Epitaxial structure and growing method for improving gallium nitride (GaN) based light-emitting diode (LED) lighting efficiency

A technology of epitaxial structure and luminous efficiency, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of reducing the composition of In quantum dots, deteriorating the quality of quantum well crystals, reducing the luminous efficiency of devices, etc., to eliminate stress and crystal defects, The effect of improving internal quantum efficiency and luminous efficiency and improving crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below: the present embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following implementation example.

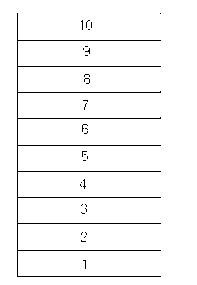

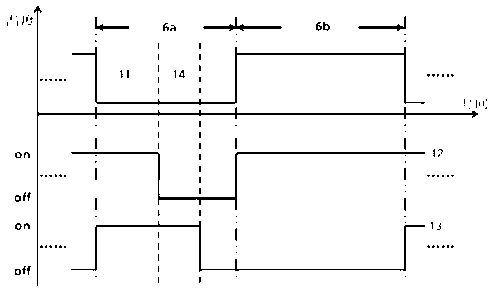

[0023] Such as figure 1 The LED epitaxial structure shown, from bottom to top, includes: substrate 1, low-temperature GaN buffer layer 2, GaN undoped layer 3, N-type GaN layer 4, multi-quantum well structure MQW5, multi-quantum well active layer 6. A low-temperature P-type GaN layer 7 , a P-type AlGaN layer 8 , a high-temperature P-type GaN layer 9 , and a P-type contact layer 10 .

[0024] A method for growing an epitaxial structure for improving the luminous efficiency of the gallium nitride-based LED, comprising the following specific steps:

[0025] Step 1: Clean the substrate 1 at a high temperature for 5-20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com