Informationized full-automatic low-clearance pile pressing equipment

A technology of pile pressing equipment and low headroom, which is applied in the field of informationized automatic low headroom pile pressing equipment, can solve problems such as manual observation, harsh construction environment, and unfavorable health and safety of welders, so as to save labor costs, improve pile pressing efficiency, Effect of improving welding speed and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

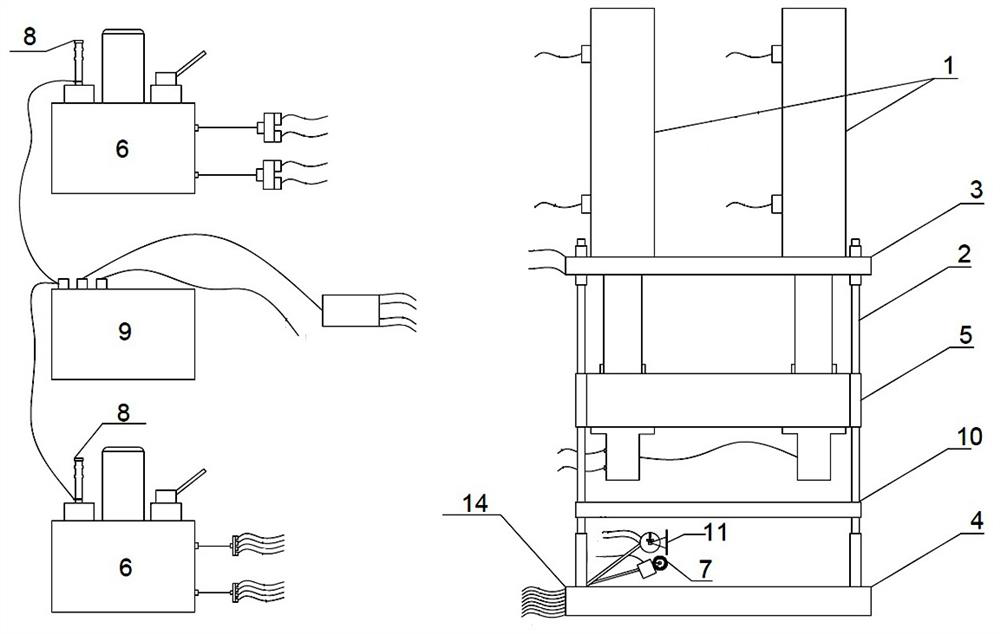

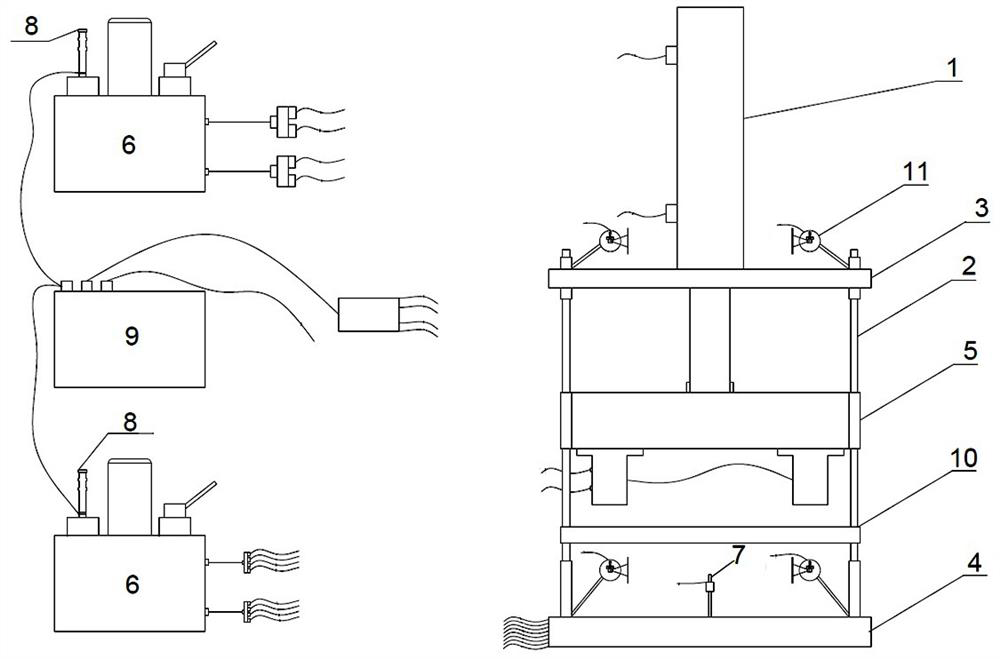

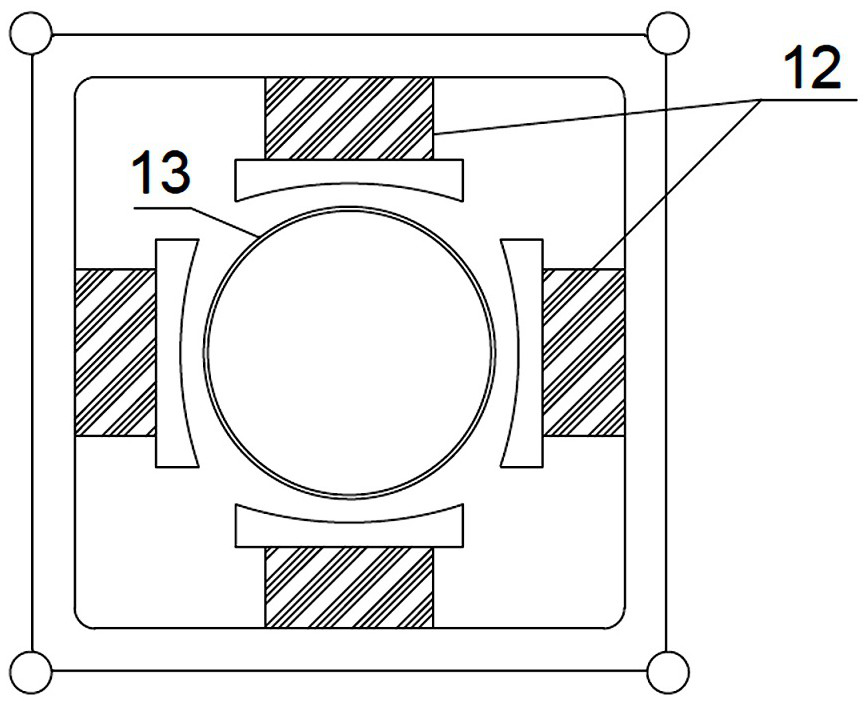

[0032] Example: such as Figure 1 to Figure 9 As shown, this embodiment relates to an information-based fully automatic low clearance pile pressing equipment, which is mainly used for jacking pile bodies. In this embodiment, the pile body is a steel pipe 13, which mainly includes a pile pressing system, a pile pressing force collection Device 8, pile length acquisition device 7, verticality acquisition device 11, verticality guide and adjustment device, automatic welding device and control host 9. The pile pressing system includes a jack 1, a force transmission column 2, an upper tray 3, a lower tray 4, a hoop 5 and an oil pump 6. Both ends of the force transmission column 2 are respectively connected with the upper tray 3 and the lower tray 4 by bolts, and the hoop 5 is located between the upper tray 3 and the lower tray 4, and the hoop 5 is used to hold and fix the steel pipe 13 tightly. In this embodiment, the number of force transmission columns 2 is four, and the four co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com