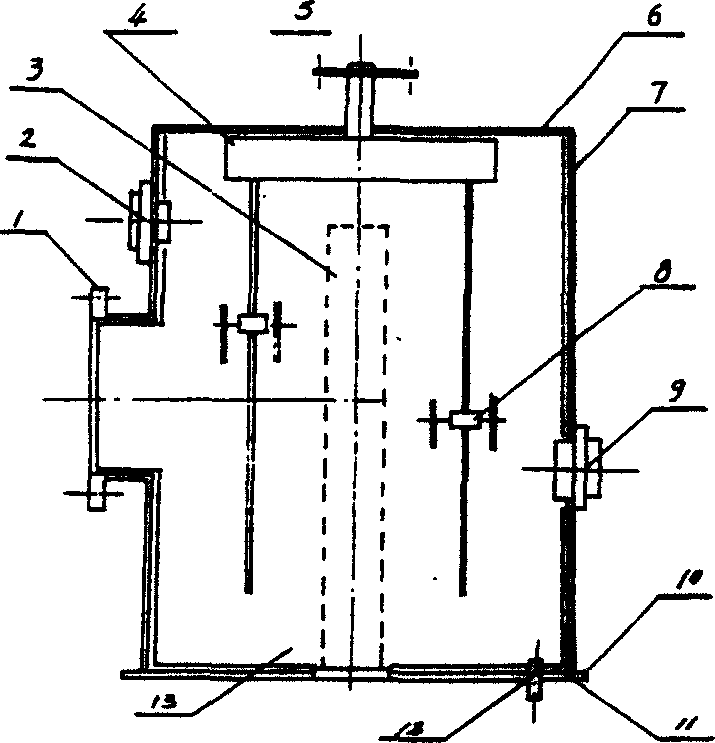

Planar magnetic sputtering-multi-station film coating apparatus

A magnetron sputtering and coating device technology, which is applied in the field of electromechanical, can solve the problem of non-adjustable speed and rotation speed, and achieve the effect of good consistency of film thickness and large loading capacity of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

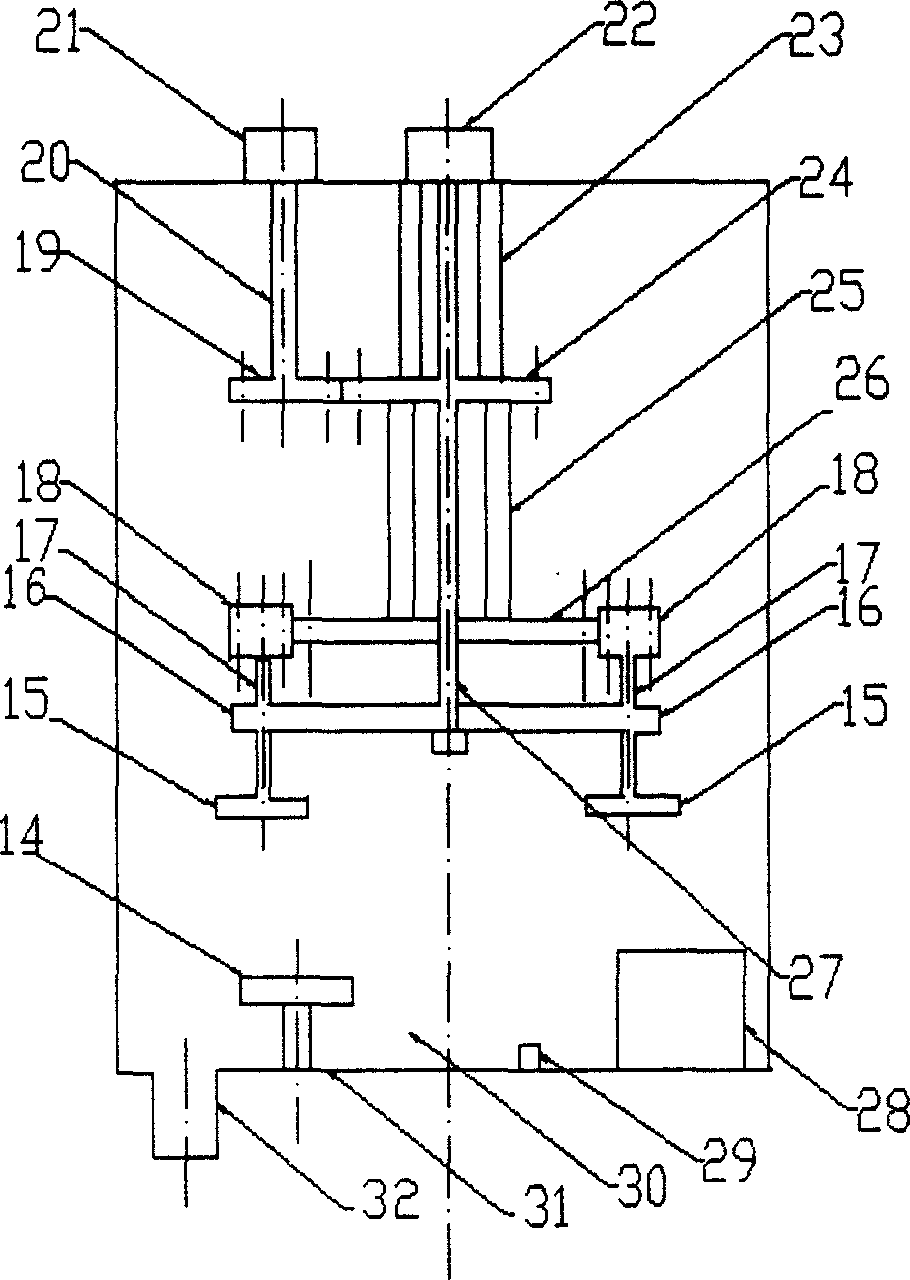

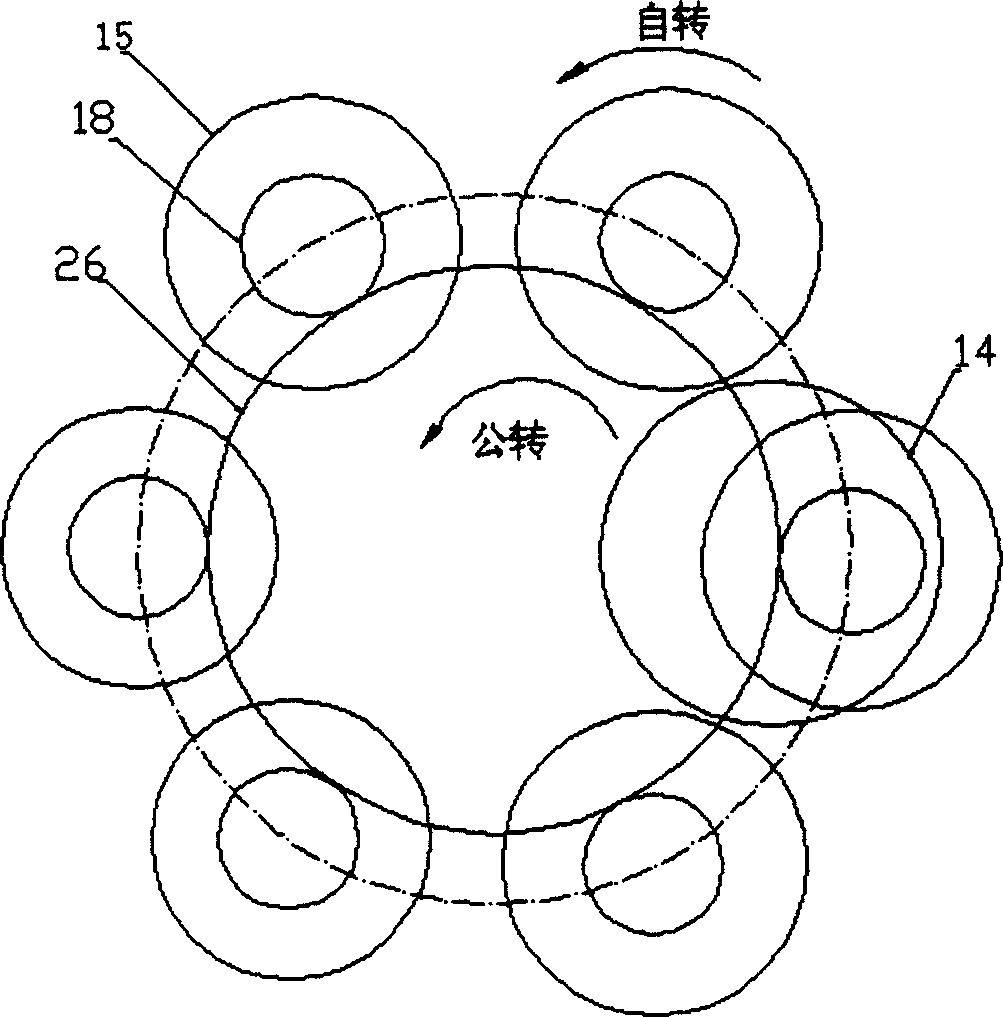

[0026] Preparation of BST (barium strontium titanate) thin film:

[0027] In the planar magnetron sputtering-multi-station coating device of the present invention, the number of workpiece clamps used is N=6, the target position is M=3, the diameter of the target is 120mm, and the center of the target is 30mm away from the center of the substrate. The selected rotation-to-revolution ratio is 5.3, and the coating time is 30 hours. Six groups of BST (barium strontium titanate) films are prepared at one time by using the device of the present invention. The thickness of the prepared BST (barium strontium titanate) films is 1 μm, and the relative deviation of the film thickness within and between sheets is less than 3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com