Patents

Literature

208results about How to "Improve piling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

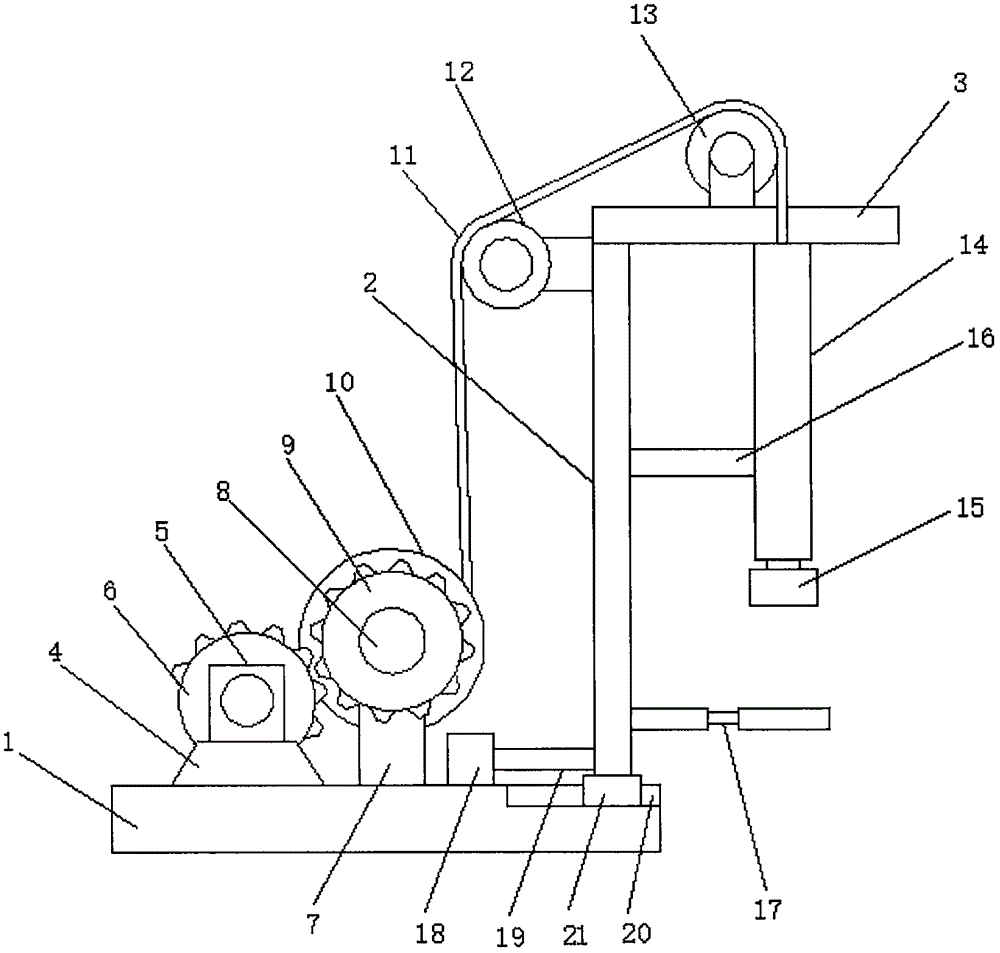

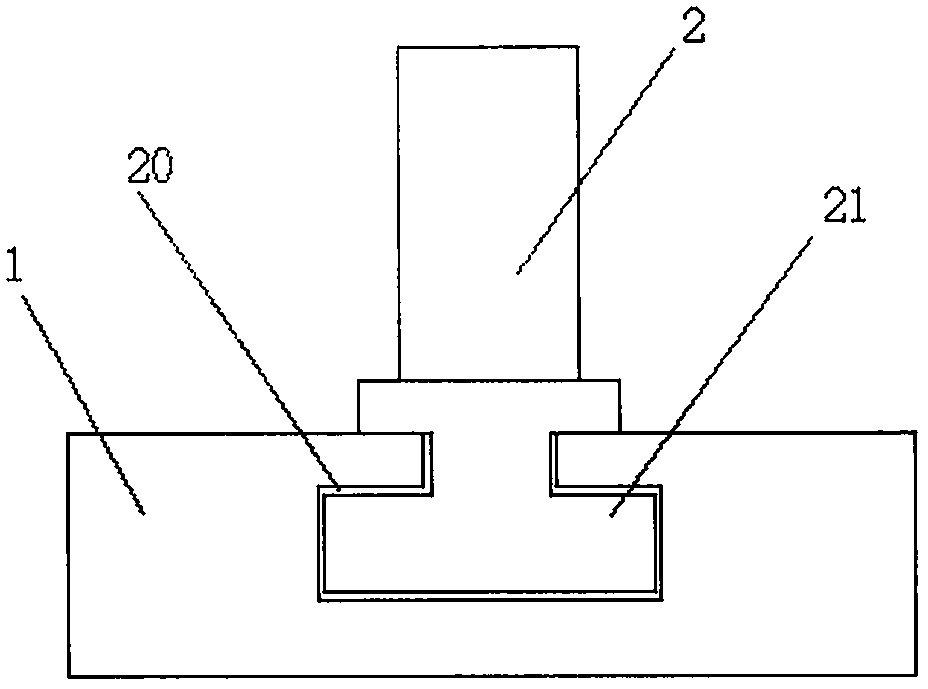

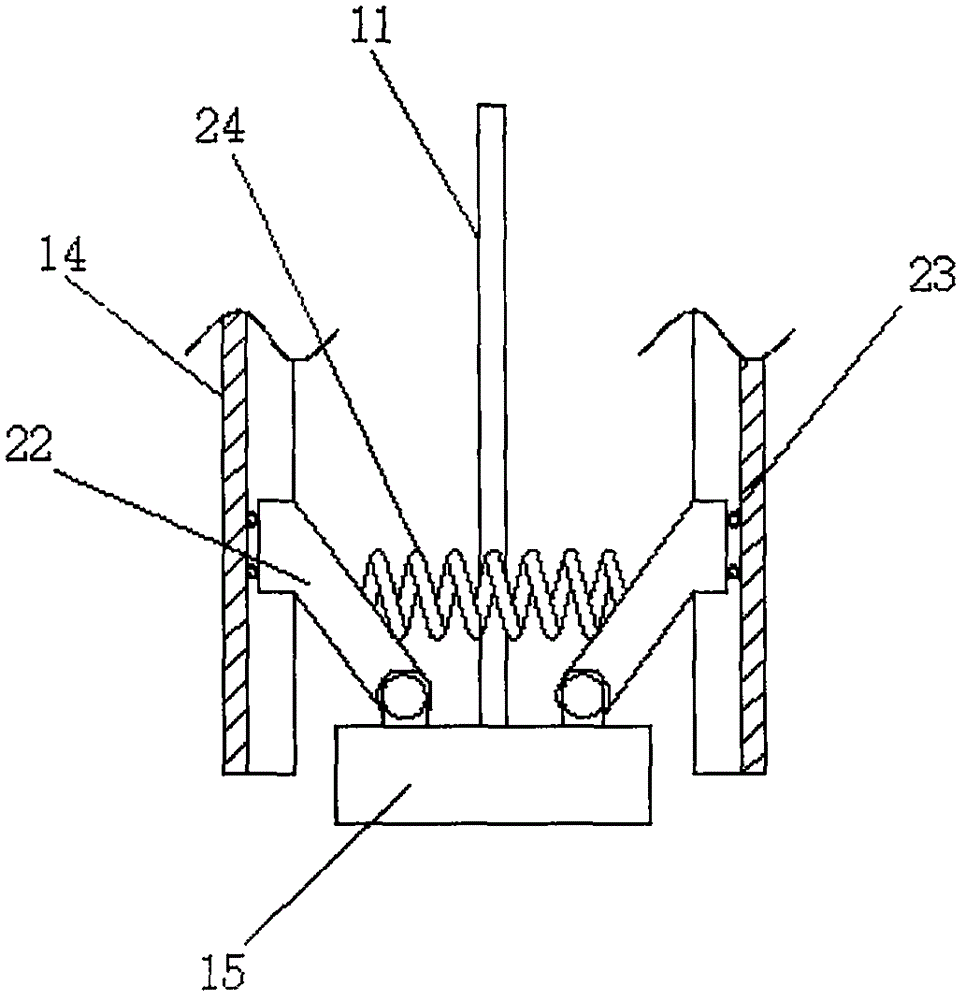

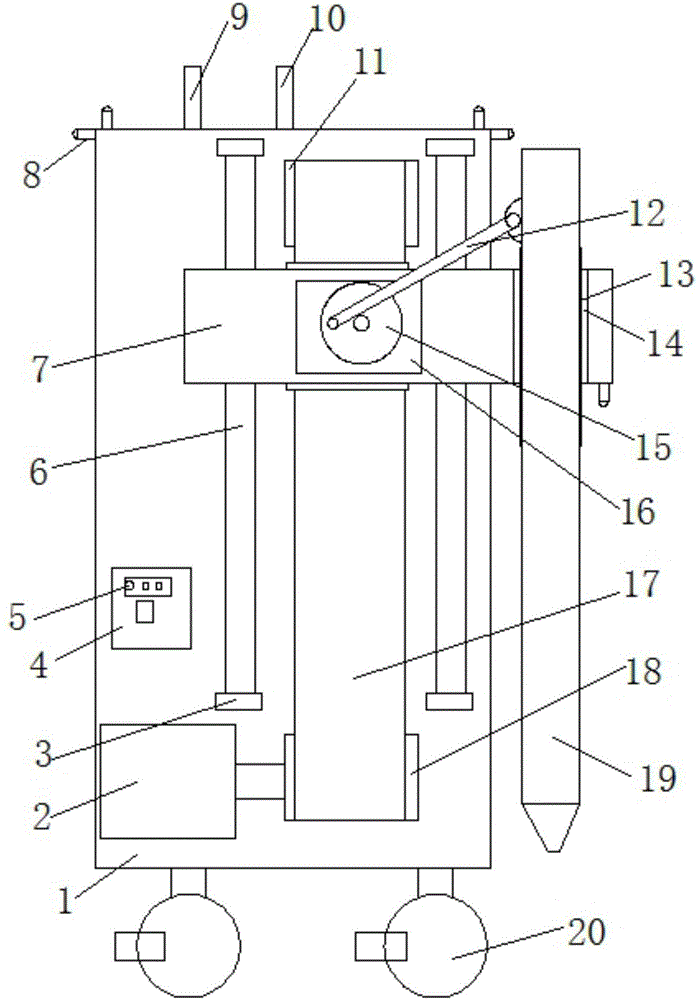

Pile driver for civil engineering

PendingCN107178083AGuaranteed uprightnessIncrease the areaBulkheads/pilesHydraulic cylinderGear wheel

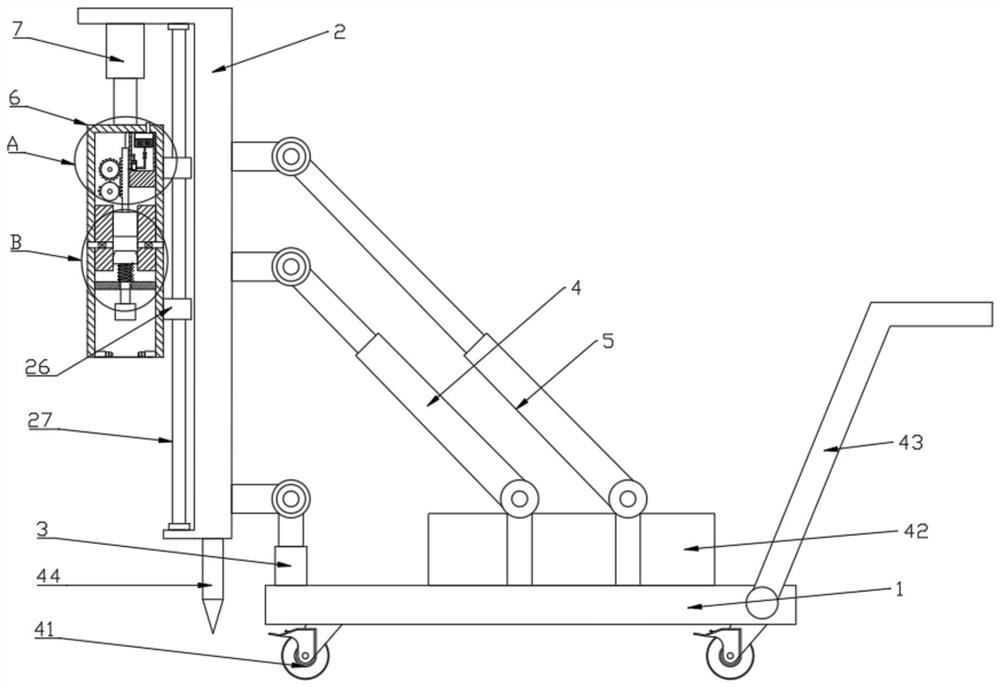

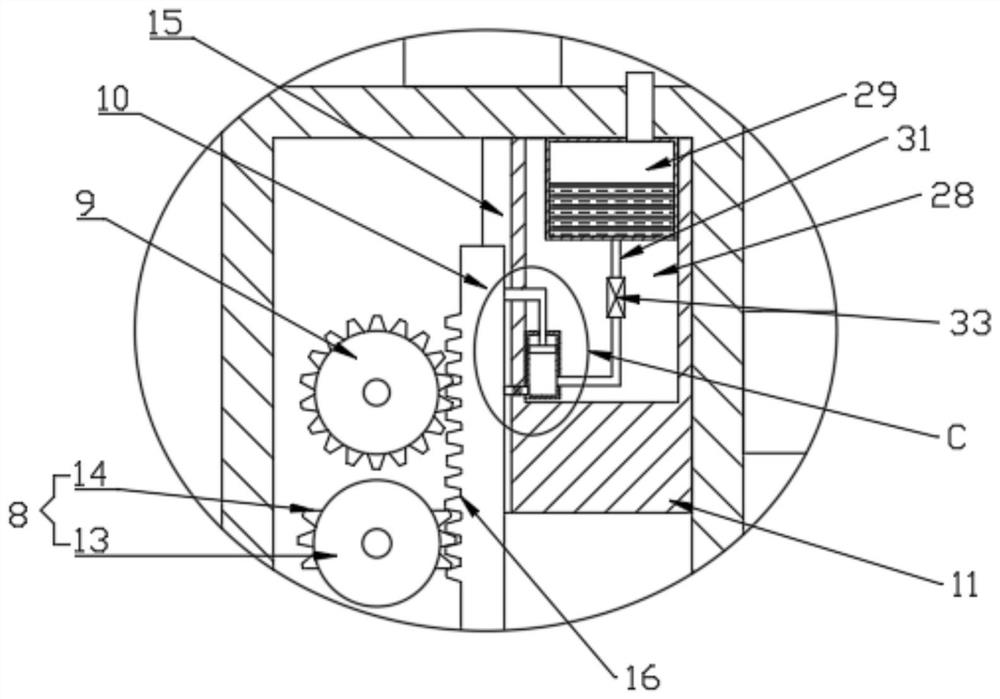

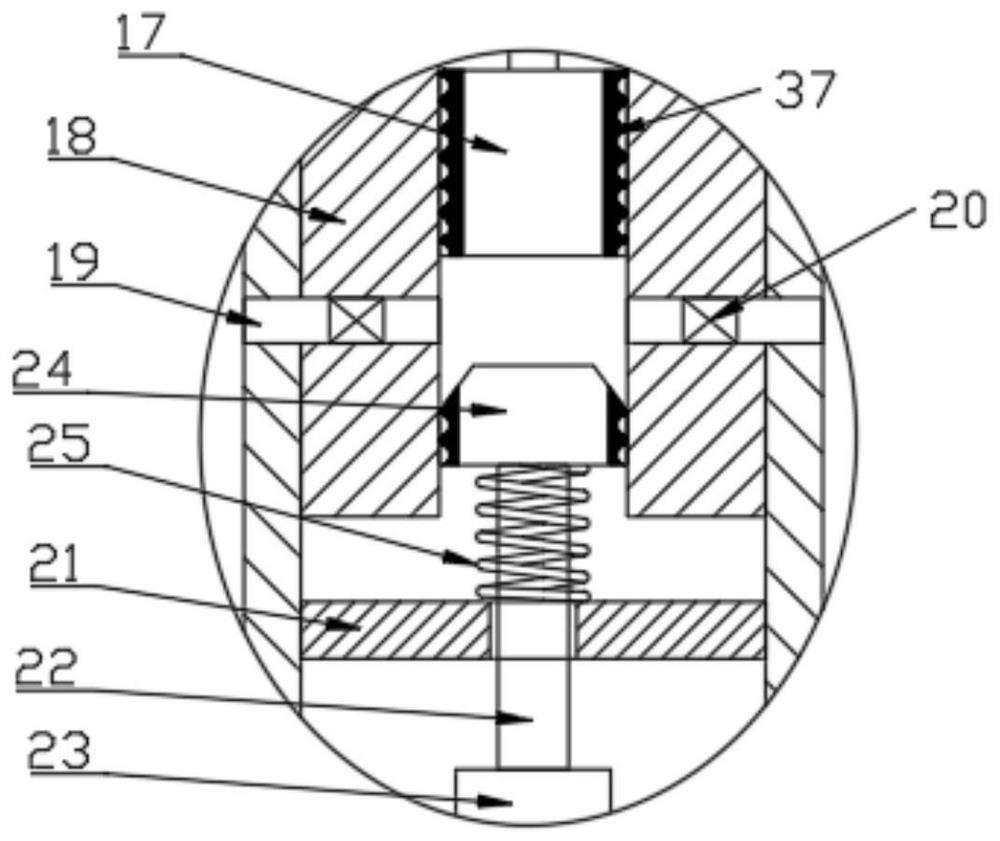

The invention discloses a pile driver for civil engineering. The pile driver for civil engineering comprises a chassis, a stand column and a crane jib. A rotation shaft of a drive motor is provided with an incomplete gear. The support is provided with a cross shaft rotationally connected with the support. The cross shaft is provided with a transmission gear and a rope reel. The stand column is provided with a first pulley. A second pulley is arranged at the top end of the crane jib. The lower end face of the crane jib is provided with two vertically downward guide sliding grooves. A pile hammer is arranged between the two guide sliding grooves. The two sides of the upper end of the pile hammer are both provided with supporting arms which are inclined and upward. A pile clamping mechanism connected with the stand column is arranged under the pile hammer. One end of a connection rod is fixedly connected with the bottom end of the stand column. The lower end of the stand column is connected with the chassis through a sliding mechanism. The chassis is provided with a hydraulic cylinder. The pile driver for civil engineering is simple in structure, good in pile driving upright performance, capable of continuously driving piles, high in pile driving efficiency, easy and convenient to operate and high in practicability.

Owner:ZHENGZHOU UNIV

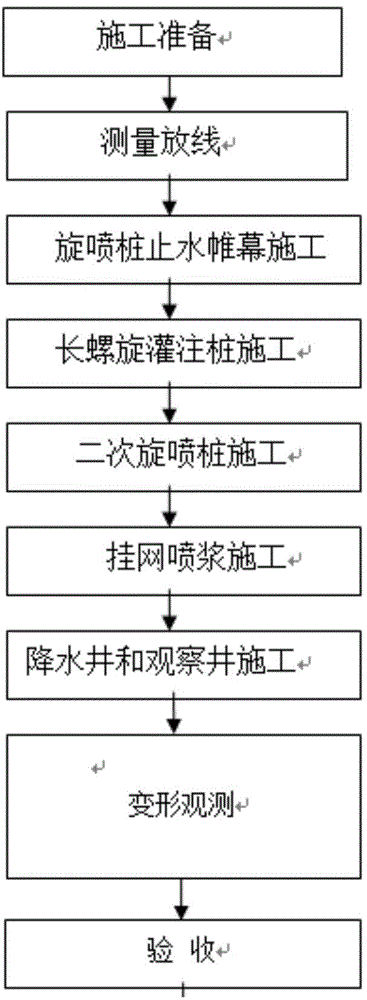

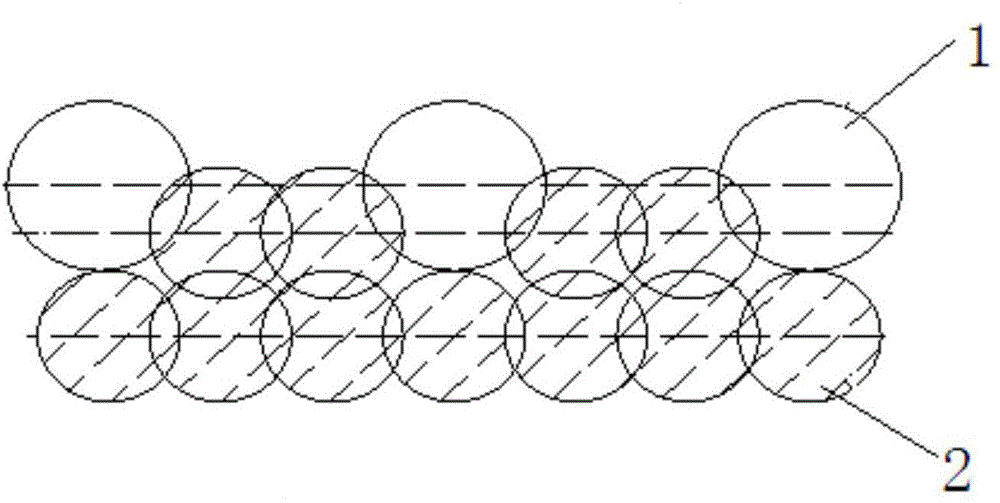

Deep foundation pit combination retaining and protecting construction method for geology with high water level and large particle size sand gravel

ActiveCN104631470ARapid Construction SupportImprove piling efficiencyExcavationsBulkheads/pilesEngineeringHigh pressure

The invention discloses a deep foundation pit combination supporting construction method for geology with high water level and large particle size sand gravel. High pressure jet grouting pile construction is conducted outside a foundation ditch retaining and protecting system, by means of a triple placing method, cement paste is injected into underground soil filling layer and sand gravel gaps, after solidifying, secant pile wall and retention wall are formed, the underground water is prevented outside the periphery the foundation ditch retaining and protecting system, and conditions are created for the construction of a support pile; when the strength of outer side jet grouting pile meets design requirements, a long auger drilling cast-in place pile begin to be constructed close to the inner side of the jet grouting pile; after perfusion pile beings maintained for 15 days, jet grouting pile construction begins to conduct to make up partial failure of waterproof curtain of the jet grouting pile in construction of retaining and protecting pile, and retaining and protecting strength and water interception effect of the retaining and protecting system are increased; at last, in an earth excavation process, bar-mat reinforcement sprayed concrete slope protection and construction of dewatering well, open trench and water-collecting well in the foundation ditch are completed well, multiple retaining and protecting forms are used for combining construction and interaction. Accordingly, the problems of retaining and protecting the geology with high water level and large particle size sand gravel and processing the geology are solved.

Owner:HEFEI CONSTR ENG GRP

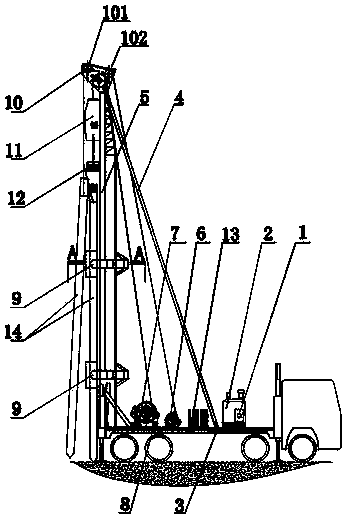

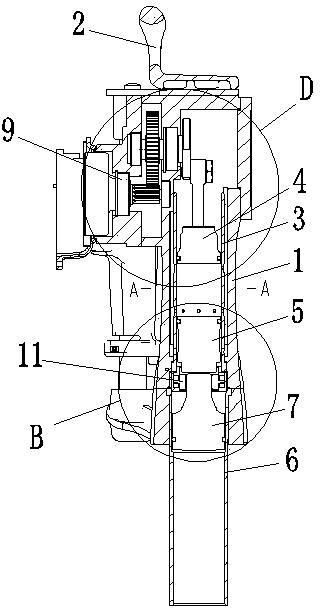

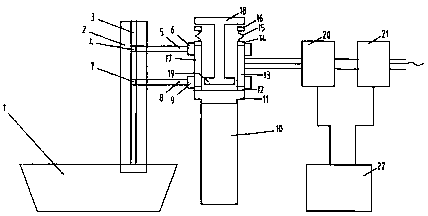

Full-automatic hydraulic piling machine using freely-lowering winch for driving heavy hammer

ActiveCN103422505AEliminate pollutionPromote environmental protectionBulkheads/pilesAutomatic controlControl system

The invention discloses a full-automatic hydraulic piling machine using a freely-lowering winch for driving a heavy hammer. The full-automatic hydraulic piling machine comprises a hydraulic control system and an electric circuit control system. The full-automatic hydraulic piling machine is provided with a pile lifting winch, the freely-lowering heavy hammer winch and automatic pile clamping mechanisms. The pile lifting winch and the freely-lowering heavy hammer winch are connected with a pile lifting control oil circuit and a heavy hammer control oil circuit respectively. The pile lifting control oil circuit and the heavy hammer control oil circuit are arranged in a hydraulic control system oil circuit in parallel. An automatic control rack hinge mechanism is arranged on the freely-lowering heavy hammer winch and connected with a PLC in the electric circuit control system. The automatic pile clamping mechanisms are arranged on a piling machine main arm, and a pile clamping system of the automatic pile clamping mechanisms is connected with the PLC. A diesel hammer is not needed for the automatic piling machine, a pile is automatically positioned, the piling process is fully automatic from beginning of the piling, operation is easy, labor is saved, efficiency is high, cost is low, and economic benefits are high.

Owner:INI HYDRAULIC

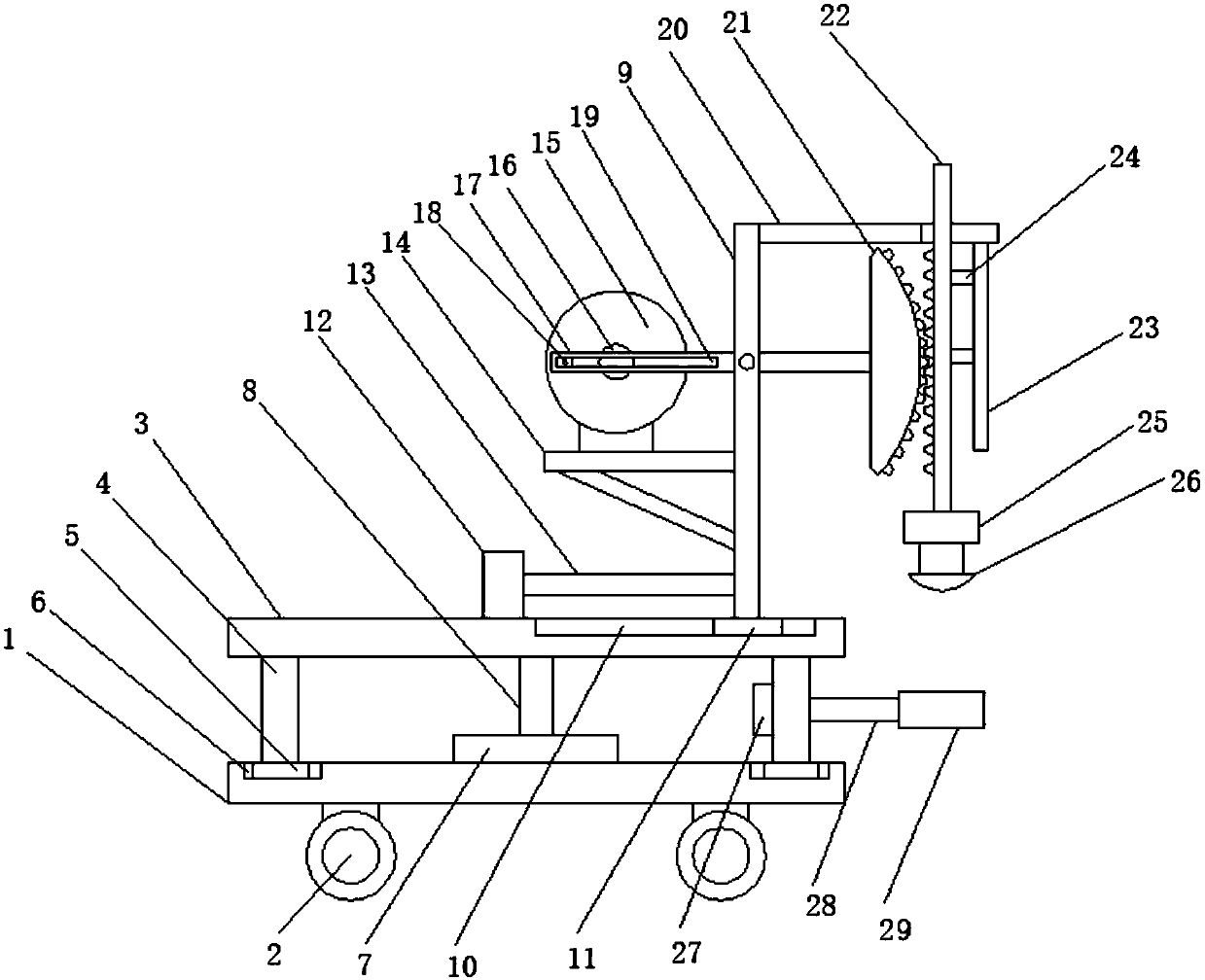

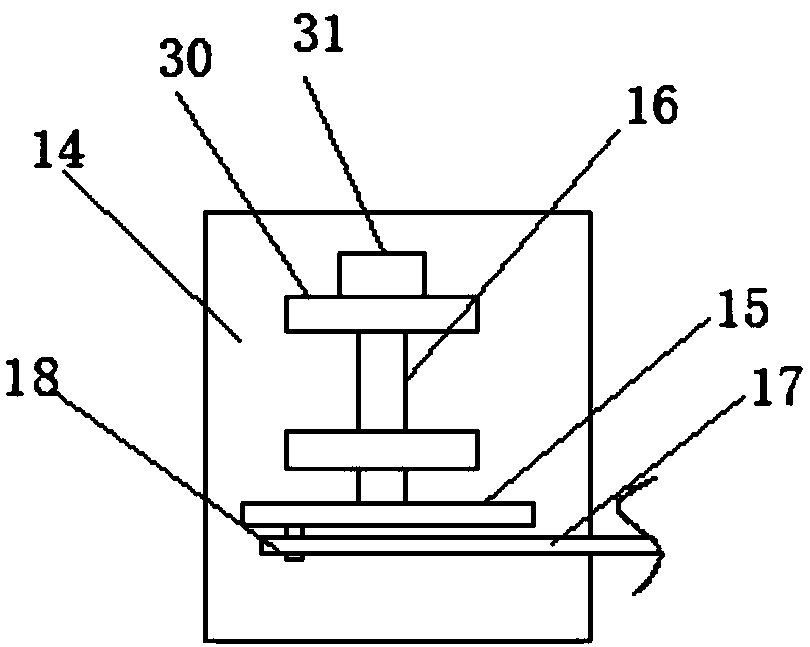

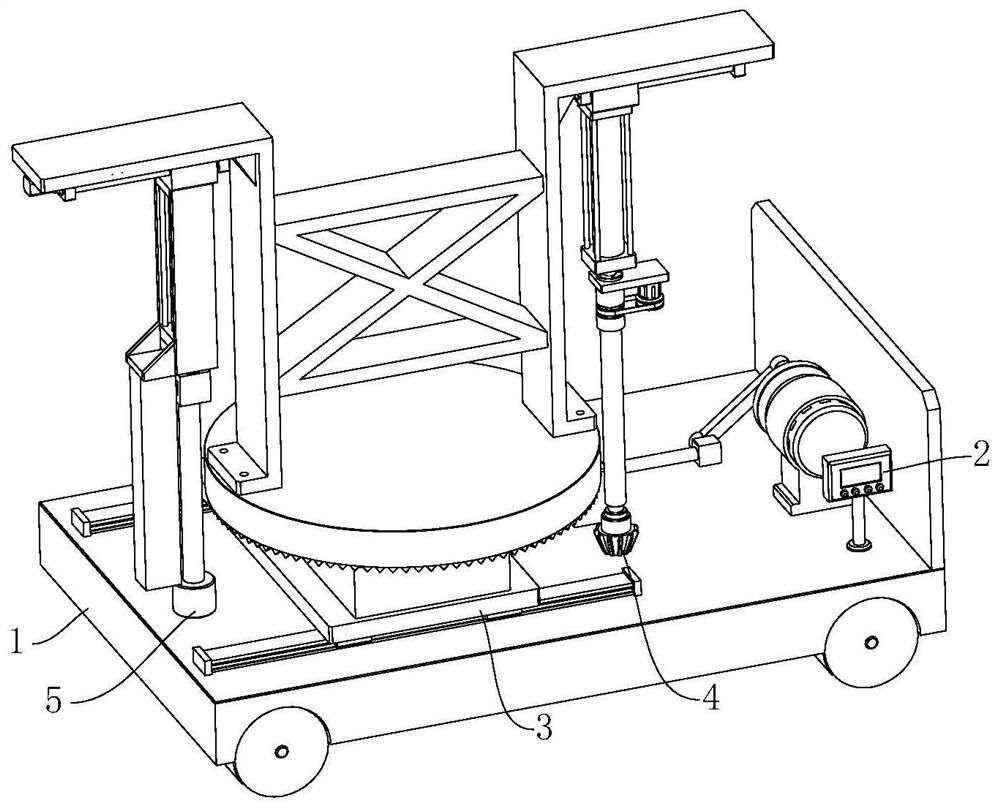

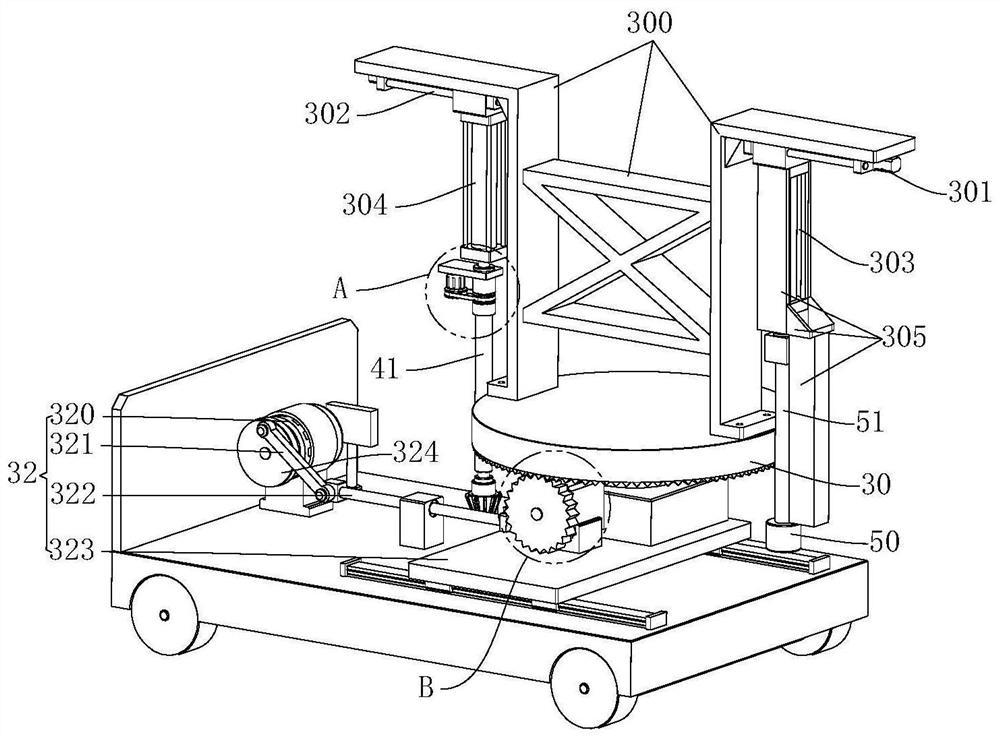

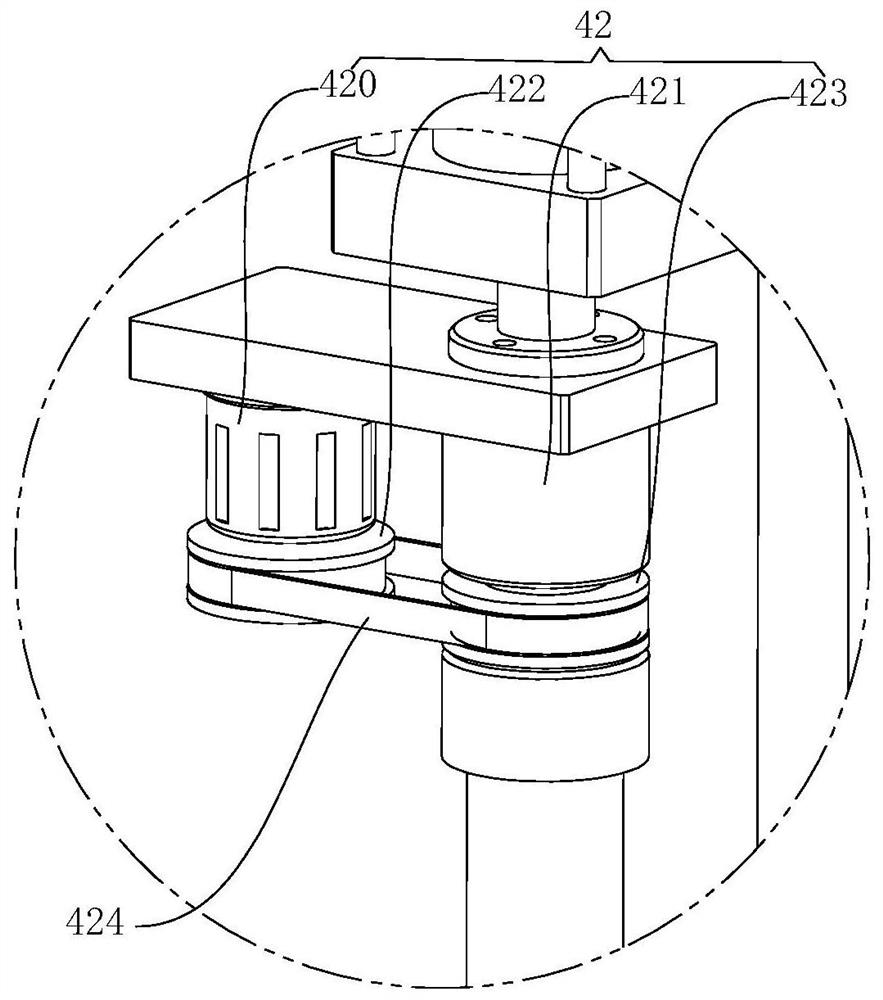

Rotary adjustable construction pile driver

PendingCN107604910AMove down quicklyImprove piling efficiencyBulkheads/pilesPhotovoltaic energy generationCircular discPile driver

The invention discloses a rotary adjustable construction pile driver which comprises a bottom plate. A circular disc parallel to the bottom plate is arranged above the bottom plate. A plurality of supporting posts arranged in a circular ring shape are arranged on the lower end surface of the circular disc. The lower ends of the supporting posts are connected with the bottom plate through a rotarysupporting mechanism. The circular disc is provided with a side plate. A supporting plate is further arranged on the left end surface of the side plate. Supports are arranged on the supporting plate,a transverse shaft is mounted on the supports, a rotating disc is arranged at the other end of the transverse shaft, an oscillating rod is arranged on one side of the end surface of the rotating disc,a driving protruding rod is arranged on the end surface of the rotating disc, a sector gear is arranged at the right end of the oscillating rod, a rack arranged vertically downward is arranged on a top plate and engaged with the sector gear, and a pile hammer is arranged at the lower end of the rack. The rotary adjustable construction pile driver provided by the invention is simple in structure,high in pile driving efficiency, adjustable in pile driving range, wide in applicability, easy and convenient to operate and high in practicability, and piles can be driven rotationally so as to adaptto pile driving of a circular fence.

Owner:ZHENGZHOU UNIV

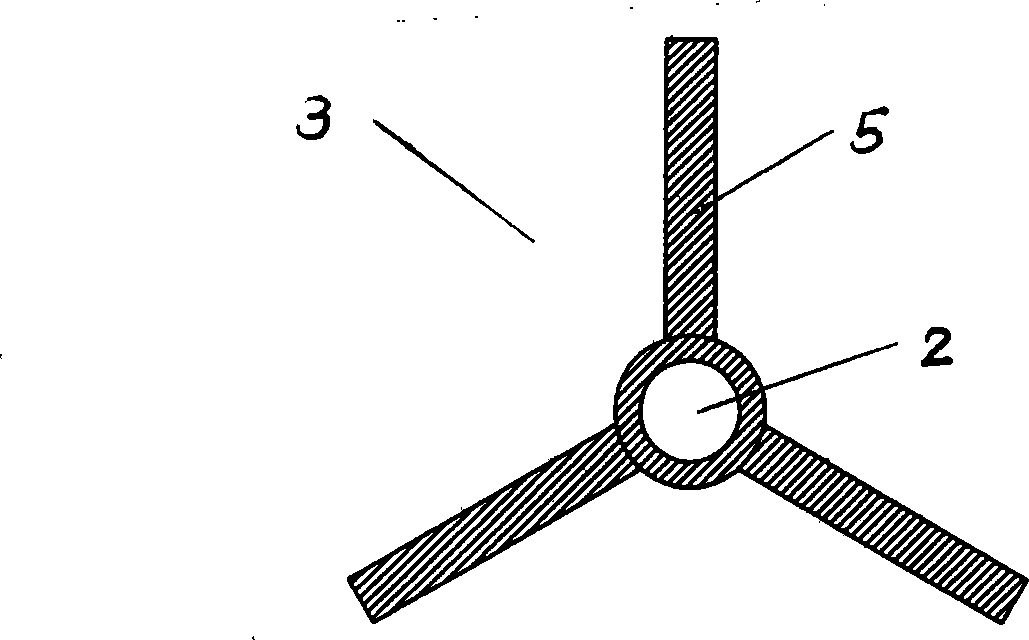

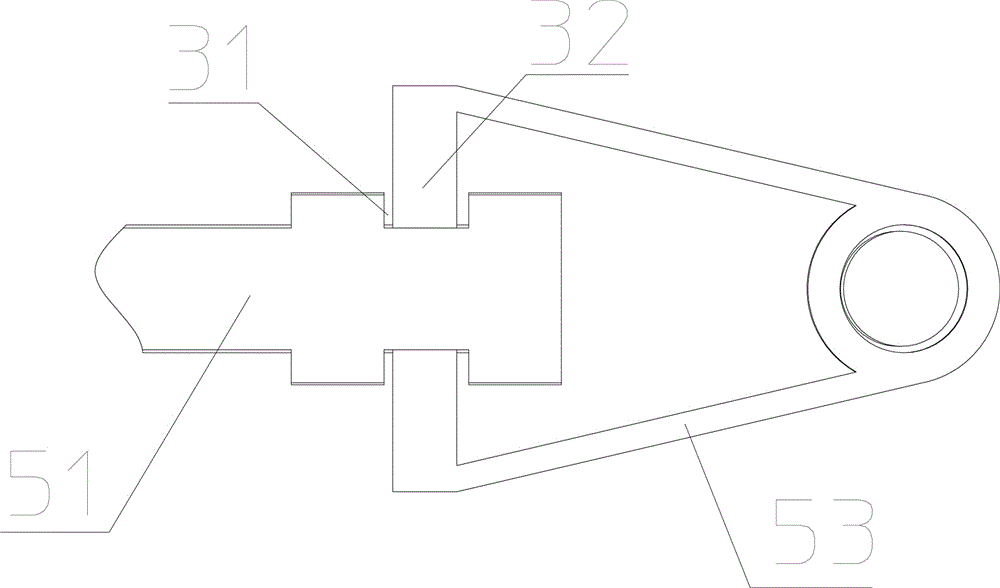

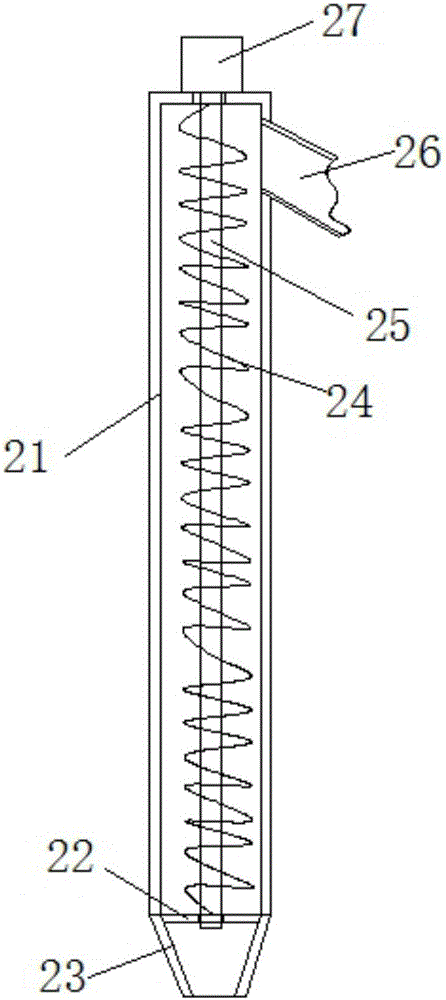

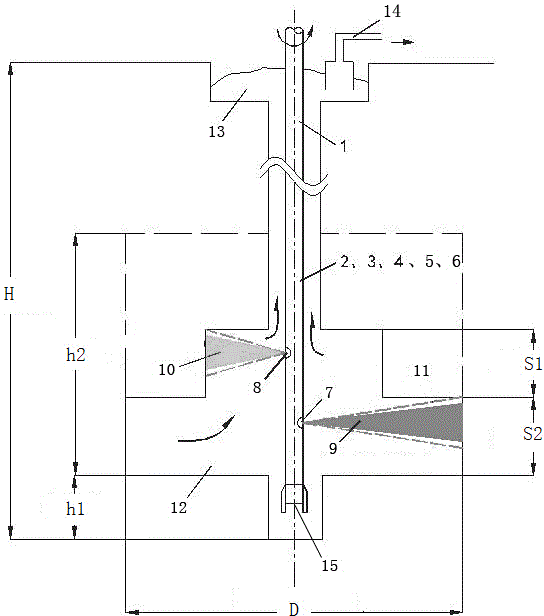

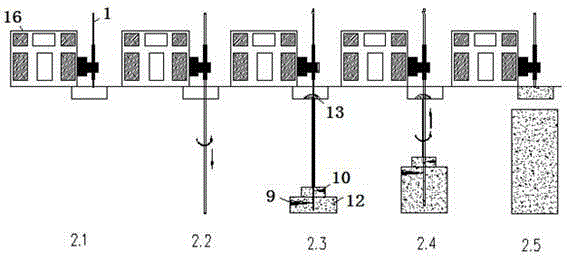

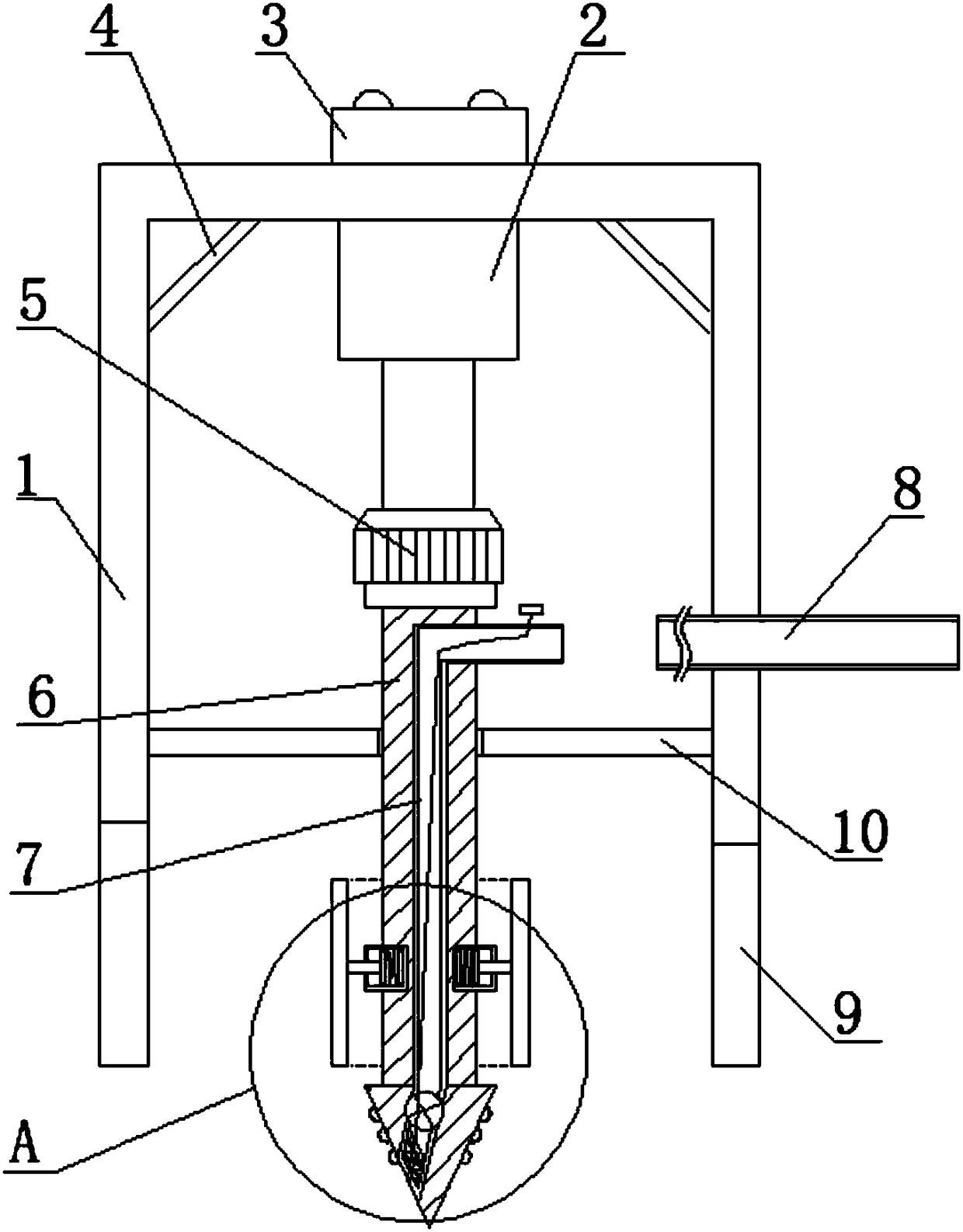

Multi-azimuth tridimensional stirring drill for mollisol or spongy soil reinforcing stirring pile

The invention discloses a multiple position tridimensional stirring drill bit used for leading soft soil or mollisol to reinforce a stirring pile, comprising a drill rod, a front drill point which is positioned at the front end of the drill rod and a multilayer main blade fixed on the drill rod; wherein, the main blade is provided with at least one group of stirring wheels which rotate by taking the main blade as a rotating shaft and does not have power in the process that the drill rod rotates. The multiple position tridimensional stirring drill bit makes use of the energy which is supplied by the rotation of the drill rod and by means of the reaction force of stratum so as to realize the rotation of the stirring wheels, thereby completing the multiple position tridimensional stirring to the stratum by combining the main blade and the stirring wheels and achieving the aim of forming the pile by stirring. The multiple position tridimensional stirring drill bit can remarkably improve the quality of pile forming and effectively reinforce the depth, which has the advantages of uniform stirring, simple structure, strong stratum adaptability, high pile forming efficiency and effectively controlling slurry return.

Owner:徐玉杰

Pile driver

The invention relates to a pile driver. The existing pile driver is usually heavy and can be normally operated by two or even more people, and an air source is very inconvenient to install and carry. The invention provides the pile driver, which comprises a box body, a lifting handle, an air cylinder, a piston, a striking hammer, a casing, a crankshaft, a connecting rod and a transmission device. The pile driver is characterized in that the pile driver further comprises an iron anvil and an iron anvil holder, the iron anvil comprises a striking part and a body used for being fit with the casing, a through hole fit with the striking part is formed in the iron anvil holder, the striking part of the iron anvil penetrates through the through hole and is fit with the striking hammer, and the body is limited by the iron anvil holder; a No.1 hole, a No.2 hole and a No.3 hole are sequentially formed in the air cylinder from bottom to top, an air passage is formed in the box body, and the No.1 hole, the No.2 hole and the No.3 hole are communicated with the air passage. The pile driver has the advantages that the structure is simple, the design is reasonable, the striking force of the striking hammer is great, the vibration is small, the operation comfort is good and the service life of sealing pieces is long.

Owner:HANGZHOU SHARP GARDEN MACHINERY

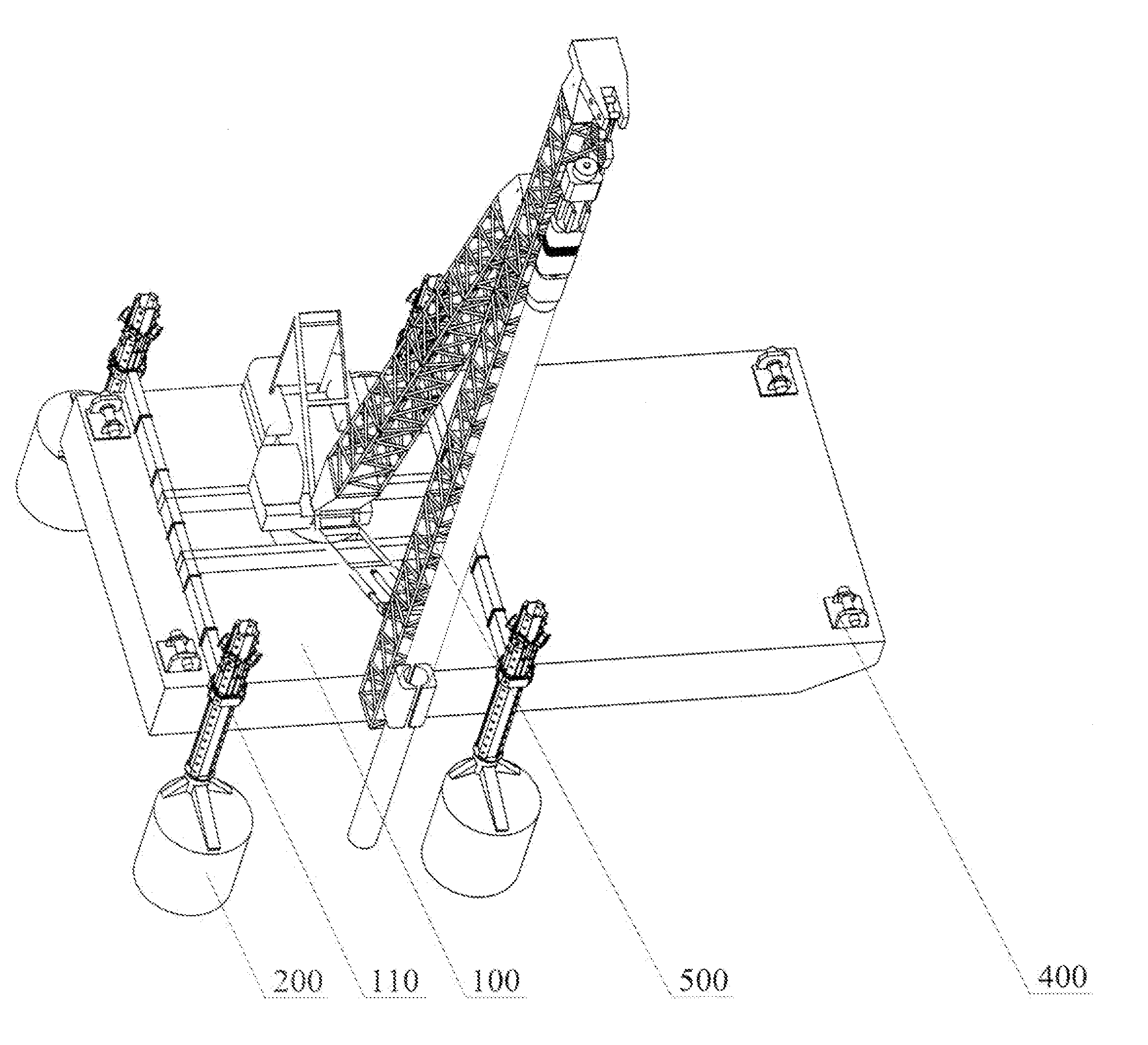

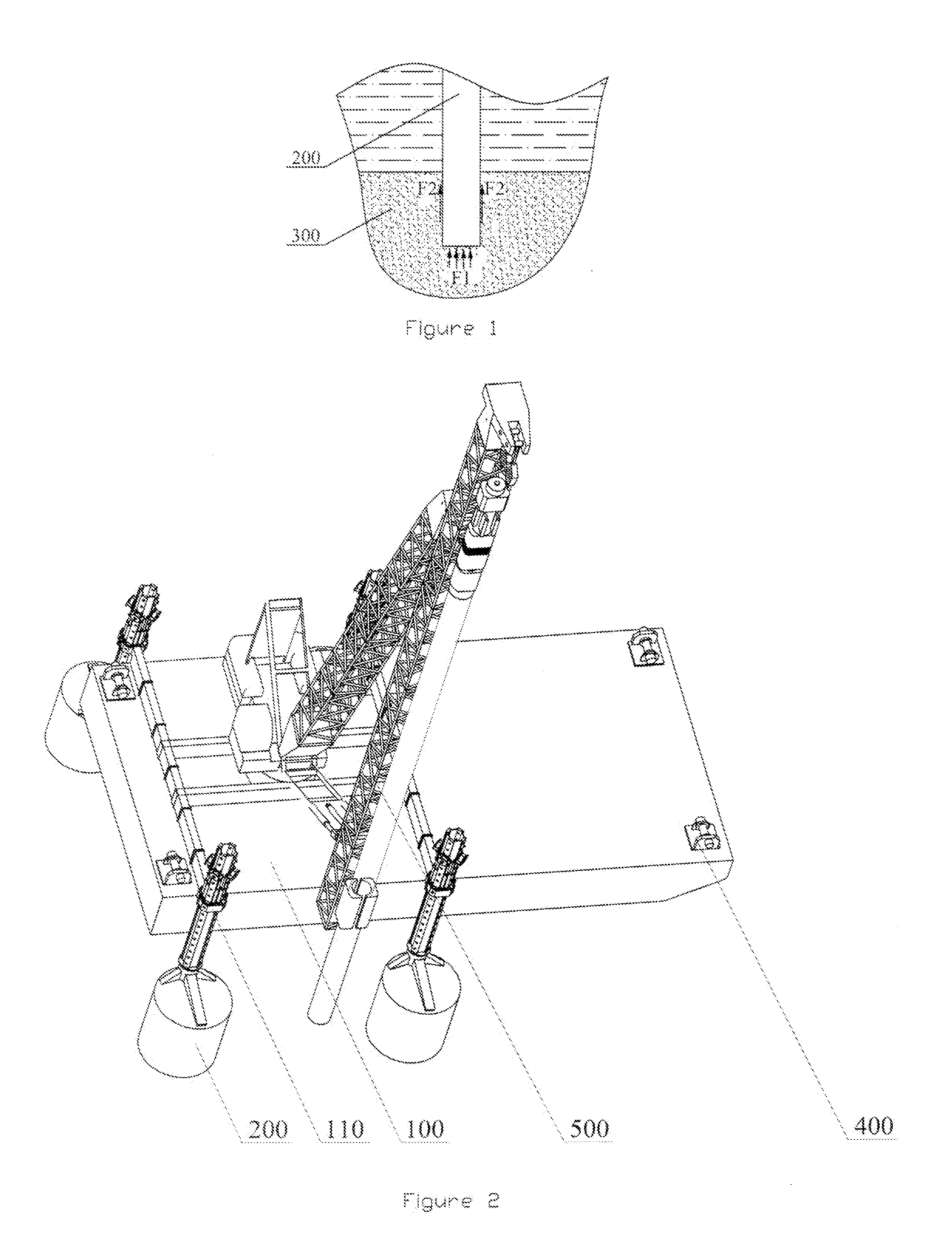

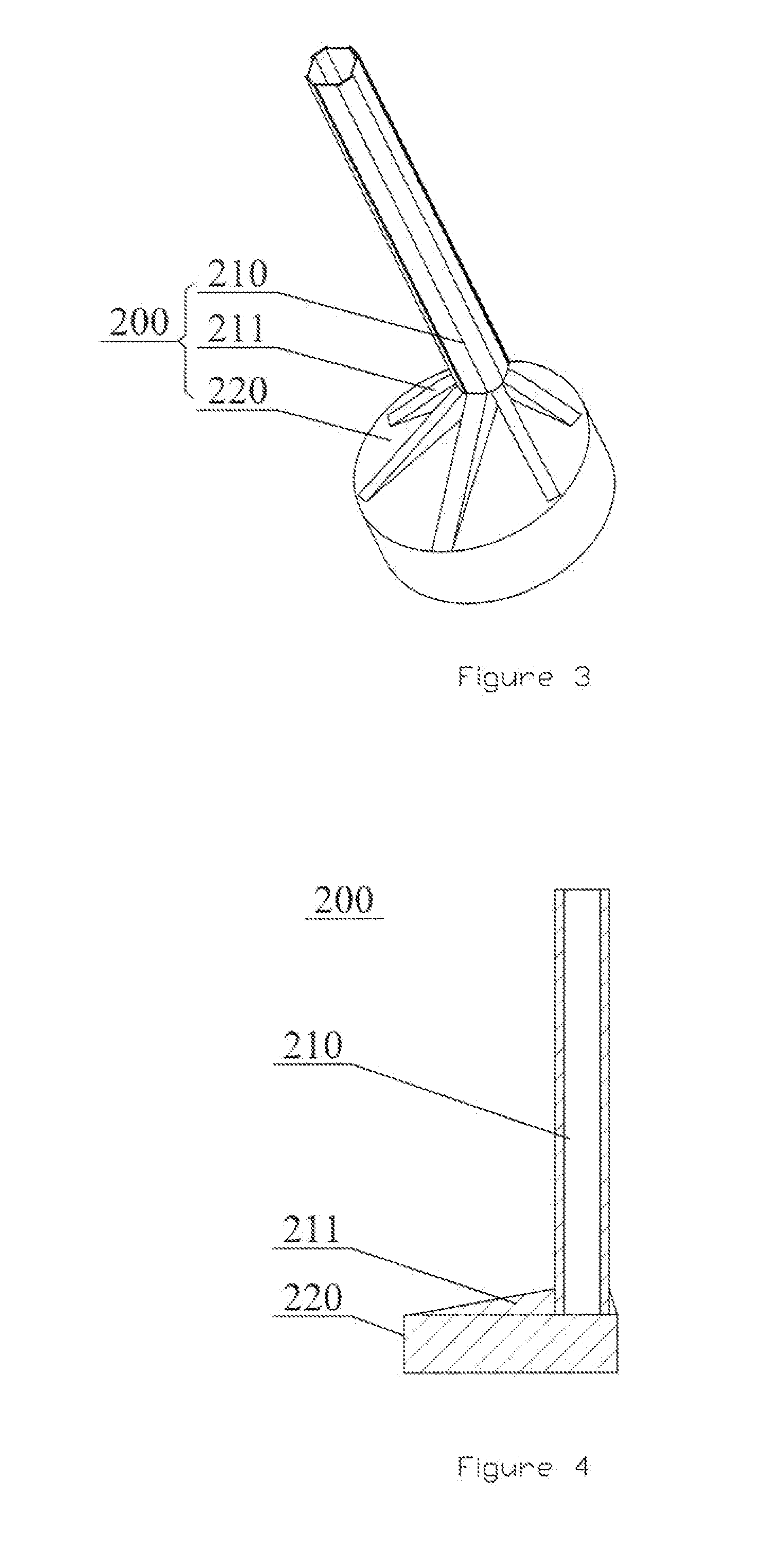

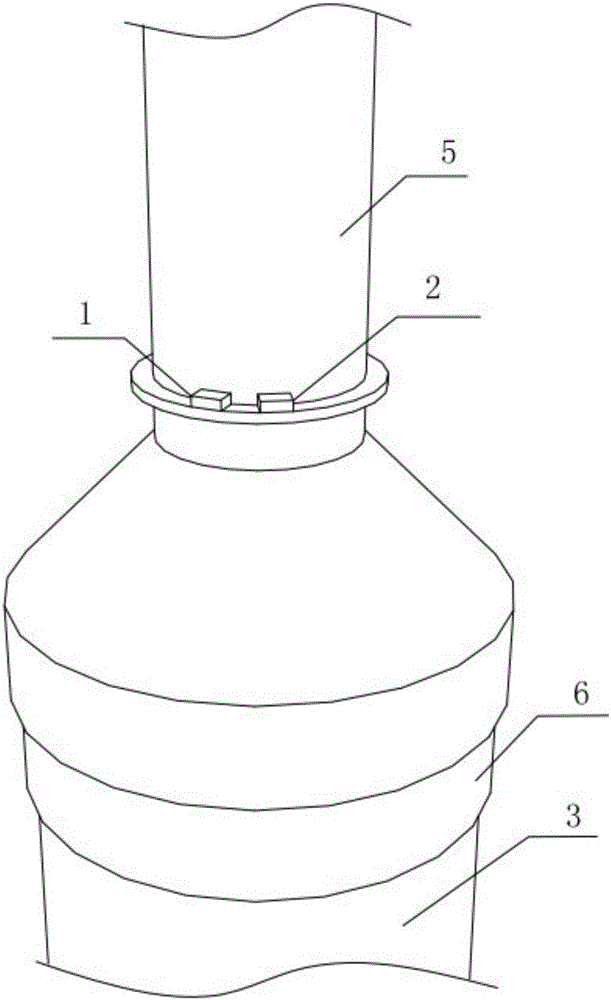

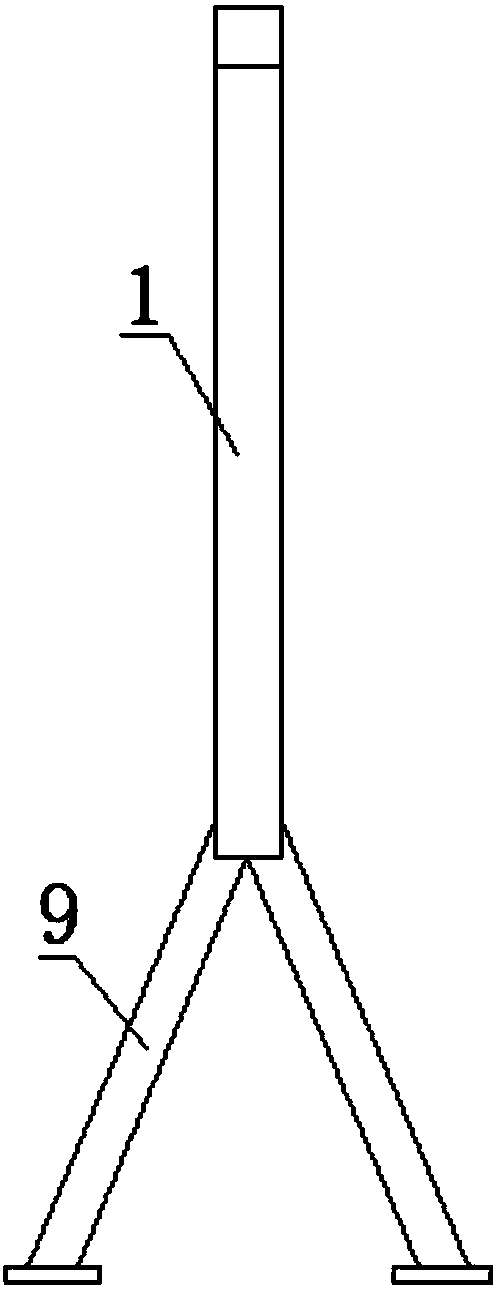

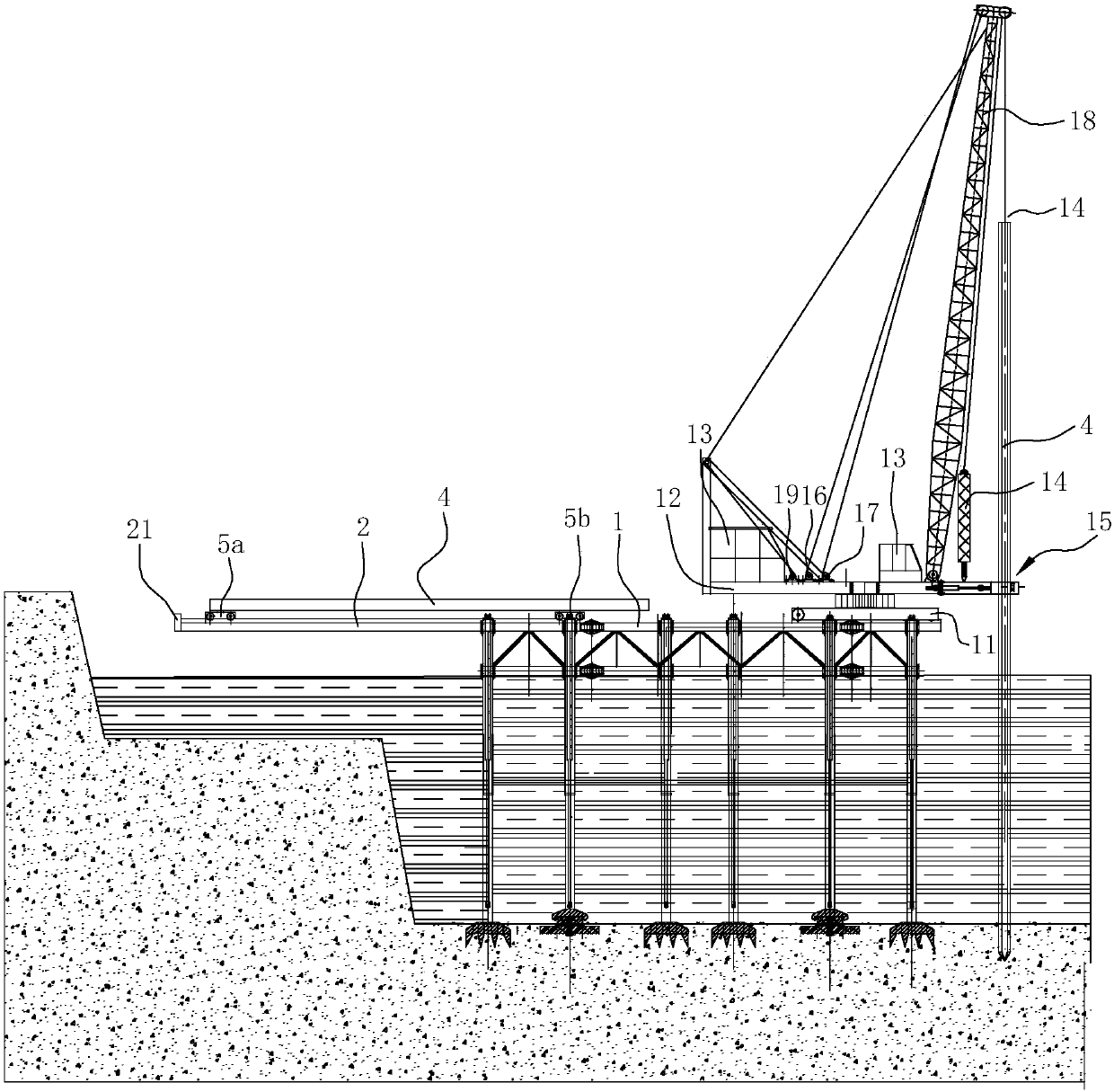

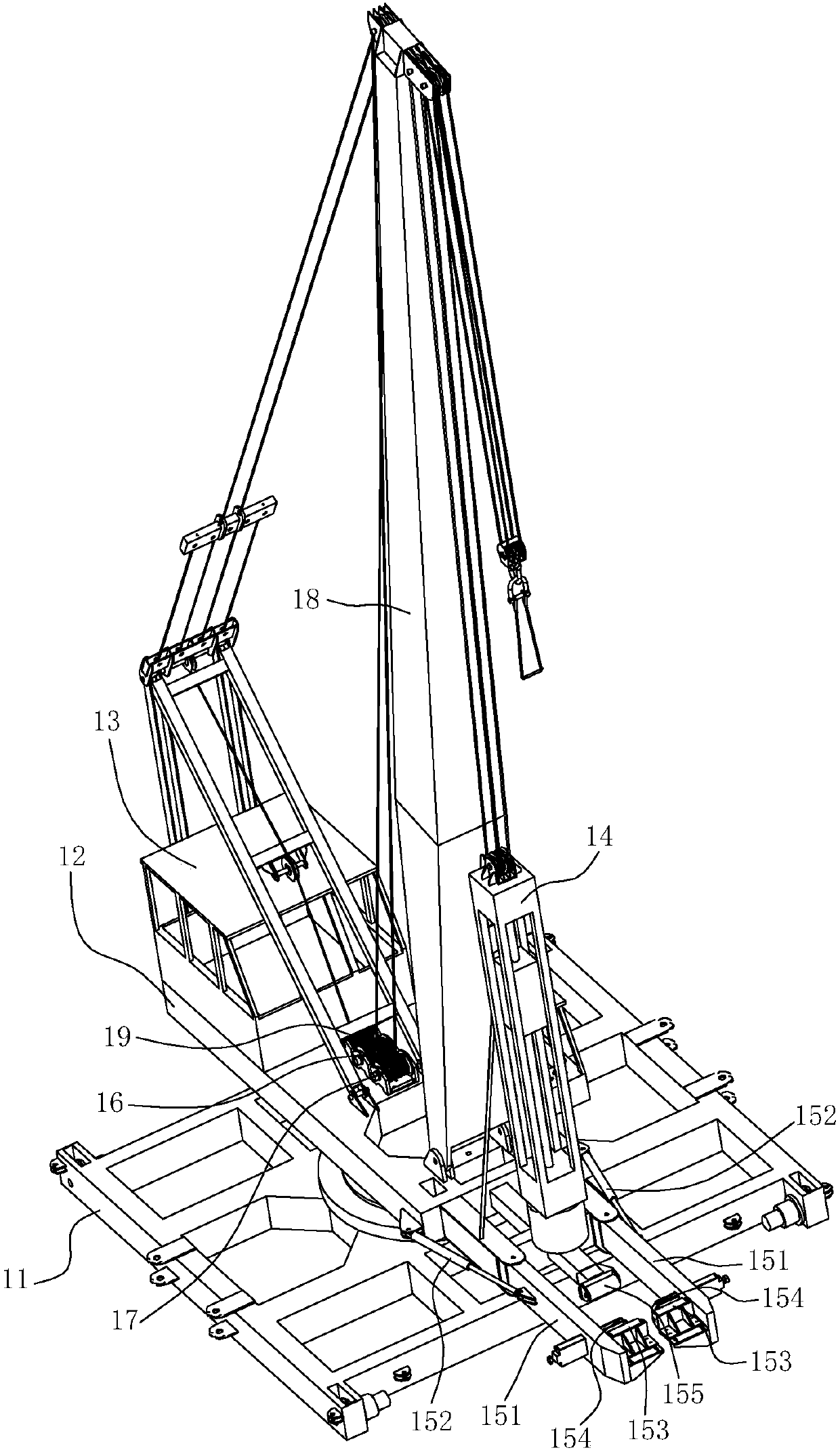

Piling barge

InactiveUS20110129301A1Improve piling efficiencyImprove work efficiencyArtificial islandsCaissonsEngineeringWinch

A piling barge is disclosed by the present invention. In the piling barge disclosed, a supporting leg includes a supporting arm extended in vertical direction. Differing from the prior art, the supporting leg further includes a supporting base. The supporting base has a transverse section larger than that of the supporting arm, an end of the supporting arm is fixed with the upper surface of the supporting base. The supporting base of the supporting leg having a larger transverse section may receive support from a larger area of mollisol ground and thus provide a larger supporting force for the hull, which enables the piling barge to perform the piling operation on sea areas with mollisol ground. A piling device of the piling barge has pile frame adjusting mechanisms, such as a luffing oil cylinder, a luffing winch mechanism and a turntable, etc., which may adjust the incline angle and the position of the pile frame, therefore the working efficiency of piling operation of the piling barge can be improved.

Owner:SANY ELECTRIC CO LTD

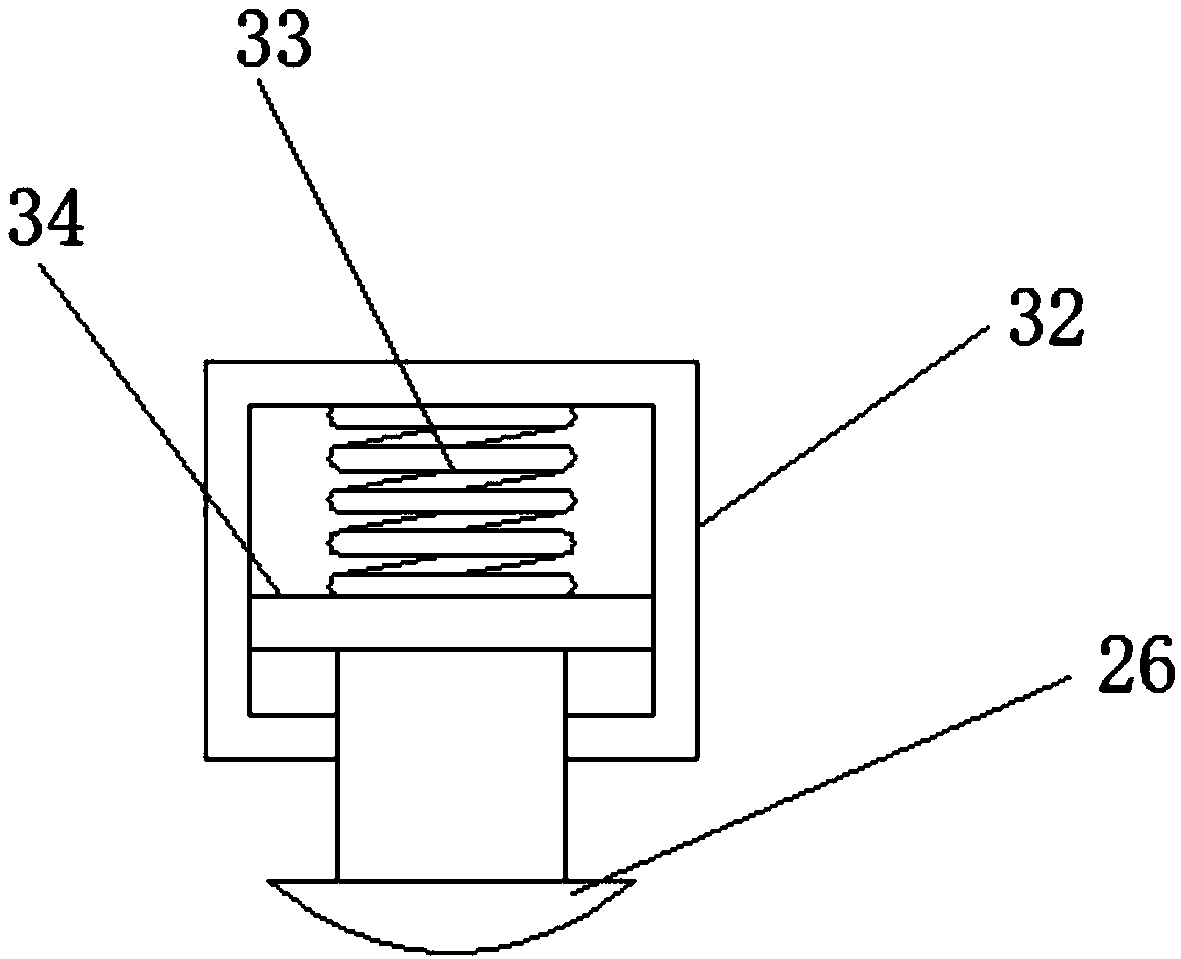

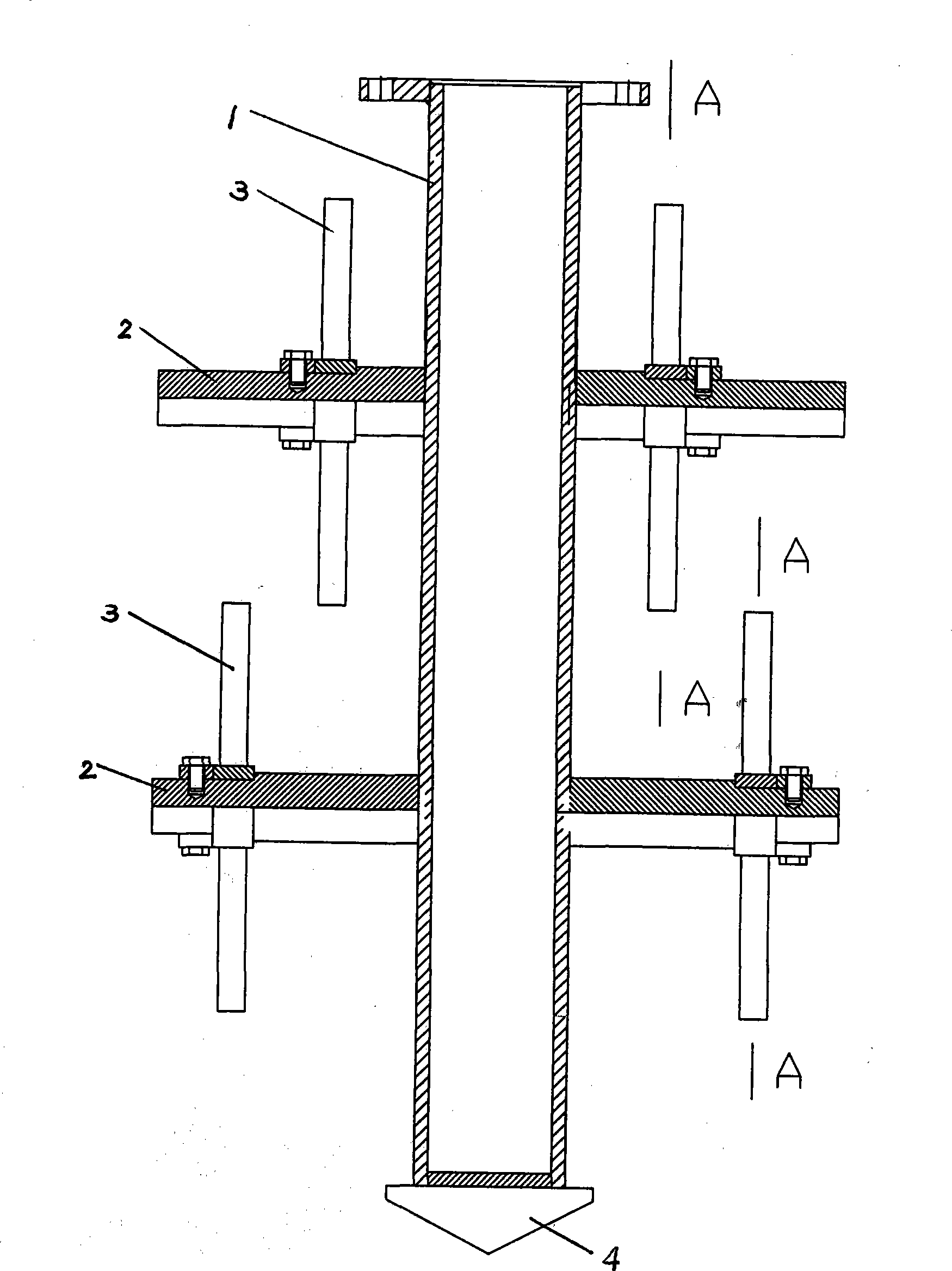

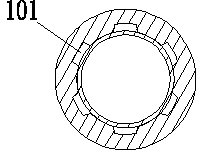

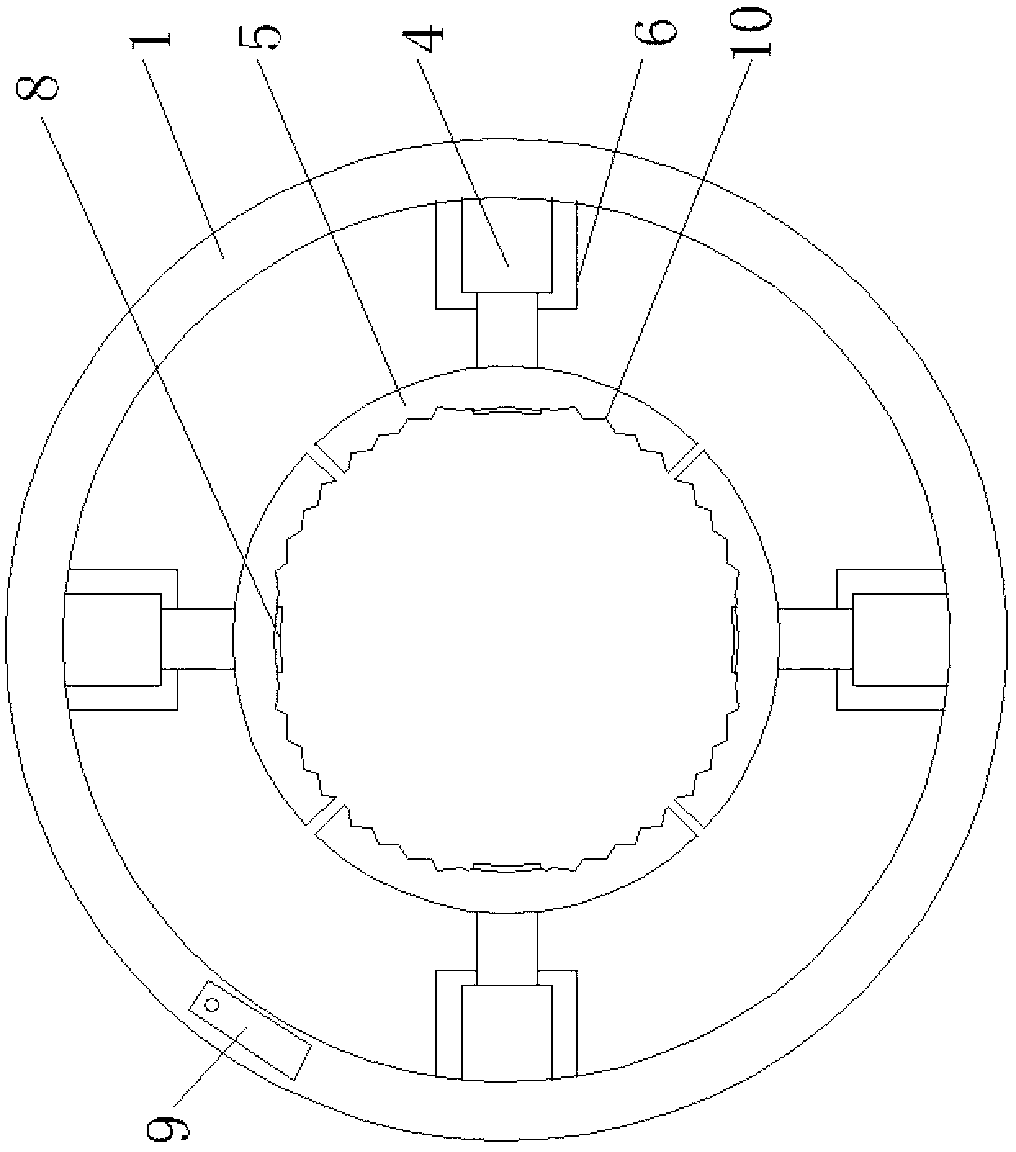

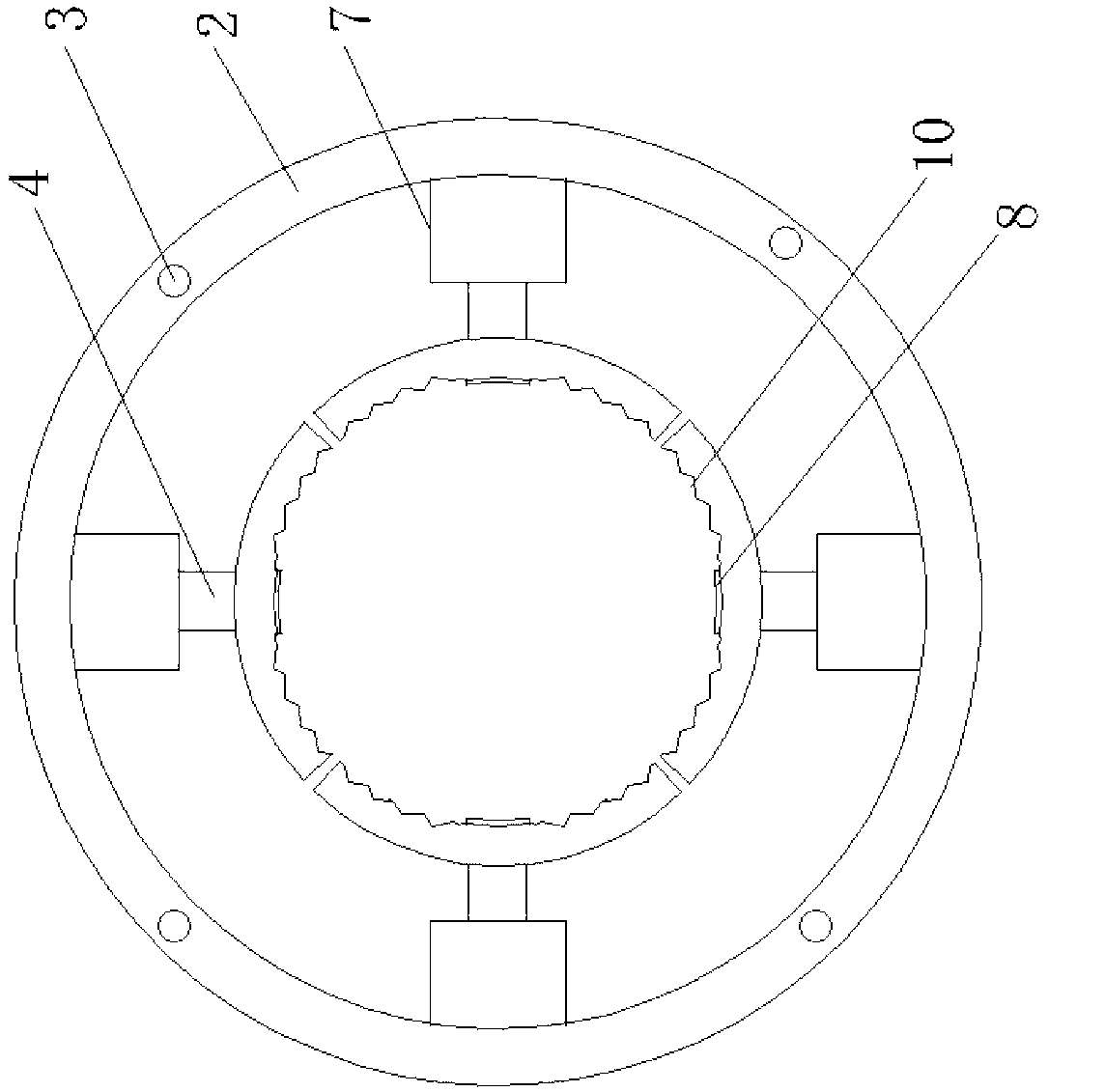

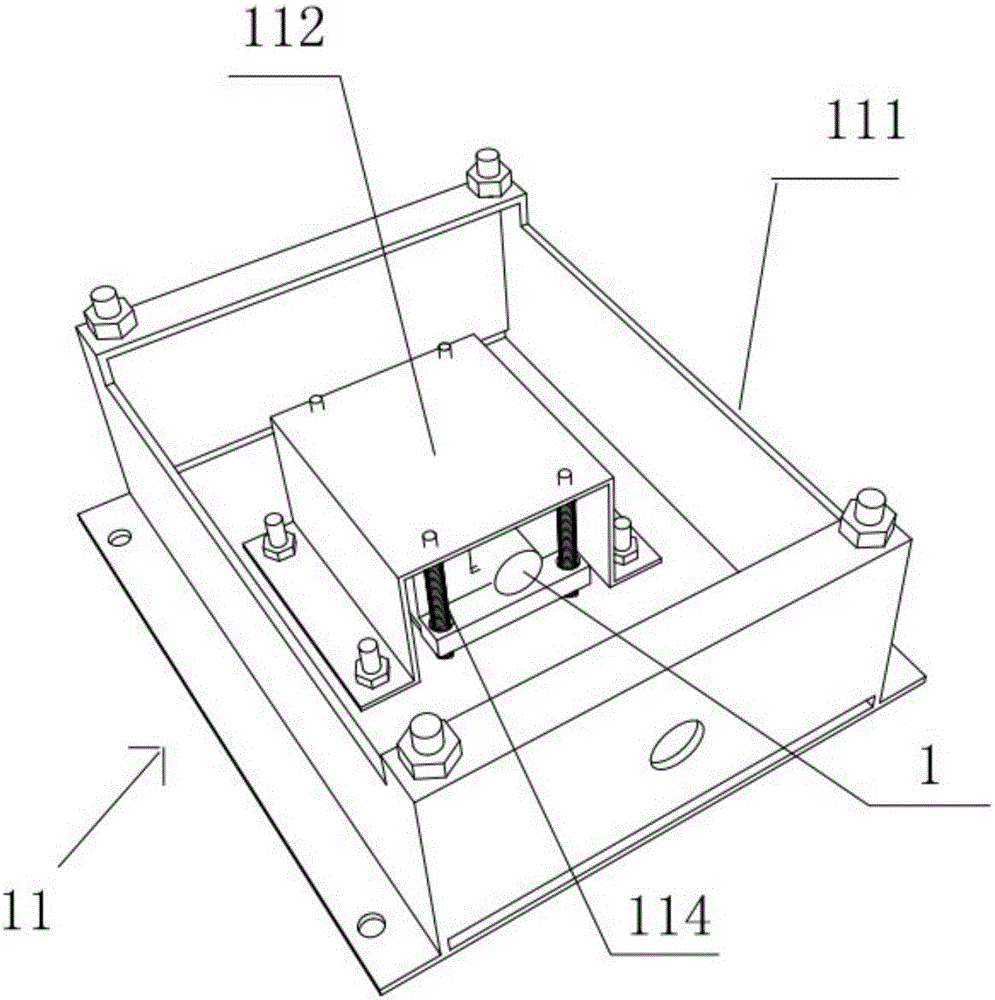

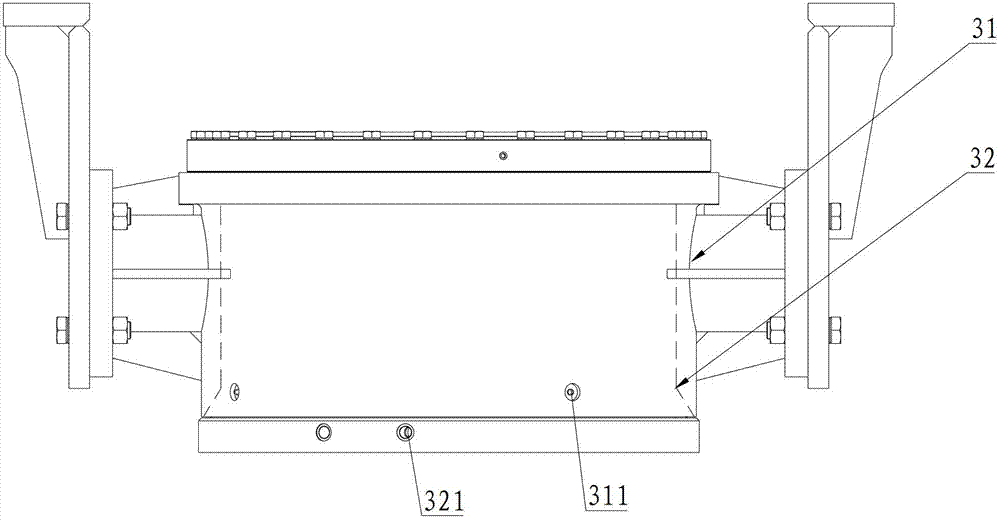

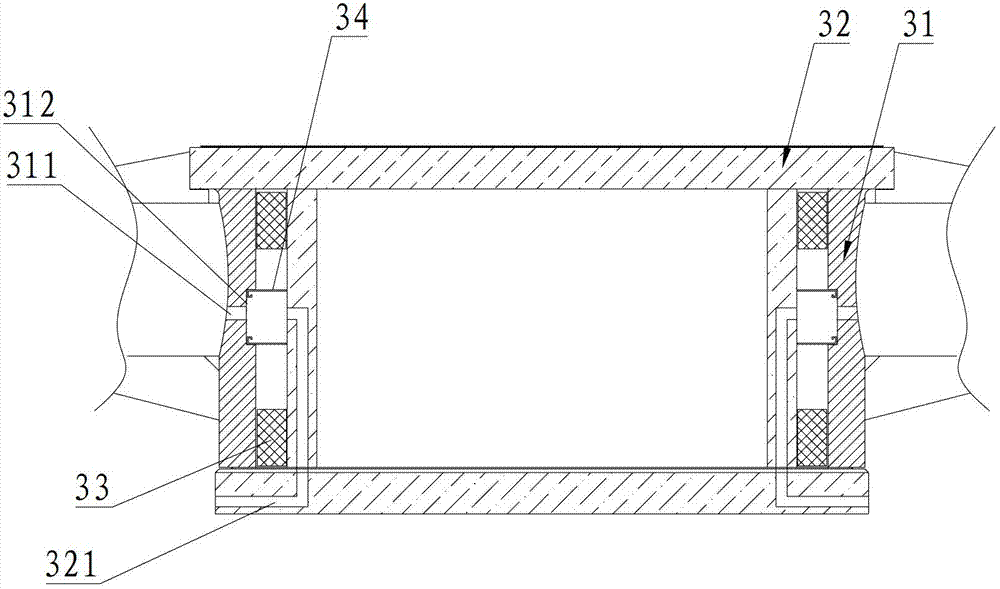

Holding device of static pressure pile driver

InactiveCN103103986AGuaranteed stabilityImprove stabilityBulkheads/pilesStructural engineeringPile driver

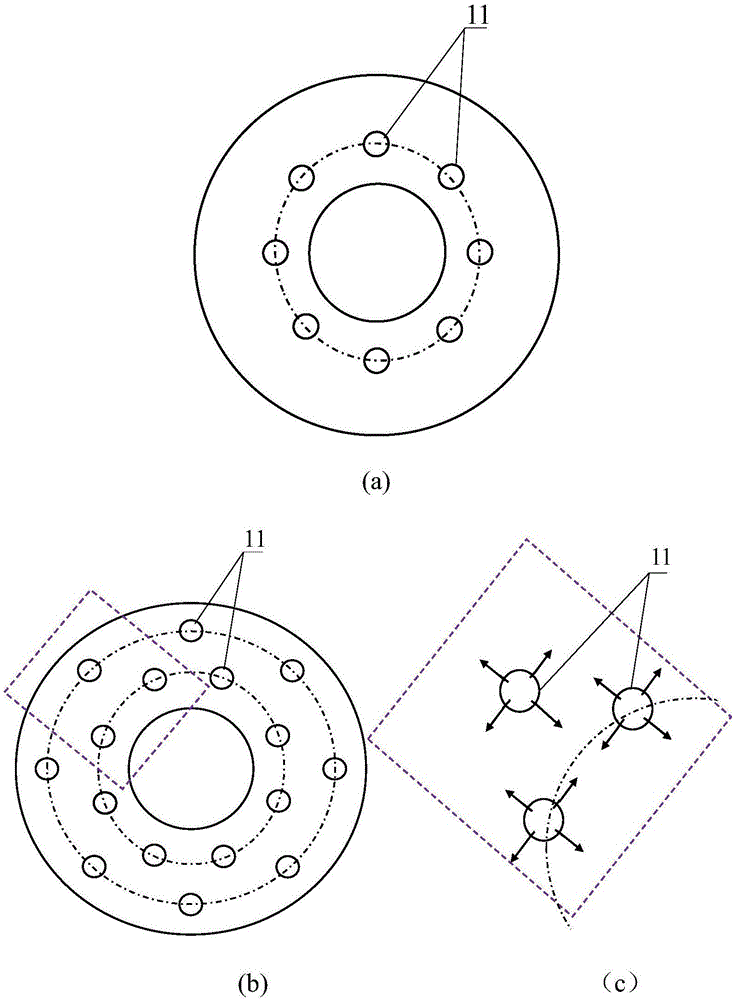

The invention relates to a holding device of a static pressure pile driver. The holding device of the static pressure pile driver comprises a circular support, and a plurality of support tables, wherein the upper layer and the lower layer of the plurality of support tables are arranged on the inner side of the circular support and the support tables stretch toward the center of the circular support, and the plurality of support tables arranged on the upper layer of the inner side of the circular support and the plurality of support tables arranged on the lower layer of the inner side of the circular support are respectively on a same horizontal level. The holding device of the static pressure pile driver is characterized in that each support table is provided with a telescopic device, one end of the telescopic device is fixedly arranged on the support table, and the other end of the telescopic device is provided with a clamping plate. The plurality of clamping plates of the support tables on the upper layer of the circular support form an upper lamping group, the plurality of clamping plates of the support tables on the lower layer of the circular support form a lower lamping group, and each clamping plate is provided with a pressure sensor. Therefore, the phenomena of uneven stress of pile bodies and instability of the pile bodies cannot occur to the holding device of the static pressure pile driver, the holding device of the static pressure pile driver can greatly improve the stability of the pile bodies in a pilling process, and therefore the efficiency of pilling is improved.

Owner:CHANGZHOU LIWEI KNIFE

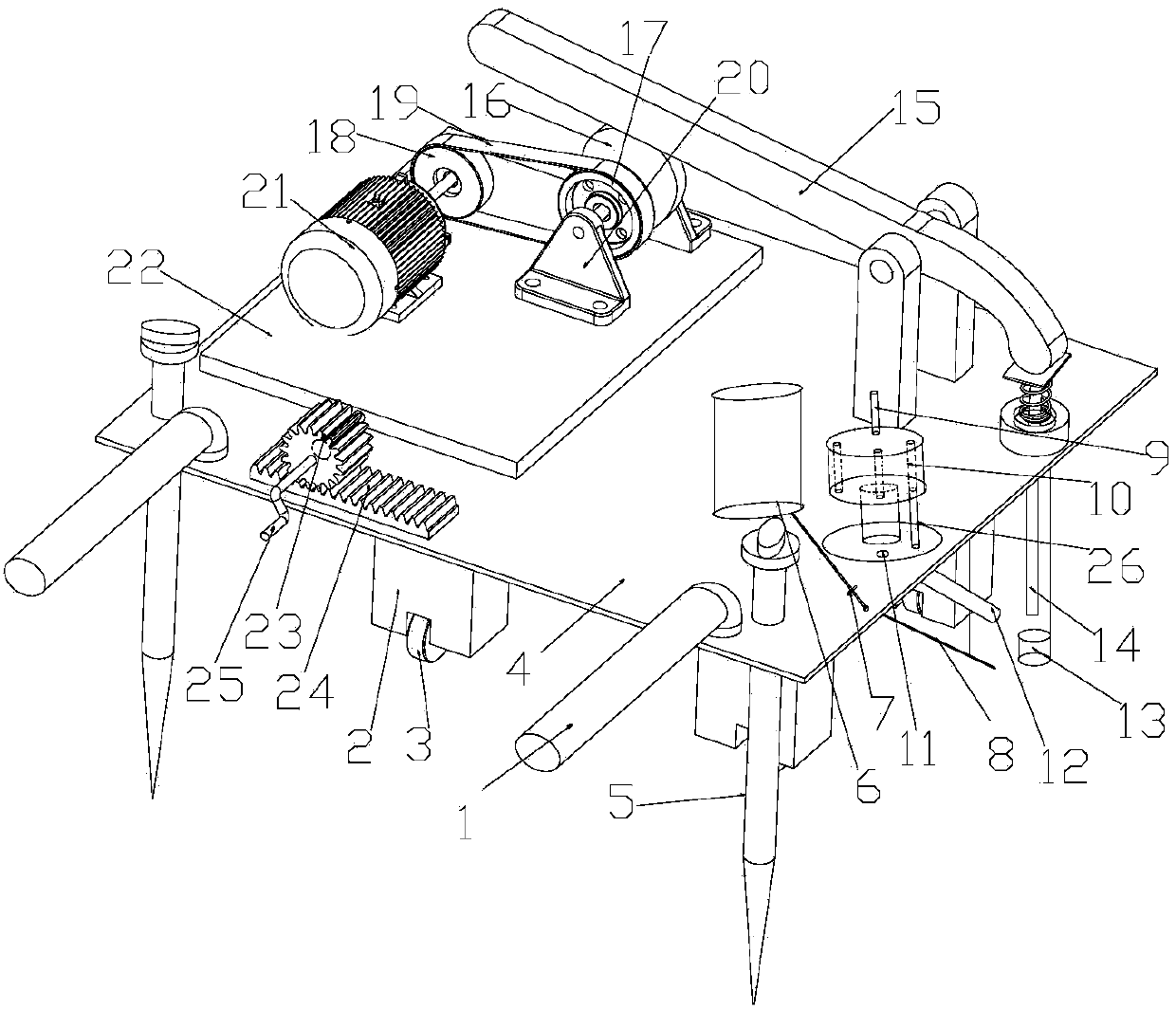

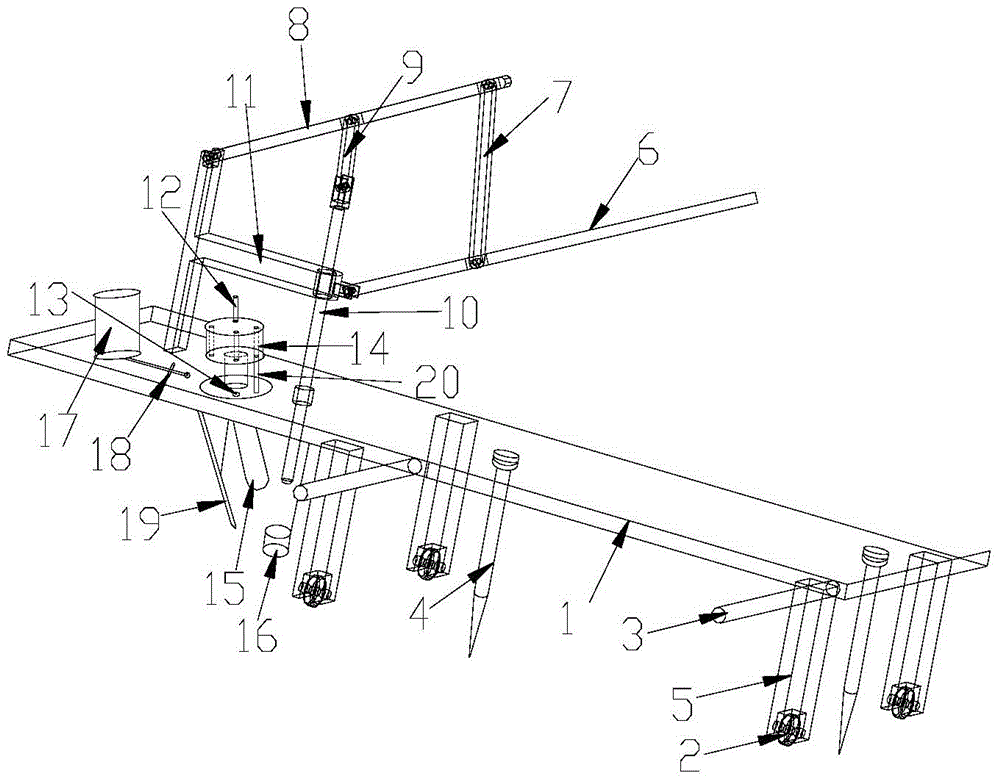

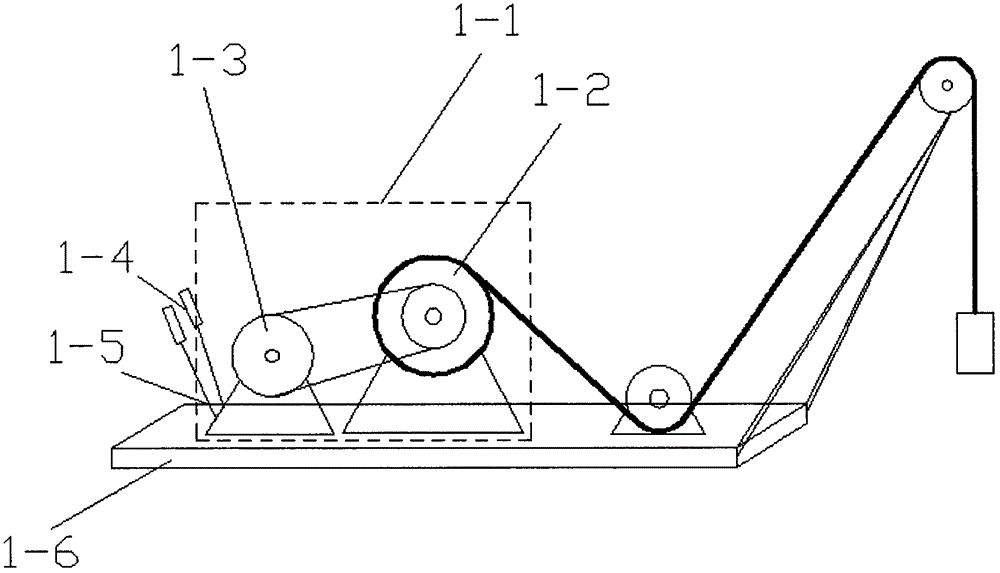

Multi-freedom-degree automatic piling device and method

InactiveCN103993600ANo tiltingImprove piling qualityBulkheads/pilesMechanical engineeringWater tanks

The invention relates to a multi-freedom-degree automatic piling device and method. The piling device comprises a piling mechanism, a water tank, a rack and a feeder which are arranged above the rack. The piling mechanism comprises a motor, a belt wheel group, a lever and an impacting rod. The motor is connected with the belt wheel group which is connected with the lever, and the lever is connected with the impacting rod. The feeder comprises a cylinder, a feeding hole, a pile transition groove and a location tube. The pile transition groove and the location tube are mounted below the rack, the pile transition groove is disposed between the location tube and the feeding hole, and the location tube is disposed below the impacting rod. The multi-freedom-degree automatic piling device is capable of arranging piles automatically, high in piling quality, convenient to use, small in size and noise, high in safety factor and high in piling efficiency.

Owner:QINGDAO UNIV OF SCI & TECH

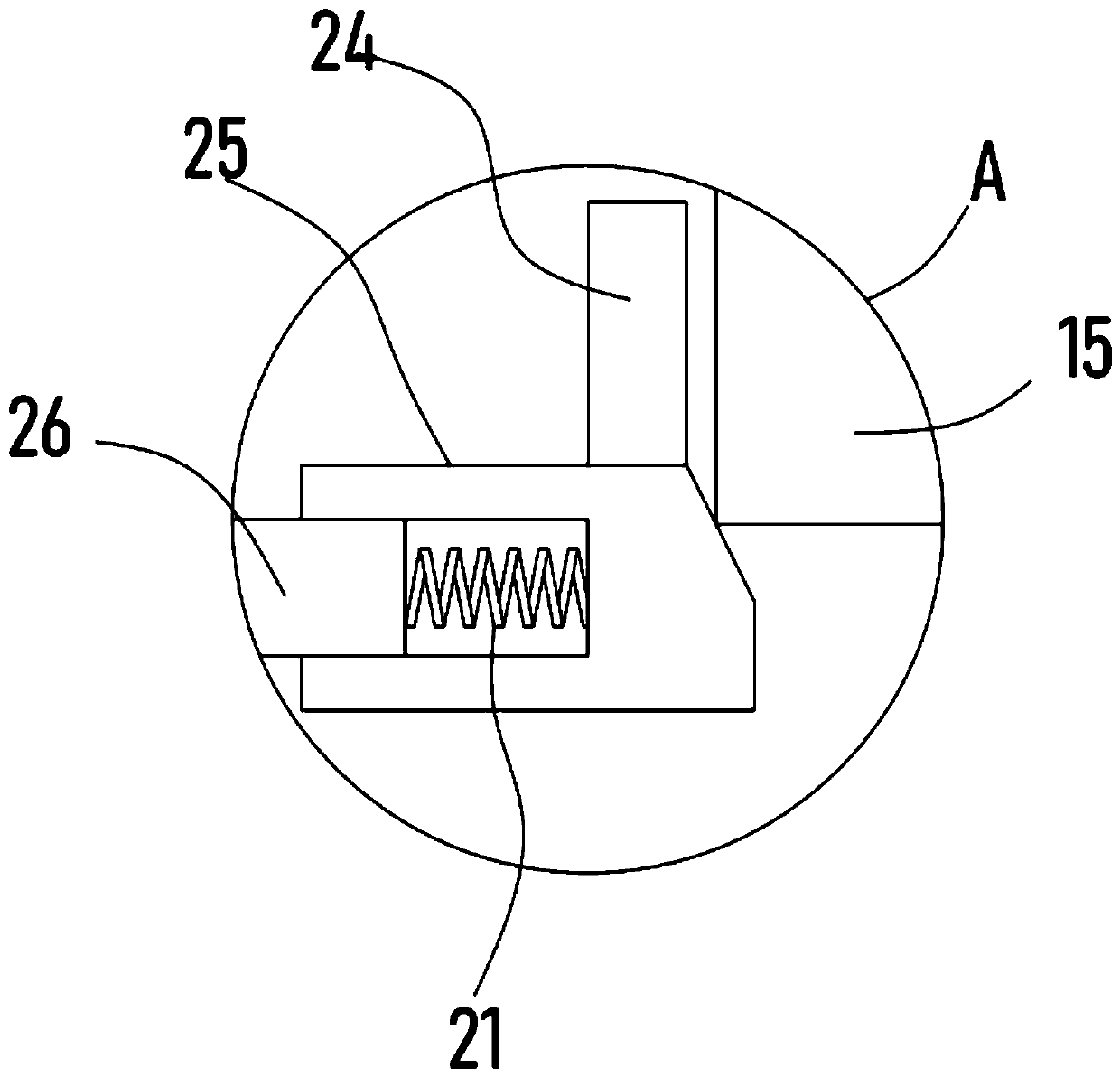

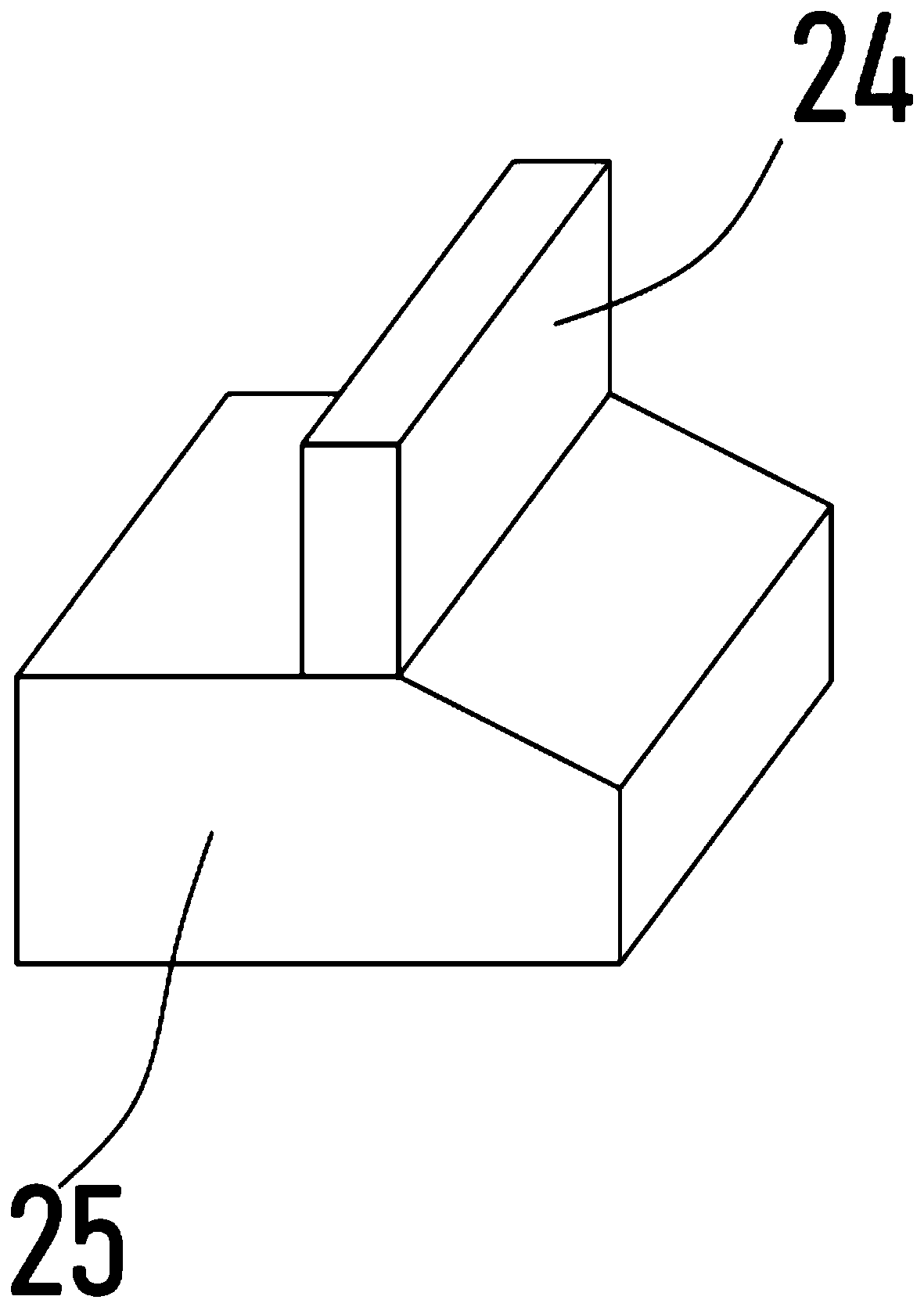

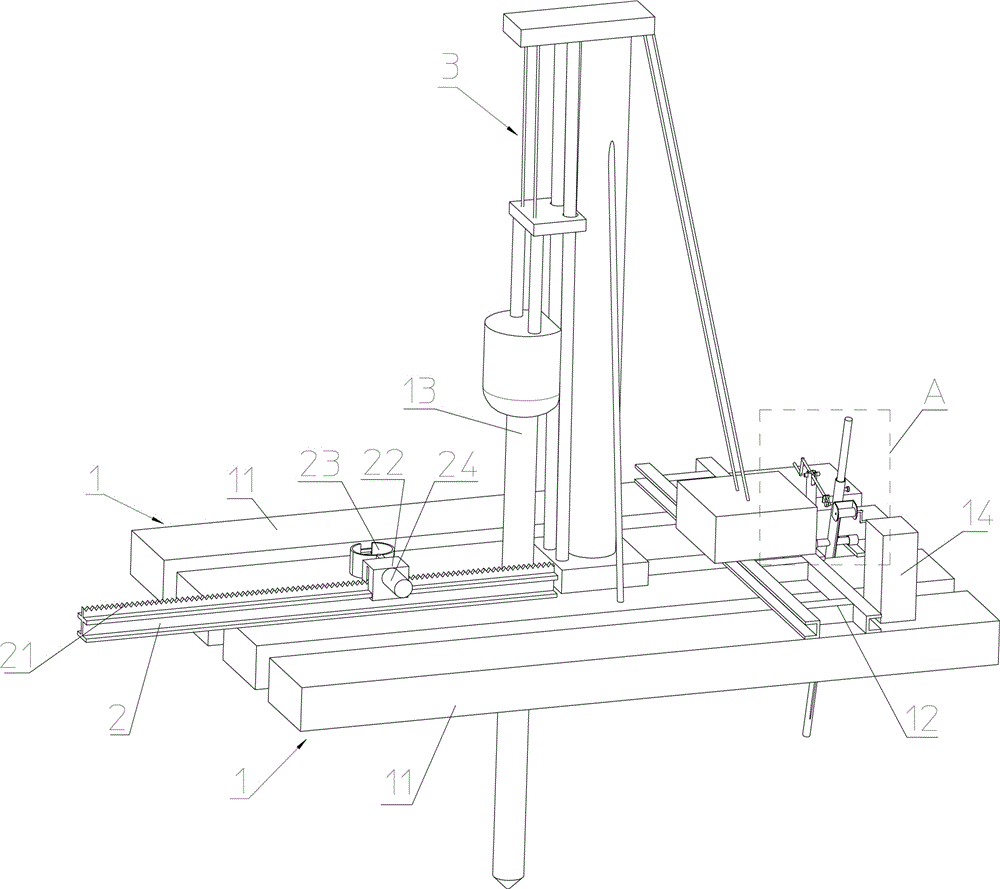

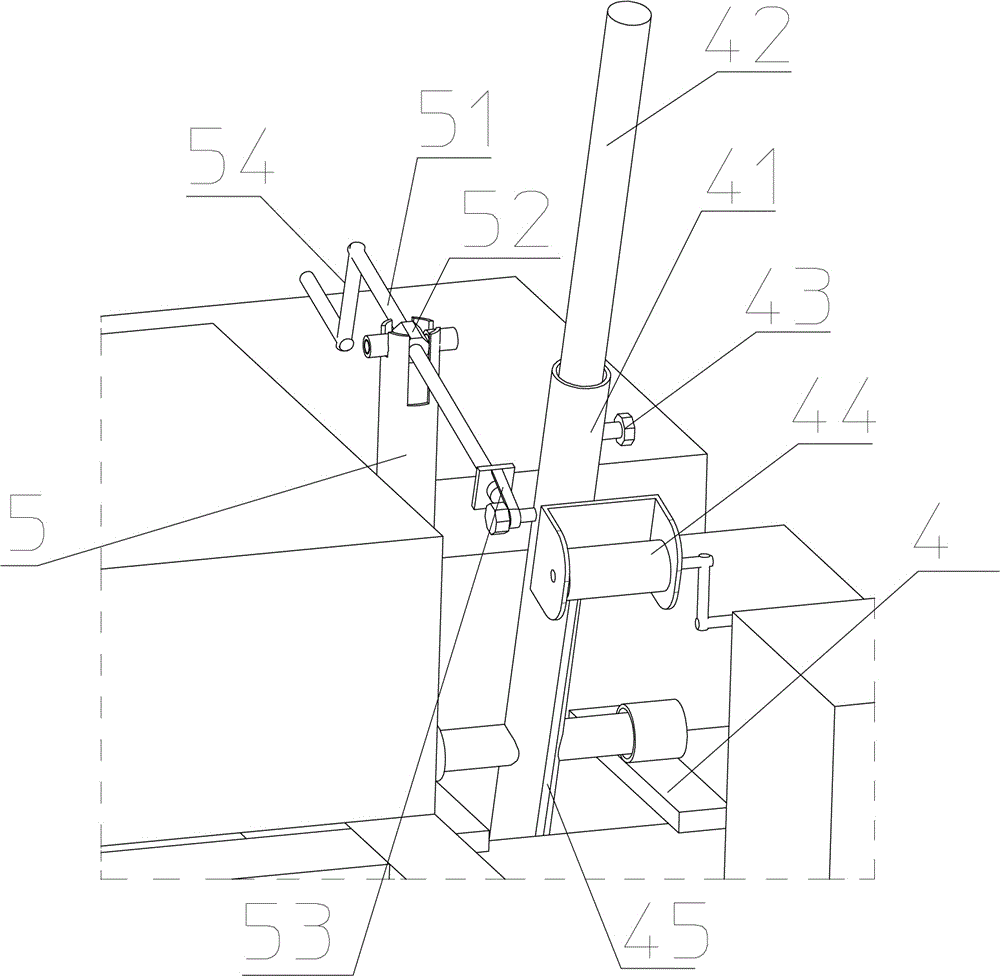

Piling device for geotechnical engineering

The invention discloses a piling device for geotechnical engineering, and relates to the technical field of piling devices. The pilling device comprises a supporting plate, and a fixing frame is fixedly installed on the supporting plate. An incomplete gear is rotationally arranged on the fixed frame. A lifting frame is fixedly arranged on the fixing frame in a lifting mode, a punching plate is horizontally and fixedly installed at the bottom end of a longitudinal sliding rod, a movable frame is transversely and slidably installed on the supporting plate, an installation hole for a pile body topenetrate through is vertically formed in the movable frame, two symmetrical limiting mechanisms are arranged on the inner side wall of the movable frame, and pile driving through holes correspondingto the pile body are vertically formed in the supporting plate. According to the invention, the pile body can be well clamped and stabilized, so that the pilling effect of the pile body during pilling is better; the pile body can be well limited through the arranged limiting mechanisms before pile driving, a constructor can conveniently place and install the pile body through the movable frame which is movably arranged, meanwhile, the piling device can adapt to pile bodies with different diameters, the installation process of the pile body is simple and fast, and the pile driving efficiency is greatly improved.

Owner:西安源丰诚工程咨询有限公司

Floating driving device

The invention discloses a floating driving device which comprises two buoyancy tank groups. The two buoyancy tank groups are arranged side by side in a spaced manner left and right, and are fixed through a cross beam to form a whole. A pile driver is arranged on the two buoyancy tank groups. A guide rail arranged in the forward and backward directions is arranged on the buoyancy tank group in front of the pile driver. A rack is arranged on the guide rail. A sliding frame is arranged on the guide rail. A hoop is arranged on one side of the sliding frame. A gear motor is arranged on the other side of the sliding frame. A gear meshed with the rack is arranged on the output shaft of the gear motor. The gear is driven by the gear motor, and then the sliding frame moves front and back along the guide rail, so that the hoop can move front and back above the gap between the two buoyancy tank groups. A left-and-right moving device is arranged on the buoyancy tank group at the back of the pile driver. A controller capable of controlling the gear motor is arranged on the buoyancy tank group at the back of the pile driver. The floating driving device has the advantage that the pile driving point of the pile driver is moved to the part above the pile position rapidly and conveniently, so that the pile driving efficiency can be greatly improved.

Owner:ZHANGJIAGANG XINGHONGDA BASE

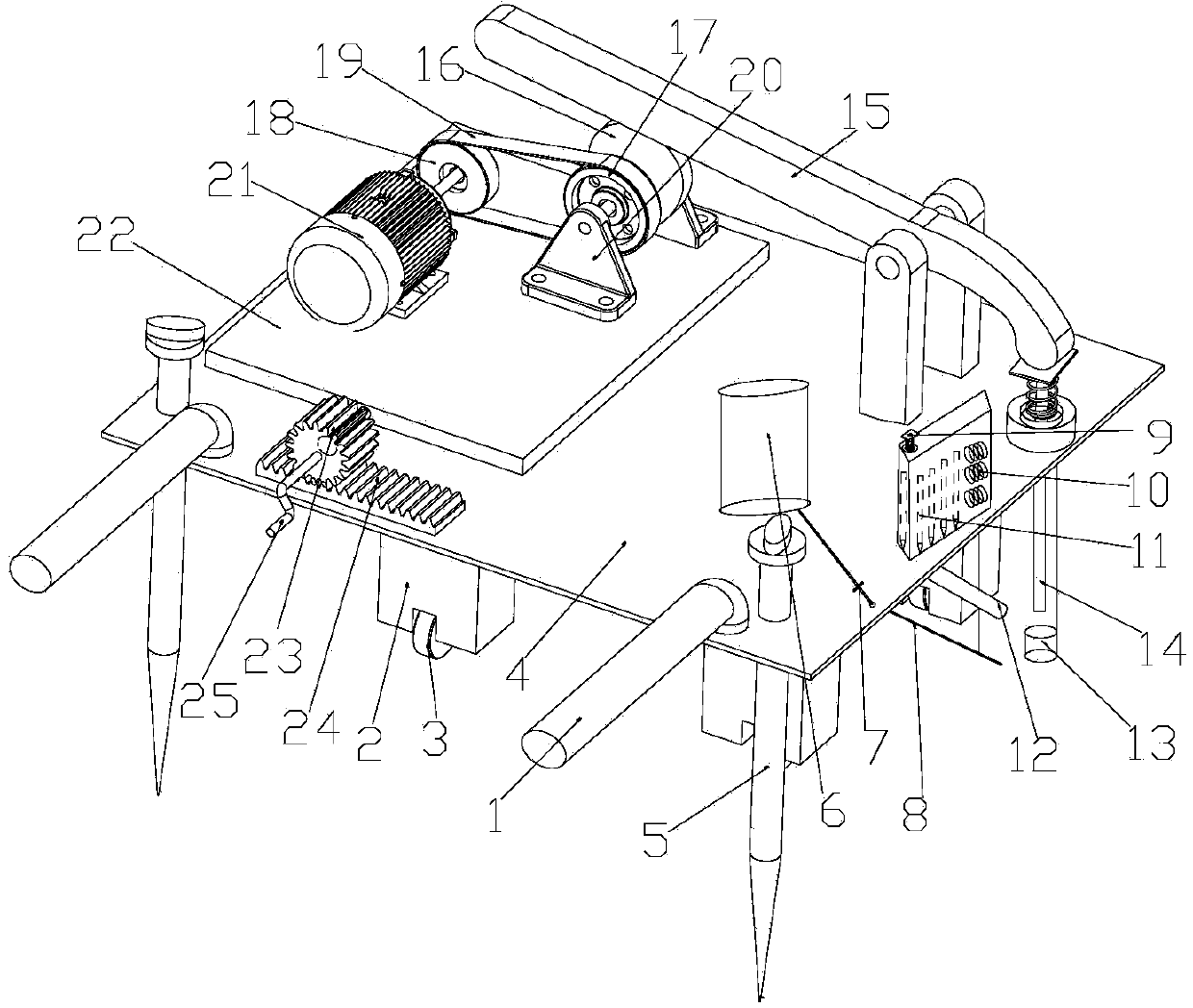

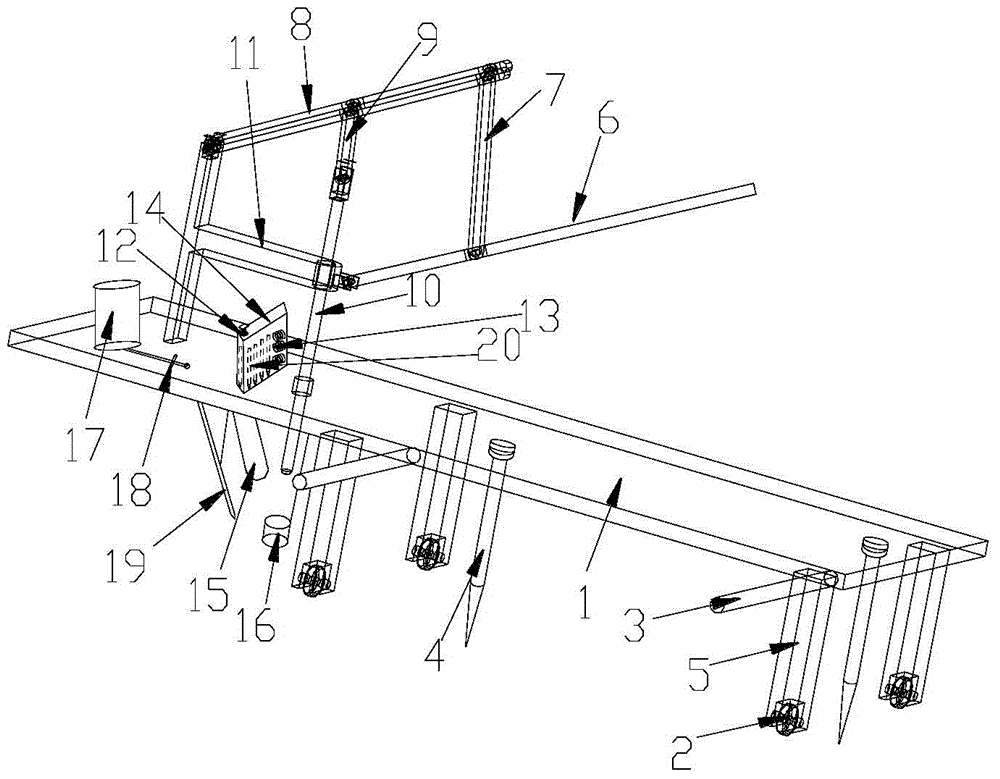

Portable automatic feeding manual pile driving equipment and pile driving method

InactiveCN103981865AImprove piling qualityIntegrity guaranteedBulkheads/pilesSafety coefficientWater tanks

The invention relates to portable automatic feeding manual pile driving equipment and a pile driving method. The pile driving equipment comprises a pile driving mechanism, a water tank, a rack and an emptying device, wherein the pile driving mechanism, the water tank and the emptying device are arranged above the rack; the pile driving mechanism comprises a compressive bar, a support supporting the compressive bar, a first connecting rod connected with the compressive bar, a rocker connected with the first connecting rod, a second connecting rod connected with the rocker, and a drop bar connected with the second connecting rod; the emptying device comprises a charging barrel, an emptying hole, a timber pile ramp pan and a locating pipe; the timber pile ramp pan and the locating pipe are arranged below the rack; the timber pile ramp pan is positioned between the locating pipe and the emptying hole; the locating pipe is positioned right below the drop bar. The portable automatic feeding manual pile driving equipment, disclosed by the invention, is pile driving equipment which has the advantages of capability of automatically placing a timber pile, high pile driving quality, convenience in use, small volume and high safety factor, and is suitable for pile driving with small pile driving workload.

Owner:QINGDAO UNIV OF SCI & TECH

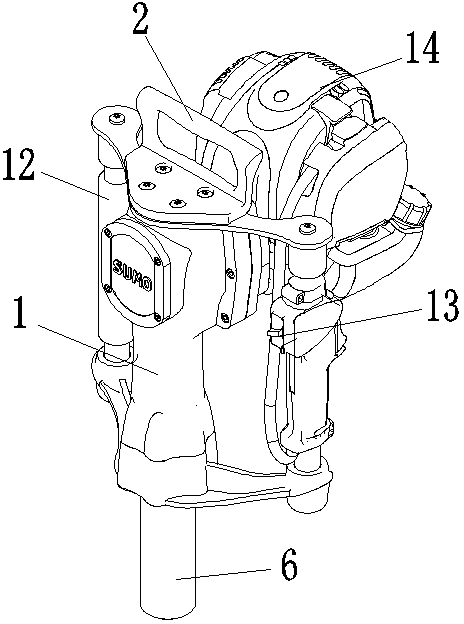

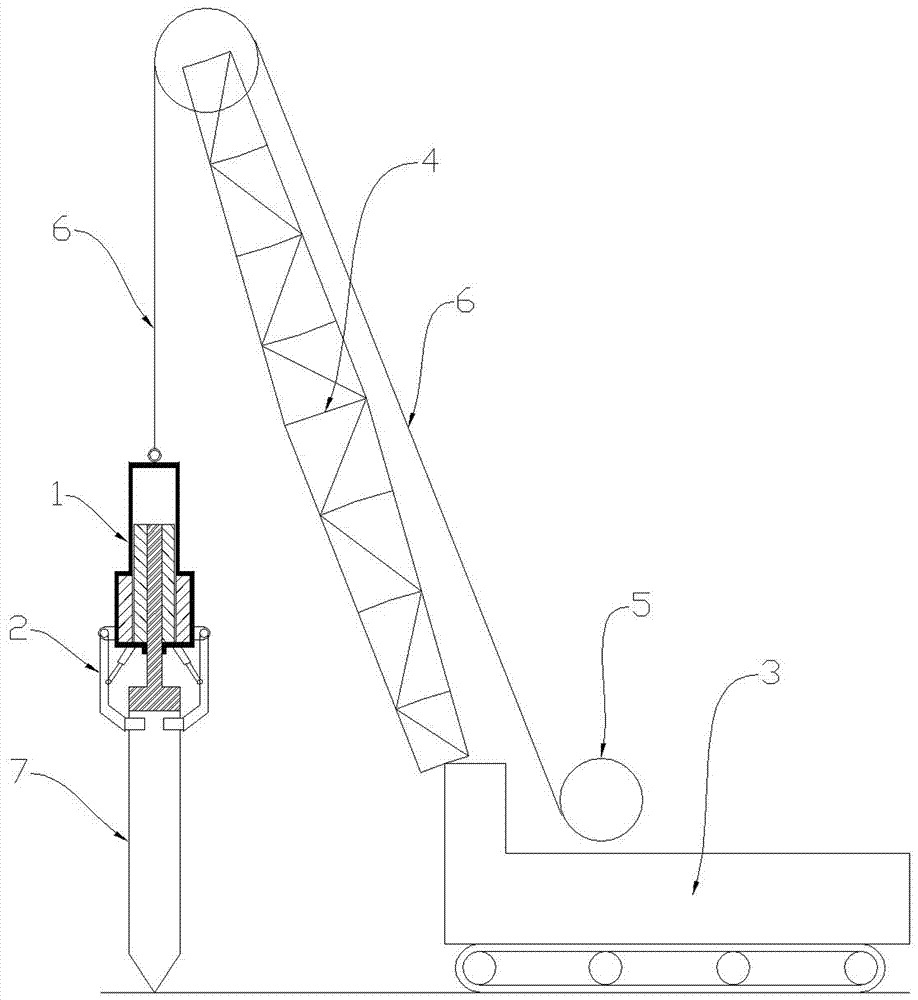

Linear motor drive based pile driver without guide frame

InactiveCN107386286AImprove piling efficiencyReduce noiseBulkheads/pilesElectric machineLinear motor

The invention discloses a linear motor drive based pile driver without a guide frame. The linear motor drive based pile driver is mainly used for construction preformed piles in the field of constructional engineering and high in pile driving efficiency and low in noise. The pile driver mainly comprises a driving device, a clamping device, a tracked vehicle, a suspension arm and a winch. An operating principle includes that the preformed piles horizontally put on the ground are clamped by the clamping device, then the winch lifts the driving device to make the preformed piles in a vertical state, the tracked vehicle moves to move the preformed piles to a pile driving station, then the driving device is started, when a linear motor stator of the driving device is connected with a positive power source, the linear motor stator moves linearly upwards and drives a hammering head to move linearly upwards, and when the linear motor stator of the driving device is connected with a reverse power source, the linear motor stator moves linearly downwards and drives a hammering head to move linearly downwards, so that the hammering head hammers the preformed piles under the repeated movement to drive the preformed piles into soil.

Owner:JINGMEN CHUANGJIA MACHINERY TECH CO LTD

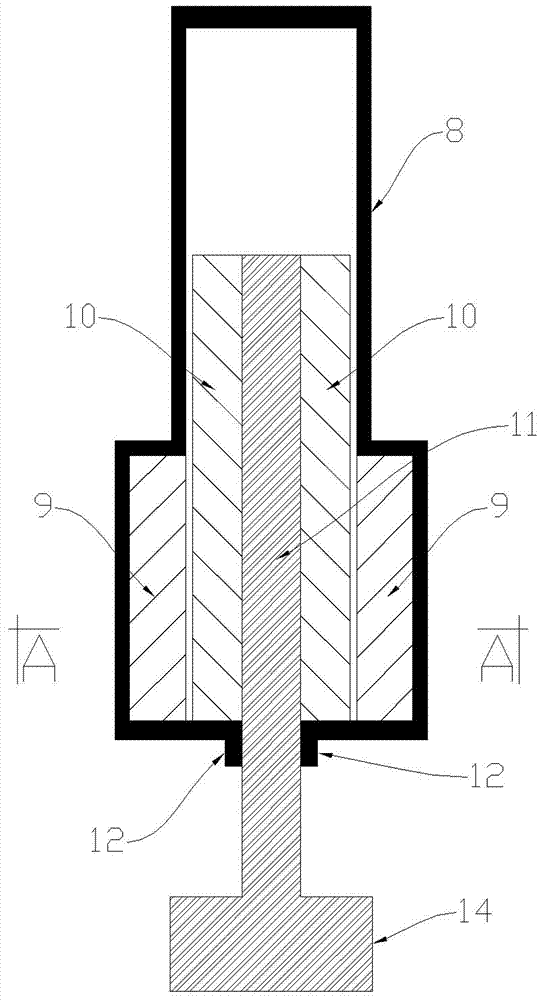

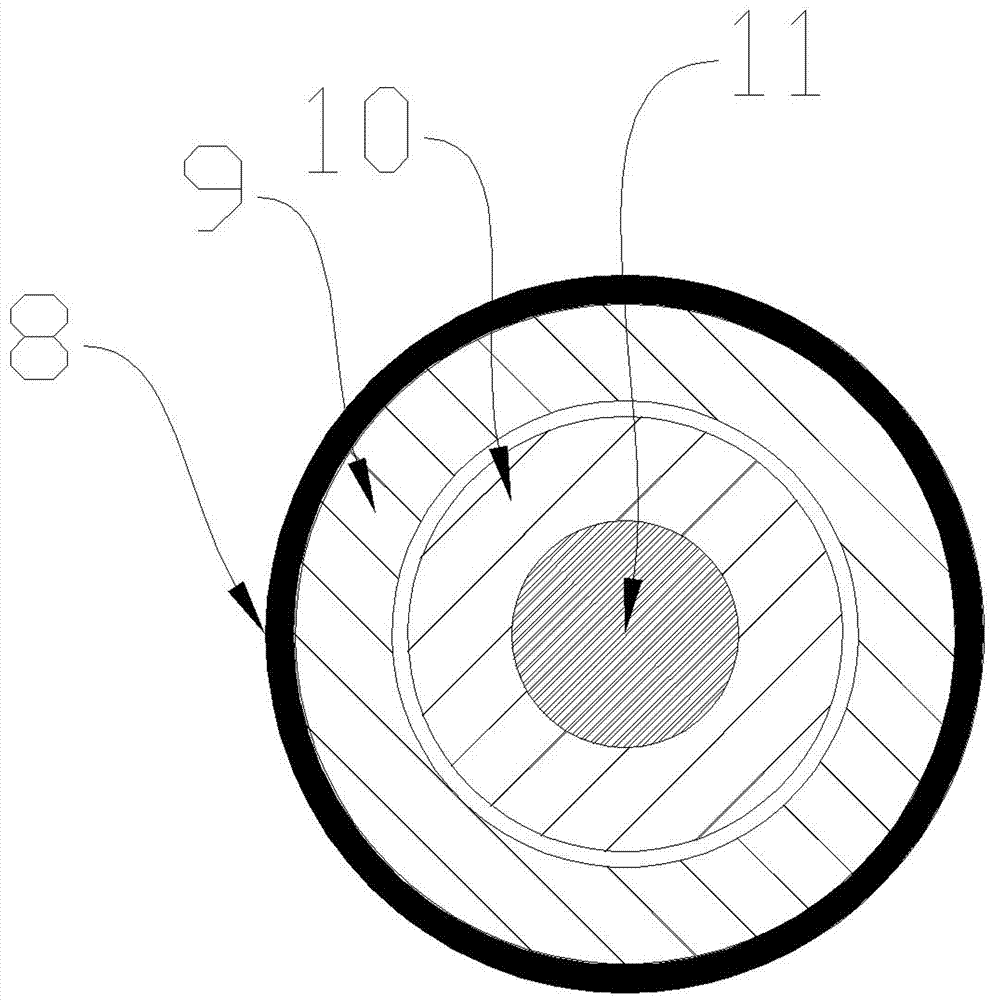

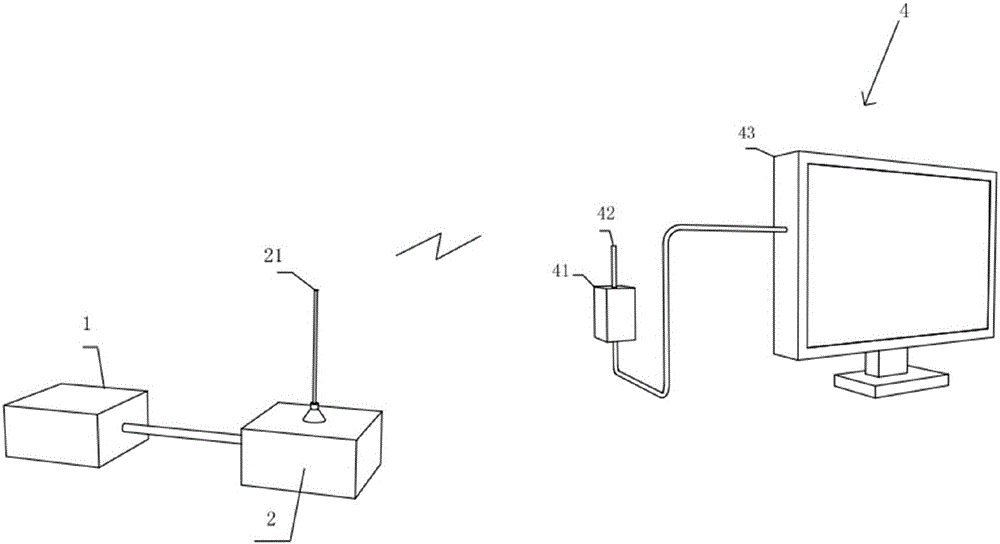

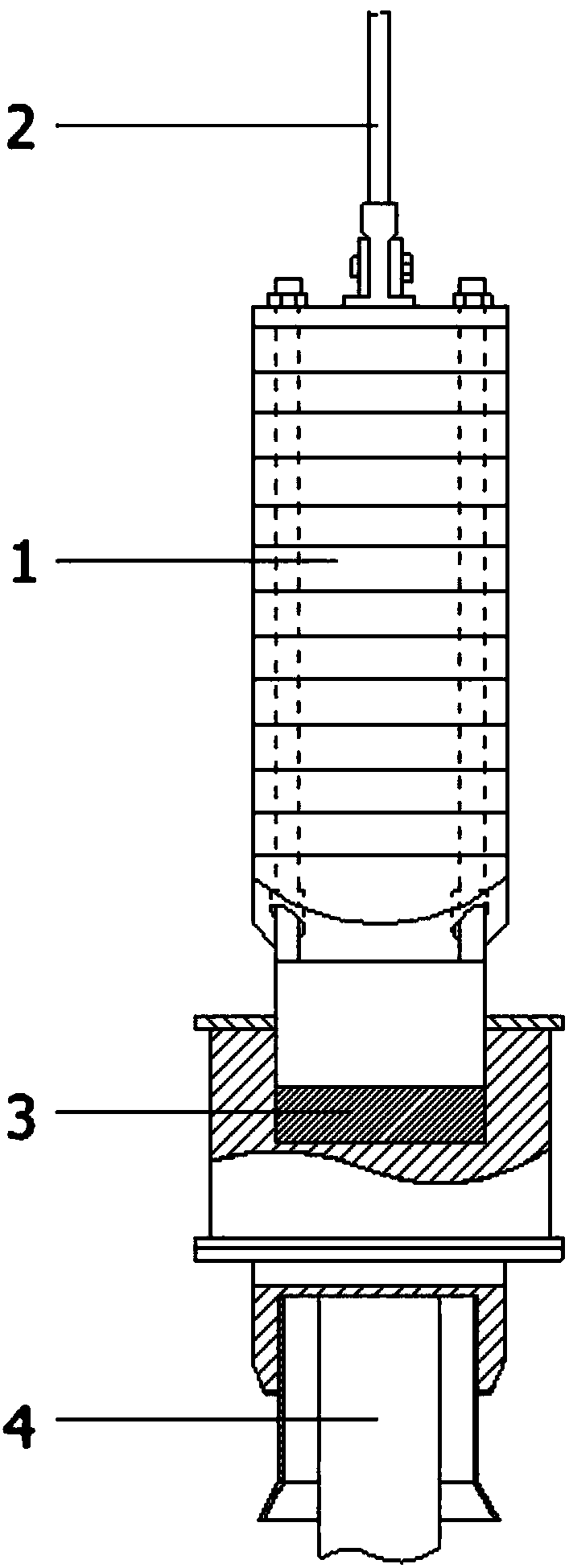

Method and device for measuring verticality of offshore wind power steel pile

InactiveCN105698758AHigh control precisionReliable Numerical BasisIncline measurementElectricityHeight difference

The invention provides a method and device for measuring the verticality of an offshore wind power steel pile. The device comprises a double-shaft clinometer, a first data transfer radio and an error feedback device used for calculating, displaying and storing verticality and radial height difference signals of the wind power steel pile according to measured data of the double-shaft clinometer. The double-shaft clinometer is arranged on one plane of a pile hammer through a first shock absorber, the plane is parallel to the piling plane of the pile hammer, the first data transfer radio is arranged on the pile hammer through a second shock absorber, and the first data transfer radio and the error feedback device carry out data exchange through a wireless transmitting antenna. According to the method and device for measuring the verticality of the offshore wind power steel pile, the verticality of the wind powder steel pile can be really monitored in the whole process, piling efficiency is improved, and a reliable numerical value basis is provided for adjustment of the verticality of the wind power steel pile.

Owner:GUANGDONG HUAERCHEN OFFSHORE WIND POWER ENG

Threaded screwing inserting bar compaction filling pile

ActiveCN103953030APowerful rock-socketing functionImprove piling efficiencyDrill bitsBulkheads/pilesEngineeringScrew thread

The invention relates to a threaded screwing inserting bar compaction filling pile, which comprises a fine threaded steel mold pipe, wherein a guide pipe for pumping concrete is inserted in the fine threaded steel mold pipe, the fine threaded steel mold pipe is connected with a rock-socketed drill bit, and the rock-socketed drill bit is formed by combining a drill bit point at the lower end, a drill bit body at the upper part and a trapezoidal threaded short pipe; a joint element is arranged between the drill bit point and the drill bit body, the drill bit body is fixedly connected with the trapezoidal threaded short pipe, the lower end of the guide pipe is inserted in the trapezoidal threaded short pipe and the drill bit body, the upper part of the drill bit point is connected with a hanging rod provided with a top groove, a first bearing plate is inserted in the top groove, the first bearing plate is welded into a whole with the hanging rod, the lower end of the guide plate is provided with a groove opening allowing a second bearing plate to be inserted in, and the second bearing plate is positioned in an inner cavity of the drill bit body. The threaded screwing inserting bar compaction filling pile has the advantages that a high rock-socketed function is realized, the filling pile is completely applicable to the foundation engineering under the hill foundation geological conditions, and in addition, the pile forming efficiency is higher.

Owner:浙江华展研究设计院股份有限公司

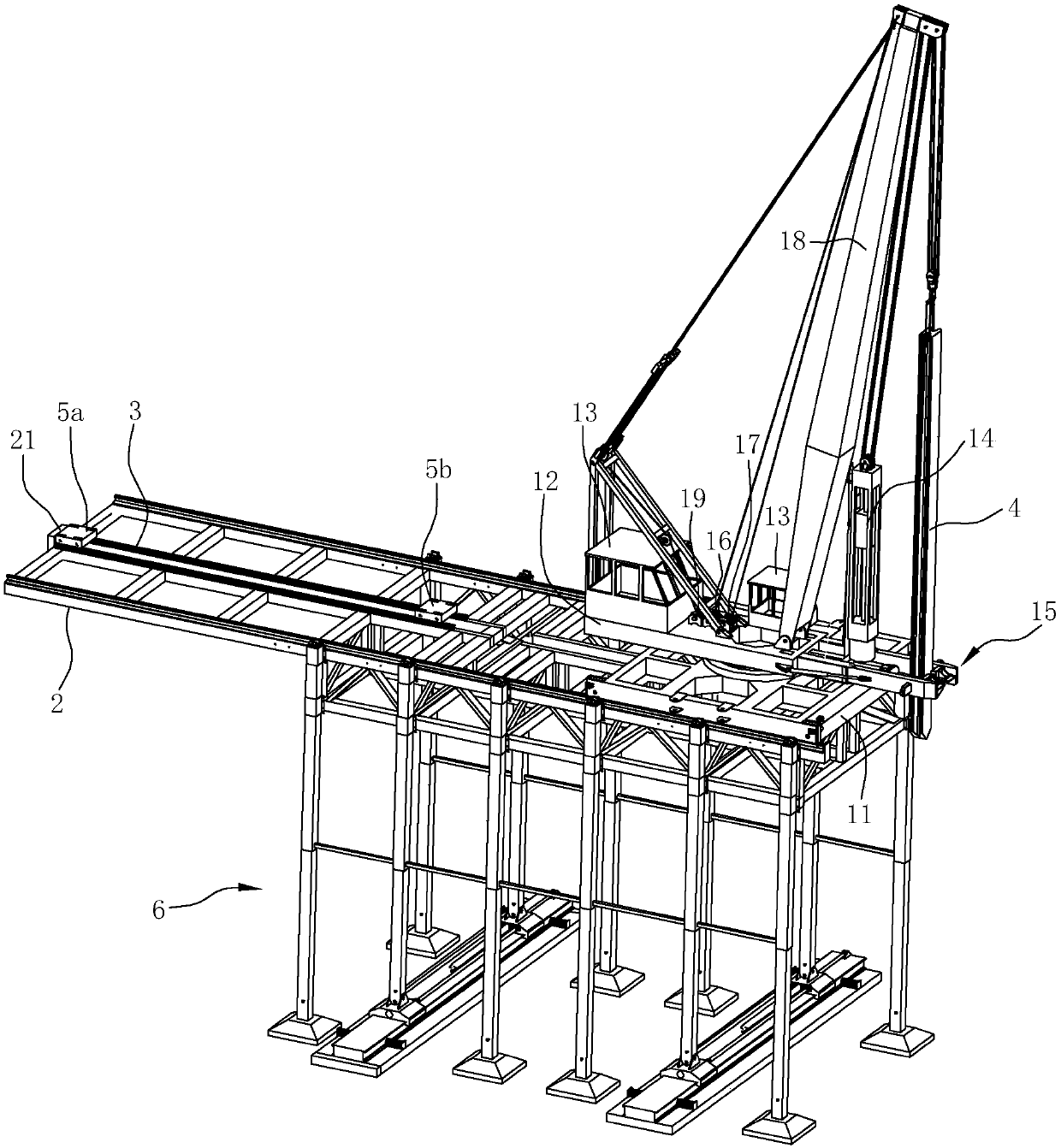

Pile work equipment

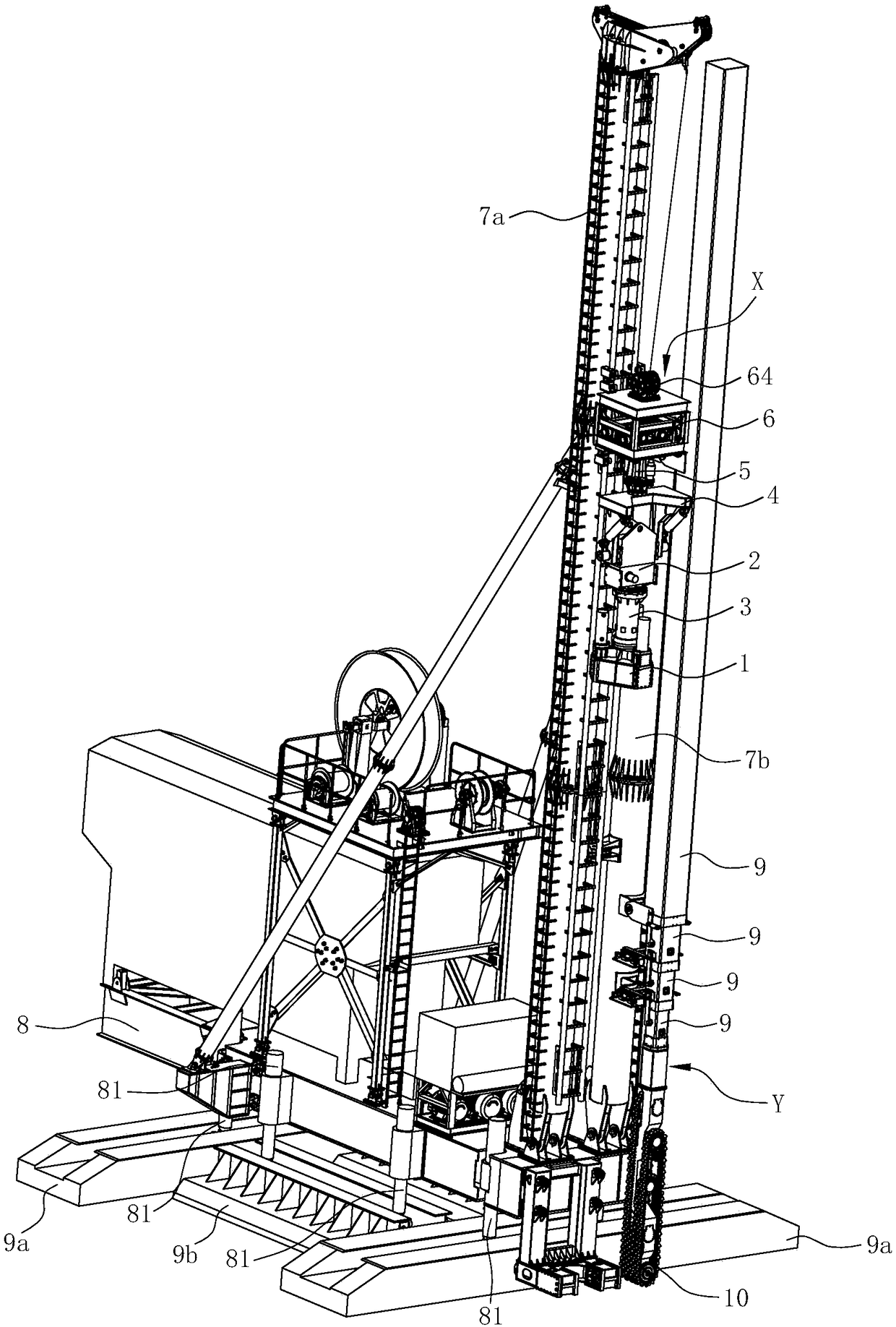

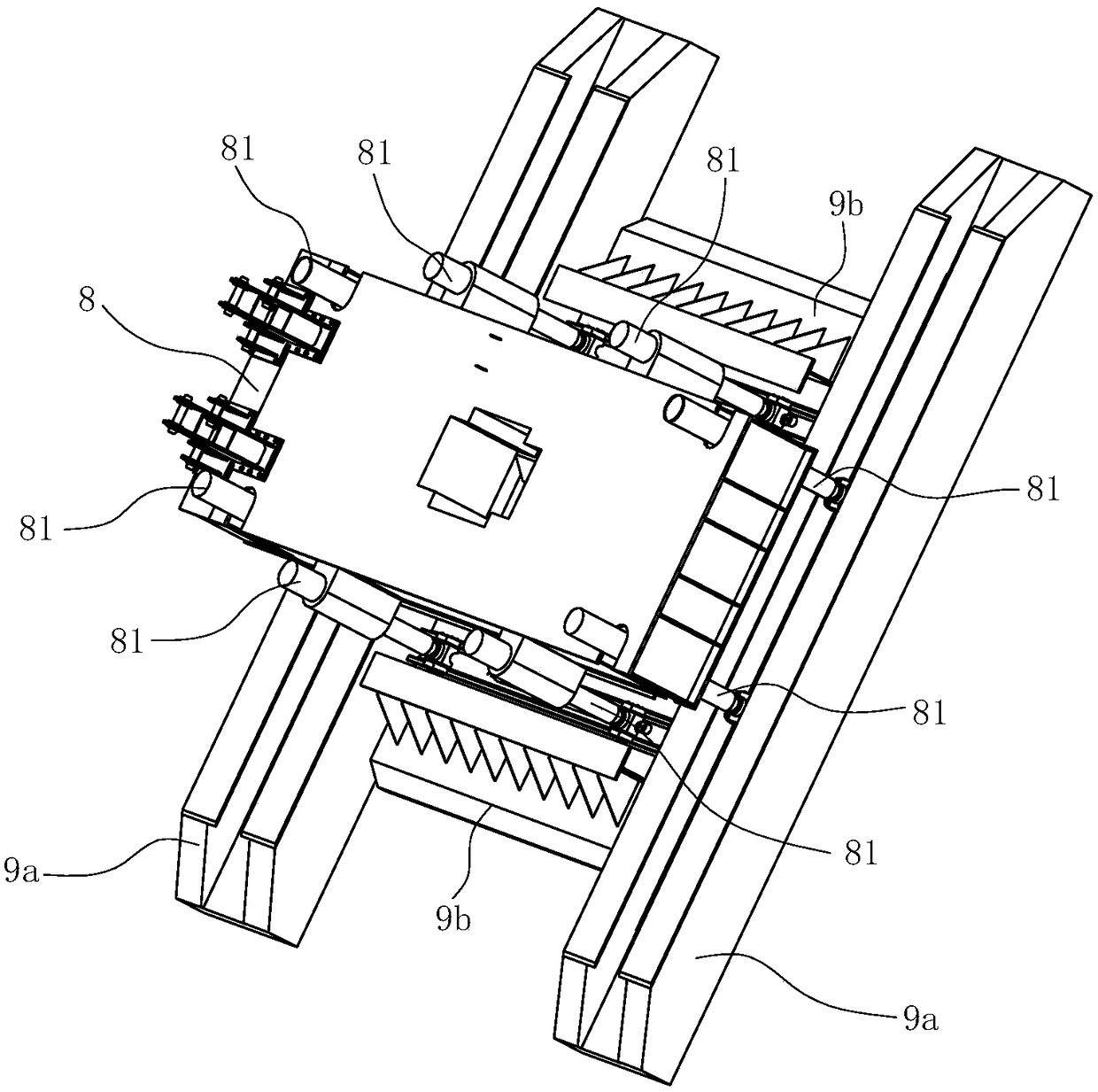

PendingCN108265708ALarge clamping forceSimple structureDerricks/mastsDirectional drillingEngineeringCement

The invention relates to pile work equipment. The pile work equipment comprises a working platform. A plurality sets of supporting legs are arranged at the bottom of the working platform, wherein twosets of the supporting legs are arranged on two transverse vessels which are arranged front and back in a spaced mode correspondingly; and the transverse vessels are provided with transverse driving structures for driving the working platform to slide left and right relative to the transverse vessels along with the supporting legs. The pile work equipment is characterized in that a first stand column and a second stand column which are arranged left and right in a spaced mode are arranged on the working platform; wherein a piling device is arranged on the first stand column and can slide up and down along the first stand column; and a cement soil stirring device is arranged on the second stand column. The cement soil stirring device and the piling device are integrated into the pile work equipment, operators do not need to arrange two devices on the construction site simultaneously, the requirement for the construction site is lowered, in addition, the piling efficiency is improved, the piling cost is reduced, and the piling time is shortened.

Owner:周兆弟

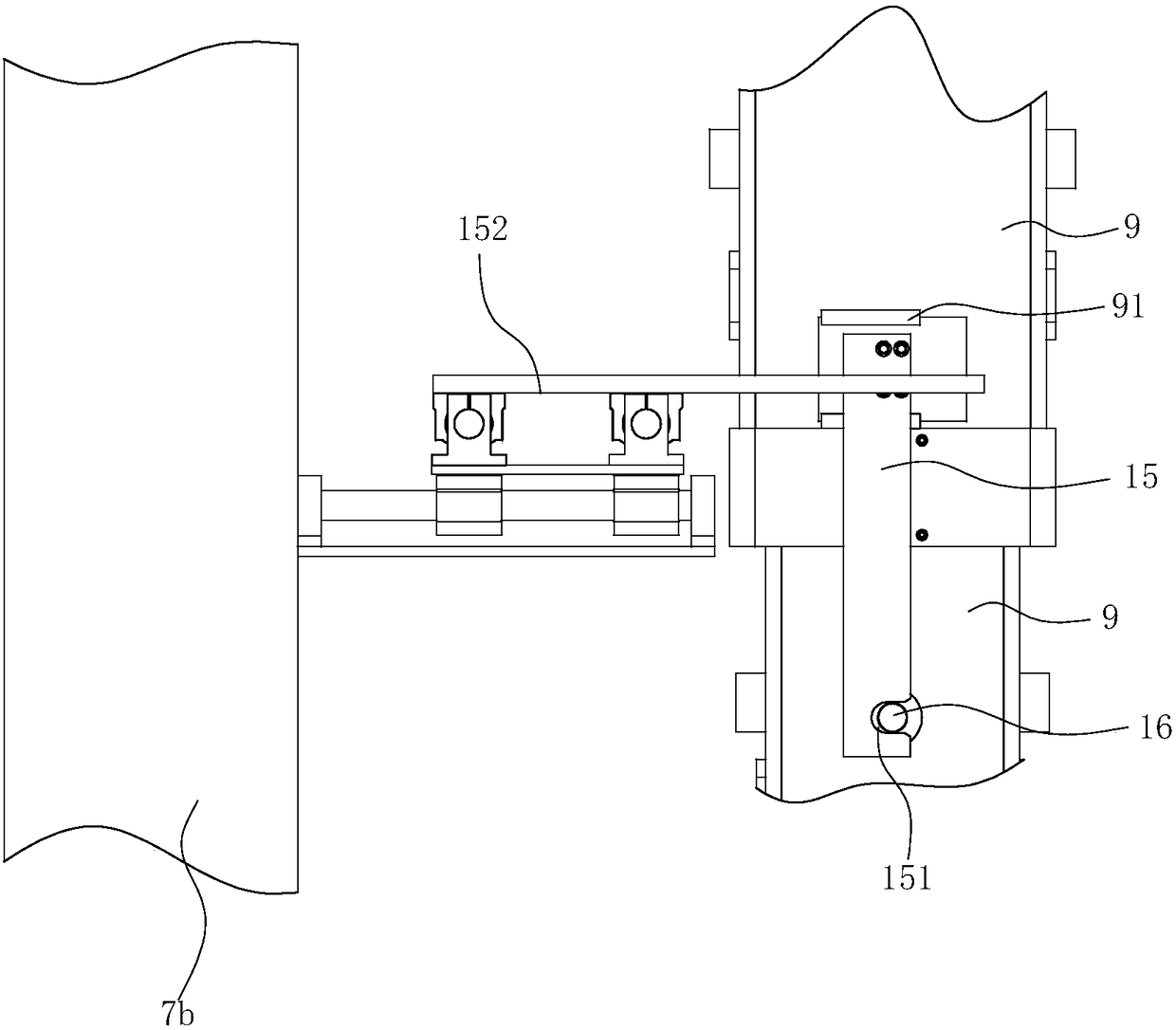

RTK technology-based precise locating system piling machine

ActiveCN106677179ADrilling process is stablePrecise positioningDrilling rodsDrilling casingsEngineeringPositioning system

The invention discloses an RTK technology-based precise locating system piling machine which comprises a machine body, wherein a wireless emitter and a wireless receiver are arranged at the top end of the machine body, wherein a driven roller is arranged at the top end of the side wall of the machine body; two perpendicularly arranged first sliding rails are arranged on the side wall of the machine body; a horizontally arranged movable frame is arranged on the first sliding rails; two perpendicularly arranged first sliding blocks are arranged on one side, close to the first sliding rails, of the movable frame; the first sliding blocks are matched with the first sliding rails; an engine is arranged at the bottom ends of the first sliding rails; an output shaft of the engine is connected with a driving roller; the driving roller is located below the two first sliding rails; the driven roller is located above a position between the two first sliding rails; a transmission belt is connected between the driving roller and the driven roller; the movable frame is fixedly mounted on the transmission belt; a first motor is arranged on the movable frame; and the first motor is fixedly mounted on the movable frame through a screw. The RTK technology-based precise locating system piling machine is simple in structure, low in cost, precise in piling location and high in piling efficiency.

Owner:无锡汉欣利建筑机械有限公司

Offshore wind power steel pipe socketed pile and pile outside grouting construction method

The invention relates to an offshore wind power steel pipe socketed pile which comprises a steel pipe pile body, pulp discharging openings are uniformly distributed in the steel pipe pile body length within the rock-socketed depth range at an equal interval, the pulp discharging openings are provided with one-way grouting valves from inside to outside, and the outer sides of the pulp discharging openings are wrapped with rubber gaskets. The invention furthermore relates to a pile outside grouting construction method. The method includes the following steps that (1), drilling construction is performed with a drilling machine to the designed depth, primary hole cleaning is performed, and then the pile foundation of the offshore wind power steel pipe socketed pile is made to sink to the designed depth; (2), secondary hole cleaning is performed, residuals at the pile bottom end of the offshore wind power steel pipe socketed pile are removed, a guide pipe is put down to be connected into the one-way grouting valves, and underwater grouting of concrete is started. The pile driving efficiency is high, grouting is complete, the pile wall and the rock wall can be combined effectively, and operation is convenient to perform.

Owner:HUADIAN HEAVY IND CO LTD

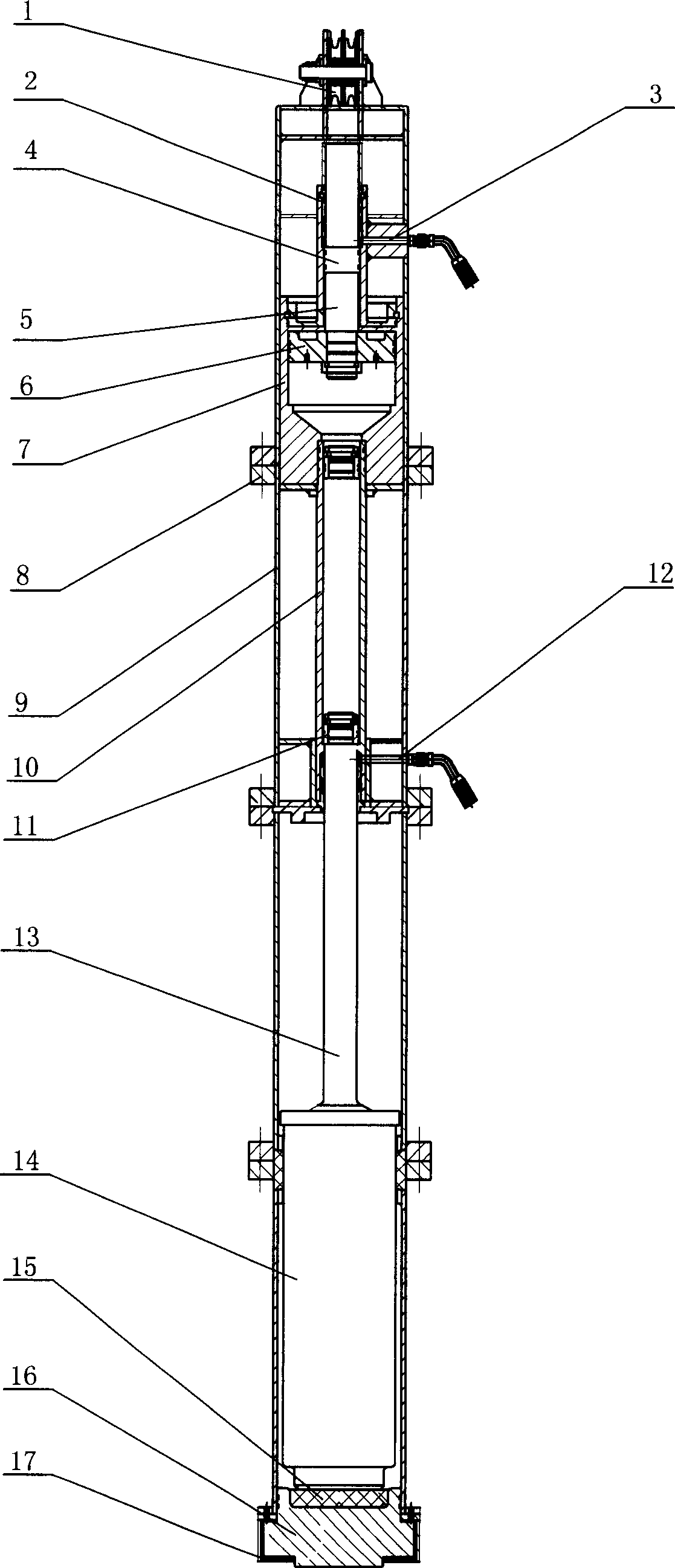

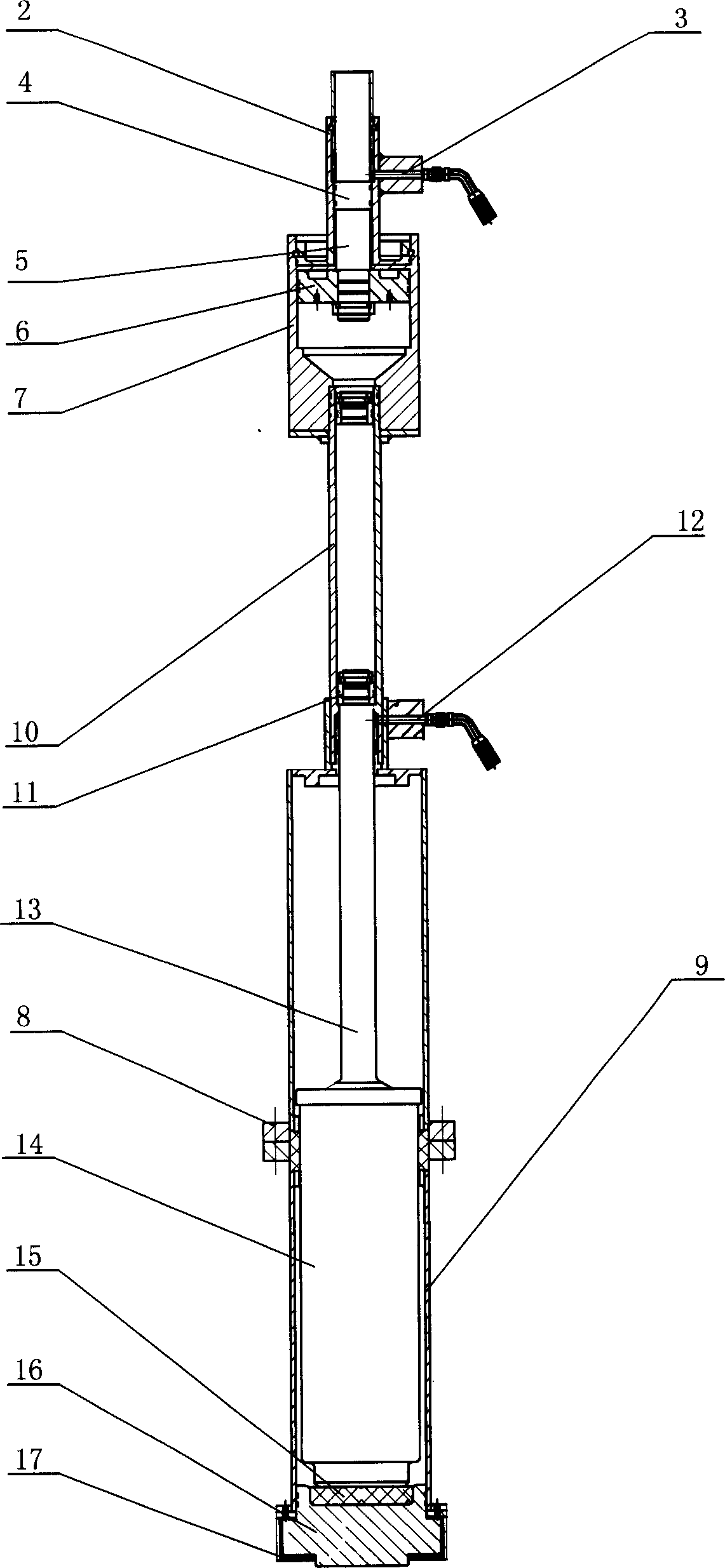

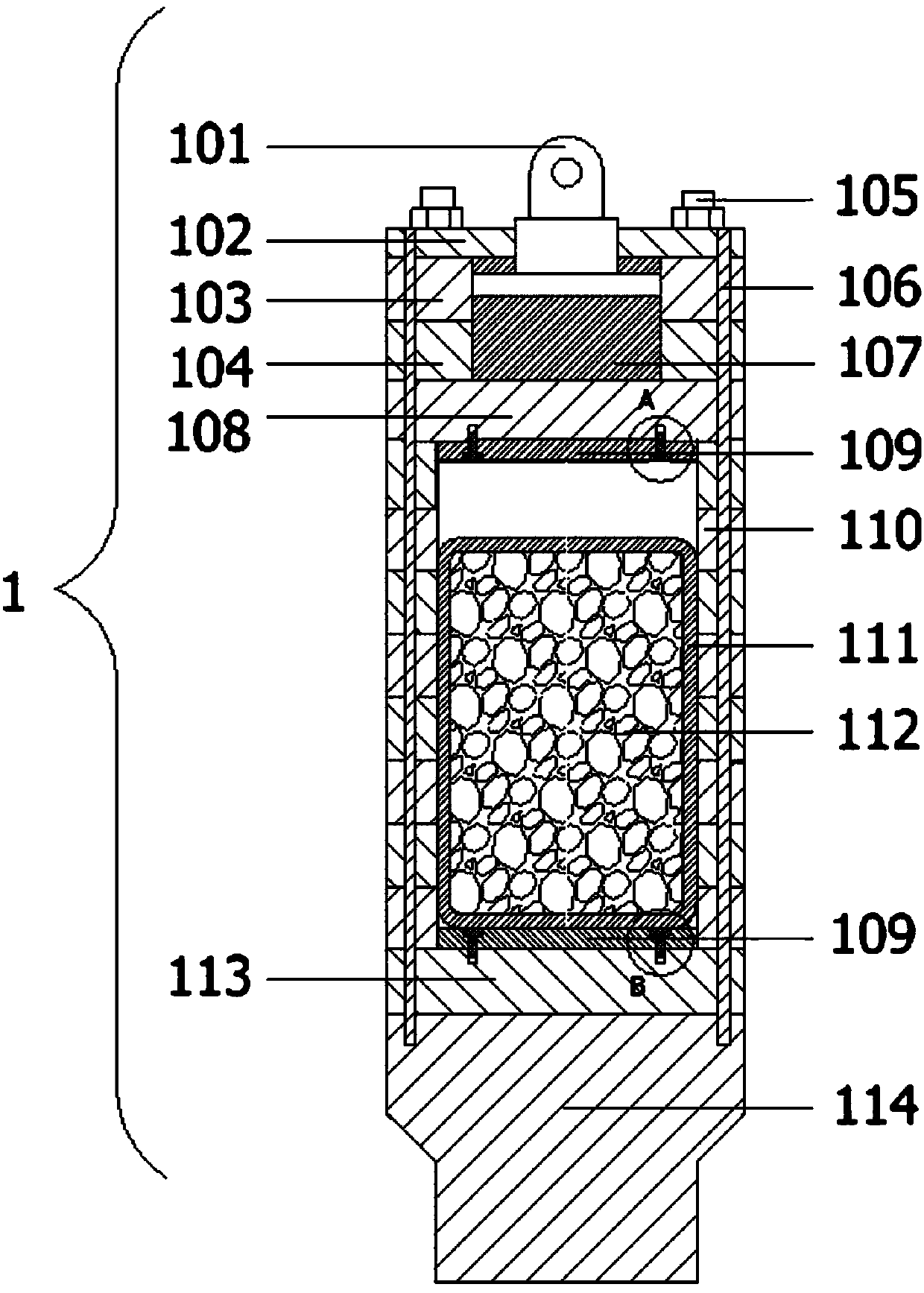

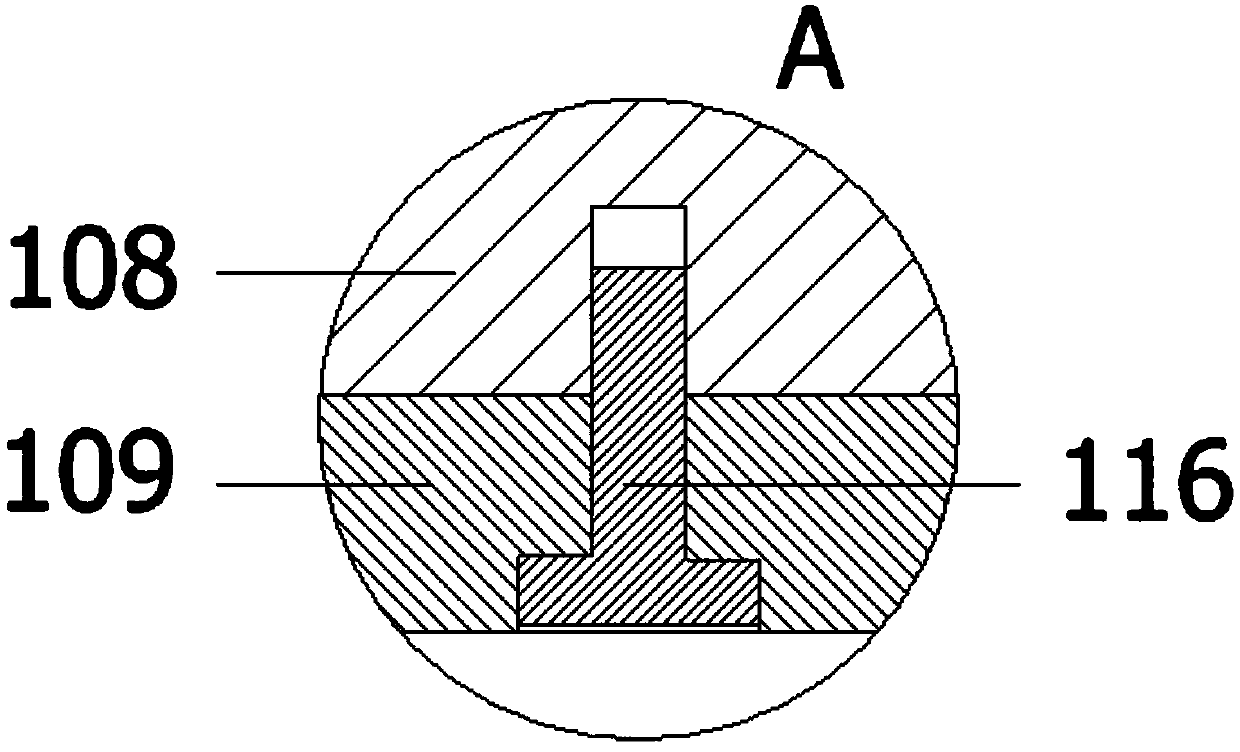

Hydraulic pile-ramming hammer

This invention discloses a hydraulic pile hammer including an outer long cylinder, a hydraulic cylinder, an oil stored cylinder and a pile hammer, in which, said hammer is set in the outer long cylinder, a piston is set in the hydraulic cylinder, a second piston is set in the oil cylinder, said two pistons are connected by a piston rod characterizing that said hydraulic cylinder is set above the outer long cylinder, a spray oil cylinder is set under the oil stored cylinder and they are connected and the cavity of the connection is filled with oil, the section of the spray is smaller than that of the stored one, a third piston is set in the spray cylinder and connected with the hammer by a push rod.

Owner:周荣珍

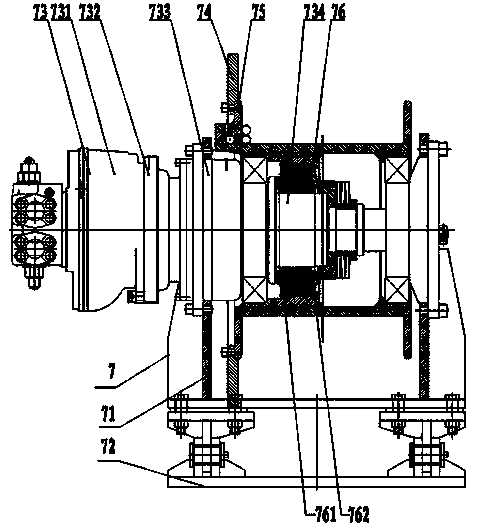

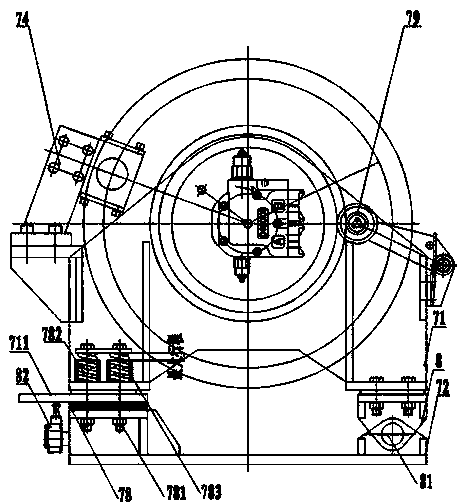

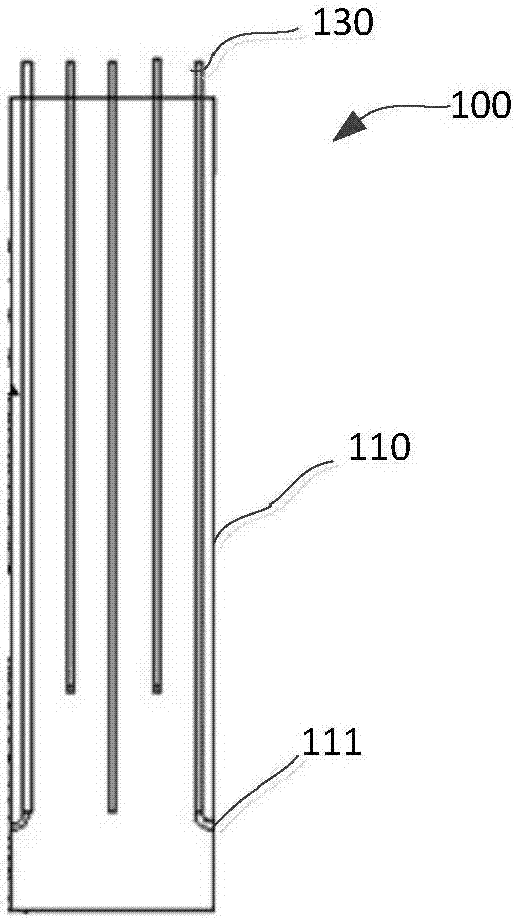

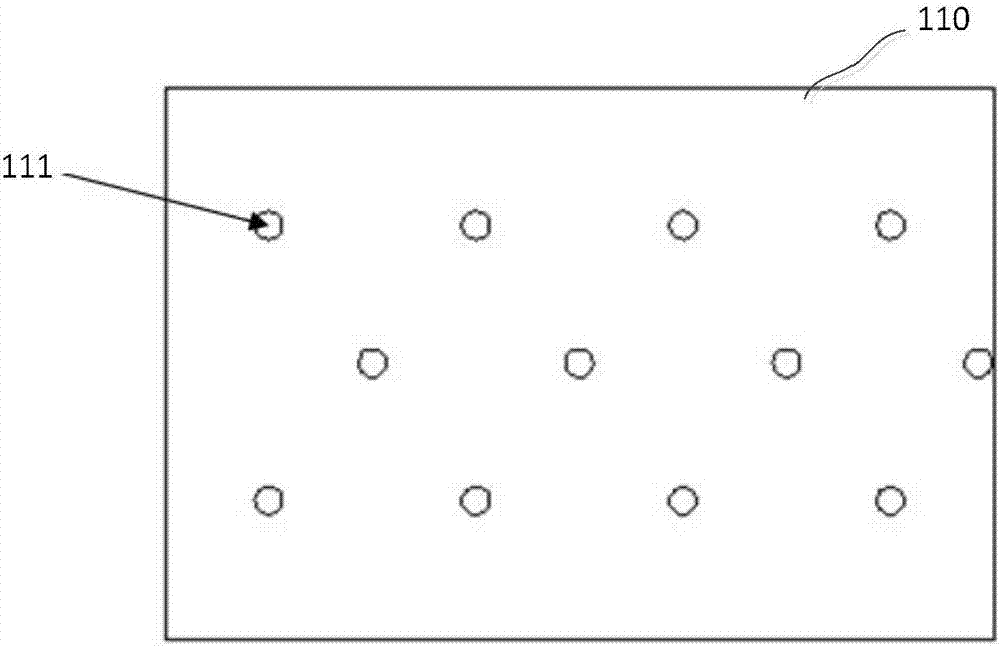

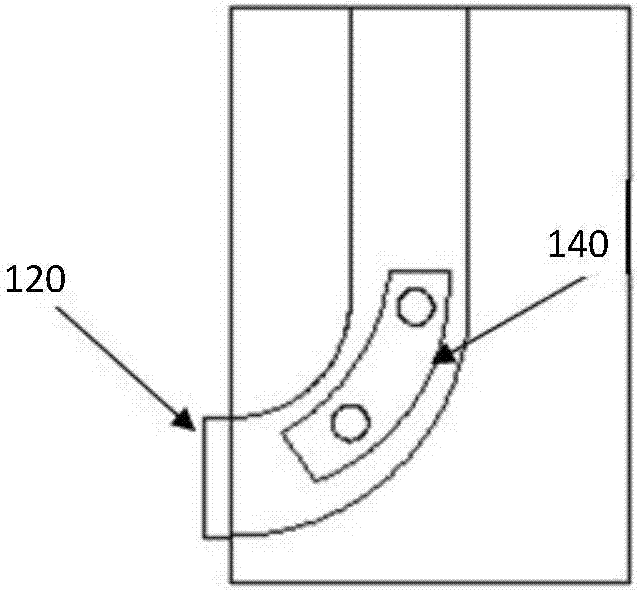

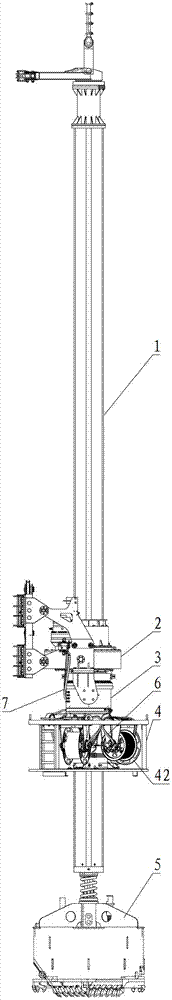

Rotary drilling rig and working device thereof

ActiveCN103075104AHigh piling efficiencyCompact structureDrilling rodsConstructionsDrill holeDrill pipe

The invention discloses a rotary drilling rig and a working device thereof. The working device comprises a power head and a drill rod, wherein the power head comprises a power head box, a revolving driving piece, a revolving connection mechanism, a revolving platform, a first hydraulic oil pipeline and an expanded-base drilling bucket arranged at the bottom of the drill rod; the revolving connection mechanism comprises a revolving part and a fixed part sleeved outside the revolving part; the fixed part is connected with the power head box and provided with a fixed oil hole; one end of the revolving part is in driving connection with the revolving driving piece, and the other end of the revolving part is connected with the revolving platform; the revolving part is provided with a revolving oil hole; an oil inlet of the revolving oil hole can be communicated with the fixed oil hole; the revolving platform is provided with a pipe winding device; one end of the first hydraulic oil pipeline is communicated with an oil outlet of the revolving oil hole; and after the first hydraulic oil pipeline is wound by the pipe winding device, the other end of the first hydraulic oil pipeline is communicated with the expanded-base drilling bucket. The working device can be used for realizing the multifunctionality of the rotary drilling rig, has hole drilling and broaching functions and has the advantages of high pile-forming efficiency, compact structure and small occupied space.

Owner:SANY HEAVY IND CO LTD (CN)

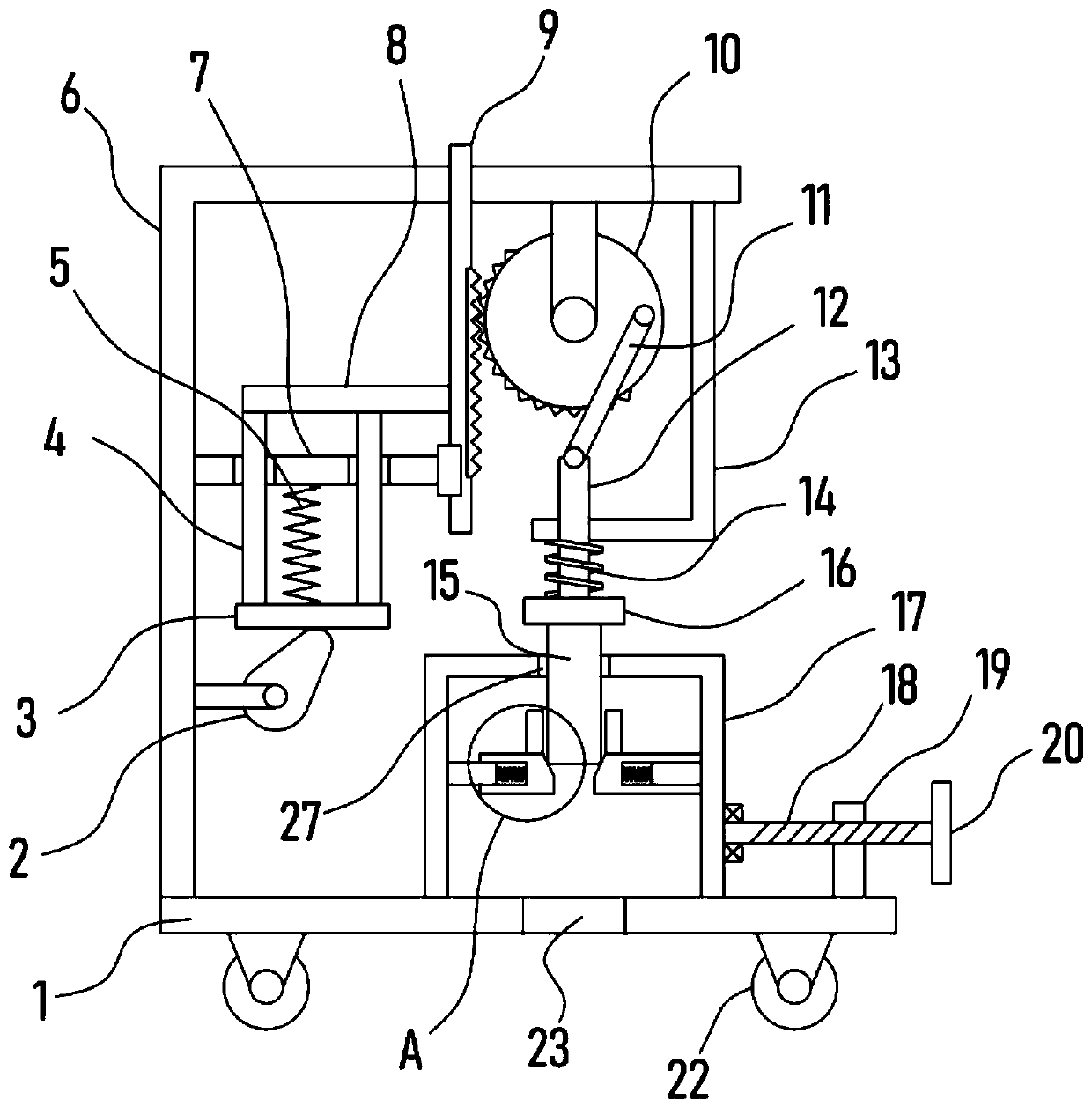

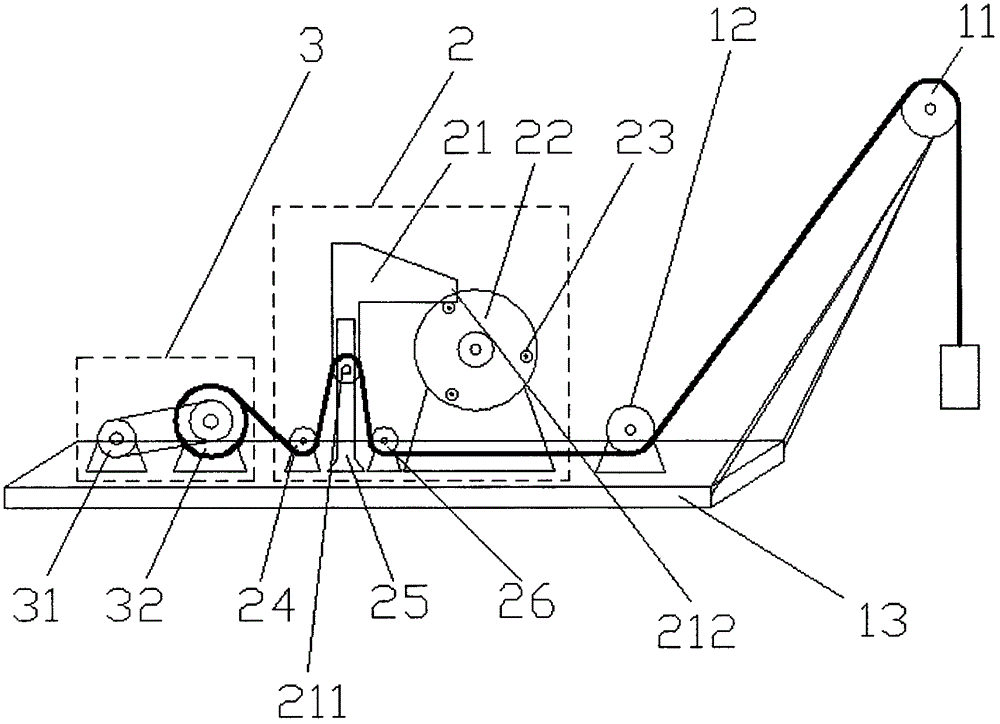

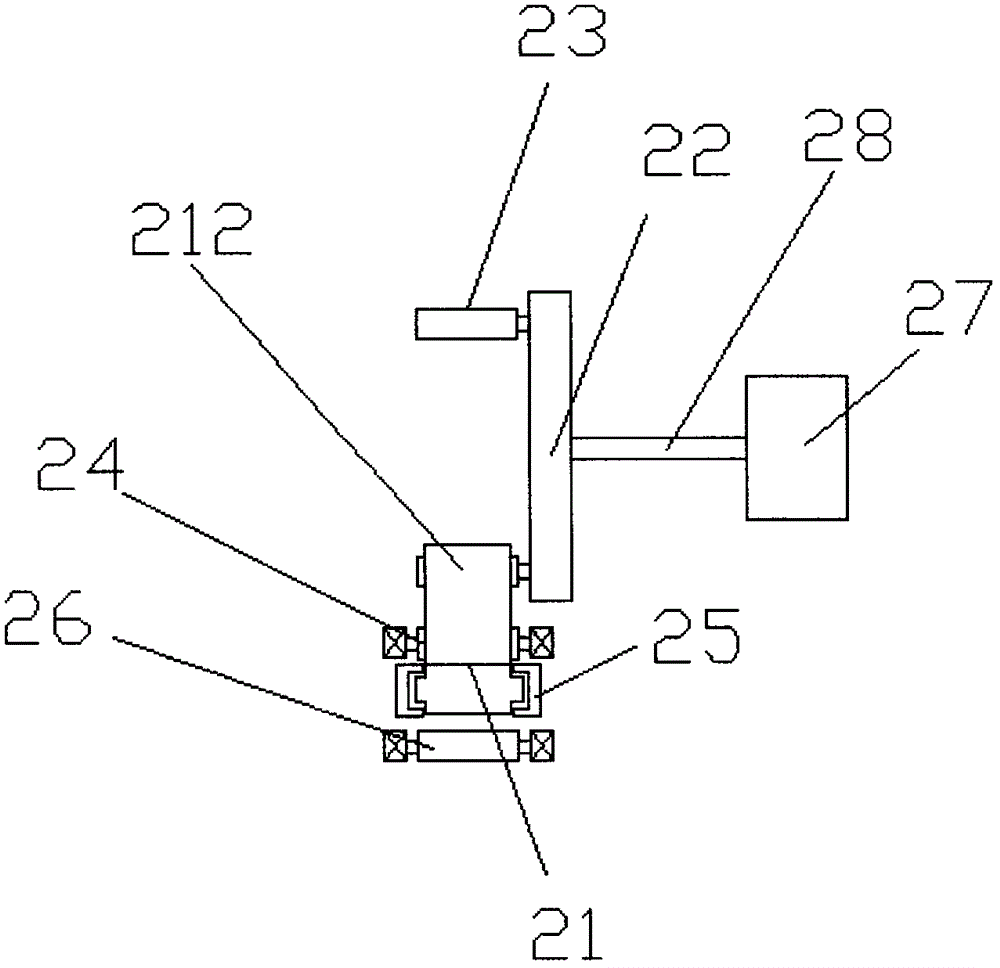

Automatic drop hammer pile driver

ActiveCN104314077AEasy to change orientationAchieve improvemeBulkheads/pilesFailure rateProgrammable logic controller

The invention relates to an automatic drop hammer pile driver and belongs to the field of building construction equipment. The automatic drop hammer pile driver comprises a motor, a lifting frame, a rotating plate, a lifting device, a tension sensor and a PLC (programmable logic controller) control system. The lifting device is mounted on the rotating plate, ascending and descending movements of a pile hammer are realized by means of detachable connection between the lifting frame and the lifting device, and repetition of the ascending and descending movements of the pile hammer is further realized by the aid of the rotating plate. By the aid of the tension sensor and the PLC control system, an automatic steel wire pay-off function of a winch can be controlled along with increase of piling depth, and accordingly automation of the drop hammer pile driver is realized, labor cost of the pile driver is reduced while failure rate of the pile driver in mechanical use is decreased, and piling efficiency is improved evidently according to field test. Moreover, the automatic drop hammer pile driver is convenient to use, simple in structure and suitable for popularization and utilization in engineering construction.

Owner:郭永

Porous pipe method large-diameter high-pressure jet grouting pile construction method

The invention relates to a porous pipe method large-diameter high-pressure jet grouting pile construction method. A high-pressure water conveying pipe, a high-pressure water compressed air conveying pipe and the like are arranged in a drill rod, the lower part of a drill bit is respectively provided with a high-pressure solidifying liquid and compressed air jet opening, a high-pressure water pipe jet opening and a compressed air water spraying opening, the positions of the high-pressure water pipe jet opening and the compressed air water spraying opening are positioned above the high-pressure solidifying liquid and compressed air jet opening, the bottom of the drill bit is provided with a high-pressure water jet opening, and the high-pressure water conveying pipe downwards jets water flow through the high-pressure water jet opening for cutting, so that the lower side of the drill pipe reaches the design pile bottom elevation, then, high-pressure water jet flow and compressed air jet flow are jetted from the high-pressure water pipe jet opening and the compressed air jet opening, high-pressure solidifying liquid and compressed air jet flow is jetted out from the high-pressure solidifying liquid and compressed air jet opening and is rotationally lifted along with the drill rod, and the peripheral soil bodies are subjected to secondary cutting, so that cement slurry and soil are stirred to be mixed into a pipe. Compared with an ordinary high-pressure jet grouting pile, the porous pipe method large-diameter high-pressure jet grouting pile has the advantage that the integral pile forming efficiency is improved by about 30 percent.

Owner:上海开普天岩土科技集团有限公司 +1

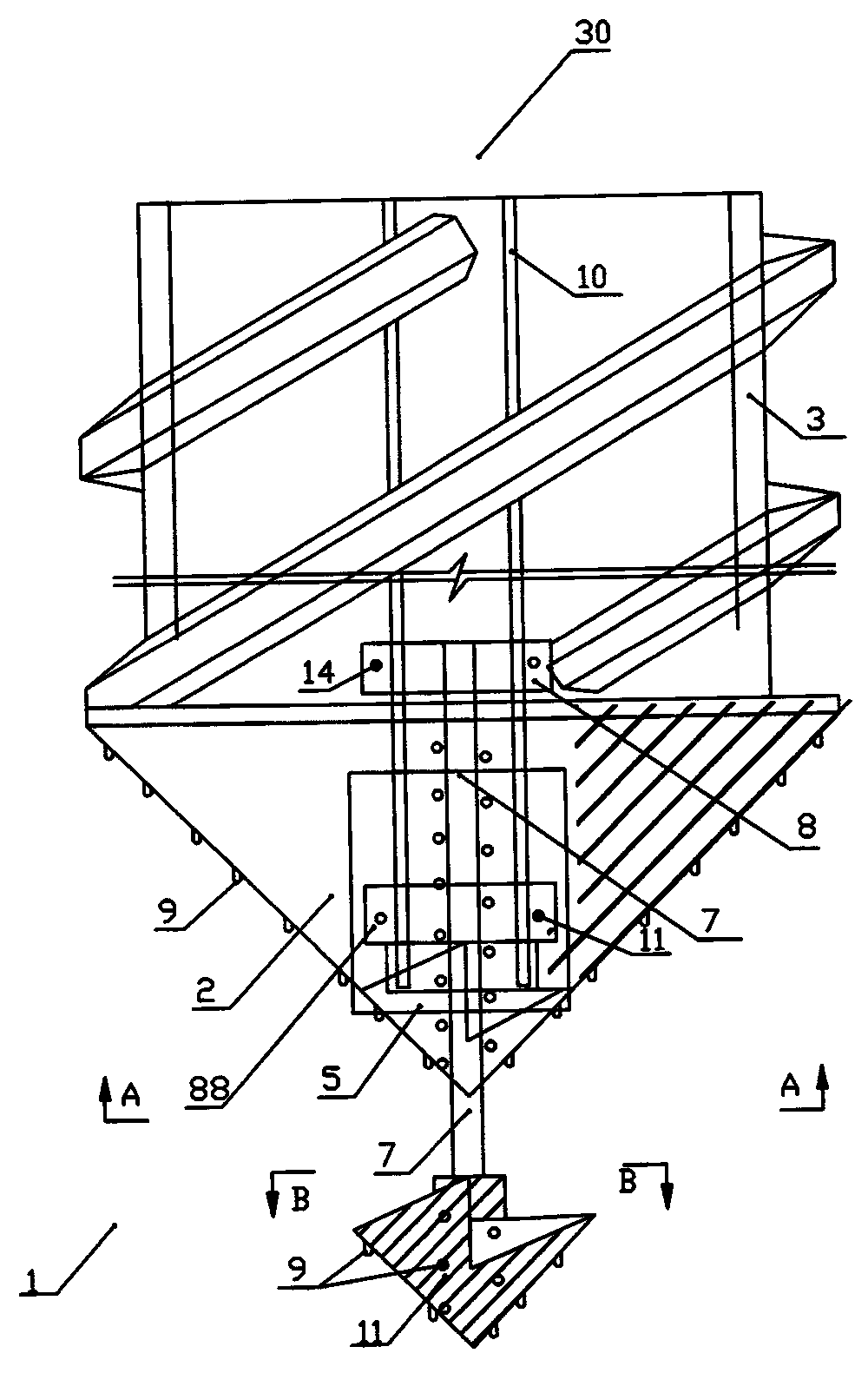

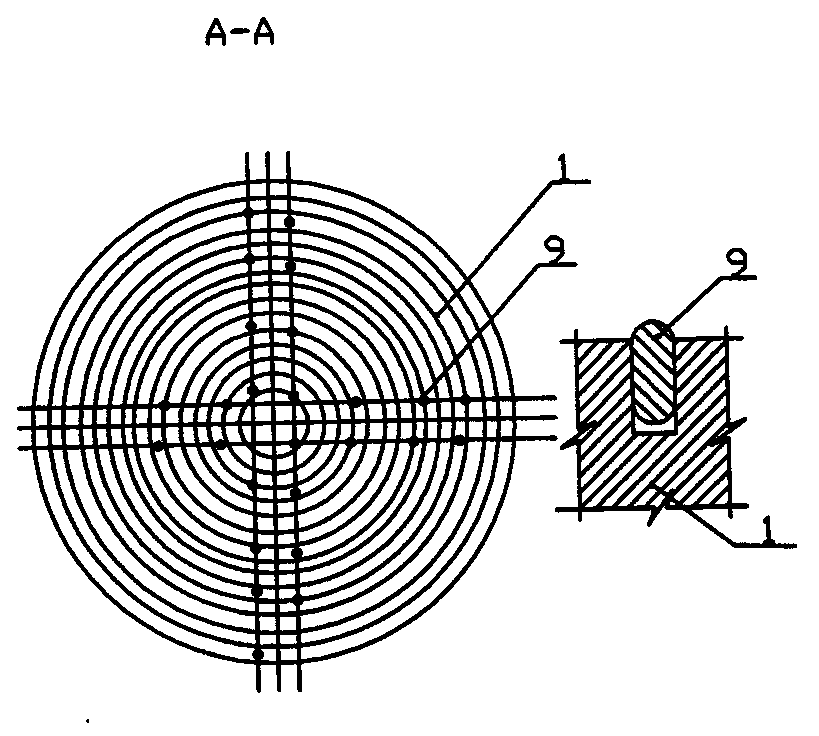

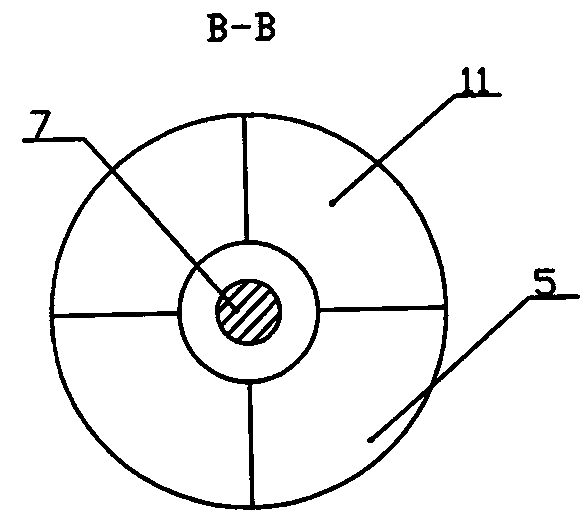

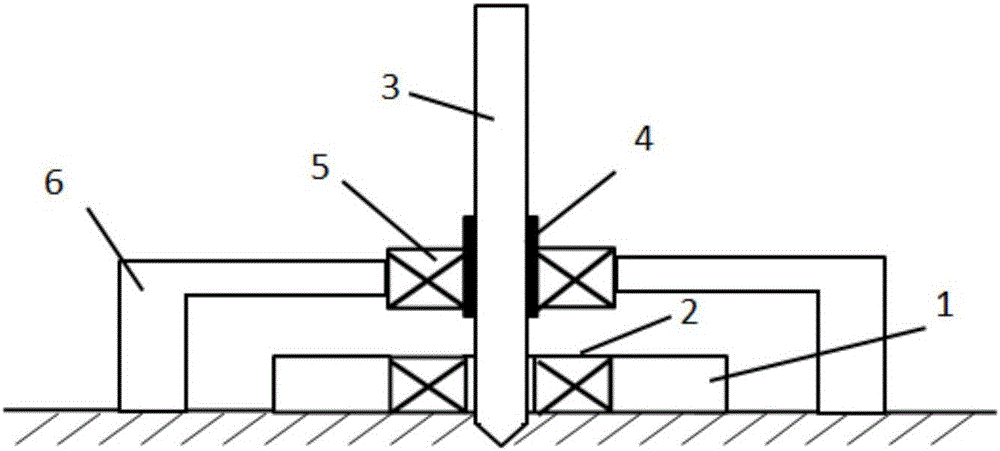

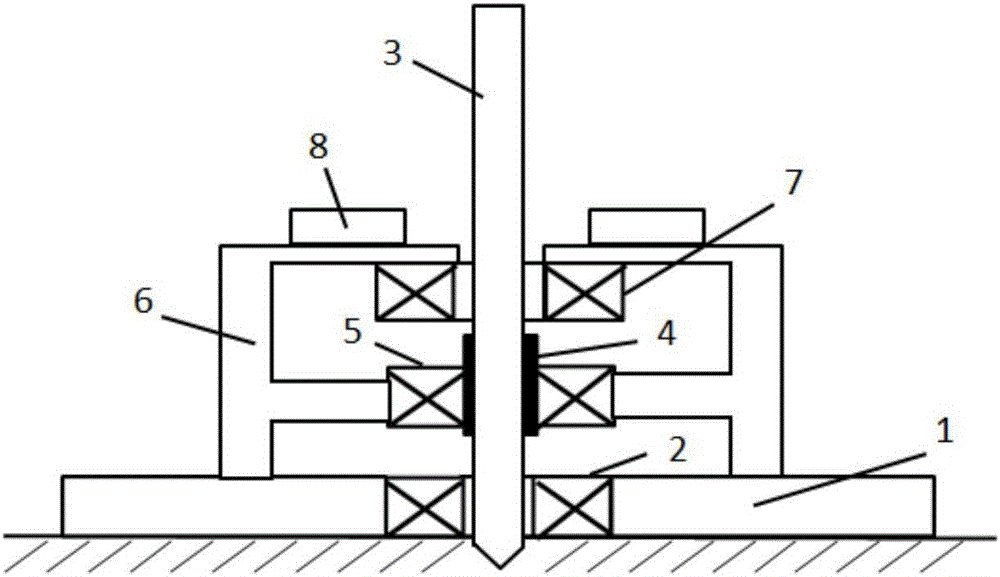

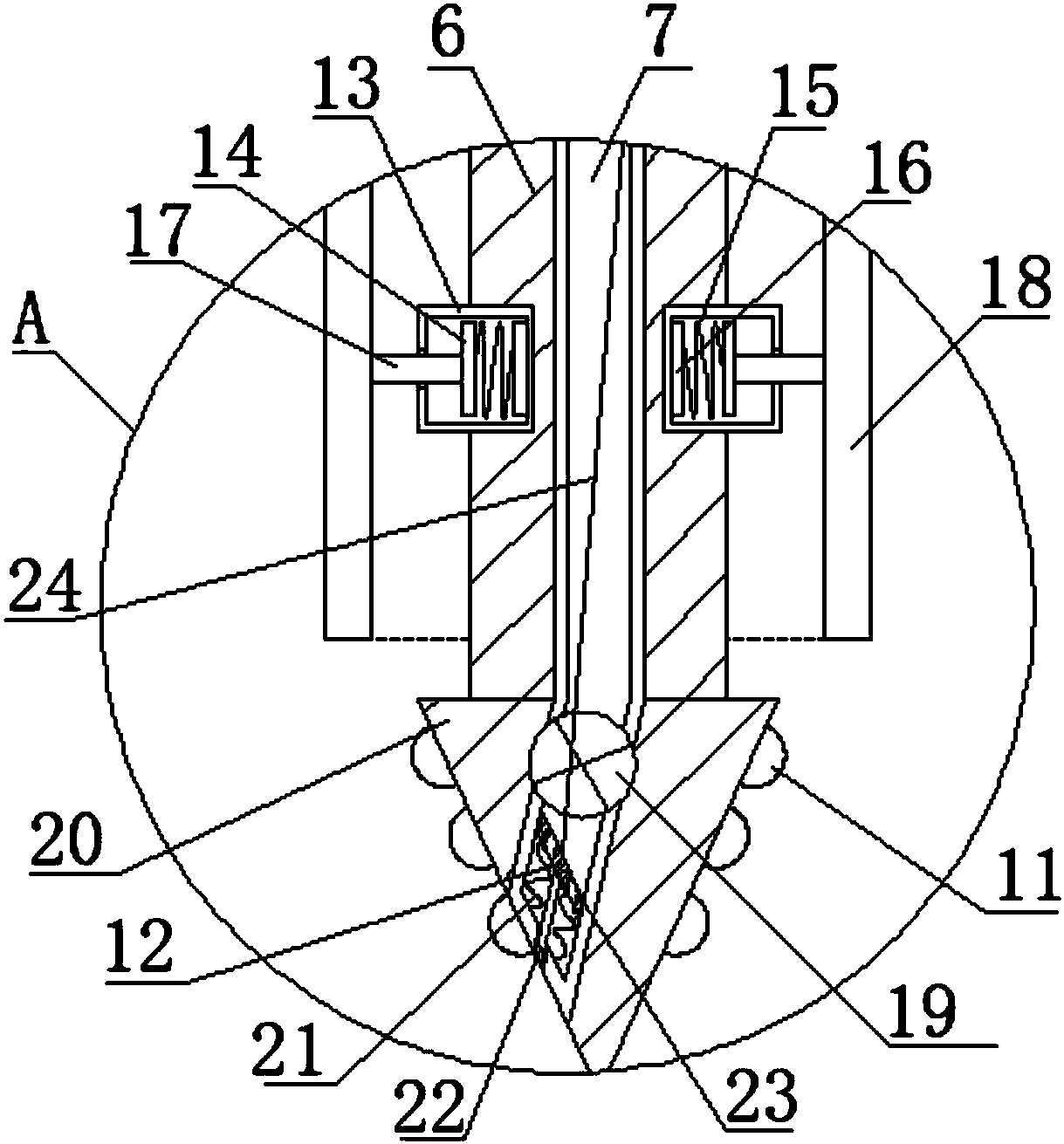

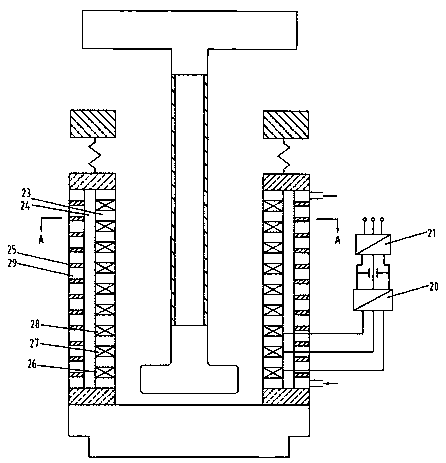

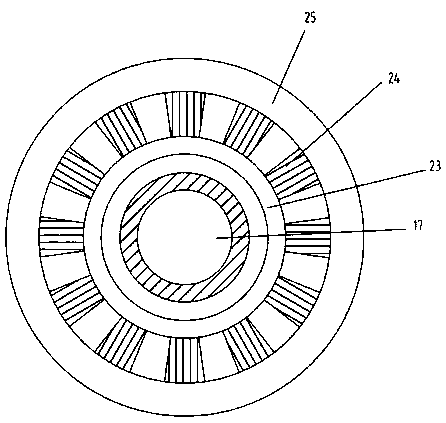

Electromagnetic piling device and electromagnetic piling method

ActiveCN105735314AReduce manufacturing costReduce equipment weightBulkheads/pilesPower flowSoil properties

The invention discloses an electromagnetic piling device and an electromagnetic piling method. The electromagnetic piling device comprises a base, a ground coil assembly, a pile, a pile clamping mechanism and a pile coil assembly. The electromagnetic piling device and the electromagnetic piling method have the advantages that impact force / static pressures which are generated during traditional piling can be completely replaced by electromagnetic repulsive / attractive force generated between the coil assemblies; different current waveforms are designed, accordingly, the electromagnetic piling force can be flexibly controlled, and the optimal piling effects can be realized; the current waveforms can be selected, so that the single piling speed can be increased, the piling efficiency can be enhanced, and the electromagnetic piling device is little in vibration and influence on surrounding soil masses; the electromagnetic piling device and the electromagnetic piling method are provided on the basis; the electromagnetic piling device is free of pollution, low in noise, convenient to mount, easy to construct, high in adaptability, expansibility and safety coefficient, is free of influence of soil properties and pile types and is particularly applicable to municipal construction and night construction requirements, in particular to pile foundation engineering in crowded building places, high-rise buildings and buildings with narrow spaces.

Owner:HUAZHONG UNIV OF SCI & TECH

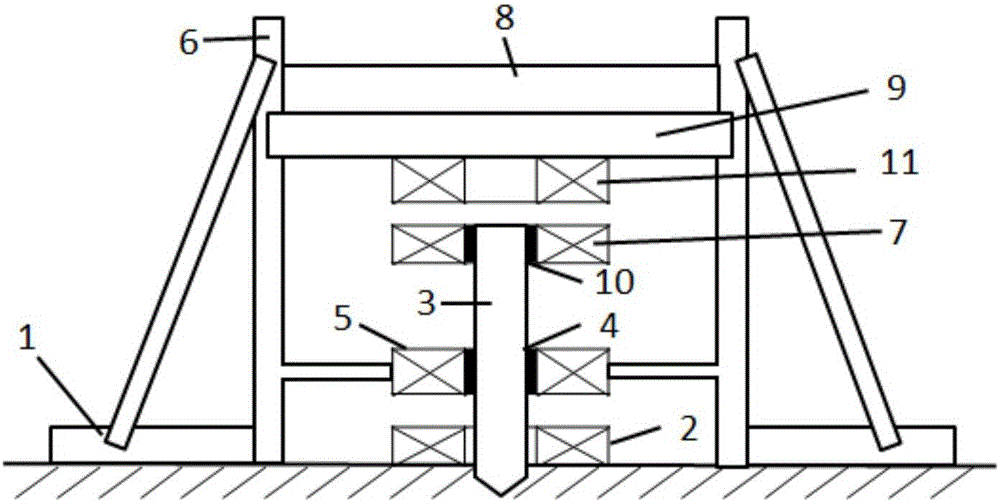

Efficient and quick piling machine for construction site

InactiveCN108547294AImprove piling efficiencyReduce processDrill bitsDerricks/mastsSlurry pumpDrill bit

The invention discloses an efficient and quick piling machine for a construction site. The efficient and quick piling machine comprises a portal frame which is of a U-shaped structure. By controllinga hydraulic telescopic rod, a motor vertically moves. At the moment, a first switch is turned on, the motor is started, and a drill bit is rotated through a connecting column, so that the ground is perforated. A friction convex block is used for increasing friction perforating force of the drill bit to improve the piling efficiency. The side walls of holes are flattened and tamped to prevent the holes from being collapsed. Through a thread and a threaded groove, a first slurry-discharging pipe and a second slurry-discharging pipe are connected together. A pull plate is pulled, through a steelwire, a baffle upwards moves, a blocking column upwards moves to be separated from a through hole, and thus the through hole communicates with a slurry-pumping hole. A third switch is turned on, a slurry pump is started, slurry in the holes can be pumped out, working procedures of perforating and slurry pumping are combined, the working procedures are omitted, the efficiency is improved, and the time and labor are saved; and a support rod and a supporting rod are both used for ensuring stability of the portal frame.

Owner:严凤河

Piling mechanism with mining function for constructional engineering, and working method

The invention relates to the field of buildings, in particular to a piling mechanism with a mining function for constructional engineering, and a working method. The piling mechanism comprises a carrier and also comprises a controller, a position regulation device, a drilling and mining device and a hammering device, wherein the position regulation device comprises a rotary disk, a driving component and a sliding component; the top of the rotary disk is fixedly provided with a supporting frame; two ends of the top of the supporting frame are symmetrically provided with a first sliding table and a second sliding table; the first sliding table and the second sliding table are independently provided with a first hydraulic rod and a second hydraulic rod in a sliding way; the drilling and mining device comprises a drill bit, a first connecting rod and a rotary component; the hammering device comprises a pile hammer, a second connecting rod and a guiding component; and the first hydraulic rod, the second hydraulic rod, the driving component, the sliding component, the rotary component and the controller are electrically connected. According to the piling mechanism with the mining function for the constructional engineering, and the working method, hole drilling and piling can be quickly carried out, and meanwhile, an interval among a plurality of pile positions can be accurately regulated according to construction requirements.

Owner:温州永安重工科技有限公司

Pile driver

The invention relates to a pile driver which comprises a main platform, wherein the main platform is used for installing pile lifting and pile driving equipment, and a supporting structure is arrangedat the bottom of the main platform. The pile lifting and pile driving equipment comprises a walking platform and a revolving platform. The pile lifting and pile driving equipment is characterized inthat the walking platform is arranged on the main platform, can slide in the length direction of the main platform and can be located, the revolving platform is arranged on the walking platform in a rotary mode and can perform 360-degree rotation relative to the walking platform, a control cabinet and lifting equipment for lifting concrete piles and hydraulic pile hammers are arranged on the revolving platform, a manipulator device which can be opened and closed is arranged at the front part of the revolving platform, the manipulator device can hold the lifted concrete piles after being closed, and the manipulator device can rotate along the revolving platform. As the manipulator device can hold the lifted concrete piles after being closed and the manipulator device can rotate along the revolving platform, the concrete piles cannot shake in a pile lifting process, and the piles can be more quickly lifted to be in place; thus, a pile driving efficiency is greatly improved.

Owner:安徽恒坤建筑科技有限公司

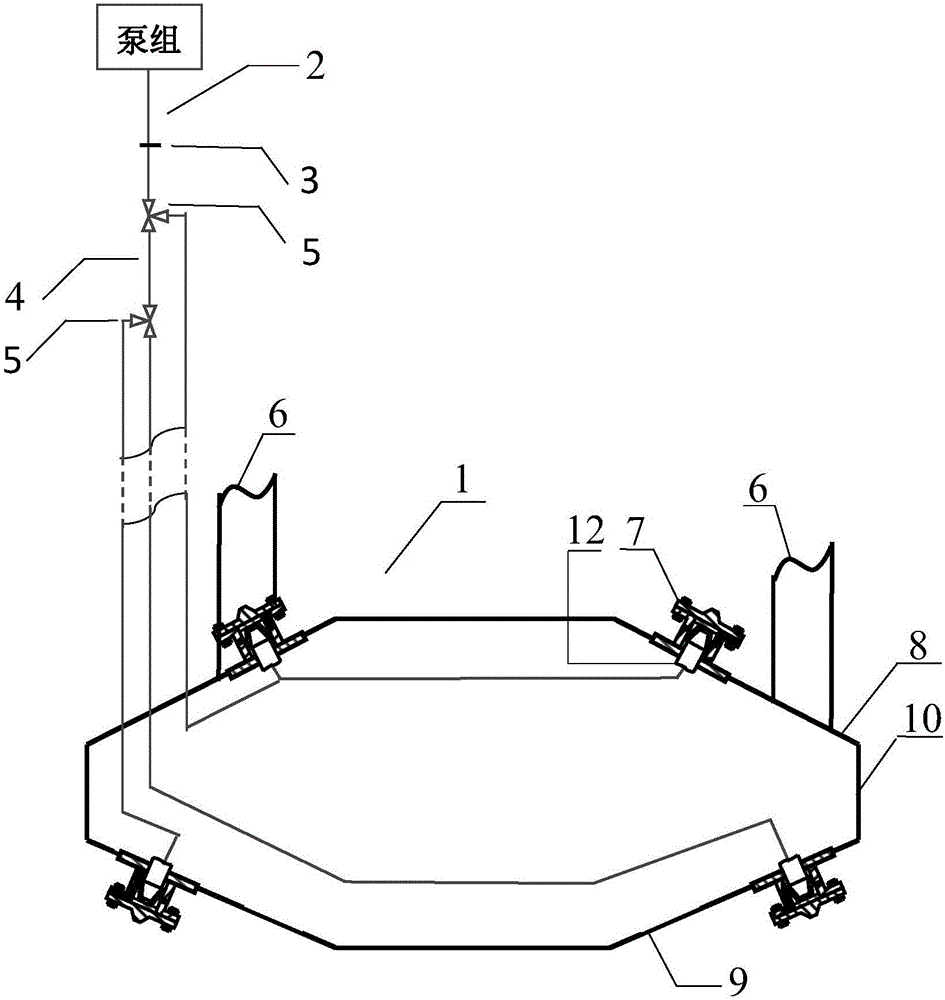

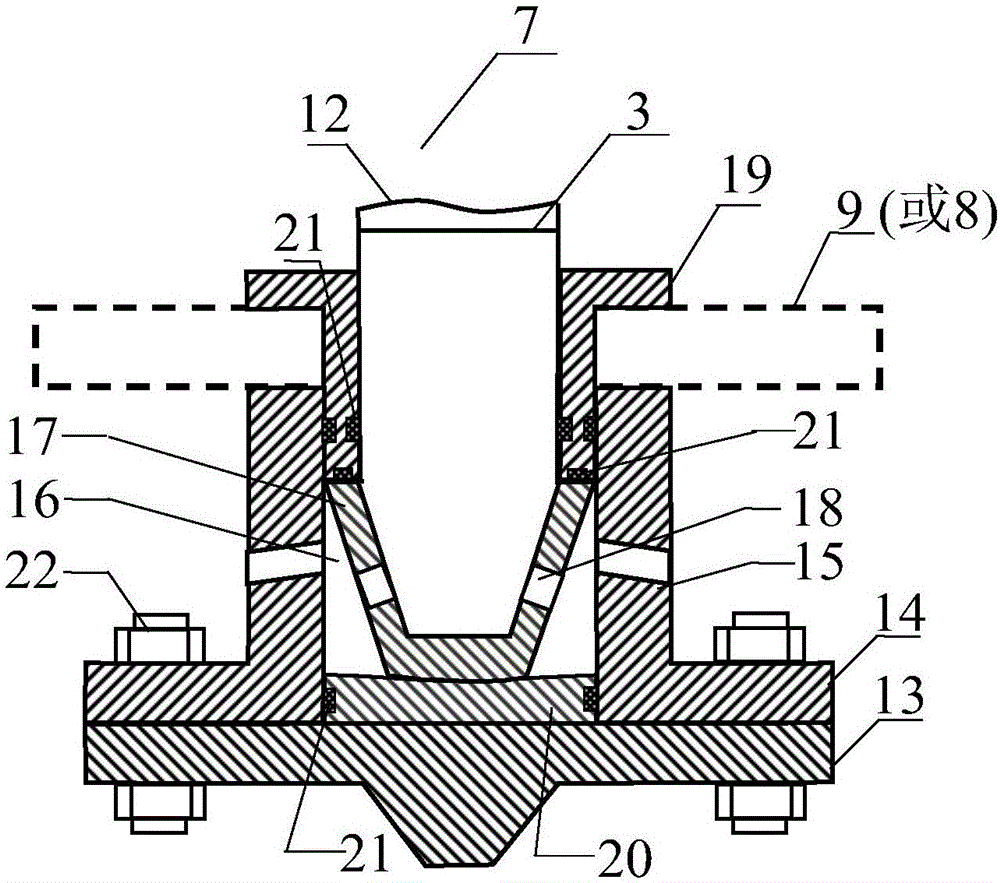

Self-elevating ocean platform pile shoe pile jetting system capable of preventing jetting pipeline from being blocked

ActiveCN106812127AEasy to cleanSolve the problem of clogged pile flushing pipelineArtificial islandsUnderwater structuresLine tubingSeabed sediment

A self-elevating ocean platform pile shoe pile jetting system capable of preventing a jetting pipeline from being blocked comprises a pile shoe, a shell of the pile shoe is composed of an upper top plate, a lower bottom plate and side plates, a circle of upper pile jetting holes are formed in the upper top plate at intervals, two circles of lower pile jetting holes are formed in the lower bottom plate at intervals, the outer sides of each upper and lower pile jetting holes are each provided with a closed type pile jetting nozzle, the nozzles are fixed to the upper top plate and the lower bottom plate in a welded mode, and water inlets of each circle of pile jetting holes are communicated with a pump set water outlet pipe through the jetting pipeline. By reasonably arranging the pile jetting holes and water outlets, the actual positions of jetting points are deeper than the lower bottom plate of the pile shoe, the extensionality is higher, a pile foundation soil body structure can be more effectively damaged, the adsorption capacity effect is restrained, the pile jetting holes are reasonably converted into the multi-directional water outlets with the smaller diameter, the effective jetting pressure is higher, and the pile jetting efficiency is higher; by adopting the closed type pile jetting nozzles, and then the problem that the jetting pipeline is blocked by seabed sediment is effectively solved by taking multistep progressive anti-blocking measures.

Owner:XI'AN PETROLEUM UNIVERSITY

Pile driver for construction site

InactiveCN112064639AStrong impactImprove piling efficiencyBulkheads/pilesGear wheelArchitectural engineering

The invention discloses a pile driver for a construction site. The pile driver comprises a bottom plate, a support and a pile driving mechanism, wherein the pile driving mechanism comprises a pile driving barrel, a driving mechanism and a clamping mechanism; the driving mechanism comprises a first gear, a second gear, a guide rod and a sliding box; and a lubricating mechanism is arranged in the sliding box. By arranging the driving mechanism, compared with a traditional pile driver which pulls a pile hammer through a steel wire rope for striking, the pile driver can drive the pile hammer to repeatedly and rapidly hammer timber piles through a motor, and the pile driving efficiency is greatly improved; and by arranging the lubricating mechanism, the lubricating mechanism is driven to discharge oil while the driving mechanism operates, thus, the driving mechanism operates more smoothly, and equipment is prevented from being disassembled and lubricated.

Owner:JIANGSU PROVINCIAL CONSTR GRP CO LTD +1

Marine electric pile driver based on linear motor

PendingCN109162277ASimple structureImprove piling efficiencyBulkheads/pilesFailure rateElectric machine

The invention discloses a marine electric pile driver based on a linear motor. The technical problems that an existing marine pile driver is poor in controllability and high in noise are solved. The marine electric pile driver based on the linear motor is composed of the linear motor, a variable-frequency controller, an energy storing device and other structural parts; the linear motor drives a pile hammer promoter to vertically move, the variable-frequency controller drives and controls the pile hammer promoter to move, and therefore control over parameters such as impact energy, impact frequency and travel is achieved; and especially implementing basic hardware conditions are provided for control over the parameters through the structural design of a linear motor stator. The marine electric pile driver based on the linear motor is simple in system structure, high in pile driving efficiency, good in controllability and low in failure rate and noise.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

Stable hydraulic pie driving equipment for buildings

InactiveCN107761730AAvoid damageRealize secondary piling operationBulkheads/pilesContact padEngineering

The invention provides stable hydraulic pile driving equipment for buildings. The stable hydraulic pile driving equipment comprises a hydraulic pile driver hammer mechanism and fixing bolts, wherein an oil cylinder piston rod is fixedly connected to the top of the hydraulic pile driver hammer mechanism, the bottom of the hydraulic pile driver hammer mechanism is in contact with a hammer pad, and apile is arranged under the hammer pad; a buffering protection pad with the same diameter as the inner rings of annular pressure blocks is fixedly mounted at the axis of the bottom of an upper pressing plate through two fixing bolts; and a buffering protection pad with the same diameter as the inner rings of the annular pressure blocks is fixedly mounted at the axis of the top of a lower pressingplate through two fixing bolts. The number of the annular pressure blocks is but not limited to eight groups and can be adjusted through increase / reduction. The height of a hollow cavity is changed bychanging the number of the annular pressure blocks, so that a steel wire mesh sleeve is temporarily separated from the bottom end surface of the hollow cavity when a hitting head descends to hit, andthen the top end surface of the hollow cavity exerts a stronger hitting force onto the steel wire mesh sleeve to facilitate improvement of the pile driving efficiency.

Owner:陈佳敏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com