Automation control method for tunnel lining construction

An automatic control and tunnel technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of difficult to guarantee the quality of lining construction, inaccurate data accounting, low level of automation control, etc. , the effect of reducing tunnel diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The greatest purpose of the present invention is to combine the lining trolley and the vibrating device for unified control, and to realize the automatic control of tunnel lining construction with the assistance of other detectors.

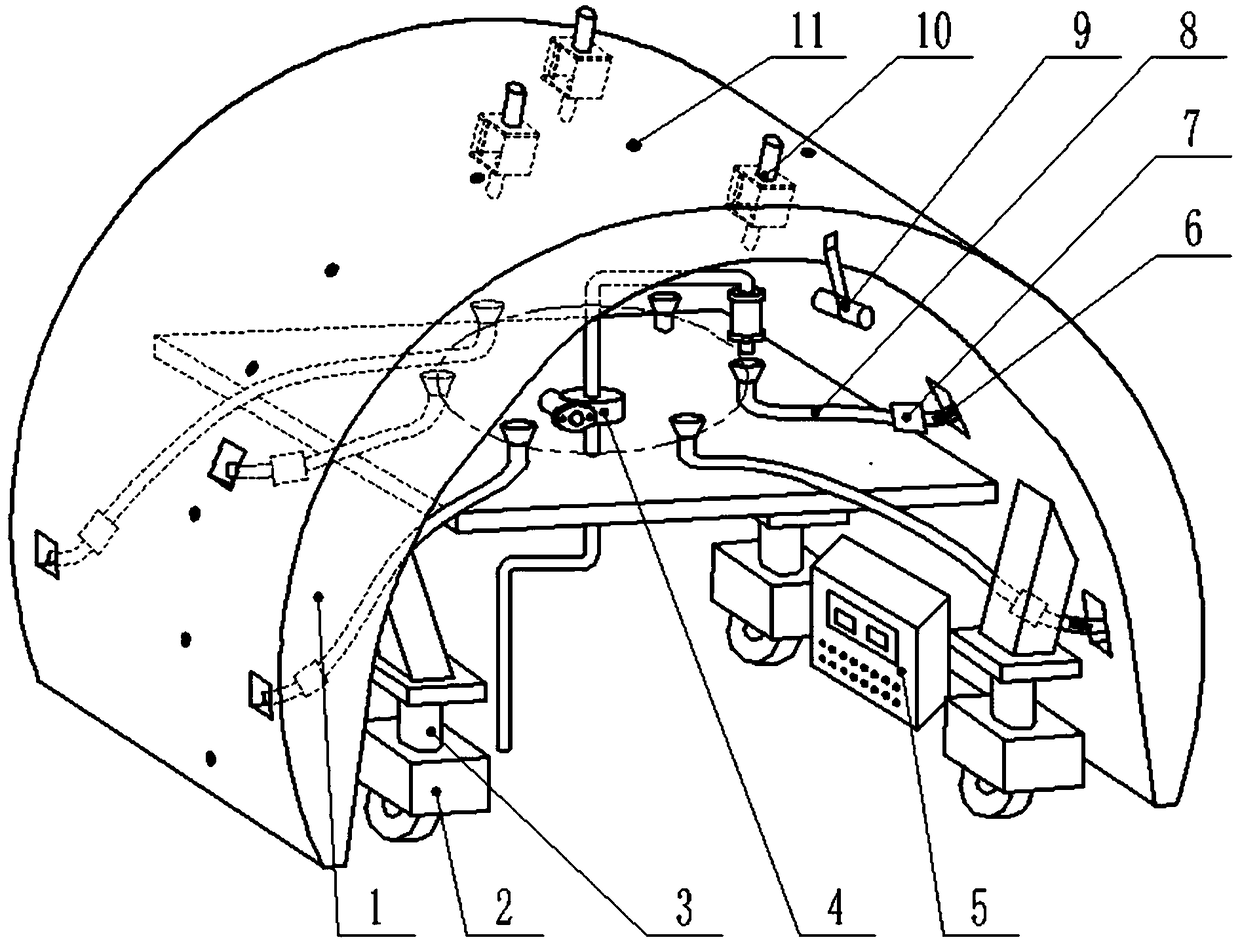

[0028] Combine below figure 1 The technical solution of the present invention is further explained, and the parts not described are subject to the technical solution, and will not be described in detail.

[0029] The lining trolley 1 is a special mechanical device for constructing tunnel lining, and the traveling mechanism 2 and the hydraulic system 3 are used for positioning the lining trolley and forming or demoulding. The concrete distributor 4 is arranged on the upper part of the tunnel lining trolley and can be connected in series with several distribution pipes 8, each distribution pipe 8 is used to quickly distribute the concrete required for pouring the tunnel lining, and a temperature sensor 6 is respectively arranged at the end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com