Patents

Literature

1568results about How to "Improve the vibration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

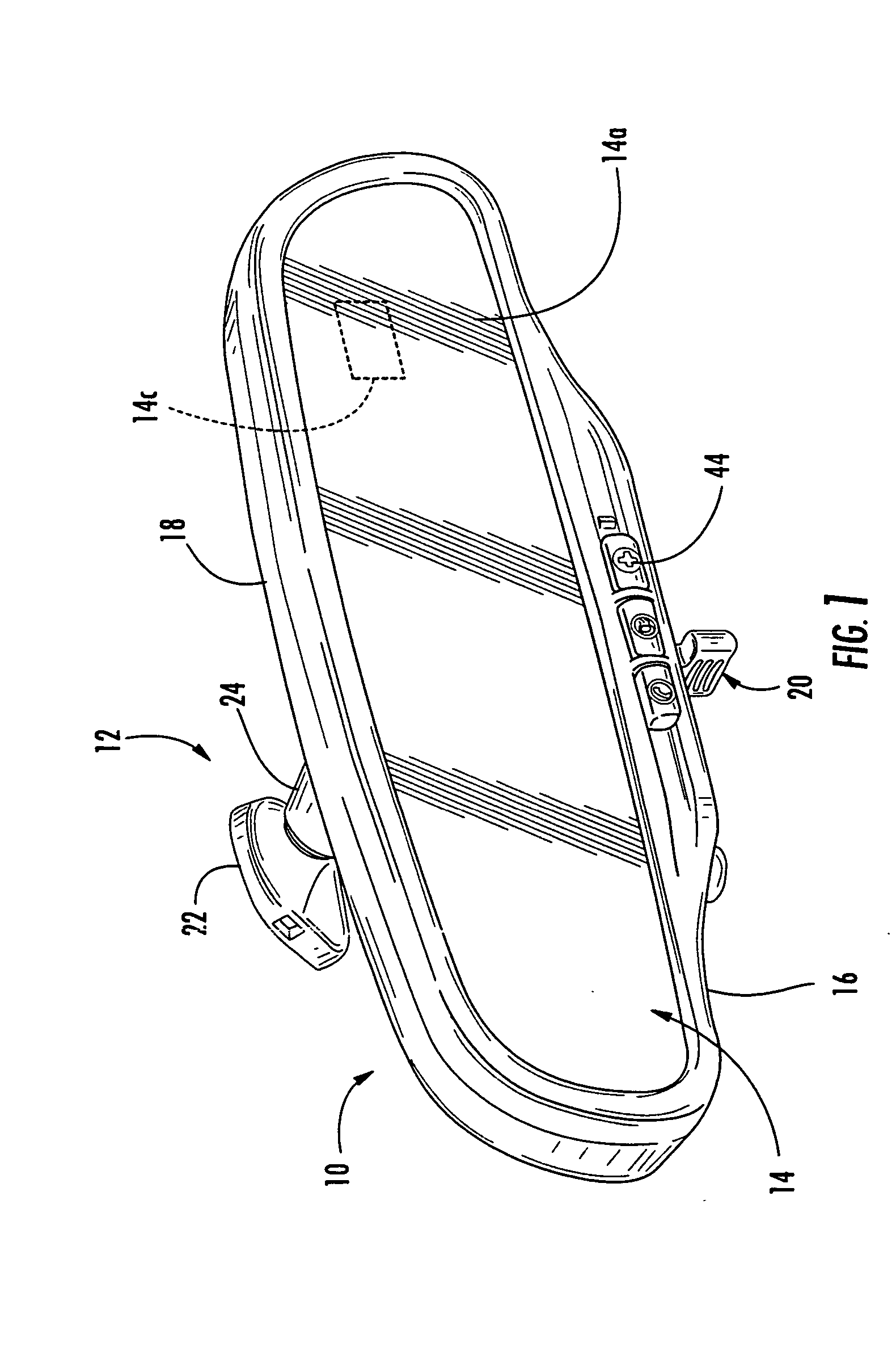

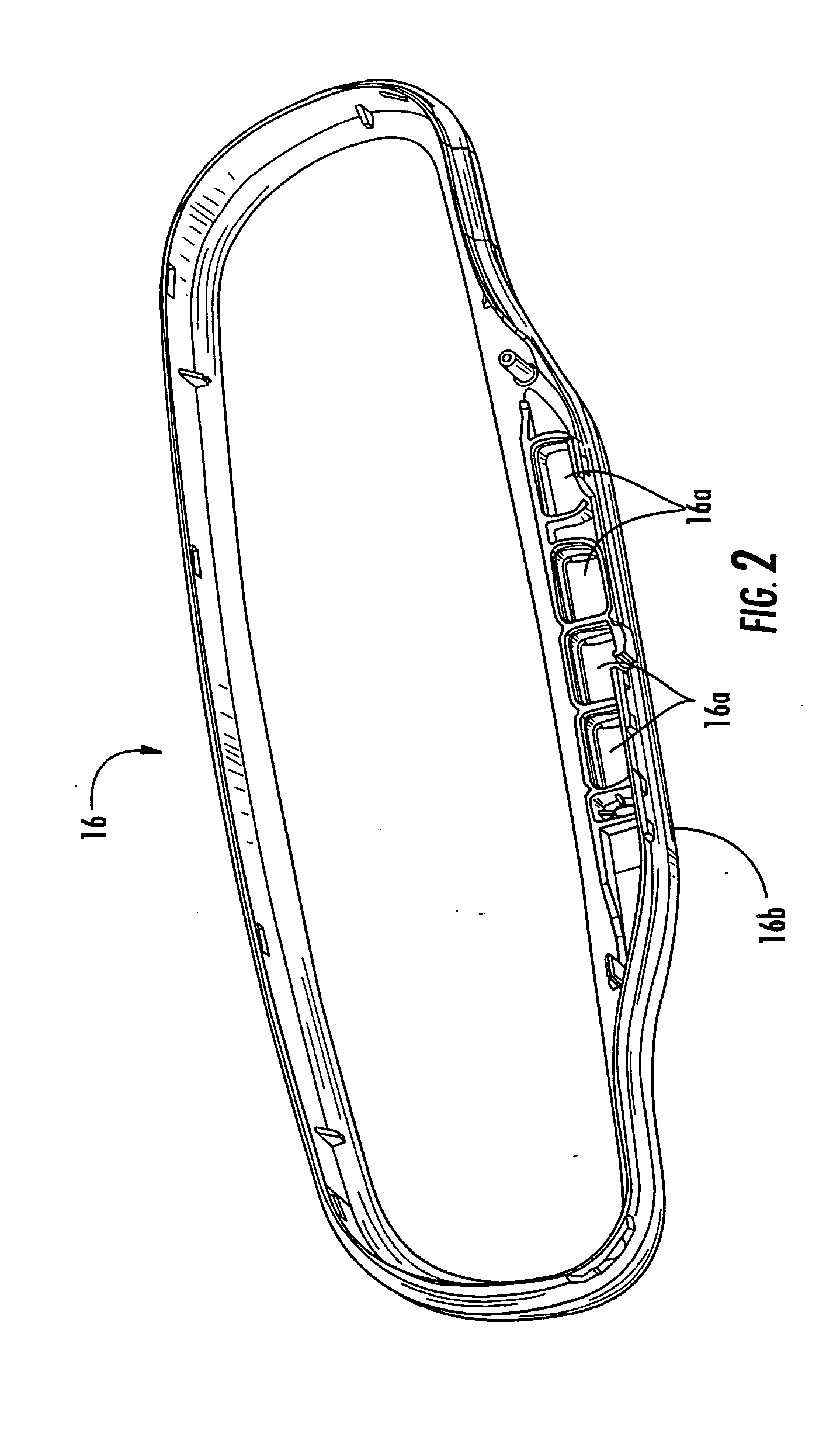

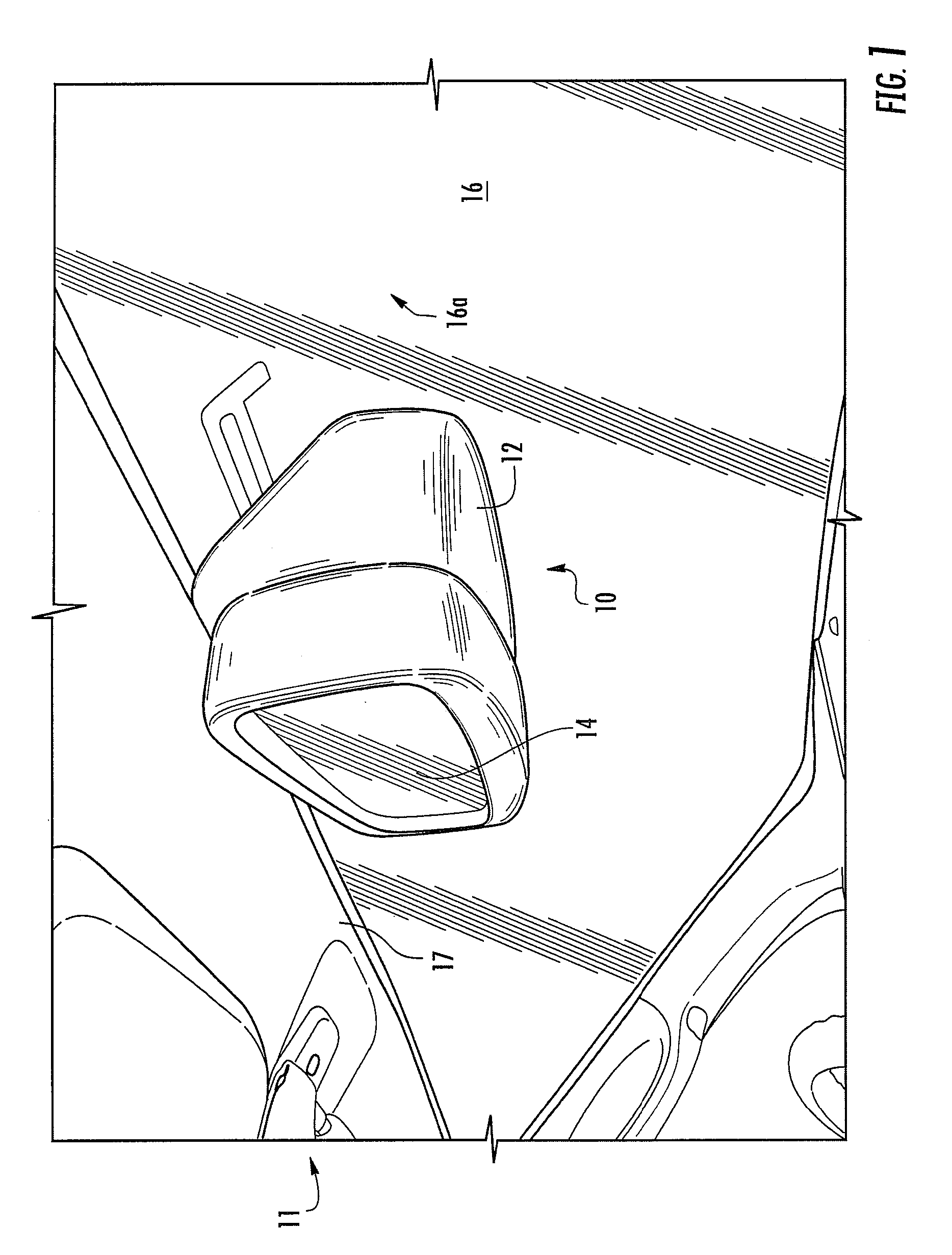

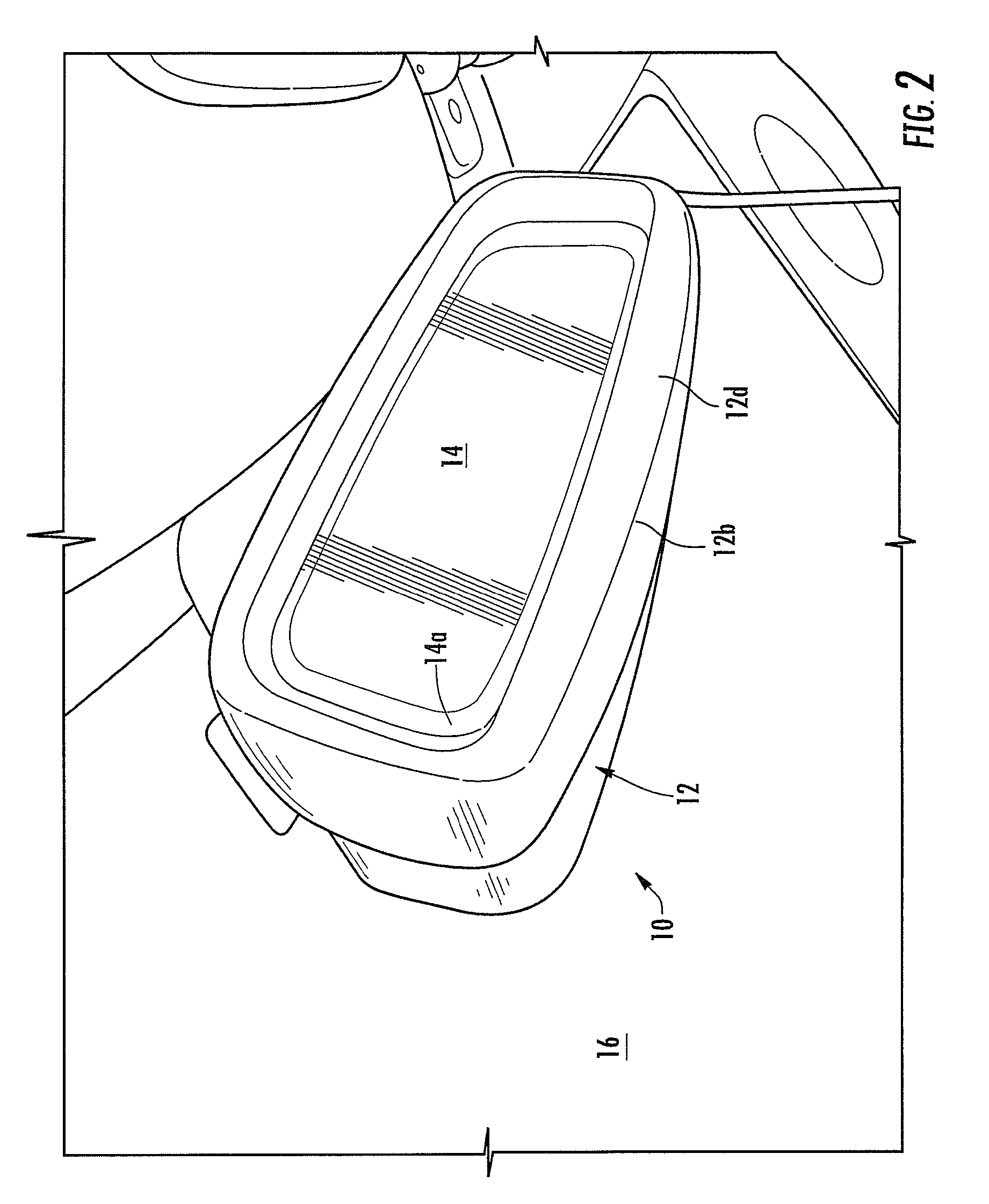

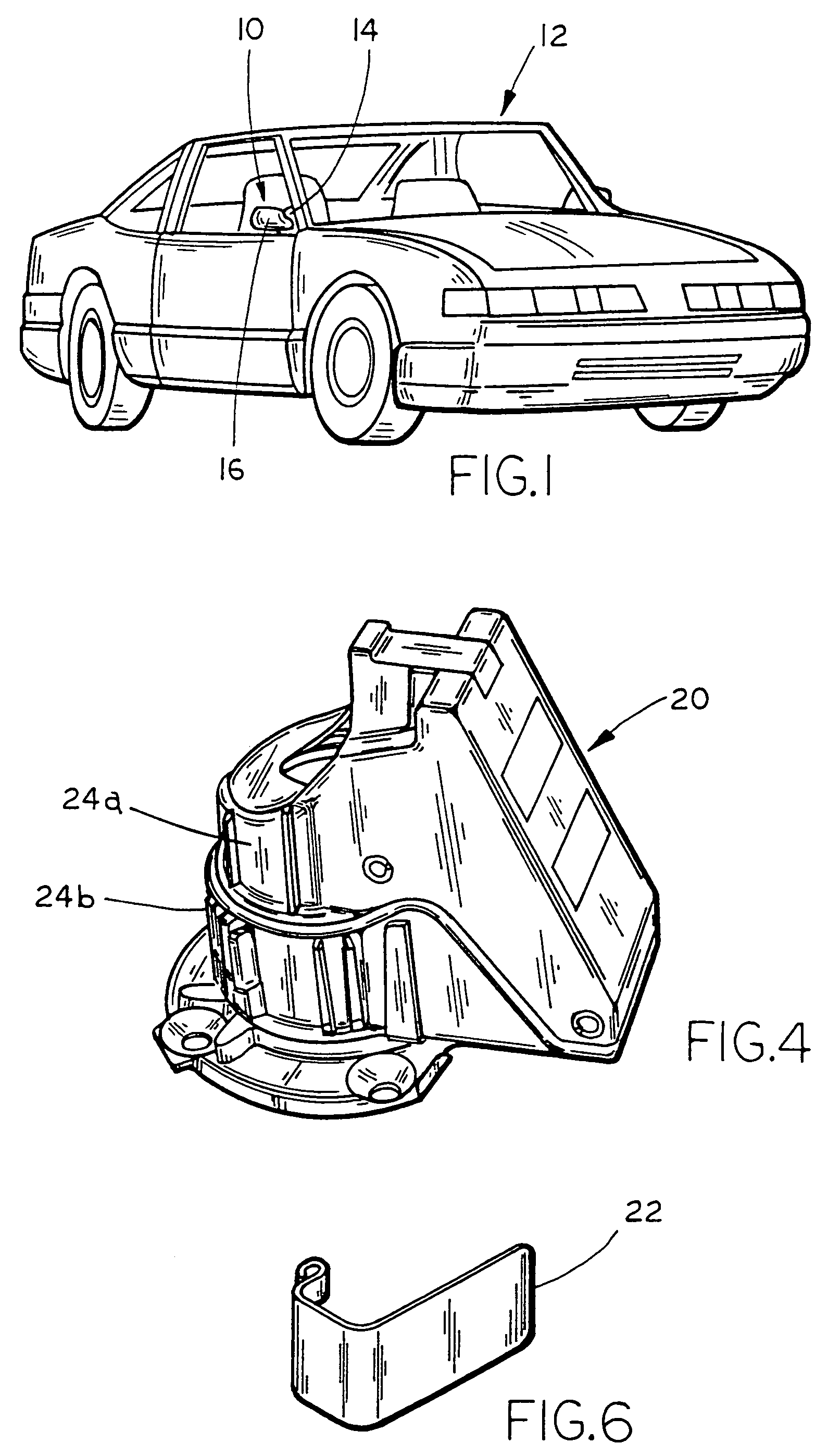

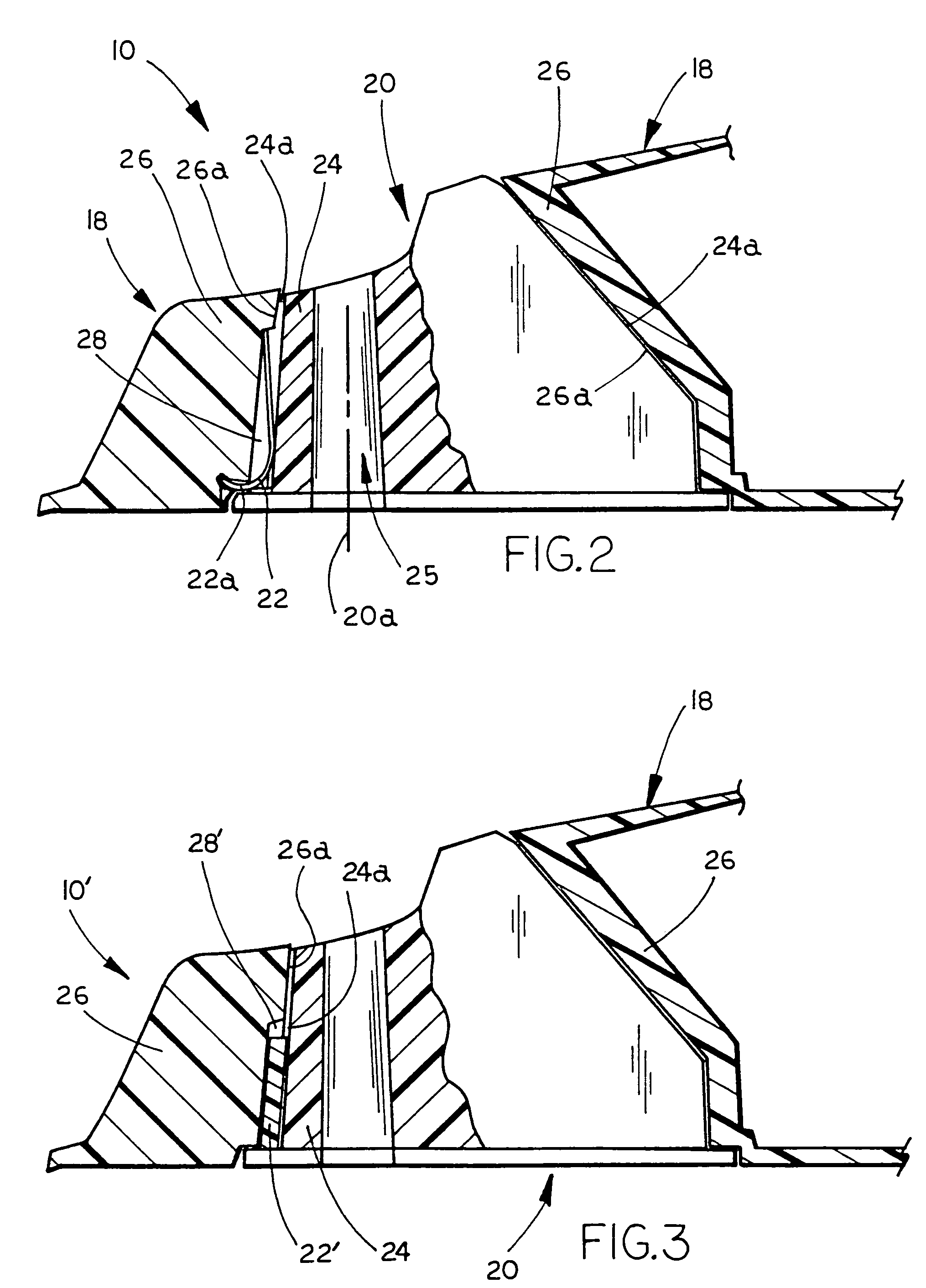

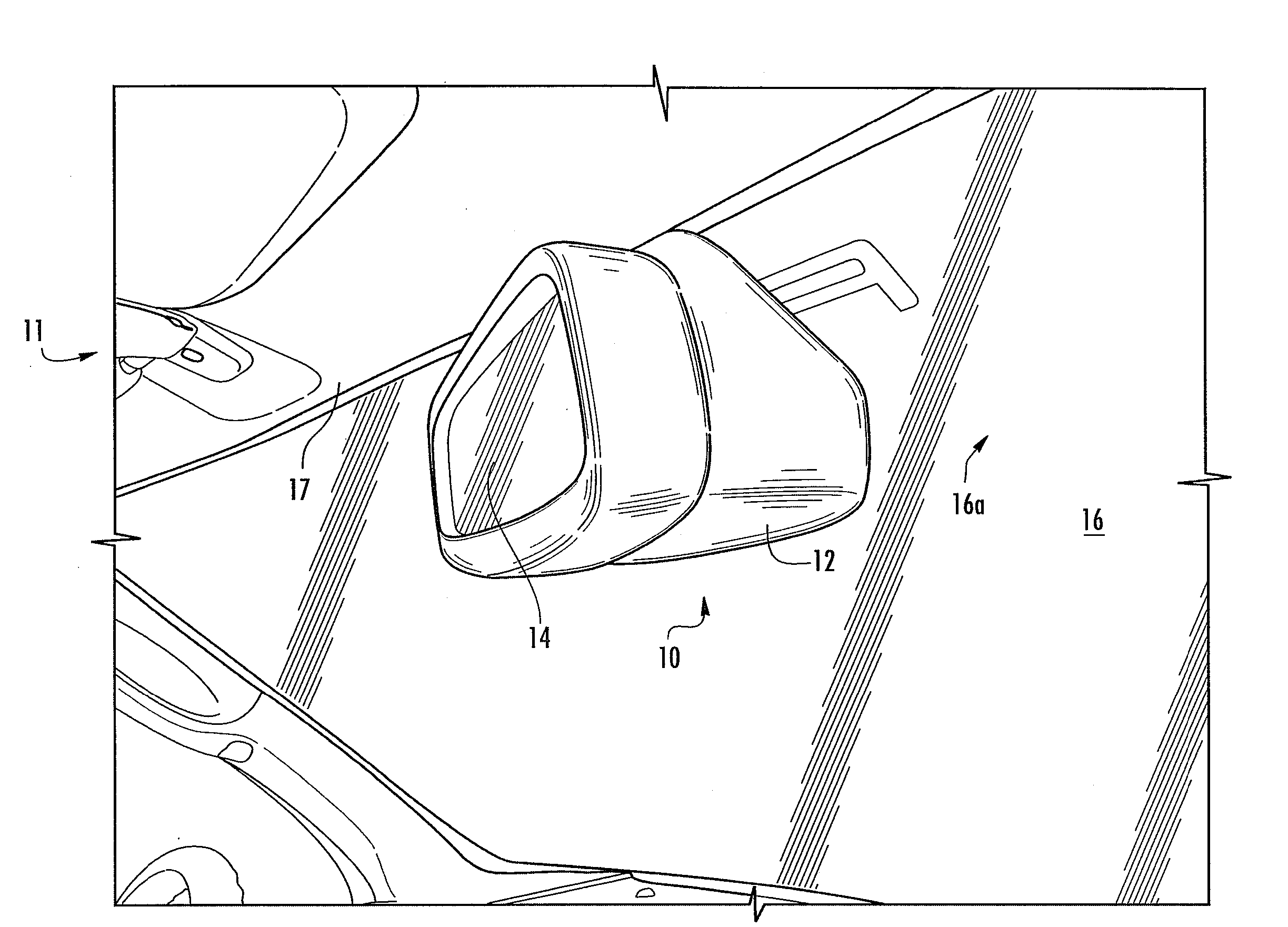

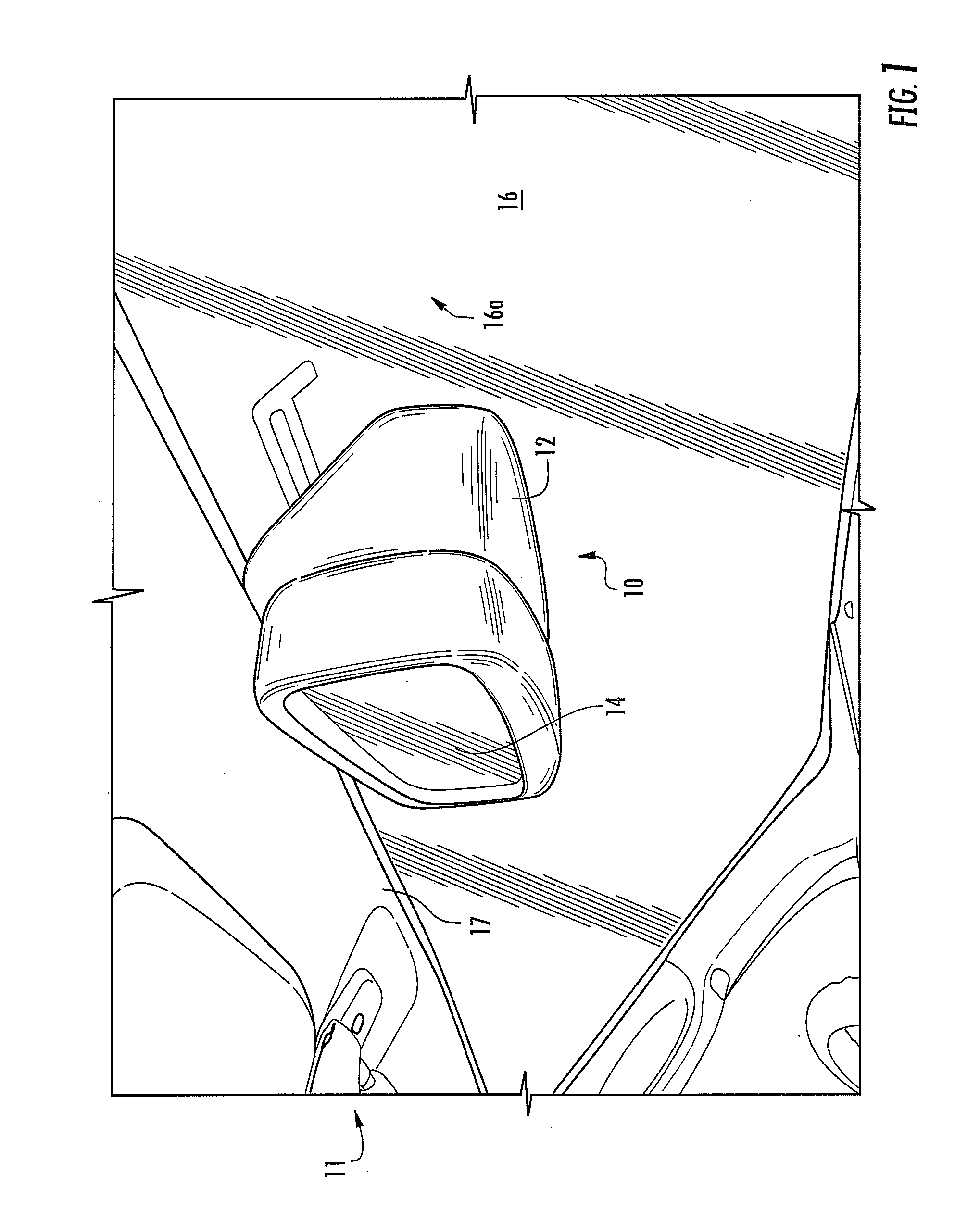

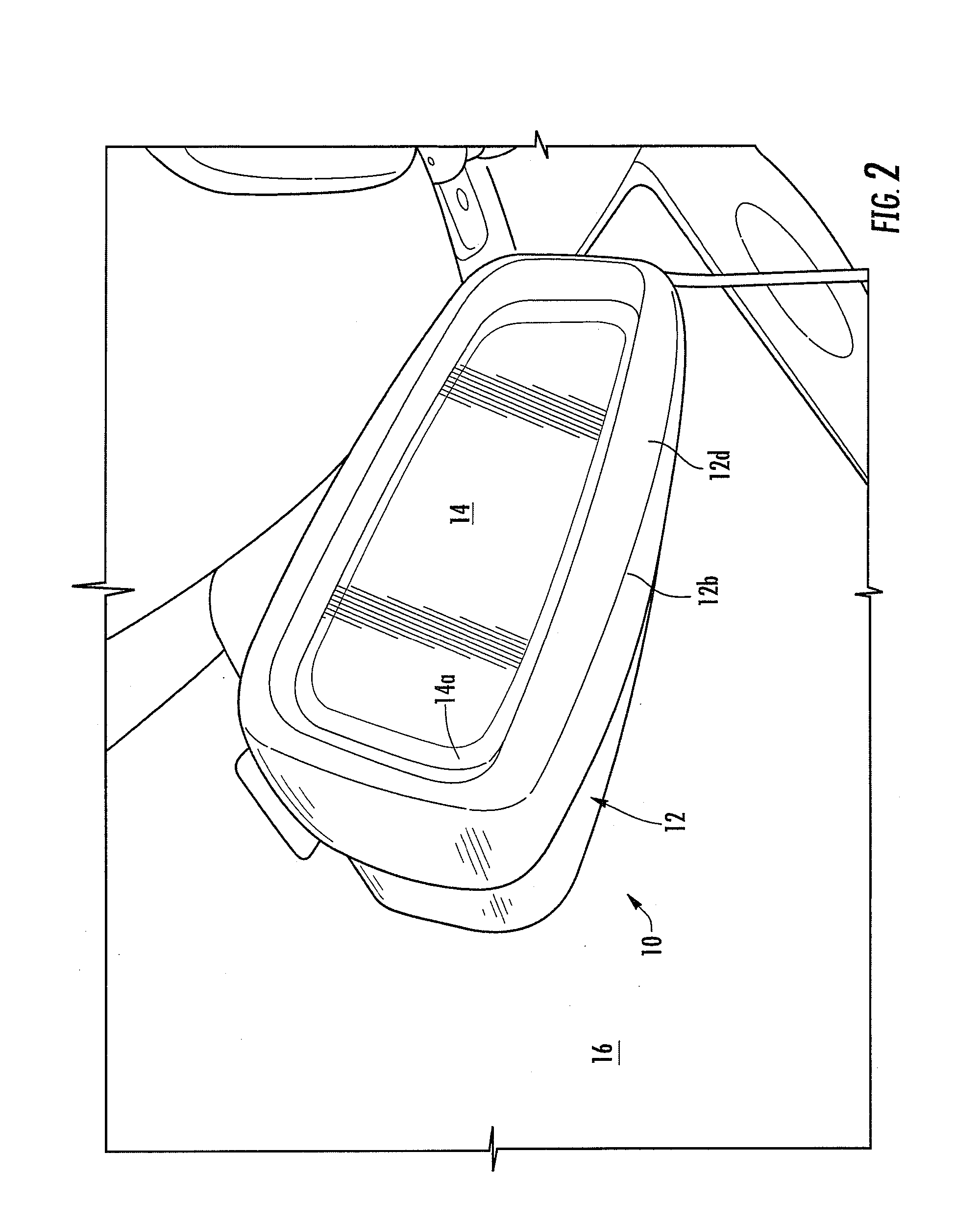

Interior rearview mirror assembly

InactiveUS7249860B2Facilitate efficient assembly of assemblyEasy to assembleMirrorsMountingsPrismEngineering

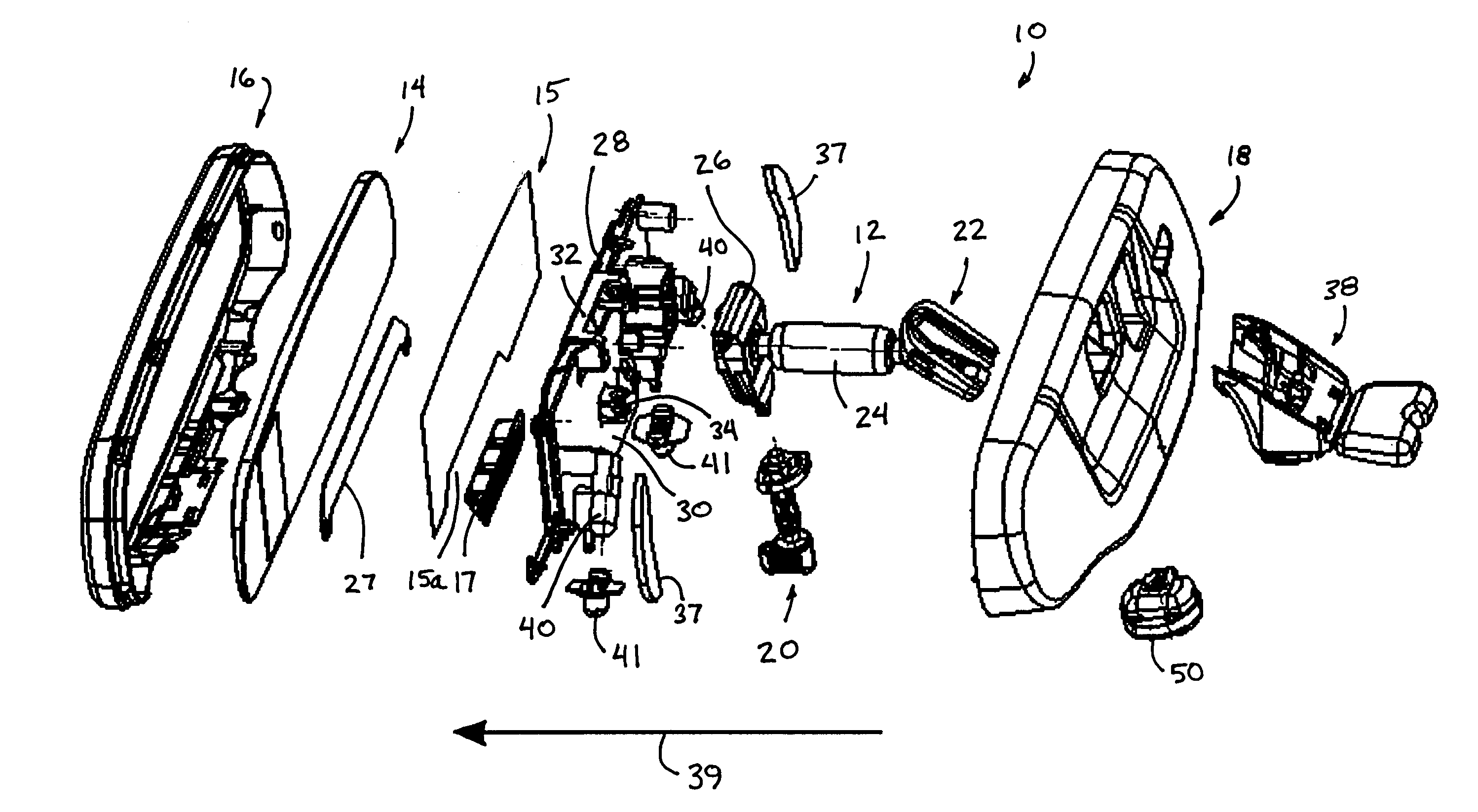

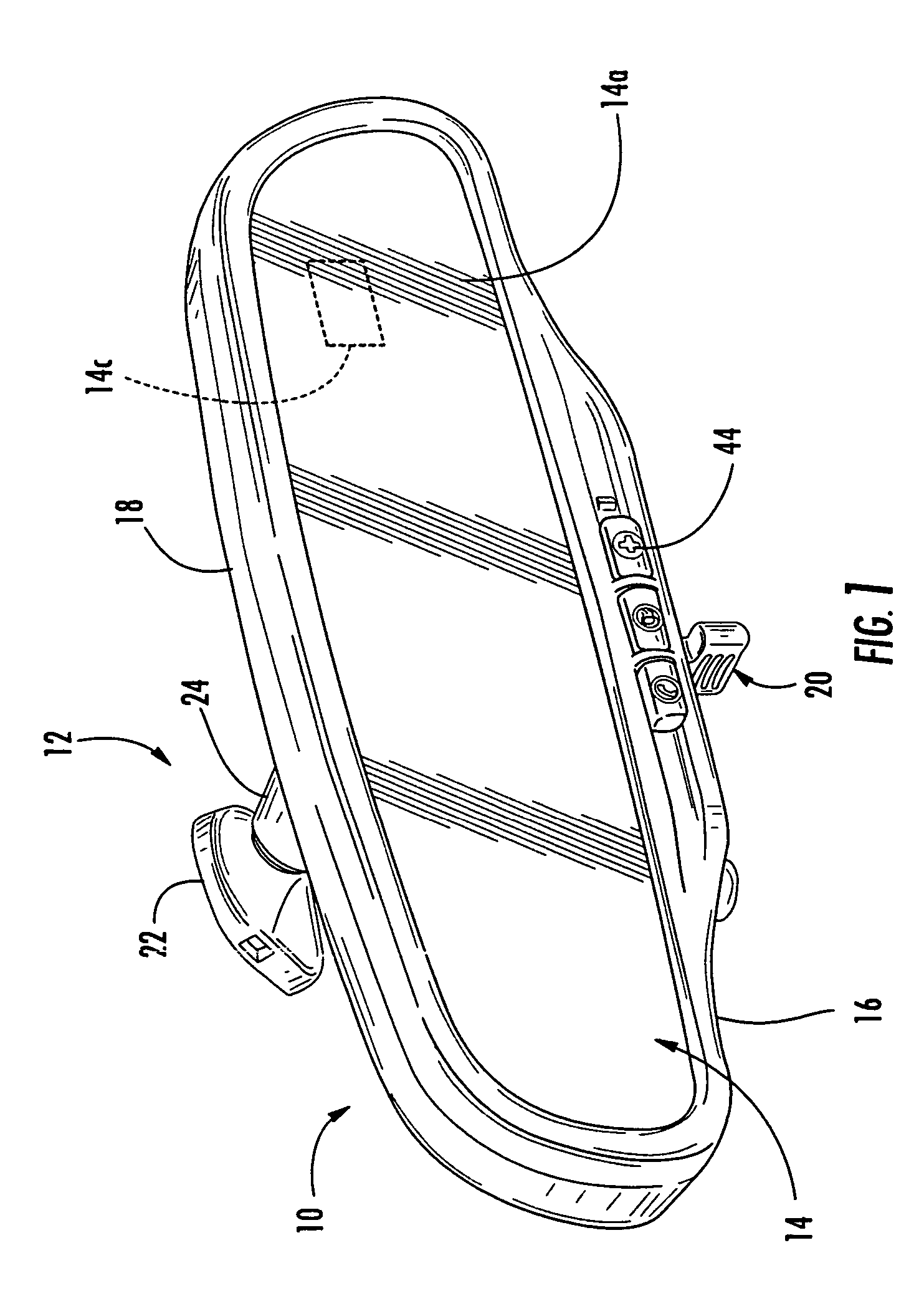

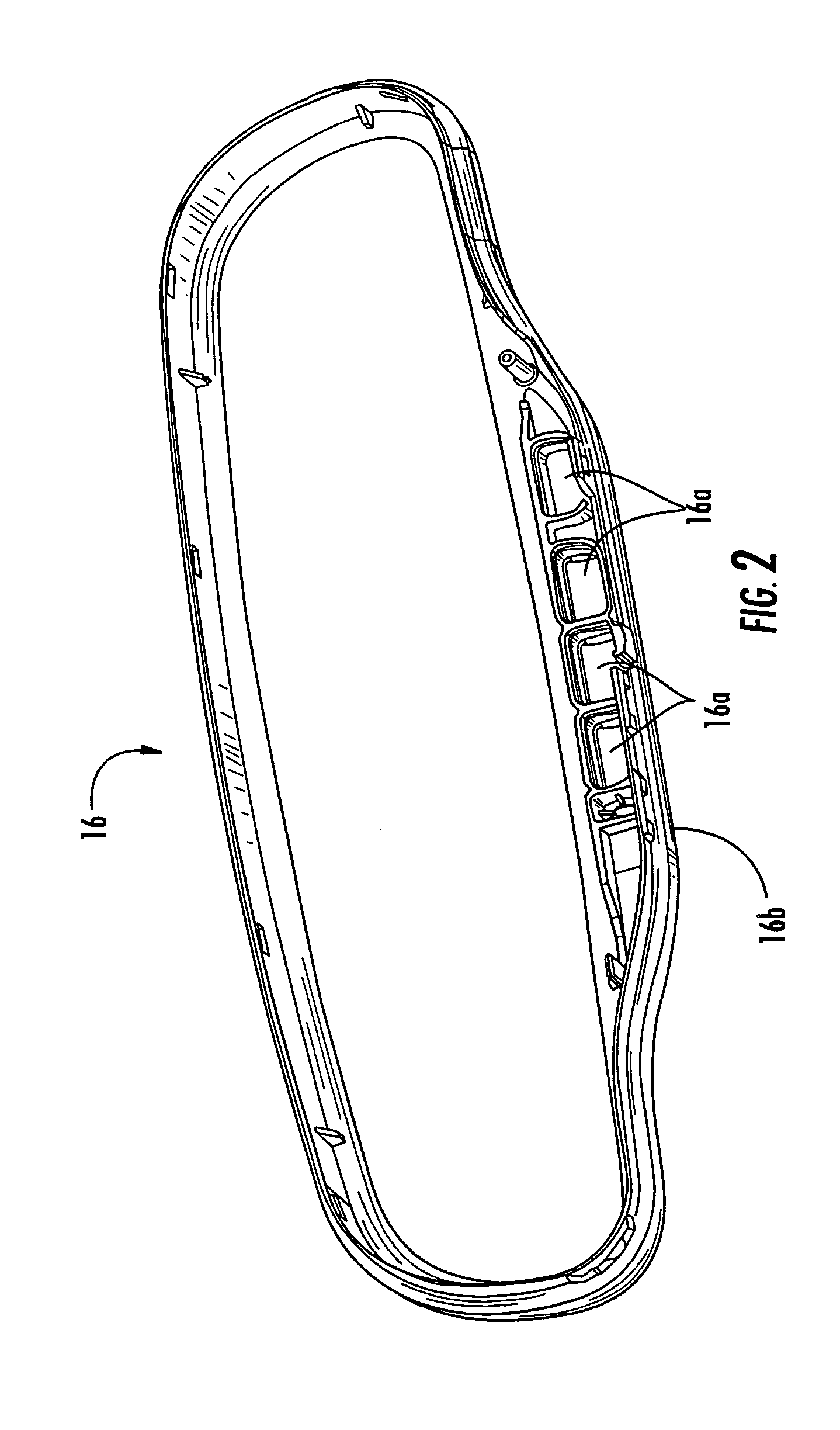

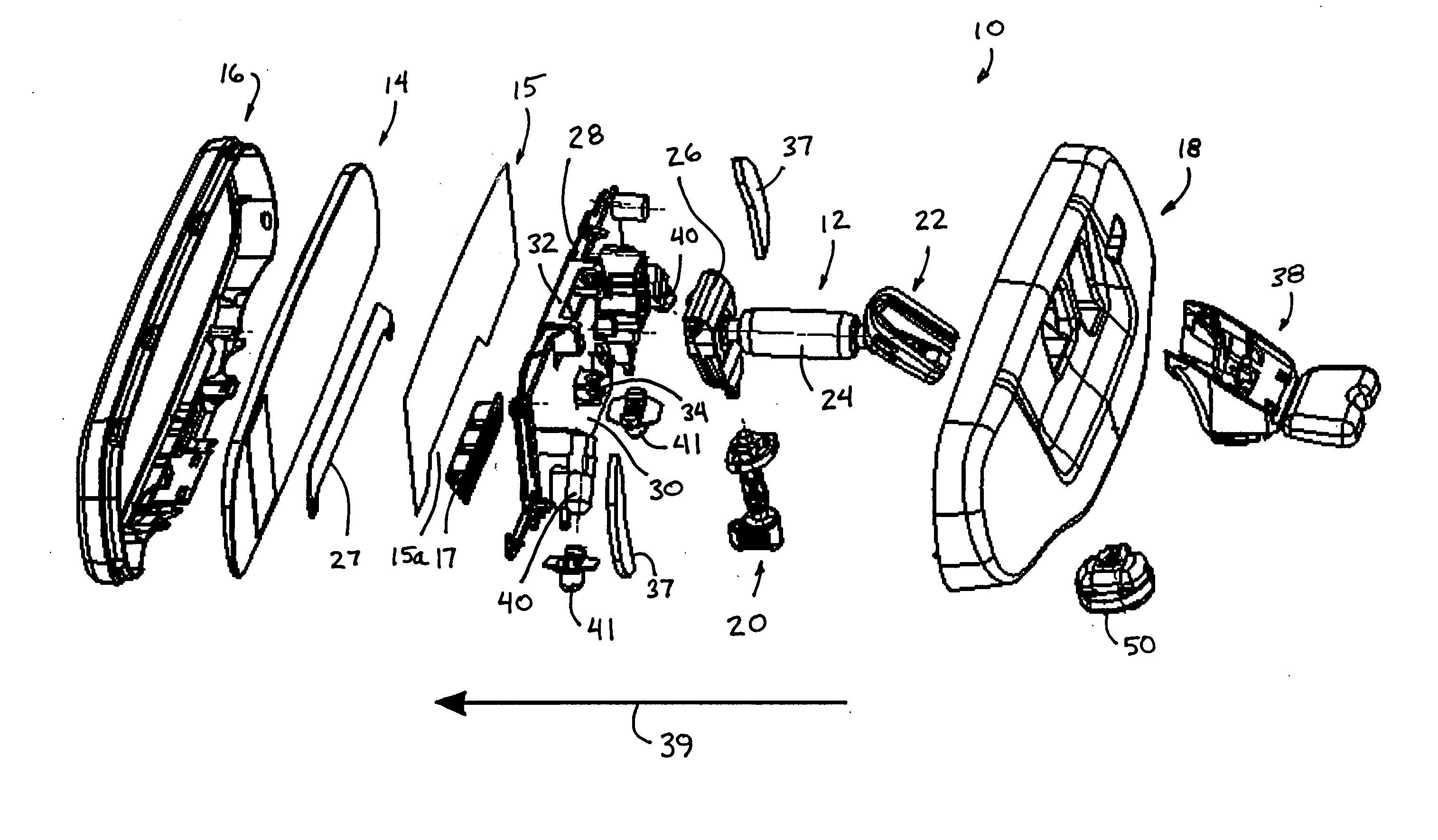

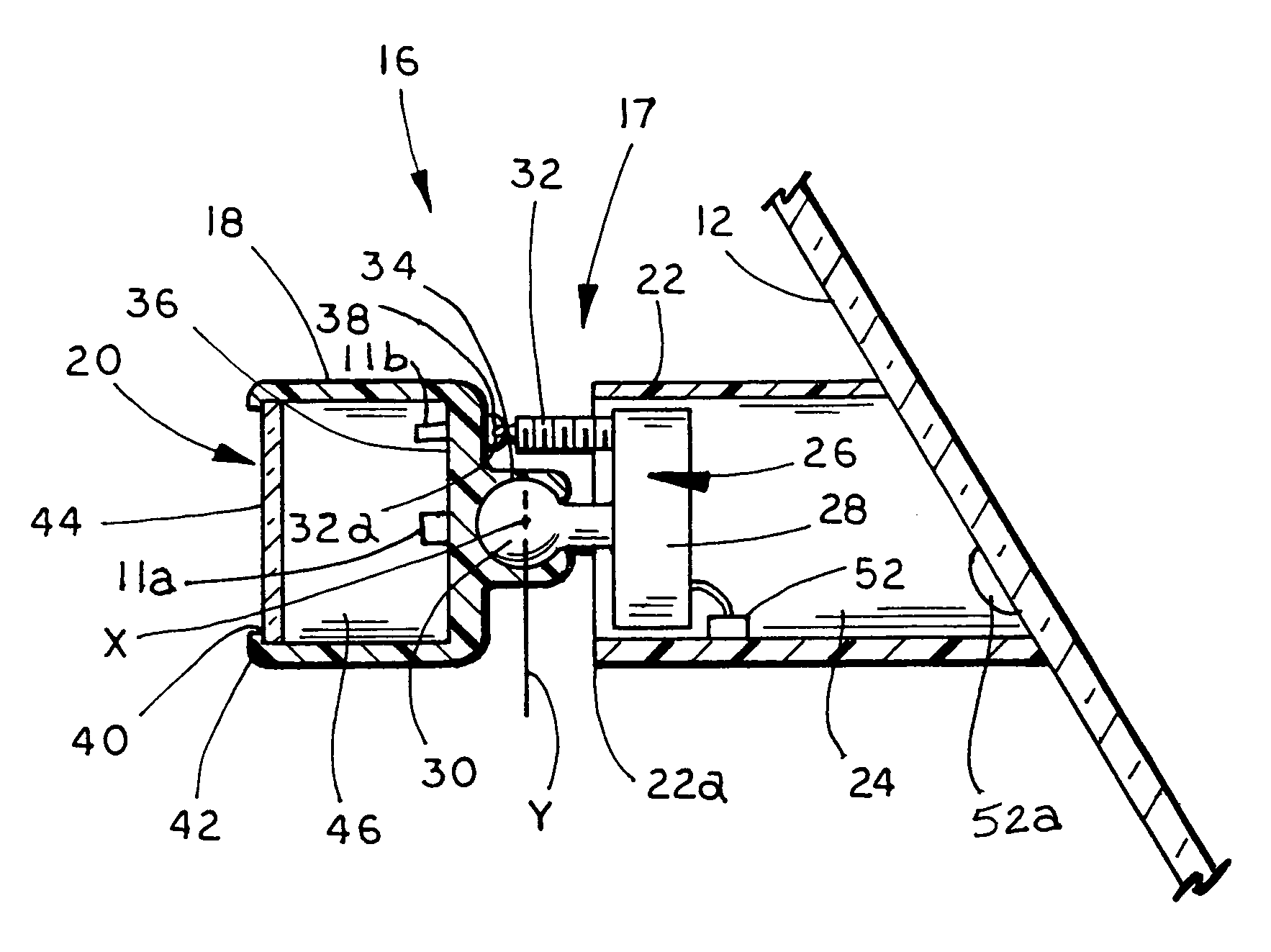

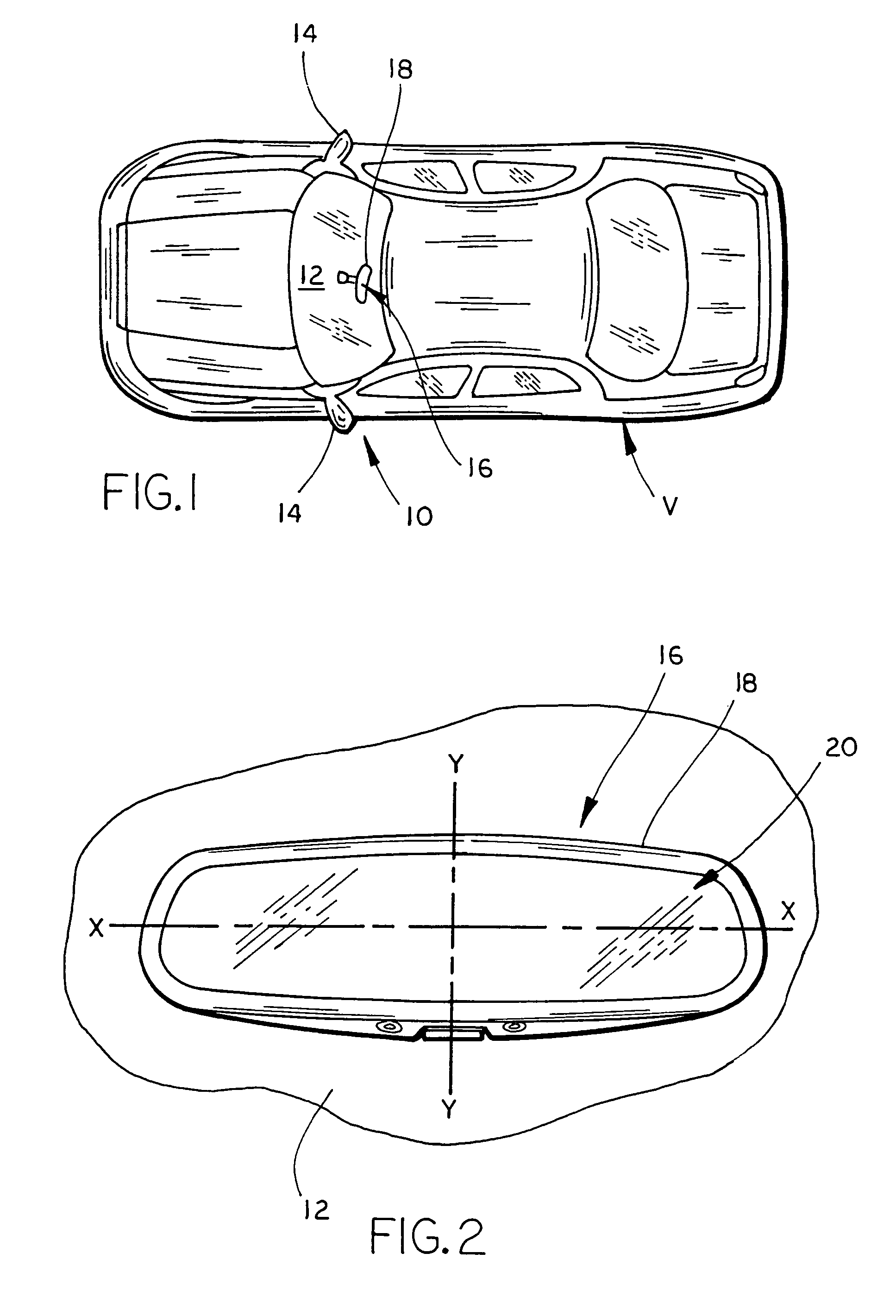

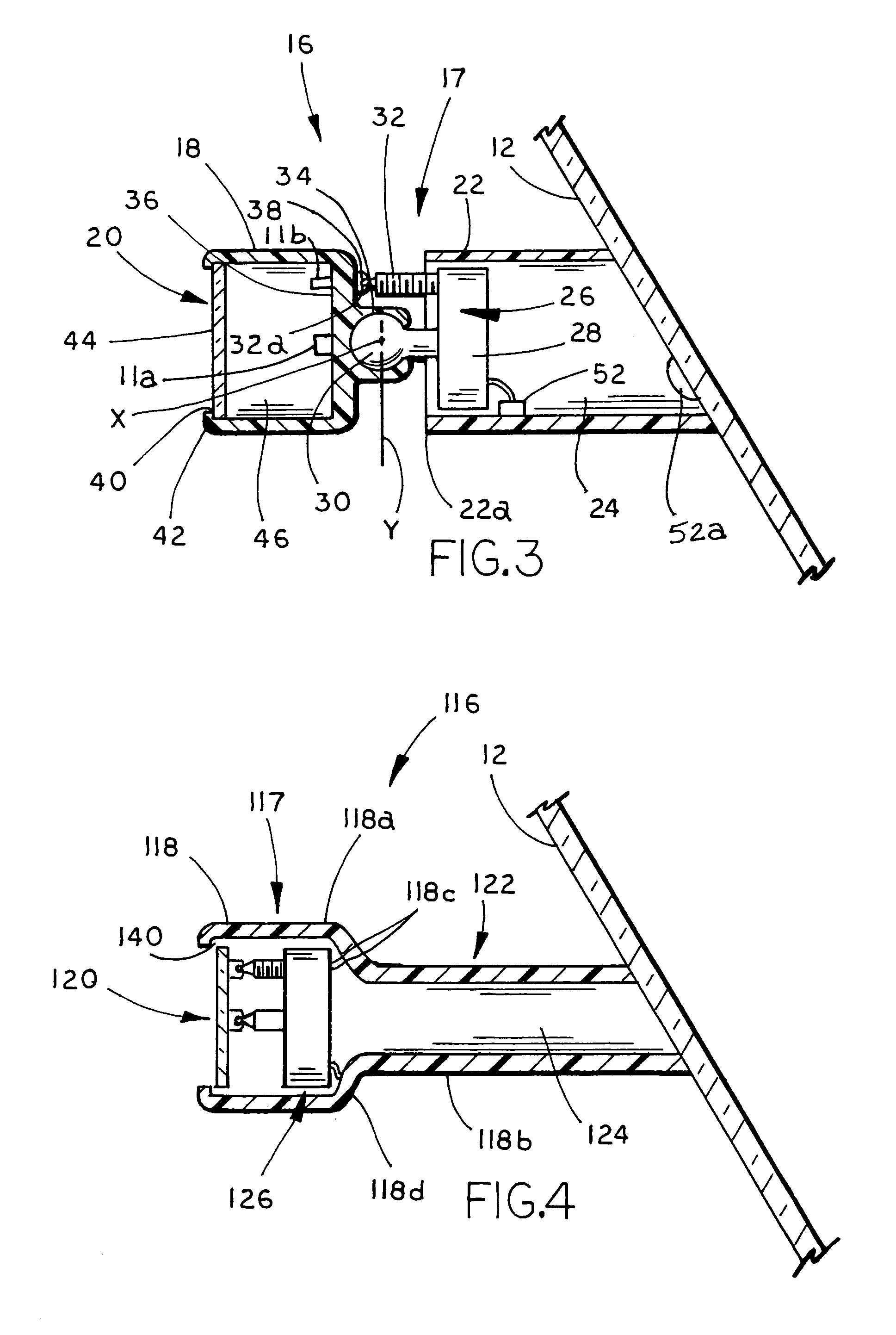

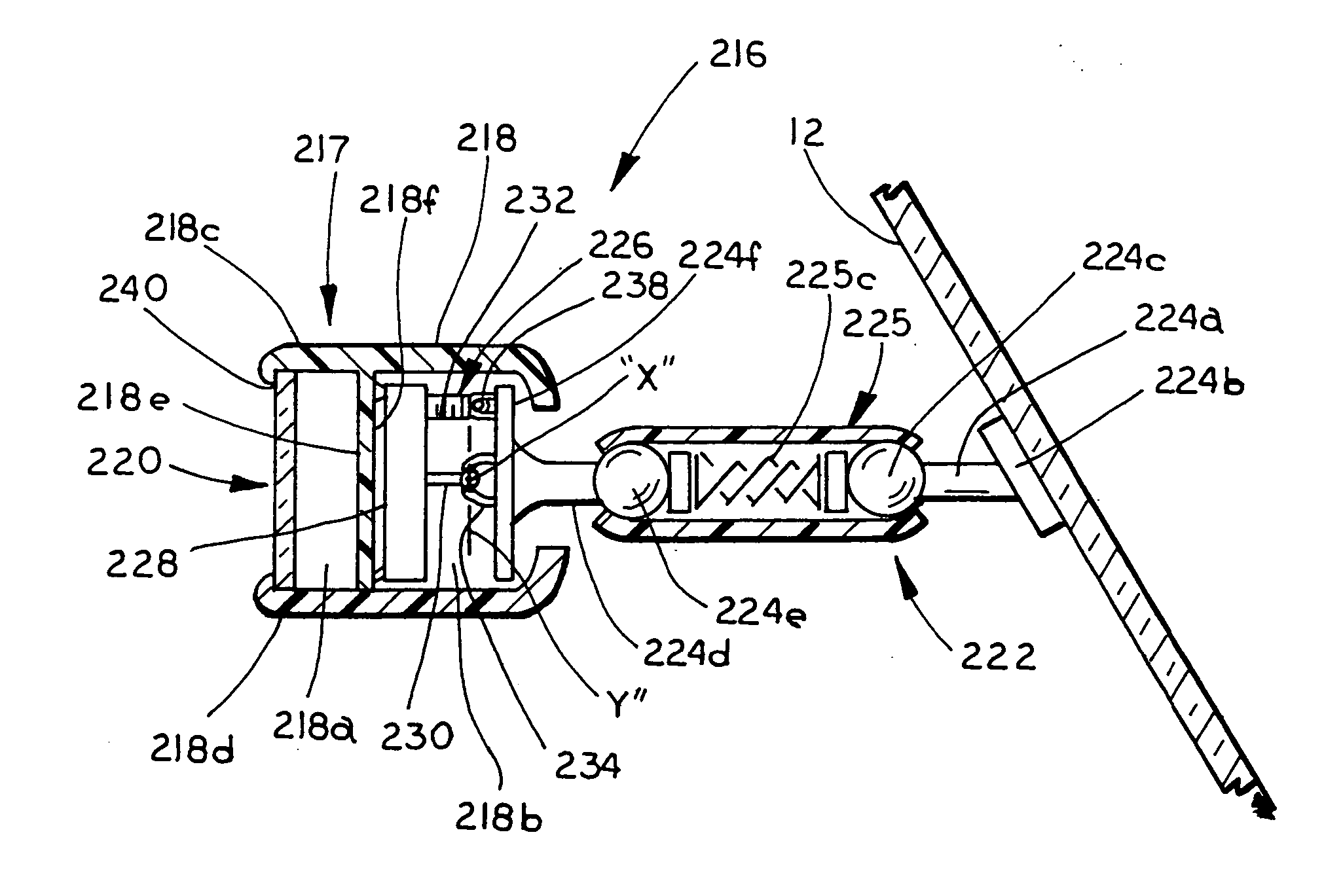

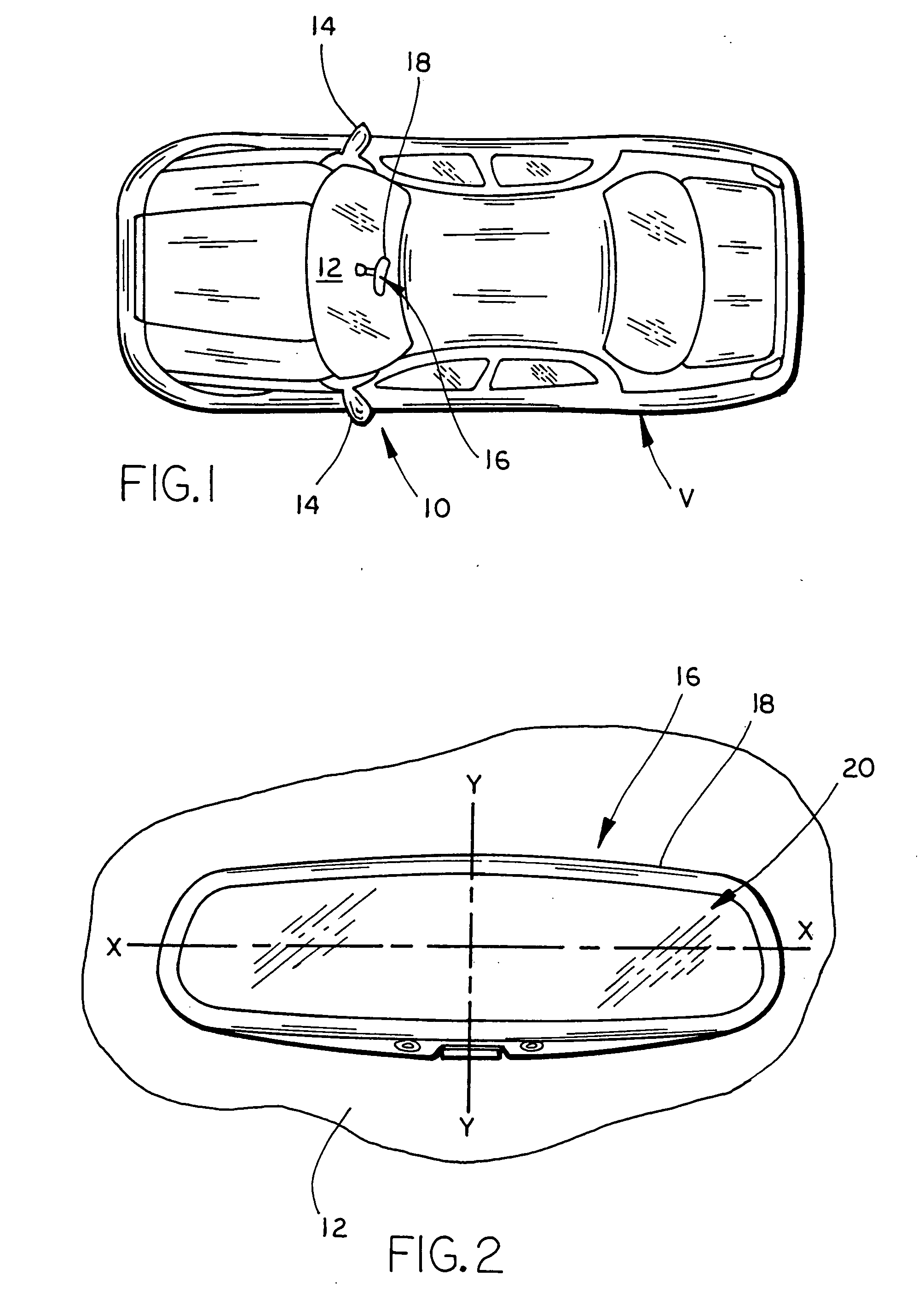

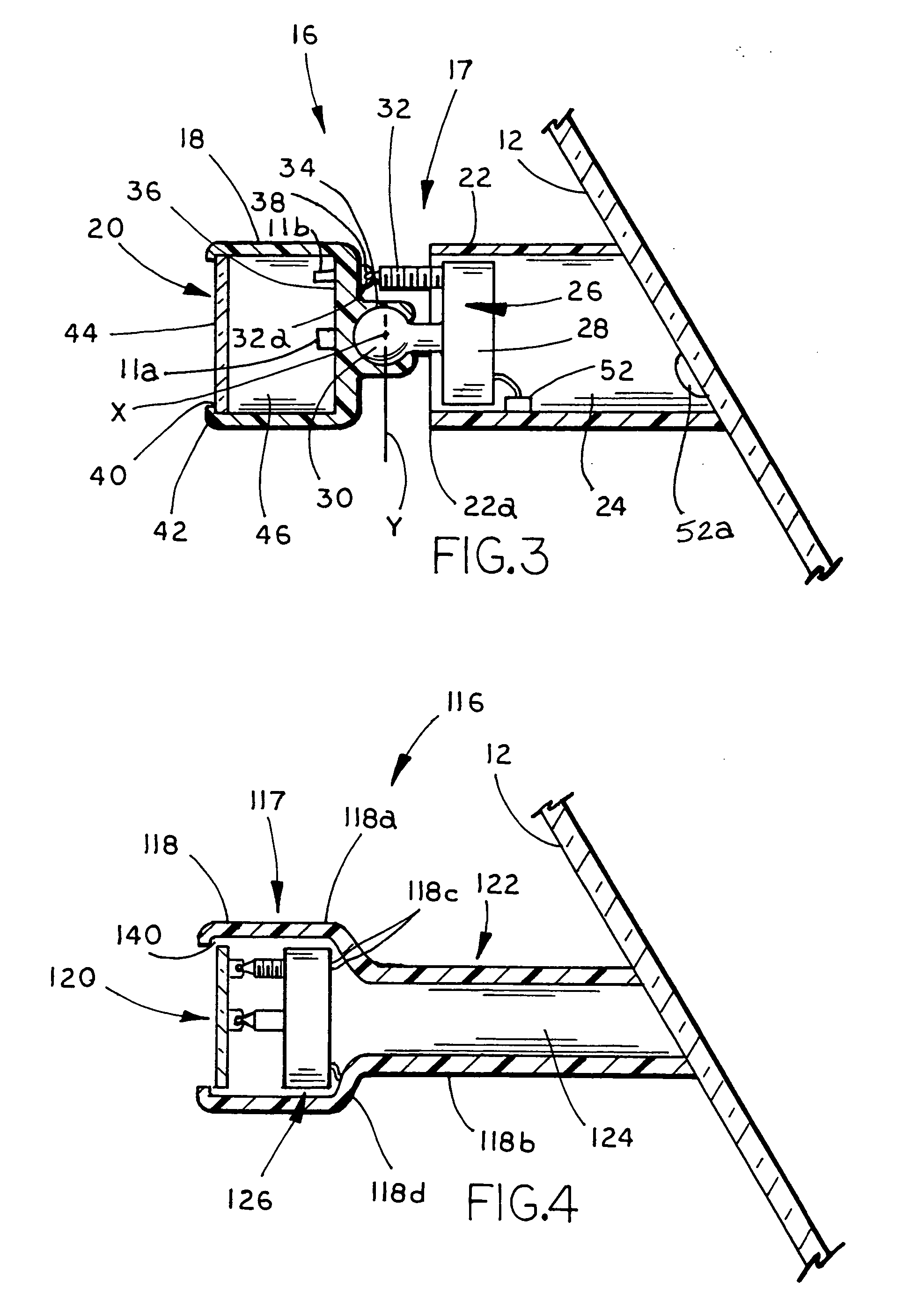

An interior rearview mirror assembly for a vehicle includes a reflective element and a casing. An attachment plate is secured to the reflective element and an electronic circuitry element, such as a printed circuit board, is attached to the attachment plate. The attachment plate includes at least one mounting member protruding through the circuit board for engaging a mounting assembly that mounts the mirror assembly to an interior portion of the vehicle and directly supports the attachment plate, along with the printed circuit board and the reflective element at an end of the mounting assembly. The mounting assembly may comprise a toggle assembly for a prismatic reflective element.

Owner:DONNELLY CORP

Interior rearview mirror assembly

InactiveUS20050078389A1Facilitate efficient assembly of assemblyEasy to assembleMirrorsMountingsPrismPrinted circuit board

An interior rearview mirror assembly for a vehicle includes a reflective element and a casing. An attachment plate is secured to the reflective element and an electronic circuitry element, such as a printed circuit board, is attached to the attachment plate. The attachment plate includes at least one mounting member protruding through the circuit board for engaging a mounting assembly that mounts the mirror assembly to an interior portion of the vehicle and directly supports the attachment plate, along with the printed circuit board and the reflective element at an end of the mounting assembly. The mounting assembly may comprise a toggle assembly for a prismatic reflective element.

Owner:DONNELLY CORP

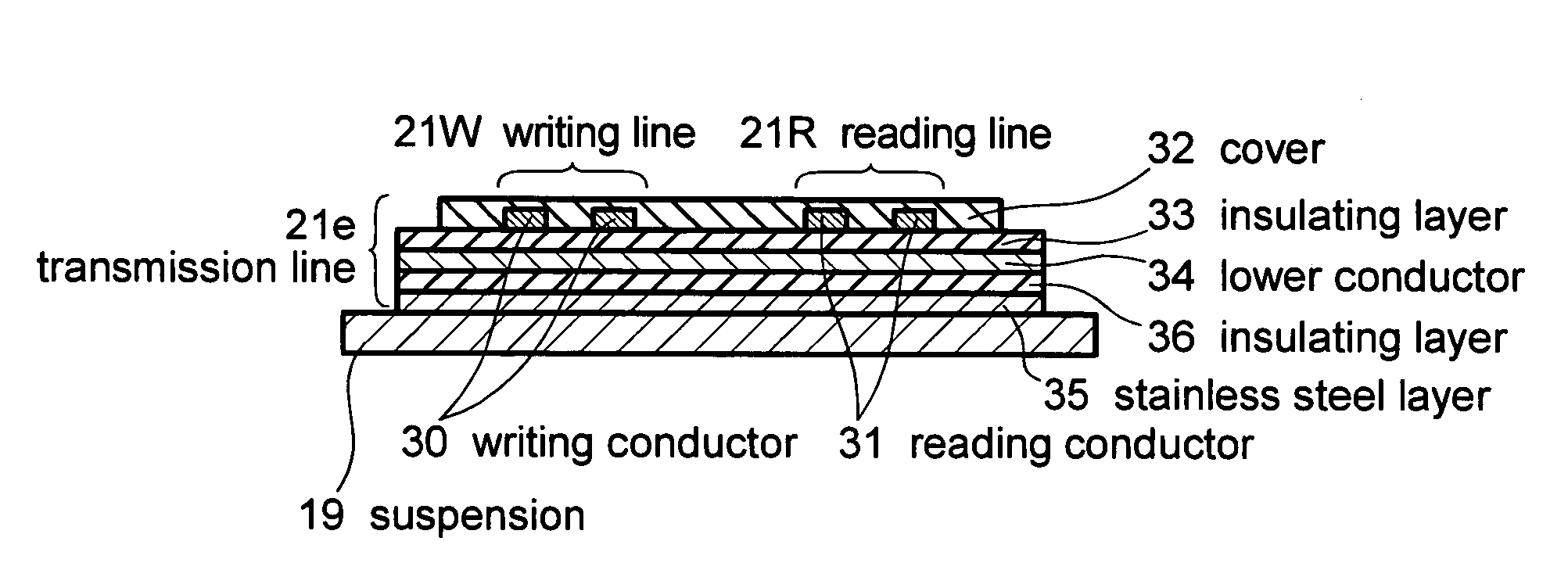

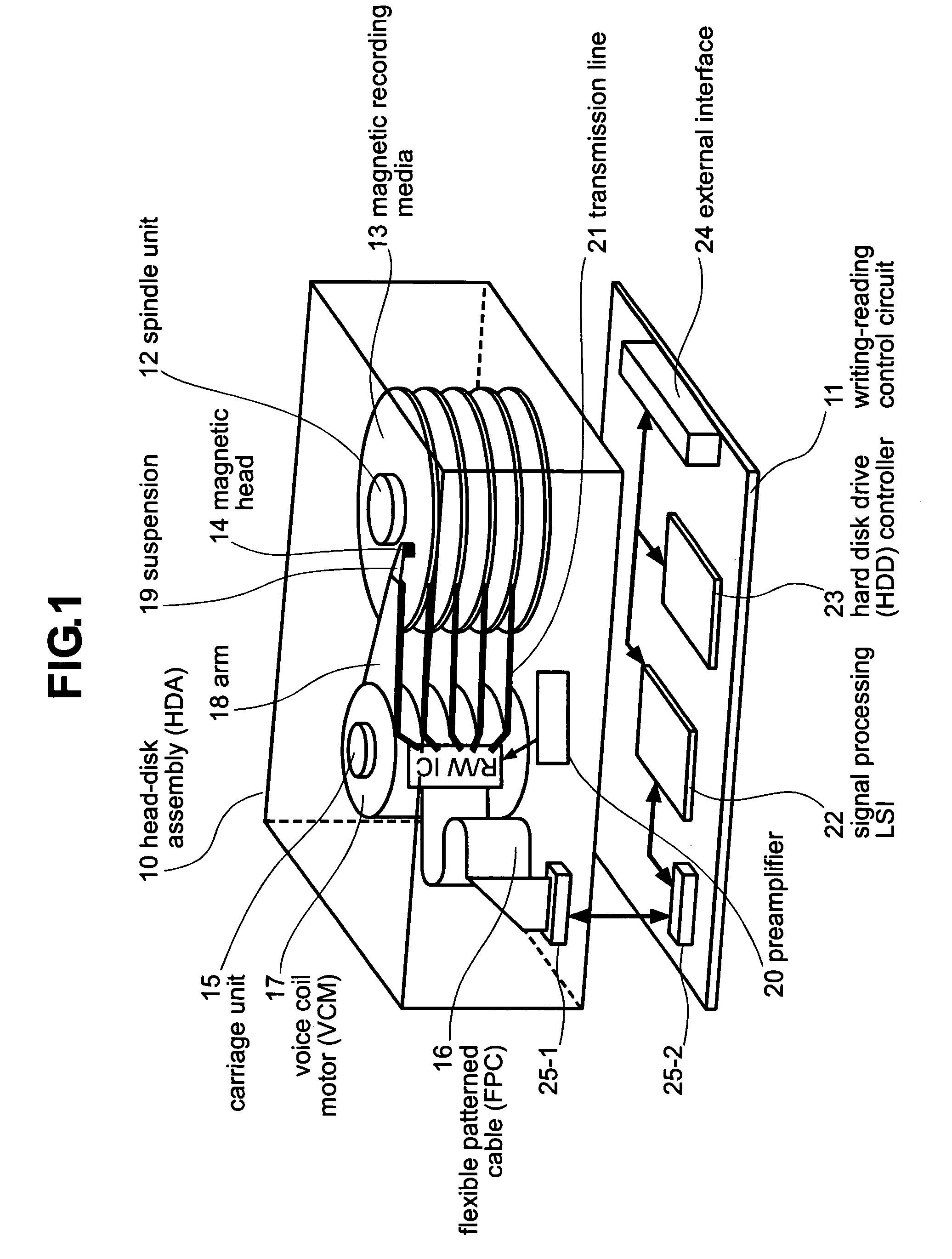

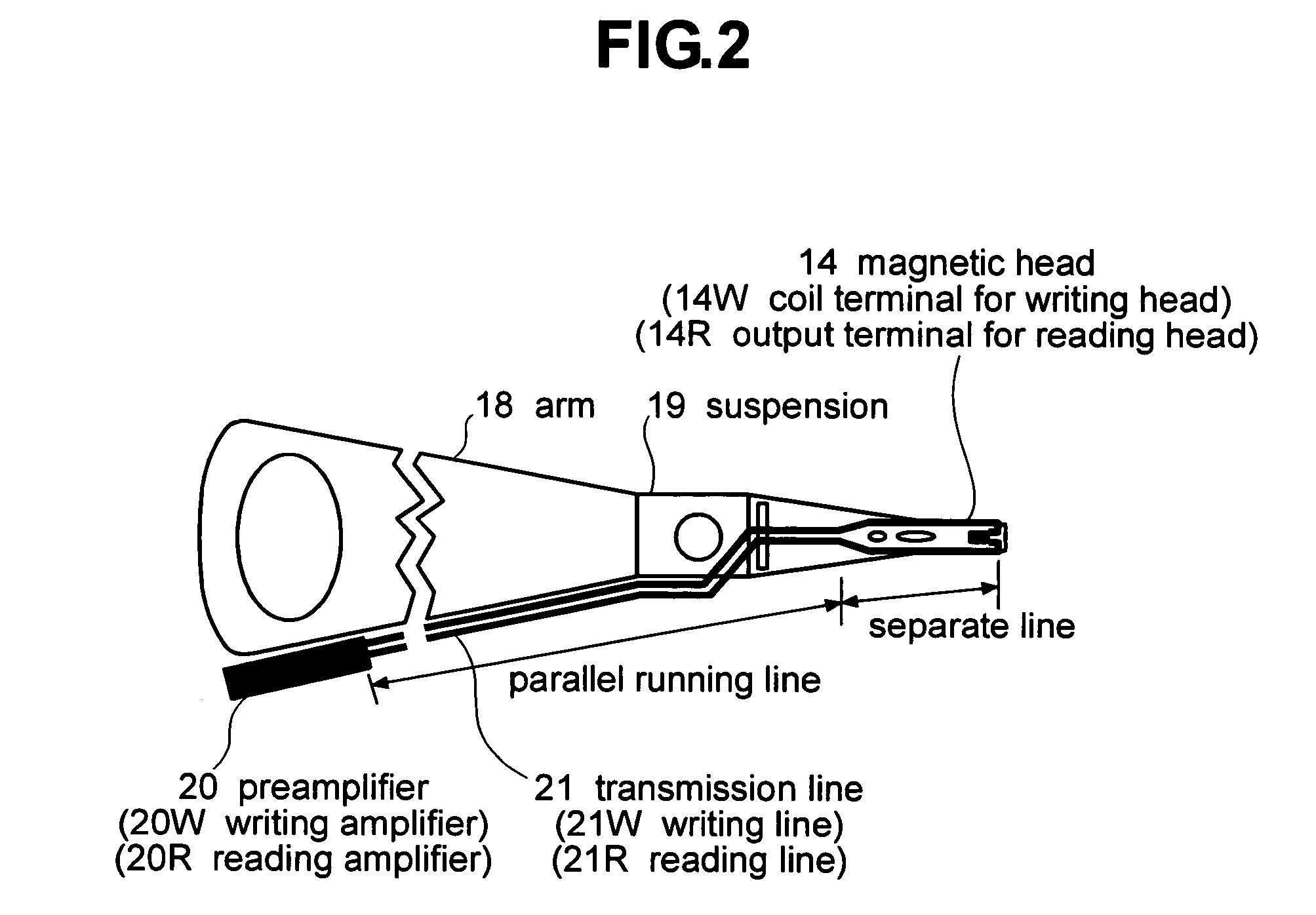

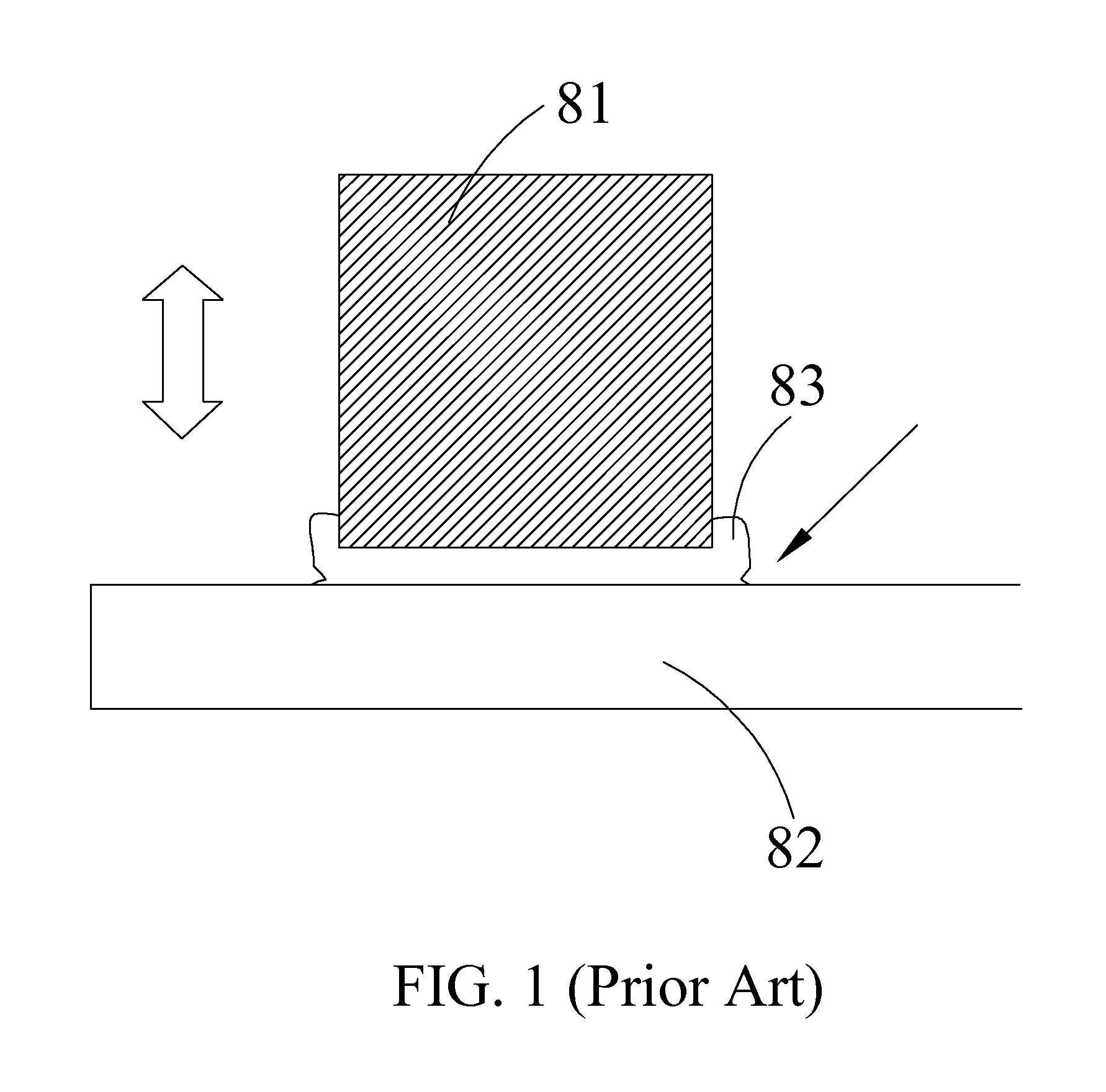

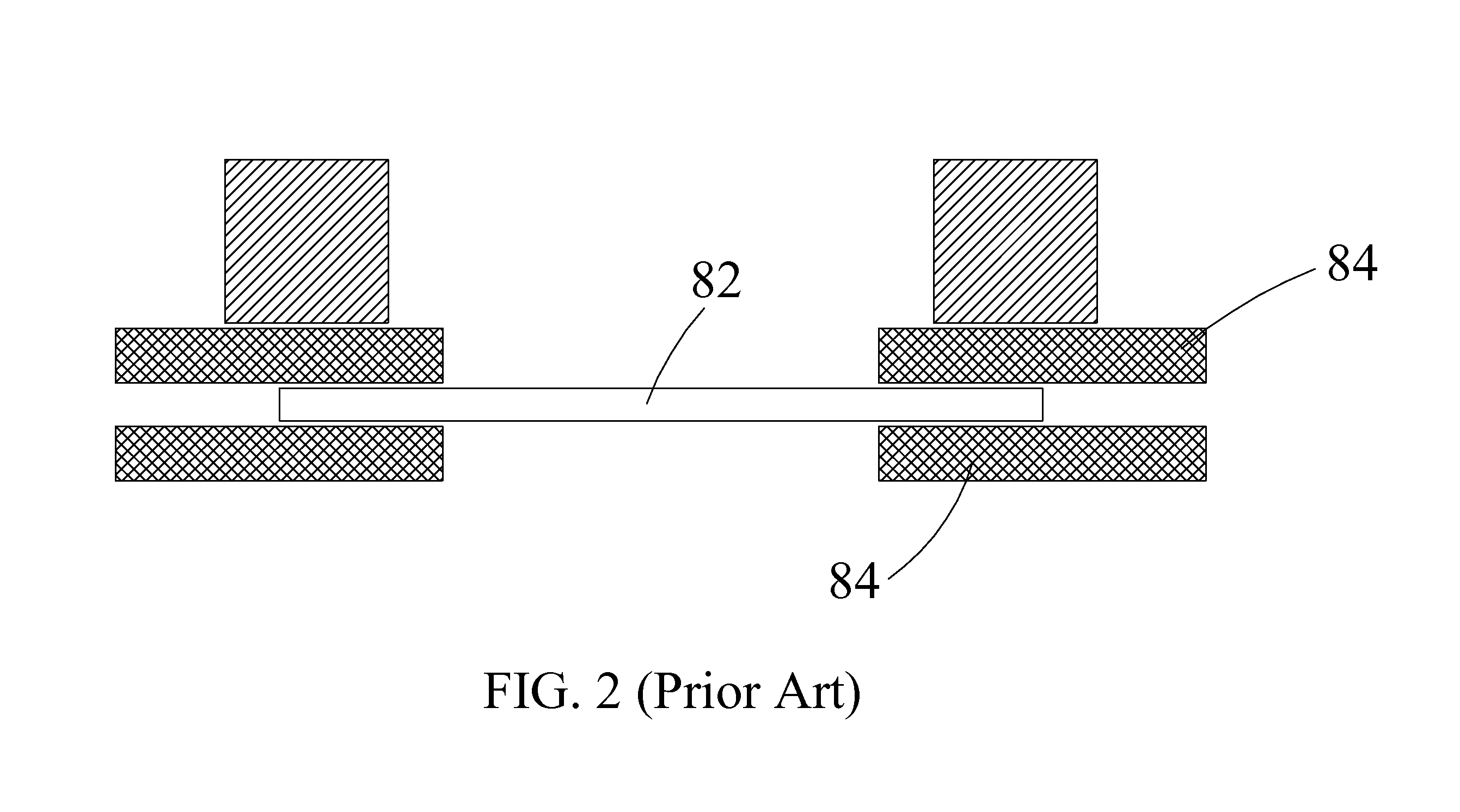

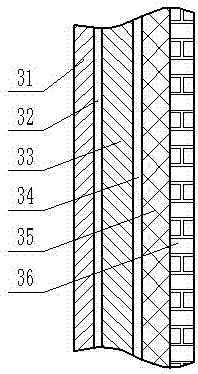

Magnetic disk drive having a suspension mounted transmission line including read and write conductors and a lower conductor

InactiveUS7319573B2Improve electrical performanceReduce transmission lossElectrotherapyMagnetotherapy using coils/electromagnetsElectrical conductorAlloy

Embodiments of the invention provide a magnetic disk drive which has improved electrical properties owing to a reduction in the loss of transmission line, improved vibration properties owing to a reduction in the stiffness of wiring around the head, and a flat impedance in the transmission line. In one embodiment, a magnetic disk drive comprises a suspension; a magnetic head coupled with the suspension and configured to write and read information to and from a magnetic recording medium; and a transmission line disposed on the suspension to transmit writing and reading information to and from the magnetic head. The transmission line includes a writing line and a reading line, a lower conductor disposed underneath the writing line and the reading line, and an insulating layer interposed between the lower conductor and the writing and reading lines. The lower conductor comprises copper or copper-based alloy and has a thickness of substantially less than 25 μm, desirably about 2-12 μm, and more desirably about 5 μm.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

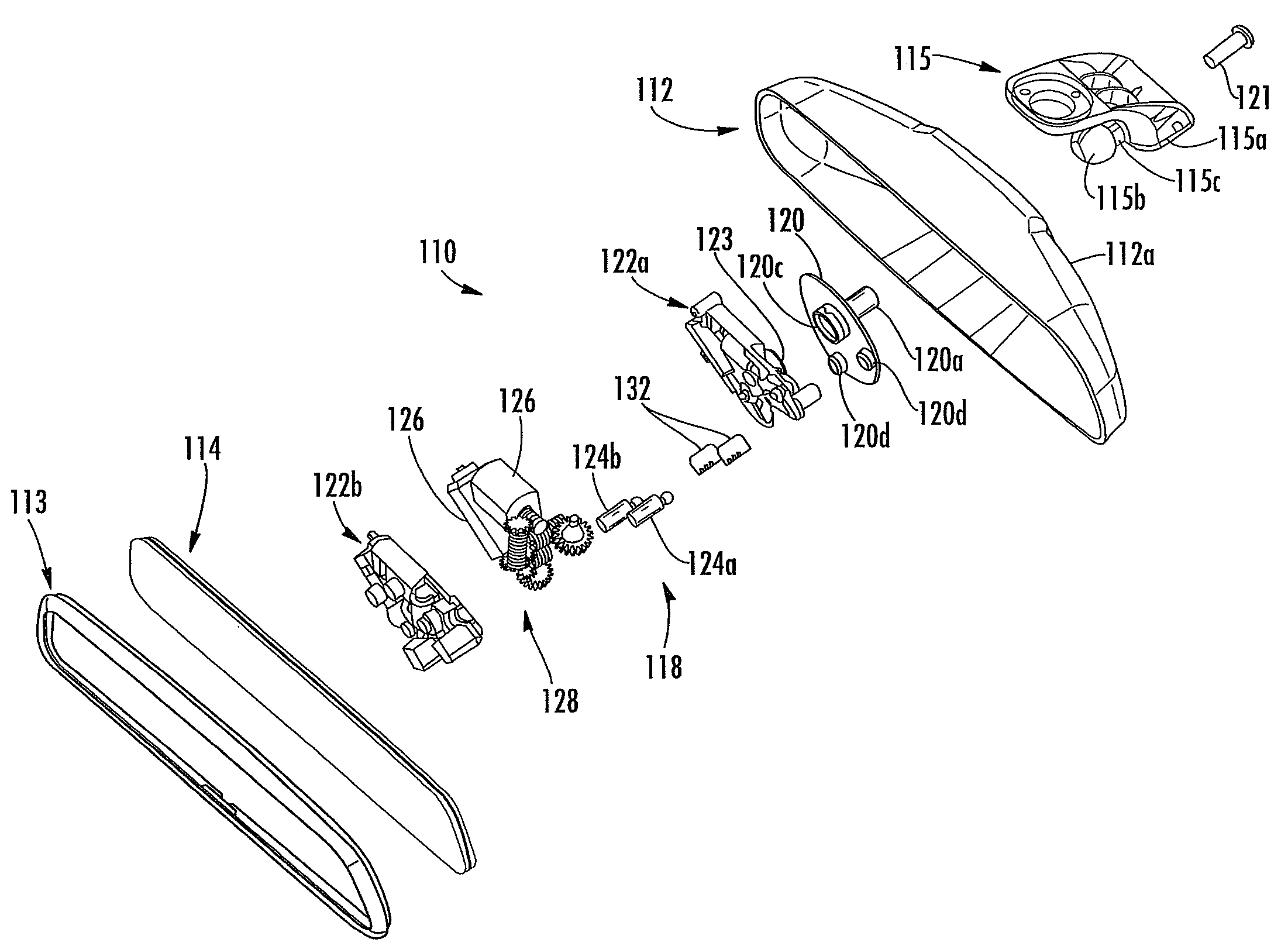

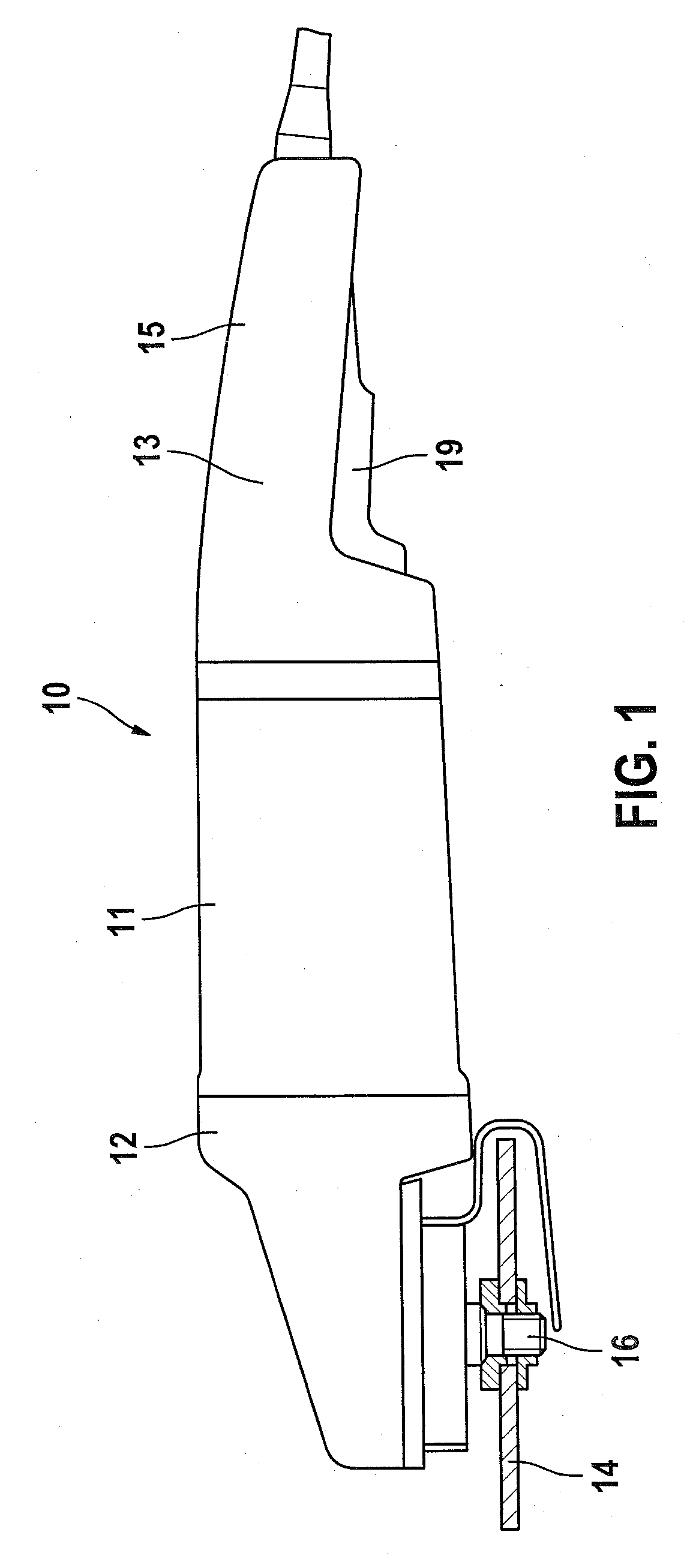

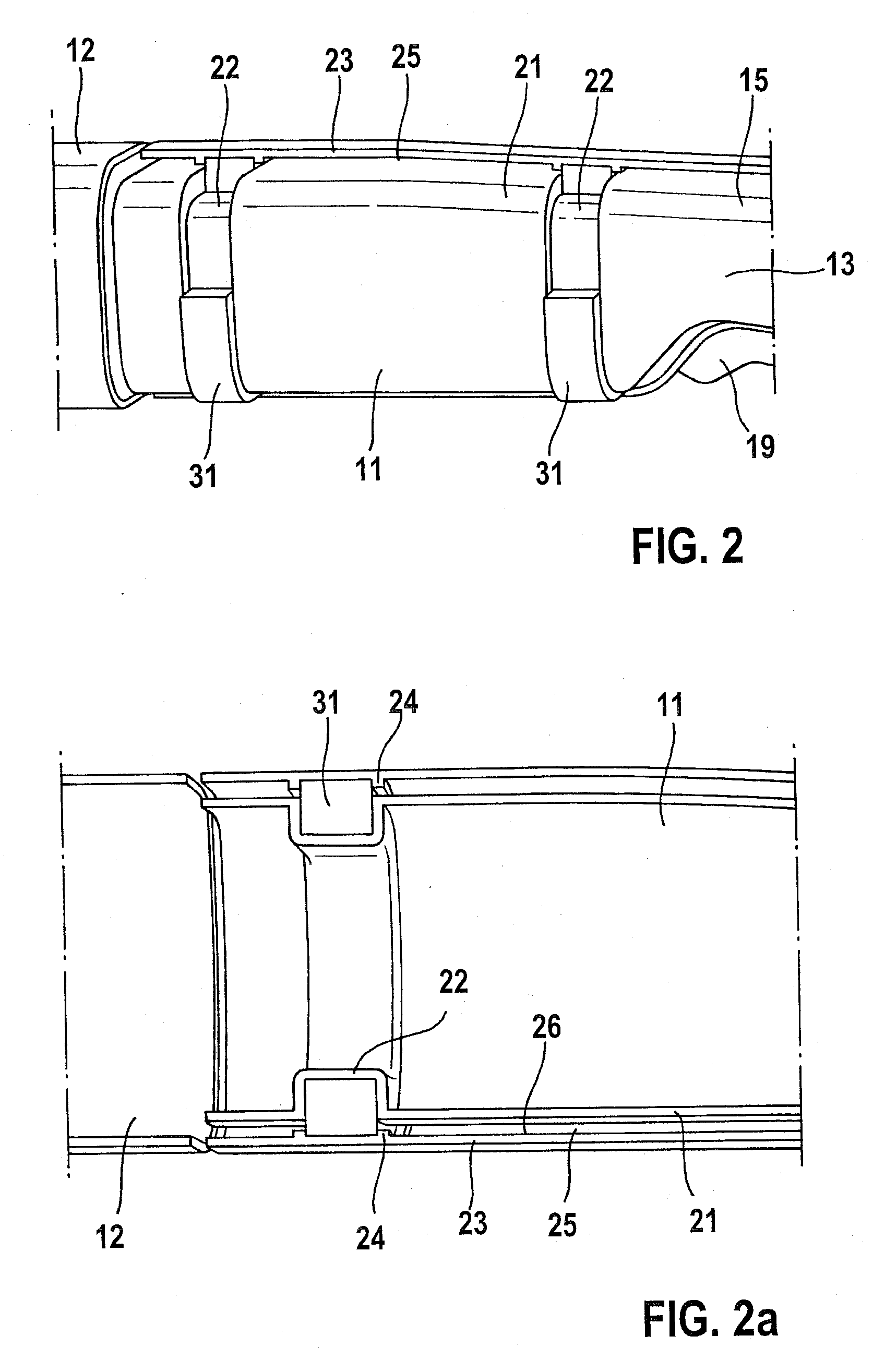

Vehicle interior rearview mirror assembly with actuator

A rearview mirror system for a vehicle includes an interior rearview mirror assembly having a mounting structure, an electrical actuator and a reflective element. The mounting structure may be configured to be detachably mounted at an attachment element adhered to an inner surface of the vehicle windshield. The mounting structure is adjustable relative to the vehicle windshield to generally vertically adjust a nominal setting of a rearward field of view of the reflective element. The electrical actuator is operable to adjust the reflective element in order to vertically and horizontally adjust a rearward field of view of the reflective element. The interior rearview mirror assembly may include an imaging sensor having a forward field of view through the vehicle windshield. The forward field of view of the imaging sensor may not be adjusted when the electrical actuator adjusts the rearward field of view of the reflective element.

Owner:DONNELLY CORP

Memory mirror system for vehicle

InactiveUS7104663B2Improved vibration characteristicsIncrease capacityMirrorsPicture framesEngineeringActuator

A vehicle memory mirror system of the present invention includes an interior rearview mirror assembly. The mirror assembly includes a mirror casing, with a reflective element, and a support, which is adapted to mount the mirror assembly to a vehicle. An electrical actuator is located interiorly of the mirror casing and is adapted to adjust the orientation of the reflective element to adjust the rearward field of view of the reflective element.

Owner:DONNELLY CORP

Vehicular mirror system

InactiveUS20070002477A1Improved vibration characteristicsIncrease capacityMountingsOptical viewingActuatorControl theory

A vehicular interior rearview mirror system includes a housing, a mounting member configured to mount to a vehicle windshield, an electrical actuator, which is supported by the mounting member with the weight of the electrical actuator being transferred to the windshield by way of the mounting member, and a reflective element. The reflective element is mounted to the electrical actuator and has a rearward field of view when mounted to the electrical actuator, which provides adjustment of the rearward field of view of the reflective element.

Owner:DONNELLY CORP

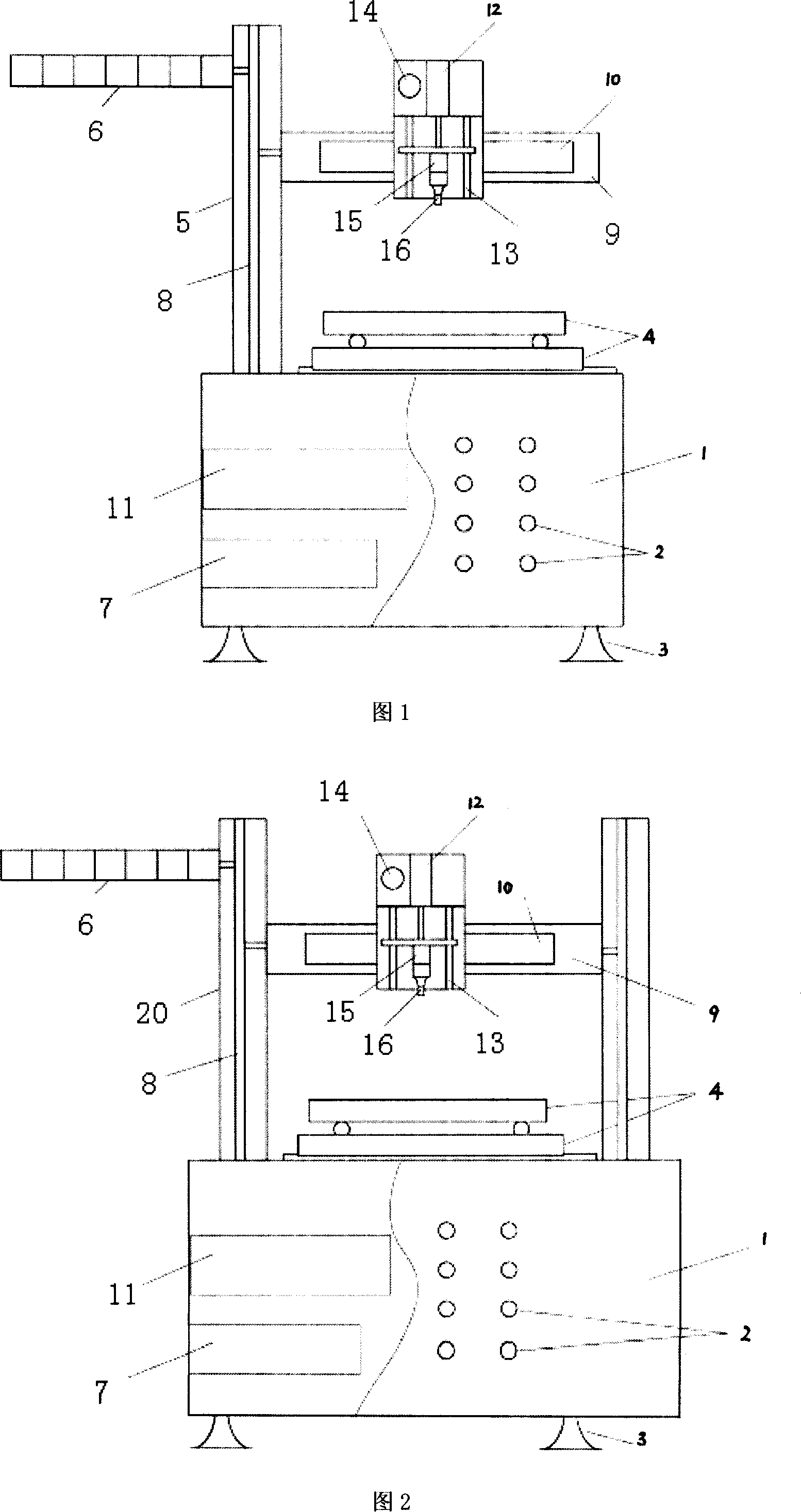

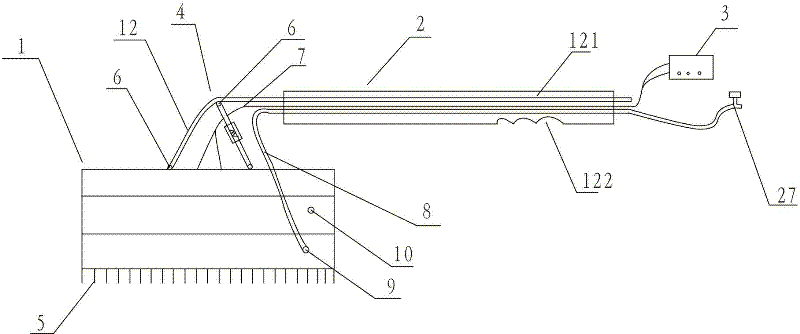

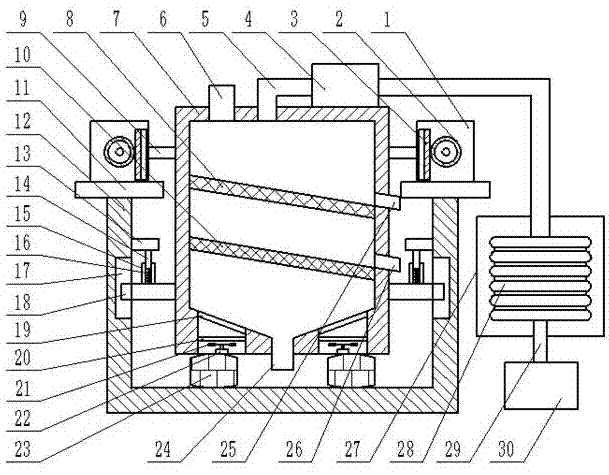

Aluminum, aluminum alloy and composite material ultrasonic vibration liquid phase welding equipment therefor

InactiveCN101011776AFlexible welding operationConvenient welding operationMechanical vibrations separationWelding/soldering/cutting articlesTemperature controlUltrasonic welding

The invention provides an ultrasonic vibrating liquid phase welding device for aluminum, aluminum alloy and other composite material, which comprises control box installed with ultrasonic generator inside, control knob and wire connecting post on the panel, clipping working bench on the upper surface of the control box, bracket on the top of the control box, temperature display panel and ultrasonic welding head installed on the bracket, one end of the electrical thermocouple connecting with the inspecting work piece, the other connecting with the temperature control module inside the control box through the wire connecting post on the control panel, temperature control module connecting with the temperature display panel, displaying the temperature from the display, ultrasonic welding head connecting with the ultrasonic generator through signal wire, with pressurizing device, energy changing device, width changing bar on the ultrasonic welding head, with the rear two connected and to connect with the first. Without using brazing flux, it can realize the welding of aluminum, aluminum alloy and other composite material.

Owner:HARBIN INST OF TECH

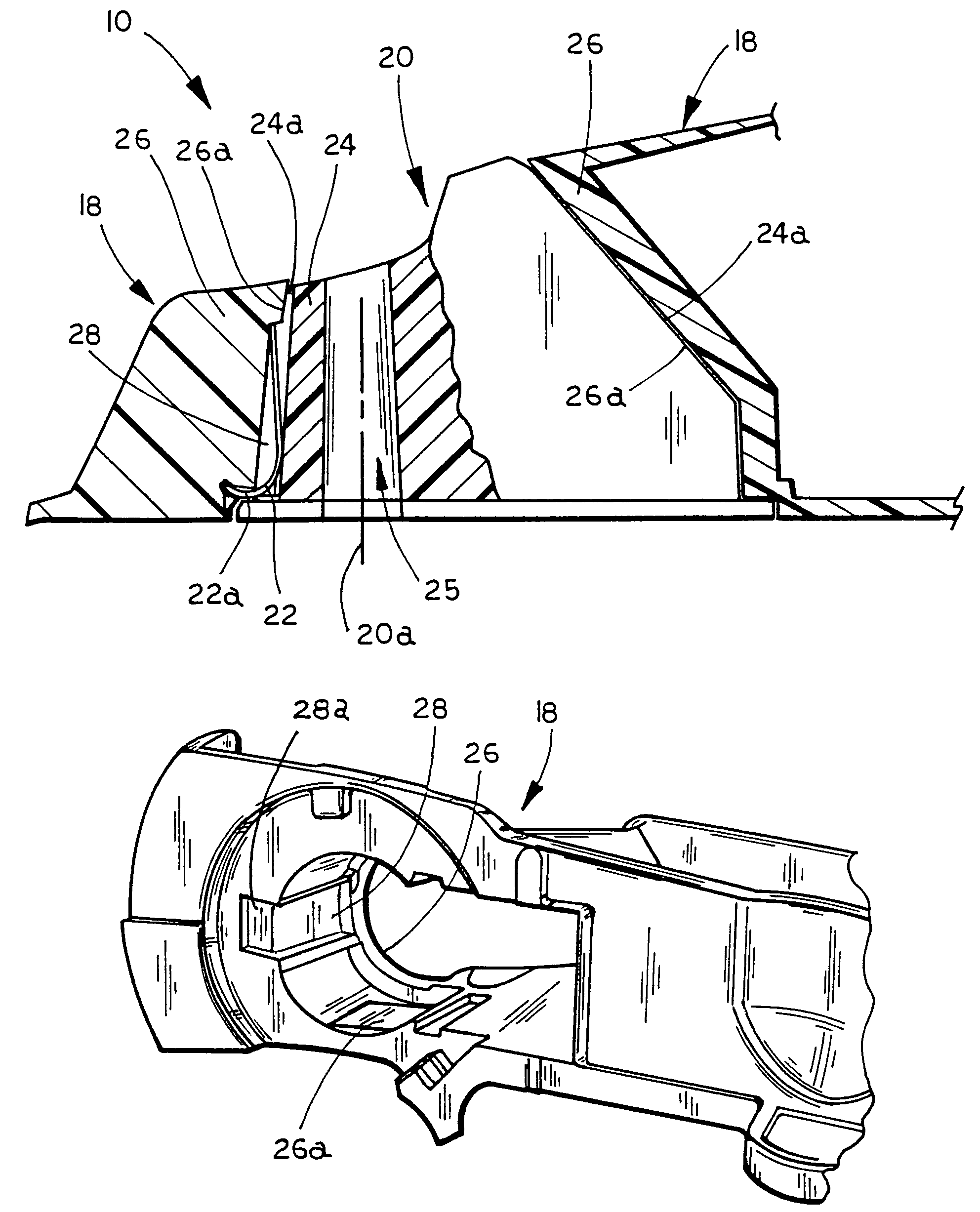

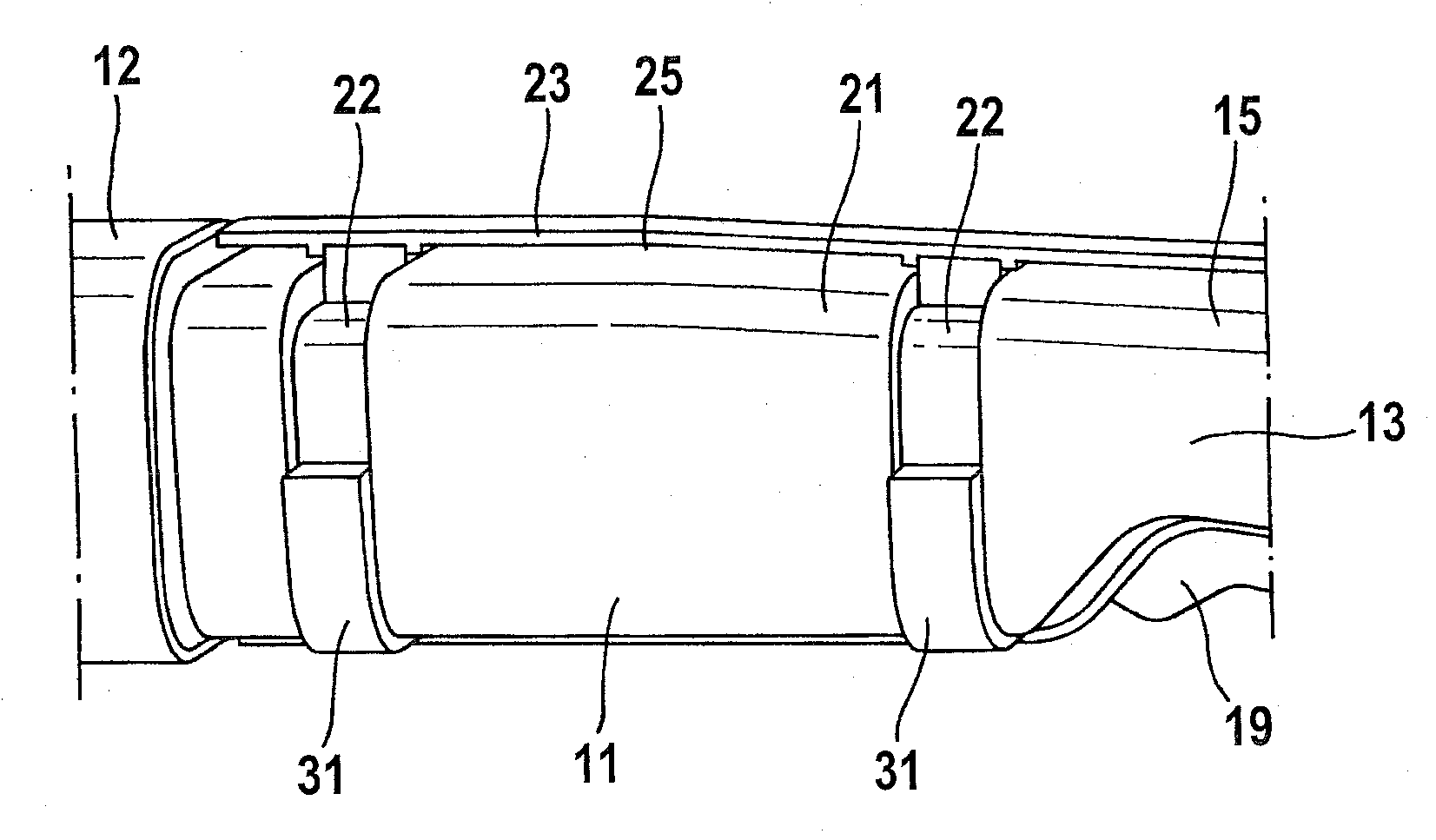

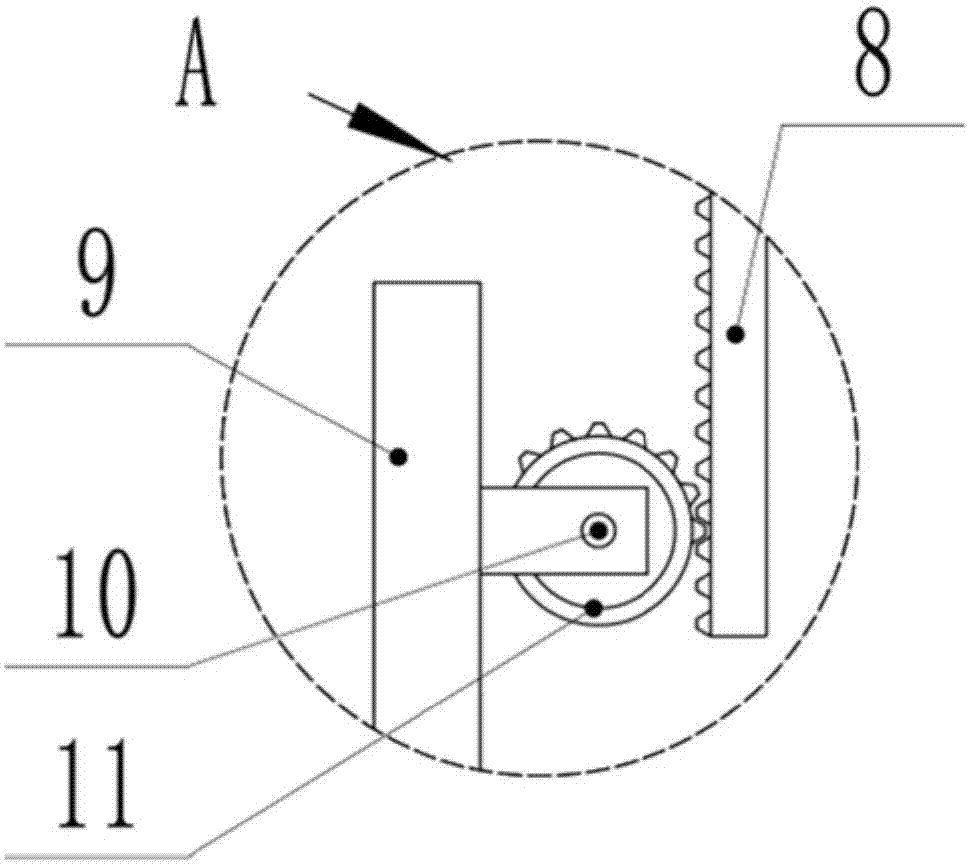

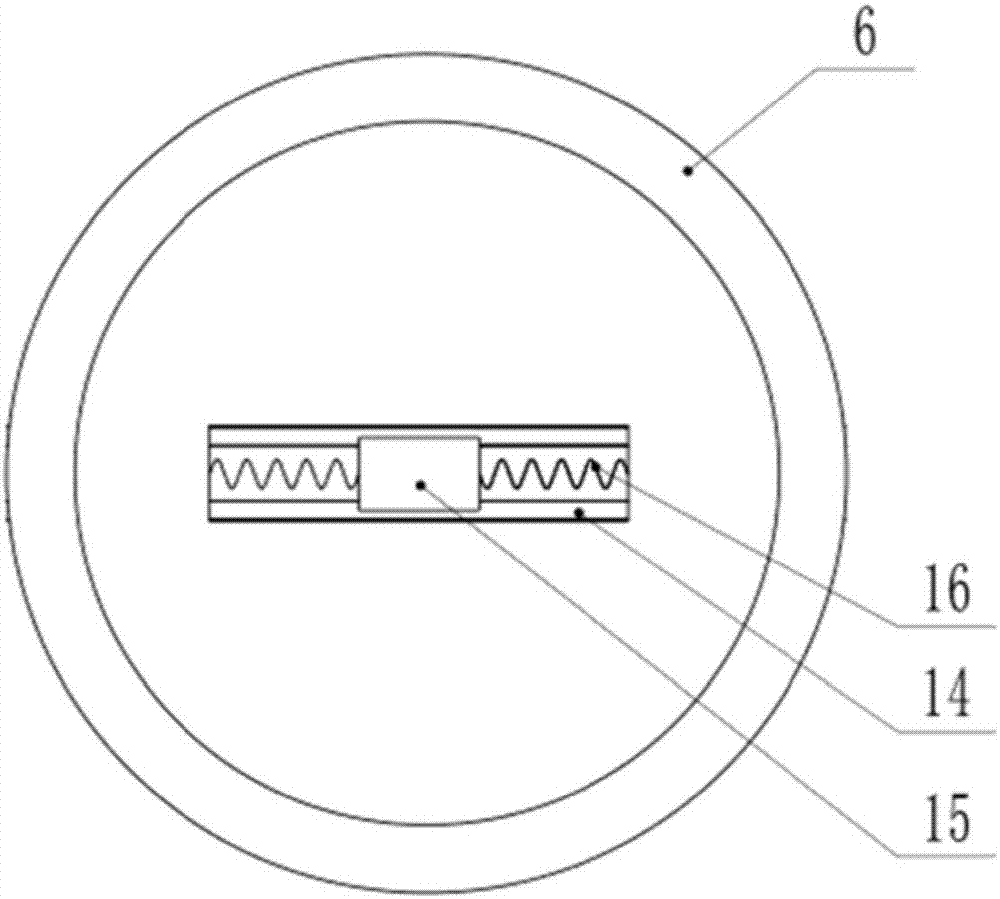

Powerfold exterior mirror assembly

InactiveUS7093946B2Limit and substantially reduce vibrationImprove the vibration effectMirrorsMountingsActuatorMechanical engineering

An exterior rearview mirror assembly for a vehicle includes a base portion mounted to the vehicle and a movable portion that is pivotable relative to the base portion via a motor or motorized actuator or powerfold unit or the like. The powerfold unit is operable to pivot the movable portion relative to the base portion. The powerfold unit is mounted at one of the movable portion and the base portion and engages a receiving portion of the other of the movable portion and the base portion. A resilient element is positioned between and at least partially in engagement with the powerfold unit and the receiving portion. The resilient element is resilient and may at least partially compress as the powerfold unit is engaged with the receiving portion, thereby reducing or dampening vibration of the head portion relative to the base portion of the mirror assembly.

Owner:DONNELLY CORP

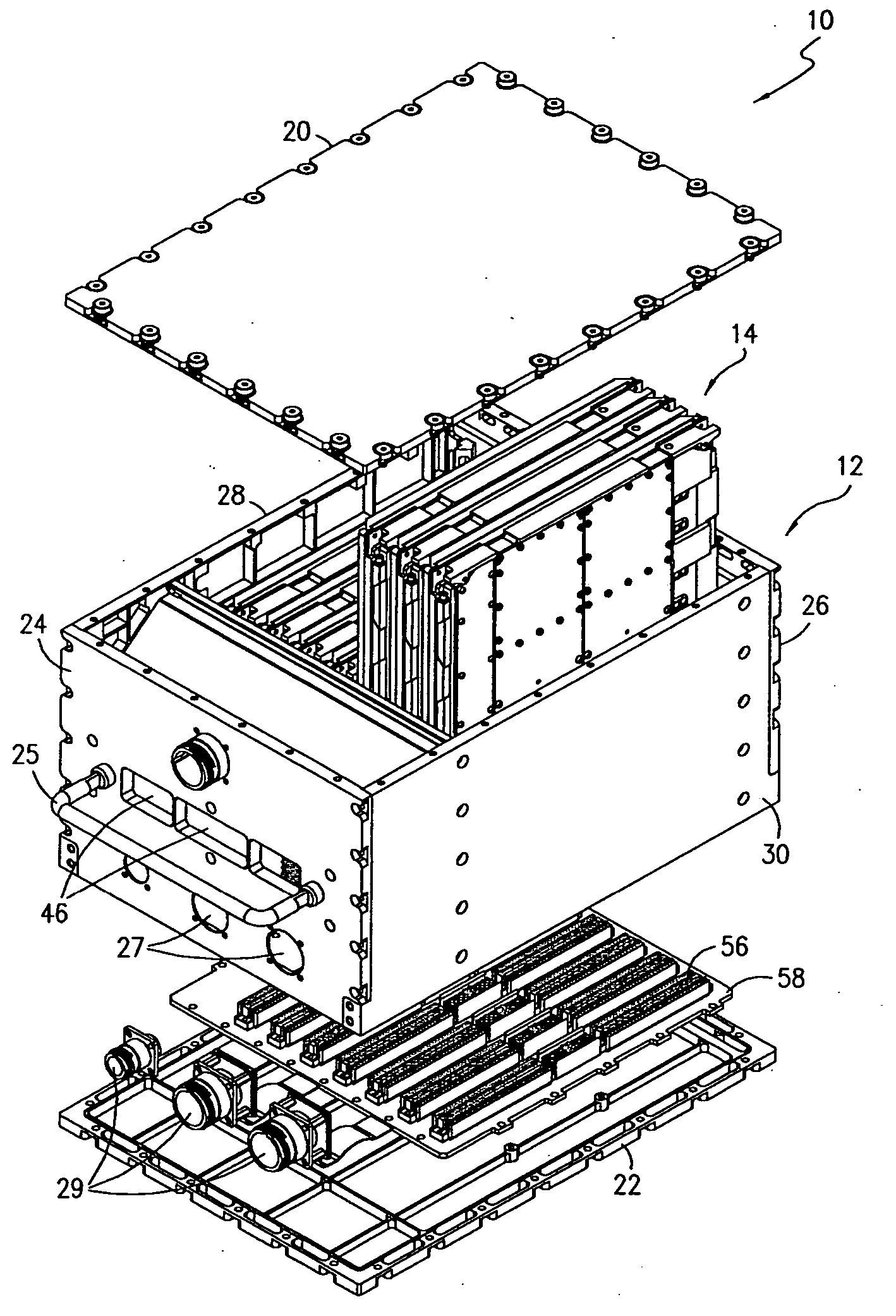

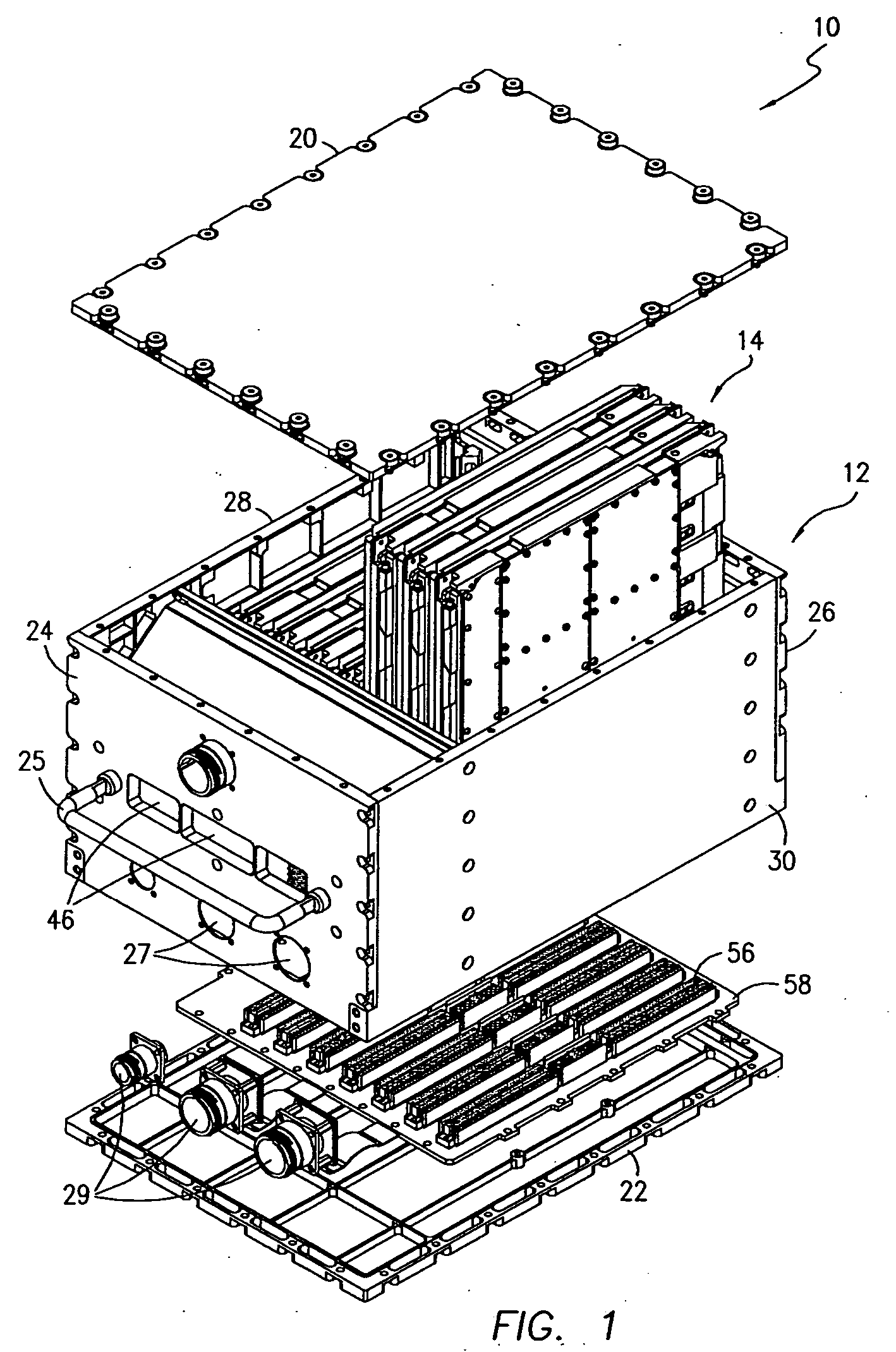

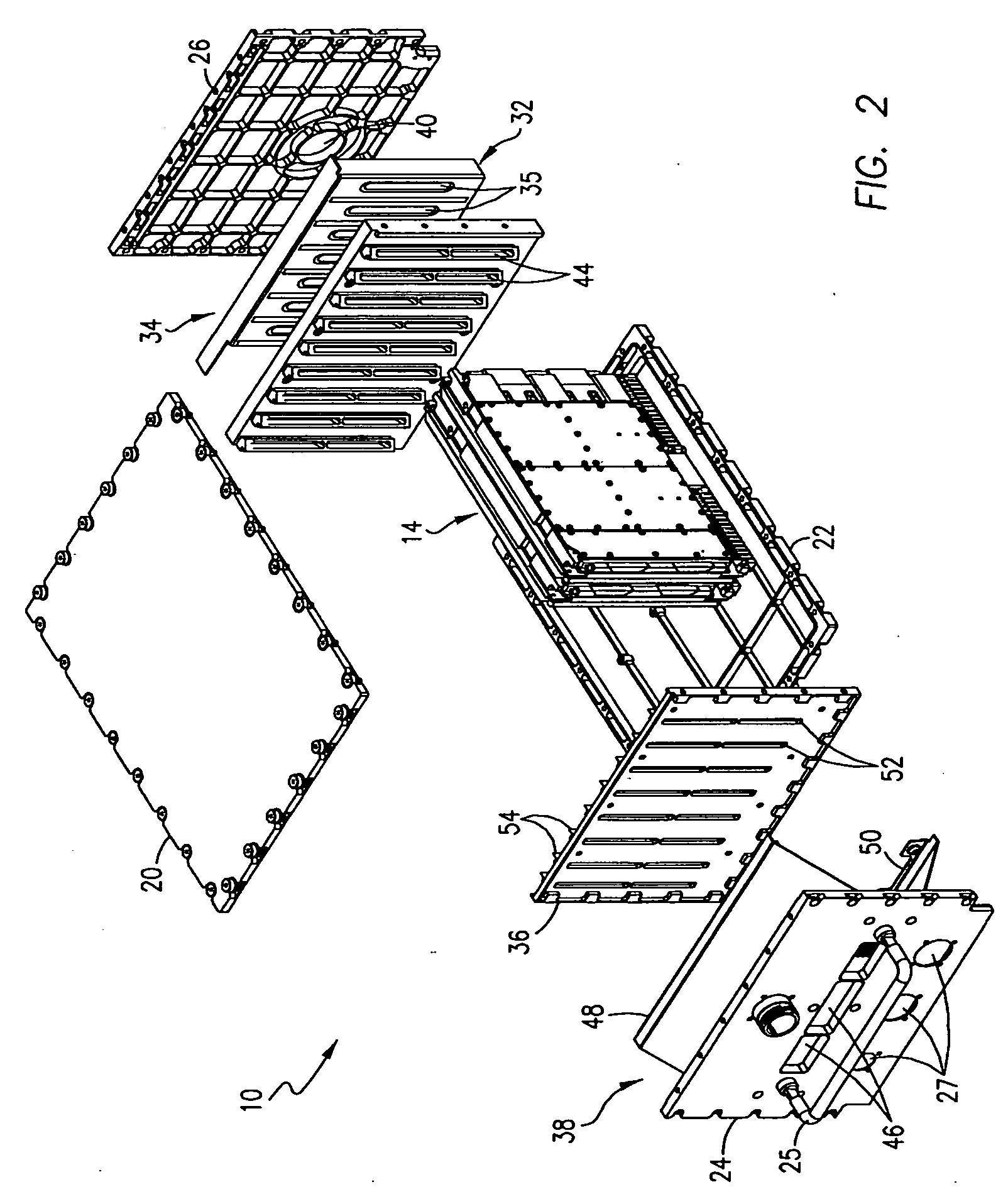

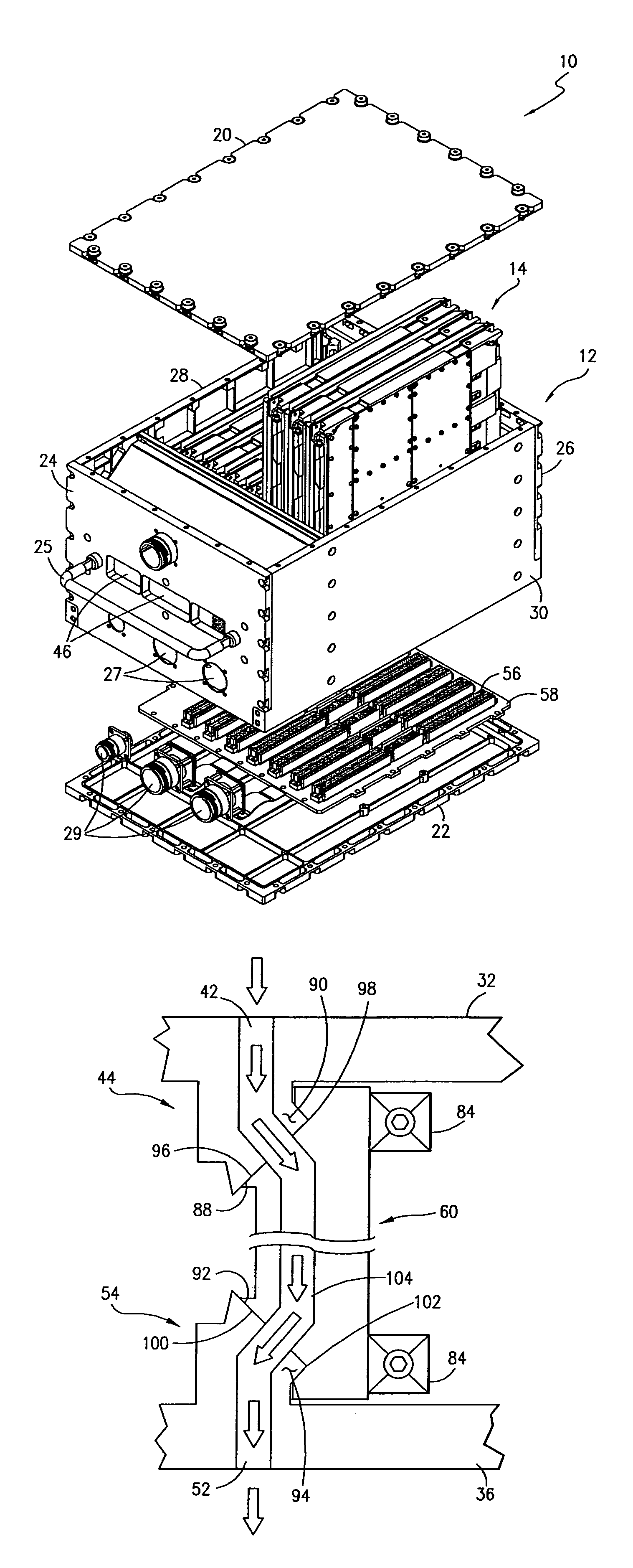

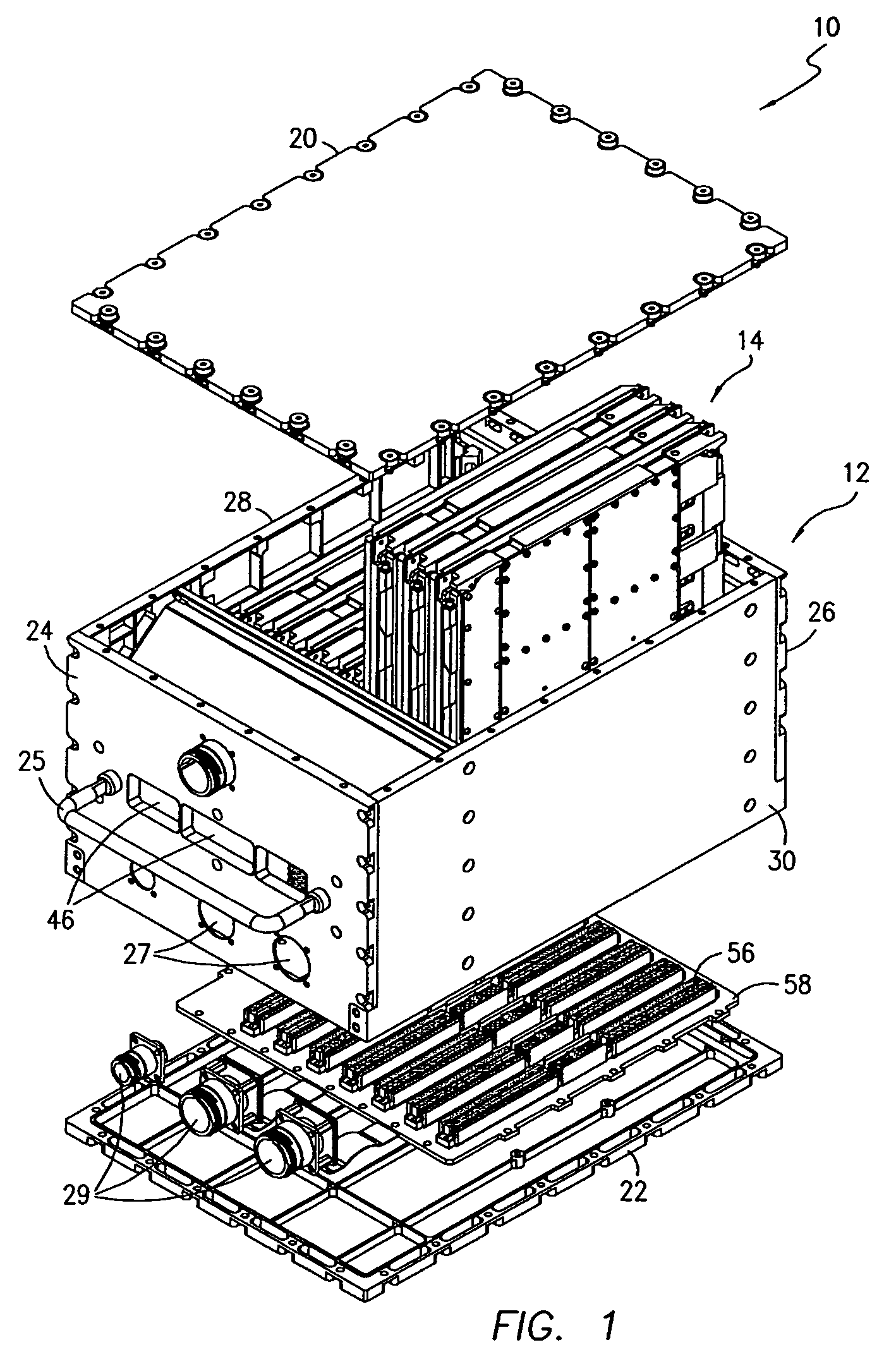

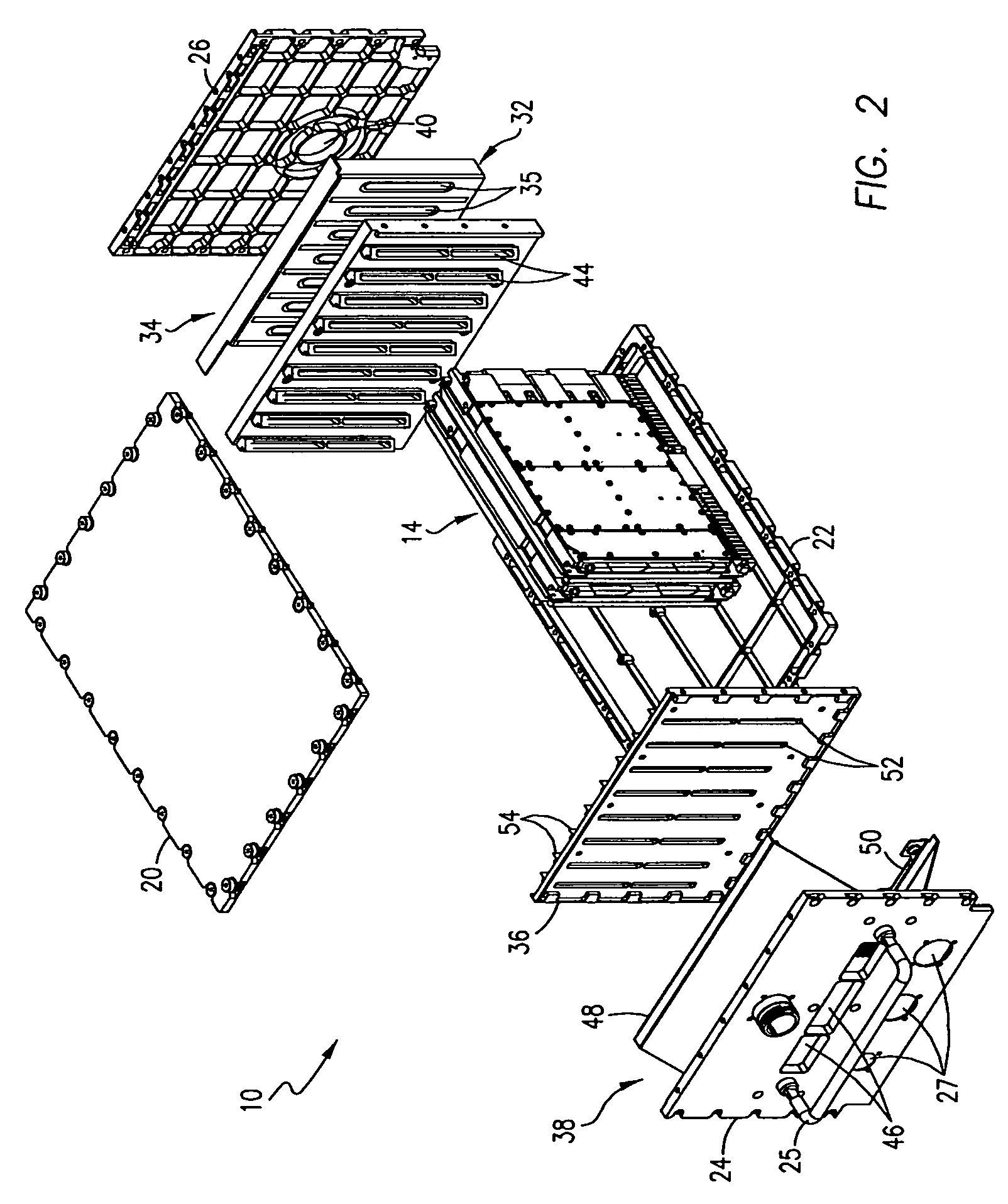

Heat exchanger system for circuit card assemblies

ActiveUS20060133033A1Raise transfer toEfficient heat transferAir heatersInsulated cablesEngineeringConductive materials

An apparatus for housing and cooling circuit card assemblies employed in communication and other systems is disclosed including a chassis having opposed end walls which are formed with a series of spaced inlet card guides and correspondingly spaced outlet card guides, respectively. A straight-pass heat exchanger is directly mounted to each circuit card assembly via thermally conductive material, and opposed ends of the heat exchanger are mounted by a wedge lock to respective inlet and outlet card guides. The heat exchanger employs unique angled interface geometry that creates a gasketless airtight joint with complimentary inlet and outlet card guide geometry through which cooling air passes.

Owner:HARRIS CORP

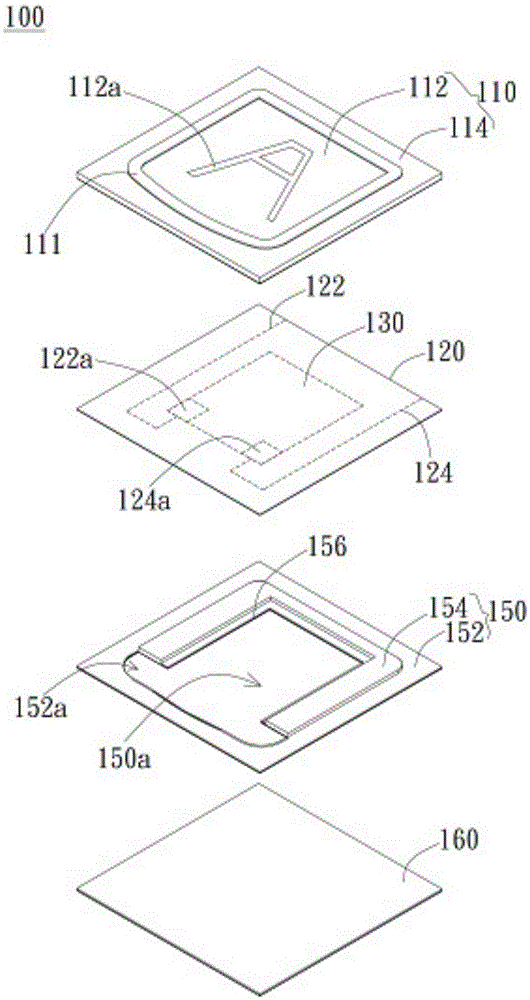

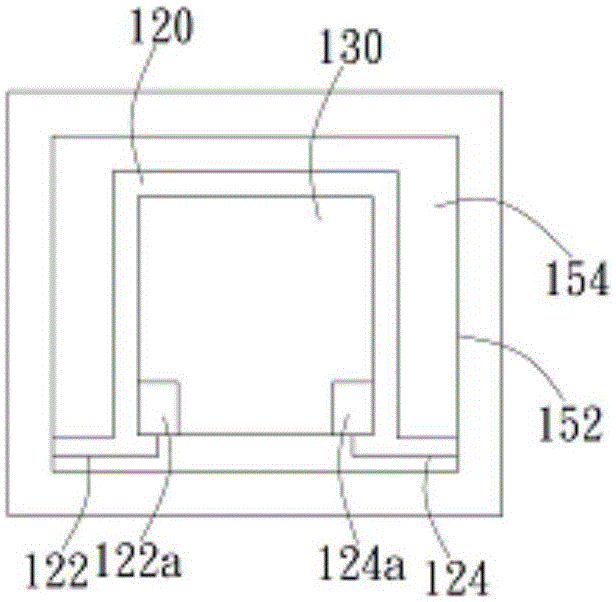

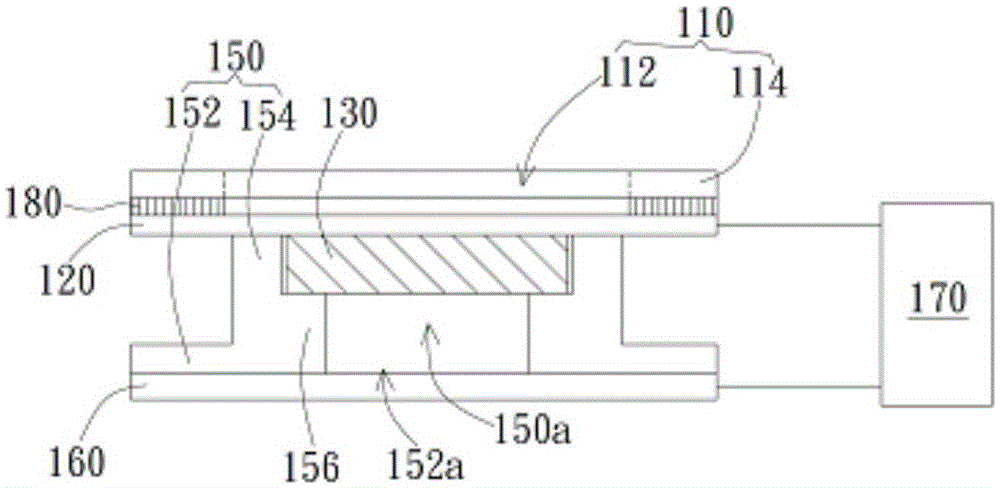

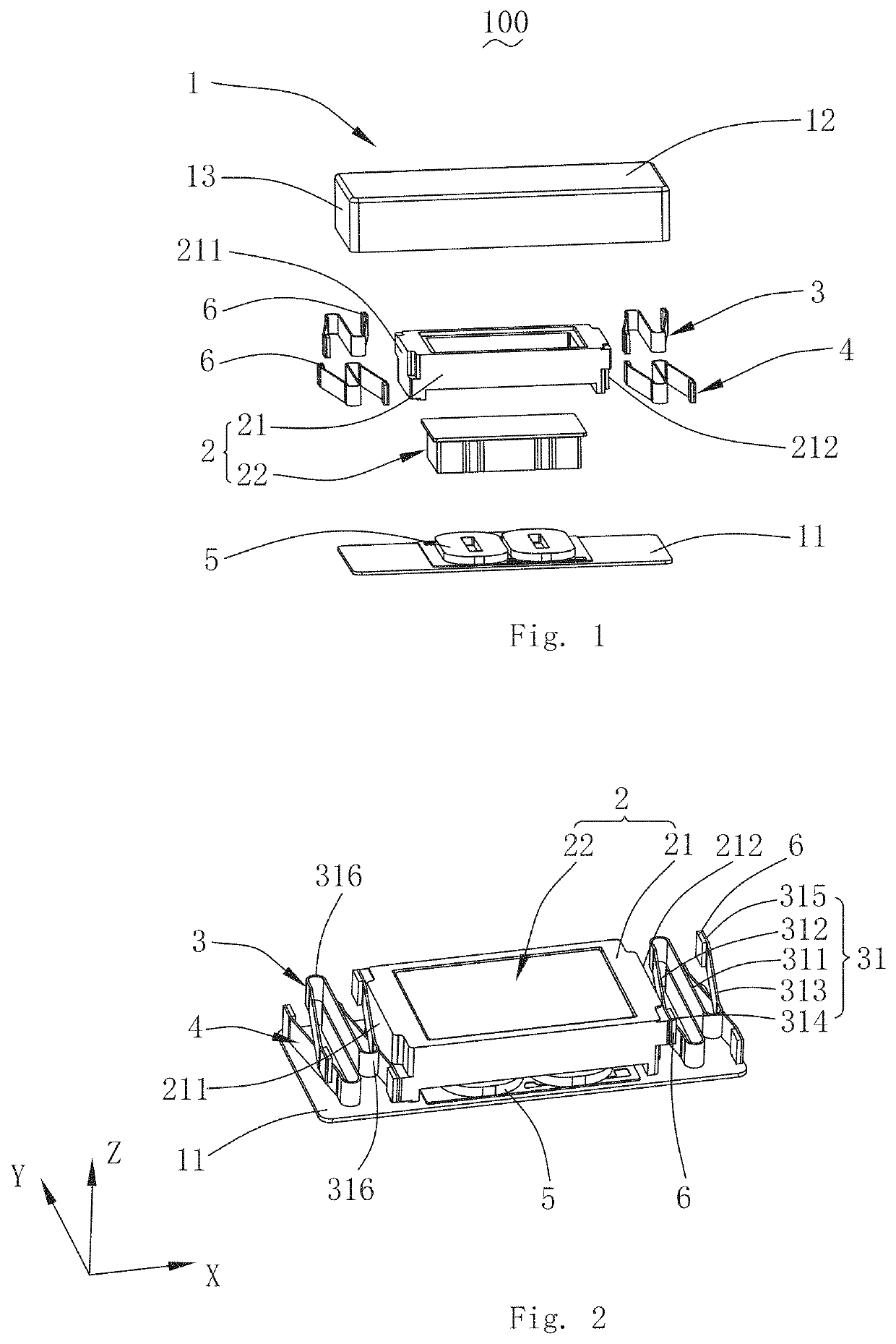

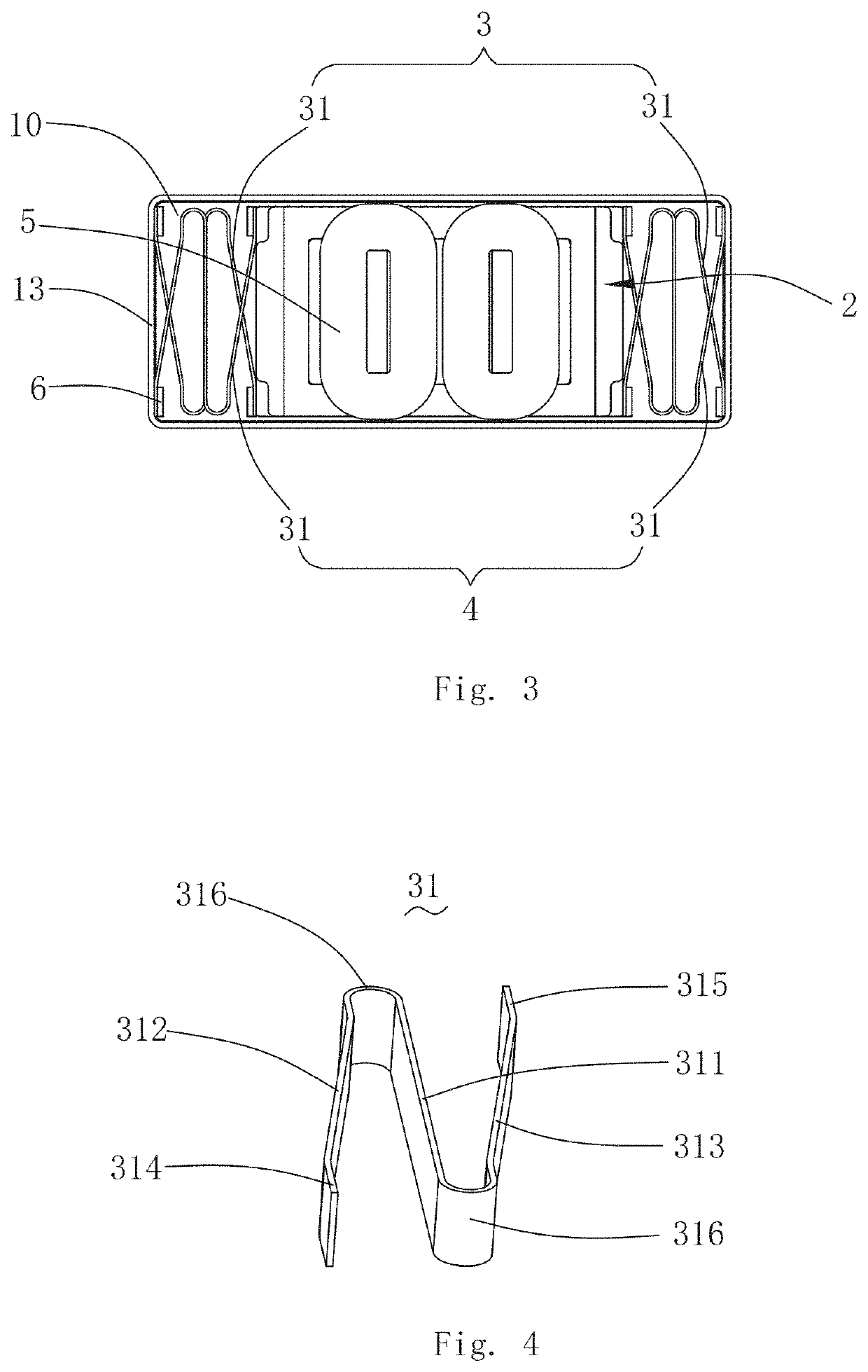

Key structure and input device

ActiveCN105097341AReduce kinetic energy lossLow costElectric switchesTactile feedbackKinetic energyInput device

The invention relates to a key structure and an input device. The key structure comprises a key cap layer, a circuit layer, a touch generator, a support structure layer and an adhesion layer, wherein the key cap layer comprises a key cap region and a peripheral region; the peripheral region is adjacent to the key cap region; the circuit layer is arranged below the key cap layer; the touch generator is electrically connected with the circuit layer; the support structure layer is arranged below the circuit layer, and comprises an accommodating space; the touch generator is located in the accommodating space; and the adhesive layer is arranged between the key cap layer and the circuit layer and corresponds to the peripheral region. According to the key structure and the input device provided by the invention, the adhesive layer is only arranged on the part (namely the peripheral region) outside the key cap region, so that the kinetic energy loss when the touch generator vibrates can be effectively reduced. Furthermore, according to the key structure and the input device provided by the invention, the vibration effect can be strengthened, the appearance design can be reinforced, the operation convenience can be improved or the cost can be reduced through the key cap layer with different structure designs and different material choices.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

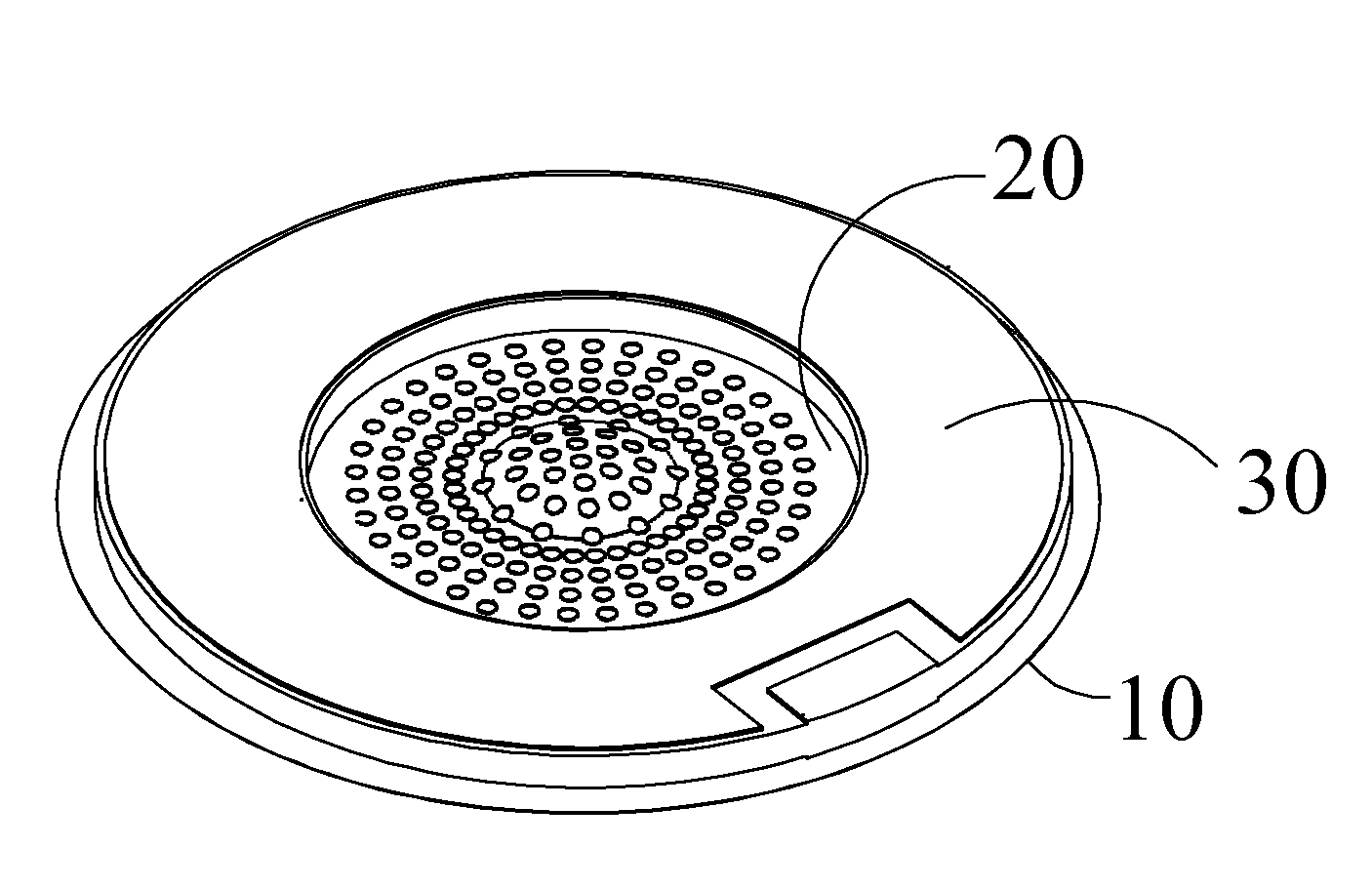

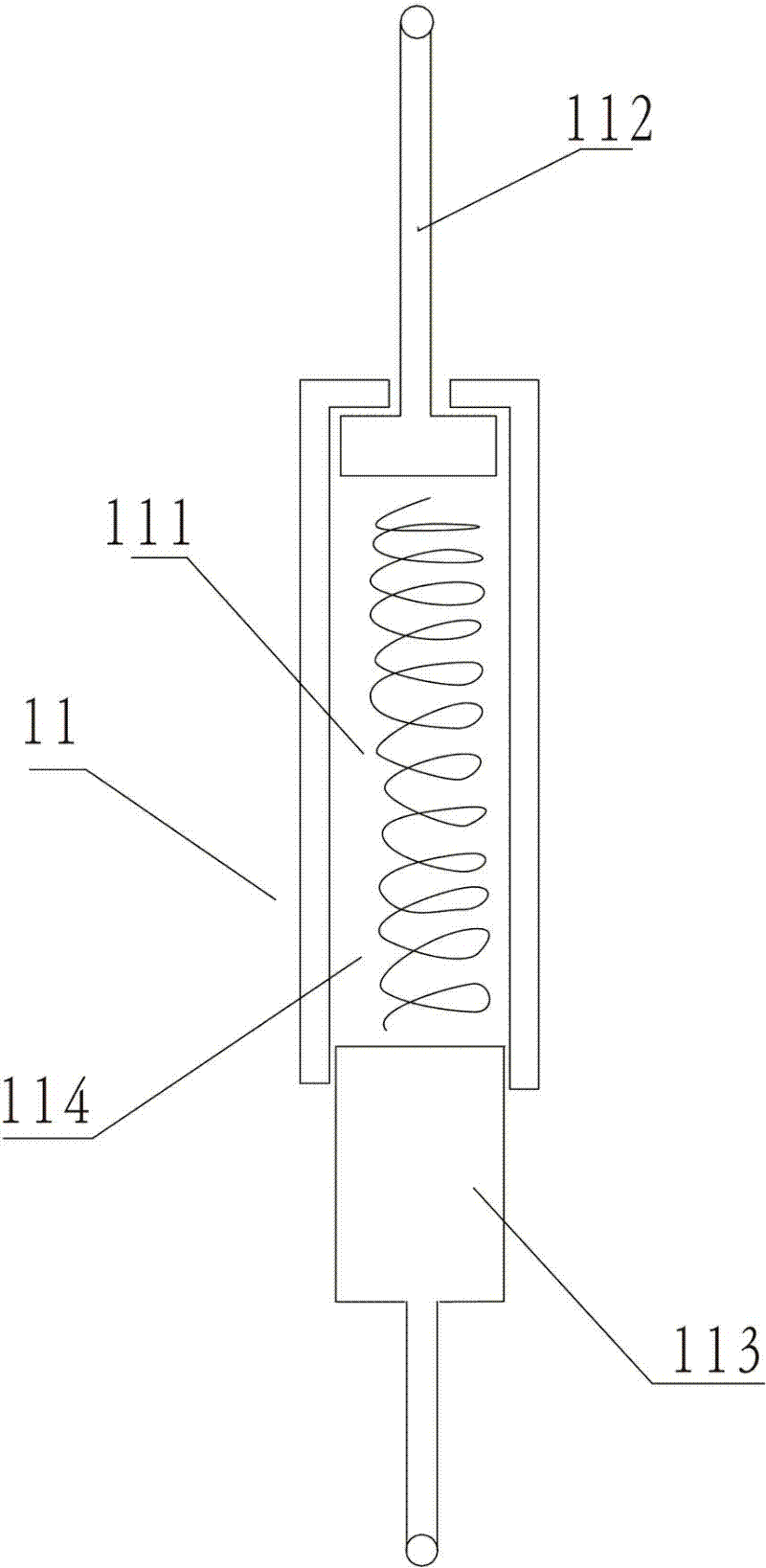

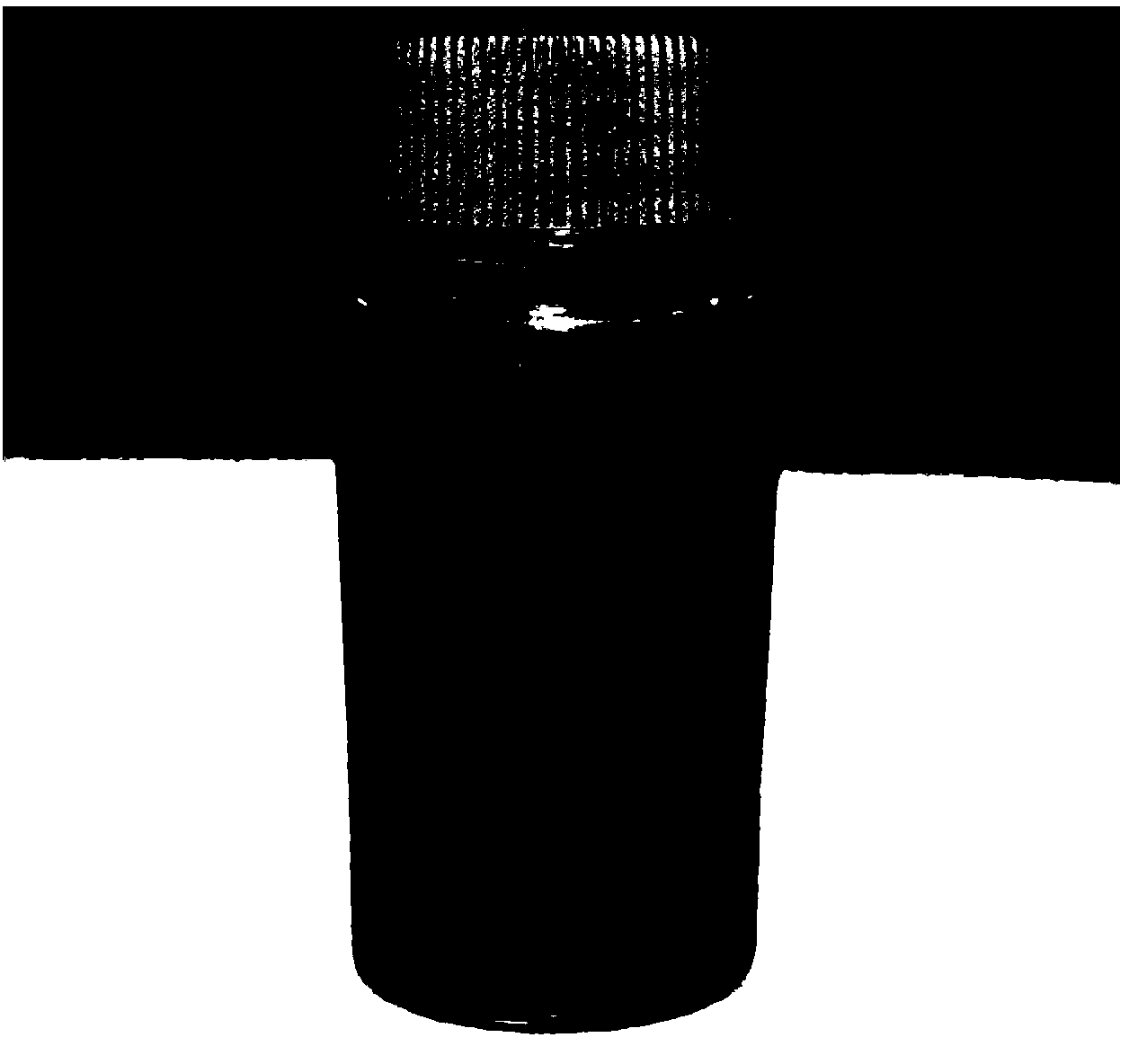

Nebulizing assembly

InactiveUS20110233302A1Improve bindingDrag minimizationMovable spraying apparatusSpray nozzlesEngineeringDrag minimization

A nebulizing assembly includes a base having a centered through hole; an nebulizing plate disposed on the base, the nebulizing plate having a radially outer area formed as a gluing section provided with a plurality of glue holes and a central area formed as a spraying section corresponding to the through hole on the base; and a piezoelectric driving element stacked on a top of the nebulizing plate and attached to the gluing section, and having a centered mist outlet. A glue layer is applied over the gluing section to fill up all the glue holes and can provide an extremely high bonding force when becoming dried to thereby firmly bond the nebulizing plate between the base and the piezoelectric driving element. The mist outlet and the through hole on the base have the same diameter to enable minimized resistance applied the whole structure to the nebulizing plate.

Owner:MICRO BASE TECH CORP

Vehicle interior rearview mirror assembly with actuator

Owner:DONNELLY CORP

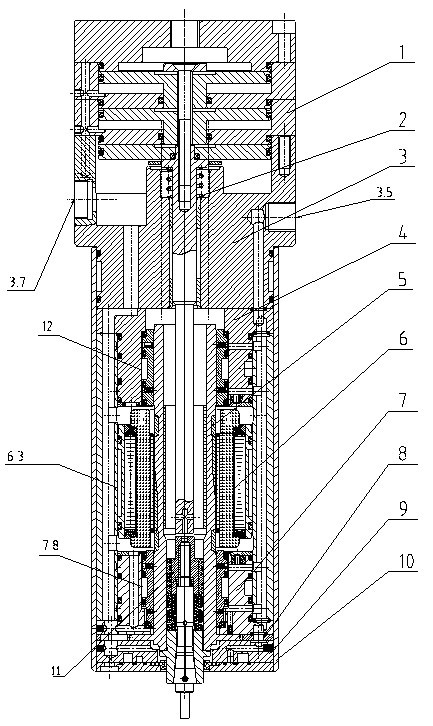

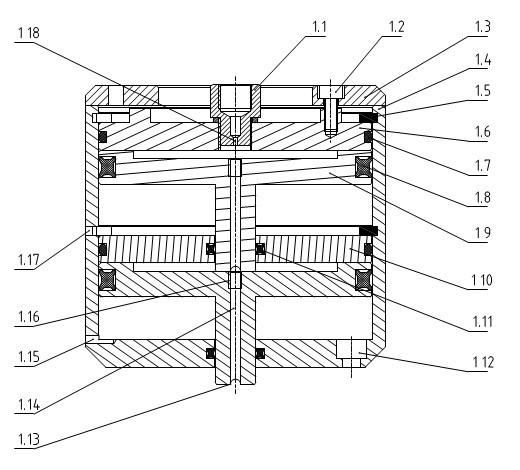

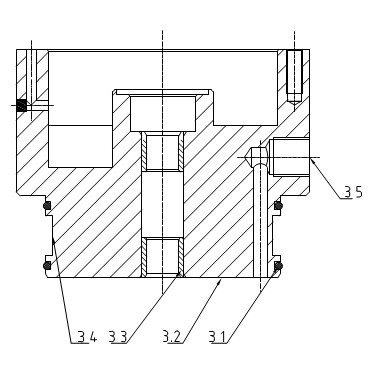

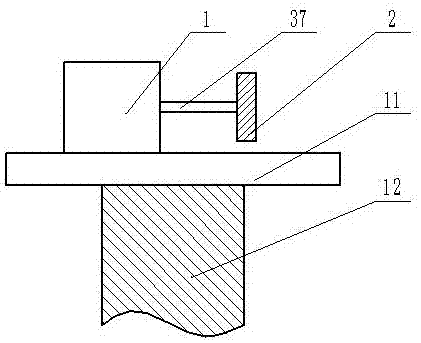

Air floatation high-speed electric main shaft

ActiveCN102078974AStable jobWork reliablyPositioning apparatusMaintainance and safety accessoriesAir bearingThrust bearing

The invention relates to an air floatation high-speed electric main shaft, in particular to an air floatation high-speed electric main shaft for a machining tool. A lower air bearing block assembly 7 is fixed on a thrust bearing 9, the upper part of the lower air bearing block assembly 7 is provided with a stator 6, the front end of a shaft core 5 is provided with a chuck accessory 11, an aluminum water jacket assembly 3 is fixed at the upper opening of a body assembly 10, and a tool changing cylinder assembly 1 is fixed on the upper part of the aluminum water jacket assembly 3; and the middle part of the shaft body of an upper air bearing 4 is provided with an upper air bearing cooling water passage 12. The main shaft is an electromechanical integrated base piece with high revolution number and high precision, has simple and compact structure, and is convenient to install, high in heat dissipation efficiency, multifunctional and convenient for popularization and application.

Owner:GUANGZHOU HAOZHI ELECTROMECHANICAL

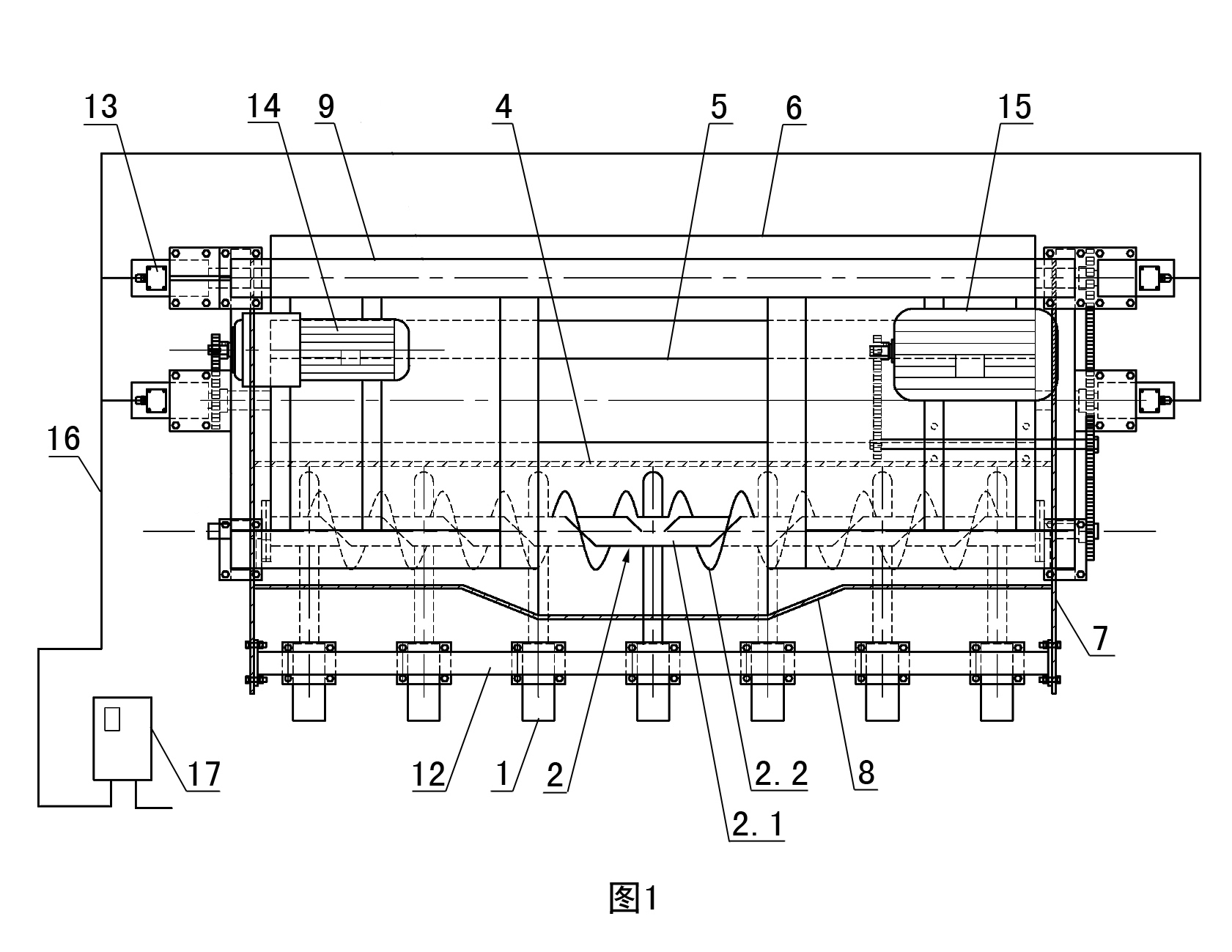

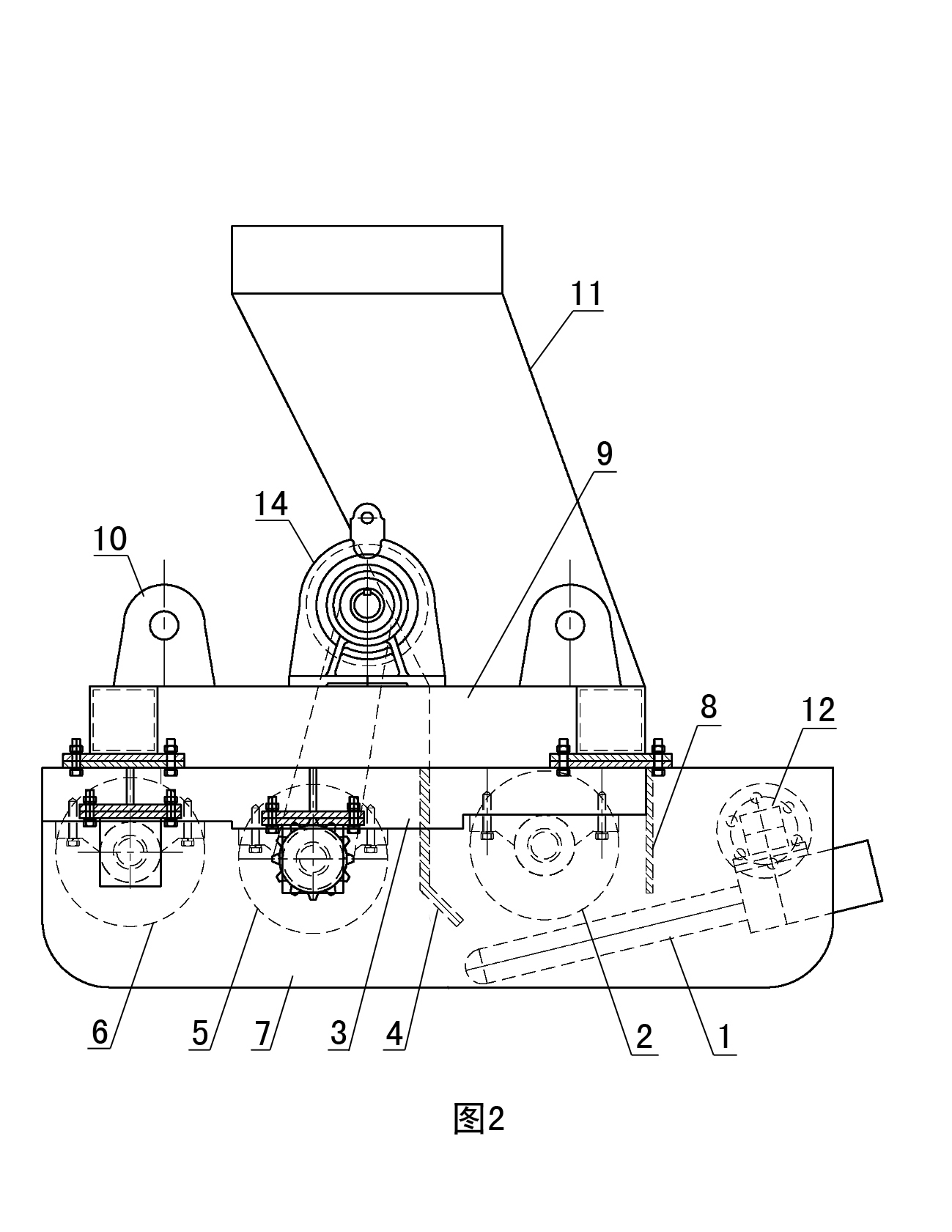

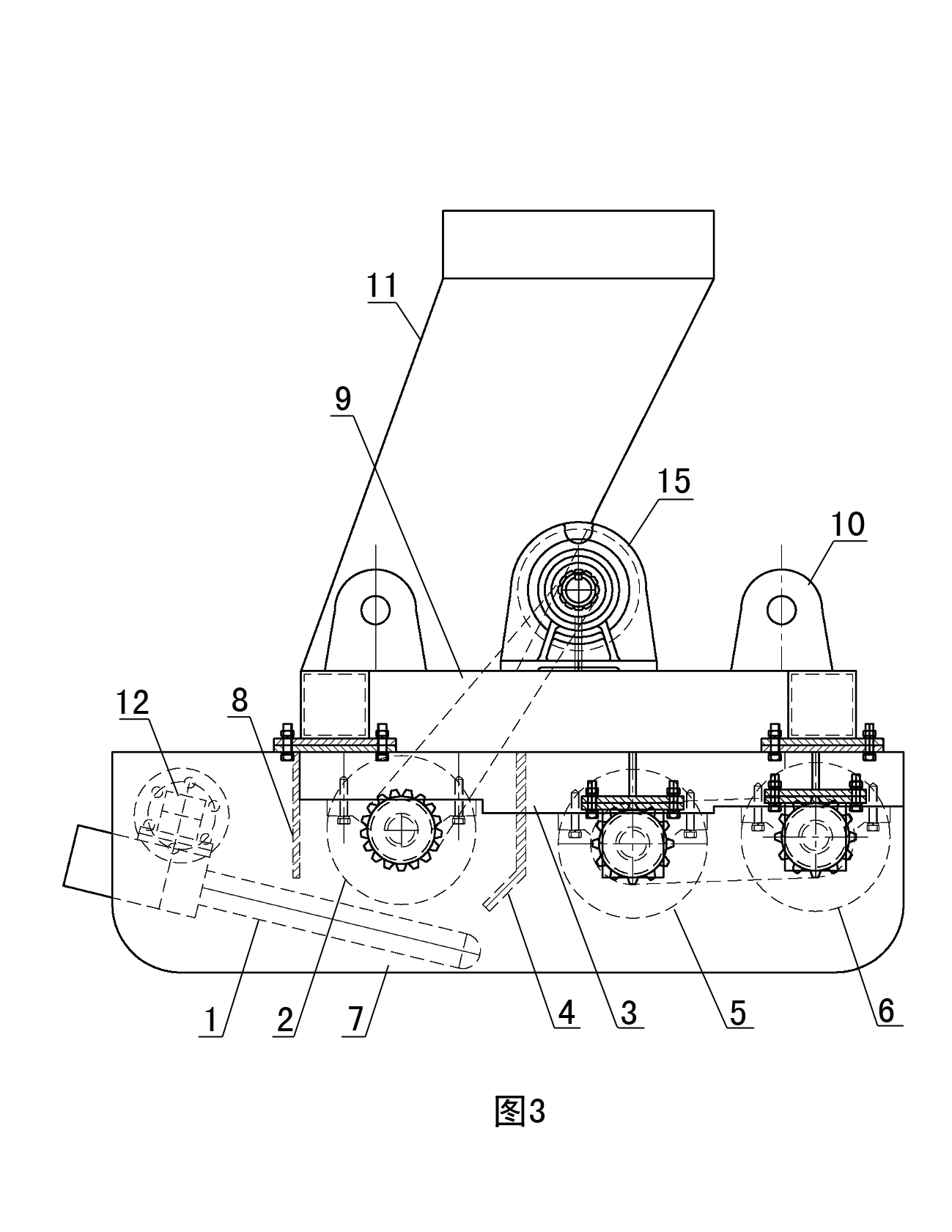

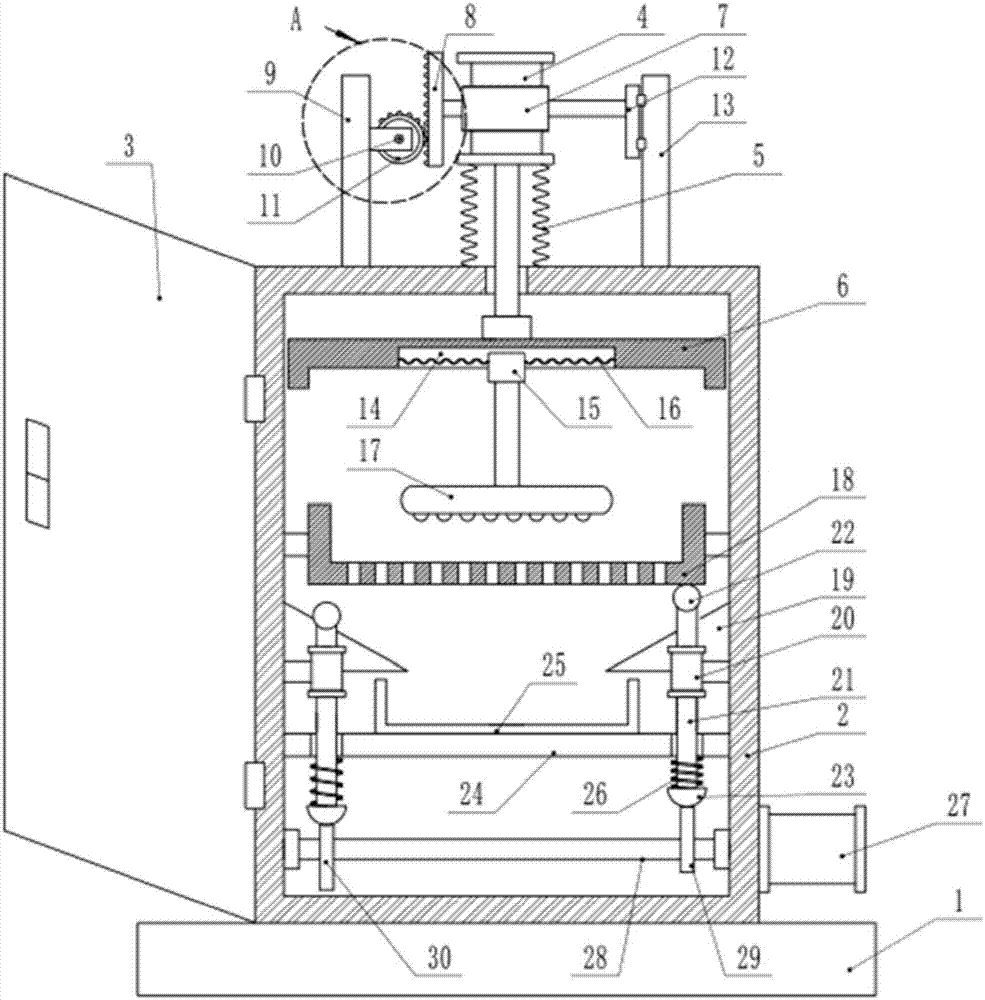

Cement-concrete paving and leveling device

InactiveCN101876159AImprove compactnessHigh compressive strengthRoads maintainenceBuilding material handlingCompressive strengthUltimate tensile strength

The invention relates to a cement-concrete paving and leveling device comprising a working stand, a cement-concrete vibrating and ramming device, a cement-concrete distributing device and a cement-concrete leveling and rolling device. The cement-concrete vibrating and ramming device, the cement-concrete distributing device and the cement-concrete leveling and rolling device are sequentially connected with the working stand from front to back; the left side and the right side of the working stand are respectively downwards connected with a side cement-concrete shielding plate; a cement-concrete vibrating and ramming rod mounting bracket is fixedly connected between the two side cement-concrete shielding plates; a cement-concrete vibrating and ramming rod, a cement-concrete allotting helix, a front cement-concrete vibrating and rolling roller and a rear cement-concrete vibrating and rolling roller are all arranged below the working stand and between the two side cement-concrete shielding plates; a cement-concrete inlet bin is fixedly connected on the upper part of the working stand; the cement-concrete outlet of the cement-concrete inlet bin is arranged above the cement-concrete allotting helix; the cement-concrete vibrating and ramming end of the cement-concrete vibrating and ramming rod extends to the downside of the cement-concrete allotting helix; a front cement-concrete shielding plate is arranged between the two side cement-concrete shielding plates and in the front of the cement-concrete allotting helix; and a measuring plate is arranged between the two side cement-concrete shielding plates and at the rear of the cement-concrete allotting helix. The cement-concrete paving and leveling device greatly improves the compactness of the concrete, thereby enhancing the compression strength of concrete, greatly prolonging service life of the paved concrete, reducing the maintenance frequency of concrete and saving manpower, materials and financial resources.

Owner:北京华洋建设开发有限公司

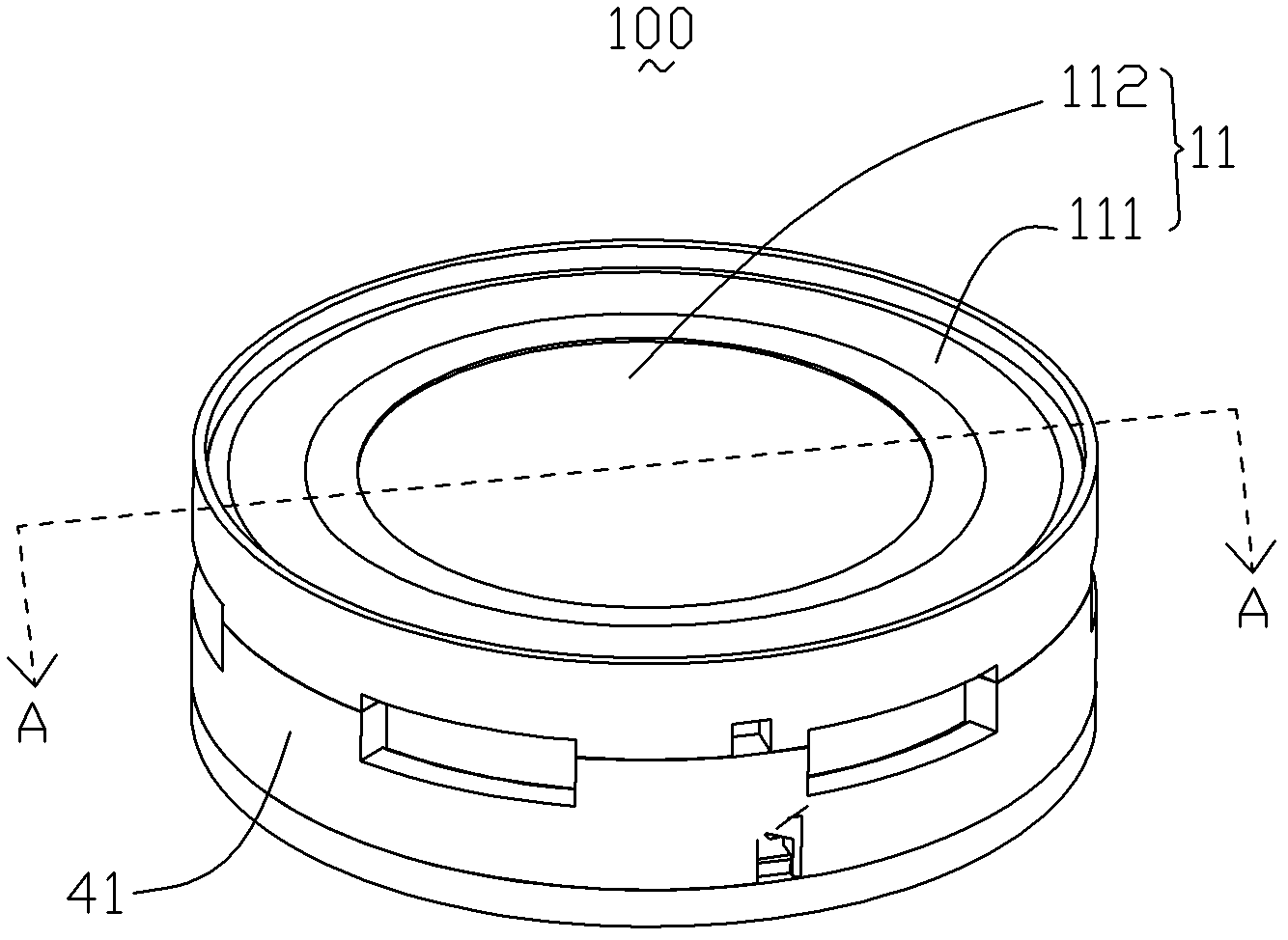

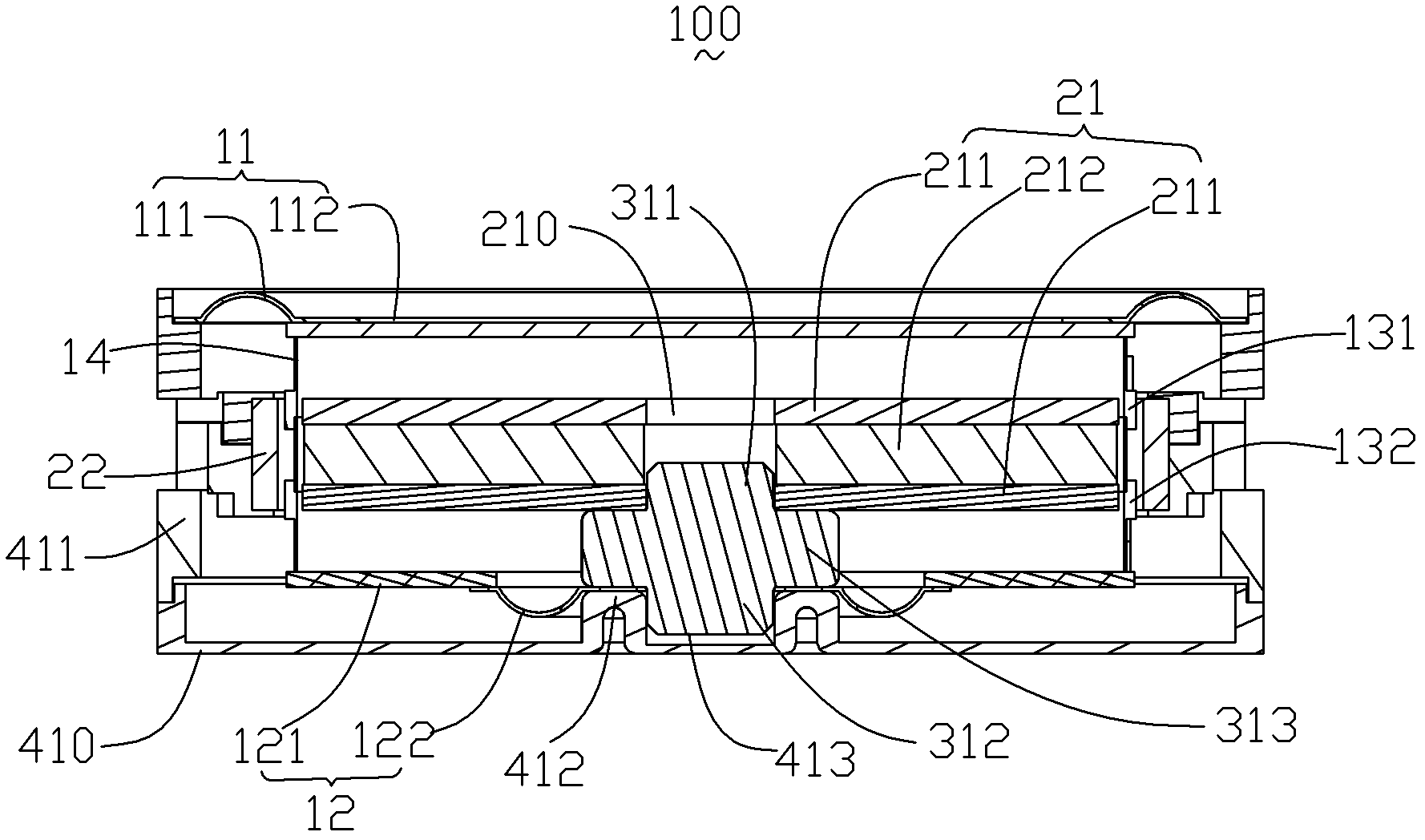

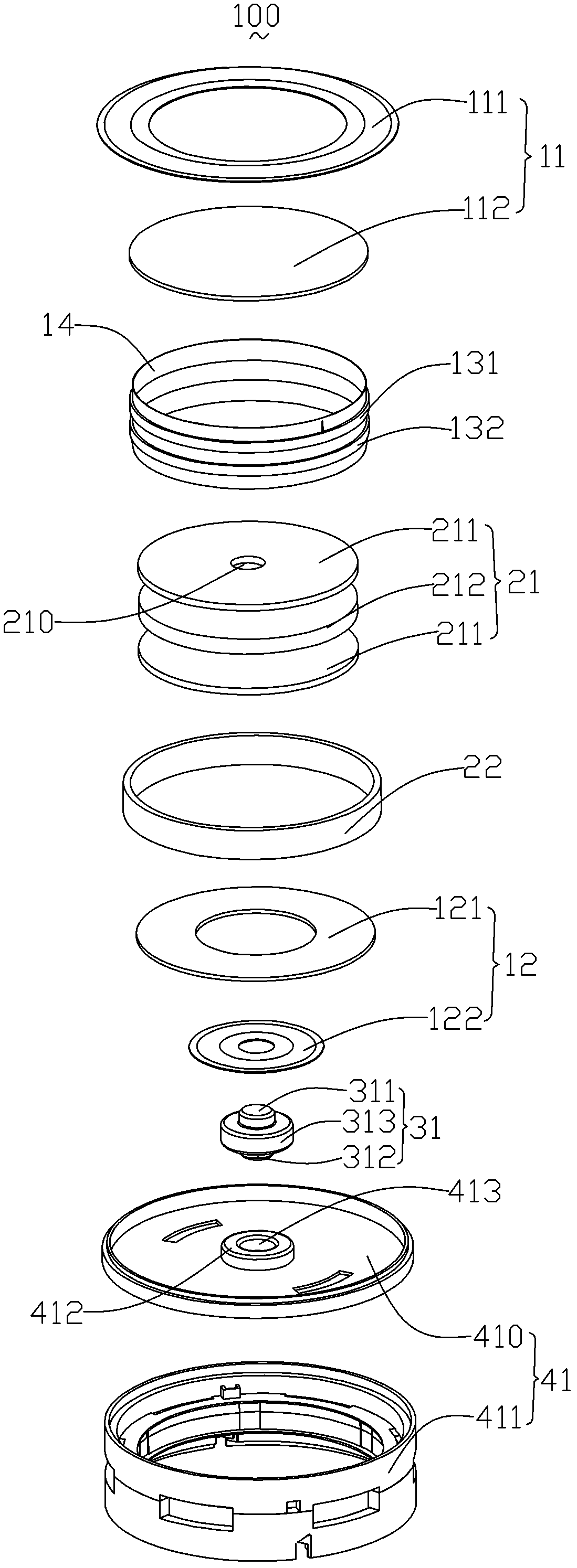

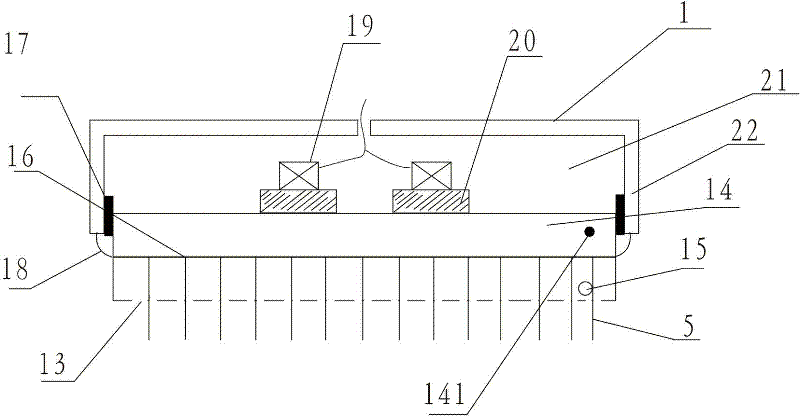

Sounder

InactiveCN102333270AStable structureImprove the vibration effectElectrical transducersEngineeringVoice coil

The invention provides a sounder which comprises a vibration system, a magnetic circuit system and a housing accommodating the vibration system and the magnetic circuit system, wherein, the magnetic circuit system comprises a magnetic frame having accommodation space and fixed on the housing and a permanent magnet assembly accommodated in the accommodation space, a magnetic gap is provided between the magnetic frame and the permanent magnet assembly, the vibration system comprises a first diaphragm and a second diaphragm which are attached to the housing and separate from each other to form a certain distance, a voice coil framework with one end connected with the first diaphragm and the other end connected with the second diaphragm, and a first voice coil and a second voice coil wound on the voice coil framework, the voice coil framework is located in the magnetic gap, and the magnetic circuit system is located between the first diaphragm and the second diaphragm. The sounder provided in the invention enables voice effects of a product to be enhanced.

Owner:AAC ACOUSTIC TECH (SHENZHEN) CO LTD +1

Heat exchanger system for circuit card assemblies

ActiveUS7180737B2Raise transfer toEfficient heat transferAir heatersInsulated cablesEngineeringConductive materials

An apparatus for housing and cooling circuit card assemblies employed in communication and other systems is disclosed including a chassis having opposed end walls which are formed with a series of spaced inlet card guides and correspondingly spaced outlet card guides, respectively. A straight-pass heat exchanger is directly mounted to each circuit card assembly via thermally conductive material, and opposed ends of the heat exchanger are mounted by a wedge lock to respective inlet and outlet card guides. The heat exchanger employs unique angled interface geometry that creates a gasketless airtight joint with complimentary inlet and outlet card guide geometry through which cooling air passes.

Owner:HARRIS CORP

Ultrasonic water-spray washing device

The invention discloses an ultrasonic water-spray washing device which is mainly used for washing vehicle bodies, doors and windows, floors and mirrors of motor vehicles. The device comprises a brush head, a brush handle, a connection part of the brush head and the brush handle, and an ultrasonic power supply; the brush head comprises an ultrasonic vibration generation room, a transducer, an ultrasonic vibration plate, a vibration transferring room, a temporary water storage room, brush bristles fixedly connected to the upper wall of the vibration transfer room, a water inlet and a plurality of water outlets; the vibration transferring room is located between the ultrasonic vibration plate and the upper plate of the water storage room; a sealing room is formed by a sealing plug in a sealing manner; transferring mediums like water, steel balls and the like are placed in the vibration transferring room, so that the vibrations with different effects can be transferred to the brushing bristles at the upper wall of the vibration transferring room, and thus, an ideal cleaning effect is achieved.

Owner:BEIJING UNION UNIVERSITY

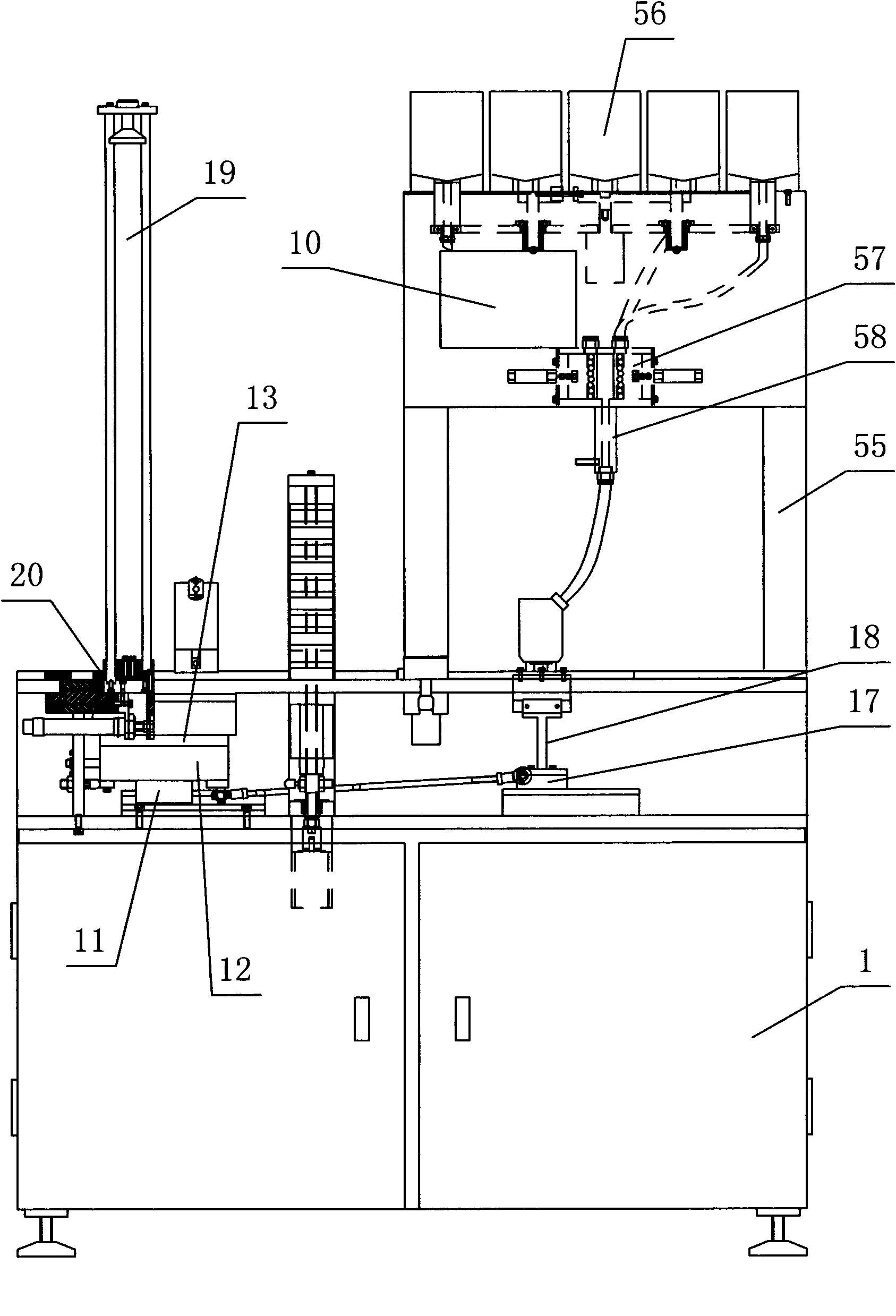

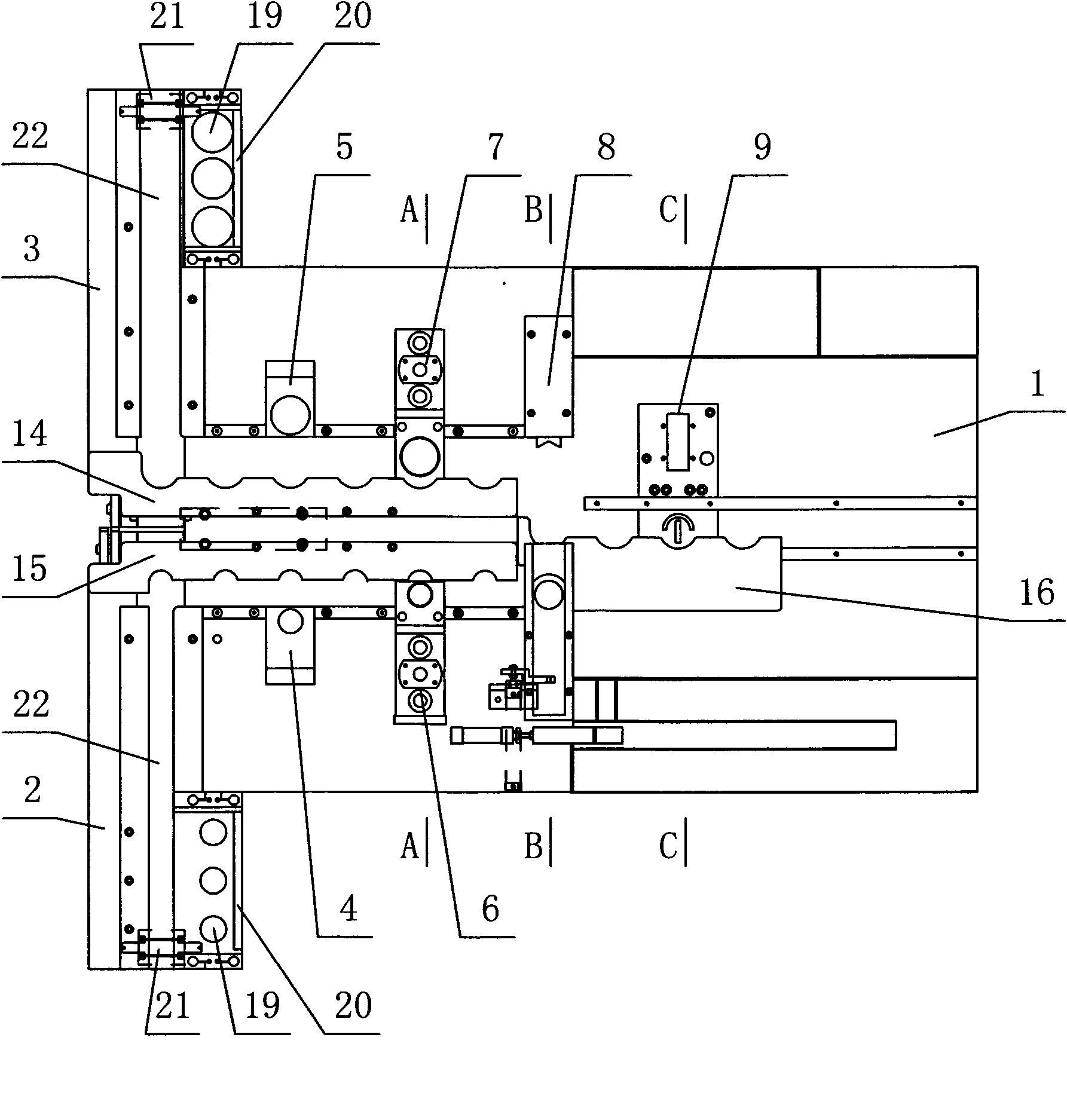

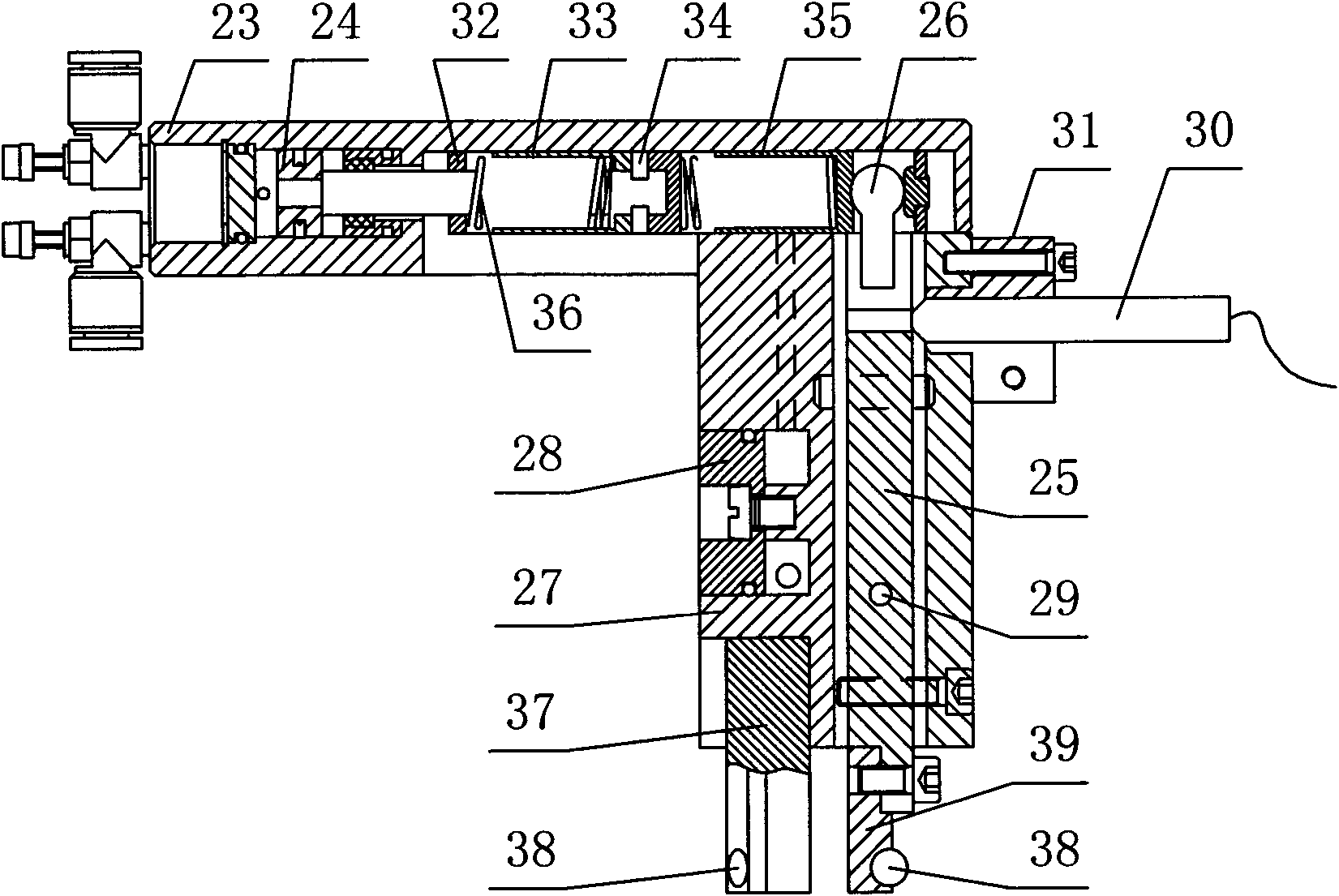

Full automatic bearing assembly machine

InactiveCN101943217AExquisite appearanceControl up and downBearing componentsEngineeringAssembly machine

The invention relates to a full automatic bearing assembly machine, a conveying device of an inner ring and an outer ring, a detecting device of the inner ring and the outer ring, a storing device of the inner ring and the outer ring, a closing device of the inner ring and the outer ring, an assembly device and a control device are sequentially arranged on the upper surface of a frame according to the processing sequence, a first shift sliding block is arranged on a linear guide track in the frame, a shift cylinder is fixed on the first shift sliding block, a telescopic rod is fixedly connected with the frame, curved mounting plates are respectively connected at the front and the back of a guide pole of a two-way cylinder which is fixed above the shift cylinder, the two curved mounting plates are respectively fixedly connected with an outer ring retainer plate and an inner ring retainer plate on the upper surface of the frame, a product shift cylinder is arranged in the position which corresponds to the assembly device in the frame, the product shift cylinder is fixed on a support above the second shift sliding block, the telescopic rod is fixedly connected with a product retainer plate on the upper surface of the frame, and the second shift sliding block is mounted on the linear guide track on the frame and connected with the shift cylinder via a connecting rod. The full automatic bearing assembly machine has reasonable structure, small volume, good running synchronization and high efficiency.

Owner:SHANDONG XUNJIE PRECISION EQUIP

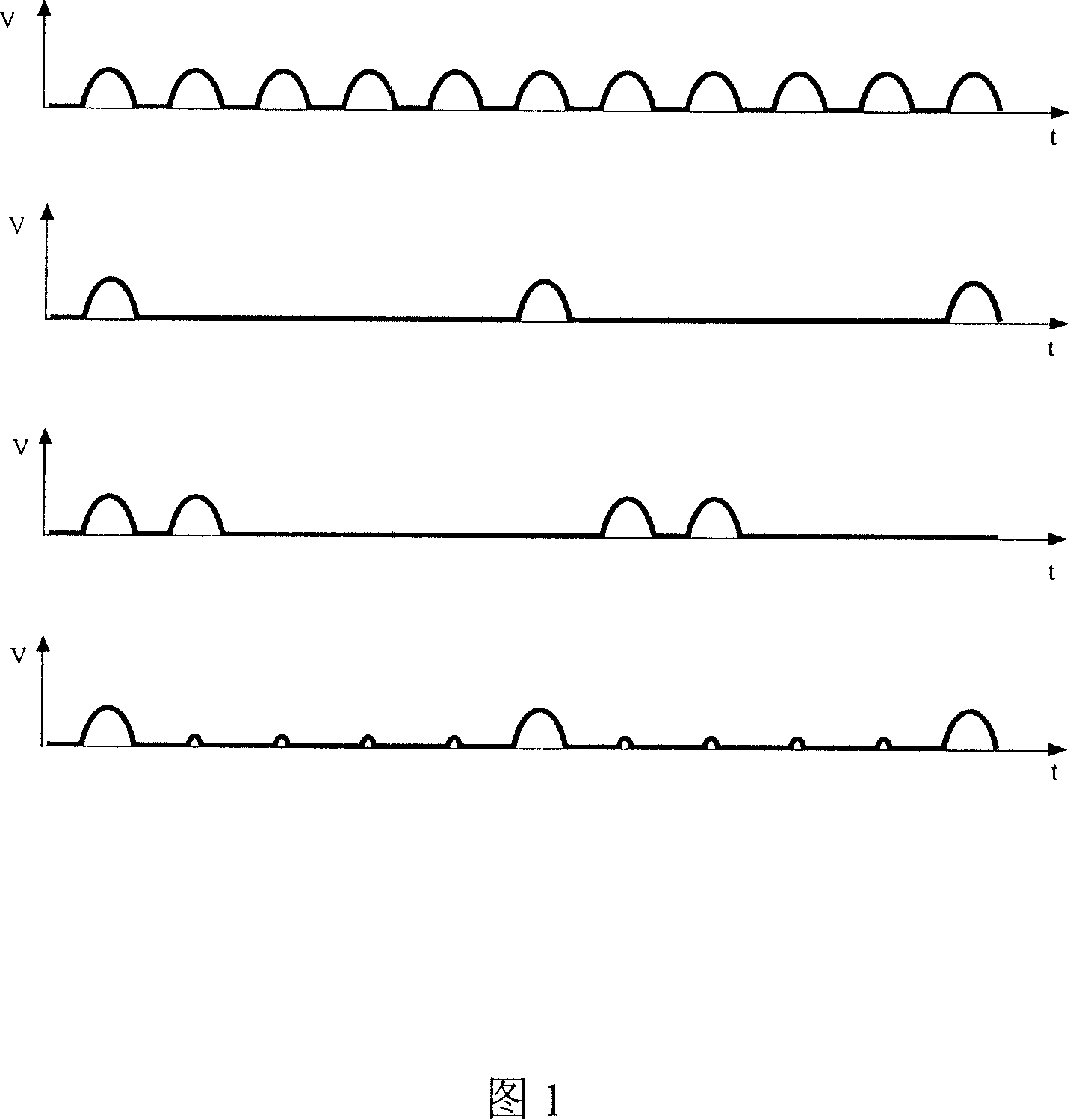

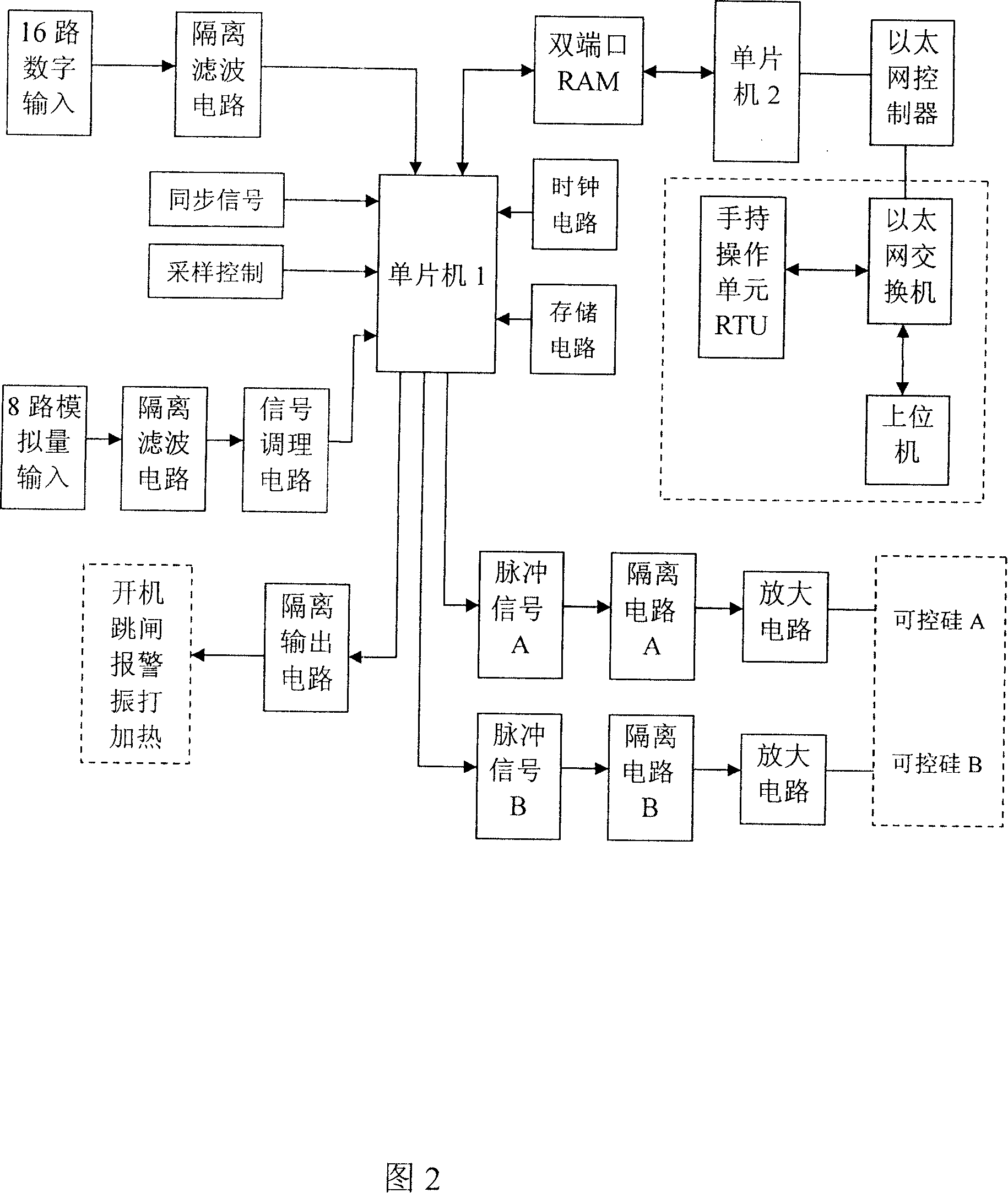

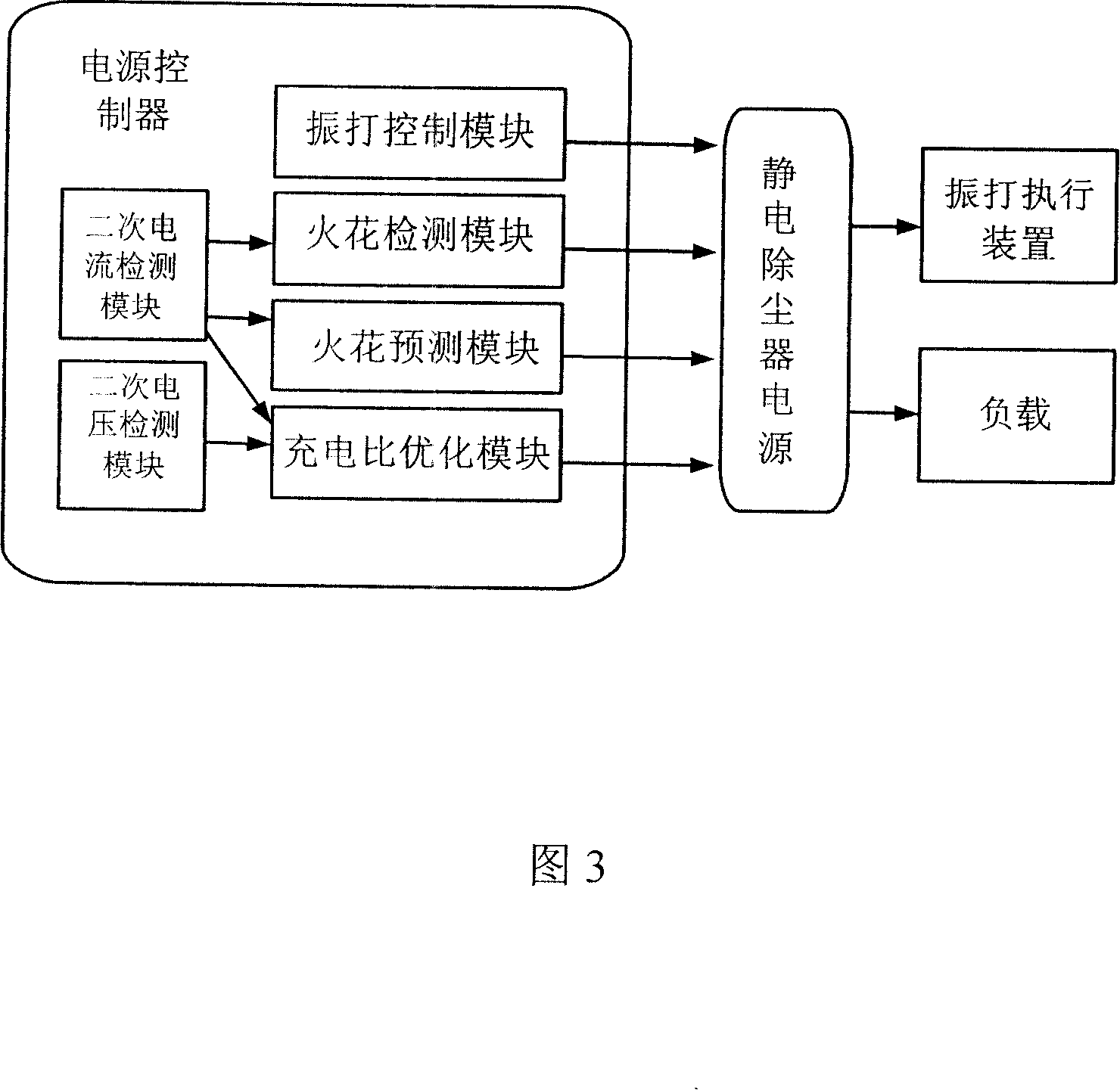

Power-supply controller of electric dust collector and long-range control system of the same

ActiveCN101152637AImprove accuracyFastTotal factory controlElectric supply techniquesElectrostatic precipitatorPower flow

The invention provides a power controller of static dust collector and a remote control system for the controller. The controller comprises a rapping control module, a spark detecting module, a spark forecasting module and a charging ratio optimization module. The rapping control module is connected with the power of the static dust collector and a rapping executing device on a dust collecting plate in correct order to generate rapping period and rapping sustaining time required by various rapping modes as well as required constant voltage under various rapping modes; the spark forecasting module carries on second derivative analysis of second current waveform and determines generation of spark in advance; the spark detecting module carries on spectrum analysis of second current with sampling rate of 64 points to decide generation of small spark; the charging ration optimizing module calculates quality factor of a dust removing polar plate according to charging ratio, second current on one side of a load and second voltage and then charging ratio required by the power of the static dust collector is realized with hereditary screening method. In addition, the invention also realizes remote control on the power controller of the in-site static dust collector.

Owner:高峻峰

Hand power tool

InactiveUS20070295522A1Tension variesImprove user friendlinessPortable percussive toolsPortable power-driven toolsHand heldPower tool

In a hand power tool having a housing which at least in part comprises an inner housing and an outer housing, and in which the inner housing and the outer housing are spaced apart from one another, at least one damping element is provided between the inner housing and the outer housing, so that the inner housing and the outer housing are decoupled from one another.

Owner:ROBERT BOSCH GMBH

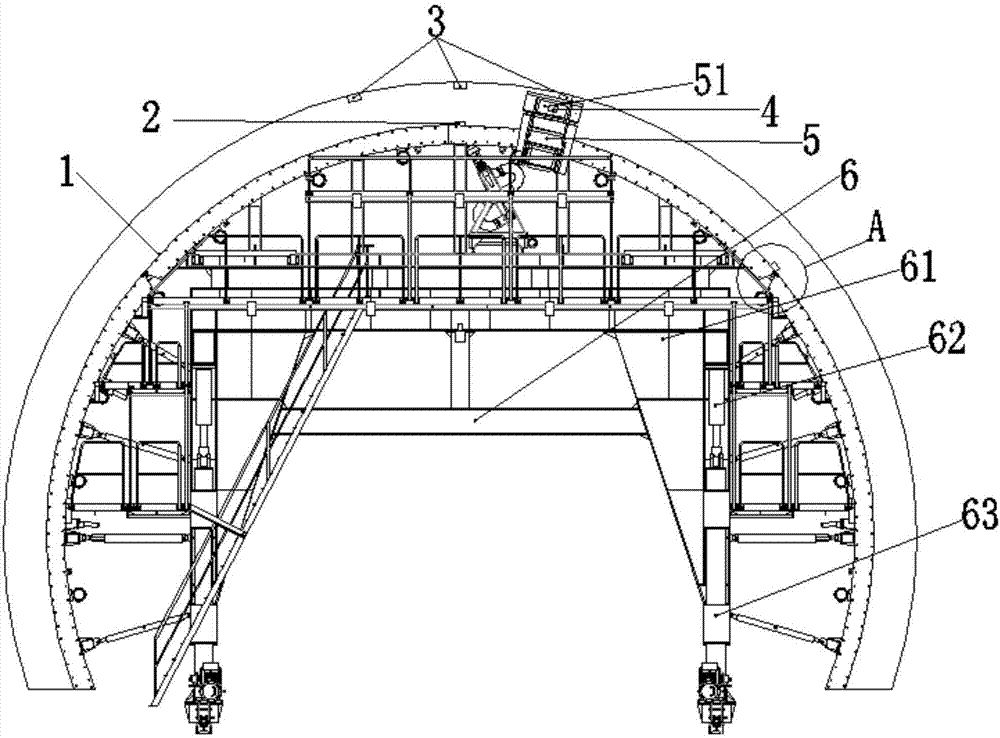

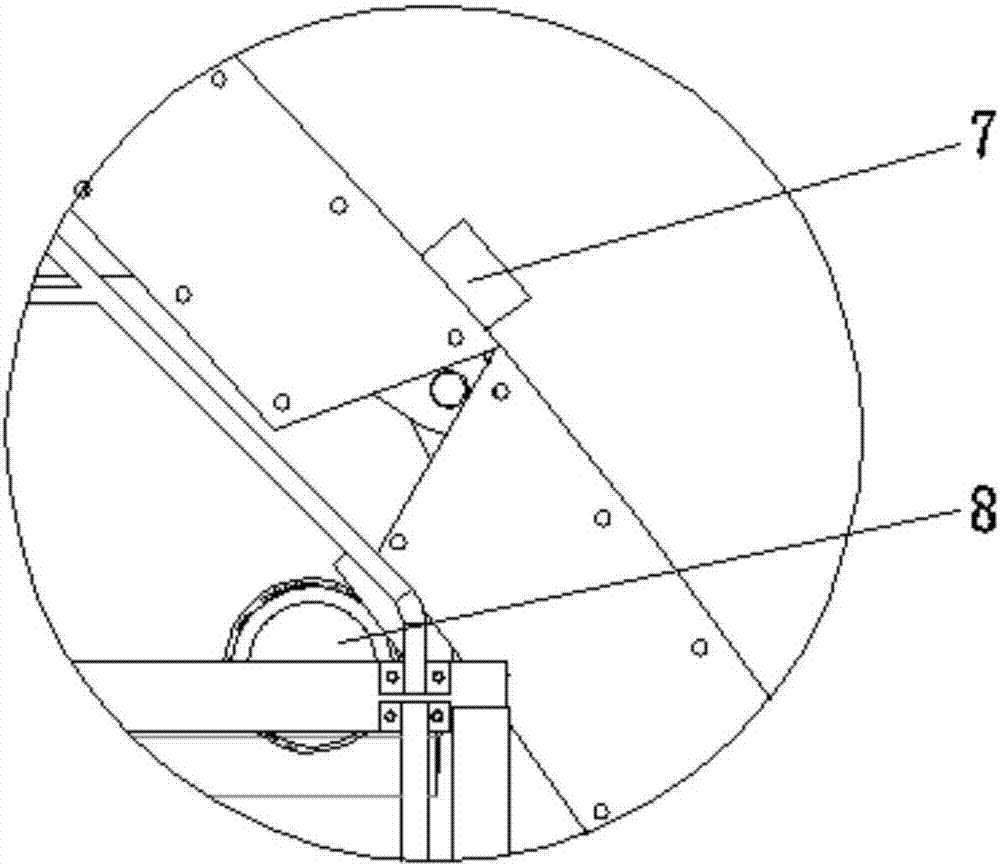

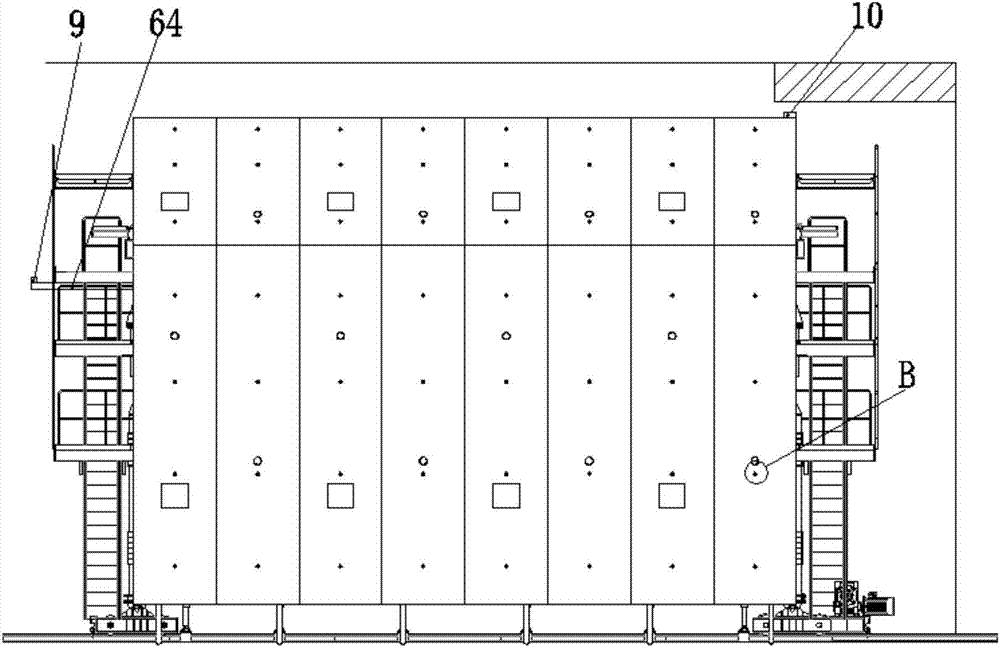

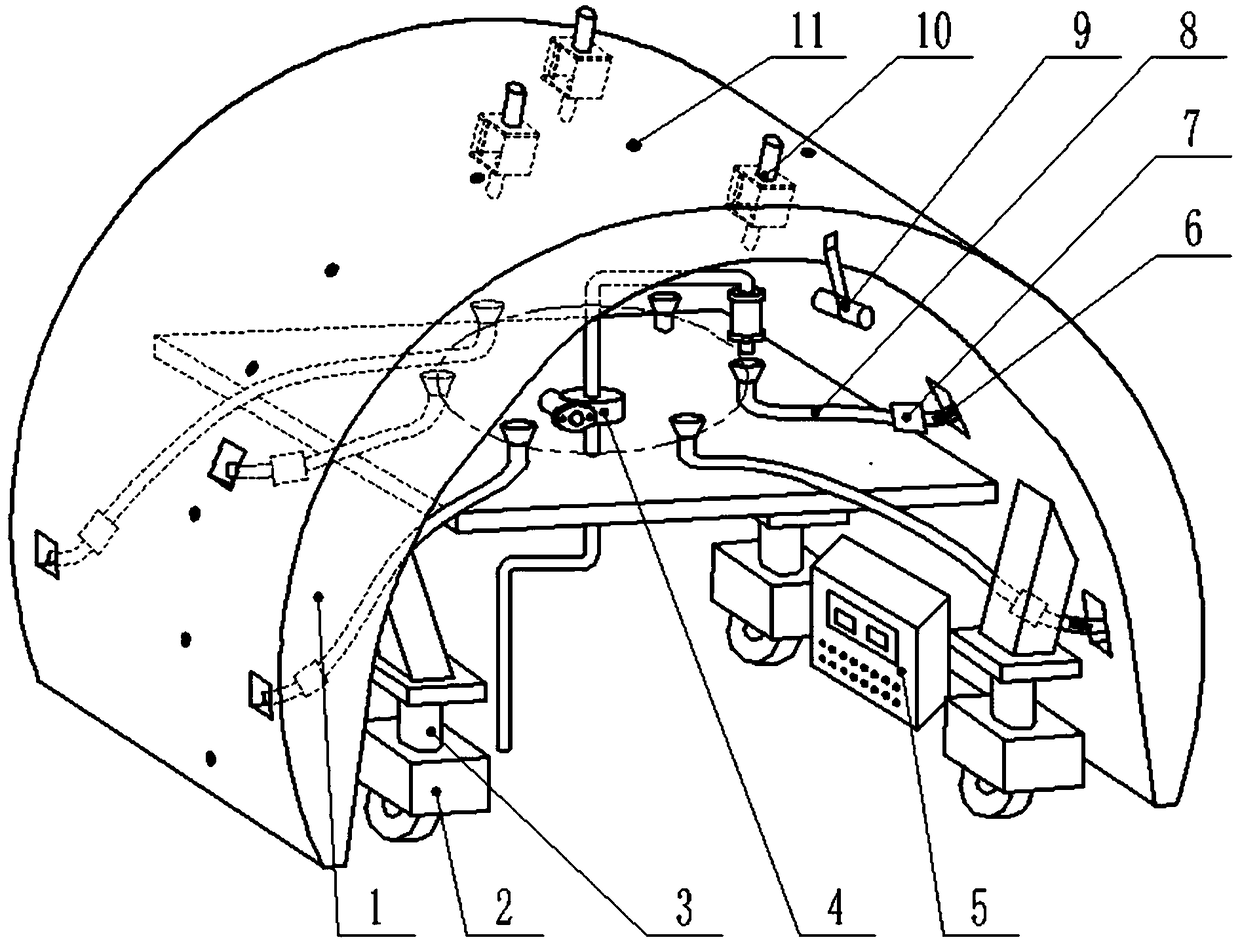

Intelligent tunnel lining trolley

PendingCN107956490AEasy loading and unloadingPlace stableUnderground chambersTunnel liningMonitoring systemSteel frame

Provided is an intelligent tunnel lining trolley, characterized by comprising a door-shaped main steel frame, a concrete pouring informationized monitoring system, an end template, a template cleaningand surface lubricating system, an automatic running gear, and a layered window-by-window pouring and cleaning system. The tunnel lining trolley is simple in structure and reasonable in design, and real-time monitoring of each parameter in a concrete pouring process is realized, automation degree of equipment is improved, cleaning and template surface lubrication operation flow are simplified. The intelligent tunnel lining trolley provides convenience for on-site management and construction, and has certain environmental protection property and very high security.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

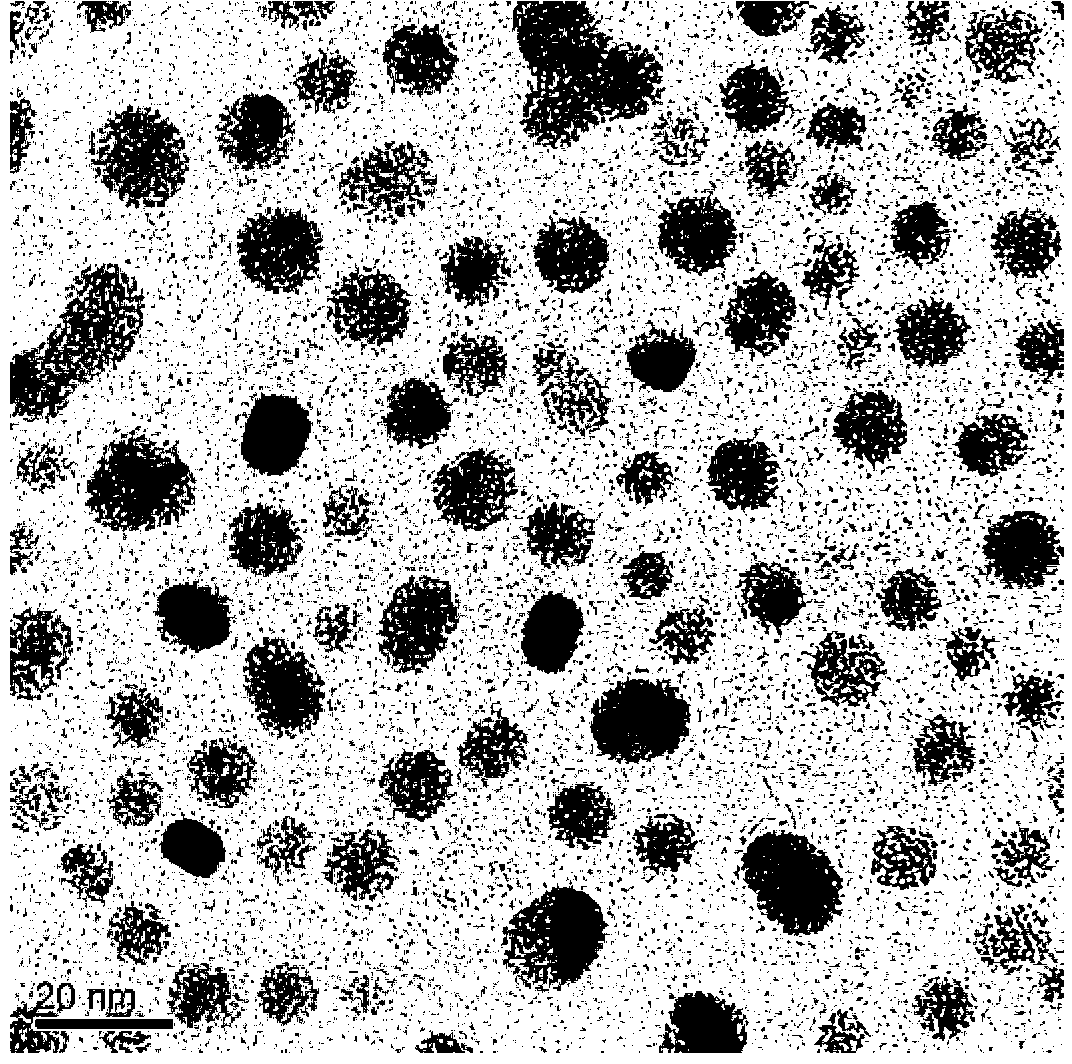

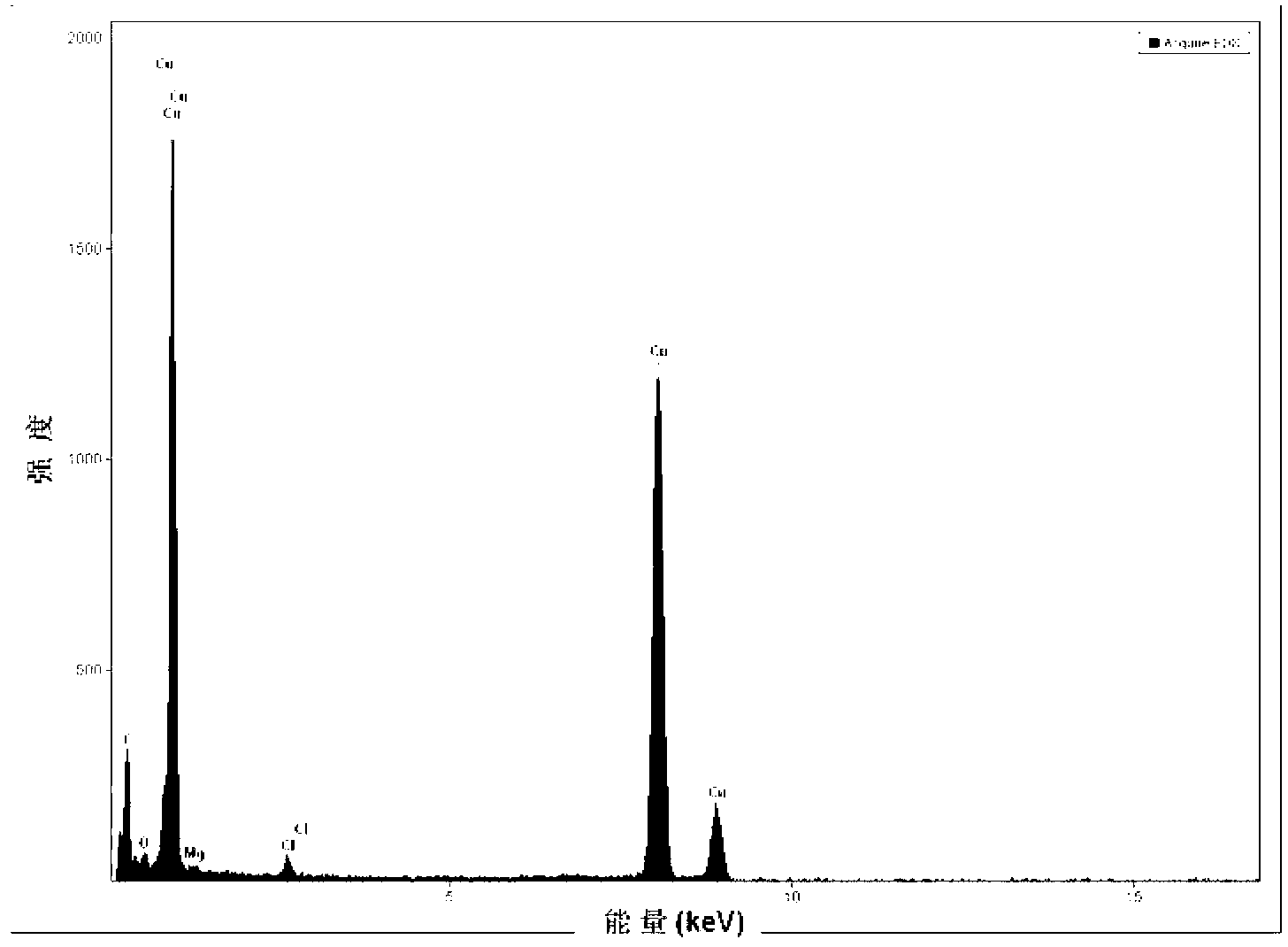

Method for preparing metal nanoparticles

The invention provides a method for preparing metal nanoparticles. By a dealloying method, firstly, precursor alloy solid fine materials containing target metal elements are prepared, secondly, the precursor alloy solid fine materials and acid solution containing hydrogen ions are in dealloying reaction under the condition of violent oscillation, the concentration of the hydrogen ions in the acid solution is controlled in the reaction process, magnesium, rare earth and other relatively active atoms preferentially react with the hydrogen ions and change into ions entering the solution, target metal atoms are freed out, and porous self-assembly and conglobation trend of the target metal atoms is effectively restrained under the condition of violent oscillation, so that uniformly scattered target metal nanoparticles are obtained. Compared with an existing method, the method is low in cost, simple in operation, green, environmentally friendly, high in preparation efficiency, high in by-product value and suitable for large-scale production, and accordingly has a fine application prospect.

Owner:赵远云

Automation control method for tunnel lining construction

ActiveCN108104838ARealize information collectionRealize automatic controlUnderground chambersTunnel liningAutomatic train controlAutomatic control

Disclosed is an automation control method for tunnel lining construction. A control system integrates all information collecting and control procedures of a traveling mechanism, a hydraulic system, aconcrete distribution device, a vibrating device, a temperature sensor, a flowmeter, a video monitor and a pressure sensor, is equipped with a GPRS wireless data transmission module, and can collect and upload information in the casting process of a tunnel lining to a project department monitoring room. The distribution device can be connected with a plurality of distribution pipes in series, thetemperature sensor is used for detecting the concrete casting temperature, and the flowmeter is used for collecting the concrete casting quantity and implementing automatic control over casting. The video monitor monitors real-time work picture information, and collects and transmits the real-time work picture information to the project department monitoring room. The vibrating device achieves vibrating automatic control operation for concrete. The pressure sensor detects and collects pressures of all points in the concrete casting process and displays the casted height of the concrete. The control system conducts concentration analysis on data collected in the casting process of the tunnel lining, gives out a control instruction, and uploads the detected data to the project department monitoring room.

Owner:中铁隧道勘察设计研究院有限公司

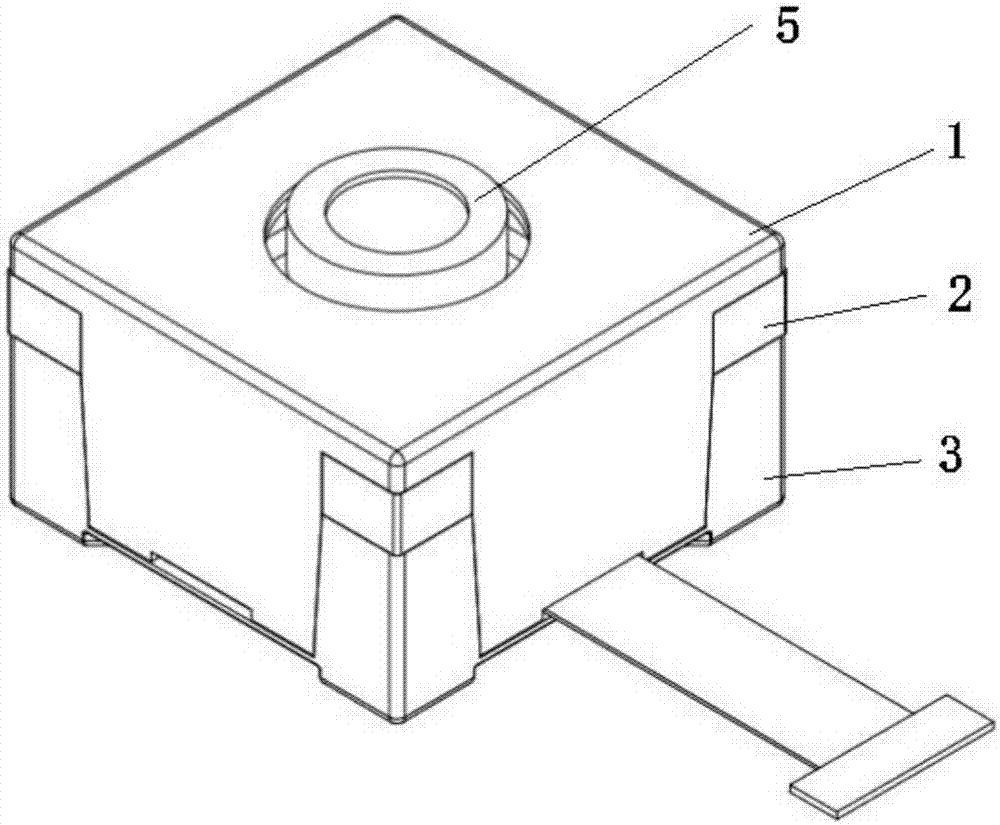

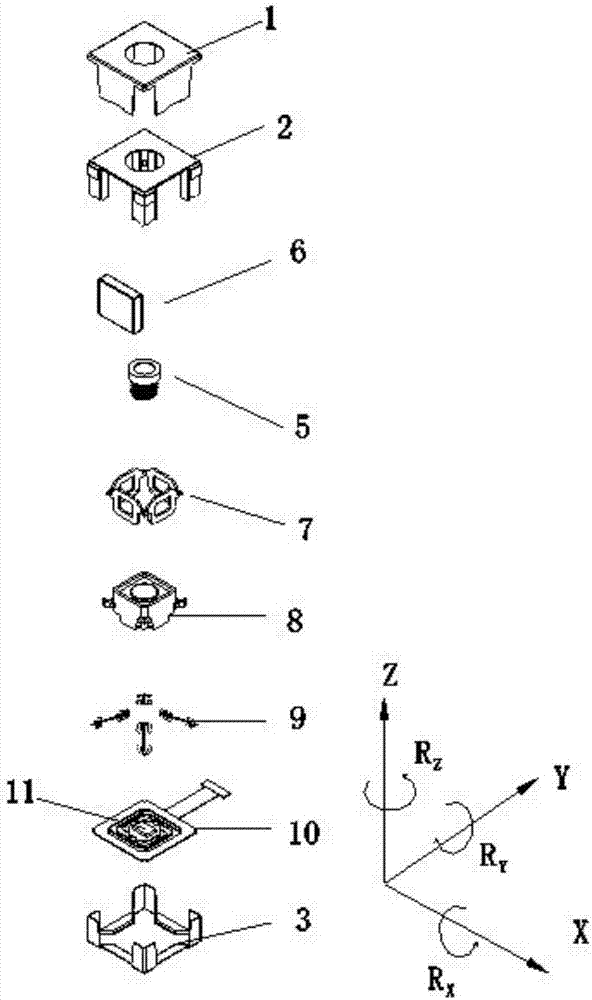

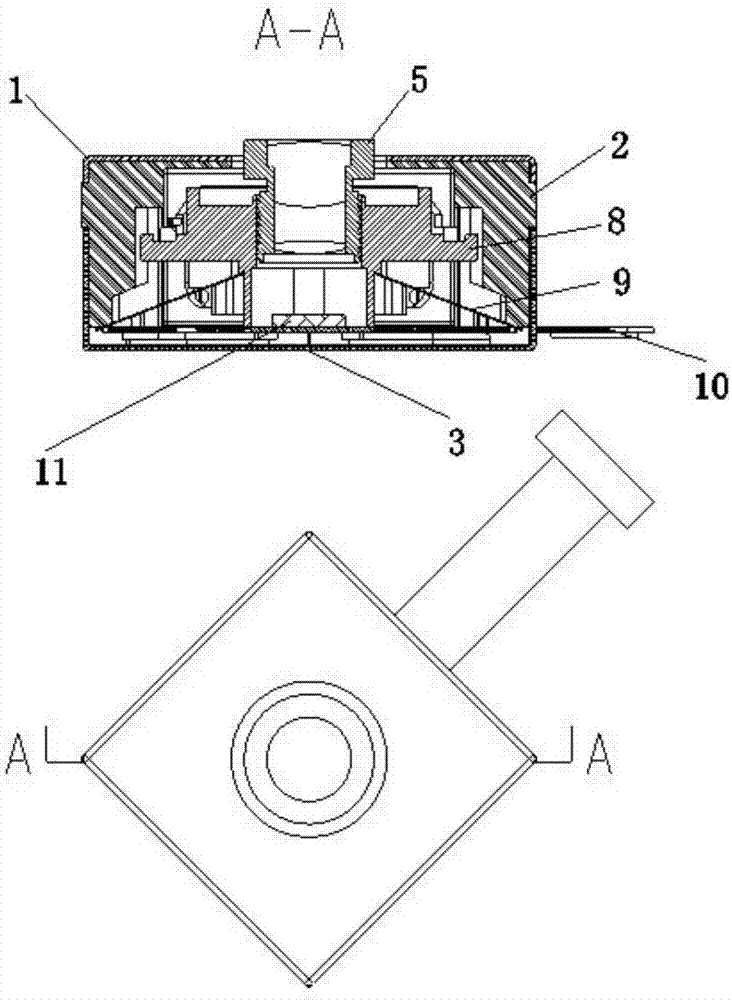

Anti-shaking miniature holder integrated with camera module group

ActiveCN107340667AAchieve rotationImplement anti-shake functionTelevision system detailsPrintersCamera moduleFriction force

The invention belongs to the technical field of anti-shaking holders, and specifically relates to an anti-shaking miniature holder integrated with a camera module group. The holder comprises a housing, a positioning seat, the camera module group, at least one magnet, at least one independent coil, and at least one spring. The independent coil and the camera module group form a movable structure, and the housing, the positioning seat and the magnet form a fixed structure. The fixed structure and the movable structure are connected with each other through the spring, thereby forming a spring vibrator system. According to the invention, a contact point of a supporting structure cannot be a contact point with a frictional force, and a nonlinear frictional force cannot appear in an anti-shaking process. The holder is better in effect of resisting the miniature vibration and the vibration with the frequently changing direction.

Owner:VISTA INNOTECH LTD

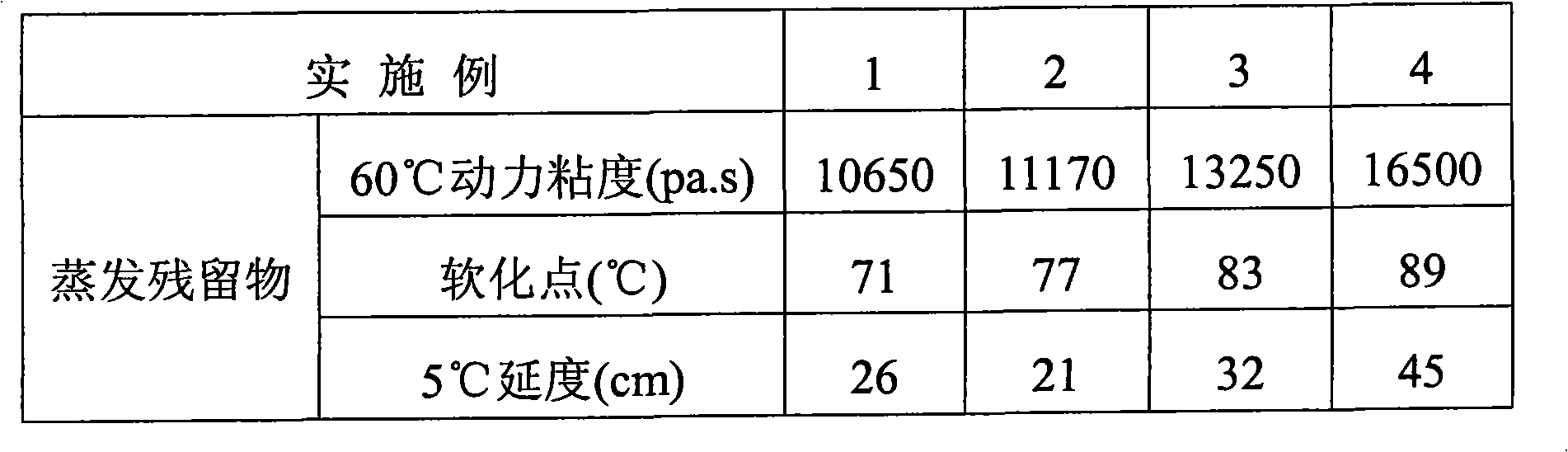

High-viscous emulsified asphalt for CA mortar and preparation method thereof

InactiveCN101643587AIncrease pHGood construction performanceBuilding insulationsAsphaltMaterials science

The invention relates to a high-viscous emulsified asphalt for CA mortar and a preparation method thereof, belonging to the field of preparation technology of the CA mortar used for a high speed railway plate-type ballastless track. The high-viscous emulsified asphalt comprises the components by weight percent: 45-65% of asphalt, 2-4% of SBS, 2-8% of SBR, 0.3-1.5% of cation-type emulsifier, 0.2-1.2% of non-ionic emulsifier, 0.5-2% of stabilizing agent, 1-4.5% of additive and the rest of water, wherein modifier includes the SBS and the SBR, and emulsifier contains the cation-type emulsifier andthe non-ionic emulsifier; and the sum of the weight percent of the components is 100%. The invention has reasonable compound design, and can effectively improve the capabilities of high and low temperature resistance of asphalt emulsified liquid.

Owner:ZHEJIANG LANTING HI TECH

Linear vibration motor

ActiveUS10710115B2Improve performanceExtended service lifeMechanical vibrations separationDynamo-electric machinesElectric machineryEngineering

Owner:AAC TECH PTE LTD

Fine grinding device for buckwheat high protein flour production and processing

InactiveCN107999203ASmall granularityAvoiding Inadequate GrindingCocoaGrain treatmentsCompression actionInterference fit

The invention discloses a fine grinding device for buckwheat high protein flour production and processing. The fine grinding device comprises a grinding box, a grinding motor, a rotary plate, a grinding device part, a grinding groove, striking balls and a receiving groove; supporting springs are connected between the grinding motor and the grinding box; an output shaft of the first driving motor faces forward; a special-shaped gear is in interference fit with the output shaft of the first driving motor; the grinding device part is arranged on the lower side of a second sliding block; two propping rods are slidingly arranged on a baffle plate; and the striking balls are arranged at the upper ends of the propping rod by threads. The grinding device part can, by adjusting the rotating speed of the grinding motor, allow centrifugal force on the rotary plate to be different, and the sliding range of the second sliding block on a second sliding rail is changed, so that the grinding range ofthe grinding device part is changed; and the grinding device part can be driven to move down integrally in the grinding process to exert compression action on buckwheat grinding, so that ground flouris small in granularity and is more delicate.

Owner:黄利伟

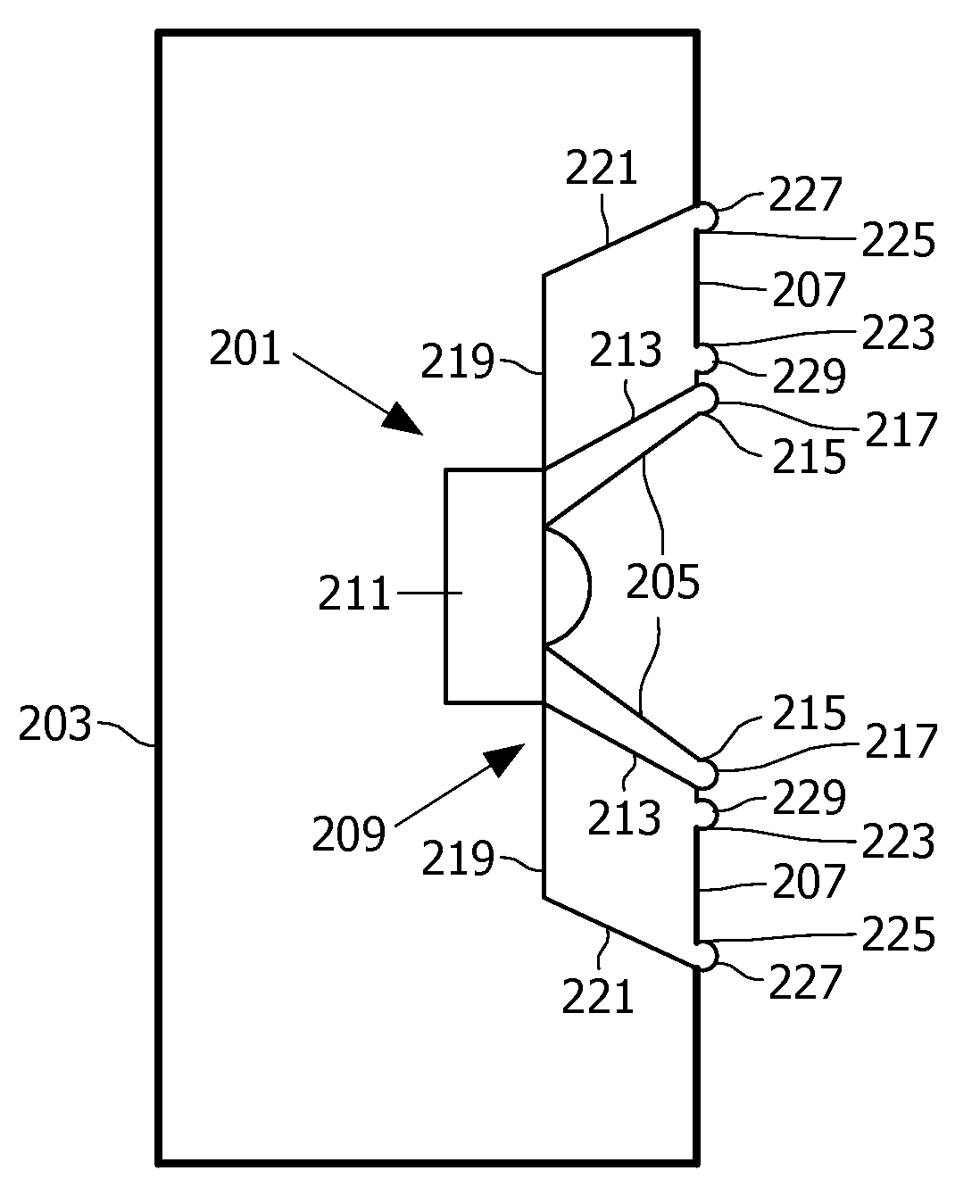

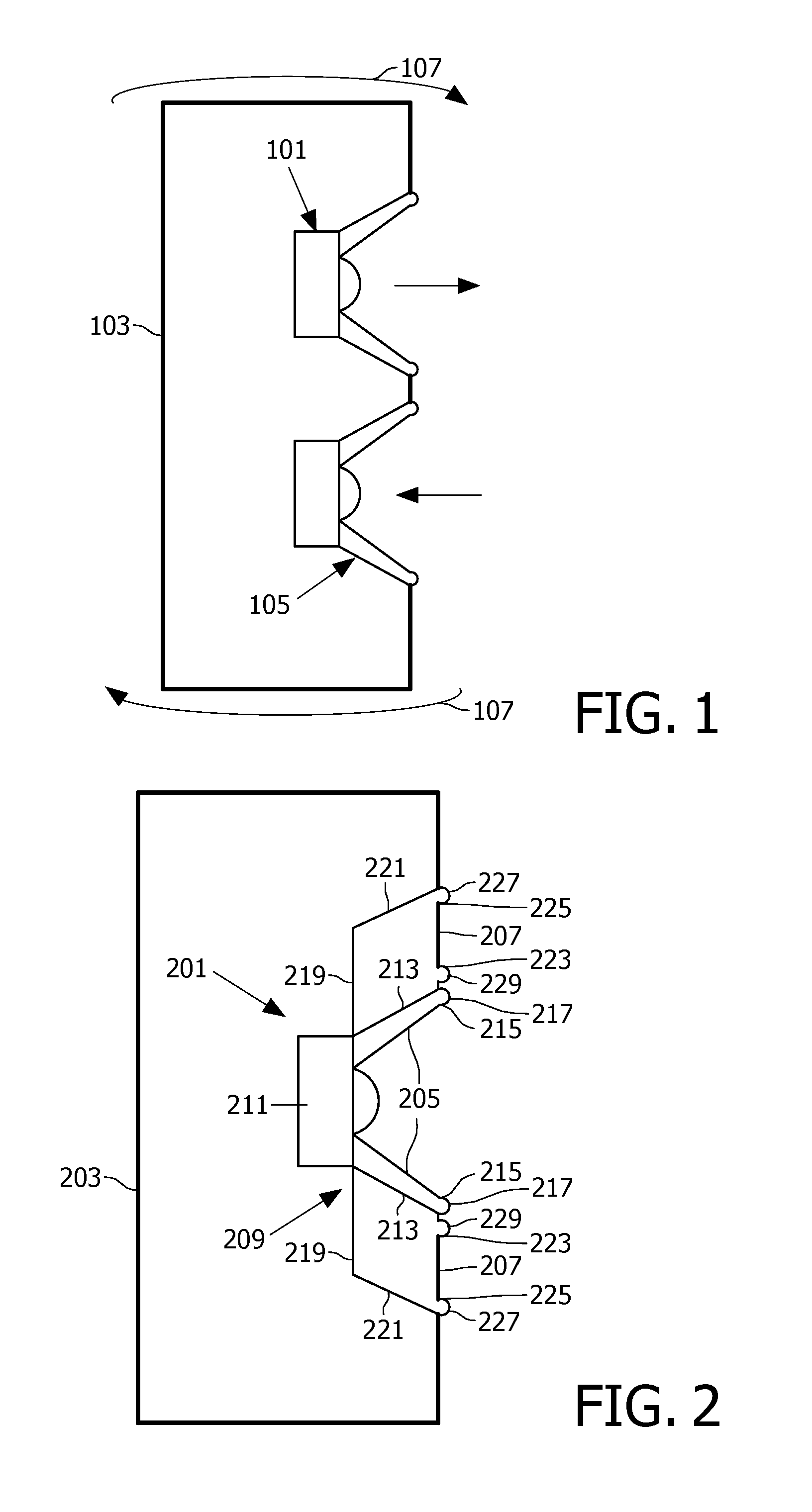

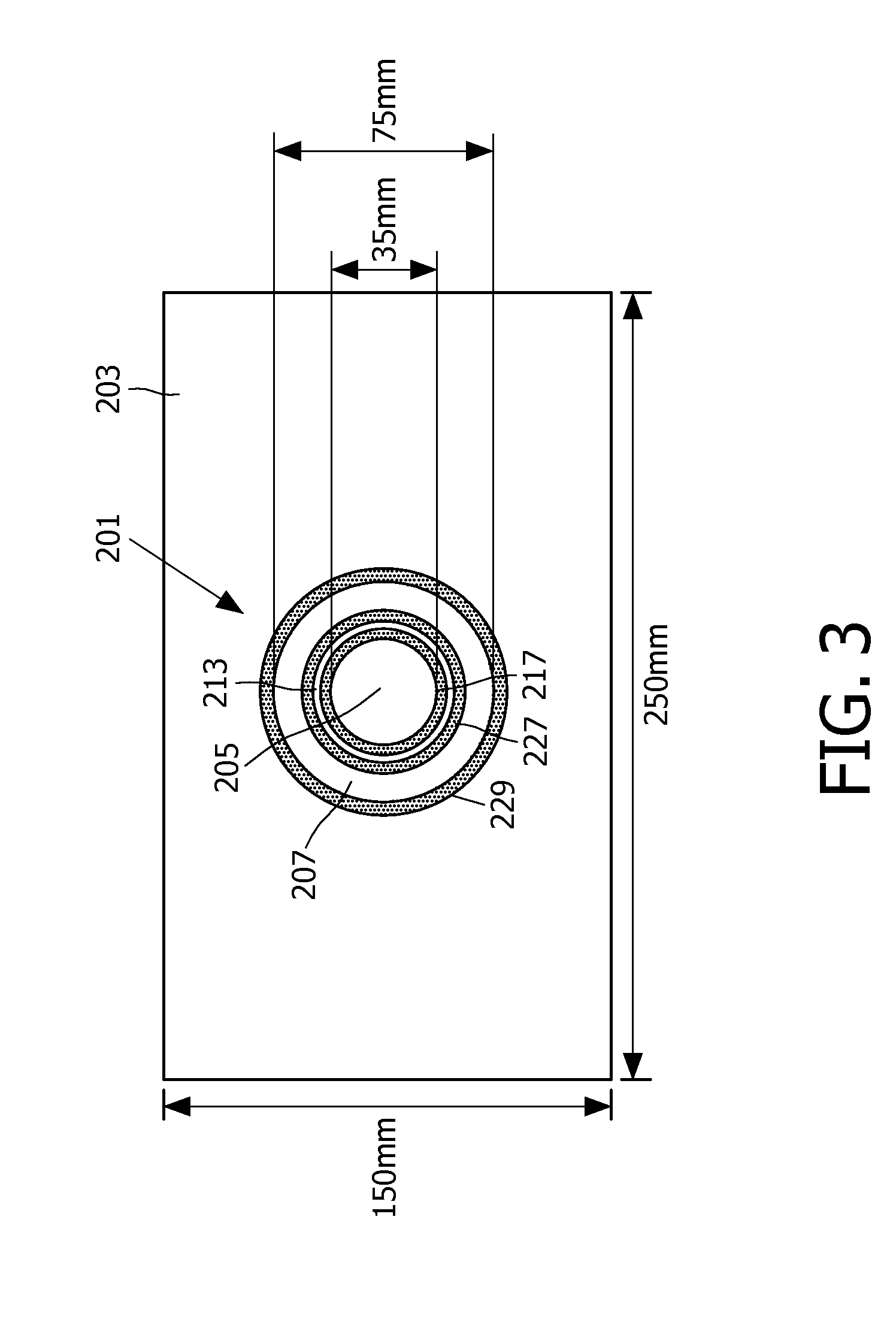

Loudspeaker driver and loudspeaker arrangement

InactiveUS20120114148A1Easy to installLow costFrequency/directions obtaining arrangementsDeaf-aid setsPassive radiatorIntegrated design

A loudspeaker arrangement comprises a loudspeaker driver (201) mounted in an enclosure (203). The loudspeaker driver (201) comprises a speaker frame (209) which forms an outer support (221) and an inner support (213). An active radiator (205) is mounted on the inner support (213) and a passive radiator (207) is mounted between and on the inner support (213) and the outer support (221). The loudspeaker driver (201) may be mounted by the outer support (221) being fixed to the enclosure (203). The passive radiator (205) allows a low frequency extension for the loudspeaker driver (201). The integrated design of the active radiator 205 and passive radiator 207 allows the radiators (205, 207) to closely interact and behave as a single unit. The approach may reduce cost, facilitate manufacturing, improve audio quality and / or reduce vibrational stress on the enclosure.

Owner:TP VISION HLDG

Self-vibrating grain drying and sieving equipment

InactiveCN107339878AImprove the vibration effectPrevent fallingSievingScreeningEngineeringVacuum pump

The invention discloses self-vibrating grain drying and sieving equipment. The equipment comprises a shell, a support and a condensation chamber; the support is arranged outside the shell, sliding blocks are fixedly connected to the middle of the outside of the shell, sliding grooves are formed in both sides of the support, and the sliding blocks are connected with the sliding grooves in a sliding mode; connecting plates are arranged at the upper ends of the sliding grooves, the connecting plates are fixedly connected with the support, and floating devices are arranged between the connecting plates and the sliding blocks; a first sieving net and a second sieving net are fixedly connected to the inner side wall of the shell from top to bottom in sequence, a dehumidification pipe is arranged at the upper end of the shell, a vacuum pump is connected to the middle of the dehumidification pipe, one end of the dehumidification pipe is communicated with the interior of the shell, and the other end of the dehumidification pipe is connected with a condensation pipe in the condensation chamber. According to the self-vibrating grain drying and sieving equipment, the structure is simple, the design is reasonable, sieving of grain is completed through self-vibrating of the shell, and the sieving quality and efficiency are improved; meanwhile, drying equipment is added, the functionality of the device is enhanced, and rapid dehumidification can be conducted, so that the drying efficiency is improved.

Owner:俞纪洪

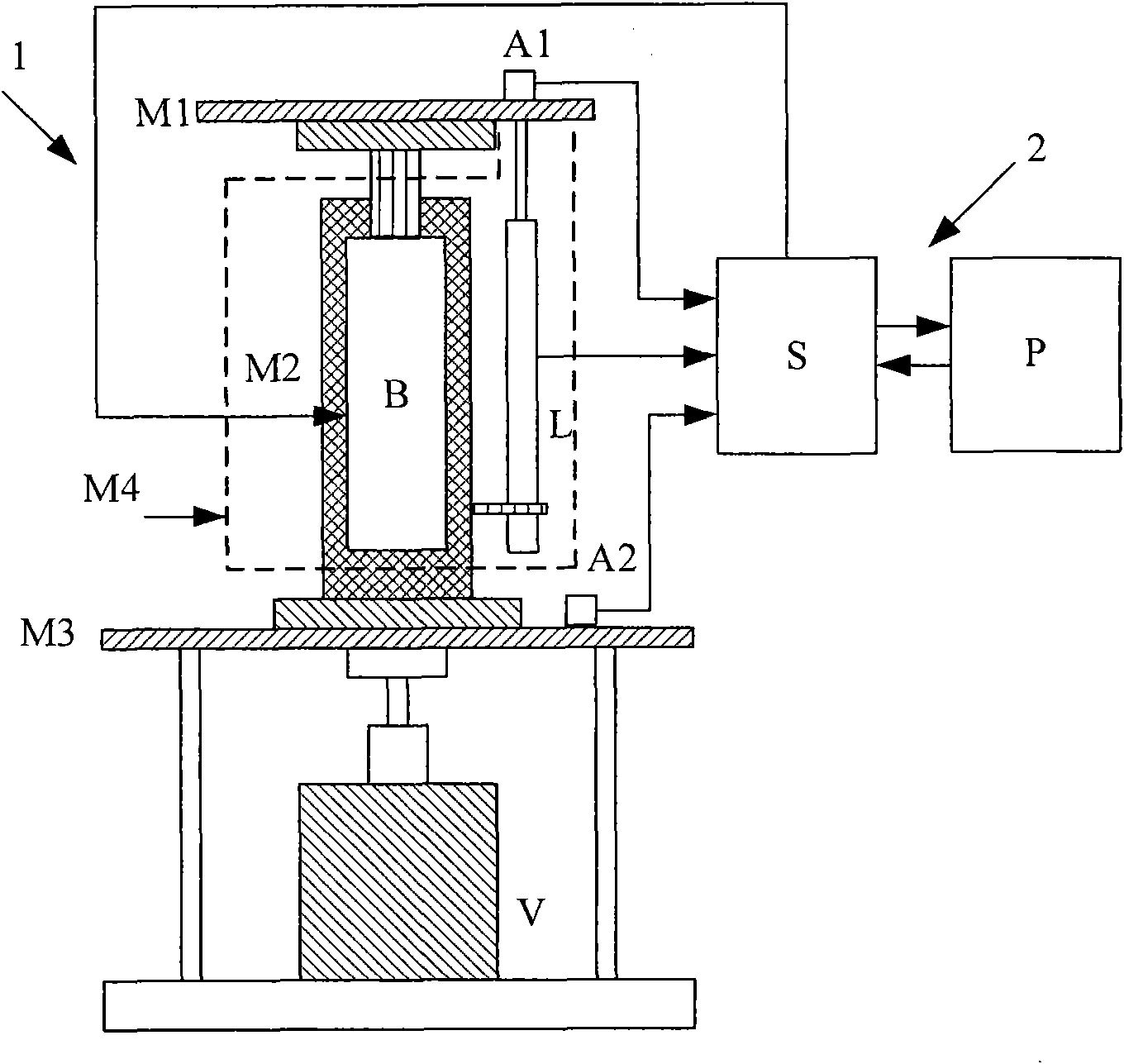

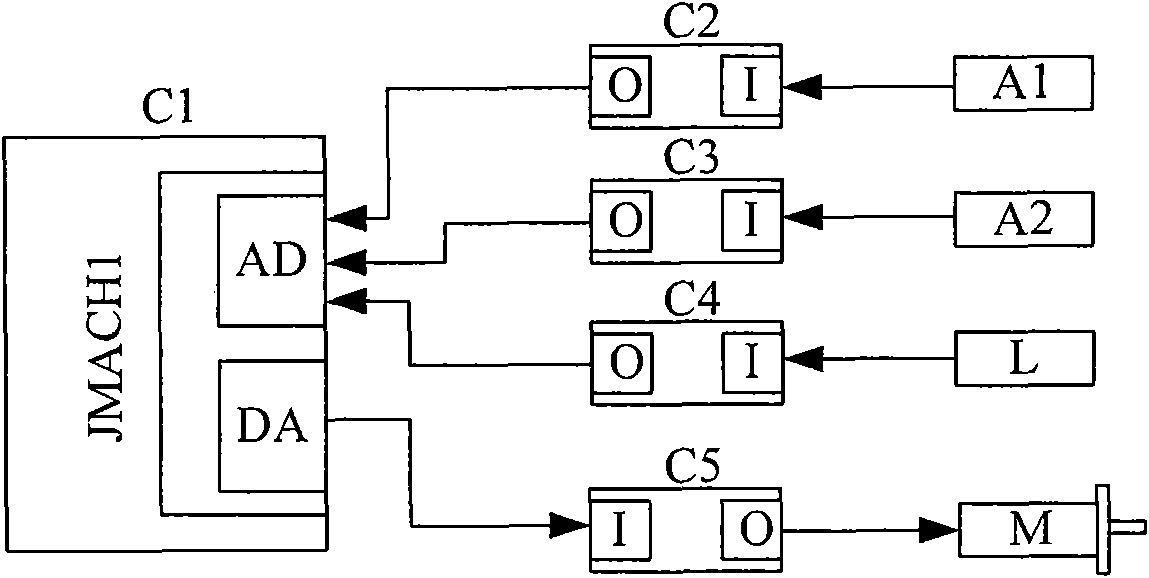

Active vibration isolation control platform

ActiveCN101609341ASimple structureReduce noiseMechanical oscillations controlEnergy industryLinear variable differential transformerExecution control

The invention discloses an active vibration isolation control platform. The active vibration isolation control platform comprises an active vibration isolation device and an active vibration isolation controller; the active vibration isolation device comprises a lower platform, a midbody and an upper platform; a voice coil motor actuator is arranged between the midbody and the lower platform; a linear variable differential transformer type displacement sensor is arranged between the upper platform and the midbody; and two three-freedom-degree acceleration sensors are arranged on the upper platform and the lower platform respectively. The vibration isolation controller is designed according to a master-slave open type control structure and consists of an upper control computer and a lower execution controller, wherein the upper control computer is a mainframe of an embedded type industrial control computer PC / 104; and the lower execution controller is an open-type controller. The active vibration isolation control platform is quite effective on low-frequency vibration isolation and is applicable to precise manufacture, precise measurement, aerospace application and other vibration isolation fields with special requirement on vibration environment.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com