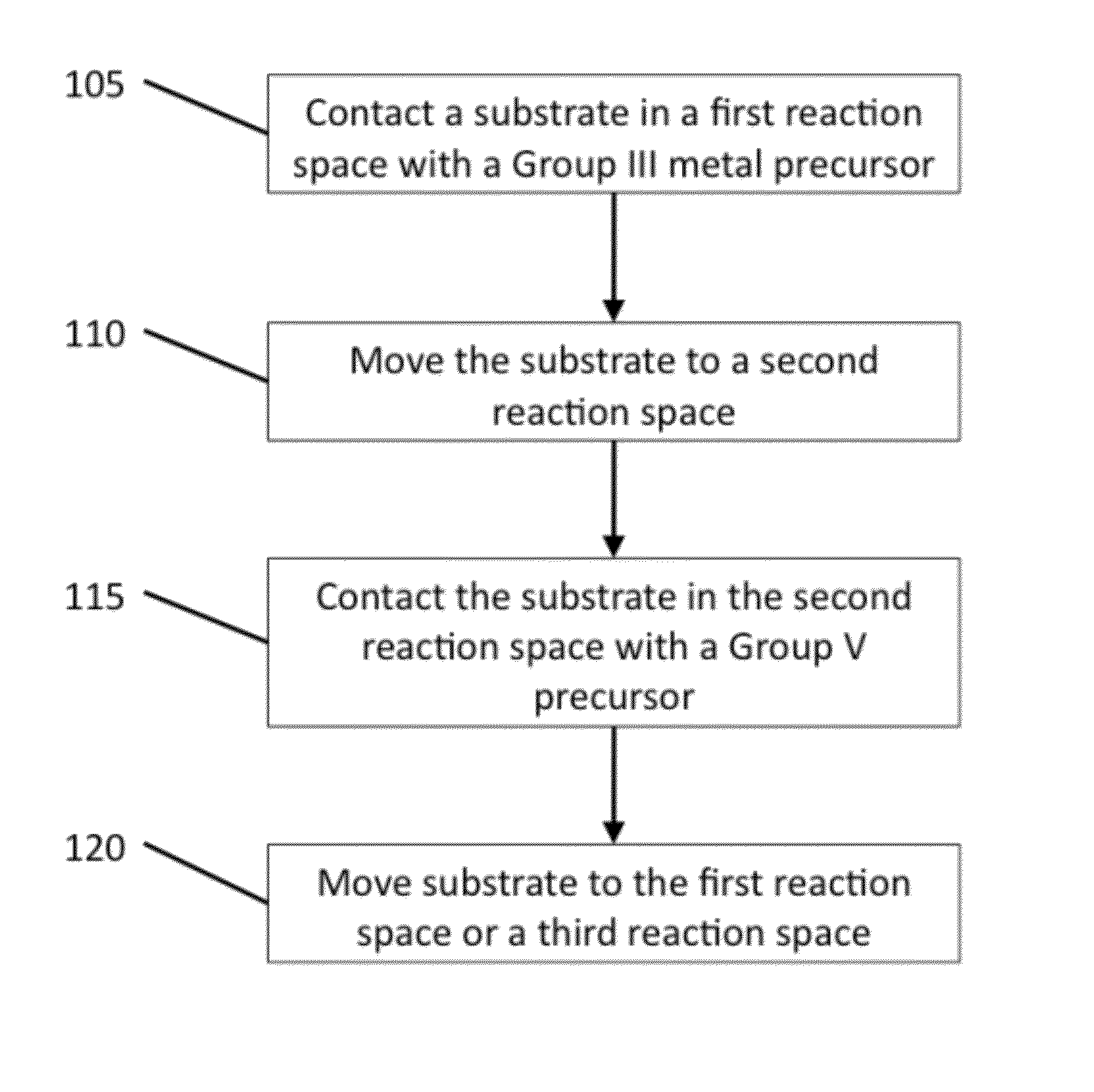

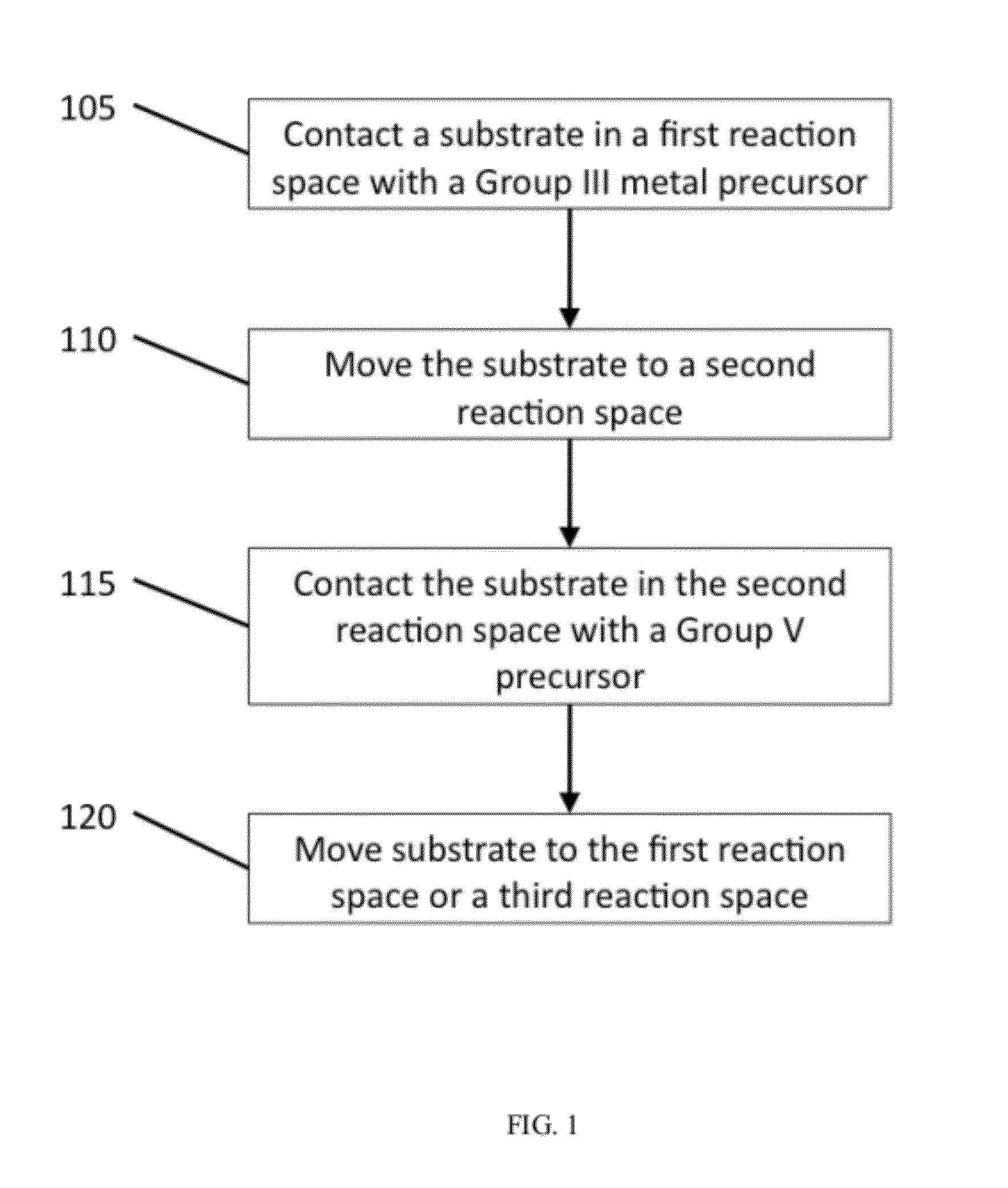

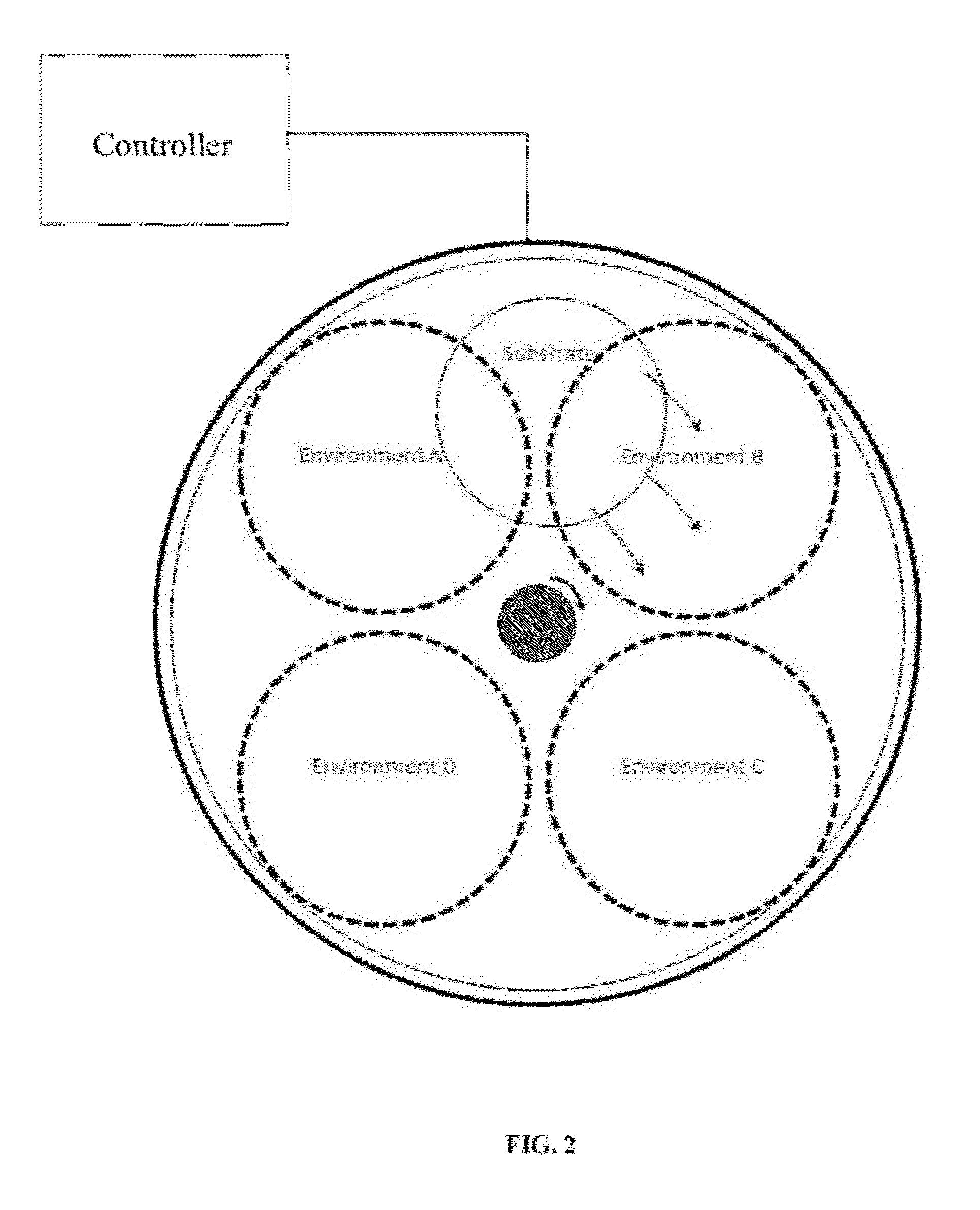

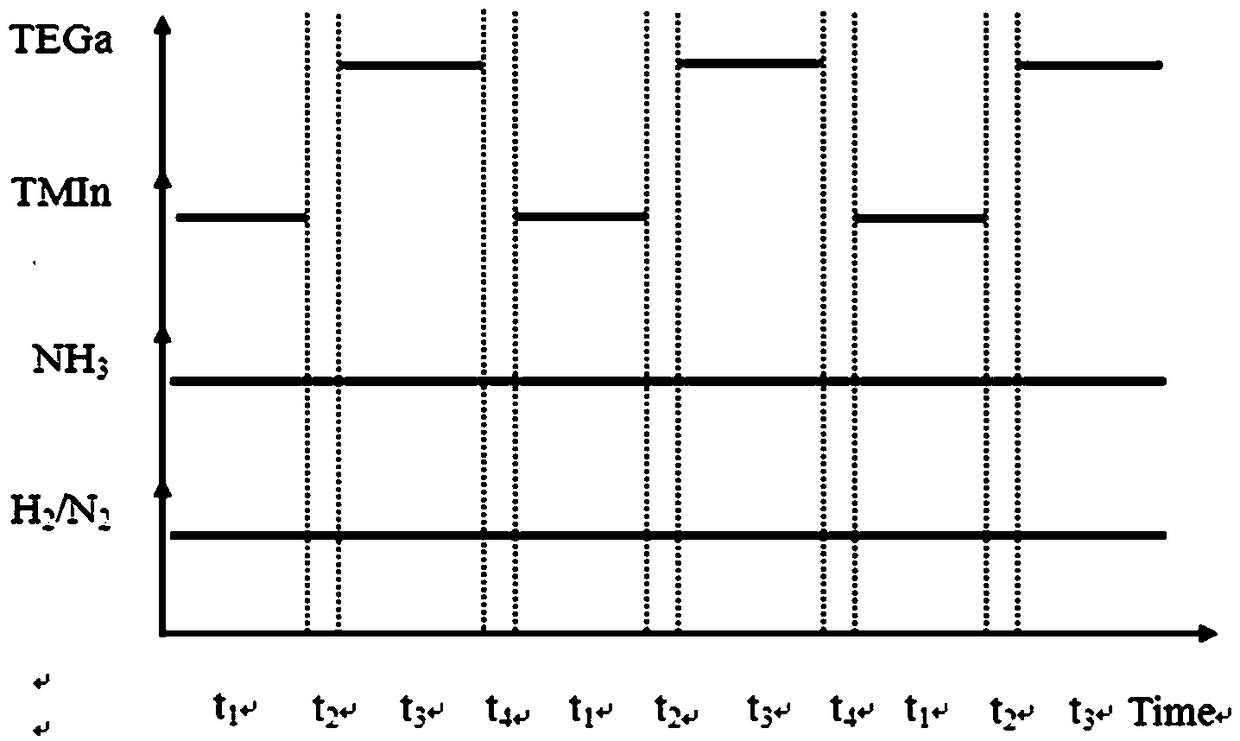

Methods and systems for forming thin films

InactiveUS8143147B1Minimize contaminationAfter-treatment apparatusPolycrystalline material growthAlloyDeposition process

A method and apparatus for the deposition of thin films is described. In embodiments, systems and methods for epitaxial thin film formation are provided, including systems and methods for forming binary compound epitaxial thin films. Methods and systems of embodiments of the invention may be used to form direct bandgap semiconducting binary compound epitaxial thin films, such as, for example, GaN, InN and AlN, and the mixed alloys of these compounds, e.g., (In, Ga)N, (Al, Ga)N, (In, Ga, Al)N. Methods and apparatuses include a multistage deposition process and system which enables rapid repetition of sub-monolayer deposition of thin films.

Owner:INTERMOLECULAR

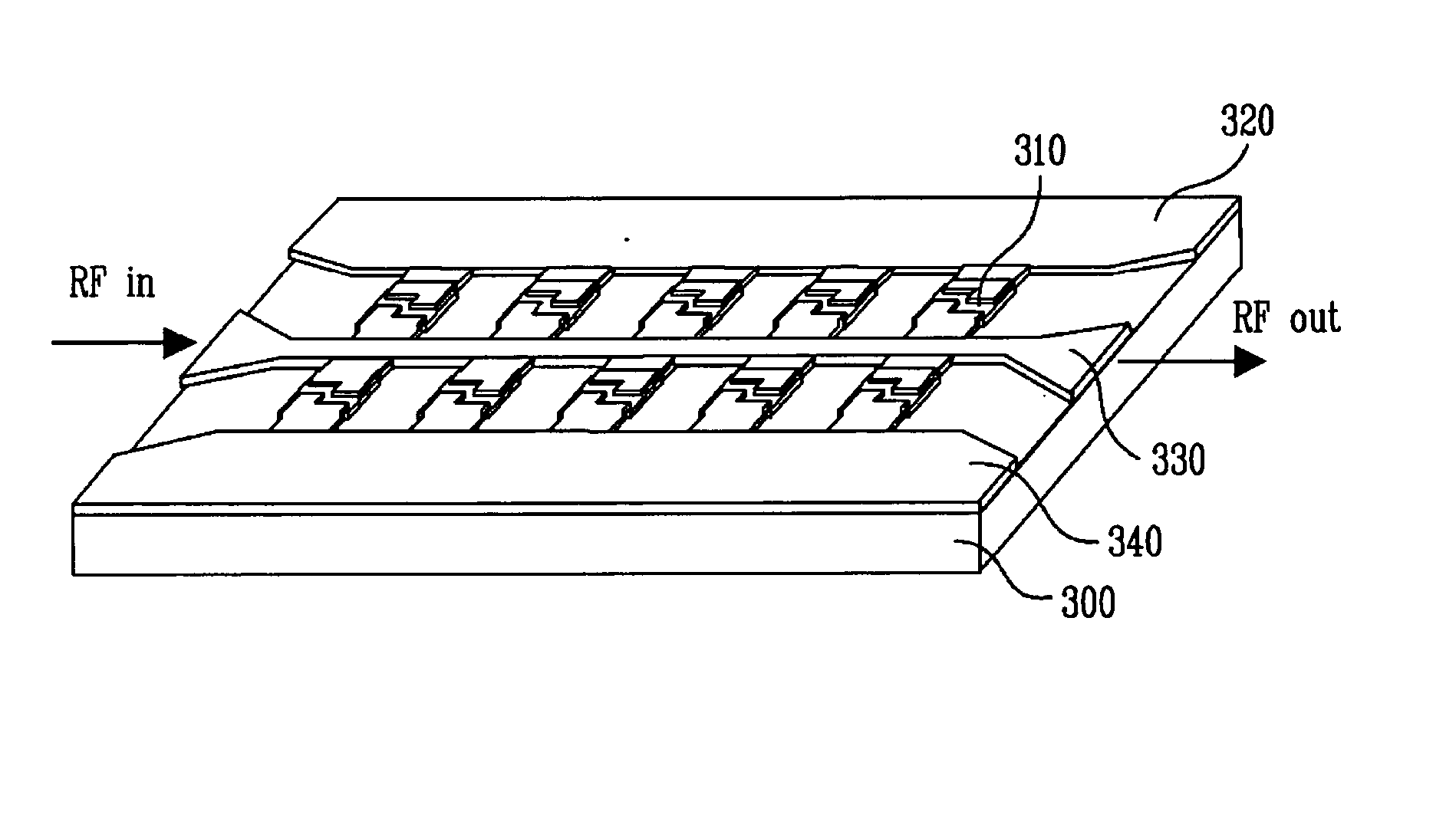

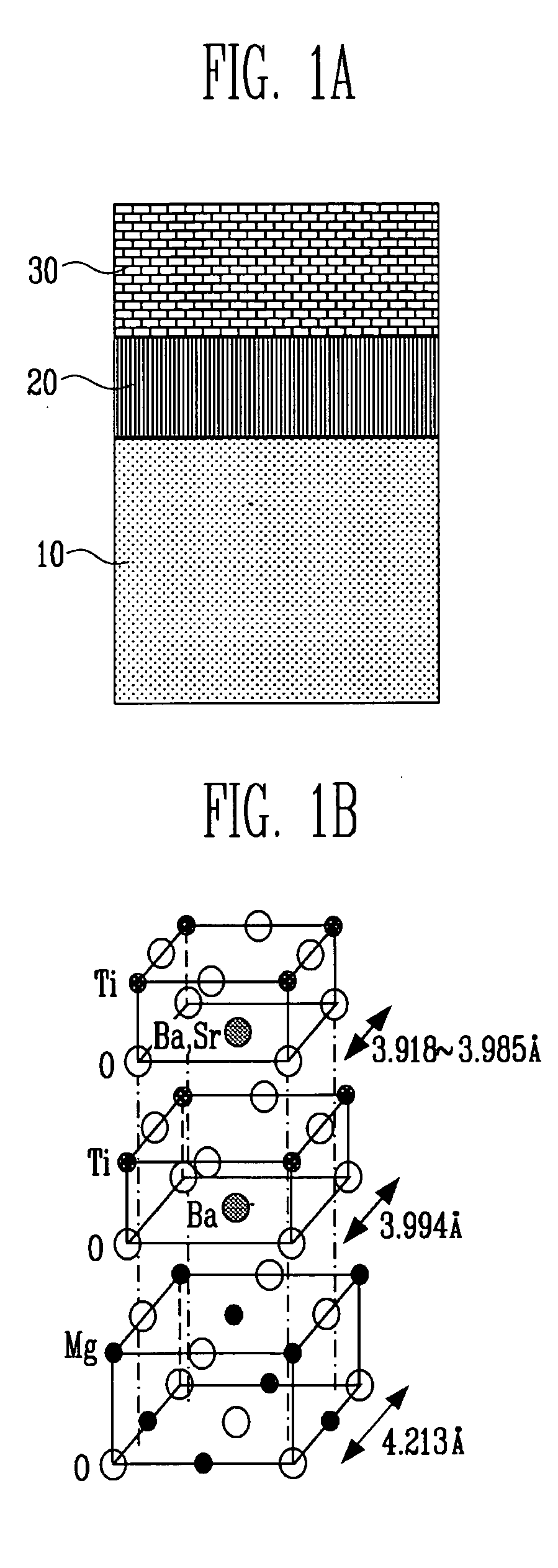

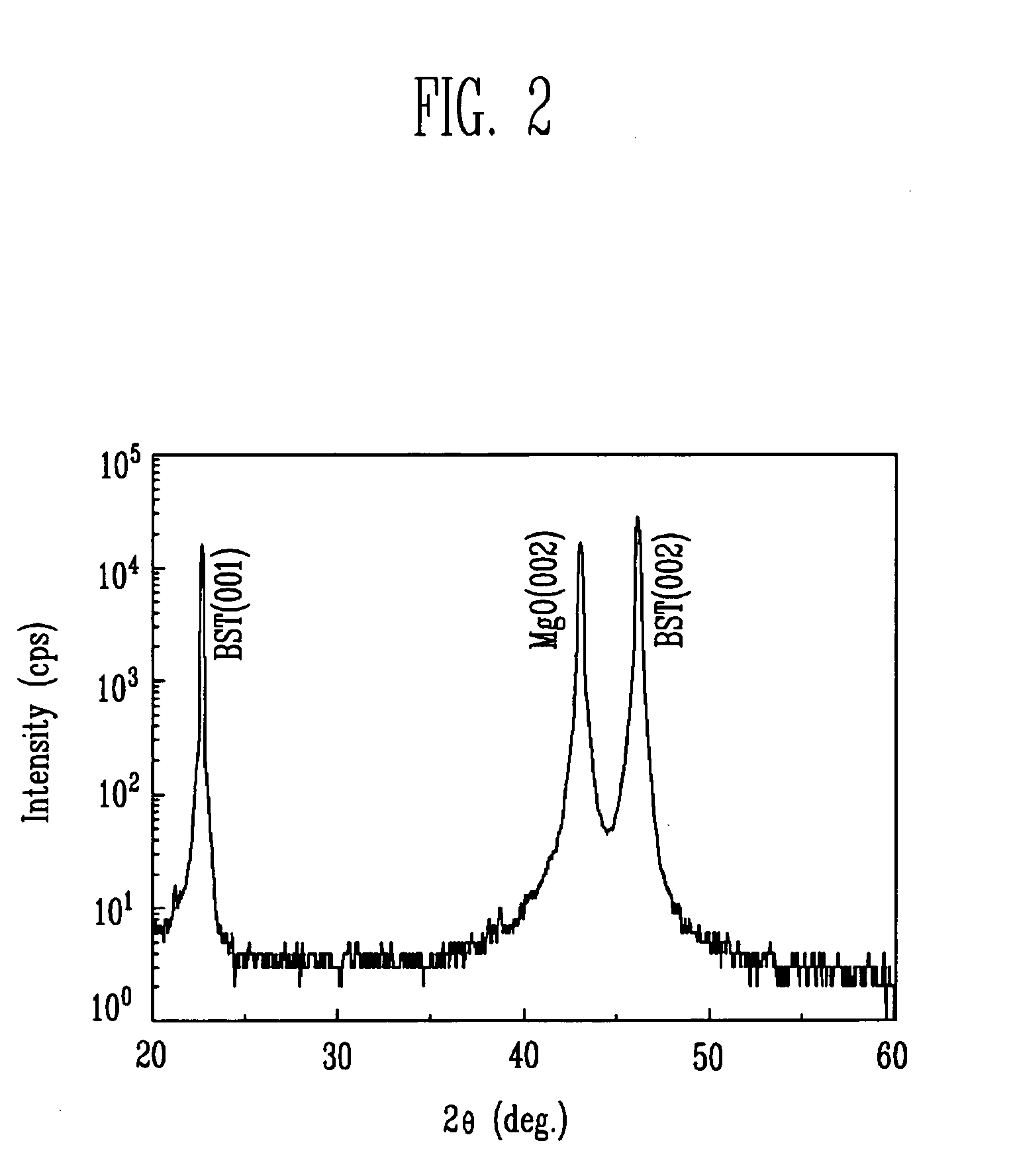

Ferroelectric epitaxial thin film for microwave tunable device and microwave tunable device using the same

InactiveUS20050128029A1Excellent dielectric propertiesImprove featuresSemiconductor/solid-state device manufacturingDelay linesUltra high speedOptoelectronics

Provided are a ferroelectric epitaxial thin film for a microwave tunable device including a ferroelectric BaTiO3 seed layer and an epitaxial (Ba1-xSrx)TiO3 thin film, and a microwave tunable device using the same, whereby it is possible to improve the microwave response property of the microwave tunable device, and to enhance the quality of the wireless communication with ultra high speed, low electric power, low cost, and high sensitivity, by using the device of the present invention as an active antenna system, a satellite communication system, or a wireless sensor system,

Owner:ELECTRONICS & TELECOMM RES INST

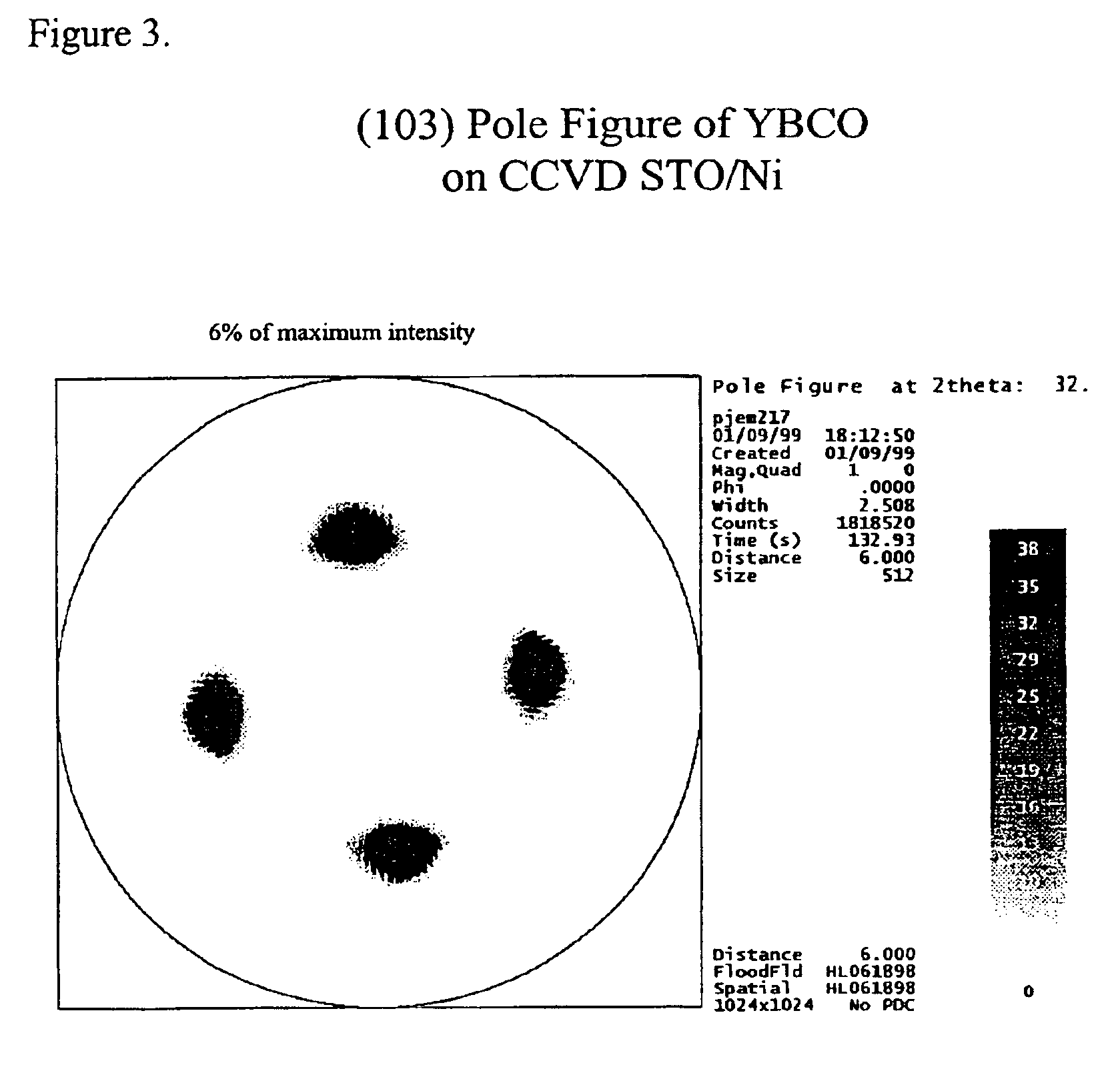

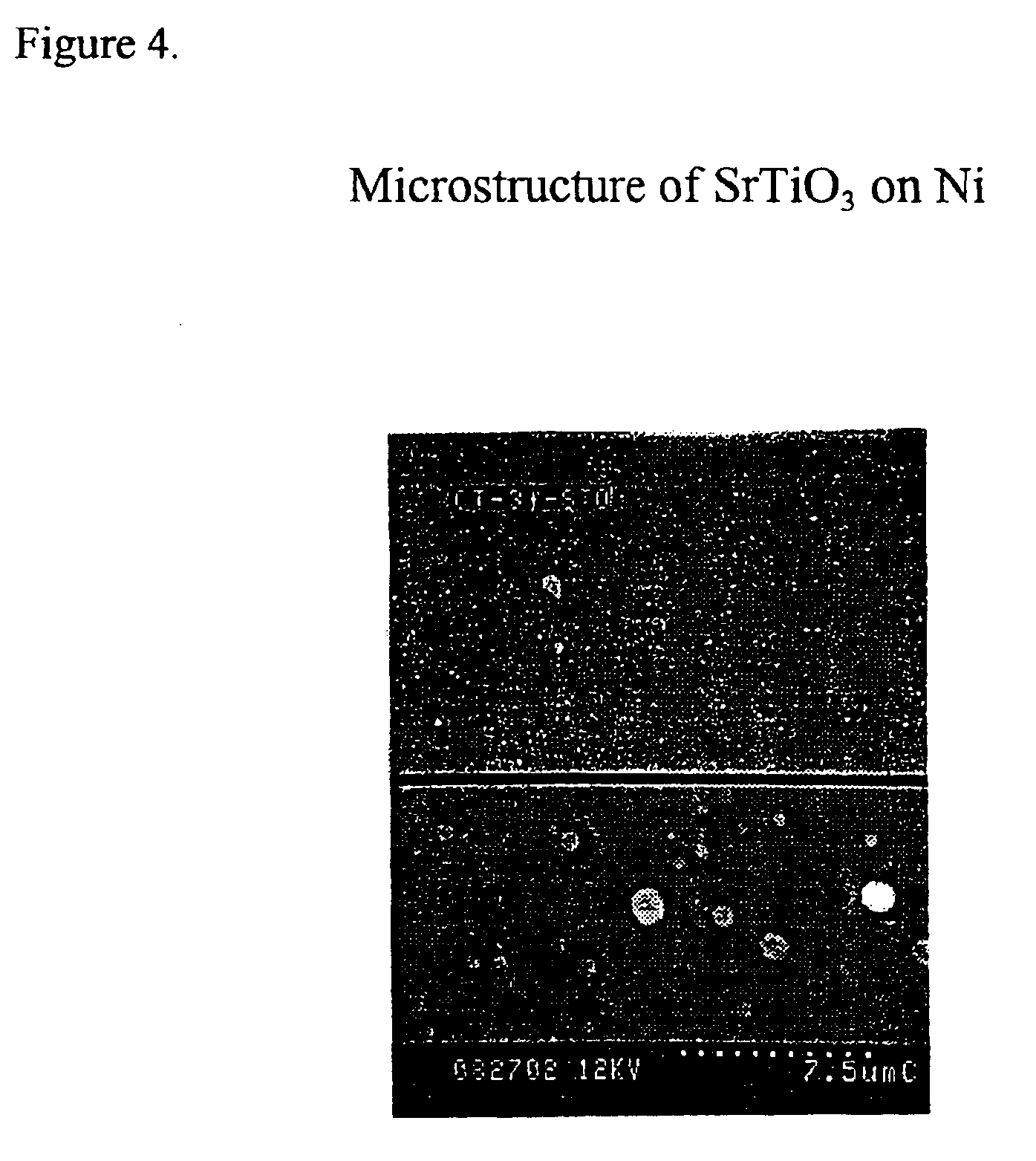

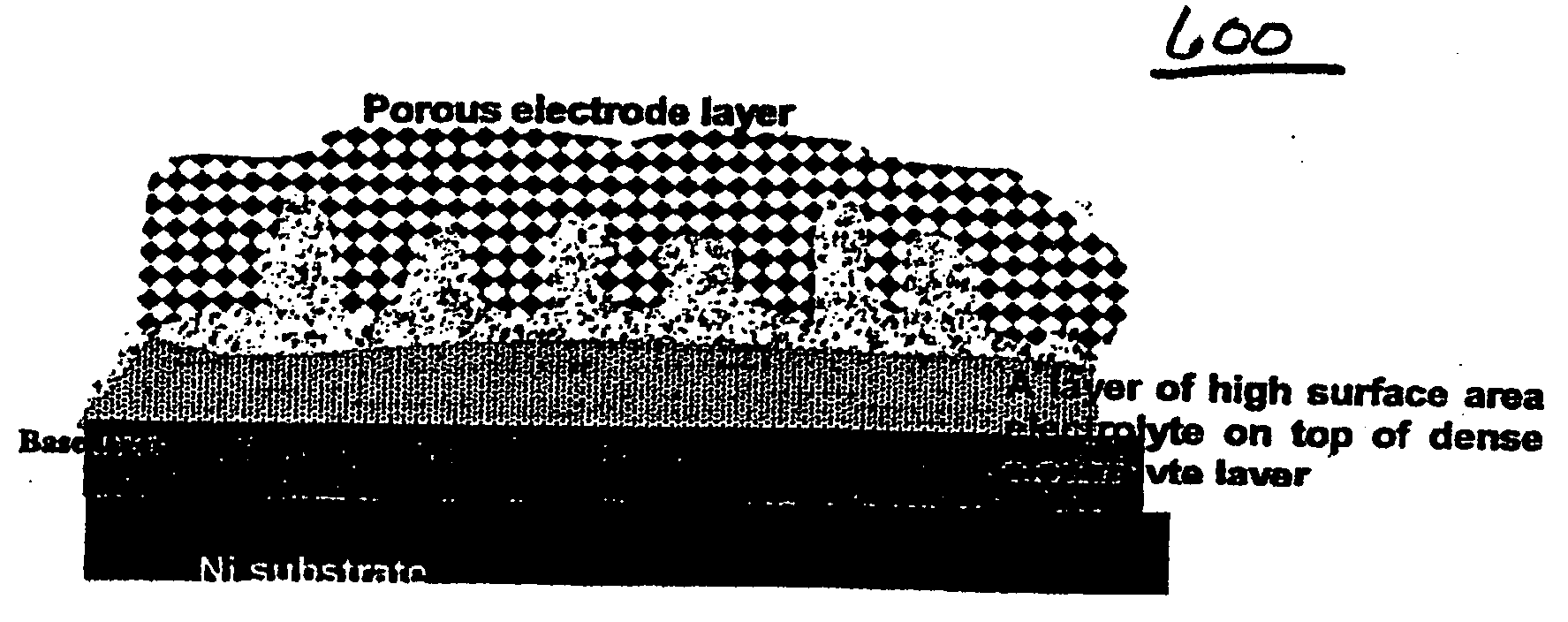

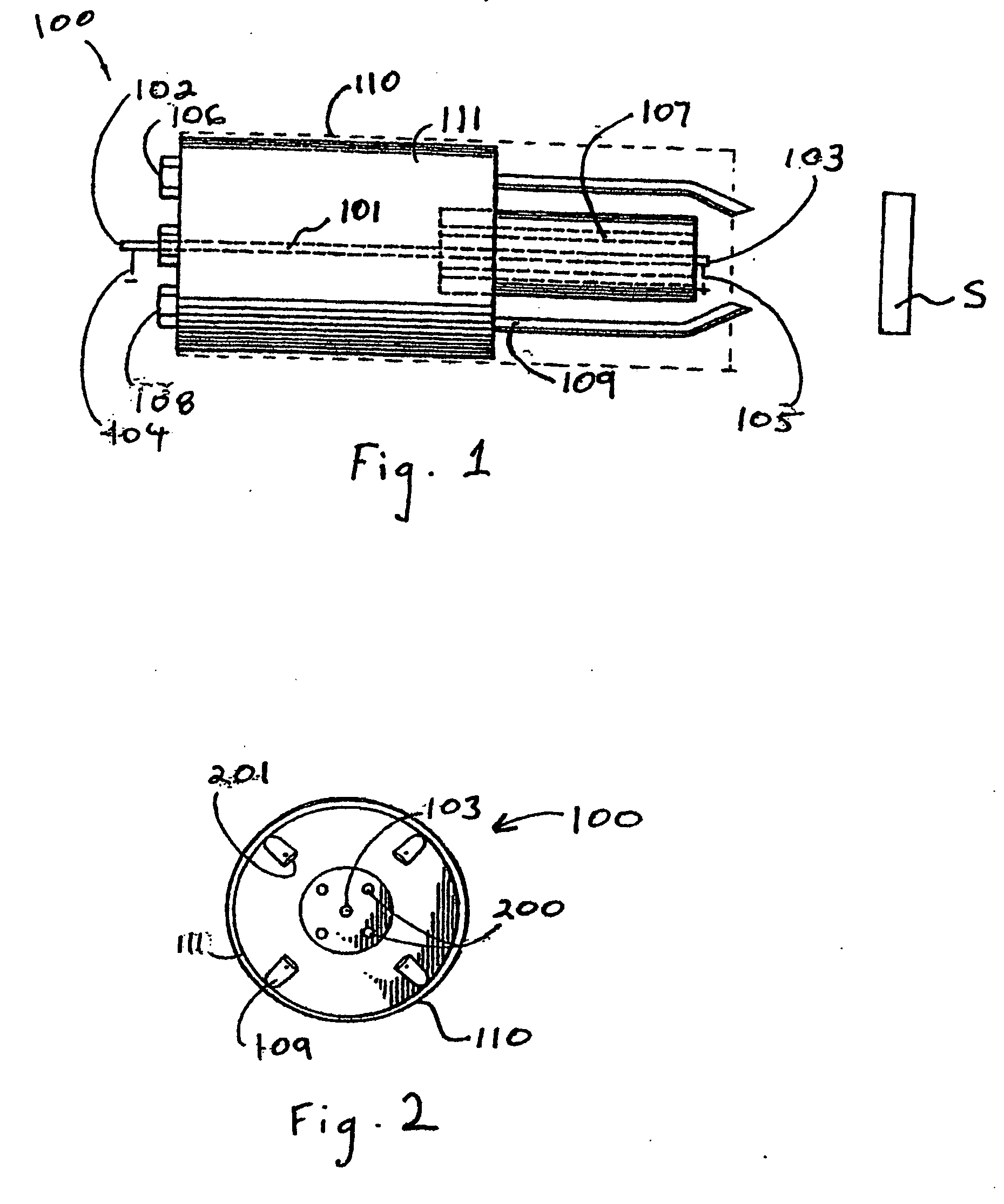

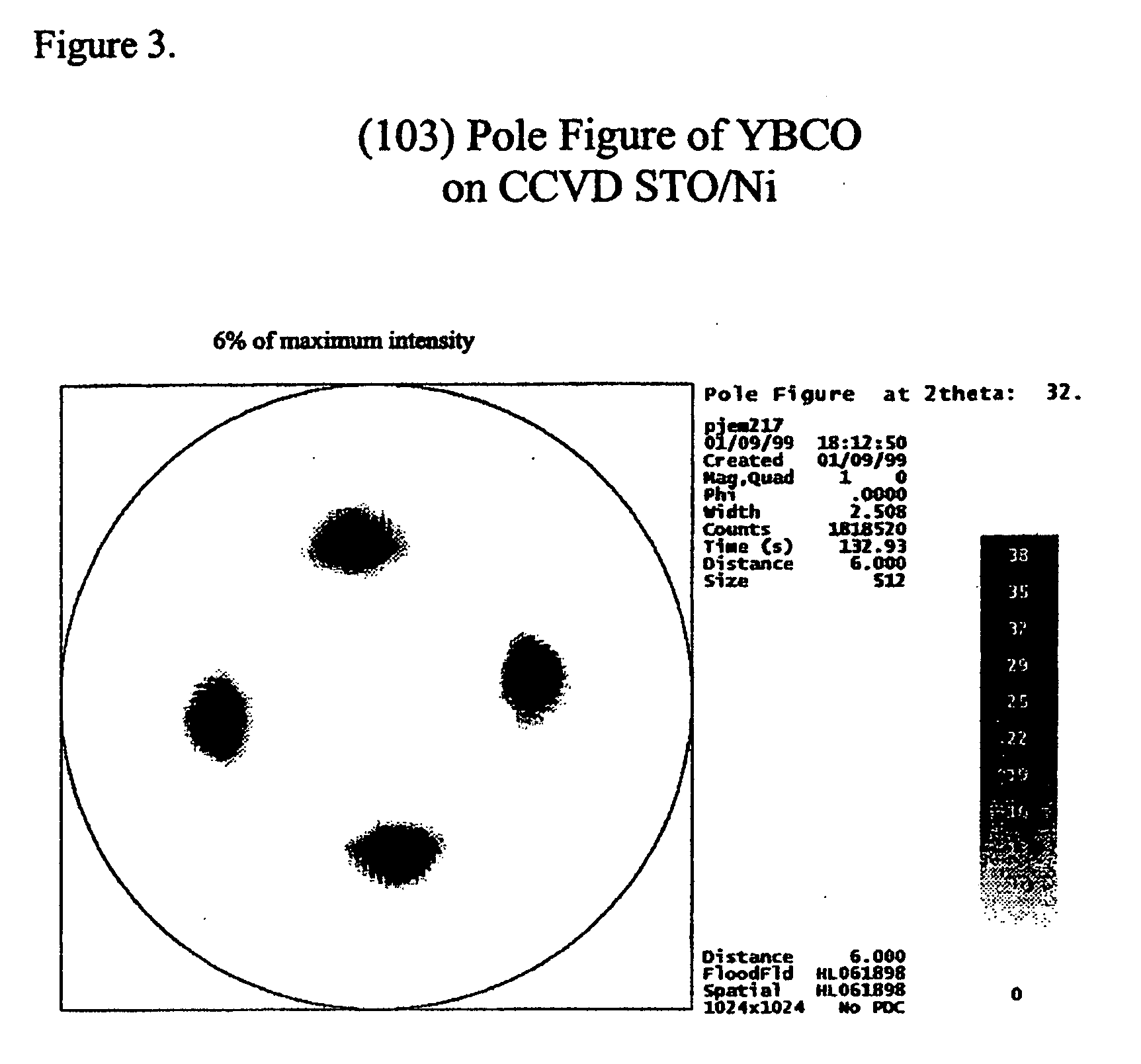

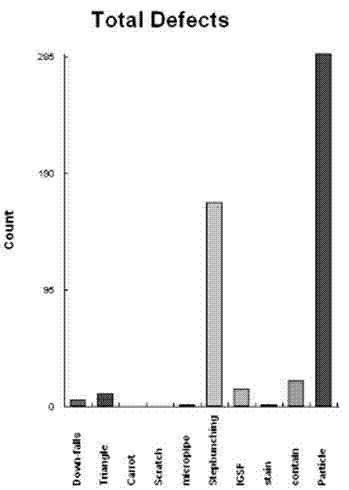

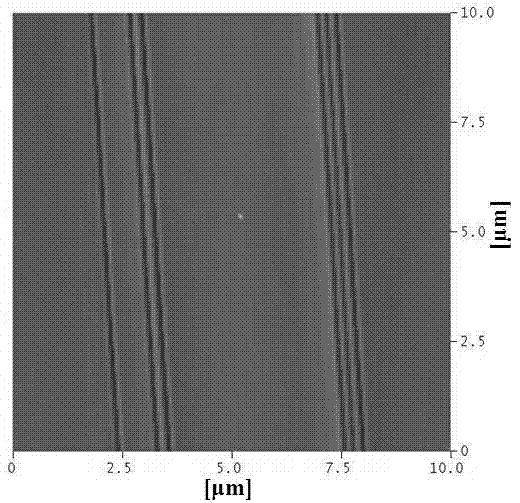

Epitaxial thin films

InactiveUS7033637B1Inhibited DiffusionReduce manufacturing costElectrolytic capacitorsFinal product manufactureCapacitanceElectrical conductor

Epitatial thin films for use as buffer layers for high temperature superconductors, electrolytes in solid oxide fuel cells (SOFC), gas separation membranes or dielectric material in electronic devices, are disclosed. By using CCVD, CACVD or any other suitable deposition process, epitaxial films having pore-free, ideal grain boundaries, and dense structure can be formed. Several different types of materials are disclosed for use as buffer layers in high temperature superconductors. In addition, the use of epitaxial thin films for electrolytes and electrode formation in SOFCs results in densification for pore-free and ideal gain boundary / interface microstructure. Gas separation membranes for the production of oxygen and hydrogen are also disclosed. These semipermeable membranes are formed by high-quality, dense, gas-tight, pinhole free sub-micro scale layers of mixed-conducting oxides on porous ceramic substrates. Epitaxial thin films as dielectric material in capacitors are also taught herein. Capacitors are utilized according to their capacitance values which are dependent on their physical structure and dielectric permittivity. The epitaxial thin films of the current invention form low-loss dielectric layers with extremely high permittivity. This high permittivity allows for the formation of capacitors that can have their capacitance adjusted by applying a DC bias between their electrodes.

Owner:MICROCOATING TECH +2

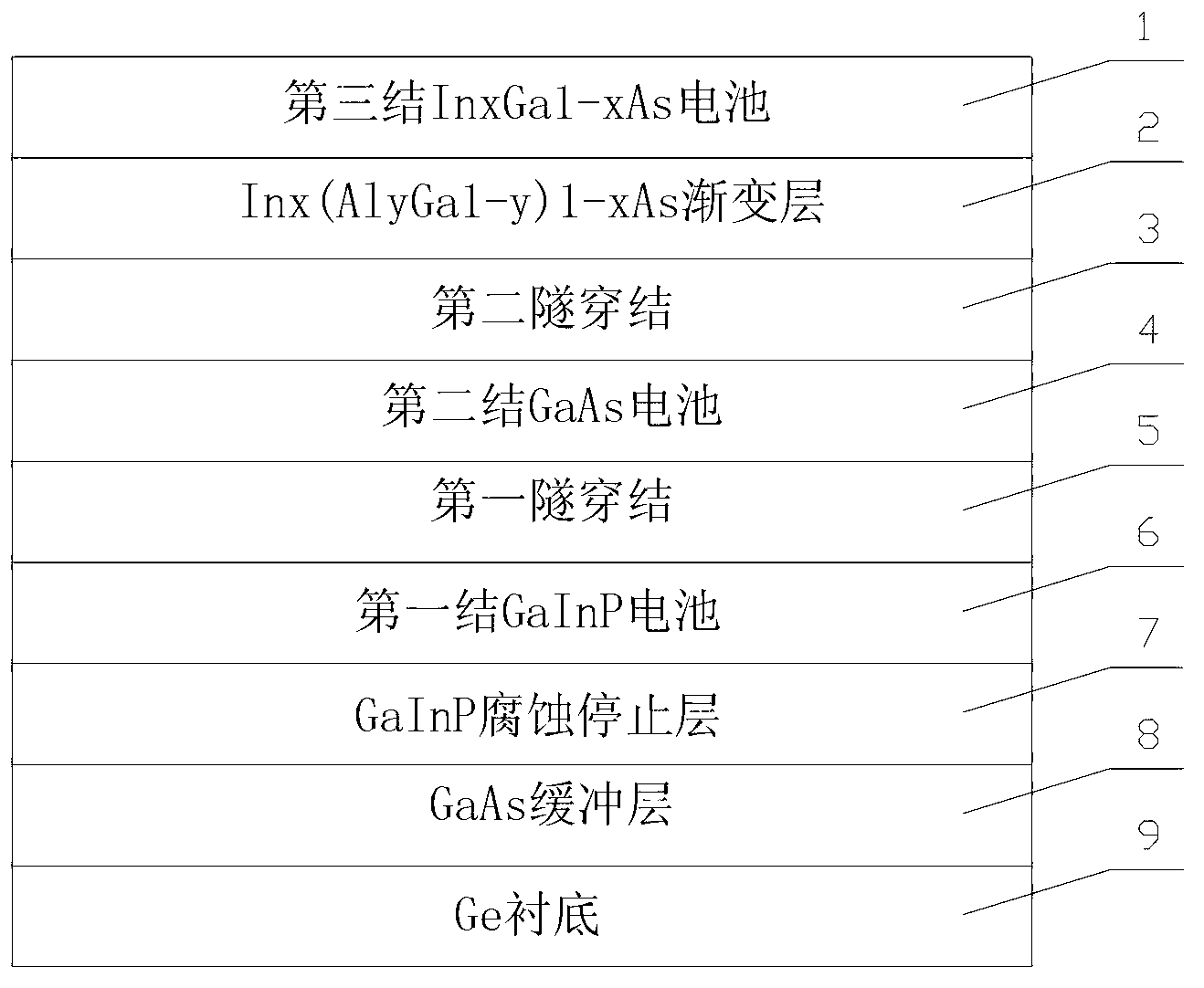

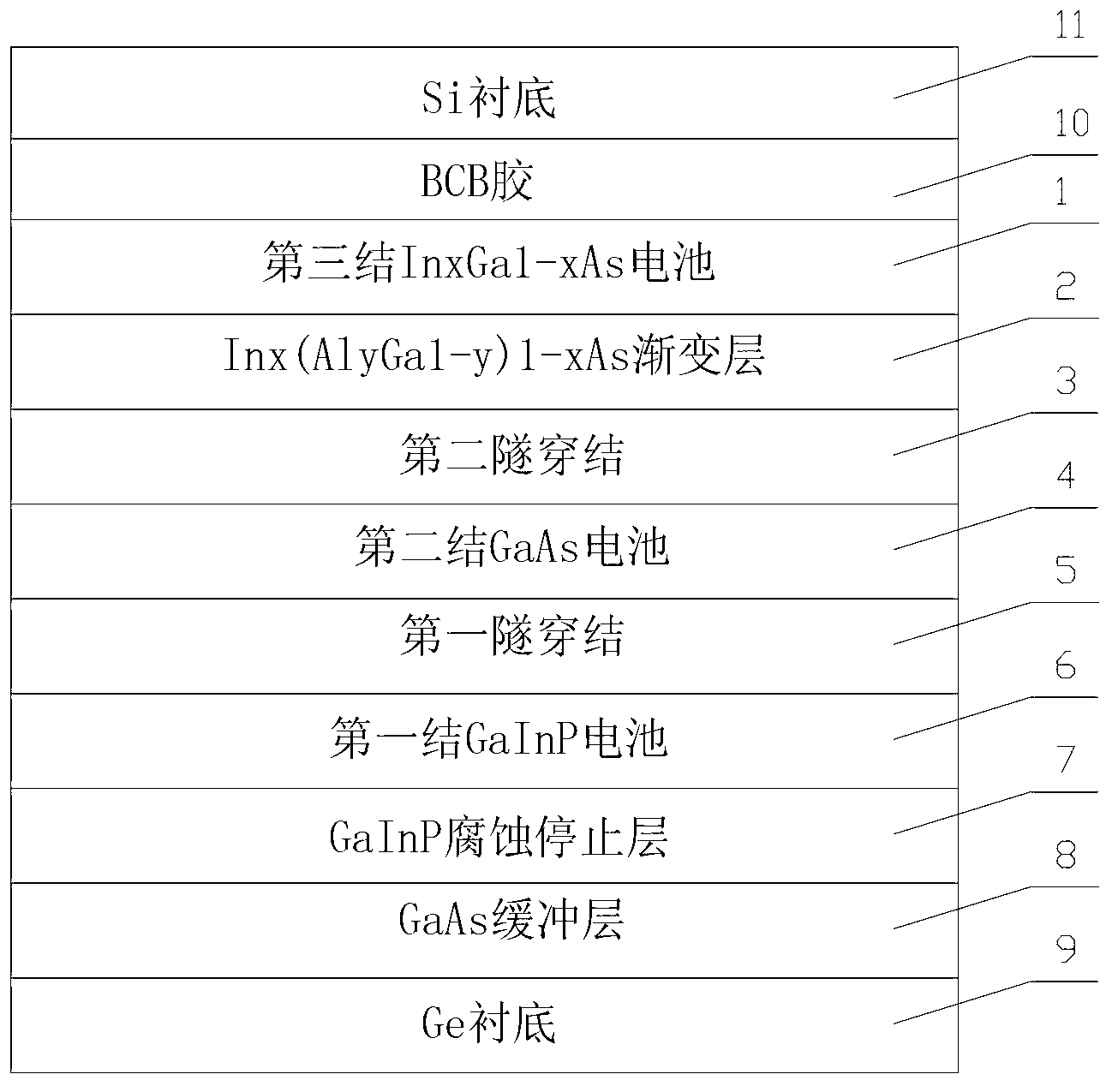

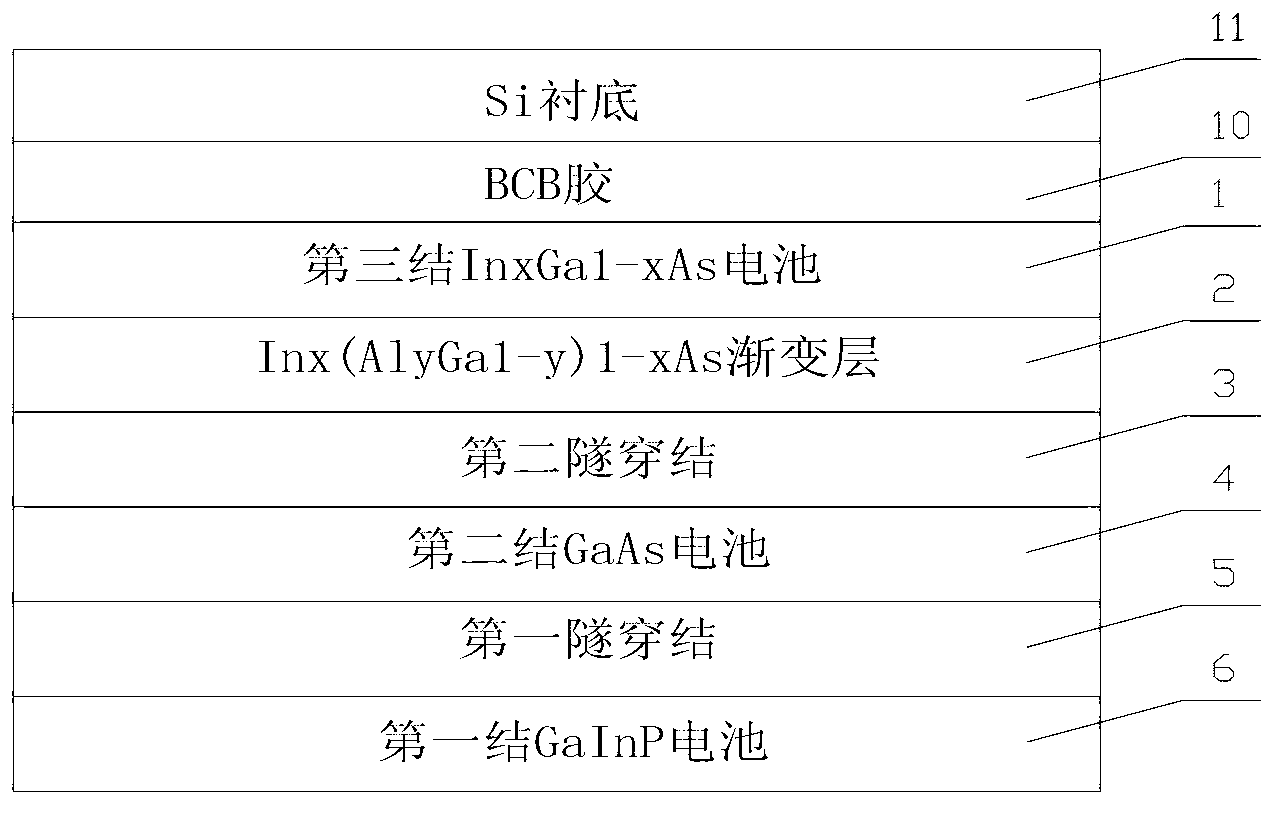

Preparation method of gallium arsenide thin-film multijunction stacked solar cells

ActiveCN103000759AImprove uniformityImprove reliabilityRenewable energy productsSemiconductor devicesIntermediate cellLow cost substrate

The invention relates to a preparation method of gallium arsenide thin-film multijunction stacked solar cells. The preparation method is characterized by including the steps of firstly, allowing for reverse growth of an epitaxial layer to prepare a GaAs three-junction solar cell; secondly, bonding the cell prepared in the step 1 to a Si substrate; thirdly, stripping a Ge substrate; fourthly, adhering a low-cost substrate; and fifthly, stripping the Si substrate. The preparation method allows for epitaxial growth of a top cell and an intermediate cell prior to growth of a bottom cell, and accordingly the lattice subjected to epitaxial growth firstly is guaranteed to match with perfect epitaxial growth of the top cell and the intermediate cell; doping uniformity and film reliability in large-area epitaxial thin films are increased, and photoelectric conversion efficiency is further improved; by the use of the low-cost support substrate lower than Ge in specific weight, the weight of the cells is reduced, the power ratio of the solar cells is increased, the cost of the cells is reduced effectively, and application prospect of the III-V compound solar cells is improved greatly.

Owner:TIANJIN LANTIAN SOLAR TECH +2

Preparation method of InGaN thin film

The invention disclose a preparation method of an InGaN thin film, belongs to the technical fields of photoelectronic material and device, and can solve the problems of rough surface, phase separationand defect caused by In segregation in the existing epitaxial growth of the high-quality InGaN thin film. The preparation method comprises the steps of enabling a GaN nucleating layer, a GaN non-intentional doped buffer layer and a medium-high-temperature GaN layer to be grown on a substrate in sequence, and then enabling the InGaN thin film to be grown. By adoption of a digital alloy growth technology to realize InGaN thin film epitaxy, and by forming multiple In(Ga)N / Ga(In)N heterogeneous interfaces and by introducing small flow hydrogen to the growth and interruption processes, thin film stress and defect density are reduced. After the growth is completed, annealing treatment is performed on the thin film, so that surface atom reconstruction and stress release are further facilitated,and the quality of the InGaN epitaxial thin film is further improved.

Owner:TAIYUAN UNIV OF TECH

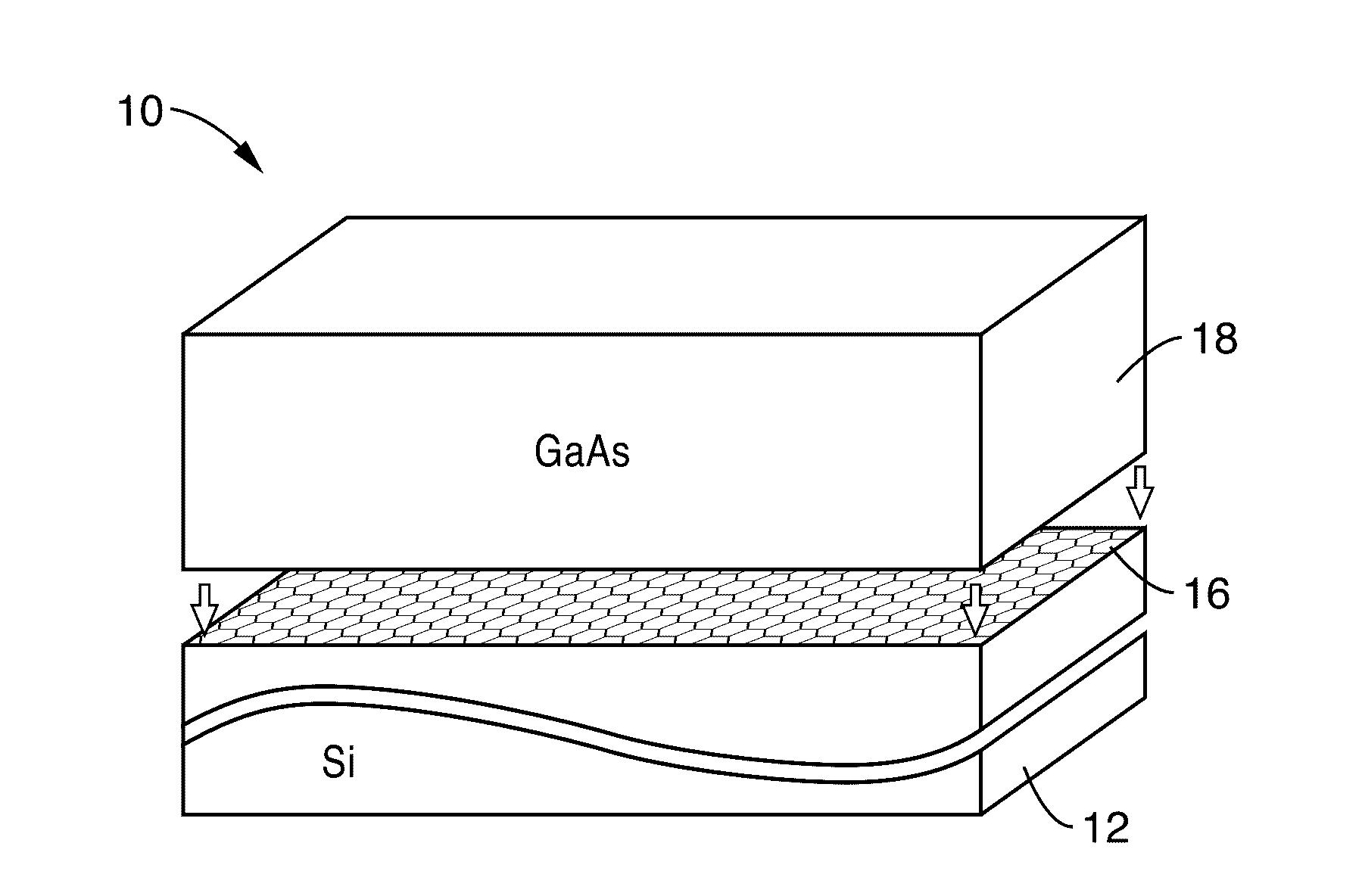

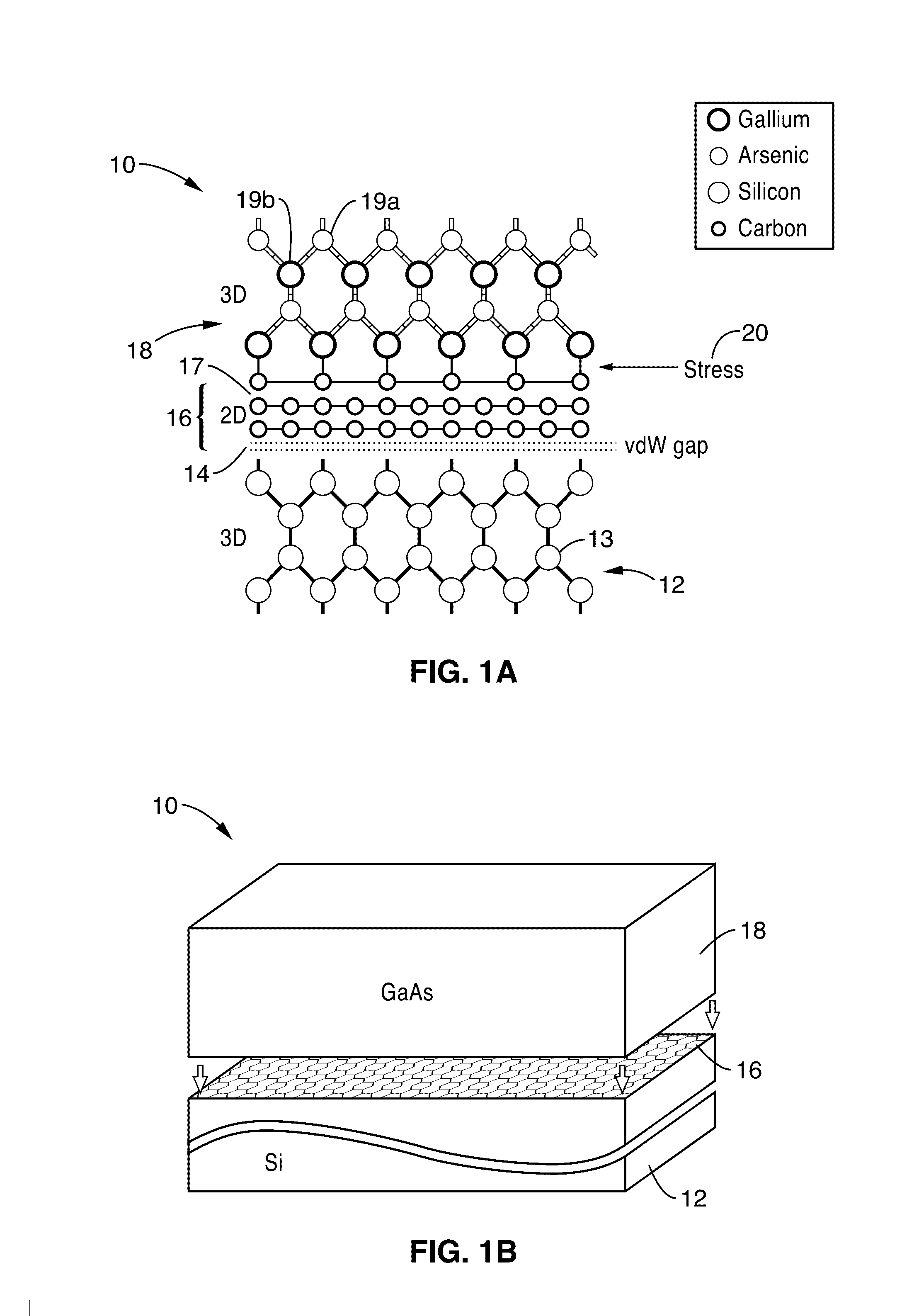

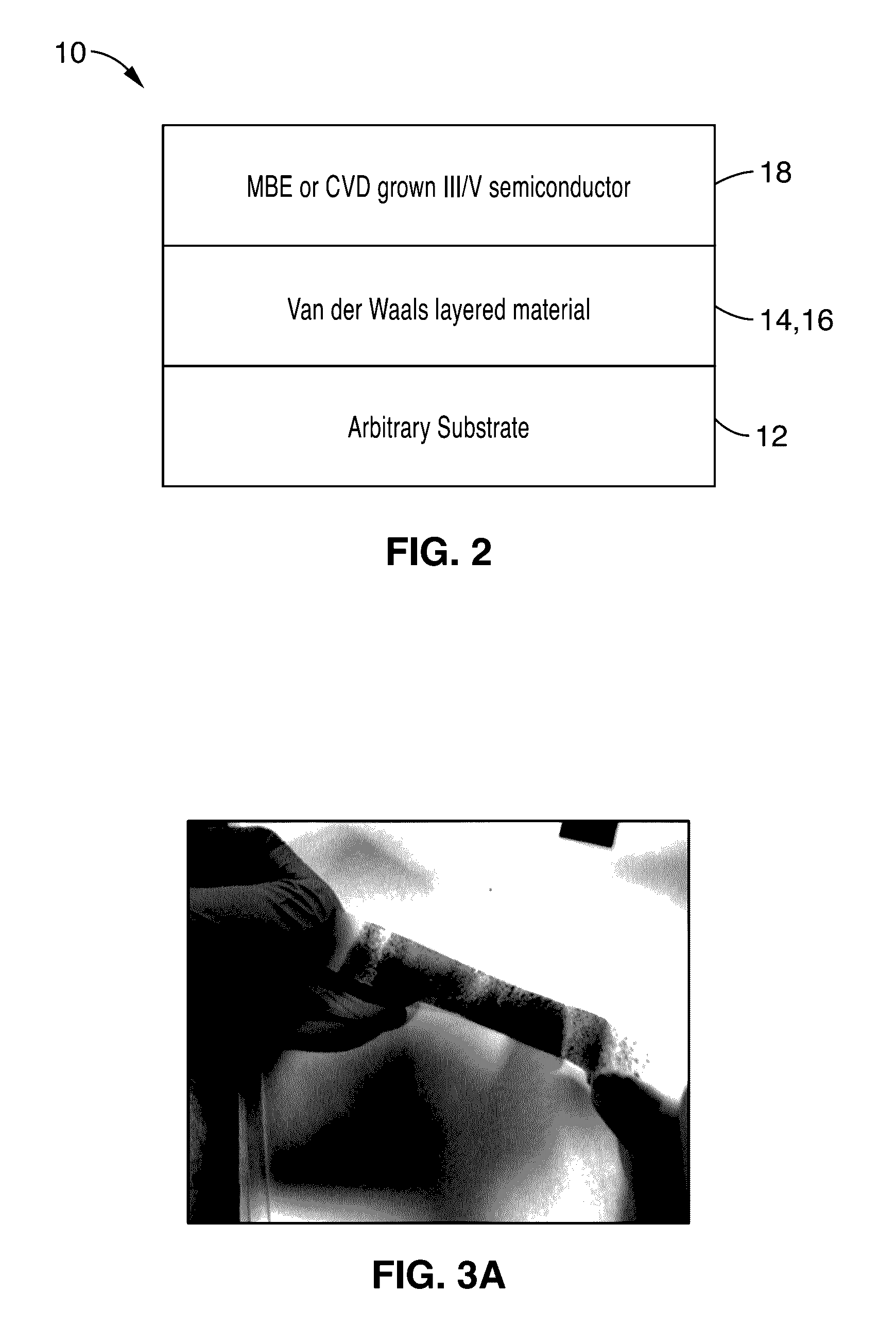

Epitaxial growth of gallium arsenide on silicon using a graphene buffer layer

InactiveUS20170047223A1Improve efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsLattice mismatch

Epitaxial growth of gallium arsenide (GaAs) on a semiconductor material (e.g., Si) using quasi-van der Waals Epitaxy (QvdWE). Prior to GaAs growth a buffer layer (e.g., graphene) is deposited which relieves lattice mismatch / thermal expansion. The low energy of the graphene surface and the GaAs / graphene interface is overcome through an optimized growth technique to obtain an atomically smooth low-temperature GaAs nucleation layer. The disclosure can be applied to optimize epitaxial thin film growth of other materials, (e.g., III-V semiconductors, such as InP, GaSb) on Si using van der Waals buffer layers such as graphene.

Owner:KING ABDULAZIZ CITY FOR SCIENCE AND TECHNOLOGY +1

Transverse epitaxial growth process of high-quality gallium nitride film

InactiveCN1389904AReduce dislocation densityQuality improvementSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGallium nitrideDislocation

The invention relates to the method of growth of gallium nitride film in high quality by the technique of extension in the lateral direction. GaN crystal seed layer is grown by use of the MOCVD, MBE or other method. The SiO2, Si3N4W etc. films are deposited on the GaN crystal seed layer with sertain graph being etched by etching method. The direction of the parallel strip opening is along the direction of GaN [1100]. The width of the mask area is 2-20 microns. The width of the GaN window area is 0.2-20 microns. Then the MOCVD or HVPE method is accepted to grow GaN in epitaxial growth till the mask layer is overspreader by the GaN. Continuing growth obtains the gallium nitride film with low dislocation density. Since HVPE providing quick growth rare, to the HVPE thick film extension can obtain GaN film even lower dislocation density.

Owner:NANJING UNIV

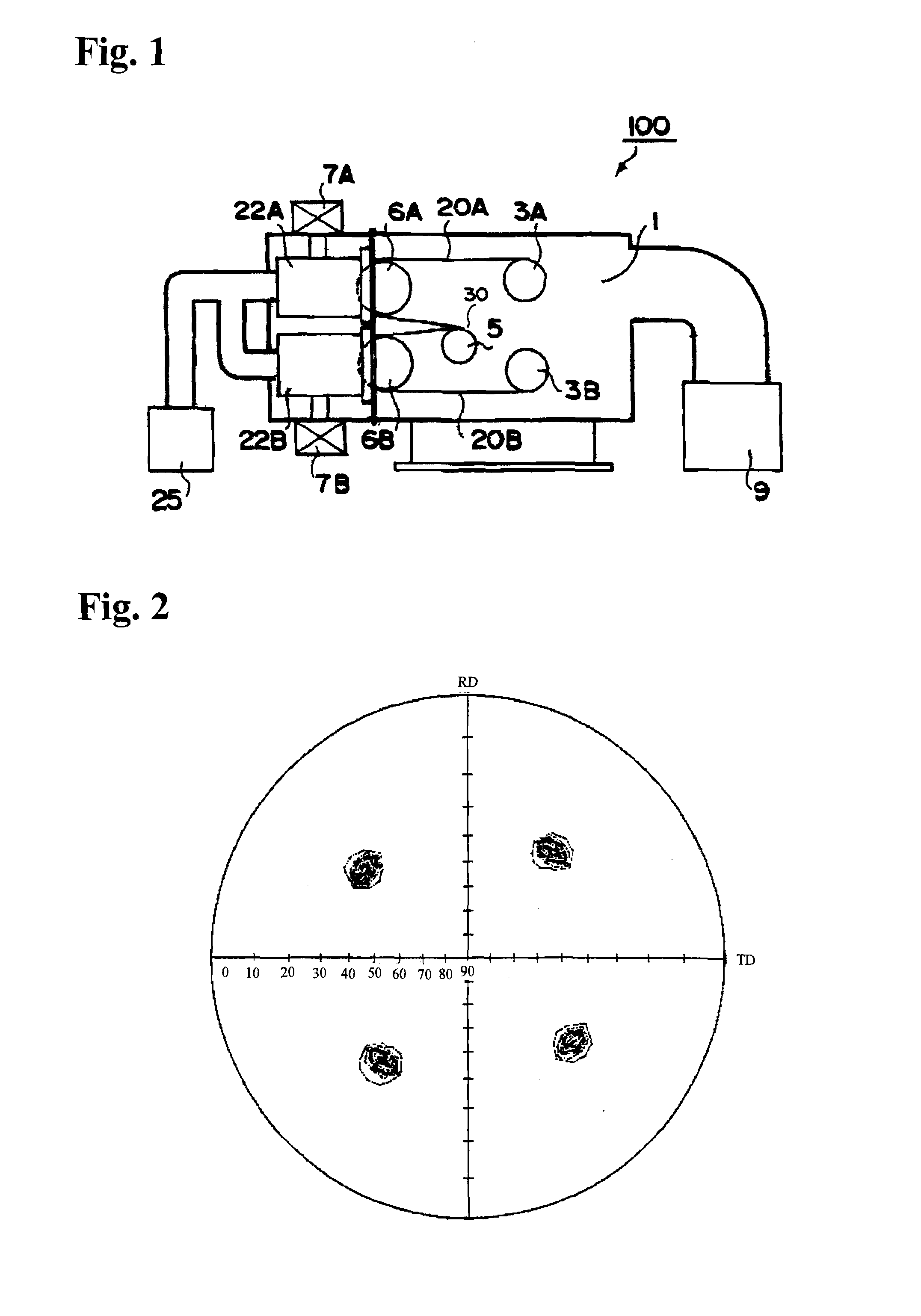

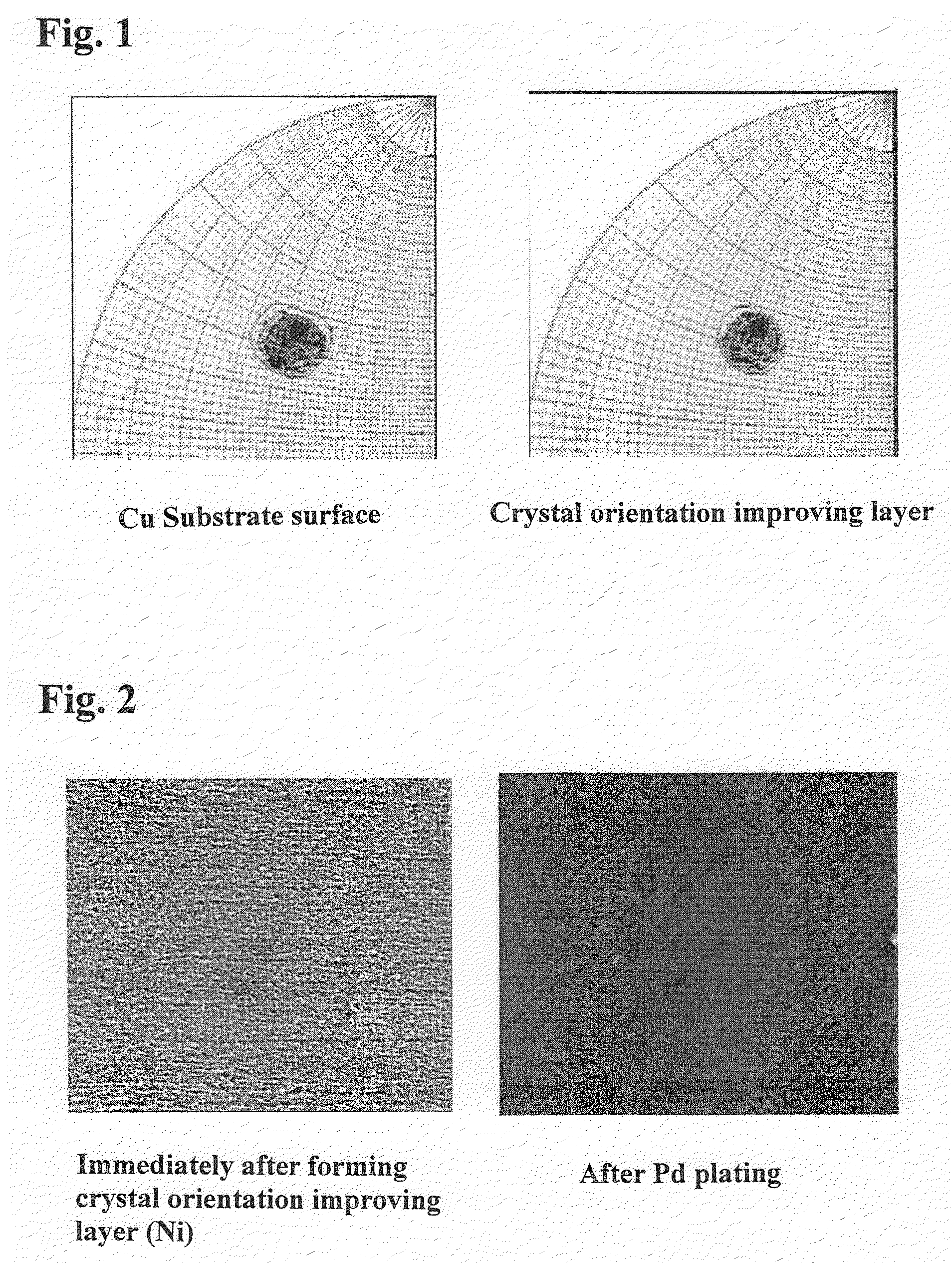

Textured substrate for epitaxial film formation and surface improving method of textured substrate for epitaxial film formation

ActiveUS20090053550A1Promote migrationRaise the degree of orientationNanotechSoldering apparatusCrystal orientationSurface roughness

Orientation degree and smoothness of a substrate surface better than those of conventional ones are provided in a textured substrate for epitaxial thin film growth. The present invention is a textured substrate for epitaxial film formation, including a crystal orientation improving layer made of a metal thin film of 1 to 5000 nm in thickness on the surface of the textured substrate for epitaxial film formation having a textured metal layer at least on one surface, wherein differences between orientation degrees (Δφ and Δω) in the textured metal layer surface and orientation degrees (Δφ and Δω) in the crystal orientation improving layer surface are both 0.1 to 3.0°. Further, when another metal different from the metal constituting this textured substrate crystal orientation improving layer is added equivalent to a thin film which is 30 nm or less, and subsequently is subjected to heat treatment, the smoothness of that surface can be improved. At this time, the surface roughness of the substrate surface becomes 20 nm or less.

Owner:TANAKA PRECIOUS METAL IND

Method for manufacturing film LED chip device based on gapless plane bonding

ActiveCN101465402AGuaranteed flatnessImprove flatnessSemiconductor devicesOptoelectronicsLaser beams

The invention discloses a preparation method of a film LED chip device based on the gapless plane bonding; the method makes use of the smooth surface of an epitaxial wafer without isolated processing to prepare a permanent or temporary substrate; then laser beams are used for unit isolated processing of devices at the interface position between the epitaxial layer and the substrate so as to ensure the combination yield rate of the substrate and the epitaxial layer, thereby ensuring the film-remaining yield rate of the epitaxial thin film layer after laser stripping and also simplifying the traditional production process.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Method for fabricating an epitaxial substrate

ActiveUS20050003641A1Sufficiently robustAvoid insufficient thicknessPolycrystalline material growthSemiconductor/solid-state device manufacturingOptoelectronicsSingle crystal

A method for fabricating an epitaxial substrate. The technique includes providing a crystalline or mono-crystalline base substrate, implanting atomic species into a front face of the base substrate to a controlled mean implantation depth to form a zone of weakness within the base substrate that defines a sub-layer, and growing a stiffening layer on a front face of the base substrate by using a thermal treatment in a first temperature range. The stiffening layer has a thickness sufficient to form an epitaxial substrate. In addition, the method includes detaching the stiffening layer and the sub-layer from the base substrate by using a thermal treatment in a second temperature range higher than the first temperature range. An epitaxial substrate and a remainder of the base substrate are obtained. The epitaxial substrate is suitable for use in growing high quality homoepitaxial or heteroepitaxial films thereon.

Owner:SOITEC SA

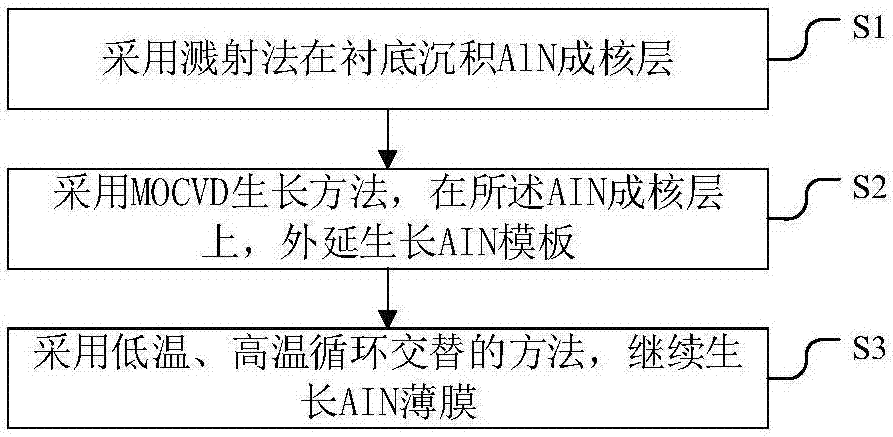

AIN epitaxial thin film preparation method

InactiveCN107083539AAtomic level surface smoothingSemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsDislocation

The embodiment of the invention discloses a method for preparing an AlN epitaxial film. The method includes: S1, depositing an AlN nucleation layer on a substrate by a sputtering method; S2, epitaxially growing an AIN template on the AlN nucleation layer by using an MOCVD growth method; S3, adopting a method of alternating low temperature and high temperature cycles, Continue to grow the AIN thin film. In the embodiment of the present invention, a layer of AlN is first sputtered by sputtering, and then the AlN film is grown by temperature modulation growth in MOCVD. Compared with the prior art, the AlN film with atomically smooth surface and low dislocation density can be prepared. .

Owner:PEKING UNIV

Epitaxial thin films

InactiveUS20050019594A1High dielectric constantReduce lossMembranesSemi-permeable membranesCapacitanceMicron scale

Epitaxial thin films for use as buffer layers for high temperature superconductors, electrolytes in solid oxide fuel cells (SOFC), gas separation membranes or dielectric material in electronic devices, are disclosed. By using CCVD, CACVD or any other suitable deposition process, epitaxial films having pore-free, ideal grain boundaries, and dense structure can be formed. Several different types of materials are disclosed for use as buffer layers in high temperature superconductors. In addition, the use of epitaxial thin films for electrolytes and electrode formation in SOFCs results in densification for pore-free and ideal grain boundary / interface microstructure, Gas separation membranes for the production of oxygen and hydrogen are also disclosed. These semipermeable membranes are formed of high-quality, dense, gas-tight, pinhole free sub-micron scale layers of mixed-conducting oxides on porous ceramic substrates. Epitaxial thin films as dielectric material in capacitors are also taught herein. Capacitors are utilized according to their capacitance values which are dependent on their physical structure and dielectric permittivity. The epitaxial thin films of the current invention form low-loss dielectric layers with extremely high permittivity. This high permittivity allows for the formation of capacitors that can have their capacitance adjusted by applying a DC bias between their electrodes.

Owner:HUNT ANDREW TYE +3

Method for reducing defects in silicon carbide epitaxial film

ActiveCN103715069AQuality improvementReduce defectsSemiconductor/solid-state device manufacturingCarbide siliconEtching

The invention discloses a method for reducing defects in a silicon carbide epitaxial film. The method is executed in horizontal hot wall-type chemical vapor deposition (CVD) equipment and comprises the following steps of 1) substrate preparing, wherein a (0001) silicon-surface silicon carbide substrate deviating towards the (11-20) direction by 4 degrees is selected; 2) pre-growth baking, wherein a reaction chamber is subjected to radio frequency induction heating after a prepared sample is delivered to a reaction chamber and before gas is injected; 3) in-situ etching, wherein an improved hydrogen H2 in-situ etching technology is employed to perform pre-growth surface pre-treatment of the substrate; and 4) epitaxial growing, wherein a silicon carbide film starts to grow when the temperature rises to an epitaxial growth temperature. The advantages are that by using the method, the defects existing in the epitaxial film based on the (0001) silicon-surface silicon carbide substrate deviating towards the (11-20) direction by 4 degrees can be effectively reduced and the quality of the epitaxial film can be increased. The characteristics are that the method of the invention is simple and easy to implement; the epitaxial technology repeatability and consistency are good; the epitaxial film quality is high; and the method is suitable for mass production.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Method for growing InGaAs film on GaAs substrate

InactiveCN102560634AEffectively filter dislocationsFacilitated releasePolycrystalline material growthFrom chemically reactive gasesPhysical chemistryThin membrane

The invention discloses a method for growing an InGaAs film on a GaAs substrate, which comprises the following steps of: (1) cleaning the GaAs substrate; (2) pre-processing the GaAs substrate; (3) deoxidizing; (4) growing a GaAs buffer layer; (5) growing a low-temperature single-layer In0.6Ga0.4As big-mismatch buffer layer; and (6) growing an In0.3Ga0.7As epitaxial film, wherein the In0.6Ga0.4As big-mismatch buffer layer and the In0.3Ga0.7As epitaxial film both can be prepared by using the molecular beam epitaxial growth or metal organic vapor deposition technology. Various defects caused by mismatch stress can be lowered by the big-mismatch buffer layer. The prepared In0.3Ga0.7As epitaxial layer has lower defect density. The method has the advantages of simple buffer layer structure, simple and convenient epitaxial growth process, low defect density of the In0.3Ga0.7As epitaxial film, high crystal quality and the like.

Owner:SOUTH CHINA UNIV OF TECH

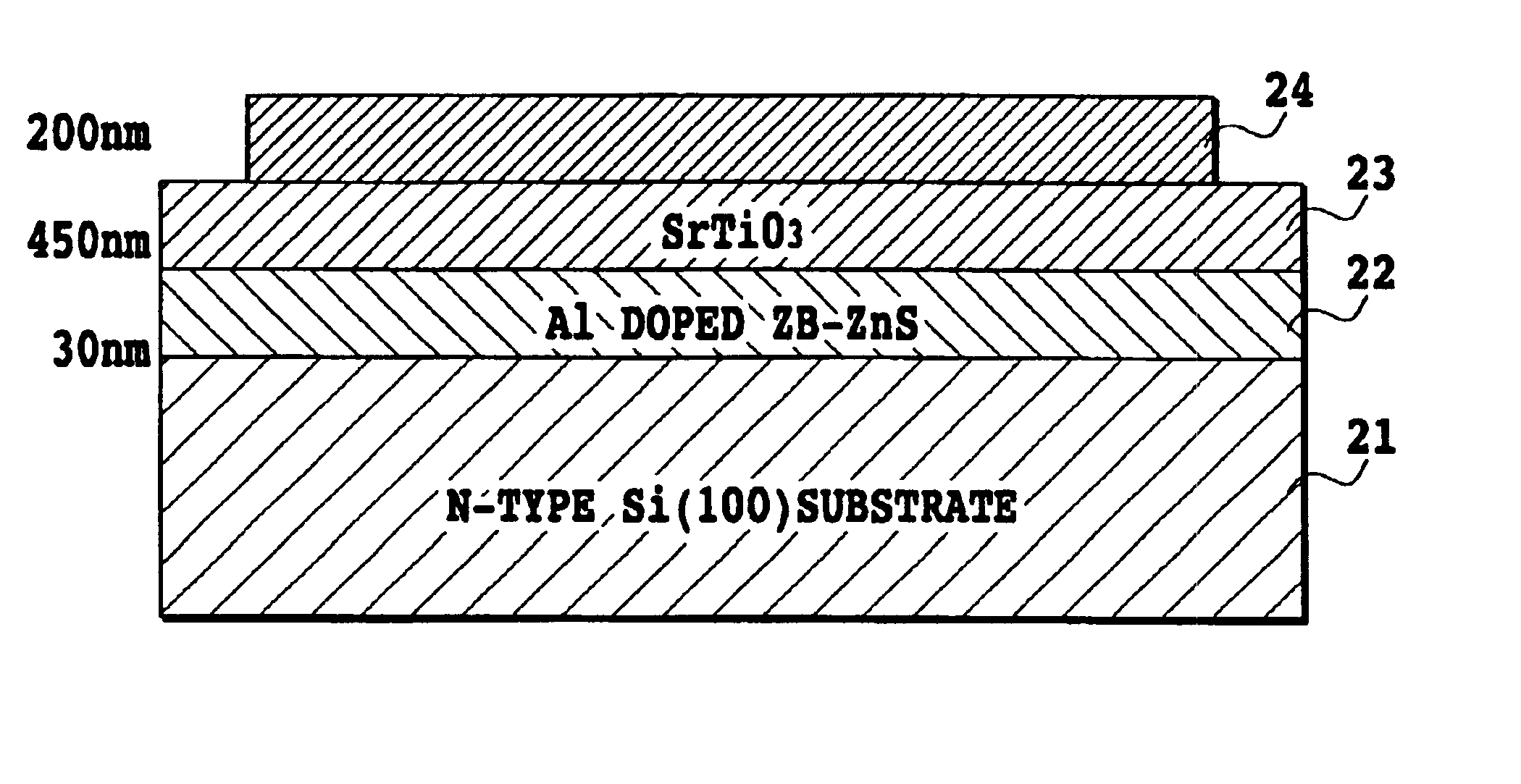

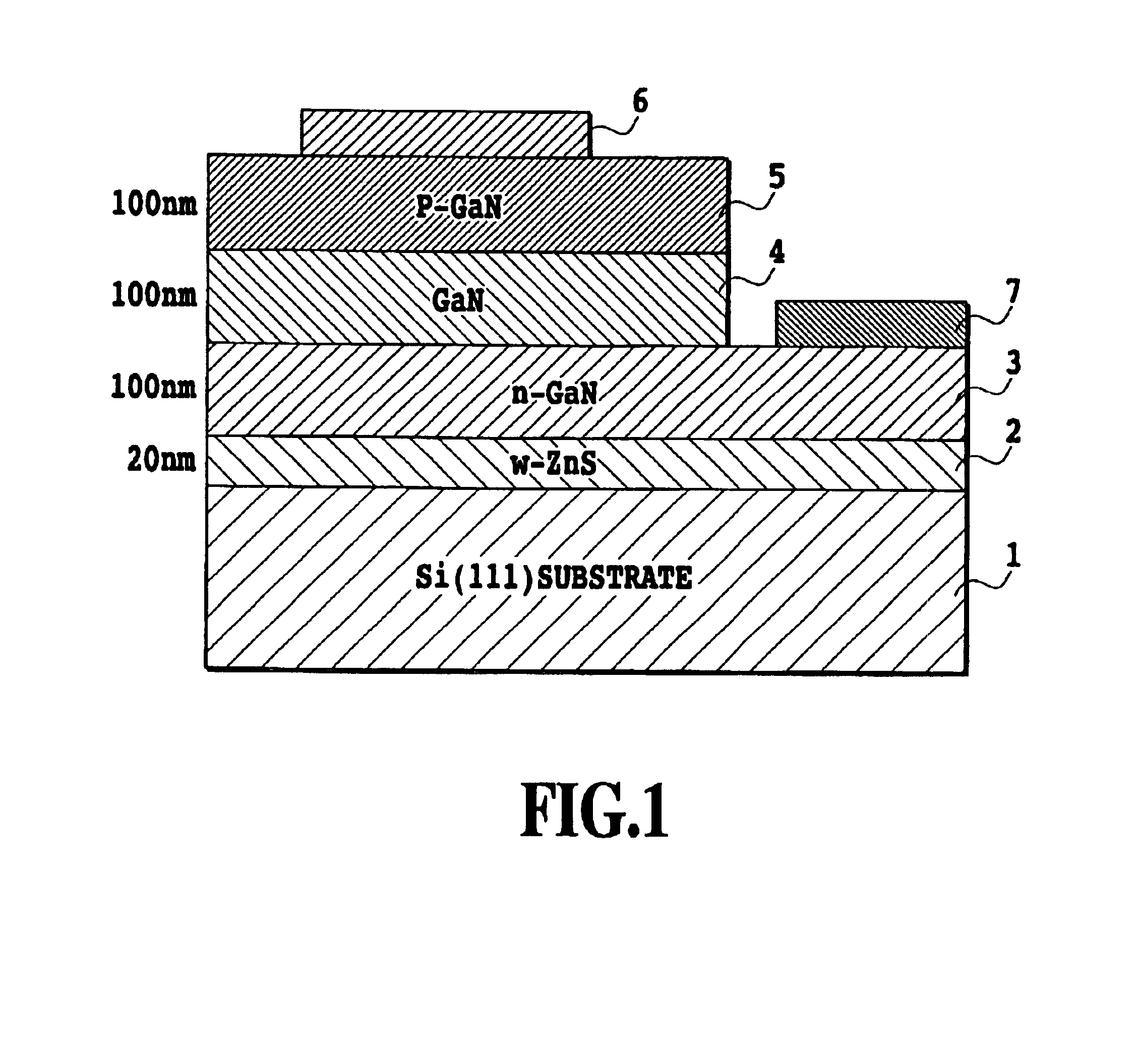

Thin film device

InactiveUS6888156B2Low costEasy to depositSemiconductor/solid-state device manufacturingSemiconductor devicesLattice defectsIonic crystal

The invention provides a thin film device where ionic crystals are epitaxially grown on a Si single crystal substrate through a proper buffer layer, and its for fabrication method. A ZnS layer is first deposited on a Si single crystal substrate. Ionic crystal thin films (an n-GaN layer, a GaN layer, and a p-GaN layer) are deposited thereon. The ZnS thin film is an oriented film excellent in crystallinity and has excellent surface flatness. When ZnS can be once epitaxially grown on the Si single crystal substrate, the ionic crystal thin films can be easily epitaxially grown subsequently. Therefore, ZnS is formed to be a buffer layer, whereby even ionic crystals having differences in lattice constants from Si can be easily epitaxially grown in an epitaxial thin film with few lattice defects on the Si single crystal substrate. The characteristics of a thin film device utilizing it can be enhanced.

Owner:NAT INST FOR MATERIALS SCI

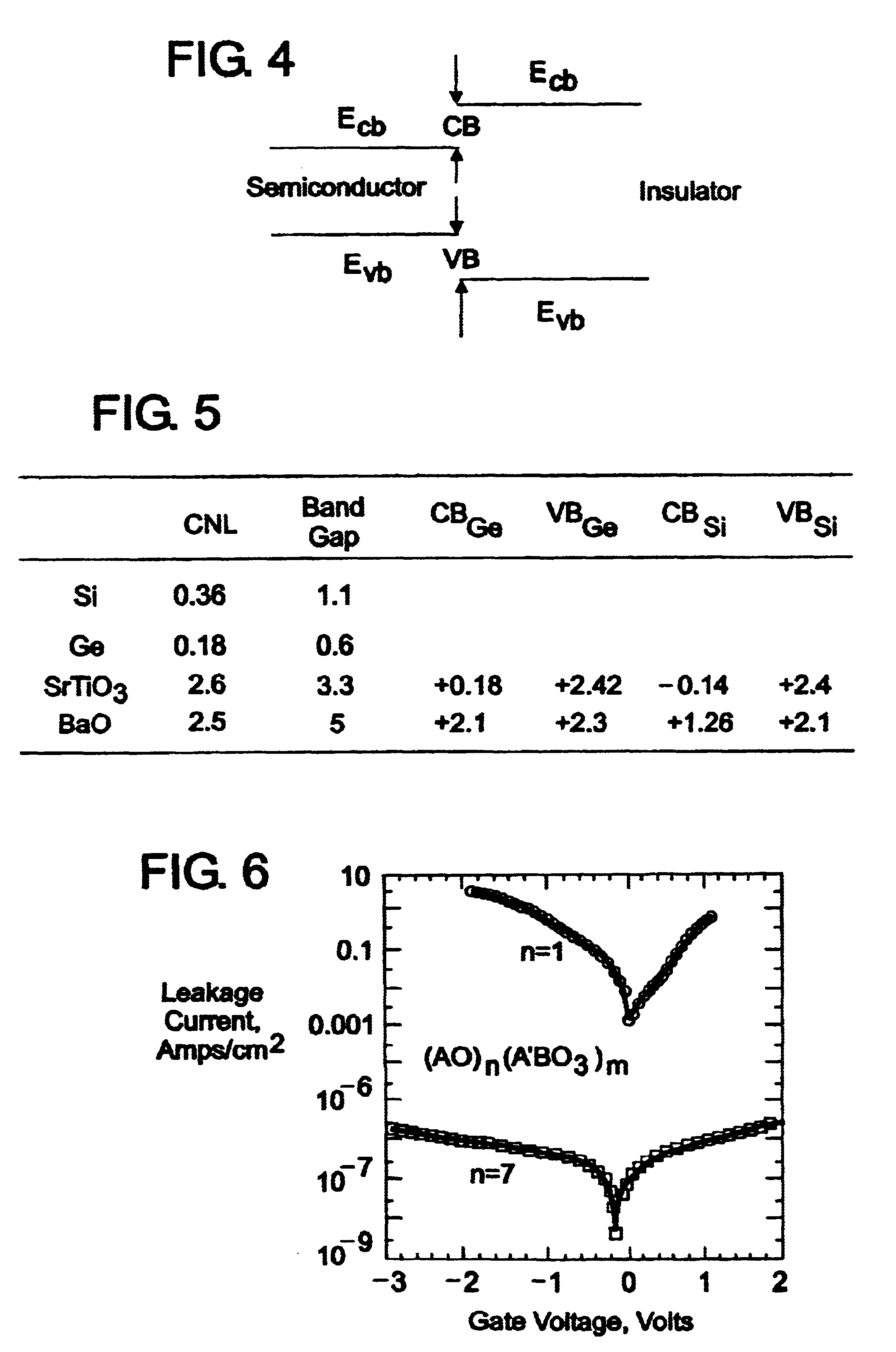

Structure and method for controlling band offset and alignment at a crystalline oxide-on-semiconductor interface

InactiveUS6652989B2Polycrystalline material growthSemiconductor/solid-state device manufacturingCrystalline oxideCell layer

A crystalline oxide-on-semiconductor structure and a process for constructing the structure involves a substrate of silicon, germanium or a silicon-germanium alloy and an epitaxial thin film overlying the surface of the substrate wherein the thin film consists of a first epitaxial stratum of single atomic plane layers of an alkaline earth oxide designated generally as (AO)n and a second stratum of single unit cell layers of an oxide material designated as (A'BO3)m so that the multilayer film arranged upon the substrate surface is designated (AO)n(A'BO3)m wherein n is an integer repeat of single atomic plane layers of the alkaline earth oxide AO and m is an integer repeat of single unit cell layers of the A'BO3 oxide material. Within the multilayer film, the values of n and m have been selected to provide the structure with a desired electrical structure at the substrate / thin film interface that can be optimized to control band offset and alignment.

Owner:UT BATTELLE LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com