Patents

Literature

614 results about "Cement grout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite materials and techniques for neutron and gamma radiation shielding

ActiveUS20050258405A1Safe and cost-effective managementIncrease volumeDiffusing elementsNuclear engineering solutionsPolymer modifiedRadioactive waste

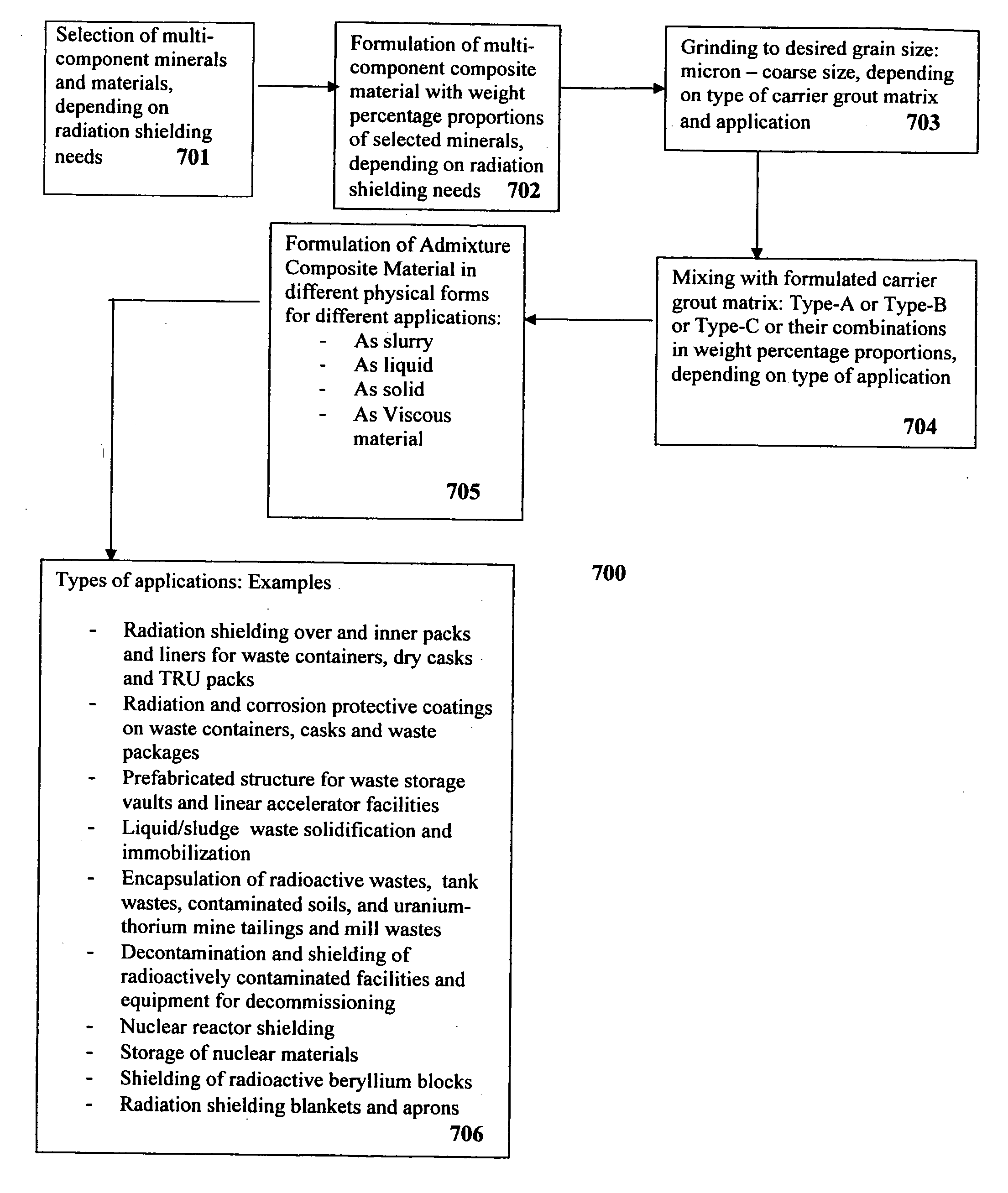

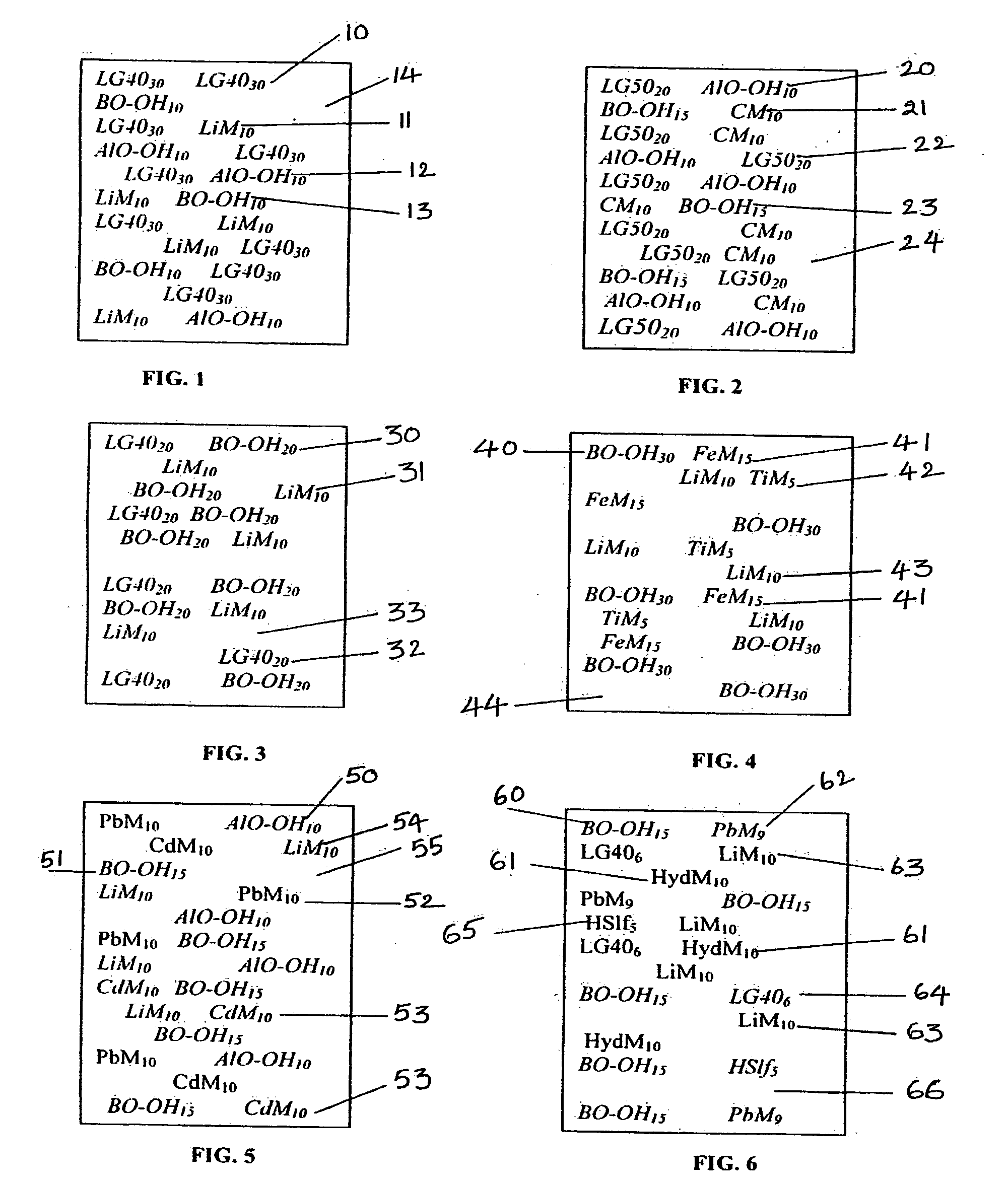

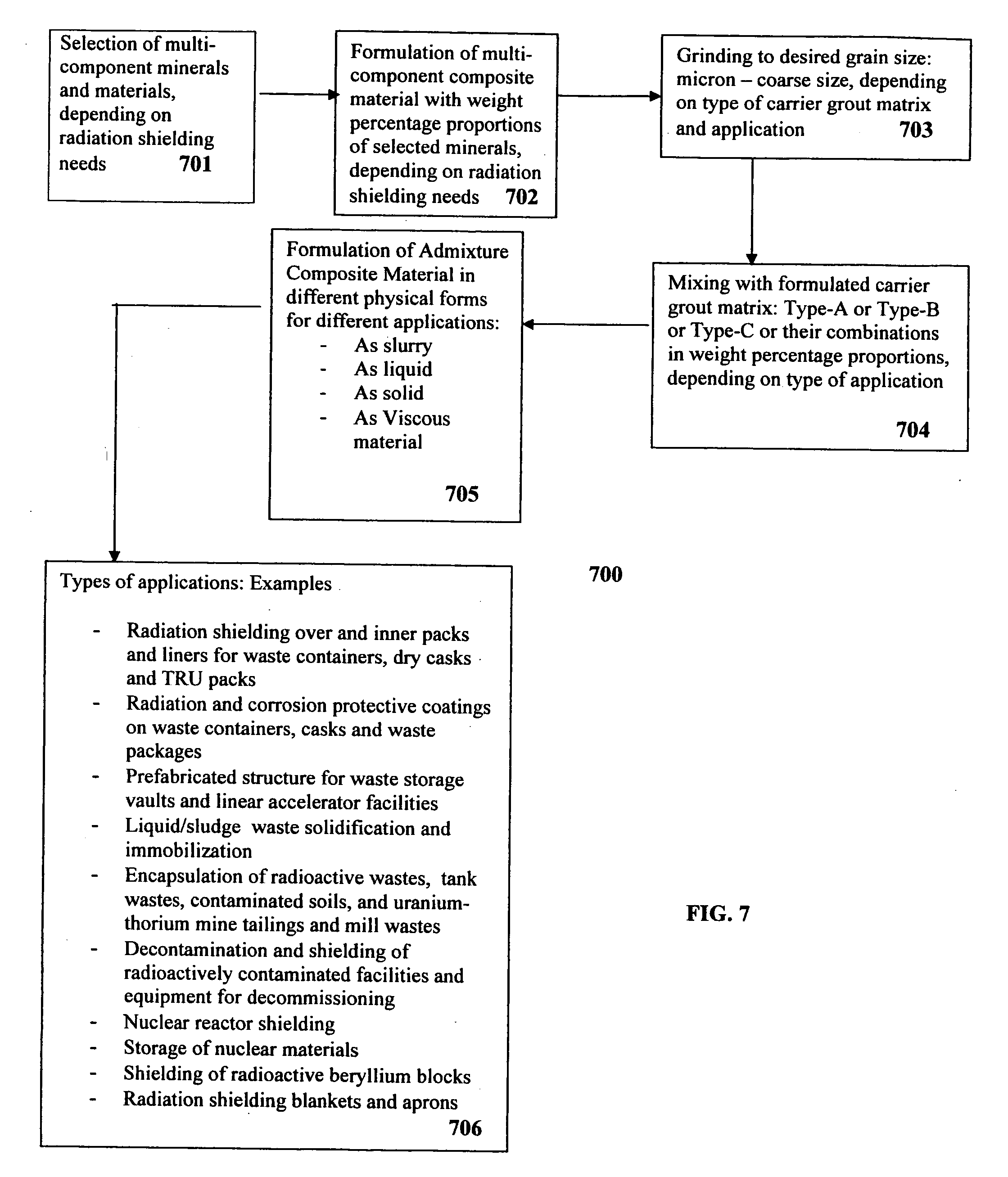

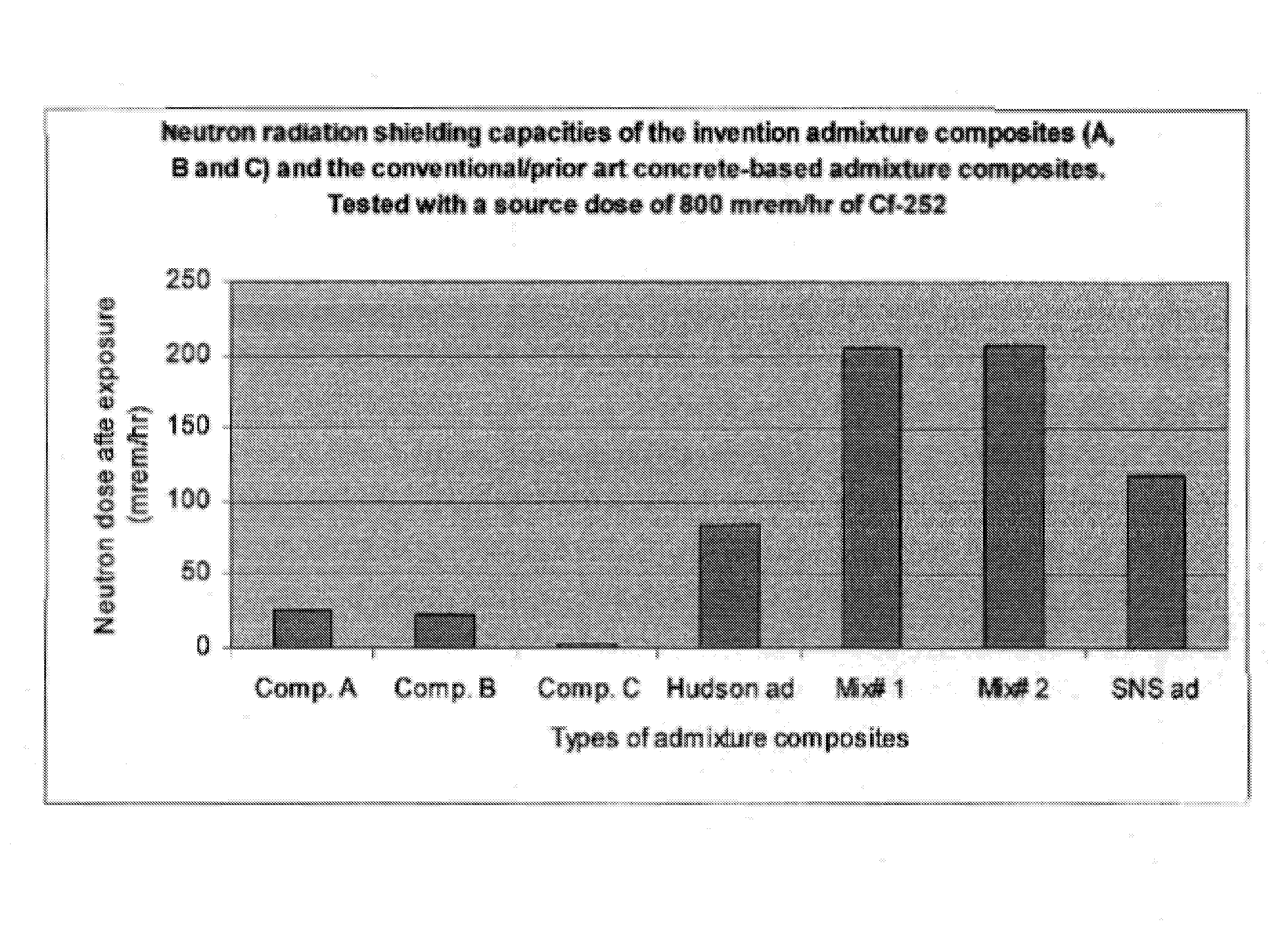

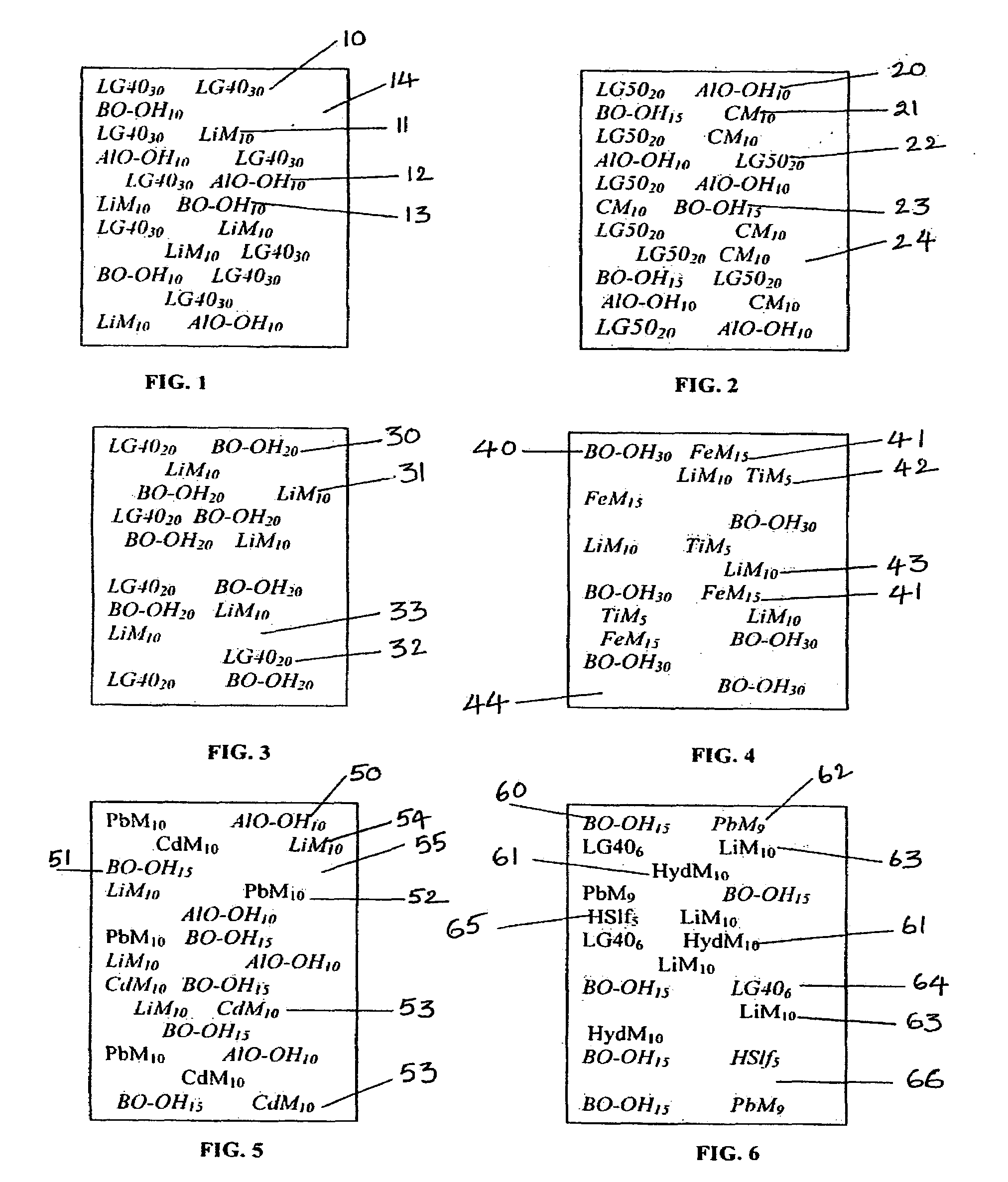

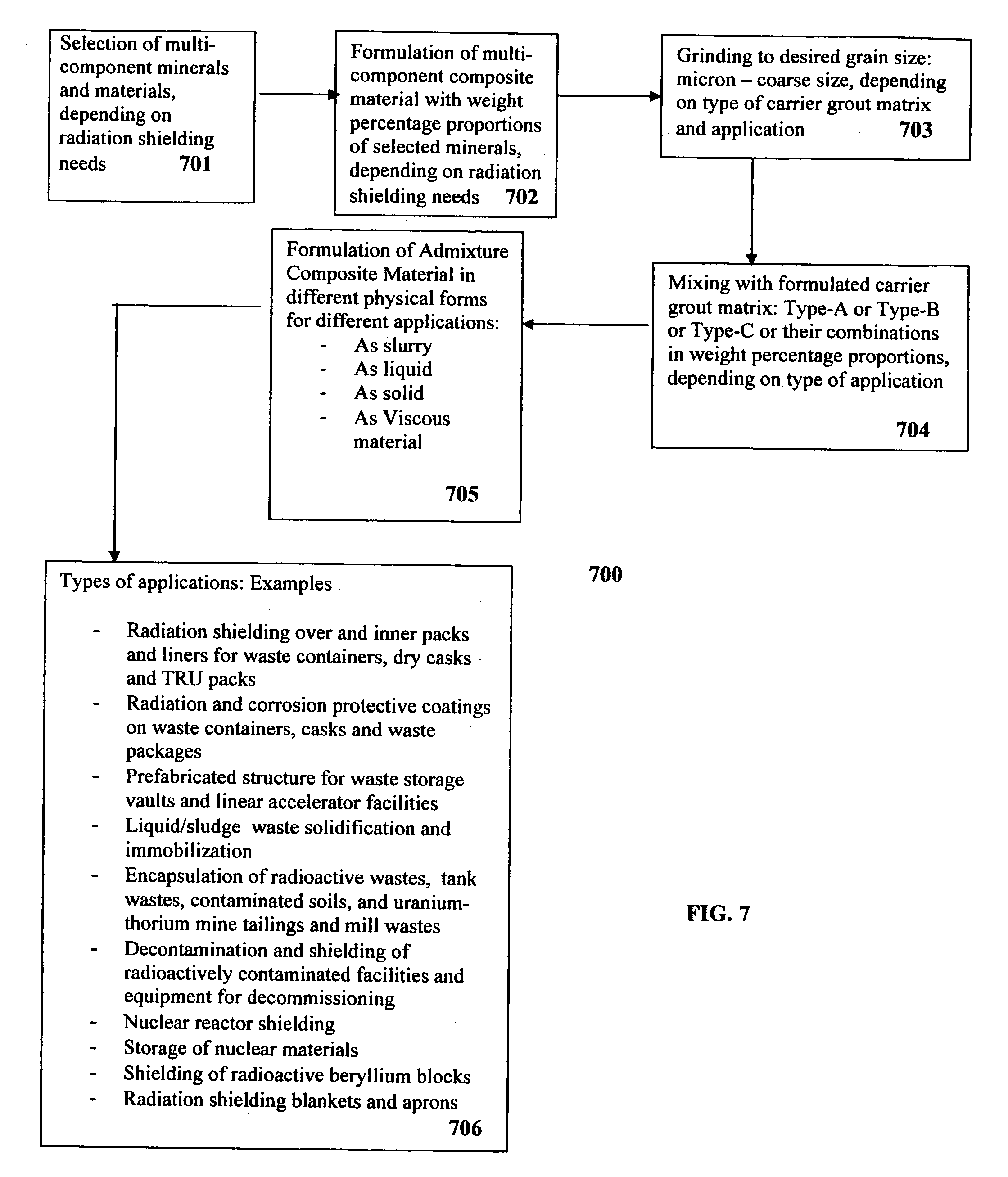

This invention deals with multi-component composite materials and techniques for improved shielding of neutron and gamma radiation emitting from transuranic, high-level and low-level radioactive wastes. Selective naturally occurring mineral materials are utilized to formulate, in various proportions, multi-component composite materials. Such materials are enriched with atoms that provide a substantial cumulative absorptive capacity to absorb or shield neutron and gamma radiation of variable fluxes and energies. The use of naturally occurring minerals in synergistic combination with formulated modified cement grout matrix, polymer modified asphaltene and maltene grout matrix, and polymer modified polyurethane foam grout matrix provide the radiation shielding product. These grout matrices are used as carriers for the radiation shielding composite materials and offer desired engineering and thermal attributes for various radiation management applications.

Owner:SAYALA DASHARATHAM

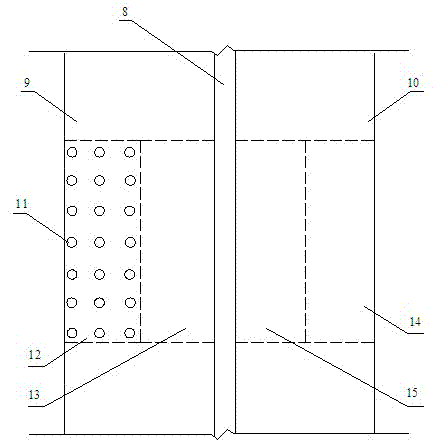

Grouting method of penetrability concrete cracks

InactiveCN103174112AChange the idea of grouting technologyIncreased durabilityFoundation engineeringMarine site engineeringChiselCement grout

The invention discloses a grouting method of penetrability concrete cracks. The grouting method of the penetrability concrete cracks comprises the steps of drilling holes, burying pipes, sealing cracks and grouting. The drilled holes comprise inclined holes and roulettes. The inclined holes are preferably distributed in the same side or two sides of the cracks. The roulettes are distributed along the cracks to the bottom portions of the cracks. The pipes are buried by gelatinization materials. The cracks are sealed through the chisel groove method and the surface crack sealing method. With regard to stable and unexpanded penetrability concrete cracks (dead cracks) or compressive zone penetrability cracks, the grouting method of the penetrability concrete cracks adopts cement grout to conduct a grouting process, not only is the grouting method environment-friendly, economical and convenient to construct, but also quality effects meet engineering requirements. Besides, durability of materials is good, and strength of the materials is high.

Owner:HUBEI GEZHOUBA TESTING

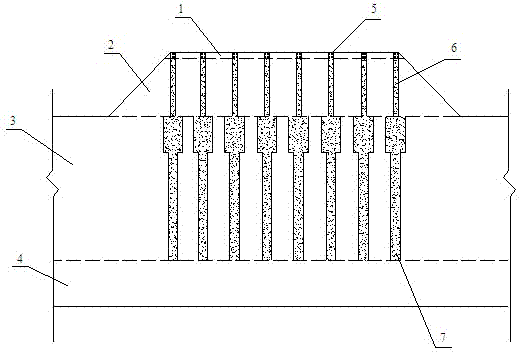

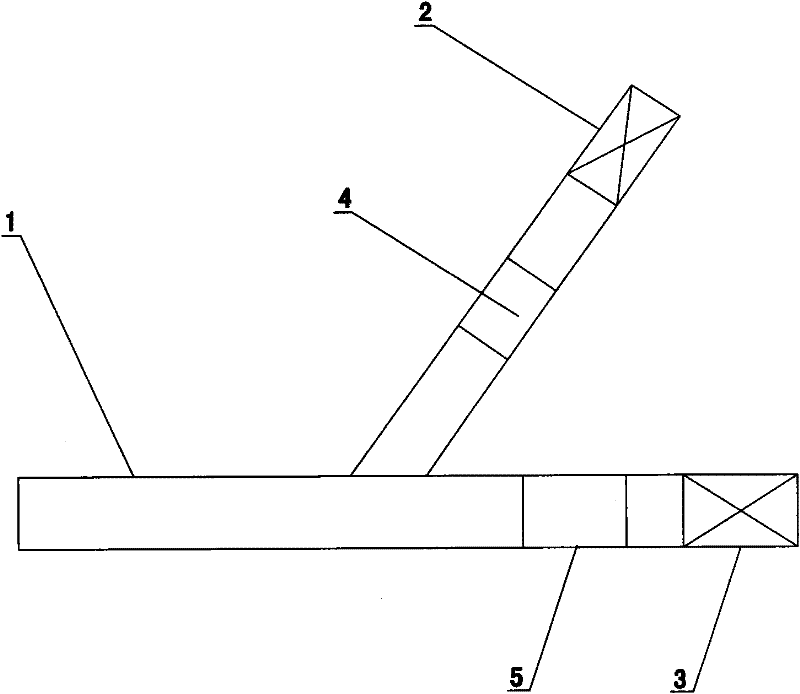

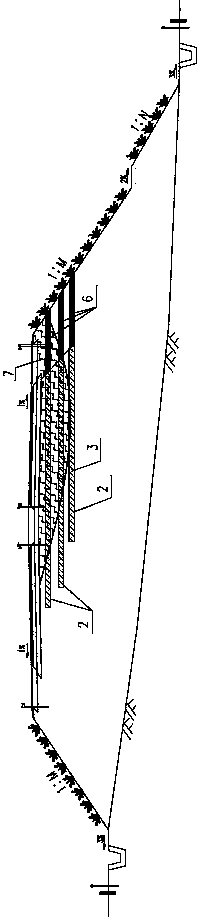

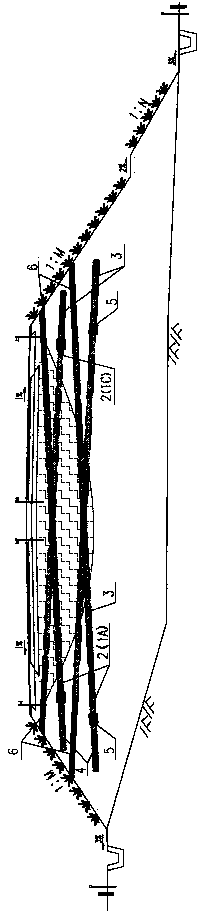

Anchored roadbed widening method

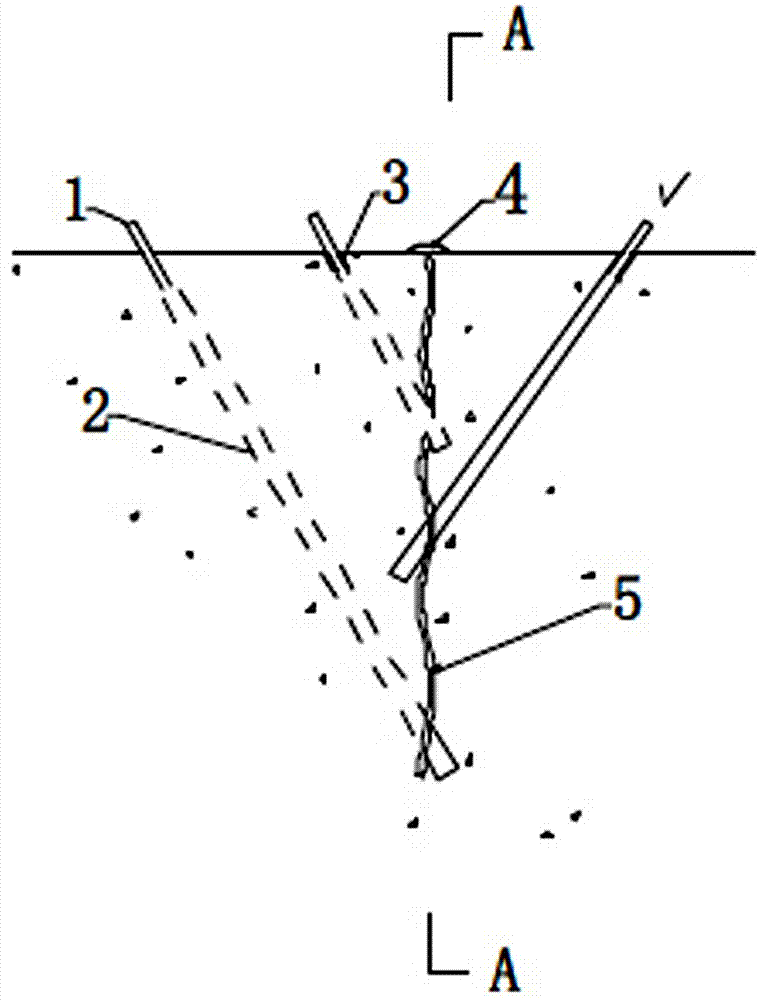

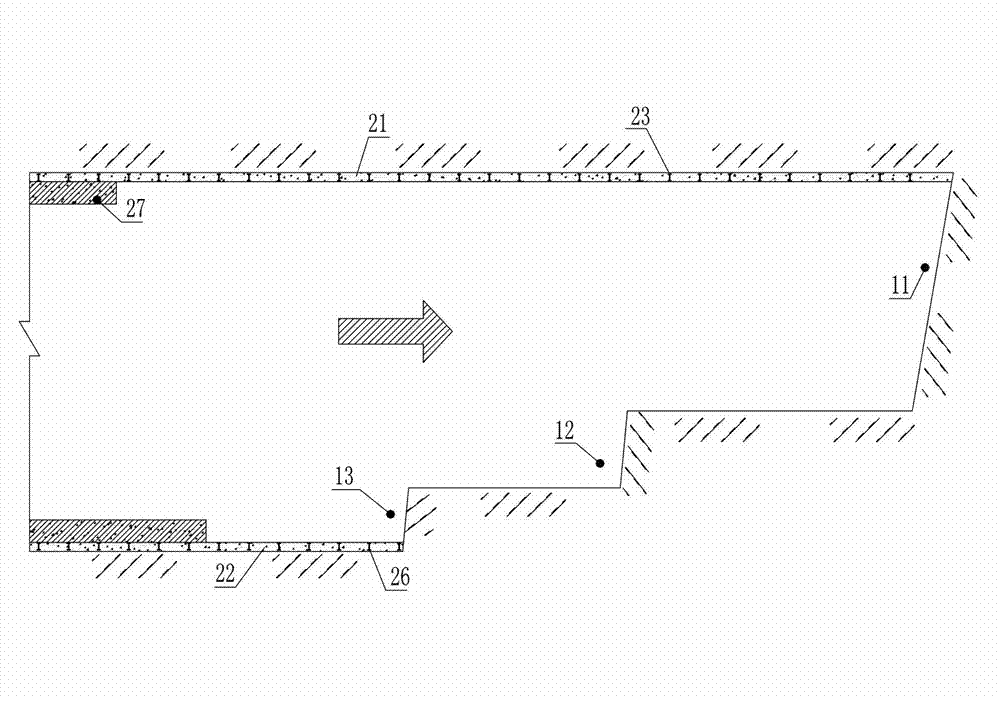

InactiveCN102619150AReduce shear deformationGuaranteed carrying capacityRoadwaysVertical planeEngineering

The invention discloses an anchored roadbed widening method, which belongs to the technical field of road construction. The anchored roadbed widening method comprises the following steps of: firstly performing slope cutting on an old roadbed slope, then excavating a step on the old roadbed slope from the ground, obliquely drilling an anchorage hole into an old roadbed at the joint of the vertical plane of the step and the horizontal plane, placing a steel bar into the anchorage hole, and casting the steel bar and the old roadbed into a whole by pouring cement grout; laying a new roadbed in layers, rolling, flatly laying a geogrid on the step of the old roadbed when the new roadbed is filled to be aligned with the step of the old roadbed provided with the anchorage drilled hole, connecting a transverse rib of the geogrid with an end hook which is bent upwards of the exposed part of the steel bar, tensing the geogrid, fixing with the lower layer of a soil body, and finally filling soil on the geogrid and rolling. According to the anchored roadbed widening method disclosed by the invention, an anchor rod technology is used for reinforcing the old roadbed slope, the geogrid and the old roadbed are connected into a whole, the geogrid can be prevented from sliding on the step of the old roadbed, the stability of the new roadbed and the old roadbed is improved, and non-uniform sedimentation can be effectively controlled.

Owner:SHIJIAZHUANG TIEDAO UNIV

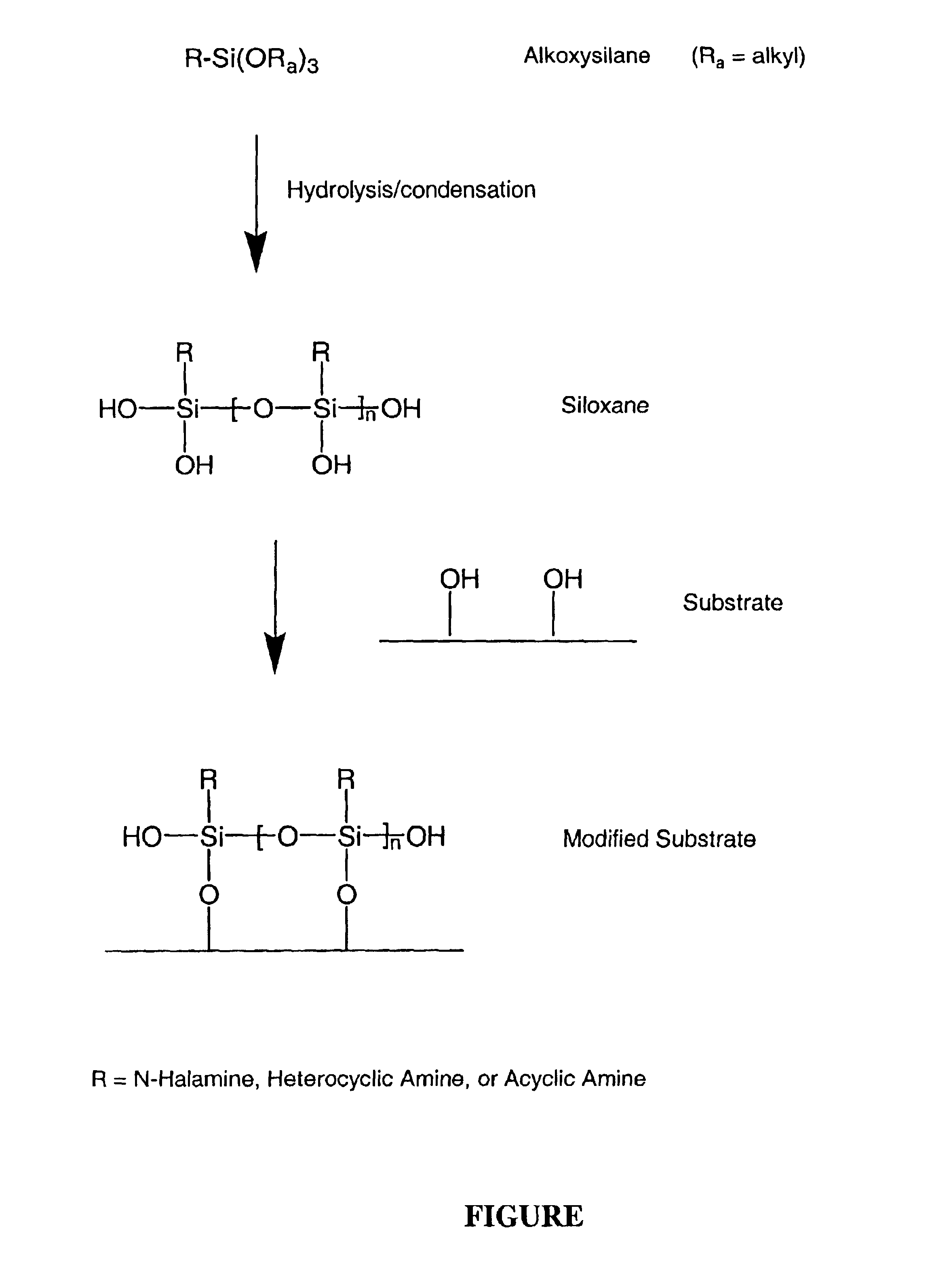

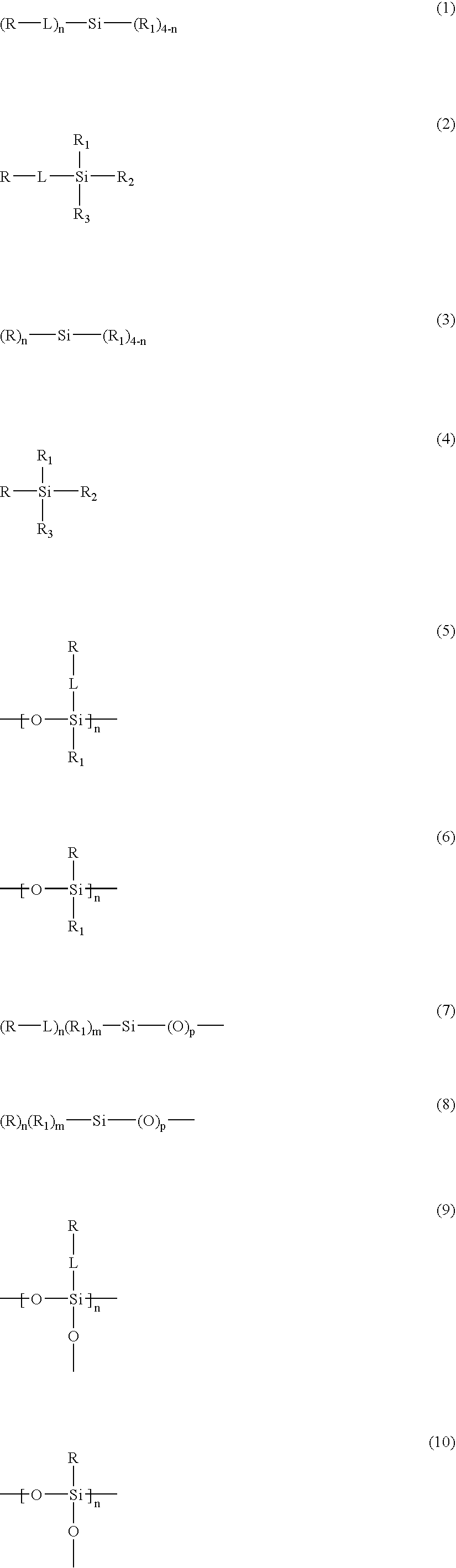

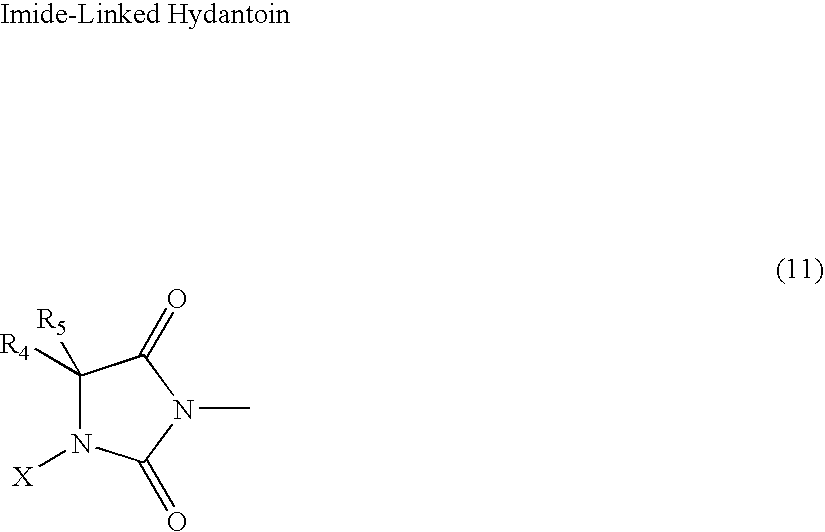

N-halamine siloxanes for use in biocidal coatings and materials

Heterocyclic and acyclic silane monomers and siloxane polymers, and their halogenated derivatives, are provided for the purpose of functionalizing surfaces or materials so as to render them biocidal upon exposure to oxidative halogen solutions. The biocidal function can be imparted either before or after bonding or adhesion to the surface or material. The biocidal surfaces and materials can then be used to inactivate pathogenic microorganisms such as bacteria, fungi, and yeasts, as well as virus particles, which can cause infectious diseases, and those microorganisms which cause noxious odors and unpleasant coloring such as mildew. Examples of surfaces and materials which can be rendered biocidal in this invention include, but are not limited to, cellulose, chitin, chitosan, synthetic fibers, glass, ceramics, plastics, rubber, cement grout, latex caulk, porcelain, acrylic films, vinyl, polyurethanes, silicon tubing, marble, metals, metal oxides, and silica.

Owner:HALOSOURCE INC +1

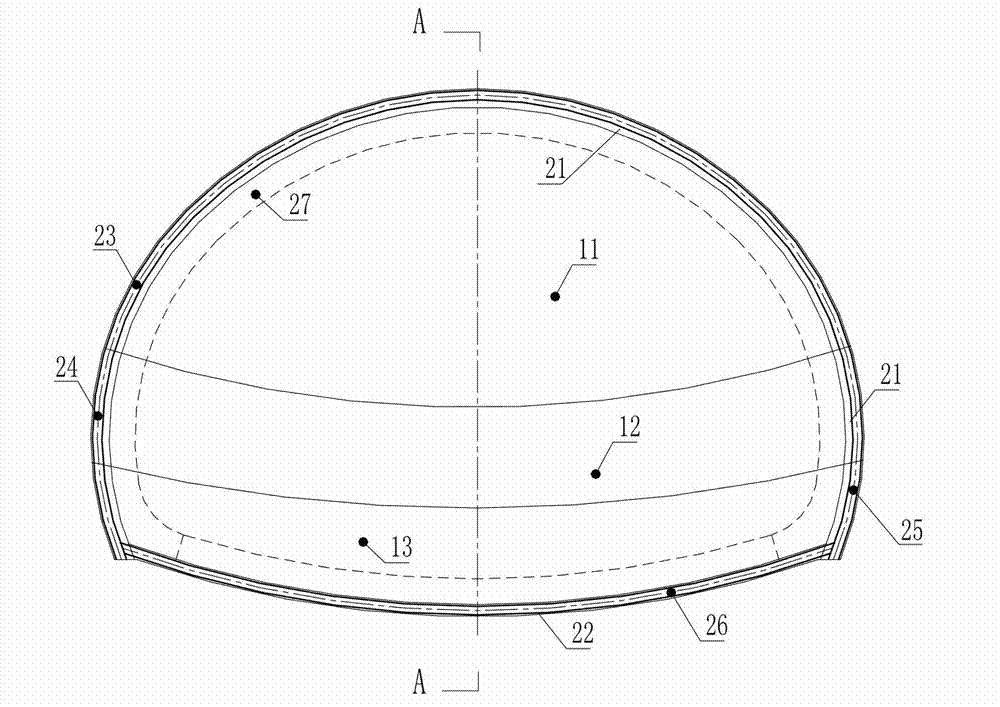

Tunnel arch exchanging construction method and construction structure in tunnel arch exchanging construction

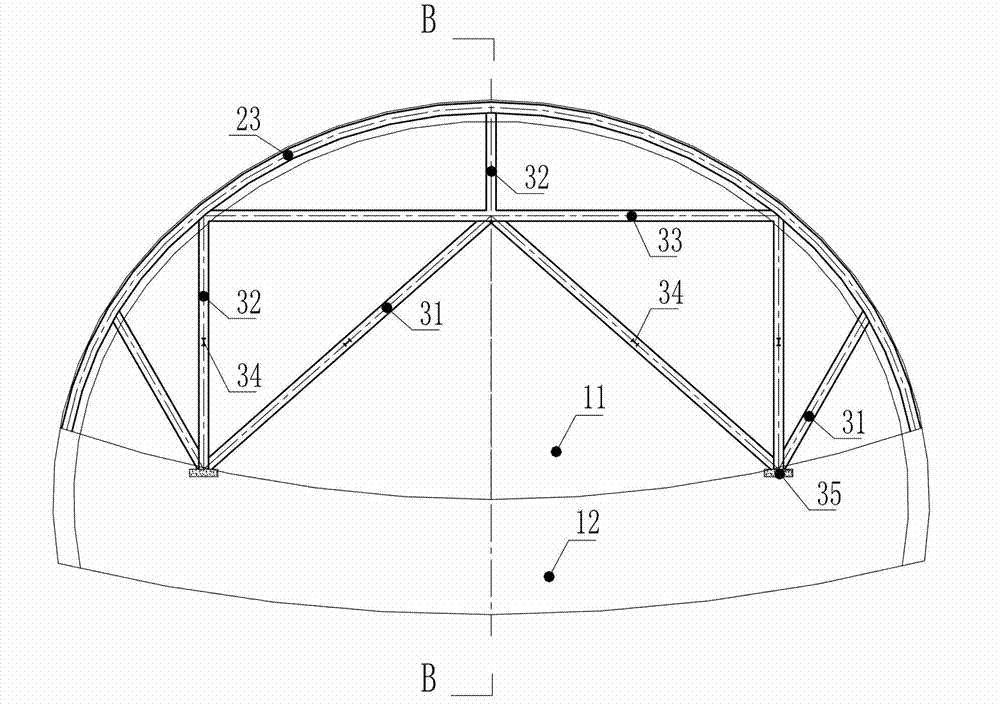

ActiveCN102733827AReduce blockingReduce riskUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel arch exchanging construction method. The tunnel arch exchanging construction method comprises the following steps of: constructing a temporary support under a tunnel transgression limit section, drilling grouting holes on arch part surfaces of tunnel primary supports, stretching steel floral tubes into the grouting holes, and grouting cement grout so as to reinforce a surrounding edge outside a tunnel excavating contour line; and setting lead tube sheds on the tunnel arch part along a circumferential direction, disassembling the primary supports finally and sequentially according to the distance of primary support steel arch frames, remaking one primary support after one primary support is disassembled, and alternately carrying out the operation of disassembling and remaking until all the arch exchanging constructions in the tunnel transgression limit section are finished. A construction structure disclosed by the invention comprises foundation beams, the temporary support and the steel arch frames, wherein foundation frames of the temporary support are arranged on the foundation beams, the top part of the temporary support is used for supporting the steel arch frames, the grouting holes and the lead tube sheds are uniformly distributed above the steel arch frames, the grouting holes are provided with the steel floral tubes, and the lead tube sheds are mainly formed by the steel floral tubes. The tunnel arch exchanging construction method and the construction structure, which are disclosed by the invention, have the advantages that the working procedure is simple and clear, the safety coefficient is high, the recovery degree of the bearing ability is quick, and the like.

Owner:HUNAN PROVINCIAL COMM PLANNING SURVEY & DESIGN INST CO LTD

Composite materials and techniques for neutron and gamma radiation shielding

ActiveUS7250119B2Increase volumeWaste loadingDiffusing elementsNuclear engineering solutionsPolymer modifiedCement grout

Owner:SAYALA DASHARATHAM

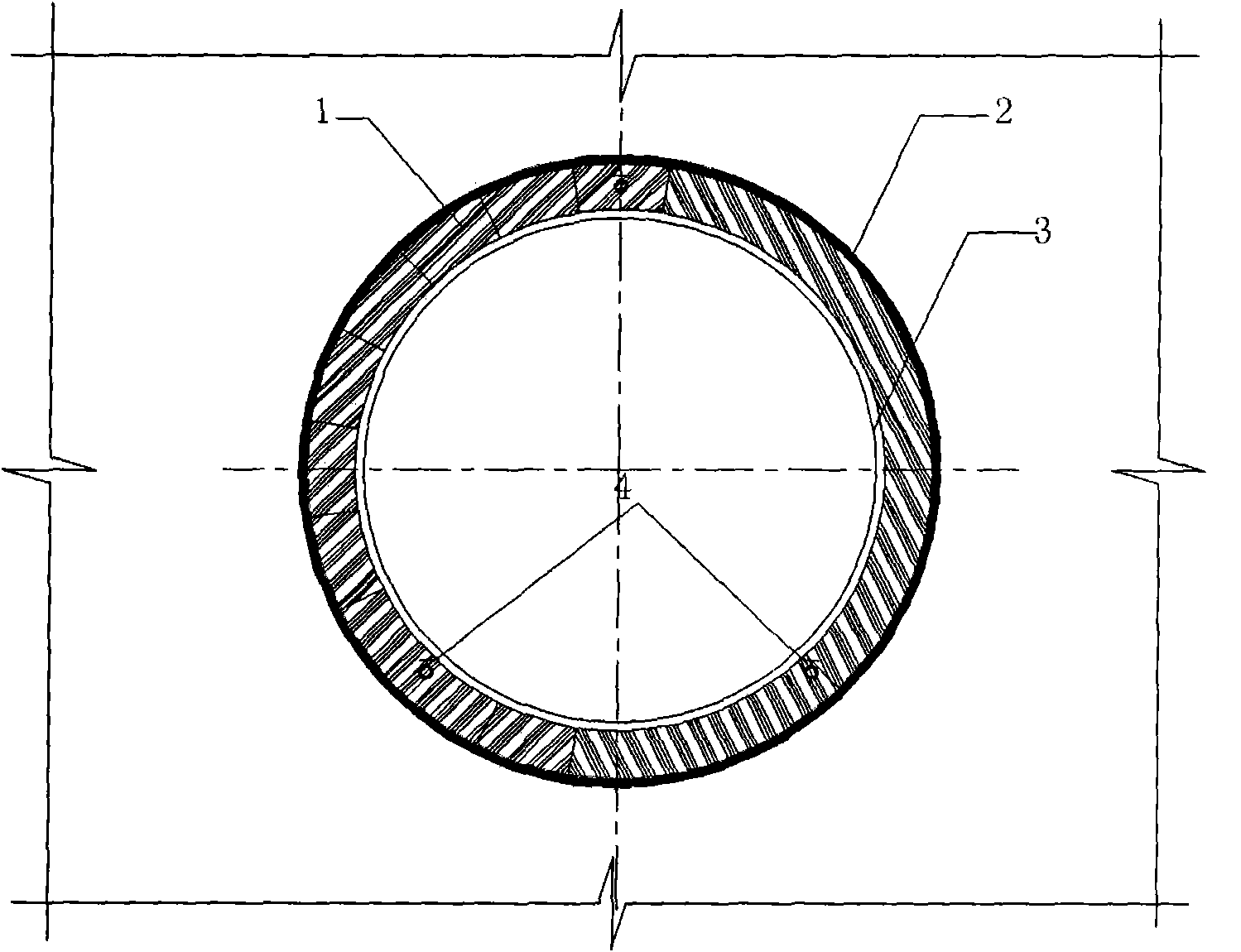

Moisture permeation and water proofing Cement grouting steel bar connecting structure of precast concrete unit

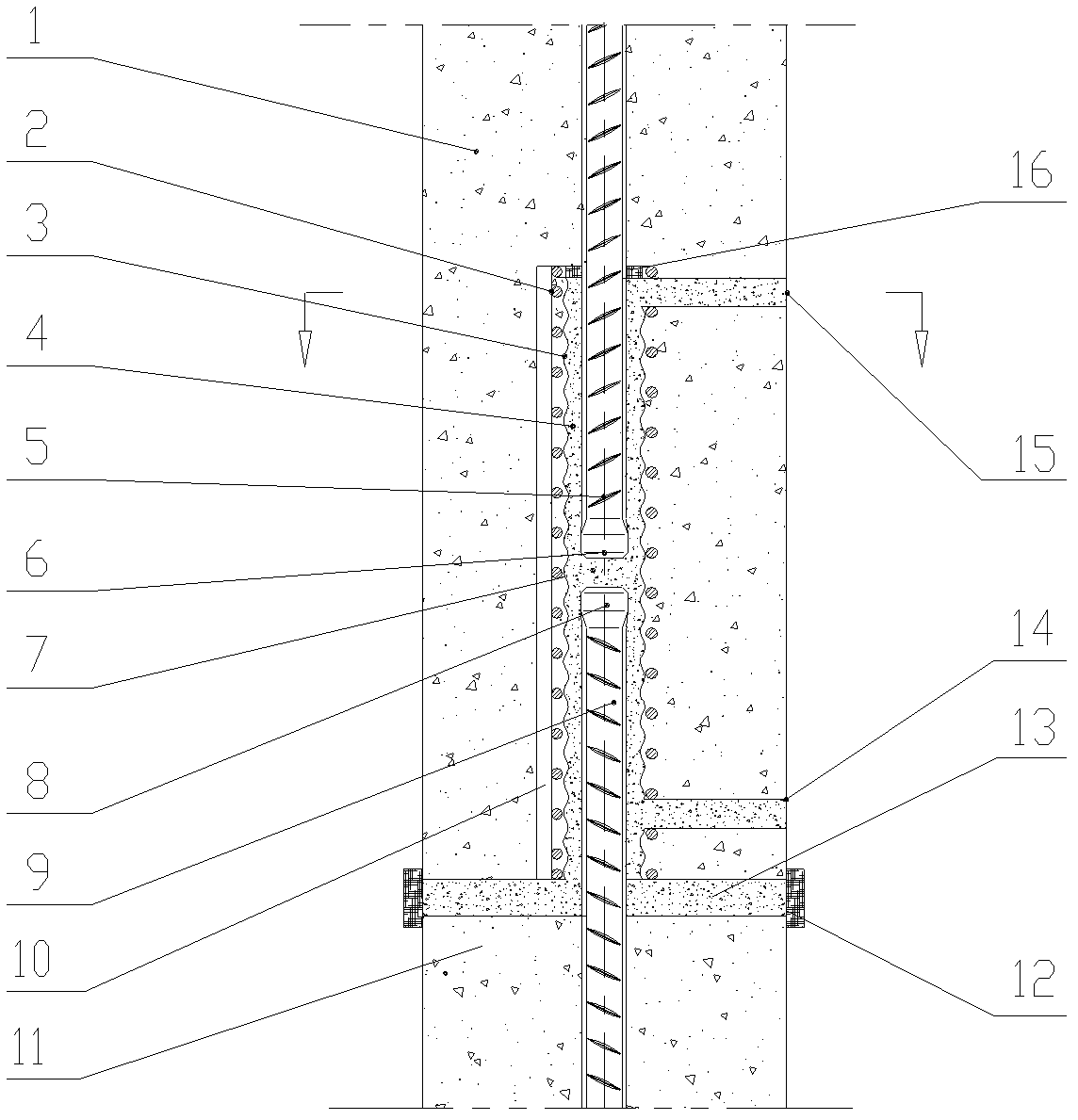

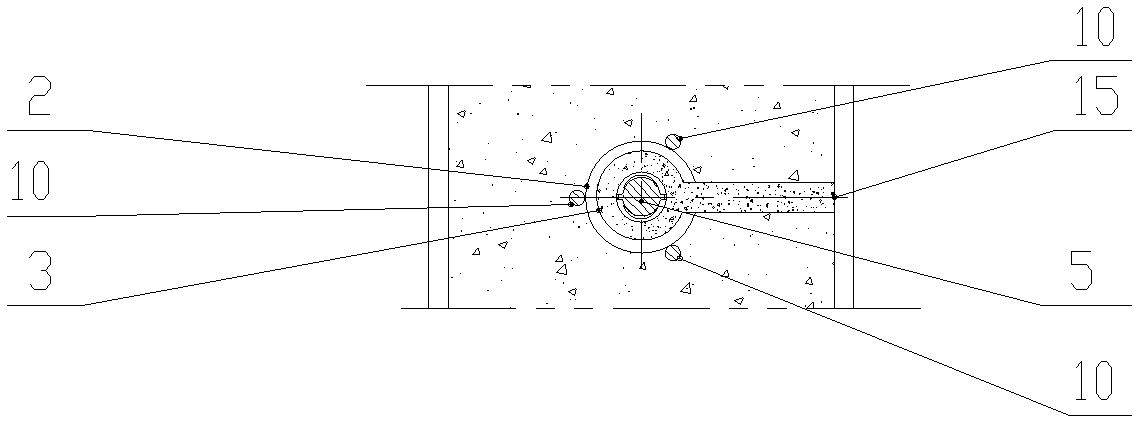

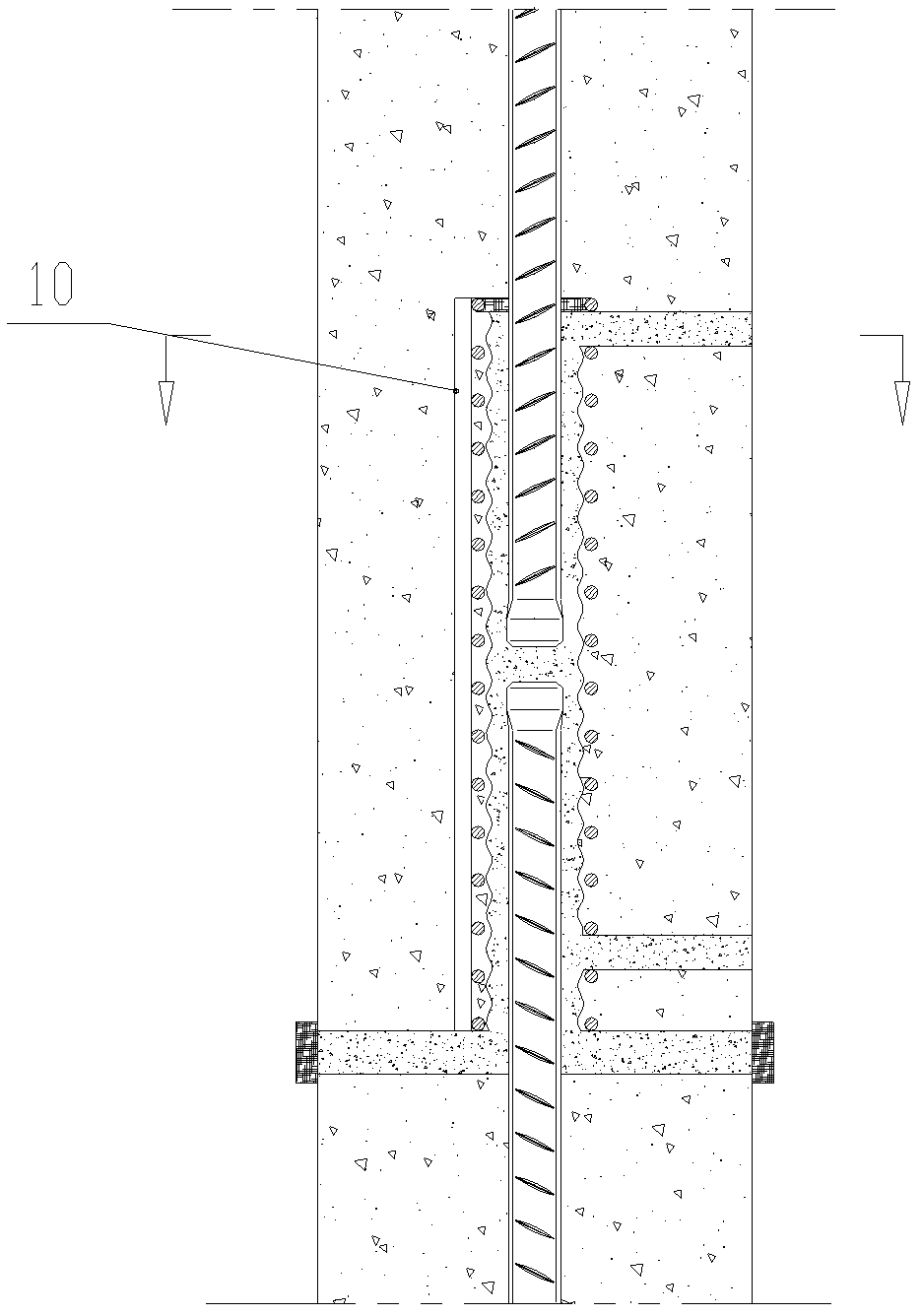

ActiveCN103216044AImprove carrying capacityImprove connection strengthBuilding reinforcementsRough surfaceMoisture permeation

The invention relates to a cement grouting steel bar connecting structure of a precast concrete unit. The cement grouting steel bar connecting structure is characterized in that steel bars connected by adopting cement grouting are butted, wherein a first connecting steel bar is embedded in a first constructional element body, simultaneously the first constructional element body is provided with a grouting connection cavity, the connection end of the first connecting steel bar is arranged in the grouting connection cavity; the inner wall of the grouting connection cavity is provided with a concave-convex rough surface; an annular metal stirrup with a longitudinal connection bar is arranged at the periphery of the grouting connection cavity along the length direction of the steel bar; the connection end of a second connecting steel bar embedded in a second constructional element body is inserted in the grouting connection cavity of the first constructional element body and is opposite to the end of the first connecting steel bar; at least one of the end parts of the first connecting steel bar and the second connecting steel bar is provided with an anchoring head, the diameter of which exceeds the original external diameter; and gaps between the inner wall of the grouting connection cavity and the connecting steel bars are filled with shrinkage-free cement or cement mortar.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

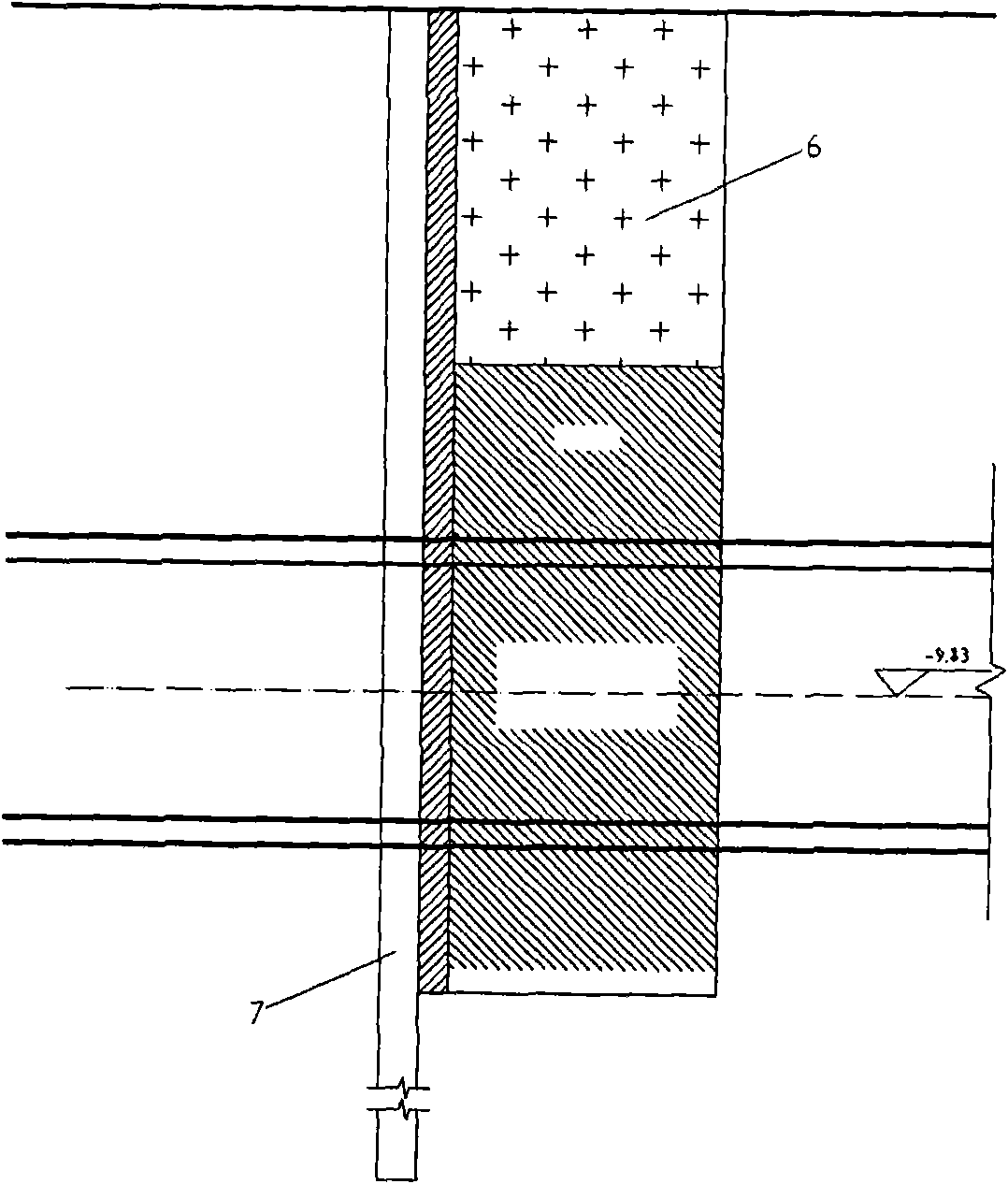

Construction method for shield holing under complicated working conditions

ActiveCN102094650AWell into the holeEnsure safetyUnderground chambersTunnel liningEngineeringCement grout

The invention relates to a construction method for shield holing under complicated working conditions. The method comprises the following steps of: 1, strengthening a shield inlet opening; 2, making a shield pass through a wall; and 3, making the shield hole, namely reducing the tunneling speed when a shield machine enters a strengthening area, wherein the tunneling speed is regulated from the original 4cm / min to the range of between 1.0 and 1.5 cm / min, and the pressure of a soil cabin is reduced to 2kg / cm<2> when the shield machine enters the strengthening area by 0 to 2.0m; the pressure of the soil cabin is reduced to 1.5kg / cm<2> when the shield machine enters the strengthening area by 2.0 to 4.0m; the pressure of the soil cabin is reduced to 1kg / cm<2> when the shield machine enters the strengthening area by 4.0 to 5.0m; and the pressure of the soil cabin is reduced to 0kg / cm<2> when the shield machine enters the strengthening area by 5.0m; and supplementing and injecting cement grout through a reserved injected hole of an air shaft bottom plate in time according to the subsidence monitoring conditions of an air shaft when the shield machine enters the bottom of the air shaft for tunneling so as to ensure the safety of the air shaft. By the construction method, the shield can favorably hole, and the safety of surrounding buildings and underground pipelines can be ensured.

Owner:SHANGHAI FOUND ENG GRP

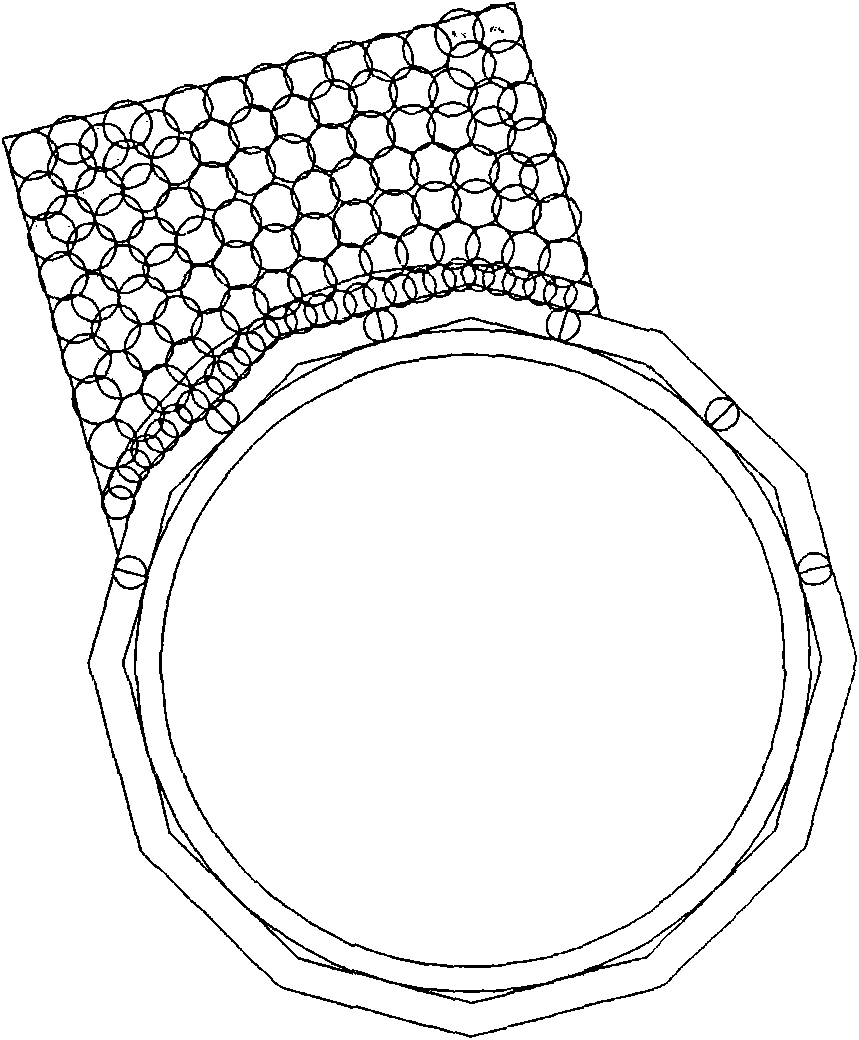

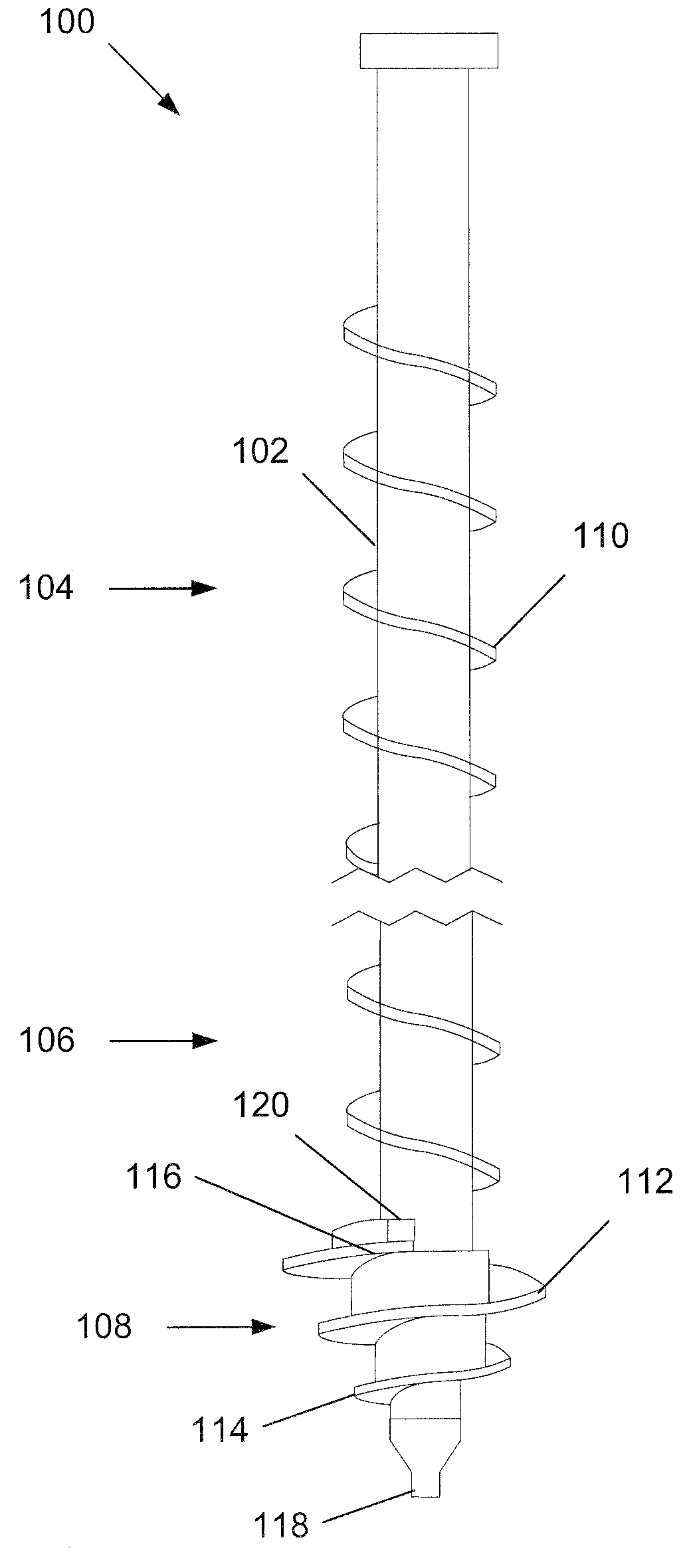

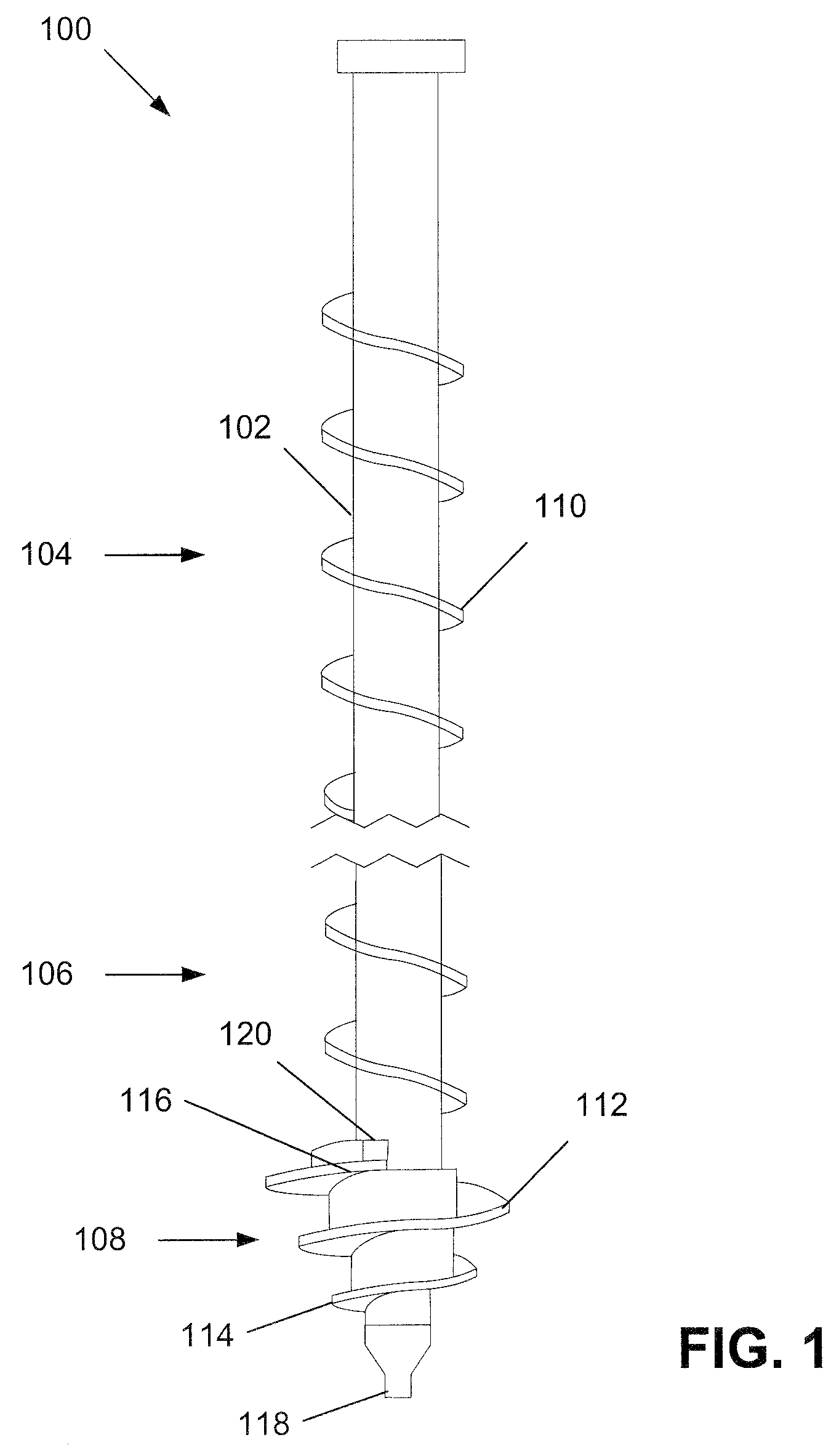

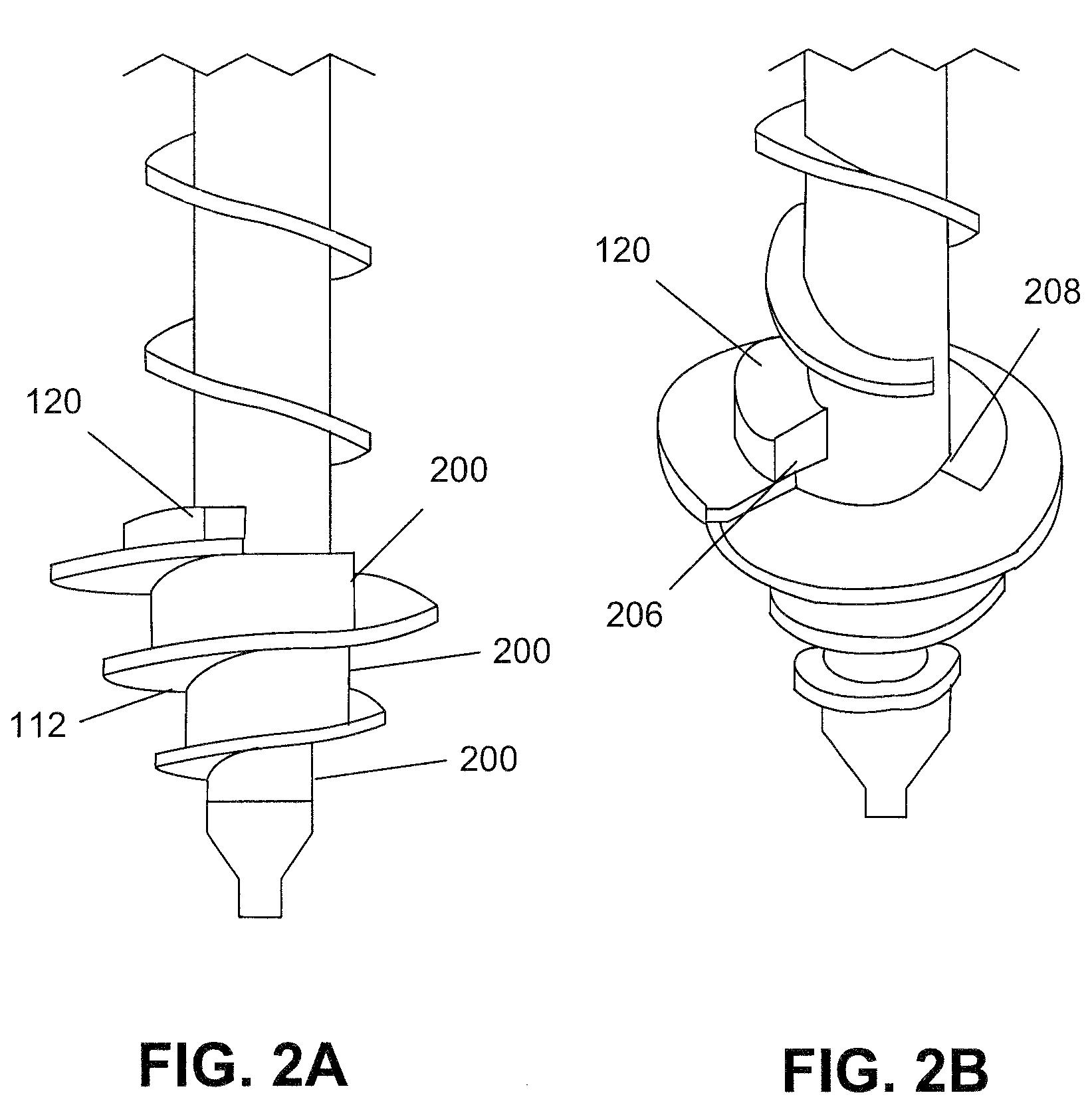

Auger grouted displacement pile

Disclosed in this specification is a method and apparatus for placing a helical pile in the soil with minimal disturbances to the soil. The helical pile has an elongated pipe with a central chamber. The pipe has a helical blade with an opening in the trailing edge of the blade where grout is extruded. The grout fills those portions of the soil which were disturbed by the blade. Advantageously, those portions of the soil which were not disturbed by the blade are not infused with grout.

Owner:STROYER BEN

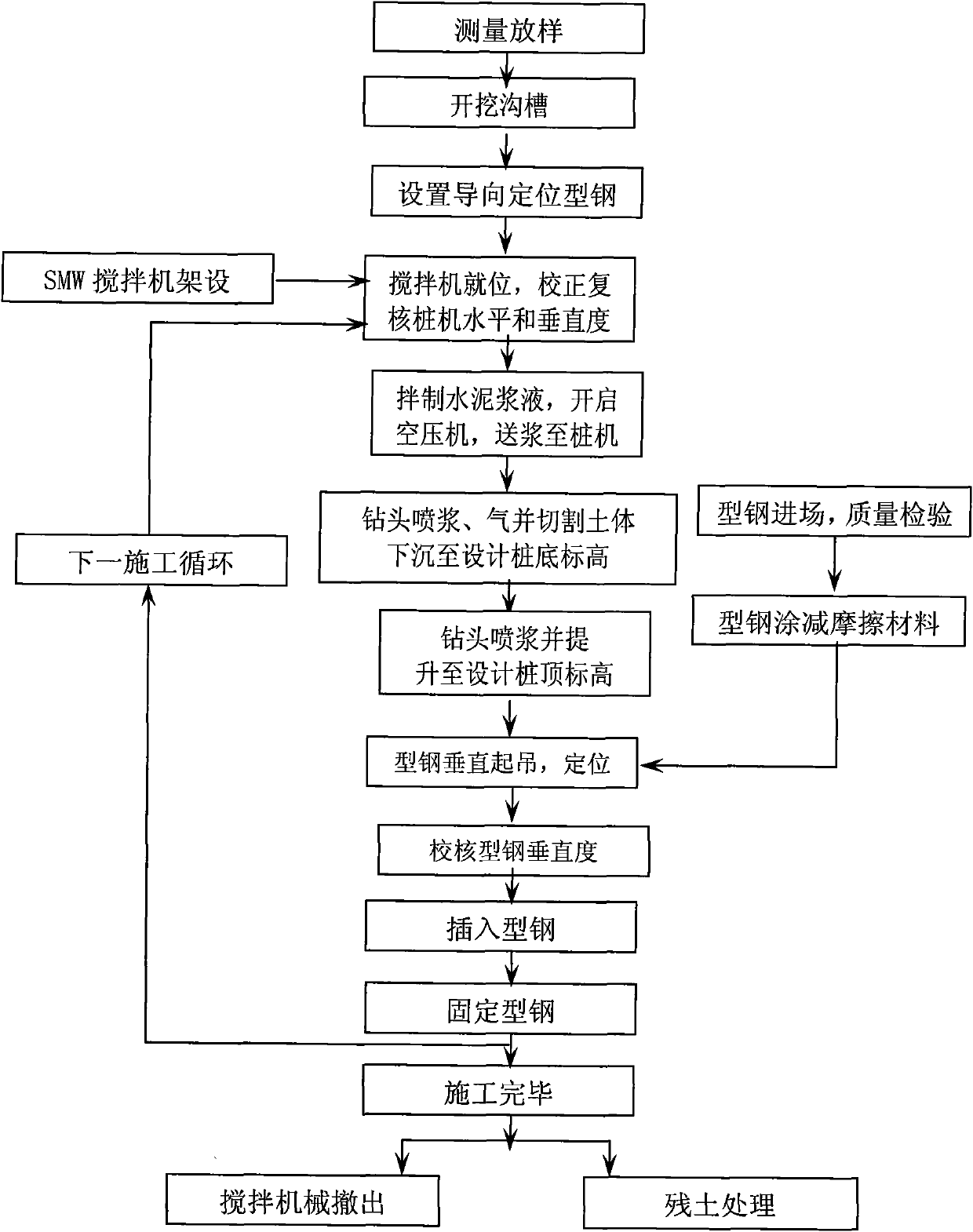

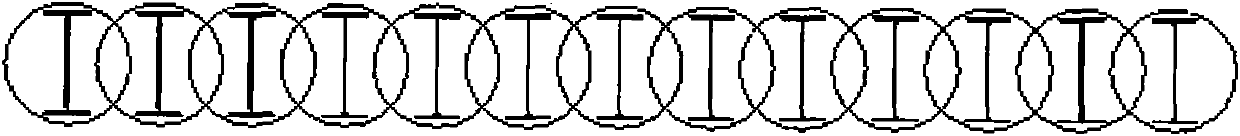

Construction method of section-steel triaxial soil-cement mixing pile

InactiveCN101768961ASolve the difficult problem of pre-stirring and sinkingSolve the problem of too long remixing process timeBulkheads/pilesSlurryEngineering

The invention discloses a construction method of a section-steel triaxial soil-cement mixing pile, comprising the following construction steps: (1) measuring paying-off positioning pile; (2) digging trench; (3) arranging guide positioning section-steel; (4) the mixer taking place, correcting and reviewing levelness and verticality of the pile driver; (5) mixing cement grout, starting an air compressor, and sending the grout to the pile driver; (6) a drill bit spraying grout, gas, cutting soil body and sinking to the elevation of designed pile bottom; (7) the drill bit spraying the grout and elevating to the elevation of designed pile top; (8) vertically lifting the section-steel and positioning the section-steel; (9) correcting and reviewing the verticality of the section-steel; (10) inserting and fixing the section-steel. The pilling process provided by the invention is suitable for cohesive soil with large compression modulus, soft ground layer which is mainly composed of cohesive soil and silty cohesive soil, mucky soil, plain fill and saturation loose sand without flowing underground water; especially for the cohesive soil with large compression modulus, the invention not only can solve the problem that the pre-mixing sinking is difficult, but also can solve the problem that the time of repeatedly-mixing process is too long.

Owner:中铁城建集团第三工程有限公司 +1

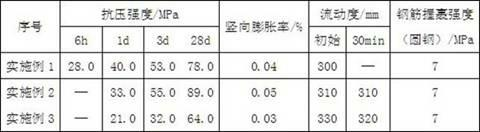

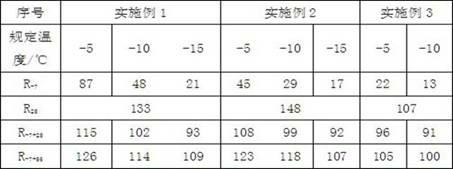

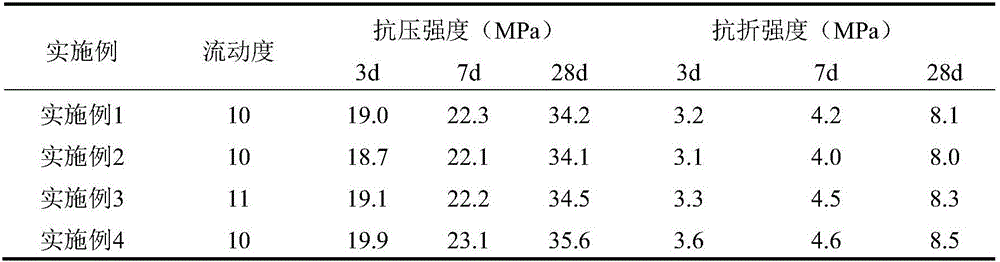

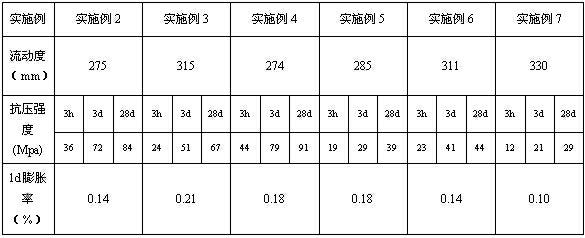

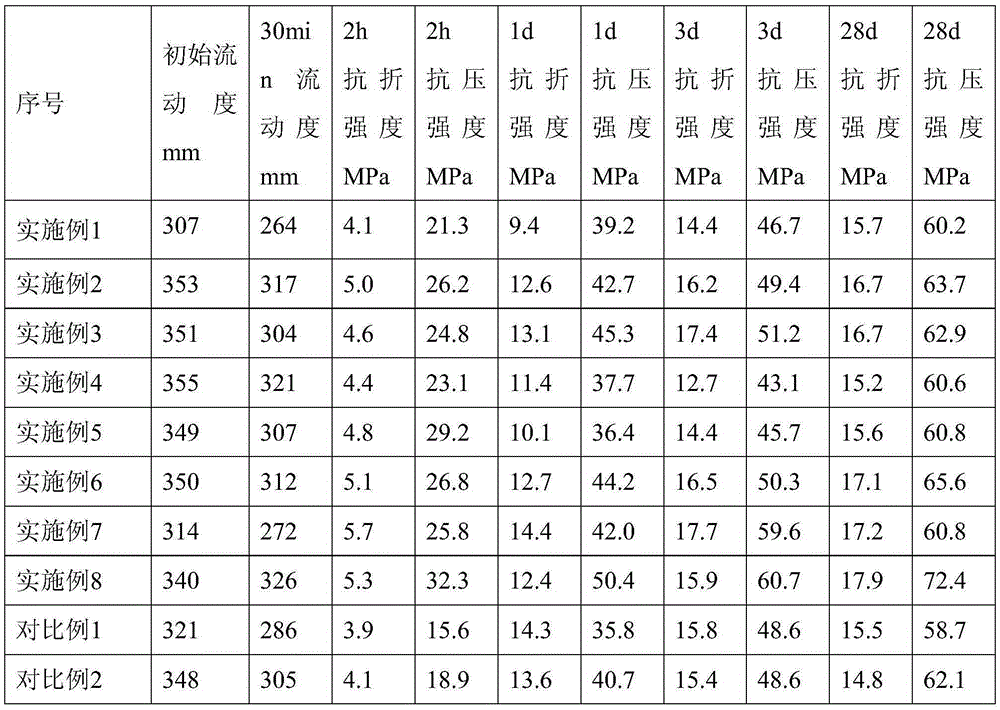

Contraction-free cement grout material

The invention relates to the field of cement grout materials, in particular relating to a property-adjustable functional contraction-free cement grout material. The contraction-free cement grout comprises the following components in percentage by weight: 30.0%-6.0% of gelled material, 0%-5.0% of anhydrite, 4.0%-6.0% of expanding agent, 0.6%-1.5% of water reducing agent, 0%-0.09% of coagulant, 0%-2% of shrinkage agent, 0%-0.06% of thickener and 40.0%-65.0% of aggregate. The grout material has the advantages of good self-flowability, no sedimentation, no bleeding, minimum inflation and no obvious contraction phenomenon; the property of the grout material can be adjusted at random according to the requirement of a building, thus the grout material is wide in adaptability, low in cost, flexible to operate and convenient to use; and the grout material can be suitable for aid repair engineering with a high strength requirement at early period, can be used for a common grout material with a general requirement, and also can be used for a superfluid grout material with large flowability.

Owner:浙江五龙新材股份有限公司

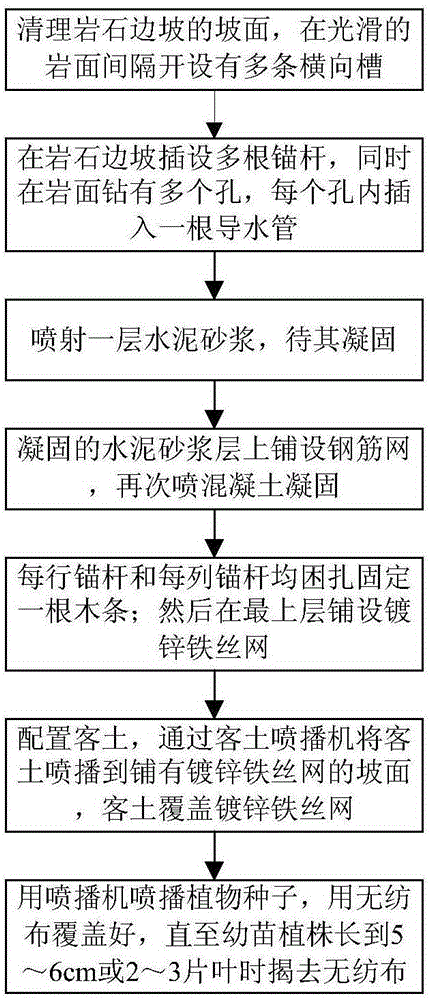

Rock slope ecological protection method

InactiveCN105220698AAchieve coverageAchieve plant coverageClimate change adaptationCoastlines protectionComing outEcological environment

The invention discloses a rock slope ecological protection method and relates to the field of rock slope ecological protection. The method includes that a slope surface of a rock slope is cleaned; multiple anchor rods are inserted into the rock slope, meanwhile, multiple holes are formed in a rock surface through drilling, and one water guide pipe is inserted into each hole; a layer of cement grout is sprayed; a steel mesh reinforcement is laid on the layer of solidified cement grout, and concrete is sprayed again for solidification; a batten is fixedly tied to each row of anchor rod and each column of anchor rod outside the solidified concrete layer; then a galvanized wire mesh is laid on the uppermost layer; borrowed soil is prepared and sprayed to the slope surface where the galvanized wire mesh is laid so as to cover the galvanized wire mesh; plant seeds are sprayed and seeded and then covered by non-woven fabrics, and the non-woven fabrics can be removed when seedlings grow to 5-6cm or 2-3 leaves come out. By means of the rock slope ecological protection method, plants are planted to cover the rock slope, the phenomena of loosening and rock scattering are avoided, potential safety hazards are eliminated, and the ecological environment is advantageously maintained.

Owner:武汉沃田生态科技有限公司

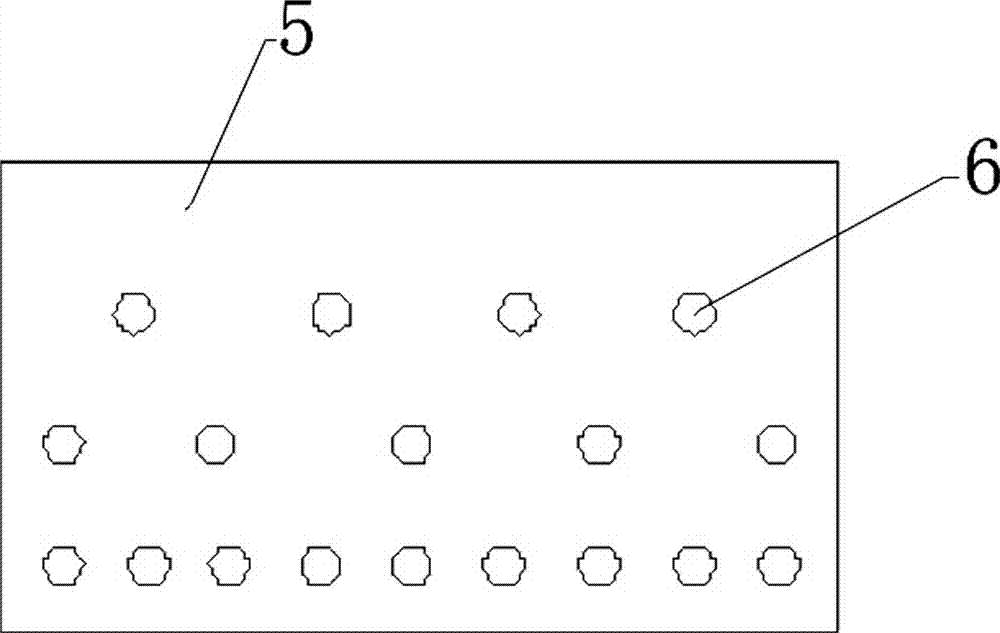

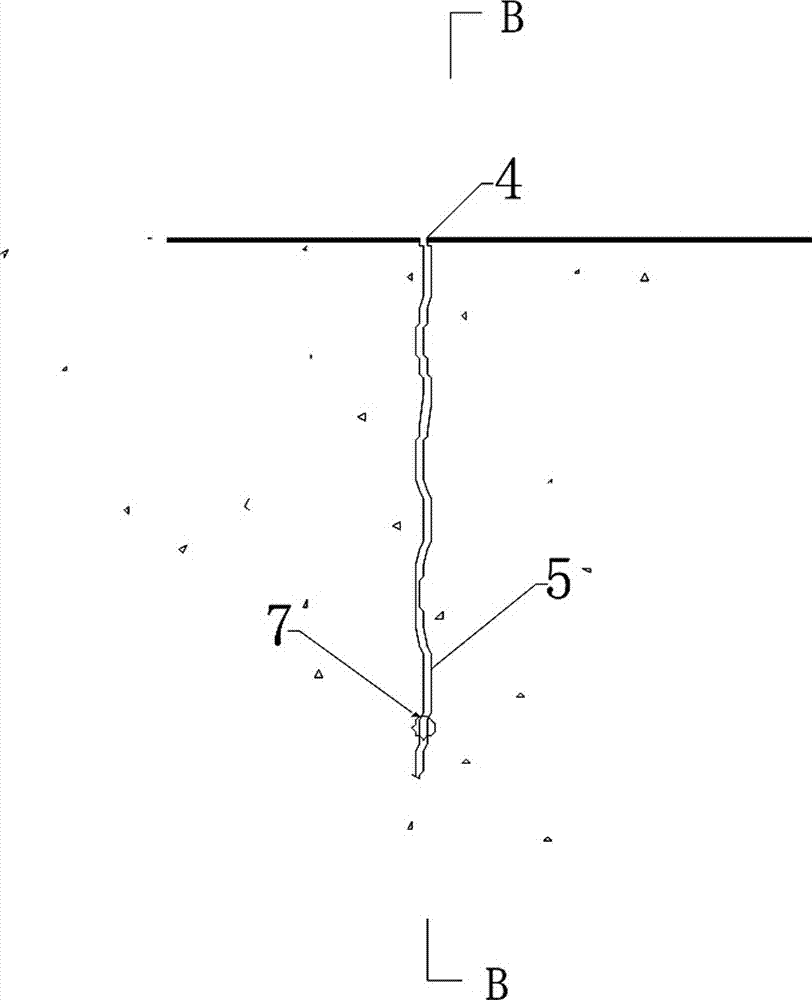

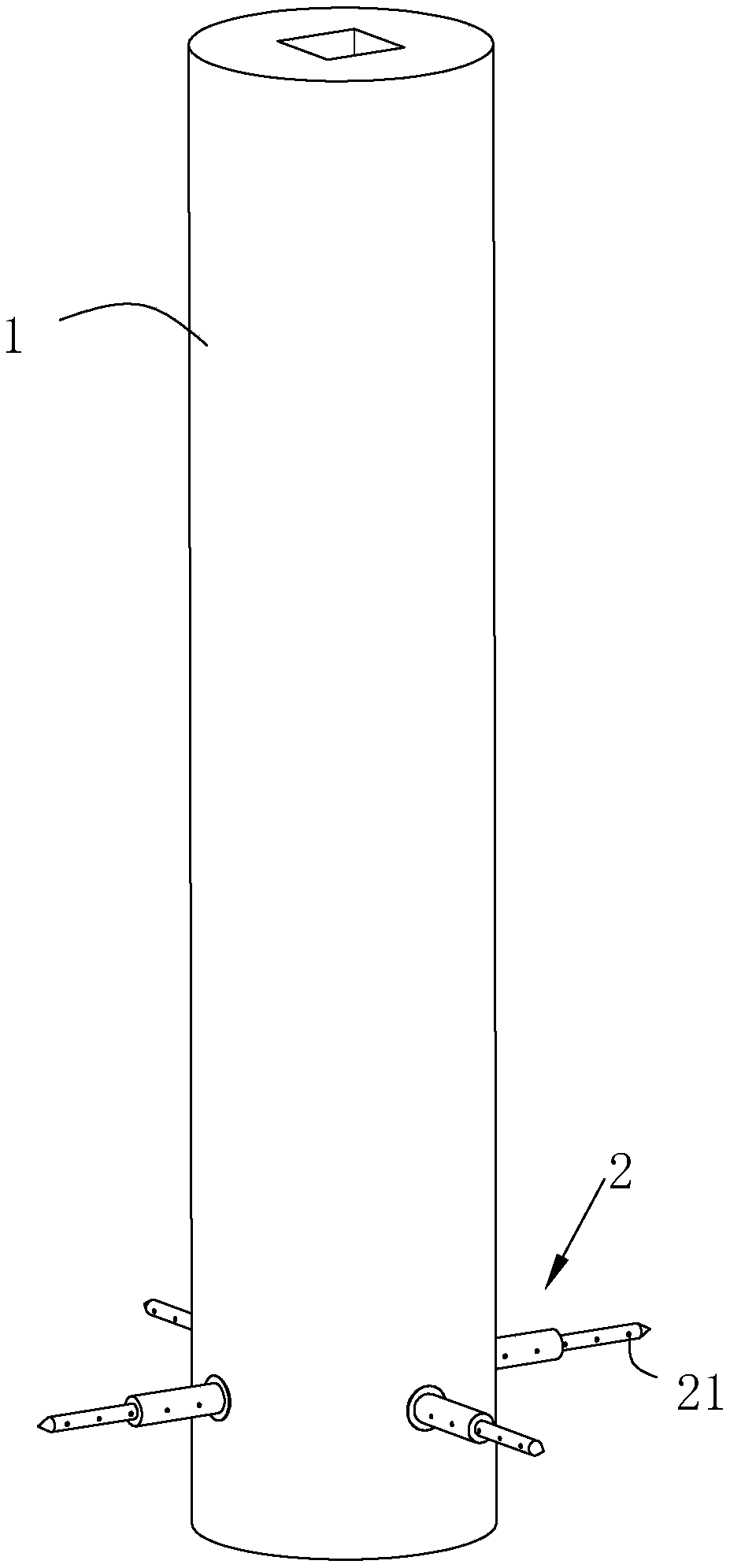

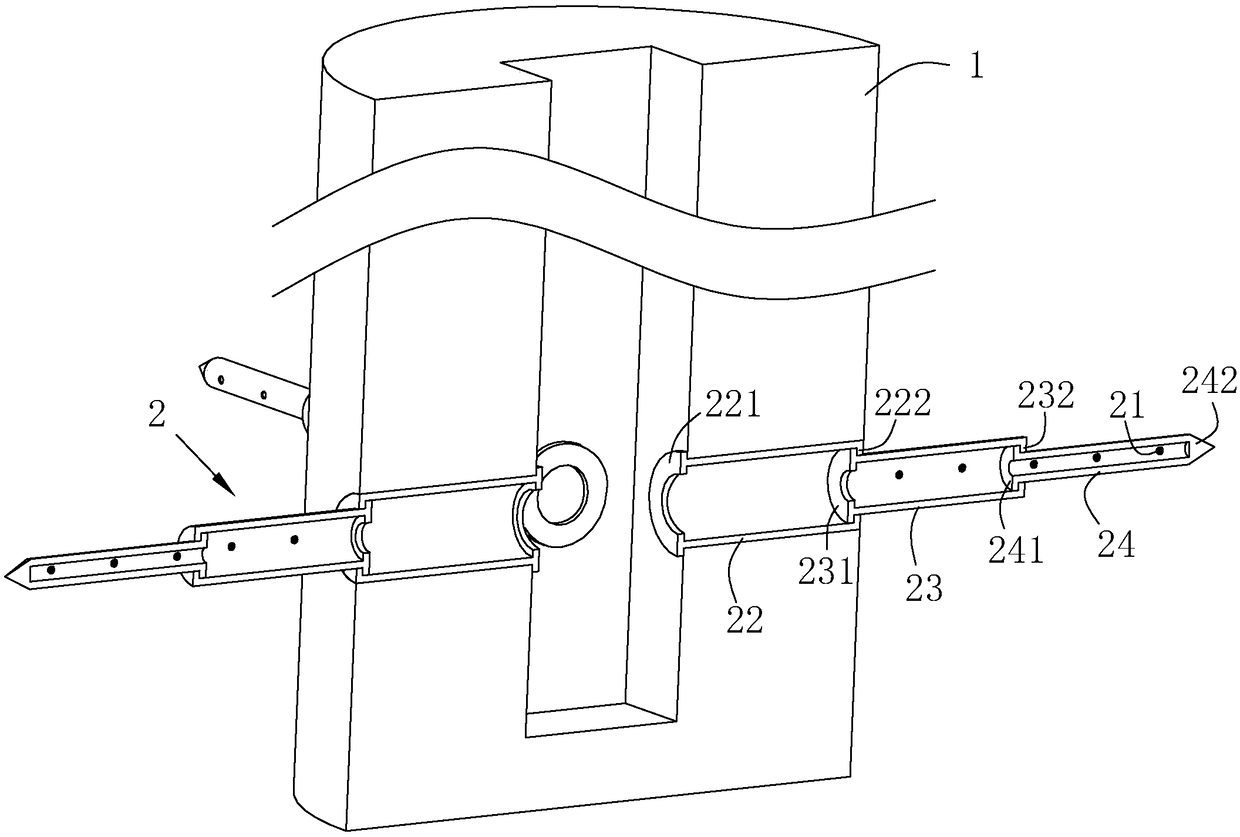

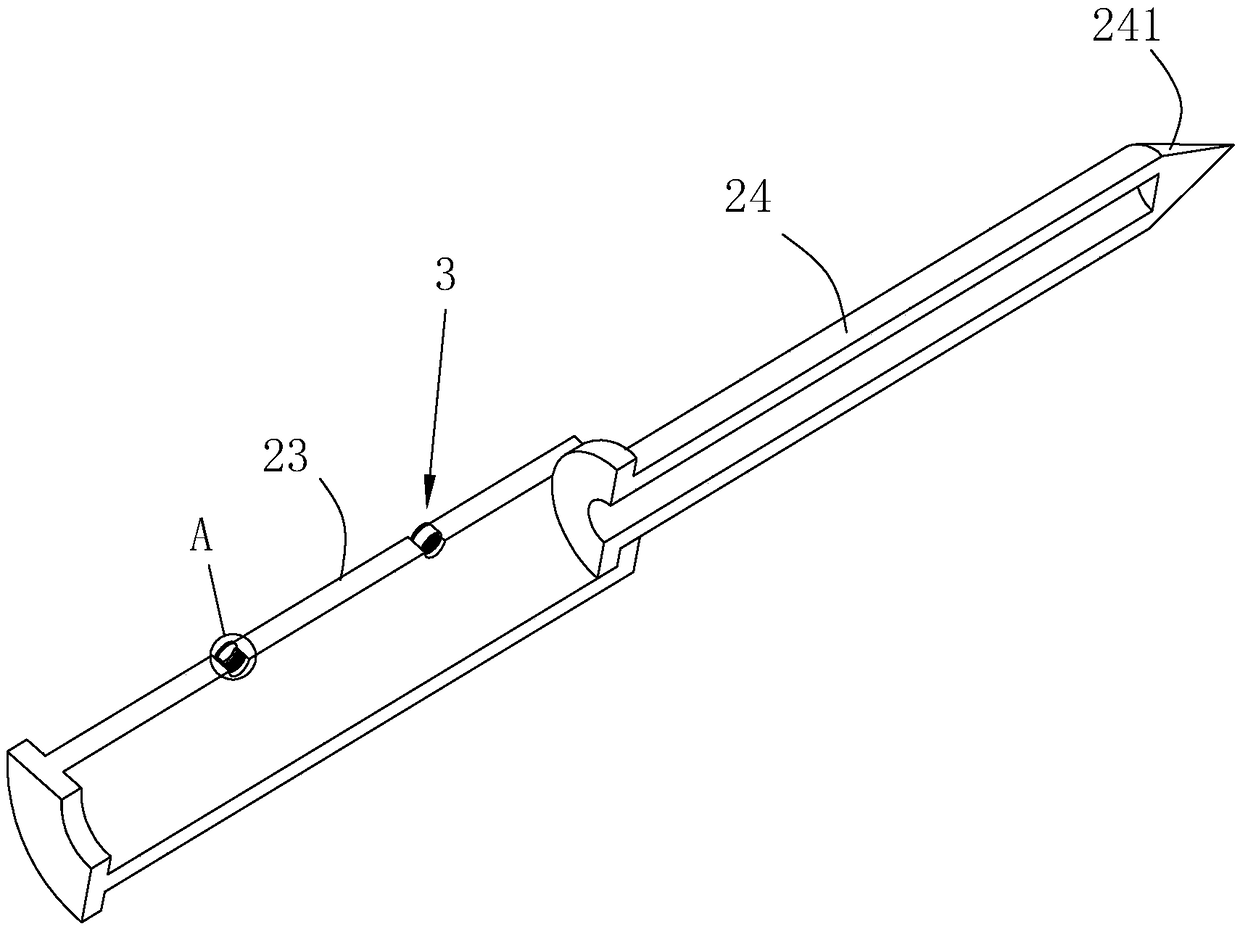

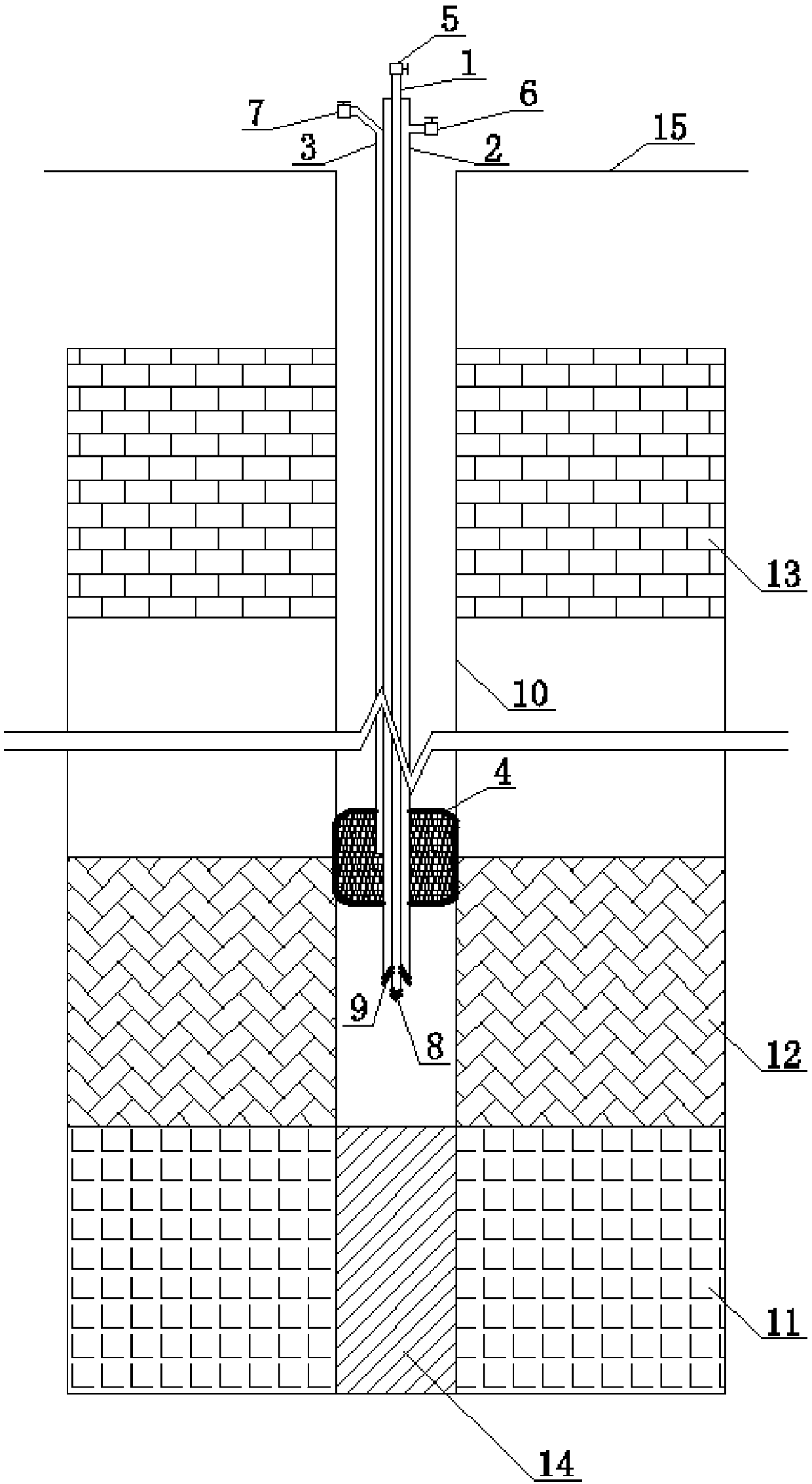

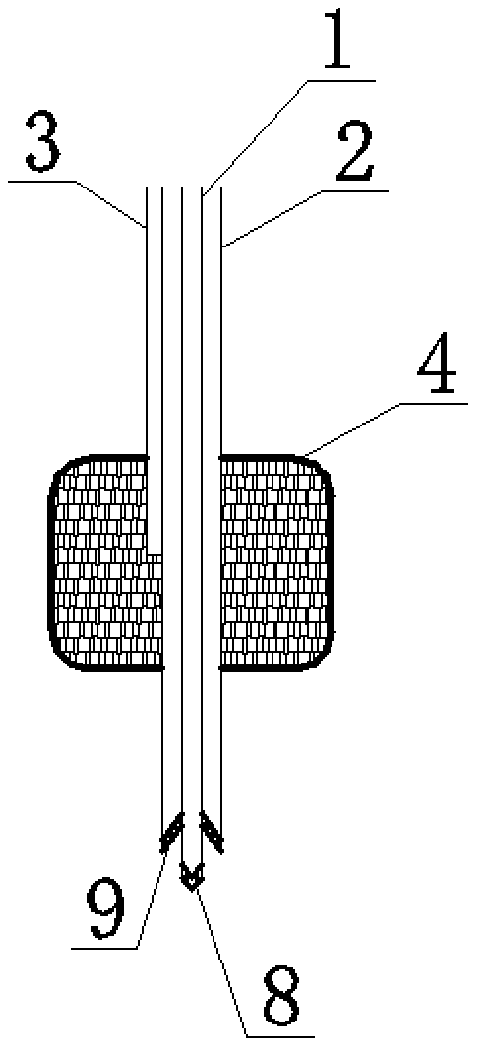

Soft foundation grouting pipe and foundation reinforcement reinforcing method using same

ActiveCN108797561AImprove reinforcementExpand the scope of groutingSoil preservationSlurryCement grout

The invention relates to the field of engineering construction, aims to solve the problem of poor foundation reinforcement effect, and provides a soft foundation grouting pipe. The technical scheme isas follows that the soft foundation grouting pipe comprises a tube body, wherein the tube body is inserted into the end of the foundation to be closed, the side wall of the pipe body is fixedly provided with a telescopic pipe penetrating through the side wall of the pipe body, when the telescopic pipe is completely contracted, the end part extending out of the telescopic pipe is located in the side wall of the pipe body, the end part, extending out of the telescopic pipe, of the telescopic pipe is closed, a plurality of grouting holes are formed in the side wall of the telescopic pipe, and aone-way valve which only allows the cement grout to flow outside the telescopic pipe is arranged on the grouting hole. The invention further provides a foundation reinforcing and reinforcing method, the foundation reinforcing and reinforcing method comprises the steps that a drill hole to be reinforced is drilled and inserted into a grouting pipe, grouting and pumping grout are carried out, a grouting pipe is rotated, grouting is carried out again, pumping grout is carried out, a grouting pipe is taken out, and drilling is carried out. According to the soft foundation grouting pipe, the telescopic pipe extends out through the hydraulic driving of the grout, the telescopic pipe extends out, and the cement grout is injected into the foundation soil from the grouting holes, so that the grouting range is large, the distribution is uniform, and the foundation reinforcing effect is good.

Owner:广东诚创建设有限公司

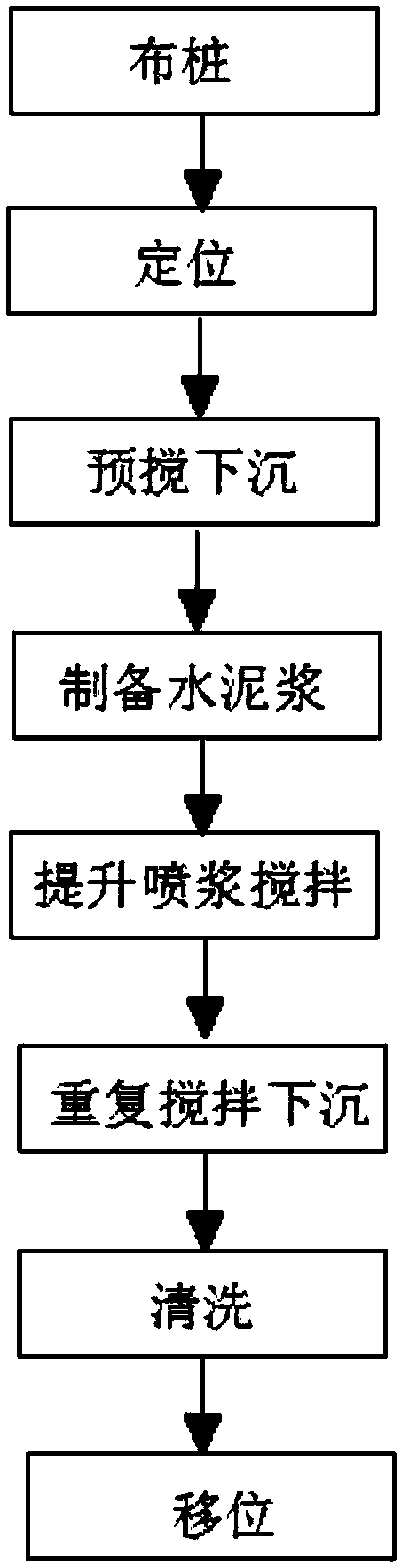

Method for reinforcing soft soil foundation by using cement-soil mixing pile

The invention relates to a method for reinforcing a soft soil foundation by using cement-soil mixing piles. The method comprises the steps of 1) arranging pile positions on the soft soil foundation; 2) lifting a mixing machine to one pile position on the soft soil foundation by using a tower crane; 3) starting up the mixing machine, wherein a mixing head cuts soil while rotating and then sinks to design depth; 4) preparing cement grout; 5) lifting the mixing head, spraying the grout and performing mixing to enable the cement grout to be fully mixed with the soil till the mixing head is lifted up to the ground; 6) repeating the step 3 to the step 5, wherein each pile requires for re-mixing and re-spraying; 7) filling clean water into an aggregate bin, starting up a grout pump to clean residual grout in all pipelines and cleaning the mixing head; and 8) moving the mixing machine to the next pile position and repeating the step 2 to the step 7 to carry out the construction of the next pile. Compared with the prior art, the method for reinforcing the soft soil foundation by using the cement-soil mixing piles has the advantages that the water-cement ratio is proper, the goal of uniform mixing is easy to realize, the pile forming quality is high, the strength is high, the construction is convenient to carry out, the construction cost is low and the economic benefits are remarkable.

Owner:STATE GRID CORP OF CHINA +2

Tunnel advanced support air circulated drilling construction method and drilling tool

InactiveCN101260784AAvoid disturbanceEnsure construction safetyEarth drilling toolsUnderground chambersPosition angleAir compressor

The invention provides a tunnel forepoling air circulating drilling construction method. The construction steps are as follows: a driller is firstly installed and is moved to the appointed hole position along a track, according to the tunnel position line, the position angle of the driller is adjusted to ensure that the driller is parallel with the tunnel position line, the driller is fastened with a frame; an air compressor is turned on, the wind pressure is controlled above 0.4MPa, and then the driller is turned on to ensure that a drill pipe drills towards the earth at a constant speed, the compressed air is sent to an aiguille part through an internal cavity of the drill pipe and air-cools the aiguille, drilling cuttings are blown out of the drill hole from the gap between the drill pipe and the earth; the inner part of the aiguille is provided with a guide drilling device; finally, the hole drilling is finished and the grout is cast, the grout is cast into the inner cavity of the drill pipe by a casting pipe, the grout is filled into the inner cavity of the drill pipe and the ring-shaped gap out of the drill pipe, and the next hole position is turned to construct. The tunnel forepoling air circulating drilling construction method solves the problems of low security and slow drilling of the earth layer, especially the fourth new loess area pipe roofing timbering construction, can avoid the landslide and minimize the potential safety hazard.

Owner:BEIJING SHOUER ENG TECH

Concrete slurry containing magnesium and its preparation process and application thereof

InactiveCN1792986AHigh activityReduce the burden onSolid waste managementFilling materialsPhosphogypsum

Owner:何金星 +1

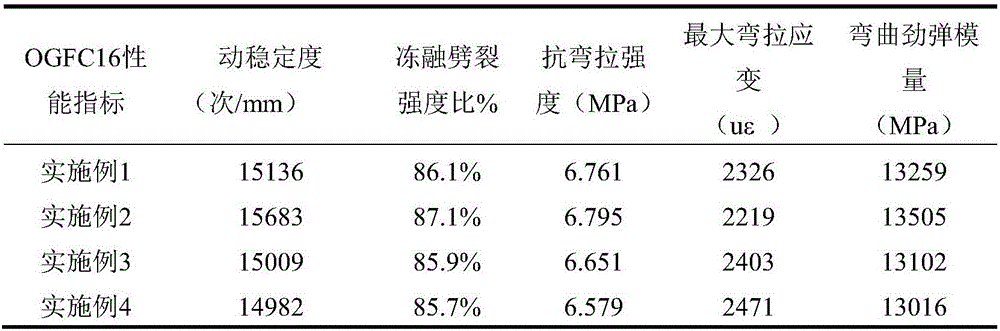

Semi-flexible pavement material, preparation method therefor and semi-flexible pavement

InactiveCN106587842AImprove crack resistanceImprove adhesionIn situ pavingsPolymer scienceCrack resistance

The invention discloses a semi-flexible pavement material, a preparation method therefor and a semi-flexible pavement. The semi-flexible pavement material is prepared from the raw materials, i.e., a cement grouting material and an asphalt mixture in parts by mass, wherein the cement grouting material contains 15-20 parts of cement, 8-10 parts of emulsified asphalt, 0.03-0.06 part of water reducing agent, 0.06-0.2 part of polypropylene fibers, 10-15 parts of mineral powder, 30-35 parts of sand, 8-10 parts of fly ash, 0.06-0.12 part of expanding agent and 0.03-0.06 part of interface modifier. According to the semi-flexible pavement material disclosed by the invention, the cement grouting material is added with the emulsified asphalt, the fly ash, the polypropylene fibers, the mineral powder, the water reducing agent, the expanding agent and the interface modifier which are mutually compounded and are in synergism, so that the cement grouting material can be easily subjected to dry shrinkage, the condition that the interfacial adhesion performance of cement-asphalt concrete is poor is improved, and thus, the crack resistance is improved. In addition, asphalt of the asphalt mixture is rubber asphalt, so that the crack resistance and adhesion property of the asphalt mixture are improved.

Owner:江苏北极星交通产业集团有限公司

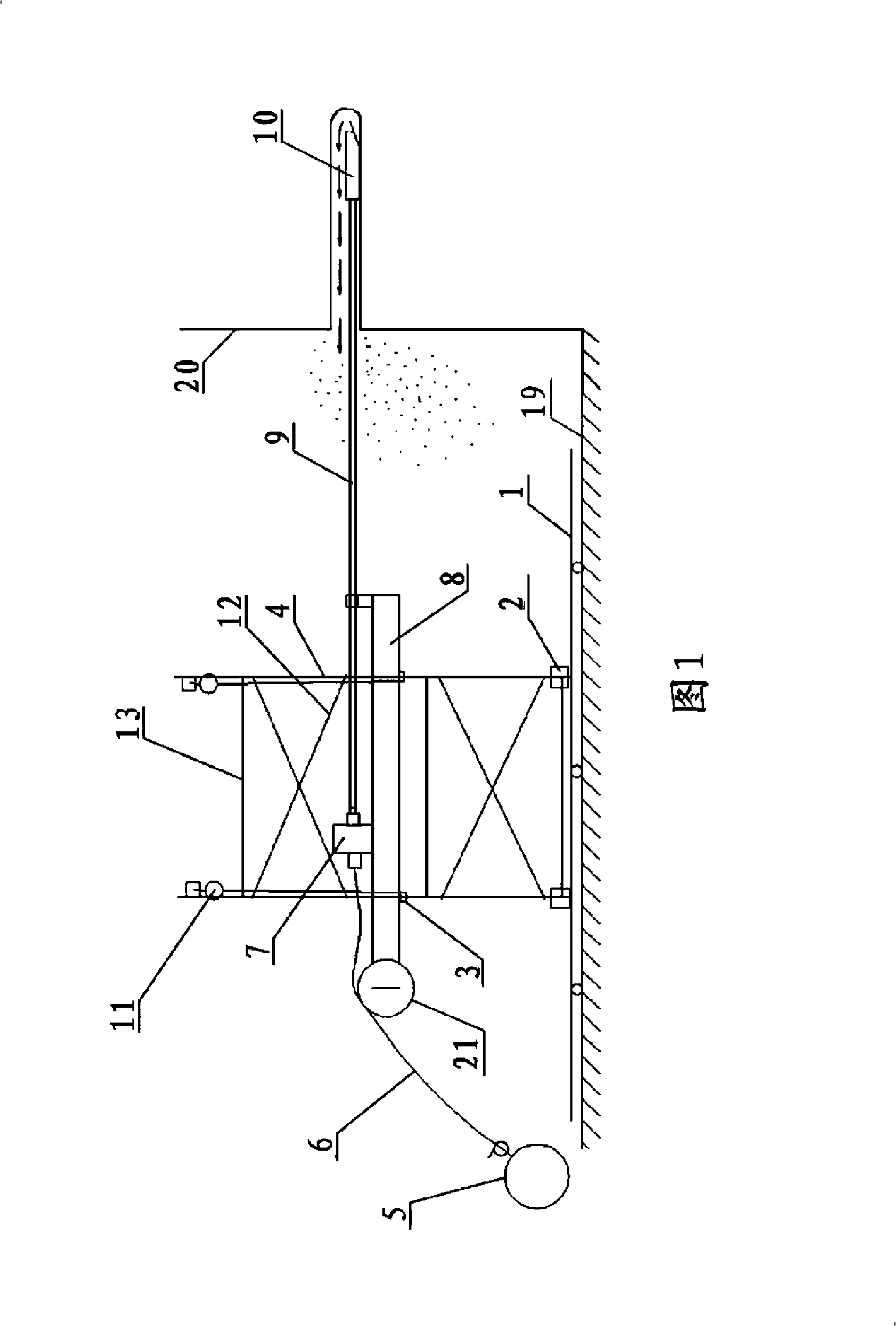

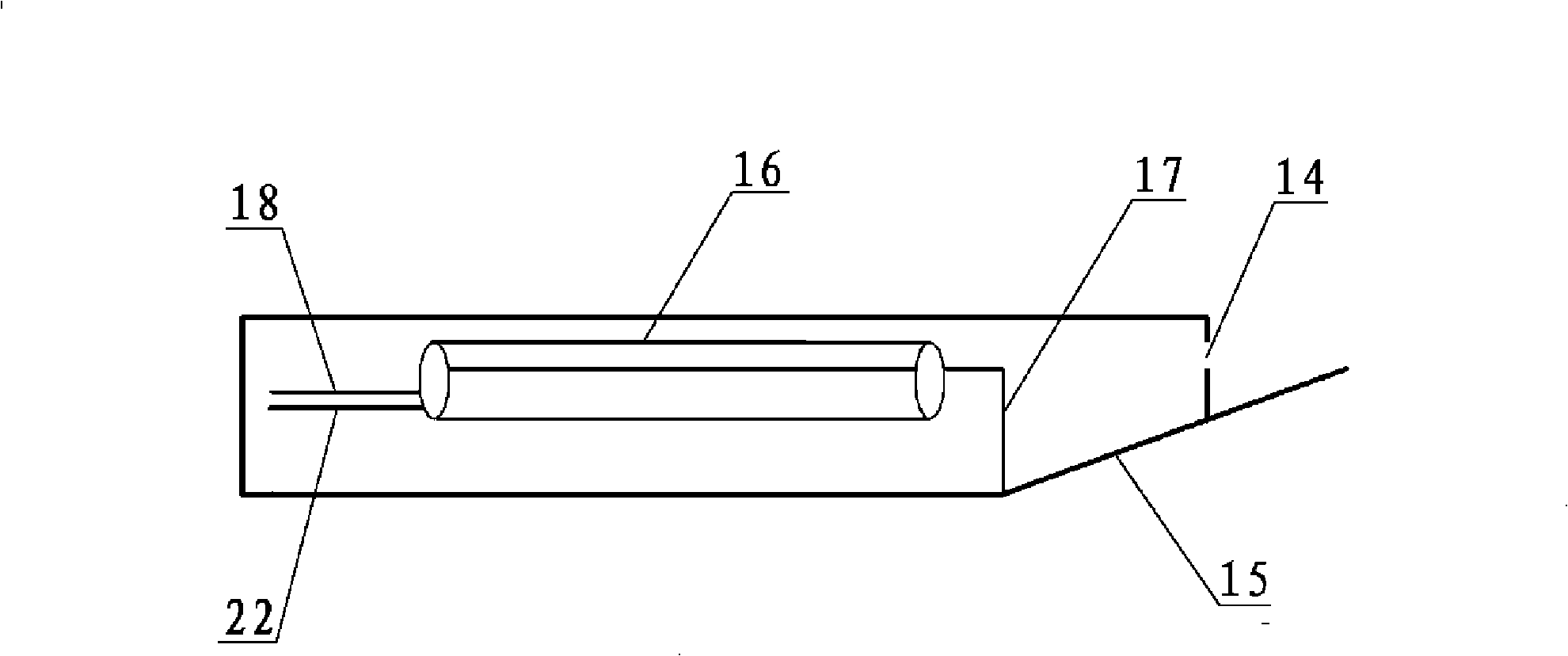

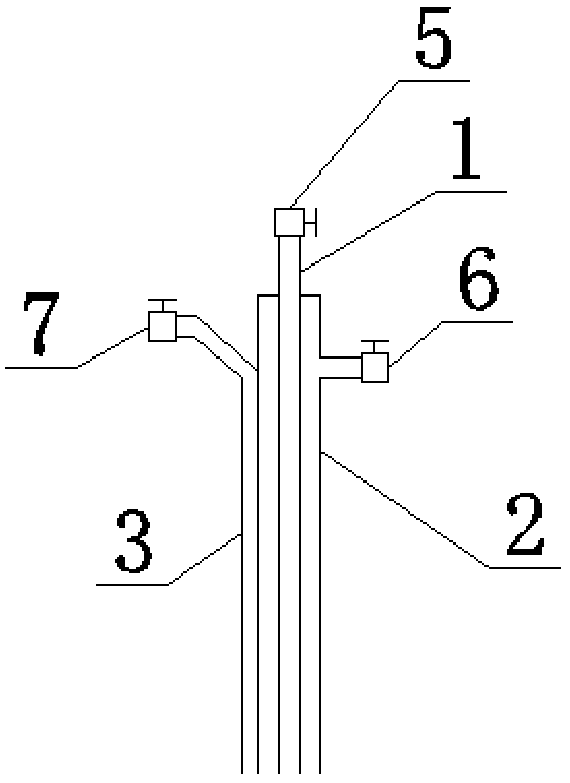

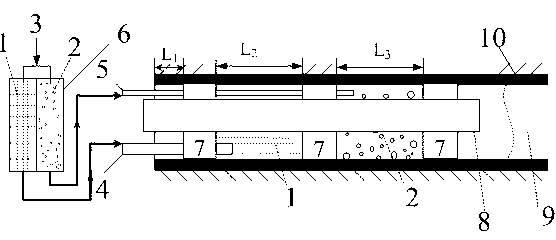

Retrograde sectional grouting device with a single grouting-stop plug and method applicable to fractured rock masses

The invention discloses a retrograde sectional grouting device with a single grouting-stop plug and a method applicable to fractured rock masses. The retrograde sectional grouting device comprises aninner pipe, an output pipe, a water injecting pipe, the expansion-type grouting-stop plug, an inner pipe valve, an outer pipe valve, a water injecting valve, an inner pipe one-way valve and an outer pipe one-way valve, wherein the expansion-type grouting-stop plug is penetrated by the outer pipe and fixed on the outer pipe, the water injecting pipe is communicated with the interior of the expansion-type grouting-stop plug, water can be injected into the expansion-type grouting-stop plug through the water injecting water to enable the expansion-type grouting-stop plug to expand, the outer pipeis used for delivering cement grout, the outer pipe valve is arranged at the grout inlet position of the outer pipe, the outer pipe one-way valve is arranged at the grout outlet position thereof to prevent grout from flowing back, the inner pipe is arranged in the outer pipe and used for delivering water slurry, the inner pipe valve is arranged at the slurry inlet position of the inner pipe, and the inner pipe one-way valve is arranged at the slurry outlet position of the inner pipe to prevent the slurry from flowing back.

Owner:SHANDONG UNIV

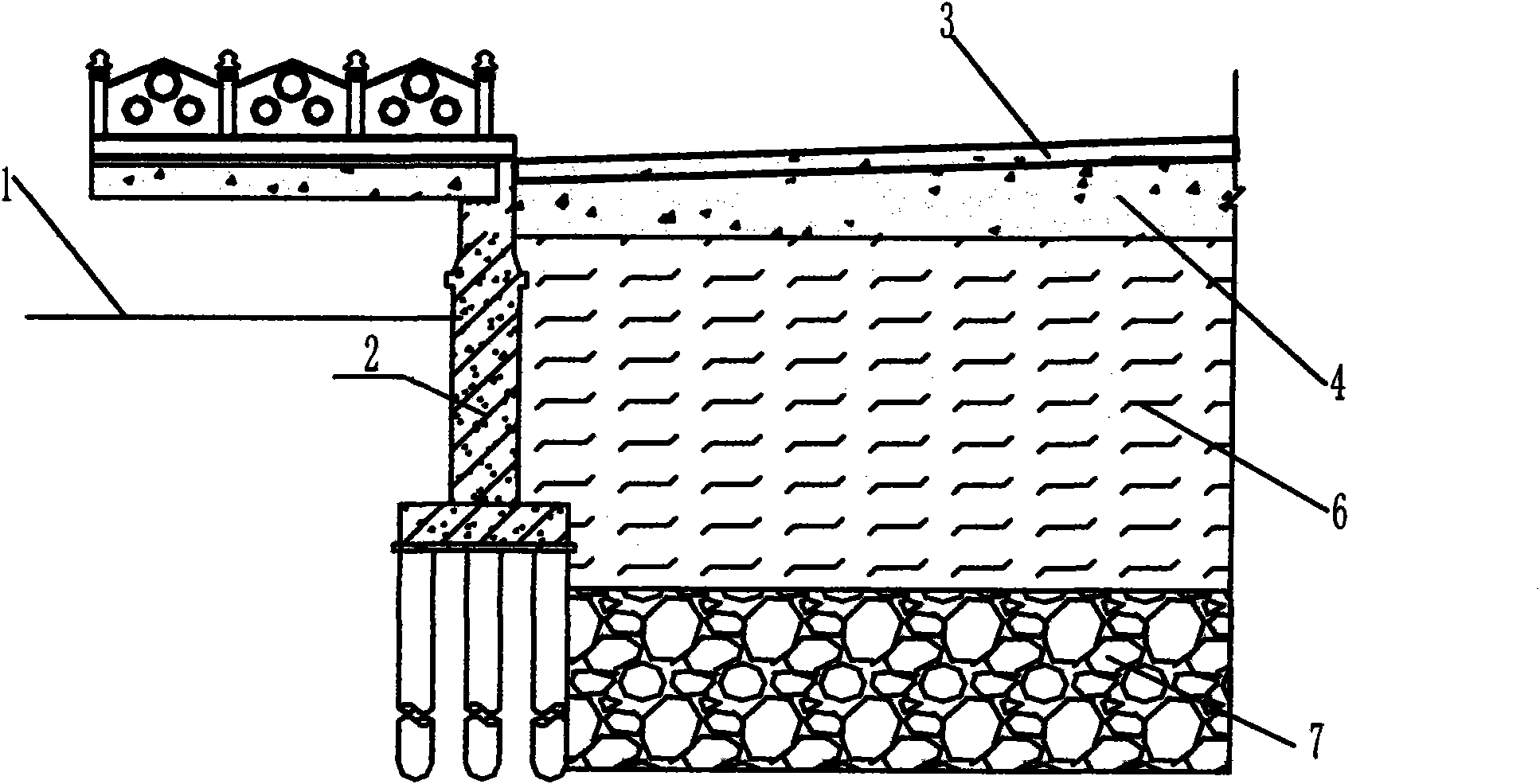

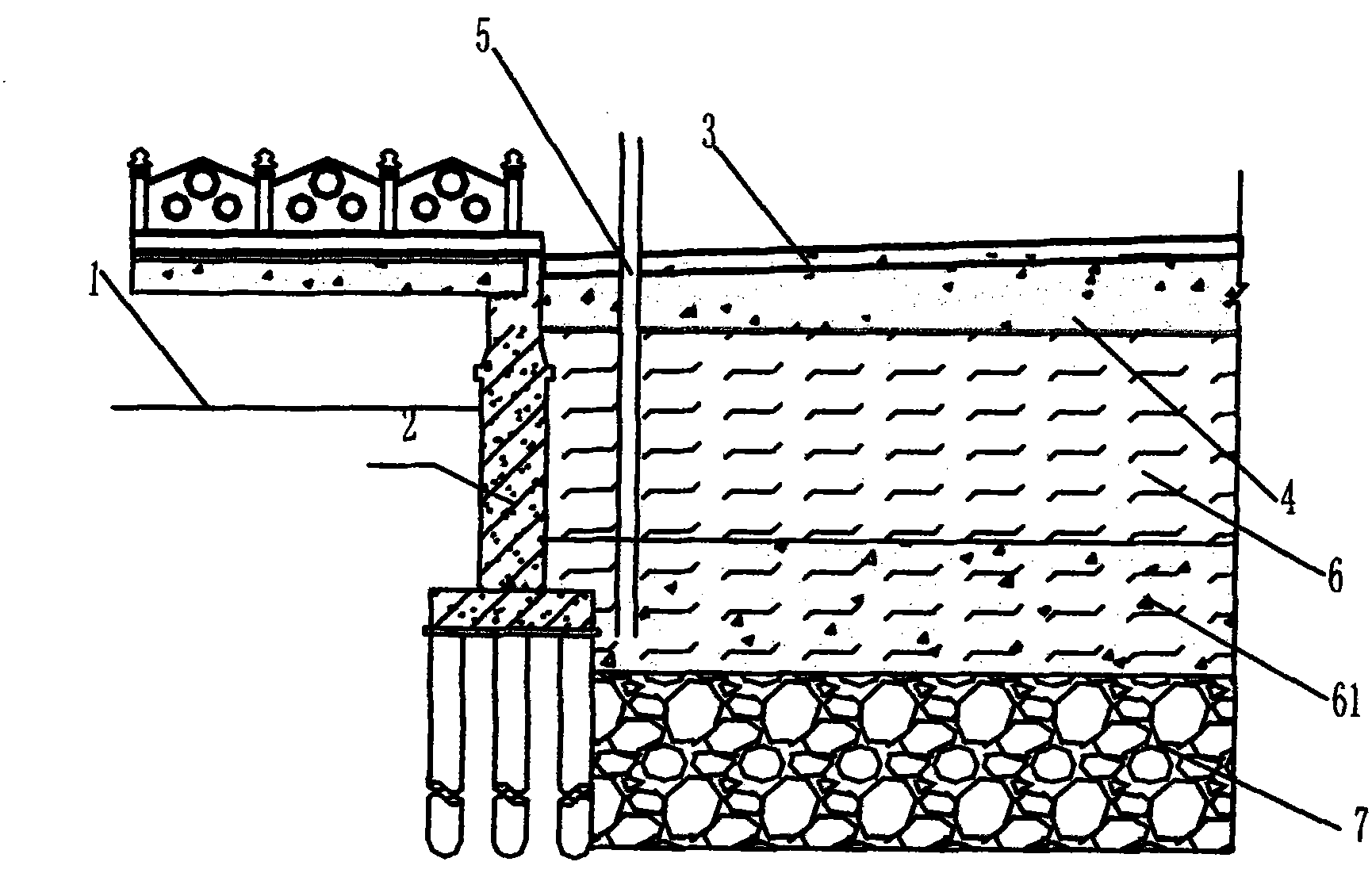

Method for reinforcing soft soil foundation settlement control pile foundation bracket of high-grade highway in use

InactiveCN102926303AOvercome the defects that affect traffic openingOvercoming the shortcomings of opening to trafficRoadwaysBulkheads/pilesDrill holeCement grout

The invention discloses a method for reinforcing the soft soil foundation settlement control pile foundation bracket of a high-grade highway in use. The method comprises the following technical steps: partitioning the highway segment to be reinforced; constructing a hoard for the first partition; arranging the hole drilling position; drilling holes to the designed depth; ejecting high-pressure cement grout into the drill holes by using a cement-grout ejecting pipe, rotating and pulling to the top surface of a soft soil layer to form high-strength cement-soil piles with variable diameters; filling cement mortar into the drill holes so that the holes in the filling of the embankment are filled with the cement mortar to the bottom surface of the pavement structure layer; filling the drilled holes in the pavement structure layer range with asphalt surface material; repeating the steps until the construction of the whole highway is finished. During the construction of the highway, vehicles can run normally; the hole drilling causes less damage to the pavement structure layer; and the piles fulfill the function of supporting the embankment, so that the post-construction settlement of the subgrade of the highway is reduced greatly. The method provided by the invention adopts simple construction procedures, is convenient to operate, is economical and efficient and has a good implementation effect.

Owner:HOHAI UNIV +1

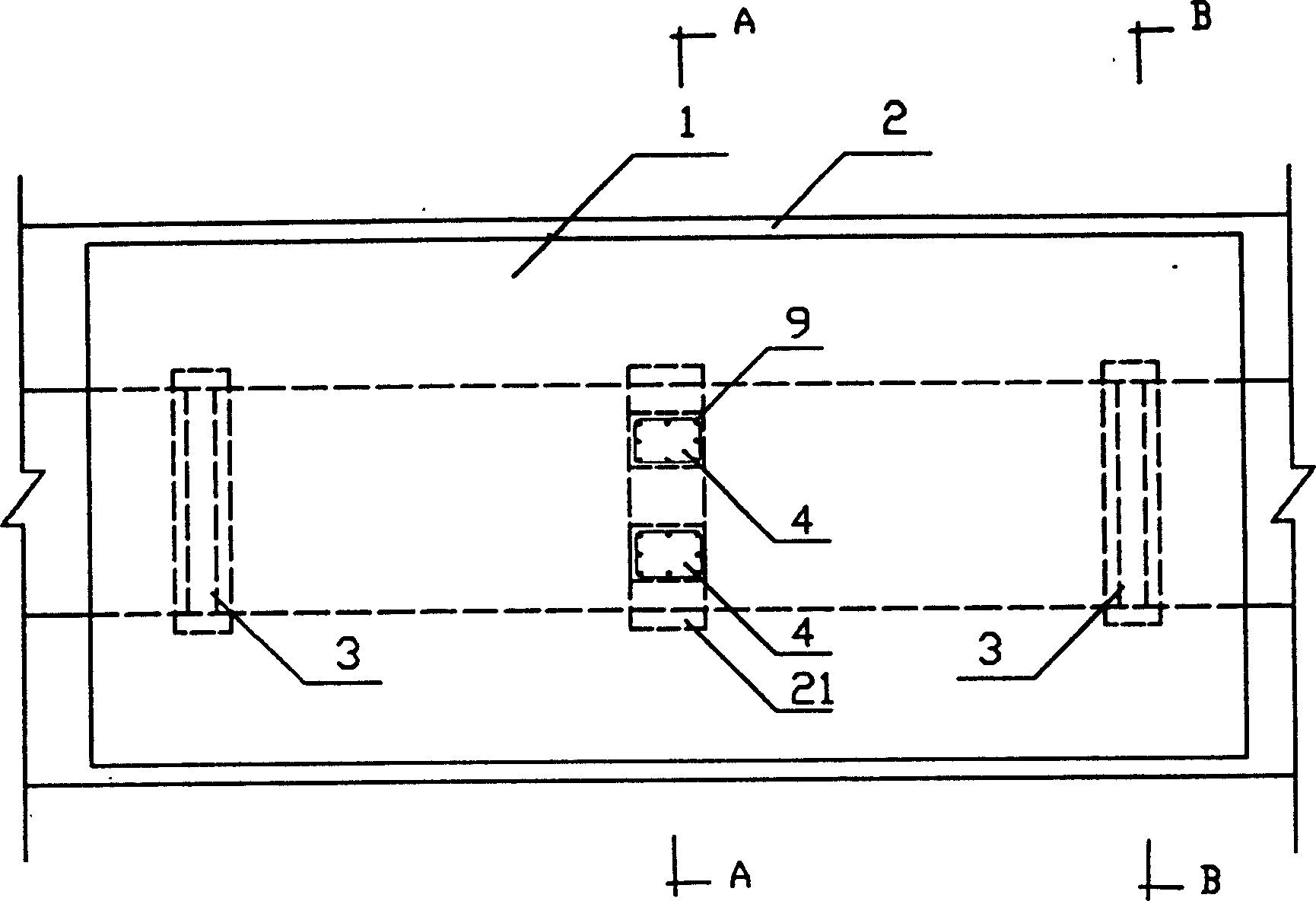

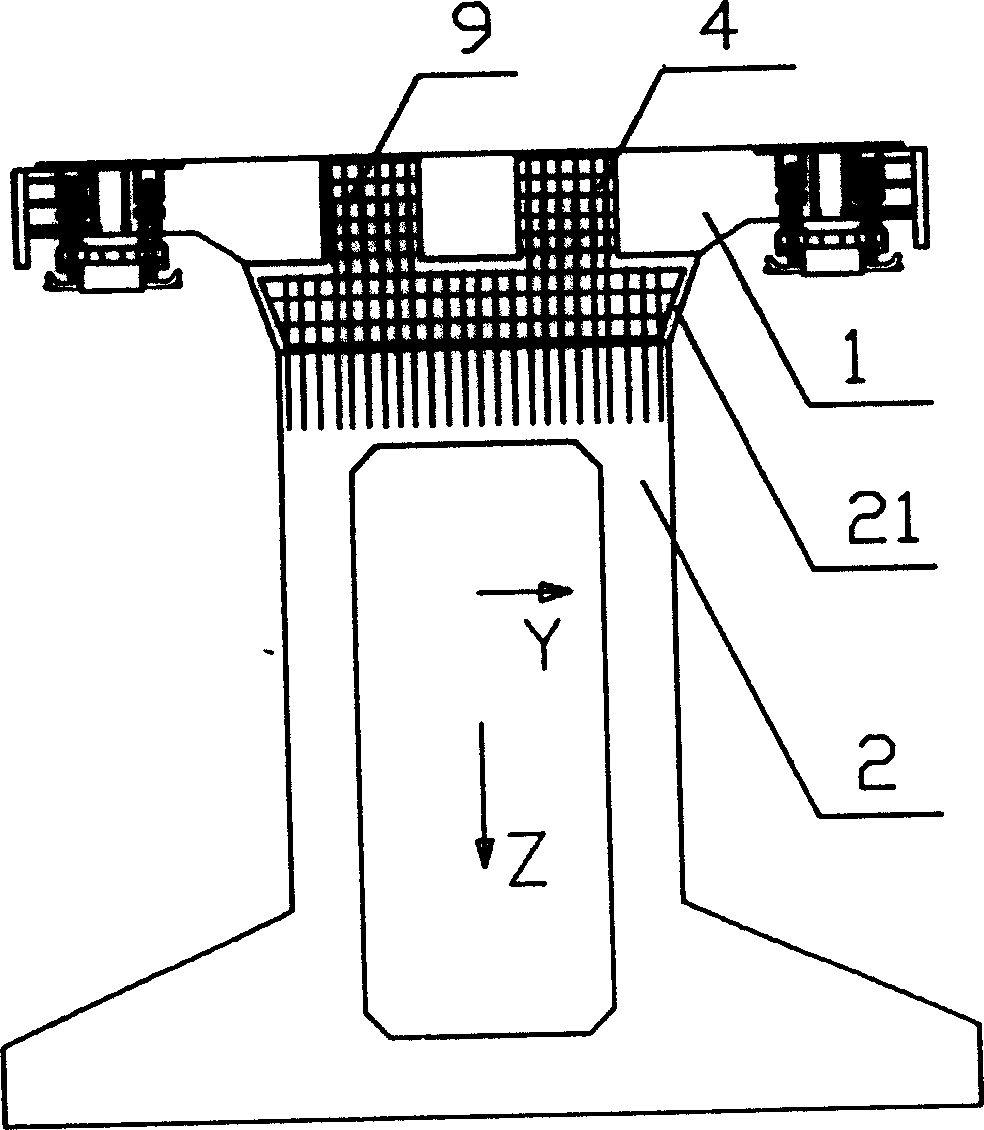

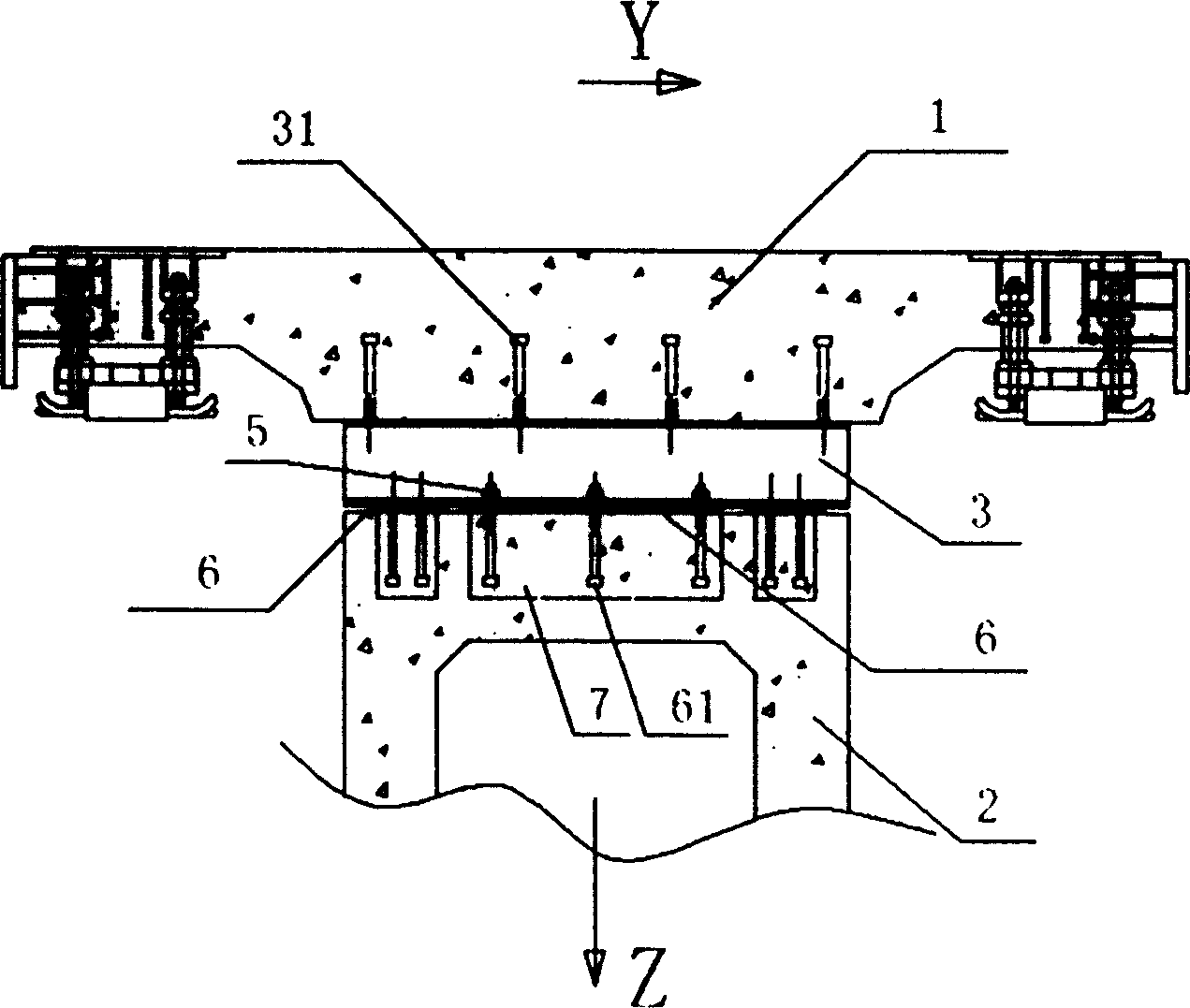

High speed magnetic suspension superimposition rail beam connection mechanism, rail beam and its producing method

ActiveCN1715561AGive full play to the advantagesNo resonanceRailway tracksBuilding constructionsSuperimpositionEngineering

The present invention provides high speed magnetic suspension superposing rail beam connecting mechanism, rail beam and the manufacture process. The rail beam connecting mechanism includes bearing steel beam and welded nail, and has reinforced cement grouted connecting part in the middle part of the rail plate to connect the rail plate and the main bearing beam. The H-shaped bearing steel beam is embedded with welded nail on two ends of the rail plate and is born between the rail plate and the main bearing beam. The present invention realizes the reliable connection between the upper functional area of the rail beam and the rail plate and between the lower base and the main bearing beam, and has simple structure, easy manufacture, fast and convenient regulation and location, and low steel consumption.

Owner:TONGJI UNIV

Magnesium phosphate cement grout material

InactiveCN102643073AImprove volume stabilityEarly hardening fastSolid waste managementMagnesium phosphateNegative temperature

The invention discloses a magnesium phosphate cement grout material, which belongs to the technical field of building materials. The magnesium phosphate cement grout material is prepared through the following components, parts by weight, 100 parts of phosphate, 100-400 parts of metal oxide, 5-150 parts of coal ash, 5-150 parts of grounded slag, 10-100 parts of thickening time control agent and 26-300 parts of water. According to the proportion, the metal oxide, the phosphate, the thickening time control agent, the coal ash and the grounded slag are mixed evenly and placed in a blender, water is added and the mixture is stirred evenly, and the magnesium phosphate cement grout material is obtained. The grout material has the advantages of being good in volume stability, large in flowing degree, indehiscent, high in early-stage strength, capable of constructing under the negative temperature and the like.

Owner:HOHAI UNIV

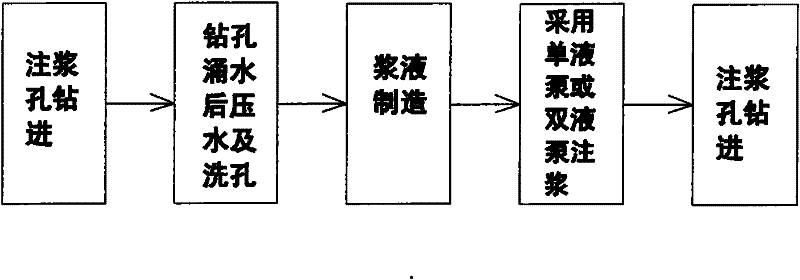

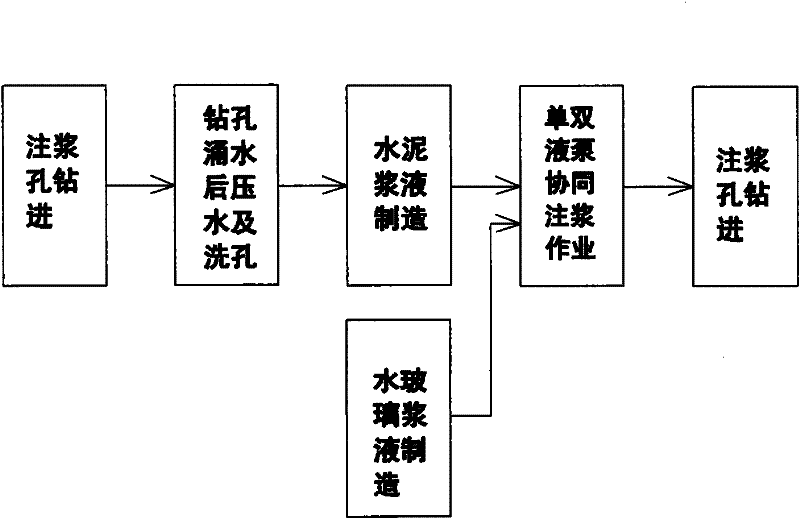

Underground grouting and water-plugging process

InactiveCN102536269AGuaranteed Diffusion RadiusReduce dosageUnderground chambersTunnel liningCement groutSlurry

The invention relates to a new process for underground grouting and water-plugging. The underground grouting and water-plugging process can effectively ensure the diffusion radius and the diffusion range of serous fluid, and reduce the using amount of cement and the labor intensity of a worker by simultaneously grouting single and bi-liquid, and the underground grouting and water-plugging process comprises the following steps of: (1) drilling a grouting hole; (2) pressing water and washing the hole after water burst from the drilled hole; (3) manufacturing the serous fluid; (4) performing grouting and water-plugging operation; and (5) drilling the grouting hole, wherein collaborative injection of single-liquid cement grout and bi-liquid cement-water glass grout is adopted in the grouting and water-plugging operation in the step (4).

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

Cement grouting material

The invention provides a cement grouting material with self-compaction and high fluidity. The cement grouting material comprises anti-cracking mortar, flow promoting components, a plasticizer, coagulation delaying components and a coagulation accelerating component. The anti-cracking mortar comprises, by mass, 4-8% of Portland cement, 38-47% of sulfate aluminum cement, 42-52% of quartz sand, 4.6-4.9% of swelling agents and 0.1-0.4% of polypropylene fibers. The flow promoting components include water reducing agents and defoaming agents. The plasticizer is cellulose ether. The coagulation delaying components include one or more of tartaric acid, sodium gluconate and citric acid. The coagulation accelerating component contains calcium hydroxide. The cement grouting material can complete grouting on the condition of self-gravity and can be grouted successfully one time during high-altitude operation of a support and an inhaul cable pipeline of a bridge with no need for vibrating or secondary grouting; construction of the material is simple since it is only required to add water; the grouting material can be used in construction at a low temperature.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

New technology for treating vehicle bump at bridge ends

InactiveCN101967794ASolve the jumpCost savingBridge structural detailsSoil preservationCement groutSlurry

The invention provides a new technology for treating vehicle bump at bridge ends, which comprises the following steps: firstly drilling holes in soil at joints of bridge ends and highways; secondly injecting cement grout into the holes drilled in first step and strengthening deep soil layers and surrounding soil layers; and thirdly after the deep soil layers are hardened, continuing to inject the cement grout, jacking up road surfaces on the upper part at the same time of strengthening weak soil layers. The new technology of the invention has the beneficial effects of not only solving the vehicle bump at the bridge ends on in-use roads, but also saving construction cost and construction period compared with other methods, not influencing normal traffic, and fundamentally solving the vehicle bump at the bridge ends, thereby having important engineering practical value in weak soil areas and being worthy of development, promotion and application.

Owner:WENZHOU UNIVERSITY

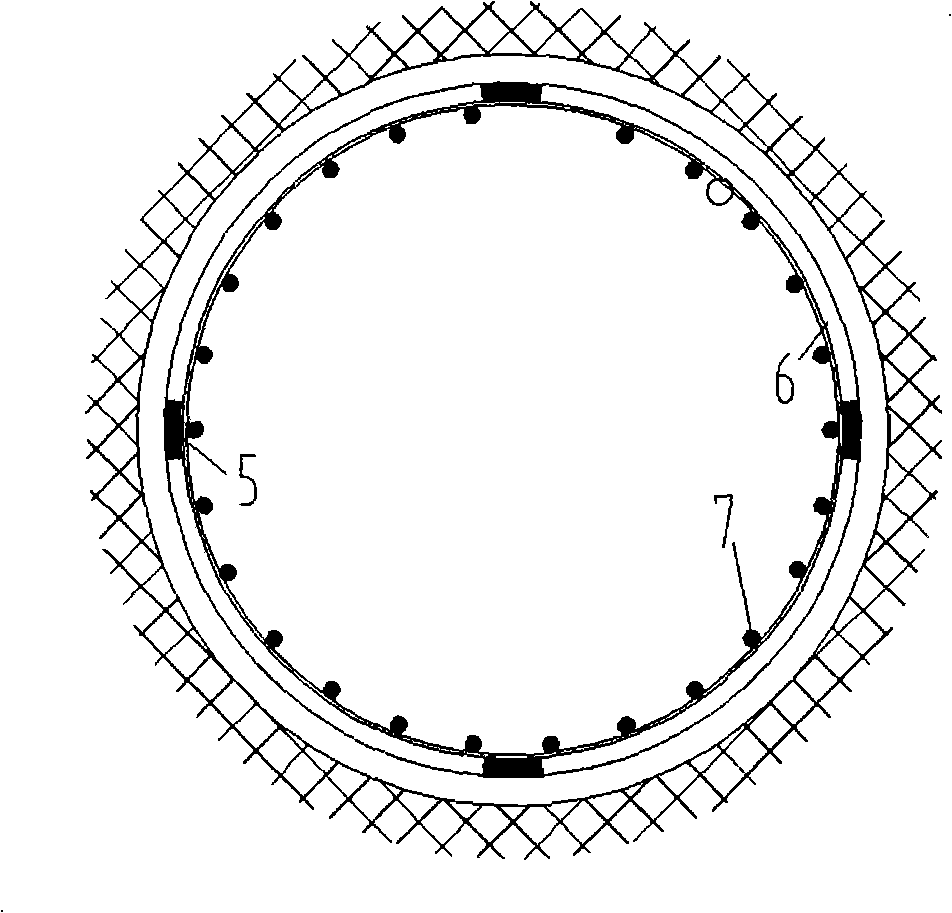

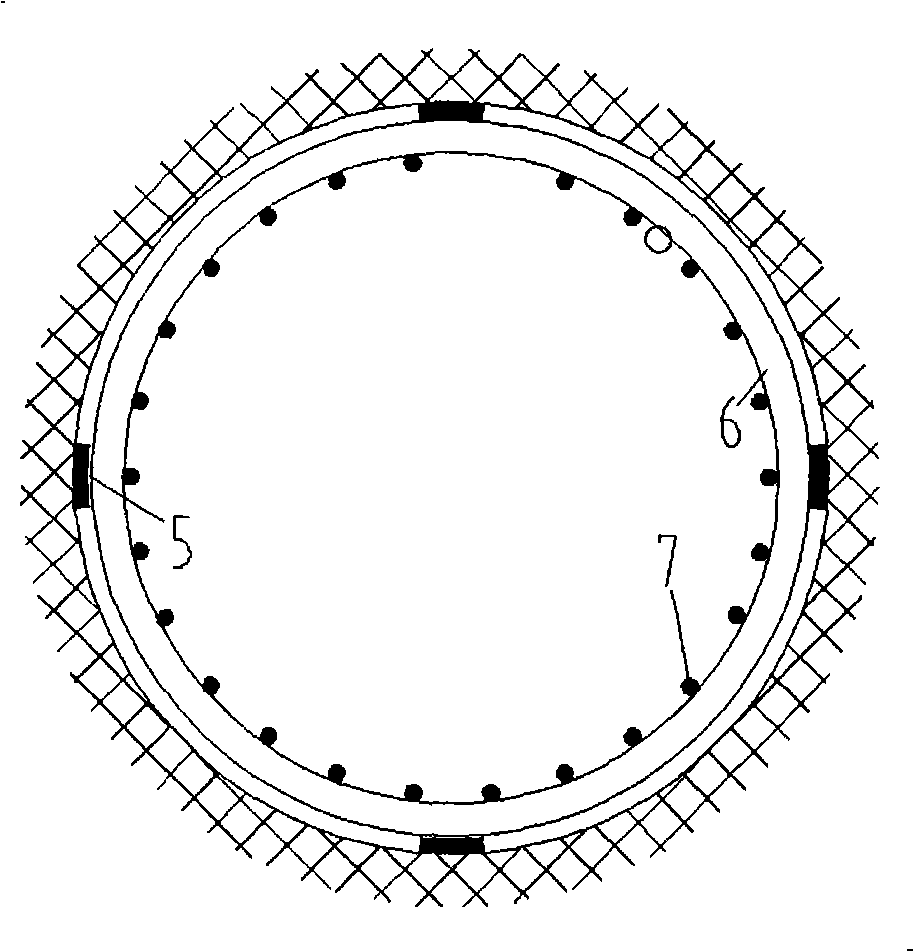

Mining-coal bed nearly horizontal gas extraction borehole sealing method

InactiveCN103195390AIncrease extraction concentrationImprove the extraction effectSealing/packingStructure of the EarthCement grout

A mining-coal bed nearly horizontal gas extraction borehole sealing method is mainly suitable for gas extraction boreholes at sites like coal faces in underground coal mines and coal roadways. The sealing method mainly includes two parts: static sealing and dynamic sealing. For a gas extraction borehole, static sealing is performed firstly and includes two times of grouting: for the first grouting, expansion cement grout is adopted to seal positions outside a fissure zone, and for the second grouting, slurry is adopted to seal positions inside the fissure zone; after a period of time, dynamic sealing is performed and includes that the expansion cement grout and the slurry are constantly grouted into the borehole by utilizing underground compressed air to enable the borehole and surrounding fractures to be always filled with the expansion cement grout and the slurry so as to realize dynamic sealing. By the method, grouting fluid can be enabled to effectively seal space inside the borehole and coal fracture areas surrounding the borehole in real time, and maximization of space and fracture sealing is realized. The mining-coal bed nearly horizontal gas extraction borehole sealing method is simple in structure, convenient to operate, low in cost and evident in effect.

Owner:SHANXI LUAN ENVIRONMENTAL ENERGY DEV +1

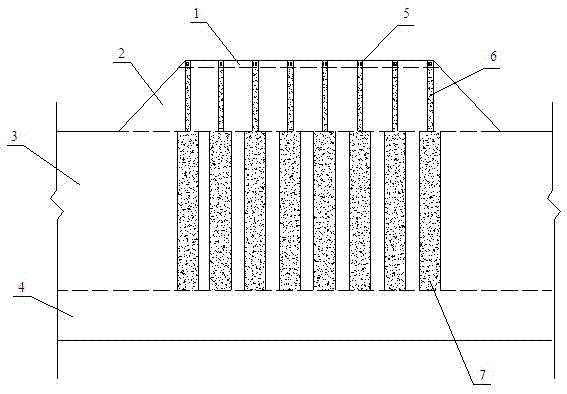

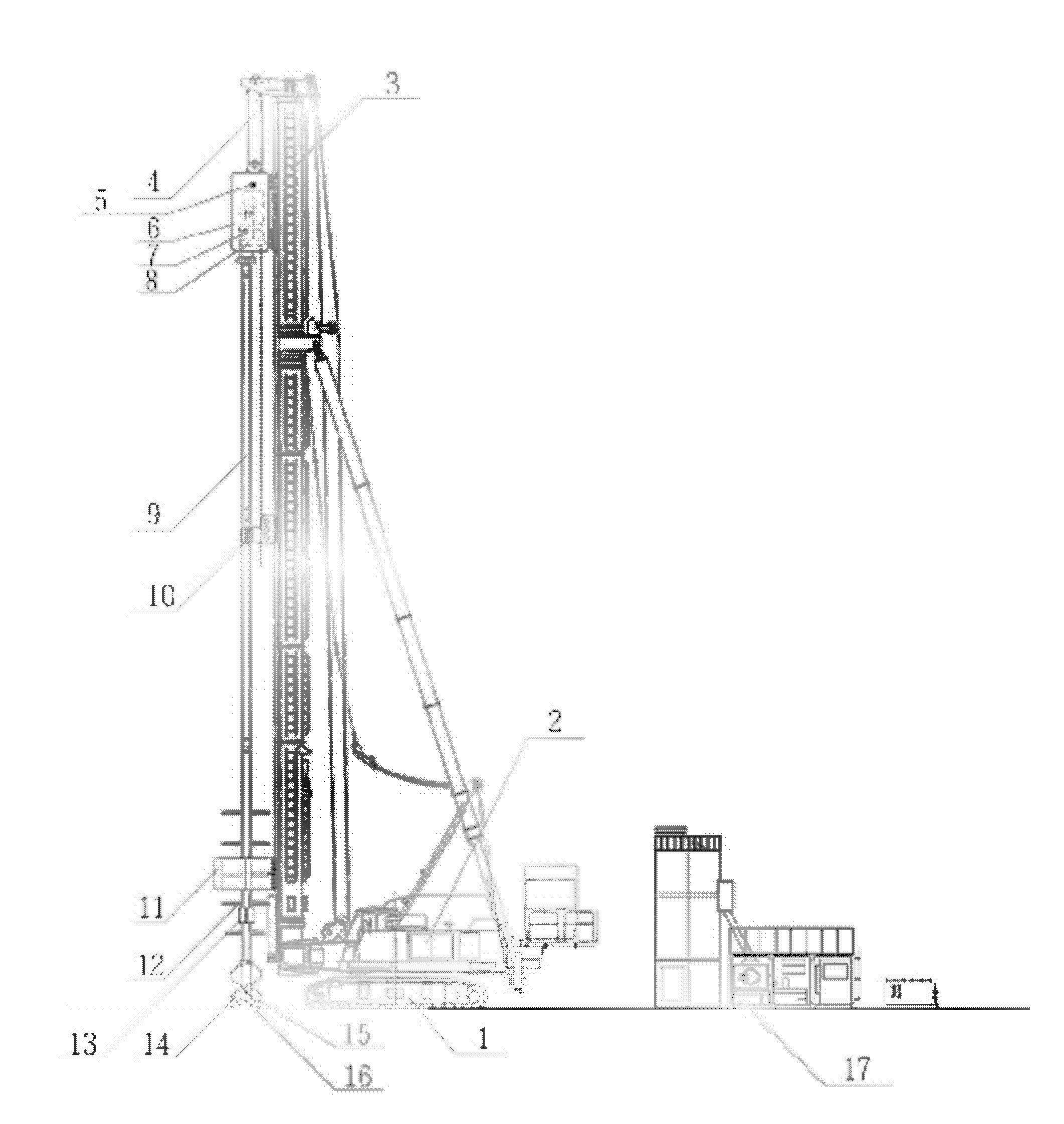

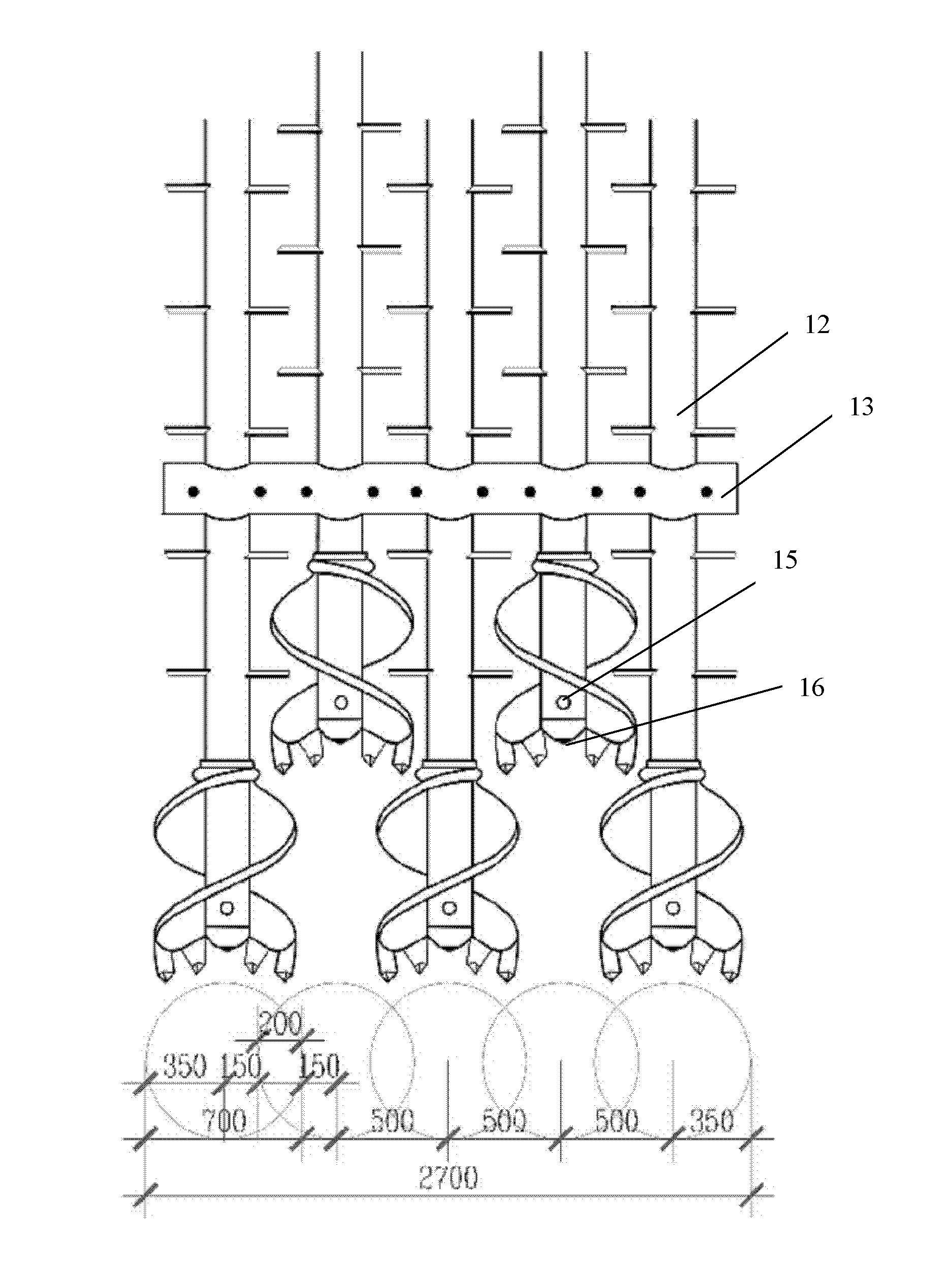

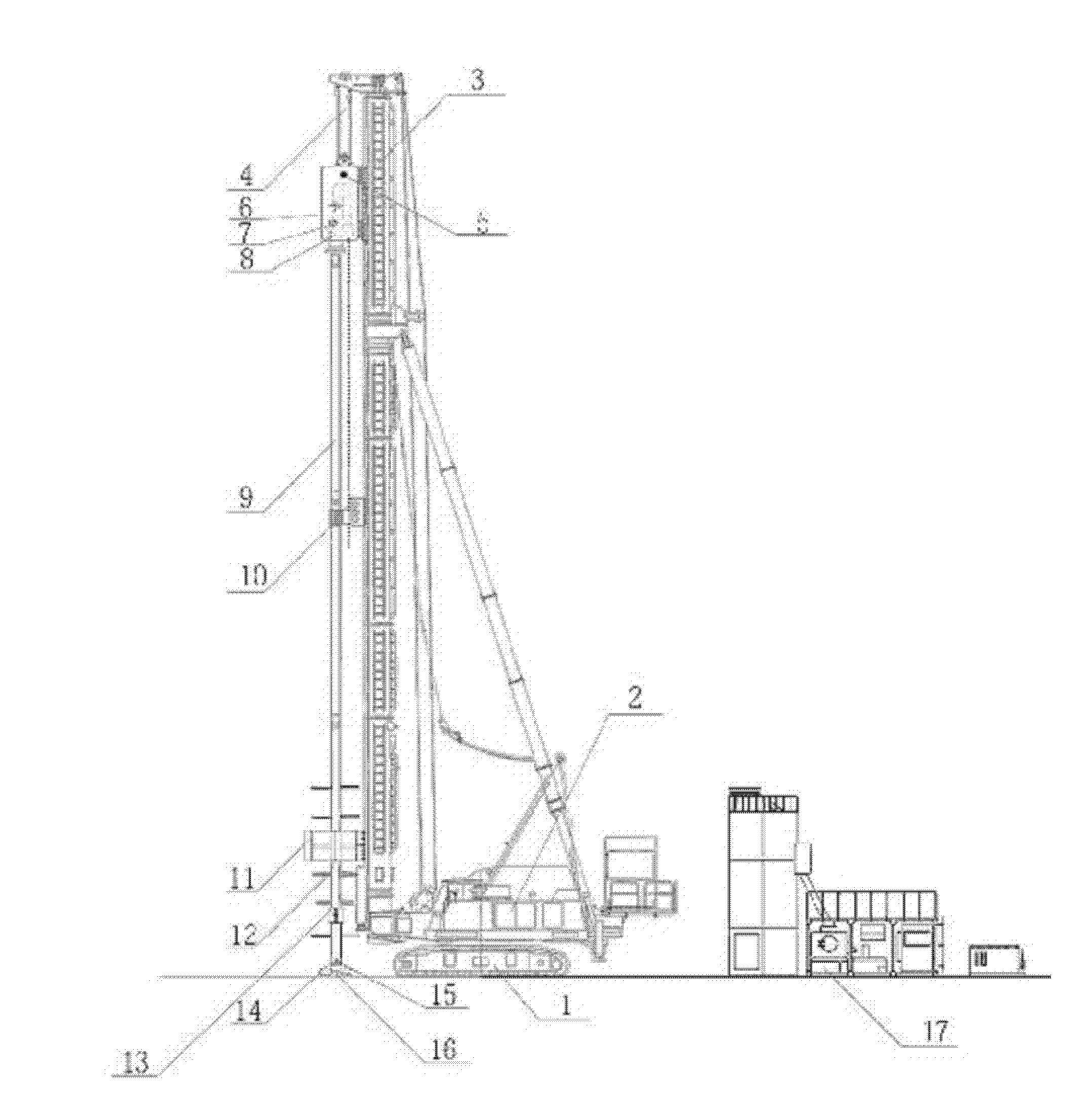

Continuous multi-shaft cement mixing pile device and construction method

InactiveCN102493438AReduce rotational loadImprove securityDrilling rodsExcavationsReducerCement grout

The invention relates to a continuous multi-shaft cement mixing pile device and a construction method; the multi-shaft continuous cement mixing pile device comprises a walking type main machine, a crawler type main machine, a winding engine, a guide rod, a steel wire rope, an air and grout inlet, a power head, a speed changing box, a reduction box, drill stems, middle supporting frames, lower supporting frames, winged drill stems, hoops, drill bits, air injection ports, grout spraying ports and a background cement grout stirring system, wherein the winding engine and the guide rod are fixed on the main machines, the power head is connected with a pulley arranged at the top end of the guide rod through the steel wire rope; the steel wire rope drives the power head to be lifted up and down; the power head is sequentially connected with the multiple drill stems through the speed changing box and the speed reducer; the middle supporting frames are arranged in the middle parts of the multiple drill stems; the lower supporting frames are arranged at the lower parts of the multiple drill stems; the winged drill stems are connected with the lower ends of the drill stems; the hoops are arranged on the winged drill stems; the drill bits are connected with the lower end of the winged drill stems; and the air injection ports and the grout spraying ports are arranged on the drill bits. Compared with the prior art, the continuous multi-shaft cement mixing pile device has the advantages of noiselessness, non vibration, ensured safety and quality, cost reduction, high efficiency, shortened construction period and the like.

Owner:SHANGHAI CHENGDI CONSTR

Cement-polyurethane composite grouting process capable of blocking water fast

InactiveCN105332719APrevent backflowNot easy to diluteUnderground chambersTunnel liningWater leakageSlurry

The invention discloses a cement-polyurethane composite grouting process capable of blocking water fast. The cement-polyurethane composite grouting process includes the steps of a, performing engineering exploration, to be more specific, designing a plurality of holes after the optimal reaction positions of polyurethane grout are determined according to the stratum cracks or the flowability of flowing water, wherein the holes should communicate water leakage points as much as possible or penetrate a plurality of stratum cracks to allow one hole to penetrate multiple stratums; b, drilling; c, grouting, to be more specific, simultaneously and alternately grouting the polyurethane grout and cement grout into all holes, using the instant foaming and curing feature, which uses water to stop water, of the polyurethane grouted first to stop and block water, using the cement grout grouted later to stop the backflow of the polyurethane so as to form a structure with grouted holes and front blocking and back protection, and repeatedly and alternately grouting for multiple times until water burst is blocked; d, continuing grouting for a certain period of time after the water burst is blocked to guarantee that blocking is completed. By the arrangement, the cement-polyurethane composite grouting process is simple in procedures, capable of blocking water fast, and capable of integrating blocking and reinforcing.

Owner:JIANGSU DINGDA BUILDING NEW TECH +1

Method for improving cementing plugging effect

The invention discloses a method of improving the effect of blocking cement; the G-graded cement is added with short-thread fibres, bridge plug materials, super-thin materials and a retarder; blockage cement grout is injected into a stratum; blockage mud cakes and a cement plug can be formed rapidly in the thief zone of the stratum, which stops the cement grout flowing to the depths of an oil layer, thereby reducing the consumption of the cement grout, protecting the oil layer and lessening the damage to blowholes. Compared with the prior cement grout, the formed paste matrix is of good toughness and shock resistance; the added super-thin materials improve the grain size distribution of the cement grout, reduce the extent of porosity of the paste matrix, and decrease the penetrability of the cement plug, thereby prolonging the service life of the cement plug. Therefore, the adoption of the cement grout and the corresponding craftworks and measures can improve the success ratio of one-time construction of blocking the cement to more than 90 percent, and can prolong the term of validity of blocking to a certain extent. The invention is quite applicable for popularization and application on the spot.

Owner:LIAOHE GASOLINEEUM EXPLORATION BUREAU

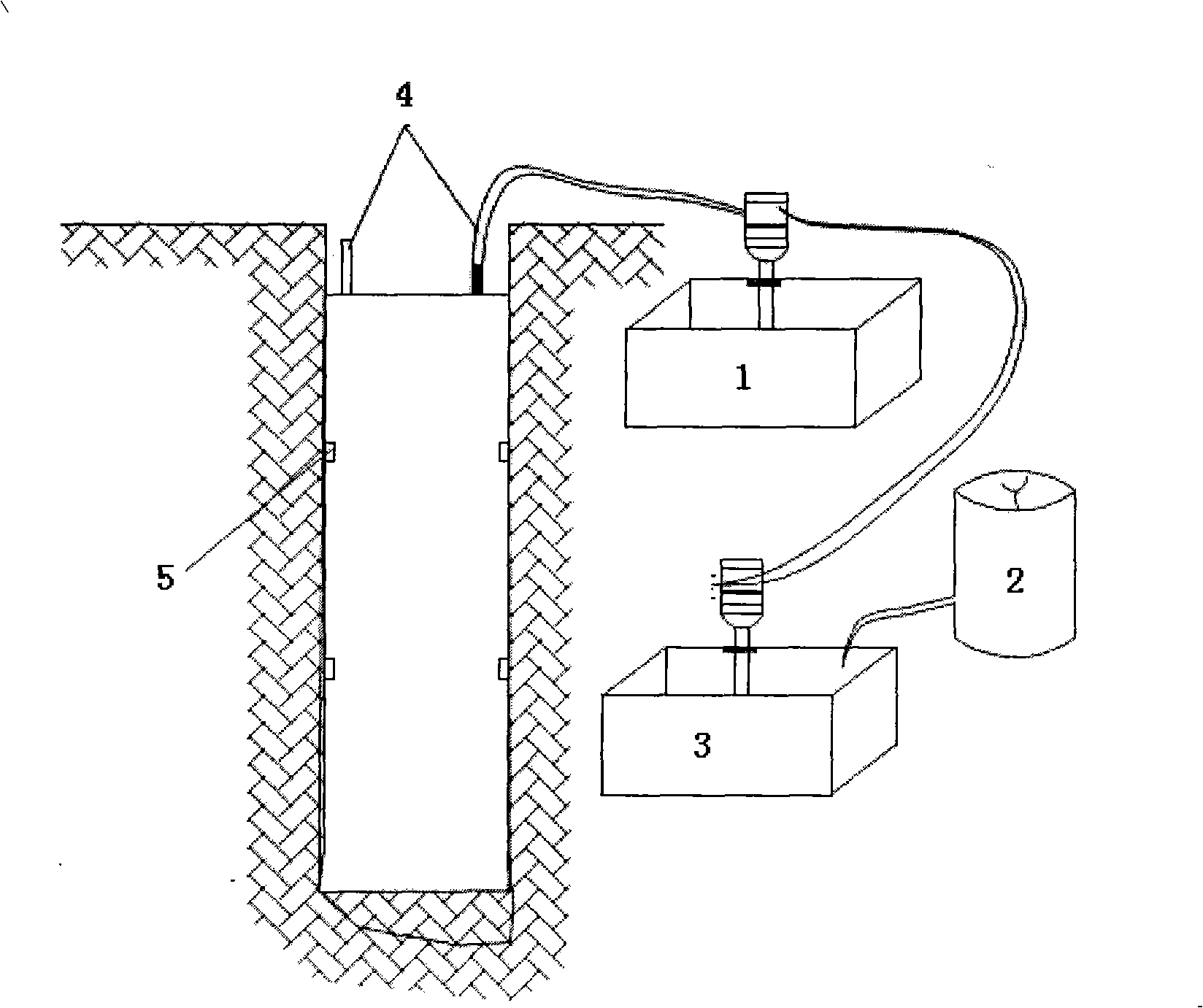

Grouter for back side grouting and its construction method

The invention relates to a pile side post-grouting grouting device and the construction method thereof, including a ground grouting device and an underground grouting device; the underground grouting device is composed of a pile body grouting guide pipe and an inner pile grouting device; both ends of the pile body grouting guide pipe are connected with the ground conveying pipe and the pile side grouting device; the pile body grouting guide pipe is distributed along the grouting section, fixedly bound with the main rib of the steel reinforcement cage and is arranged in a drilled hole togetherwith the steel reinforcement cage; the pile side grouting device is composed of an annular high-pressure hose and a grouting device; the annular high-pressure hose is communicated with the pile body grouting guide pipe and is fixedly connected with the bored pile steel reinforcement cage. During the pile forming process of the bored pile, the pile side post-grouting grouting device and the construction method prearrange the grouting pipelines on a plurality of positions on the pile body, distribute the annular high-pressure hose outside the grouting section and mount the grouting device; a high-pressure grouting pump is adopted when pile body concrete reaches certain strength; the cement grout is injected into the pile lateral through the grouting pipelines to improve the pile lateral mudcover; the pile lateral soil mass intensity is improved at the same time, so as to improve the bearing capacity of the pile and reduce the skirt pile settlement.

Owner:SHANGHAI FOUND ENG GRP

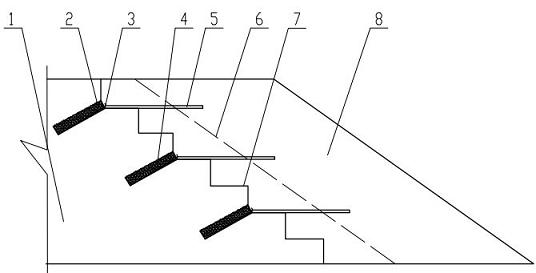

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com