Patents

Literature

99 results about "Linear machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

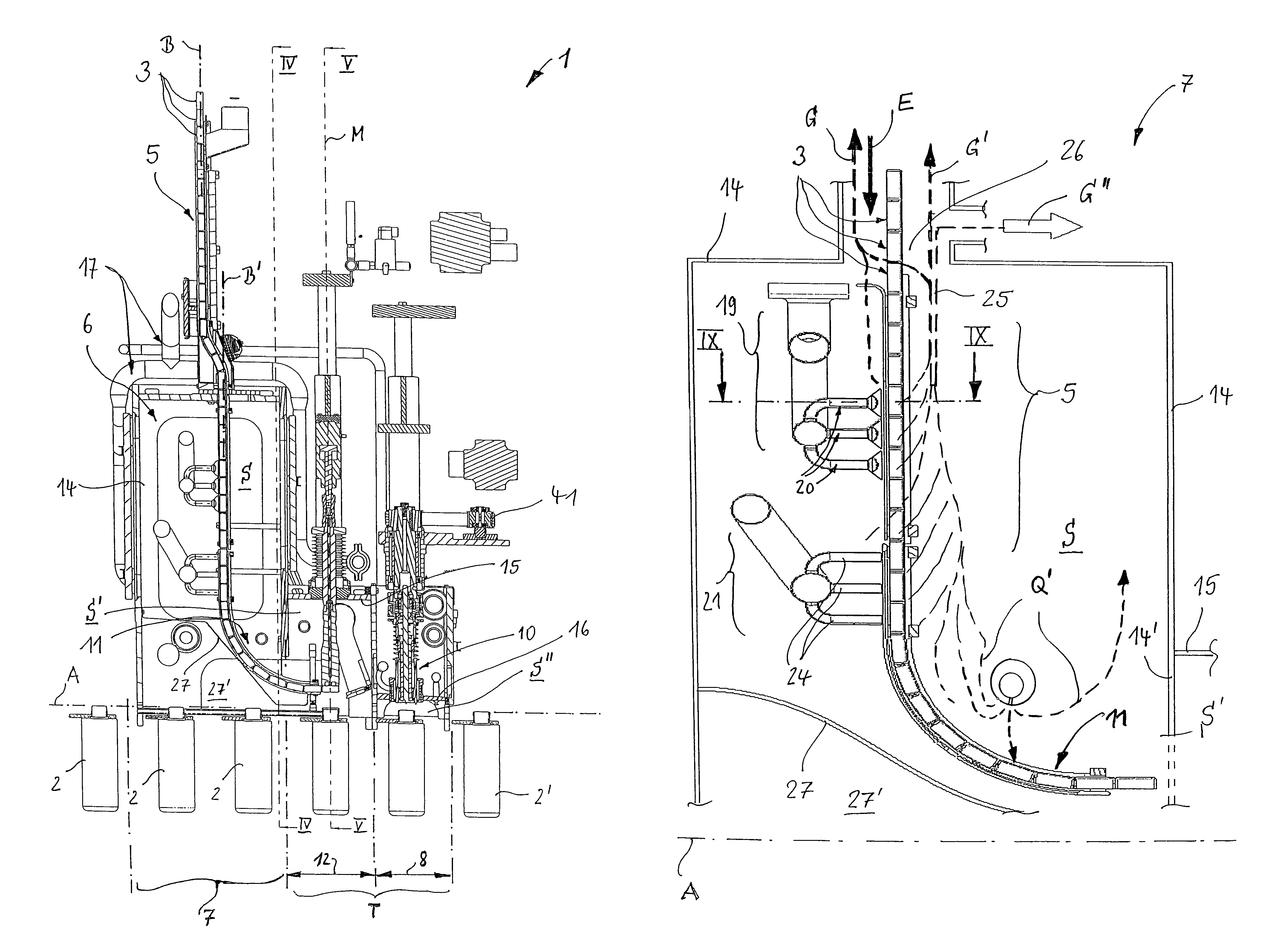

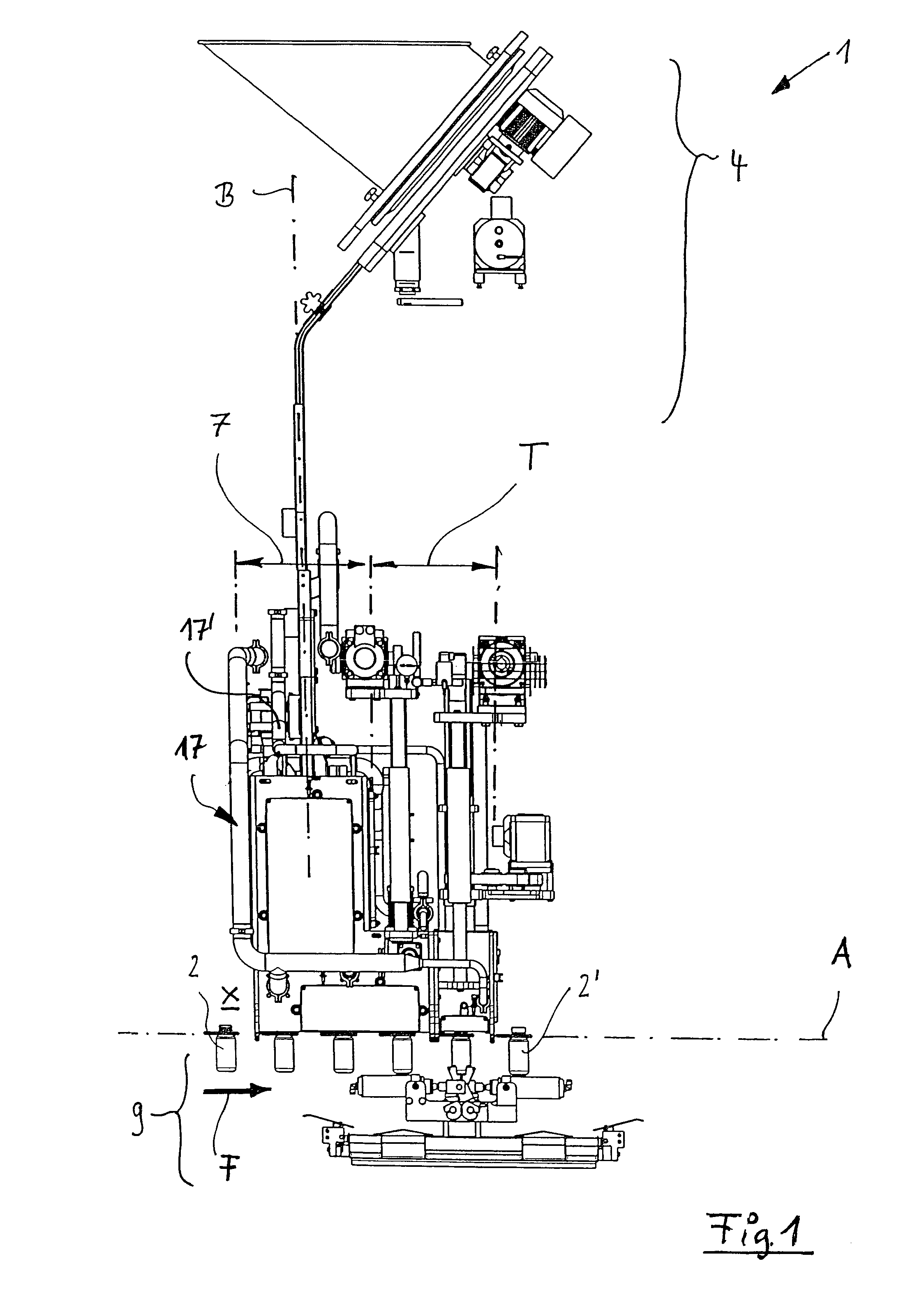

Method and Machine for Closing Bottles with Sterile Caps

ActiveUS20070006550A1Improve throughputImprove protectionCapsThreaded caps applicationSterile environmentLinear machine

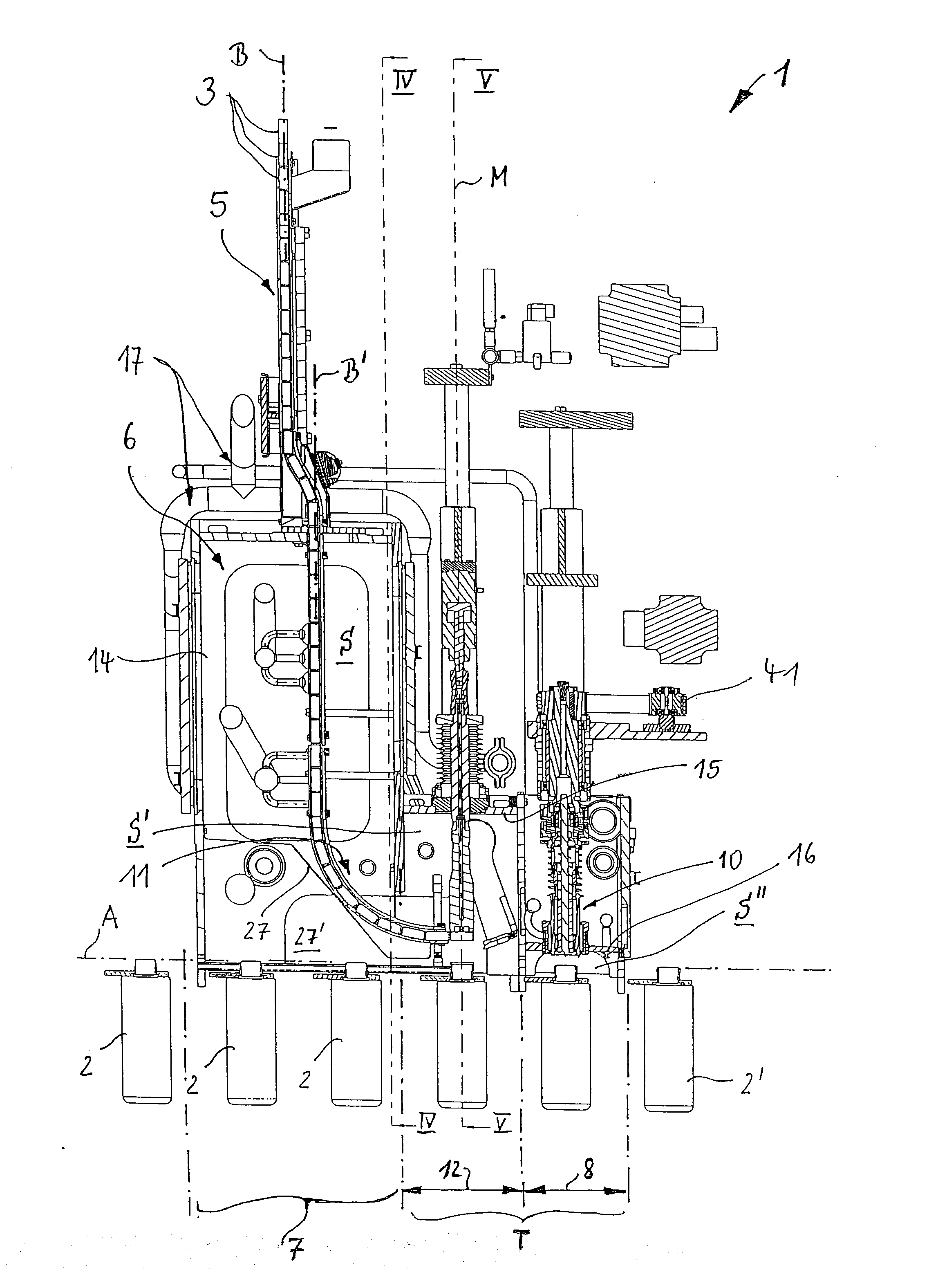

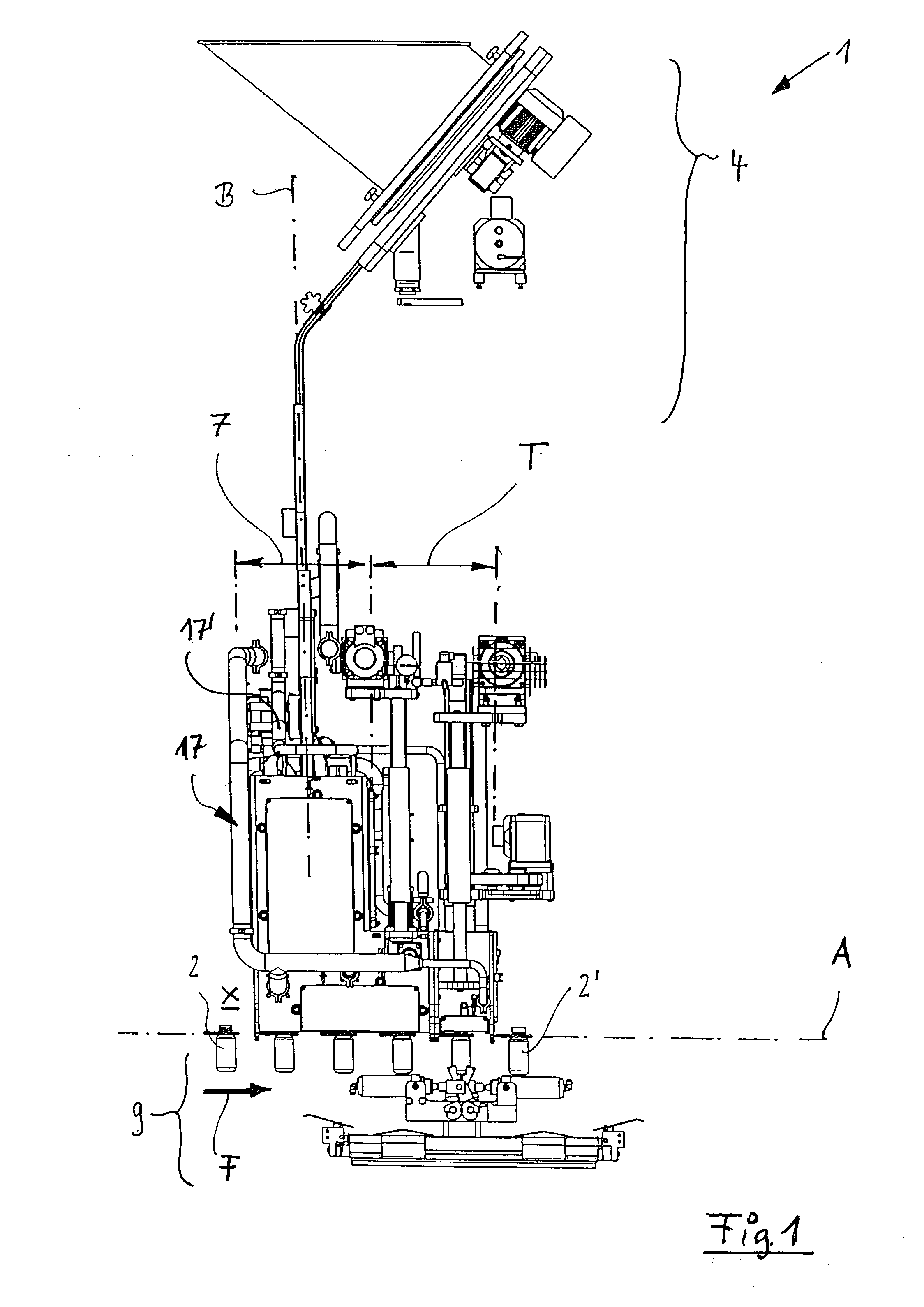

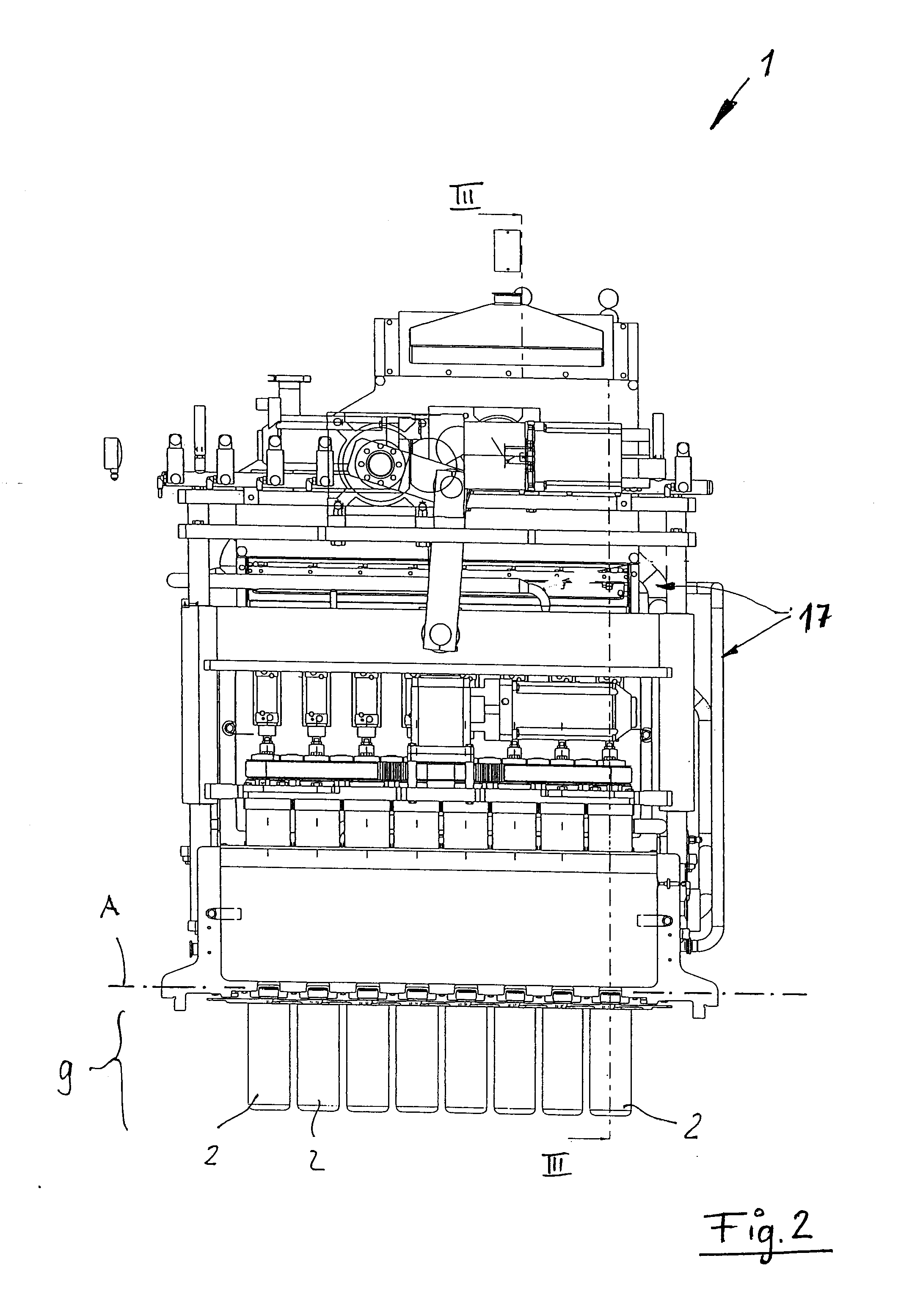

For closing bottles with sterile caps, the caps are placed in a non-sterile environment in a vertical arrangement and are supplied vertically to a first sterile area. The interior of the caps is arranged to be accessible horizontally. The caps are sterilized in the first sterile area and transferred to a second sterile area where the caps are placed onto bottles. Subsequently, the bottle is closed with the cap. The machine for sterile closing of bottles with caps has a sterilization device with an individualization device for picking up caps and a vertical transport path feeding the caps to the sterilization chamber. A placing device receives the caps from the sterilization device and places the caps onto bottles. A closing device closes the bottles with the cap placed thereon. The sterilization device, the placing device, and the closing device operate as synchronized modules of a linear machine.

Owner:KHS CORPOPLAST GMBH & CO KG

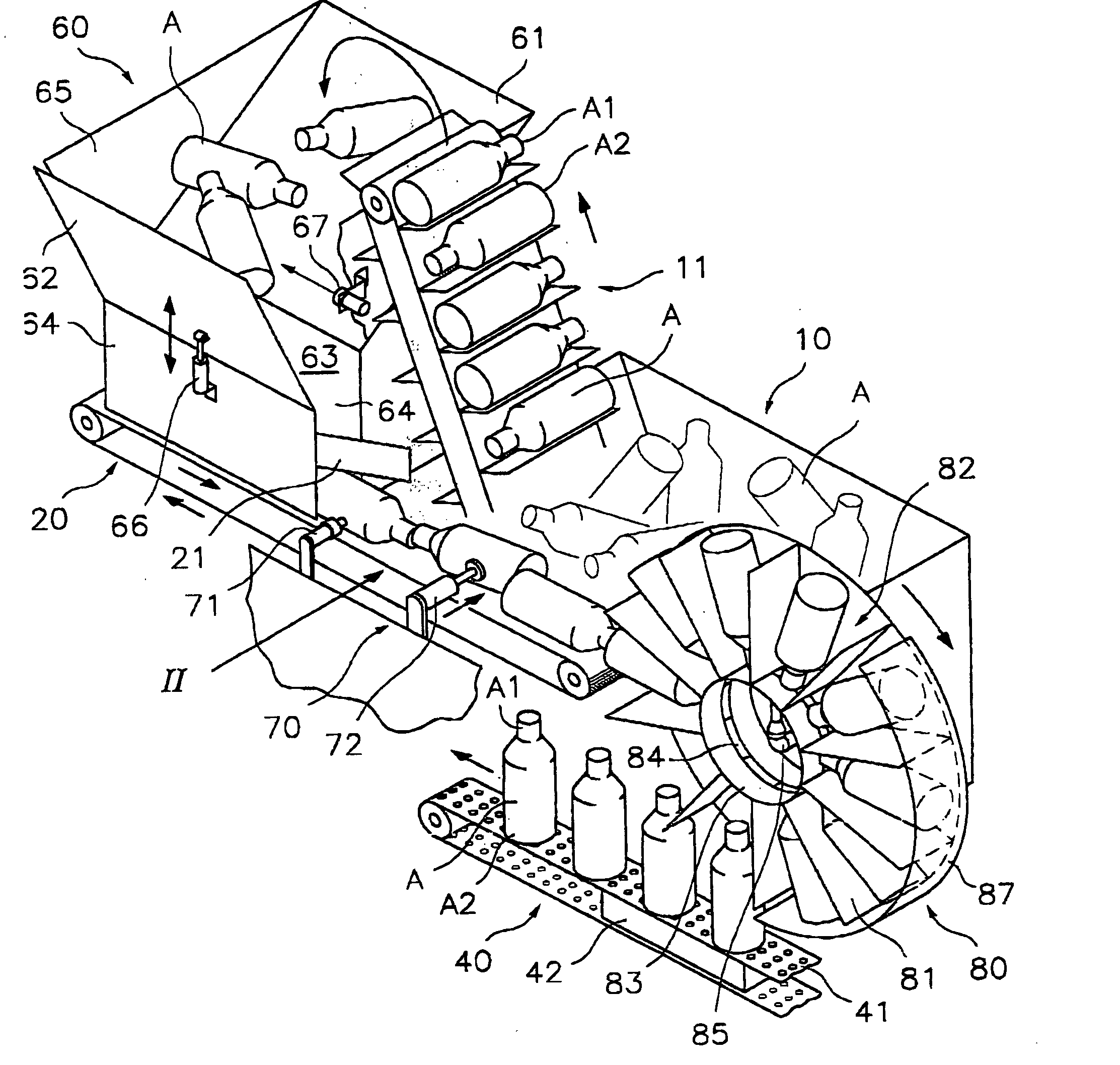

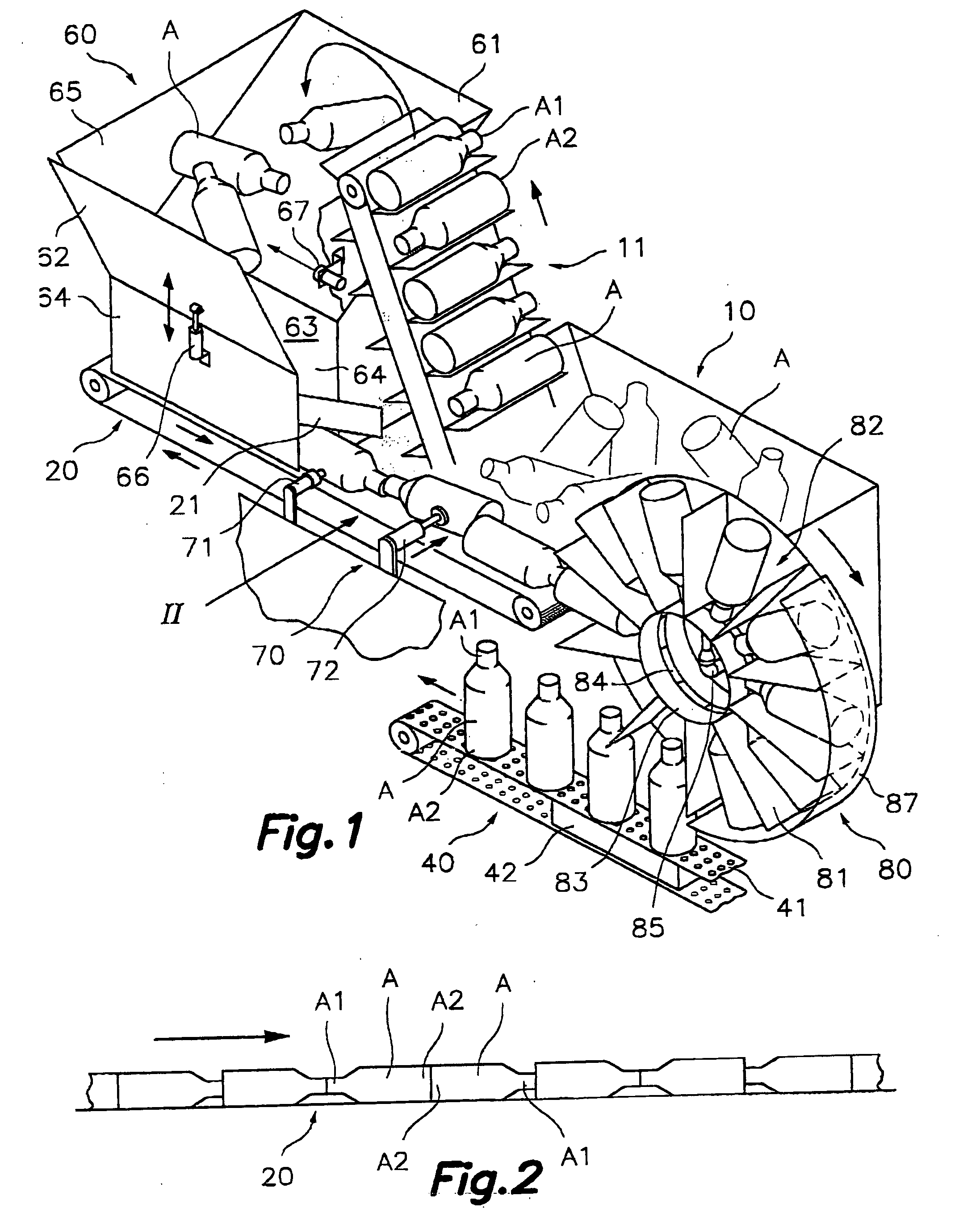

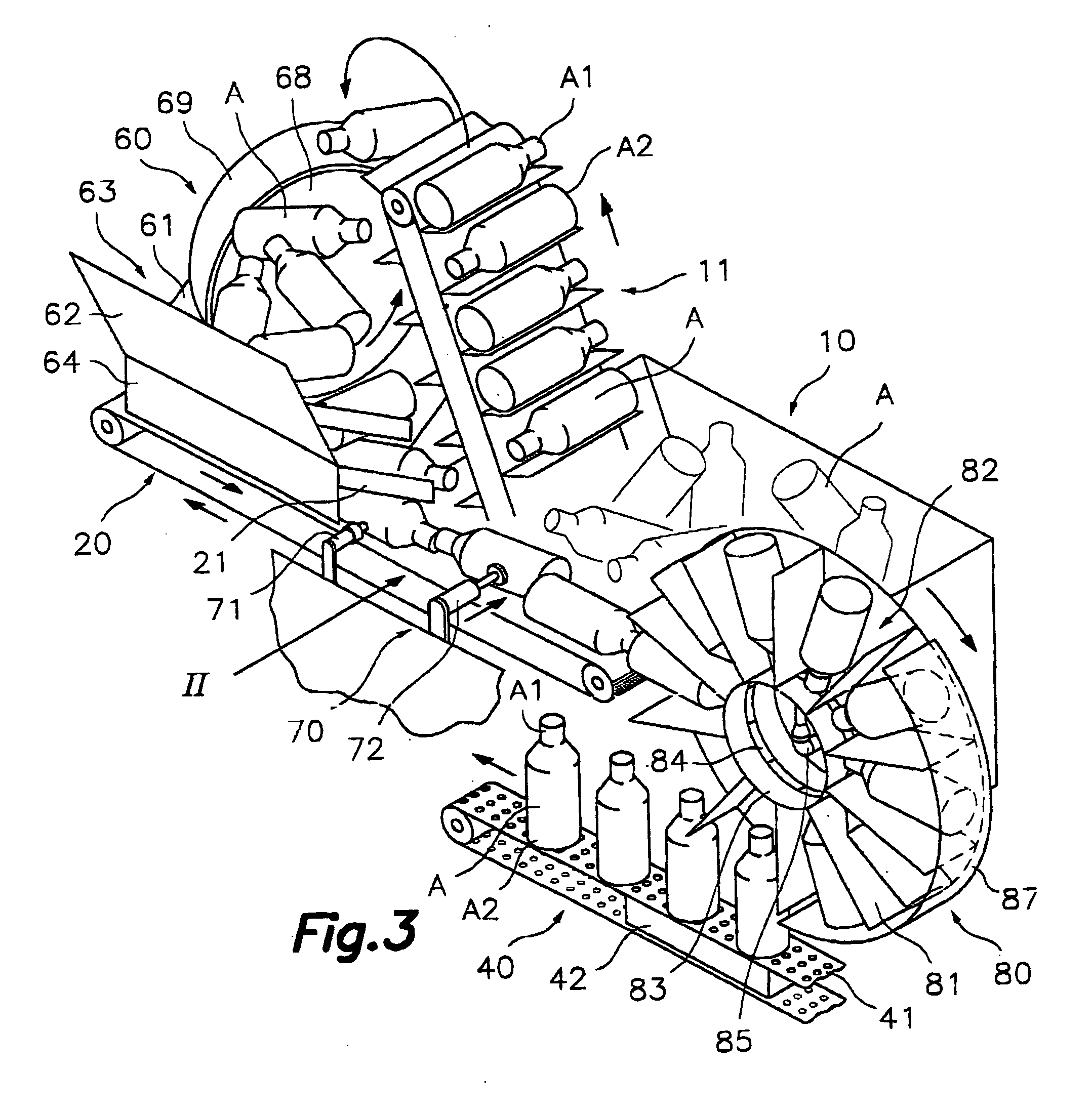

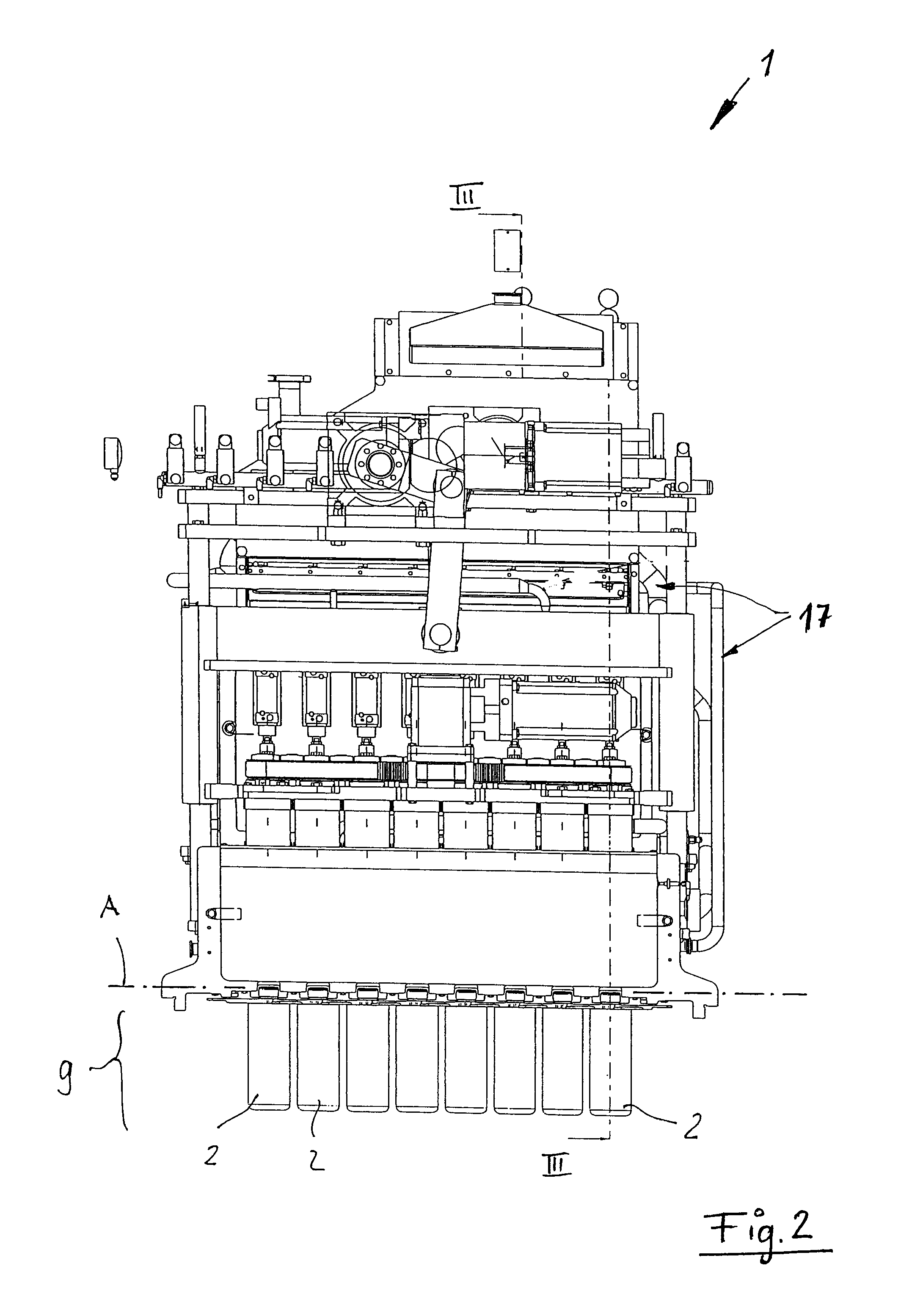

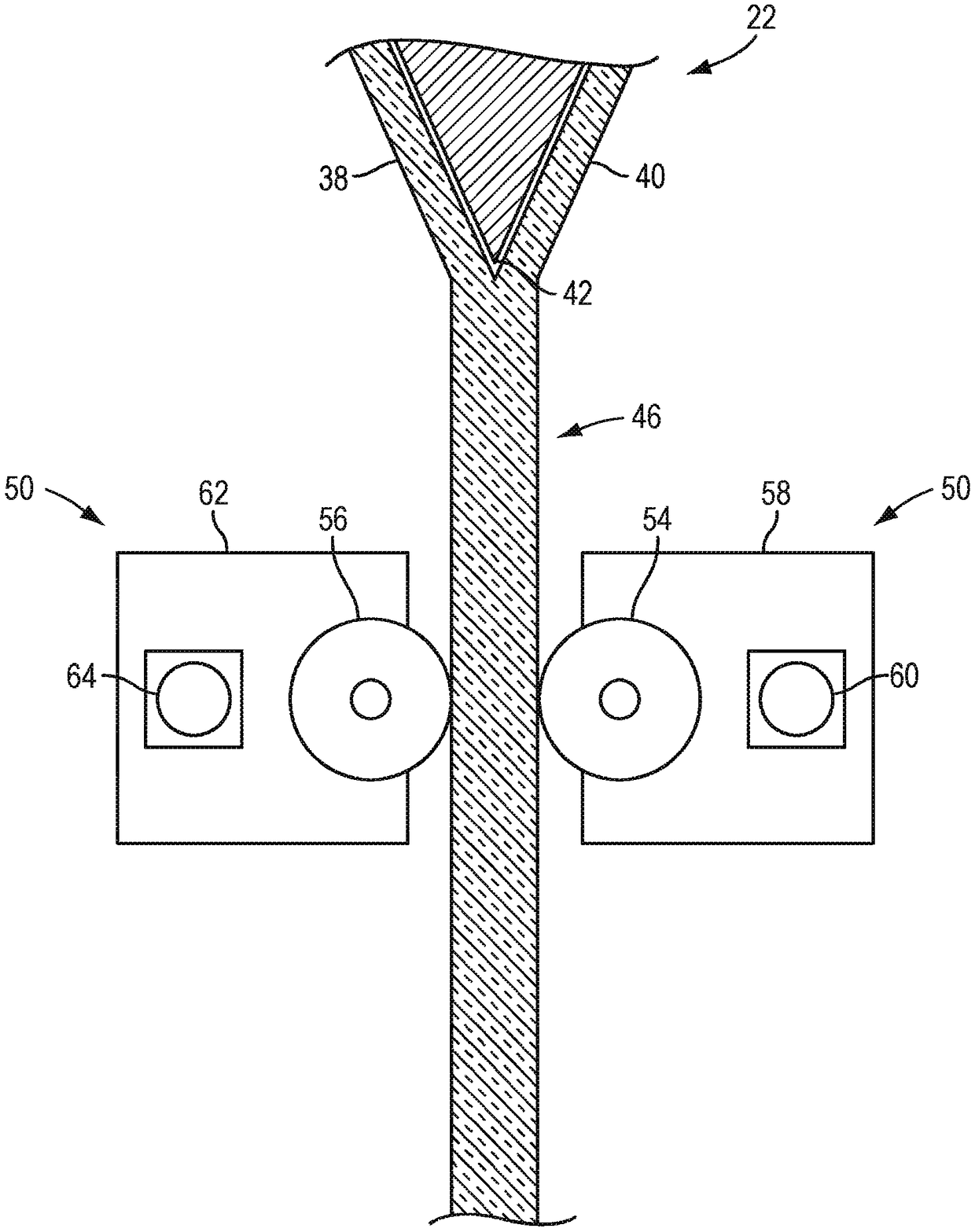

Automatic linear machine for orienting and aligning articles

The machine is intended for articles (A) having a different geometric configuration (A1) on one of their ends. Said machine has a linear transport device (20) for the articles (A) in lying position which has been pre-oriented in longitudinal direction with respect to said different geometric configuration (A1) that is located either in the front or back part relative to the direction of advancement of said transporting device (20). The machine also comprises a positioning station (80) of the articles (A) orienting the articles vertically and associated with the transporting device (20) and output transporting means (40) of the articles (A) that are oriented in vertical position and aligned. The machine also includes lifting means (11) to transfer the articles (A) from a bulk container (10) to a feed device (60) having first and second inclined plane (61, 62), converging in a chute space (63) on the transporting device (20). The positioning station (80) comprises a rotating element (81) provided with cavities (82) for receiving the articles (A) in a substantially radial position and with the geometric configuration (A1) in the desired position.

Owner:SALA JAIME MARTI

Method and machine for closing bottle with sterile caps

ActiveUS7536839B2Easy to operateImprove throughputCapsDecorative coversSterile environmentLinear machine

Owner:KHS CORPOPLAST GMBH & CO KG

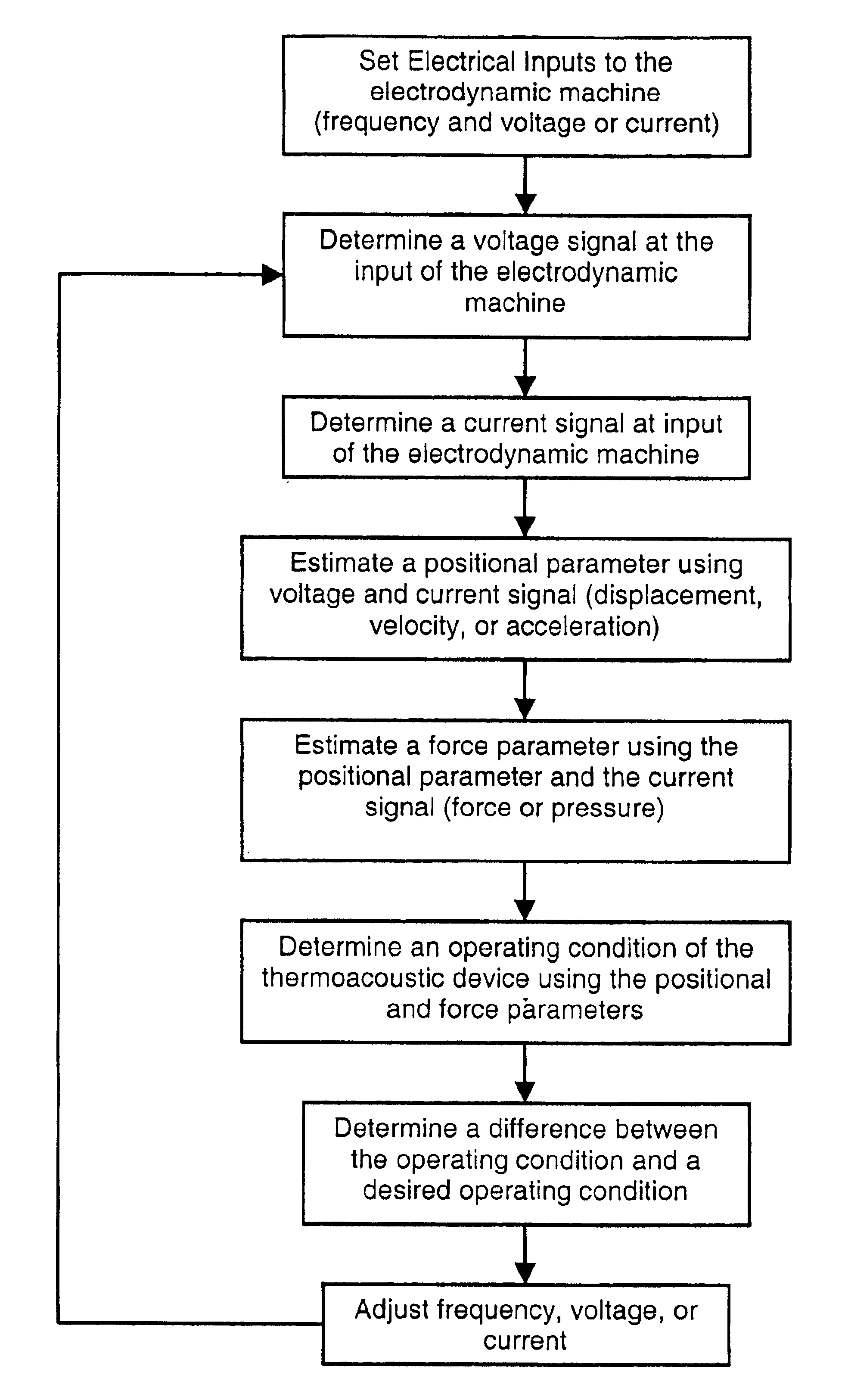

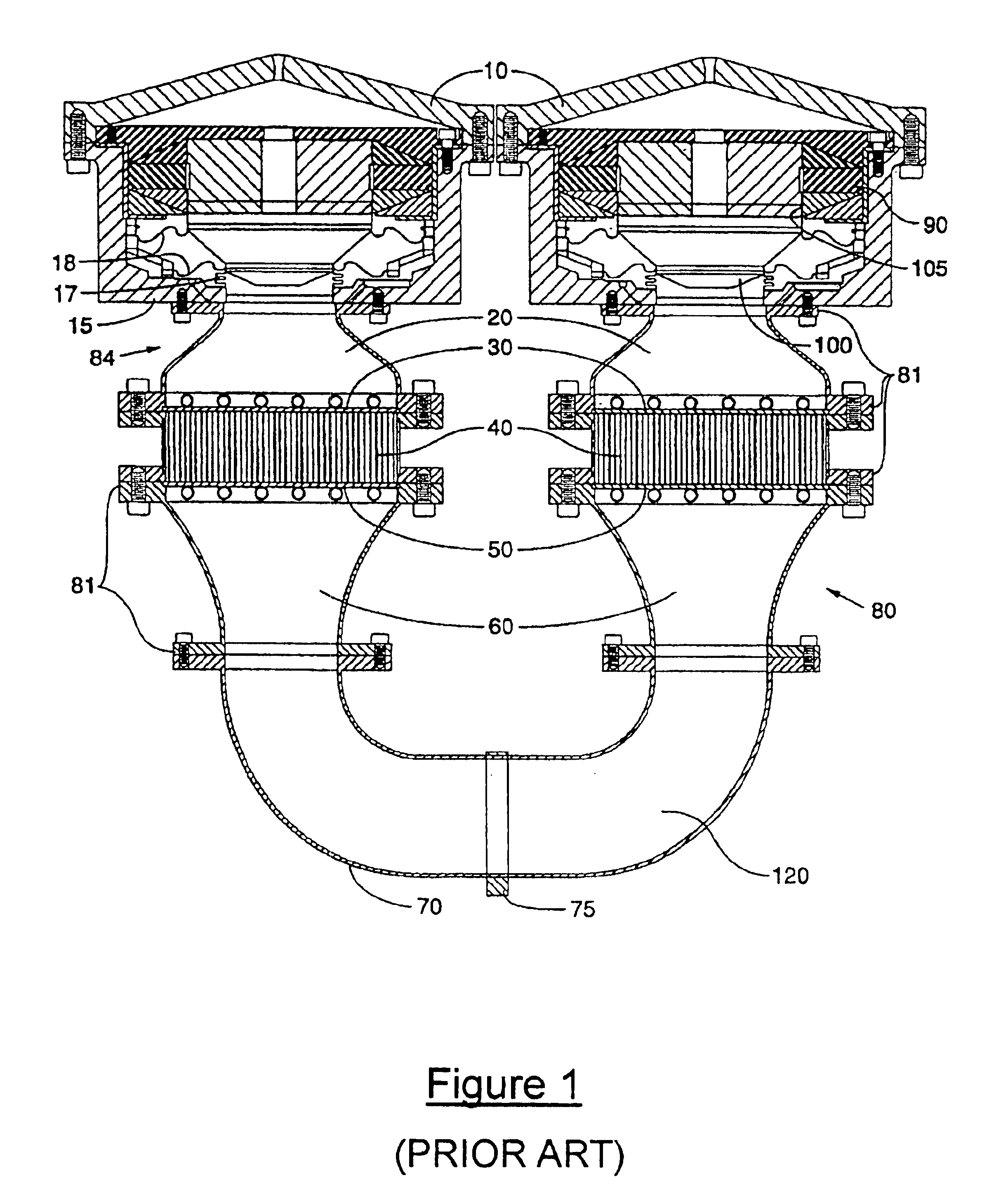

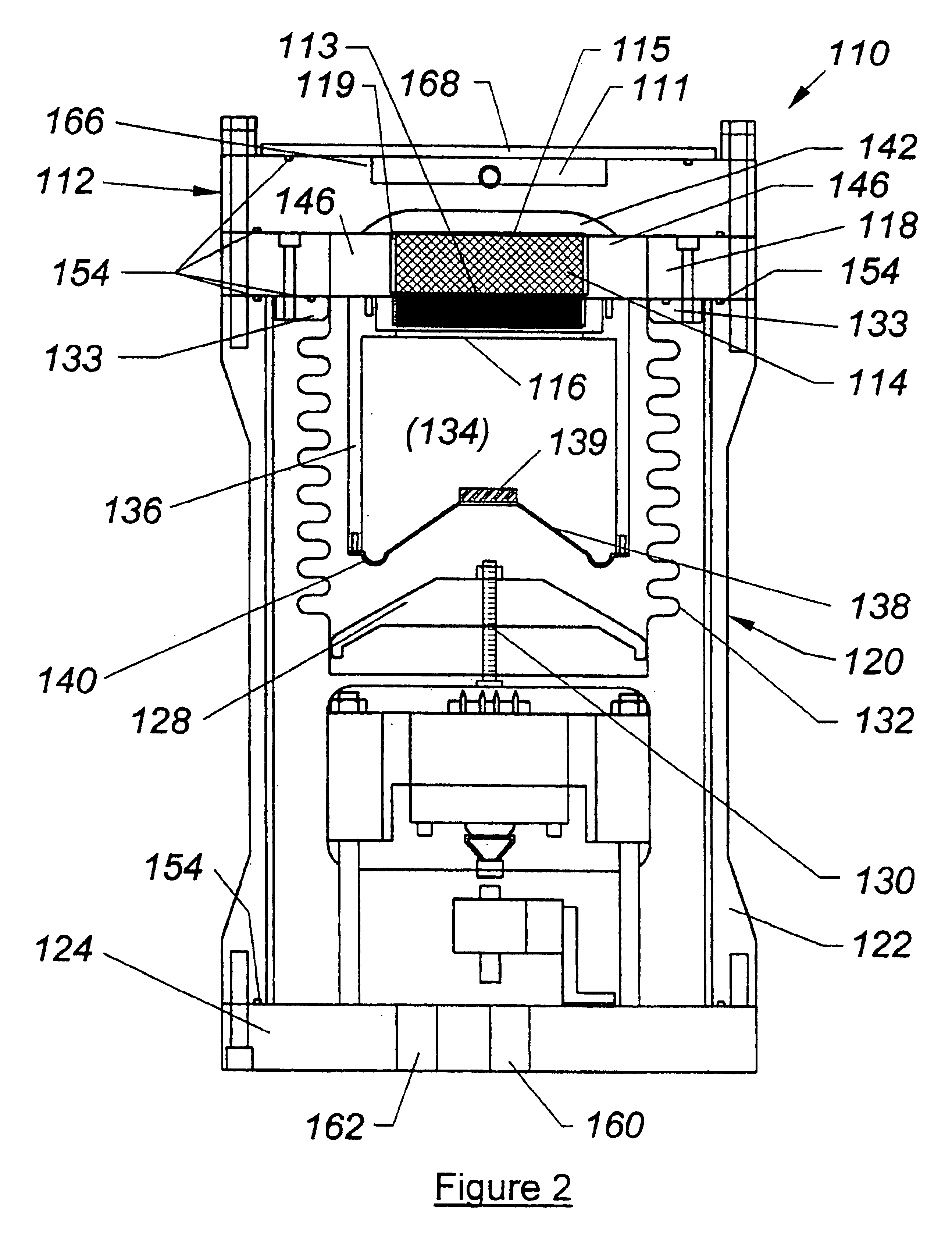

Sensorless control of a harmonically driven electrodynamic machine for a thermoacoustic device or variable load

ActiveUS6883333B2Reduce the differenceMotor/generator/converter stoppersDC motor speed/torque controlHarmonicLinear machine

The present invention provides a method of sensorless control of a linear reciprocating electrodynamic machine used for driving a thermoacoustic device, and / or a similar frequency dependent load. Sensorless control is accomplished by estimating the state of predetermined performance parameters at the linear machine through the use of a system model. Thereafter, the method comprises providing a control means operative to obtain the estimated performance parameters and cause manipulation of at least one input parameter to the linear machine such that desired performance parameters are obtained in view of the estimated performance parameters.

Owner:PENN STATE RES FOUND

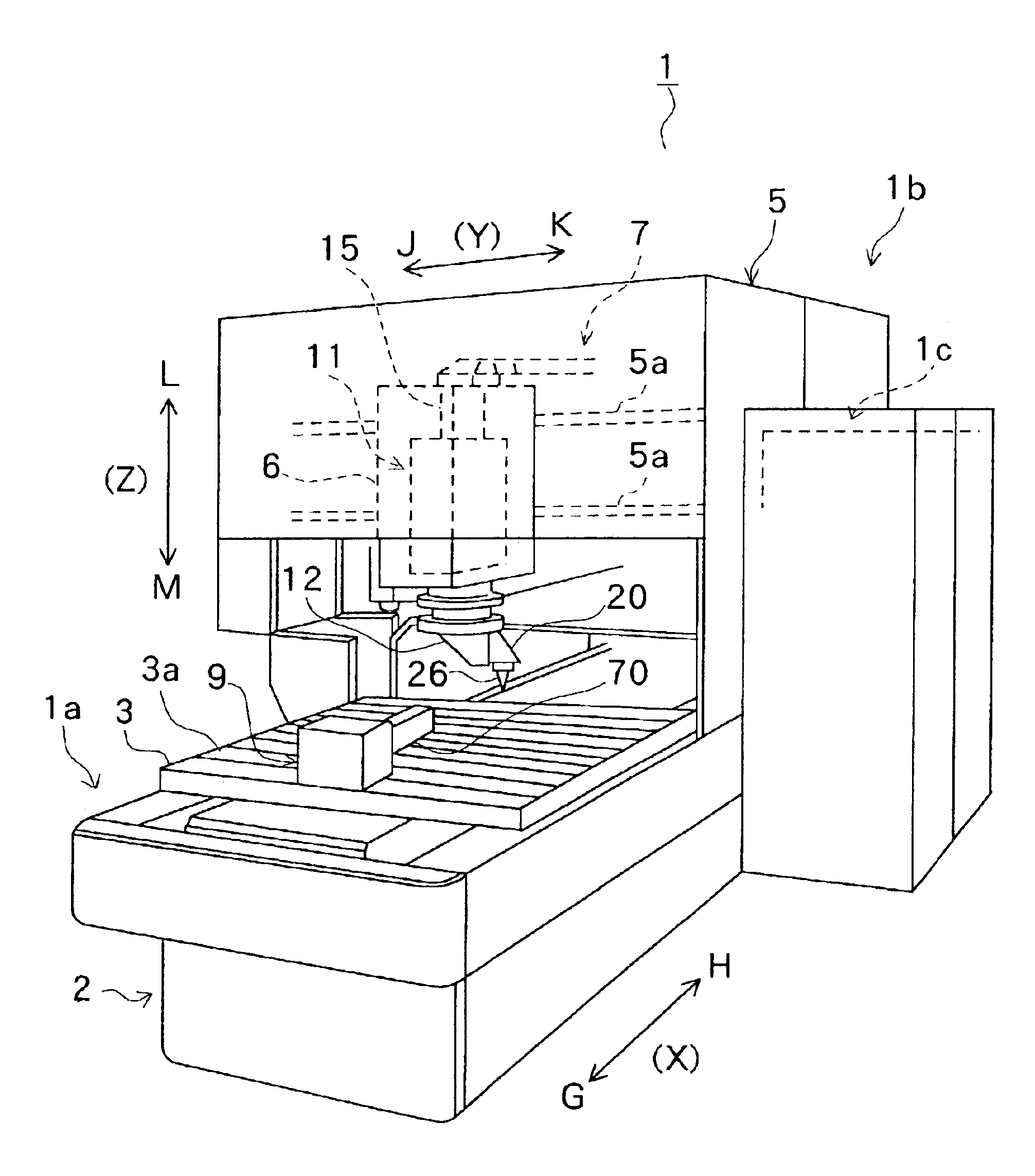

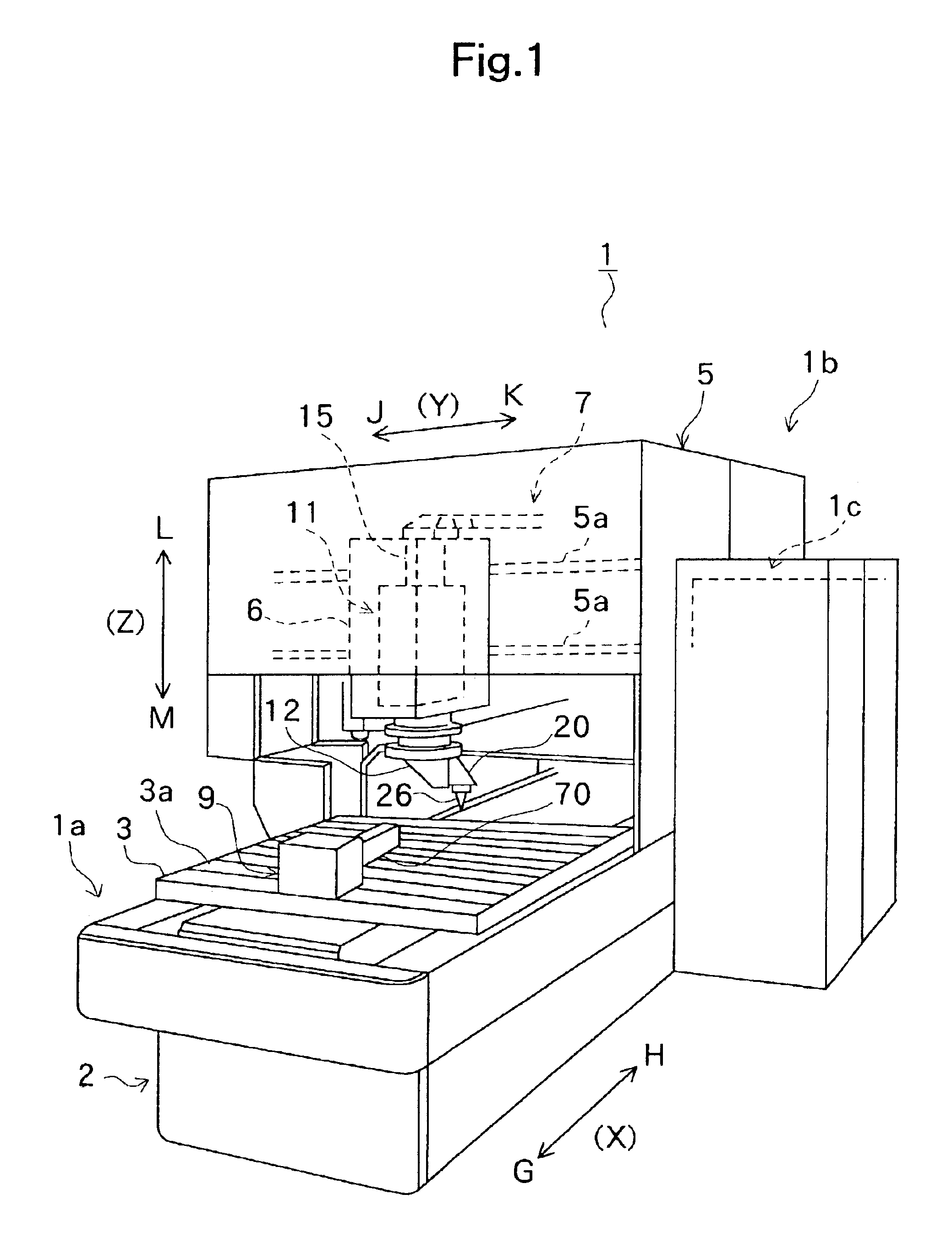

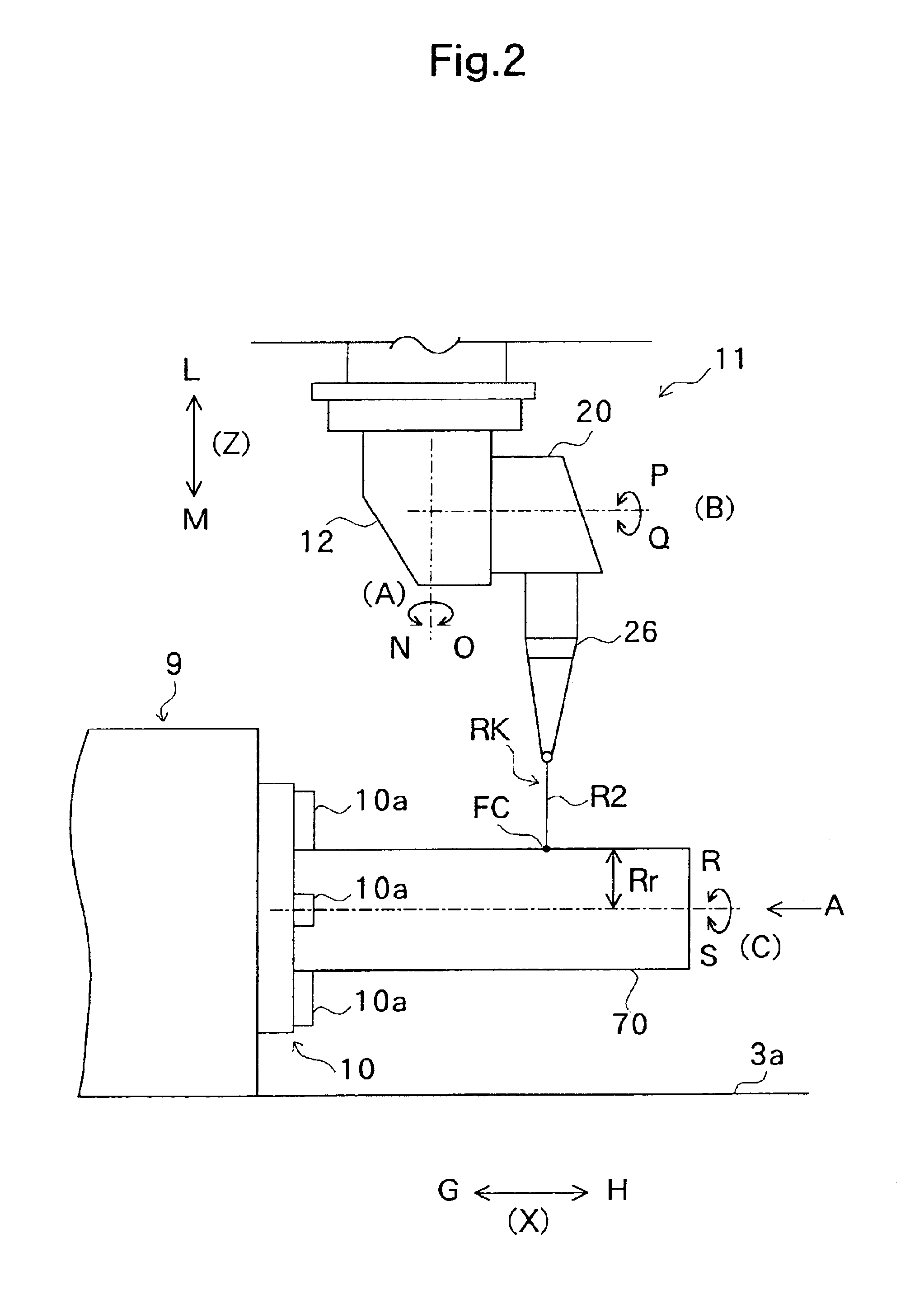

Three dimensional linear machining apparatus

InactiveUS6930275B2OptimizationEnsure correct executionComputer controlSimulator controlRotational axisMachine control

At the time of execution of concurrent six-axes cylindrical interpolation instruction wherein a start point, an intermediate point, an end point and feed speed are instructed in a machining program PRO, a machining data computing portion 59 computes angular velocity of first, second, and third rotational axis directions and moving speed of first, second and third axial directions so as to correspond the feed speed of a torch with respect to a workpiece with the feed speed instructed in the machining program PRO, and the machining control portion 55 simultaneously controls the first, second and third axes and the first, second and third rotational axes on the basis of the angular velocity and the moving speed which are computed so as to rotate a chuck holding the workpiece and to move the torch, so that machining on the workpiece is executed.

Owner:KAISHA KABUSHIKI

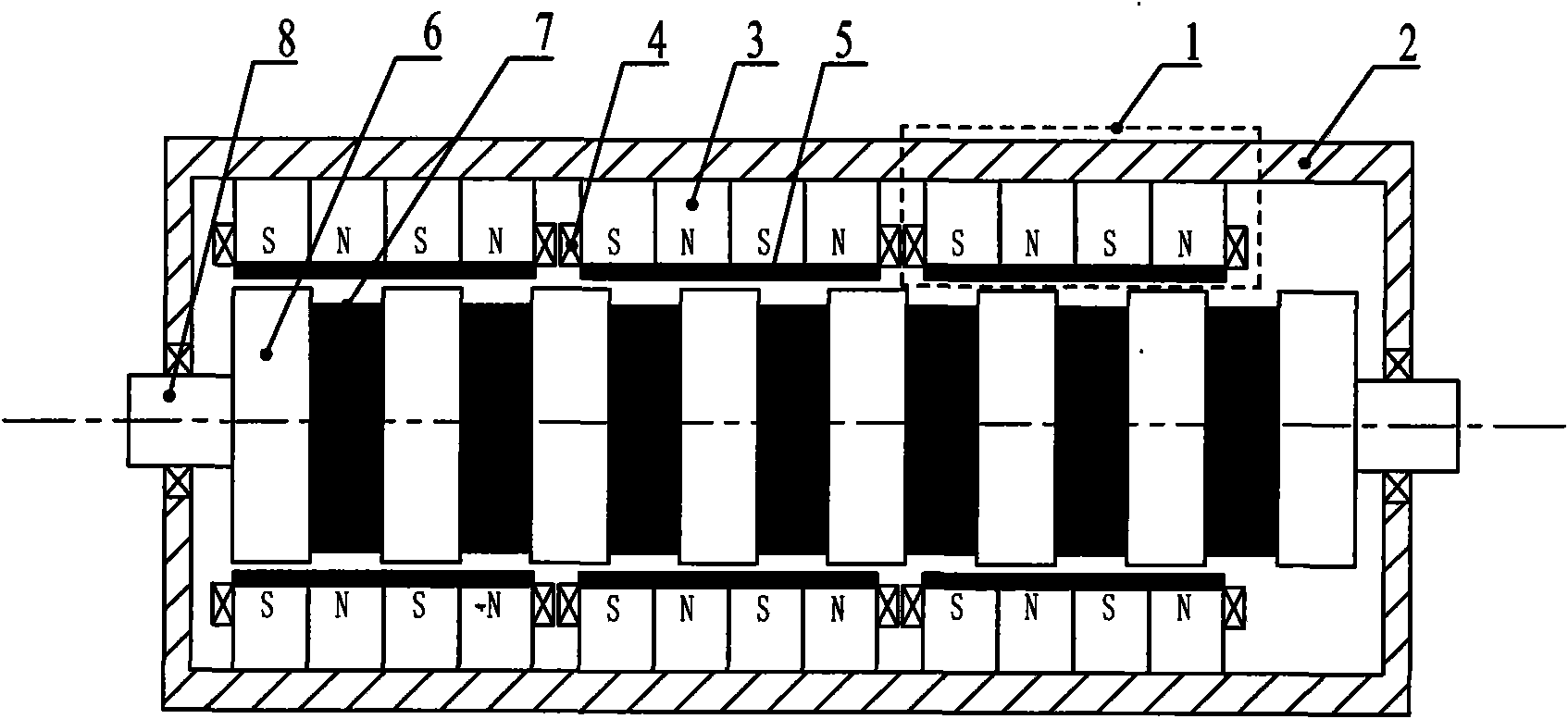

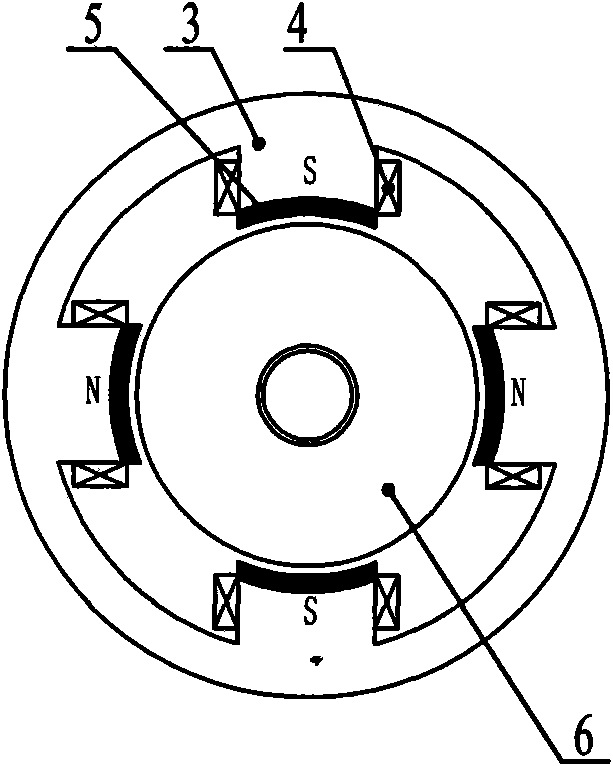

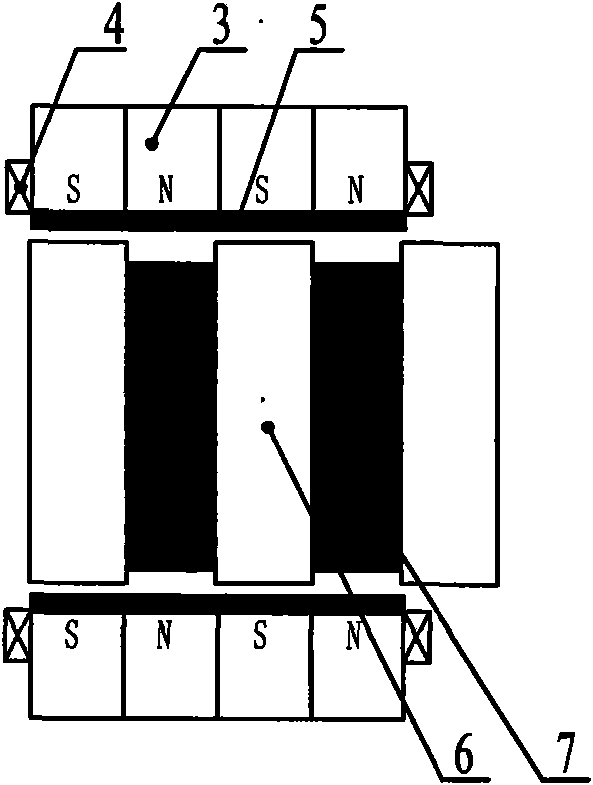

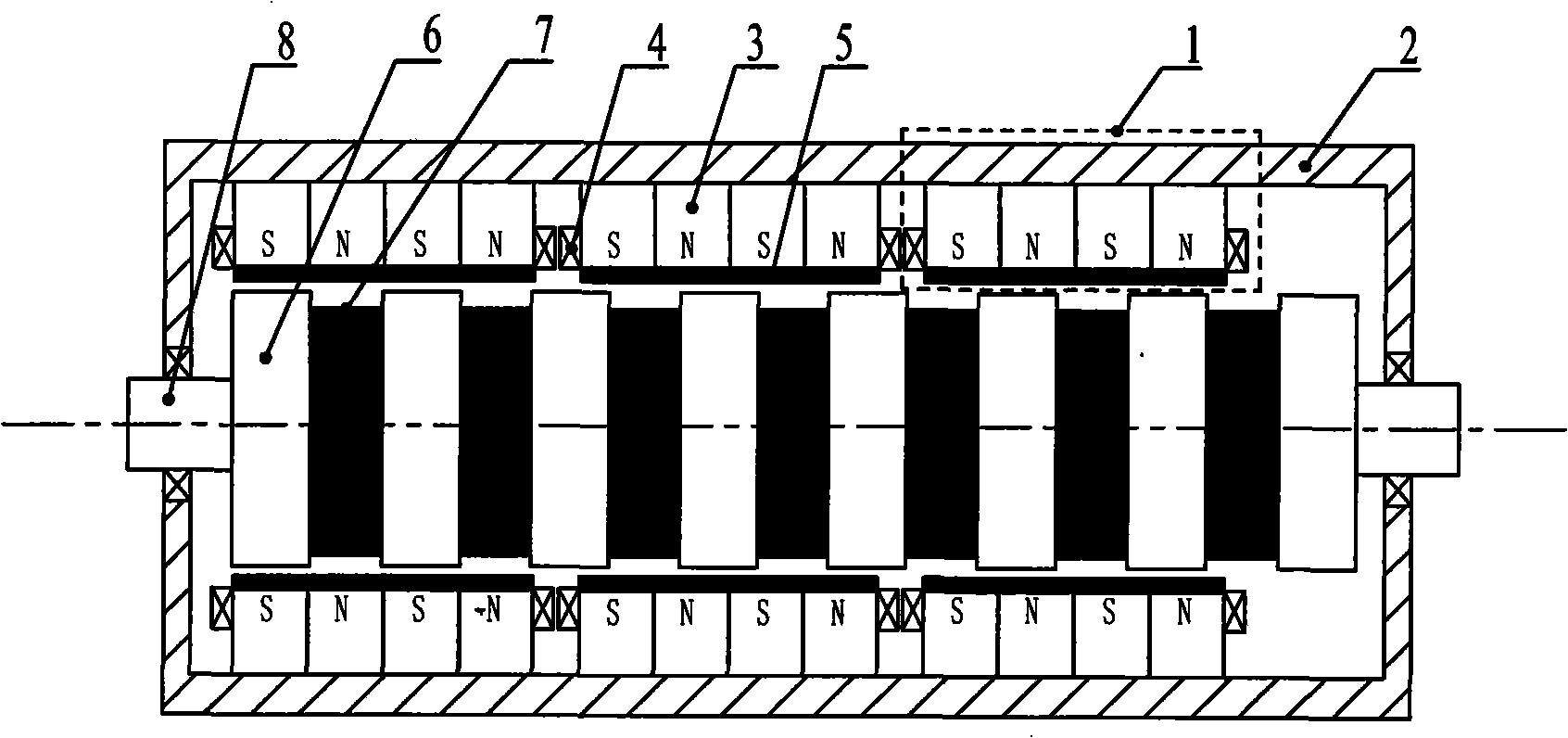

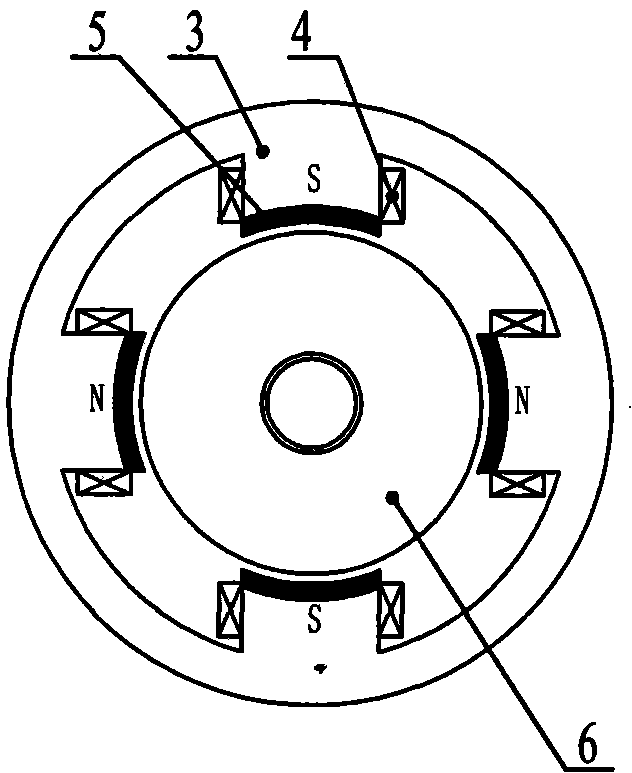

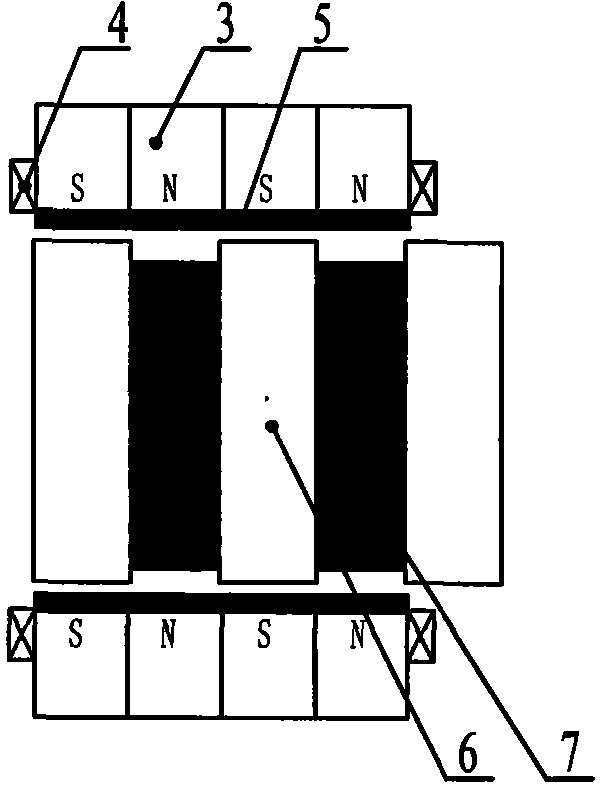

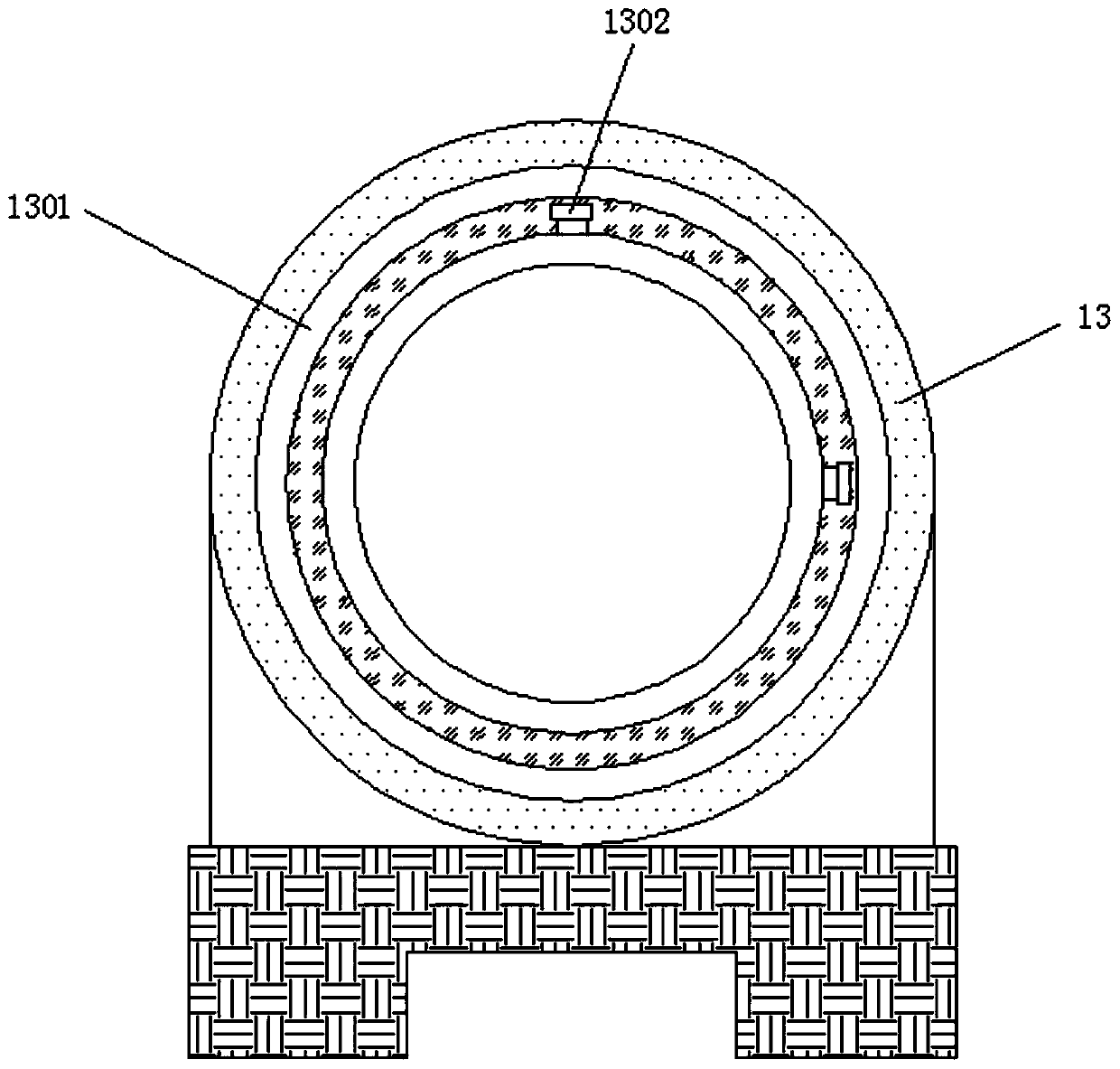

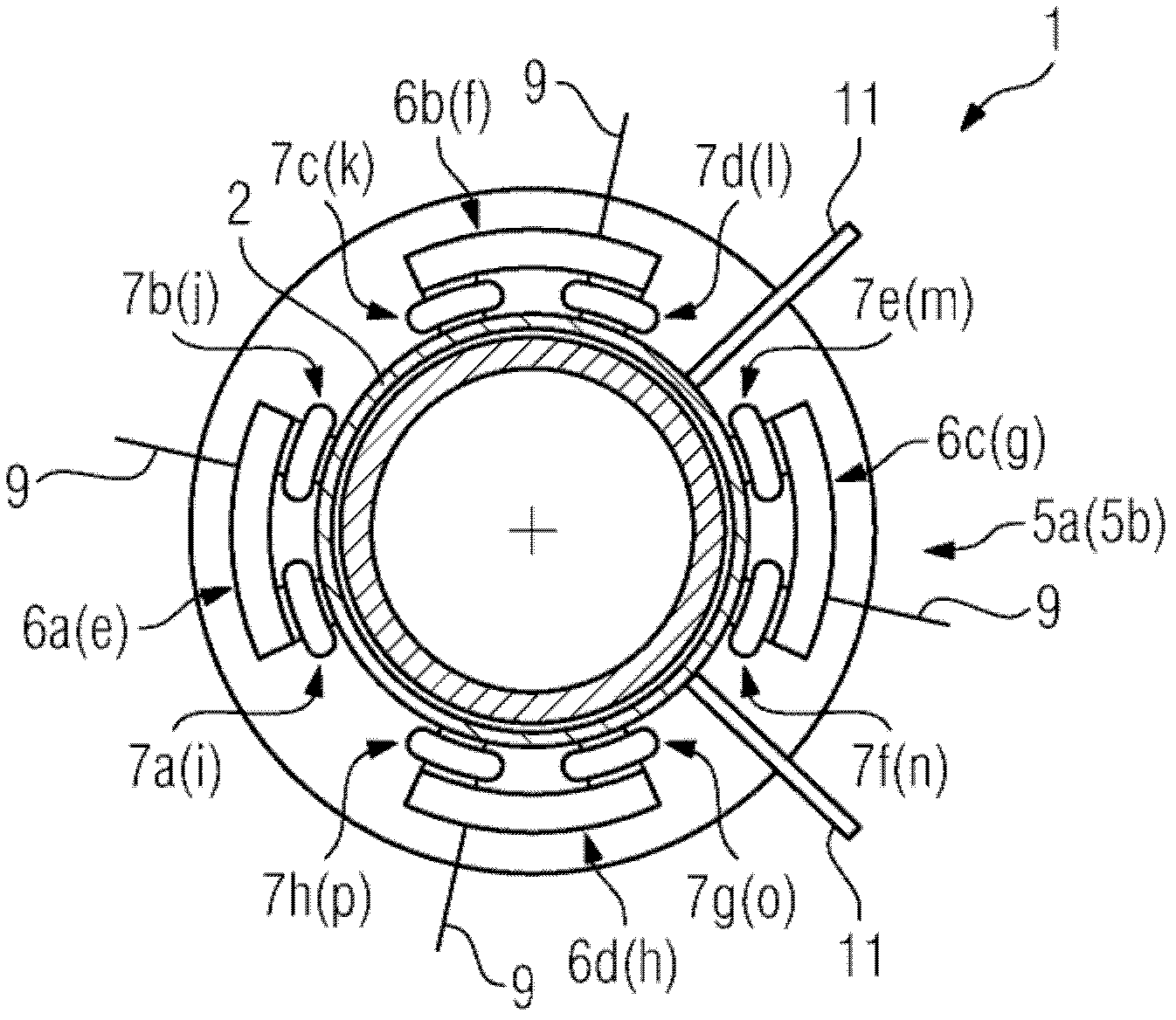

Cylinder type flux-reversal linear machine

InactiveCN101552535ASimple structureIncrease thrust densityPropulsion systemsElectric machineEddy current

The present invention relates to a cylinder type flux-reversal linear machine. The invention relates to the field of electric machine and settles the problems of low efficiency, large eddy current loss, complex technique and effect to control precision and dynamic characteristic in prior linear machine. The armature core of phase unit according to the nveition is an annular core which is uniformly installed with 2n teeth on the inner circumstance, wherein n is a natural number. The armature winding of phase unit is a concentrated winding. Each coil is corresponding winded on each tooth of armature core of phase unit. The winding directions of coils on adjacent teeth are opposite. All coils on the teeth of armature core of same phase unit are connected in series to a same phase unit armature winding. The phase unit armature windings are connected in series or in parallel to each phase armature winding. A permanent magnet is adhibited on the teeth of armature core of phase unit. The phase unit armature core center distance taut between two adjacent phase armature units in axial direction and the tooth pitch taup of secondary teeth along the axial direction satisfy a relationship: taut=ktaup+ / -(1 / m)taup, wherein k and m are natural numbers, and m is a phase number and is larger than or equal to 3. The cylinder type flux-reversal linear machine not only can be used as a motor, but also can be used as a generator.

Owner:HARBIN INST OF TECH

Cylinder type flux-reversal linear machine

InactiveCN101552535BSimple structureIncrease thrust densityPropulsion systemsElectric machineLinear machine

Owner:HARBIN INST OF TECH

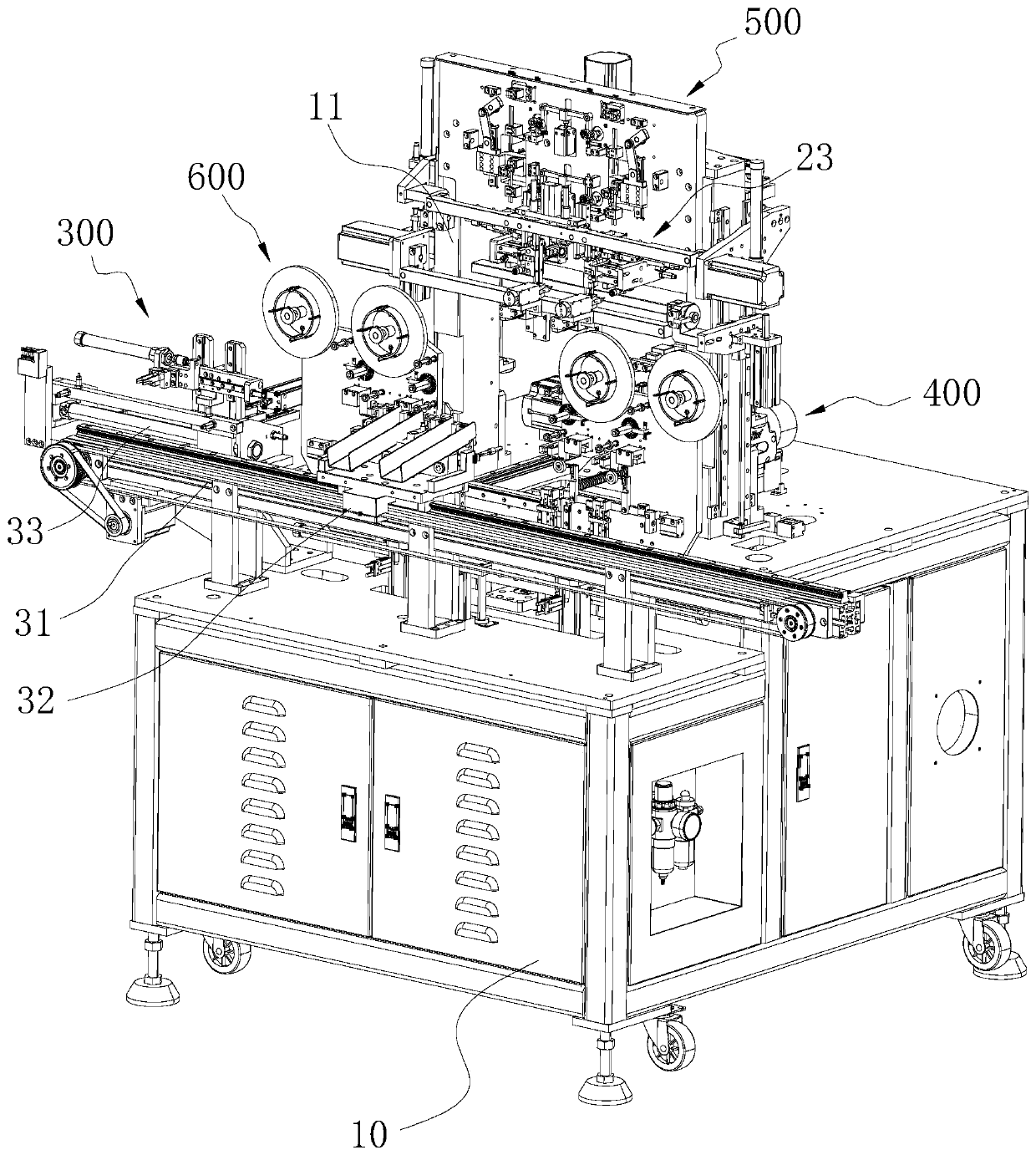

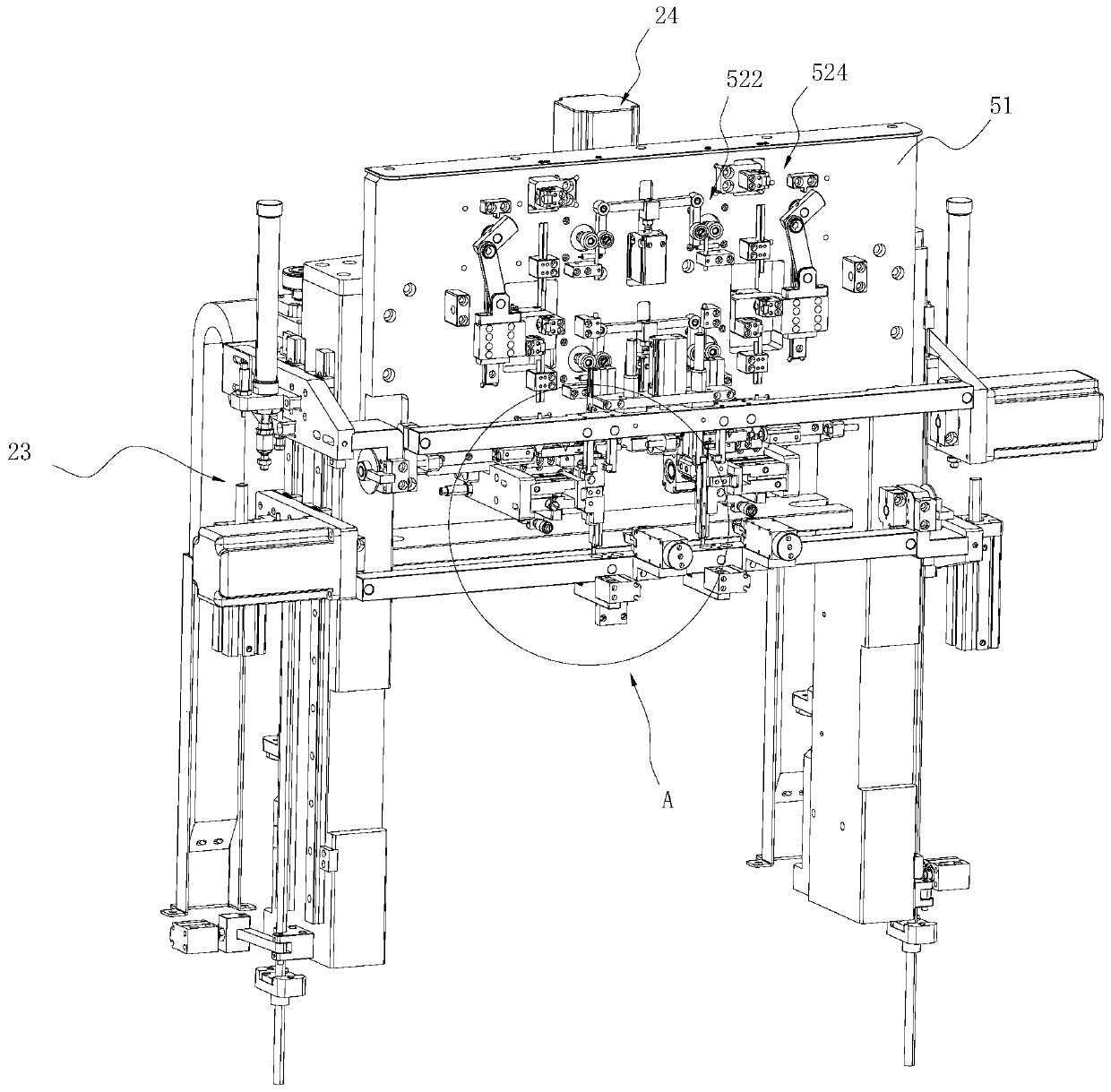

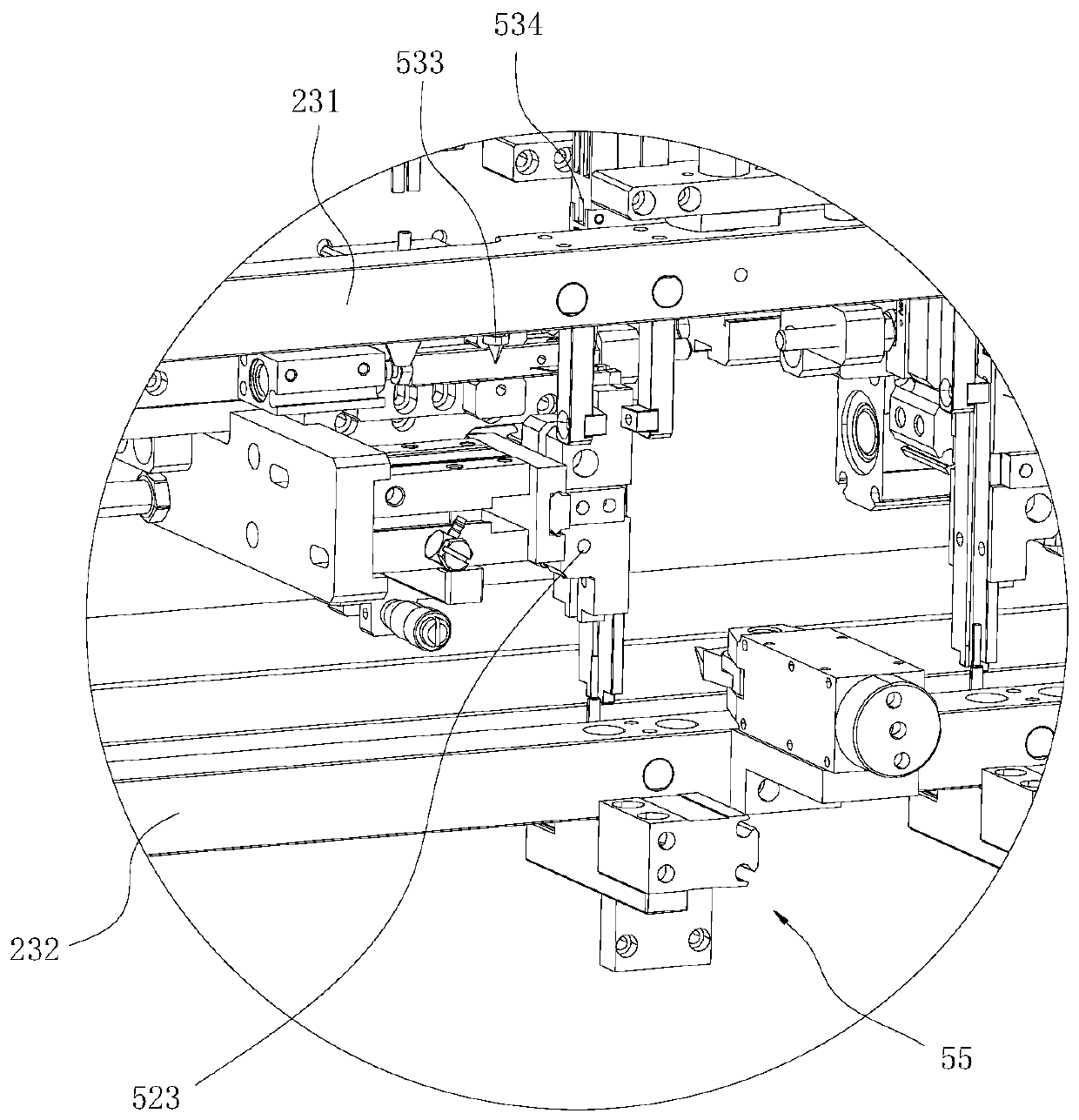

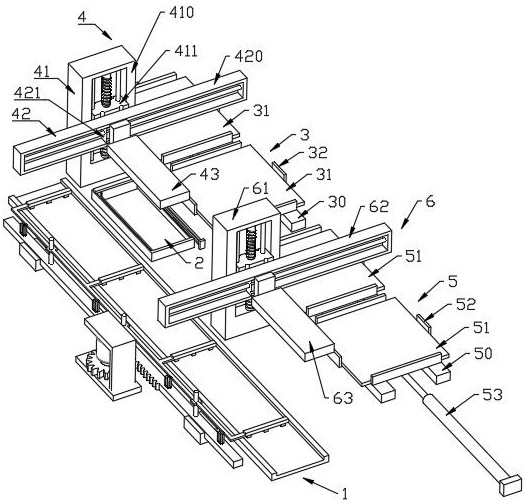

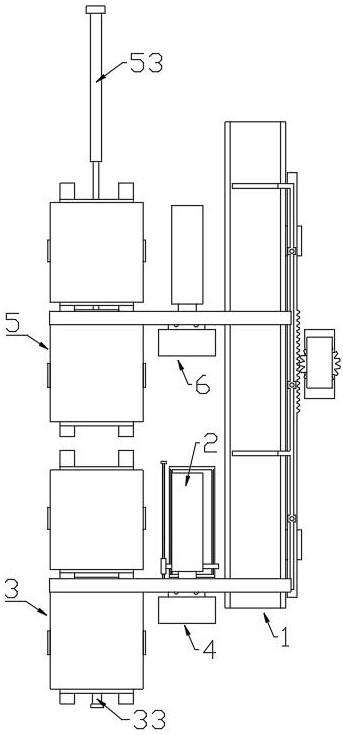

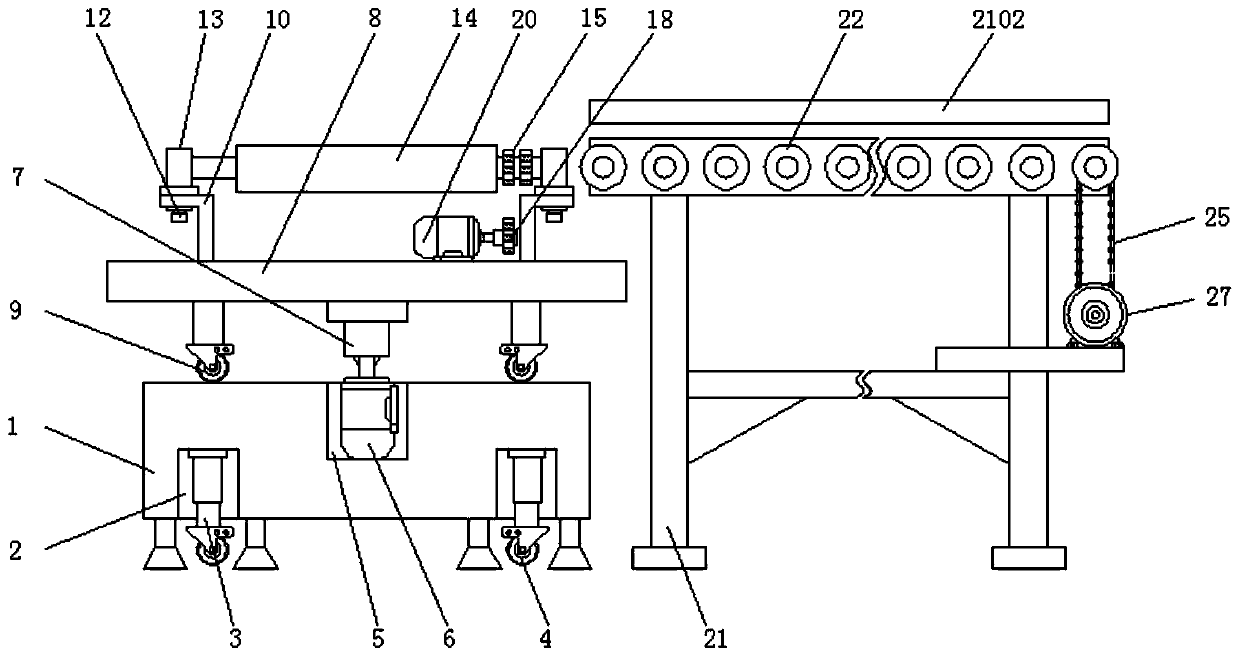

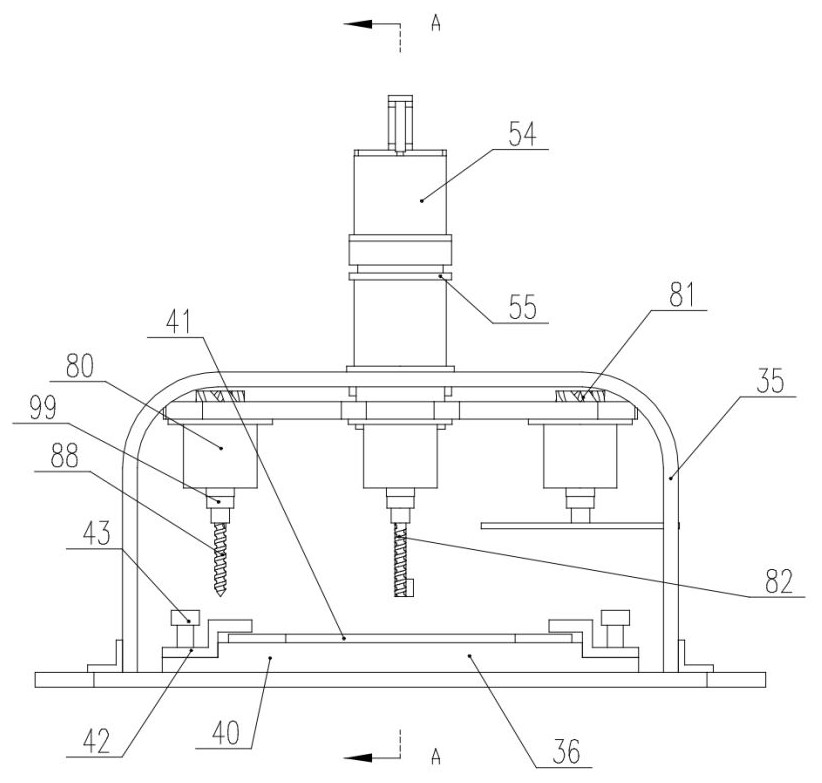

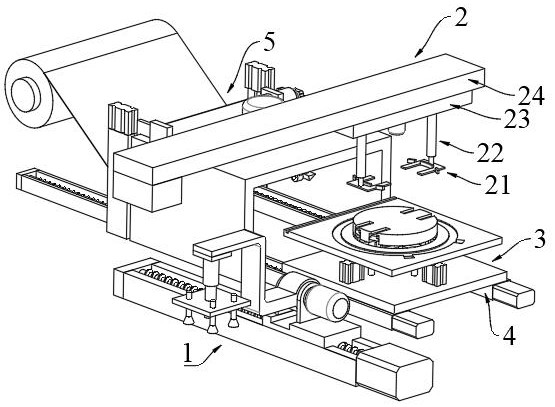

Transformer pipe penetrating, winding and rubber coating all-in-one machine

PendingCN110875130AIncrease productivitySimplify the path of movementCoils manufactureWire rodTransformer

The invention belongs to the transformer production equipment technology field, and especially relates to a transformer pipe penetrating, winding and rubber coating all-in-one machine. The machine comprises a machine base, a driving device, a rotating main shaft displacement device, a wire rod pipe penetrating conveying device, a wire head and wire tail pin winding guide pin device and a double-side rubber coating device. The machine base is provided with a portal frame. The driving device comprises a first guide rail, a first driving mechanism, a moving mechanism, a first linear mechanism anda second linear mechanism, the first guide rail is arranged on the portal frame, the moving mechanism is connected with the first guide rail, the first driving mechanism drives the moving mechanism,the first linear mechanism is arranged on the machine base, and the second linear mechanism is arranged on the first linear mechanism. The rotating main shaft displacement device is arranged on the second linear mechanism. The wire rod pipe penetrating conveying device is arranged on the portal frame, and the wire head and wire tail pin winding guide pin device comprises a wire head pin winding mechanism and a wire tail pin winding mechanism. The double-side rubber coating device is arranged on the machine base. The machine has the advantages that a component moving stroke can be reasonably distributed, and production efficiency of a transformer is improved.

Owner:东莞市微米精密自动化设备有限公司

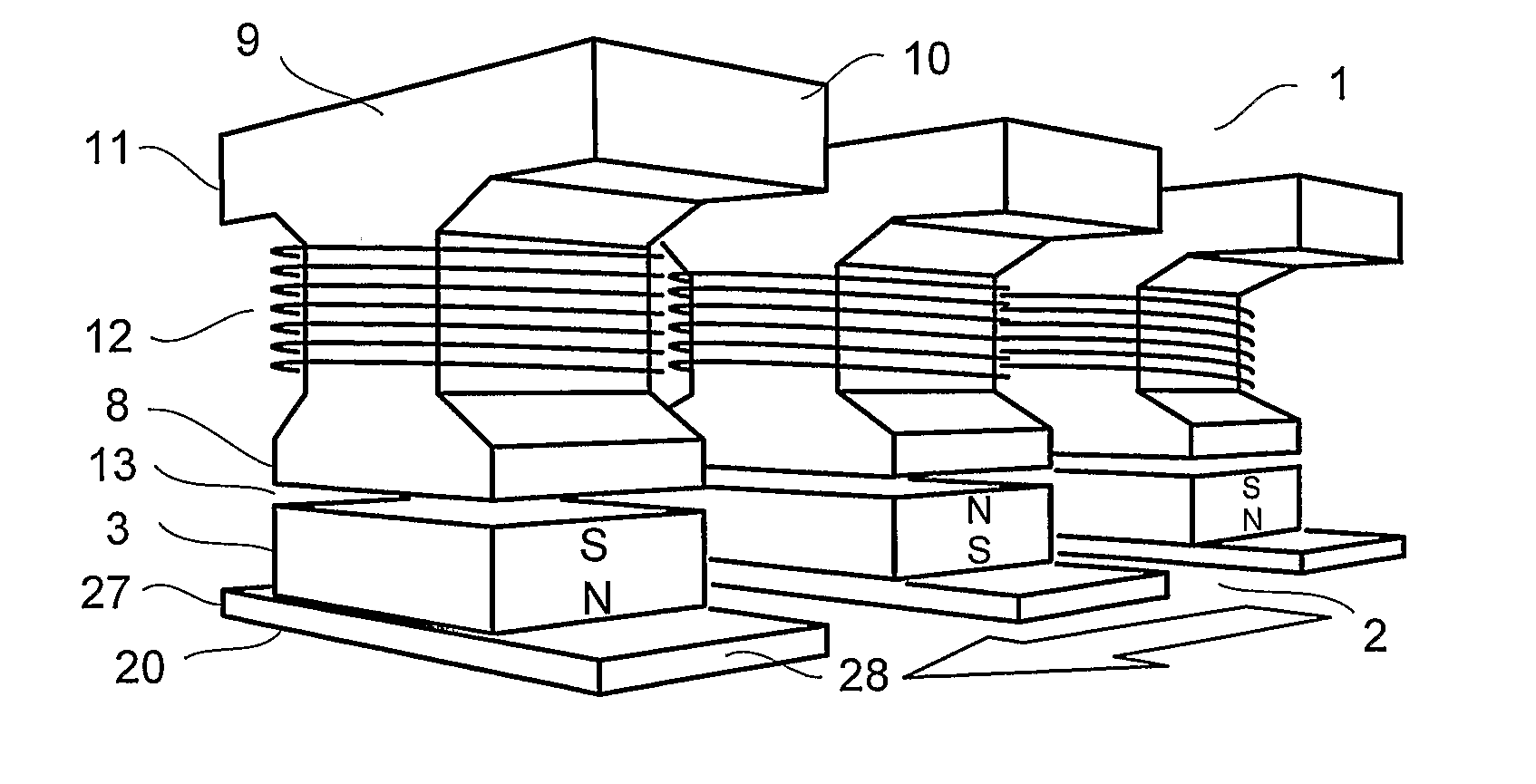

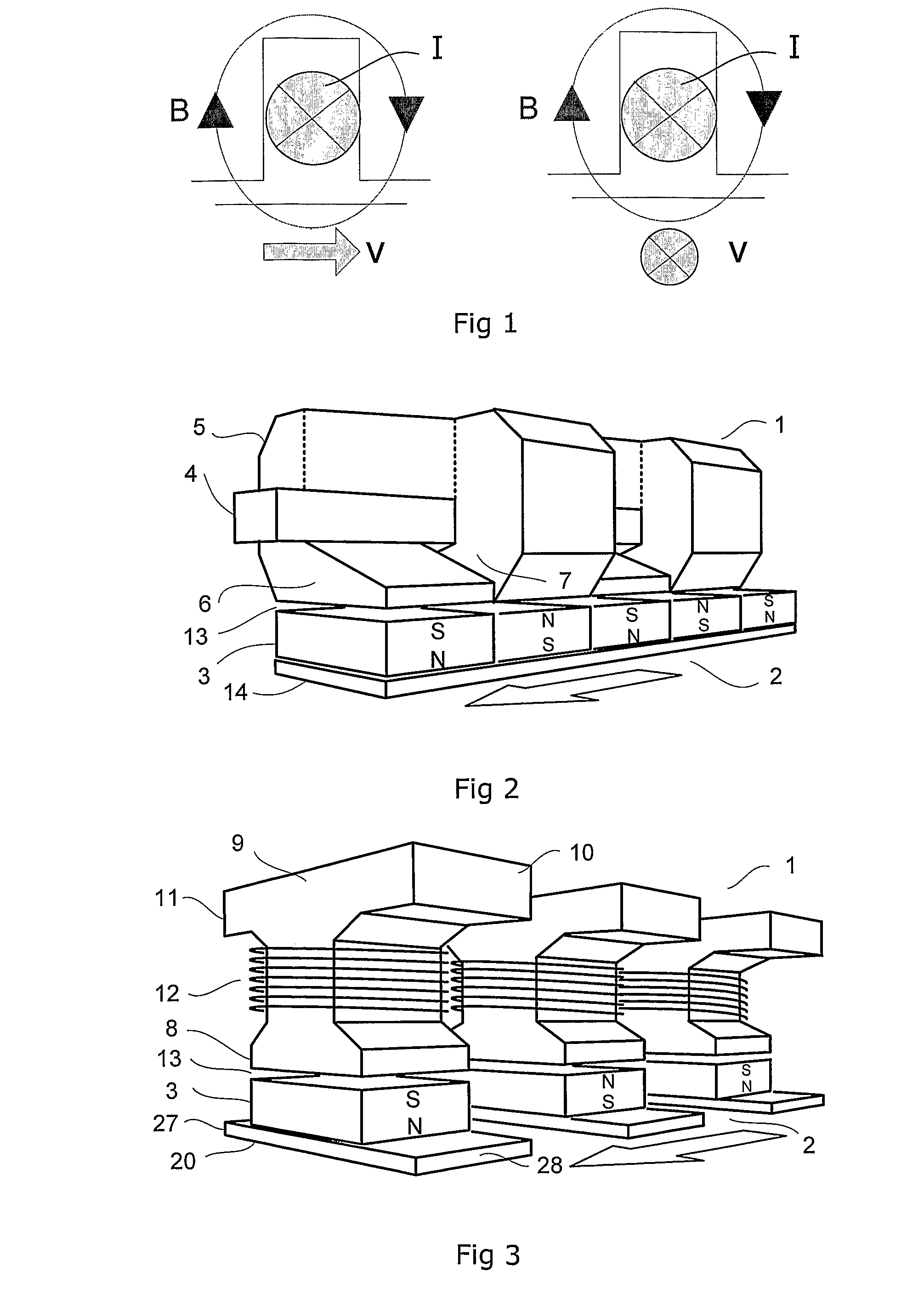

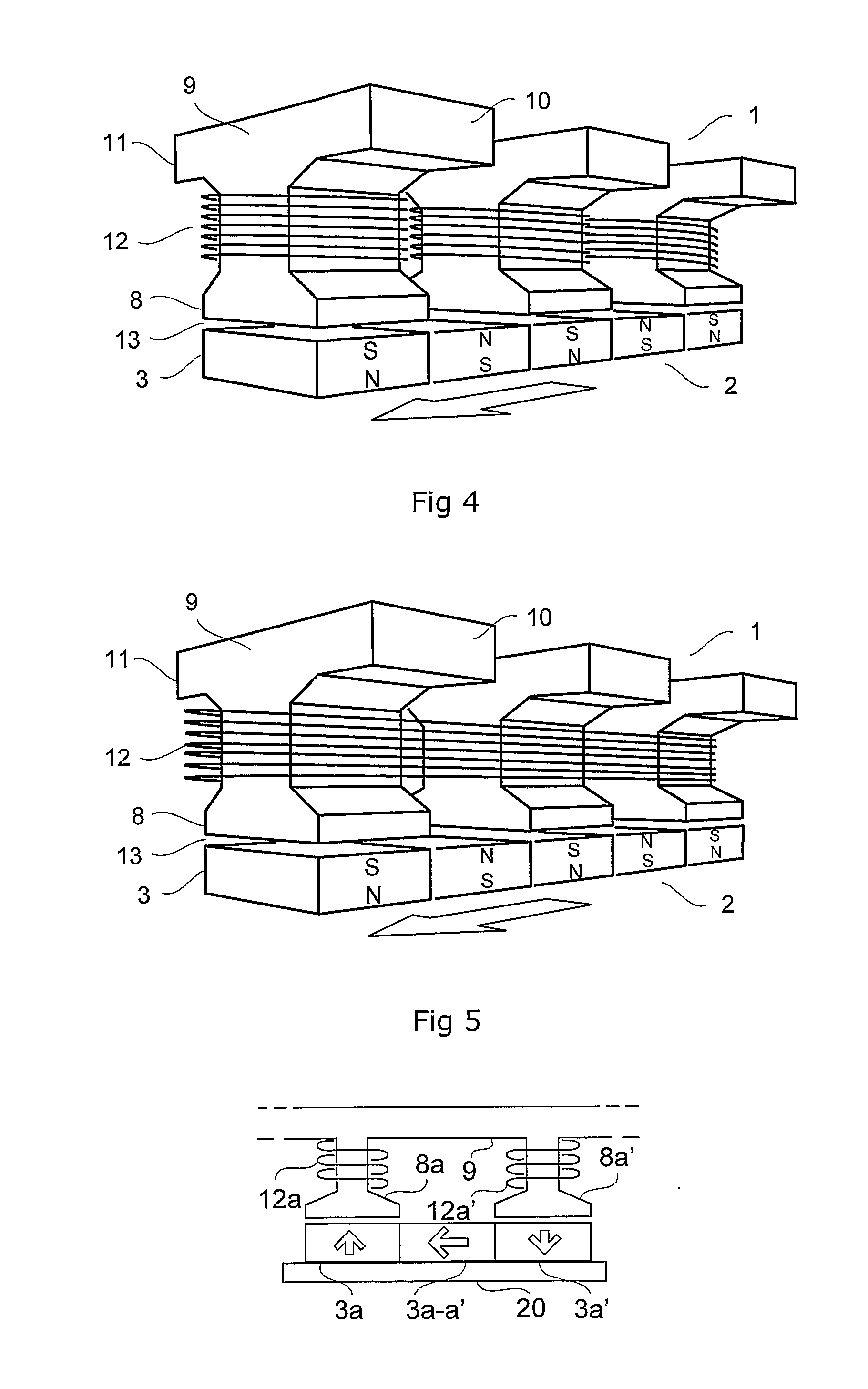

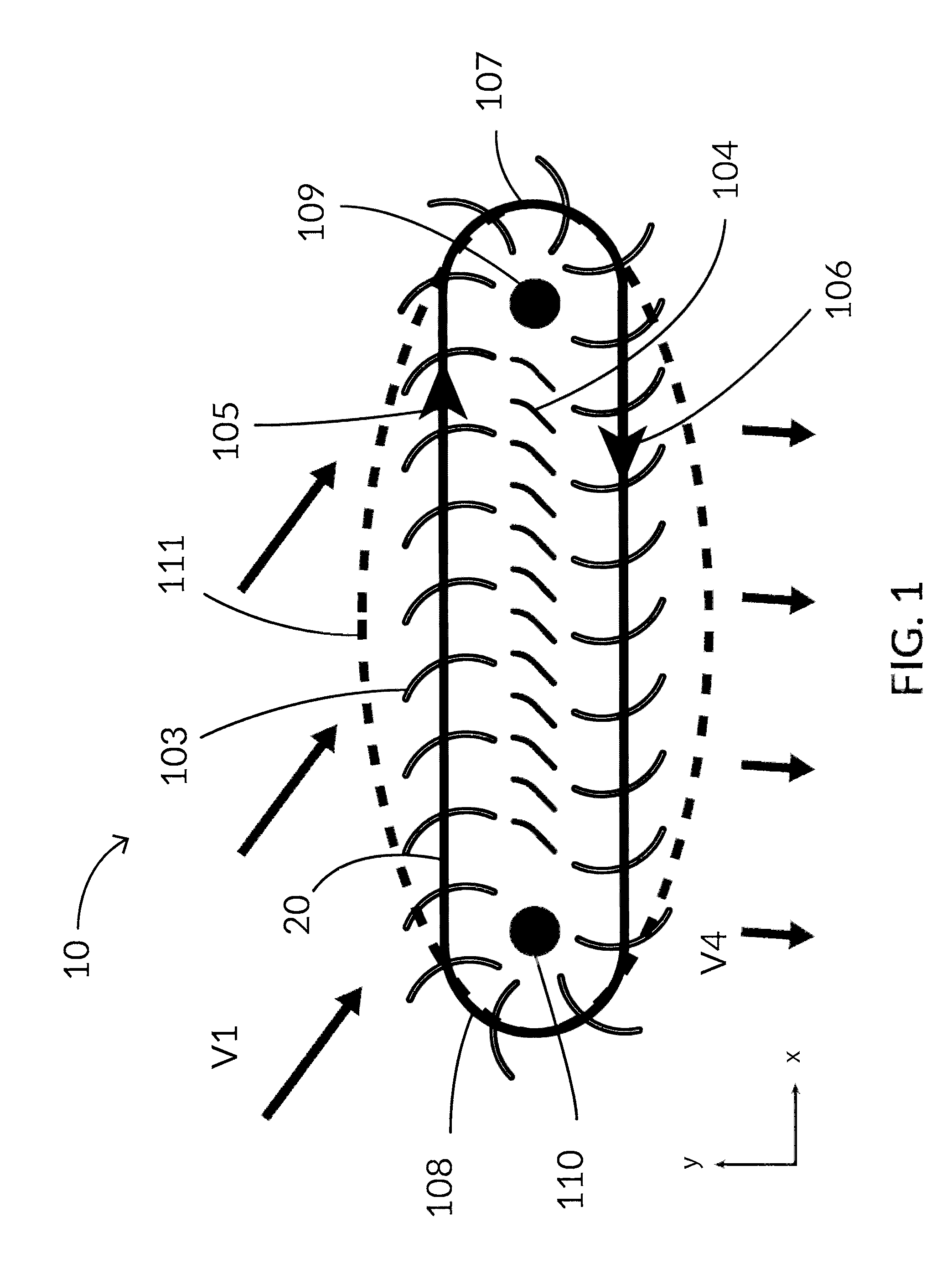

Linear Transverse Flux Machine

InactiveUS20080309171A1Increased torque densitySimple designMagnetic circuitPropulsion systemsTransverse fluxLinear transverse

A transverse flux linear machine including a first interacting part including an electric winding and a second interacting part including a plurality of magnetic poles. The first and second interacting parts are movable relative to each other and defining between them an airgap.

Owner:ABB RES LTD

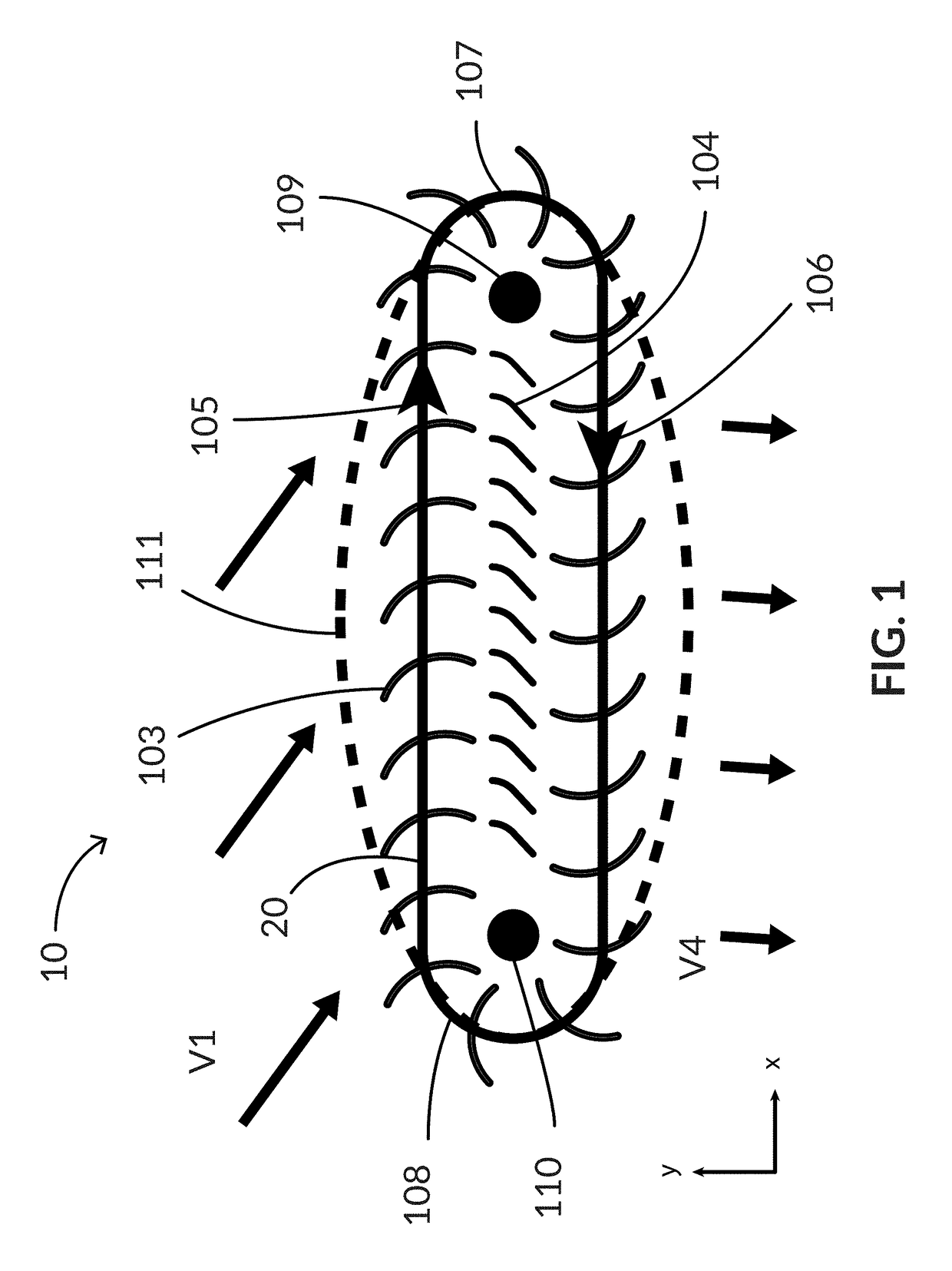

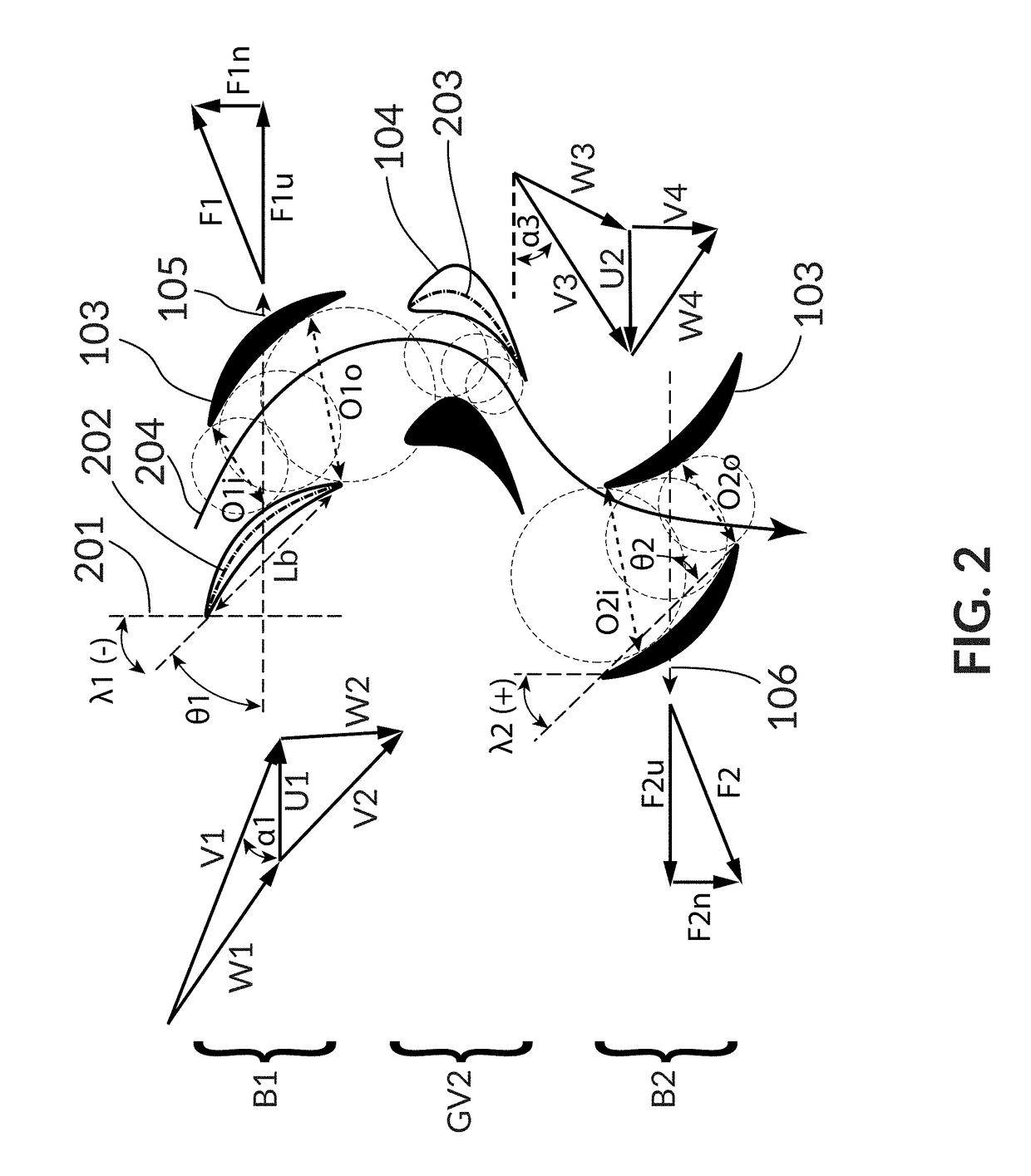

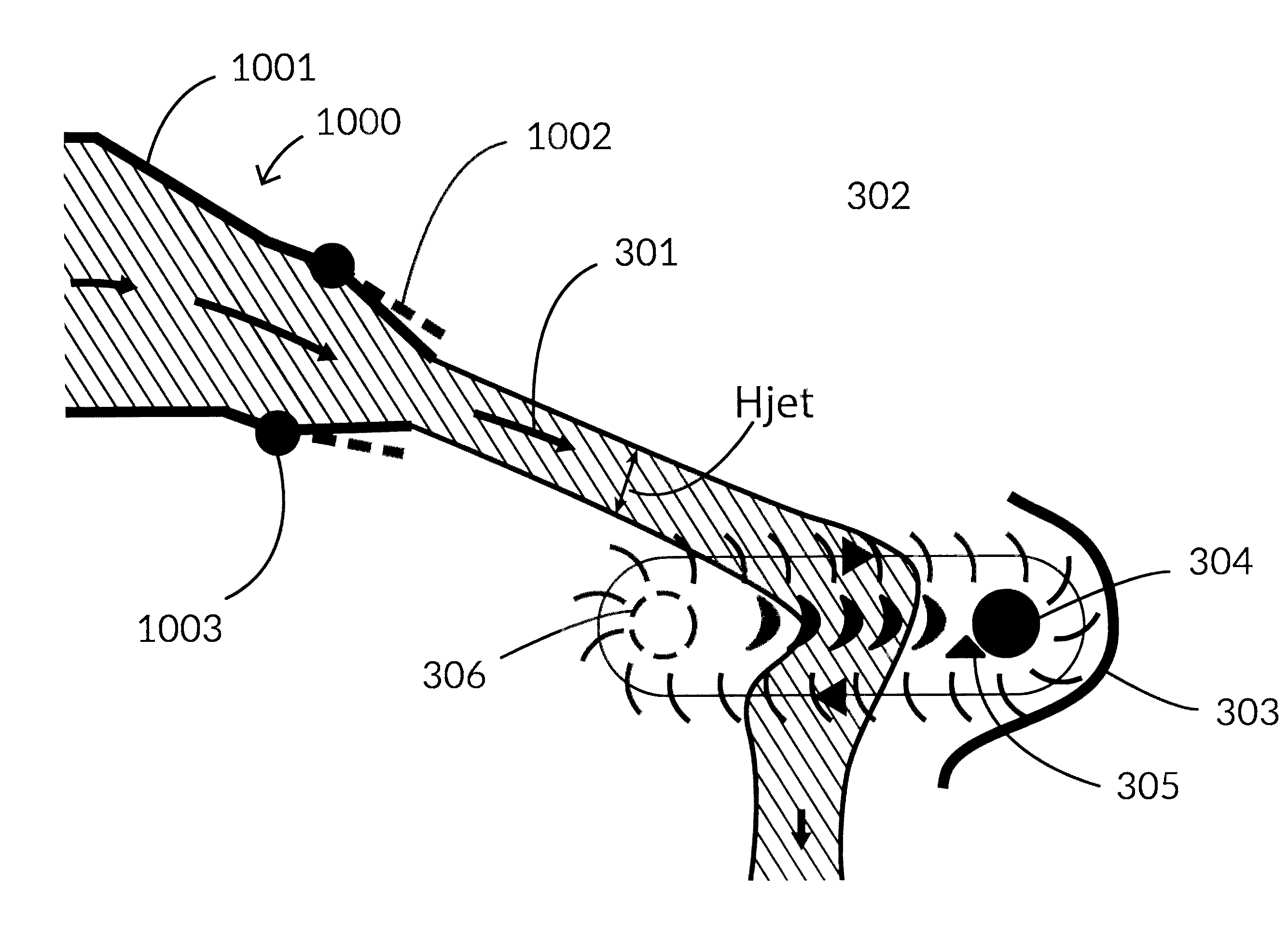

Hydraulic turbine

InactiveUS20170204830A1Improve efficiencySimple designHydro energy generationEngine componentsLinear machineLinearity

Disclosed herein are linear hydraulic turbines in which the linear machine converts the majority of available energy in the flowing water into useful torque directly in the runner, leaving the outflow with very little velocity.

Owner:NATEL ENERGY

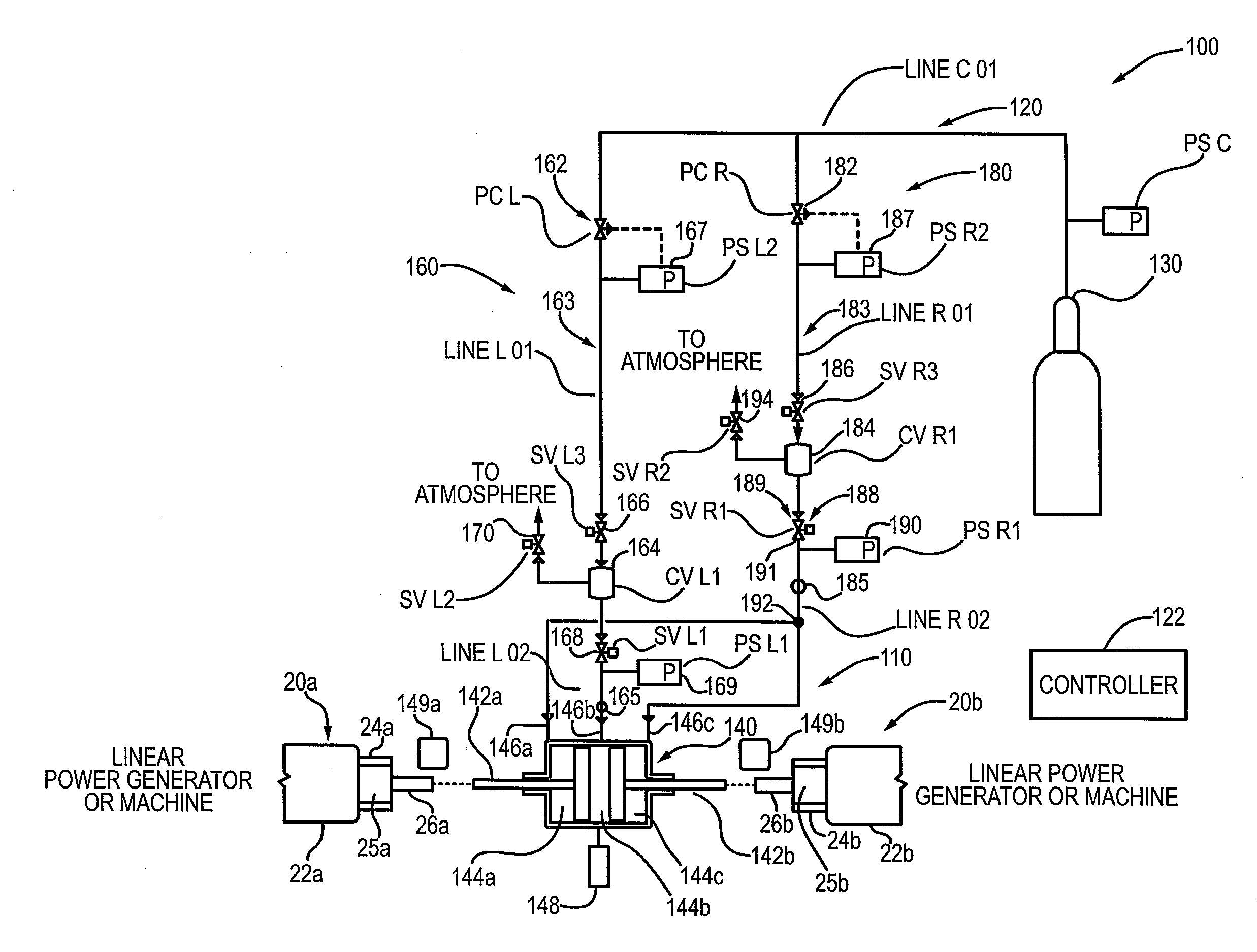

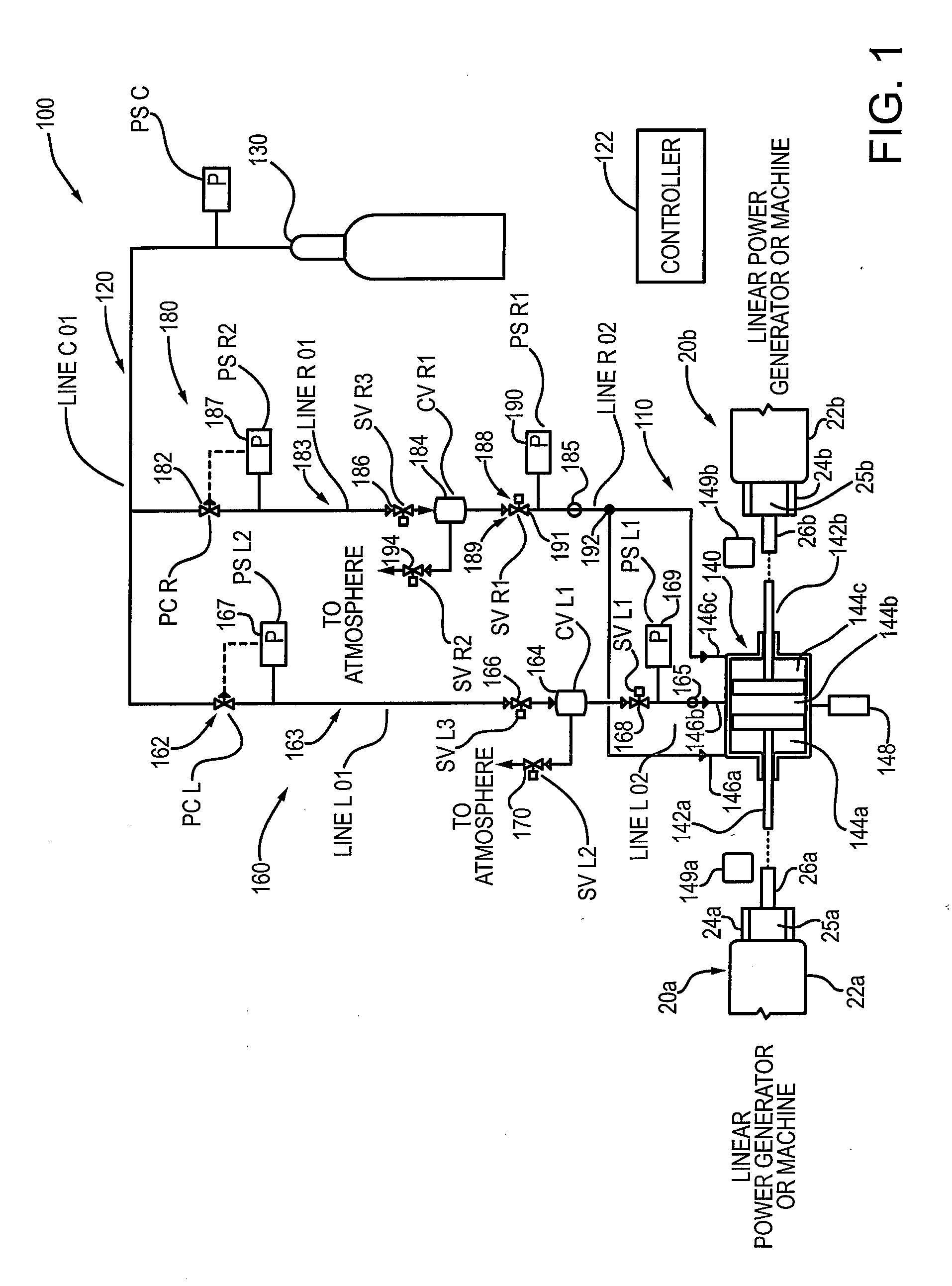

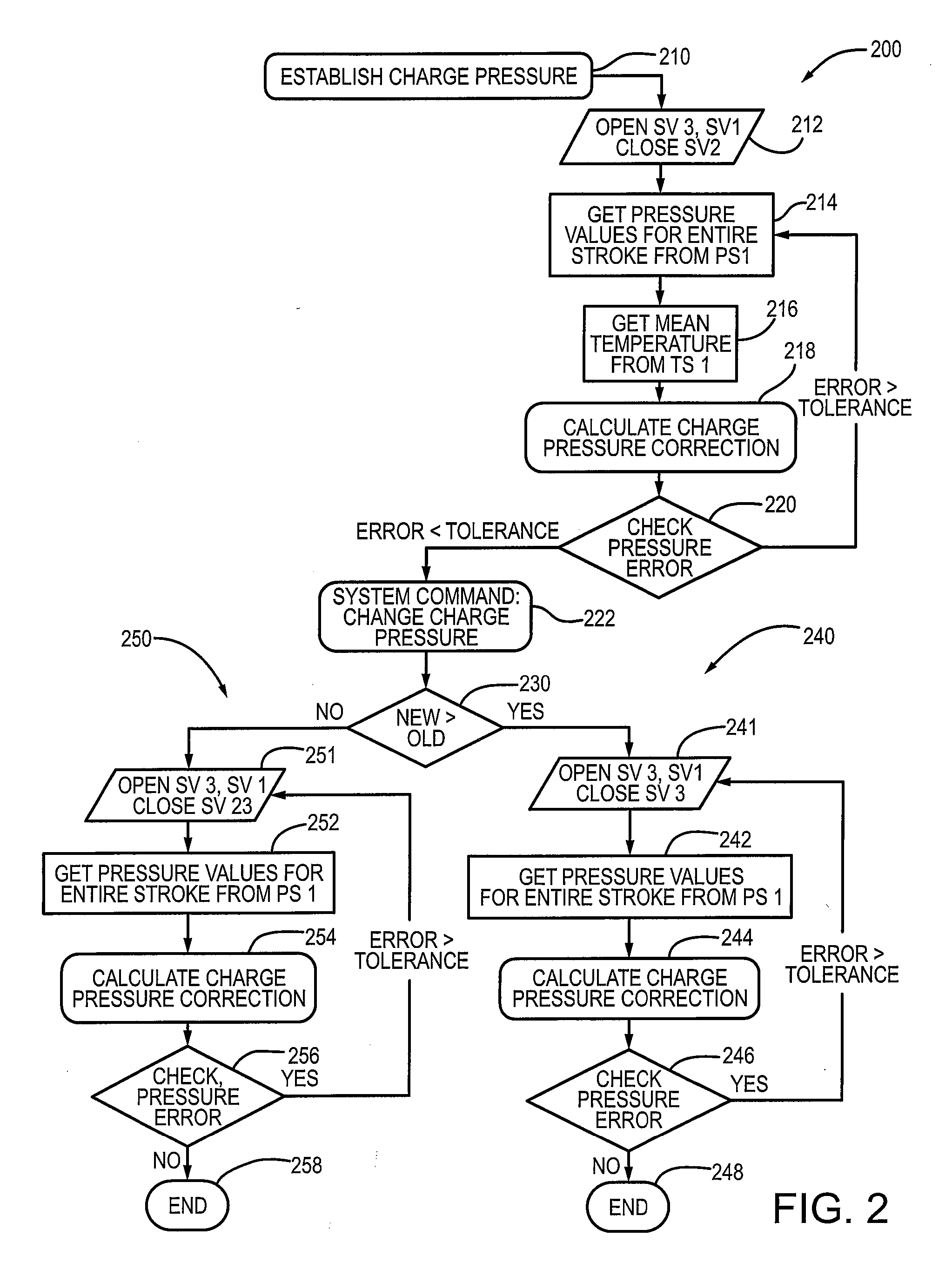

Gas spring with dynamically controllable damping

A gas spring suitable for controlling motion of a linear power generator or a linear machine. According to an embodiment, the gas spring comprises a cylinder and a pressure control network. The cylinder comprises two pistons in a coaxial arrangement and three controllable gas volumes or chambers. Each of the pistons includes a piston rod or shaft that is configured to couple to respective drive shaft(s) on the linear power generator. The pressure control network is operatively coupled to each of the three gas volumes and configured with a controller to control the gas pressure in the gas volumes to vary the resistance of the pistons to the movement of the respective drive shaft(s) on the linear power generator. According to another embodiment, the cylinder comprises one piston and two controllable gas volumes or chambers operatively coupled to the pressure control network.

Owner:MILINKOVIC MIRO

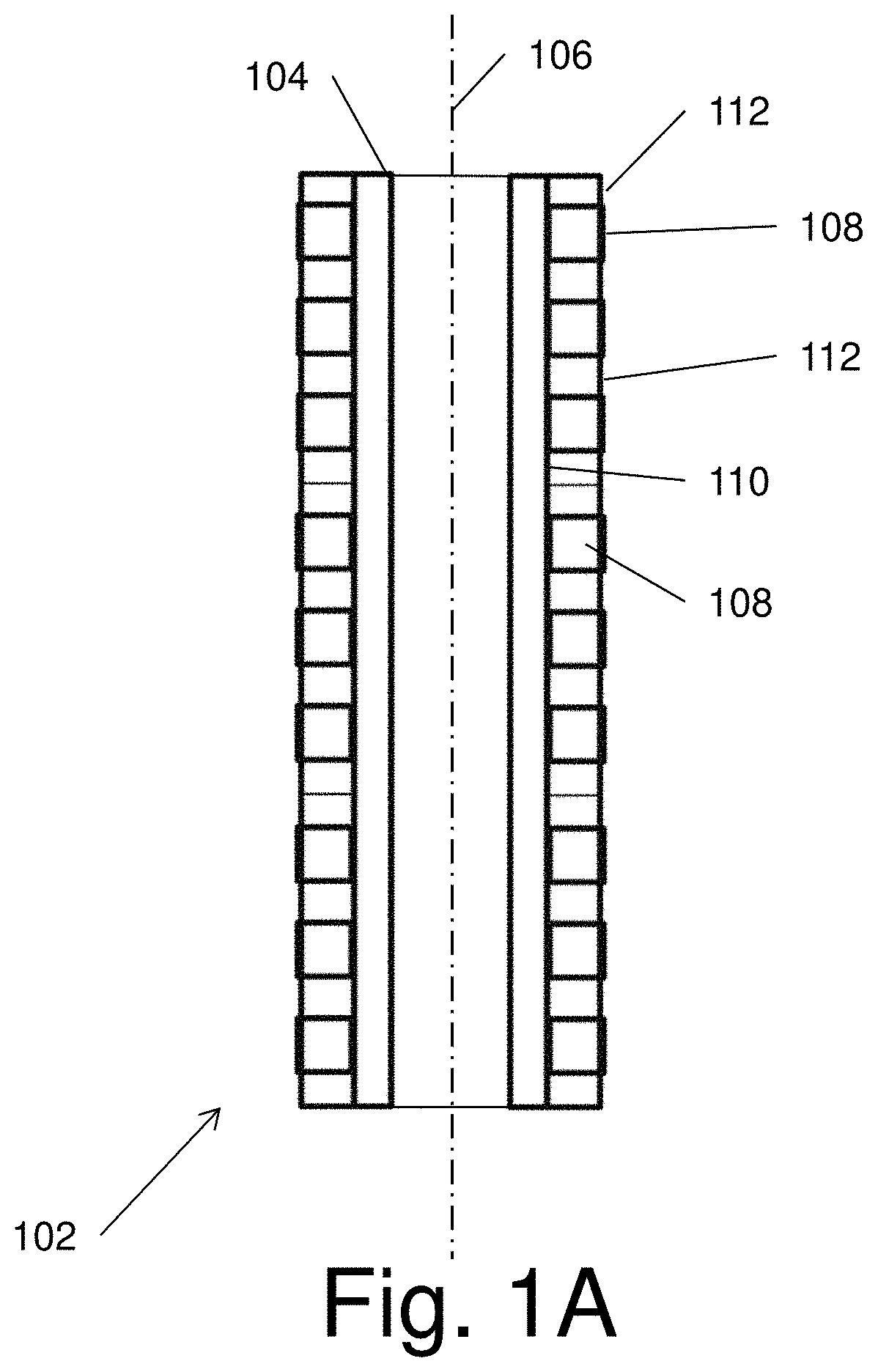

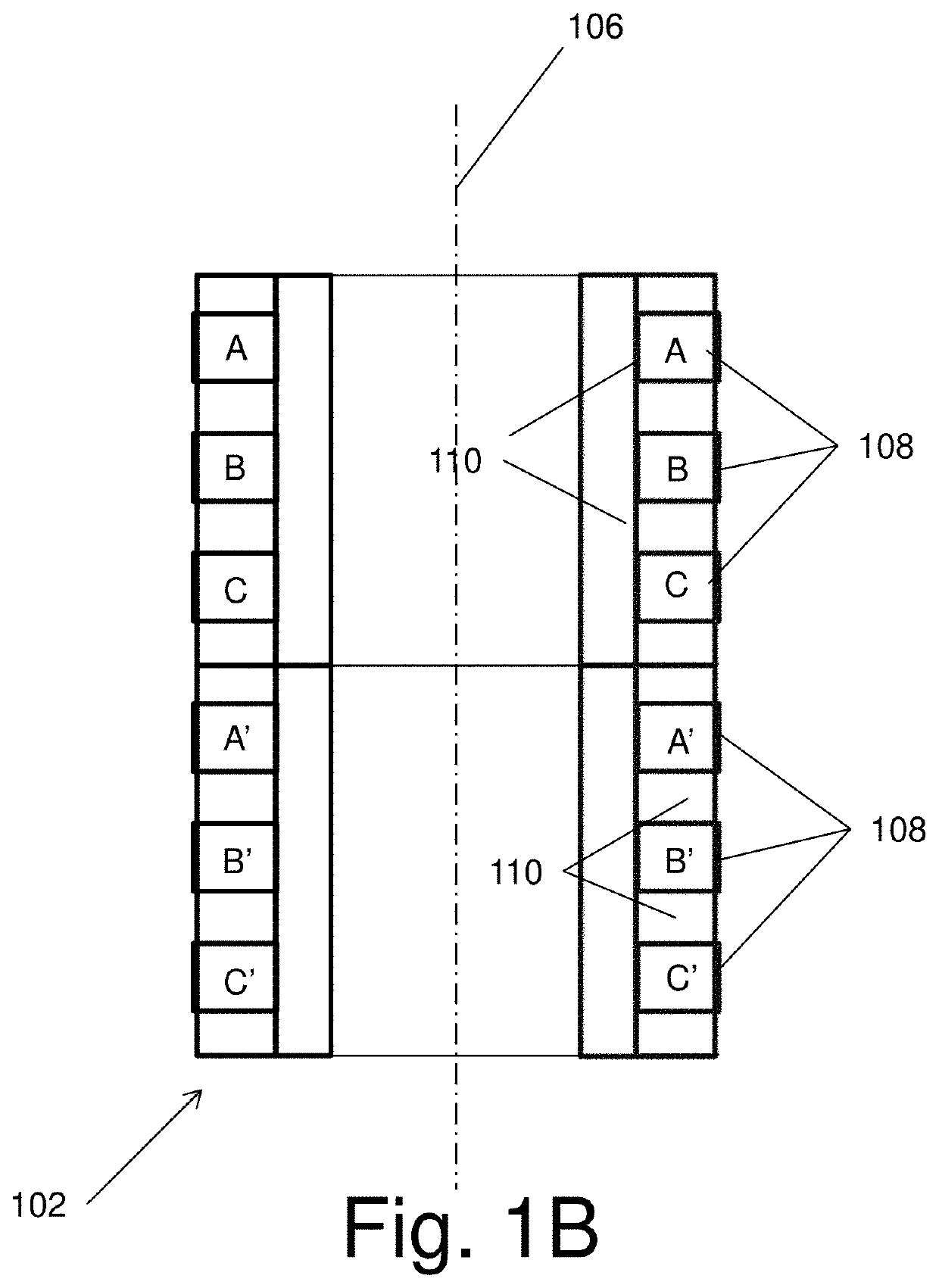

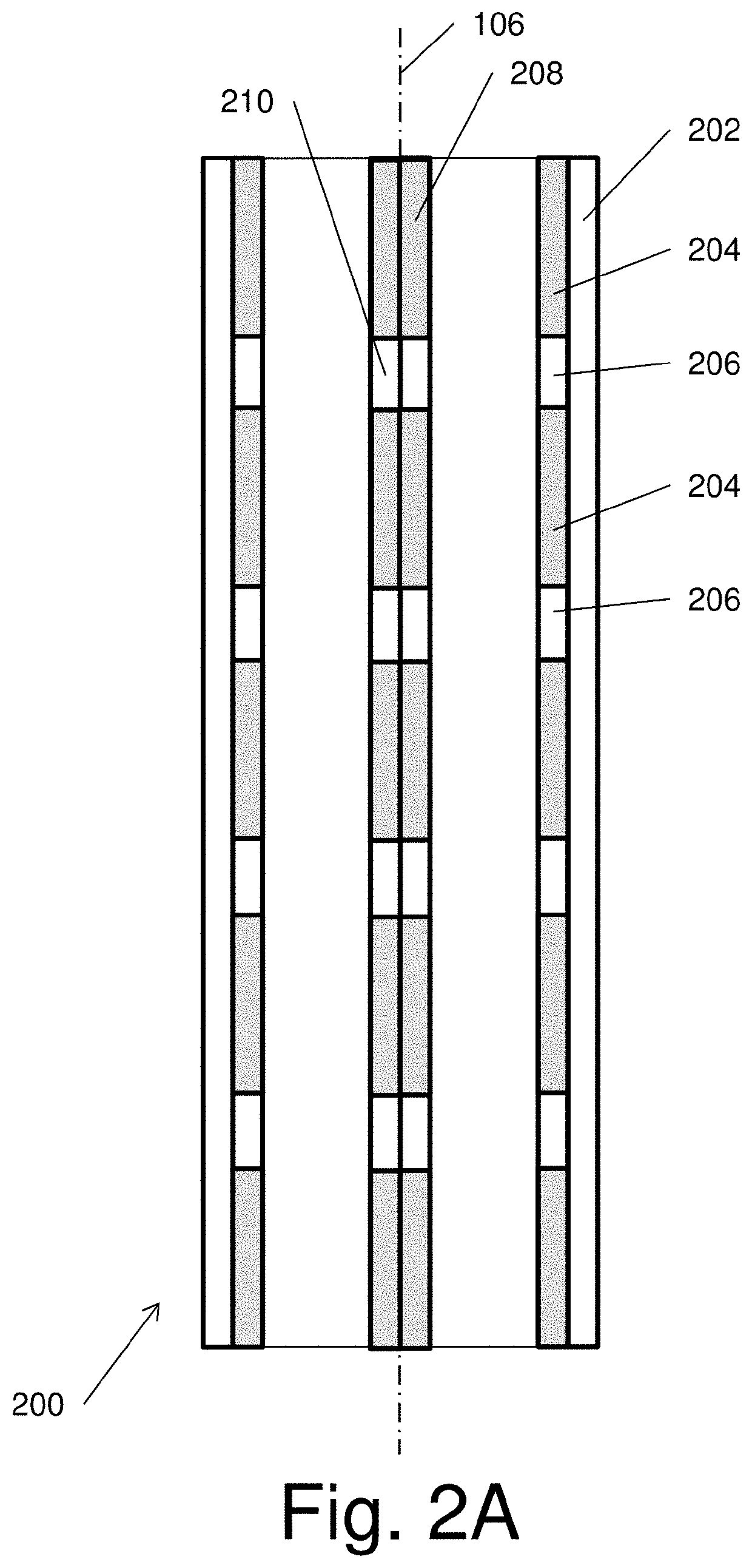

Linear machine

InactiveUS20100301685A1Propulsion systemsWindings conductor shape/form/constructionElectrical conductorStator coil

Linear machine with a stator and a rotor, which are separated by an air gap and have at least one stator coil and / or one rotor coil respectively. The stator or rotor has a soft magnetic iron body with a stator back or rotor back, on which grooves are formed at a distance from each other, forming teeth. In the grooves, multiple conductor bars of the stator coil or rotor coil are arranged in rows. On the faces of the stator or rotor, end connectors which connect the conductor bars and extend over multiple grooves are present. Each conductor bar has a cavity on the face of at least one of its ends. Each end connector has an extension, which is arranged and dimensioned in such a way as to engage in an electrically conducting manner into the respective cavity of the conductor bar, on its section facing the respective front end of the conductor bars.

Owner:COMPACT DYNAMICS

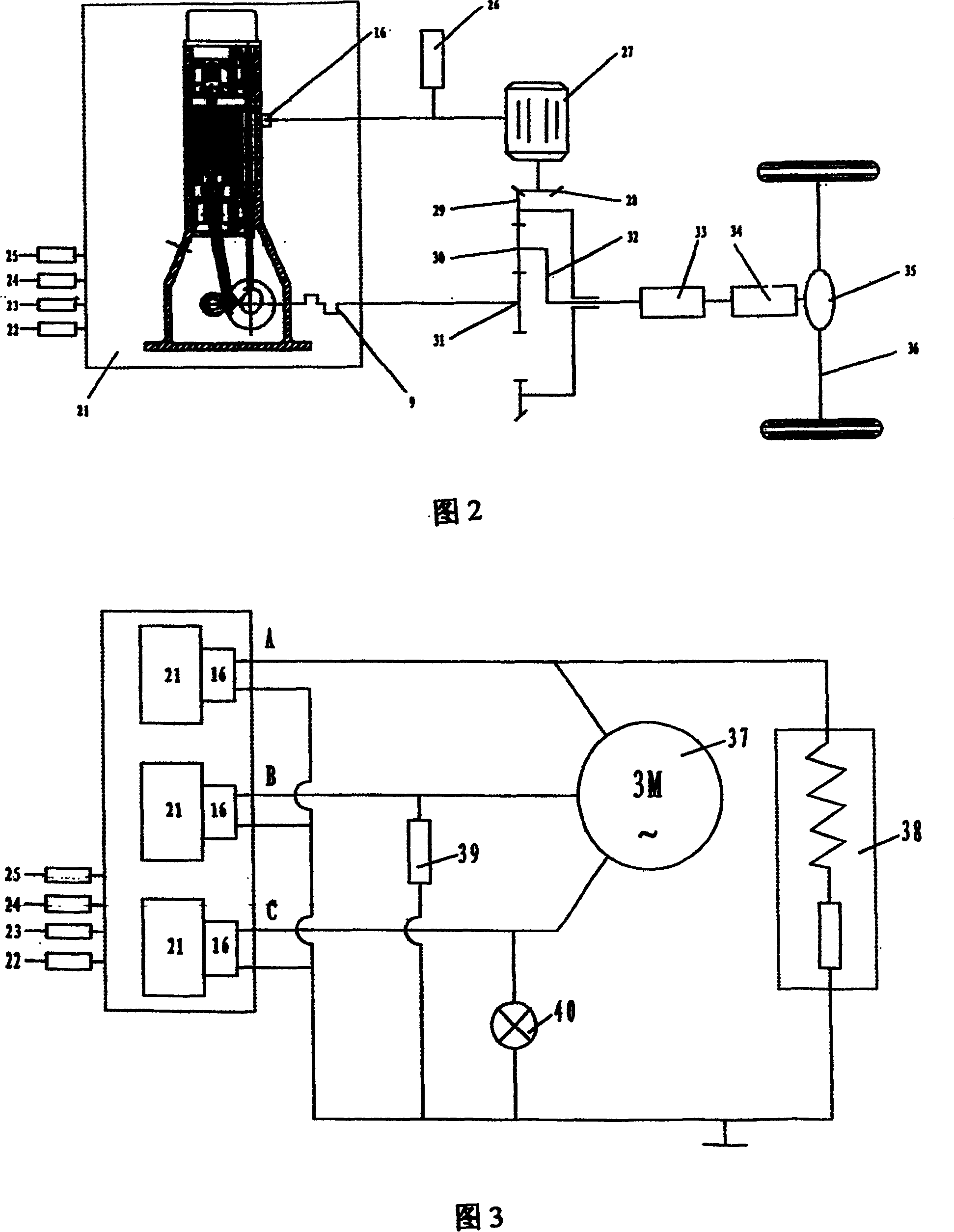

Internal combustion type mechanical and electric energy output method and apparatus therefor

InactiveCN100363603CReduce stressReduce friction lossHot gas positive displacement engine plantsMechanical energyEngineering

The invention discloses an internal-burning type machine and fluid two-tier power output method and device, which is characterized by the following: the first working chamber finishes the transformation of heat energy into line mechanical energy; the second working chamber finishes the diverting of line mechanical energy and transforms part of line mechanical energy into two paths; one path is transmitted to the third or first working chamber and the other path is transformed into power to output directly according to the electromagnetic induction elementary; the third working chamber finishes the transformation of line mechanical energy into rotary mechanical energy to output through crank-flywheel component; the piston-plunger component in the second working chamber finishes the power diverting function, which anchors the crank-flywheel as well as generates power from the relative movement of rotor component winding coil.

Owner:QINGDAO UNIV +1

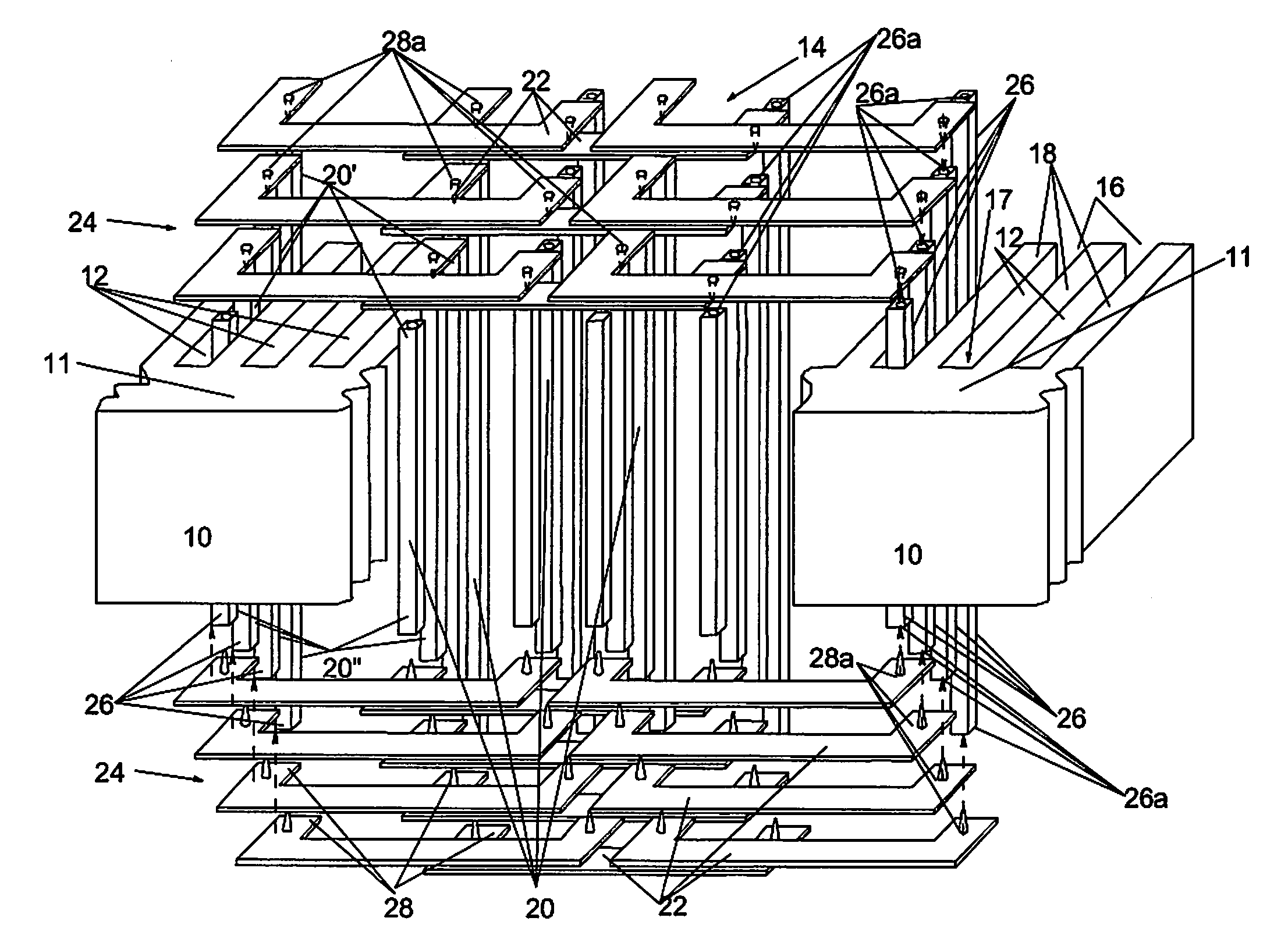

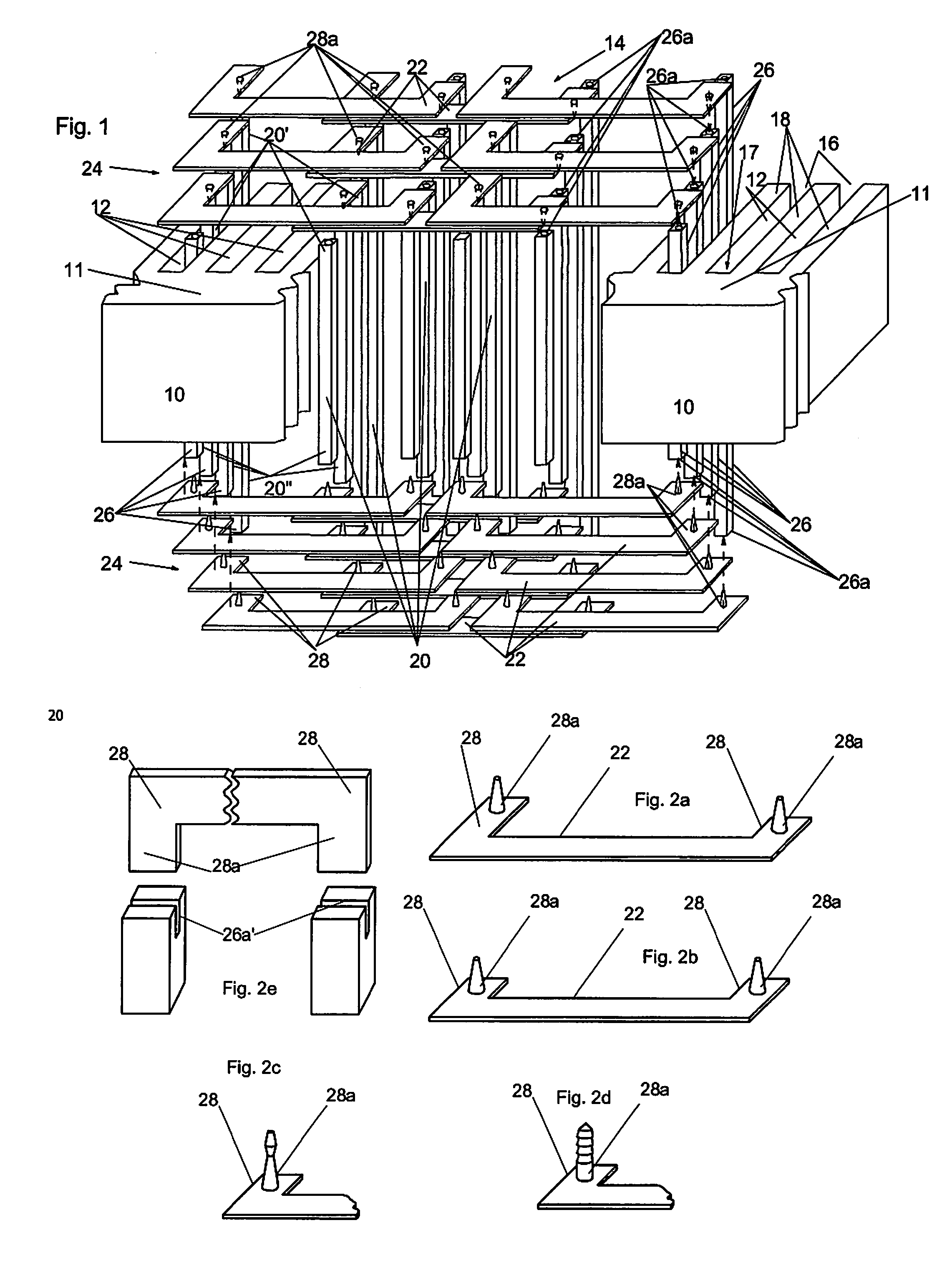

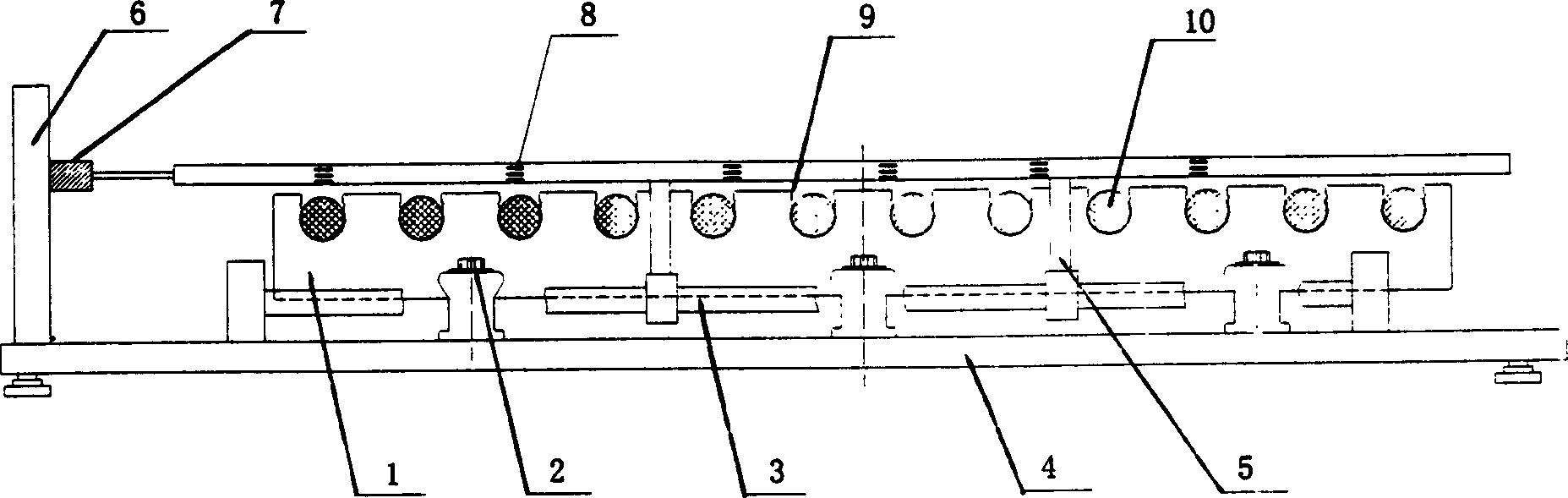

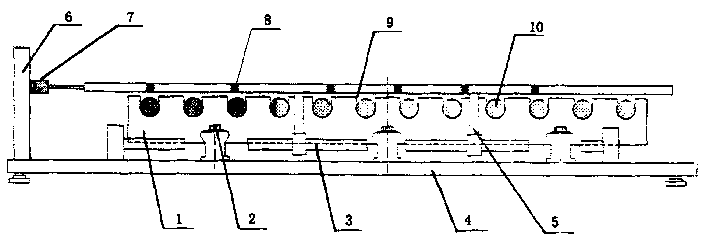

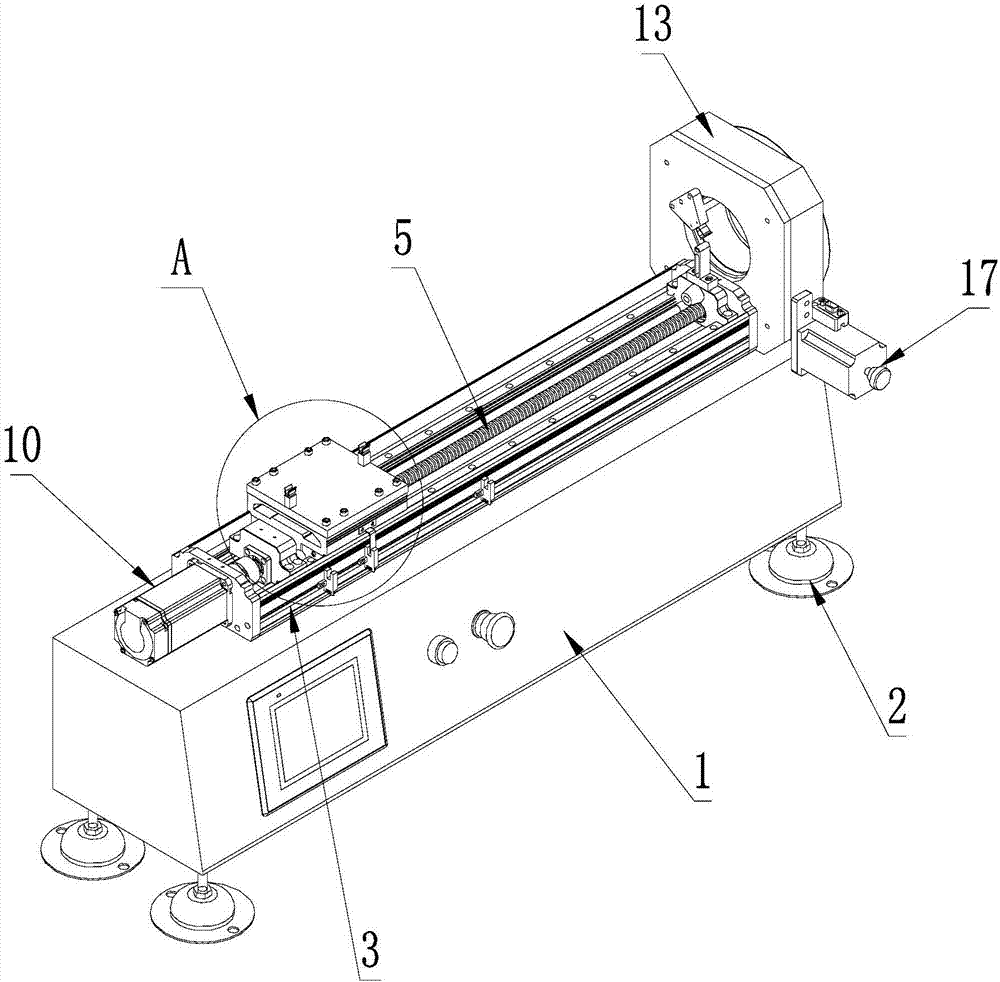

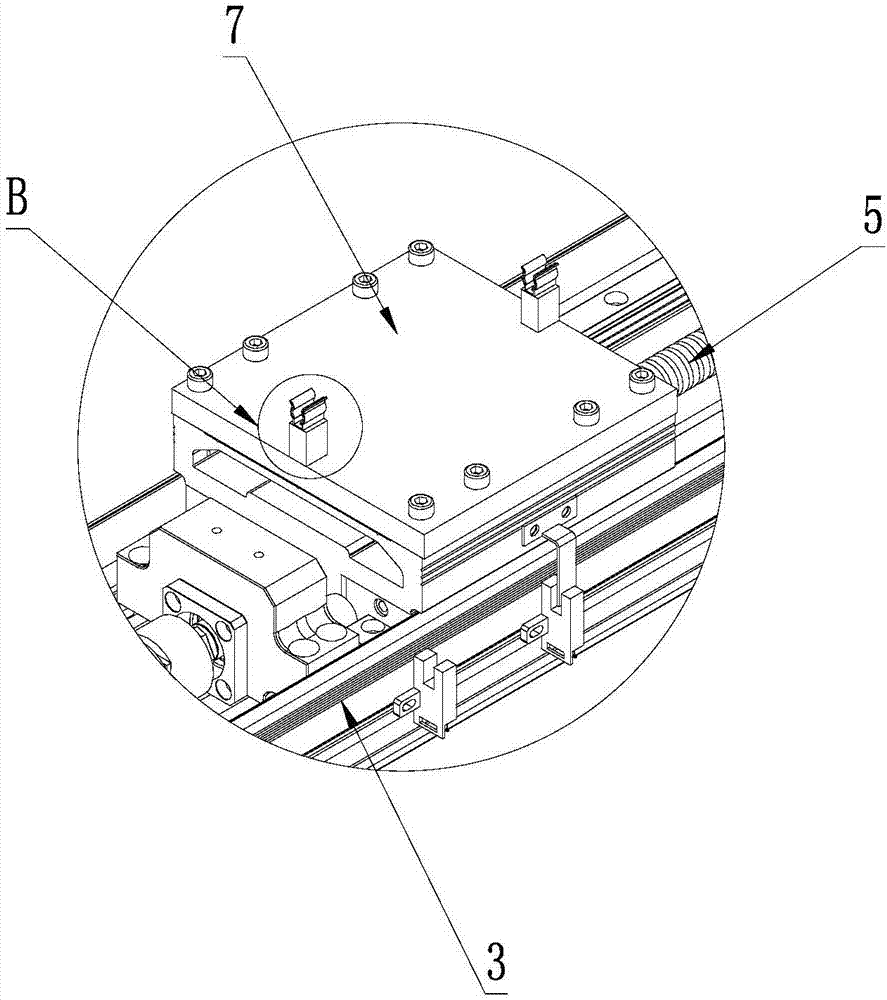

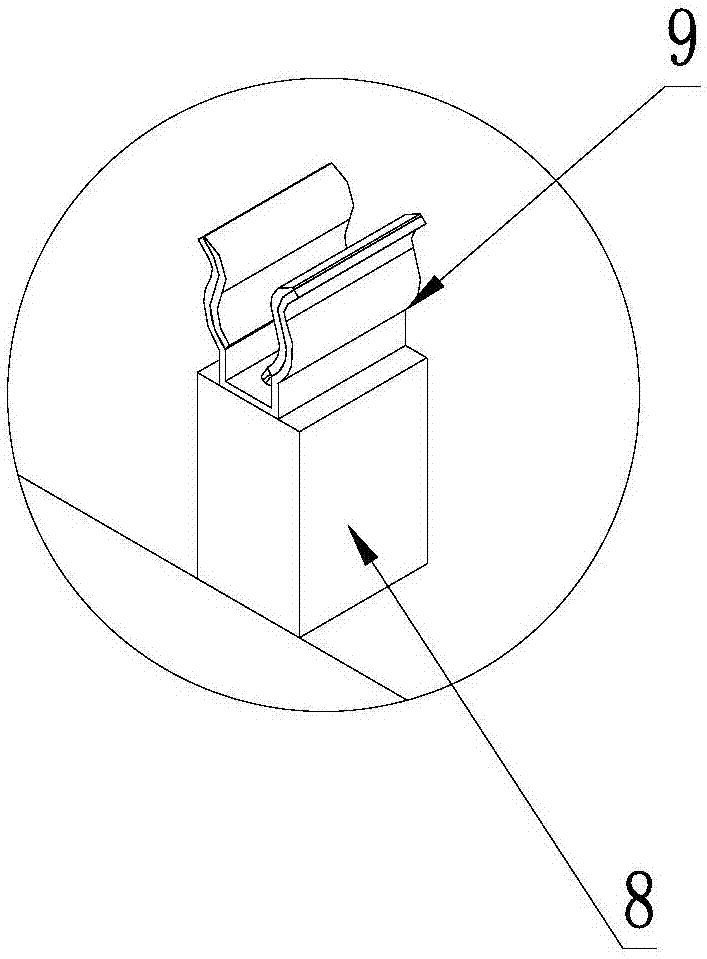

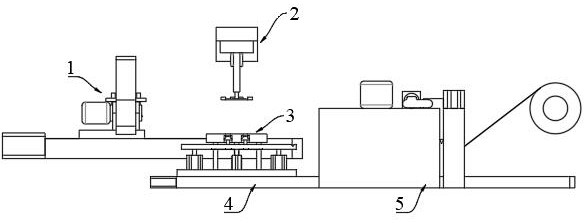

Long-stator linear machine electromagnetic performance off-line testing device

InactiveCN1460865AGuaranteed electromagnetic performanceFulfil requirementsForce measurementMagnetic property measurementsPull forceTransformer

The off-line testing equipment of electromagnetic performance of long-stator linear motor includes a testing platform, on its surface a guideway is set, one end of said testing platform is equipped with a fixed supporting frame on which one end of a pulling sensor with high accuracy is connected, said testing platform also is equipped with several fastening bolts. Said off-line testing equipment also includes a rotor steel plate connected with the above-mentioned guideway by means of supporting frame, said rotor steel plate has several holes, every hole interior is equipped with a group of electrodynamic induction coils, every group container three electrodynamic induction coils, and every induction coil is series-connected with A.C. electric meter. The long-stator to be tested is fixed on the testing platform.

Owner:TONGJI UNIV +2

Integrated packaging device for surface-mounted diode

ActiveCN112366162AFit fastSeamless connectionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringLinear machine

The invention discloses an integrated packaging device for a surface-mounted diode. The device comprises a conveying mechanism; a glue groove which is arranged on one side of the conveying mechanism in the length direction; a chip bearing mechanism which comprises a first bracket and two groups of first four-way limiting plates formed on the first bracket, wherein a chip template is arranged between each group of first four-way limiting plates; a first stroke mechanism which is located at one end of the glue groove and comprises a first lifting mechanism, a first horizontal linear mechanism and a core adhering plate; a jump piece bearing mechanism which comprises a second bracket and two groups of second four-way limiting plates formed on the second bracket, wherein a jump piece template is arranged between each group of second four-way limiting plates; and a second stroke mechanism which comprises a second lifting mechanism, a second horizontal linear mechanism and a pneumatic suctioncup. By means of a core feeding mechanism, a jump piece pasting mechanism and the like which are arranged along a lead frame conveying line, the stepping type continuous conveying of lead frames is achieved, gluing, core pasting and core feeding can be efficiently completed, jump piece pasting can be completed in the conveying process, and the process efficiency is greatly improved.

Owner:四川晶辉半导体有限公司

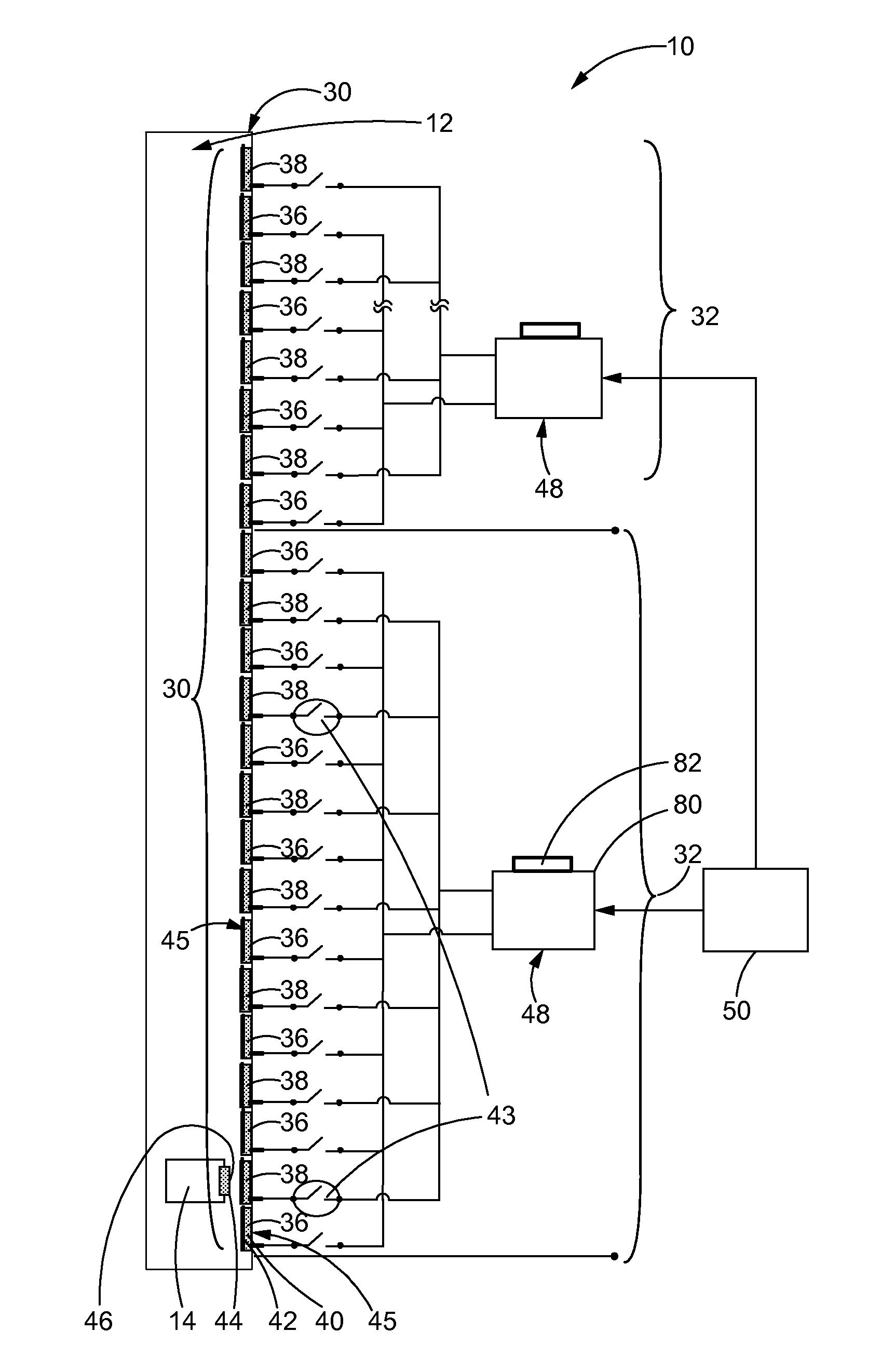

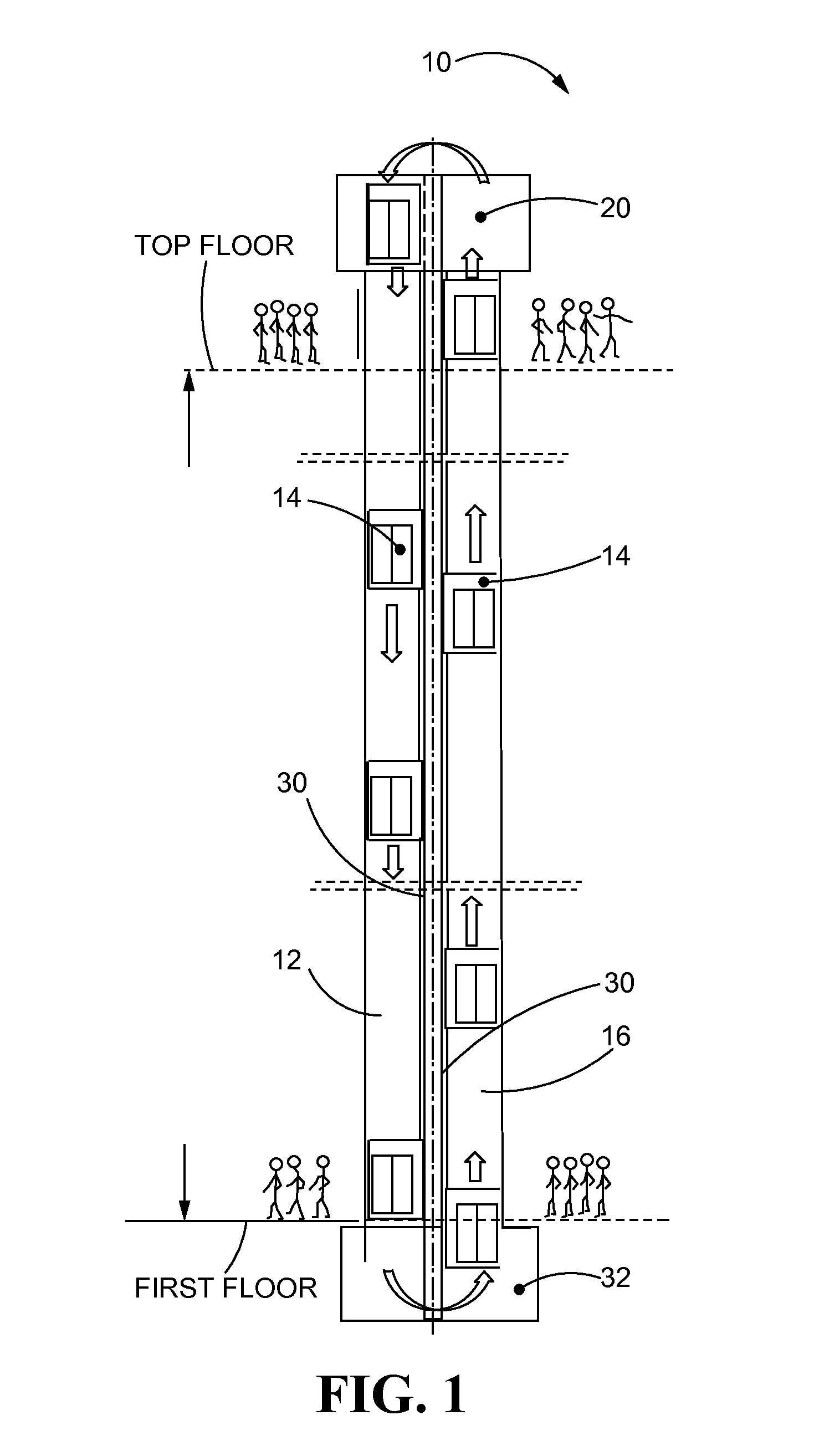

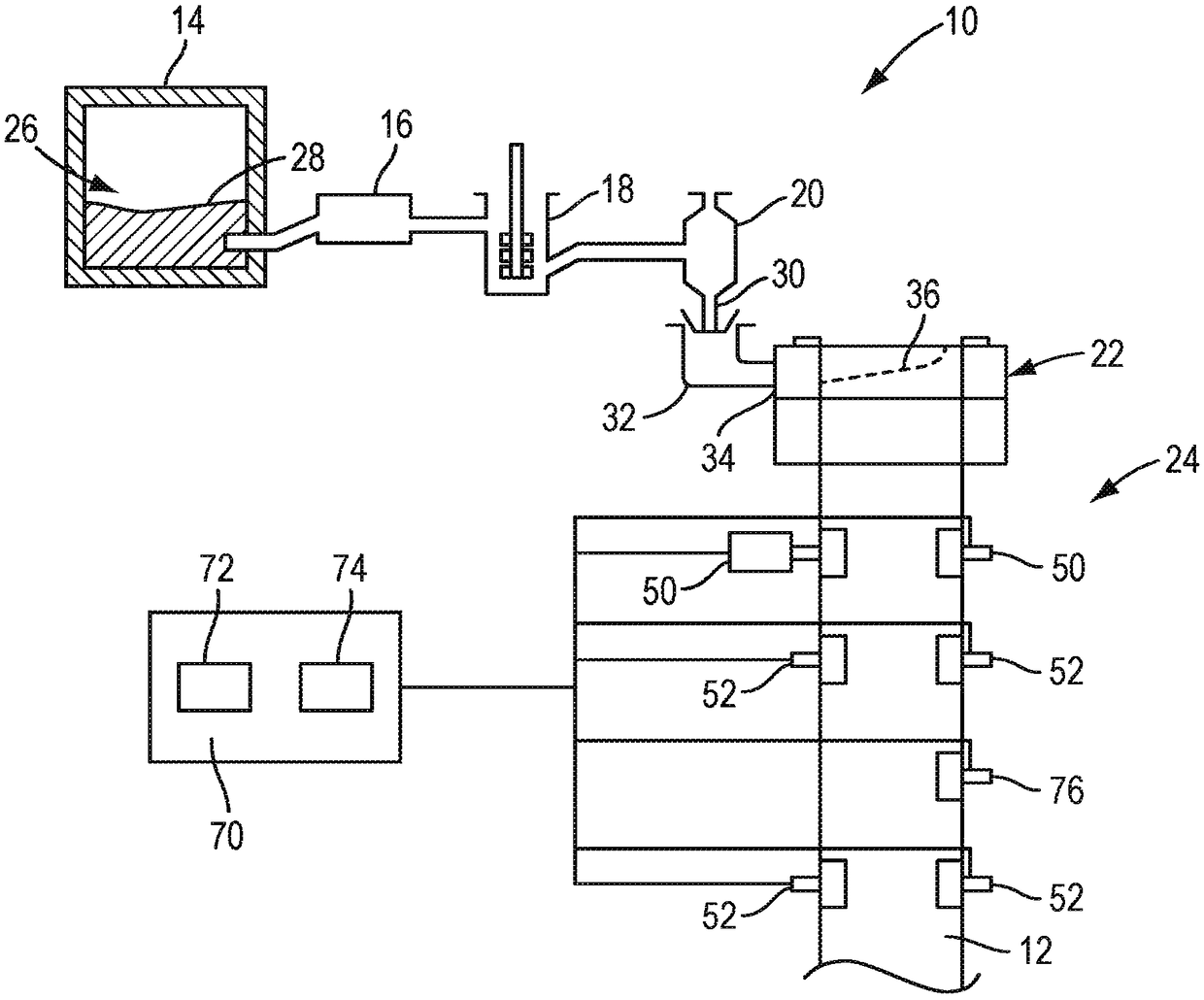

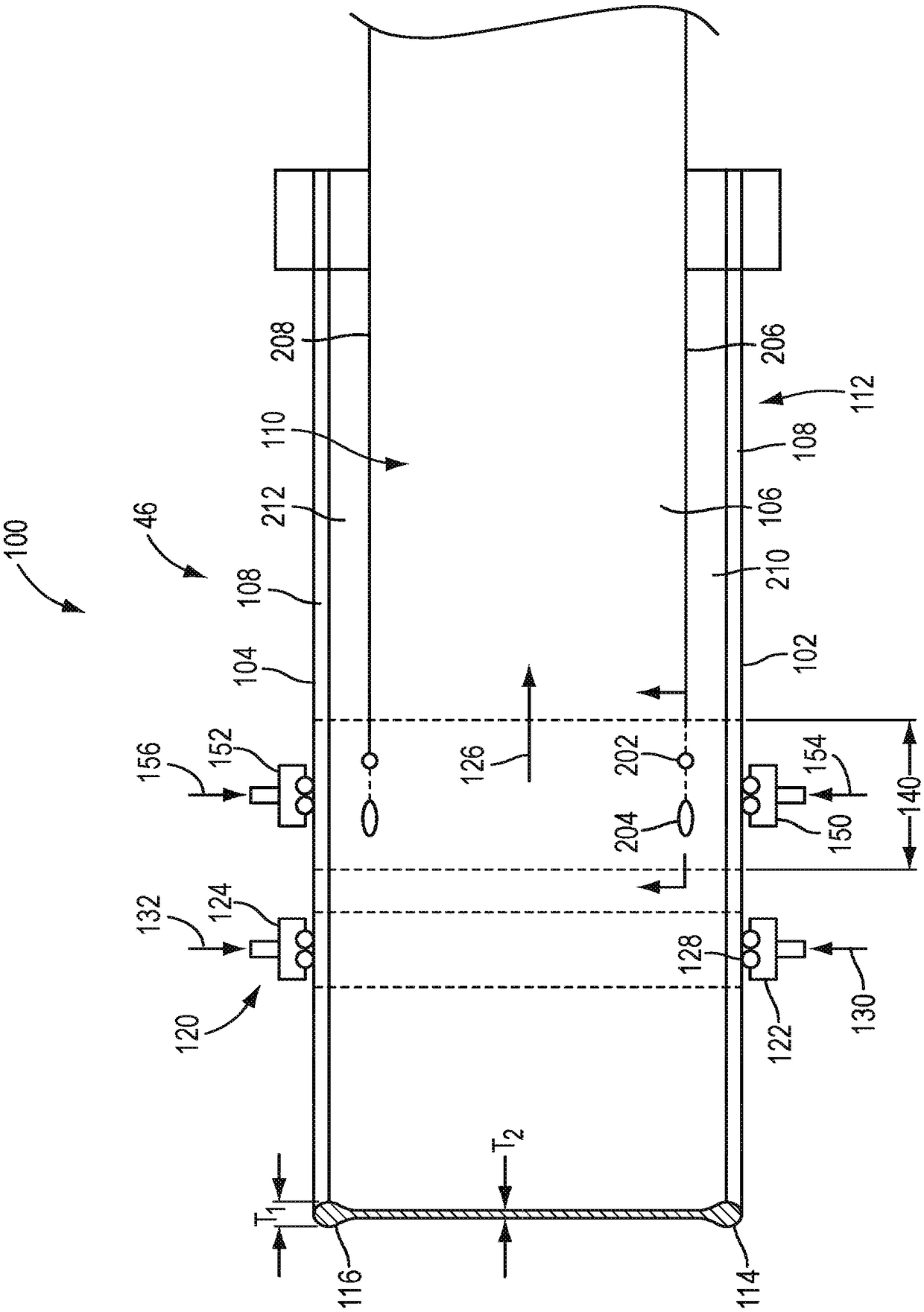

Motor drive for linear machines with distributed windings

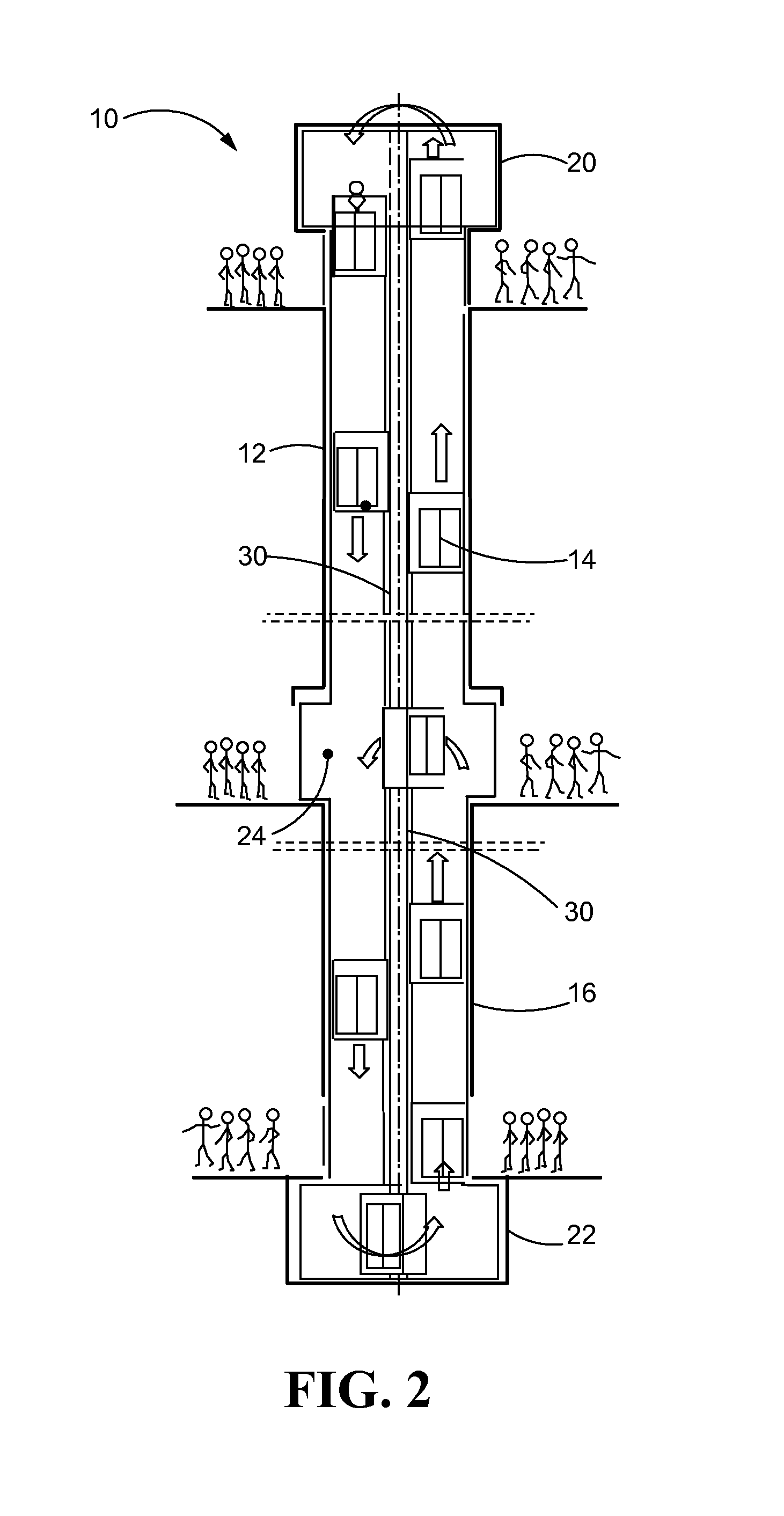

A linear propulsion system (10) and method of assembling and testing the same is disclosed. The linear propulsion system (10) may comprise a track (30), a vehicle (14), a mover (44) mounted to the vehicle (14), and a dual inverter system (48). The track (30) may comprise a first plurality (36) of stator sections (45) interleaved with a second plurality (38) of stator sections (45). The dual inverter system (48) may include first and second multi-phase inverters (52a, 52b) that share input hardware (54).

Owner:OTIS ELEVATOR CO

Device for calibrating temperature field of verification furnace automatically using standard thermocouples

PendingCN107314829AControl does not driftThermometers using electric/magnetic elementsUsing electrical meansElectric machineryEngineering

The invention relates to a device for calibrating the temperature field of a verification furnace automatically using standard thermocouples. The device includes a base, a fixing mechanism used for fixing standard thermocouples, a linear mechanism capable of fixing and driving a mobile thermocouple arranged in parallel with a standard thermocouple to move along the length direction of the standard thermocouple, a rotary mechanism capable of fixing and driving a rotary thermocouple arranged in parallel with a standard thermocouple to rotate about the standard thermocouple with the axis of the standard thermocouple as the center, and a controller. During use, a stepper motor is controlled through a main switch and a command button or software on a touch screen, the linear mechanism and the rotary mechanism are driven to move, and the standard thermocouple for linear motion and the standard thermocouple for rotation are driven to move. The thermal electromotive force measured is transmitted to the controller, the temperature at a measuring point in a furnace is calculated, and the temperature and the temperature field are displayed on the touch screen until the end of test, calibration or verification.

Owner:北京中航瑞科科技有限公司

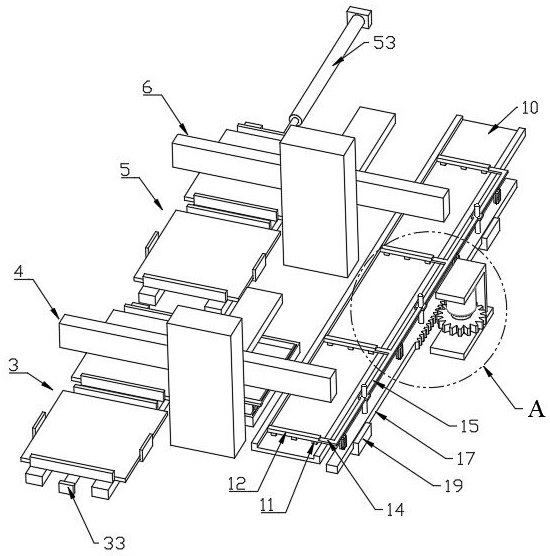

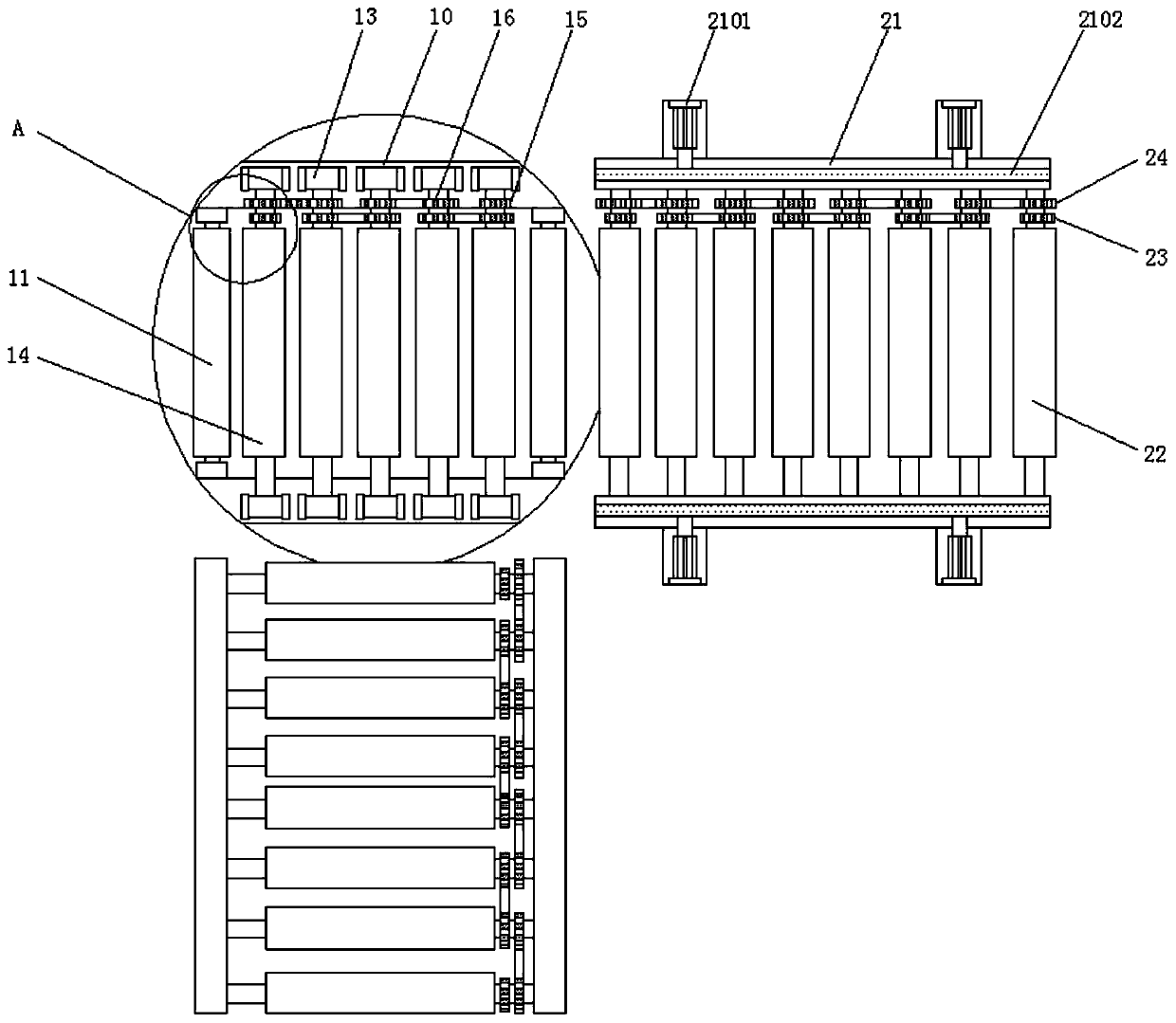

Roller conveyer with object reversing function

InactiveCN111547479ARealize commutationEasy dockingSupporting framesRoller-waysRotary stageGear wheel

The invention discloses a roller conveyer with an object reversing function. The roller conveyer comprises a reversing machine frame and a linear machine frame. First installing grooves are formed inthe reversing machine frame. First electric telescopic rods are arranged at the inner top ends of the first installing grooves. Meanwhile, first universal wheels are arranged at the lower ends of thefirst electric telescopic rods. The linear machine frame is arranged on the right side of the reversing machine frame. The inner side wall of the linear machine frame is rotationally connected with second power rollers. Third gears are arranged on the second power rollers. The third gear on the right side is connected with a gear shaft through a fourth chain. A third motor is arranged on the reversing machine frame. By means of the roller conveyer with the object reversing function, by arranging a first motor, a first rotating shaft, a rotating table and second universal wheels, the rotating table is driven by the first rotating shaft to adjust the direction under the action of the first motor according to actual situations, so that objects can be conveniently conveyed in multiple directions; and the second universal wheels slide in cooperation with an annular slide rail, so that the effect of stably supporting the rotating table is realized.

Owner:睿丰自动化科技海门有限公司

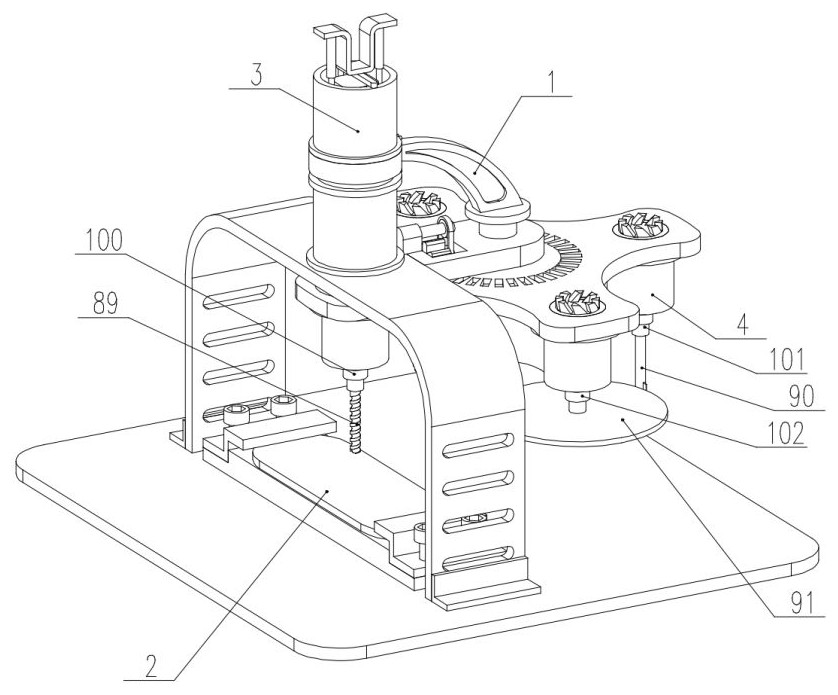

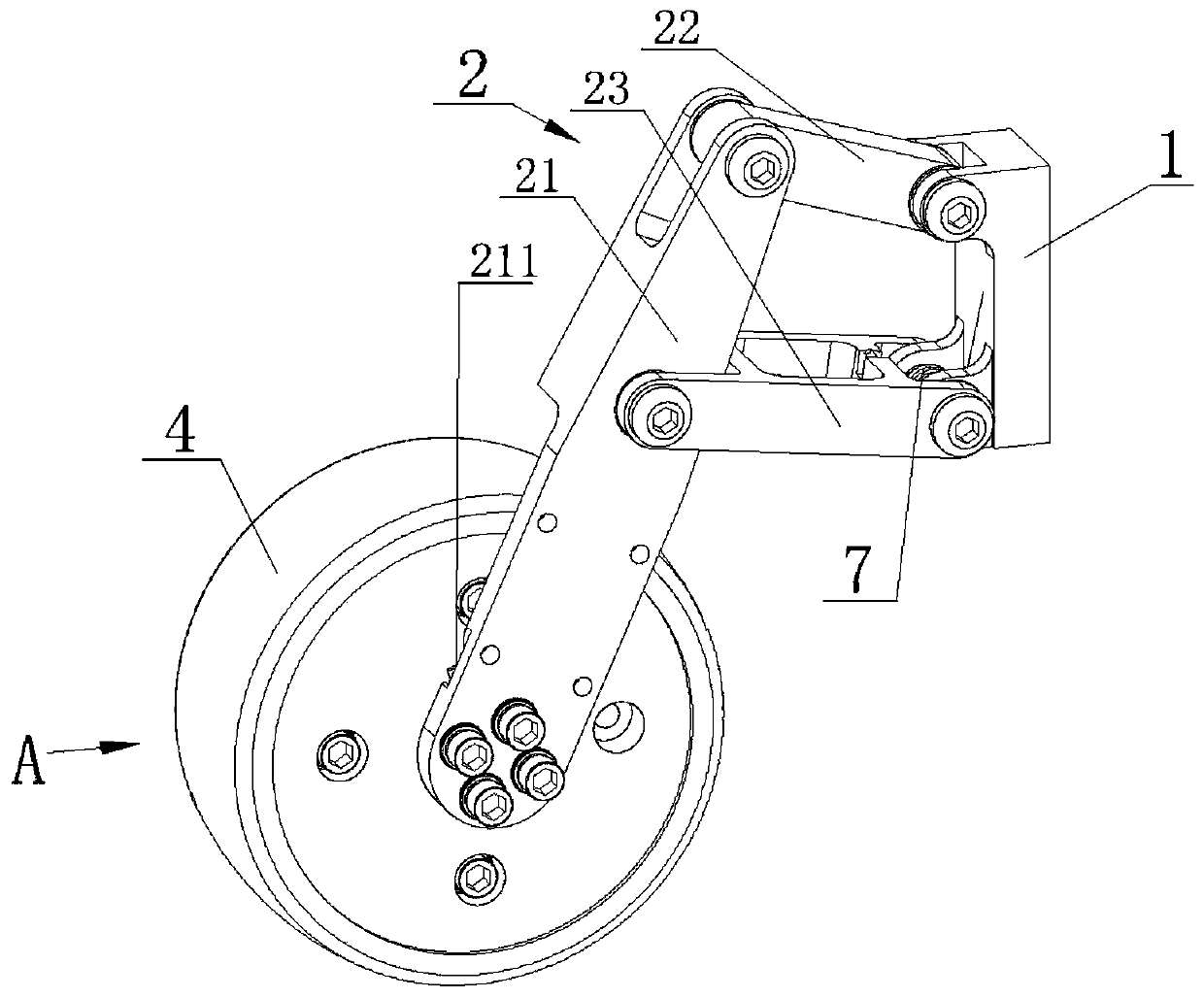

Miniature linear machining center based on electromagnetic clutch principle and using method

ActiveCN113560900AReduce in quantityInhibit sheddingOther manufacturing equipments/toolsElectromagnetic clutchAdhesive

The invention discloses a miniature linear machining center based on an electromagnetic clutch principle and a using method thereof. The miniature linear machining center comprises an electromagnetic clutch type tool changing locking mechanism, a pressure bonding type anti-falling positioning base, an integrated protection type lifting driving sleeve and an elastic telescopic tool fixing transmission mechanism. The invention belongs to the technical field of integrated machining, and particularly relates to the miniature linear machining center based on the electromagnetic clutch principle and the using method. The position of a tool rest is fixed through an electromagnetic clutch structure, and the relative fixing strength of a workpiece and the base is improved through the base based on pressure-sensitive adhesive under the condition that excessive limiting structures do not exist; and the tool changing action is conducted through the tool capable of elastically stretching out and drawing back, and the problems that a small integrated machining center in the current market is complex in structure, low in integration level, high in maintenance difficulty, tedious in operation step and the like are effectively solved.

Owner:徐州清歌机械制造有限公司

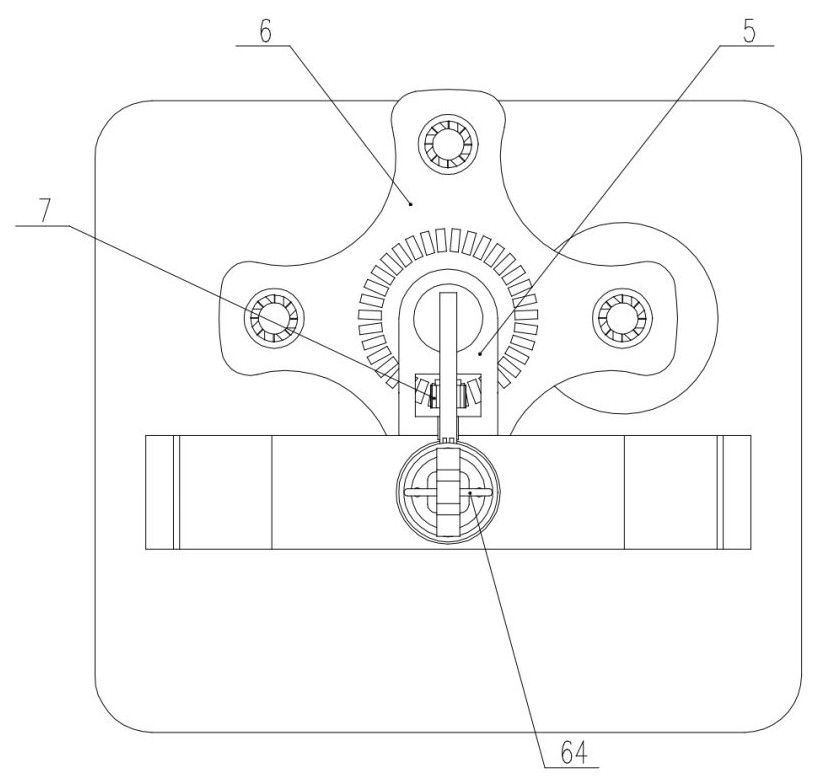

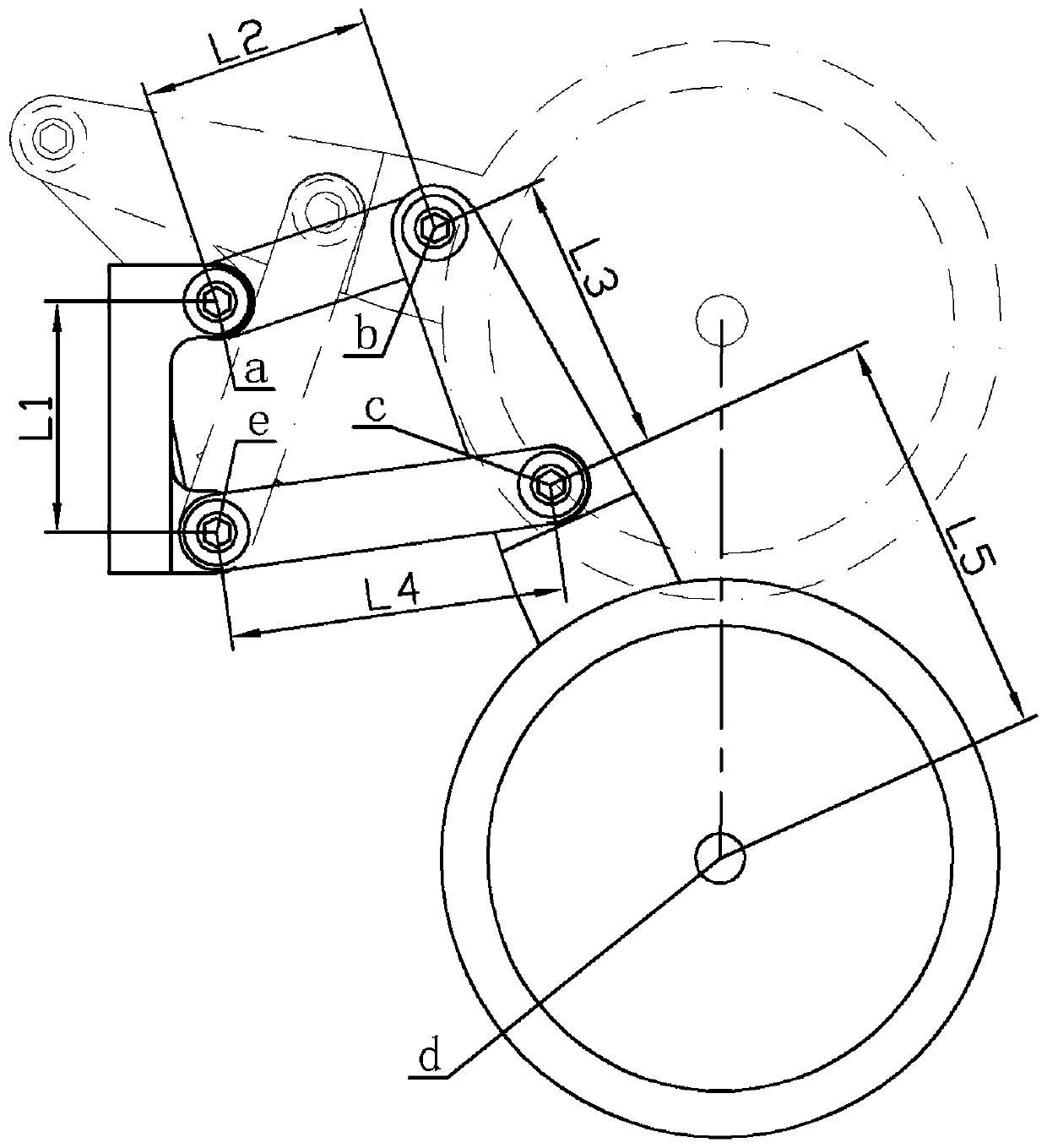

Displacement detection wheel, robot chassis and movable robot

PendingCN110815194APrevent slippingEasy to installProgramme-controlled manipulatorUsing electrical meansLinear machineControl theory

The invention discloses a displacement detection wheel, a robot chassis and a movable robot. The displacement detection wheel comprises a fixed support, an axle and a displacement wheel rotationally installed on the axle. The end face of the axle is in rigid connection with a magnetoelectric encoder. The displacement wheel is in rigid connection with a strong magnet arranged face to face with themagnetoelectric encoder at an interval. The axle is connected with the fixed support through a Hawken linear mechanism. A torsional spring used for pushing the displacement wheel to be tightly attached to the ground is connected between the Hawken linear mechanism and the fixed support. According to the displacement detection wheel, the displacement wheel is free of transverse displacement duringupward movement through the Hawken linear mechanism, and the displacement detection wheel can be installed conveniently on the premise that an existing regional space is not changed; force is applieddownwards to the displacement wheel through the torsional spring, the displacement wheel is tightly attached to the ground, and then slipping of the displacement wheel can be effectively avoided; andthe strong magnet and the magnetoelectric encoder are installed on the displacement wheel and the axle, the displacement of the robot is measured by the magnetoelectric encoder, and the cost is low.

Owner:湖南合控智能技术有限公司

Linear machine

InactiveUS20210044191A1Windings insulation materialNon-rotating vibration suppressionMagnetic polesEngineering

Disclosed are various embodiments for a linear machine having a magnetic torque tunnel stator comprising an outer core assembly formed of a plurality of exterior permanent magnets couple to the inside retaining wall of a tube, where adjacent exterior permanent magnets are separated by an exterior ring spacer of ferromagnetic material, and an interior core assembly having a plurality of interior permanent magnets coupled to the outside wall of a central core, where adjacent interior permanent magnets are separated by an interior ring spacer of ferromagnetic material, the magnetic poles of the exterior and interior permanent magnets configured to face each other, and a coil winding assembly armature configured to be slidably positioned within the magnetic torque tunnel of the stator.

Owner:LINEAR LABS

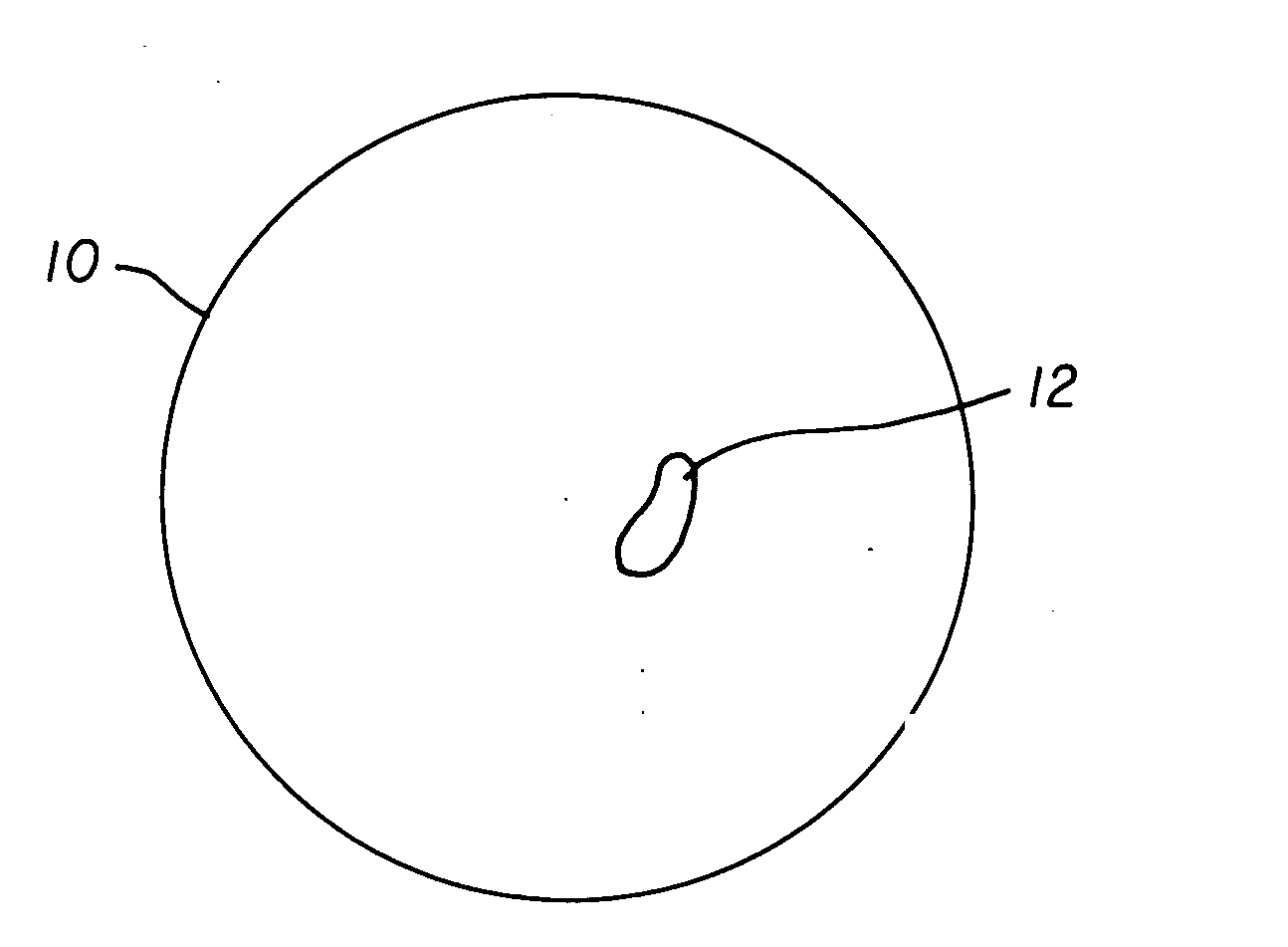

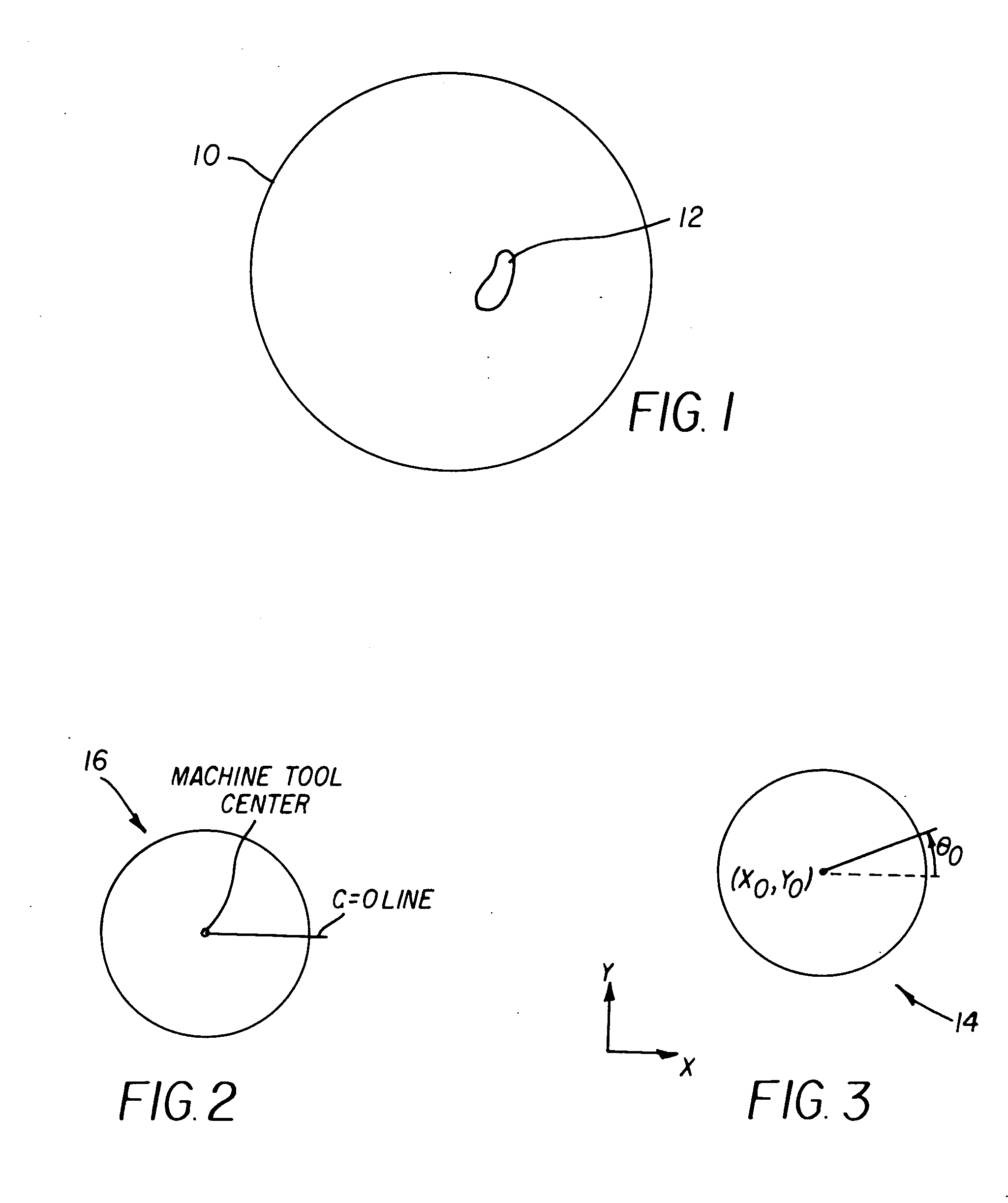

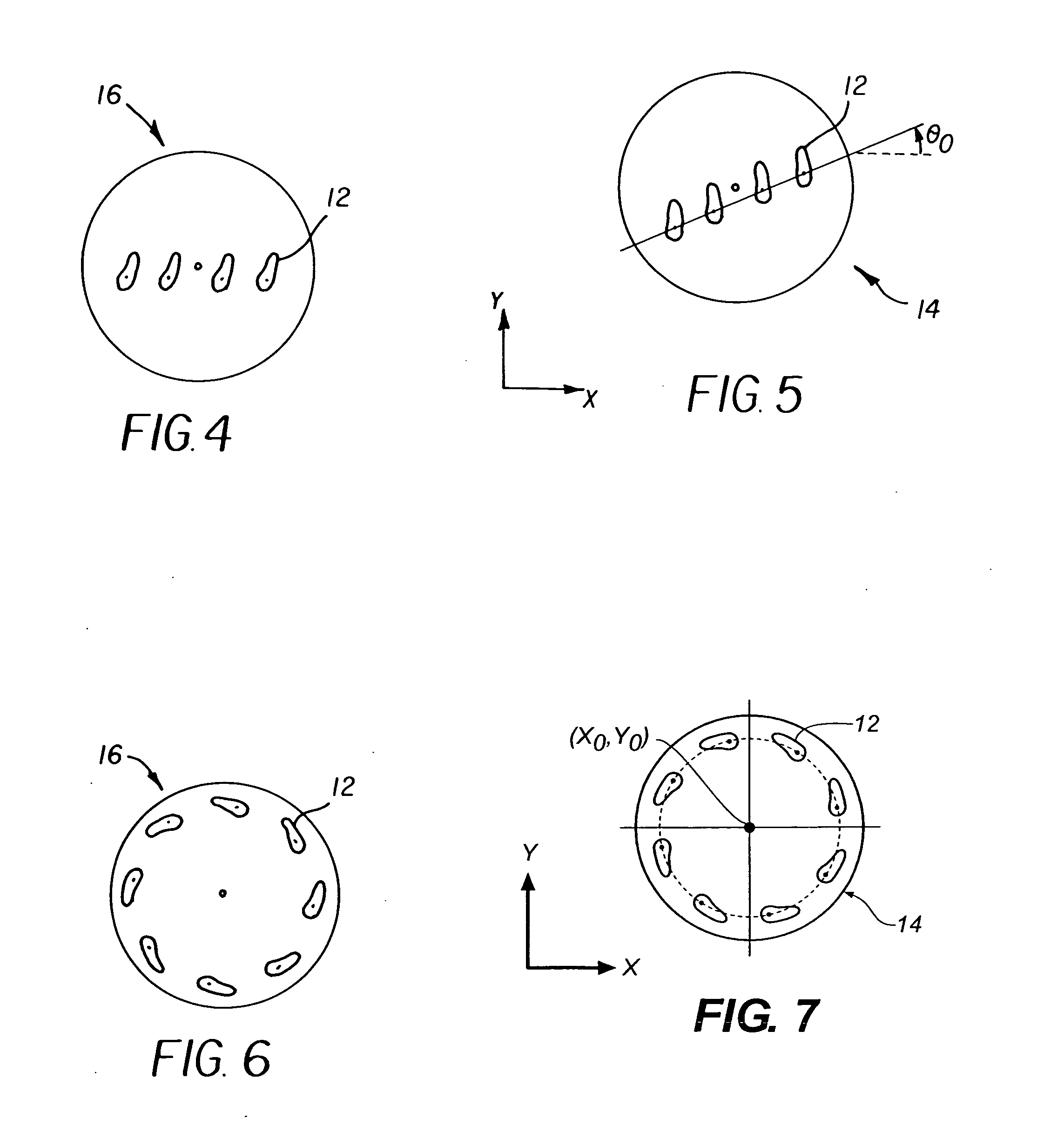

Method for machine tool and profilometer coordinate registration

A method for registering machine tool and profilometer coordinates, wherein the machine tool defines a C-axis having a zero position, C=0, comprises loading a sacrificial workpiece into the machine tool; cutting several first features in a surface of the sacrificial workpiece and producing a linear machine tool motion across the workpiece; determining the centroid of each first cut feature; fitting a line to the centroids of the first cut features; and measuring angle θ0 of the line relative to the C-axis zero position. The angle θ0 is the departure in profilometer coordinates from the C=0 line. The method includes moving the machine tool to a fixed radius; cutting several second features in a surface of the sacrificial workpiece and producing a circular machine tool motion across the workpiece; determining the centroid of each second cut feature; fitting a circle to the centroids of the second cut features; and determining a center of the circle. The center of the circle is the machine tool center in profilometer coordinates.

Owner:EASTMAN KODAK CO

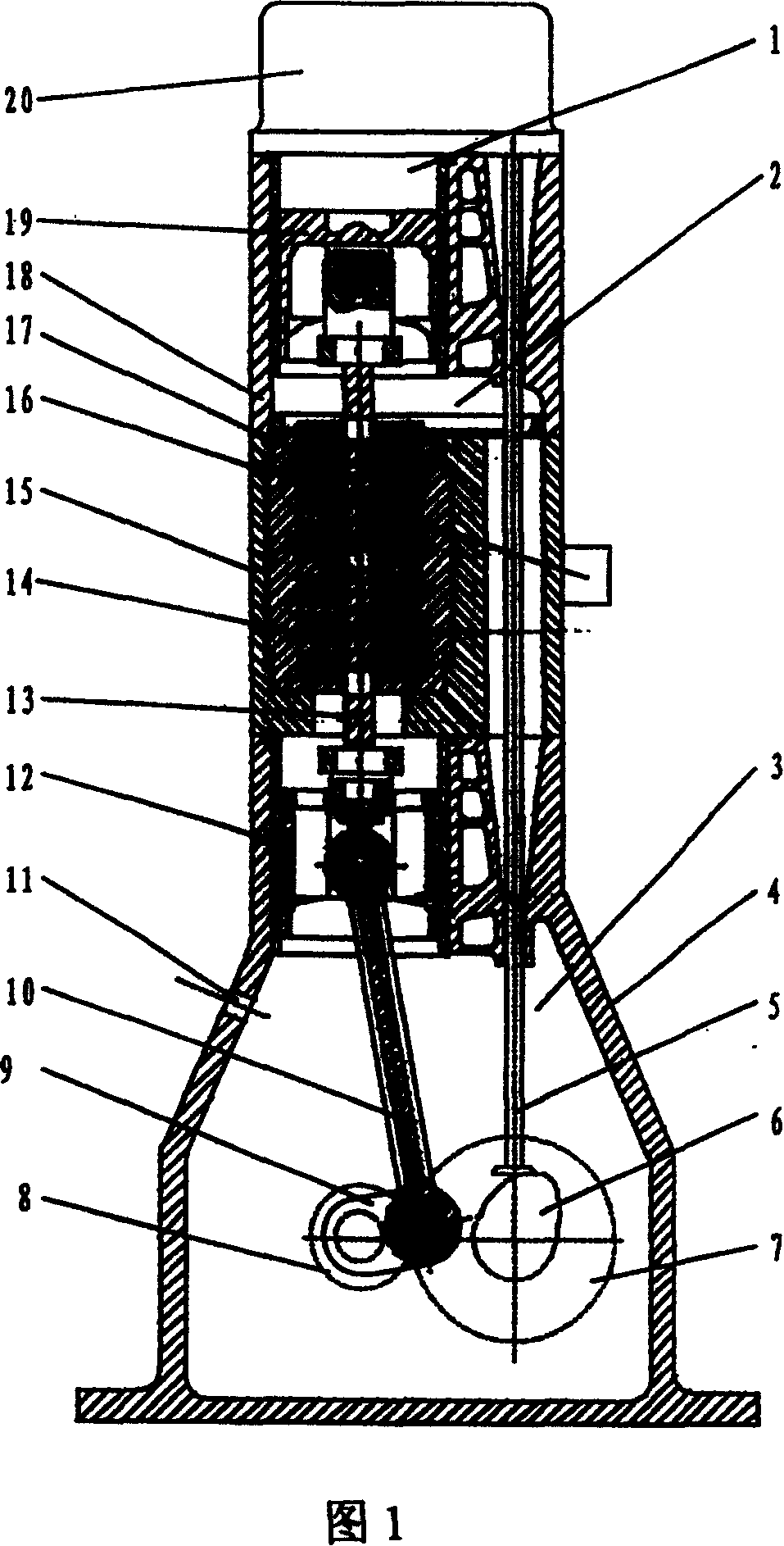

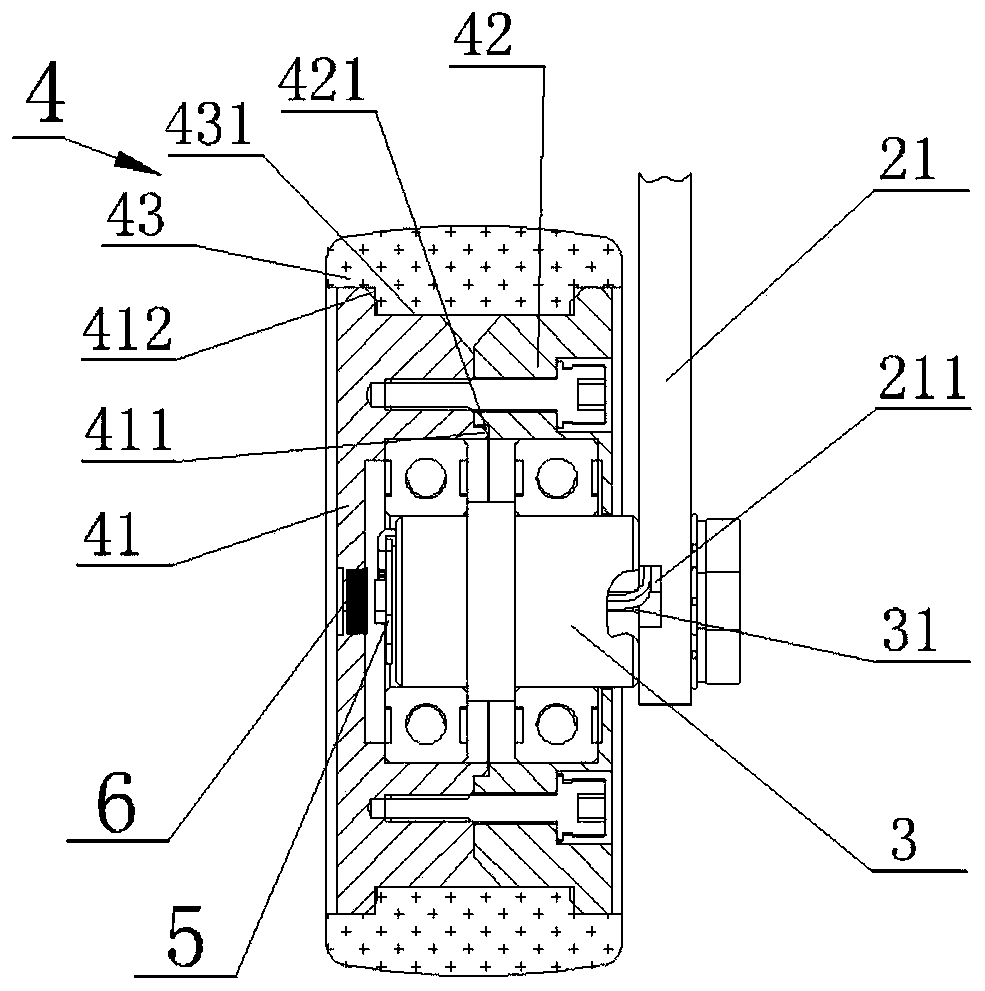

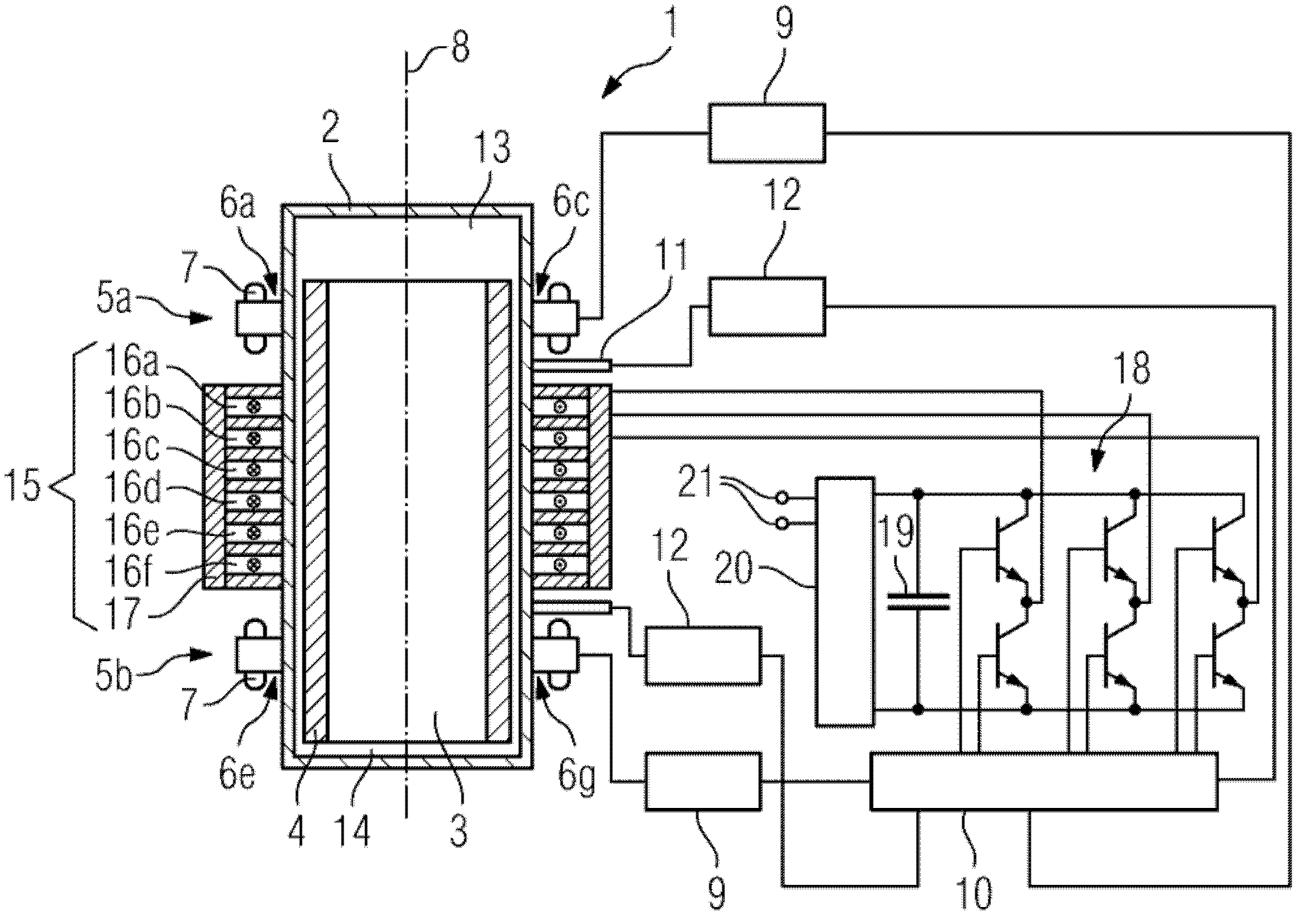

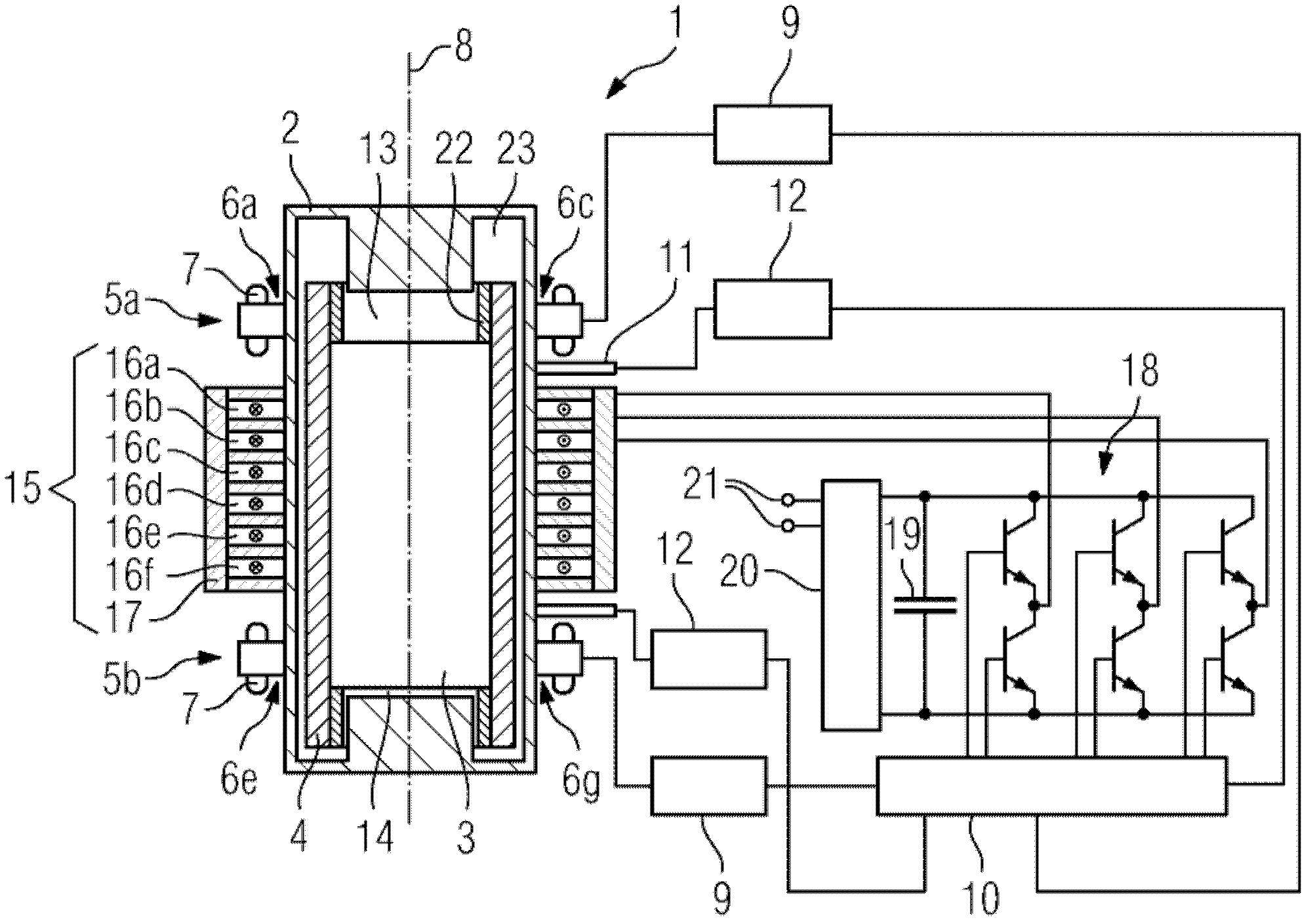

Piston engine having magnetic piston bearing

InactiveCN102482994AReduce frictionProduction economyLinear bearingsMagnetic bearingsMagnetic bearingEngineering

The present invention relates to a piston engine (1). Said engine comprises a housing (2) and a piston (3). The piston (3) is magnetically and movably disposed in the housing (2). A device (7) for magnetically supporting the piston (3) is fixedly mounted relative to the housing (2). A linear machine (15) in conjunction with the magnetic bearing of the piston (3) can prevent friction and thus result in a machine for converting mechanical into electric energy without having to lubricate and with reduced mechanical effort.

Owner:SIEMENS AG

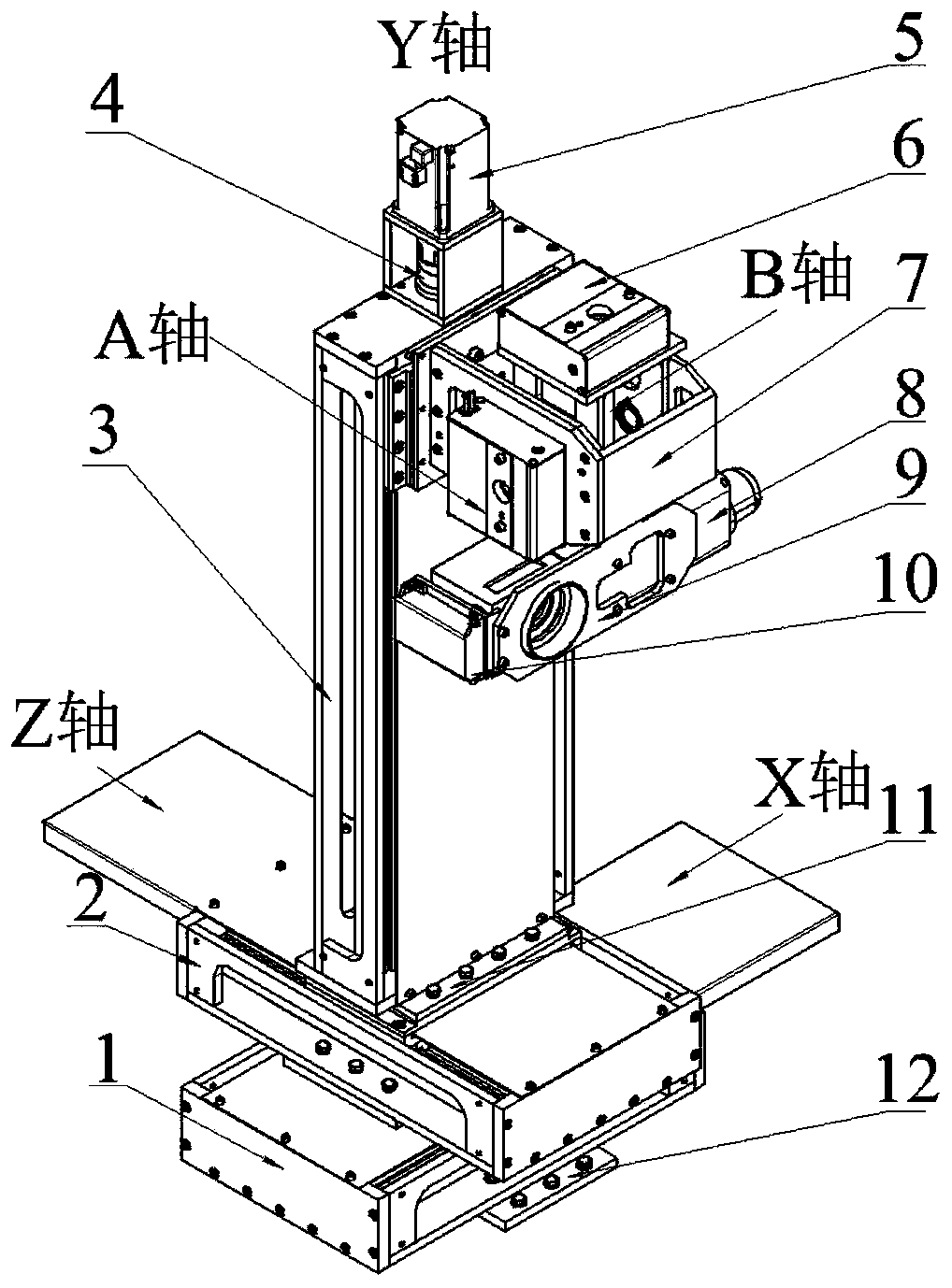

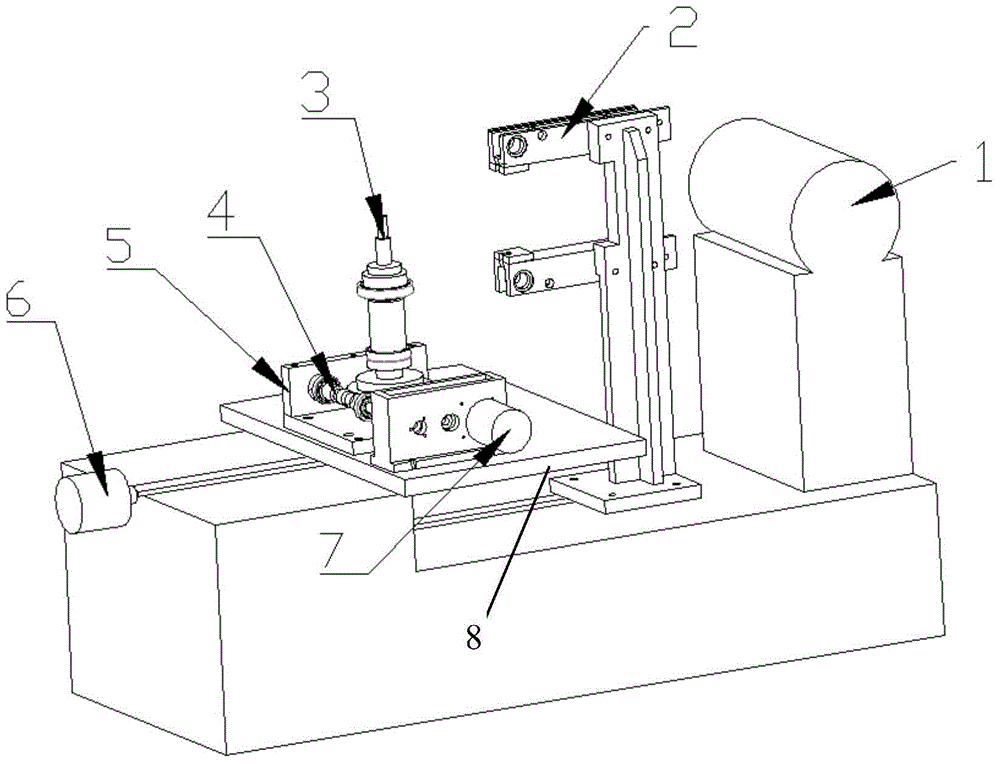

Non-contact type cast ingot laser marking device, work method and analogy method

InactiveCN110142516AAchieve positioningRealize functionLaser beam welding apparatusLaser scanningLinear machine

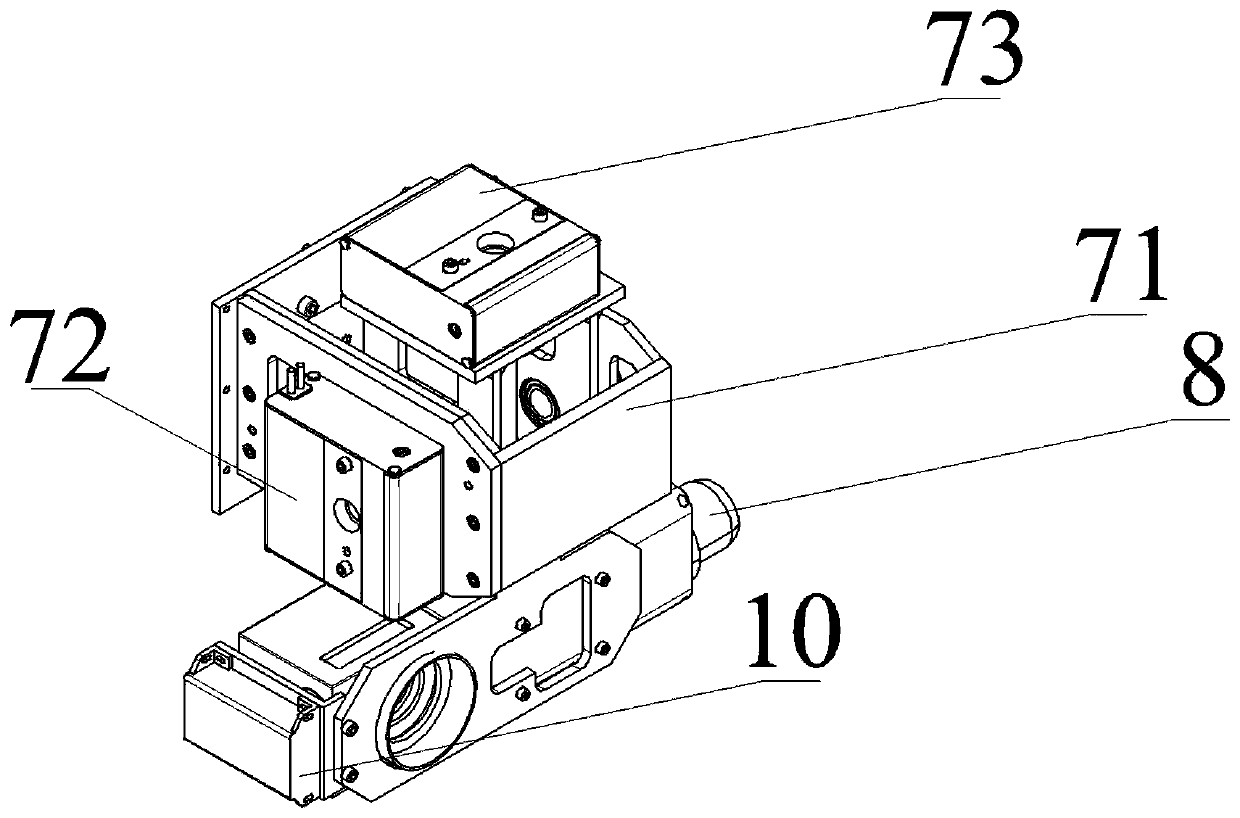

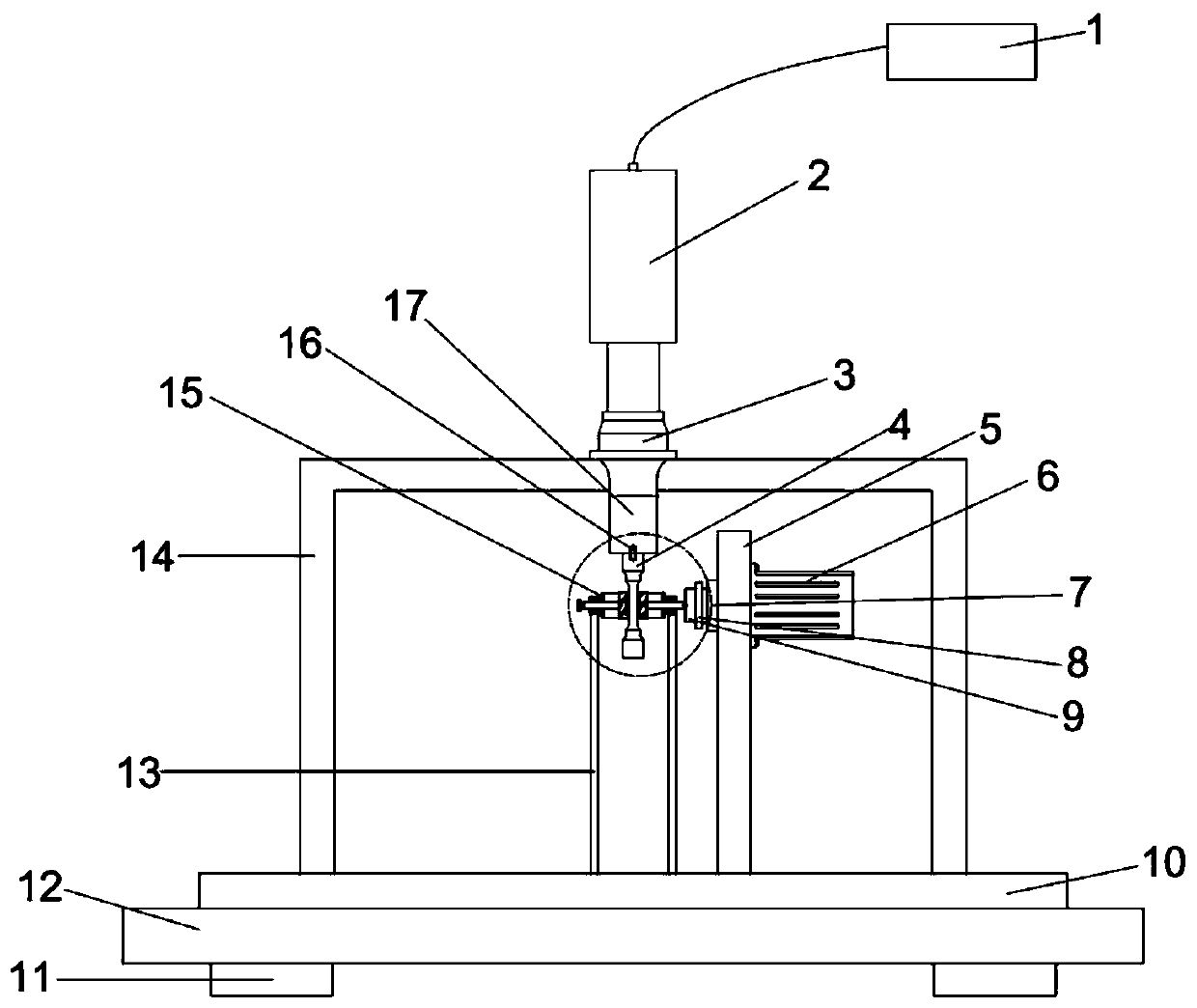

A non-contact type cast ingot laser marking device comprises a three-directional feed system, linear mechanisms, a swing table (7), a laser marking unit, a three-dimensional line laser scanner (10) and an overall machine base (12). The three-directional feed system comprises an X-direction feed system, a Y-direction feed system and a Z-direction feed system. The linear mechanisms correspondingly comprise an X-axis actuating mechanism (1), a Y-axis actuating mechanism (3) and a Z-axis actuating mechanism (2). The three-way feed system drives the corresponding linear mechanisms. The X-directionfeed system, the Z-direction feed system, the X-axis actuating and the Z-axis actuating mechanism are arranged on the overall machine base, and the Y-direction feed system and the Y-axis actuating mechanism are perpendicular to the overall machine base. The swing table is connected with the Y-axis actuating mechanism and swings in the up-down and left-right directions. The laser marking unit comprises a laser marking head (8) and a laser marking head support (9). The laser marking head is fixed to the swing table by the laser marking head support, and the three-dimensional line laser scanner is fixed to the support. The invention also provides a work method and an analogy method.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Fretting wear test device based on ultrasonic technology

InactiveCN110702549ASimple structureEasy to operateVibration testingInvestigating abrasion/wear resistanceVibration amplitudeClosed loop feedback

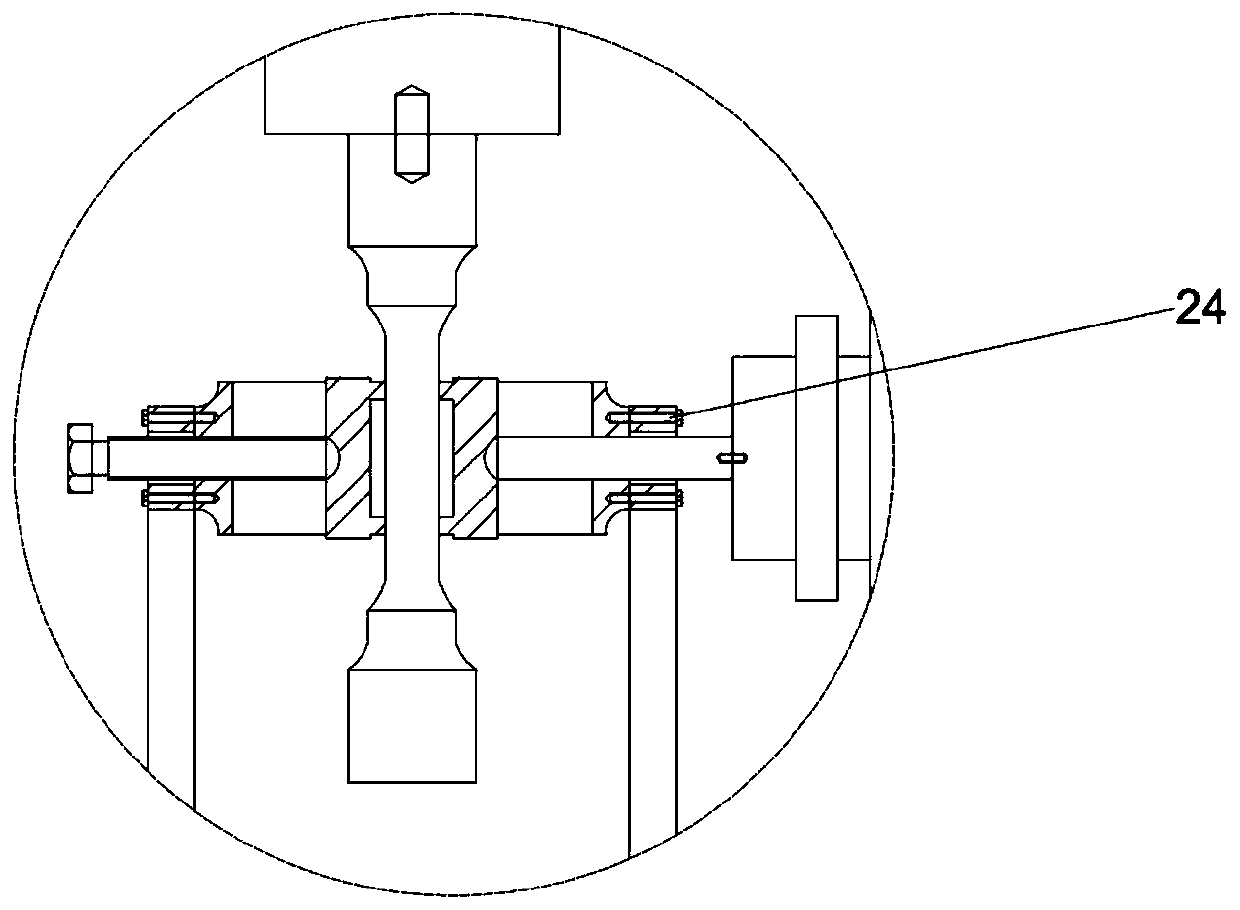

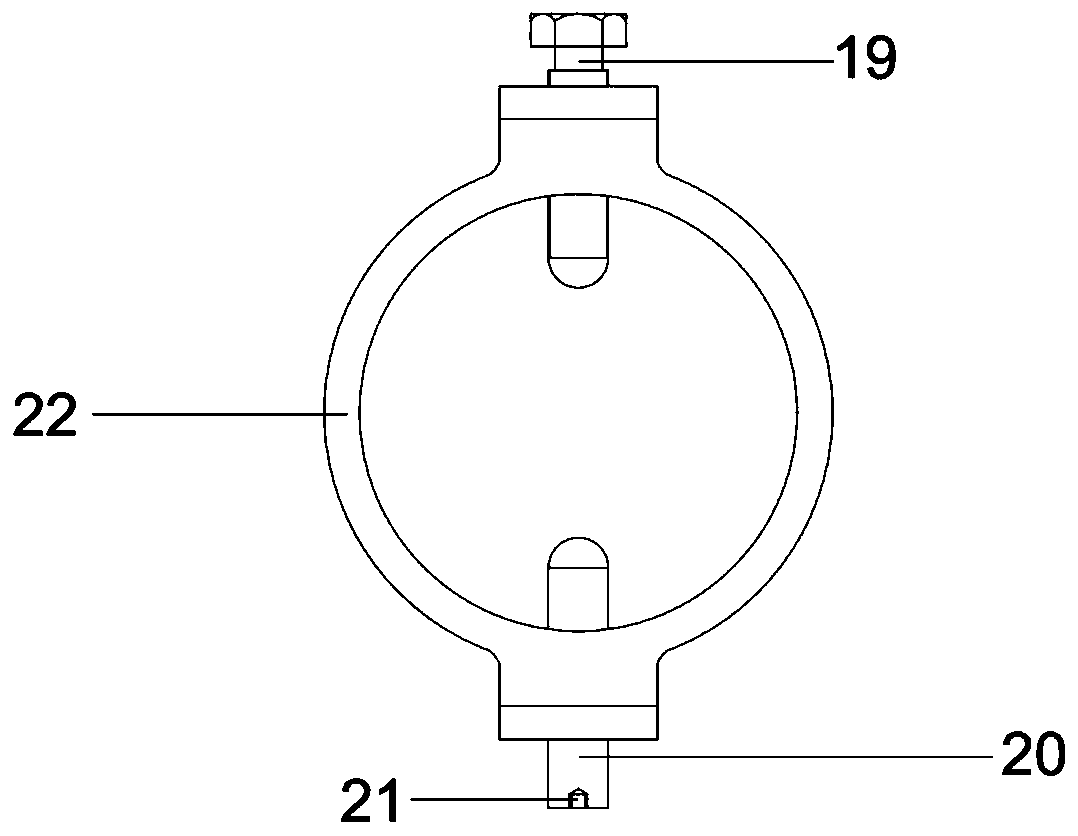

The invention discloses a fretting wear test device based on an ultrasonic technology. The fretting wear test device is composed of an ultrasonic generator, a servo electric cylinder, a force sensor,a loading device, a driving device and a data acquisition device; a loading head is pushed by the servo electric cylinder to make contact with fretting pads to apply positive pressure to a test part;and the force sensor acquires a positive signal, sets a computer data processing device to form closed loop feedback control with the acquired positive pressure signal to keep a load applied by the loading device constant. The fretting wear test device is simple in structure and convenient to operate, the various parts are fixed and supported by a bottom plate and a fixing platform, the stabilityis good, and the advantages of being high in reliability and precision are achieved; and a transducer is adopted to convert ultrasonic signals into reciprocating linear mechanical motion of a vibrating head, vibration displacement is amplified by an amplifier to serve as an excitation source for forming fretting wear between a friction pair, the vibration frequency is high, the amplitude is adjustable, the test time can be shortened, and the test cost can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

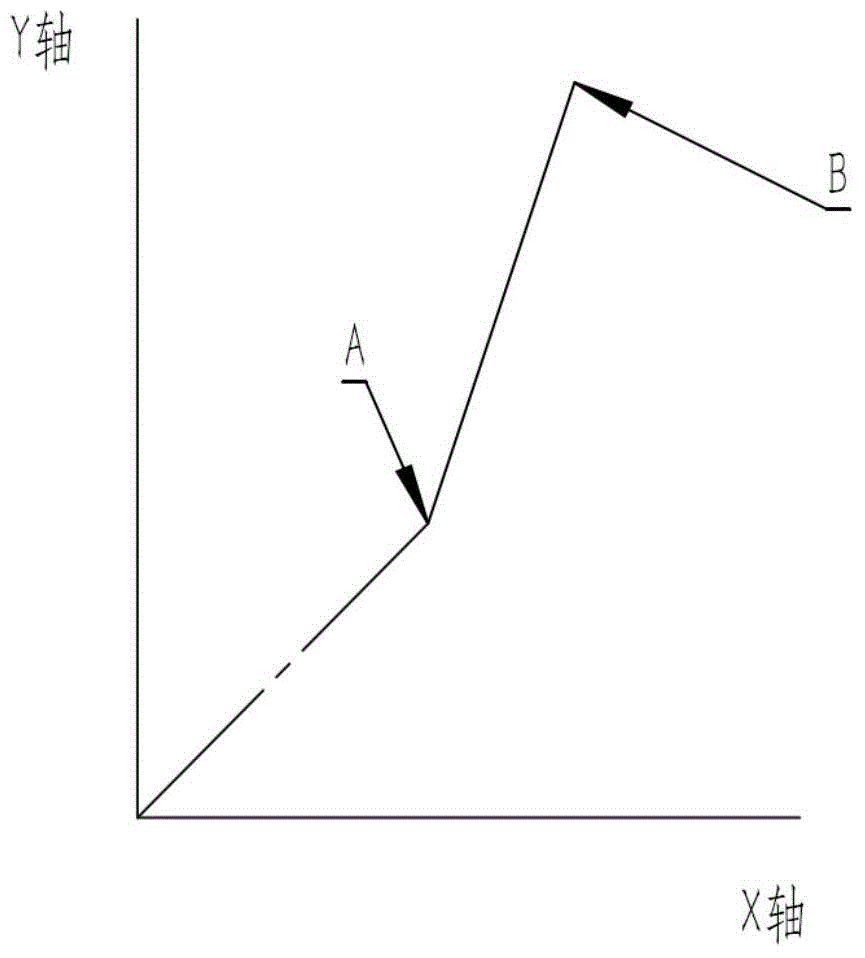

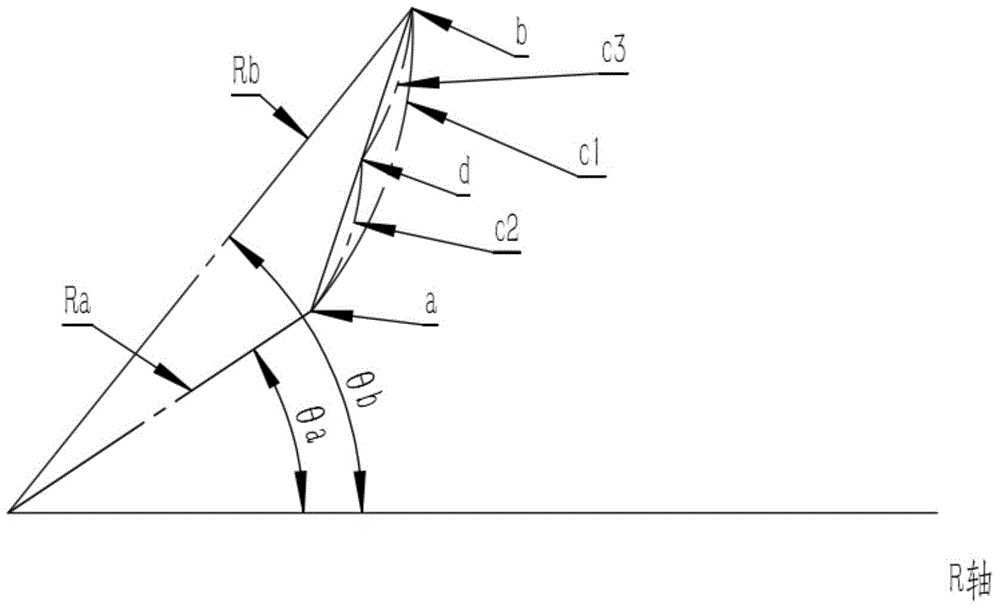

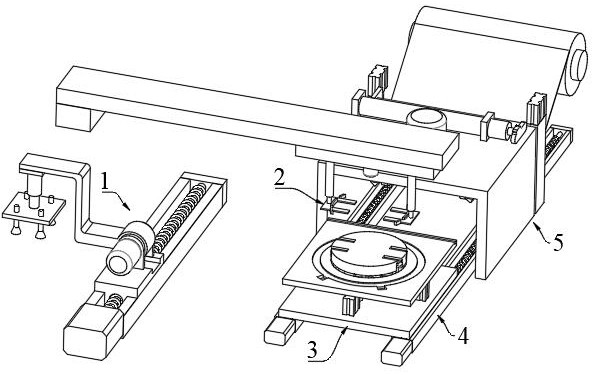

Polar coordinate circular sawblade linear cutting method and linear cutting apparatus based on same

ActiveCN105014154AAchieve reductionImplement autocodingMetal sawing tool makingElectrical-based machining electrodesControl systemWire cutting

The invention discloses a polar coordinate circular sawblade linear cutting method and a linear cutting apparatus based on the same. According to the cutting method, the linear cutting of a circular workpiece is realized by converting coordinate values of polar coordinates into programming codes; the linear cutting apparatus based on the polar coordinate circular sawblade linear cutting method comprises a wire conveying mechanism, a driving mechanism, a control system and a rotating mechanism. The polar coordinate circular sawblade linear cutting method has the beneficial effects that each fundamental figure of a cutting track is cut into n small sections; the polar coordinate values of a start point and an end point of each small section are solved; programming codes of each small section are generated; the actions of the rotating mechanism and a linear mechanism are controlled by the programming codes to realize cutting the workpiece; due to the application of the linear cutting method, secondary workpiece processing start point alignment is not needed, the processing of the circular workpiece can be completed in one step, and the radial jump precision is improved.

Owner:临沂先行锯业有限公司

Wafer feeding device and wafer film pasting device

ActiveCN113327878AAutomate operationsReduce manual labor intensitySemiconductor/solid-state device manufacturingConveyor partsWaferElectric machine

The invention discloses a wafer feeding device and a wafer film pasting device. The wafer feeding device comprises a grabbing mechanism, a switching mechanism and a bearing mechanism, wherein the grabbing mechanism comprises a first vertical air cylinder, a pneumatic suction cup arranged at the movable end of the first vertical air cylinder and a zigzag-shaped frame, the fixed end of the first vertical air cylinder is connected to one end of the zigzag-shaped frame, the other end of the zigzag-shaped frame is connected with a rotating shaft, the rotating shaft is connected with an output shaft of a rotating motor, the rotating shaft is rotationally matched with the pair of supporting plates, the supporting plates and the rotating motor are arranged on a sliding base, and the sliding base is arranged on a first linear mechanism; the switching mechanism comprises a second linear mechanism arranged above the grabbing mechanism, a distance adjusting mechanism arranged at the movable end of the second linear mechanism, a pair of second vertical air cylinders connected with the distance adjusting mechanism, and a switching frame connected to the movable ends of the second vertical air cylinders; and the bearing mechanism comprises a bearing table arranged on the base through a supporting column and is used for bearing a wafer. The wafer film pasting device comprises the wafer feeding device, a film pasting assembly and the like. Automatic wafer feeding and automatic film pasting are achieved, the labor intensity is reduced, automatic operation is achieved, and the efficiency is high.

Owner:四川明泰微电子有限公司

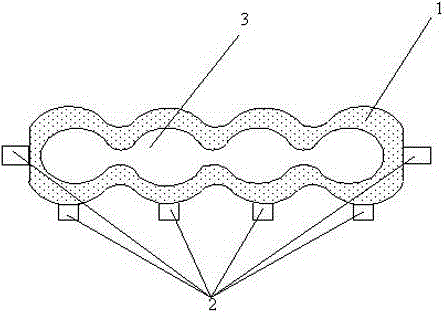

Method for carrying out evaporative pattern casting on dry cylinder liner machine body and model thereof

InactiveCN104668462ASolve the real problemQuality improvementFoundry mouldsFoundry coresLinear machineMaterials science

The invention discloses a method for carrying out evaporative pattern casting on a dry cylinder liner machine body. The method particularly comprises the following steps that a foaming material is adopted to manufacture a lost foam pattern of the dry cylinder liner machine body; pre-coated sand is adopted to manufacture a pre-coated sand core of a water sleeve portion of the dry cylinder linear machine body, and a plurality of positioning core heads are arranged on the pre-coated sand core; the pre-coated sand core with the positioning core heads is loaded into the position, corresponding to the water sleeve portion, of the lost foam pattern; and the lost foam patter is stuck together. The method further discloses an evaporative pattern casting model, manufactured through the method, of the dry cylinder liner machine body. The evaporative pattern casting model comprises a lost foam pattern body, and the lost foam pattern body and the dry cylinder liner machine body are the same in structure; the water sleeve portion of the lost foam pattern body is provided with the pre-coated sand core; the positioning core heads are arranged on the pre-coated sand core, and are located on side face auxiliary holes in the water sleeve portion; and one end of each positioning core head is connected to the pre-coated sand core, and the other end of each positioning core head stretches out of the corresponding side face auxiliary hole. The pre-coated sand core technology and the positioning core head technology are combined for solving the problems that molten metal leaks, and the sand core is prone to shifting.

Owner:QINGDAO DAYUN MACHINERY

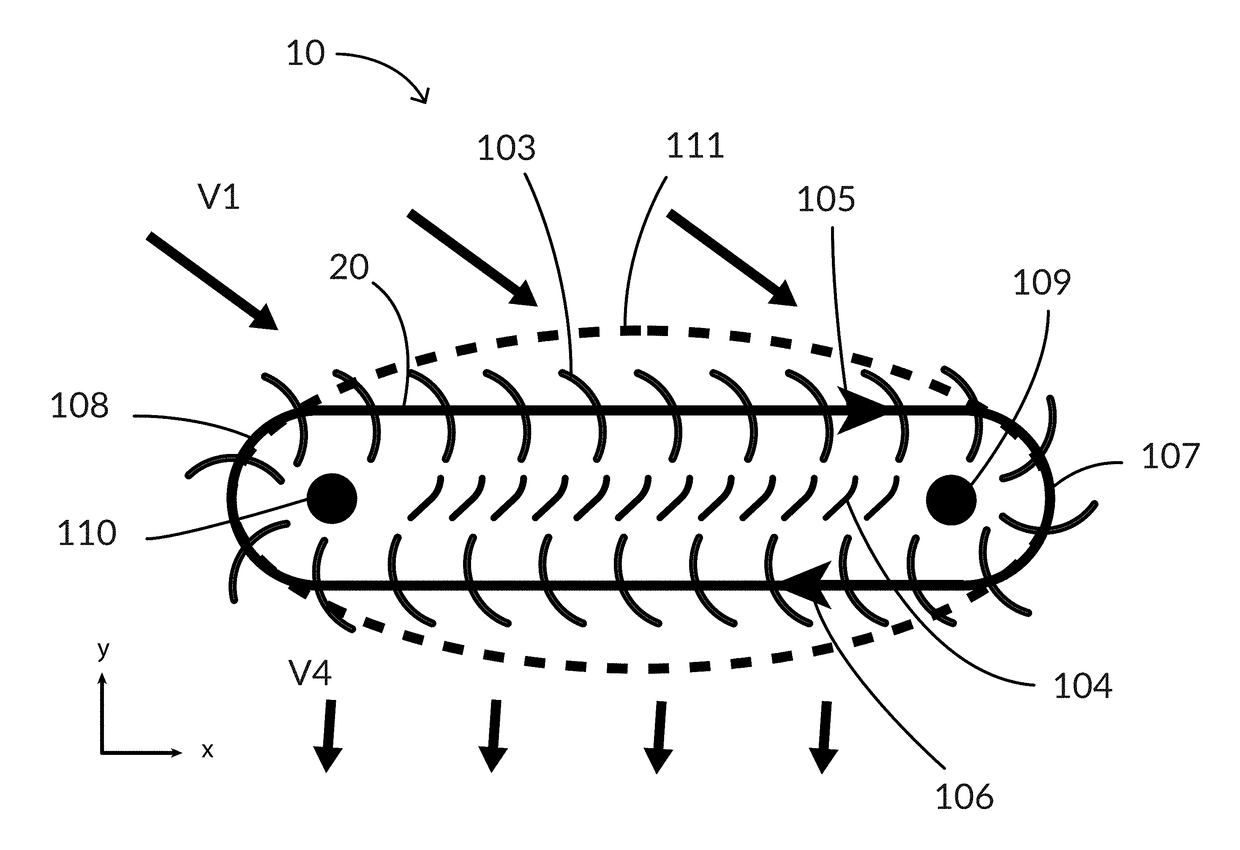

Hydraulic turbine

ActiveUS20160327011A1Improve efficiencyIncreased Design FreedomHydro energy generationReaction enginesLinear machineHydraulic pressure

Disclosed herein are linear hydraulic turbines in which the linear machine converts the majority of available energy in the flowing water into useful torque directly in the runner, leaving the outflow with very little velocity.

Owner:NATEL ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com