Patents

Literature

84results about How to "Amplitude controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

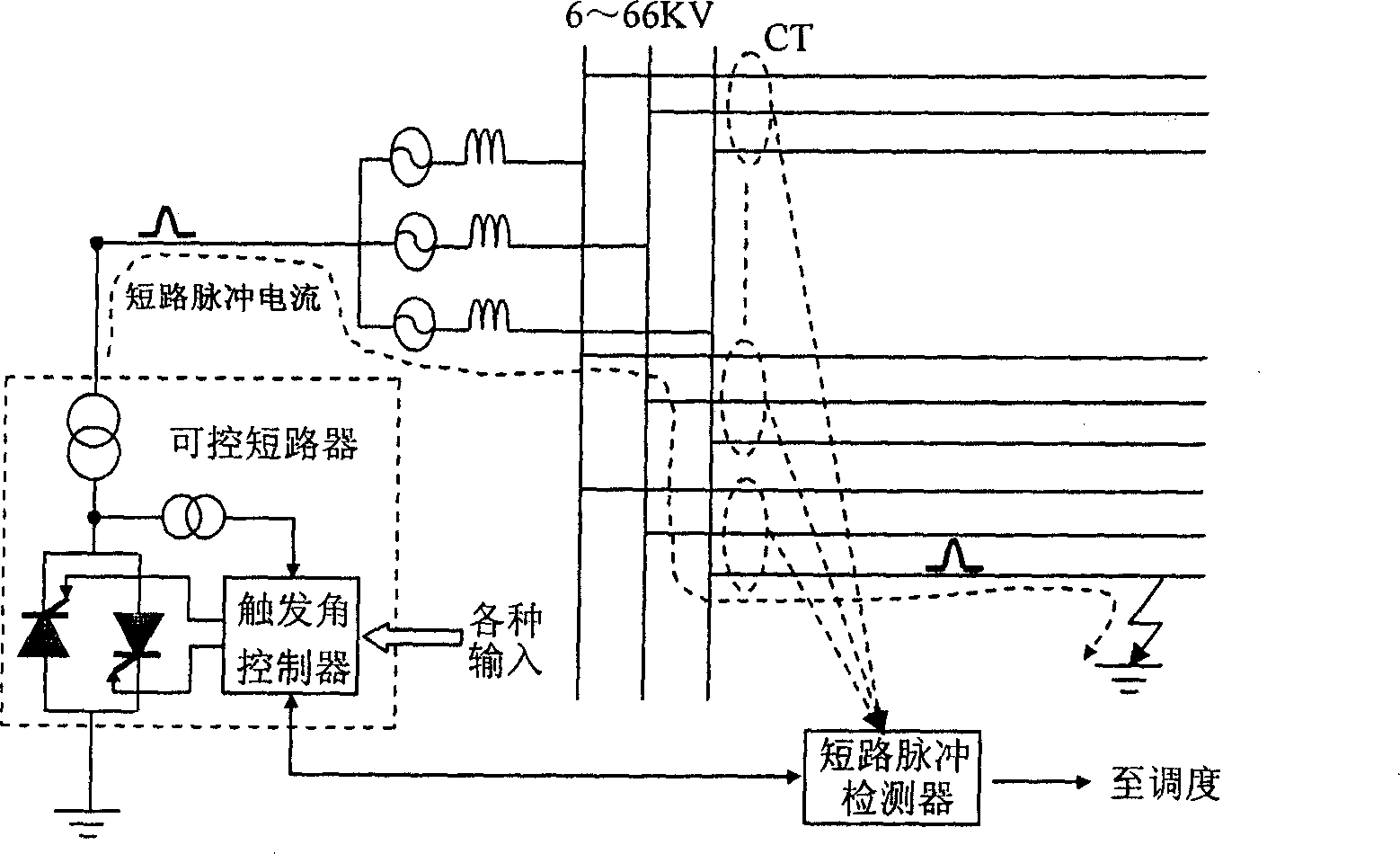

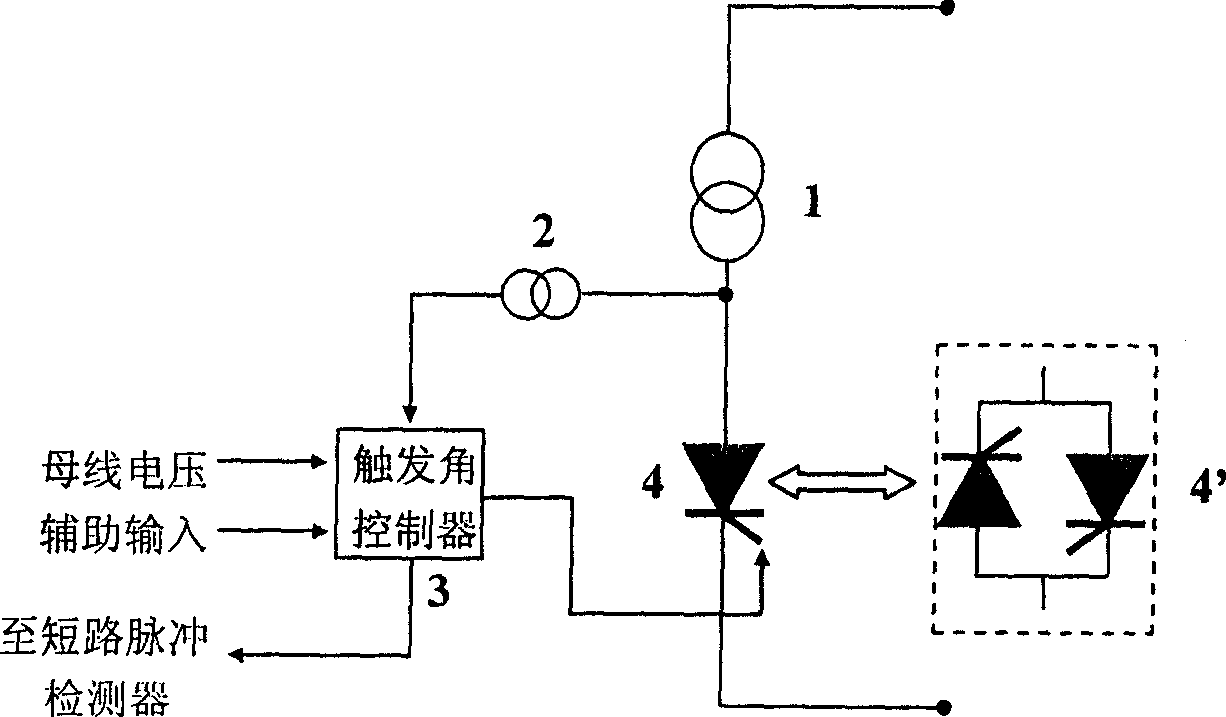

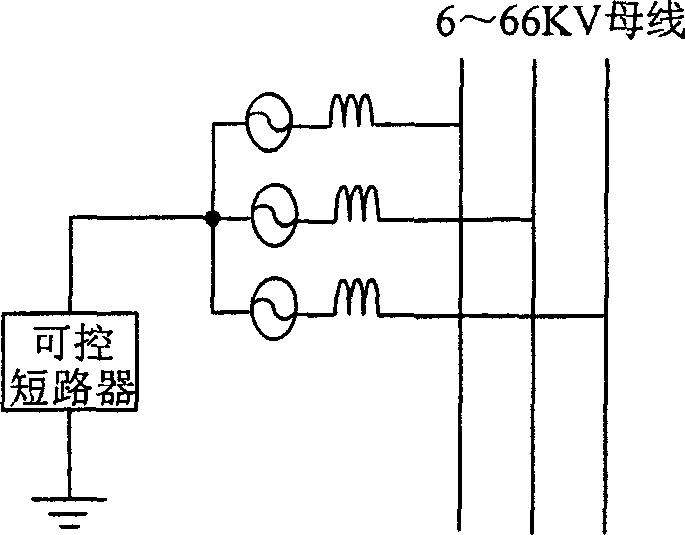

Single-phase ground wire selecting equipment and method of neutral-point uneffect earthed system

InactiveCN1912642AAmplitude controllableHigh strengthFault locationArrangements responsive to excess currentVoltage polarityElectrical polarity

A method for selecting wire of single phase earthing in neutral point noneffective earthing system includes making instant short circuit between neutral point and ground at position near two ends voltage polarity from positive to negative over zero by short circuiter set between neutral point and ground when single phase earthing is occurred in neutral point noneffective earthing system and state is stabilized in order to generate a short circuit pulse current being used to judge earthing line through short circuit detector. The device for realizing said method is also disclosed.

Owner:徐文远 +1

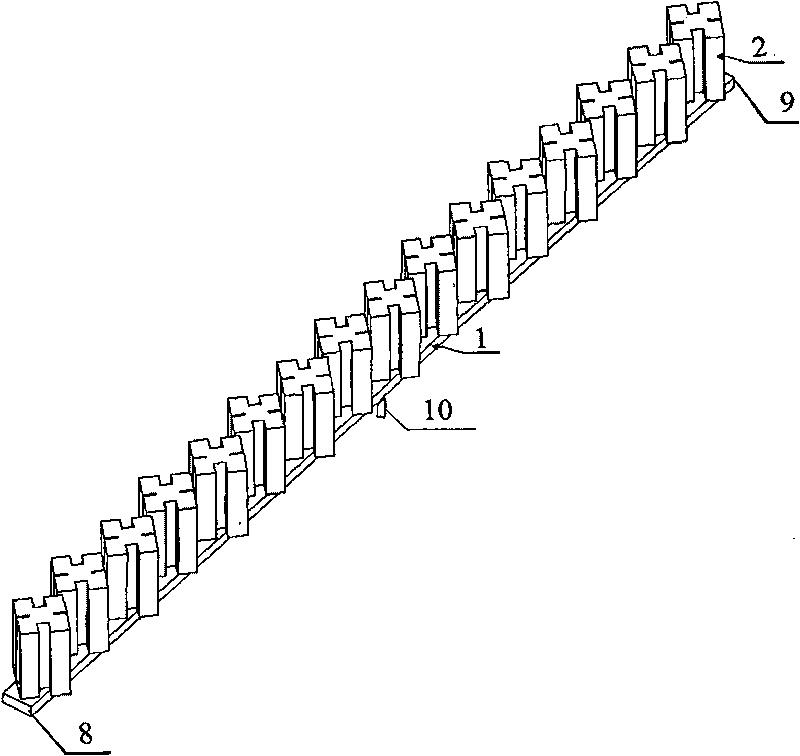

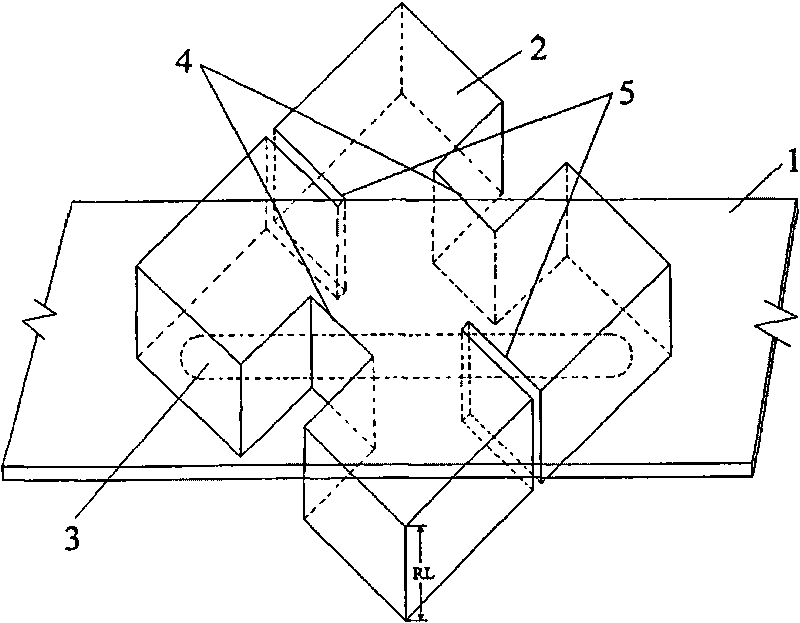

Circular polarization waveguide standing-wave antenna

ActiveCN101702467AAchieve circular polarizationReduced Radiation EfficiencySlot antennasDiagonalTraveling-wave antenna

The invention relates to a circular polarization waveguide standing-wave antenna which solves the problems of low efficiency, wave beam orientation changed along with the frequency and the like of the prior circular polarization waveguide gap traveling-wave antenna. Both sides of the center line of the longitudinal wide edge of a feed waveguide tube with a rectangular cross section are evenly distributed and provided with more than two coupling gaps in a staggered way, and the middle part of the wide edge at one side of the feed waveguide tube is provided with a coaxial connector; both ends of the feed waveguide tube are sealed, a four-ridge metal ridge radiation waveguide is arranged at the coupling gaps at the wide edge of the feed waveguide tube, and the diagonal line of the opening face of the four-ridge metal ridge radiation waveguide and the coupling gaps are on the same straight line. The invention can realize that energy enters a waveguide cavity and is completely radiated out, and the radiation efficiency of the antenna is greatly enhanced; the problem of inconsistent orientation of wave beams with different working frequencies of the waveguide traveling-wave antenna is solved, and the tracking of the antenna to a satellite is easy.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

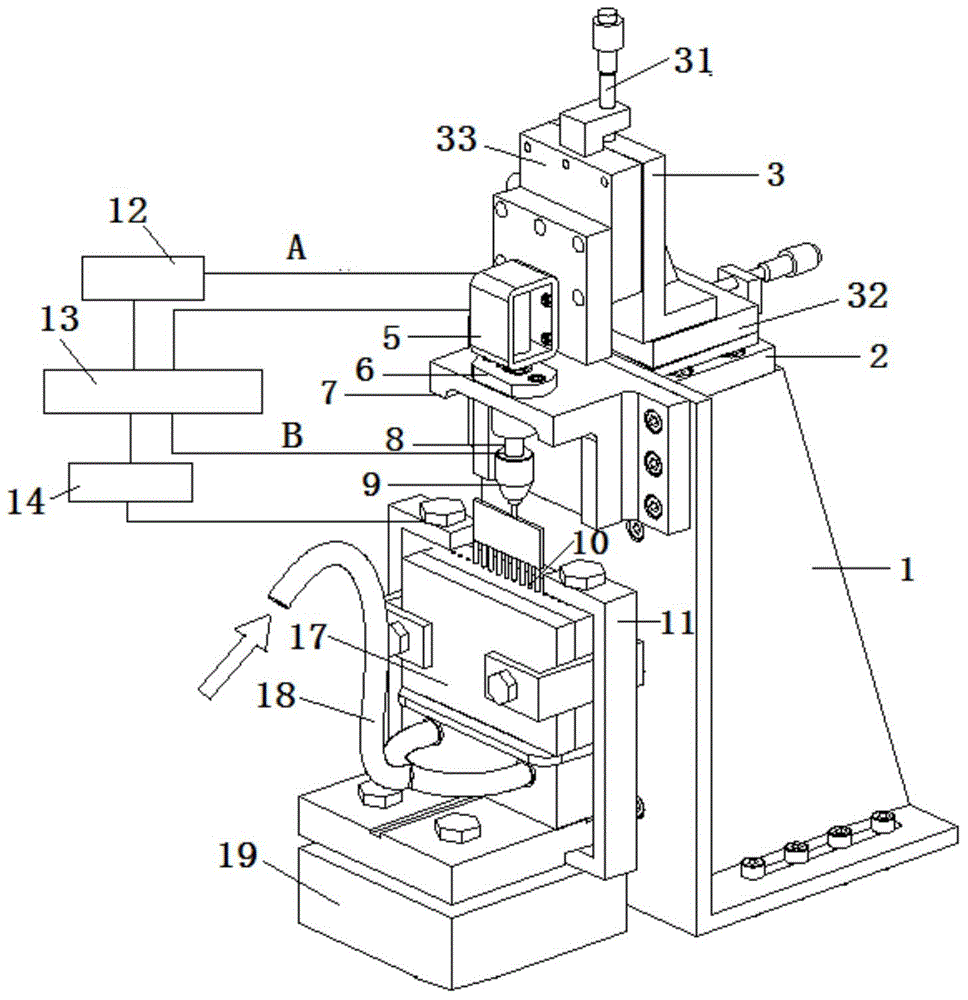

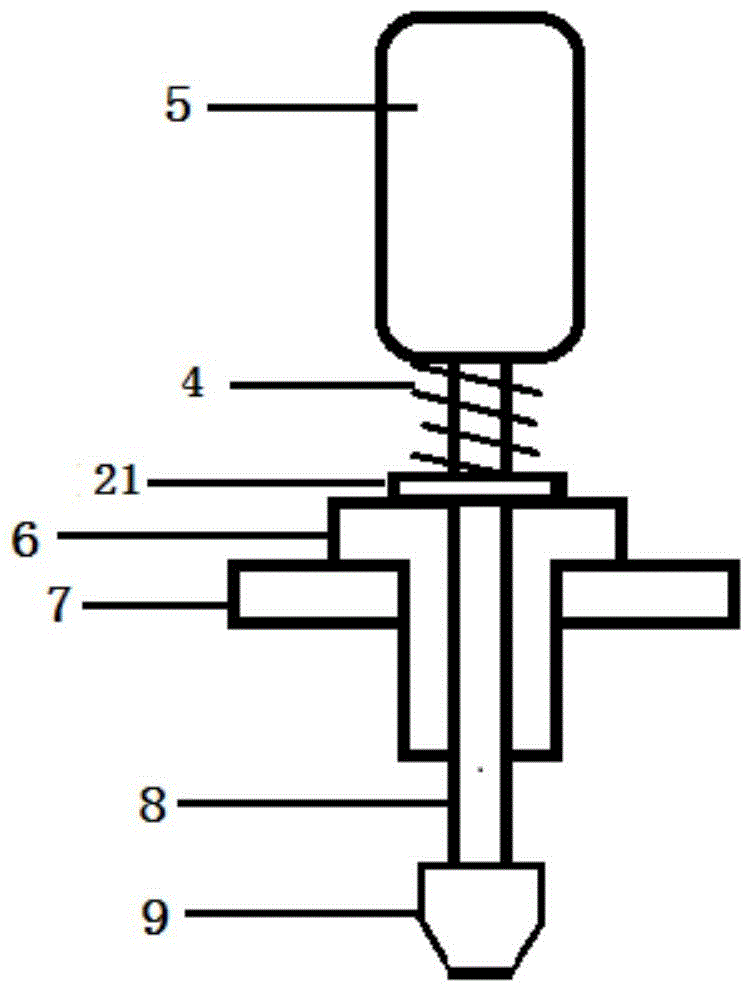

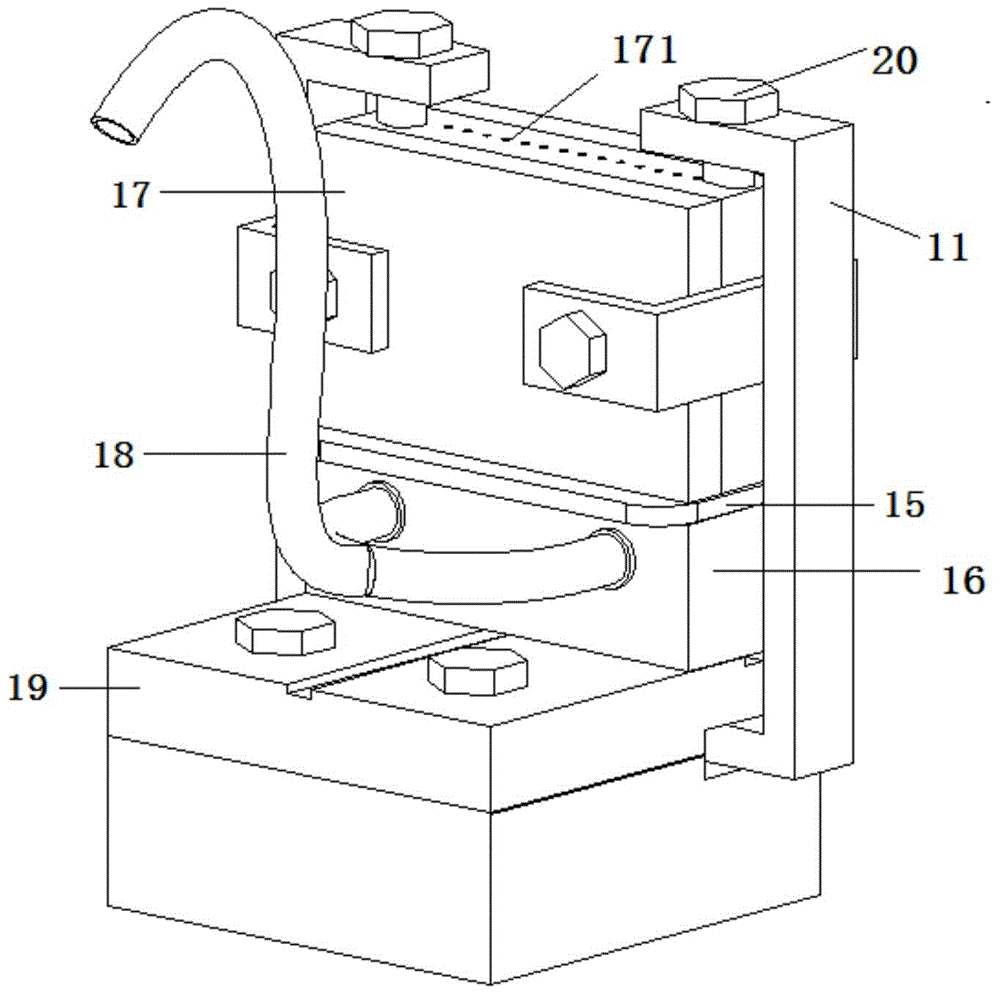

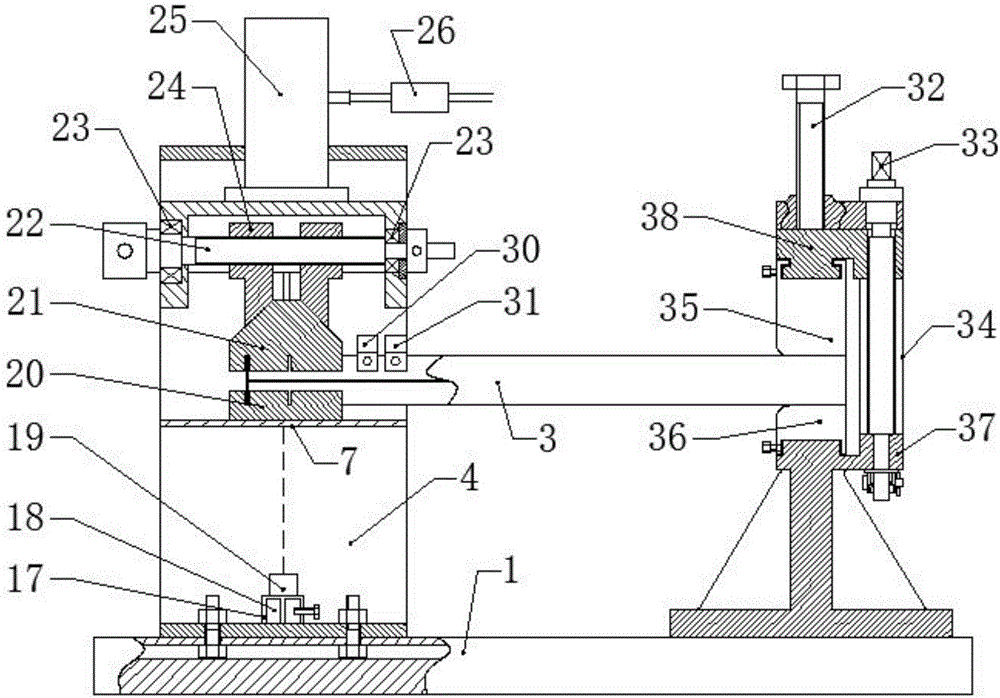

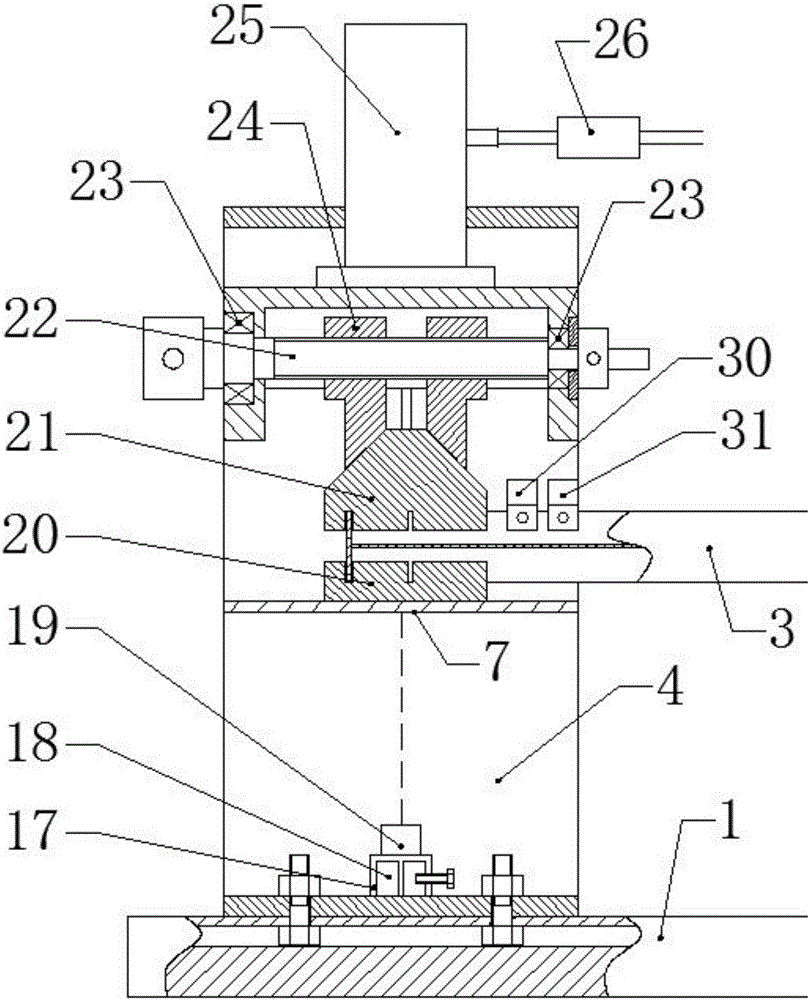

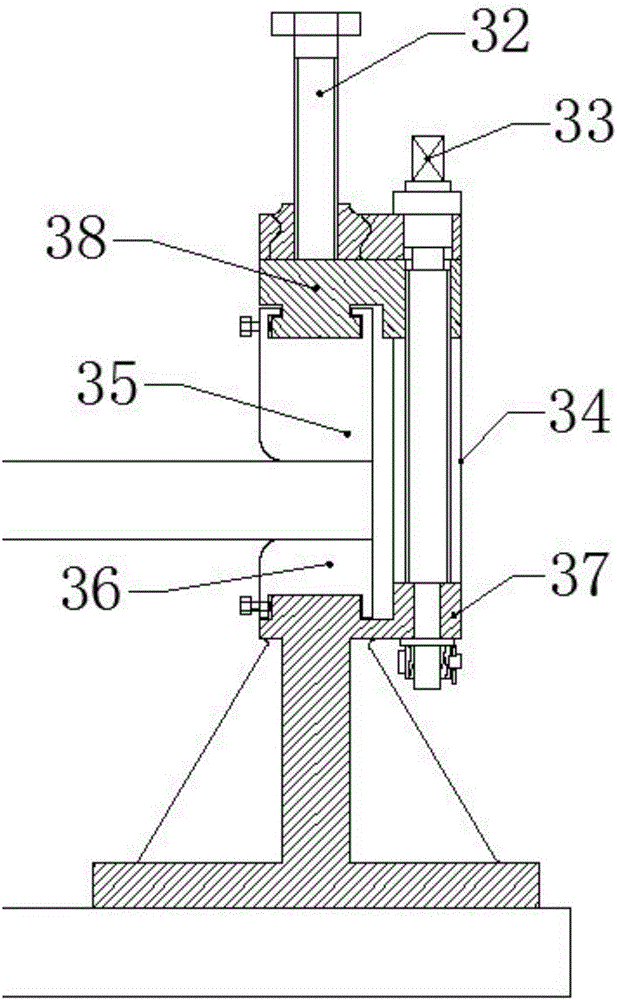

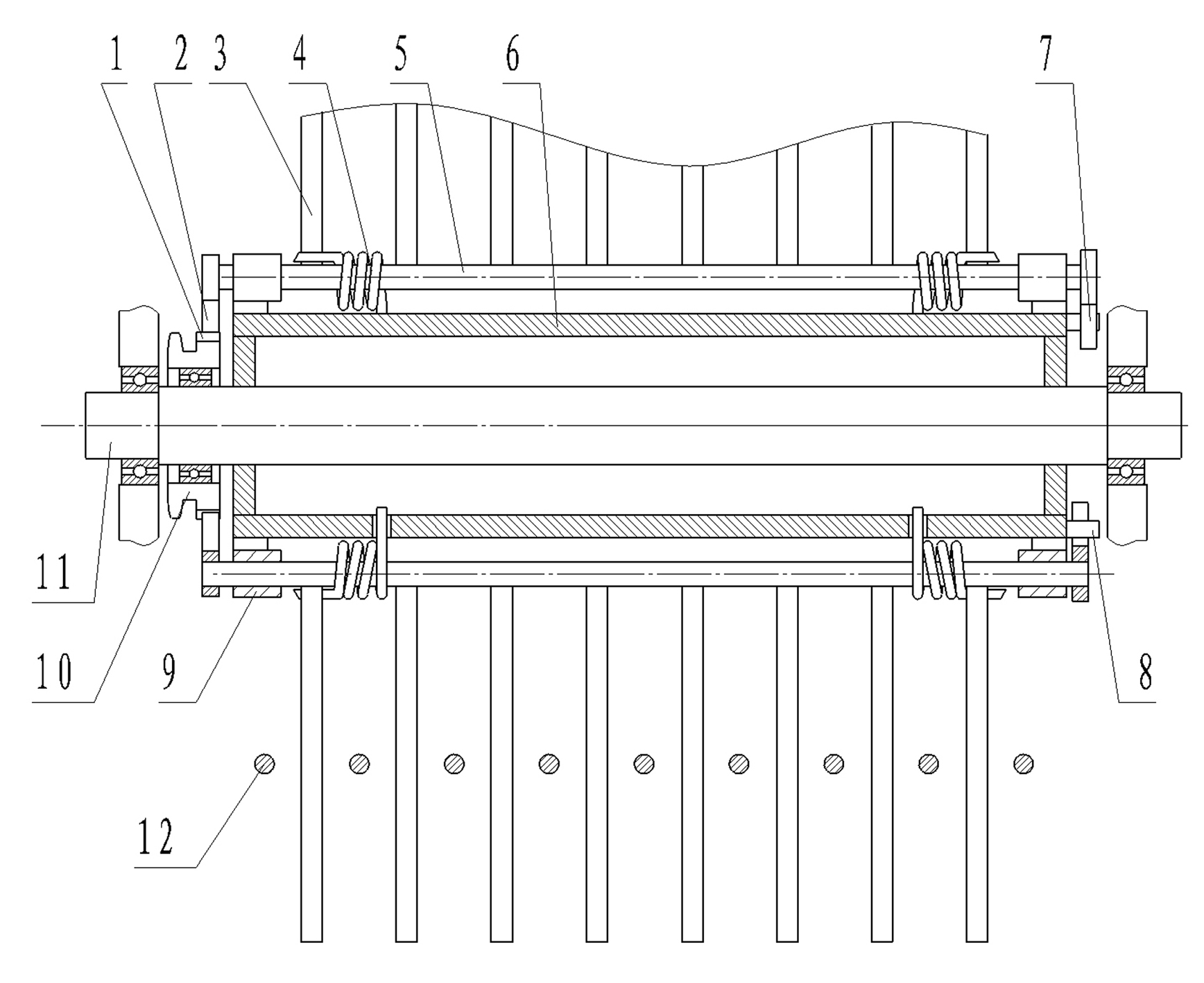

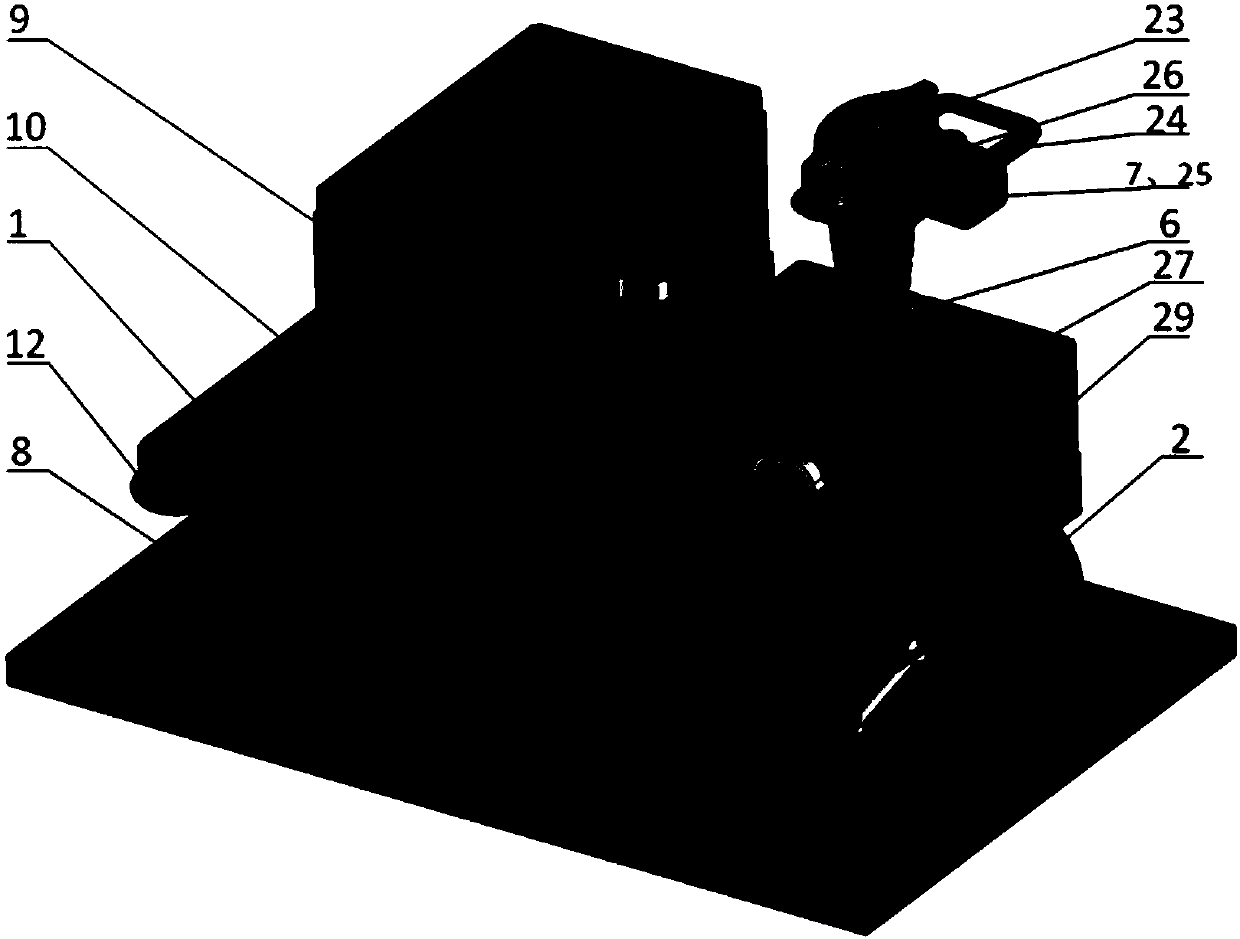

Low-frequency vibration and electrolytic machining device for tool electrodes

ActiveCN104827144AAdjustable electrode amplitudeAdjustable vibration frequencyMachining electric circuitsElectrical-based machining electrodesRubber ringElectrolysis

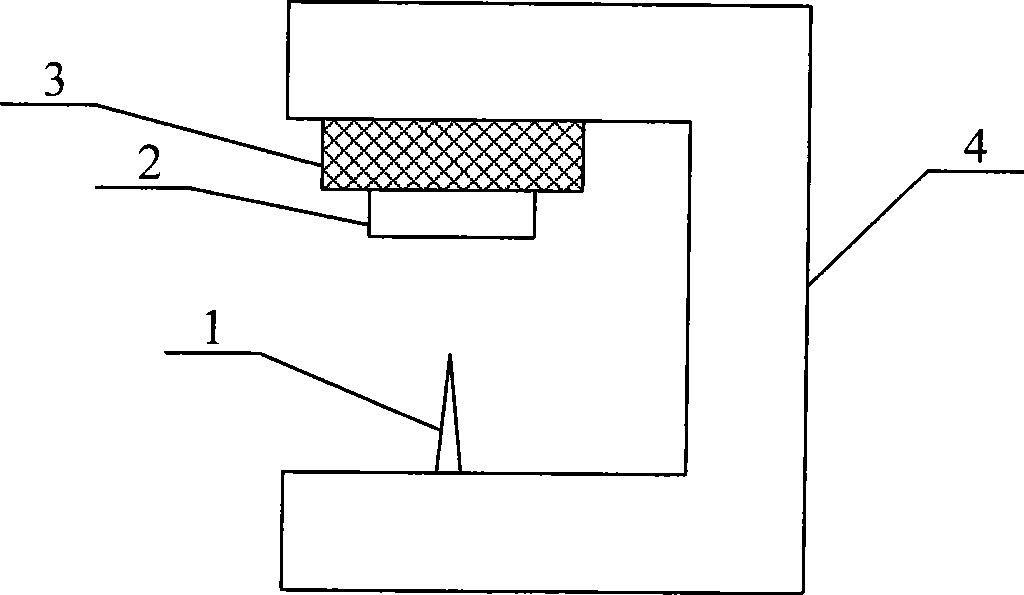

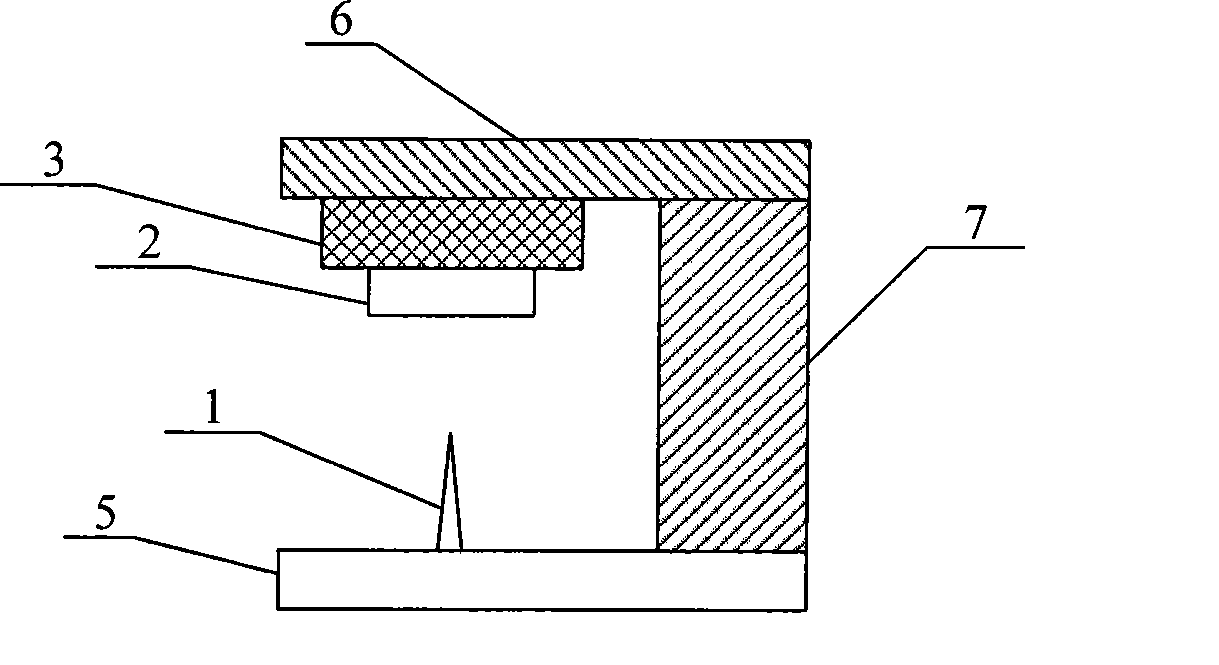

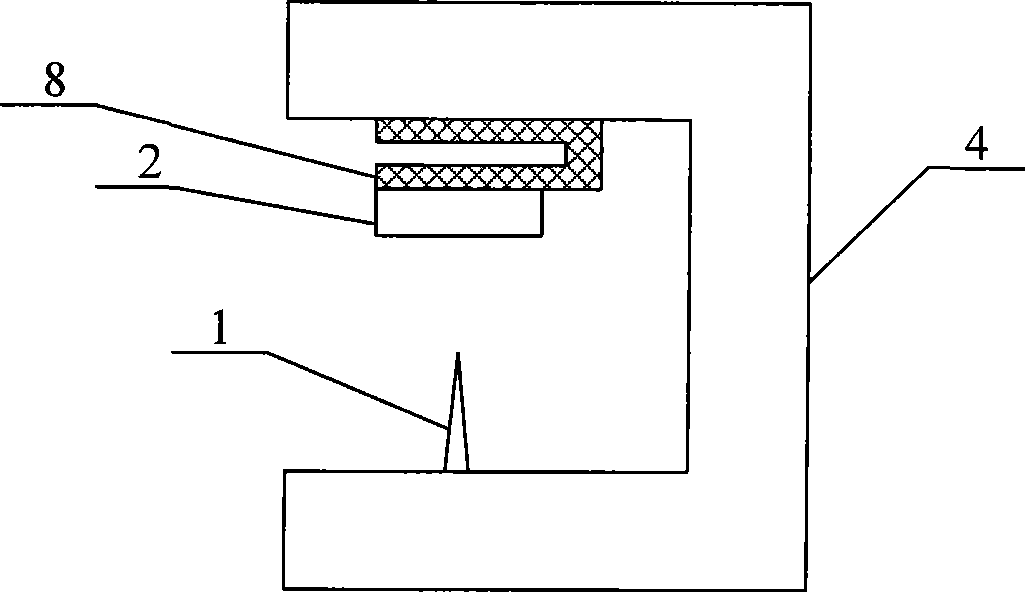

Provided is a low-frequency vibration and electrolytic machining device for tool electrodes. The top surface of a workpiece is provided with through holes, above which the tool electrodes are arranged. The tool electrodes are arranged on an adjusting rack. A horizontal adjusting plate of a displacement table is arranged on a base. A shell of an electromagnetic coil is fixed onto a vertical adjusting plate of the displacement table. An iron column of an electromagnet is wounded by a coil. The coil, a multi-loop time relay and a stabilized voltage supply are connected end to end to form a driving loop. The upper end of a vibrating shaft is inserted into the hollow iron column. The lower end of the vibrating shaft orderly penetrates through a support table and a linear bearing and then is connected with the tool electrodes via a universal chuck. A solution tank is arranged in a fixing seat of a fixing device. The workpiece is erected into the solution tank. The through holes of the workpiece are communicated with the solution tank via an outlet arranged in a rubber ring. A clamp is arranged on the fixing seat. The clamp and the vibrating shaft are made by conductive material. The clamp, the vibrating shaft, the multi-loop time relay and a machining power supply are connected end to end in order to form an electrolytic loop.

Owner:ZHEJIANG UNIV OF TECH

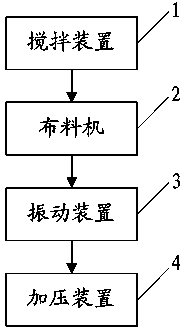

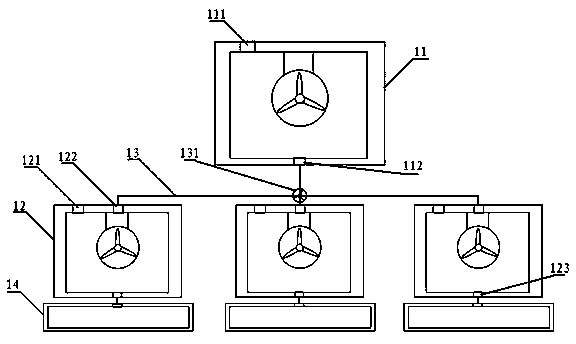

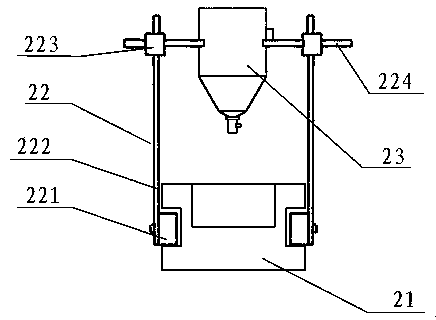

Artificial stone production system

ActiveCN104385436AWell mixedNot stickyCeramic shaping plantsFeeding arrangmentsAutomatic controlEngineering

The embodiment of the invention discloses an artificial stone production system, comprising a stirring device, a material distributing machine, a vibrating device and a pressurizing device, wherein the stirring device is used for evenly mixing raw materials; the material distributing machine is used for distributing the materials according to artificial stone textures; the vibrating device is used for vibrating the distributed materials; the pressurizing device is used for pressing the vibrated materials to form a green body; the stirring device, the material distributing machine, the vibrating machine and the pressurizing device are sequentially connected with one another through a conveyer. The artificial stone production system is applied to the field of artificial stone production; the productive task can be finished according to presetting; particularly, high-quality and high-fidelity simulation artificial stone can be prepared; automatic control can be achieved; the artificial stone production system has the characteristics of being high in production efficiency and high in product percent of pass.

Owner:贺州市鸿源岗石有限公司

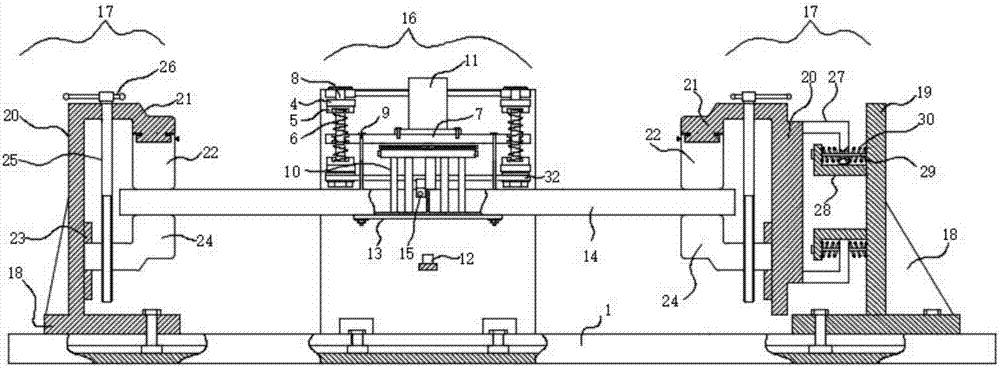

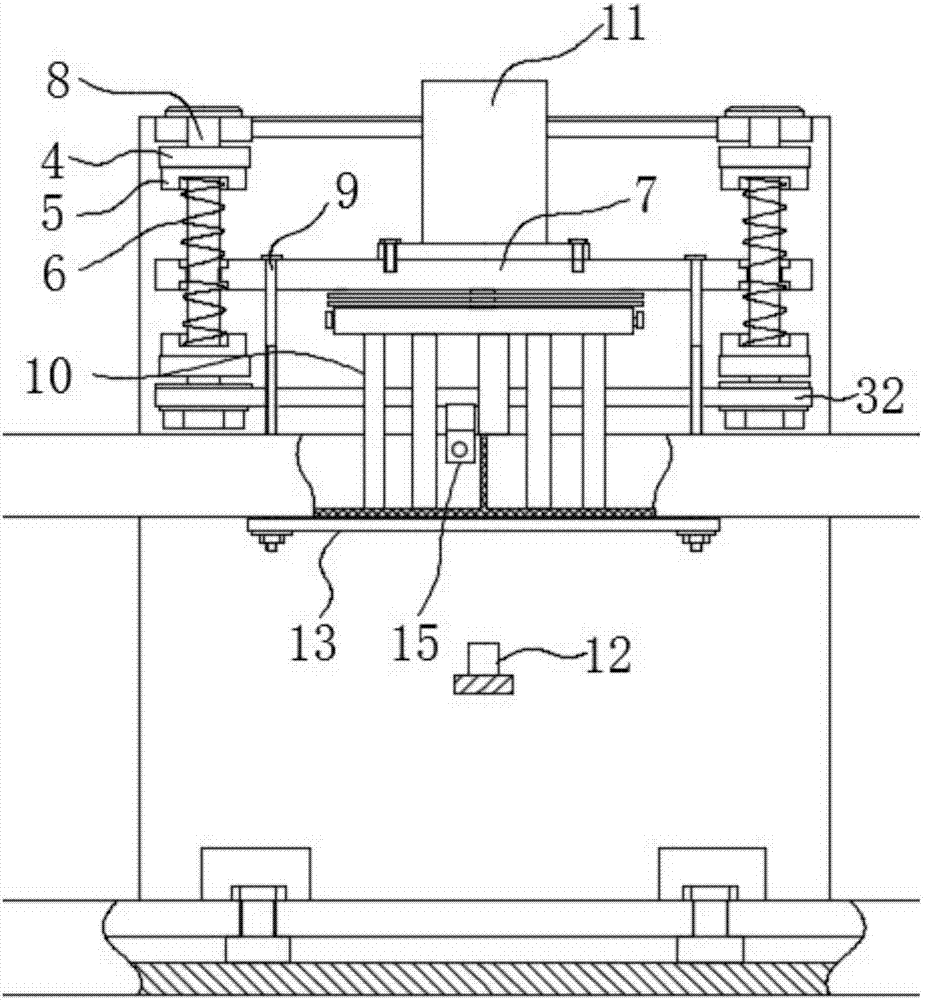

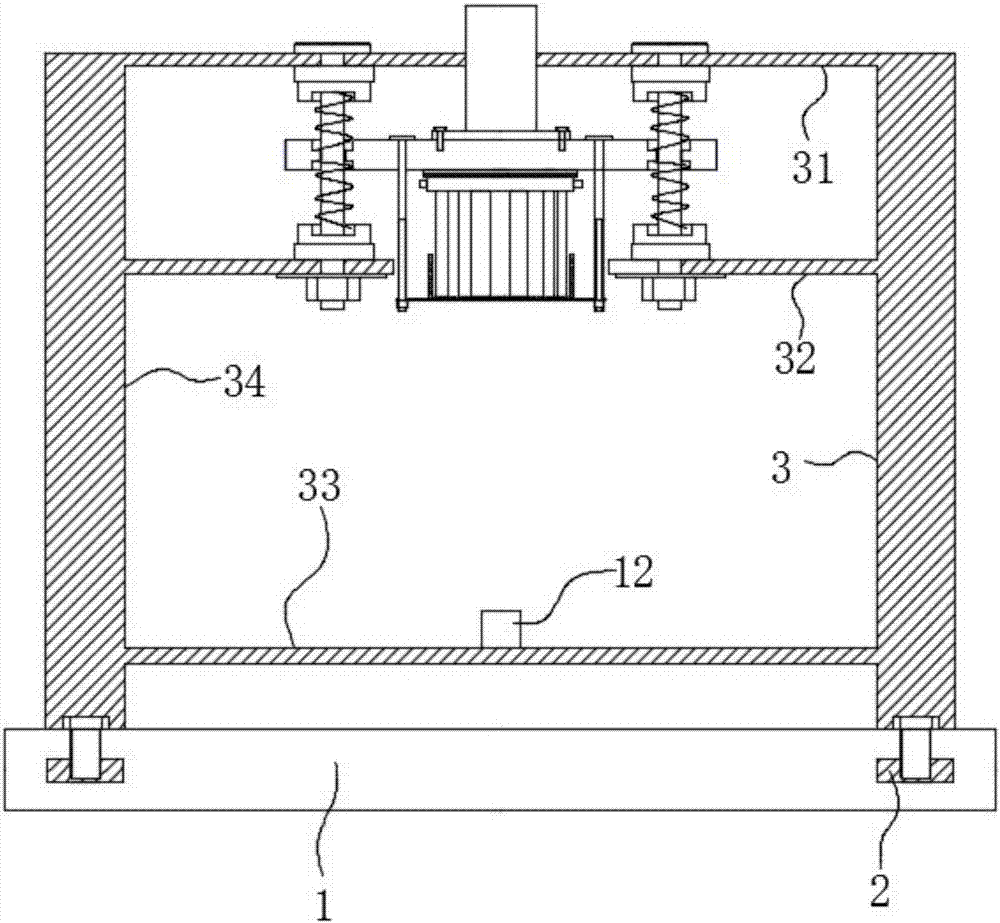

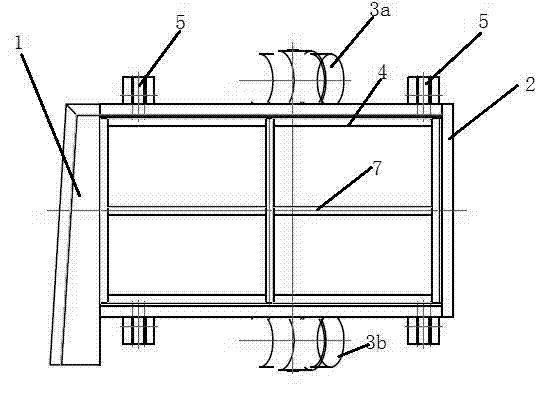

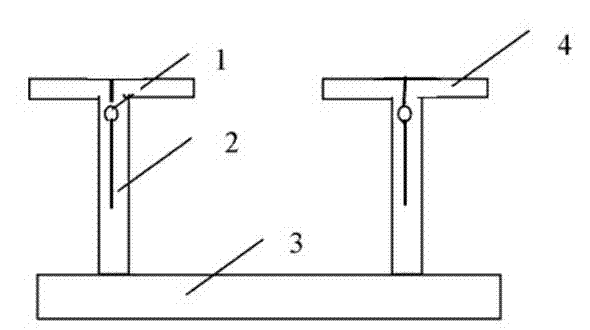

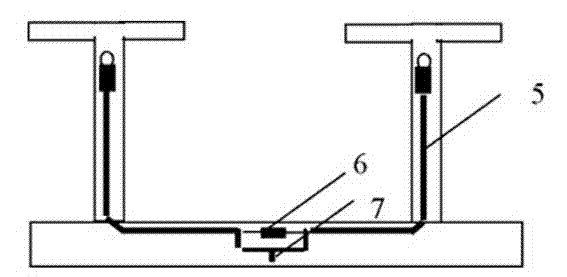

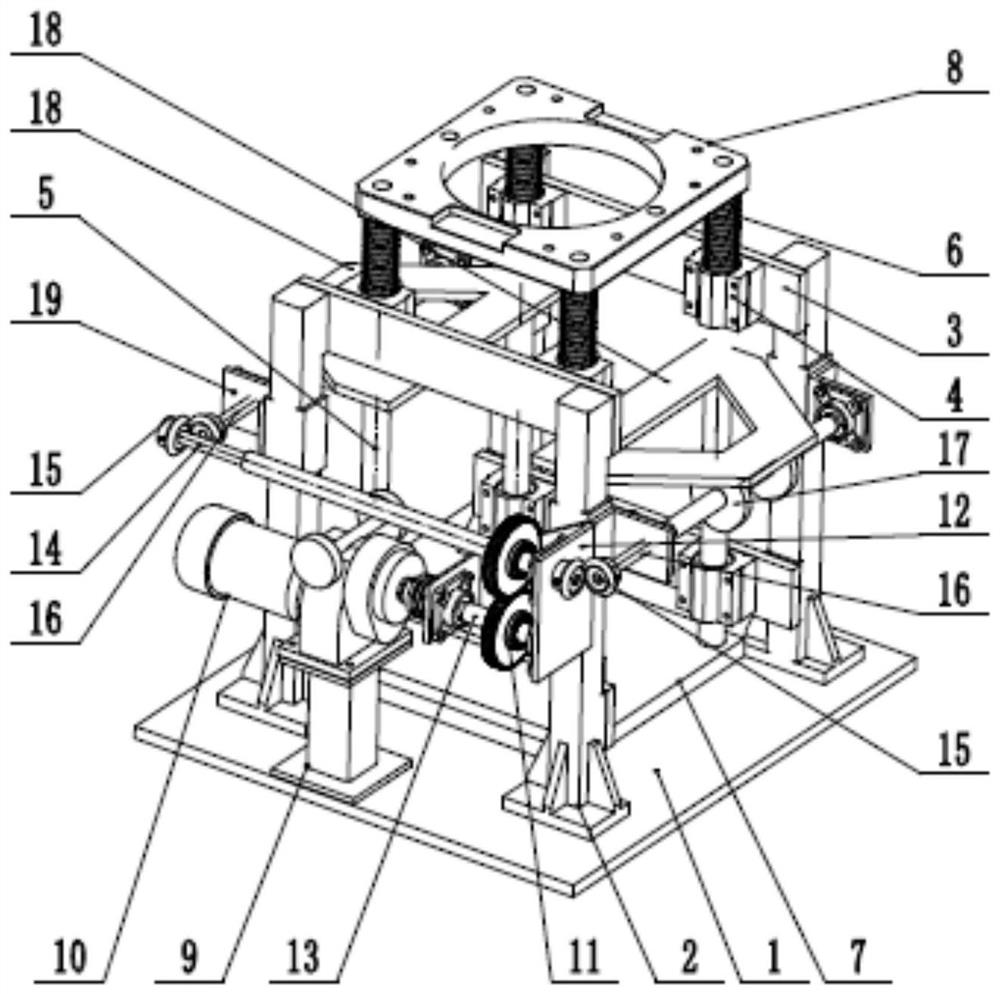

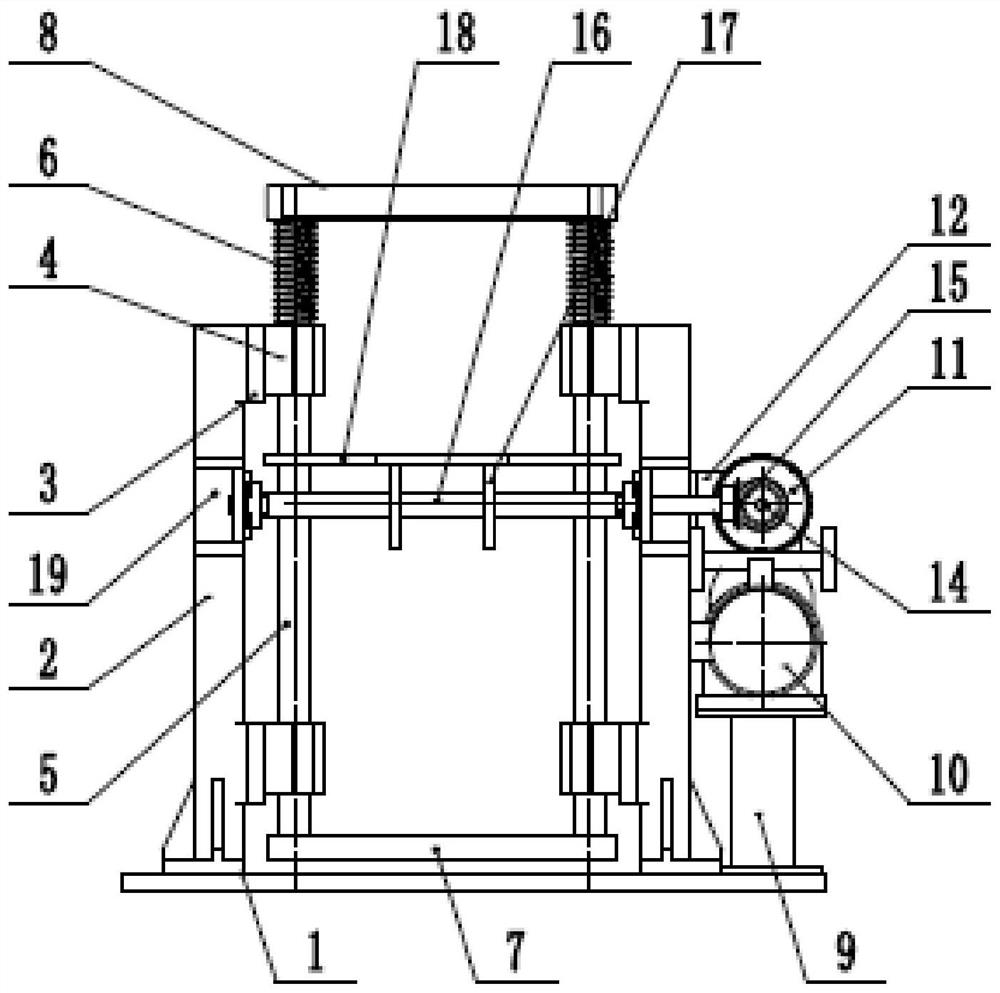

Simply supported type vibrating aging platform for beam component

ActiveCN107460303AWith universal adjustabilityGuaranteed stabilityProcess efficiency improvementFatigue damageVibration exciter

The invention discloses a simply supported type vibrating aging platform for a beam component. The two ends of a base of the platform are provided with end head clamping tools. The middle of the base of the platform is provided with an exciting vibration source testing device. The exciting vibration source testing device comprises a U-shaped bracket. The upper end of the U-shaped bracket is provided with a hanging plate. The upper end of the hanging plate is provided with an electric vibration exciter. The lower end of the hanging plate is connected with a horizontal supporting plate. A pressing clamping tool is arranged between the hanging plate and the supporting plate. The beam component is provided with an acceleration sensor. The bottom of the U-shaped bracket is provided with a laser displacement sensor. The pressing clamping tool comprises a rotating disc. A sliding groove is formed in the bottom surface of the rotating disc. An adjusting screw rod is arranged in the sliding groove. The adjusting screw rod is provided with a pressing plate. An end head of the adjusting screw rod is coaxially provided with an adjusting gear and an adjusting rotary knob. The upper end of the rotating disc is provided with a center shaft. The center shaft is provided with a gear disc and a nut ring. The edge of the bottom surface of the gear disc is provided with a gear ring meshing with the adjusting gear. By means of the simply supported type vibrating aging platform for the beam component, vibration exciting can be achieved under first order inherent frequency of the component, aging processing is conducted on the component, residual stress is eliminated, and the fatigue damage and crack development of the component are reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

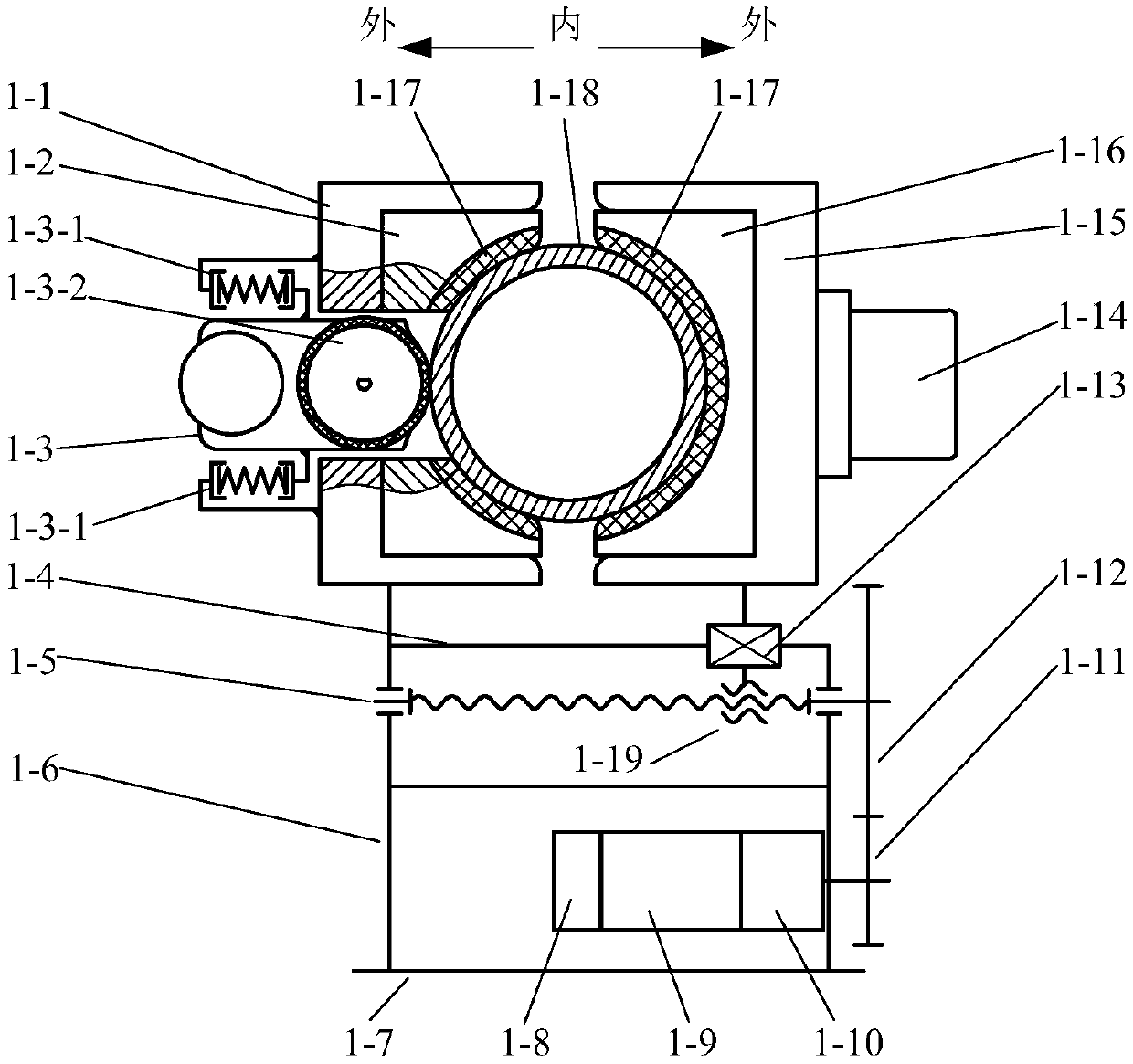

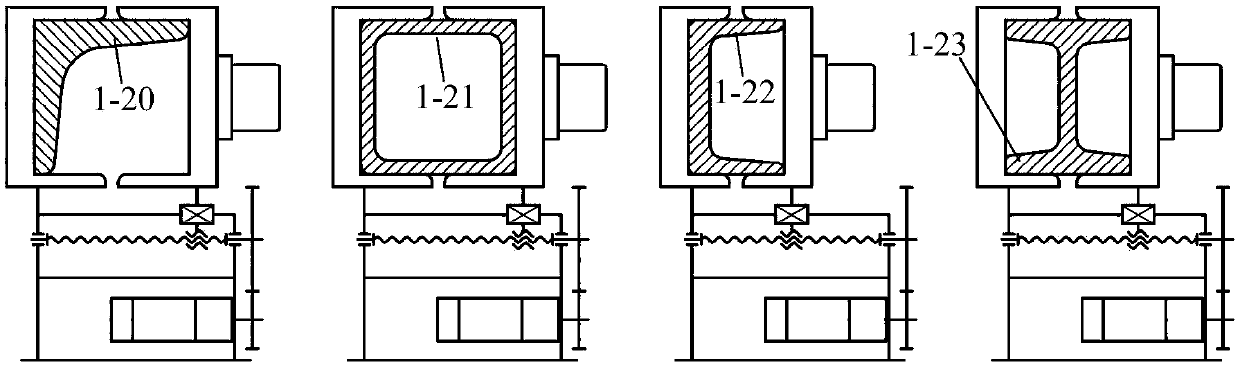

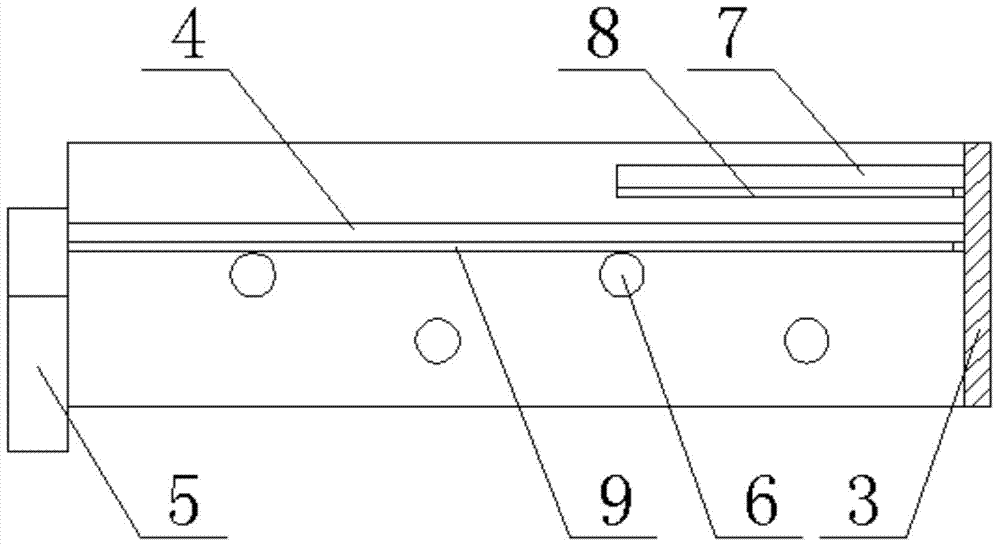

Underground turbine hydraulic power vibration well cementing device

InactiveCN104278964AAmplitude controllableSimple structureVibration devicesWell cementingEngineering

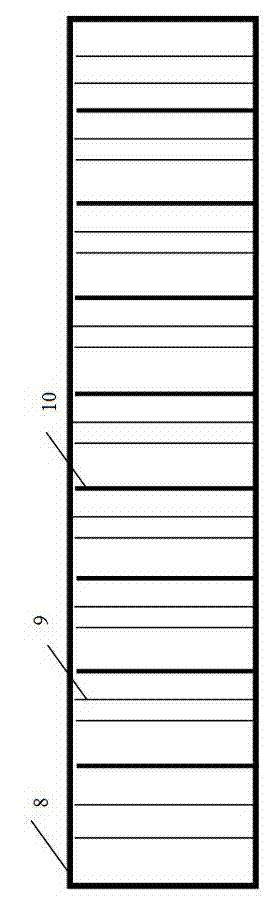

The invention relates to an underground turbine hydraulic power vibration well cementing device which is composed of a turbine mechanical vibration section, a hydraulic power mechanical vibration section and a guiding shoe. The underground turbine hydraulic power vibration well cementing device is characterized in that a support (2), a turbine stator (3), a conventional turbine rotor (4) and an eccentric turbine rotor (5) are located in a turbine section cylinder (1) from top to bottom in sequence; the support (2) and the turbine stator (3) are fixed to the turbine section cylinder (1) through screws (7), and an eccentric sleeve (6) is connected and fixed to the eccentric turbine rotor (5) through a key; a circulation hole (9) is formed in a hydraulic power cylinder (8); the outer ring of a hollow piston (10) is sleeved with a compression spring (11); the upper portion of the hollow piston (10) is restrained by an inner upper step of the hydraulic power cylinder (8), and the lower end of the compression spring (11) is installed on an inner lower step of the hydraulic power cylinder (8). According to the underground turbine hydraulic power vibration well cementing device, ideal radial vibration and axial vibration superposition can be obtained by adjusting the step of a turbine and the size of the hollow piston, so that the amplitude of a mechanical vibration device is adjustable, and the underground turbine hydraulic power vibration well cementing device has the advantages of being simple in structure, low in cost, easy to manufacture, convenient to use and good in application effect.

Owner:YANGTZE UNIVERSITY

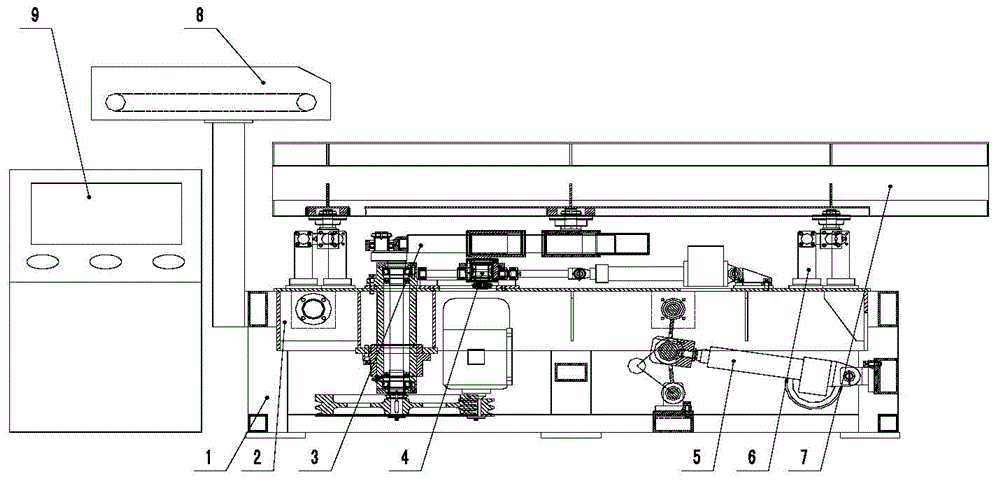

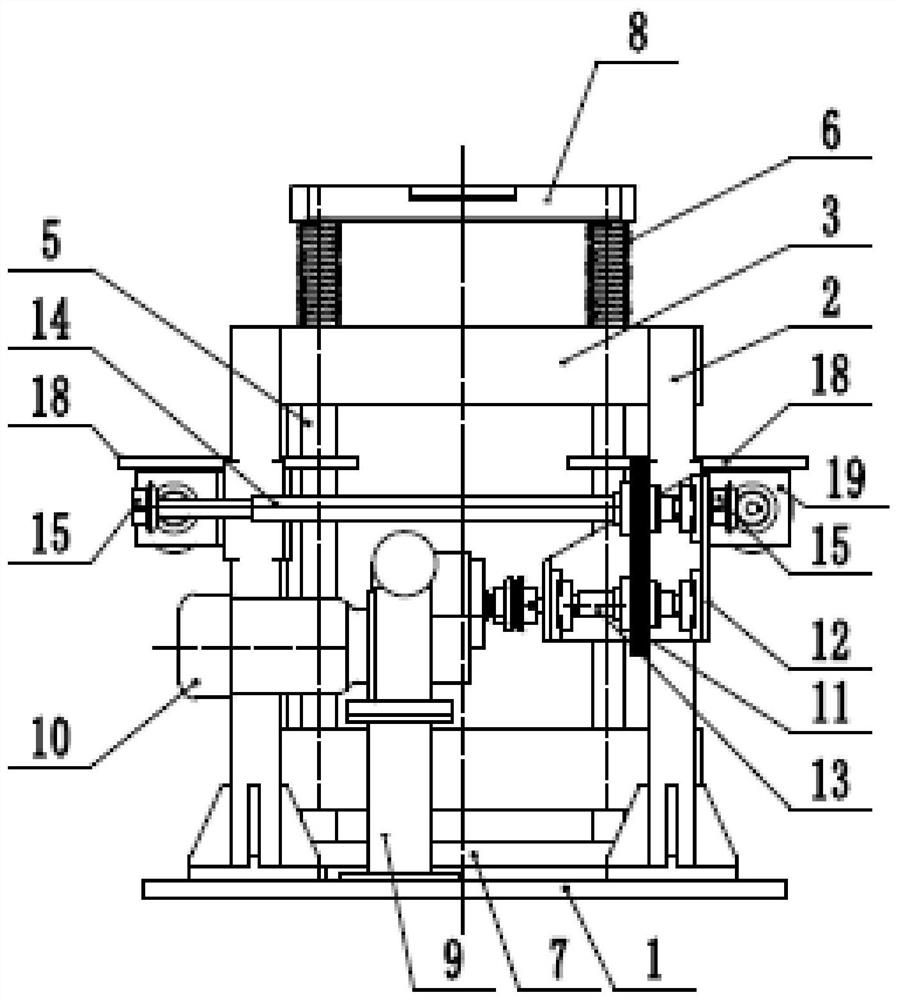

Vibration experimental platform for thin-walled member fatigue test

The invention discloses a vibration experimental platform for a thin-walled member fatigue test. The vibration experimental platform comprises an excitation source test device and an end clamp on a platform base; the excitation source test device comprises a U-shaped bracket; a laser displacement sensor is disposed on the bottom of the U-shaped bracket; first hinge pins are disposed on both sides of the upper end of the U-shaped bracket; the first hinge pins are sleeved by boxes; damping springs are arranged between each box and both ends of the corresponding box; piston vibration exciters are disposed on the tops of the boxes; first screws are disposed in the boxes; each first screw is provided with two symmetrical wedges; the lower ends of the wedges are in contact with a upper splint; the bottom cover of each box is provided with a lower splint; the upper and lower splint are cooperating with each other to form a clamp for sandwiching the thin-walled member; and a speed sensor and an acceleration sensor are arranged on one end of the excitation source test device on the thin-walled member. The vibration experimental platform can equivalently regenerate the fatigue process of an aviation aluminum alloy thin-walled component in a relatively short period, and calculates and evaluates the service life of the component.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

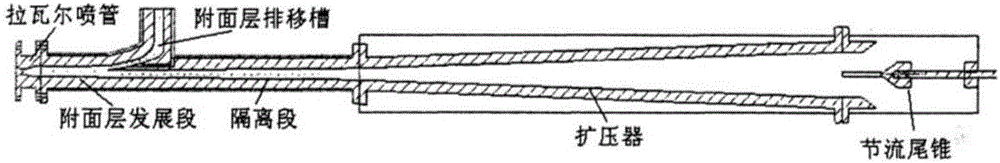

Apparatus for generating fluctuating counter pressure in air inlet test

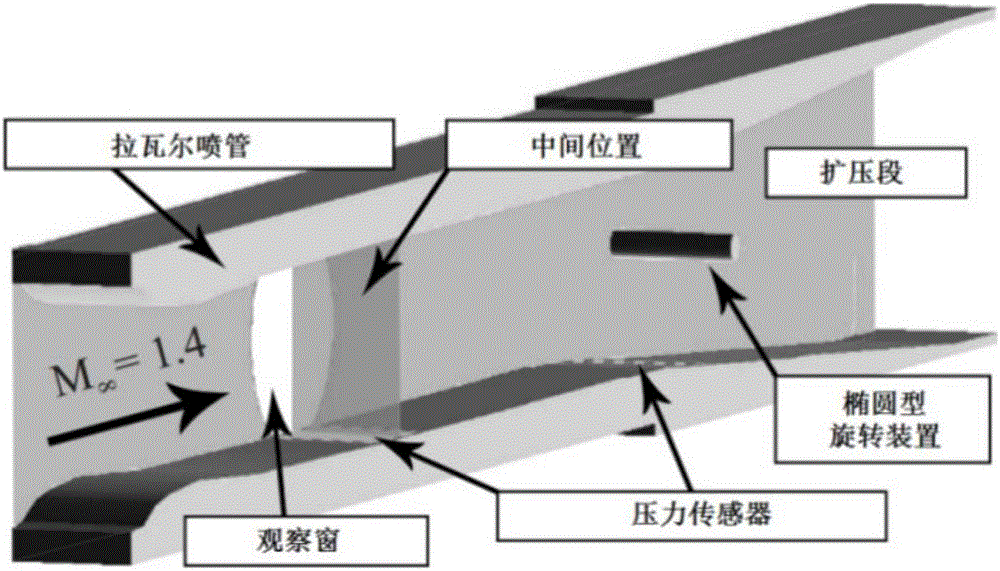

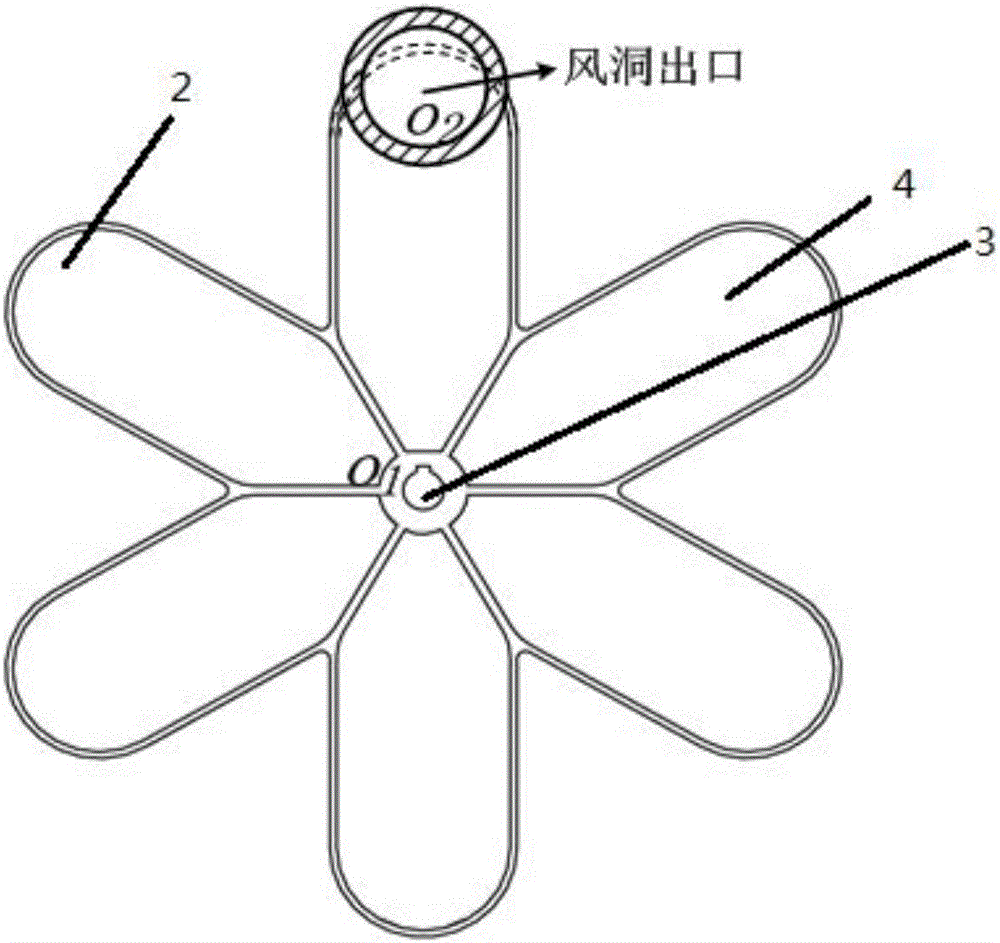

ActiveCN106441918AReduce motor speedHighly pulsating backpressure signalGas-turbine engine testingAerodynamic testingEllipseThrottle

The invention discloses an apparatus for generating fluctuating counter pressure in an air inlet test. The apparatus includes a throttle rotary vane which is mounted on the outside of a wind tunnel outlet and a drive mechanism which drives the throttle rotary vane to rotate. The throttle rotary vane includes more than 2 rotary vanes and is driven by the drive mechanism to rotate. Each rotary vane, when rotating, can alternatively block a certain area of the wind tunnel outlet so as to generate a throttle. Compared with throttle blockage cones and rotation ellipse methods of prior art, according to the invention, the apparatus can generate a fluctuating counter pressure signal of higher frequency and having adjustable time-average value, vibration and frequency. Also, according to the invention, to generate a fluctuating counter pressure signal of the same frequency requires less rotation speed of the motor.

Owner:NAT UNIV OF DEFENSE TECH

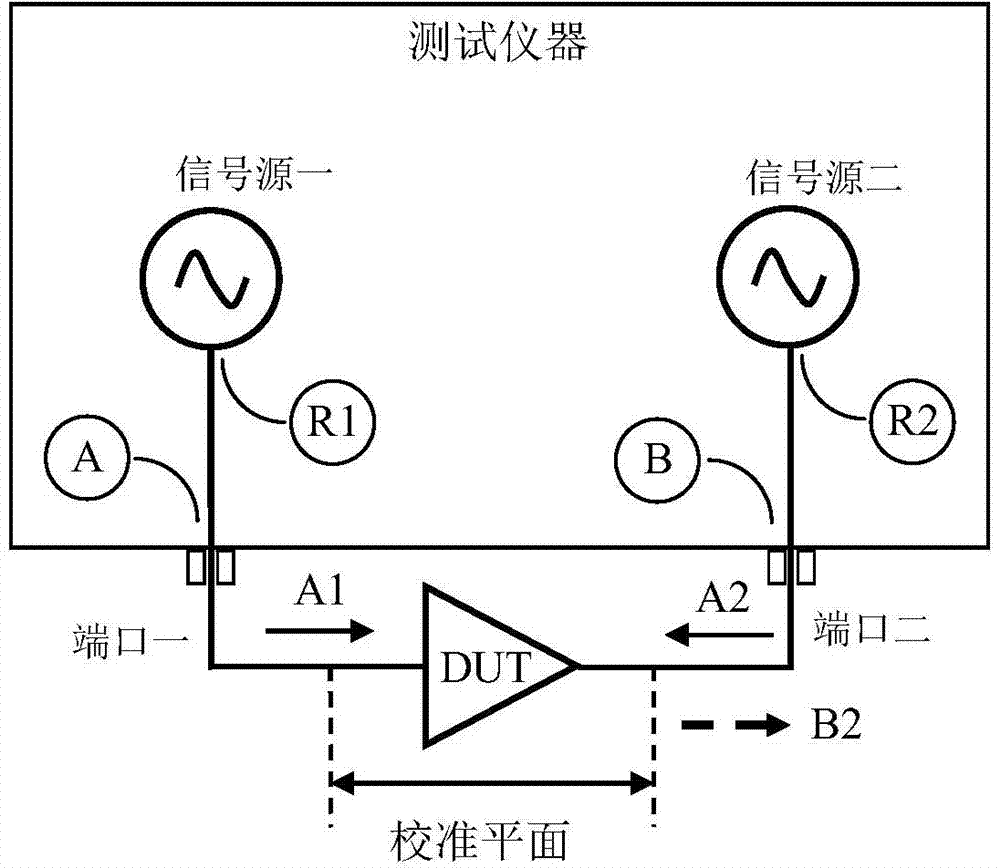

Precise representation method of matching characteristics of power transistor

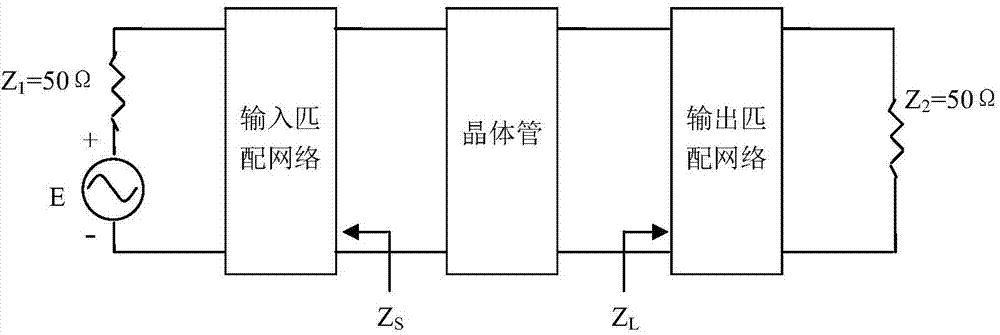

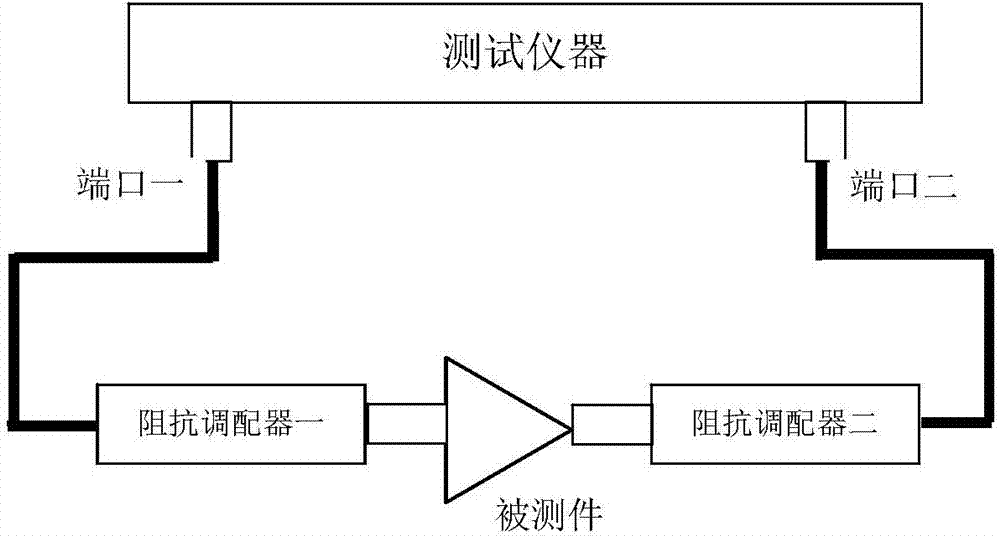

ActiveCN103576071ACovers a wide frequency rangeFast testIndividual semiconductor device testingOhmEngineering

The invention discloses a precise representation method of matching characteristics of a power transistor. The precise representation method is characterized in that variation of input / output impedance values of a tested power transistor is achieved through control of a relative phase of two signal sources inside a testing instrument, and pursuantly, main performance indexes such as gain, output power and the like of the tested piece under different impedance conditions are measured; and a test result indirectly provides main parameters of a matching circuit when the transistor is encapsulated into an amplifier as well as main performance parameters that the transistor can reach in an optimal matching state. The precise representation method of the matching characteristics of the power transistor has the characteristics that the coverage frequency range is wide, the test speed is high, and variation of the input / output impedance of the tested piece in the whole impedance chart is achieved; and the method can be further used for parameter measurement of a transistor whose input / output impedance is not 50 ohms.

Owner:CHINA ELECTRONIS TECH INSTR CO LTD

Truss climbing robot capable of swinging and grasping long-distance truss rod and control method thereof

ActiveCN109048961AImprove gripEliminate the effects of motion detectionProgramme-controlled manipulatorJointsGyroscopePhase difference

The invention provides a truss climbing robot capable of swinging and grasping a long-distance truss rod and a control method thereof, and relates to a robot and a control method thereof. The truss climbing robot capable of swinging and grasping the long-distance truss rod solves the problem that an existing truss climbing robot cannot reliably grasp a far truss rod and cannot continuously move ina truss structure. A friction material is additionally arranged on the inner side of claws of the robot to provide greater damping torque. A gyro sensor is additionally arranged on the claws to eliminate effect of slip of a friction wheel during high-speed swinging, feedback data comprehensively considering a friction wheel rotation-retraction feedback mechanism and a gyro are given, a method forfeeding back a movement state of underactuated joints is generated, a method of excitation control based on phase difference is proposed, and a swinging rod grabbing control method initiated from a natural overhanging state and a continuous movement control method are proposed. The swinging rod grabbing experiment initiated from the natural overhanging state and continuous movement simulation andexperiment are carried out, and the effectiveness of the proposed method is verified. The truss climbing robot capable of swinging and grasping the long-distance truss rod and the control method thereof can apply to the field of truss climbing robots.

Owner:HARBIN INST OF TECH

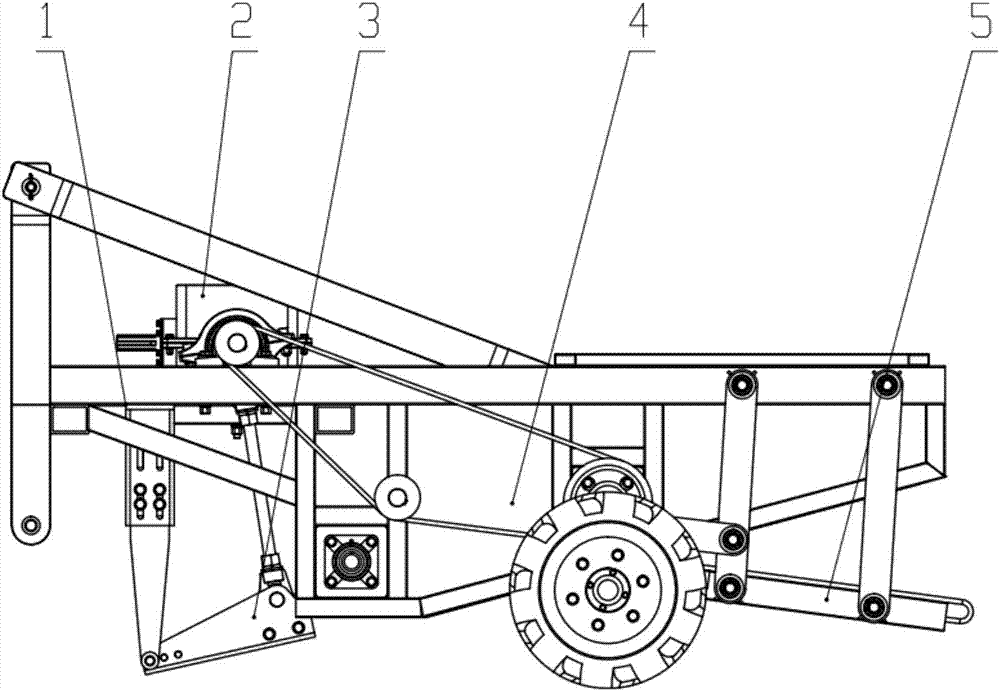

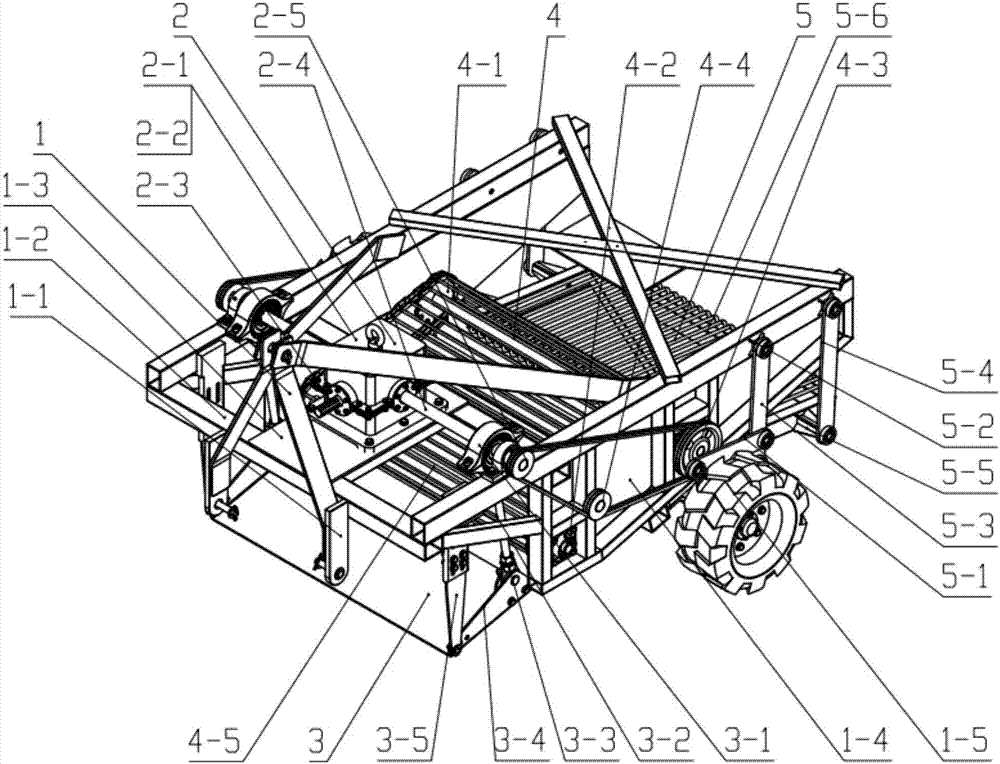

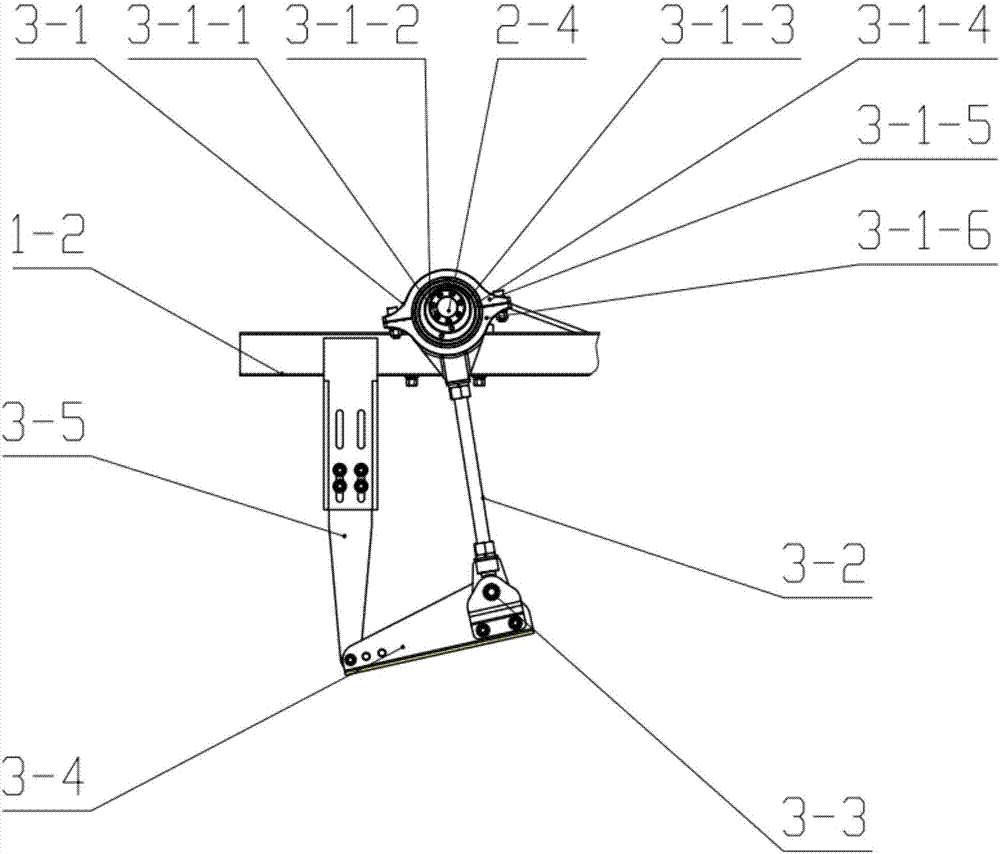

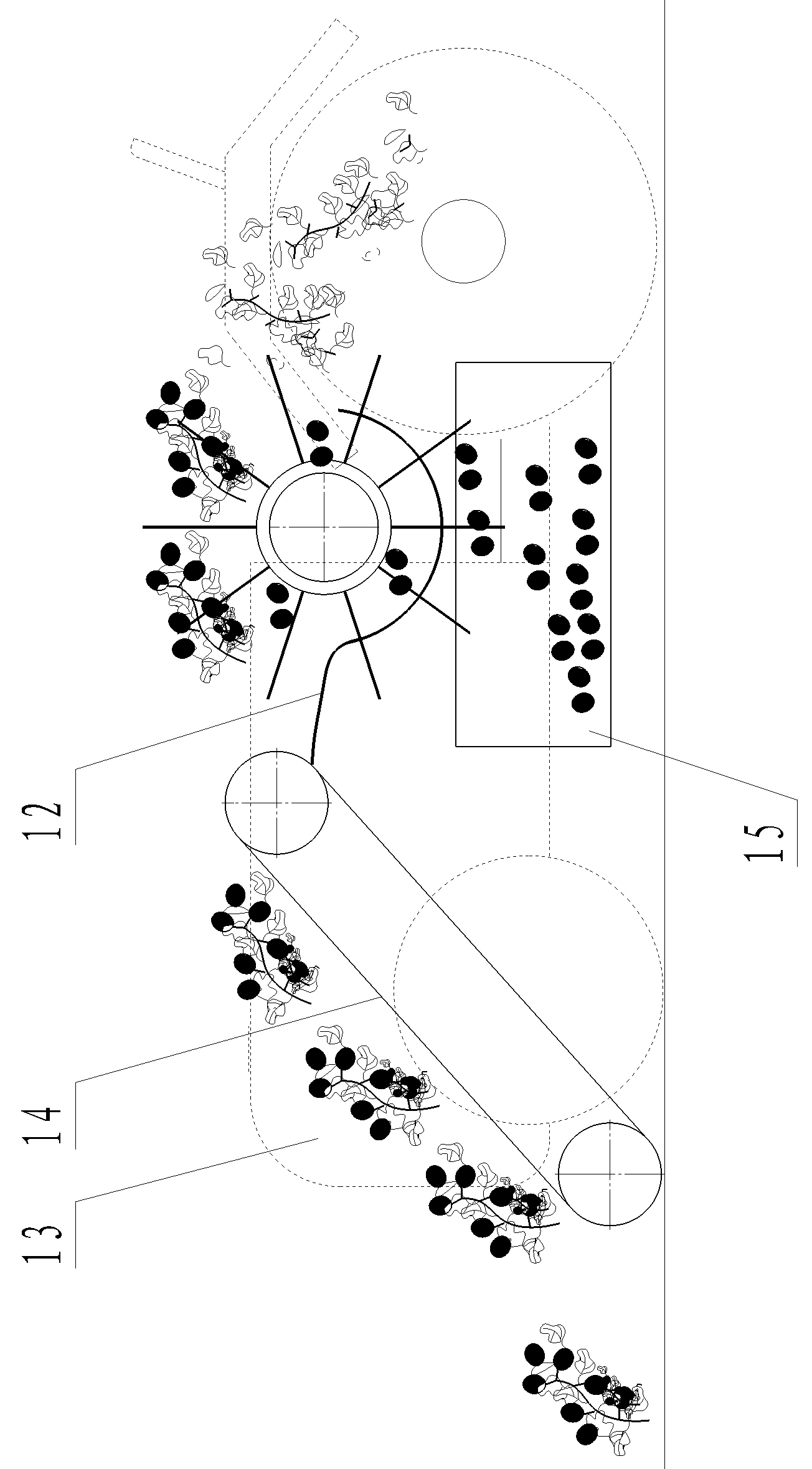

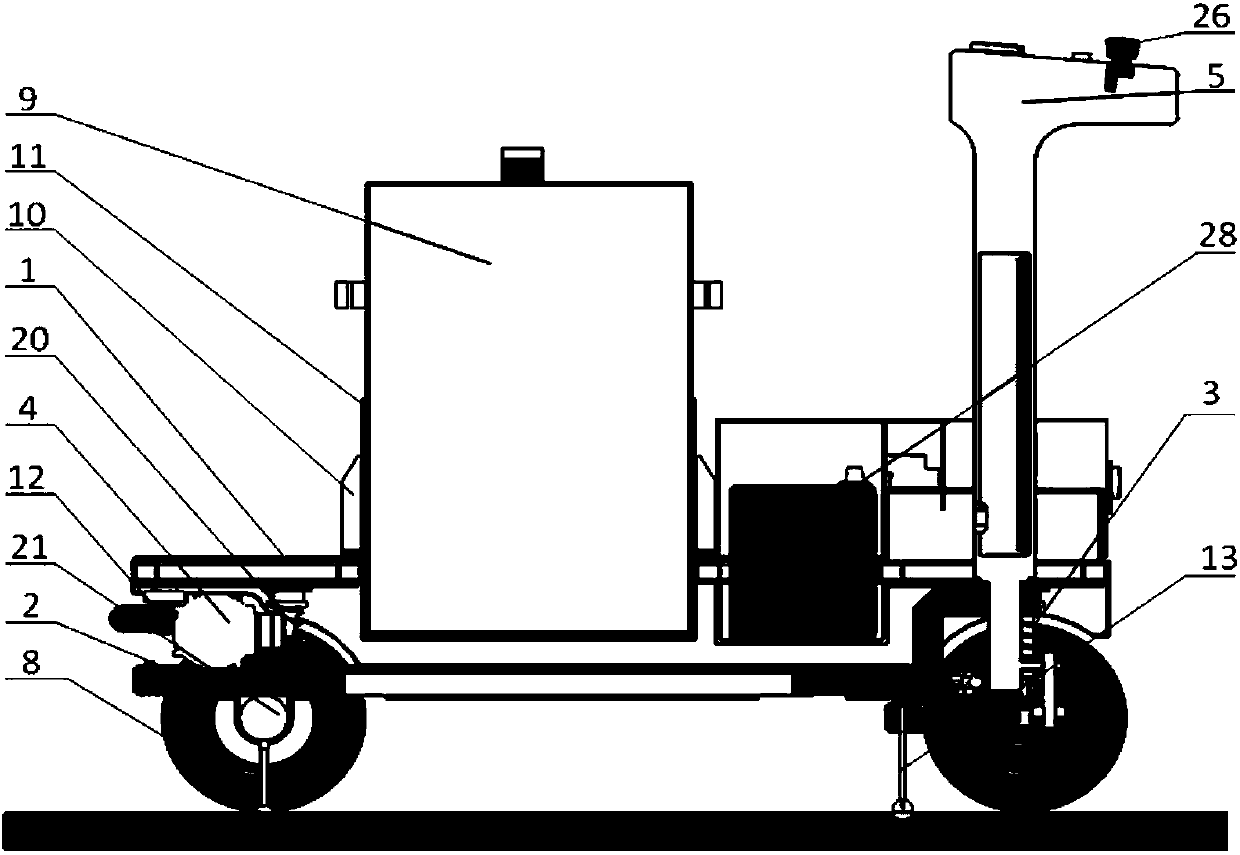

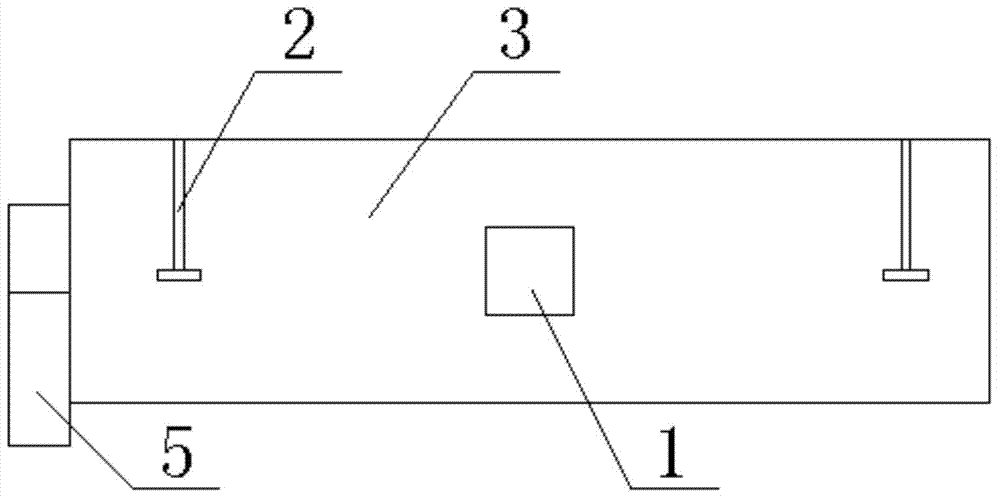

Vibratory digging harvester for winter potato

The invention relates to a vibratory digging harvester for winter potato, comprising a frame, a gearbox, a vibratory digging device, a two-stage conveyer and a separation mechanism, with the gearbox,the vibratory digging device, the two-stage conveyer and the separation mechanism mounted on the frame. The gearbox powers the vibratory digging device, the two-stage conveyer and the separation mechanism. The vibratory digging device comprises a vibratory digging blade to dig crops. The two-stage conveyer comprises a conveying chain screen to convey and primarily screen silt. The separation mechanism comprises a vibratory flow-combing slide mesh to screen silt, the front end of the conveying chain screen is positioned at the rear of the digging blade, and the rear end of the conveying chain screen is positioned above the front end of the vibratory flow-combing slide mesh. The vibratory digging harvester for winter potato is simple in structure and convenient to operate, has adjustable positions and adjustable vibrational amplitude, digging depth and penetrating angle, may arrive at optimal digging as practice requires so as to achieve reduced digging drag, increased potato exposure rate and reduced damage rate, has a promising market in the harvest of potato and other tubers, and is a harvesting machine for potato and other tuberous crops.

Owner:SOUTH CHINA AGRI UNIV

Tomato harvesting and separating device and tomato harvester using same

InactiveCN102077734ASimple structureHigh vibration frequencyHarvestersVibration amplitudeEngineering

The invention discloses a tomato harvesting and separating device and a tomato harvester using the same. The tomato harvesting and separating device comprises a grid screen (12) and an elastic tooth roller (6), wherein an elastic tooth rod (5) is axially arranged on the circumference of the elastic tooth roller (6); elastic teeth (3), a return spring (4) and a swinging rod (2) are arranged on the elastic tooth rod (5); a vibrating and swinging cam (10) coaxial with the elastic tooth roller (6) is arranged at the end part of the elastic tooth roller (6) in the position corresponding to the swinging rod (2); and a tooth-shaped bulge (1) is arranged on the circumference of the vibrating and swinging cam (10), and the tooth-shaped bulge (1) is capable of ejecting the swinging rod (2) to enable the elastic tooth rod (5) to rotate in a bearing seat (9). Compared with the prior art, the separating device in the invention is simple in structure, high in vibrating frequency, adjustable in vibration amplitude, easy for controlling, good in vibrating effect, low in power loss and reliable in work.

Owner:SHIHEZI UNIVERSITY

Water-coal-slurry vibrating screen

InactiveCN102641839ASolve the function of buffering and vibration isolationPlay the role of shock absorberSievingScreeningCoal slurryPhysics

The invention discloses a water-coal-slurry vibrating screen, comprising a block discharging groove, a screen body and vibrating excitation source, wherein the block discharging groove is arranged on one end of the screen body; a vibrating groove body and a stainless steel trapezoid bar sieve net are arranged in the screen body; the vibrating excitation source is two vibrating motors mounted on two sides of the screen body respectively; the two vibrating motors are started simultaneously and has inverse rotating directions; four angle arms of the screen body are provided with a support base; and the bottom part of the support base is provide with a rubber spring. According to the invention, the water-coal-slurry vibrating screen is characterized by stable working, high screening efficiency, adjustable amplitude, low power consumption, small volume, light weight, small noise, long service life, convenient maintenance and convenient preservation.

Owner:江阴市东发机械设备制造有限公司

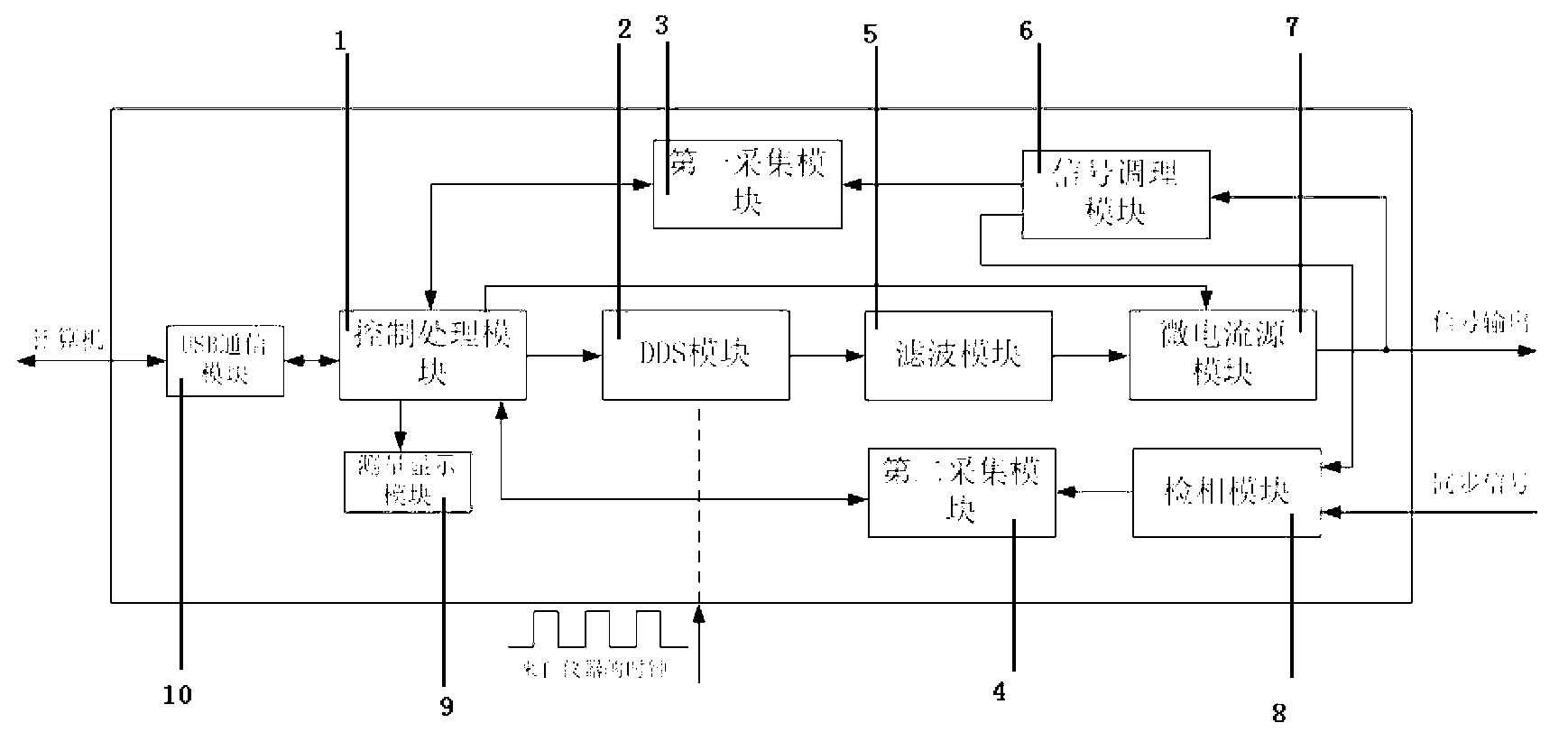

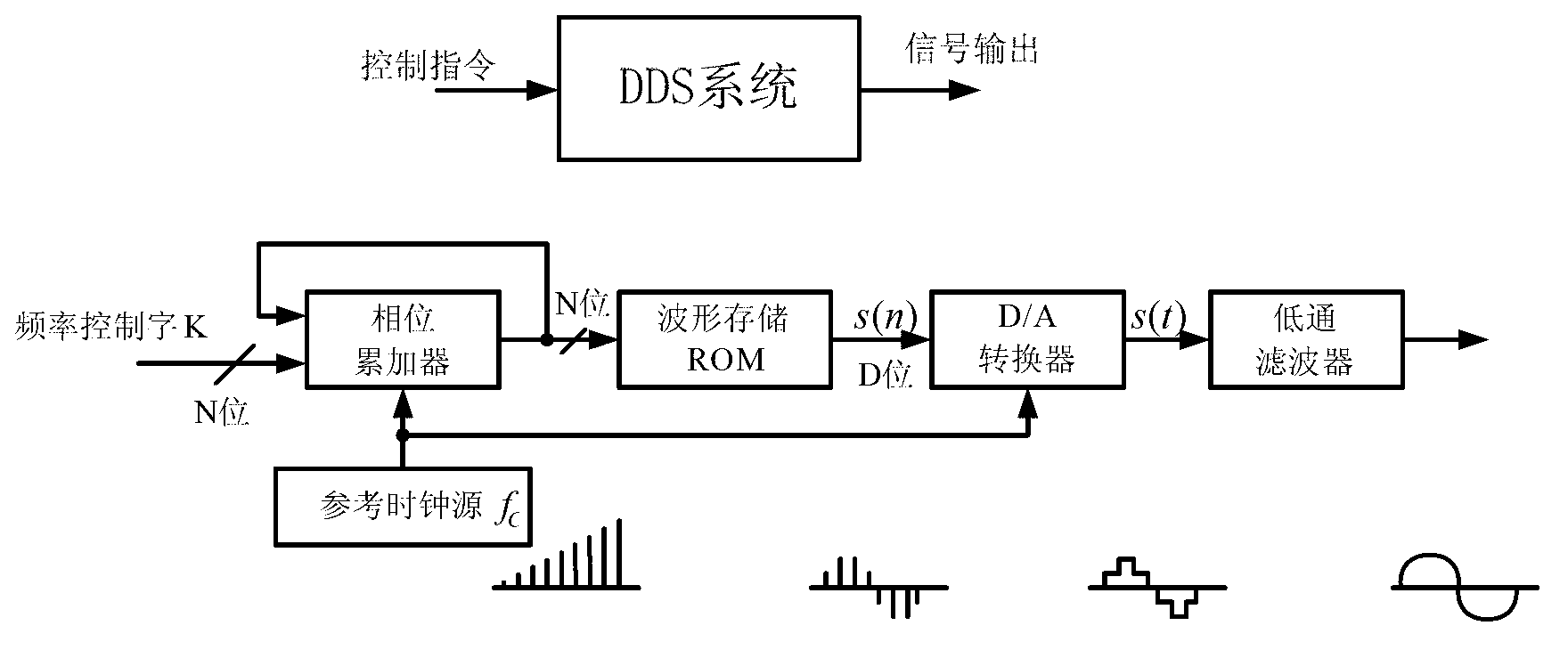

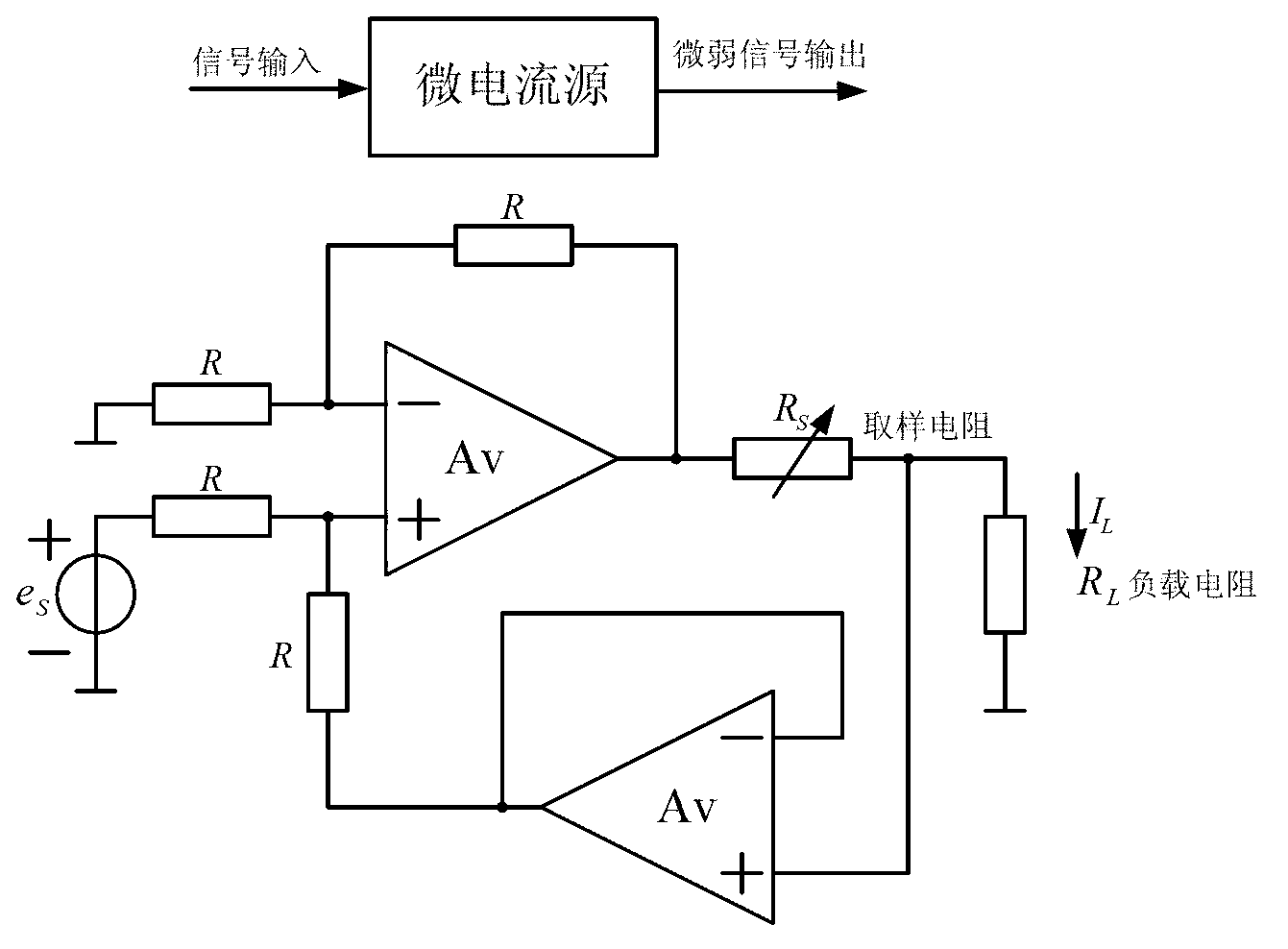

Weak signal generation device

InactiveCN102937019AAdjustable frequencyAmplitude controllableSurveyPulse automatic controlSignal conditioningComputer module

The invention discloses a weak signal generation device. A control processing module is connected with two acquisition modules and connected with a computer, a DDS (direct digital synthesis) module, a measurement display module and a micro-current source module; the DDS module is connected with a filtering module; the filtering module is connected with the micro-current source module; the micro-current source module is connected with a signal conditioning module; the signal conditioning module is connected with a first acquisition module and a phase detection module respectively; and an output end of the phase detection module is connected with a second acquisition module. The weak signal generation device disclosed by the invention can communicate with the computer; a clock signal from a logging instrument is used as the clock signal of the DDS module, and a synchronous signal from the logging instrument is connected into the phase detection module of the device; and through the device, the frequency is adjustable, the amplitude is controllable, the output signal can be automatically synchronized with a logging transmission signal, and signal parameters can be calibrated and displayed.

Owner:XI'AN PETROLEUM UNIVERSITY

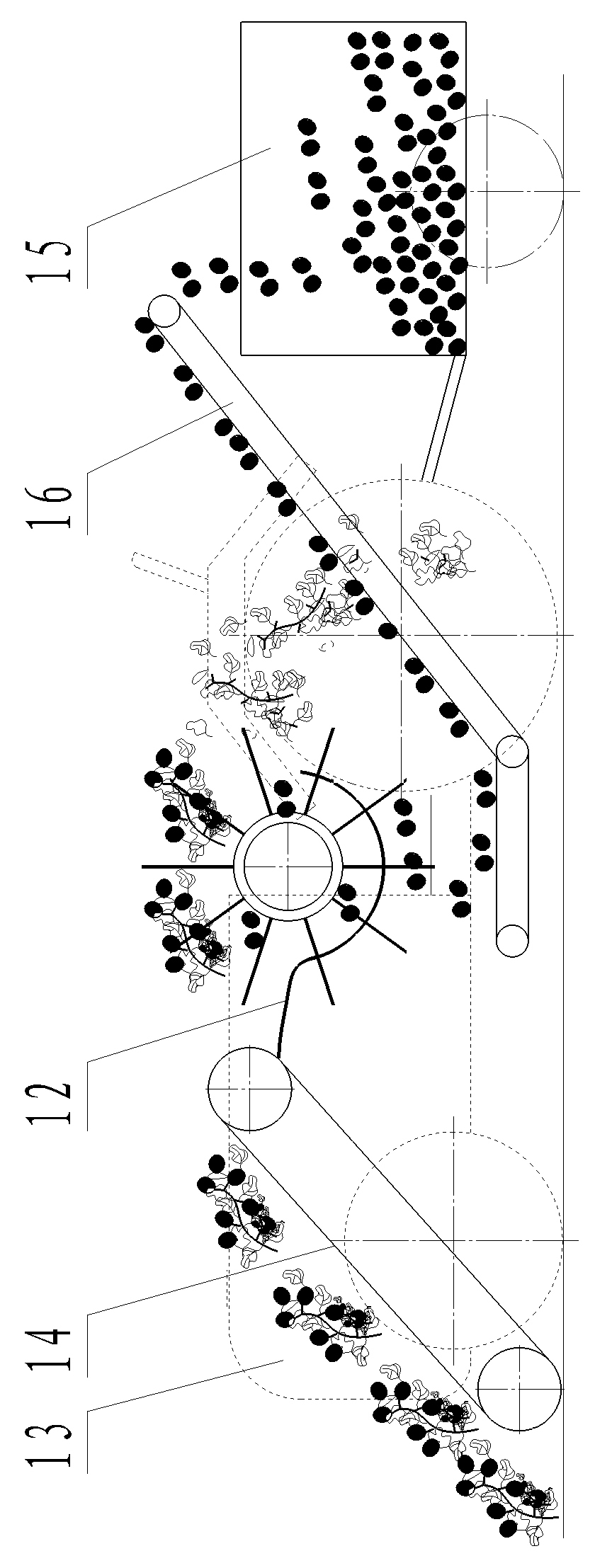

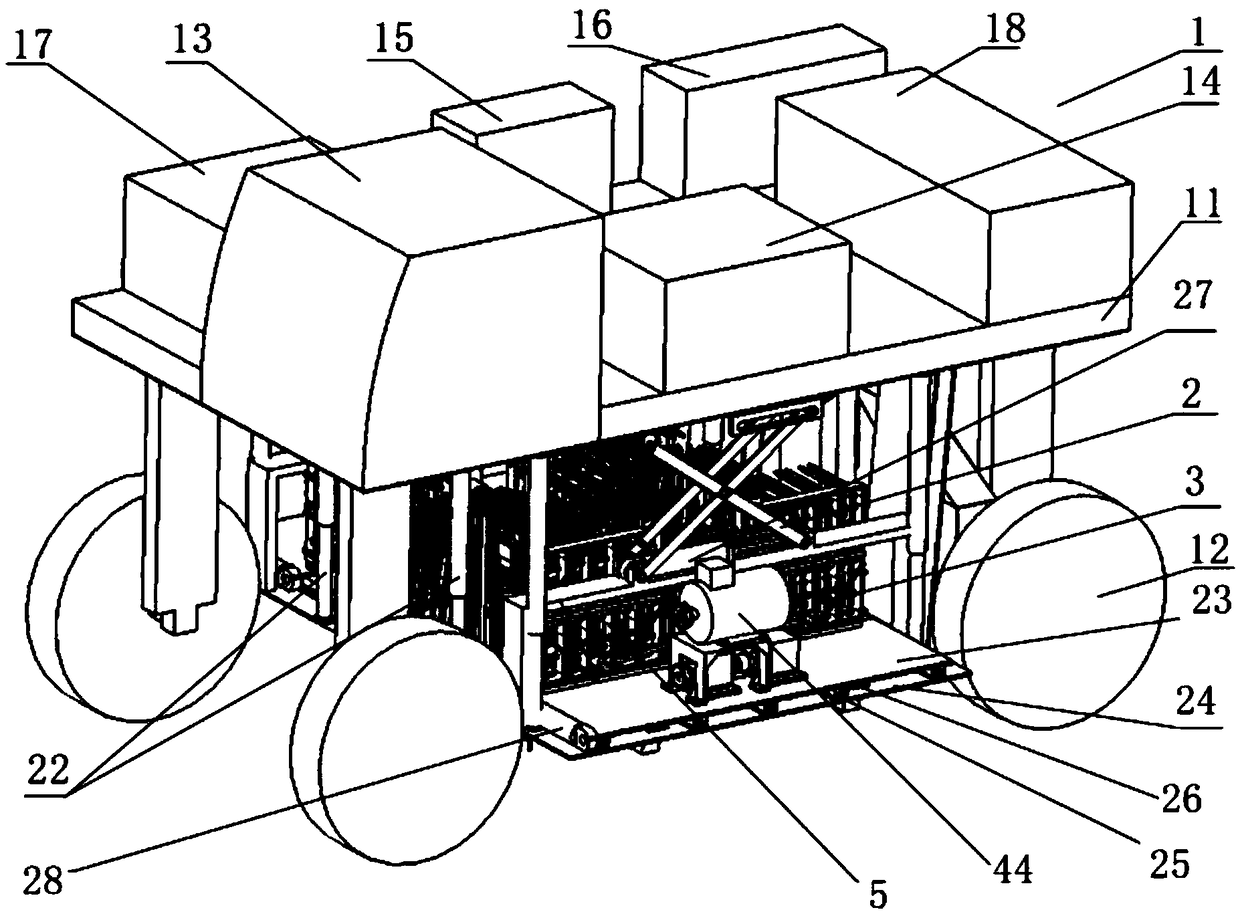

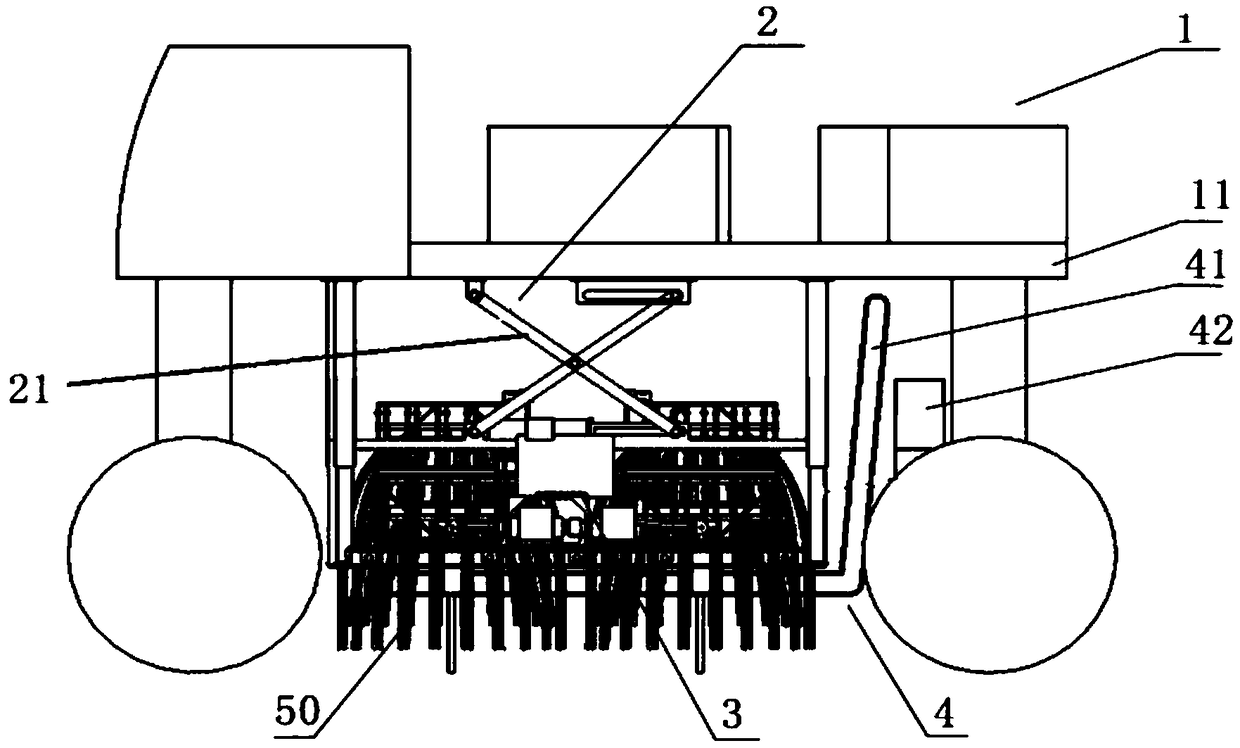

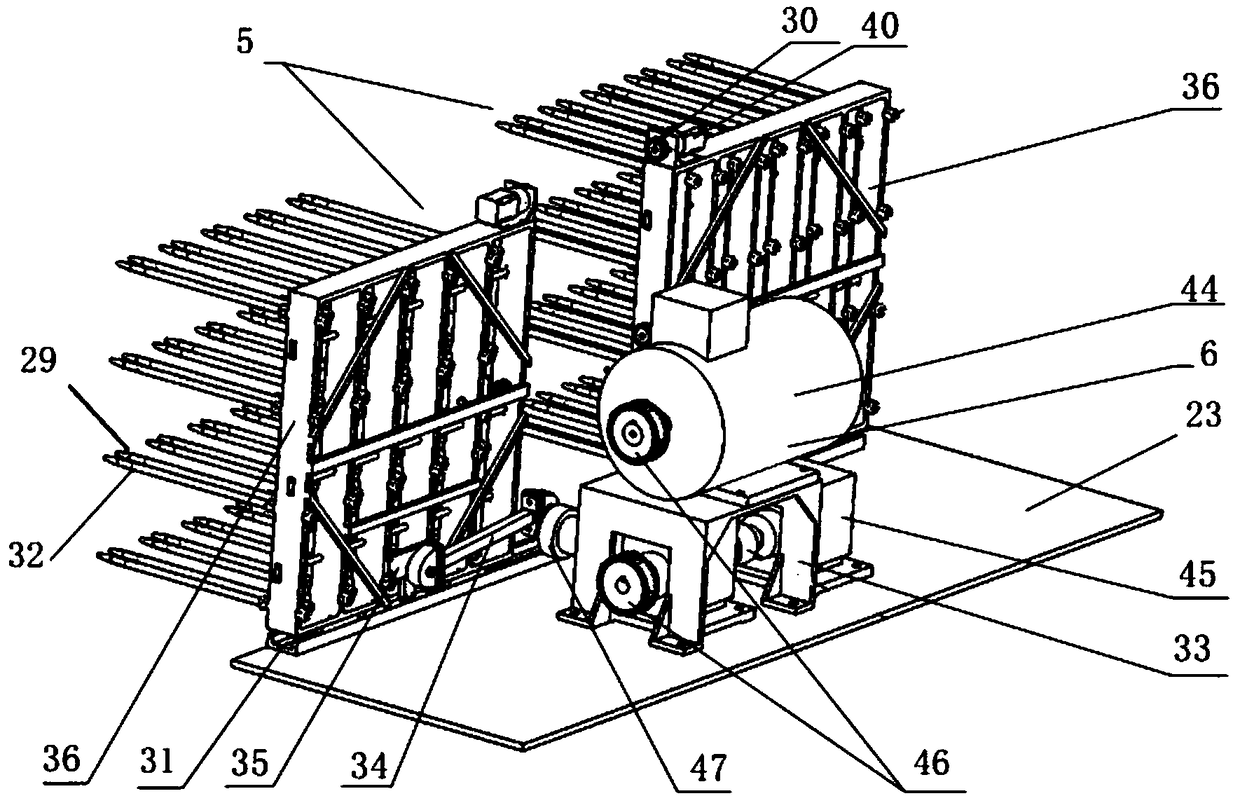

Vibrating lycium chinensis harvesting vehicle

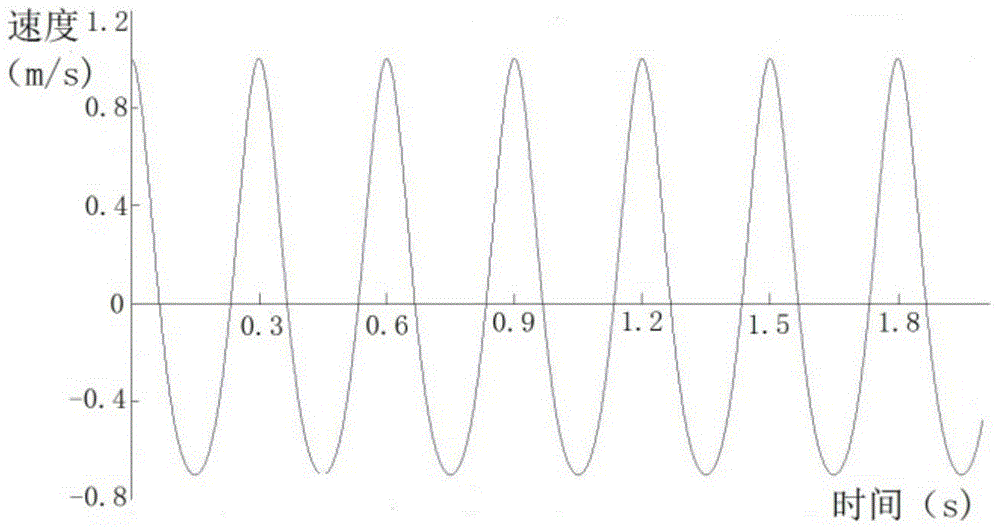

ActiveCN109005918AAdjustable vibration frequencyAmplitude controllablePicking devicesLycium barbarum fruitConveyor belt

The invention relates to a vibrating lycium chinensis harvesting vehicle, and solves the defect that a lycium chinensis harvesting device cannot meet actual use requirements compared with the prior art. A scissor lifting platform comprises a scissor frame, the top of the scissor frame is fixedly mounted on the bottom of a chassis, the bottom of the scissor frame is fixedly provided with a liftingplatform assembly, a vibrating harvesting assembly is mounted on the lifting platform assembly, a lycium chinensis storage assembly comprises a skirt conveyor belt and a collection box mounted on a high ground clearance body, the skirt conveyor belt is mounted on the bottom of the lifting platform assembly by a connecting rod, a blanking end of the skirt conveyor belt is located below the vibrating harvesting assembly, and a feed end of the skirt conveyor belt is located above the collection box. The vehicle can carry out multi-point clamping opposite vibrating harvesting for large-area lyciumchinensis fruits of different varieties and ages, and can operate multiple lycium chinensis trees simultaneously.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

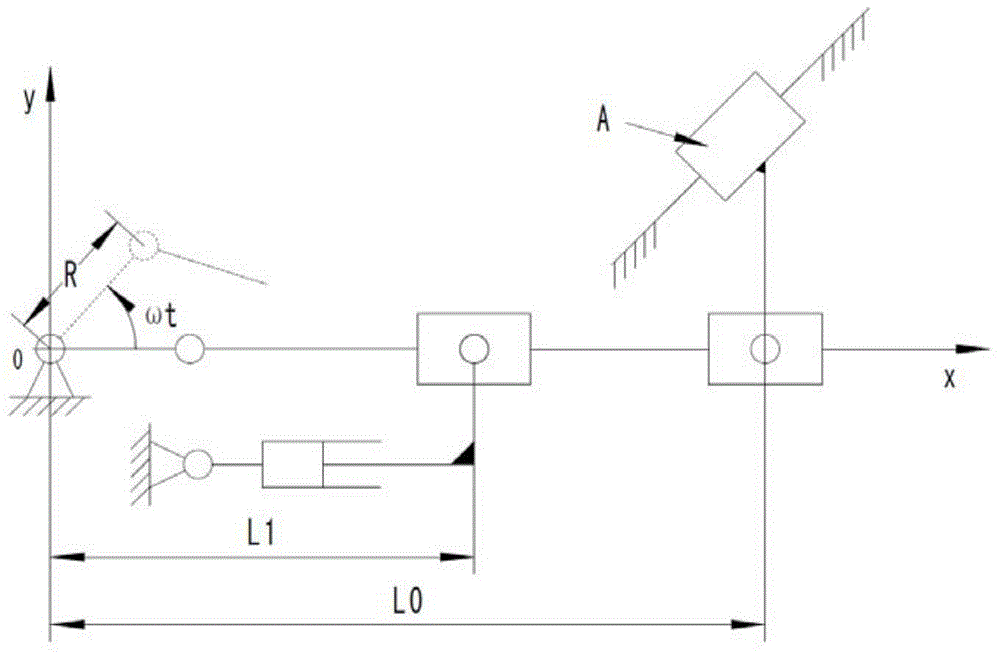

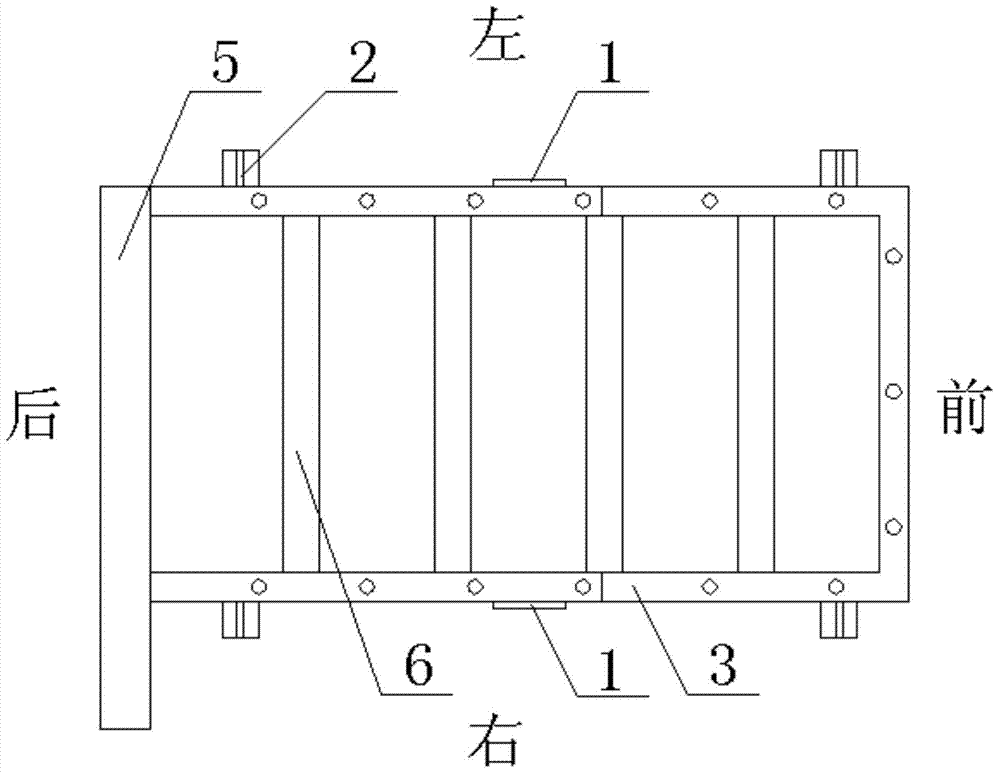

Under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine

ActiveCN104472737ALarge forward rotation energyHigh forward rotation energyPre-extraction tea treatmentVibration amplitudeEngineering

The invention relates to an under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine. The under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine comprises a rack, a lathe bed, an under-actuated multi-rod horizontal vibration system for realizing continuous vibration and shaping of the tea leaves, an amplitude real-time adjusting system, a real-time boiler bath vertical angle adjusting system, a boiler bath vibration direction adjusting structure, a furnace-boiler integrated bath, a dynamic flow weighing system and an intelligent control system, wherein the amplitude real-time adjusting system is used for adapting to the amplitude modulation in a vibration shaping process of different varieties of tea leaves in different picking times; the real-time boiler bath vertical angle adjusting system is used for controlling the vertical angle of the boiler bath during tea leaf vibration shaping; the boiler bath vibration direction adjusting structure is used for changing the motion trail of the tea leaves in the boiler bath and improving the tea leaf shaping quality; the furnace-boiler integrated bath is used for improving the energy utilization rate; the dynamic flow weighing system is used for controlling the flow rate of the tea leaves; and the intelligent control system is used for comprehensively and intelligently adjusting the heating temperature, the vibration frequency and the vibration amplitude of the shaping machine.

Owner:ZHEJIANG UNIV OF TECH

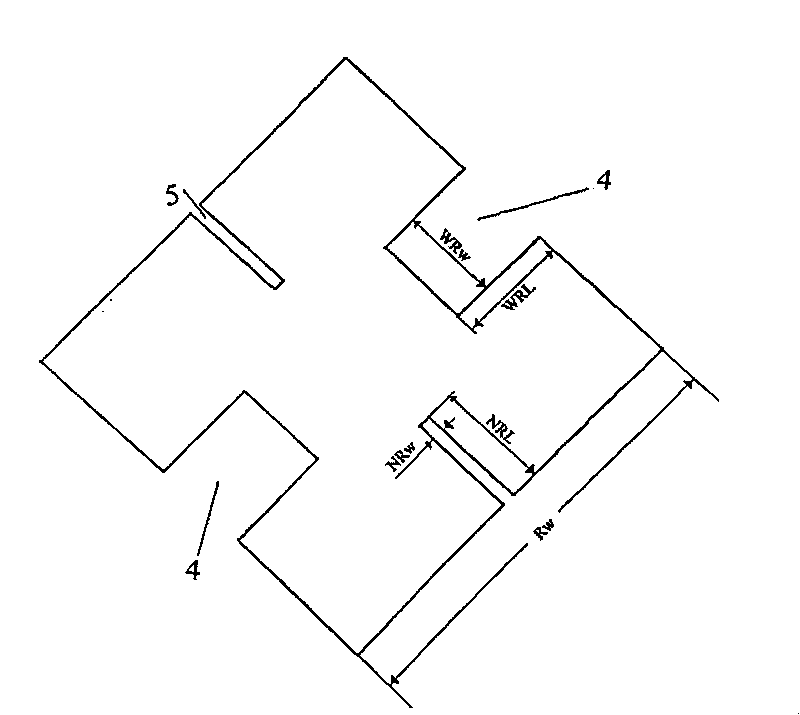

Half-wave dipole array element and micro-strip array antenna formed by same

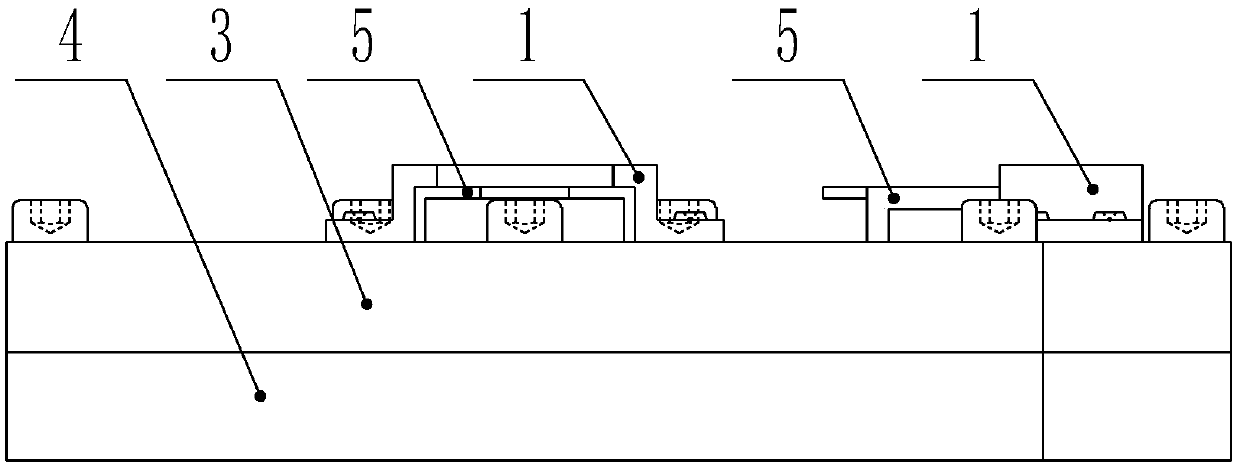

InactiveCN103367875AAmplitude controllableFlexible detectionAntenna arraysRadiating elements structural formsPhysicsMicrostrip array antenna

The invention discloses a half-wave dipole array element and a micro-strip array antenna formed by the half-wave dipole array element. The array element comprises a copper-coated substrate, wherein two half-wave dipoles are arranged on the substrate; impedance matching holes and impedance matching slots are arranged in the front surfaces of the half-wave dipoles; transmission micro-strip lines are arranged on the back surfaces of the half-wave dipoles; and the upper ends of the transmission micro-strip lines are connected with the impedance matching slots after passing through the impedance matching holes, and the lower ends of the transmission micro-strip lines are connected with feed interfaces and matching resistors. According to the scheme, the coalition of sampled signals of the antenna are completed through a processor, the amplitudes and phase positions of micro-strip elements in multiple micro-strip arrays are regulated by utilizing a digital signal processing technology, a needed directional diagram is formed in space, and a mechanical rotating system is no longer needed.

Owner:LUOHE VOCATIONAL TECH COLLEGE

Probe-fixing and example-oscillating non-micro rod scanning force microscope lens

InactiveCN101424611ANeedle shape is goodGood effectSurface/boundary effectInstrumental componentsSmall amplitudeScanning tunneling microscope

The invention relates to a non-microbot scanning force microscope body of a fixed probe and oscillated sample type, in particular to a scanning probe microscope which comprises a probe, a sample, a vibrator and a localizer, wherein the localizer is arranged between the probe and the vibrator, and the probe points to the sample fixed on the vibrator; the localizer comprises an XYZ positioning piezoelectric tube, a probe seat and a vibrator seat, the probe seat and the vibrator seat are respectively arranged at both ends of the XYZ positioning piezoelectric tube, and the probe and the vibrator are respectively fixed on the probe seat and the vibrator seat; the probe is a discrete non-microbot probe, and the vibrator is a piezoelectric vibrator, a crystal vibrator, a quartz crystal vibrator or a quartz micro fork. The invention has the advantages that the discrete non-microbot probe, such as an STM (Scanning Tunneling Microscope) probe, can be used, the cost of the probe is greatly decreased for benefiting the occurrence and the popularization of a microscope with better scanning force, the use of the crystal vibrator with high-quality factors can improve the frequency resolution and the measurement accuracy, and the addition of an auxiliary vibrator between the localizer and the vibrator can also obtain small-amplitude vibration so as to improve the measurement sensitivity of short range force and the atom resolution.

Owner:UNIV OF SCI & TECH OF CHINA

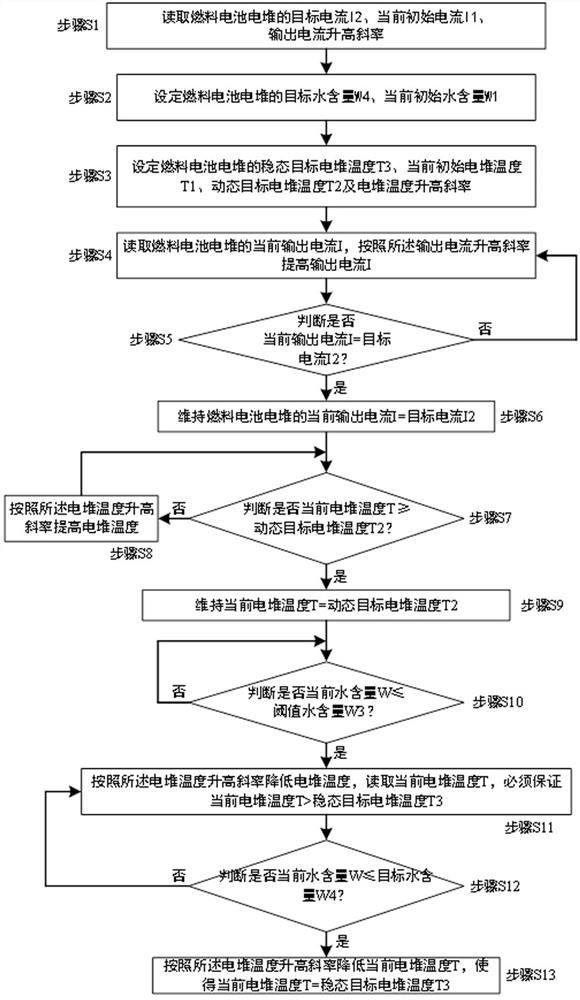

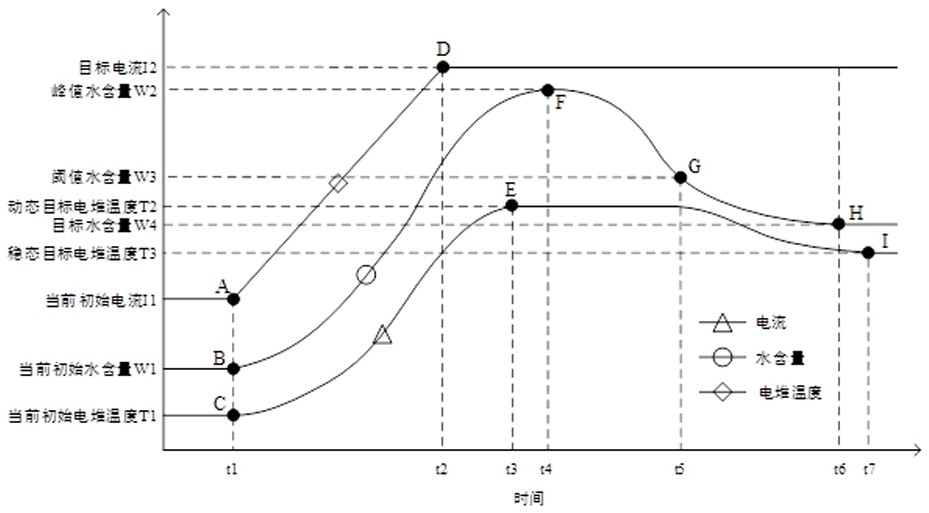

Control method of fuel cell system

ActiveCN113036188AExcessive increase in water content is controllableAmplitude controllableWater management in fuel cellsMotive system fuel cellsAutomotive engineeringBattery system

The invention discloses a control method of a fuel cell system, and belongs to the field of fuel cells. According to the control method of the fuel cell system provided by the invention, the temperature of the fuel cell stack is controlled by controlling the current of the fuel cell stack, and finally the water content is controlled. According to the control method of the fuel cell system, in a period of time after the output current of the fuel cell system is rapidly increased and the output current is stabilized, the excessive increase amplitude of the water content in the fuel cell stack is controllable, and the water content can be rapidly recovered to the balanced water content corresponding to the output current.

Owner:亿华通动力科技有限公司

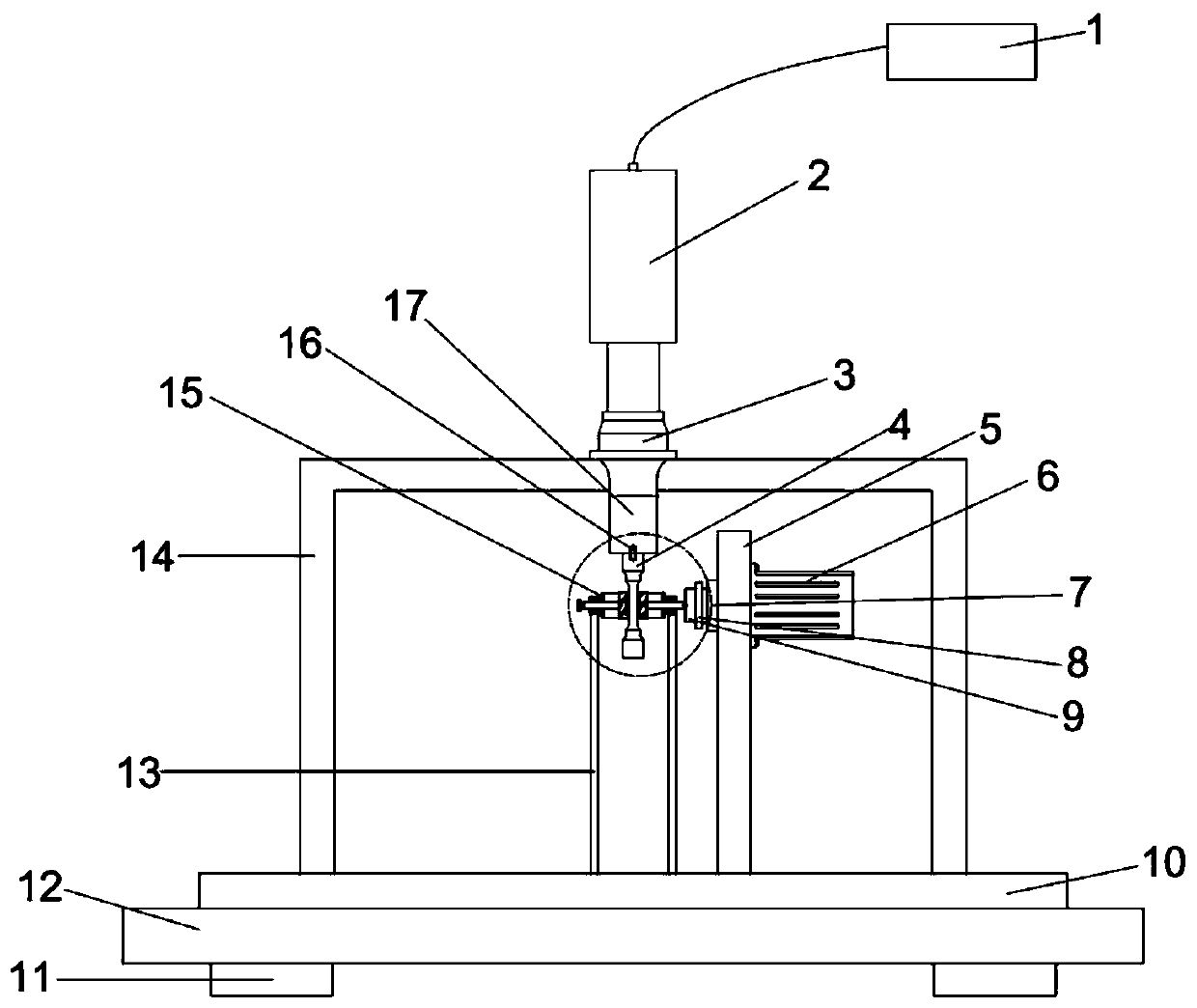

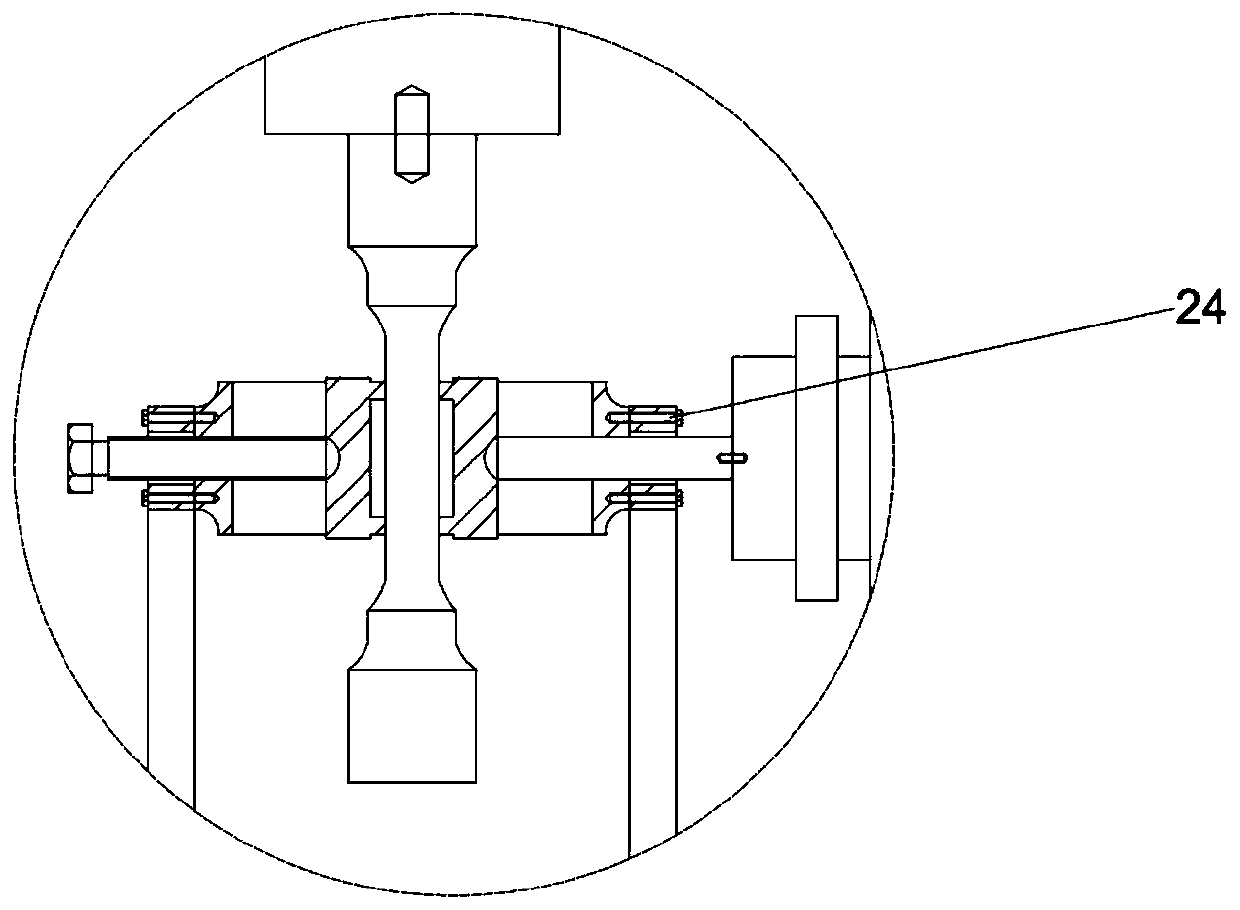

Fretting wear test device based on ultrasonic technology

InactiveCN110702549ASimple structureEasy to operateVibration testingInvestigating abrasion/wear resistanceVibration amplitudeClosed loop feedback

The invention discloses a fretting wear test device based on an ultrasonic technology. The fretting wear test device is composed of an ultrasonic generator, a servo electric cylinder, a force sensor,a loading device, a driving device and a data acquisition device; a loading head is pushed by the servo electric cylinder to make contact with fretting pads to apply positive pressure to a test part;and the force sensor acquires a positive signal, sets a computer data processing device to form closed loop feedback control with the acquired positive pressure signal to keep a load applied by the loading device constant. The fretting wear test device is simple in structure and convenient to operate, the various parts are fixed and supported by a bottom plate and a fixing platform, the stabilityis good, and the advantages of being high in reliability and precision are achieved; and a transducer is adopted to convert ultrasonic signals into reciprocating linear mechanical motion of a vibrating head, vibration displacement is amplified by an amplifier to serve as an excitation source for forming fretting wear between a friction pair, the vibration frequency is high, the amplitude is adjustable, the test time can be shortened, and the test cost can be reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

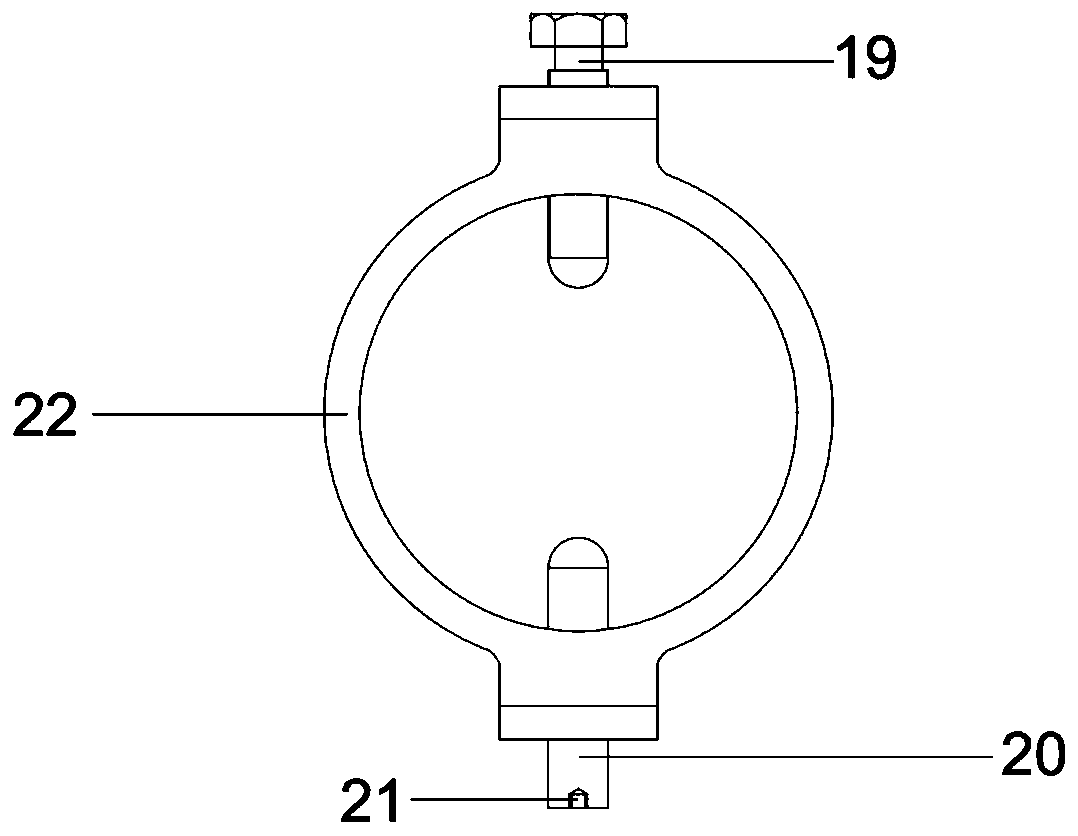

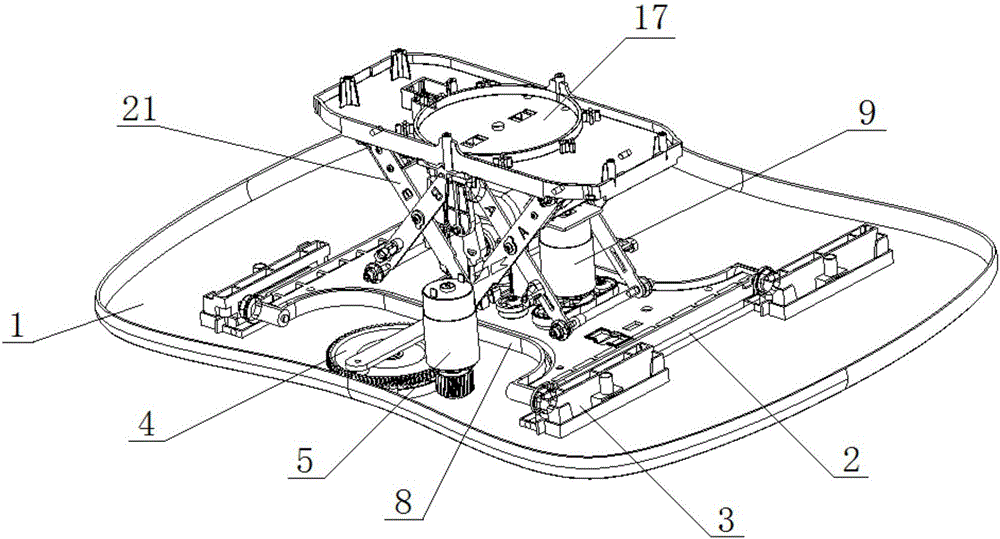

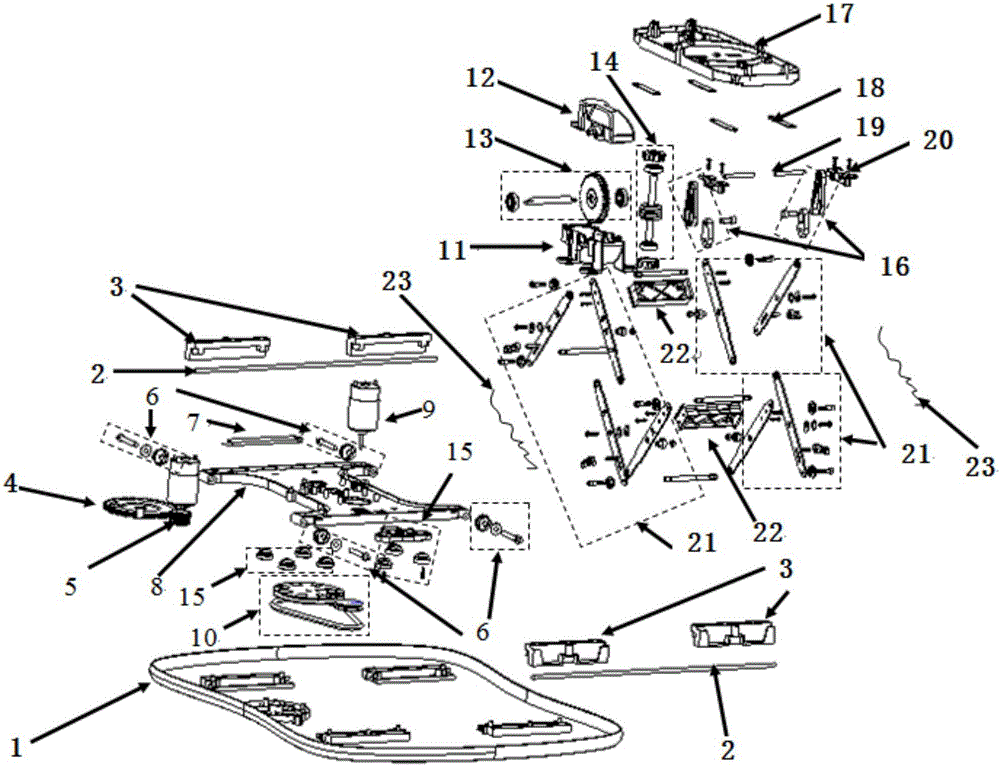

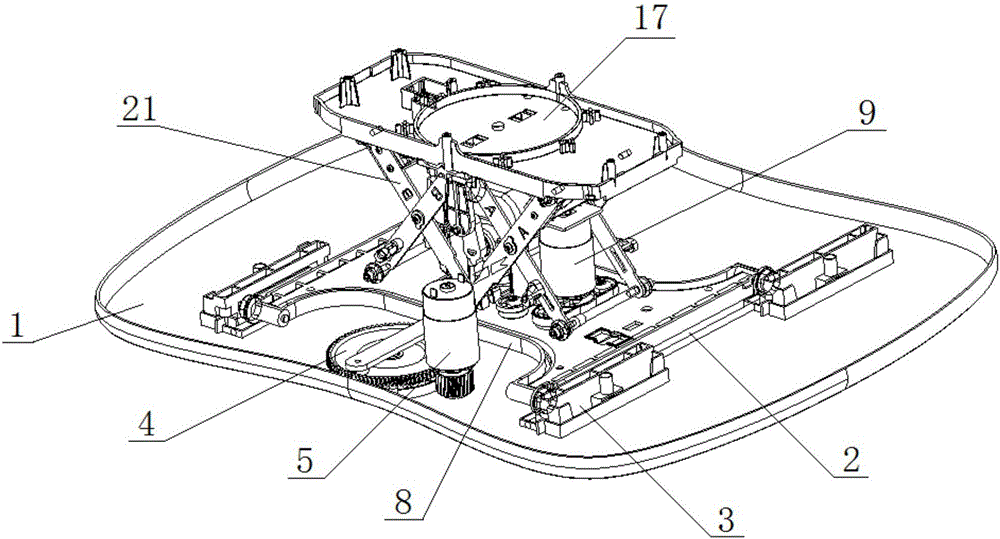

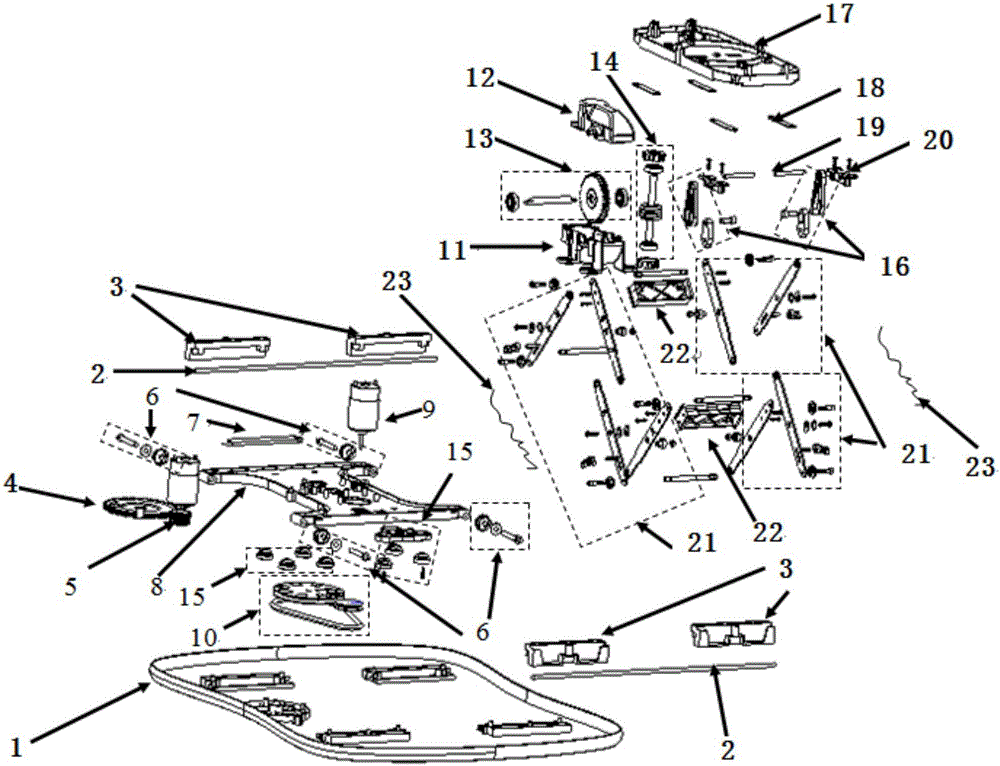

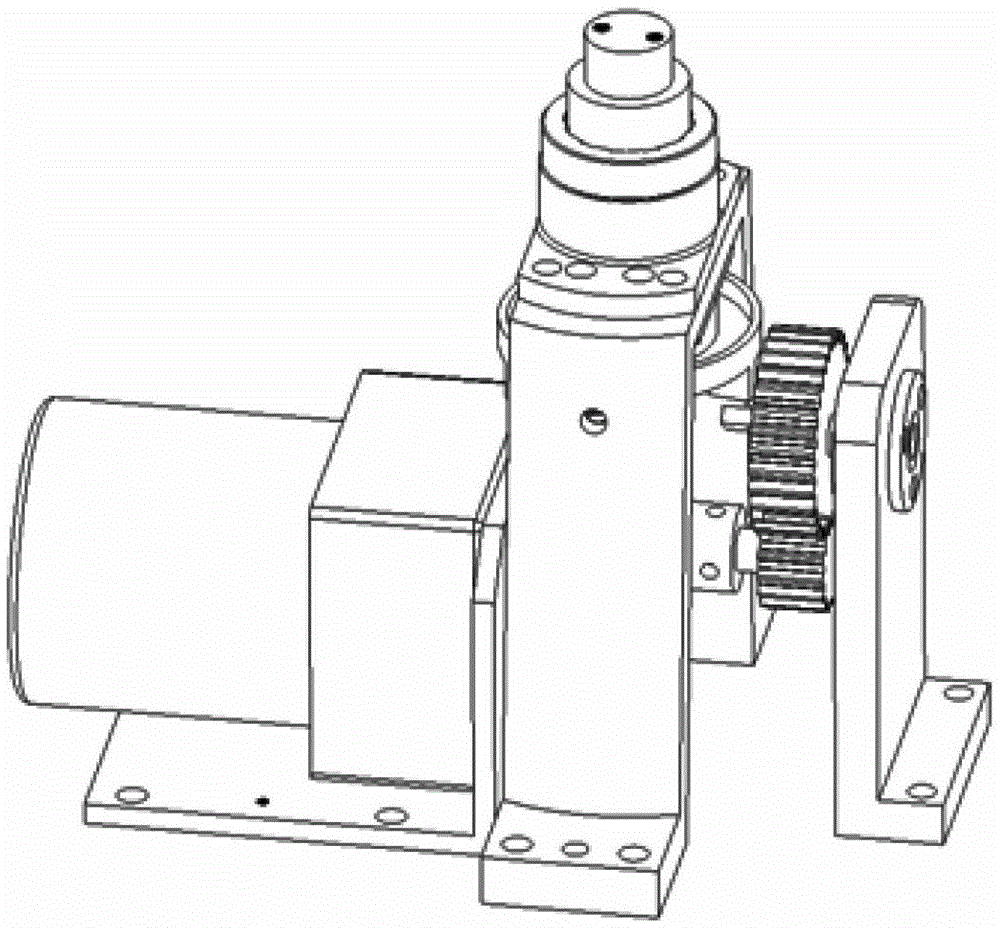

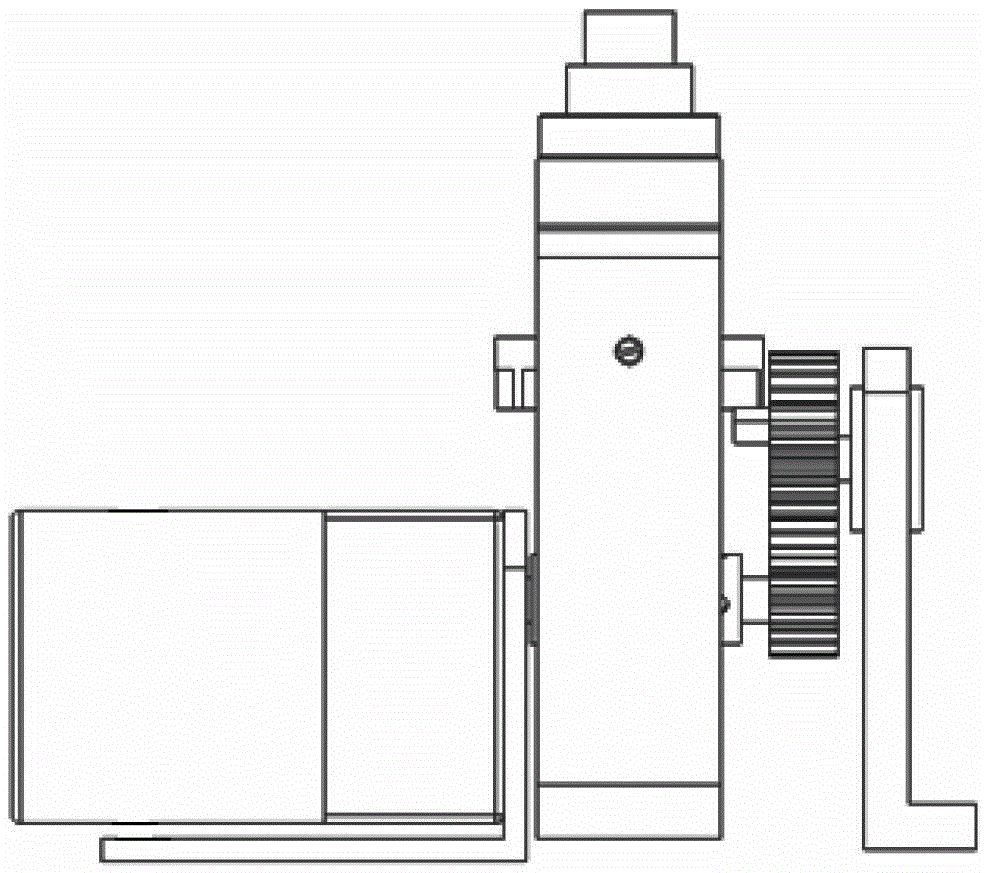

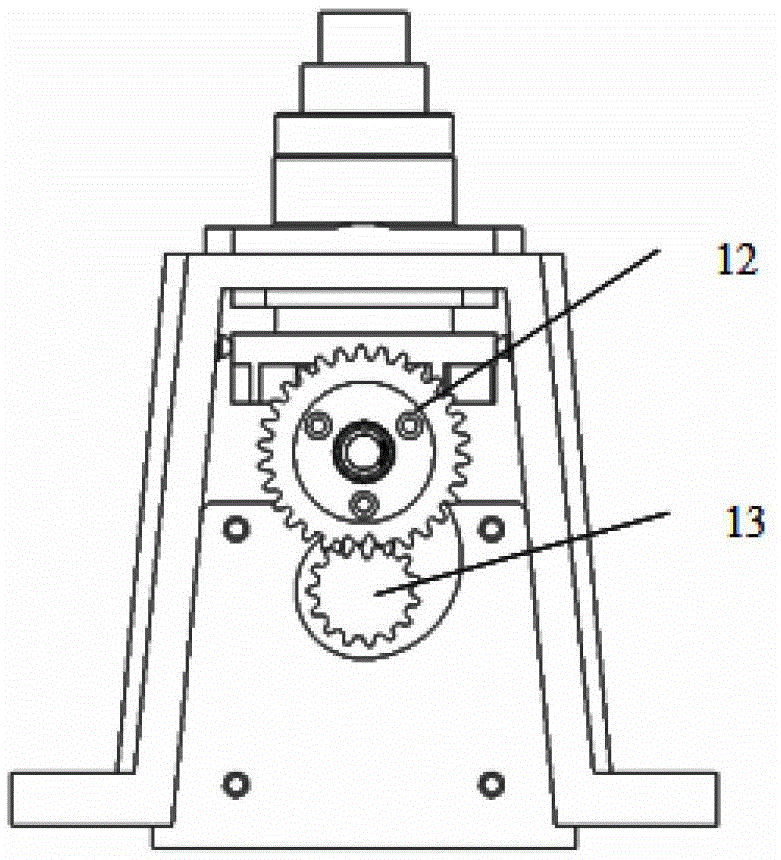

Electric cradle motion mechanism

Owner:WUHU GUANGYING IND CO LTD

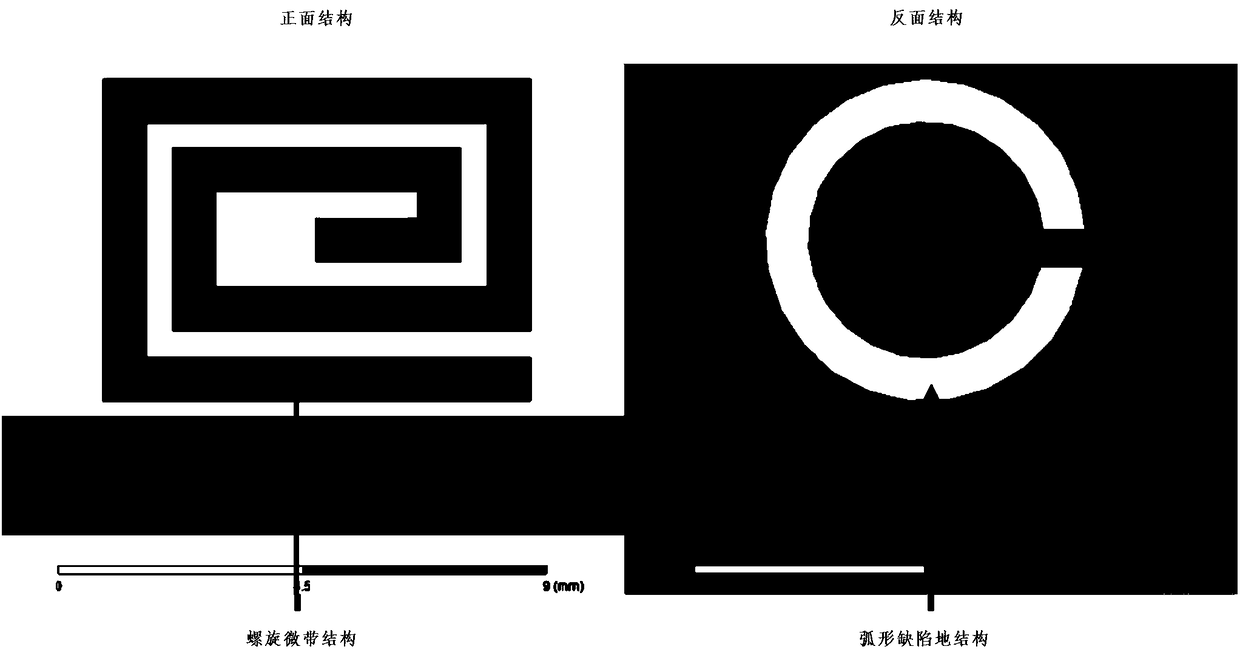

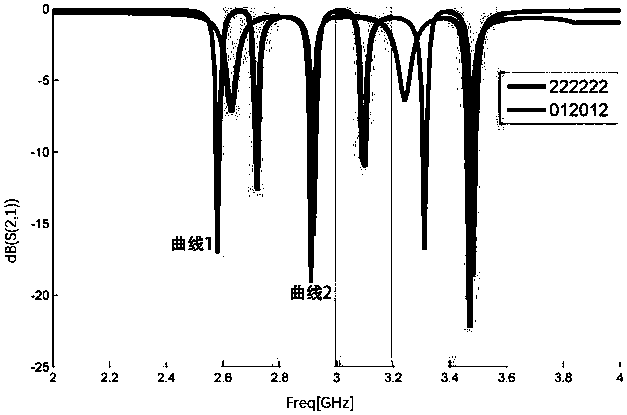

Information capacity expansion method for chipless RFID electronic tag

PendingCN108133253AIncrease information capacityIncrease capacityRecord carriers used with machinesChipless RFIDFrequency characteristic

The invention discloses an information capacity expansion method for a chipless RFID electronic tag and relates to an optimization technology for chipless RFID tags. According to the method, information capacity of the chipless RFID electronic tag is expanded, an arc-shaped defected ground structure is innovatively added against the defect that a chipless RFID tag of an original structure has small capacity, the tag realizes hybrid coding by use of frequency characteristics and amplitude characteristics of signals, and therefore the information capacity of the tag is increased.

Owner:TONGJI UNIV

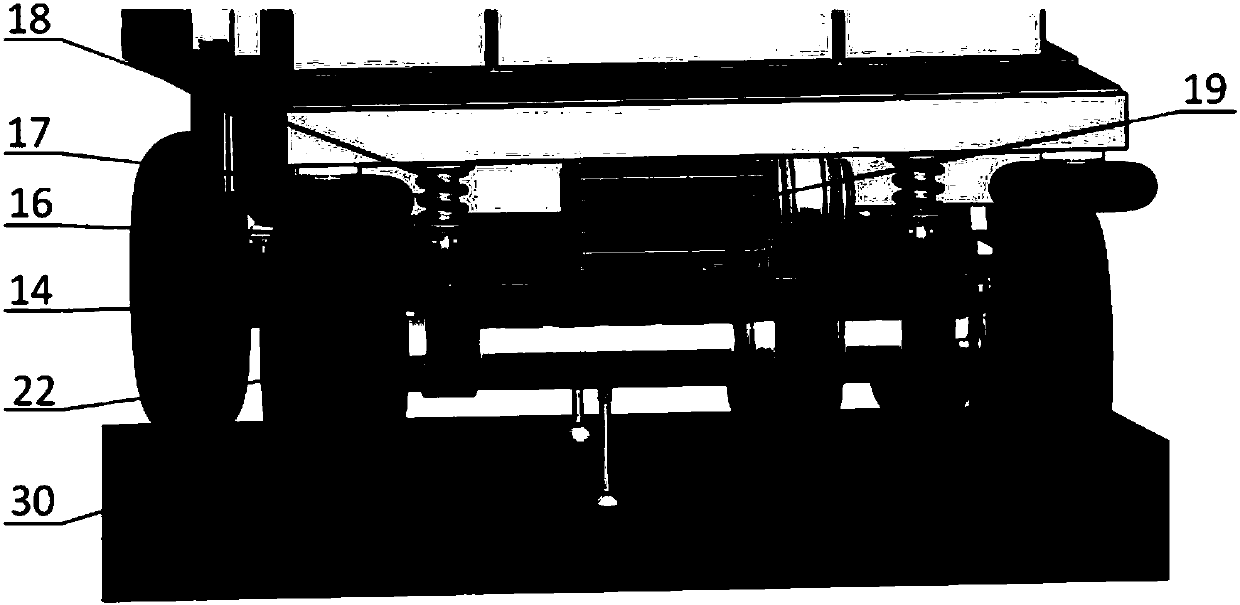

Shock-absorption electric vehicle for transferring liquid-state explosives between workshops

ActiveCN107696856AFirmly connectedGuaranteed temperatureItem transportation vehiclesResilient suspensionsLiquid stateControl system

The invention discloses a shock-absorption electric vehicle for transferring liquid-state explosives between workshops. The shock-absorption electric vehicle comprises the parts of a vehicle body 1, avehicle axle 2, a shock-absorption system 3, a driving system 4, a control system 5, a power supply system 6, a braking system 7, a wheel set 8, a thermal container 9 and the like. The shock-absorption system 3 adopts a shock-absorption spring 17 and a guiding column 18, the resonant frequency of the vehicle is calculated through the deadweight capacity and the sensitivity of the explosives, andfurther a model needed by the spring is determined; and multiple protection measures are taken, and an explosion-proof electric machine, reliable grounding, the thermal container, an anti-collision wheel, electroconductive rubber and the like are included, explosive-proof treatment is conducted on an electric control part, and therefore the electric control part can be suitable for transferring the liquid explosives. According to the shock-absorption electric vehicle for transferring the liquid-state explosives between the workshops, the structure is simple, maintenance is simple and convenient, vibration is controllable, and the shock-absorption electric vehicle can adapt to different deadweight capacities and different sensitivity requirements of the liquid explosives by adjusting the model of the spring.

Owner:XIAN MODERN CHEM RES INST

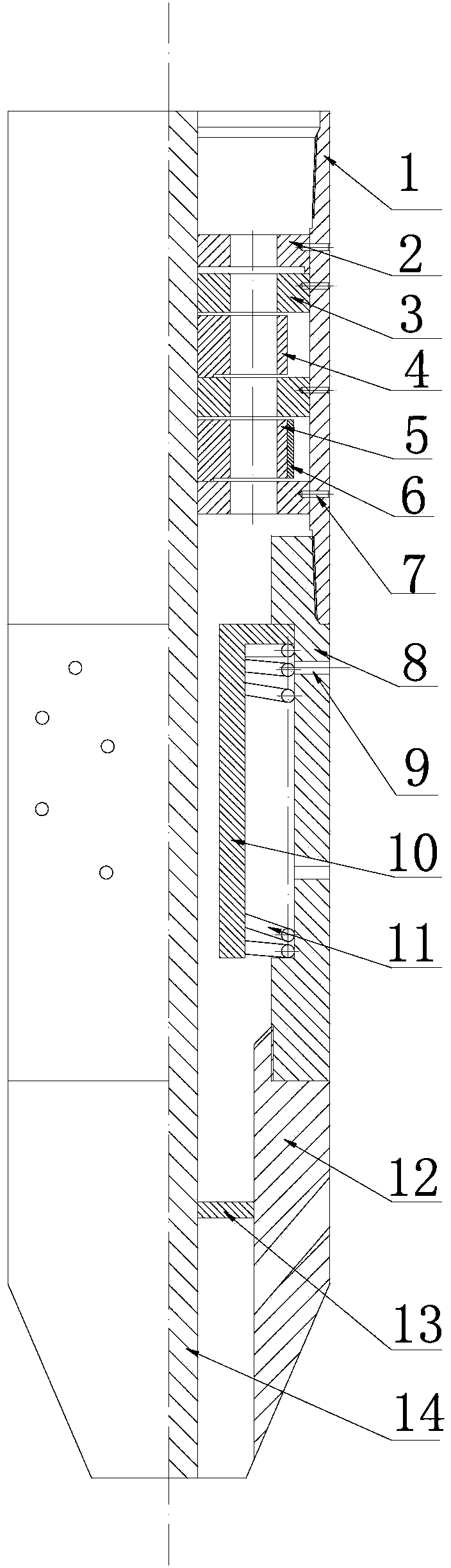

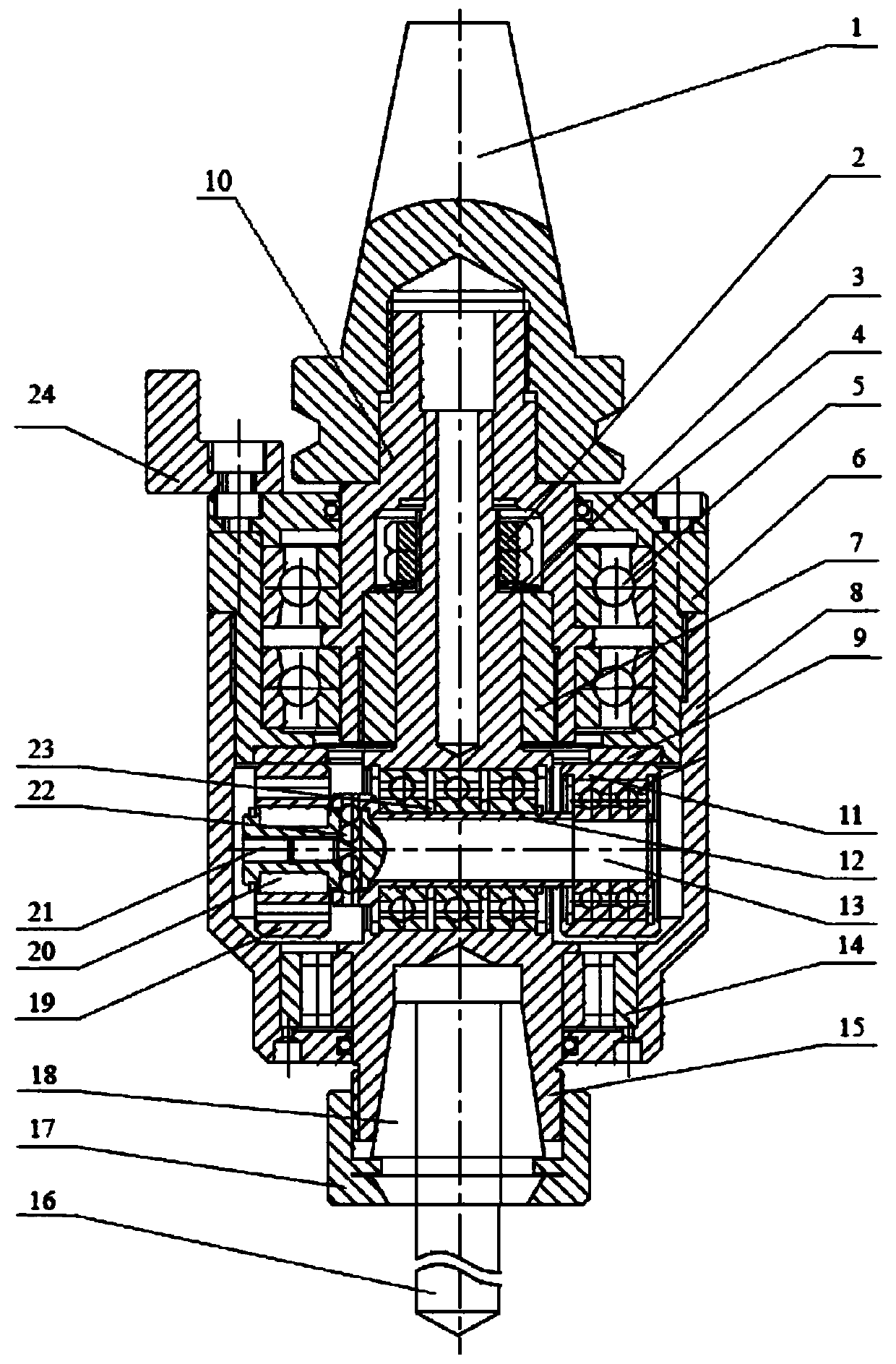

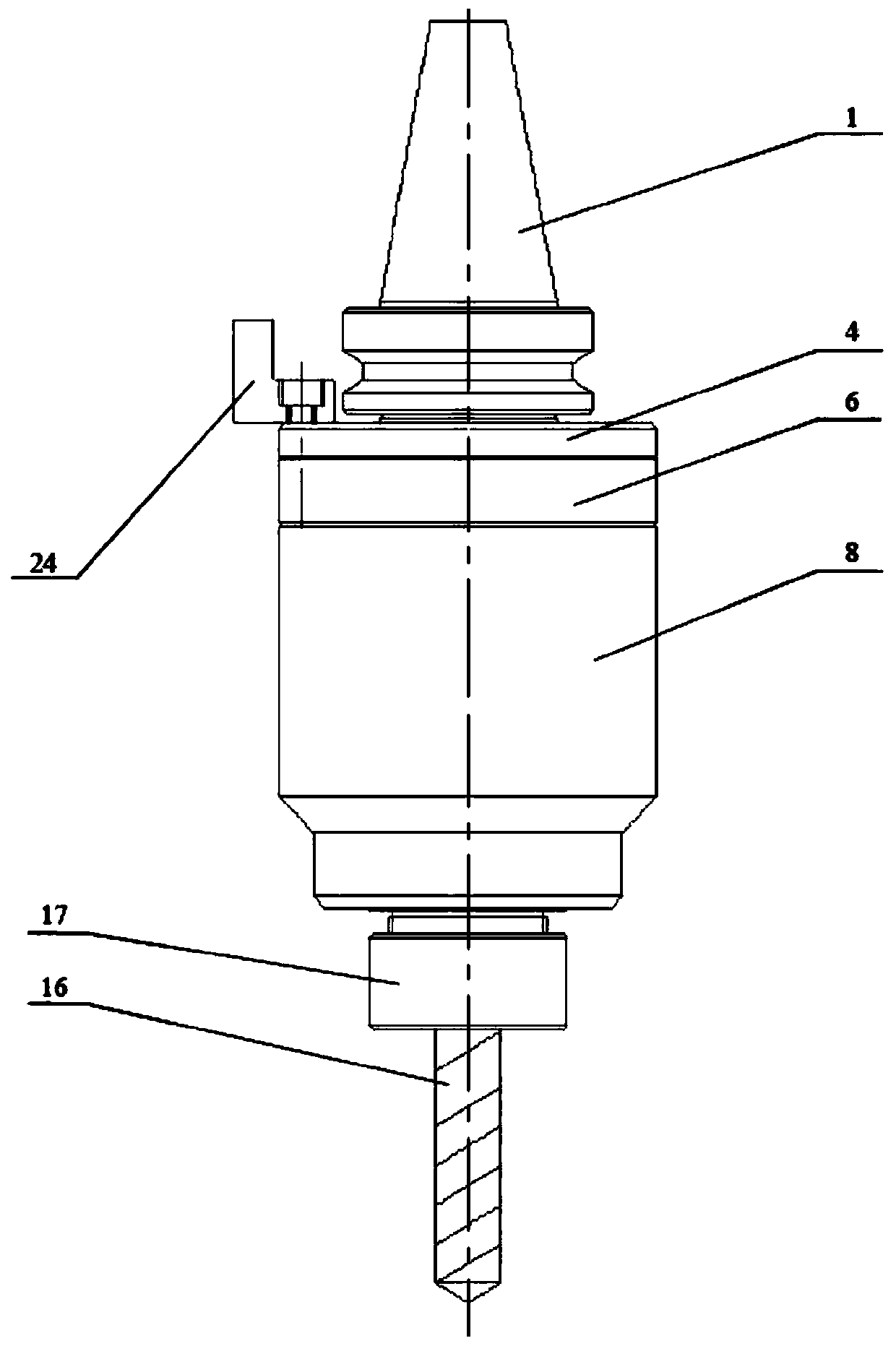

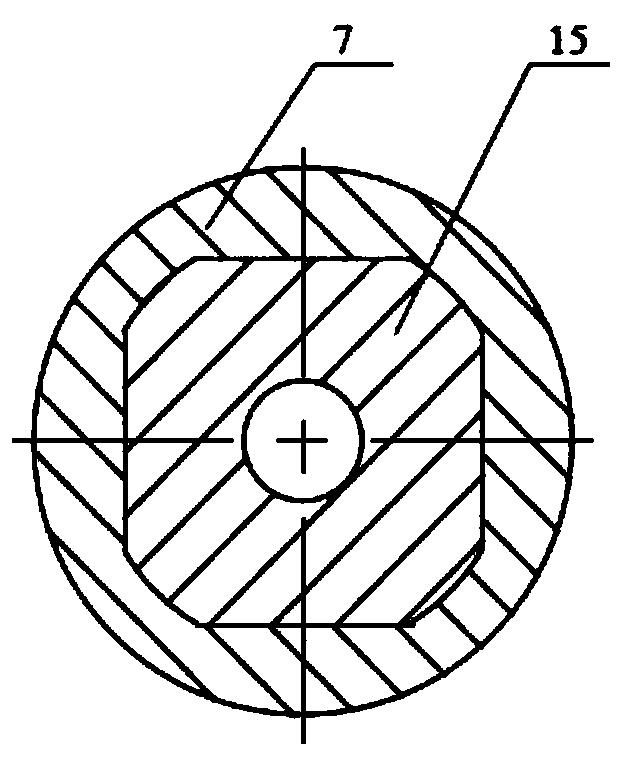

Low-frequency axial vibration drilling knife handle

InactiveCN110480068ASimple driveCompact structureTurning machine accessoriesMechanical vibrations separationBall bearingWear resistant

The invention discloses a low-frequency axial vibration drilling knife handle. The low-frequency axial vibration drilling knife handle comprises a taper handle, one end of a straight handle is installed inside the taper handle far away from a taper tip, the outer side, close to the end part of the taper handle, of the straight handle is provided with at least two angular contact ball bearings, theangular contact ball bearings are located on the two sides of a boss of the straight handle, a vibrating main shaft is installed in the straight handle, a wear-resistant transmission sleeve is arranged on the outer side of a special-shaped shaft of the vibrating main shaft in a sleeve mode, the wear-resistant transmission sleeve is connected with the inner side of the straight handle, a radial cylindrical hole is arranged in a vibration main shaft body close to the bottom of the special-shaped shaft, an eccentric shaft assembly is installed in the cylindrical hole, a taper hole is formed towards the vibration main shaft body along the other end of the vibration main shaft, an elastic chuck is arranged in the taper hole, a drill bit is clamped in the elastic chuck, a cylindrical roller bearing is installed on the outer side of the other end of the vibration main shaft, a locking nut is installed on the outer side of the end part of the vibration main shaft, and the end part of the elastic chuck is clamped in the locking nut. According to the low-frequency axial vibration drilling knife handle, the rotary motion of the machine tool main shaft is converted into rotary motion and low-frequency axial vibration of the vibration main shaft, and the universality is wide.

Owner:XIAN UNIV OF TECH

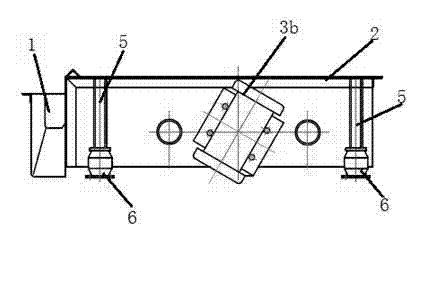

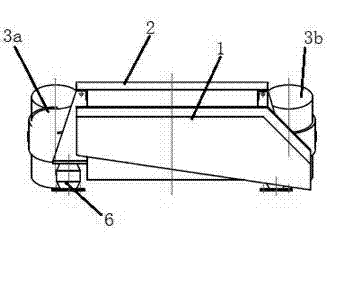

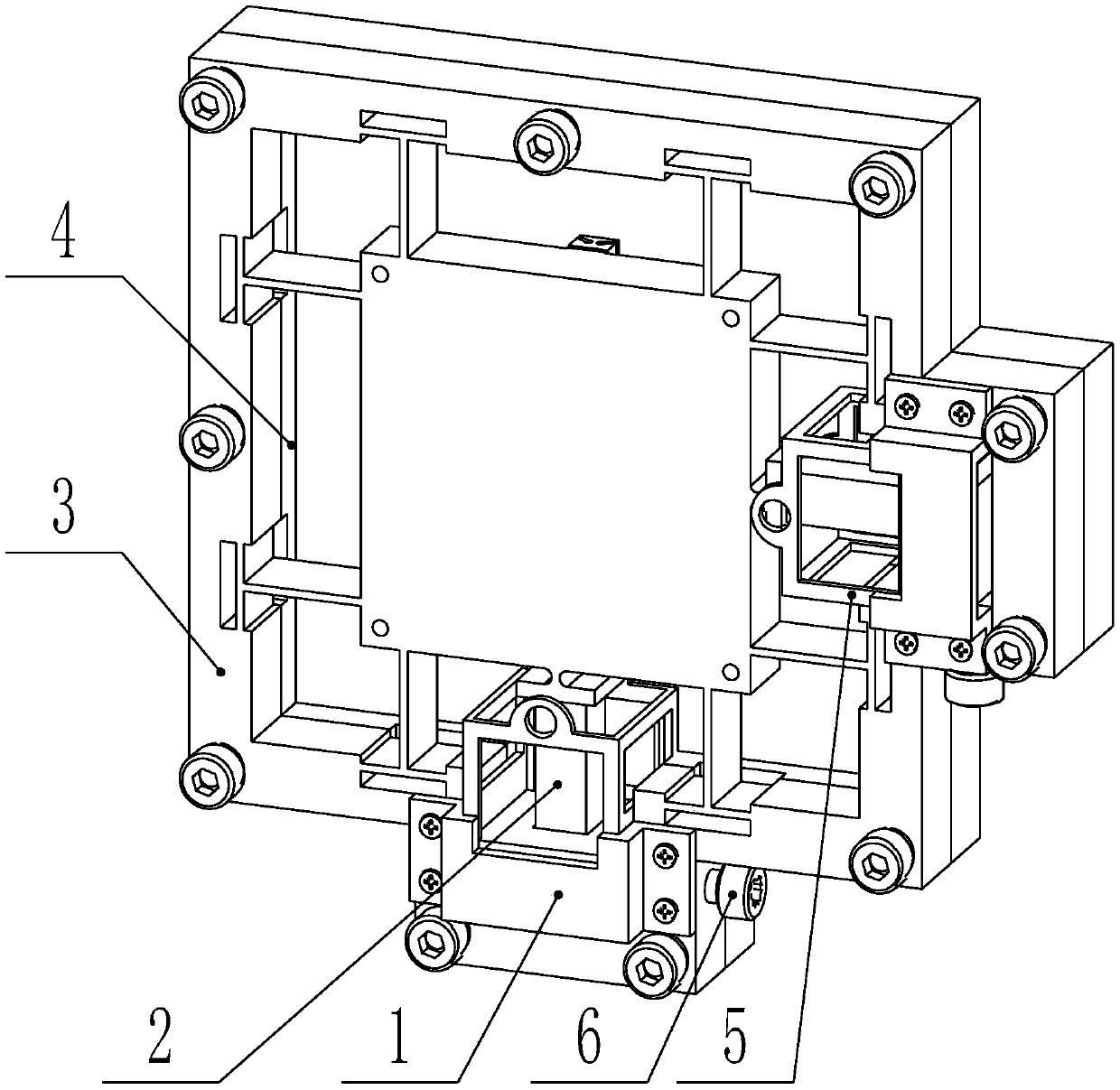

Two-dimensional compliant vibration platform with wedge pre-tightening

PendingCN109530198AIncreased operating frequency rangeAmplitude controllableMechanical vibrations separationEngineeringWedge prism

The invention discloses a two-dimensional compliant vibration platform with wedge pre-tightening. The platform includes driving sources, a compliant vibration platform, a base and wedge pre-tighteningdevices. The compliant vibration platform includes arc type flexible hinges, outer straight beam type flexible hinges, a work table, inner straight beam type flexible hinges and a compliant vibrationplatform outer frame. When the driving sources in two directions move at the same time, the work table generates mechanical vibration in two directions so as to realize two-dimensional vibration assisted processing. The driving sources provide micron-level vibration for the work table through the arc type flexible hinges. The outer straight beam type flexible hinges and the inner straight beam type flexible hinges are arranged symmetrically about the work table so as to realize the decoupling motion of the work table and provide guarantee for the high precision motion of the vibration platform. The vibration platform uses the wedge pre-tightening devices, and so the adjustment is more intuitive and the pre-tightening force is even. The driving sources of different types and sizes are pre-tightened by adjusting the position of pre-tightening screws, and so the adaptability is strong.

Owner:HEBEI UNIV OF TECH

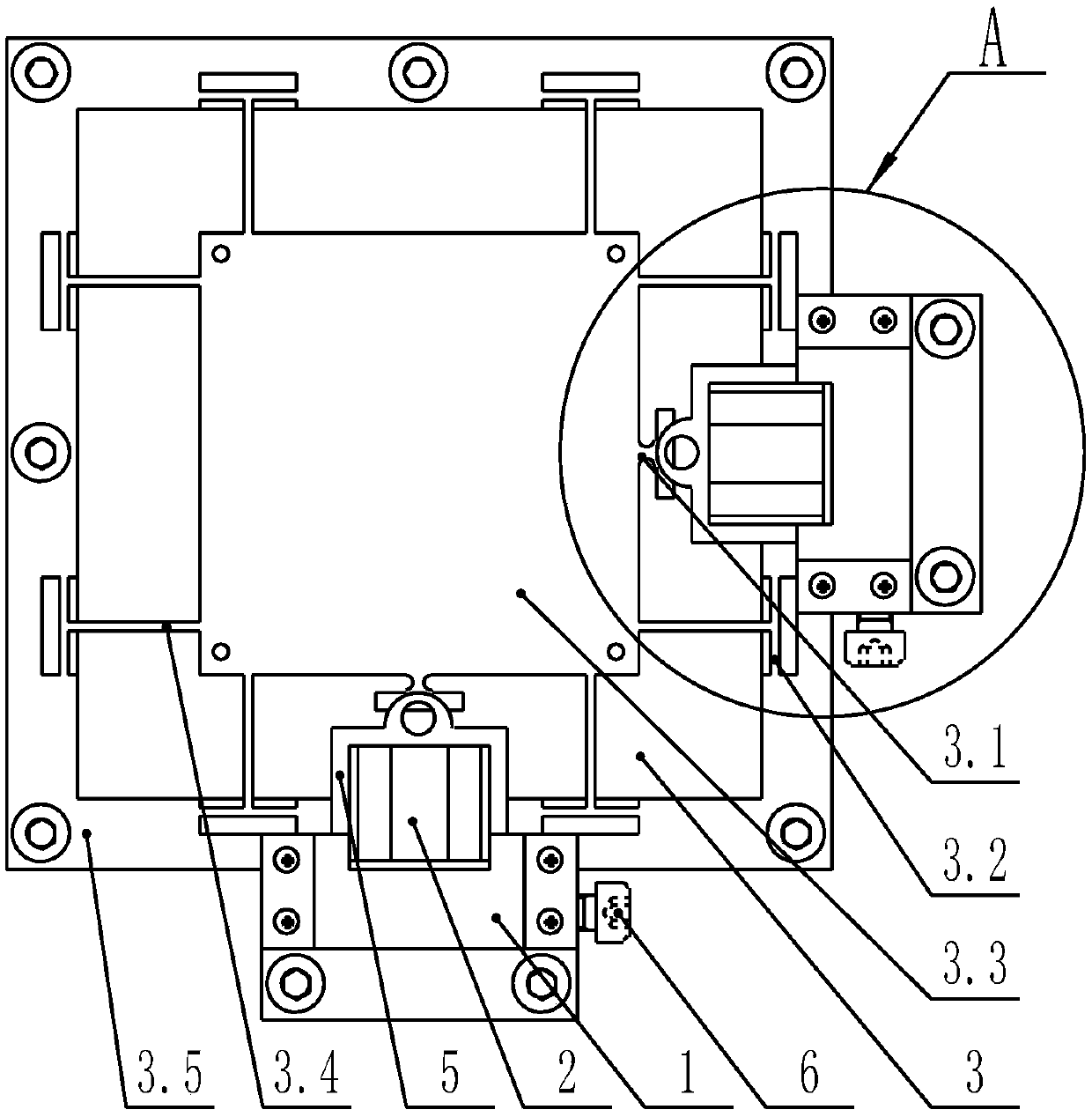

Vibration mechanism and high-precision locating charging vibration device

The invention discloses a vibration mechanism and a high-precision locating charging vibration device. The problem that different materials cannot achieve the optimal vibration effect due to a fixed amplitude of an existing vibration platform is solved. The vibration mechanism comprises a guide shaft connected with a vibration platform, a controlled part detachably and fixedly connected with the guide shaft, and a cam arranged on one side of the controlled part and further provided with a power source. In the working state, when the cam is driven by the power source to be in the controlled state, the cam can be in contact with the controlled part so that the controlled part is moved in the axial direction of the guide shaft. The vibration mechanism has the advantages of being adjustable in amplitude, convenient in adjustment, simple in structure, small in influence on overall vibration and the like.

Owner:中国兵器装备集团自动化研究所有限公司

Buffering self-flow vibrating screen

InactiveCN103537428AAmplitude controllableAvoid direct impactSievingScreeningFilter effectComputer science

Owner:QINGDAO KAIYUAN GRP

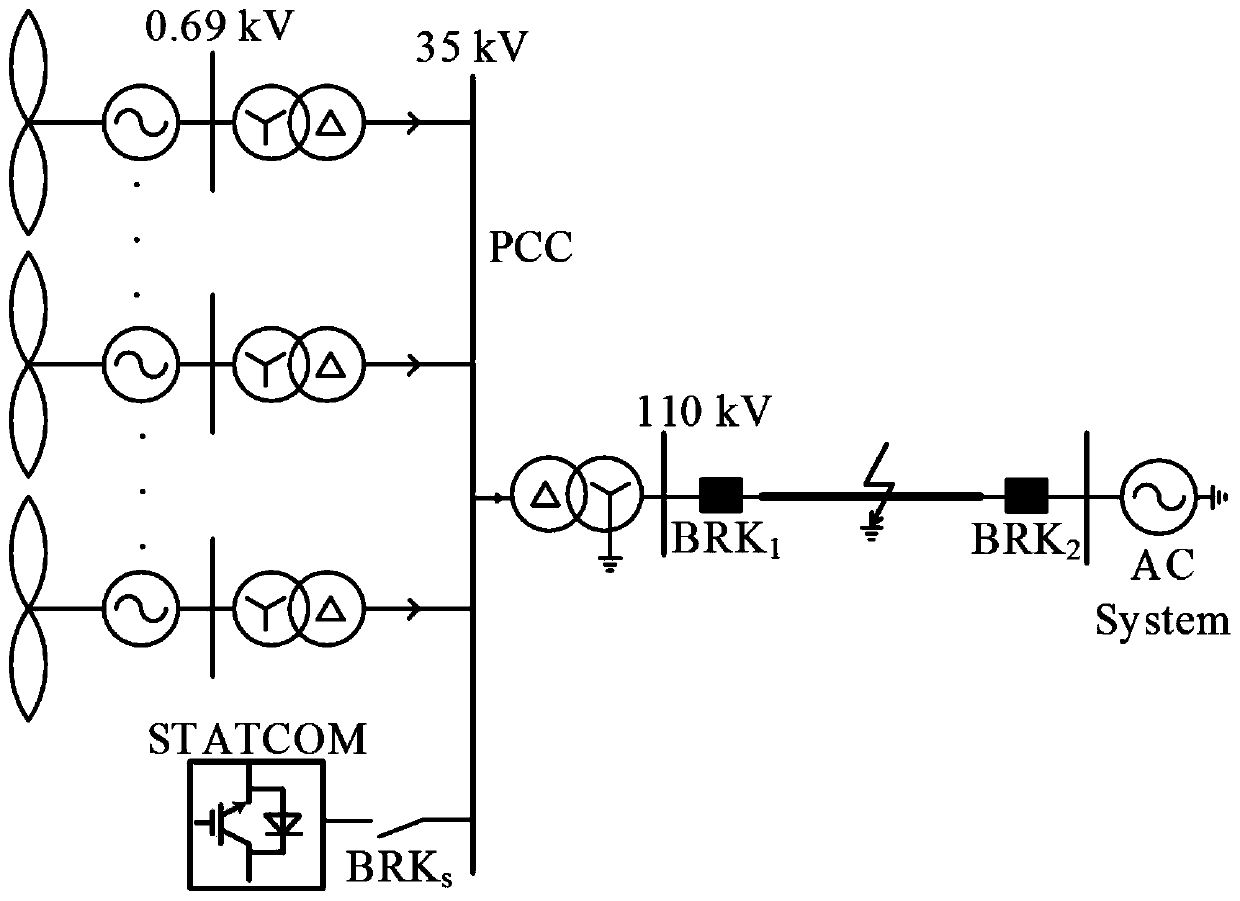

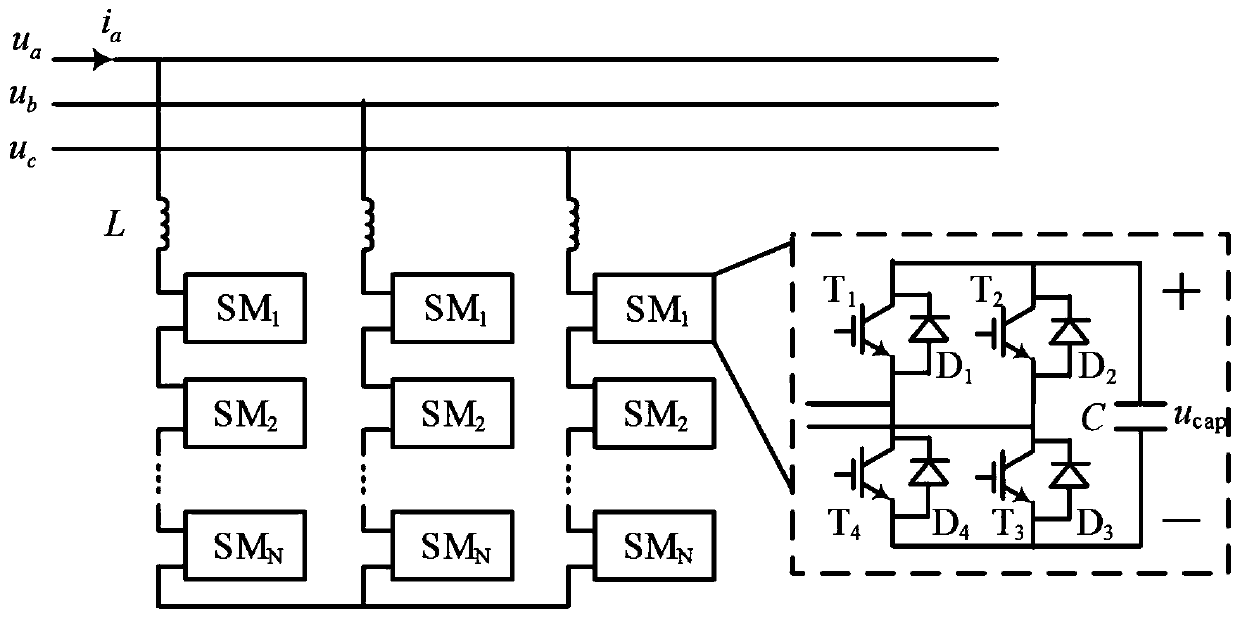

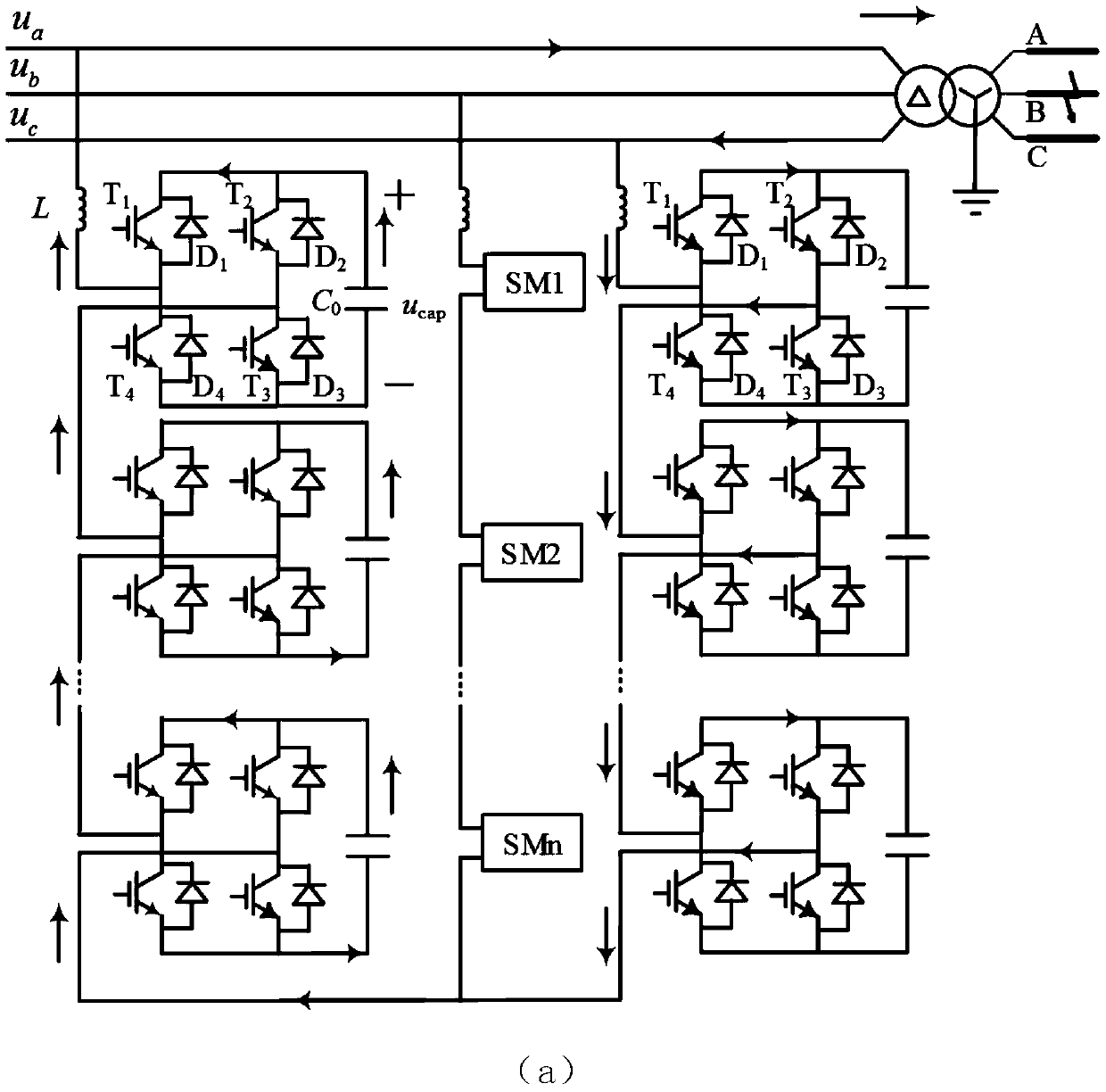

Active three-phase reclosing system and method for 110kV single-loop outgoing line of wind power plant

InactiveCN111313432APrevent overcurrentGuaranteed uptimeFlexible AC transmissionSingle network parallel feeding arrangementsCapacitanceControl theory

The invention discloses an active three-phase reclosing system and method for a 110kV single-loop outgoing line of a wind power plant. The method comprises: after line fault tripping, closing a STATCOM grid-connected circuit breaker and a circuit breaker on the side, close to the wind power plant, of the line, and controlling switching of a STATCOM full-bridge sub-module capacitor according to a preset additional control strategy to inject a pre-selected characteristic signal into the fault line, wherein the characteristic signal is the maximum current amplitude selected according to the duration of signal injection and the endurance capability of the power electronic device, and the duration time is obtained by setting a three-phase fault of a near-end outlet of the outgoing line; and realizing fault property discrimination of the fault line according to the predetermined propagation characteristic difference of the characteristic signals in different fault types, not reclosing the power transmission line when it is judged that the fault continuously exists, and reclosing the converter when it is judged that the fault disappears. Self-adaptive reclosing is achieved through the wind power line 110kV overhead line grid-connected system, safe and reliable operation of the system is ensured, power failure losses are reduced, and direct benefits and indirect benefits are quite remarkable.

Owner:XI AN JIAOTONG UNIV +1

Moving mechanism used for electric cradle

Owner:WUHU GUANGYING IND CO LTD

A New Tap Density Meter

ActiveCN103234864BTo achieve the purpose of circumferential rotationAmplitude controllableSpecific gravity measurementElectric machineryEngineering

Owner:丹东百特仪器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com