Rotating wheel transmission mechanism with bunker self-rotating function

A technology of turning wheels and functions, applied in the field of packaging machinery, can solve the problems of the entrance of germ transmission, the difficulty of transformation of hard box horizontal packaging, finger contact with filter tips, etc., and achieve the effect of easy achievement, small difficulty of equipment transformation, and transformation of achievements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

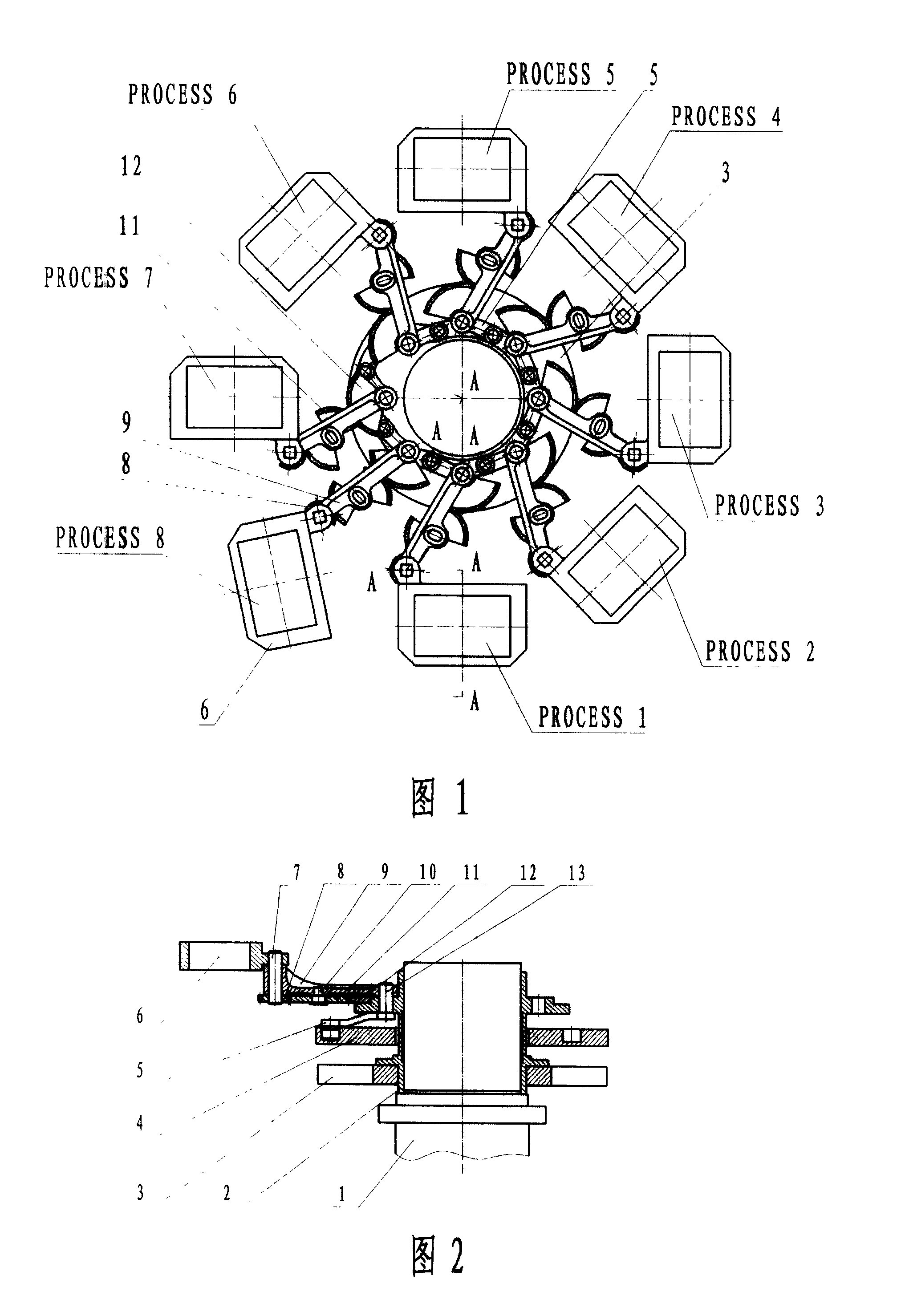

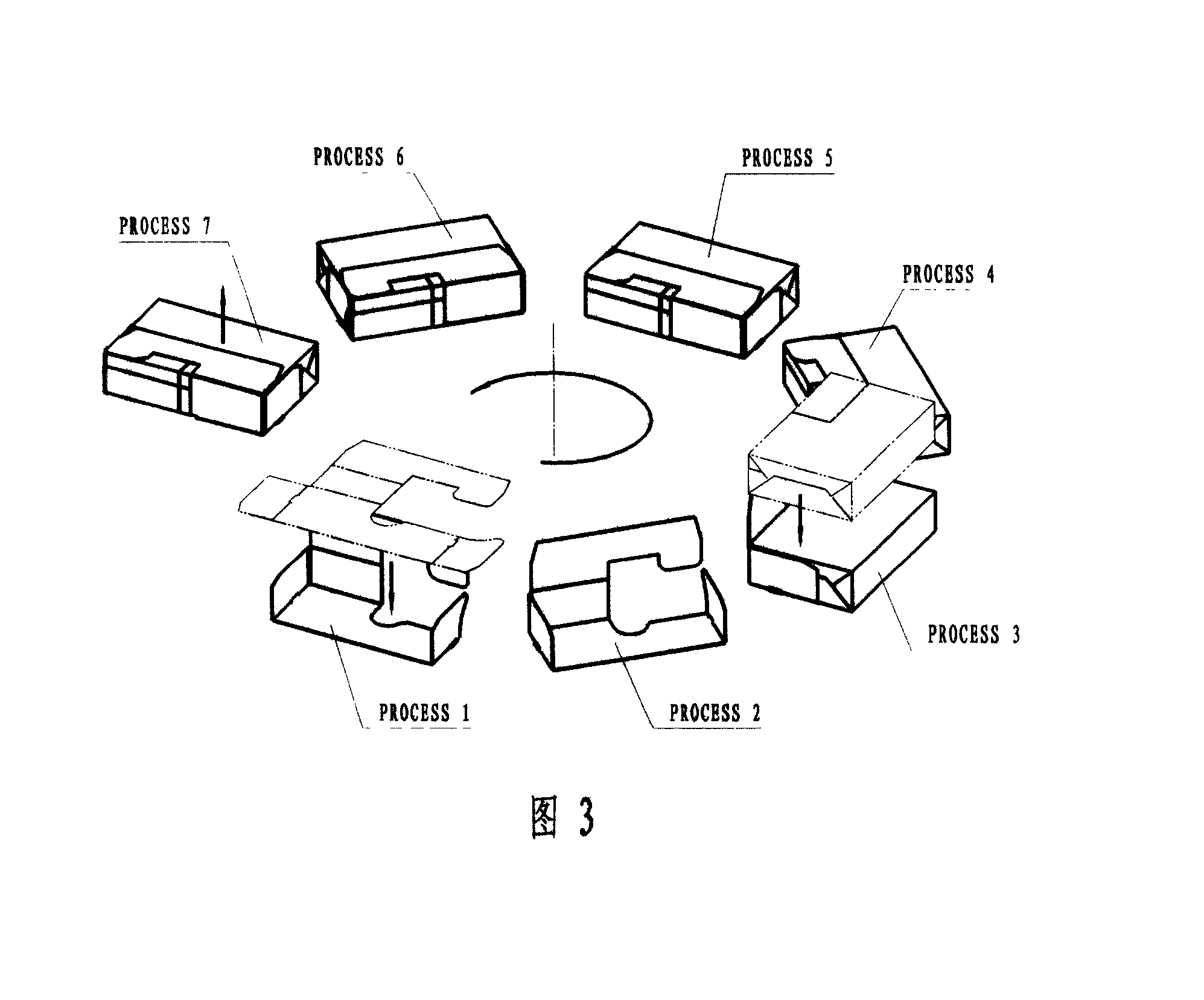

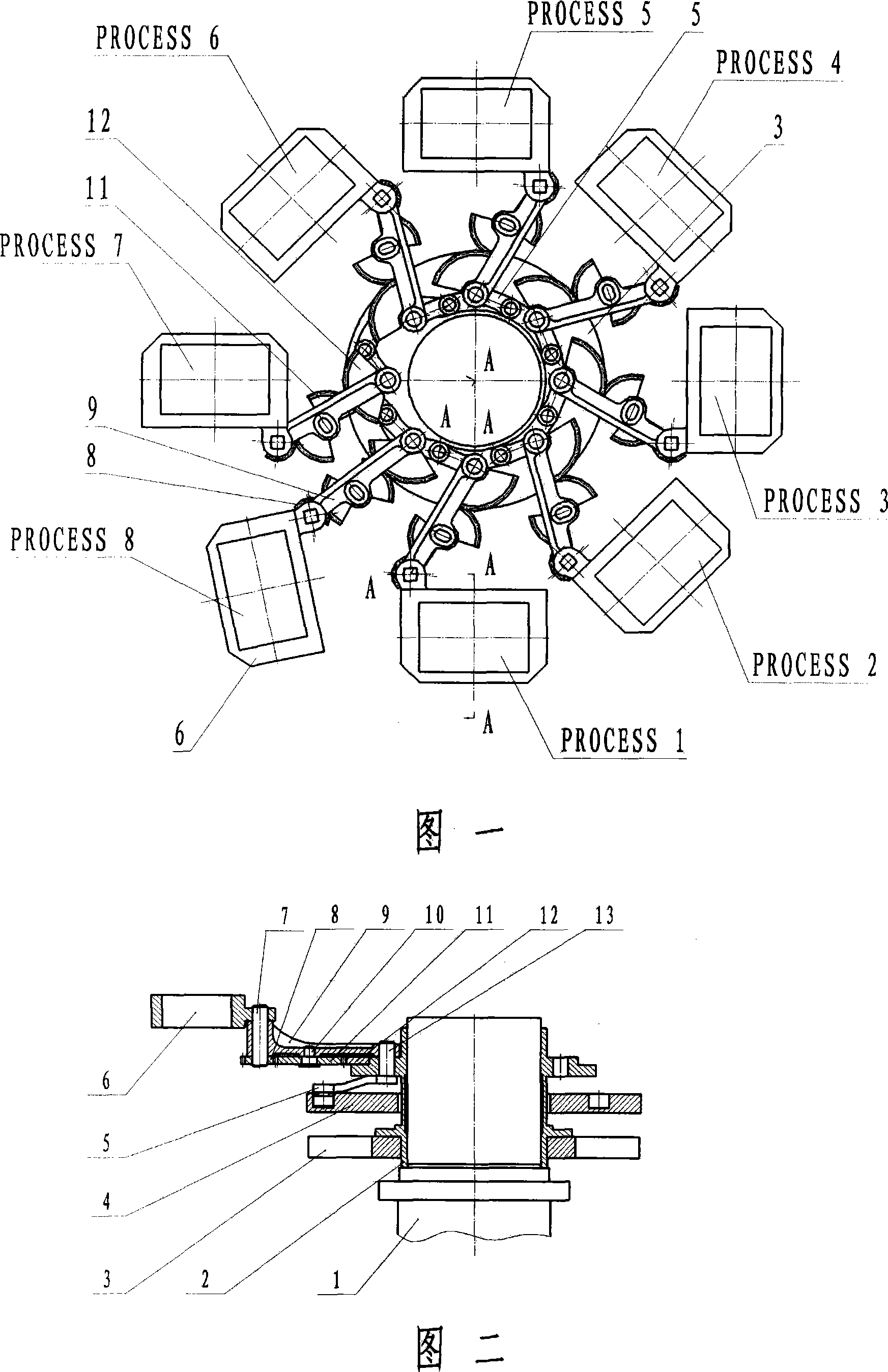

[0011] As shown in Figure 1, the 8 index wheel mechanism of the rotatable feed bin 6 supported by the support fork 9. During the movement from PROCESS1 to PROCESS6, the bin 6 is arranged vertically; during the movement from PROCESS6 to PROCESS7, the support point of the bin 6 is changed by the swing of the support pendulum 9 to make it rotate horizontally; during the movement from PROCESS7 to PROCESS8 The supporting pendulum 9 swings back to the middle position of the stroke, and at the same time, the intermediate wheel 11 is designed as a butterfly gear to ensure that the butterfly gear 11 on the pendulum adjacent to PROCESS7 and PROCESS8 does not interfere; during the movement from PROCESS8 to PROCESS1 Bar 9 gets back to the original position, and feed bin 6 returns to longitudinal arrangement and completes a motion cycle.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com