Device for feeding container closures

A feeding device and closure technology, applied in the direction of tightly closing containers with lids, closures, bottle/container caps, etc., can solve problems such as inability to eliminate pathogenic factors, inability to perform ionizing radiation, and endangering the sterilization of closures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

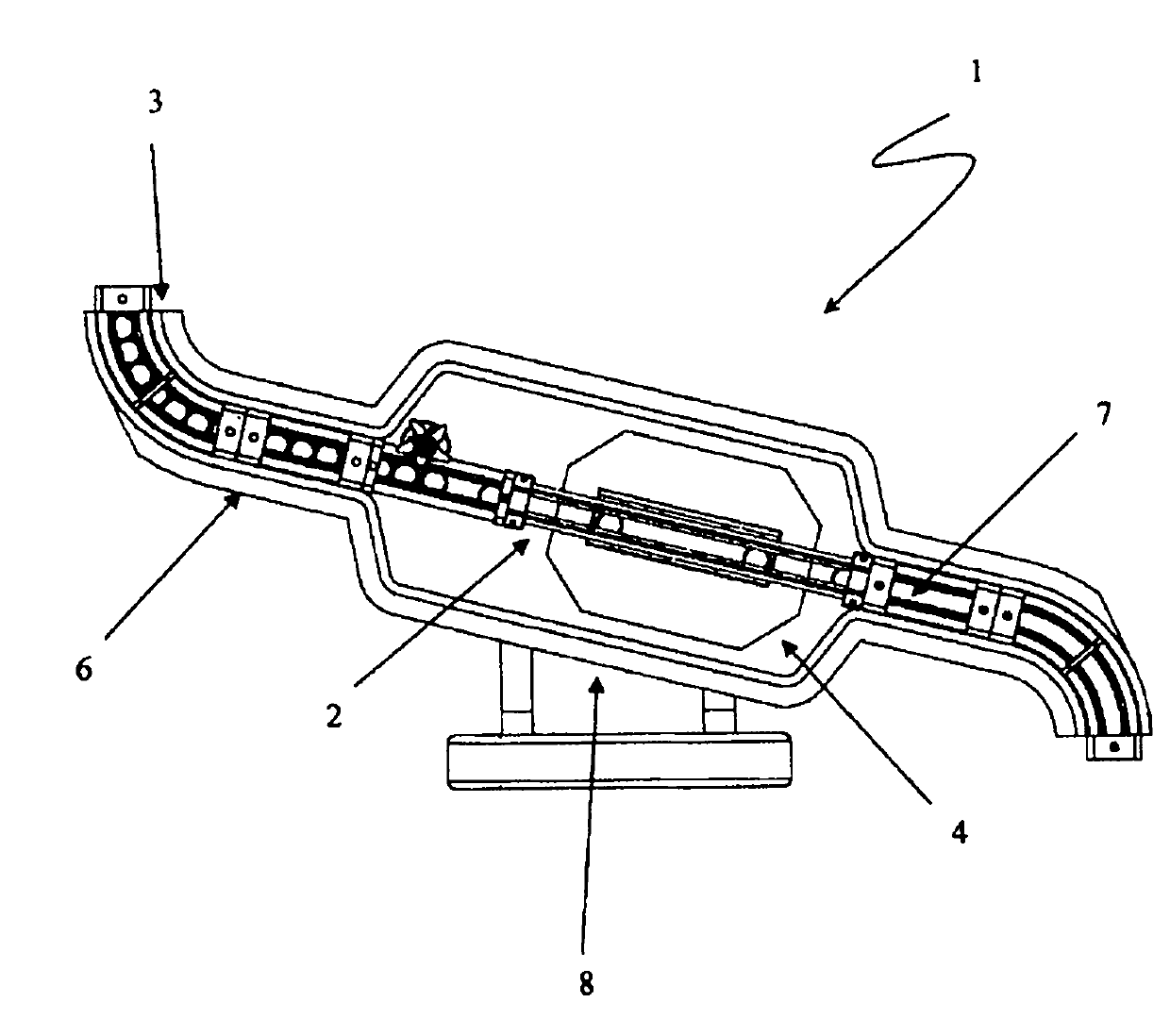

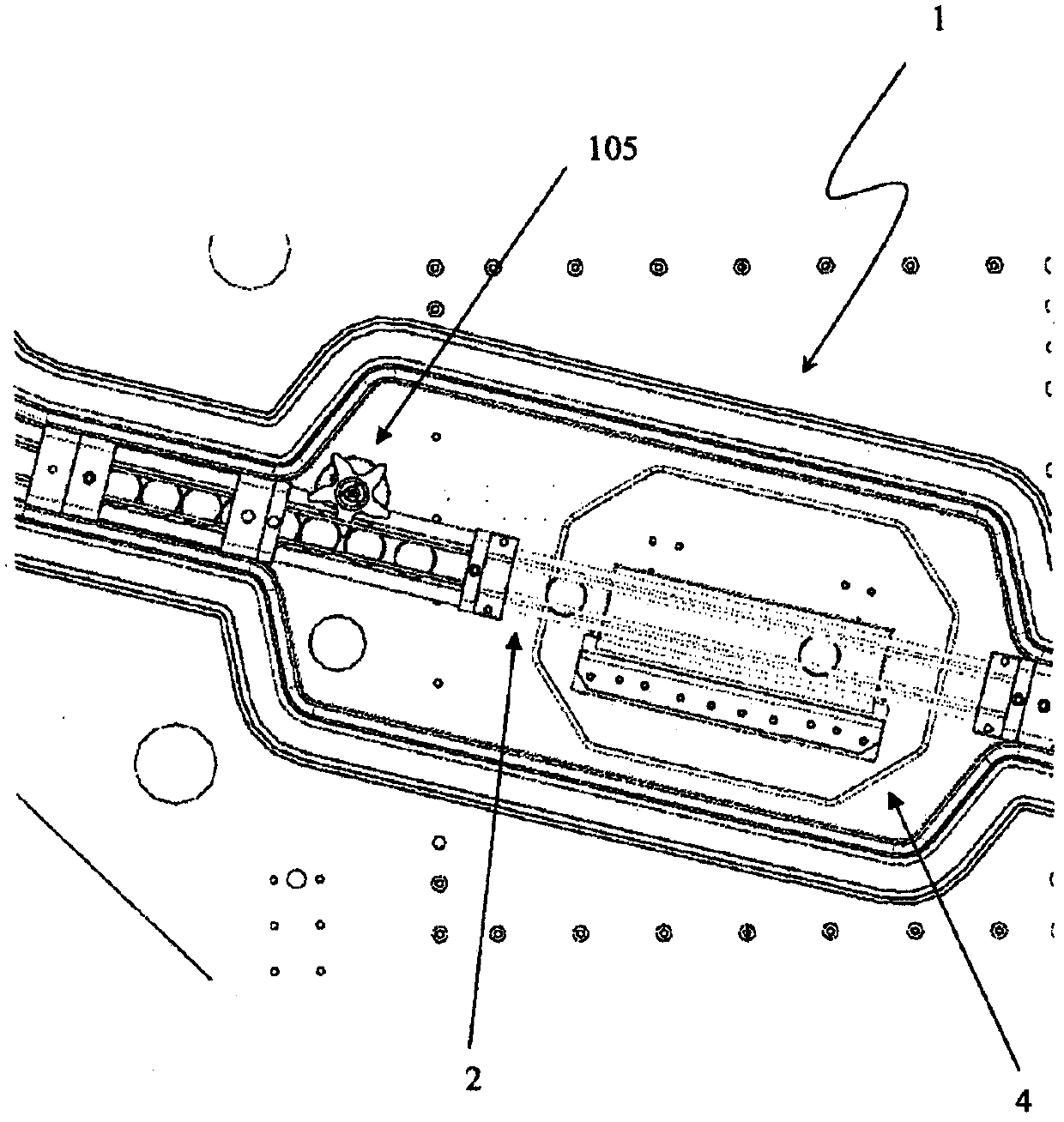

[0027] With reference to the figures, a device for feeding container closures to a sterilization plant is indicated generally by the reference number 1 .

[0028] The device 1 comprises a guide 2 having an inlet 3 for closures, usually caps and bungs, which is in communication with a loader or hopper (not shown) for storing the closures and feeds closures to be processed.

[0029] The device 1 can be associated with a closure processing station 4 which is preferably included in the sterilization apparatus.

[0030] The device 1 includes spacer means so that the closures are fed to the processing station 4 one at a time at evenly spaced time intervals. In particular, said spacing means are operatively associated with guide means 2 and positioned upstream of said processing stations 4 .

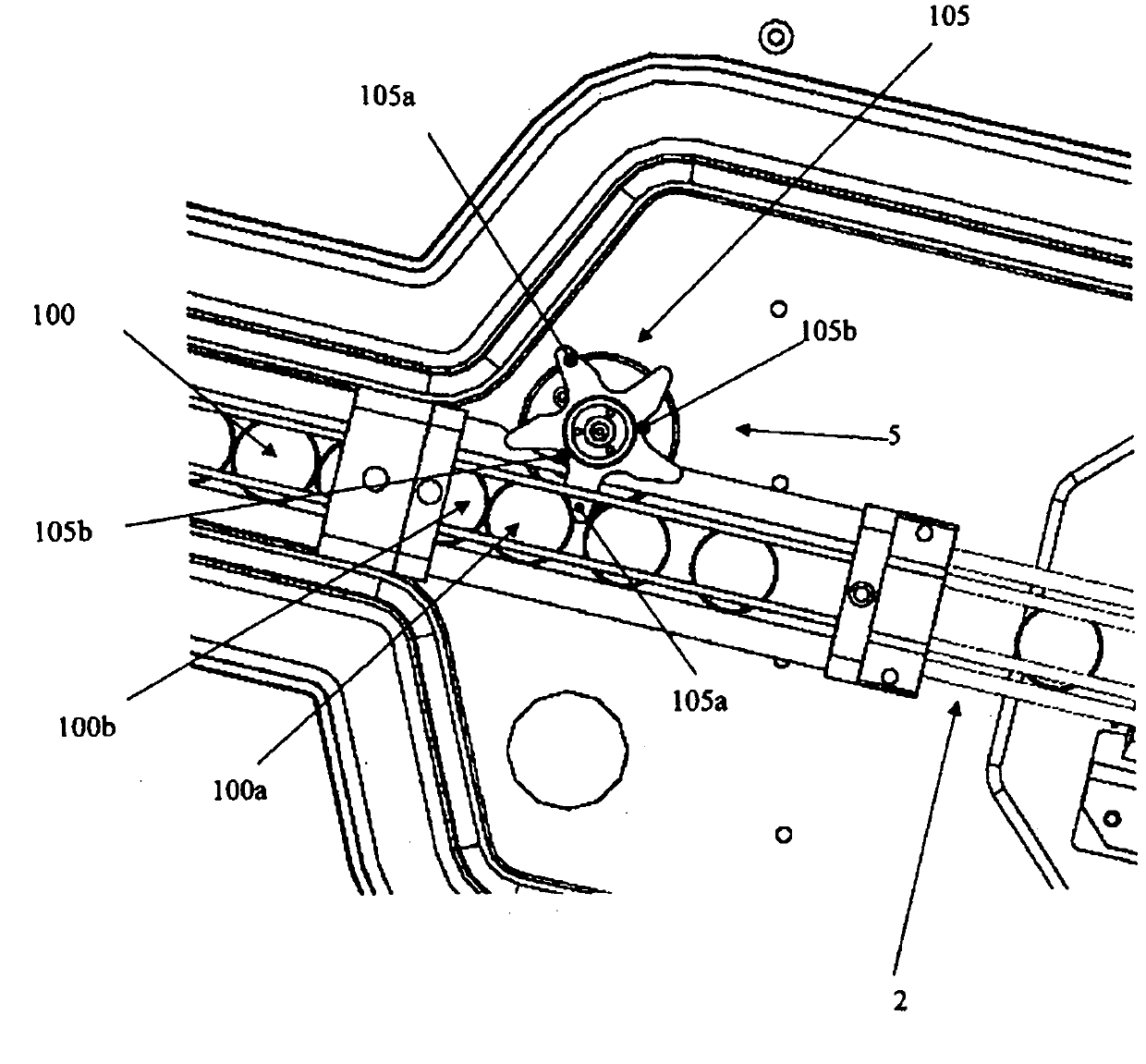

[0031] specific reference image 3 , the spacing means comprise a separating element 5 which is operable to act on a line of closures 100 so as to feed the leading closure in the queue 100a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com