Under-actuated multi-rod type intelligent tea leaf continuous-vibration shaping machine

An under-actuated and slitting machine technology, applied in the field of tea processing machinery, can solve the problems of long sliver forming time, low processing precision, and non-adjustable pot amplitude, etc., and achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

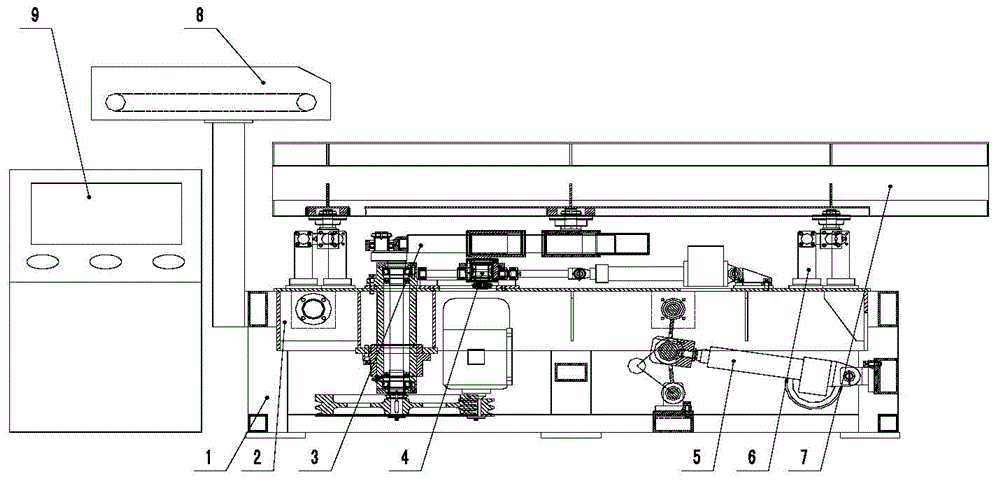

[0069] The present invention will be further described below in conjunction with the accompanying drawings.

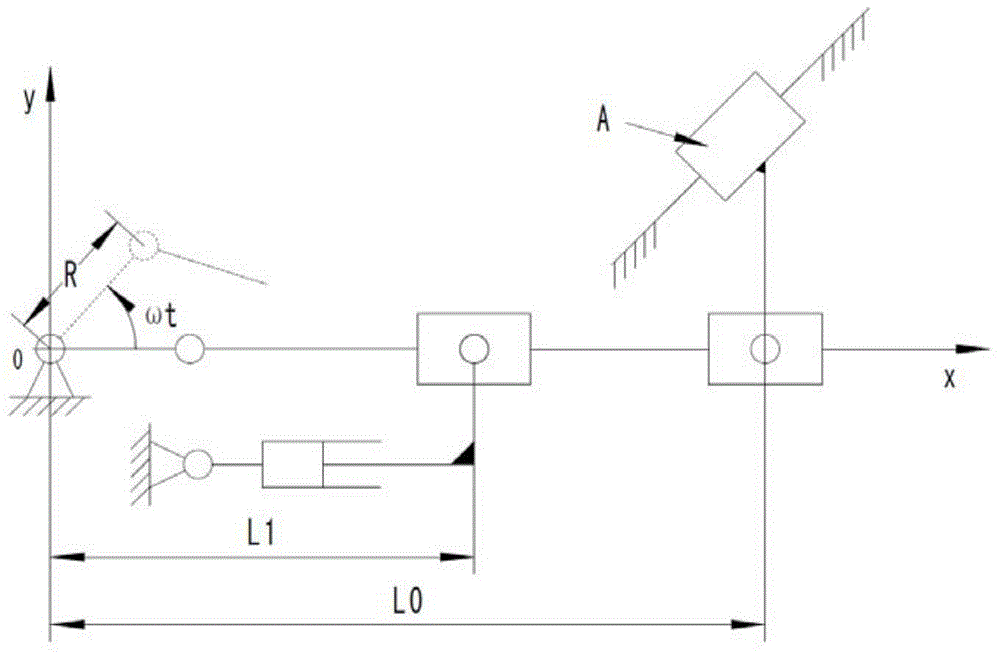

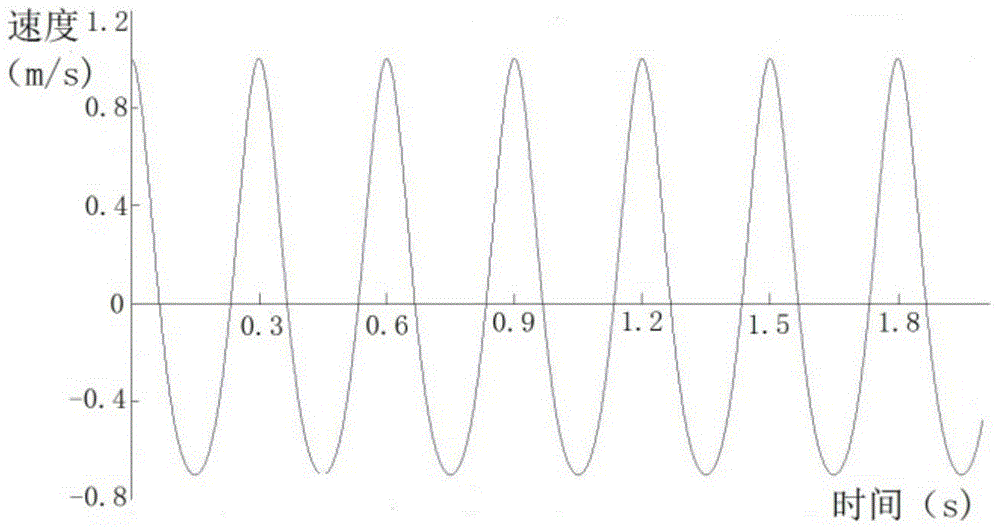

[0070] Such as image 3 As shown, an underactuated multi-rod intelligent tea continuous vibrating machine is characterized in that it includes a frame 1, a bed 2 and an underactuated multi-rod horizontal vibration system 3 for realizing continuous tea vibrating. A real-time amplitude adjustment system for adjusting the amplitude of tea leaves in the process of vibrating strips in order to adapt to different types and picking periods. The movement track in the tank, the vibration direction adjustment structure of the tank to improve the quality of tea strips 6, the integrated boiler tank for improving energy utilization rate 7; the dynamic flow weighing system for tea flow control 8; Through the adjustment of heating temperature, vibration frequency and amplitude, the tea continuous vibration system intelligent control system 9 is realized for tea continuous vibration ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com