Activated char activating devices and methods thereof

An activation method and activated carbon technology, which is applied in the field of activation furnace, can solve the problems of enlarging the activation furnace, increasing the height of the activation furnace, and complex structure, etc., and achieve the effect of realizing independent balance, shortening the activation time, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment describe in further detail:

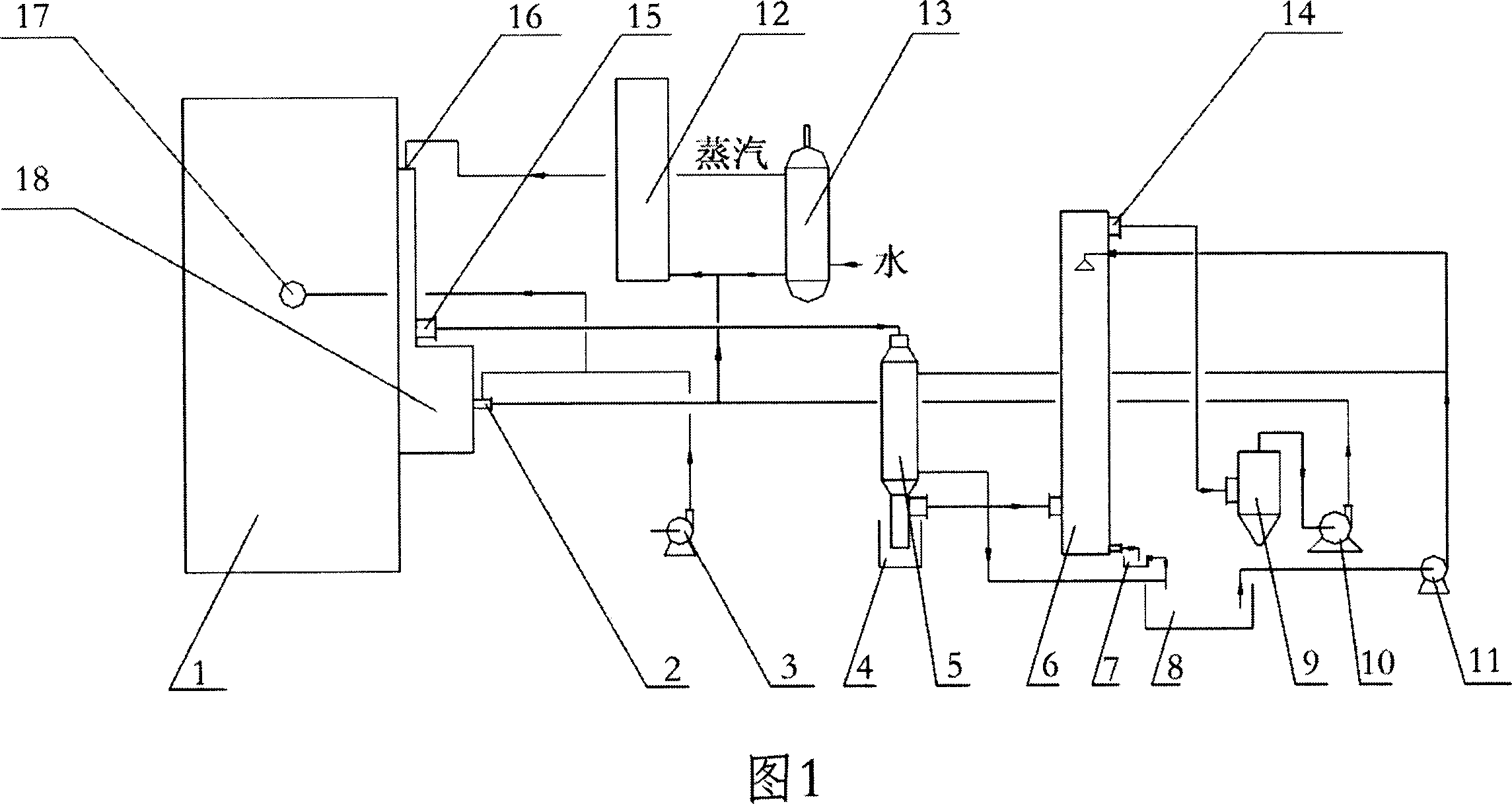

[0021] The activated carbon activation device is composed of a shutter type activation furnace and a gas circulation system.

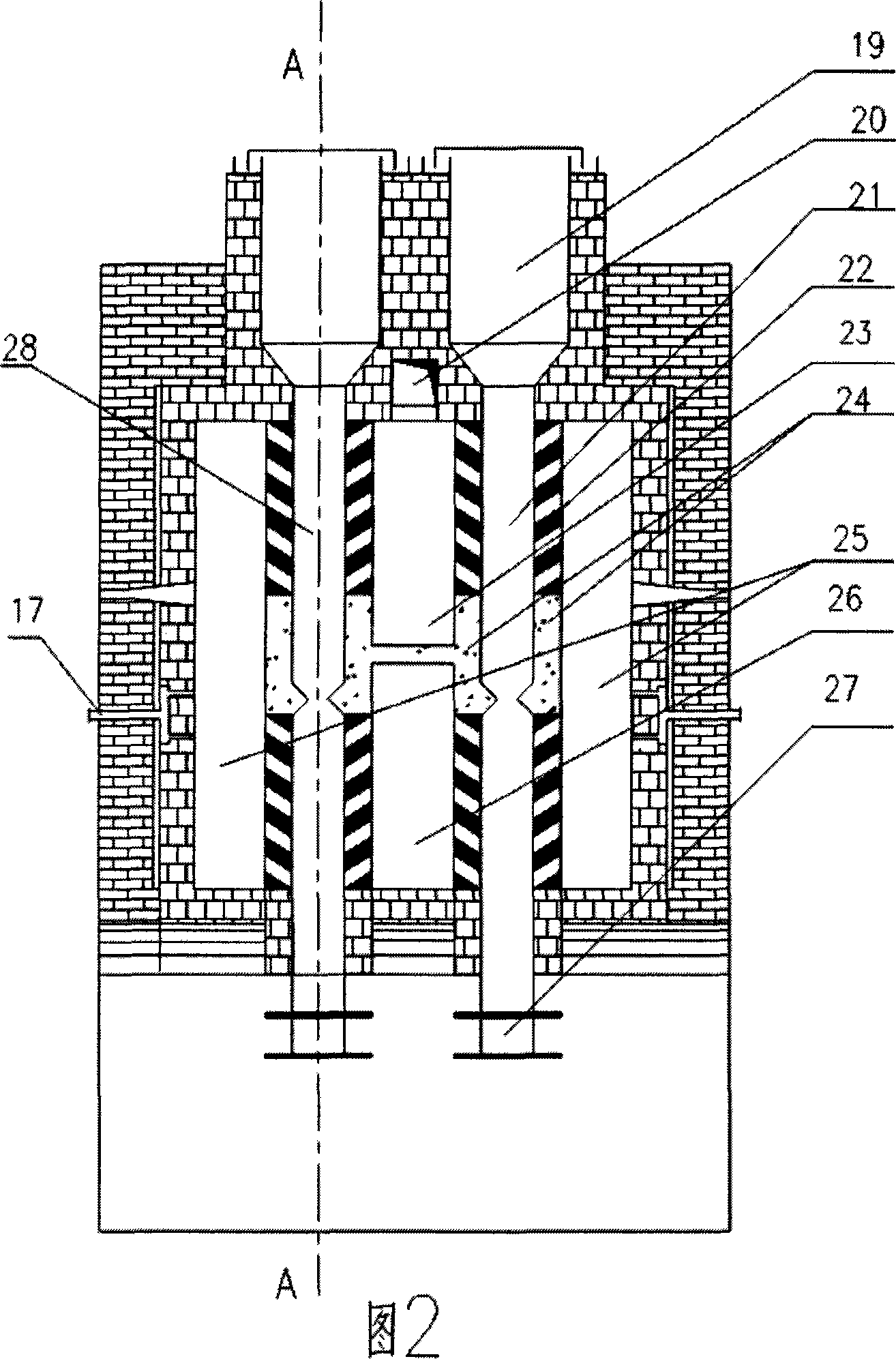

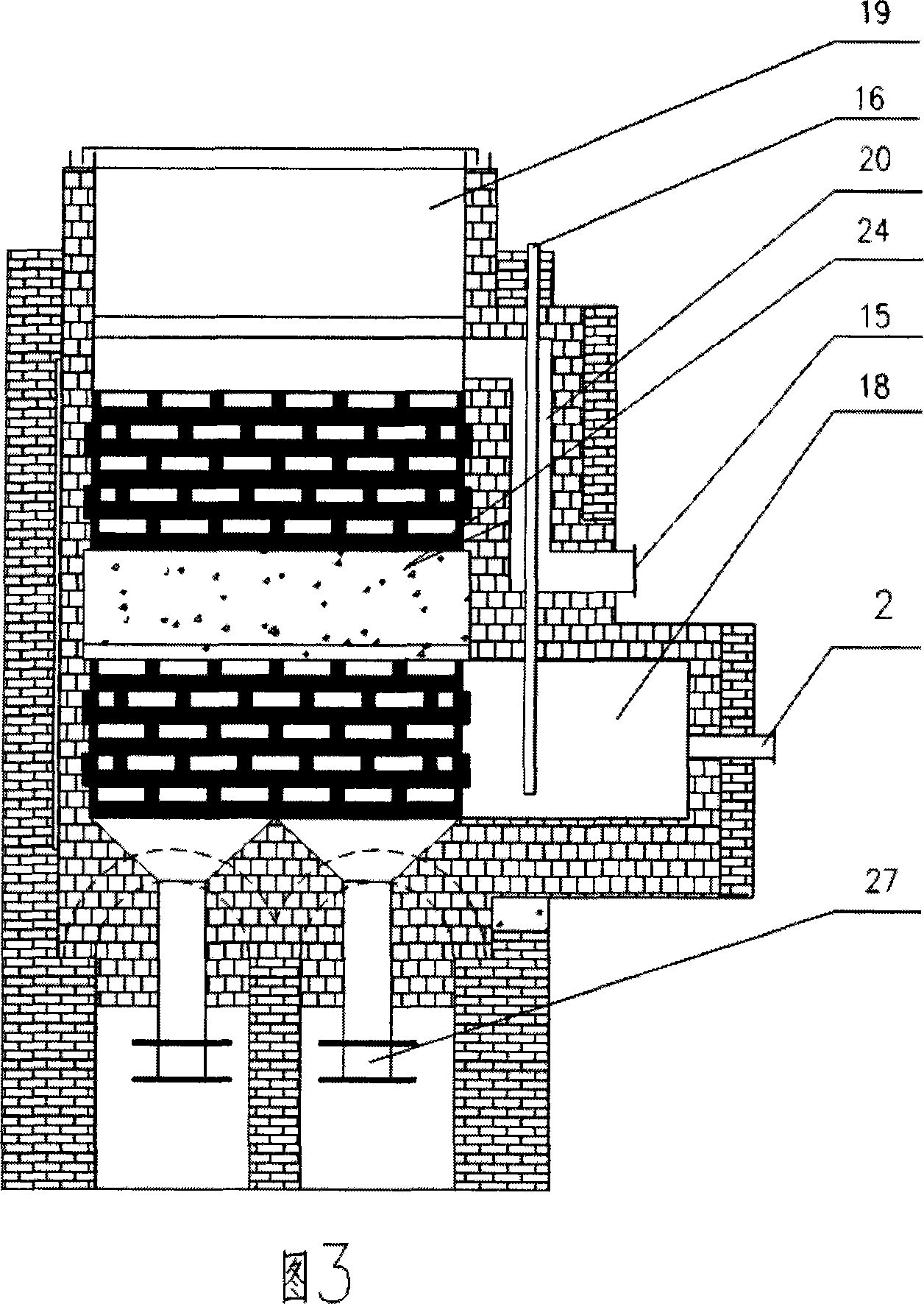

[0022] There are two activated product passages 21 and 28 in the louvered activation furnace. The activated product passages 21 and 28 are formed by stacking louver bricks 22 with oblique openings. There is an intermediate smoke exhaust between the activated product passages 21 and 28. Road 23, activated product passages 21, 28 tops are respectively provided with silos 19, and the middle part of the middle exhaust duct is provided with an isolation belt 24, and the isolation belt 24 divides the middle flue duct into an upper flue duct 23 and a lower flue duct 26, The upper flue 23 communicates with the flue gas outlet 20, the outside of the activation product passage 21, 28 is provided with a side flue 25, the bottom of the activation product passage is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com