Patents

Literature

198results about "Rotating screw stopper insertion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Container closure

InactiveUS6902075B2Achieve stabilizationHigh elongationCapsThreaded caps applicationWaddingEngineering

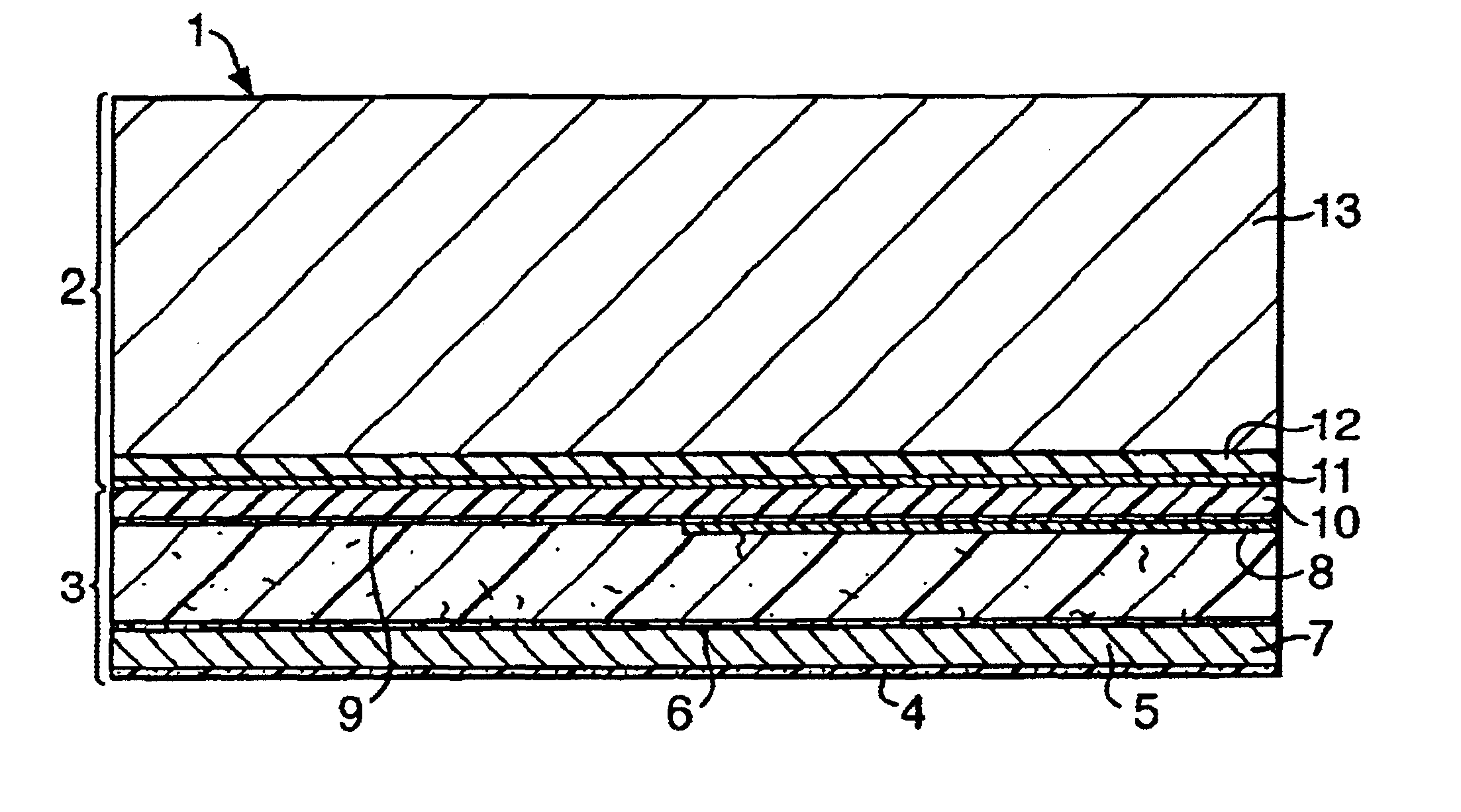

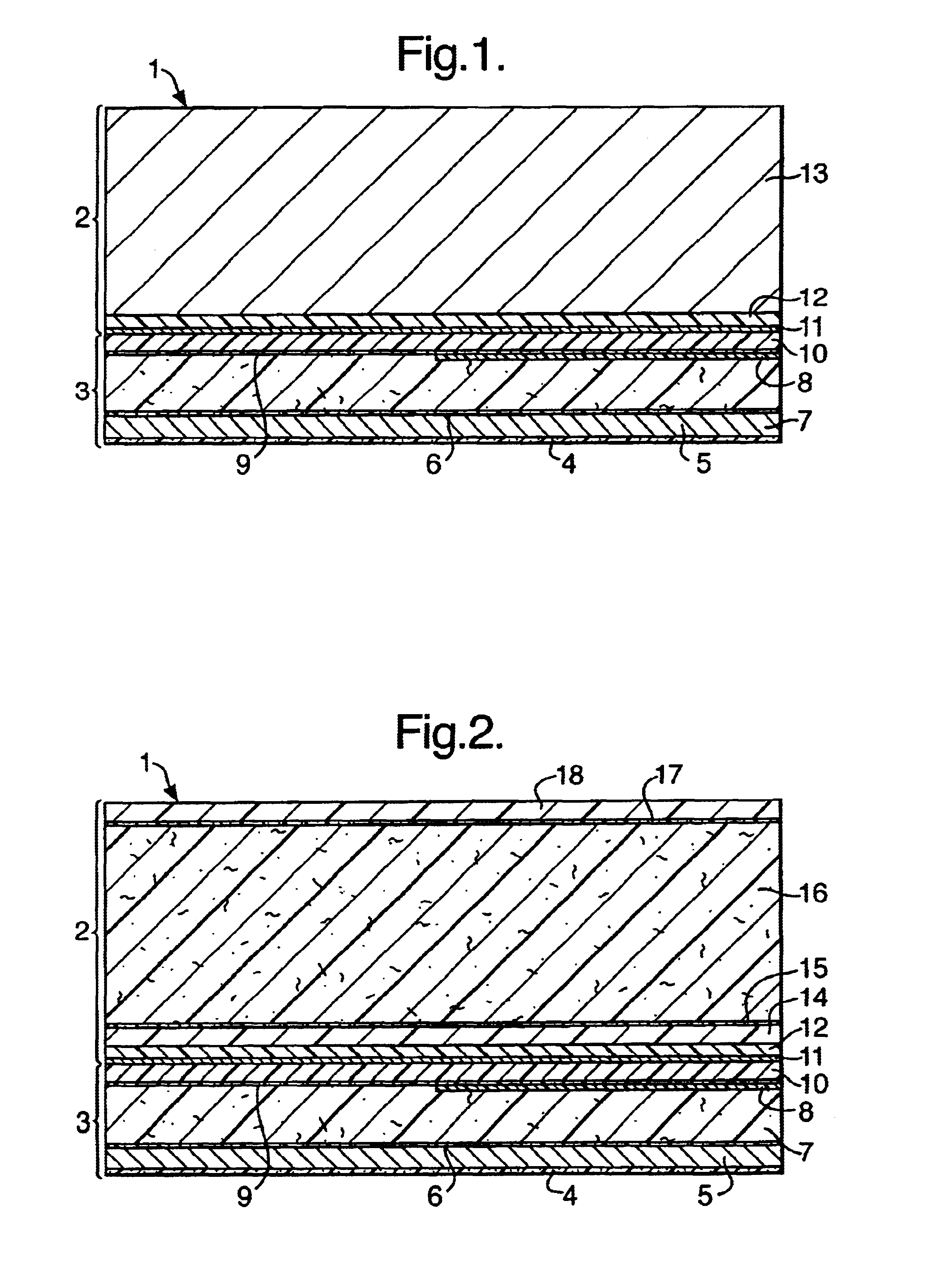

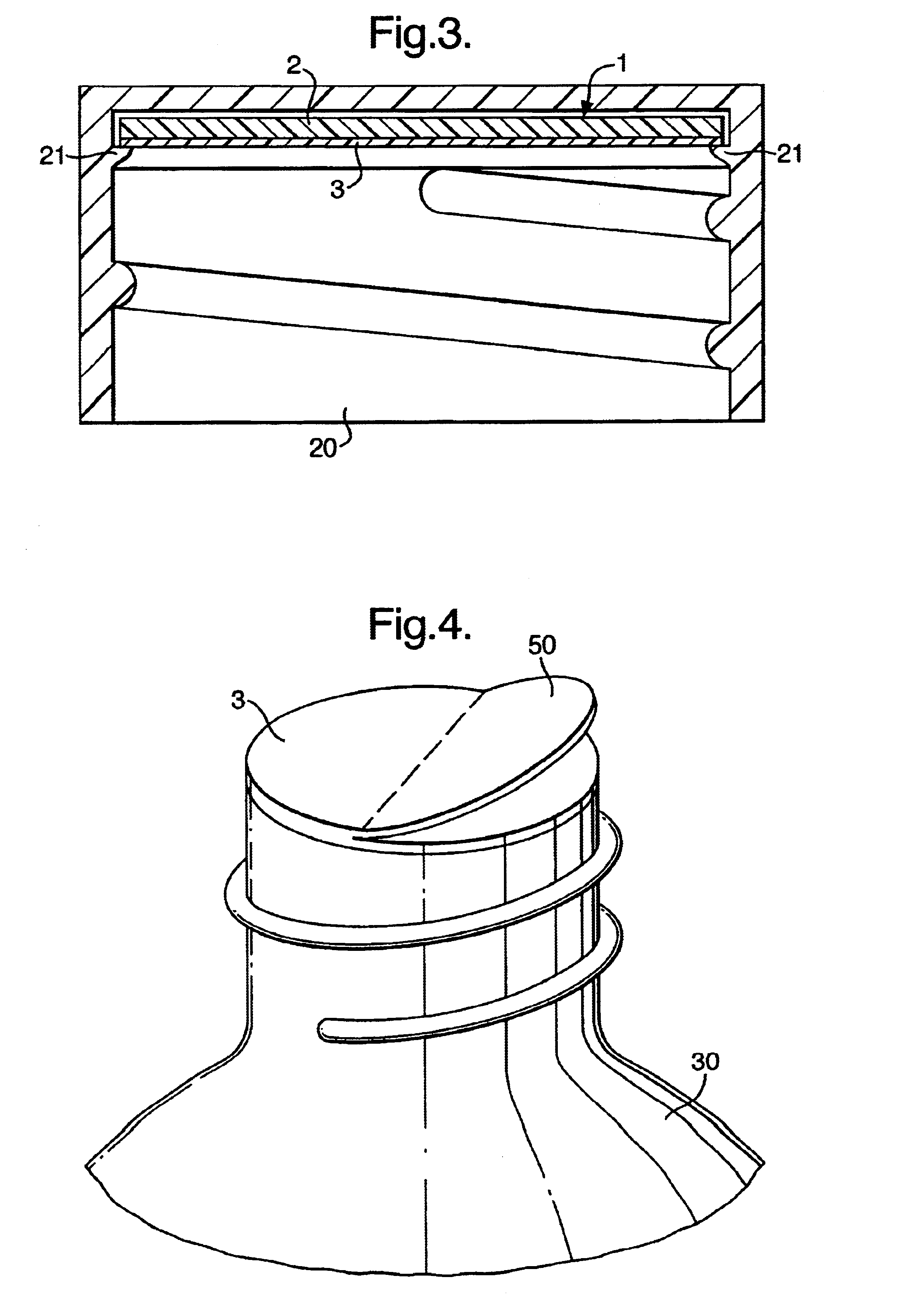

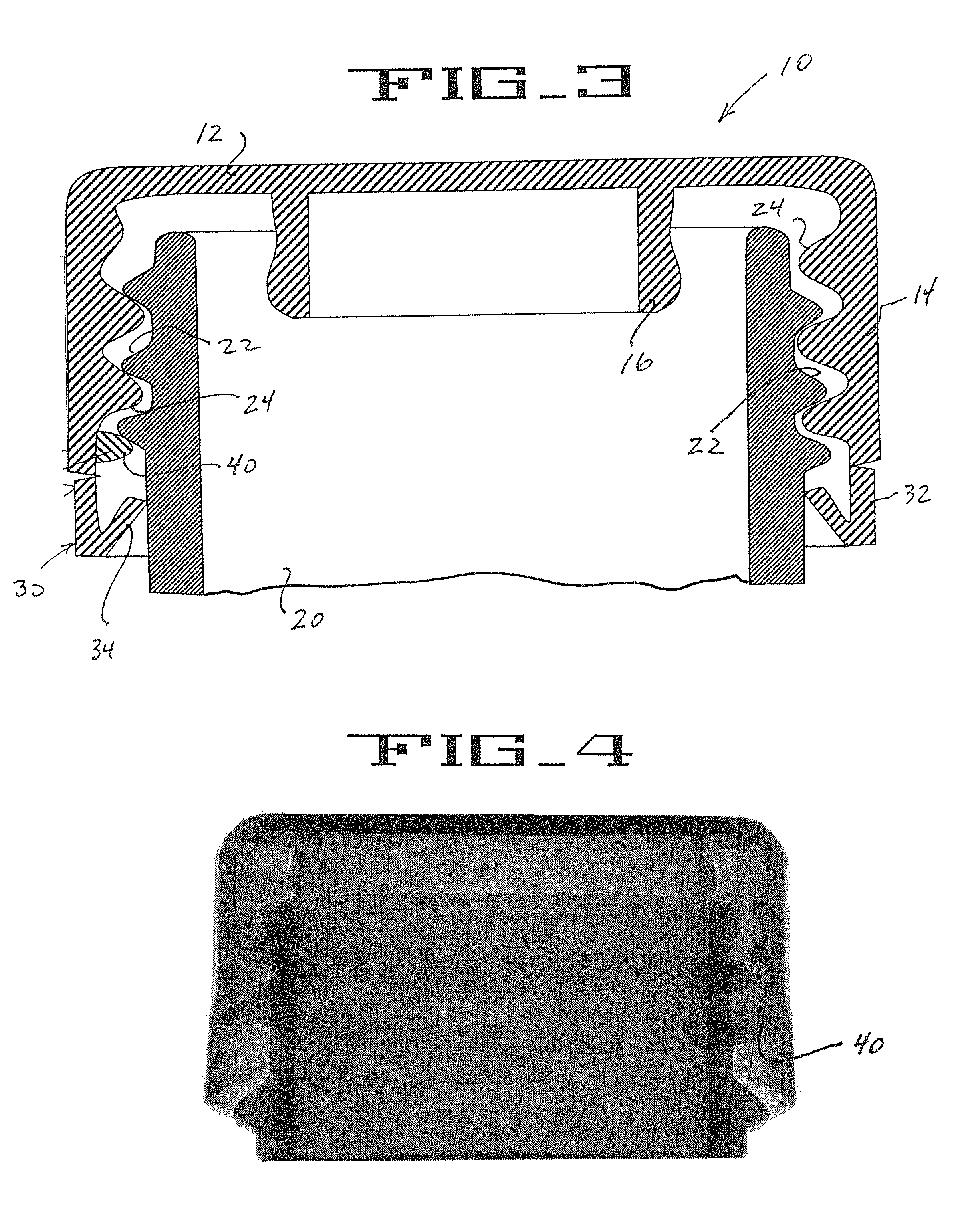

A one-component seal and wadding system (1) for a screw-cap includes a seal (3) having lower layers (4,5) forming an induction heating sealable system for attaching the seal (3) to the neck of a container, a seal substrate (6) including a free tab (50) lying wholly within the circumference of the seal, a layer of liner (2), and an attachment element (10,11,12) including a release layer (11) for attaching the seal substrate (7) including the tab (50) to the wadding (2).

Owner:SELIG SEALING PROD INC

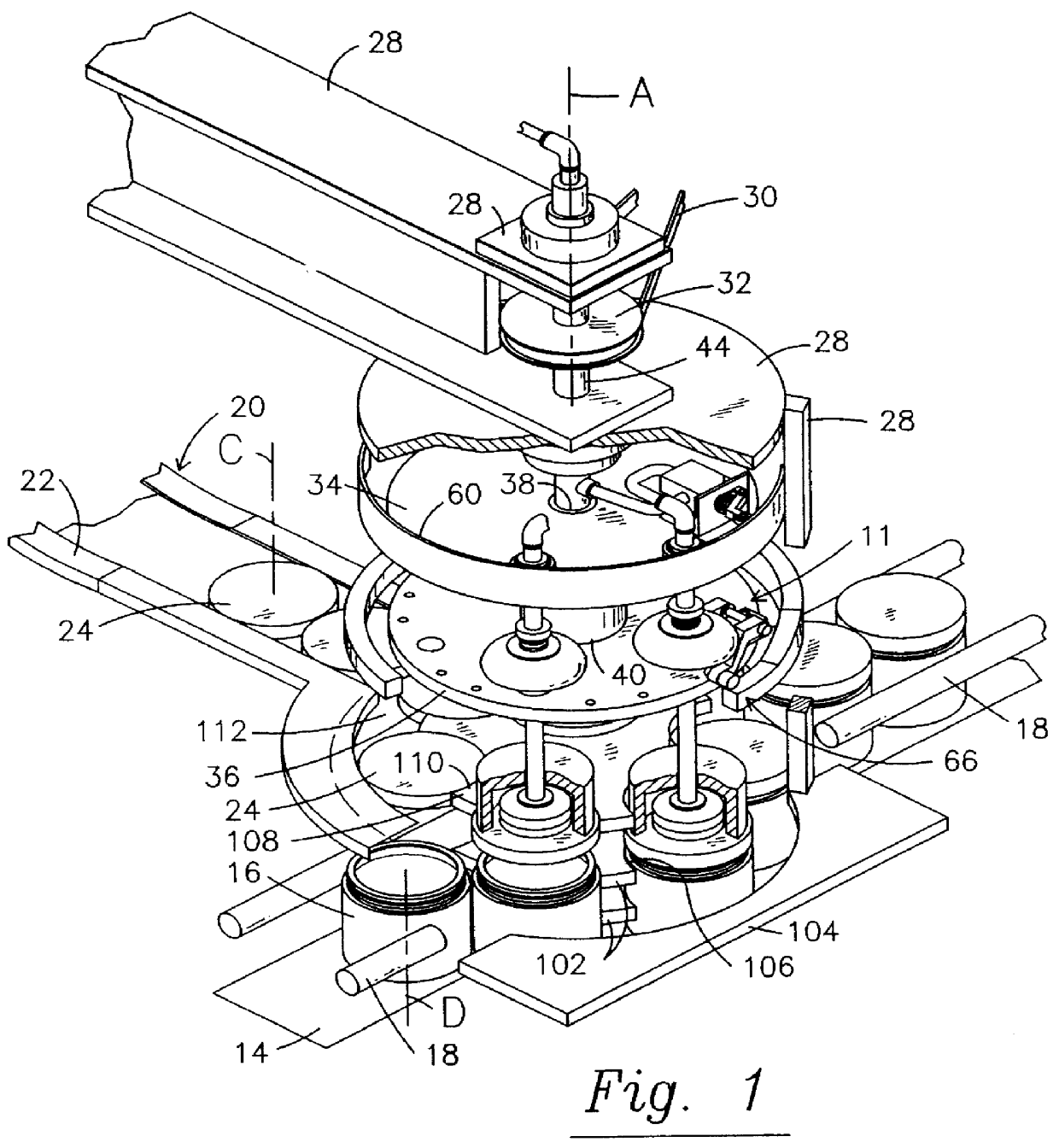

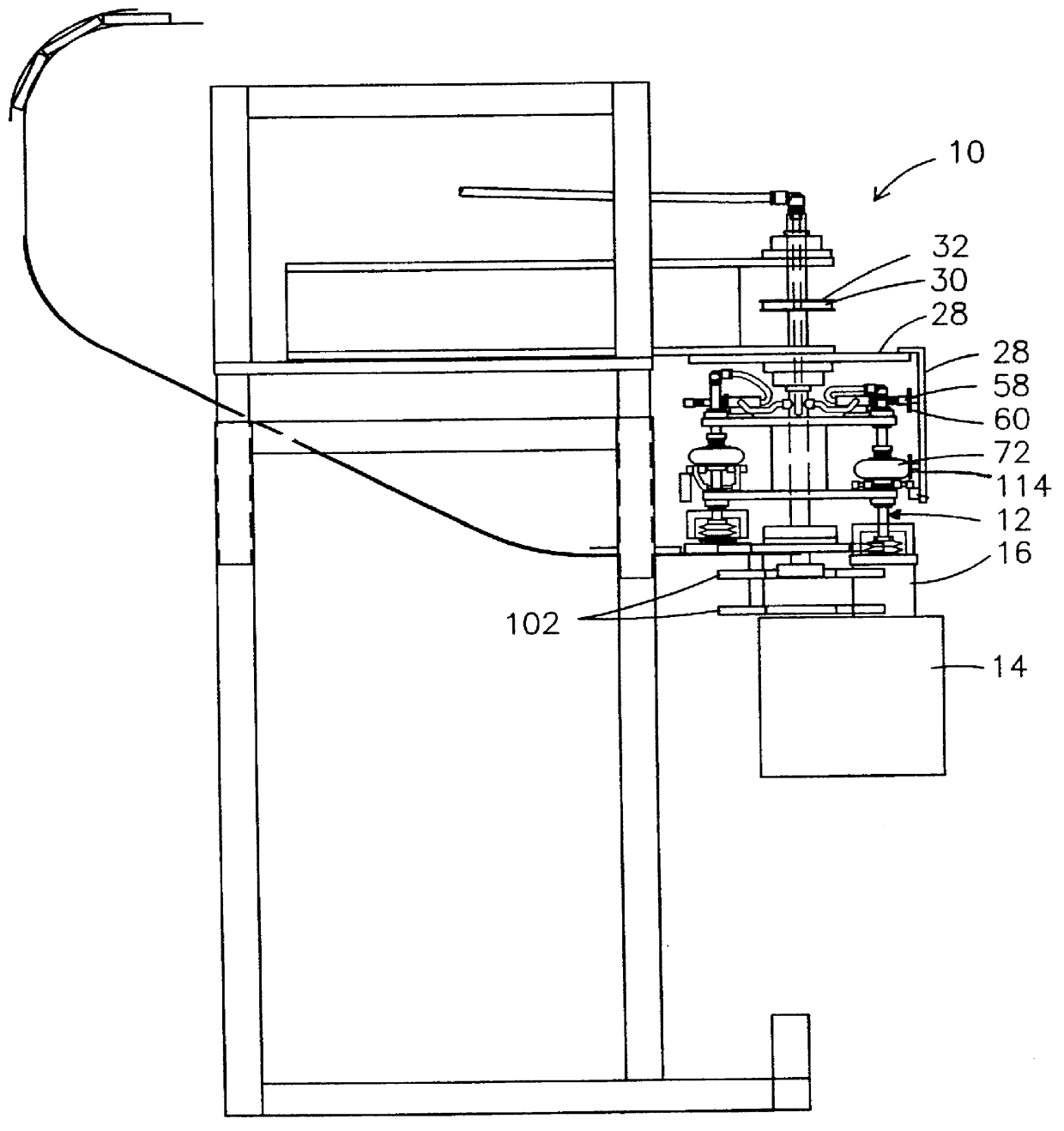

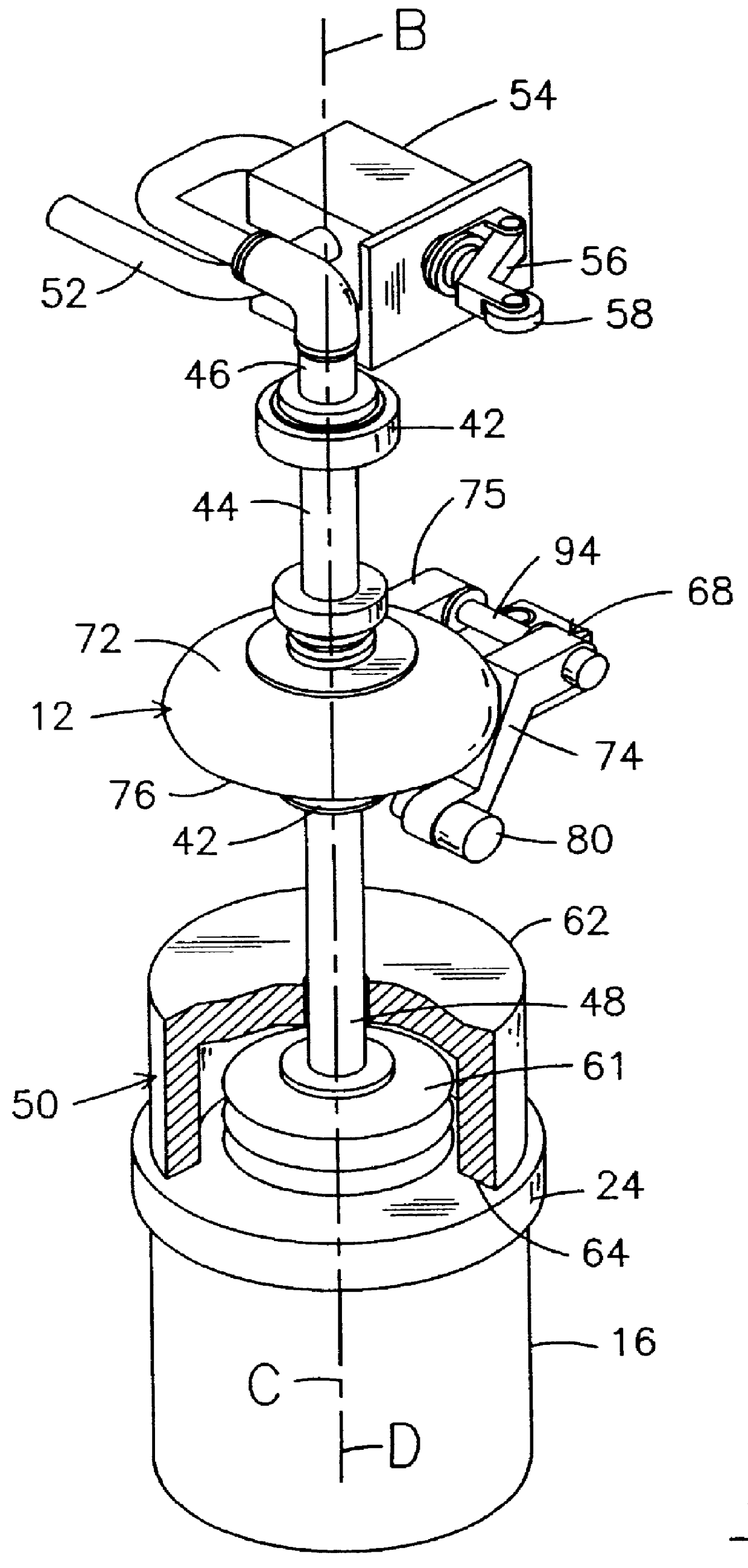

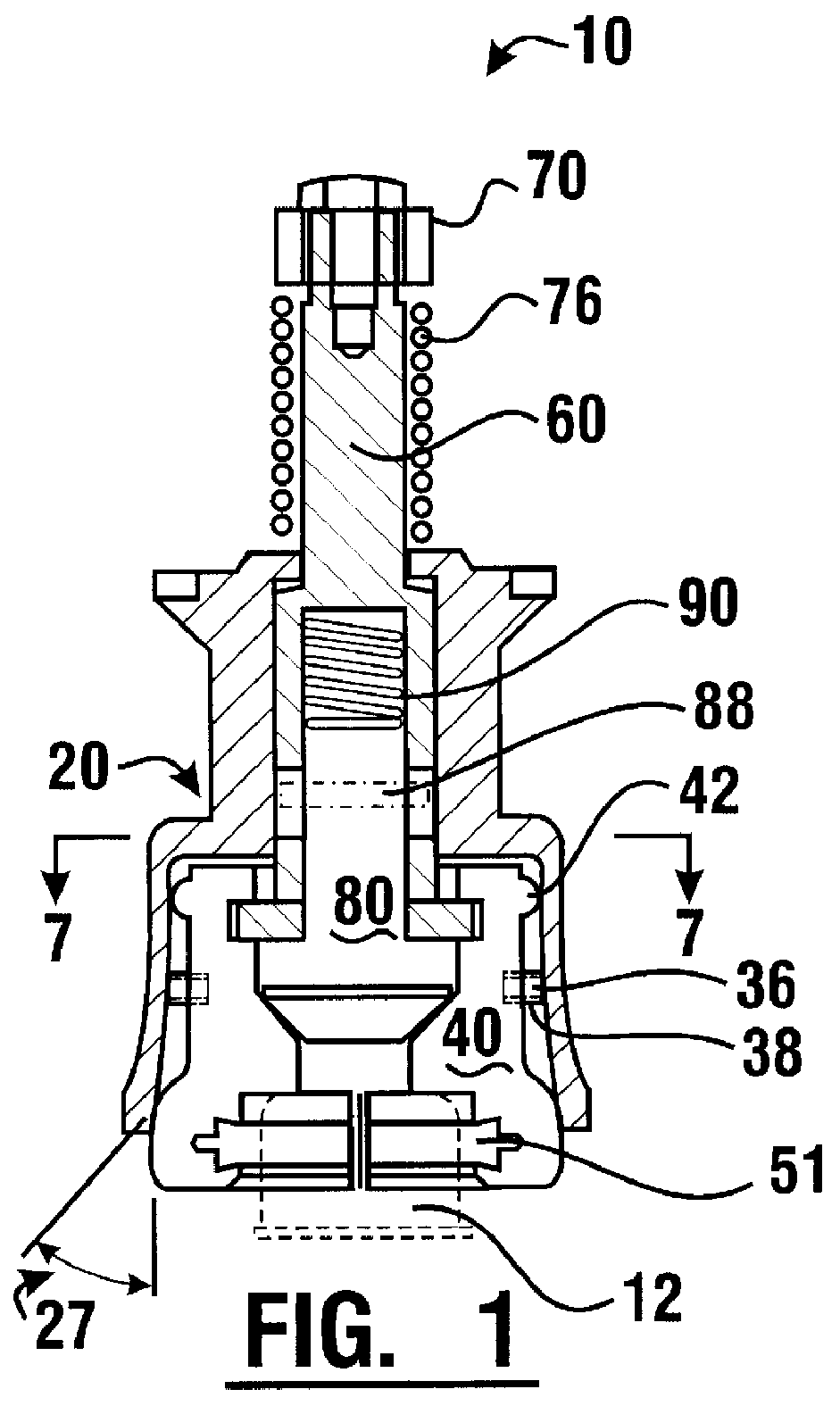

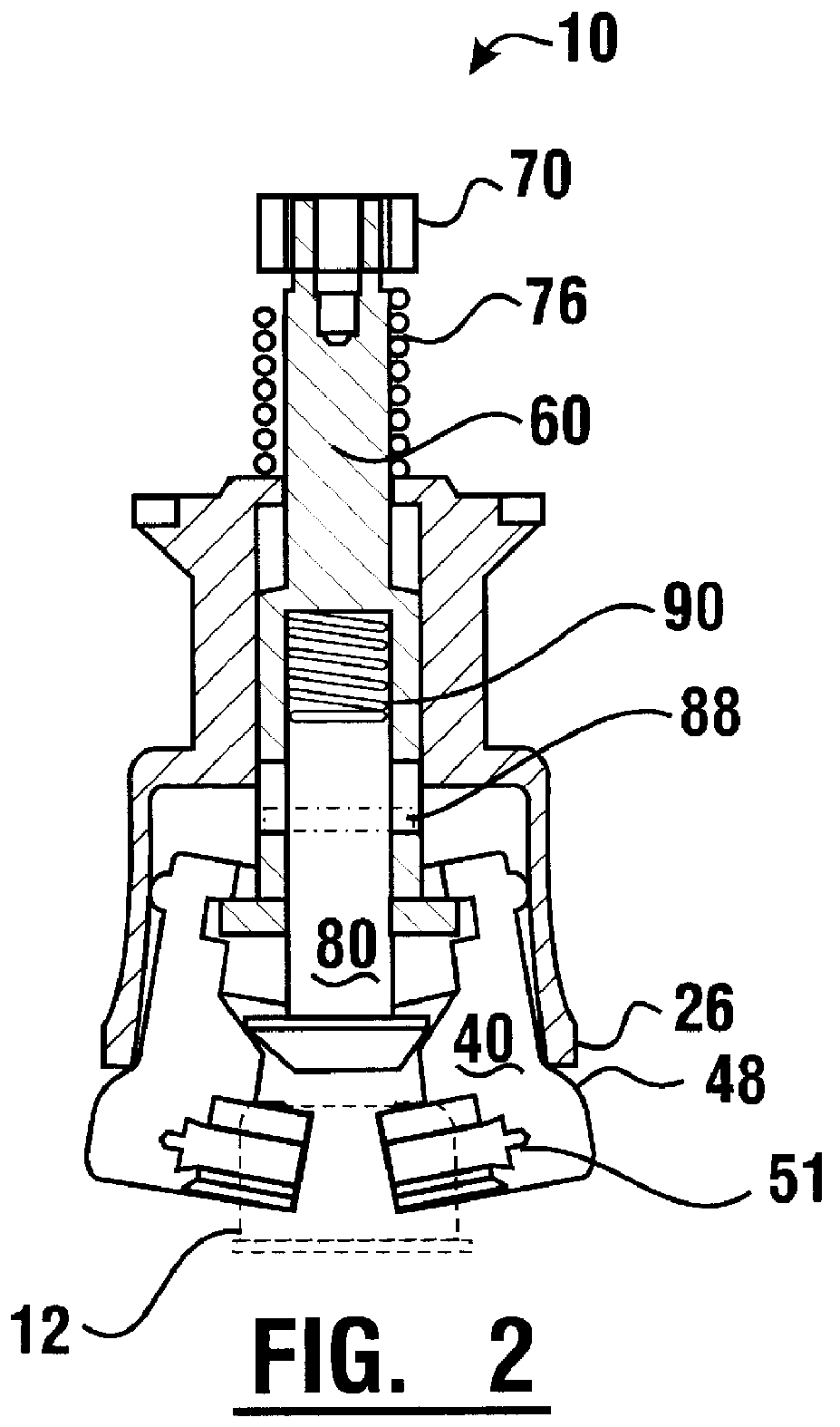

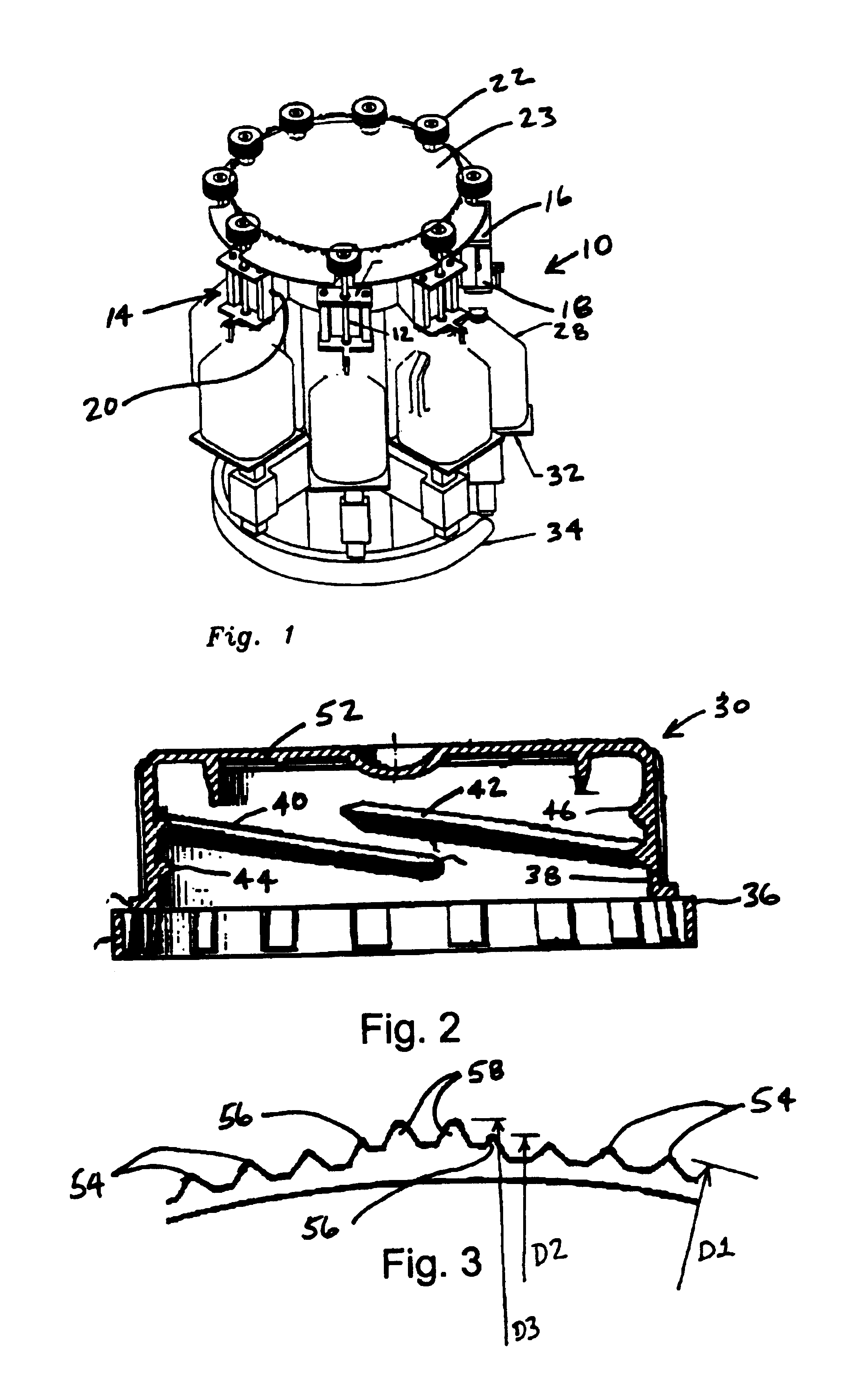

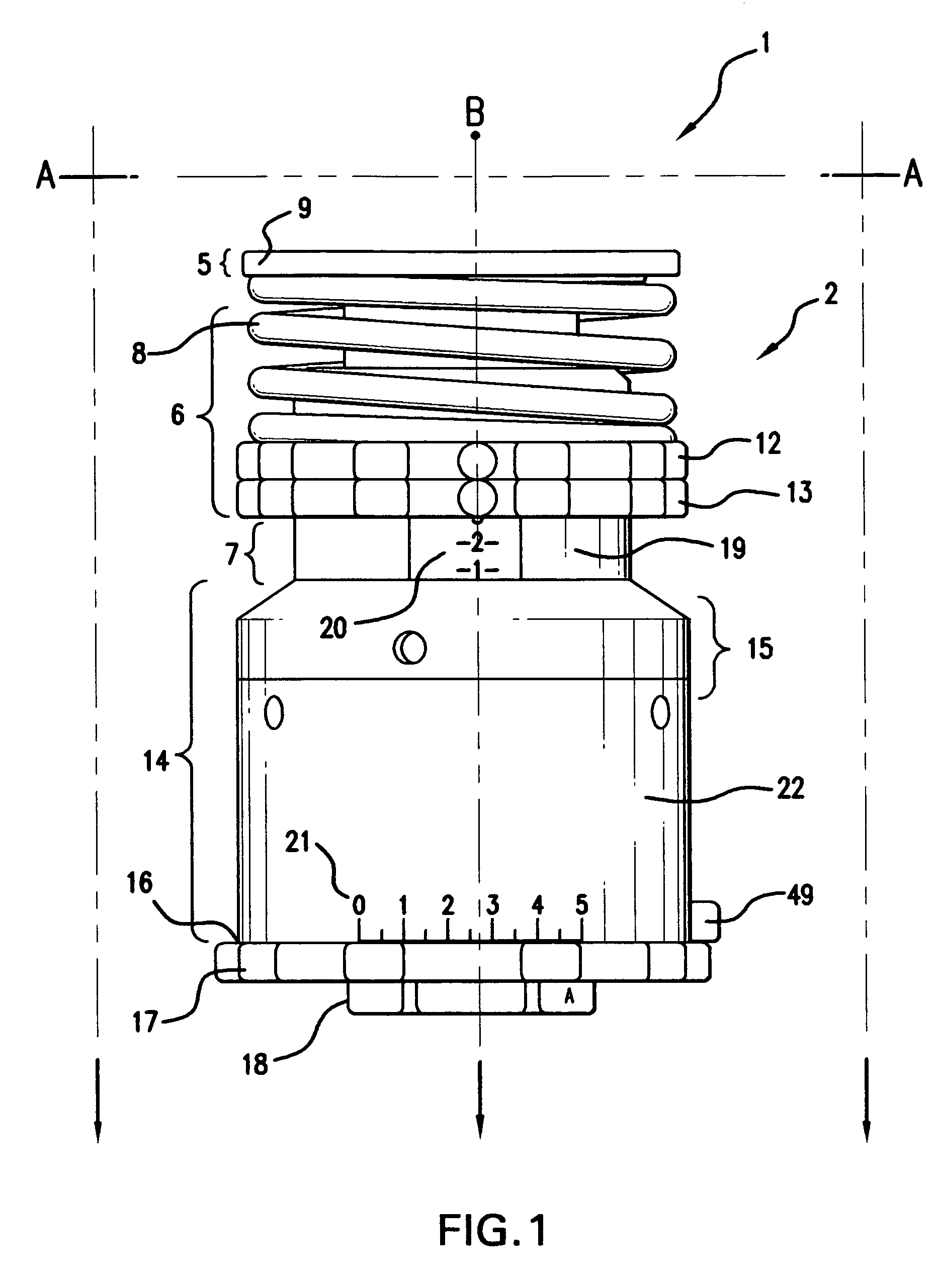

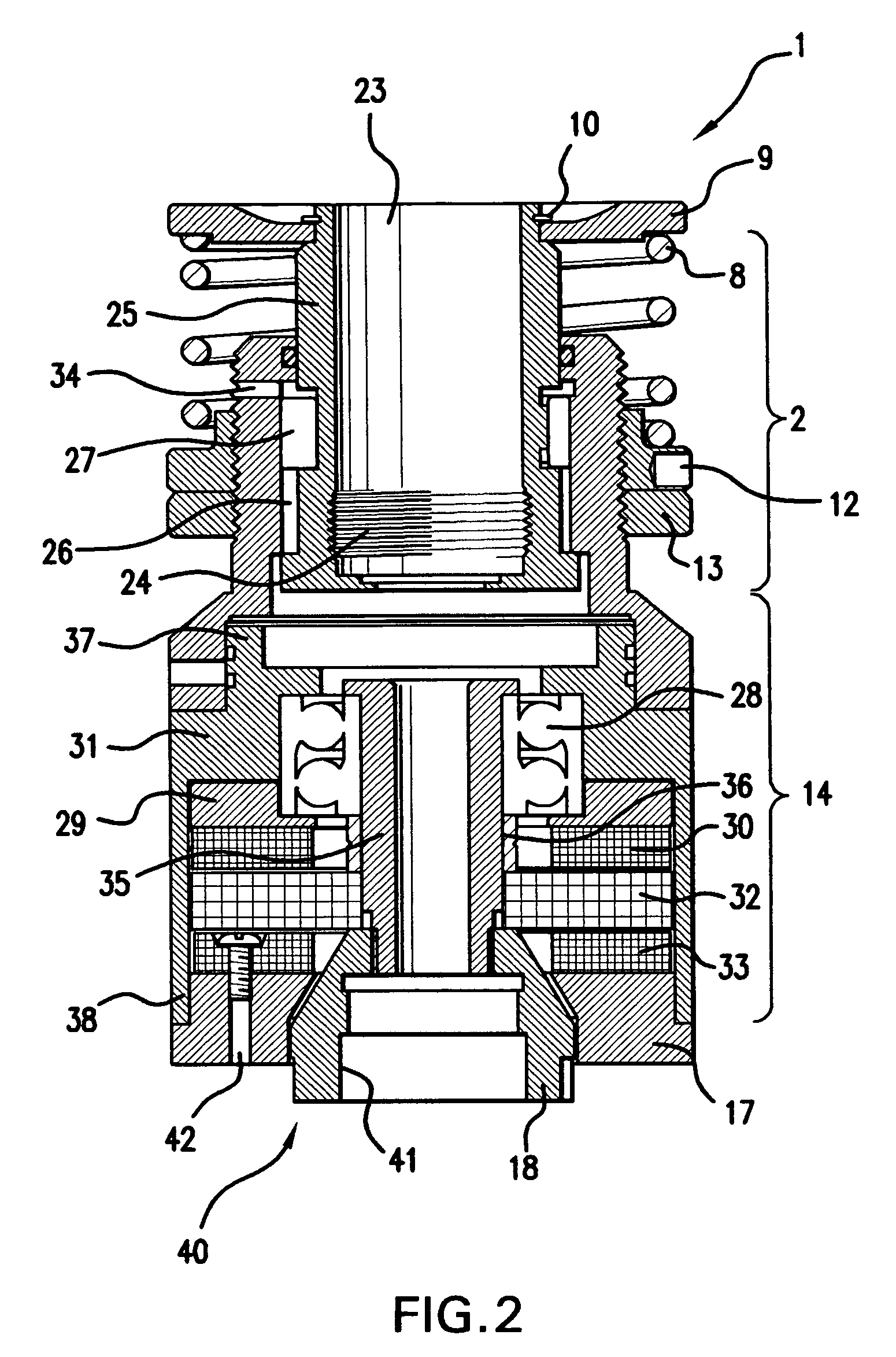

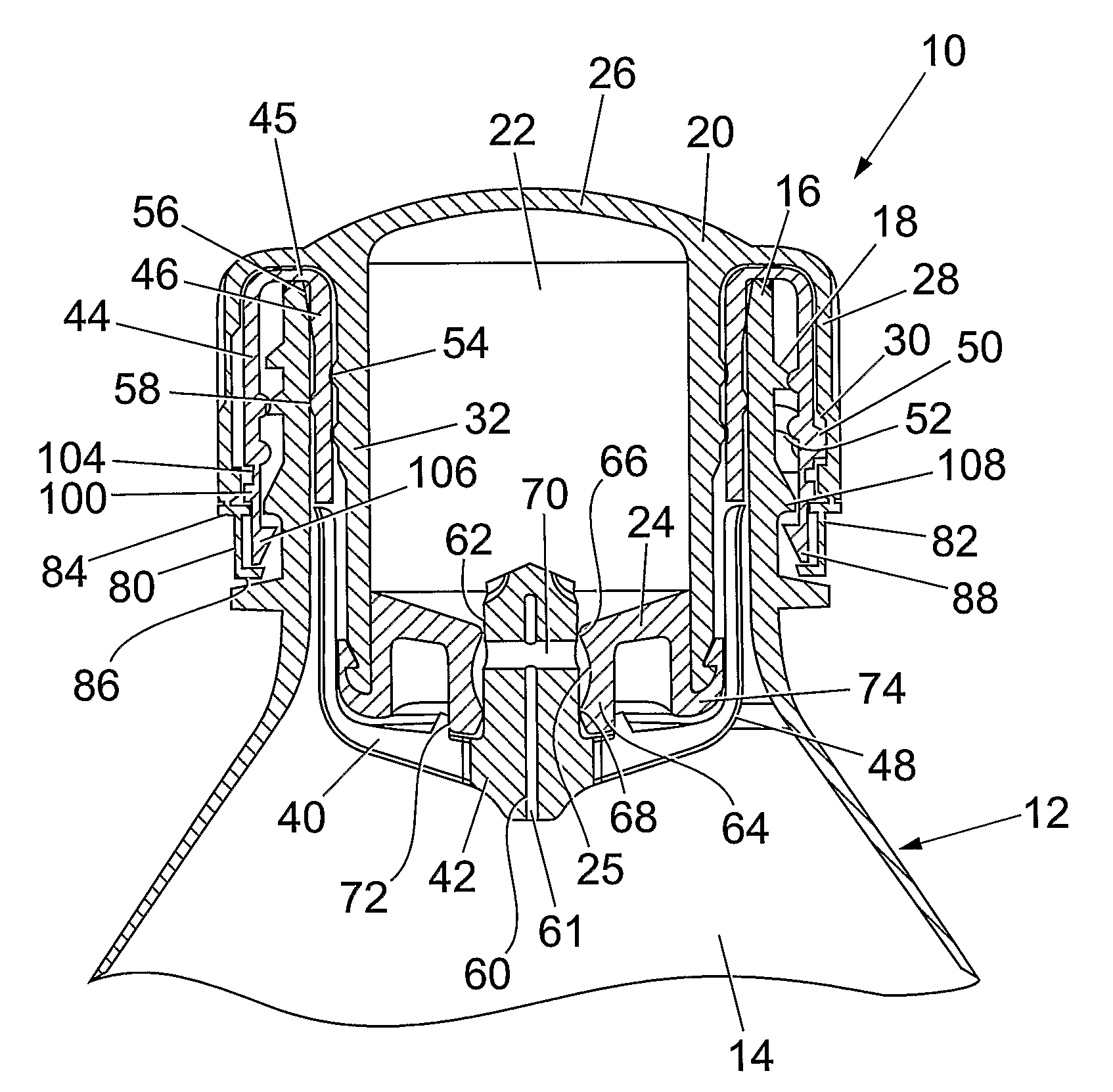

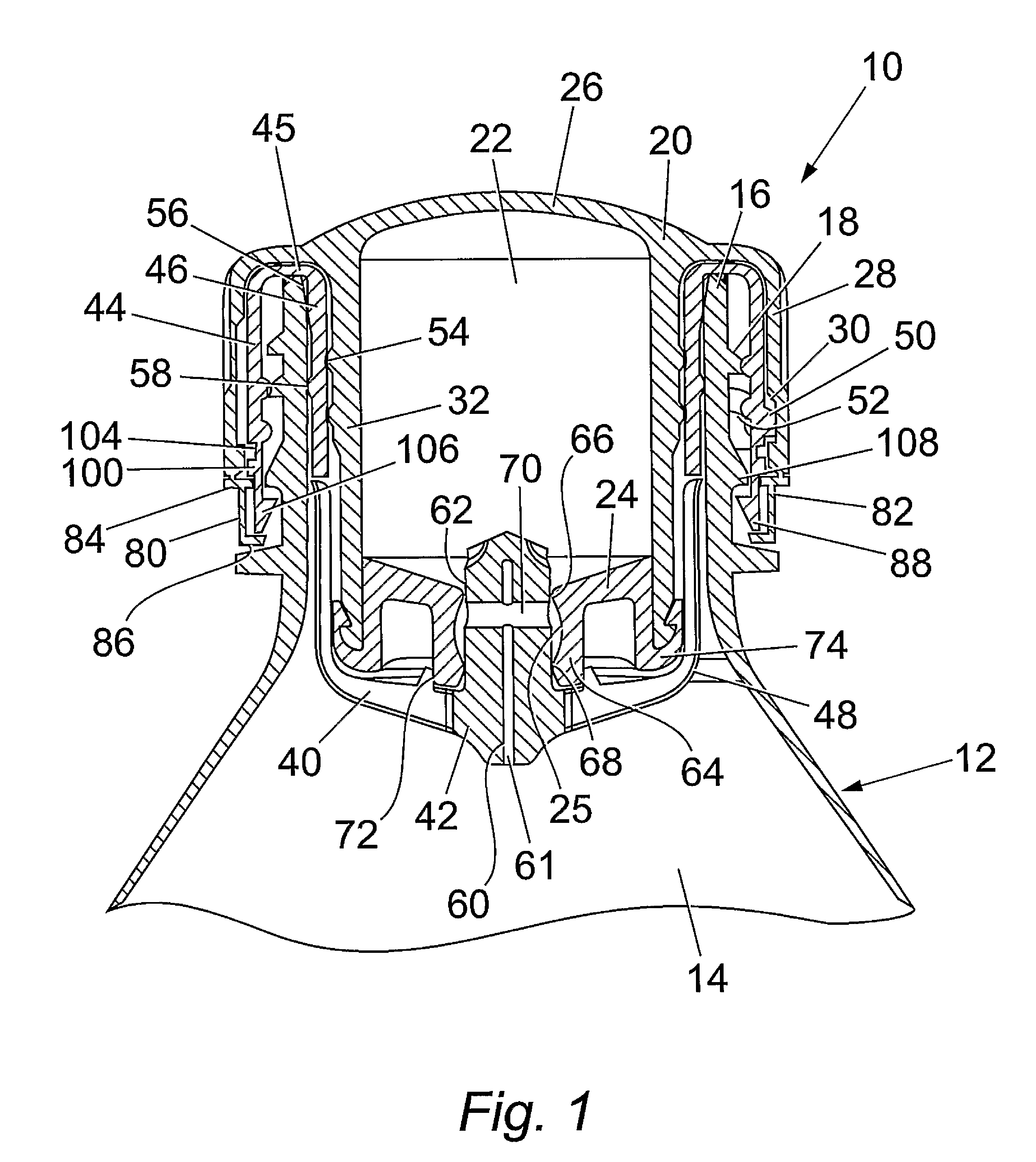

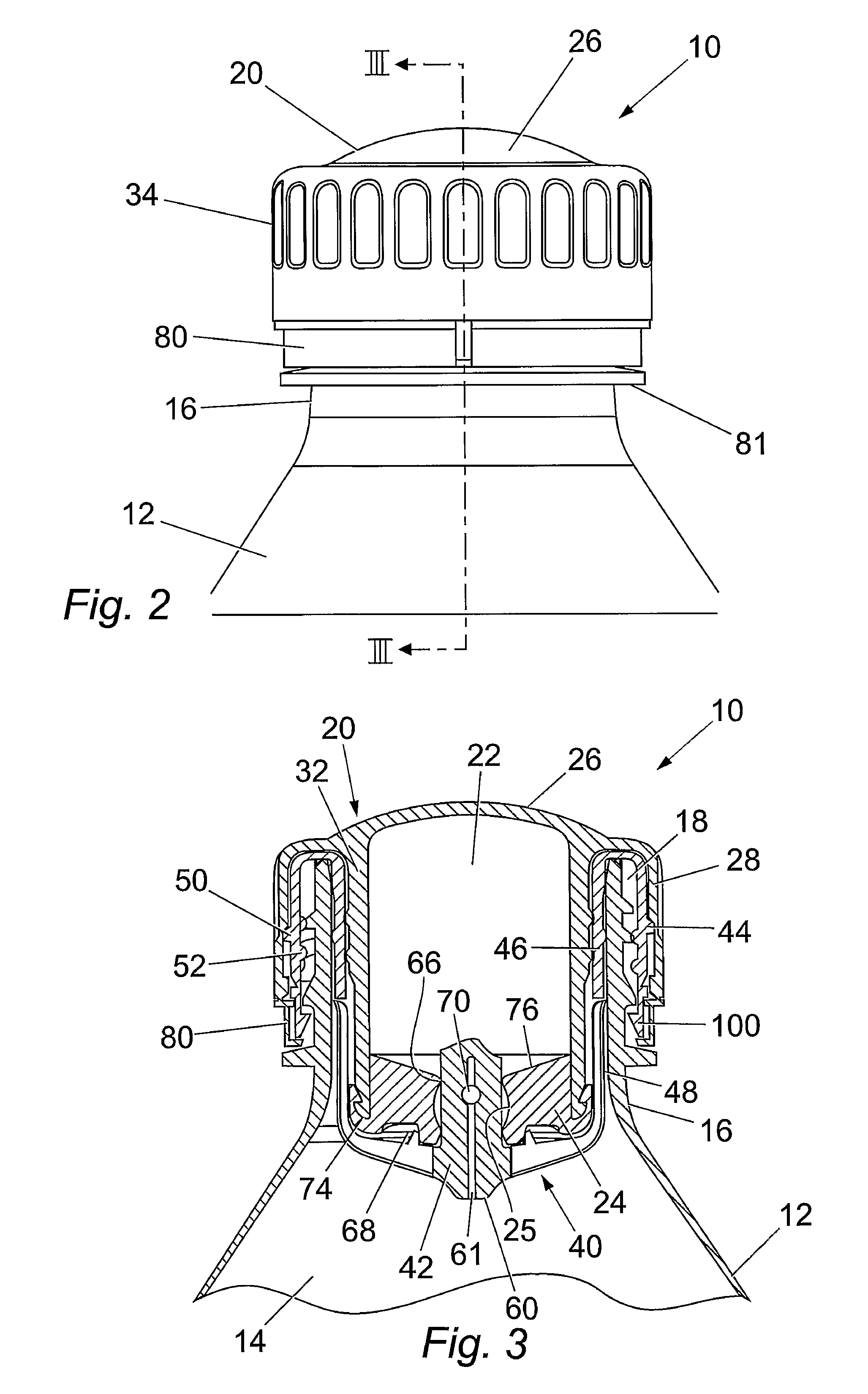

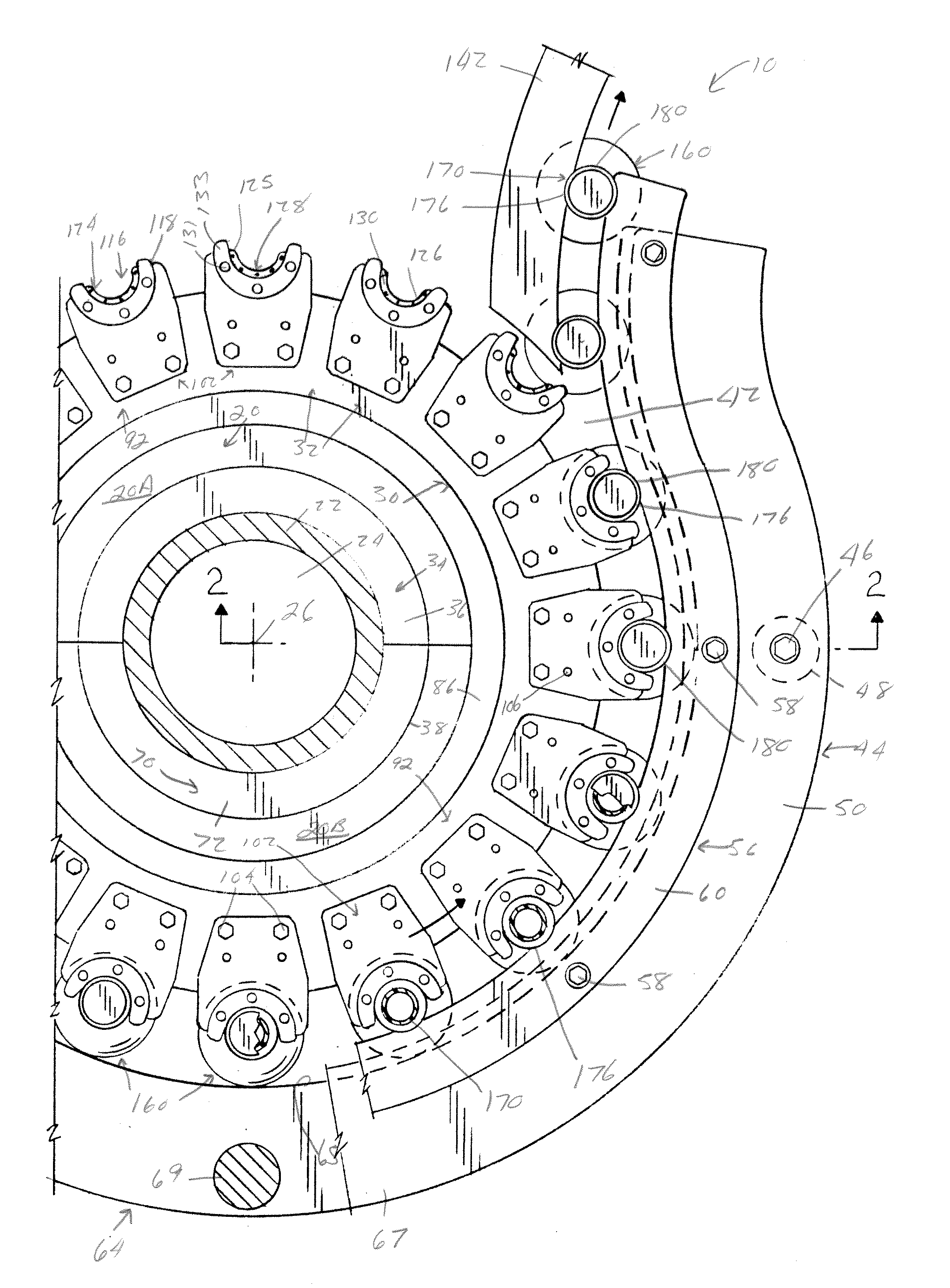

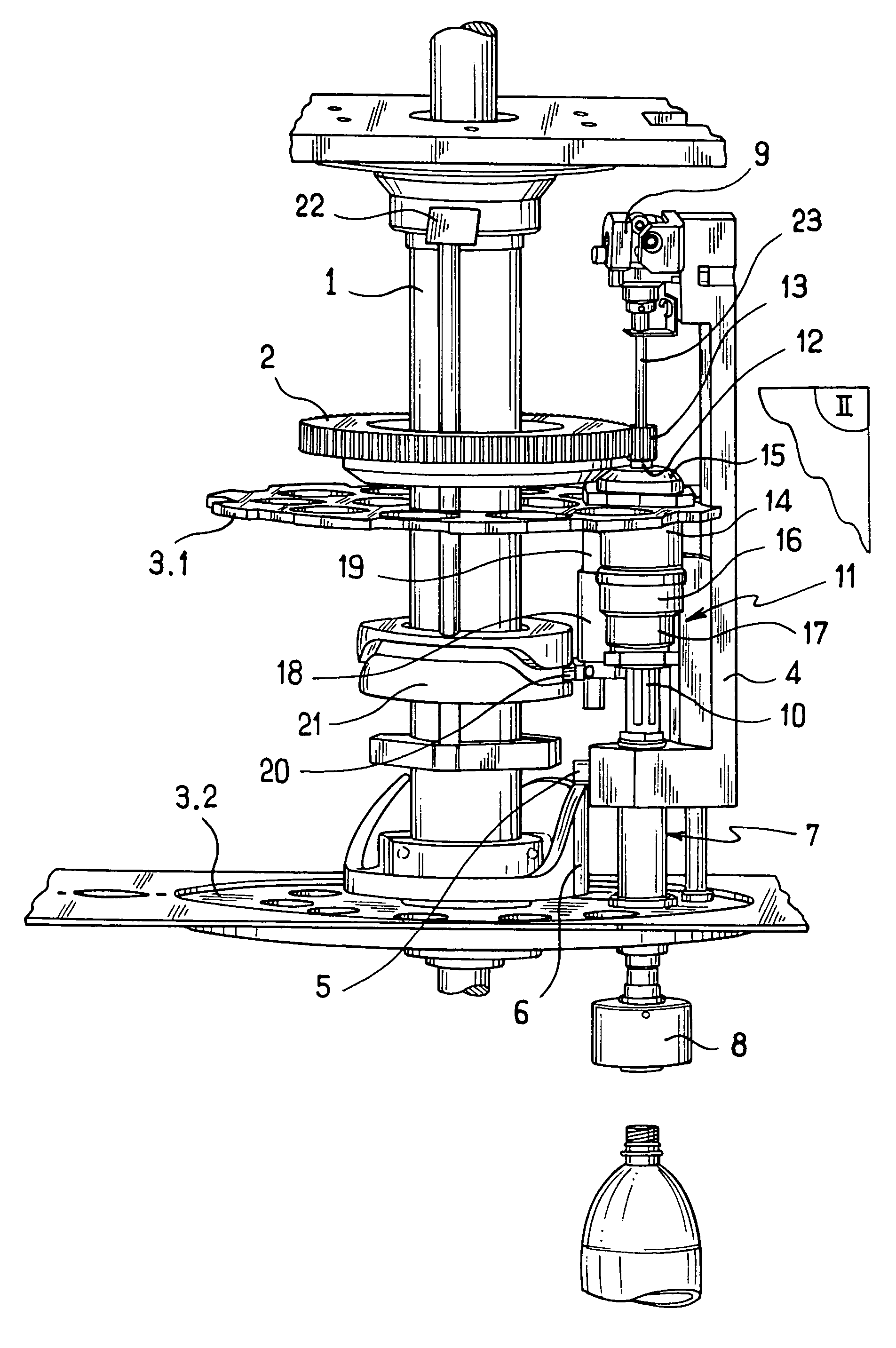

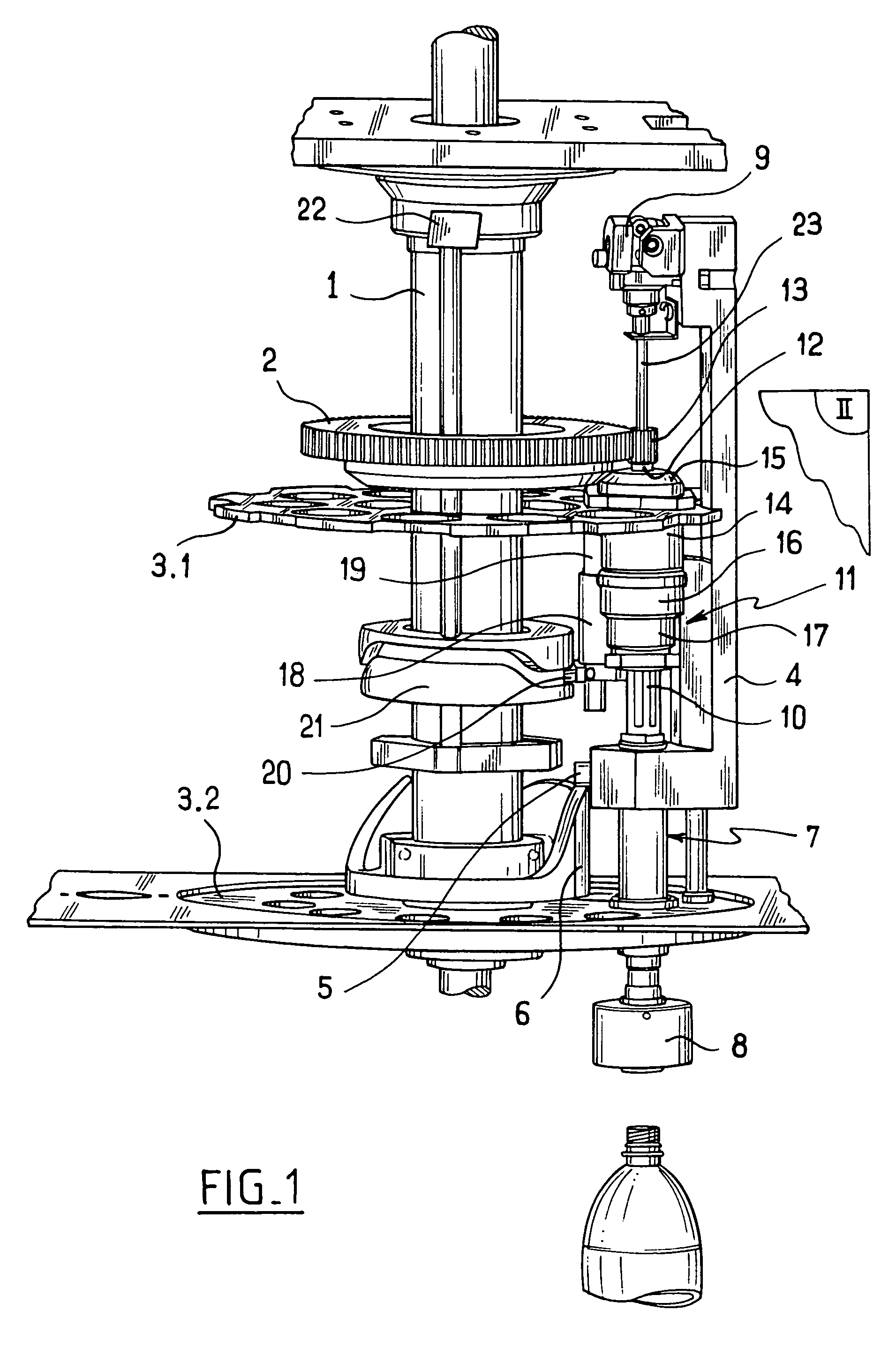

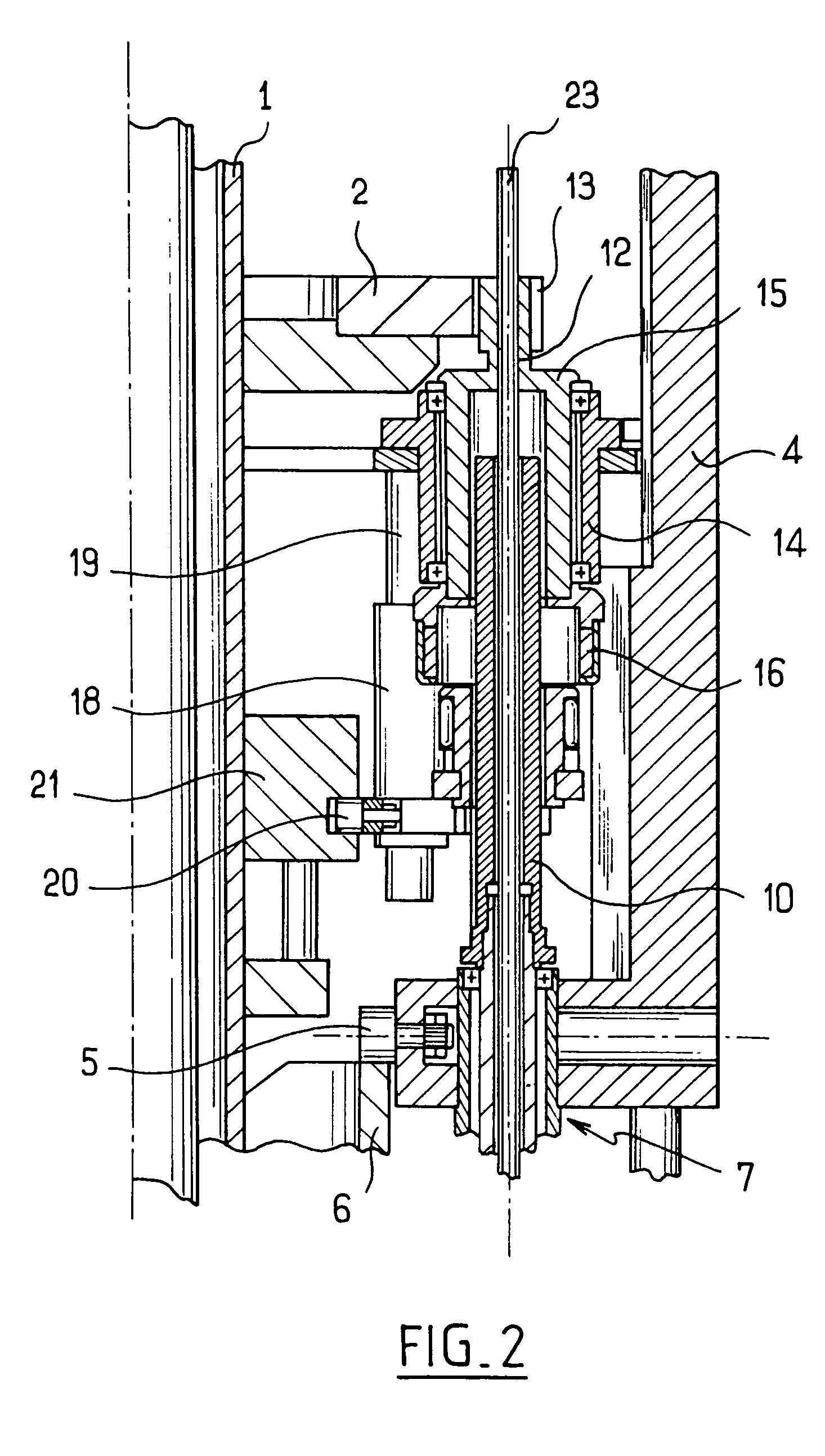

Apparatus and method for a capping machine

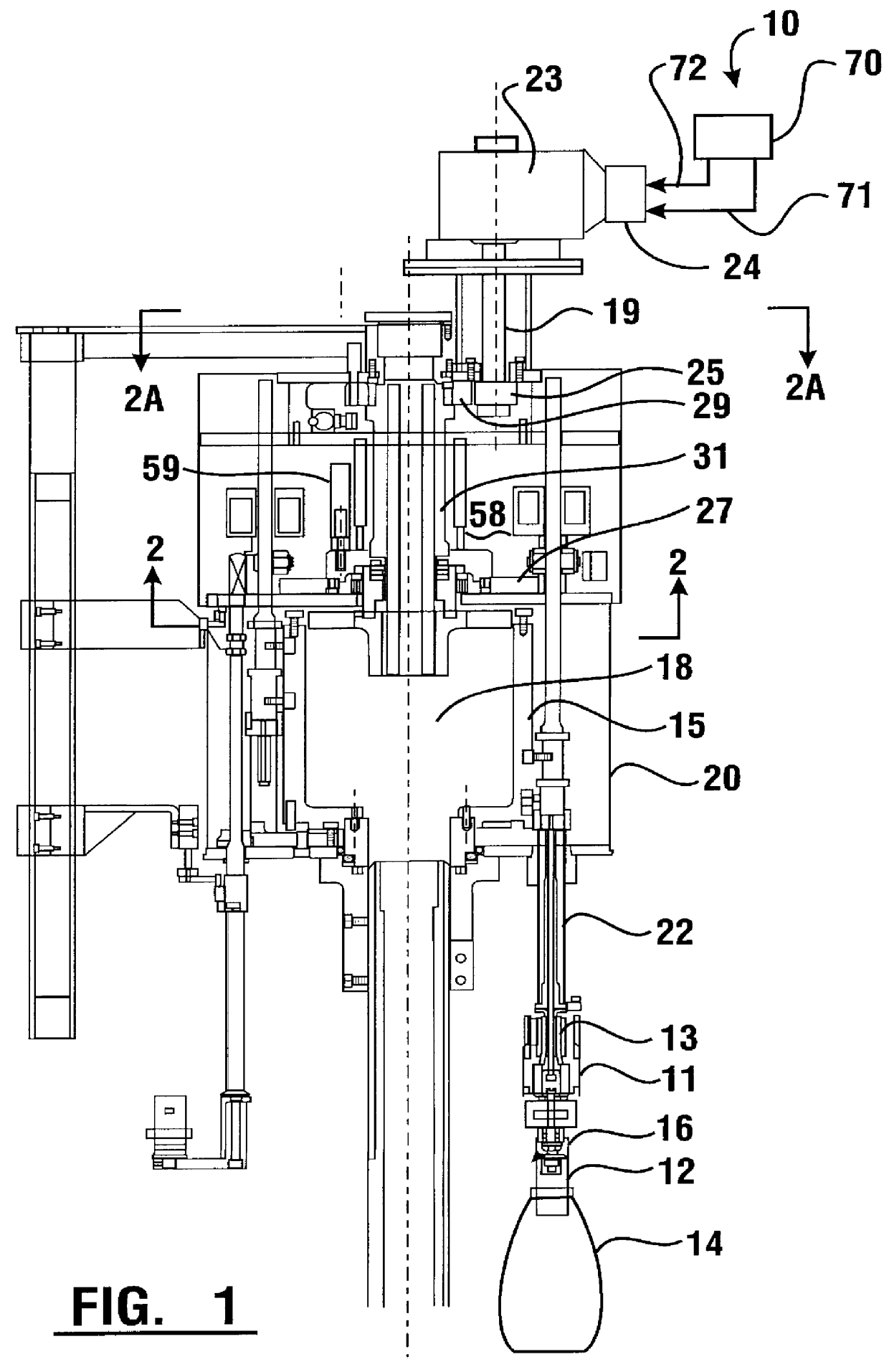

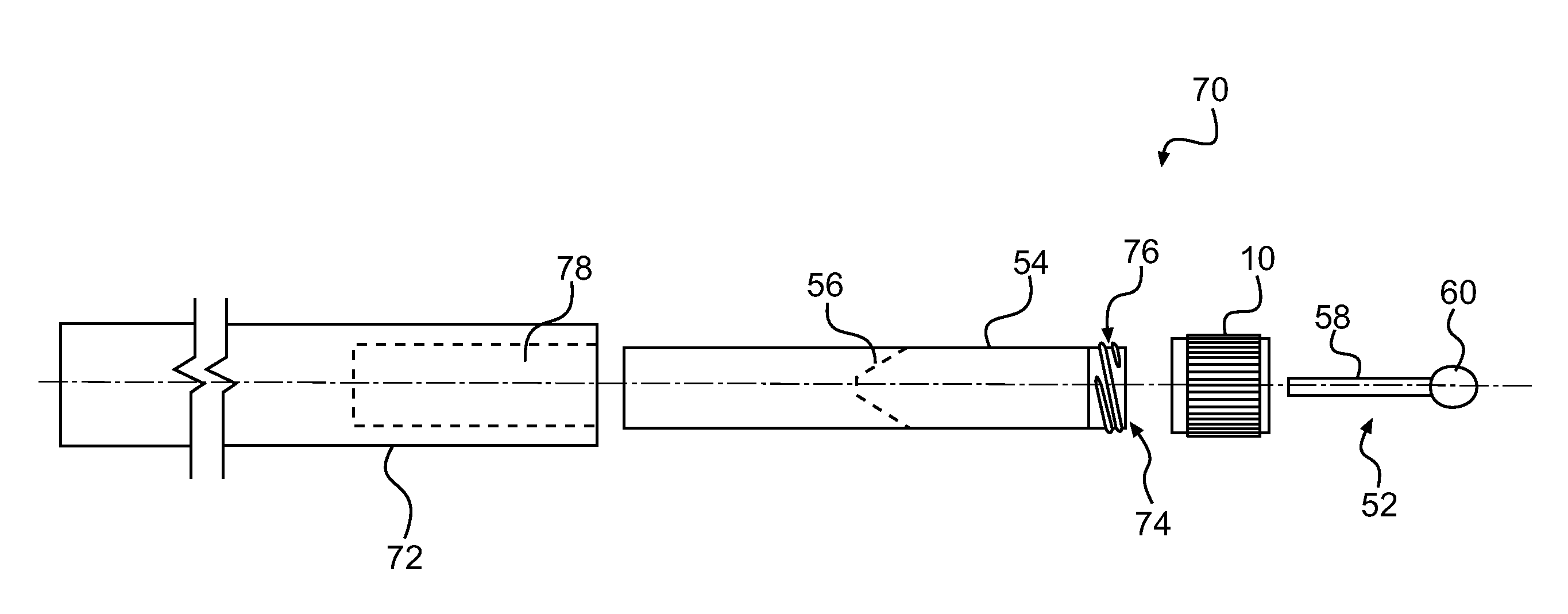

A capping machine (10) and method for installing a cap (12) having a threaded portion onto a container (14) having a threaded portion, the threaded portion of the cap corresponding to the threaded portion of the container, the capping machine having a rotatable turret (20) and a rotatable cap chuck (16) which grips the cap and positions the cap on the container. The cap chuck is rotated by a spindle (22) driven by a servo motor (24) at adjustable and reversible rotational velocities independent of the rotational velocity of the turret. The number of rotations of the cap is determined by monitoring the number of rotations of the servo motor compared to the number of rotations of the turret and is transmitted to a spindle drive control(70). The torque imparted to the cap is monitored by a torque monitor (50) and is transmitted to the spindle drive control. The rotational velocity of the cap is adjustable in response to the compared monitored number of rotations and monitored torque. The capped container is released from the cap chuck after a selected number of rotations of the cap onto the container has been made. Caps applied outside a selected range of monitored torques and number of rotations are tracked and rejected.

Owner:PNEUMATIC SCALE CORP

Closing means

InactiveUS20120186194A1Increase flexibilityImprove controllabilityCapsThreaded caps applicationLinear motionGear wheel

A closing means for containers including a transport means for the containers having a drive and at least one closing unit for applying a closure by a linear motion along a central line and a rotary motion about the central line, wherein the rotary motion is applied by rolling off two gear members. To achieve a structurally simple and flexible embodiment the first one of the gear members is connected with a separate drive independent of the drive of the transport means.

Owner:KRONES AG

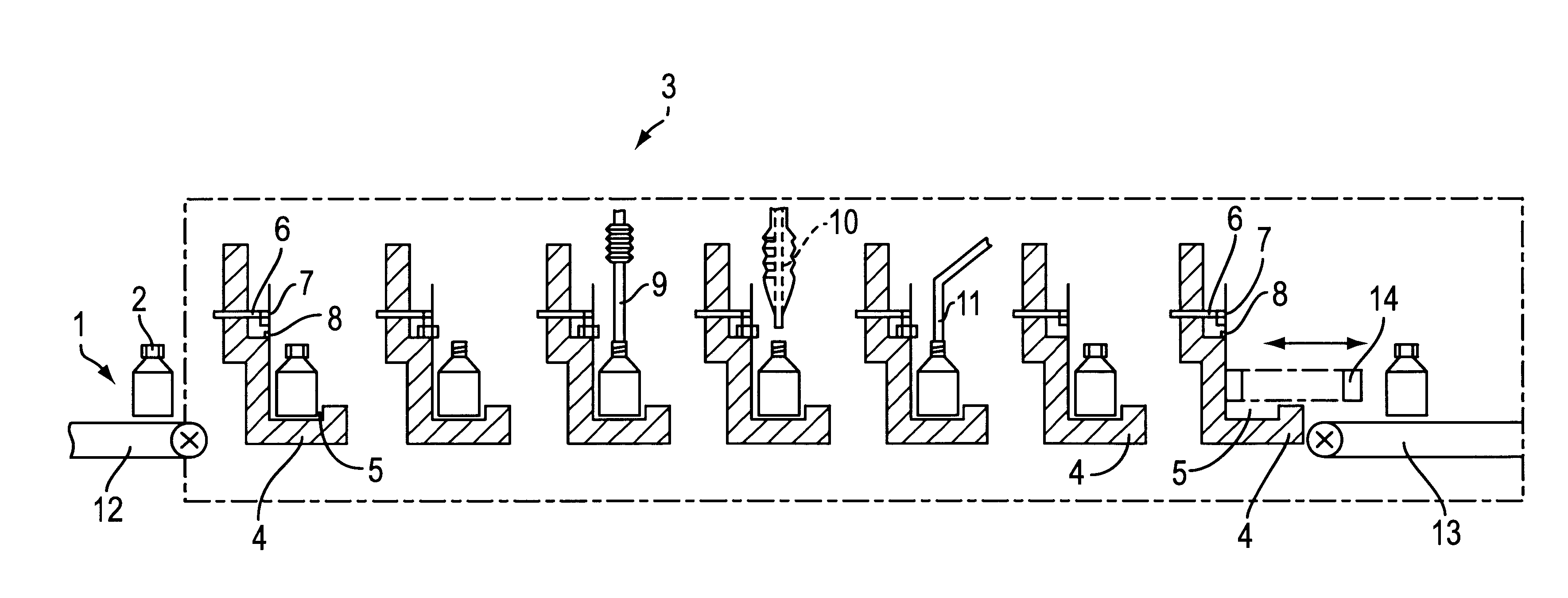

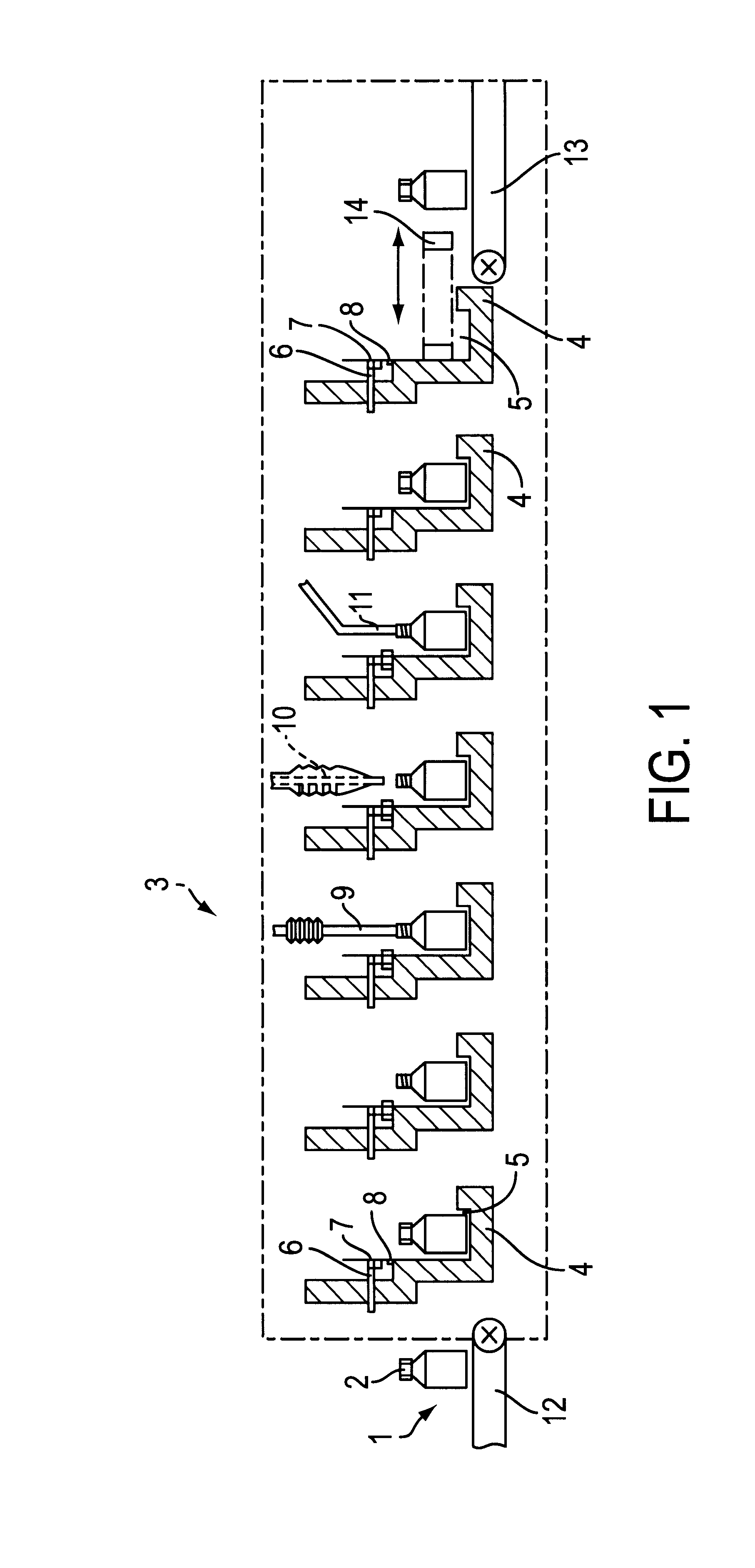

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

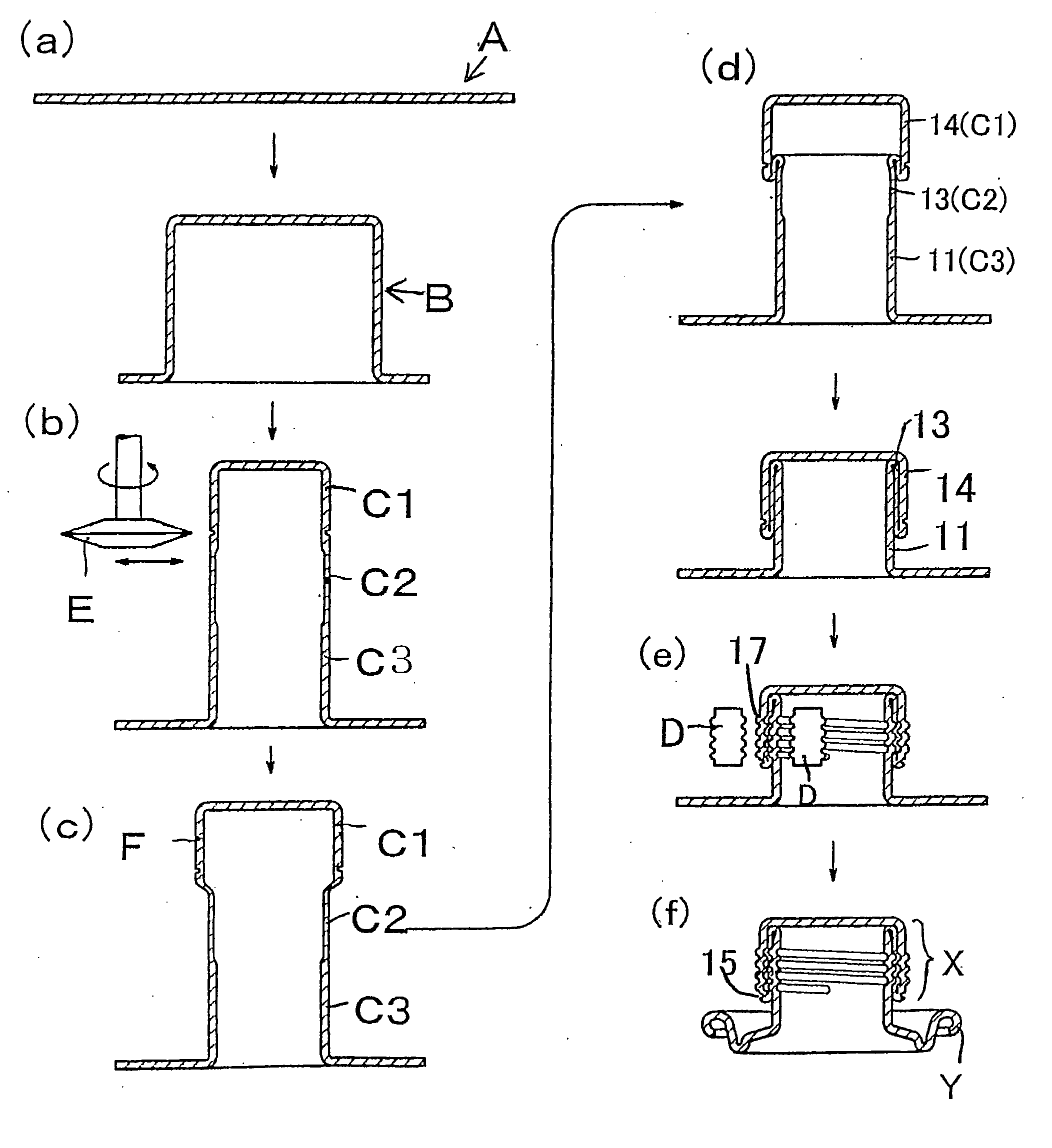

Container sealing structure, container with the sealing structure, and method of manufacturing the sealing structure

InactiveUS20050205575A1Easily breakableImprove tamper resistanceCapsThreaded caps applicationMechanical engineering

Owner:TOYO SEIKAN KAISHA LTD

Method of handling, filling and sealing packaging containers

InactiveUS6256964B1Simplify handling and transportAvoid damage and dirt contaminationOpening closed containersPower operated devicesHermetic packagingProcessing plants

A method of handling, filling and sealing prefabricated packaging containers that are provided with a closure device is disclosed. The packaging containers are transported in the closed state to a processing plant in which the closure device is opened, the packaging container and closure device are sterilized, and thereafter the packaging container is filled with the desired liquid contents. The same closure device that was removed from the packaging container is then reapplied to seal the container.

Owner:TETRA LAVAL HLDG & FINANCE SA

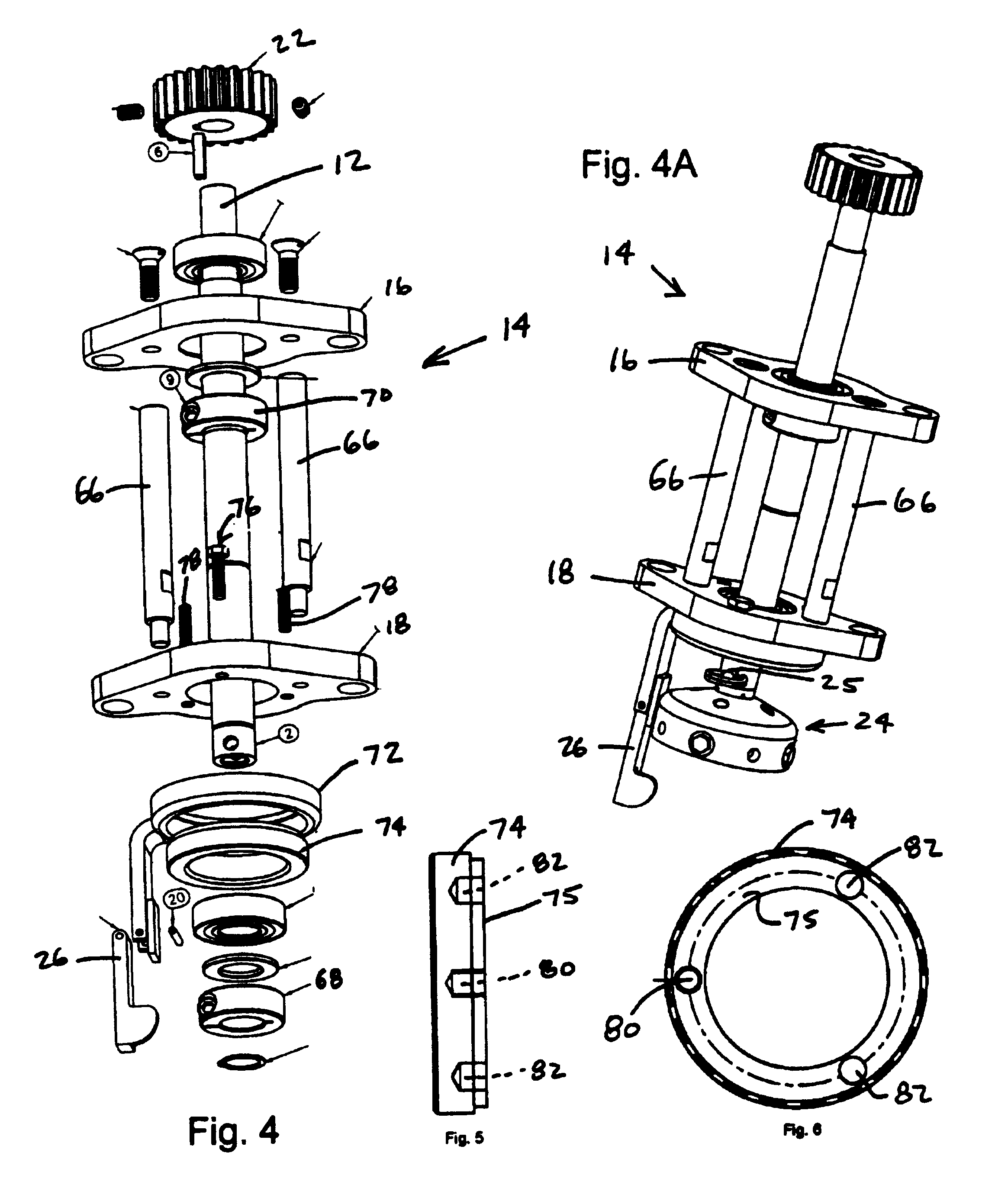

Apparatus and method for pre-capping containers

An improved pre-capping machine and method for pre-capping containers that are advanced along a predetermined path by standard conveyor systems. The present invention pretightens caps, plugs, overcaps and other fitments to ensure that they are squarely placed on the containers, without damage to the containers, in preparation for their final closure. The apparatus comprises a spindle assembly, having a longitudinal spindle axis, that is connected to a frame for movement of the spindle assembly along the spindle axis. The spindle assembly comprises a cap gripper that is configured to hold a cap centered over the open end of a container so that axes through the cap, the open end of the container and the spindle assembly generally coincide. To place a cap on the container, the spindle is released for free movement along the spindle axis.

Owner:NEW ENGLAND MACHINERY

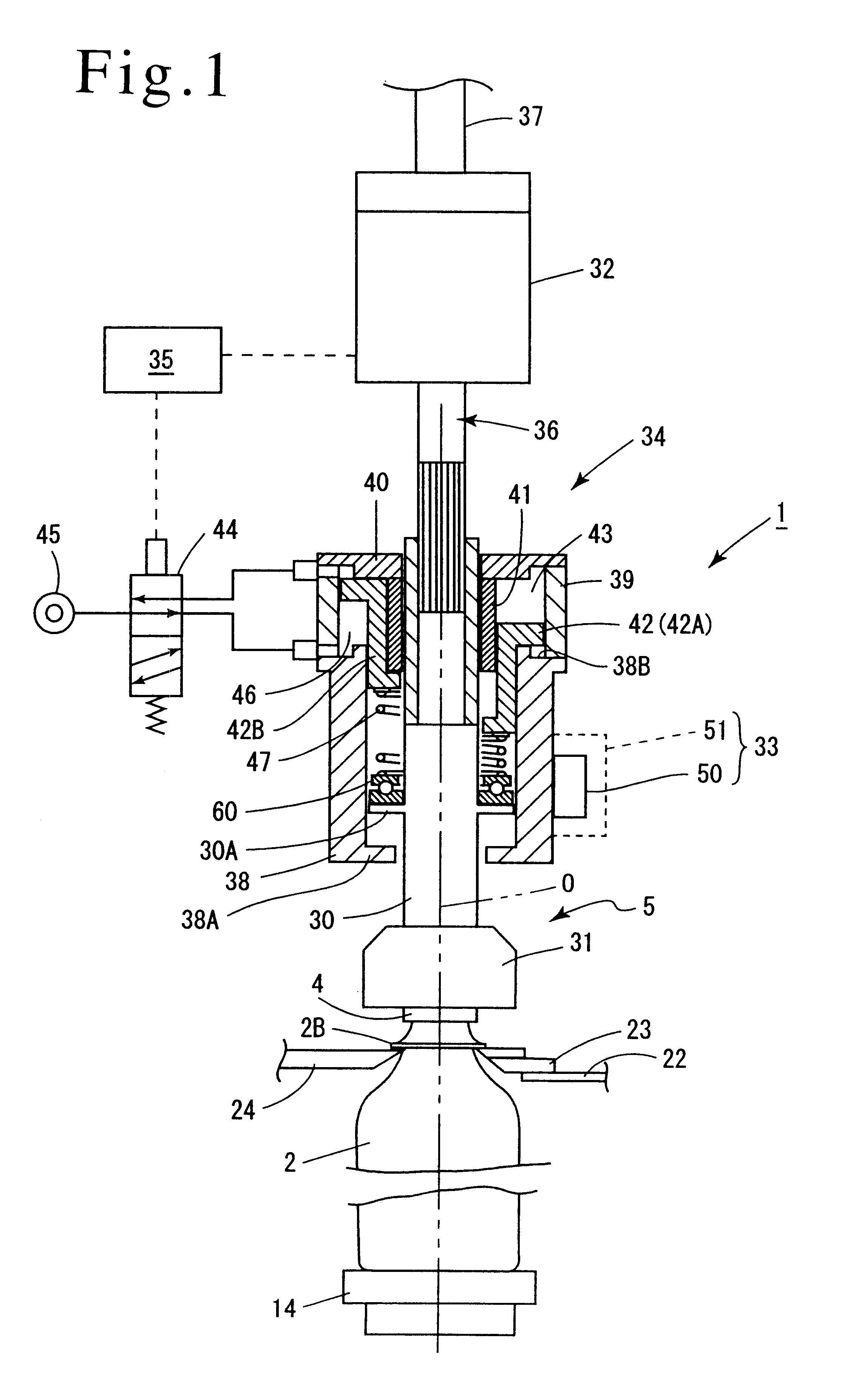

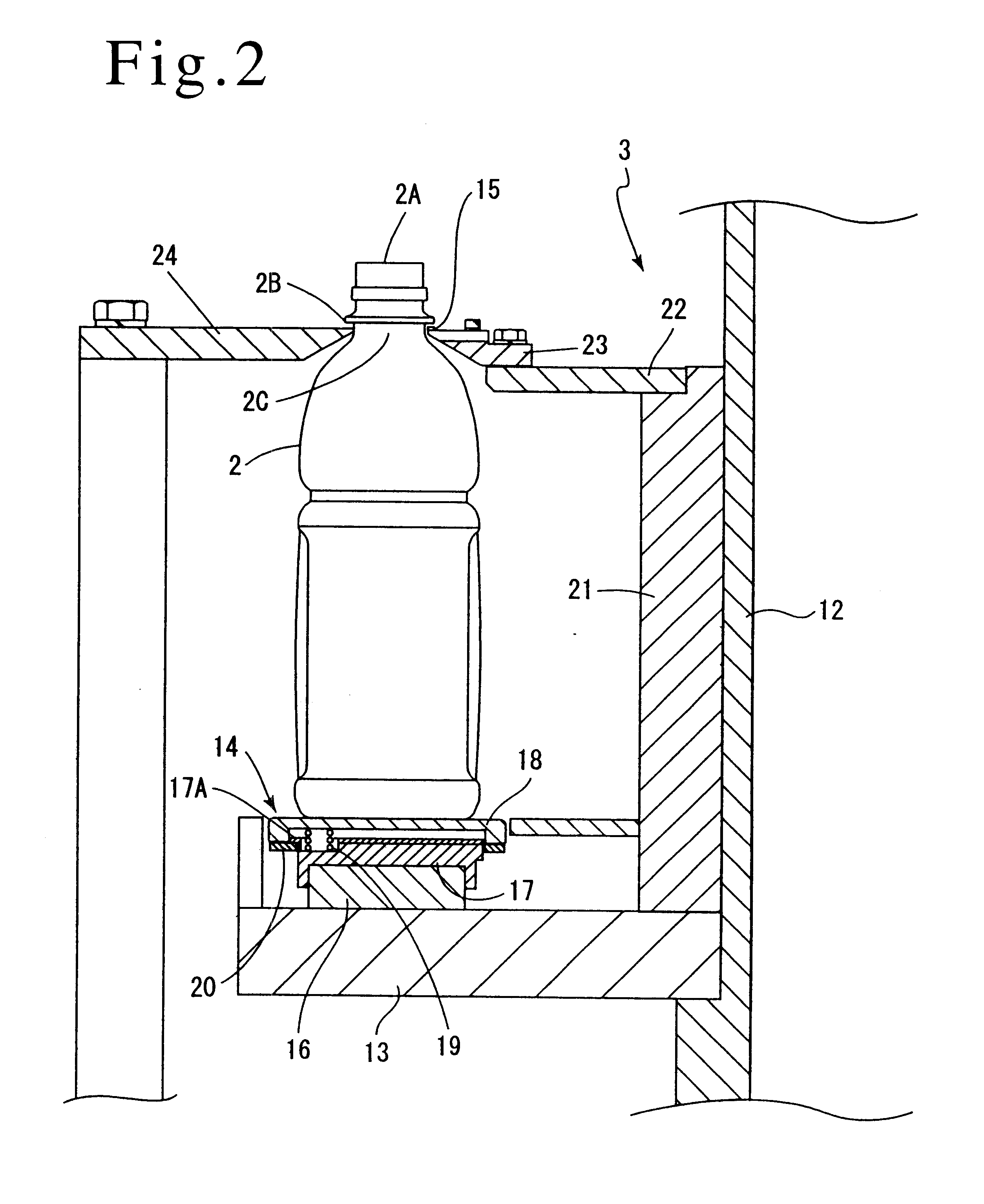

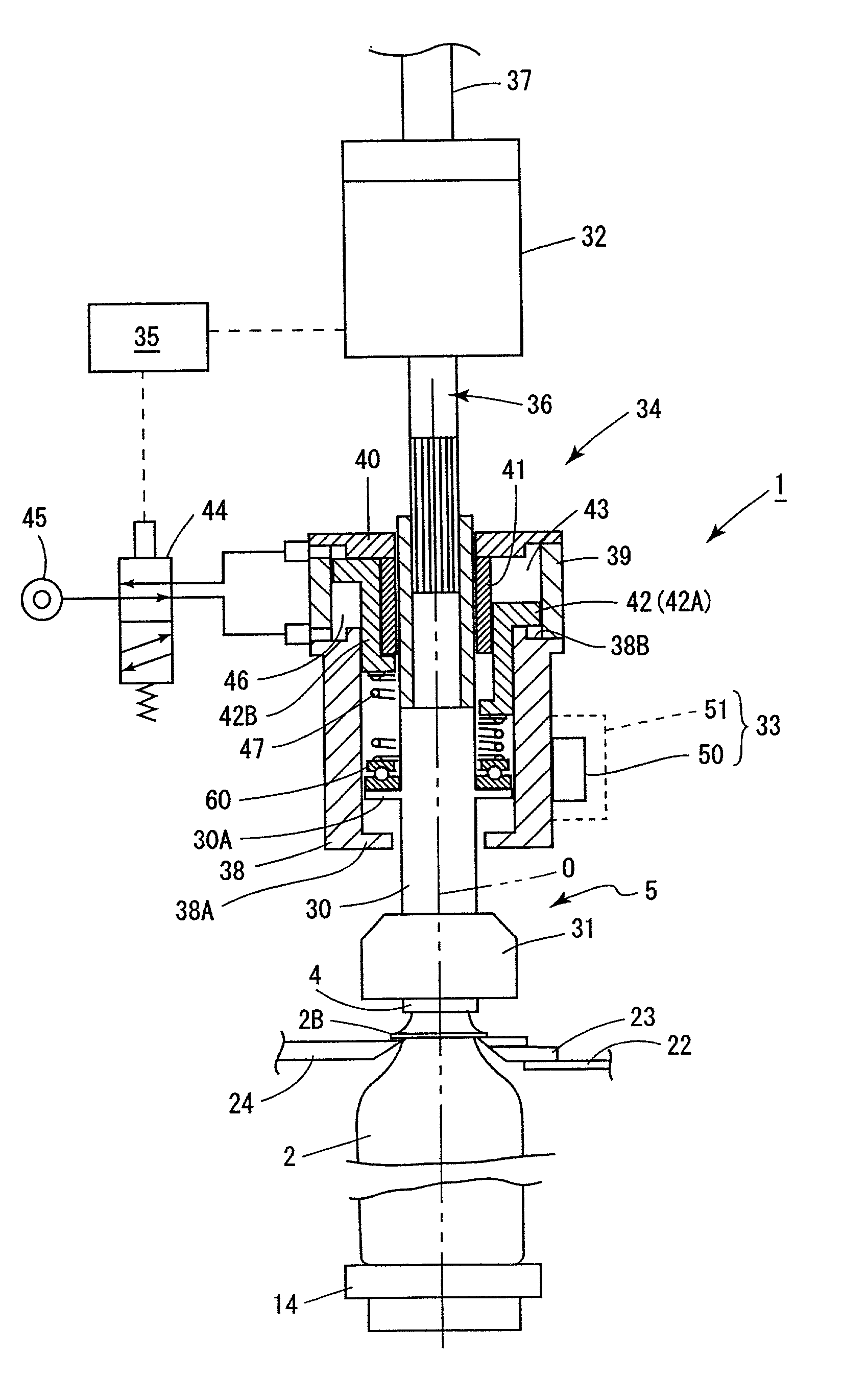

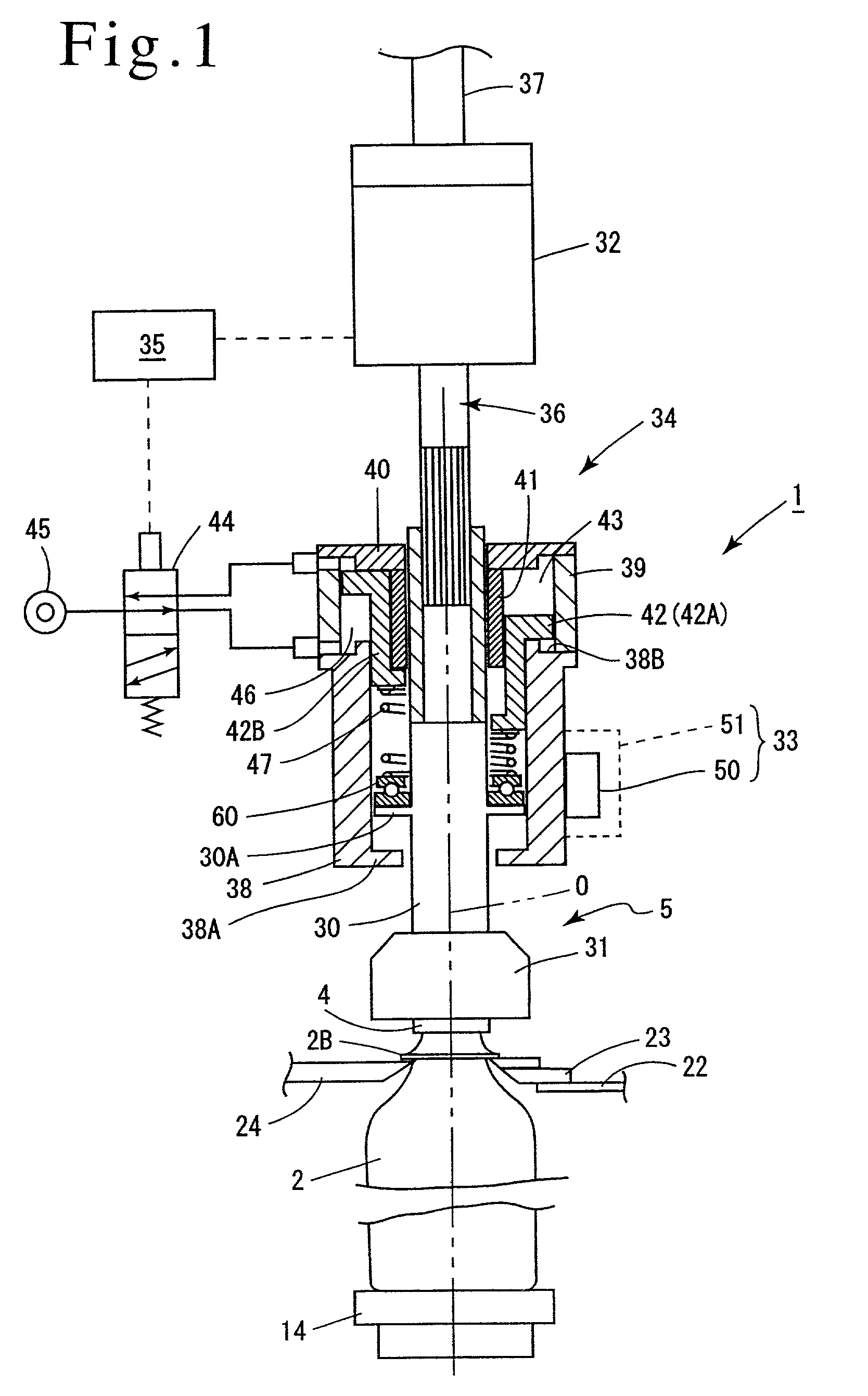

Screw capper

A screw capper includes a capping head which comprises a chuck for holding a cap, a motor for driving the chuck for rotation, a cam mechanism for elevating the chuck, and an air cylinder for imparting a load to the chuck. A load imparted by the air cylinder is controlled by a controller to be zero from the beginning of a screwing and tightening operation until an angle of rotation of the chuck exceeds a specific angle where the load is changed, and is controlled to a higher value upon detection of an angle of rotation of the chuck which exceeds the specific angle in the course of the screwing and tightening operation. The arrangement allows a reliable screwing and tightening to be achieved as compared with the prior art while preventing a damage to threads or the occurrence of a cocked cap.

Owner:SHIBUYA IND CO LTD

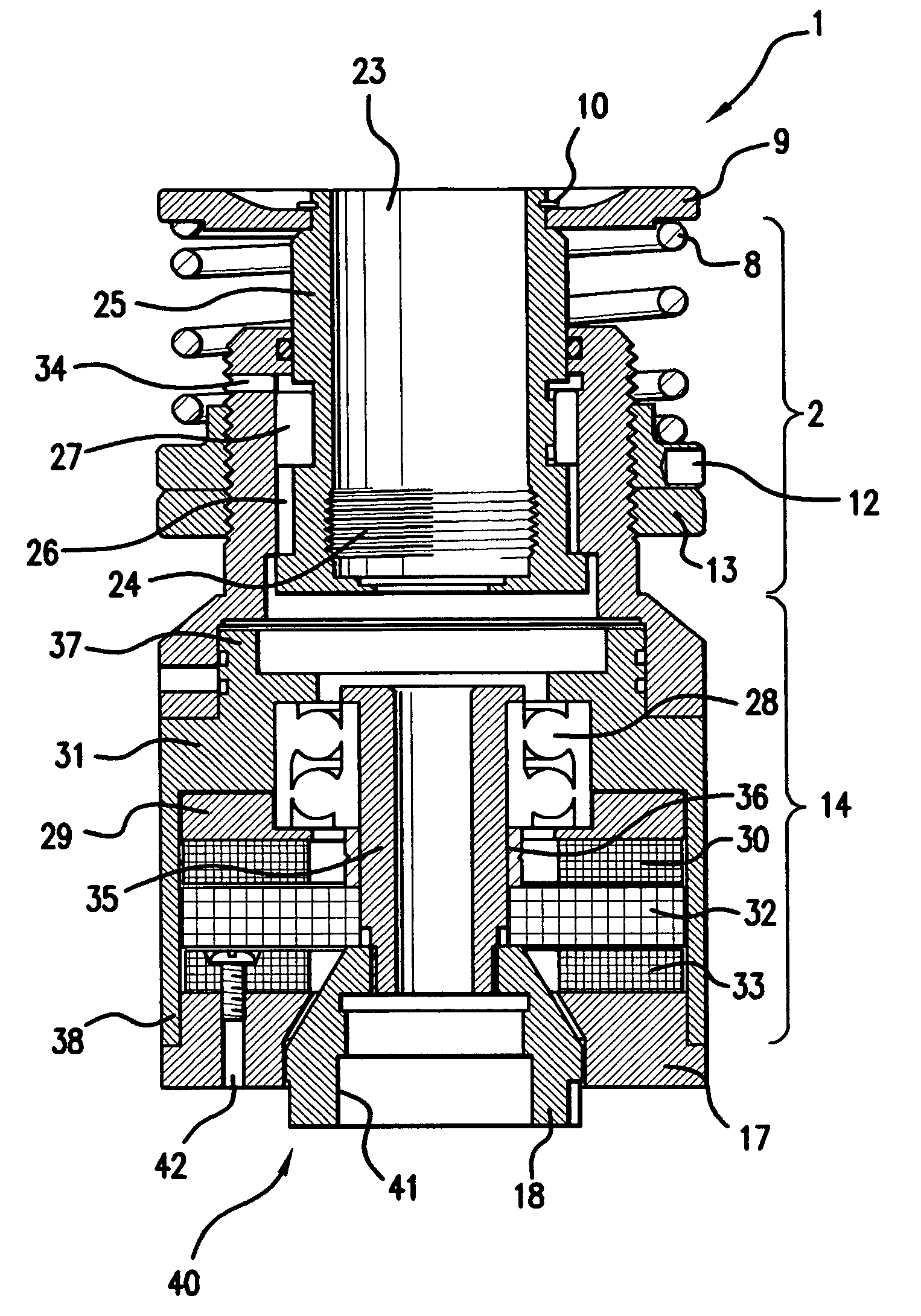

Chuck for capping machine

Owner:PNEUMATIC SCALE CORP

Assembly and system for connecting a closure to a syringe

An assembly for closing the discharge nozzle of a syringe which is pre-filled with a drug or medication. A syringe in combination with a connecting structure removably maintain and support the closure in an operative orientation, which facilitates the rotational attachment of the syringe and the closure when the closure is in mating engagement with the connecting structure. A subsequent removal of the syringe and connected closure from the container or other type of connecting structure is thereby facilitated. The need for an individual to directly handle or touch the closure during its attachment to the syringe is restricted or eliminated. The closure assembly preferably also includes a tamper evident structure which reduces the chances of tampering with the syringe in order to access its contents.

Owner:VIITELLO JONATHAN J +2

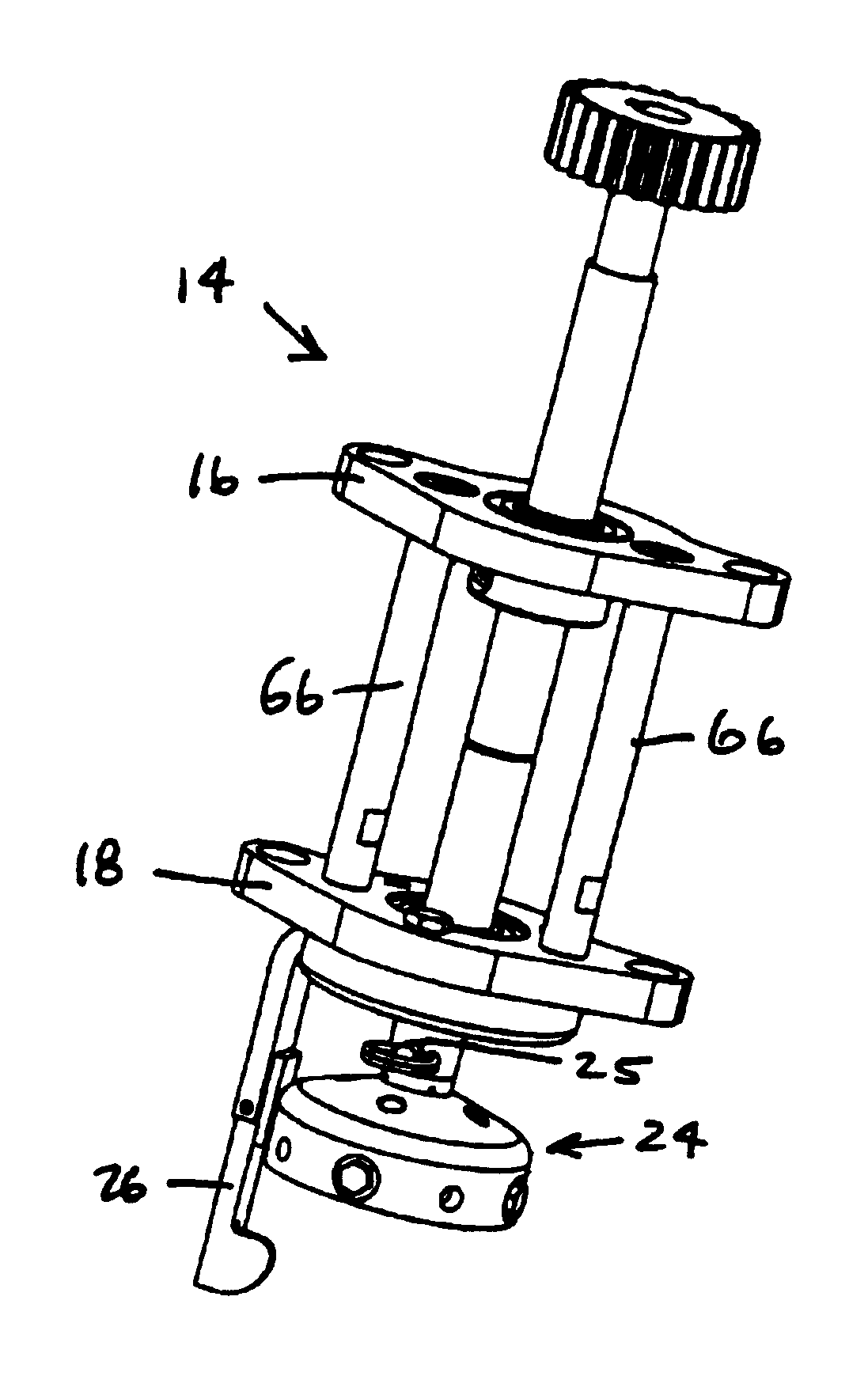

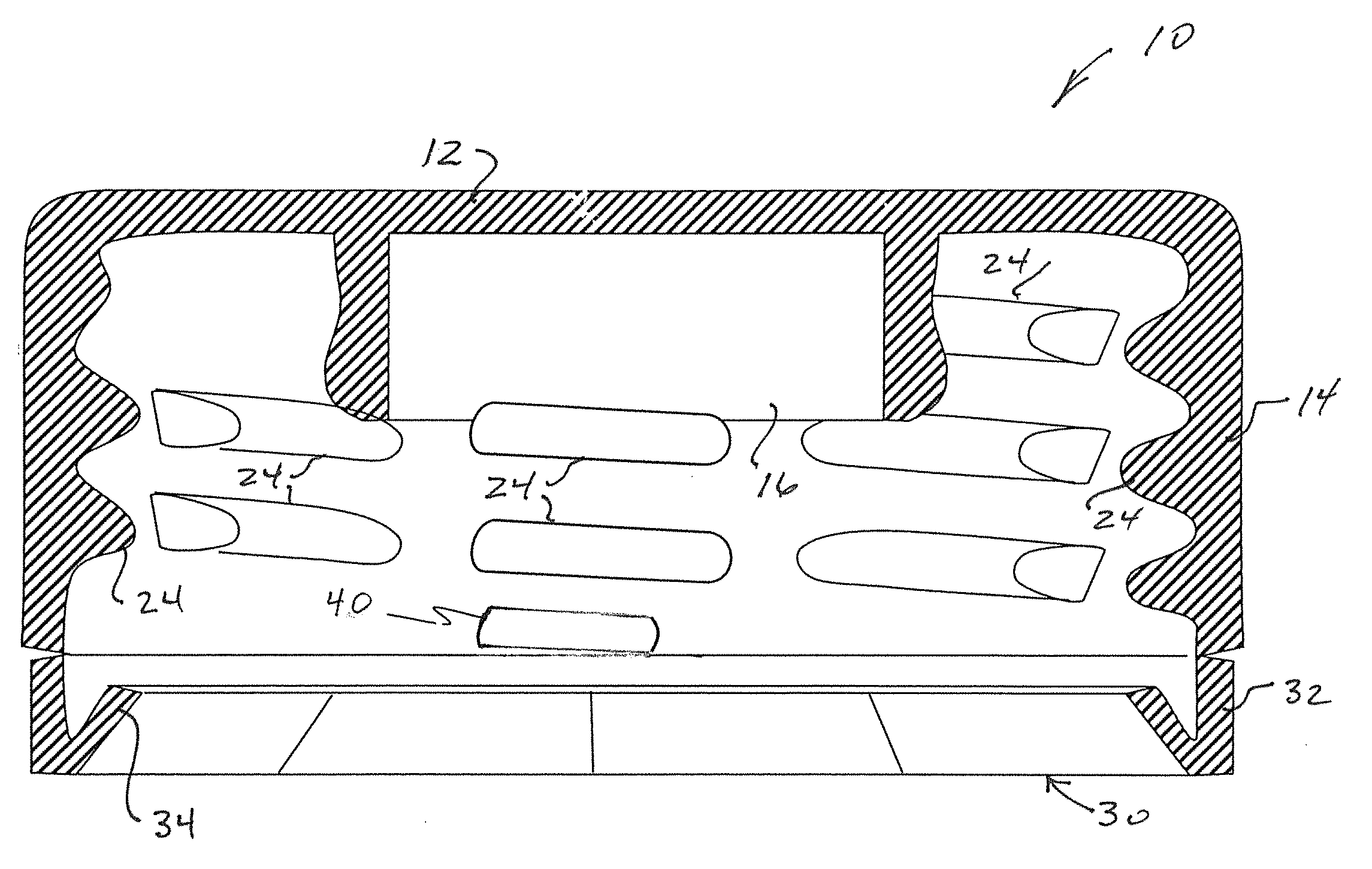

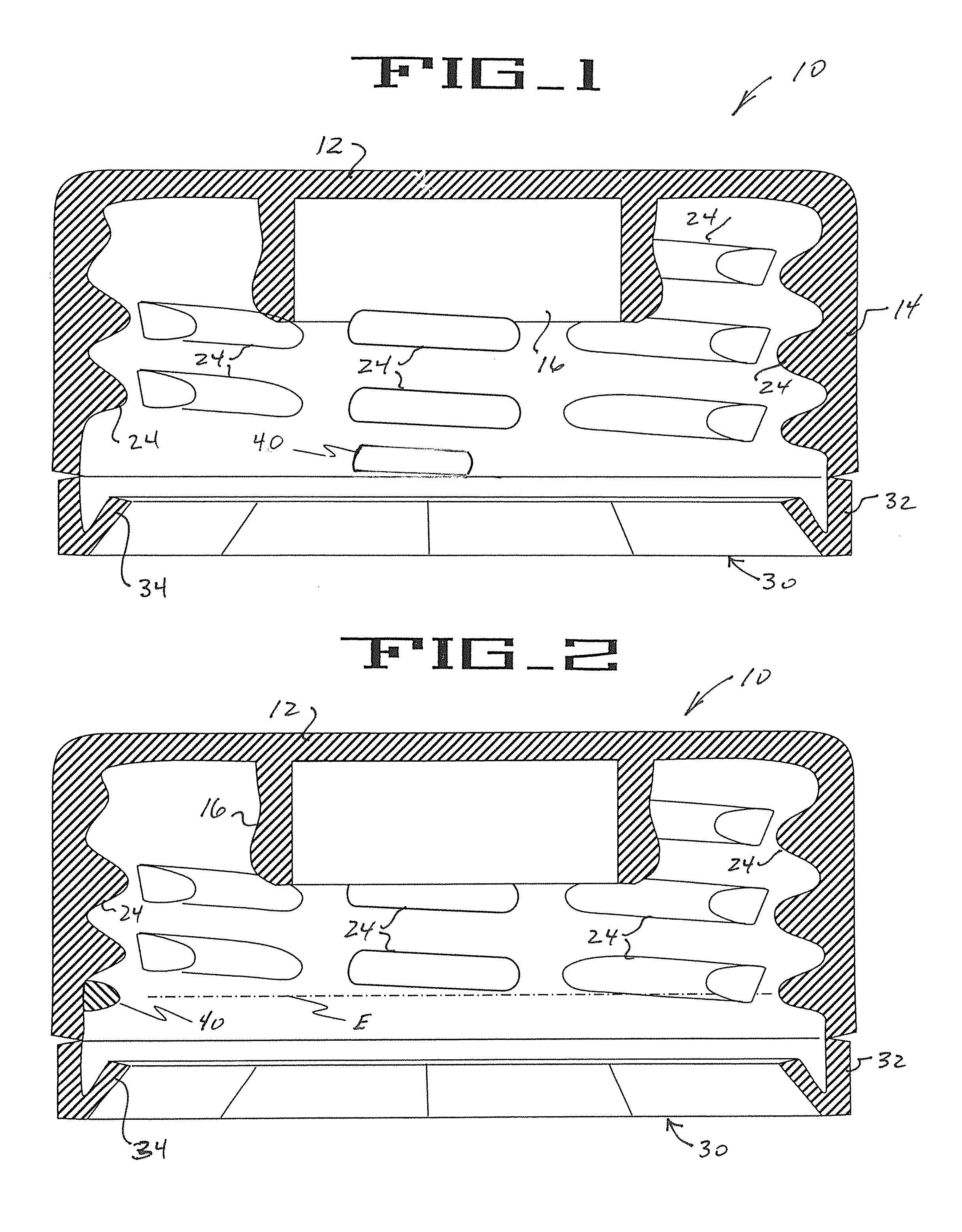

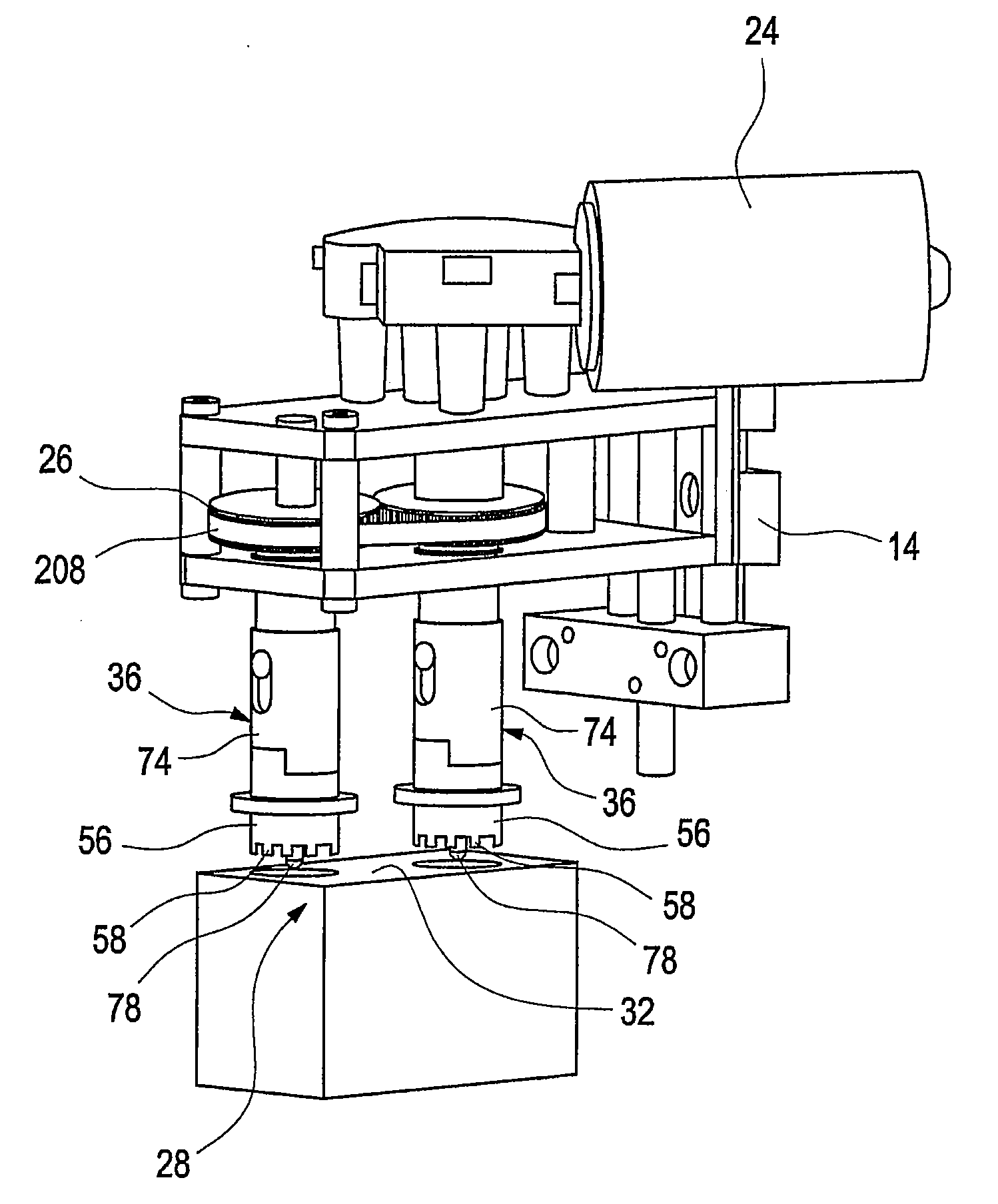

Tube capper/decapper

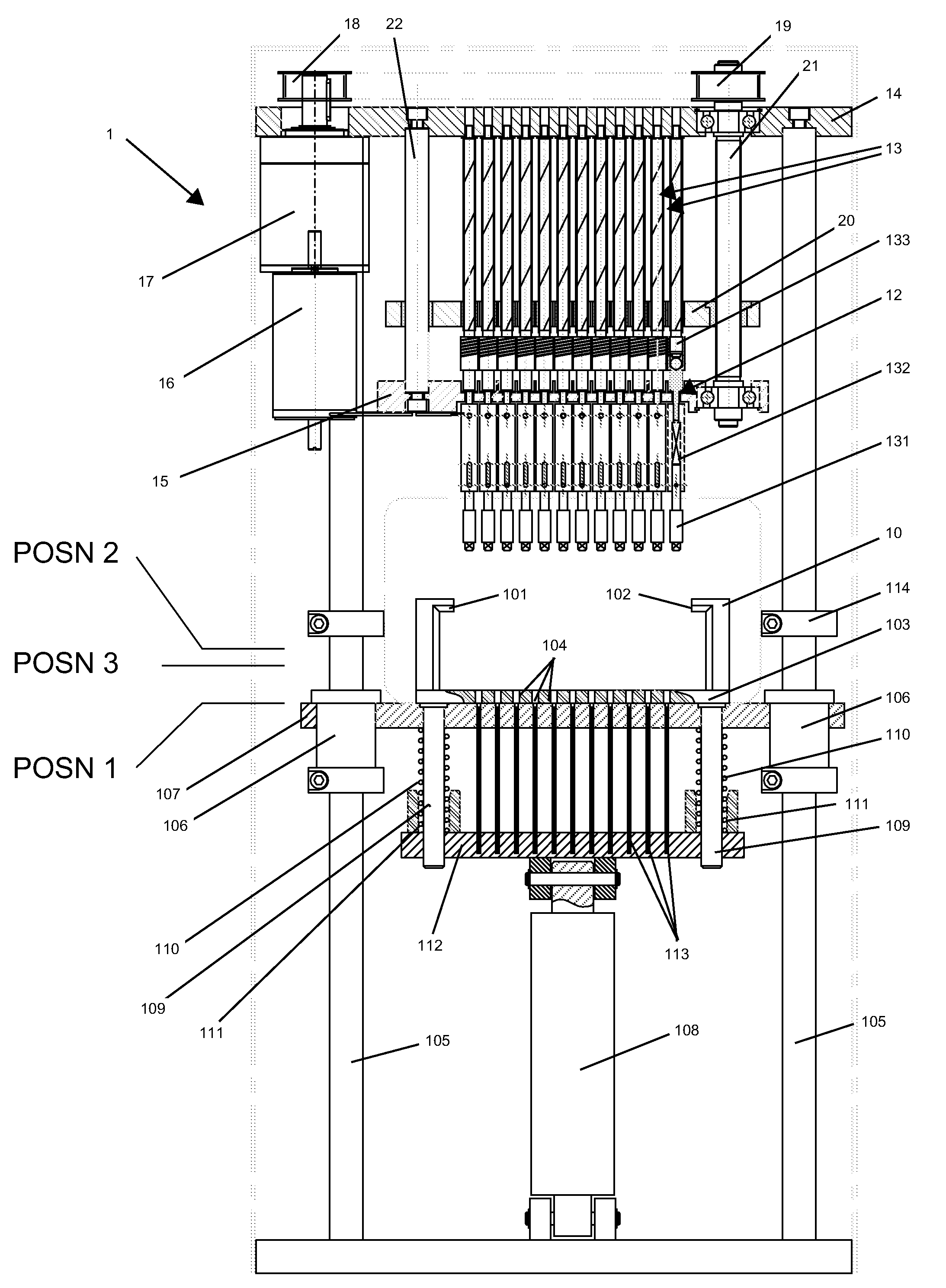

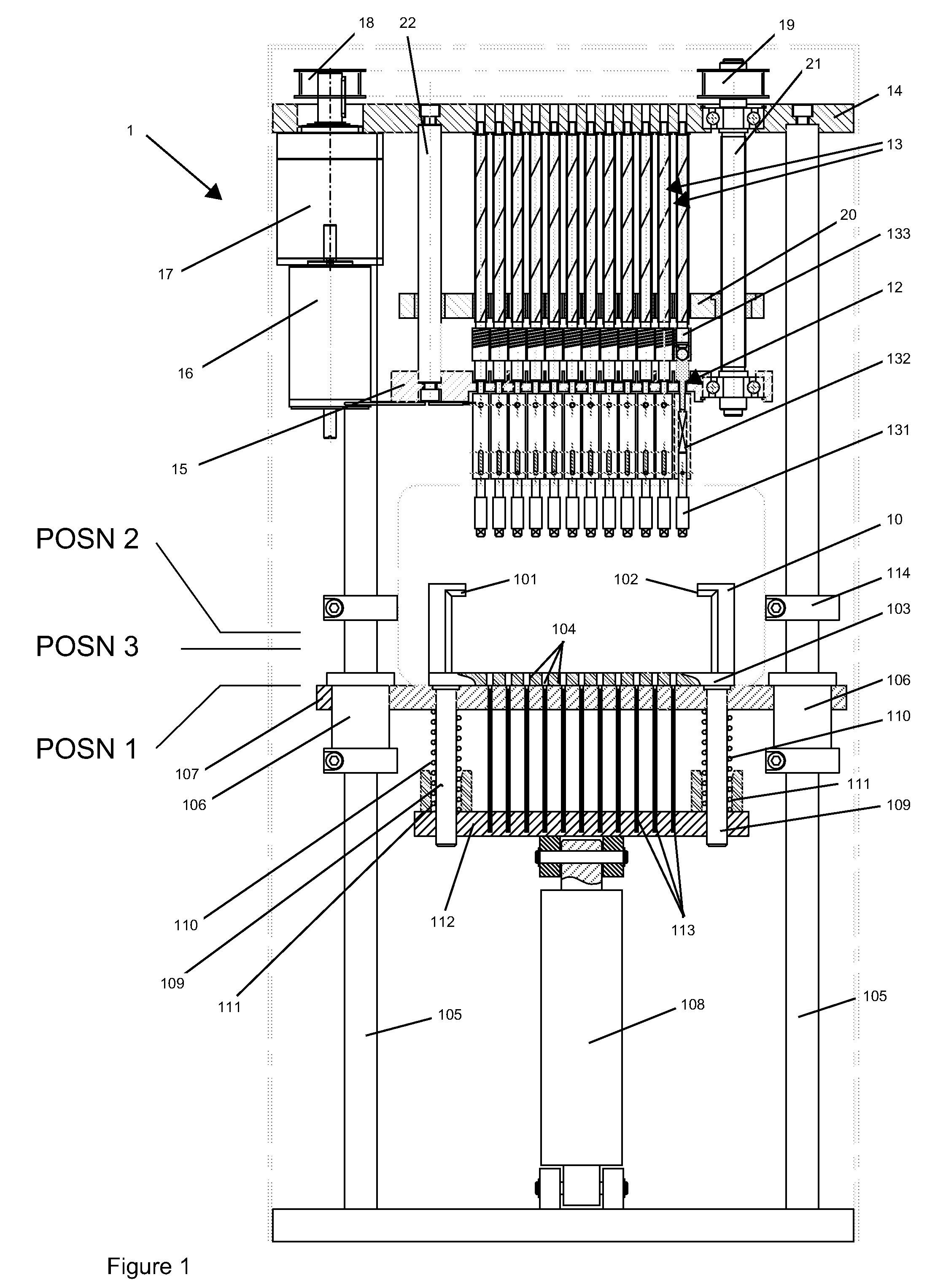

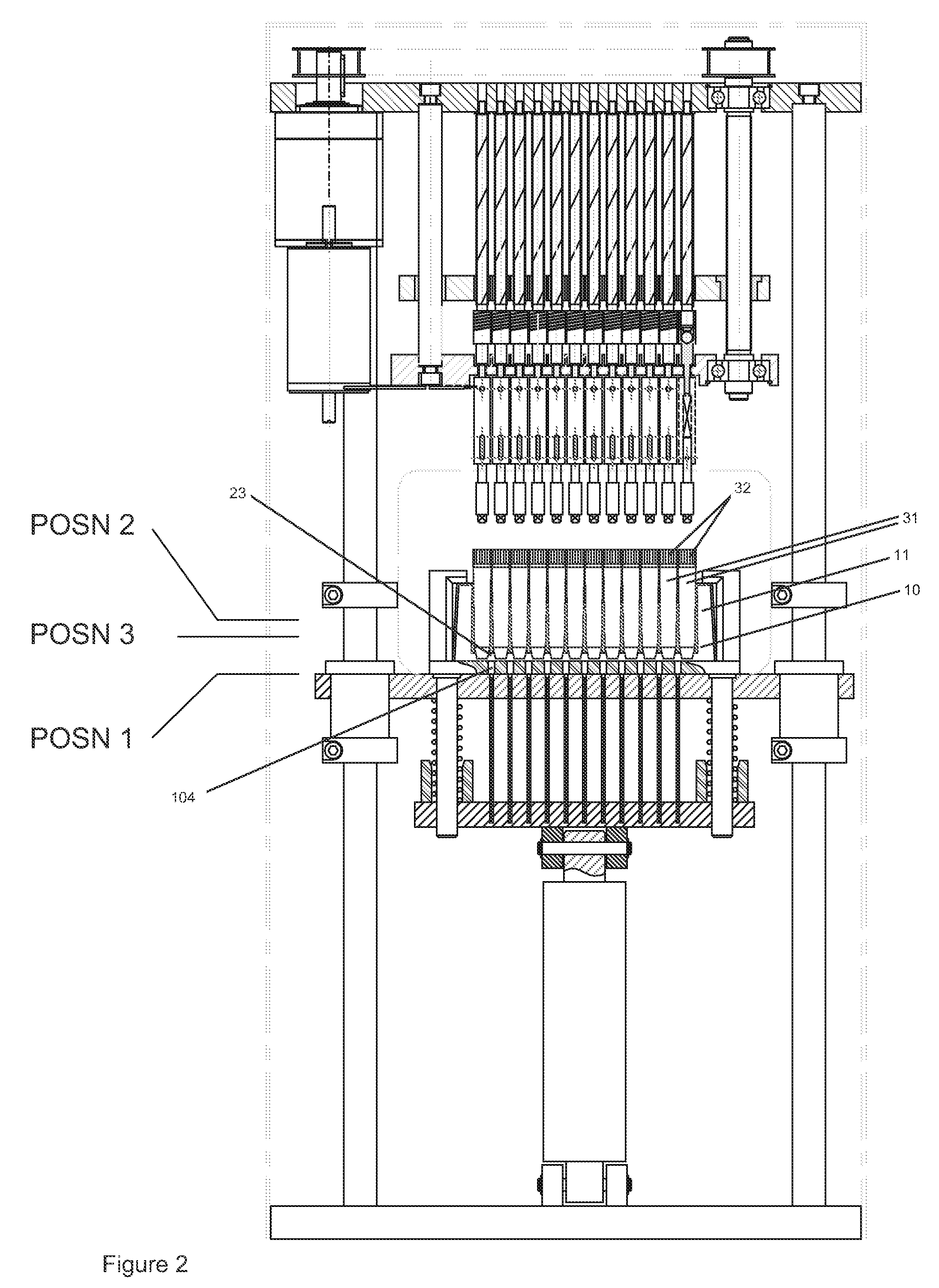

A capper / de-capper system 1 has a rack support 10 for supporting a rack 11 containing a plurality of capped tubes 31 in a given position. A head unit 12 supports a two-dimensional array of capping / de-capping spindles 13, each of which includes a clutch 133 and a capping / de-capping spigot 131 or socket, the spindles being aligned with the tube positions defined in the rack. A drive mechanism 108 moves the tubes and the head unit relatively towards and away from one another in use, when a rack containing capped tubes is disposed in the rack support, causing engagement and disengagement of the capping / de-capping spigots or sockets with and from the tube caps 32. A spindle drive system 15-22 provides simultaneous rotation of the capping / de-capping spigots or sockets together after engagement with the caps, either to detach caps from the tubes or attach caps to the tubes.

Owner:THE AUTOMATION PARTNERSHIP CAMBRIDGE

Closure, containing apparatus, and method of using same

A closure for a container has a closure body having a first cylindrical portion and a second cylindrical portion opposite the first portion. The closure also has a connector disposed in at least one of the first and second portions. The connector is adapted to connect one of a sample collection device and an applicator to the closure. A containing apparatus including the closure, a container, and optionally one of a sample collection device and an applicator is also disclosed. A method of using the containing apparatus is also disclosed.

Owner:DNA GENOTEK

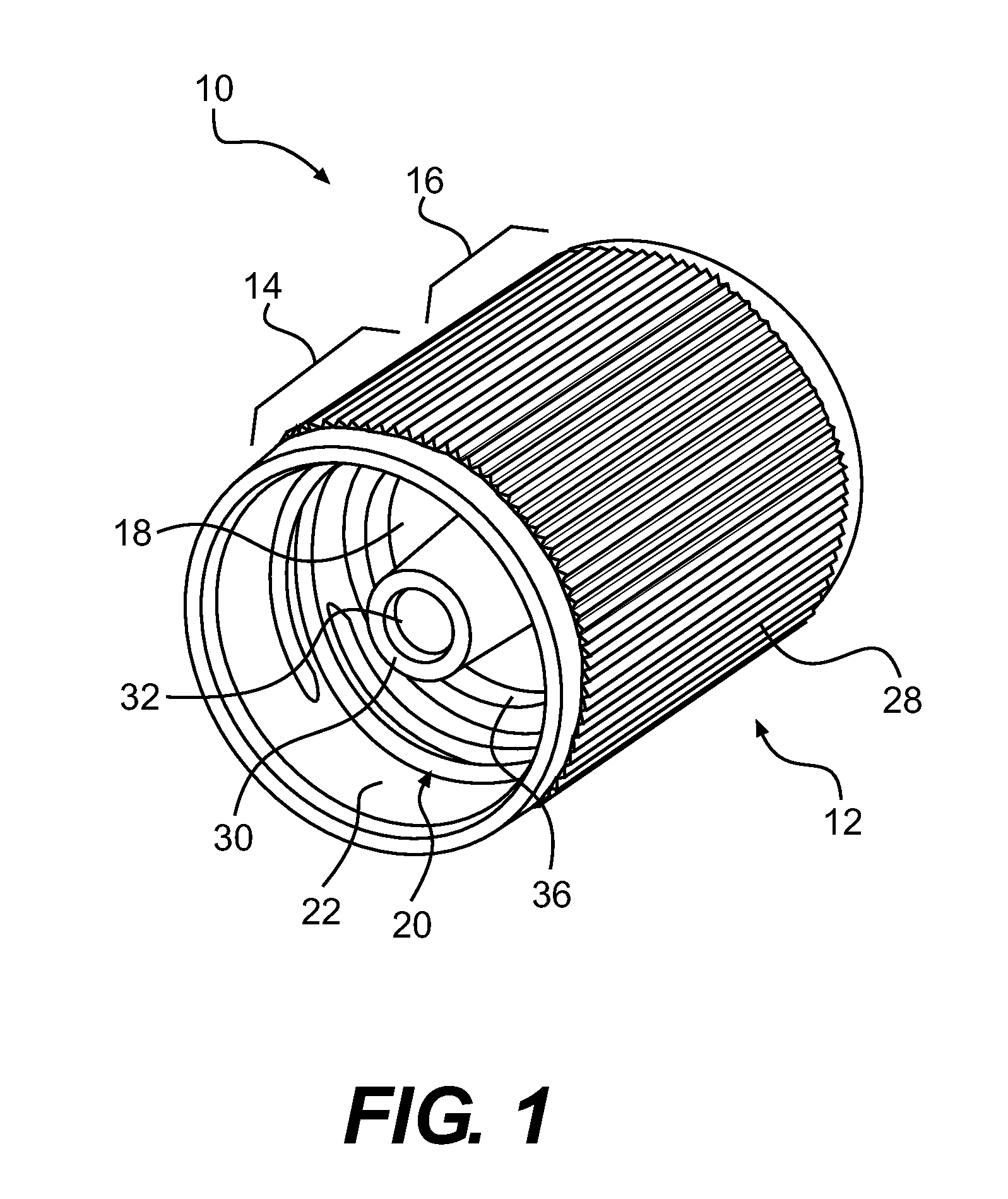

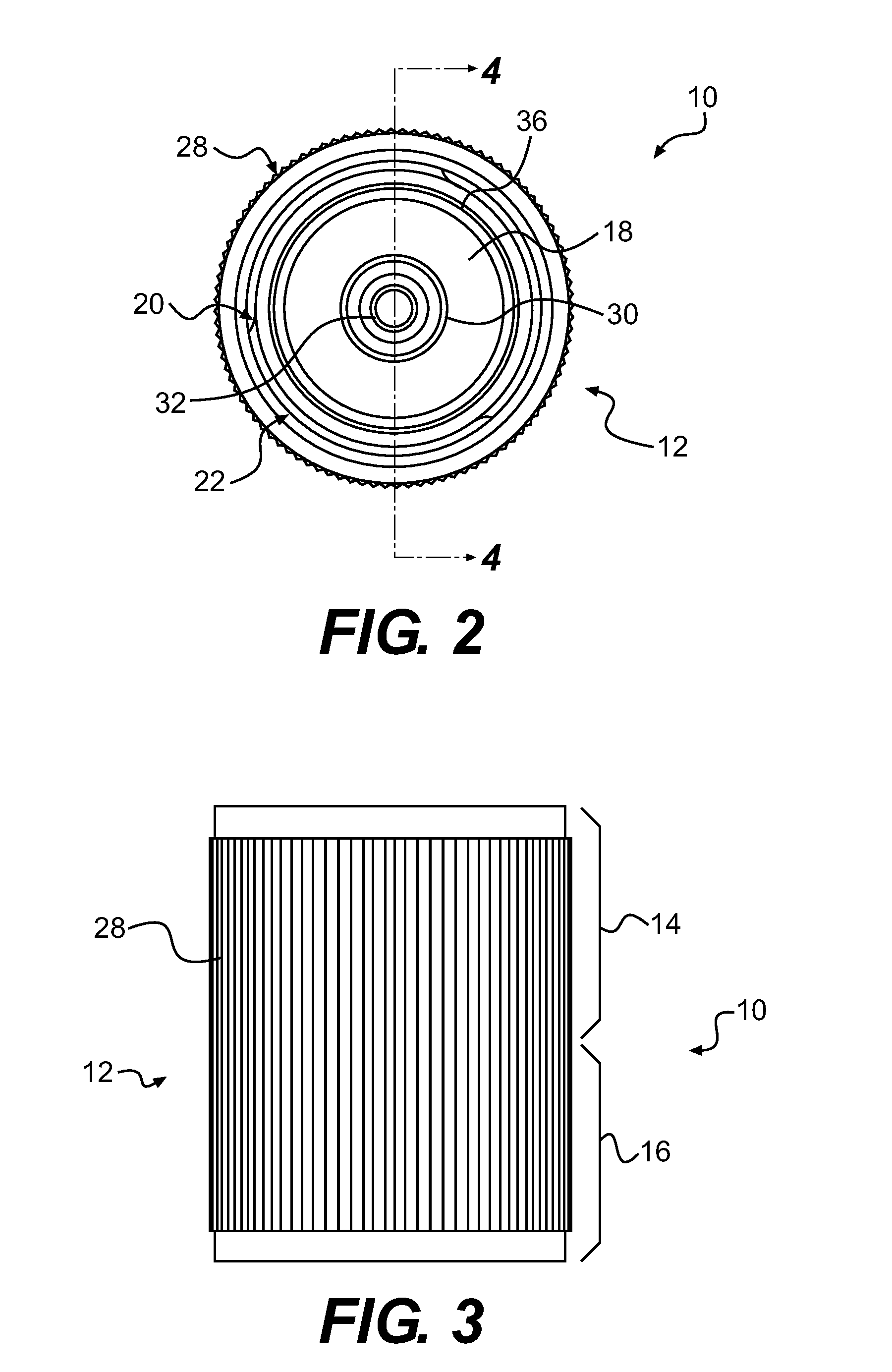

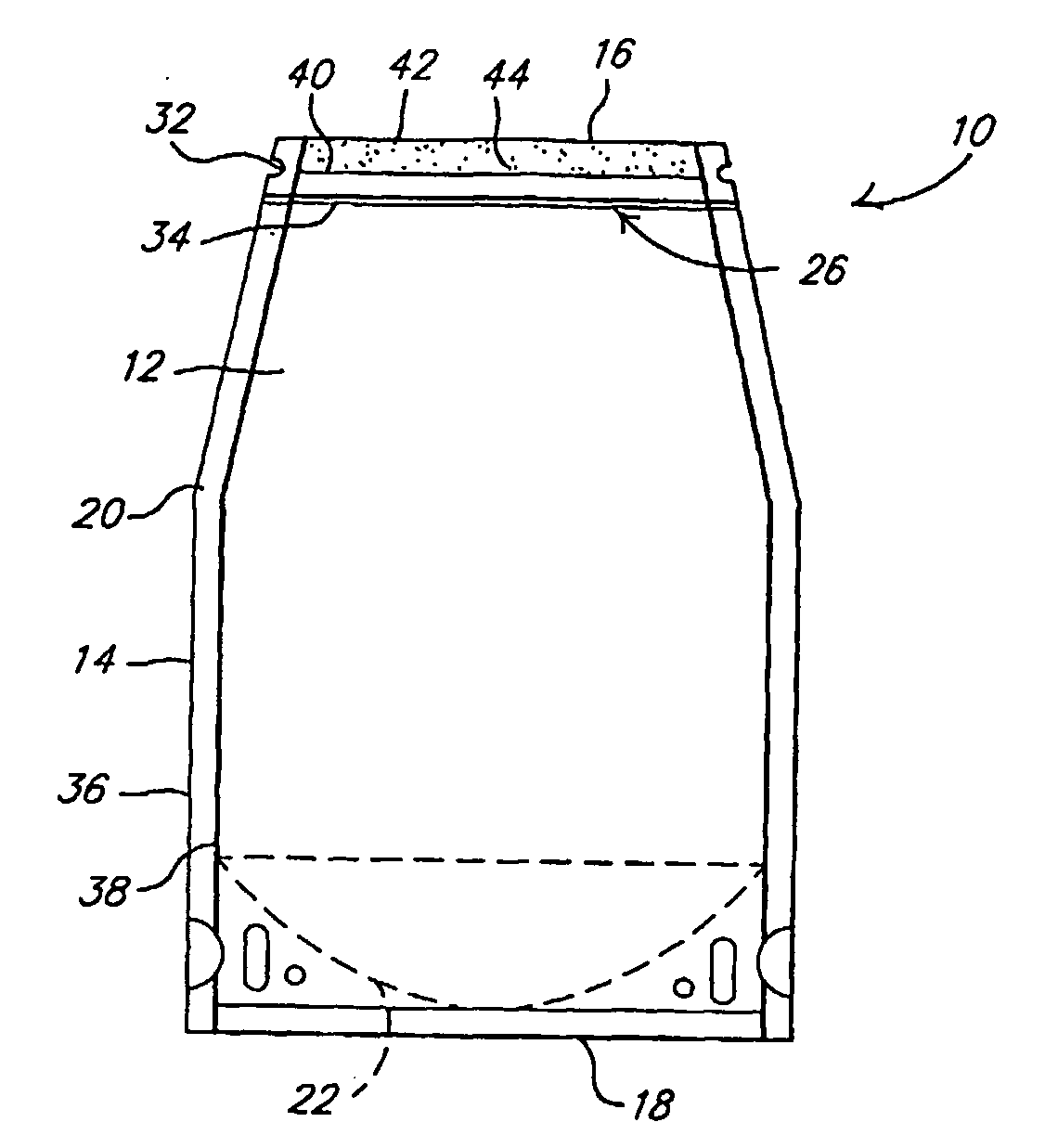

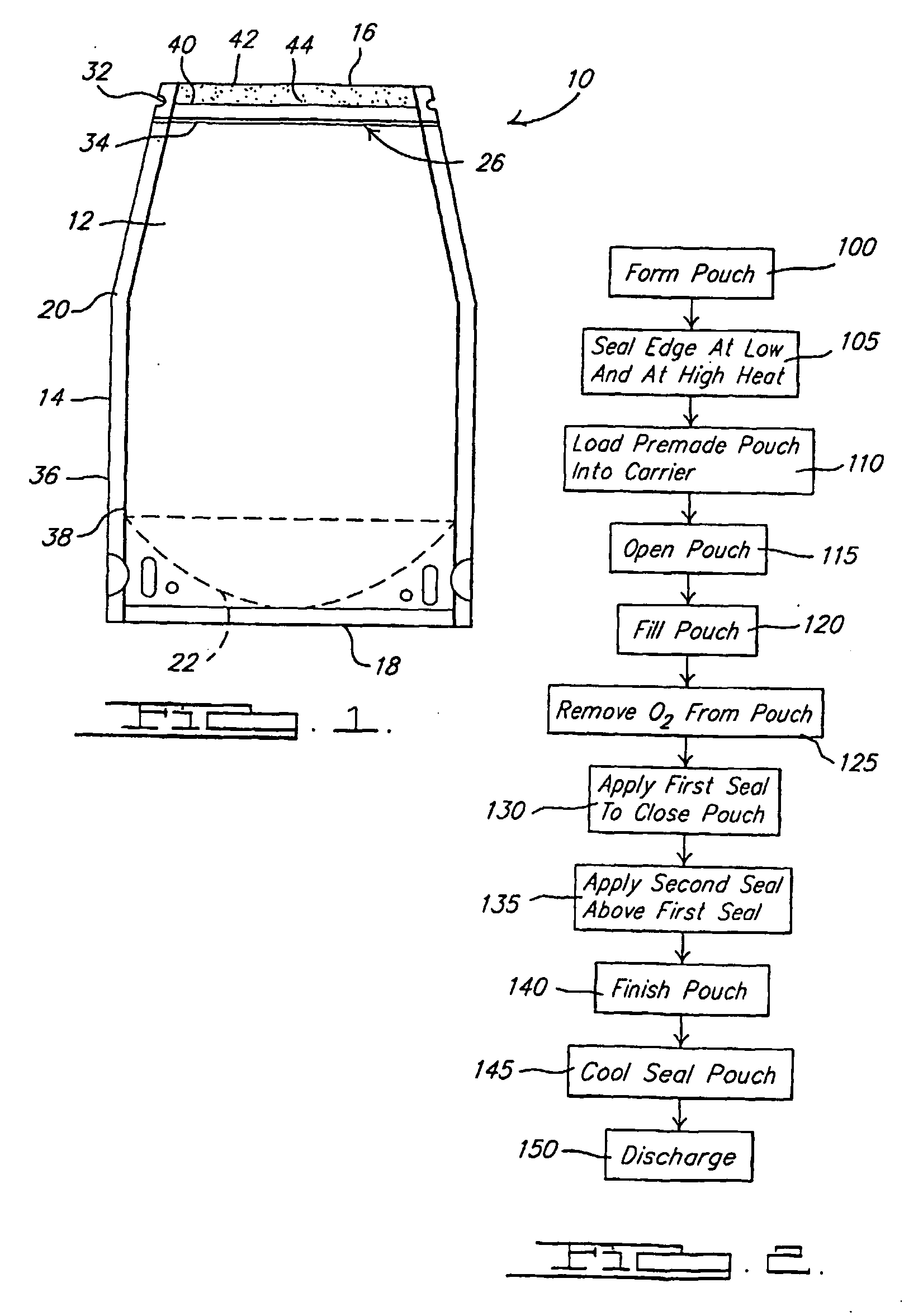

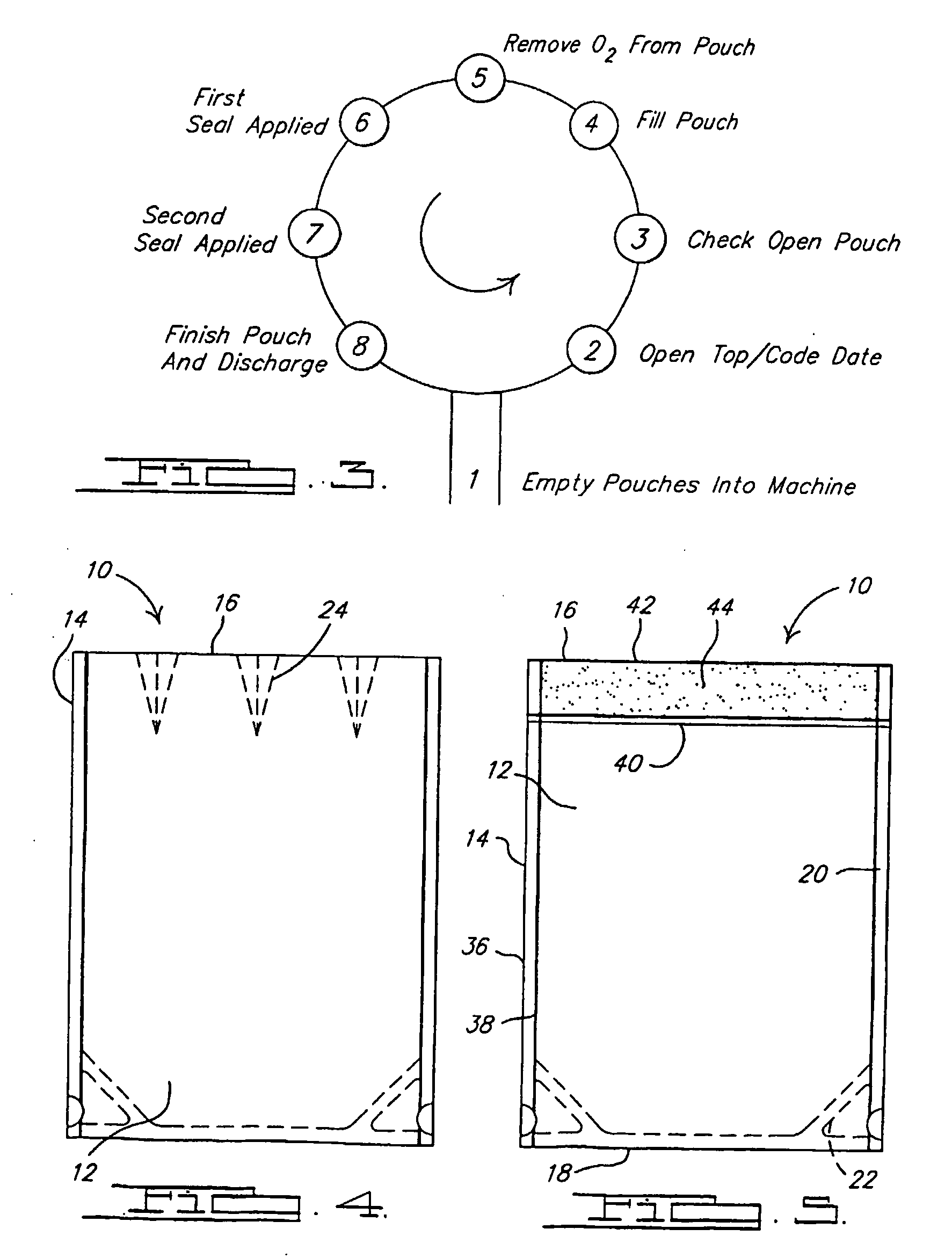

Flexible pouch and method of forming a flexible pouch

InactiveUS20050271306A1Cost-effective manufacturingReduce heatCapsThreaded caps applicationEngineeringFront panel

A flexible pouch for packaging a product, such as a carbonated beverage, is provided that includes a front panel and a back panel each having an upper edge, a lower edge opposite the upper edge, and side edges extending therebetween the upper and lower edges. The pouch includes a first closing seal extending along an upper edge of the joined front and back panel formed a predetermined length from the open edge so that there is no dead space inside the pouch between the product and the first closing seal and a second closing seal outside the first closing seal, to form a pocket trapping some of the product between the first closing seal and the second closing seal. A method of forming and filling the pouch includes the steps of forming each panel and joining two panels by scaling together the side edges and lower edge. The method also includes the steps of opening the pouch and filling the pouch with the product. The method further includes the steps of closing the filled pouch by forming a first closing seal extending along an upper edge of the pouch a predetermined length from the upper edge, such that there is no dead space inside the pouch between the product and the first closing seal, and forming a second seal between the first closing seal and the upper edge thereby trapping the product between the first closing seal and the second closing seal, and finishing the pouch.

Owner:POUCH PAC INNOVATIONS

Plastic closure, closure and container package, and method of manufacture

Owner:BERRY PLASTICS CORP

Method and machine for closing bottle with sterile caps

ActiveUS7536839B2Easy to operateImprove throughputCapsDecorative coversSterile environmentLinear machine

Owner:KHS CORPOPLAST GMBH & CO KG

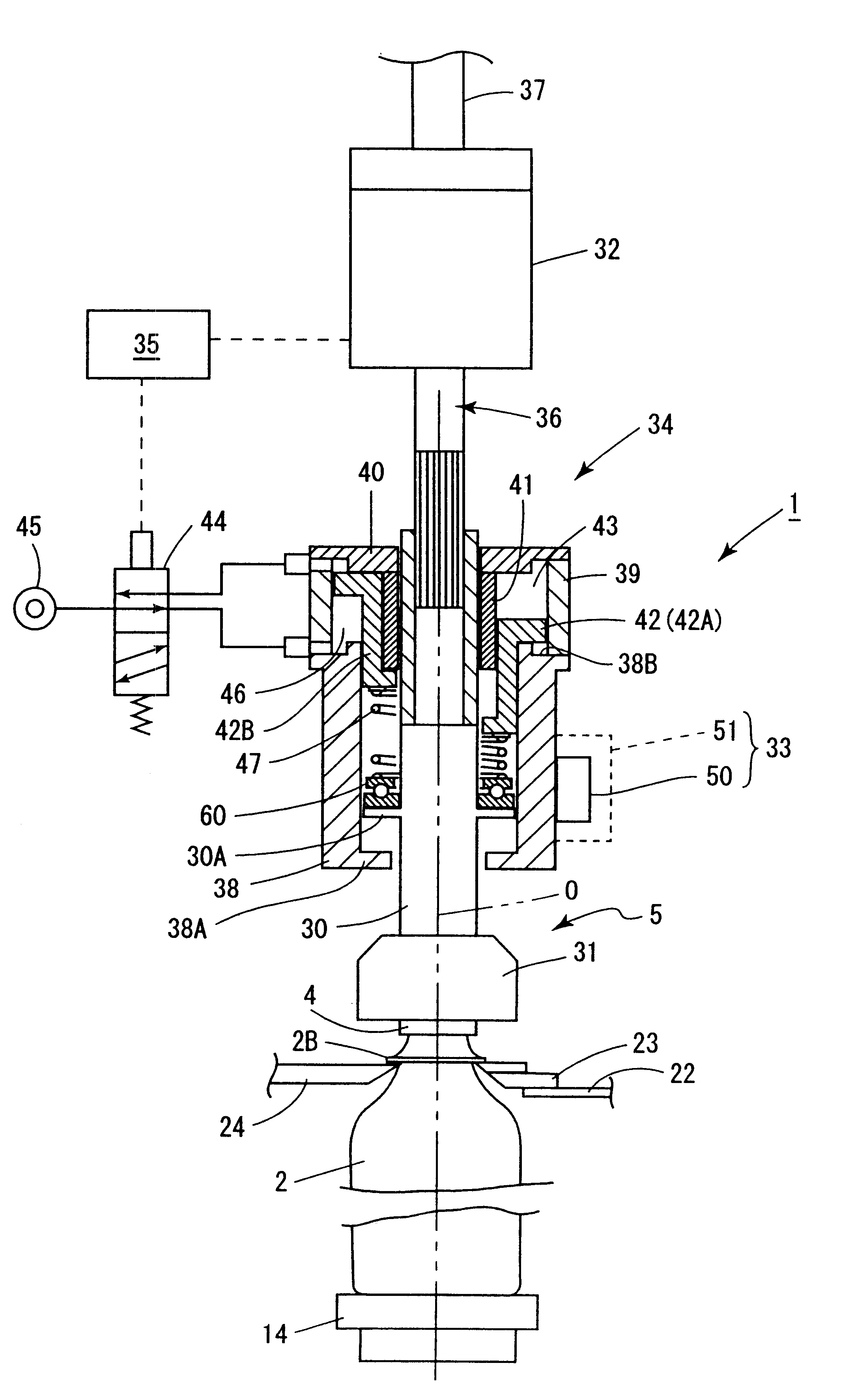

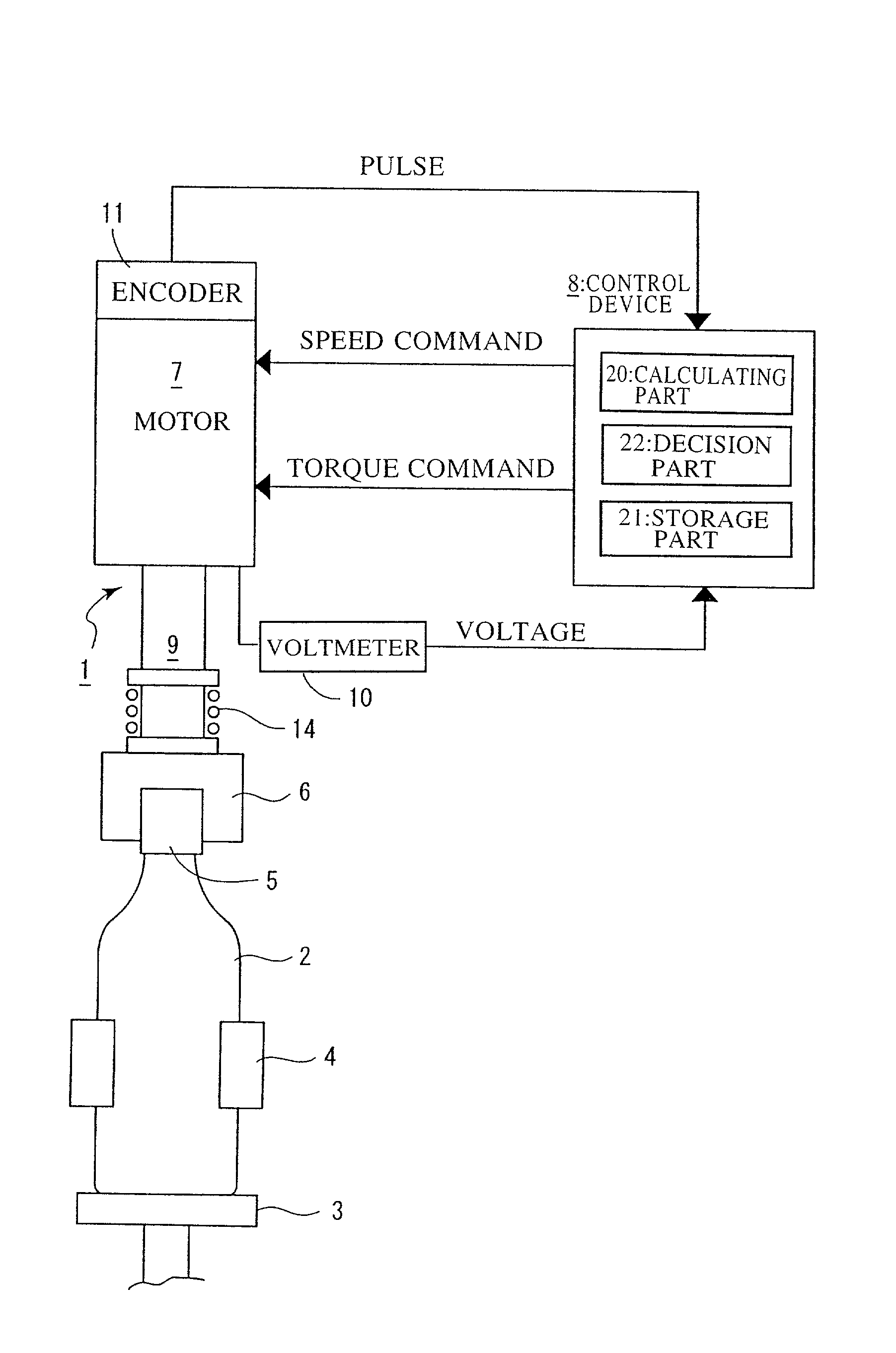

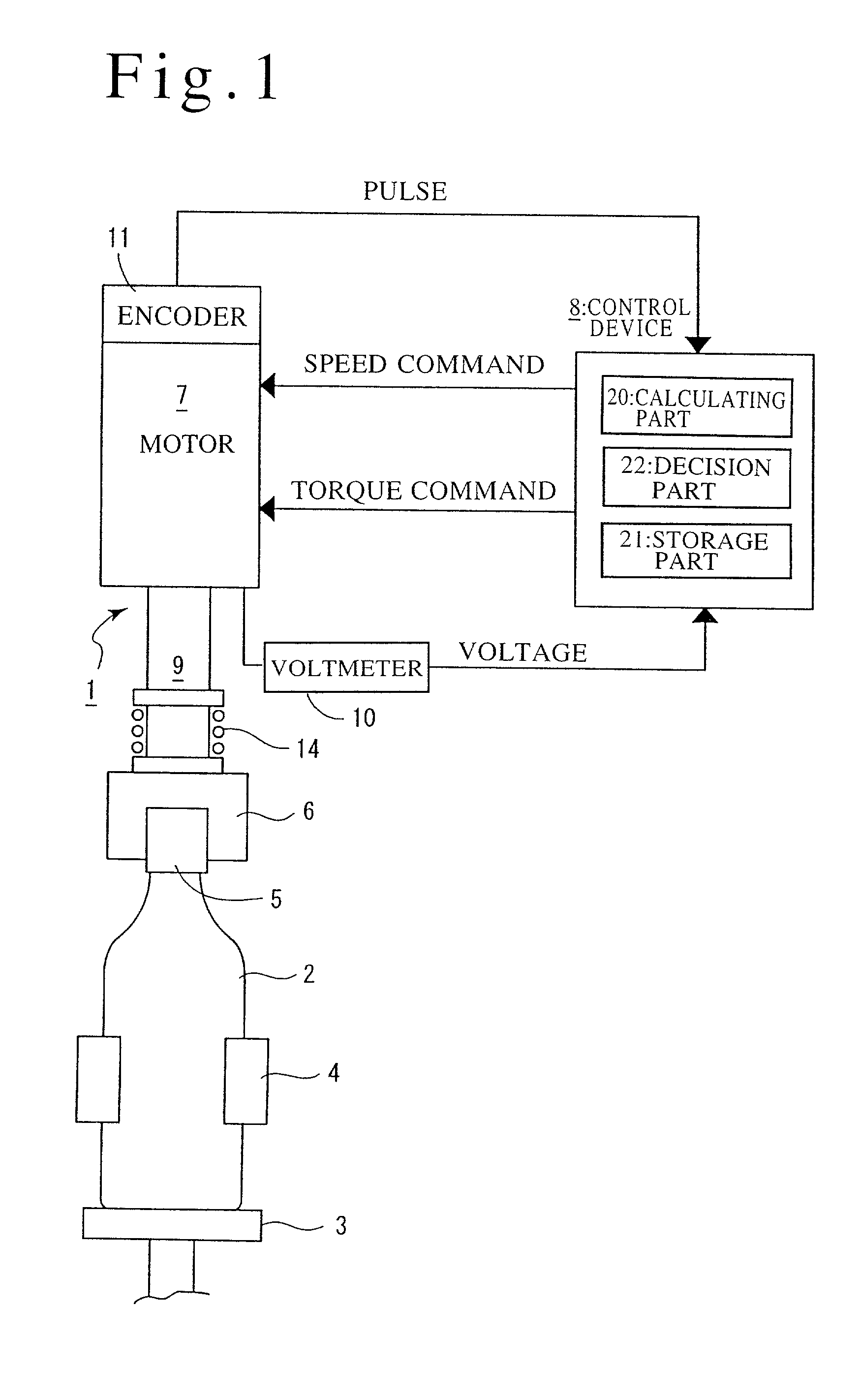

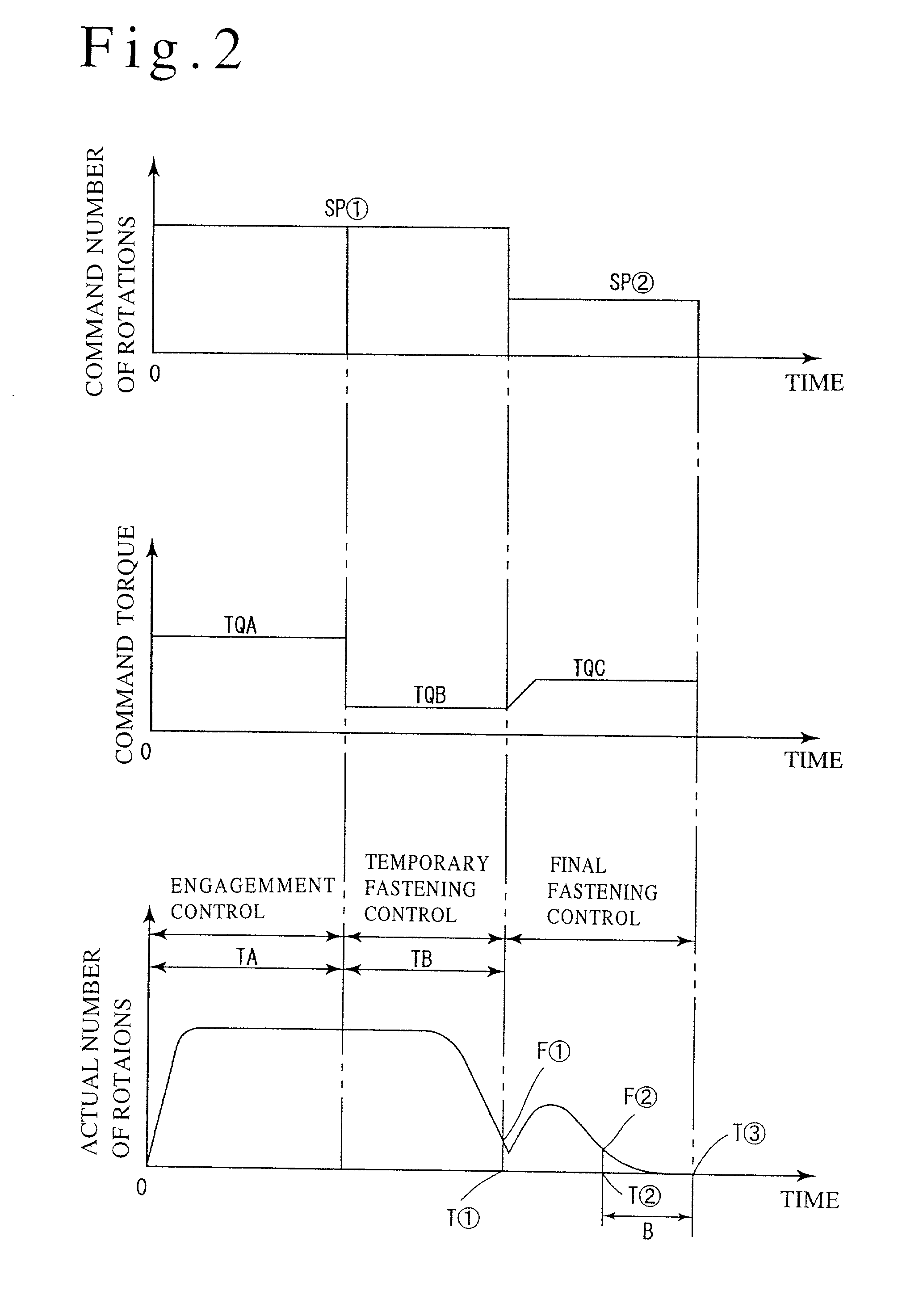

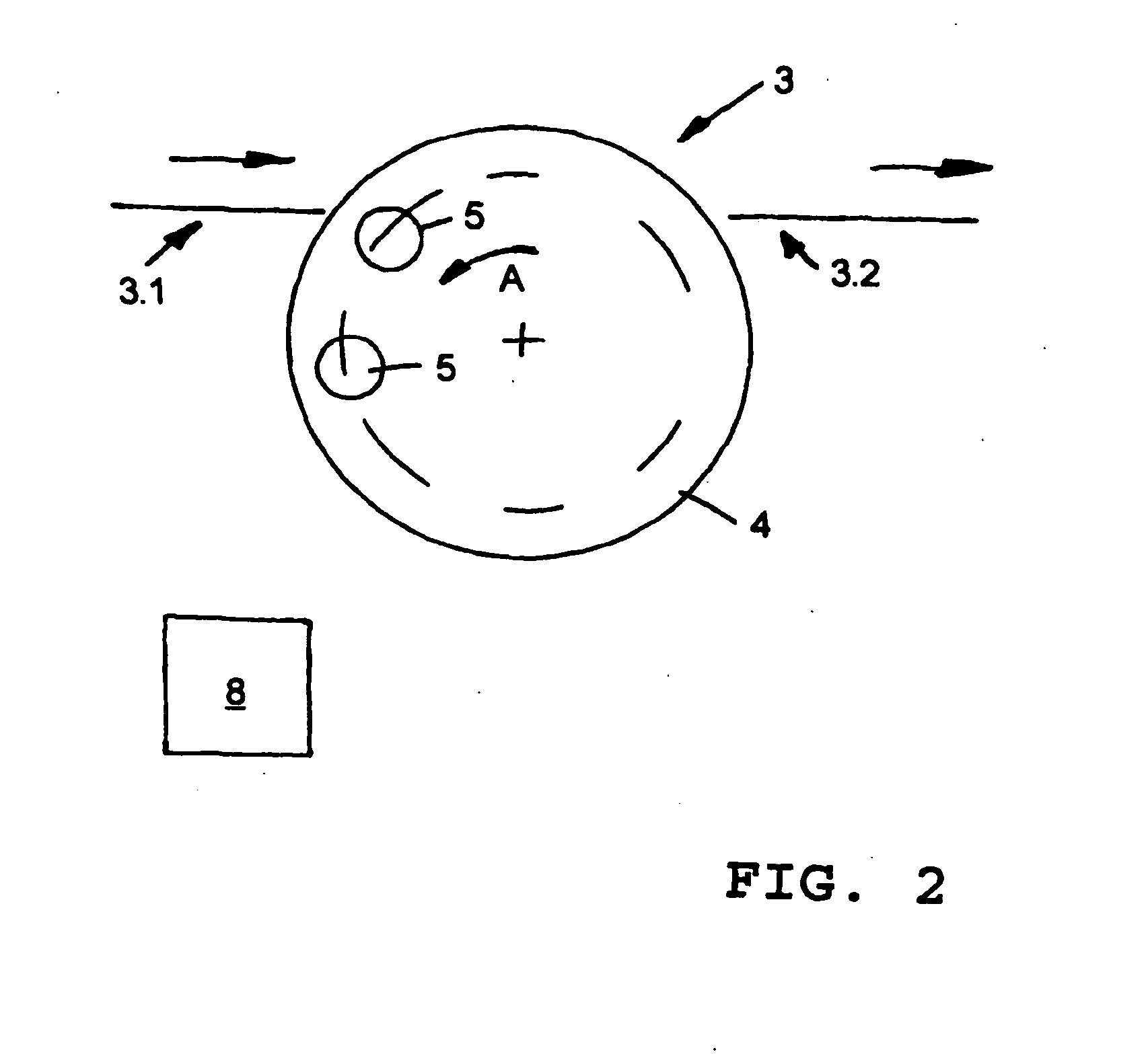

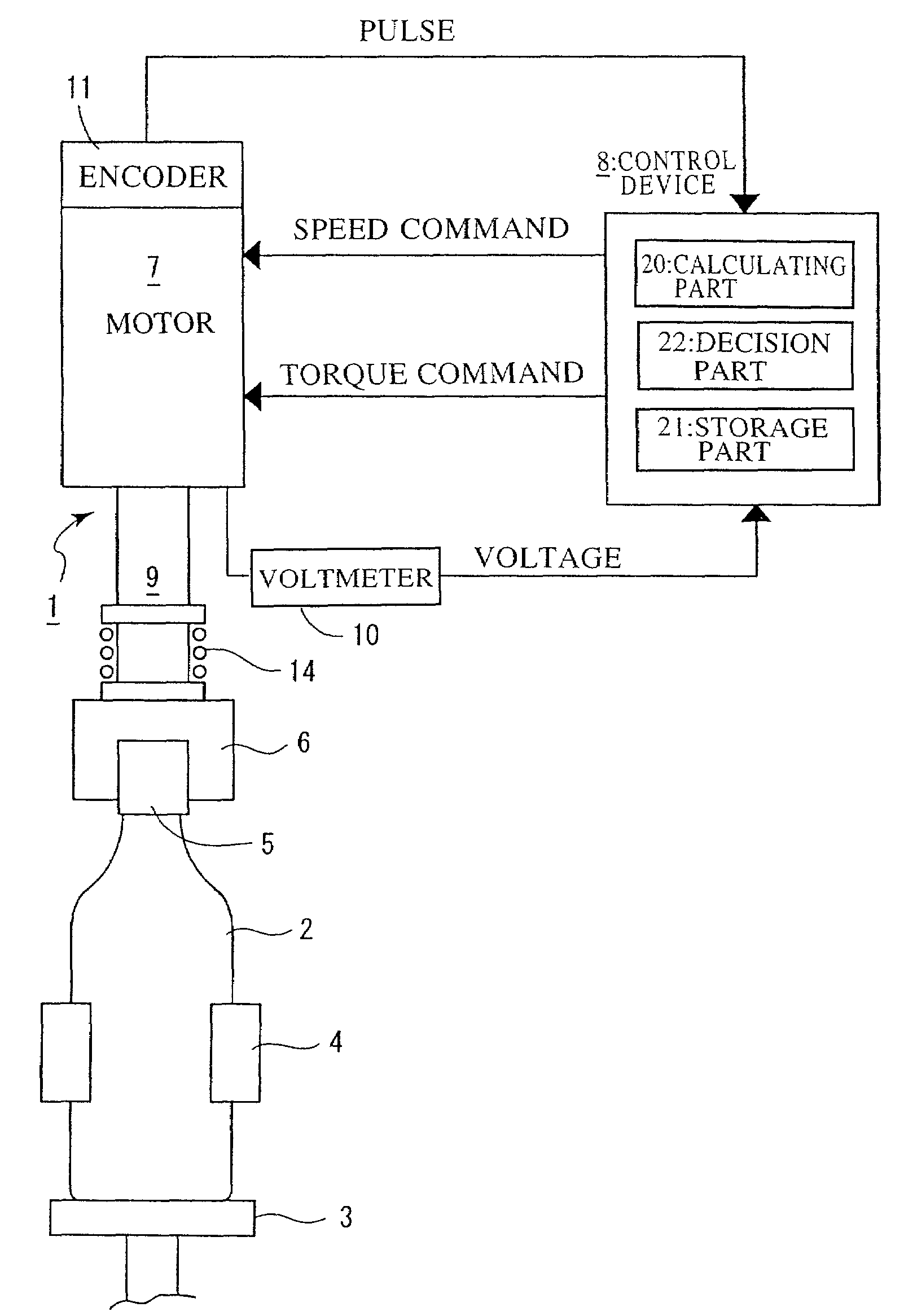

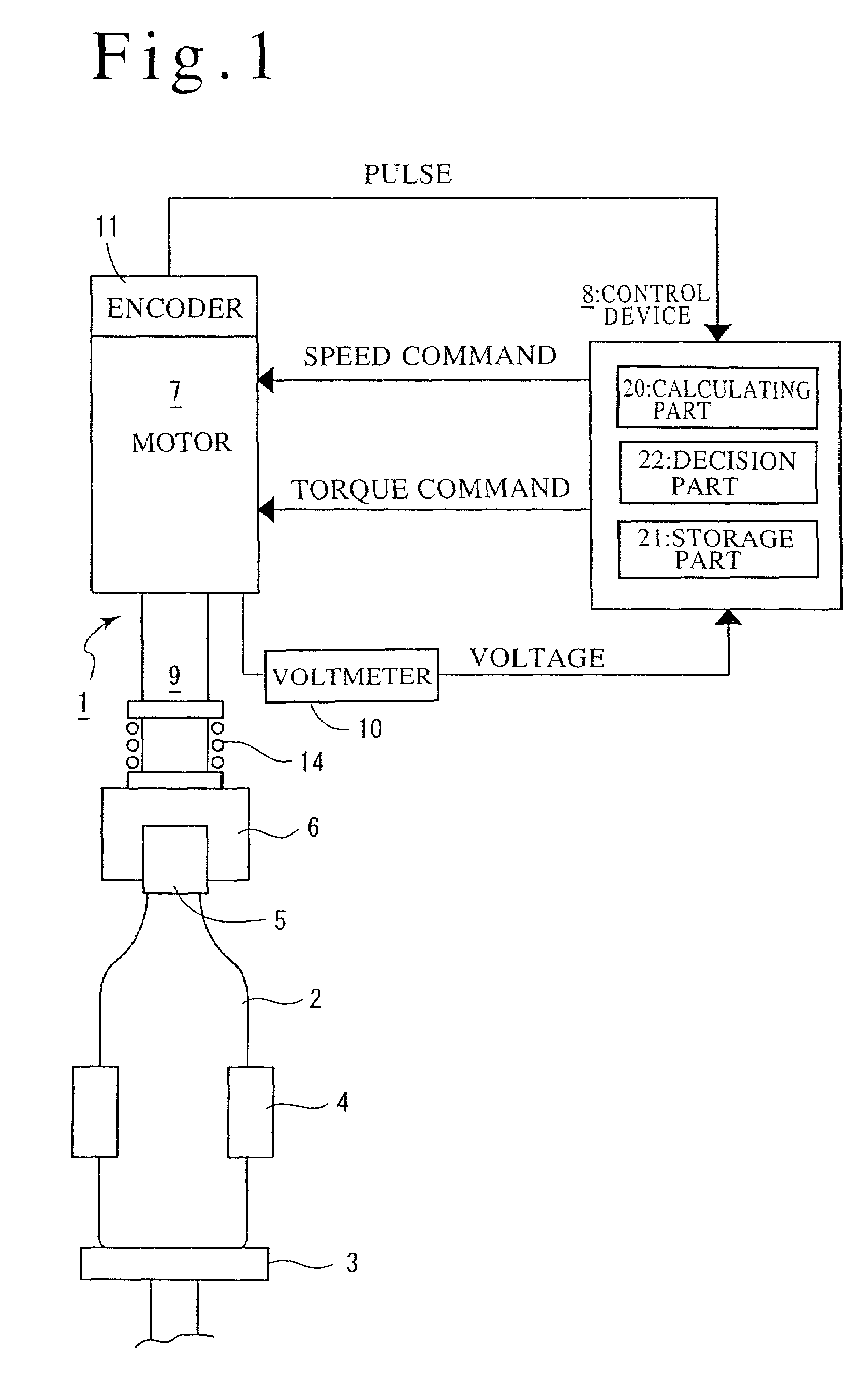

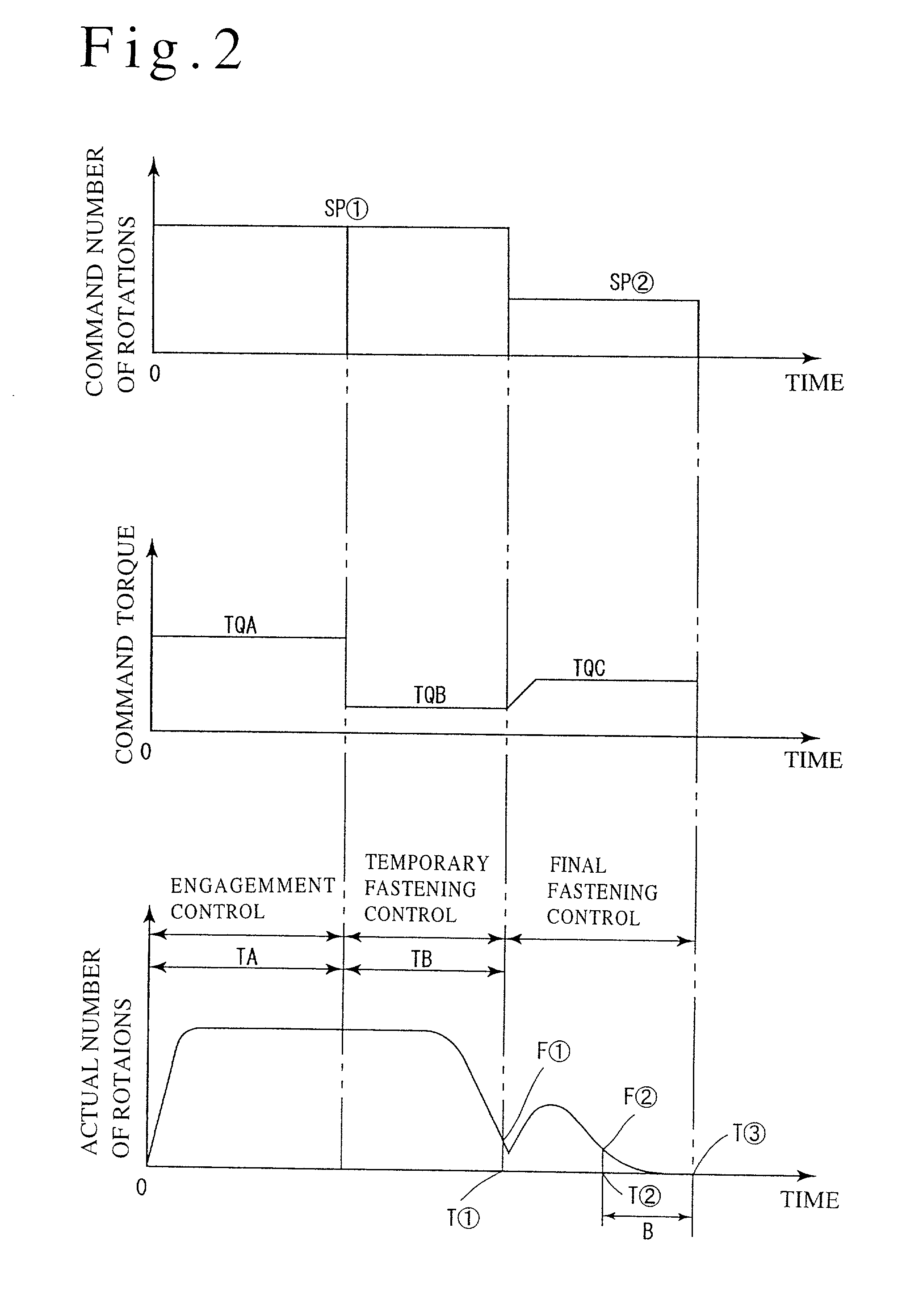

Capping method and capping apparatus

A screw capper 1 includes a capping head 6 which grips a cap 5, a servo motor 7 which rotates the capping head, a voltmeter 10 which measures the torque of the capping head, an encoder 11 which detects the rotational angle of the capping head, and a control device 8 which controls the servo motor. In the screw capper, when whether rotational fastening is acceptable is to be determined during the rotational fastening, the measured value of the encoder is measured from a predetermined measurement starting point until a rotational fastening completion point, and if the measured rotational angle is in the range of an acceptable decision angle which is set in advance, it is determined that the rotational fastening has been acceptably performed, whereas if the measured rotational angle is not in the range of the acceptable decision angle, it is determined that the rotational fastening is unacceptable. In the screw capper, defective rotational fastening can be detected, and reductions in costs can be realized compared to a case where a device for detecting such defective rotational fastening is separately provided.

Owner:SHIBUYA IND CO LTD +1

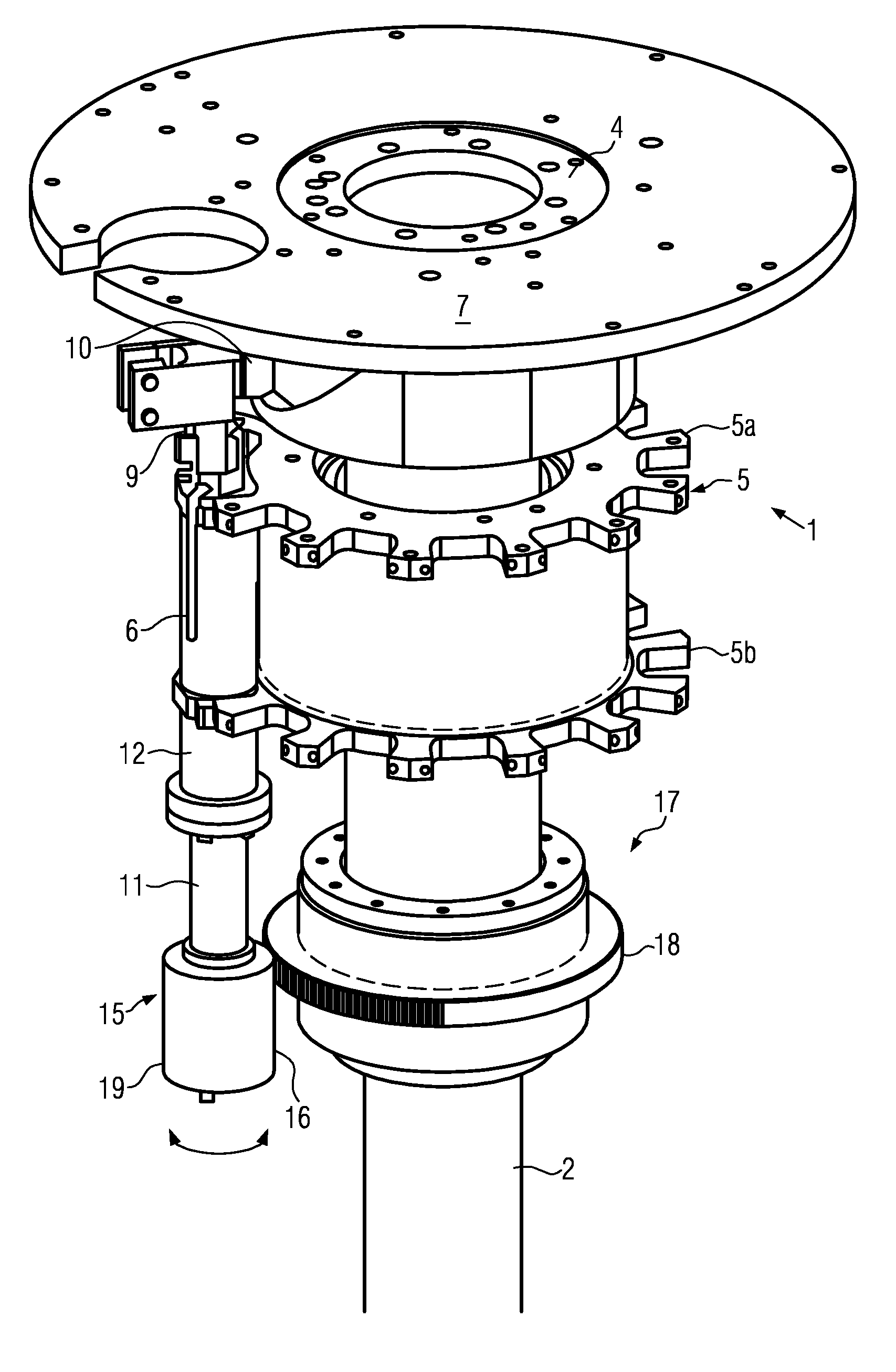

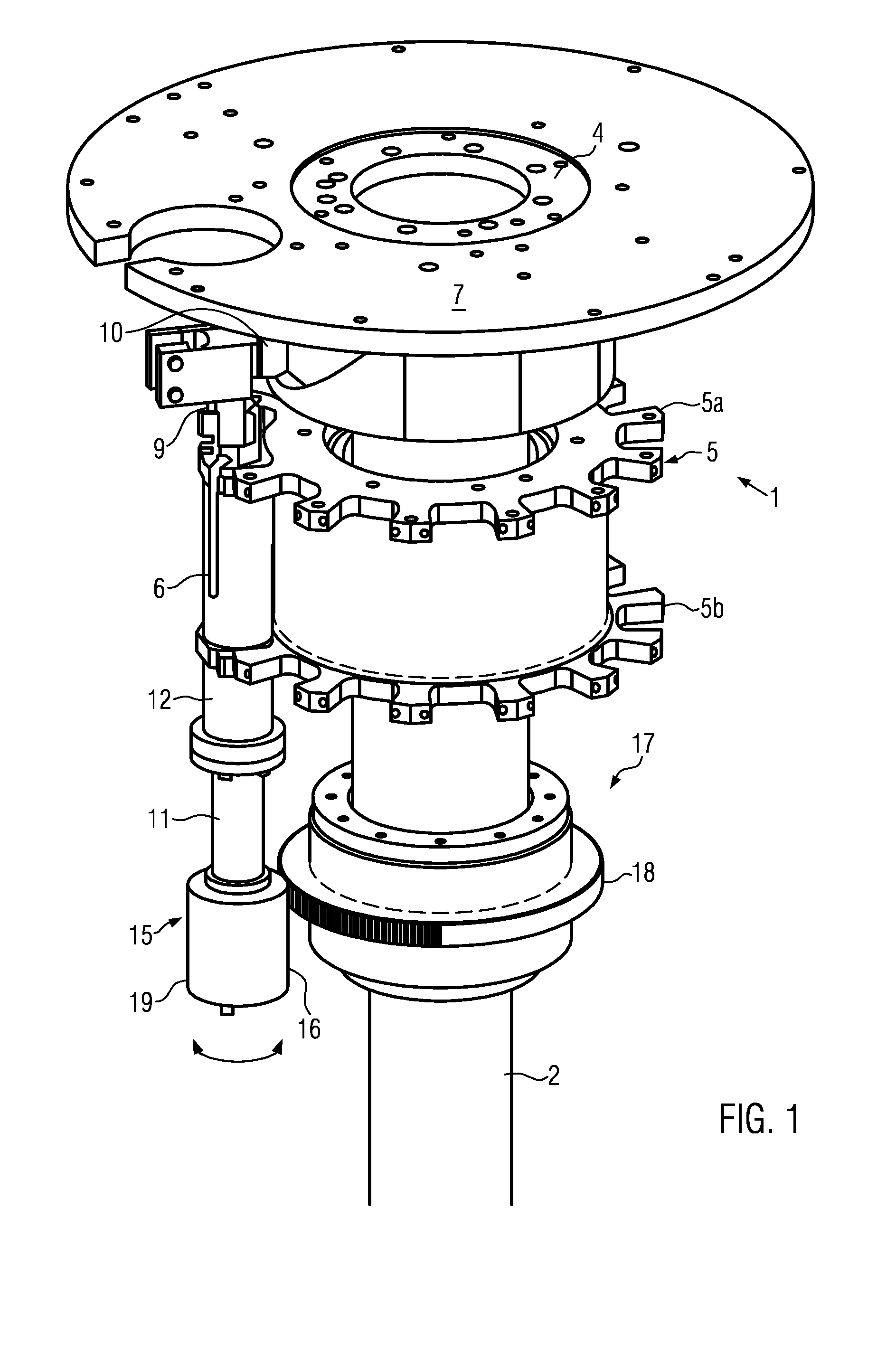

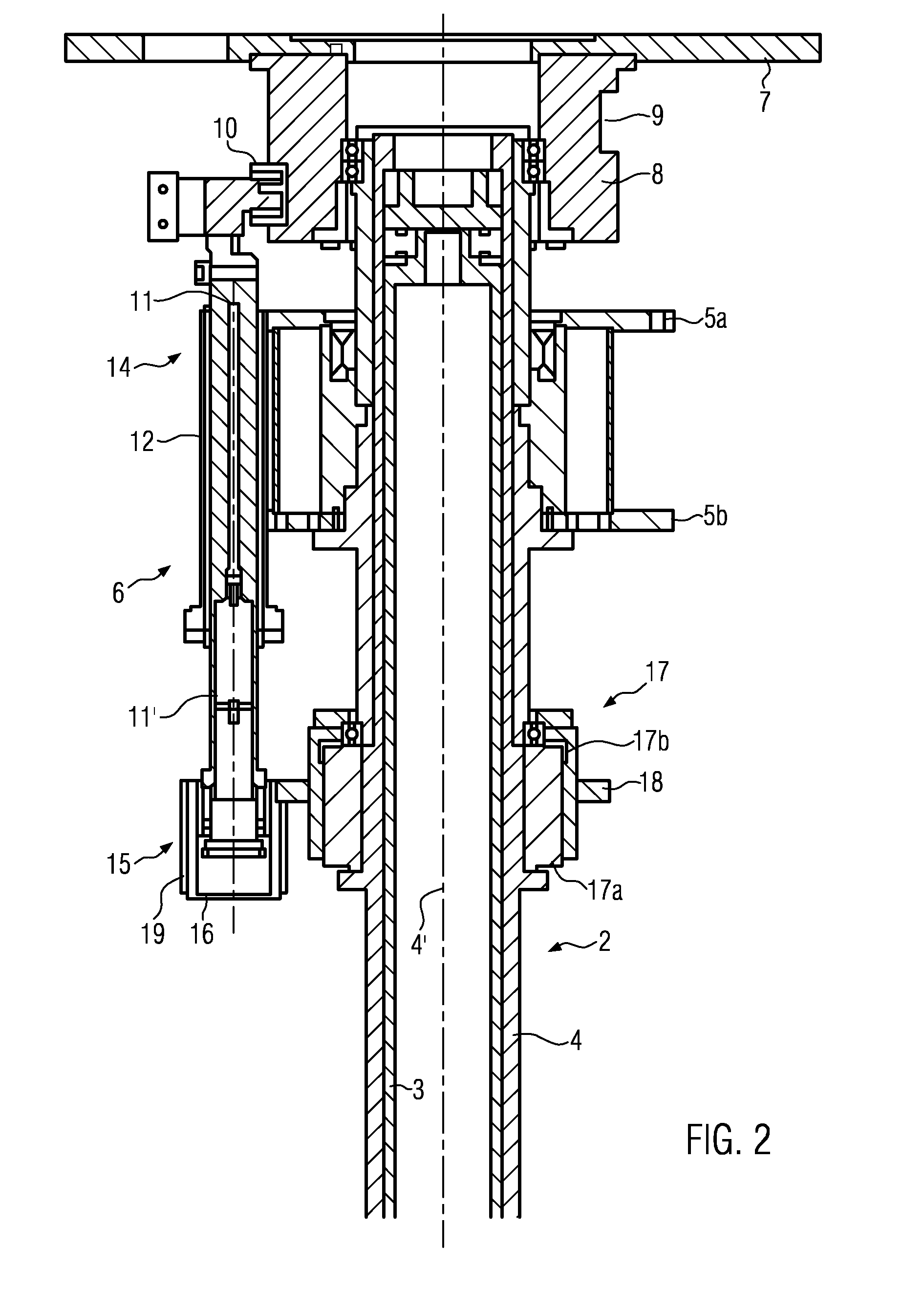

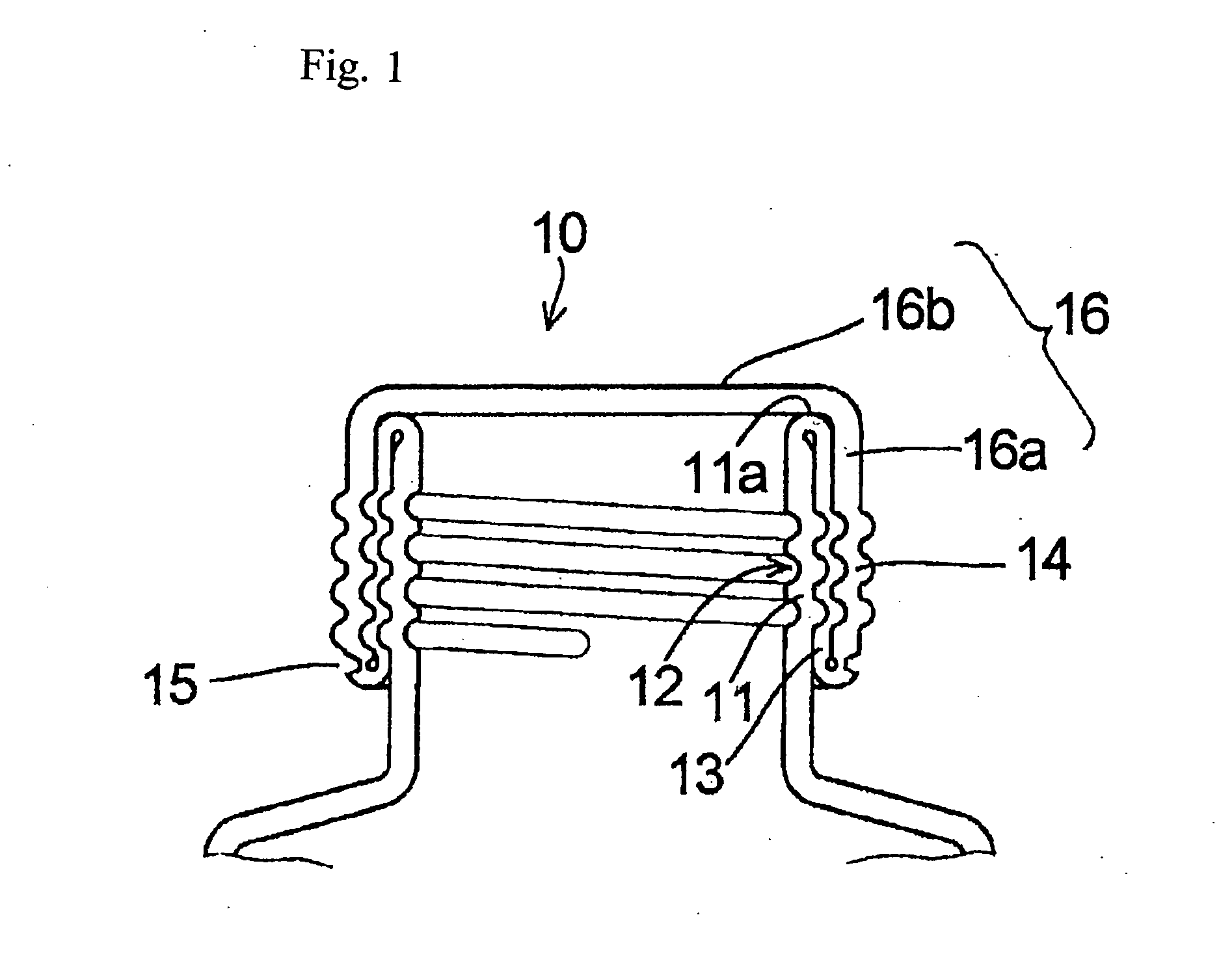

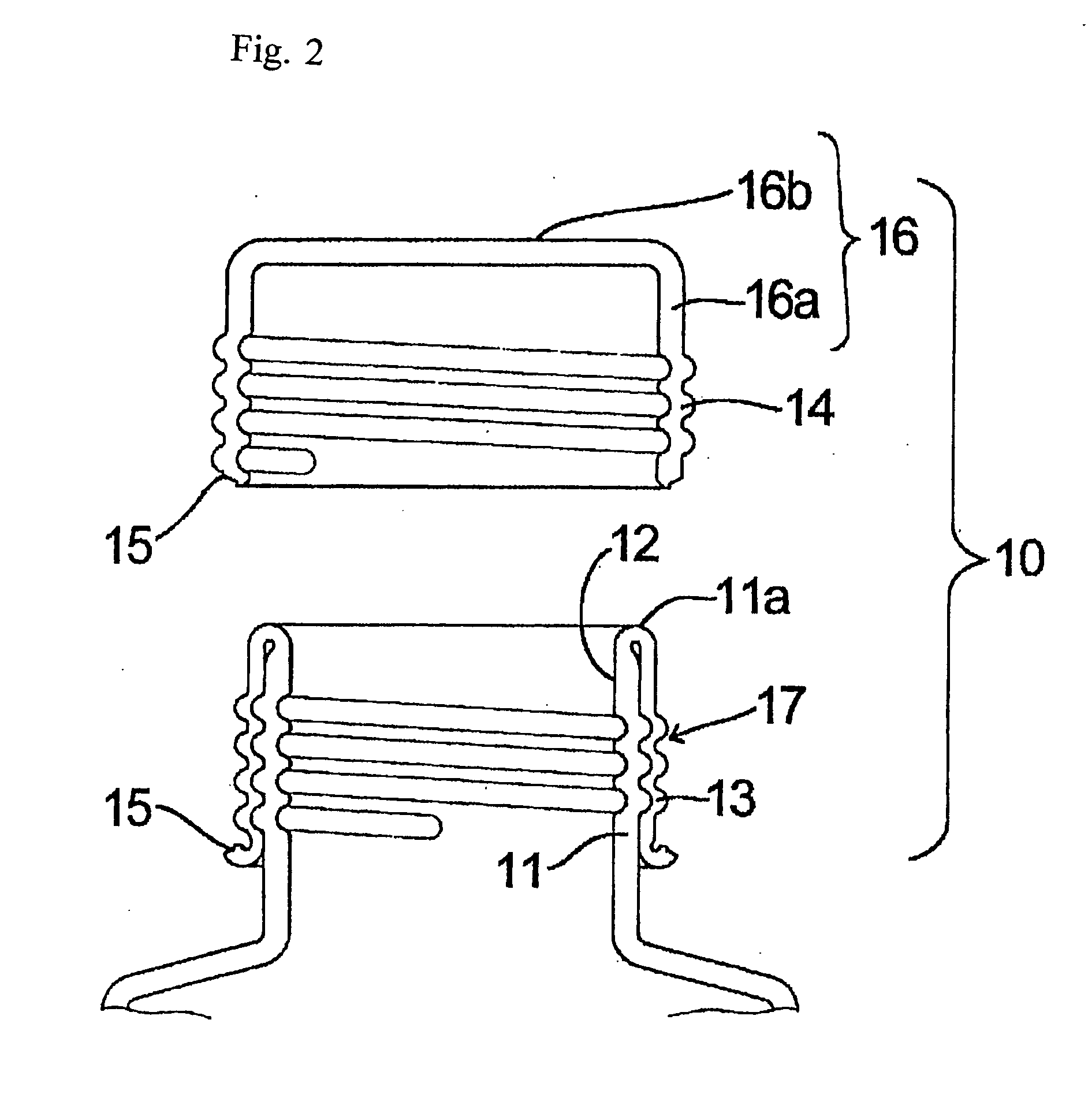

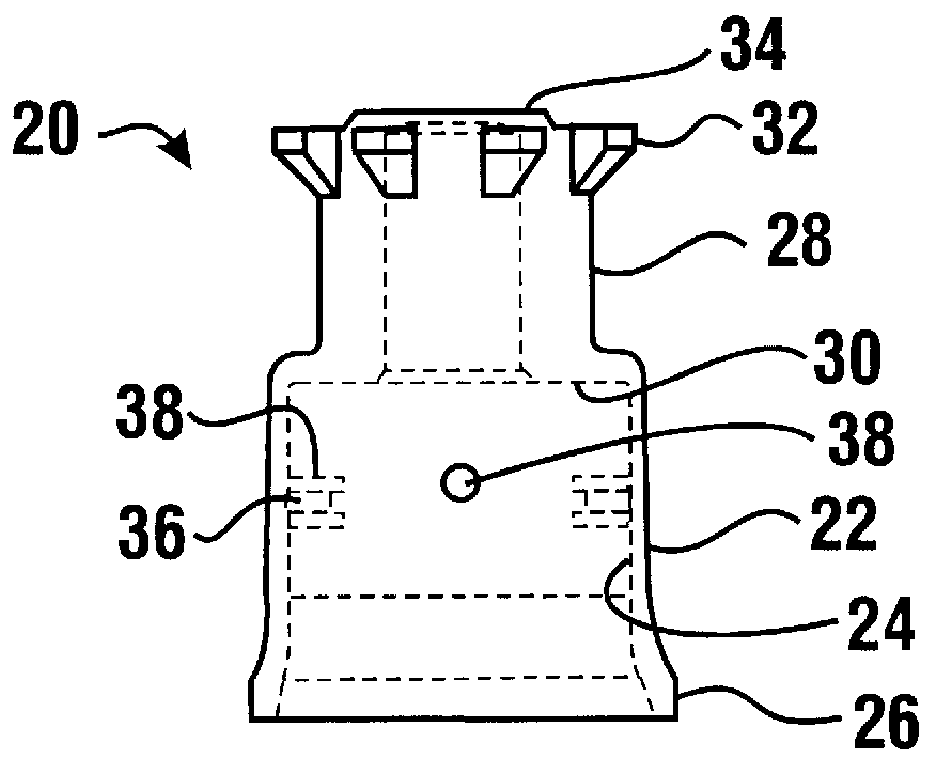

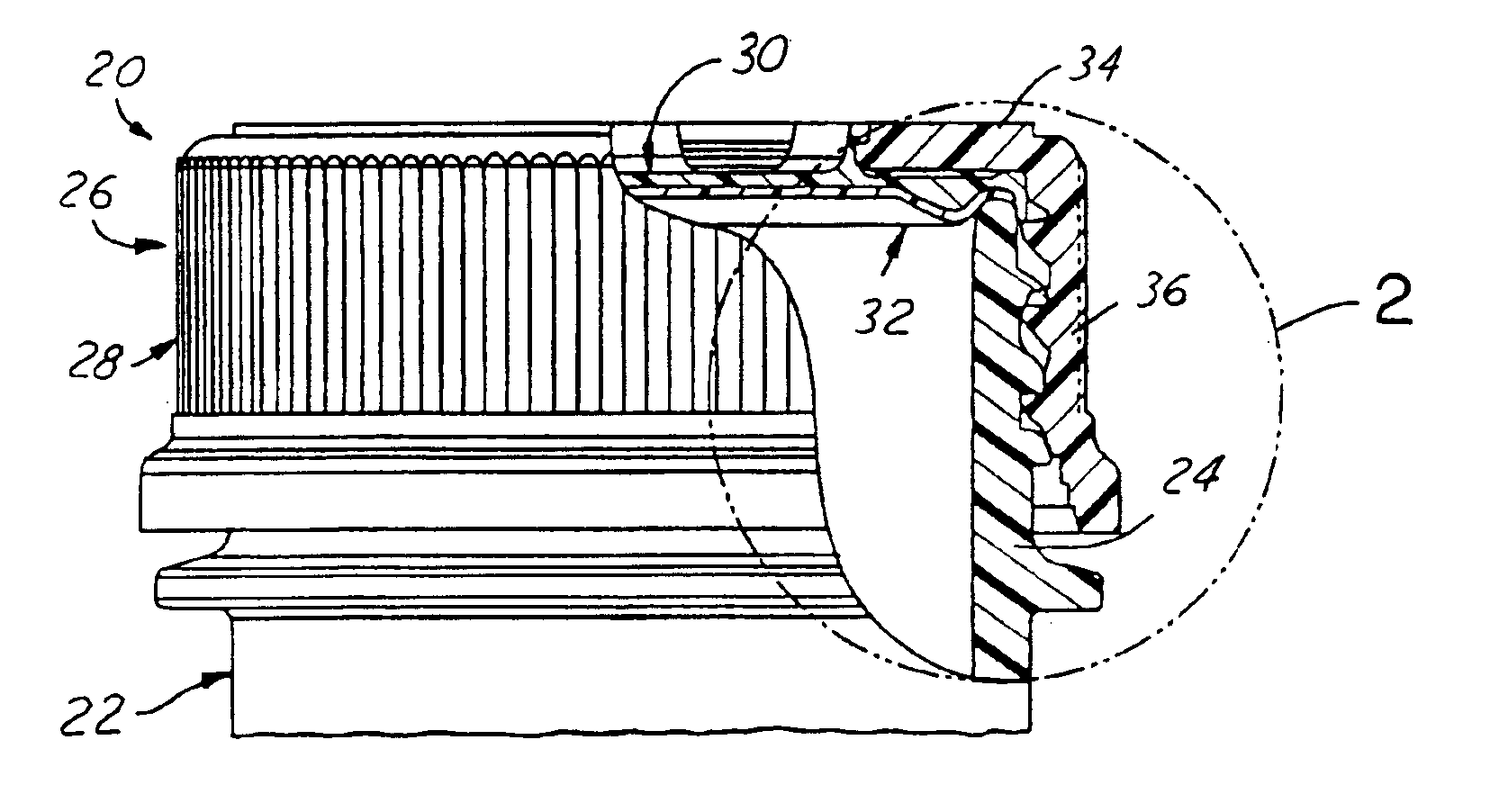

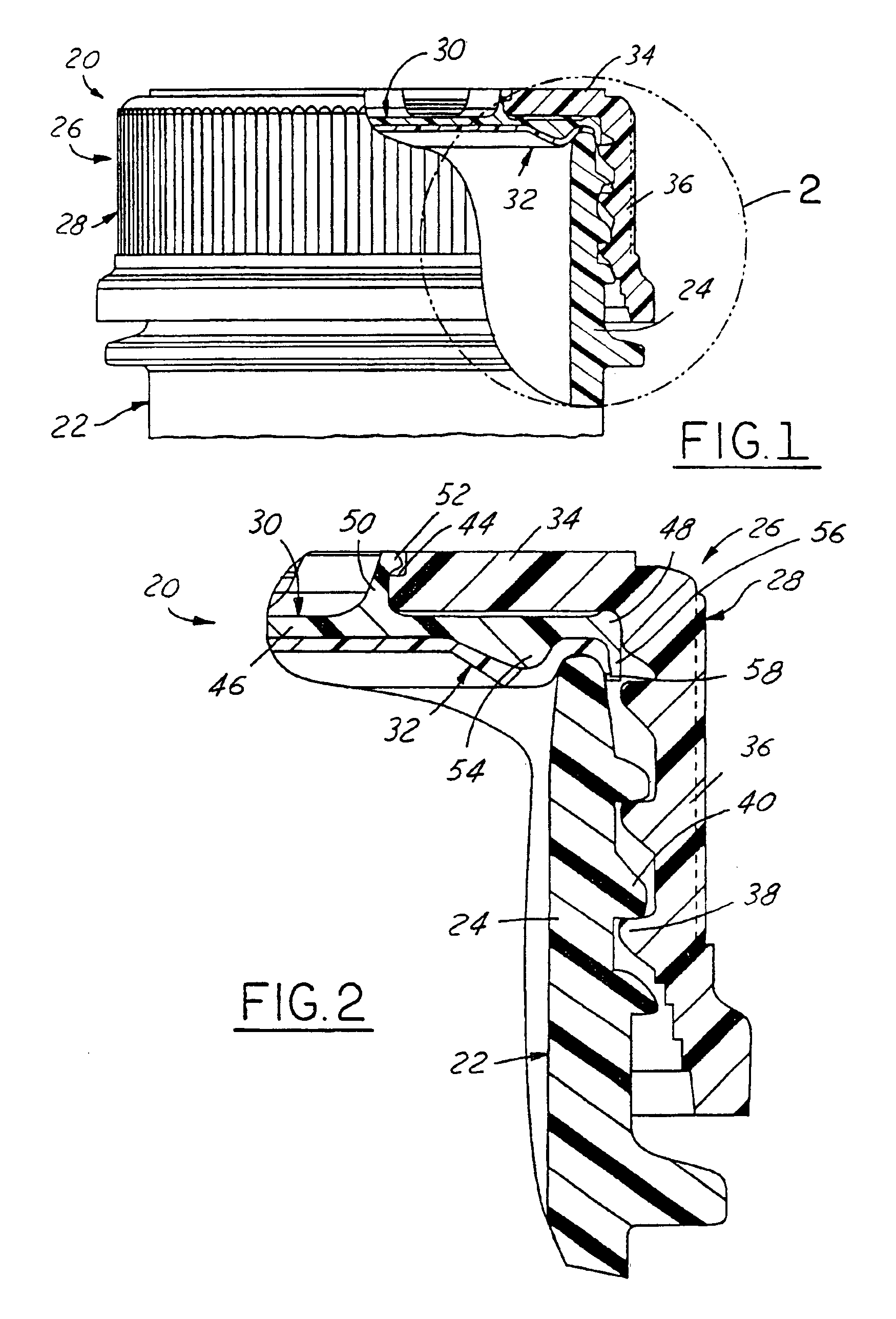

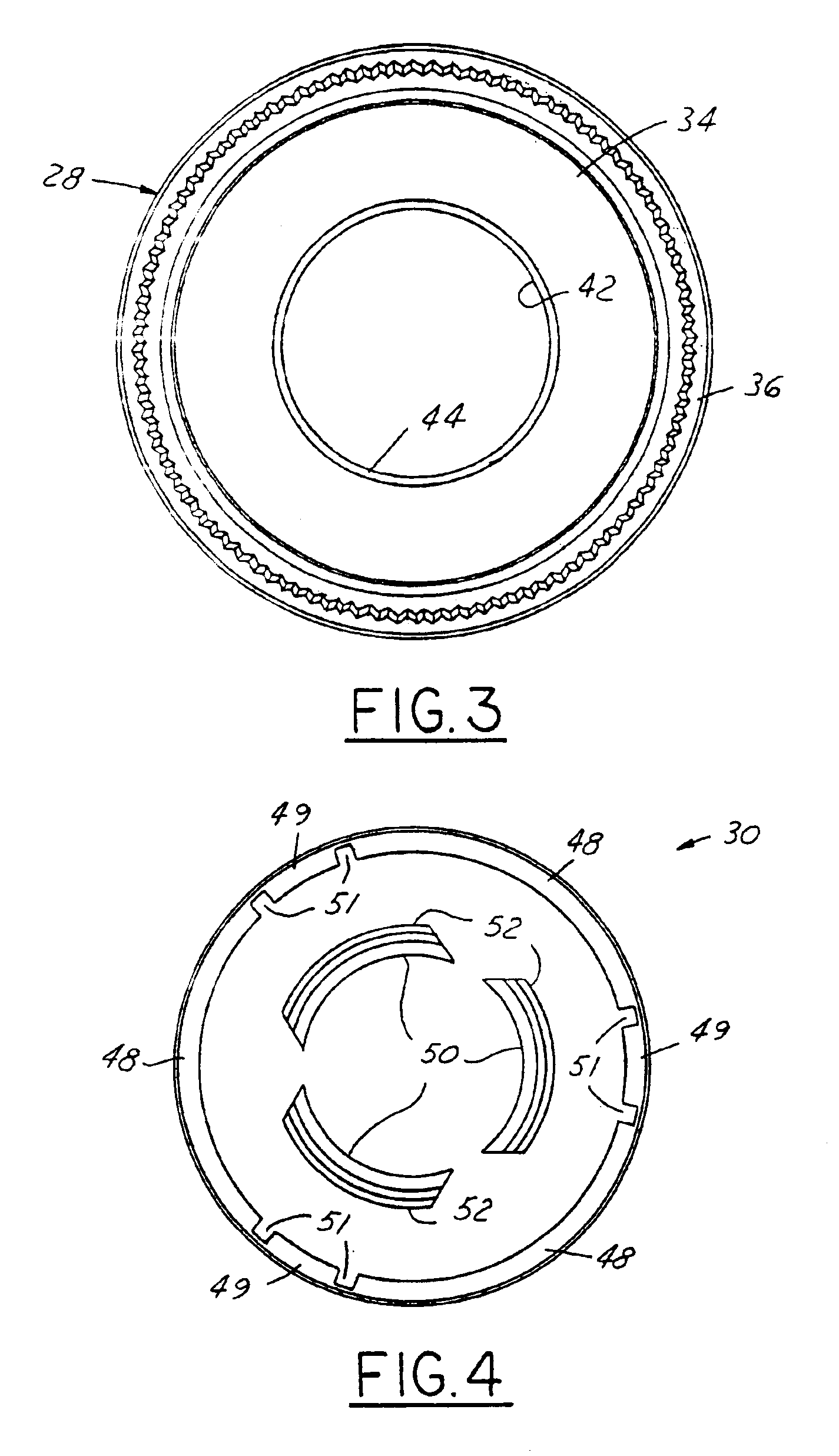

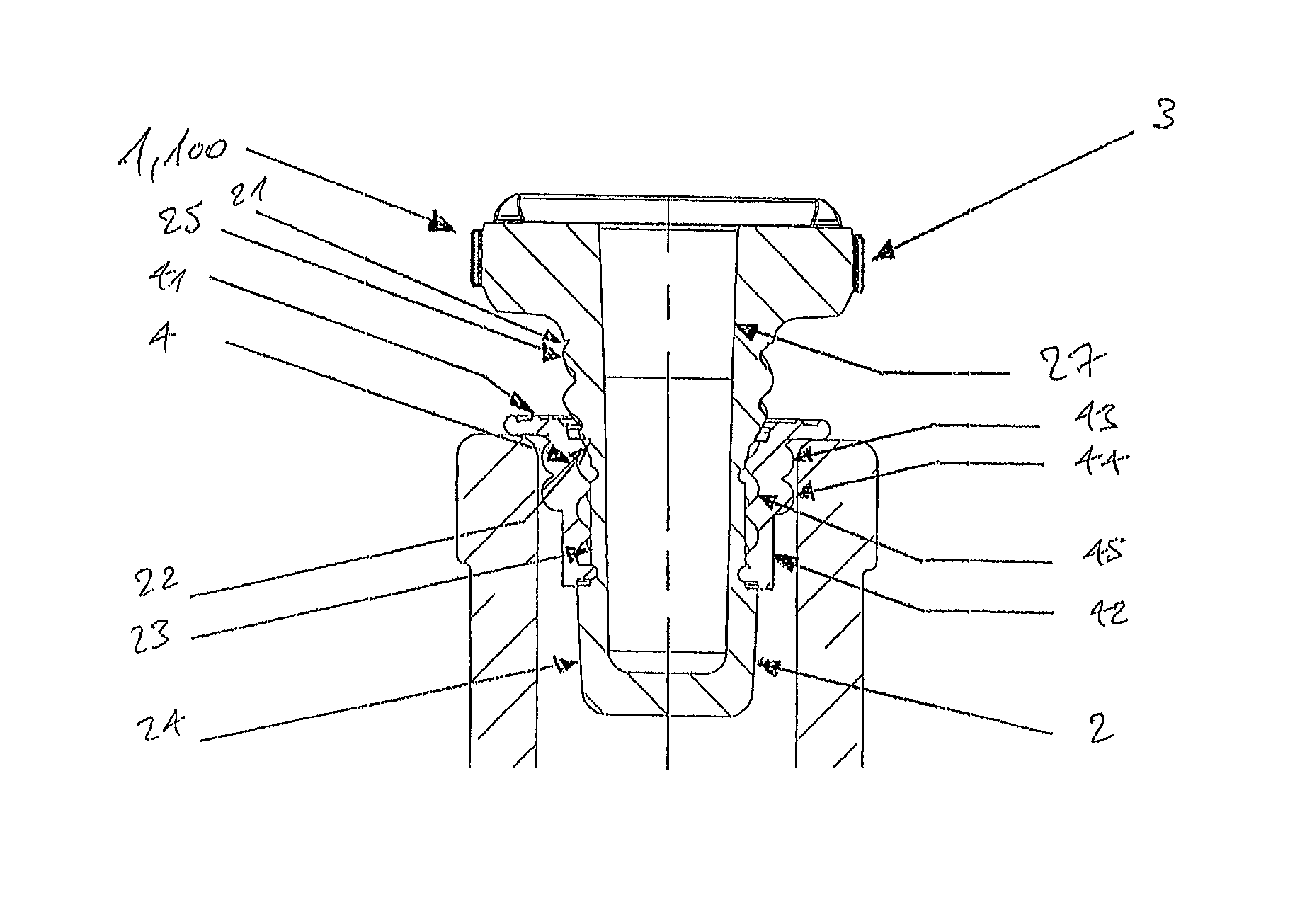

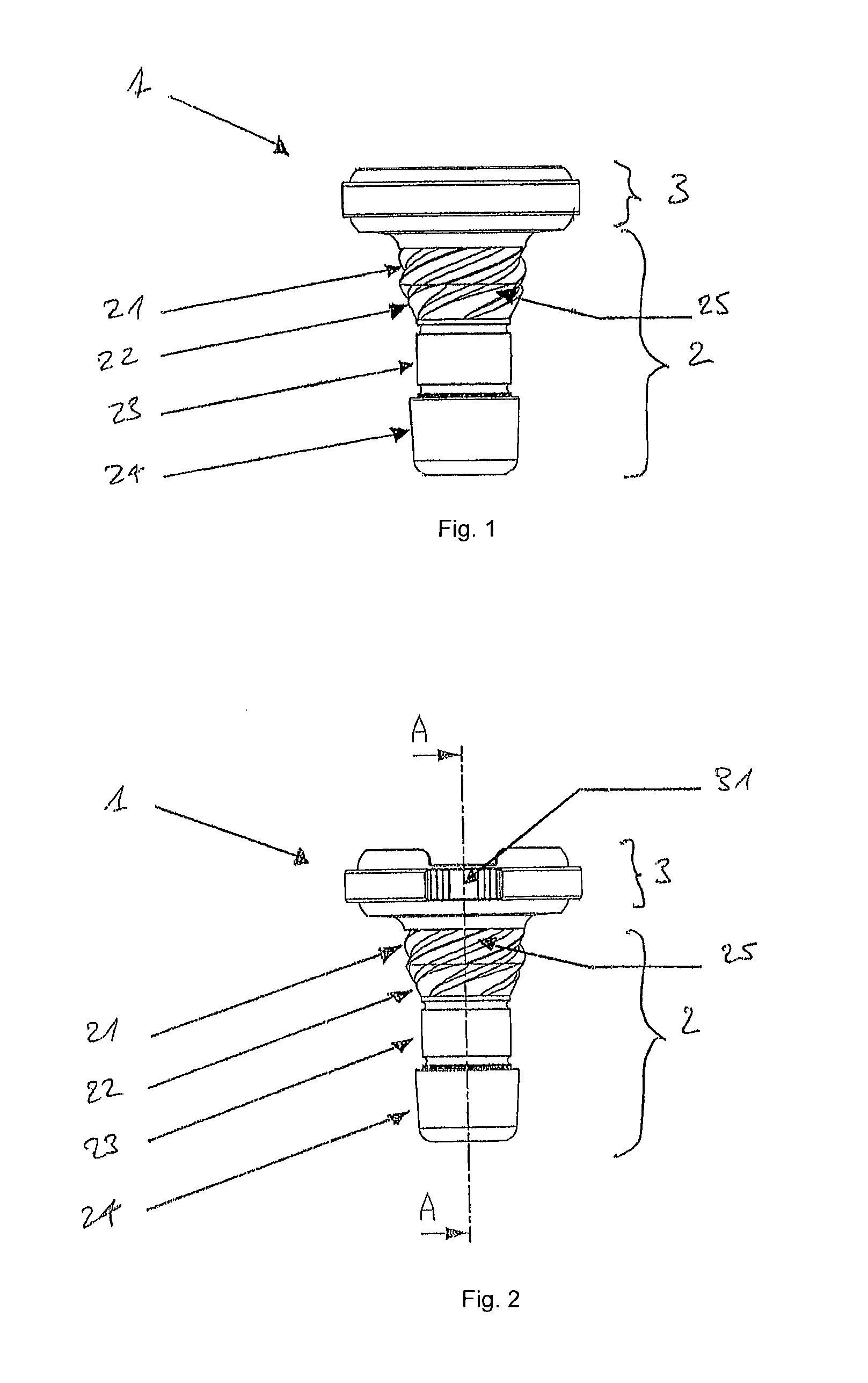

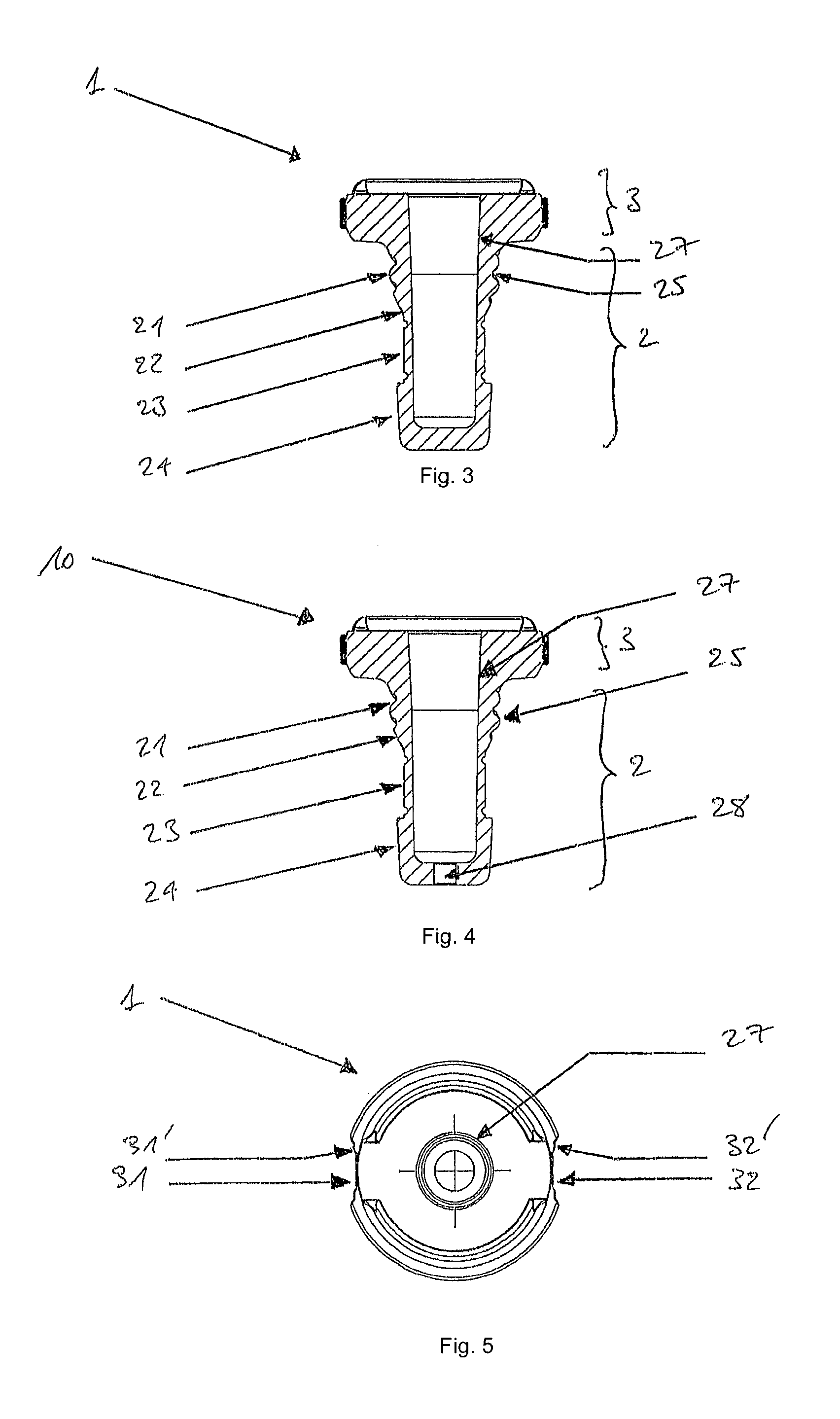

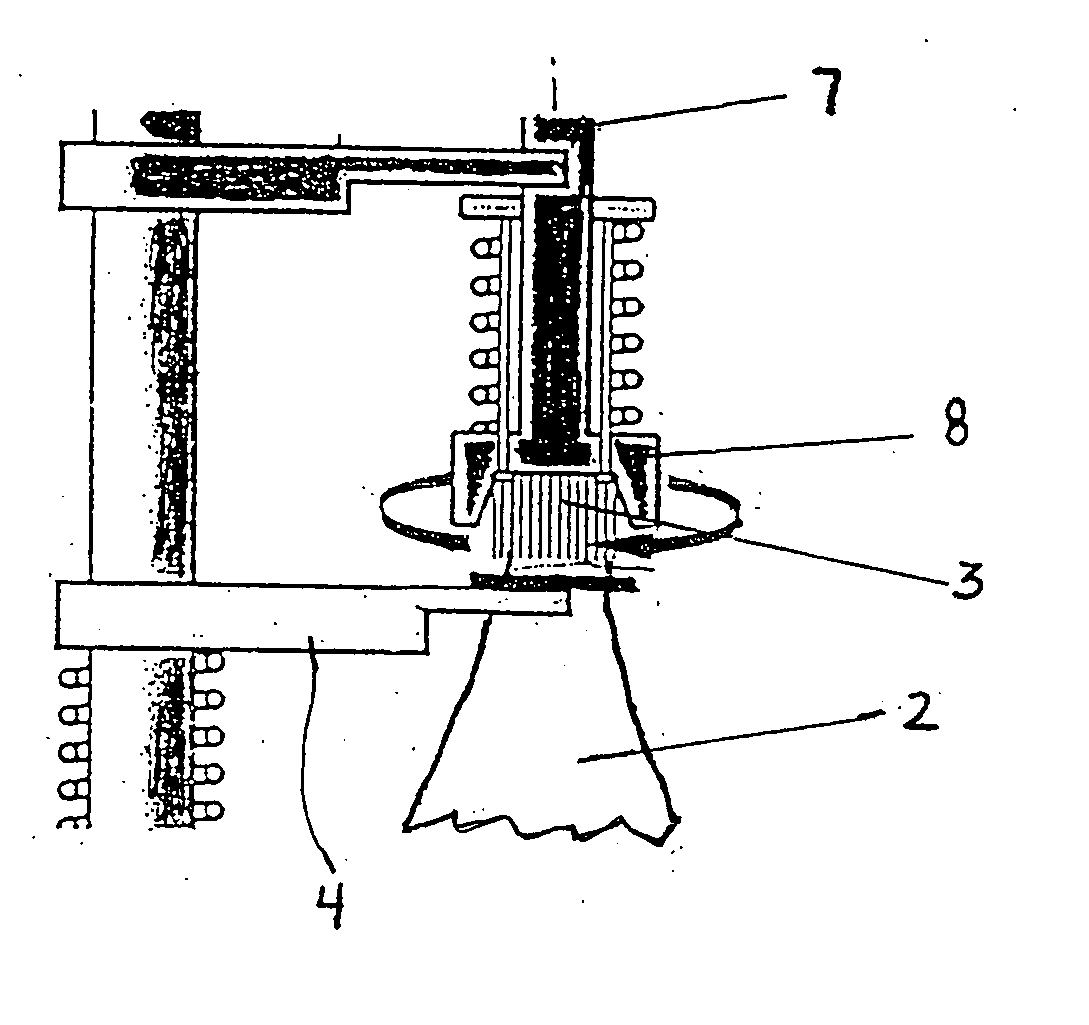

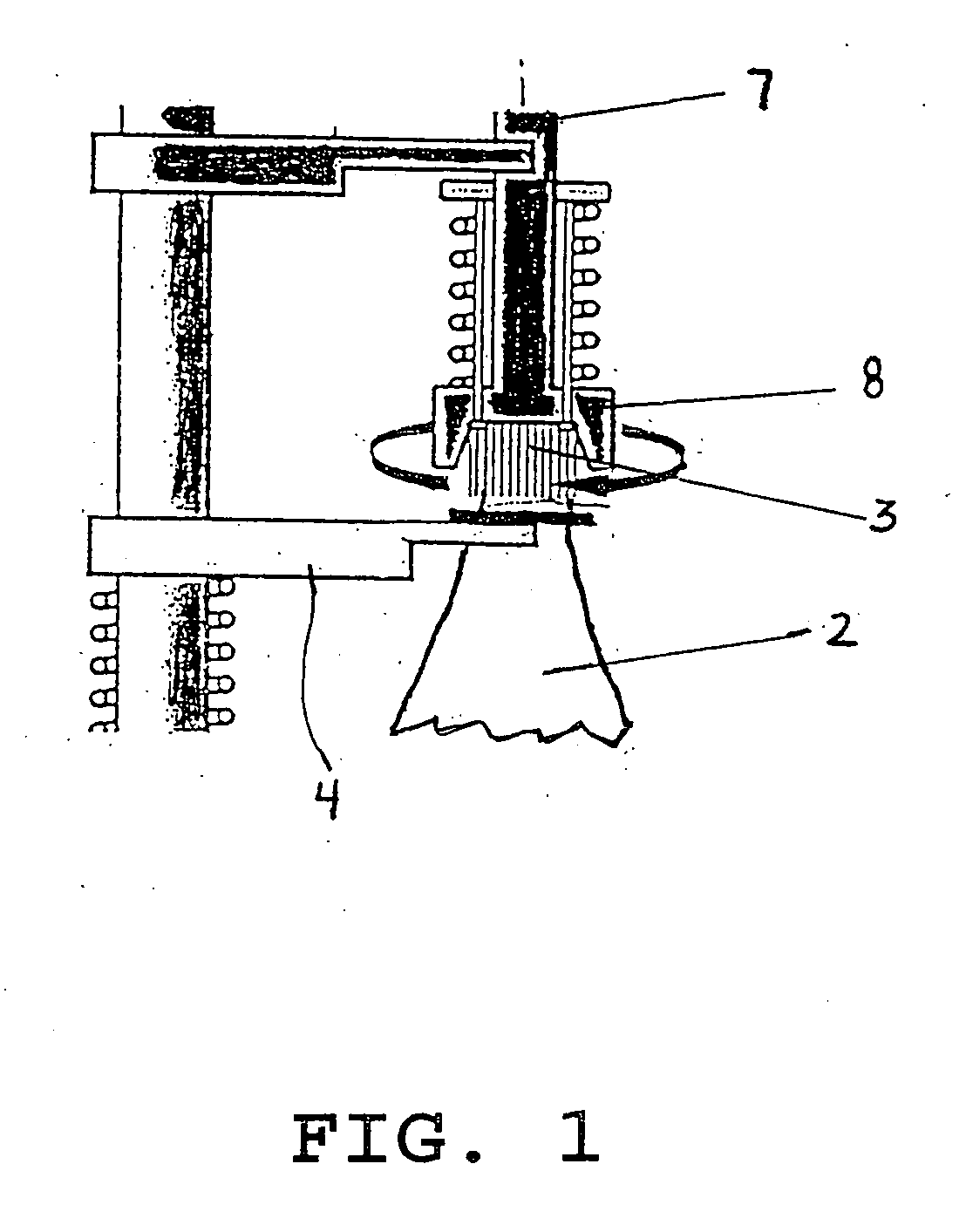

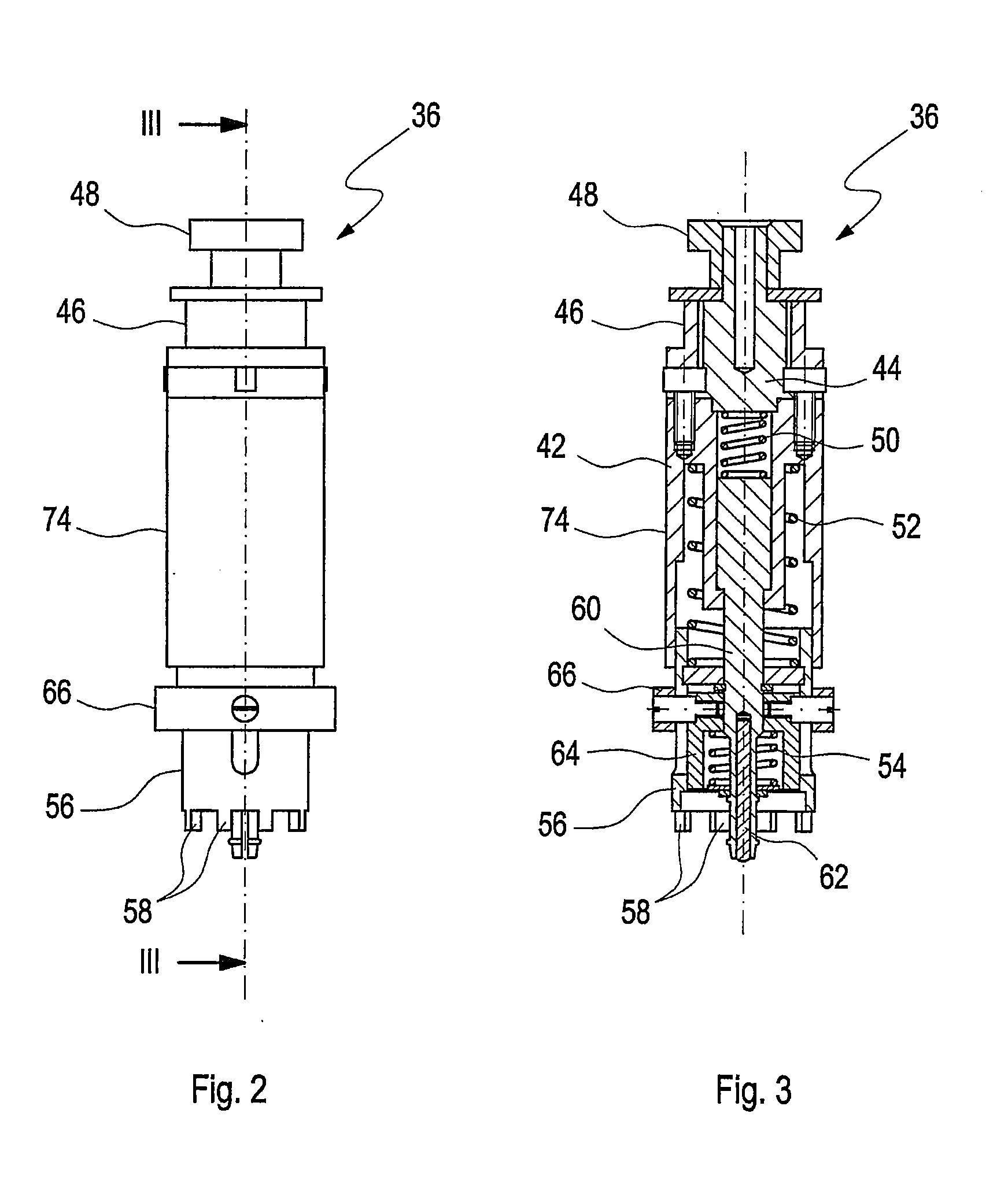

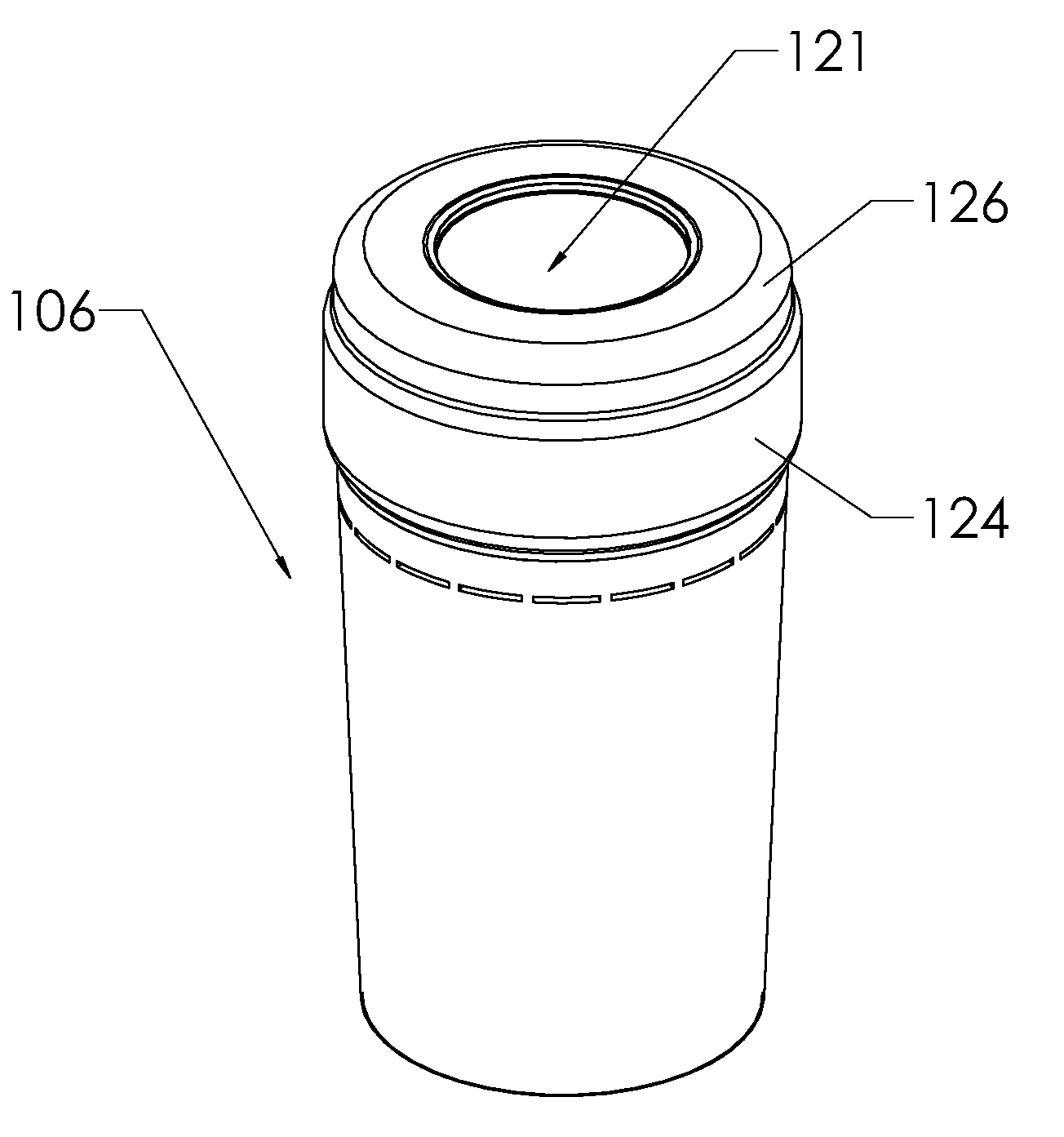

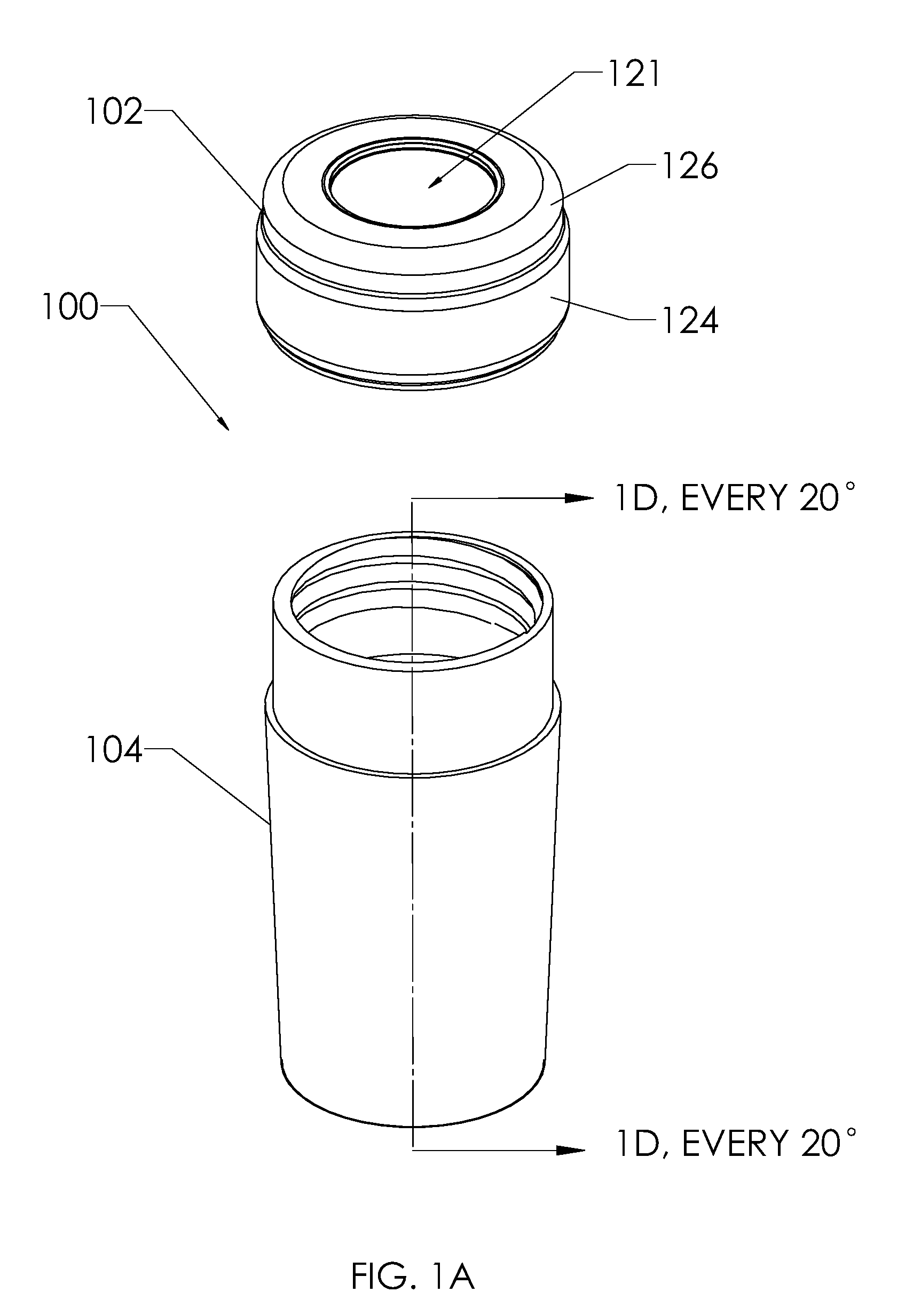

Stopper for a bottle and sealing element for said stopper

InactiveUS9493274B2Improve sealingProcess economyClosure with auxillary devicesRotating screw stopper insertionEngineeringBottle

A stopper for a bottle and a sealing element for sealing the stopper in the mouth of the bottle, which is separate from the bottle. The stopper comprises a stopper part for introduction into a mouth of the bottle, and a head part for remaining outside the mouth of the bottle, the head part having a diameter that is larger than that of the stopper part, wherein the stopper part comprises a an interlocking mechanism for engaging with a counterpart interlocking mechanism of the sealing element. The sealing element is forced against an inner wall of the mouth, thereby being brought into a sealed position, upon introducing the stopper part into the mouth, in which sealed position the stopper is held on the bottle. The interlocking mechanisms permit bringing the sealing element into an unsealed position by an unsealing action which comprises rotating the stopper with respect to the bottle.

Owner:PATENT ROOM P5 S A R L

Container closure system

InactiveUS6945011B2Prevent peelingSimplify and facilitate applicationCapsThreaded caps applicationFast releaseEngineering

A system for sealing threaded containers. The system includes a clutch-free spindle assembly which is easily disassembled and cleaned. The special interface between the exterior surface of the cap an the gripping jaws of the chuck allow the system to operate without the moving parts and complications that attend the use of clutch. The spindle assembly features an easily adjustable stop arm and a quick release pin for removing and cleaning the chuck. The chuck has several passageways for the rapid infusion of cleaning fluid.

Owner:BLACKHAWK MOLDING

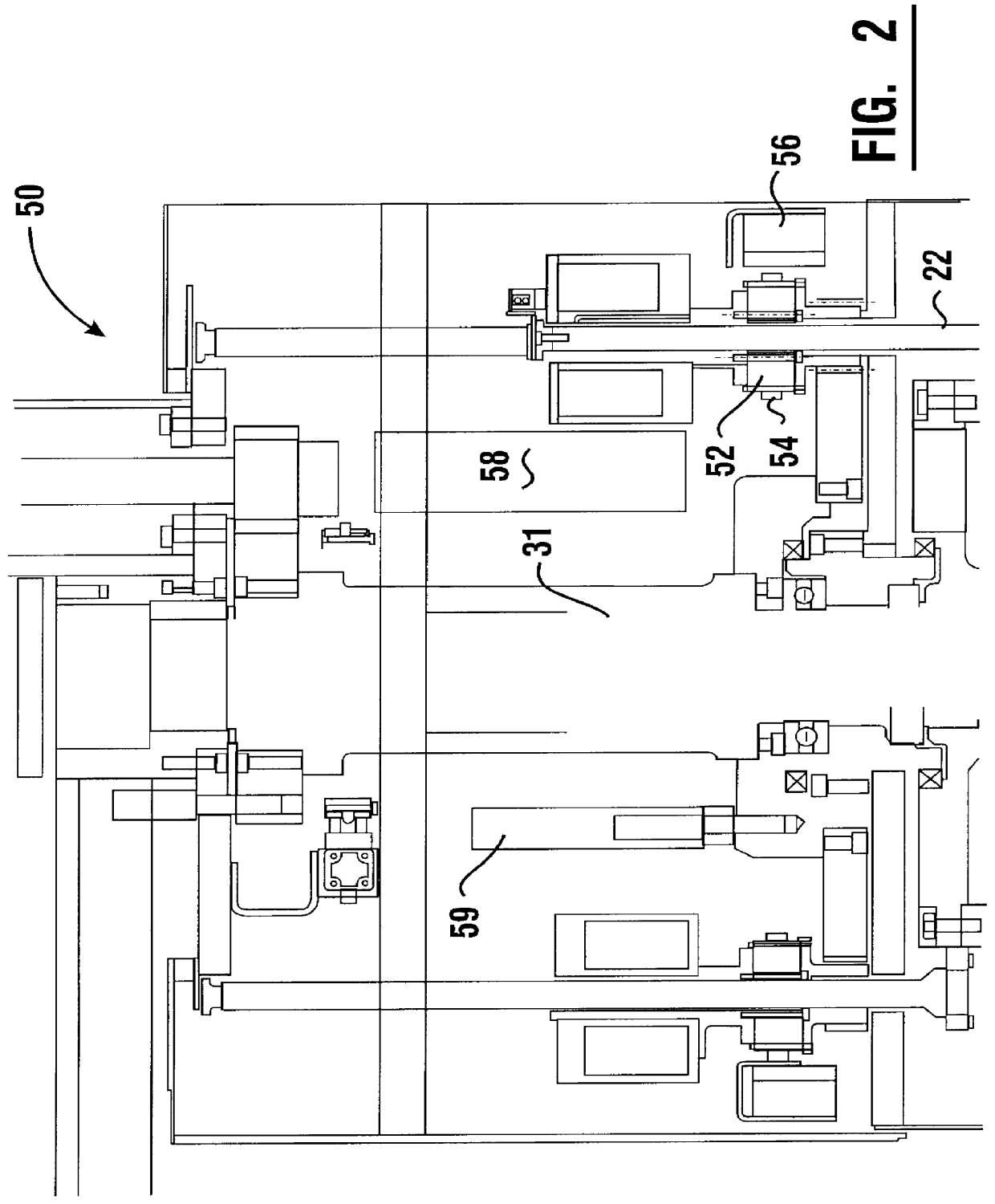

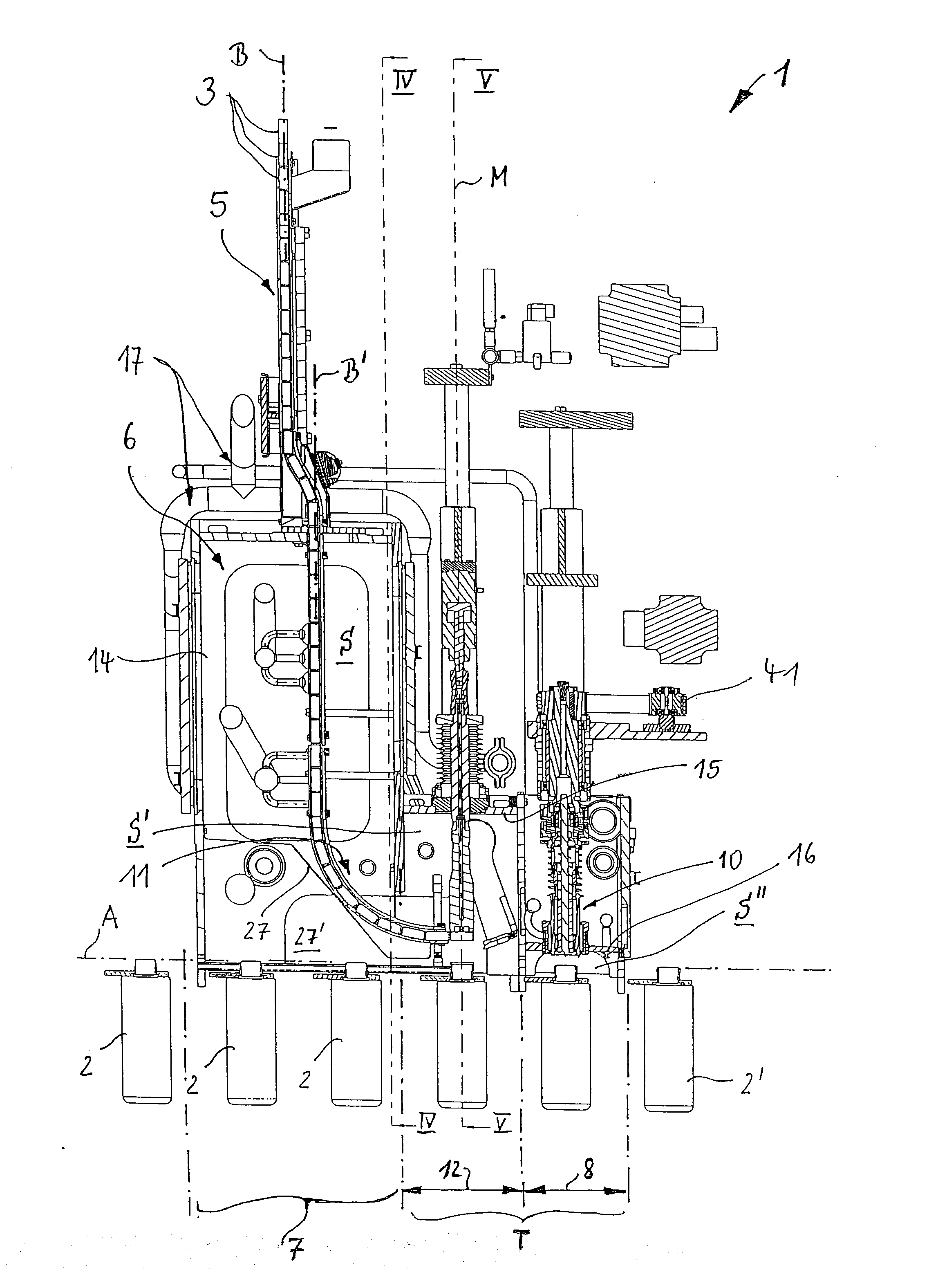

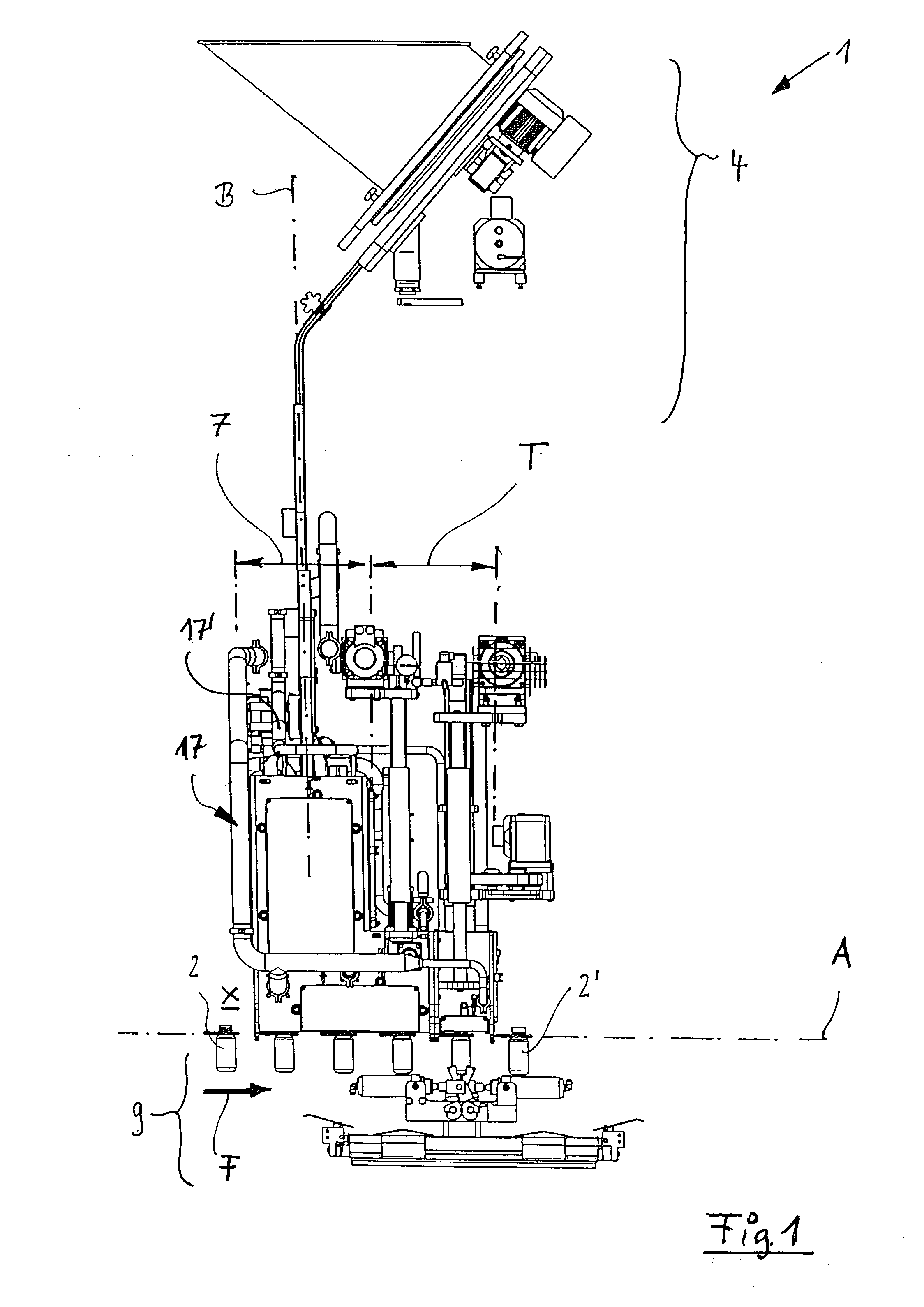

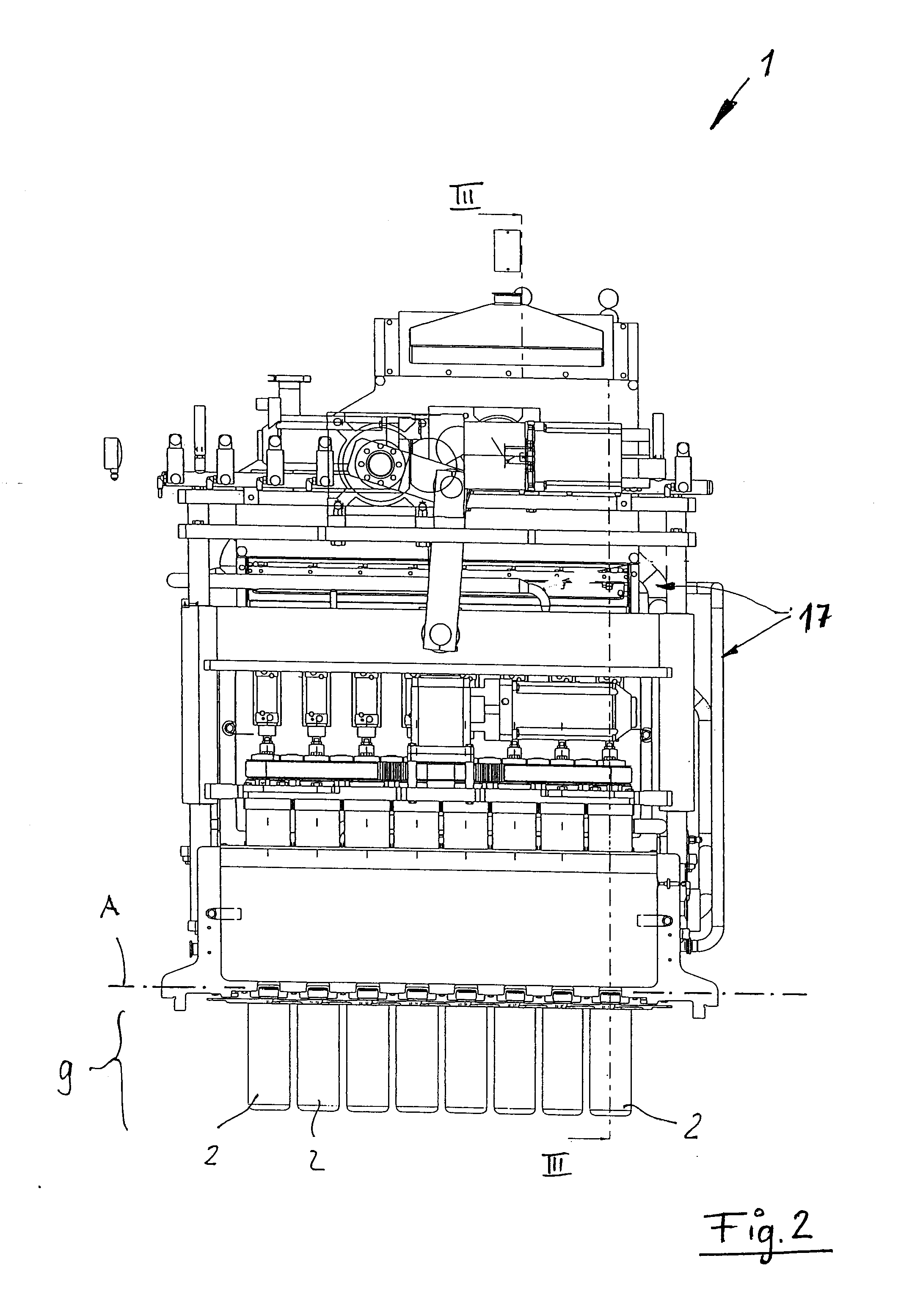

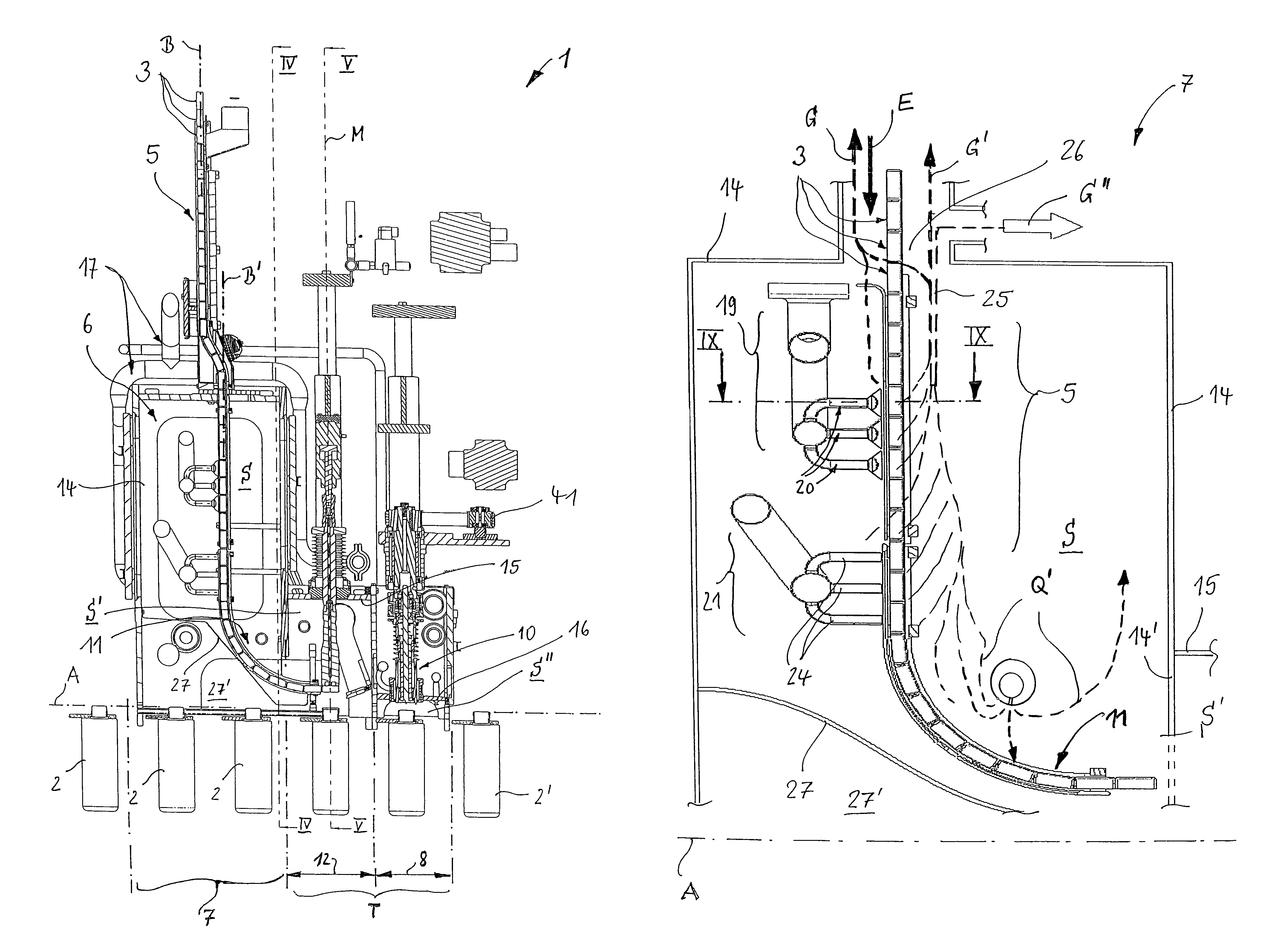

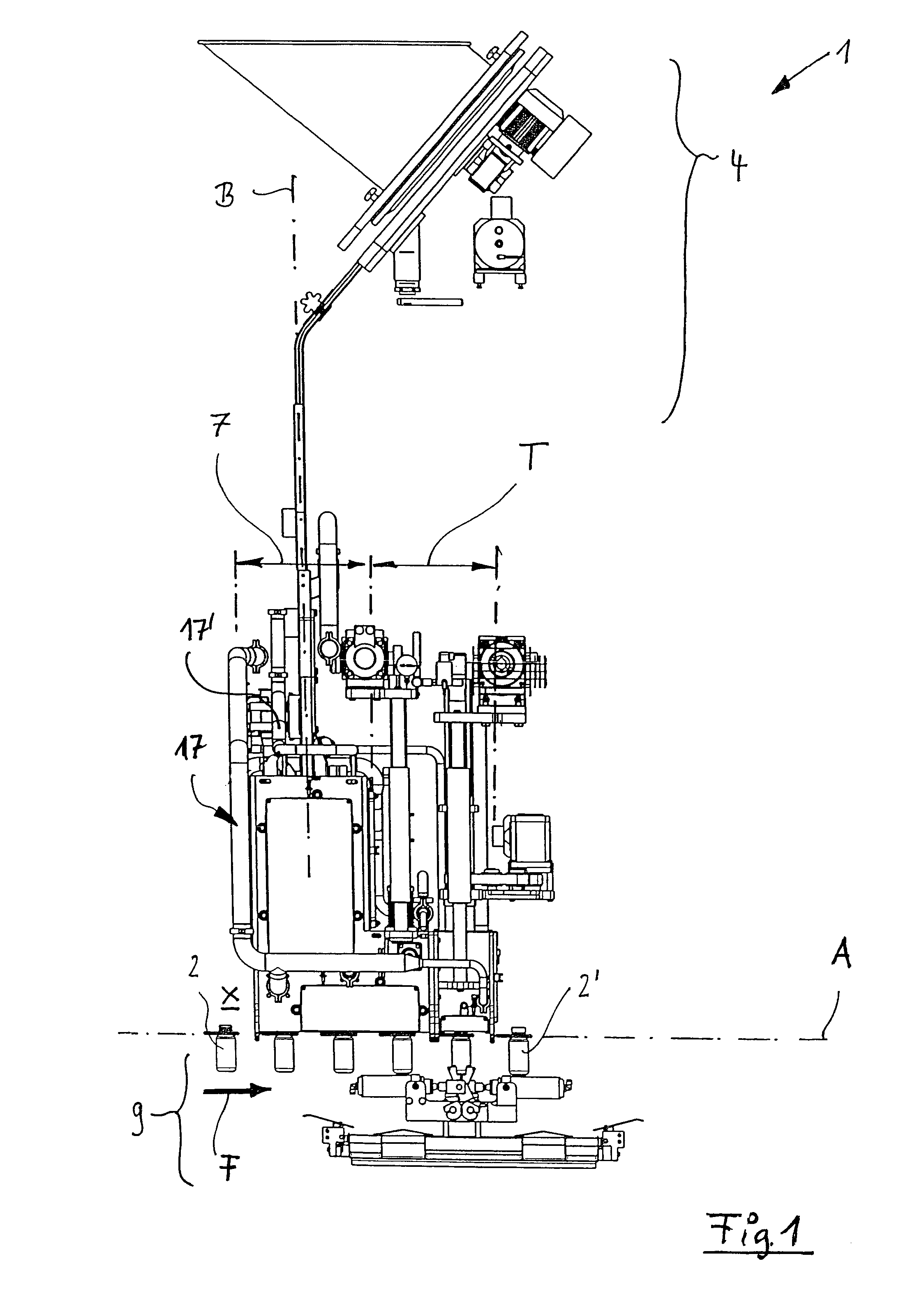

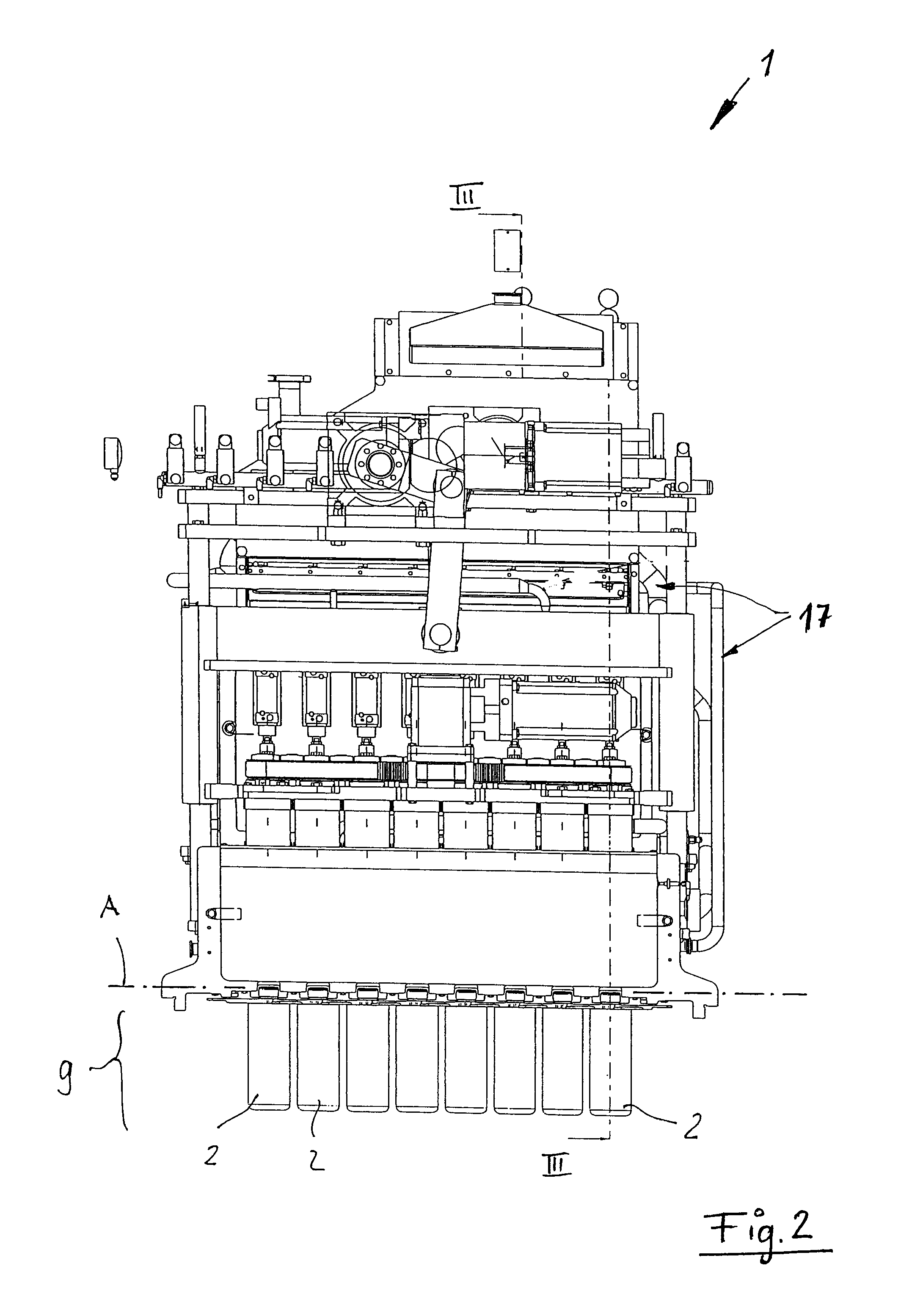

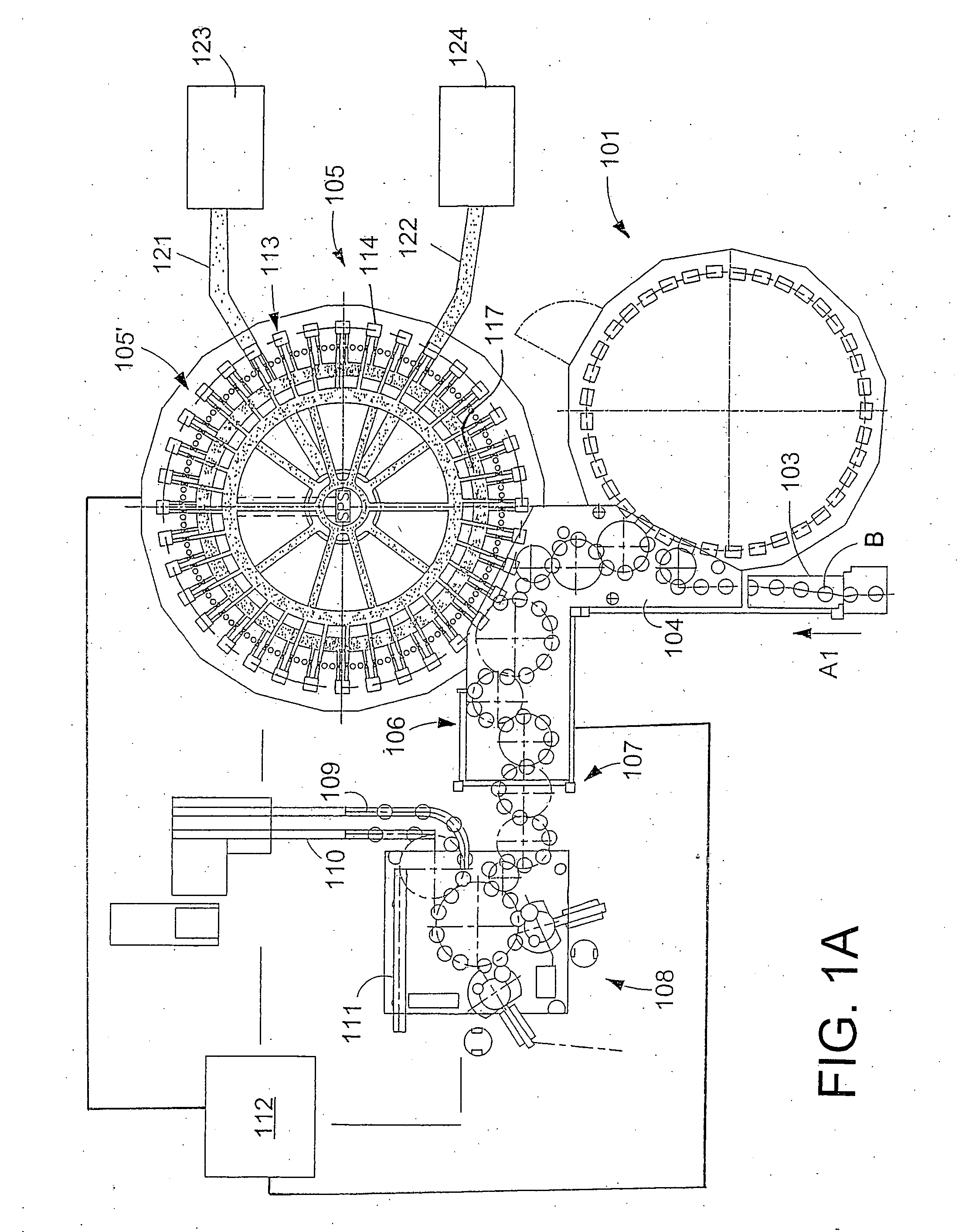

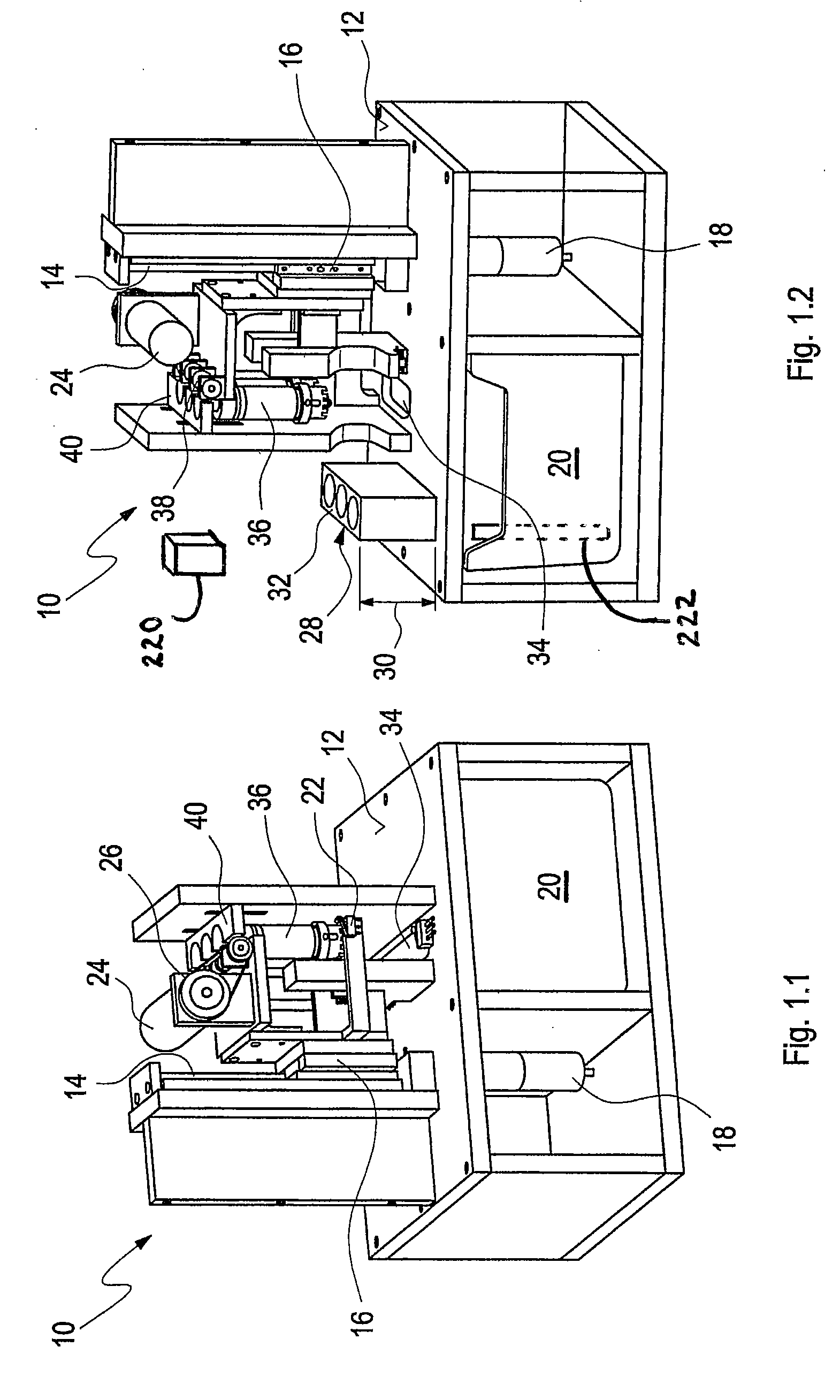

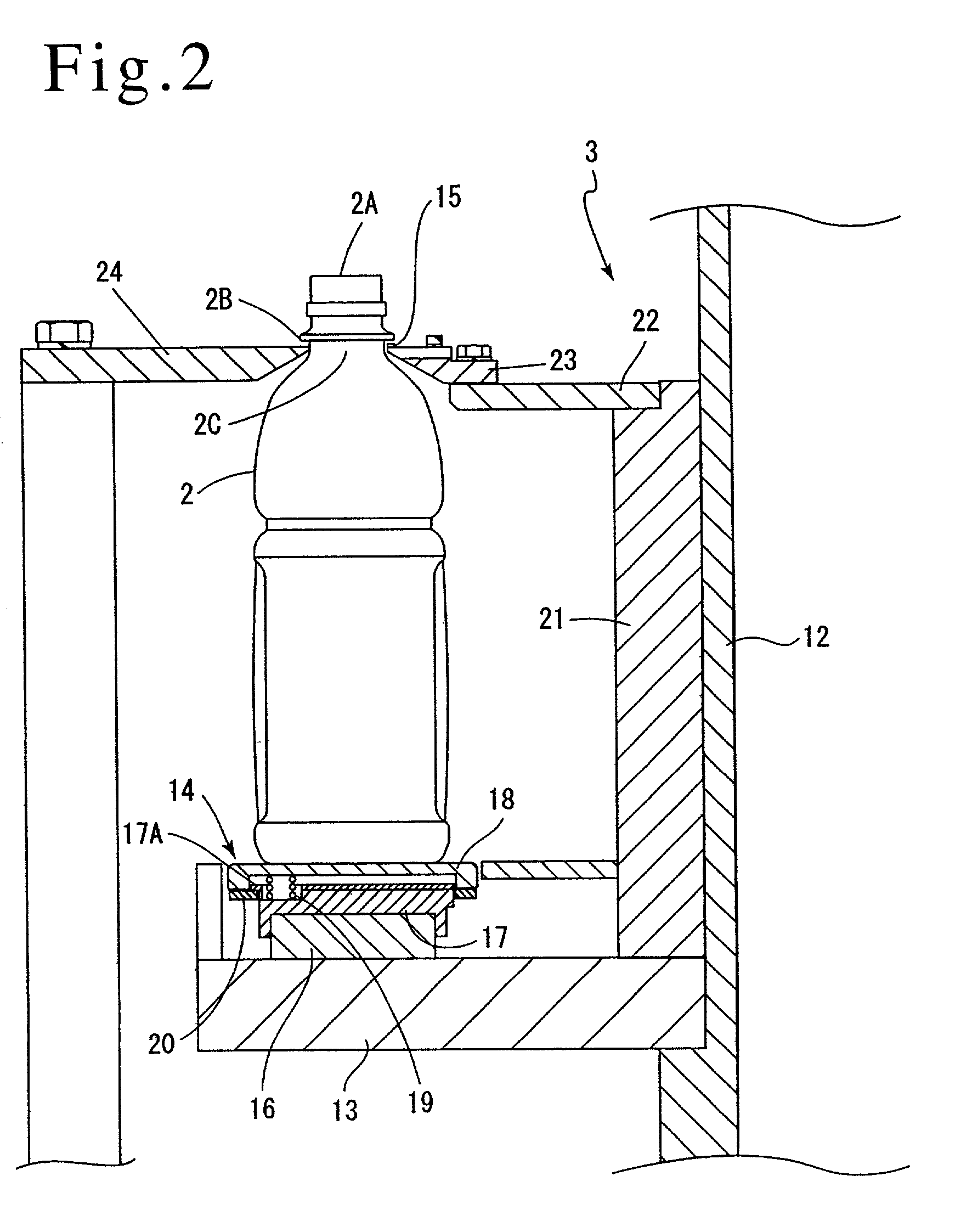

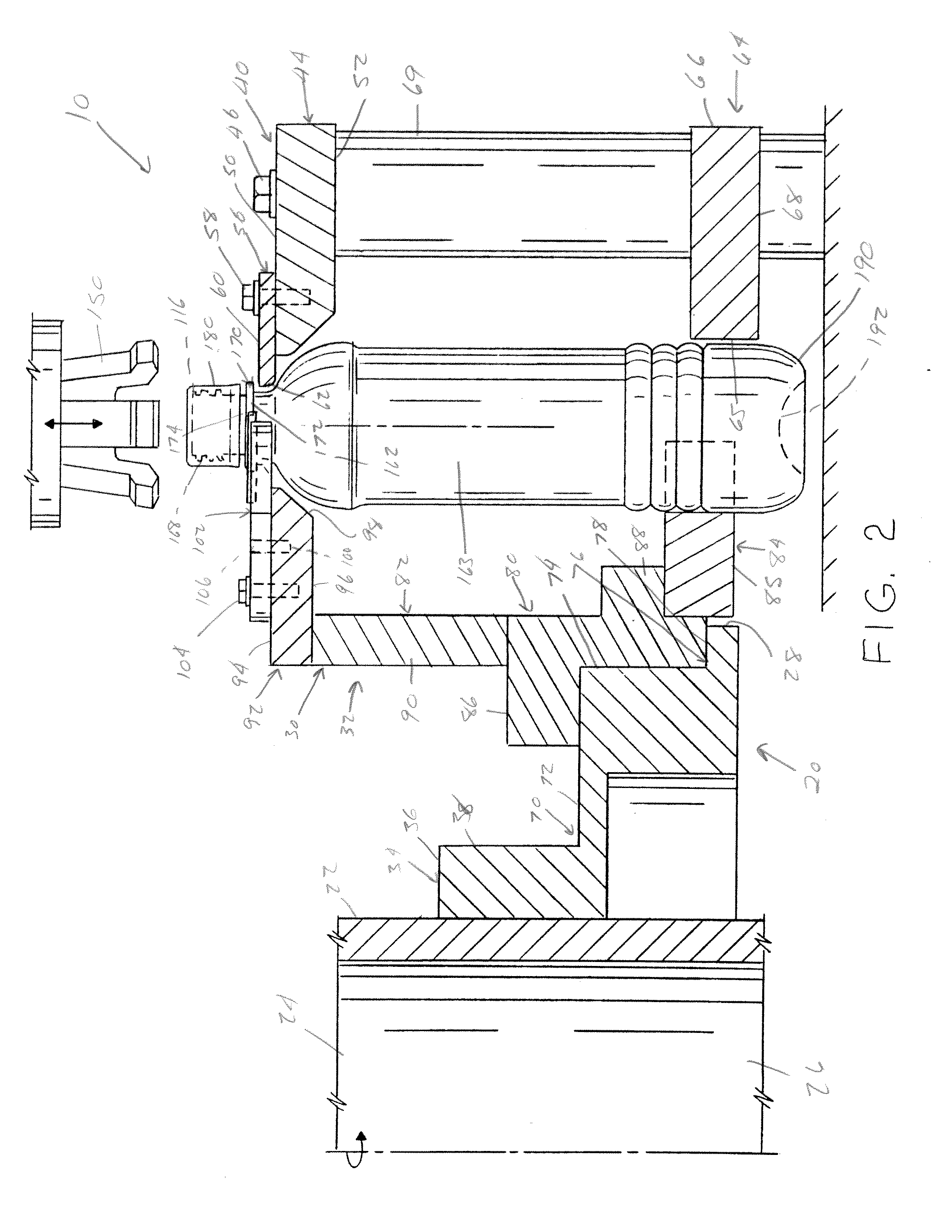

Beverage bottling plant for filling bottles with a liquid beverage filling material having a closing machine for closing containers

InactiveUS20050150193A1Improve reliabilityImprove securityClosing machinesCapsFilling materialsTrademark

A beverage bottling plant for filling bottles with a liquid beverage filling material, and a method for the operation of a closing machine and a closing machine for the closing of bottles or similar containers with closures or screw caps by screwing on the closure or cap, with a plurality of closing positions formed on the periphery of a rotor that circulates around a vertical machine axis, to which positions the containers to be closed are transferred at a container inlet and the closed containers are removed at a container outlet, whereby each closing position has a container carrier and a screw shaft that is provided on its lower end with a screw head and is mounted so that it can rotate around an axis, whereby each of these screw shafts can be driven by its own drive motor, whereby above the closing positions a mounting space (13) is formed which rotates together with the main column. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Capping head with a magnetic clutch

Owner:PRECISION TORQUE CONTROL

Closure with application guide

InactiveUS9126726B2Prevent closure tilting or cockingFacilitate threaded applicationCapsThreaded caps applicationEngineeringScrew thread

Owner:CLOSURE SYST INT INC

Decapping system

Decapping system for opening or closing reagent containers or cartridge systems closed by a lid the which is removed and secured by a rotational movement and method thereof are disclosed. The decapping system has a centering unit that the at its lower end provides a snap-in element which engages the lid, and a plurality of simultaneously driven and vertically movable screwing heads which compensates for variable heights and / or sizes of cartridge systems to be processed.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

Method of testing, determining, and adjusting a final closing torque of a beverage bottle or container closing machine and an apparatus for performing the method

Method of testing, determining, and adjusting a final closing torque of a beverage bottle or container closing machine and an apparatus for performing the method. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

Capping method and capping apparatus

A screw capper 1 includes a capping head 6 which grips a cap 5, a servo motor 7 which rotates the capping head, a voltmeter 10 which measures the torque of the capping head, an encoder 11 which detects the rotational angle of the capping head, and a control device 8 which controls the servo motor. In the screw capper, whether rotational fastening is acceptable is to be determined during the rotational fastening, the measured value of the encoder is measured from a predetermined measurement starting point until a rotational fastening completion point, and if the measured rotational angle is in the range of an acceptable decision angle which is set in advance, it is determined that the rotational fastening has been acceptably performed, whereas if the measured rotational angle is not in the range of the acceptable decision angle, it is determined that the rotational fastening is unacceptable.In the screw capper, defective rotational fastening can be detected, and reductions in costs can be realized compared to a case where a device for detecting such defective rotational fastening is separately provided.

Owner:SHIBUYA IND CO LTD +1

Screw-capsule for wine bottles

InactiveUS20110036839A1Function increaseReduce energy consumptionCapsThreaded caps applicationWine bottleDiffusion barrier

A plastic screw cap has a threaded top portion and tabs of varying heights disposed around an inner circumference of a lower sleeve-portion. These tabs clasp a land disposed on a container neck to restrain the sleeve portion on the neck when the cap is unscrewed. A threaded top portion mates with threads on the container above the land. A sealing liner and diffusion barrier disposed at the bottle opening, together with a crush-resistant cap structure, prevent wine leakage and control oxygen ingress. Typically, the plastic cap is threaded onto the container neck, forming a tamper-evident seal. When unscrewed, the plastic-cap top moves up the container threads, exerting a pull on the sleeve portion, which is restrained due to the closure tabs acting on the land. Between the closure tabs and the threaded top is a breakaway line, which tears due to the removal forces. This tear evidences tampering.

Owner:GARDNER WILLIAM A

Container closure having means for introducing an additive into the contents of the container

A closure device with a fluid chamber containing an additive. The additive can be introduced and mixed into a liquid on the container by the closure device. The closure device includes a cap member having a fluid chamber and a housing having a plug member. The cap member is provided with a primary engagement member which engages with a corresponding primary engagement member provided on the housing to allow the cap member to be lifted relative to the housing from a closed position in which the plug member closes an aperture in the fluid chamber to an open position in which the plug member is at least partially withdrawn from the aperture, thereby allowing the additive to pass from the fluid chamber to the liquid in the bottle. The closure device enables mixing of the additive and liquid in the bottle without opening the closure.

Owner:GIZMO PACKAGING LTD

Screw capper

A screw capper includes a capping head which comprises a chuck for holding a cap, a motor for driving the chuck for rotation, a cam mechanism for elevating the chuck, and an air cylinder for imparting a load to the chuck. A load imparted by the air cylinder is controlled by a controller to be zero from the beginning of a screwing and tightening operation until an angle of rotation of the chuck exceeds a specific angle where the load is changed, and is controlled to a higher value upon detection of an angle of rotation of the chuck which exceeds the specific angle in the course of the screwing and tightening operation. The arrangement allows a reliable screwing and tightening to be achieved as compared with the prior art while preventing a damage to threads or the occurrence of a cocked cap.

Owner:SHIBUYA IND CO LTD

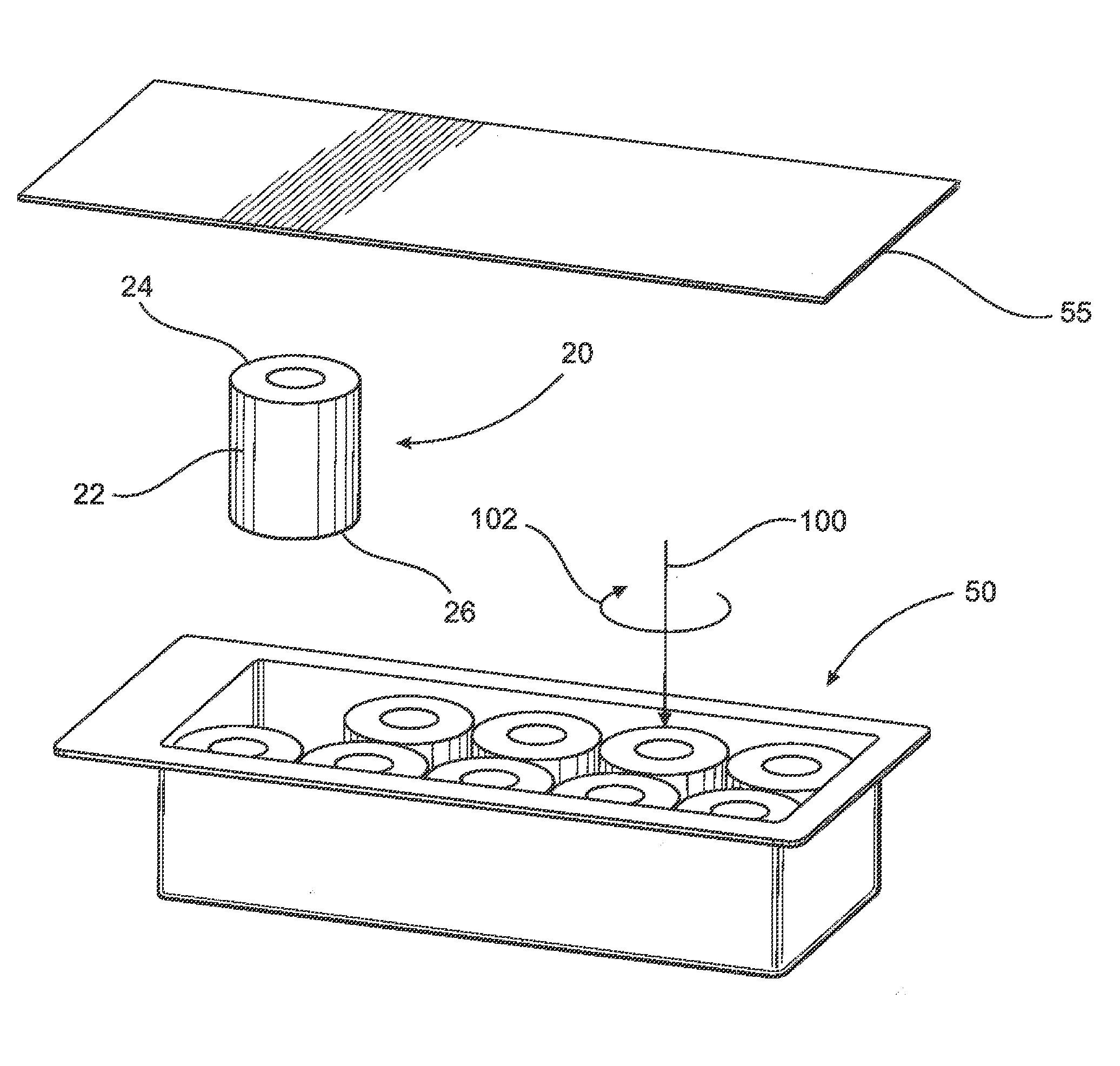

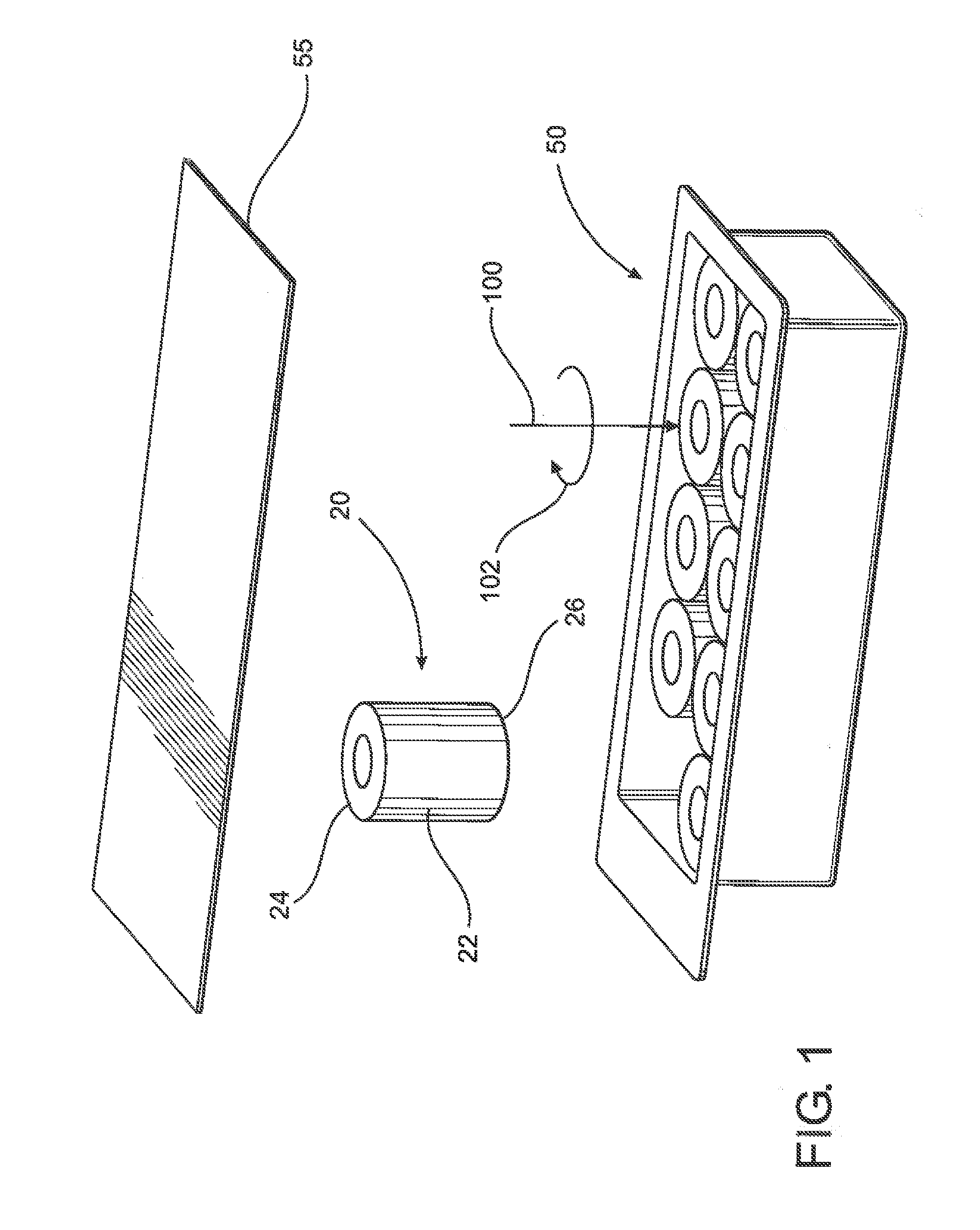

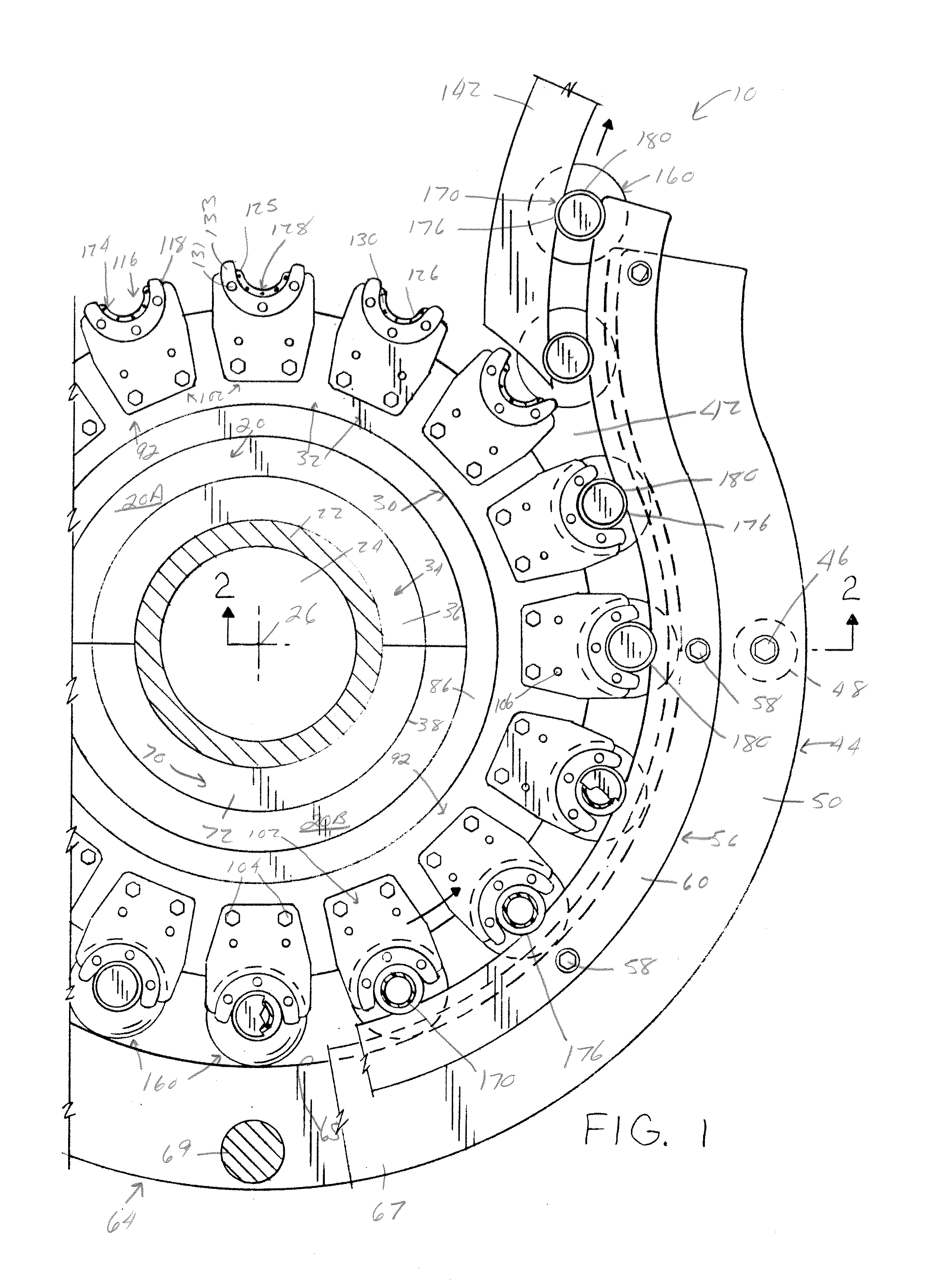

Apparatus and method to prevent bottle rotation

InactiveUS20120017546A1Reduction and elimination of compressive forceReduce eliminate such damageCapsThreaded caps applicationBottleFlange

A bottle support plate for use in a rotary capping machine to apply caps onto the upper threaded neck of one or more containers having a circular flange as the containers are moved along a generally circular path by a star wheel. The bottle support plate includes a pocket that at least partially supports and at least partially mates with the flange of the container to at least partially inhibit rotation of the container during the threading of a cap on an upper threaded neck of the container. The pocket includes a support ledge having an upper surface, a neck cavity, a ledge wall extending upwardly from the upper surface of said support ledge and a non-smooth surface on upper surface of the support ledge. The ledge wall is designed to be at least partially mateable with at least a portion of an outer peripheral edge of the flange of the container. The neck cavity is designed to receive a portion of a neck of the container that is located below the container flange. The non-smooth surface is designed to engage a portion of the bottom surface of the bottle flange and inhibit or prevent rotation of the bottle when a cap is twisted onto the upper threaded neck of the container.

Owner:BEVCORP

Device for screwing caps onto receptacles

InactiveUS7334380B2Simple and inexpensive for adjusting the clamping torqueStop rotatingCapsThreaded caps applicationDrive shaftScrew cap

A device for screwing caps onto receptacles, the device comprising a rotary spindle having a first end provided with a cap gripper head and a second end connected to a two-portion clutch member, one of which portions is constrained to rotate with the second end of the rotary spindle, and the other of which portions is constrained to rotate with a drive shaft on the same axis as the spindle and associated with a drive member, wherein the portions of the clutch member comprise a magnetic bell and a magnetic core having dimensions suitable for enabling it to be engaged in the bell, the device further comprising a displacement member for displacing the bell and the core relative to each other between a position in which the core is engaged in the bell and a position in which the core is disengaged from the bell.

Owner:SERAC GROUP

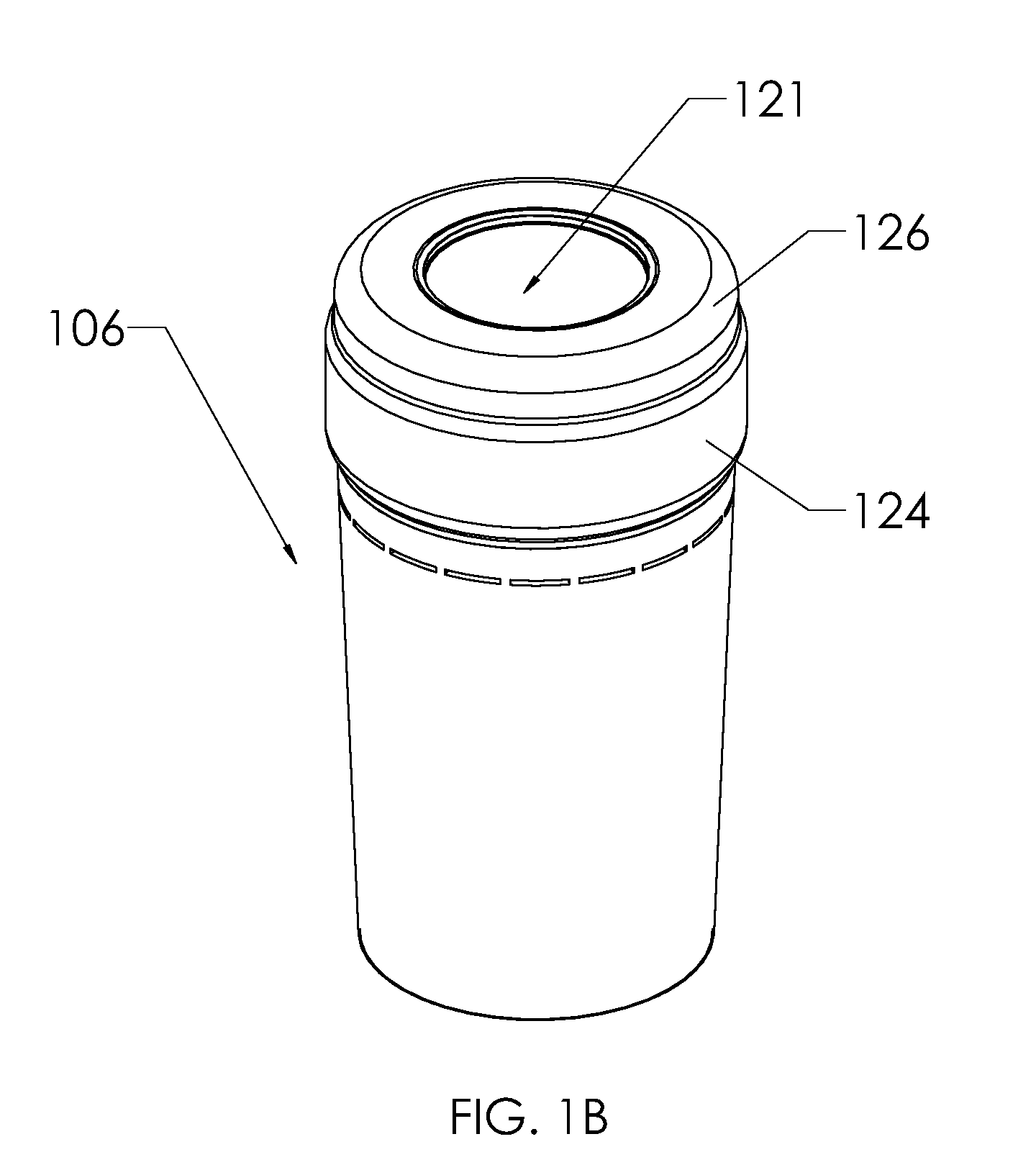

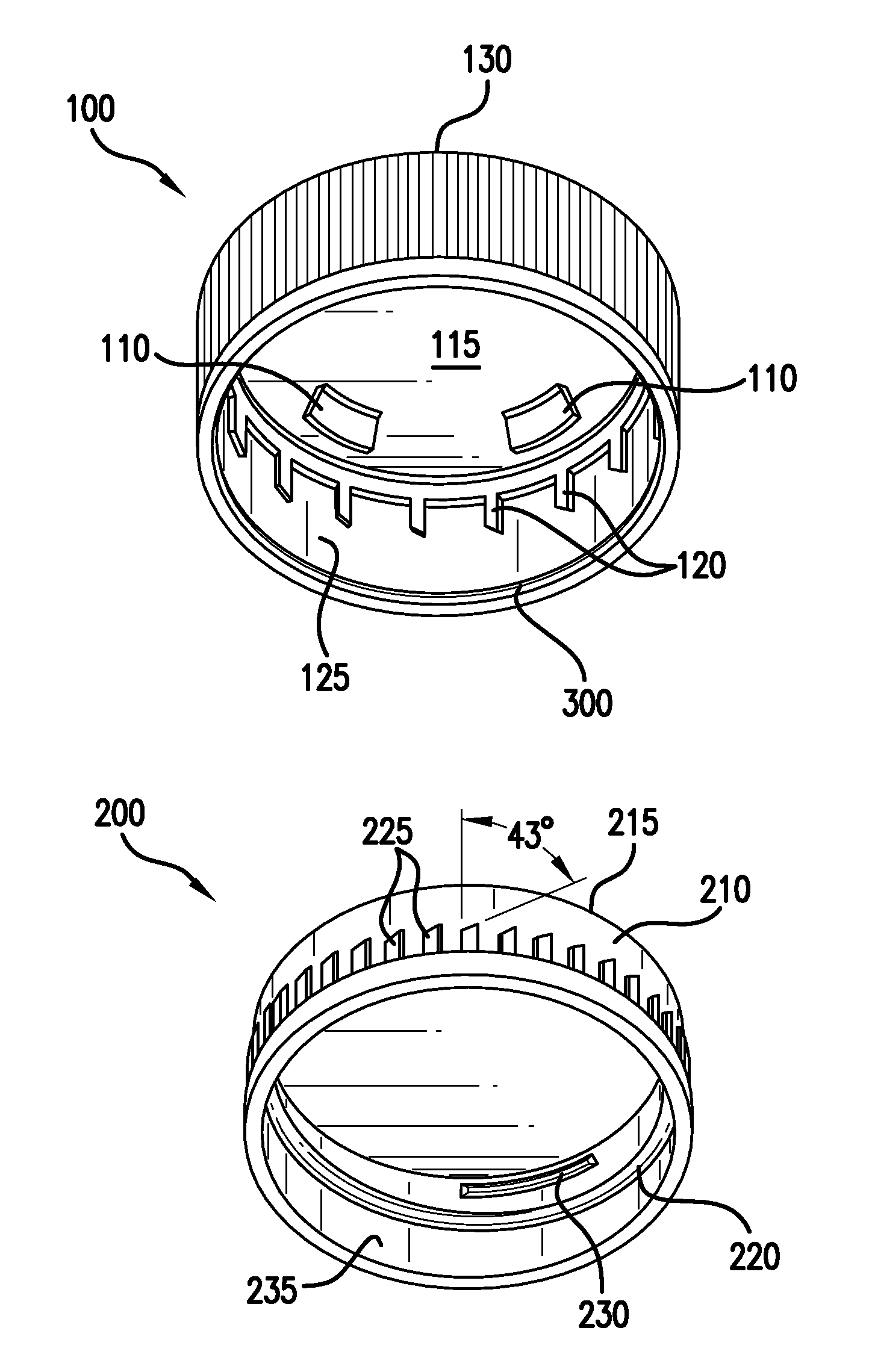

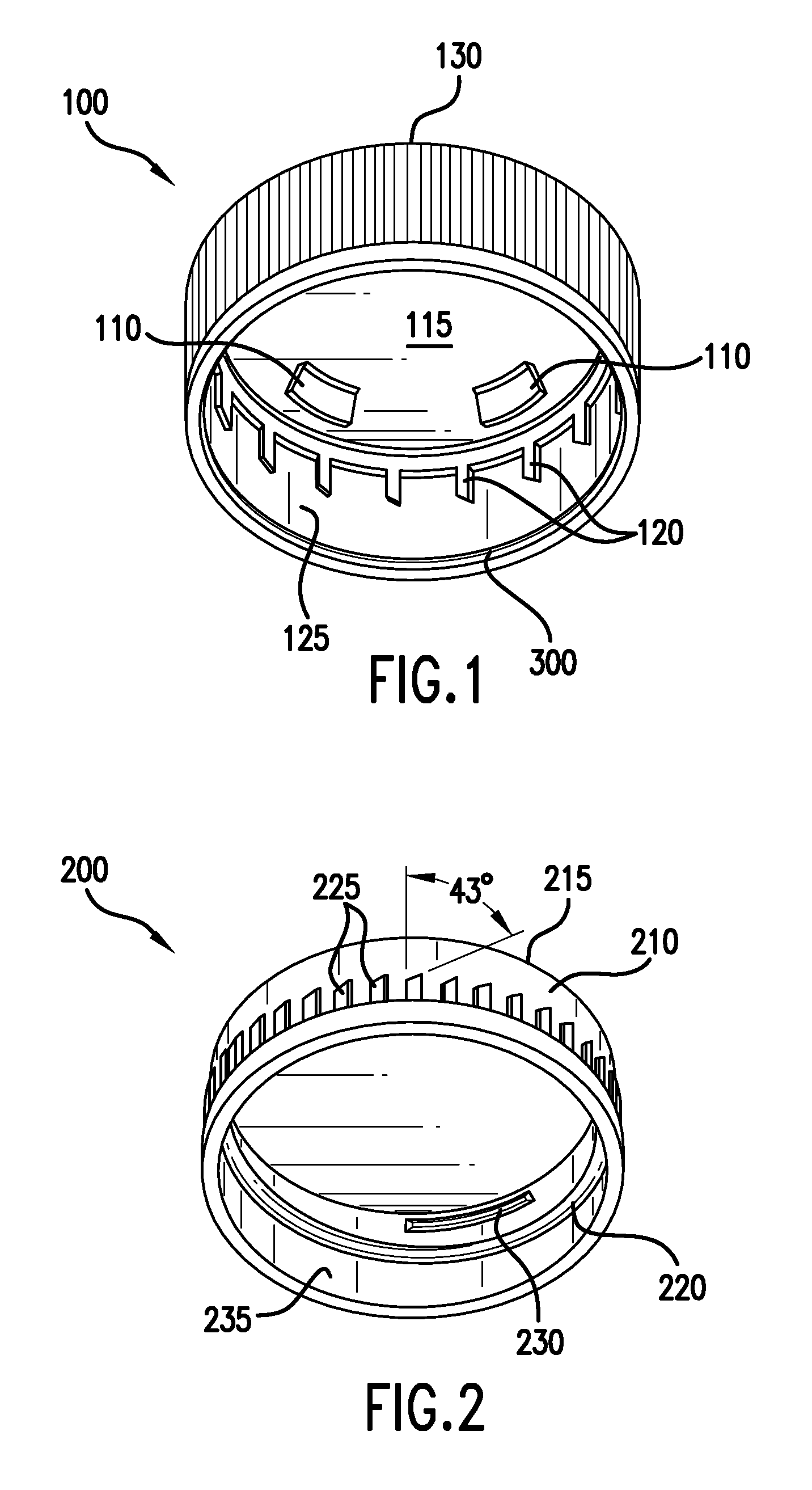

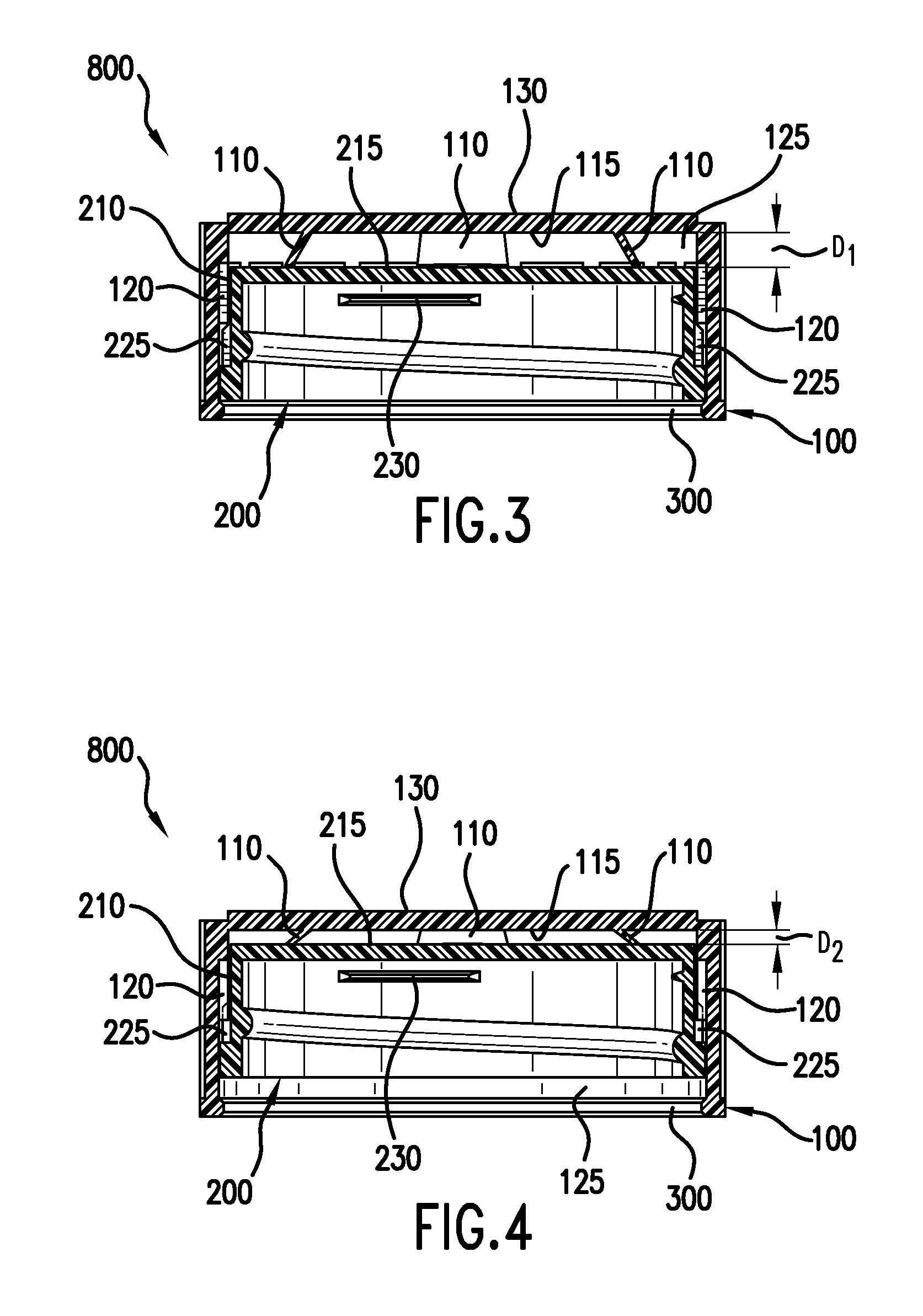

Child-resistant cap

A child resistant cap assembly for a bottle is disclosed comprising an inner cap and outer cap. When an external pressure is applied to the outer cap, the teeth on the outer cap engage with the inner cap. While engaged, the cap assembly is rotated in a counter clockwise direction to unfasten or unscrew the cap assembly from the bottle.

Owner:MS SHRIJI POLYMERS INDIA PVT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com