Three-dimensional dynamic production management system for prefabricated component field

A production management system and a technology for prefabricated components, which are applied in data processing applications, image data processing, instruments, etc., can solve the problems of increased secondary handling costs, time-consuming, and low efficiency of prefabricated components, and achieve automatic calculation and solution. Low efficiency of transportation and the effect of material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

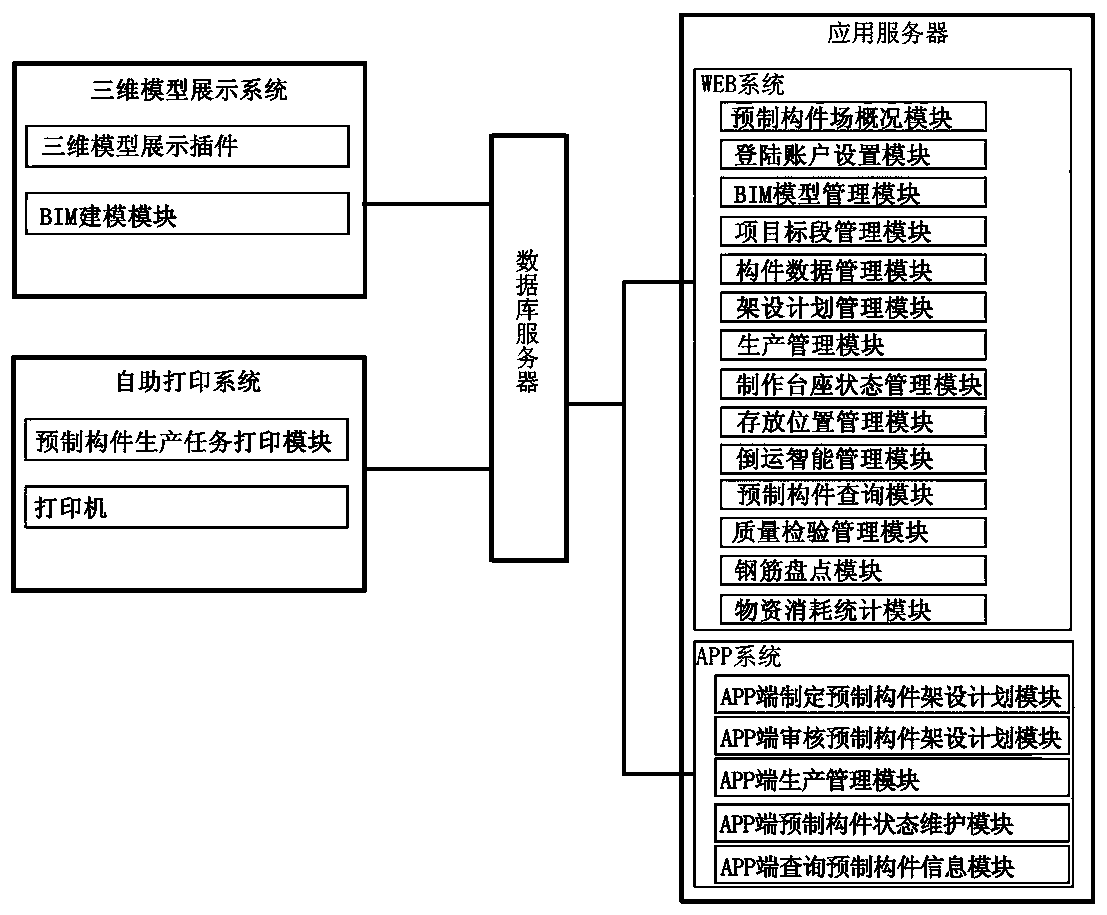

Method used

Image

Examples

Embodiment 2

[0037] On the basis of Embodiment 1, the operation process of the three-dimensional dynamic production management system for the prefabricated component field is as follows:

[0038] (1) Data collection: Before applying the present invention, the following materials need to be prepared: the floor plan of the prefabricated component yard, and the general atlas of prefabricated components. The component data Excel form is sorted out from the general atlas of prefabricated components. The above-mentioned component data Excel form includes component number, length, volume, concrete cover thickness, theoretical concrete quantity and design reinforcement quantity and other data.

[0039] (2) Numbering of pedestals: After the above data are collected, the pedestals of the completed prefabricated component yards need to be numbered next. In order to make the numbering permanent, red paint can be used to paint the surface of the pedestals.

[0040] (3) Establish the BIM model of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com