Patents

Literature

117 results about "Temperature modulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature modulation alters the kinetic of the sensor through changes in the operational temperature of device. The operating modulation voltage, also consequently the operating temperature, of the sensor changes periodically either by square (rectangular) or triangular or sine waveform [10].

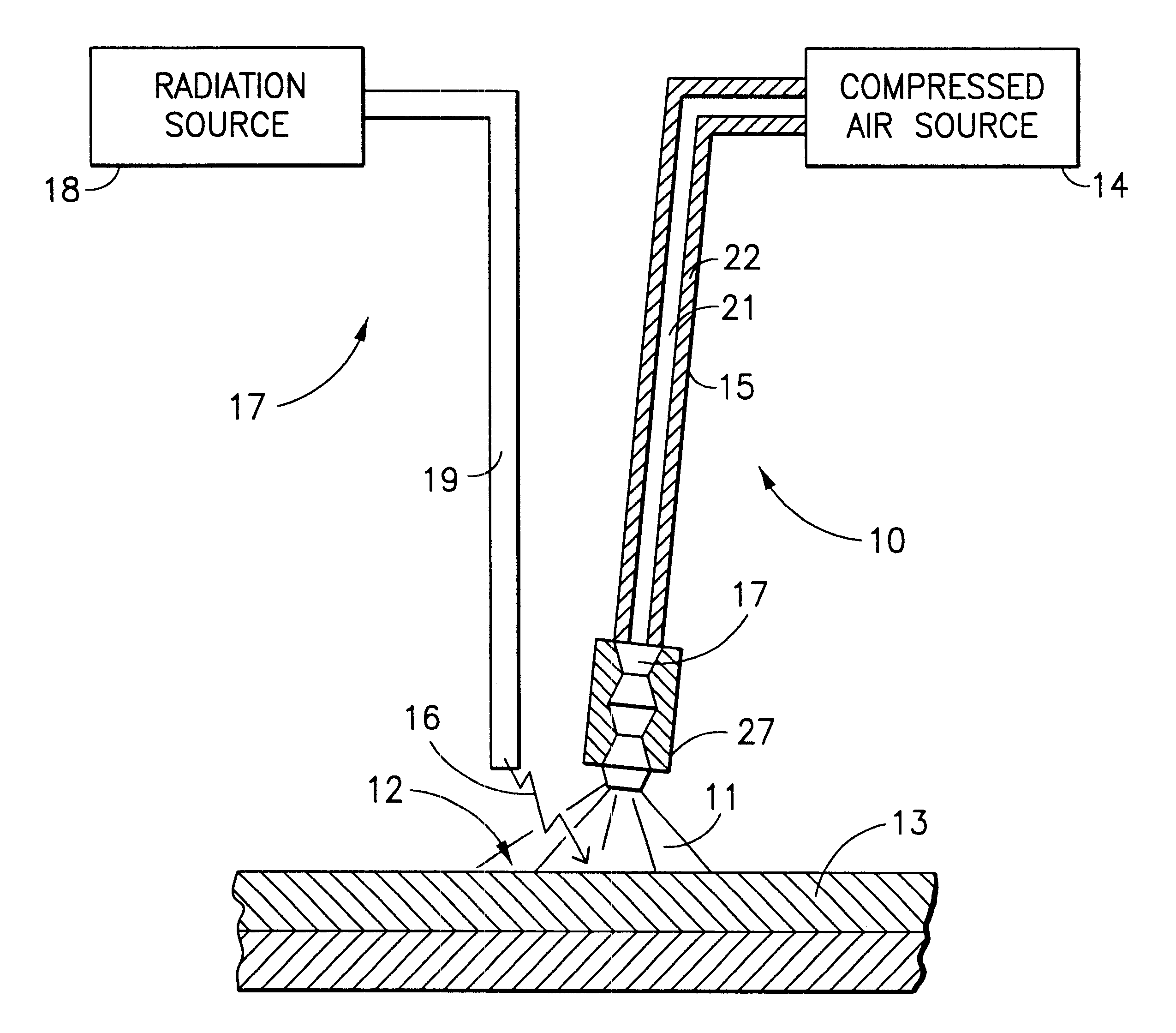

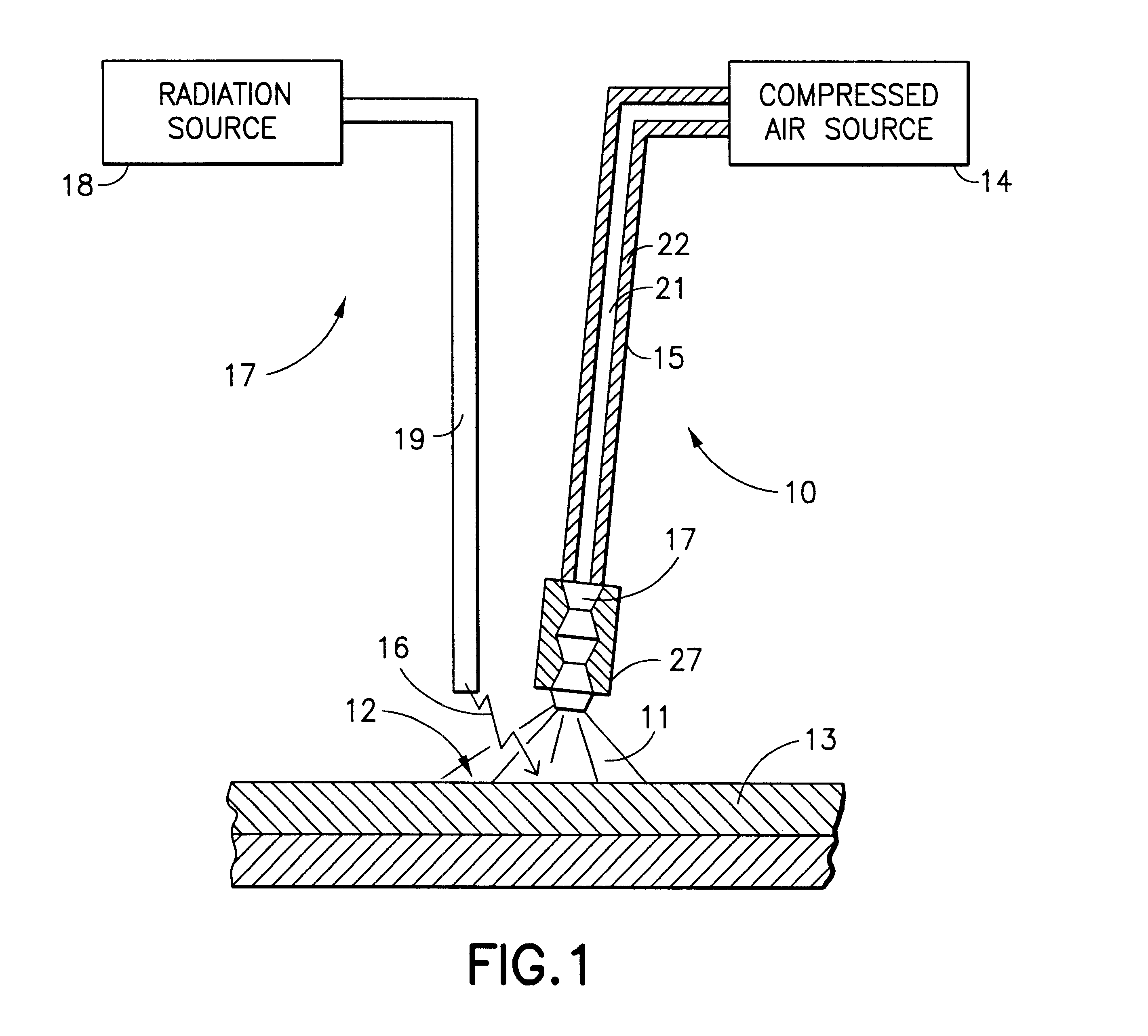

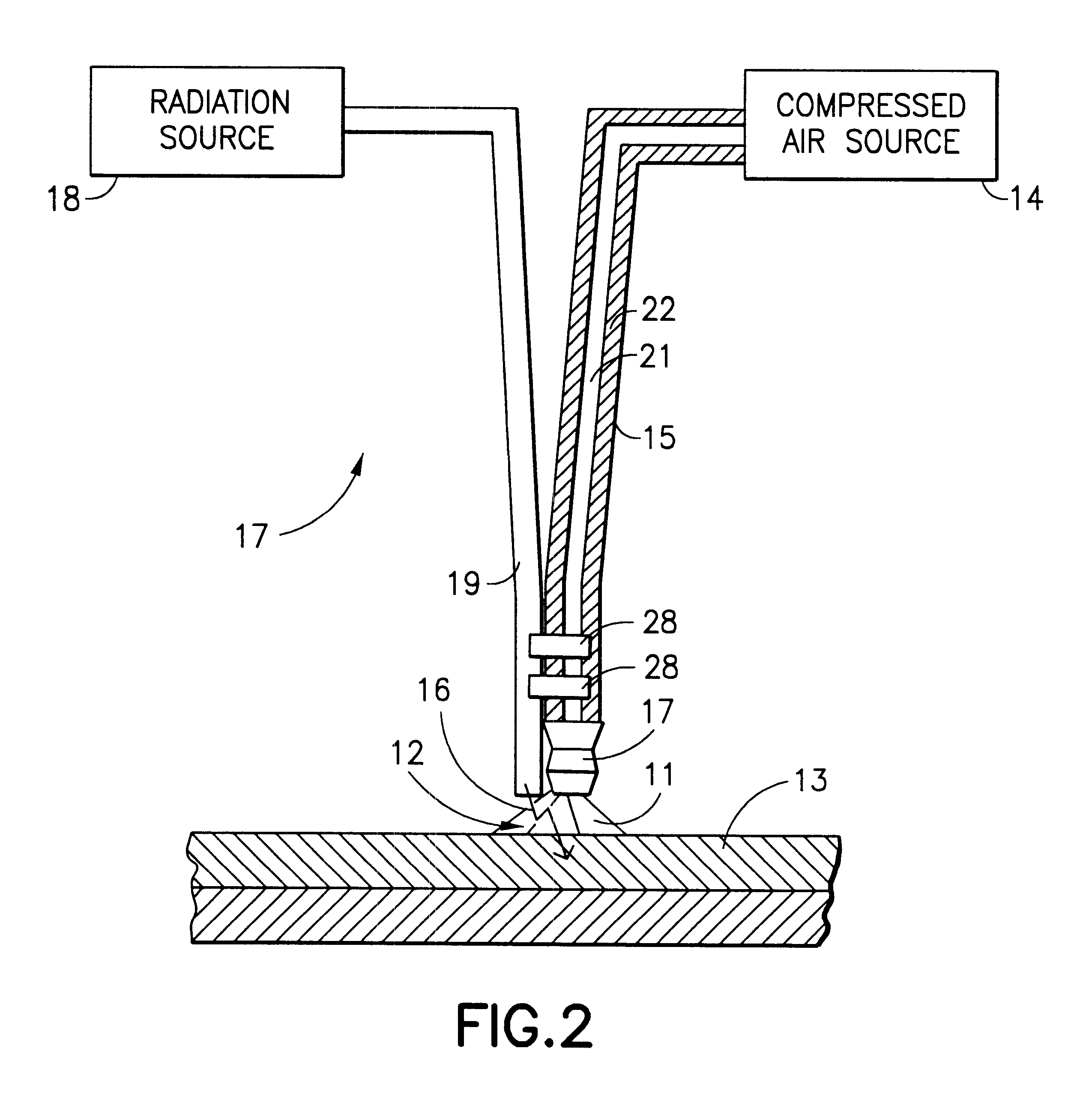

Method and apparatus for temperature control of biologic tissue with simultaneous irradiation

InactiveUS6475211B2Reduce usageLow costDiagnosticsSurgical instrument detailsTemperature controlTemperature modulation

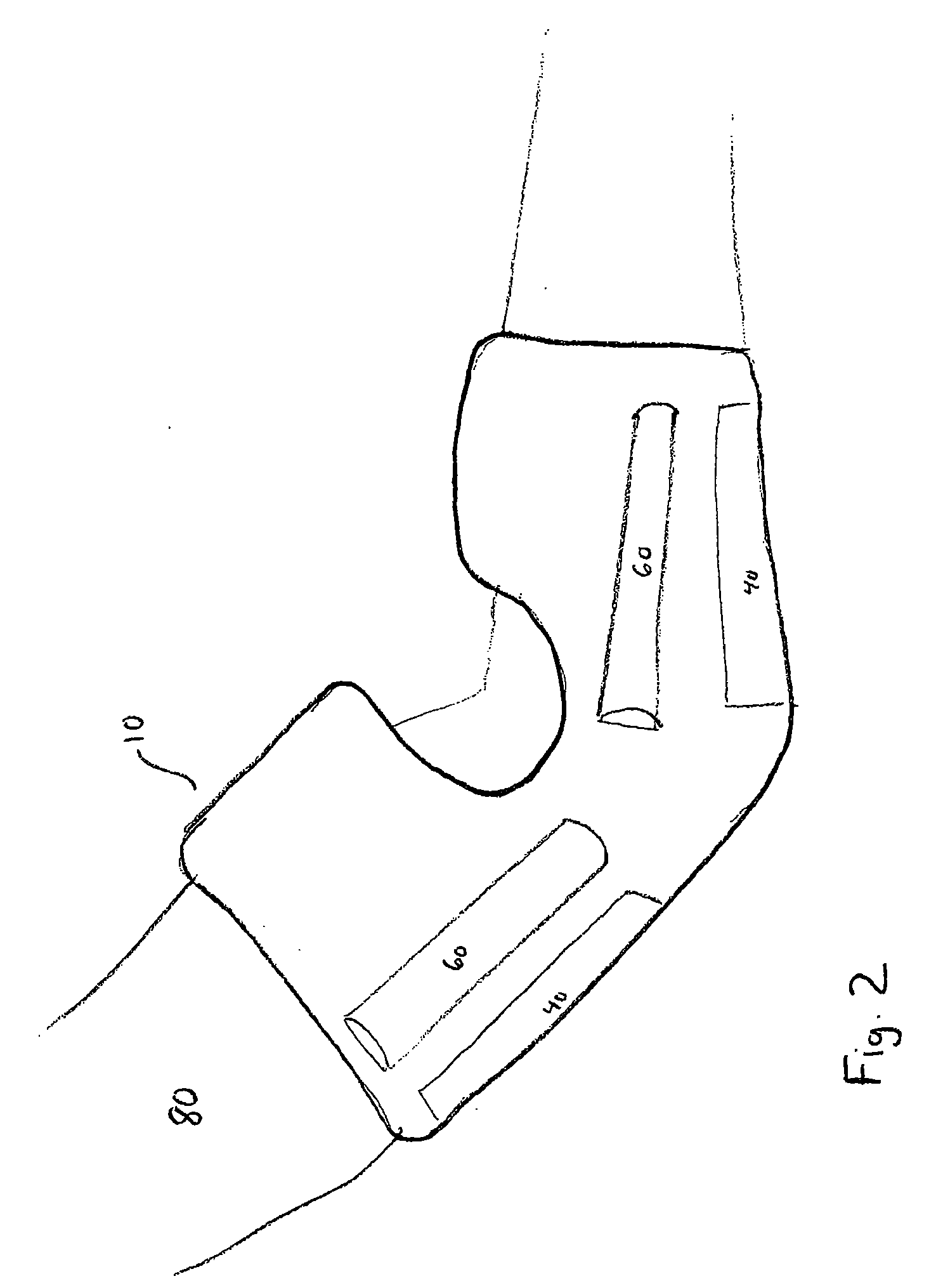

A method and apparatus for treatment of the skin or other biologic tissue includes the ability to subject said skin or other tissue to temperature modulation and radiation, simultaneously. The apparatus that delivers warm or cold material to the treatment site to effect this modulation of temperature may be attached to the apparatus that delivers radiation or it may be a separate entity, that could be utilized with a variety of radiation generating equipment.

Owner:COOL LASER OPTICS

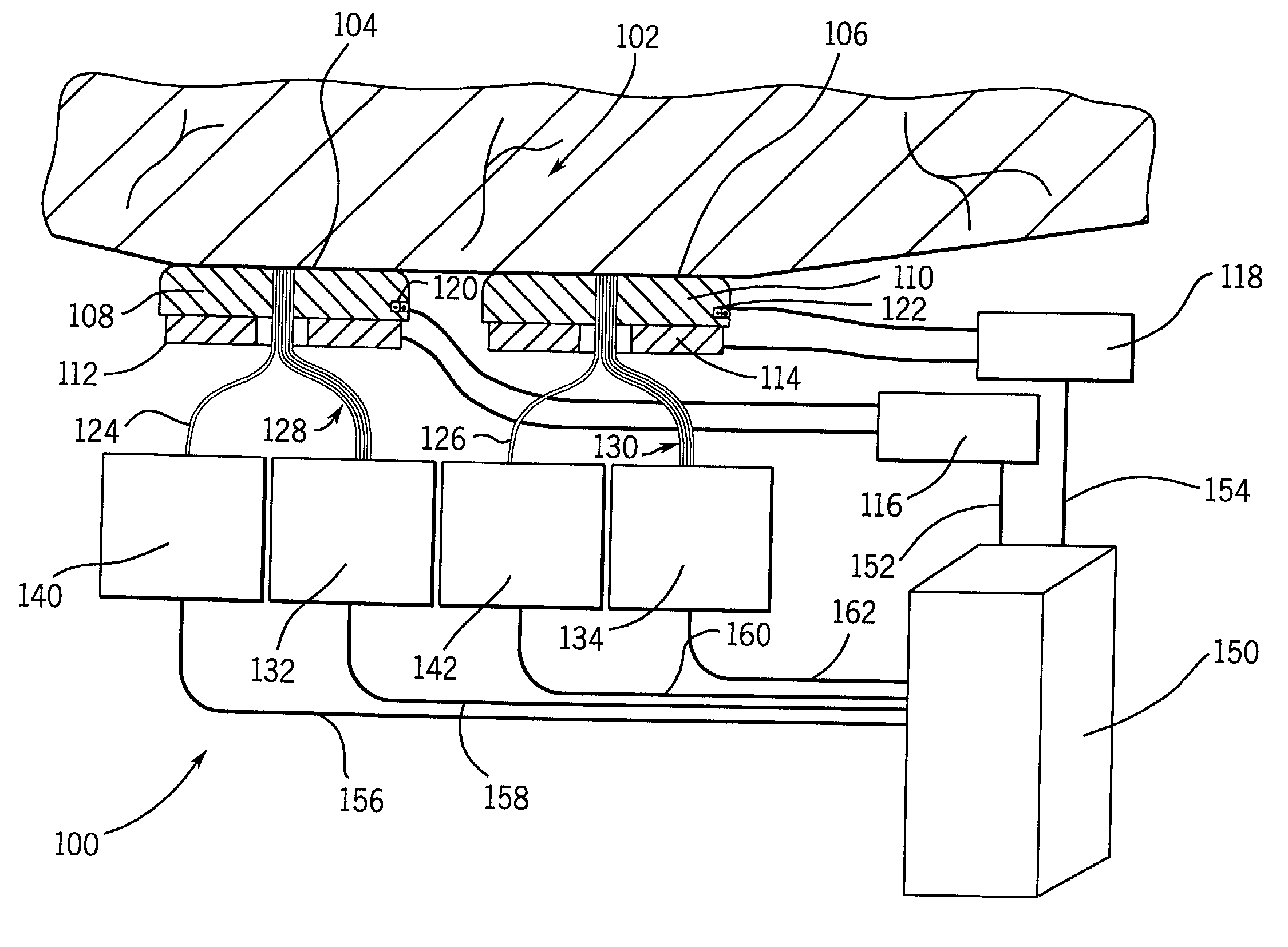

Method for optical measurements of tissue to determine disease state or concentration of an analyte

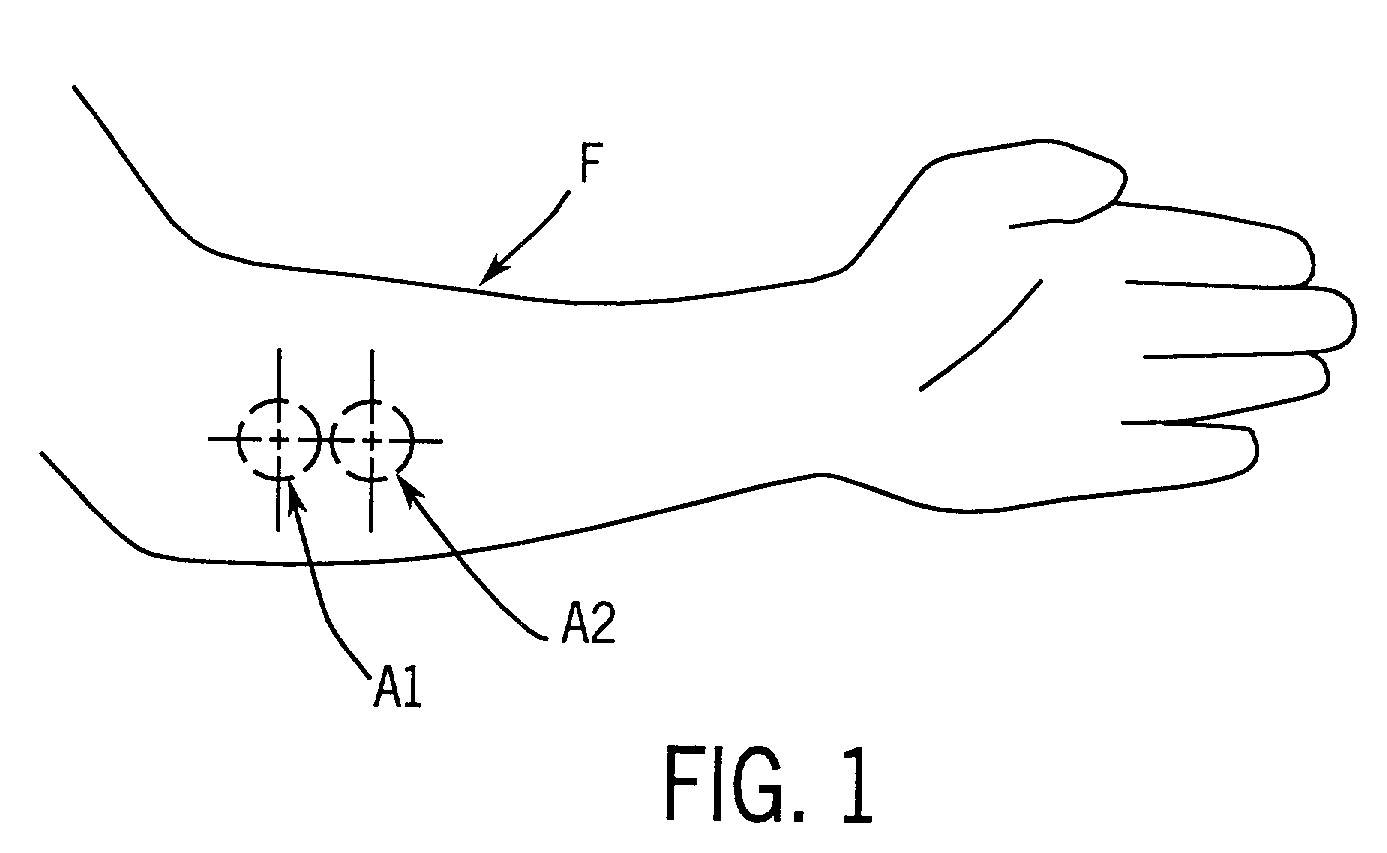

A method for collecting optical data at two morphologically similar, substantially non-overlapping, and preferably adjacent, areas on the surface of a tissue, while the temperature in each area is being maintained or modulated according to a temperature program. The optical data obtained are inserted into a mathematical relationship, e.g., an algorithm, that can be used to predict a disease state (such as the diabetes mellitus disease state) or the concentration of an analyte for indicating a physical condition (such as blood glucose level). This invention can be used to differentiate between disease status, such as, for example, diabetic and non-diabetic. The method involves the generation of a calibration (or training) set that utilizes the relationship between optical signals emanating from the skin under different thermal stimuli and disease status, e.g., diabetic status, established clinically. This calibration set can be used to predict the disease state of other subjects. Structural changes, as well as circulatory changes, due to a disease state are determined at two morphologically similar, but substantially non-overlapping areas on the surface of human tissue, e.g., the skin of a forearm, with each area being subjected to different temperature modulation programs. In addition to determination of a disease state, this invention can also be used to determine the concentration of an analyte in the tissues. This invention also provides an apparatus for the determination of a disease state, such as diabetes, or concentration of an analyte, such as blood glucose level, by the method of this invention.

Owner:ABBOTT DIABETES CARE INC

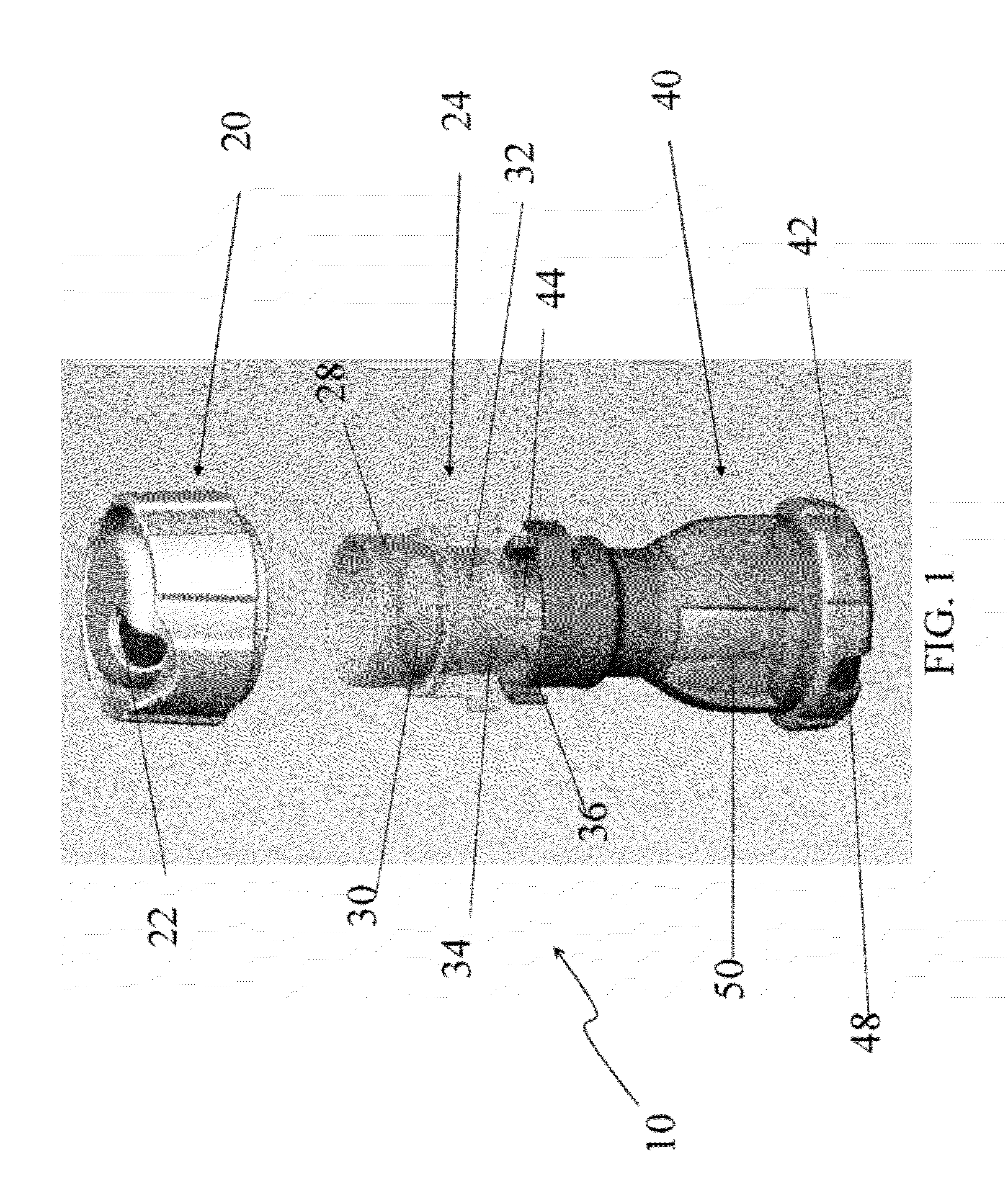

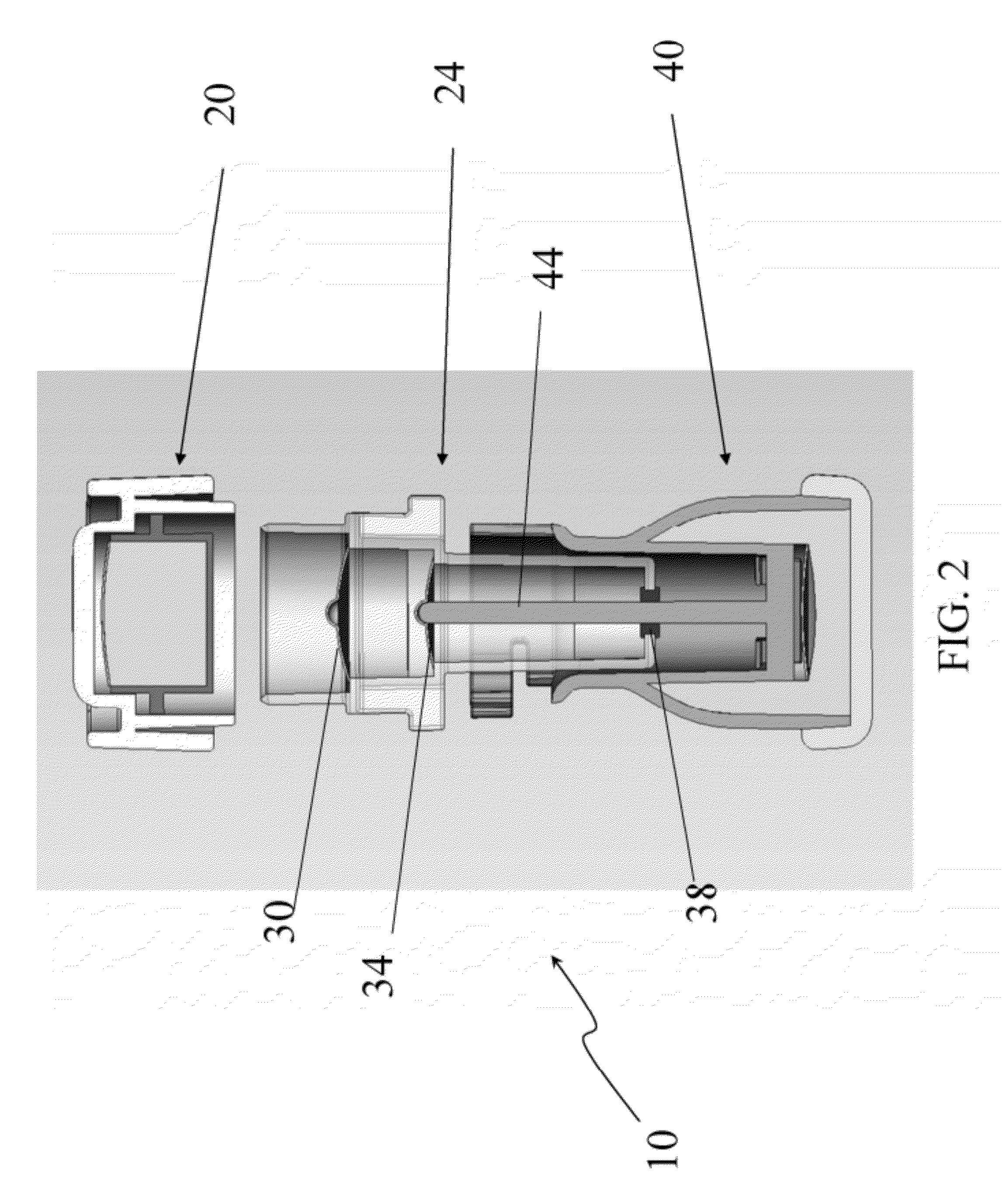

Vibrating therapy device

InactiveUS20070255187A1Easy to disassembleChiropractic devicesVibration massageHands freePhysical therapy

A device for providing therapy to a user including vibration and temperature modulation. The device provides mobile temperature modulation capabilities, mobile vibration capabilities, or a combination of the two. The device provides advantages to a person or animal including the ability to utilize the device in a hands-free manner. The device may also provide, under certain circumstances, pain relief or healing therapy to a person or animal.

Owner:BRANCH ALAN P

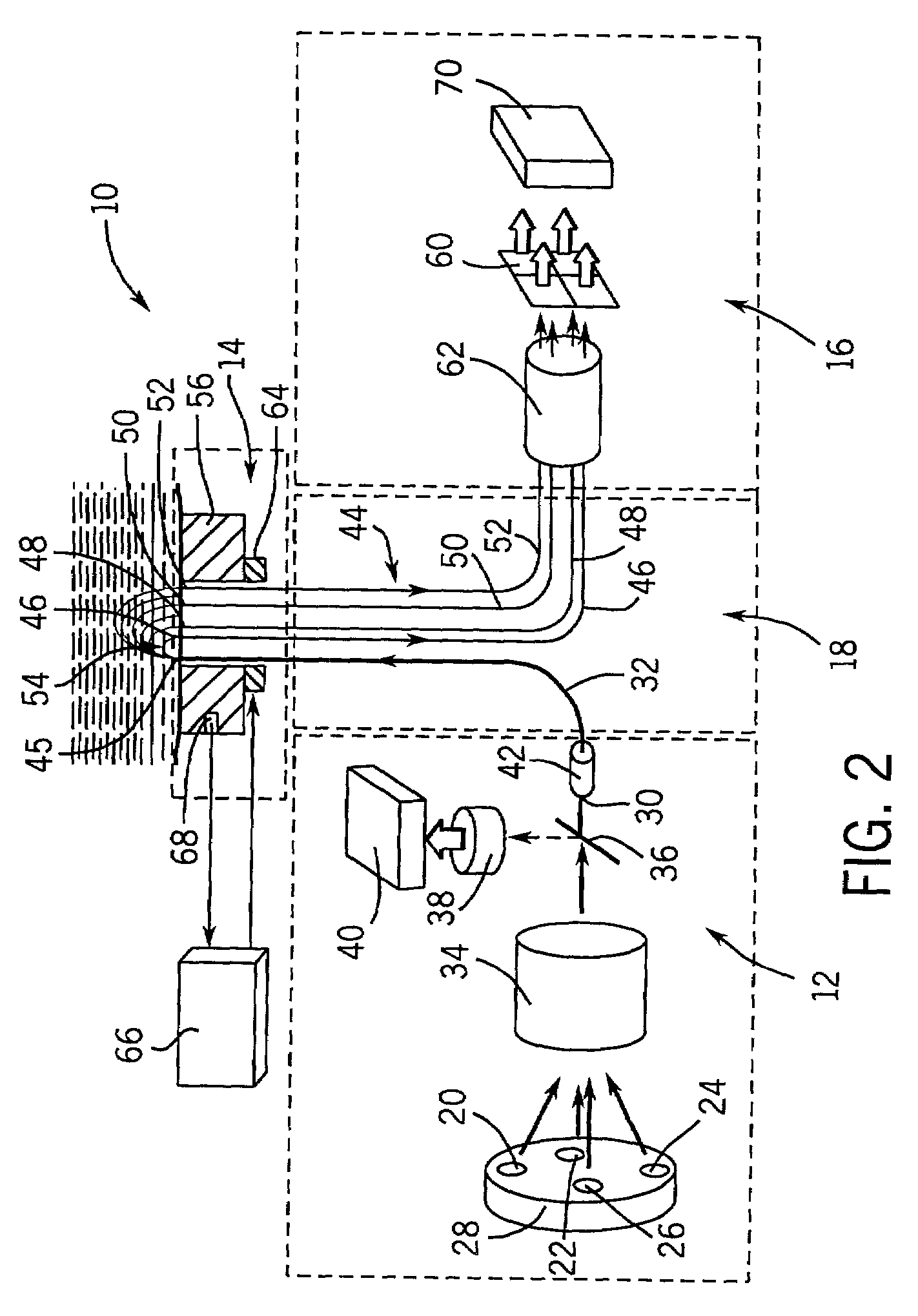

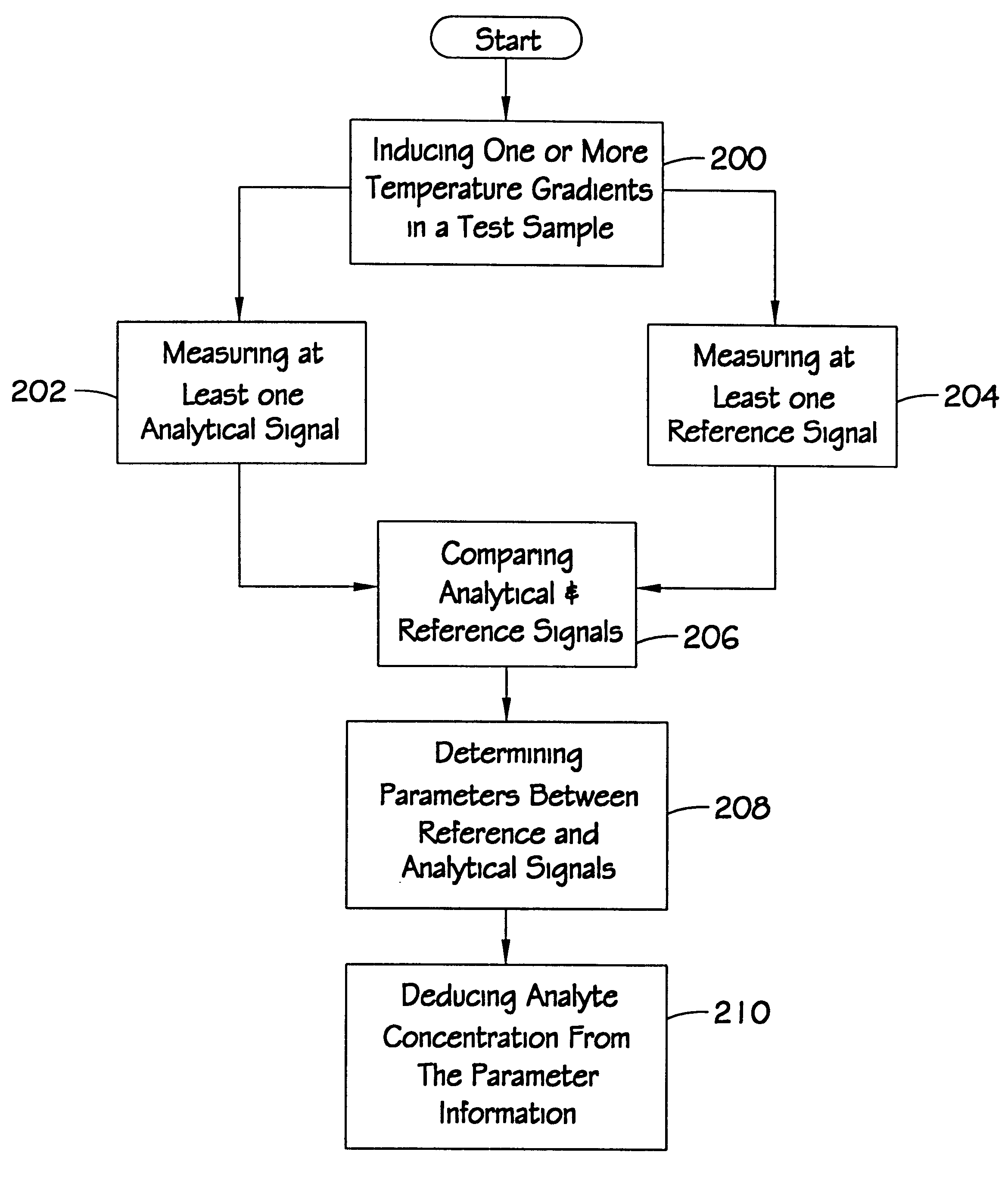

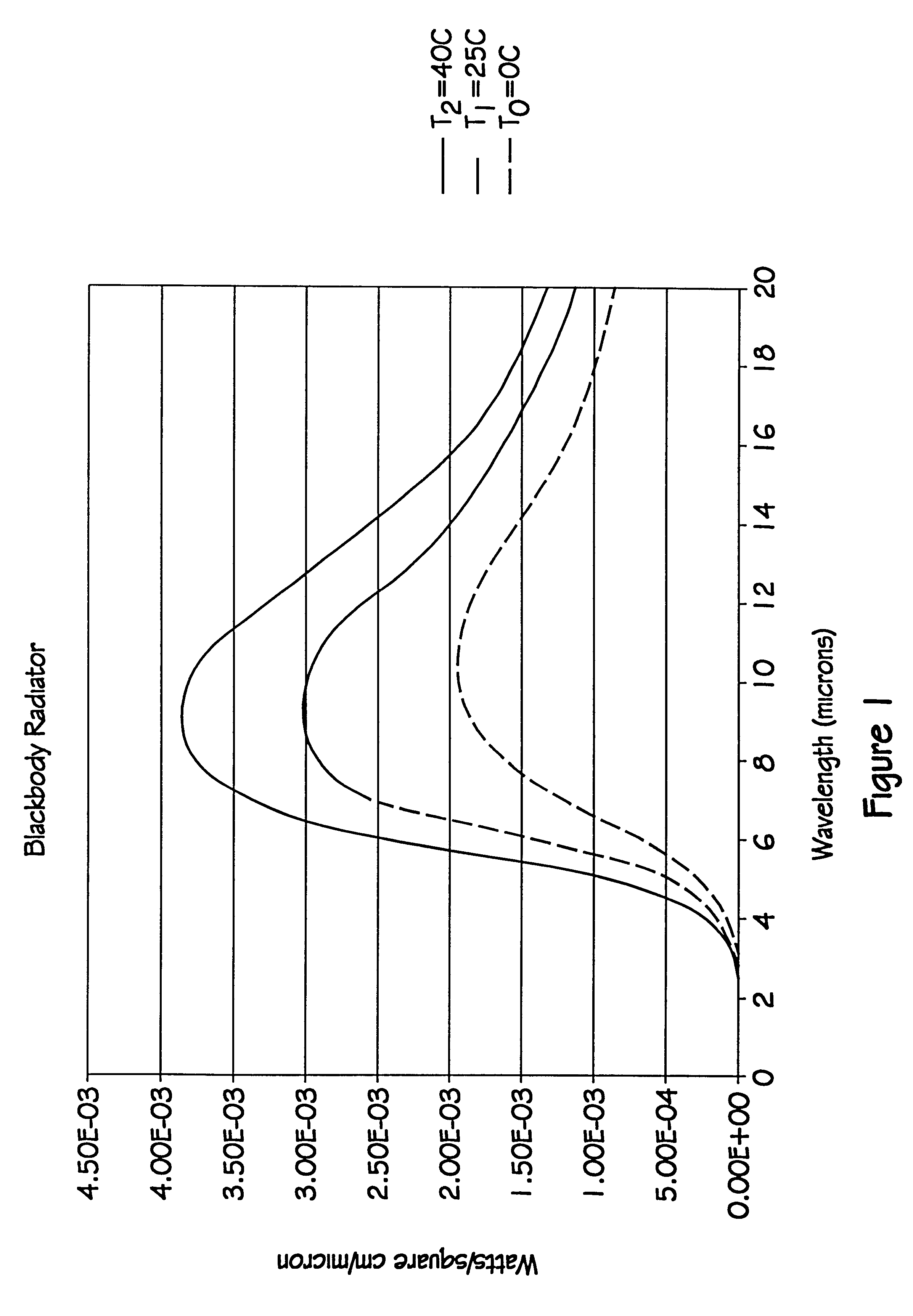

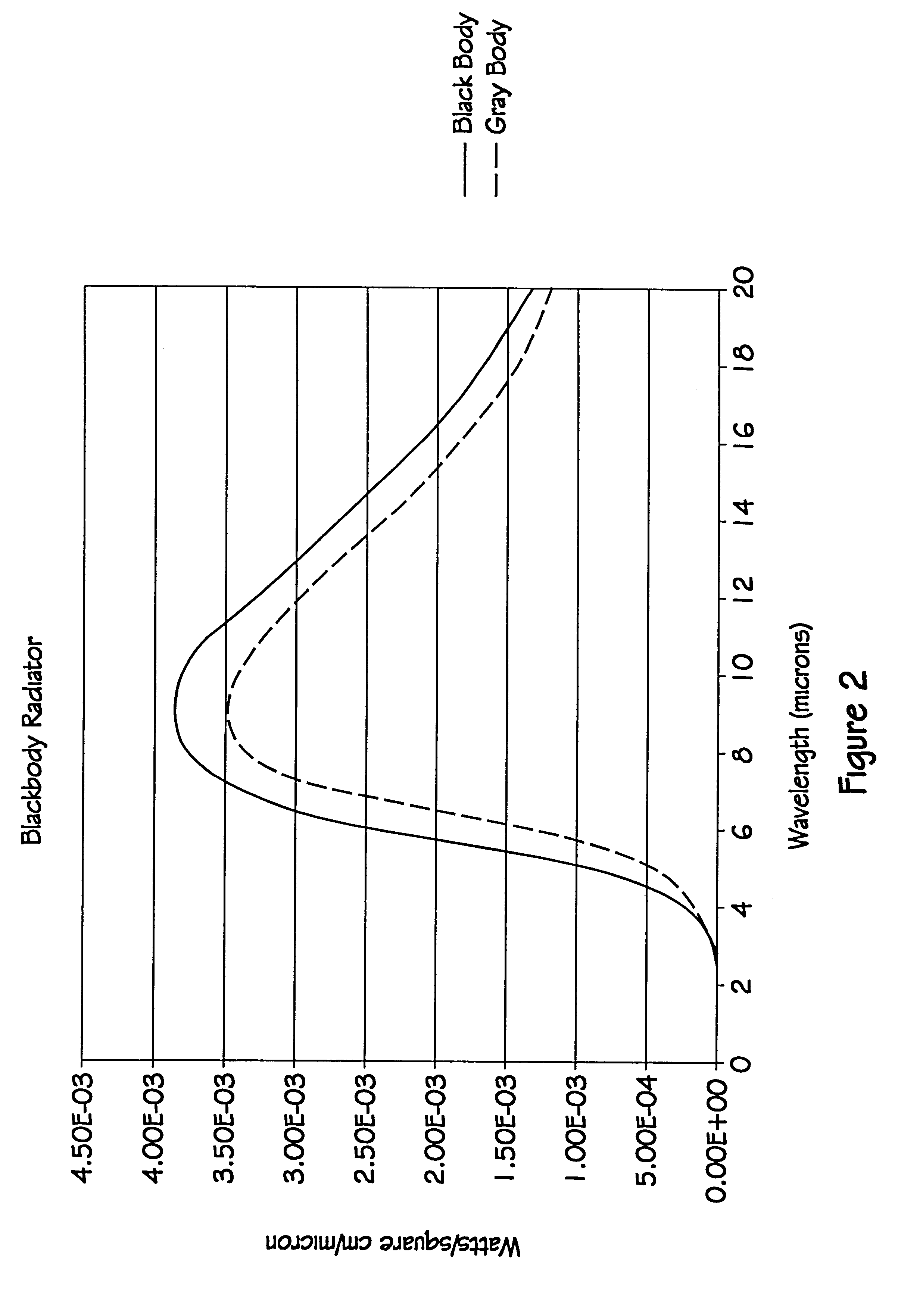

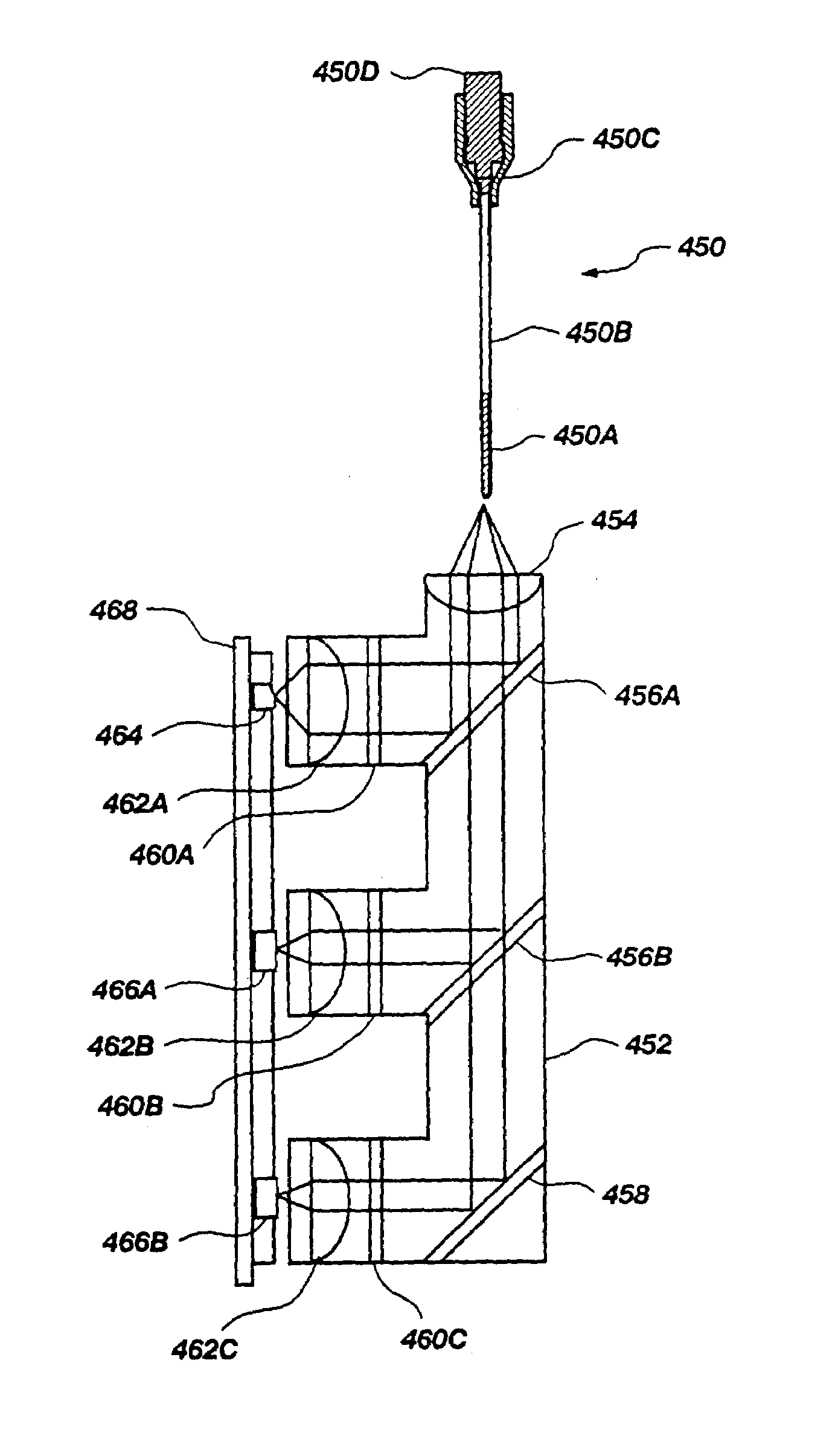

Method for determining analyte concentration using periodic temperature modulation and phase detection

InactiveUS6161028AThe process is convenient and fastExtreme accuracyRadiation pyrometryDiagnostics using lightContinuous measurementAnalyte

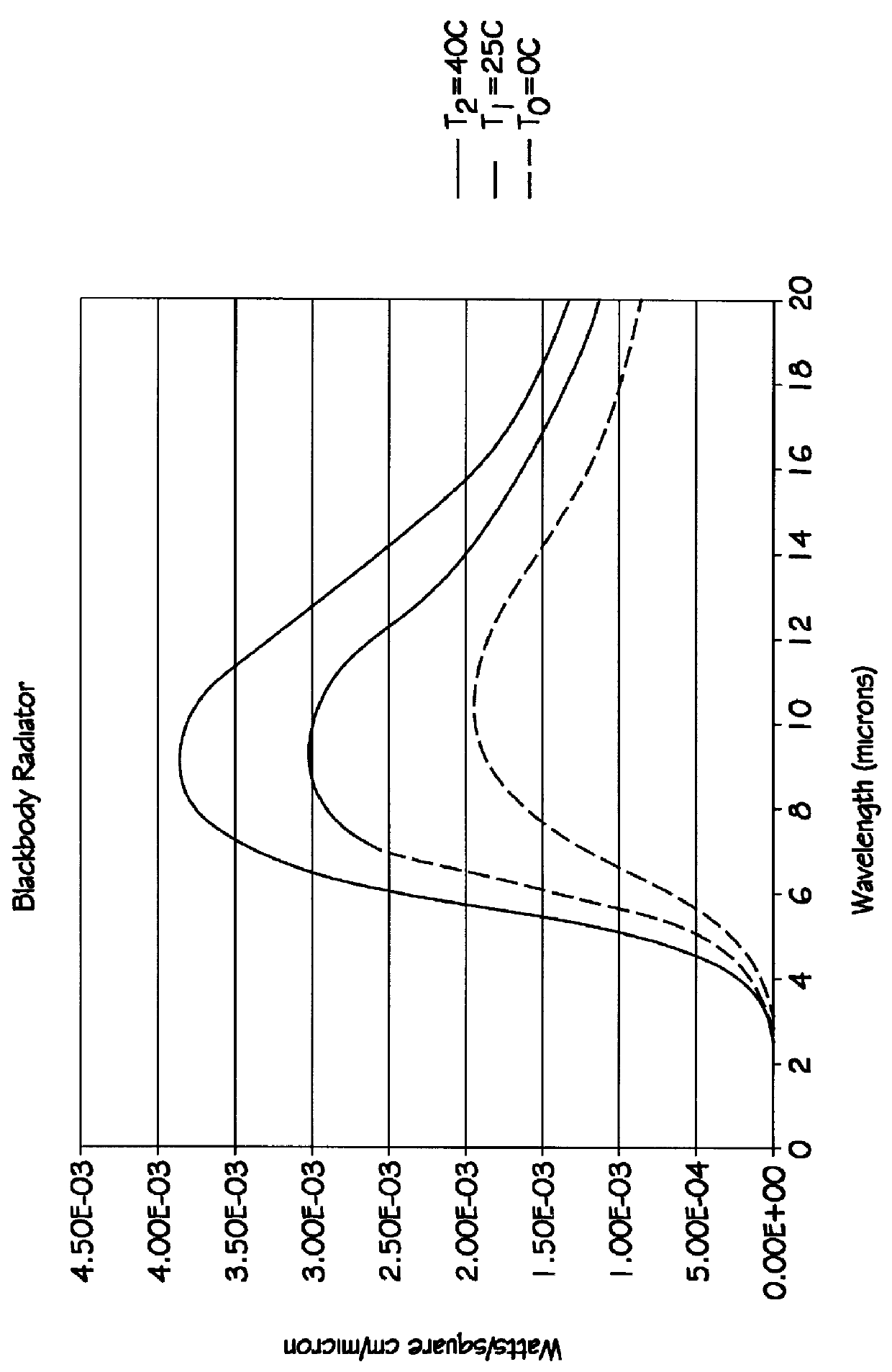

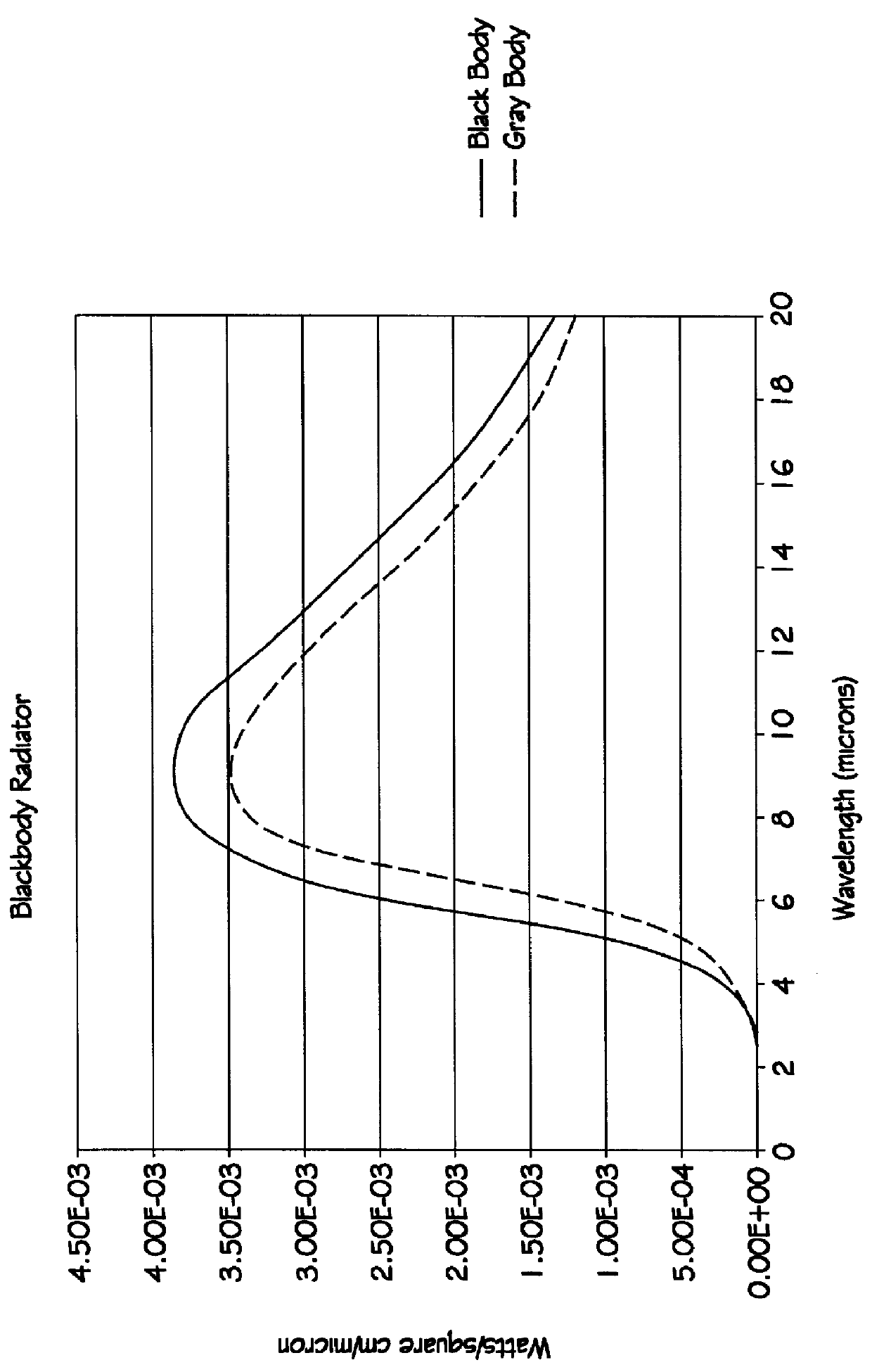

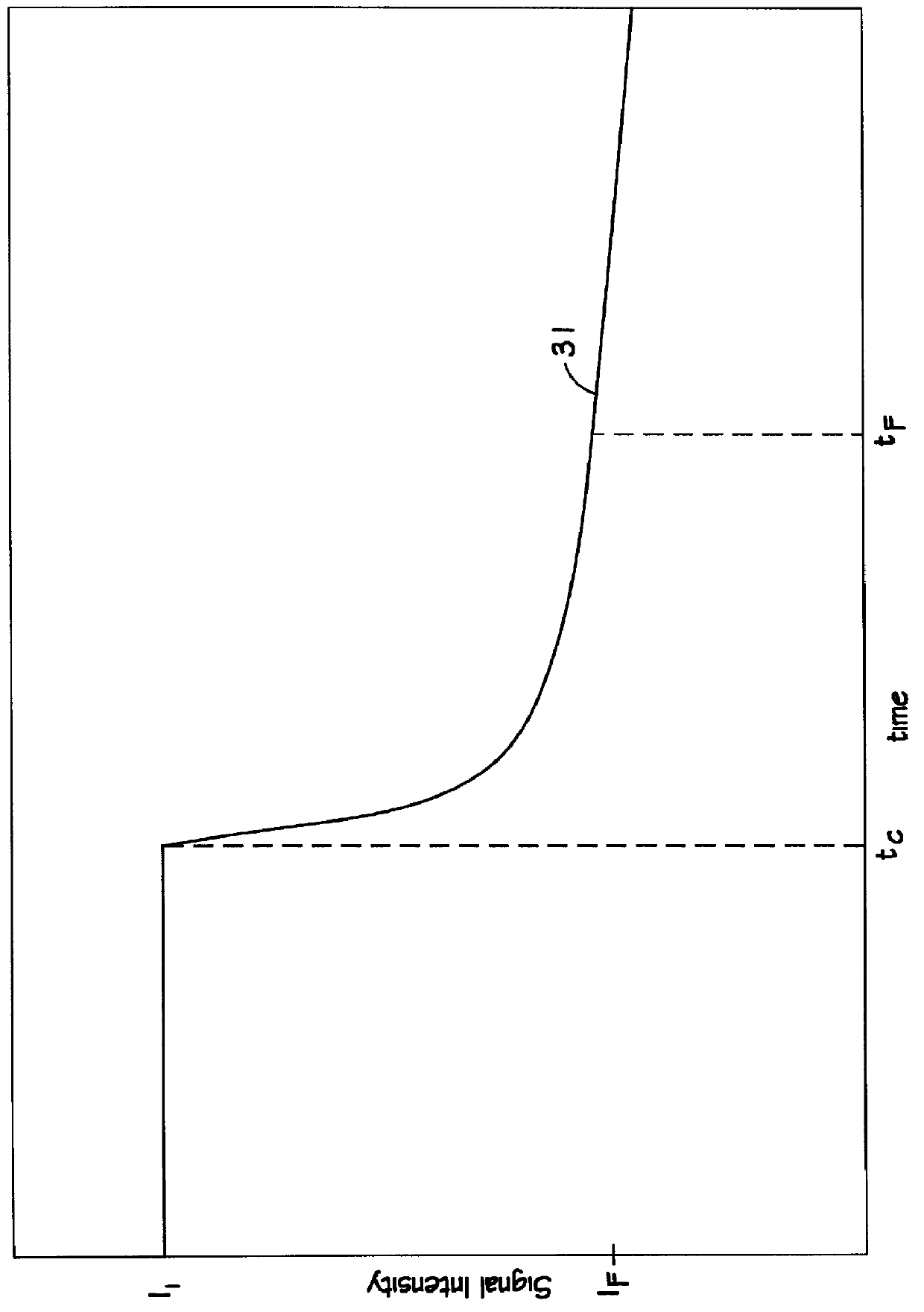

A method of determining the analyte concentration of a test sample is described. A temperature gradient is introduced in the test sample and infrared radiation detectors measure radiation at selected analyte absorbance peak and reference wavelengths. Reference and analytical signals are detected. In the presence of the selected analyte, parameter differences between reference and analytical signals are detectable. These parameter differences, having a relationship to analyte concentration, are measured, correlated, and processed to determine analyte concentration in the test sample. Accuracy is enhanced by inducing a periodically modulated temperature gradient in the test sample. The analytical and reference signals may be measured continuously and the parameter difference integrated over the measurement period to determine analyte concentration.

Owner:OPTISCAN BIOMEDICAL

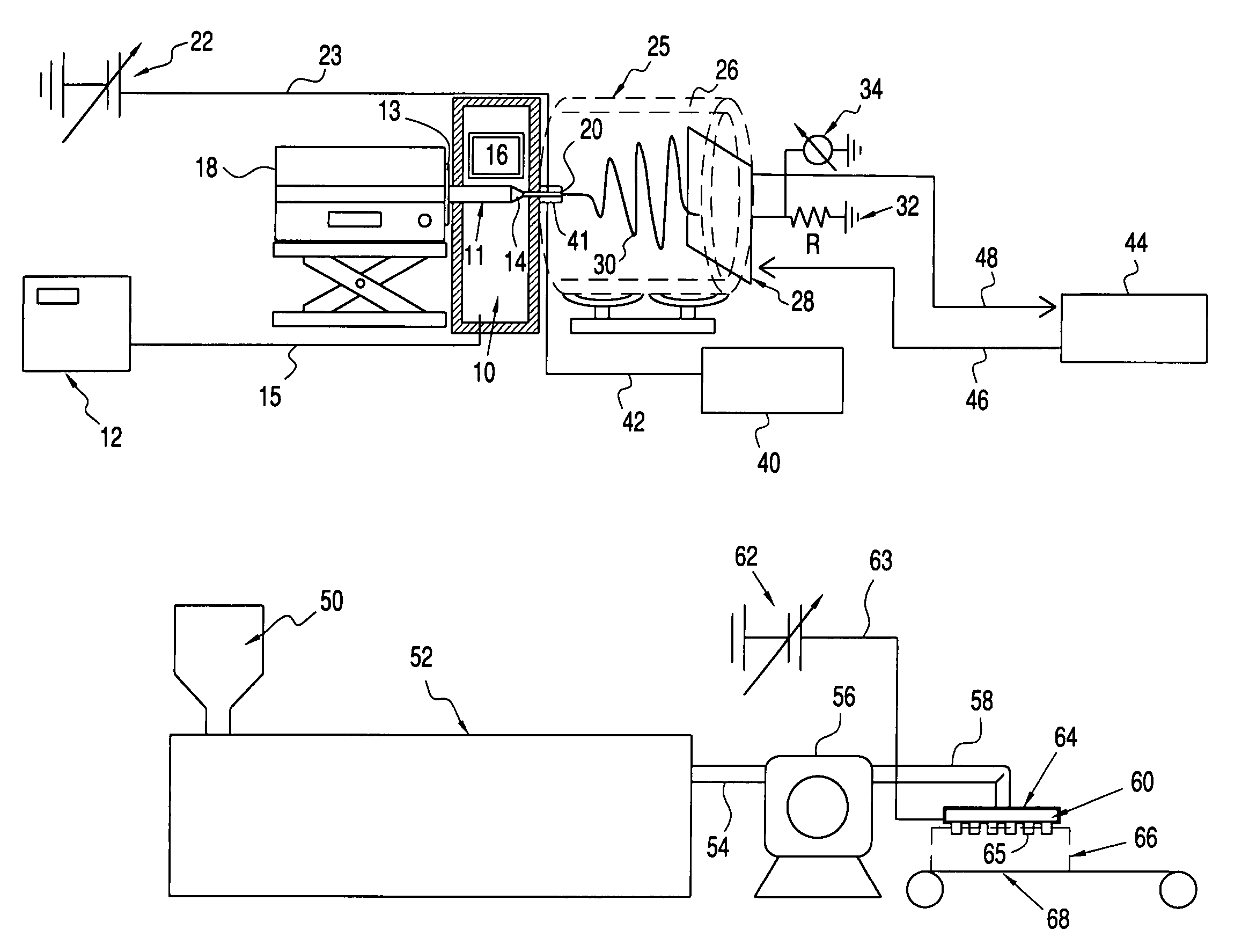

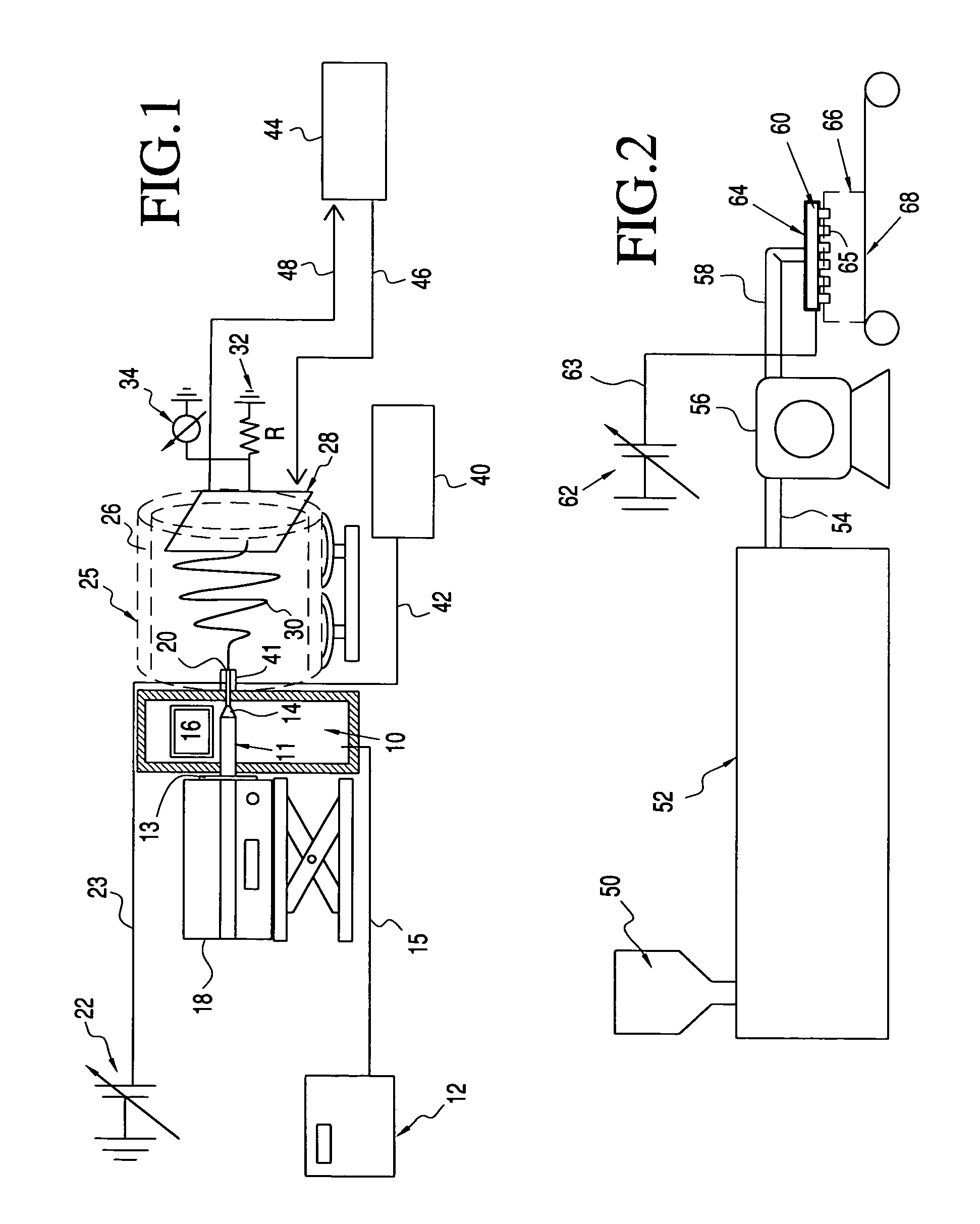

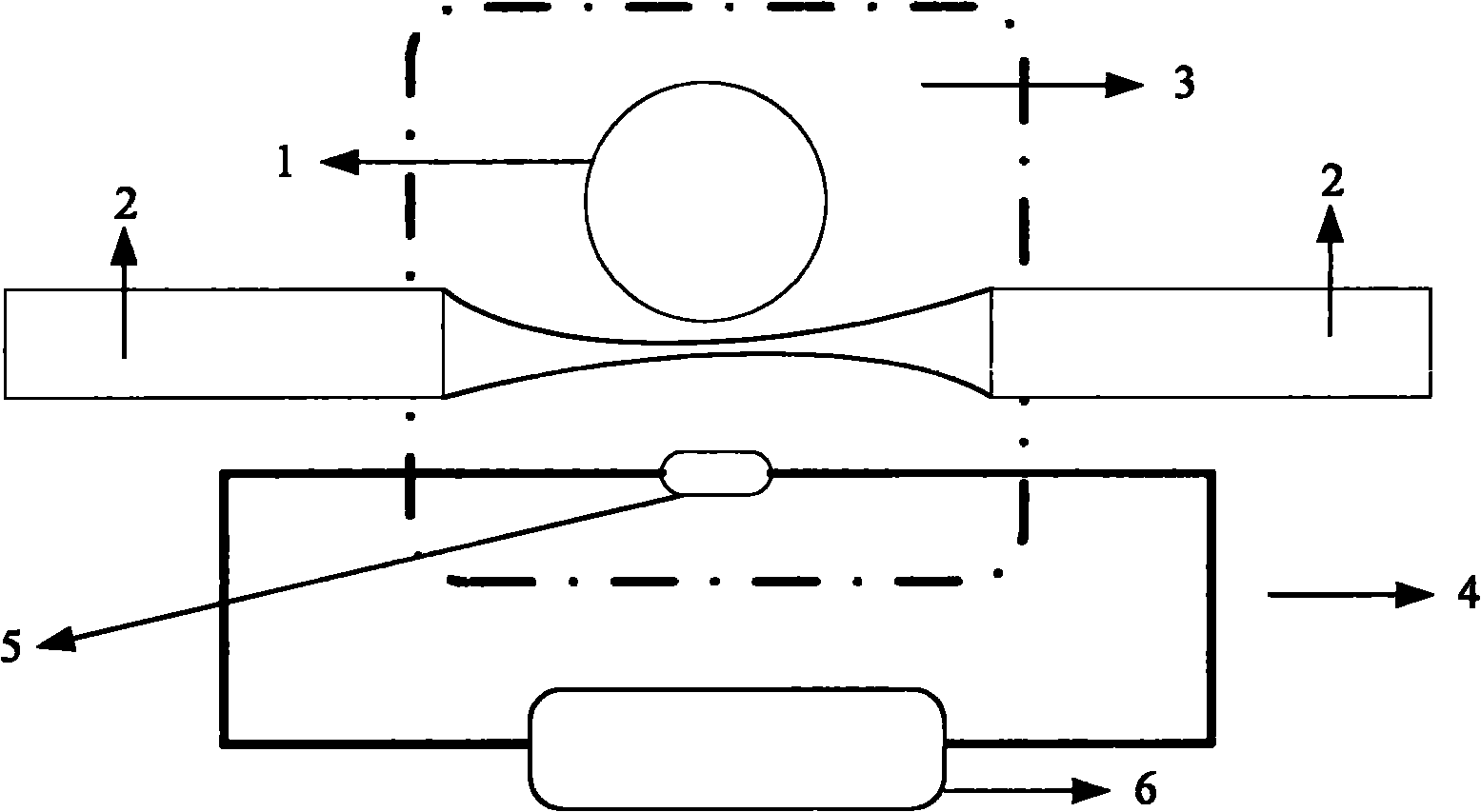

Apparatus and method for elevated temperature electrospinning

ActiveUS7326043B2Avoid disadvantagesConfectioneryWood working apparatusElectrical resistance and conductanceSpinning

Elevated temperature electrospinning apparatus comprises a pump upstream of or containing a resistance heater, means to shield applied electrostatic field from the resistance heater, and a temperature modulator for modulating temperature in the spinning region.

Owner:CORNELL RES FOUNDATION INC

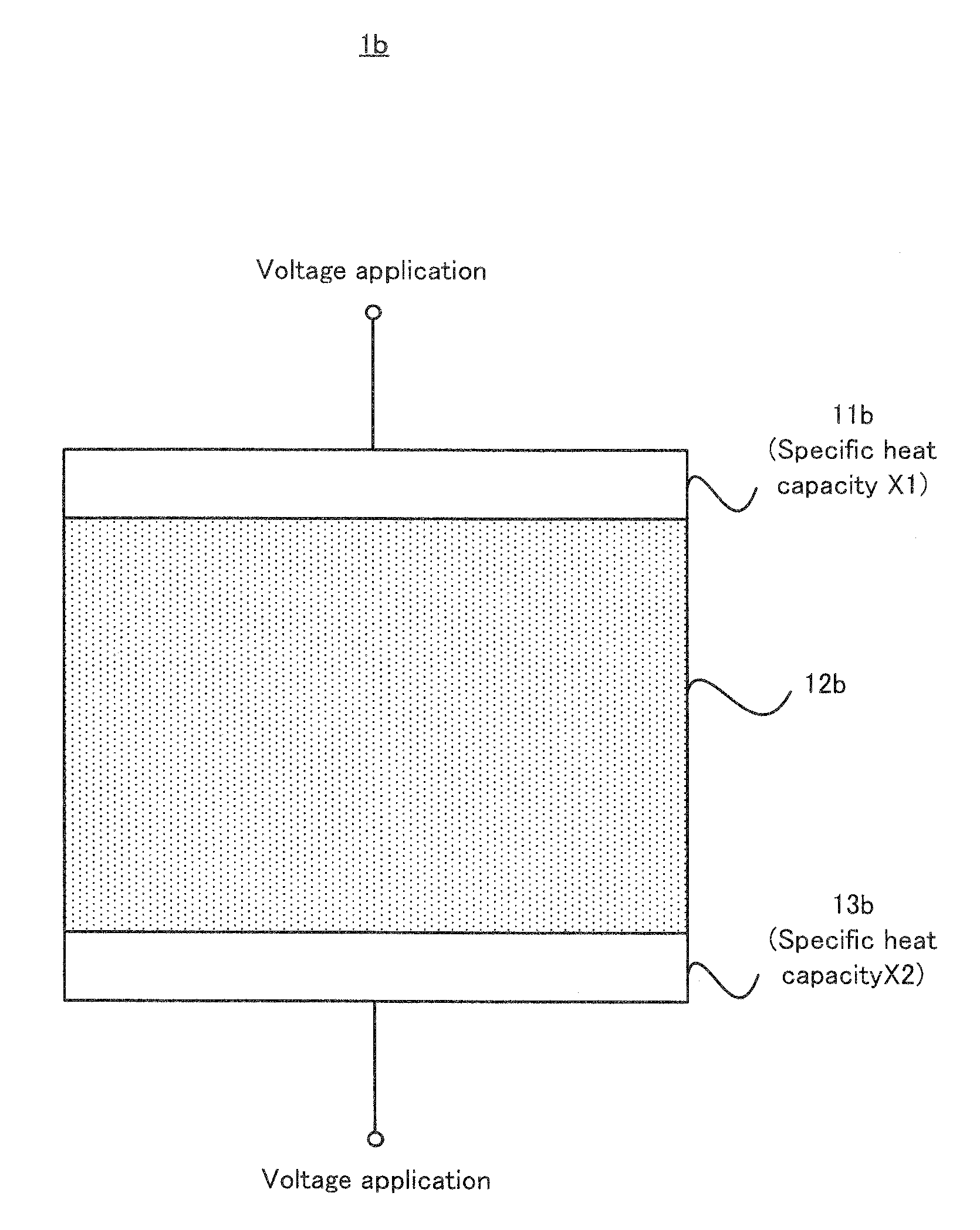

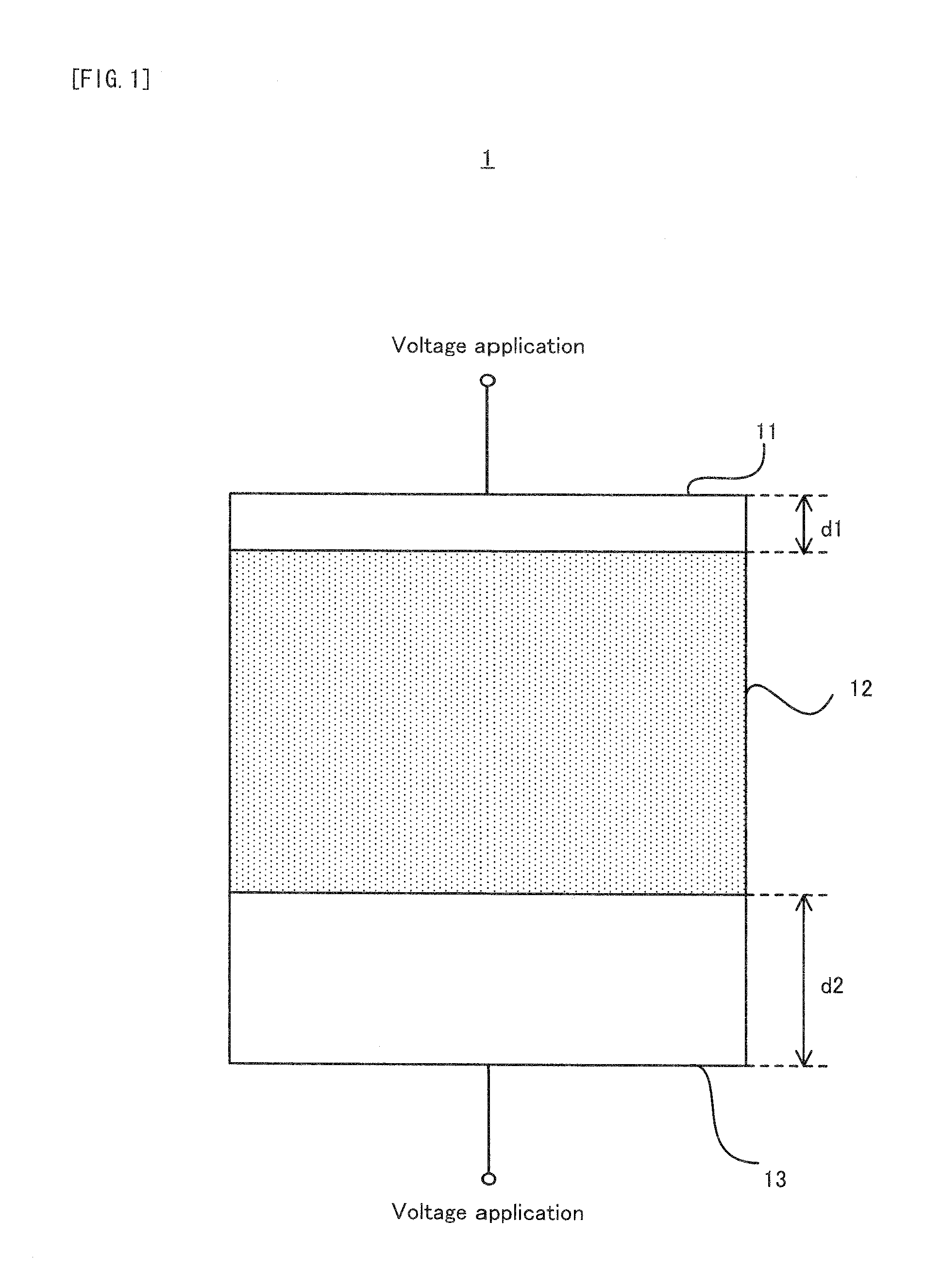

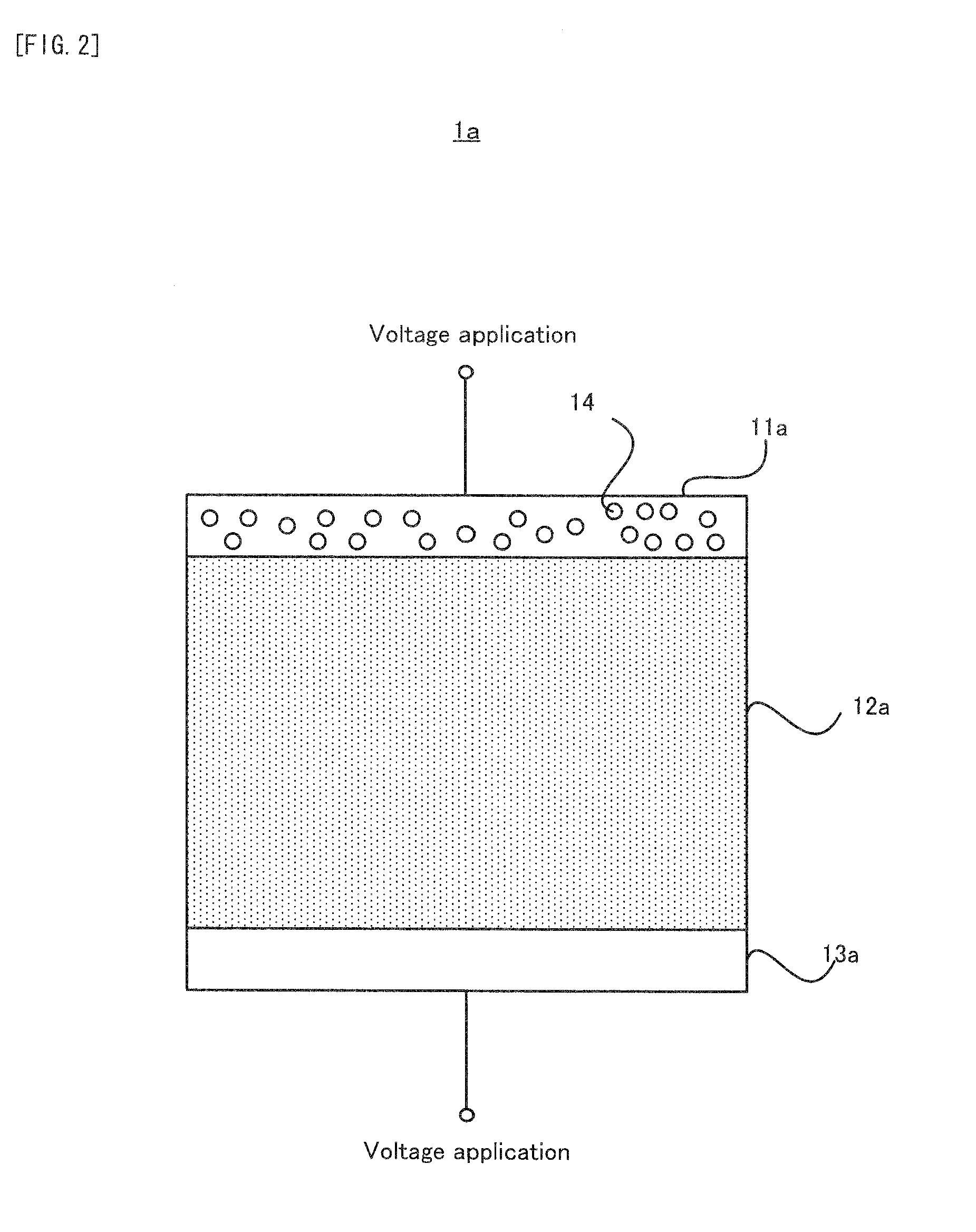

Thermal sound generating device

InactiveUS20100054502A1Low efficiencyReduce componentsThermoelectric device with peltier/seeback effectElectrothermic-effect transistorAcoustic waveTemperature modulation

A thermoacoustic generating apparatus (1) is for generating acoustic waves by temperature modulation of solids, and is provided with: a thermoelement layer (12); a first electrode layer (11), laminated on one surface of the thermoelement layer; and a second electrode layer (13), laminated on the other surface of the thermoelement layer.

Owner:PIONEER CORP

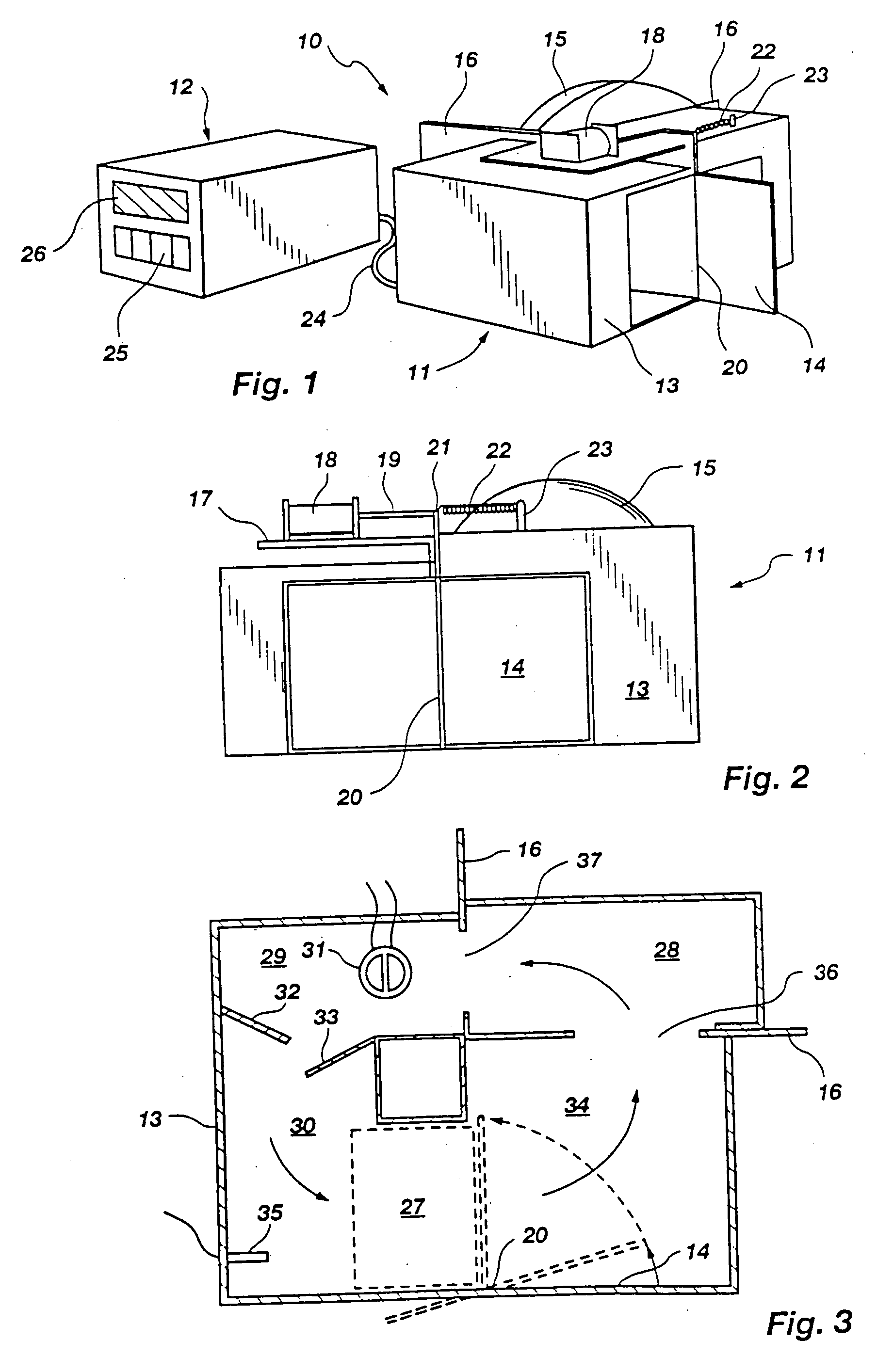

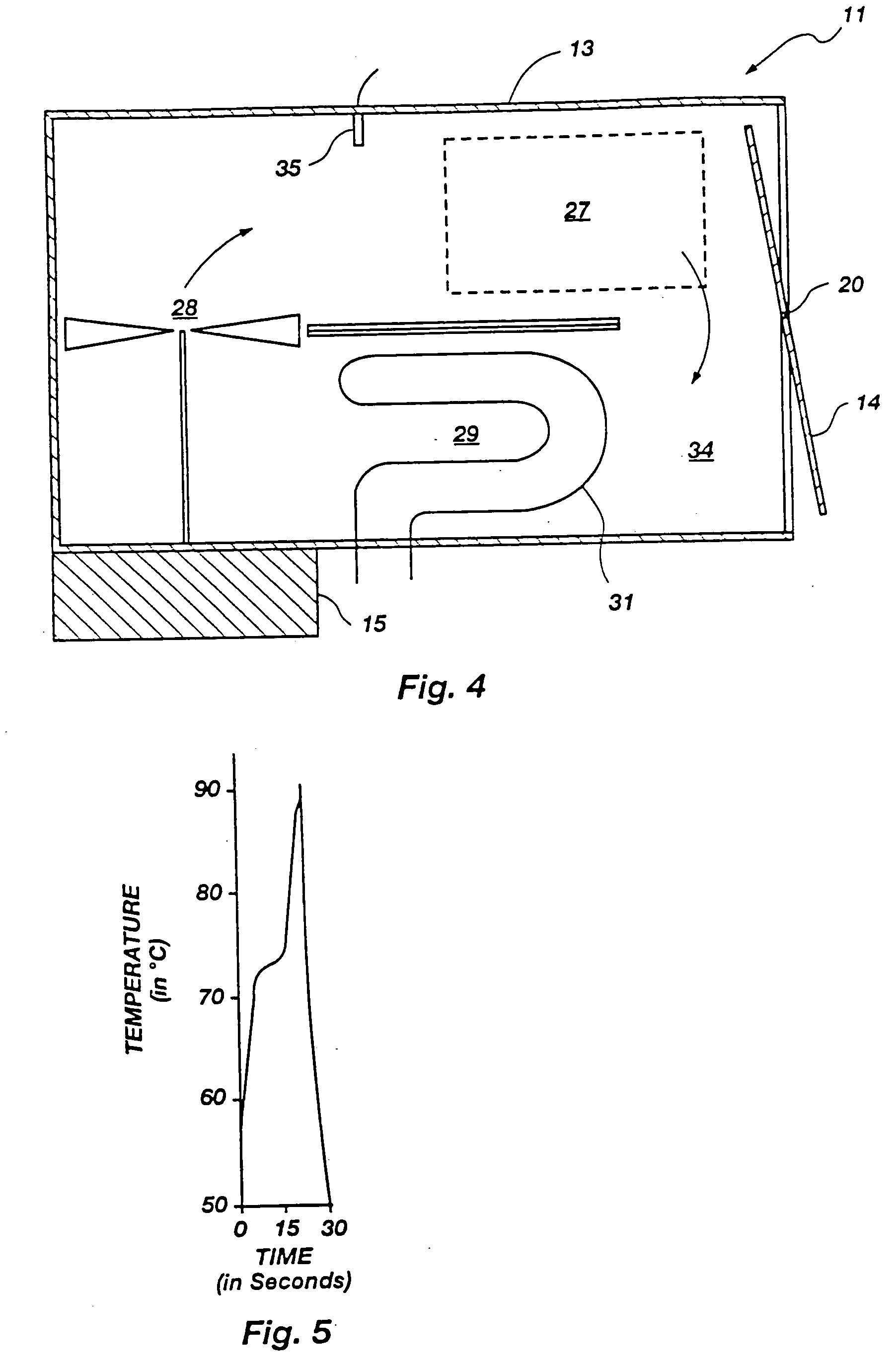

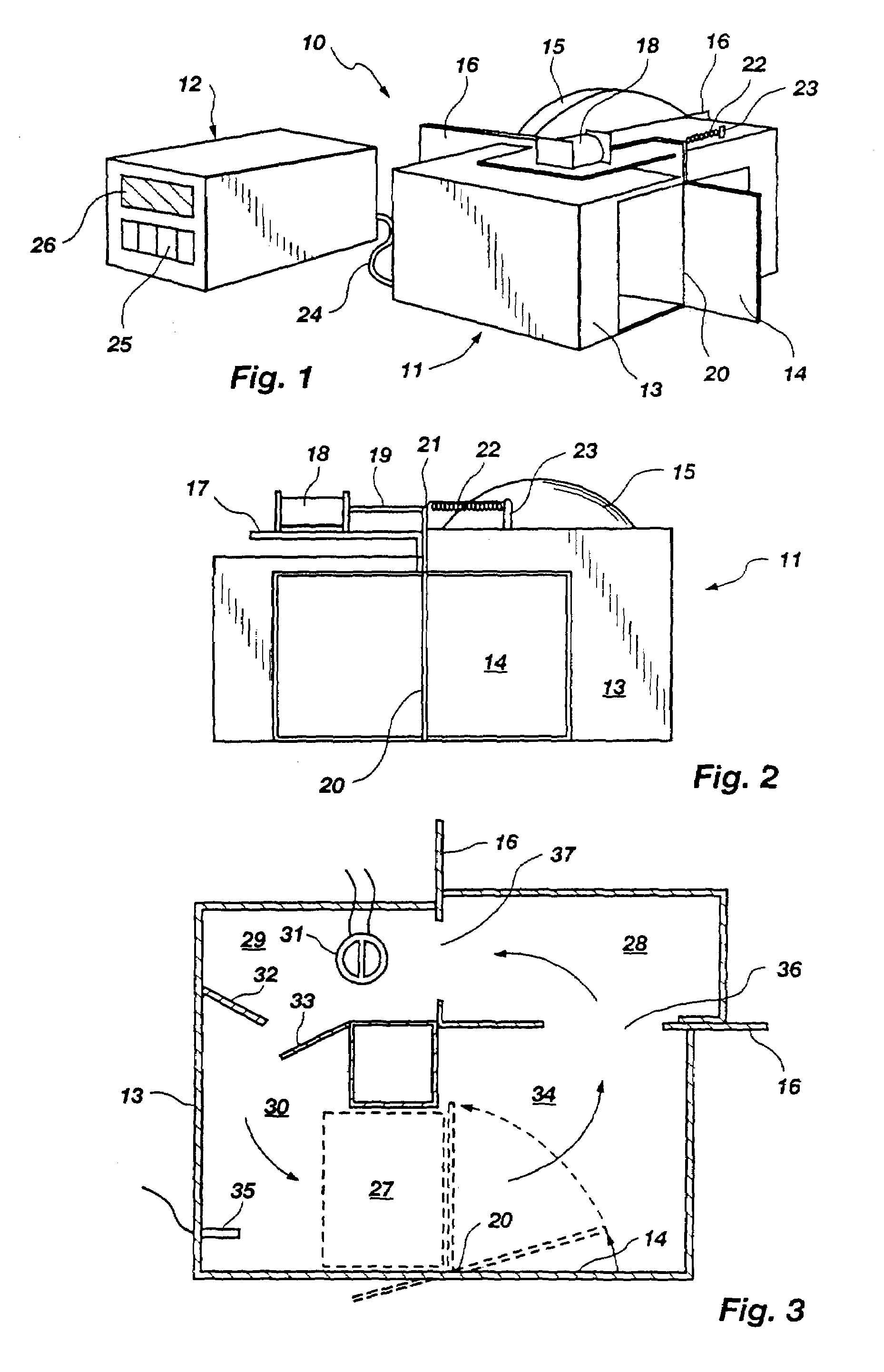

Container for carrying out and monitoring biological processes

InactiveUS20050064582A1Easy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsFluorescenceDna amplification

A thermal cycling method and device is disclosed. The device comprises a sample chamber whose temperature can be rapidly and accurately modulated over a range of temperatures needed to carry out a number of biological procedures, such as the DNA polymerase chain reaction. Biological samples are placed in containers each comprising a reservoir and a reaction portion, wherein the reaction portion has a small volume. The small volume reaction portion permits the rapid and accurate temperature modulation. With an optically transmissible reaction portion, DNA amplification may be monitored by fluorescence during PCR.

Owner:UNIV OF UTAH RES FOUND

Method for determining analyte concentration using periodic temperature modulation and phase detection

InactiveUS6556850B1The process is convenient and fastExtreme accuracyRadiation pyrometryDiagnostics using lightContinuous measurementAnalyte

A method of determining the analyte concentration of a test sample is described. A temperature gradient is introduced in the test sample and infrared radiation detectors measure radiation at selected analyte absorbance peak and reference wavelengths. Reference and analytical signals are detected. In the presence of the selected analyte, parameter differences between reference and analytical signals are detectable. These parameter differences, having a relationship to analyte concentration, are measured, correlated, and processed to determine analyte concentration in the test sample. Accuracy is enhanced by inducing a periodically modulated temperature gradient in the test sample. The analytical and reference signals may be measured continuously and the parameter difference integrated over the measurement period to determine analyte concentration.

Owner:OPTISCAN BIOMEDICAL

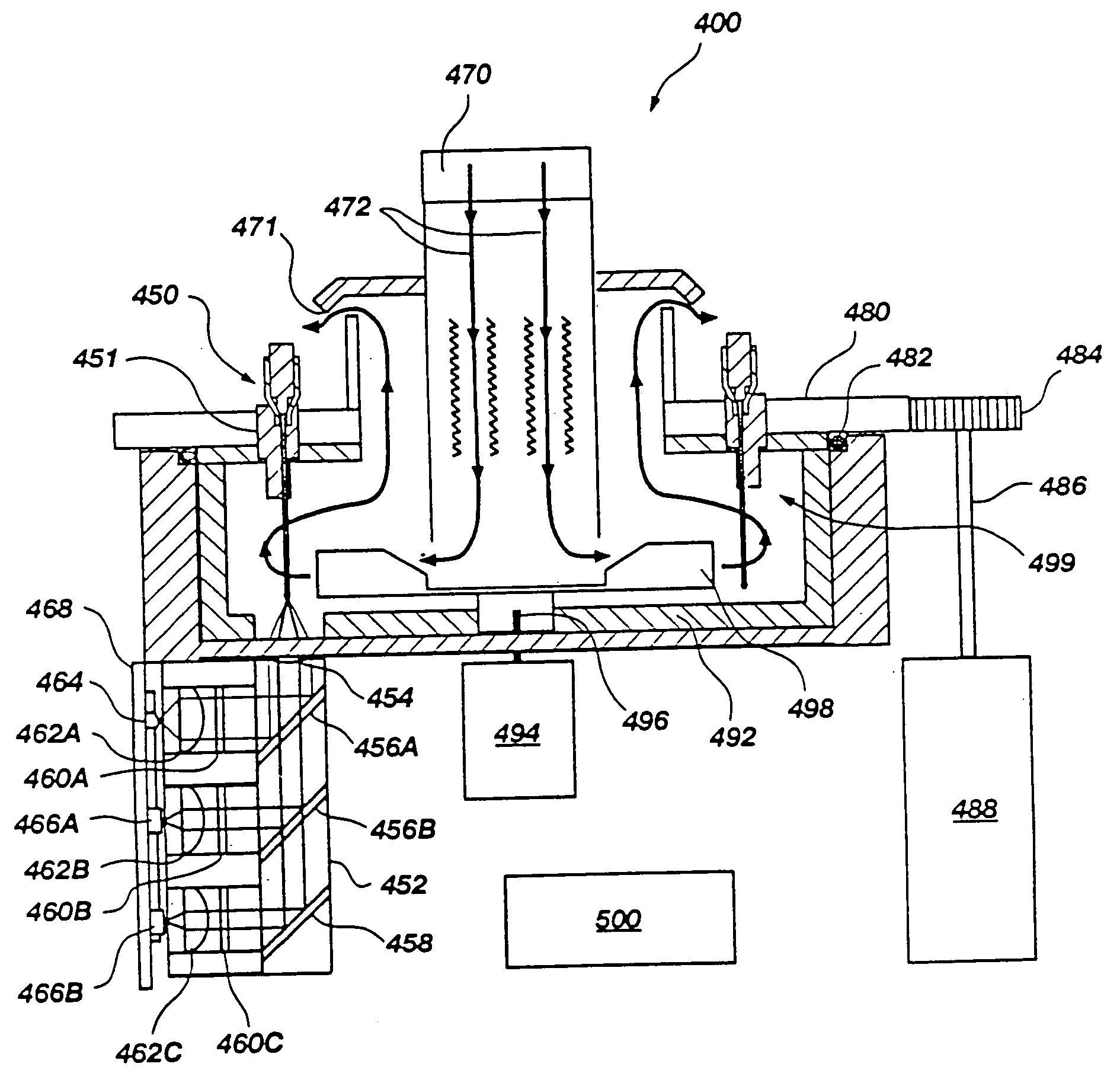

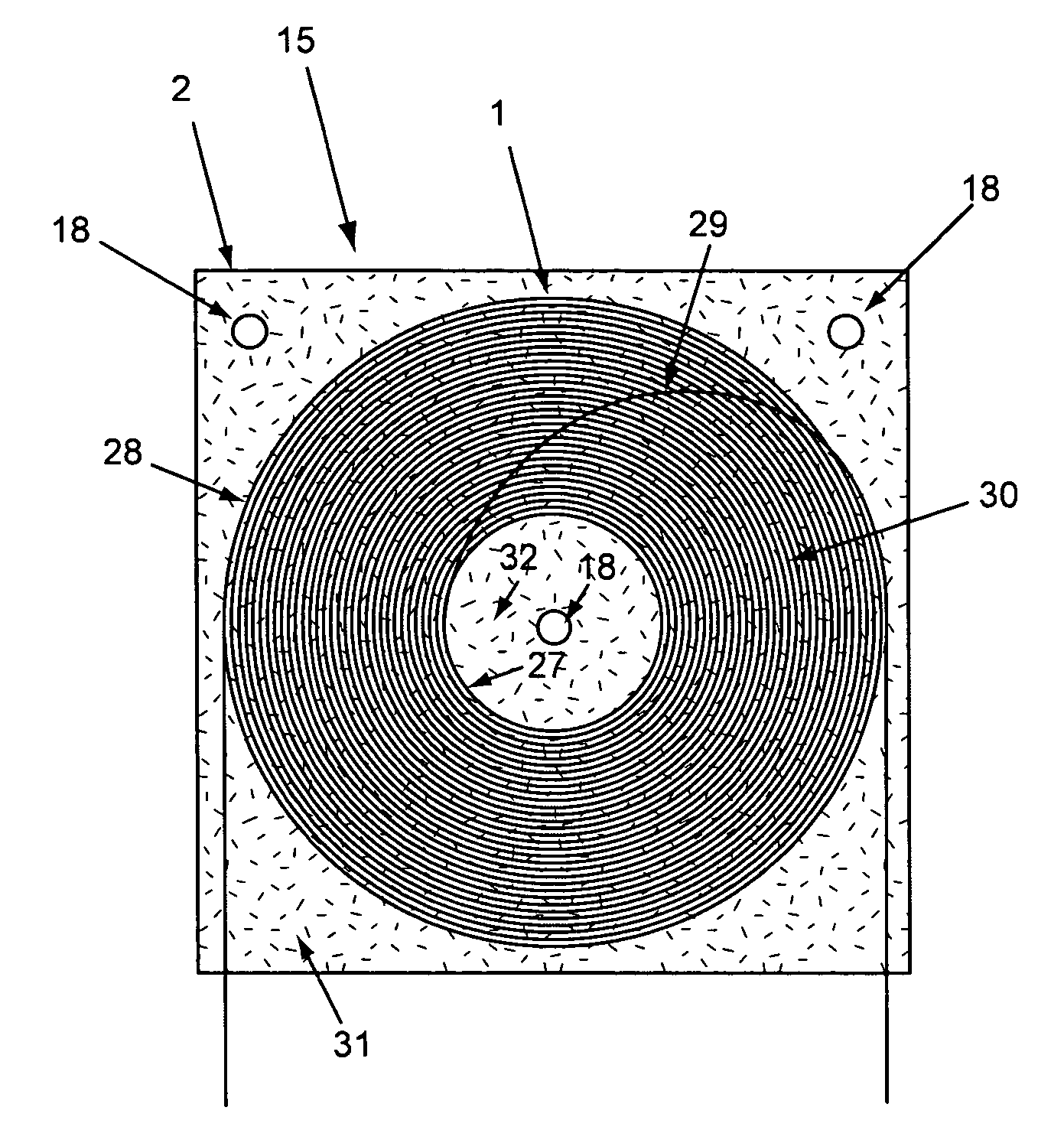

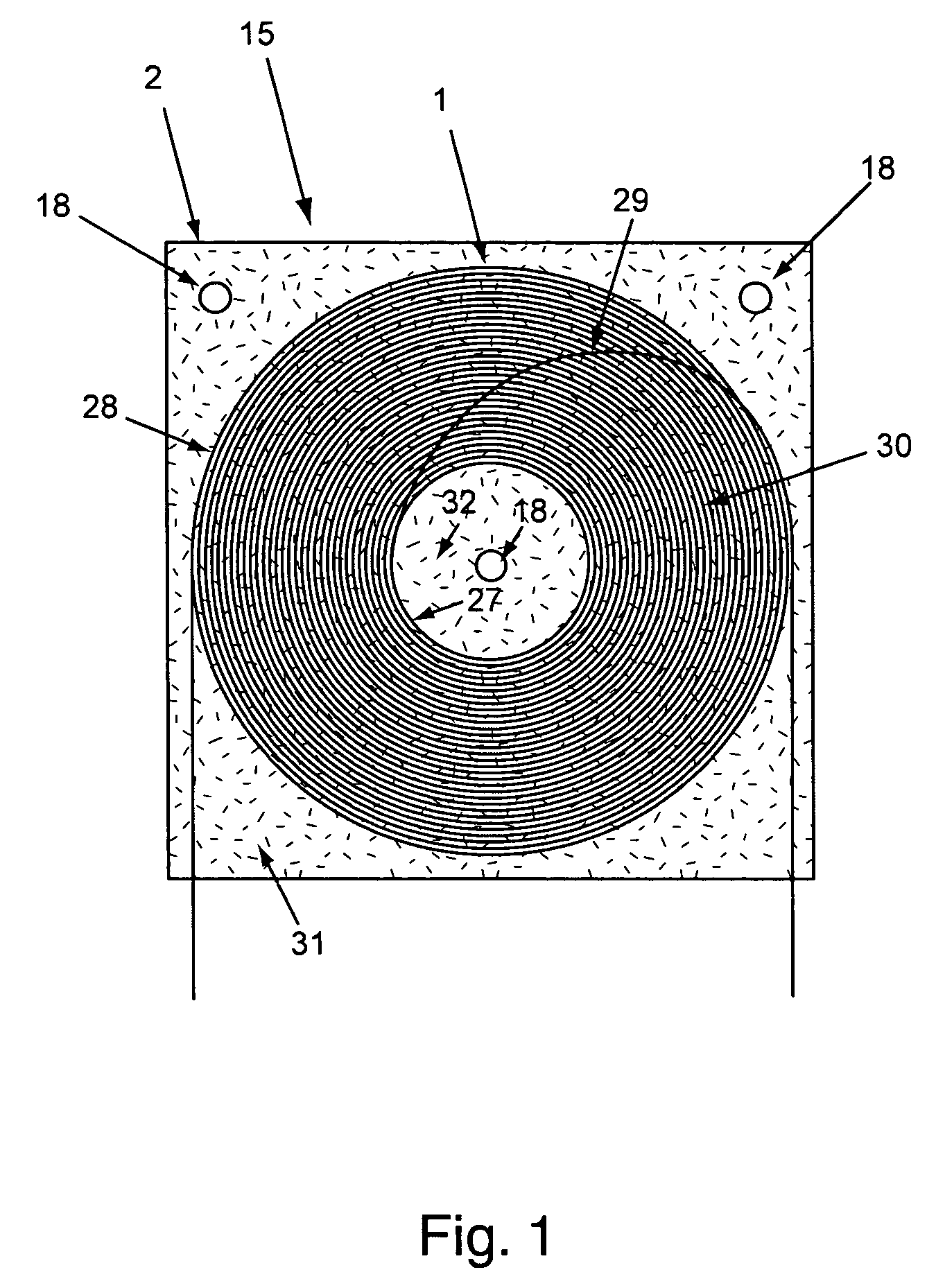

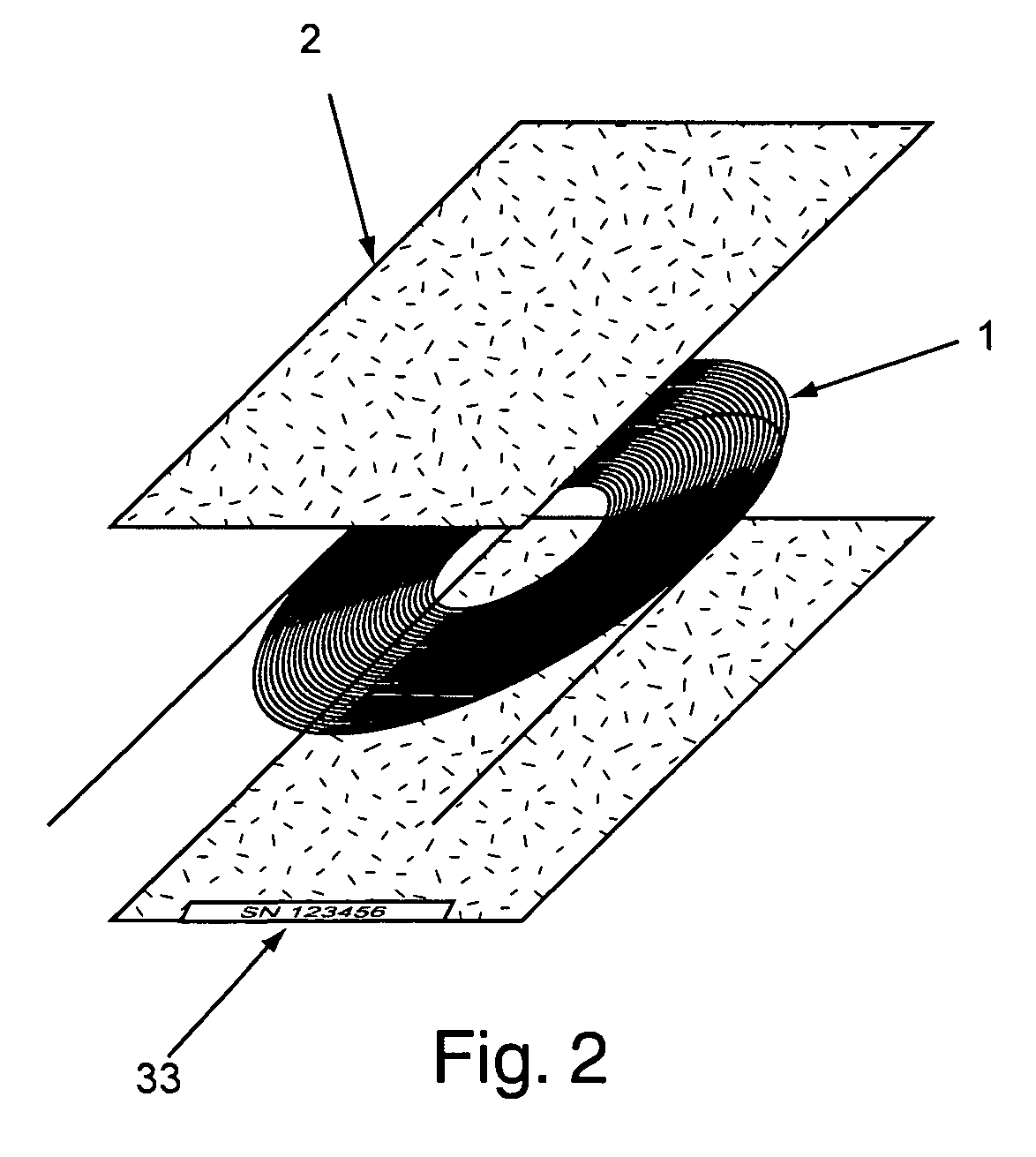

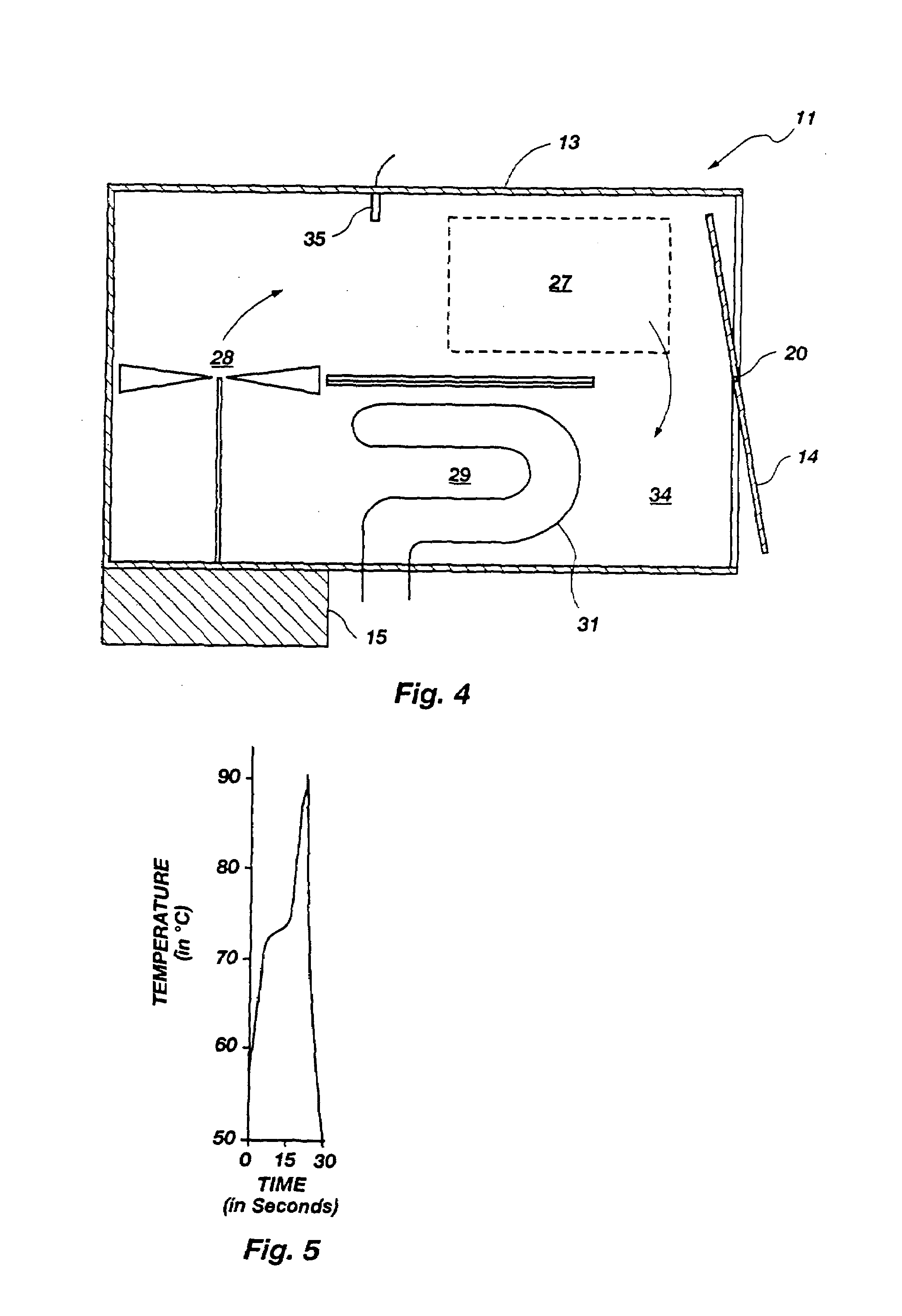

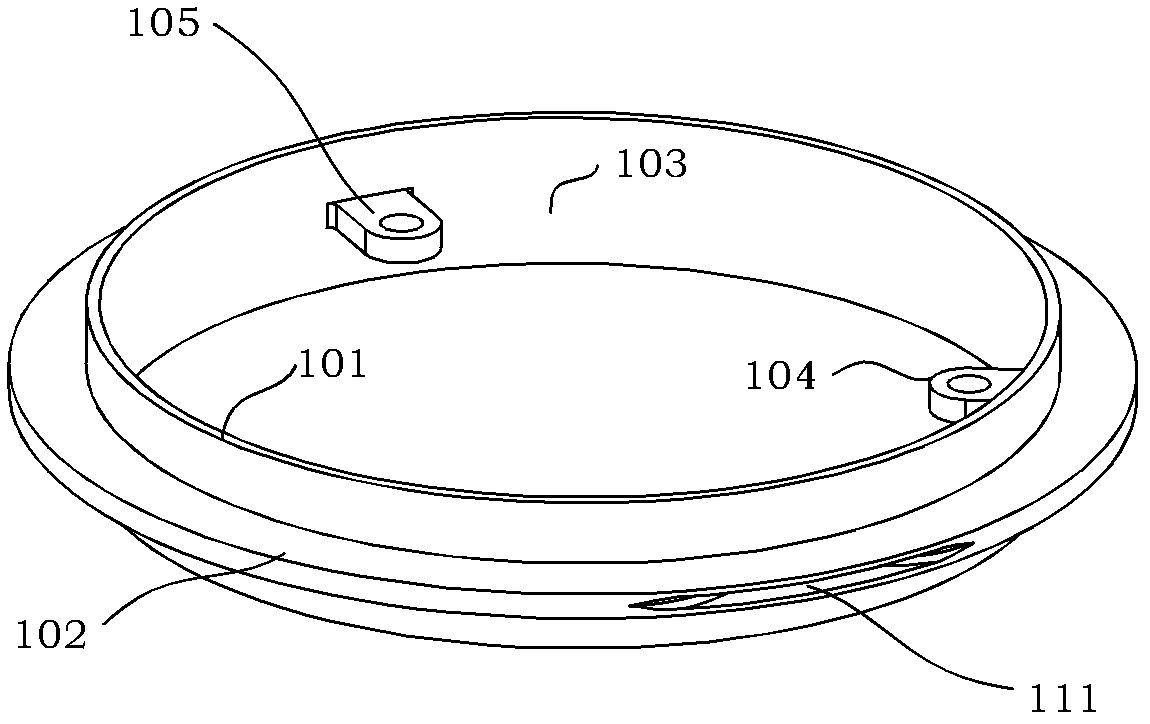

Flat spiral capillary column assembly with thermal modulator

InactiveUS20060283324A1Reduce the temperatureEfficient executionComponent separationDispersed particle separationCapillary gas chromatographyCapillary Tubing

The nature of this invention encompasses the creation of a capillary gas chromatography (GC) column assembly and a thermal modulator used to heat or cool the column assembly in a very thermally and chromatographically efficient manner. The GC column assembly described herein consists of capillary GC column material, such as fused silica or metal capillary tubing, which is constrained to lie in a flat, ordered, spiral pattern and then encased between two thin opposing surfaces. The resulting column assembly is flat, dimensionally stable and can be very efficiently thermally modulated. The resulting column assembly also takes up very little space, has very little thermal mass, and can be easily and accurately manufactured. The column assembly can be adapted for chromatographic use by affixing it to the surface of a thermal modulator described herein by means of adhesive force or by mechanical compression, and then by attaching the free ends of the exposed column material to the input and output ports of the chromatographic device. The temperature of the thermal modulator and capillary column assembly is to be controlled by the chromatographic device or by standalone temperature controlling electronics. The thermal modulator described herein contains an element for temperature modulation of the capillary column assembly to which it is attached and a temperature sensing element for providing accurate temperature feedback to the controlling electronics. The overall result of this when coupled to a chromatographic device is maximally efficient chemical separations in a small space with minimal power consumption.

Owner:ROQUES NED J

Container for carrying out and monitoring biological processes

InactiveUS7273749B1Easy to controlBioreactor/fermenter combinationsHeating or cooling apparatusFluorescenceDna amplification

A thermal cycling method and device is disclosed. The device comprises a sample chamber whose temperature can be rapidly and accurately modulated over a range of temperatures needed to carry out a number of biological procedures, such as the DNA polymerase chain reaction. Biological samples are placed in containers each comprising a reservoir and a reaction portion, wherein the reaction portion has a small volume. The small volume reaction portion permits the rapid and accurate temperature modulation. With an optically transmissible reaction portion, DNA amplification may be monitored by fluorescence during PCR.

Owner:UNIV OF UTAH RES FOUND

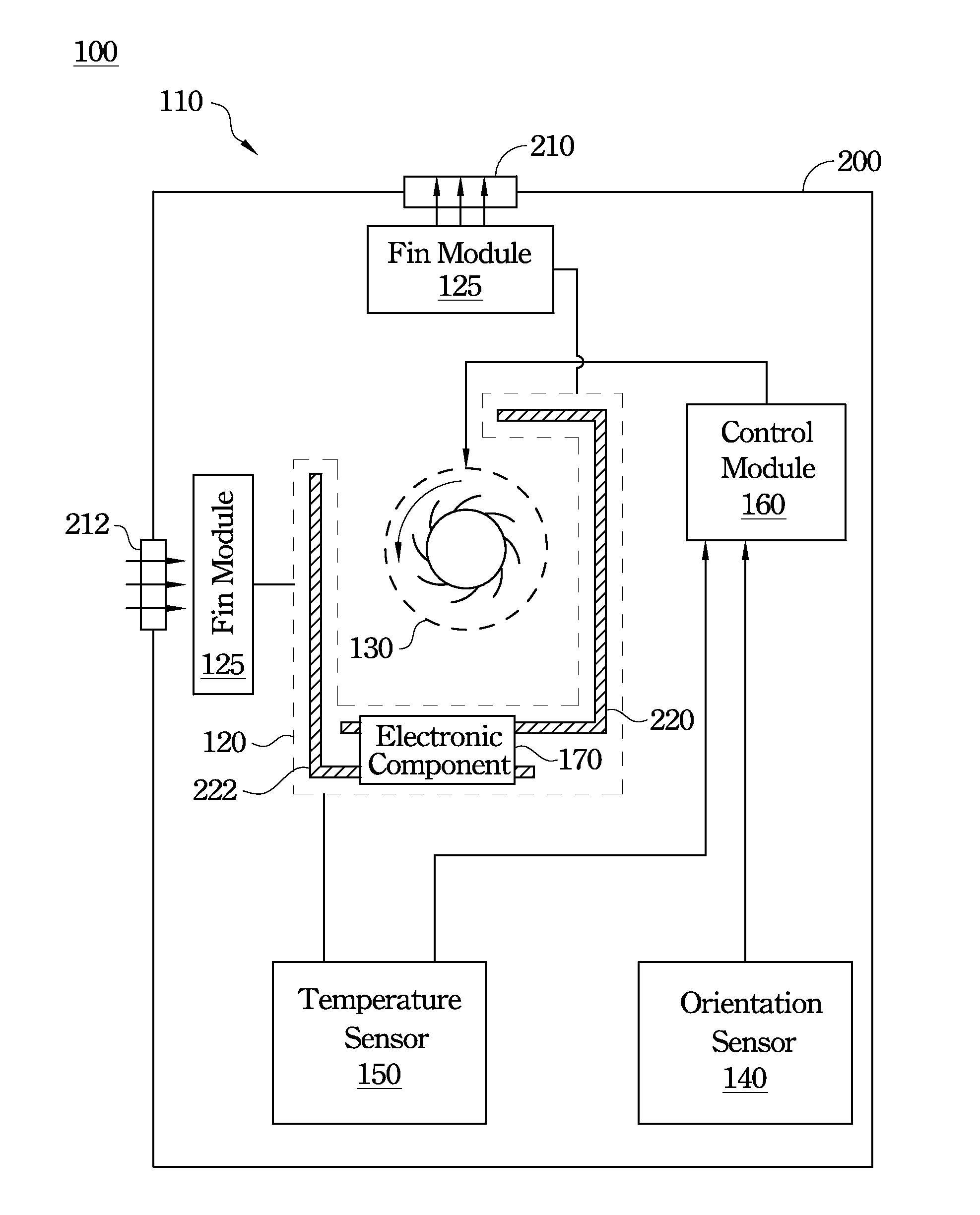

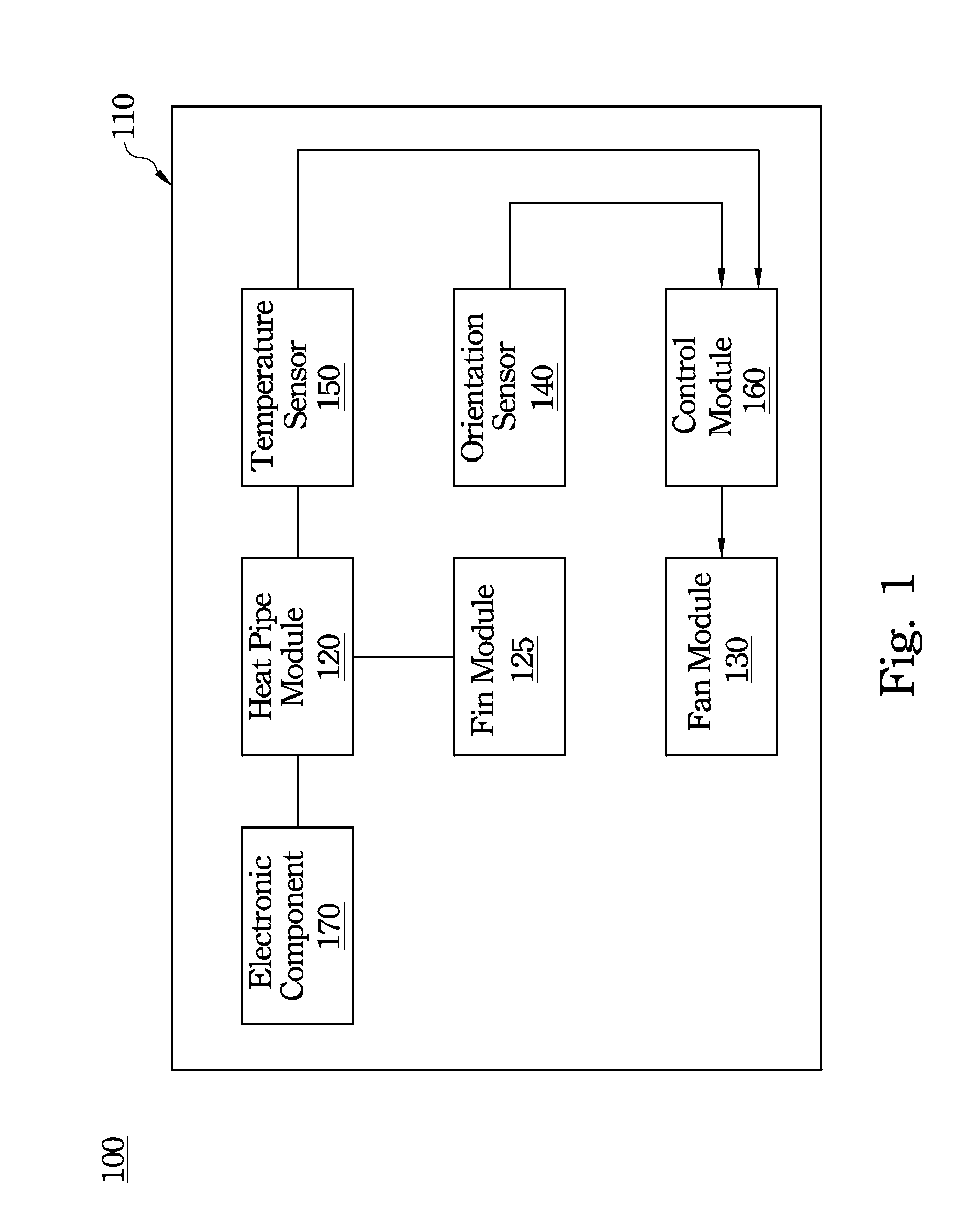

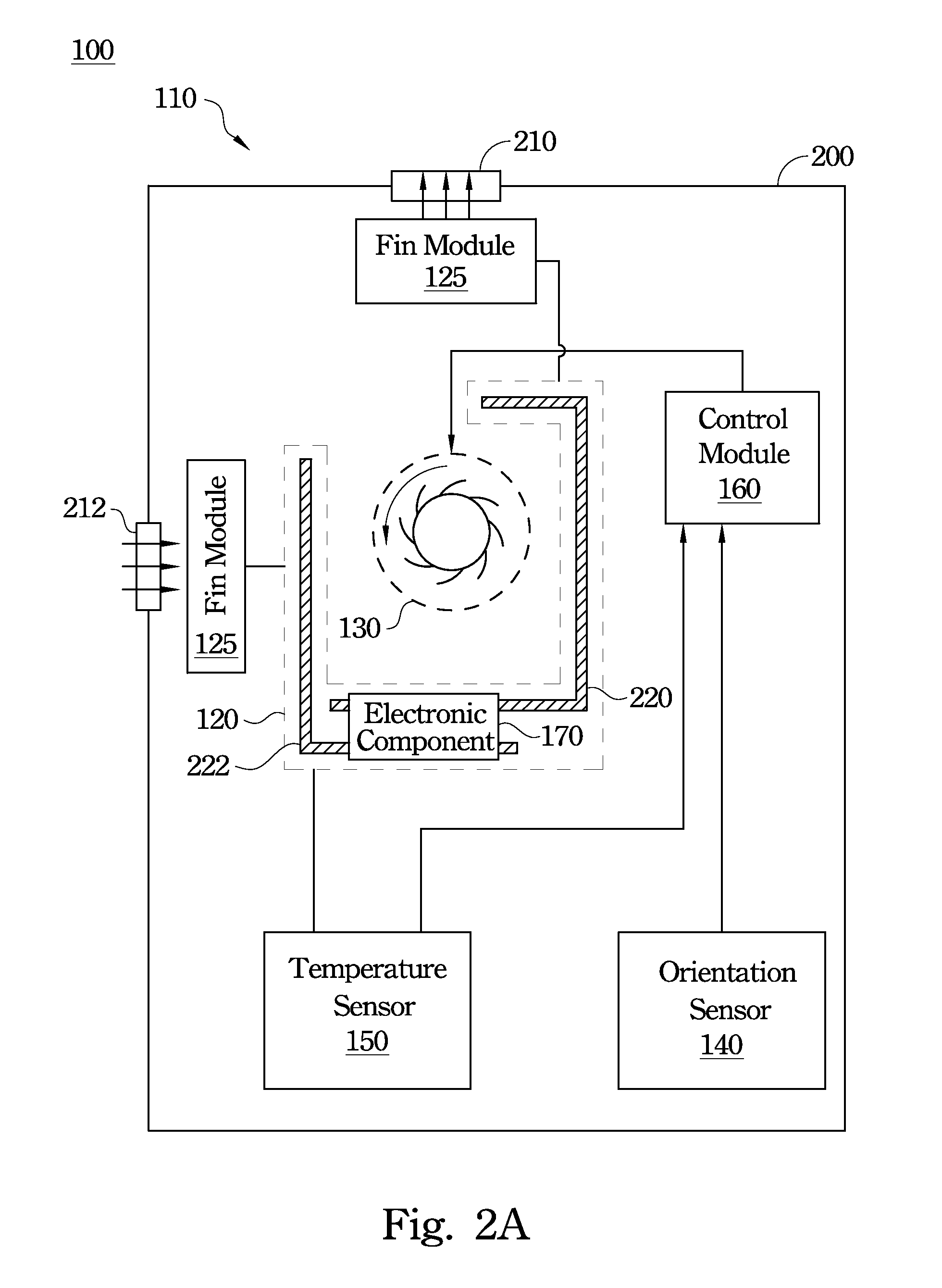

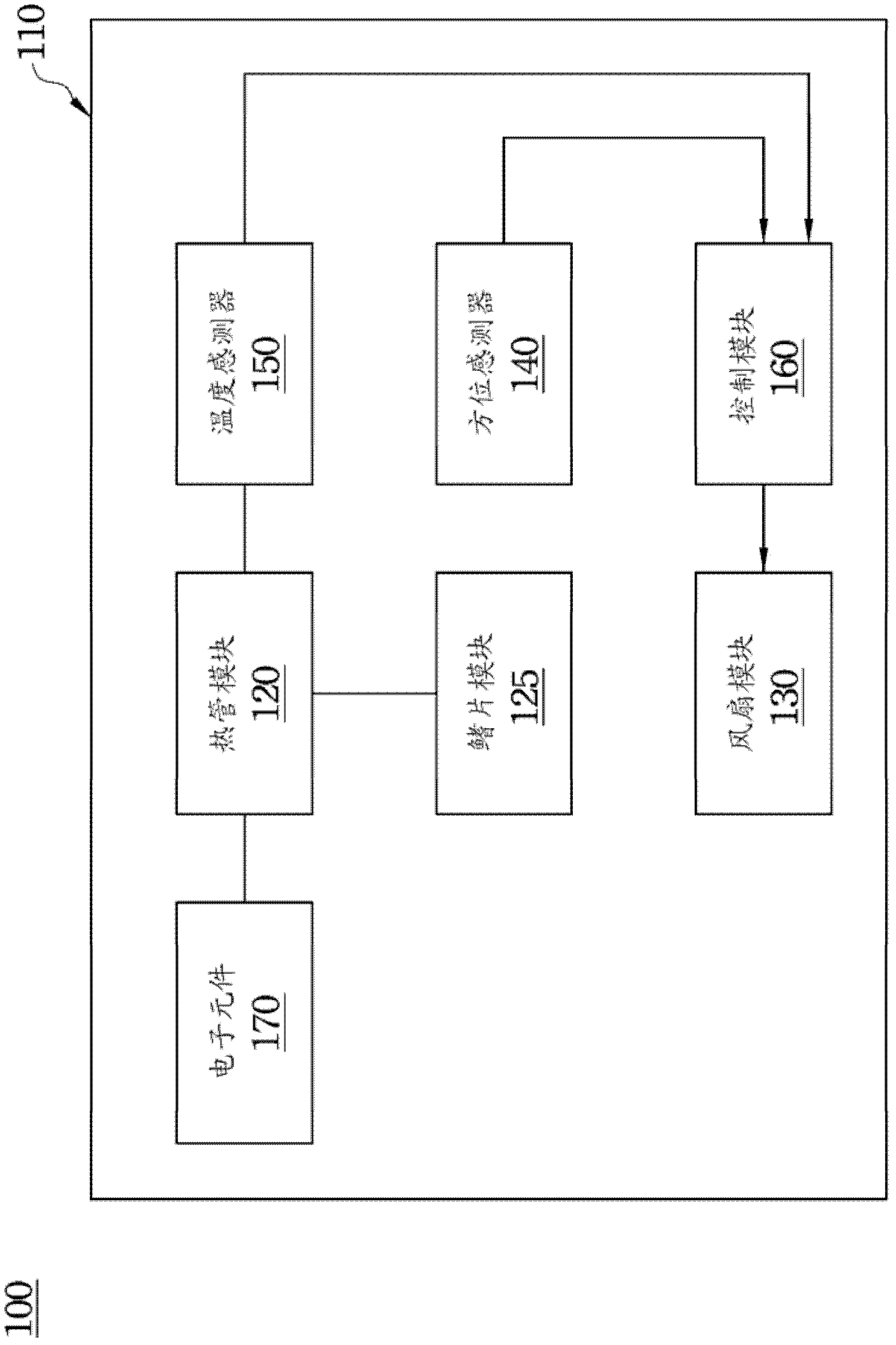

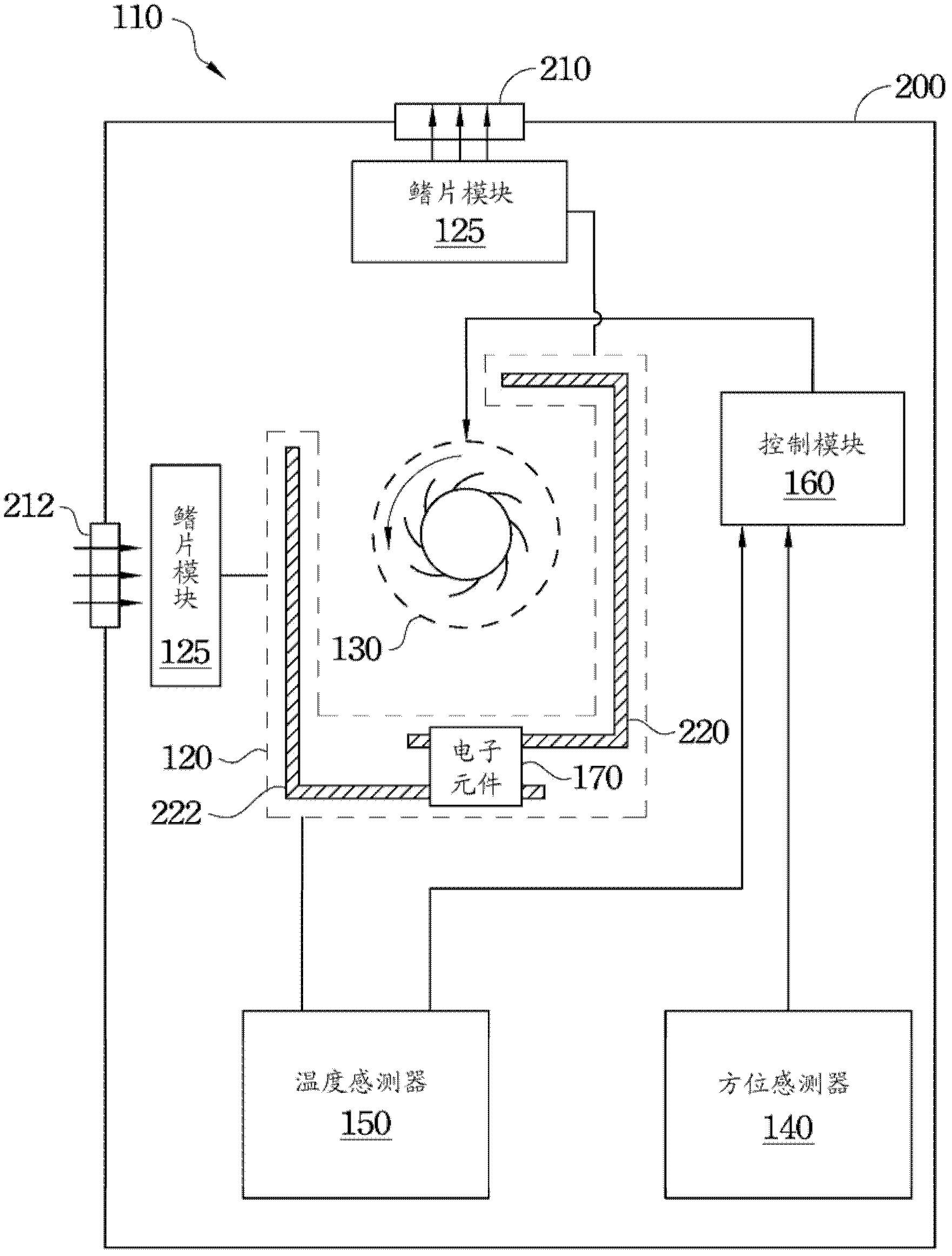

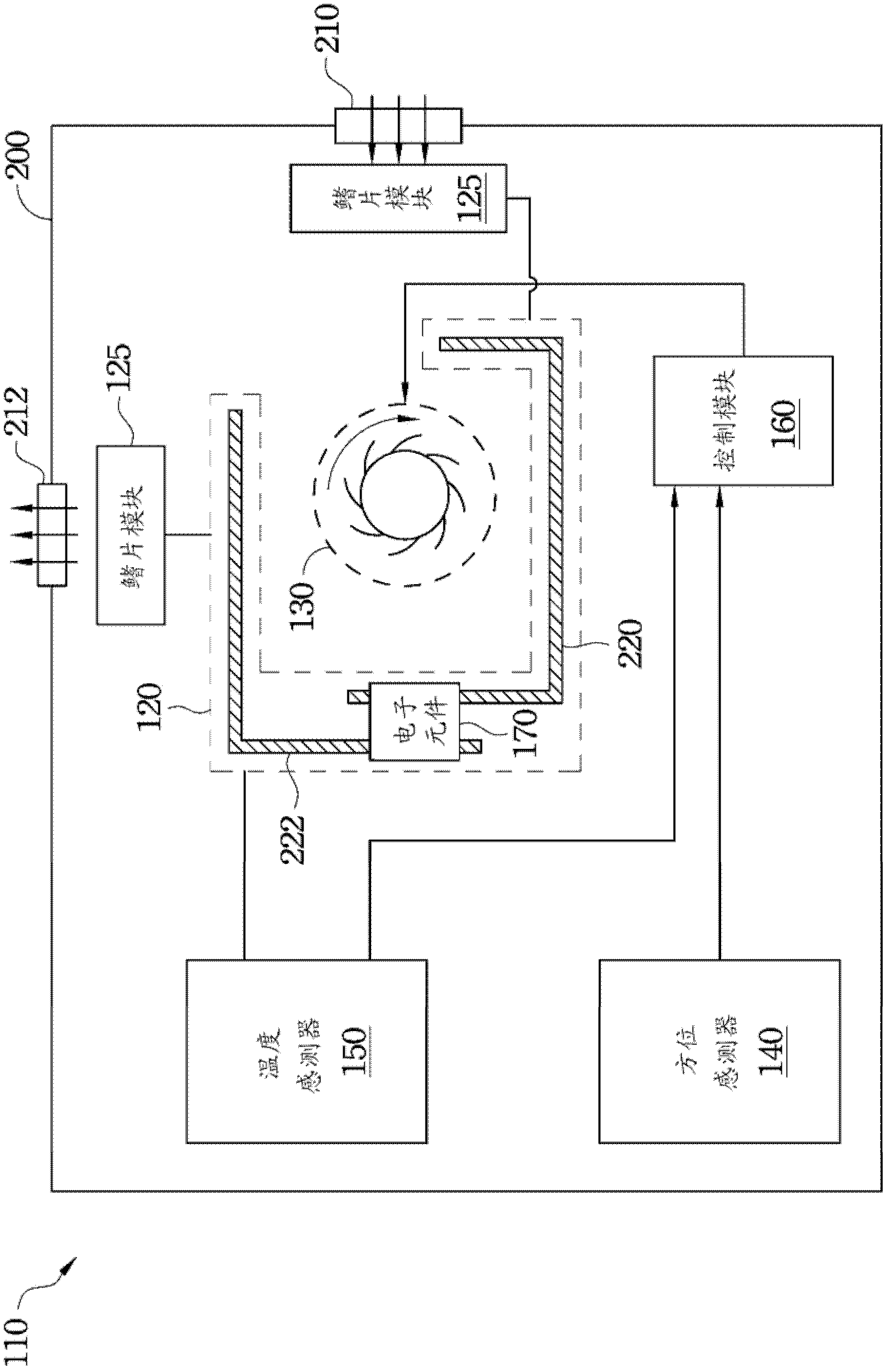

Electronic device and temperature modulation method thereof

InactiveUS20130081779A1Heat dissipation performance can be improvedImprove system stabilityAir-treating devicesDigital data processing detailsEngineeringElectronic component

An electronic device and a temperature modulation method are disclosed herein. The electronic device includes a system body, a heat pipe module, a fan module, an orientation sensor, a temperature sensor and a control module. The system body includes an electronic component. The heat pipe module is connected to the electronic component. The fan module is installed in the system body. The orientation sensor can detect an orientation of the system body and output an orientation-sensing signal based on the orientation. The temperature sensor can detect a temperature of the heat pipe module and output a temperature-sensing signal based on the temperature. The control module can control rotation of the fan module according to at least one of the orientation-sensing signal and the temperature-sensing signal.

Owner:QUANTA COMPUTER INC

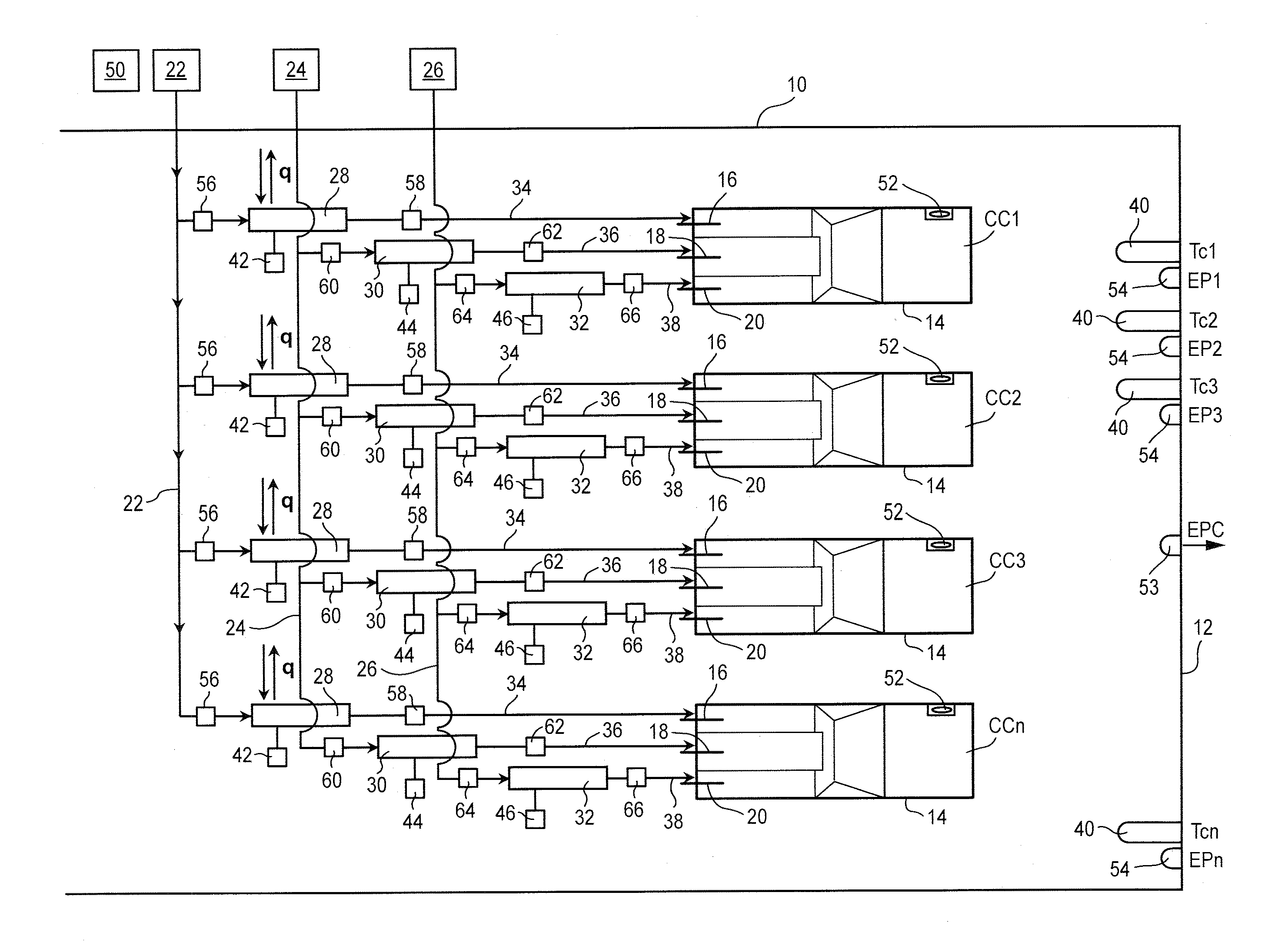

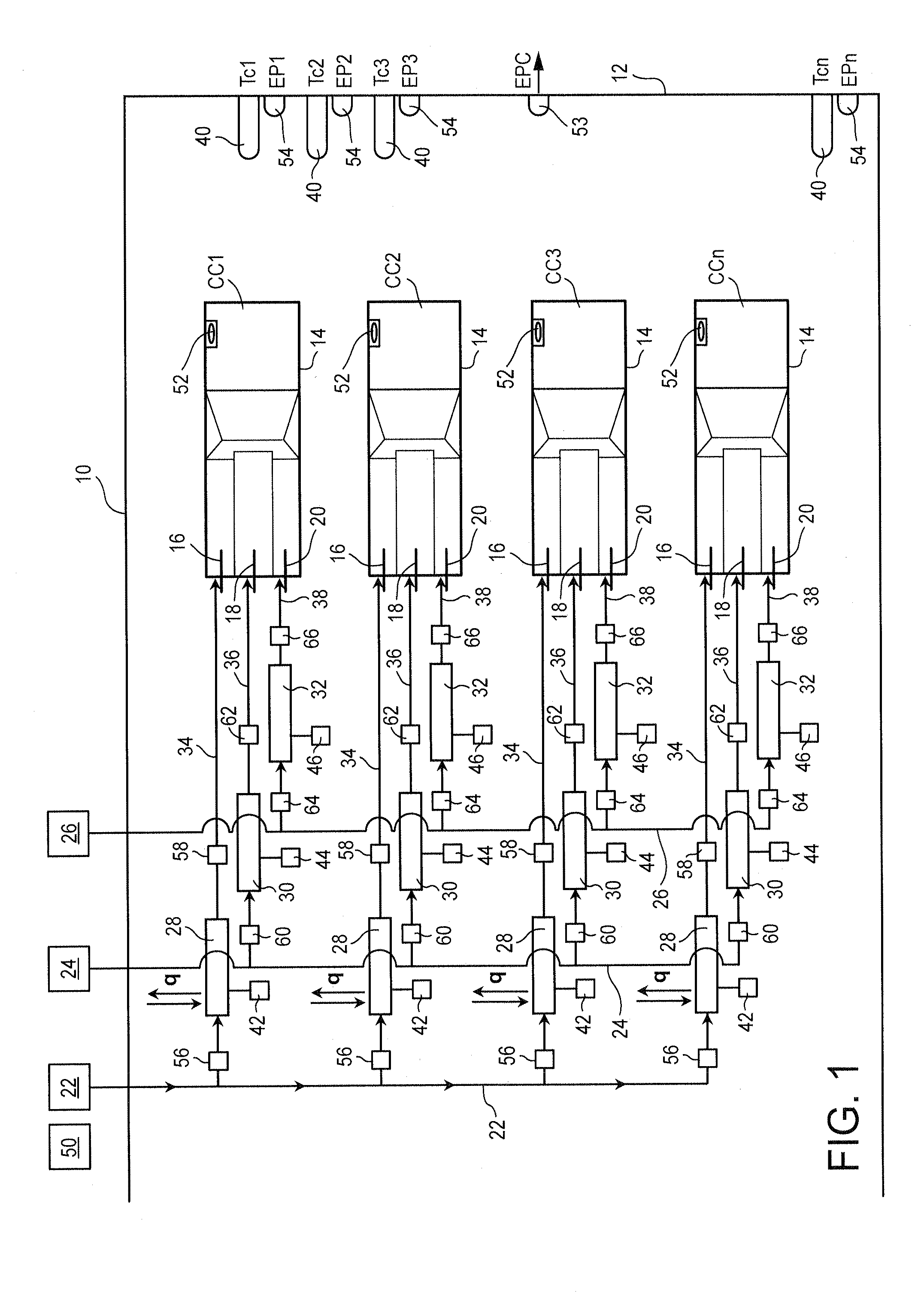

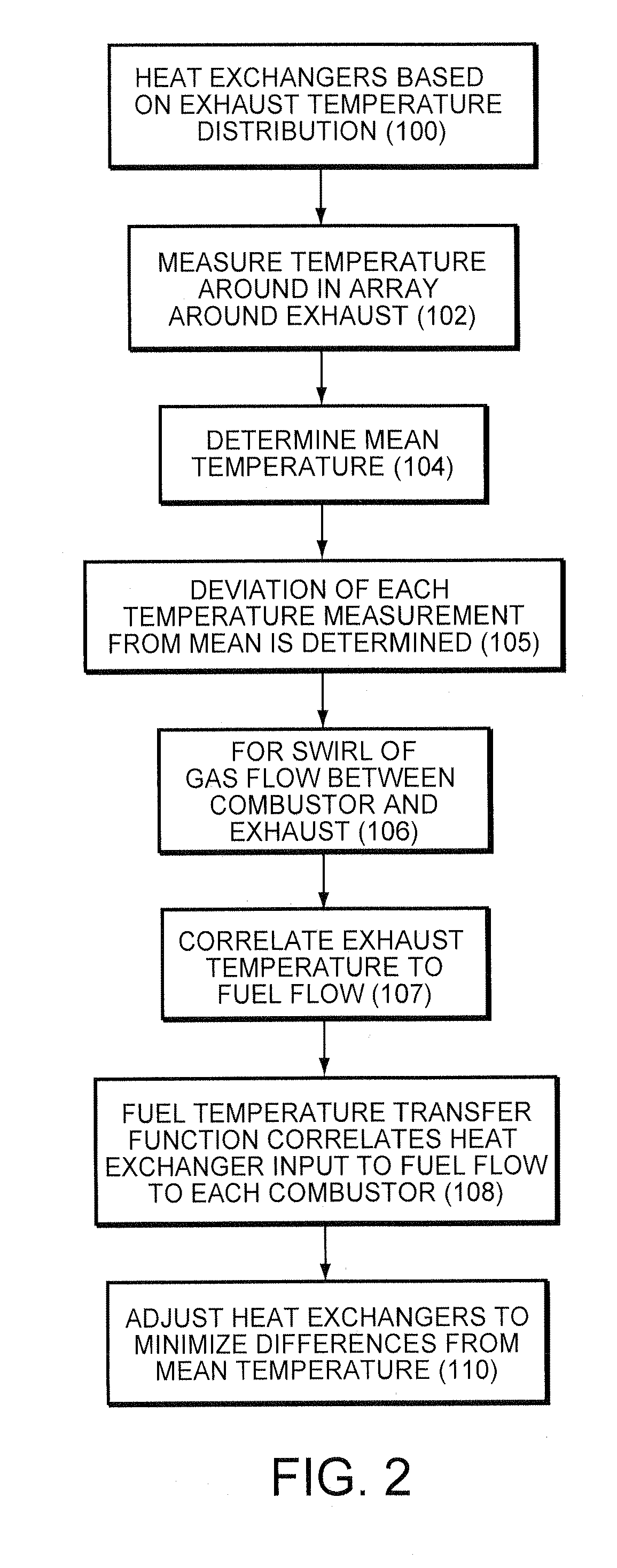

Systems and methods for bulk temperature variation reduction of a gas turbine through can-to-can fuel temperature modulation

InactiveUS20130014514A1Reduce biasReduce variationLiquid fuel feeder/distributionContinuous combustion chamberTemperature controlCombustion chamber

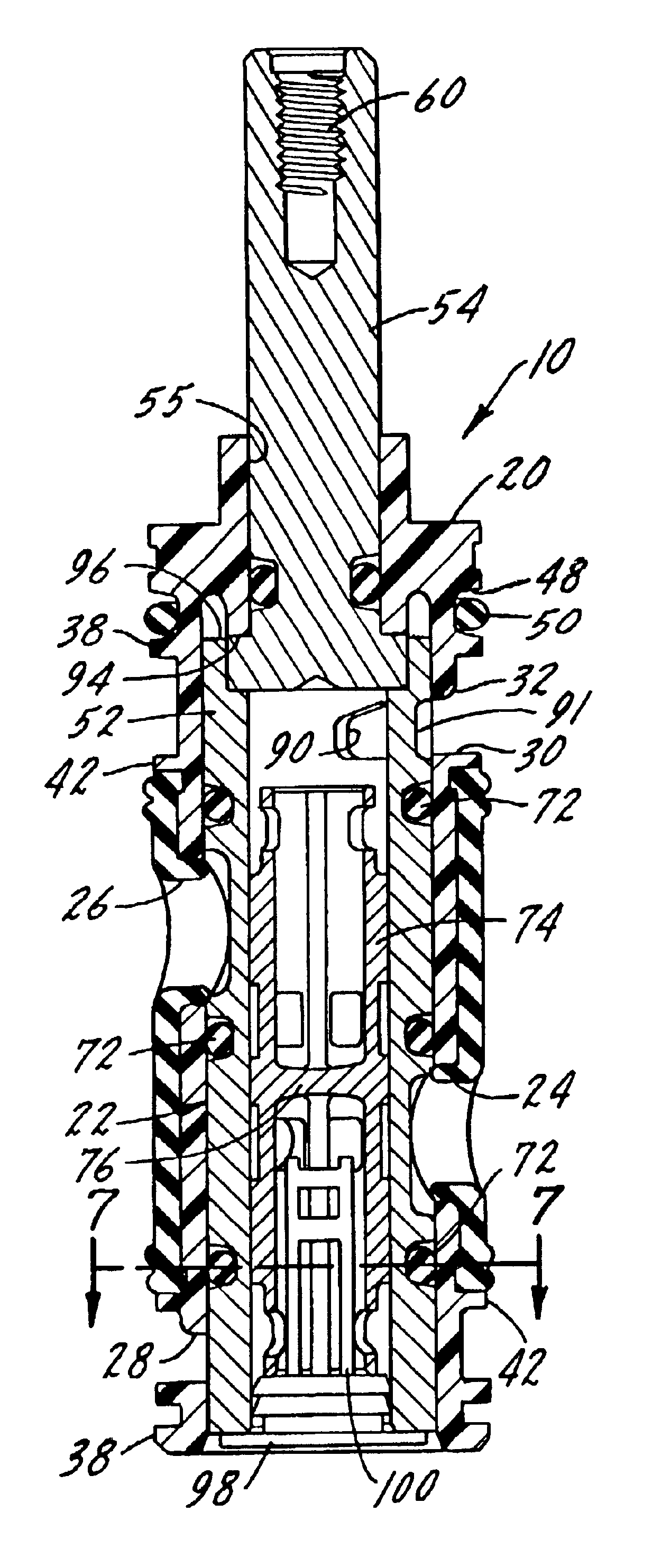

A gas turbine includes a plurality of combustion chambers; at least one fuel nozzle for each of the combustion chambers; at least one fuel line for each fuel nozzle in each of the combustion chambers; at least one heat exchanger for each fuel line configured to adjust a temperature of a fuel flow to each fuel nozzle; and a controller configured to control each of the heat exchangers to reduce temperature variations amongst the combustion chambers.

Owner:GENERAL ELECTRIC CO

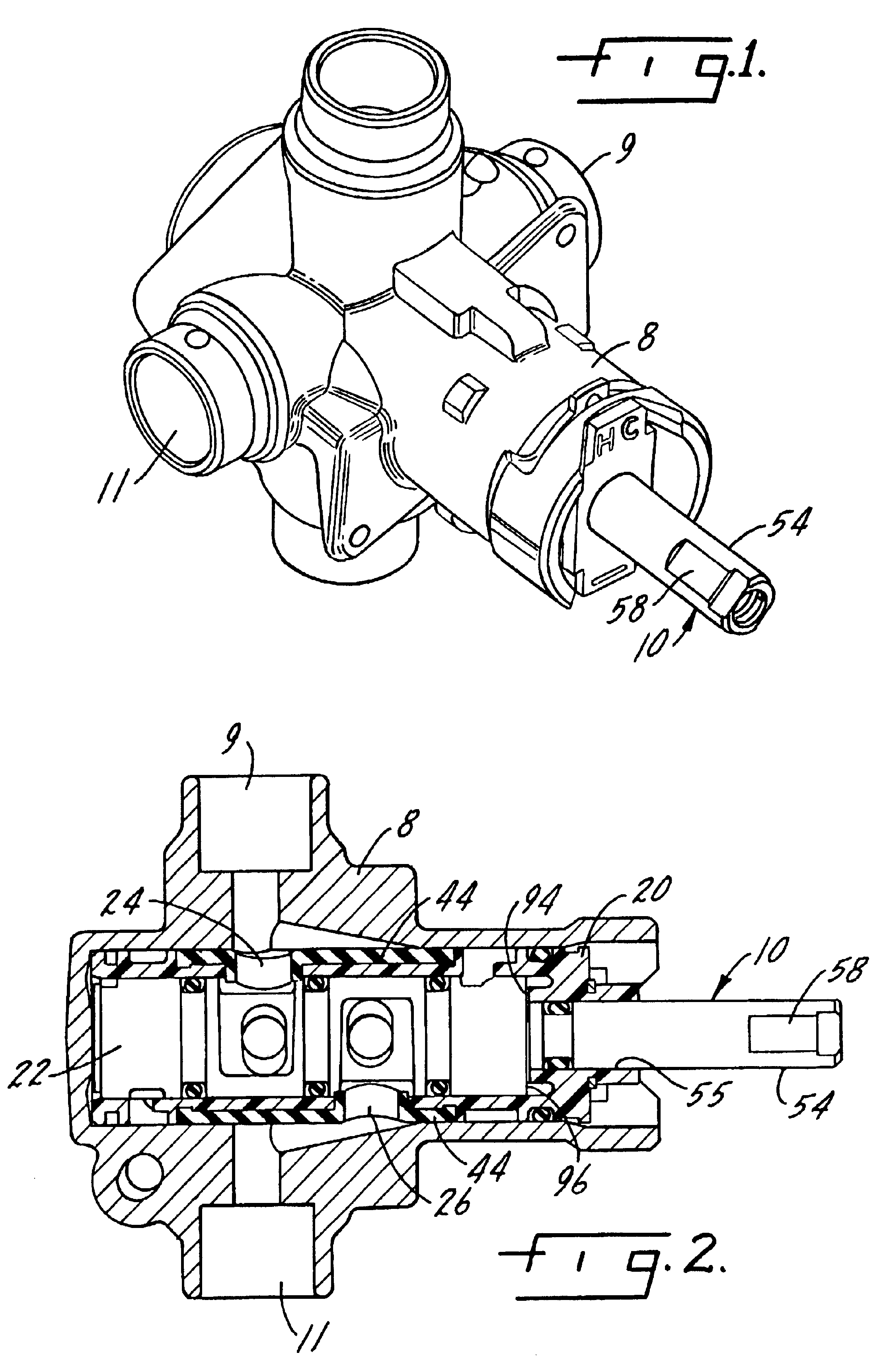

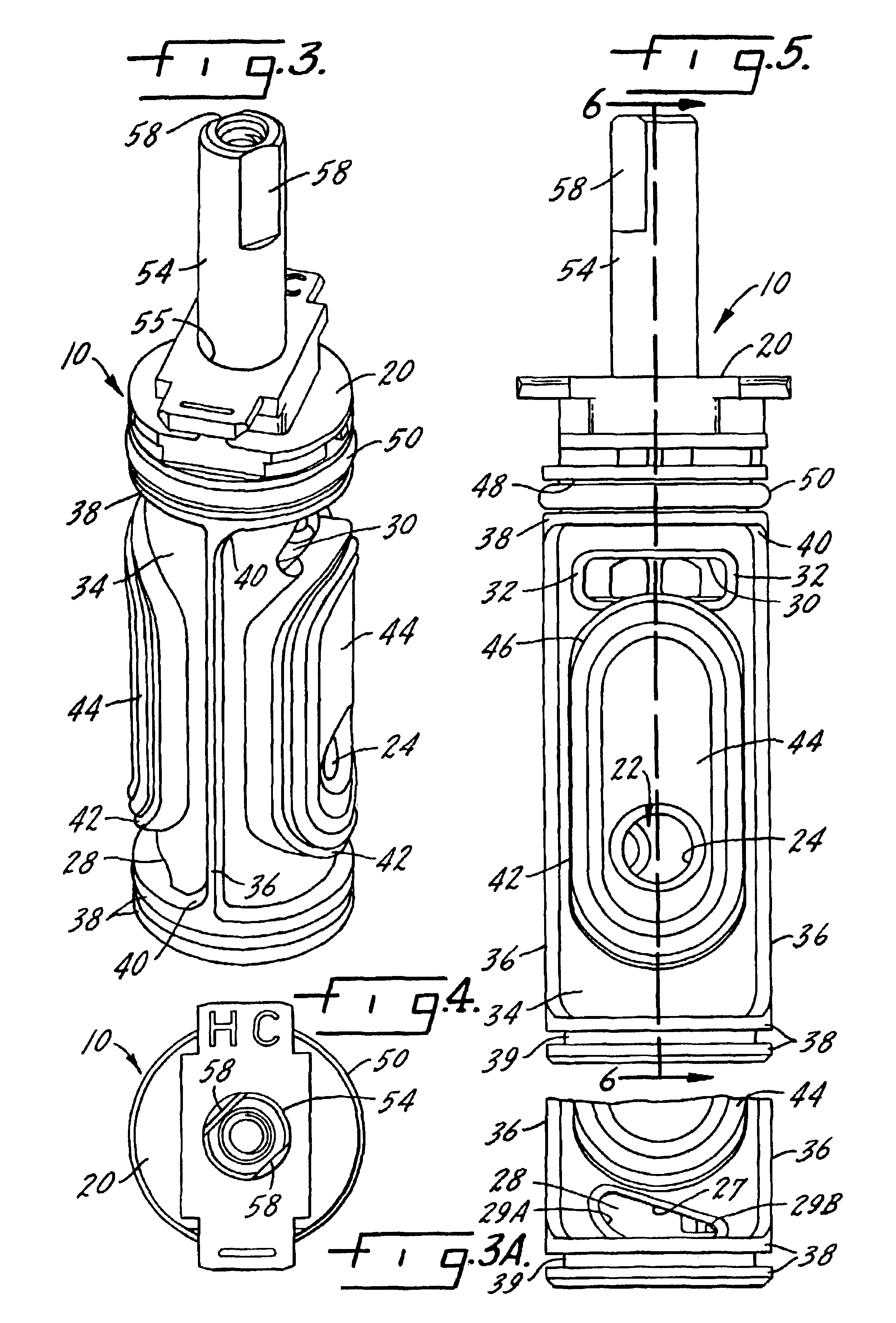

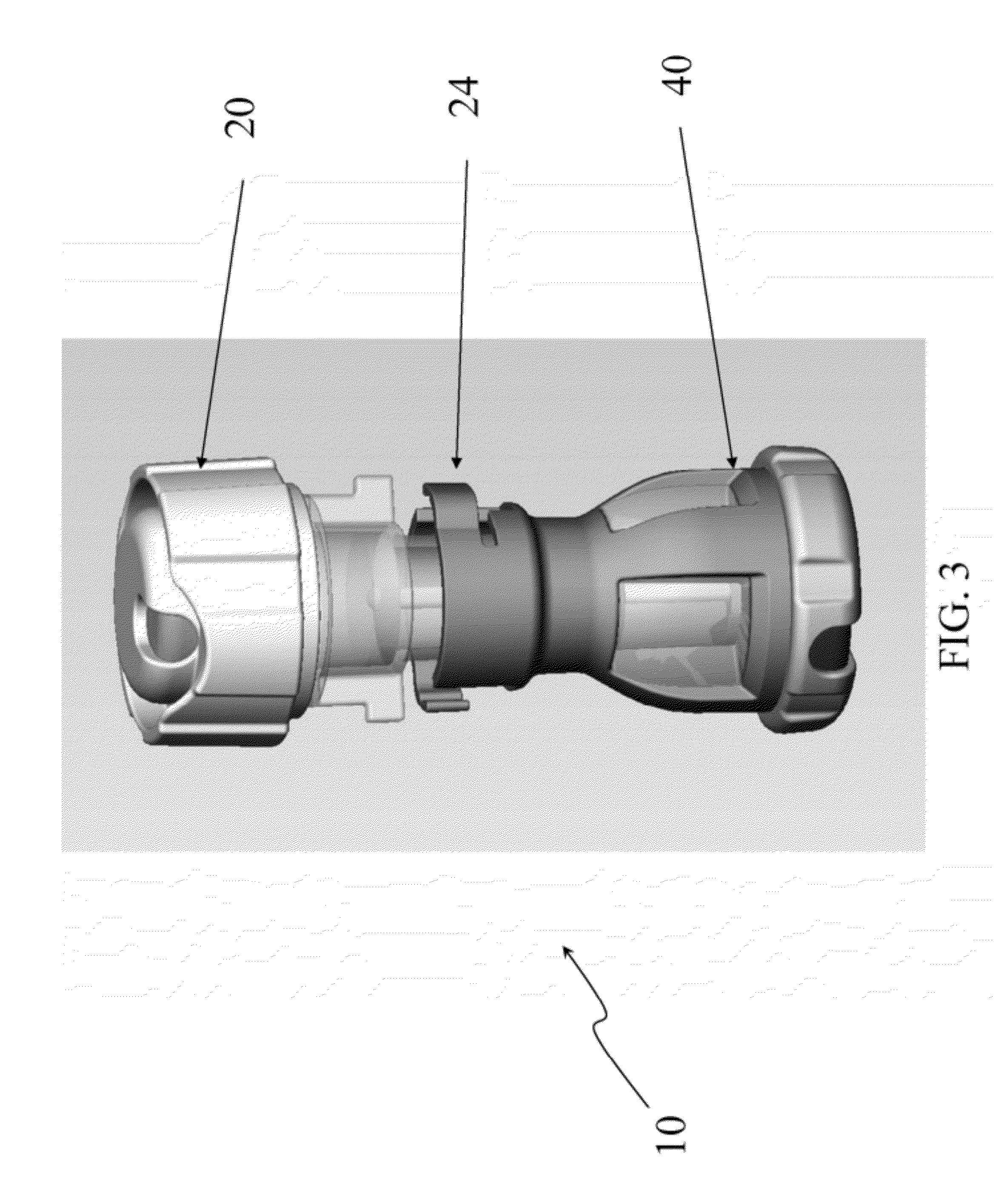

Mixing valve with graduated temperature modulation

InactiveUS6877523B2Additional componentControl over water temperatureControlling ratio of multiple fluid flowsMultiple way valvesEngineeringThermal water

A valve assembly for mixing hot and cold water includes a generally cylindrical sleeve having hot and cold inlets and outlets and a rotatable non-reciprocal valve member positioned therein to control the mixture of hot and cold water in the outlet stream. The valve member has a hollow stem tube having hot and cold inlet and outlet ports which are rotatably engageable with the hot and cold inlets and outlets of the sleeve. The sleeve hot water outlet is generally larger than the sleeve cold water outlet. The sleeve and stem tube inlets and outlets are not limited to a particular shape and / or geometry. The fluid engagement between the sleeve hot and cold water outlets and the stem tube hot and cold water outlets provides a large mixed water temperature range.

Owner:FB GLOBAL PLUMBING GRP LLC

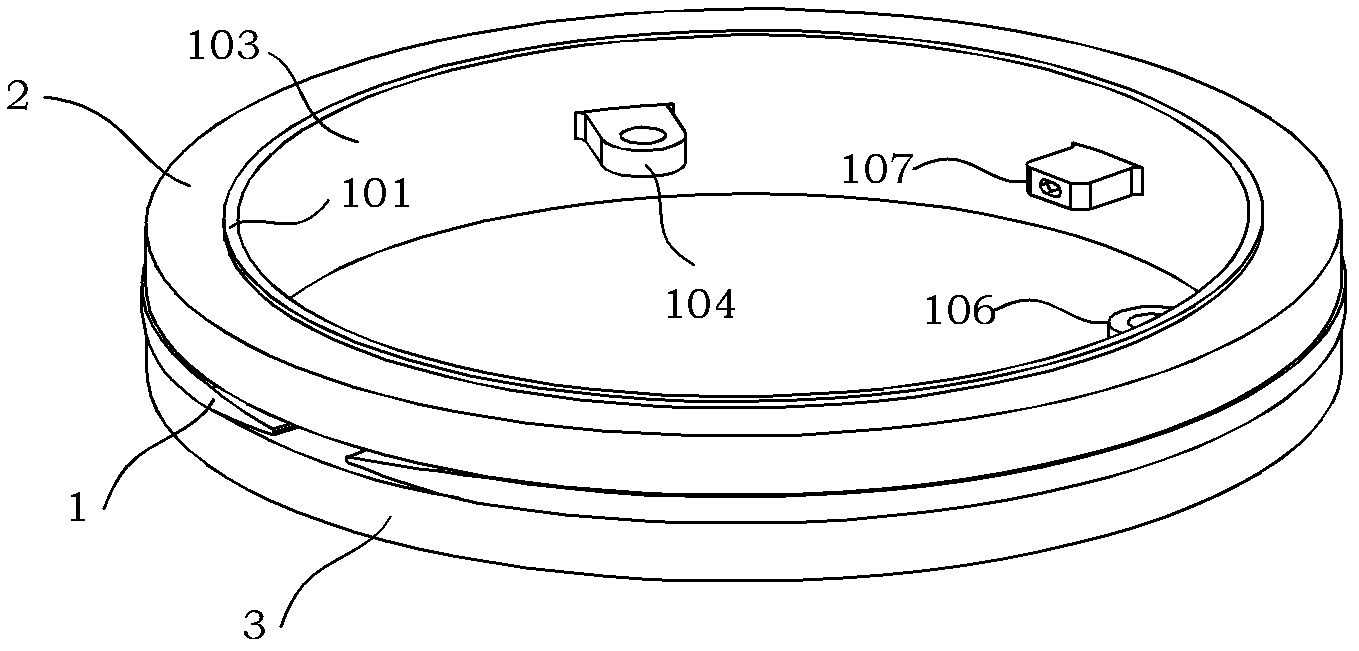

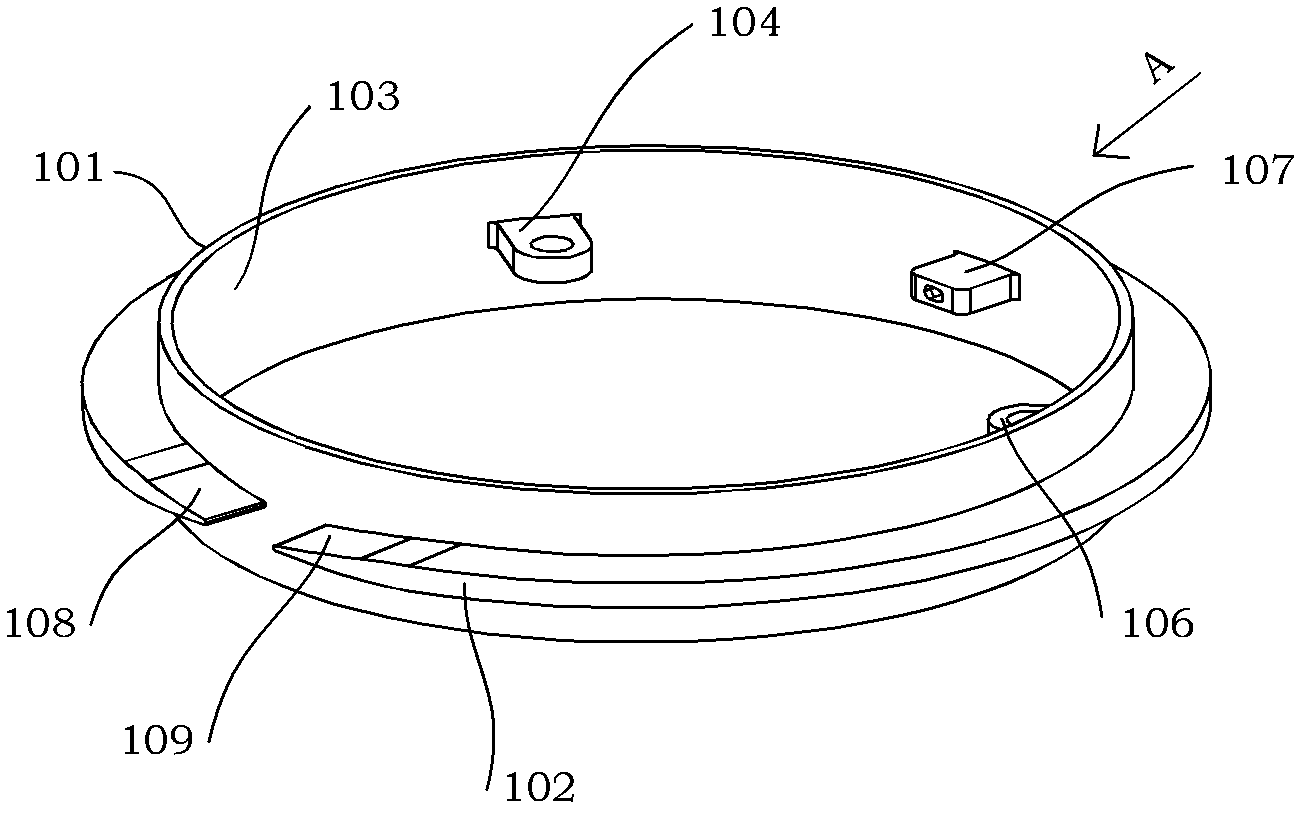

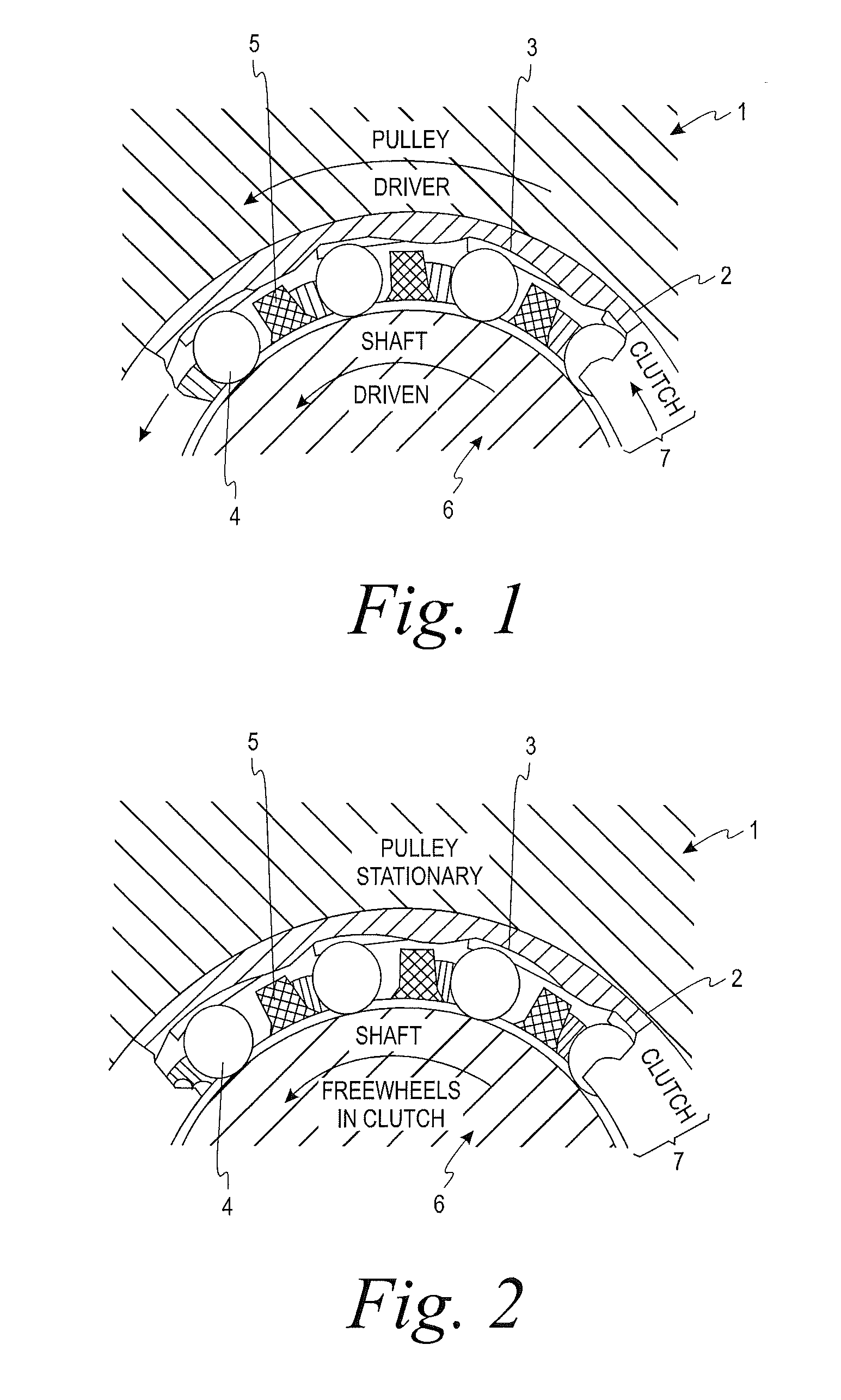

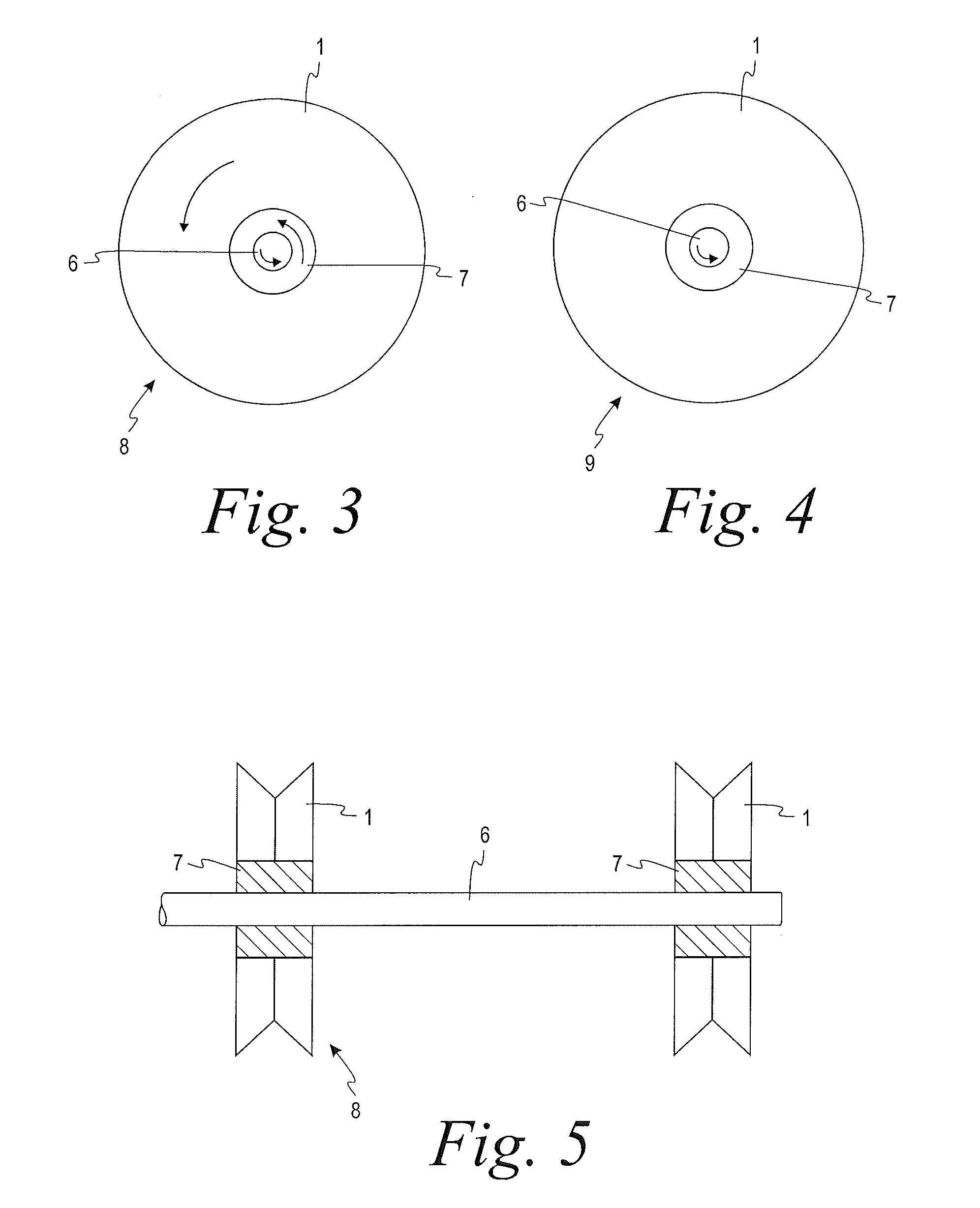

Fiber-optic loop structure wound in vertically symmetrical cross manner for fiber-optic gyroscope and winding method

The invention discloses a fiber-optic loop structure wound in a vertically symmetrical cross manner for a fiber-optic gyroscope. The fiber-optic loop structure comprises a fiber-optic loop skeleton which comprises a wrapping post and a middle flange, wherein the middle flange is arranged at the periphery of the wrapping post, the middle flange is provided with a fiber passing notch, horizontally run-though bellmouth orifices are arranged on the wrapping post and the middle flange and are located at the symmetrical positions of the fiber passing notch, and a fiber outlet is formed on the middle flange. A vertically symmetrical crosswise winding method for the fiber-optic gyroscope comprises the following steps: 1, setting the midpoint of an optical fiber at the position of the fiber passing notch of a fiber-optic loop; 2, winding the optical fiber; and 3, leading the optical fiber into the fiber outlet. According to the invention, a fiber-optic coil is divided into an upper part and a lower part, and each of the two parts has one side which is free of structural restriction and is not compressed in conditions of vibration and temperature variation; and through cross winding, the coils at two sides both have forward and reverse optical fibers which are the same in length, so that temperature gradients in axial and radial directions have the same temperature modulation effect on the optical fibers.

Owner:BEIHANG UNIV

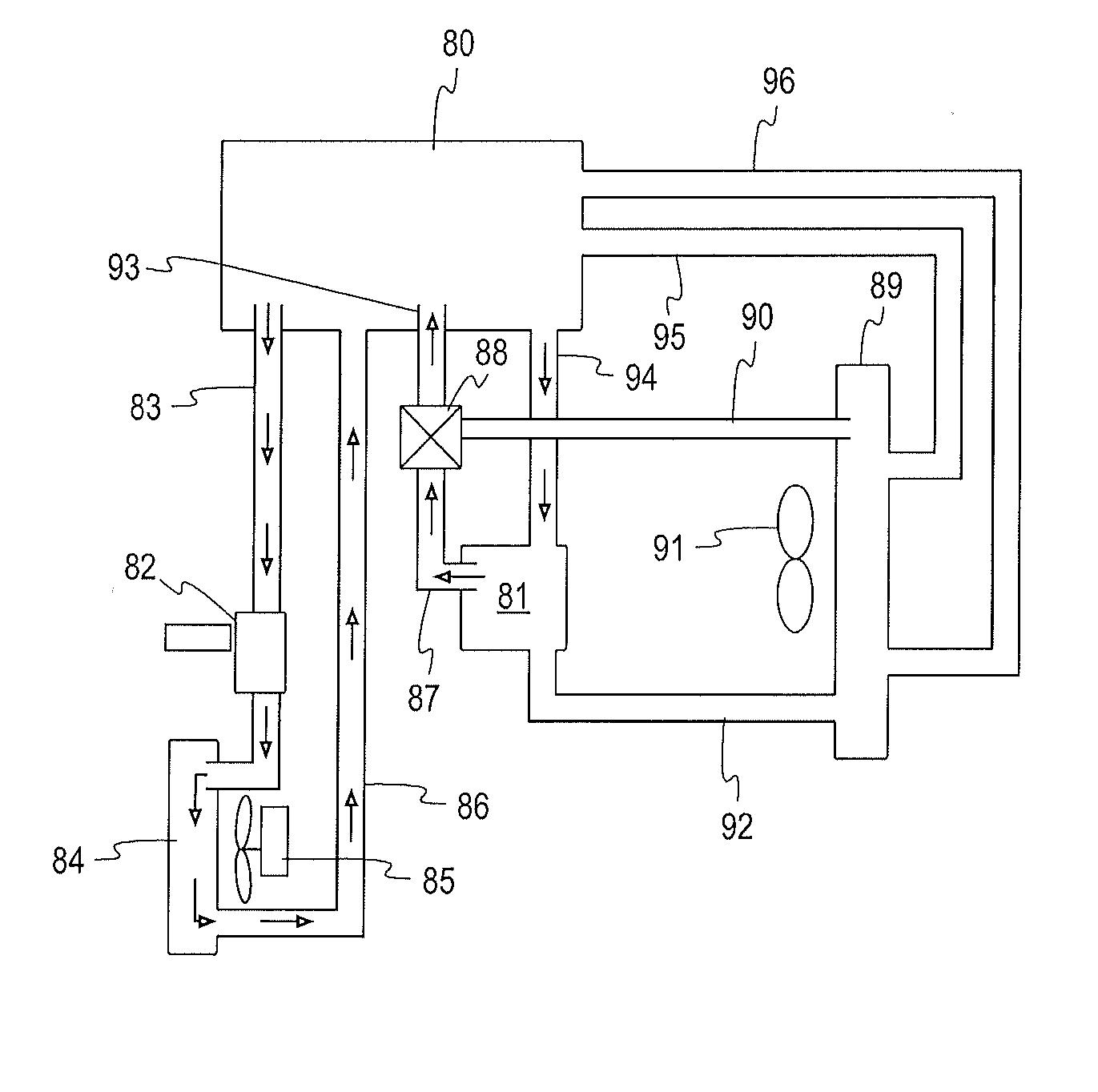

Drive isolation system for traction engine driven accessories

InactiveUS20110114405A1Lower initial costReduce weightPower installationsVehicle heating/cooling devicesEnergy recoveryAuxiliary power unit

An energy recovery interior heating system has a modified mechanical or electrical drive isolation system for vehicles such as trucks. This permits a standard air conditioning compressor pump to be driven from multiple power inputs thereby providing any hybrid or non-hybrid vehicle with continuous engine-on heating and / or air conditioning, limited time engine-off heating and air conditioning and two types of engine-off air conditioning temperature modulation. Another combination of the heating and air conditioning systems would permit the continuation of heating and cooling on hybrid vehicles when they are stationary and their traction batteries are fully charged and the vehicle is operating only on the electric motors for traction or work load power. This invention also provides internal combustion engine-off heating and A / C on these types of vehicles. Another embodiment uses the drive isolation system to integrate auxiliary power unit (APU) functions as part of the traction engine of over the road trucks.

Owner:AUTOTHERM ENERGY SYST

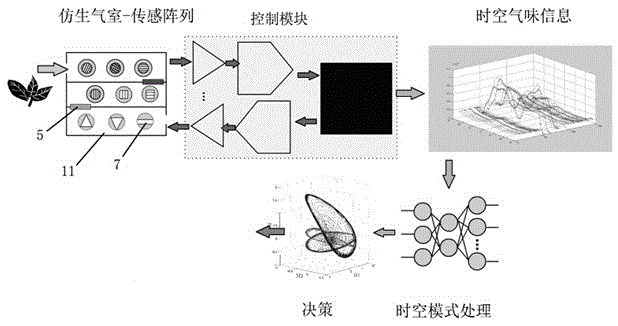

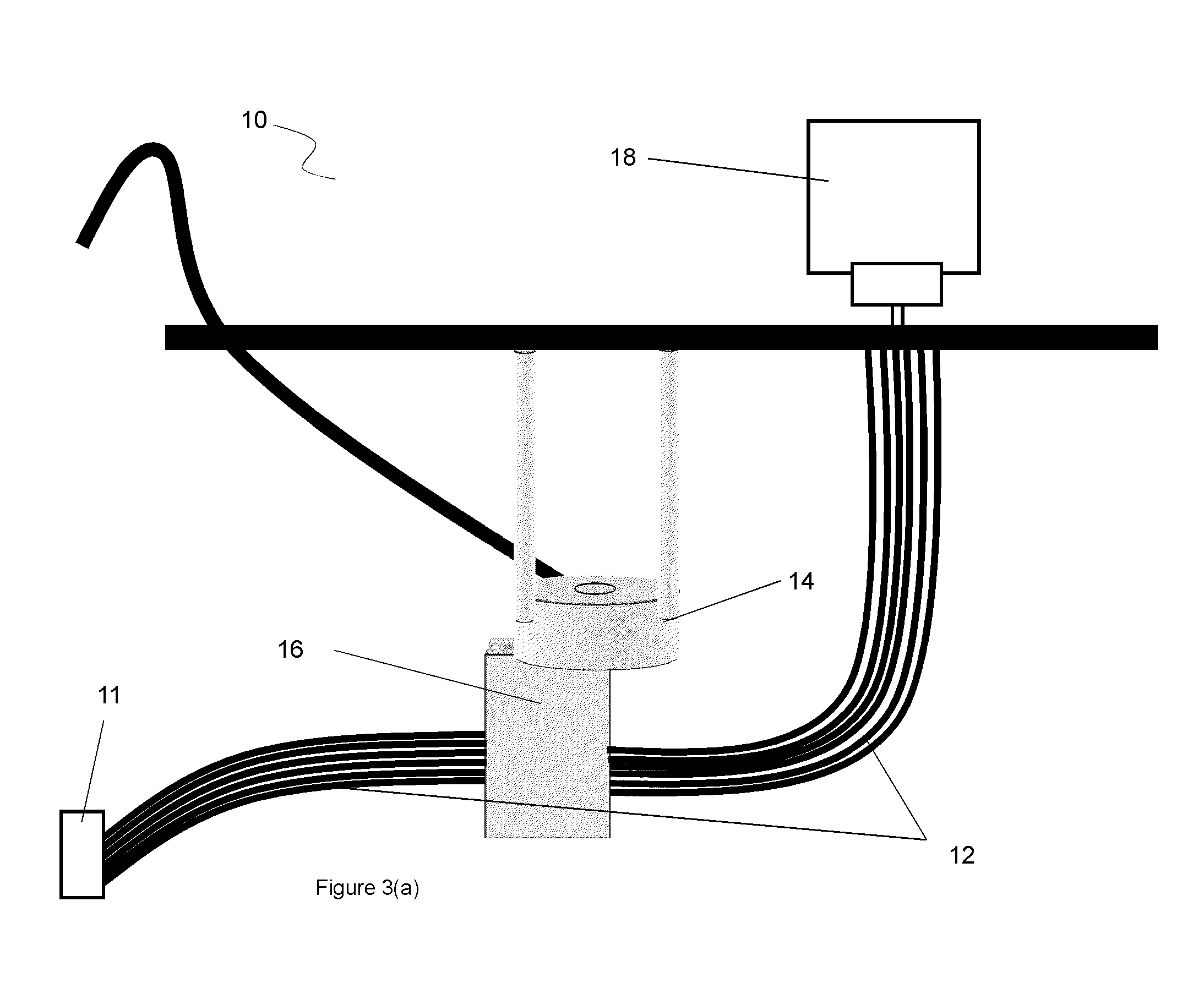

Bionic detection device and method for electronic nose time-space smell information

InactiveCN105572202ARich odor fingerprint informationChange sensitivityMaterial analysis by electric/magnetic meansResponse processDiffusion

The invention relates to a bionic detection device and method for electronic nose time-space smell information. A gas sensing array and a bionic air chamber are constructed in conjunction with a temperature modulation technology and a film retardation technology, and smell information data of various substances to be identified are acquired to be identified in a classified way through a subsequent mode identification algorithm. The method comprises the following steps: changing the sensitivity and selectivity of a sensor specific to different smell components through the temperature modulation technology, forming a scanning response process specific to different components of complex smell, and acquiring rich time sequence signals of different sensors in the array; setting different breathable films / semi-breathable films in an air path, simulating biological nasal cavity and mucus functions according to the characteristic of difference of diffusion transmission rates of various gas components, and acquiring the difference through the sensors distributed at different positions, namely, spatial information reflecting air chamber spreading of the smell. By adopting the method, the time-space information of the complex gas components is acquired, and a signal foundation is laid for fine identification of complex smell.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

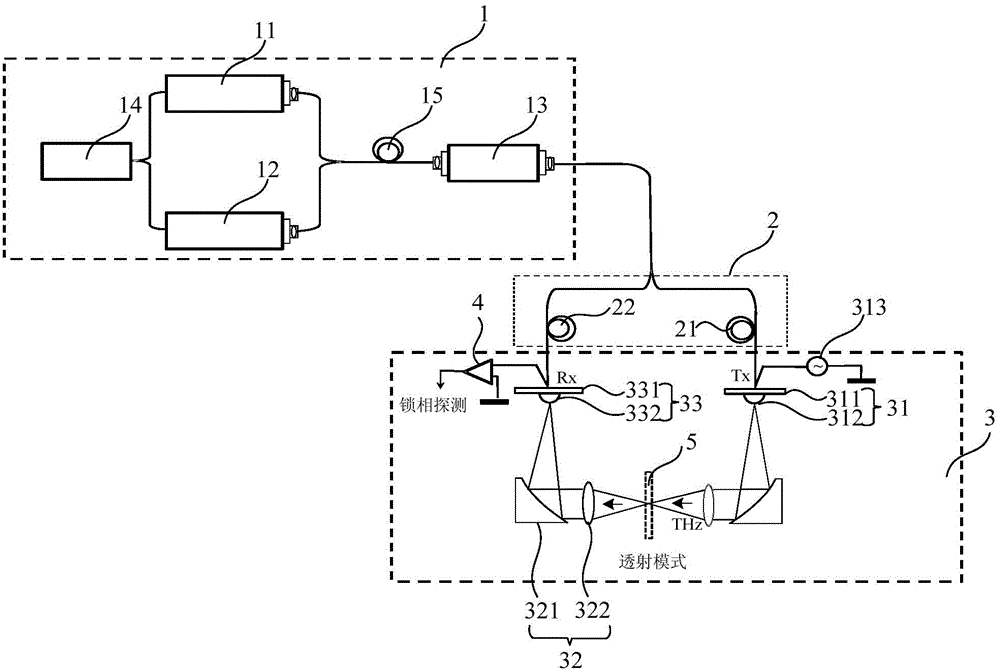

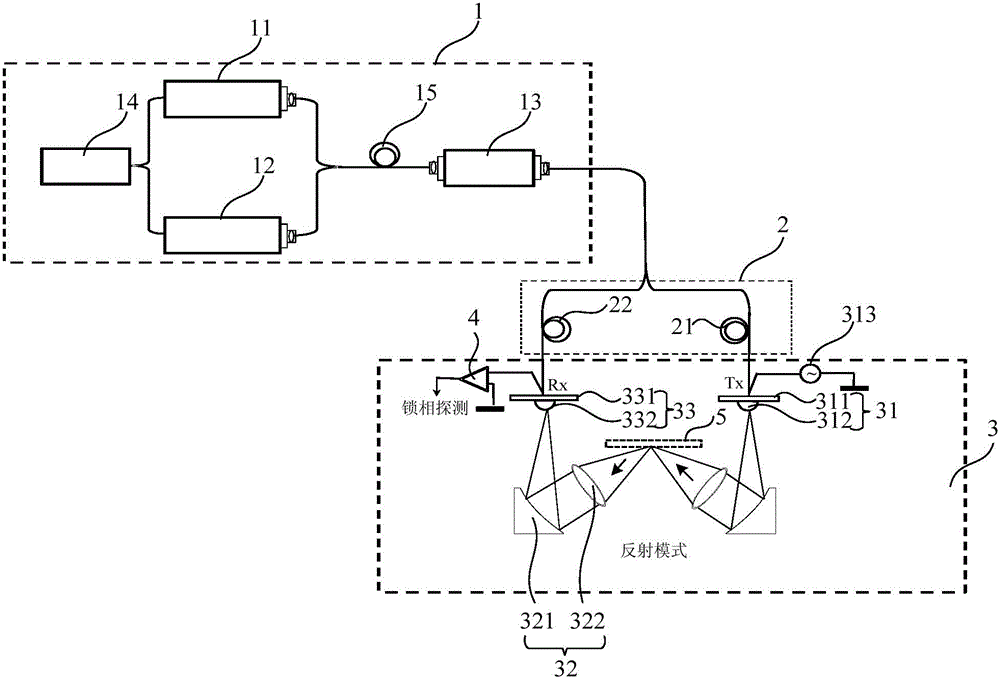

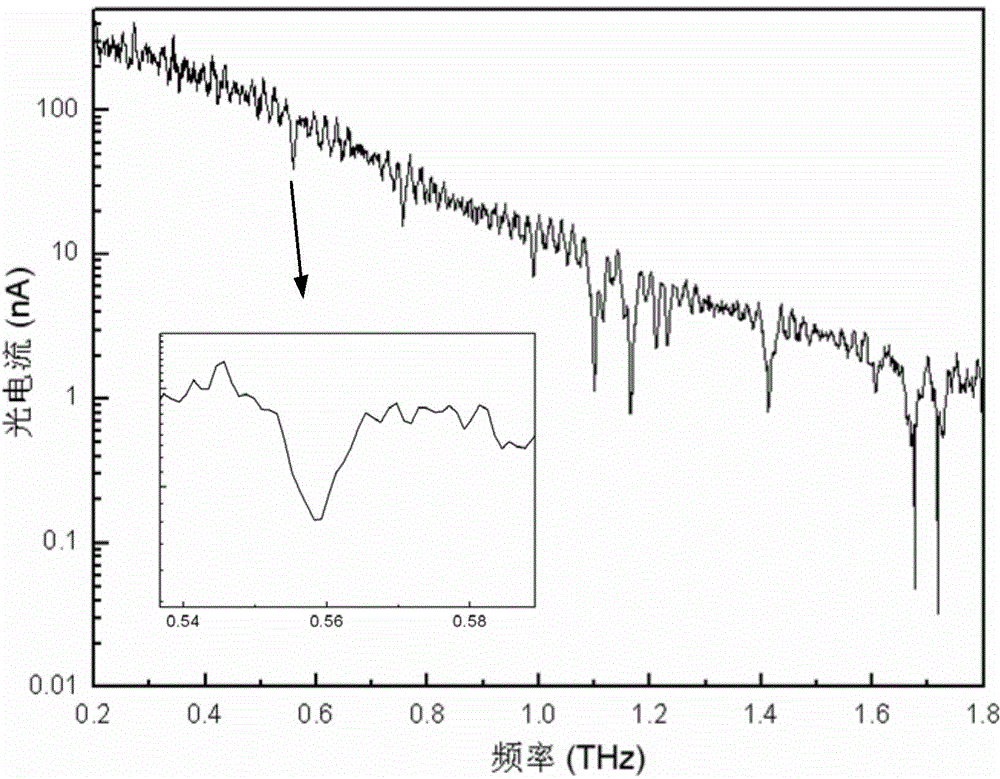

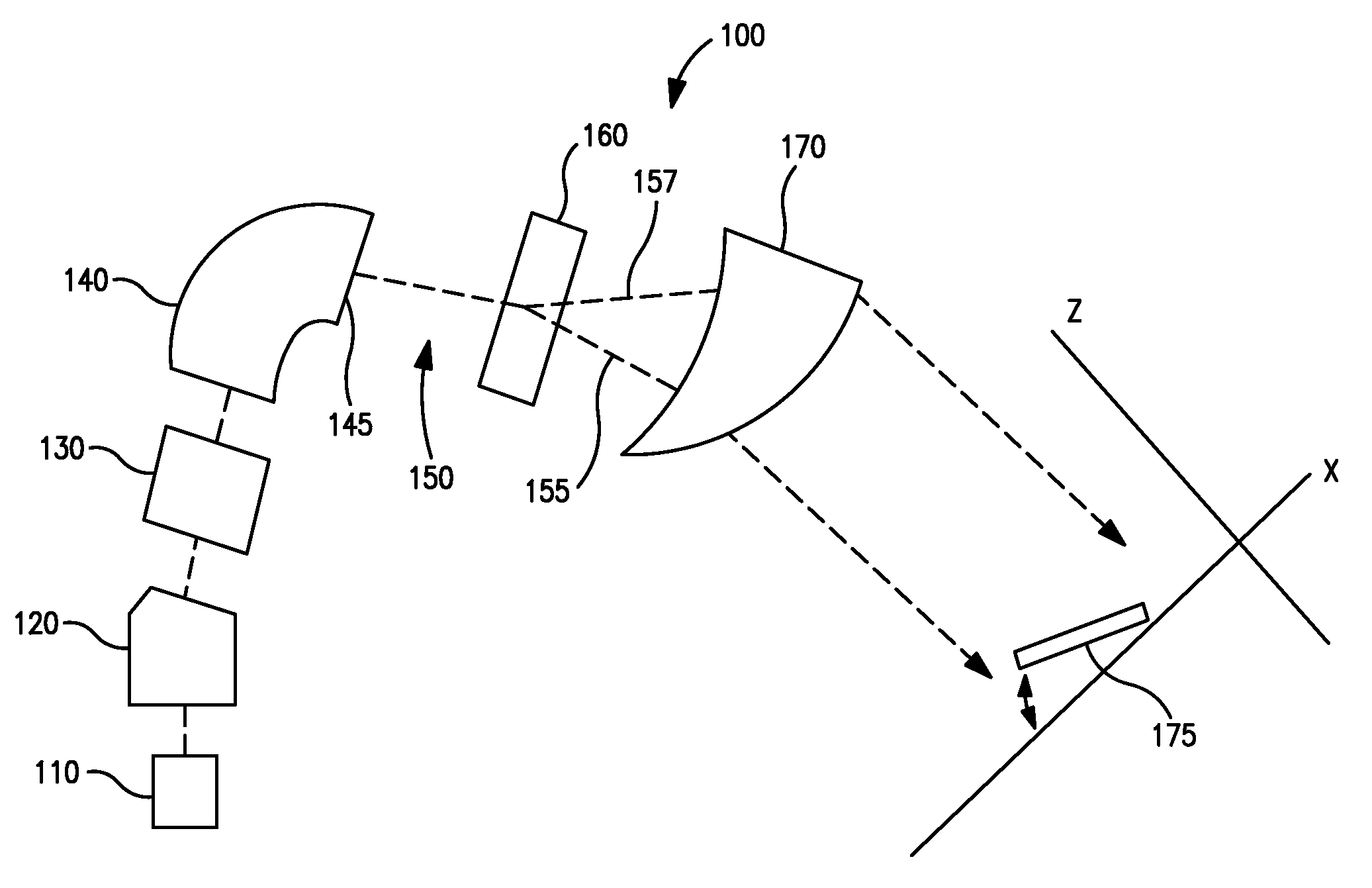

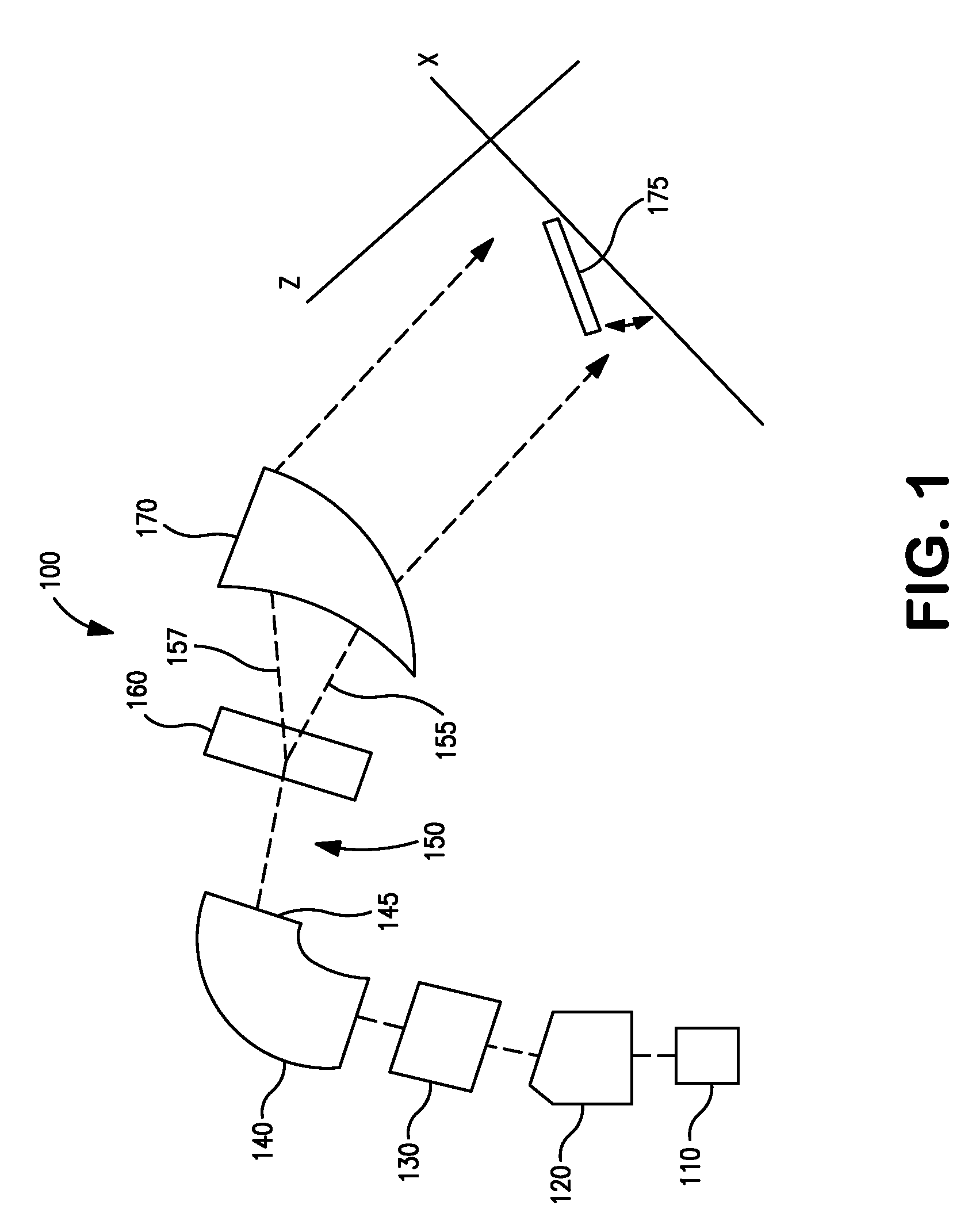

Method and system for realizing continuous terahertz spectrum detection

InactiveCN104458645AAchieving Phase ModulationAverage signal-to-noise ratioMaterial analysis by optical meansExternal biasTerahertz radiation

The invention provides a method and a system for realizing continuous terahertz spectrum detection. A pair of high-stability single longitudinal mode near-infrared lasers serve as seed light sources, a laser signal is modulated by utilizing optical fibers, and continuous terahertz waves are radiated outwards under external bias potential by virtue of an optical mixer; and the terahertz waves are subjected to coherent detection at a signal receiving end by adopting a photoconductive switch and an antenna. The temperature modulation is performed on the lasers, and wide bandwidth difference frequency continuous terahertz radiation output is realized. Compared with a common terahertz time-domain impulse spectral system, the system has the advantages that the spectral resolution acquired by the technology is greatly improved, and the system has an excellent effect of promoting the development of terahertz spectroscopy and related fields.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Assay Tube

InactiveUS20120115212A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAssayFluorescence

A non-instrumented biochemical assay device, such as a device for the processing of clinical specimens for molecular diagnostic applications. In one embodiment, an assay device comprises a lid which covers a reagent tube, which is disposed on a base. The platform utilizes chemical heating and optional temperature modulation by phase change material to prepare the sample and to amplify the target nucleic acid using Loop-Mediated Isothermal Amplification. The device features a simple indicator for a positive reaction, for example turbidity or fluorescence.

Owner:PROGRAM FOR APPROPRIATE TECHNOLOGY IN HEALTH

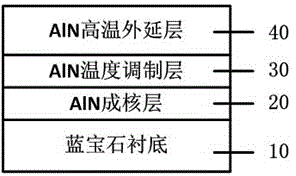

Growth method for improving quality of aluminum nitride film crystal by temperature modulation

ActiveCN104593861AImprove crystal qualityImprove performancePolycrystalline material growthFrom chemically reactive gasesCooking & bakingEpitaxial material

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Electronic device and temperature modulation method thereof

InactiveCN103034307AImprove cooling effectImprove stabilityDigital data processing detailsTemperature control using electric meansEngineeringElectronic component

Owner:QUANTA COMPUTER INC

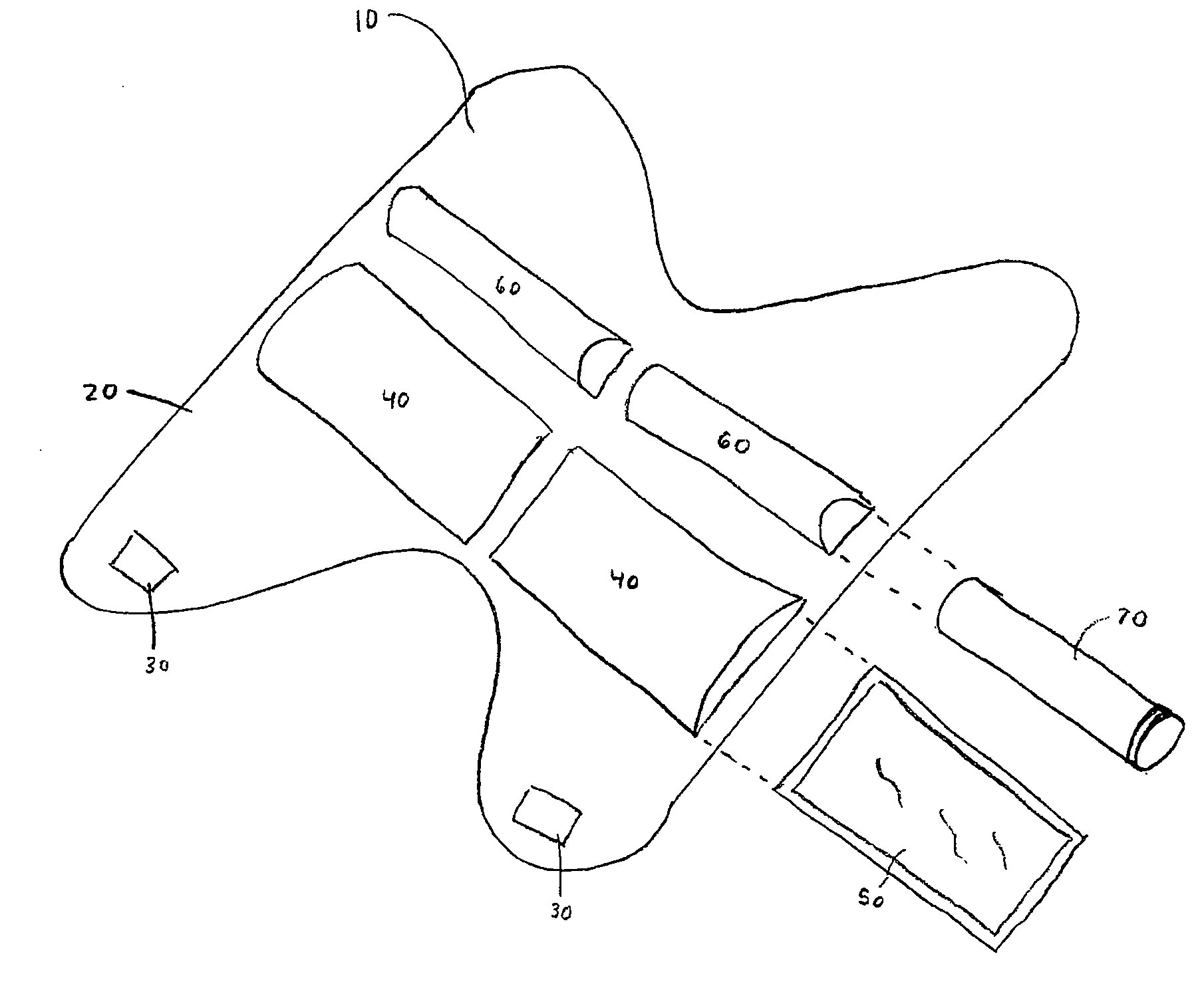

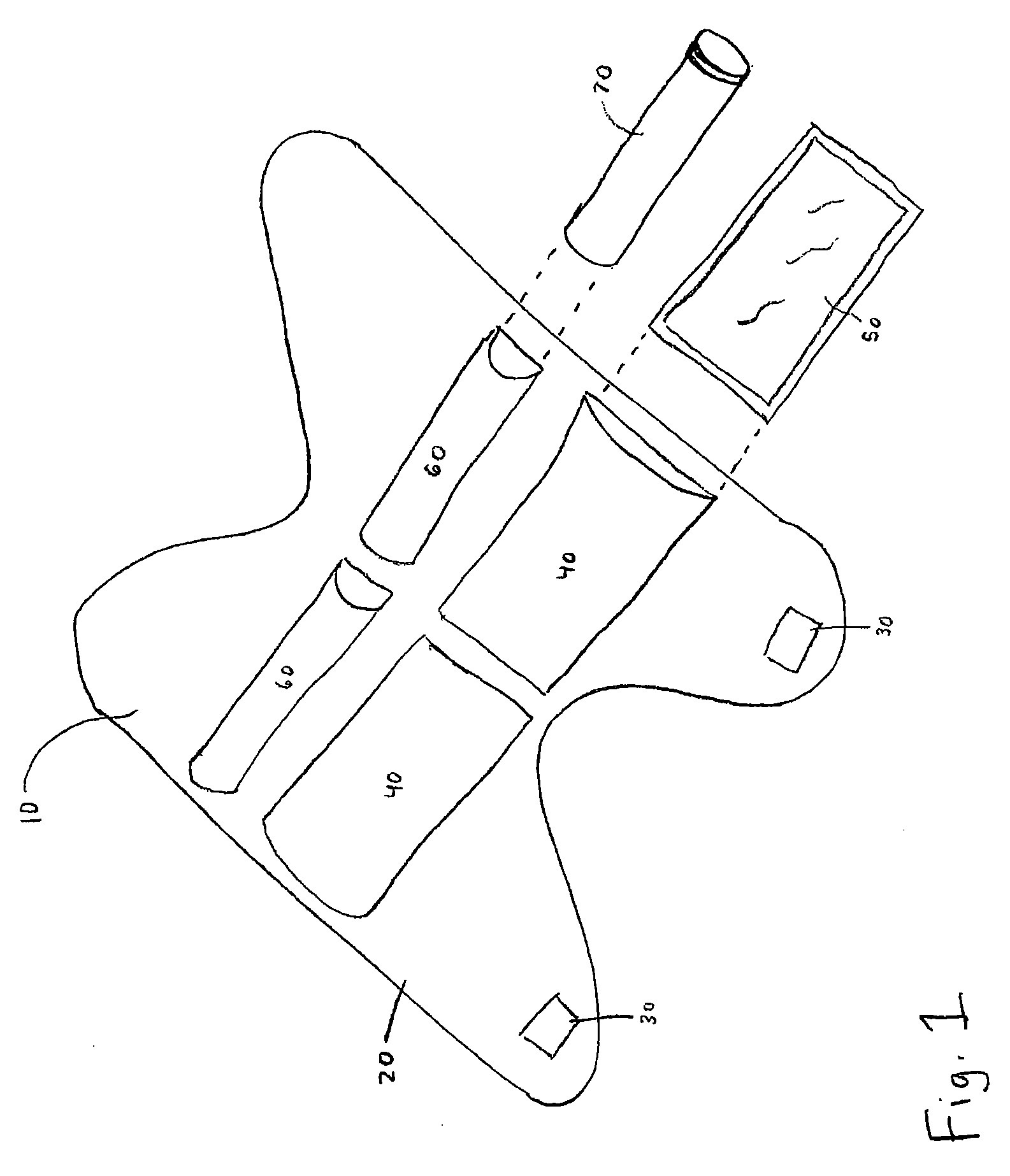

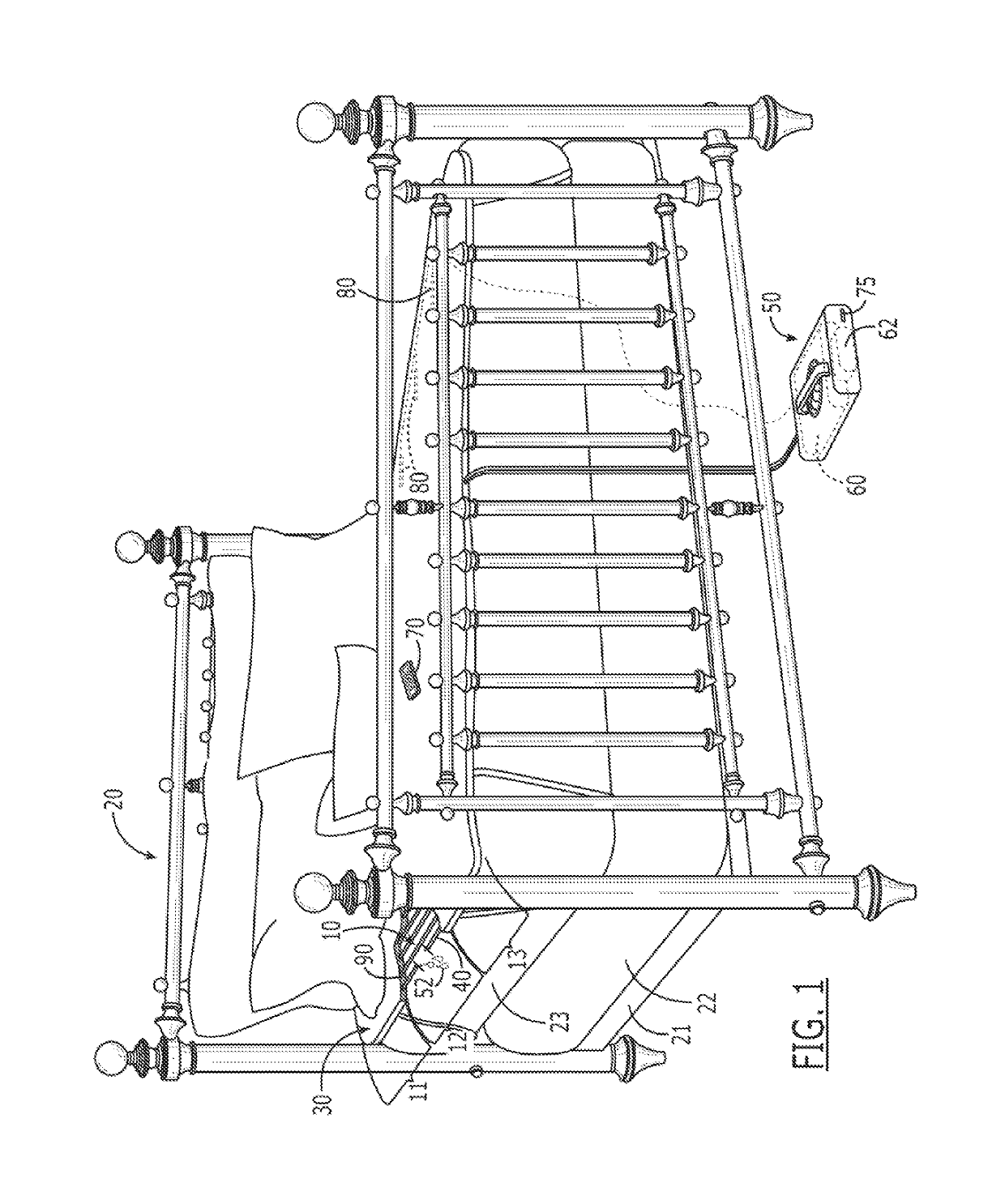

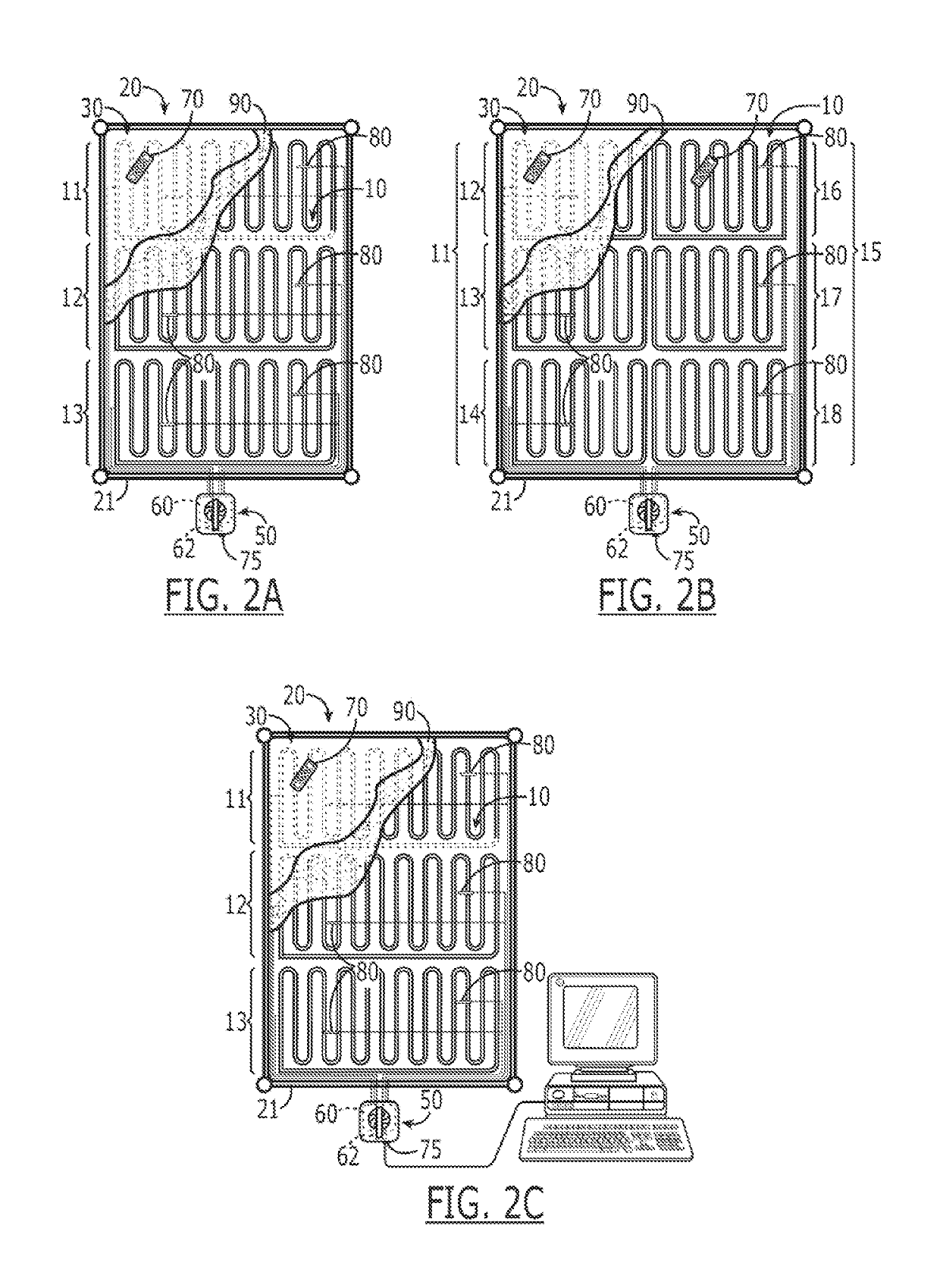

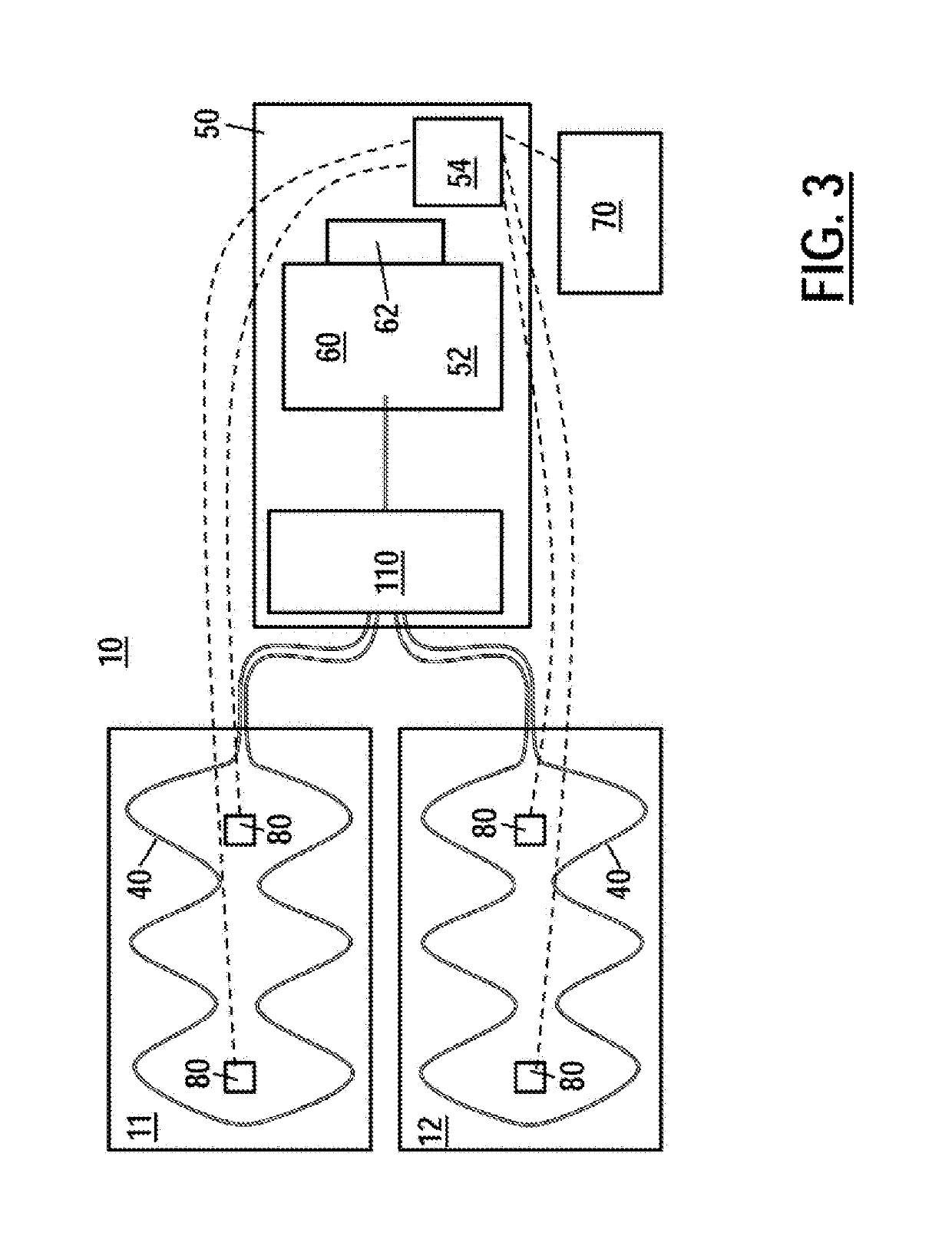

Multi-zone temperature modulation system for bed or blanket

A temperature modulation system for a bed, blanket, or other furniture includes a fluid for moderating temperature change, a number of conduit circuits for directing the fluid through respective zones, a control unit including a thermoelectric device for modulating temperature of the fluid, and a pump. Each of the conduit circuits selectively and independently directs fluid through its respective zone in order to produce a temperature within the zone that is independent of the temperature outside the zone. The system also includes an arrangement of one or more zones in an arrangement in which the control unit is programmed to vary the zone temperature over time according to a schedule.

Owner:SLEEP SOLUTIONS

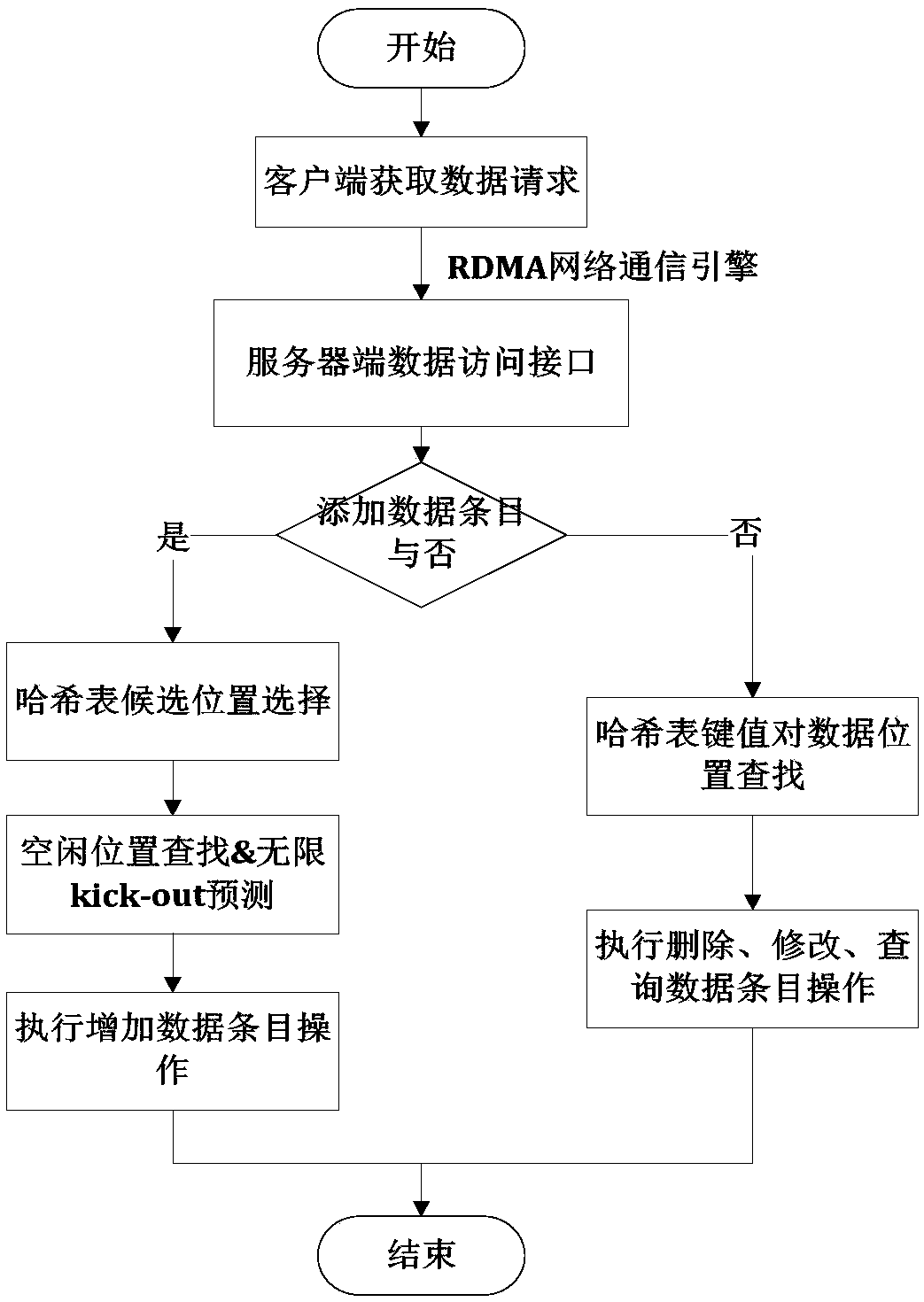

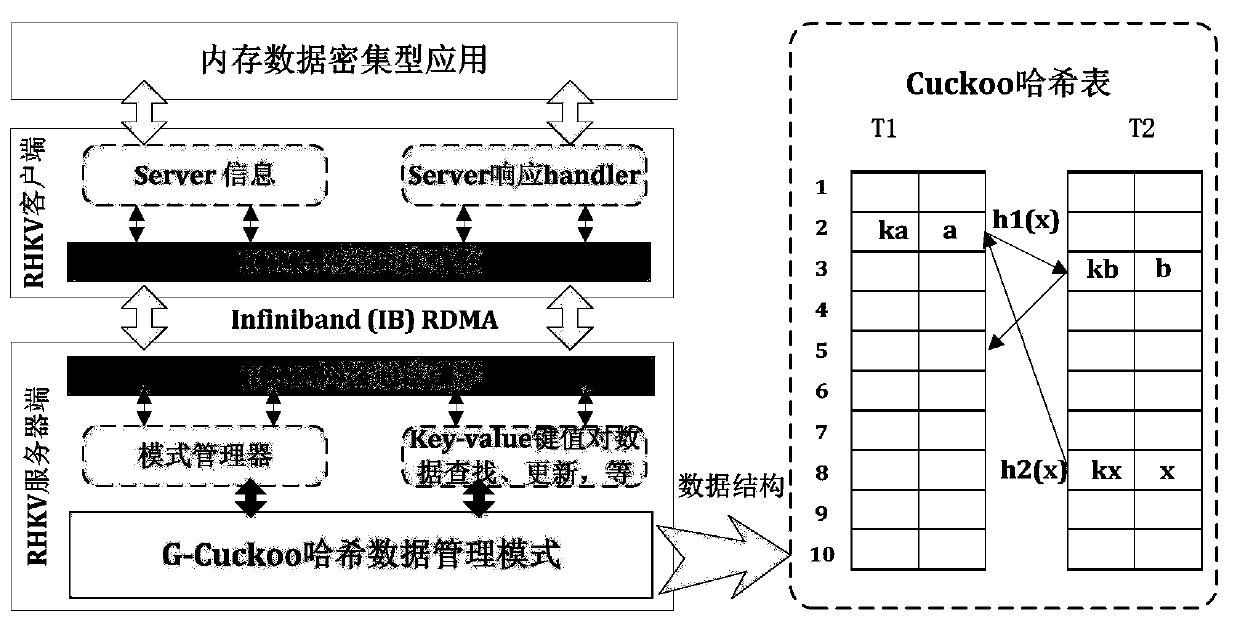

Elastic Key-Value pair data storage method based on RDMA and HTM

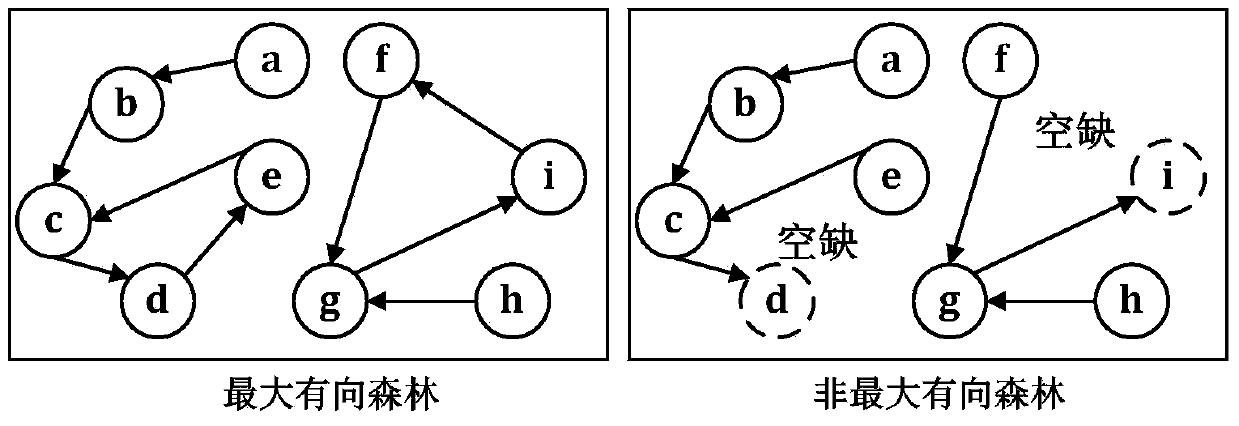

ActiveCN110069431AAlleviate the infinite loop problemImprove throughputTransmissionSpecial data processing applicationsPaired DataPrimitive operation

The invention provides an elastic Key-Value pair data storage method based on RDMA (Remote Direct Memory Access) and HTM (High Temperature Modulation). A server-client architecture mode is designed and followed, and the method comprises the steps that at a server side, an improved G-Cuckoo Hash data management mode is given in combination with a Hashmap; the kick-out infinite loop between Hash tables caused by searching for idle positions in the data insertion process is avoided. the bottleneck problem of key value pair storage performance caused by round response required by the traditional network message transmission between the client and the server is analyzed; an Infiniband remote direct memory access RDMA technology is used, an RDMA network communication engine is designed, a data access request is received, and a data request result is sent back; a hardware transaction memory HTM technology is utilized to realize a two-section lock protocol lock operation and ensure the atomiccharacteristics of data operation; and a key value is used for self-verifying the check code of the data to guarantee data consistency. The basic operation speed of the key value on the data can be greatly improved.

Owner:SHANGHAI JIAO TONG UNIV

Method for realizing output of optical microcavity coupling system by temperature modulation and coupling structure thereof

InactiveCN101957479AAchieve temperature controlSolve technical problems in developmentCoupling light guidesTemperature controlEngineering

The invention provides a method for realizing output of an optical microcavity coupling system by temperature modulation and a coupling structure thereof. The coupling structure is mainly characterized in that one side of the coupling system is equipped with a microheater, a lead of the microheater is connected with a temperature control device, and the whole optical microcavity, a coupler and the microheater are accommodated in a packaging body by an optical transparent packaging material. The method is characterized in that output of the optical microcavity coupling system is regulated and stabilized by adjusting and controlling the temperature of the optical microcavity coupling system. The invention solves the technical problems for developing relevant devices in the technical field and provides a feasible and simple-structure technical scheme.

Owner:ZHONGBEI UNIV

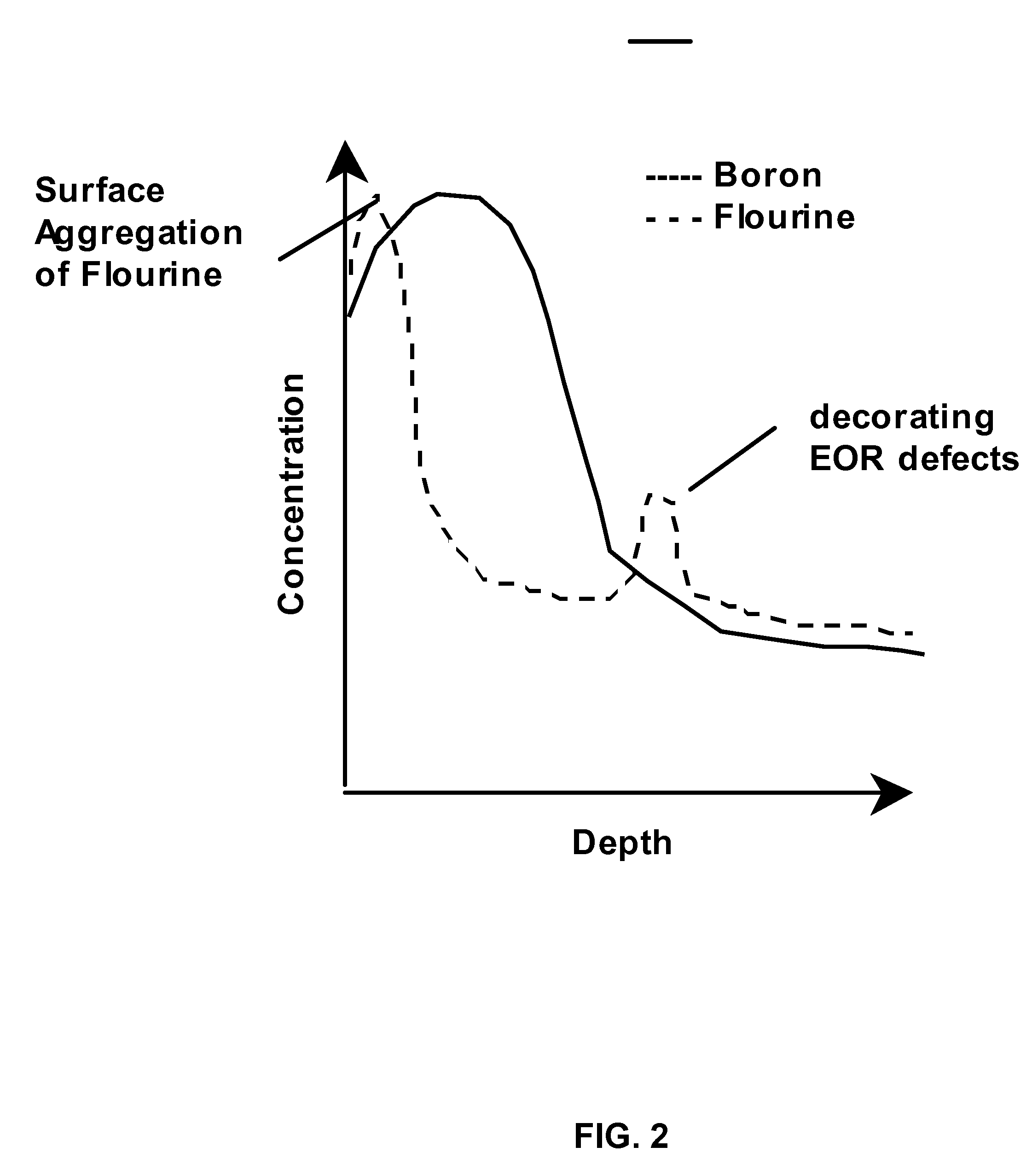

Thermal modulation of implant process

ActiveUS7868306B2Minimize EOR defectsMaximize and minimize regionMaterial analysis using wave/particle radiationElectric discharge tubesDopantTemperature modulation

Owner:VARIAN SEMICON EQUIP ASSOC INC

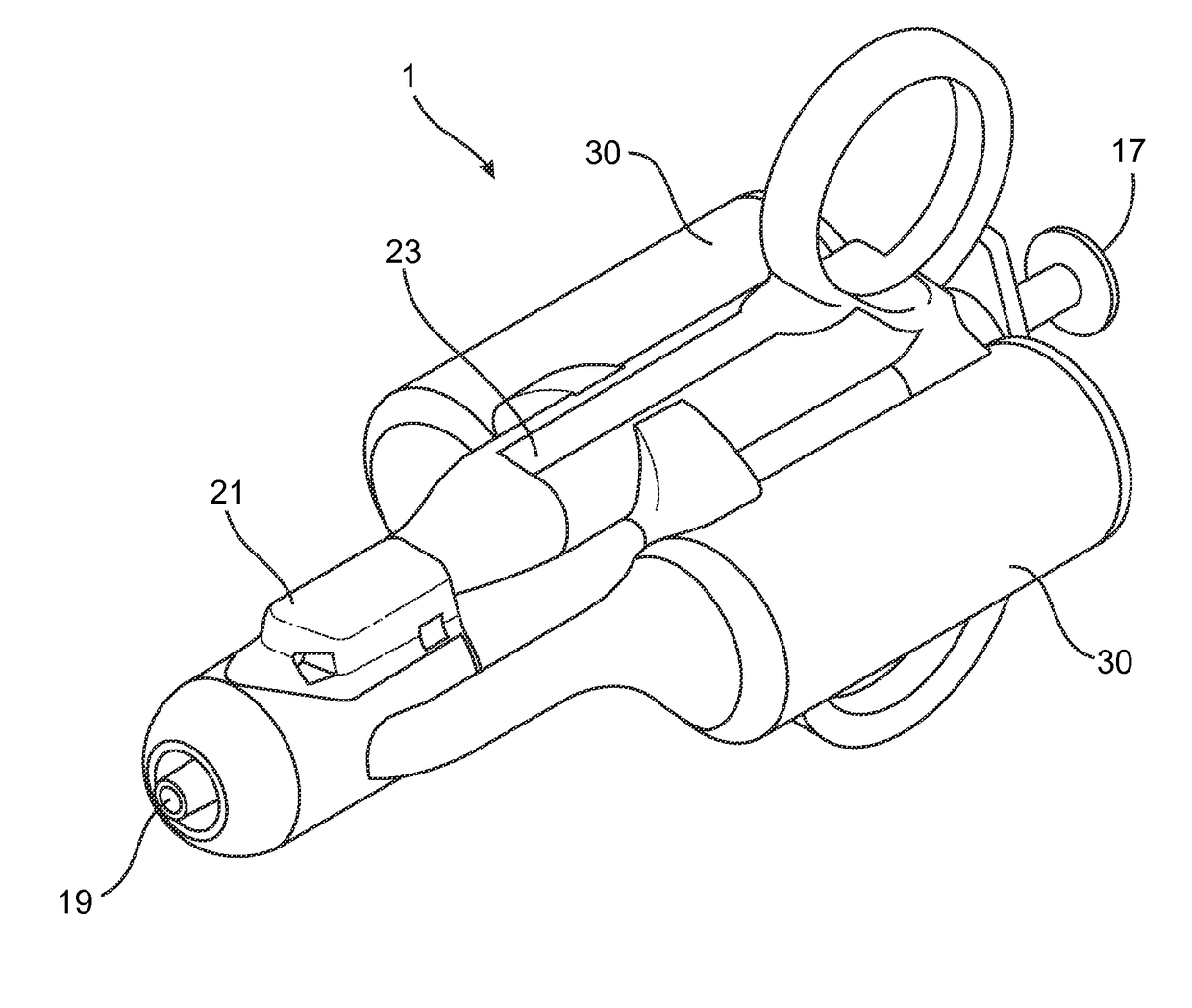

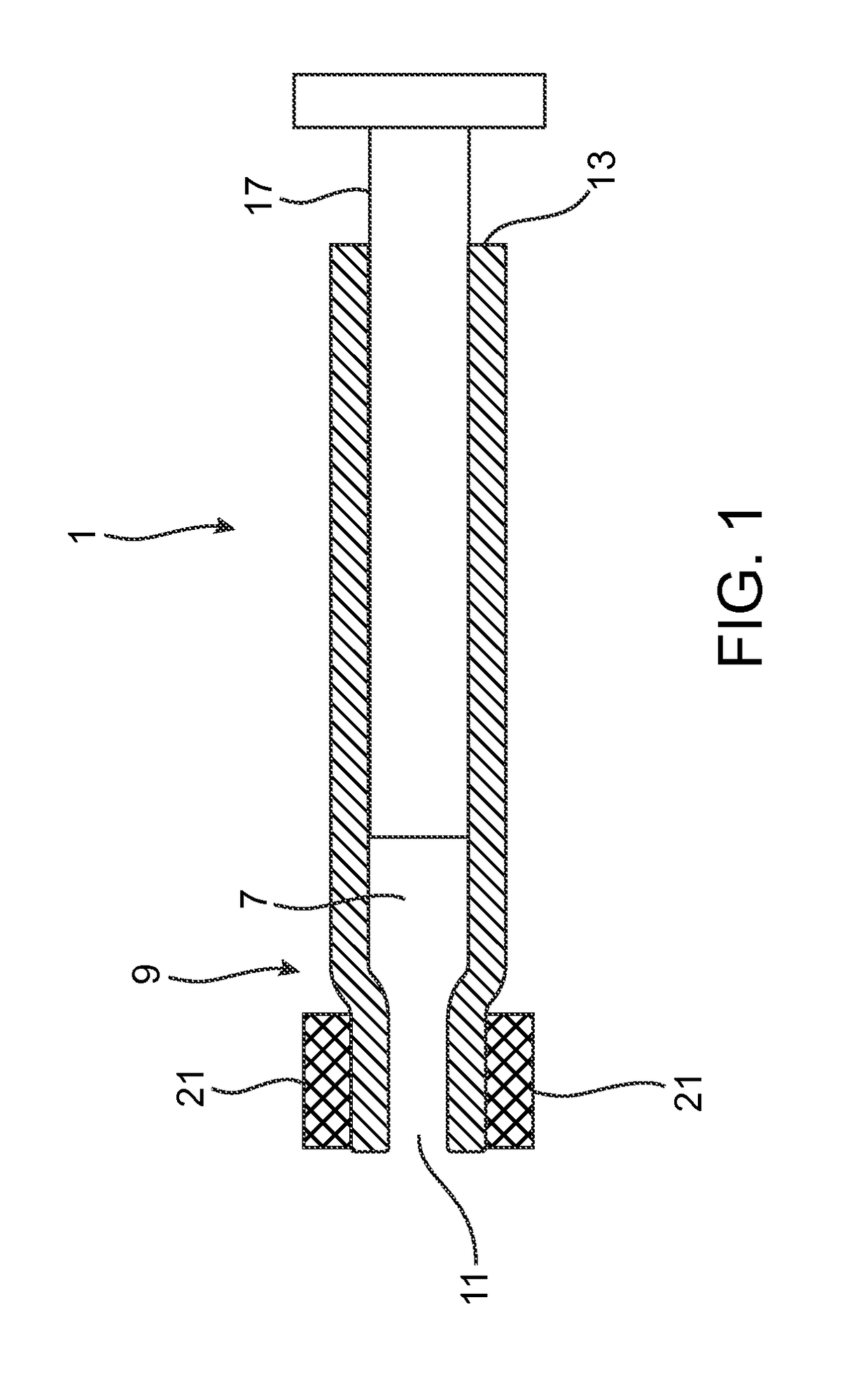

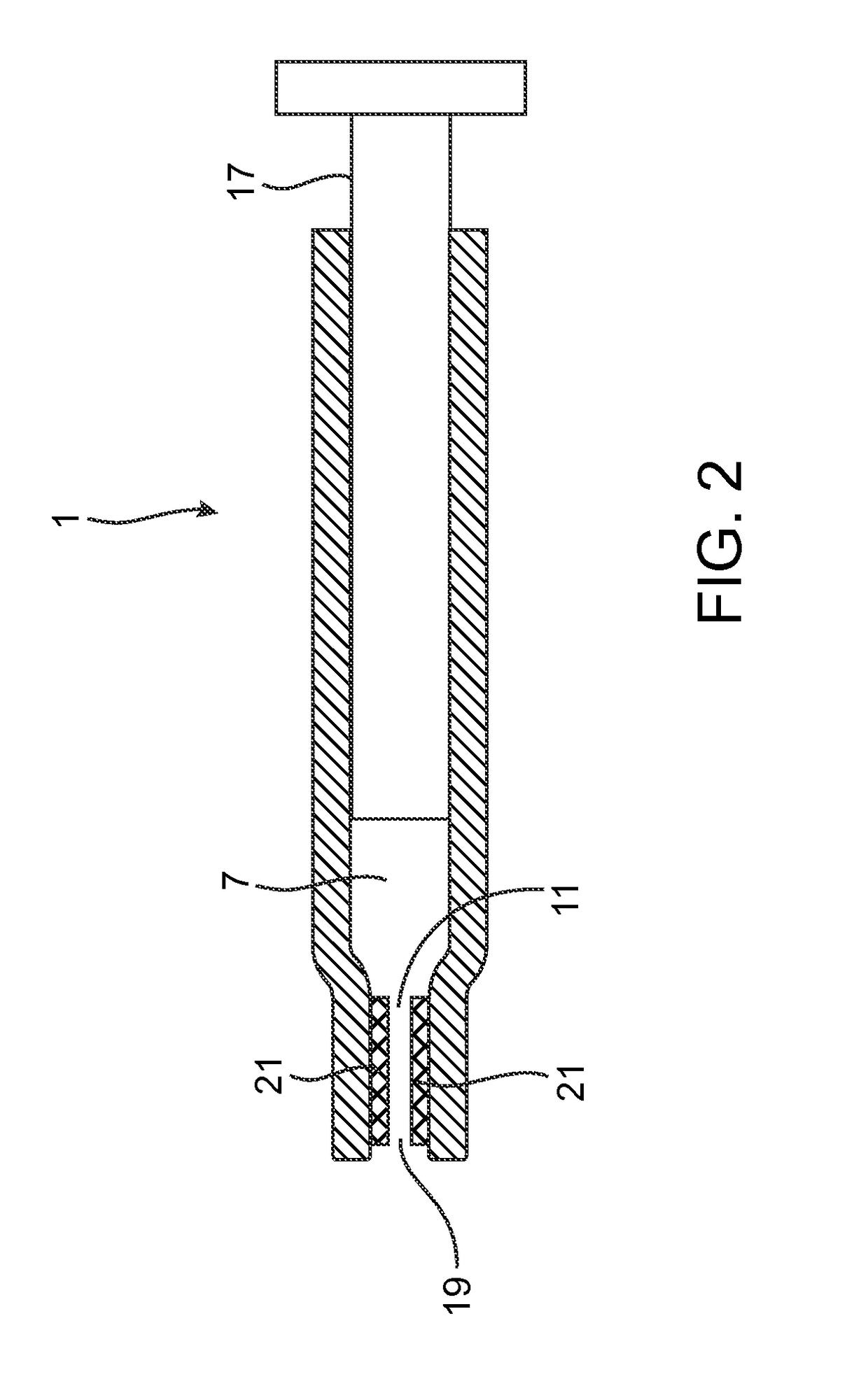

Syringe with temperature modulation capabilities

Owner:TAUTONA GROUP

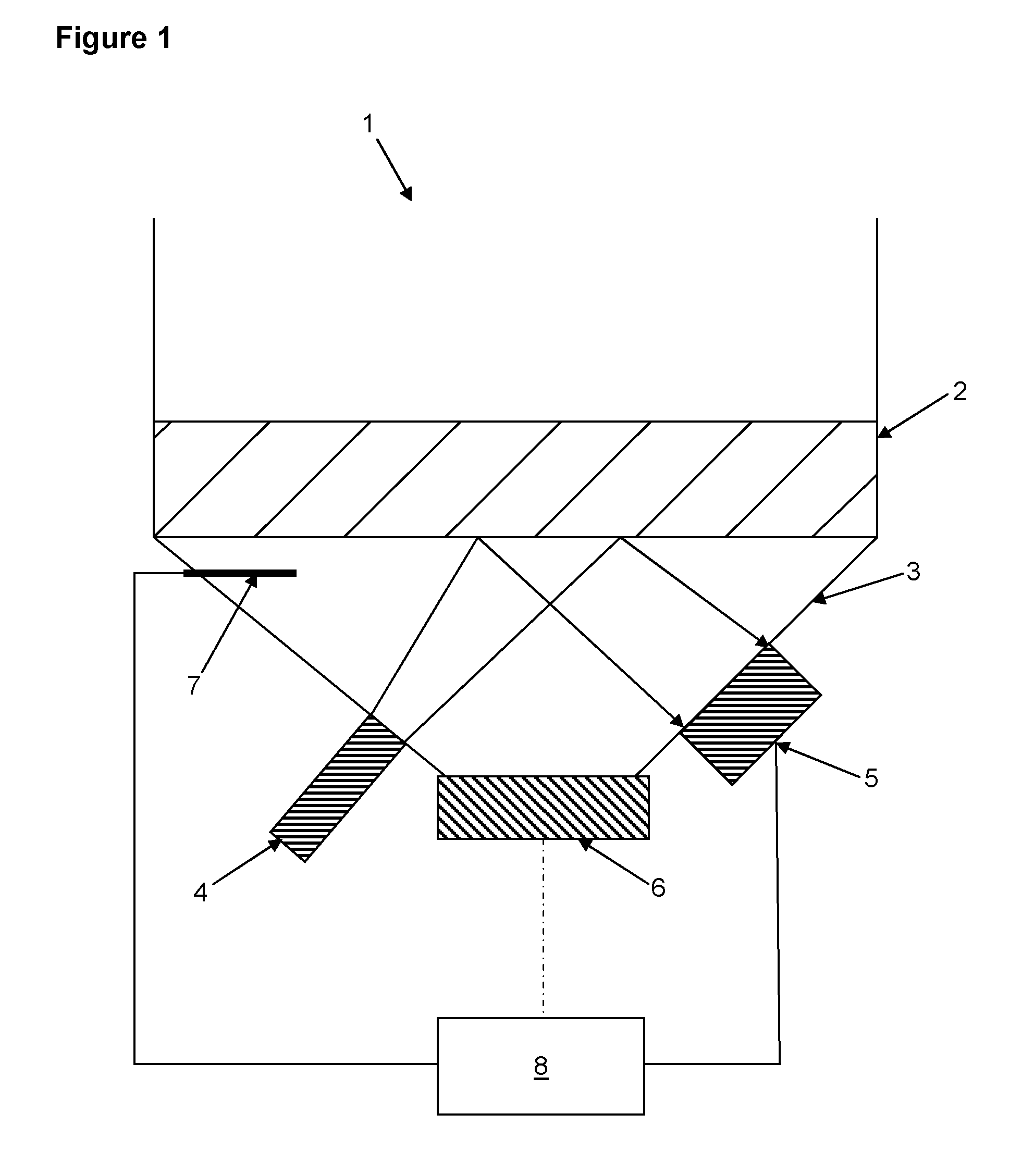

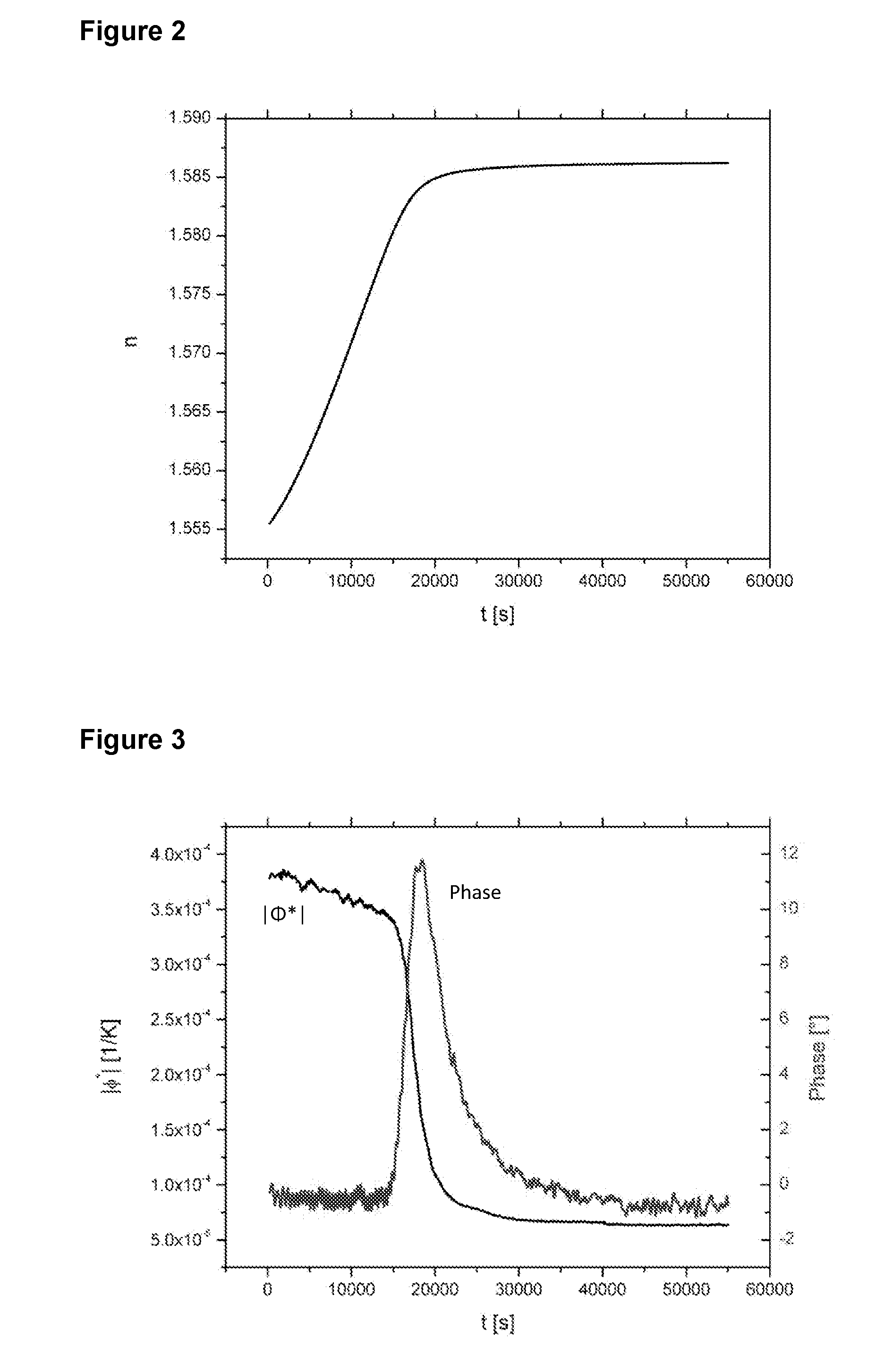

Temperature Modulated Refractive Index Measurement

ActiveUS20130155395A1Less complexSmall amplitudePhase-affecting property measurementsTemperature controlControl system

The present invention is directed to temperature modulated refractive index measurement. In accordance with the invention a method for determination of the complex temperature coefficient of the refractive index of a sample is provided, wherein the determination of the complex temperature coefficient of the refractive index of the sample is based on a refractive index measurement. Furthermore, the refractive index of the sample is measured over a period of time, wherein the temperature of the sample is modulated over said period of time and the complex temperature coefficient of the refractive index is calculated on the basis of the refractive index measurement over the period of time and the temperature modulation over the period of time. Additionally, a measurement system, in particular comprising a temperature control system and a processing system to carry out the above method, is disclosed.

Owner:ANTON PAAR OPTOTEC

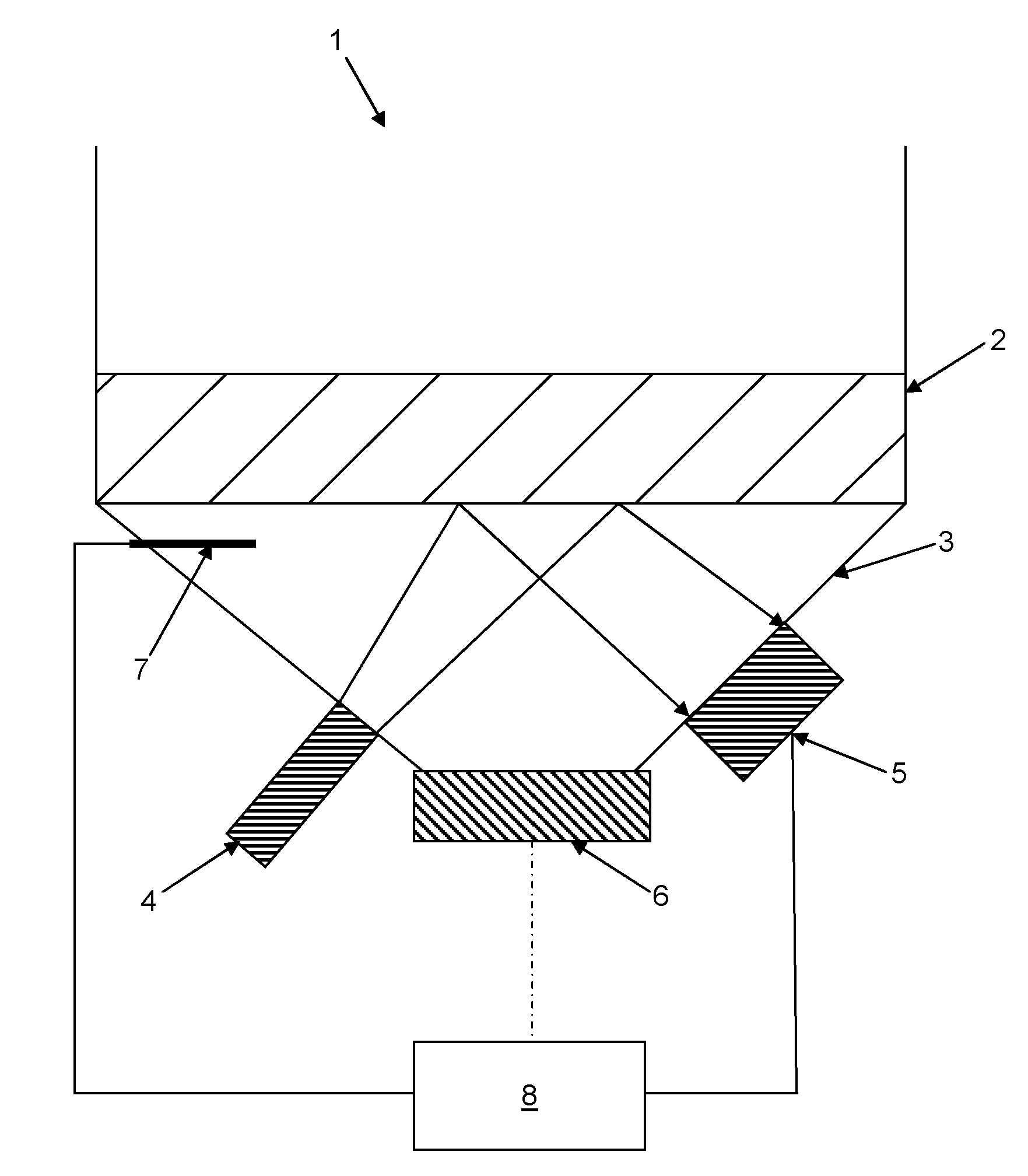

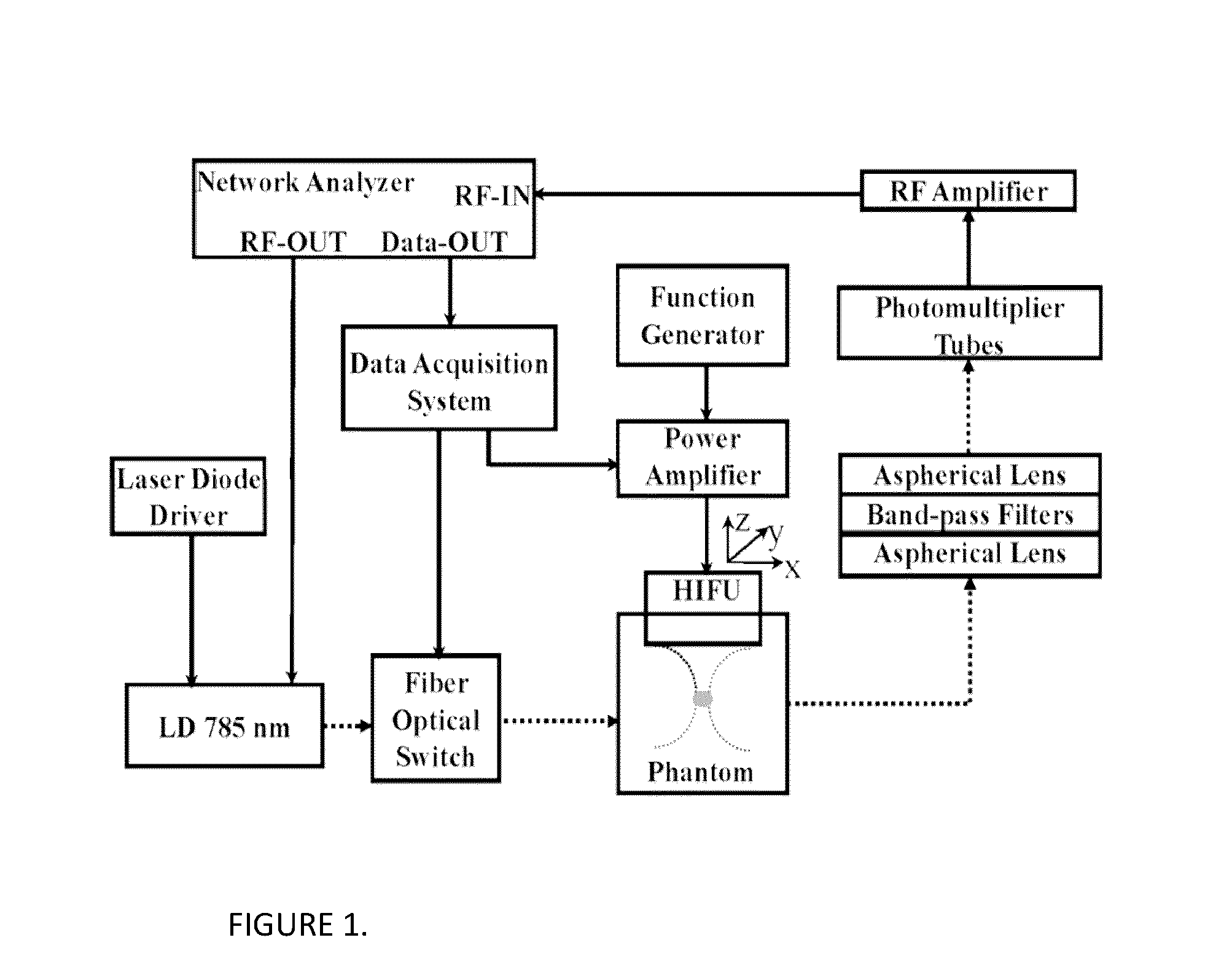

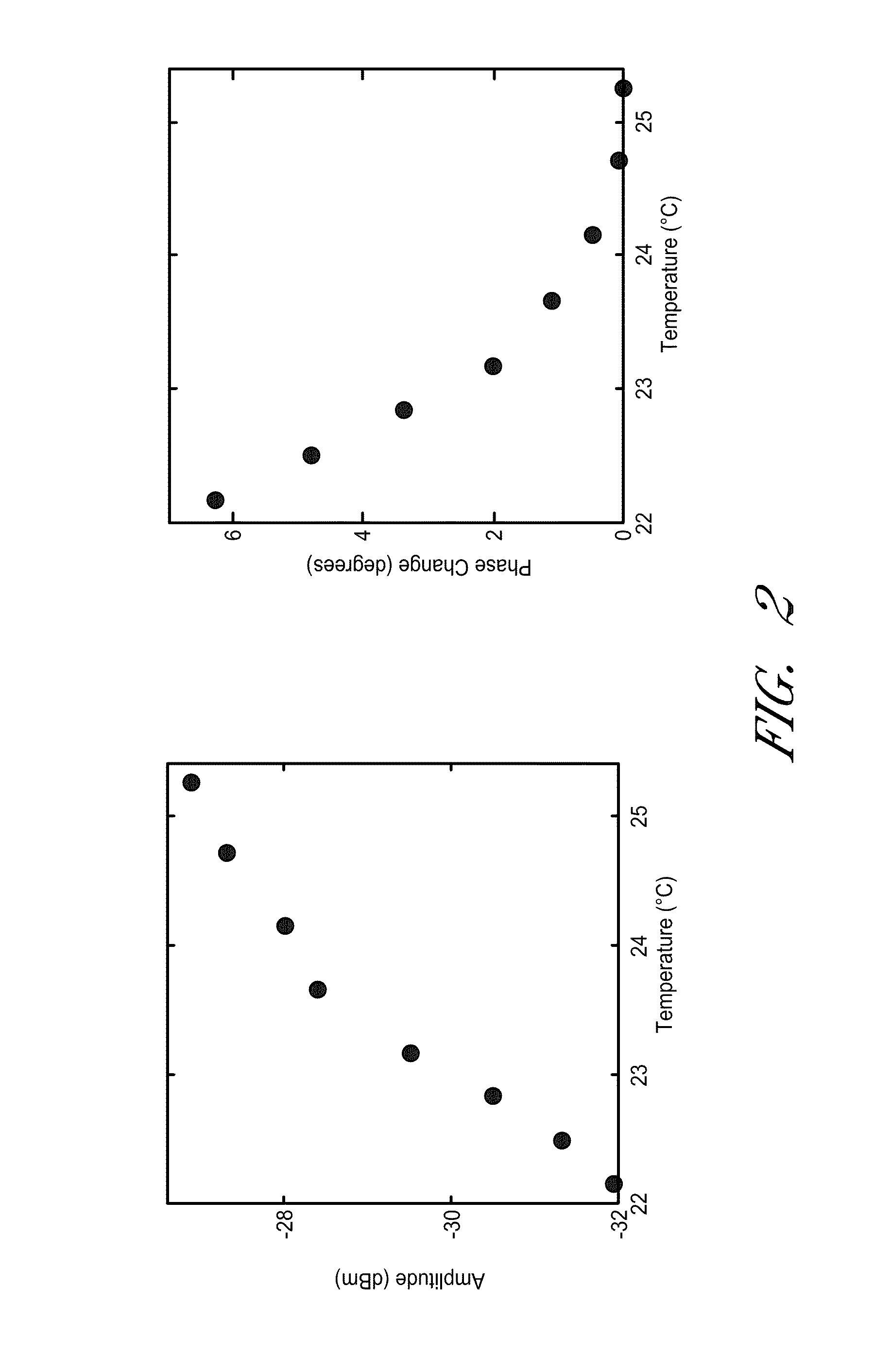

Temperature-modulated fluorescence tomography

ActiveUS20130189188A1Ultrasonic/sonic/infrasonic diagnosticsSurgeryHigh intensityHigh-intensity focused ultrasound

Aspects of the disclosure relate to fluorescence imaging, and more particularly to the use of temperature modulation in a tissue site with a modulator such as high intensity focused ultrasound to modulate the emission signal emitted by temperature-sensitive optical fluorescence reporters.

Owner:RGT UNIV OF CALIFORNIA

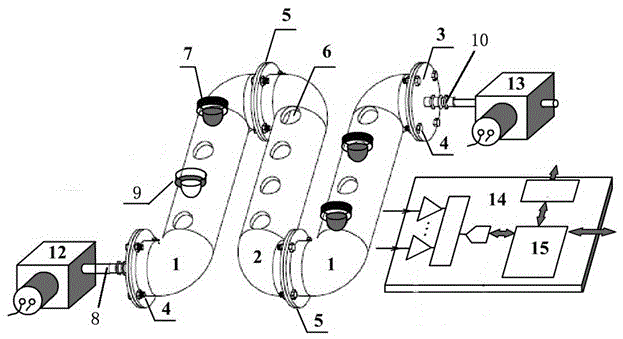

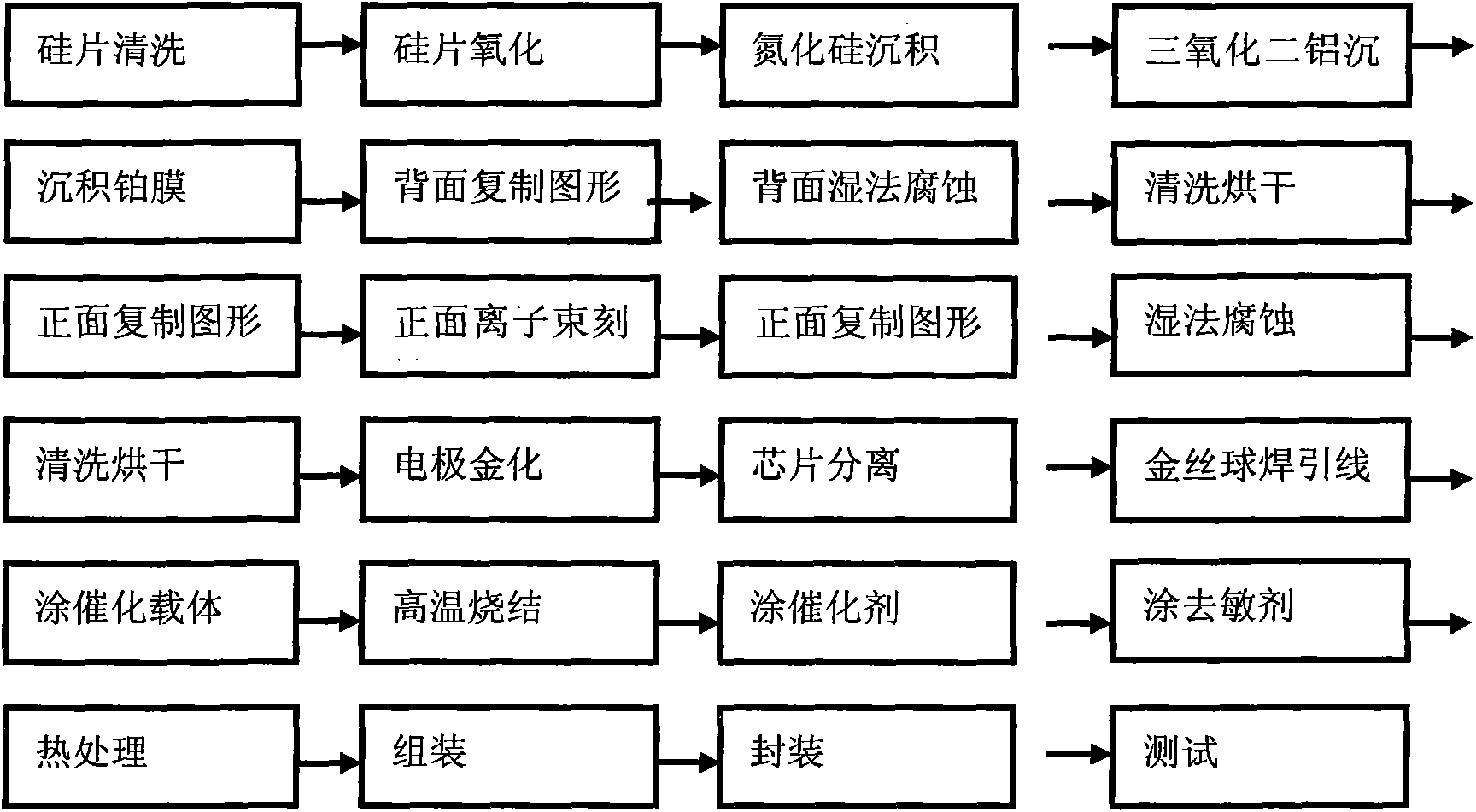

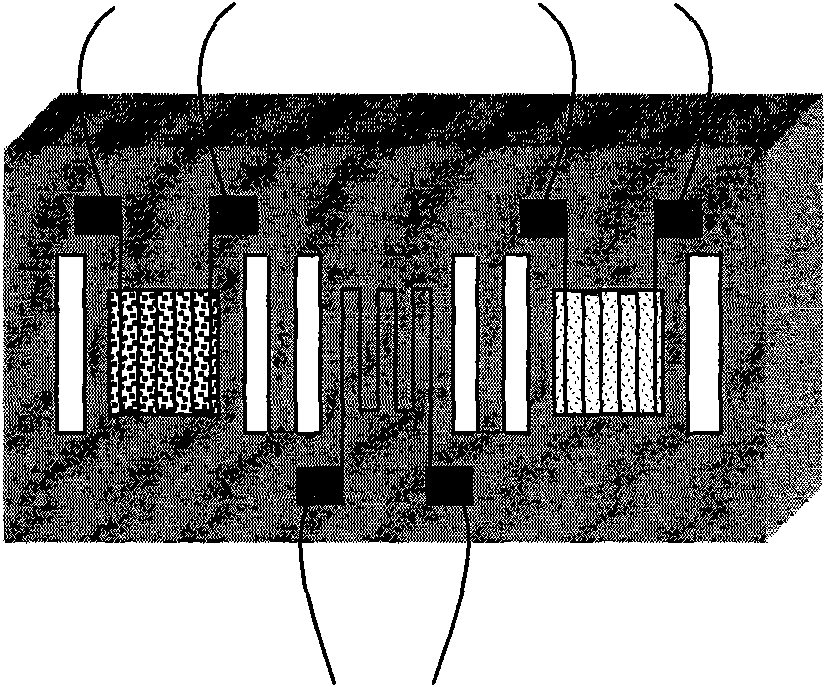

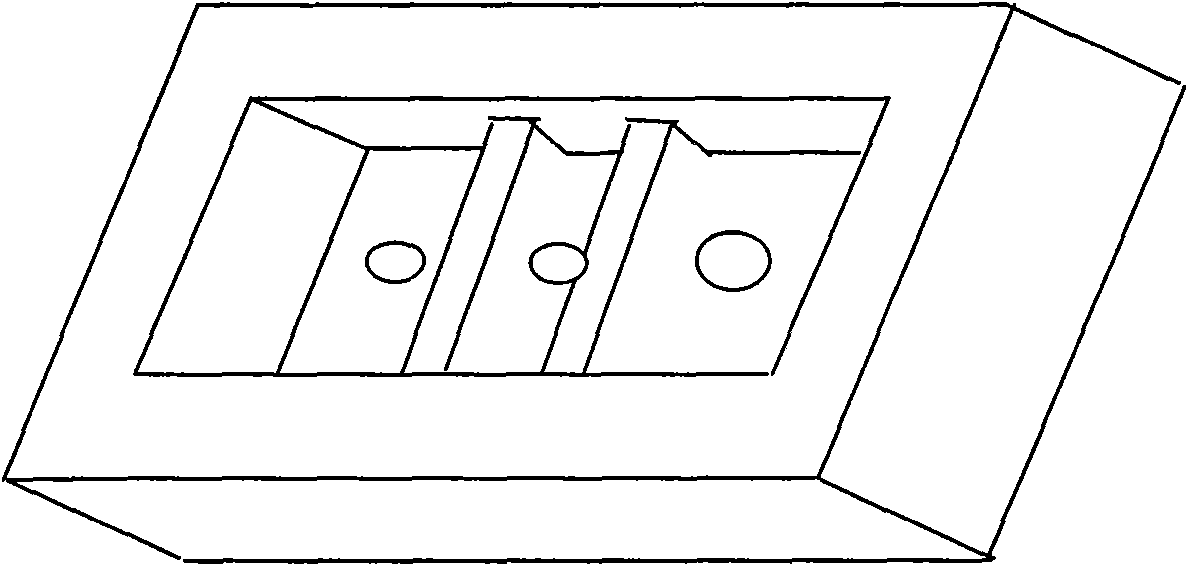

Manufacturing method of three-leg catalytic micro gas sensor with temperature modulation

InactiveCN102103106ANot easy to integrateDecorative surface effectsMaterial resistanceEtchingSilicon oxide

The invention provides a micromachining and manufacturing method of a gas sensor with temperature modulation. After a single crystal silicon wafer is subjected to dry oxidation by adopting an IC (Integrated Circuit) process, a silicon nitride dielectric isolation layer and an aluminum oxide dielectric isolation layer are deposited, and a platinum film is deposited by utilizing a sputtering process; patterns are copied on the other side of the single crystal silicon wafer, and a silicon cup is micromachined; a mask is subjected to photoetching and the platinum film is etched by using ion beams to form a gas sensitive unit, a gas compensation unit and a temperature sensitive unit resistor; the mask is subjected to photoetching, and an aluminum oxide layer, a silicon nitride layer, a silicon oxide layer and single crystal silicon are subjected to wet etching in sequence to form a plurality of three-leg chip units; internal leads are welded; aluminum oxide catalytic carrier slurry is coated and sintered; and a catalyst and a desensitizer are coated and subjected to thermal treatment at high temperature to form a gas sensitive chip. The method settles the problems which are present in a catalytic gas sensor owing to manual operation, realizes the integration of a plurality of sensitive units of the sensor, raises the consistency, the reliability and the detection precision of the sensor, and lowers the power consumption.

Owner:NO 49 INST CHINESE ELECTRONICS SCI & TECH GRP

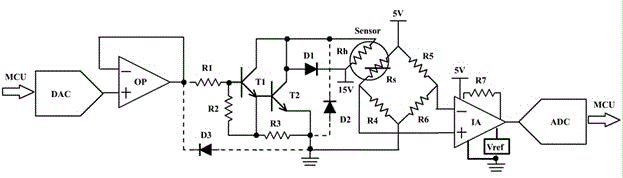

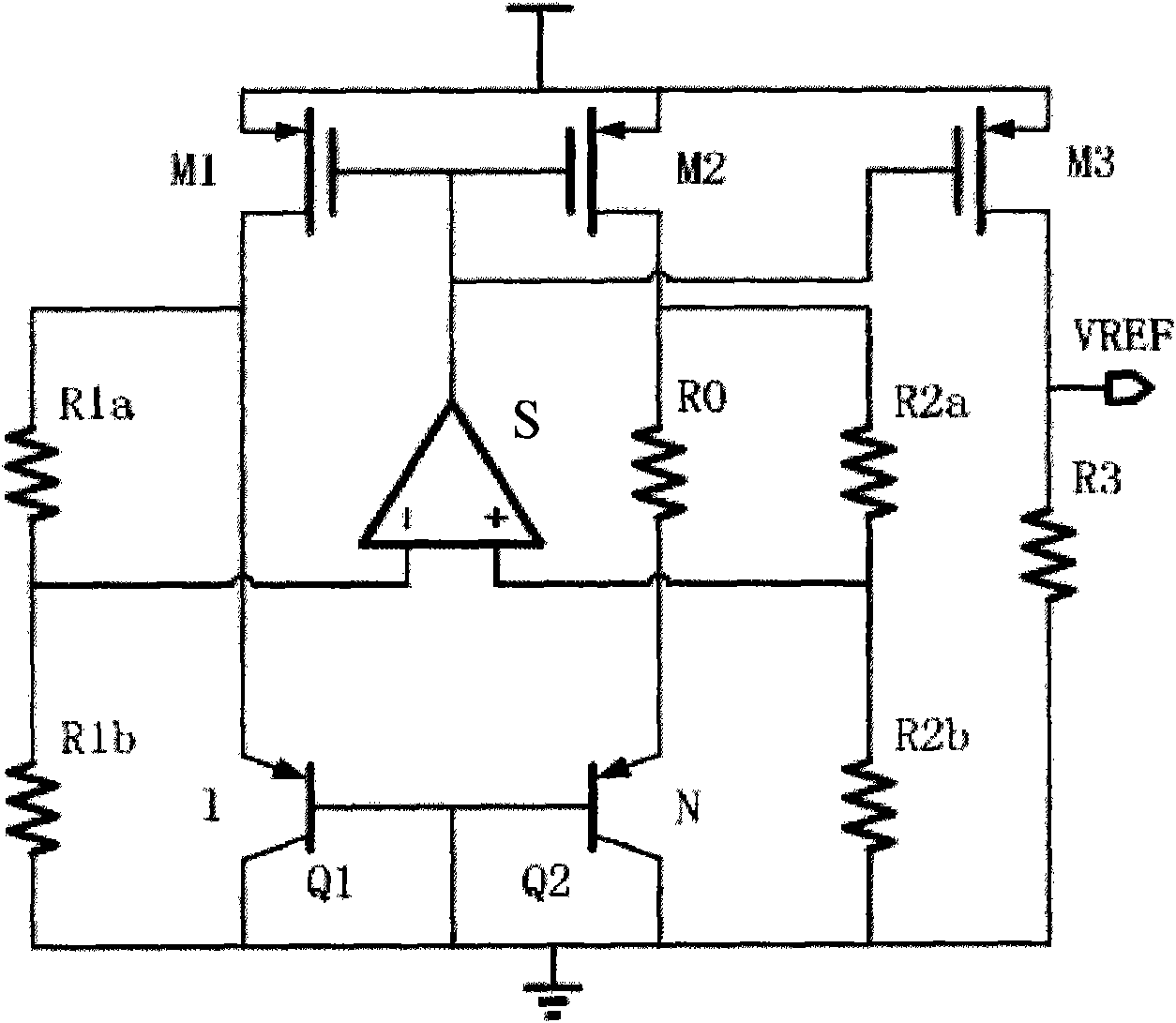

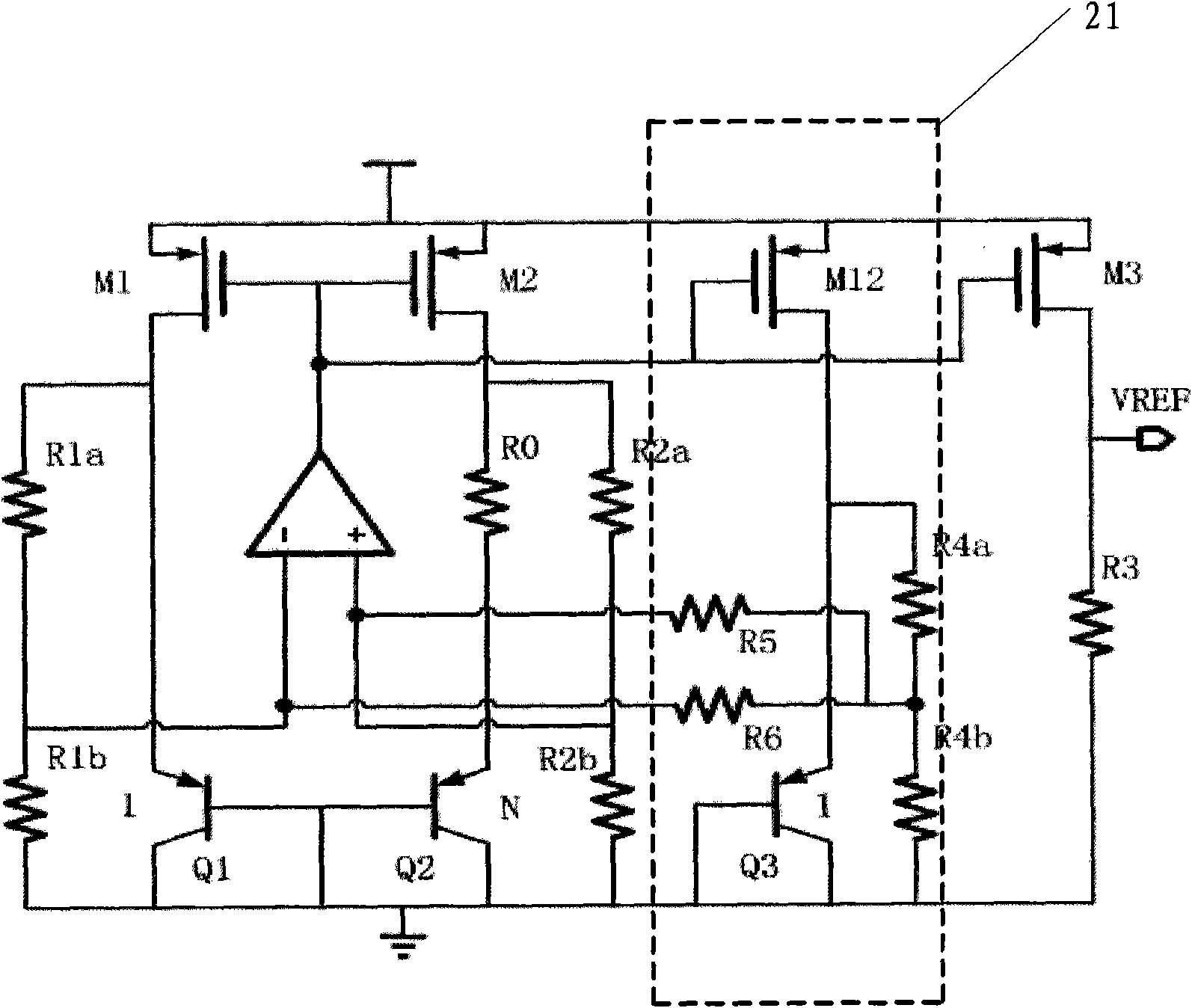

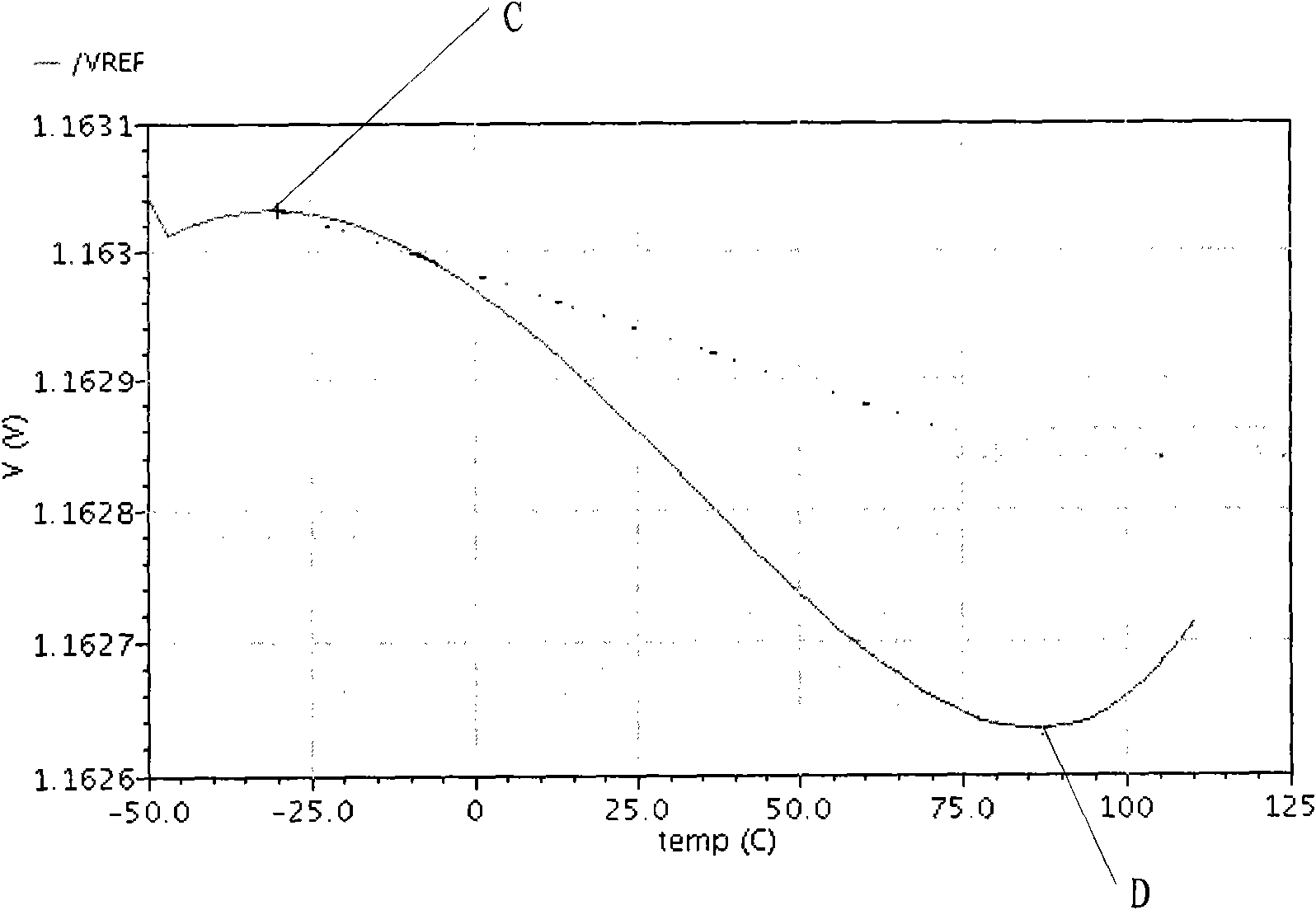

CMOS (Complementary Metal-Oxide Semiconductor) band-gap reference voltage generation circuit

InactiveCN101840243AImprove stabilityElimination of Second Order Temperature Modulation EffectsElectric variable regulationElectrical resistance and conductanceCMOS

The invention provides a CMOS (Complementary Metal-Oxide Semiconductor) band-gap reference voltage generation circuit for output of the reference voltage, comprising a first CMOS, a second CMOS, a third CMOS, a first triode, a second triode, an amplifier and a fourth CMOS. The base electrode of the fourth CMOS is connected with the output end of the amplifier, the source electrode of the fourth CMOS is connected with the source electrodes of the first CMOS, the second CMOS and the third CMOS, the base electrode and the connecting electrode of the third triode are grounded. The emitting electrode of the third triode is connected with the drain electrode of the fourth CMOS. The CMOS band-gap reference voltage generation circuit, by adding a branch and a plurality of resistors, eliminates the second-order temperature modulation effect of the triode in the original circuit effectively and improves the stability of the band-gap reference voltage generation circuit.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

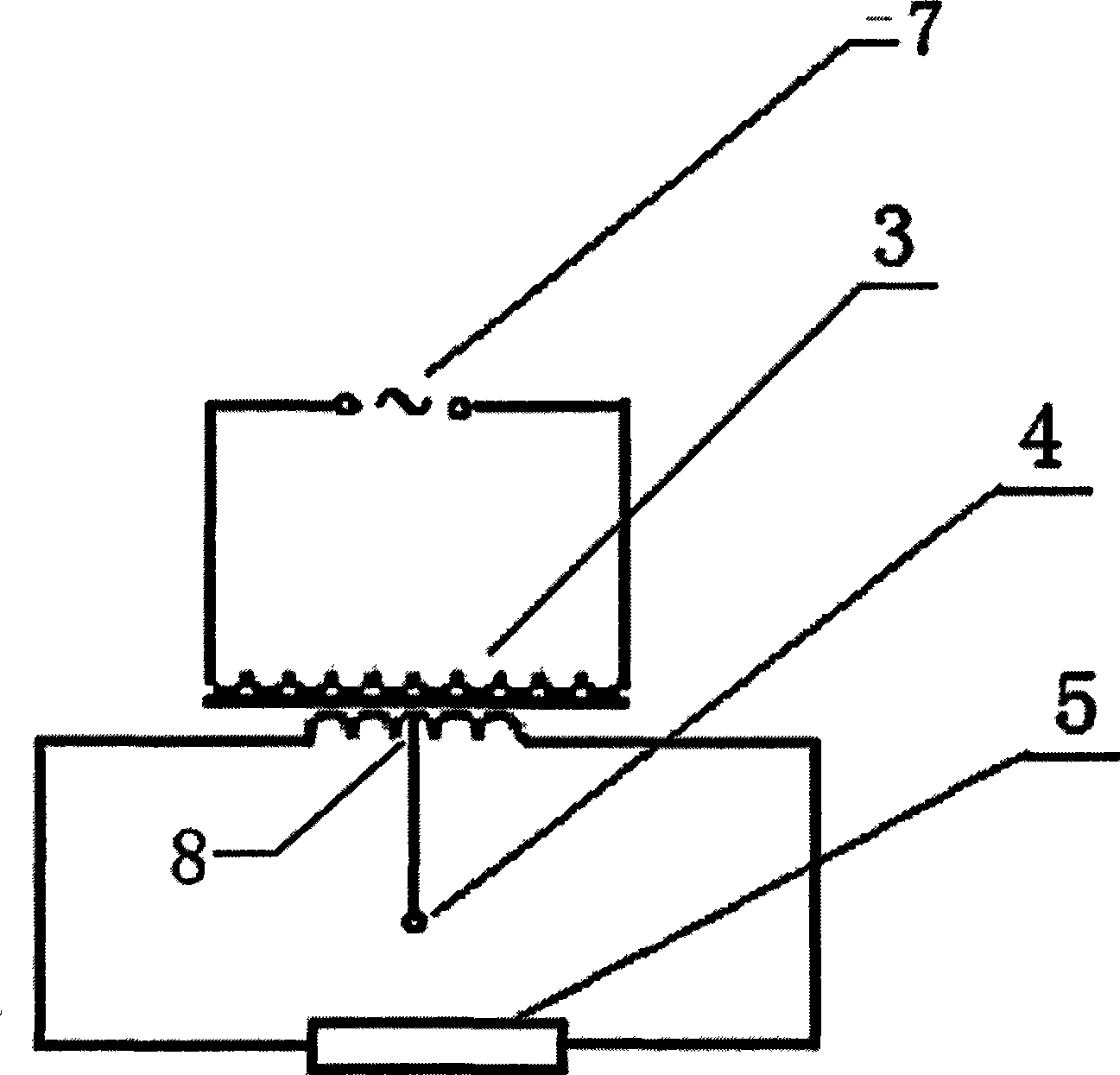

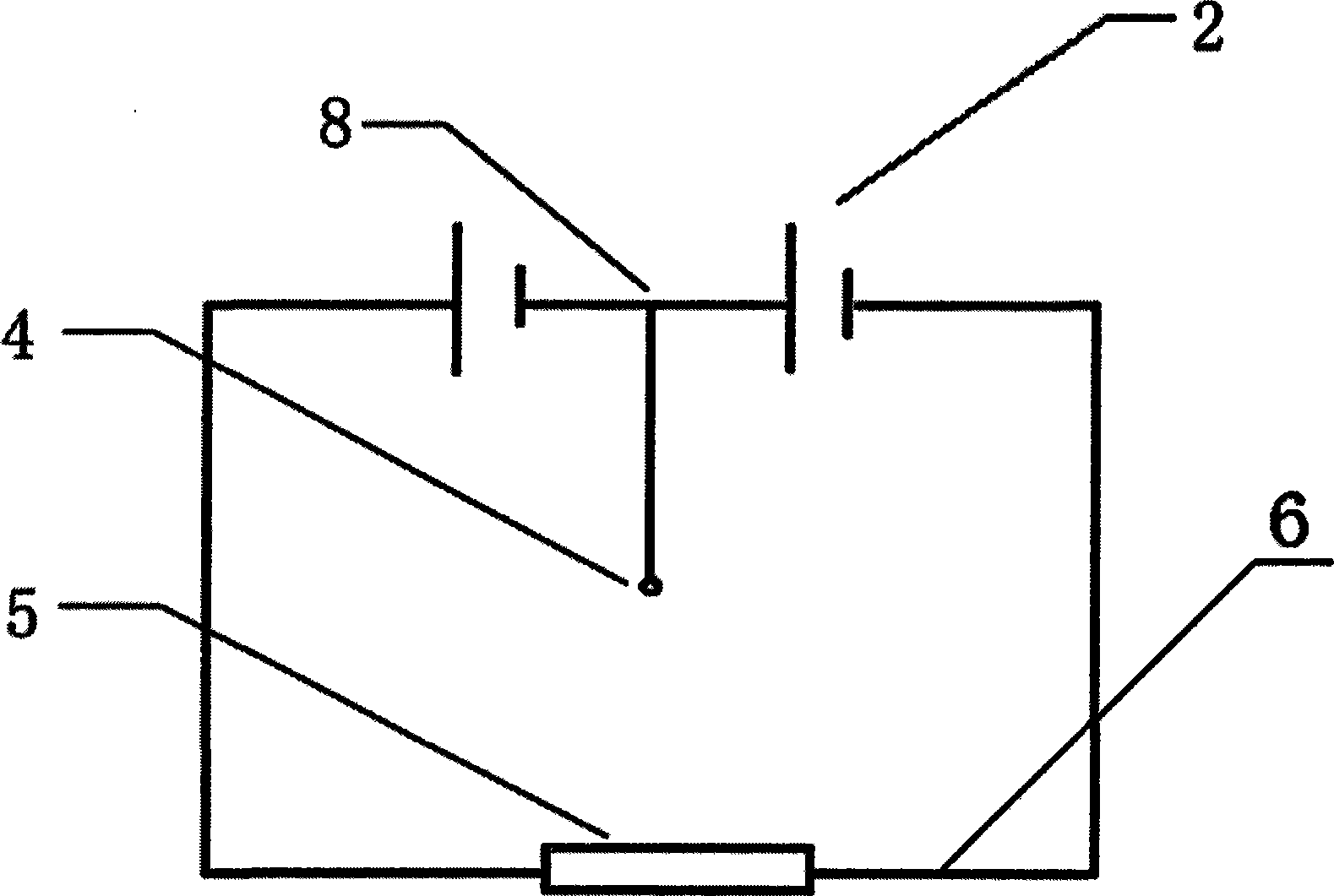

Temperature modulating electro-chemical electrode and its heating method

InactiveCN101368929ASimple structureEliminate distractionsMaterial electrochemical variablesTransformerEngineering

The invention provides a temperature modulation electrochemical electrode and a heating method thereof; the electrode is composed of a power supply which can be an AC power or a DC power supply, a transformer, a measurement connector, a working electrode and a metal wire; the working electrode is processed with rapid temperature modulation through AC or DC; the temperature modulation electrochemical electrode keeps the advantages of the original thermal electrode in quickly and easily controlling the electrode temperature, improving the mass transfer rate of the system, increasing the detection sensitivity, lowering the detection limit and removing the pollutants on the electrode surface. Moreover, compared with the symmetrical structural design of the original thermal electrode, the invention simplifies the structure and can effectively eliminate the interference on electrochemical detection caused by the heating of current, so that the heating and the detection can be carried out atthe same time to achieve a better application effect; besides, the invention provides a plurality of practical and new thermal electrode materials, and has a wider application range.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com