High-flux planetary ball mill

A planetary ball mill, high-throughput technology, applied in the fields of powder metallurgy and ceramic materials, which can solve the problems of low efficiency and small number of powders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

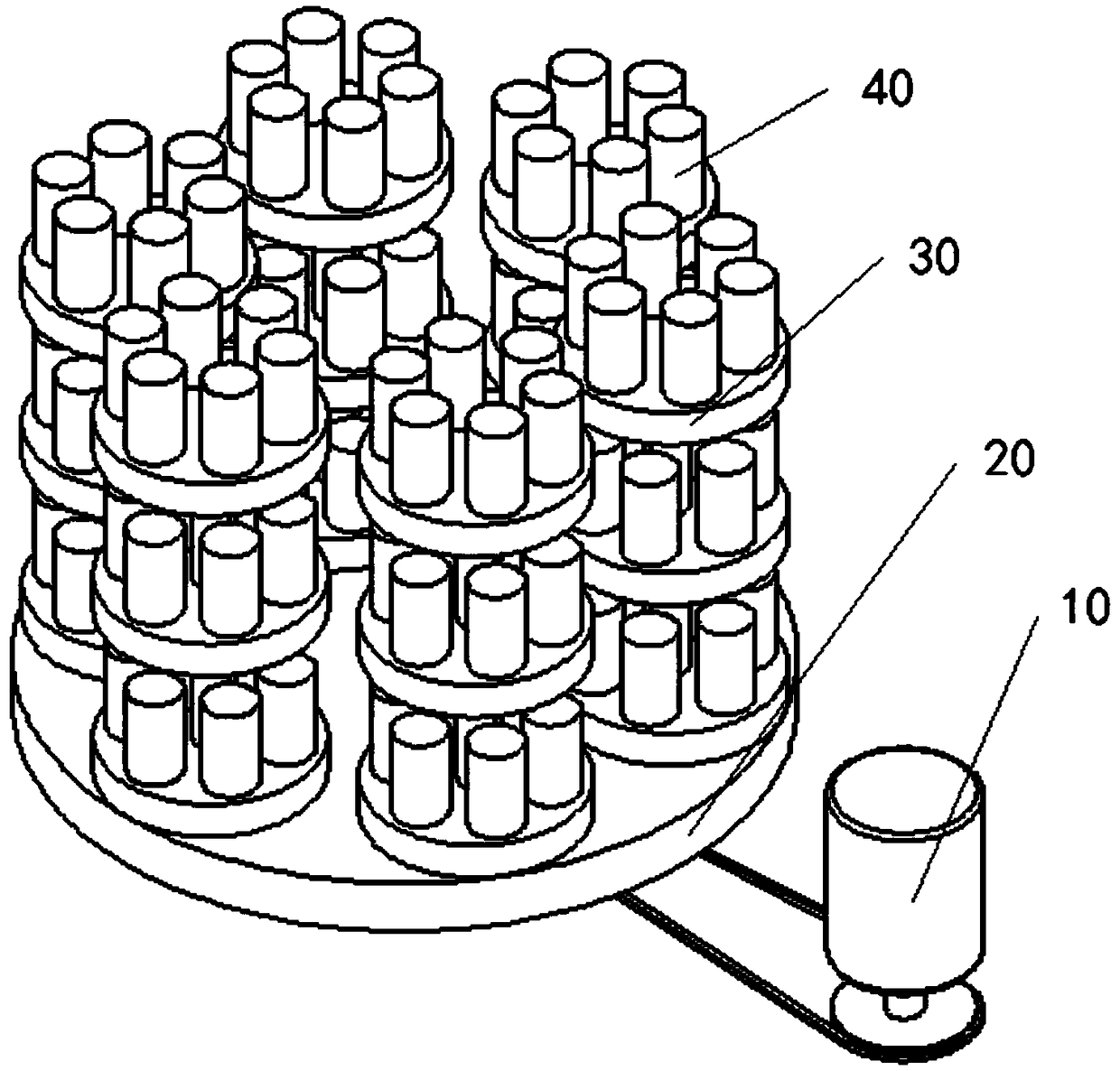

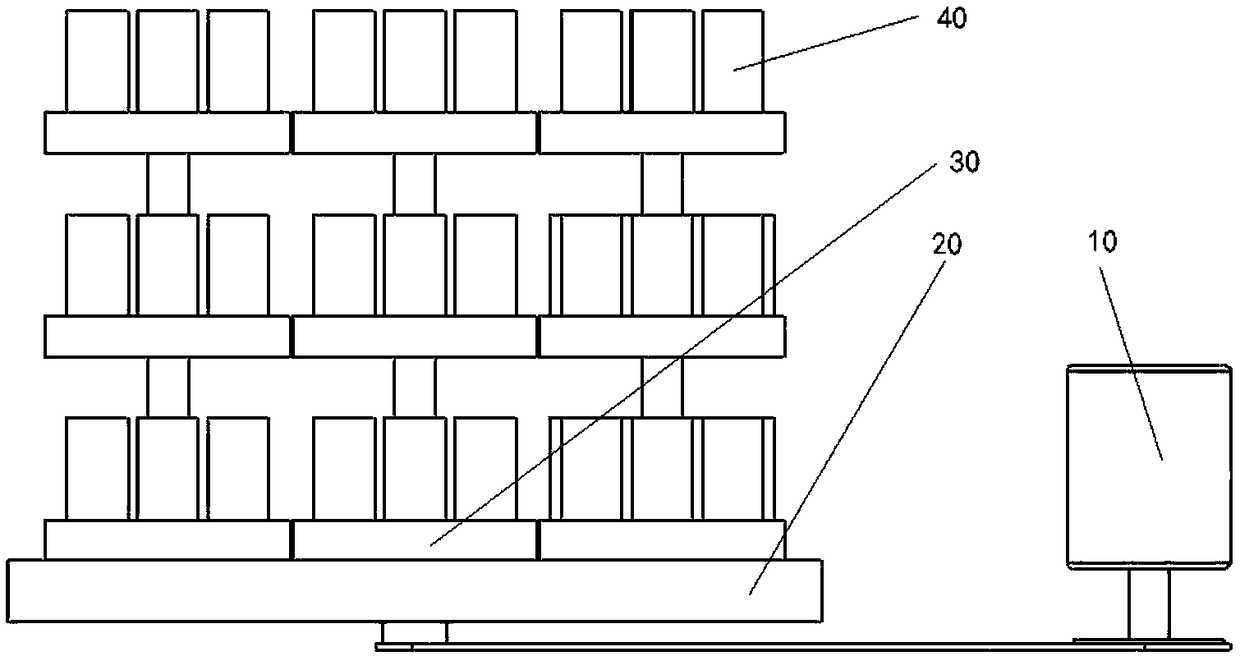

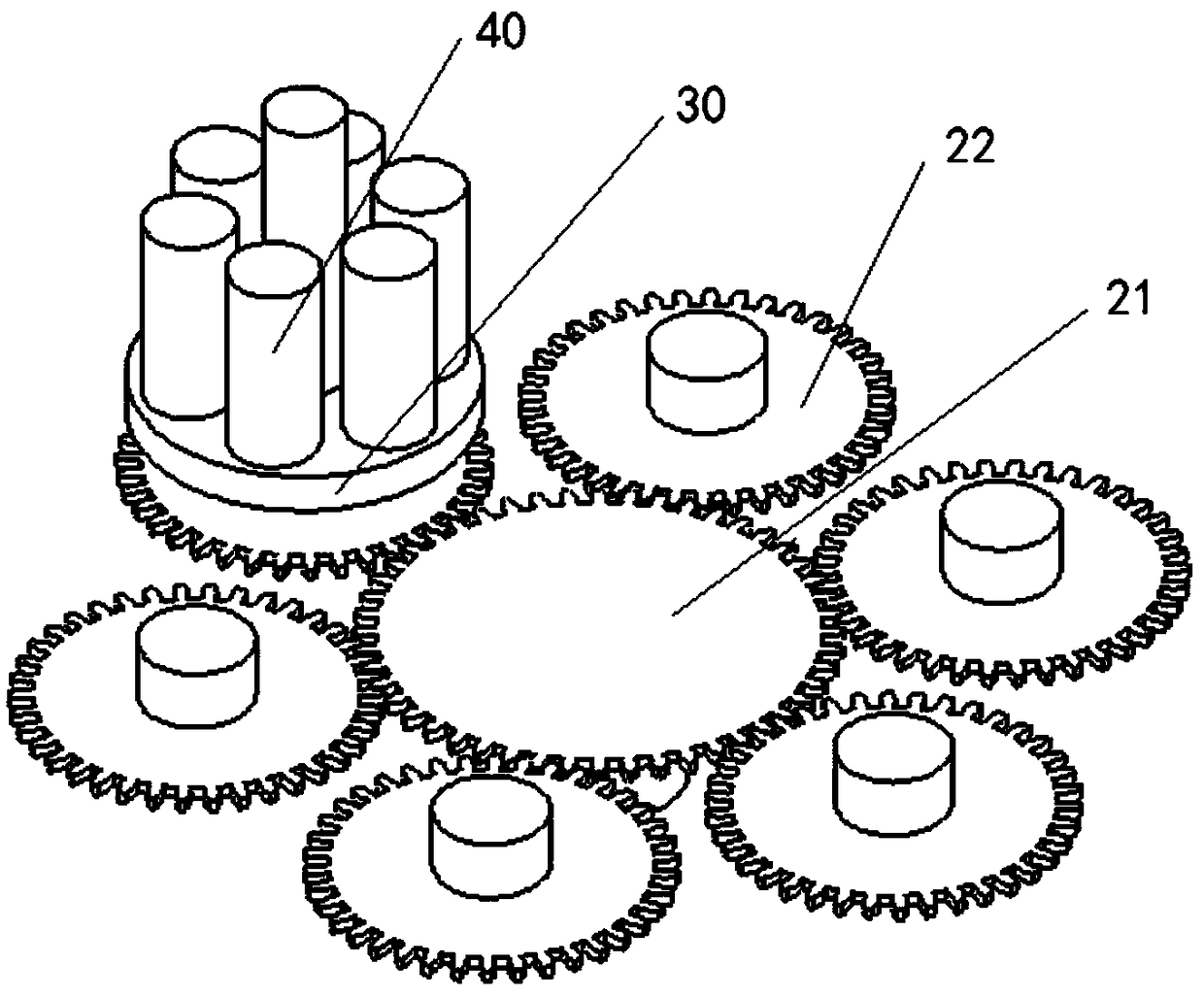

[0028] Such as figure 1 , figure 2 As shown, the high-throughput planetary ball mill in this embodiment includes a primary turntable 20 and a secondary turntable 30 , and a transmission mechanism that drives the primary turntable 20 and the secondary turntable 30 to rotate. Such as image 3 As shown, the main structure of the transmission mechanism is a planetary gear train structure, which includes the motor 10, the first driving gear 21, the first driven gear 22 and the first ring gear sleeved on the outer periphery of the primary turntable 20; the first gear The ring is a fixed part, and the primary turntable 20 can rotate in the first ring gear. A cavity is provided in the primary turntable 20, and the first driving gear 21 and the first driven gear 22 are all located in the cavity. The first driving gear 21 is connected to the center of the primary turntable 20 through a rotating shaft, and the first driving gear The lower end of the rotating shaft of the gear 21 exte...

Embodiment 2

[0034] Such as Figure 5 , Image 6 As shown, the difference between the second embodiment and the first embodiment lies in the number of secondary turntables 30 , the number of layers and the number of ball milling tanks 40 . In embodiment two, the secondary turntable 30 is provided with six altogether, and each secondary turntable 30 is provided with four layers altogether, and each layer of the secondary turntable 30 is provided with six ball milling tanks 40, therefore, ball milling The number of tanks 40 is 6×4×6=144, that is, 144 grinding experiments can be performed at one time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com