Protease composite enzyme and application thereof

A protease and compound enzyme technology, applied in the protease compound enzyme and its application fields, can solve the problems of decreased wool strength, not using chemical reagents, low market prospect, etc. Effects of skin damage and avoidance of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

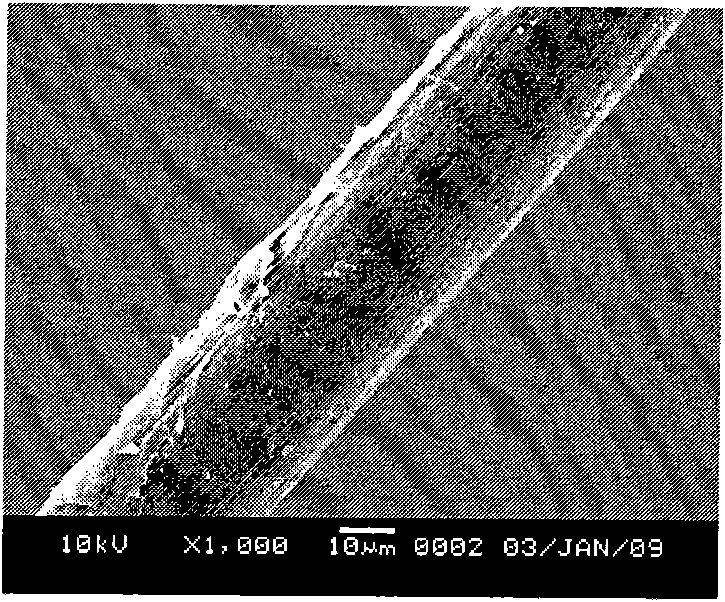

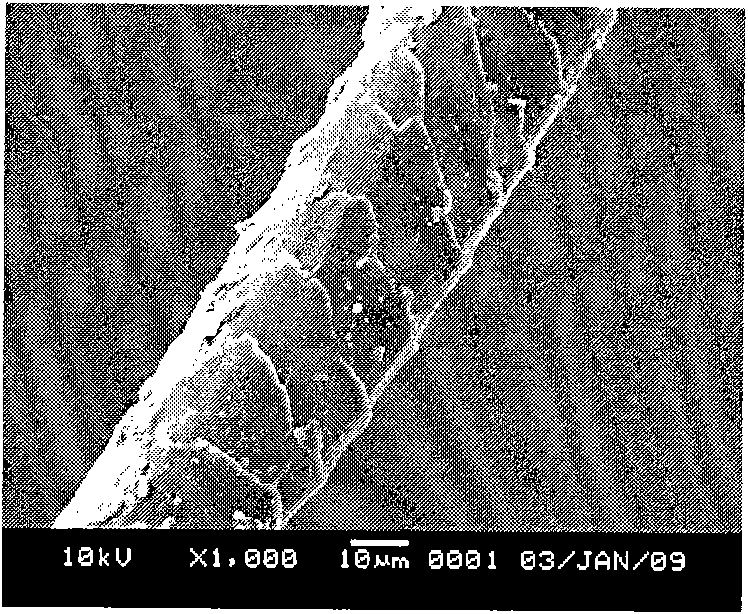

Image

Examples

Embodiment 1

[0045] Stenotrophomonas maltophilia (Stenotrophomonas maltophilia) DHHJ (CGMCC No.2231) (a strain producing keratinase and its application, the application number is disclosed in 2007101719394) is used as the production strain, and the following medium is used for cultivation : Wool powder 2g, KCl 0.05g, NaCl 0.05g, disodium hydrogen phosphate 0.5g, potassium dihydrogen phosphate 0.05g, water 100ml, pH7.5, placed in a 500mL Erlenmeyer flask, at 40°C and 150rpm, Culture solution was obtained after constant temperature cultivation for 72 hours. Ultrasound (150W, 3 minutes) to break the wall, filter the bacteria, add 10%-40% ammonium sulfate, stir to dissolve, place at 4°C for 12 hours, centrifuge at 10000rpm for 10-20 minutes to obtain a precipitate, add 0.05mol / L pH7.8 Tris-HCl 100mL dissolved, lyophilized after dialysis to obtain protease compound enzyme enzyme powder;

[0046] After centrifugation, the protease activity was 14U / mL, and the disulfide bond reductase activity w...

Embodiment 2

[0049] Streptomyces olivaceus (Waksman) Waksman et Henrici) (CGMCCNo.4.943) (purchased from China Committee for the Collection of Microorganisms, Beijing) was used as the production strain, and the following medium was used for cultivation: soluble starch 2g, wool powder 1g, MgSO 4 ·7H 2 O 0.05g, KCl 0.05g, FeSO 4 ·7H 2 O 0.001g, K 2 HPO 4 0.05g, 100ml of water, pH 6.5, placed in a 500mL Erlenmeyer flask, under the conditions of 28°C and 150rpm, cultured at a constant temperature for 72 hours to obtain a culture solution. After centrifugation, the supernatant (extracellular fluid) was obtained, the protease activity was 12U / mL, and the disulfide bond reductase activity was 5U / mL. Utilize the extracellular enzyme lyophilized powder obtained from the fermentation broth, use it to treat wool fabric: lyophilized enzyme powder is dissolved in 0.05mol / L PBS (pH7.8) with 0.5%, bath ratio 1: 25, 50 ℃ for 70 minute.

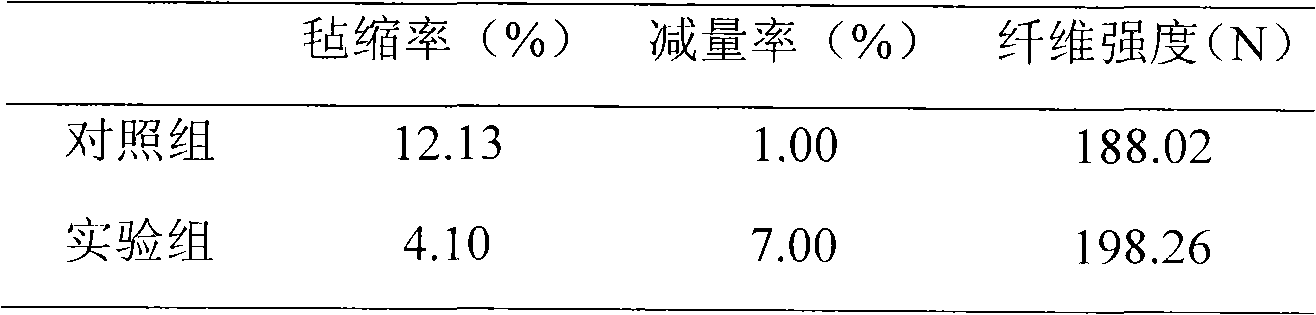

[0050] Felt shrinkage (%)=(1-area of wool fabric after trea...

Embodiment 3

[0056] Aspergillus carneus (Van.Teighem) Blochwitz (CGMCC No.3.3920) (purchased from China Committee for the Collection of Microorganisms, Beijing) was used as the production strain, and the following medium was used for cultivation: sucrose 2.0g, wool powder 1g, MgSO 4 ·7H 2 O 0.05g, KCl 0.05g, FeSO 4 ·7H 2 O 0.001g, K 2 HPO 4 0.1g, 100ml of water, pH 6.2, placed in a 500mL Erlenmeyer flask, under the conditions of 28°C and 150rpm, cultured at a constant temperature for 72 hours to obtain a culture solution. After centrifugation, the bacteria were obtained, and the wall was broken by ultrasonic wave (150W, 3 minutes) to obtain the intracellular enzyme, the protease activity was 7U / mL, the disulfide bond reductase activity was 8U / mL, and ammonium sulfate was added 10%-40% , stirred and melted, placed at 4°C for 24 hours, centrifuged at 10,000 rpm for 10 minutes to obtain a precipitate, added 0.05mol / L Tris-HCl 100mL with pH 7.8 to dissolve, dialyzed and freeze-dried to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com