High-quality AlN epitaxial film, preparation method of high-quality AlN epitaxial film and application of high-quality AlN epitaxial film

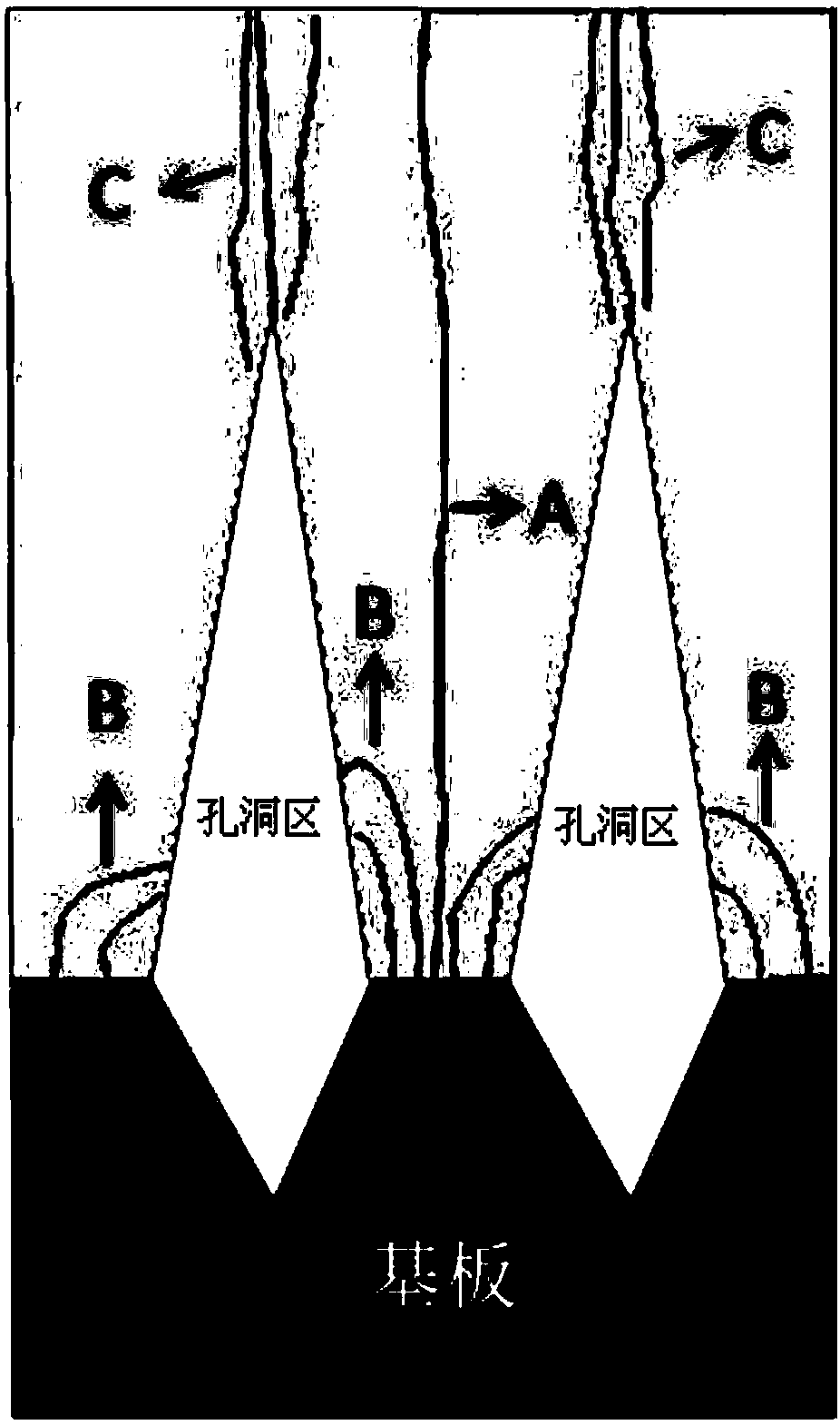

An epitaxial thin film, lateral epitaxy technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, semiconductor/solid-state device manufacturing, etc. Atomic level flatness and other problems, to achieve the effect of low dislocation density, elimination of cracks, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

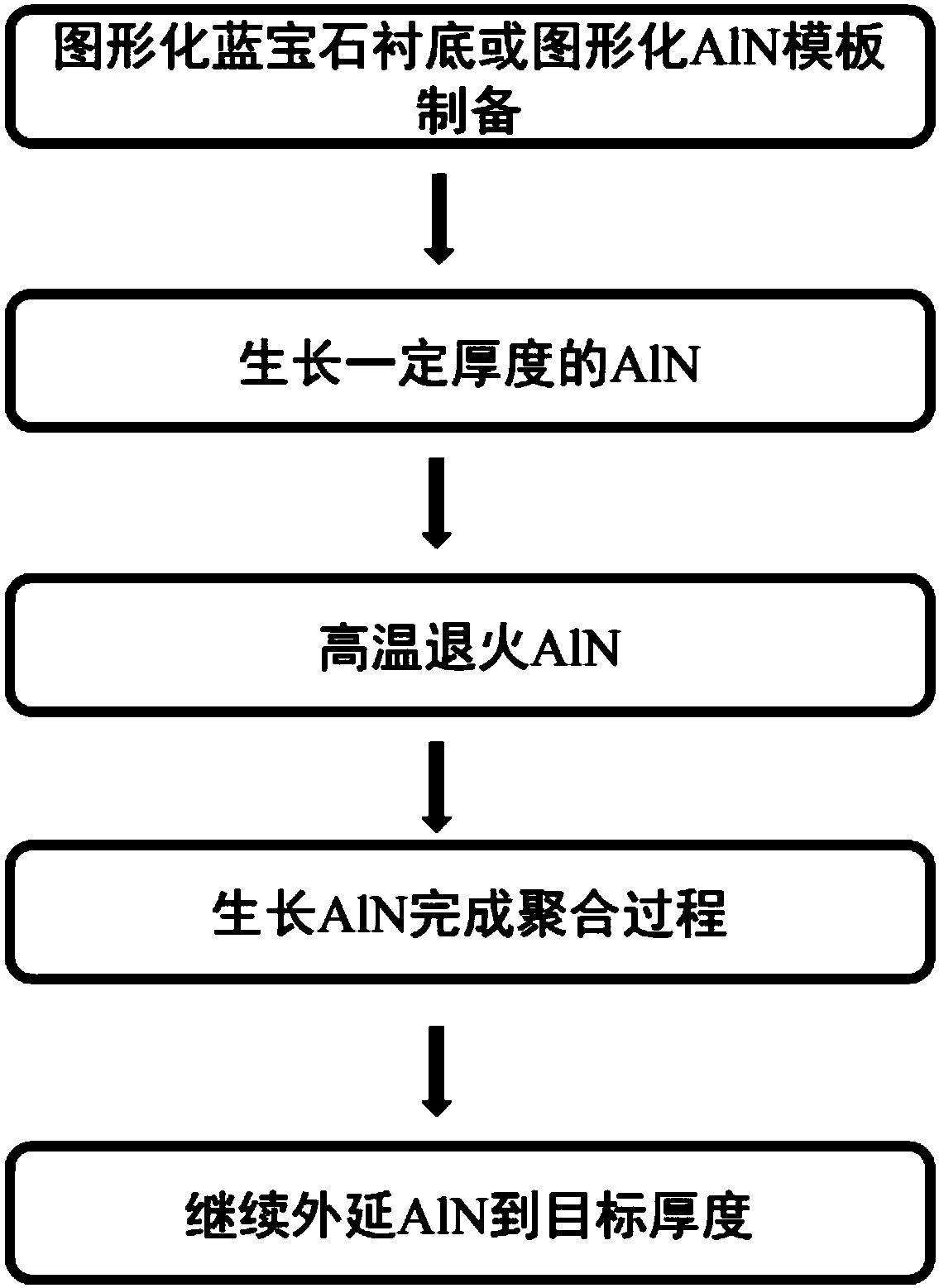

[0048] Embodiment 1 (taking the preparation of sapphire substrate as an example)

[0049] S1: Prepare a concave patterned sapphire substrate, the specific steps are:

[0050] 1) First use PECVD to deposit SiO with a thickness of 200nm on a 2-inch c-plane sapphire substrate 2 , and then spin coat TU7-220 glue with a thickness of 300nm.

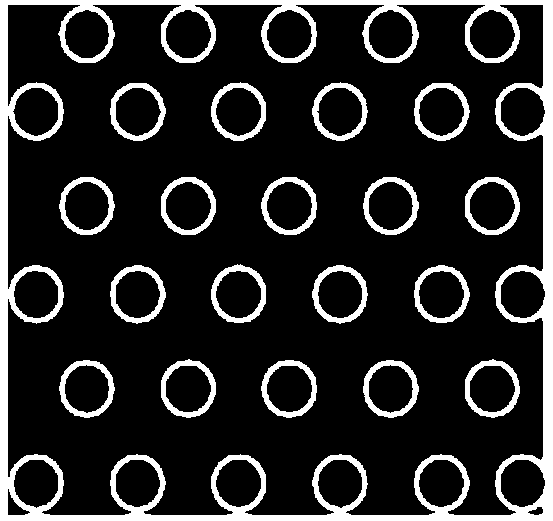

[0051] 2) Using a nano imprinter The pattern transfer polymer on the embossing template (the table size is 400nm) with a period of 1.2 microns and a circular hole diameter of 800nm is placed on the polymer, and then the pattern on the polymer is embossed on the embossing glue under the condition of ultraviolet exposure.

[0052] 3) Using ICP to transfer the pattern to SiO with imprinting glue as a mask 2 superior.

[0053] 4) with SiO 2 Use H as a mask 2 SO 4 and H 3 PO 4 The mixed solution corrodes the sapphire at a temperature of 270°C, and transfers the pattern to the sapphire substrate.

[0054] 5) The remaining SiO on the sapp...

Embodiment 2

[0060] Example 2 (taking growth on a concave patterned AlN template as an example)

[0061] S1: Prepare a concave AlN template substrate, the specific steps are:

[0062] 1) Prepare an AlN template with a thickness of 1 micron using MOCVD equipment (3×2”Aixtron CCS FP-MOCVD). SU8 glue is placed on the AlN template with a thickness of 600nm.

[0063] 2) Using a nano imprinter The pattern transfer polymer on the embossing template (the mesa size is 350nm) with a period of 1 micron and a circular hole diameter of 650nm is placed on the polymer, and then the pattern on the polymer is embossed on the embossing glue under the condition of ultraviolet exposure.

[0064] 3) ICP is used to transfer the embossing glue as a mask pattern to the AlN template, and the hole depth is 300 nanometers.

[0065] 4) Remove the remaining SU8 glue on the AlN template with acetone to obtain a nanopatterned AlN template, and thoroughly clean the substrate and dry it.

[0066] S2: Place the prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com