Airing device for rice processing

A drying device, rice technology, applied in application, lighting and heating equipment, drying solid materials without heating, etc., can solve the problems of dynamic and uniform drying of rice, low efficiency, etc., to improve drying efficiency, facilitate transfer, and improve anti-dumping sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

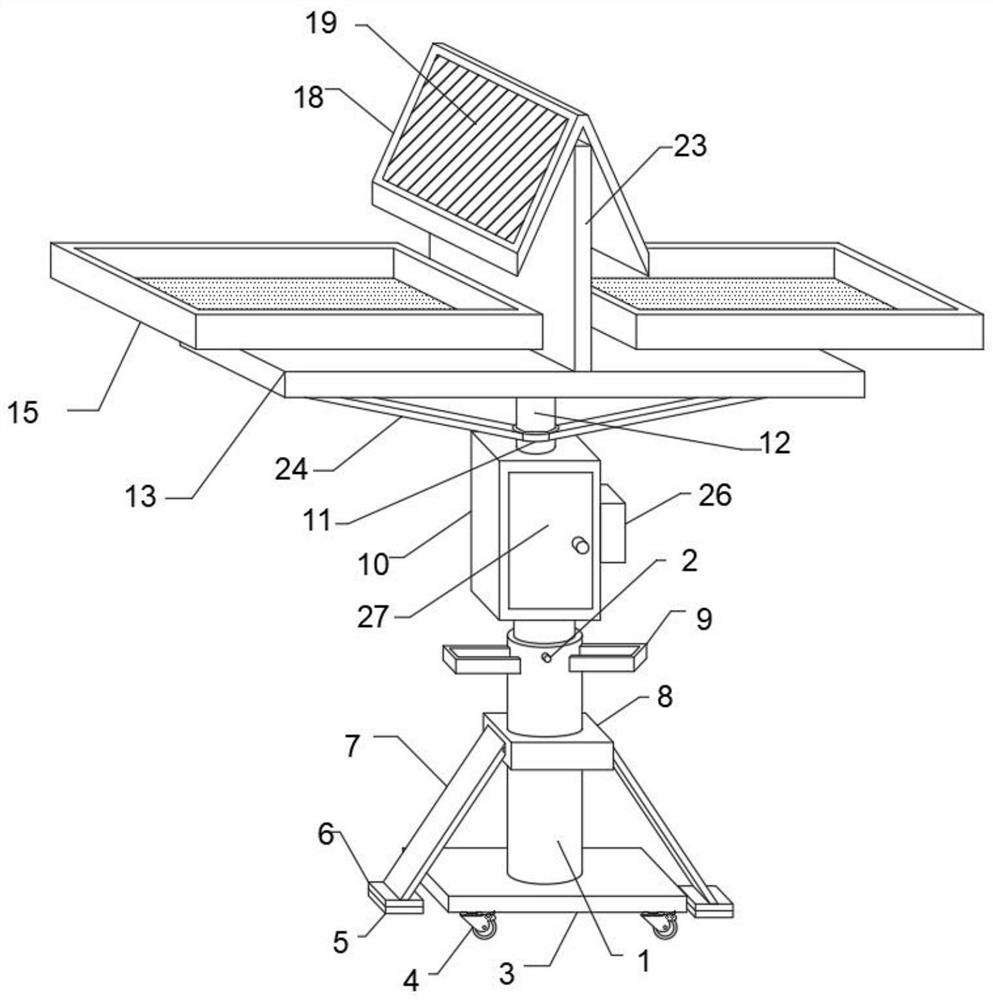

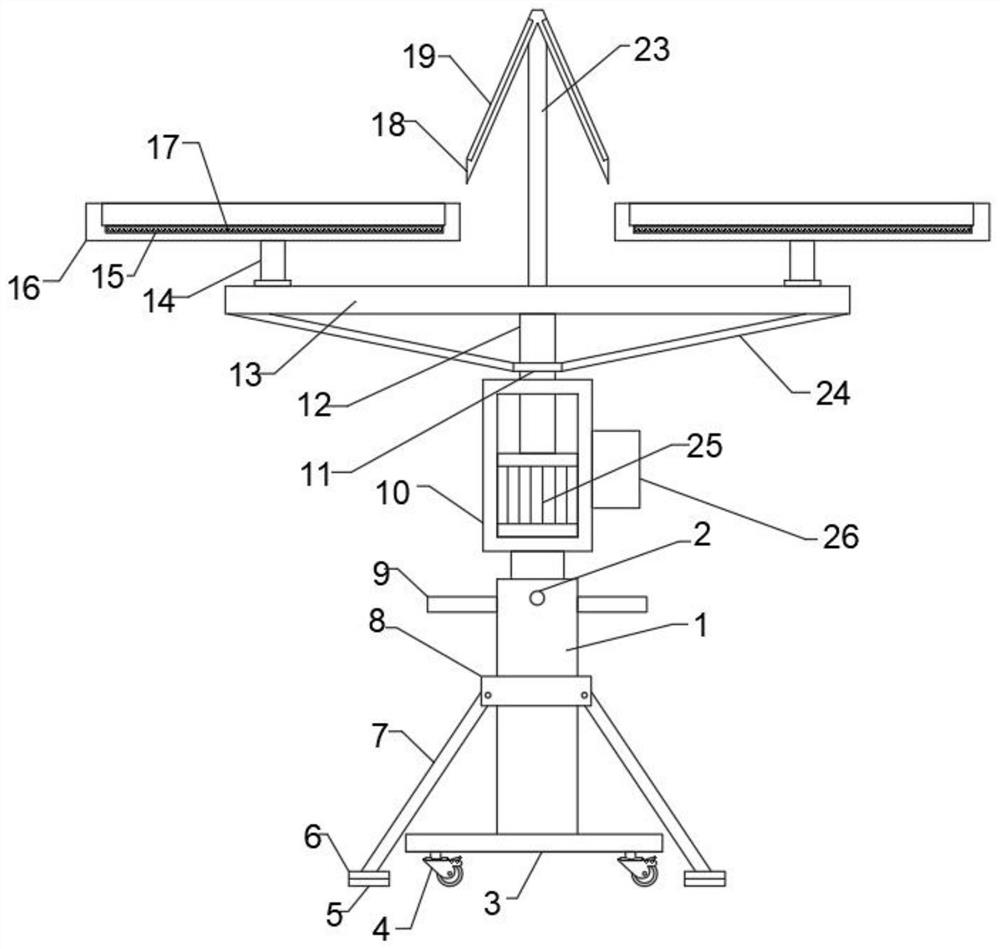

[0023] refer to Figure 1-2 , a drying device for rice processing, comprising a telescopic rod 1, the bottom of the telescopic rod 1 is fixedly connected with a bottom plate 3, the four corners of the bottom outer wall of the bottom plate 3 are fixedly connected with pulleys 4, the top of the telescopic rod 1 is fixedly connected with an equipment box 10, and the telescopic rod 1 1. The outer wall is threadedly connected to the limit bolt 2. The outer wall of the equipment box 10 is rotatably connected to a cover plate 27. The inner wall of the equipment box 10 is fixedly connected to a motor 25. The top of the equipment box 10 is rotatably connected to a first rotating shaft 12. The bottom of the first rotating shaft 12 is connected to The motor 25 is fixedly connected, the top of the first rotating shaft 12 is fixedly connected with a bearing plate 13, and both ends of the outer wall of the top of the bearing plate 13 are rotatably connected with a second rotating shaft 14, a...

Embodiment 2

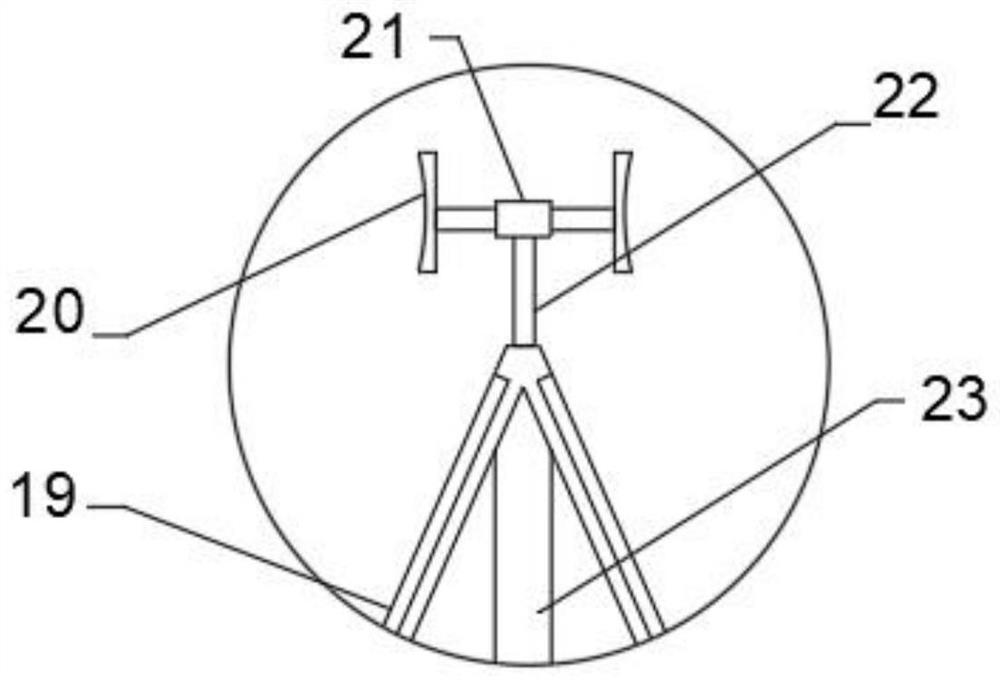

[0029] refer to image 3 , a drying device for rice processing, the top of the support frame 18 is fixedly connected with a connecting rod 22, the top of the connecting rod 22 is rotatably connected with a connector 21, and the outer walls at both ends of the connector 21 are fixedly connected with a reflector 20.

[0030] Working principle: by setting the top of the support frame 18 and the two ends of the connecting piece 21 connected by the connecting rod 22, the reflector 20 is fixedly connected, so that when the device is in the open air, the rotating reflector 20 can refract the light and protect the birds. Carry out light repelling to prevent rice from being eaten by birds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com