Vibration mechanism and high-precision locating charging vibration device

A technology of vibrating mechanism and vibrating device, which is applied in the direction of weapon accessories, ammunition, offensive equipment, etc., can solve the problem that different materials cannot obtain the best vibration effect, achieve good vibration effect, ensure positioning accuracy, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

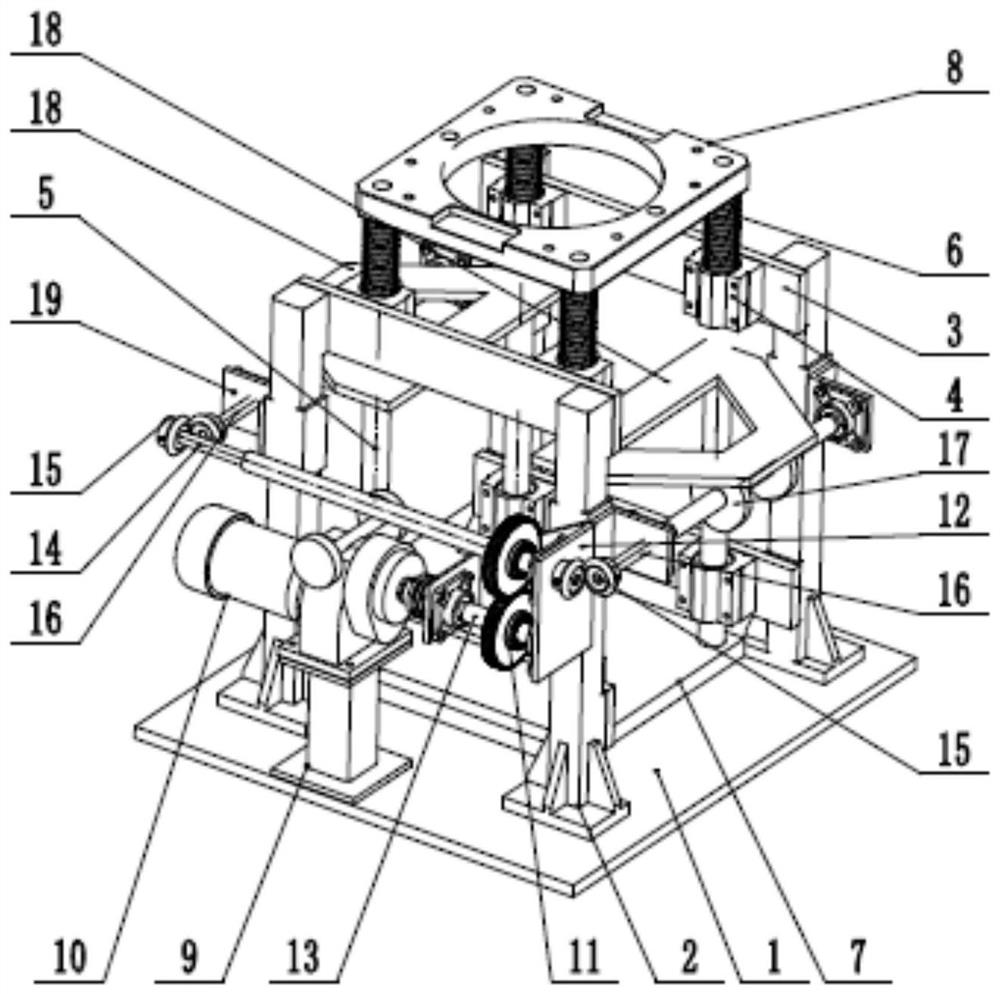

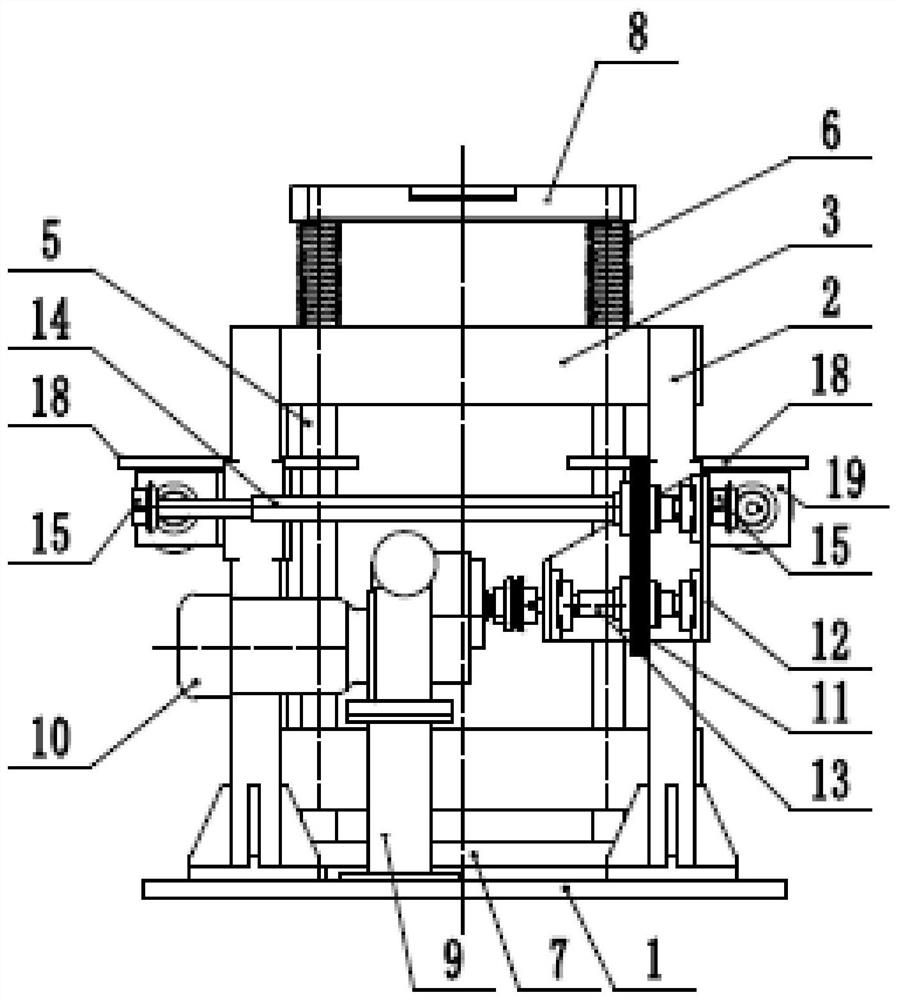

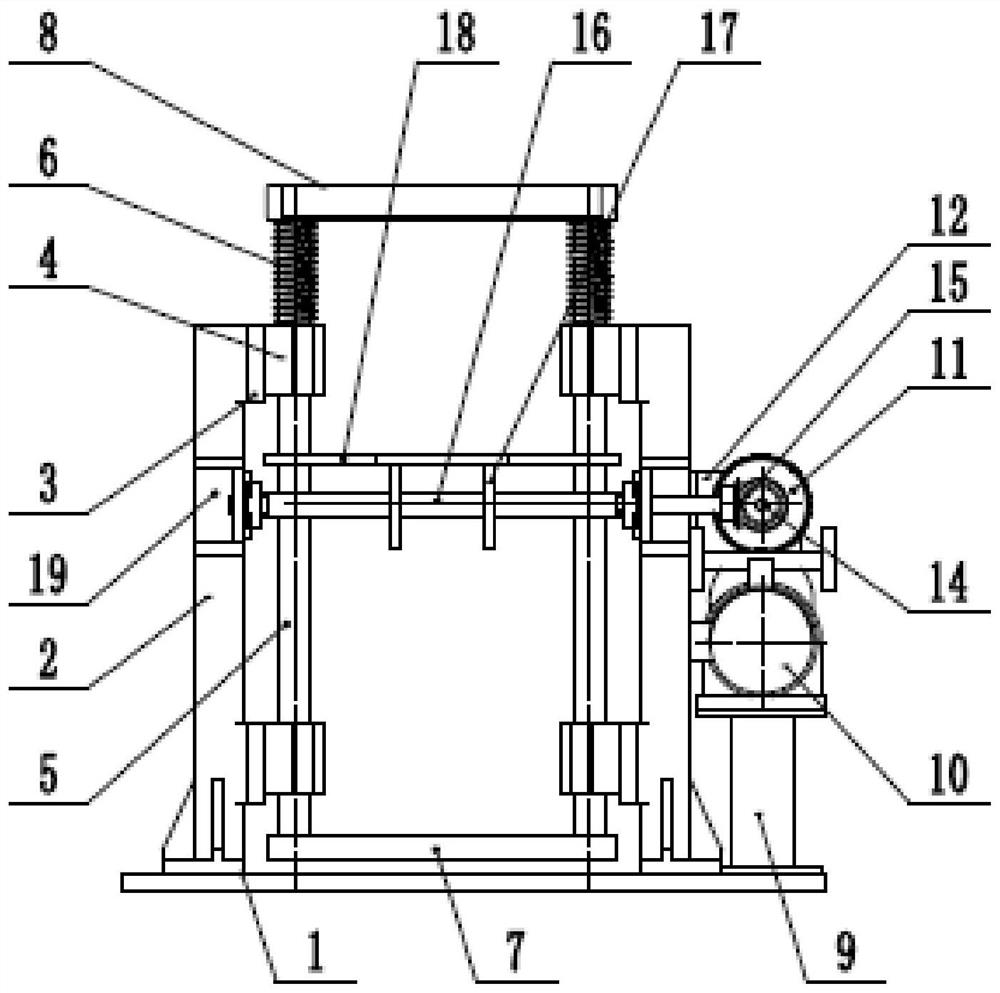

[0036] A vibrating mechanism, see figure 1 , comprising: a guide shaft 5 for connecting with the vibration platform 8; a controlled part 18, which is detachably fixedly connected with the guide shaft 5; a cam 16, which is arranged on one side of the controlled part 18 On the side, the cam 16 is also equipped with a power source; in the working state, when the cam 16 is in a controlled state driven by the power source, the cam 16 can be in contact with the controlled control 18 so that the controlled 18 moves along the axial direction of the guide shaft 5.

[0037]Specifically, the guide shaft 5 is strip-shaped, and the cross-sectional shape of the guide shaft 5 in the direction perpendicular to the axial direction is not limited, such as commonly used circles, squares, triangles, ellipses, polygons, etc., preferably It is circular, and the detachable fixed connection between the controlled part 18 and the guide shaft 5 can be implemented through some conventional methods in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com