Growth method for improving quality of aluminum nitride film crystal by temperature modulation

A thin-film crystal and growth method technology, applied in crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of low lateral growth rate, large consumption of reactant, polycrystalline growth of epitaxial layer, etc. The method is simple and easy effect of reducing dislocation density and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

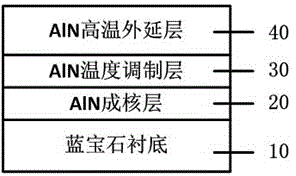

[0015] A growth method for improving the crystal quality of an aluminum nitride thin film by using temperature modulation, comprising the following steps:

[0016] (1) Use metal-organic chemical vapor deposition (MOCVD) equipment, the substrate is a (0001) surface sapphire substrate 10, and hydrogen gas is introduced as a carrier gas, and the substrate is placed in a metal-organic chemical vapor deposition system and heated at a high temperature of 1050 ℃, high pressure 100torr and heating and baking for 3min to clean the surface of the substrate;

[0017] (2) Introduce hydrogen as a carrier gas, reduce the temperature to 950°C, and the pressure is 50torr. Introduce ammonia gas with a flow rate of 300 sccm, and simultaneously inject trimethylaluminum with a flow rate of 100 sccm. Epitaxial growth on the substrate at low temperature Aluminum nitride nucleation layer 20; the thickness of the aluminum nitride nucleation layer is 20nm;

[0018] (3) Introduce hydrogen as a carrier...

Embodiment 2

[0021] A growth method for improving the crystal quality of an aluminum nitride thin film by using temperature modulation, comprising the following steps:

[0022] (1) Use metal-organic chemical vapor deposition (MOCVD) equipment, the substrate is a (0001) sapphire substrate 10, and hydrogen gas is introduced as a carrier gas, and the substrate is placed in a metal-organic chemical vapor deposition system and heated at a high temperature of 1500 ℃, high pressure 150torr, heating and baking for 4min to clean the surface of the substrate;

[0023] (2) Introduce hydrogen as a carrier gas, reduce the temperature to 900°C, and the pressure is 75 torr. Introduce ammonia gas with a flow rate of 600 sccm, and simultaneously inject trimethylaluminum with a flow rate of 125 sccm. Epitaxial growth on the substrate at low temperature Aluminum nitride nucleation layer 20; the thickness of the aluminum nitride nucleation layer is 25nm;

[0024] (3) Introduce hydrogen as a carrier gas, keep...

Embodiment 3

[0027] A growth method that uses temperature modulation to improve the crystal quality of aluminum nitride films (such as figure 1 shown), including the following steps:

[0028] (1) Metal-organic chemical vapor deposition (MOCVD) equipment is used, the substrate is a (0001) sapphire substrate 10, hydrogen is introduced as a carrier gas, the substrate is placed in a metal-organic chemical vapor deposition system, and heated at a high temperature of 1100 ℃, high pressure 200torr heating and baking for 5min, clean the substrate surface;

[0029] (2) Introduce hydrogen as a carrier gas, reduce the temperature to 950°C, and the pressure is 100 torr. Introduce ammonia gas with a flow rate of 1000 sccm, and simultaneously inject trimethylaluminum with a flow rate of 150 sccm. Epitaxial growth on the substrate at low temperature Aluminum nitride nucleation layer 20; the thickness of the aluminum nitride nucleation layer is 30nm;

[0030] (3) Introduce hydrogen as a carrier gas, kee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com