Method for producing a sand aggregate

A manufacturing method and condensate technology, applied in chemical instruments and methods, building structures, applications, etc., can solve problems such as infrastructure impacts, water resource scarcity, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

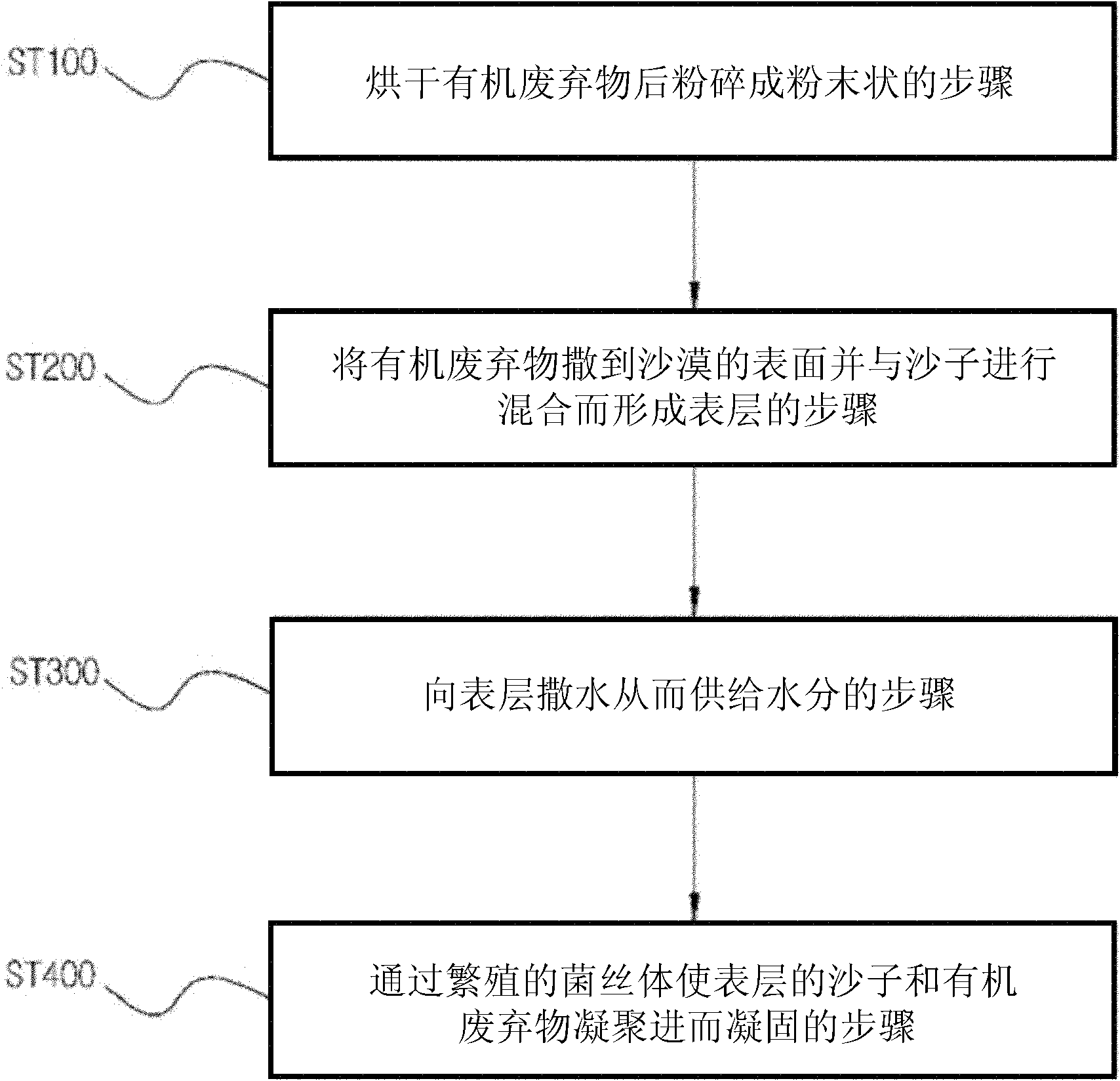

Method used

Image

Examples

Embodiment 1

[0076] [Example 1: Manufacture of sand aggregates for preventing blowing sand]

[0077] Naturally dry the agricultural and sideline products (or organic waste) mixed with corn stalks, soybean stalks, chili stalks, sesame stalks, ephedra stalks, cosmos stalks, radish stalks and cabbage leaves at 10-30°C and use them for pharmaceutical purposes. A pulverizer (manufactured by Young Dong Machinery Co., Ltd. in Daegu, Korea) pulverizes the above-mentioned organic waste into a powder with a mesh size of 100 to 200. Then, 1 to 2 cc of Aspergillus niger (Purchased: KCCM) and Penicillium islandicum (Penicillium islandicum) (Purchased: KCTC) as filamentous fungi were mixed with 100 cc of the above-mentioned organic waste powder, and Streptomyces griseus (purchase place: KCTC) (hereinafter referred to as soil microbe).

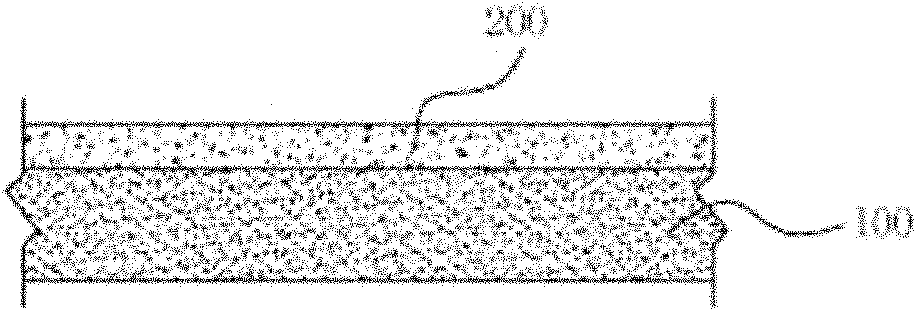

[0078] After uniformly mixing 37.5 liters of organic waste powder mixed with soil microorganisms and 112.5 liters of sand (amount ratio 1:3) (manual mixing), fill the w...

Embodiment 2

[0081] [Example 2: Fertilization process of sand]

[0082] Naturally dry the agricultural and sideline products (or organic waste) mixed with corn stalks, soybean stalks, chili stalks, sesame stalks, ephedra stalks, cosmos stalks, radish stalks and cabbage leaves at 10-30°C and use them for pharmaceutical purposes. A pulverizer (manufactured by Young Dong Machinery Co., Ltd. in Daegu, Korea) pulverizes the above-mentioned organic waste into a powder with a mesh size of 100 to 200. Then, 1 to 2 cc of Aspergillus niger (Purchased: KCCM) and Penicillium islandicum (Penicillium islandicum) (Purchased: KCTC) as filamentous fungi were mixed with 100 cc of the above-mentioned organic waste powder, and Streptomyces griseus (purchase place: KCTC) (hereinafter referred to as soil microbe).

[0083] After uniformly mixing 25 liters of organic waste powder mixed with soil microorganisms and 125 liters of sand (amount ratio 1:5) (manual mixing), fill the wooden frame with length 100cm × w...

Embodiment 3

[0088] [Example 3: Manufacture of sand aggregates corresponding to each sand source]

[0089] A powder mixed with soil microorganisms was prepared by using the organic waste powder and soil microorganisms in the same manner as in Example 1. Then, after uniformly mixing 37.5 liters of organic waste powder mixed with soil microorganisms and 112.5 liters of sand (produced in Korea) (amount ratio 1:3) by hand (manual mixing), pour it into a styrofoam plastic with a length of 100 cm × width 100 cm × height 30 cm The box is filled to 10cm high. Then, inside the foam plastic frame of length 100cm * width 70cm * height 30cm, fill the top of the foam plastic frame that is divided into 6 (respectively length 25cm * width 30cm * height 30cm) 3cm high hand mixing (hand mixing ) of 37.5 liters of organic waste powder mixed with soil microorganisms and 112.5 liters of sand (collected from Mongolia) (amount ratio 1:3), filled 3 cm below with 37.5 liters of organic waste mixed with soil micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com