Transmission device of continuous curved surface polishing machine

A transmission device and polishing machine technology, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding machine parts, etc., can solve the problems of large space, occupation, low frequency of use, etc., and achieve simple implementation and positioning The effect of improving inspection and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

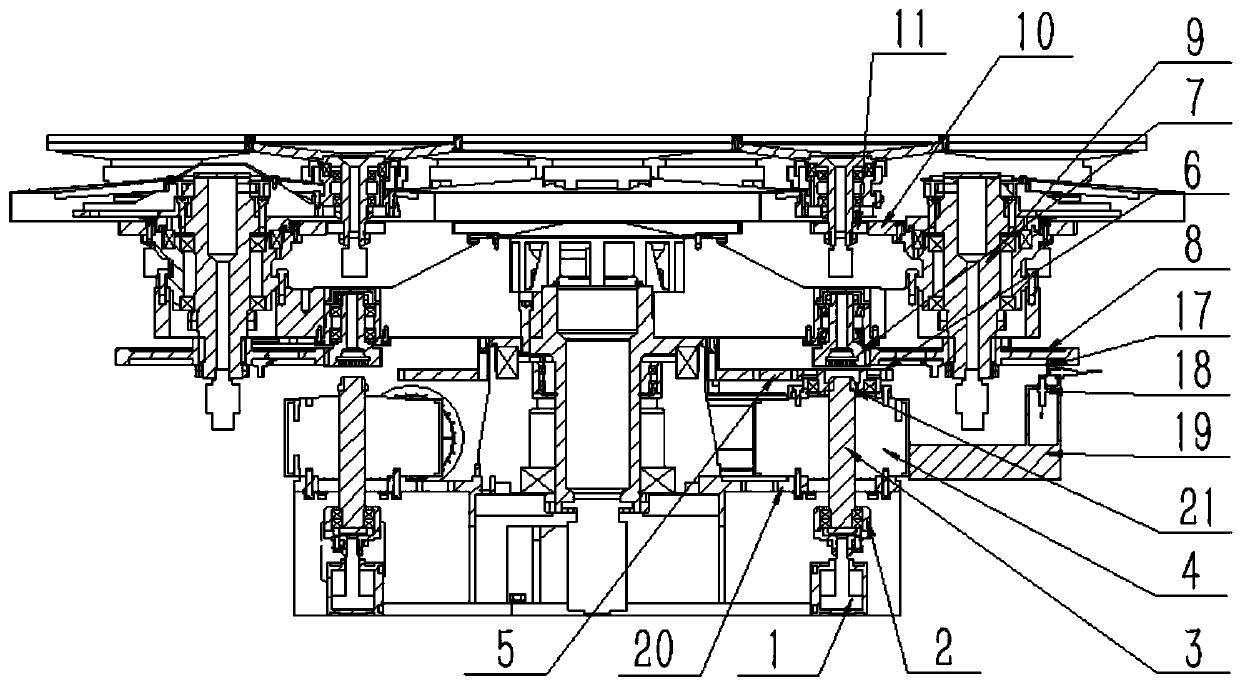

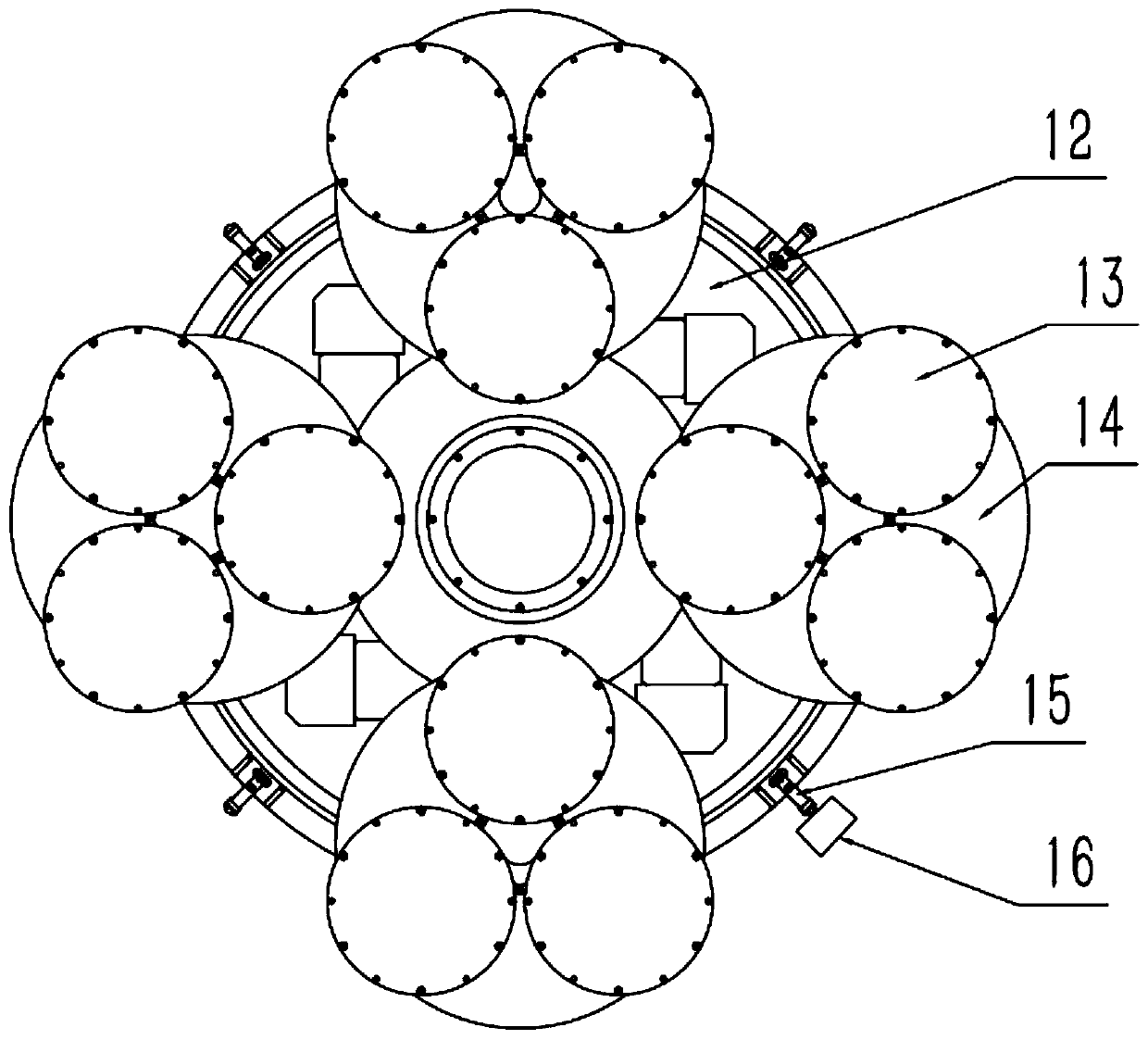

[0017] refer to figure 1 and figure 2 , a transmission device for a continuous curved surface polishing machine, including an indexing rotating disk 12, four single-station assemblies 14 are evenly distributed on the indexing rotating disk 12, and three single-station assemblies 14 are evenly distributed on each single-station assembly 14 The rotary assembly 13 is also provided with a cylinder 1, a bearing seat 2, a clutch spline shaft 3, a reducer 4, a large plate station gear 5, a station pinion 6, a gear shaft 7, a station driving gear 8, and a station drive shaft 9. Station transmission large gear 10, self-rotation gear 11, stroke bumper 15 and stroke switch 16; the lower part of the cylinder 1 is fixed to the box by screws, and the upper piston rod is connected to the bearing seat 2, and the bearing seat 2 passes through the bearing Connected with the clutch spline shaft 3, the clutch spline shaft 3 passes through the reducer 4 and moves up and down vertically with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com