Method for growing InGaAs film on GaAs substrate

A substrate and thin film technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problem of difficult to precisely control composition, thickness, and crystal quality, low minority carrier lifetime of GaInNAs epitaxial materials, and limited quad-junction stacking. Solar cell current density and other issues, to achieve the effect of suppressing the fluctuation of the interface, simplifying the epitaxial growth process, and simplifying the buffer layer structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the following examples.

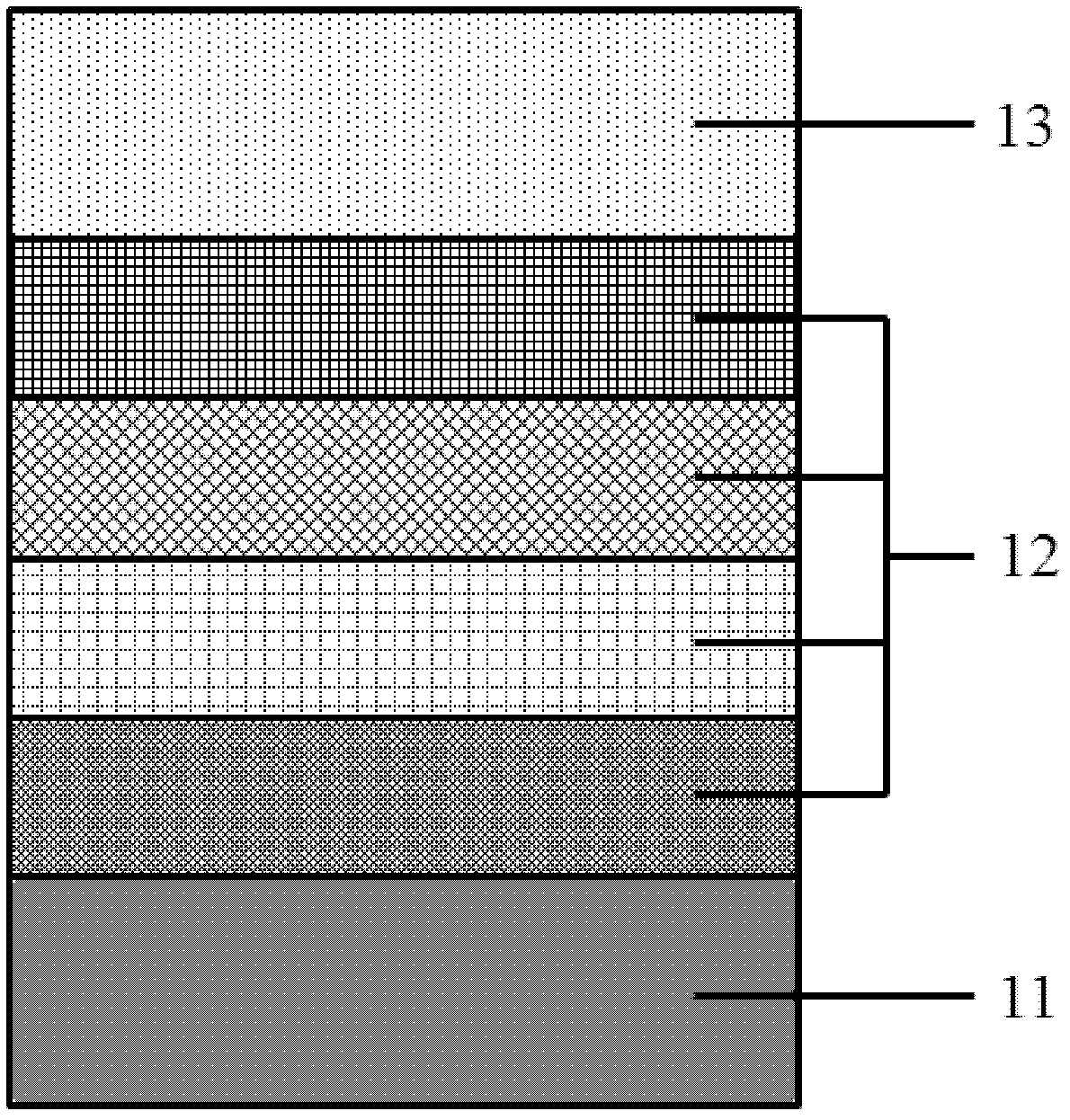

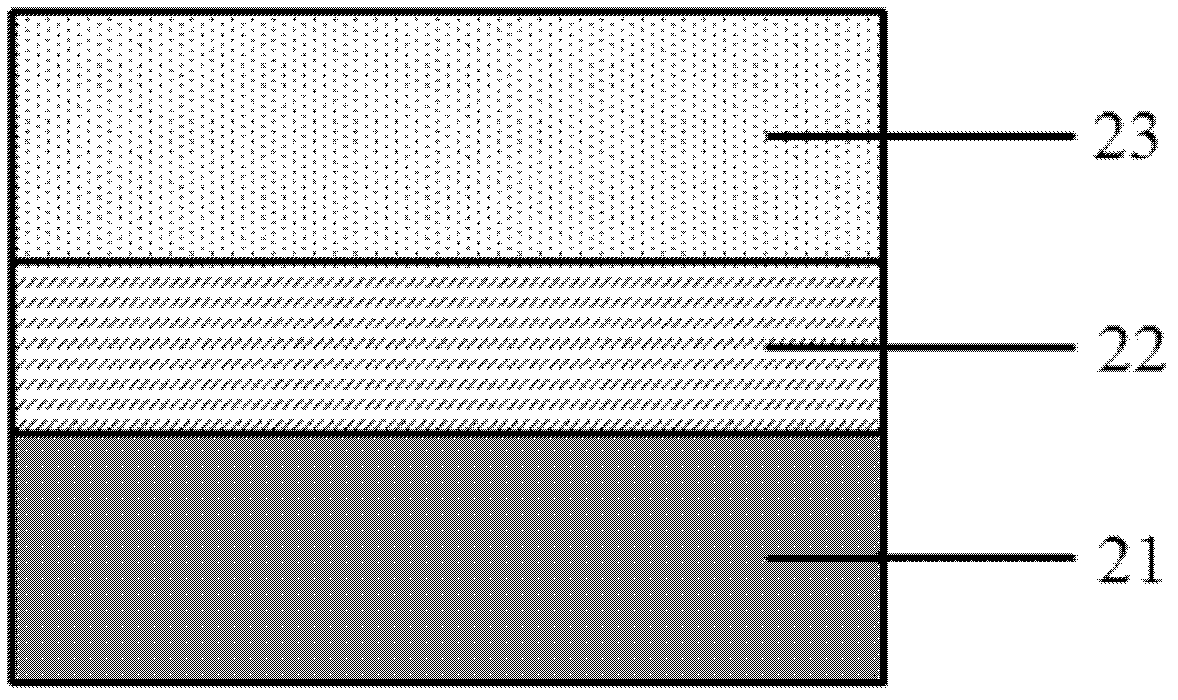

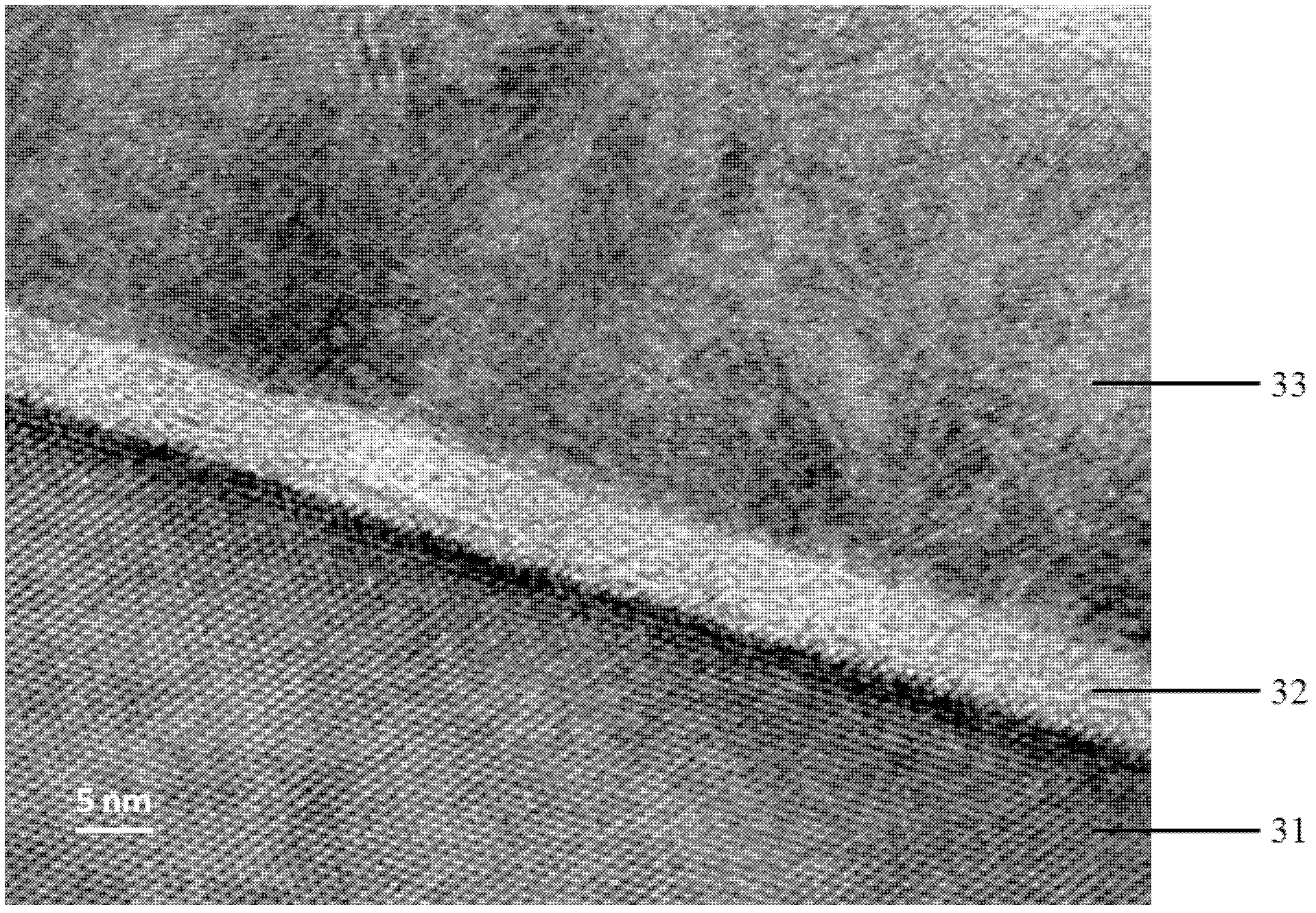

[0037] Such as figure 2 , image 3 shown. It is the method for growing an InGaAs thin film on a GaAs substrate of the present invention, comprising the following steps:

[0038] (1) GaAs substrate cleaning

[0039] The epitaxial substrate adopts (001) crystal orientation n-GaAs substrate. Ultrasonic removal of dirt particles on the surface of the GaAs substrate; washing with trichlorethylene, acetone, and methanol to remove surface organic matter; placing the GaAs substrate in 60°C H 2 SO 4 :H 2 o 2 :H 2 Etching in O (5:1:1) solution for 2 minutes; cleaning with HCl to remove surface oxides and organic matter; rinsing with deionized water; drying the cleaned GaAs substrate with filtered dry nitrogen;

[0040] (2) GaAs substrate pretreatment

[0041] After the GaAs substrate is cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com