Fretting wear test device based on ultrasonic technology

A technology of fretting wear and testing equipment, which is applied in measuring equipment, vibration testing, testing wear resistance, etc., can solve problems such as poor anti-interference ability, low precision, low reliability, and large driving force, and achieve reliability and The effect of high precision, shortened test time, and reduced time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] This embodiment is a fretting wear test device based on ultrasonic technology.

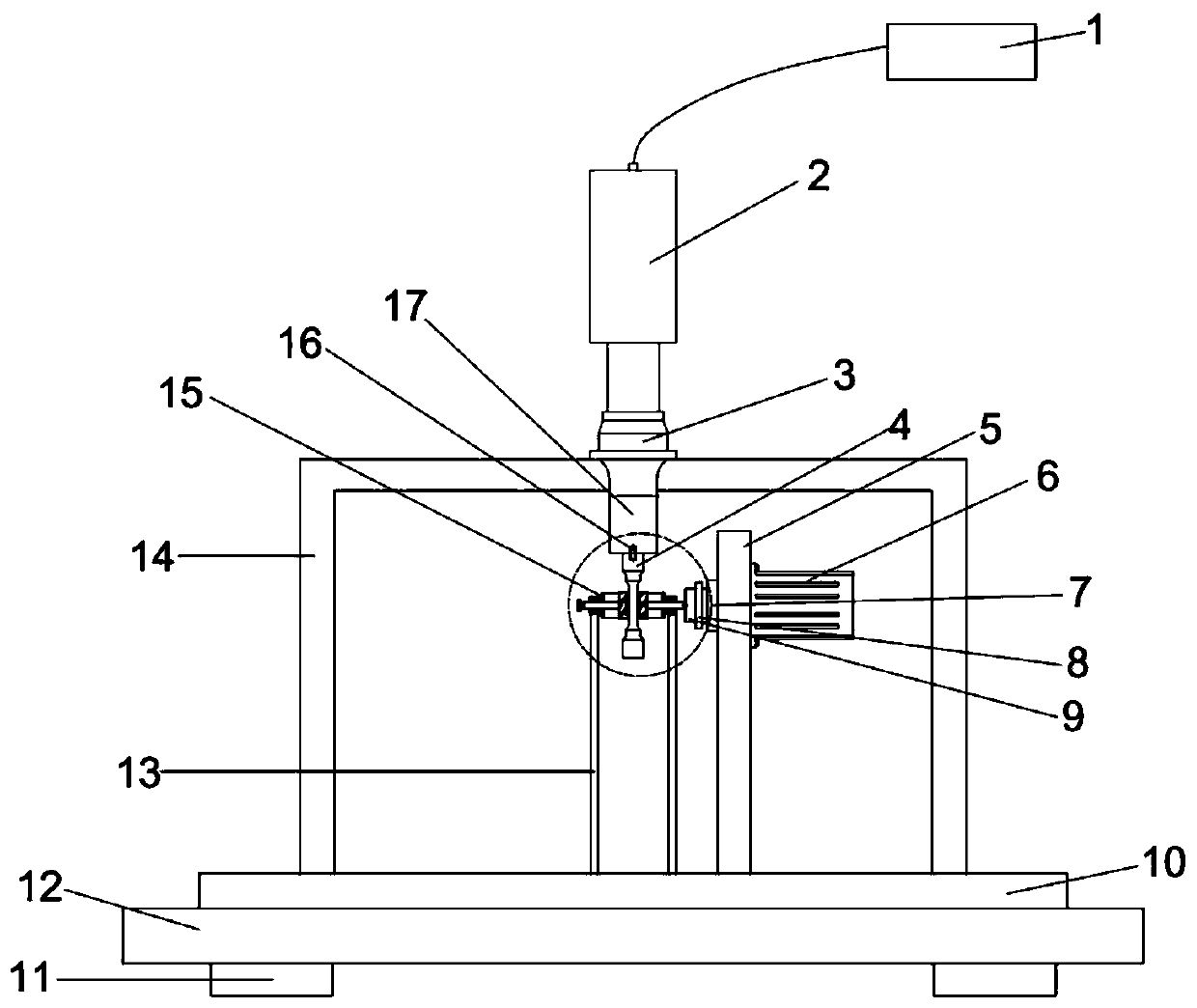

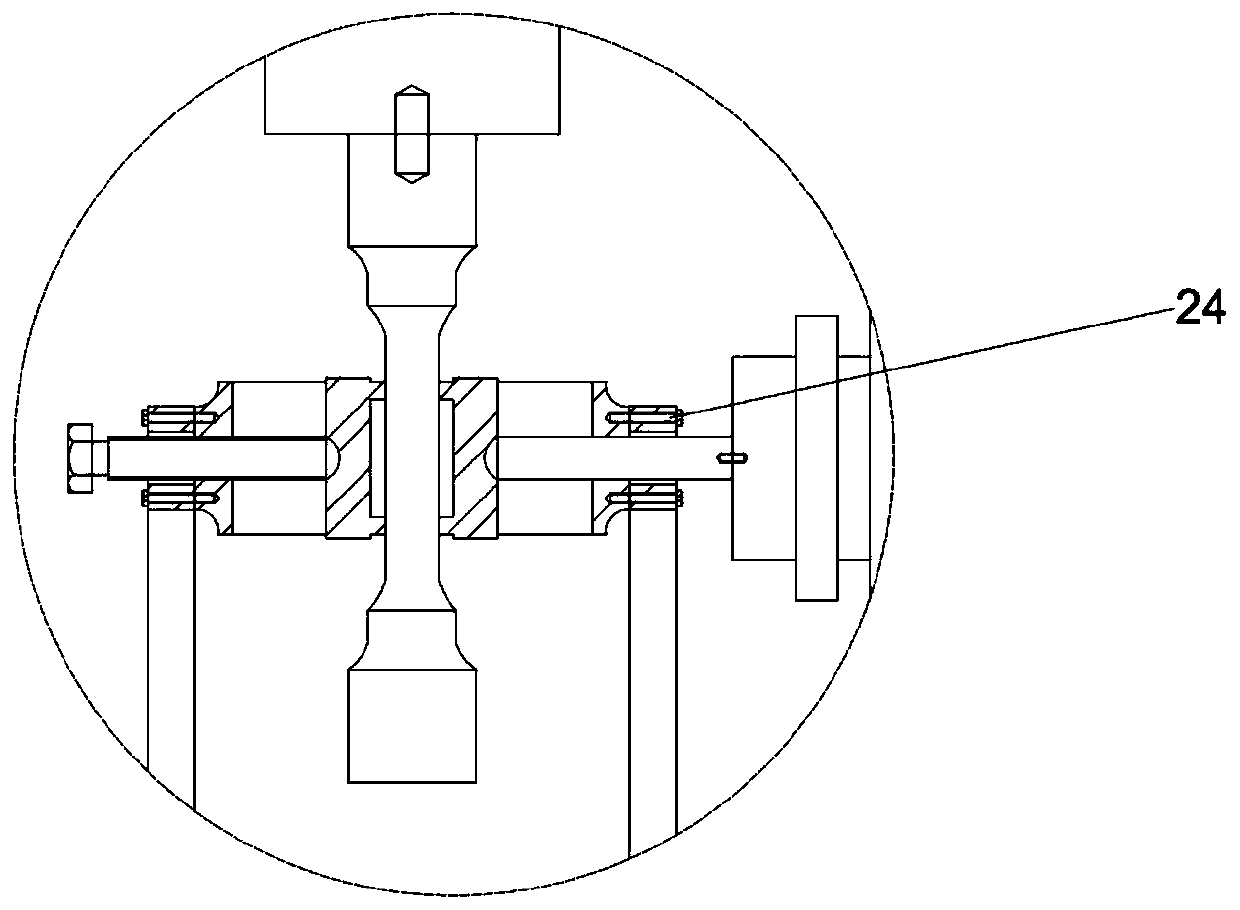

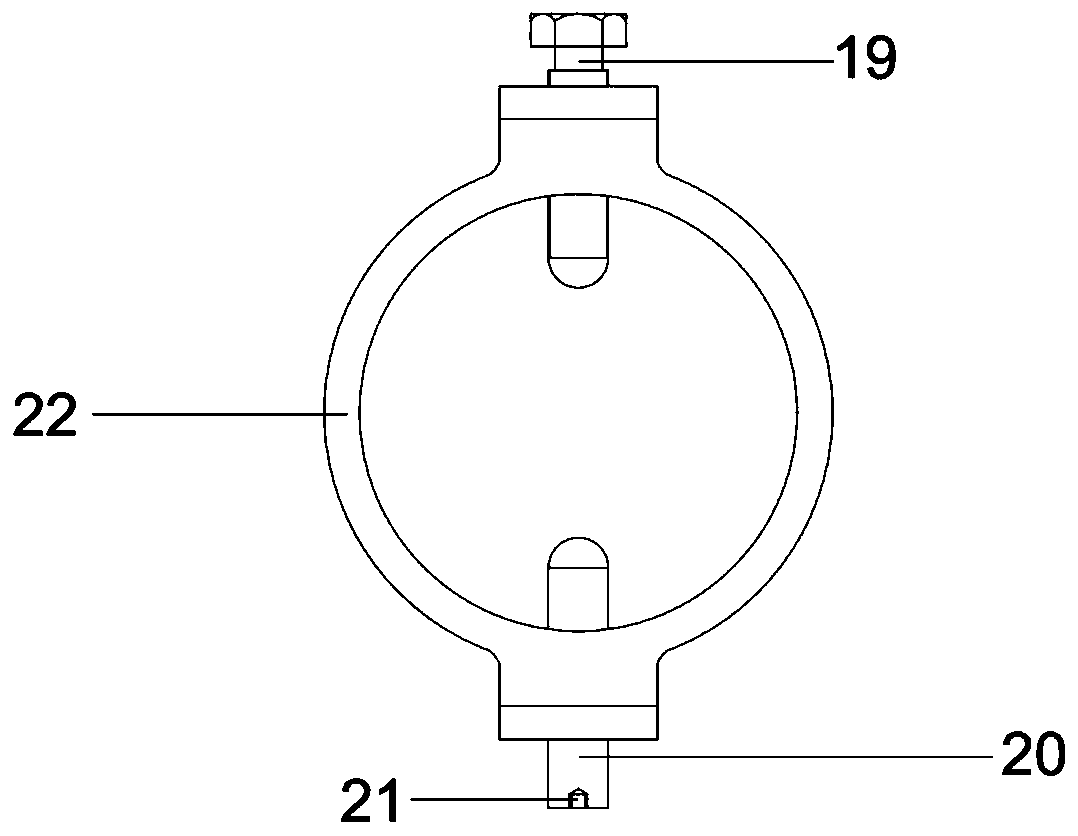

[0025] refer to Figure 1 to Figure 5 , this embodiment is based on the ultrasonic technology fretting wear test device, which consists of an ultrasonic generator 1, an electric cylinder bracket 5, a servo electric cylinder 6, an electric cylinder joint 7, a force sensor 8, a pad 9, a fixed platform 10, a support pad 11, The bottom plate 12, the loading device bracket 13, the amplifier bracket 14, the loading device 15, the driving device and the data acquisition device are composed; wherein, the bottom plate 12 is made of high-strength steel, and the bottom plate 12 provides support for each component; the bottom of the bottom plate 12 is equipped with a support Pad 11, the supporting pad 11 is used for height adjustment, by adjusting the height of the supporting pad 11, the bottom plate is always in a horizontal state. The fixed platform 10 is located at the top of the base plate, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com