Patents

Literature

75 results about "Vapour phase epitaxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

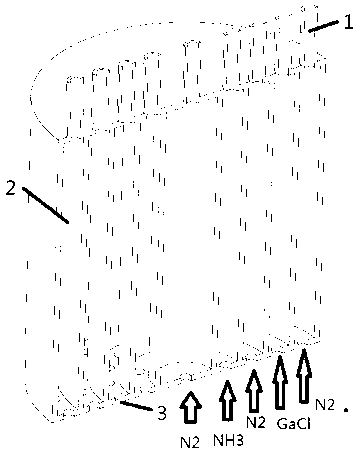

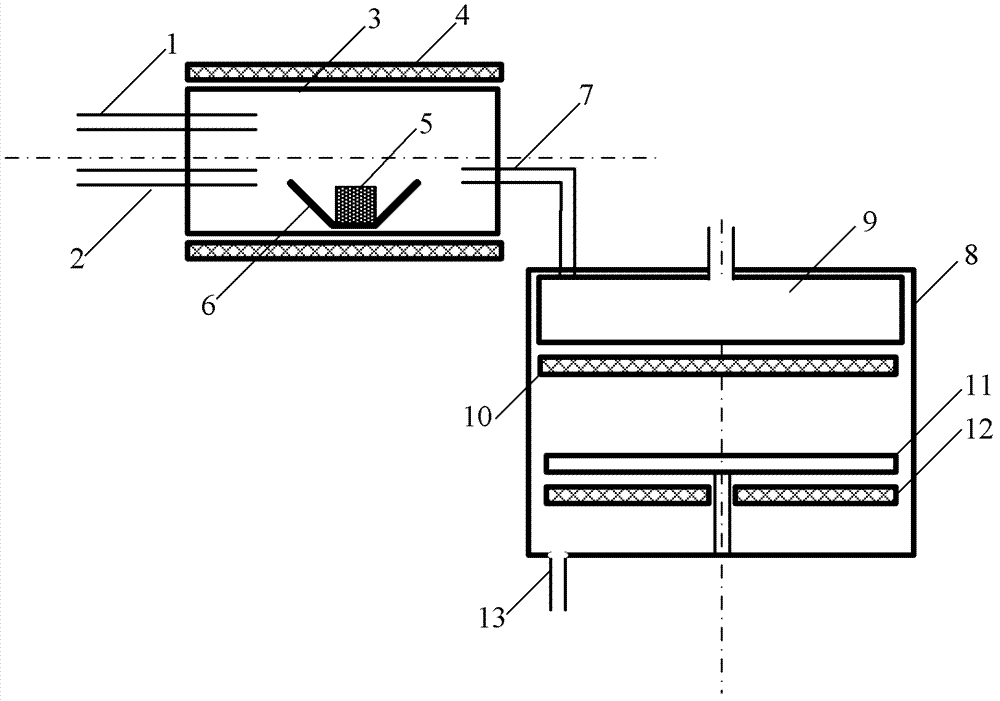

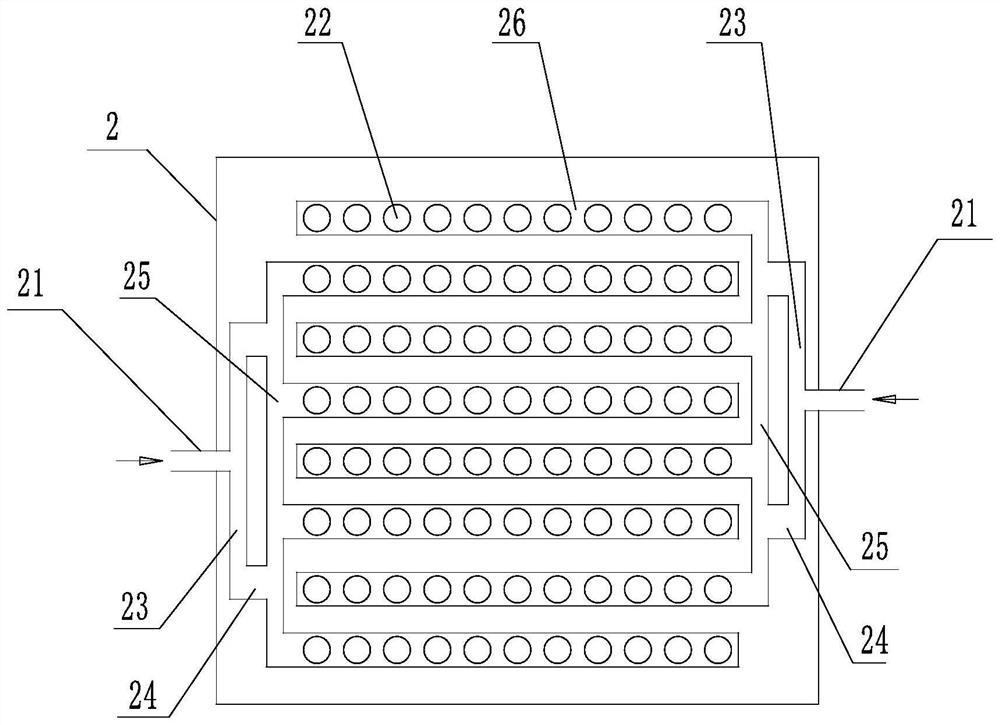

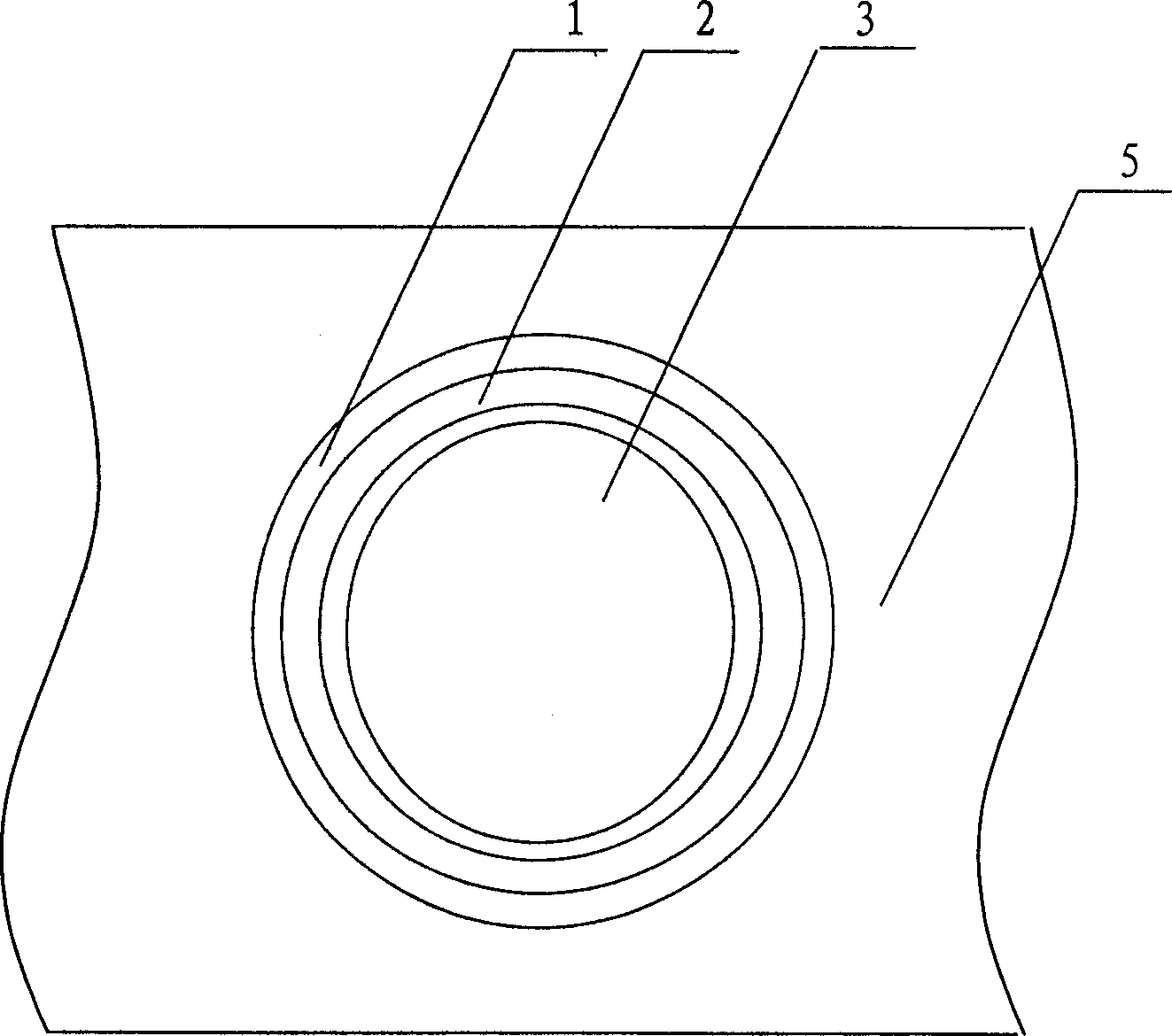

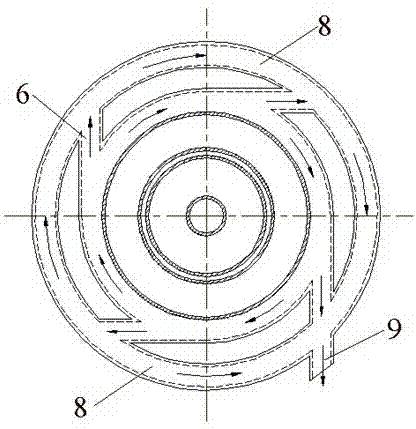

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

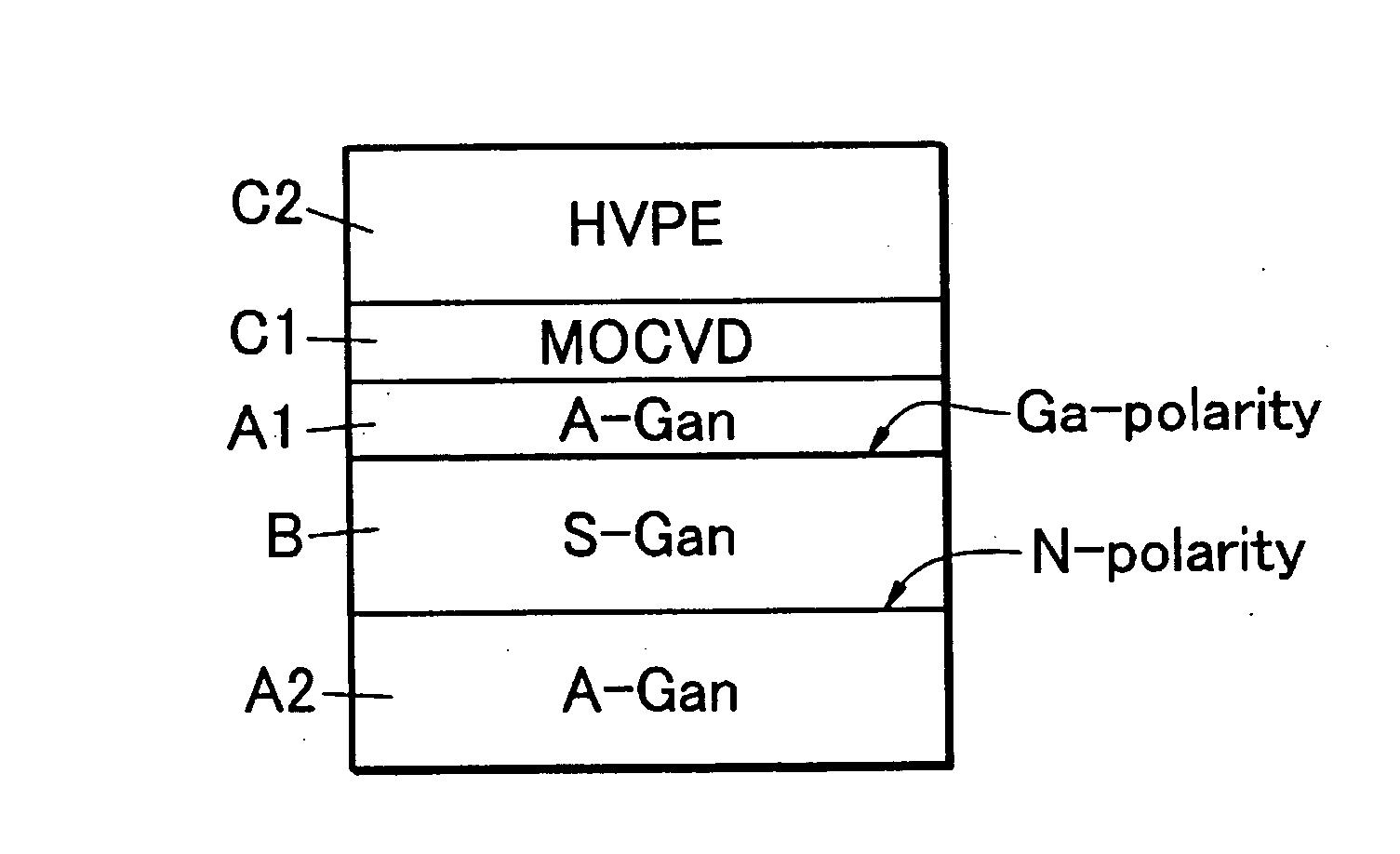

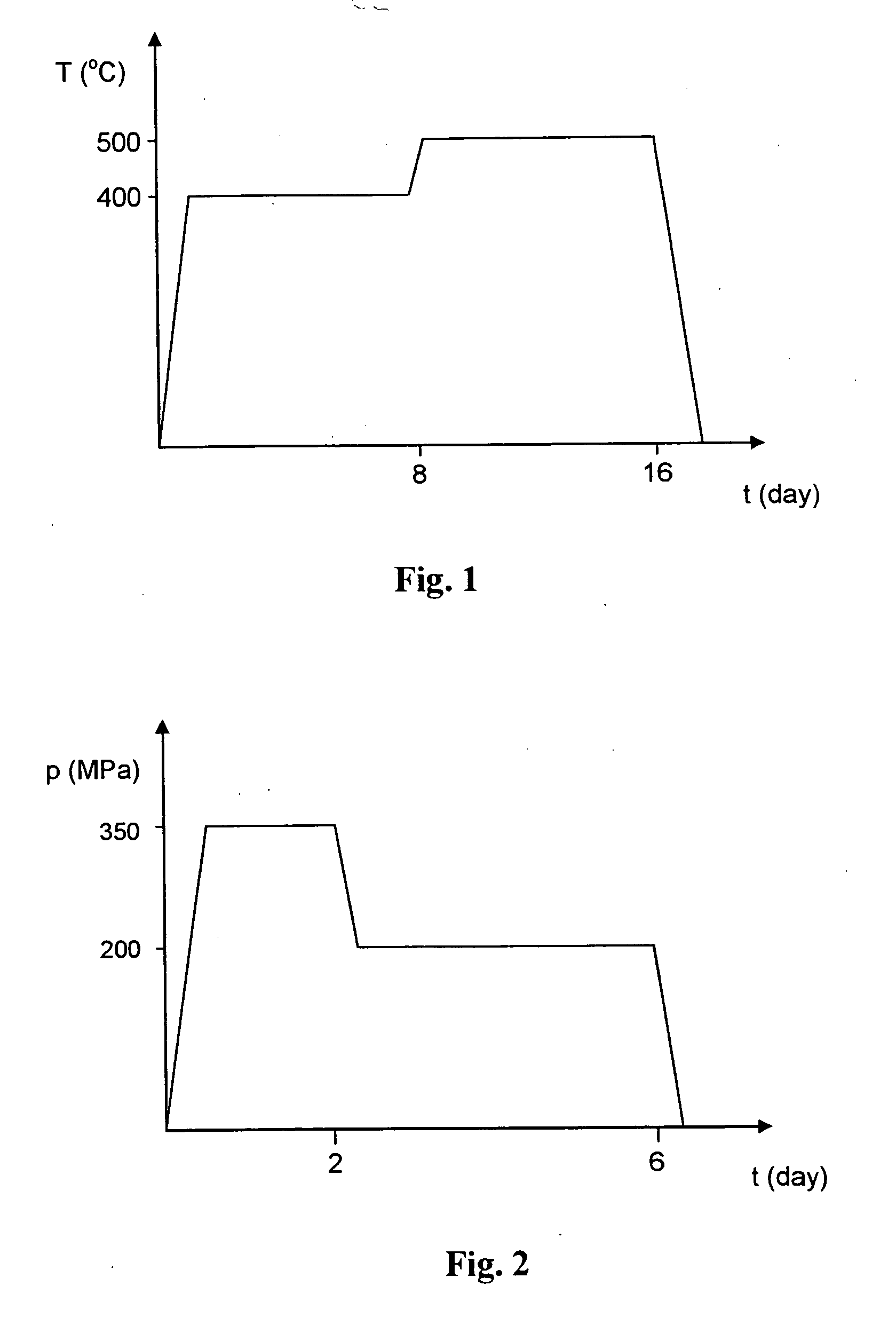

Template type substrate and a method of preparing the same

ActiveUS20060057749A1Improve surface propertiesImprove crystal qualityPolycrystalline material growthSemiconductor/solid-state device manufacturingMOSFETVapour phase epitaxy

The template type substrate is used for opto-electric or electrical devices and comprises A) a layer of bulk mono-crystal nitride containing at least one element of alkali metals (Group I, IUPAC 1989) and B) a layer of nitride grown by means of vapor phase epitaxy growth wherein the layer A) and the layer B) are combined at non N-polar face of the layer A) and N-polar face of the layer B). Therefore, the template type substrate has a good dislocation density and a good value of FWHM of the X-ray rocking curve from (0002) plane less than 80, so that the resulting template type substrate is very useful for the epitaxy substrate from gaseous phase such as MOCVD, MBE and HVPE, resulting in possibility of making good opto-electric devices such as Laser Diode and large-output LED and good electric devices such as MOSFET.

Owner:AMMONO SP Z O O (PL) +1

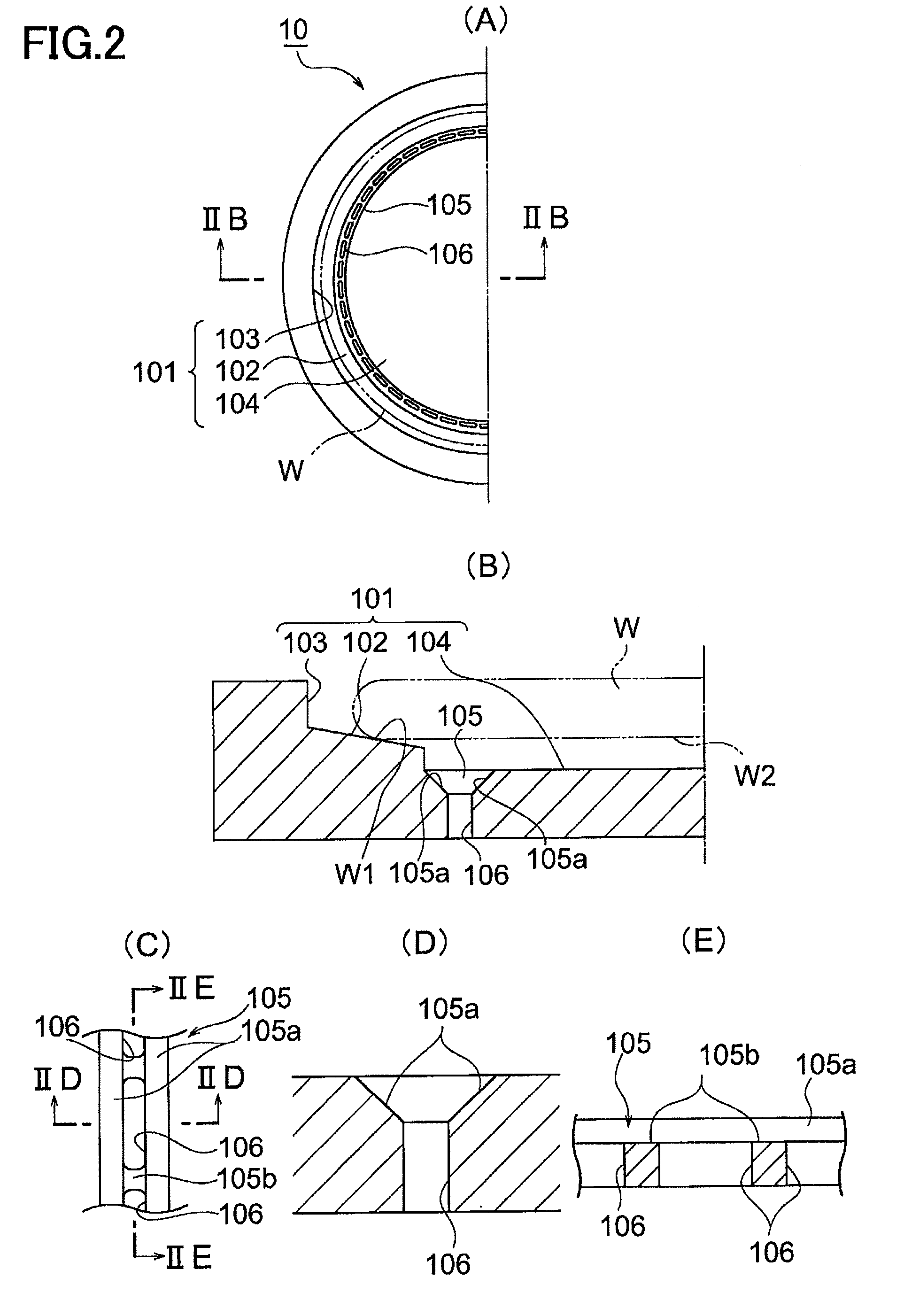

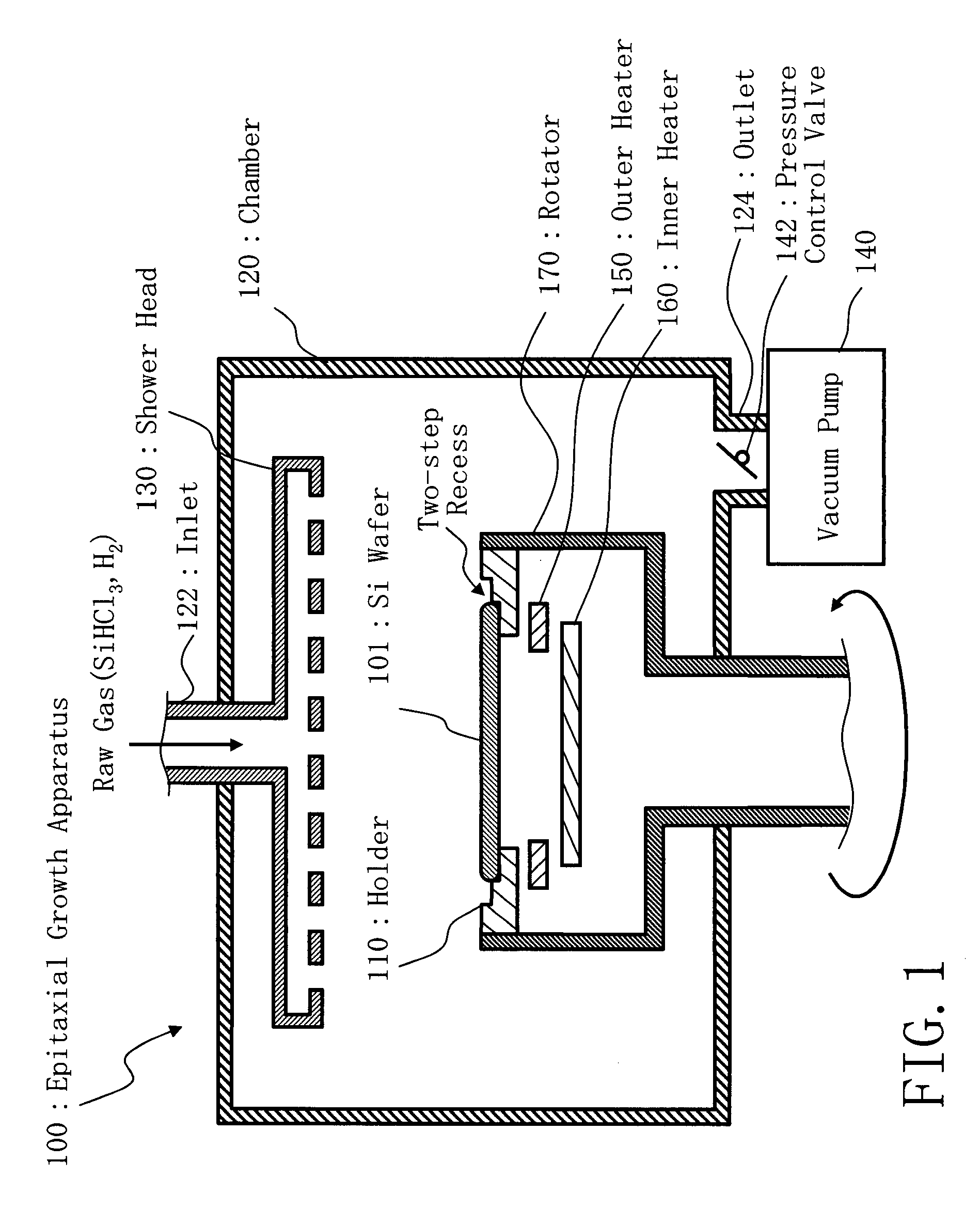

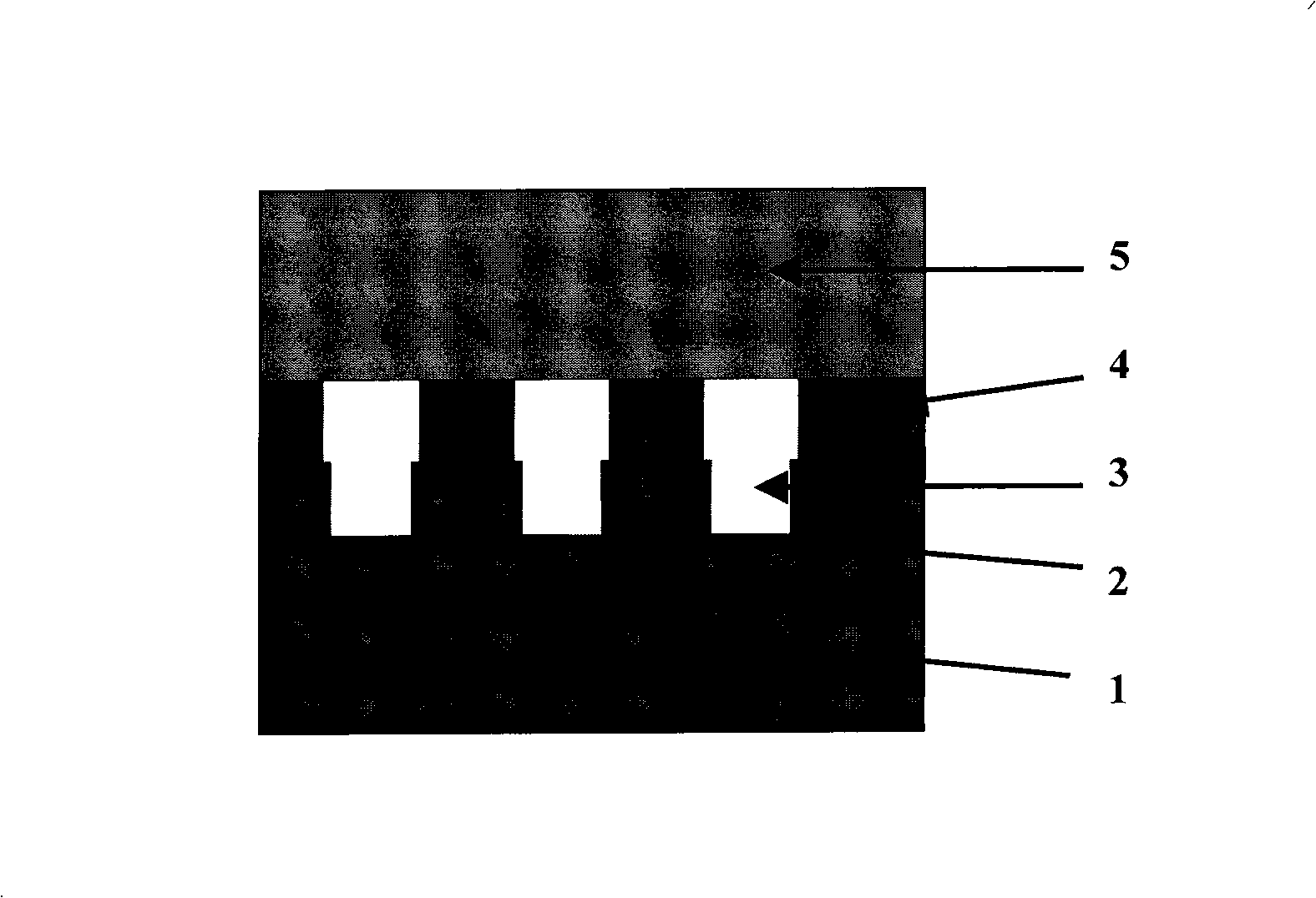

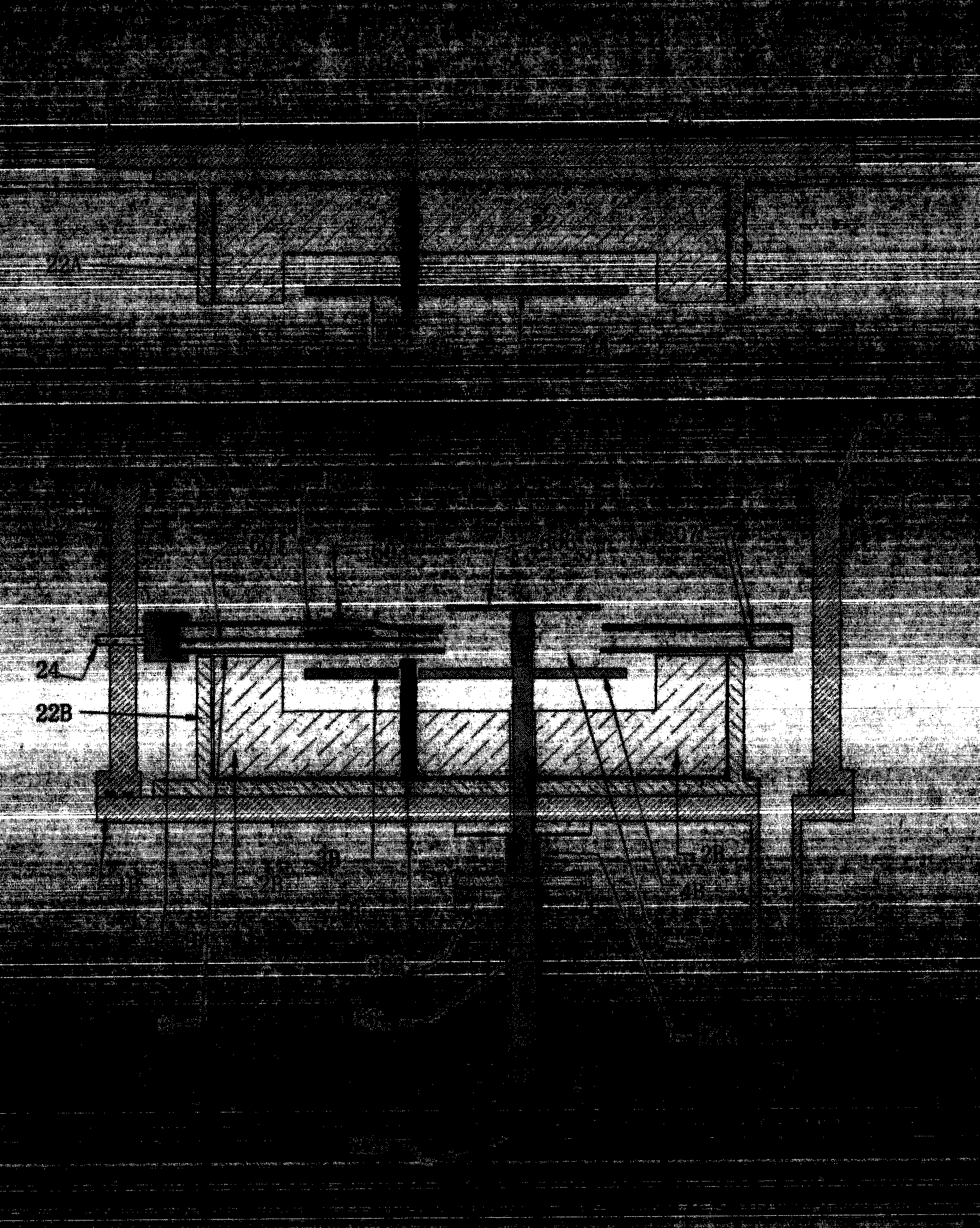

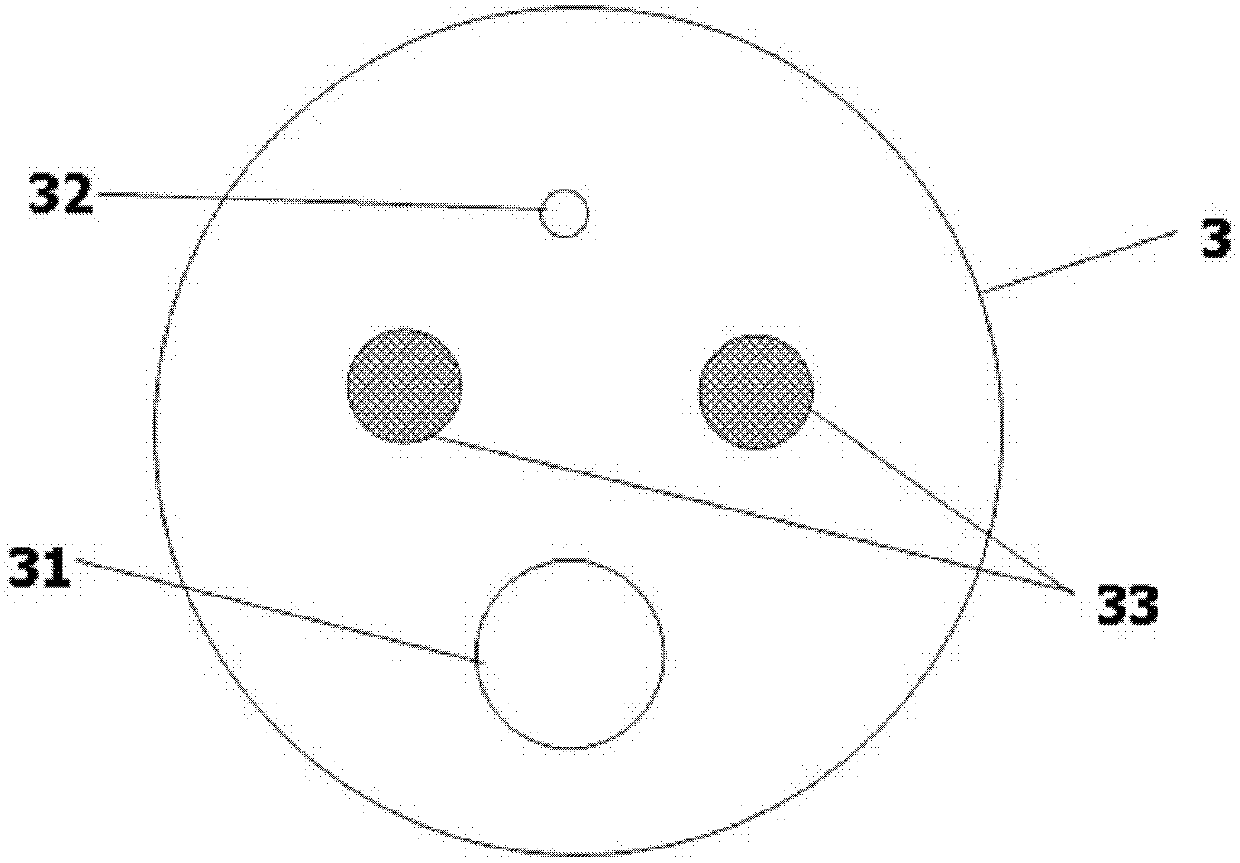

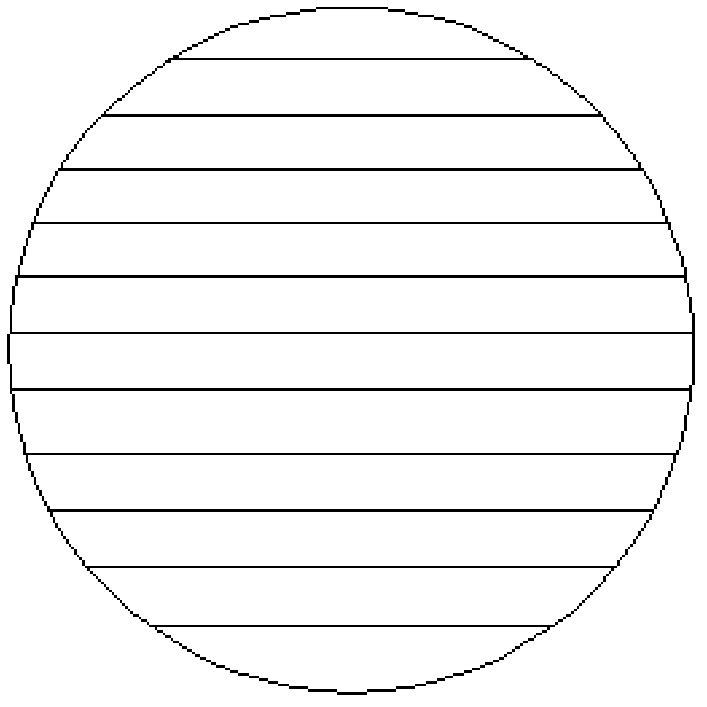

Susceptor for vapor phase epitaxial growth device

ActiveUS20090235867A1Prevent slippingSemiconductor/solid-state device manufacturingFrom chemically reactive gasesVapour phase epitaxySusceptor

There is provided a susceptor for a vapor phase epitaxial growth device, by which skidding at the time of loading a silicon wafer is prevented and the wafer can be loaded at a fixed position of the susceptor: wherein a ring-shaped groove having sloping planes widening toward a surface of the susceptor are formed on the outermost circumference of the bottom surface; and gas release openings penetrating through to the back surface of the susceptor are formed, each having a sectional area of 2.0 to 3.0 mm2 and a ratio of all opening areas is 0.25 to 0.5% on the bottom surface.

Owner:SUMCO CORP +1

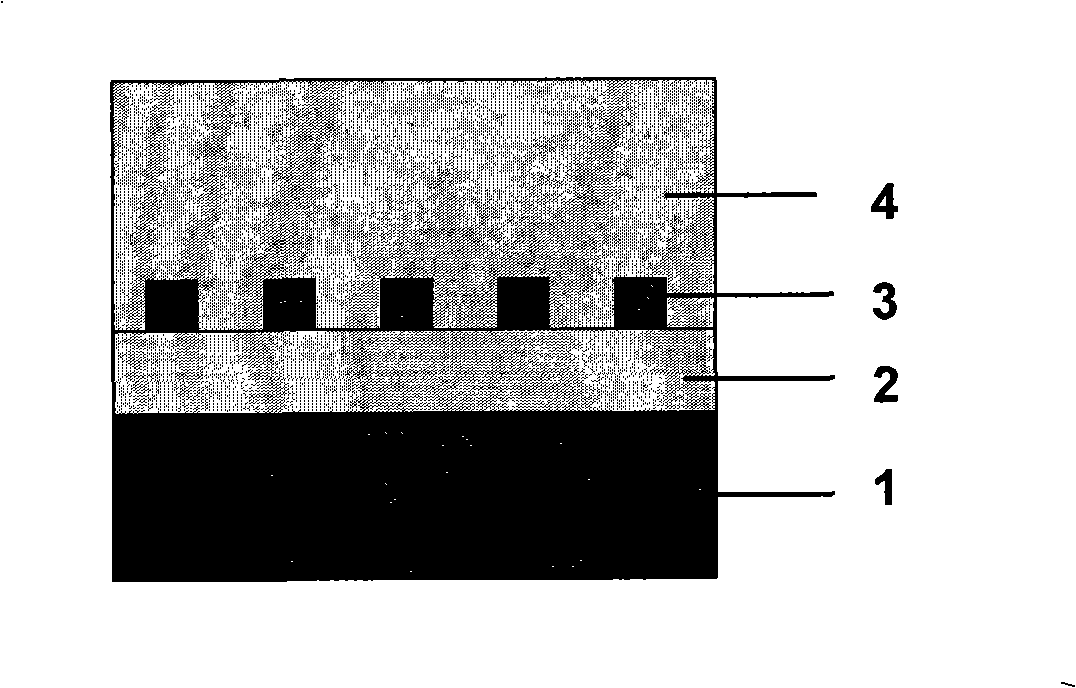

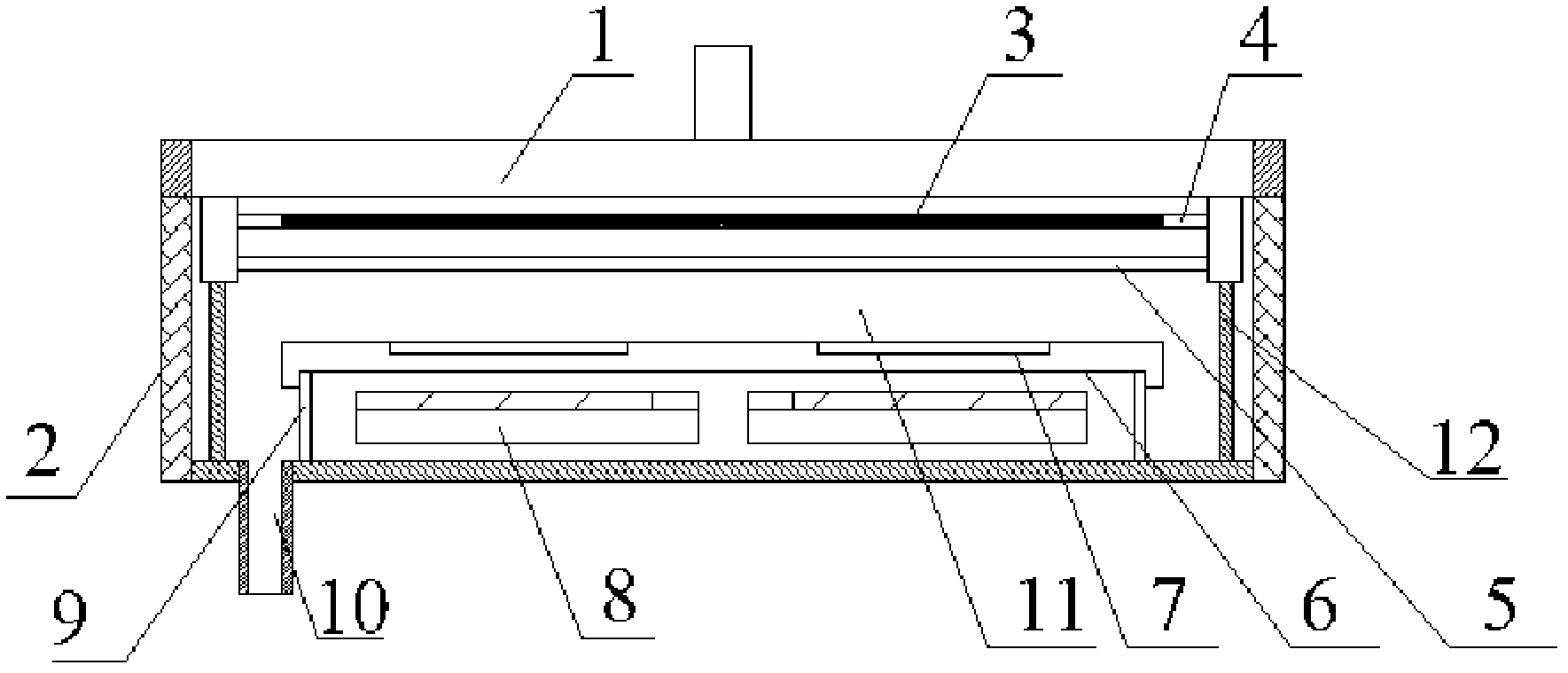

Thin film type thermoelectric converter and a measuring method

InactiveCN101515002AReduce the impact of measurement resultsThermoelectric device with peltier/seeback effectThermometers using electric/magnetic elementsMetrologyAlternating current

The invention discloses a thin film type thermoelectric converter and a measuring method, relating to the electricity metrology technology. The thin film type thermoelectric converter comprises an SiO2-Si3N4-SiO2 three-layer thin film sandwich structure taking a silicon chip as substrate and growing on the substrate by the method of low pressure chemical vapor phase epitaxy, thermocouples, heaters and a contact electrode; wherein, two heaters are arranged on both sides of a thermocouple side by side. In the converter of the invention, when measuring, alternating current and direct current respectively flow through the two heaters at the same time; temperature difference caused by AC and DC power is output on the thermocouples and AC power and DC power are directly compared to ensure that the changes of the ambient temperature and temperature gradient have greatly reduced effects on the measuring results.

Owner:NAT INST OF METROLOGY CHINA

Growth of SiO2 nanometer mask in gallium nitride film by HVPE method and method thereof

InactiveCN101320686AQuality improvementReduce dislocation densitySemiconductor/solid-state device manufacturingManufacturing technologyGas phase

The invention relates to a silicon dioxide nano particle dot matrix mask used in a GaN film of hydride gas phase epitaxial growth, and a preparation method thereof, characterized by that a SiO2 nano particle lattie is used as a mask for GaN transversely epitaxial over growth. A layer of metal Al is evaporated by electron beam on a GaN form board firstly. Porous anode alumina (AAO) is prepared by electrochemistry then. A layer of dielectric SiO2 layer is deposited then. AAO is removed by acid solutionor aqueous alkali. Therefore, dot matrix distribution of SiO2 nano particle is obtained on the GaN form board. After cleaning treatment, the form board as a substrate is put in a HVPE reaction chamber for GaN thick film growth. The invention simplifies the photo-etching mask manufacturing technology greatly, and reduces the size of the mask to nanometer level, while metal Al and SiO2 layer can be prepared through electron beam evaporation and sputtering method for batched production.

Owner:DAHOM FUJIAN ILLUMINATION TECH

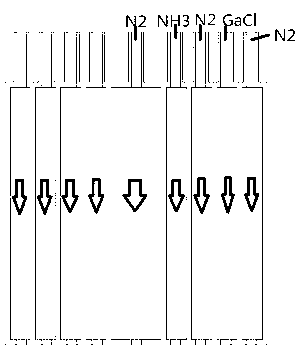

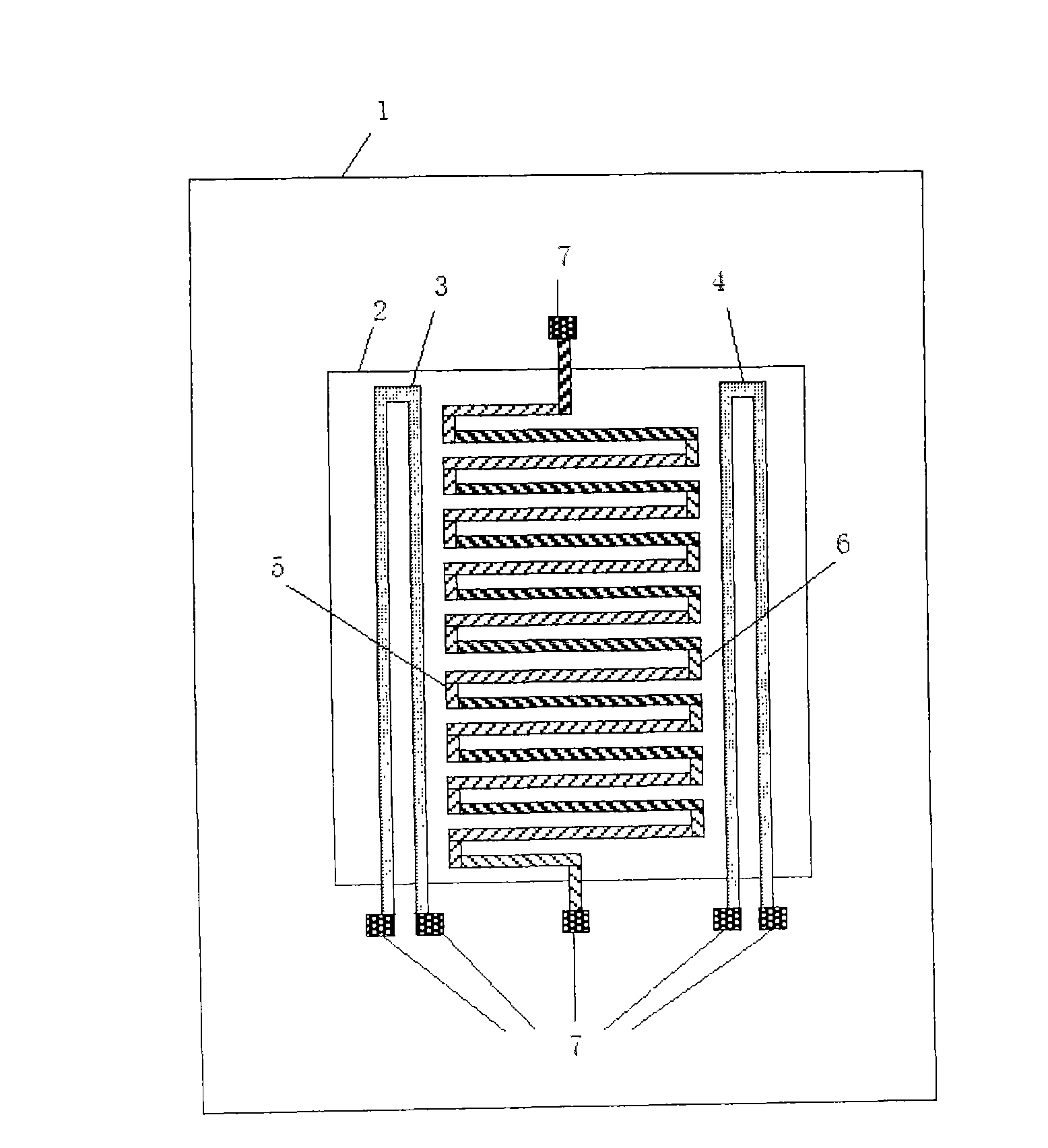

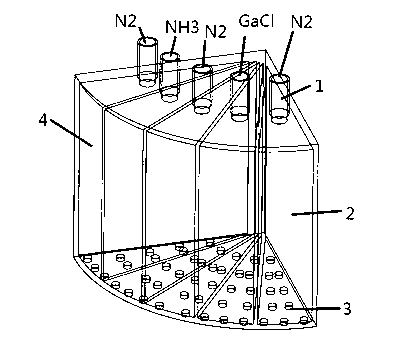

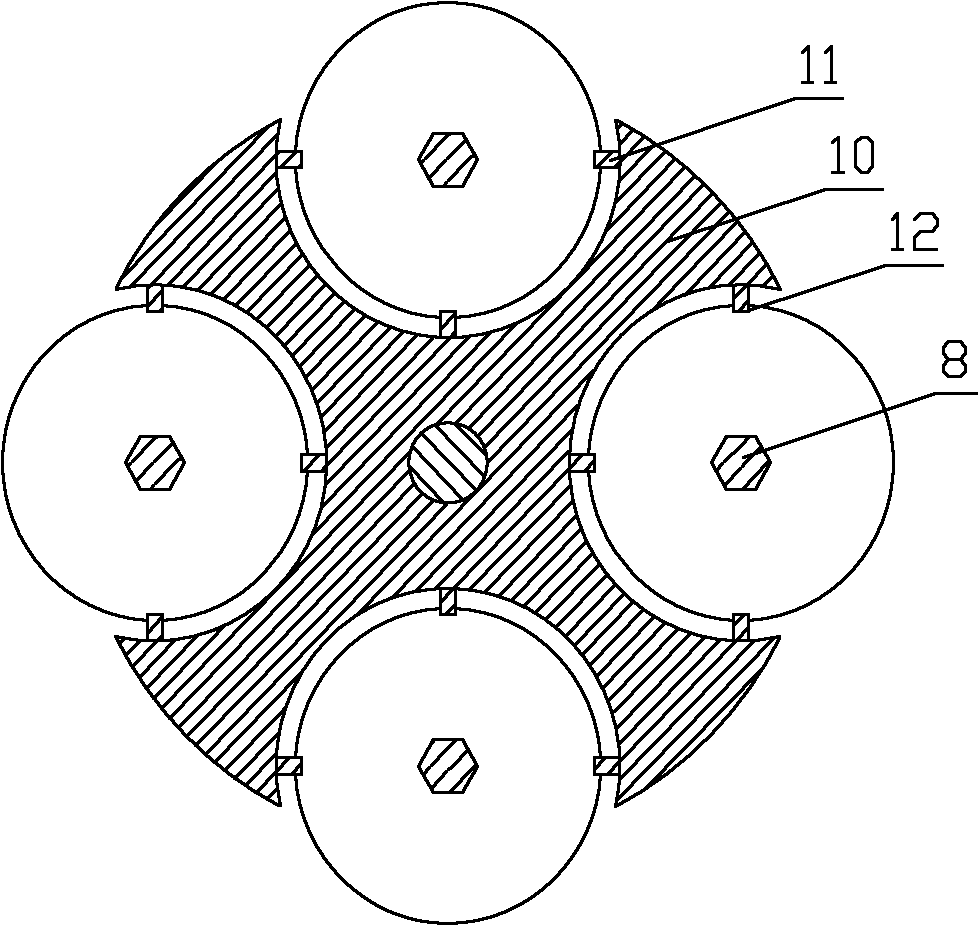

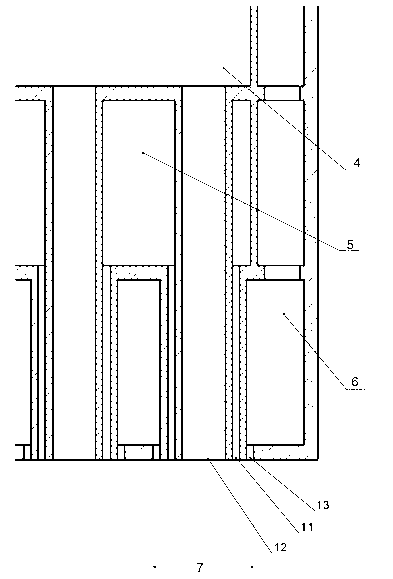

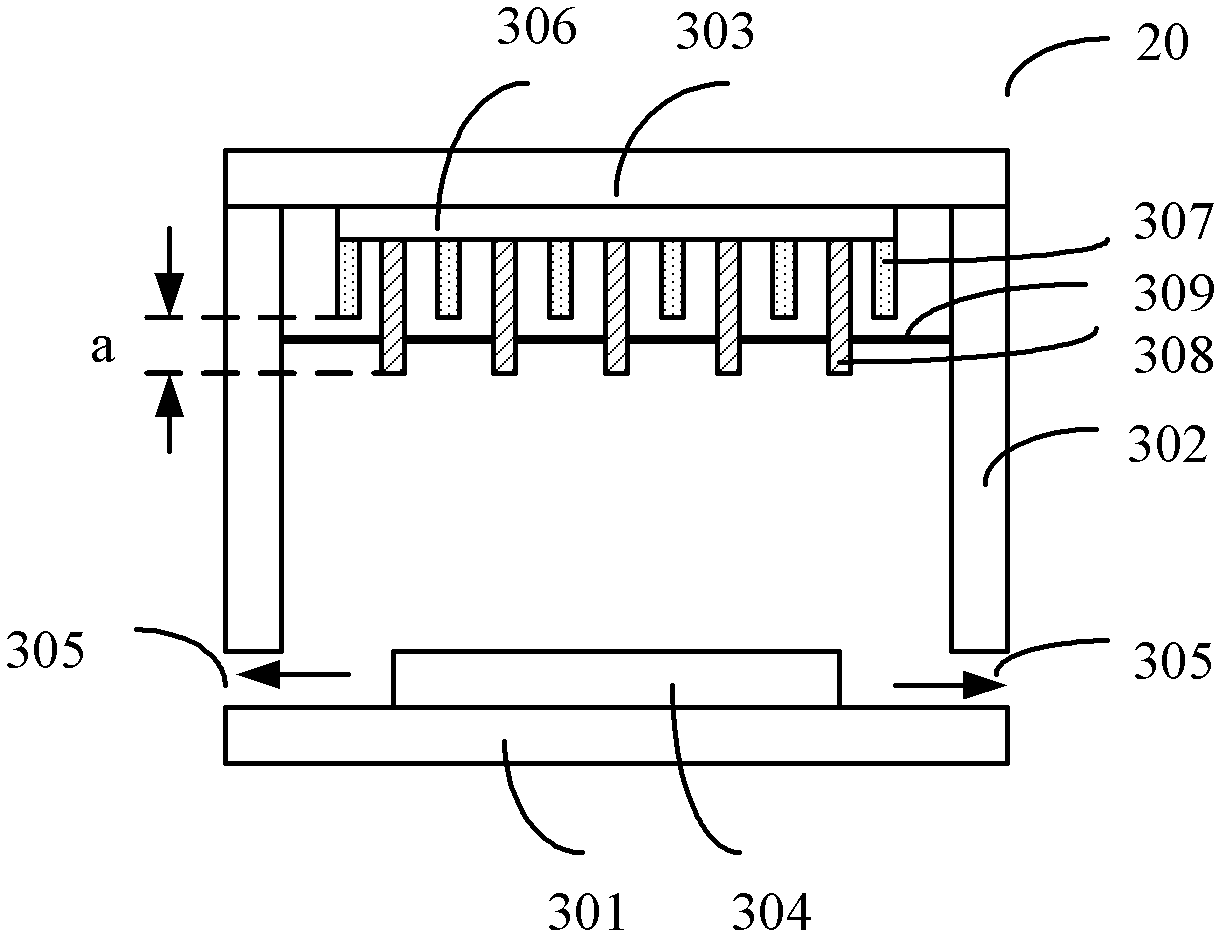

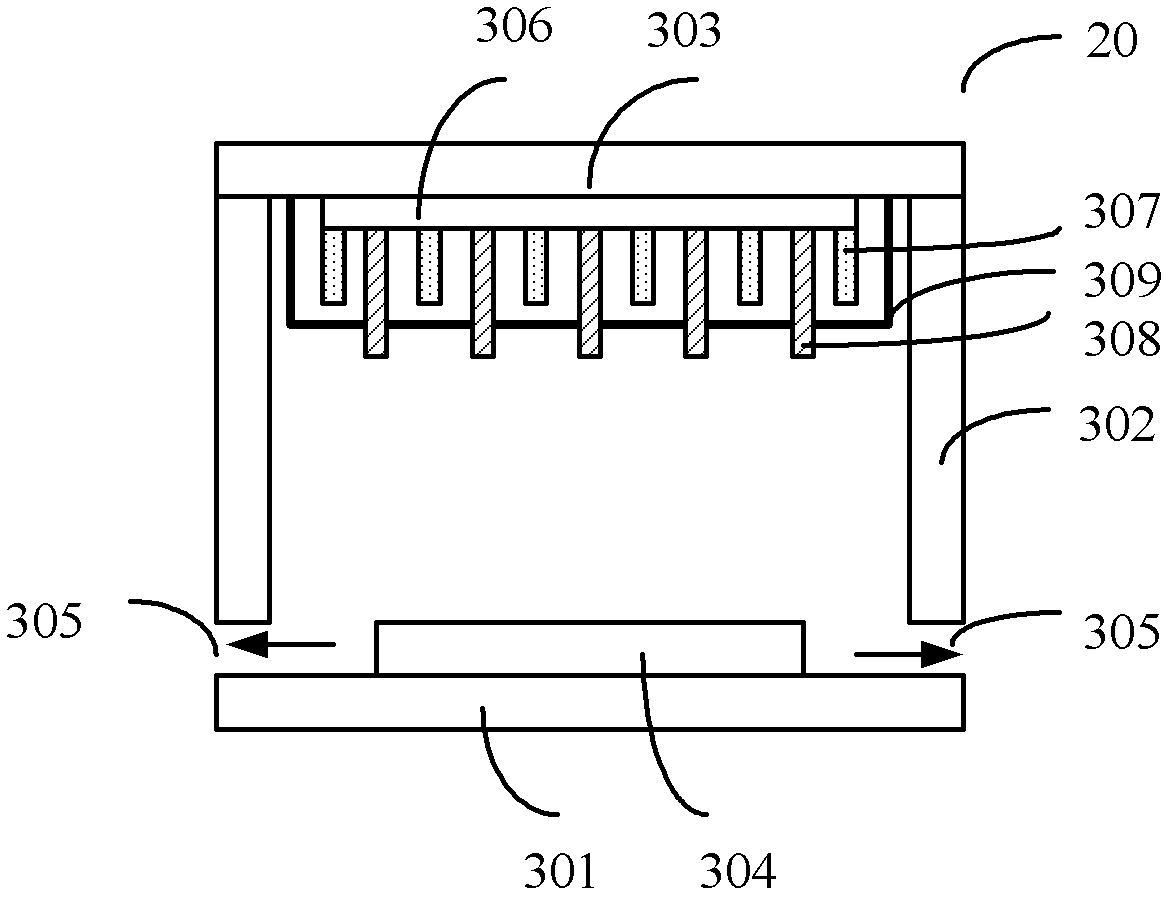

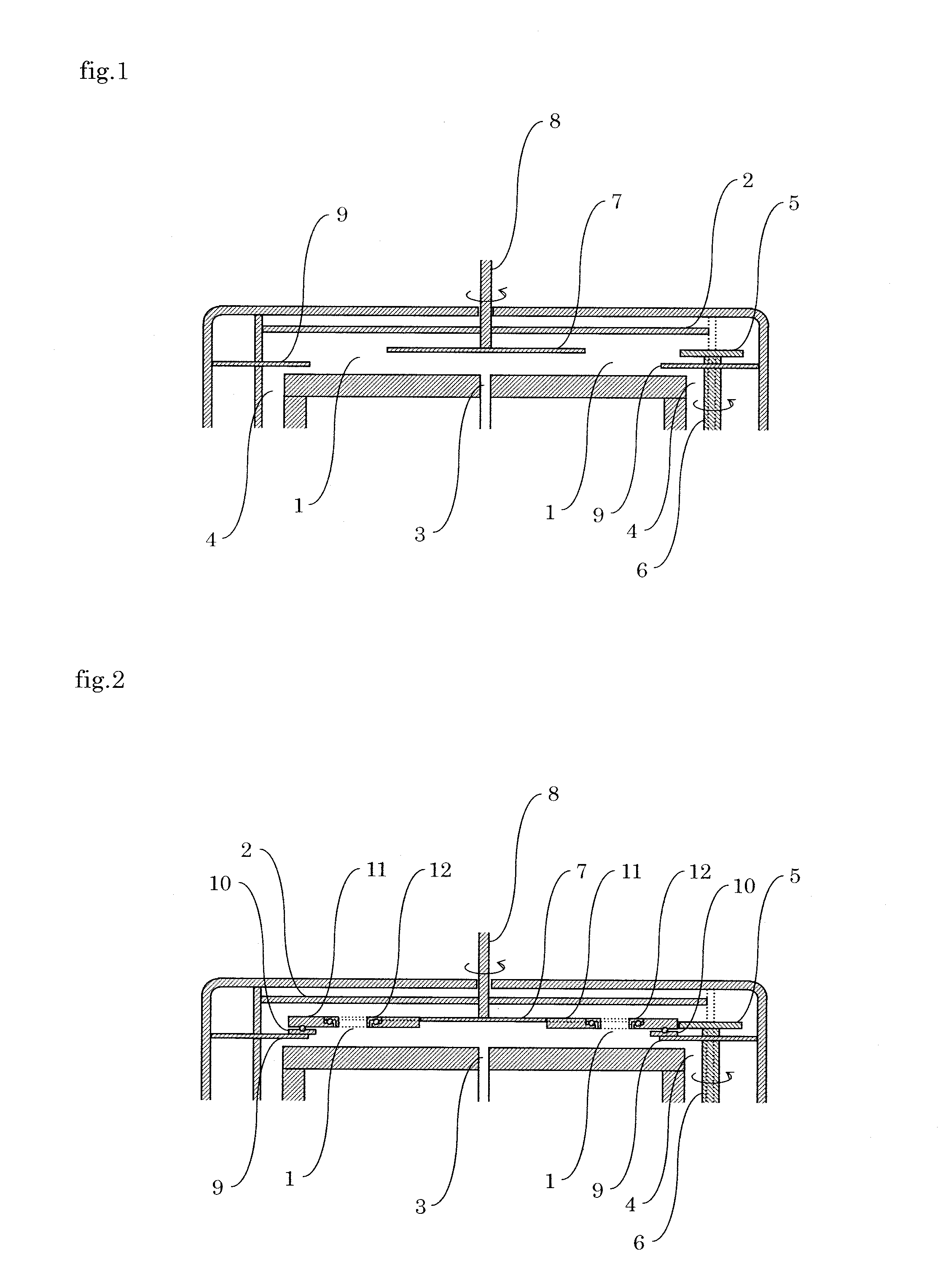

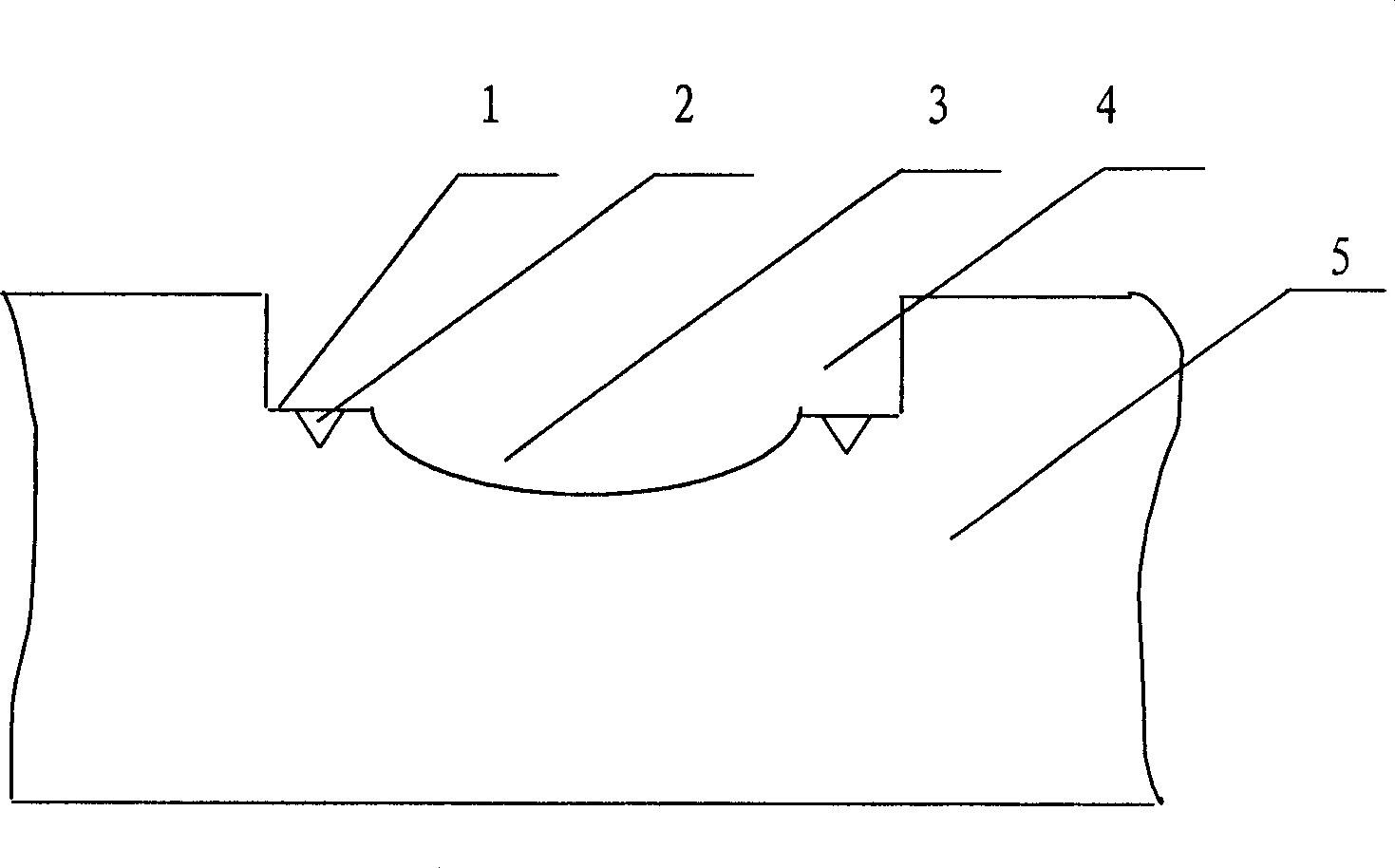

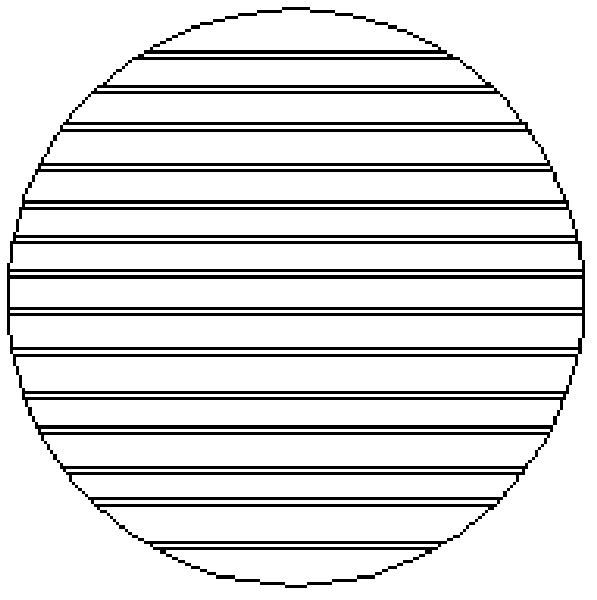

Fan-shaped spray head structure for vapor phase epitaxy of material

ActiveCN103103501ARealize mass productionIncrease productivityFrom chemically reactive gasesChemical vapor deposition coatingVapour phase epitaxyHigh volume manufacturing

The invention discloses a fan-shaped spray head structure for vapor phase epitaxy of a material. A first precursor, a second precursor and various protective gases are sufficiently mixed in a large-area reaction region to form a relatively uniform flow field. The structure disclosed by the invention comprises more than one gas inlet pipeline; a controller for detecting and controlling the gas inlet flow rate and flow is arranged on the gas inlet pipeline; more than one fan-shaped independent isolation region is arranged in a cavity of the spray head; a sealing plate at the top end of the isolation region is connected with the gas inlet pipeline; one and more gas nozzles are formed on a gas outlet baffle at the bottom end of the isolation region; and a round reaction cavity is arranged below the spray head. According to the invention, large-scale production of III group-nitride semiconductor material is realized, and the production efficiency of the III group-nitride semiconductor material is improved.

Owner:SINO NITRIDE SEMICON +1

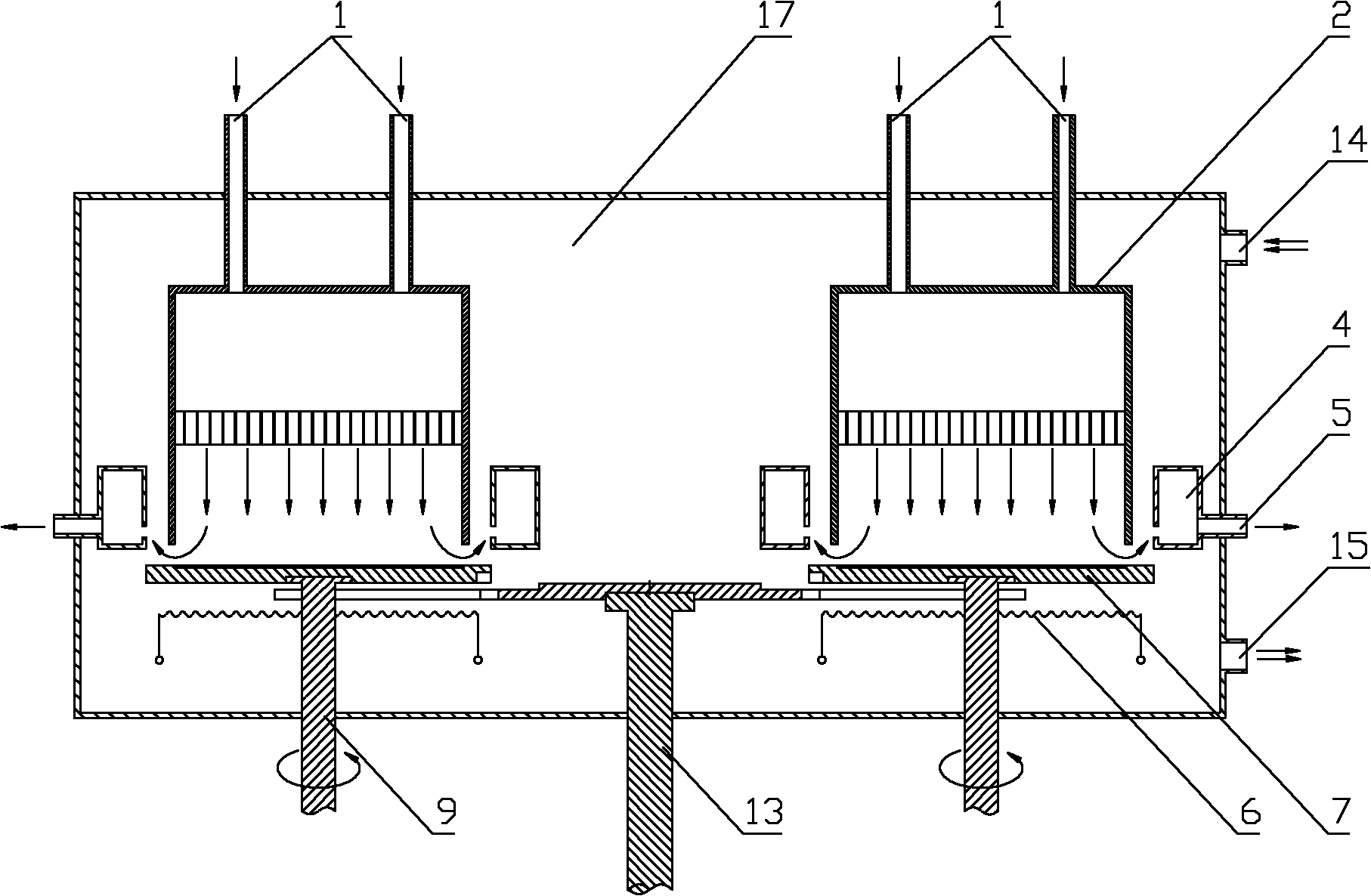

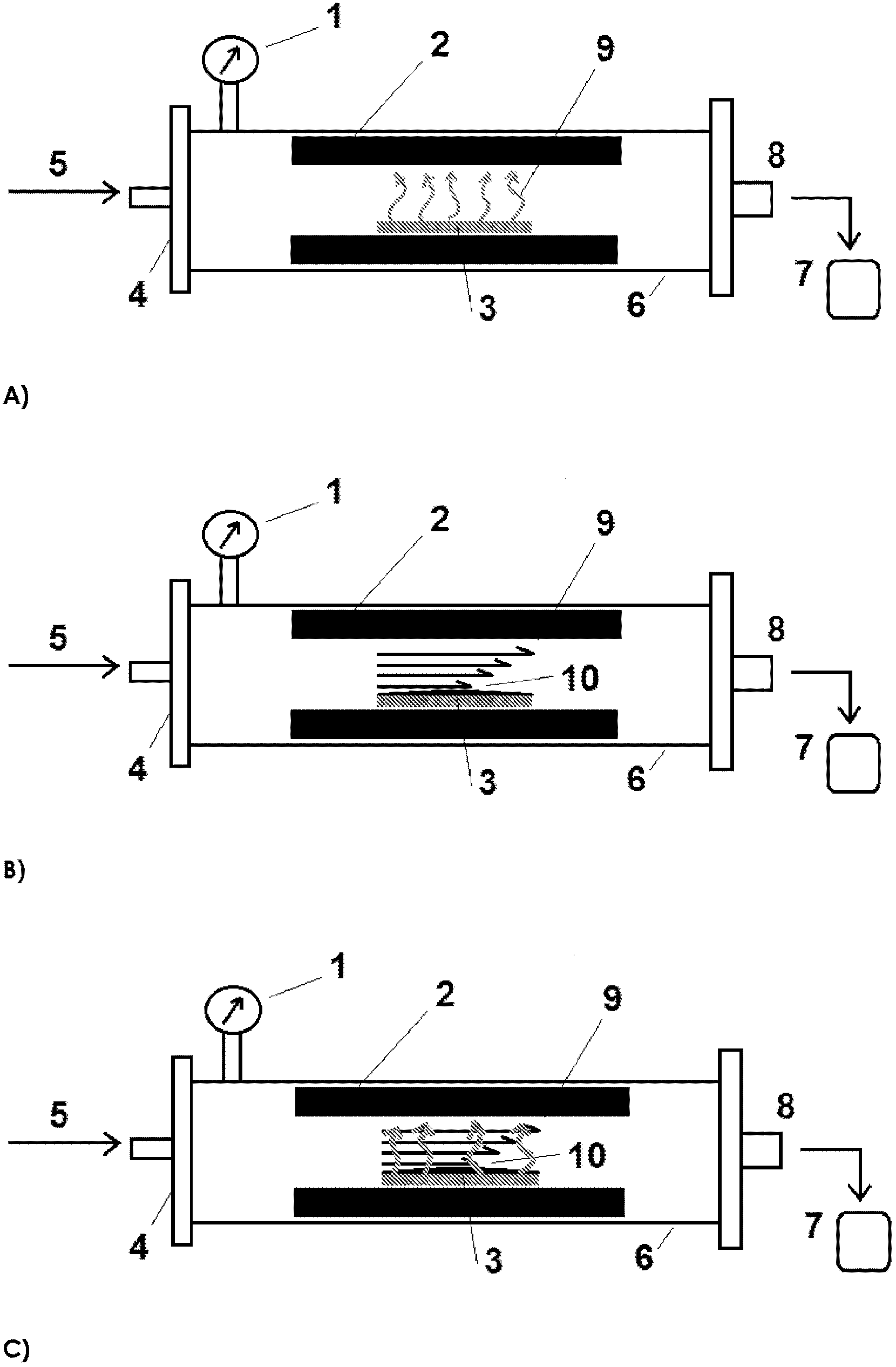

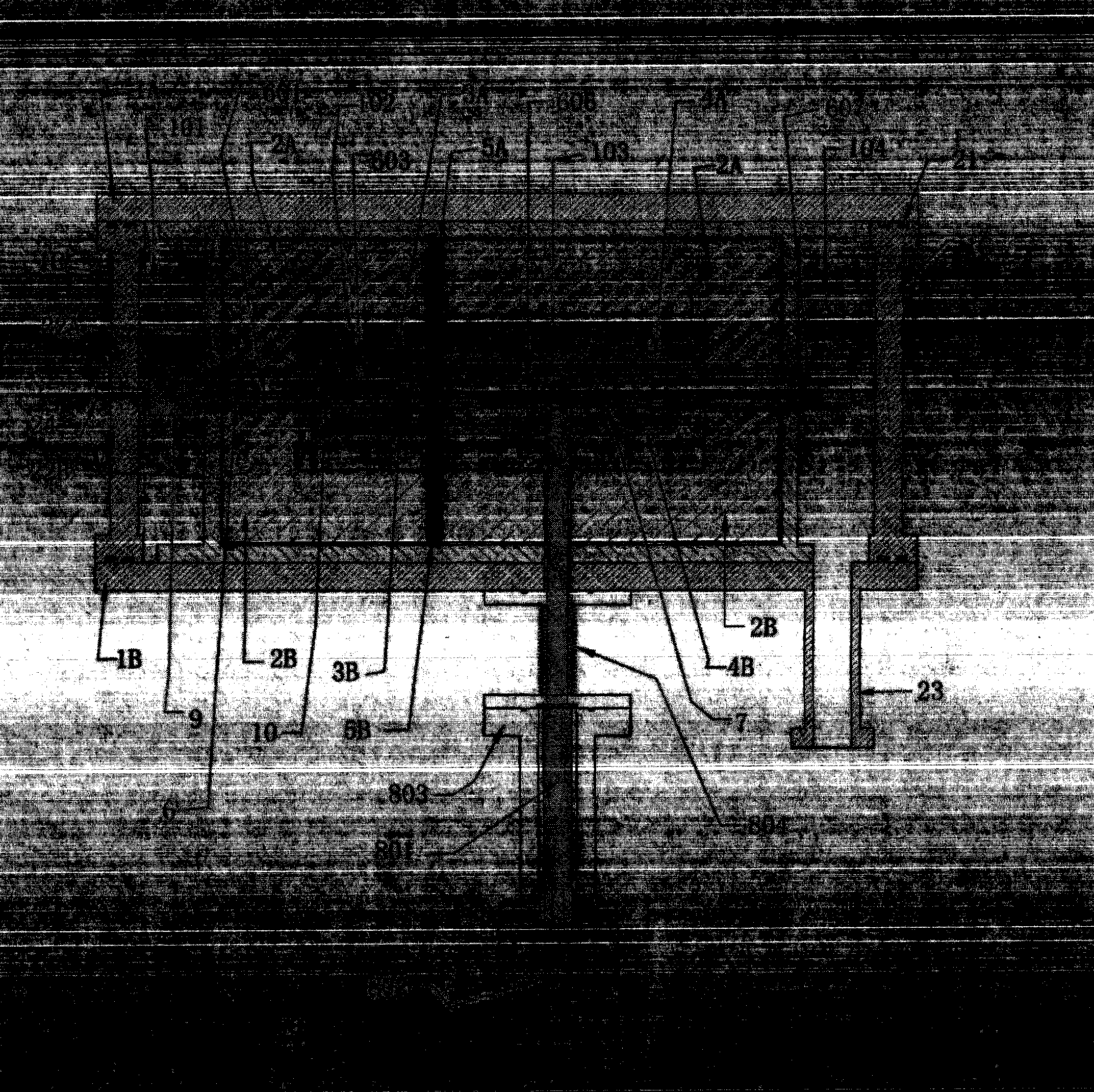

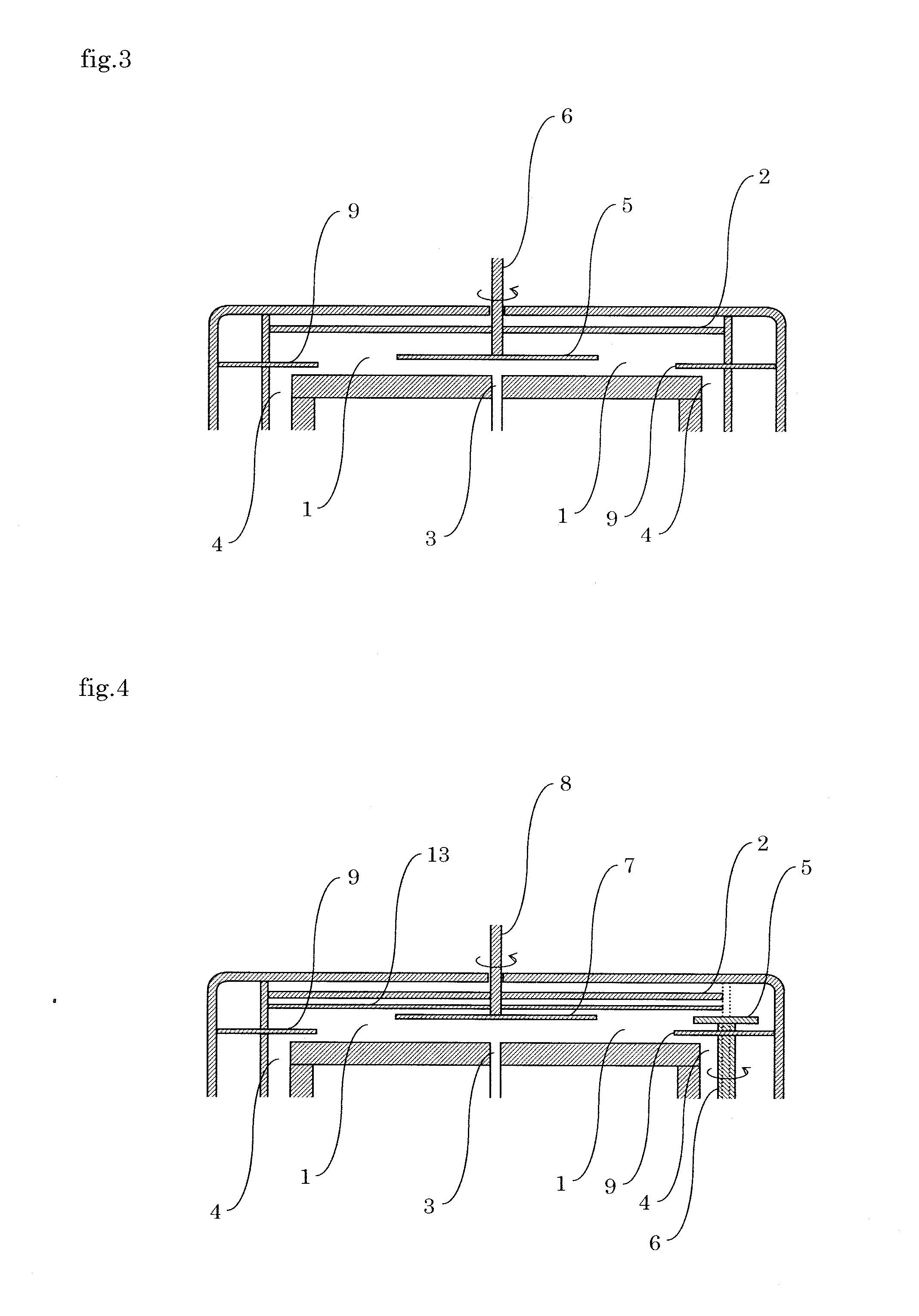

Vapor phase epitaxy device and vapor phase epitaxy method

ActiveCN102181923ASolving Thickness Control ProblemsQuality improvementFrom chemically reactive gasesVapour phase epitaxyQuantum well

The invention discloses a vapor phase epitaxy device and a vapor phase epitaxy method. The disclosed vapor phase epitaxy device comprises a reaction chamber, a plurality of reaction gas spraying heads arranged in the reaction chamber, a plurality of trays corresponding to the plurality of reaction gas spraying heads, and a power shaft driving the trays, wherein the power shaft comprises revolution shafts and a plurality of rotation shafts, the rotation shafts correspond to the trays one by one; and the trays are respectively connected with the corresponding rotation shafts, or connected with the revolution shafts and the corresponding rotation shafts alternatively. By utilizing the vapor phase epitaxy device and the vapor phase epitaxy method, the flow instability in the chemical vapor phase epitaxy can be reduced effectively, the spurious response times can be decreased, also the problem of the thickness of a quantum well can be solved effectively, different selections can be provided for the growing process of different heterogenous junctions, and the quality of semiconductor elements can be improved.

Owner:ZHEJIANG YUNFENG NEW ENERGY TECH

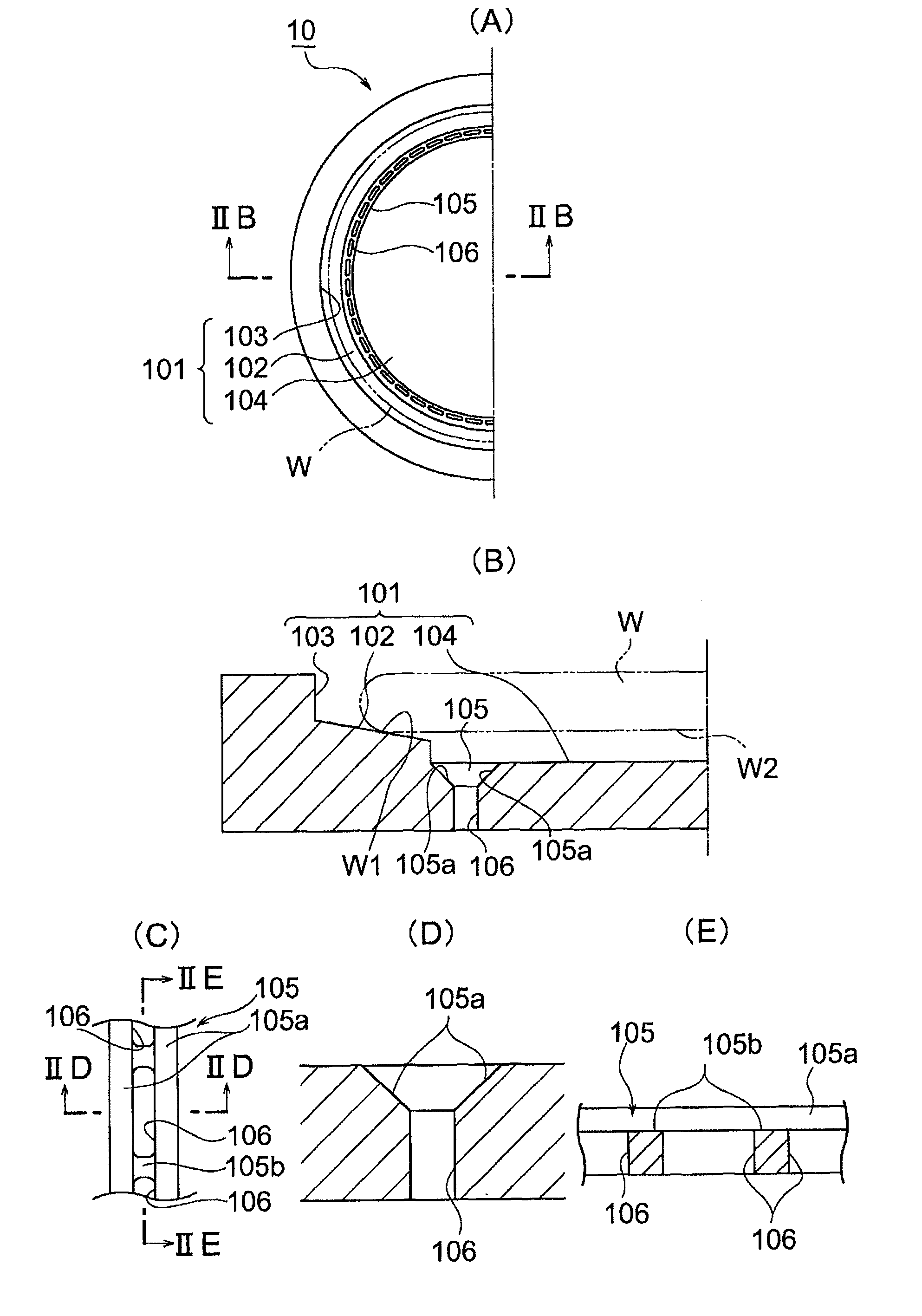

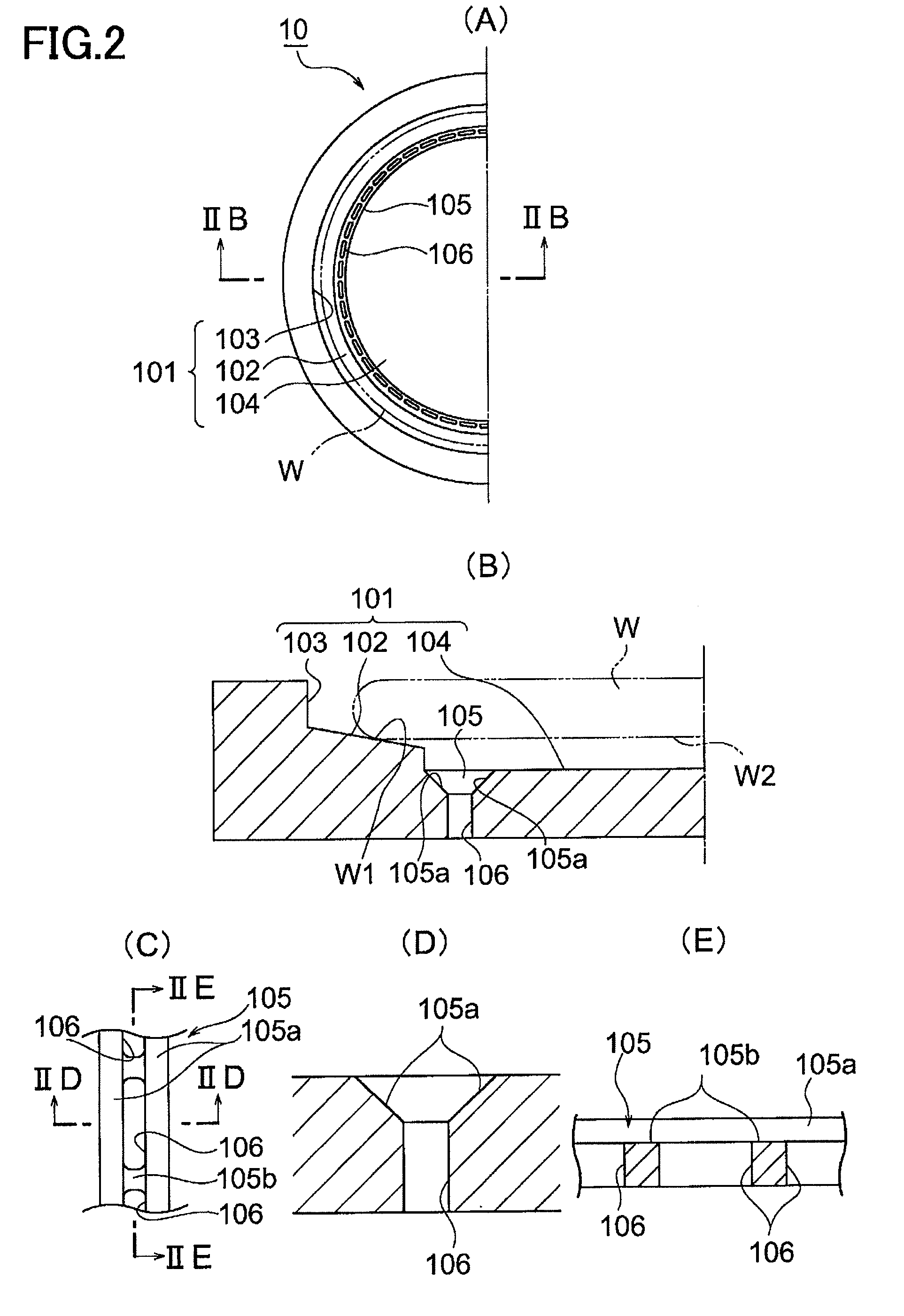

Susceptor for vapor phase epitaxial growth device

ActiveUS9017483B2Prevent slippingSemiconductor/solid-state device manufacturingFrom chemically reactive gasesVapour phase epitaxyWafering

There is provided a susceptor for a vapor phase epitaxial growth device, by which skidding at the time of loading a silicon wafer is prevented and the wafer can be loaded at a fixed position of the susceptor: wherein a ring-shaped groove having sloping planes widening toward a surface of the susceptor are formed on the outermost circumference of the bottom surface; and gas release openings penetrating through to the back surface of the susceptor are formed, each having a sectional area of 2.0 to 3.0 mm2 and a ratio of all opening areas is 0.25 to 0.5% on the bottom surface.

Owner:SUMCO CORP +1

Method for improving photoelectric detector performance by cutting band gap wavelength in lattice matching system

InactiveCN102176489APromote growthNo significant increase in difficultyFinal product manufactureSemiconductor devicesVapour phase epitaxyElectron

The invention relates to a method for improving photoelectric detector performance by cutting band gap wavelength in lattice matching system. The method comprises the following steps of: growing a buffer layer, a light absorption layer and a wide band gap cap layer which hare matched with lattices on a substrate by using an MBE (molecular beam epitaxy) method or metallorganics vapour phase epitaxy method to obtain an epitaxial structure of a photoelectric detector, wherein the band gap of the light absorption layer can be cut and set during the growth process, and the wide band gap is selected on the premise of meeting cut-off wavelength requirement of the long wave end of the photoelectric detector. According to the invention, the material growing method is simple; by cutting and setting the band gap of the light absorption layer of the photoelectric detector, the device performance can be obviously improved under the condition of basically not changing the original design of the device, and the detectivity can be enhanced by more than three times. The method is not only suitable for manufacturing photoelectric detectors in different kinds of III-V compound material systems, but also suitable for manufacturing other types of photoelectric devices and electronic devices; and the application of the method can be widened to other material systems. The method has a good application prospect.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

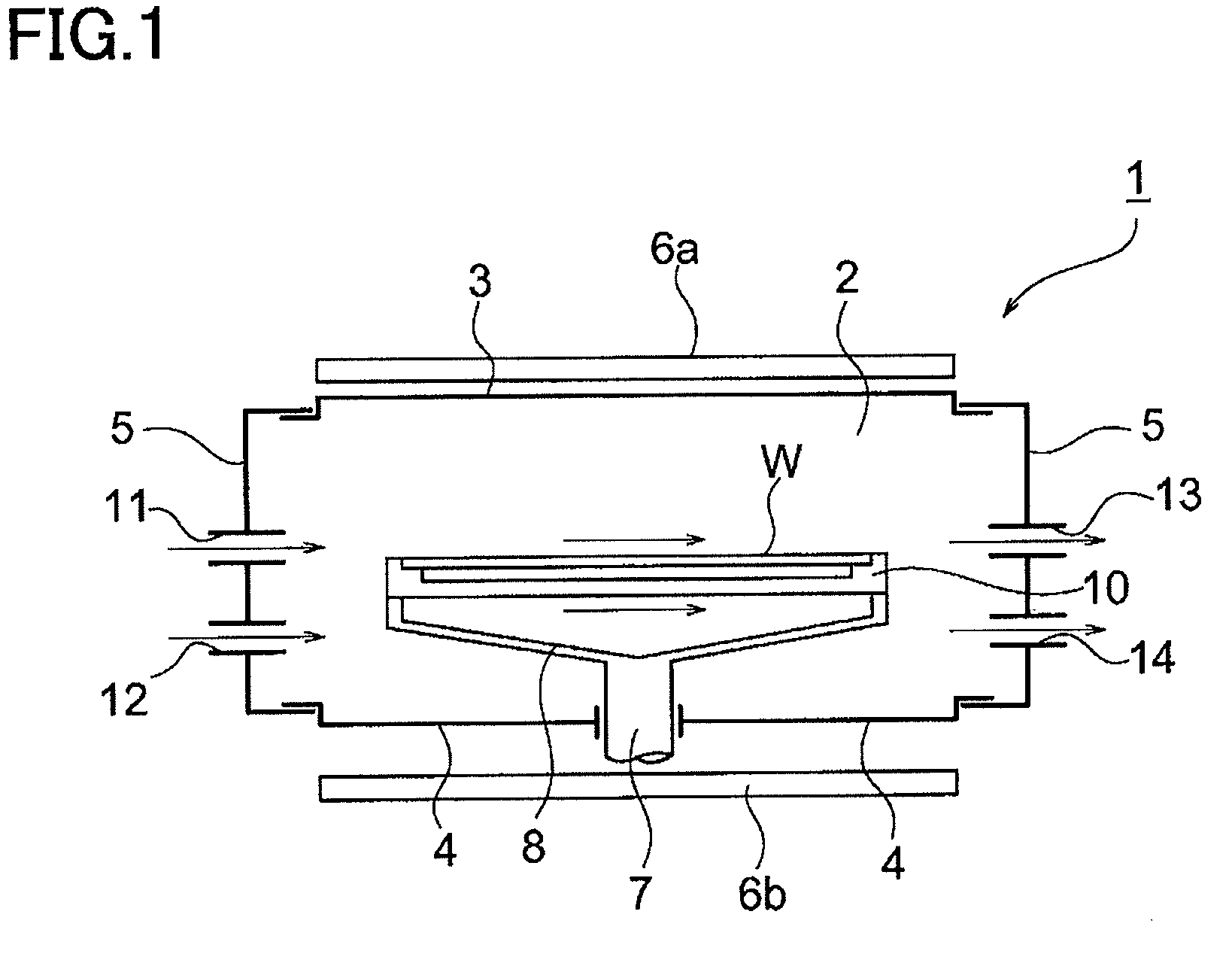

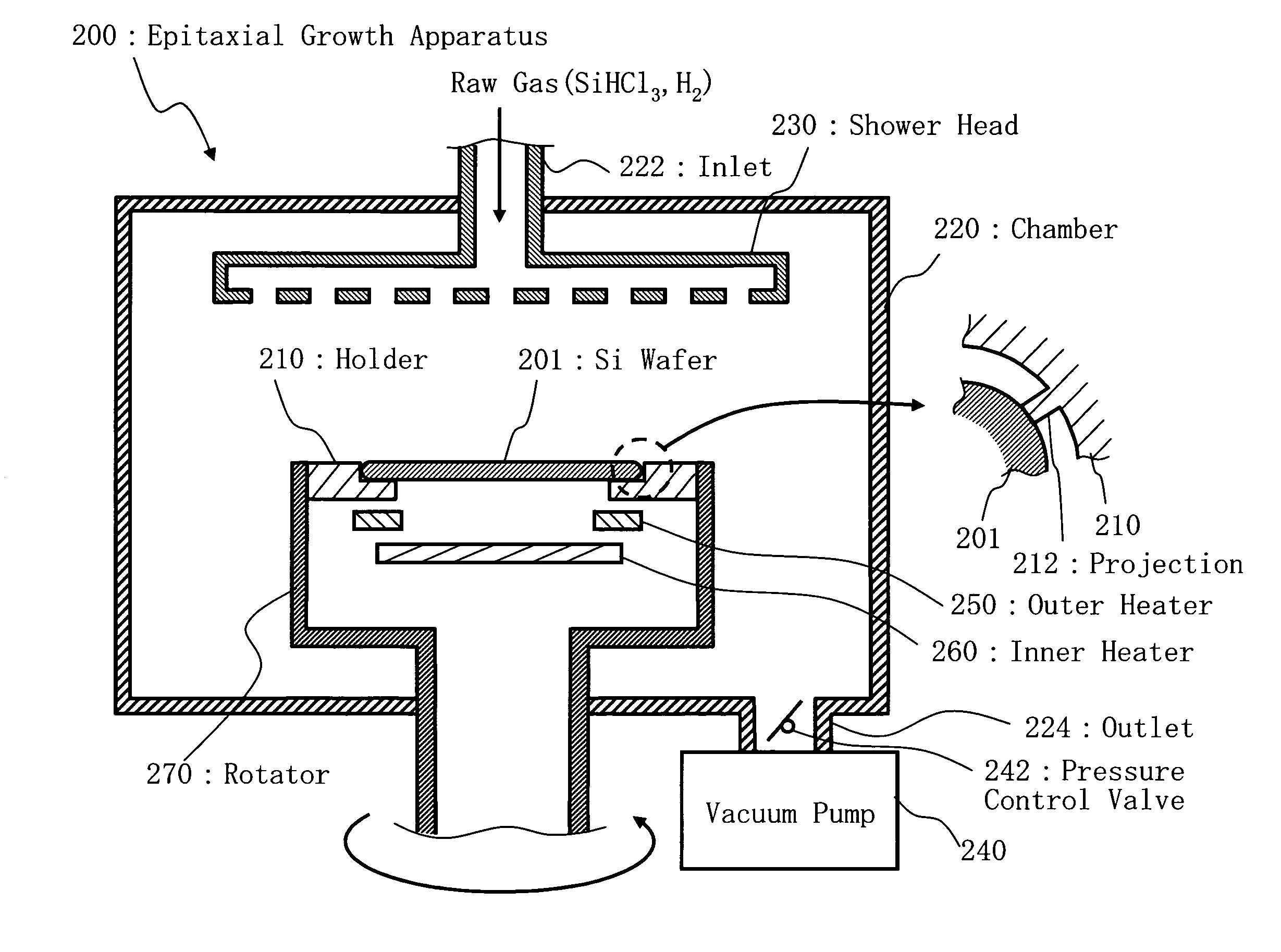

Vapor-phase epitaxial growth method and vapor-phase epitaxy apparatus

InactiveUS8007588B2Polycrystalline material growthSemiconductor/solid-state device manufacturingVapour phase epitaxyGas phase

A vapor phase epitaxial growth method using a vapor phase epitaxy apparatus having a chamber, a support structure holding thereon a substrate in the chamber, a first flow path supplying a reactant gas for film formation on the substrate and a second flow path for exhaust of the gas, said method includes rotating the substrate, supplying the reactant gas and a carrier gas to thereby perform vapor-phase epitaxial growth of a semiconductor film on the substrate, and during the vapor-phase epitaxial growth of the semiconductor film on the substrate, controlling process parameters to make said semiconductor film uniform in thickness, said process parameters including flow rates and concentrations of the reactant gas and the carrier gas, a degree of vacuum within said chamber, a temperature of the substrate, and a rotation speed of said substrate.

Owner:NUFLARE TECH INC

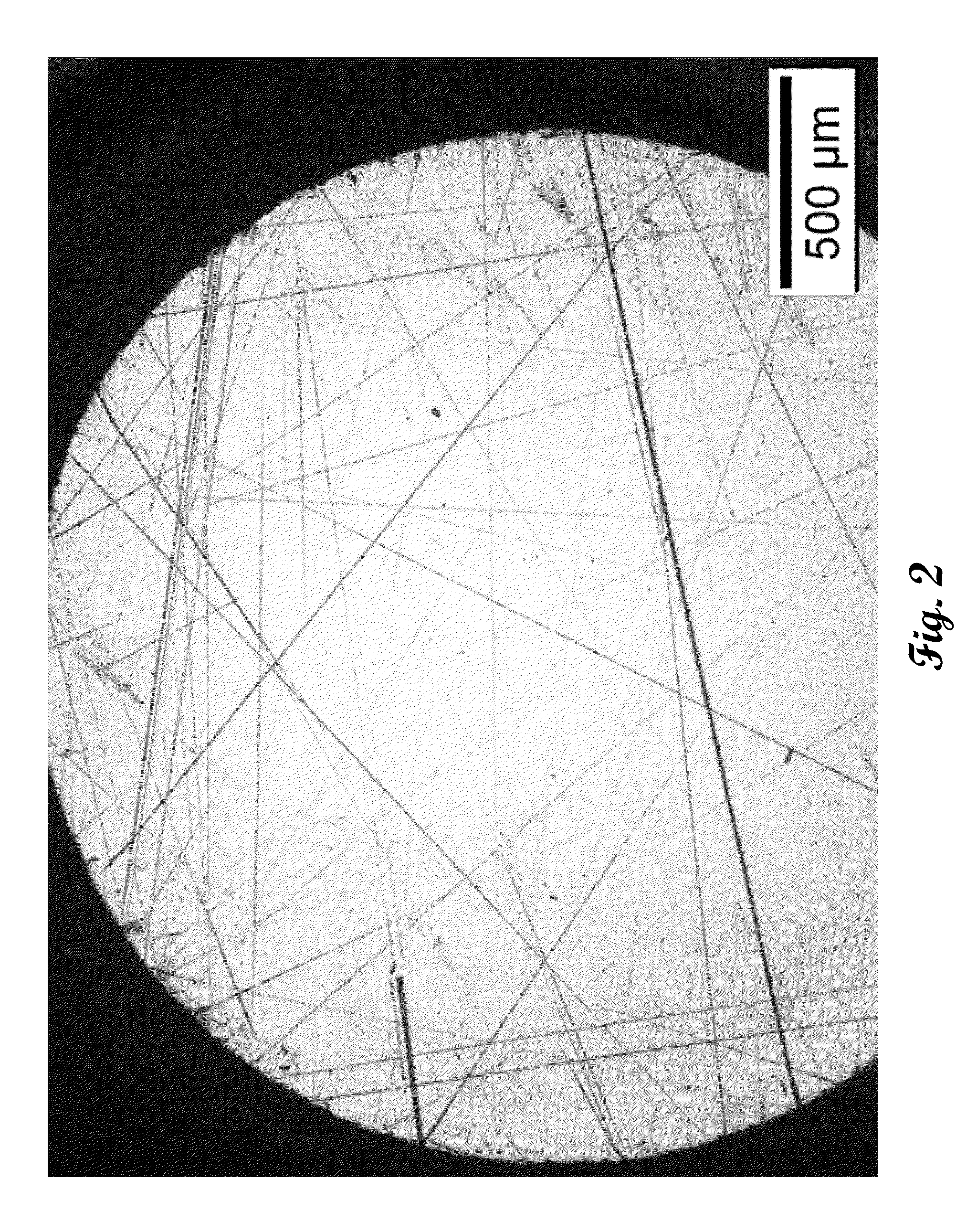

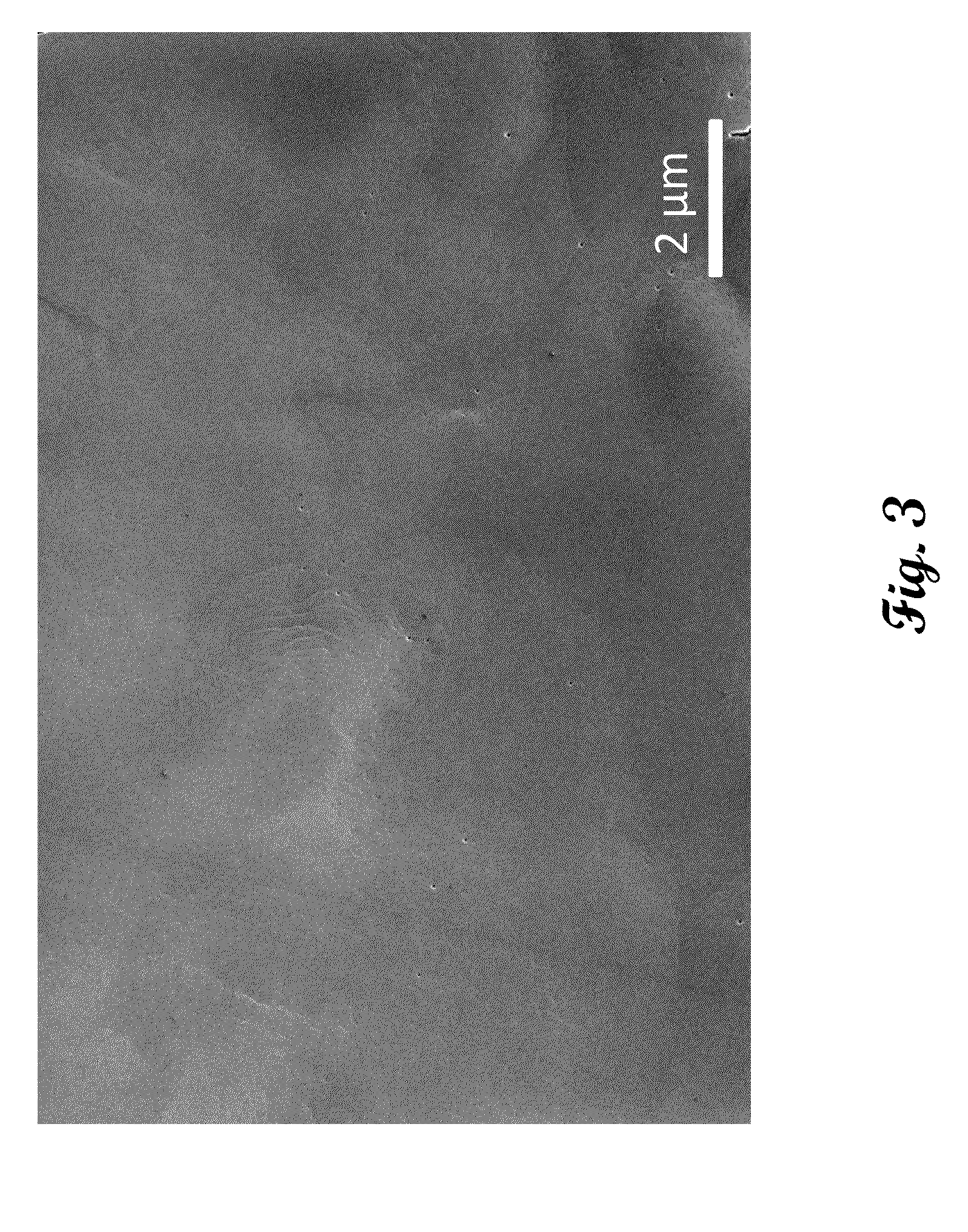

Method of Gallium Nitride growth over metallic substrate using Vapor Phase Epitaxy

InactiveUS20110117376A1Advanced technologyAbsence of scratch and stepPolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyGas phase

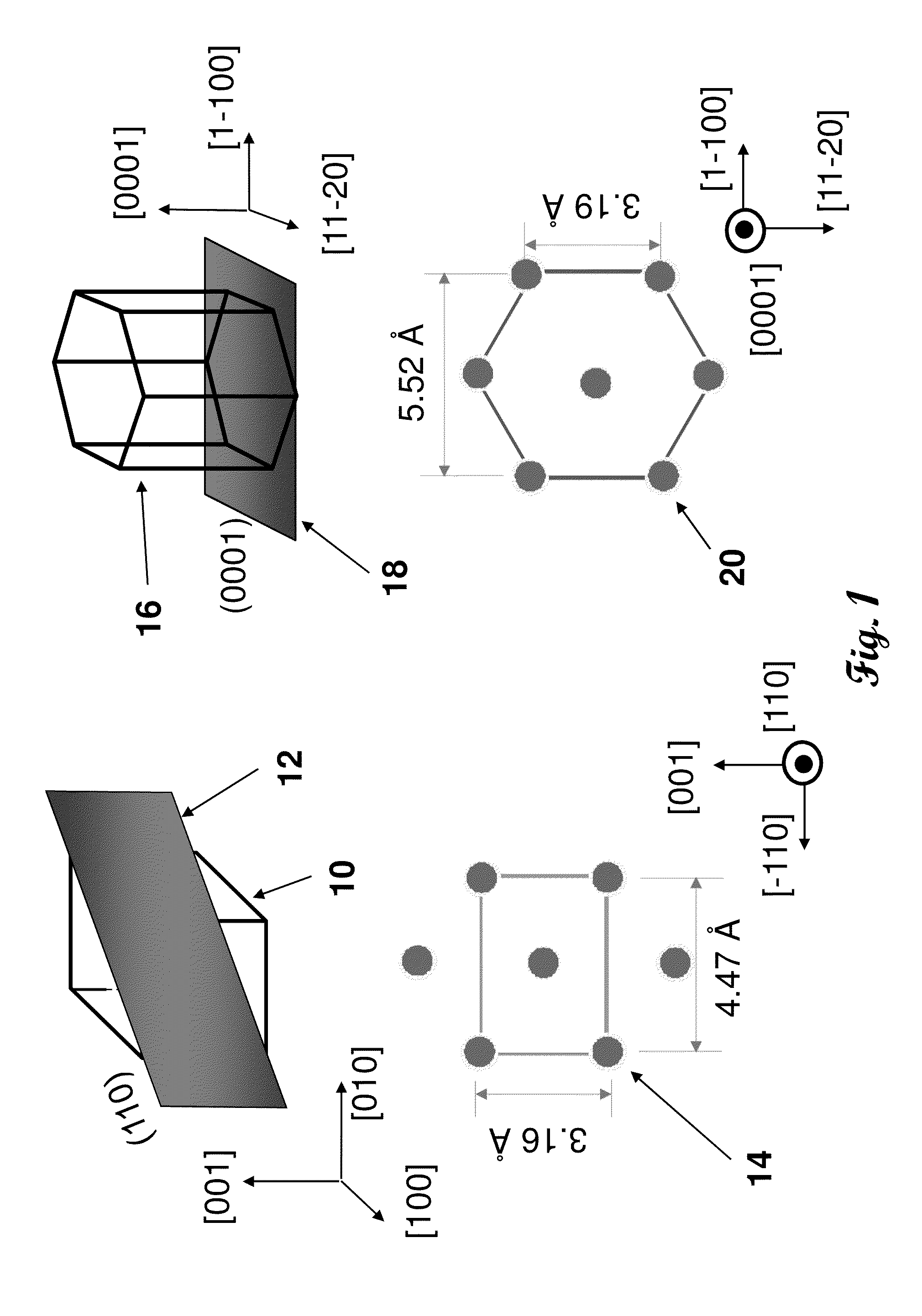

The current invention introduces a method of crystal film's growth of Gallium Nitride and related alloys over a novel class of the substrates using Vapor Phase Epitaxy technique. This said novel class of the substrates comprises single crystal lattice matched, partially matched or mismatched metallic substrates. The use of such substrates provides exceptional thermal conductivity and application flexibility, since they can be easily removed or patterned by chemical etching for the purposes of additional contact formation, electromagnetic radiation extraction, packaging or other purposes suggested or discovered by the skilled artisan. In particular, if patterned, the remaining portions of the said substrates can be utilized as contacts to the semiconductor layers grown on them. In addition, the said metallic substrates are significantly more cost effective than most of the conventional substrates. The use of Vapor Phase Epitaxy allows growing the epitaxial layers with different and / or variable alloy composition, as well as heterostructures and superlattices.

Owner:ZHU MINGWEI +2

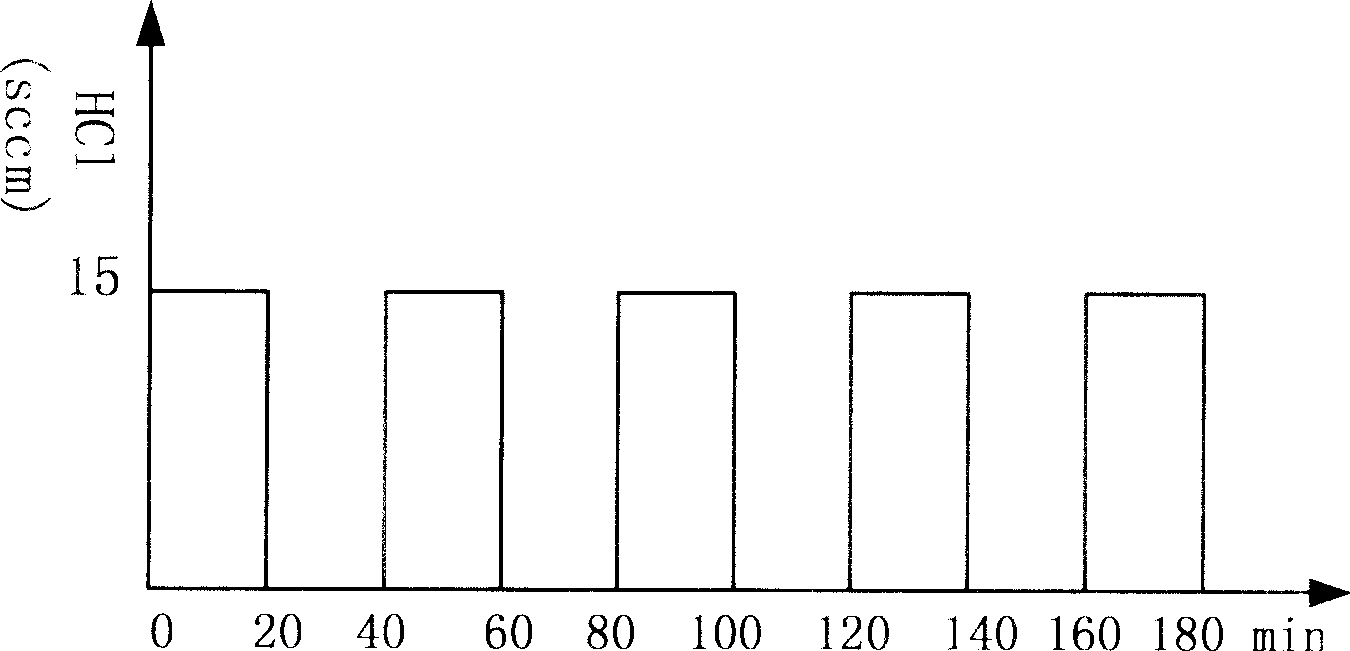

Method for changing polar of gallium nitride epitaxial layer grown by hydride vapour phase epitaxy method

InactiveCN1832112AImprove performanceWill not introduce pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingVapour phase epitaxyGallium nitride

This invention relates to a method for altering the pole of GaN epitaxial layer grown by HVPE characterizing in applying a method of interrupting HCl growth, which first of all penetrates NH3 to nitride the Sapphire under high temperature then penetrates HCl to grow GaN, this time, the GaN film surface shows N pole, then closes HCl after growing for a period of time and continues NH3 for 1-60min, then opens the HCl to grow GaN film continuously and operates like this for 2-10 times, the pole of GaN turns to Ga of a smooth surface from a rough N pole surface and the dislocation density is reduced and the crystal quality is increased.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Method of graphene manufacturing

ActiveCN102933491AMaterial nanotechnologyPolycrystalline material growthVapour phase epitaxyCvd graphene

The present invention relates to a method for manufacturing graphene by vapour phase epitaxy on a substrate comprising a surface of SiC, characterized in that the process of sublimation of silicon from the substrate is controlled by a flow of an inert gas or a gas other than an inert gas through the epitaxial reactor. The invention also relates to graphene obtained by this method.

Owner:INST TECH MATERIAL ELEKT

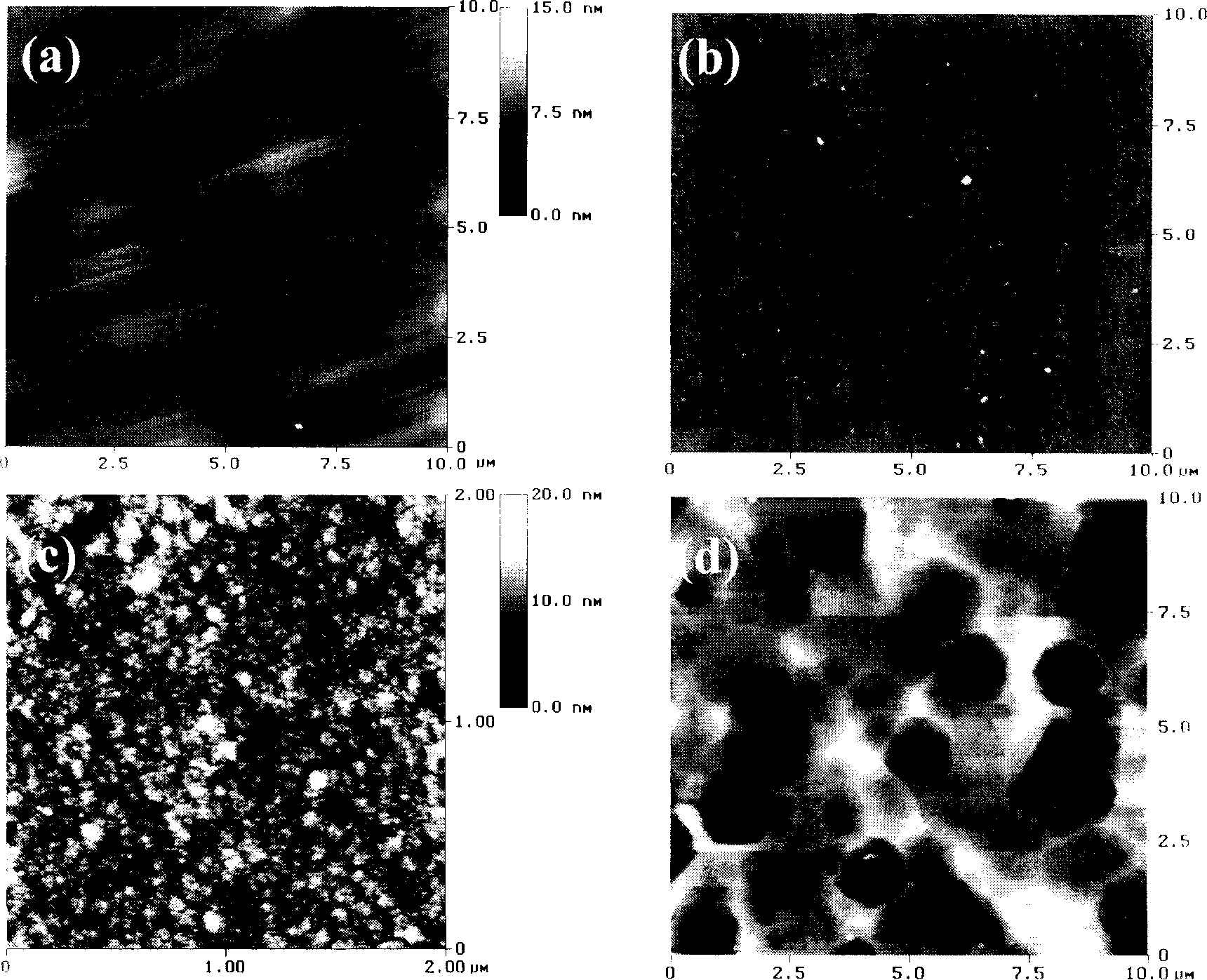

Porous material substrate used in GaN film grown by HVPE method and method thereof

InactiveCN101514484ARelease internal stressQuality improvementPolycrystalline material growthFrom chemically reactive gasesGallium nitridePlasma etching

The invention relates to a nano-porous material substrate used in hydride vapor phase epitaxy (HVPE) gallium nitride (GaN) film and a preparation method thereof. The invention is characterized in that composite nano-porous material is taken as a substrate for epitaxially growth of a thick film GaN, and the quality of crystalloid can be improved, meanwhile, the substrate can be conveniently stripped. A metal Al thin layer is firstly sedimentated on a GaN template taking Si as the substrate, even porous meshed anodic aluminum oxide (AAO) is formed by an electrochemic method, porous GaN material is obtained by erosion of technologies such as induced coupling plasma etching (ICP) and the like, and the bottom of the holes are exposed outside the surface of the Si substrate; on this basis, a corrosion method is adopted to realize the corrosion for Si and obtain the composite nano-porous structure; by the superficial treatment, the Si is covered with a SiNx layer or SiO2 layer, so as to meet the requirements of subsequent epitaxial growth. After being washed, the product is put into an HVPE system, and the thick film GaN layer grows. The invention greatly simplifies the technique for manufacturing a mask film by photoetching, and is suitable for scientific experiments and batch production.

Owner:DAHOM FUJIAN ILLUMINATION TECH

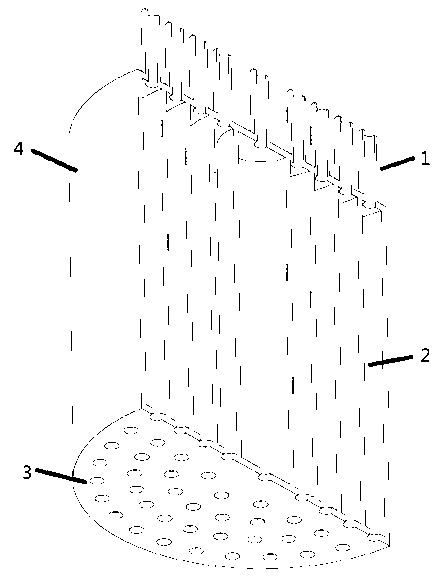

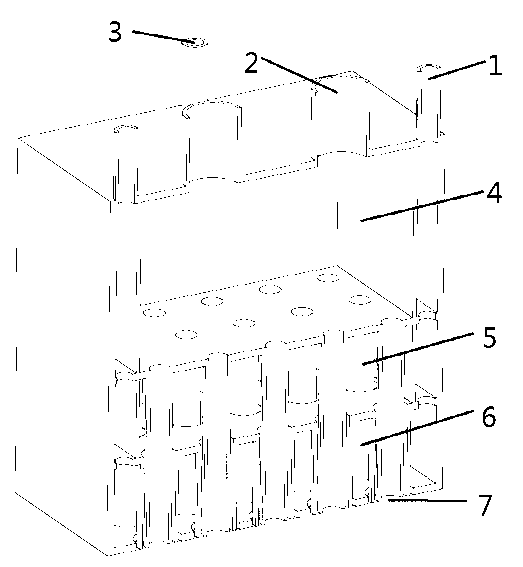

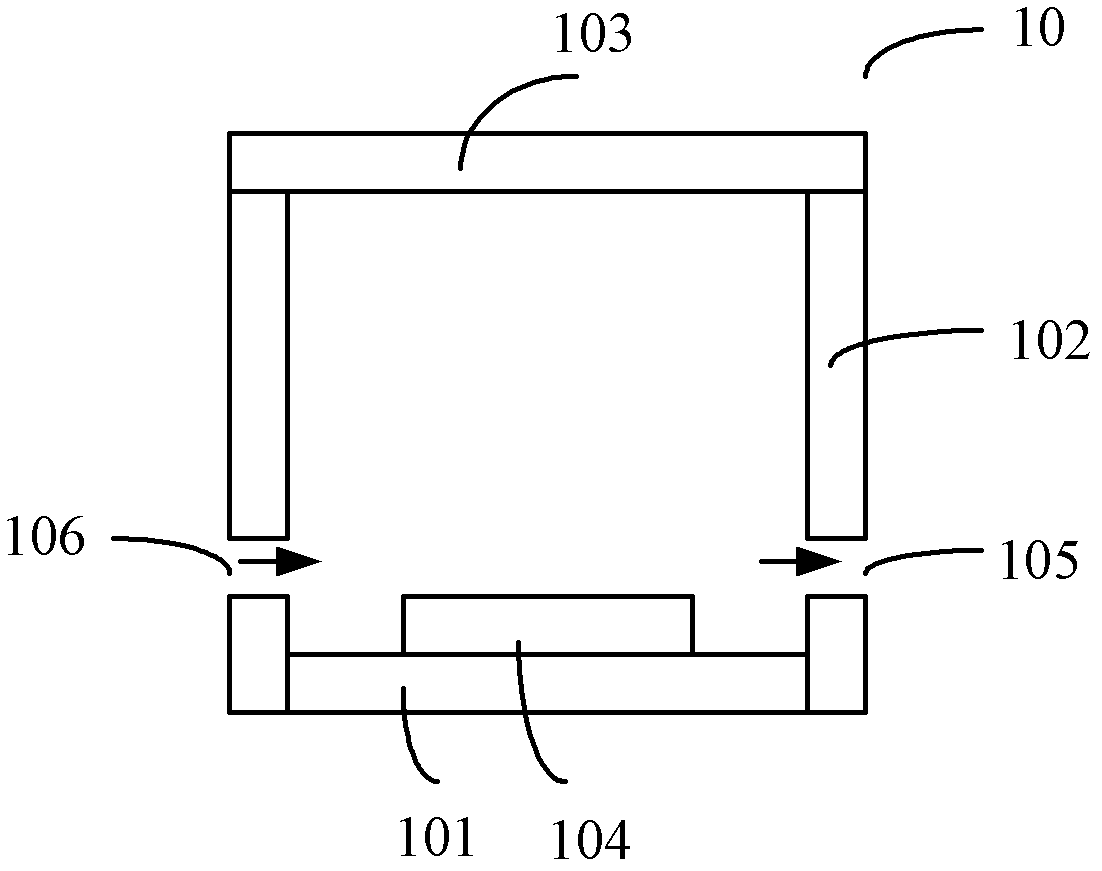

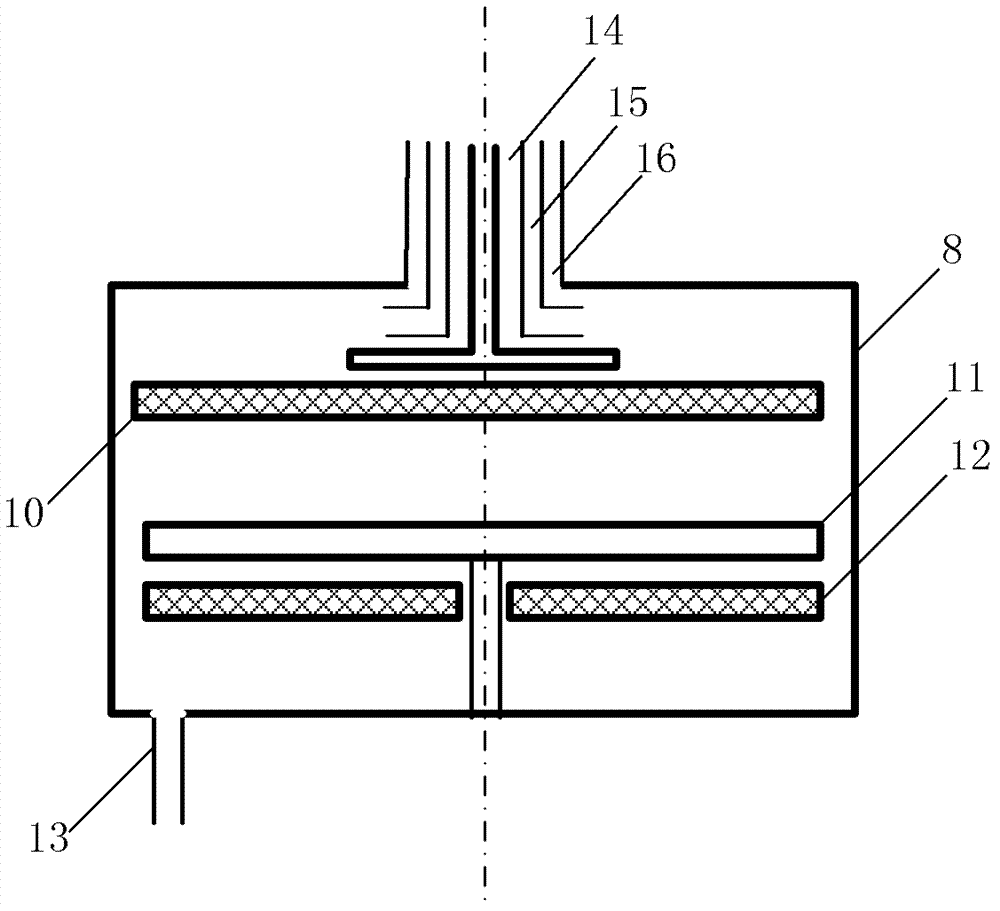

Square spray nozzle structure for vapor phase epitaxy of material

ActiveCN103060906ASolving Mixing ProblemsIncrease productivityFrom chemically reactive gasesChemical vapor deposition coatingVapour phase epitaxySpray nozzle

The invention discloses a square spray nozzle structure for vapor phase epitaxy of a material. The square spray nozzle structure solves the problem of providing a uniform precursor mixture for a large substrate and a large deposition region. The square spray nozzle structure is characterized in that multiple independent isolation regions are sequentially formed in a square spray nozzle from top to bottom, the top of the square spray nozzle is provided with input pipelines communicated with the isolation regions, multiple gas spray pipes are arranged at the bottom of the isolation regions, and nozzle orifices of the gas spray pipes are arranged at the bottom of the square spray nozzle. According to the square spray nozzle structure, a precursor and various gases are mixed and then deposit on the surface of the substrate through the independent isolation regions and the combined utilization manner of the multiple spray nozzles, and the production efficiency is improved.

Owner:SINO NITRIDE SEMICON +1

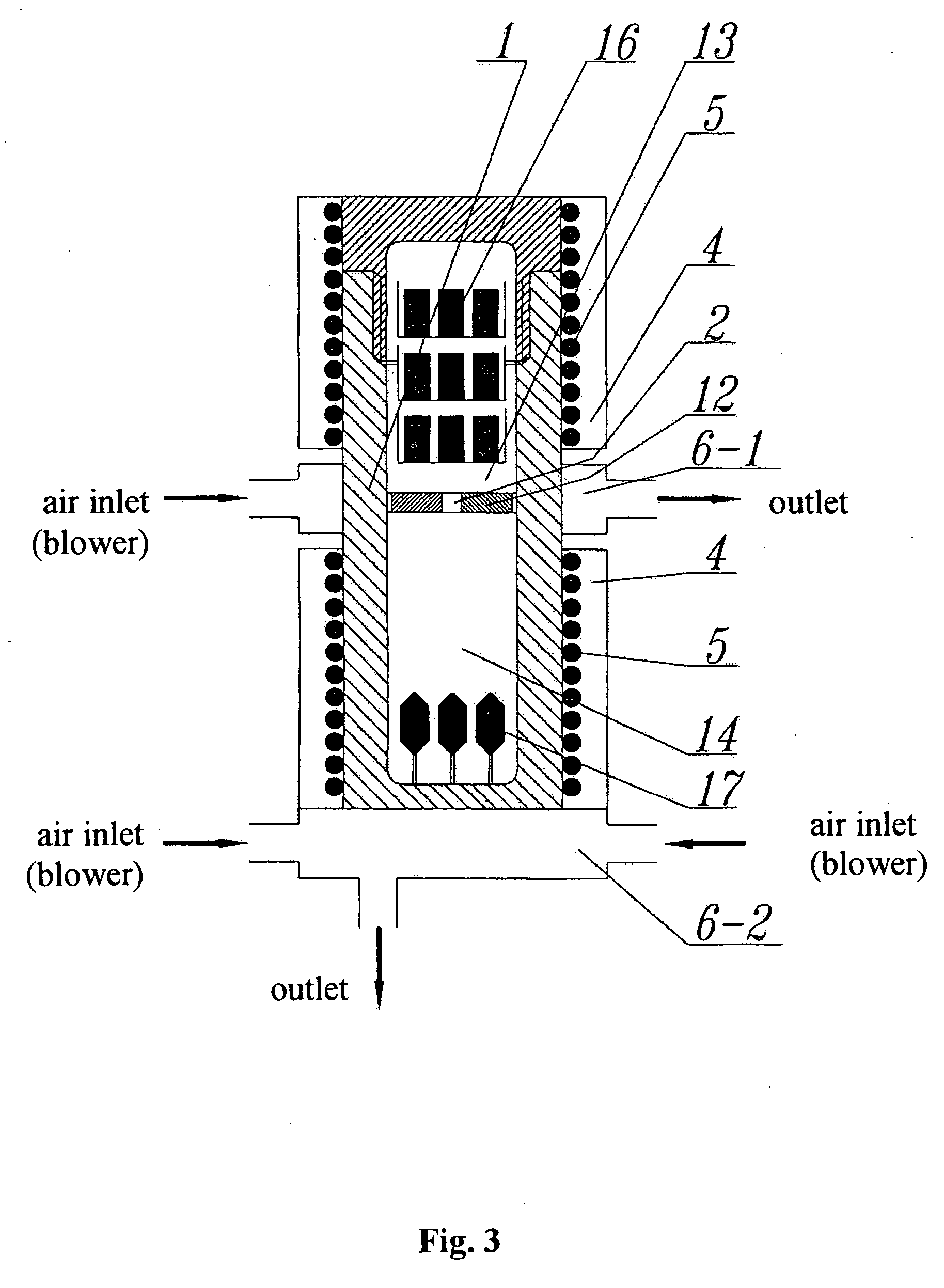

Hydride vapour phase epitaxy equipment

The invention discloses hydride vapour phase epitaxy (HVPE) equipment. The hydride vapour phase epitaxy equipment comprises a water-cooling stainless steel vacuum chamber, an insulating layer, a source heater, a substrate heater, a chamber thermal insulation device, an internal reaction chamber, a substrate tray, a rotating mechanism, an air jet hole, a metal boat, a sample inlet, a sample outlet and the like. Compared with conventional HVPE equipment, the HVPE equipment provided by the invention has the advantages that firstly, the water-cooling stainless steel chamber is used for replacing a conventional quartz chamber, and secondly, a built-in heater in the vacuum chamber is used for replacing a conventional external heater.

Owner:刘祥林

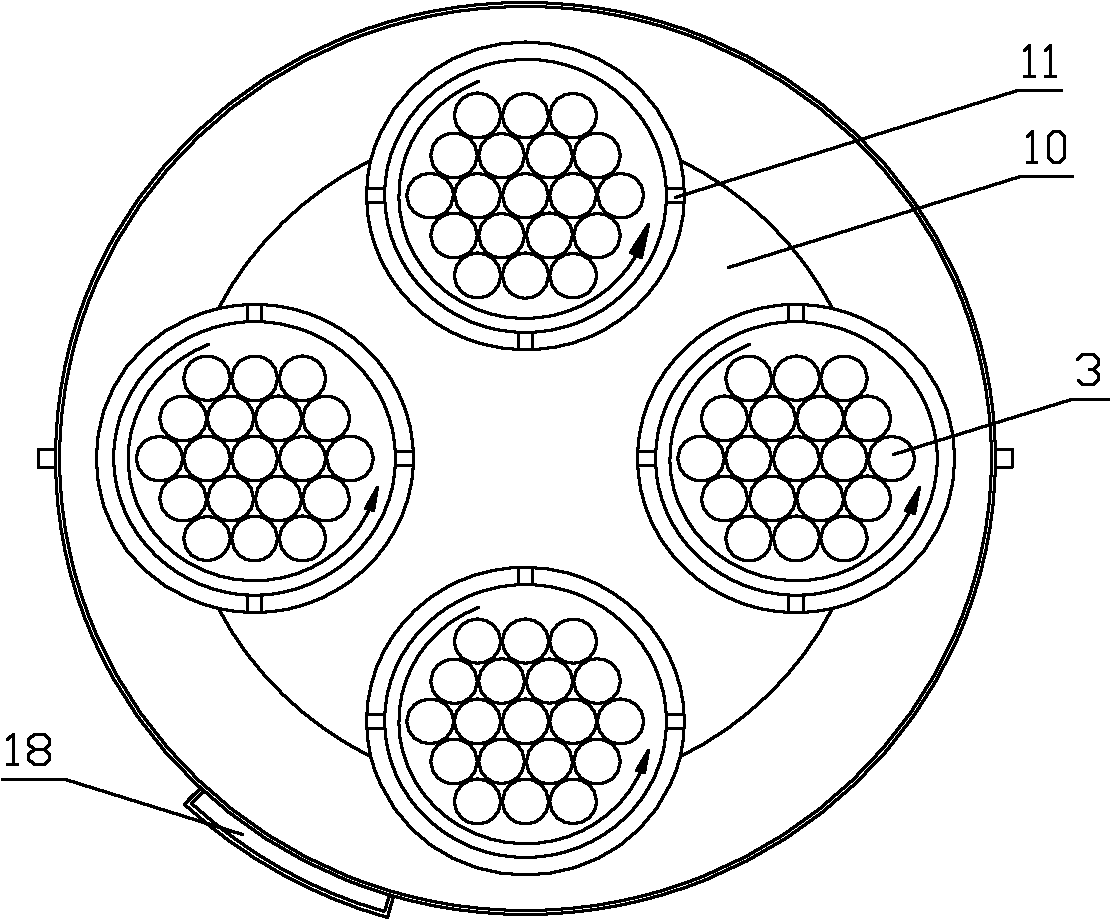

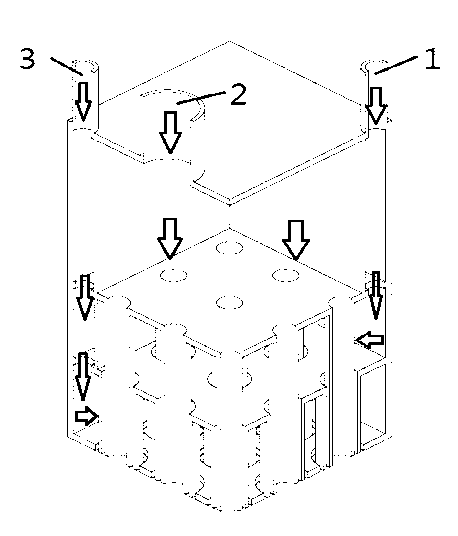

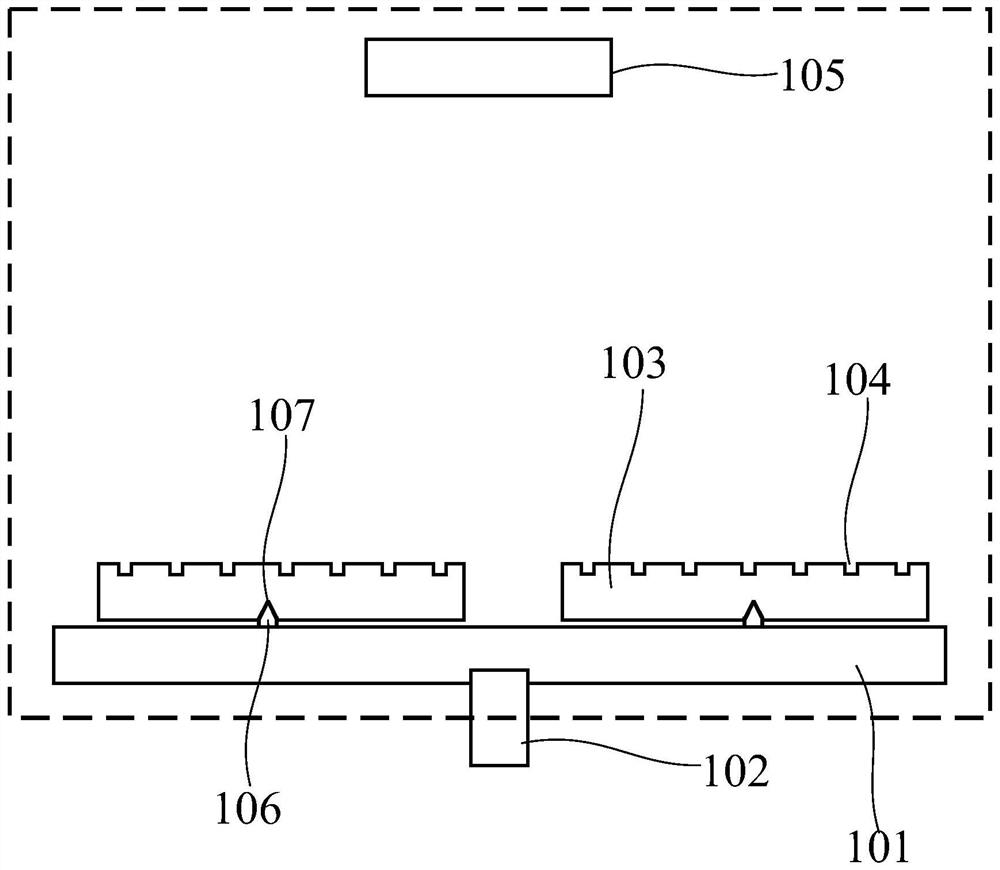

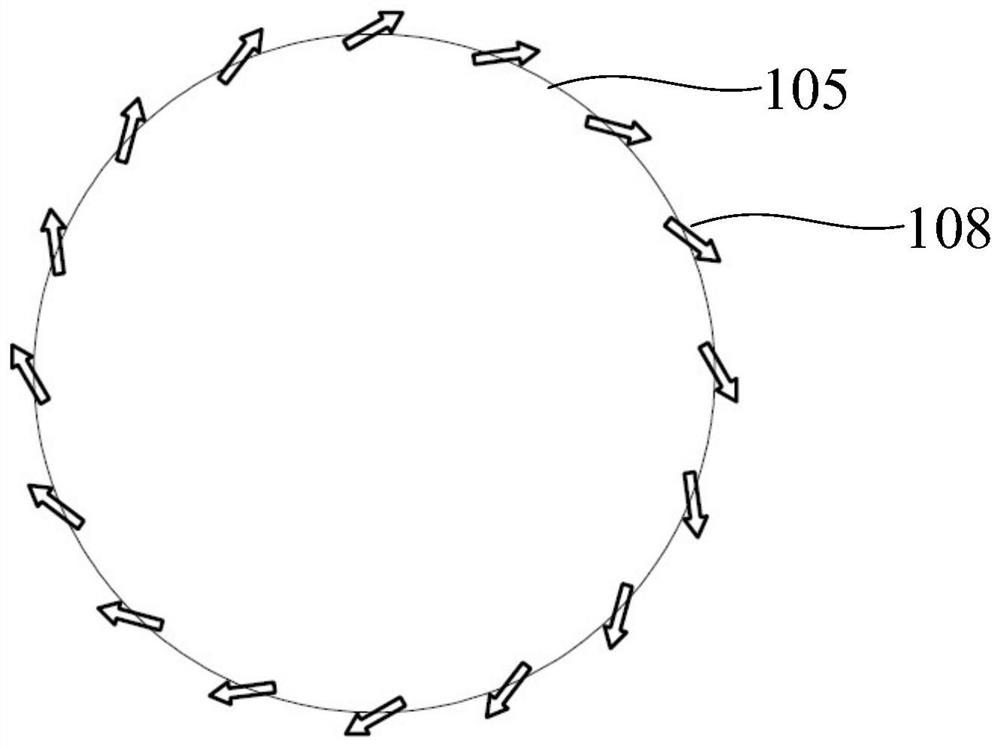

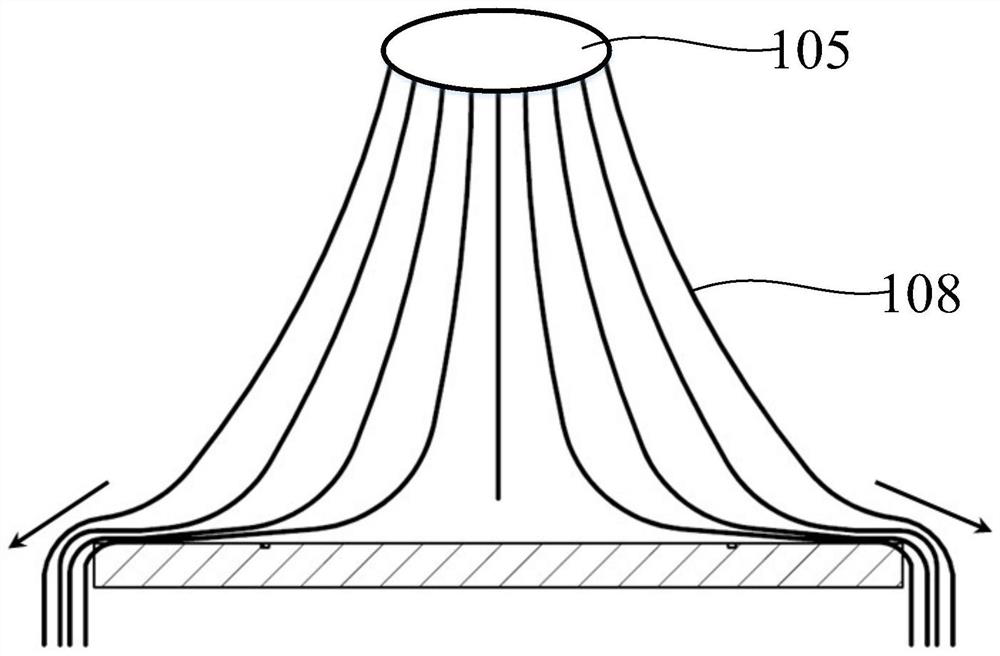

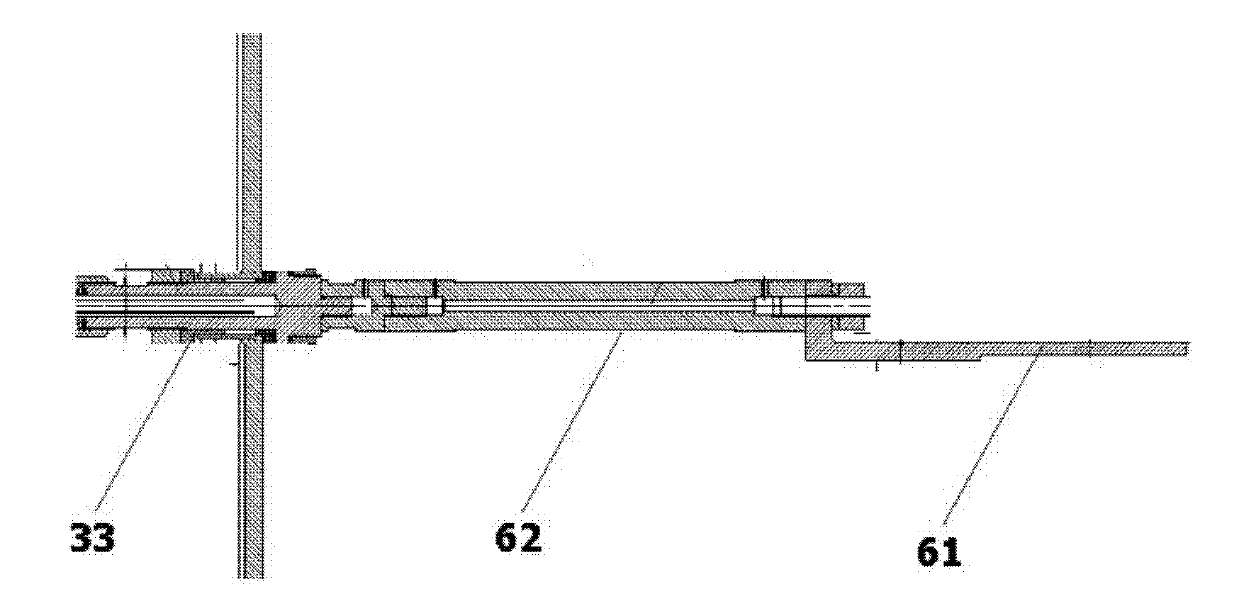

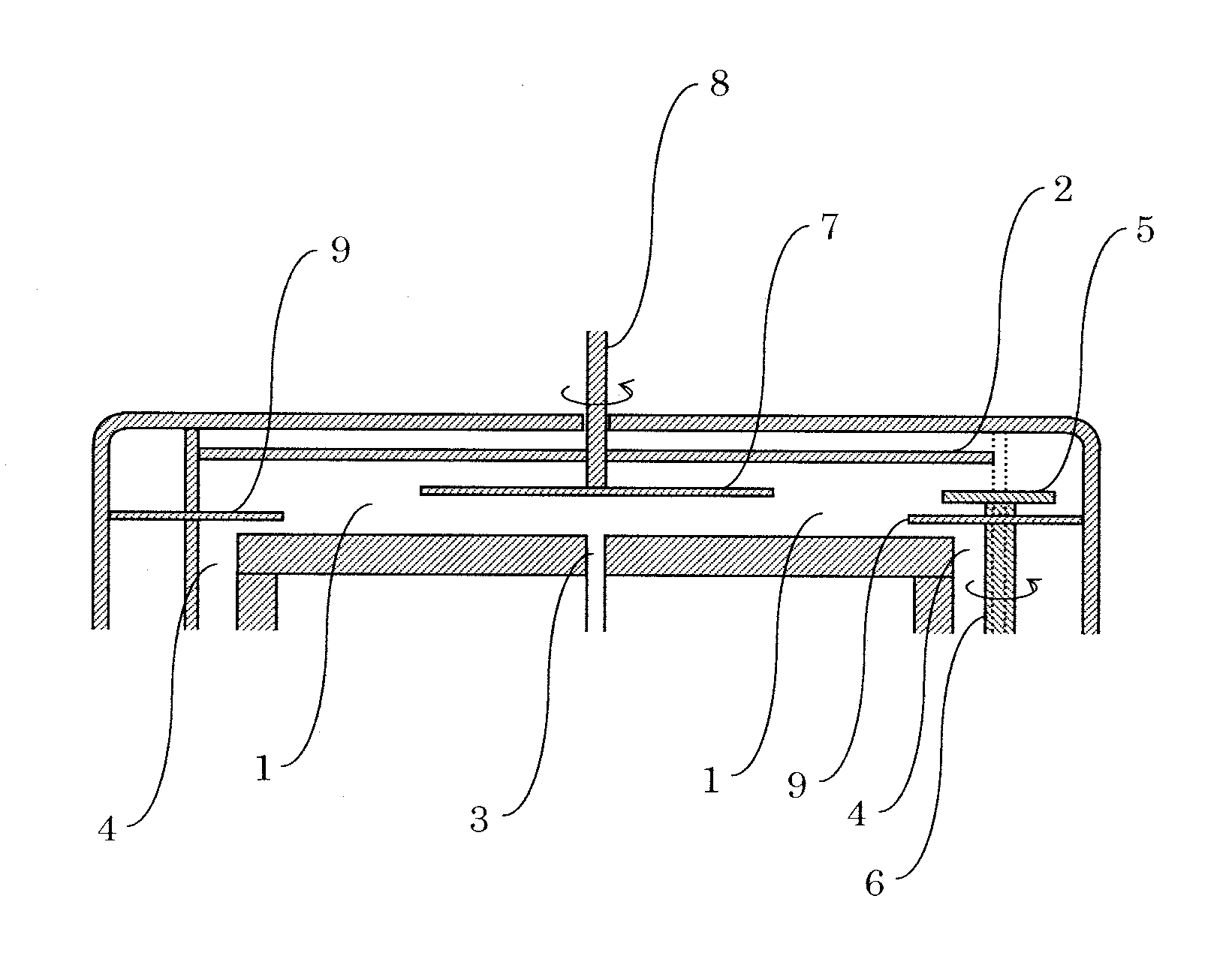

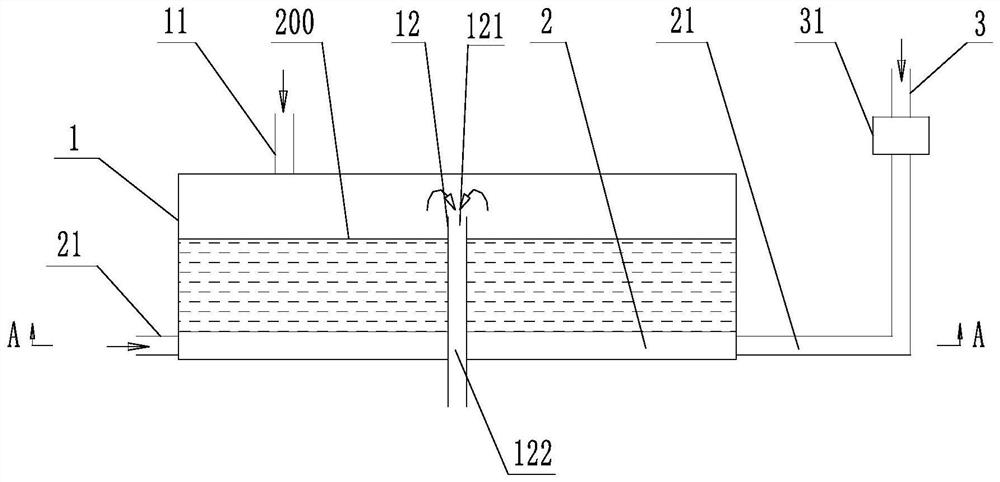

Drainage rotary substrate carrying device and vapor-phase epitaxy equipment

ActiveCN111607784AAchieve revolutionImprove yieldElectric discharge tubesChemical vapor deposition coatingVapour phase epitaxyRotational axis

The invention provides a drainage rotary substrate carrying device and vapor-phase epitaxy equipment. The drainage rotary substrate carrying device comprises a gas source device, a mother disc, a rotating device and a son disc, wherein the gas source device is used for providing source gas of vapor-phase epitaxy and the flowing mode of the source gas comprises rotary flowing; the mother disc is located below the gas source; the rotating device is connected to the mother disc so as to provide rotary power to the mother disc; and the son disc is used for carrying a substrate, the son disc is connected to the mother disc through a rotating shaft, and a volute runner is arranged on the son disc for guiding the source gas rotating rotatably to flow in the volute runner so as to drive the son disc to rotate. By pushing the son disc to rotate by the source gas in a volute line flowing mode on the surface of the son disc, planetary rotation of the device is achieved. According to the device, it is not needed to inject gas to the son disc additionally, so that a condition that residual gas damages the atmosphere of the edge of the substrate is avoided and the yield of epitaxial wafers is improved, and meanwhile, high purity flow and related gas control components can be further saved, so that the cost of the equipment is lowered greatly.

Owner:SINO NITRIDE SEMICON

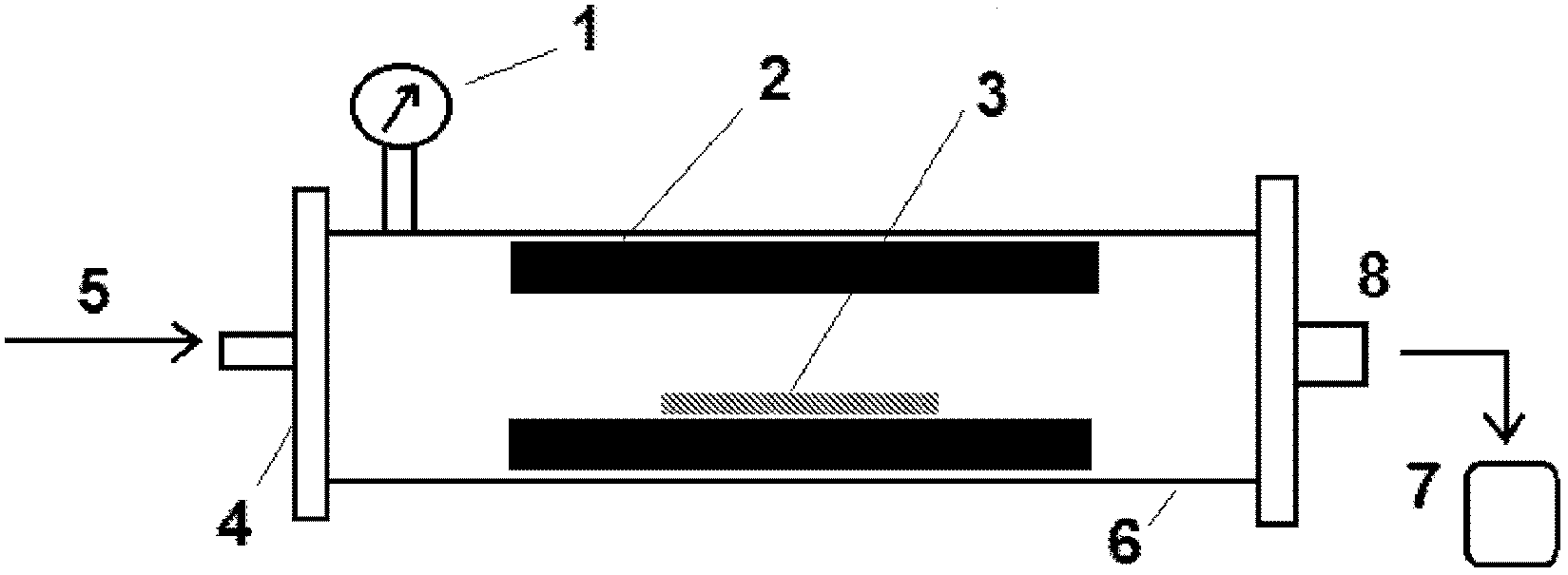

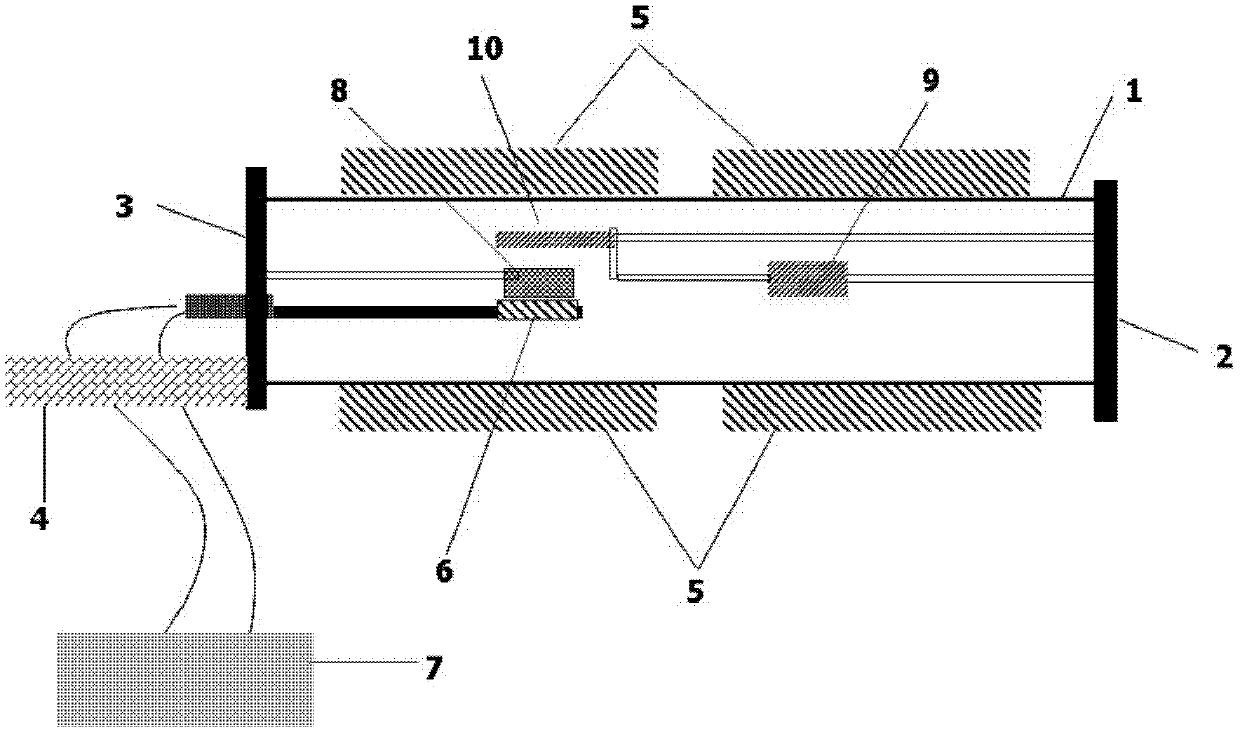

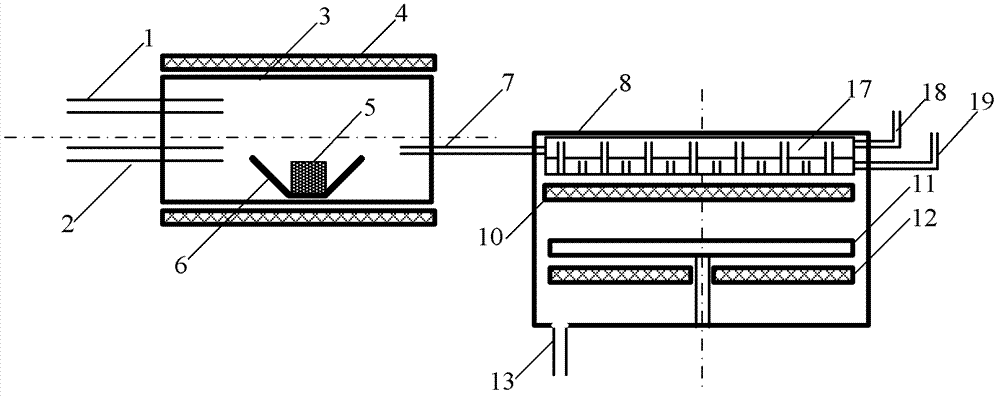

Dual heating vapor phase epitaxial growth system

InactiveCN103276444AAchieve growthStable jobFrom chemically reactive gasesMaterial growthVapour phase epitaxy

The invention discloses a dual heating hydride vapor phase epitaxial (HVPE) growth system which comprises an epitaxial growth chamber which is horizontally or vertically arranged, a dual heating device, a sample table, a metal source reactant accommodating device and a spraying device, wherein the dual heating device comprises an external heater and an internal heater; the samples are arranged on the sample table; a metal source is arranged in the metal source reactant accommodating device; the spraying device is positioned above the sample table and is connected with a second air inlet hole outside the epitaxial growth chamber; and the spraying device is used for spraying the reaction gas input from the second air inlet hole and the metallic compound entering from the metal source reactant accommodating device on the surface of the sample so as to promote the material growth. According to the dual heating device, the growth temperature of the HVPE reaction system is improved, and the high temperature area of more than 1500 is obtained in a quartz reaction area, so that the epitaxial growth of AlN and other materials can be realized; and moreover, according to the provided dual heating HVPE growth system, the energy consumption can be reduced, and the temperature control precision is improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

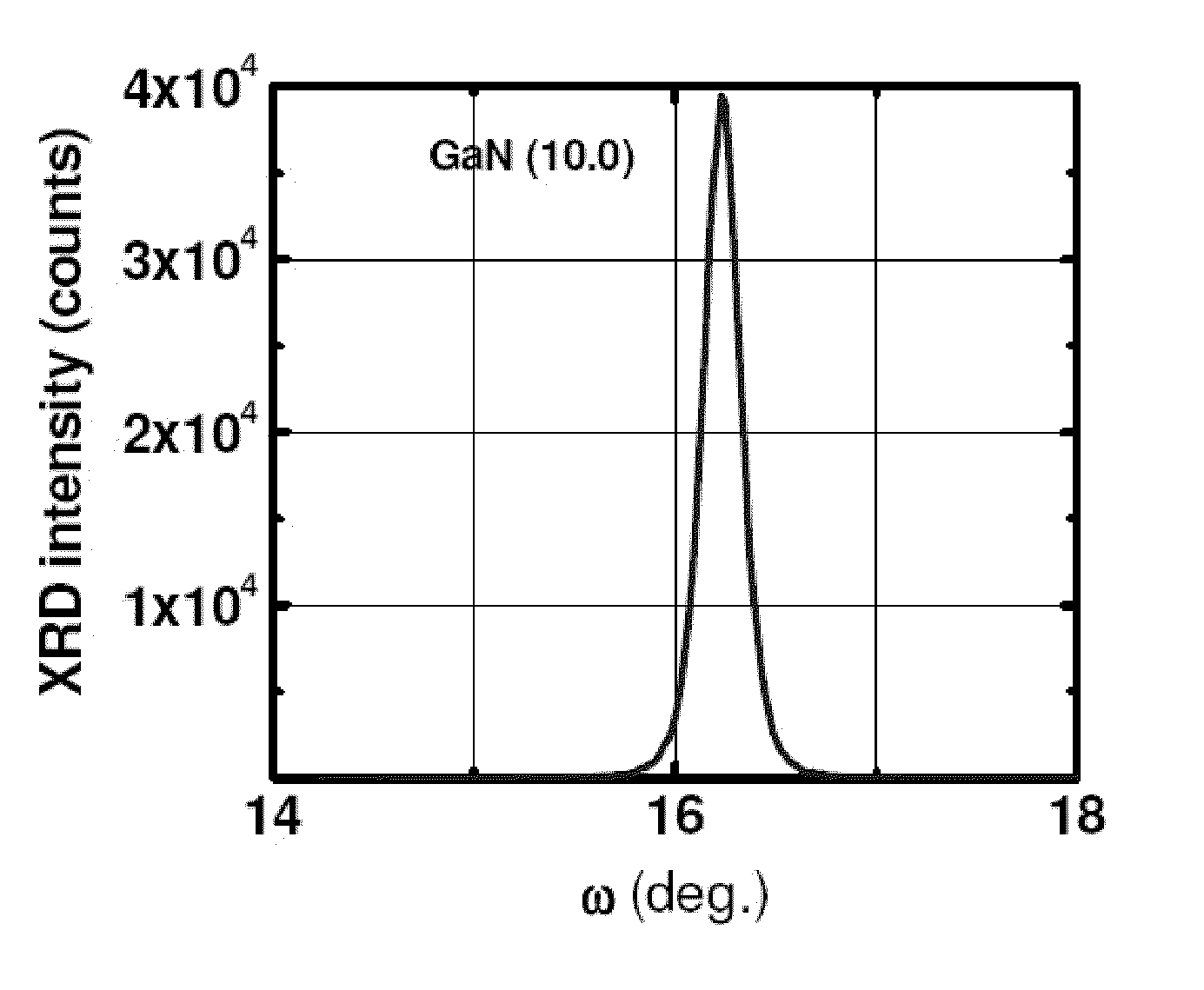

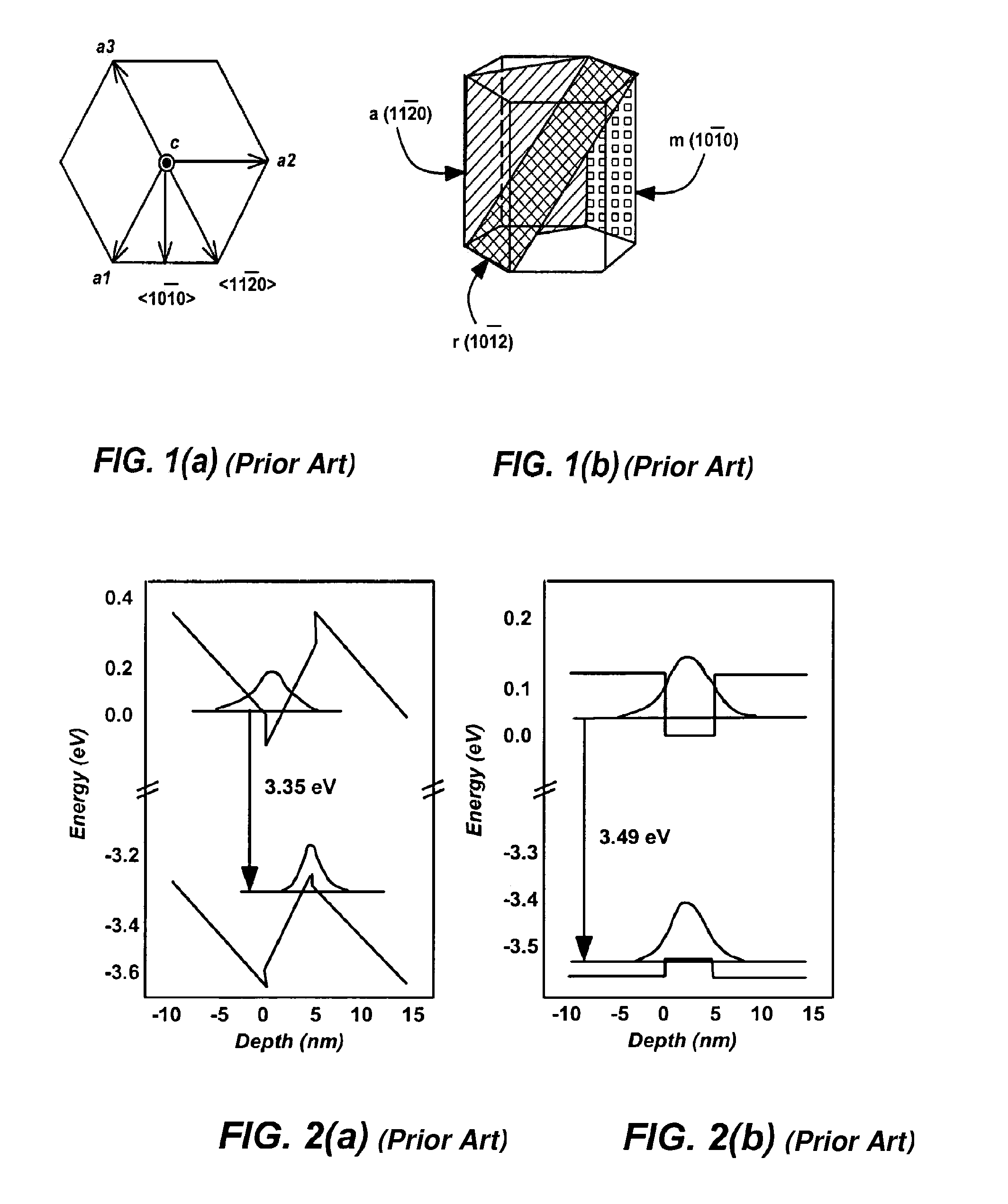

Growth of planar non-polar {10-10} M-plane gallium nitride with hydride vapor phase epitaxy (HVPE)

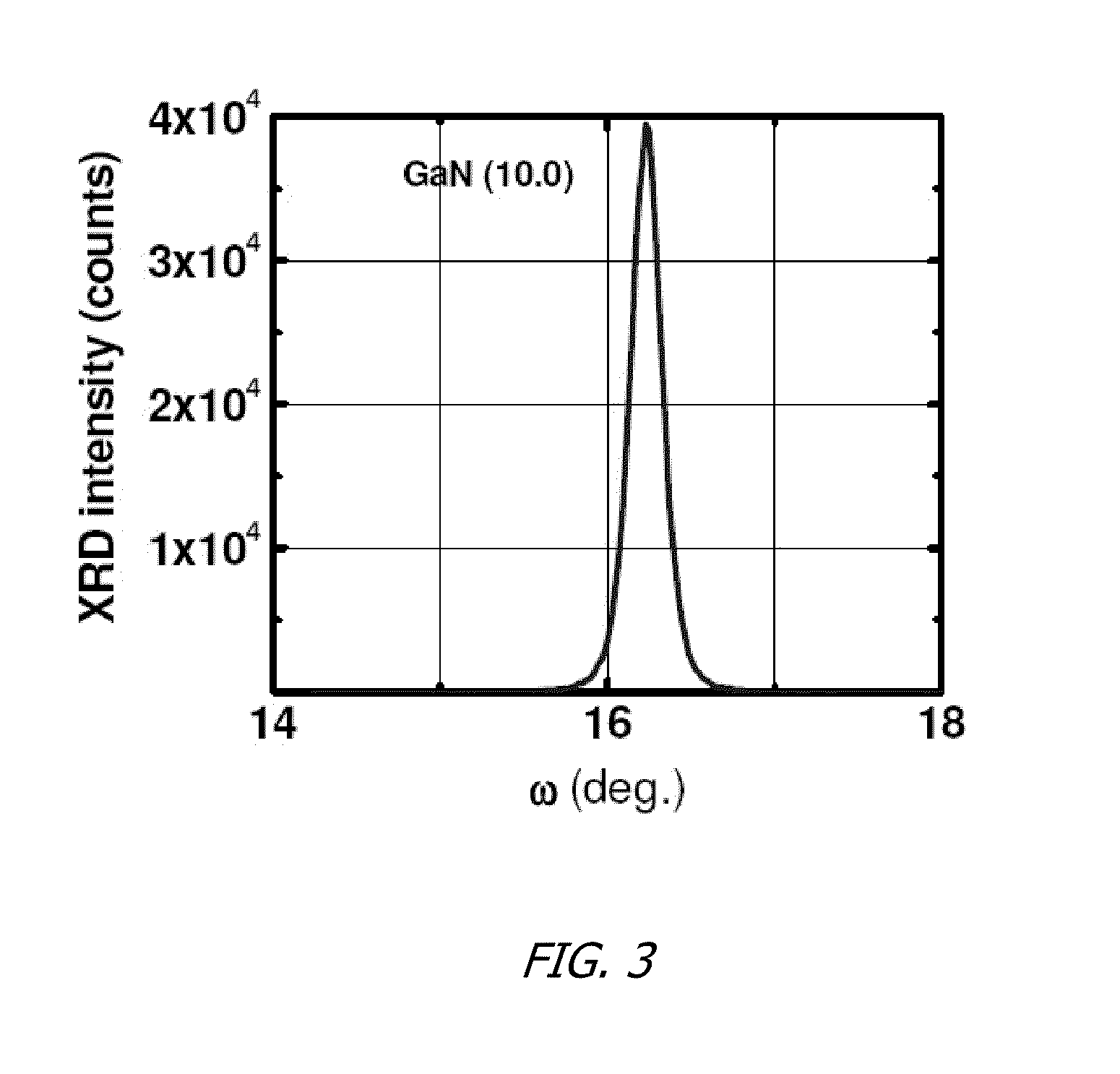

ActiveUS8629065B2Polycrystalline material growthSemiconductor/solid-state device manufacturingVapour phase epitaxyAlternative methods

A method of growing planar non-polar m-plane III-Nitride material, such as an m-plane gallium nitride (GaN) epitaxial layer, wherein the III-Nitride material is grown on a suitable substrate, such as an m-plane Sapphire substrate, using hydride vapor phase epitaxy (HVPE). The method includes in-situ pretreatment of the substrate at elevated temperatures in the ambient of ammonia and argon, growing an intermediate layer such as an aluminum nitride (AlN) or aluminum-gallium nitride (AlGaN) on the annealed substrate, and growing the non-polar m-plane III-Nitride epitaxial layer on the intermediate layer using HVPE. Various alternative methods are disclosed.

Owner:OSTENDO TECH INC

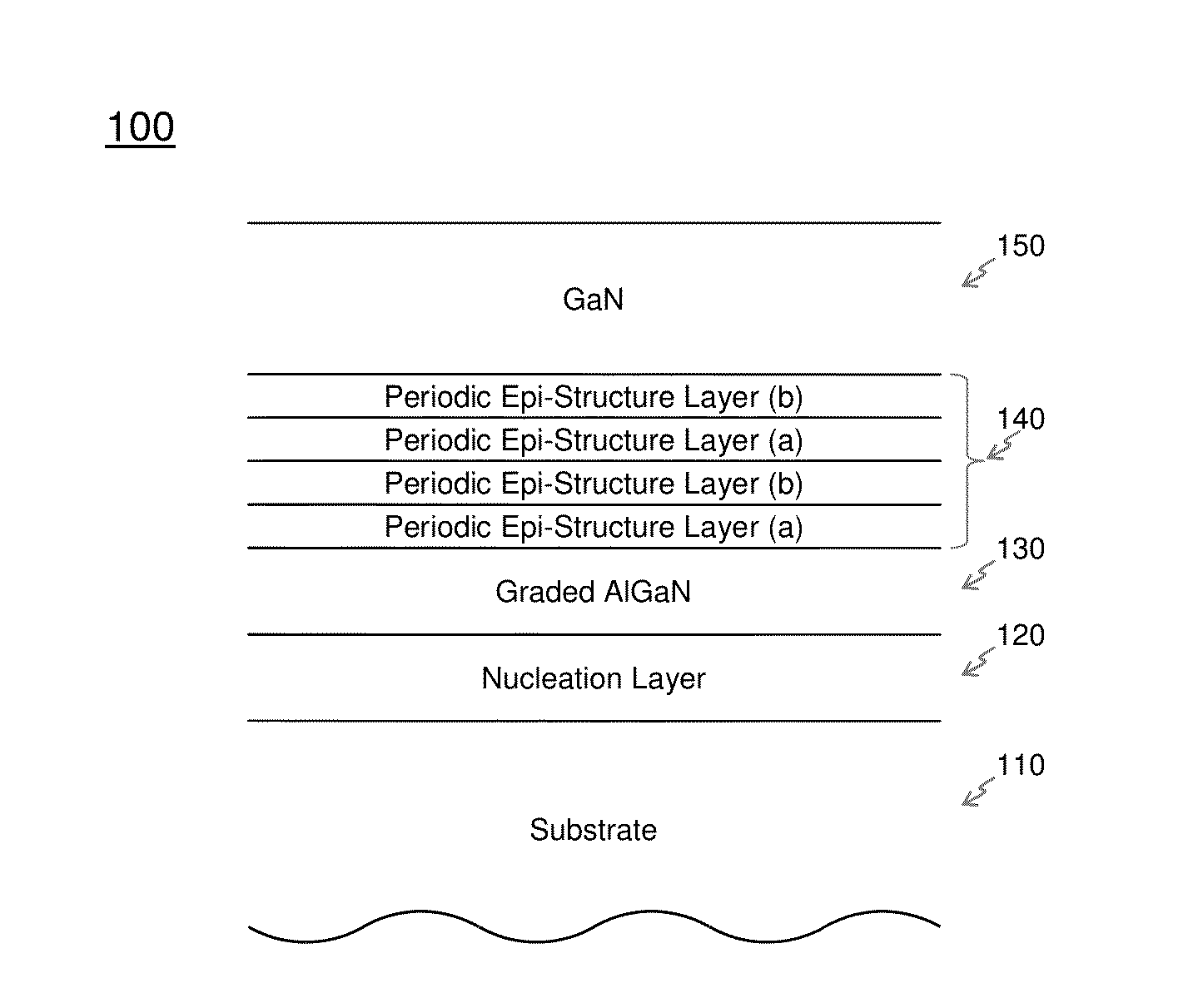

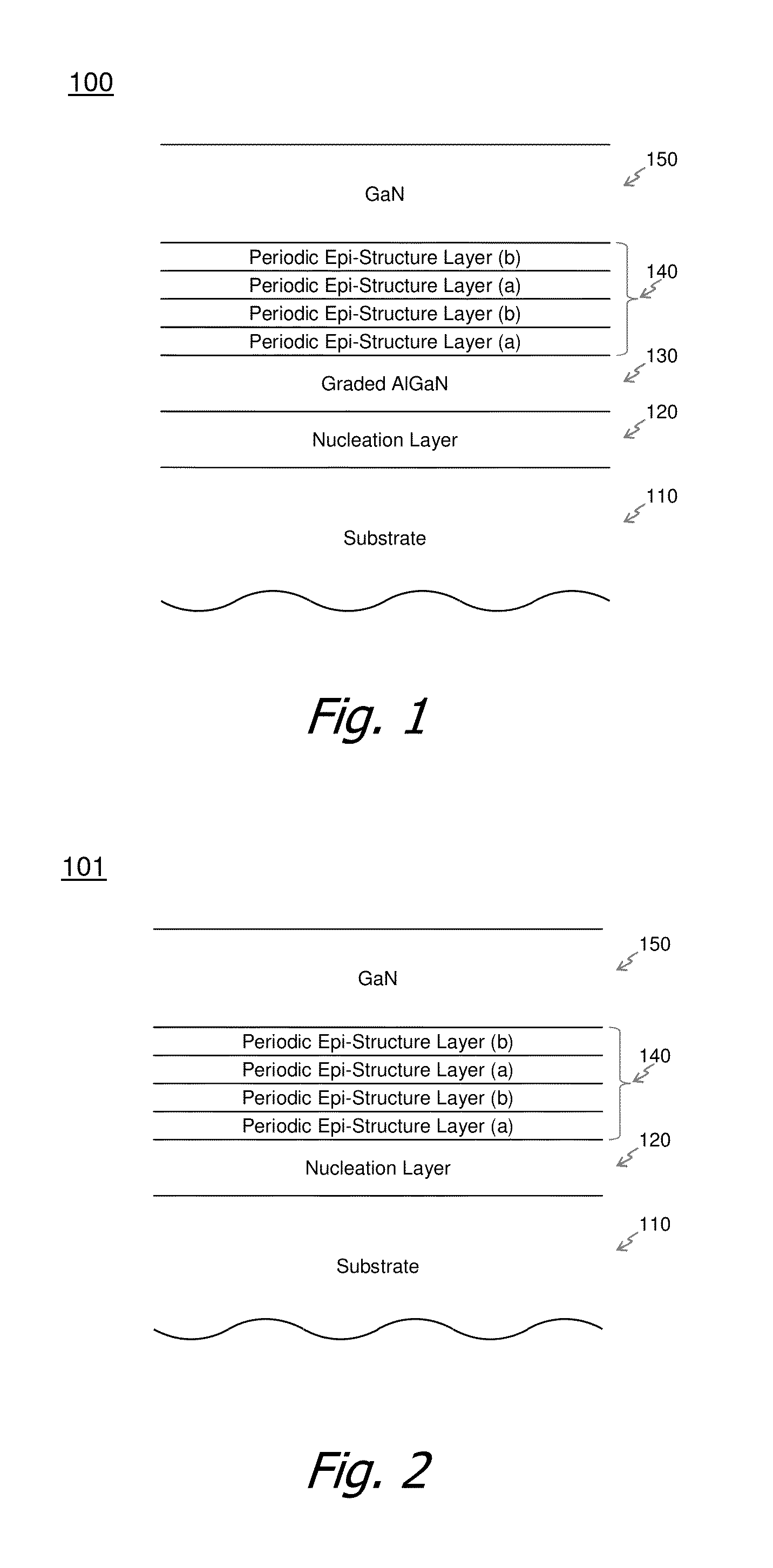

Semi-Polar III-Nitride Films and Materials and Method for Making the Same

ActiveUS20140353685A1Polycrystalline material growthSemiconductor/solid-state device manufacturingSurface roughnessVapor phase

A method has been developed to overcome deficiencies in the prior art in the properties and fabrication of semi-polar group III-nitride templates, films, and materials. A novel variant of hydride vapor phase epitaxy has been developed that provides for controlled growth of nanometer-scale periodic structures. The growth method has been utilized to grow multi-period stacks of alternating AlGaN layers of distinct compositions. The application of such periodic structures to semi-polar III-nitrides yielded superior structural and morphological properties of the material, including reduced threading dislocation density and surface roughness at the free surface of the as-grown material. Such enhancements enable to fabrication of superior quality semi-polar III-nitride electronic and optoelectronic devices, including but not limited to transistors, light emitting diodes, and laser diodes.

Owner:OSTENDO TECH INC

Vapor phase epitaxy device

ActiveCN103132138AImprove uniformityUniform flow rateFrom chemically reactive gasesVapour phase epitaxyGas phase

A vapor phase epitaxy device comprises a bottom plate, an upper cover plate, side walls located between the bottom plate and the upper cover plate and a substrate on the bottom plate. The bottom plate, the upper cover plate, the side walls and the substrate constitute a reaction cavity. The vapor phase epitaxy device further comprises at least four air discharge ports distributed at lower ends of the side walls at equal included angles, and a heating device located on the upper cover plate and opposite to the substrate, wherein the at least four air discharge ports are used for discharging air in the reaction cavity, and a plurality of heating lamp tubes are distributed on the heating device. The vapor phase epitaxy device improves uniformity of an epitaxy layer.

Owner:SEMICON MFG INT (SHANGHAI) CORP

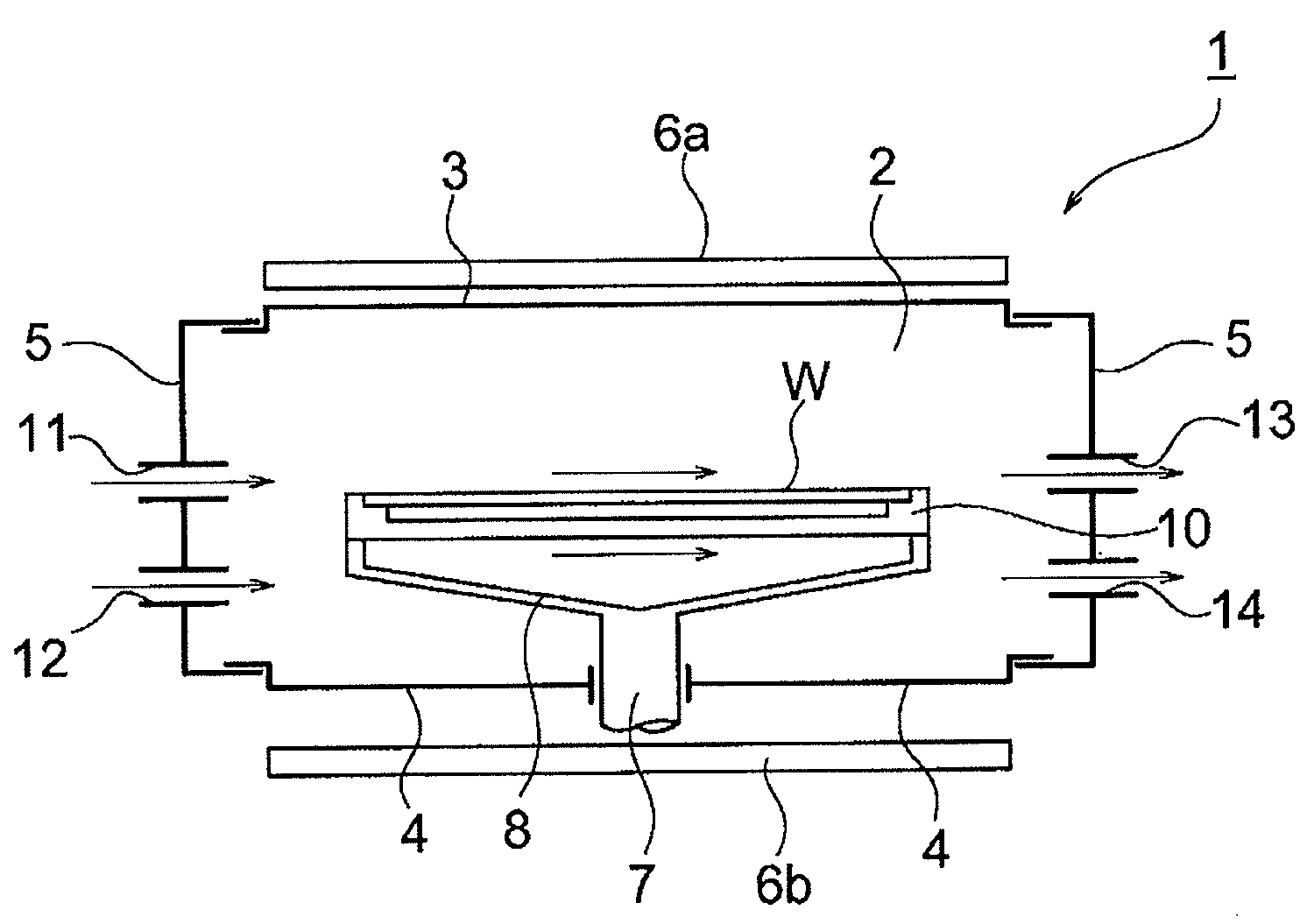

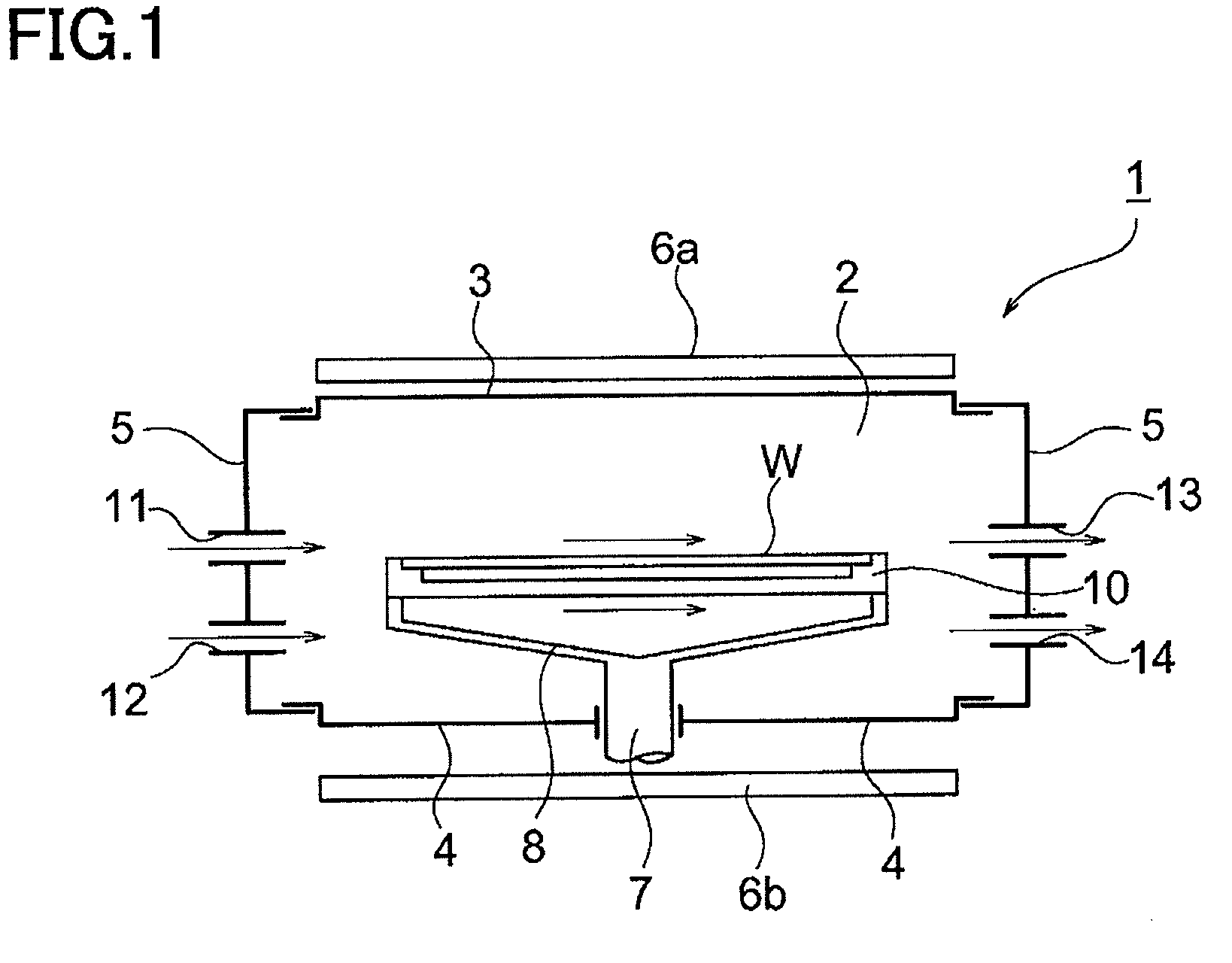

Cleaning apparatus and cleaning method for components of metal organic chemical vapor deposition device

InactiveUS20130074876A1Shorten operation timeEfficient removalSemiconductor/solid-state device manufacturingCleaning using toolsGas phasePhysical chemistry

A cleaning apparatus a metal organic chemical vapor deposition (MOCVD) device incorporating a susceptor rotatably holding the plurality of substrate holders through a rotating mechanism of a bearing; and a cleaning method for efficiently removing deposits from components of the device. The cleaning apparatus includes storage for the susceptor and the plurality of substrate holders; a means for rotating the susceptor and / or a means for rotating the plurality of substrate holders; a heater; a cleaning gas-introducing port; and a cleaning gas-discharging port. The susceptor holding the plurality of substrate holders is stored in the cleaning apparatus after the device is used for vapor phase epitaxy, and cleaning gas is introduced to the susceptor while the susceptor and / or each of the substrate holders is rotated, so as to remove deposits deposited during vapor phase epitaxy.

Owner:JAPAN PIONICS

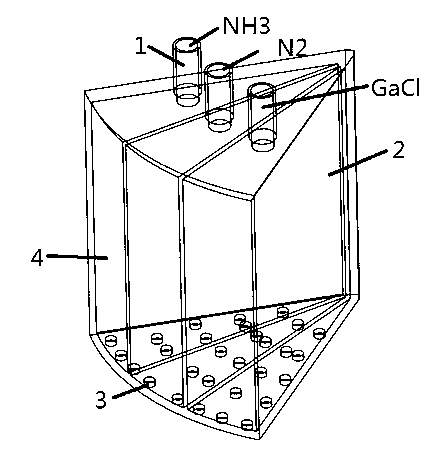

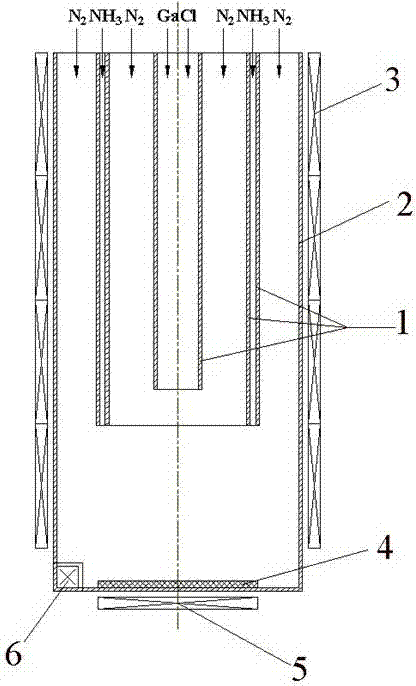

Vapor-phase epitaxy deposition apparatus realizing nitride crystal homoepitaxy

InactiveCN103088414AQuality improvementPromote growth ratePolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyGas phase

The invention relates to a vapor-phase epitaxy deposition apparatus realizing nitride crystal homoepitaxy. The device comprises a metal chloride supply chamber and a vapor-phase epitaxy reaction chamber. A heating device and a ventilation pipe are arranged outside the supply chamber. A quartz vessel is arranged inside supply chamber for accommodating a metal source. A reaction gas feeding device is arranged on the upper part of the vapor-phase epitaxy reaction chamber. A sheet carrier palate is arranged inside the vapor-phase epitaxy reaction chamber and is used for accommodating substrate materials. Heating devices are arranged above and below the sheet carrier plate. The device provided by the invention has the advantage that the heating devices are arranged above and below the sheet carrier plate, such that temperature gradient distribution in the reaction chamber is changed. Advantages of hydride vapor-phase epitaxy and metal organics chemical vapor-phase epitaxy are composed, such that nitride hydride epitaxy and metal organics epitaxy are realized in a same reaction chamber. Therefore, thick film and thin film epitaxial growth are realized, and homoepitaxy is realized. The invention can also be used in a process for improving an independent metal organics epitaxy process through changing the temperature gradient in the reaction chamber. Therefore, nitride crystal quality can be improved, and device performance can be improved.

Owner:甘志银

Hydride vapor phase epitaxy gallium boat structure

ActiveCN112126976AExtended pathImprove conversion ratePolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyEngineering

The invention relates to the technical field of semiconductors, and discloses a hydride vapor phase epitaxy gallium boat structure which comprises a boat body, and further comprises a gallium source inlet formed in the top of the boat body. A liquid gallium source is contained in the boat body. A reactant outlet pipeline arranged in the boat body, the top end of thereactant outlet pipeline is higher than the liquid level of theliquid gallium source, the bottom end of the reactant outlet pipeline penetrates out of the bottom wall of the boat body; a gas distribution disc is also arranged on thebottom wall in the boat body, a hydrogen chloride inlet is formed in the side face of the gas distribution disc, at least one hydrogen chloride outlet is formed in the top end of a pipeline of the gas distribution disc, and each hydrogen chloride outlet is located below the liquid level of the liquid gallium source. The gallium boat structure has the advantages that the hydrogen chloride conversion rate is high, the contact area of hydrogen chloride and a liquid gallium source is large, and the hydrogen chloride path is effectively prolonged.

Owner:紫石能源有限公司

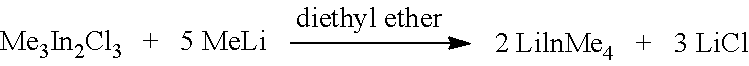

Method for producing alkyl-indium compounds and the use thereof

ActiveUS20160207942A1High yieldHigh purityGroup 3/13 element organic compoundsVapour phase epitaxyIndium

The invention relates to a method for the cost-effective and environmentally friendly production of alkyl indium sesquichloride in high yield and with high selectivity and purity. The alkyl indium sesquichloride produced according to the invention is particularly suitable, also as a result of the high purity and yield, for the production, on demand, of indium-containing precursors in high yield and with high selectivity and purity. As a result of the high purity, the indium-containing precursors that can be produced are particularly suitable for metal organic chemical vapour deposition (MOCVD) or metal organic vapour phase epitaxy (MOVPE). The novel method according to the invention is characterised by the improved execution of the method, in particular a rapid process control. Owing to targeted and extensive use of raw materials that are cost-effective and have a low environmental impact, the method is also suitable for use on an industrial scale.

Owner:UMICORE AG & CO KG

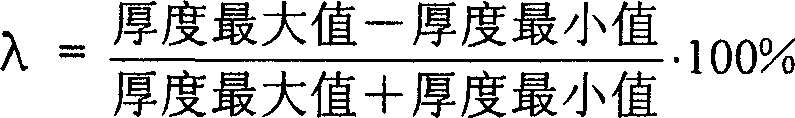

Homogeneous-thickness silicon-phase epitaxial-layer growth device and method

InactiveCN1896340AAvoid temperature differenceConsistent thicknessPolycrystalline material growthFrom chemically reactive gasesMetal impuritiesEngineering

The present invention discloses a growth device and process of a silicon vapor epilayer and aims at providing a growth device and a process with homogeneous epilayer, convenient operation and high efficiency. The growth device includes a base body, a fixing slot on the base body, a step of 1-3mm wide on the edge of the fixing slot bottom, an annular groove of 1-3mm deep on the step and an arcual concave of 1-5mm deep below the step. The top of the annular groove is 1-3mm wide. The growth process includes the following steps: the silicon substrate wafer is positioned in the fixing slot with the upper surface of the substrate wafer 0.1-1mm lower than the upper surface of the base, and the epilayer grows. This invention has simple arts and crafts, provides homogeneous epilayer, controls the distribution area of the slip lines and removes the contaminative layer of metal impurities on the surface, improving the quality of the silicon epilayer and ensuring the performance of the product.

Owner:HEBEI UNIV OF TECH

Hydride vapor phase epitaxy device

InactiveCN103132140AImprove crystal qualityScalablePolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxySimple Organic Compounds

The invention discloses a hydride vapor phase epitaxy device. The hydride vapor phase epitaxy device comprises a vapor phase epitaxy reaction chamber. An upper part of the vapor phase epitaxy reaction chamber is provided with an air inlet device. A quartz boat is arranged below the air inlet device. A lower part of the vapor phase epitaxy reaction chamber is provided with a slide tray. Heaters are arranged below and above the slide tray. The heater below the slide tray is isolated from a reaction zone by a slide tray support. The bottom of the vapor phase epitaxy reaction chamber is provided with an exhaust port. The hydride vapor phase epitaxy device can realize preparation of a metal chloride in the vapor phase epitaxy reaction chamber and realize material epitaxy, and has a simple structure. The heaters below and above the slide tray can adjust temperature gradient distribution in the vapor phase epitaxy reaction chamber so that material crystal quality is improved. The hydride vapor phase epitaxy device has an extensible design and can be combined with metallo-organic compound vapor phase epitaxy equipment.

Owner:甘志银

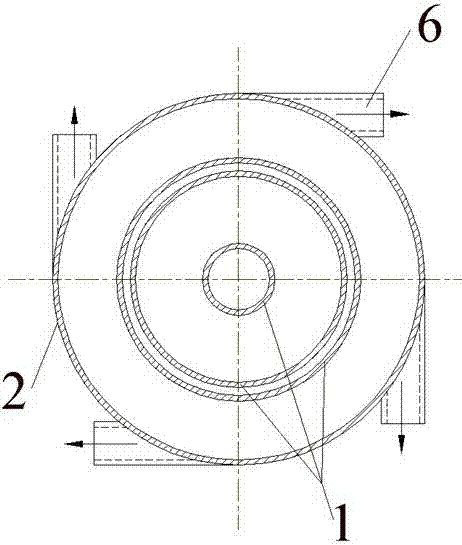

Reactor and method for vapor phase epitaxy of nitride semiconductor material

ActiveCN103789823AIncreasing the thicknessImprove uniformityPolycrystalline material growthFrom chemically reactive gasesVapour phase epitaxyBuffer strip

The invention discloses a reactor and a method for hydride vapor phase epitaxy (HVPE) of a nitride semiconductor material. The reactor comprises an axial symmetrical cylindrical reaction cavity, a concentric annular spray nozzle, a heater, a graphite boat, a substrate and the like, wherein the graphite boat and the substrate are heated by adopting resistance wire or infrared light irradiation; three to six gas outlet channels with rectangular cross sections are arranged in the tangential direction of the outer wall of the bottom end of the cavity; a concentric annular buffer strip is arranged among the outlet channels and the inner wall of the cavity, and a concentric annular flow collecting channel is arranged on the peripheries of the outlet channels; the outlet channels are communicated with the flow collecting channel. The reactor disclosed by the invention has the advantages that reactant gas forms micro-rotational flow in the effective growing zone of the substrate, so that the epitaxial growth thickness and the uniformity of components are obviously improved; as a graphite boat rotating device and auxiliary assemblies in a conventional reactor are omitted, the reactor is simplified, energy-saving and convenient to maintain, and the adverse impact of the rotating movement instability on the epitaxial growth is also eliminated.

Owner:SINO NITRIDE SEMICON +1

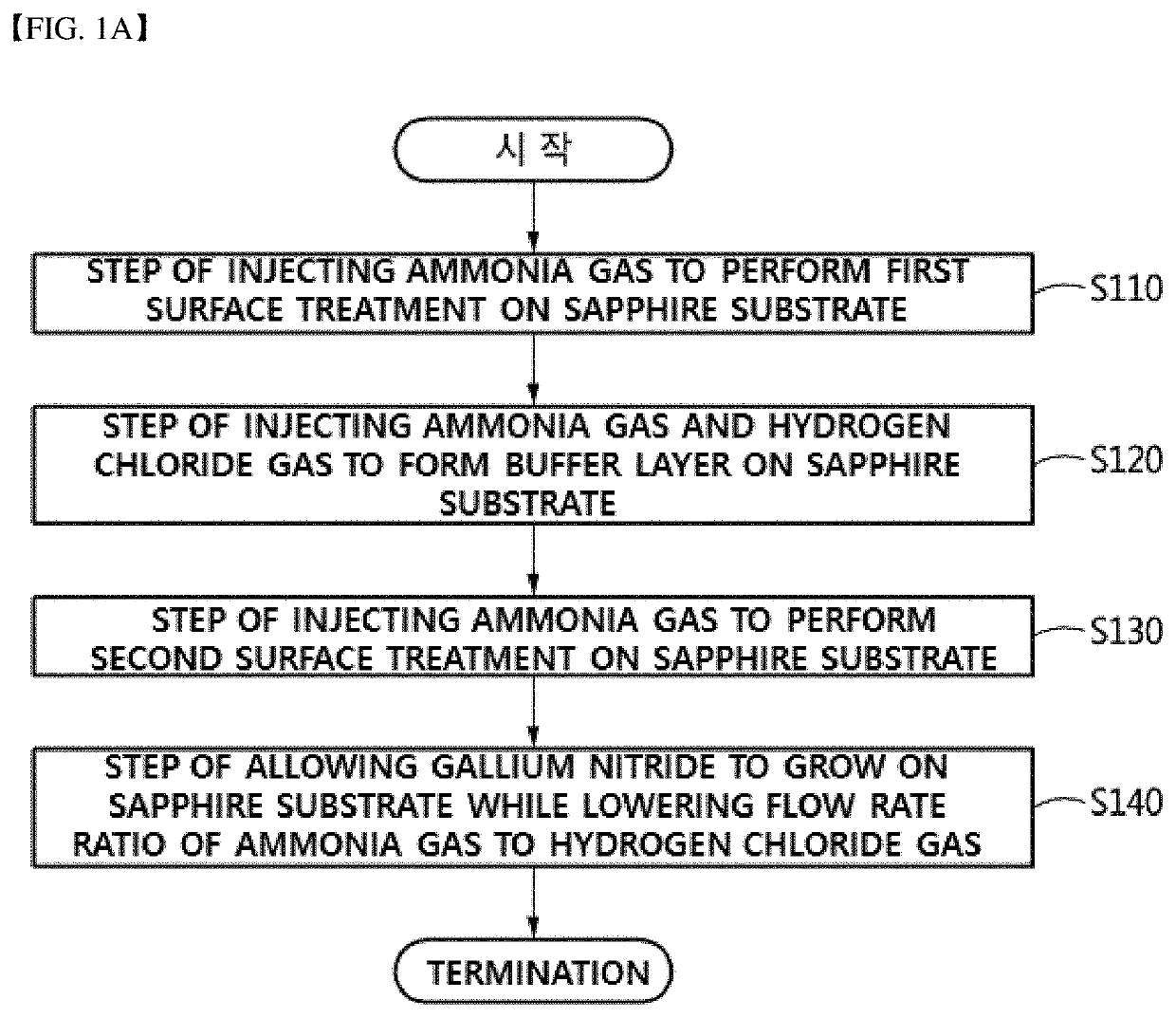

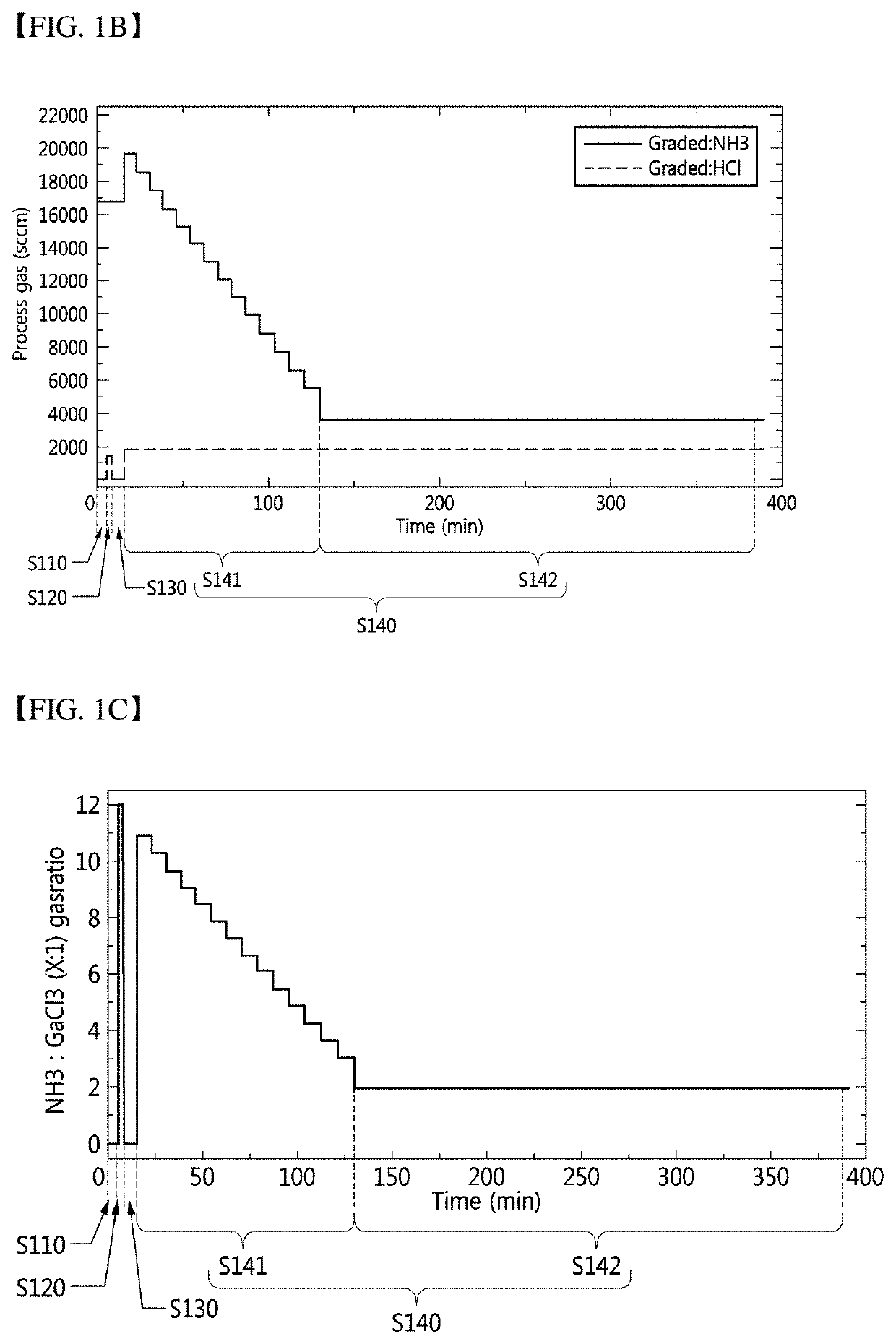

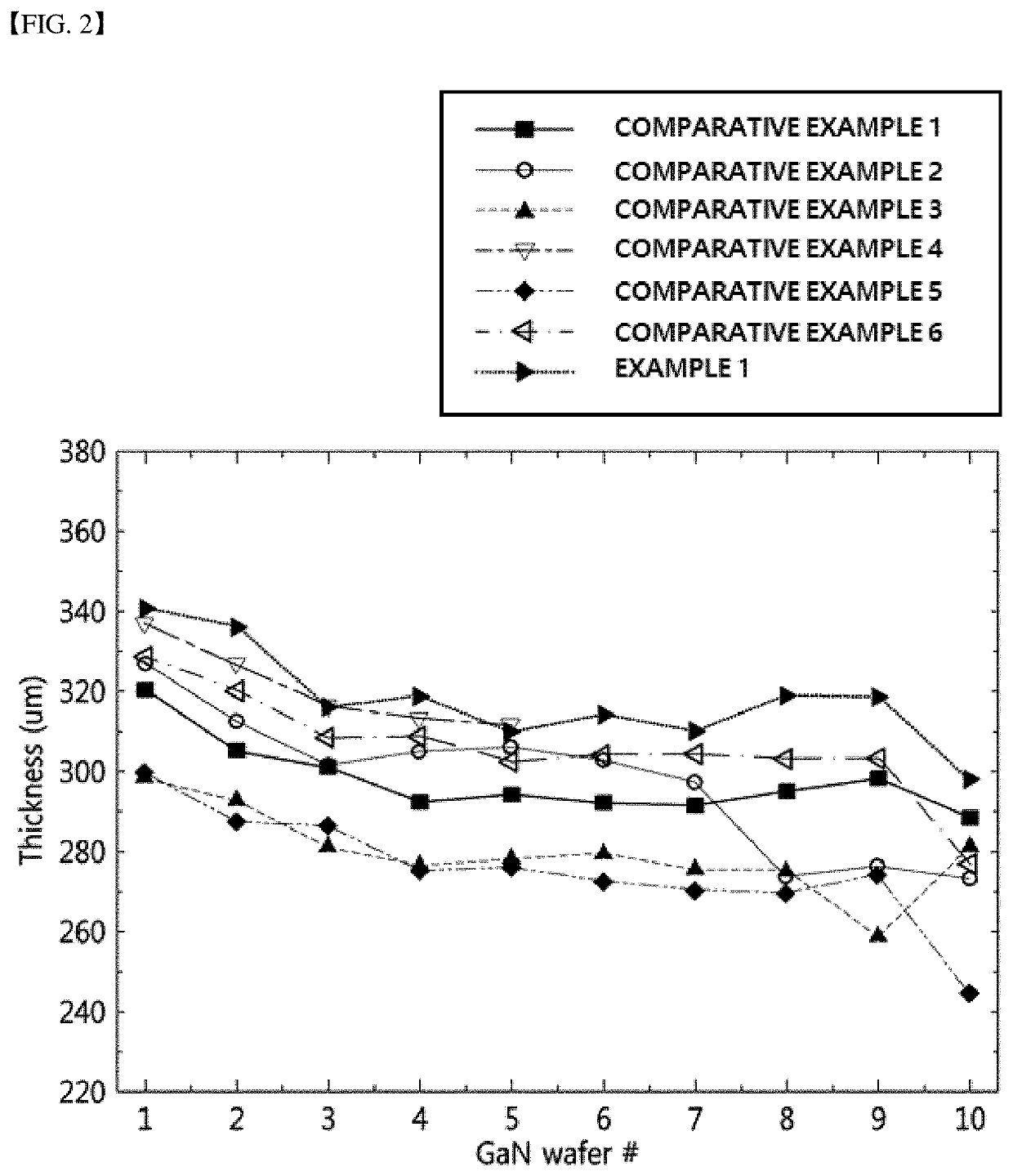

Method for manufacturing gallium nitride substrate using the hydride vapor phase epitaxy

ActiveUS20190371597A1Reduce the ratioPreventing poly galliumSemiconductor/solid-state device manufacturingSemiconductor devicesVapour phase epitaxyGallium nitride

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

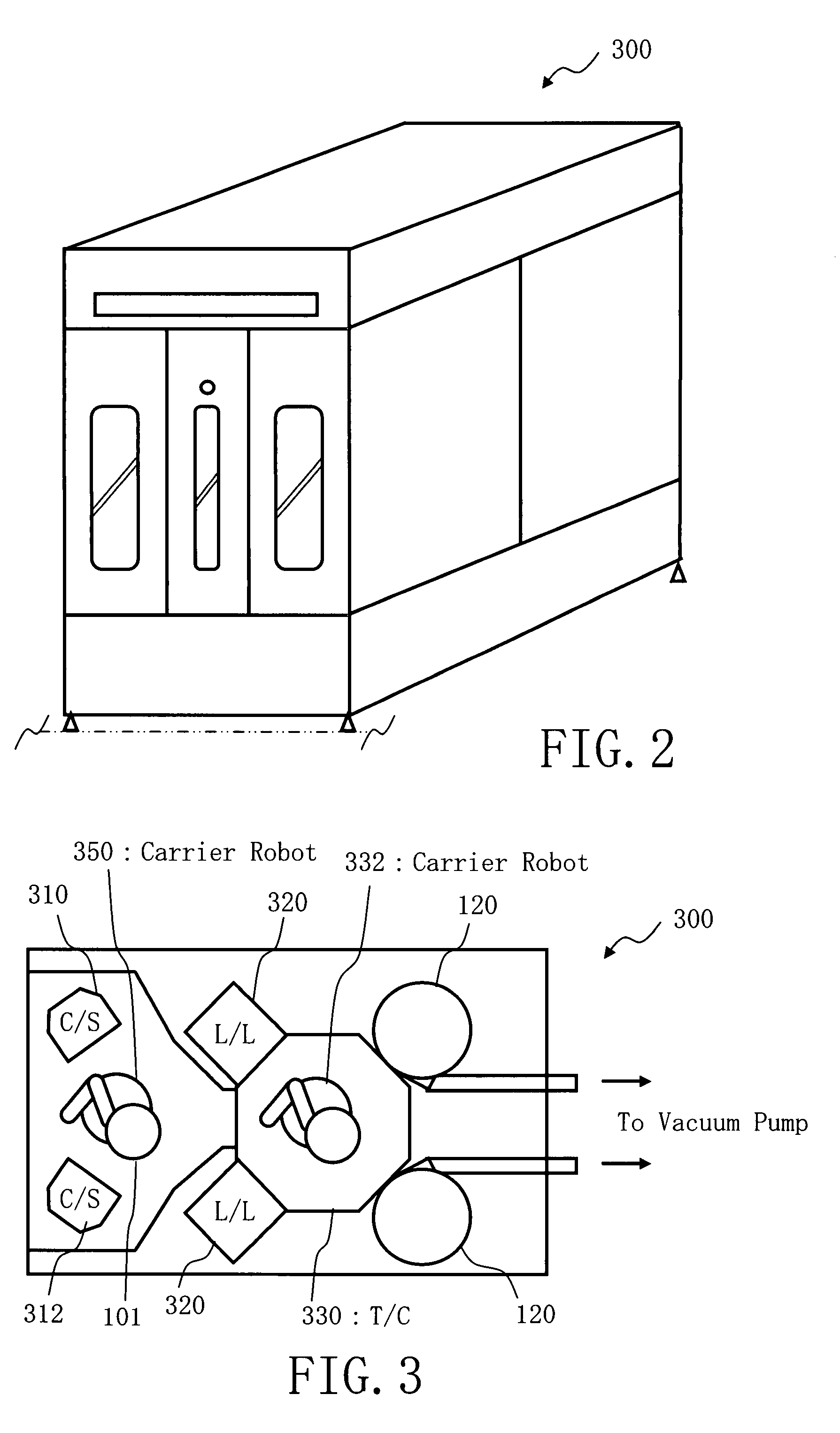

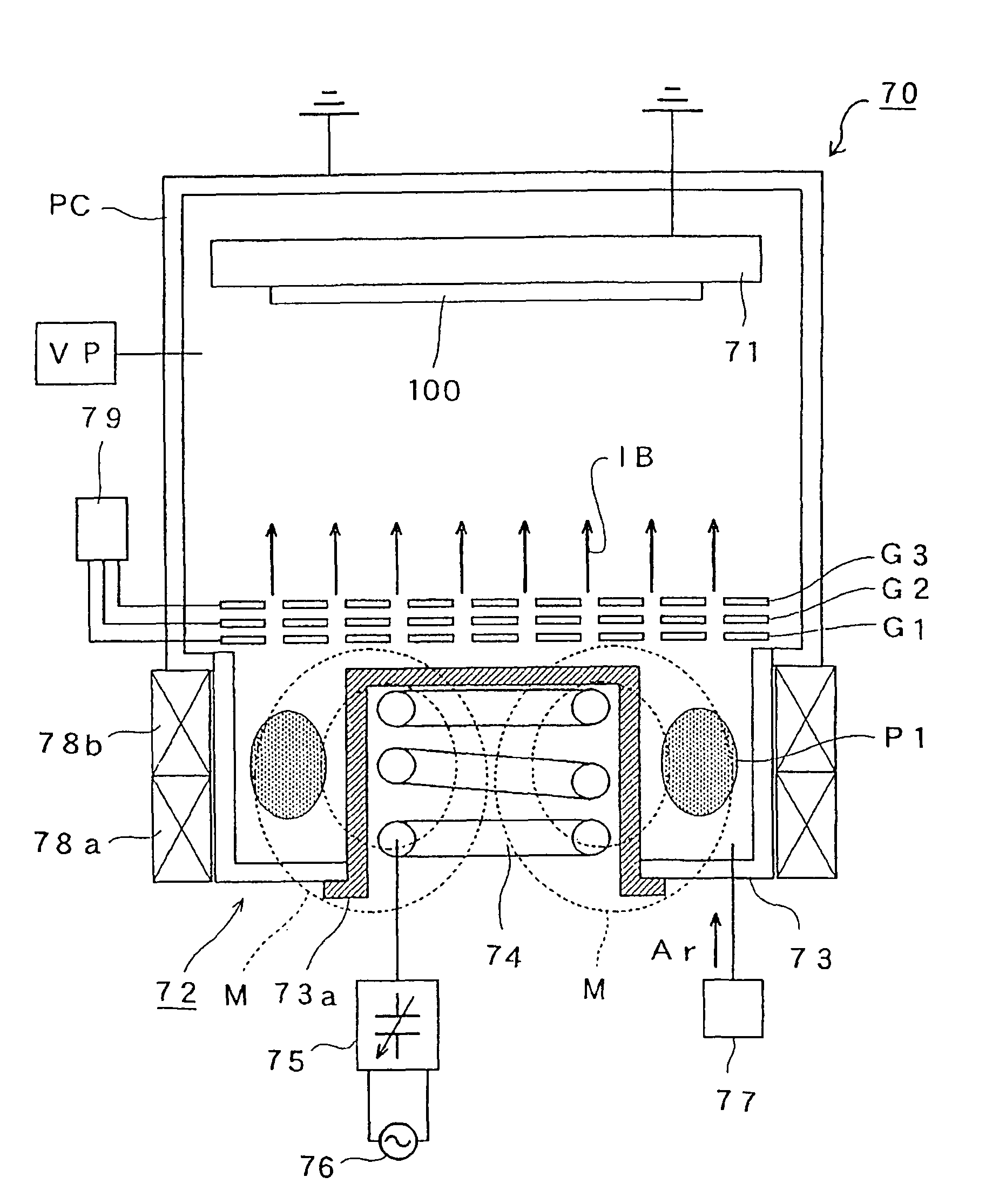

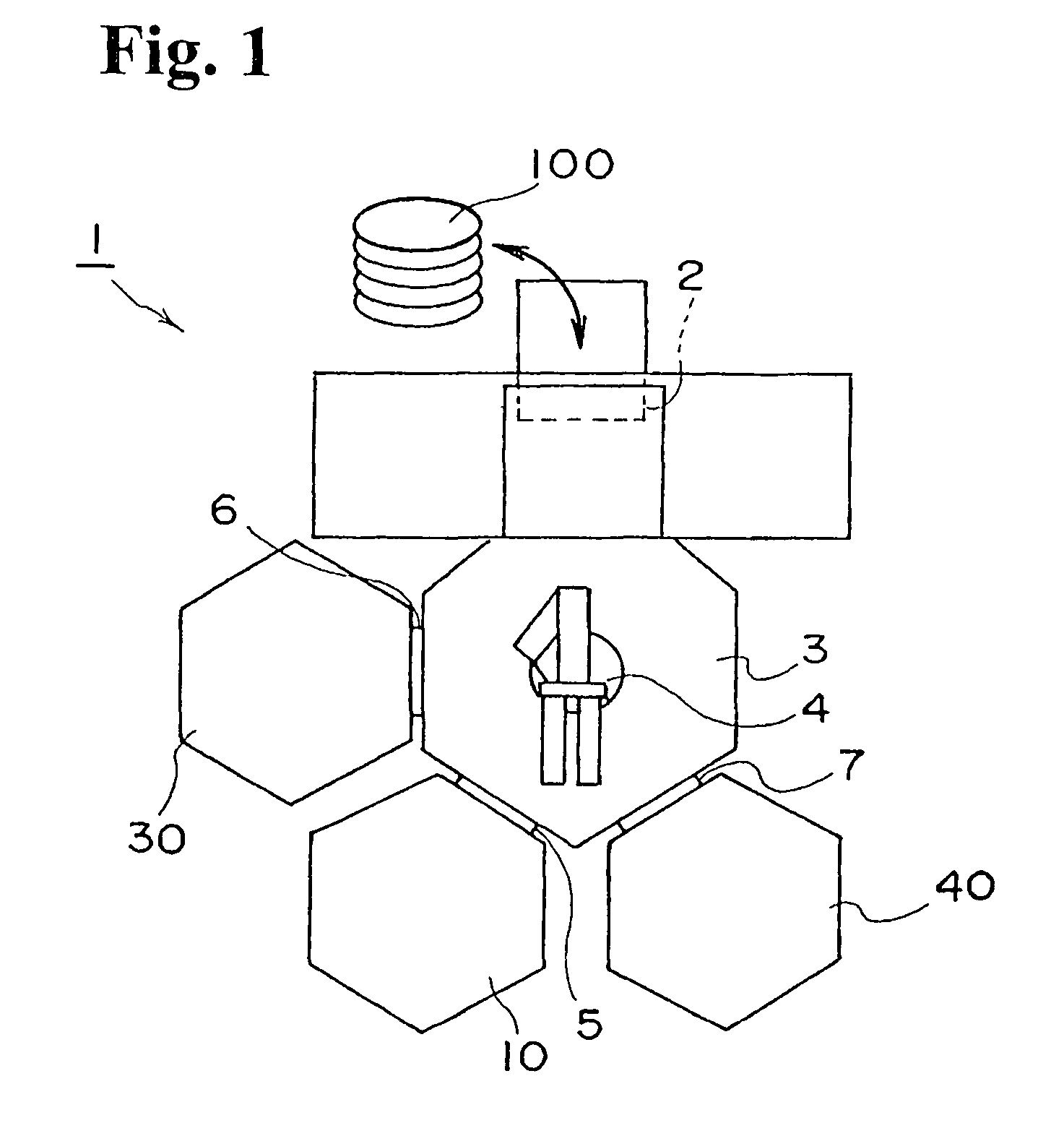

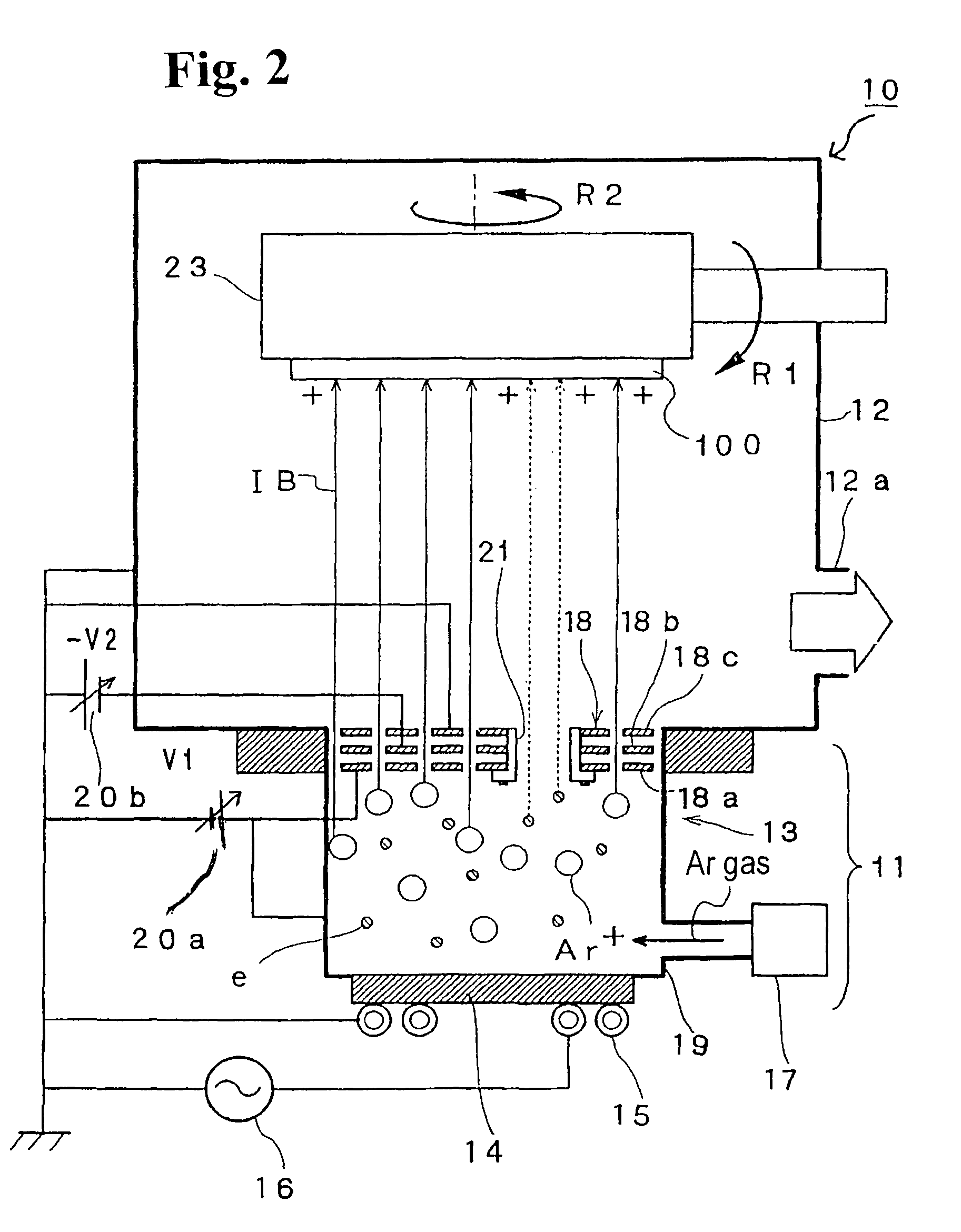

Composite coating device and method of forming overcoat on magnetic head using the same

InactiveUS7862694B2Eliminate the effects ofVacuum evaporation coatingSputtering coatingElectron cyclotron resonanceSputter deposition

A composite coating device includes first to third processing chambers. The first processing chamber performs an ion beam etching as a pretreatment process in which an ion beam is irradiated on a surface of a magnetic head at a predetermined angle and the surface is removed for a predetermined depth. The second processing chamber performs a magnetron sputter deposition as a shock absorbing coating formation process in which a shock absorbing coating is formed on the pretreated surface. The third processing chamber performs an electron cyclotron resonance plasma chemical vapor epitaxy or a cathode arc discharge deposition as an overcoat formation process in which an overcoat is formed on the shock absorbing coating. A preparation chamber communicates with the first to third processing chambers through opening and closing devices for transferring the magnetic head.

Owner:SHIMADZU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com