Continuous multi-shaft cement mixing pile device and construction method

A technology of mixing piles and cement-soil, which is applied in earthwork drilling, drilling equipment and methods, excavation, etc., which can solve the problems of insufficient starting power, poor stability, and high labor intensity, and achieve the reduction of lap joint cold joints and the rotation load Good effect of lightening and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

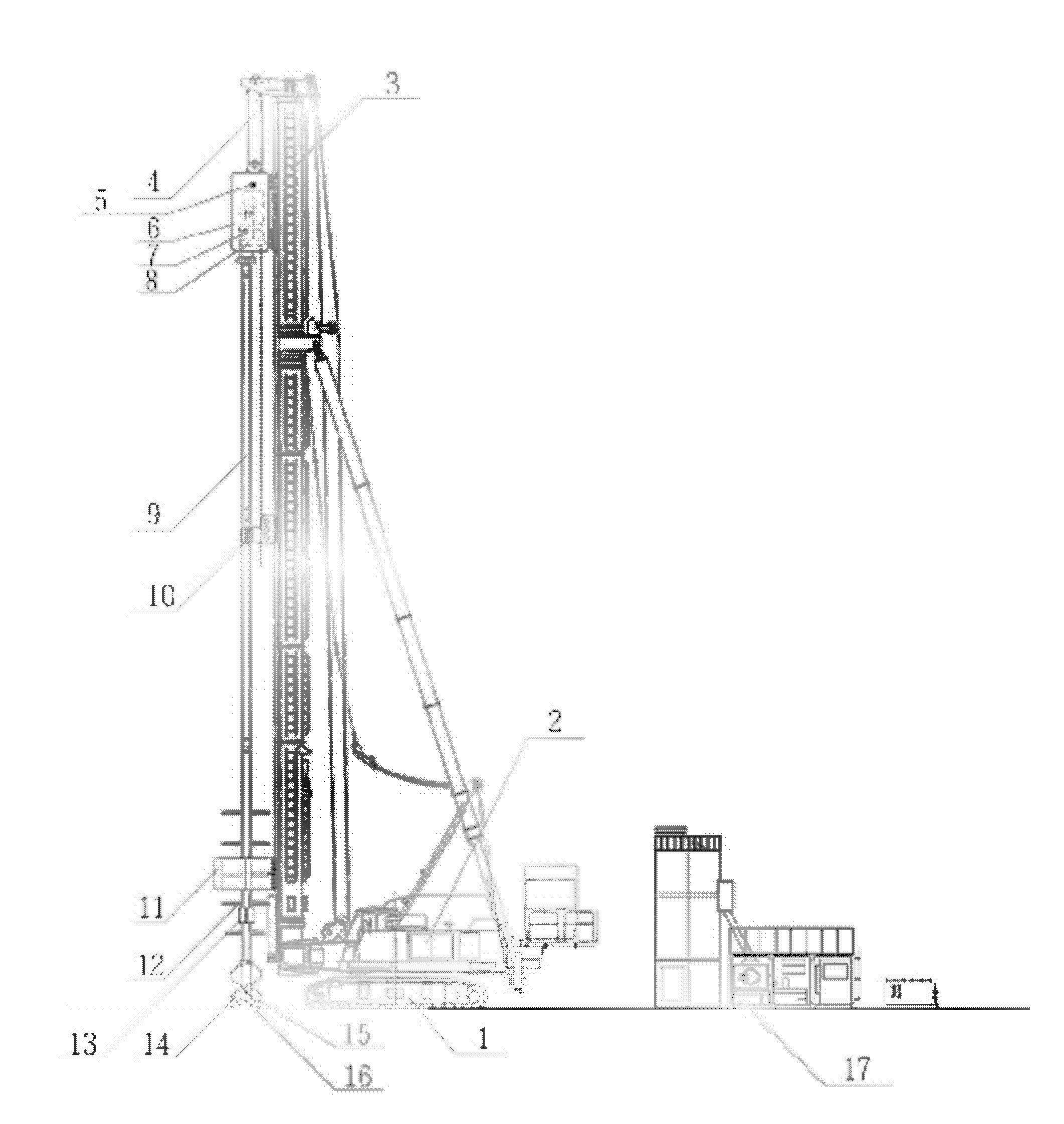

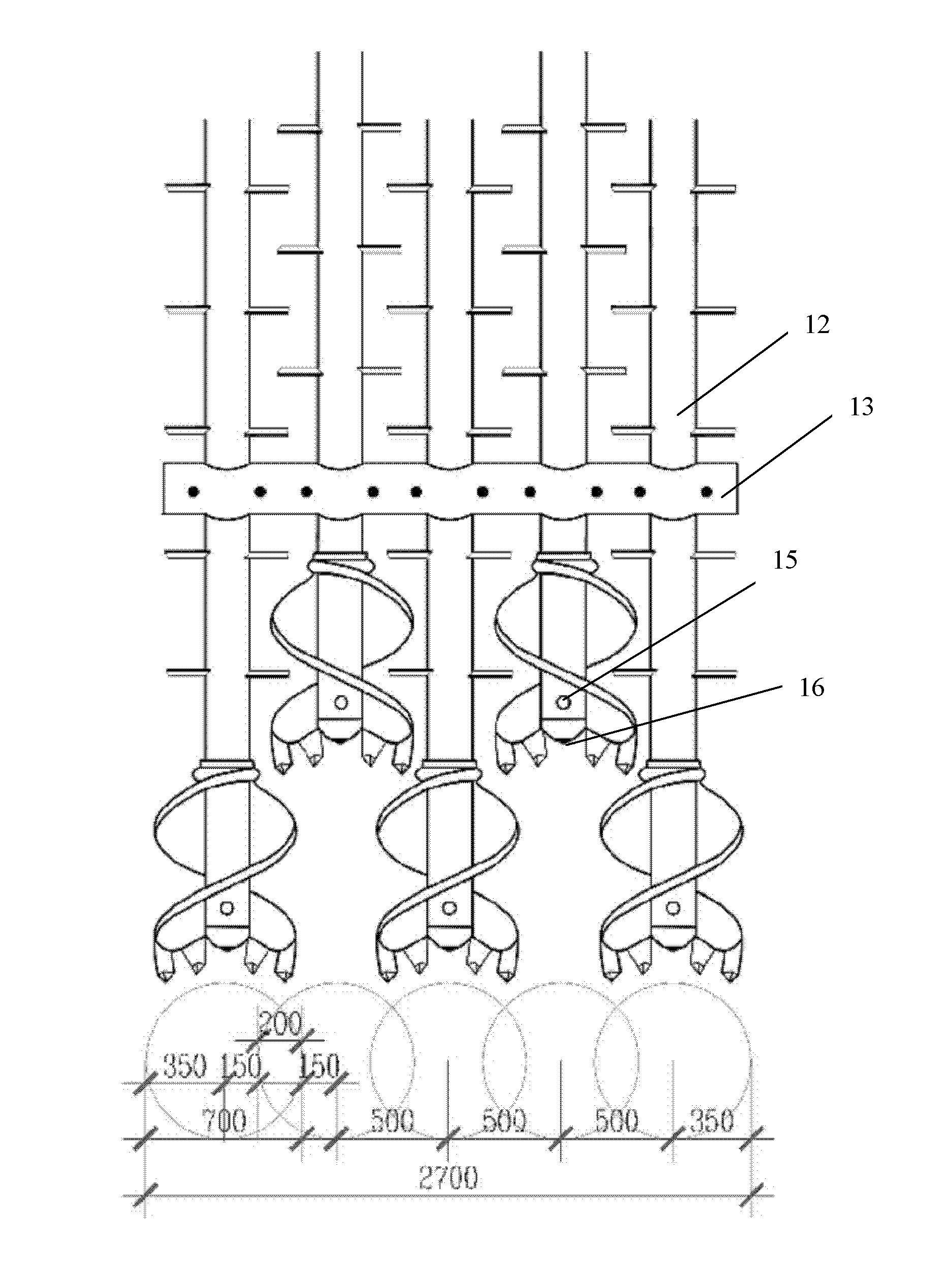

[0033] Such as Figure 1~2 As shown, a multi-axis cement-soil continuous mixing pile device includes a crawler-type and walking-type main engine 1, a winch 2, a guide rod 3, a steel wire rope 4, an air inlet for slurry 5, a power head 6, a gearbox 7, Reducer 8, drill pipe 9, intermediate support frame 10, lower support frame 11, winged drill pipe 12, hoop 13, drill bit 14, air injection port 15, spray port 16, the hoist 2 and guide rod 3 are fixed On the host machine 1, the power head 6 is connected to the top pulley of the guide rod 3 through the wire rope 4, and the wire rope 4 drives the power head 6 to go up and down, and the power head 6 is connected to five drill pipes through the gearbox 7 and the reducer 8 in turn. 9. The middle part of the five drill pipes 9 is provided with an intermediate support frame 10, and the lower part is provided with a lower support frame 11. The lower ends of each drill pipe 9 are connected with winged drill pipes 12, and the winged drill p...

Embodiment 2

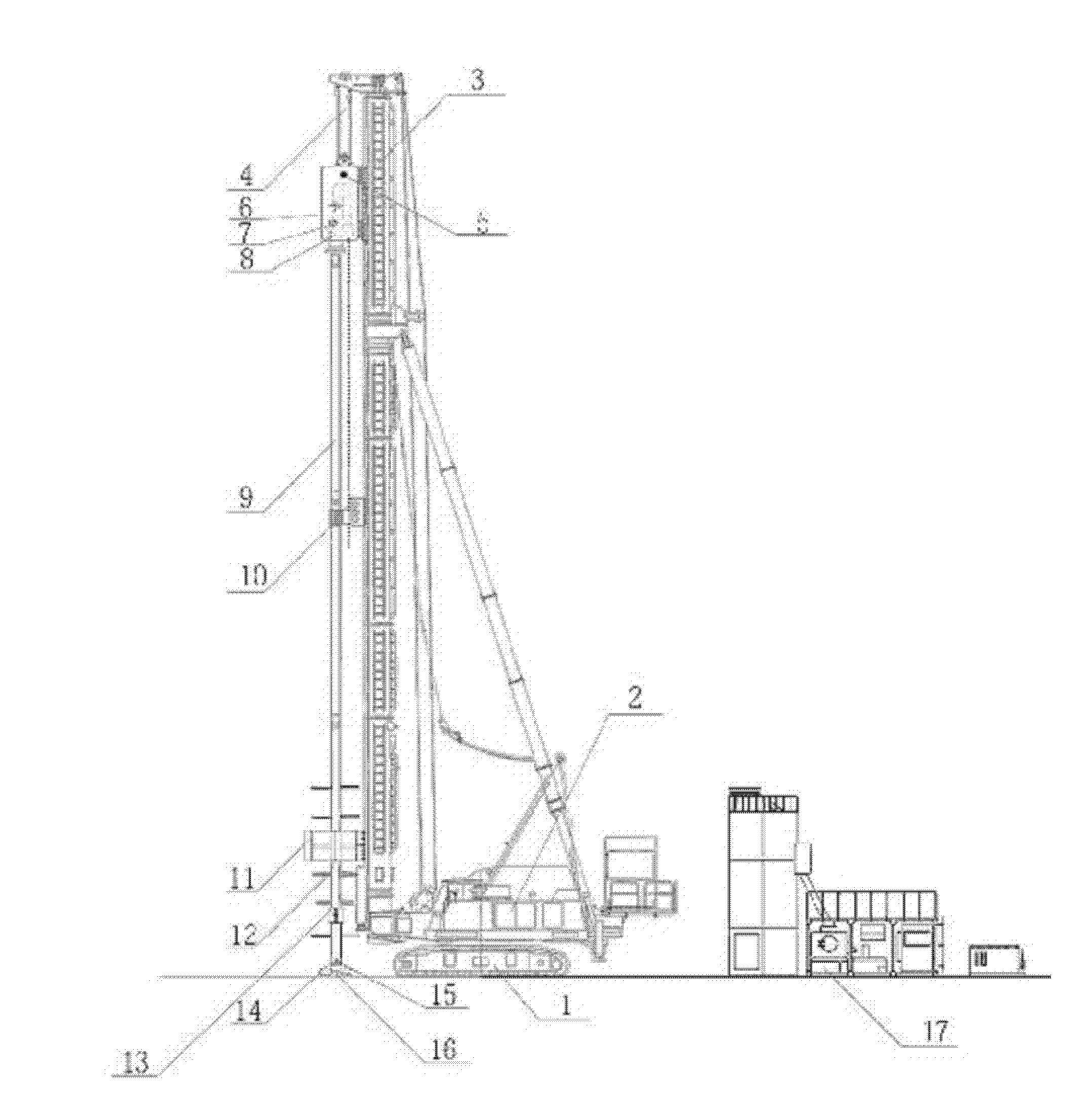

[0049] Such as Figure 3-4 As shown, a multi-axis cement-soil continuous mixing pile device, the drill bit 13 is a rake drill bit. All the other are with embodiment 1.

[0050] Described drilling rod can be set 3-7 as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com