Novel high-efficiency environment-protective dust-free polisher

A polishing machine and high-efficiency technology, applied in the field of polishing machines, can solve the problems of polluting the working environment of the workshop, cumbersome operation, flying metal flying chips and dust, etc., and achieve the effect of improving polishing accuracy, avoiding flying dust and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

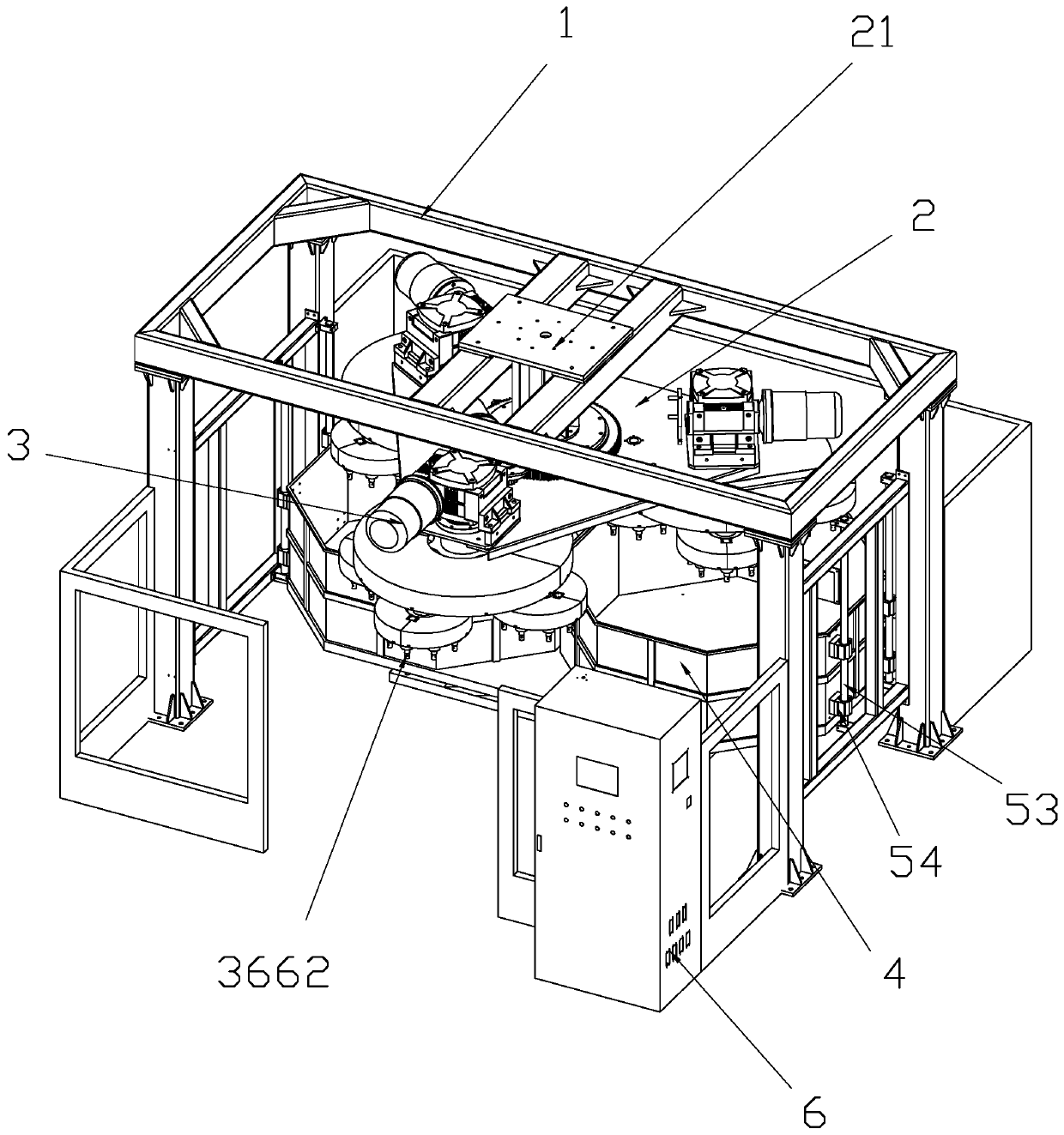

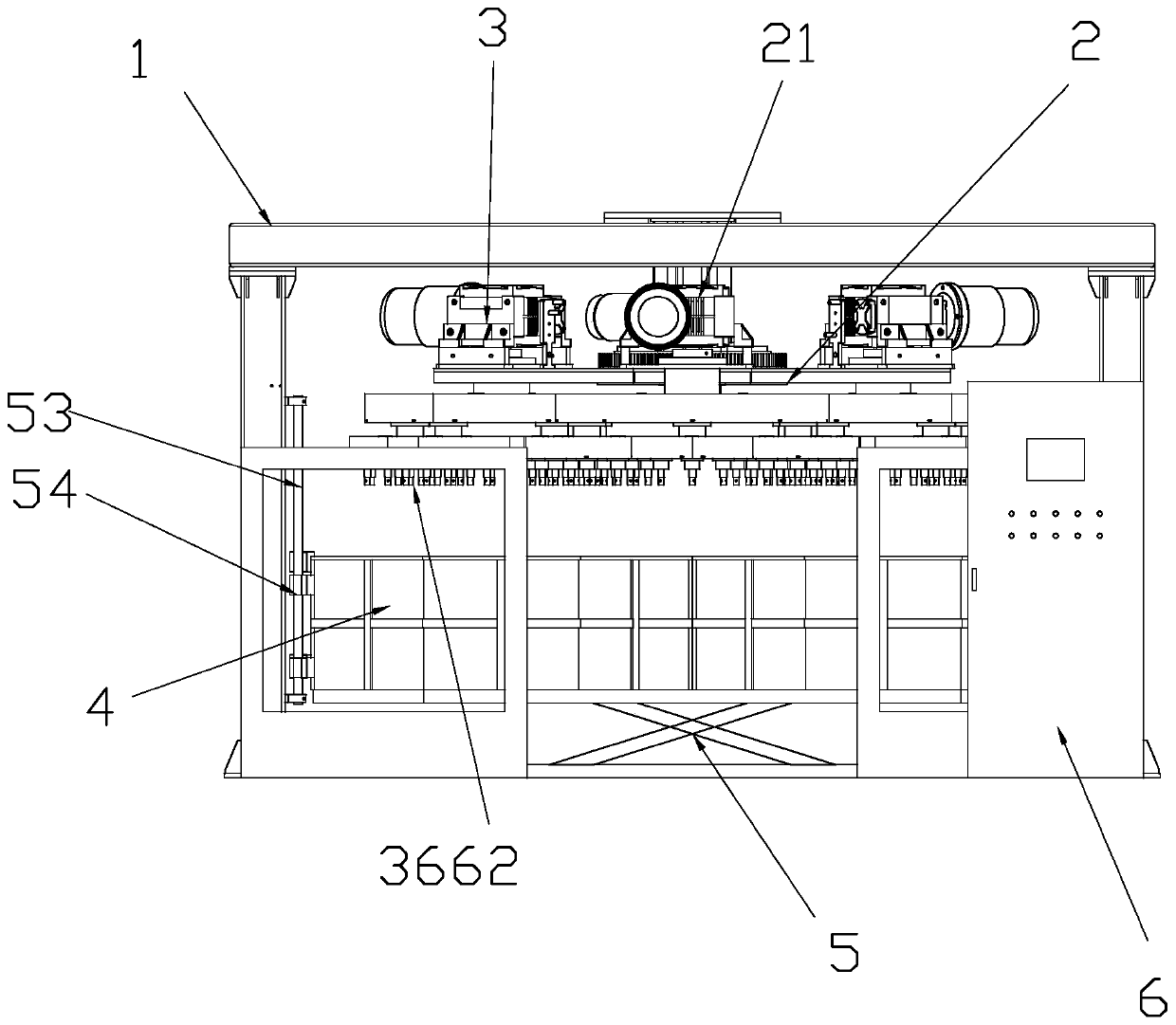

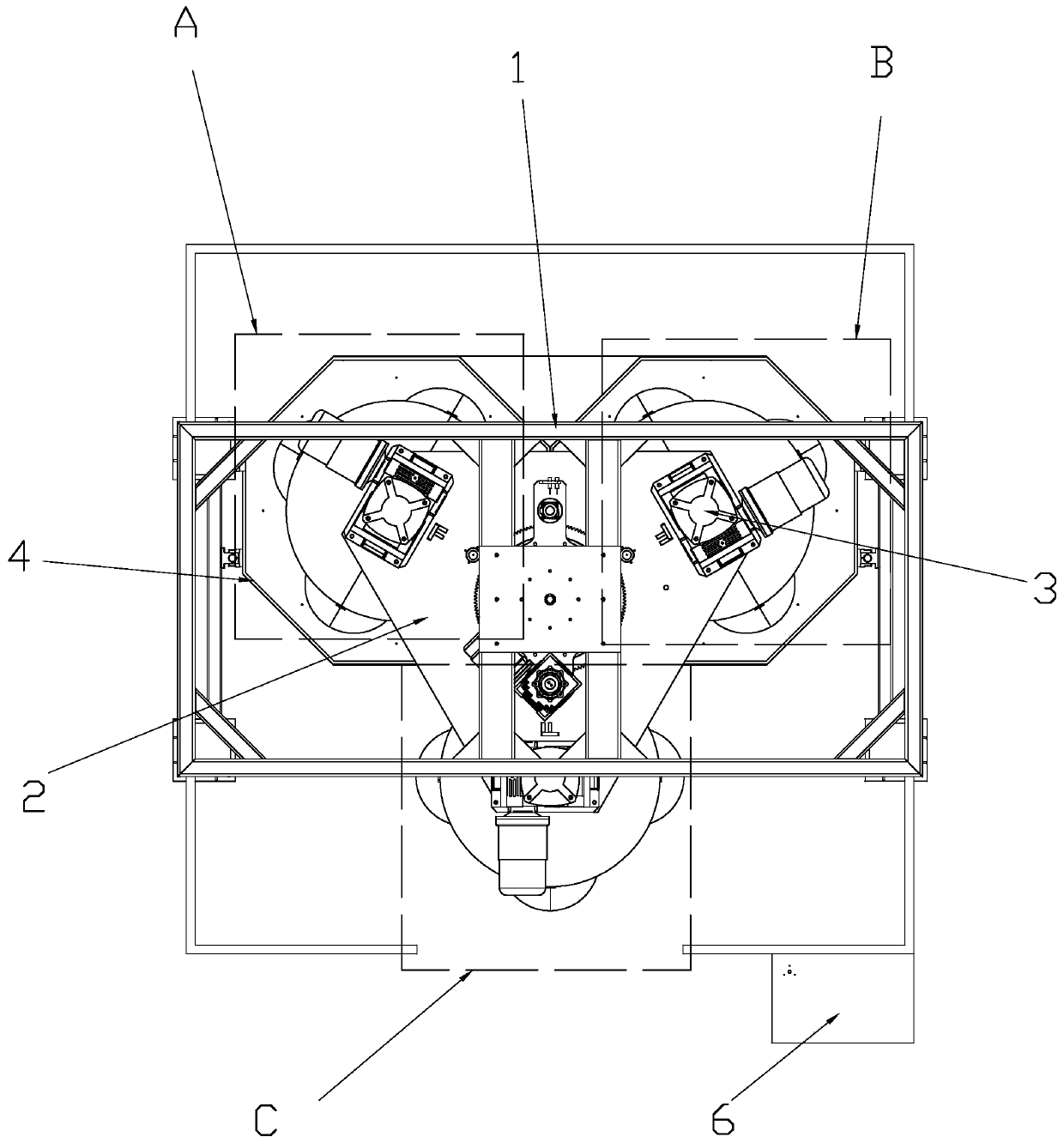

[0042] Such as Figure 1-Figure 14 As shown, a new type of high-efficiency, environmental protection and dust-free polishing machine includes a frame 1, a station switching mechanism 2 is provided on the frame 1, and at least three groups are arranged on the station switching mechanism 2 to move through the station switching mechanism 2. The rotating mechanism 3, the frame 1 forms the first processing station A, the second processing station B and the loading and unloading station C according to the moving path of the rotating mechanism 3, and the rotating mechanism 3 is provided with a clamp 3662 for clamping the product to be thrown , the fixture 3662 performs revolution and rotation actions through the rotating mechanism 3, and there are at least two polishing barrels 4 for loading polishing particles under the first processing station A and the second processing station B. The bottom of the polishing barrel 4 is provided with a polishing Bucket 4 is pushed to the barrel li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com