Buffering self-flow vibrating screen

A vibrating screen and self-flow technology, applied in the direction of filter screen, solid separation, grid, etc., can solve the problems of large volume of coal-water slurry filter, time-consuming and laborious maintenance, complex structure, etc., to achieve high screening efficiency and improve filtration. effect, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and example the present invention will be further described:

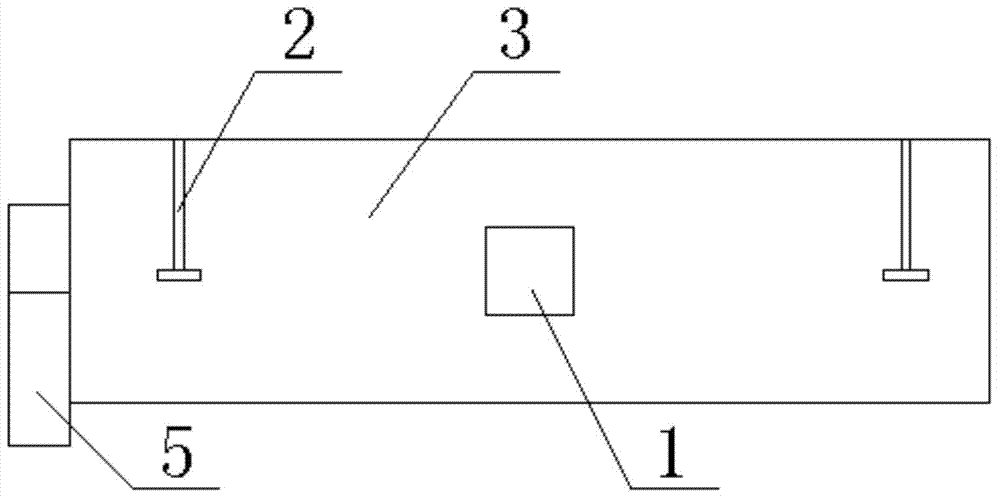

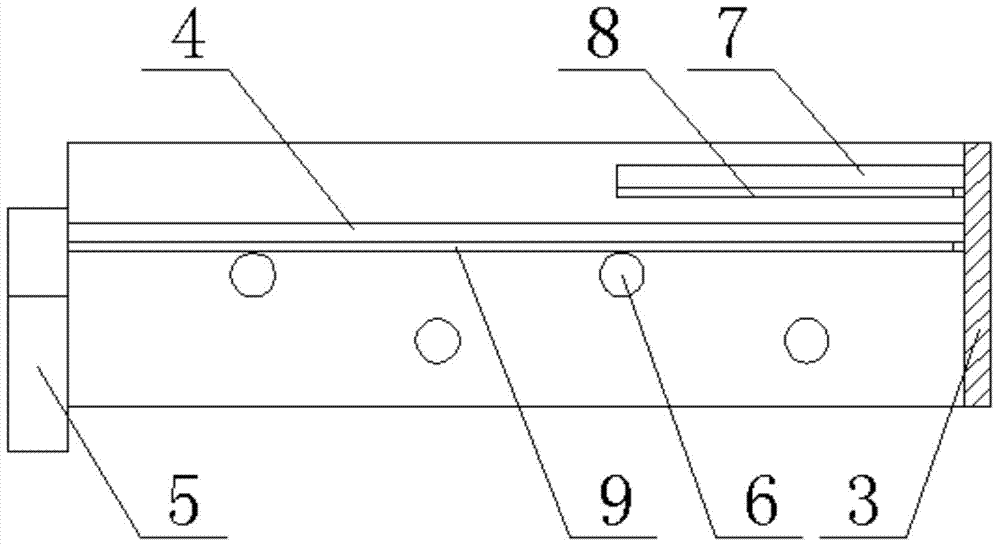

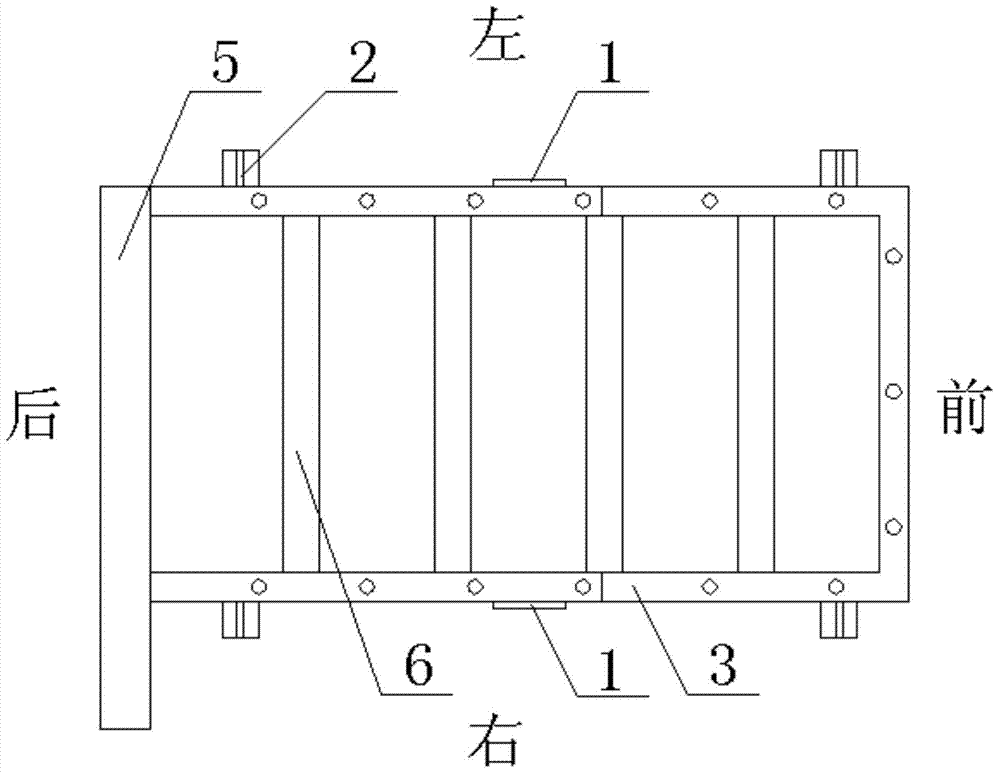

[0015] Such as Figure 1 to Figure 5 As shown, a buffer self-flowing vibrating screen in this embodiment includes: a vibrating screen main body 3, a main screen support 4, a debris chute 5 and a buffer screen support 7, and the left and right sides of the vibrating screen main body 3 Each is equipped with a vibrating motor 1, the top, bottom and rear of the vibrating screen main body 3 are open, and the remaining surfaces are closed surfaces; the main screen support 4 and buffer screen support 7 are installed in the inner cavity of the vibrating screen main body 3 And the buffer screen support 7 is positioned above the main screen support 4, the length of the main screen support 4 is greater than the length of the buffer screen support 7, the main screen support 4 and the buffer screen support 7 are all set There is a screen, the four corners of the vibrating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com