Patents

Literature

72results about How to "Achieve revolution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

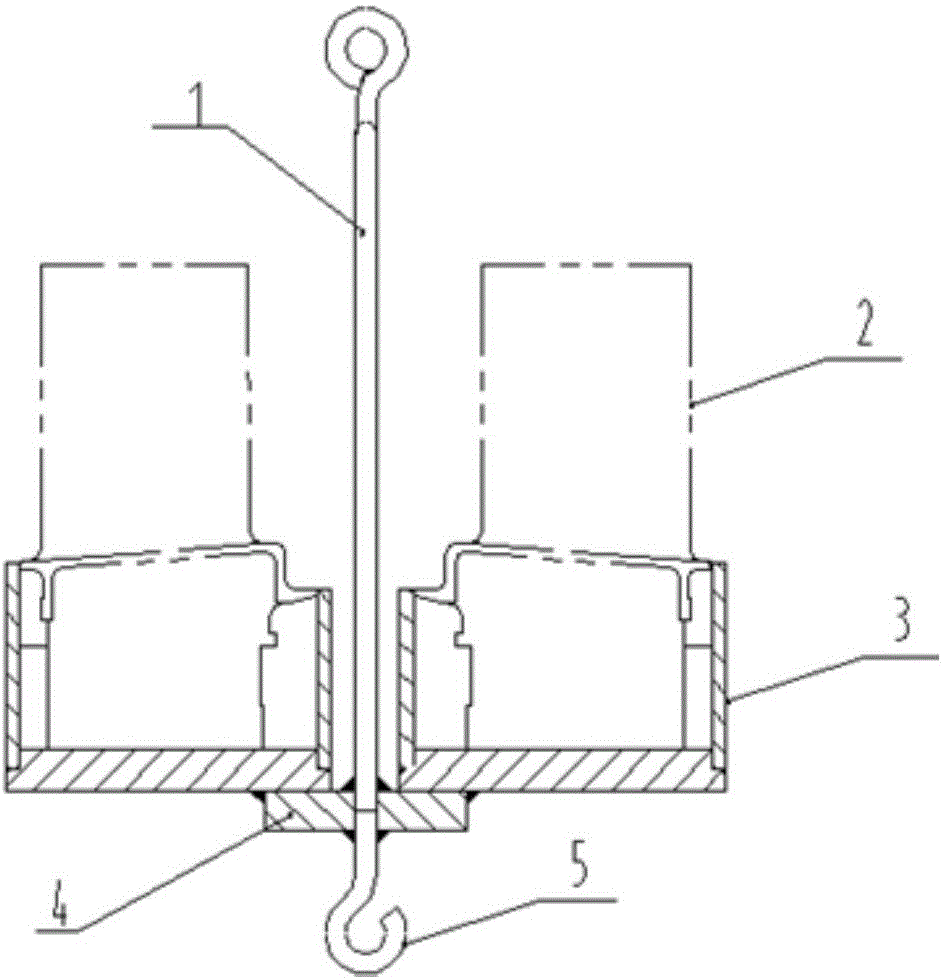

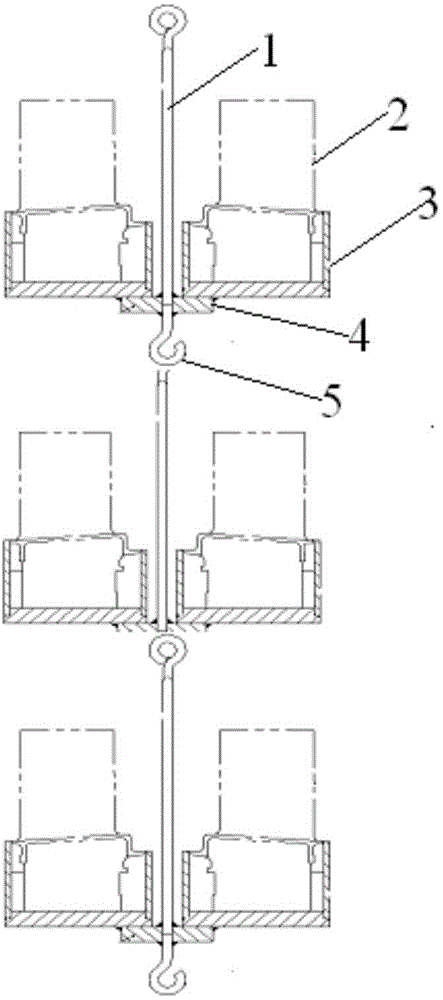

Tool for depositing coating on multi-arc ion plating equipment and usage method thereof

ActiveCN104404454AGuaranteed uniformityEasy to useVacuum evaporation coatingSputtering coatingTurbine bladeEngineering

The invention discloses a tool for depositing a coating on multi-arc ion plating equipment and a usage method thereof. The tool comprises a pull bar, positioning boxes, a connection plate and suspension hooks; two ends of the pull bar are provided with the suspension hooks, the bottom end of the pull bar is provided with the connection plate, and the positioning boxes used for putting turbine blades are arranged on the connection plate at two sides of the pull bar. The provided tool is simple in structure, convenient for maintenance, novel in design and convenient and rapid for mounting and dismounting. The tool protects a tenon, and also guarantees the uniformity of the thickness of the coating on various areas of the turbine blades and a margin plate upper surface, in other words, the usage performance of the coating is guaranteed. The tool protects the tenon through a physical shielding principle, the blade bodies simultaneous realize revolution and rotation in the coating process, two blades are arranged in a parallel way, and all blades are uniformly coated to form coatings by controlling the distance between the turbine working blades to not generate the physical shielding phenomenon.

Owner:AECC AVIATION POWER CO LTD

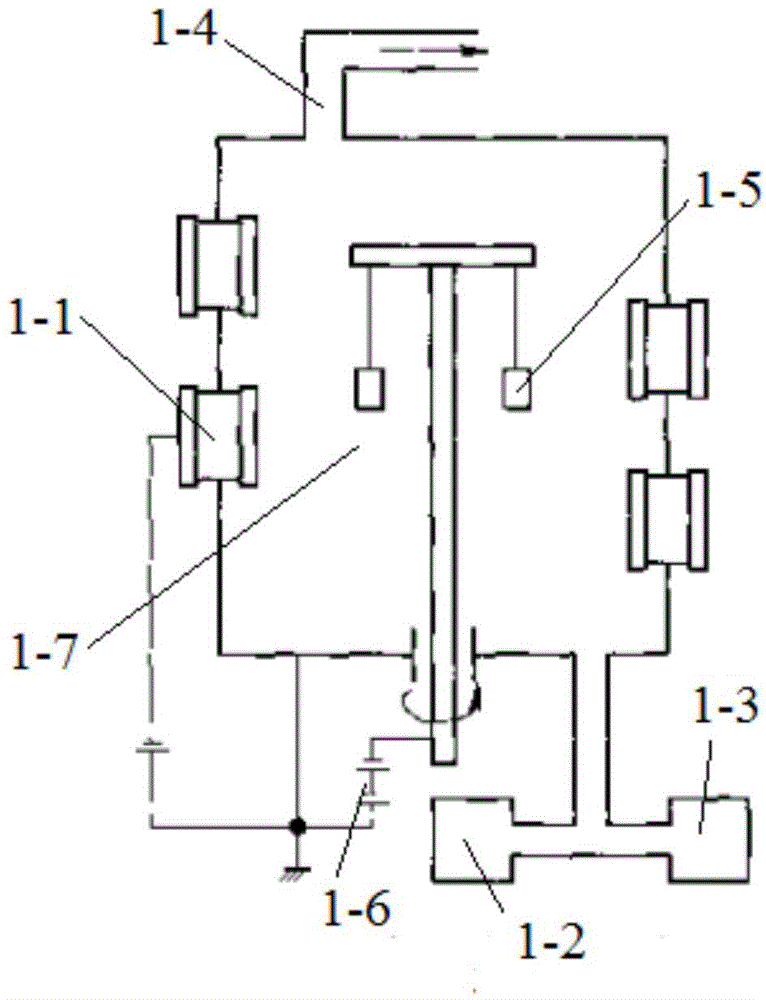

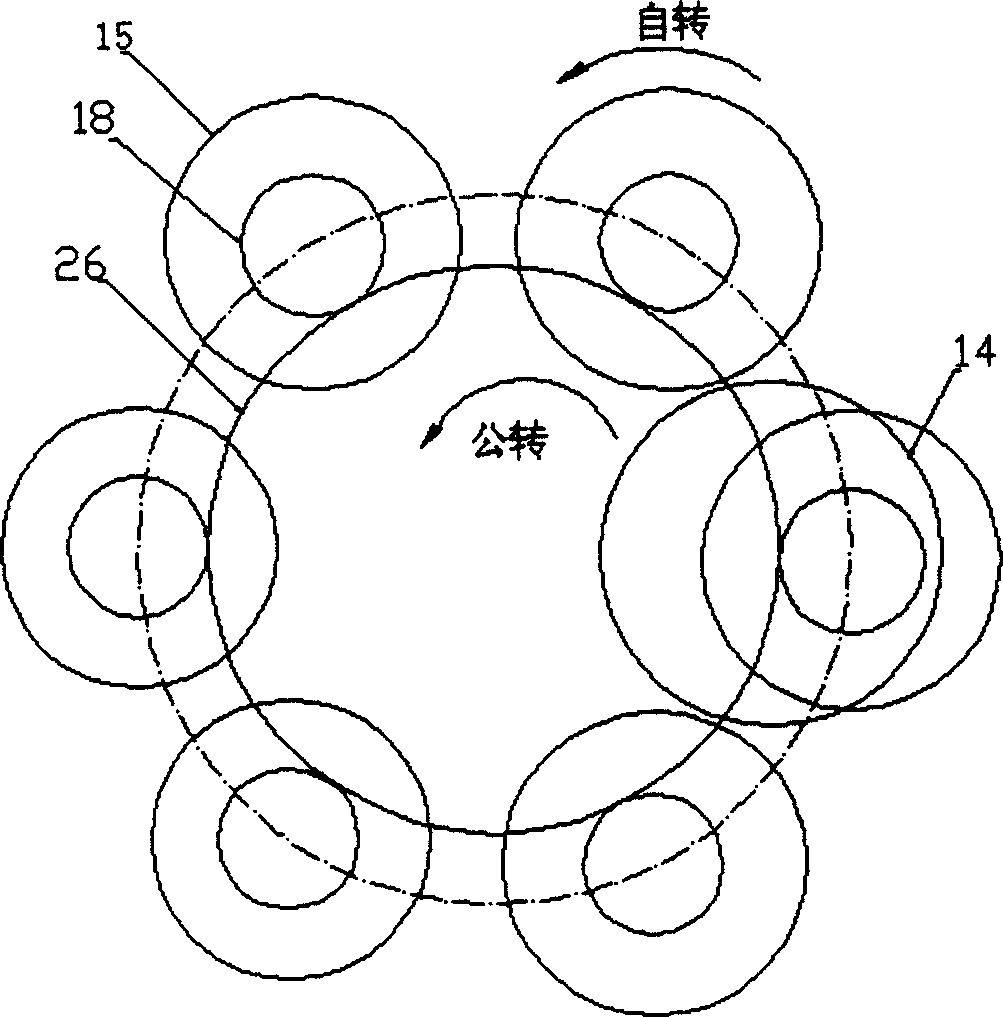

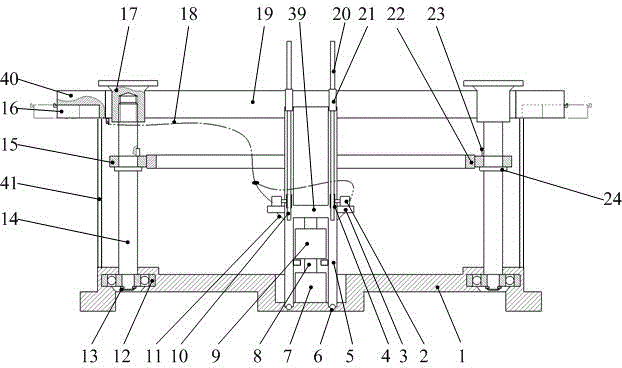

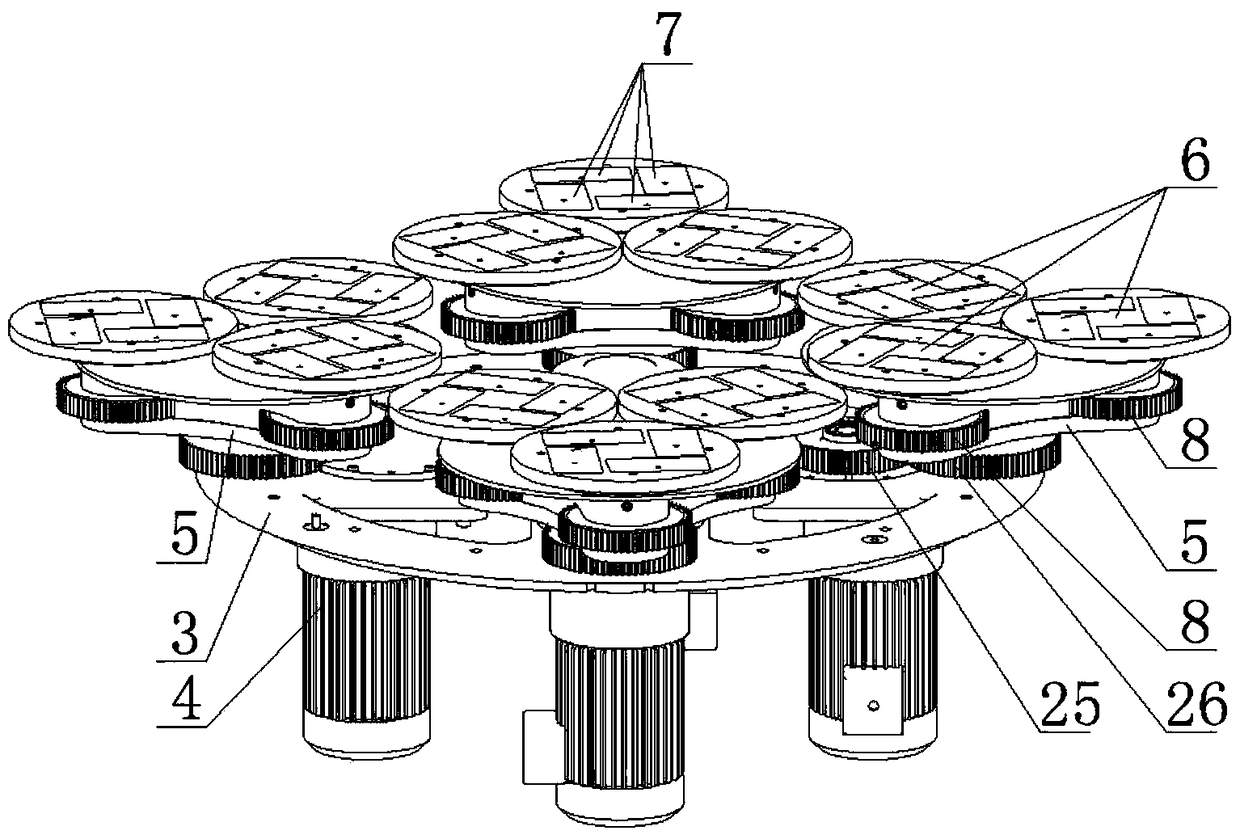

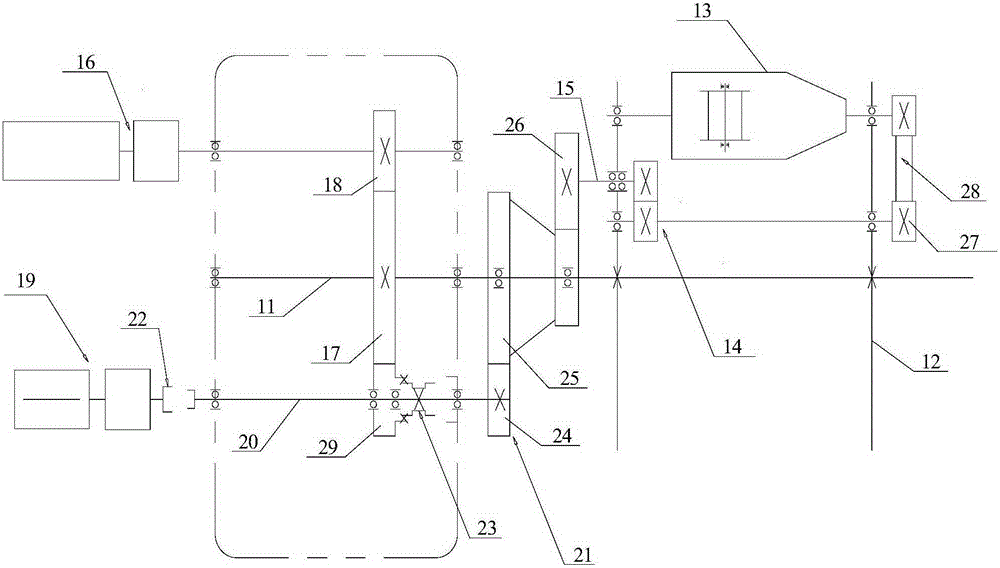

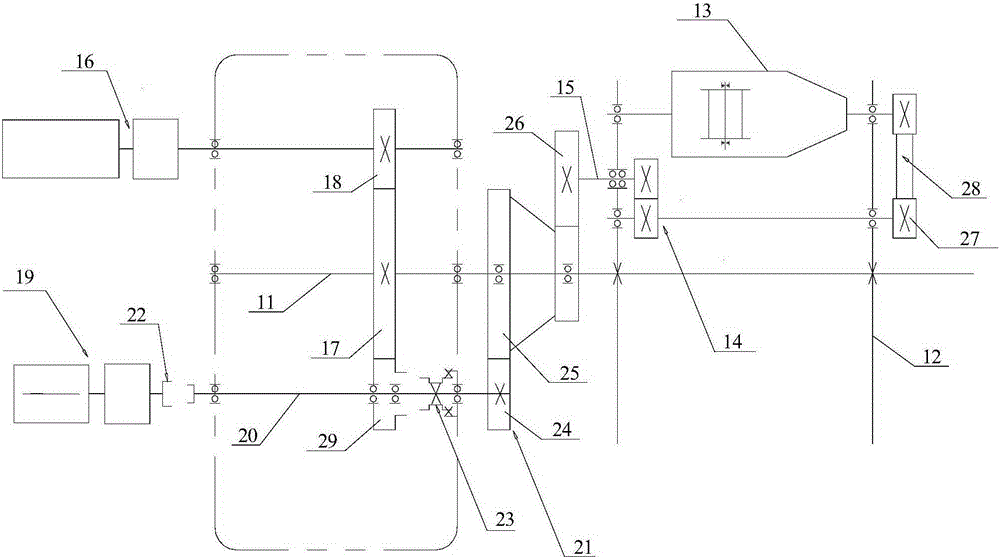

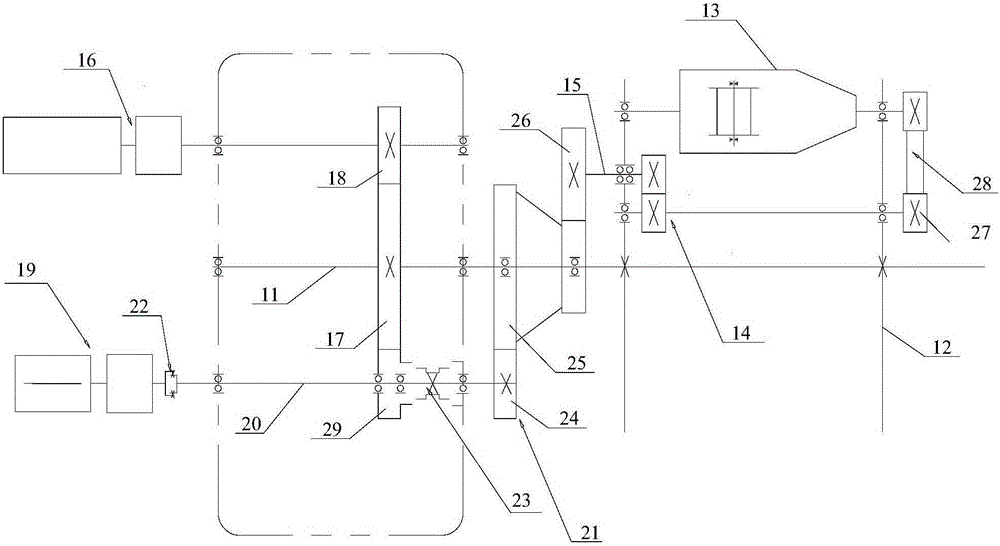

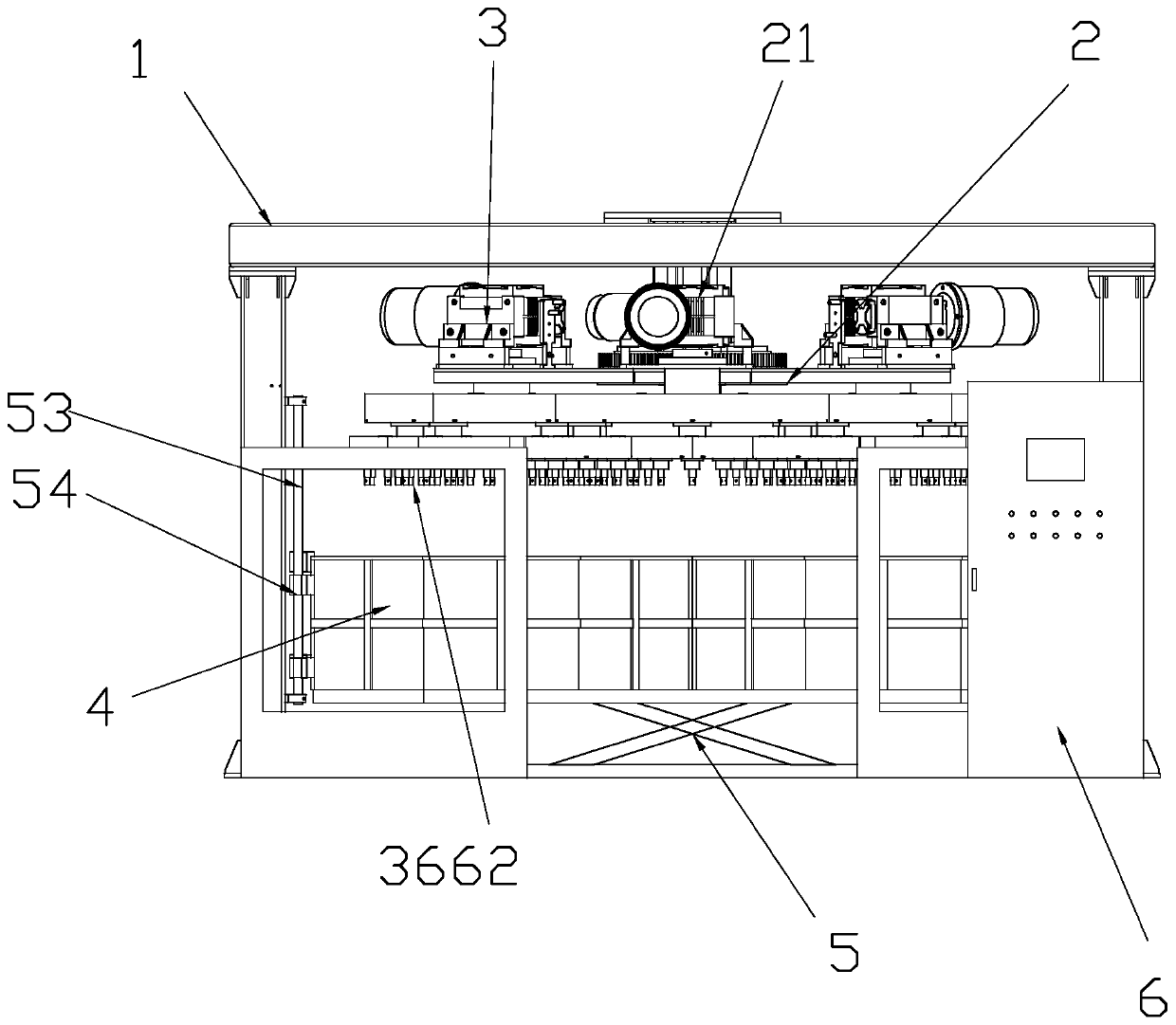

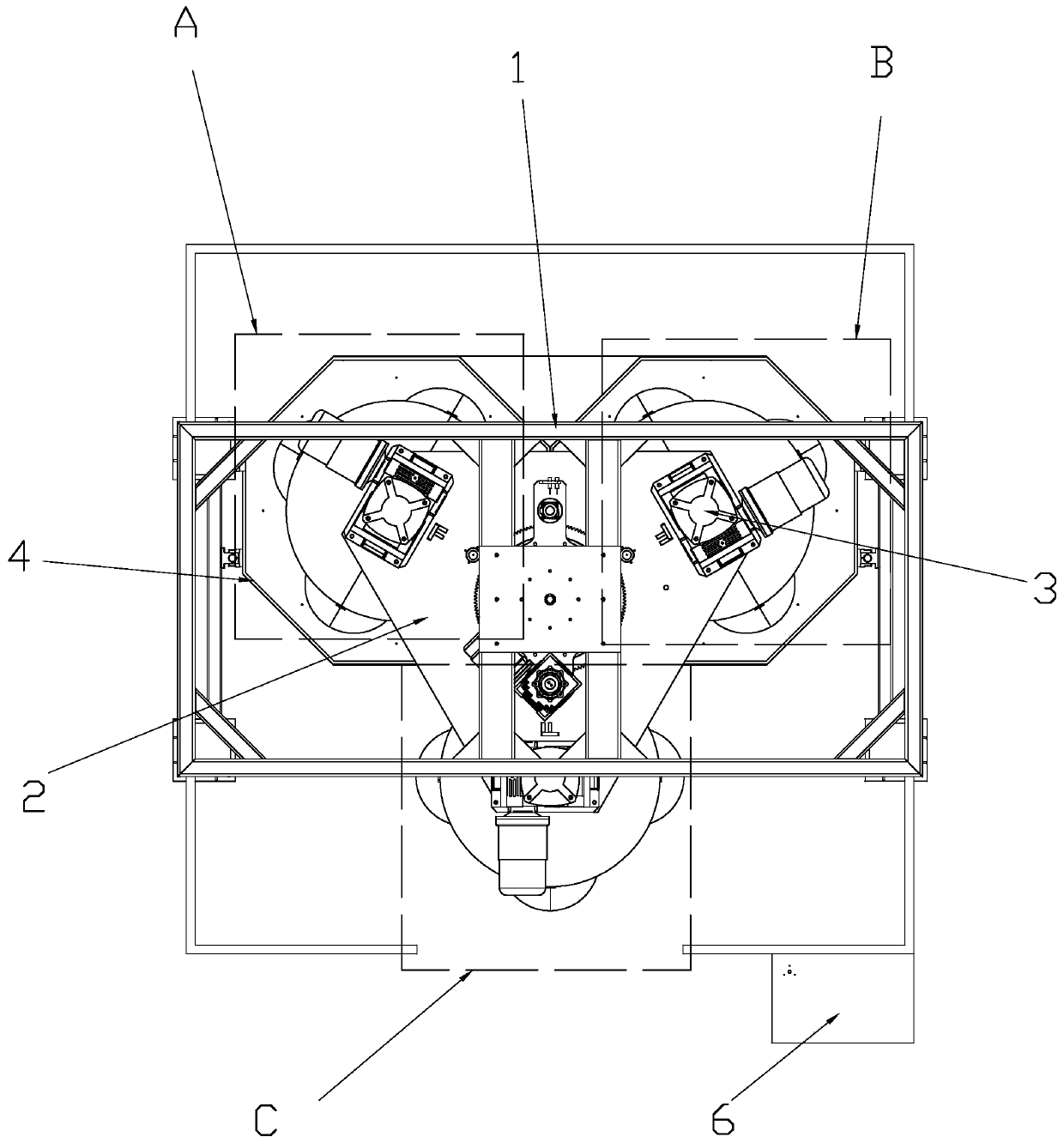

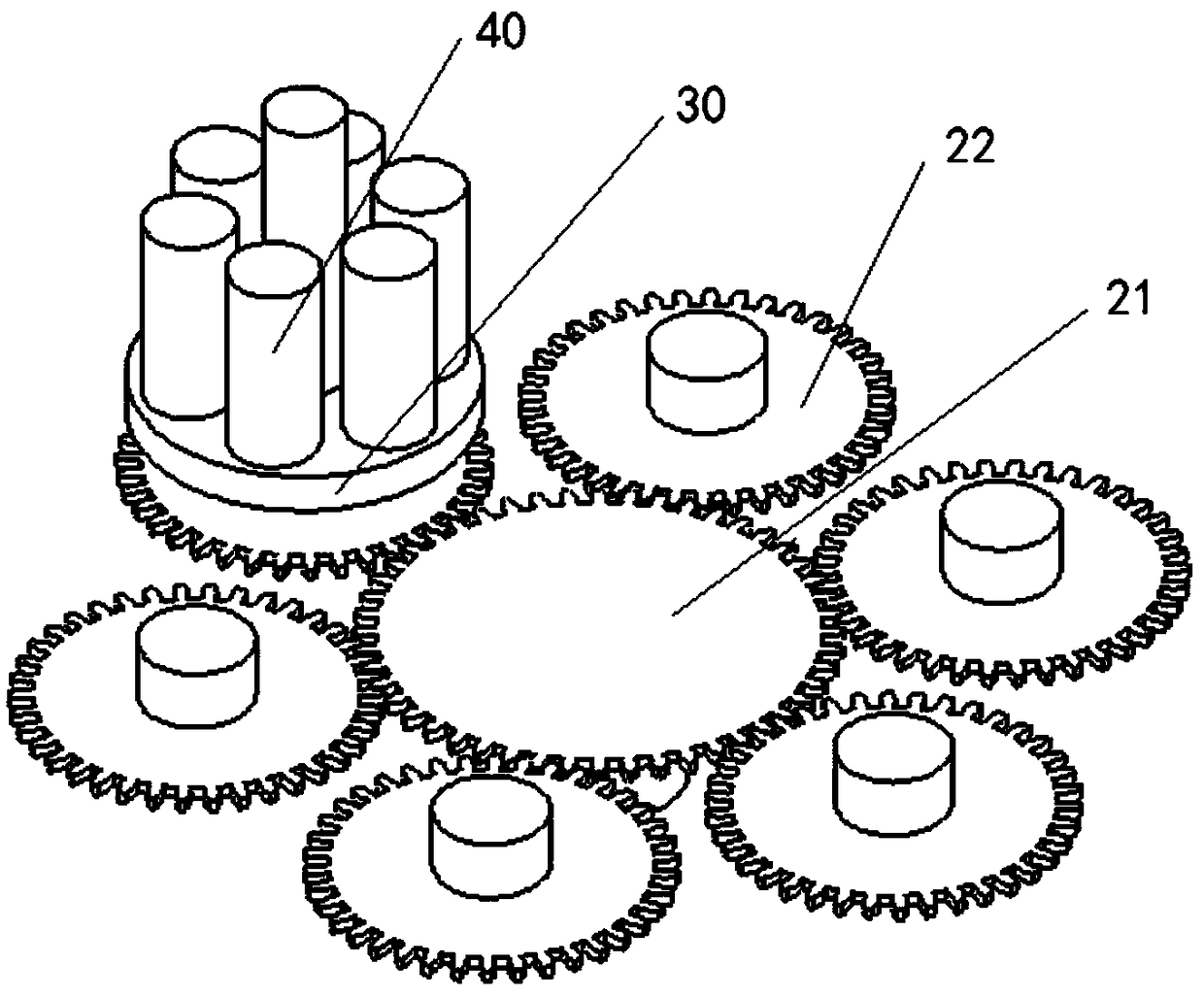

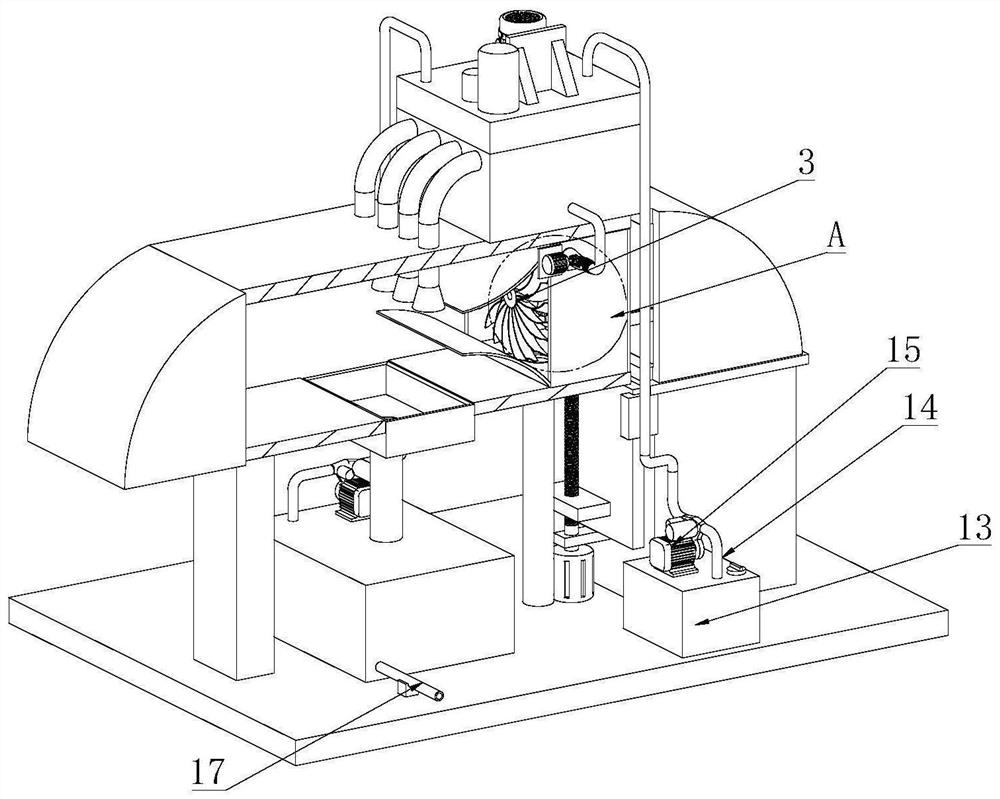

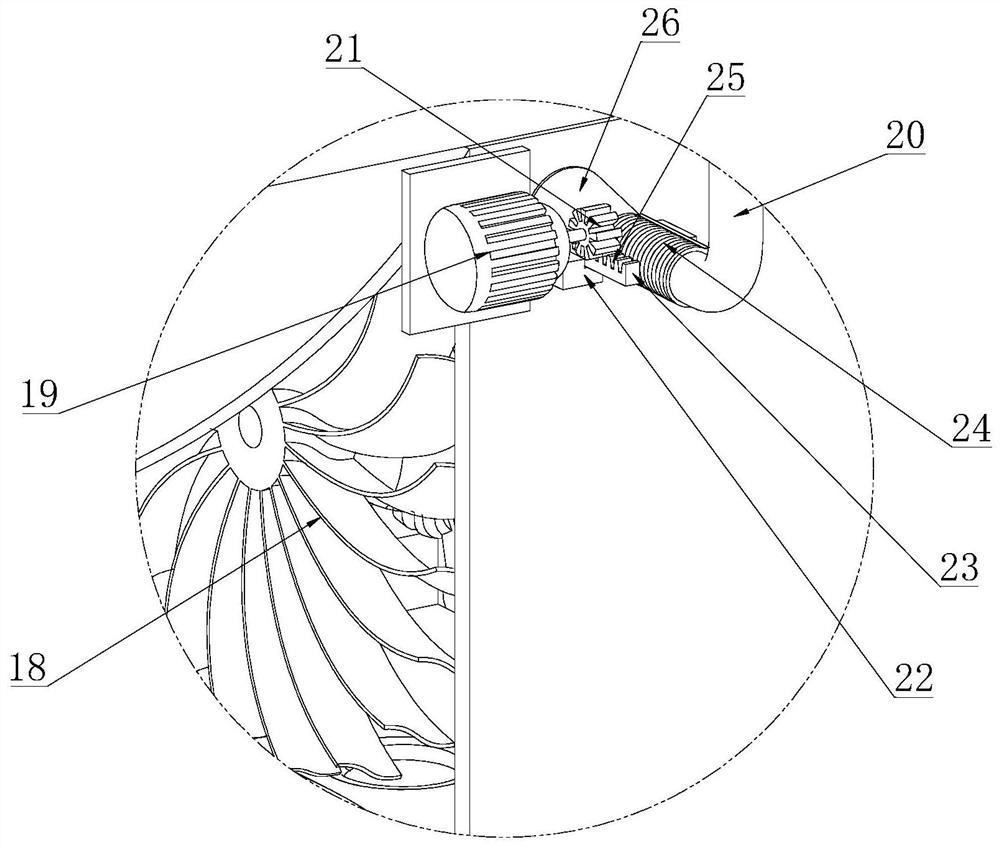

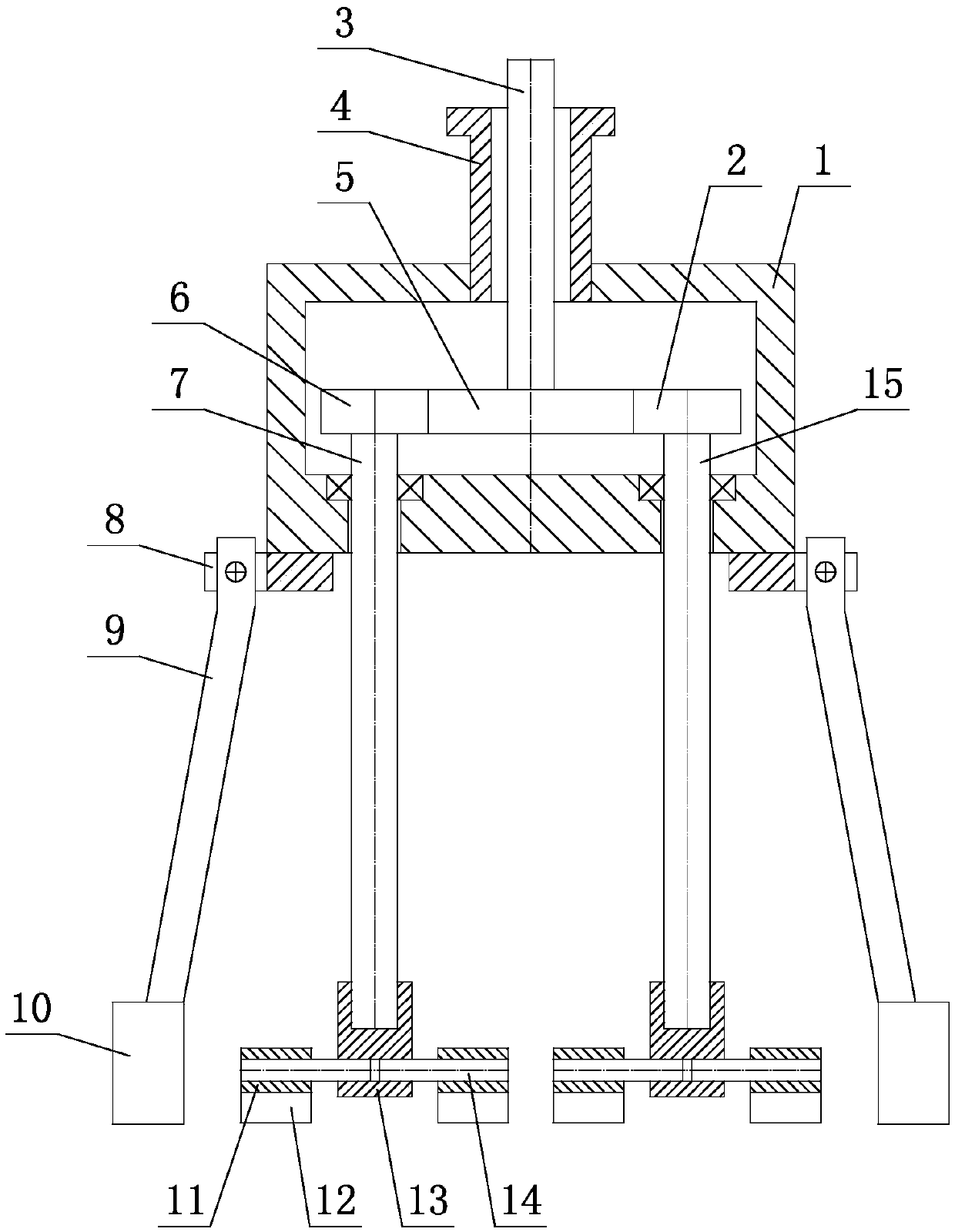

Planar magnetic sputtering-multi-station film coating apparatus

InactiveCN1614078ALarge workpiece loadAchieve revolutionVacuum evaporation coatingSputtering coatingSputteringGear wheel

The invention was involved in plain magnetic force control sputter, namely multi-position coating machine. The machine consist of target of plain magnetic force control sputter (14), workpiece holder (15), heater (28), aeration vent (29), evacuated chamber (30), vacuum group (32), rotor plate (16), joint lever (17), small gear wheel (18), small gear wheel (19), joint lever (20), electric machine of rotation (21), electric machine of revolution (22), joint lever (23), mediate gear wheel (24), joint lever (25), large wheel (26) and joint lever (27). The method had some characteristics, such as many work position, fine metallic-membrane plating uniformity and easy to extend.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

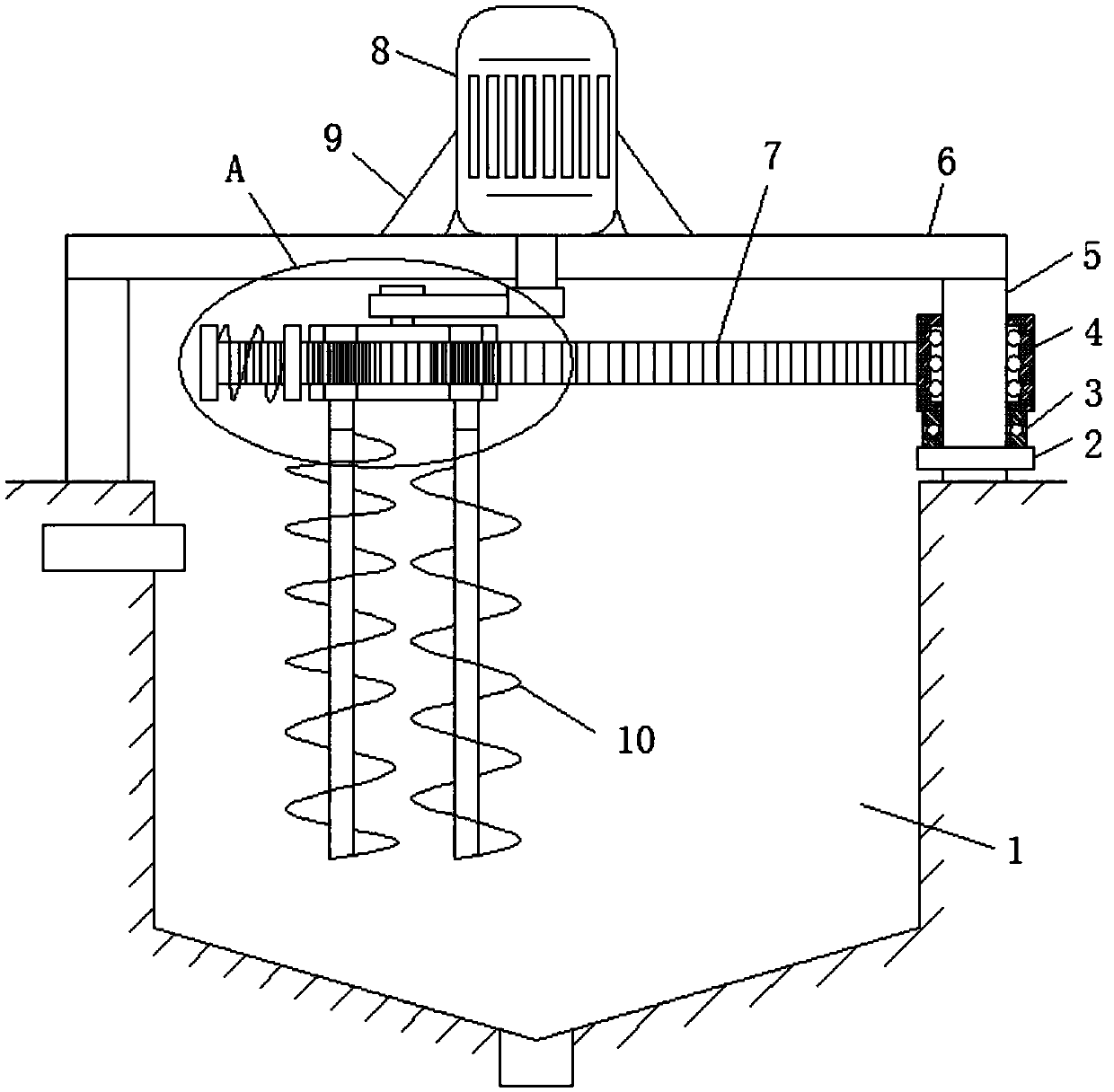

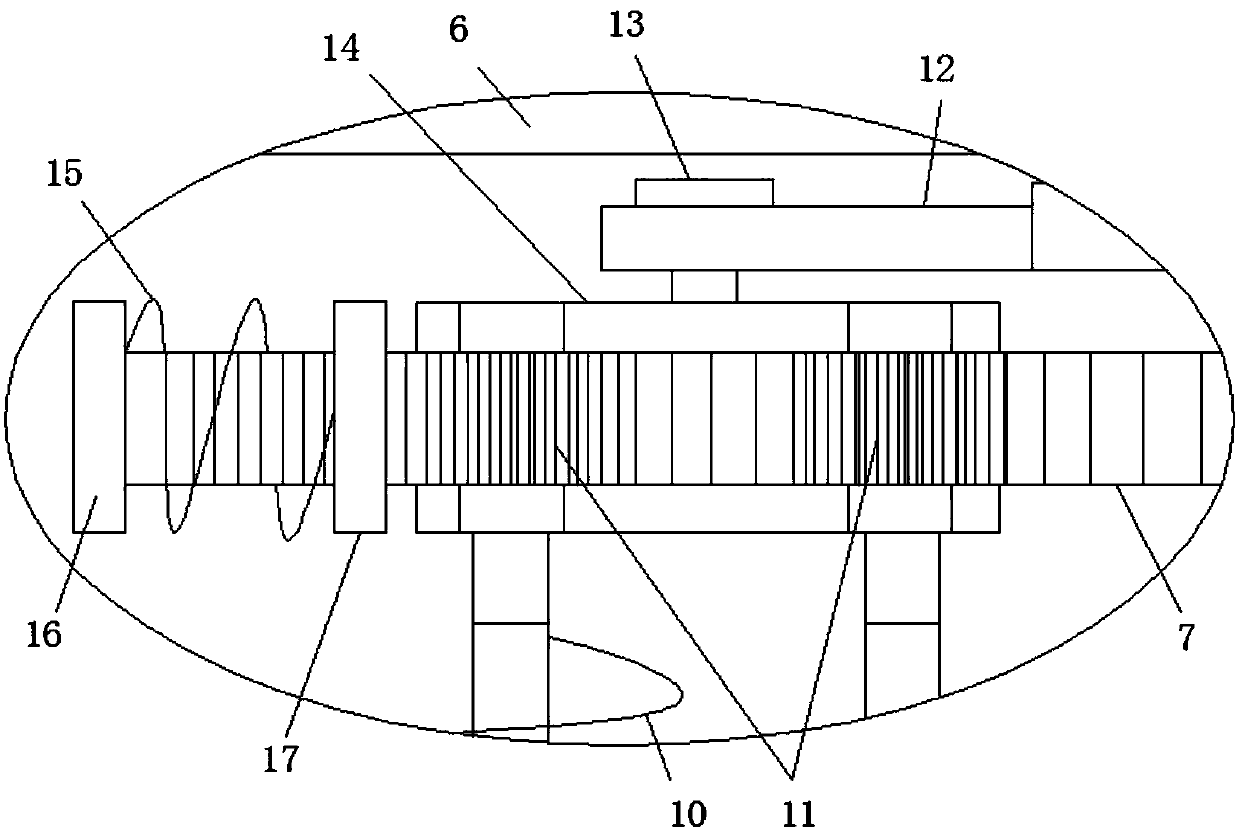

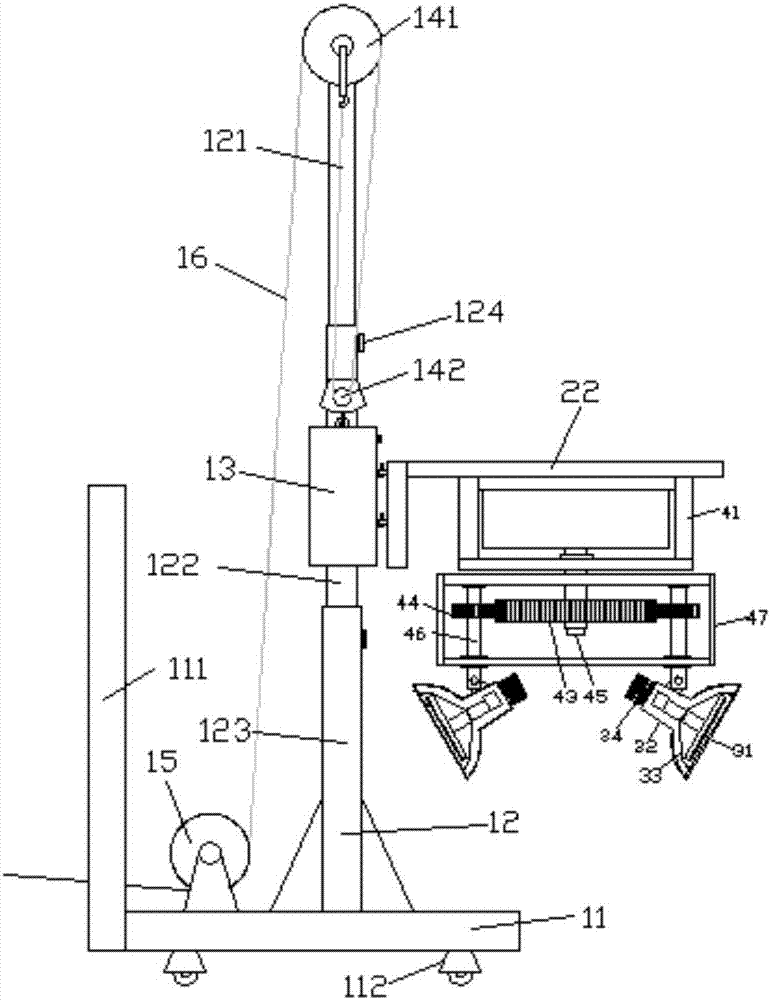

High-efficient sewage stirring device

InactiveCN107824096ACushion the shockReduce frictionRotary stirring mixersTransportation and packagingBiochemical engineeringSewage

The invention discloses a high-efficient sewage stirring device, which comprises a sewage pond; an end opening part of the sewage pond is fixedly connected with paired upright posts, and one end of each of the paired upright posts far from the sewage pond is fixedly connected with a cross plate; one side of the cross plate far from the upright post is provided with a motor, and the motor is fixedly connected with the cross plate through a motor frame; an output shaft of the motor crosses through the cross plate and extends to the sewage pond, one end of the motor output shaft extended to the sewage pond axially is fixedly sleeved with a crank; one end of the crank far from the motor is hinged with a lug, one end of the lug far from the crank is fixedly connected with a slide block; a rackis glidingly connected to the slide block. By means of a swaying guide rod mechanism, the revolution of the stirrer in the sewage pond is realized; the rack meshed with the gear is arranged on the guide rod, thus the stirrer acquires power from the rack, the revolution and autogiration of the stirrer are realized; the high-efficient sewage stirring device is simple in structure, good in stirring effect, high in efficiency and easy to popularize.

Owner:合肥挺泰环保科技有限公司

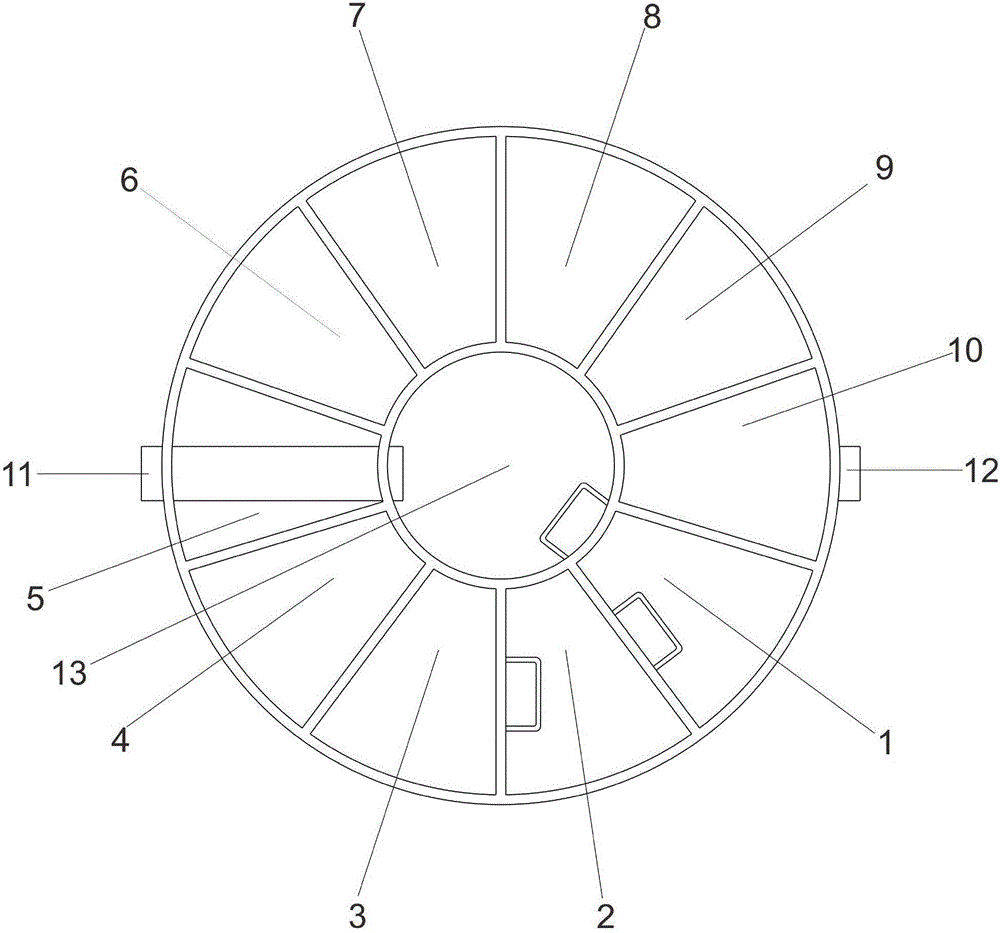

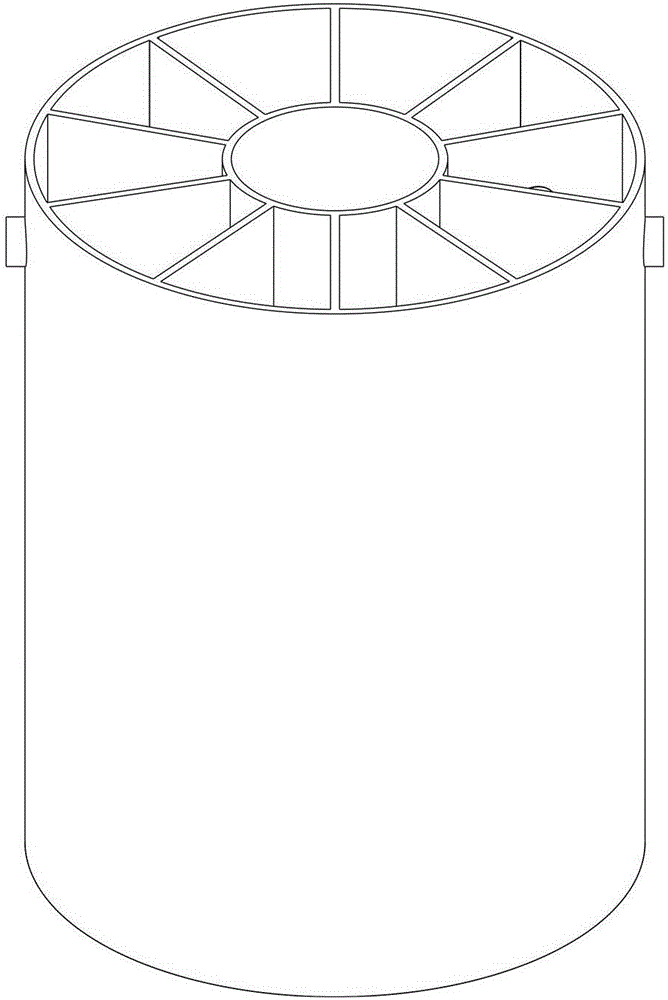

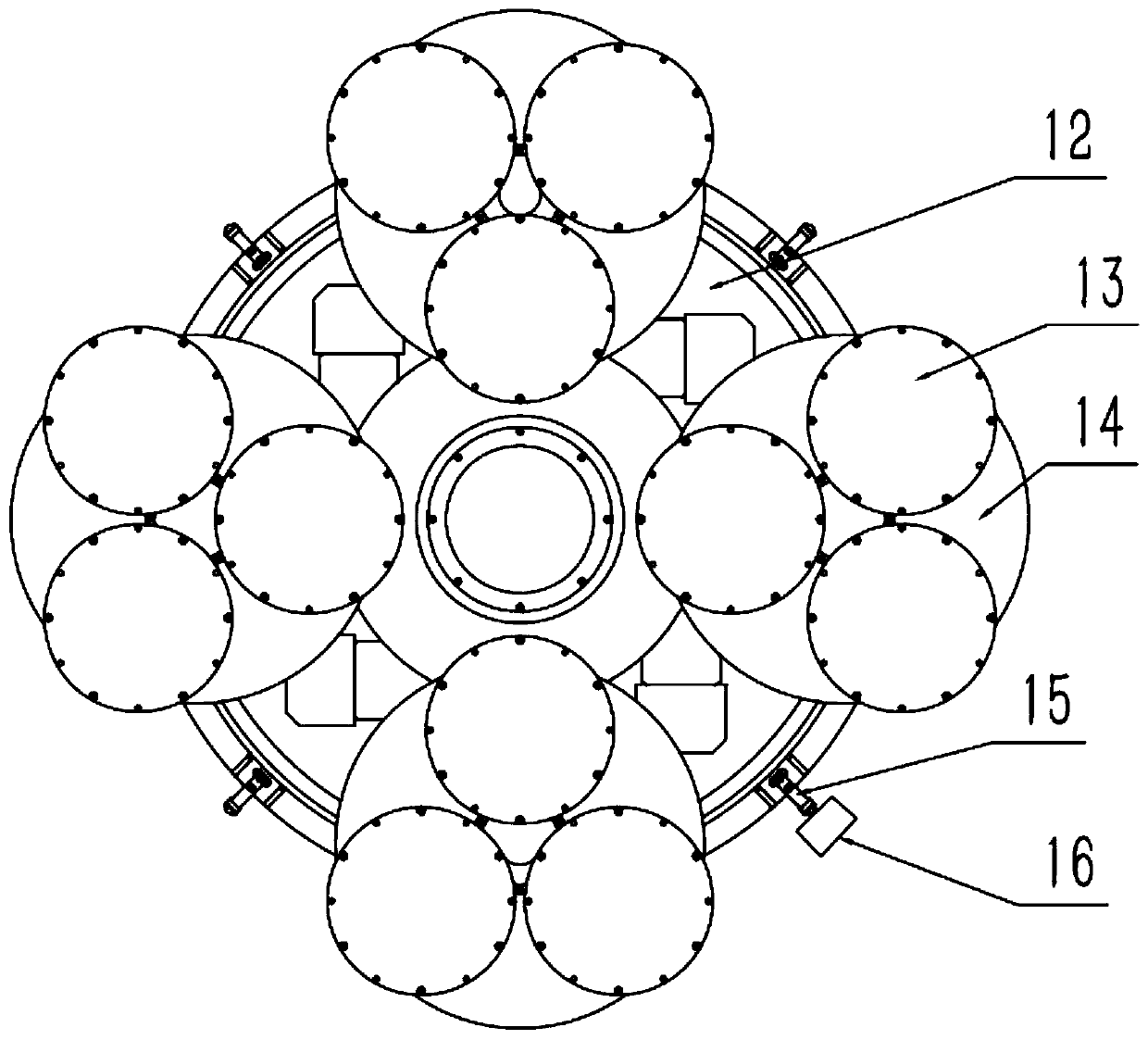

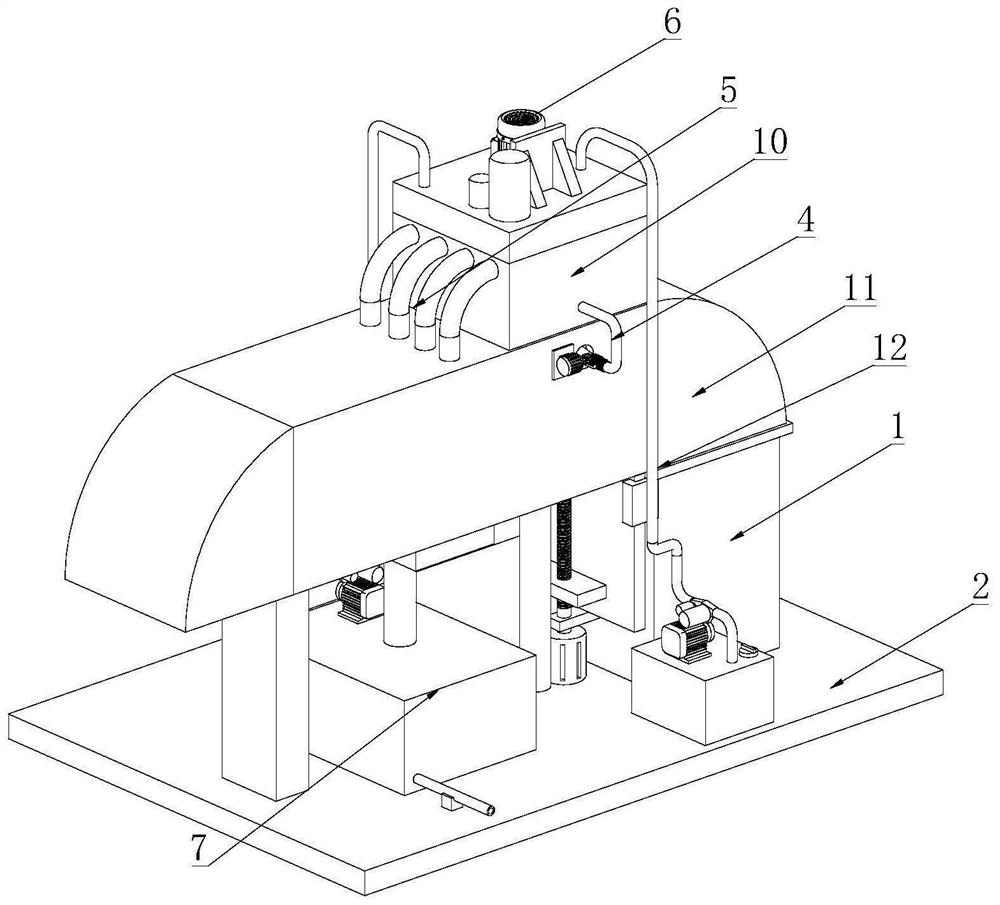

Scattered sewage treatment device and method for treating sewage by using scattered sewage treatment device

PendingCN106630478AReduce volumeFlexible handlingTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesMedicineSewage

The invention belongs to the field of sewage treatment, and particularly relates to a scattered sewage treatment device and method for treating sewage by using the scattered sewage treatment device. The device comprises a central treatment tank, wherein the central treatment tank is a first septic chamber; ten treatment tanks are arranged on the periphery of the central treatment tank and surround the periphery of the central treatment tank; the ten treatment tanks clockwise and sequentially comprise a second septic chamber, a third septic chamber, six aerobiotic / anoxic synchronous tanks, a clarifying tank and a clear water tank. The design philosophy of scattered sewage treatment is proposed, integrated sewage treatment equipment is small in size and is carried flexibly, space of a building is saved effectively, and utilization costs for lands are reduced; and the investment of a pipe network is reduced to a maximum extent, and sewage can be locally collected, treated and reused from the source. By a highly integrated sewage treatment technology, good denitrification conditions can be provided under the anoxic condition, and the denitrification effect of a system is strengthened. The standing time of sewage in a reactor is shortened, occupied area of the reactor is greatly reduced, and the market prospect and the economic value are quite high.

Owner:YUNNAN HEXUN ENVIRONMENTAL TECH CO LTD

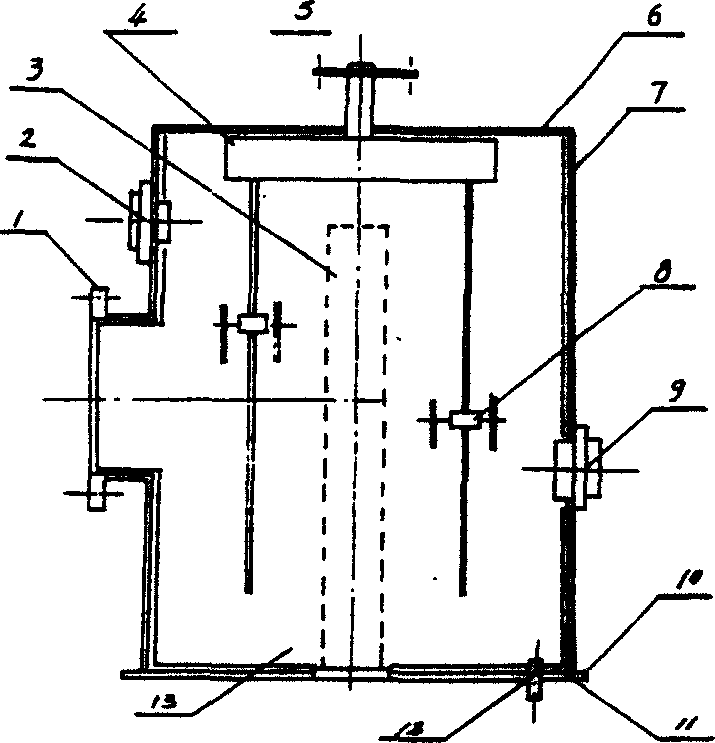

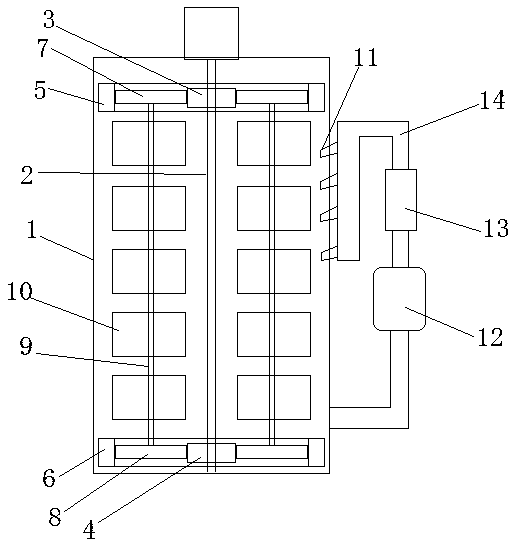

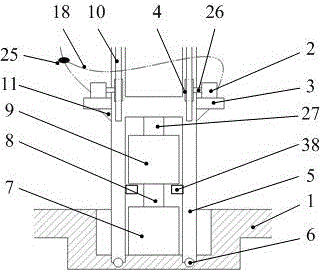

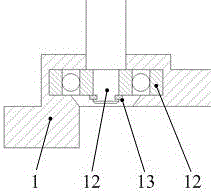

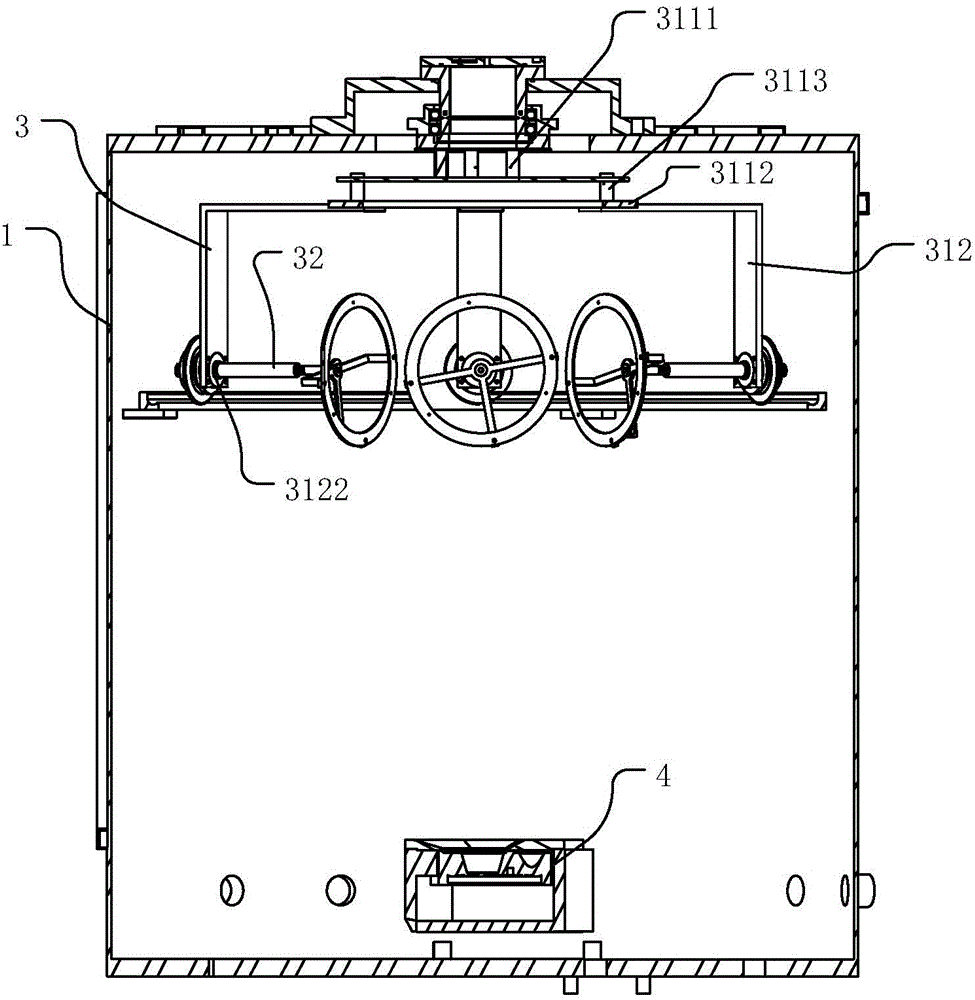

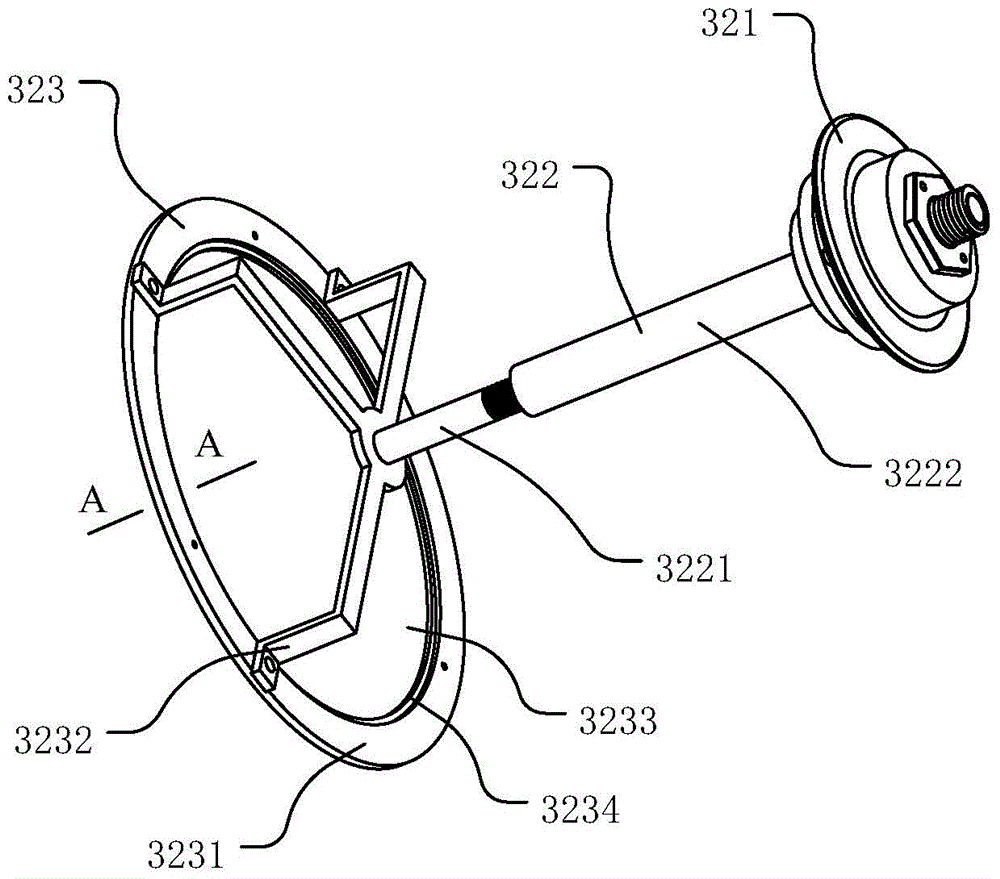

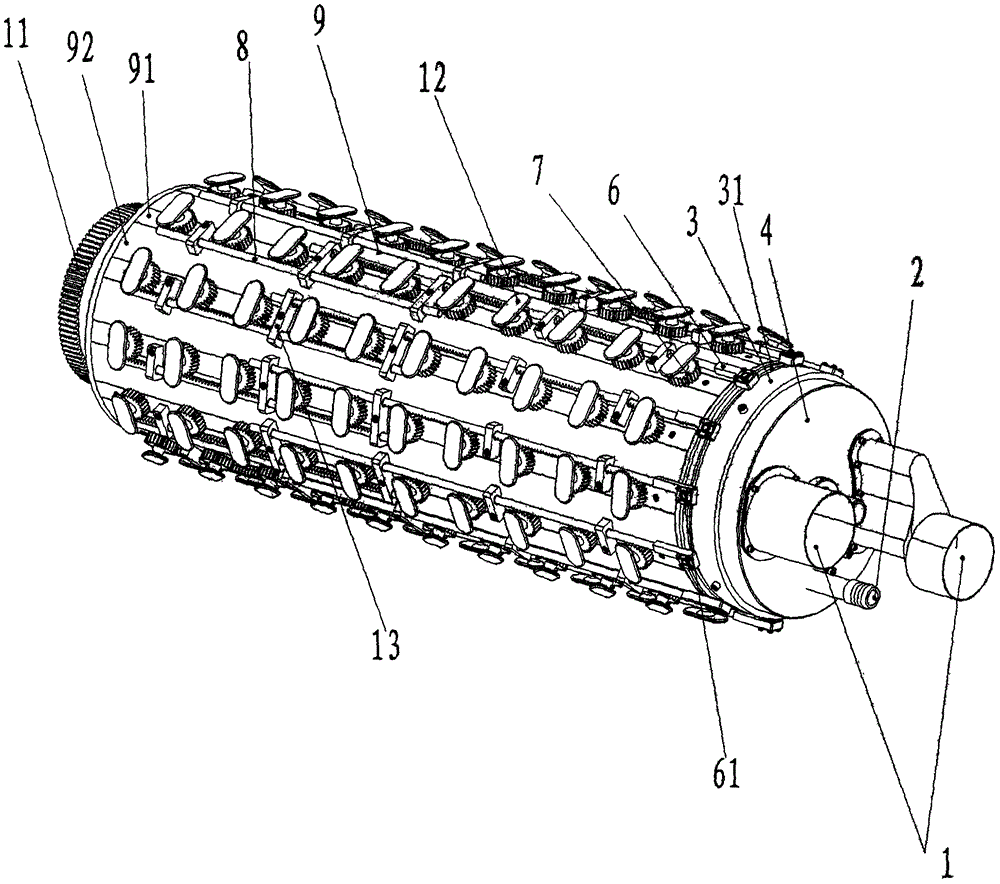

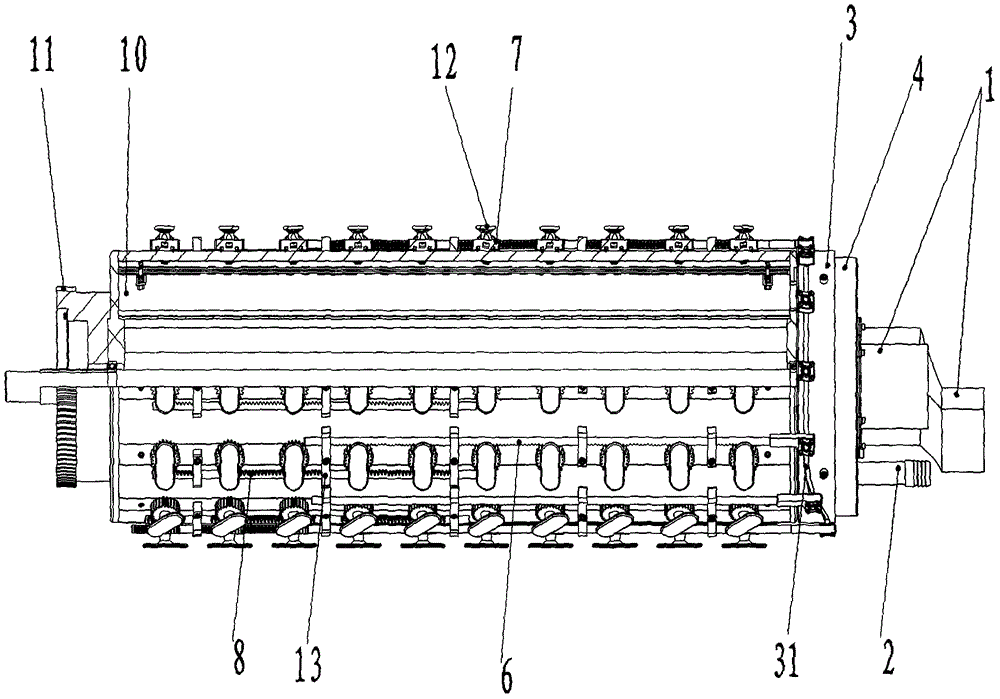

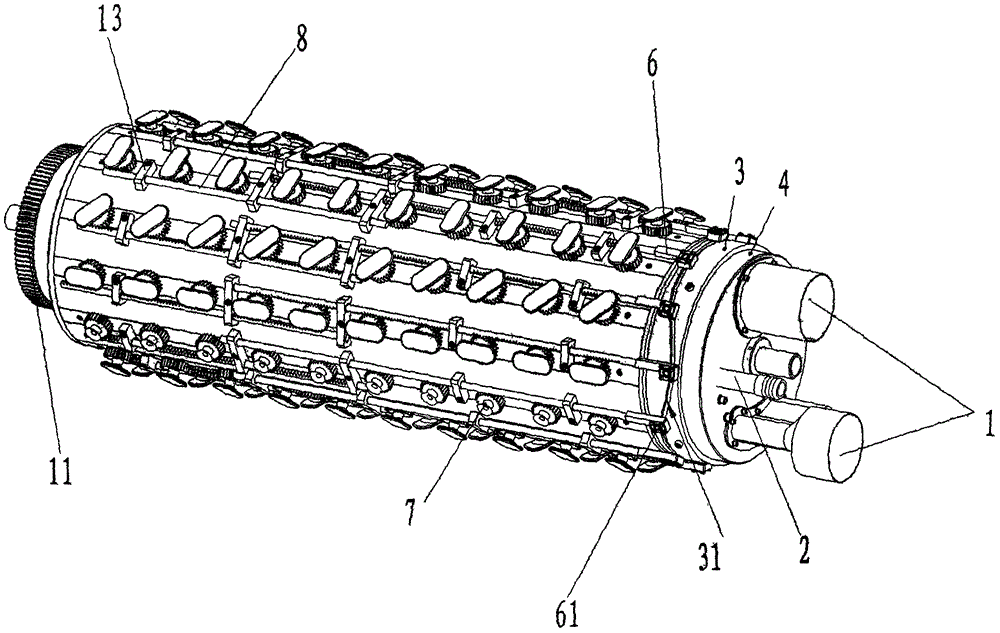

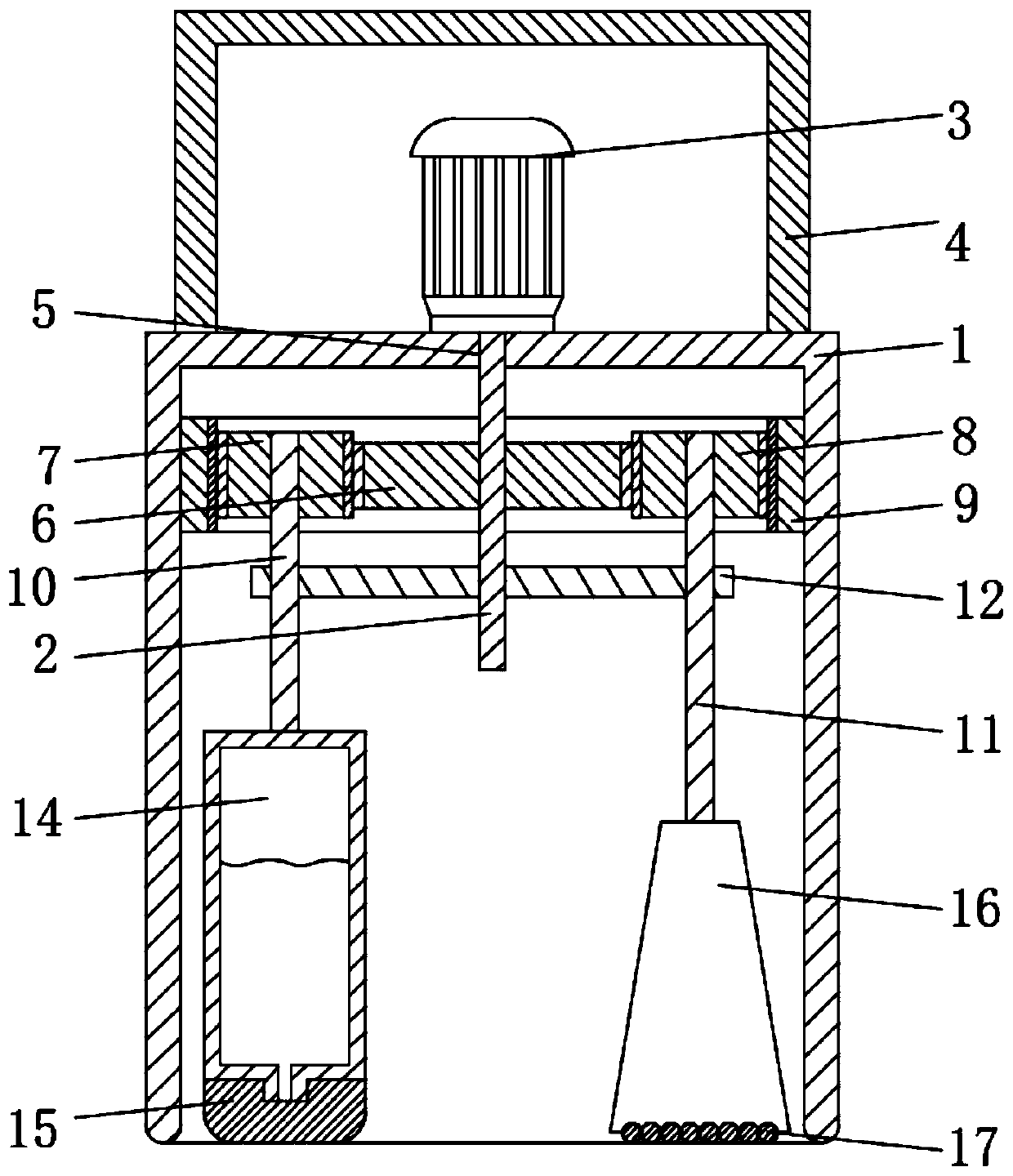

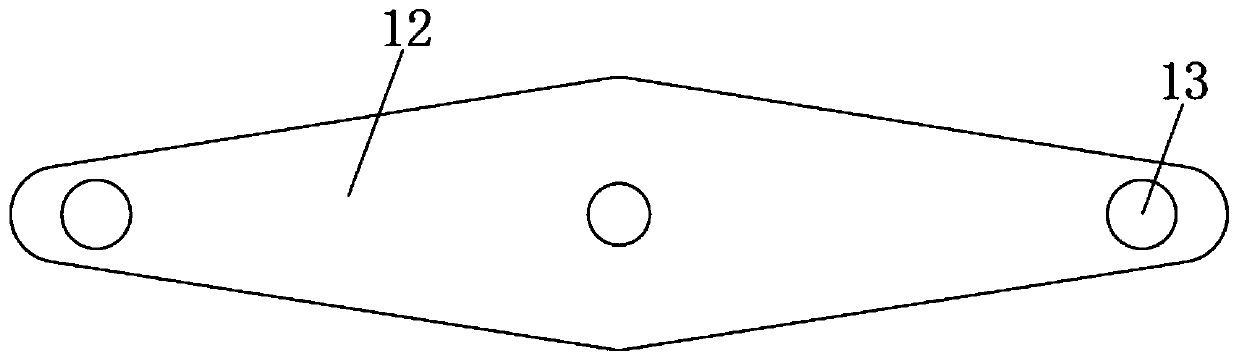

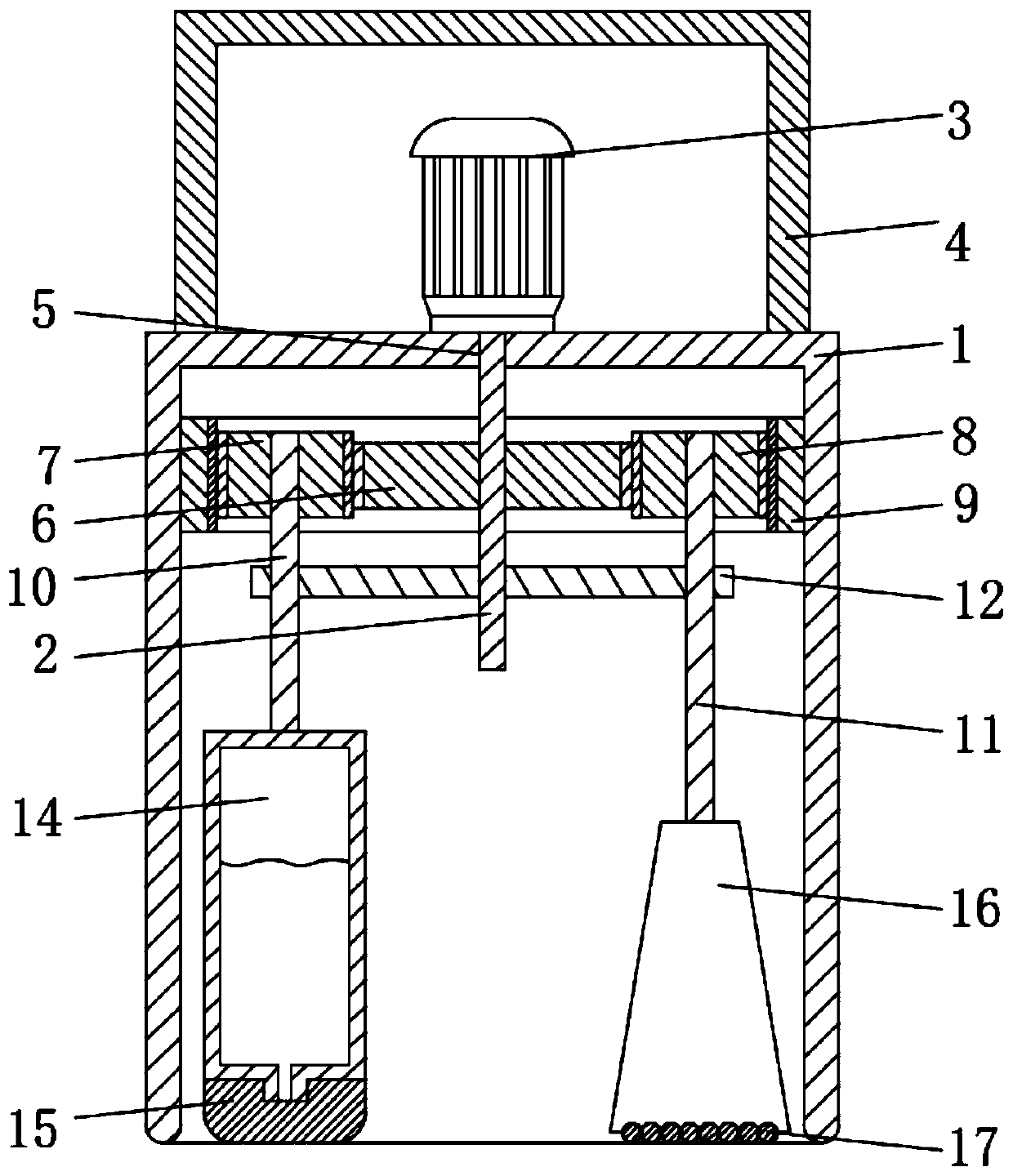

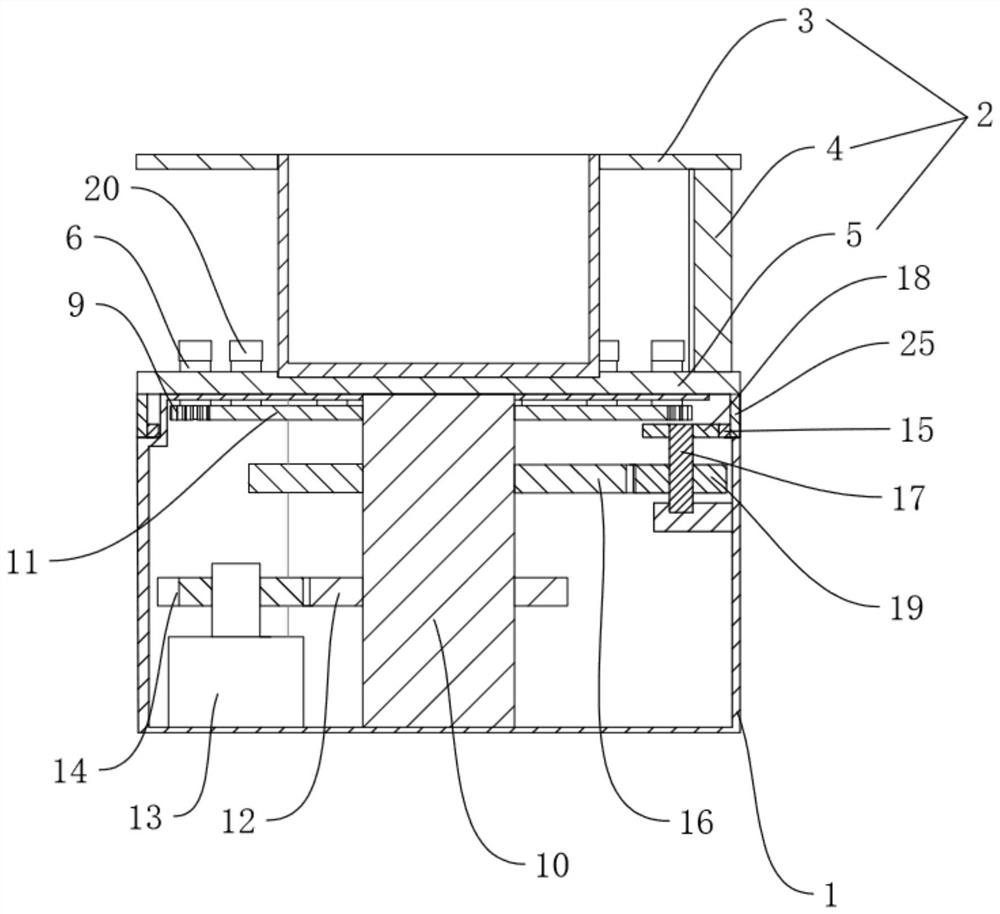

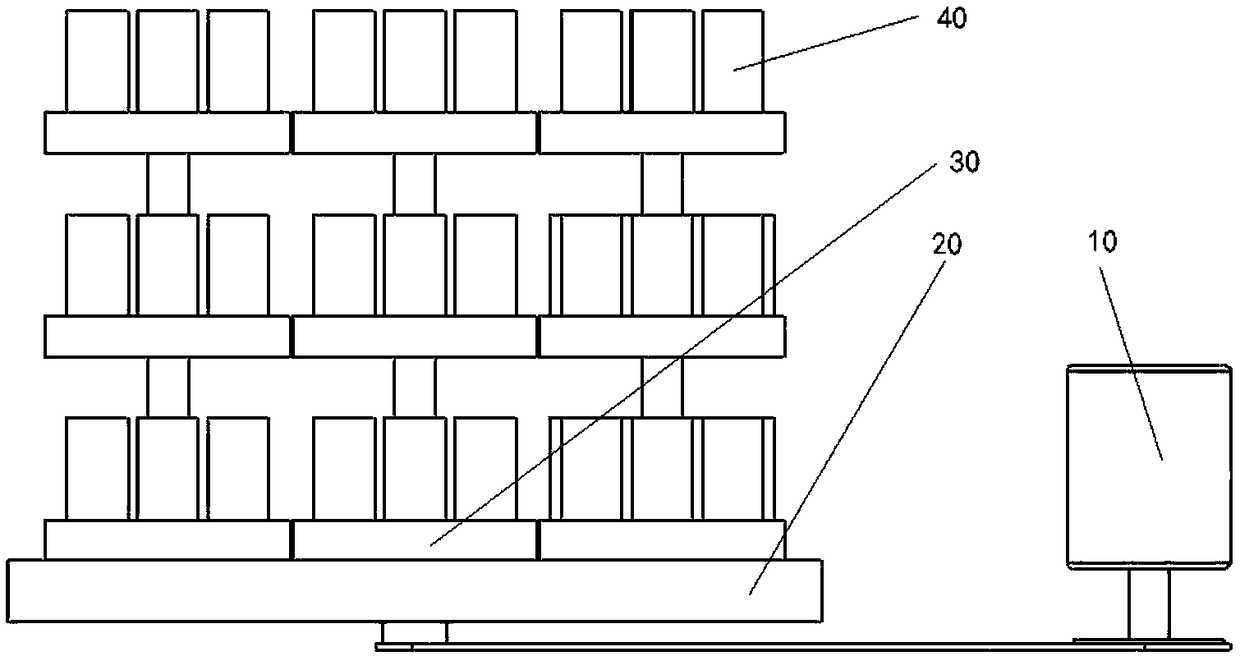

Heat drying equipment for polar plate

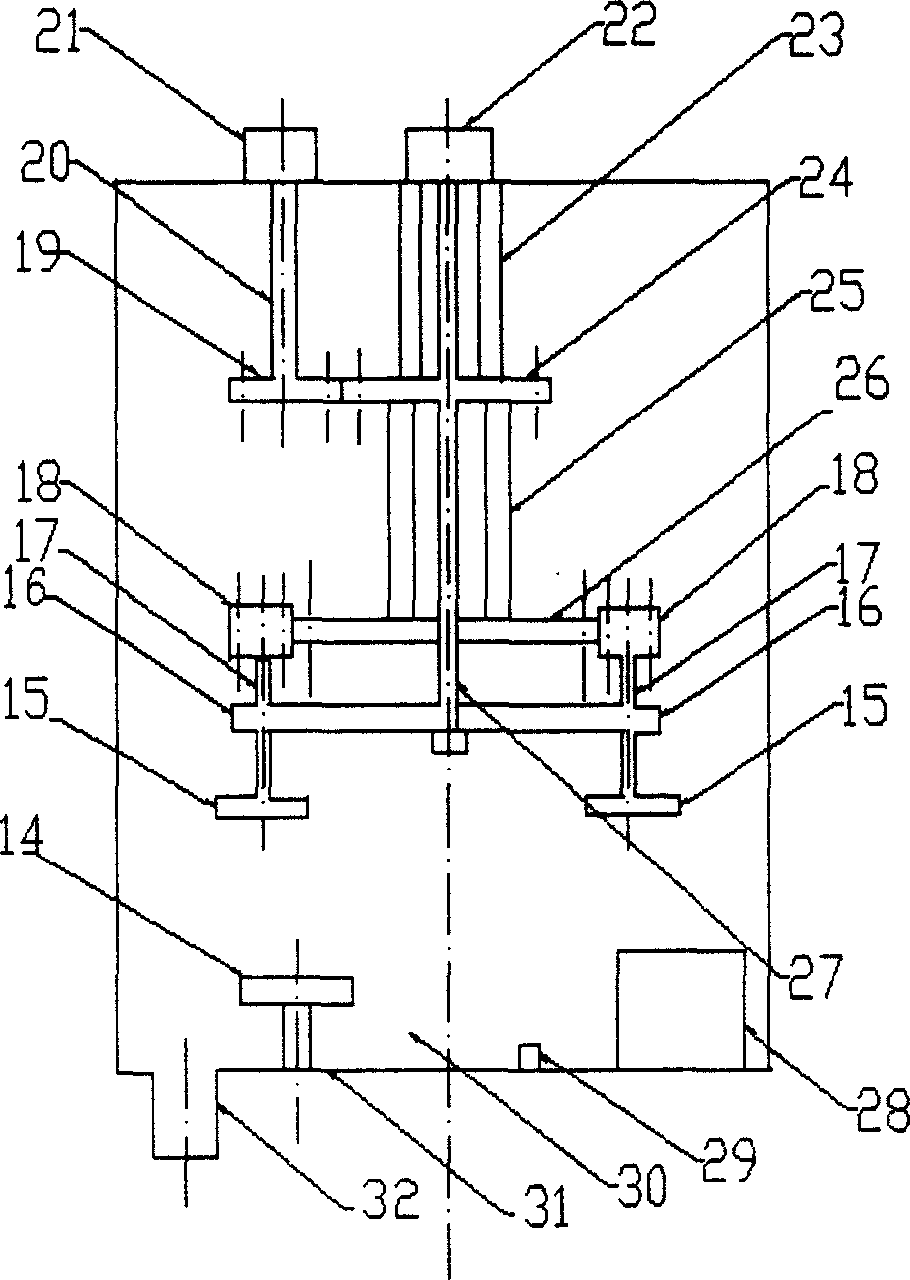

InactiveCN109237902AAchieve revolutionAchieve rotationDrying gas arrangementsDrying machines with non-progressive movementsGear driveEngineering

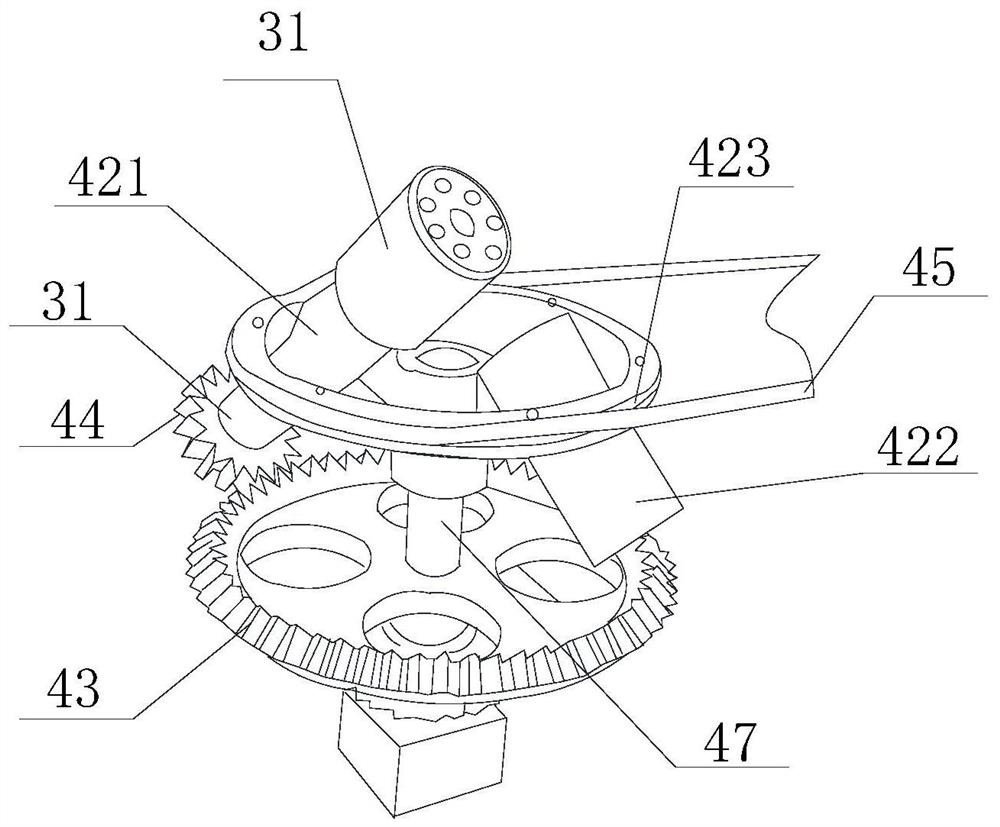

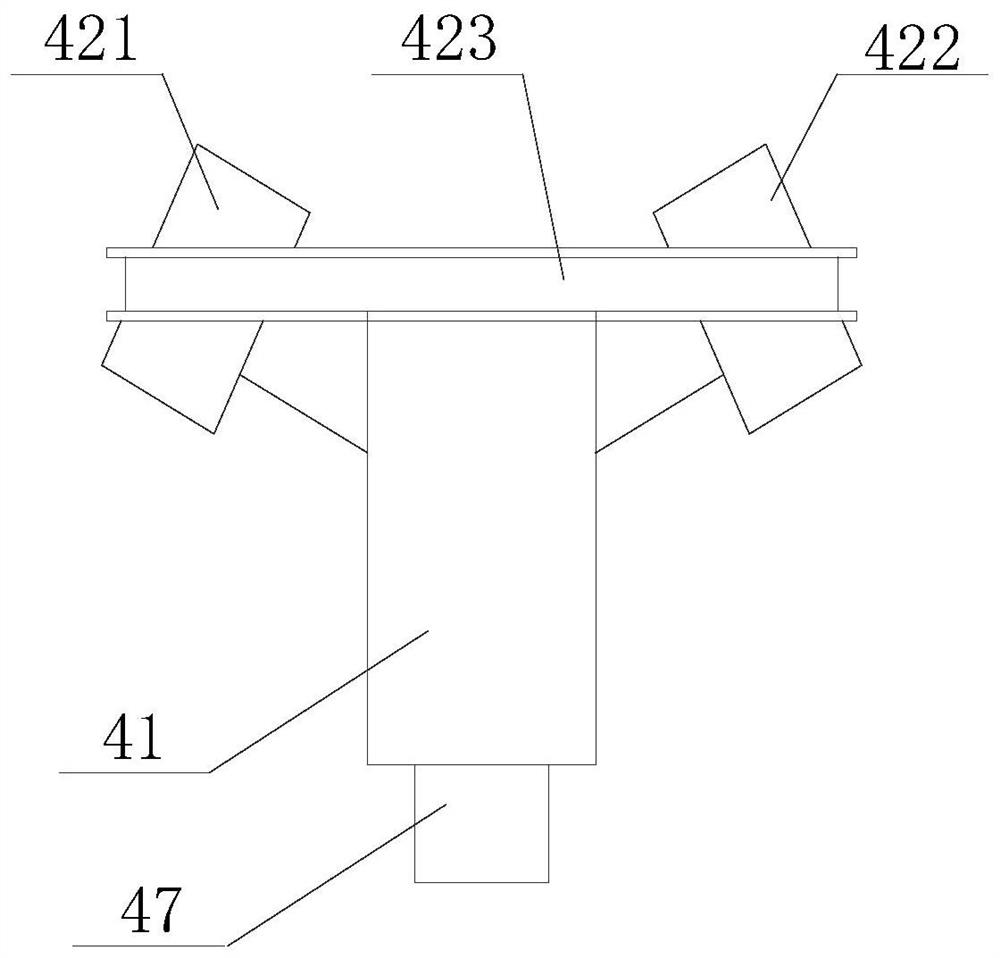

The invention discloses heat drying equipment for a polar plate. The equipment comprises a drying cylinder, a center rotation shaft is arranged in the center of the drying cylinder, an upper drive gear is arranged at the upper end of the center rotation shaft, and a lower drive gear is arranged at the lower end of the center rotation shaft; an upper gear ring is arranged on the portion, close to the upper portion, in the drying cylinder, a lower gear ring is arranged on the portion, close to the lower portion, in the drying cylinder, an upper driven gear is arranged between the upper drive gear and the upper gear ring, and a lower driven gear is arranged between the lower drive gear and the lower gear ring; an auxiliary rotation shaft is fixedly arranged between the upper driven gear and the lower driven gear, and a net frame is arranged on the auxiliary rotation shaft; a drying air nozzle is installed on the side wall of the drying cylinder. Compared with the prior art, the heat drying equipment for the polar plate has the advantages that through rotation of the center rotation shaft, the upper drive gear and the lower drive gear drive the upper driven gear and the lower driven gear to synchronously rotate around the center rotation shaft and also conduct axial rotation at the same time, orbit motion and axial rotation of the polar plate in the net frame are achieved, multidirectional drying is conducted through the drying air nozzle, the drying effect is good, and the efficiency is high.

Owner:JIANGSU HUAXING ELECTRICAL TECH

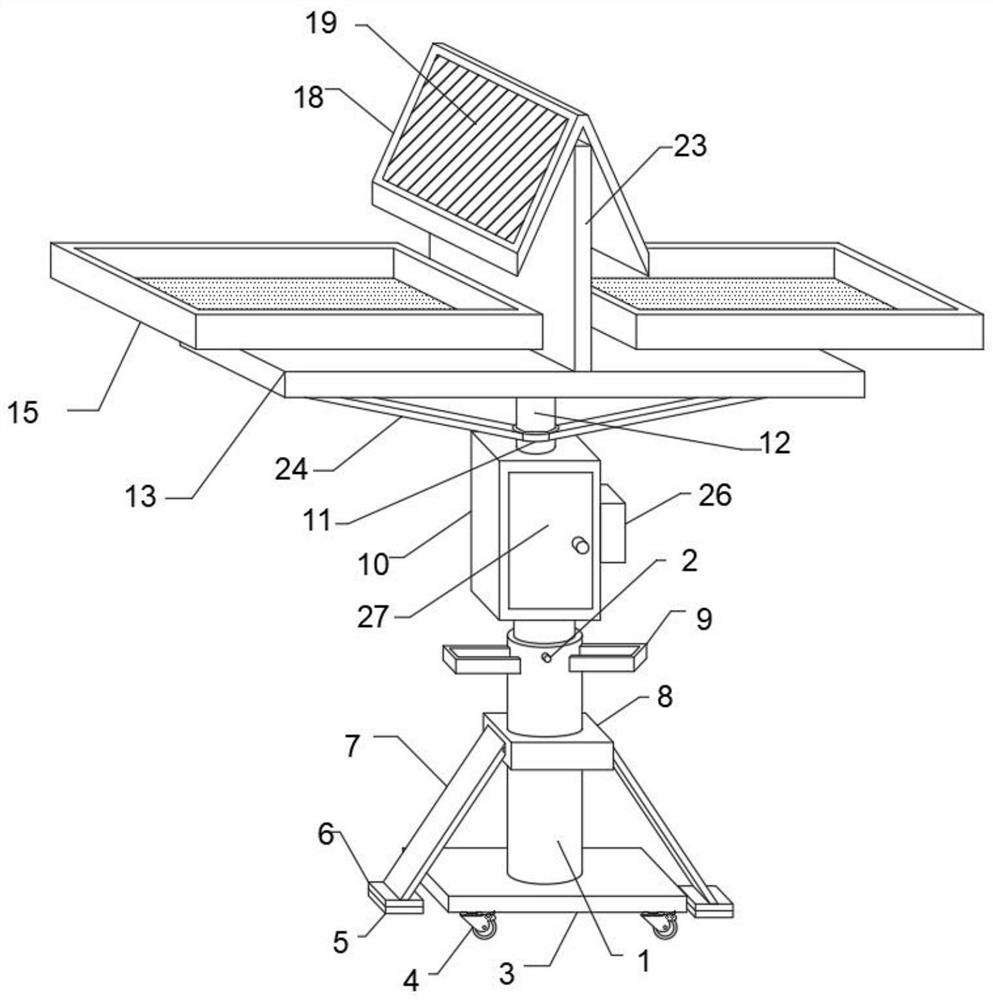

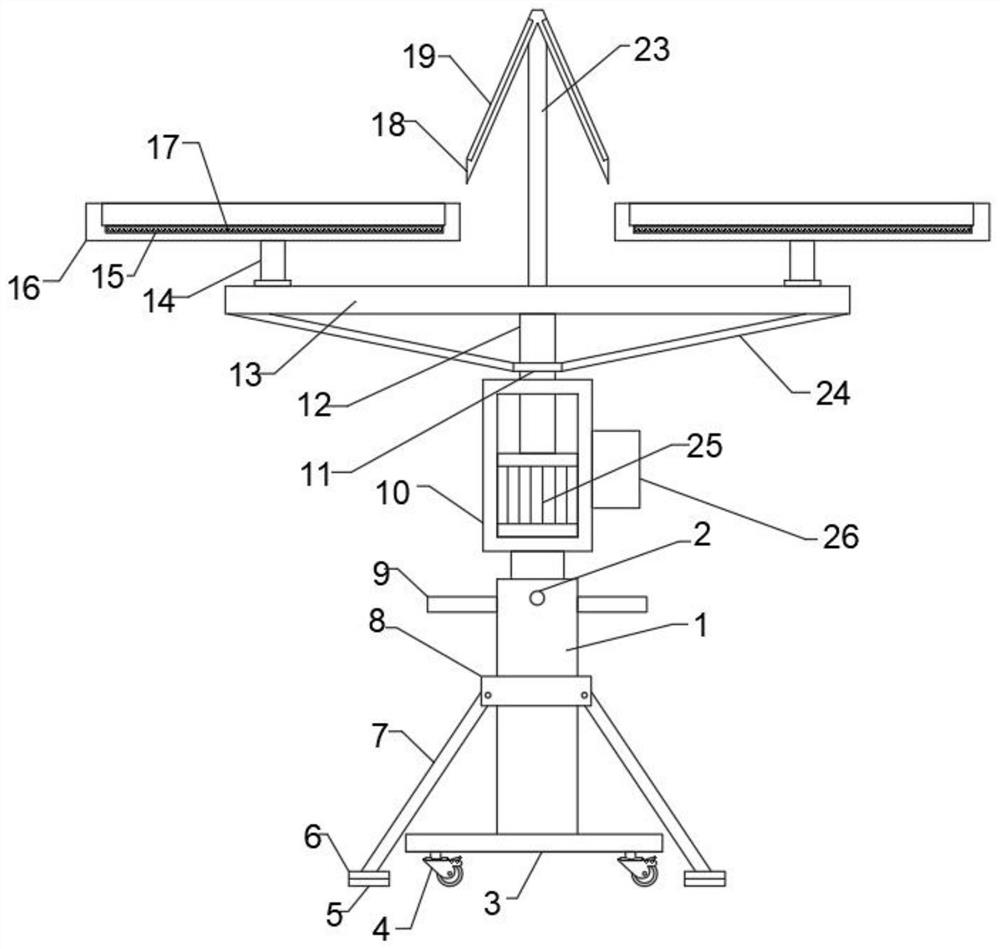

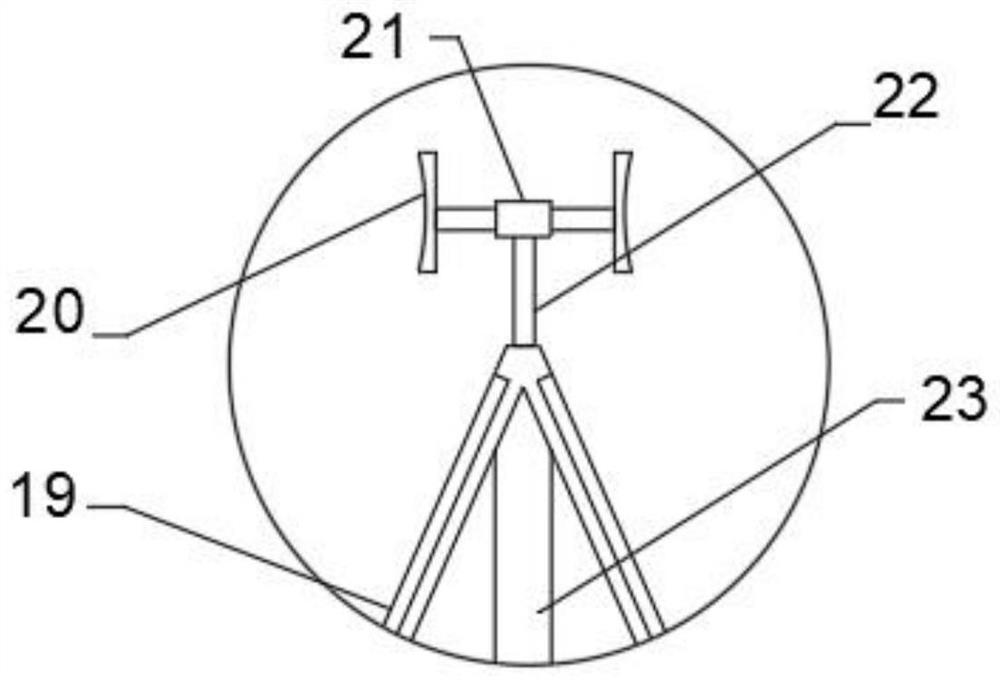

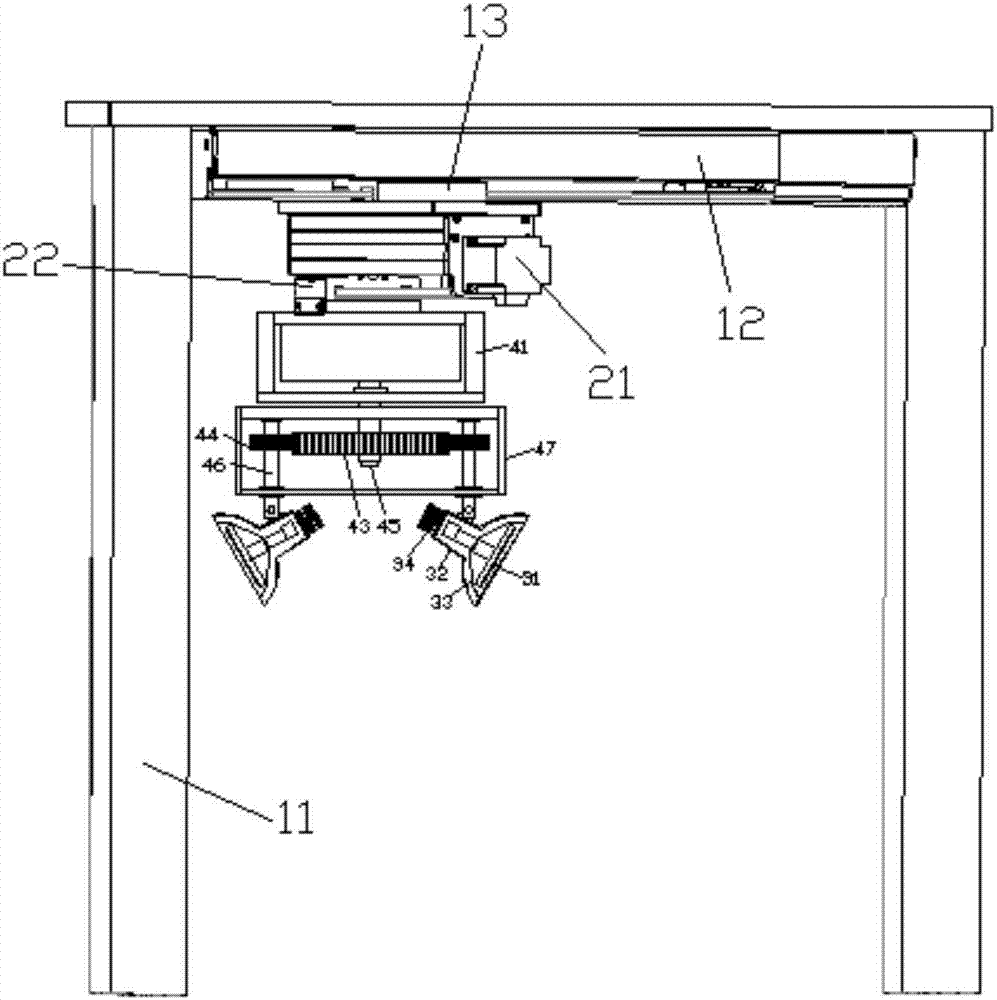

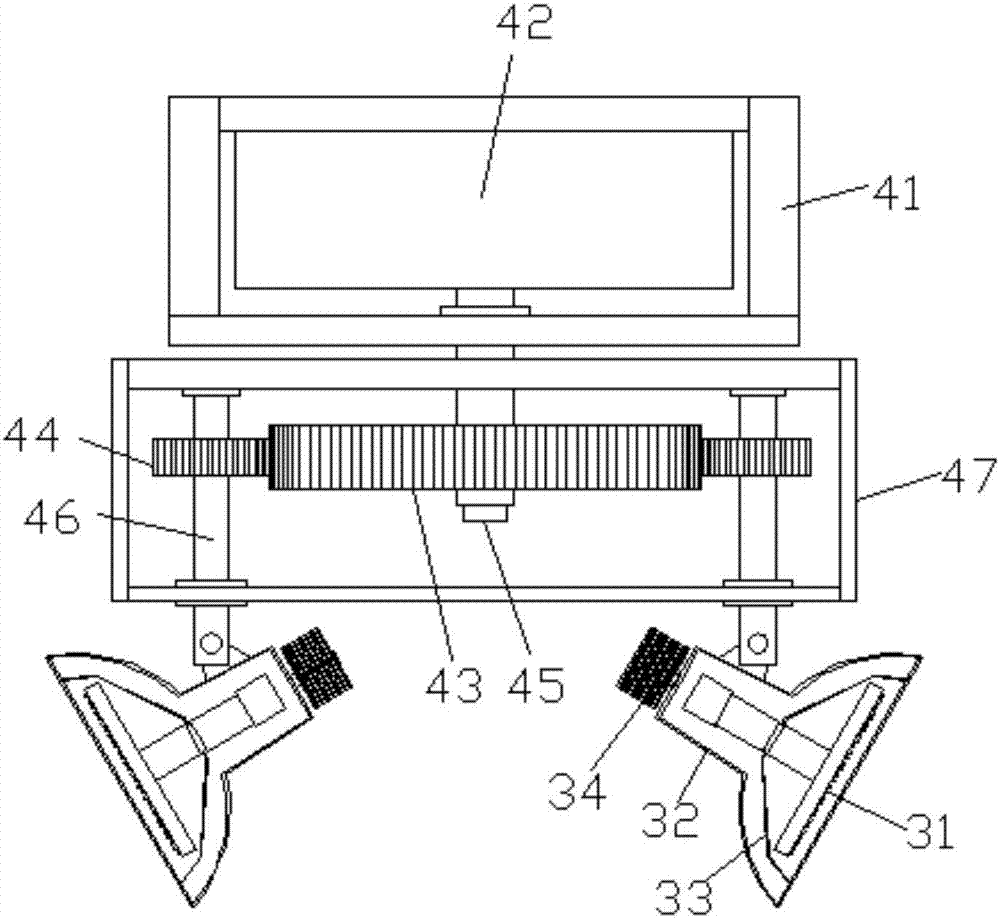

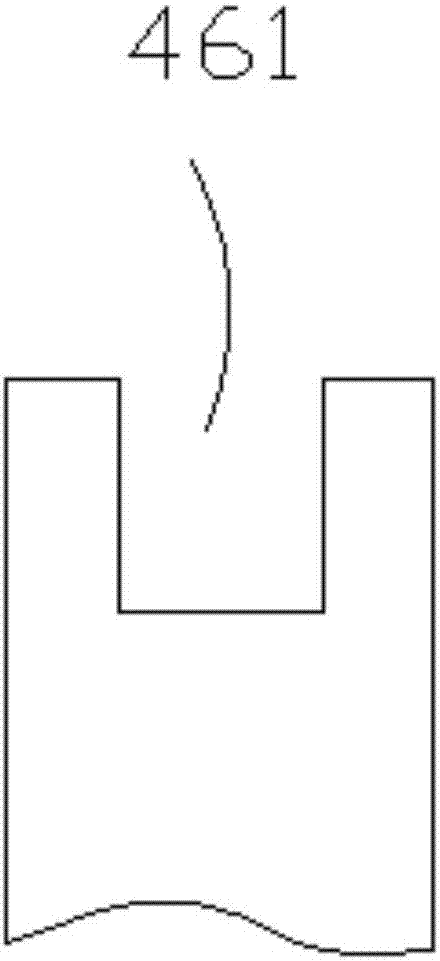

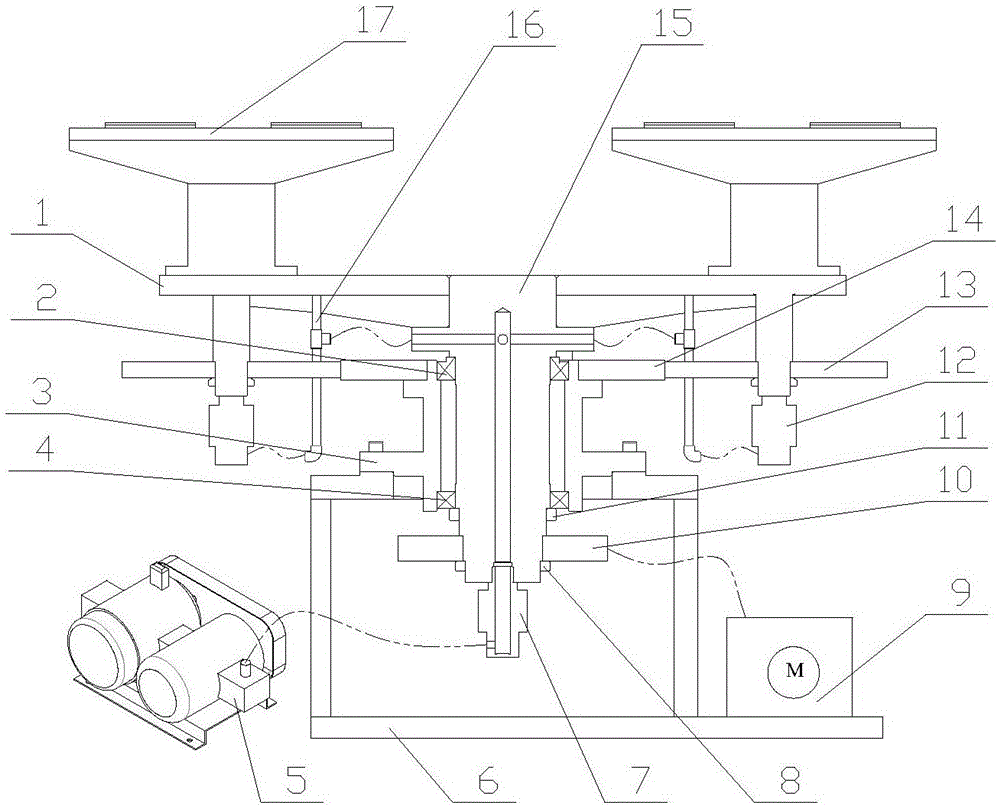

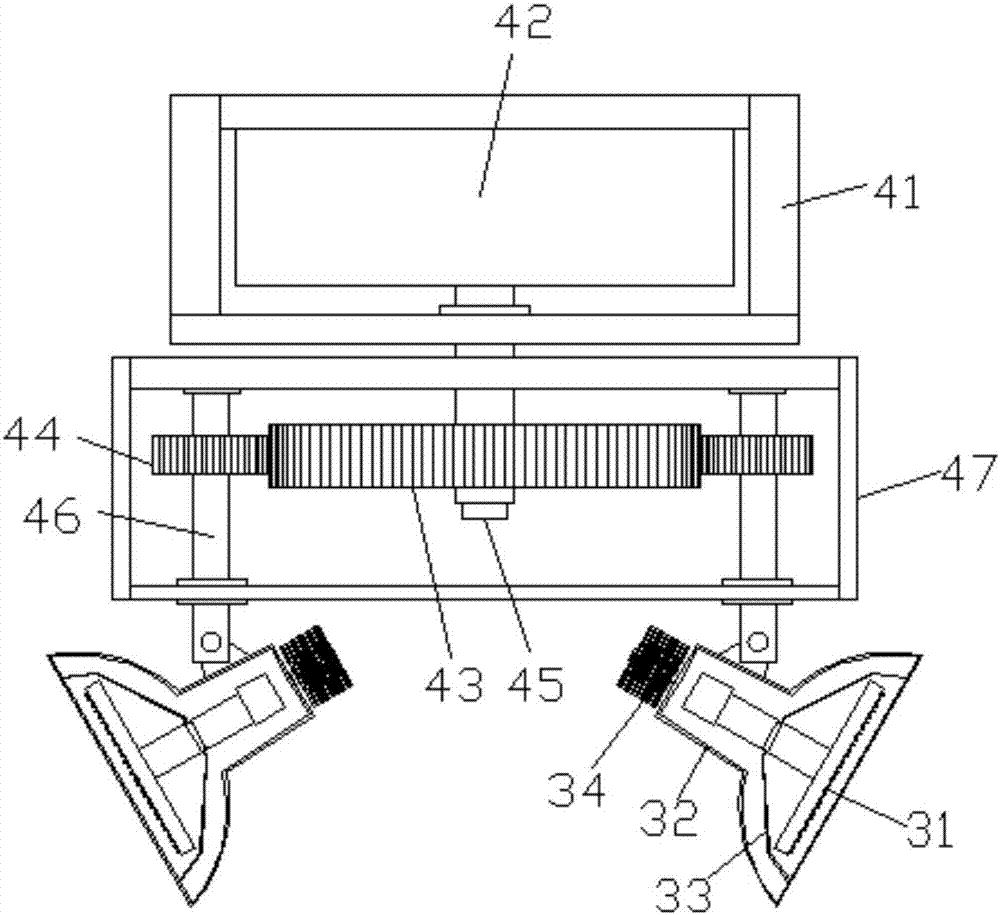

Multifunctional table capable of doing revolution and autorotation

The invention provides a multifunctional table capable of doing revolution and autorotation. The multifunctional table mainly comprises a table plate, a base, a revolution device and an autorotation device, and is characterized in that dinner plates on the table can do regular slow autorotation during the revolution. The revolution of the diner dishes on the multifunctional table is realized through the revolution device; the autorotation of the diner dishes on the multifunctional table is realized through the autorotation device; the power driving and the flat panel television hiding can be realized through an H-shaped rotating support frame; through a servo motor, an ascending and descending gear and a rack, the ascending or the descending of a flat panel television is realized; and through a rotating frame A and a rotating gear A with the same tooth number, the slow regular autorotation of the diner dishes can be realized.

Owner:UNIV OF JINAN

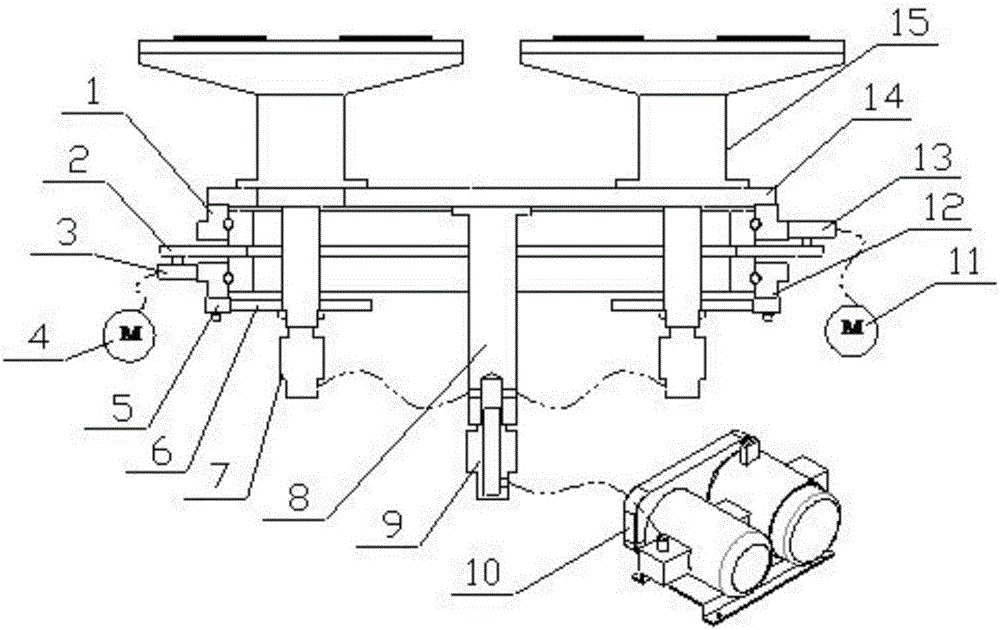

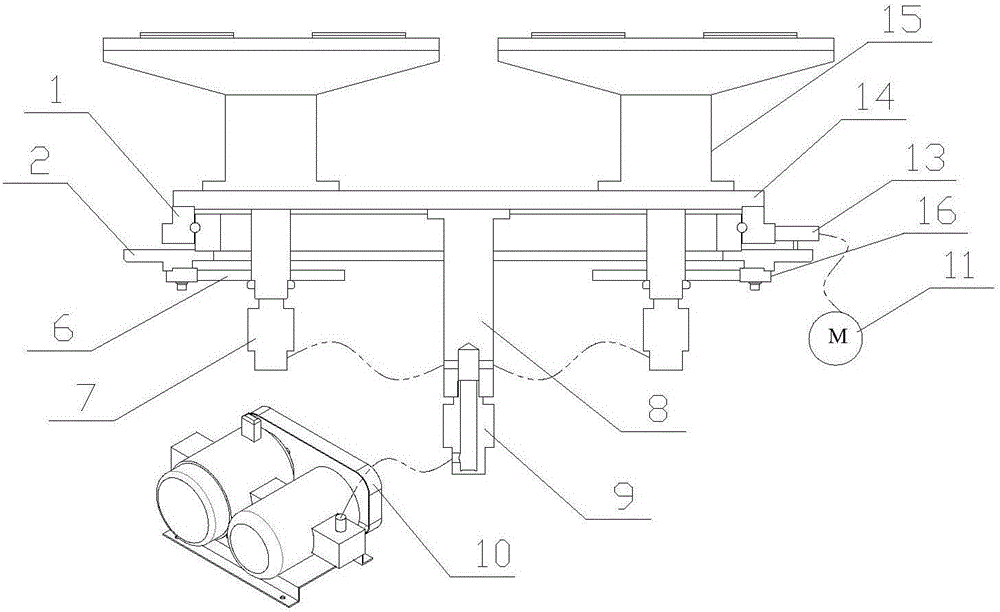

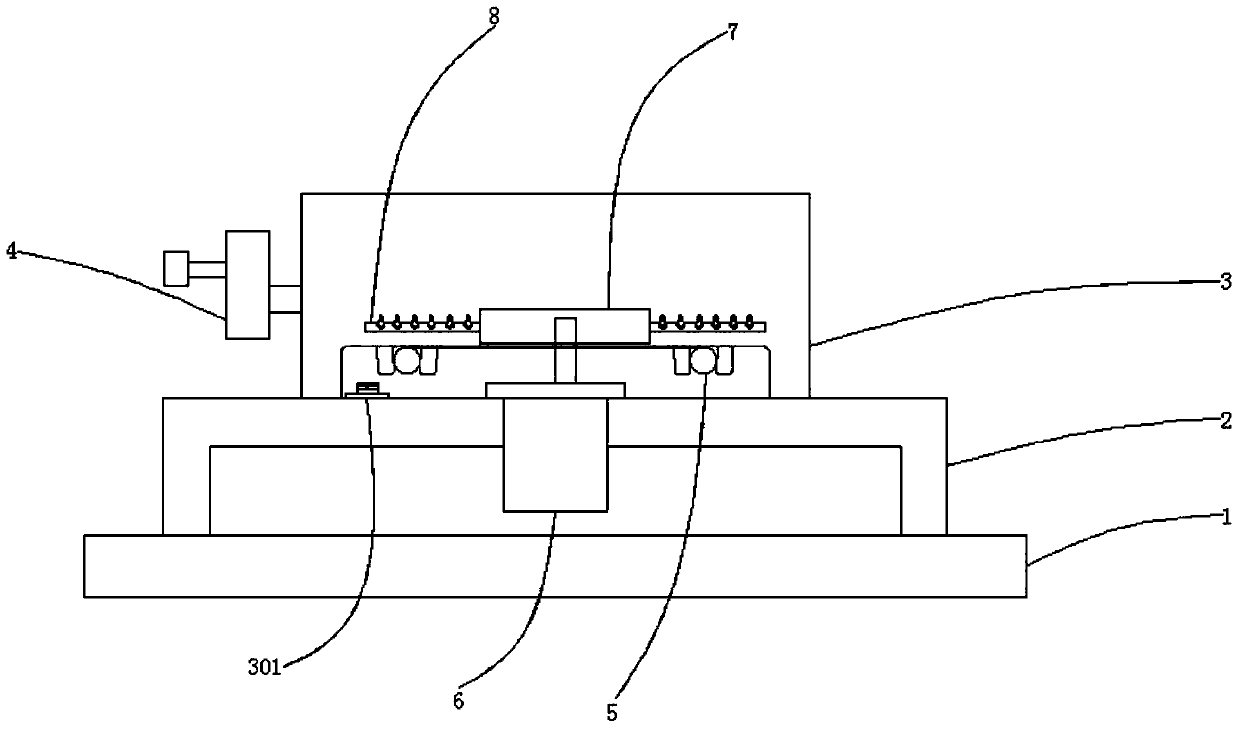

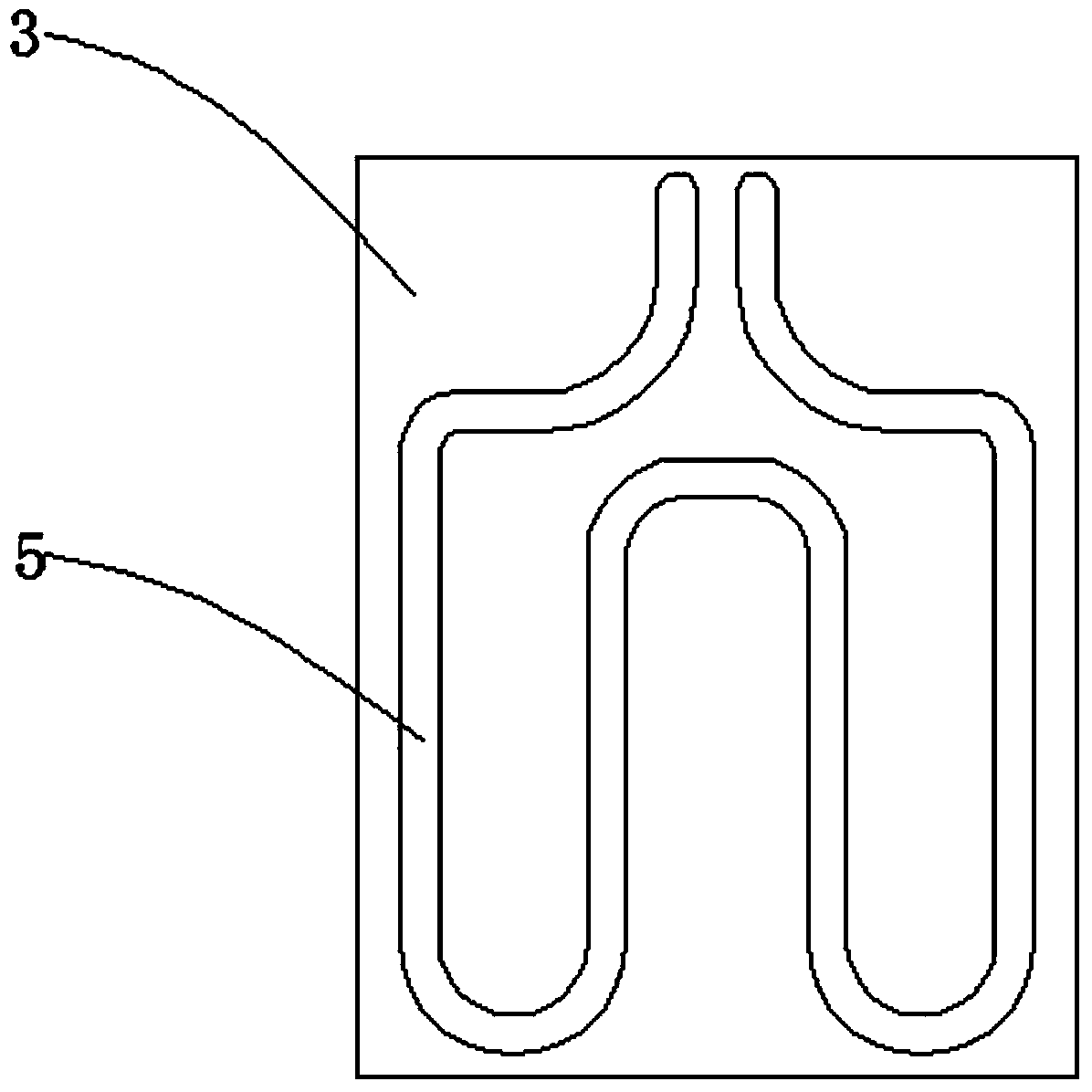

Deposition-evaporation system and deposition-evaporation transmission device

ActiveCN104911547AImprove uniformitySuitable for mass productionVacuum evaporation coatingSputtering coatingNanostructureVacuum evaporation

The invention relates to a deposition-evaporation system and a deposition-evaporation transmission device. The deposition-evaporation system is used for performing inclined evaporation-deposition on substrates and comprises a power mechanism, a deposition-evaporation transmission device and a vacuum evaporator, wherein the power mechanism is connected with the deposition-evaporation transmission device and is used for driving the deposition-evaporation transmission device to rotate; the vacuum evaporator is positioned below the deposition-evaporation transmission device; the evaporation source of the vacuum evaporator is arranged opposite to deposition-evaporation transmission device; and the longitudinal center line of the evaporation source is parallel with the plane of the substrate. The deposition-evaporation system provided by the invention has the advantages that a plurality of substrates can be evaporated, the rotating speed of each substrate can be adjusted, and the inclined angle of each substrate can be adjusted, is beneficial for increasing productivity and reducing production cost, and is applicable to batch production of inclined angle evaporation nanostructure films.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

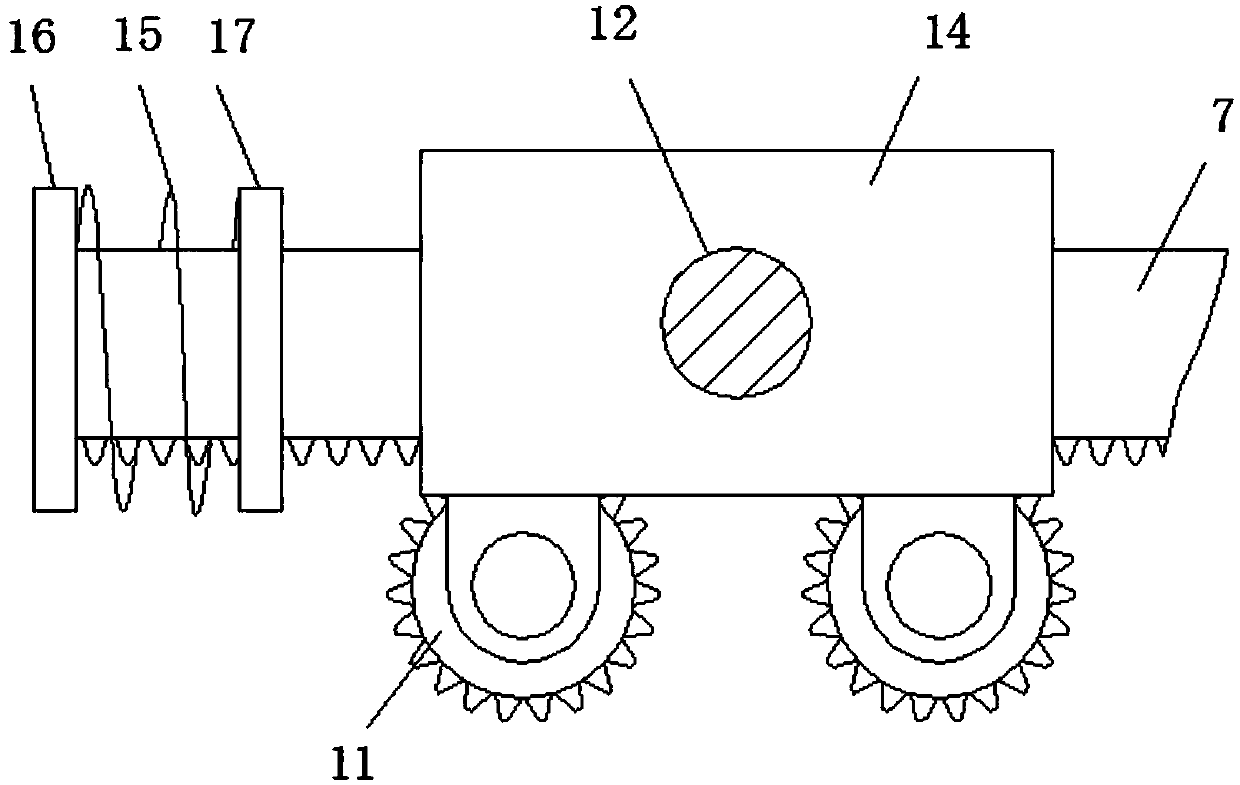

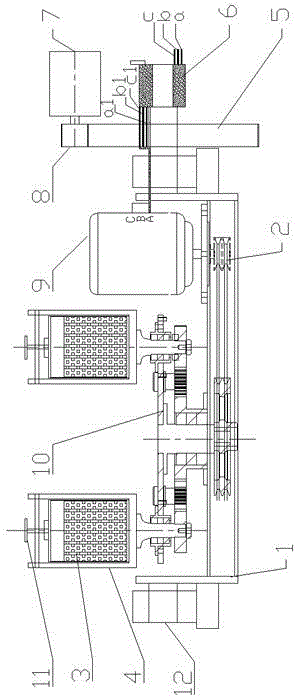

Multi-station sweeping equipment

PendingCN109108789AStable supportImprove stabilityGrinding carriagesGrinding work supportsEngineeringSteering control

The invention provides multi-station sweeping equipment, and belongs to the technical field of machinery. The multi-station sweeping equipment solves the problems that prior multi-station sweeping equipment cannot realize independent rotation speed and steering control of each station and has low working efficiency. The multi-station sweeping equipment comprises a bed body on which a frame is arranged. A rotating seat and a driving structure I for driving the rotating seat to rotate are arranged on the bed body. A sweeping assembly is arranged on the frame. A positioning assembly arranged corresponding to the sweeping assembly and used for positioning a workpiece is arranged on the rotating seat. By means of the multi-station sweeping equipment, multi-station simultaneous processing of a plurality of groups of workpieces can be realized, independent rotation speed and steering control of each station can be achieved, and operators can assemble and disassemble pieces conveniently, so that the processing efficiency is greatly improved, and the labor intensity of workers is effectively reduced.

Owner:CSIC CHONGQING INTELLIGENT EQUIP ENG DESIGN

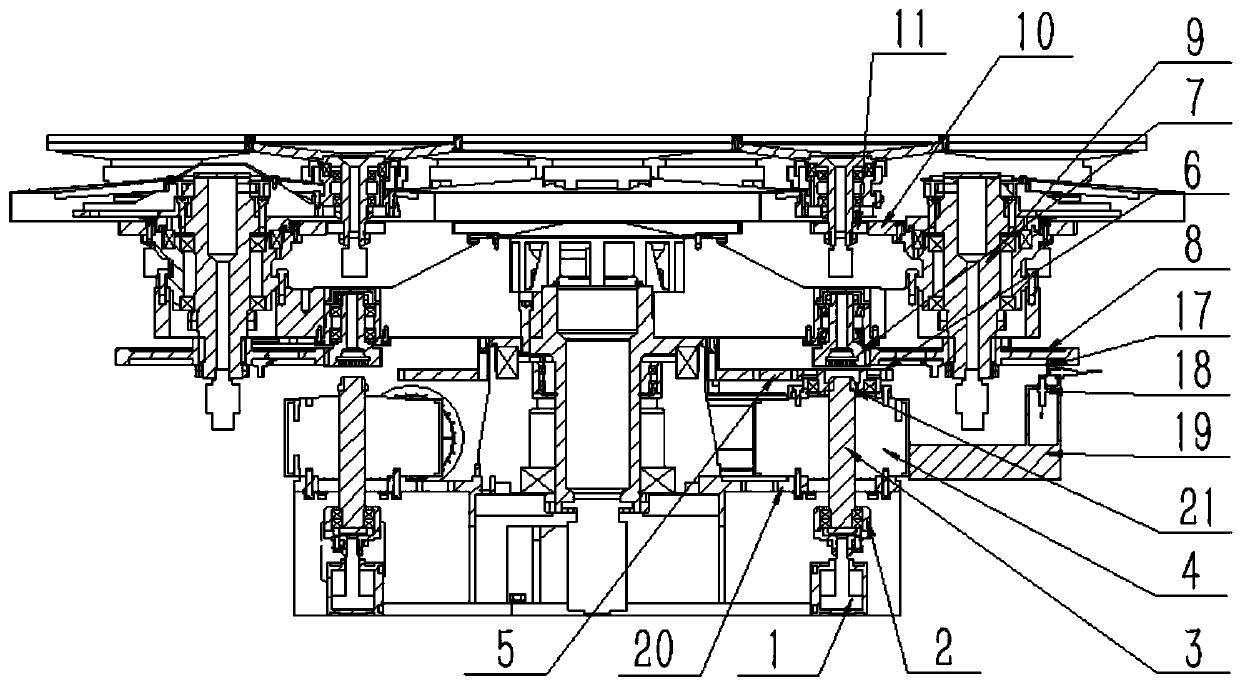

Adsorption and drive system of polishing machine

ActiveCN106078500AImproved polishing trajectoryImprove polishing efficiencyPolishing machinesGrinding drivesControl theoryAdsorption effect

The invention discloses an adsorption and drive system of a polishing machine. The adsorption and drive system of the polishing machine comprises a turn table bearing I, a supporting plate, a gear I, tooth rings, gears II, rotary joints I, a central shaft, a rotary joint II, a turn table bearing II, a gear III, a mounting plate and swinging components, wherein the turn table bearing I is mounted at the upper part of the supporting plate; the mounting plate is fixedly arranged on the turn tale bearing I; the central shaft and the swinging components are fixedly arranged on the mounting plate; the gear III is meshed with the turn table bearing I; the turn table bearing II is mounted at the lower part of the supporting plate; the gear I is meshed with the turn table bearing II; the tooth rings are located on the turn table bearing II; the gears II are mounted on the swinging components, and are meshed with the tooth rings; the swinging components are provided with adsorption passages; the rotary joints I are mounted at the bottoms of the swinging components, and communicate with the adsorption passage; the central shaft is provided with an air ventilating hole; the air ventilating hole is connected with the rotary joints I through air pipes; and the rotary joint II is mounted at the bottom of the central shaft, and communicates with the air ventilating hole. The adsorption and drive system of the polishing machine has the characteristics that an adsorption effect on a work piece is good, a polishing trajectory can be improved, the polishing efficiency is increased, and the like.

Owner:HUNAN YUJING MACHINE

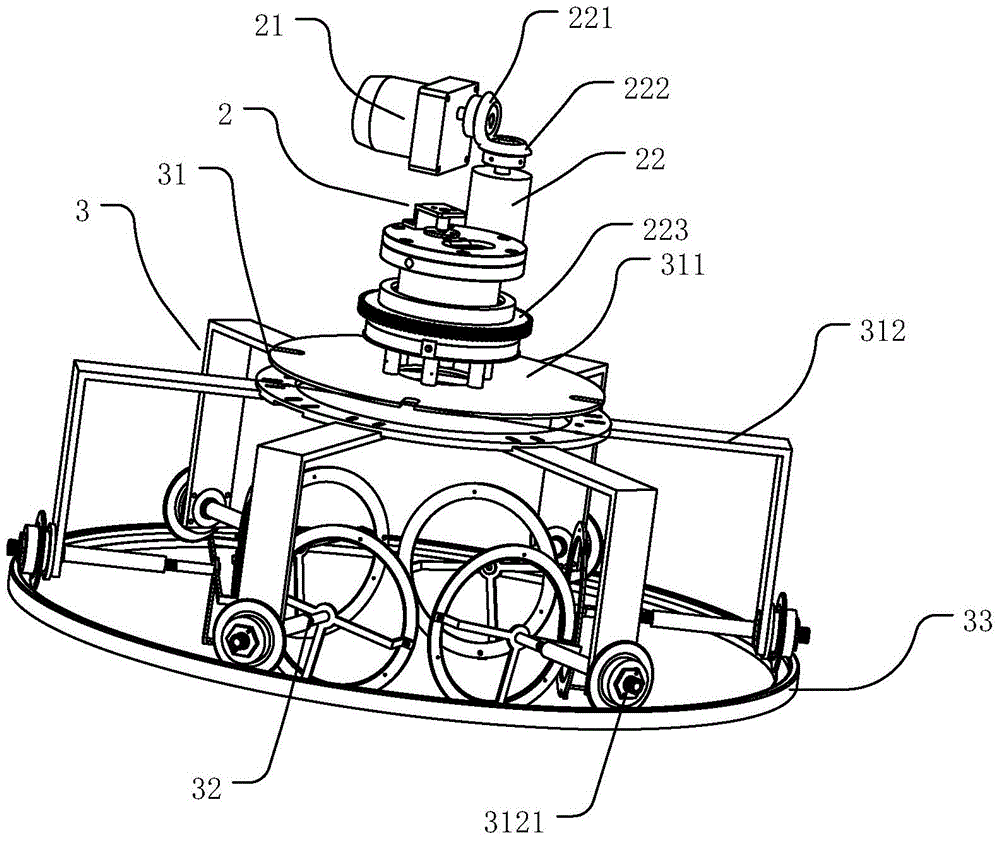

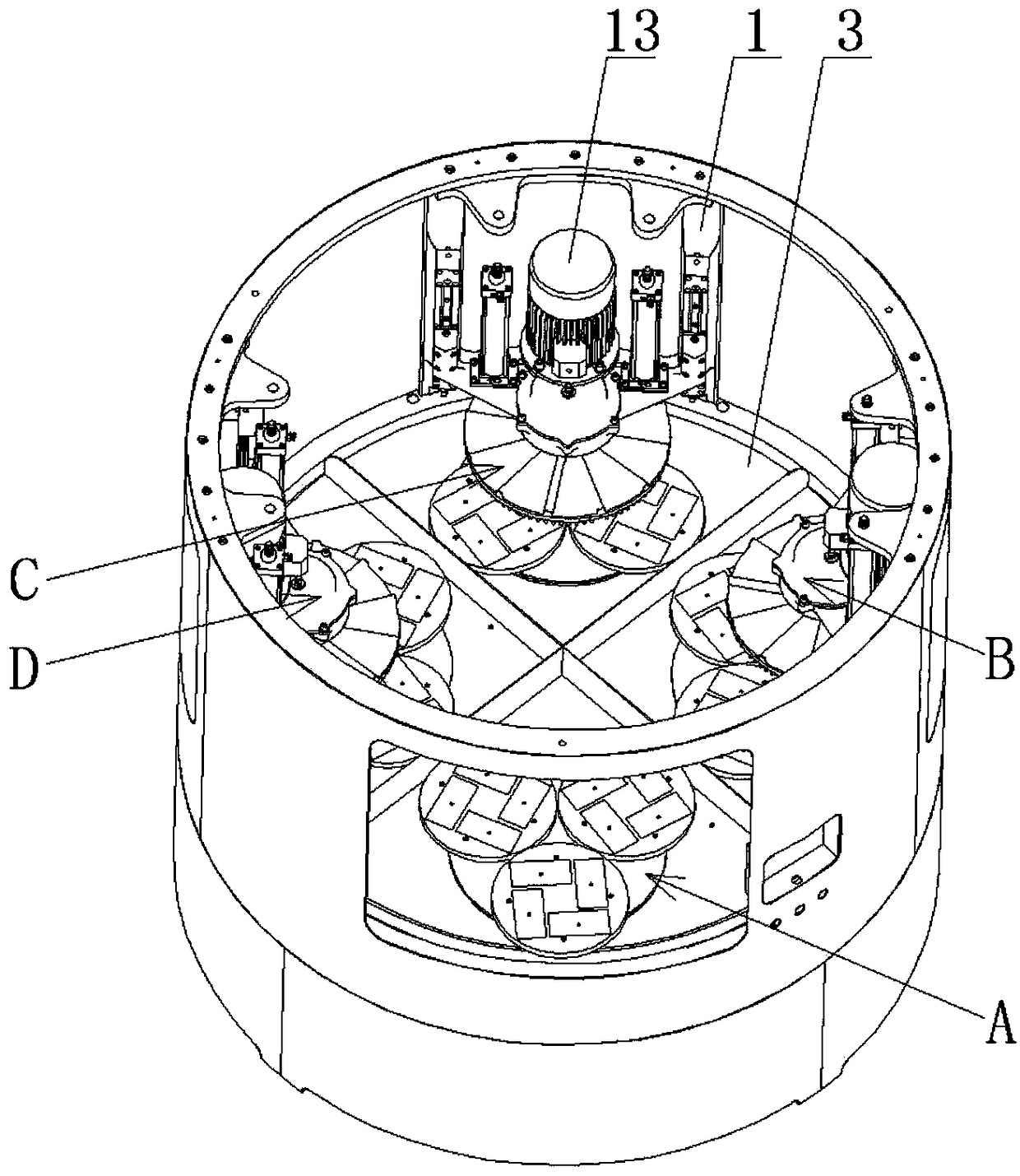

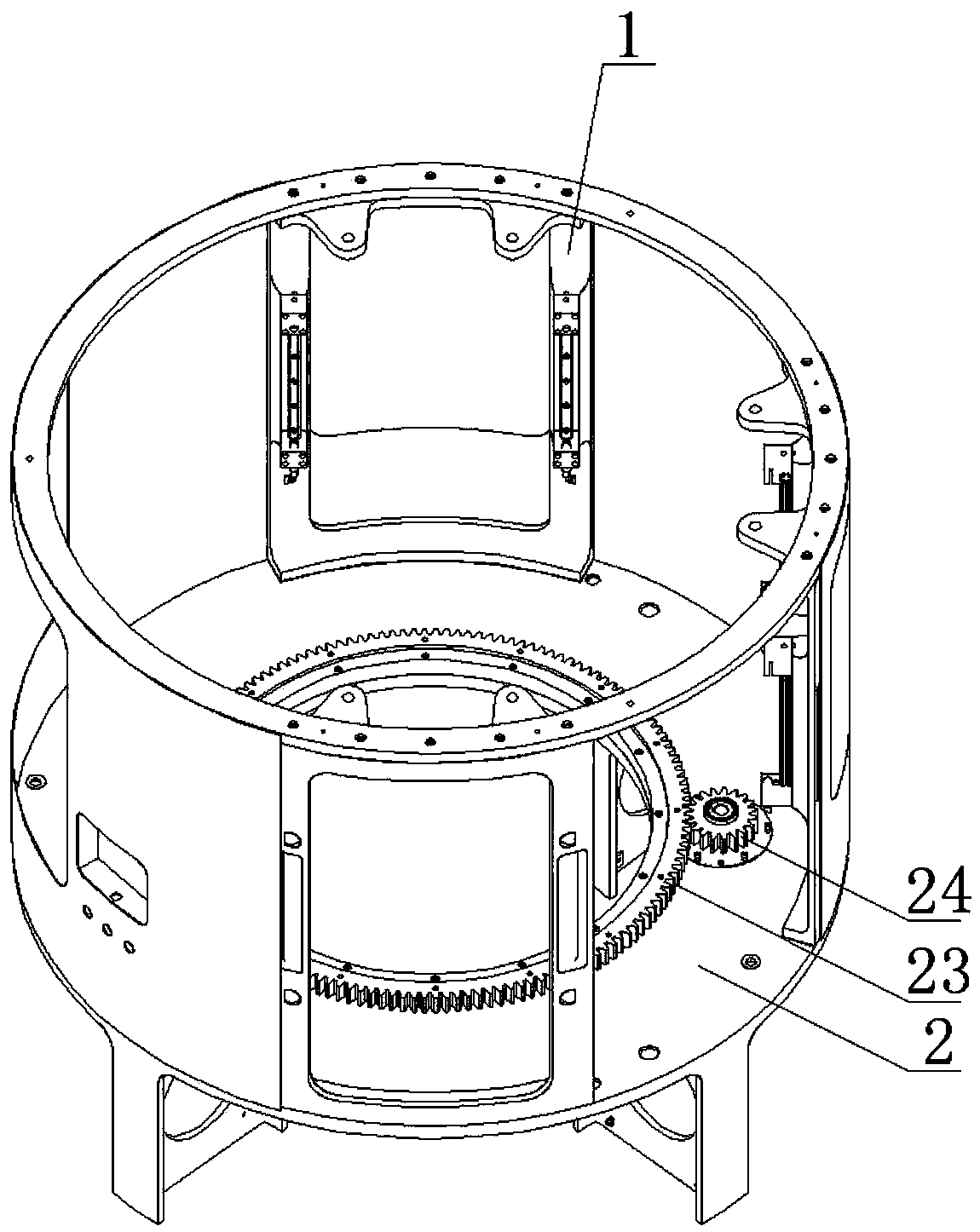

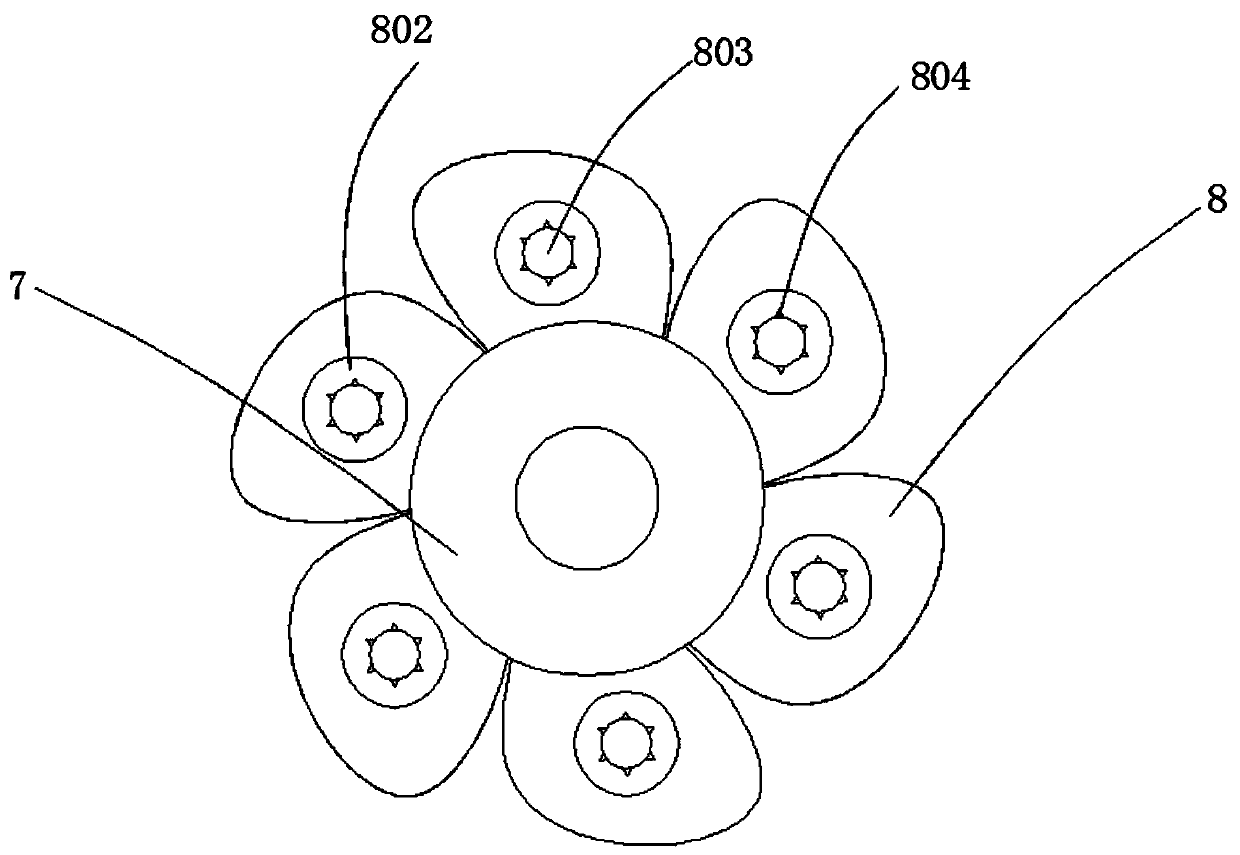

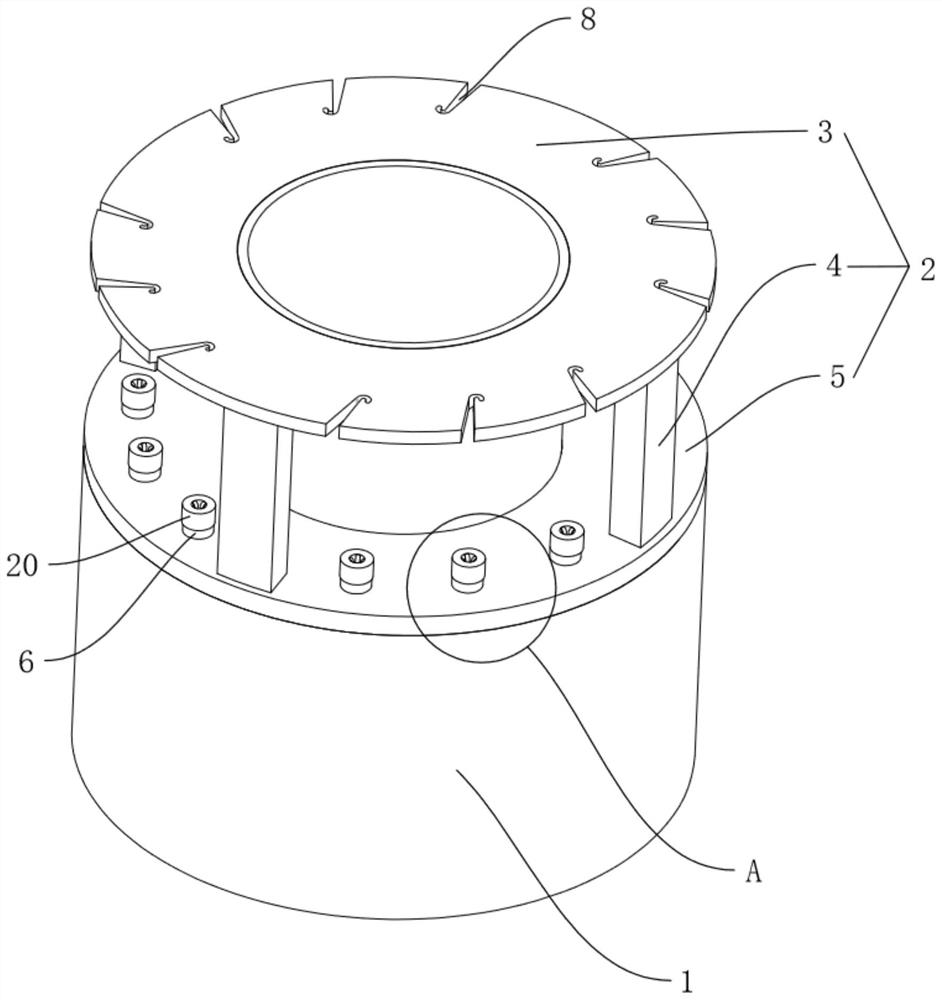

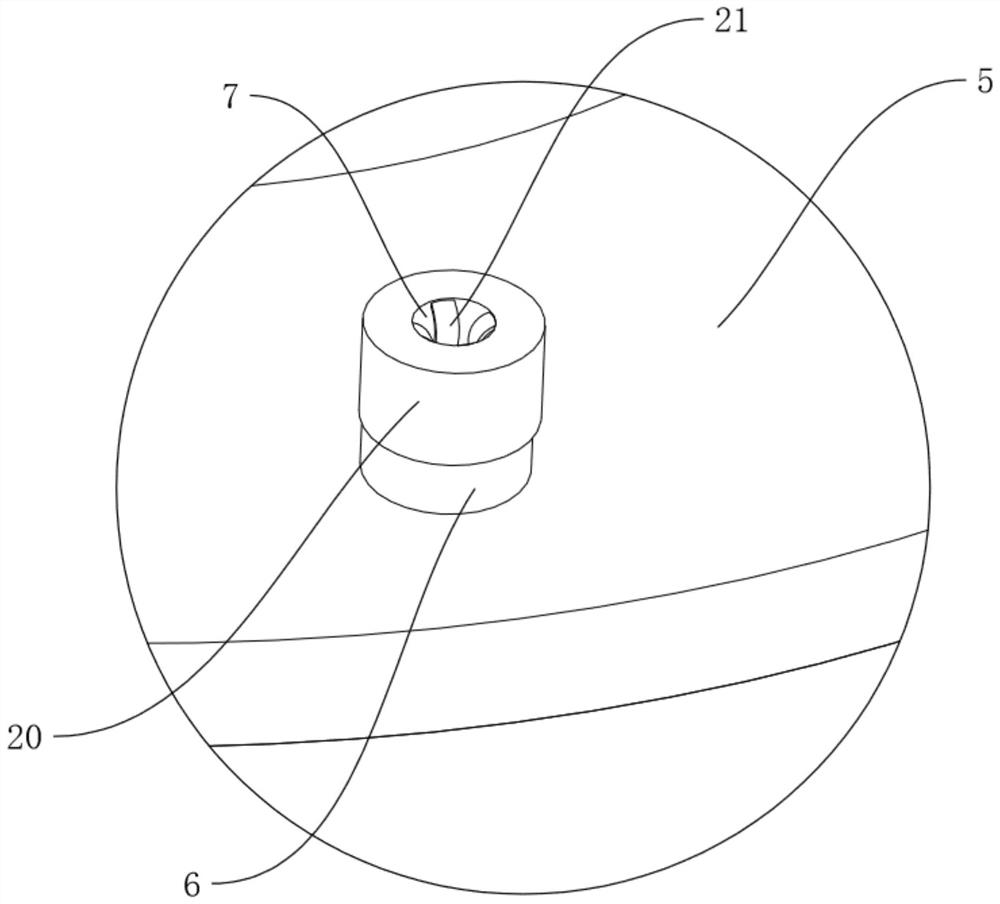

All-directional planetary ball mill

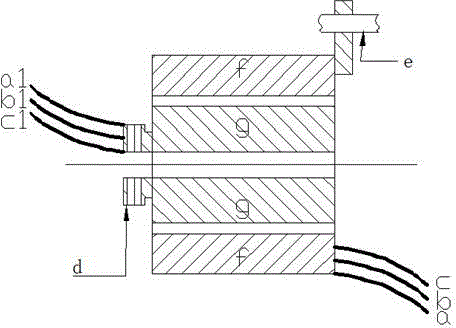

The invention relates to an all-directional planetary ball mill. According to the technical scheme, the all-directional planetary ball mill comprises a rotating frame (1), a transmission motor (9), a planetary transmission mechanism (10), grinding tanks (3) and grinding tank bases (4); the transmission motor (9) drives the planetary transmission mechanism (10) through a belt wheel (2), and the planetary transmission mechanism (10) drives the grinding tanks (3) to rotate through the grinding tank bases (4); the rotating frame (1) is fixed to the planetary transmission mechanism (10), a large gear (5) is installed on a shaft of the rotating frame (1), and a gear motor gear (8) and the large gear (5) are driven through a gear motor (7) to achieve transmission. The all-directional planetary ball mill is characterized by further comprising a via hole slip ring (6), wherein the via hole slip ring comprises a stator (f) and a rotor (g), and a terminal wire of the transmission motor (9) is connected with a stator wire and a rotor wire of the via hole slip ring to achieve electric conduction. The all-directional planetary ball mill can achieve all-directional 360-degree turnover movement and meanwhile has the advantages of being free from maintenance, convenient to assemble, capable of achieving sealing and insulation and high in safety.

Owner:长沙天创粉末技术有限公司

Cage strander and untwisting system thereof

ActiveCN106638069AAchieve revolutionRealize the percentage back twist modeRope making machinesGear driveDrive shaft

Owner:HEFEI SMARTER TECH GROUP CORP

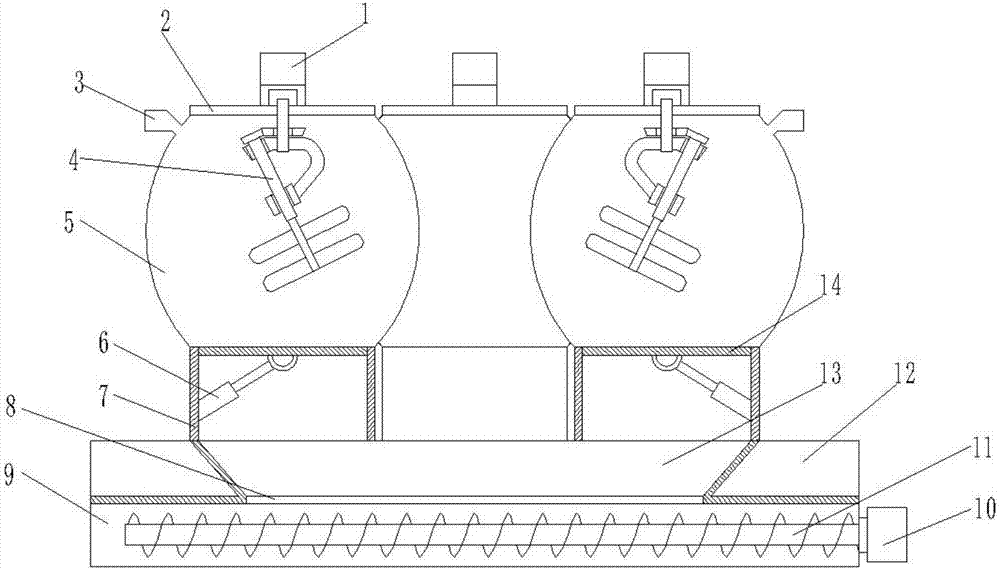

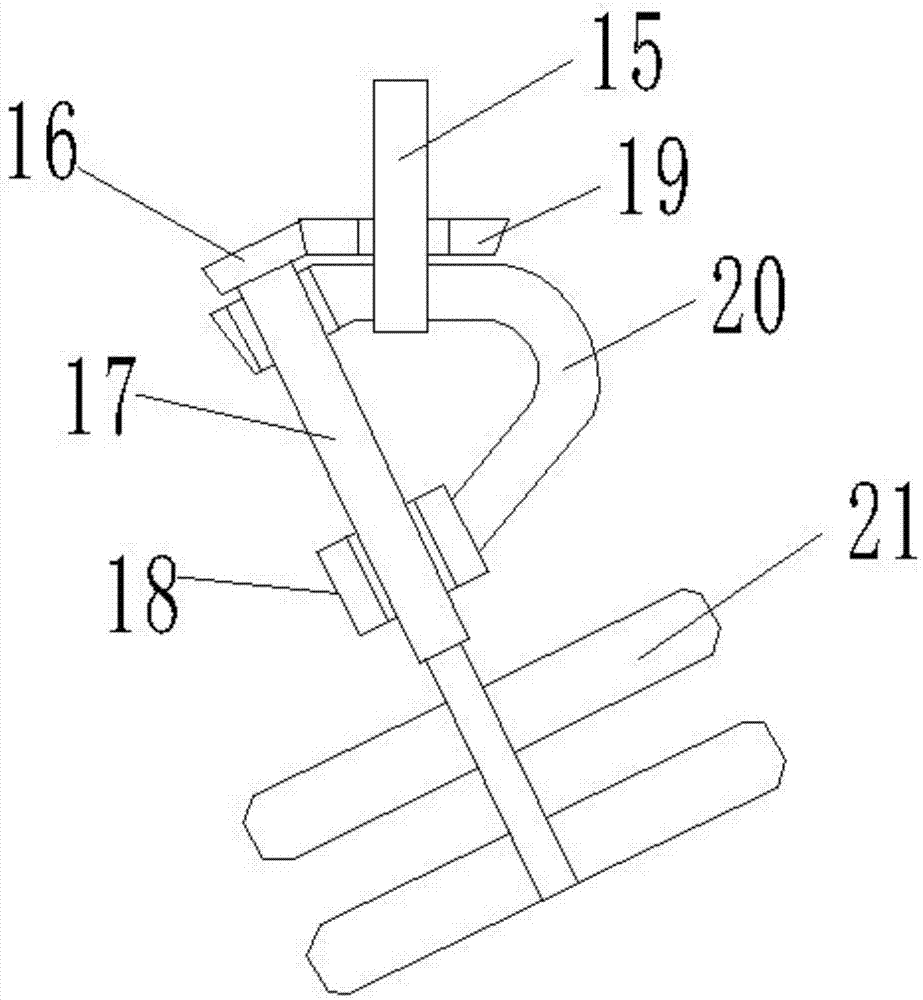

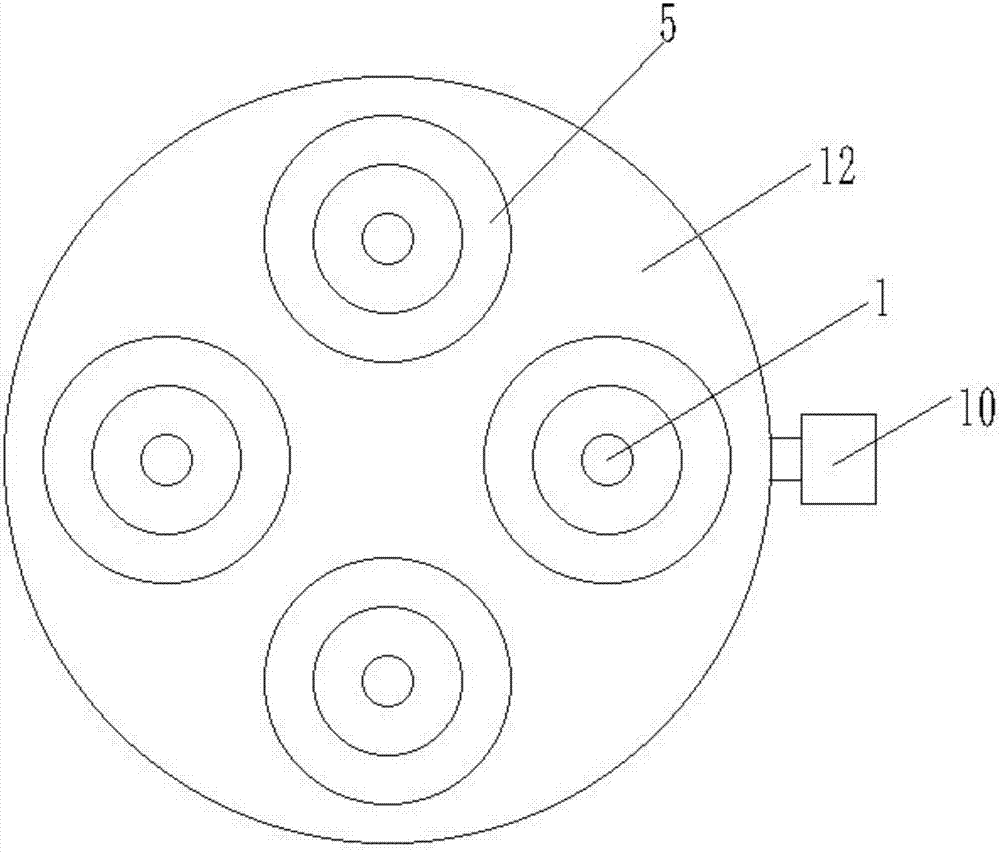

Planetary concrete stirring equipment

InactiveCN107363998AAchieve revolutionAchieve rotationDischarging apparatusCement mixing apparatusGear wheelEngineering

The invention discloses a planetary concrete mixing equipment, which comprises a mixing motor, a bucket cover, a mixing device, a mixing bucket, a feeding bin and a base. The base is fixed with a plurality of mixing buckets, and the top opening of each mixing bucket is All are equipped with a bucket cover, and a stirring motor is installed on the bucket cover. The output end of the stirring motor is connected with the stirring device placed in the mixing bucket. One side of the mixing bucket is provided with a feeding port. The bottom of each mixing bucket is All are equipped with a feeding channel; the base is provided with a funnel-shaped collecting bin, and a plurality of the feeding channels are kept in communication with the collecting bin. The beneficial effect of the present invention is: when the rotating shaft rotates, the swing arm is synchronized Rotation realizes the revolution of the stirring shaft, and at the same time, the cooperation between the active bevel gear and the driven bevel gear can also realize the self-rotation of the stirring shaft, so as to achieve a better stirring effect, and there are multiple mixing barrels installed on the base, which can be processed at the same time A large amount of concrete, and the processing efficiency is high, and the operation is convenient.

Owner:广西综改咨询服务有限公司

Airing device for rice processing

PendingCN112284104AEasy to transportImprove drying efficiencyDrying solid materials without heatDrying chambers/containersElectric machineryAgricultural engineering

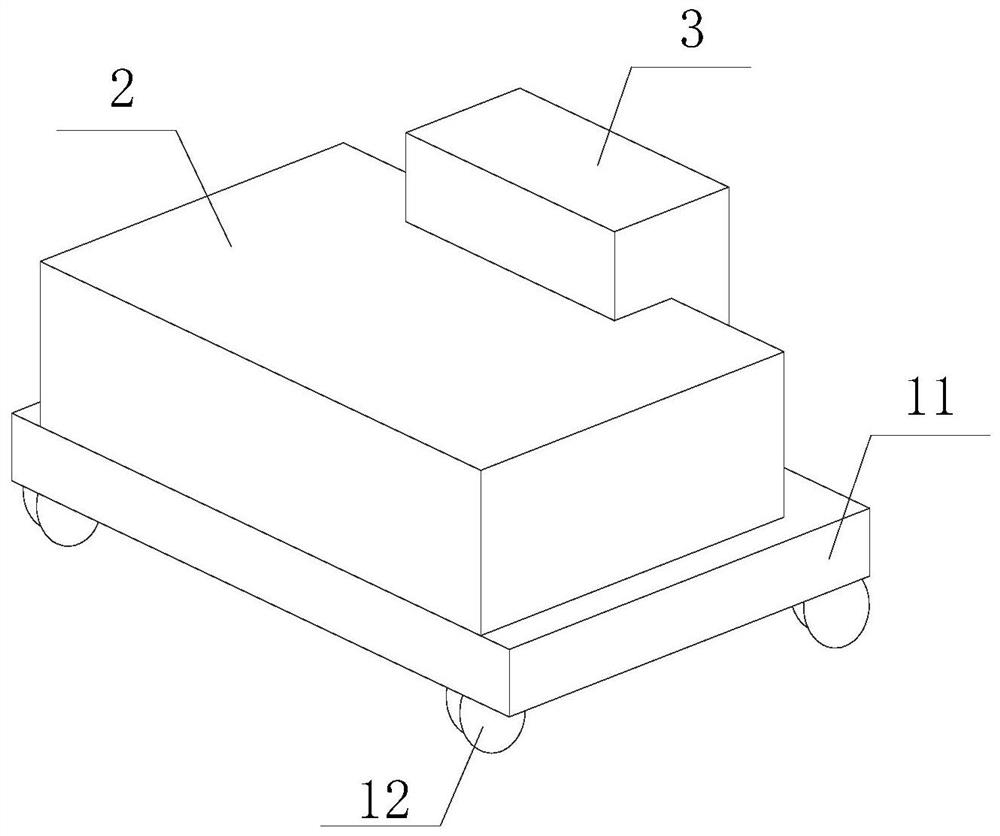

The invention discloses a airing device for rice processing. The airing device comprises a telescopic rod, wherein a bottom plate is fixedly connected to the bottom of the telescopic rod, sliding wheels are fixedly connected to the four corners of the outer wall of the bottom of the bottom plate, an equipment box is fixedly connected to the top of the telescopic rod, and a limiting bolt is in threaded connection with the outer wall of the telescopic rod; and the outer wall of the equipment box is rotationally connected with a cover plate. According to the airing device, by arranging the sliding wheels at the bottom of the bottom plate, the airing device has the moving capacity, and transferring of the airing device is facilitated; and a motor arranged on the inner wall of the equipment boxdrives a first rotating shaft to rotate, a bearing plate at the top of the first rotating shaft is driven to rotate, and finally airing plates on the bearing plate revolves, and the airing plates andthe bearing plate are connected through second rotating shafts, so that the airing plates can rotate under manual pushing, and rice on the airing plates can be dynamically aired; and the equipment box and the bottom plate are connected and fixed through the telescopic rod, so that the airing height can be adjusted.

Owner:湖北冠田农业科技有限公司

Stage lighting device

InactiveCN107191850AAchieve rotationAchieve revolutionMechanical apparatusLighting support devicesStage lightingGear wheel

The invention discloses a stage lighting device. A first slide rail is fixedly connected to a supporting beam, a first slide block and a first electric push rod are connected to the first slide rail, and a second slide rail is fixed on the first slide block. , the second slider and the second electric push rod are connected to the second slide rail; the installation frame is fixed on the second slider, the driving shaft is connected to the installation frame in rotation, the drive motor is fixed on the installation frame, and the driving gear and the turntable frame are fixedly connected to the driving shaft, and the driving gear is placed inside the turntable frame, the two driven shafts are rotatably connected to the turntable frame, the two driven gears are respectively fixedly connected to the two driven shafts, and the two slave The driving gears are all meshed with the driving gears, the lampshade is hinged on the driven shaft through bolts, the reflector is arranged in the lampshade, the lighting lamp body is arranged in the reflector, and the heat sink is fixed on the outer wall of the lampshade. The driving motor is turned on, and when the driving motor drives the turntable frame to rotate, the illuminating lamp rotates on its own. The invention has good effect and simple structure.

Owner:NANJING YA XIN LIGHTING CO LTD

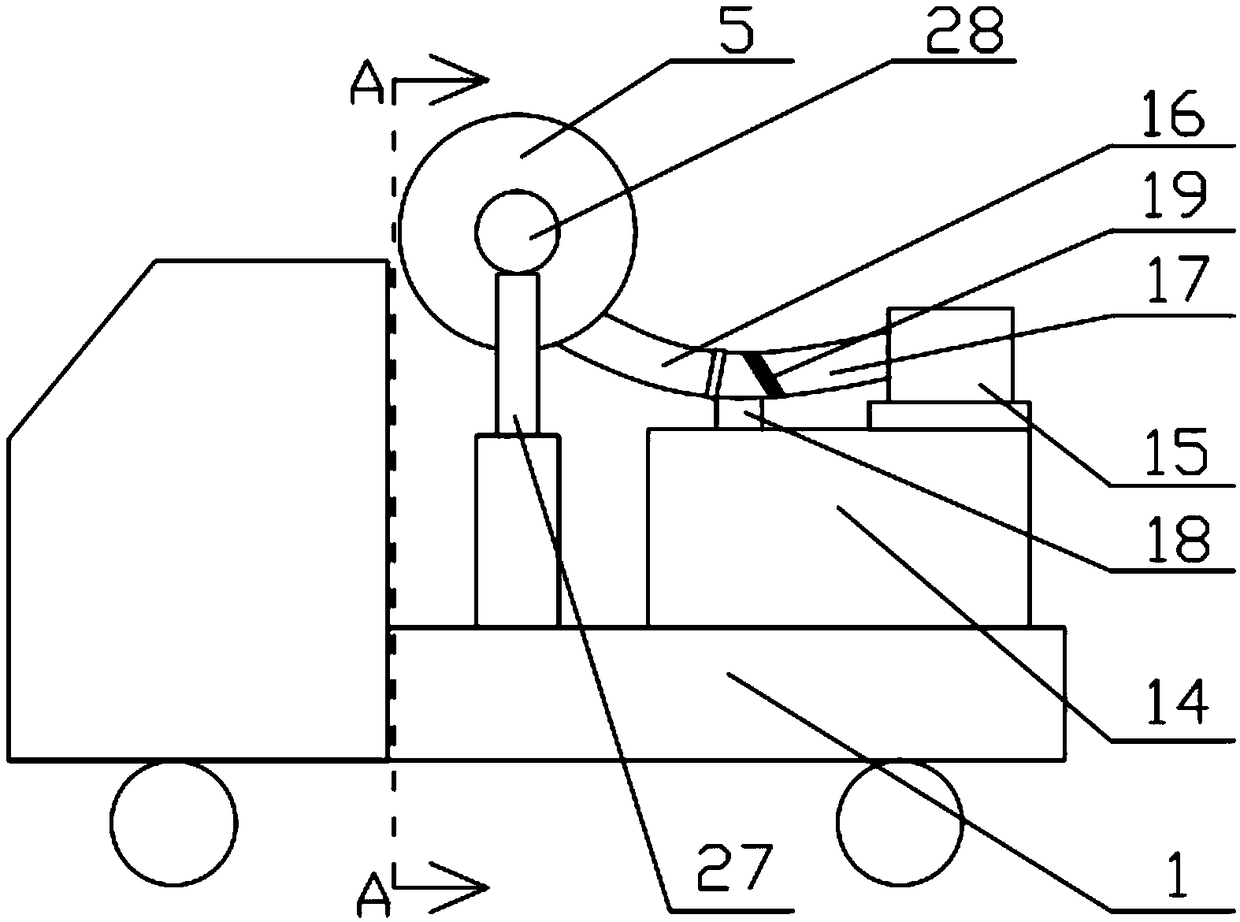

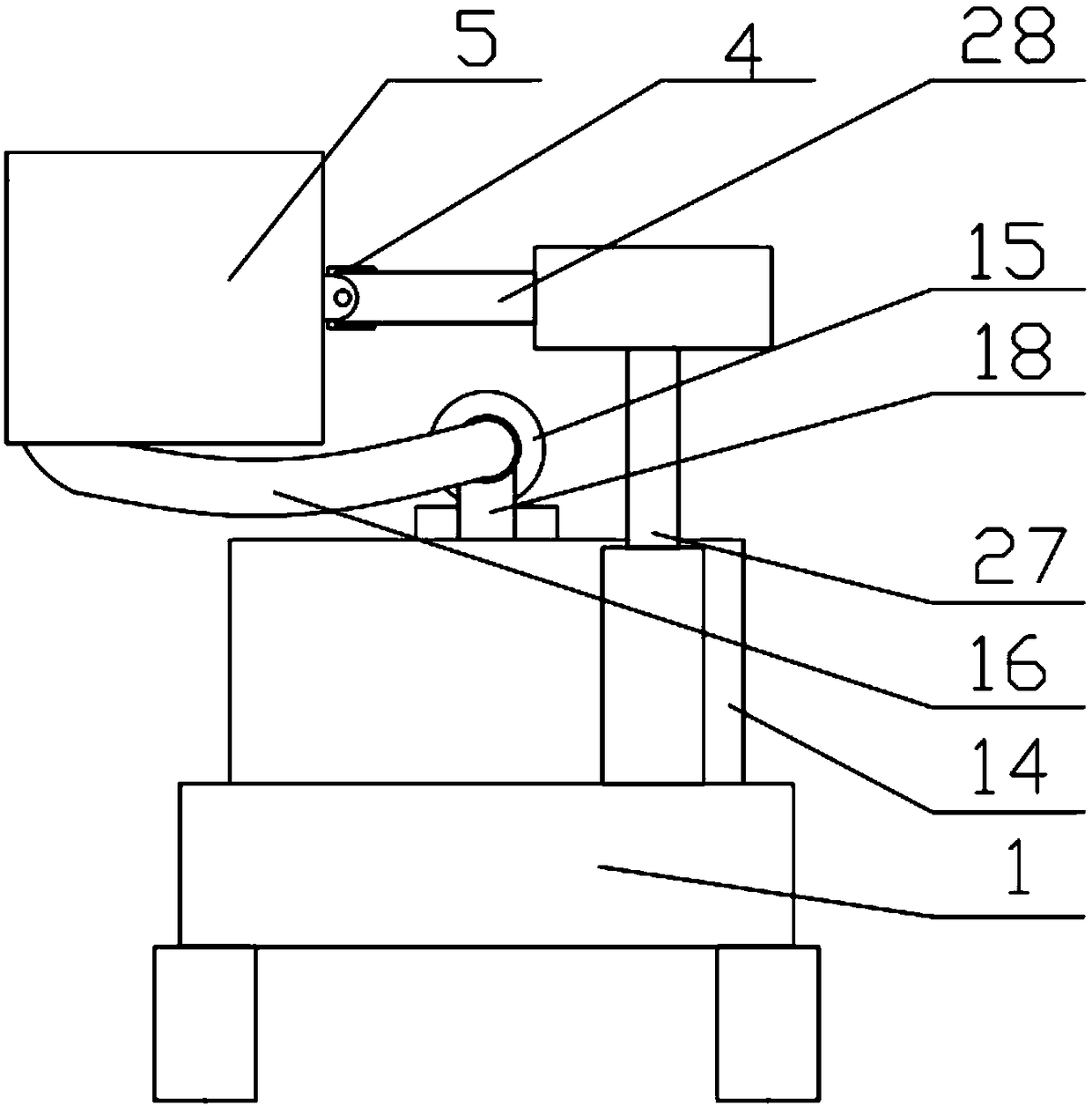

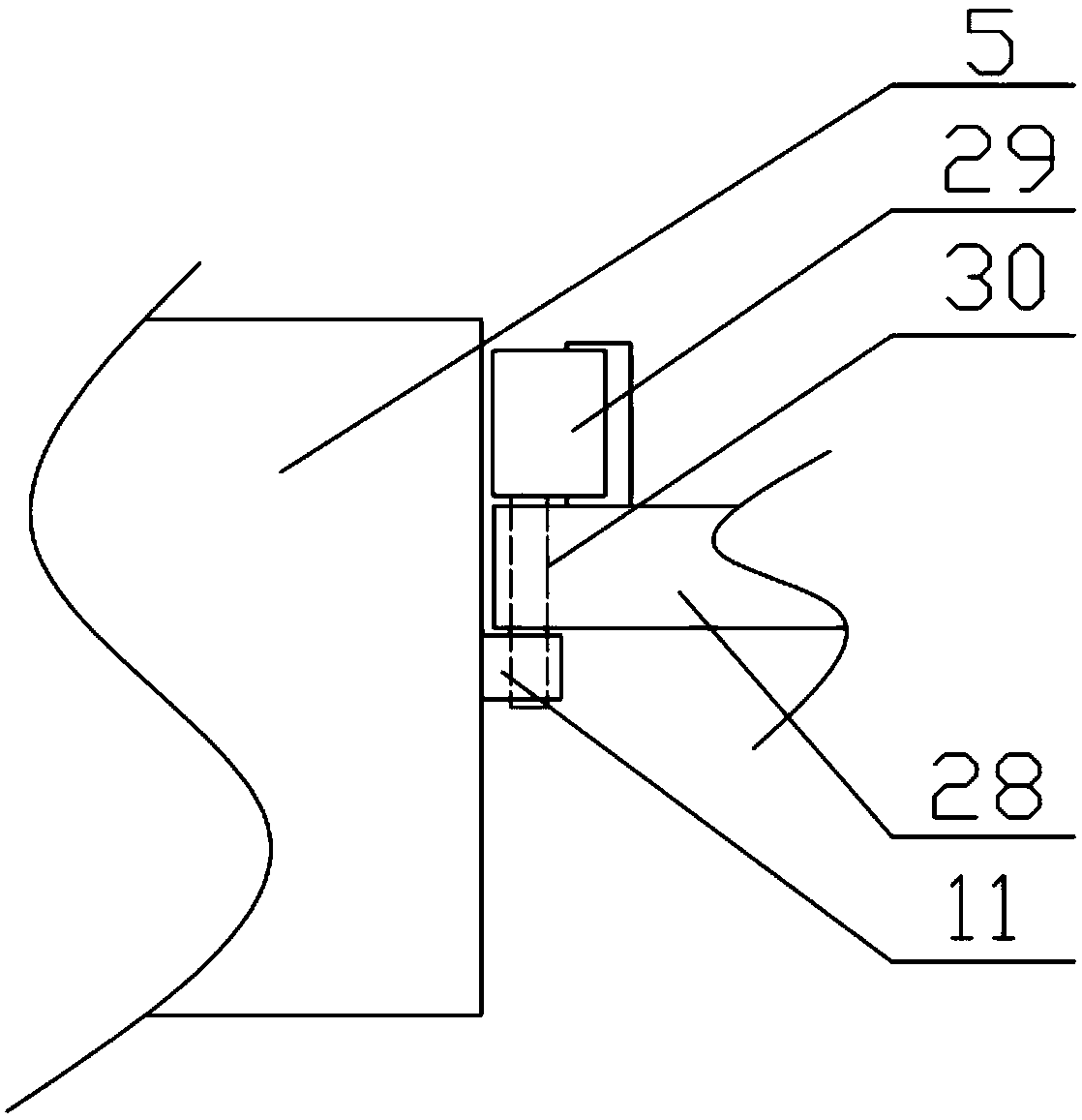

Branch pruning machine for green belts

InactiveCN108901426AImprove shear efficiencyExpand the scope of one-time cuttingCuttersCutting implementsEngineeringThrough transmission

The invention discloses a branch pruning machine for green belts, and belongs to the field of environmental construction management. The branch pruning machine comprises a carrying vehicle and a branch pruning device; the branch pruning device comprises a pruning mechanism, an adjusting mechanism and a branch recycling mechanism; the pruning mechanism comprises a main cutter wheel, auxiliary cutter wheels, a cutting motor, a transmission component and a protection cylinder cover, the main cutter wheel is directly driven by the cutting motor, the main cutter wheel externally engages with the auxiliary cutter wheels through gear teeth, and the inner wall of the protection cylinder cover is provided with rack rings which engage with the auxiliary cutter wheels; the interior of the main cutterwheel is provided with double layers of pruning blades, a front-layer pruning blade is directly connected with the output shaft of the cutting motor, and the free end of the front-layer pruning bladeis fixed on a wheel ring sleeve, a rear-layer pruning blade sleeves the output shaft of the cutting motor through a bearing, and rotating directions of the two layers of the pruning blades are opposite through transmission of the transmission component; and a filter net is arranged in a suction pipe. The branch pruning machine disclosed by the invention has a wider range of primary pruning, largepruning strength, more complete pruning and high pruning efficiency, facilitates saving energy, and has higher application value.

Owner:ANHUI NORMAL UNIV

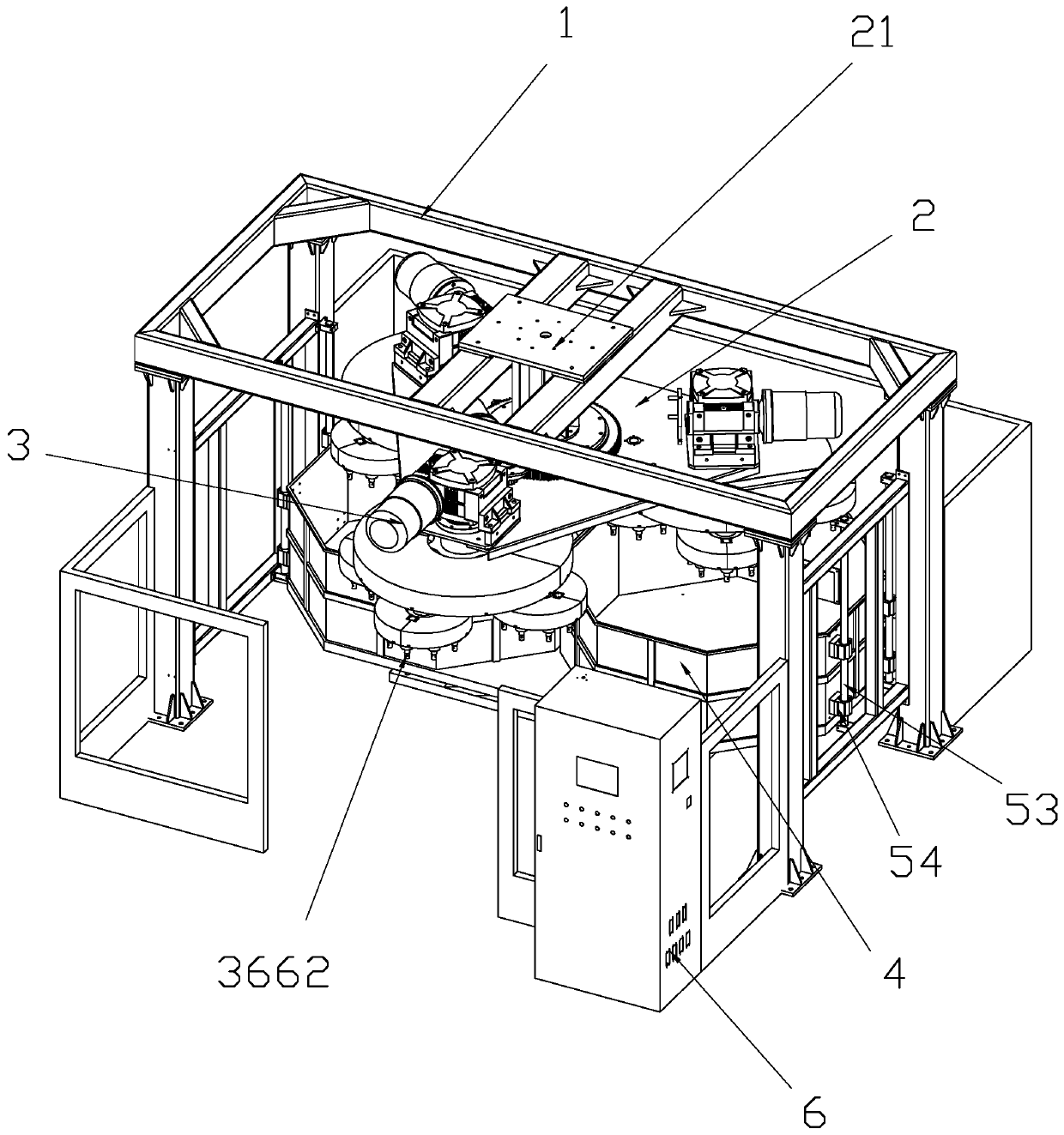

Transmission device of continuous curved surface polishing machine

PendingCN109940500AAchieve revolutionImprove efficiencyPolishing machinesGrinding drivesDrive shaftGear wheel

The invention discloses a transmission device of a continuous curved surface polishing machine. The transmission device comprises an index rotary disc. More than two single-station assemblies are uniformly distributed on the index rotary disc. Rotary assemblies are arranged on each single-station assembly. Air cylinders, bearing pedestals, clutch spline shafts, reducers, big disc station gears, station small gears, gear shafts, station driving gears, station transmission shafts, station transmission big gears, self-rotating gears, travel collision blocks and travel switches are further arranged. A transmission body of the transmission device is novel in structure and simple in implementing method, coarse grinding and precision polishing can be performed at a time, the production efficiencyis improved, and positioned detection of the single-station assemblies can be achieved.

Owner:宇晶机器(长沙)有限公司

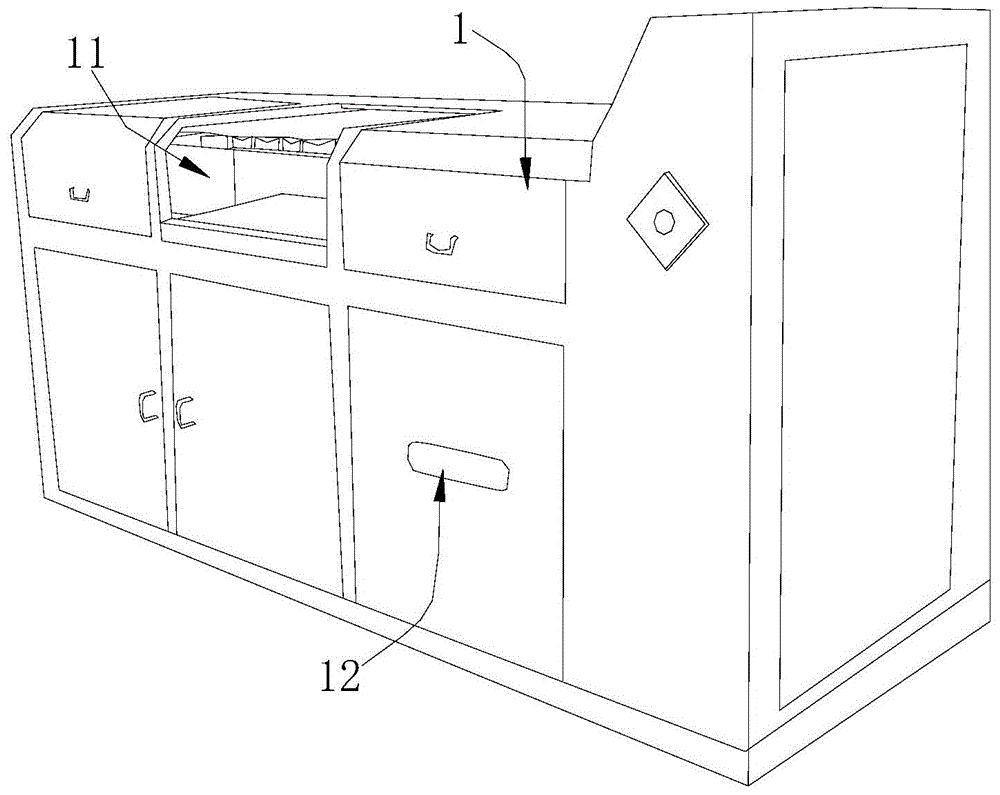

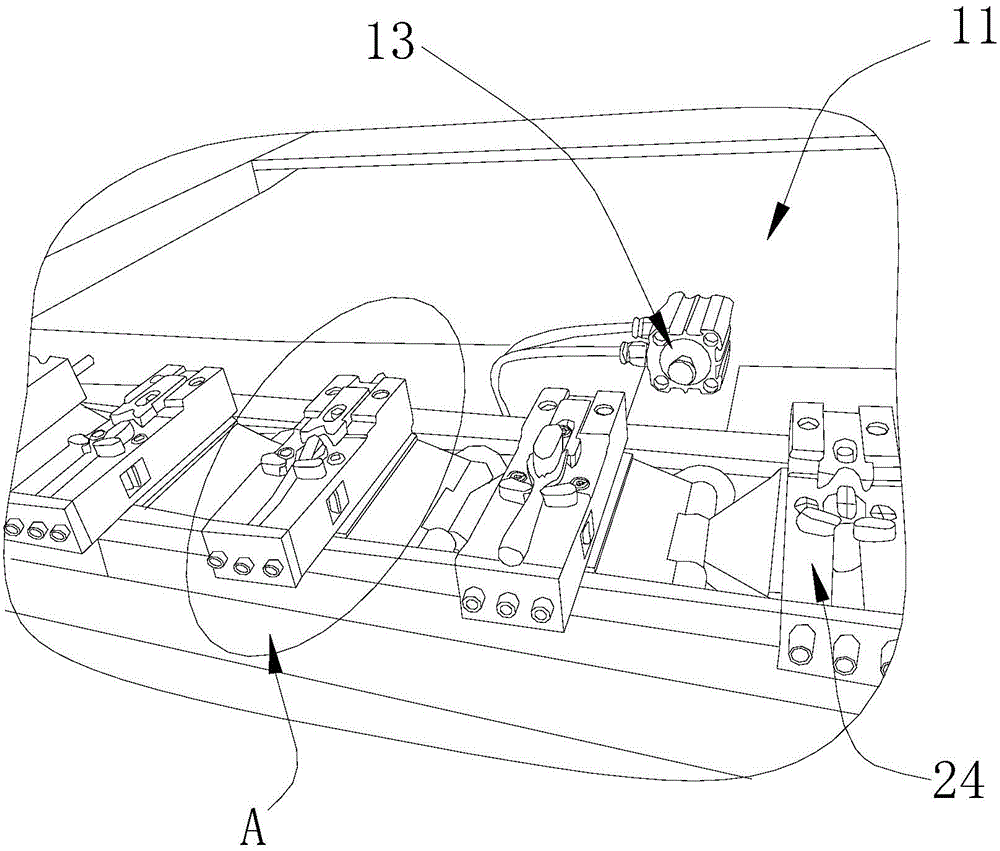

Brush bristle grinding equipment

The invention relates to a brush processing machine, in particular to brush bristle grinding equipment, which comprises a machine box, a material delivery mechanism and a bristle grinding mechanism, wherein the material delivery mechanism and the bristle grinding mechanism are arranged in the machine box, the machine box is provided with a material feeding opening and a material discharging opening, the material feeding opening is used for putting to-be-processed brushes, the material discharging opening is used for discharging finished brushes, a material charging cylinder is arranged in the material feeding opening of the machine box, a material discharging hopper is arranged in the machine box, the output end of the material discharging hopper corresponds to the material discharging opening, a material discharging cylinder is arranged above the input end of the material discharging hopper, the material delivery mechanism comprises a stepping motor, a material delivery belt and a plurality of brush clamps, the material delivery belt is driven by the stepping motor, the brush clamps are regularly and fixedly arranged at the outer surface of the material delivery belt at the equal intervals, the output end of the material charging cylinder and the output end of the material discharging cylinder are in intermittent fit with the brush clamps, the bristle grinding mechanism comprises a machine frame, a revolution motor, a plurality of rotational motors and a plurality of bristle grinding groups, and the revolution motor, the rotational motors and the bristle grinding groups are arranged on the machine frame. The brush bristle grinding equipment has the technical advantages that the manual operation is convenient, and smoothness of the bristles of the produced finished brushes is high.

Owner:南通创通日用品有限公司

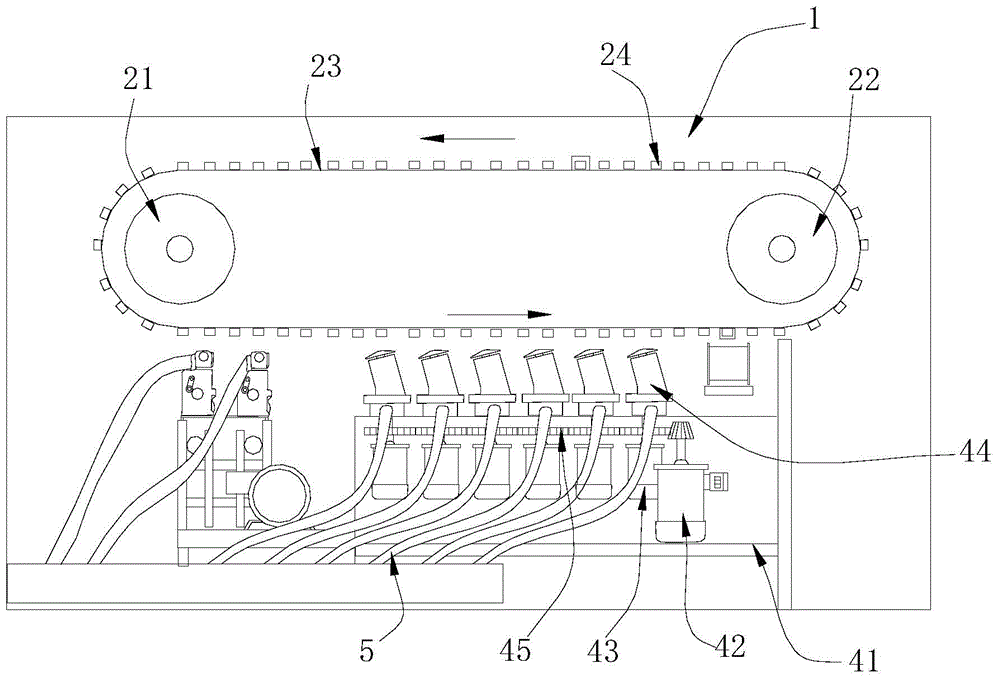

Suction roller device for baked food

ActiveCN106081217ASmall footprintIncrease productivityPackaging biscuitsAutomatic controlMotor drive

The invention discloses a suction roller device for baked food. The suction roller device for the baked food comprises cylinder cams, driven pieces, sucker gears, racks, air distribution blocks, a sealing end cover, a roller and a large gear set; 12 sub-air-cavities are arranged in the roller; a servo motor drives the large gear set which drives a suction roller body to rotate; according to the driven pieces, under the intervention effect of curved grooves of the cylinder cams, suckers on the sub-air-cavities can make sucker rotating bodies automatically rotate by 90 degrees before cake placement according to the cake placement design requirement matched with a packaging machine in advance; under the intervention of the air distribution blocks, the sub-air-cavities in movement perform automatic switching between negative pressure, positive pressure and zero pressure according to the design requirement of preset cake suction and placement position points; and when the suction roller rotates to the lowest end position point, namely the cake placement position, the sub-air-cavities communicate with air blowing holes of the air distribution blocks, the negative pressure is converted into the positive pressure, baked products are blown down to a packaging and conveying line, and the baked products enter the packaging machine. The suction roller device for the baked food is high in automatic control degree, small in occupied area and capable of obviously improving the production efficiency and saving labor and cost.

Owner:ZHEJIANG RIBON INTELLIGENT EQUIP CO LTD

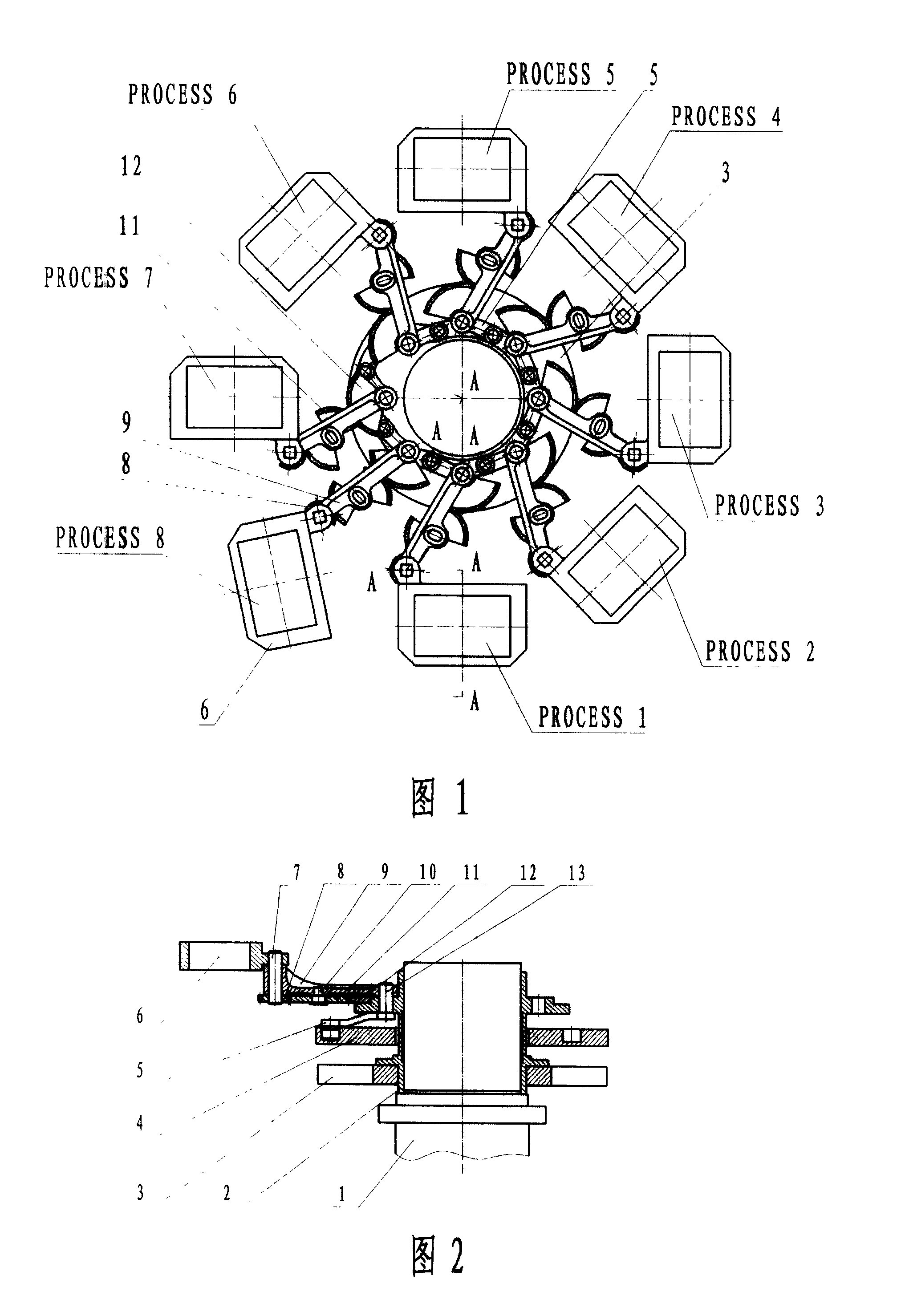

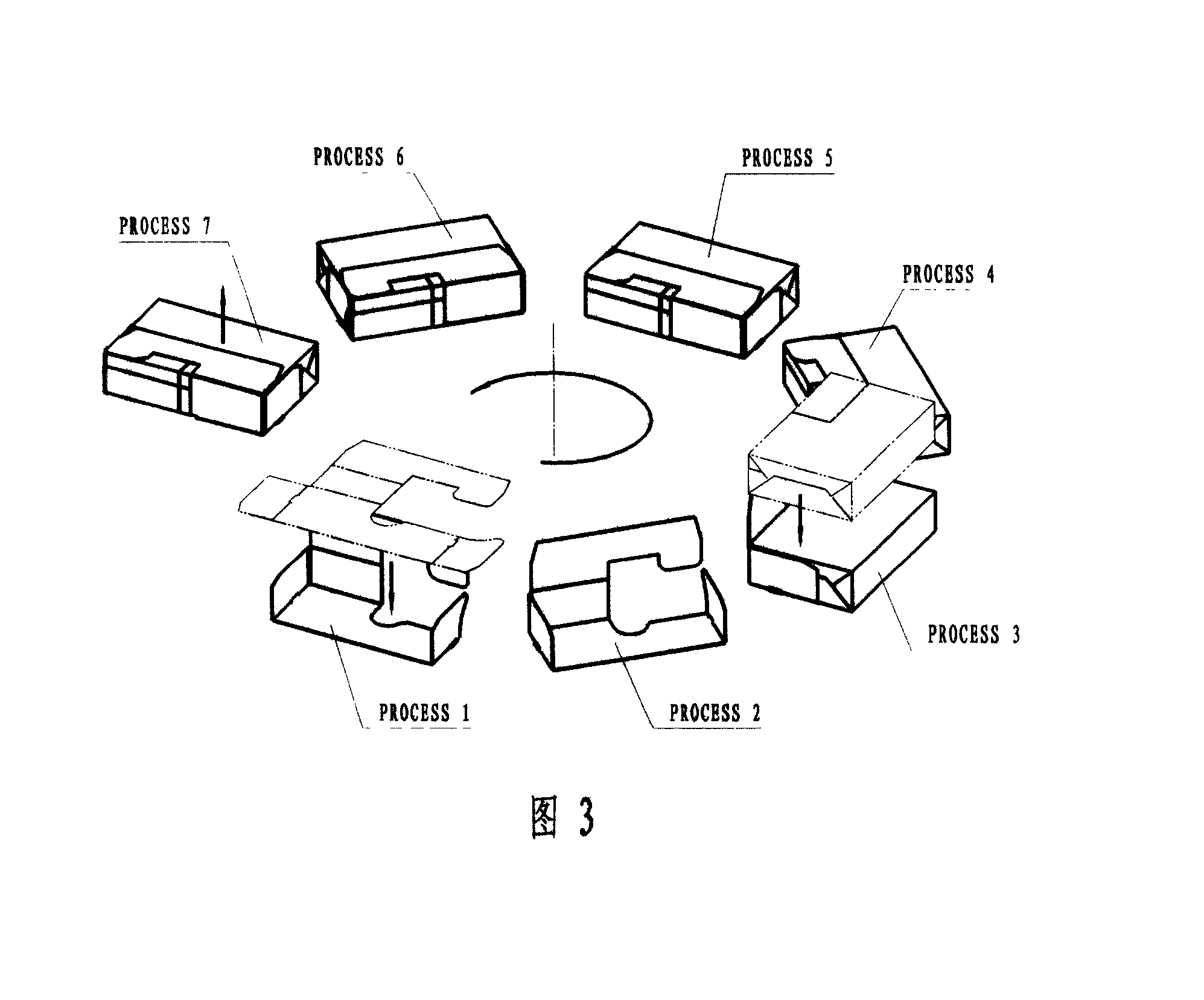

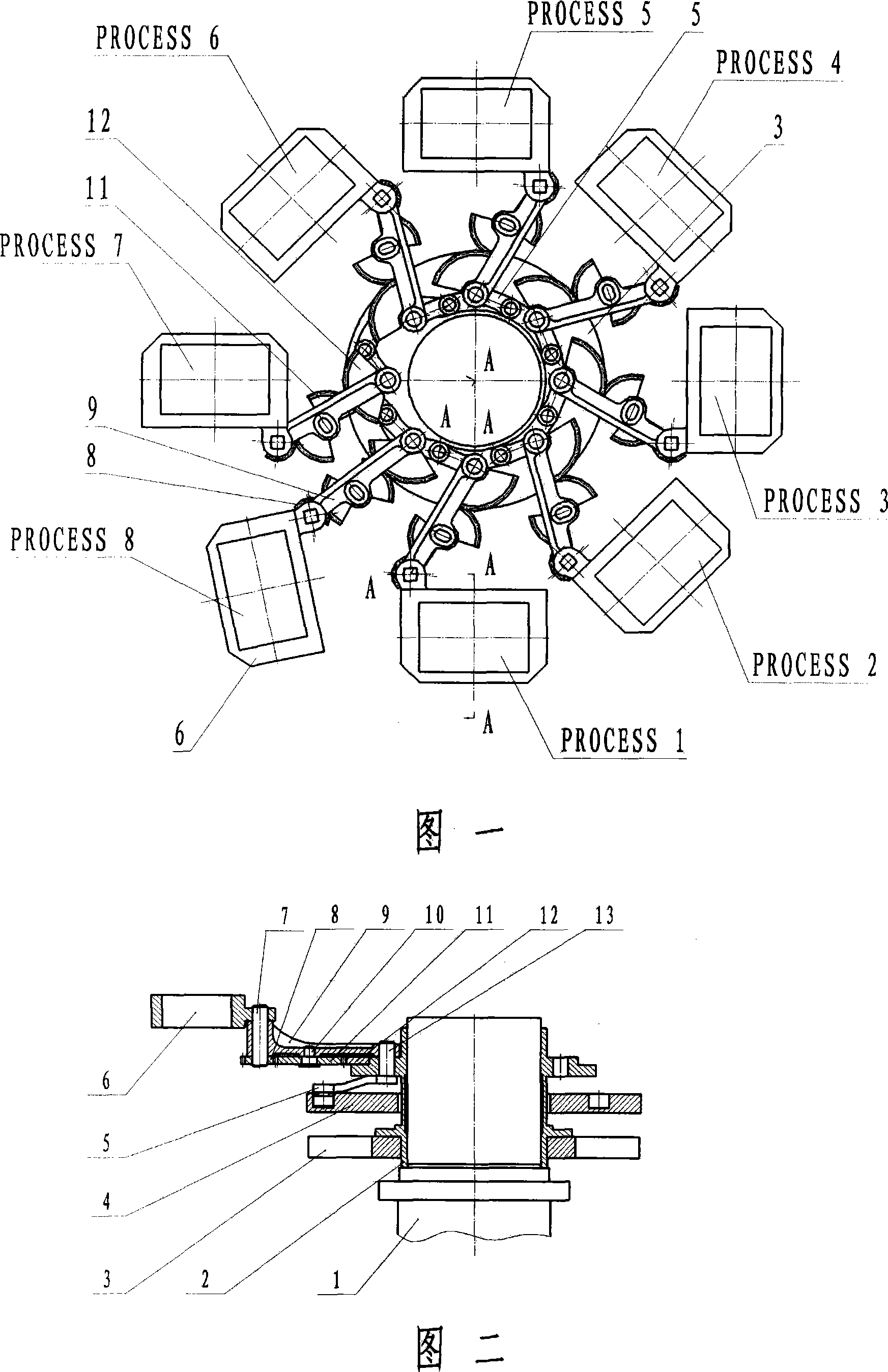

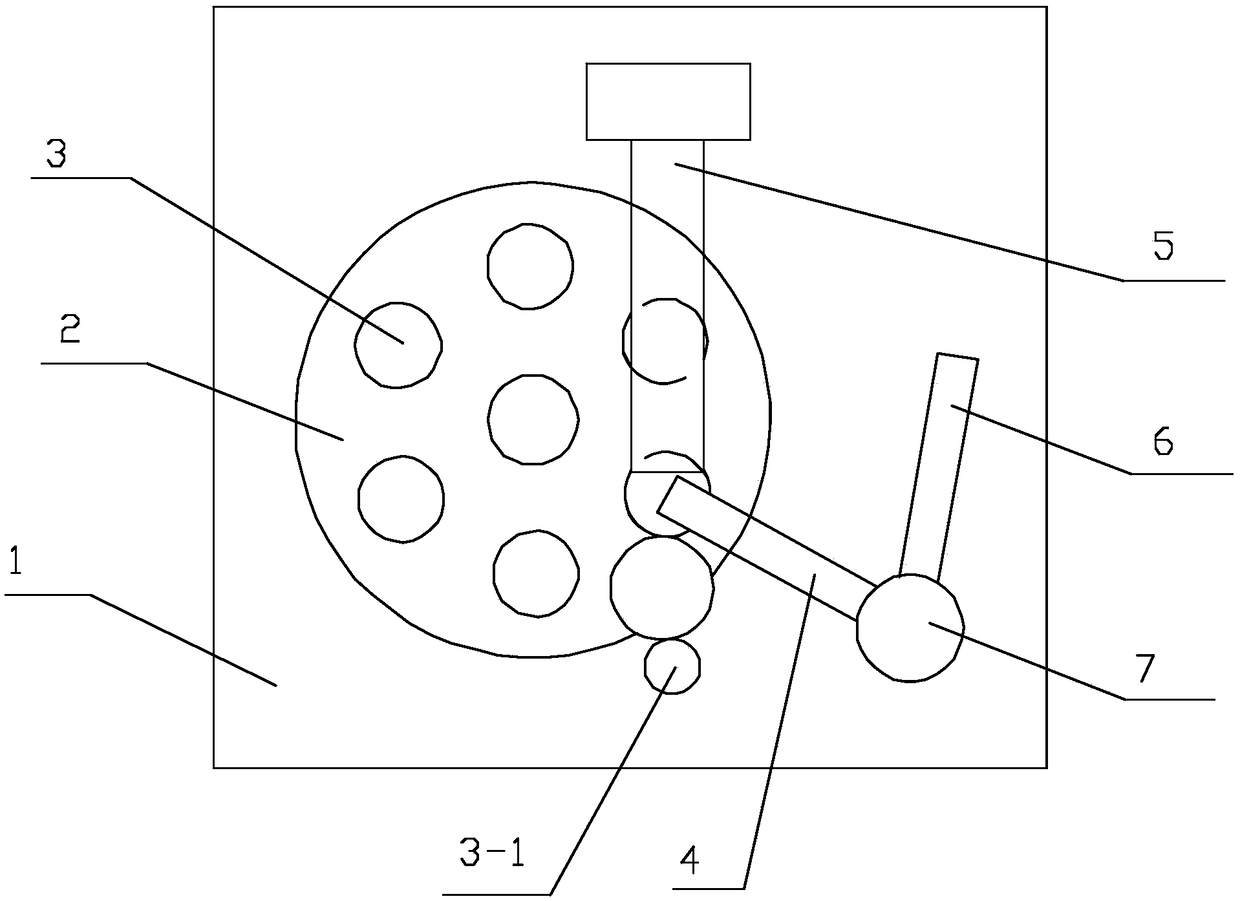

Rotating wheel transmission mechanism with bunker self-rotating function

InactiveCN101168386AAchieve revolutionAchieve rotationPackaging cigaretteConveyor partsTransmission functionRotation function

The invention relates to a rotary wheel device with chamber self-rotation function, which can realize indexing rotary wheel transmission that rotates material on horizontally around a main shaft and rotates in special area, wherein when an indexing slot wheel 3 rotates a rotary wheel 2, a fixed slot cam 4 via the change of a slot curvature swings a swing stem 5 at preset position, to swing a support swing stem 9 to demand position at next station, and under the control of a positioning gear 12, a butterfly gear 11 and an arc gear 8, a material chamber 6 can rotate to demand position and rotate around the axis of a rotary wheel 2 synchronously, thereby realizing the indexing rotary wheel transmission function rotates material horizontally around a main shaft and rotates in special area. The indexing slot wheel 3 is fixed at lower portion of the rotary wheel 2, and the gear 11 is designed as butterfly gear wheel, to avoid interference of the butterfly gears 11 on nearby swing stems of PROCESS 7 and PROCESS 8.

Owner:BEIJING WANJIANG TECH

Novel high-efficiency environment-protective dust-free polisher

PendingCN110936283AAchieve revolutionRich demandEdge grinding machinesPolishing machinesPolishingEngineering

The invention relates to a novel high-efficiency environment-protective dust-free polisher. The polisher comprises a frame, a station switching mechanism is arranged on the frame and is provided withthree rotation mechanisms, a moving path of the frame rotation mechanisms forms a first processing station, a second processing station and an unloading station, each rotation mechanism is provided with clamps, the clamps make revolution and rotation by the rotation mechanism, two polishing barrels are arranged under the first and second processing stations respectively, each polishing barrel is internally provided for a polishing material suitable for production processing, and a barrel lifting mechanism meeting product polishing needs is arranged at the bottom of the polishing barrel. Thus,a product on the clamps is polished comprehensively without blind areas by the polishing barrels, the polishing precision is improved, and flying dust is avoided; the unloading station is arranged tounload the product in the polishing process, and the production efficiency is improved; and the barrel lifting mechanism are arranged, so that it is not required to life the rotation mechanisms duringpolishing, and the problems that frequent calibration is needed and energy consumption due to too large driving force is too high due to low precision when the too heavy rotation mechanism are liftedfor long time are solved.

Owner:浙江珂斯顿机器人科技有限公司

Drying device with stirring device

InactiveCN104180624AAchieve revolutionStir wellDrying machines with non-progressive movementsDrying solid materialsMotor driveEngineering

The invention discloses a drying device with a stirring device. The drying device comprises a working table, a machine frame, a heating box, a temperature controller, a heating tube, a motor, a stirring pillar and stirring plates, wherein the machine frame is arranged at the top of the working table; the heating box is arranged at the top of the machine frame and is in threaded connection with the machine frame; the temperature controller is arranged on the left side wall of the heating box, and in threaded connection with the heating box; the heating tube is arranged at the bottom of the heating box, and is riveted with the heating box; the motor is arranged at the bottom of the machine frame and is in threaded connection with the machine frame; the stirring pillar is arranged at the inner bottom end of the heating box, and is in tight connection with the motor; the stirring plates are arranged at the periphery of the stirring pillar, are sectorial, and are in welded connection with the stirring pillar. The drying device has the advantages that the heating box is heated through the heating tube, and the motor drives the stirring pillar to rotate, so that the stirring plates conduct orbit motion in a fixed direction, and scatter pillars spin optionally to ensure sufficient stirring of a raw material and uniform heating, and improve the drying quality; the power source of a temperature limiter at the bottom of the heating box is cut off due to abnormal heating, so that the safety factor is improved.

Owner:ANHUI SUQI CHEM

Walking can scraping physiotherapy device and using method thereof

ActiveCN109998878AAchieve revolutionAchieve rotationSuction-kneading massageAgricultural engineering

The invention discloses a walking can scraping physiotherapy device and a using method thereof. The walking can scraping physiotherapy device comprises a scraping can, a driving mechanism, a transmission mechanism, a medicinal wine coating device and a friction device; the driving mechanism is arranged in the scraping can, the transmission mechanism is connected to the driving mechanism, the medicinal wine coating device and the friction device, and the transmission mechanism, the medicinal wine coating device and the friction device are all disposed in the scraping can. The driving mechanismcan simultaneously drive the operation of the medicinal wine coating device and the friction device under the transmission action of the transmission mechanism, is efficient and quick, and is compactand ingenious in structure.

Owner:浙江高创盟知识产权咨询有限公司

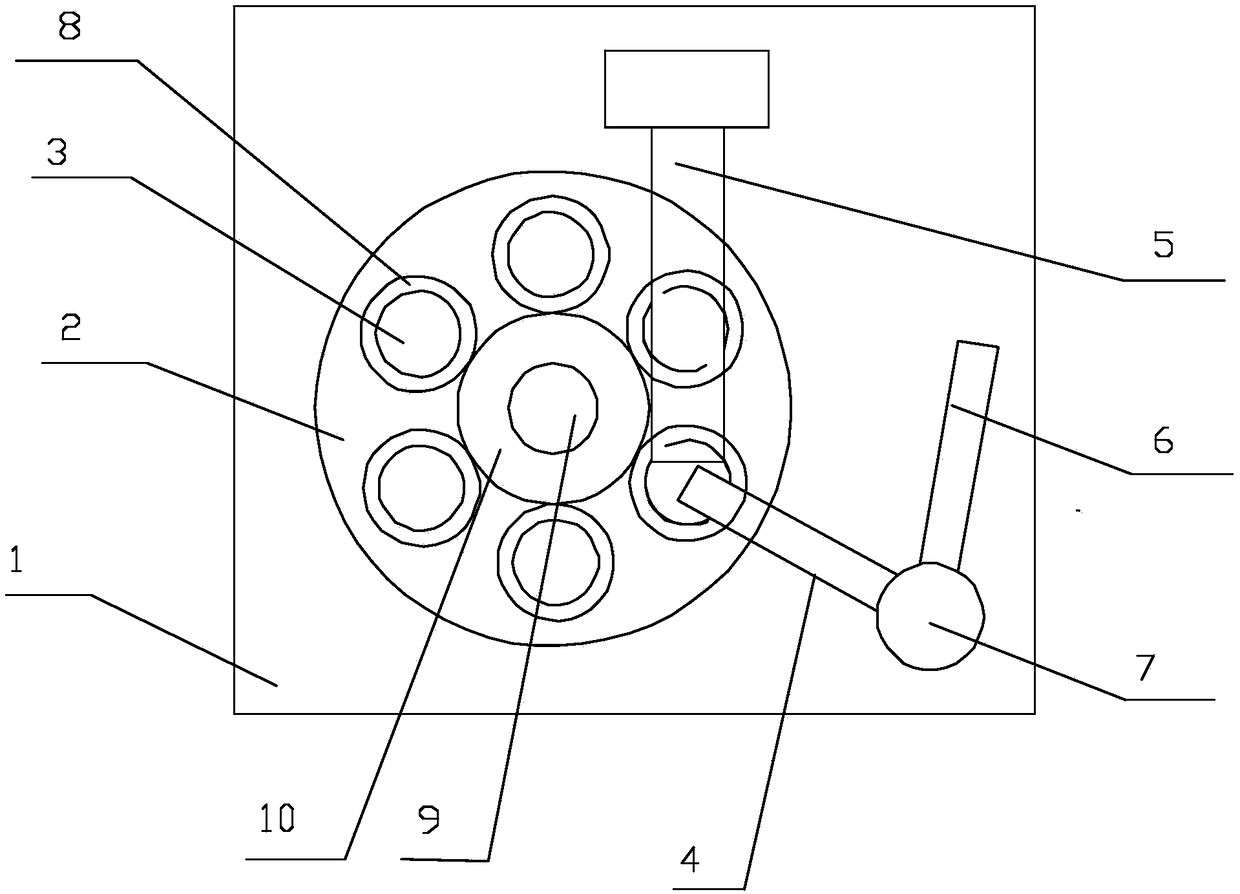

Spreading device for testing of soil alkali-hydrolyzable nitrogen content

ActiveCN109490509AEasy to operate continuouslyImprove test efficiencyEarth material testingLaboratory glasswaresContinuous operationEngineering

The invention provides a spreading device for testing of soil alkali-hydrolyzable nitrogen content. The spreading device comprises a supporting frame, a rotating disc, a plurality of diffusion dishes,a first driving mechanism, a second driving mechanism, a soil adding mechanism and an auxiliary material adding mechanism. The spreading device for testing of the soil alkali-hydrolyzable nitrogen content has advantages that the diffusion dishes are uniformly, peripherally and rotationally arranged on the rotating disc, revolution of the multiple diffusion dishes on the rotating disc is realizedthrough rotation of the rotating disc, and position changing of each diffusion dish is realized, and accordingly convenience in continuous operation of each diffusion dish is achieved, and testing efficiency is improved; in an operating process, by rotation of the diffusion dishes, spreading uniformity in the diffusion dishes can be improved; by the soil adding mechanism and the auxiliary materialadding mechanism, and automatic adding of materials into an outer chamber of the diffusion dish at a feeding station can be realized.

Owner:合肥中科方舟机器人技术有限公司

Adsorption and transmission system of polishing machine

ActiveCN106078501AImproved polishing trajectoryImprove polishing efficiencyPolishing machinesGrinding drivesGear wheelVacuum pump

The invention discloses an adsorption and transmission system of a polishing machine. The adsorption and transmission system comprises a mounting plate, a bearing I, bearing seats, a bearing II, a vacuum pump, a support, a rotating connector I, a driving device, a gear I, a rotating connector II, gears II, a gear III, a central shaft, guiding components and rotating components, wherein the central shaft is mounted on the bearing seat through the bearing I and the bearing II; the gear I is mounted at the bottom of the central shaft; the gear III is mounted at the top of the bearing seat; the rotating components are fixed to the mounting plate; the gears II are mounted on the rotating components; the gears II mesh with the gear III; the guiding components are fixed to the mounting plate; the rotating connector II is mounted at the bottoms of the rotating components, and are connected with the bottoms of the rotating components through an air pipe; the tops of the guiding components are connected with an air vent in the central shaft through the air pipe; the rotating connector I is mounted at the bottom of the central shaft; and the vacuum pump is connected with the rotating connector I through the air pipe. The adsorption and transmission system has the characteristics that the adsorption effect is good, the polishing track can be improved, the polishing efficiency is improved, and the like.

Owner:HUNAN YUJING MACHINE

Automatic rotating barbecue grill

InactiveCN112294133ARealize the revolution functionEasy to replaceRoasters/grillsEngineeringStructural engineering

The invention discloses an automatic rotating barbecue grill that is characterized by comprising a base, the base is rotationally connected with an oven frame, the oven frame comprises a top plate, asupporting plate and a bottom plate, a plurality of rotating shafts are rotationally arranged on the bottom plate, inserting grooves allowing skewers to be inserted are formed in the upper end faces of the rotating shafts, and a plurality of clamping grooves allowing the skewers to be clamped are formed in the side wall of the top plate; autorotation assemblies for driving the rotating shafts to rotate are arranged between the base and the multiple rotating shafts, a revolution assembly for driving the furnace frame to rotate is arranged between the base and the furnace frame, and the furnaceframe is vertically arranged in the rotating axial direction. The automatic rotating barbecue grill can drive skewers to revolve around the base while driving the skewers to rotate, and the skewers are convenient to take and place.

Owner:嘉兴嗨呗可食品有限公司

Conveniently-lifted illumination lamp structure for stage

InactiveCN107178767ASimple structureEasy to carryLighting applicationsMechanical apparatusDrive shaftDrive motor

The invention discloses a stage lighting structure which is convenient for lifting. A mounting rod is vertically and fixedly connected to a base, a guide sleeve is sleeved on the mounting rod, a movable pulley is connected with the guide sleeve, and a rain shield is hung on the guide sleeve; It is connected under the rain shield, the drive shaft is rotatably connected to the mounting frame, the drive motor is fixed on the mounting frame, and the output shaft of the drive motor is fixedly connected to the drive shaft, and the drive gear and the turntable frame are fixedly connected to the drive shaft. The two driven shafts are rotatably connected to the turntable frame, and the two driven gears are respectively fixedly connected to the two driven shafts. The lampshade is hinged on the driven shaft through bolts, the reflector is set inside the lampshade, and the lighting body is set on the reflector. Inside, the cooling fins are fixed on the outer wall of the lampshade. The invention is convenient for transportation. The lighting lamp is raised and lowered by pulling the traction rope, the driving motor is turned on, and while the driving motor drives the turntable frame to rotate, the lighting lamp rotates automatically when the driving gear and the driven gear mesh with each other.

Owner:NANJING YA XIN LIGHTING CO LTD

Heat dissipation device for machining workshop

InactiveCN113289809AImprove work efficiencyExpand the scope of workDomestic cooling apparatusLighting and heating apparatusRotational axisWater storage

The invention is suitable for the technical field of workshop heat dissipation, and provides a heat dissipation device for a machining workshop. The heat dissipation device comprises a walking device, a water storage device and a spraying device; the walking device comprises a bottom plate, a buffer device and walking wheels, and the water storage device is located above the bottom plate; the spraying device comprises a nozzle, a water outlet pipe and an adjusting device, the nozzle is connected with the water outlet pipe through a connecting rod, and a universal rotating head is mounted between the water outlet pipe and the connecting rod; the adjusting device comprises a shell, an adjusting piece, a bevel gear and a straight gear; the adjusting piece comprises a vertical rod and an inclined pipe; a belt groove is arranged on the inclined pipe; a rotating belt is sleeved with the belt groove; the inclined pipe comprises a first inclined pipe and a second inclined pipe; the first inclined pipe is sleeved with the connecting rod; the bevel gear is connected with the shell through a fixed block; and the adjusting piece is connected with the shell through a rotating shaft, and a through hole for containing the nozzle is arranged on the shell. Therefore, heat dissipation of the machining workshop can be effectively achieved, the heat dissipation efficiency is improved, and the maintenance cost is reduced.

Owner:WEIFANG UNIV OF SCI & TECH

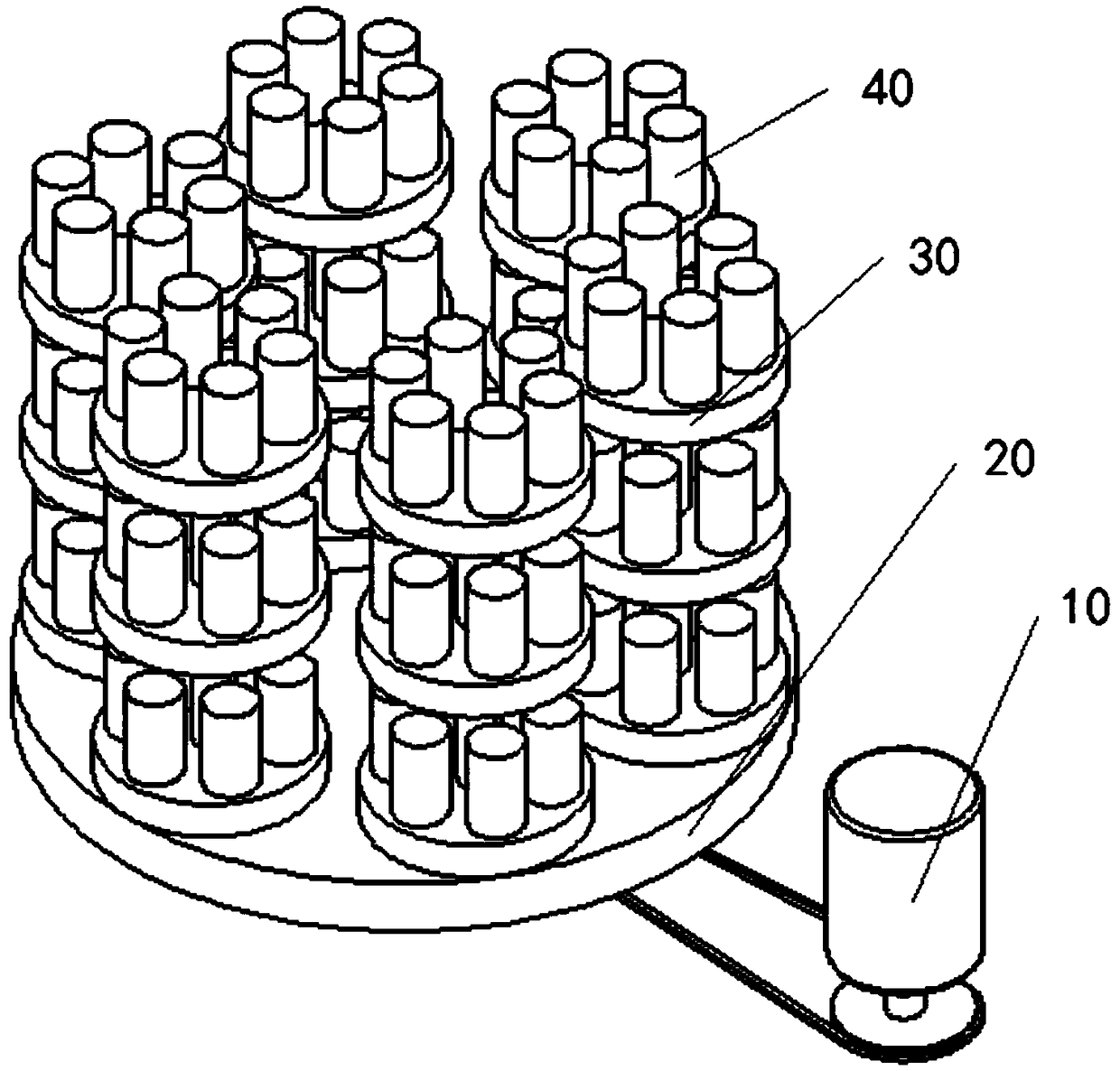

High-flux planetary ball mill

The invention relates to the technical fields of powder metallurgy and ceramic materials and particularly discloses a high-flux planetary ball mill. The high-flux planetary ball mill comprises a first-stage rotary plate and a second-stage rotary plate, wherein the first-stage rotary plate is driven by a transmission mechanism to rotate, the second-stage rotary plate can be driven to rotate aroundthe rotation center of the first-stage rotary plate in the rotation process of the first-stage rotary plate, the second-stage rotary plate is provided with multiple layers, and a plurality of ball milling tanks are arranged on each layer of the second-stage rotary plate in an array mode. The multiple ball milling tanks of the ball mill can operate at the same time and grind hundreds of sets of powder of different ingredients and types at the same time within the unit time, and thus the test requirements for high flux and high efficiency are met.

Owner:KUNMING UNIV OF SCI & TECH

Traditional Chinese medicine waste gas purification treatment equipment device

ActiveCN113546500AReduce use costEffective purificationCombination devicesDispersed particle filtrationWater storageWater storage tank

The invention relates to the technical field of waste gas treatment devices, and in particular, relates to a traditional Chinese medicine waste gas purification treatment equipment device which comprises a base, a public smoke exhaust pipeline, an exhaust assembly, a purification assembly, a stirring assembly, a recycling assembly and a self-cleaning assembly; the exhaust assembly is arranged at the top of the public smoke exhaust pipeline, and the purification assembly is arranged at the top of the exhaust assembly; the purification assembly comprises a water storage tank, the stirring assembly is arranged in the water storage tank, the recycling assembly is arranged on the top of the base, and the self-cleaning assembly is arranged beside the exhaust assembly. The device is designed for a whole processing workshop or a public smoke exhaust pipeline, the use cost is low, and large-scale popularization is facilitated; under the action of the exhaust assembly and the purification assembly, oil fume can be effectively purified, the influence of the oil fume on the environment and harm to people are reduced; and automatic cleaning of the device can be achieved under the action of the self-cleaning assembly, and troubles and high later use cost caused by manual cleaning are avoided.

Owner:江西富景环保技术有限公司

Stirring rotor for chemical engineering

InactiveCN109589838AAchieve rotationAchieve revolutionRotary stirring mixersTransportation and packagingMechanical engineeringEngineering

The invention relates to a stirring rotor for chemical engineering, and belongs to the technical field of stirring rotors. The stirring rotor comprises a tank body which is horizontally arranged, a sleeve vertically runs through the top of the tank body, and a vertical shaft vertically runs through inside the sleeve; a fixed gear is arranged at the bottom of the vertical shaft in the tank body ina sleeving manner, and first rotating shaft vertically runs through the bottom of the tank body and is arranged on the tank body through a bearing; a second rotating shaft vertically runs through thetank body on the left side of the first rotating shaft and is arranged on the tank body through a bearing; a first rotary gear meshed with the fixed gear is arranged on the first rotating shaft in thetank body; a second rotary gear meshed with the fixed gear is arranged on the second rotating shaft in the tank body, and stirring components are arranged at lower ends of the first and second rotating shafts. According to the stirring rotor, rotation and revolution of the stirring components can be realized, and the stirring effect is improved.

Owner:重庆伊莱卡实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com