Patents

Literature

226results about "Closing machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

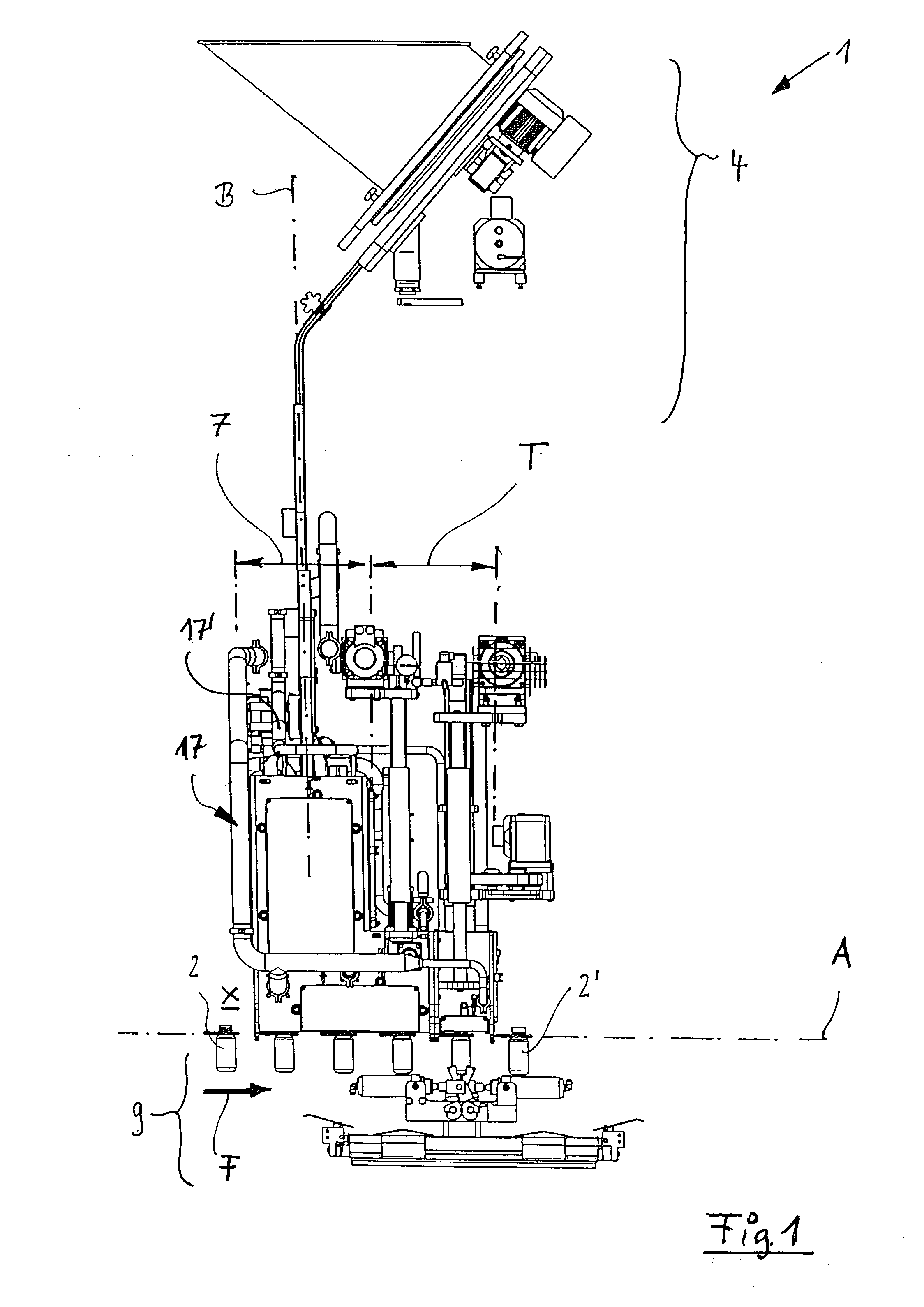

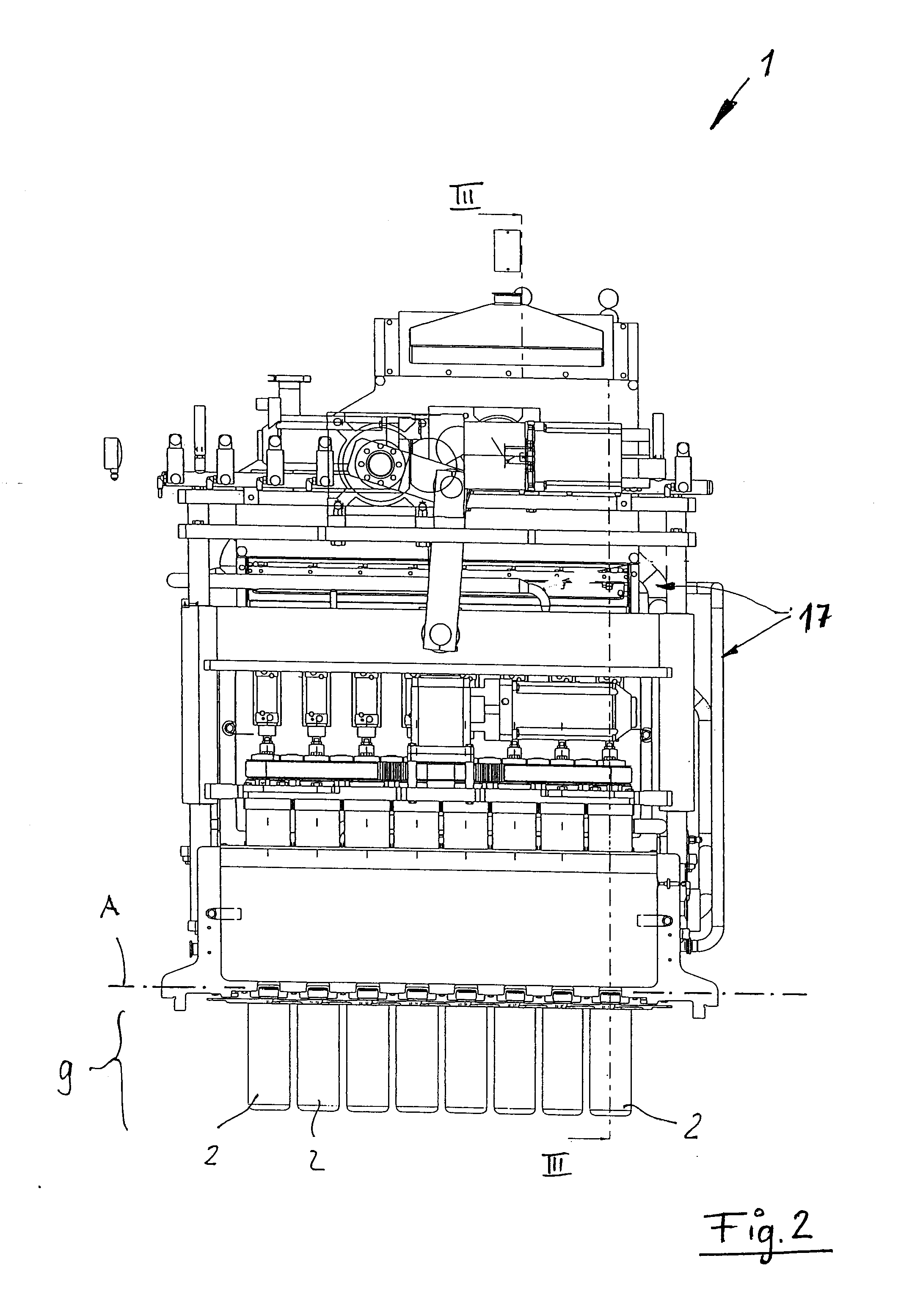

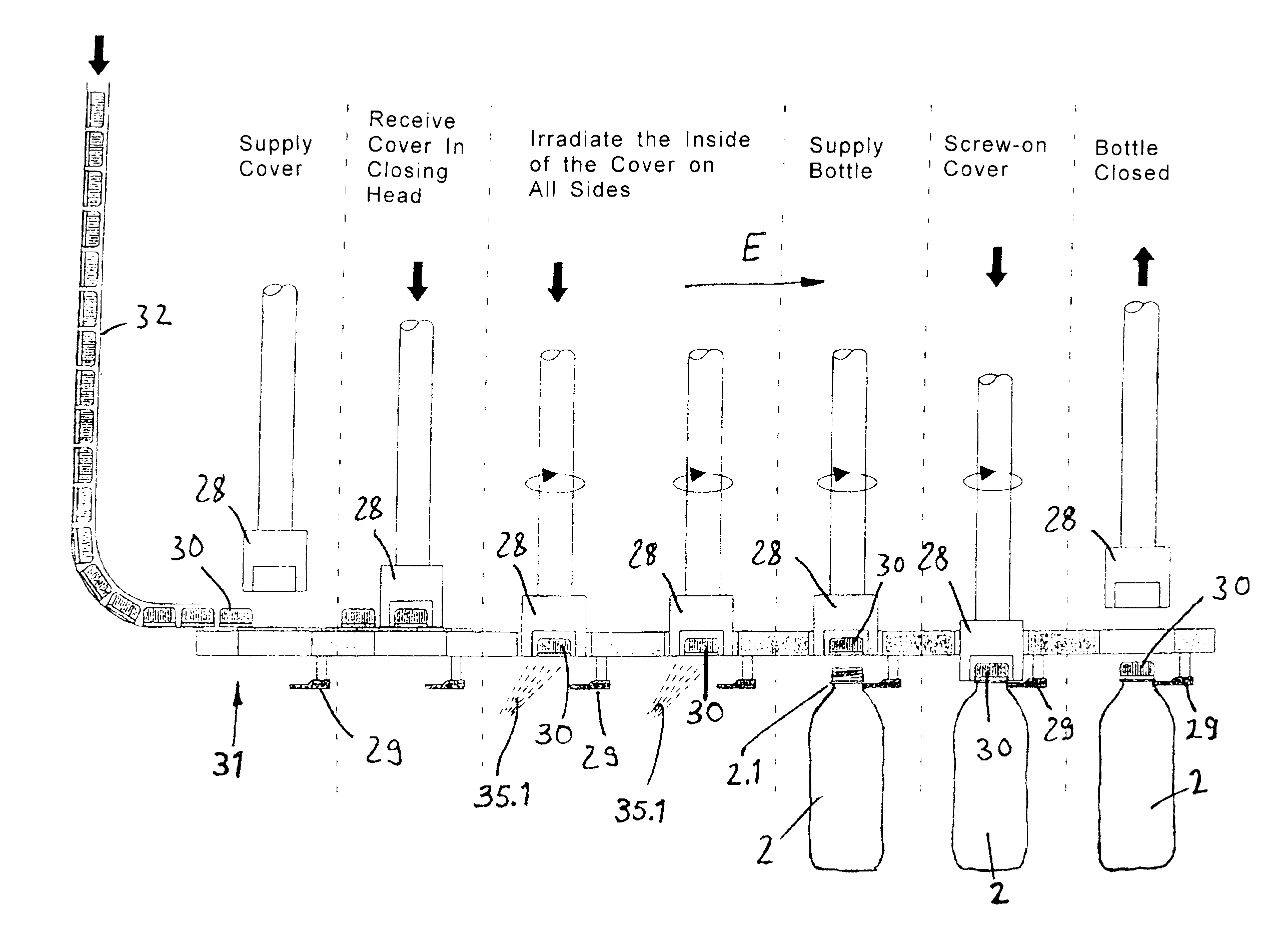

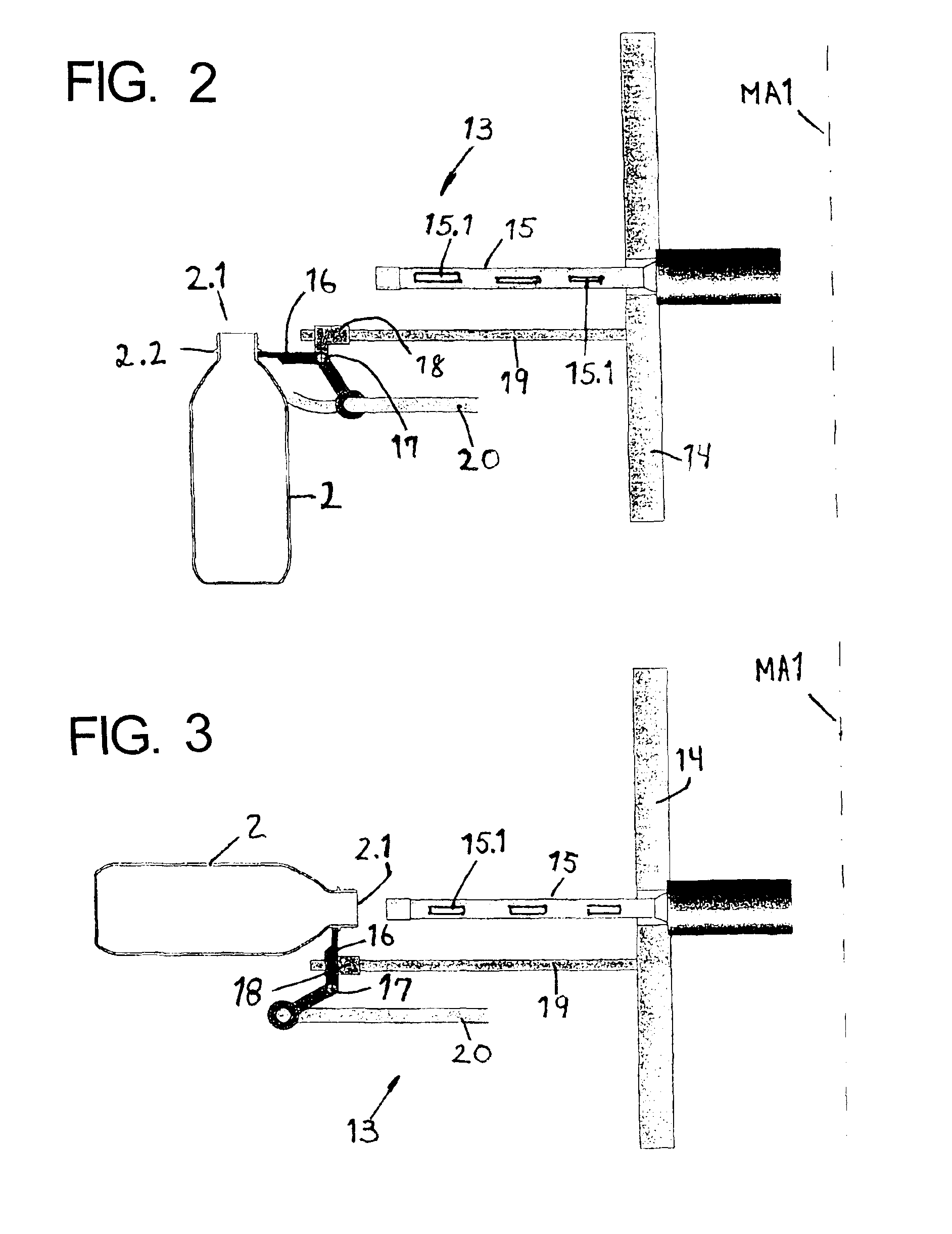

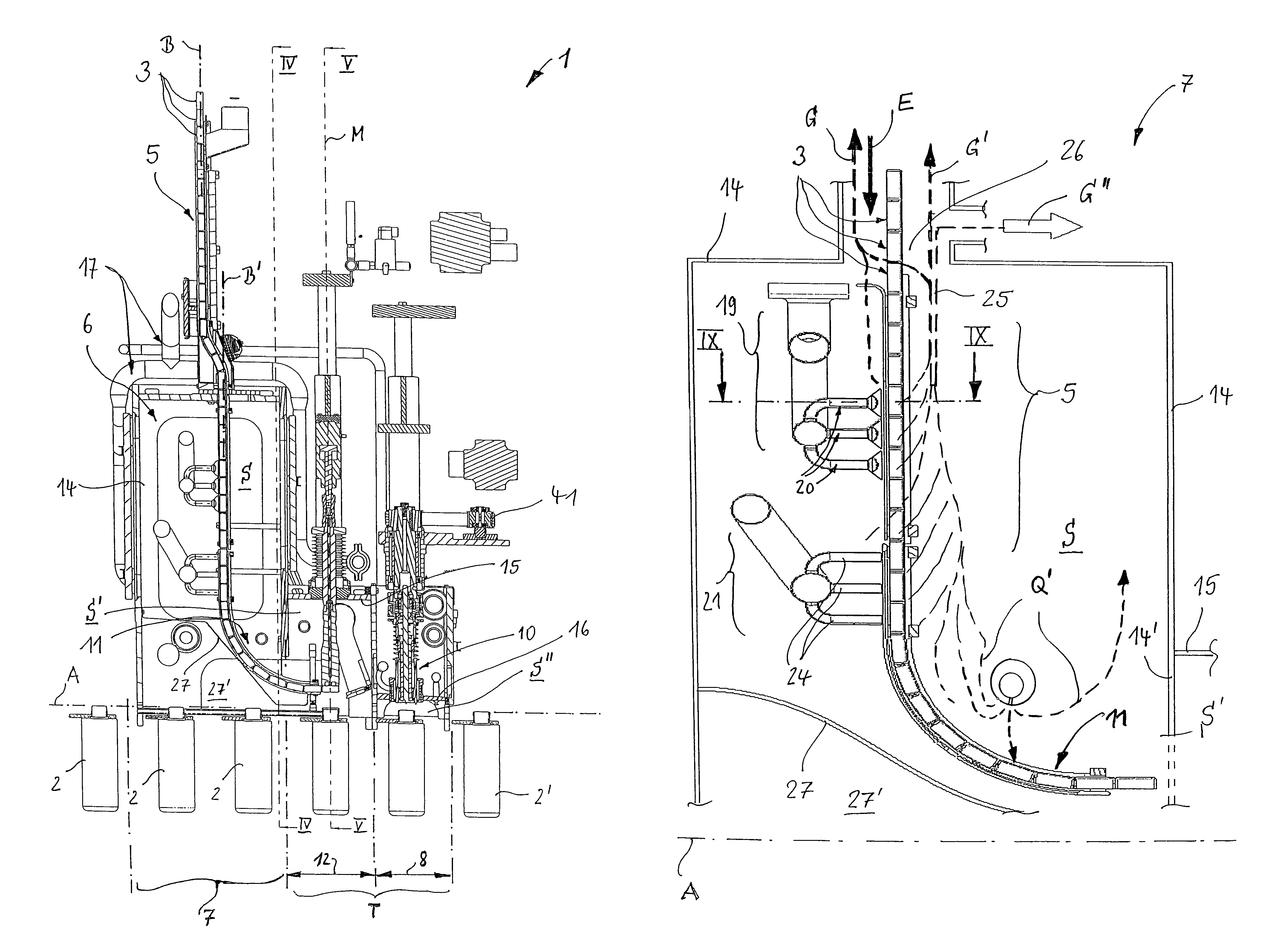

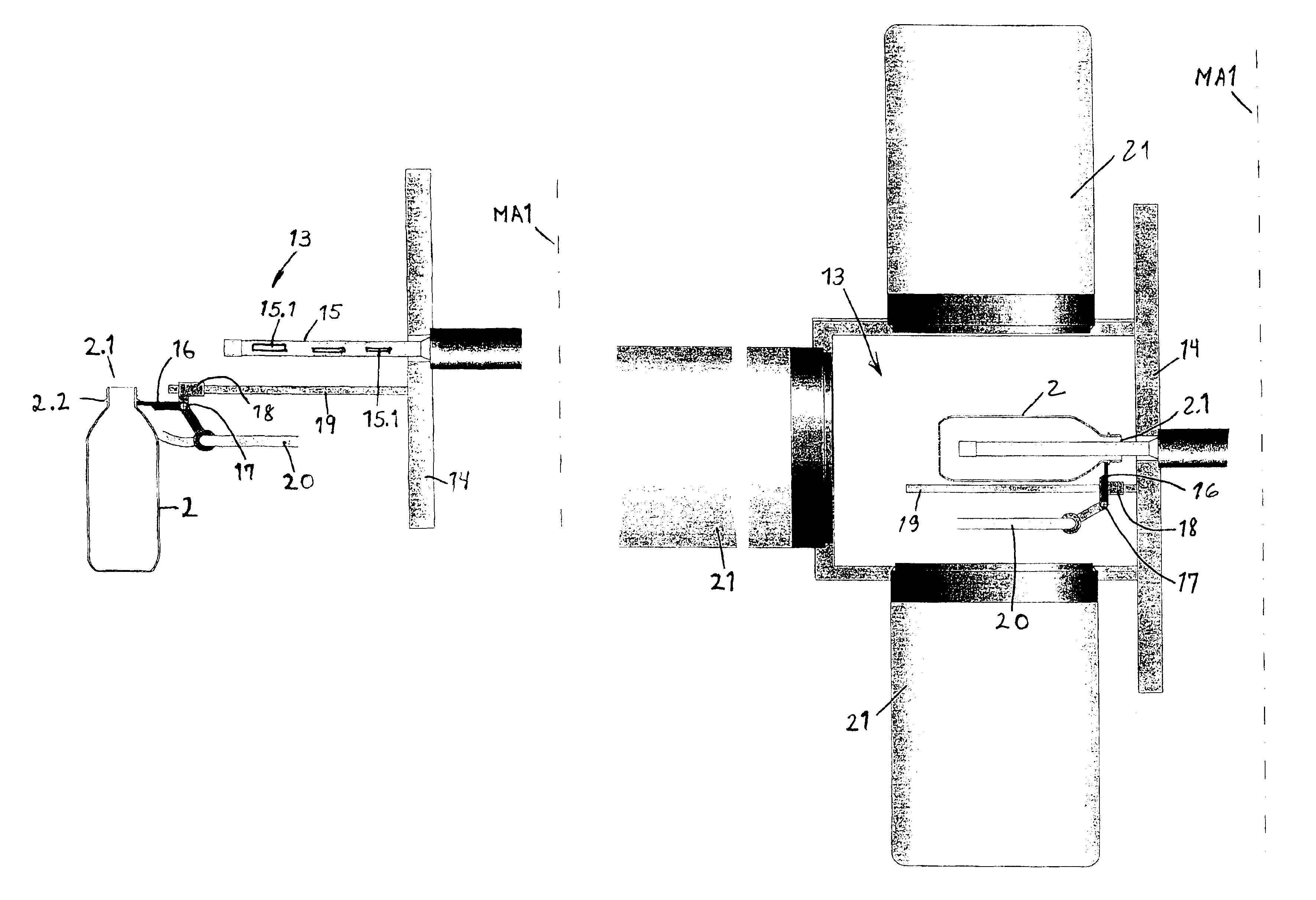

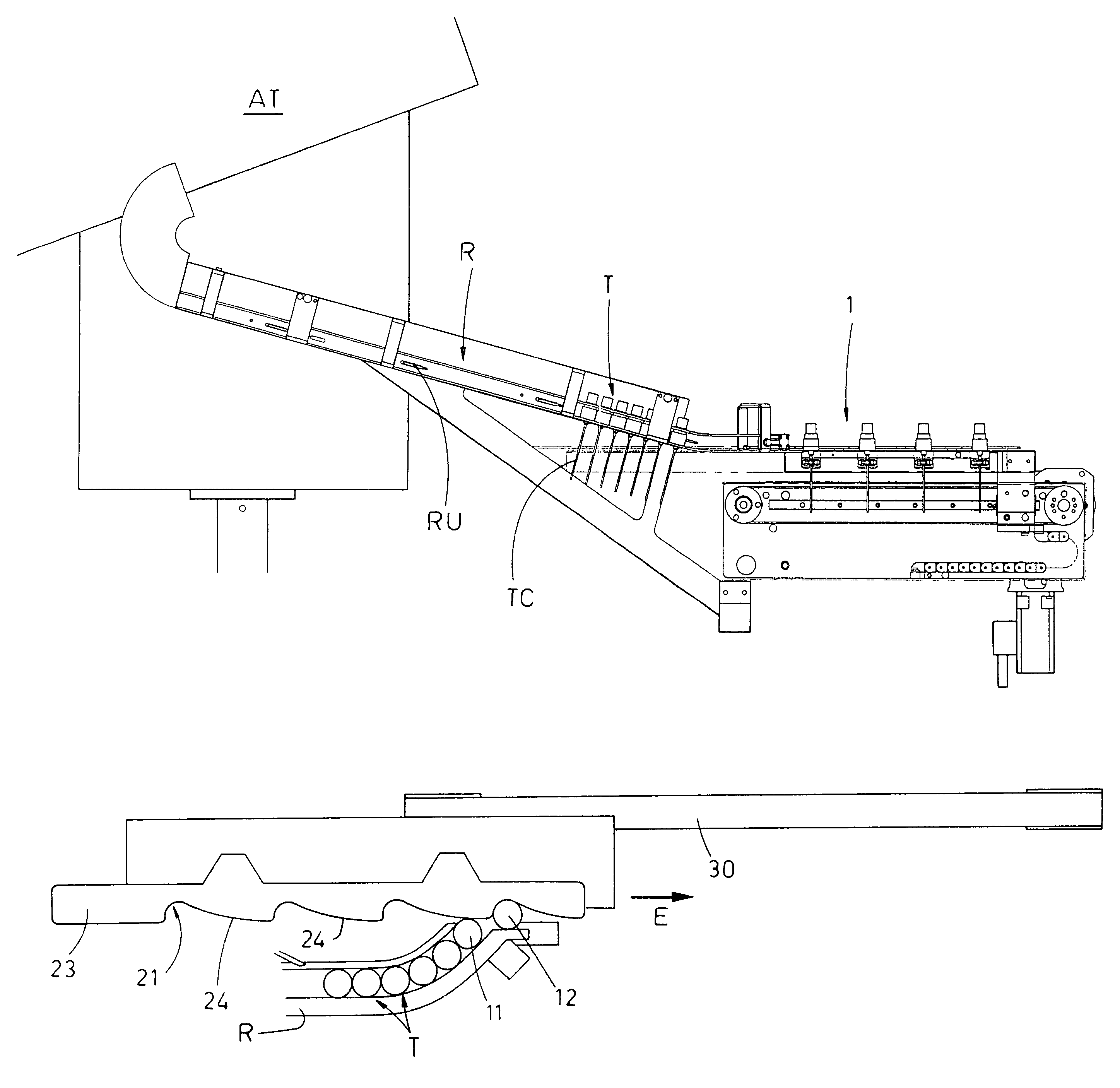

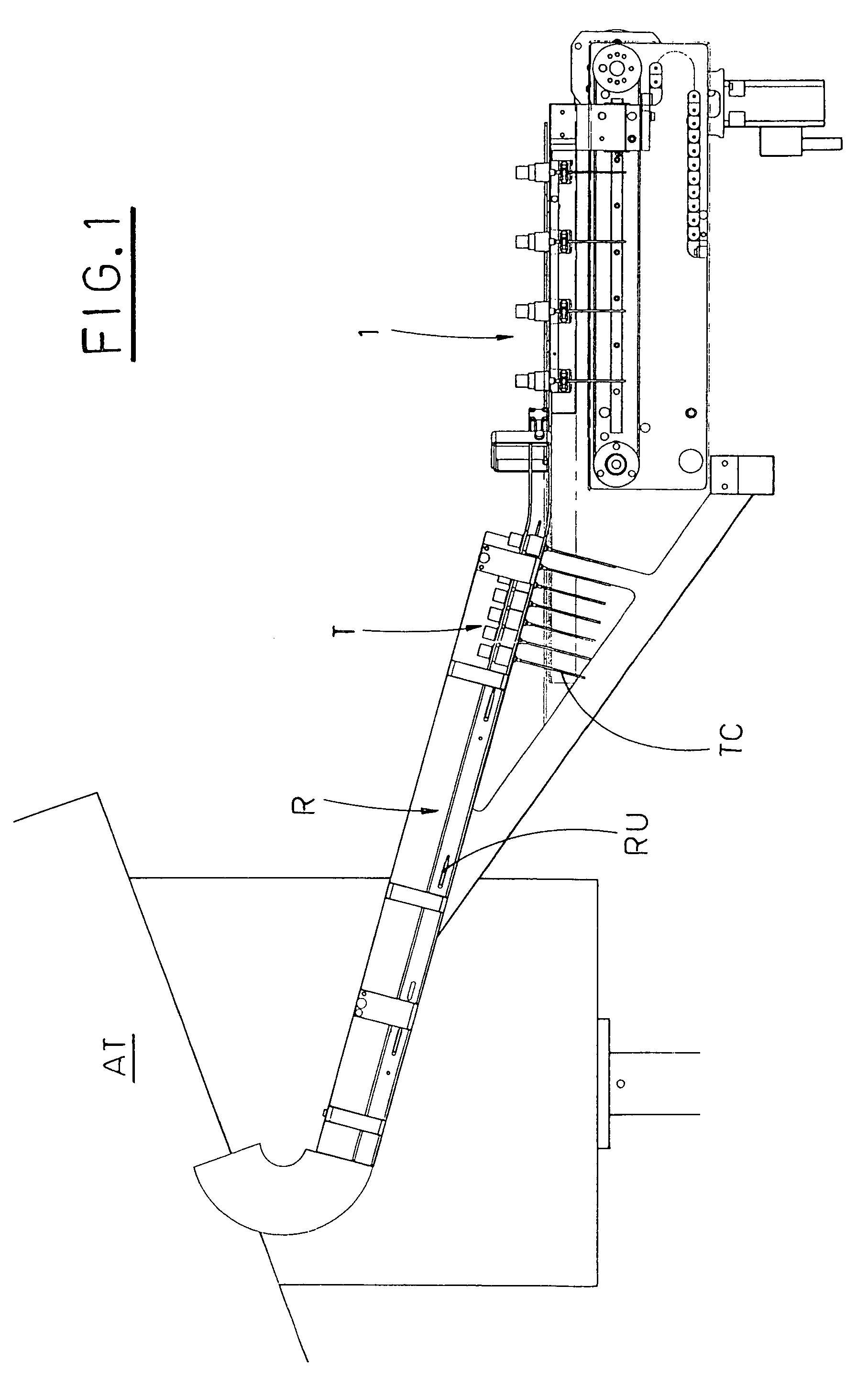

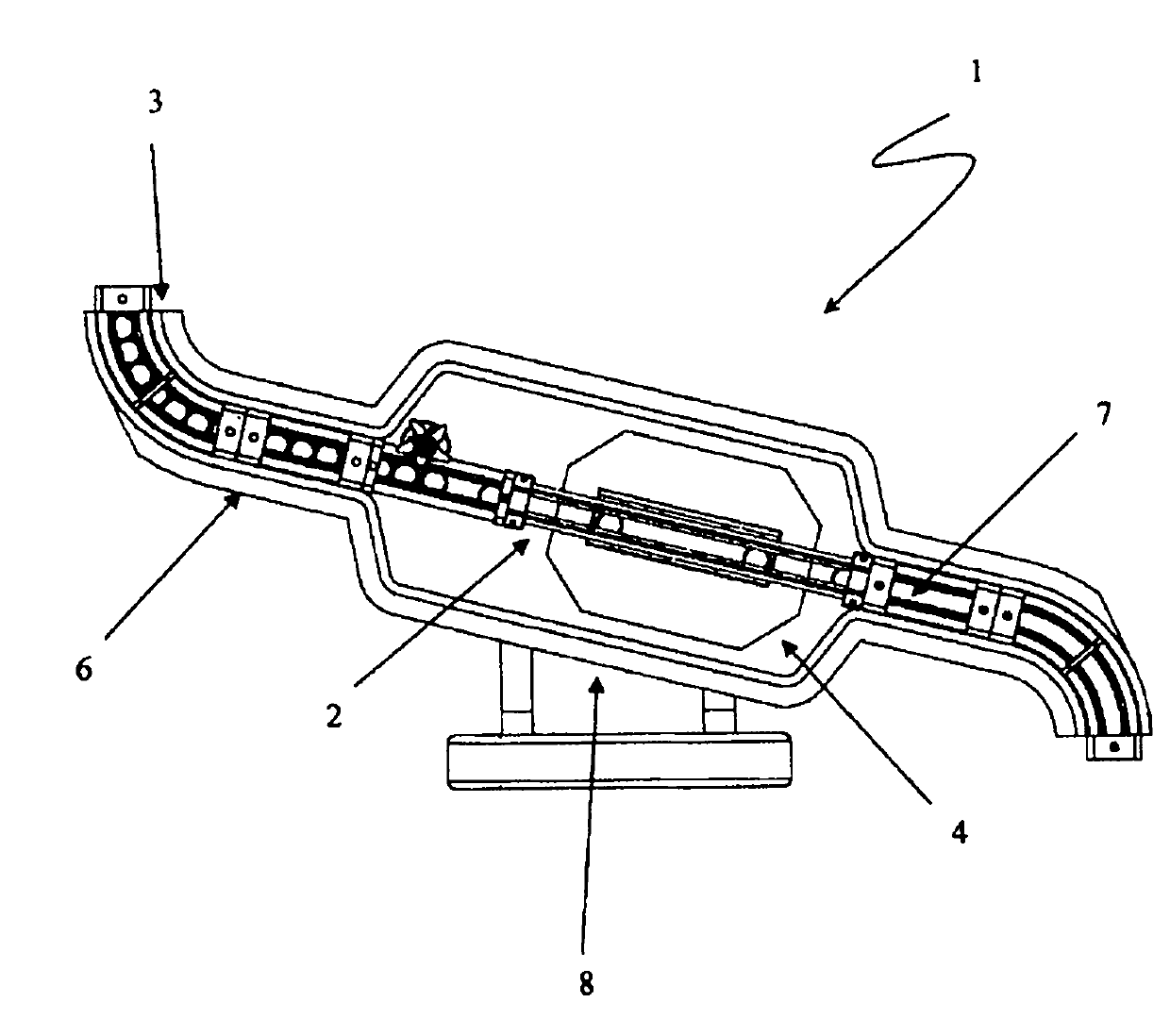

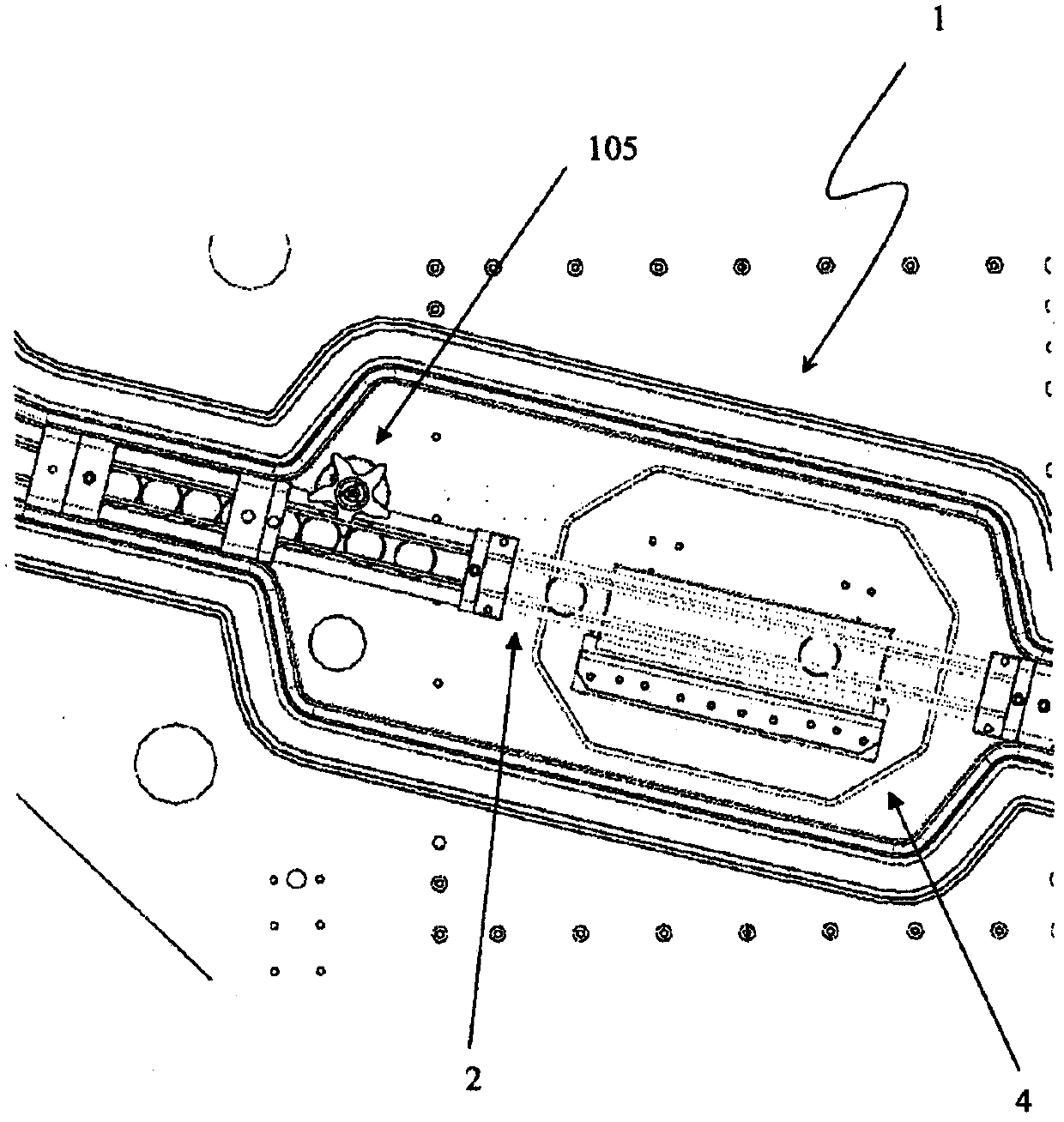

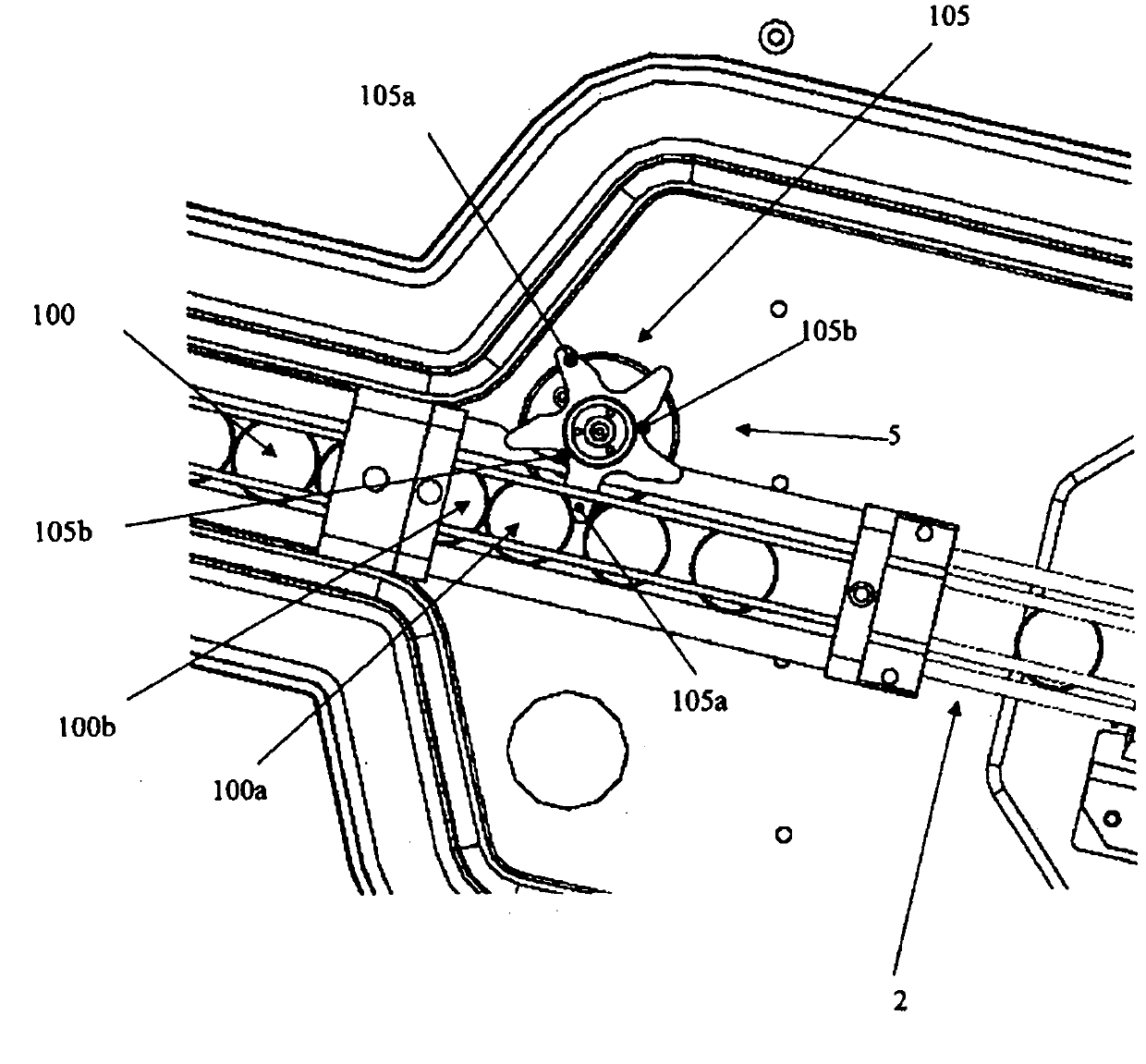

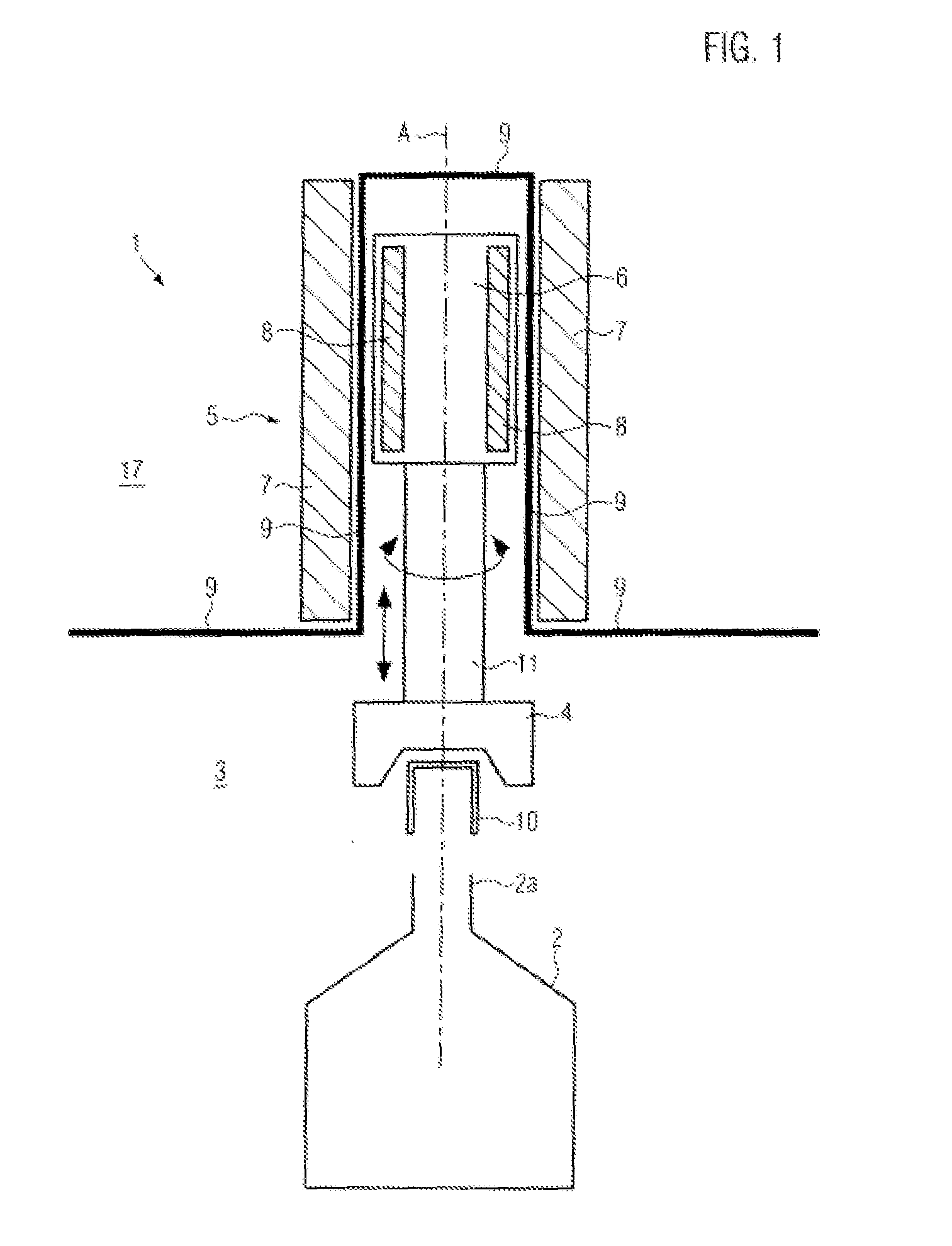

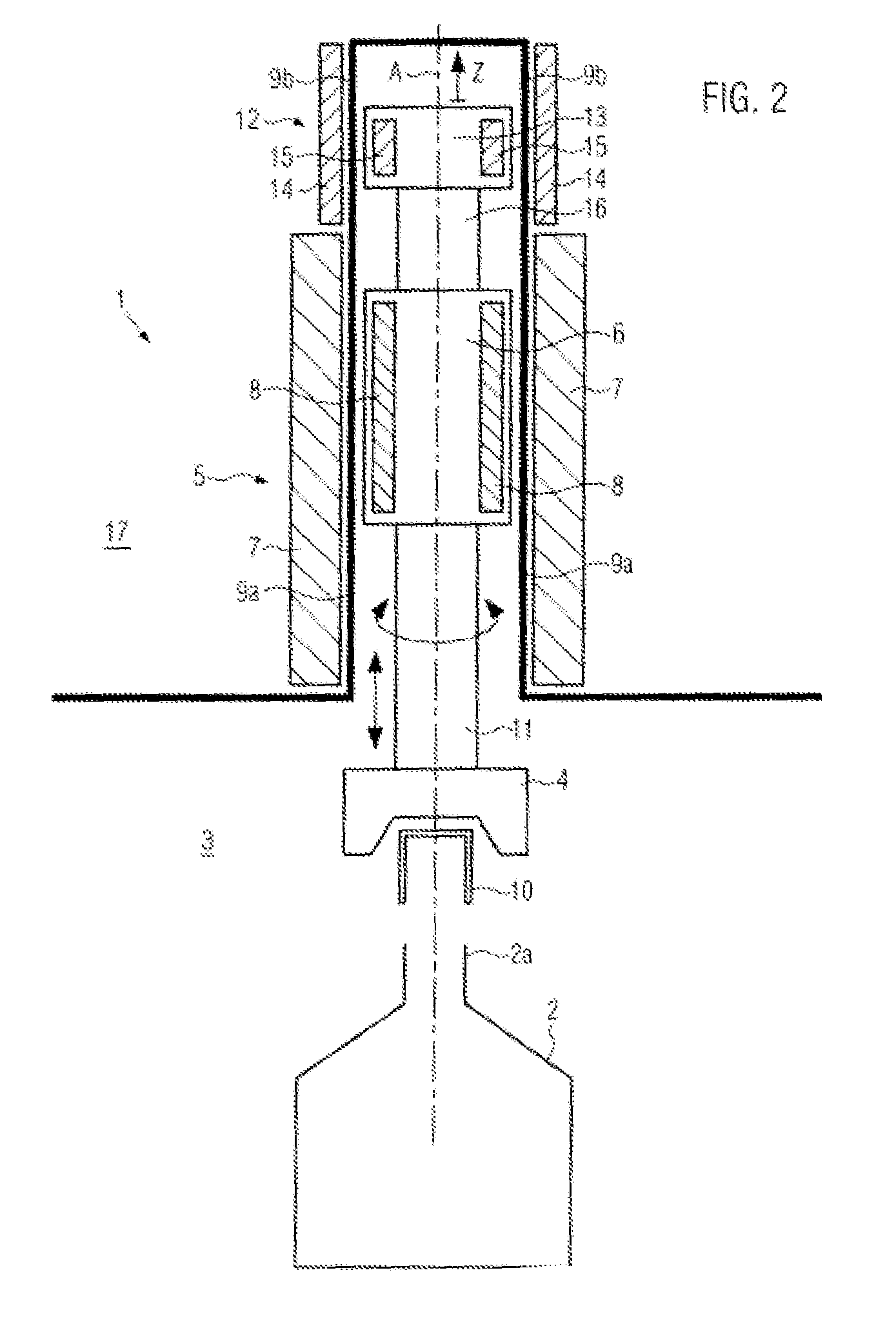

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

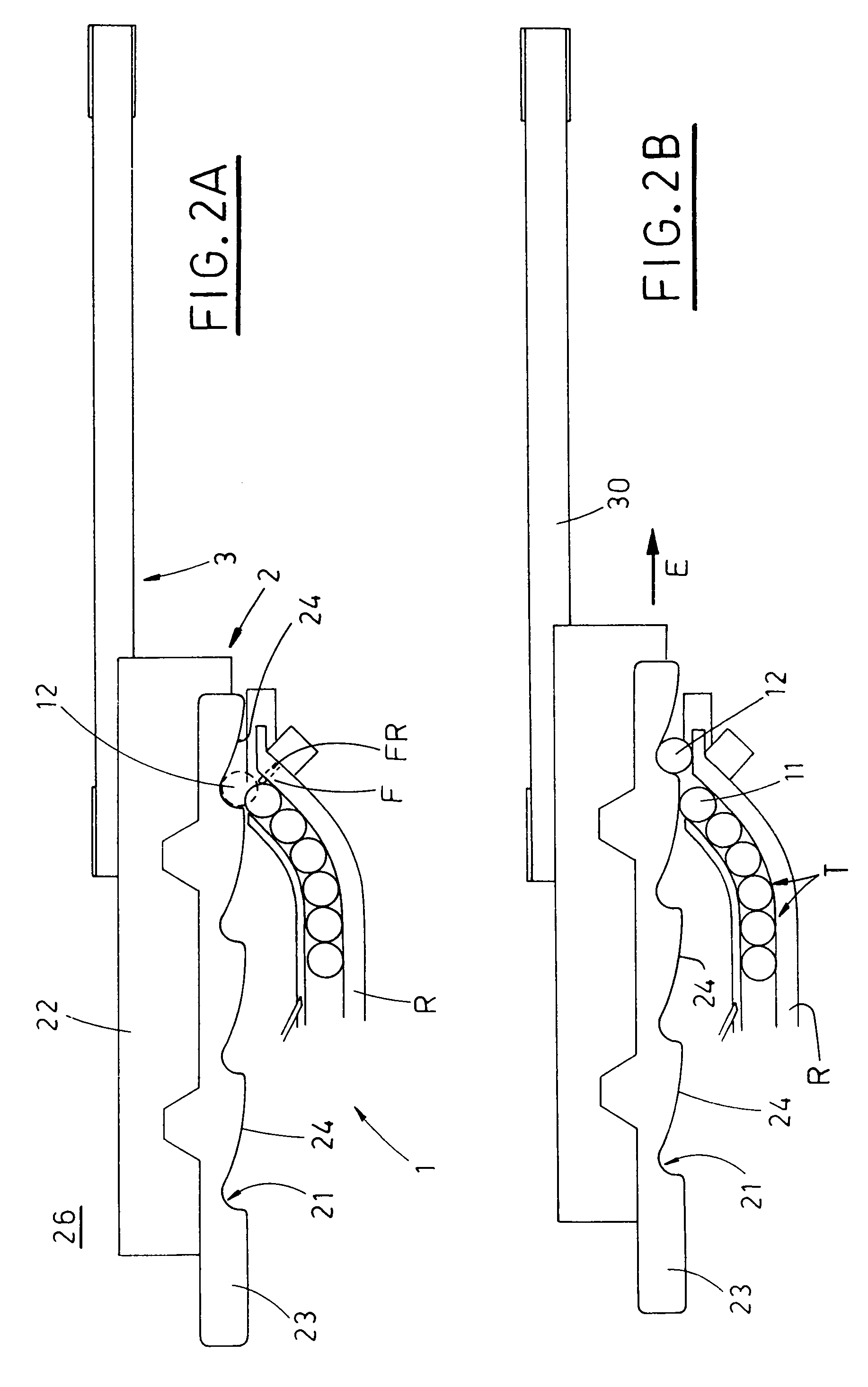

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

Method and apparatus for treating packaging and an installation for filling and closing packaging, including an apparatus for treating packaging

ActiveUS20110016829A1Increase doseReduce radiation intensityClosing machinesCapsTrademarkConstruction engineering

A method and apparatus for treating packaging and an installation for filling and closing packaging, including an apparatus for treating packaging. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

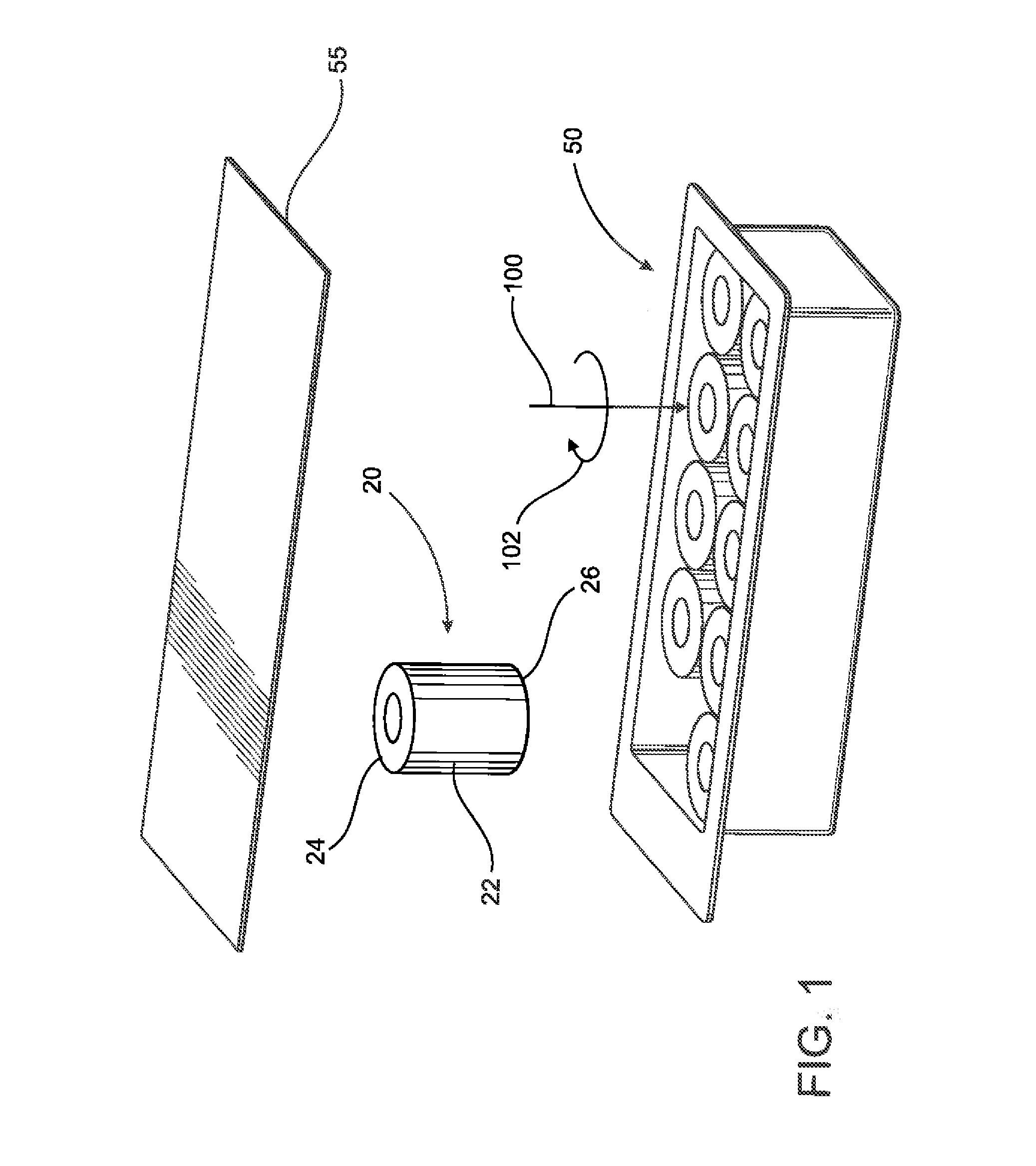

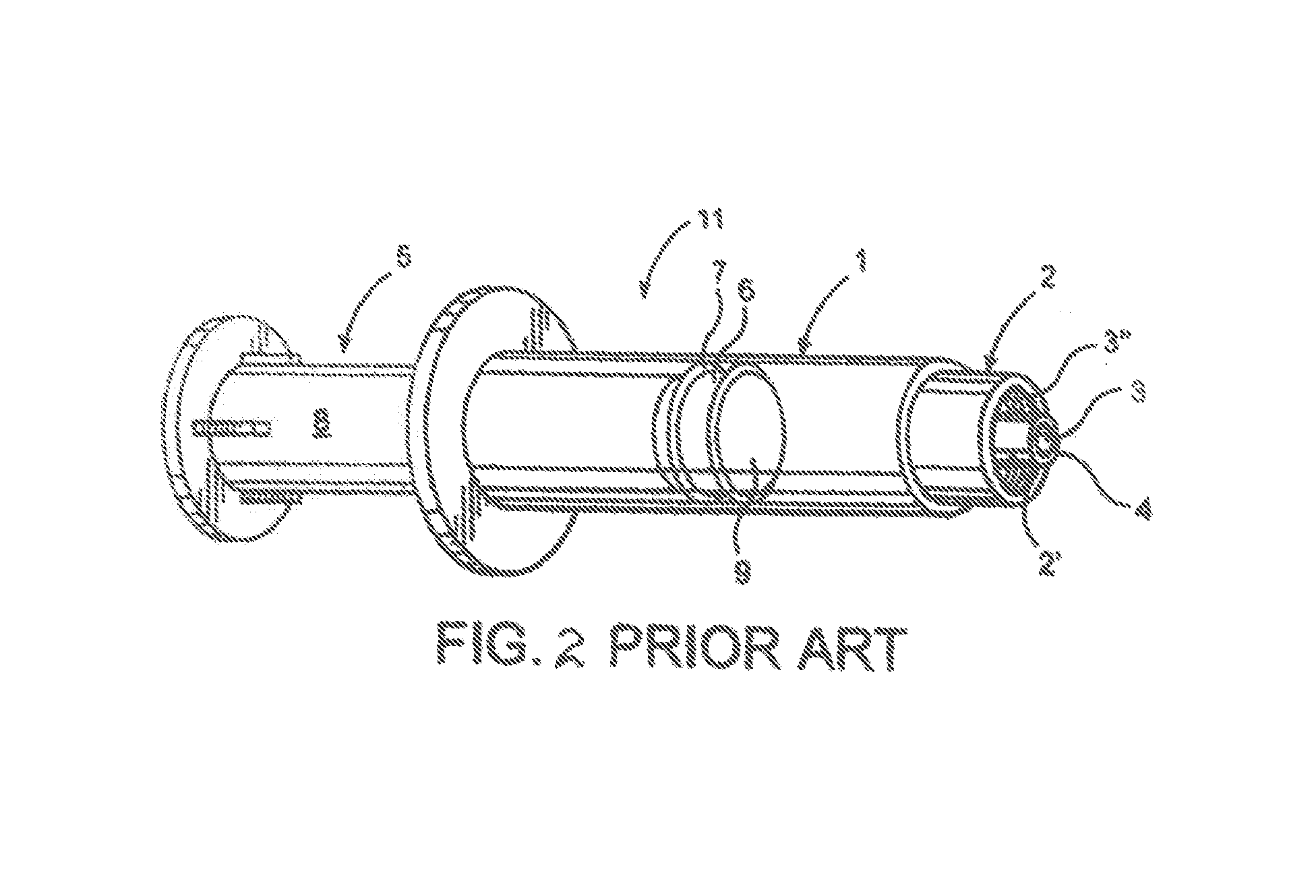

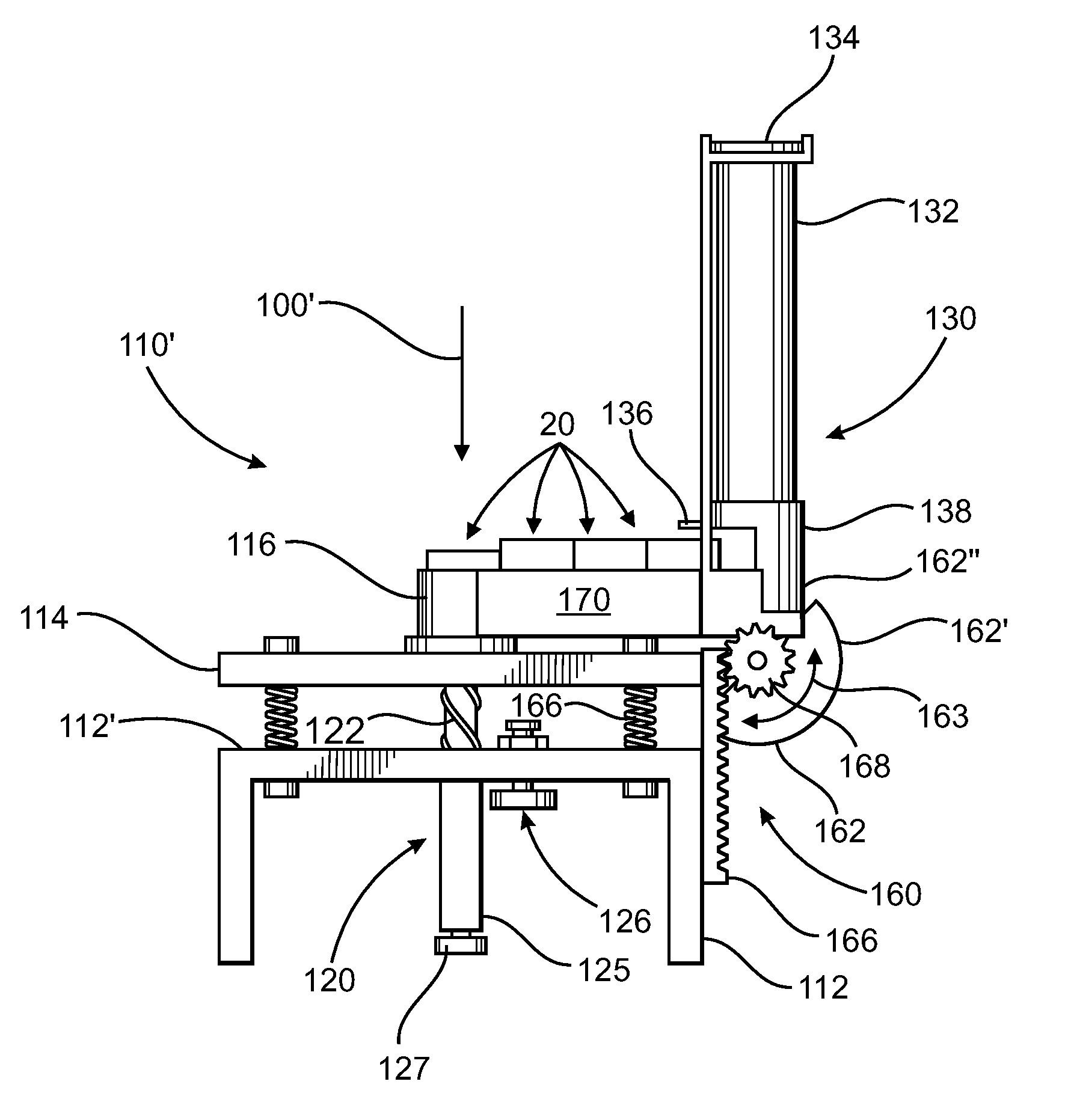

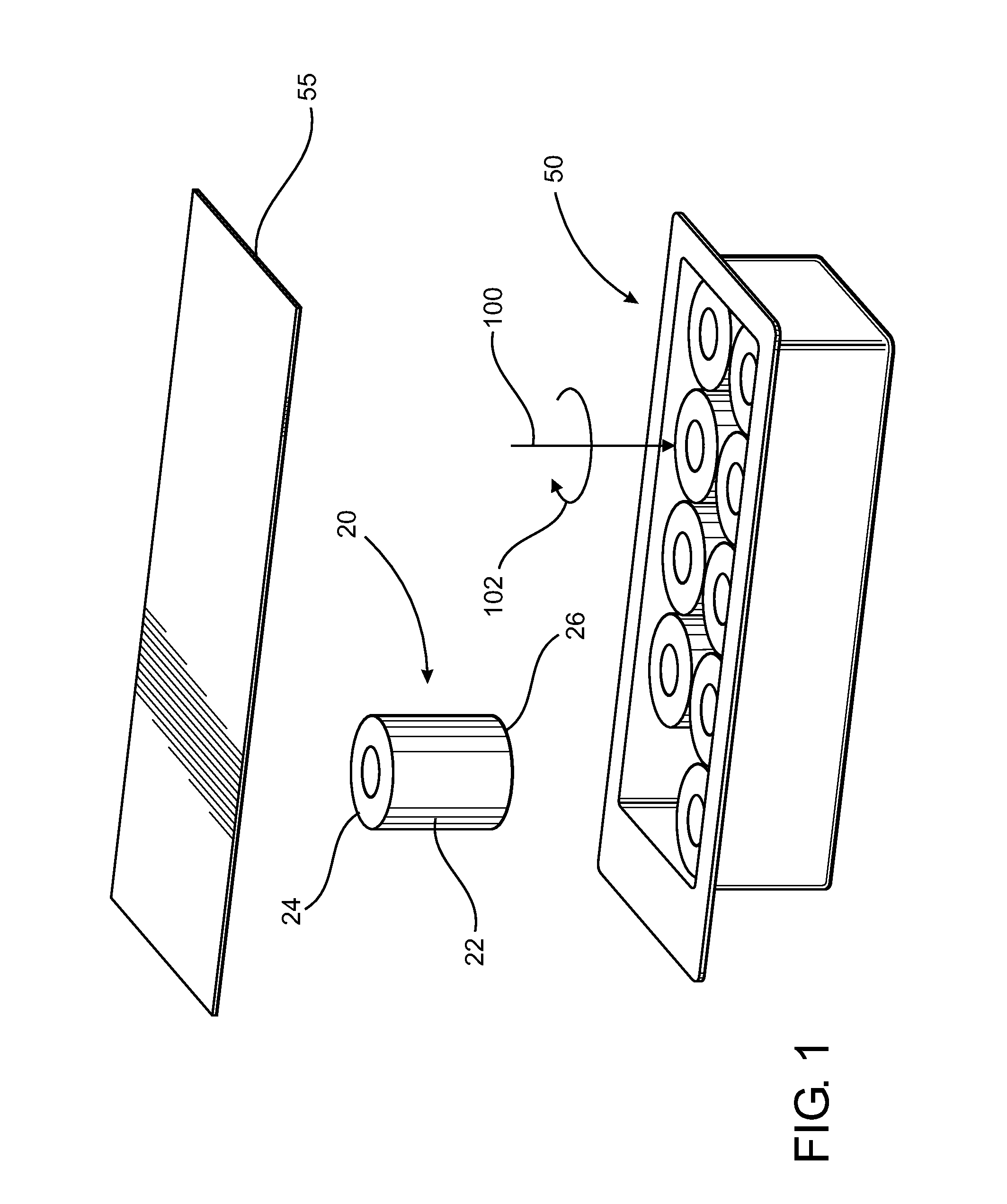

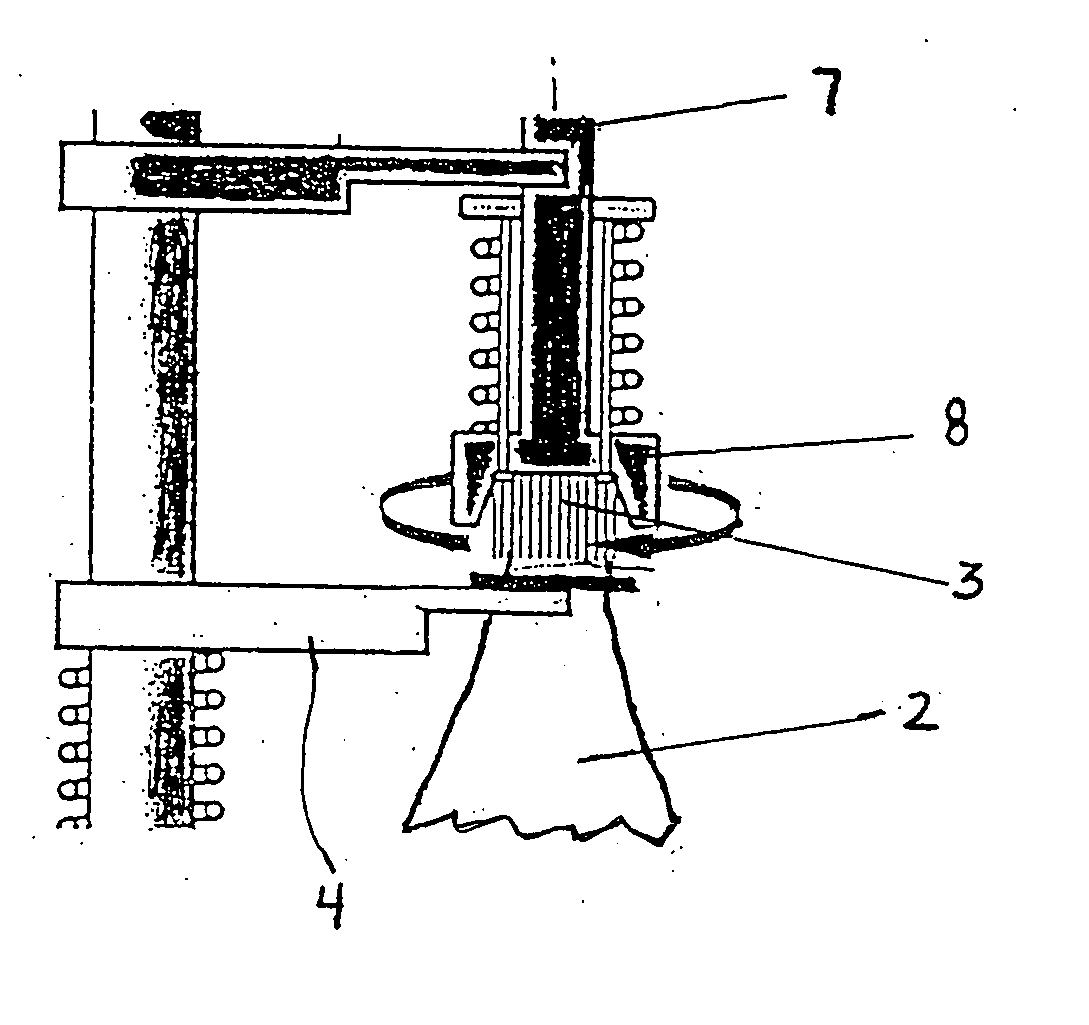

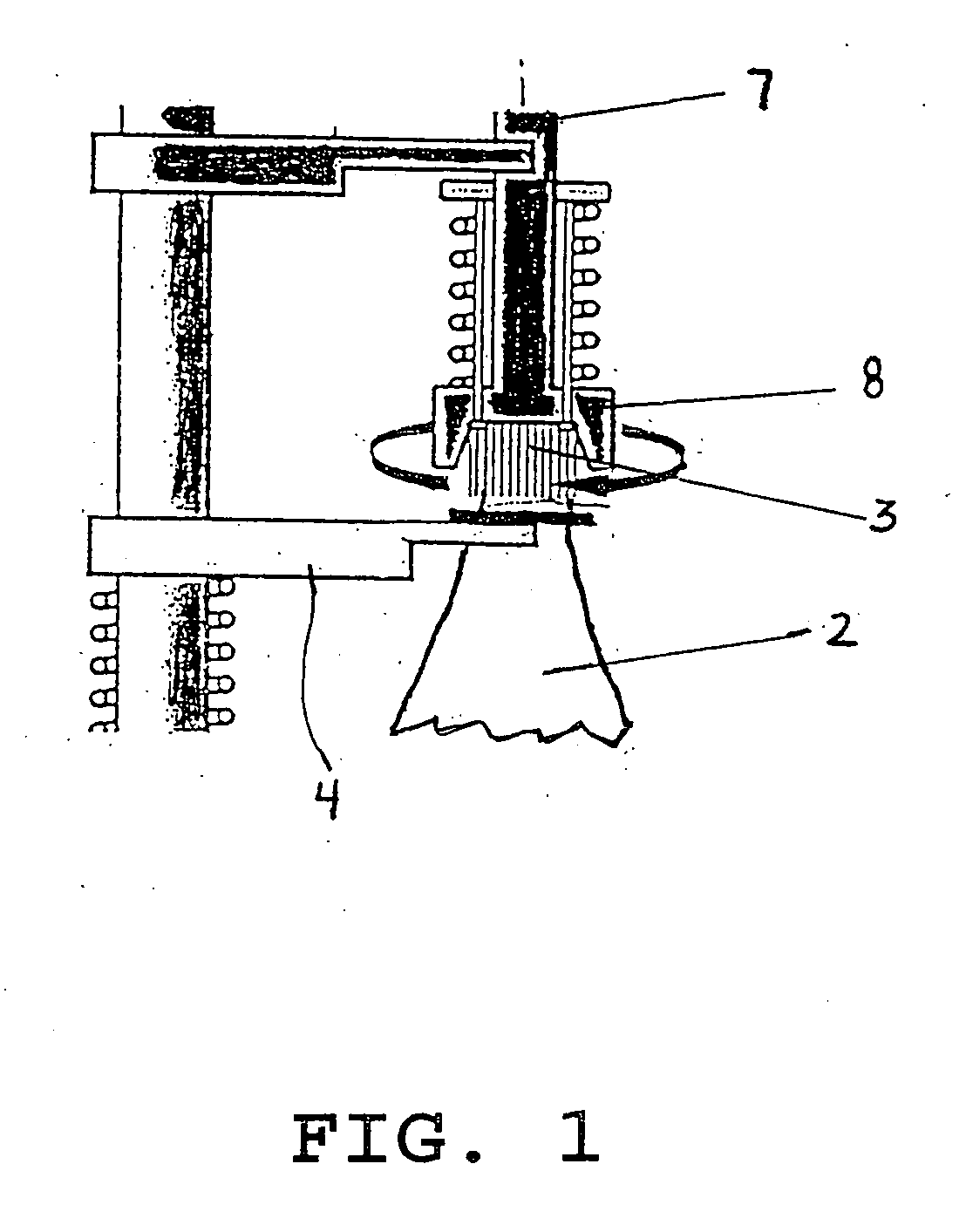

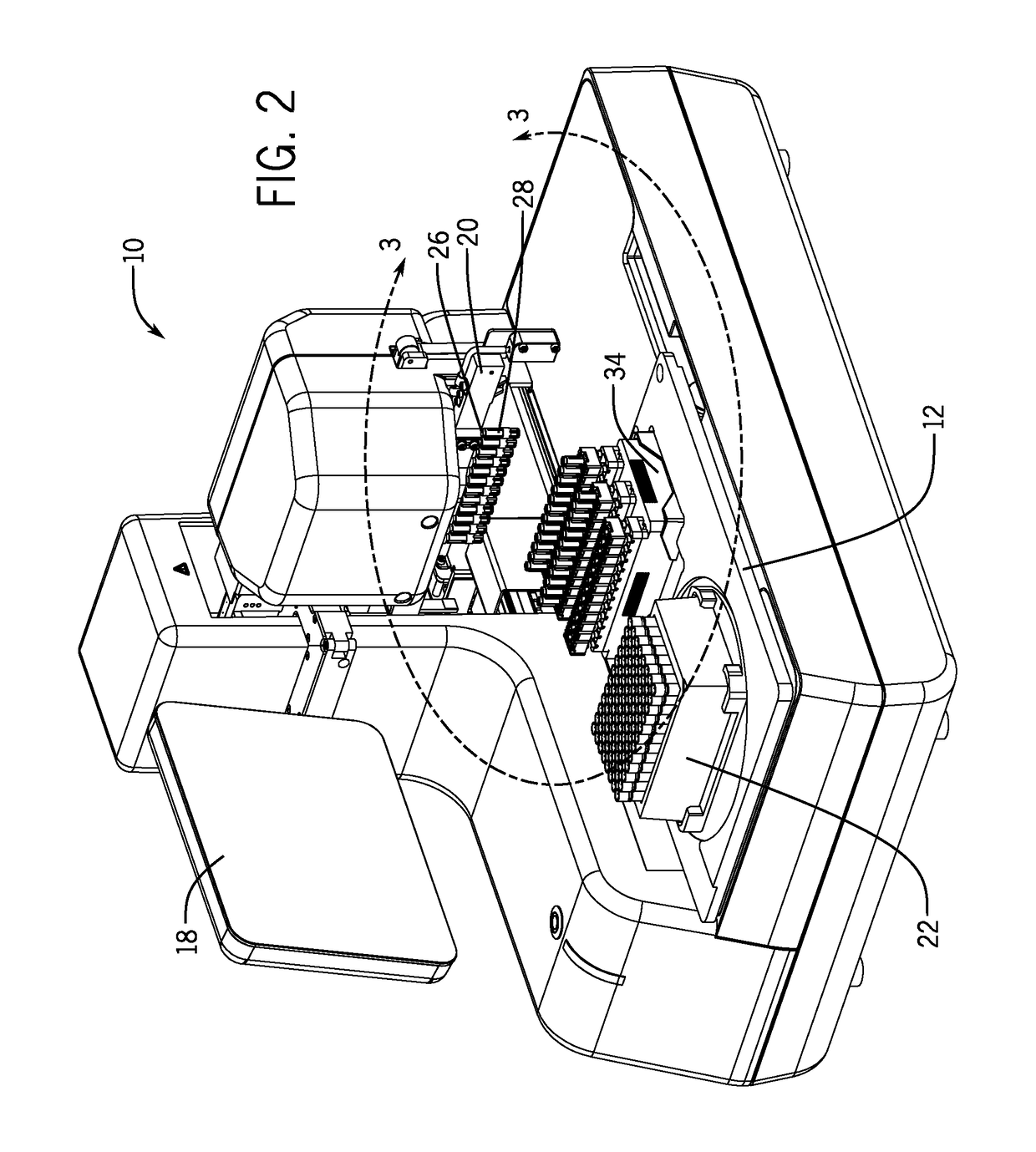

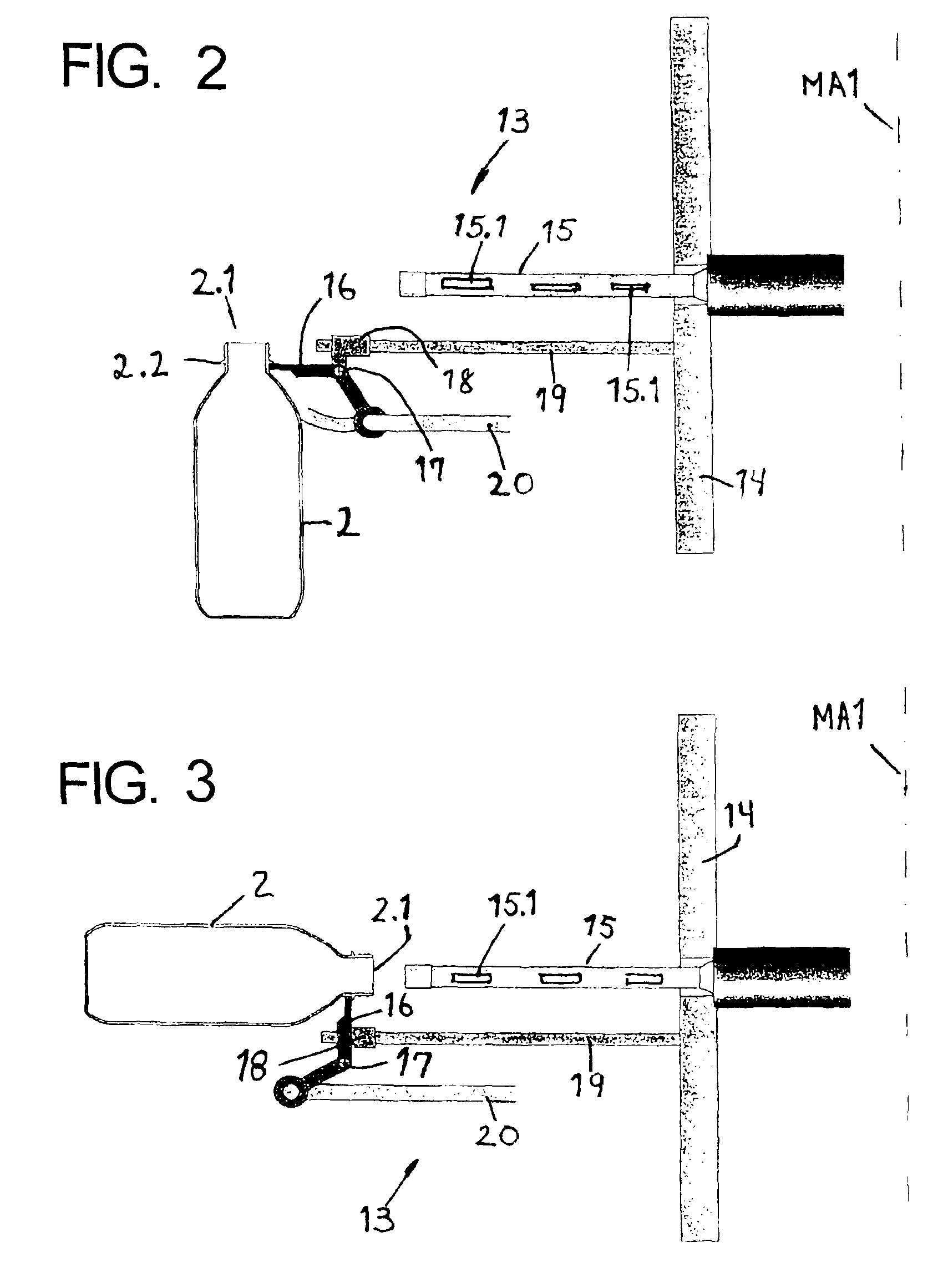

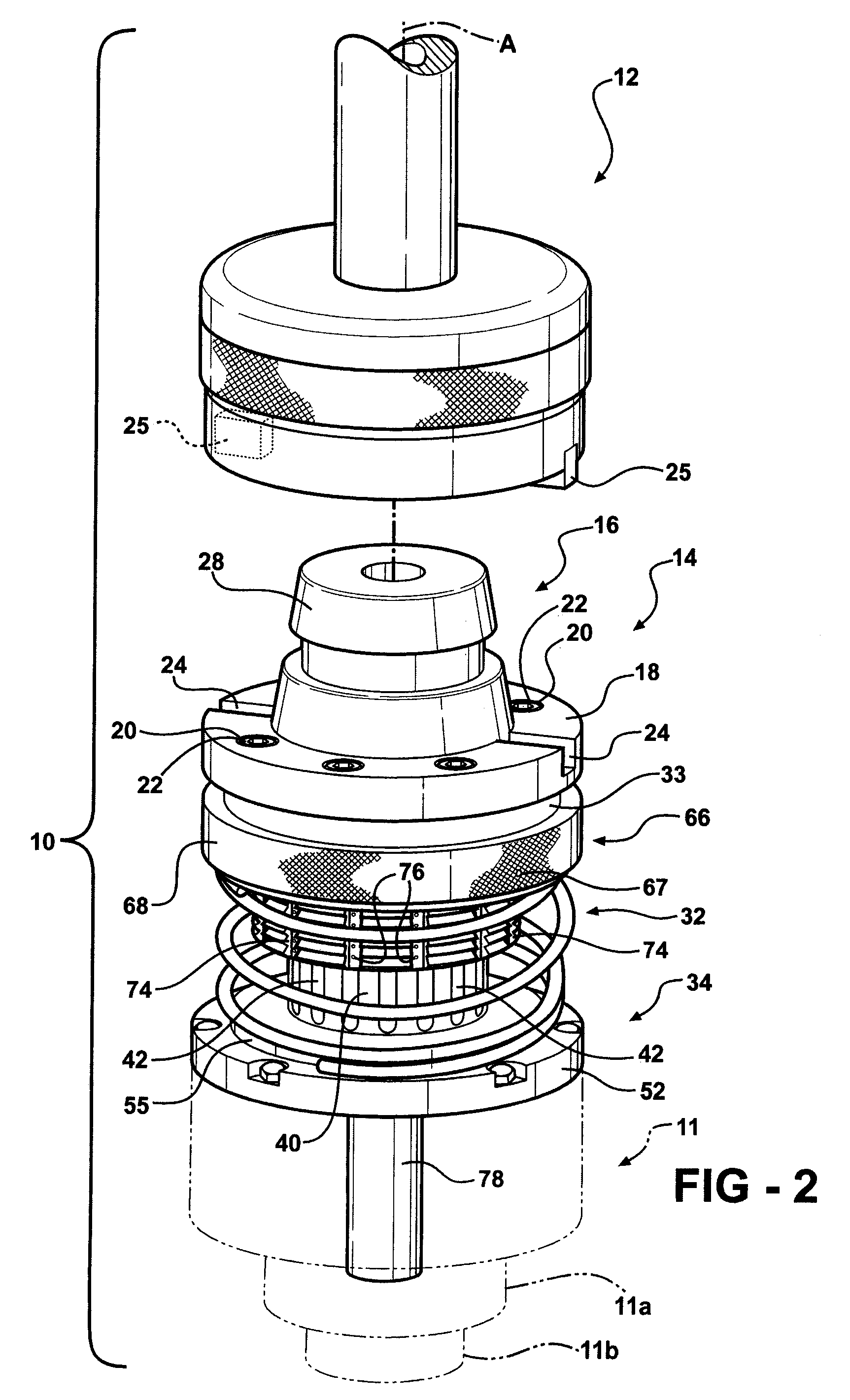

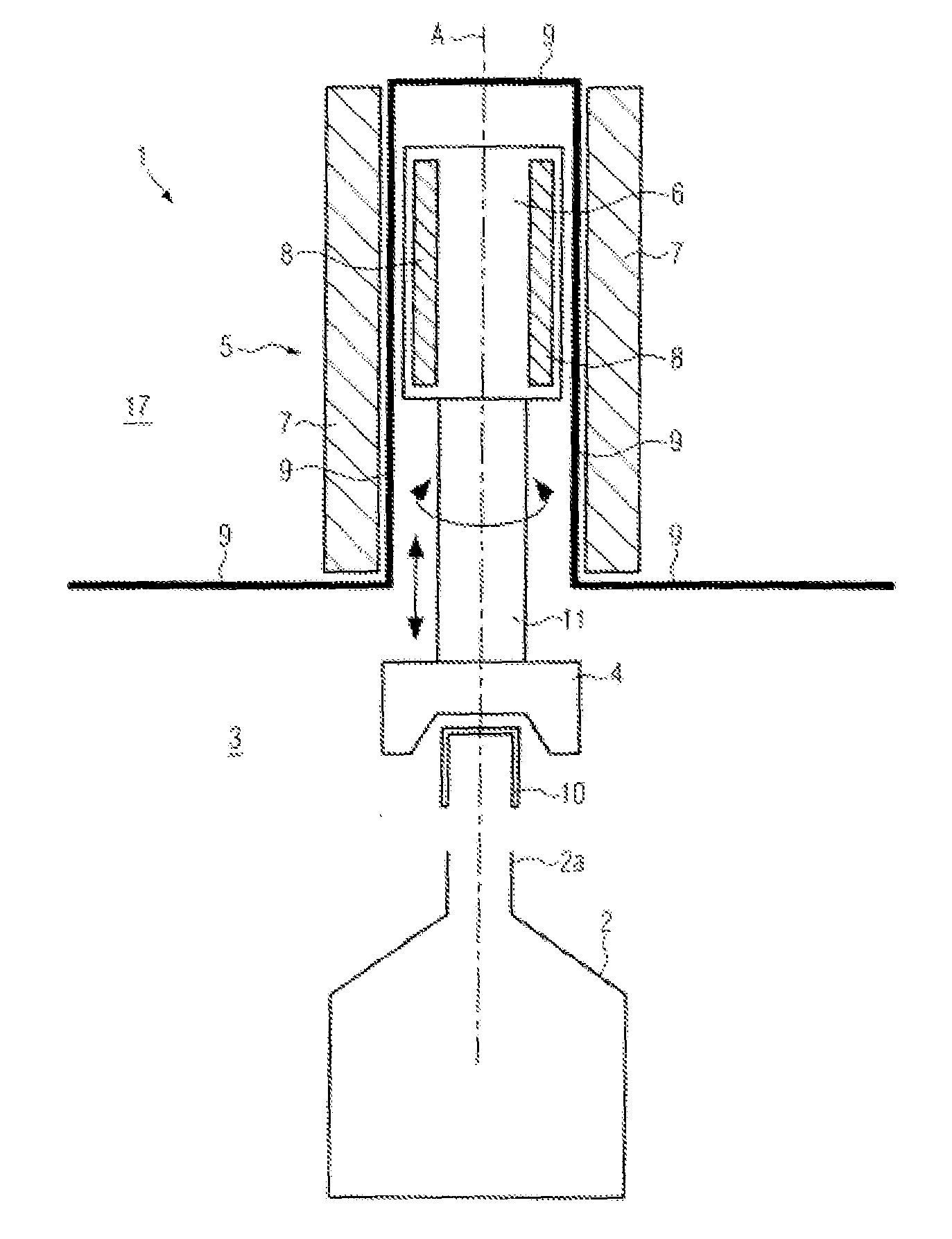

Assembly and system for connecting a closure to a syringe

ActiveUS8591462B1Facilitate gravitational feedEasy to exportClosing machinesInfusion syringesEngineeringNozzle

An assembly for closing the discharge nozzle of a syringe which is pre-filled with a drug or medication. A syringe in combination with a connecting structure removably maintain and support the closure in an operative orientation, which facilitates the rotational attachment of the syringe and the closure when the closure is in mating engagement with the connecting structure. A subsequent removal of the syringe and connected closure from the container or other type of connecting structure is thereby facilitated. The need for an individual to directly handle or touch the closure during its attachment to the syringe is restricted or eliminated. The closure assembly preferably also includes a tamper evident structure which reduces the chances of tampering with the syringe in order to access its contents.

Owner:MEDICAL DEVICE ENG

Assembly and system for connecting a closure to a syringe

An assembly for closing the discharge nozzle of a syringe which is pre-filled with a drug or medication. A syringe in combination with a connecting structure removably maintain and support the closure in an operative orientation, which facilitates the rotational attachment of the syringe and the closure when the closure is in mating engagement with the connecting structure. A subsequent removal of the syringe and connected closure from the container or other type of connecting structure is thereby facilitated. The need for an individual to directly handle or touch the closure during its attachment to the syringe is restricted or eliminated. The closure assembly preferably also includes a tamper evident structure which reduces the chances of tampering with the syringe in order to access its contents.

Owner:VIITELLO JONATHAN J +2

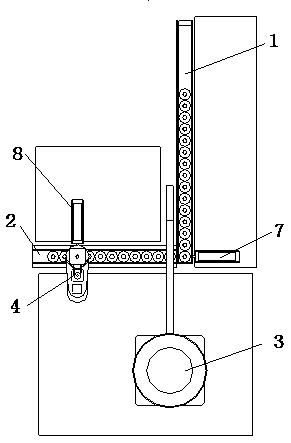

Automatic cover opening or closing and carrying device for sample test tube

ActiveCN104444983AImprove work efficiencyLow costClosing machinesThreaded caps applicationMicrobial inoculationElectric machinery

The invention relates to an automatic cover opening or closing and carrying device for a sample test tube, and solves the technical problems of low efficiency, high cost, easy bacterial infection of operators and negative influence caused by artificial and environmental factors during manual operation of an existing microorganism sample test tube. The device comprises a machine table, a test tube clamping vertical movement electric cylinder, a test tube top rotary motor, a test tube clamping bottom rotary electric cylinder, a test tube clamping electric cylinder and a test tube cover opening clamping electric cylinder, wherein the test tube clamping bottom rotary electric cylinder is connected with the machine table; the test tube clamping vertical movement electric cylinder is connected with the test tube clamping bottom rotary electric cylinder; the test tube clamping electric cylinder and the test tube top rotary motor are connected with the test tube clamping vertical movement electric cylinder respectively; the test tube clamping electric cylinder is provided with two clamping jaws; the test tube top rotary motor is connected with a cover screwer; the test tube cover opening clamping electric cylinder is connected with the machine table and provided with two clamping jaws. The device is widely applied to the technical fields of microorganism inoculation, clinics, chemicals, environments and the like.

Owner:WEIHAI SHILI ELECTRONICS TECH

Assembly and system for connecting a closure to a syringe

Owner:MEDICAL DEVICE ENG

Method and machine for closing bottle with sterile caps

ActiveUS7536839B2Easy to operateImprove throughputCapsDecorative coversSterile environmentLinear machine

Owner:KHS CORPOPLAST GMBH & CO KG

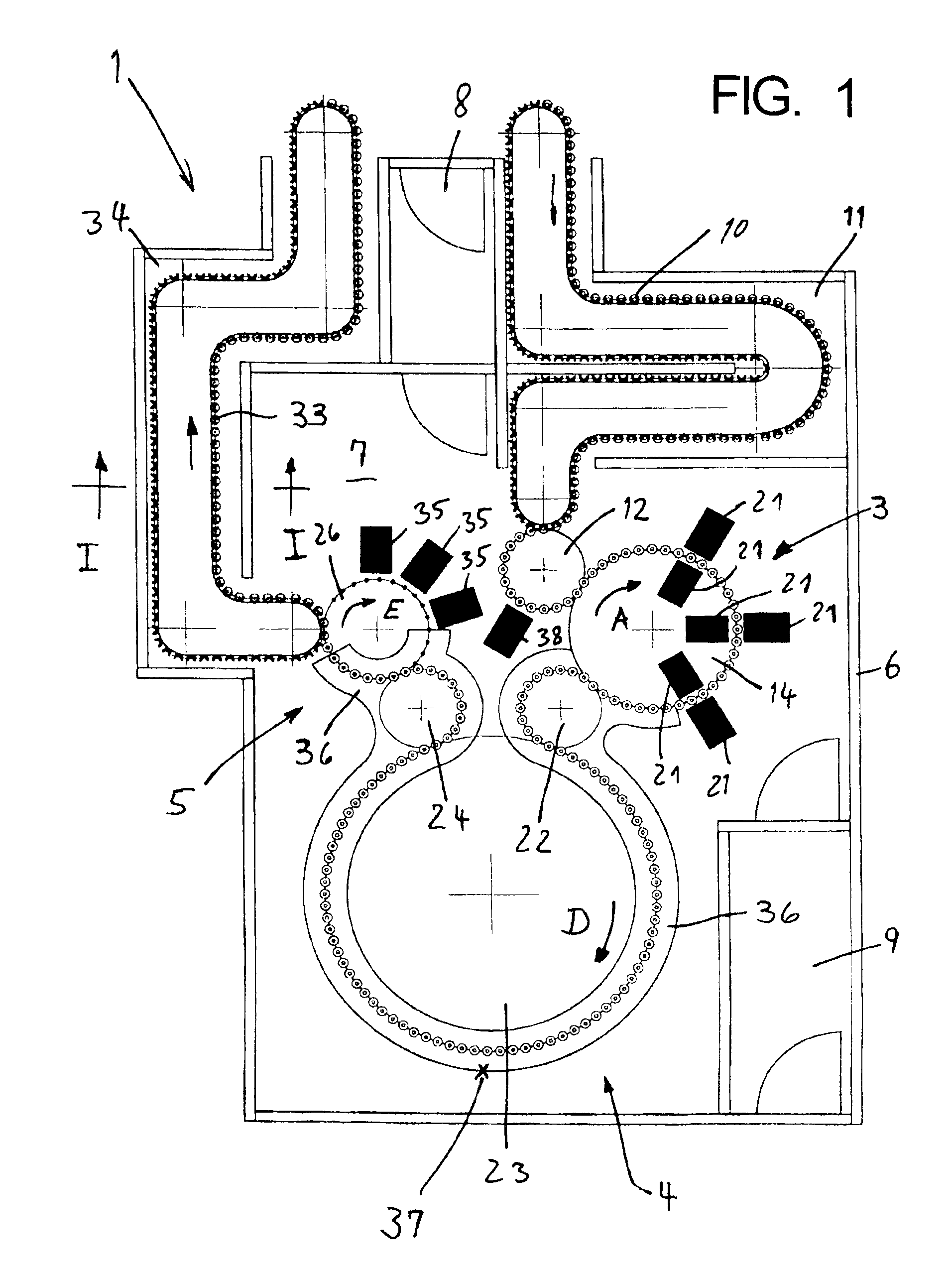

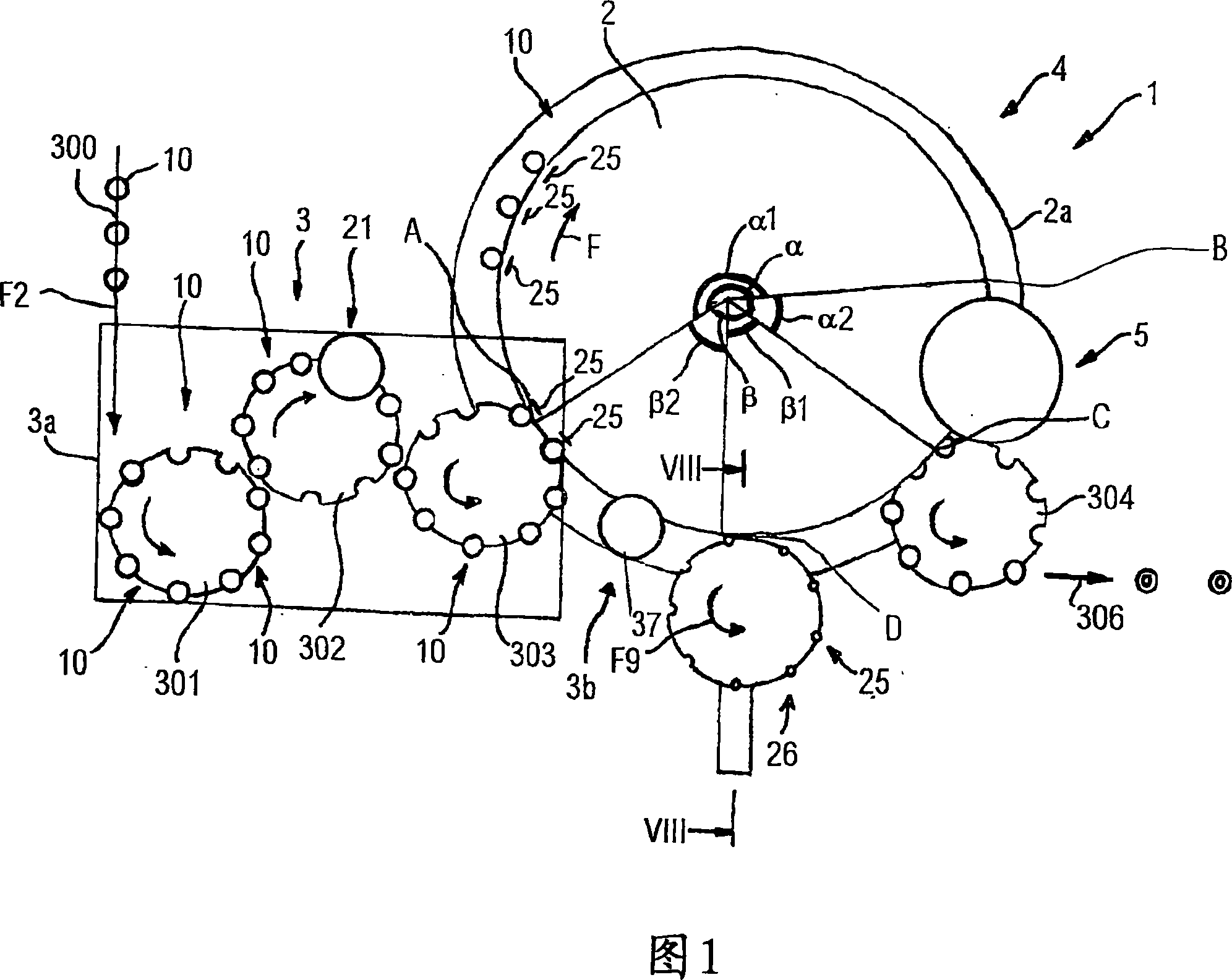

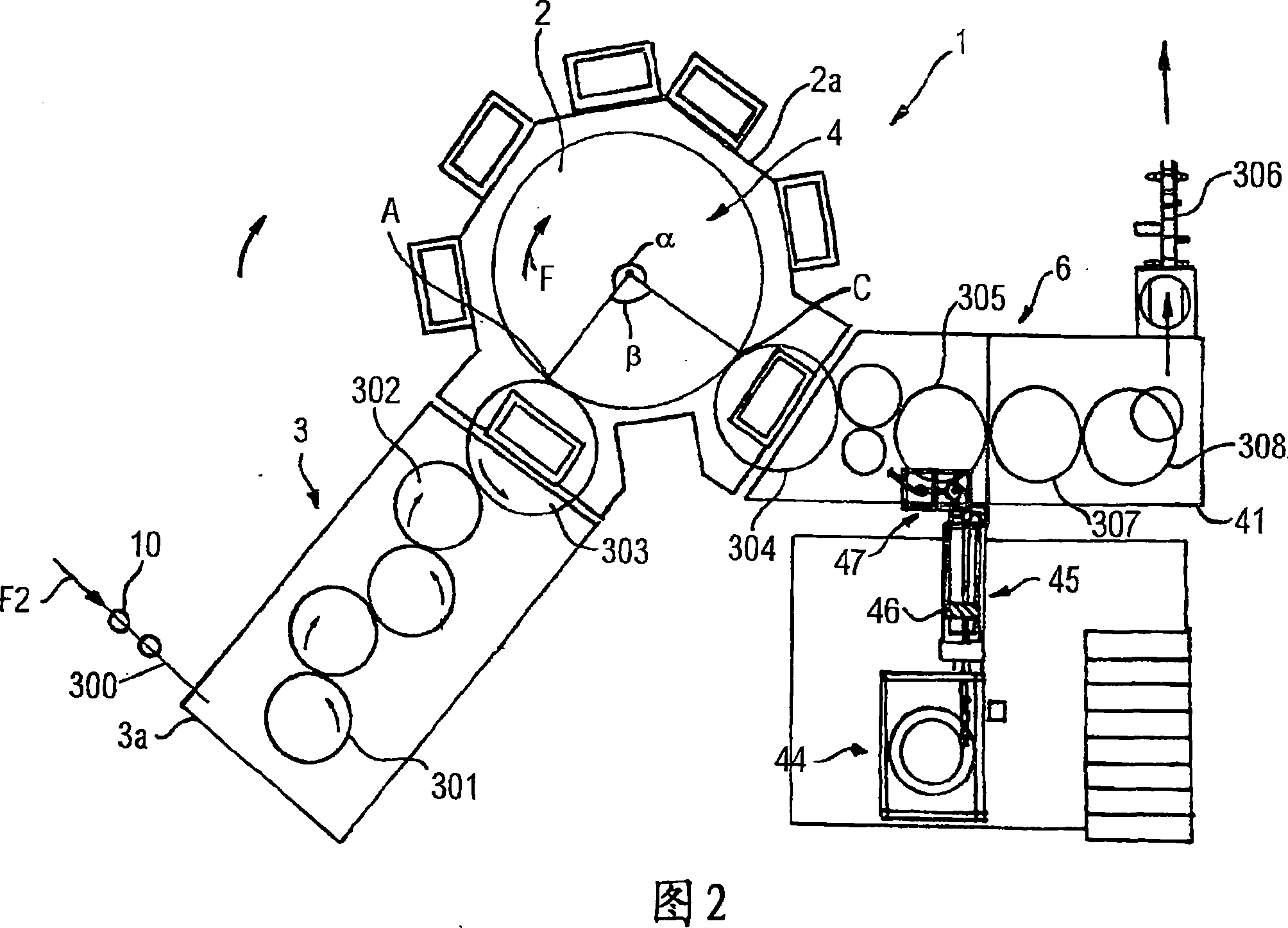

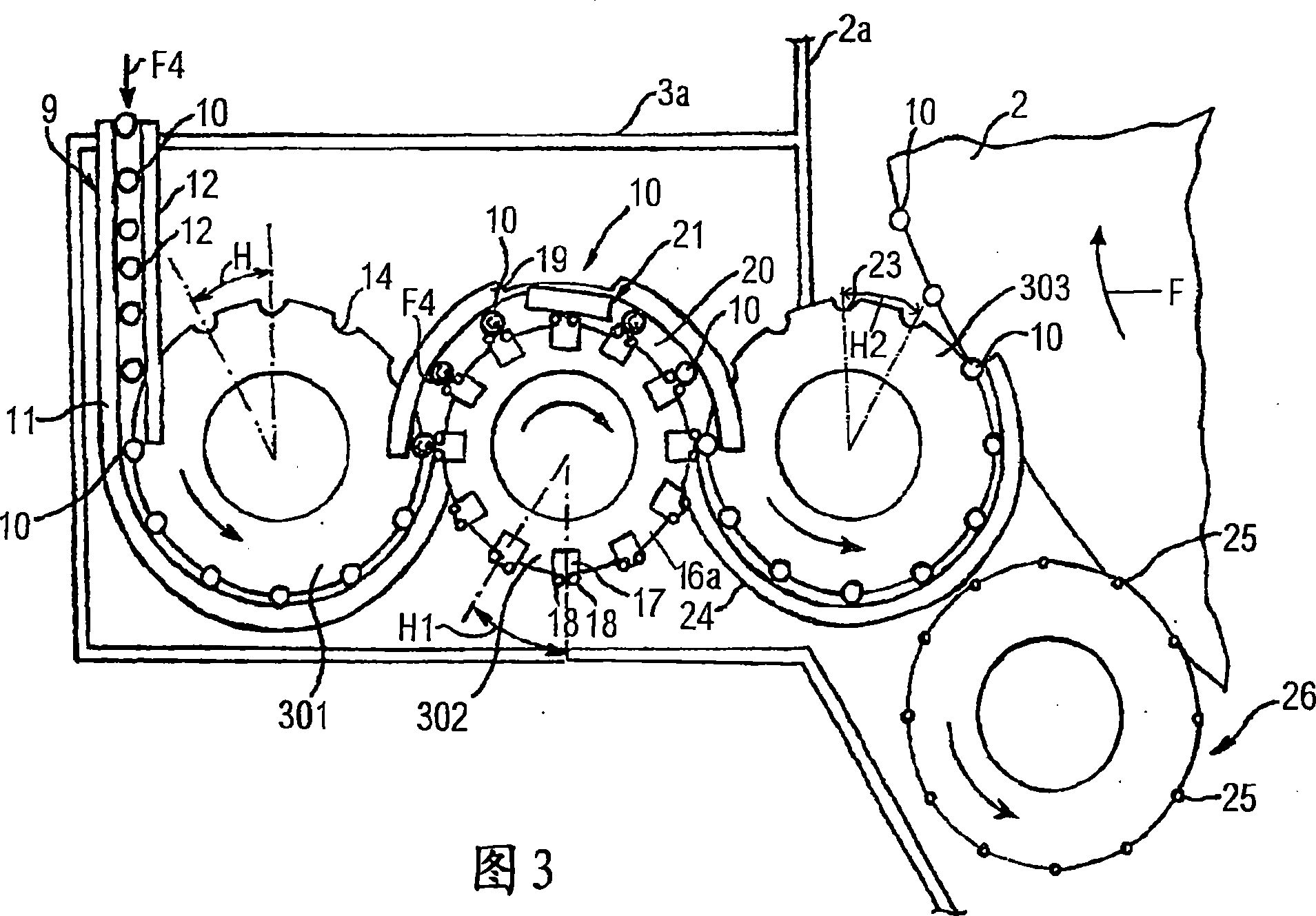

Apparatuses and methods for sterilising and filling components of packaging units, particularly bottles and/or caps

InactiveCN1968888AImprove sterilization efficiencyEffective sterilizationClosing machinesCapsEngineeringBottle

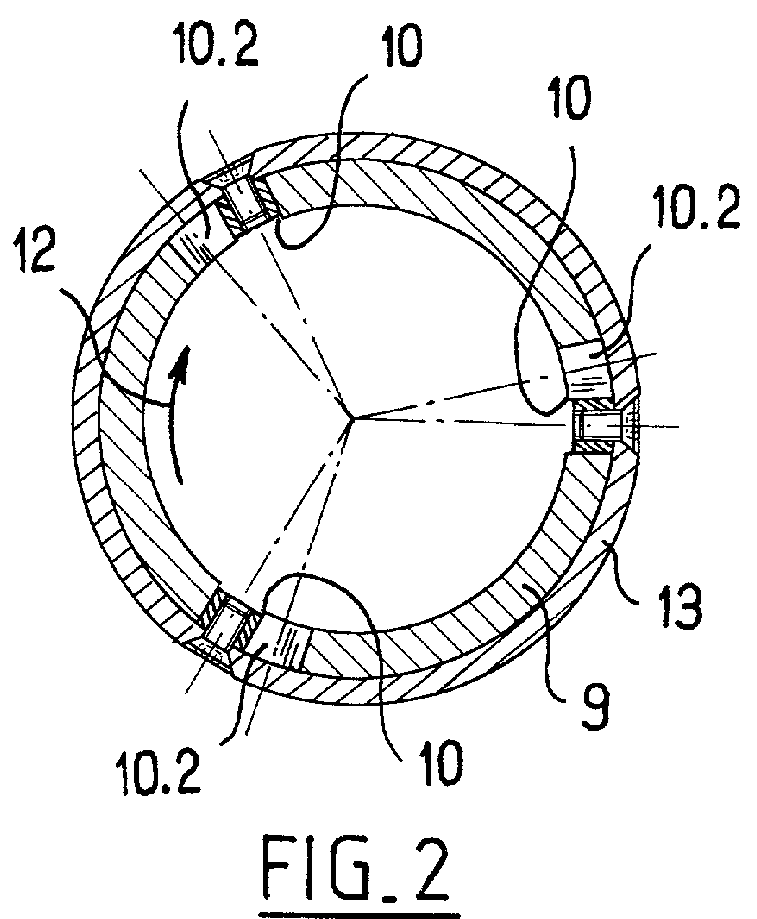

An apparatus comprises rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2) for conveying along a curved path components (10, 25) of packaging units comprising containers (10) and container closures (25), filling means (30) for filling with a product said containers (10) on said rotating conveying means (301, 302, 303, 2; 301, 160, 303, 2), sterilising means (21, 37) for sterilising at least part of said components (10, 25) mounted along said path and comprising irradiating means arranged to emit radiation.

Owner:SIDEL S. P. A.

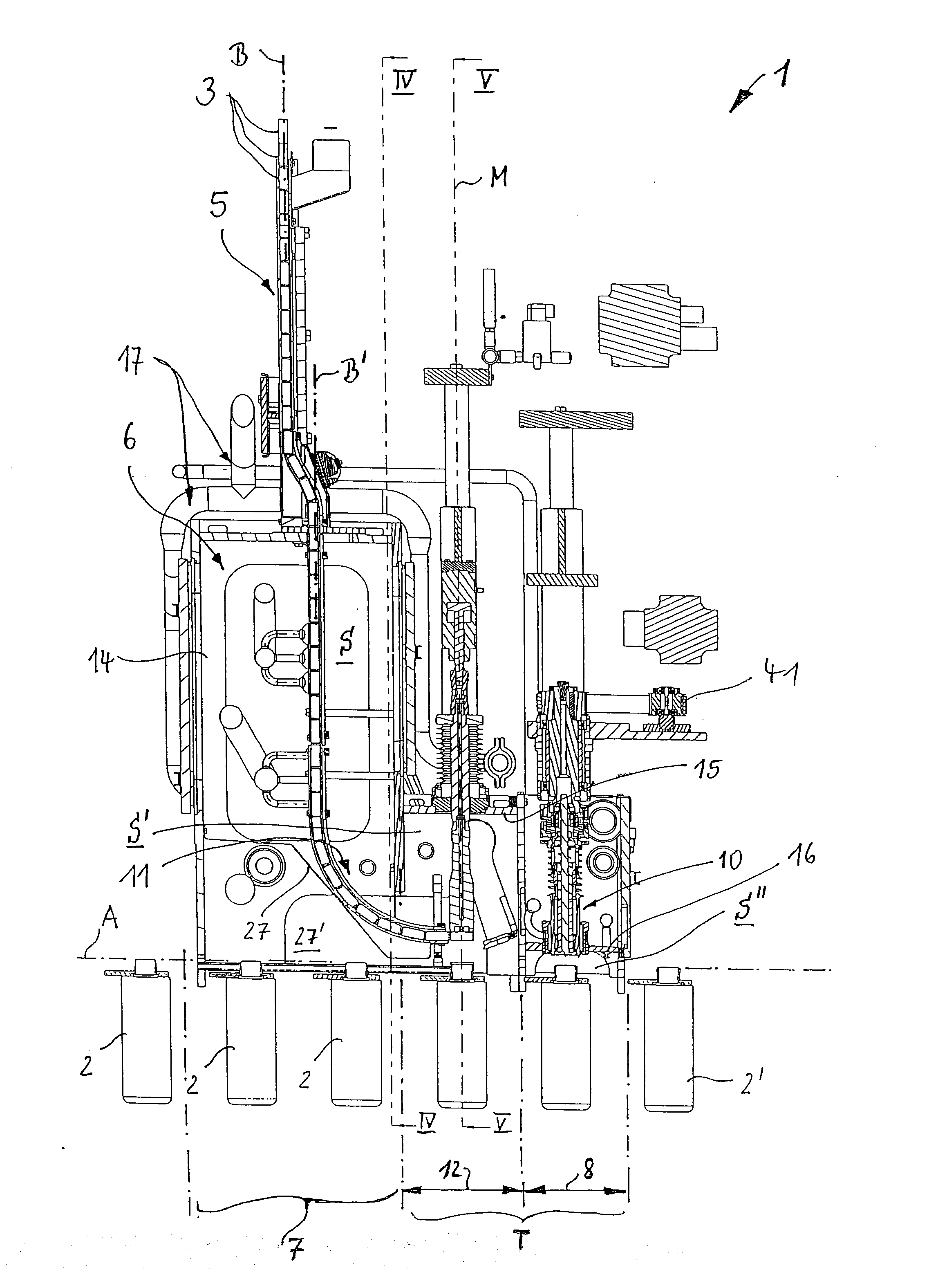

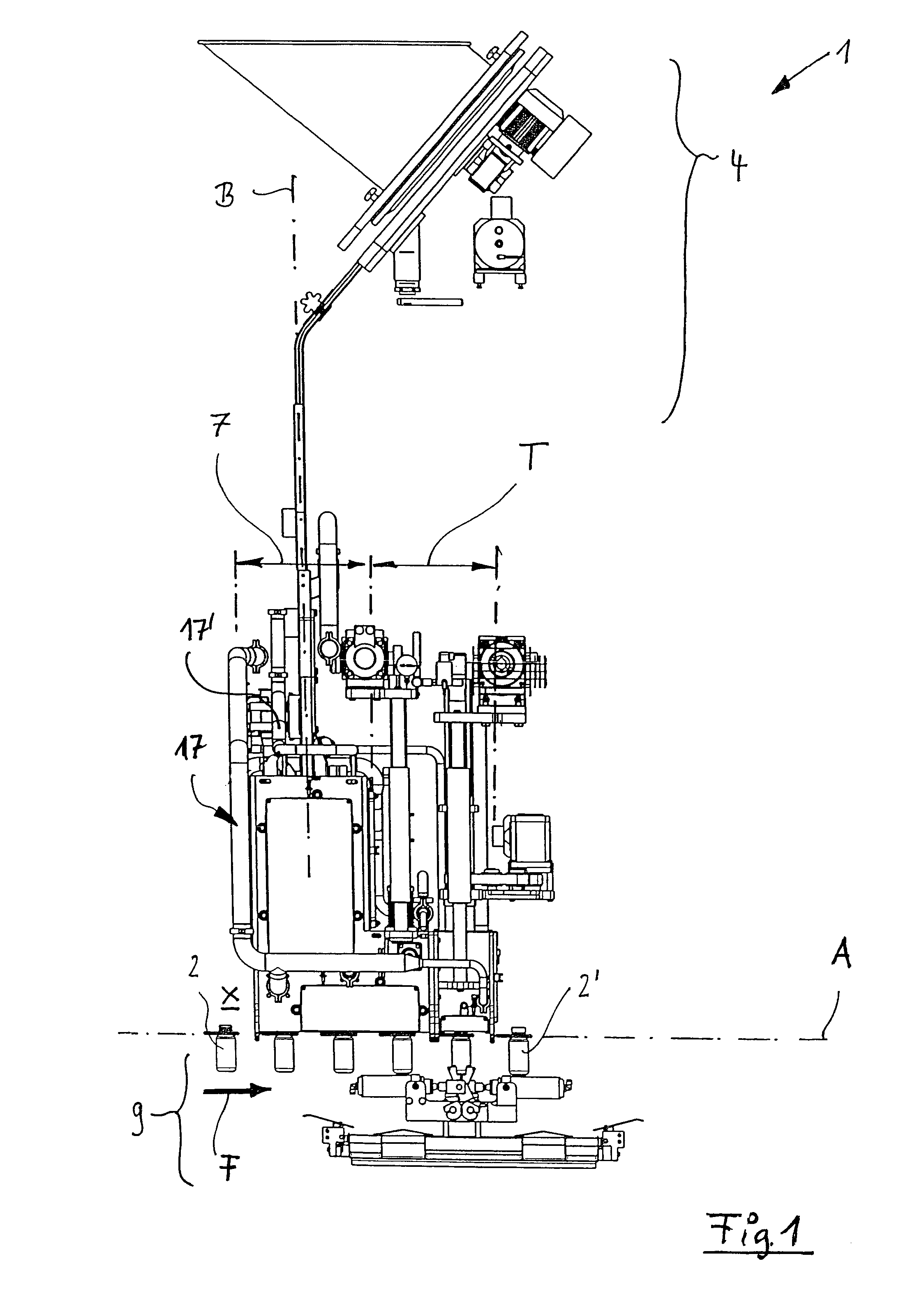

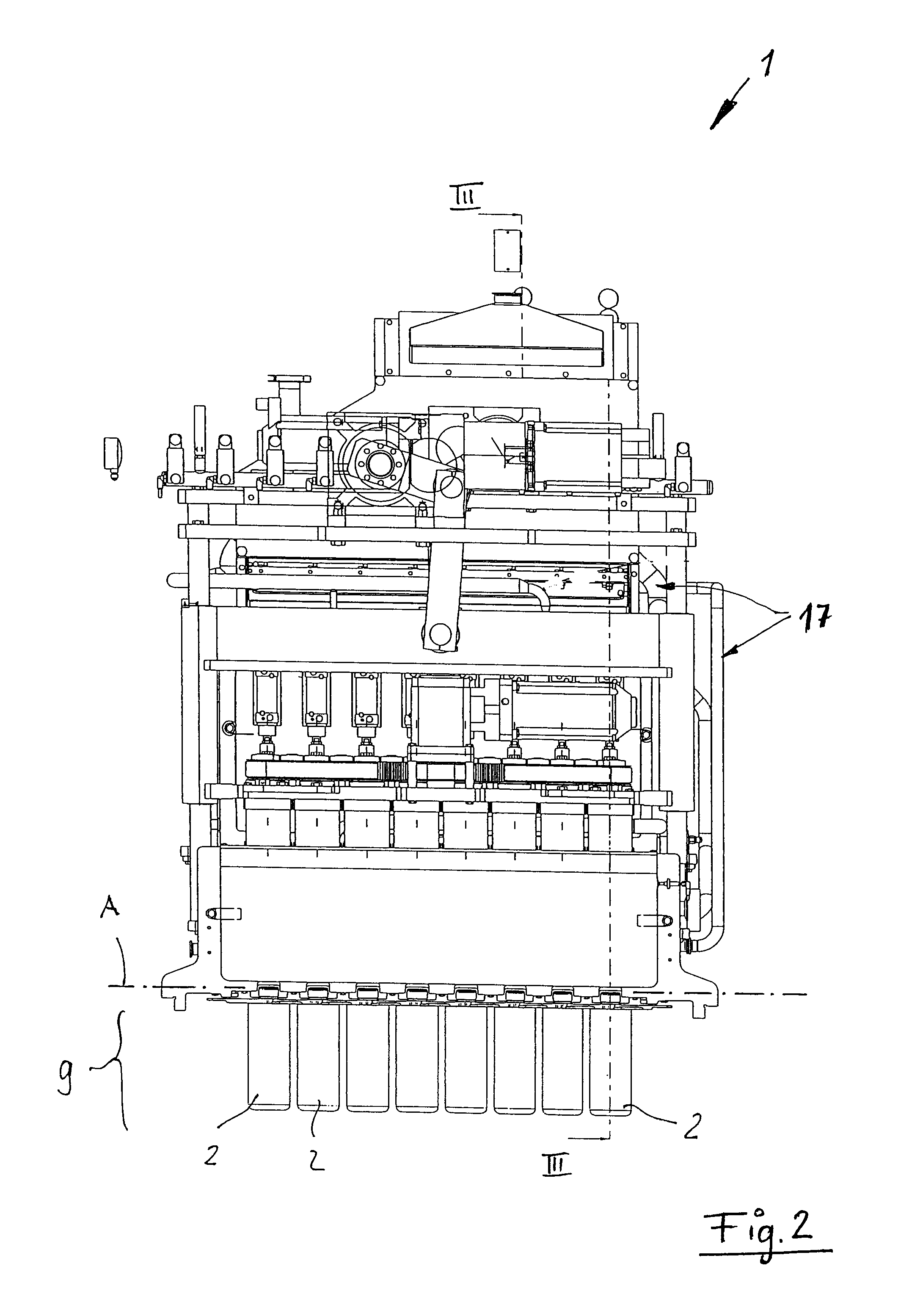

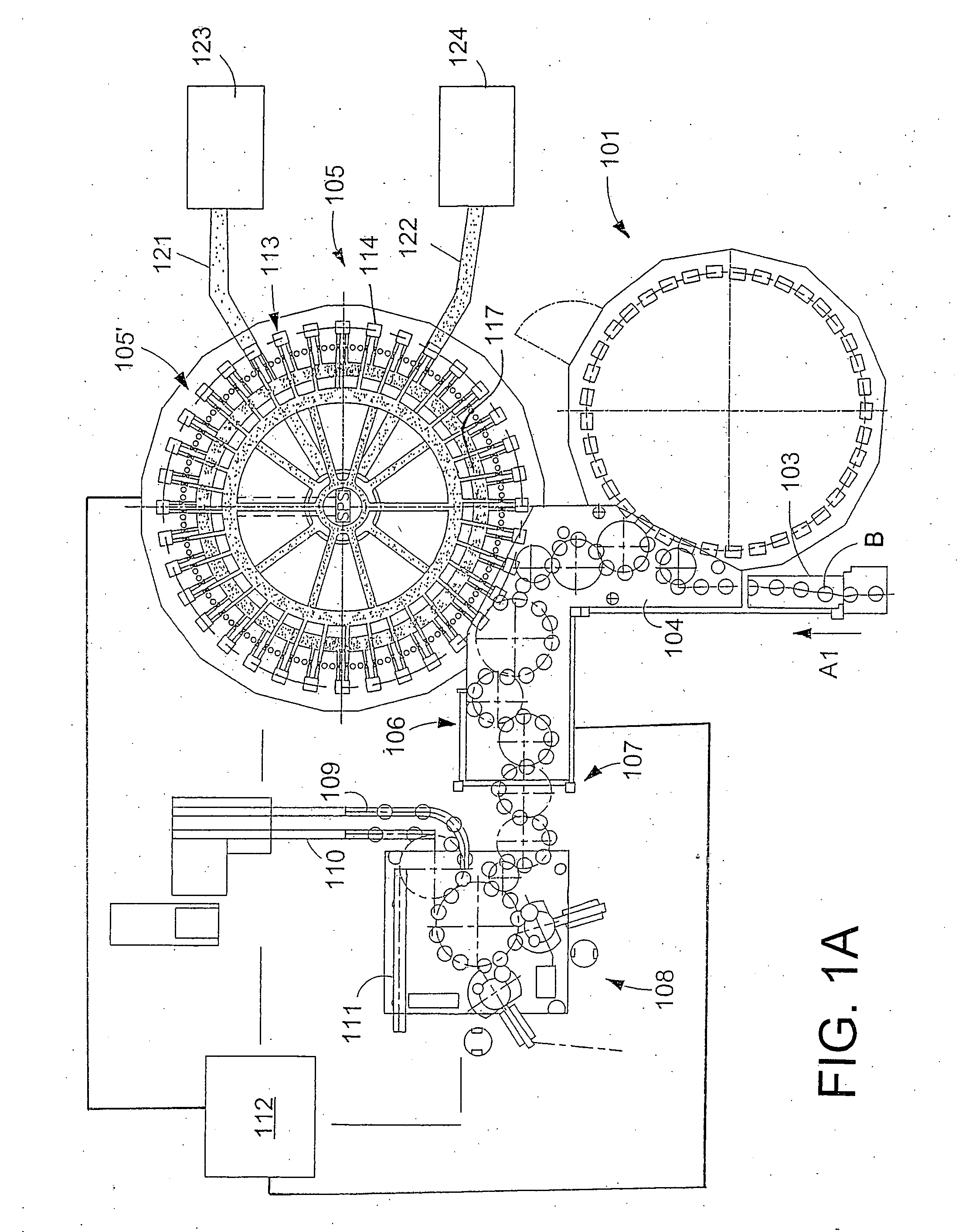

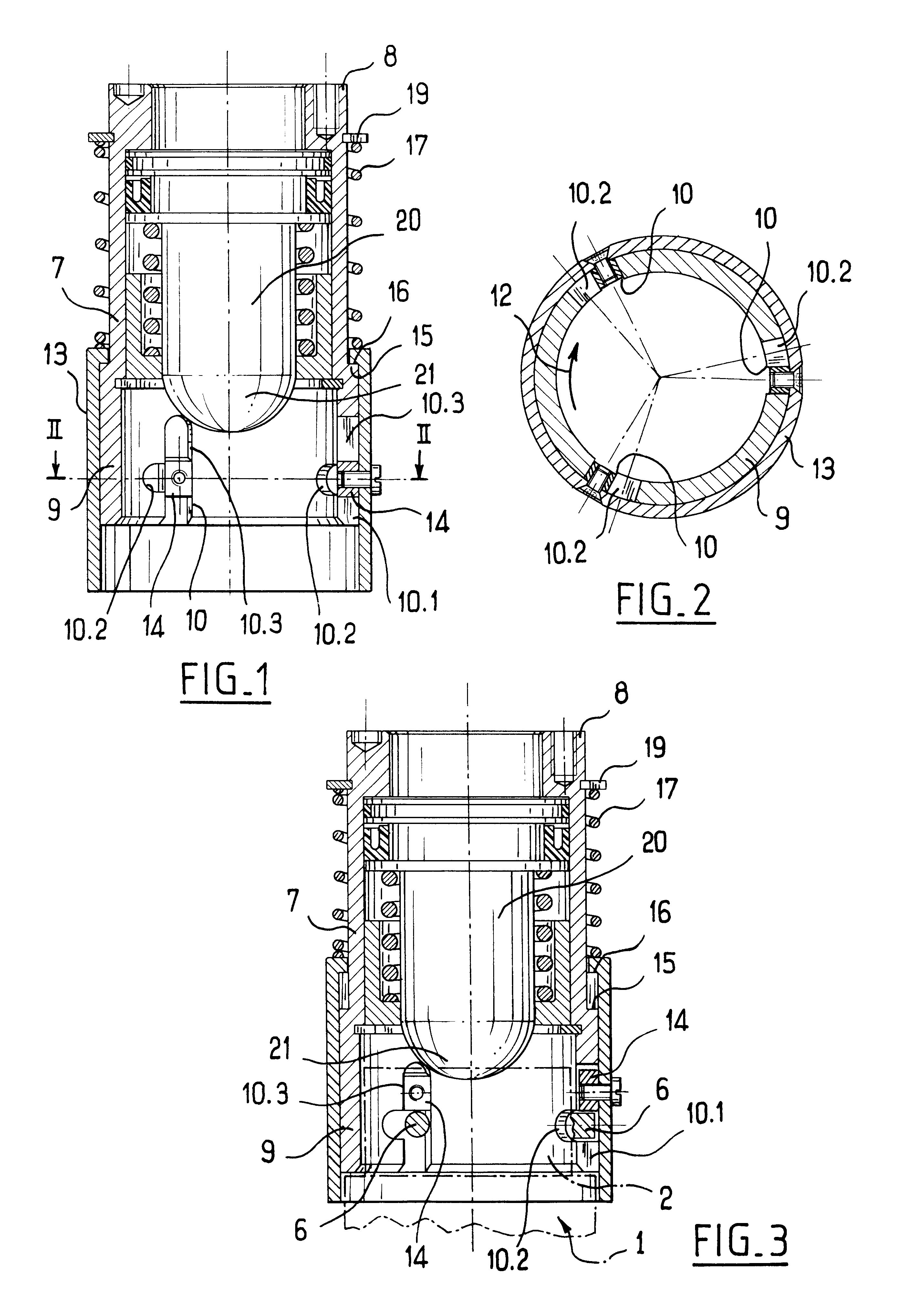

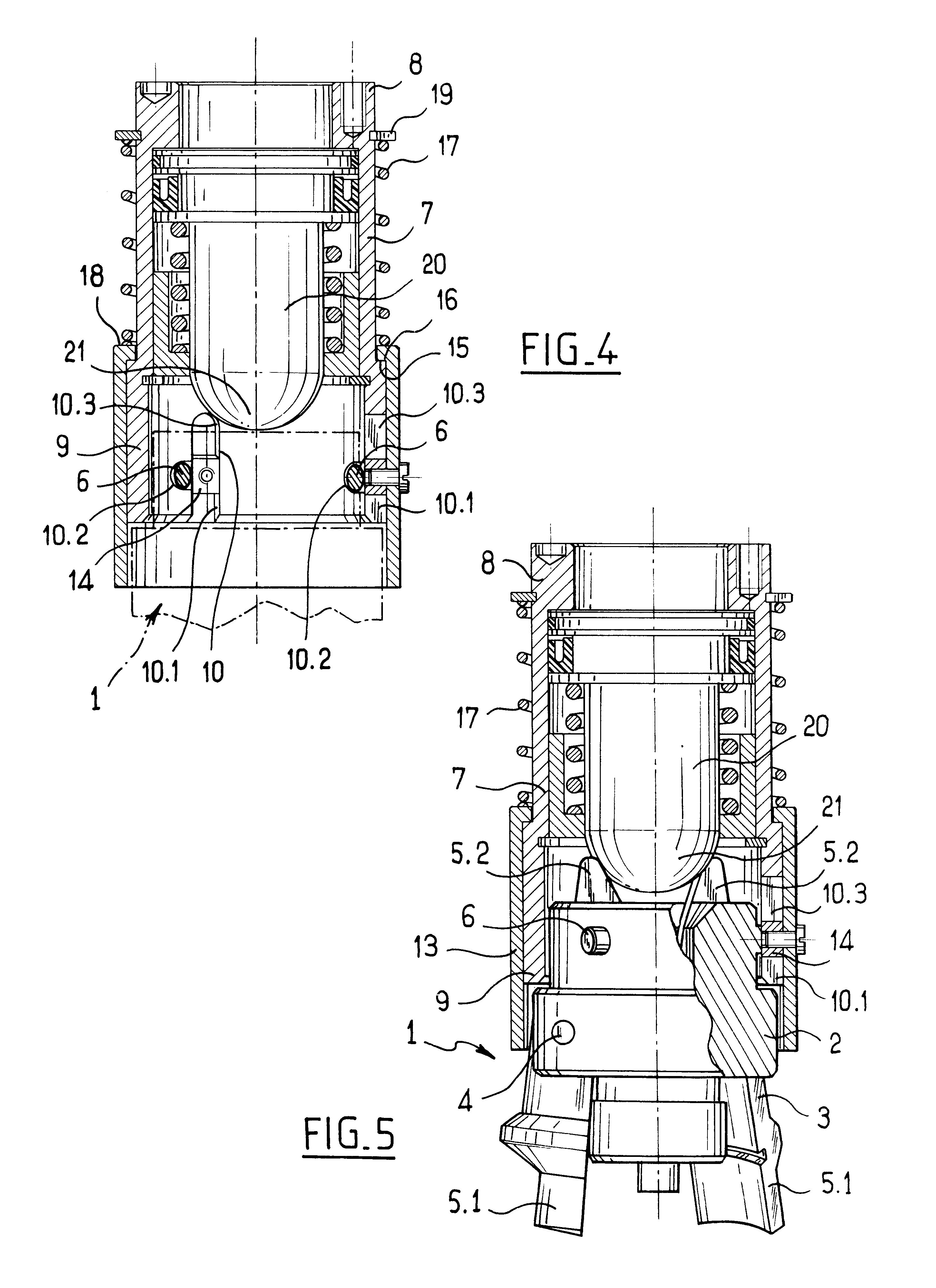

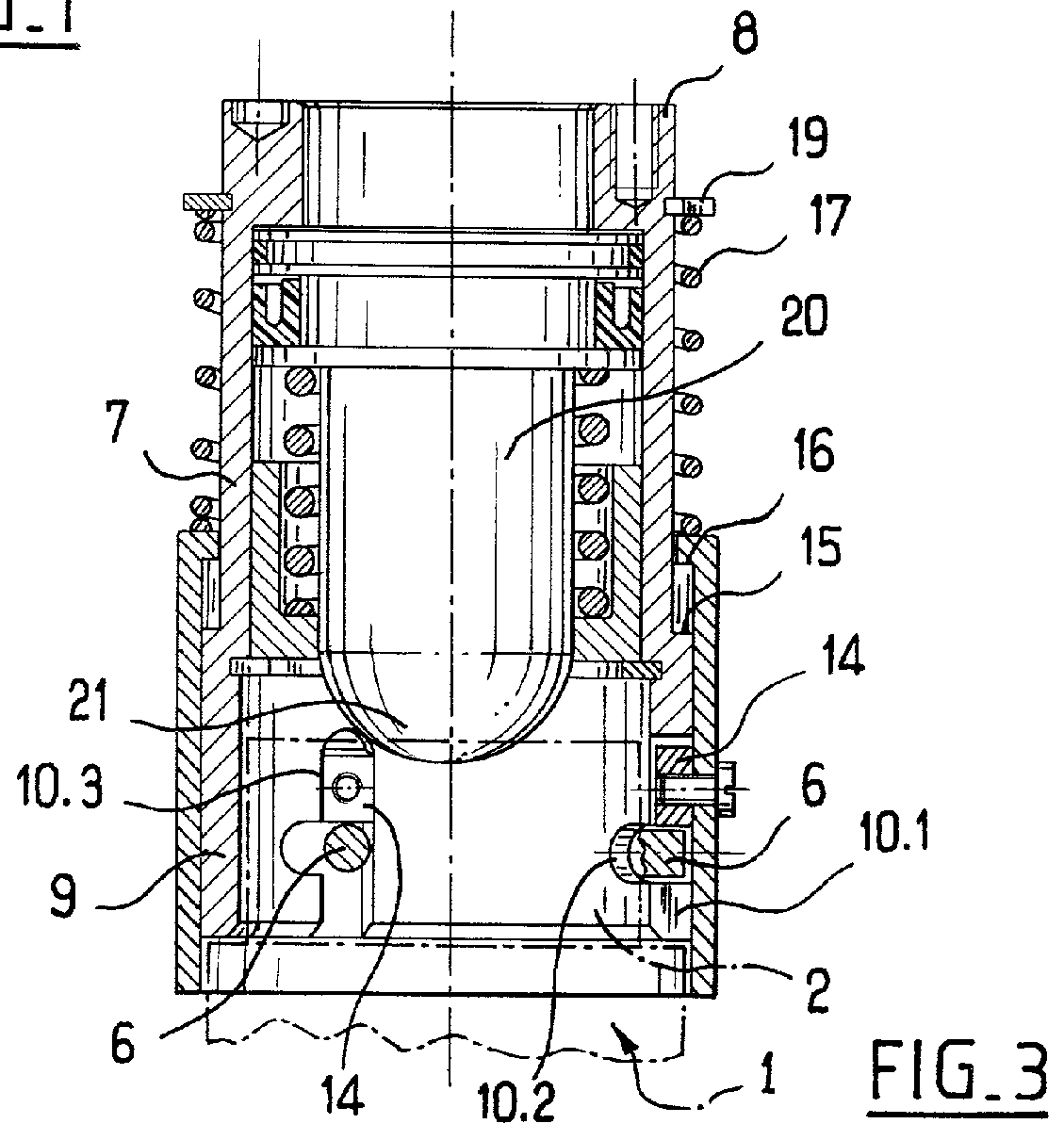

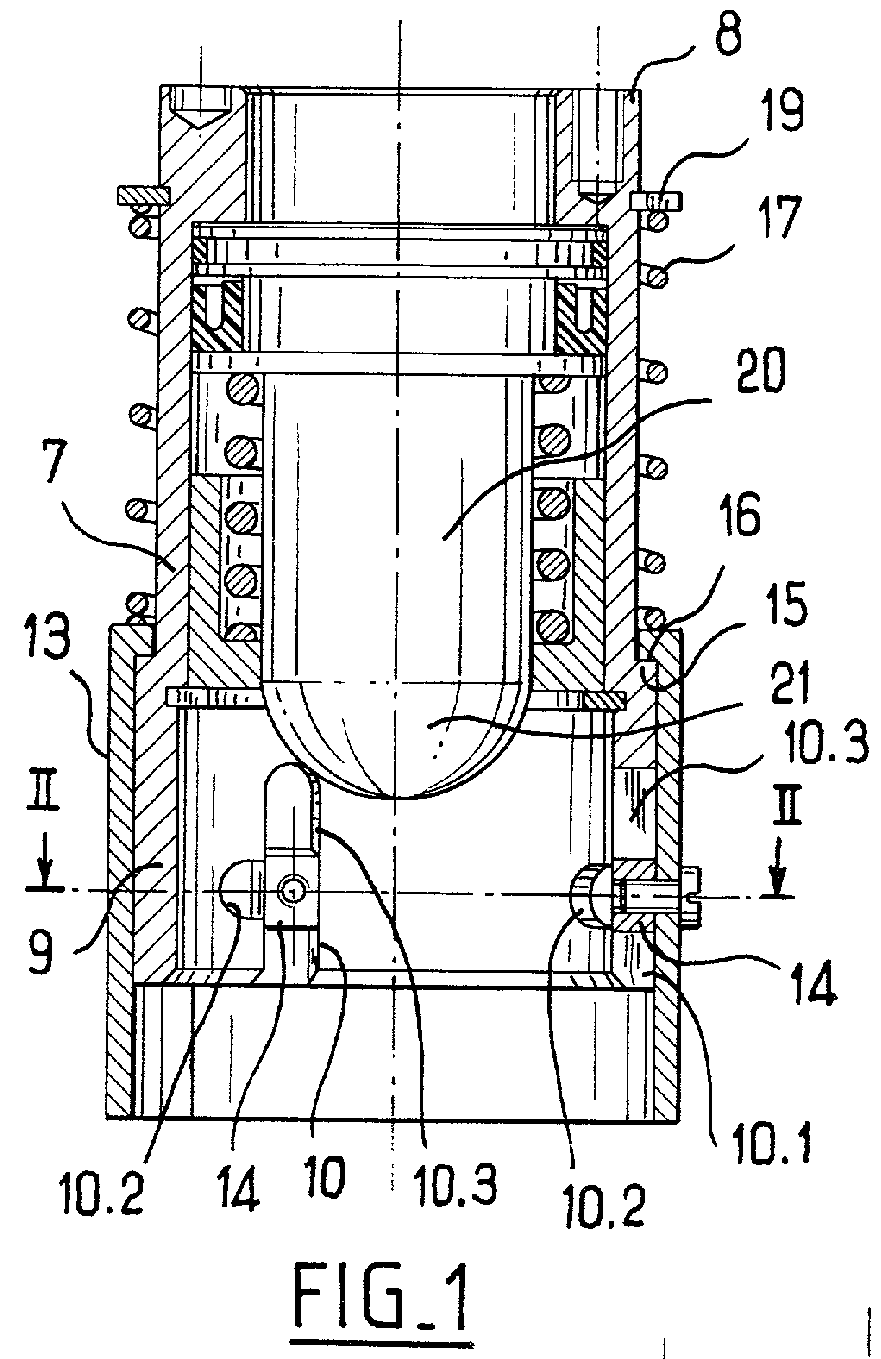

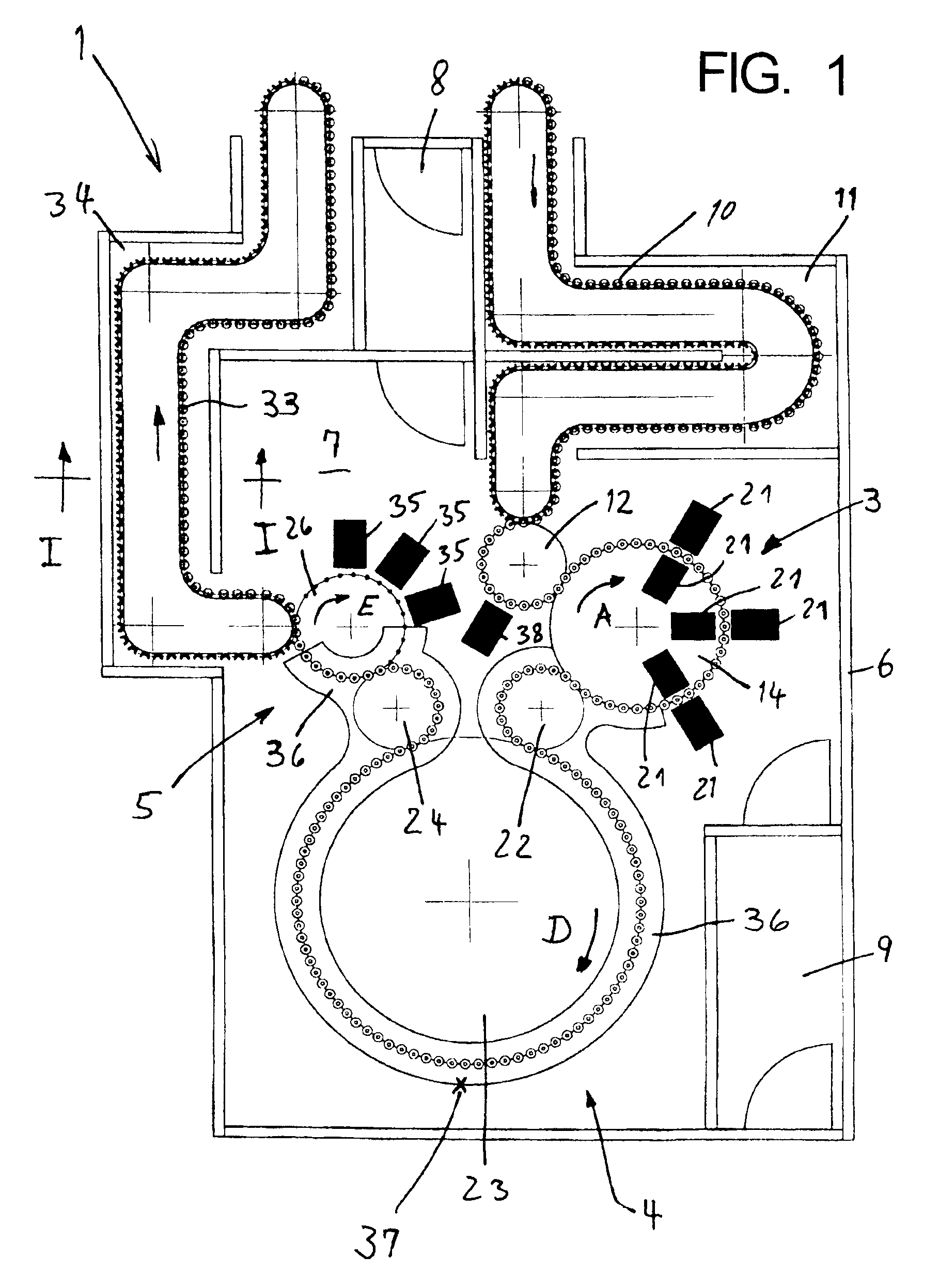

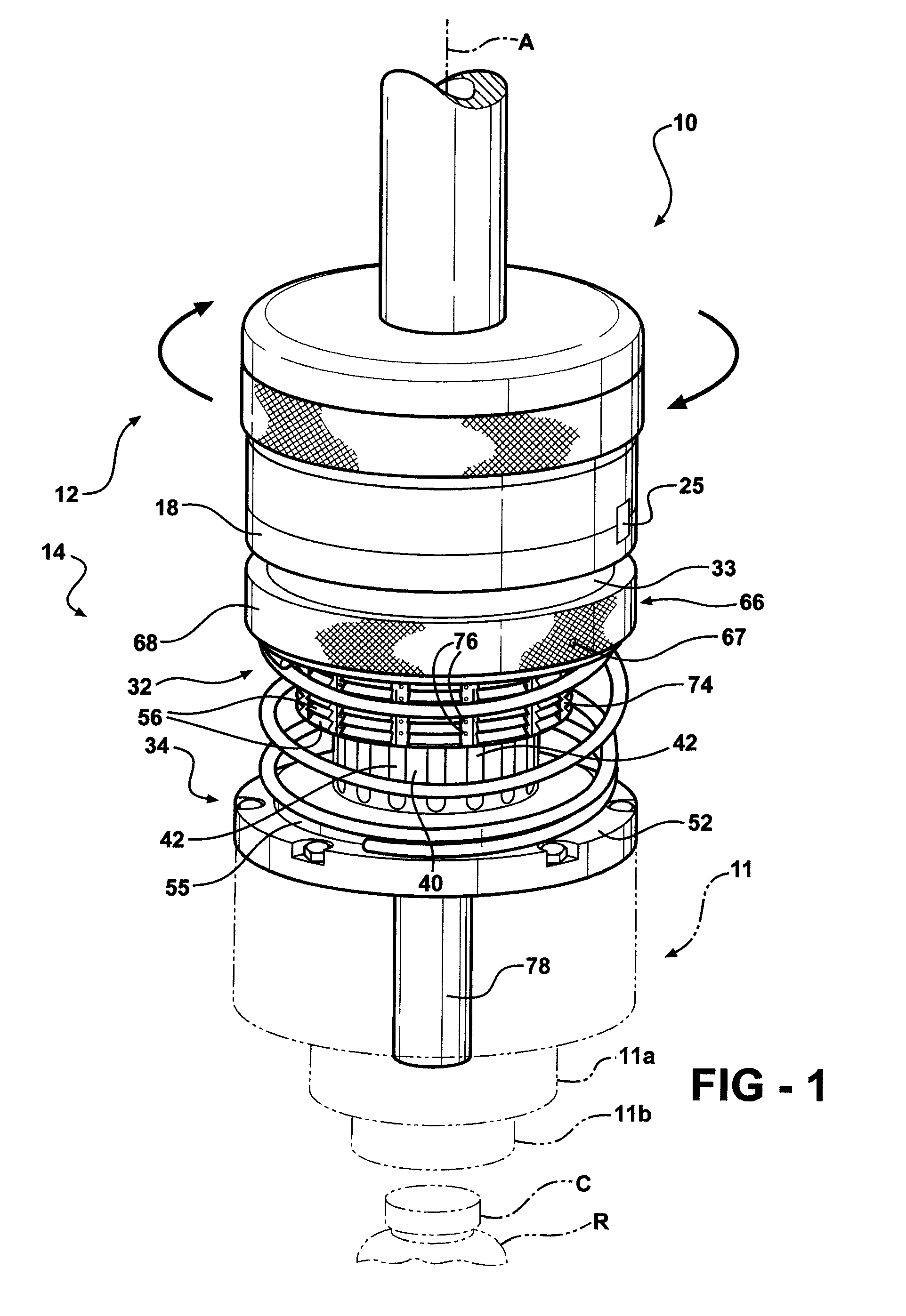

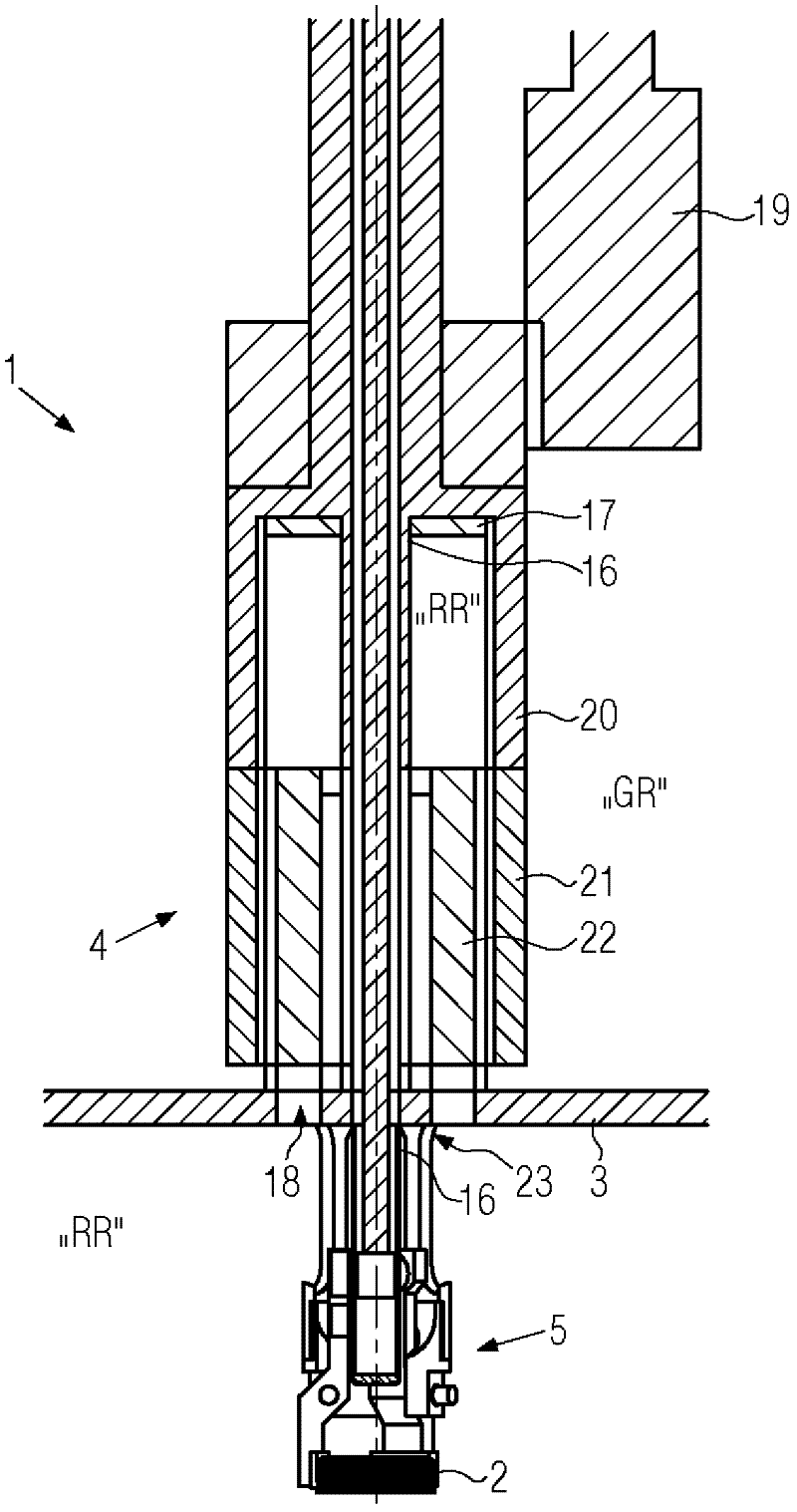

Beverage bottling plant for filling bottles with a liquid beverage filling material having a closing machine for closing containers

InactiveUS20050150193A1Improve reliabilityImprove securityClosing machinesCapsFilling materialsTrademark

A beverage bottling plant for filling bottles with a liquid beverage filling material, and a method for the operation of a closing machine and a closing machine for the closing of bottles or similar containers with closures or screw caps by screwing on the closure or cap, with a plurality of closing positions formed on the periphery of a rotor that circulates around a vertical machine axis, to which positions the containers to be closed are transferred at a container inlet and the closed containers are removed at a container outlet, whereby each closing position has a container carrier and a screw shaft that is provided on its lower end with a screw head and is mounted so that it can rotate around an axis, whereby each of these screw shafts can be driven by its own drive motor, whereby above the closing positions a mounting space (13) is formed which rotates together with the main column. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

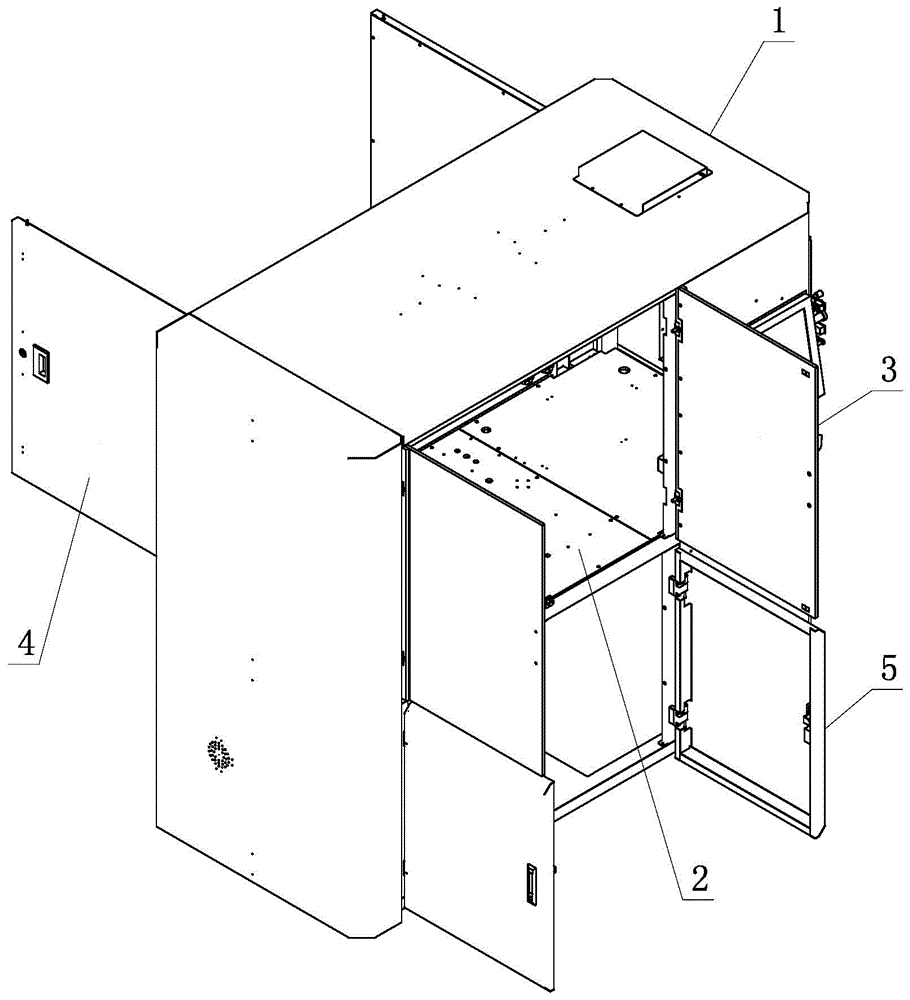

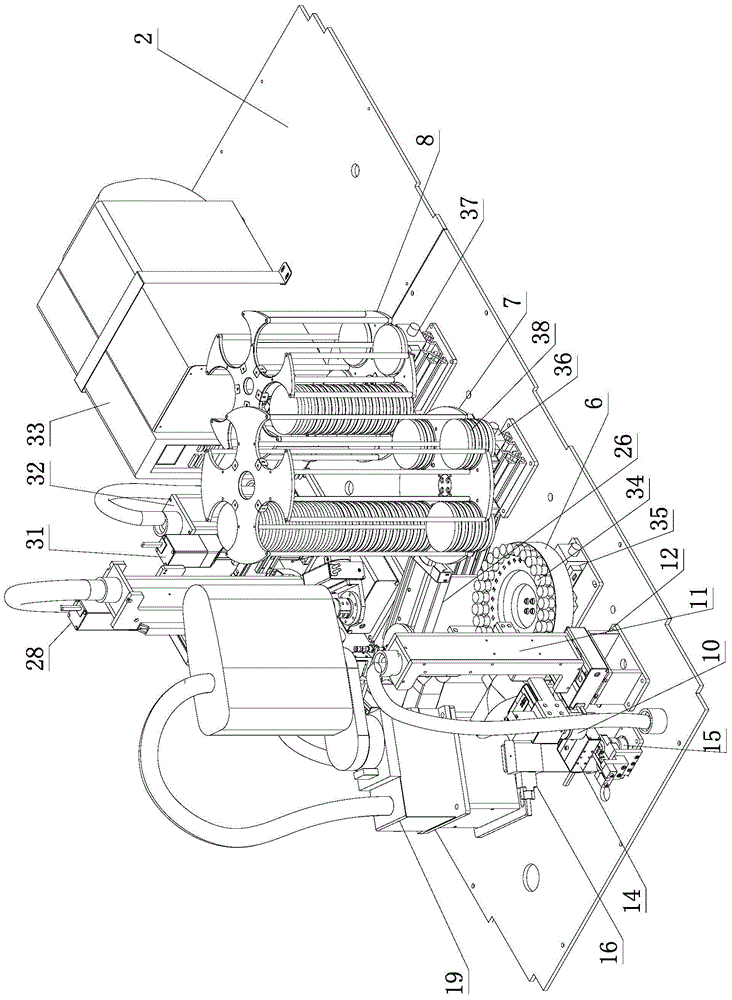

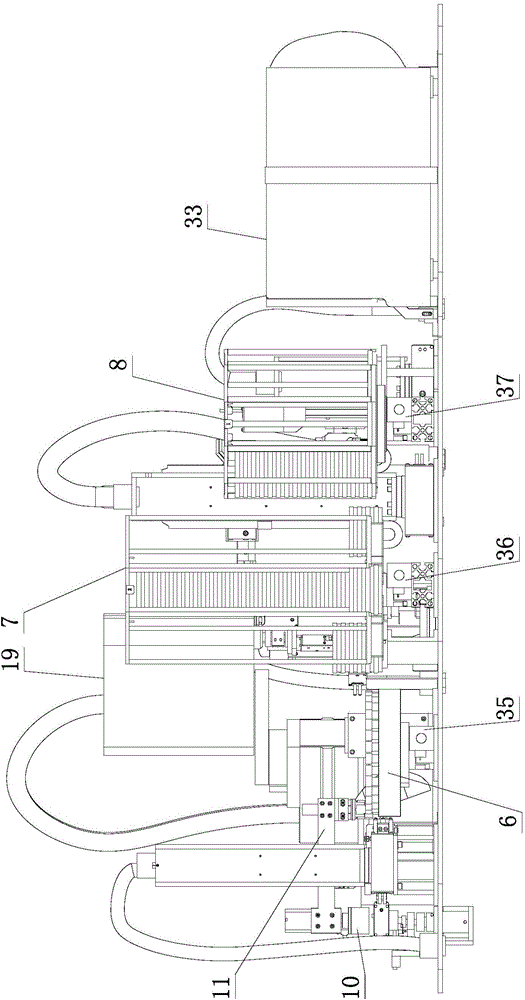

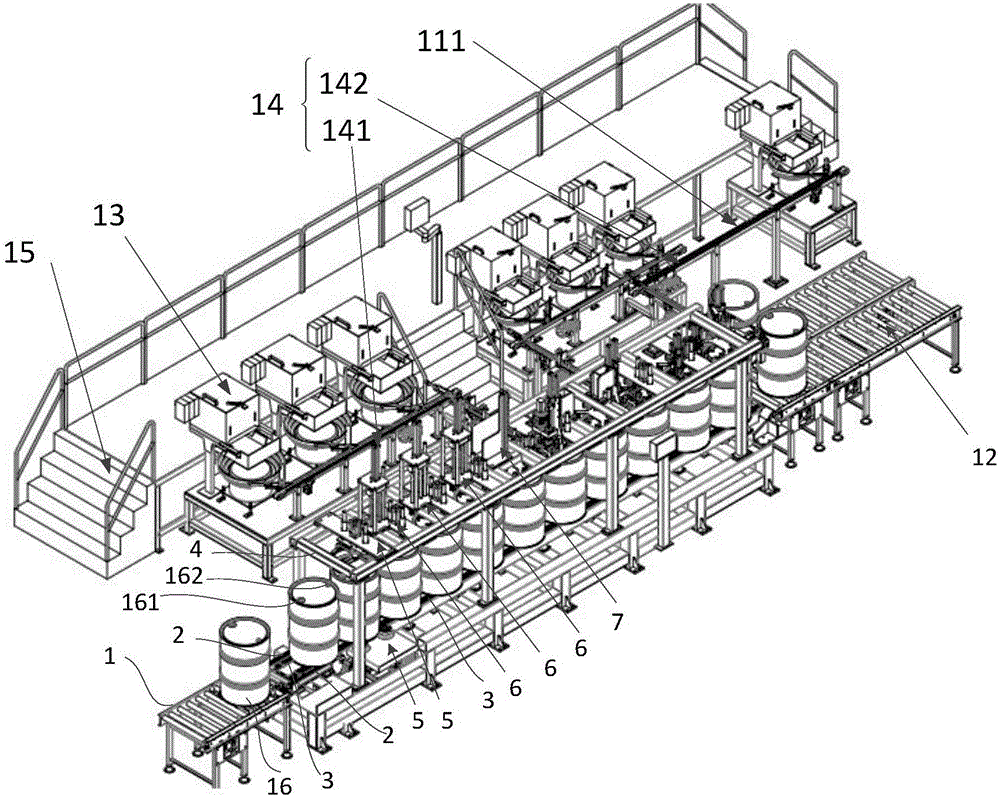

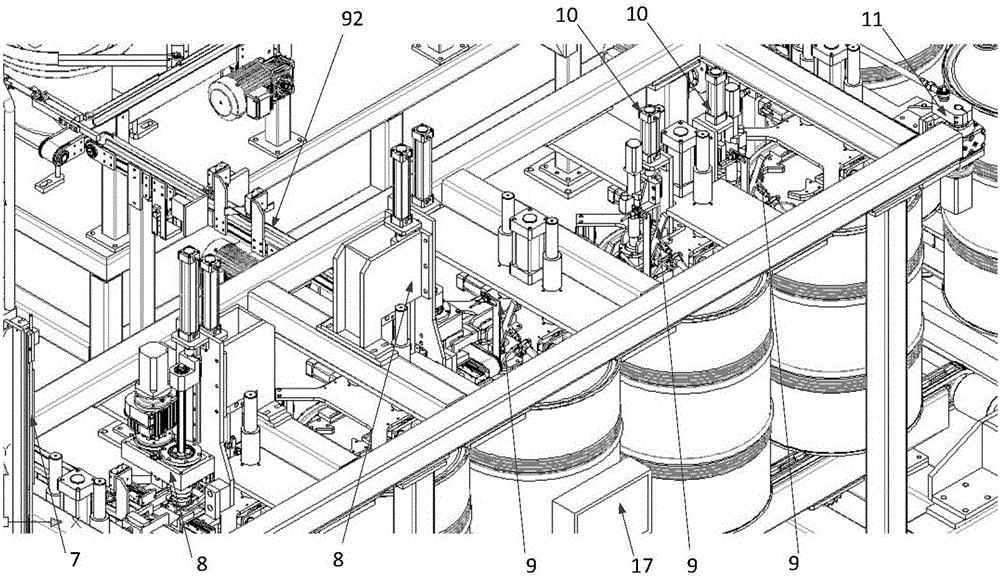

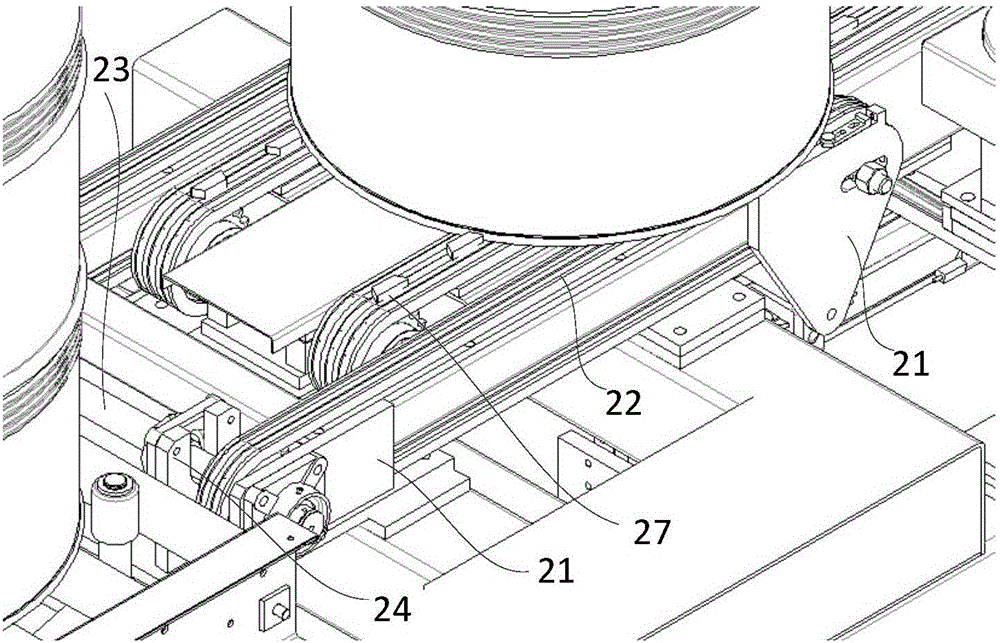

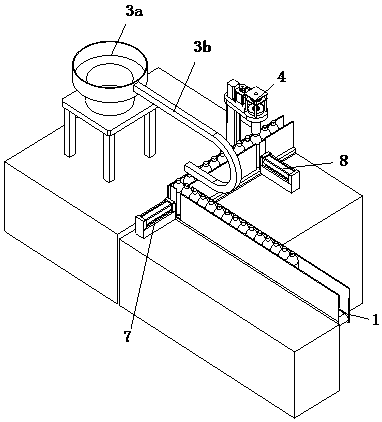

Automatic inflation cover tightening system

ActiveCN105836686ARealize automatic fillingEasy to installClosing machinesCapsControl systemEngineering

The invention provides an automatic inflation cover tightening system. The automatic inflation cover tightening system comprises a barrel body conveying system for conveying barrel bodies, a main machine frame and a control system connected with the barrel body conveying system, and further comprises large opening and small opening positioning devices, dry air injection devices, an inert gas injection device, a barrel cover conveying device, barrel cover pre-tightening devices, barrel cover tightening mechanisms, a sealing cover mechanism and an outlet conveyor. Each dry air injection device comprises a first injection device body and a second lifting pressing device used for pressing barrel bodies downwards. The barrel cover pre-tightening devices are used for pre-tightening barrel covers. The barrel cover tightening mechanisms are used for tightening barrel covers and each comprise a tightening gun unit for tightening barrel covers and a second vertical lifting mechanism for driving the tightening gun unit to move. The sealing cover mechanism comprises a sealing cover taking mechanism, a sealing cover conveyor connected with the control system, and a second lifting pressing device. The outlet conveyor is connected with the control system and arranged at an outlet of the automatic inflation cover tightening system. The automatic inflation cover tightening system provided by the invention relieves the manual labor intensity, improves production efficiency and can lower production cost and management cost for enterprises.

Owner:SHANGHAI JISHENG AUTOMATIC MACHINERY SYST

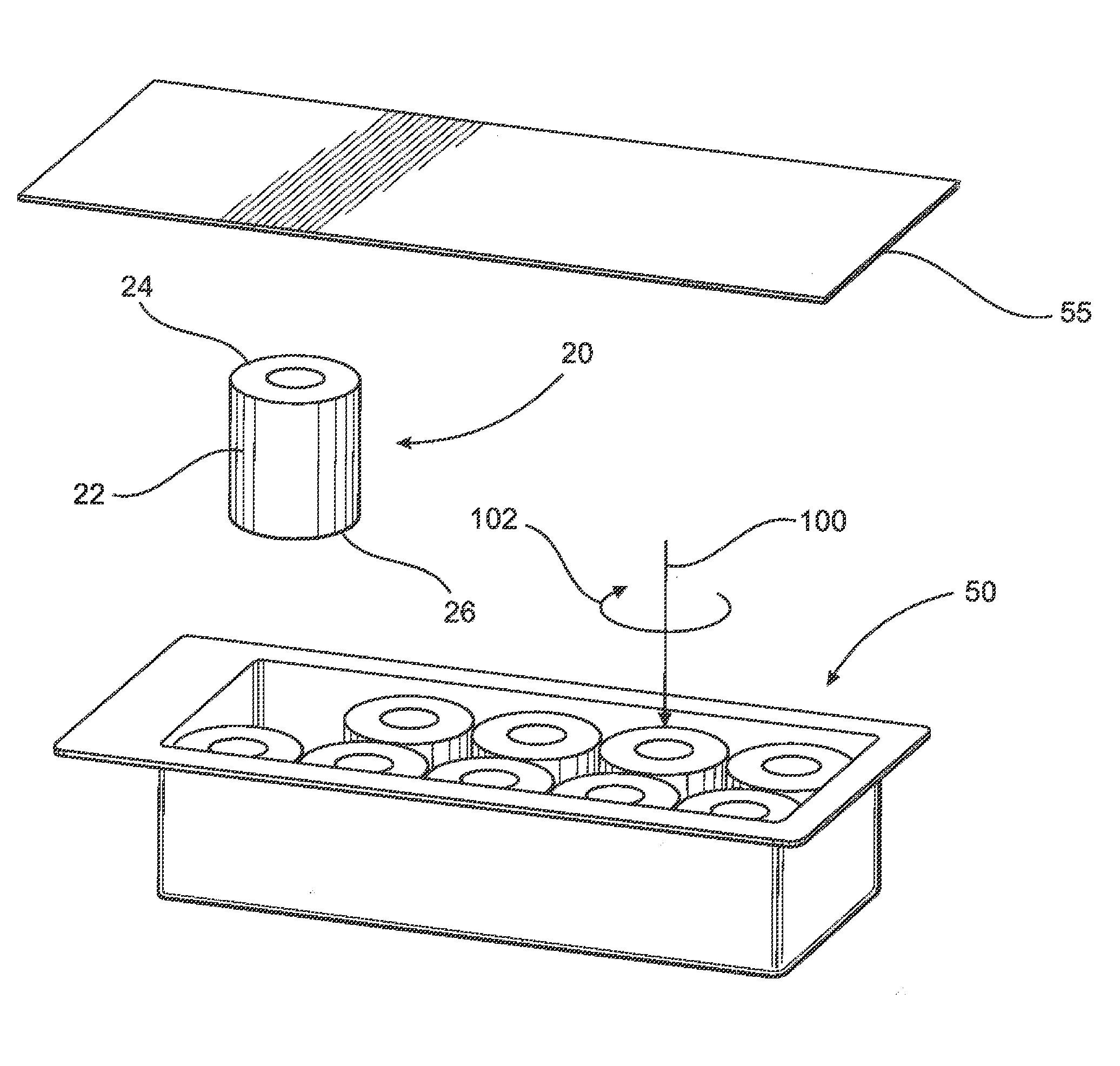

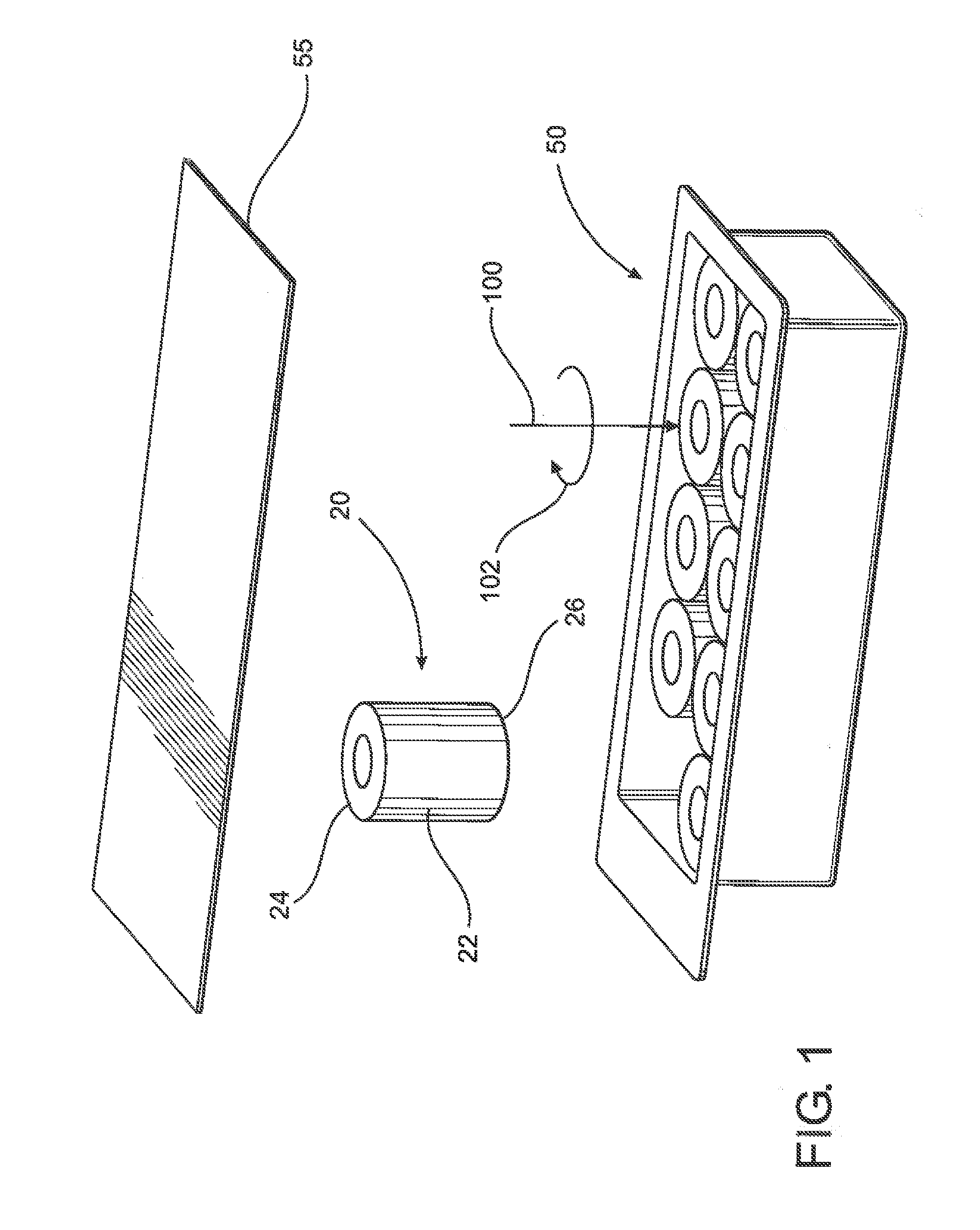

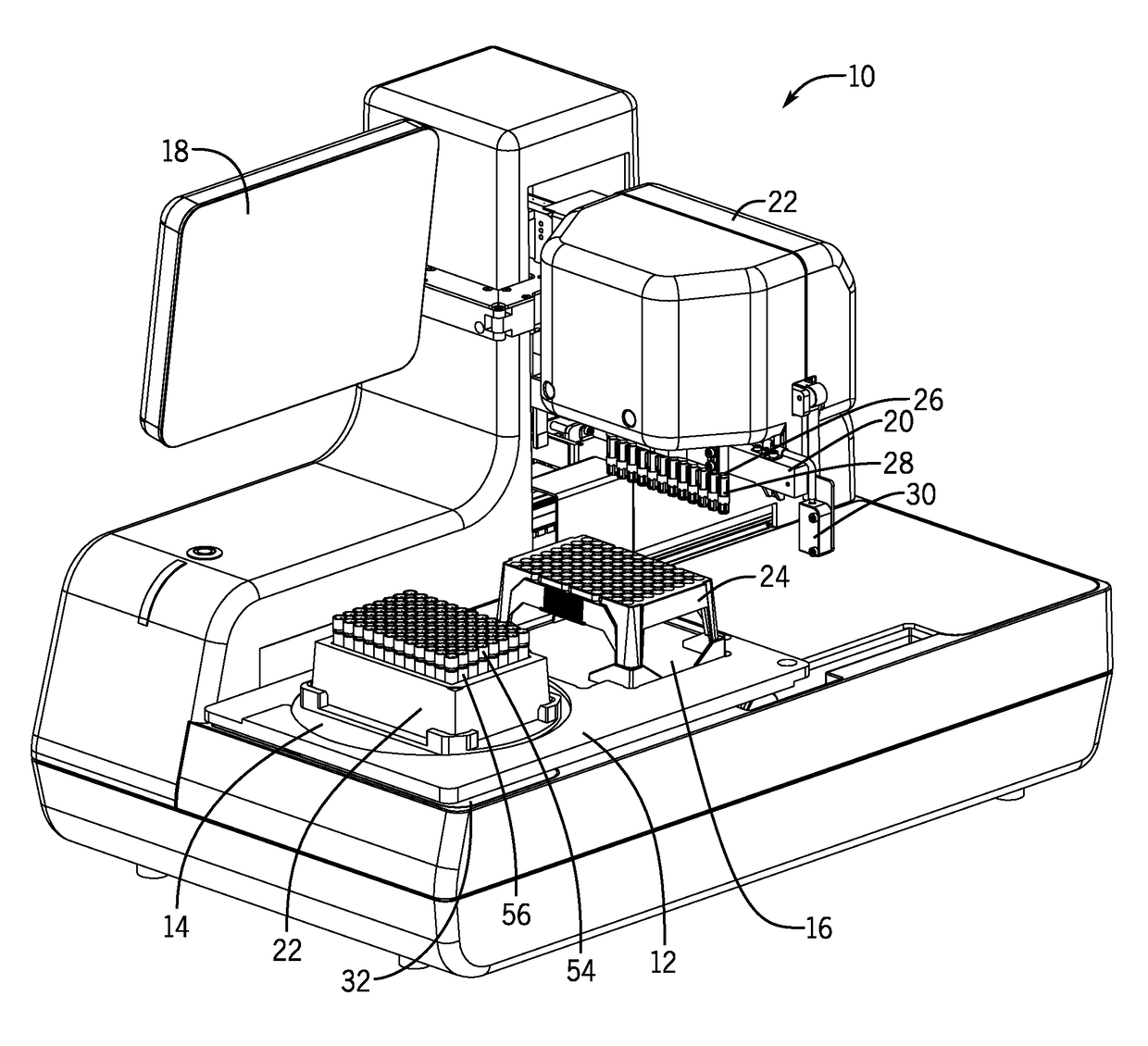

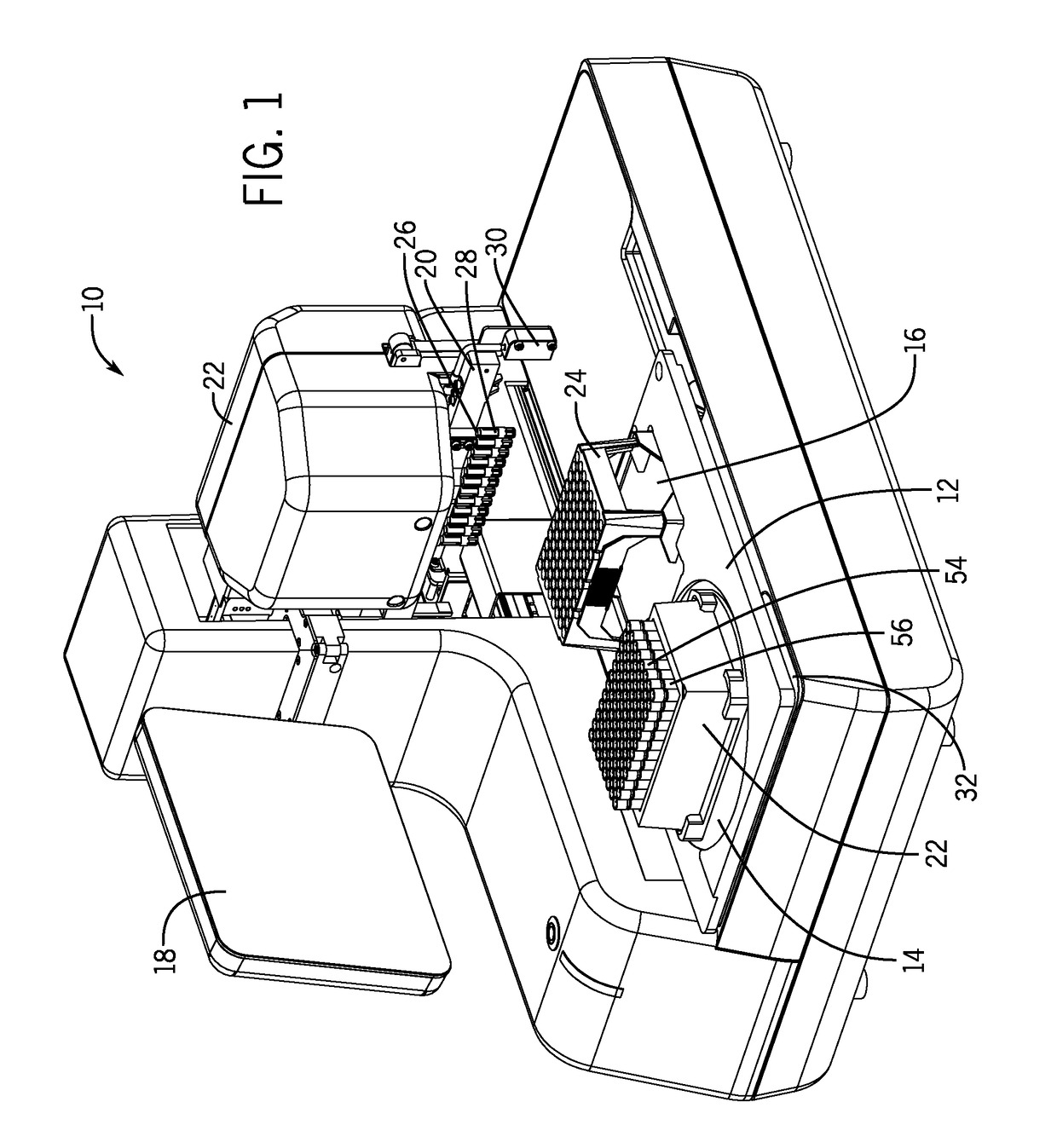

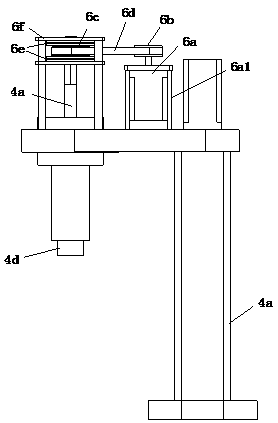

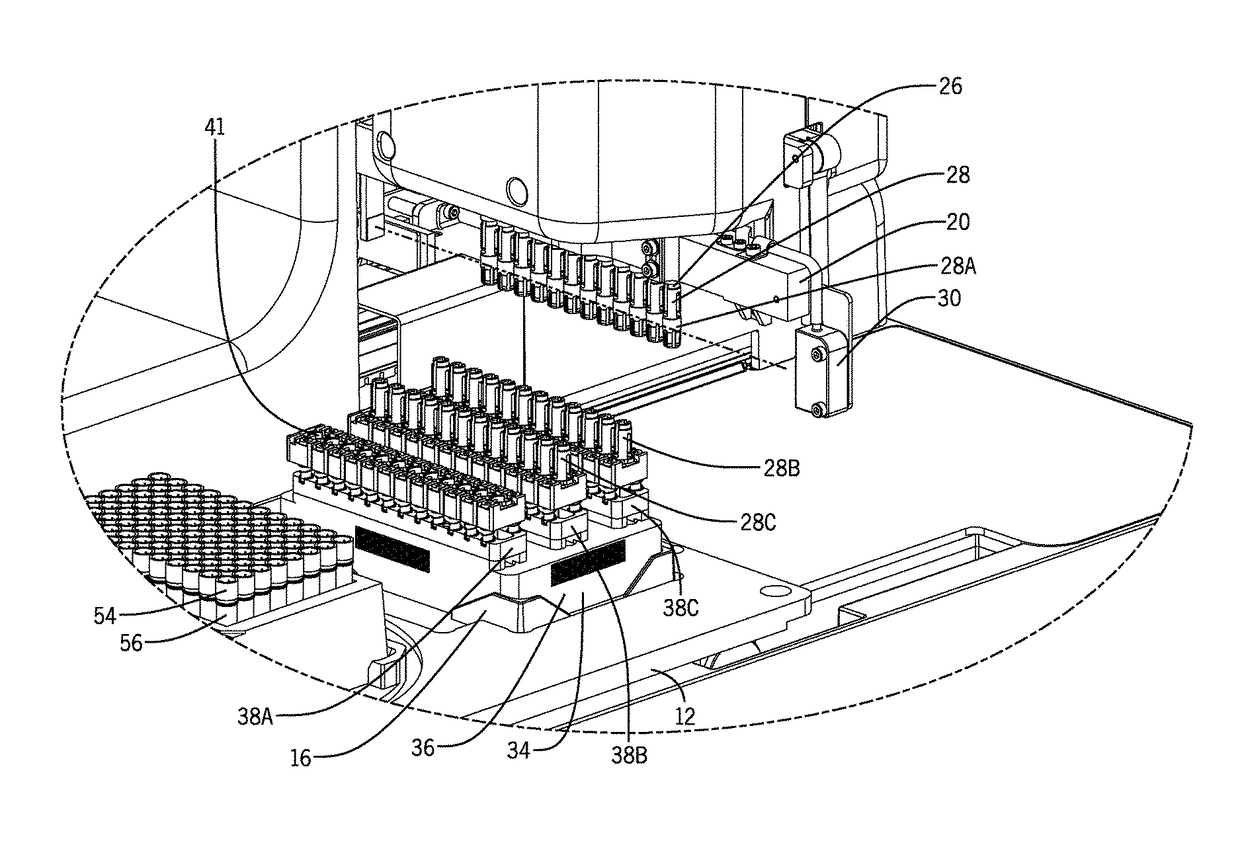

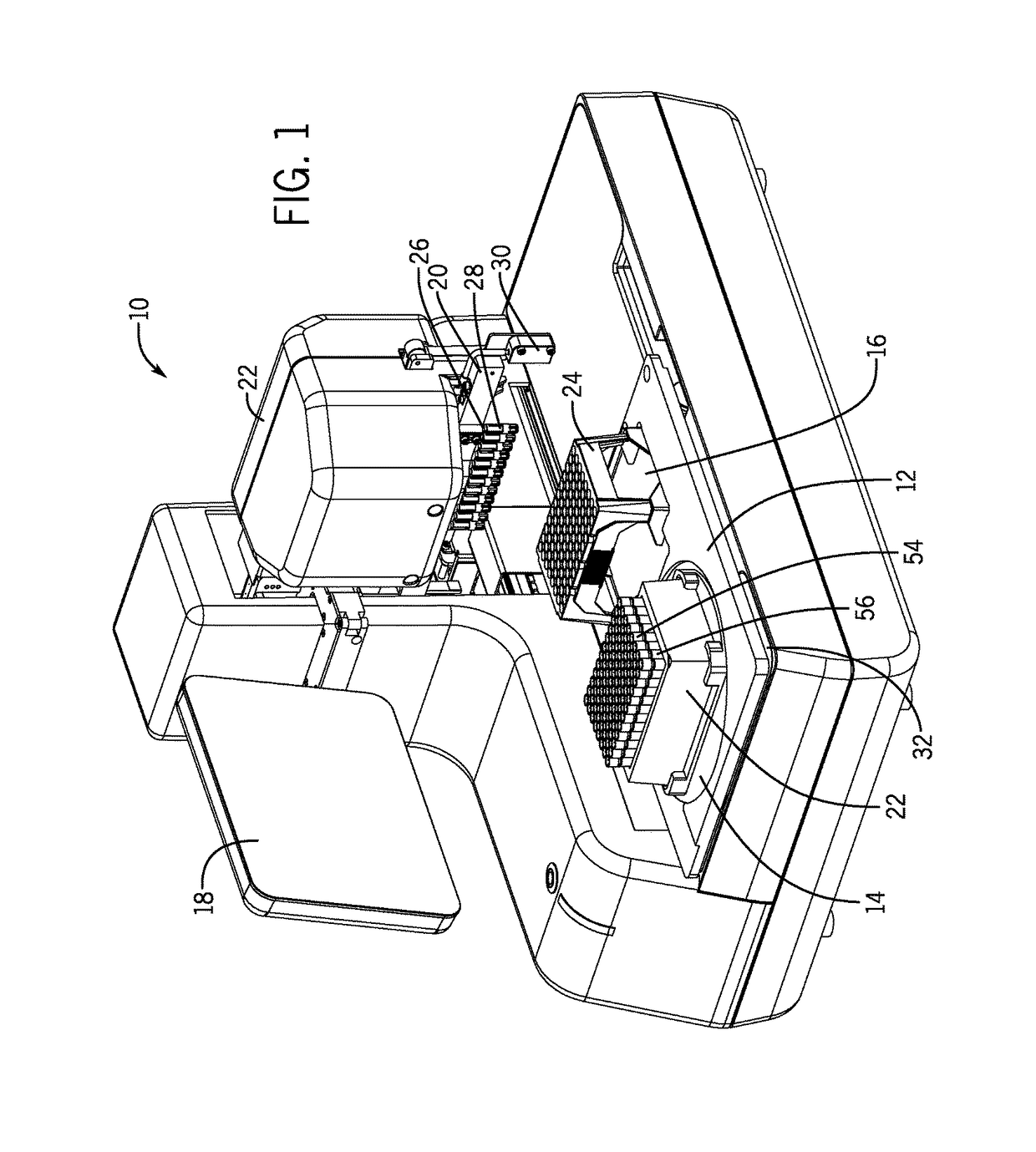

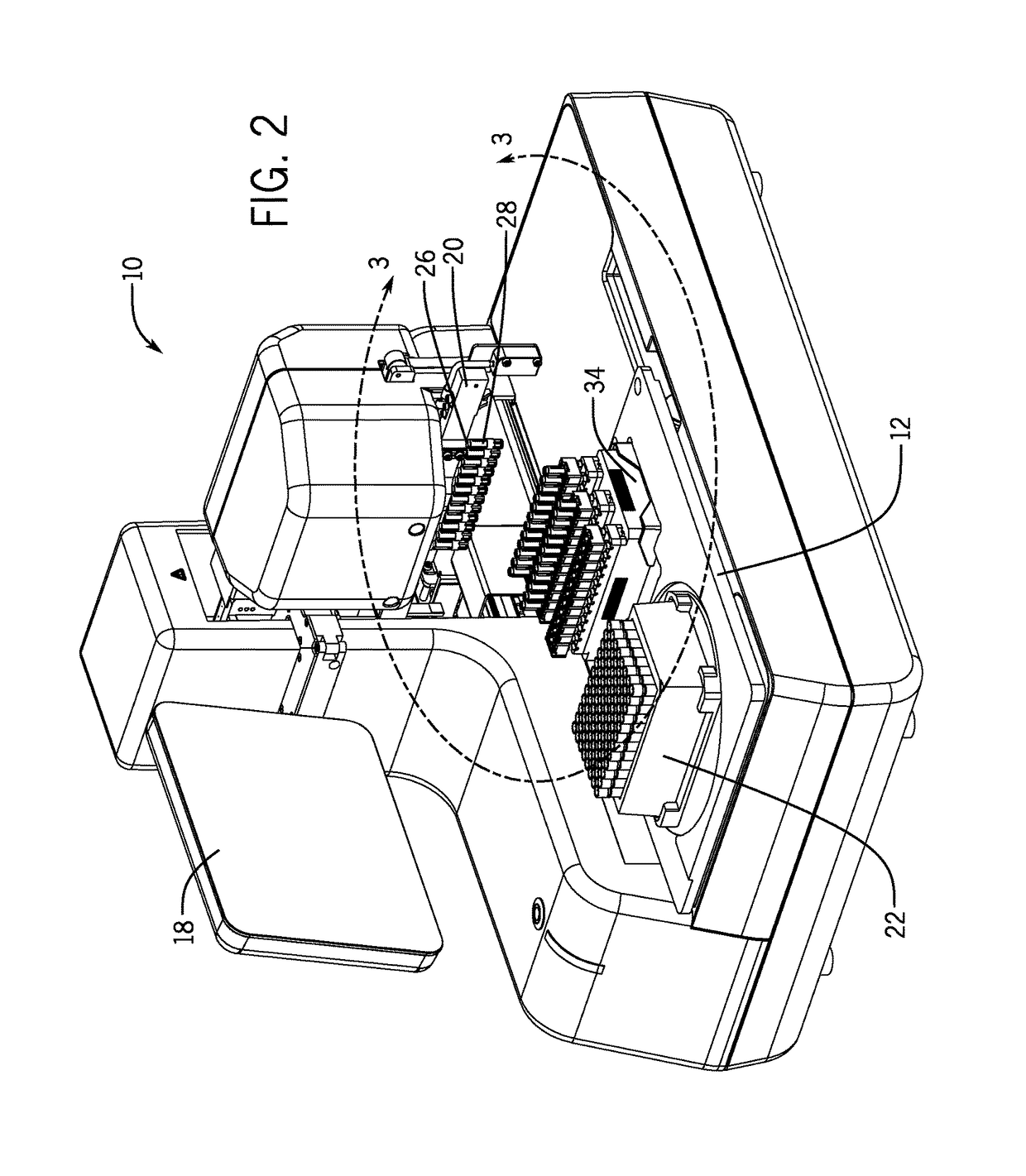

Automated Bit Exchange for Laboratory Sample Tube Capping and Decapping Machines

A laboratory capper, decapper or combination capper / decapper includes a deck containing with a nest designed to hold an SBS-formatted tube storage rack, and a bit exchange magazine assembly containing one or more sets of adapter bits. The adapter bits are mounted on and unloaded from motor driven fittings, and are exchanged in order to cap or decap laboratory sample tubes or vials that have different head configurations. The bit exchange magazine assembly enables the bit to be exchanged robotically.

Owner:HAMILTON STORAGE TECH

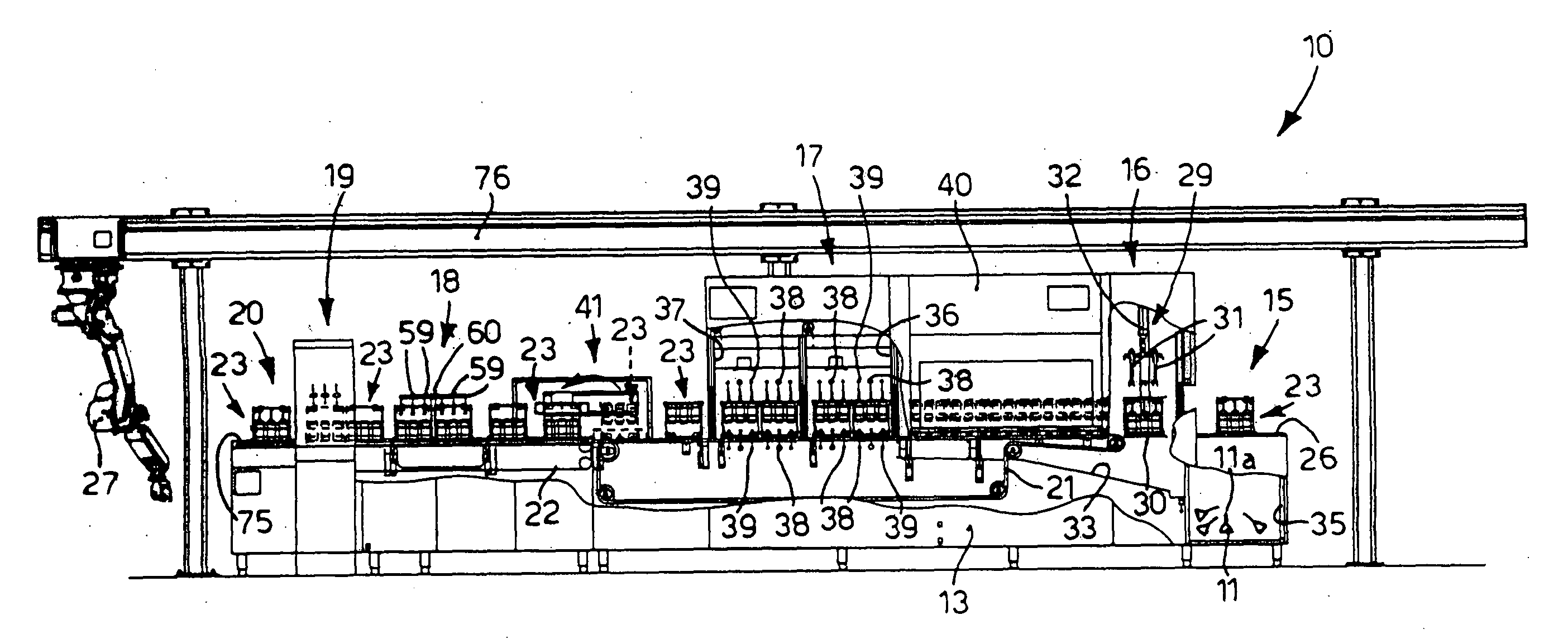

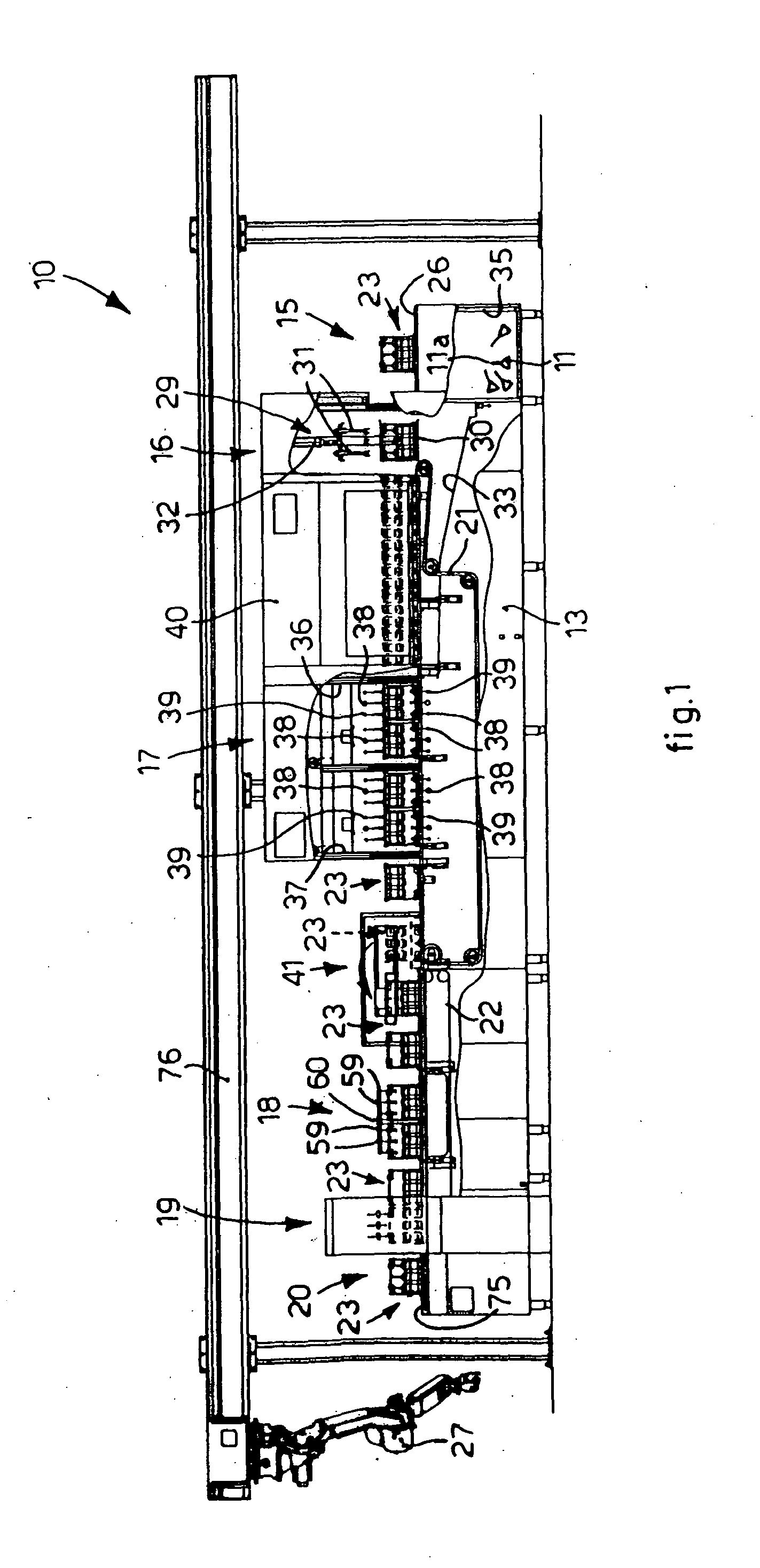

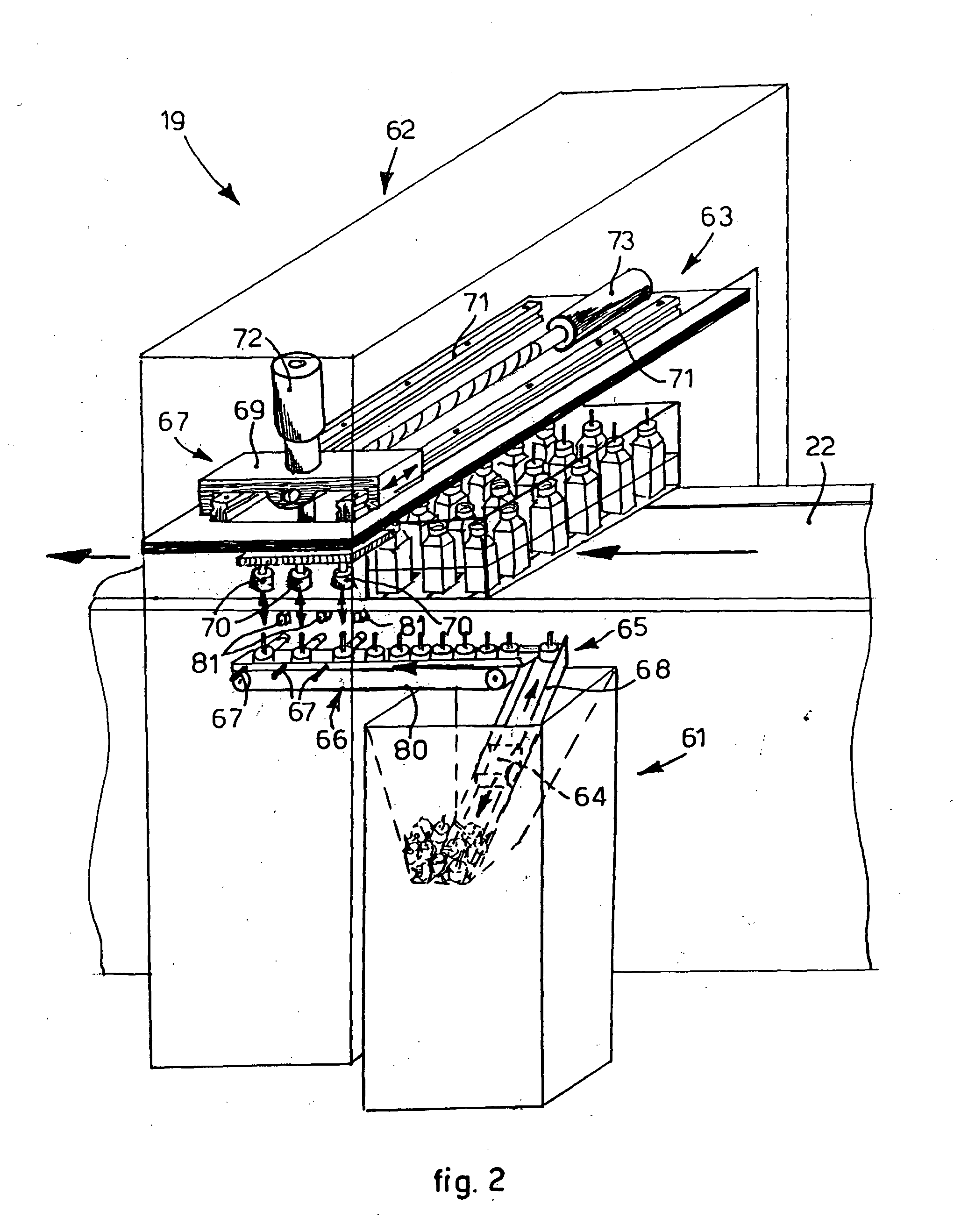

Machine and method for treating containers of liquids, and loading device for said containers

ActiveUS20120110952A1Simple and economic and efficientReduce manual interventionClosing machinesCapsEngineeringMechanical engineering

Machine (10) and method for treating containers (12) of liquids comprising a loading station (15) into which baskets (23) are loaded containing, according to a desired pattern of disposition, the containers (12) to be subjected to washing, a filling station (18) in which the washed containers (12) are filled with new liquid, and a re-closing station (19) in which the containers (12) are closed by the relative lids (11). The re-closing station (19) comprises a closing device (63) provided with gripper members (70) by means of which the lids (11) are picked up and positioned so as to close the containers (12), and loading members (66) that automatically direct the lids (11) toward the closing device (63) in a manner consistent with the desired pattern of disposition of the containers (12) in the baskets (23). The closing device (63) comprises movement members (69) that move the gripper members (70) automatically between a pick-up position in correspondence with the loading members (66) and a position of closure in correspondence with the containers (12). The loading members (66) comprise stop elements (67), able to be selectively activated to automatically dispose the lids (11) in a manner consistent with the predetermined pattern of disposition of the containers (12).

Owner:STEELCO

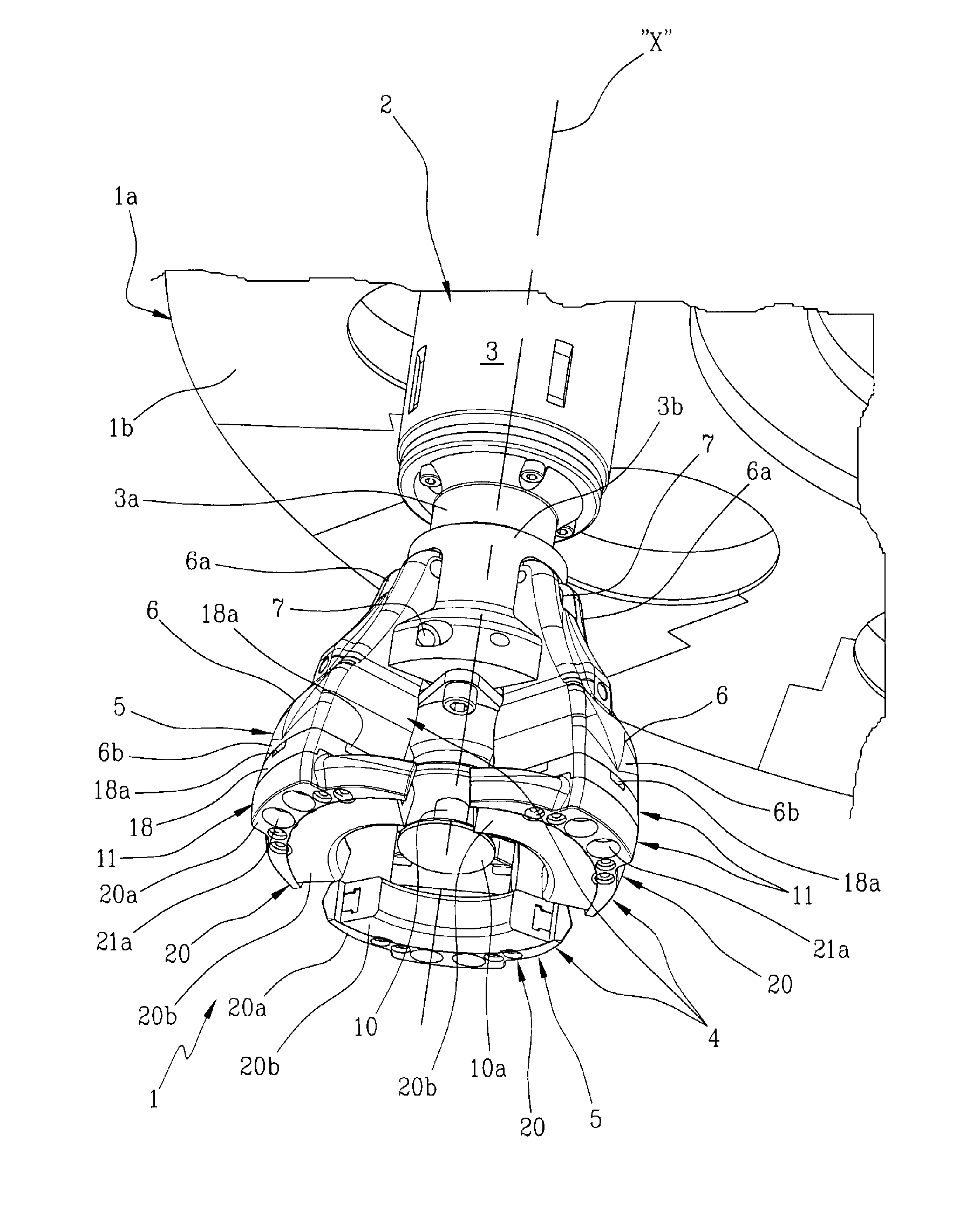

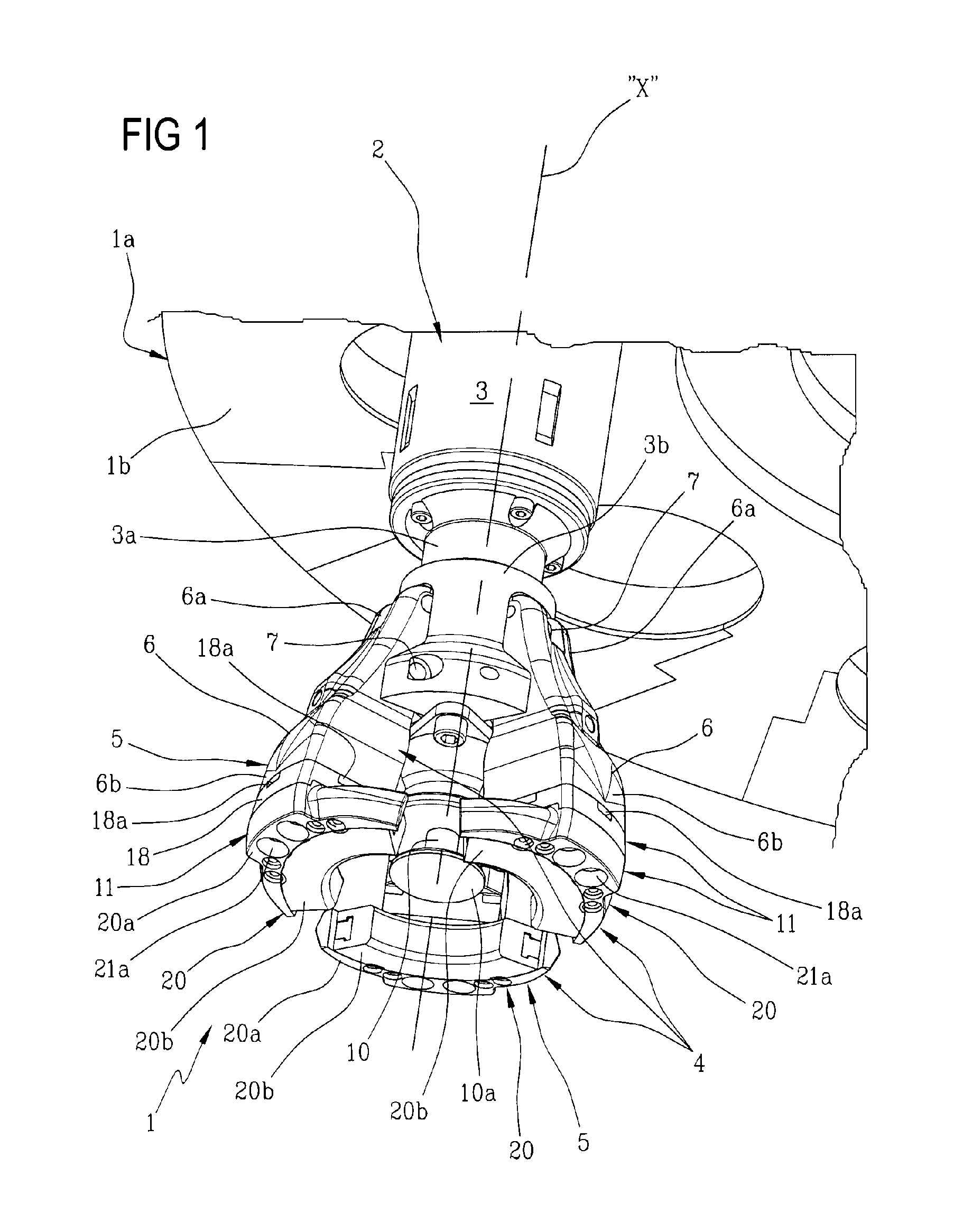

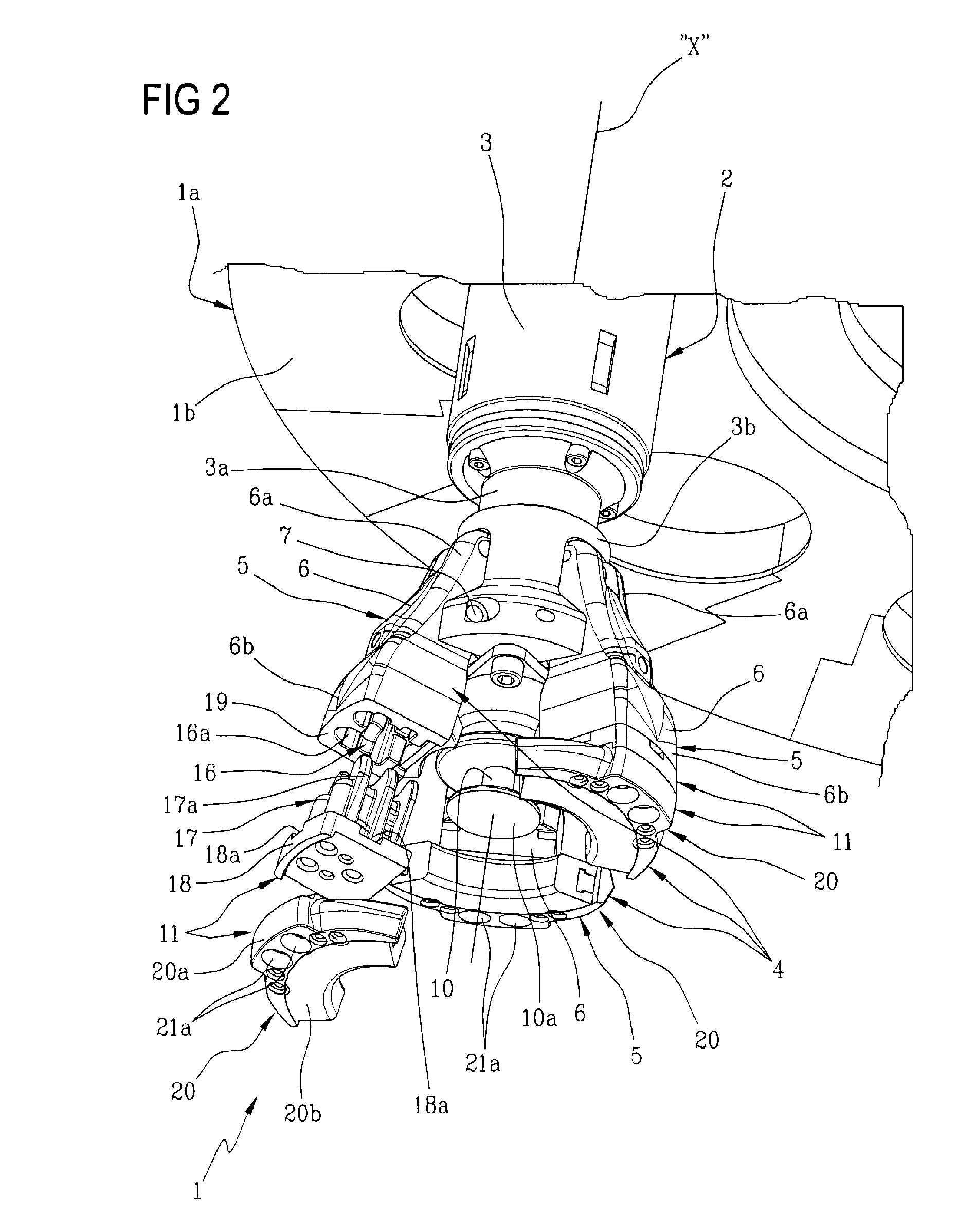

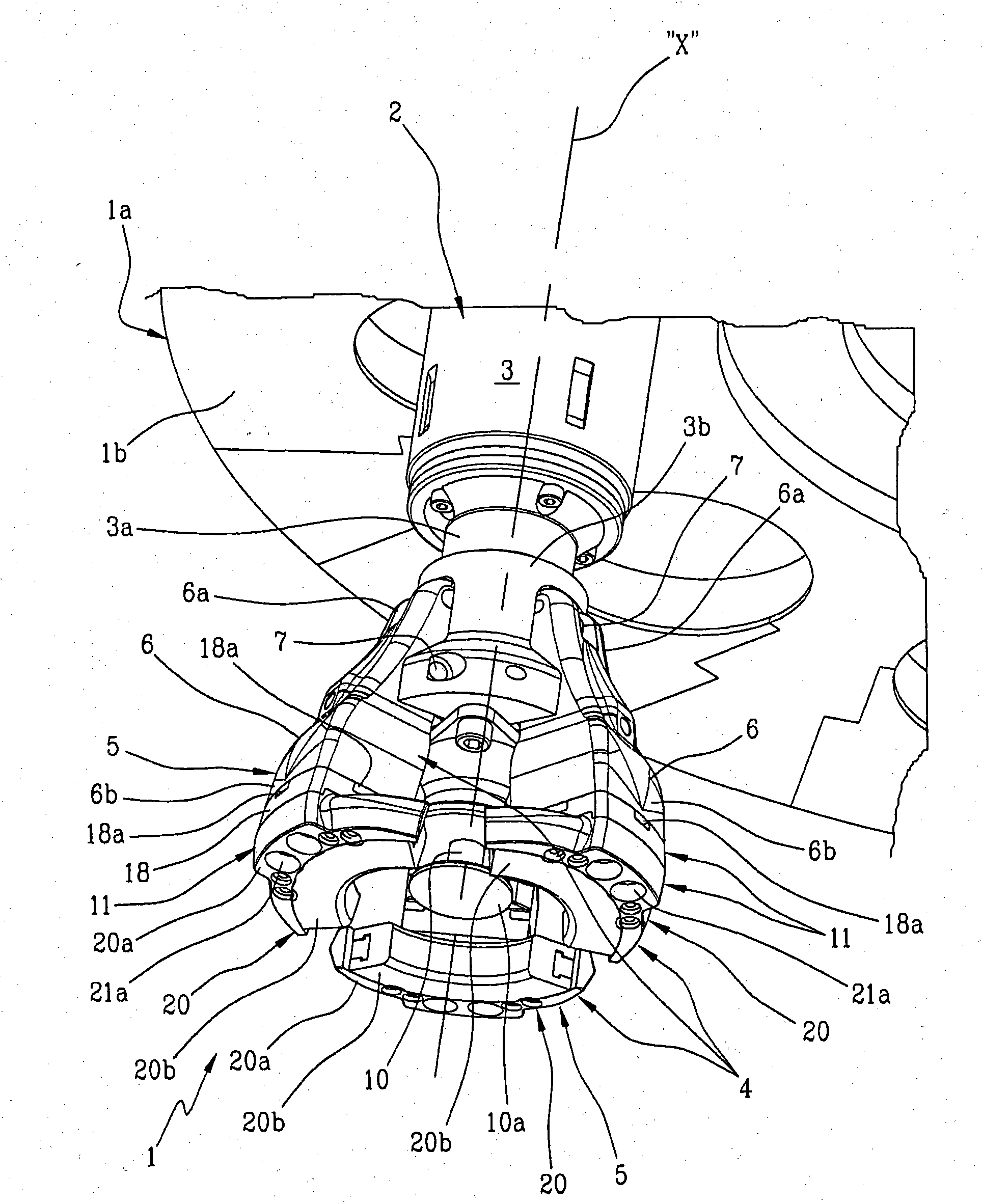

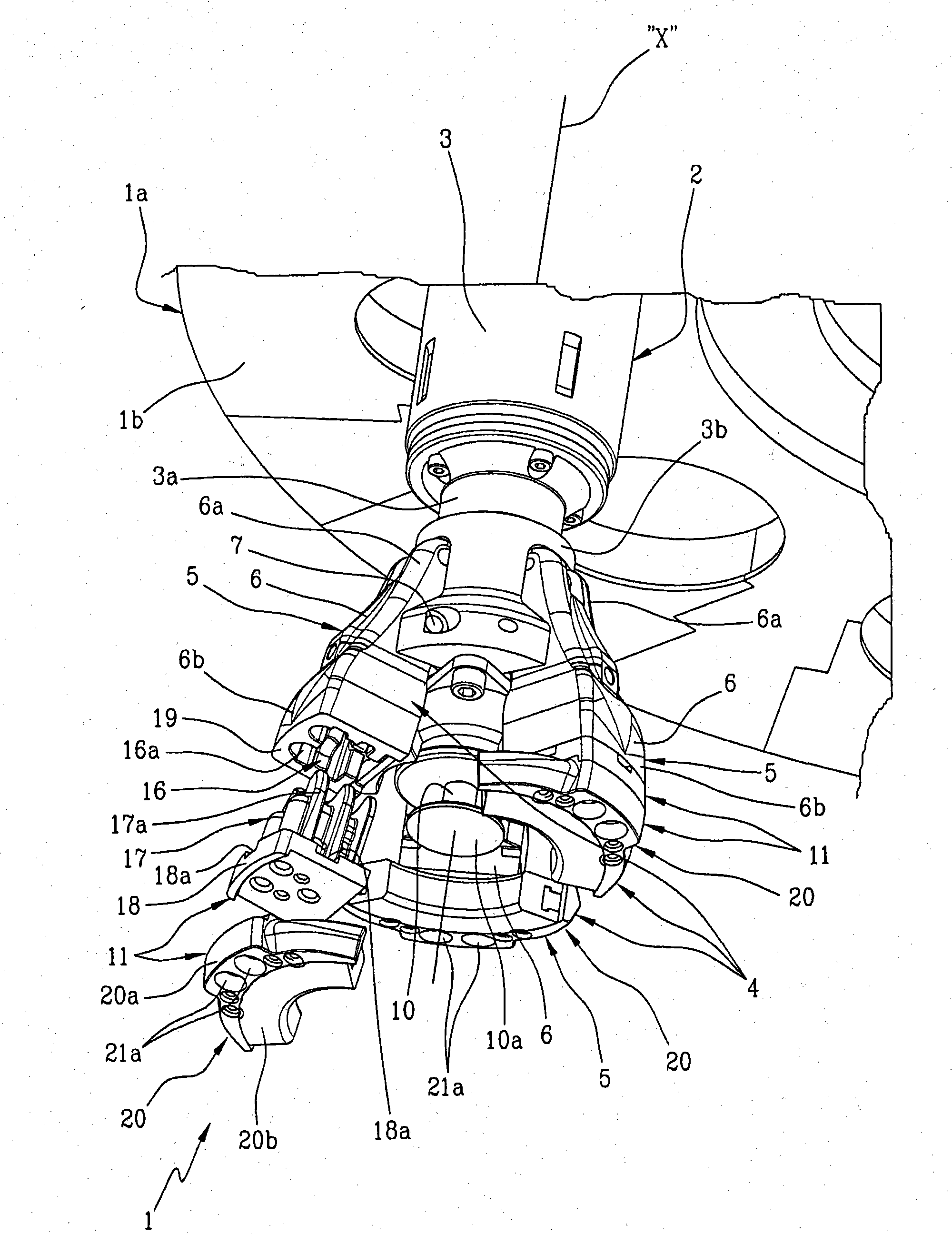

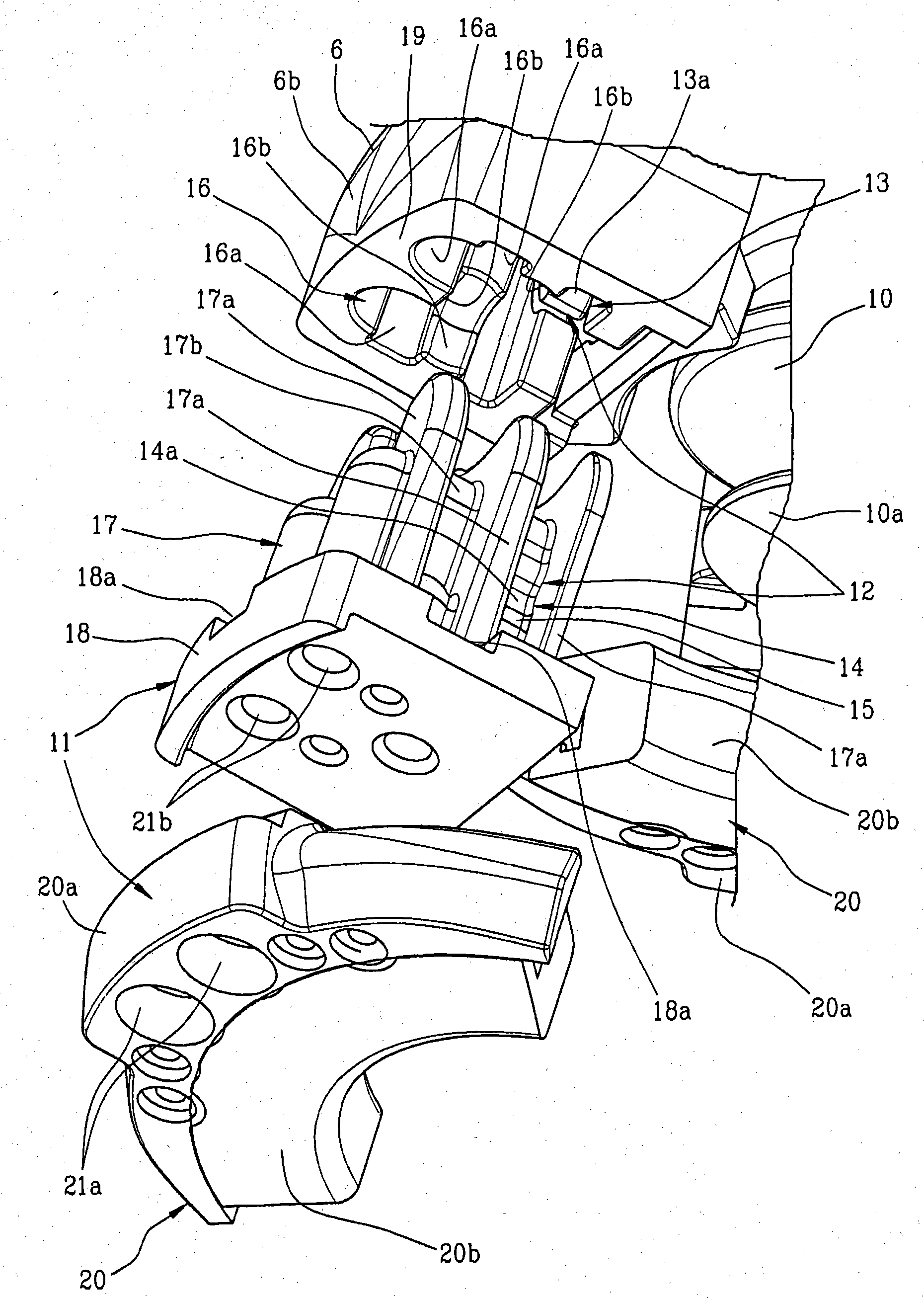

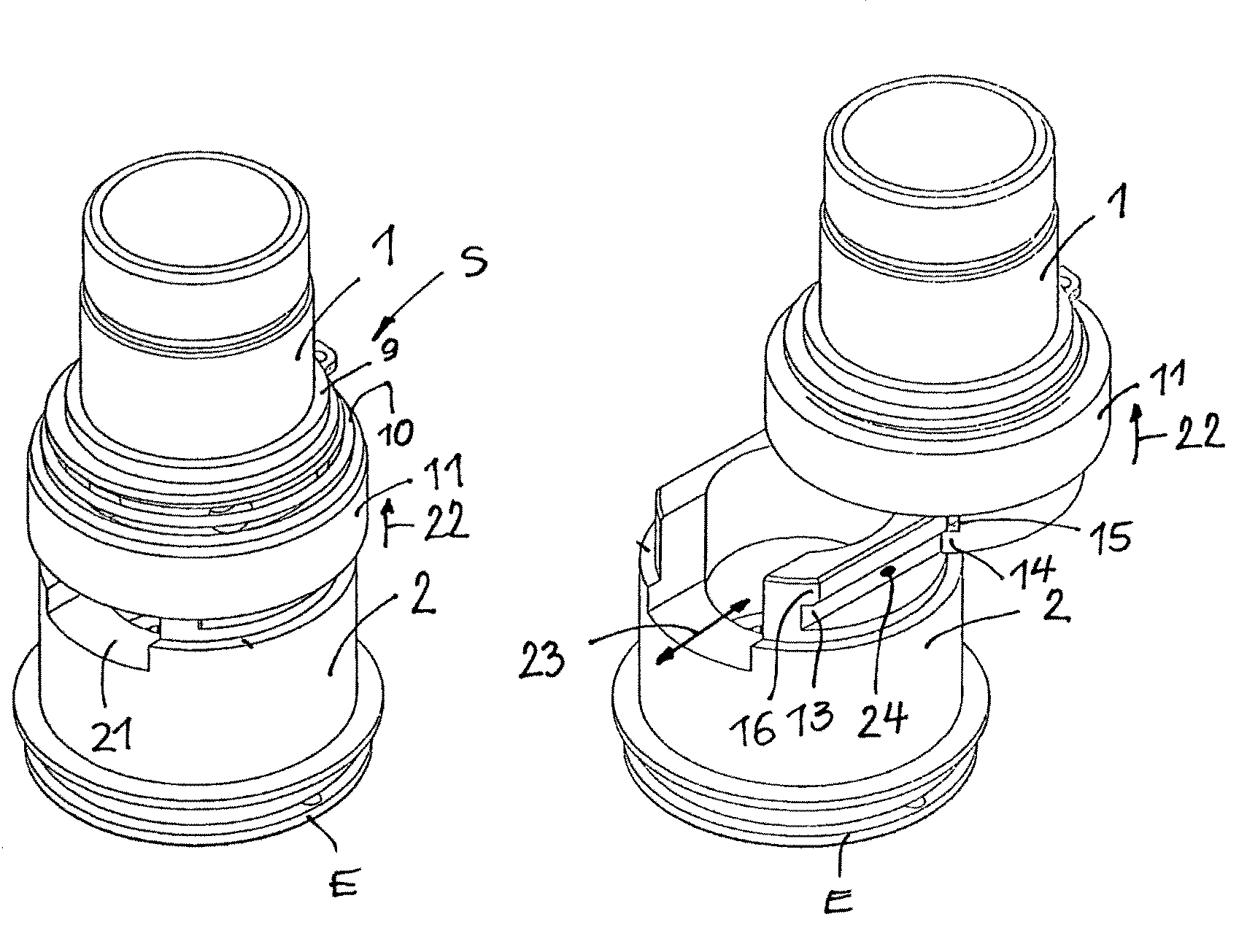

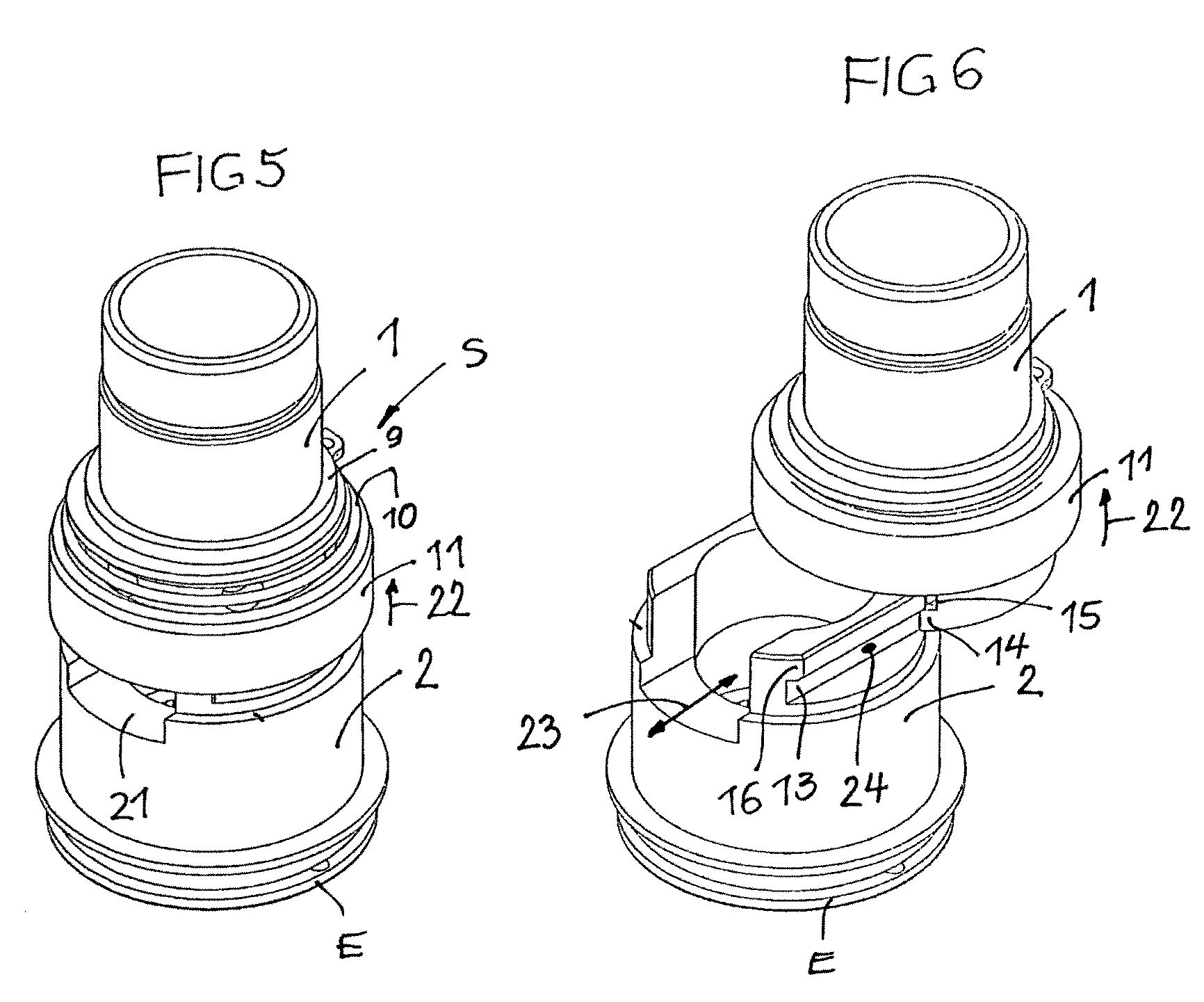

Gripping apparatus for capping assemblies in container packaging machines

Capping assemblies (2) of the type fitted to capping units (1a) in a machine for packaging containers filled with fluid or powdered products are equipped with a gripping apparatus (1) comprising a gripper (4) with three arms (5), each carrying an adapter (20) furnished with a pad (20b) offered in direct contact to the cap, through which the gripping action is applied. Each adapter (20) is secured to a fitting (17, 18) insertable into a socket (16) afforded by the bottom of a structural member (6) that forms the main part of each arm (5) and is hinged to the movable head of a relative capping assembly (2); when inserted into the structural member (6), the fitting (17, 18) is retained automatically by a snap lock mechanism (12) incorporated into the arm (5), which can be released subsequently by introducing the tip of a screwdriver into a slot (18a) created in the side of the fitting (17, 18) and levering the components apart.

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

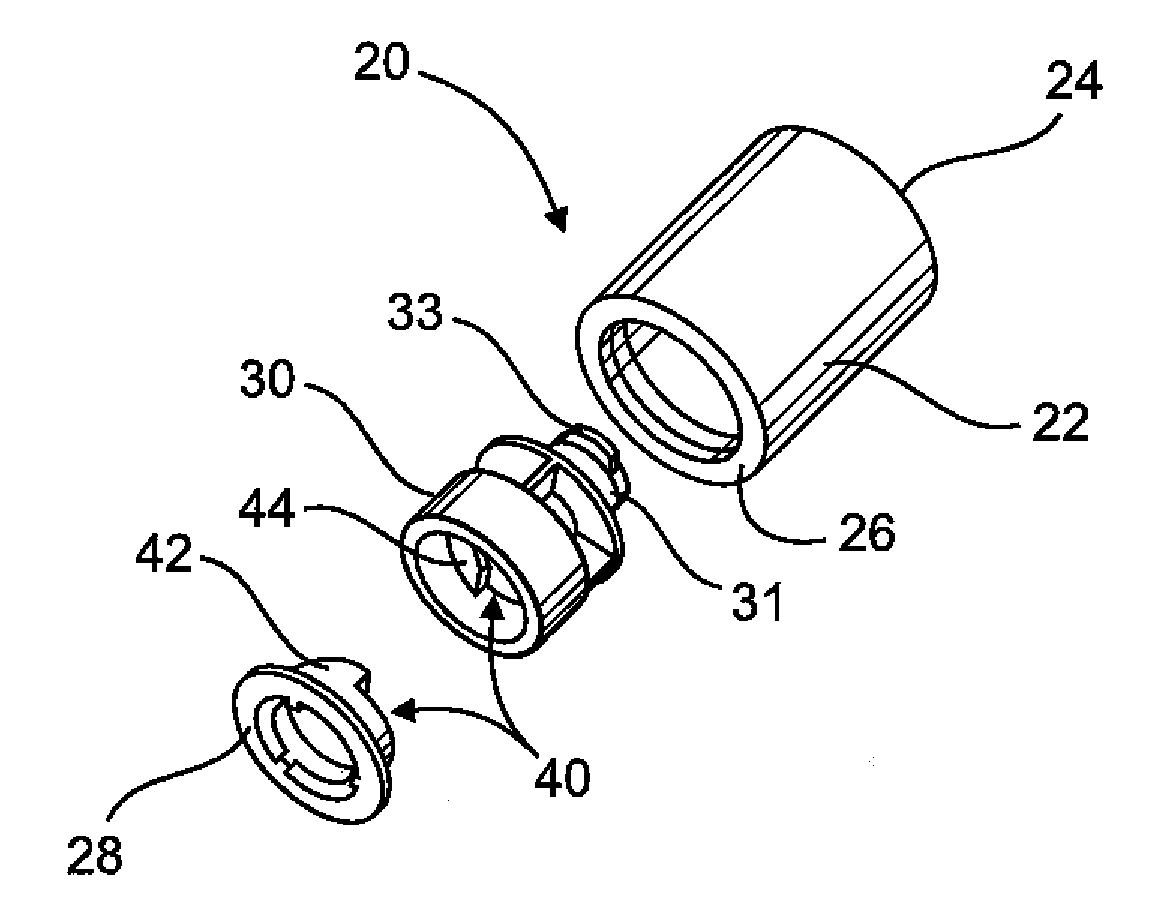

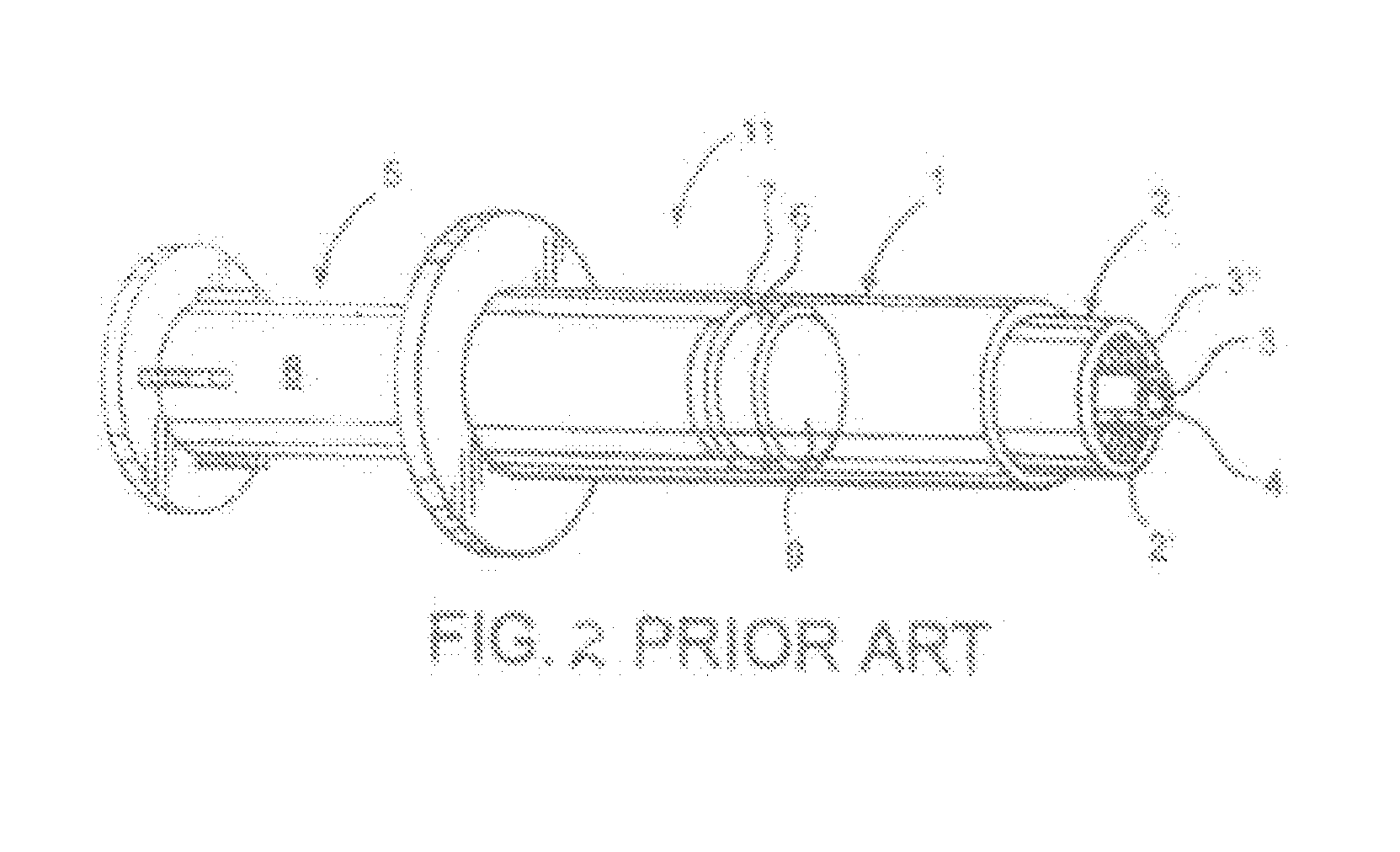

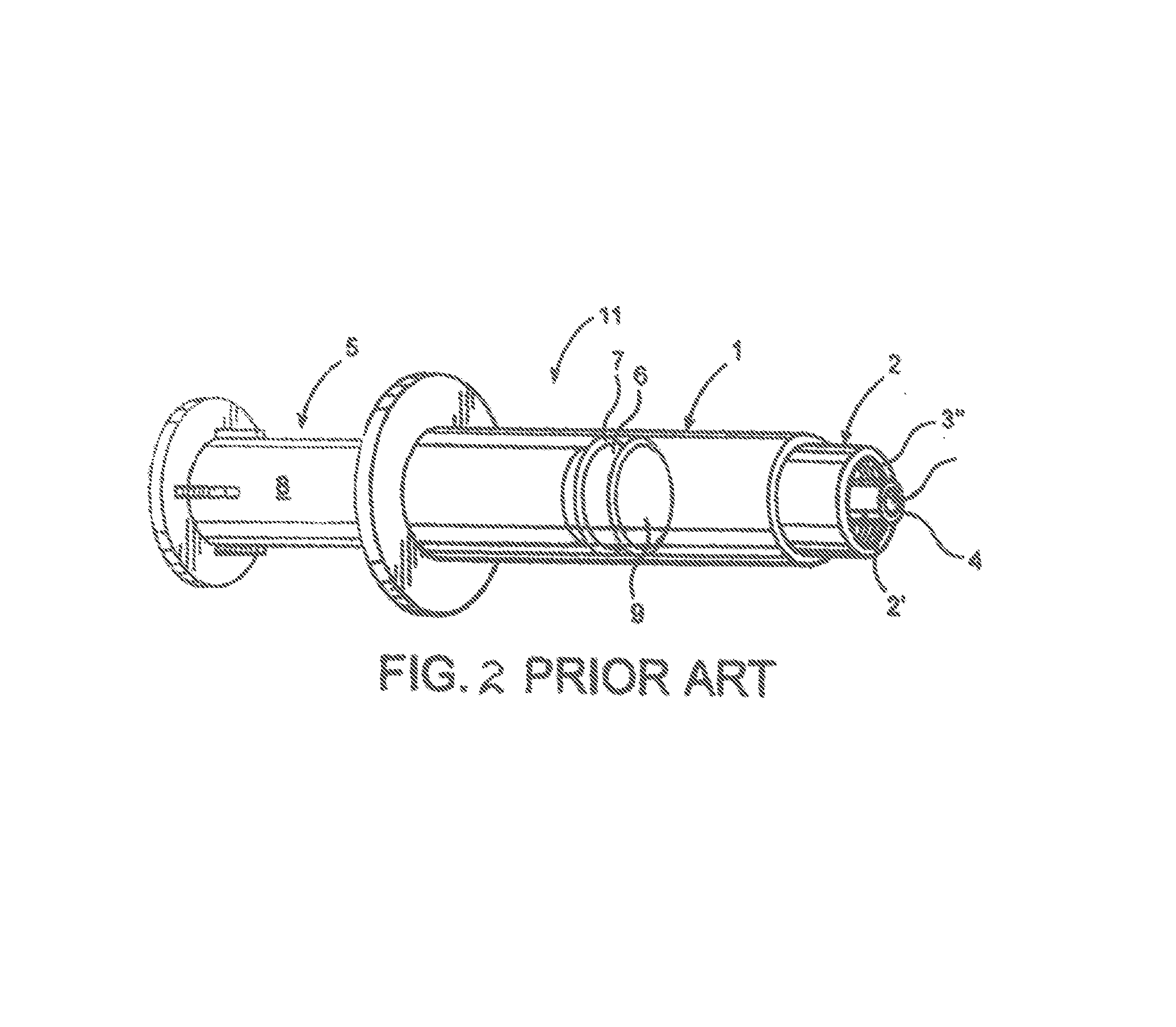

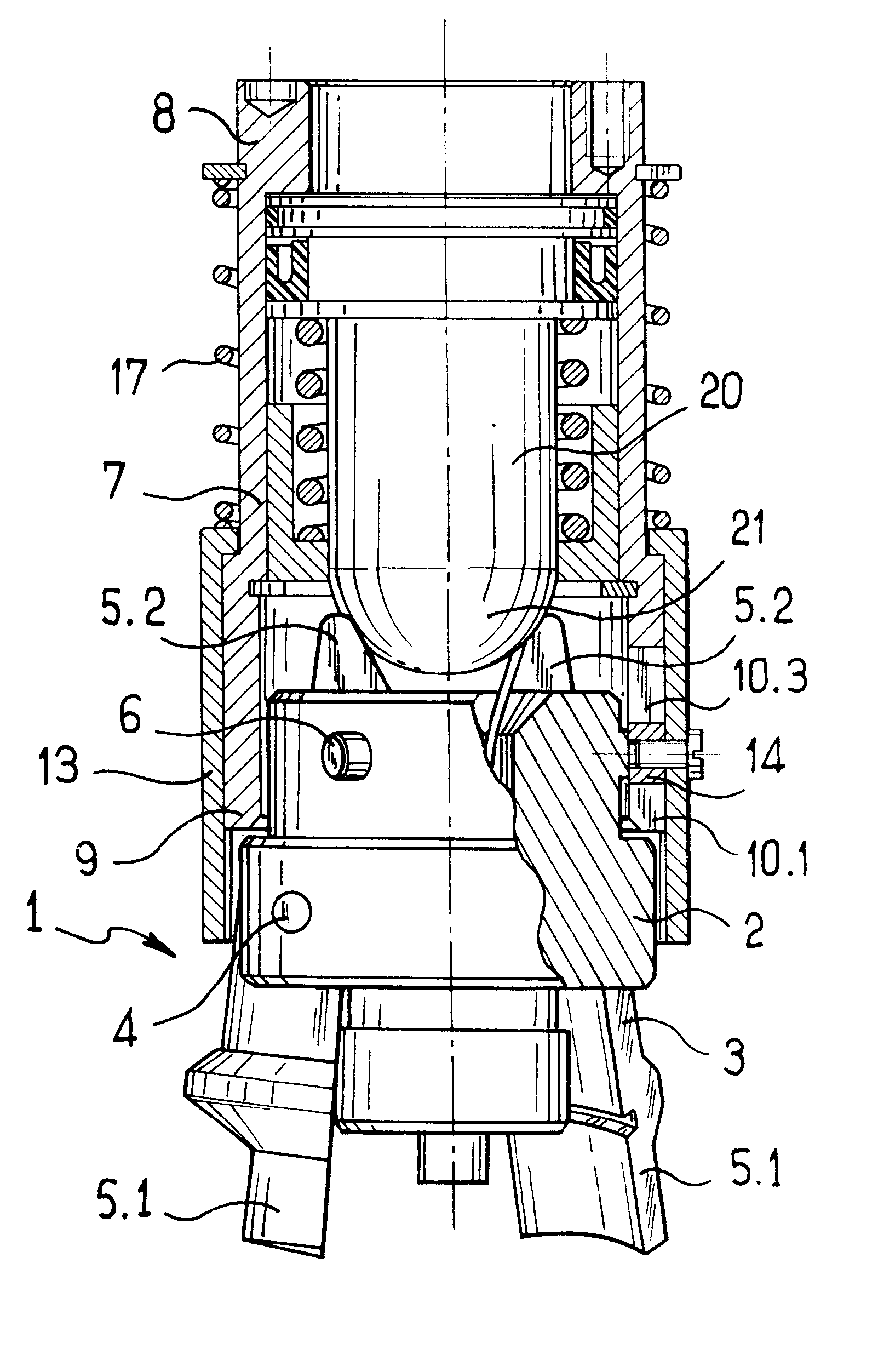

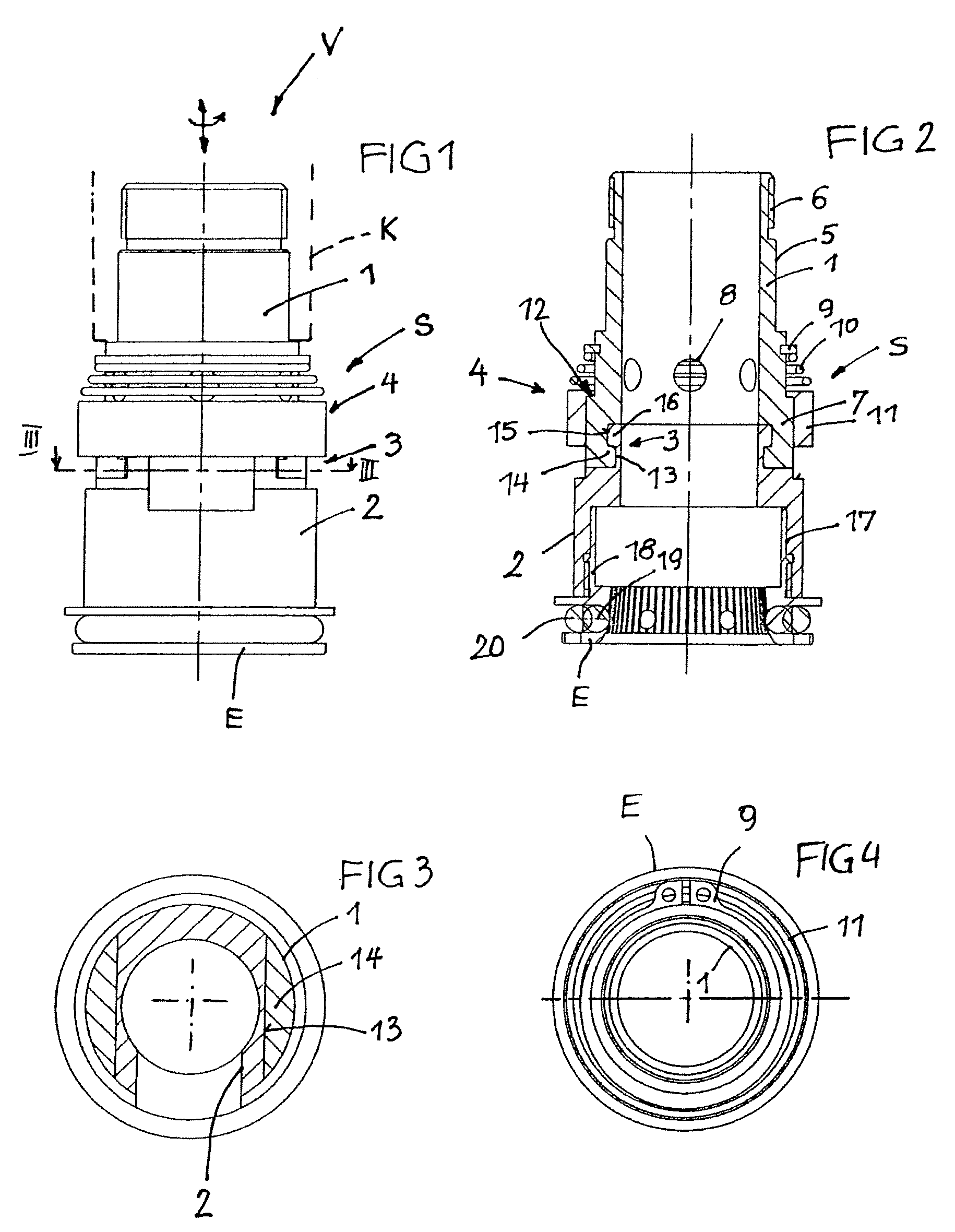

Screw-tightening spindle fitted with a removable chuck

InactiveUS6543204B2Positive lockAddressing slow performanceCapsThreaded caps applicationMoving jawFree edge

Owner:SERAC GROUP

Screw-tightening spindle fitted with a removable chuck

InactiveUS20010054273A1Positive lockAddressing slow performanceSleeve/socket jointsClosing machinesMoving jawEngineering

A screw-tightening spindle comprising a drive sleeve associated with a chuck comprising a cylindrical support member fitted with moving jaws, the cylindrical support member being provided externally with at least one stud extending radially outwards, the sleeve including at least one slot having a first segment opening out in a free edge of the sleeve and a second segment having an end portion forming an angle relative to the sleeve suitable for retaining the stud in the end portion of the slot when the stud is engaged therein, the sleeve being fitted with a ring having at least one stop extending radially inwards and received in the slot, the ring being mounted on the sleeve to slide between a locking position in which the stop extends in the first segment of the slot in register with the second segment, and an unlocking position in which the stop is retracted into a third segment of the slot.

Owner:SERAC GROUP

A gripping apparatus for capping assemblies in container packaging machines

Capping assemblies (2) of the type fitted to capping units (Ia) in a machine for packaging containers filled with fluid or powdered products are equipped with a gripping apparatus (1) comprising a gripper (4) with three arms (5), each carrying an adapter (20) furnished with a pad (20b) offered in direct contact to the cap, through which the gripping action is applied. Each adapter (20) is secured to a fitting (17, 18) insertable into a socket (16) afforded by the bottom of a structural member (6) that forms the main part of each arm (5) and is hinged to the movable head of a relative capping assembly (2); when inserted into the structural member (6), the fitting (17, 18) is retained automatically by a snap lock mechanism (12) incorporated into the arm (5), which can be released subsequently by introducing the tip of a screwdriver into a slot (18a) created in the side of the fitting (17, 18) and levering the components apart.

Owner:AZIONARIA CONSTR MASCH AUTOMATICHE A C M A SPA

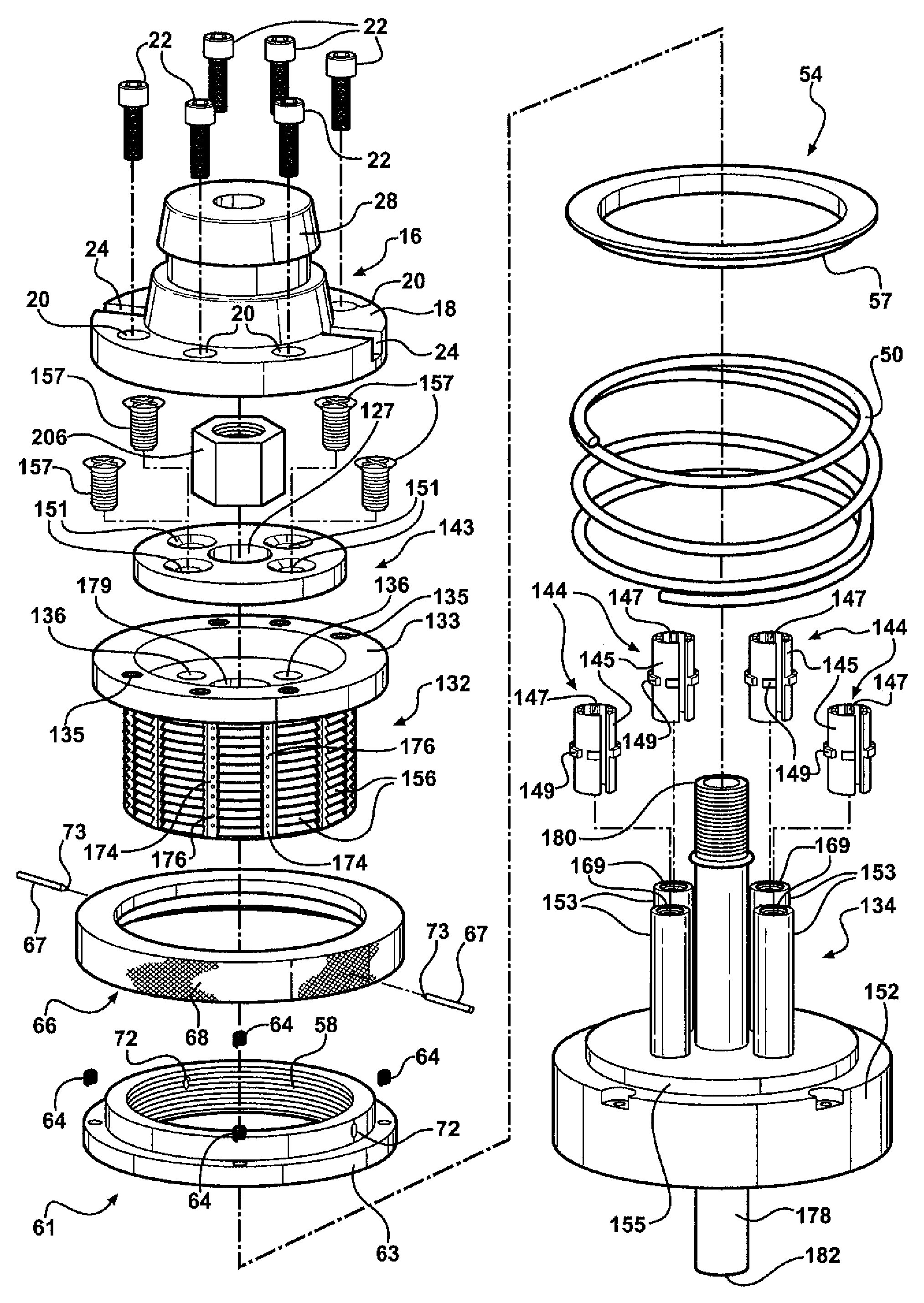

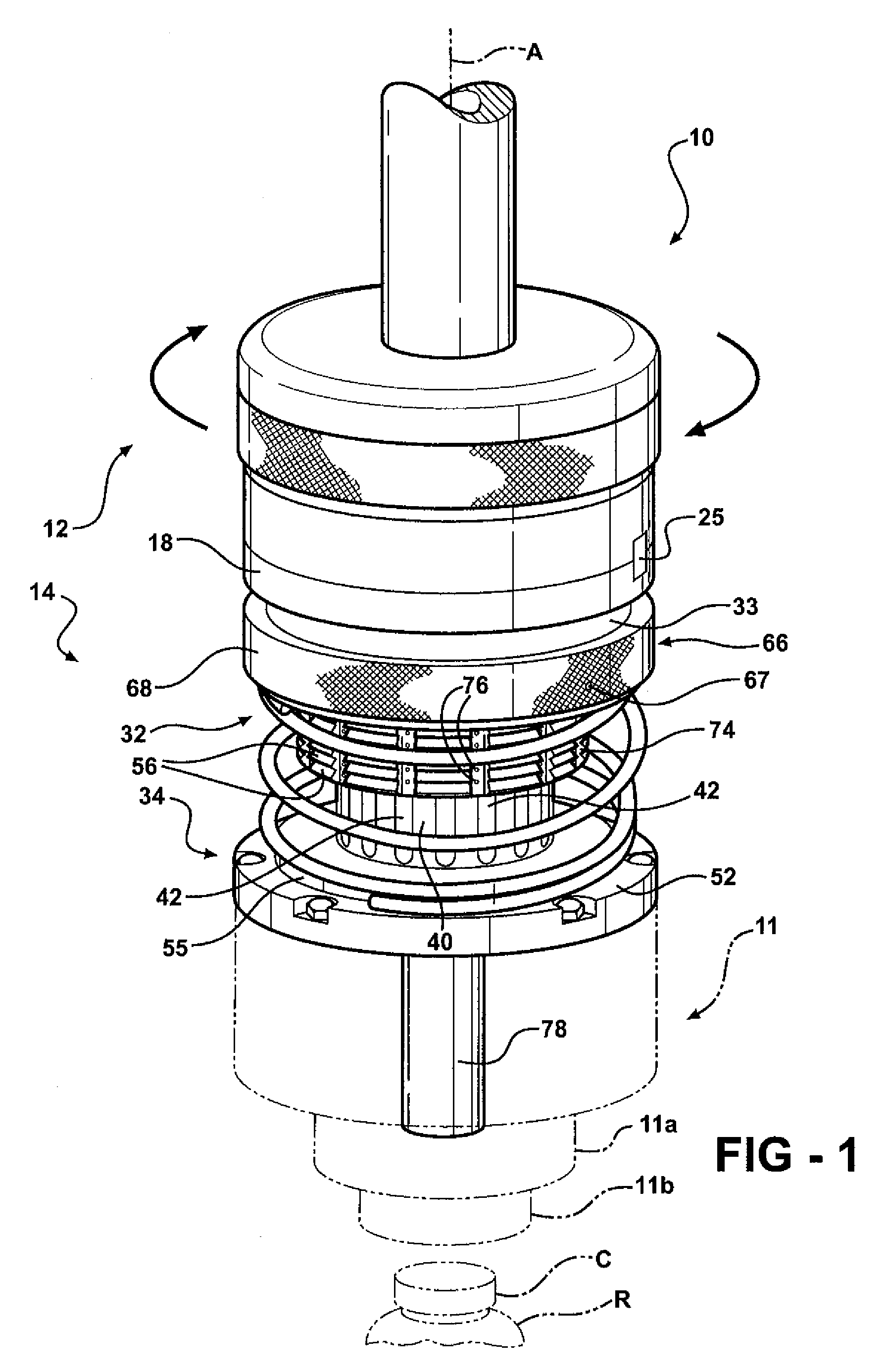

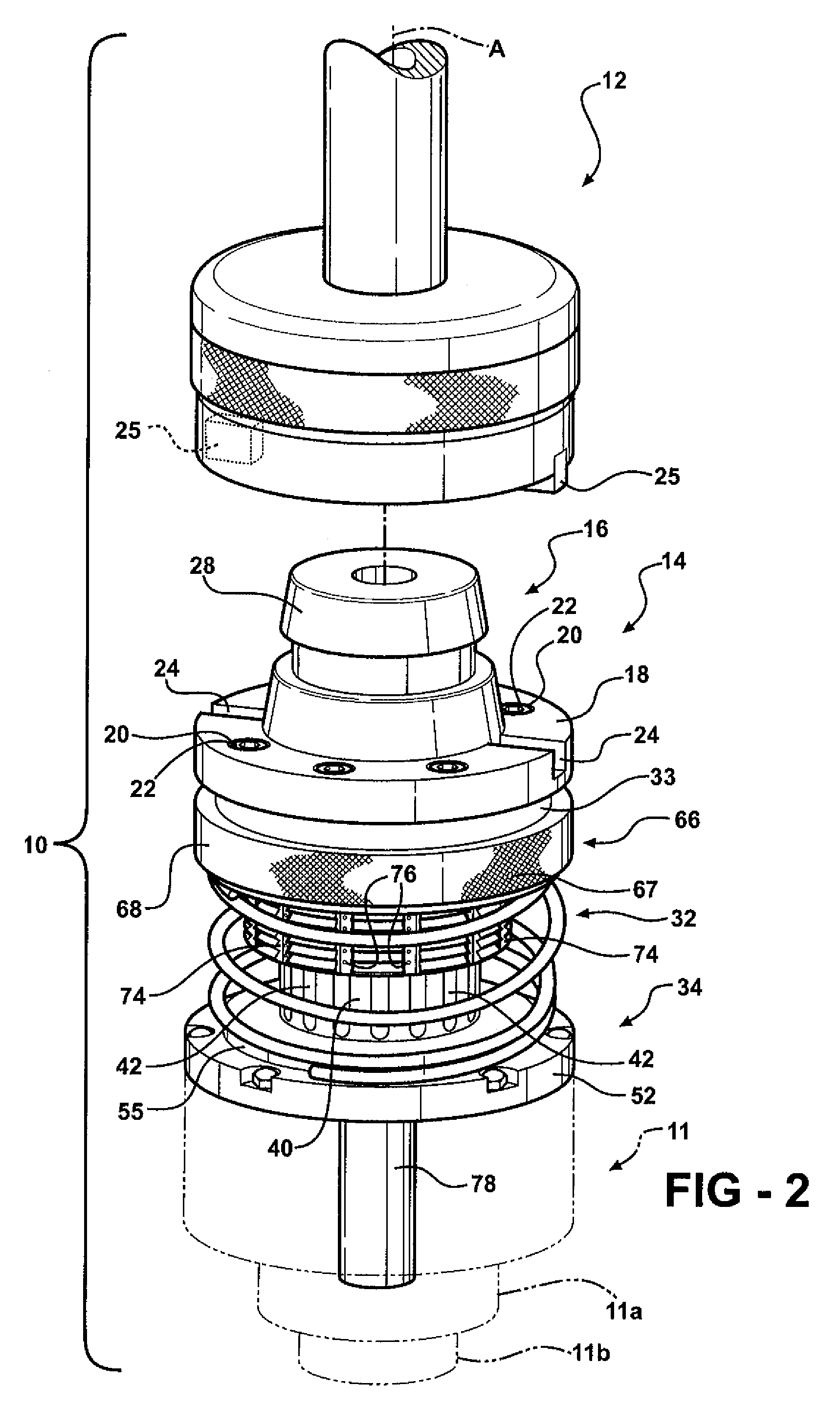

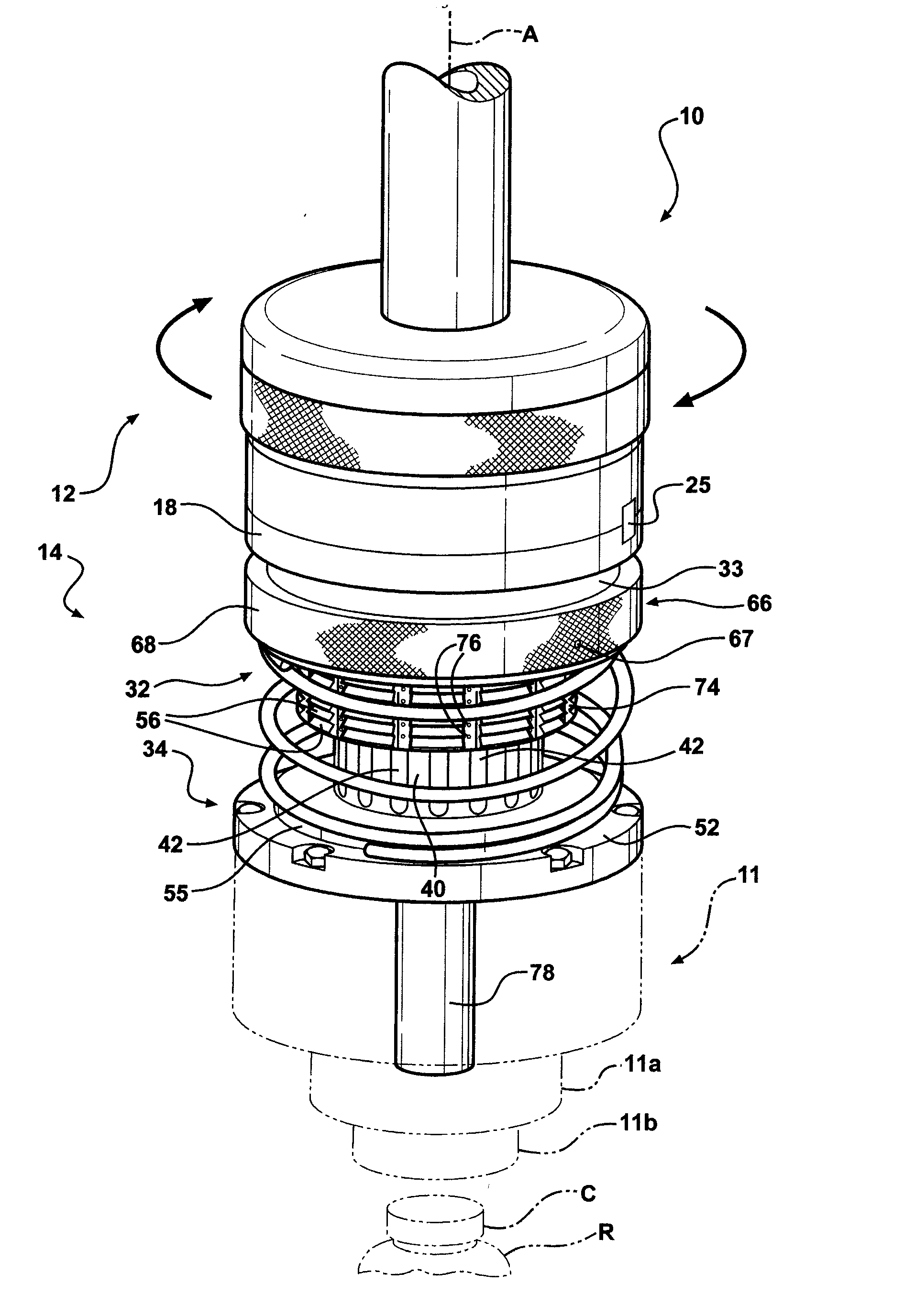

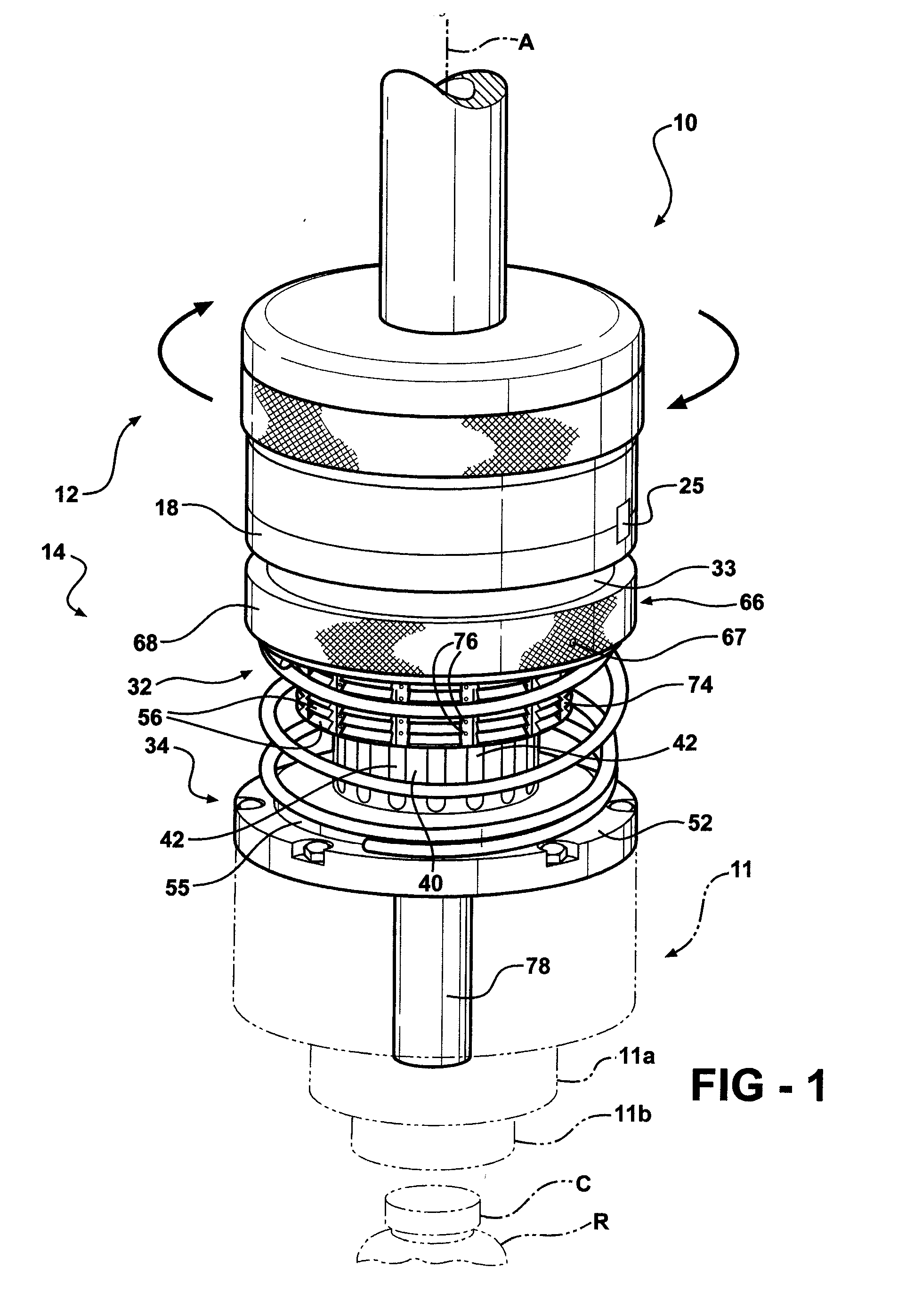

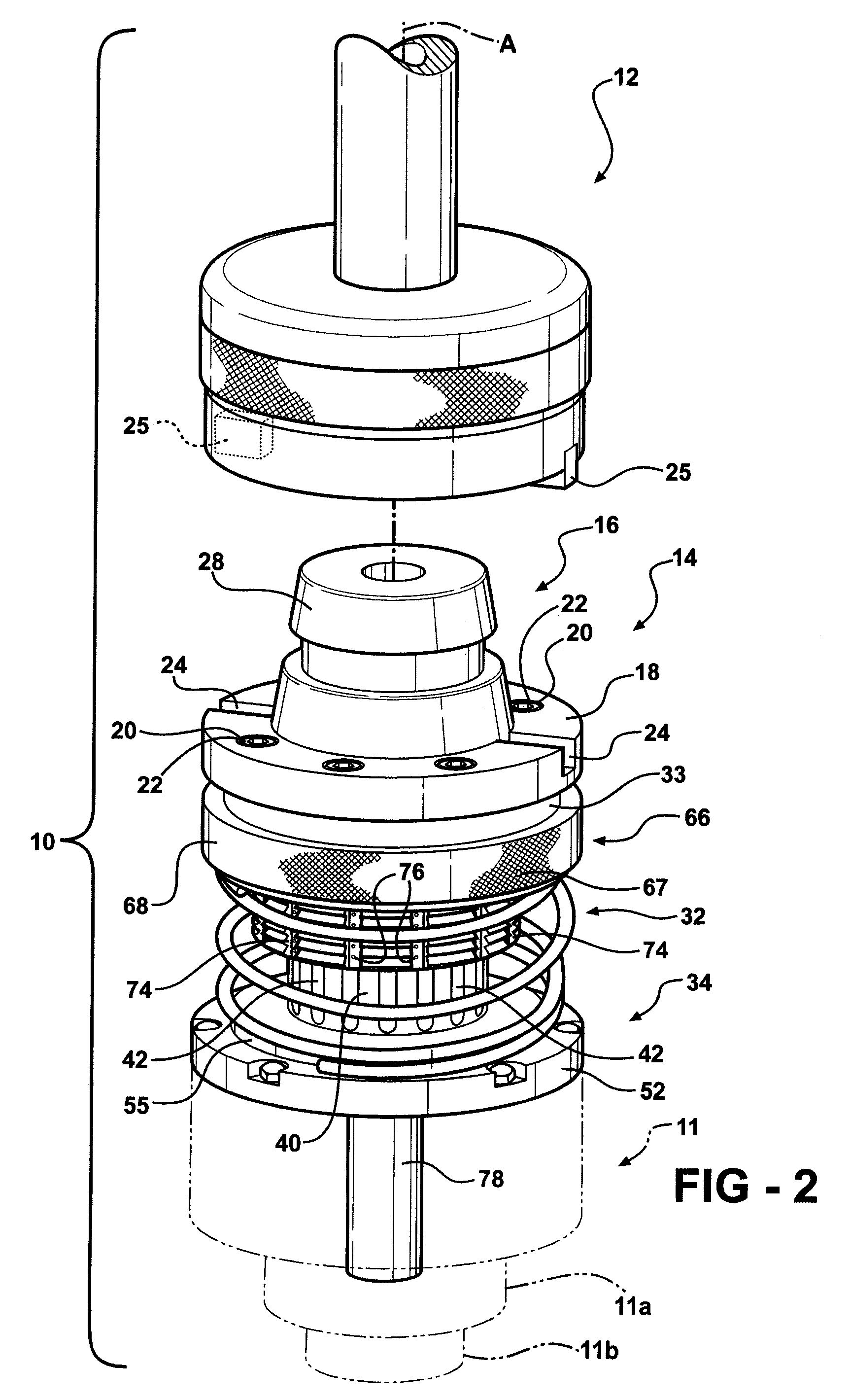

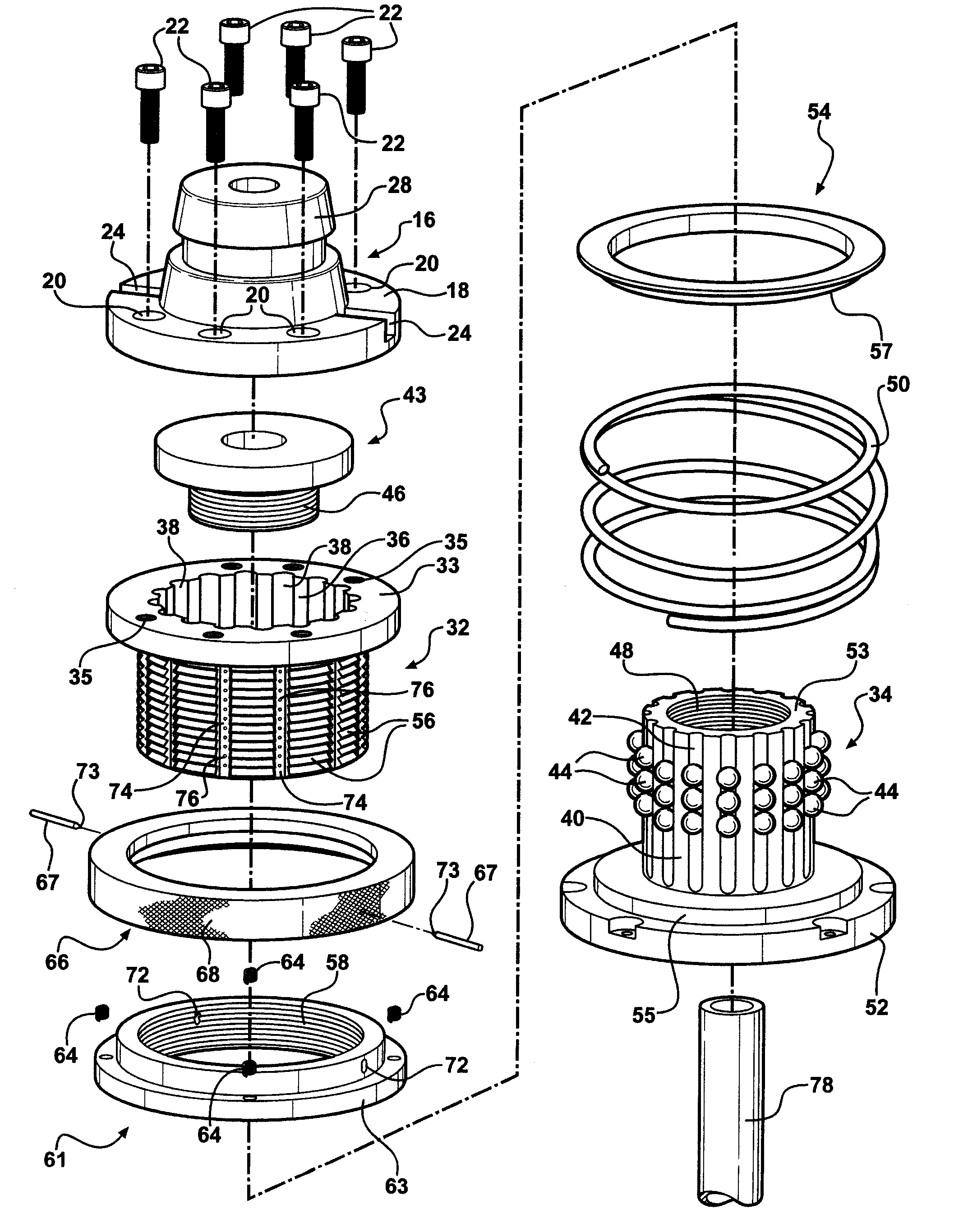

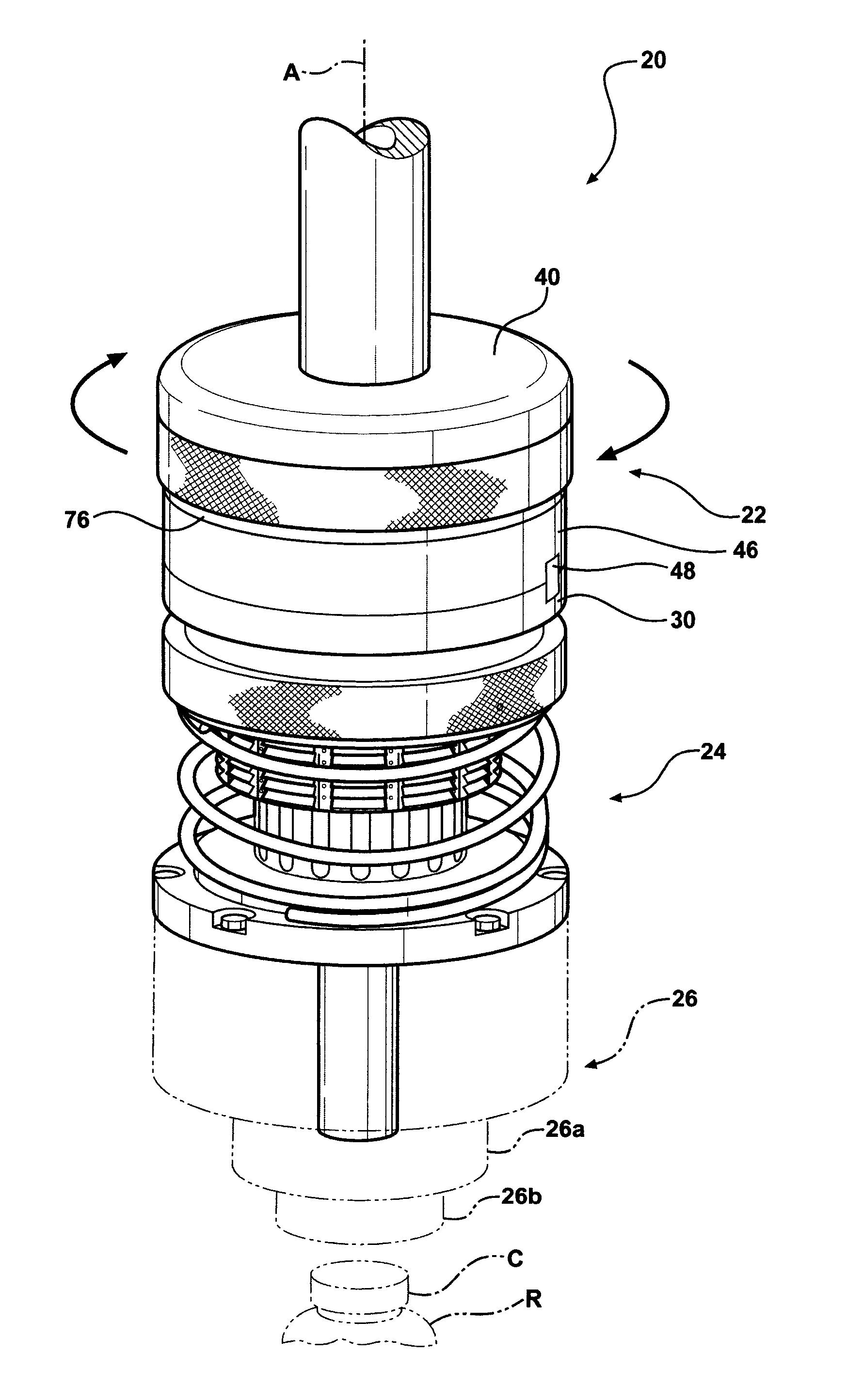

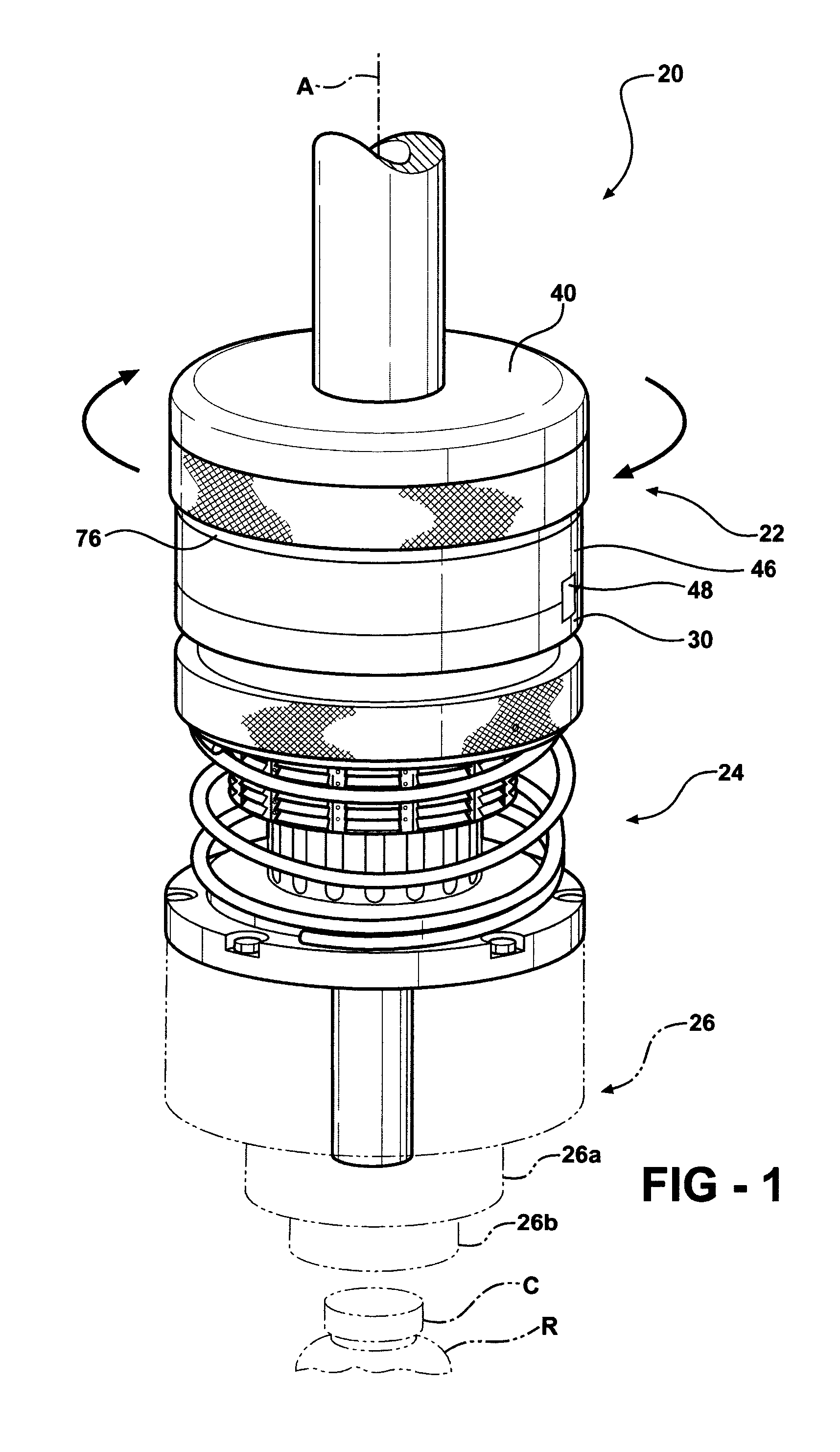

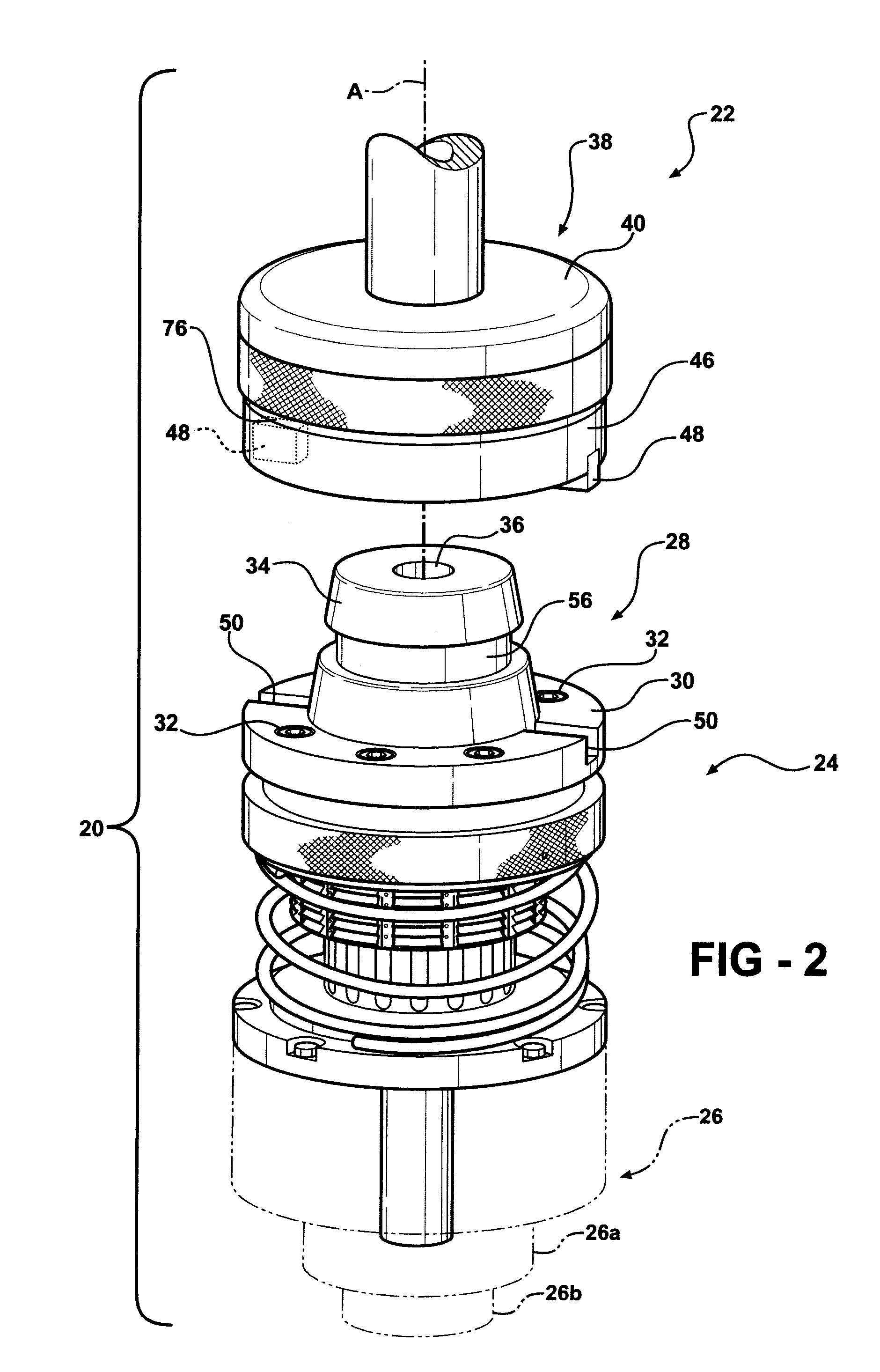

Capping device with bearing mechanism having a plurality of bearing members between a drive member and a capper body

A capping device fits caps onto containers by applying an axial force to the caps as they are threaded onto the containers. The capping device utilizes a drive member rotatable about an operational axis for imparting rotation to a capper body slidably coupled to the drive member. A helical spring urges the capper body away from the drive member with a biasing force. A bearing mechanism allows relative free sliding movement of the capper body relative to the drive member. The bearing mechanism includes a plurality of bearing members. In one embodiment, the bearing members are bushings. In another embodiment, the bearing members are ball bearings.

Owner:ADCOR INDS

Method of sterilizing bottles with electron radiation and a sterilizing arrangement therefor

ActiveUS9302896B2Reduce radiation intensityReduce energy consumptionClosing machinesCapsElectron radiationEngineering

Owner:KHS GMBH

Device for singling out items coming from a feeder

In a device for singling out items coming from a feeder, with the feeder comprising an outlet channel for conveying the items an end section, compacting air jets are placed along the outlet channel for gathering the items one behind the other according to a continuous row, at the end section. The device is equipped with and abutment and catching comb for singling out a series of single and successive leading items of the row of items at the end section, and a driving belt moves the abutment and catching comb according to a direction of extraction at the end section, for abutting and catching a series of single and successive leading items and for transferring and placing the series of singled out items at a handling station.

Owner:MARCHESINI GROUP SPA

Capping device with force adjustment mechanism and method of adjusting

InactiveUS20070084152A1Improve consistencyReduce dirtSleeve/socket jointsClosing machinesCoil springAxial force

A capping device fits caps onto containers by applying an axial force to the caps as they are threaded onto the containers. The capping device utilizes a drive member rotatable about an operational axis for imparting rotation to a capper body slidably coupled to the drive member. A helical spring urges the capper body away from the drive member with a biasing force. An adjustment mechanism adjusts the biasing force thereby adjusting the axial force applied to the caps as they are threaded onto the containers. A pair of retaining pins move between a latched position to prevent adjustment of the biasing force and an unlatched position to allow adjustment of the biasing force. The retaining pins are biased in the latched position to prevent inadvertent adjustment of the biasing force during use.

Owner:BEVCORP

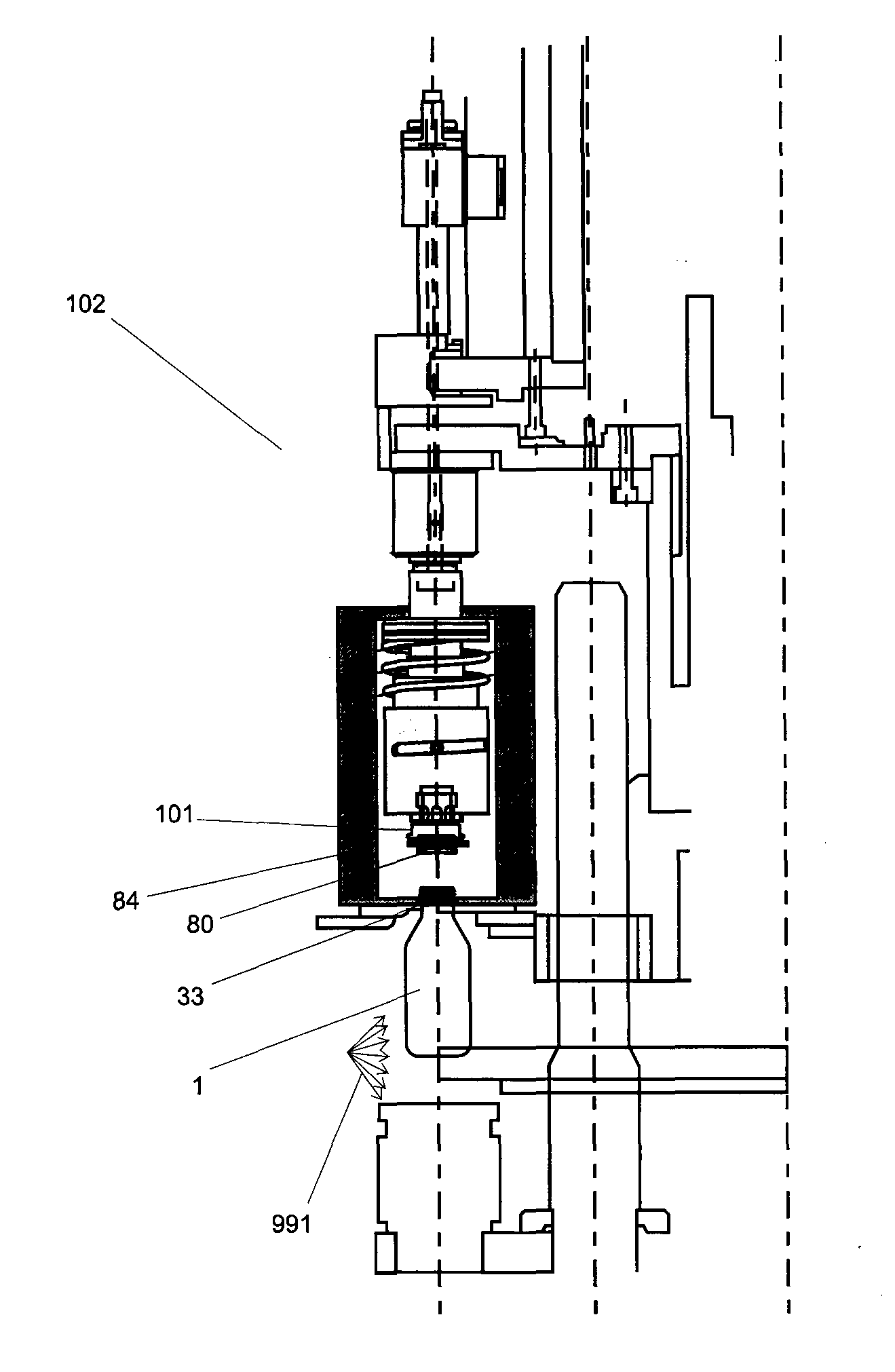

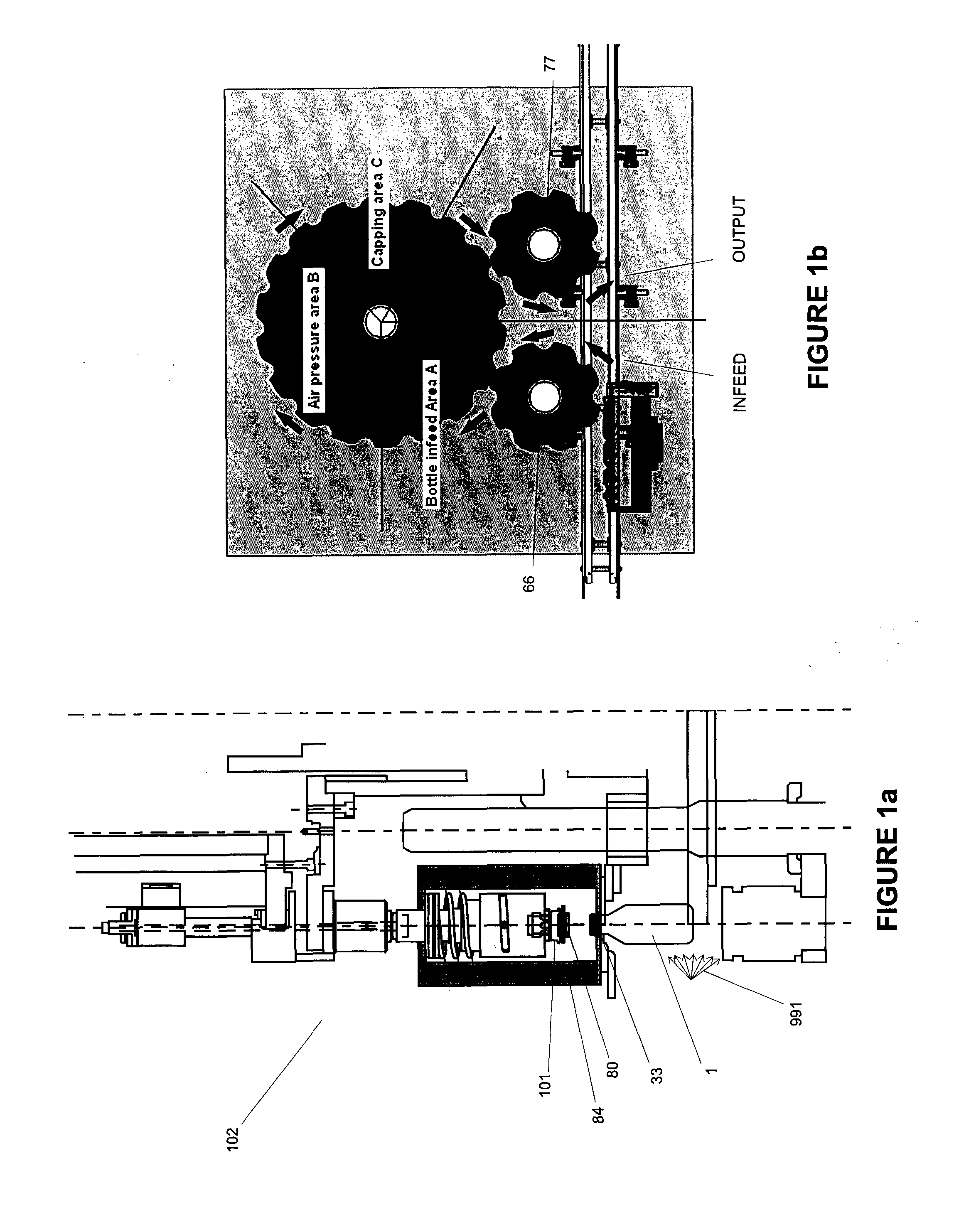

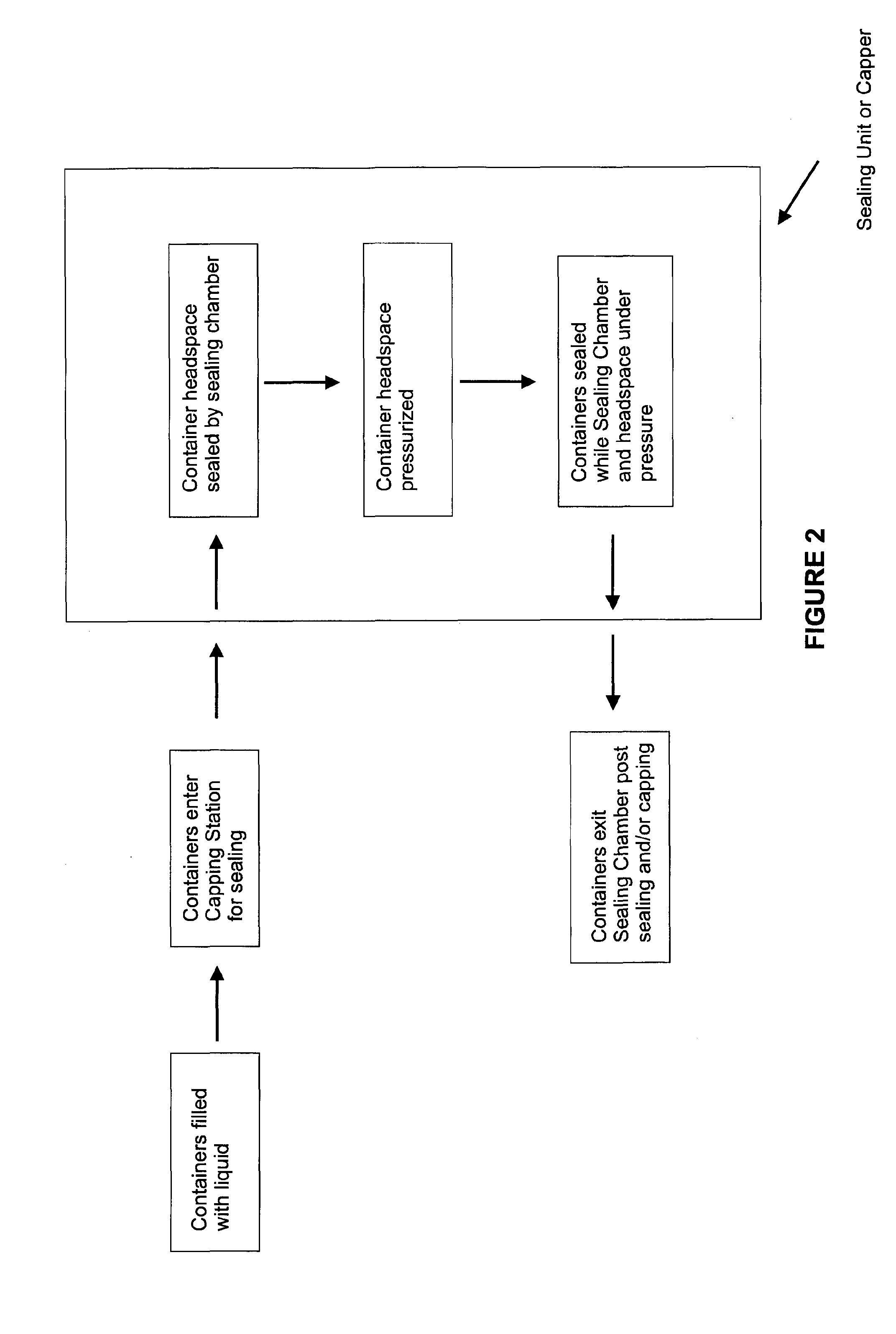

Controlled container headspace adjustment and apparatus therefor

InactiveUS20130239522A1Minimal coolingGreat control over structureClosing machinesSterilising/aseptic filling operationsEngineeringMechanical engineering

A sealing and pressure dosing apparatus, and container filling method, including a capping machine (102) which receives containers (1). Closures (80) are applied to the containers (1) immediately following the raising of pressure within the containers (1) by a pressure dosing system in a pressure sealing changer (84). Preferably a cooling system is integrated with the capping machine.

Owner:MELROSE DAVID MURRAY

Device for closing containers with screw caps including quick change mechanism for closing element

Owner:KRONES AG

Capping device with force adjustment mechanism and method of adjusting

InactiveUS7331157B2Avoid adjustmentImprove consistencySleeve/socket jointsClosing machinesCoil springAxial force

A capping device fits caps onto containers by applying an axial force to the caps as they are threaded onto the containers. The capping device utilizes a drive member rotatable about an operational axis for imparting rotation to a capper body slidably coupled to the drive member. A helical spring urges the capper body away from the drive member with a biasing force. An adjustment mechanism adjusts the biasing force thereby adjusting the axial force applied to the caps as they are threaded onto the containers. A pair of retaining pins move between a latched position to prevent adjustment of the biasing force and an unlatched position to allow adjustment of the biasing force. The retaining pins are biased in the latched position to prevent inadvertent adjustment of the biasing force during use.

Owner:BEVCORP

Bottle cap tightening machine

InactiveCN107792821ATighten to achieveRealize automatic tighteningClosing machinesThreaded caps applicationDrive shaftEngineering

The invention relates to the field of automation equipment, in particular to a bottle cap tightening machine, comprising a conveyor belt, a material rail, a feeding mechanism and a tightening mechanism, the conveying direction of the conveyor belt is perpendicular to the guide of the material rail, and the discharge end of the conveyor belt It is connected with the feeding end of the material rail, and the side of the discharge end of the conveyor belt is provided with a pushing device matched with the material rail. The feeding mechanism and the tightening mechanism are distributed along the guiding interval of the material rail. One side of the material rail A positioning device arranged opposite to the tightening mechanism is provided. The invention can realize the automatic tightening of bottle caps. The tightening mechanism adopts a rotatable rotating shaft installed inside the lifting screw rod, and a tightening head is installed at the bottom of the rotation. The lifting of the screw rod drives the rotating shaft to go up and down synchronously, and the rotation drives the tightening. The head rotates to tighten the bottle cap. The mechanism for driving the screw rod up and down and the mechanism for driving the rotating shaft are independent of each other, so that the structure is simpler, the cost is lower, and the maintenance is easier.

Owner:乔合祥

Capping device with quick release mechanism and methods of releasing and re-connecting

InactiveUS20070084151A1Reduce the amount of operationFacilitated releaseSleeve/socket jointsClosing machinesFast releaseEngineering

A capping device fits caps onto containers by applying an axial force to the caps as they are threaded onto the containers. The capping device utilizes a spindle rotatable about an operational axis for imparting rotation to a capper unit. A connector coupled to the capper unit is releasably coupled to the spindle by a quick release mechanism. The quick release mechanism is normally biased in the locked position and is configured to automatically move from the unlocked position back to the locked position when the connector mates with the spindle as a user re-connects the capping unit back to the spindle. Methods of releasing and re-connecting the capping unit to the spindle are also disclosed.

Owner:ADCOR INDS

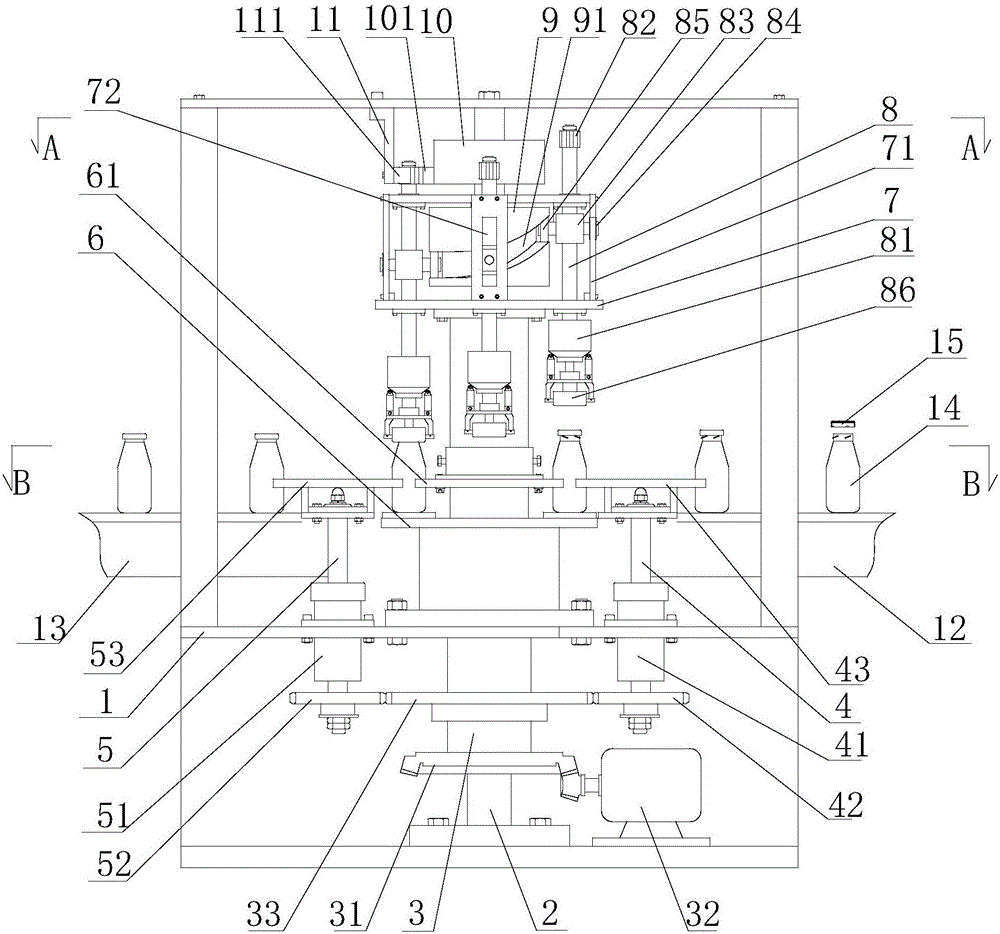

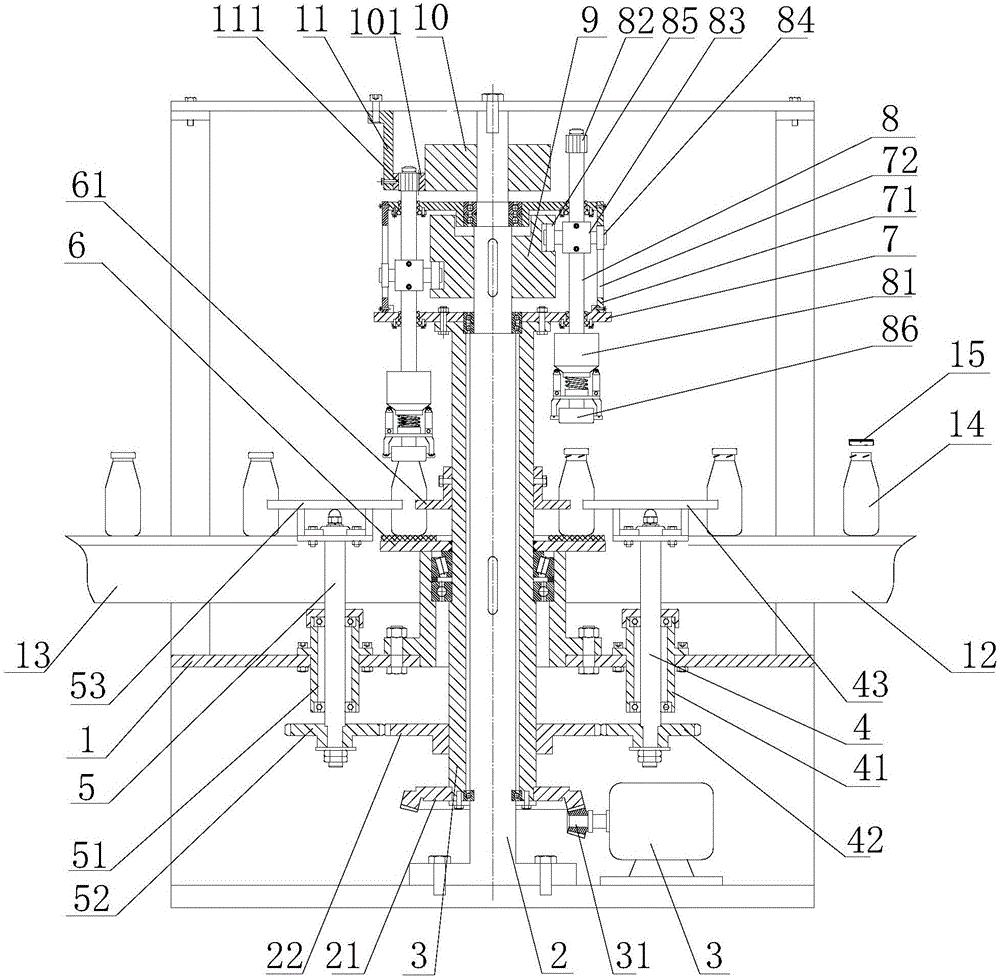

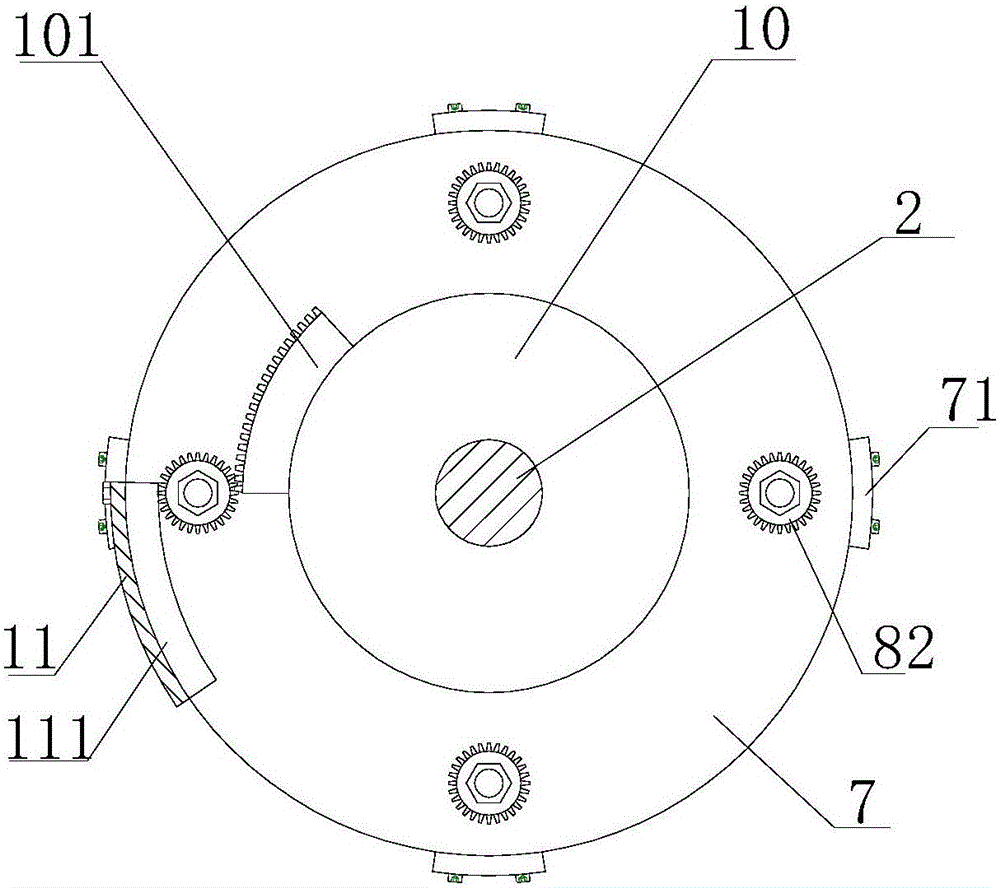

Three-screw-cap beverage bottle cap screwing machine

ActiveCN105967124AMake sure not to moveAvoid deformation and scrappingClosing machinesCapsDrive wheelEngineering

The invention discloses a three-screw-cap beverage bottle cap screwing machine. The three-screw-cap beverage bottle cap screwing machine comprises a machine frame, a bottle inlet conveying mechanism and a bottle outlet conveying mechanism. The machine frame is provided with a stand column. The stand column is provided with a sleeve shaft. A drive wheel is arranged at the lower end of the sleeve shaft and driven by a motor. The sleeve shaft is provided with a bottle guiding mechanism and a cap screwing mechanism. The bottle guiding mechanism comprises a cap pressing rotary disc, a cap pressing stirring disc and a stirring disc in-out drive wheel, all of which are arranged on the sleeve shaft. A bottle inlet mechanism is arranged at the position of the bottle inlet conveying mechanism. The three-screw-cap beverage bottle cap screwing machine has the following beneficial effects that firstly, bottle caps can be grasped by self-locking type cap claws, outward enlarging of the bottle caps is avoided, and it is ensured that the bottle caps are kept with the original shape unchangeable; secondly, the bottle caps can be centralized by reversely rotating the sleeve caps firstly, and clamping blocks of the bottle caps are made to fall onto the lower sides of threads; thirdly, the bottle caps are forwards rotated and screwed, in the bottle cap screwing process, it is guaranteed that the cap screwing mechanism only rotates by a circle and does not rotate at other time through the arrangement of an arc rack, and the phenomenon that the caps are excessively screwed, and consequently the bottle cap clamping blocks deform and are scraped is avoided; and fourthly, in the cap rotating and screwing process, it can be ensured that bottle bodies are fixed through bottle holding guide discs.

Owner:湘潭林海机械制造有限公司

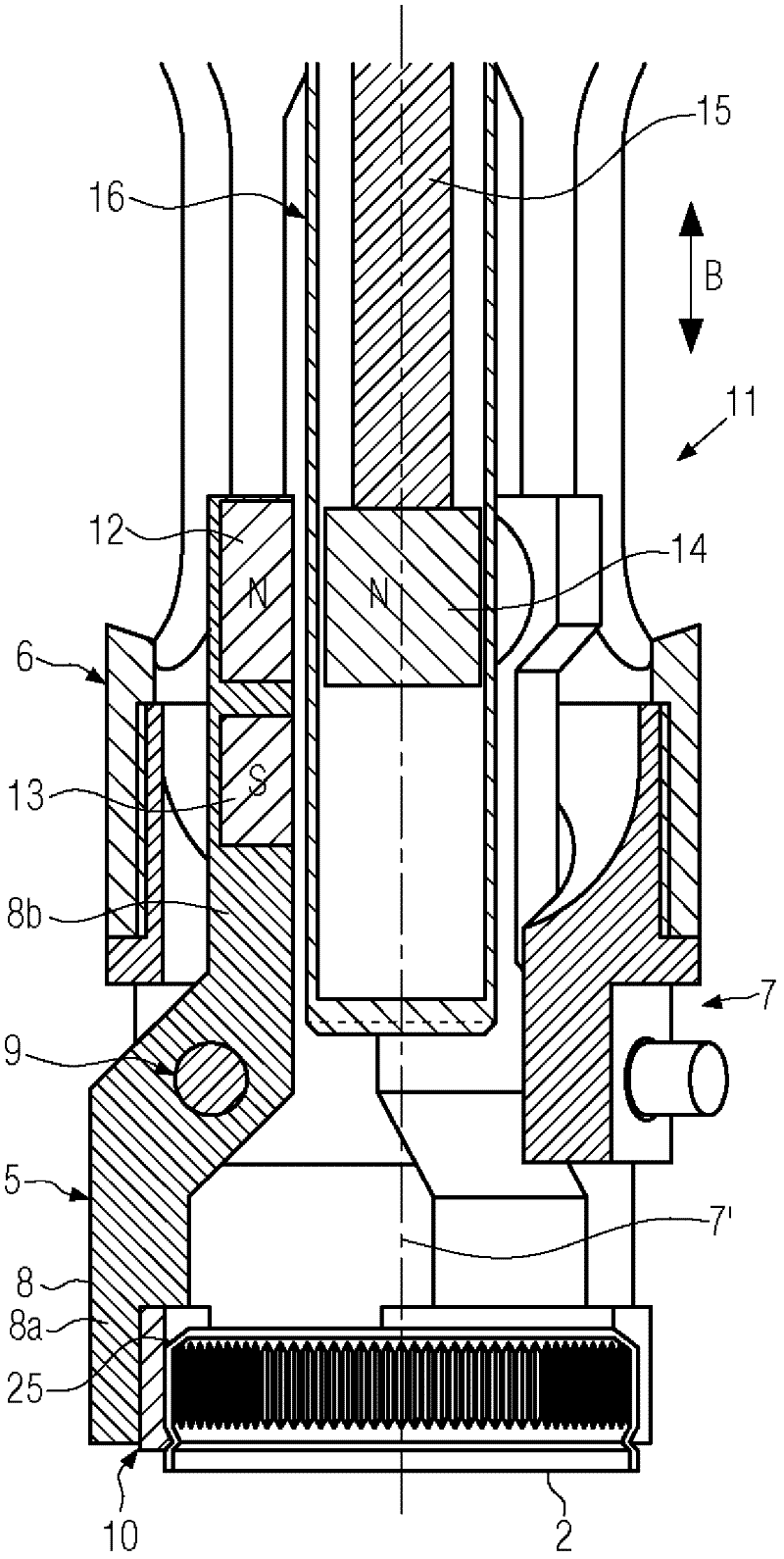

Locking tool

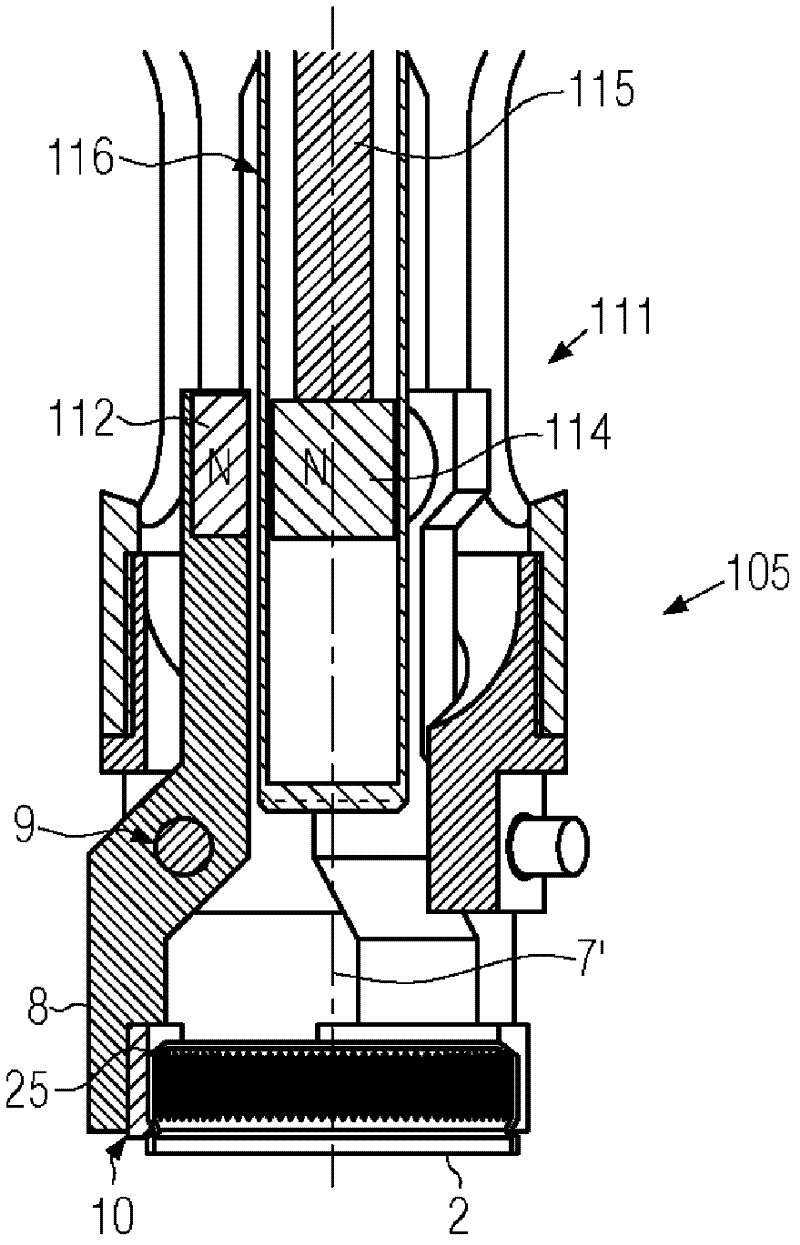

A closing tool for a closing machine for placing a closure on a container, where a holding force is applied to the closure by means of a gripping device. In order to obtain a universal embodiment for the closing tool the gripping device is provided with a magnetic actuator, such as with permanent magnets, for applying the holding force.

Owner:KRONES AG

Automated bit exchange method and apparatus for laboratory sample tube capping and decapping machines

A laboratory capper, decapper or combination capper / decapper includes a deck containing with a nest designed to hold an SBS-formatted tube storage rack, and a bit exchange magazine assembly containing one or more sets of adapter bits. The adapter bits are mounted on and unloaded from motor driven fittings, and are exchanged in order to cap or decap laboratory sample tubes or vials that have different head configurations. The bit exchange magazine assembly enables the bit to be exchanged robotically.

Owner:HAMILTON STORAGE TECH

Device for feeding container closures

InactiveCN102026905ACompletely processedAvoid formingClosing machinesCapsEngineeringMechanical engineering

Owner:GEA PROCOMAC

Closer for containers

ActiveUS20130333325A1Disadvantageous effectLess-expensive to manufactureClosing machinesCapsBottleElectric motor

A closer for containers, in particular bottles, with a closing head acting in a clean room and with an electric motor comprising at least one rotor and at least one stator, with the closing head connected with the rotor, and an element for clean room separation is formed between the rotor and the stator.

Owner:KRONES AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com