Patents

Literature

1657 results about "Blowing down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In mathematics, blowing down is a type of geometric modification in algebraic geometry. It is the inverse operation of blowing up. On an algebraic surface, blowing down a curve lying on the surface is a typical effect of a birational transformation. The curves that blow down, to a non-singular point, are of a special kind: they are rational curves, with self-intersection number −1.

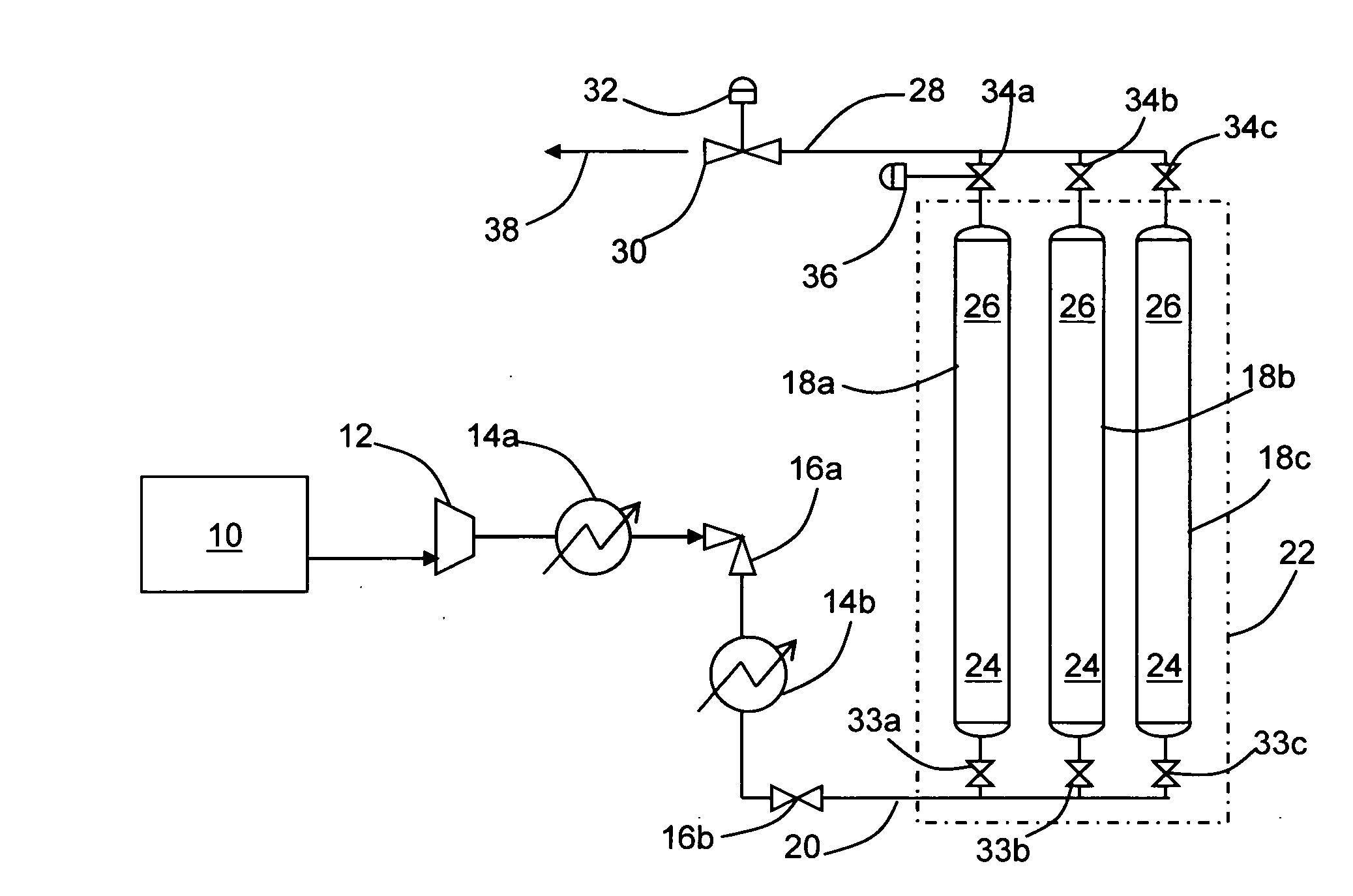

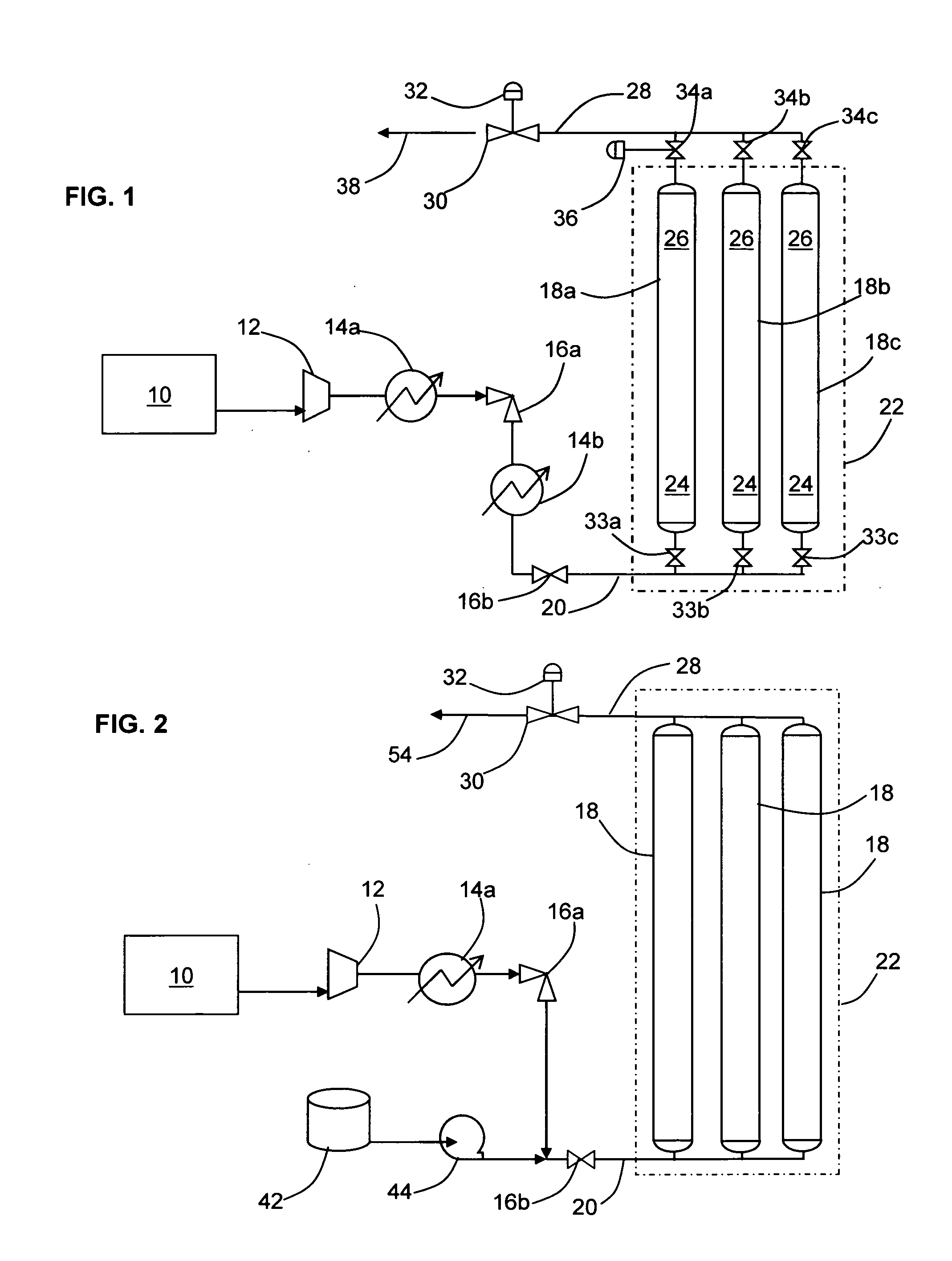

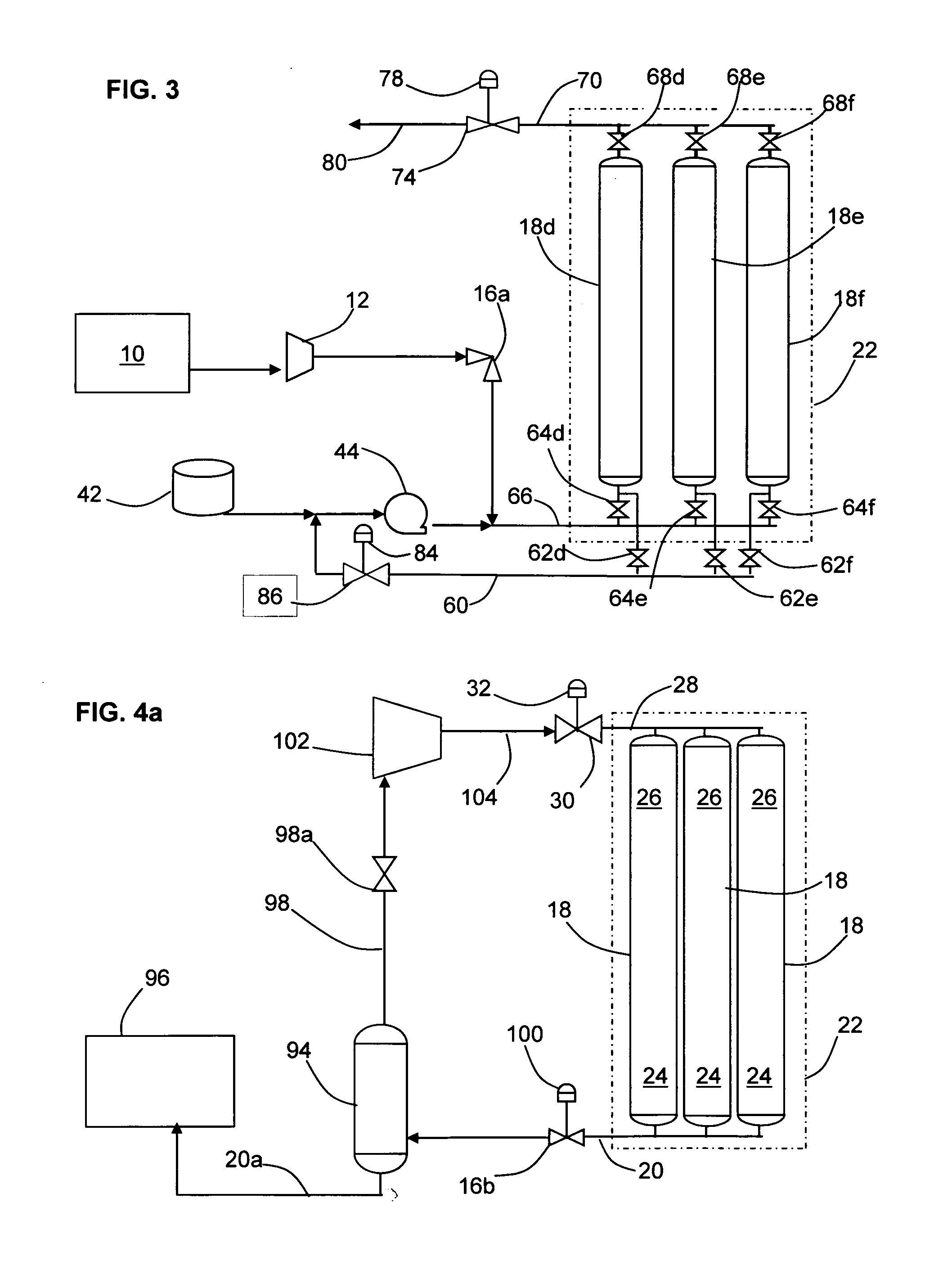

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS20080209916A1Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionCompressed fluid

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

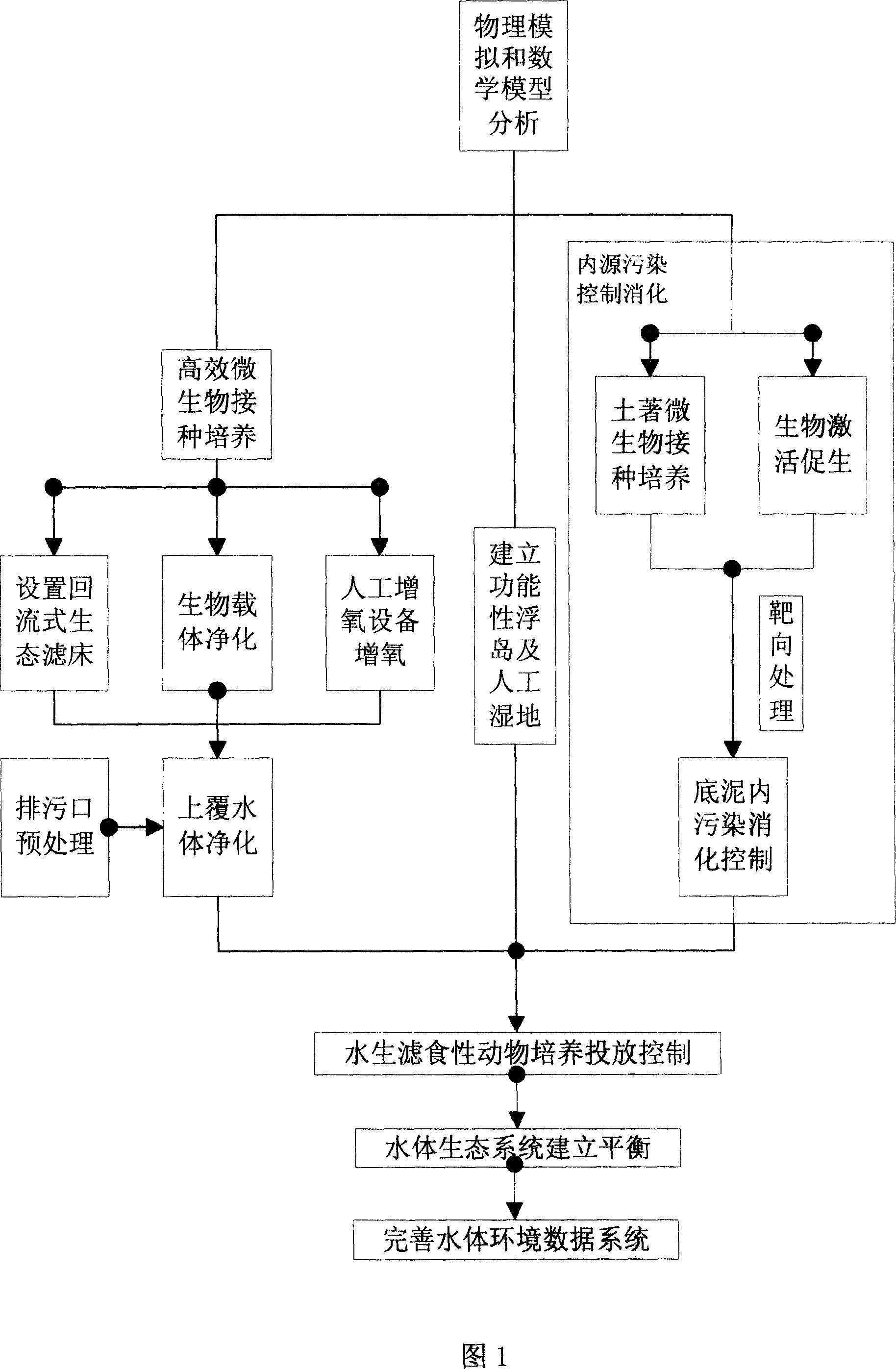

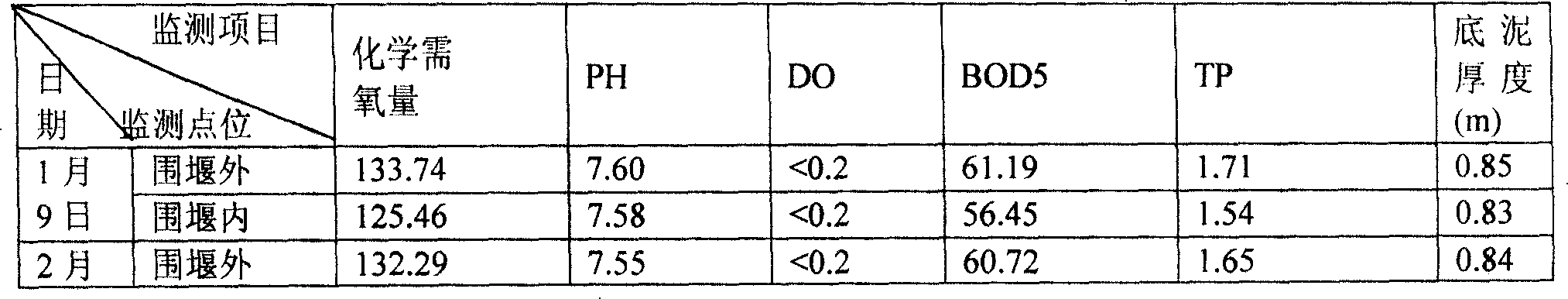

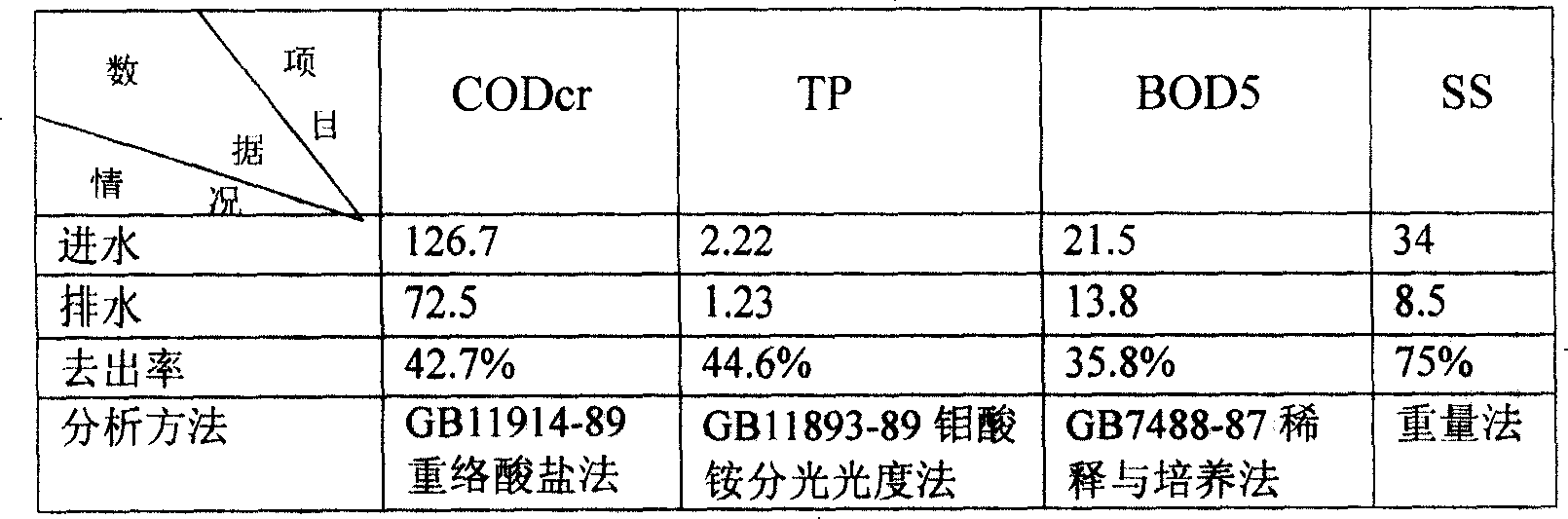

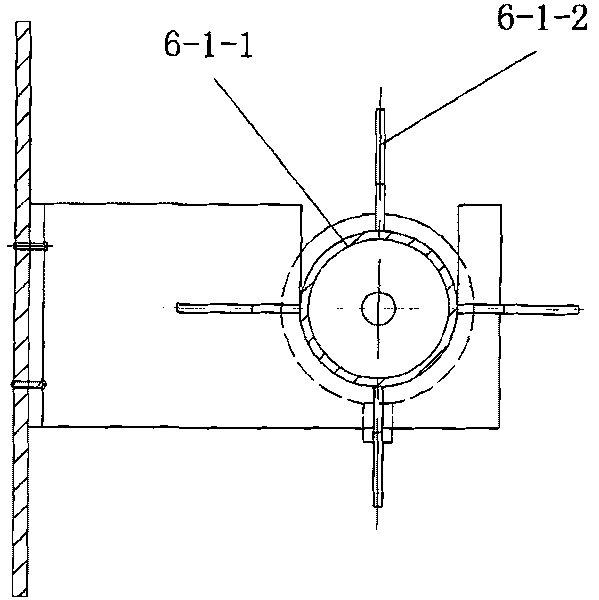

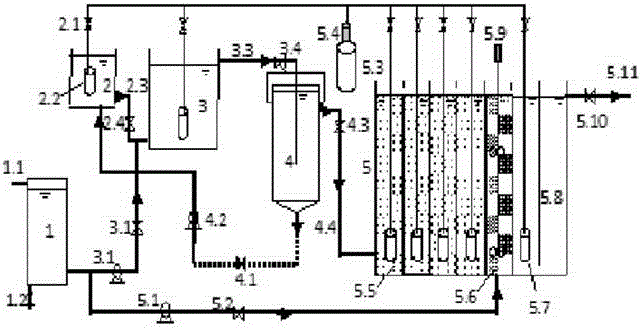

Stereo in-situ ecological urban water system repairing process

InactiveCN101021062AControl survivalPurify waterEnergy based wastewater treatmentHydraulic engineering apparatusMicrobial inoculationConstructed wetland

The stereo in-situ ecological urban water system repairing process tackles polluted water via the quantitative analysis on the water. The technological scheme includes physical simulation and mathematic model analysis, microbe inoculation and culture, constituting refluxing ecological filter bed, purification with biocarrier, artificial aeration, purifying upper water, pre-treatment in the blow down port, establishing water ecological system balance, perfecting water environment data, etc. The present invention realizes the comprehensive tackling of urban water system.

Owner:上海中渠生态环保科技有限公司

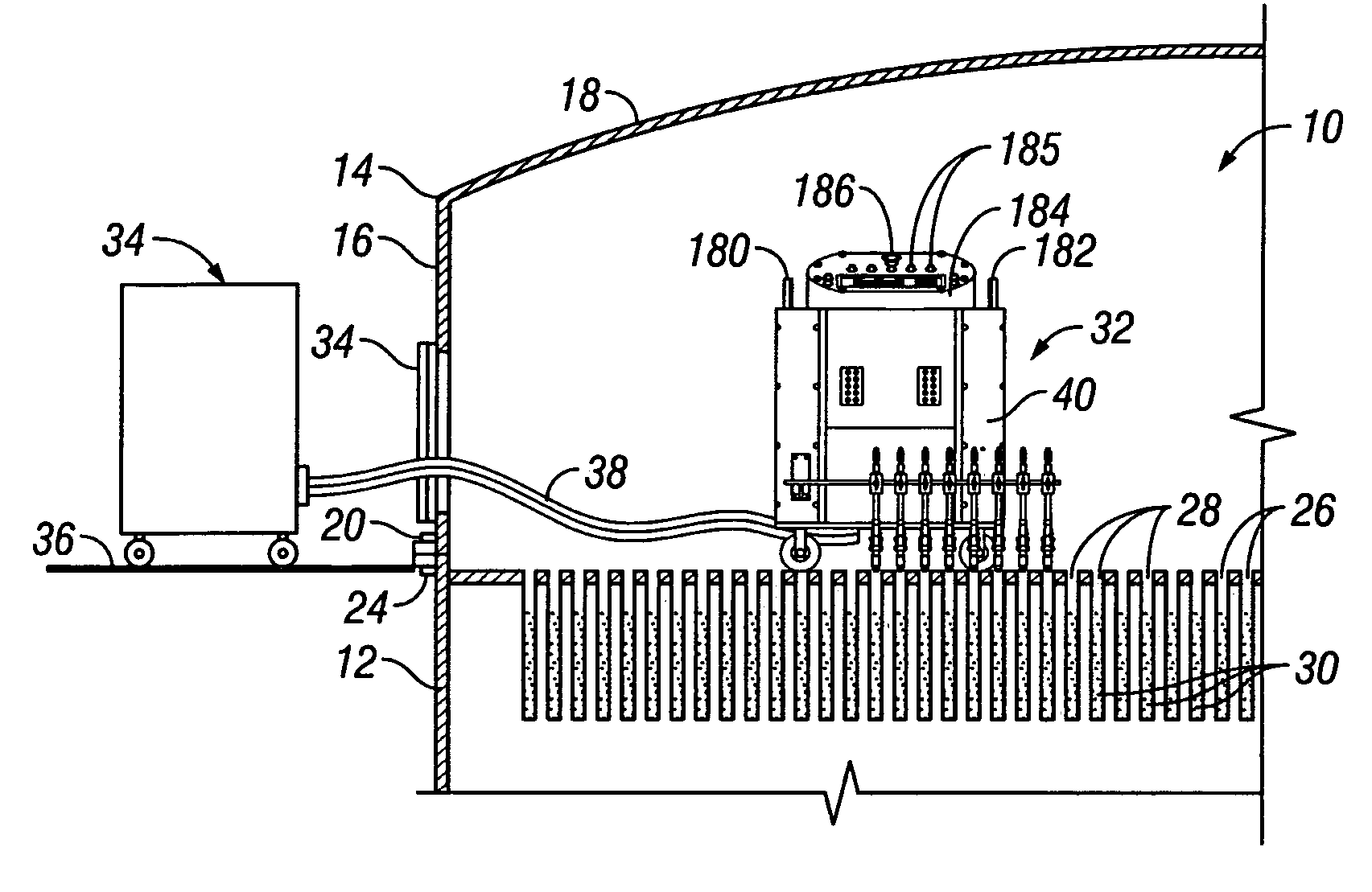

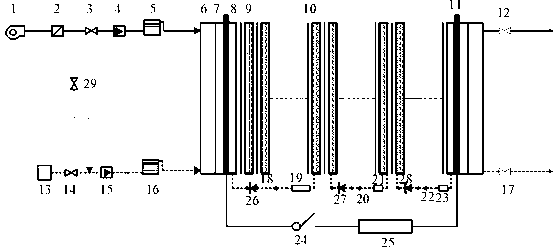

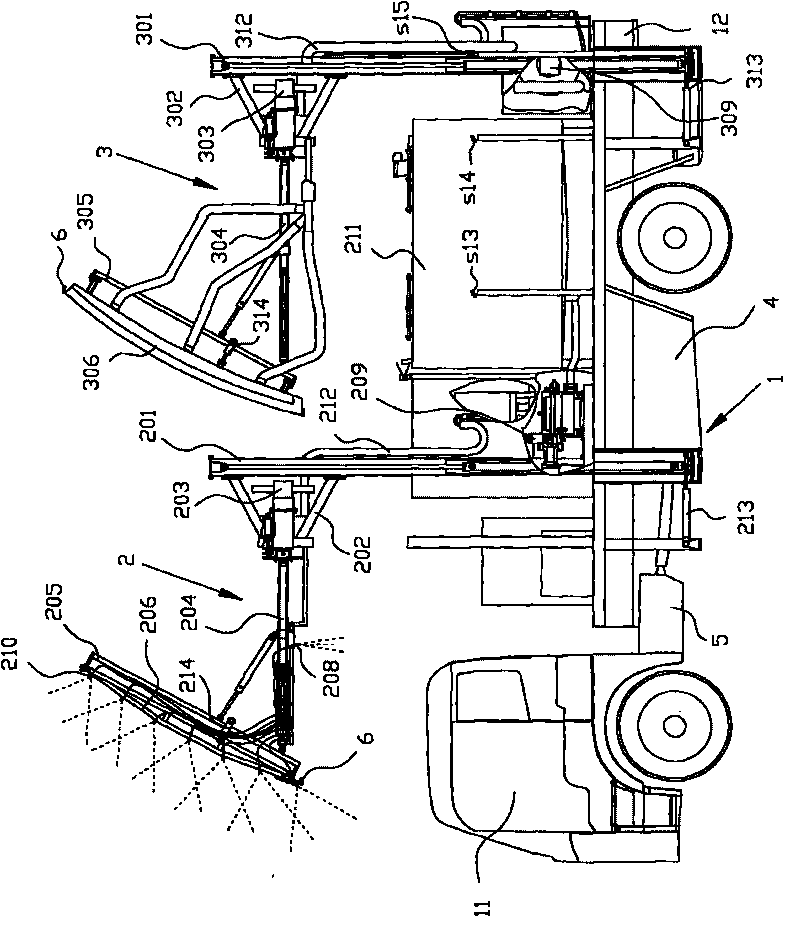

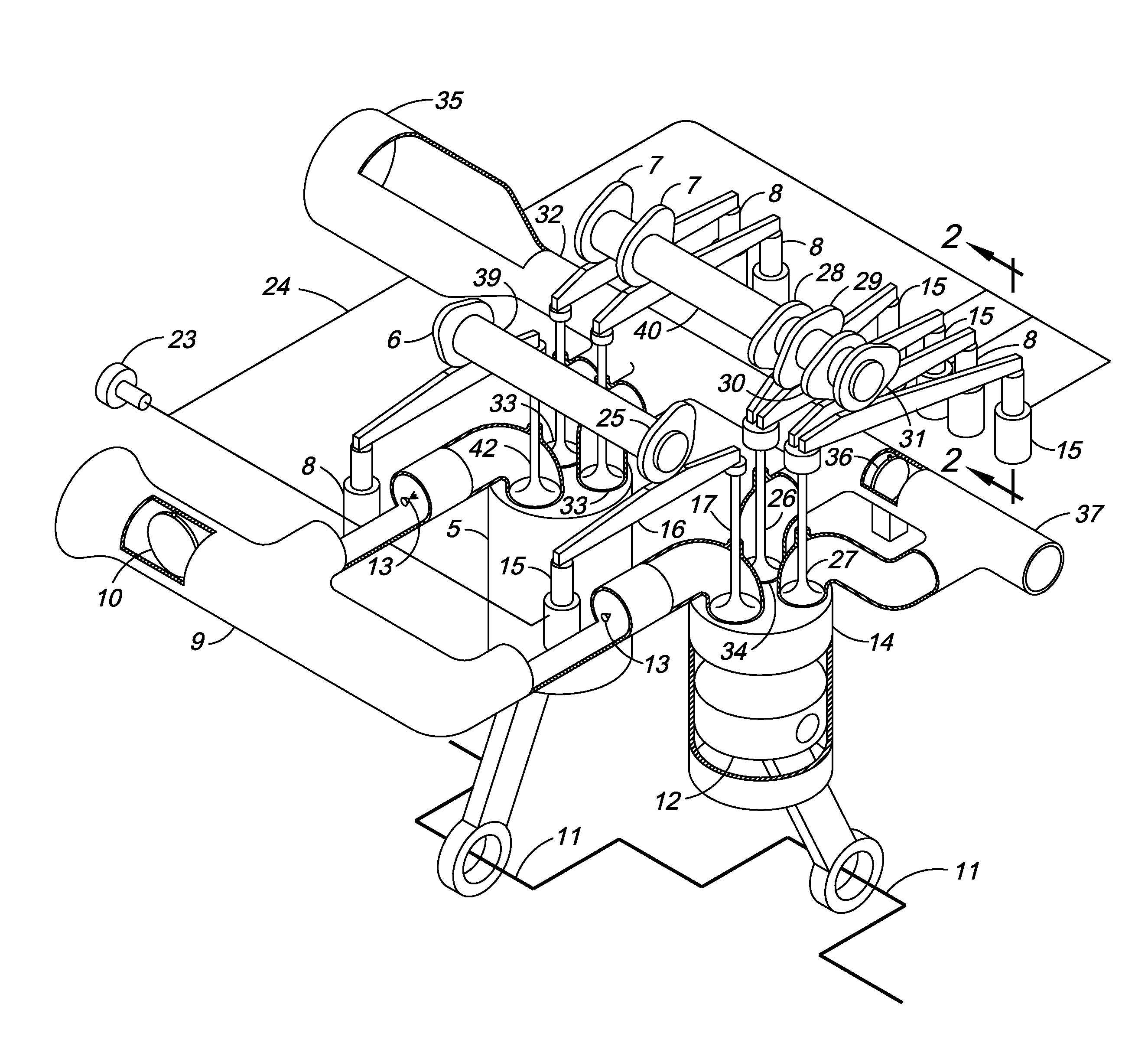

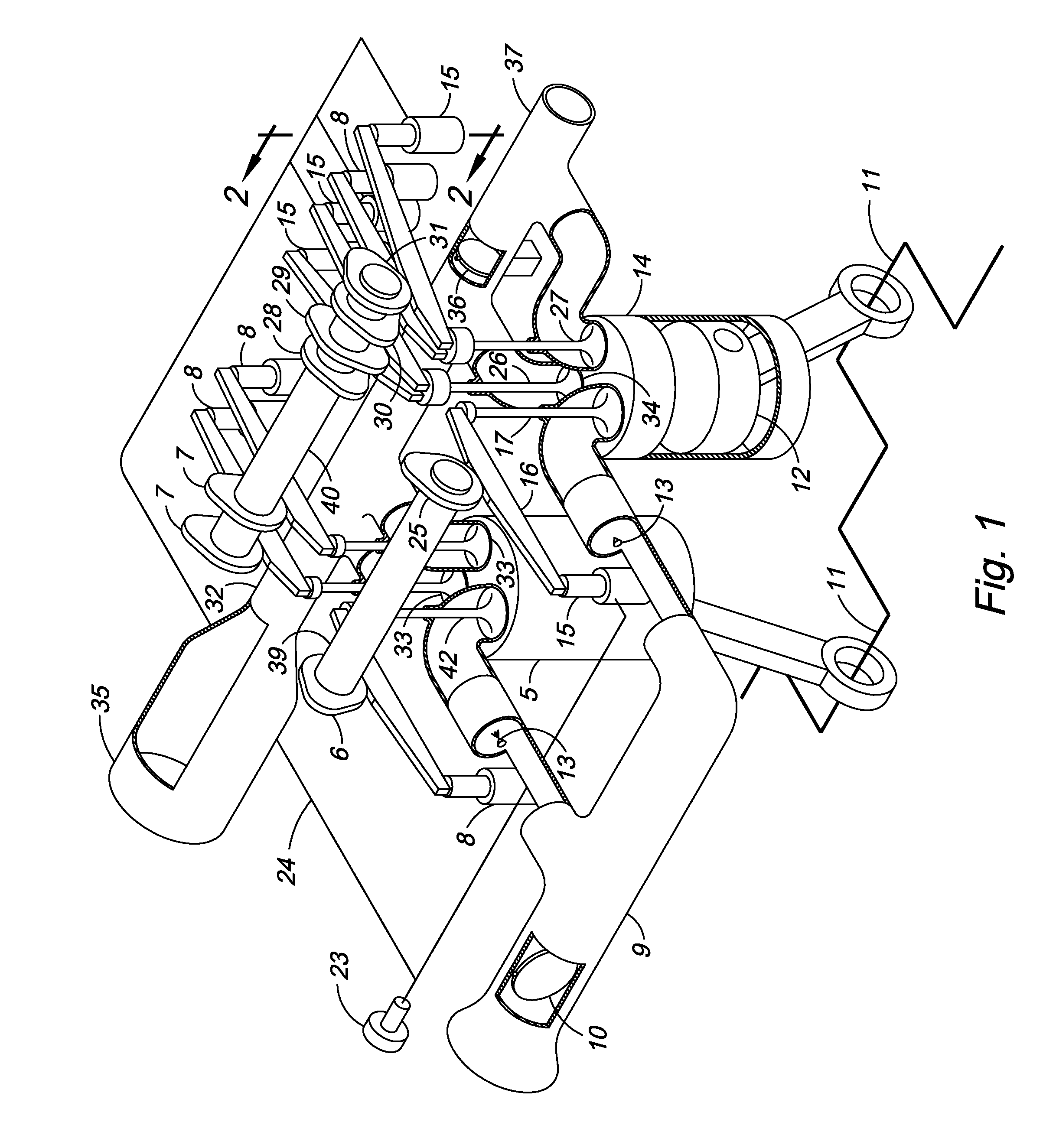

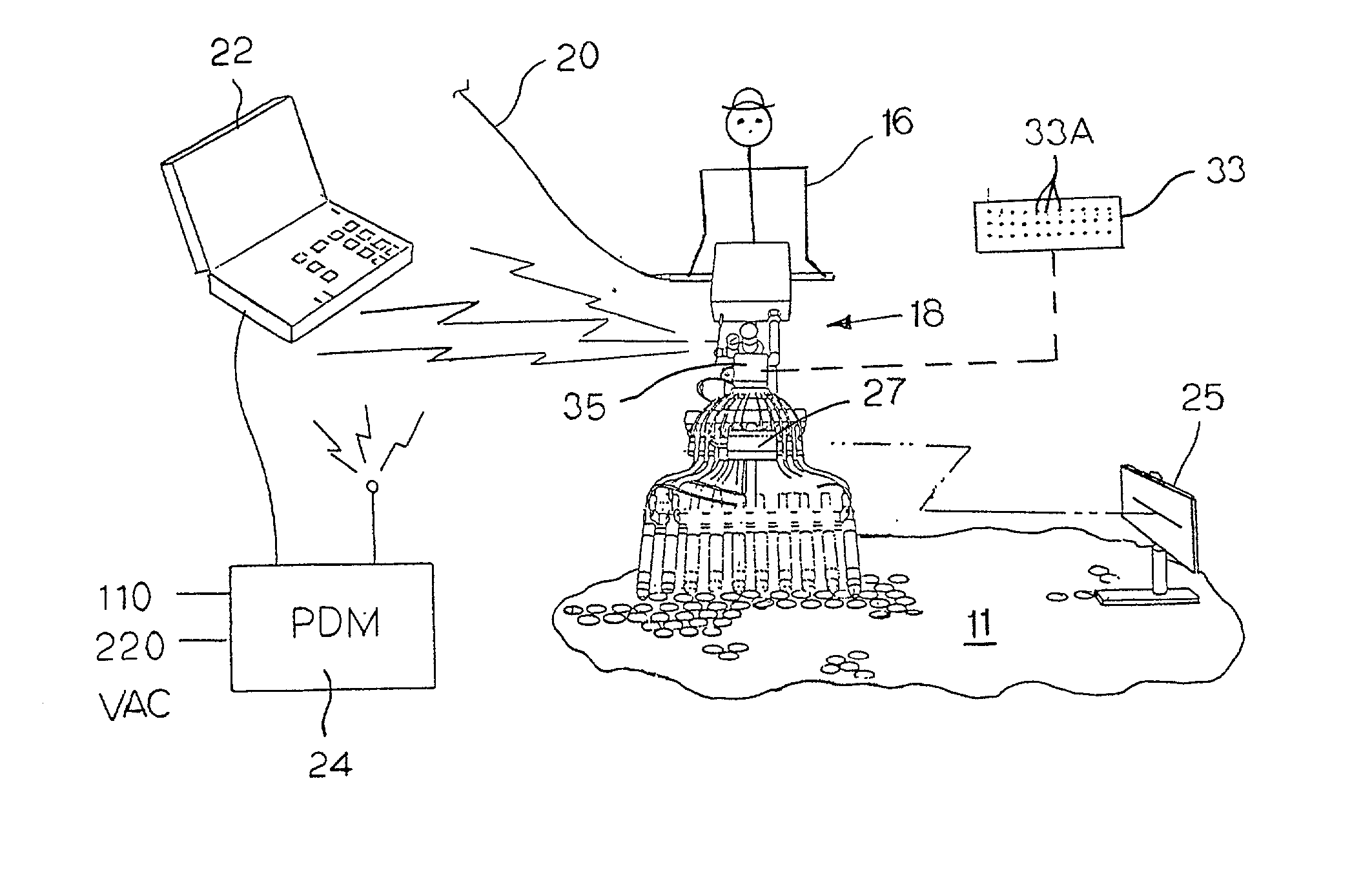

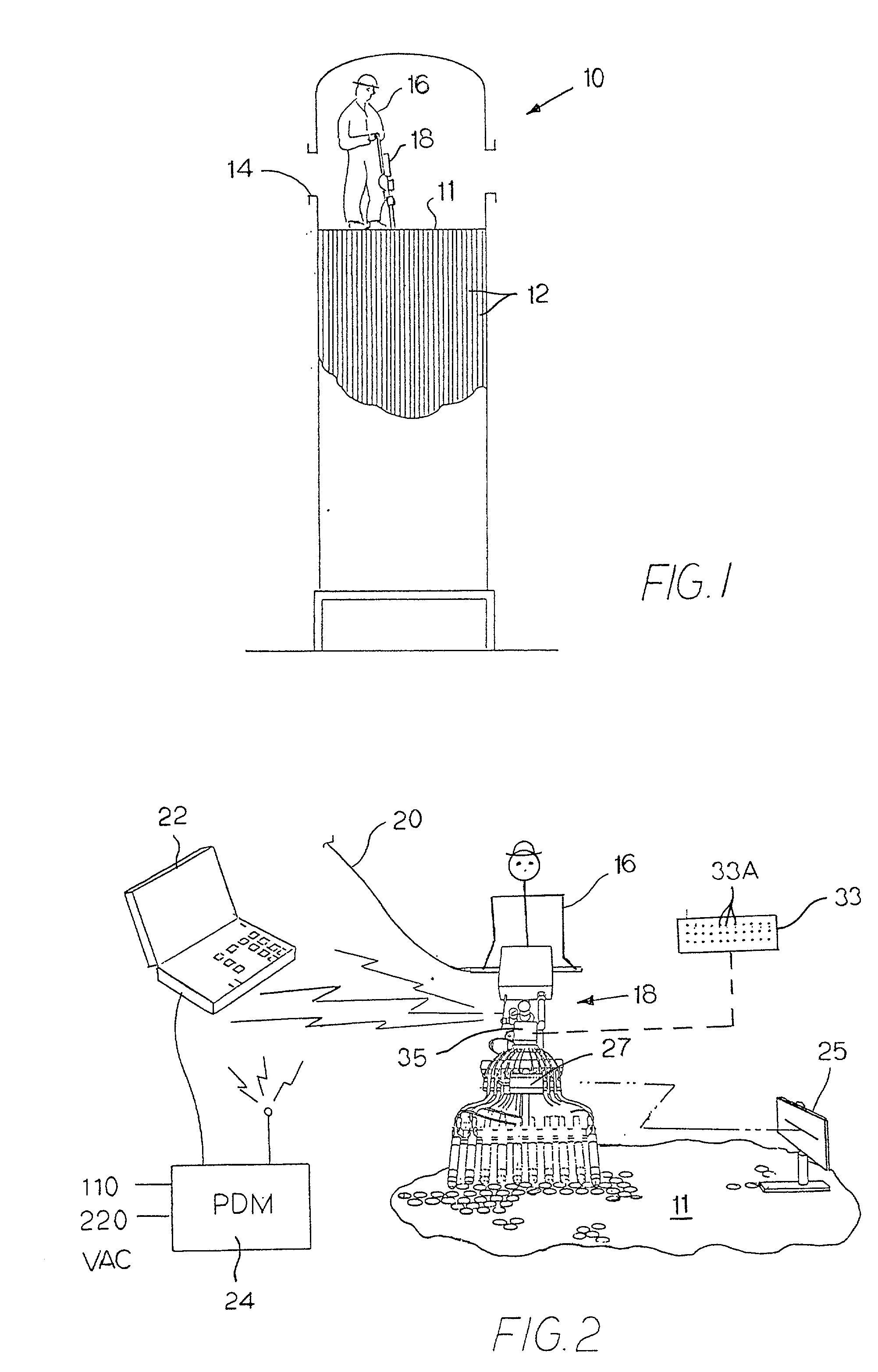

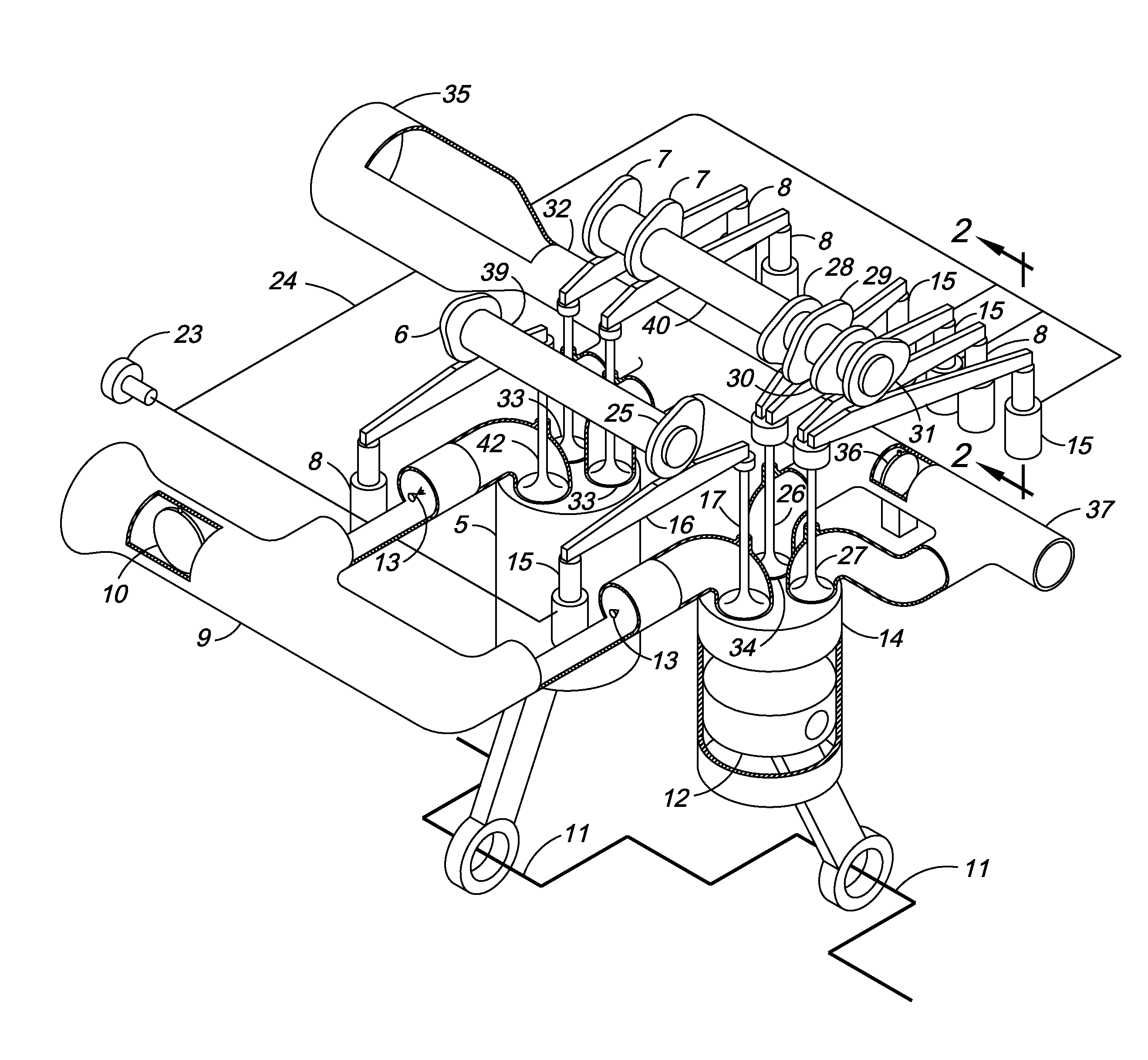

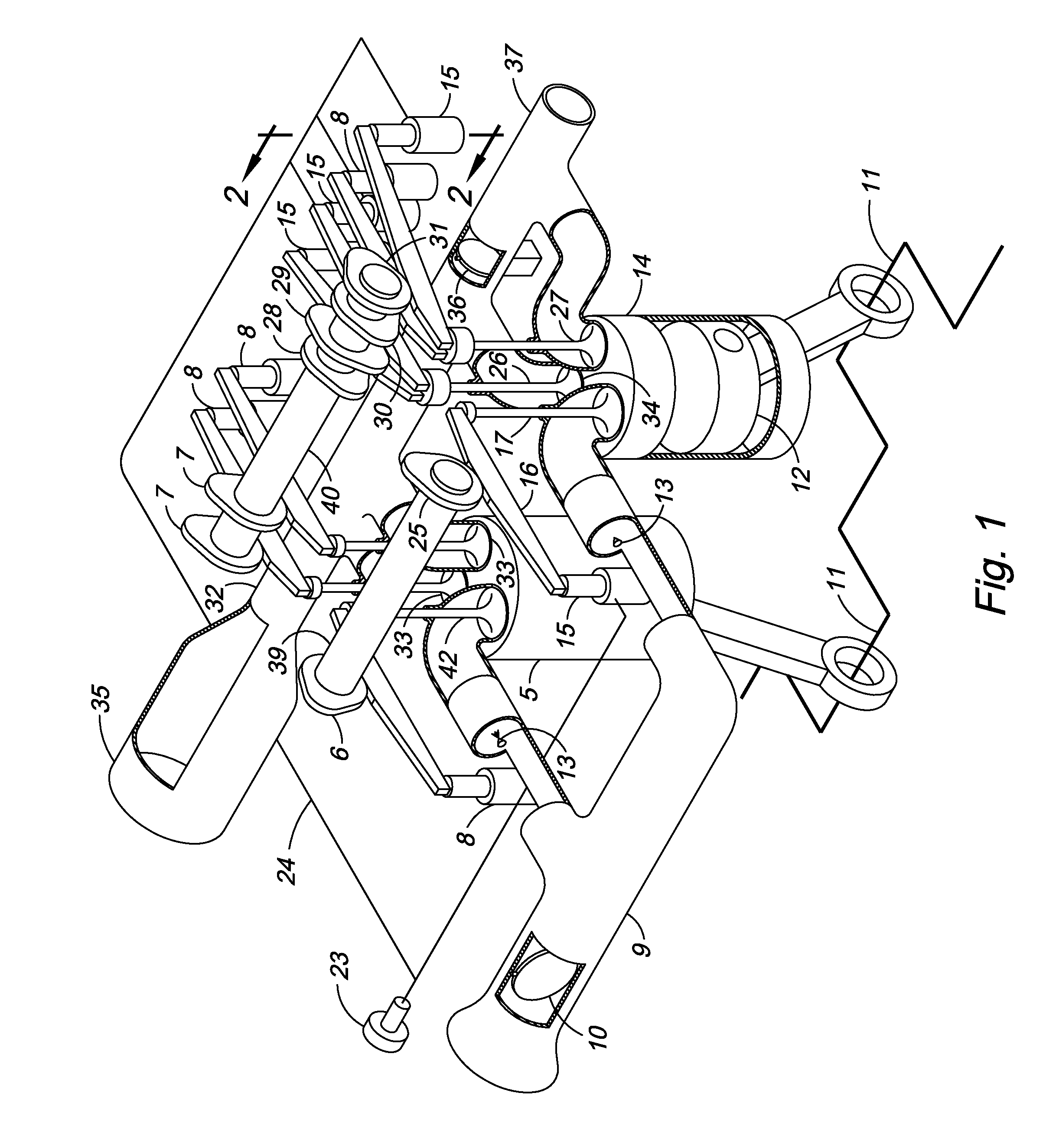

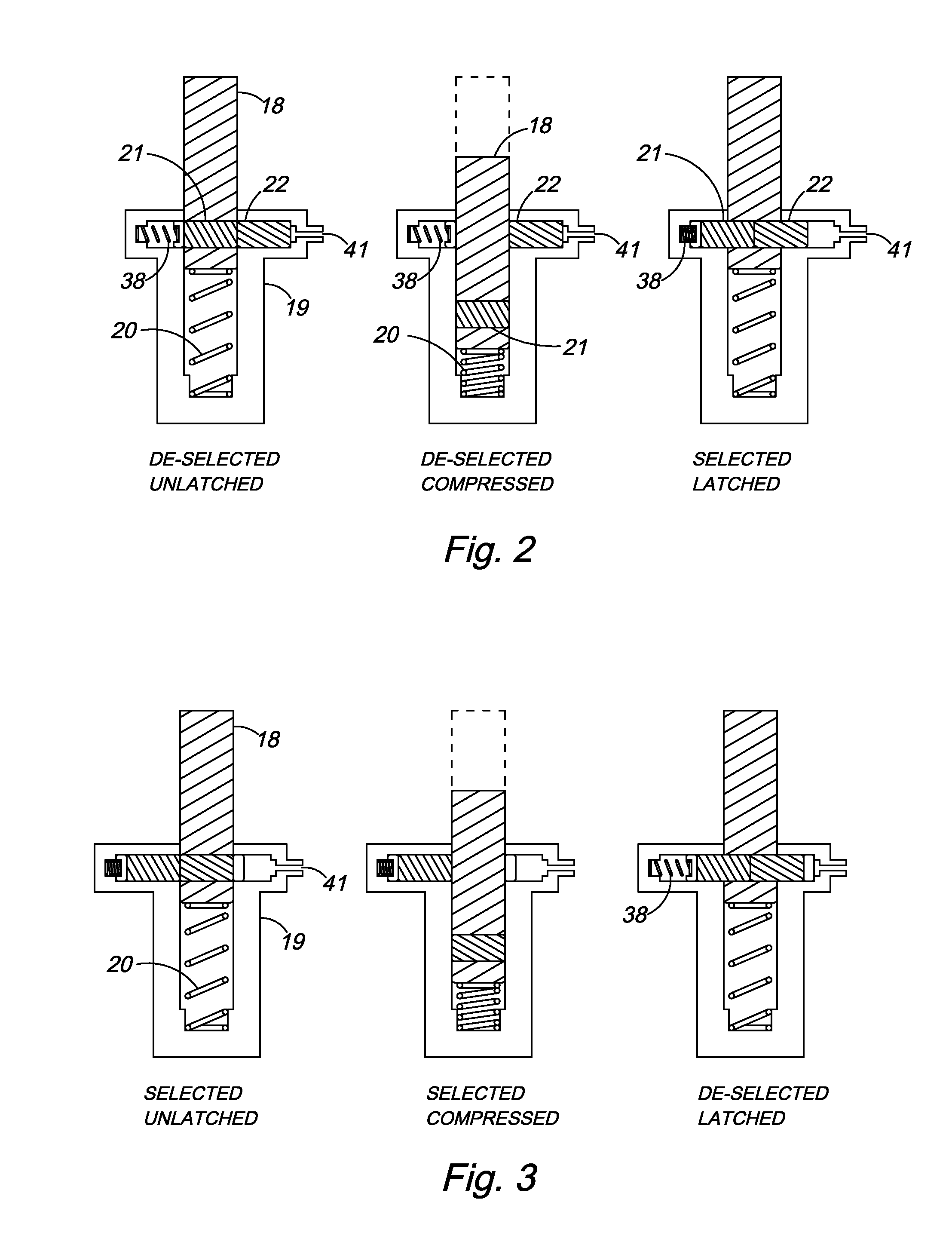

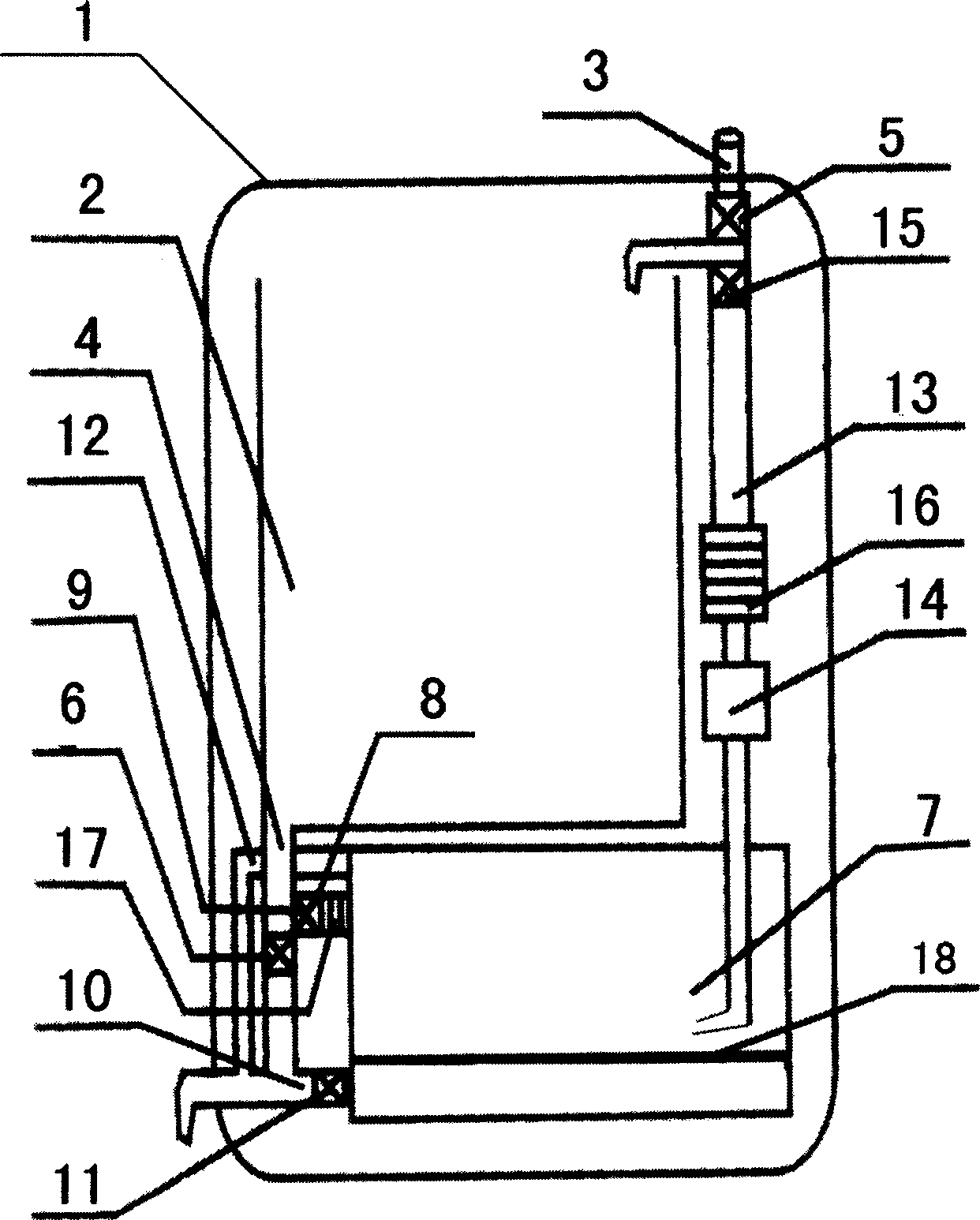

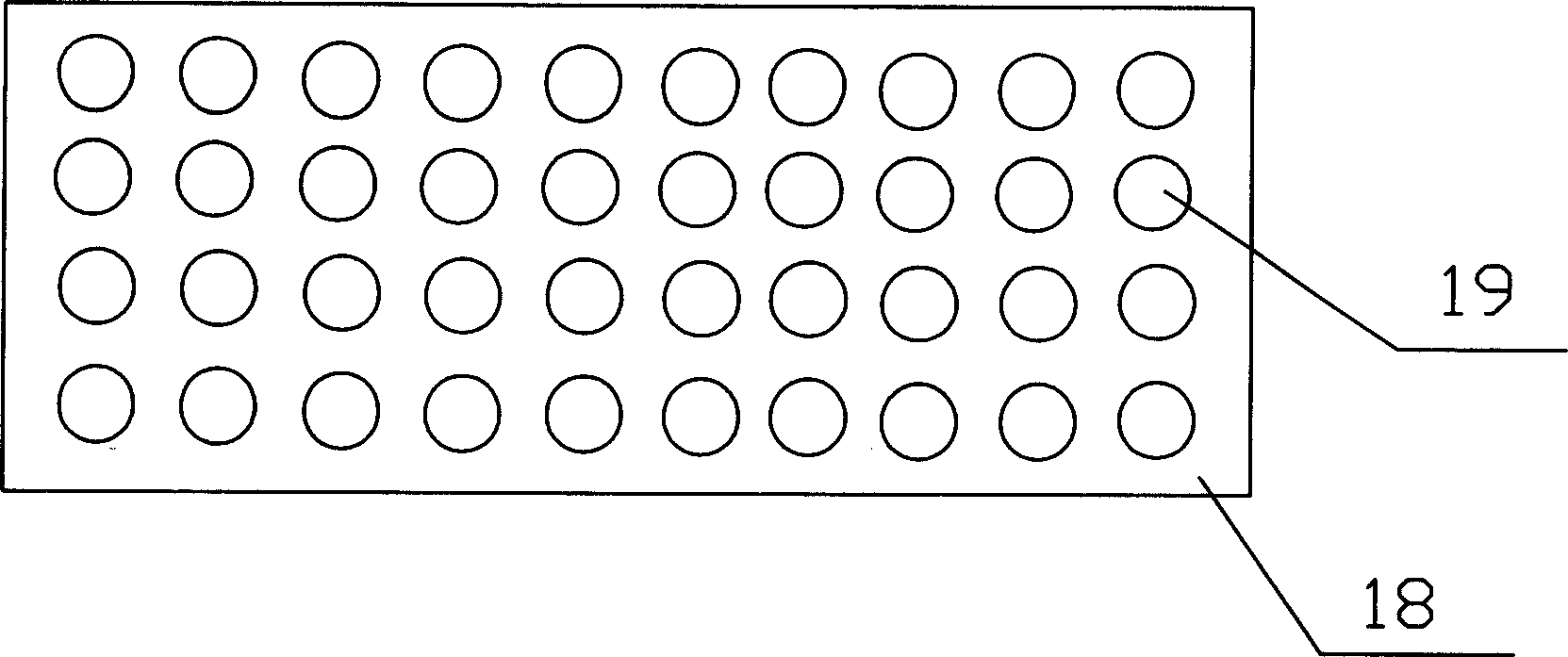

Method and apparatus for differential pressure testing of catalytic reactor tubes

ActiveUS6981422B1Efficient testingMinimizes servicing timeProcess control/regulationMaterial strength using tensile/compressive forcesDifferential pressureEngineering

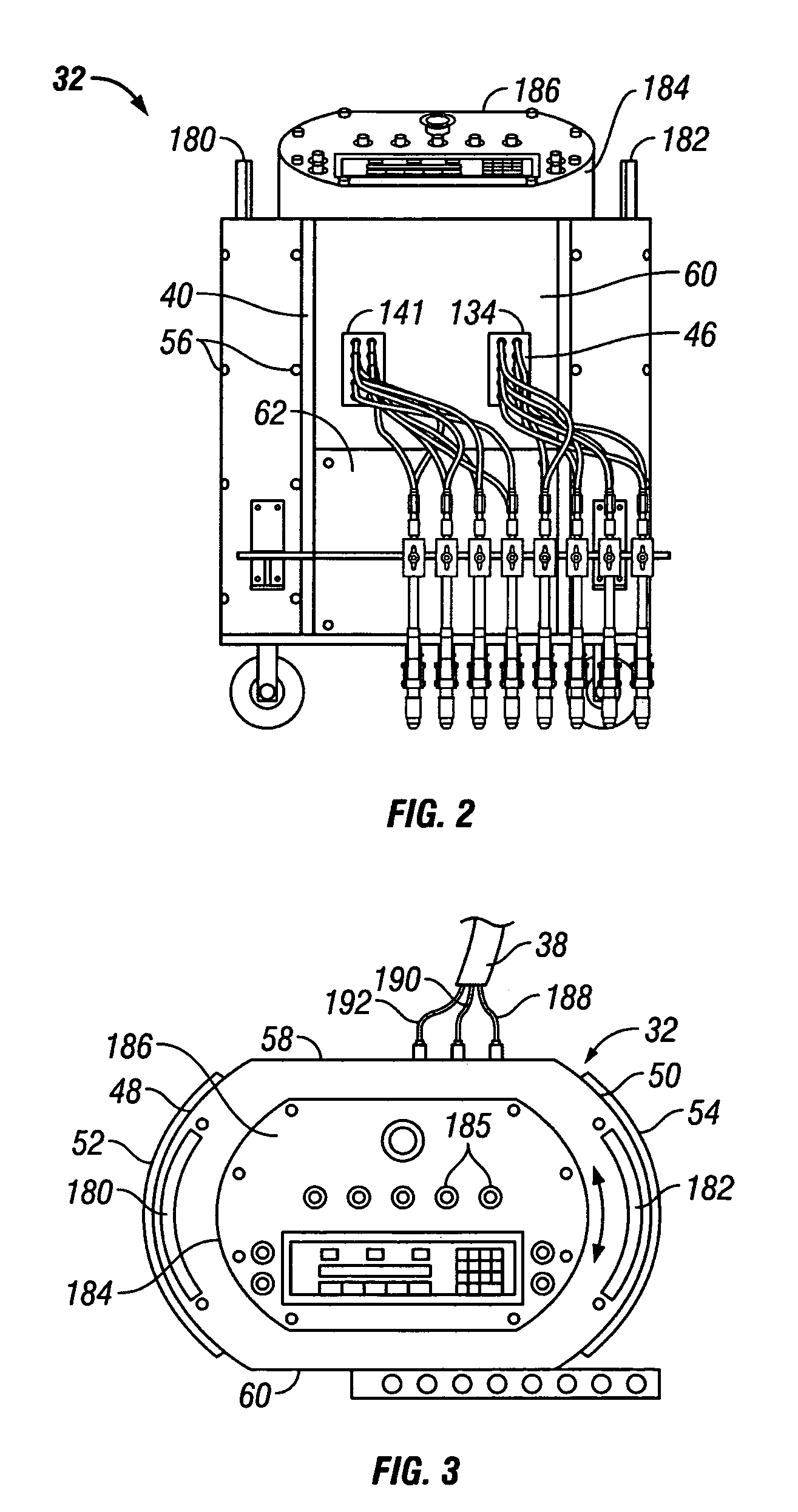

A multi-tube differential pressure (Delta P) testing system for testing catalyst filled tubes of tube and shell type catalytic reactors has at least one mobile test unit for movement on the upper tube sheet of a catalytic reactor. An array of test probes is mounted to the mobile test unit and is selectively positionable in sealed gas pressure communicating engagement within the upper ends of selected reactor tubes. A pressure testing gas delivery system is interconnected with the test probes and selectively communicates pressurized gas to the testing tubes at a blow-down pressure or selected test pressure determined by restricted orifices. A differential pressure measurement system measures the back-pressure resulting from application of test pressure to individual reactor tubes and having a computer receiving electronic back-pressure measurement data and producing an electronic and / or visual record correlated with a reactor tube numerical sequence and identifying the resulting back-pressure of each reactor tube of the multi-tube test. The testing system is capable of selectively electronically counting in normal sequence and in inverted sequence to accommodate test unit orientation and incorporates a separate manually positioned testing wand to accommodate tube positions of the reactor that cannot be readily accessed by one or more of the array of test probes.

Owner:WINDLASS METALWORKS

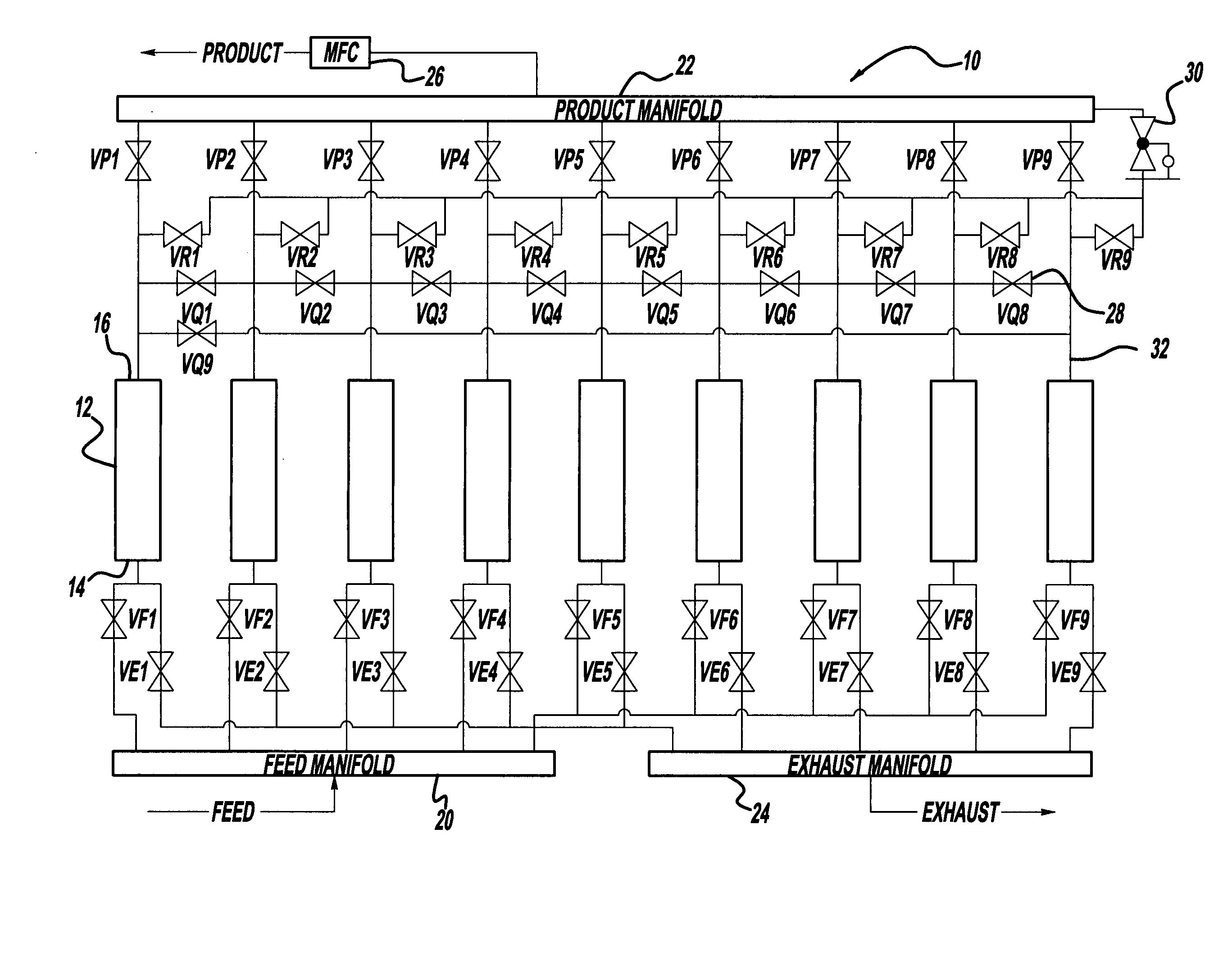

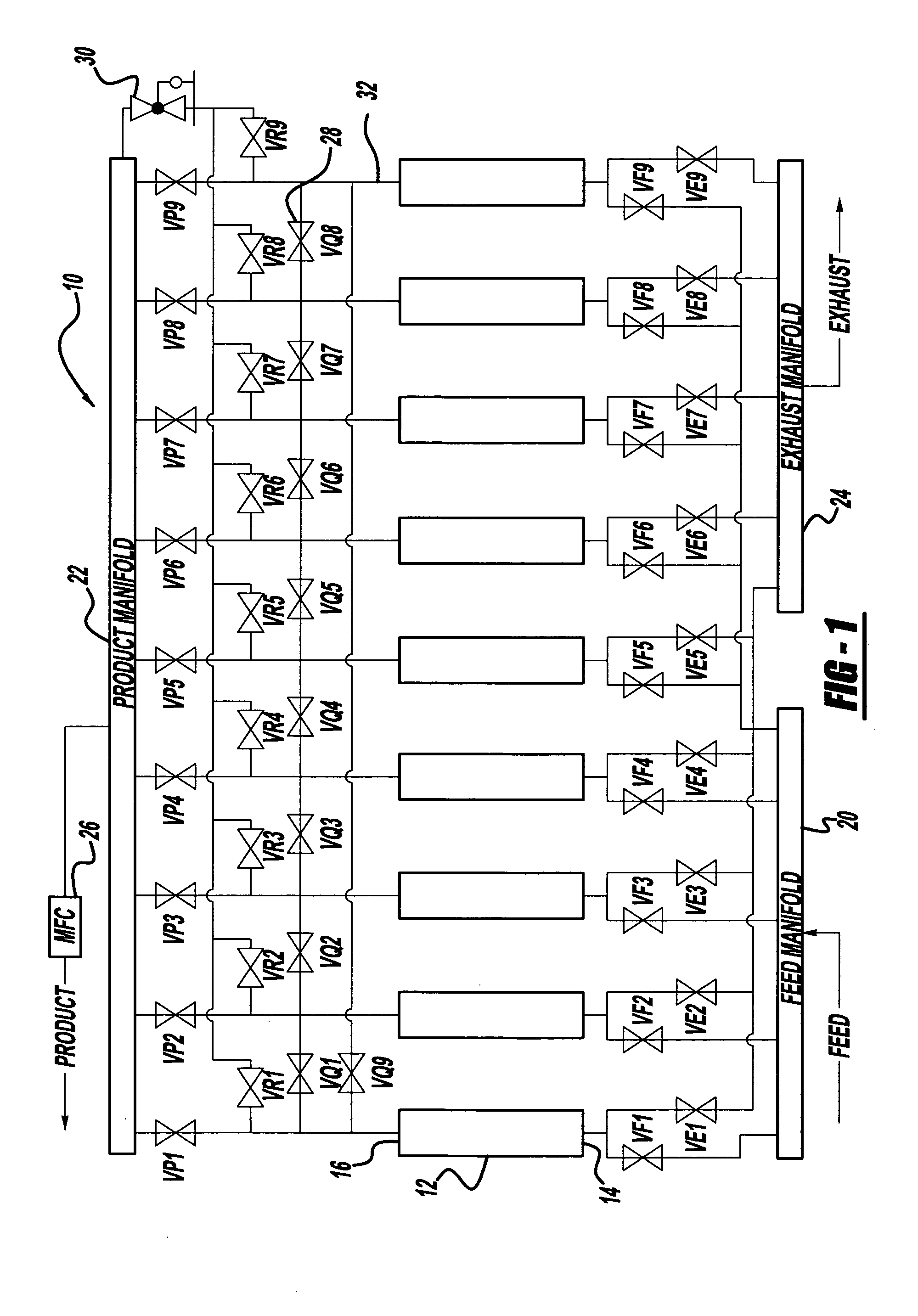

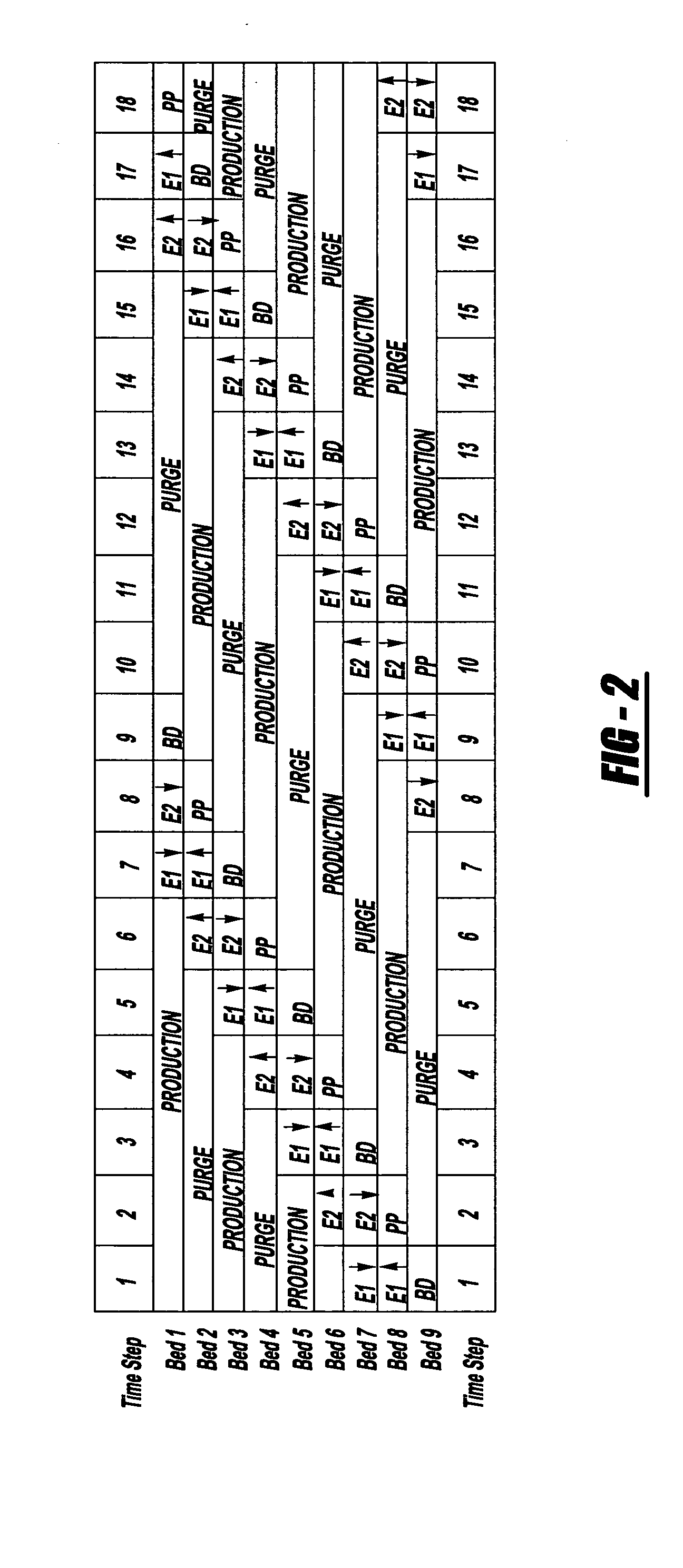

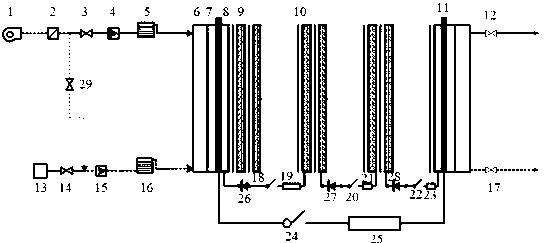

Hydrogen purification process using pressure swing adsorption for fuel cell applications

A PSA system that purifies a feed gas, such as a reformate gas in fuel cell system. The PSA system includes a series of vessels housing an adsorbent or combination of adsorbents that adsorb carbon monoxide, carbon dioxide, nitrogen, water and methane in the reformate gas. The adsorbent vessels are connected to each other and a feed manifold, a product manifold and an exhaust manifold through suitable conduits, where the gas flows are controlled by a product rotating valve and feed rotating valve or a series of open / shut valves. A specialized PSA cycle controls the valves so that the vessels cycle through various stages of equalization, blow-down, purge, pressurization and production to purify the feed gas.

Owner:GENERAL MOTORS COMPANY

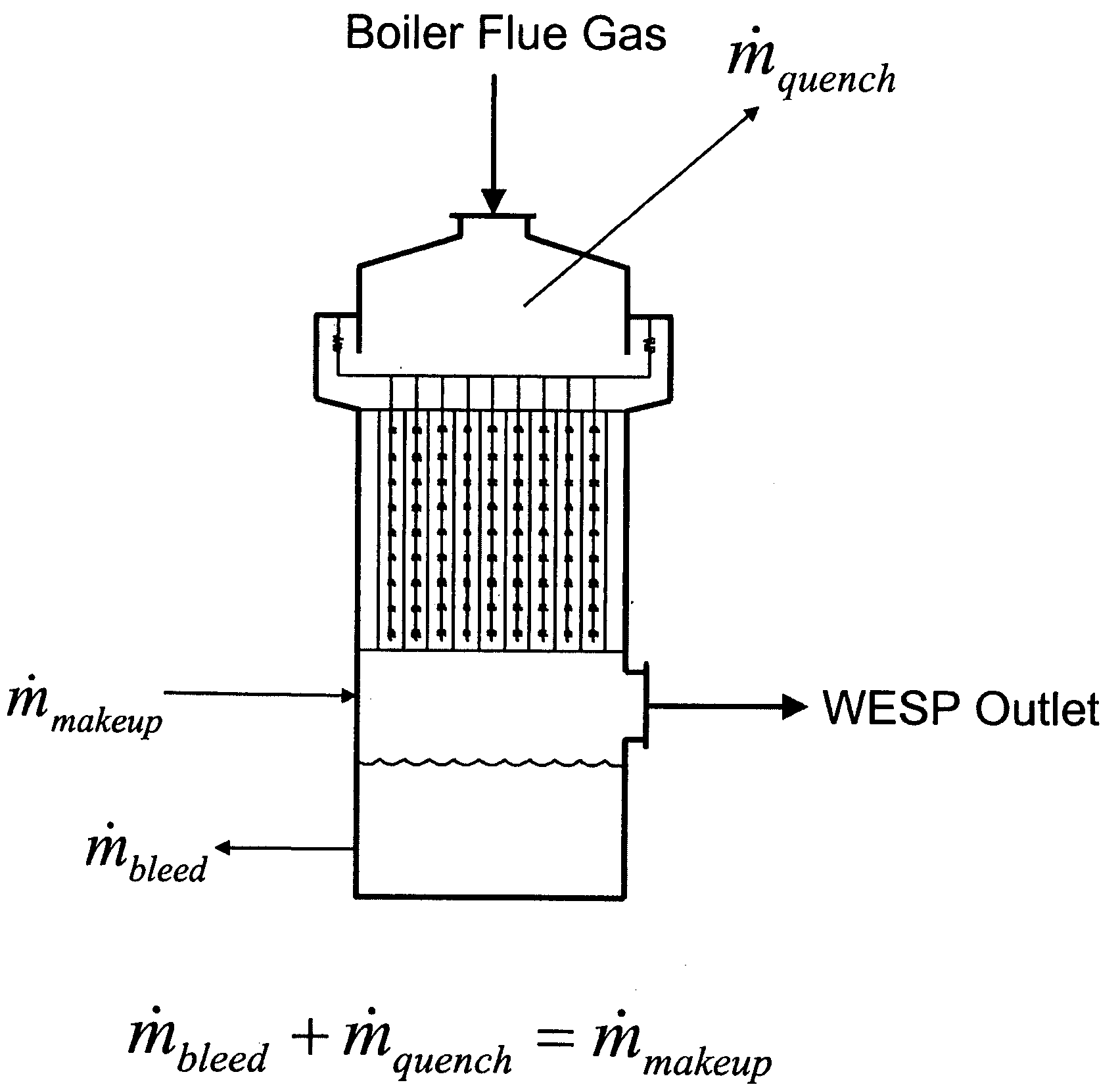

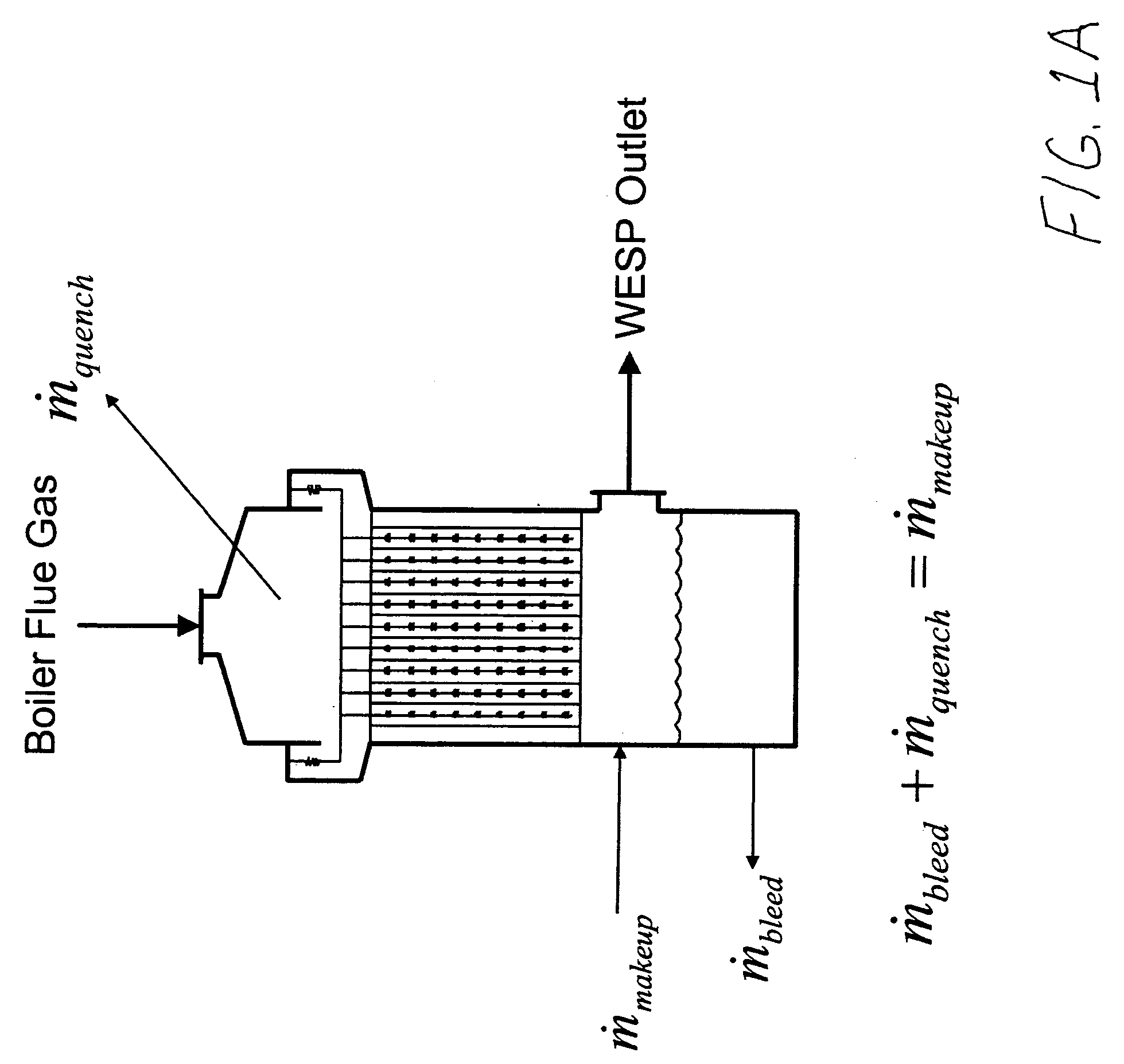

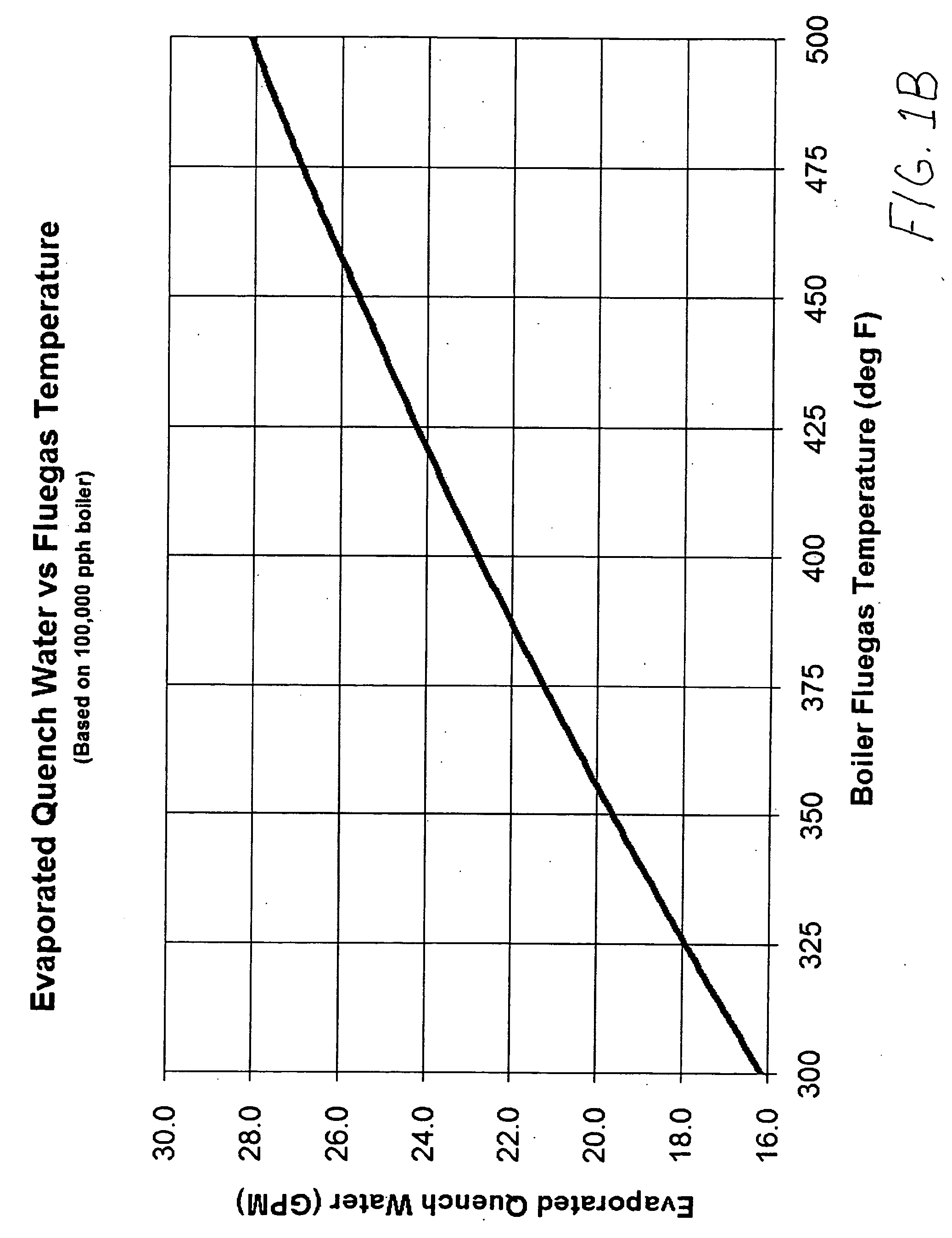

Method and apparatus for eliminating or reducing waste effluent from a wet electrostatic precipitator

ActiveUS20100043634A1Lower requirementReducing bleed water waste effluentExternal electric electrostatic seperatorThin material handlingFlue gasWaste stream

A method and apparatus are provided for reducing significantly or to zero the waste effluent from a system including a boiler and a wet electrostatic precipitator, the waste effluent comprising blow down water discharged by the boiler during a blow down operation and bleed water discharged by the wet electrostatic precipitator. The method comprises collecting the blow down water, providing the collected blow down water to the wet electrostatic precipitator as a makeup water supplement, evaporating a portion the bleed water and leaving residual bleed water, providing the evaporated bleed water to the wet electrostatic precipitator as a further makeup water supplement, and using the residual bleed water to quench ash produced by combustion of solid fuel by the boiler. The apparatus includes an evaporator that provides direct contact between hot boiler flue gas and the bleed water such that a portion of the flue gas is quenched before being provided to the wet electrostatic precipitator.

Owner:ZENVIRO TECH HLDG INC

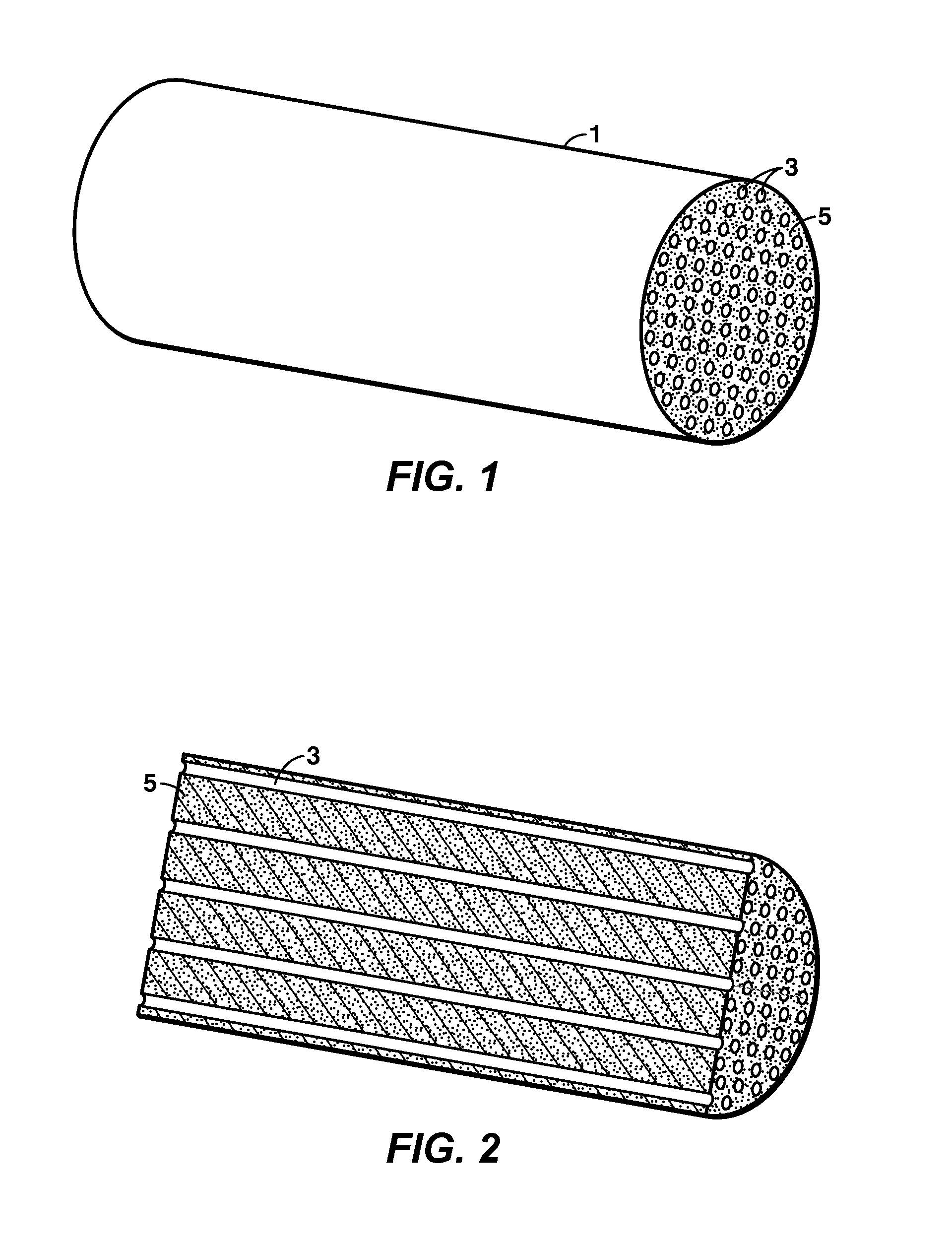

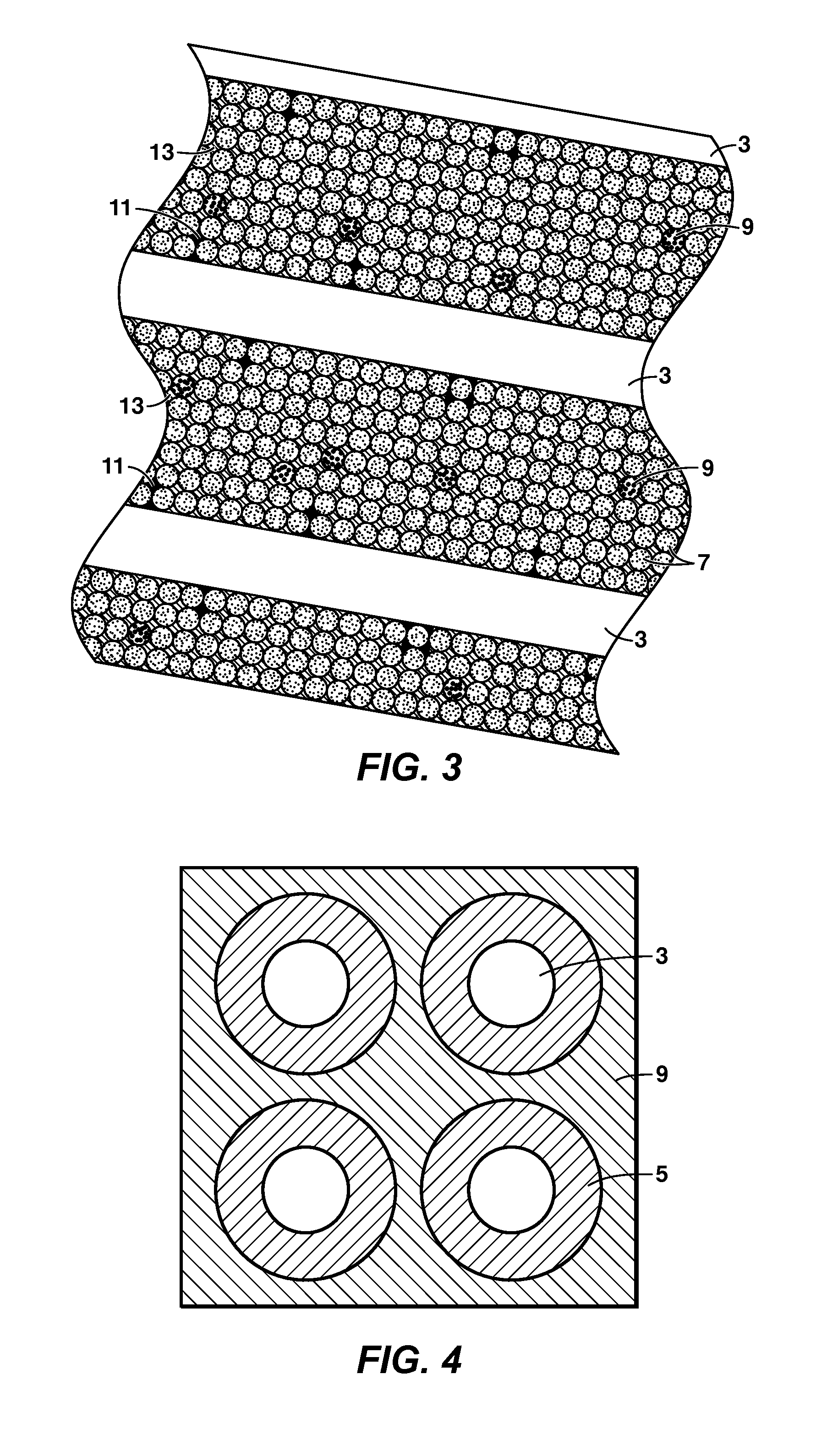

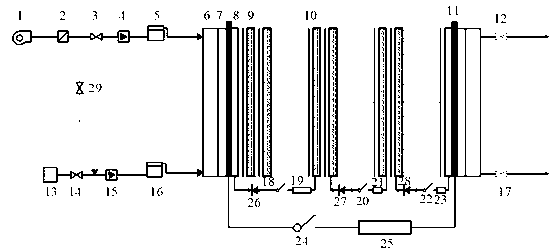

Methods of removing contaminants from hydrocarbon stream by swing adsorption and related apparatus and systems

A pressure swing adsorption process for removal of CO2 from natural gas streams through a combination of a selective adsorbent material containing an effective amount of a non-adsorbent filler, adsorbent contactor design, and adsorption cycle design. The removal of contaminants from gas streams, preferably natural gas streams, using rapid-cycle swing adsorption processes, such as rapid-cycle pressure swing adsorption (RC-PSA). Separations at high pressure with high product recovery and / or high product purity are provided through a combination of judicious choices of adsorbent material, gas-solid contactor, system configuration, and cycle designs. For example, cycle designs that include steps of purge and staged blow-down as well as the inclusion of a mesopore filler in the adsorbent material significantly improves product (e.g., methane) recovery. An RC-PSA product with less than 10 ppm H2S can be produced from a natural gas feed stream that contains less than 1 mole percent H2S.

Owner:EXXONMOBIL UPSTREAM RES CO

Starting and shutdown control method for proton exchange membrane fuel cell

InactiveCN103259031AReduce voltageReduce time consumptionFuel cell auxillariesLoad circuitElectrical battery

The invention provides a starting and shutdown control method for a proton exchange membrane fuel cell. According to the method, a whole fuel cell stack is divided into a plurality of cell modules; each cell module is connected with a modularized discharging circuit which is composed of a control switch, an auxiliary load and a crystal diode in mutual series connection; each modularized discharging circuit and a main load circuit are in series connection and are respectively connected with the cathode end and the anode end of the fuel cell; an air source is connected with the anode end of the fuel cell through an air blow-down valve; and air is used to purge residual hydrogen at the anode. During starting control, hydrogen is used to purge the anode, and the auxiliary load is used to control the voltage of the cell; and during shutdown control, introduction of air and introduction of hydrogen are successively stopped, a closed system of the auxiliary load is used for discharging, and introduction of air is cooperatively used for purging of the anode. The invention has the following advantages: consumption of time during shutdown of the fuel cell is reduced; the concentration of residual oxygen at the cathode is lowered down; reversal of poles of a single cell in the modules is prevented, and the phenomenon of reversal of poles of the fuel cell in the processes of shutdown discharging and air purging is prevented; and the system of the fuel cell is more simplified and is convenient to operate.

Owner:WUHAN UNIV OF TECH

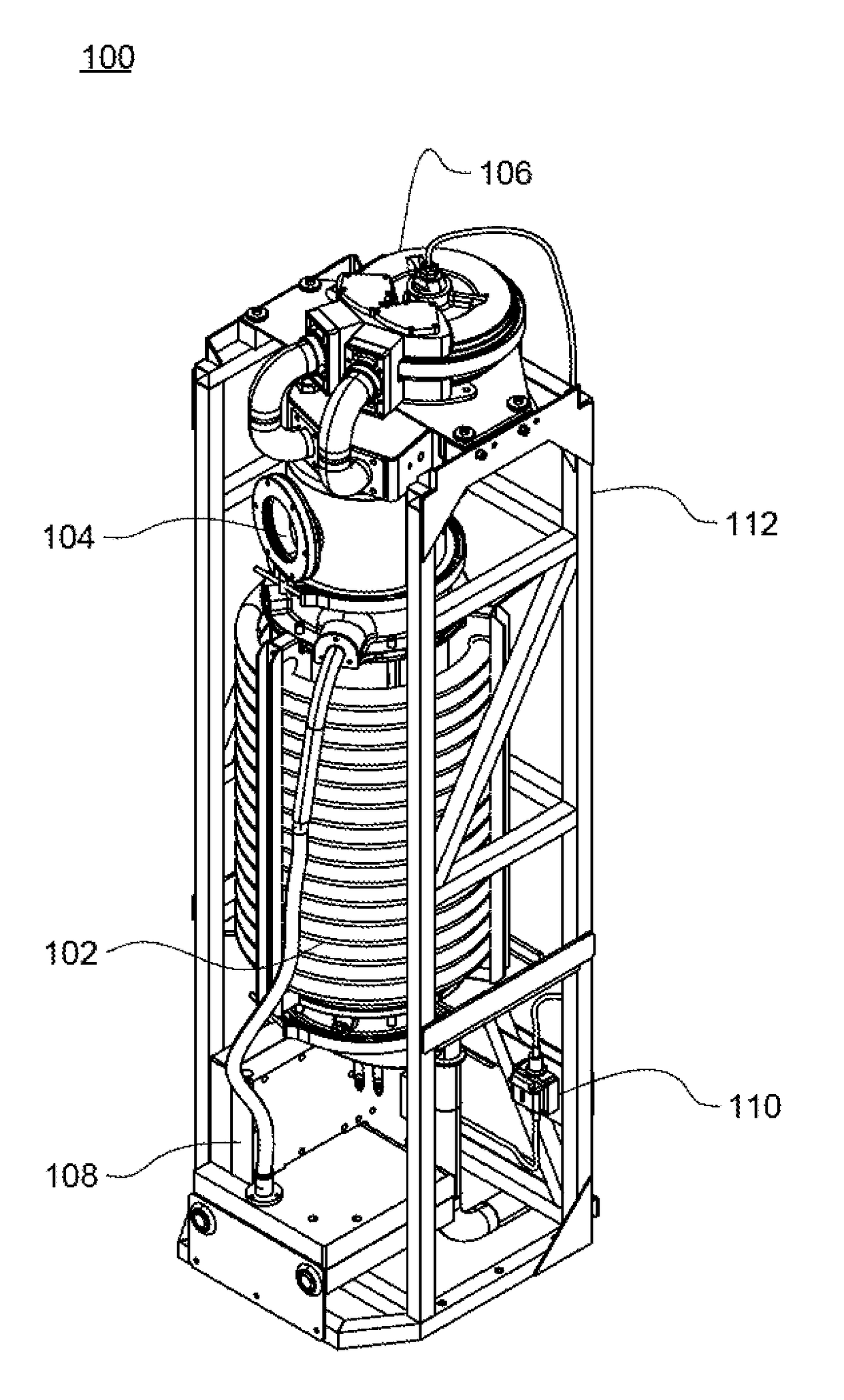

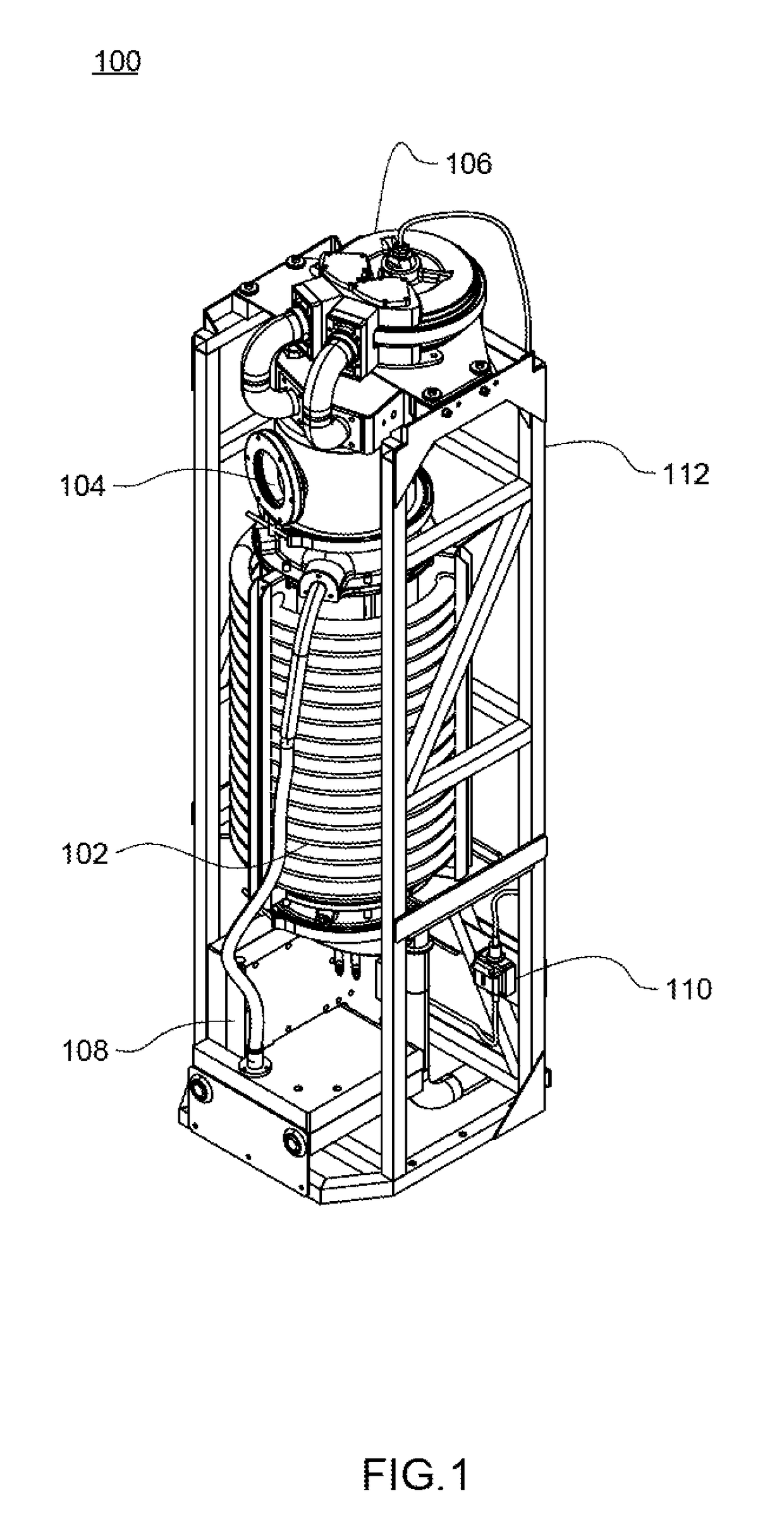

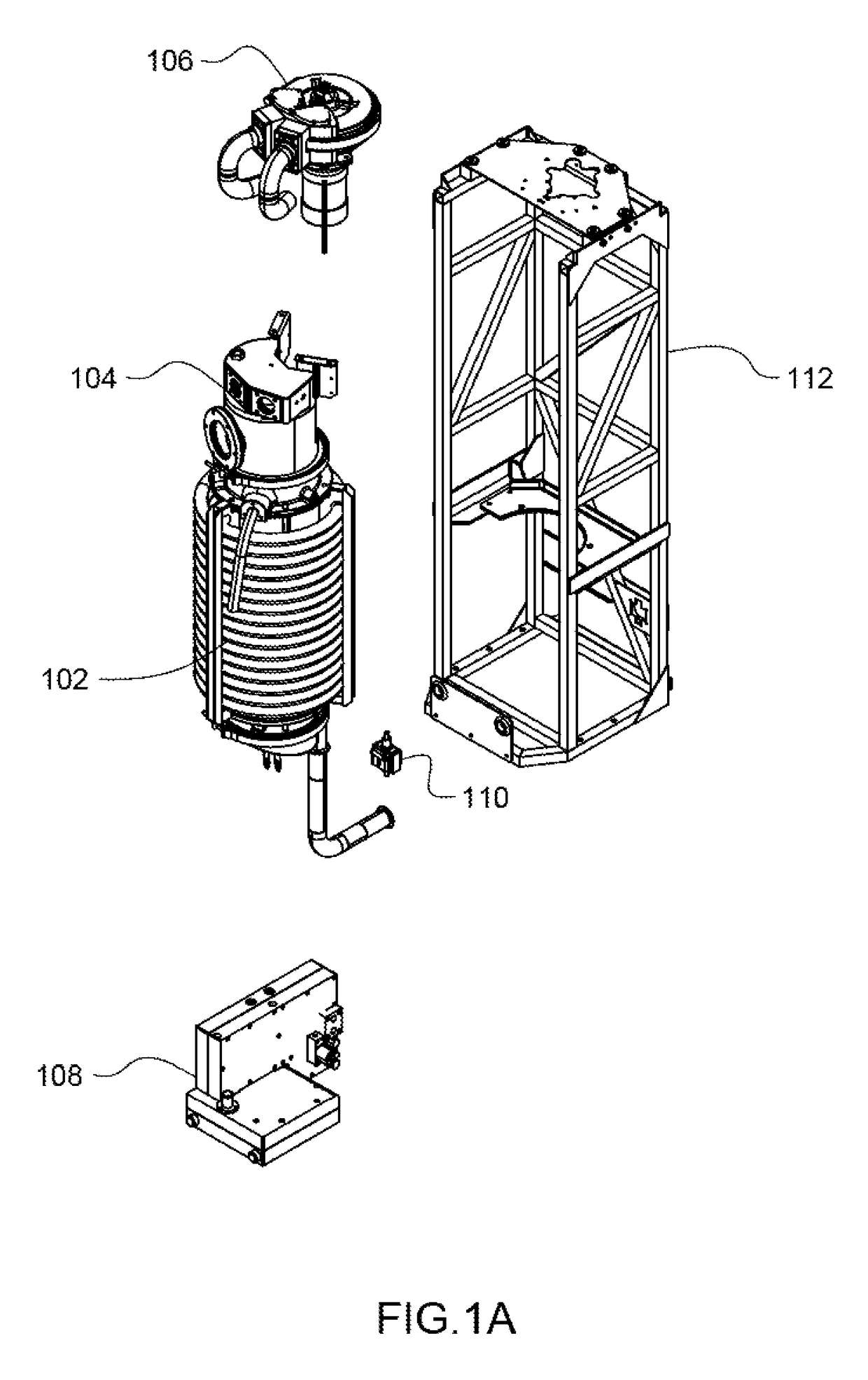

Water vapor distillation apparatus, method and system

ActiveUS9604858B2Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

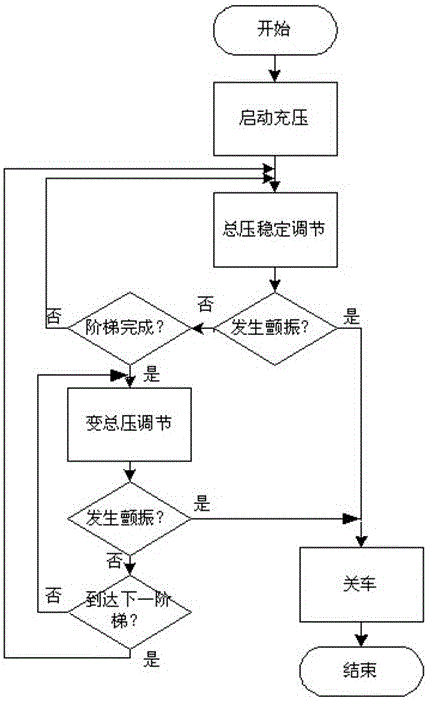

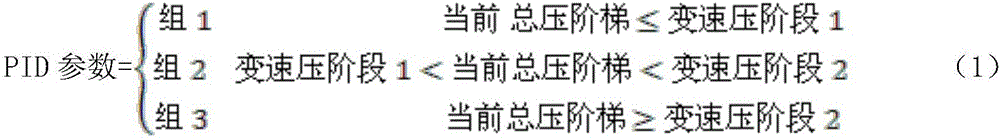

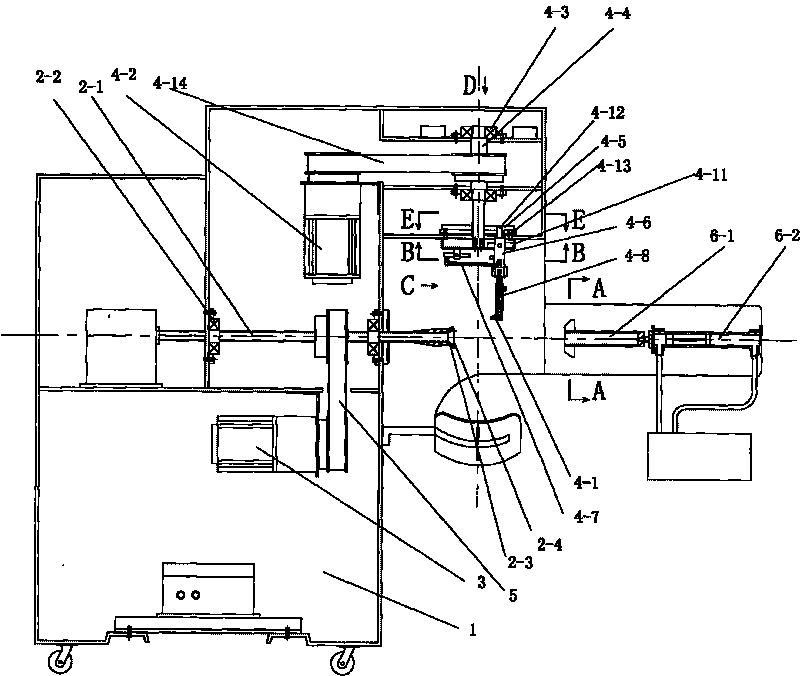

Method for controlling adjusting dynamic pressure flow field for large direct-current blow-down supersonic wind tunnel

ActiveCN106527519AHigh control precisionTotal pressure rise rate controllableFluid pressure control using electric meansEngineeringDynamic pressure

The invention, which relates to the field of supersonic wind tunnel test control, discloses a method for controlling an adjusting dynamic pressure flow field for a large direct-current blow-down supersonic wind tunnel. With the method provided by the invention, a problem that the supersonic flutter testing requirement can not be met because multi-step total pressure control can not be realized at single flight and the total pressure rising rate can not be controlled according to the conventional supersonic wind tunnel control method can be solved. The method comprises: wind tunnel starting and pressurizing are carried out and a flow field s established; a total pressure is adjusted stably; an adjusting dynamic pressure is adjusted; and flying machine closing is carried out by the wind tunnel. And different closing strategies are employed based on different situations, so that flying machine closing is realized securely by the wind tunnel. With the method, the requirement on adjusting dynamic pressure flow field control of the supersonic wind tunnel by a flutter test is met. The method has advantages of reliable operation, convenient parameter giving, low total pressure control overshooting, and high precision.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

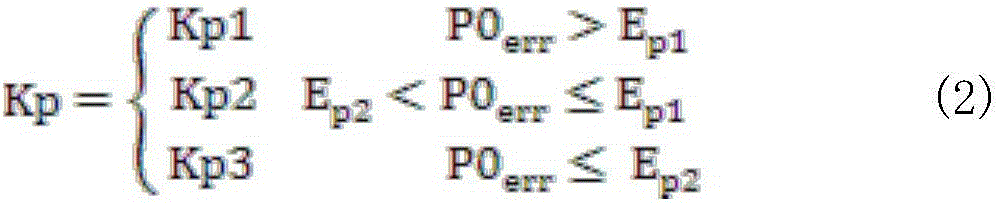

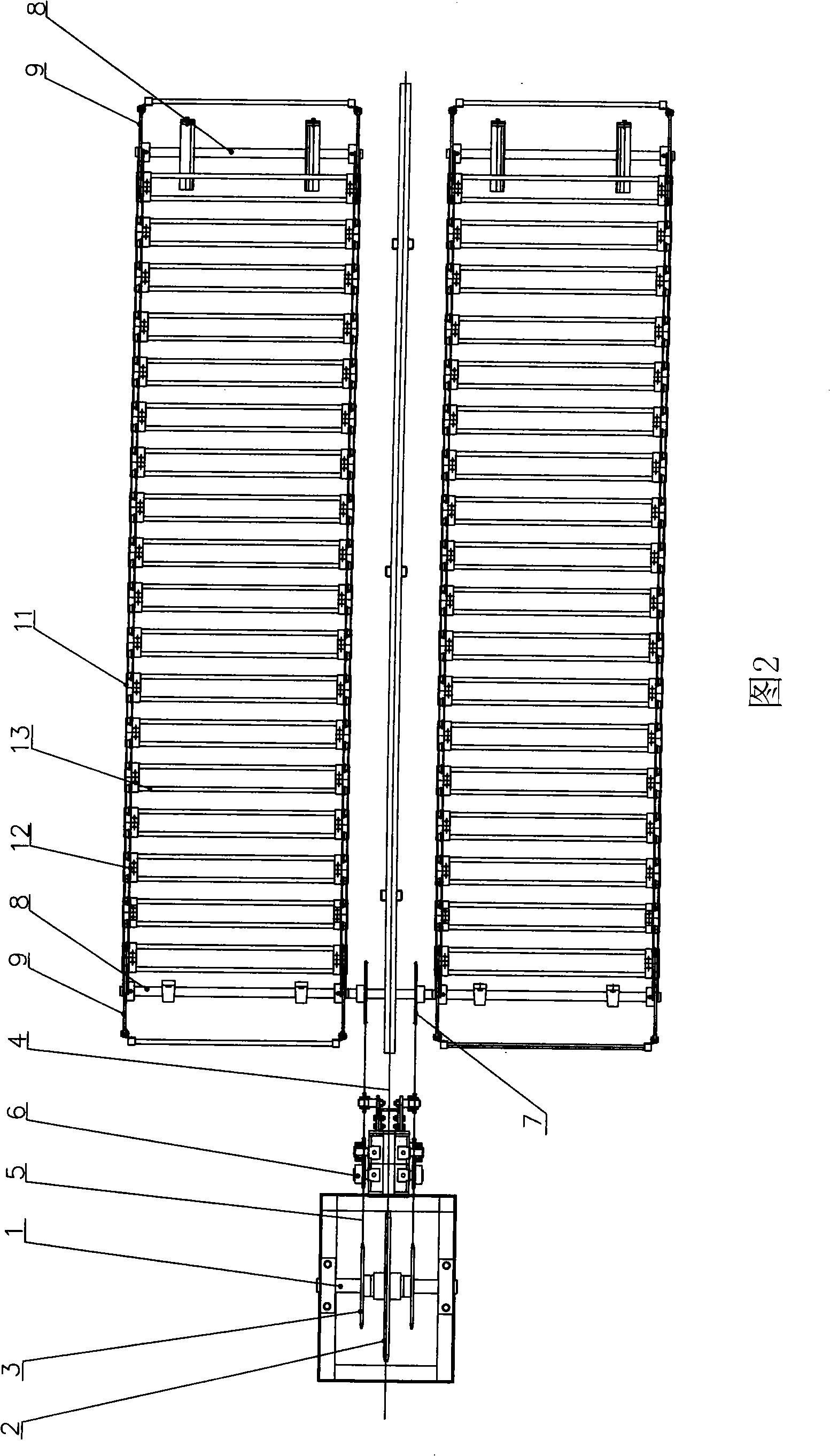

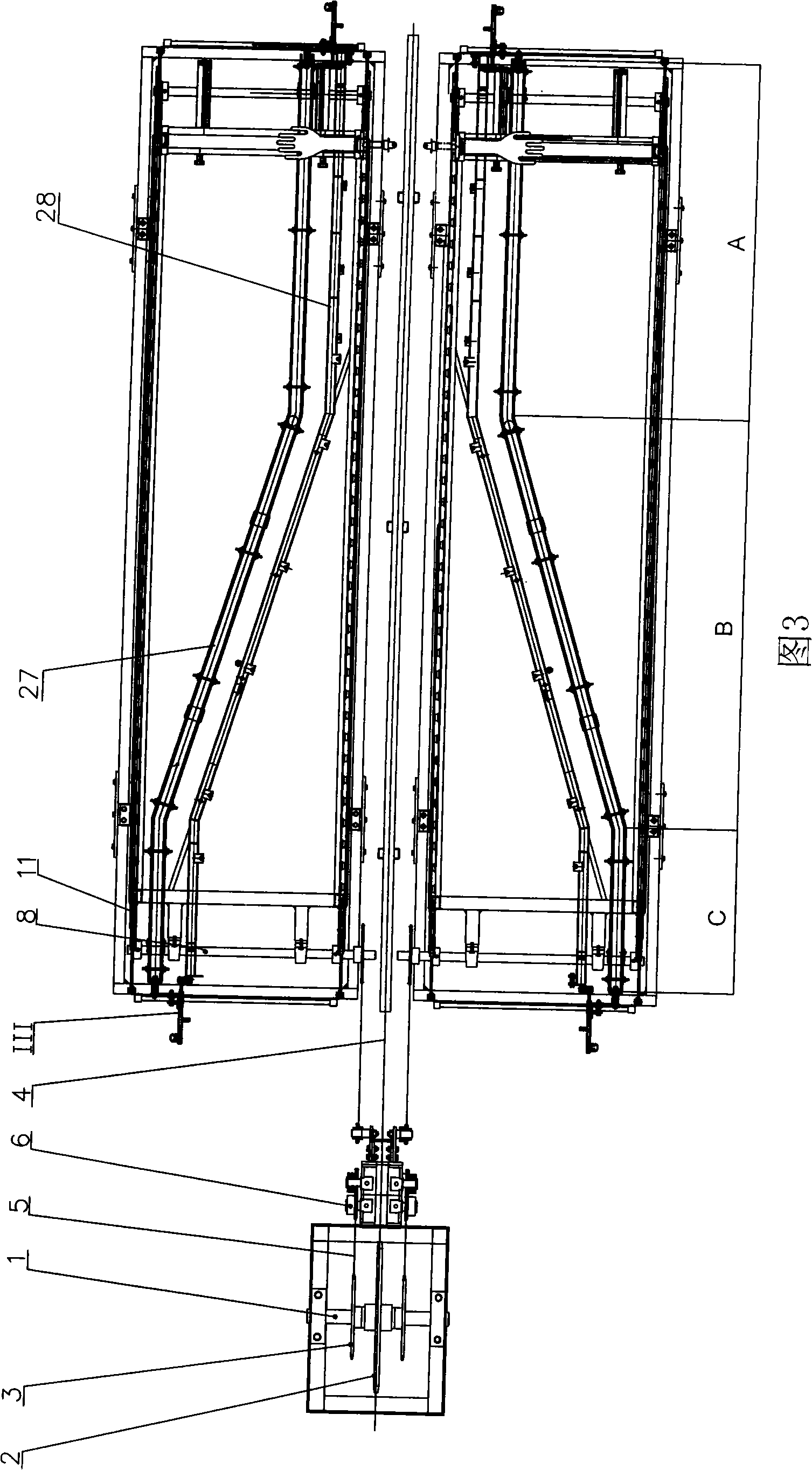

On-line automatic ingot stripper for glue gloves

The invention relates to a rubber glove online automatic demoulding machine, comprising a synchronous force grasping mechanism, a guide rail control mechanism, glove demoulding mechanisms, a glove blowing-aside mechanism and a glove blowing-down mechanism, wherein, a drive sprocket of the synchronous force grasping mechanism is engaged with a main drive chain for transmitting hand molds on a glove production line so as to transmit the power to the guide rail control mechanism; the glove demoulding mechanisms corresponding to the hand molds one by one are arranged on the guide rail control mechanism and can carry out circular movements of lengthwise synchronous moving, transverse separate moving and mechanical claw opening and closing, so as to complete the whole set of operations for glove demoulding; the glove blowing-aside mechanism and the glove blowing-down mechanism are respectively corresponding to the positions of initially grasping the hand mold and finally demoulding a glove by the mechanical claw, so that the glove can be blown to sleeve on the mechanical claw or blown down from the mechanical claw, thereby realizing full automation of glove demoulding. The rubber glove online automatic demoulding machine has quick demoulding speed, less operators, low cost, good product quality and high yield, and can completely replace manual operation.

Owner:杨志勇

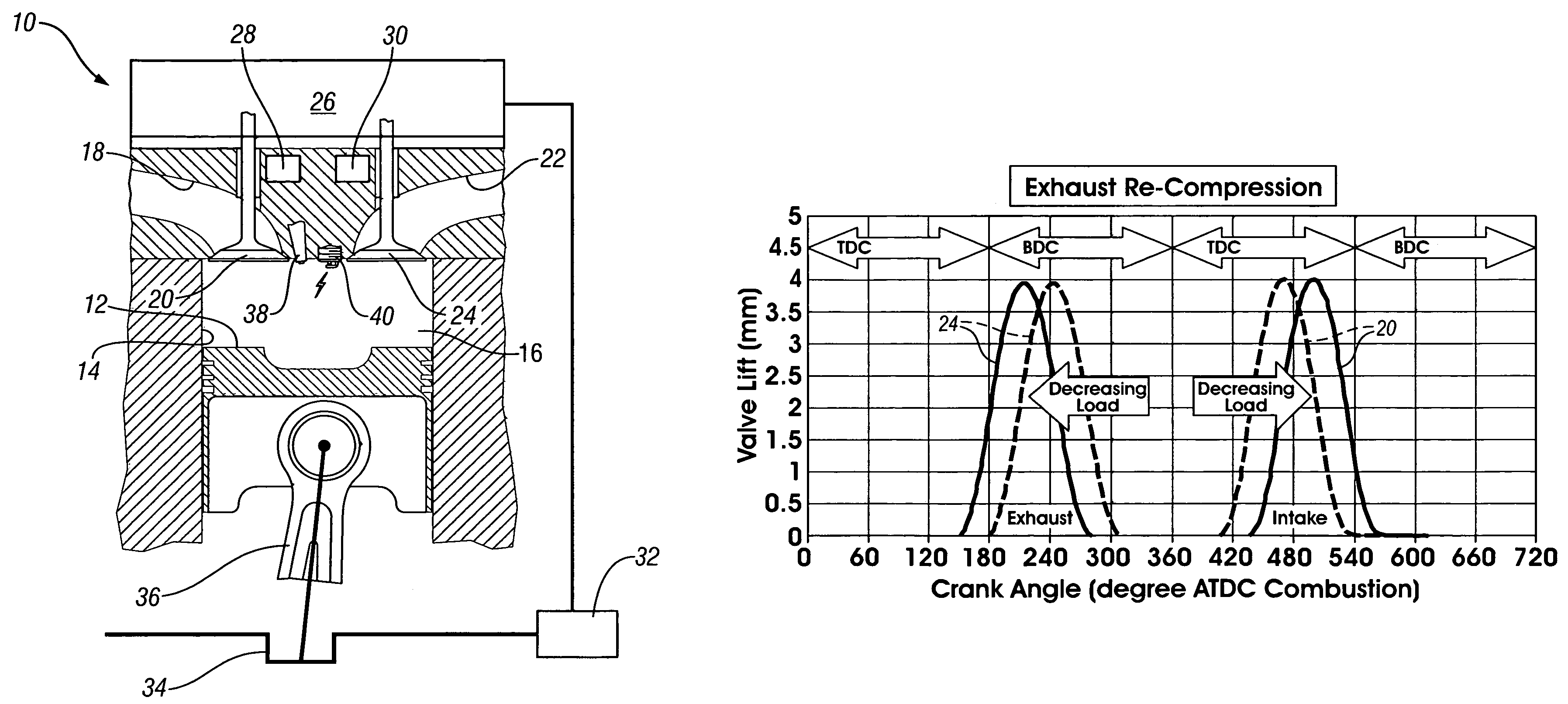

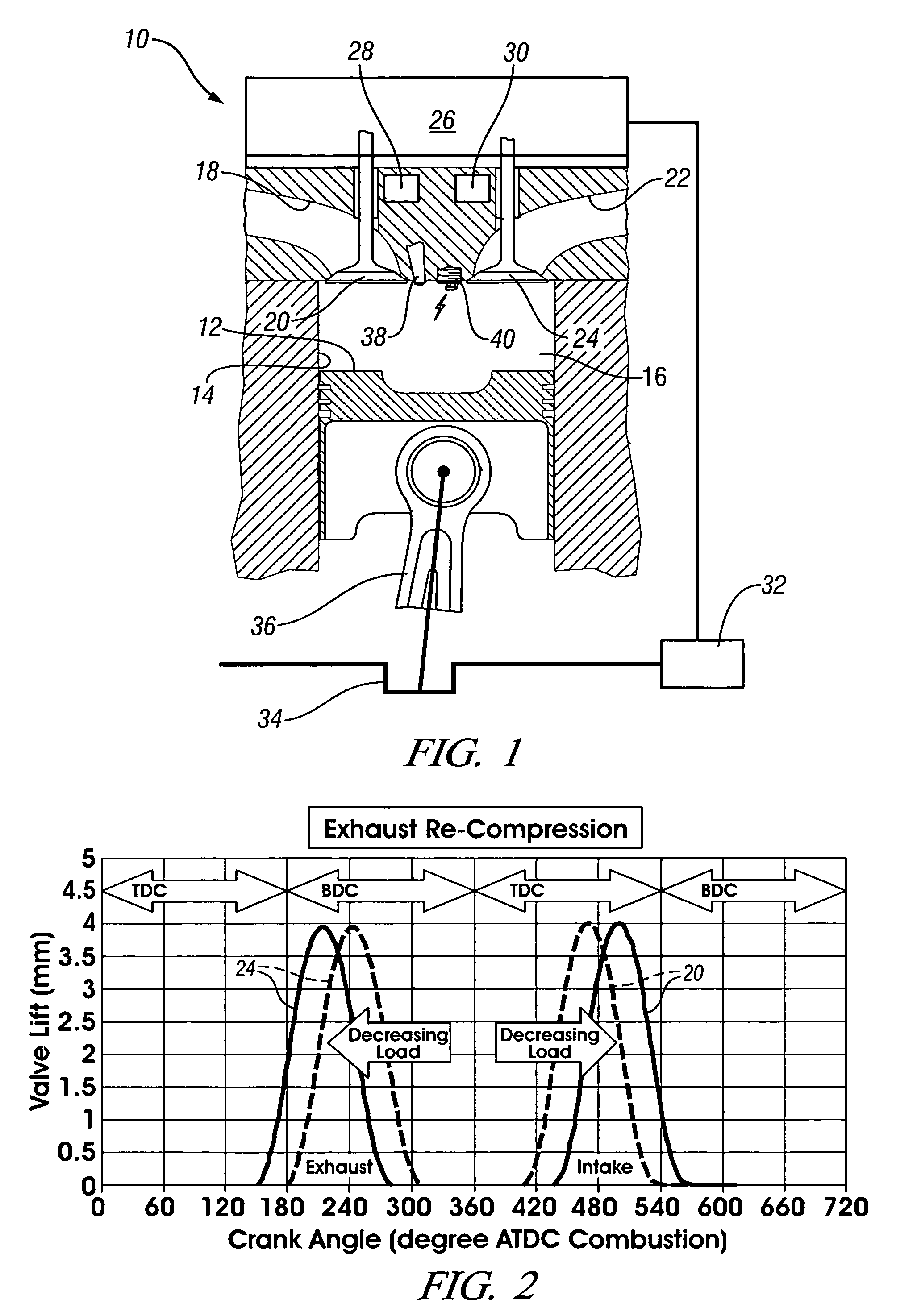

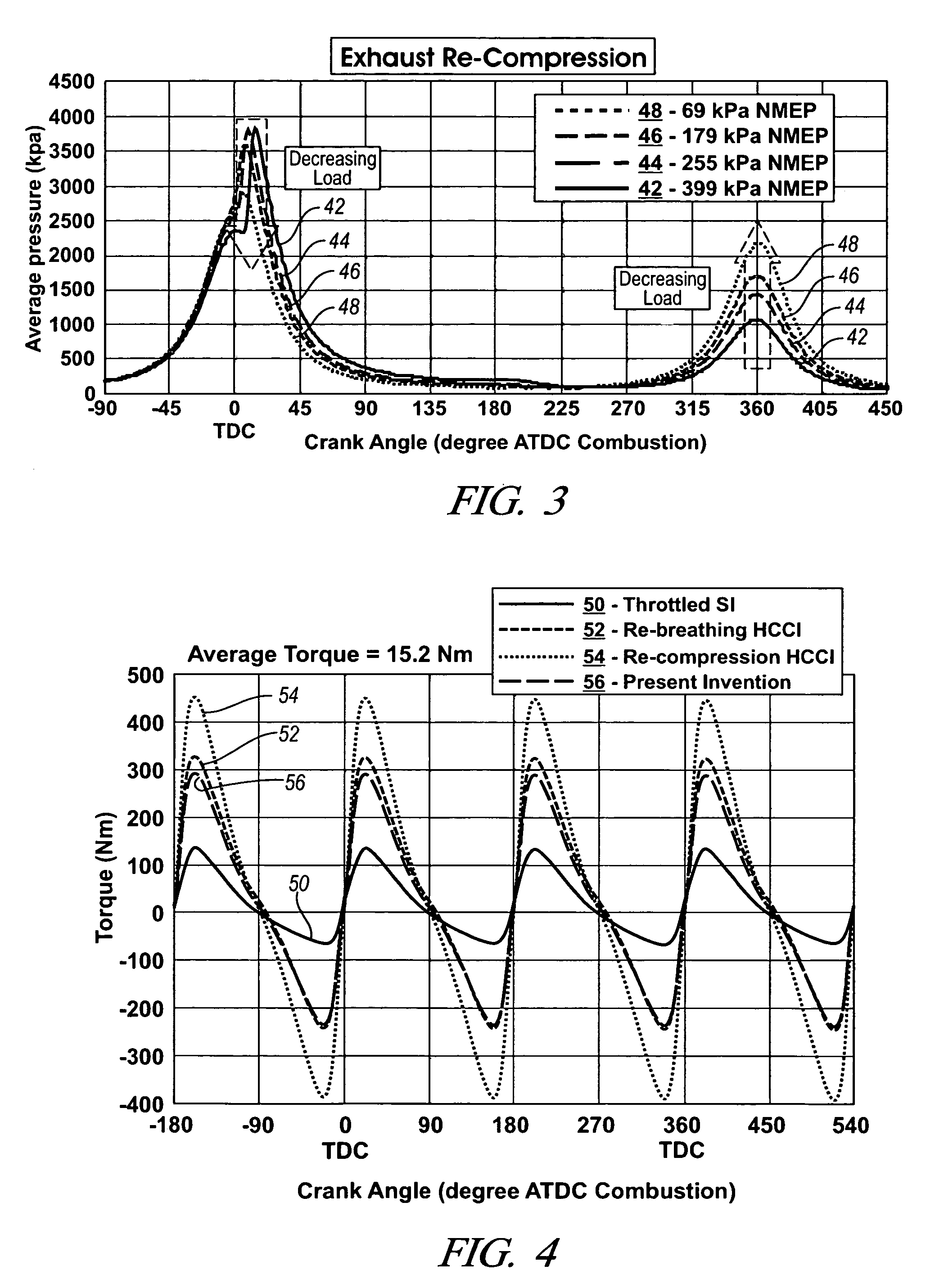

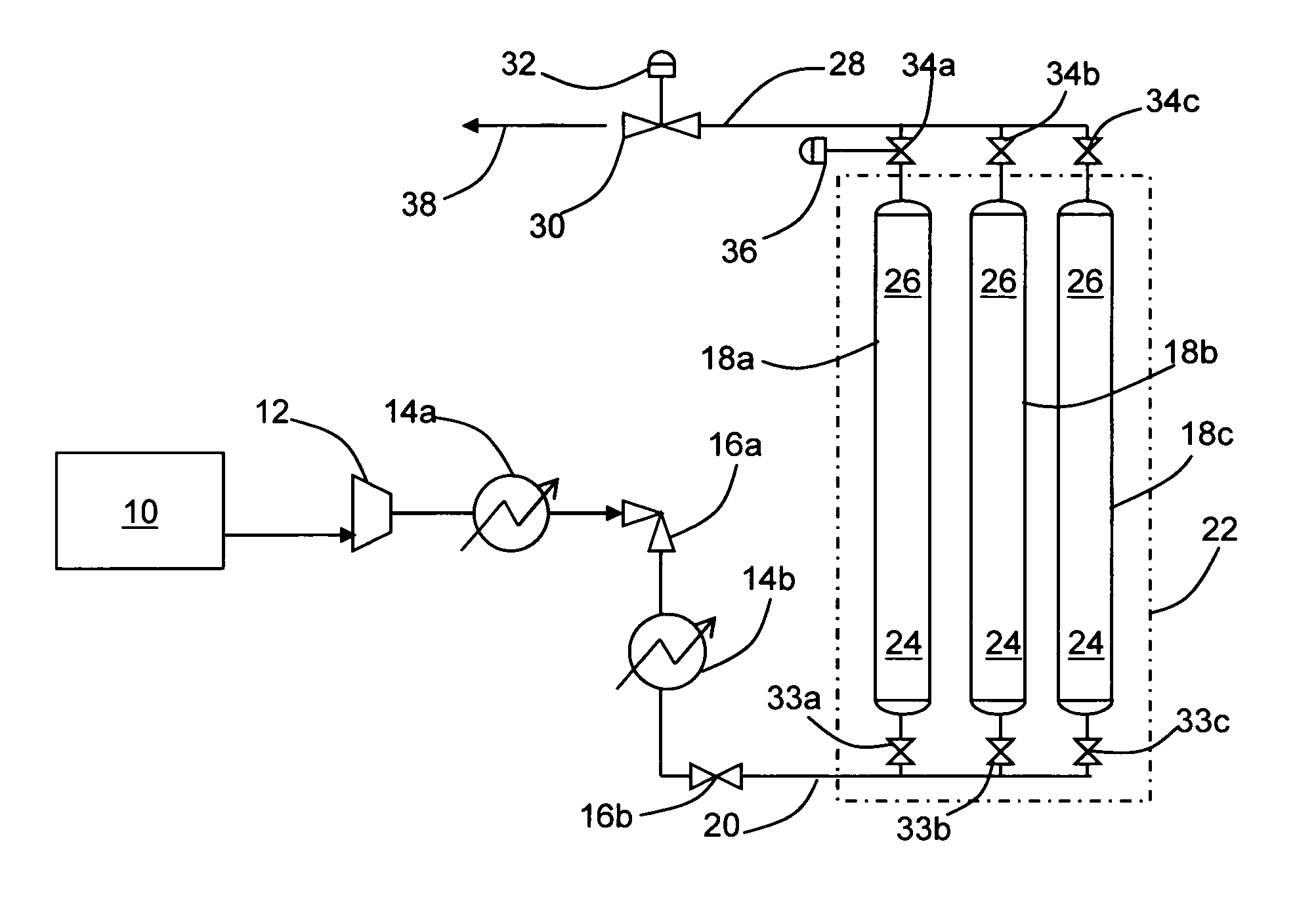

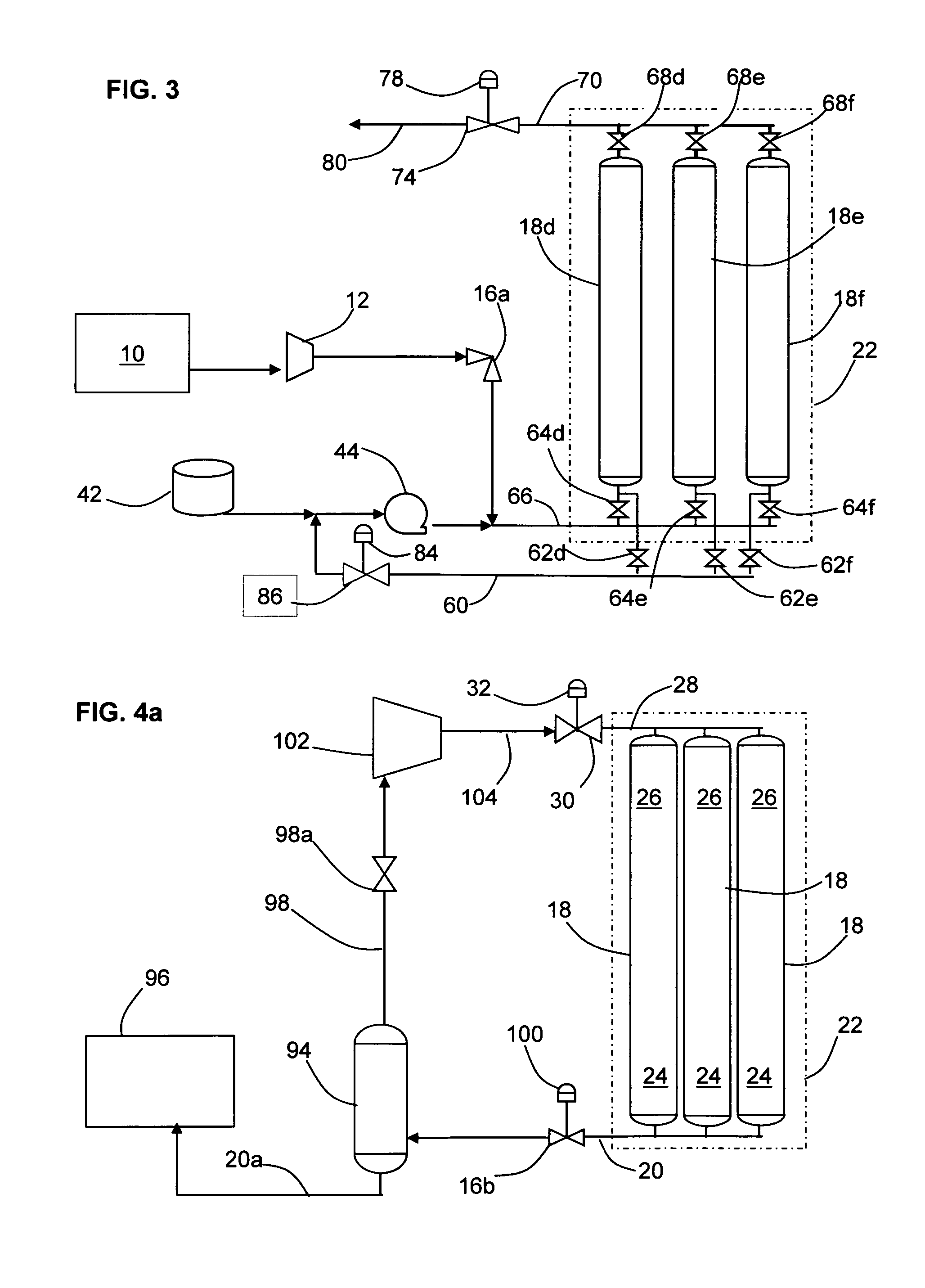

Four stroke engine auto-ignition combustion

ActiveUS7059281B2Electrical controlNon-fuel substance addition to fuelExhaust valveGasoline direct injection

A method of operating a four-stroke gasoline direct-injection controlled auto-ignition combustion engine includes opening both the intake and exhaust valves during terminal portions of the expansion strokes and initial portions of the contraction strokes, injecting fuel directly into the combustion chamber for mixing with retained gases and igniting the fuel near the ends of the contraction strokes. In the process, combustion gases are expanded to produce power during major portions of the expansion strokes, combusted gases are blown down into the exhaust outlet and the air inlet and are partially redrawn into the cylinder with fresh air during the terminal portions of the expansion strokes so the air charges are heated by the hot exhaust gases. Portions of the charges re-expelled and the remaining portions of the charges and injected fuel are compressed for ignition of the dilute fuel / air and exhaust gas mixture. Substantial reductions of NOx emissions result from the method.

Owner:GM GLOBAL TECH OPERATIONS LLC

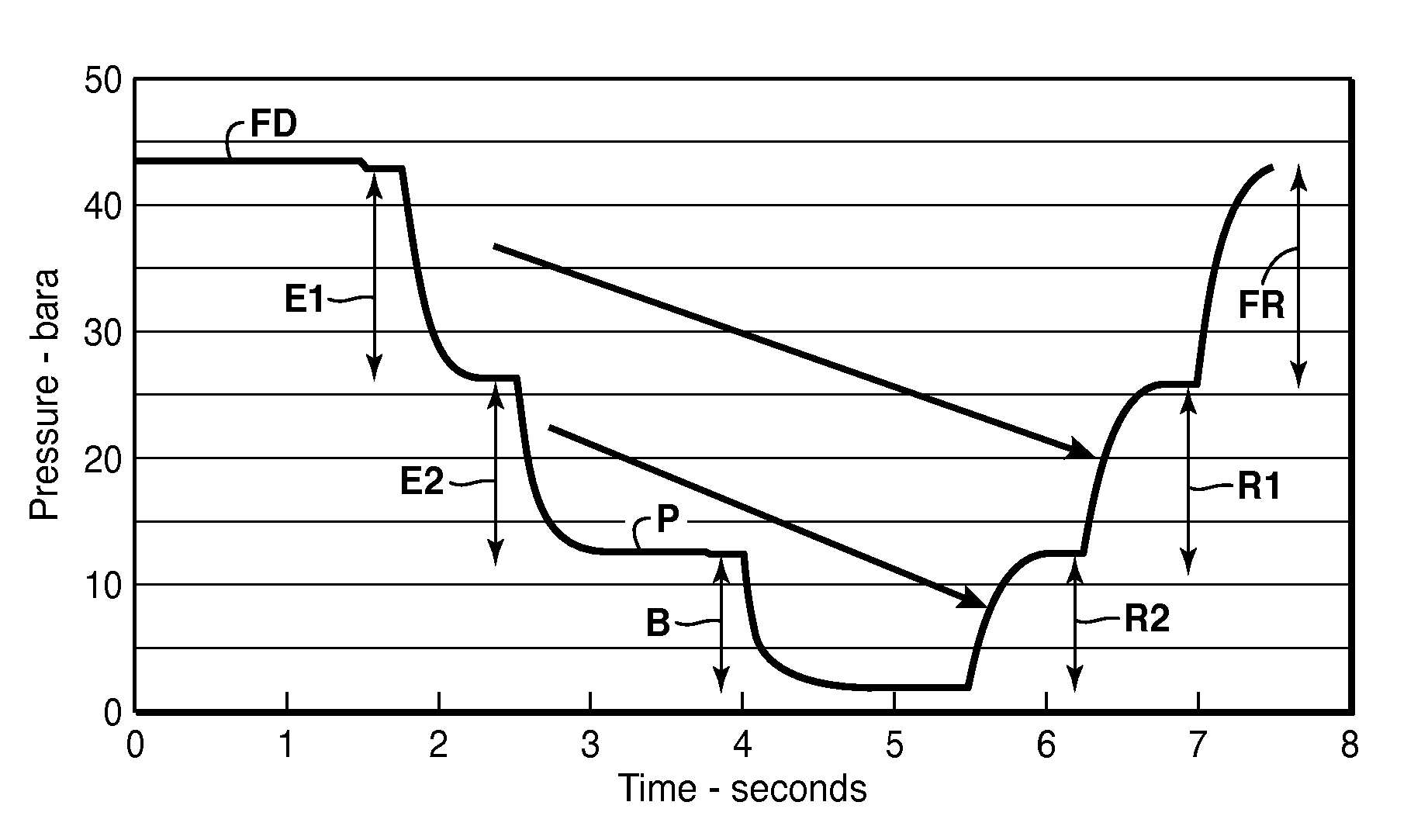

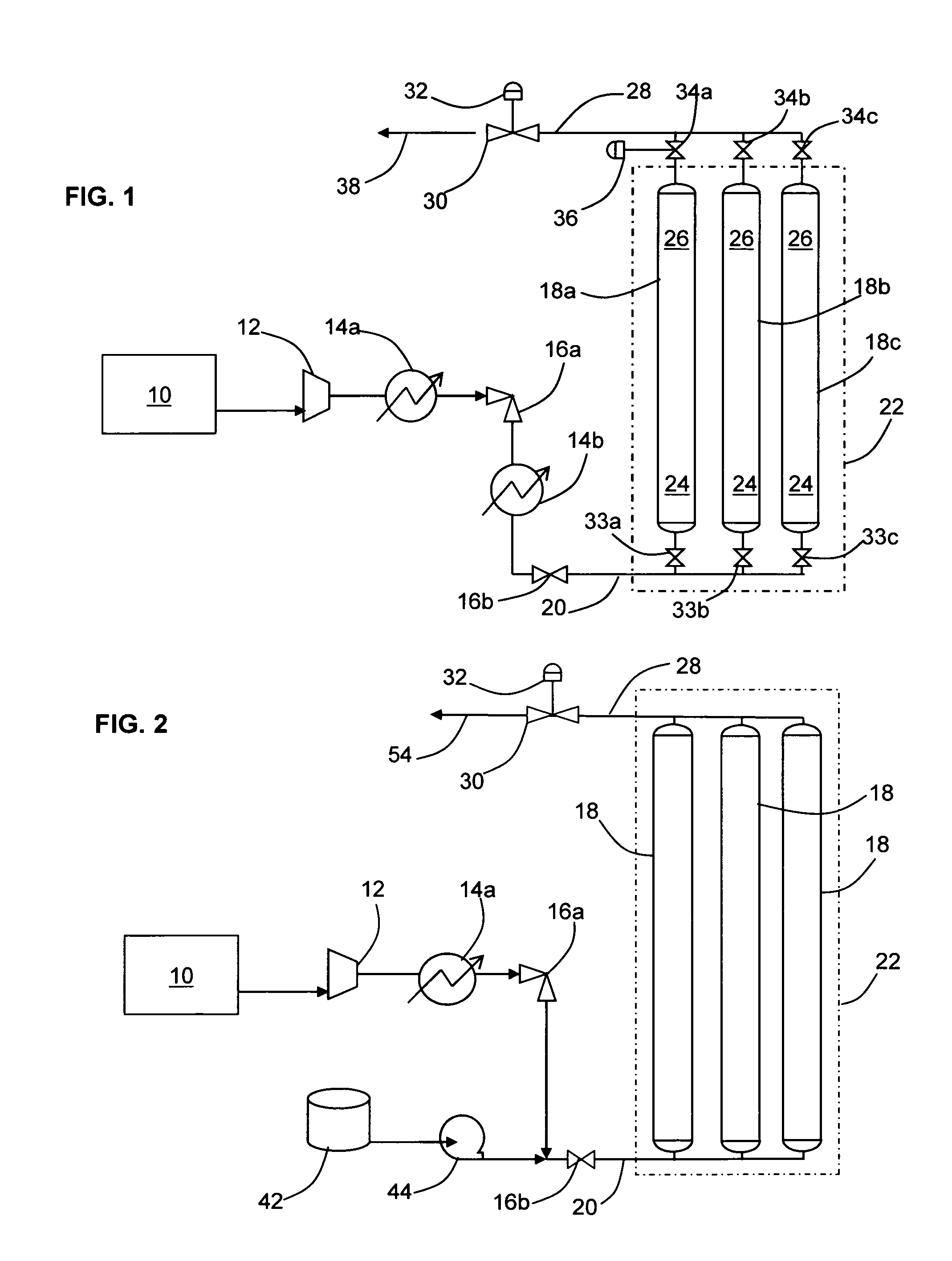

Apparatus and method for flowing compressed fluids into and out of containment

ActiveUS8281820B2Adjustable temperatureGas handling applicationsGas handling/storage effectsChemical compositionDifferential pressure

Methods for loading a compressed fluid, such as natural gas, into and discharging the compressed fluid out of containment are provided. The compressed fluid is injected into a bottom portion of a container system for storage and / or transport until a target pressure is reached after which gas is withdrawn from an upper portion of the container system at a rate to maintain the target pressure while the compressed fluid is injected in the bottom portion. The compressed fluid is cooled through an expansion valve and by refrigerated chillers or by injecting a cold liquid of the same chemical composition as the compressed fluid, such as liquid natural gas, into the compressed fluid prior to injection into the container system. Withdrawal or discharge from the container system to a receiving facility begins with blow down from the bottom portion of the container system without a displacement fluid and continues until pressure falls below an acceptable differential pressure. The discharge stream is passed through a separator and a light gas from the separator is pressurized and injected into an upper portion of the container system to drive the compressed fluid out the bottom. The light gas is pressurized using either a compressor or a heated tank system, where two vessels operate in parallel, trapping and heating the light gas and then discharging to the container system from one while filling the other and alternating the operation between the two.

Owner:WHITE CHARLES N +1

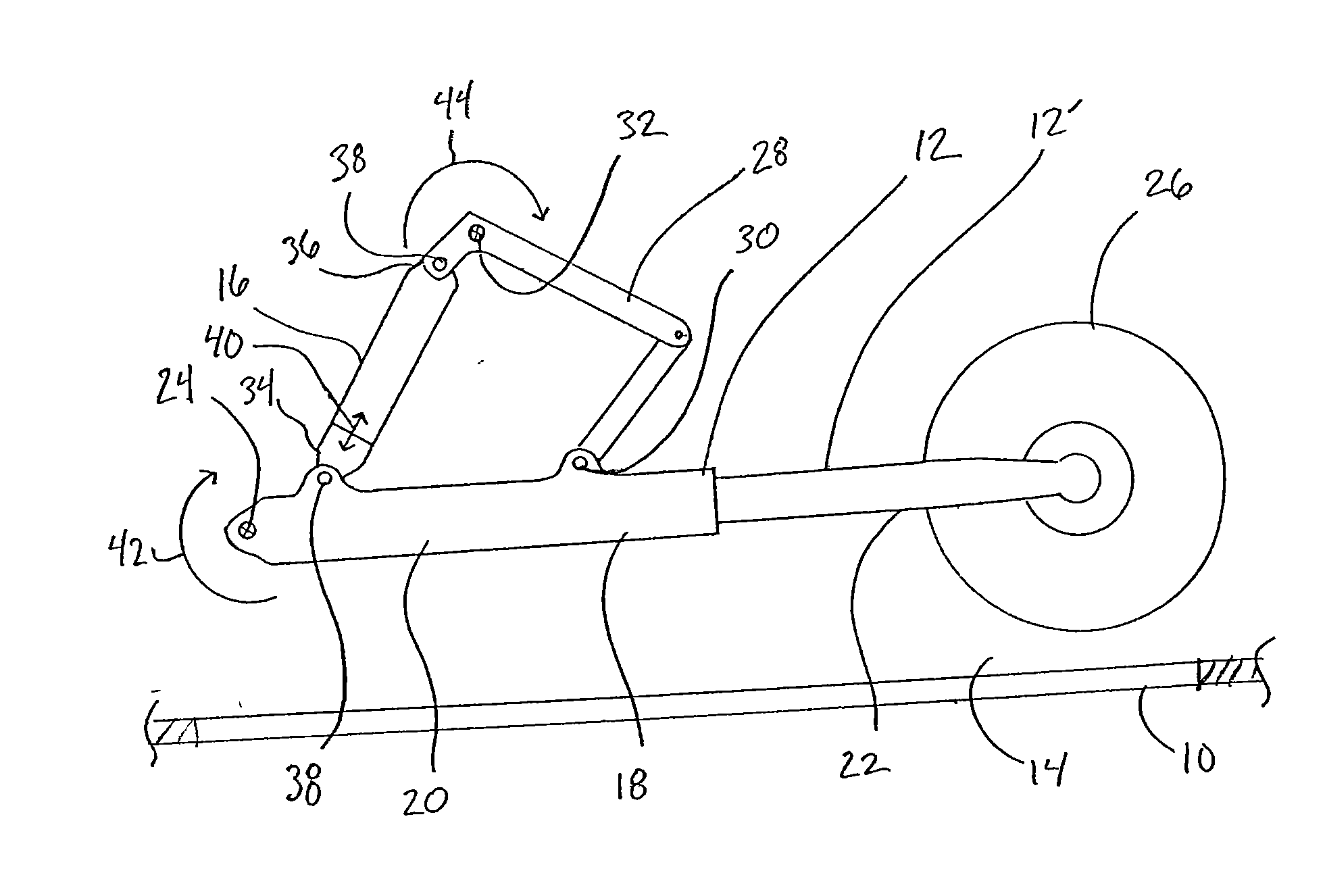

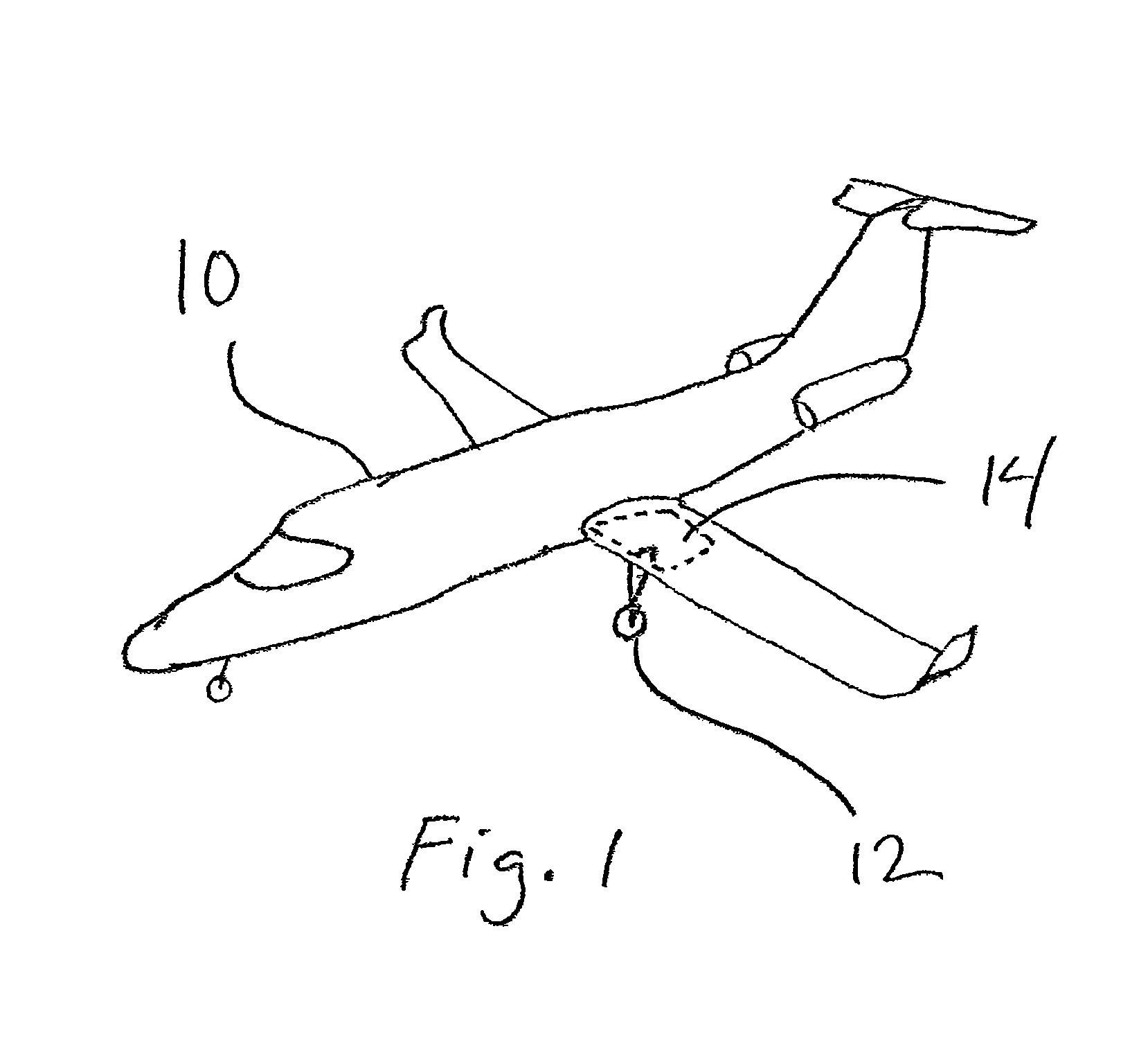

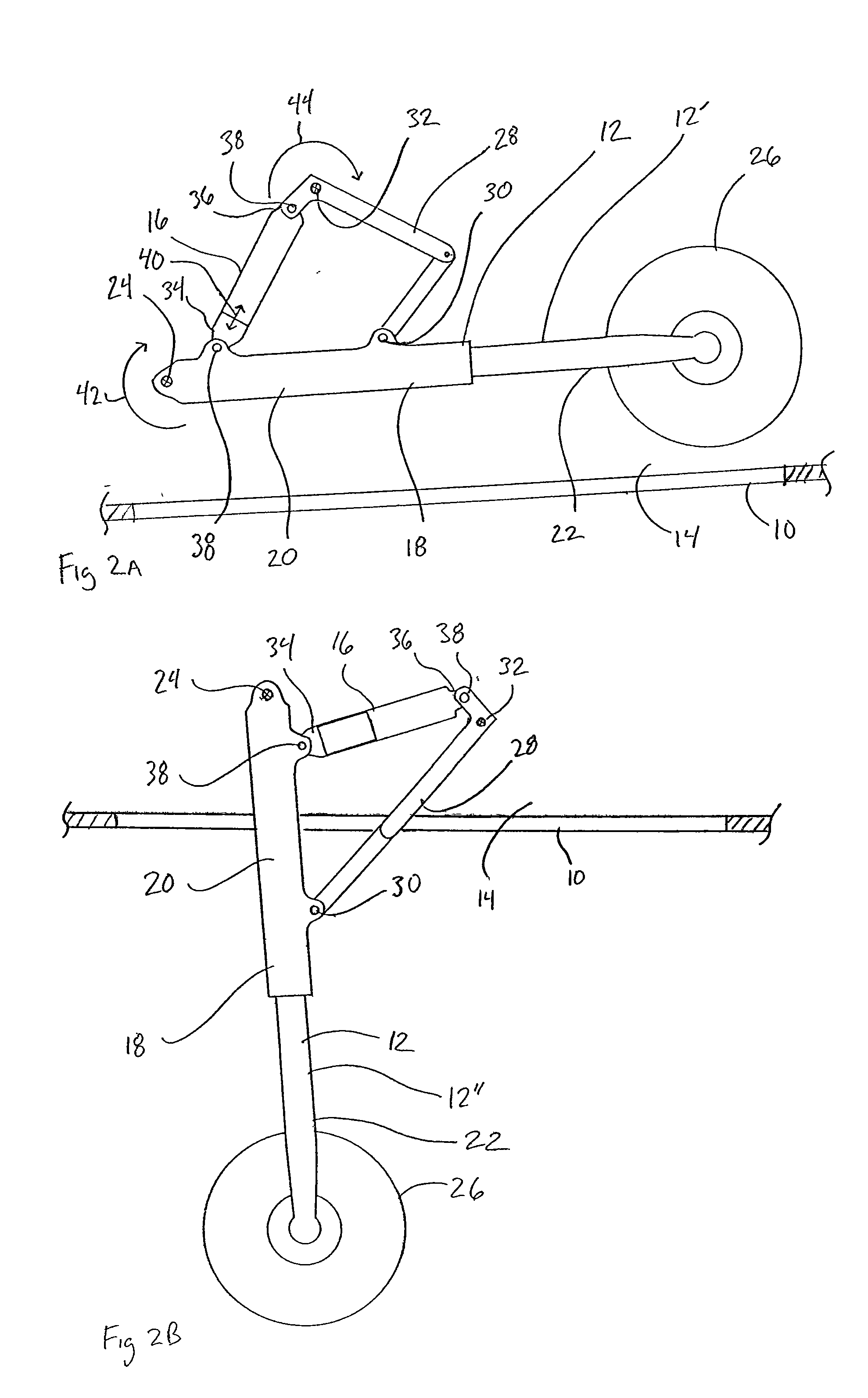

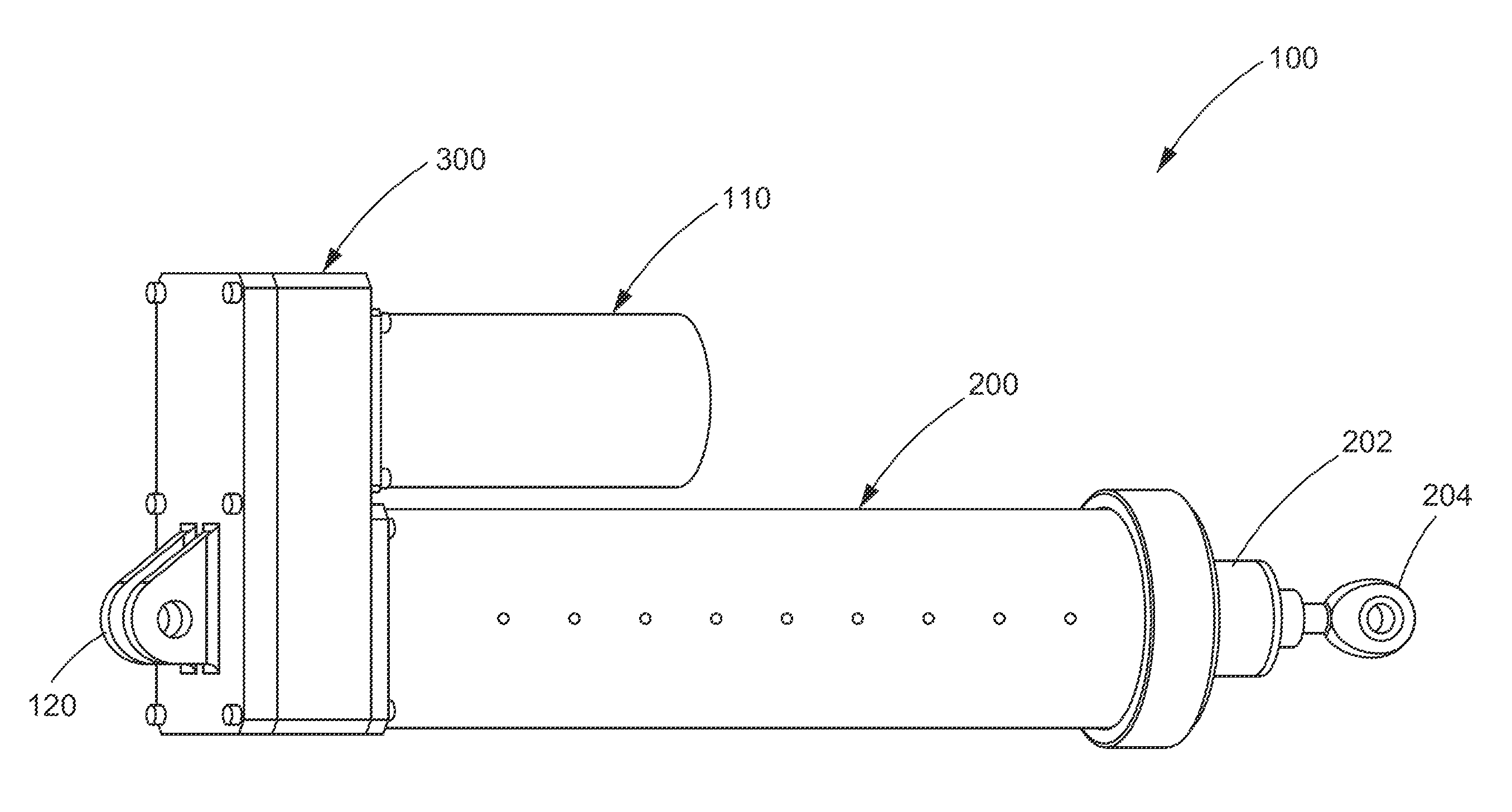

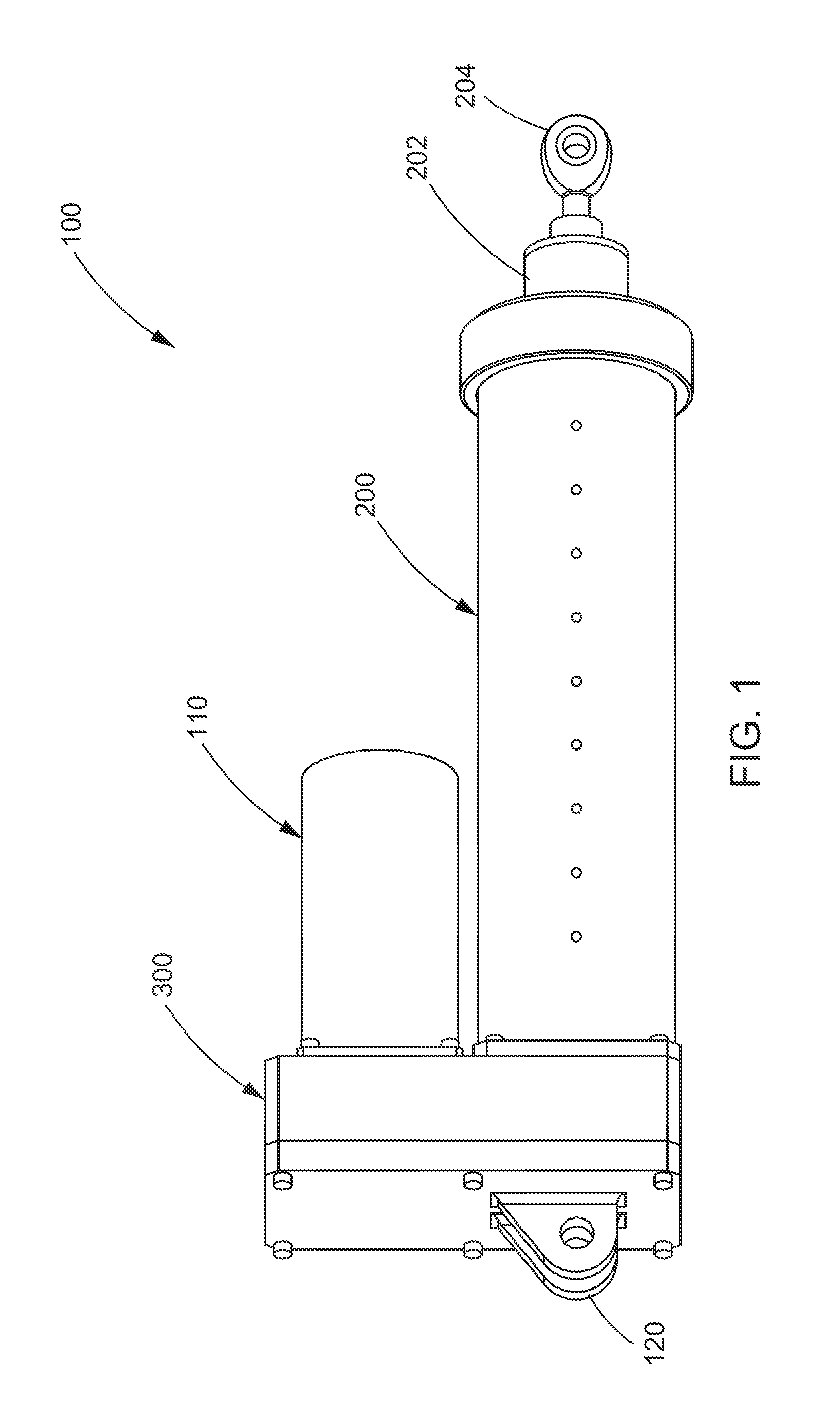

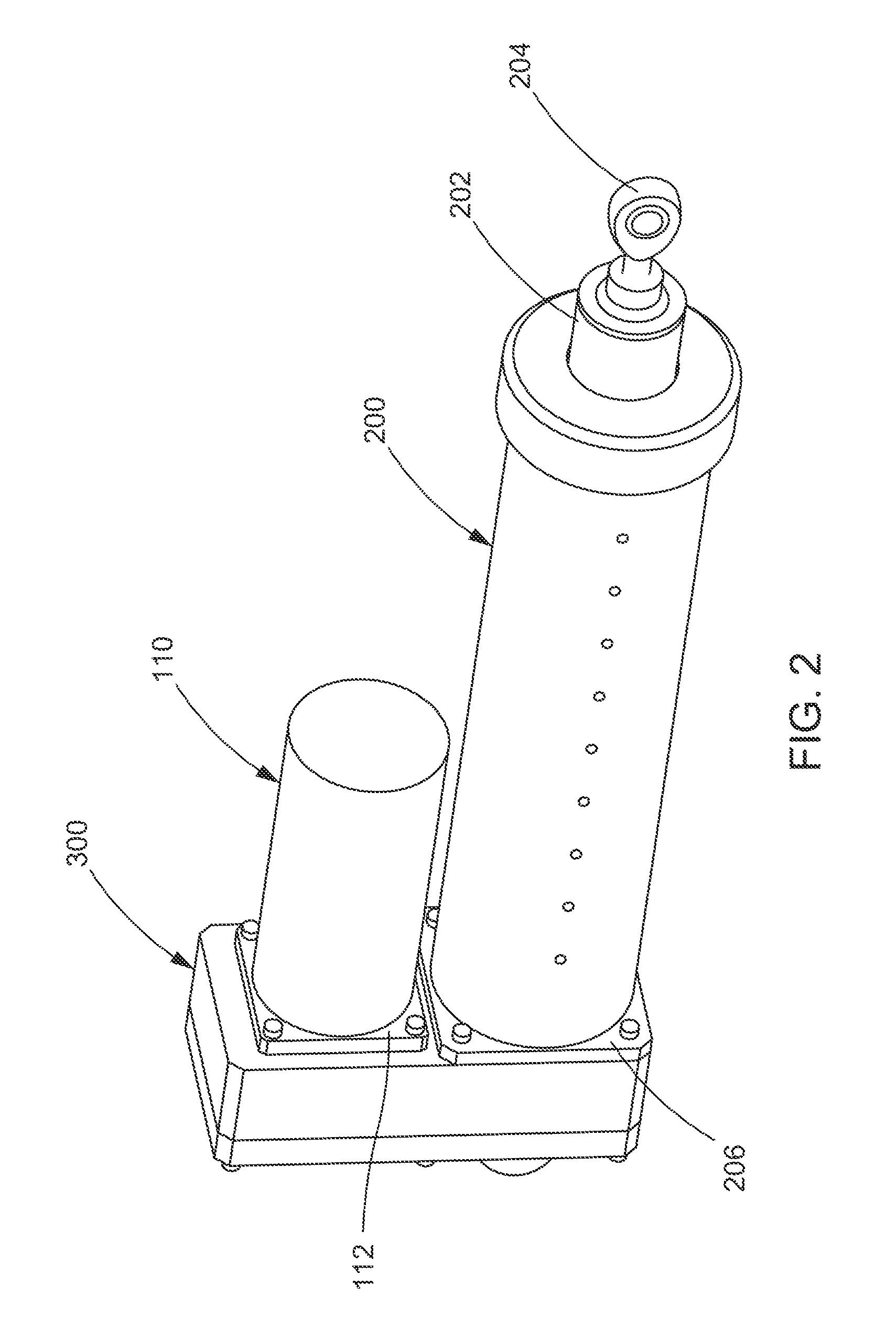

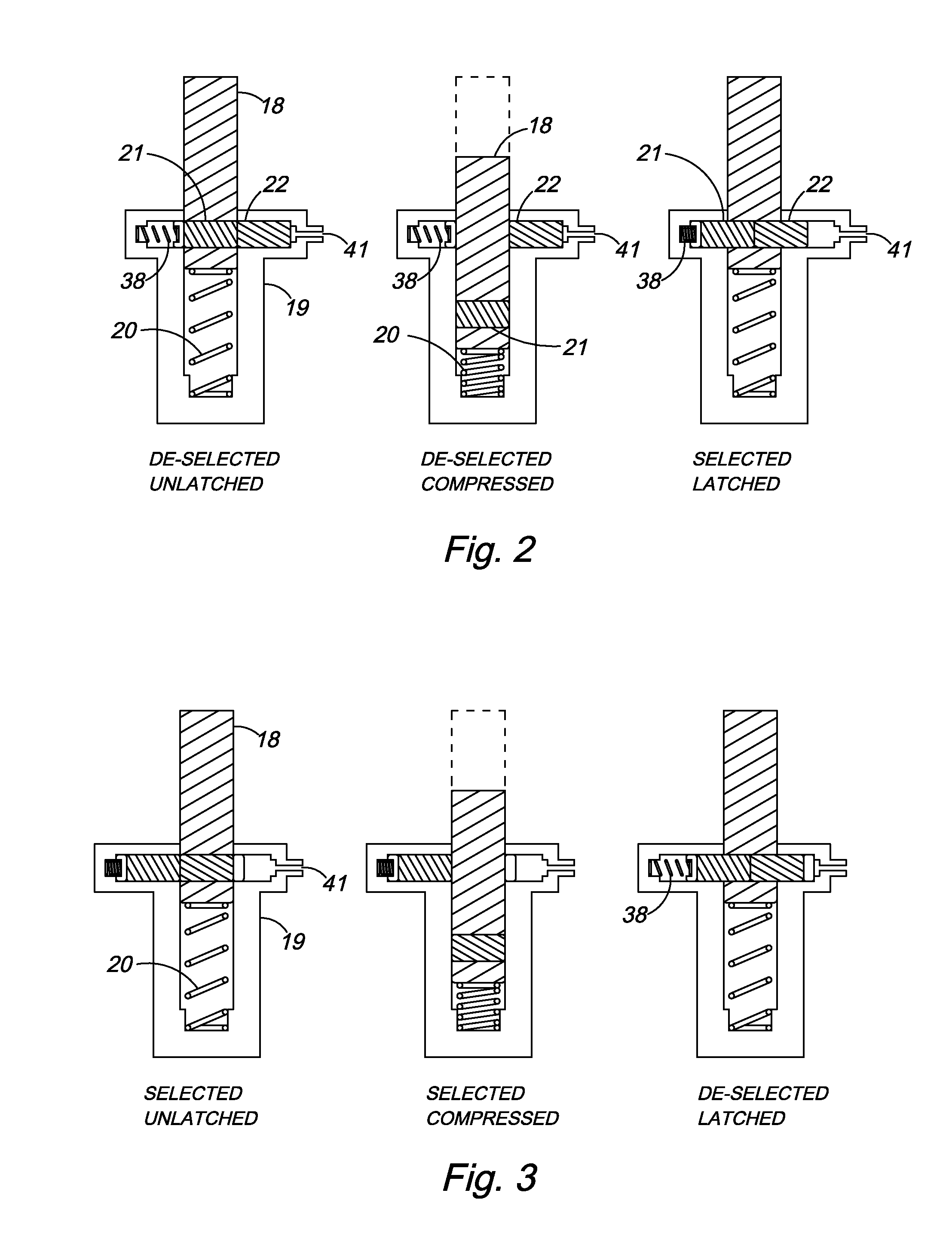

Pneumatic Blow-Down Actuator

An electromechanical linear actuator includes a pneumomechanical back-up system to ensure extension of retractable landing gear for landing an aircraft. Structurally, the linear actuator includes a stator forming a channel for receiving a ball screw. Further, the actuator includes a ball screw housing forming a chamber for receiving the ball screw. Specifically, the ball screw and the housing are in threaded engagement to translate rotation of the ball screw into axial extension of the housing. To power electromechanical extension of the actuator, the ball screw is selectively engaged to a motor with a gear train. Importantly, fluid communication between the ball screw housing and a pressurized fluid is selectively provided by a valve. If electromechanical extension of the actuator fails, the gear train is disconnected from the ball screw and the pressurized fluid is introduced into the chamber to drive pneumomechanical extension.

Owner:SPECTRUM AERONAUTICAL

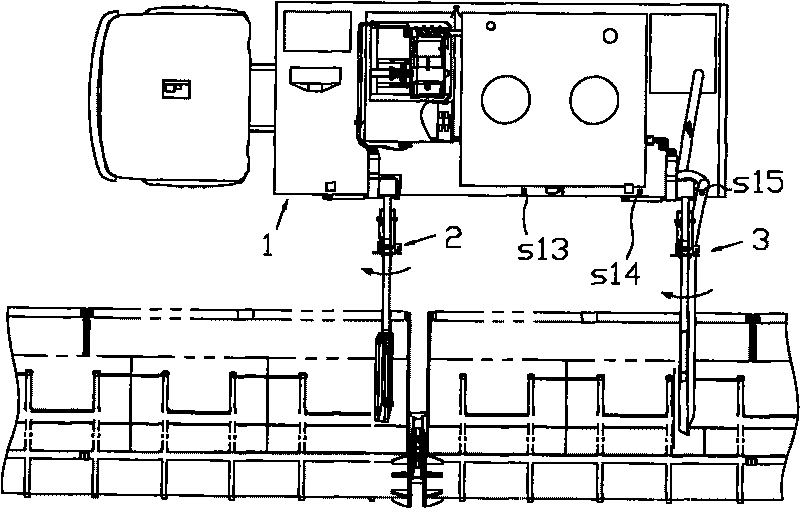

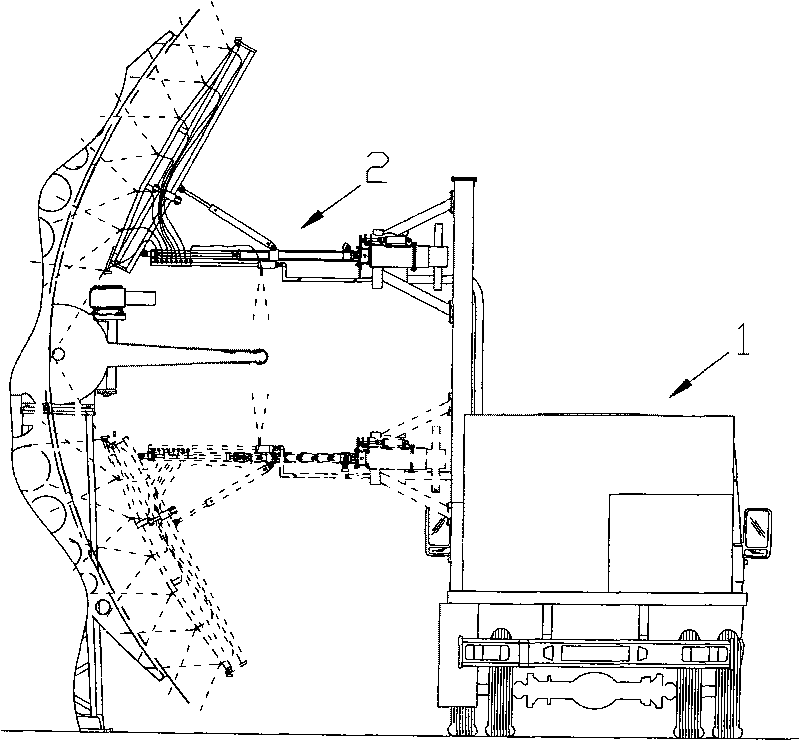

Sewer flushing vehicle for grooved type solar thermal power generating thermal collectors

The invention discloses a sewer flushing vehicle for grooved type solar thermal power generating thermal collectors. The sewer flushing vehicle comprises a vehicle body, a cleaning system and a blow-drying system, wherein the vehicle body comprises a driving cab and a chassis, the cleaning system arranged on the chassis is used for cleaning glass and thermal collecting tubes of the grooved type solar thermal power generating thermal collectors, and the blow-drying system arranged on the chassis is used for blow-drying of the cleaned grooved type solar thermal power generating thermal collectors by aid of hot air at a certain temperature. By aids of the cleaning system and the blow-drying system, the thermal collectors can be dried under high temperature after finishing cleaning, impurities such as dust and the like are not easy to be attached. Particularly in cold winter when washed water can be frozen, by utilizing a fast blow-drying function of the sewer flushing vehicle, the cleaned thermal collectors can be dried fast through a high-flow high-pressure vortex fan with certain temperature raise, and then the sewer flushing vehicle can be operated normally instantly. Besides, accumulated snow remaining on thermal collector condenser lenses and the thermal collecting tubes of the thermal collectors in winter can be blown down forcedly by the sewer flushing vehicle.

Owner:中金盛唐新能源科技(北京)有限公司

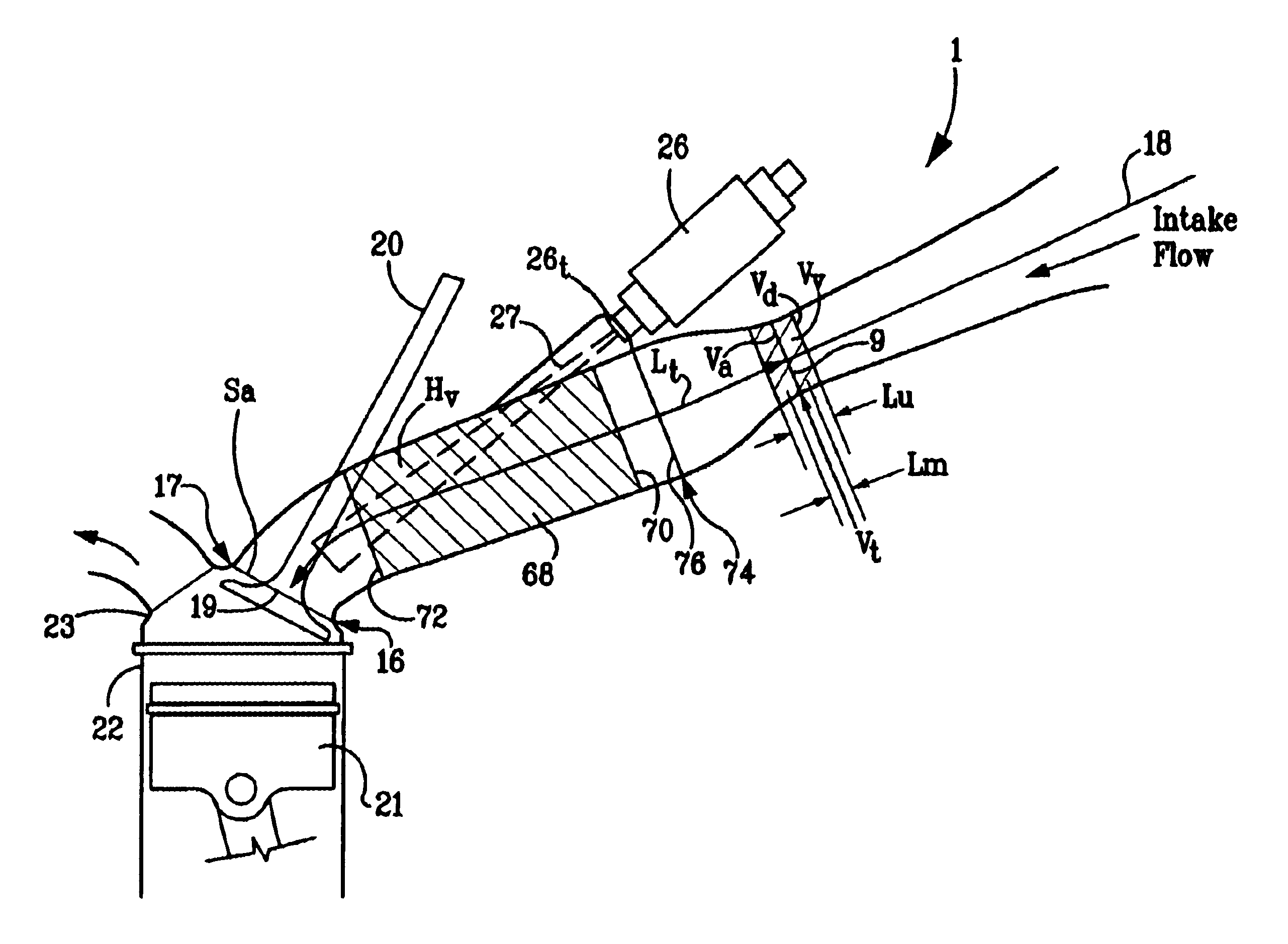

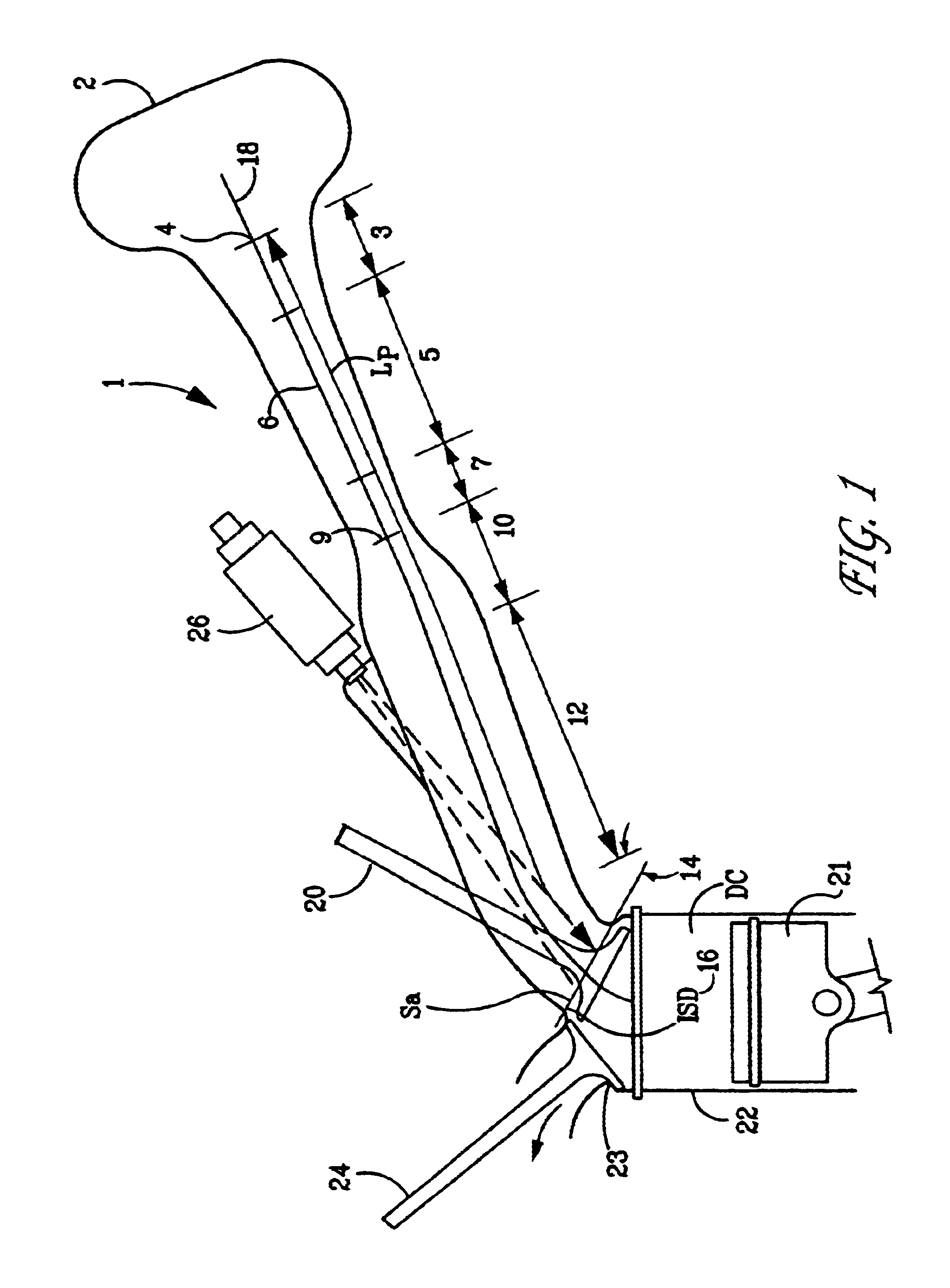

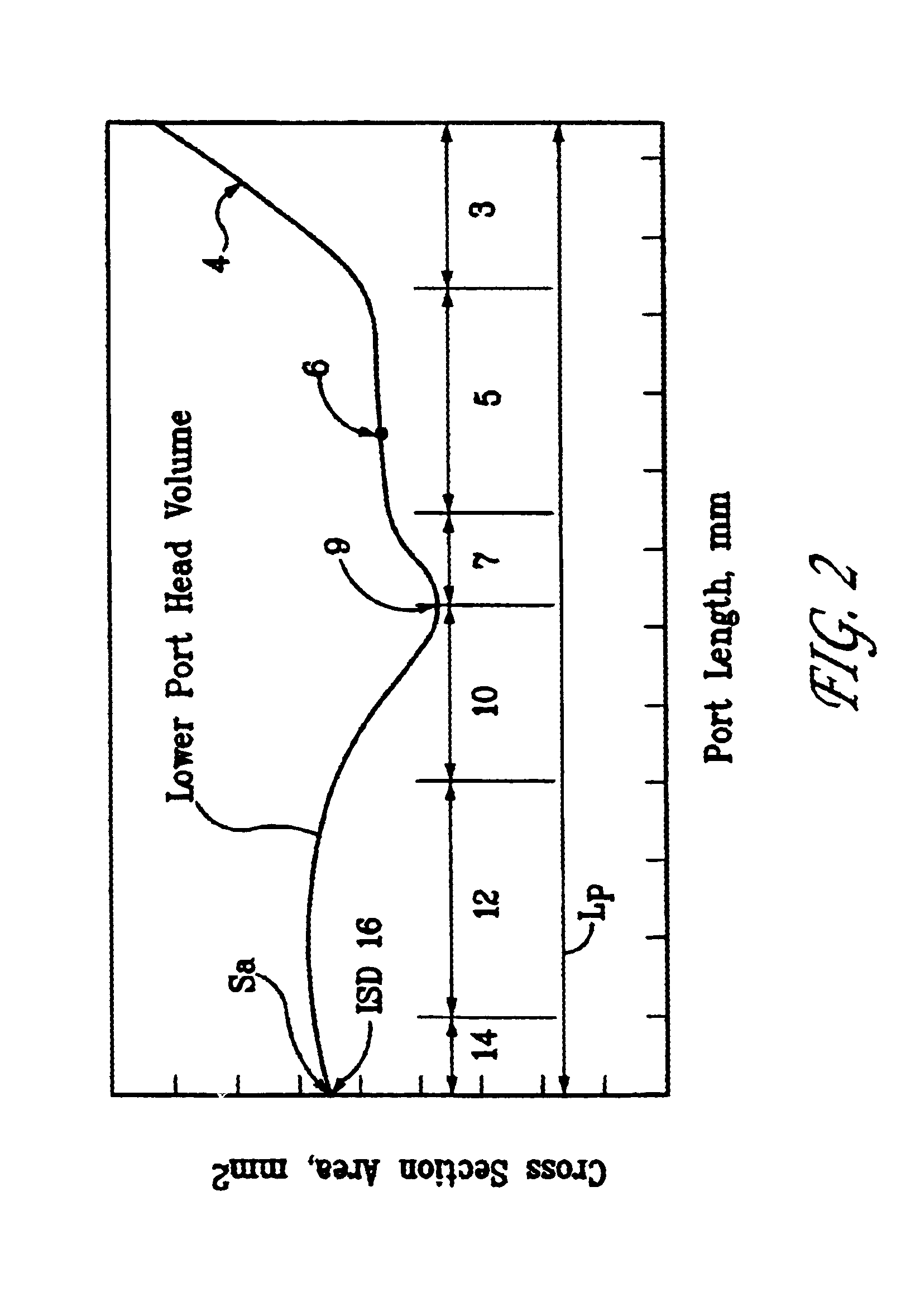

Intake port

InactiveUS6848408B1Efficient processMinimal lossInternal combustion piston enginesAir intakes for fuelCombustionInlet valve

The volumetric efficiency and power of internal combustion engines is improved with an intake port having an intake nozzle, a venturi, and a surge chamber. The venturi is located almost halfway upstream the intake port between the intake valves and the intake plenum enabling the venturi throat diameter to be exceptionally small for providing an exceptionally high ram velocity and an exceptionally long and in turn high efficiency diffuser flowing into the surge chamber. The intake port includes an exceptionally large surge chamber volume for blow down of the intake air into the working cylinder of the engine.

Owner:MENDLER EDWARD CHARLES

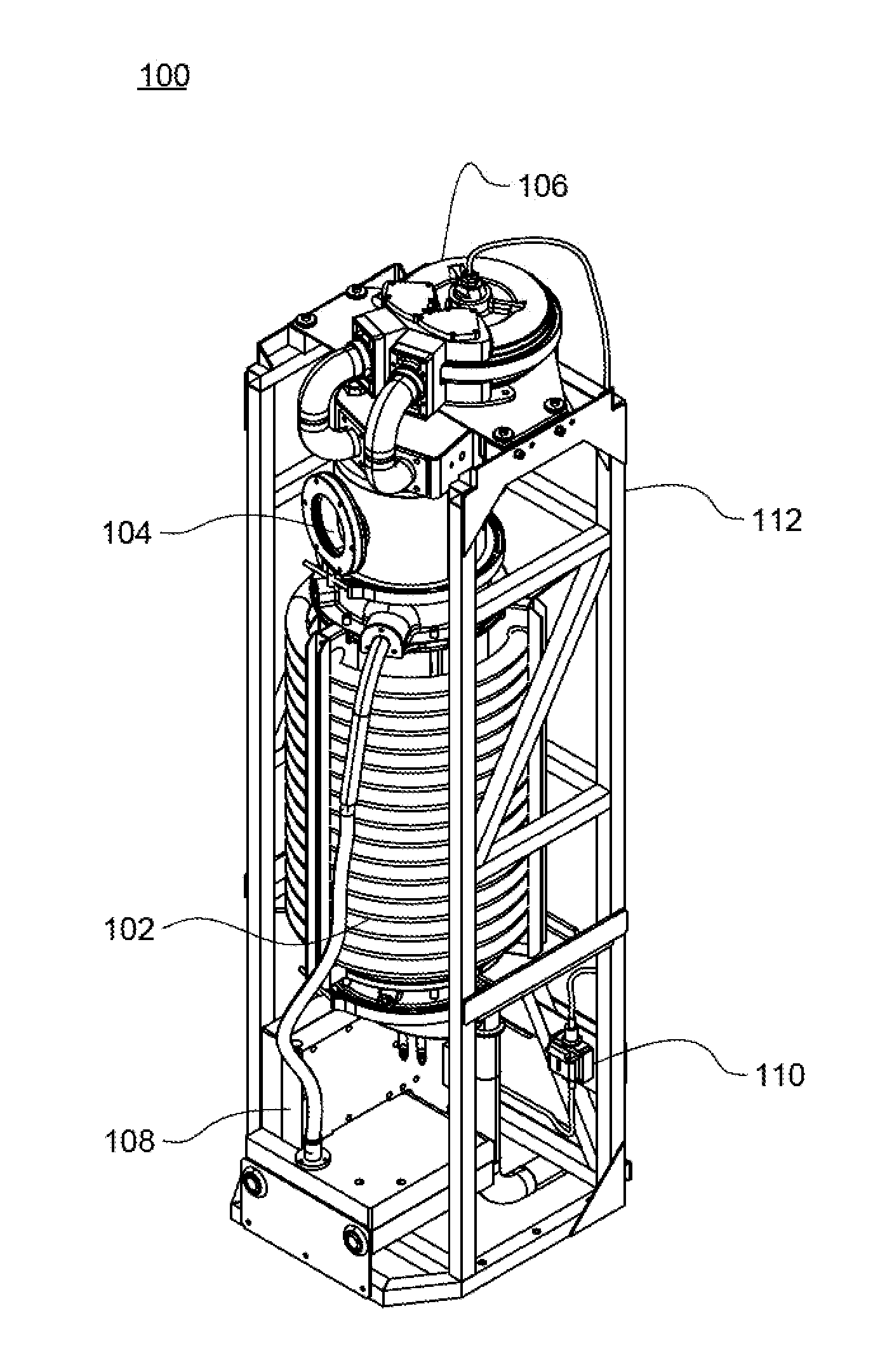

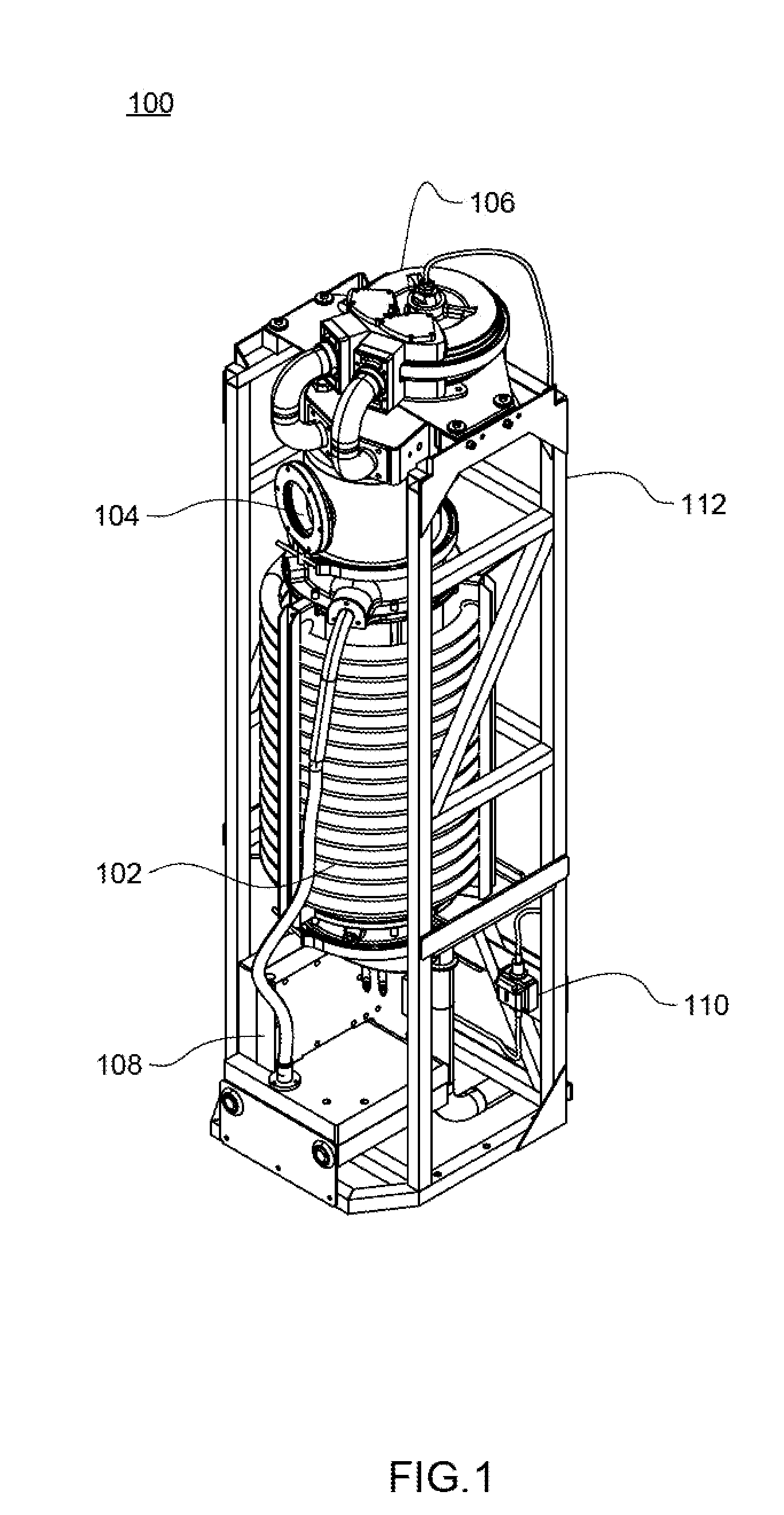

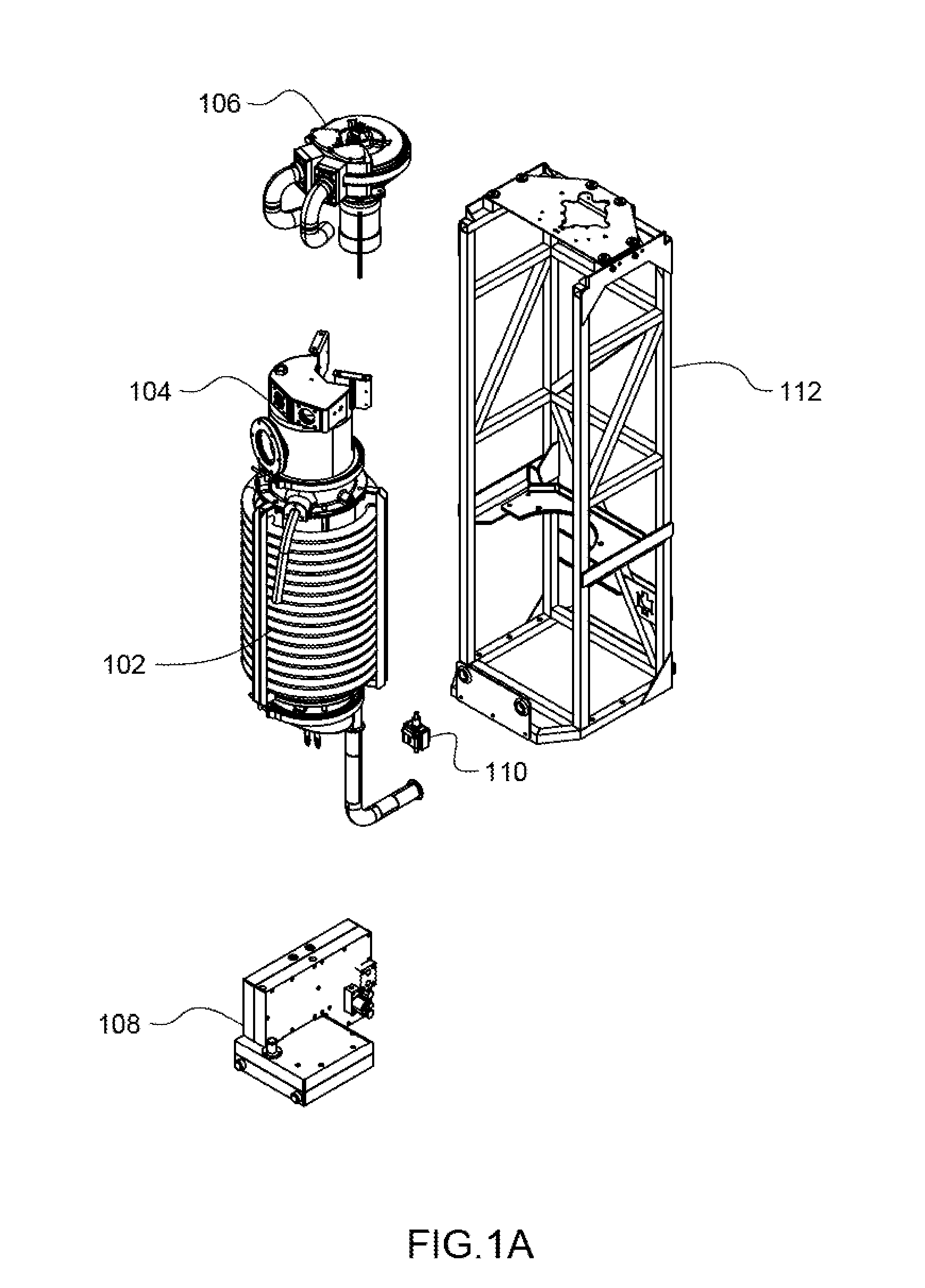

Water Vapor Distillation Apparatus, Method and System

ActiveUS20140183025A1Water treatment parameter controlDistillation regulation/controlWater vaporControl system

A fluid vapor distillation system. The system includes a control system for controlling a fluid vapor distillation apparatus including a blow down controller for controlling a blow down valve, a source flow controller for controlling a source flow valve, and a blow down level sensor in communication with a blow down controller and a source flow controller, the blow down level sensor sends signals related to the blow down level to the blow down controller and the source flow controller indicative of the blow down level, wherein the source flow controller actuates the source flow valve based at least on the blow down level sensor signals, and wherein the blow down controller actuates the blow down valve based at least on the blow down level sensor signals, whereby the blow down level and the source flow level are maintained using the blow down level sensor signals as input.

Owner:DEKA PROD LLP

Blow Down Actuator Assembly

An actuator assembly includes an actuation member, a release member, and a source of pressurized gas, wherein during a normal mode of operation, the actuation member and the release member are engaged to move in unison, and wherein during an emergency mode of operation, pressurized gas automatically decouples the actuation member from the release member to move separately. In accordance with yet other aspects of the present disclosure, an electro-mechanical actuator includes an electro-mechanical drive system and an integrated backup system operated by a gas generator, wherein when the backup system is activated, the electro-mechanical drive system is decoupled and the actuator moves to a predetermined position and mechanically locks in place.

Owner:AEROCONTROLEX GROUP

Equipment for automatically peeling, decoring and splitting fruit and method for automatically controlling equipment

InactiveCN101690605AAvoid damageNo loss of qualityFruit stoningProgramme control in sequence/logic controllersAutomatic controlPesticide residue

The invention relates to equipment for automatically peeling, decoring and splitting fruit and a method for automatically controlling the equipment, aiming at overcoming the defects that the prior equipment using a steel needle damages the pulp and reduces the quality of the pulp or causes the fruit to be processed for the second time and the pulp to be more easily subjected to cross pollution by pesticide residue. The equipment comprises a stand, a main shaft assembly, a main shaft rotating motor, a peeling knife assembly, a fruit decoring and splitting slotting tool assembly, an air control circuit and a control circuit. The method for automatically controlling the equipment comprises the following steps: the fruit is adsorbed on a main shaft suction nozzle; the vacuum degree in a pipe is raised; signals are sent by a pressure sensor and then are transmitted to a programmable logic controller (PLC) to start the main shaft rotating motor and a cutter shaft rotating shaft; and the peeling knife assembly is controlled by the PLC to peel the fruit and the fruit decoring and splitting slotting tool assembly is controlled by the PLC to decore and split the fruit and blow down the fruit on the main shaft suction nozzle through the signals sent by three proximity switches which are sequentially arranged at the periphery of an upright shaft.

Owner:哈尔滨特宝能源技术服务有限公司

Selective Compound Engine

InactiveUS20090301086A1Improve fuel efficiencyReduce cylinder compression ratioCombustion enginesHot gas positive displacement engine plantsExhaust valveFuel efficiency

The fuel efficiency of an internal combustion reciprocating piston engine may be increased through selective secondary expansion of exhaust gas in the engine cylinders in order to recover exhaust gas energy which is otherwise wasted by cylinder blow-down at the end of the power stroke. Exhaust valve cam switching, intake valve deactivation, multiple exhaust valves, a specialized exhaust manifold arrangement and an exhaust gas diverter valve can be configured to enable a reciprocating engine to selectively operate in efficient eight stroke cycle compound mode when moderate engine power is demanded, then revert to conventional four stroke cycle non-compound mode operation when high engine power is demanded, without stopping the engine. For a road vehicle application, the benefit is substantially reduced highway cruising fuel consumption, while incurring minimal impact on engine weight, minimal impact on engine manufacturing cost, and no adverse impact on vehicle acceleration performance, hill climbing performance or trailer towing performance.

Owner:RALSTON MARK DIXON

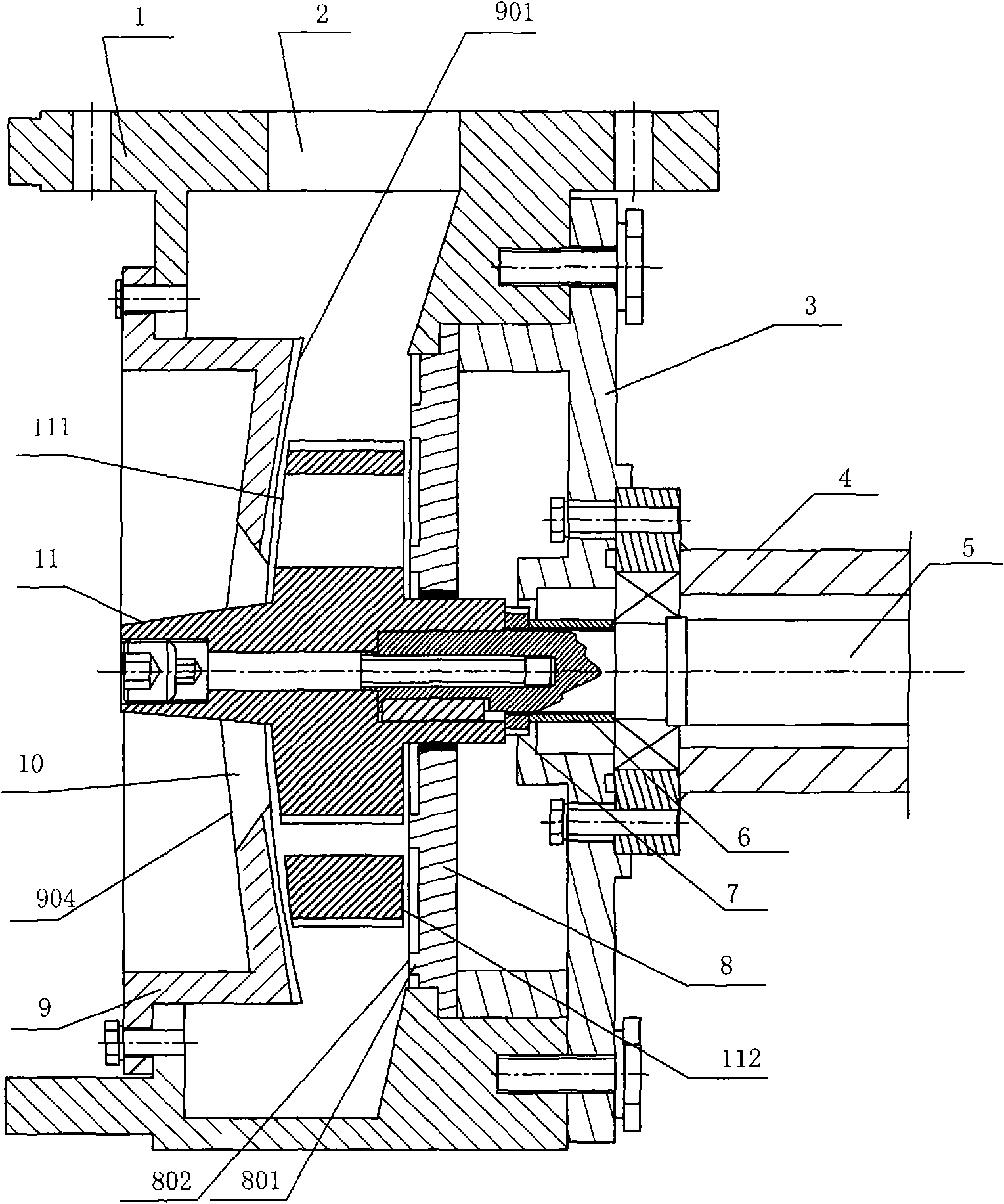

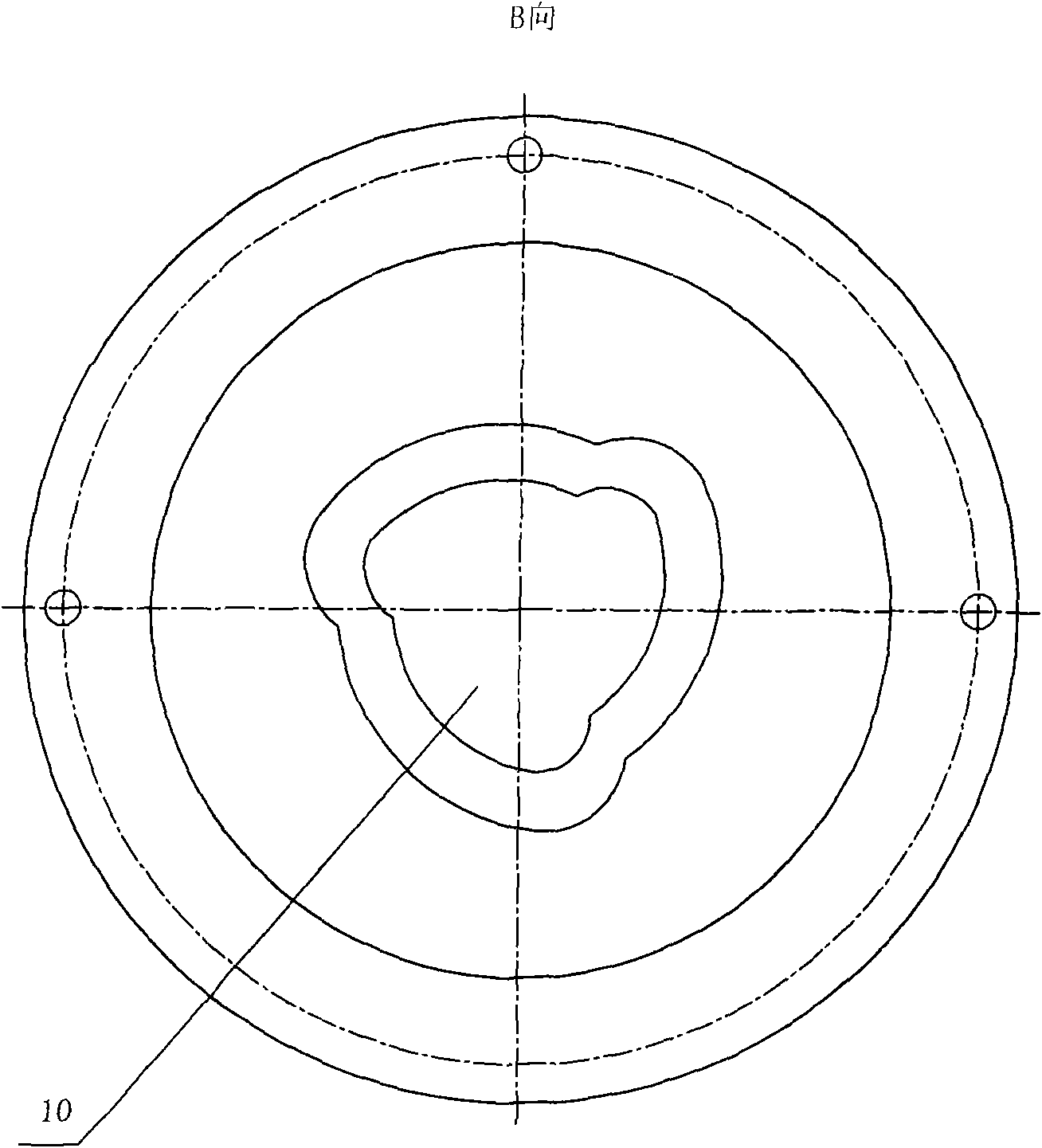

Cut-up type blow-down pump

Aiming at the defect of easy blow-down pump winding in the prior art, the invention discloses a cut-up type blow-down pump which can effectively cut long fibers and is not easily blocked. The cut-up type blow-down pump comprises a pump body, a motor, an impeller arranged in the pump body and a motor shaft connected with the motor and the impeller. The motor shaft is sheathed by a bush. The pump body is formed by fixedly connecting a base, a front cover and a rear cover. The impeller is arranged between the front cover and the rear cover. The body of the front cover is provided with a materialinlet through which materials can enter. A surface position of the front cover, which is positioned in the pump body, is provided with a front cover stationary cutter which is cooperated with the impeller during cutting. The base is provided with a material outlet through which materials can be discharged. The material inlet takes the shape of heart.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

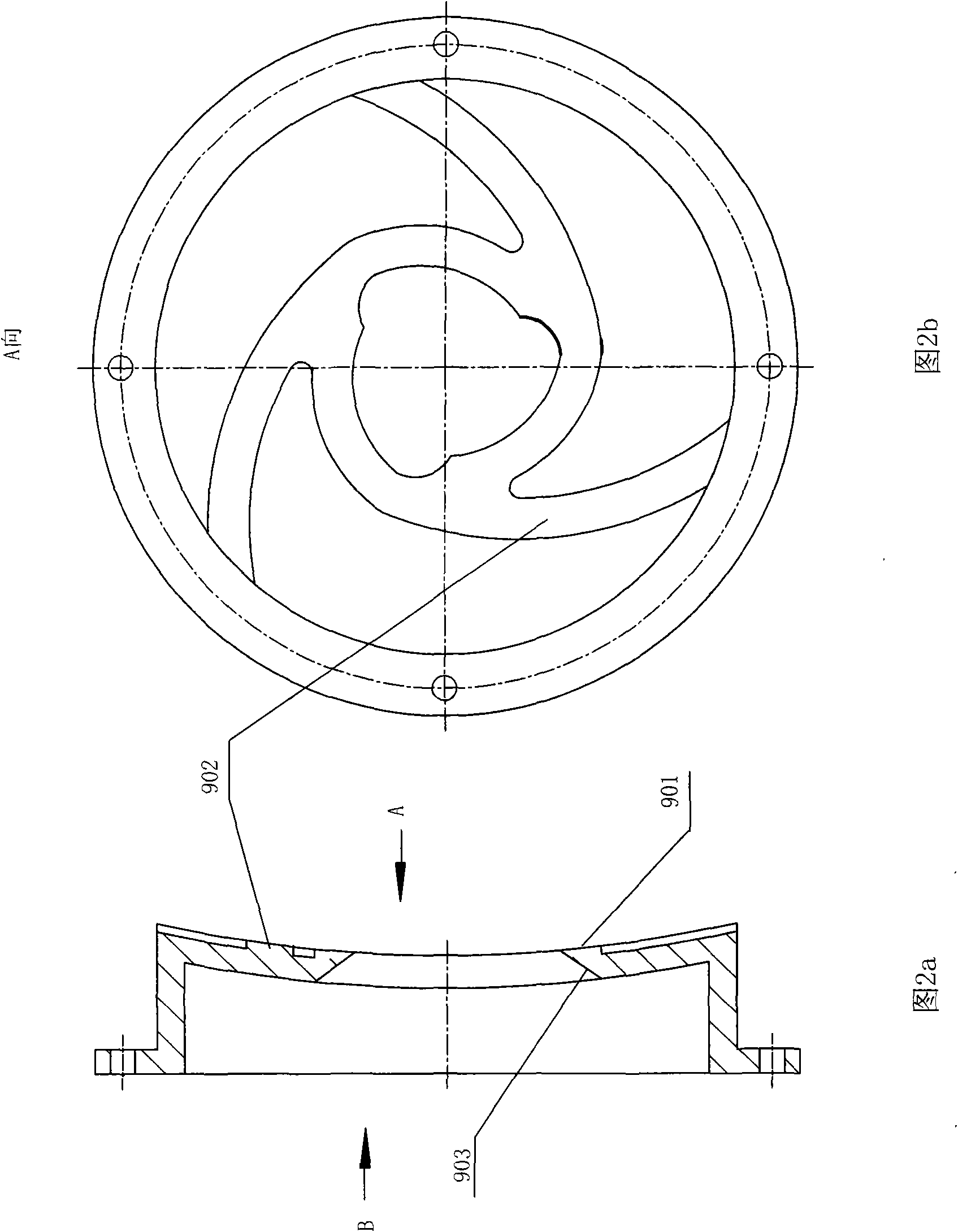

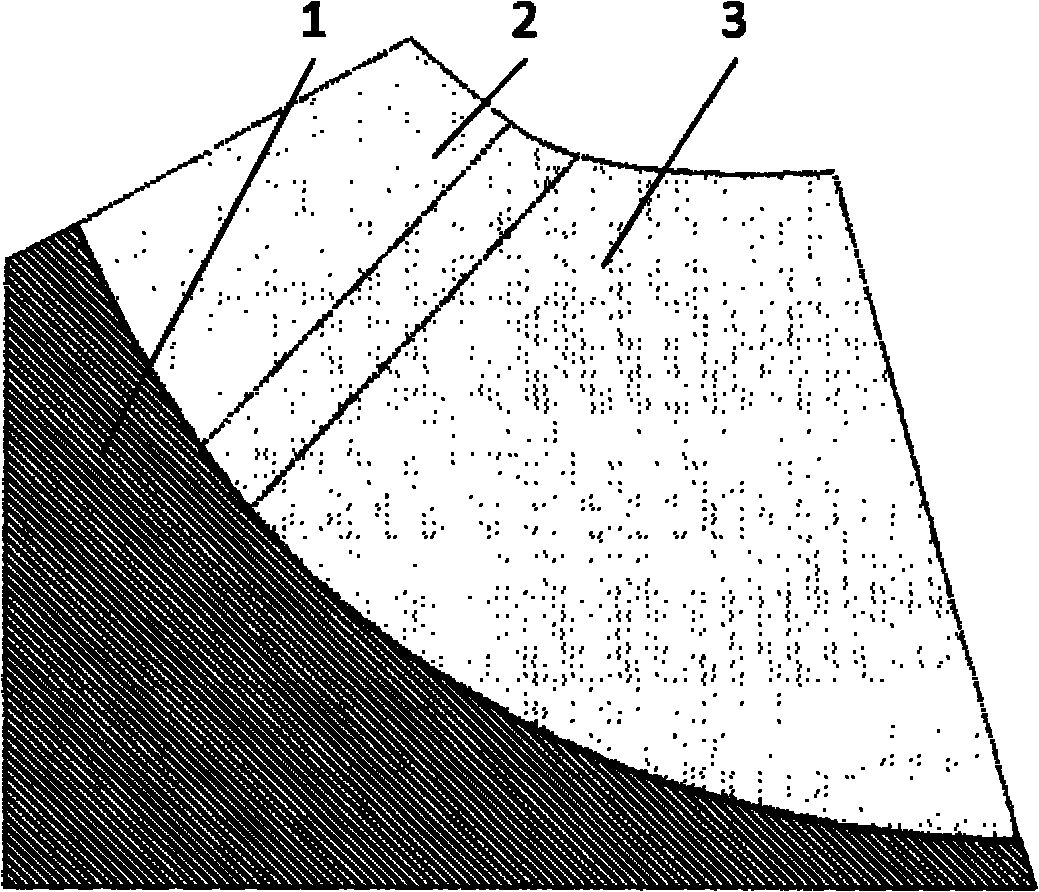

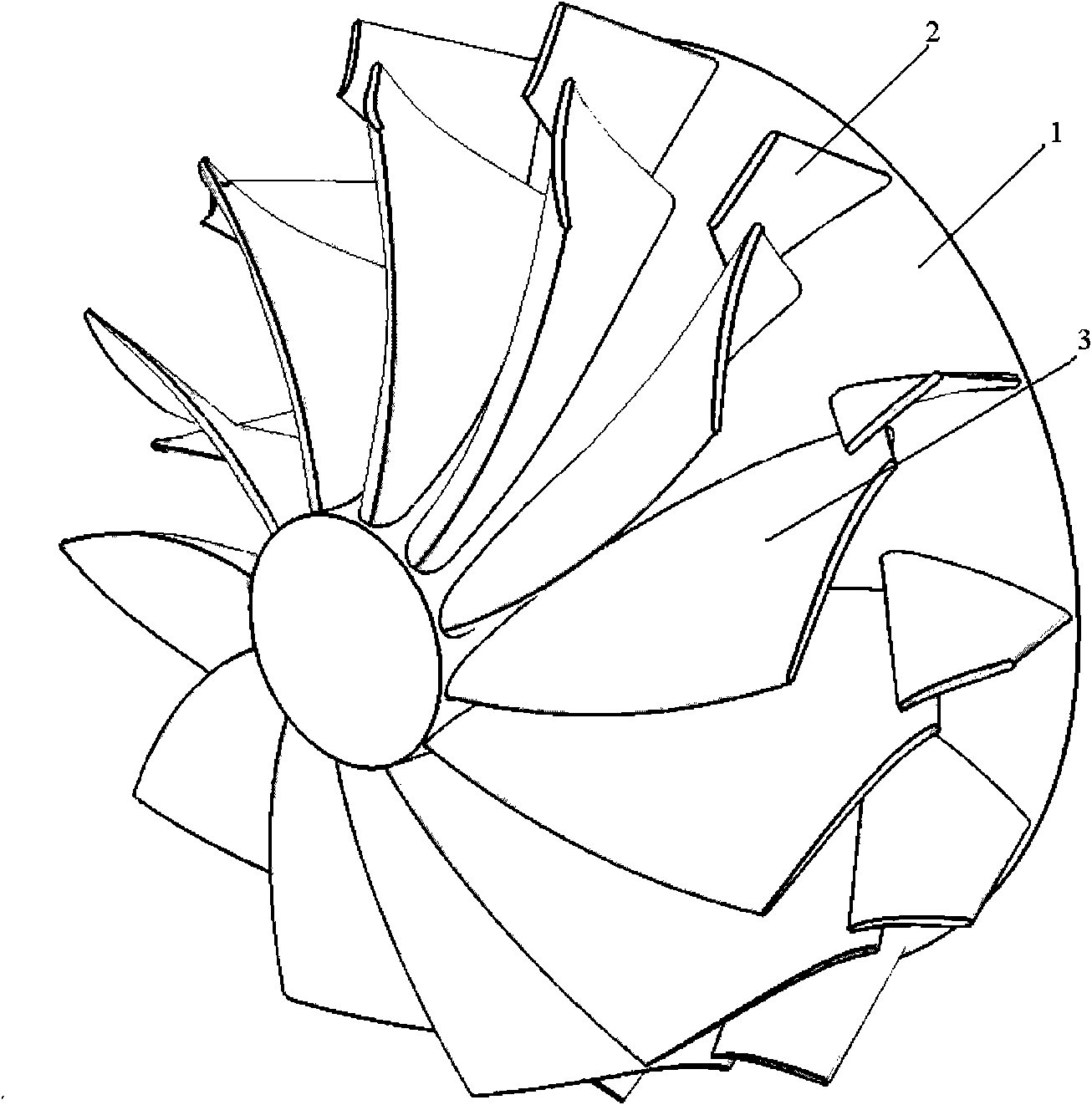

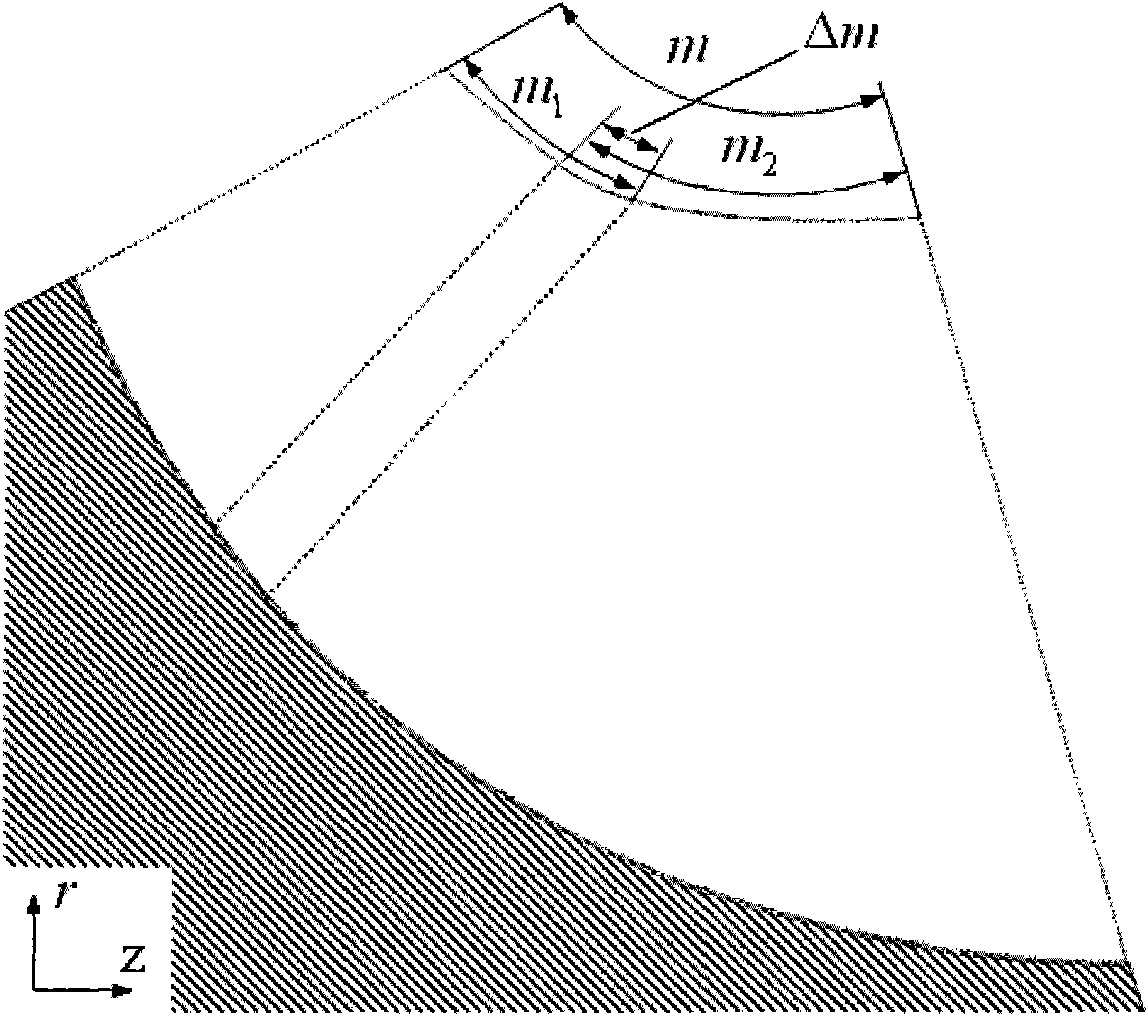

Tandem blade type mixed-flow or radial-flow turbine

InactiveCN101915126AImprove performanceInhibition of flow separationInternal combustion piston enginesBlade accessoriesMixed flowPulse charge

The invention relates to the technical field of blade type fluid machines, in particular to a tandem blade type mixed-flow or radial-flow turbine comprising a hub, front-row blades and back-row blades, wherein the ratio of the numbers of the tandem blade type front-row Z1 and the numbers of the back-row blades Z2 is 1:1 or 1:2, the ratio variation range of the lengths of the front-row and back-row blades is 0.1-0.5, the variation range of relative circumferential angles between the front edges of the back-row blades and the tail edges of the front-row blades is 0-2 pi / Z1, and the variation range of the distances between the tail edges of the front-row blades and the front edges of the back-row blades is -0.3 to 0.3 of the total blade chord length. By the airflow blowing-down function generated by a gap between the front-row blades and the back-row blades, the flow separation close to the front edges of the blades is restrained, the secondary flow is weakened, the efficient running range is enlarged, and the whole performance of the turbine under undersign conditions and pulse charging conditions is improved.

Owner:TSINGHUA UNIV

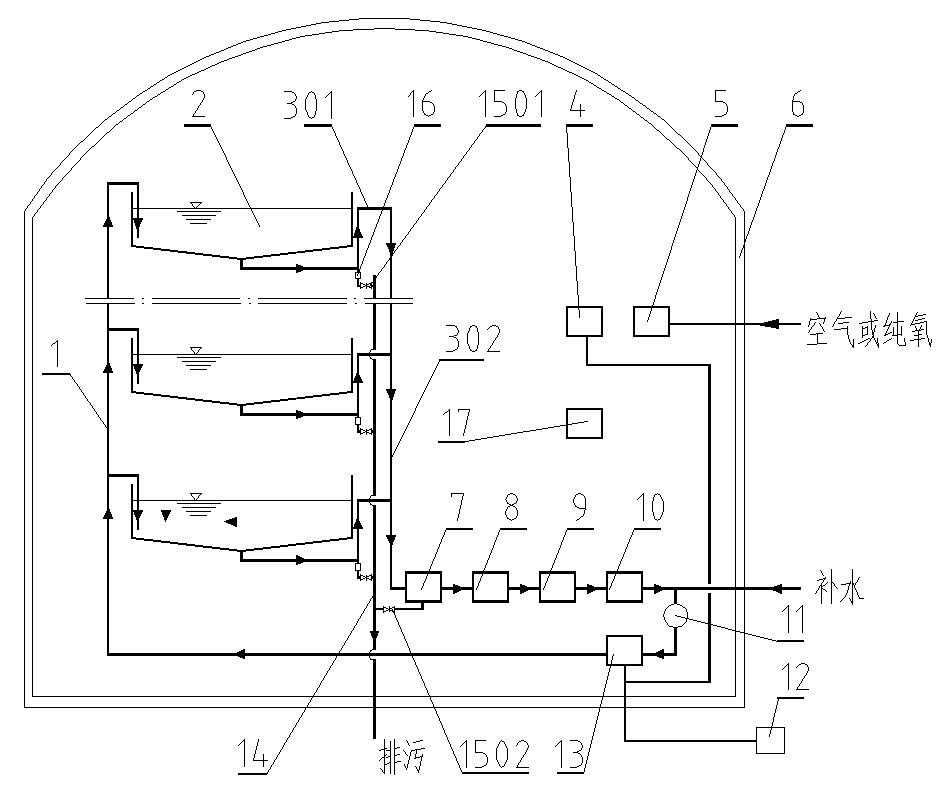

Closed-type constant-temperature multi-layer water circulation turtle cultivation system

InactiveCN103181362AAchieve purification effectAchieve reuseAnimal husbandryEcological environmentBiological filter

The invention discloses a closed-type constant-temperature multi-layer water circulation turtle cultivation system which comprises a multilayer turtle cultivation pool devices, a cultivation water environment adjusting device, an indoor air environment adjusting device and a cultivation system operation control device, wherein the multilayer turtle cultivation pool device comprises a plurality of turtle cultivation pools, circulating water return pipes, circulating water outlet branch pipes and main circulating water outlet pipes, primary solid liquid precipitation devices, blow-down valves and pollution discharge blow-down pipes; the cultivation water environment adjusting device comprises a solid-liquid separator, a blow-down valve, a sterilizer, a protein separator, a biological filtering device or tank, a circulating pump and a water heating device; and the indoor air environment adjusting device comprises an air heating device, an air oxygenating device and an insulation building. According to the closed type constant-temperature multi-layer water circulation turtle cultivation system, turtle cultivation environments can be comprehensively controlled, the land, the water and the energy are saved, an optimal ecological environment suitable for turtles to rapidly grow is established, turtle cultivation is free of drugs, and healthy and safe food sanitation requirements are met.

Owner:ZHEJIANG UNIV

Quantitative recovery method for long-term blowing-down of blast furnace

InactiveCN102994671AEasy to operateGuaranteed stable workBlast furnace detailsRecovery methodRecovery stage

The invention discloses a quantitative recovery method for the long-term blowing-down of a blast furnace, belonging to the technical field of blast furnace iron-making. A long-term blowing-down and furnace condition recovery process is divided into four phases, namely, a blowing-down operation phase, a blowing-down phase, a blowing-in operation phase and a furnace condition recovery phase by taking air quantity control as a core, according to the focused work in each phase of the long-term blowing-down and furnace condition recovery process of the blast furnace. The quantitative recovery method has the advantages of standardizing the long-term blowing-down recovery phase of the blast furnace and the control standards of various parameters, and providing a guarantee on the safety and the high efficiency of the recovery process.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

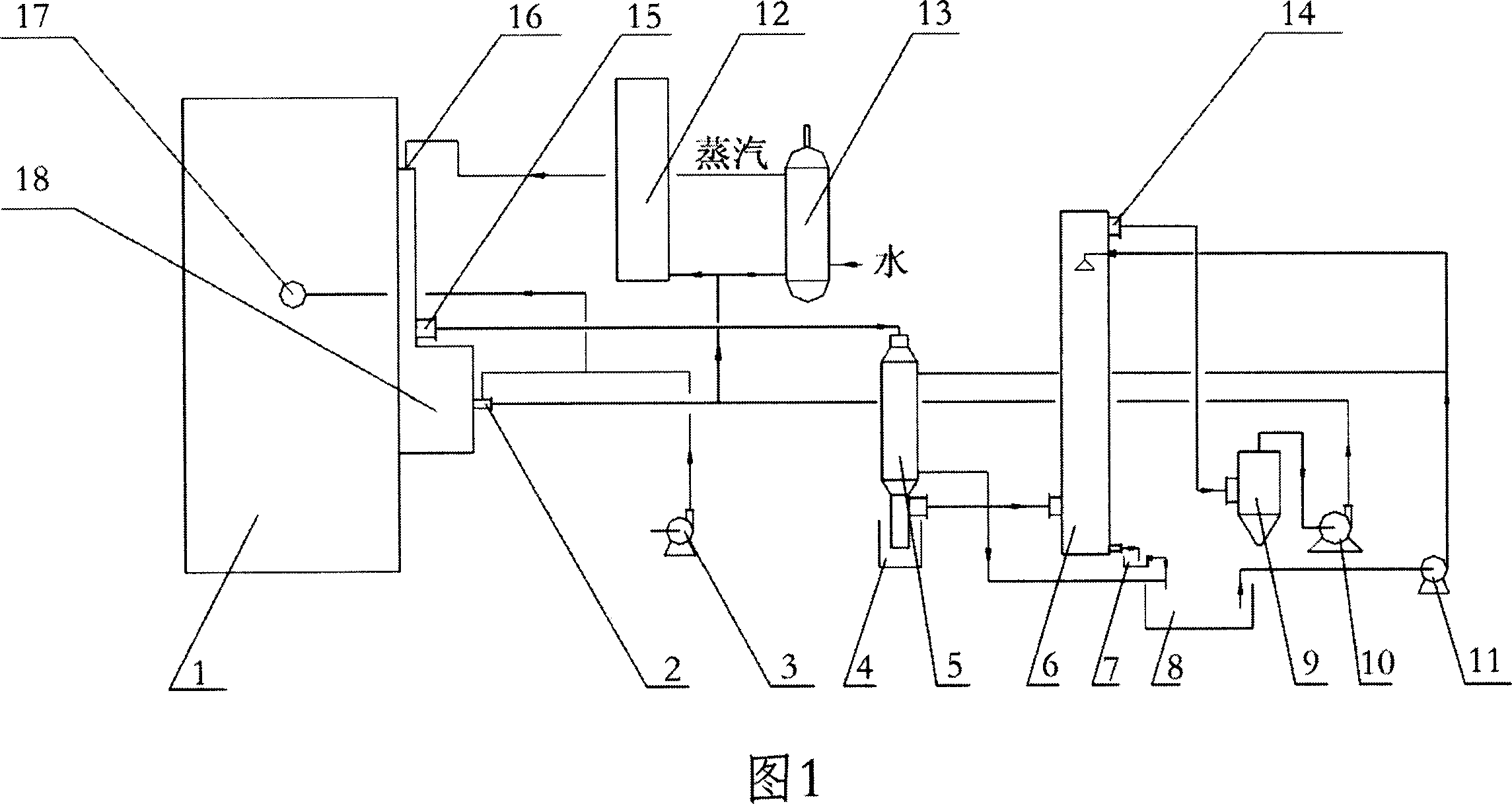

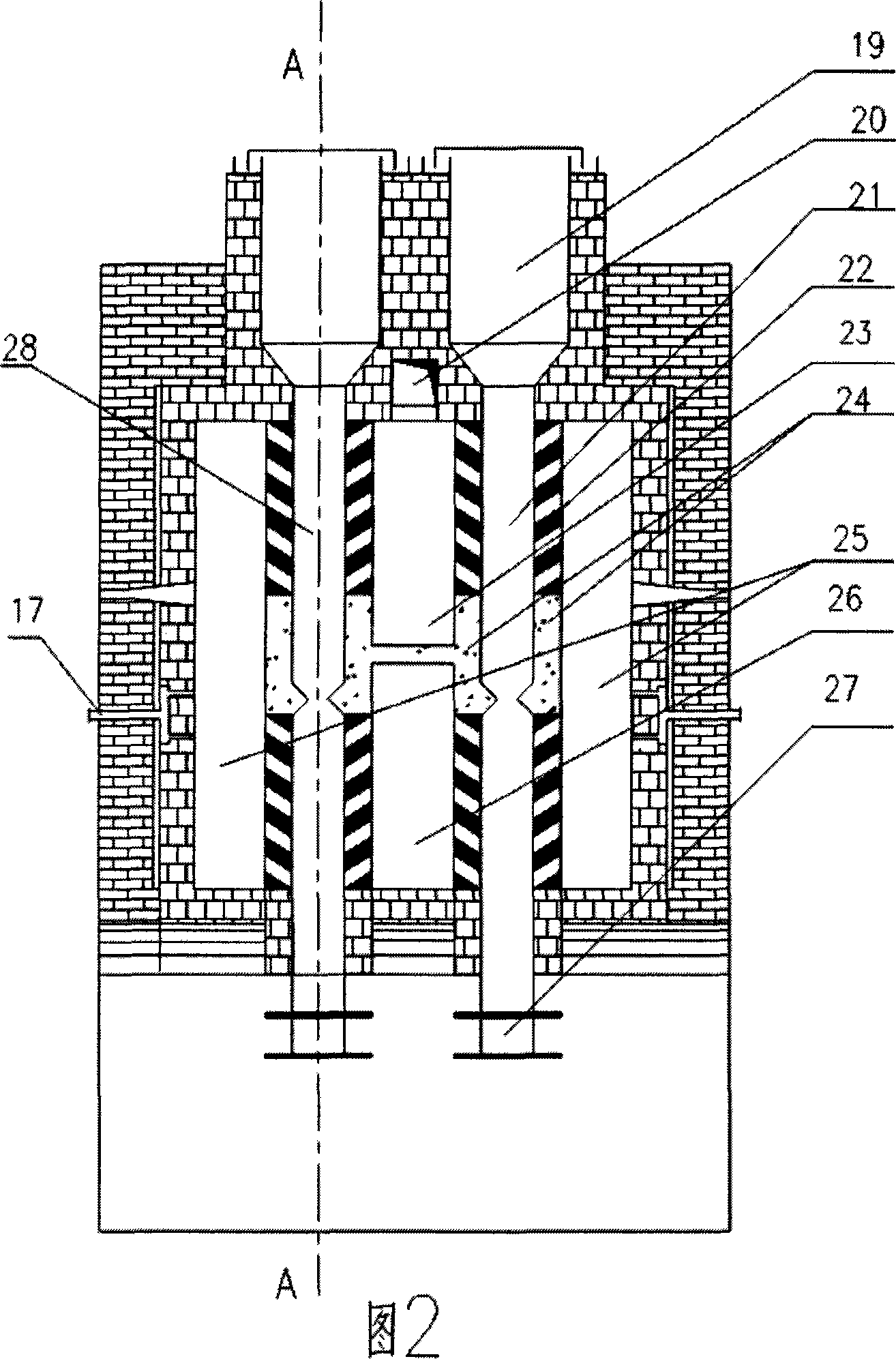

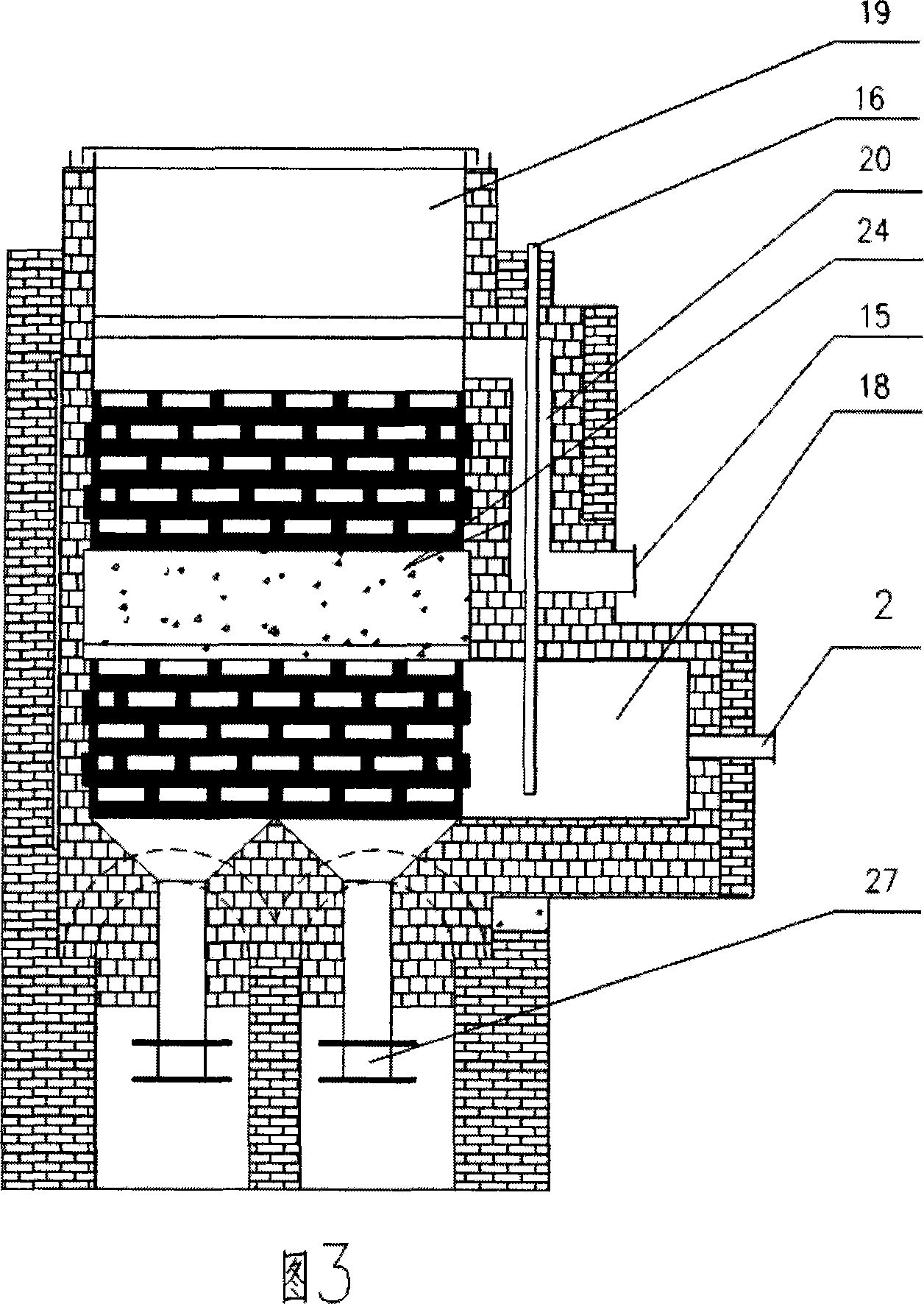

Activated char activating devices and methods thereof

The present invention discloses active carbon activating apparatus and process. The activating apparatus consists of one louver type activating furnace and one gas circulating system. The activating furnace laid with louver bricks has one activating channel with one middle flue and two side flues, one combustor communicated to the activating channel in the lower part, and one discharge unit in the bottom. The gas circulating system consists of activating gas outlet, heat exchanger, spraying tower, steam-water separator, gas blower, gas nozzle, afterheat boiler, combustor and blow-down stack connected through pipeline. The technology of the present invention may be applied in activating active carbon of different granularity, and has short activating period, convenient operation and other advantages.

Owner:傅方堃

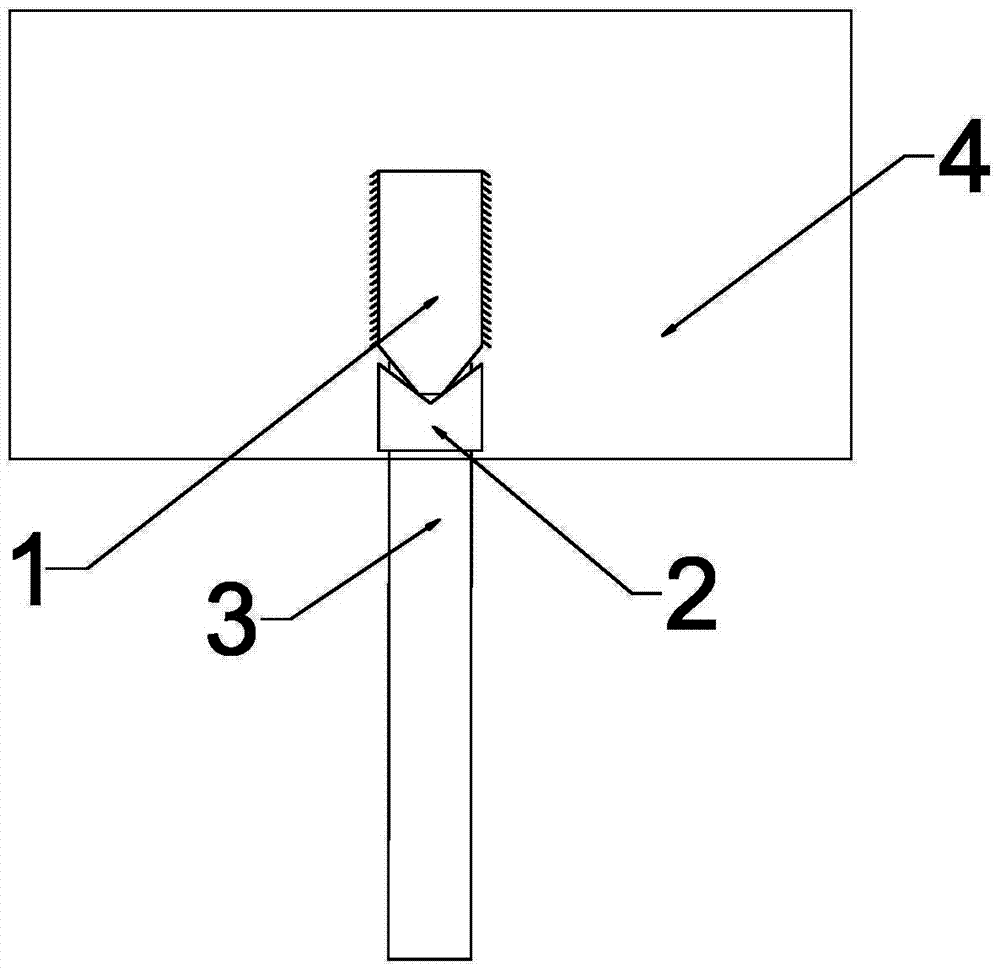

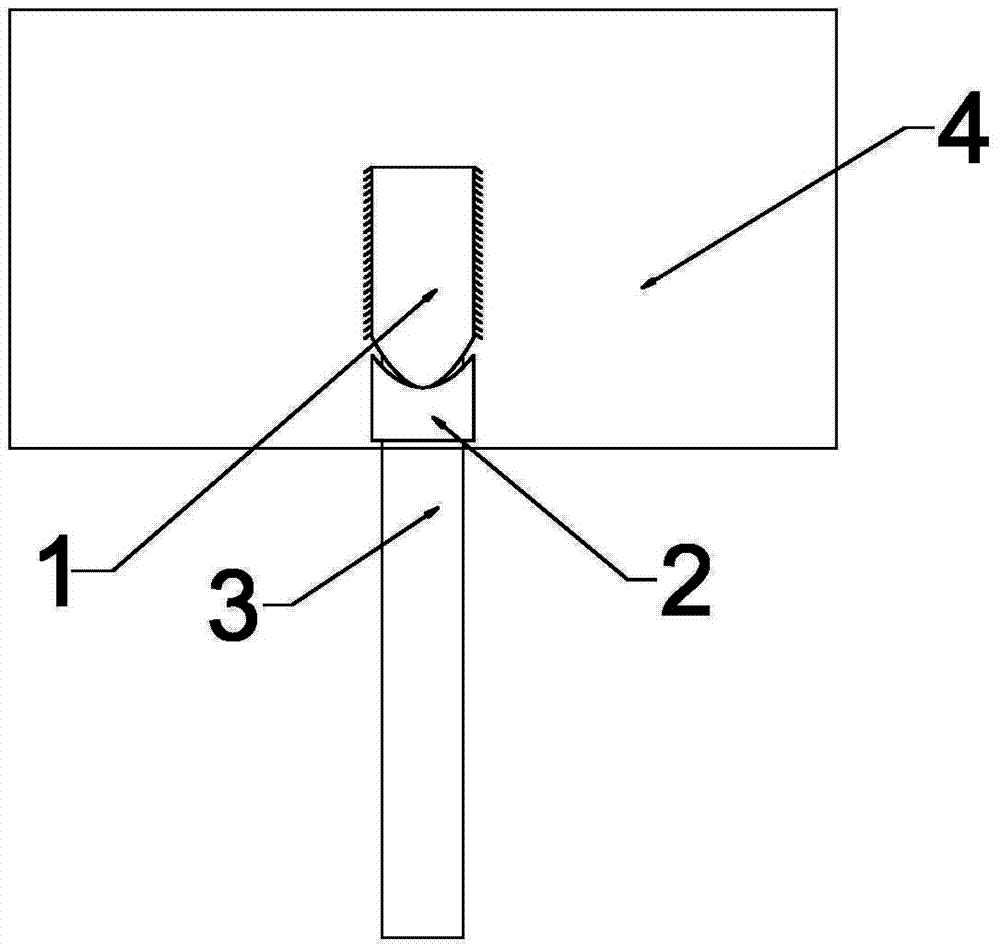

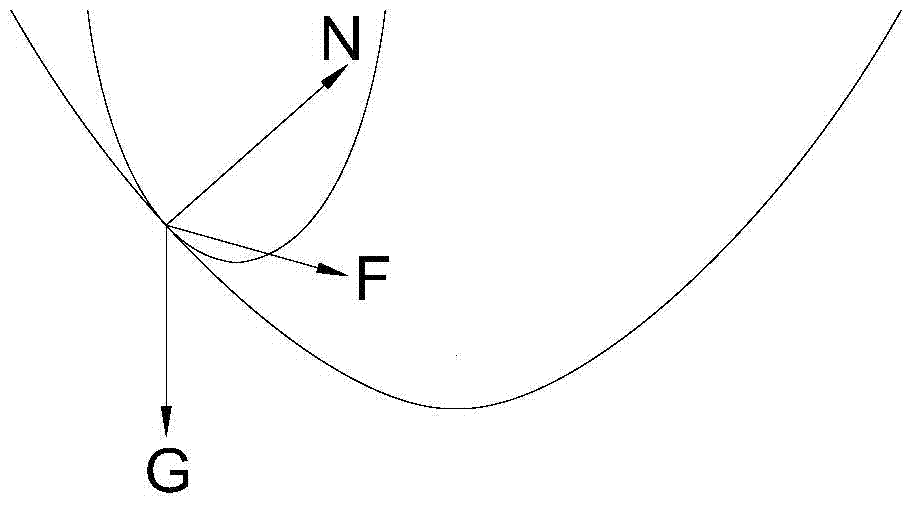

Advertising board

The invention provides an advertising board, and relates to the field of advertisement equipment. The advertising board comprises a supporting column, a support, a rotary base and an advertisement box, the support is arranged on the upper portion of the supporting column in a sleeved mode and is fixed with the supporting column, at least one concave port is formed in the support, the rotary base is arranged on the supporting column in a sleeved mode and is arranged above the support, a protrusion matched with the concave port is arranged on the rotary base, and the rotary base is fixedly connected into the advertisement box. The advertising board has the advantages that due to the fact that the protrusion of the rotary base is matched with the concave port of the support, the advertising board rotates when wind blows, and can automatically recover to perform the display effect when no wind blows or wind is small. The advertising board has the display function, cannot be blown down easily when wind power is large and resets when no wind exists or the wind is small, cost is saved, and the service life of the advertising board is prolonged.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

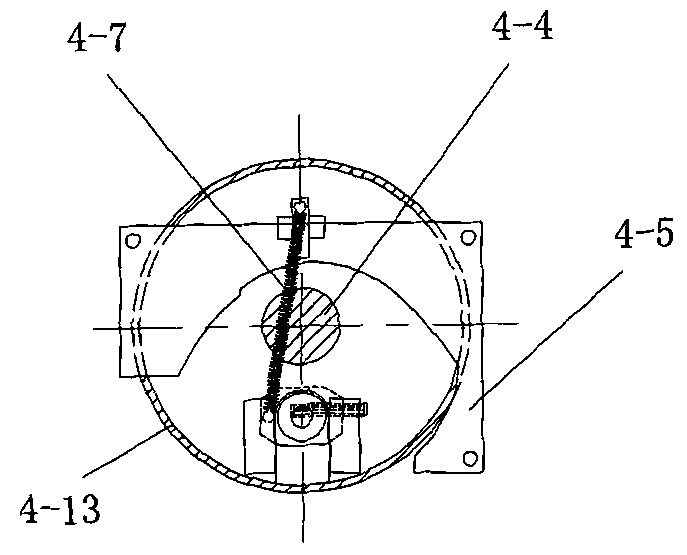

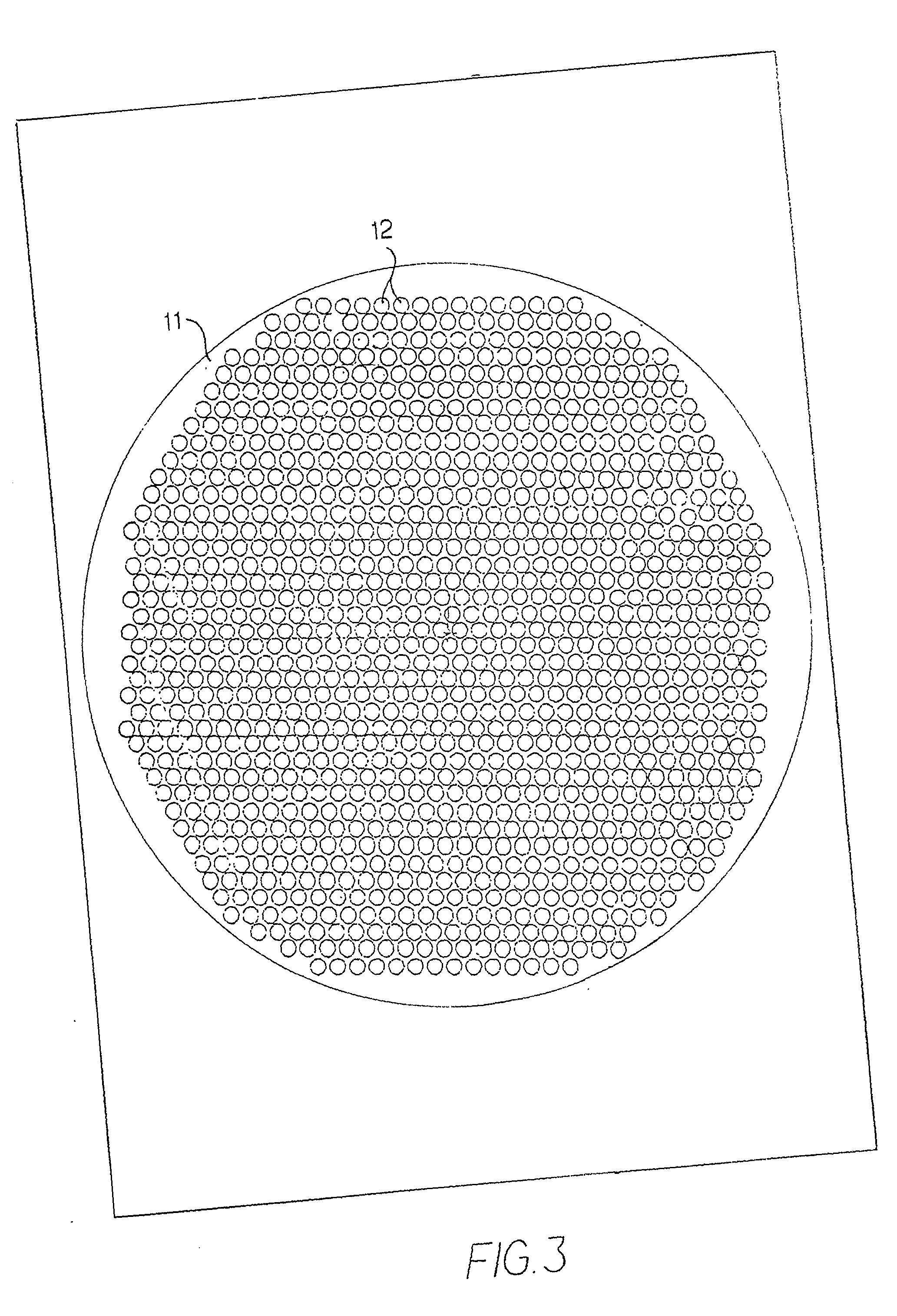

Device and method for blowing down and measuring the back pressure of chemical reactor tubes

InactiveUS20020129642A1Improve abilitiesAccurate and useful resultDetection of fluid at leakage pointInflated body pressure measurementGraphicsChemical reactor

A device for measuring the back pressure in chemical reactor tubes includes many automated features. Inflatable tube seals may be automatically inflated. The device may measure several tubes at once. It may transmit data electronically to a remote computer for analysis and graphic display.

Owner:TUBEMASTER INC

Selective compound engine

InactiveUS8028665B2Unrestricted power capacityEngine expansion ratio is doubledCombustion enginesHot gas positive displacement engine plantsExhaust valveInlet valve

The fuel efficiency of an internal combustion reciprocating piston engine may be increased through selective secondary expansion of exhaust gas in the engine cylinders in order to recover exhaust gas energy which is otherwise wasted by cylinder blow-down at the end of the power stroke. Exhaust valve cam switching, intake valve deactivation, multiple exhaust valves, a specialized exhaust manifold arrangement and an exhaust gas diverter valve can be configured to enable a reciprocating engine to selectively operate in efficient eight stroke cycle compound mode when moderate engine power is demanded, then revert to conventional four stroke cycle non-compound mode operation when high engine power is demanded, without stopping the engine. For a road vehicle application, the benefit is substantially reduced highway cruising fuel consumption, while incurring minimal impact on engine weight, minimal impact on engine manufacturing cost, and no adverse impact on vehicle acceleration performance, hill climbing performance or trailer towing performance.

Owner:RALSTON MARK DIXON

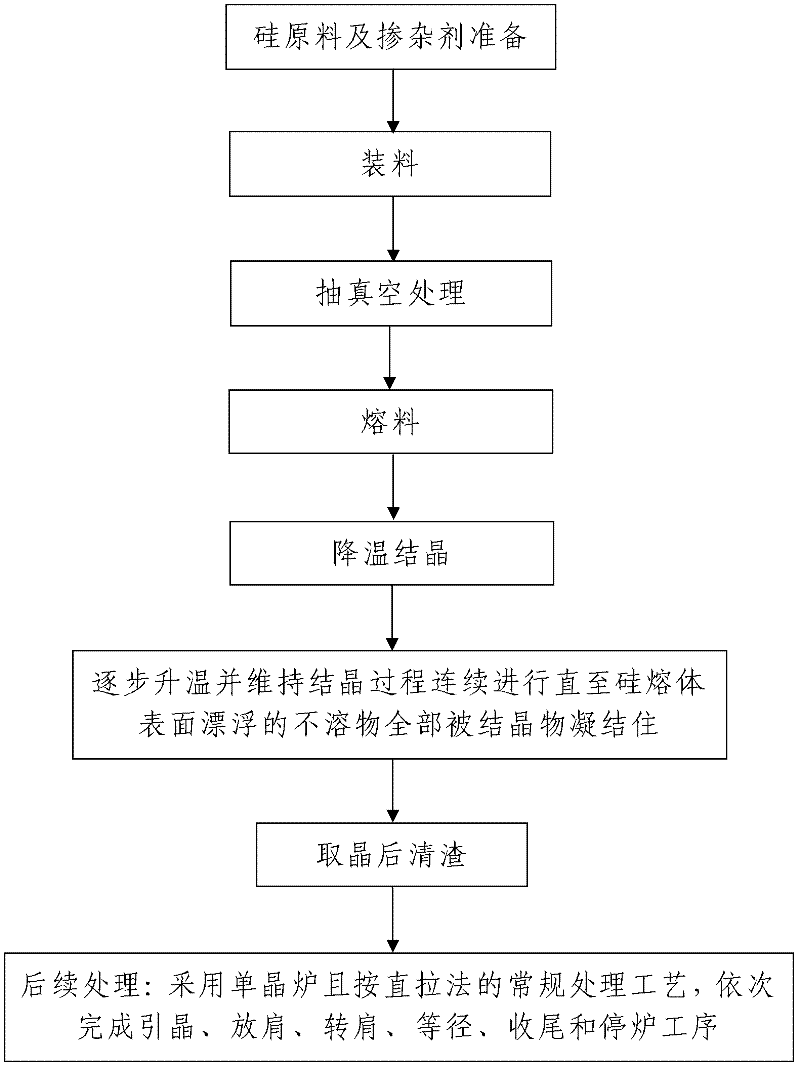

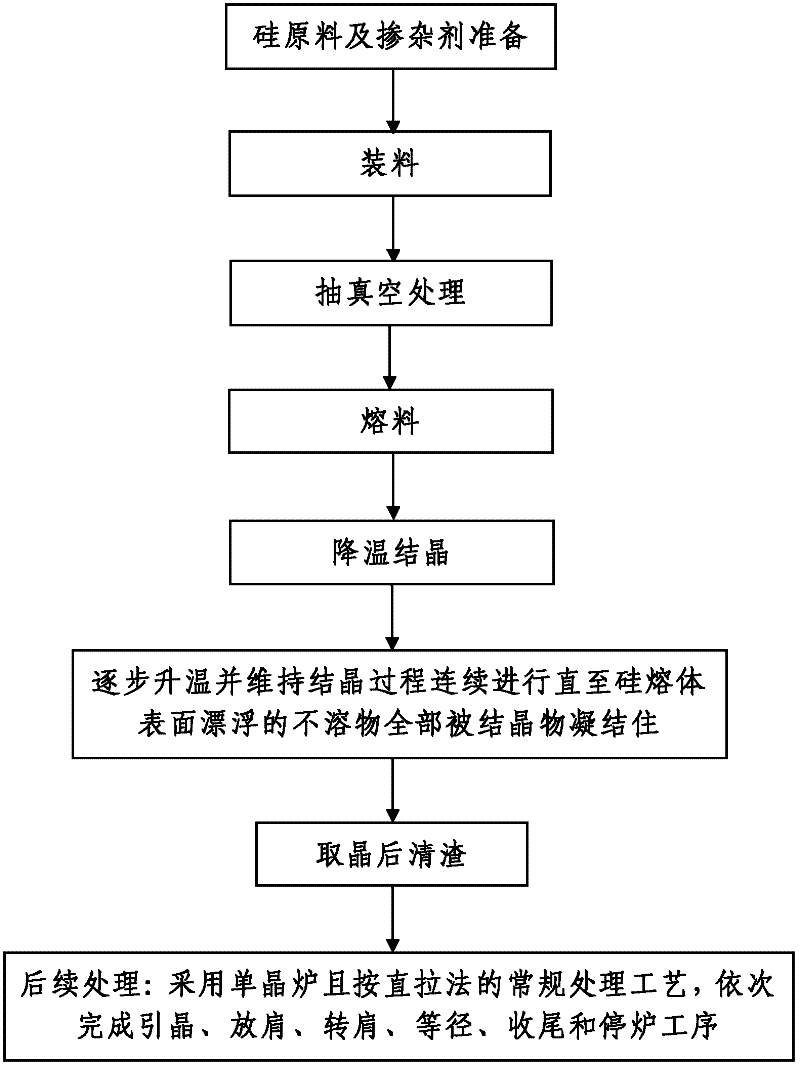

Process for producing Czochralski silicon single crystal

InactiveCN102242397AReasonable designThe process steps are simplePolycrystalline material growthBy pulling from meltDopantSlag

The invention discloses a process for producing a Czochralski silicon single crystal, which comprises the following steps of: 1, preparing a silicon raw material and a doping agent; 2, charging; 3, vacuumizing; 4, melting; 5, extracting slag, namely 501, performing cooling crystallization, 502, gradually heating, and keeping the crystallization process continuously performed until insoluble substances floating on the surface of a silicon melt are completely condensed by the crystal, and 503, taking the crystal out, and removing the slag; and 6, performing subsequent treatment, namely finishing crystal leading, shoulder expanding, shoulder rotating, diameter equalizing, ending and blowing down processes in turn by using a single crystal furnace according to the conventional treatment process of a Czochralski method to obtain the finished silicon single crystal formed by pulling. The process is reasonable in design, simple in steps, convenient to implement, easy to master and good in using effect, can effectively ensure the quality of the produced silicon single crystal, and can solve the practical problems that slag removing time is difficult to master, the slag extracting effect is poor, the produced silicon single crystal has low purity, and the like.

Owner:XIAN HUAJING ELECTRONICS TECH

Water-saving washing machine with water circulating purification function

InactiveCN1737242AReasonable cycle structureTo achieve the purpose of saving waterOther washing machinesTextiles and paperWater savingDraining tube

This invention relates to a decontamination cycle laundry machine, which comprises the laundry machine casing, a washing tub set outside the casing, a controller used for controlling the laundry machine, an inlet solenoid valve set inside the inlet pipe, an outlet solenoid valve set inside the outlet pipe, a decontamination cycle water saving device, and a water storage tank, wherein on the top of the tank it has an inlet pipe connected with the outlet pipe of the washing tub, and the inlet pipe has an outlet solenoid valve; the bottom of the water storage tank is connected with the blow-down pipe and the blow-down valve, and the top of the water storage tank has an overflow pipe; between the water storage tank and the inlet pipe of the washing tub it has an tank outlet pipe, and a pump set in the tank outlet pipe, inside the outlet pipe it has a water-supply magnetic valve; every magnetic valve is electric connected with the controller.

Owner:方曙光

Low-energy-consumption municipal sewage nitrogen removal method based on enhanced carbon capture and anaerobic ammonia oxidation

ActiveCN106830573AEnhanced biosorption efficiencyReduce the degree of carbon oxidationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentEnergy recoveryNitrogen gas

The invention discloses a low-energy-consumption municipal sewage nitrogen removal method based on enhanced carbon capture and anaerobic ammonia oxidation. A raw water tank is a closed tank and is provided with an overflow pipe and a blow-down pipe; a bio-stabilization reactor and a biological adsorption reactor are respectively in a high DO environment and a low DO environment; the municipal sewage carbon capture is enhanced by improving the ability of adsorbing organic matters through microbes; a biological nitrogen removal reactor is sequentially divided into a low DO aerobic zone, an anoxic zone, an aerobic zone and a settling zone; a shortcut nitrification-anaerobic ammonia oxidation reaction is carried out in the low DO aerobic zone, and ammonia nitrogen is converted into nitrogen and partial nitrate nitrogen; organic matters in partial raw water serve as a carbon source, and advanced nitrogen removal is realized through the shortcut nitrification-anaerobic ammonia oxidation reaction. In order to avoid the ammonia nitrogen existing in the effluent, the aerobic zone is increased at the rear end of the anoxic zone, and the residual ammonia nitrogen in the sewage is oxidized into nitrate; and finally, the sewage is discharged through the settling zone. According to the method, the municipal sewage energy recovery efficiency can be improved, and the advanced nitrogen removal is realized.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com