Patents

Literature

256 results about "Microbial inoculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microbial Inoculation. Simply stated, microbes or bacteria are composed of cells within an outer wall. Bacterial bodies resemble car tyres with inner tubes. The inner tube represents the actual bacterial cell. Unlike a tyre casing, the bacterial cell is porous, allowing most molecules access to the cell body.

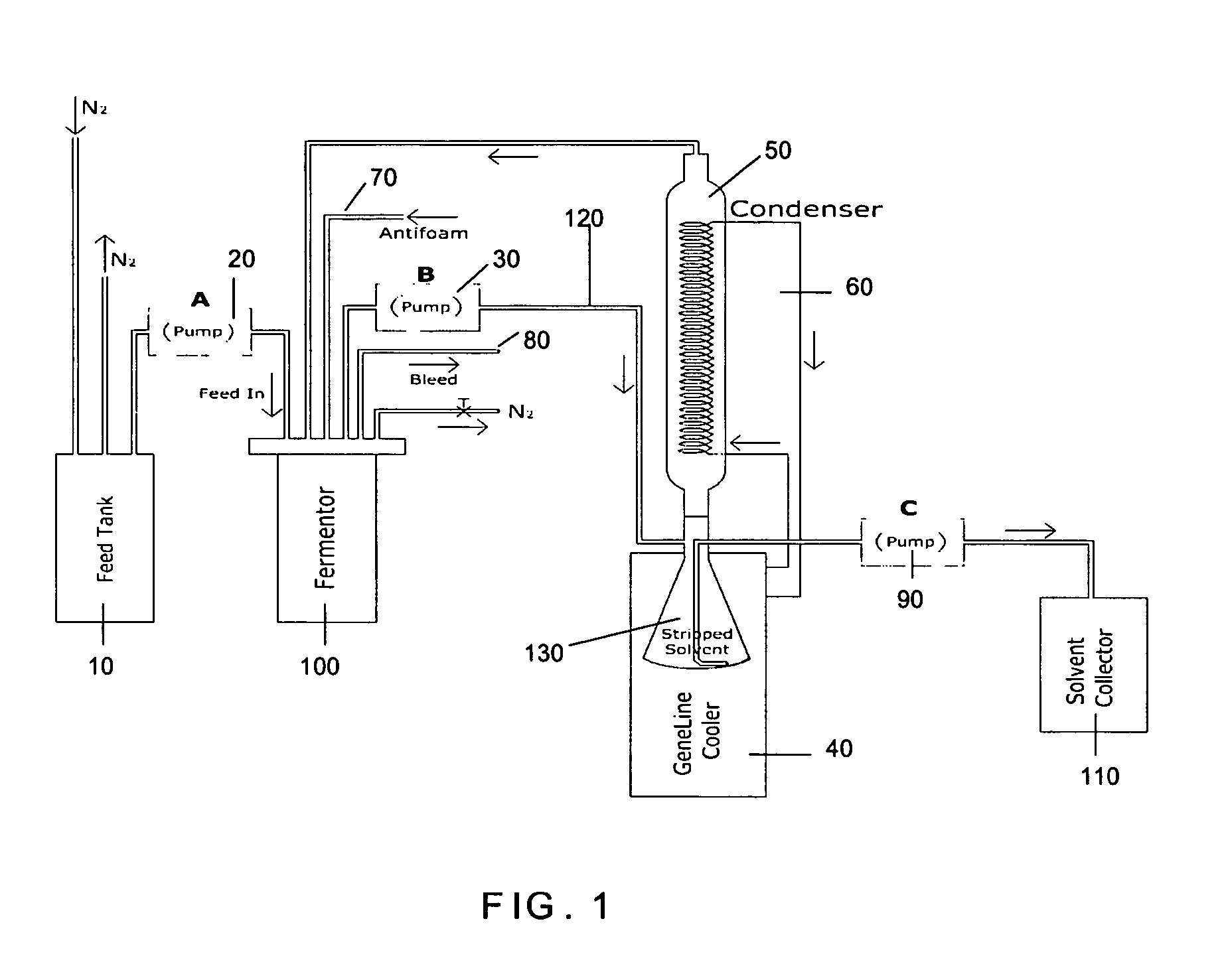

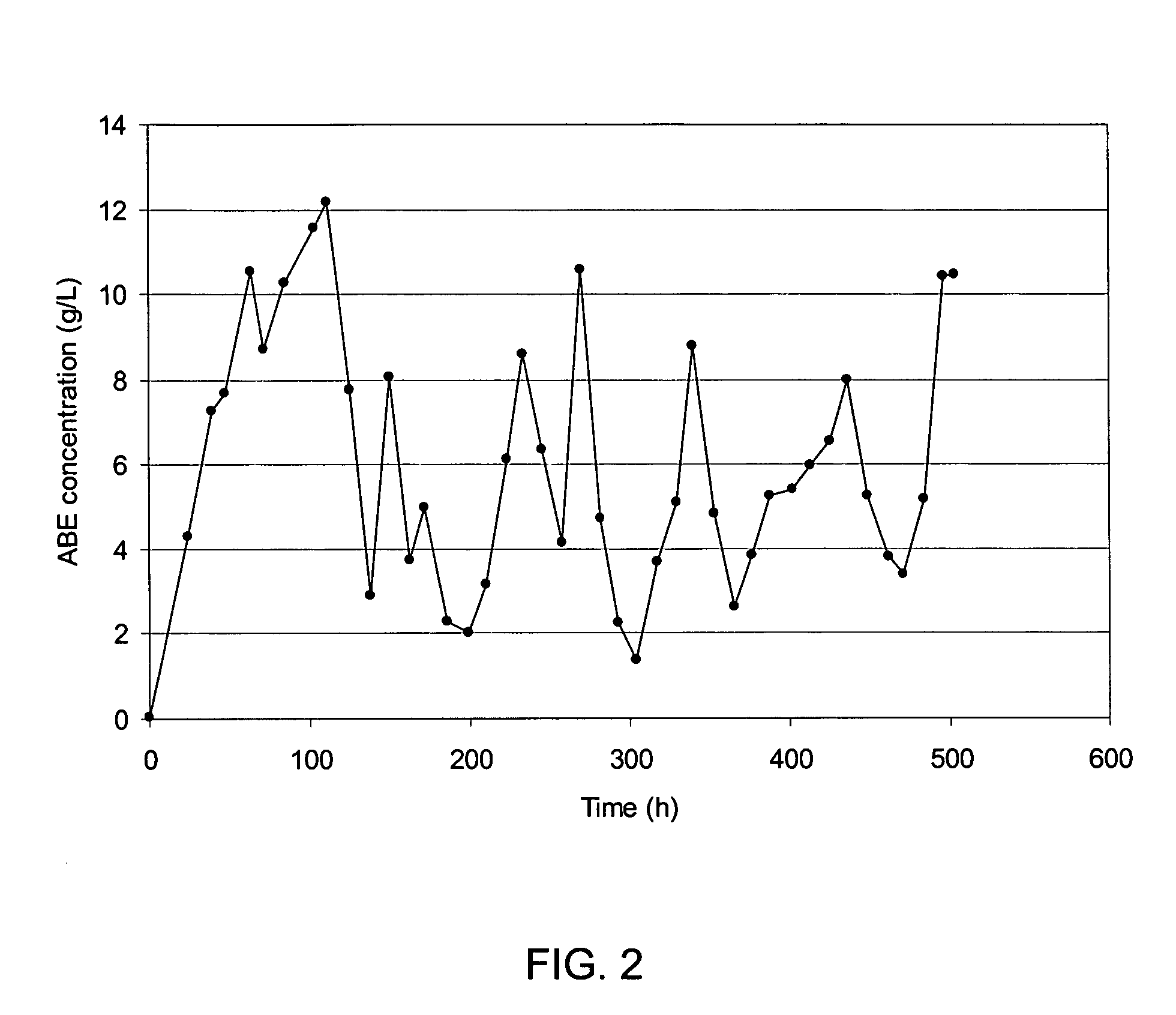

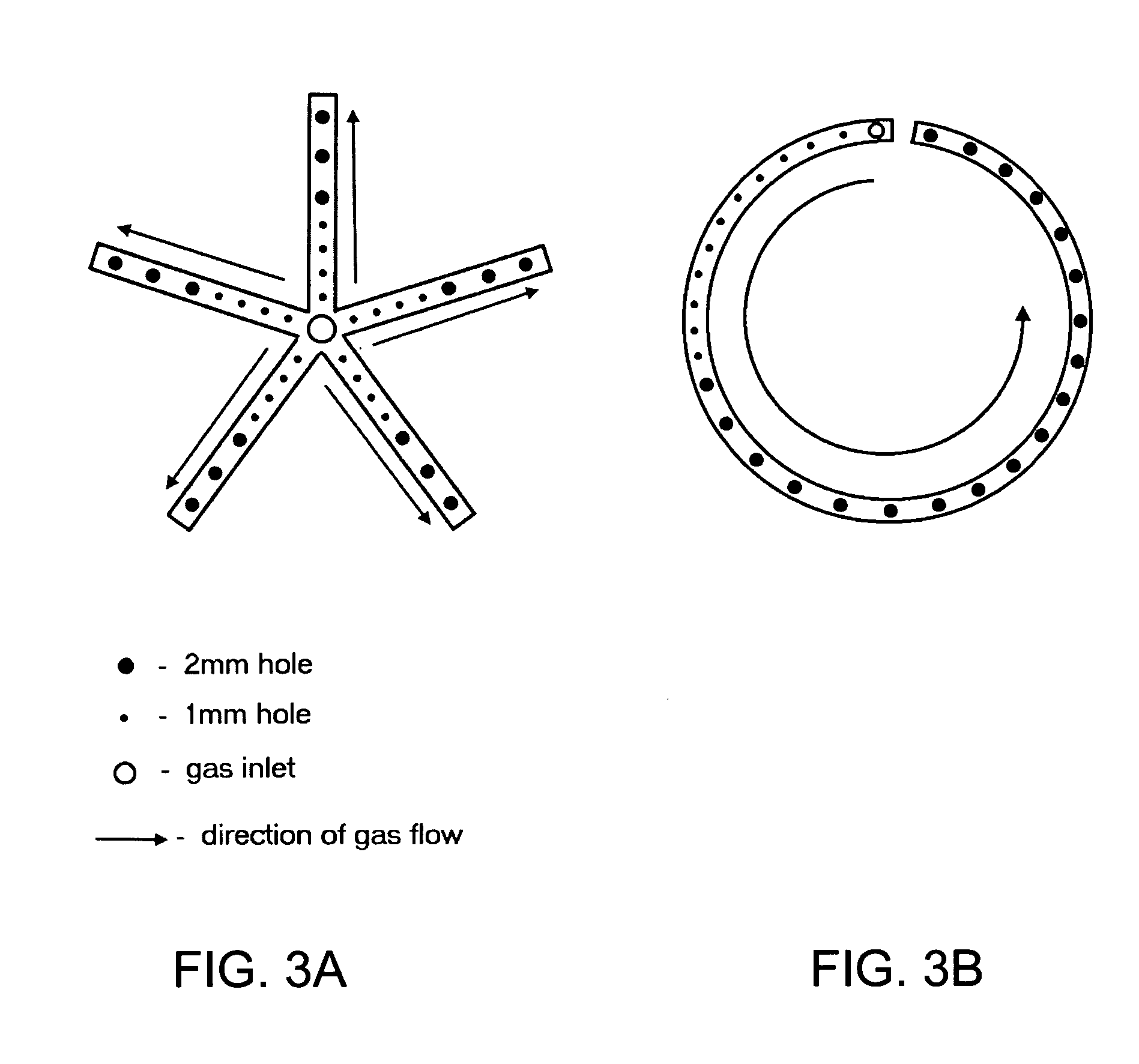

Process for continuous solvent production

InactiveUS20050089979A1High solventProducing strainBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationSolvent

A continuous process for production of solvents, particularly acetone-butanol-ethanol (ABE) using fermentation of solventogenic microorganisms and gas stripping is provided. The solventogenic microorganisms are inoculated in a nutrient medium containing assimilable carbohydrates (substrate) and optional other additives. Control of the solventogenic microorganism concentration in the fermentor (cell concentration) and the assimilable carbohydrate concentration in the fermentor, along with removal of solvents formed results in a continuous process for production of solvents.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

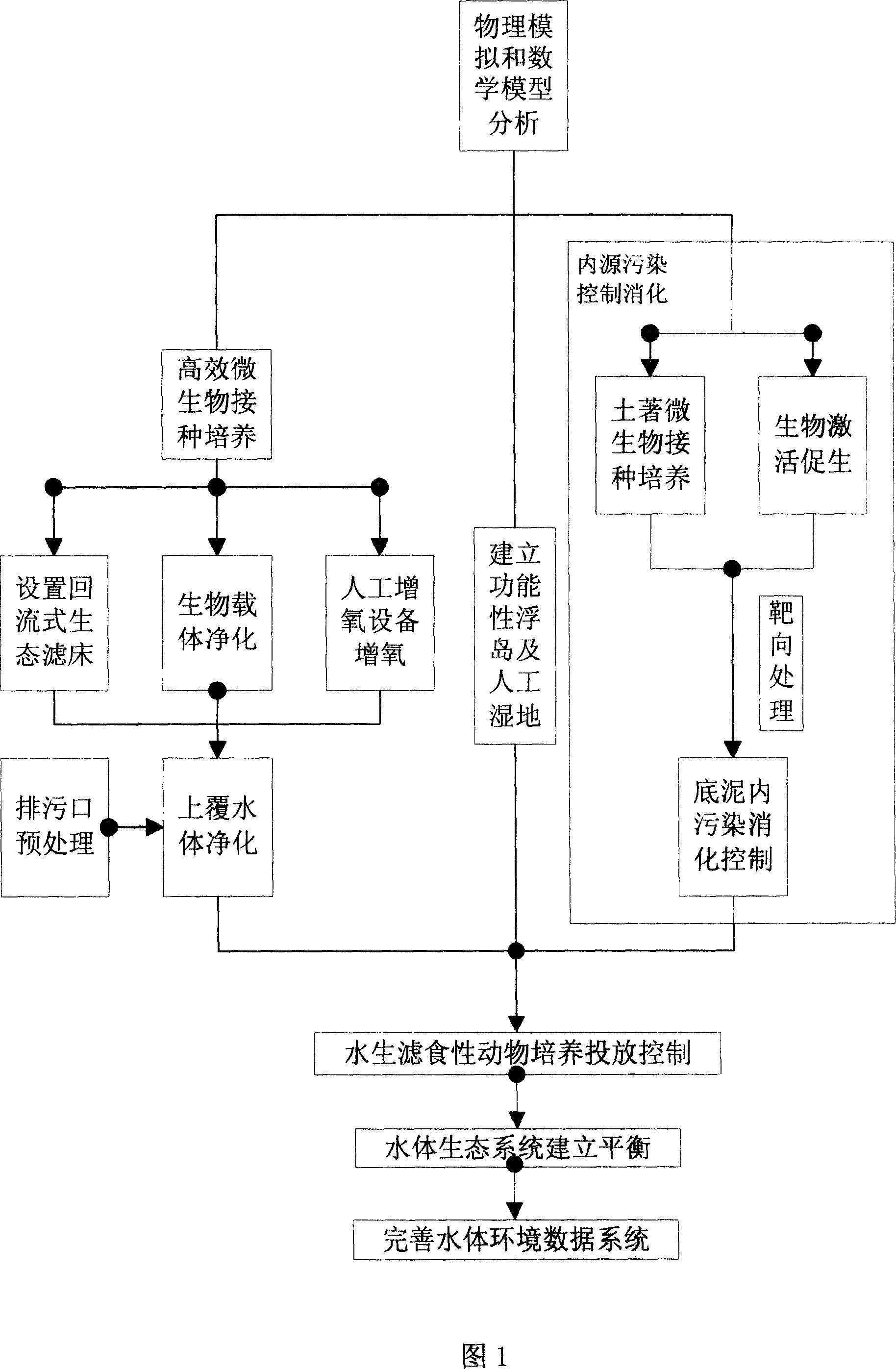

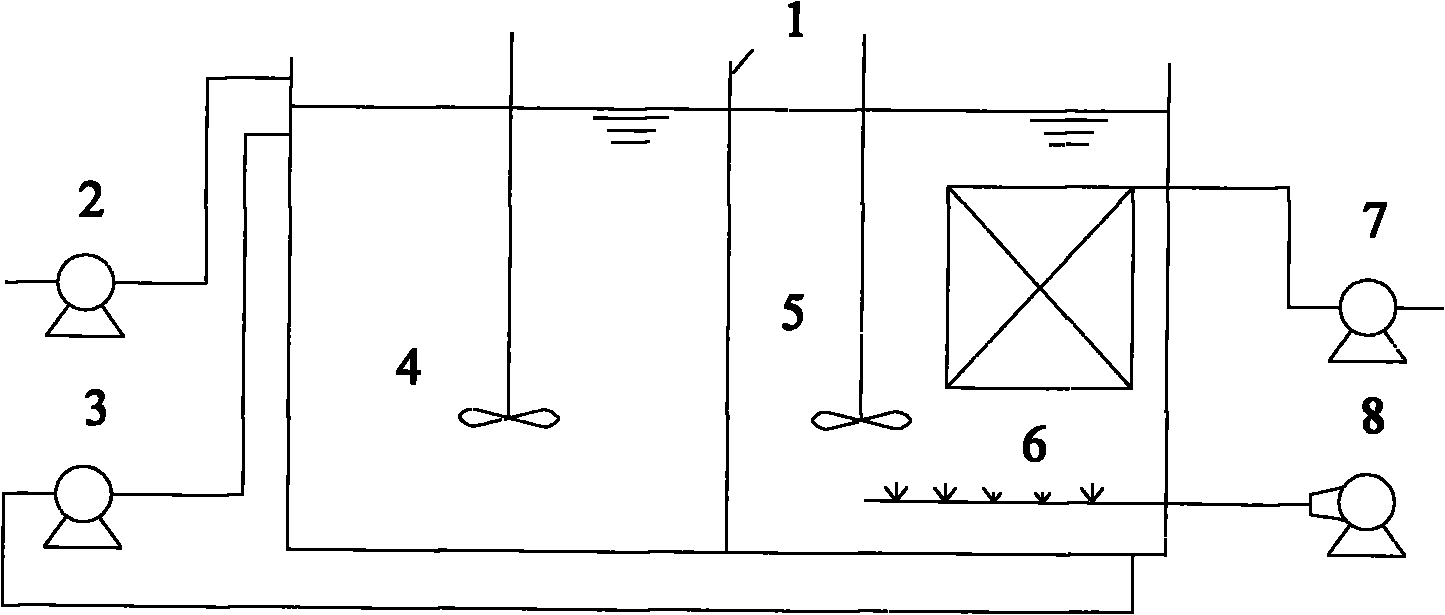

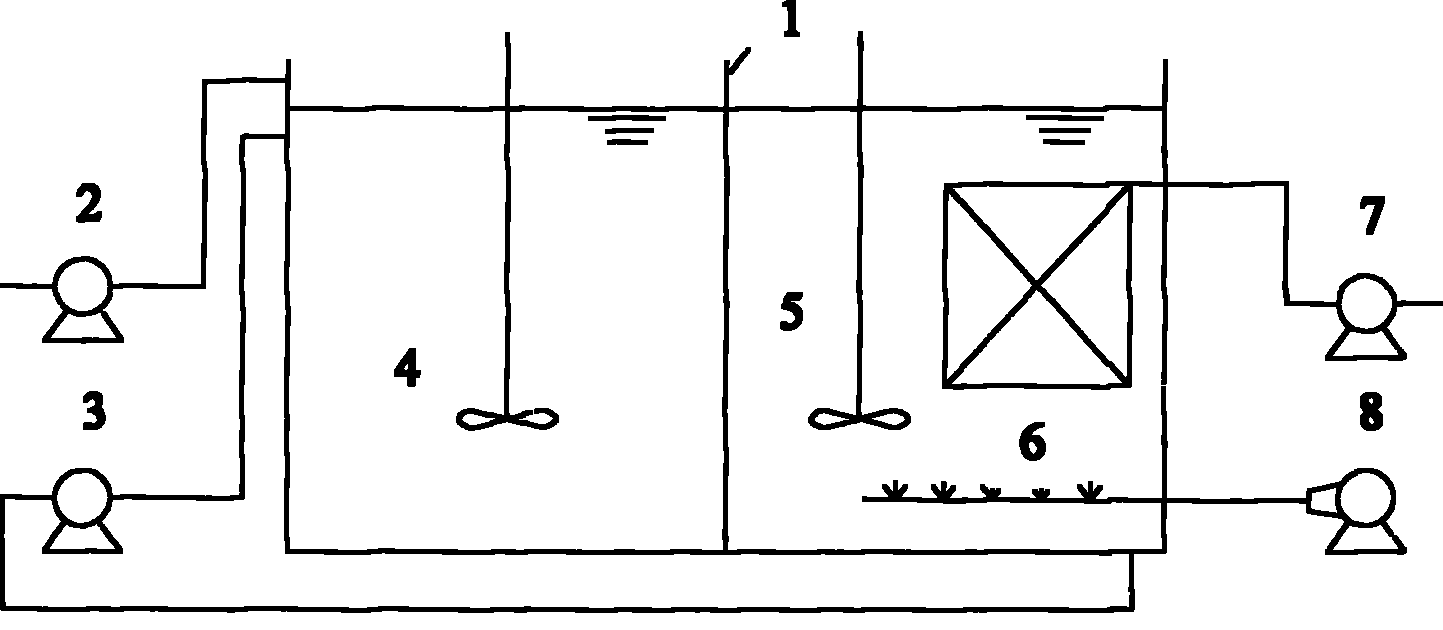

Stereo in-situ ecological urban water system repairing process

InactiveCN101021062AControl survivalPurify waterEnergy based wastewater treatmentHydraulic engineering apparatusMicrobial inoculationConstructed wetland

The stereo in-situ ecological urban water system repairing process tackles polluted water via the quantitative analysis on the water. The technological scheme includes physical simulation and mathematic model analysis, microbe inoculation and culture, constituting refluxing ecological filter bed, purification with biocarrier, artificial aeration, purifying upper water, pre-treatment in the blow down port, establishing water ecological system balance, perfecting water environment data, etc. The present invention realizes the comprehensive tackling of urban water system.

Owner:上海中渠生态环保科技有限公司

Active substances for use in cosmetic and/or pharmaceutical products, obtainable from the fermentation of plant components and/or plant extracts

Processes for producing cosmetic and / or pharmaceutical active components which comprise: (a) providing a fermentation broth comprising a plant component selected from the group consisting of plant constituents, plant extracts and mixtures thereof; (b) inoculating the fermentation broth with a microorganism; and (c) fermenting the microorganism-containing fermentation broth to produce an active component; are described along with cosmetic and / or pharmaceutical preparations containing such active components and methods of using the same to treat the skin and / or hair.

Owner:COGNIS FRANCE SA

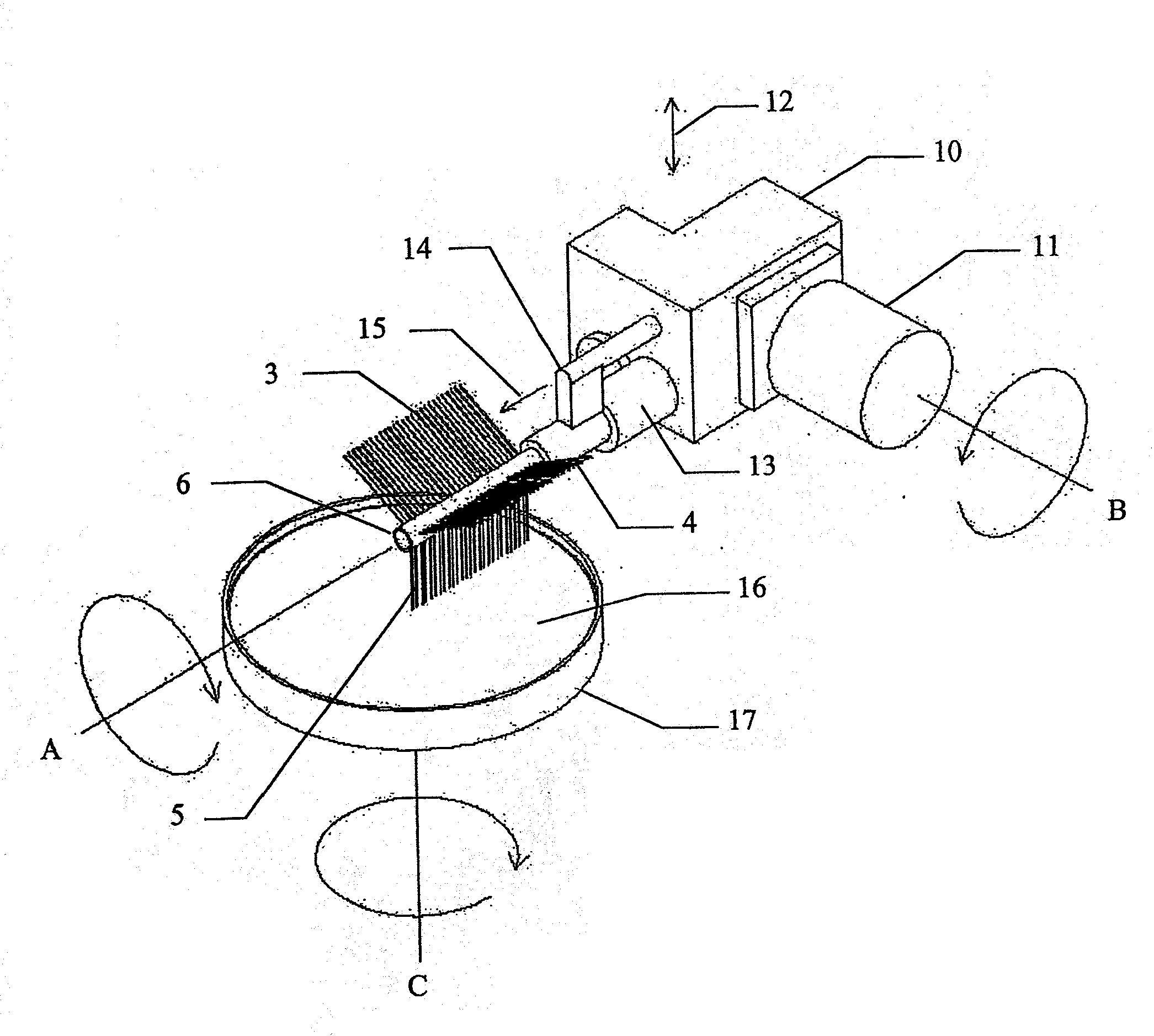

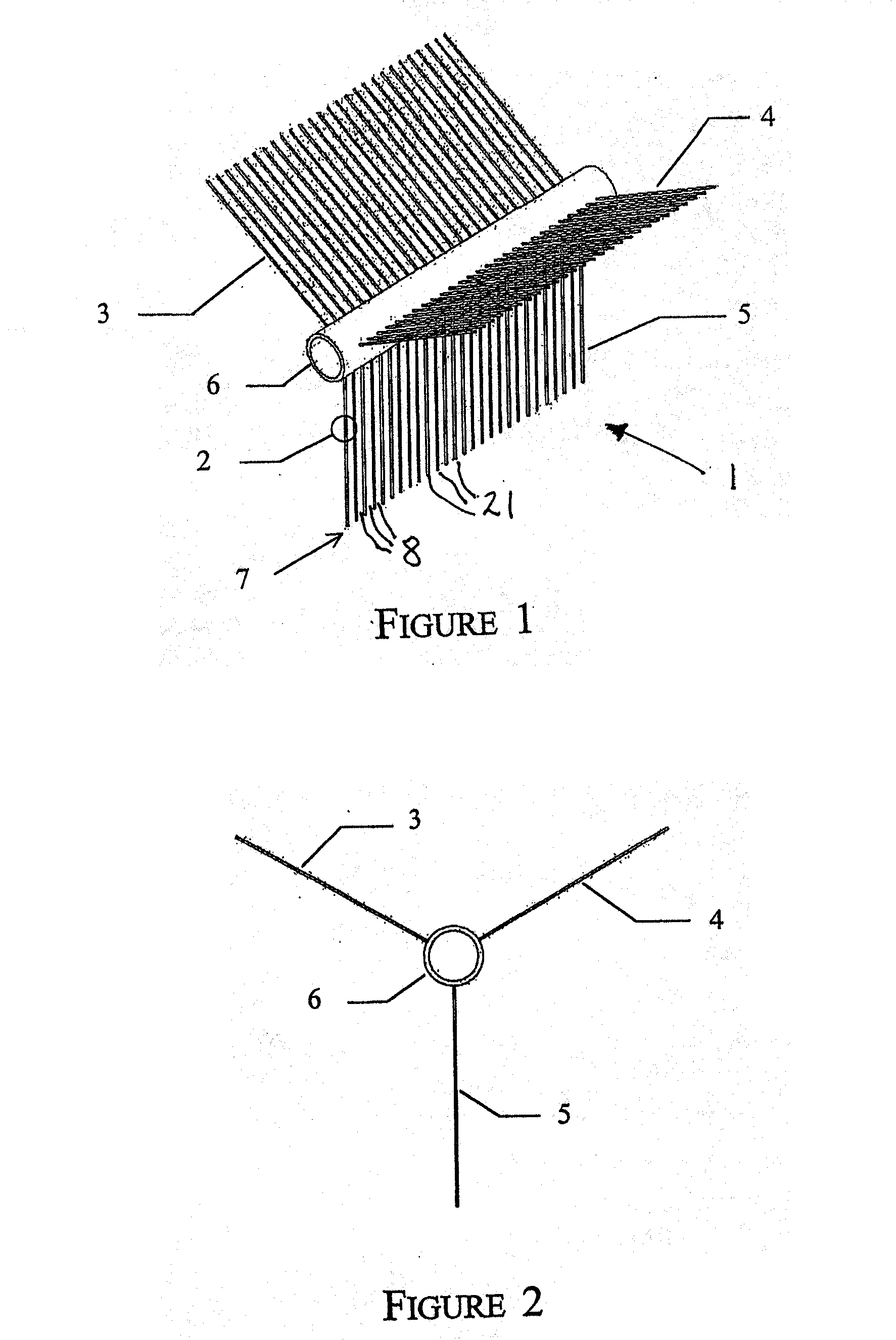

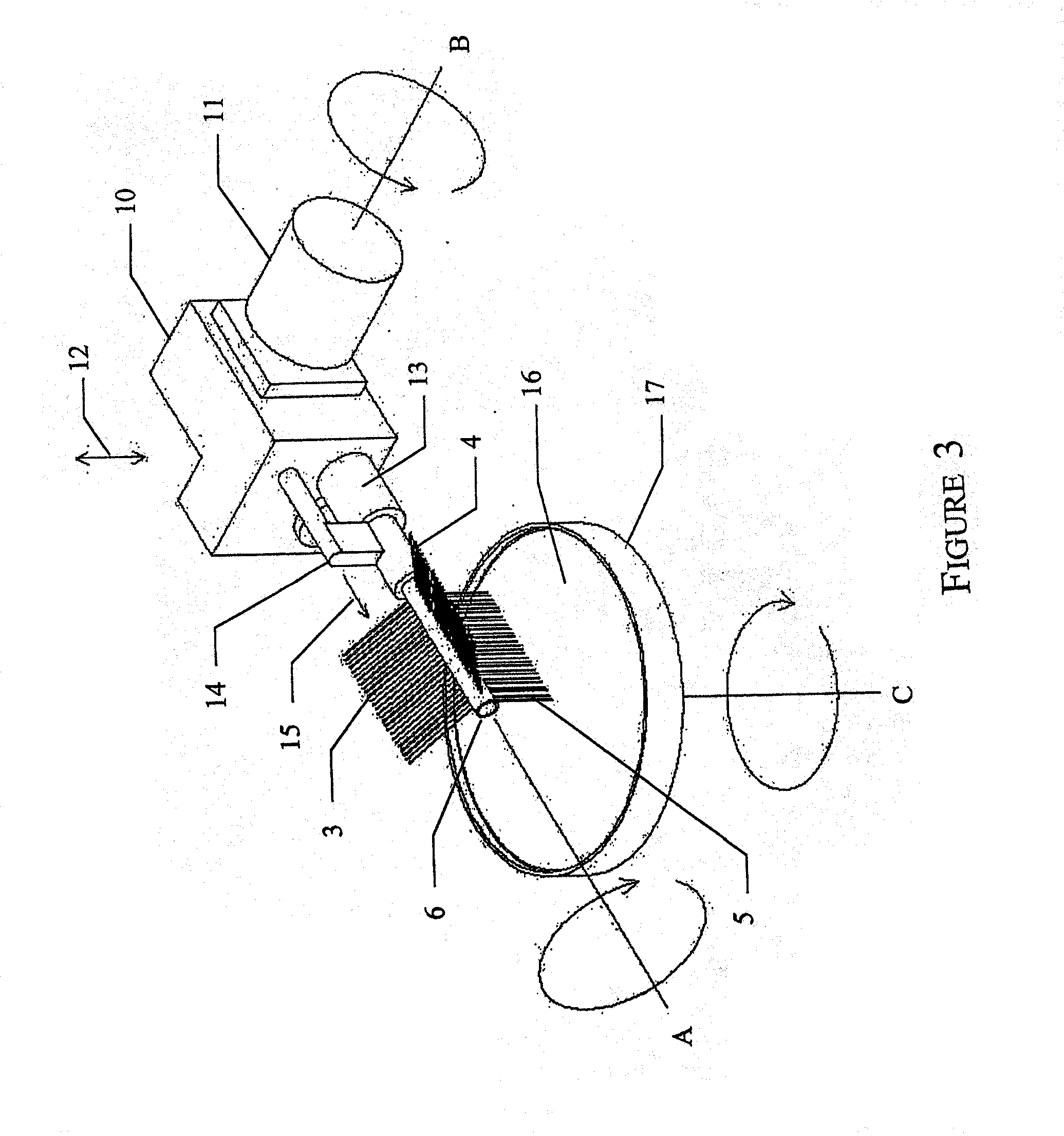

Microbial streaking device

ActiveUS20070202564A1Minimize potentialBioreactor/fermenter combinationsBiological substance pretreatmentsMicrobial inoculationMicroorganism

A streaker device for streaking a microbial inoculum for single colonies on the surface of a solid growth medium. The streaking device has a row of spaced apart contact surfaces for contact with the surface of the solid growth medium. The spaced apart contact surfaces are resiliently flexibly supported by a common support member so as to accommodate variations in depth of growth medium. The spaced apart contact surfaces may be provided on lowermost part of axially curved portions of plastics straps, that are angled backwardly. It is found that formation of a single band can give separation into single colonies. Also provided is an automatic streaking apparatus.

Owner:AUTOBIO DIAGNOSTICS CO LTD

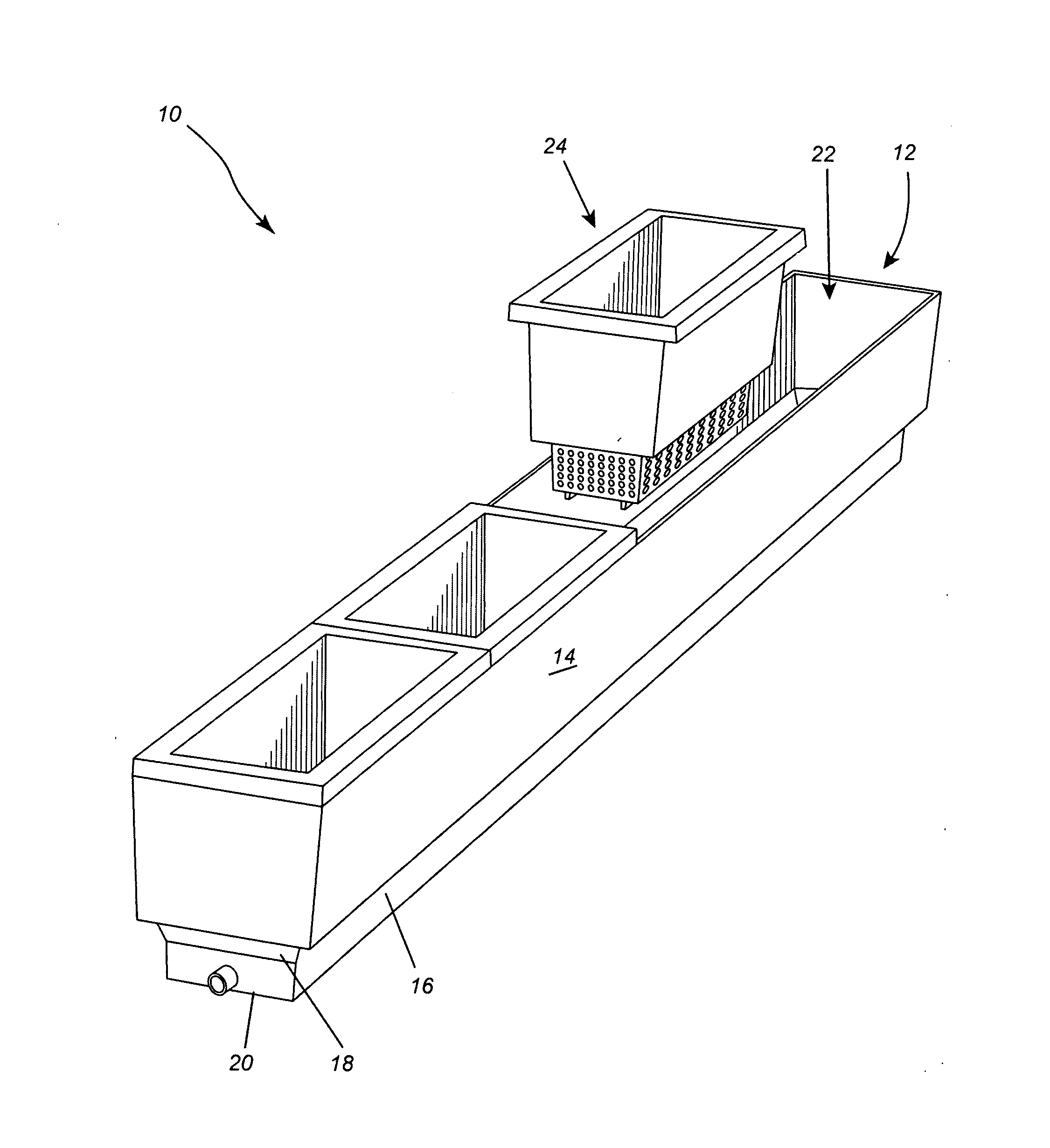

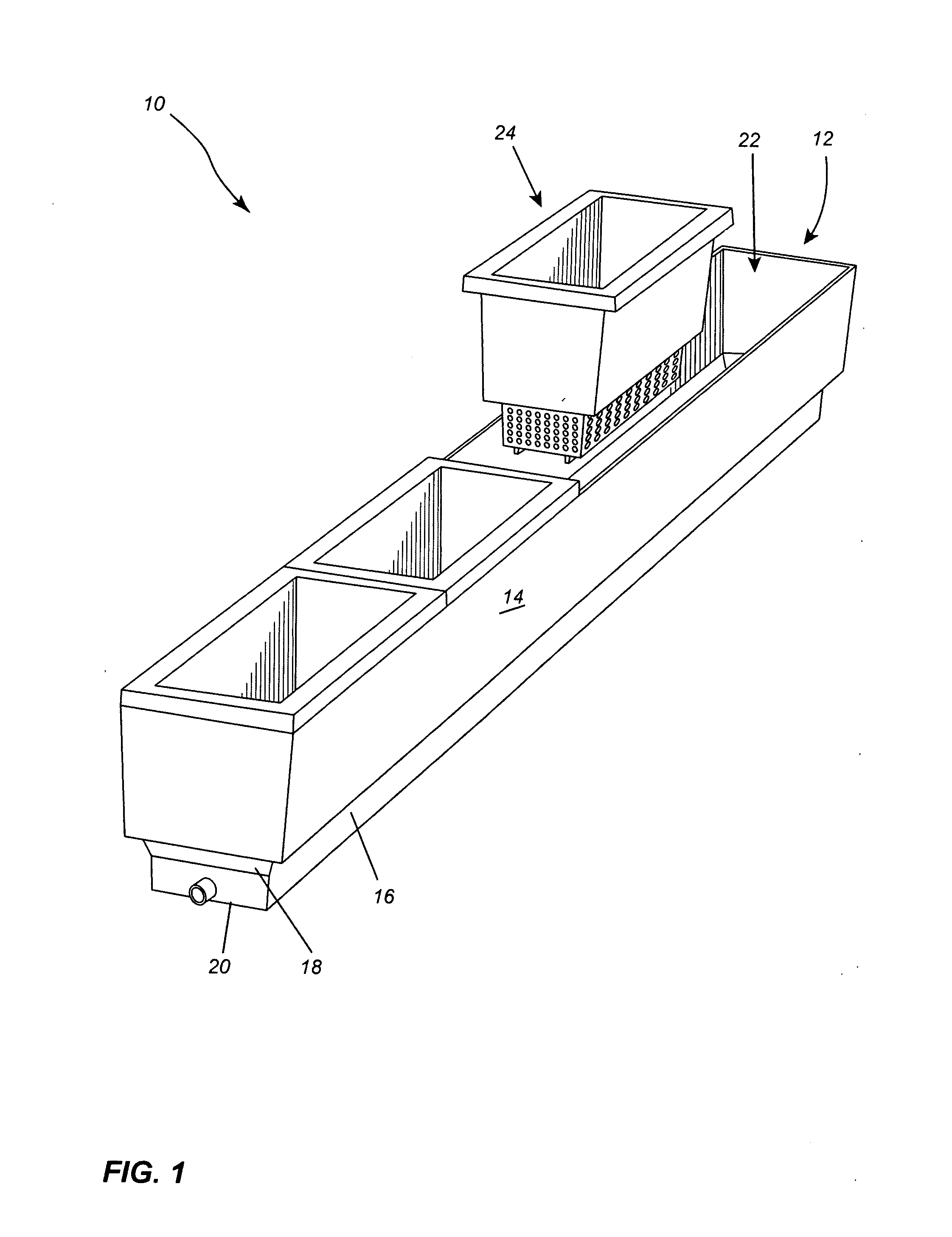

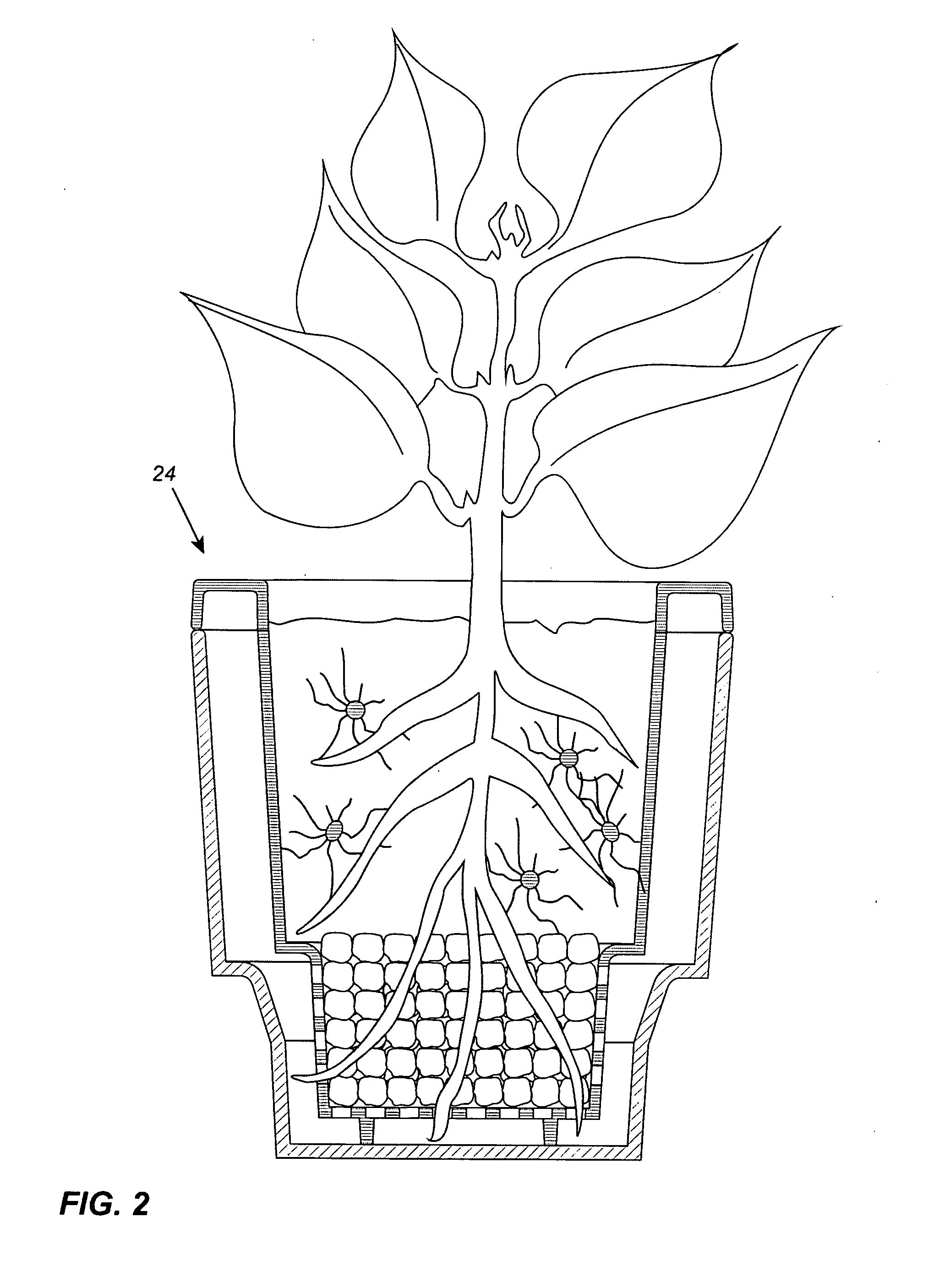

Continuous bioprocess for organic greenhouse agriculture

InactiveUS20150237807A1Avoid waterAvoid Fertilizer WasteSelf-acting watering devicesCultivating equipmentsMicrobial inoculationArbuscular mycorrhizal fungi

A method of plant cultivation which comprises inoculating plants in a plant growing system comprising a container and an insert therefore, the microbial inoculant containing at least one species from the following group of microorganisms comprising arbuscular mycorrhizae associated bacteria, plant growth promoting rhizobacteria, yeast microorganisms and substrate conditioning bacteria.

Owner:BIOPONIX TECH

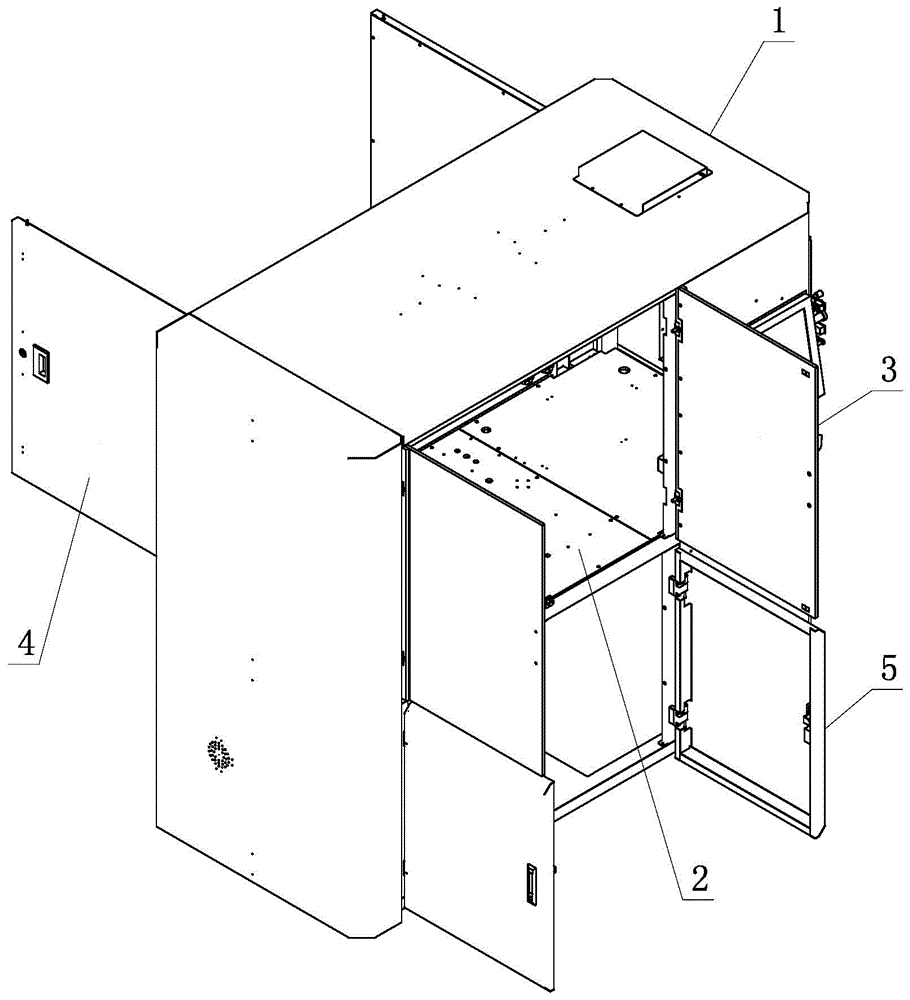

Automatic cover opening or closing and carrying device for sample test tube

ActiveCN104444983AImprove work efficiencyLow costClosing machinesThreaded caps applicationMicrobial inoculationElectric machinery

The invention relates to an automatic cover opening or closing and carrying device for a sample test tube, and solves the technical problems of low efficiency, high cost, easy bacterial infection of operators and negative influence caused by artificial and environmental factors during manual operation of an existing microorganism sample test tube. The device comprises a machine table, a test tube clamping vertical movement electric cylinder, a test tube top rotary motor, a test tube clamping bottom rotary electric cylinder, a test tube clamping electric cylinder and a test tube cover opening clamping electric cylinder, wherein the test tube clamping bottom rotary electric cylinder is connected with the machine table; the test tube clamping vertical movement electric cylinder is connected with the test tube clamping bottom rotary electric cylinder; the test tube clamping electric cylinder and the test tube top rotary motor are connected with the test tube clamping vertical movement electric cylinder respectively; the test tube clamping electric cylinder is provided with two clamping jaws; the test tube top rotary motor is connected with a cover screwer; the test tube cover opening clamping electric cylinder is connected with the machine table and provided with two clamping jaws. The device is widely applied to the technical fields of microorganism inoculation, clinics, chemicals, environments and the like.

Owner:WEIHAI SHILI ELECTRONICS TECH

Combined anoxic/aerobic enhanced biological activated carbon dynamic membrane nitrogen and phosphorus removal process

ActiveCN101863590AGood removal effectIncrease microbial biomassTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentMicrobial inoculationNitrifying bacteria

The invention relates to a combined anoxic / aerobic enhanced biological activated carbon dynamic membrane nitrogen and phosphorus removal process. Enhanced biological activated carbon is cultured by using a microorganism inoculation and acclimatization method; and after domestic sewage is treated, effluent is filtered by a dynamic membrane which is pre-coated with the enhanced biological activated carbon. Powdered activated carbon is added to maintain the high sludge concentration in a reactor. The high sludge concentration can reinforce endogenous denitrification; the problem of nitrogen and phosphorus removal in a treatment process is solved by using a biological phosphorus removal process of the aerobic phosphorus uptake of phosphorus-accumulating bacteria synthetically; the solid-liquid separation of mixed liquid is realized by using the high-efficiency entrapment capability of the dynamic membrane, so that the effluent is filtered. The reactor used by the invention has the advantages of compact structure, simple construction, high contamination removal efficiency and convenient operation, management and maintenance. In the process, advanced nitrogen and phosphorus removal treatment can be performed under the condition of not adding extra carbon sources, and the effluence can meet the national recycled water standard. Dominant bacteria such as loss-easy nitrifying bacteria, denitrifying bacteria, phosphorus-accumulating bacteria and the like are grown in a way that the bacteria are attached to the surface of the powdered activated carbon. The enhanced biological activated carbon dynamic membrane has the advantages of large flux, short hydraulic retention time and capability of improving treatment efficiency.

Owner:TONGJI UNIV

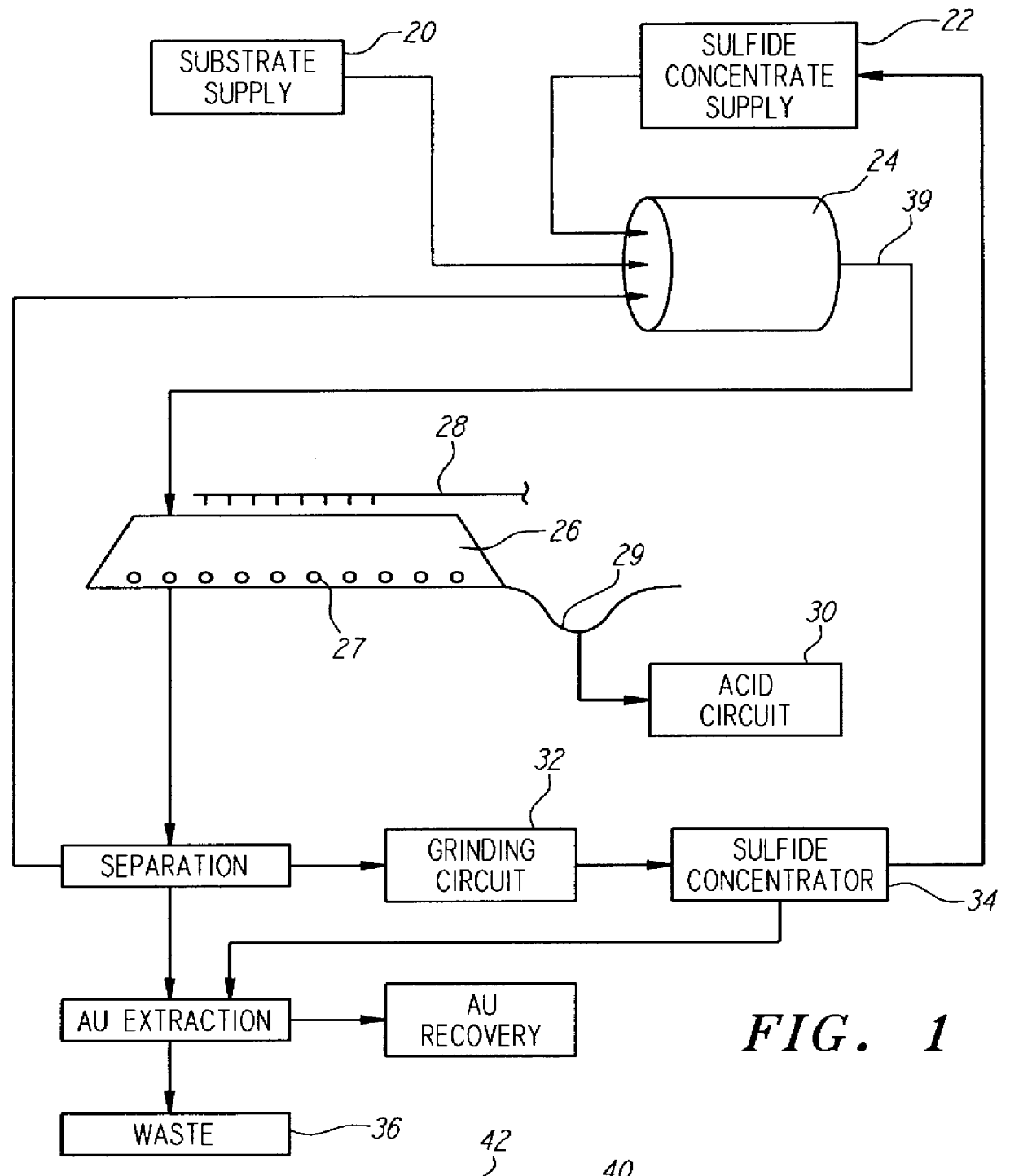

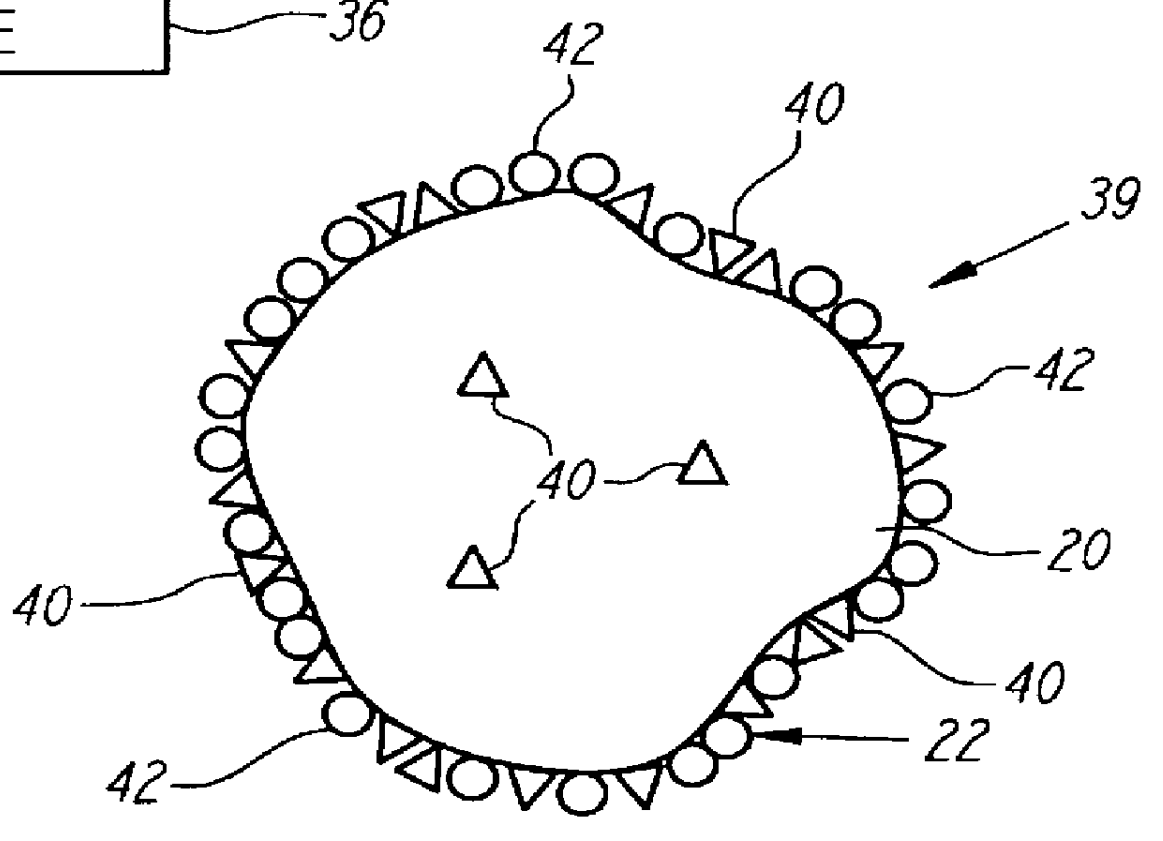

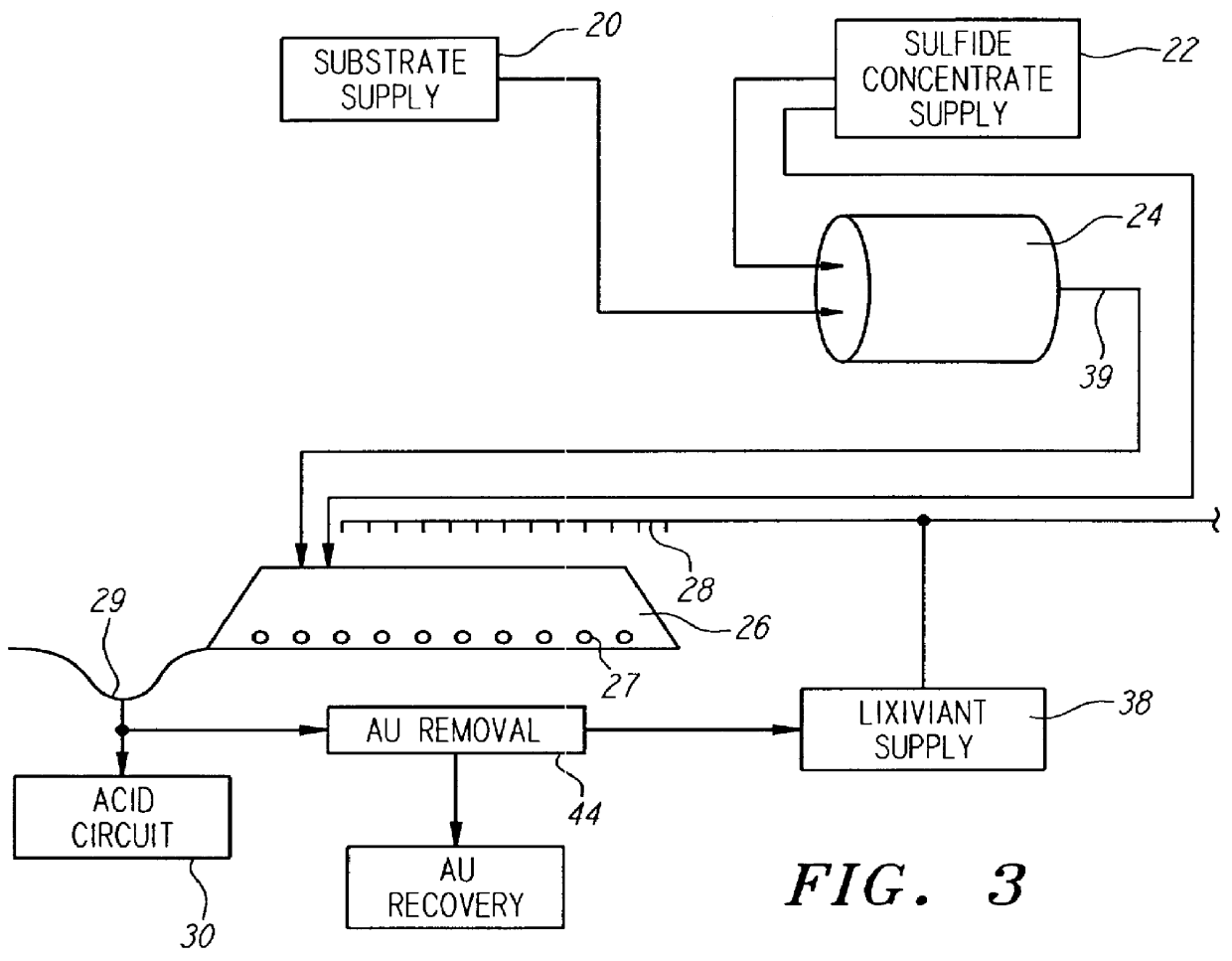

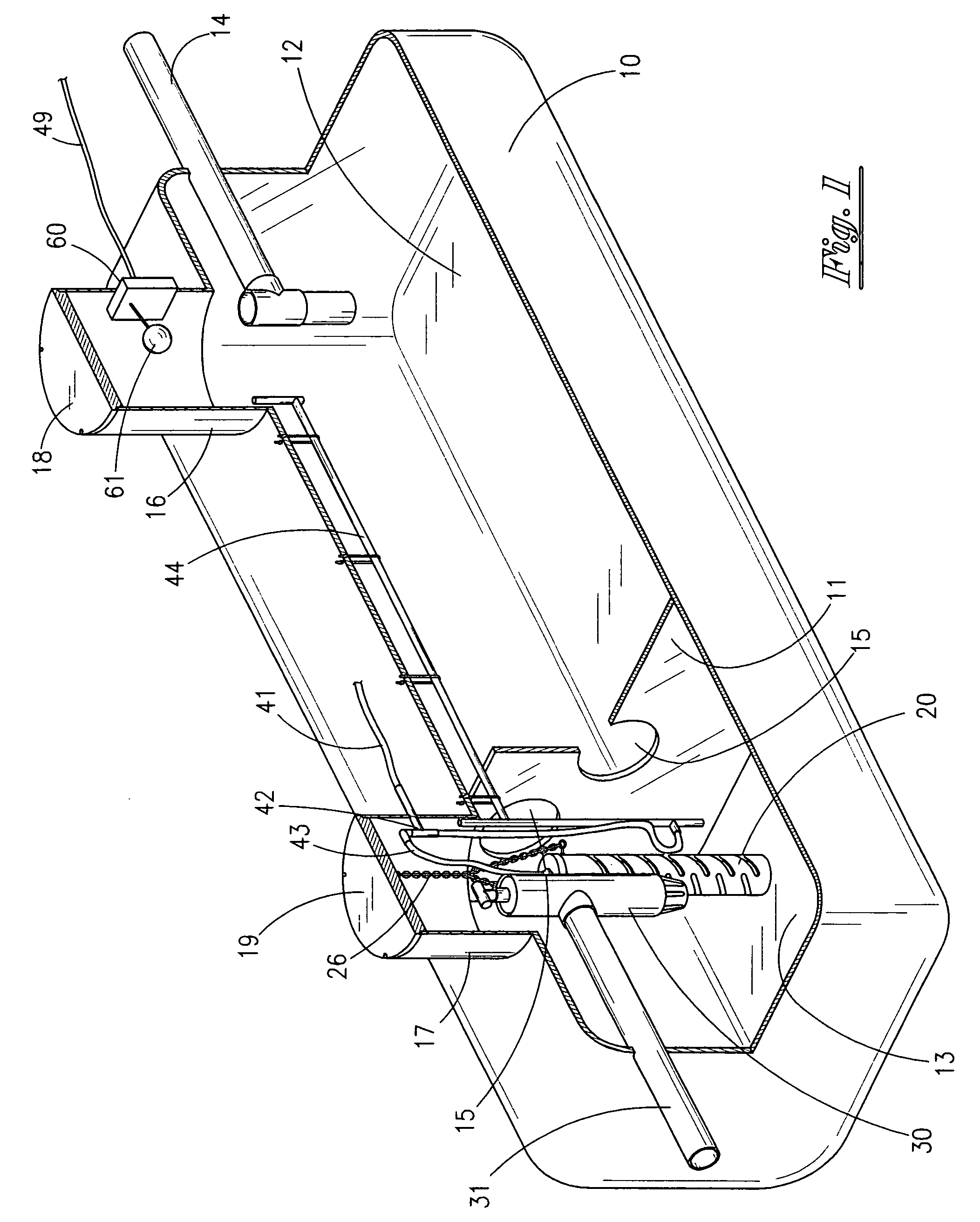

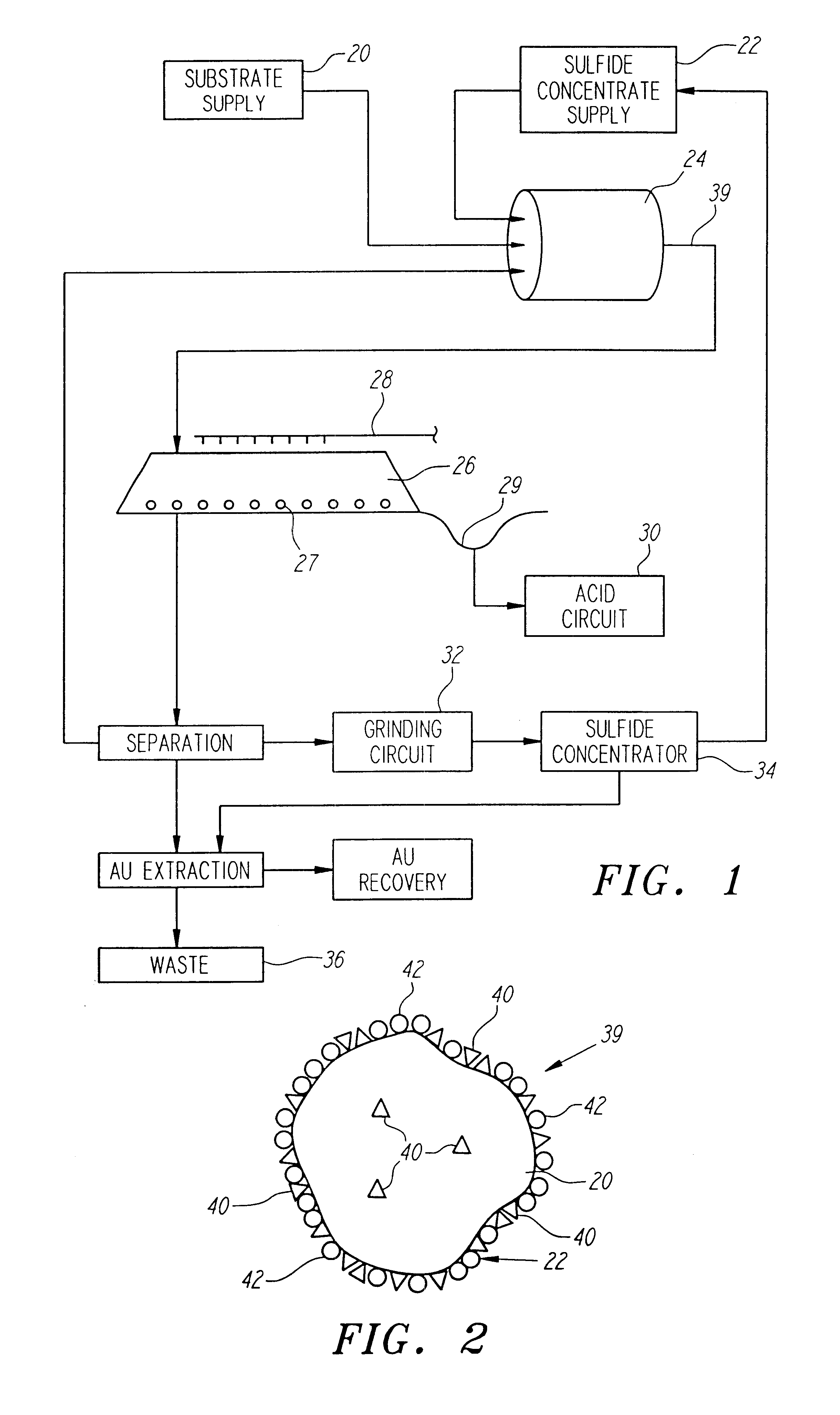

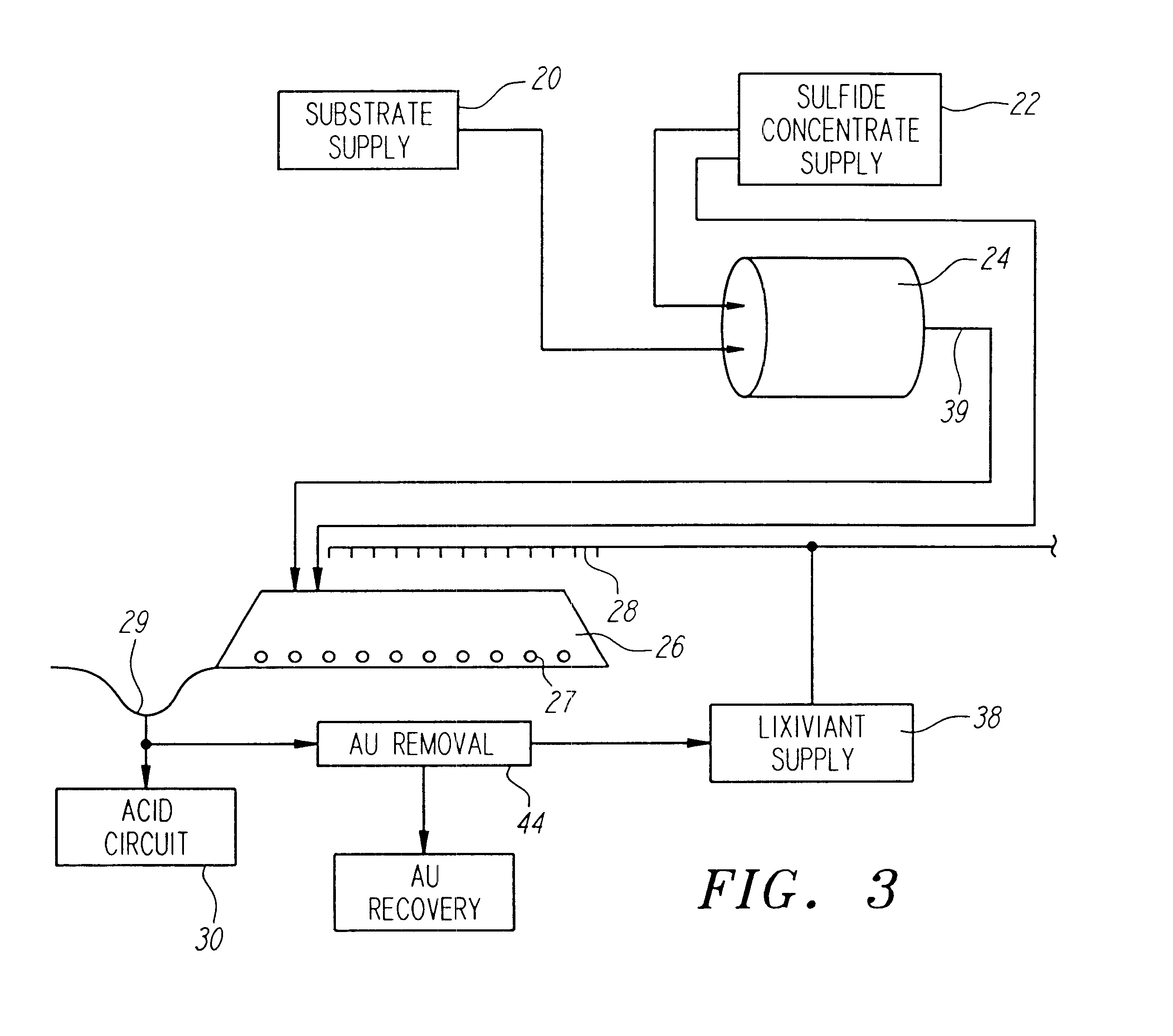

Method of biotreatment for solid materials in a nonstirred surface bioreactor

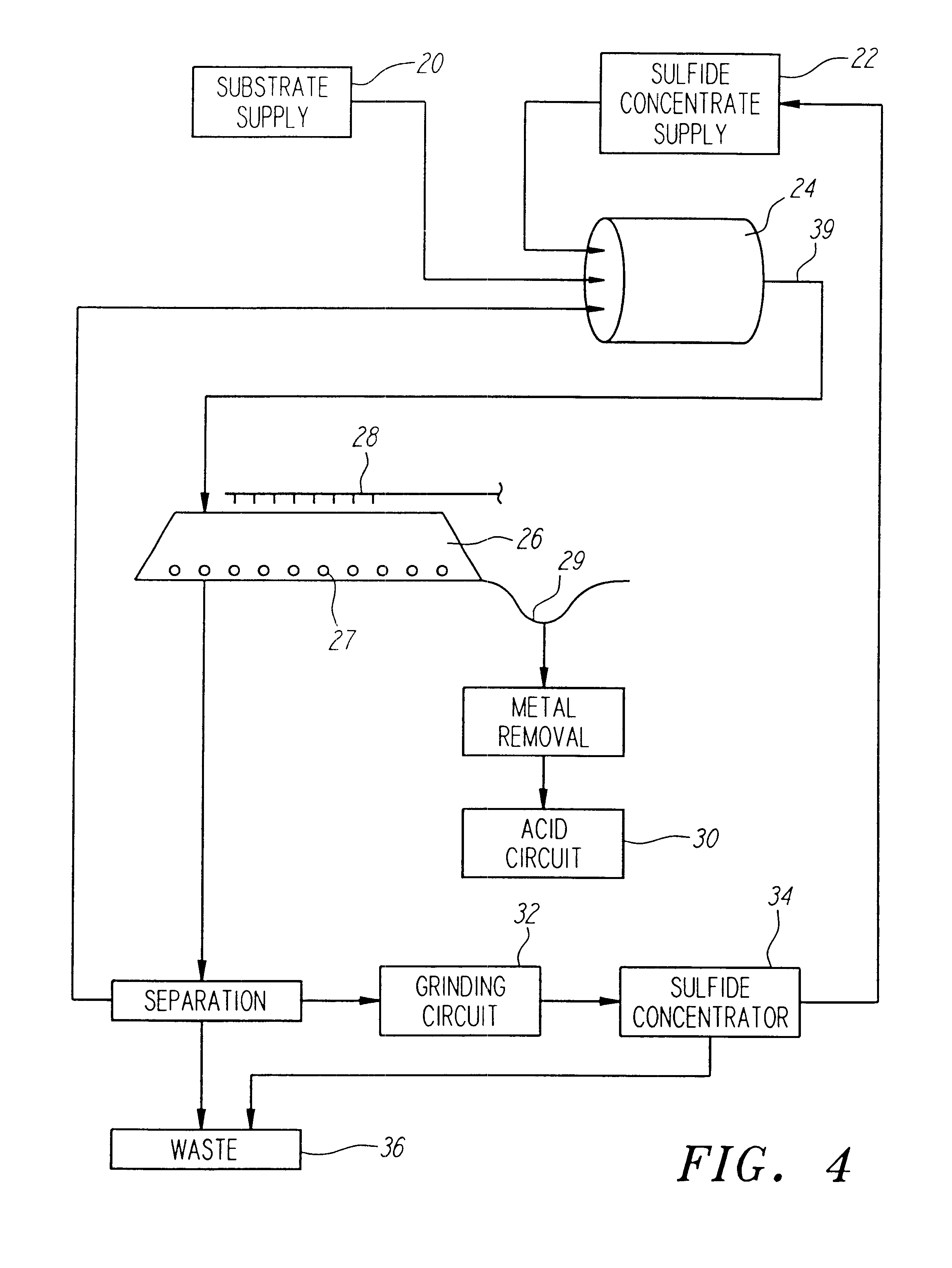

InactiveUS6159726AIncrease capacitySpeed up the processSolvent extractionSolid waste disposalMicrobial inoculationSulfide minerals

A method of biotreating a solid material to remove an undesired compound using a nonstirred surface bioreactor is provided. According to the method the surface of a plurality of coarse substrates is coated with a solid material to be biotreated to form a plurality of coated coarse substrates. The coarse substrates have a particle size greater than about 0.3 cm and the solid material to be biotreated has a particle size less than about 250 mu m. A nonstirred surface reactor is then formed by stacking the plurality of coated coarse substrates into a heap or placing the plurality of coated coarse substrates into a tank so that the void volume of the reactor is greater than or equal to about 25%. The reactor is inoculated with a microorganism capable of degrading the undesired compound in the solid material, and the solid material is then biotreated in the surface bioreactor until the undesired compound in the solid material is degraded to a desired concentration. Preferably the thickness of the solid material coating on the plurality of coarse substrates is less than about 1 mm and the void volume of the reactor is greater than or equal to about 35%. The process is useful for many different biotreatment processes, including the bioremediation of contaminated soils, the desulfurization of coal, and the biooxidation of refractory sulfide ores and concentrates. In bioremediation applications, the undesired compound is typically an organic compound. In coal desulfurization and refractory sulfide ore biooxidation applications, the undesired compound is sulfide minerals.

Owner:GEOSYNFUELS LLC (US)

Solid carrier based microbial inoculants and method for manufacturing of such product

InactiveUS20060243011A1Efficient storagePreserve viabilityBiocideAlkali orthophosphate fertiliserMicrobial inoculationCelsius Degree

Solid carrier-based microbial inoculants can be advantageously used for natural phosphorous supply of plant, biological control of soil born plant pathogens, biological degradation of organic contaminants, soil life and fertility improvement which solid carrier containing phosphorus, made of animal bone charcoal, and having grain size advantageously between 0.001 mm and 10 mm, pore size between 10 and 60,000 nanometer, macro porous structured, the specific area is between 1 and 500 m2 / g, and the external and / or internal surface and / or internal pores are biologically active colonized with aerobic soil microorganisms under less than 30 degree Celsius temperature. Also described is a method for manufacturing and application of Nitrogen free solid carrier-based microbial inoculants which carrier is produced from animal bone by carbonisation process between 300 degree Celsius and 1000 degrees Celsius material core temperature in absence of ocygen, followed by cooling to below 50 degrees Celsius core temperature.

Owner:SOMEUS EDWARD

Fermentation method for changing methane into resource by using water hyacinth and application of product produced thereby

InactiveCN101275150AFast gas productionStable gas supplyBio-organic fraction processingClimate change adaptationMicrobial inoculationActivated sludge

The present invention provides an energy regeneration fermentation method of water hyacinth biogas and its product utilization, belonging to environmental protection and new energy technical field. The method includes: water hyacinth biogas is directly fermented after grinded, or water hyacinth liquid is fermented, pH is adjusted to 6-8; the adjustment of C / N is 20-30:1, microbial inoculation is processed by anaerobic activated sludge and established biogas slurry, the inoculation amount is 10-40%; the temperatures are set 20-40 DEG C in winter, 40-55 EDG C in summer; the broth is extracted from the bottom of the fermentor by a water pump, then the fermenting material is sprayed from the top of the fermentor, and evenly distributed by mechanical stirring. The biogas of the invention has 70% methane average content, much more than common material, and having large gas produce, stable supply quantum, large gas production rate, the slag is fully utilized. The technology not only resolves problem of environmental pollution caused by water hyacinth, but also providing cleaning energy and good quality fertilizer, feed, fit for treatment and ecological restoration of eutrophic lake and other waters.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Pelletization process

InactiveUS6309680B1Good hydrolysis yieldEffective contactWort preparationTea extractionMicrobial inoculationFood flavorings

A process for the production of a fermenting material which includes the steps of forming a dough by adding water to a dried gluten in an amount of from at least 19% to 60% by weight, pelletizing the dough to form pellets, and sterilizing the pellets by steam treatment. The gluten may be rice gluten, corn gluten, wheat gluten or combinations thereof. Also, a fermenting material obtained by this process. This fermenting material can be inoculated with a microorganism and fermented to form a fermention product that can be used as a food sauce, flavoring or seasoning additive.

Owner:GIVAUDAN SA

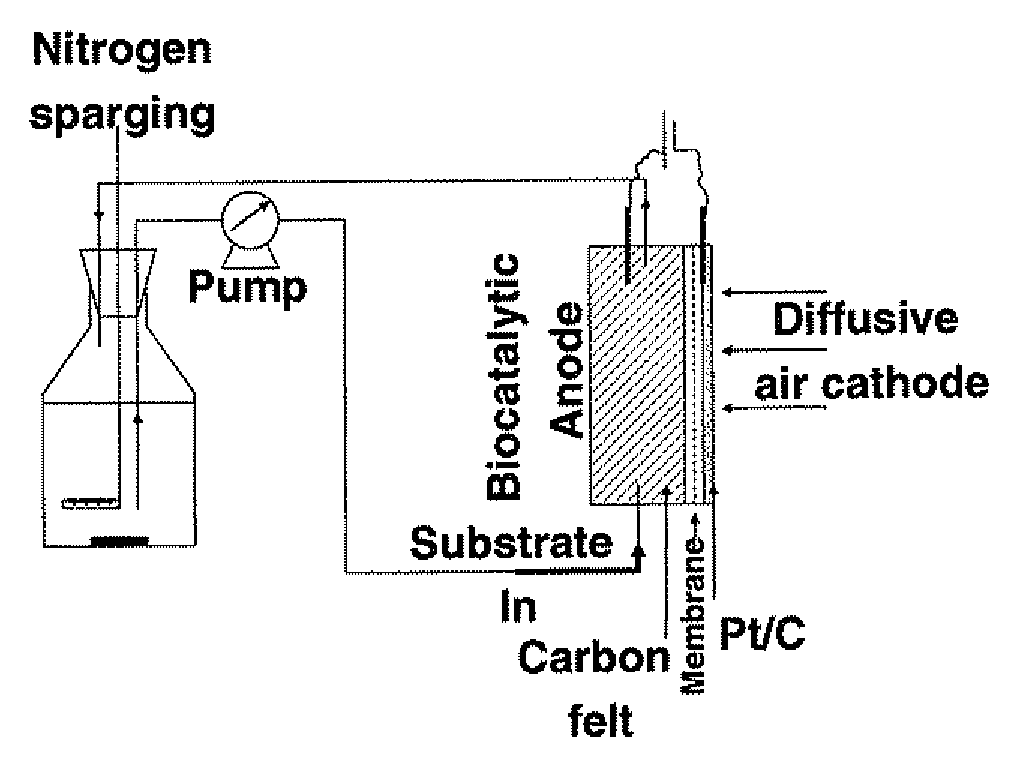

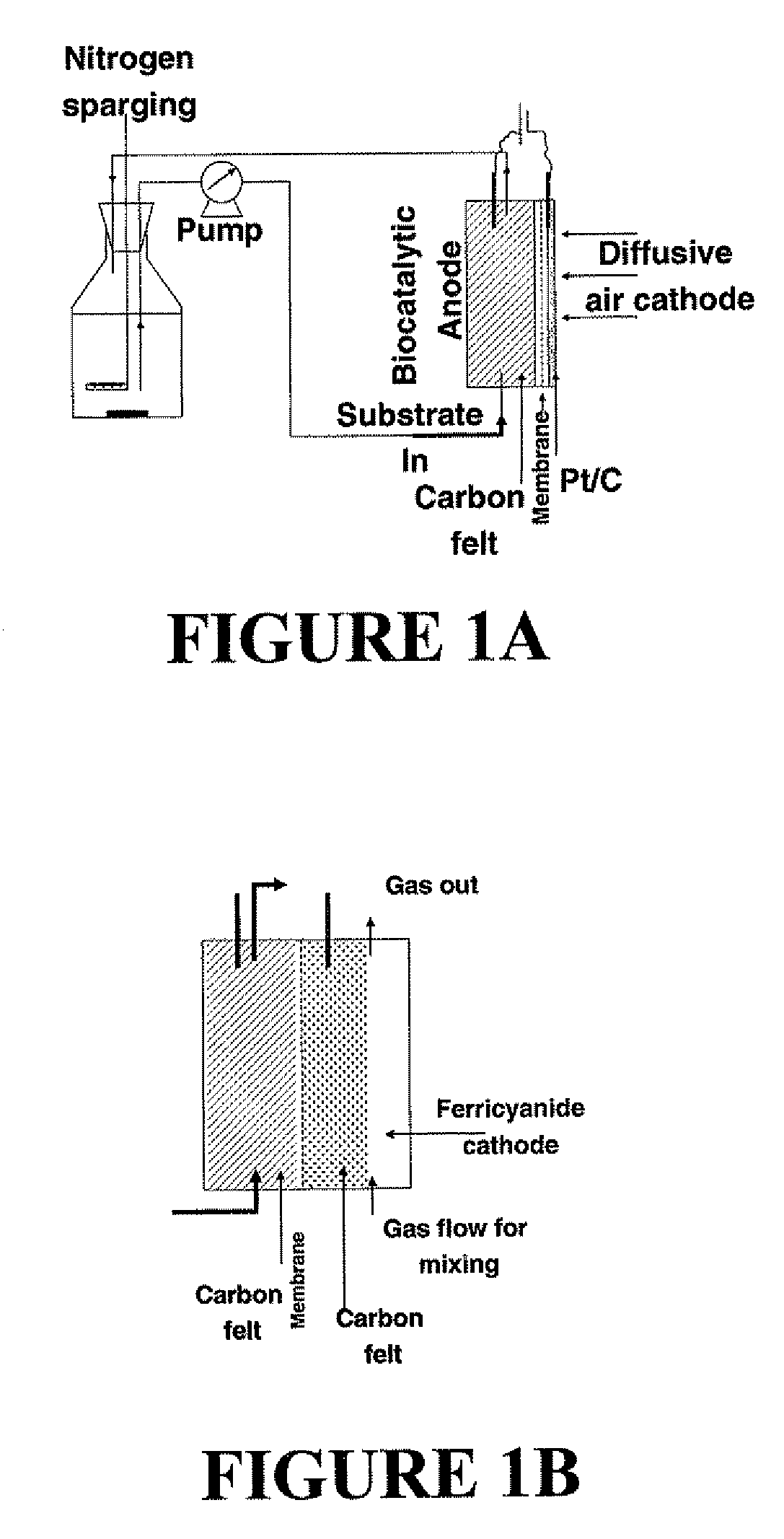

Microbial fuel cell with improved anode

ActiveUS7695834B1Lower resistanceIncrease productionCell electrodesBiochemical fuel cellsMicrobial fuel cellMicrobial inoculation

The present invention relates to a method for preparing a microbial fuel cell, wherein the method includes: (i) inoculating an anodic liquid medium in contact with an anode of the microbial fuel cell with one or more types of microorganisms capable of functioning by an exoelectrogenic mechanism; (ii) establishing a biofilm of the microorganisms on and / or within the anode along with a substantial absence of planktonic forms of the microorganisms by substantial removal of the planktonic microorganisms during forced flow and recirculation conditions of the anodic liquid medium; and (iii) subjecting the microorganisms of the biofilm to a growth stage by incorporating one or more carbon-containing nutritive compounds in the anodic liquid medium during biofilm formation or after biofilm formation on the anode has been established.

Owner:UT BATTELLE LLC

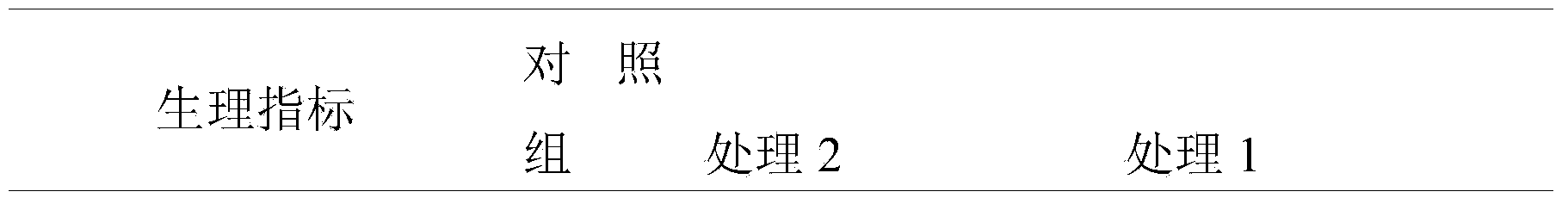

Biological organic-inorganic compound fertilizer with rare earth elements and synergist

The invention relates to a biological organic-inorganic compound fertilizer with rare earth elements and a synergist. Problems that the Chinese fertilizer utilization rate is not high, the agricultural product quality decreases and environmental and ecological problems caused by fertilizing excess fertilizers in agriculture fertilization can be solved by the compound fertilizer. The compound fertilizer has the advantage of containing nitrogen, phosphor, potassium, a microbial inoculation, an organic matter, rare earth elements and a synergist. The compound fertilizer possesses a high fertilizer effect, and can achieve that after fertilizing on corns in dry fields can be omitted based on an agricultural test in three years. The product provided in the invention is prepared from livestock manure, industrial byproducts and the like through a compound fertilizer production apparatus or a compound fertilizer mixing production apparatus. So resources and energy can be saved, and circular economy, energy saving and emission reduction and sustainable development can be largely promoted. The product has a high apparent fertilizer utilization rate, and allows the agricultural product quality to be improved, usage cost by farmers to be low and economic benefits of enterprises to be twice than economic benefits with common compound fertilizers.

Owner:国彦平

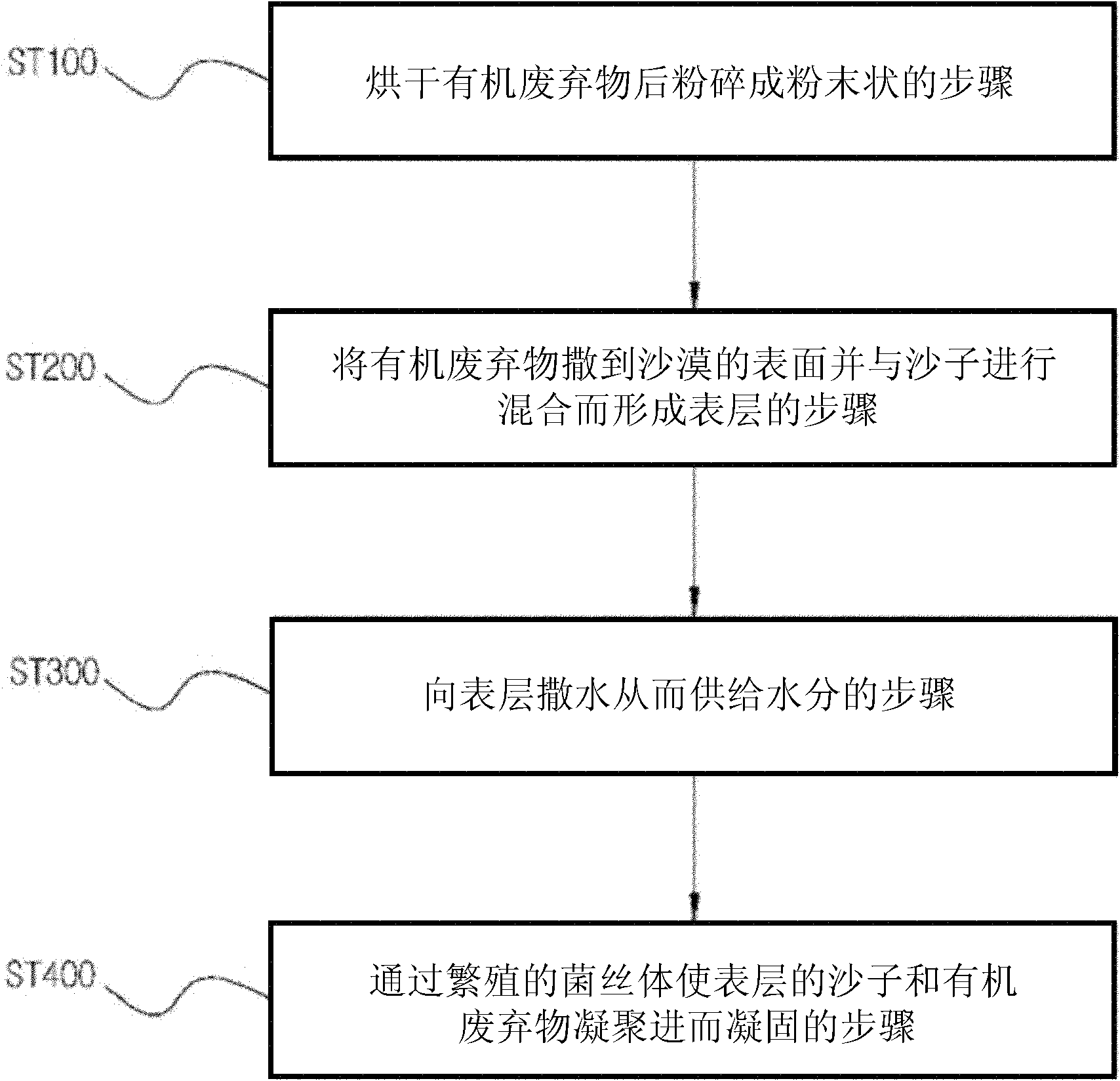

Method for producing a sand aggregate

InactiveCN102159667AConducive to afforestationPrevent sand and dust phenomenonAgriculture tools and machinesOther chemical processesMicrobial inoculationBrick

The present invention relates to a method for producing a sand aggregate, comprising: (a) a step of producing organic waste powders or by-product powders; (b) a step of mixing the organic waste powders or the by-product powders produced in step (a) with soil microbes; (c) a step of mixing the resulting material obtained in step (b) with sand to inoculate the sand with the soil microbes; and (d) a step of supplying water to the resulting material obtained in step (c), and aggregating particles of the organic waste powders and the sand by the growing mycelia of the soil microbes. The present invention produces a sand aggregate (preferably, sand cake, precast pavers or bricks, etc.) or reforms (preferably, fertilizes) sand using organic waste (or by-products), to reutilize waste (or by-products) and to thus prevent soil or water from being contaminated by organic waste (or by-products). Further, when the present invention is applied to the sand in which plants grow poorly, the sand is fertilized to promote the growth of symbiotic microorganisms, and to raise plants and suppress the use of chemical fertilizers and agricultural pesticides, thus activating environmentally-friendly green farming. Meanwhile, when the present invention is applied to the desert of China, which causes yellow dust storms, sand and red clay are provided with anti-scattering properties, to thereby prevent yellow dust storms and environmental contamination and damage to animals and plants caused by the yellow dust storms.

Owner:李愚坪

Comprehensive fermentation method for alga marsh gas and products therefrom

InactiveCN1970776AIncrease production capacityConducive to the sustainable development of agricultureWaste based fuelFermentationMicrobial inoculationBiotechnology

The invention discloses a fermenting method and product of algae methane power in the environment protective and new-energy technical domain, which comprises the following steps: adjusting the rate of carbon and nitrogen; controlling dried ferment; seeding microbe; controlling temperature; circulating ferment liquid; stirring; utilizing methane, liquid and slag effectively. The method makes methane content to 74%, which supplies gas stably.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Stable Microbial Inoculants and Methods for Production of Them

InactiveUS20080107689A1Efficient use ofEasy to manufactureFungiBacterial antigen ingredientsMicroorganismMicrobial inoculation

The invention relates to an inoculant in the form of a stable storage paste including a microorganism, a solid carrier, one or more protective substances, and water. The invention further relates to a method for producing of the inoculant using a growth medium including a solid carrier.

Owner:VERDERA

Preparation method for bamboo shoot enzyme food

InactiveCN106616592AGuaranteed Active IngredientsImproves antioxidant activitySugar food ingredientsYeast food ingredientsMicrobial inoculationMicroorganism

The invention discloses a preparation method for bamboo shoot enzyme food, and belongs to the field of food processing. The method comprises the following steps: (1) raw material pre-treatment; (2) material mixing; (3) fermentation; (4) treatment after fermentation. The bamboo shoot enzyme food is fermented and ripened by taking fresh bamboo shoots as raw materials, simulating natural generation conditions of an enzyme, and performing natural fermentation or microbial fermentation, or combining the natural fermentation and the microbial fermentation, wherein the fermenting time is long; a stock solution of a bamboo shoot enzyme is obtained. The bamboo shoot enzyme obtained with the preparation method disclosed by the invention effectively ensures the active ingredients of the bamboo shoots and has good antioxidant activity; finally, a food product which has improved components or flavour and has special nutrition and healthcare functions is obtained.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Complex cover material for refuse landfill and application method thereof

InactiveCN103406328AWell-developed pore structureReduce odorLandfill technologiesSolid waste disposalVegetationSocial benefits

The invention discloses a complex cover material for a refuse landfill. The complex cover material is composed of charcoal, mineralization garbage and incineration ash which are uniformly mixed, the mass ratio of the charcoal to the mineralization garbage to the incineration ash is (3-4) to (3-5) to (1-4), the filling density of the complex cover material is 0.6-1.1 g / cm<3>, the particle size range of the cover material is 5-20 mm, and the specific surface area of the material is 150-280 m<2> / g. The complex cover material provided by the invention utilizes the carrier action of the charcoal, the inoculation action of deodorization microorganisms of the mineralization garbage and the partial hydration gelatification of the incineration ash, so that the stench release amount of garbage and the discharge of greenhouse gases are greatly reduced, and vegetations are supplied with good nutrition; the complex cover material has the advantages of low cost, simple preparation and easy disposition; meanwhile, the mineralization garbage and sludge in a landfill are fully utilized, the utilization of local materials is realized, the effects of recycling garbage, treating waste with waste, reducing the garbage volume occupancy of the landfill and improving environmental protection are achieved, and social benefits and economic benefits are greatly improved; the complex cover material provided by the invention is suitable for the landfill covering treatment of garbage.

Owner:SHANGHAI JIAO TONG UNIV

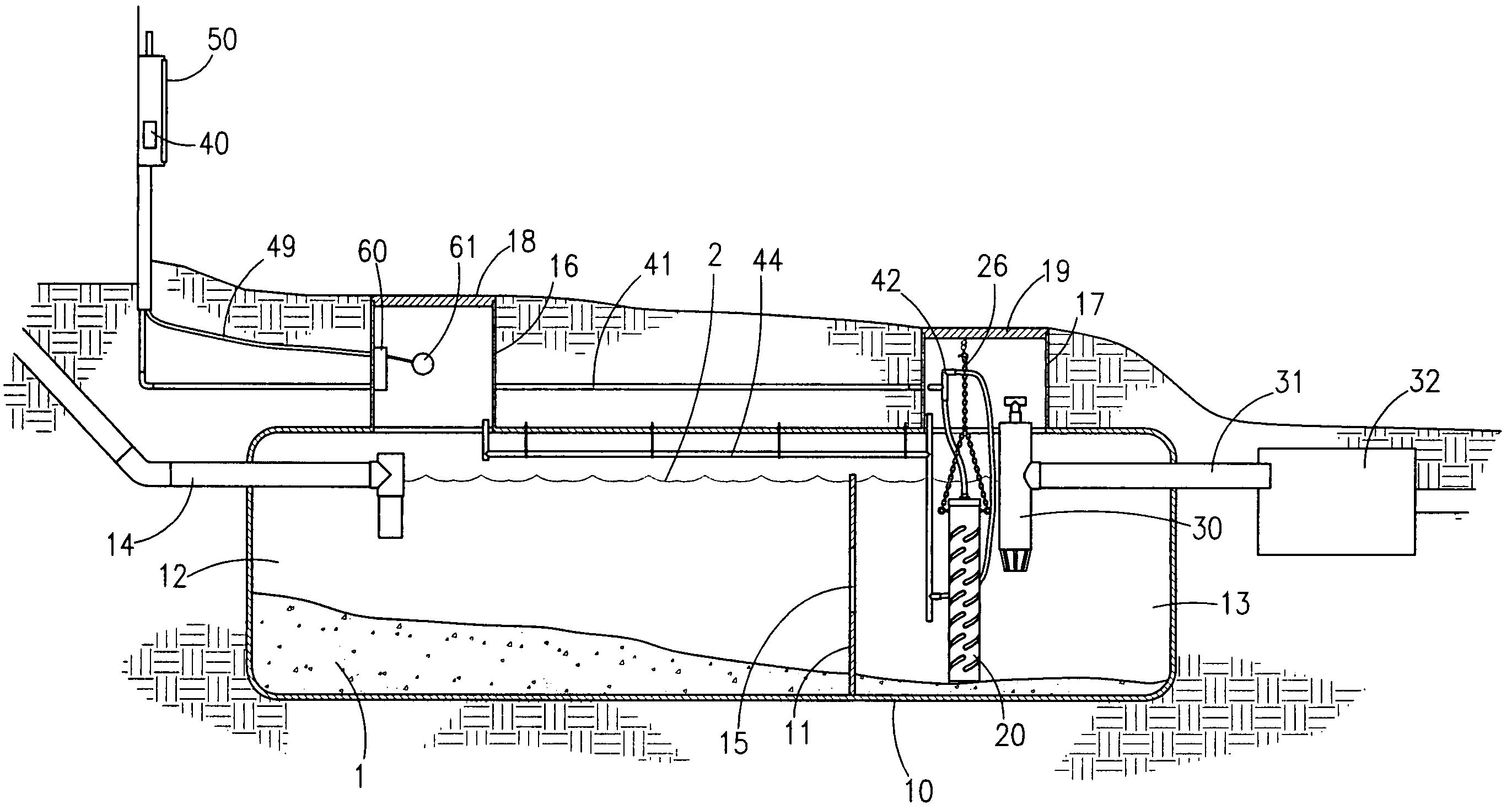

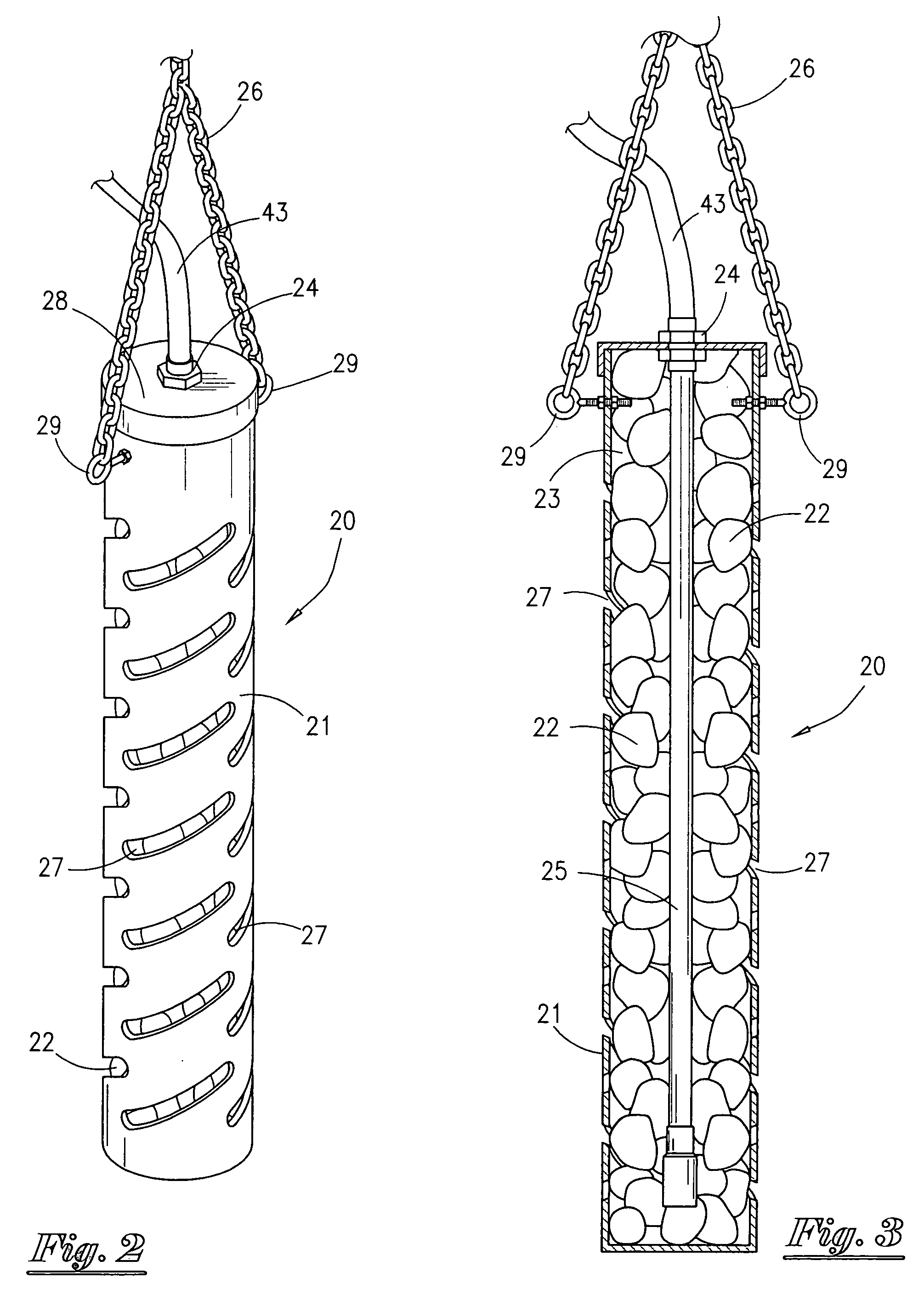

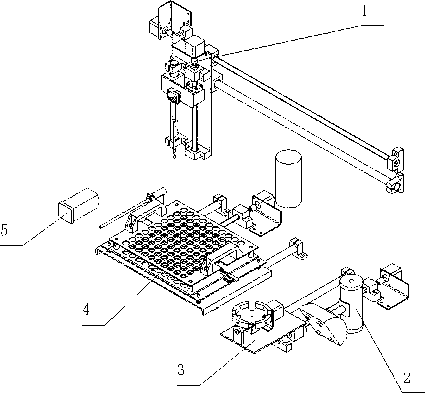

Method and apparatus for on-site treatment of waste water

InactiveUS20090255871A1Improve effluent discharge qualityReduce eliminateWater treatment parameter controlTreatment using aerobic processesMicrobial inoculationSites treatment

A method and apparatus is provided for continuous microbial seeding of waste-laden water directly within septic tanks and similar treatment facilities in order to improve quality of effluent discharge, thereby reducing or eliminating problems commonly associated with such effluent (including, but necessarily limited to, clogging of conventional drain fields). Waste water to be treated flows into a multi-chambered treatment tank. At least one bio-reactor is installed in such tank, and provides for in-situ growth of desired microbial populations within said tank. The present invention allows for demand growth and improved mineralization of wastes both inside the tank, as well as downstream of the treatment tank.

Owner:DAVIS TOMMY MACK

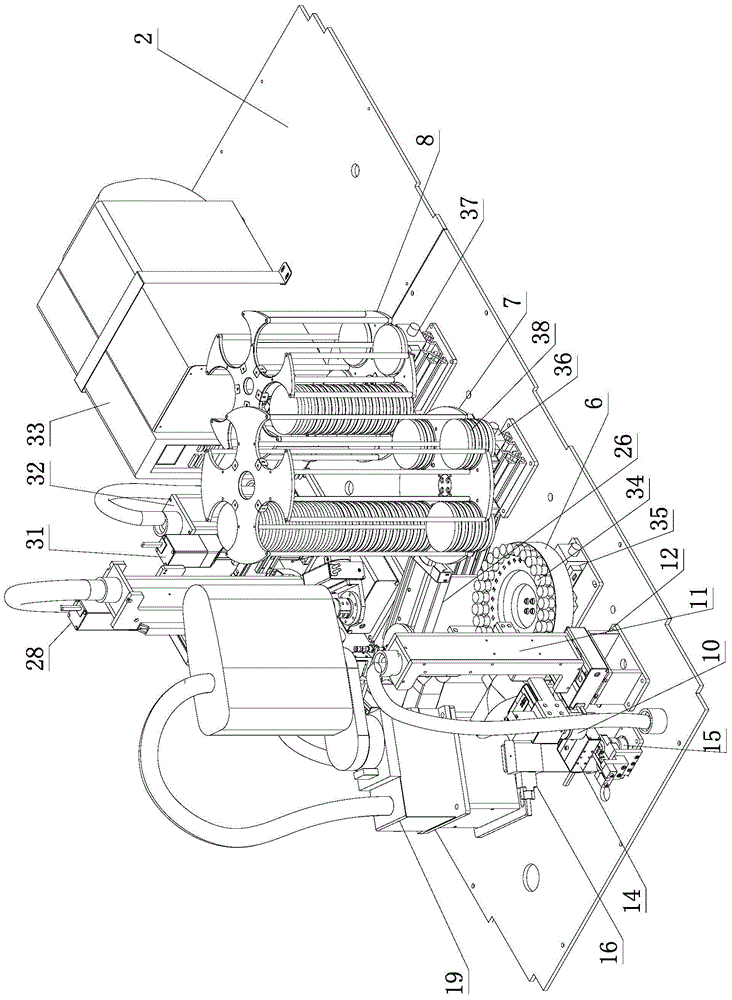

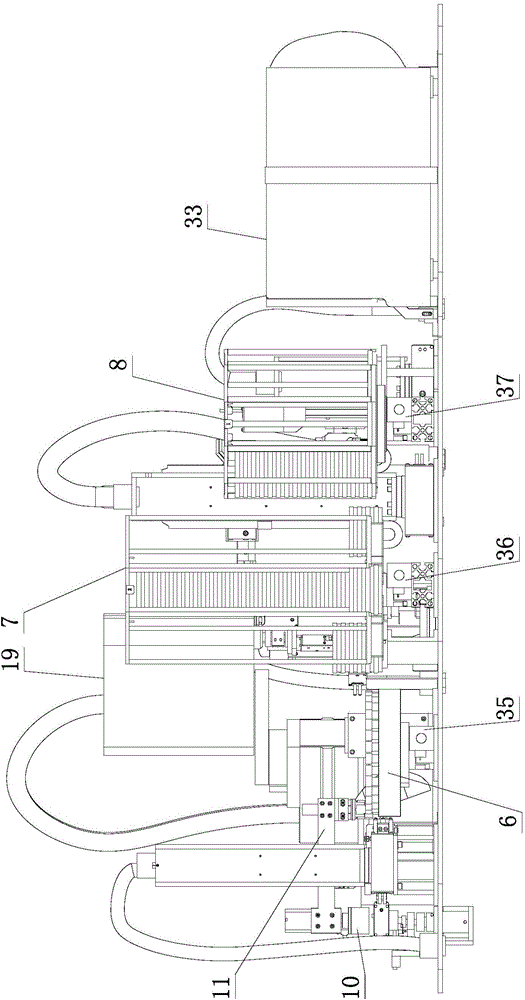

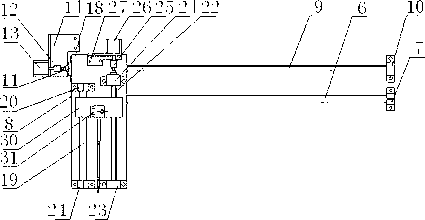

Automatic microbial inoculation instrument

ActiveCN102757891AEfficient separationGuaranteed accuracyBiological material testing proceduresMicrobial inoculationMicroorganism

An automatic microbial inoculation instrument comprises a base and an instrument rear wall. The base and the instrument rear wall are mutually perpendicular to form an instrument supporting frame, a Petri dish control mechanism (3) and a sample delivery mechanism (4) are arranged on the base, and an inoculation ring moving mechanism (1) is arranged on the rear wall of the instrument. The automatic microbial inoculation instrument has the advantages that an inoculation method, namely a multi-region marking method which is accepted by most clinical microorganism personnel, is adopted, single strains can be separated more effectively, and sample misjudgment due to technical irregularity of clinical microorganism operators can be avoided; consumable cost in use of the instrument is equivalent to the cost of manual operations, so that accuracy of clinical sample inspection is guaranteed while enthusiasm in use of the instrument in hospital departments is improved; and the automatic microbial inoculation instrument enables hospital profits to be maximized in term of economic conditions, and single strain groups can be separated more accurately to enable more accuracy in detection by the automatic microbial inoculation instrument in term of medicine.

Owner:李松华

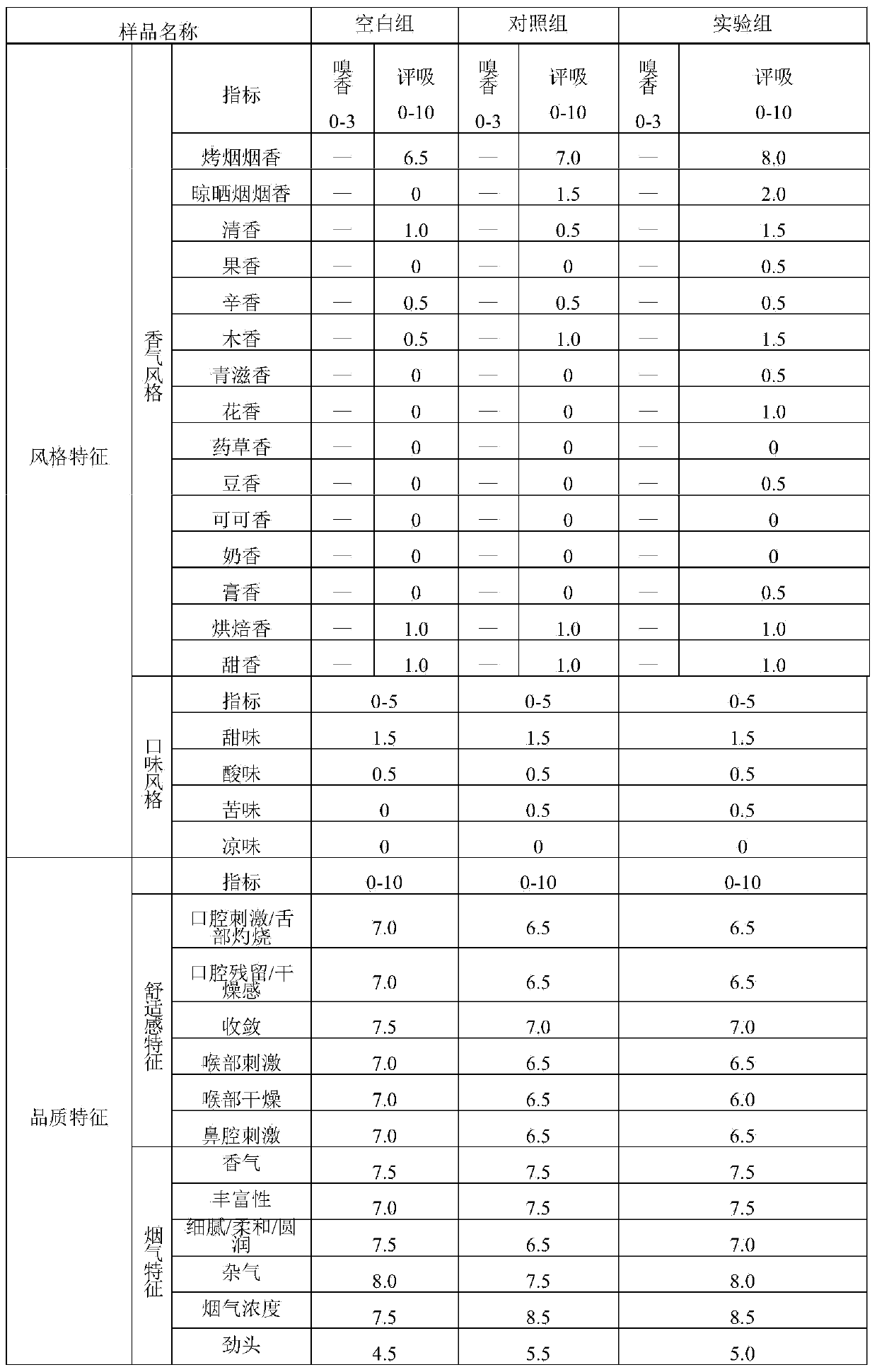

Aroma-enhancing puffed tobacco stem particles and preparation method and application thereof

ActiveCN103989246AAvoid the problem of excessive burnt smellFully fixedTobacco treatmentTobacco smoke filtersMicroorganismMicrobial inoculation

The invention discloses aroma-enhancing puffed tobacco stem particles and a preparation method and application thereof. The preparation method of the aroma-enhancing puffed tobacco stem particles comprises the steps that a micropore structure is formed in each tobacco stem, and the tobacco stems are dried and smashed after being fixed and formed to form particles; the tobacco stem particles are inoculated with a compound aroma-generating microorganism, fermental cultivation and drying are carried out on the tobacco stem particles and the compound aroma-generating microorganism, and then the aroma-enhancing puffed tobacco stem particles can be obtained. The compound aroma-generating microorganism is formed by compounding bacillus subtilis, Trichoderma reesei, Aspergillus niger and Hansenula polymorpha according to the wet-cell mass ratio of 5:2:1:1. According to the aroma-enhancing puffed tobacco stem particles and the preparation method and application thereof, the tobacco stems serve as raw materials to be processed to obtain the puffed tobacco stem particles, then the compound aroma-generating microorganism is added, and serving as a filter material of a filter tip, the finally-obtained aroma-enhancing puffed tobacco stem particles have the advantages of being high in filter efficiency, strong in adsorption capacity, free of offensive odors and consistent with tobacco in aroma and have good application prospect.

Owner:GUANGZHOU AOJIAN PERFUME

Method of biotreatment for solid materials in a nonstirred surface bioreactor

InactiveUS6410304B2Increase capacitySpeed up the processSolvent extractionSolid waste disposalMicrobial inoculationSulfide minerals

A method of biotreating a solid material to remove an undesired compound using a nonstirred surface bioreactor is provided. According to the method the surface of a plurality of coarse substrates is coated with a solid material to be biotreated to form a plurality of coated coarse substrates. The coarse substrates have a particle size greater than about 0.3 cm and the solid material to be biotreated has a particle size less than about 250 mum. A nonstirred surface reactor is then formed by stacking the plurality of coated coarse substrates into a heap or placing the plurality of coated coarse substrates into a tank so that the void volume of the reactor is greater than or equal to about 25%. The reactor is inoculated with a microorganism capable of degrading the undesired compound in the solid material, and the solid material is then biotreated in the surface bioreactor until the undesired compound in the solid material is degraded to a desired concentration. Preferably the thickness of the solid material coating on the plurality of coarse substrates is less than about 1 mm and the void volume of the reactor is greater than or equal to about 35%. The process is useful for many different biotreatment processes, including the bioremediation of contaminated soils, the desulfurization of coal, and the biooxidation of refractory sulfide ores and concentrates. In bioremediation applications, the undesired compound is typically an organic compound. In coal desulfurization and refractory sulfide ore biooxidation applications, the undesired compound is sulfide minerals.

Owner:GEOSYNFUELS LLC (US)

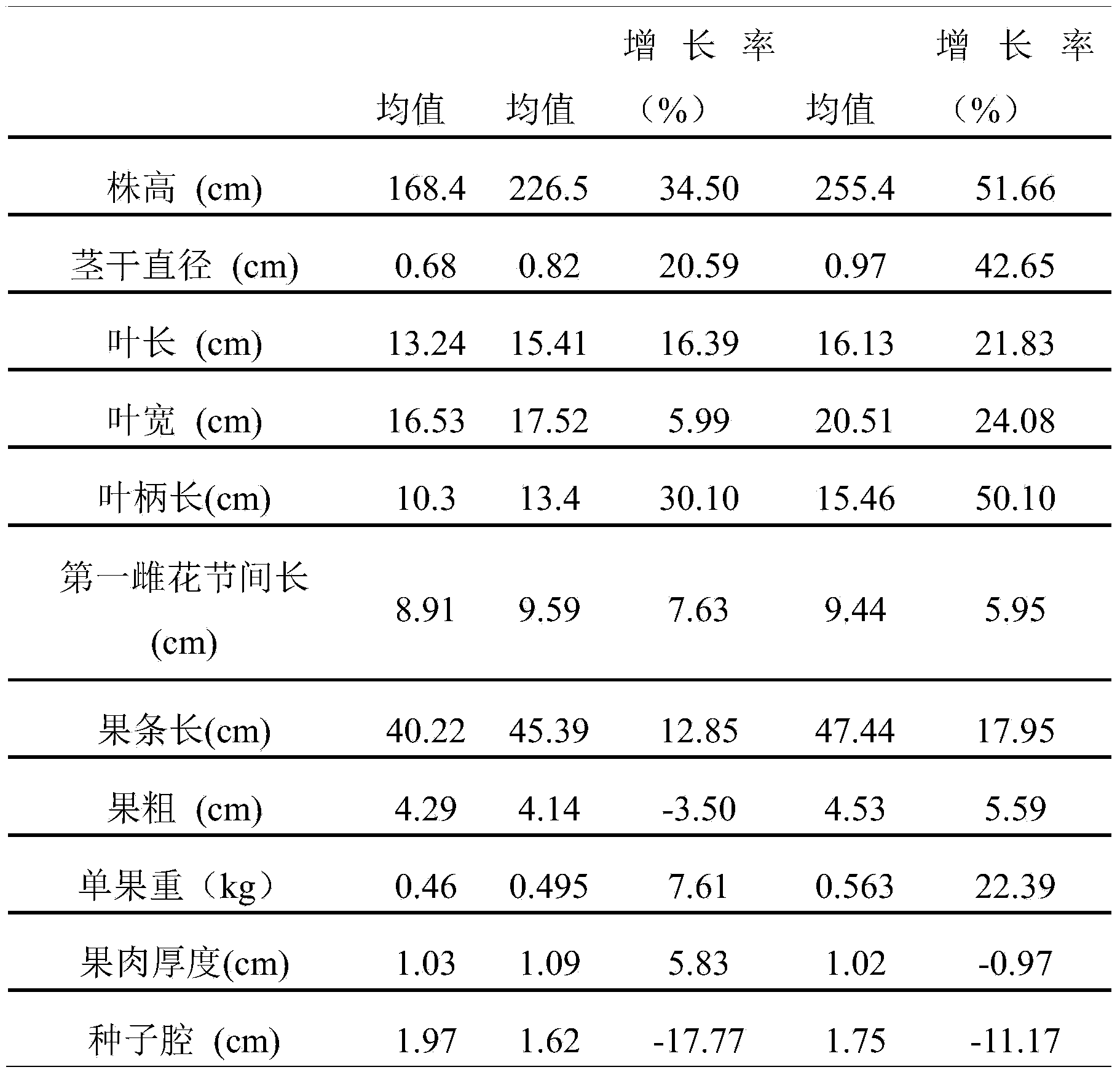

Composite organic fertilizer prepared from vegetable wastes and preparation method of composite organic fertilizer

InactiveCN104291886APromote growth and developmentReduce pests and diseasesCalcareous fertilisersBio-organic fraction processingBiotechnologyCompound organic

The invention discloses a composite organic fertilizer prepared from vegetable wastes. The composite organic fertilizer is a fermented product which is obtained by fermenting a composite microbes and the vegetable wastes, wherein the composite microbe is a mixture of bacillus mucilaginosus, bacillus subtilis, tiny bacillus, bacillus megatherium, pseudomonas aeruginosa, plant lactic acid bacteria and azotobacter chroococcum, the number ratio of all the strains is 1:(7-8):(4-6):(3-5):(1-3):(3-5):(1-2), and the total amount of viable bacteria is 2.0*10<9>-3.0*10<9> CFU / mL. The invention also discloses a preparation method of the composite organic fertilizer. The preparation method comprises the following steps: inoculating the microbes to prepare a culture medium; and adsorbing by using an adsorbent, and fermenting the vegetable wastes to obtain compost. The compost prepared by the preparation method disclosed by the invention can be used for promoting the growth development of plants, and reducing plant diseases and insect pests and reducing the use amount of the inorganic fertilizer, so that the vegetable wastes are effectively used, and pollution of wastes to farm environments is reduced.

Owner:MICROBIOLOGY INST OF SHAANXI

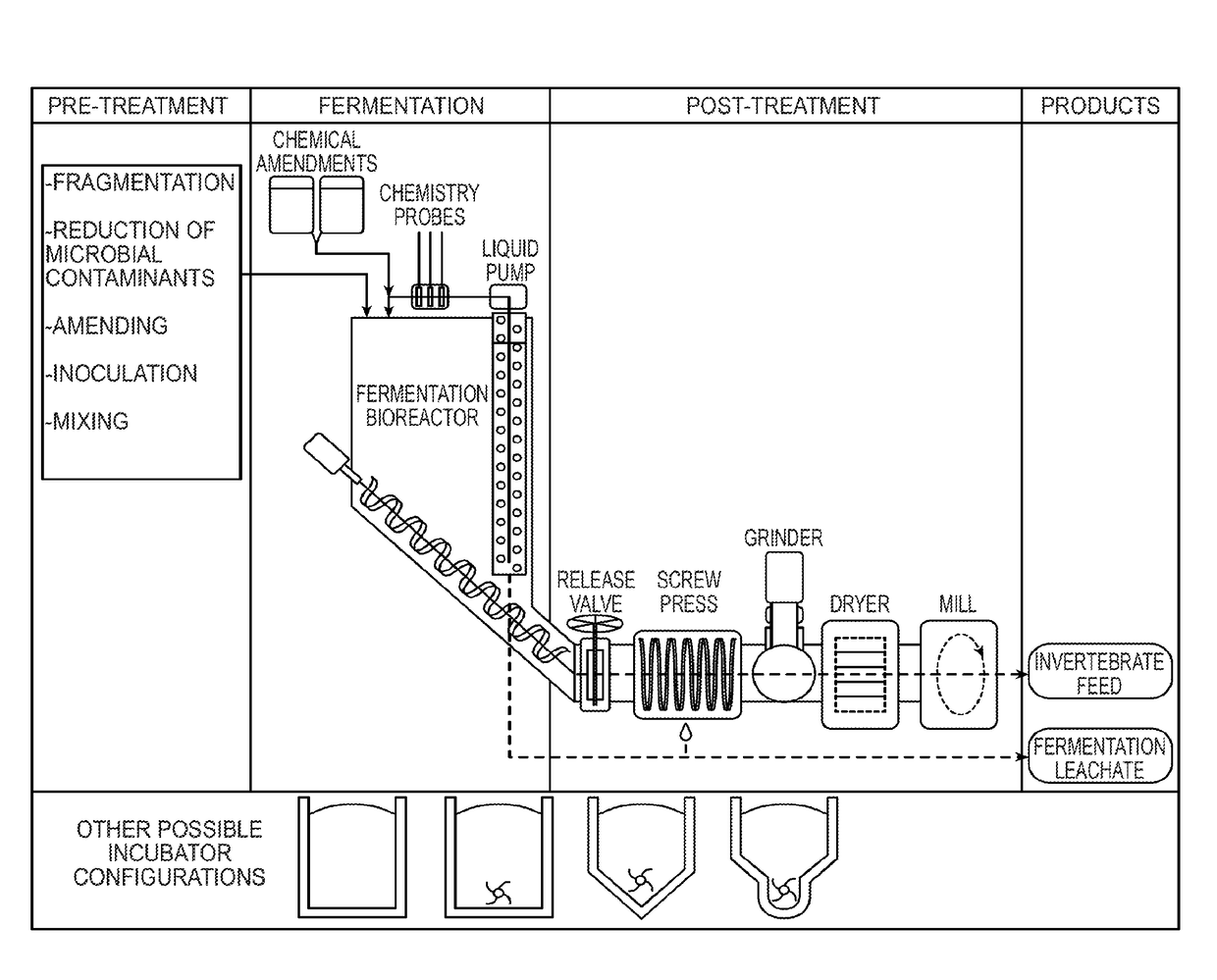

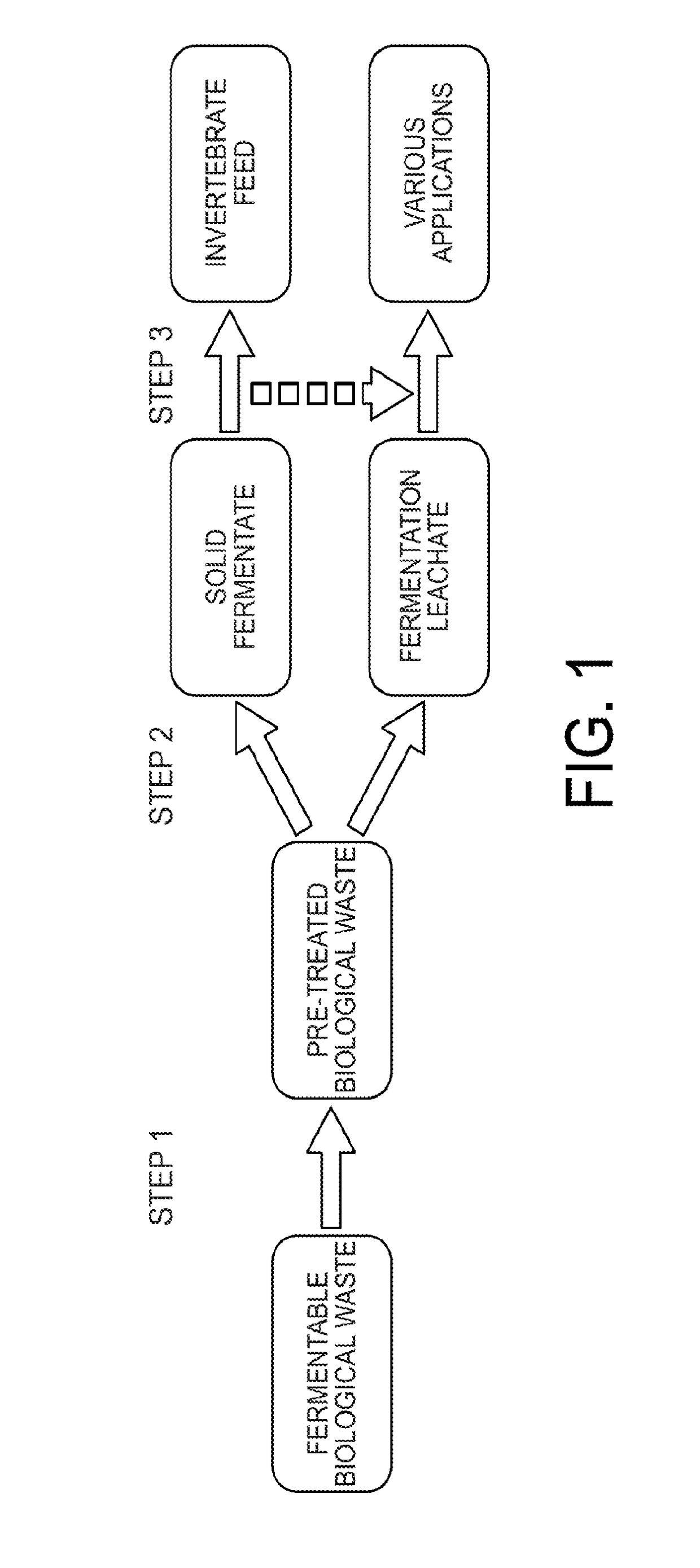

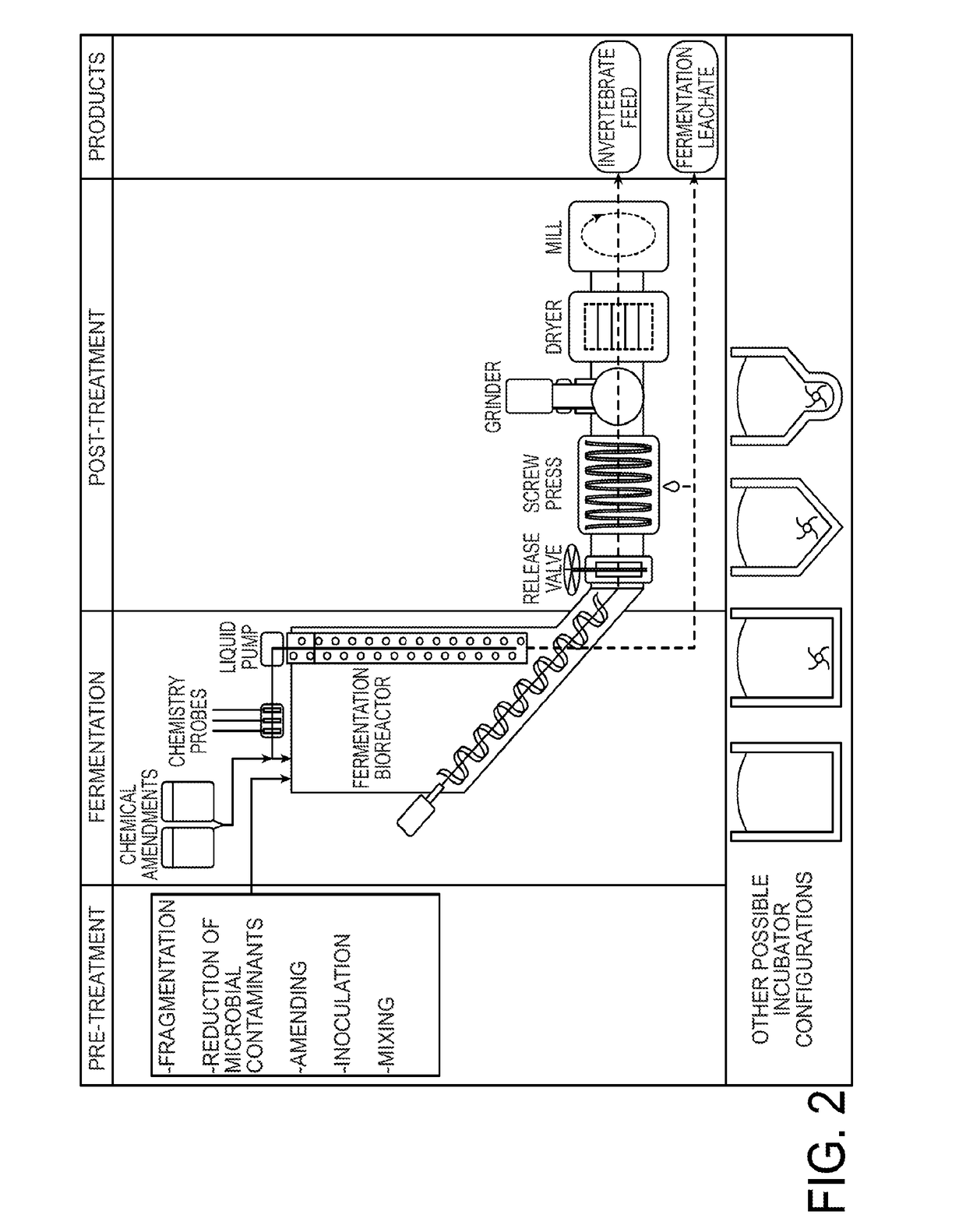

Method for converting food waste and other biological waste into invertebrate feed

ActiveUS20170265496A1Solid waste disposalTransportation and packagingMicrobial inoculationBiological waste

Biological waste such as food, organic or other biologically-derived waste is converted into shelf-stable and health-safe invertebrate feed. The method for converting includes pre-treating waste by fragmenting, reducing microbial contaminants, optionally amending with components that optimize fermentation, inoculating with microorganisms and mixing. Fermentation takes place in a bioreactor and produces fermentation leachate and solid fermentate. In the post-treatment steps, the solid fermentate is separated from the fermentation leachate. The solid fermentate is ground, dewatered and milled. The solid fermentate can be used as an invertebrate feed with or without further processing.

Owner:RIVER ROAD RES

Processing method of Fuzhuan tea using summer and autumn raw tea

InactiveCN105831311AShorten aging timeGuaranteed uniformityPre-extraction tea treatmentMicrobial inoculationSteaming

The present invention discloses a processing method of Fuzhuan tea using summer and autumn raw tea. The Fuzhuan tea is prepared by the following steps: raw material rapid aging, golden flower fungus (eurotium cristatum) powder preparing, sieving and blending, steaming and pile-fermenting, humidifying and steaming, inoculating, pressing and shaping, regulating and flower-shape fungus forming, drying, etc. By controlling tea leaves and environment temperature and humidity, and applying microbial inoculation technology, raw material aging is accelerated, growth and reproduction of the eurotium cristatum are induced and regulated, product processing cycle is shortened, the growth of the "golden flowers" is promoted, infectious microbe contamination is reduced, and the stability of the product quality is improved.

Owner:XIANYANG JINGWEI EIGHT TEA CO LTD

Microbial inoculant compositions and uses thereof

InactiveUS20190124917A1Enhancing yield traitMitigate nitrate contaminationBiocideAgriculture gas emission reductionMicrobial inoculationBiotechnology

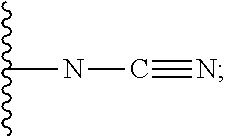

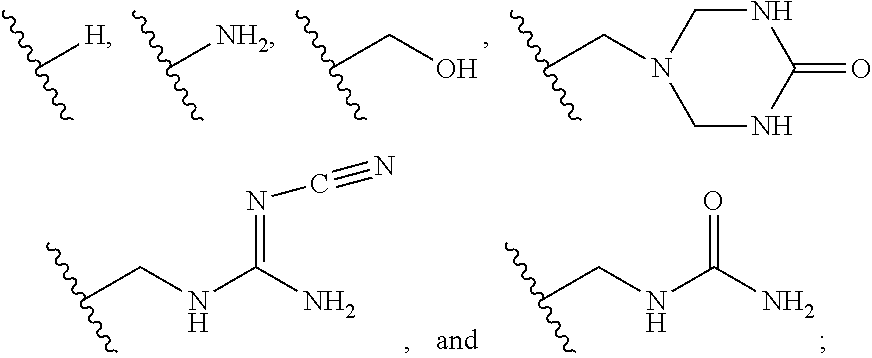

The present invention provides novel microbial inoculant compositions for uses in promoting plant growth, plant productivity and / or soil quality. The novel microbial inoculant compositions comprise one or more microbial species, one or more urease inhibitors and / or nitrification inhibitors. The present invention also provides fertilizer compositions comprising said microbial inoculant compositions.

Owner:KOCH AGRONOMIC SERVICES LLC

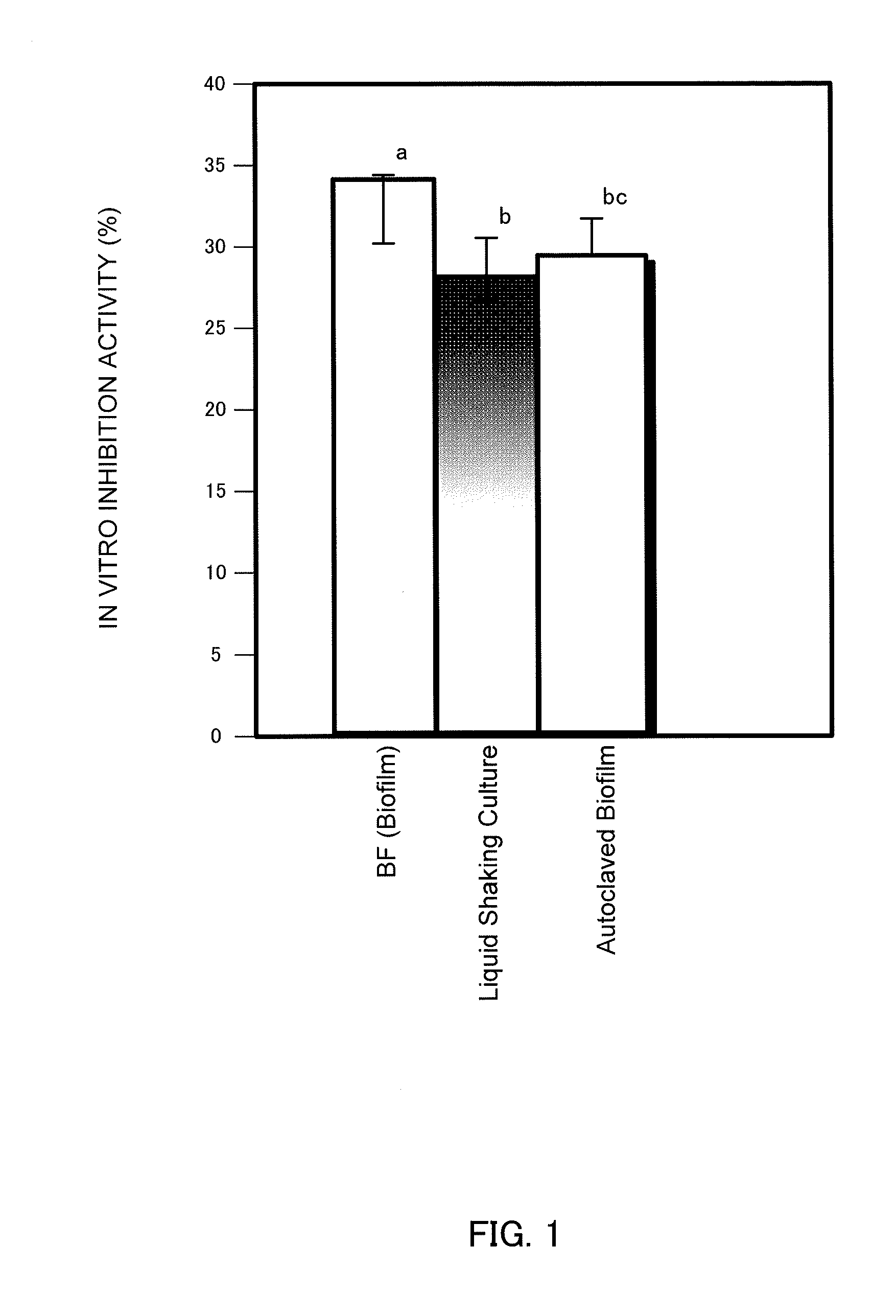

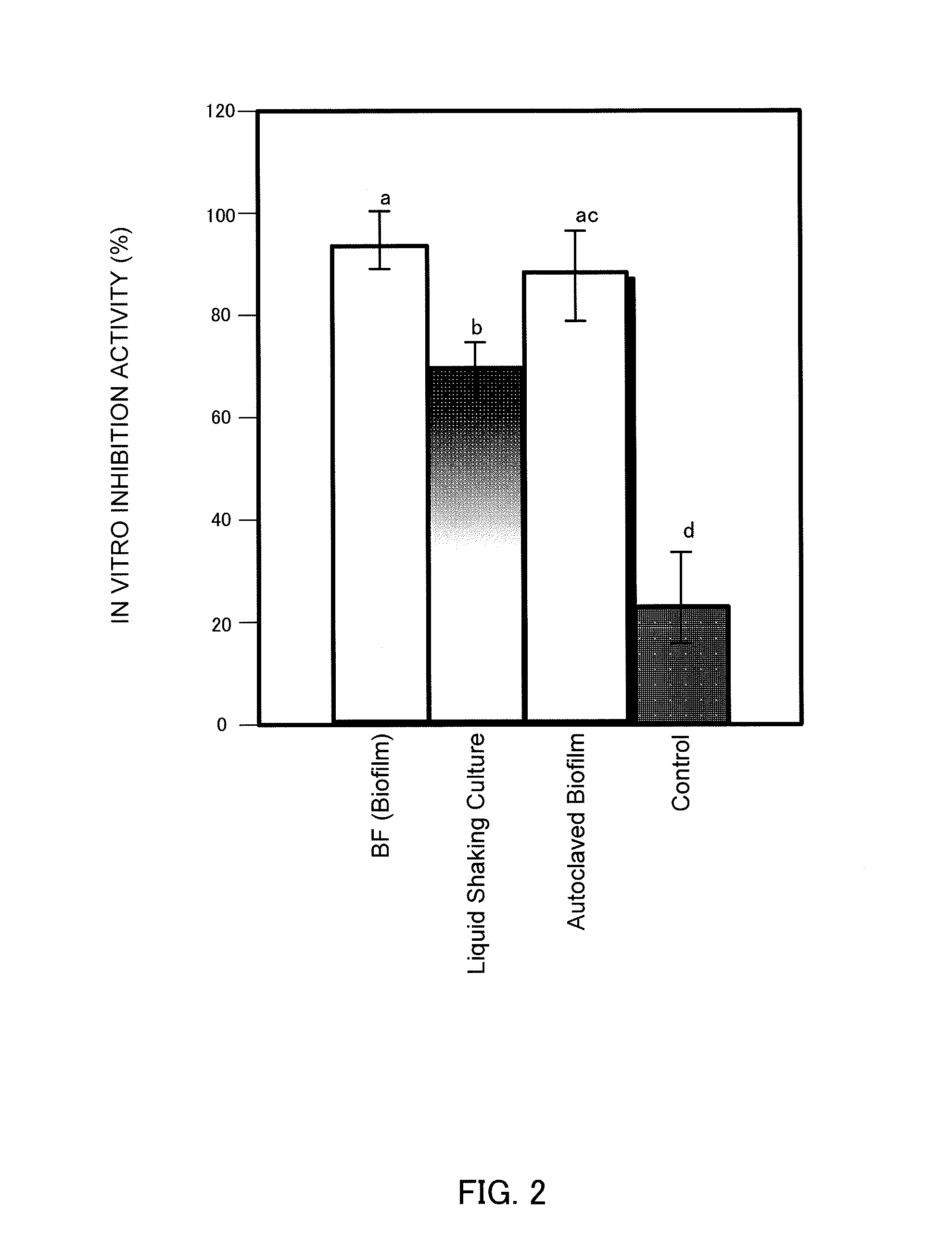

Seed having inoculated with bacterial bilfilm

Disclosed are: a seed having resistance to diseases; and a method for inoculating a microorganism into a seed for the purpose of controlling diseases. As a result of intensive studies, it is found that diseases of a crop can be controlled by inoculating a biofilm of a Bacillus bacterium into a seed of the crop.Specifically disclosed are; a seed inoculated with a biofilm of a Bacillus bacterium and a method for inoculating a biofilm of a Bacillus bacterium into a seed.

Owner:ALPS BUSINESS CREATION

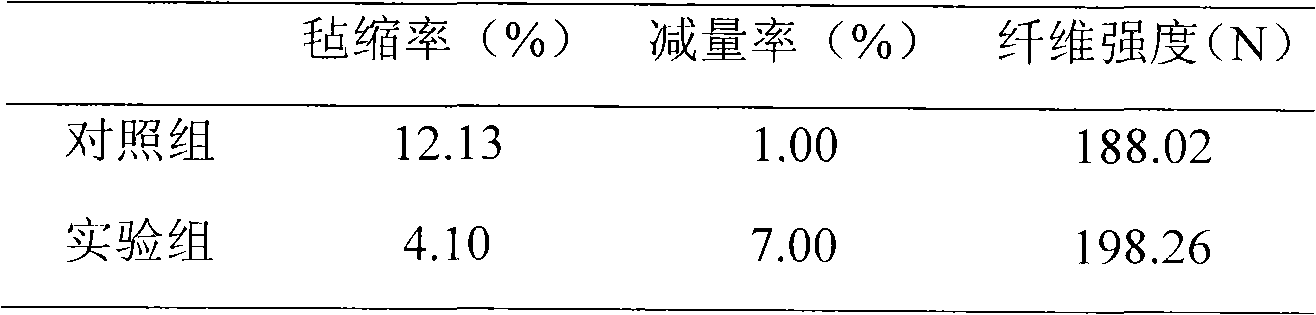

Protease composite enzyme and application thereof

InactiveCN101935642AHas disulfide reductase activityTo achieve the purpose of anti-feltingHydrolasesBiochemical fibre treatmentMicrobial inoculationFreeze-drying

The invention relates to a protease composite enzyme and application thereof. A preparation method comprises the following steps of: inoculating microbes into a culture medium, placing the culture medium on a shaker at the temperature of between 25 and 40 DEG C and the rotating speed of 120 to 200 revolutions per minute to culture the microbes for 24 to 96 hours, performing enzyme or ultrasonic wall breakage or non wall breakage treatment, filtering bacteria, adding ammonium sulfate into the culture medium to settle protein, centrifuging the solution, adding Tris-HCl into the solution for dissolution, and freeze-drying the sediment after dialysis; or inoculating microbes into the culture medium, fermenting the culture medium for 23 to 72 hours at the temperature of 30 DEG C, culturing the microbes for 24 to 72 hours at the stirring speed of 120 to 600rpm, stopping fermentation, and filtering or centrifuging bacteria. The composite enzyme can be directly acted on various wool spinning fabrics and saves chemical reagent pretreatment and oxidation pretreatment in the conventional treatment process; the application method is simple and suitable for industrialized production; and the felting resistance and mechanical strength of the treated wool or wool fabrics are improved, and the felting rate of the treated wool fabric is less than 5 percent.

Owner:DONGHUA UNIV

Microbes capable of degrading phenol and cyanogen in coking waste water and method for treating coking waste water by using same

InactiveCN101974459AGood removal effectBacteriaTreatment using aerobic processesMicrobial inoculationVolatile phenols

The invention discloses microbes capable of degrading phenol and cyanogen in coking waste water and a method for treating coking waste water by using the same, which relate to microbes for degrading phenol and cyanogen in coking waste water and a method for treating waste water by using the same. The invention solves the problem that micromolecule harmful substances in the coking waste water treatment process, such as volatile phenol and cyanides, are difficult to remove. The microbes capable of degrading the phenol and the cyanogen in the coking waste water comprise bacillus subtilis BHF3-4, bacillus JhqK9-1 and acid-producing klebsiella JhqM8. The method for treating the coking waste water comprises the following steps: 1. inoculating the microbes capable of degrading the phenol and the cyanogen in the coking waste water to a membrane biological reactor (MBR); 2. and treating the coking waste water. When the method is used for treating the coking waste water, the removal rate of the volatile phenol in the coking waste water can reach 99.6-99.9%, and the removal rate of cyanides can reach 99.5-99.7%, thus, the outlet water can reach the Chinese first-class emission standard.

Owner:INST OF MICROBIOLOGY HEILONGJIANG ACADEMY OF SCI

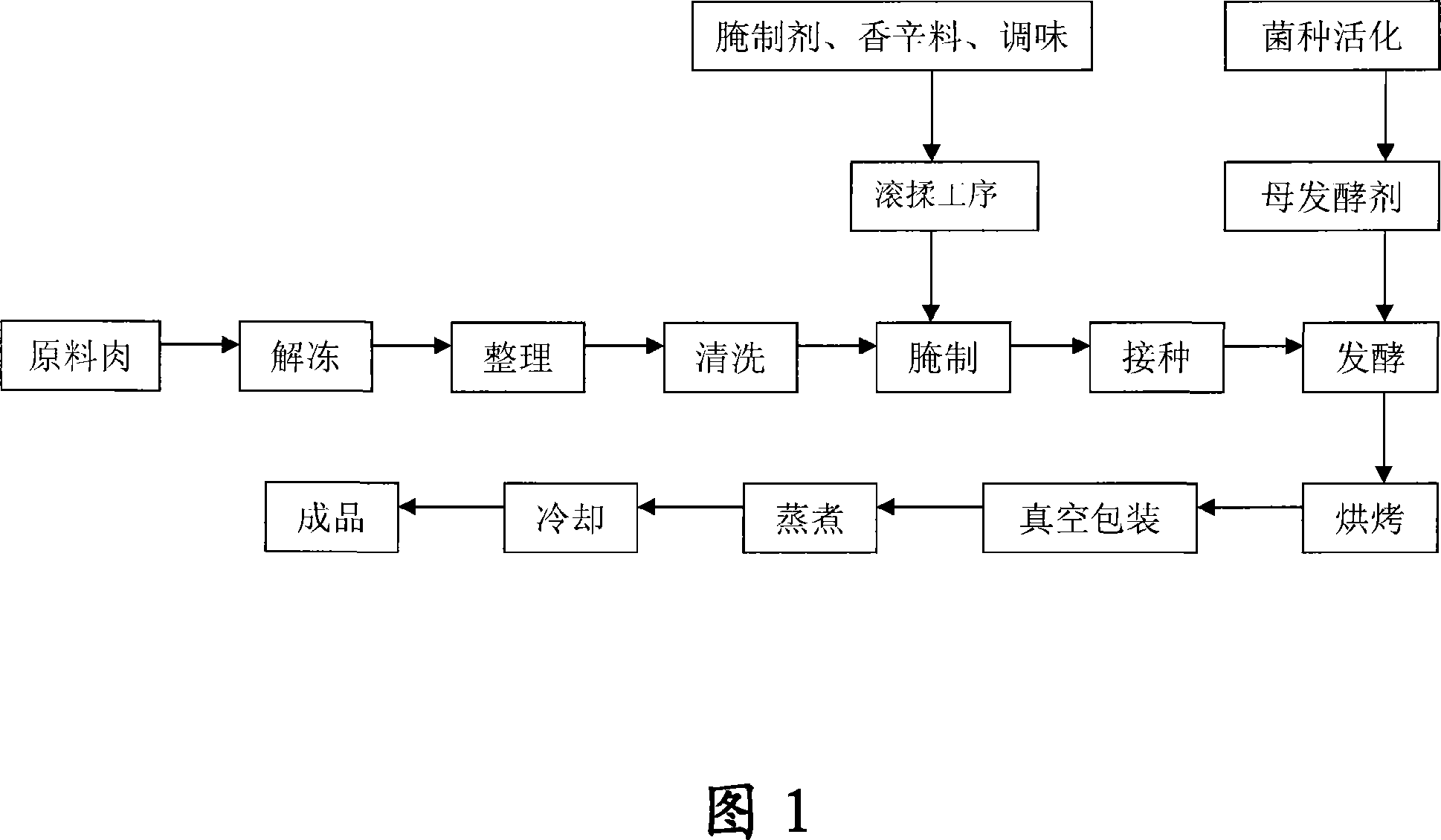

Fermented horse meat product and preparation method thereof

The present invention discloses a fermented horse meat food and its preparation method. The formula for preparing fermented horse meat includes the following components: (by using 100kg of horse meat weight as reference) 4%-6% of edible salt, 5%-20% of sugar, 0.3%-0.4% of phosphate, 0.003%-0.005% of nitrite, 0.5%-0.7% of sodium ascorbate, 0.4%-0.6% of white pepper, 0.1%-0.15% of sage, 0.1%-0.15% of nutmeg, 0.05%-0.1% of cassia bark, 0.2%-0.3% of coriandrum sativum, 0.2%-0.8% of garlic, 0.1%-0.2% of basil and 3% of composite inoculum. Its preparation method includes the following steps: selecting materials, defrosting, finishing, cleaning, pickling, making fermentation, roasting and vacuum packaging so as to obtain the invention horse meat food.

Owner:XINJIANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com