Multi-azimuth tridimensional stirring drill for mollisol or spongy soil reinforcing stirring pile

A technology for mixing piles in soft soil, applied in the field of multi-directional three-dimensional mixing drill bits, which can solve the problems that the forward and reverse mixing blades cannot be arranged in multiple layers, the pile-forming strength is limited, and the mixing intensity is low, so as to improve the effective reinforcement depth and stratum Strong adaptability and the effect of improving the pile quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0017] The working principle of the mixing pile of the present invention is the same as that of the prior art, and the prior art can be referred to, so it will not be described again. The difference between the present invention and the prior art is that the structure of the mixing drill bit is different, and the following detailed description:

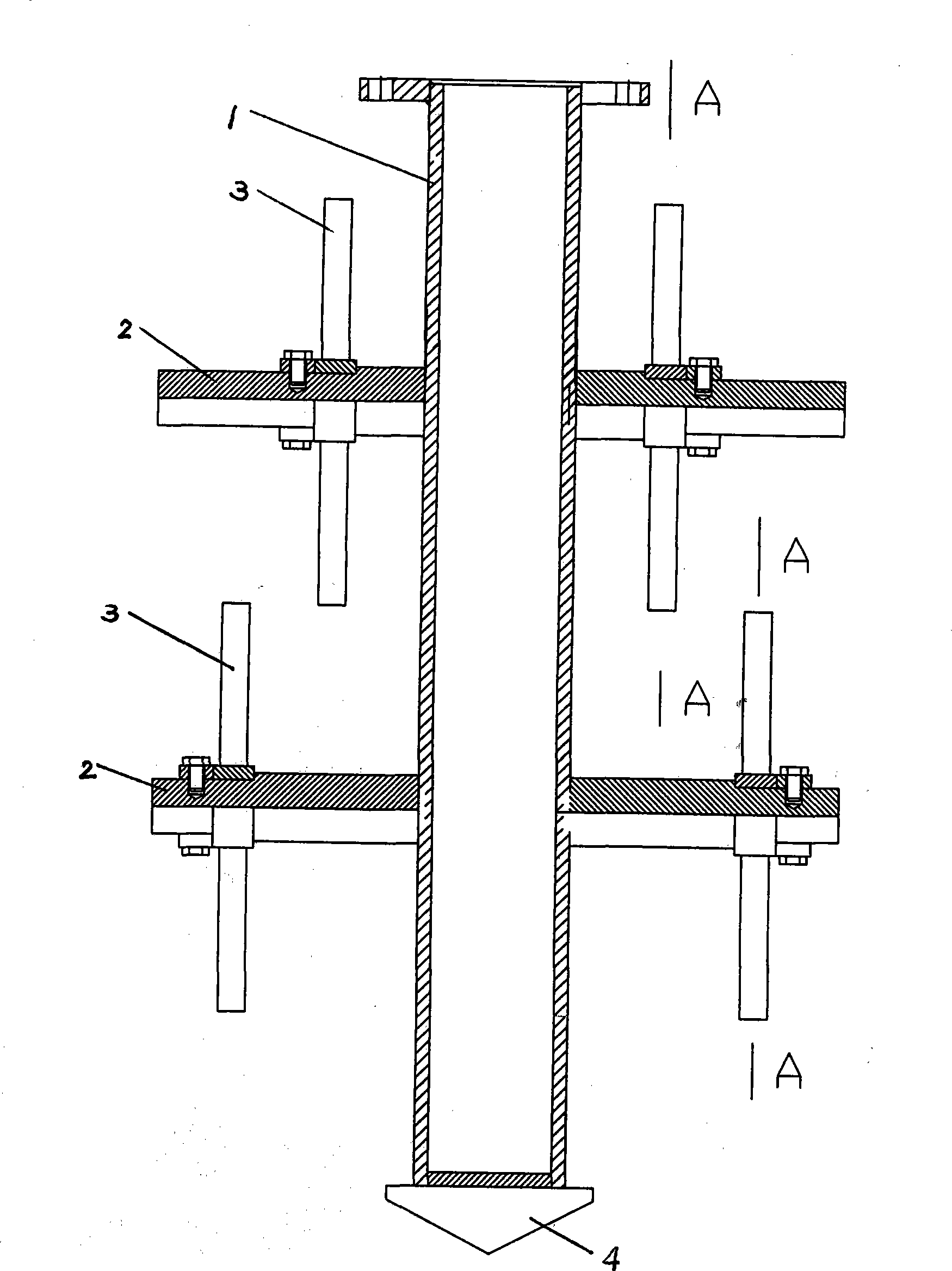

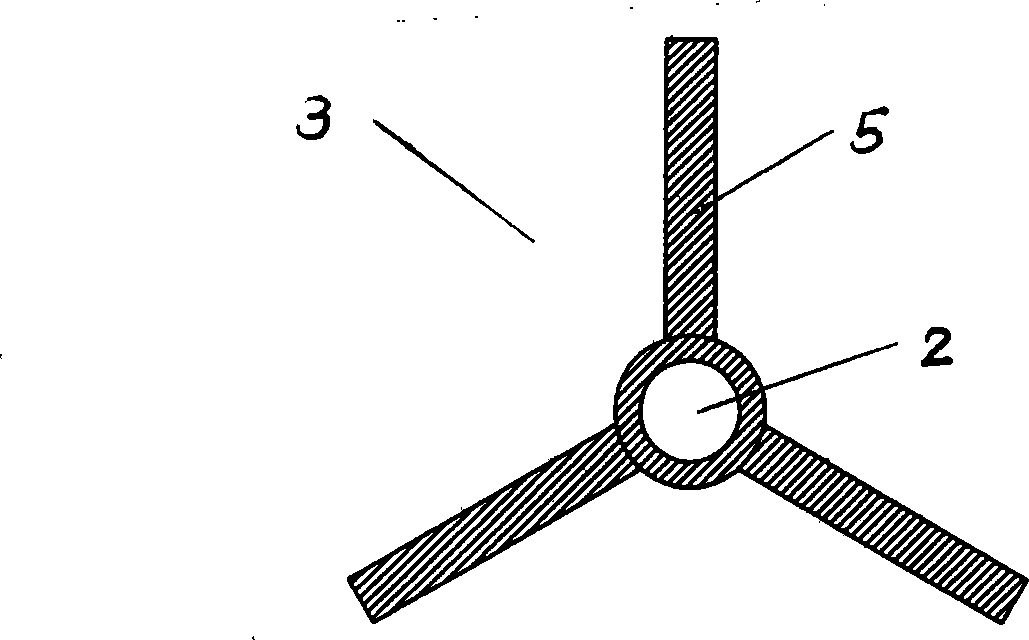

[0018] like figure 1 , 2 As shown, the multi-directional three-dimensional mixing drill bit for soft soil or soft soil reinforcement mixing pile of the present invention includes a drill rod 1, a front drill tip 4 positioned at the front end of the drill rod 1 and a main blade 2 fixed on the drill rod 1, Each main blade 2 is provided with a group of non-powered stirring wheels 3 that rotate with the main blade 2 as the rotation axis during the rotation of the drill pipe 1 . The main blade 2 is at 90 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com