Method for reducing defects in silicon carbide epitaxial film

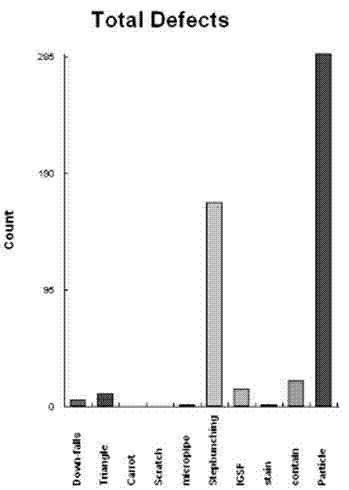

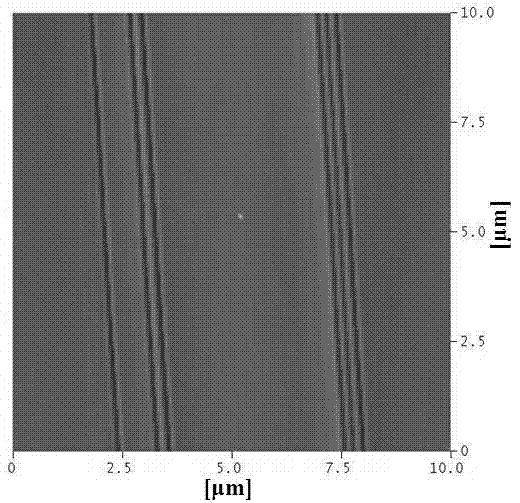

A technology of silicon carbide and silicon carbide on the silicon surface, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unfavorable device manufacturing, a large number of step-like morphology of epitaxial films, and unsatisfactory effect of eliminating defects. Achieve the effect of high epitaxial film quality, simple and easy method, and reduce defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Select the (0001) silicon surface 4H-SiC conductive substrate with a 4° bias to the direction and perform standard cleaning on it for use;

[0031] 2) Place the substrate on a hot graphite base, send it into the reaction chamber, and evacuate it to -6 mbar;

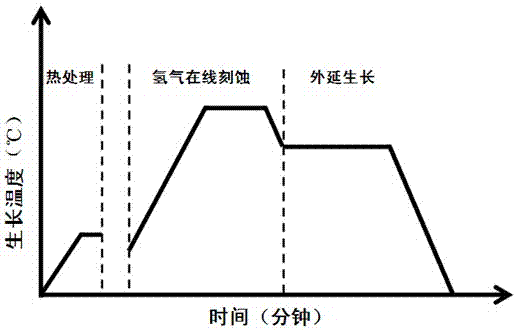

[0032] 3) After the prepared sample is sent to the reaction chamber and before the gas is introduced, the graphite reaction chamber (including the base) coated with tantalum carbide is heated by radio frequency induction, the radio frequency power is 5KW, the processing time is 15min, and the temperature is raised to 200°C;

[0033] 4) in H 2 The flow rate is 75L / min and the pressure of the reaction chamber is 100mbar. Slowly raise the temperature to 1570°C, keep the temperature constant for 10 minutes, and cool down to the epitaxial growth temperature of 1550°C in 10 minutes to remove surface damage and contamination, and at the same time help reduce Delay delay defects;

[0034] 5) The temperature is stabi...

Embodiment 2

[0037] 1) Select the (0001) silicon surface 4H-SiC high-purity semi-insulating substrate with a 4° bias to the direction and perform standard cleaning on it for use;

[0038] 2) Place the substrate on a hot graphite base, send it into the reaction chamber, and evacuate it to -6 mbar;

[0039] 3) After the prepared sample is sent to the reaction chamber and before the gas is introduced, the graphite reaction chamber (including the base) coated with tantalum carbide is heated by radio frequency induction, the radio frequency power is 6KW, the processing time is 20min, and the temperature is raised to 240°C;

[0040] 4) in H 2 The flow rate is 75L / min and the pressure of the reaction chamber is 100mbar. Slowly raise the temperature to 1590°C, keep the temperature constant for 5 minutes, and cool down to the epitaxial growth temperature of 1580°C in 10 minutes to remove surface damage and contamination, and at the same time help reduce Delay delay defects;

[0041] 5) The temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com