Suction roller device for baked food

A drum and food technology, applied in the field of orderly and integrated small package feeding devices, can solve the problems of increasing product costs, reducing work efficiency, increasing labor costs, etc., to reduce floor space, improve production efficiency, and save labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is described in detail below. The embodiment of the present invention is only for illustrating a specific structure, and the scale of the structure is not limited by the embodiment.

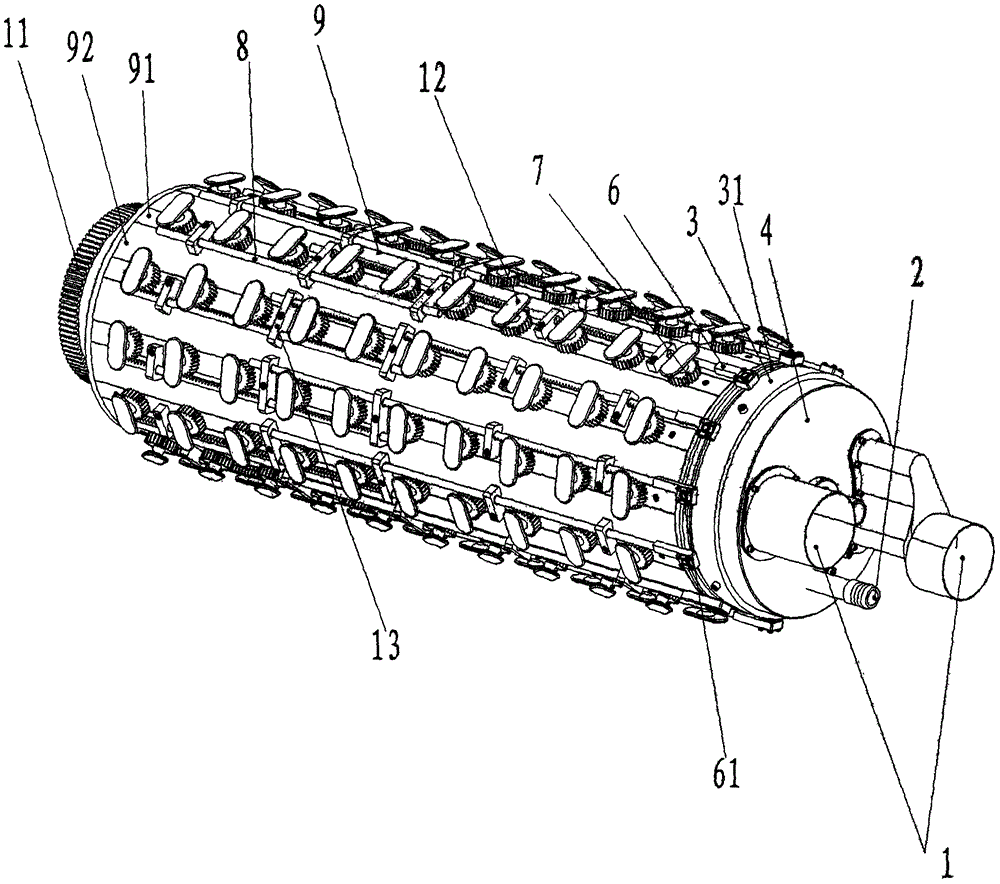

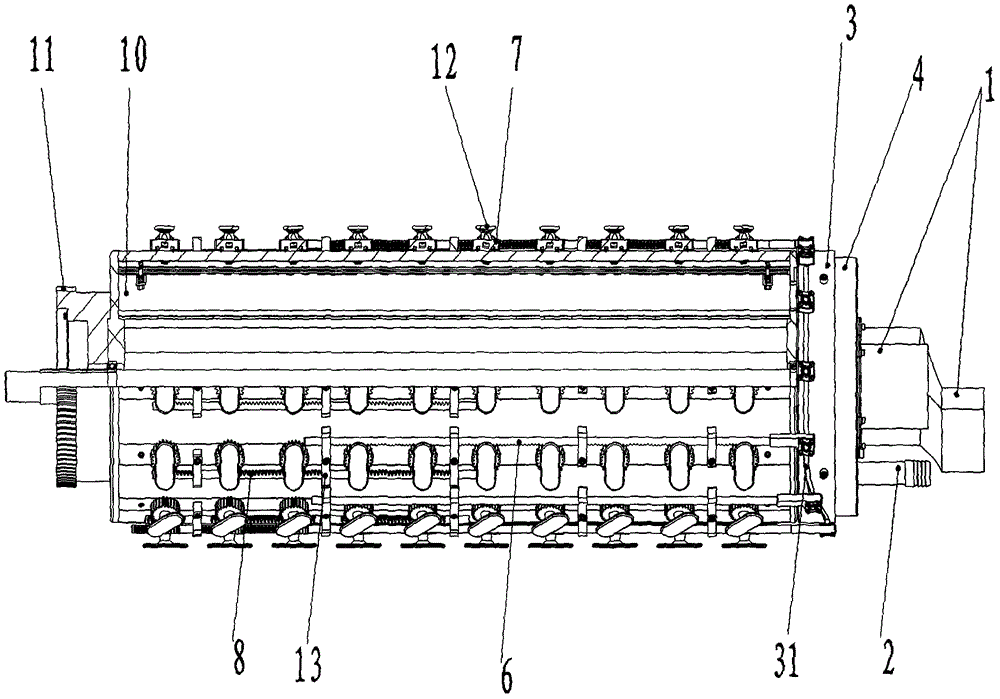

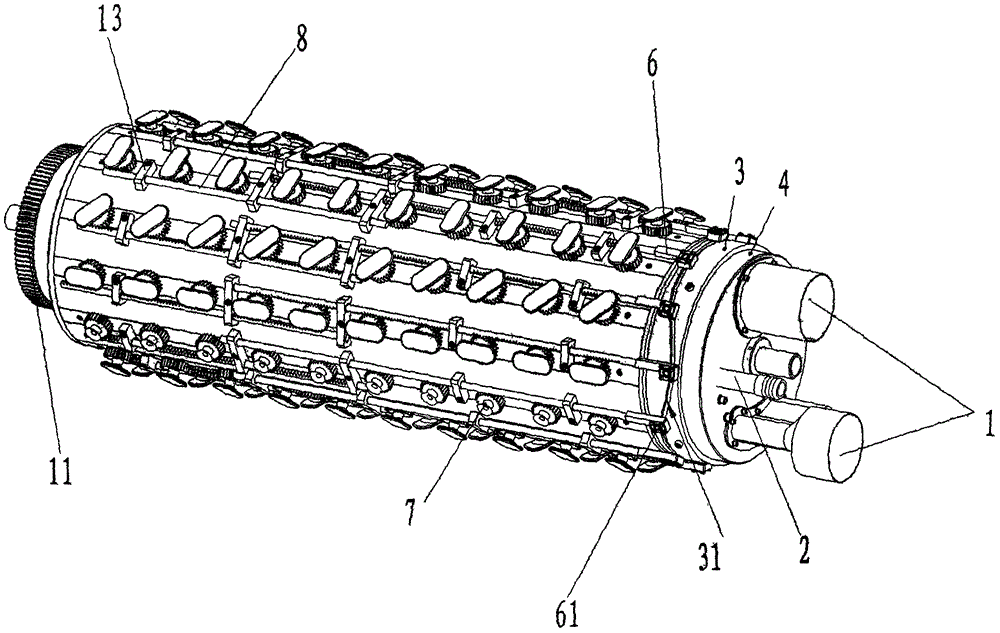

[0025] Such as Figure 1 to Figure 6 As shown, the baked food suction roller device of the present invention includes:

[0026] The sealing end cover 4 includes a cover body 41, a sealing ring 42 and an end cover flange 43. The cover body 41 is provided with at least two suction ports 1 and one blowing port 2, and the suction port 1 is connected with the suction inlet of the dust collector. Connection; the end cover flange 43 is connected to the drum 9, and the 12 holes on the end cover flange are connected with the 12 sub-air chambers 15 on the drum 9, and the end cover flange 43 and the cover body 41 are sealed by the sealing ring 42 , and form a total air cavity 14. An air distribution block 5 is placed between the inner end cover flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com