Patents

Literature

152 results about "Drill stem test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A drill stem test (DST) is a procedure for isolating and testing the pressure, permeability and productive capacity of a geological formation during the drilling of a well. The test is an important measurement of pressure behaviour at the drill stem and is a valuable way of obtaining information on the formation fluid and establishing whether a well has found a commercial hydrocarbon reservoir.

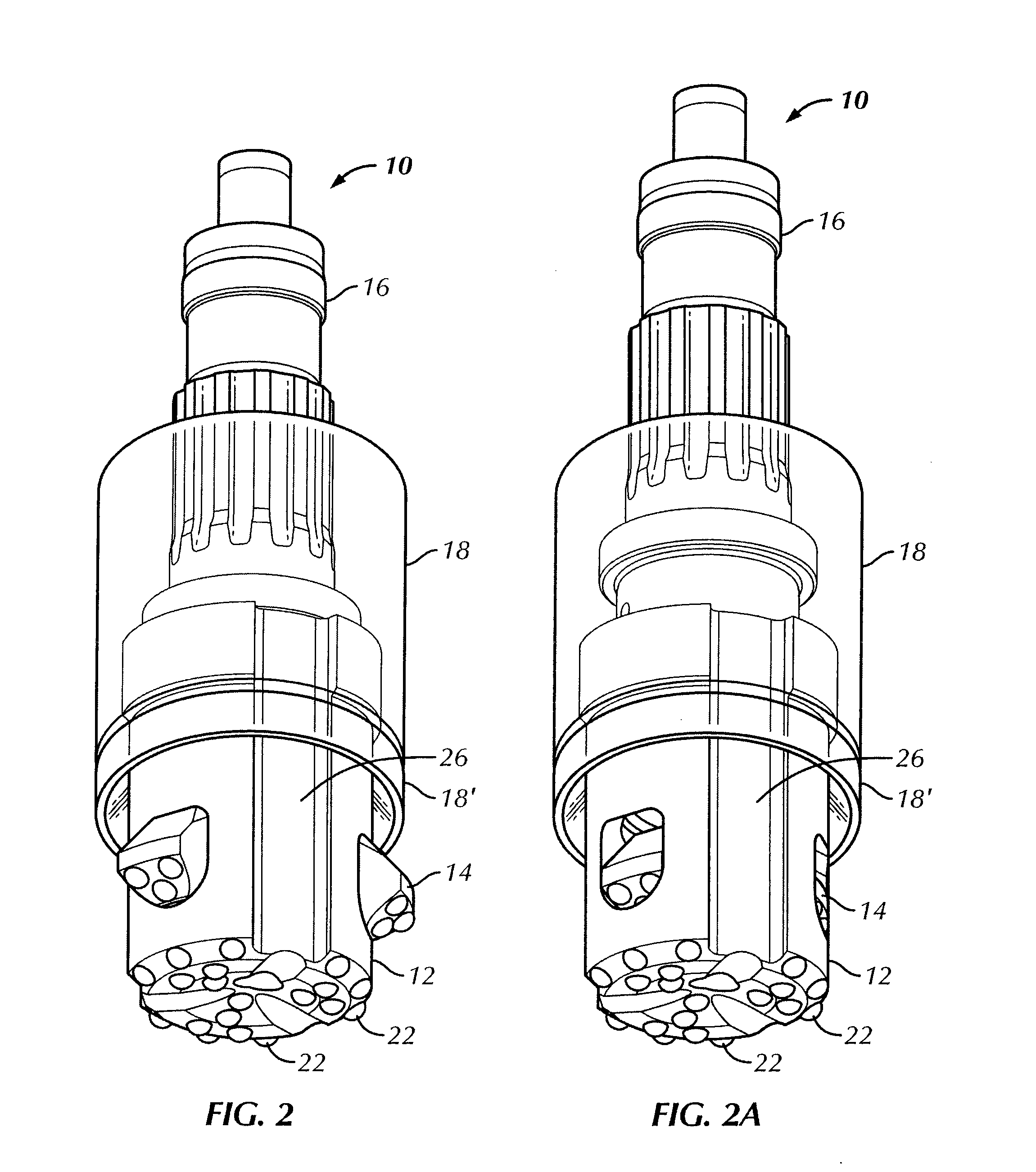

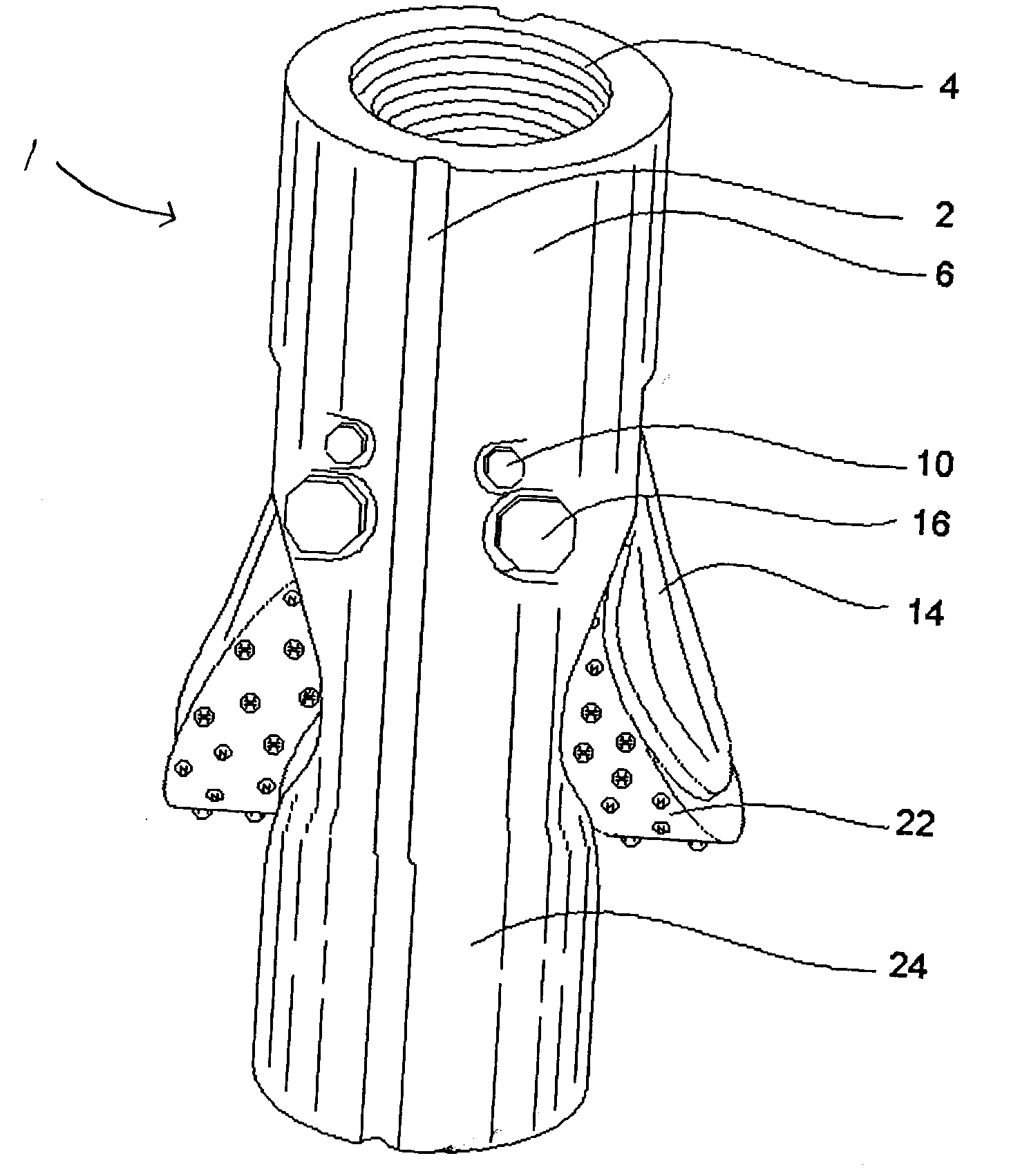

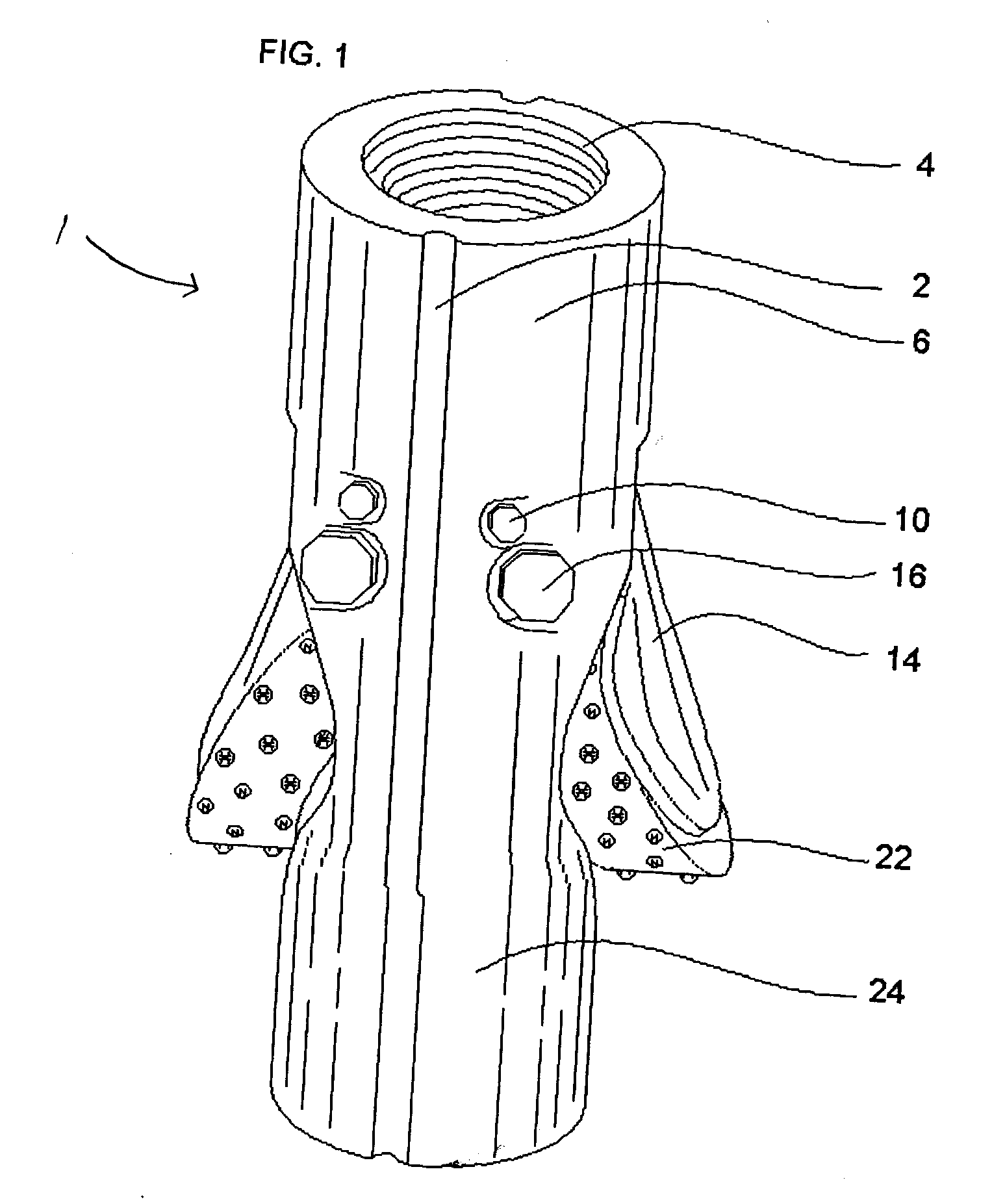

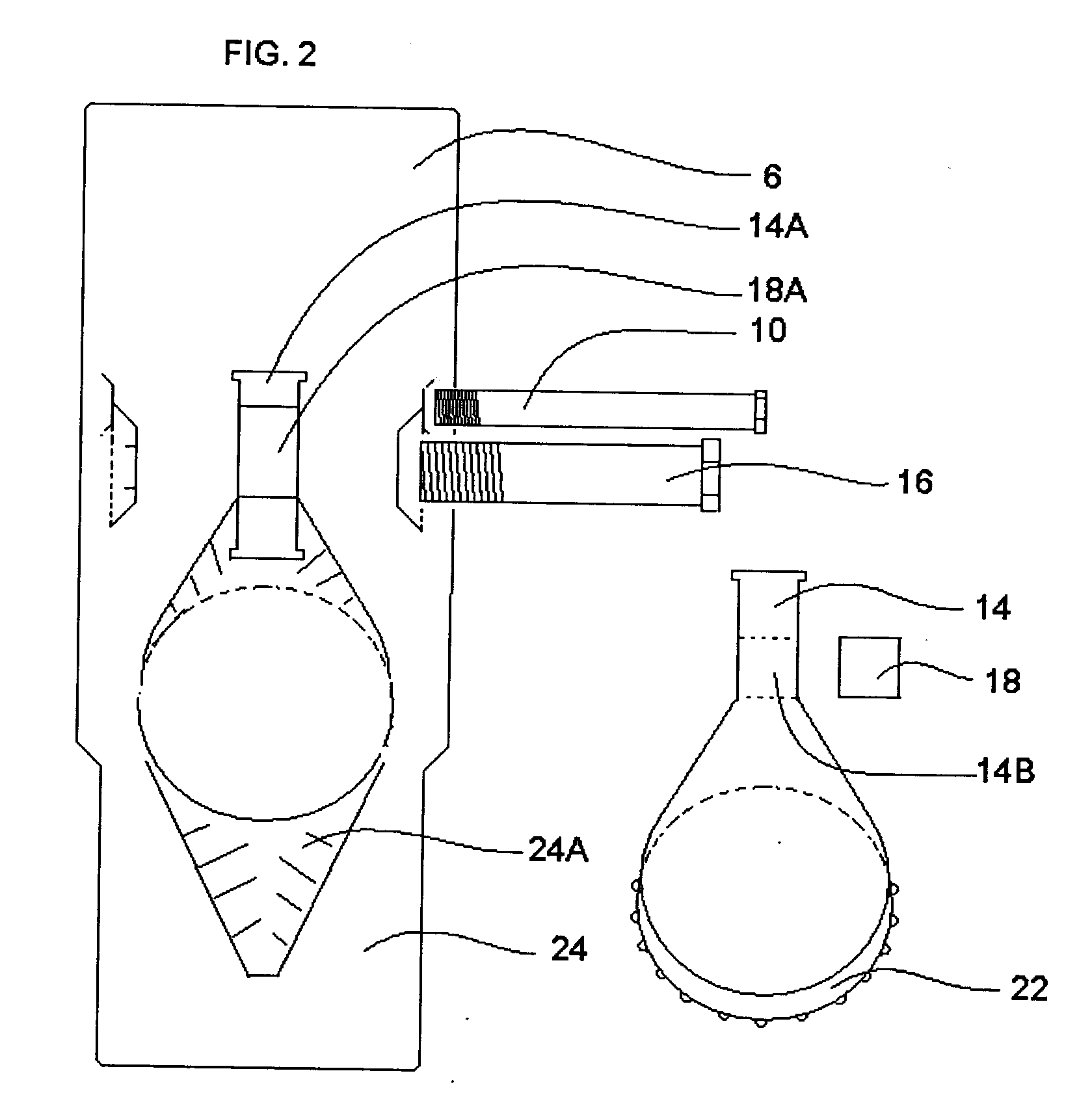

Multiple zone testing system

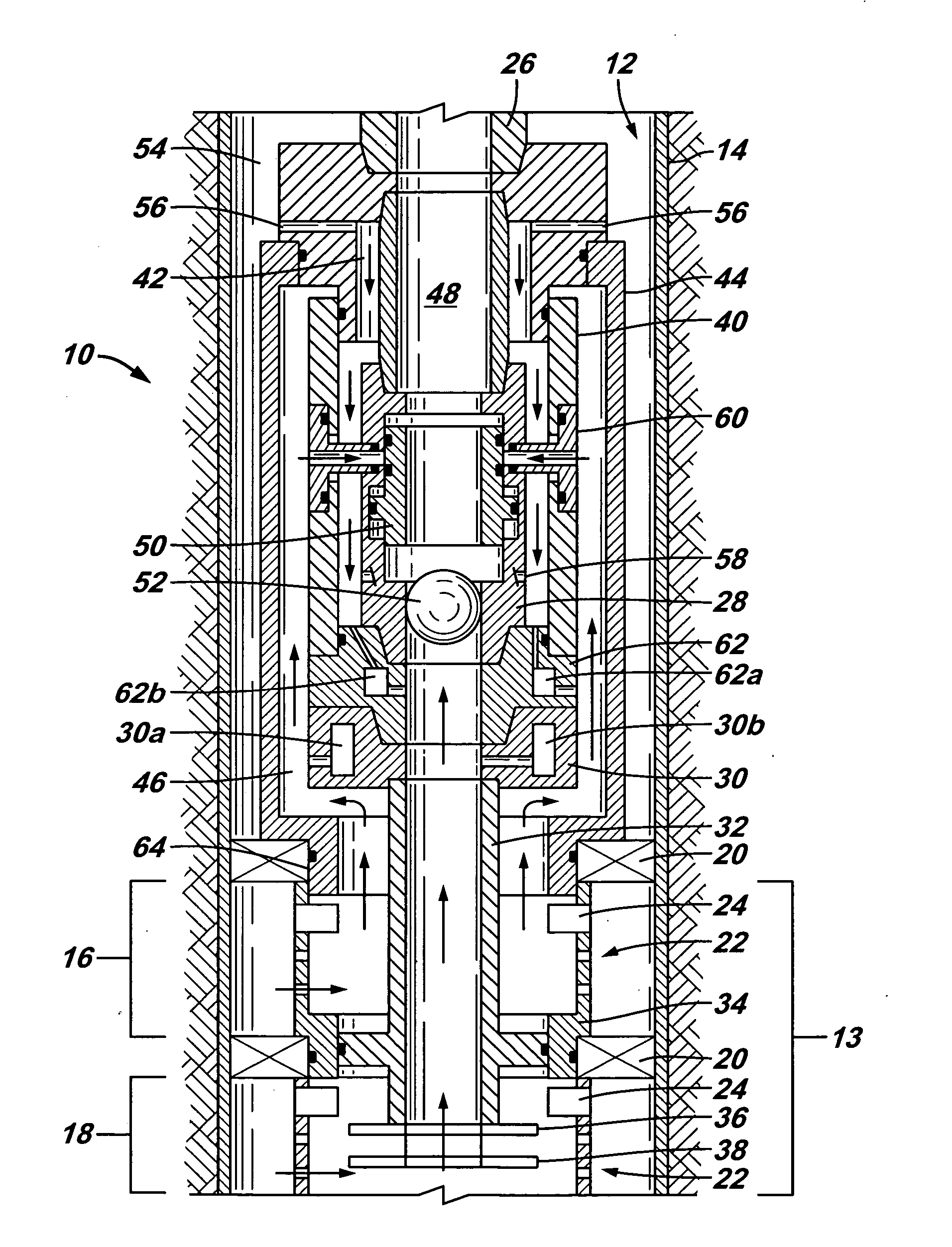

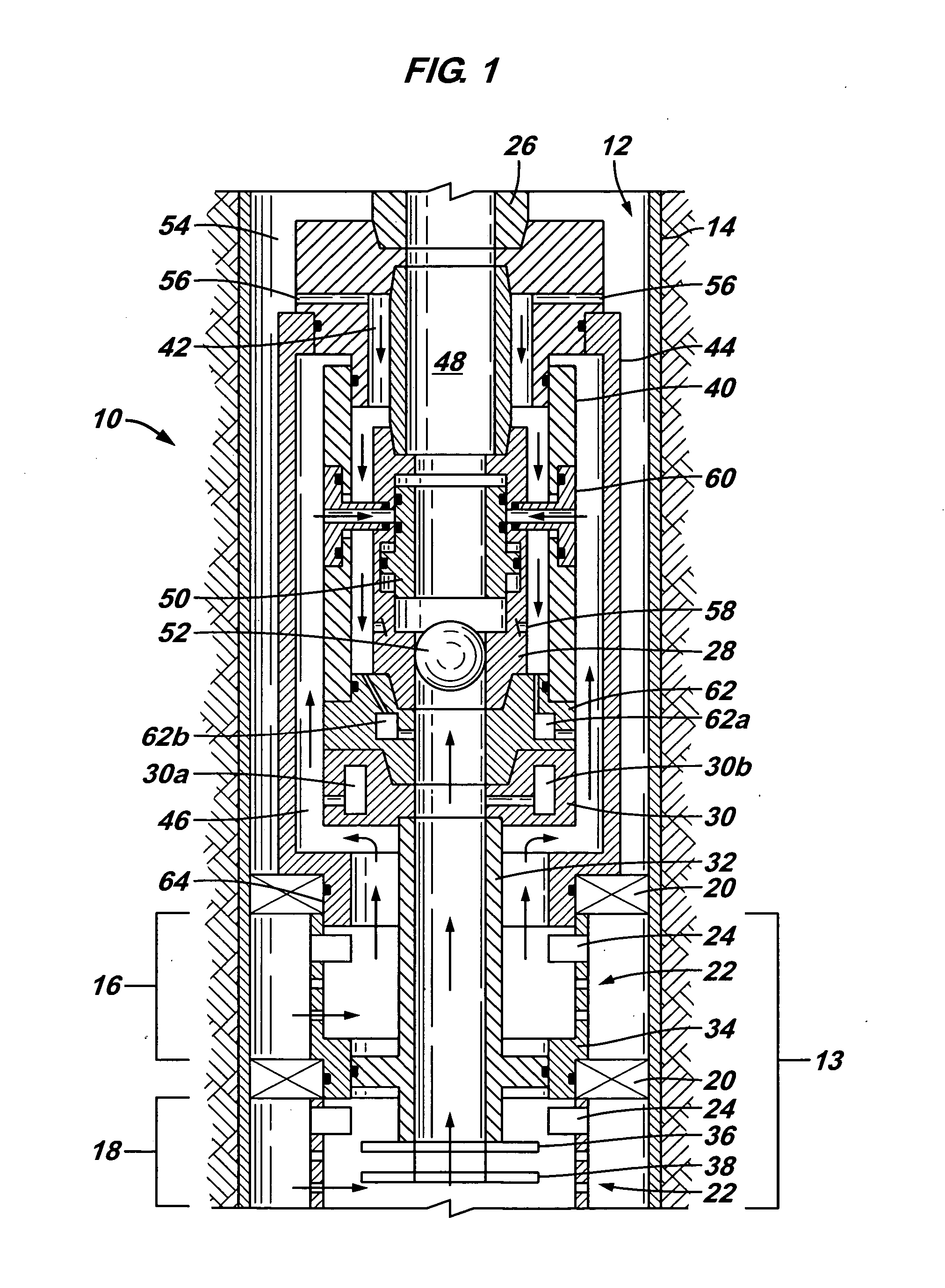

InactiveUS20050077086A1Facilitates singular testingEasy to testEarth drilling toolsSurveyTester deviceIndustrial engineering

A method and system for drillstem testing multiple zones in a well with a single testing trip into the well. A multiple zone tester is landed in the lower completion to form separate controllable flow paths from each of the zones. The multiple zone testing system facilitates testing each zone singularly and performing commingled tests without pulling out of the well.

Owner:SCHLUMBERGER TECH CORP

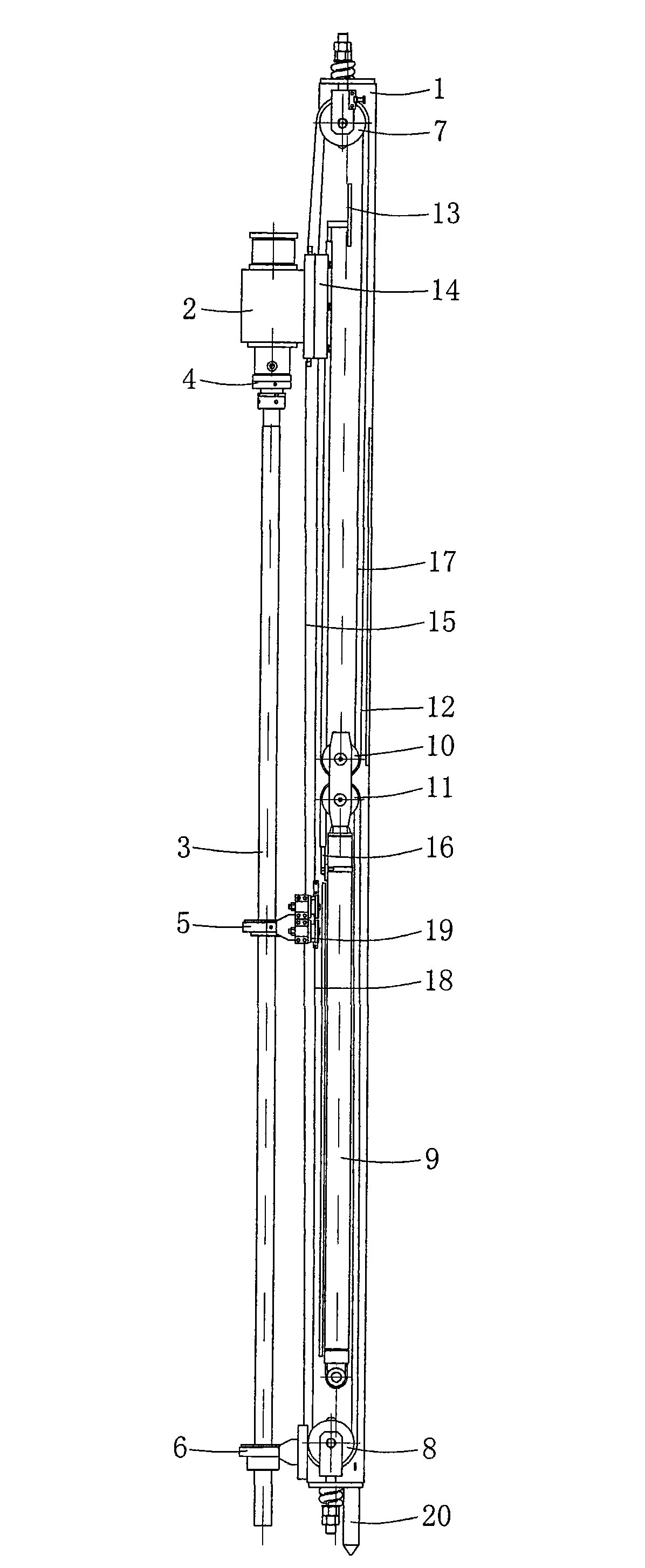

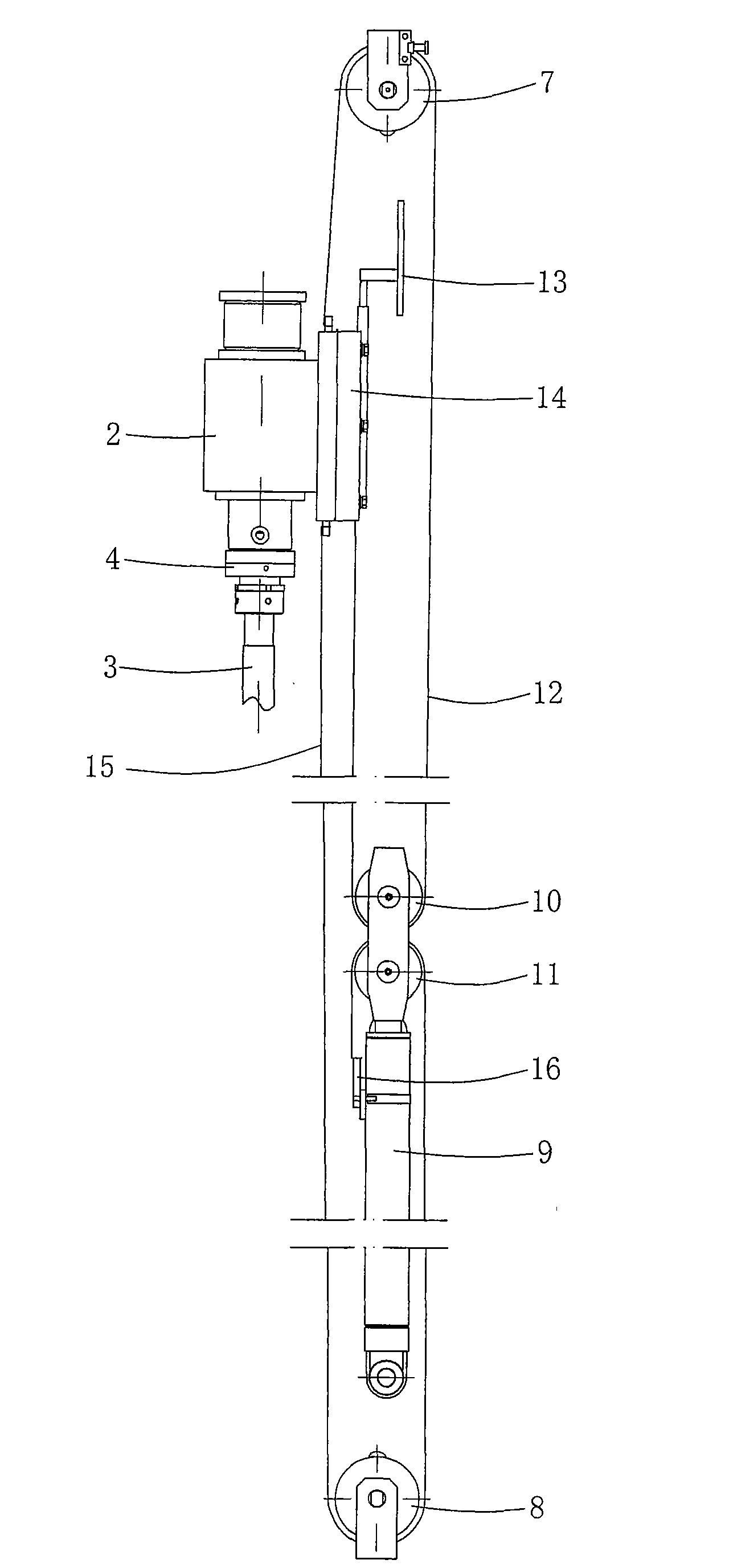

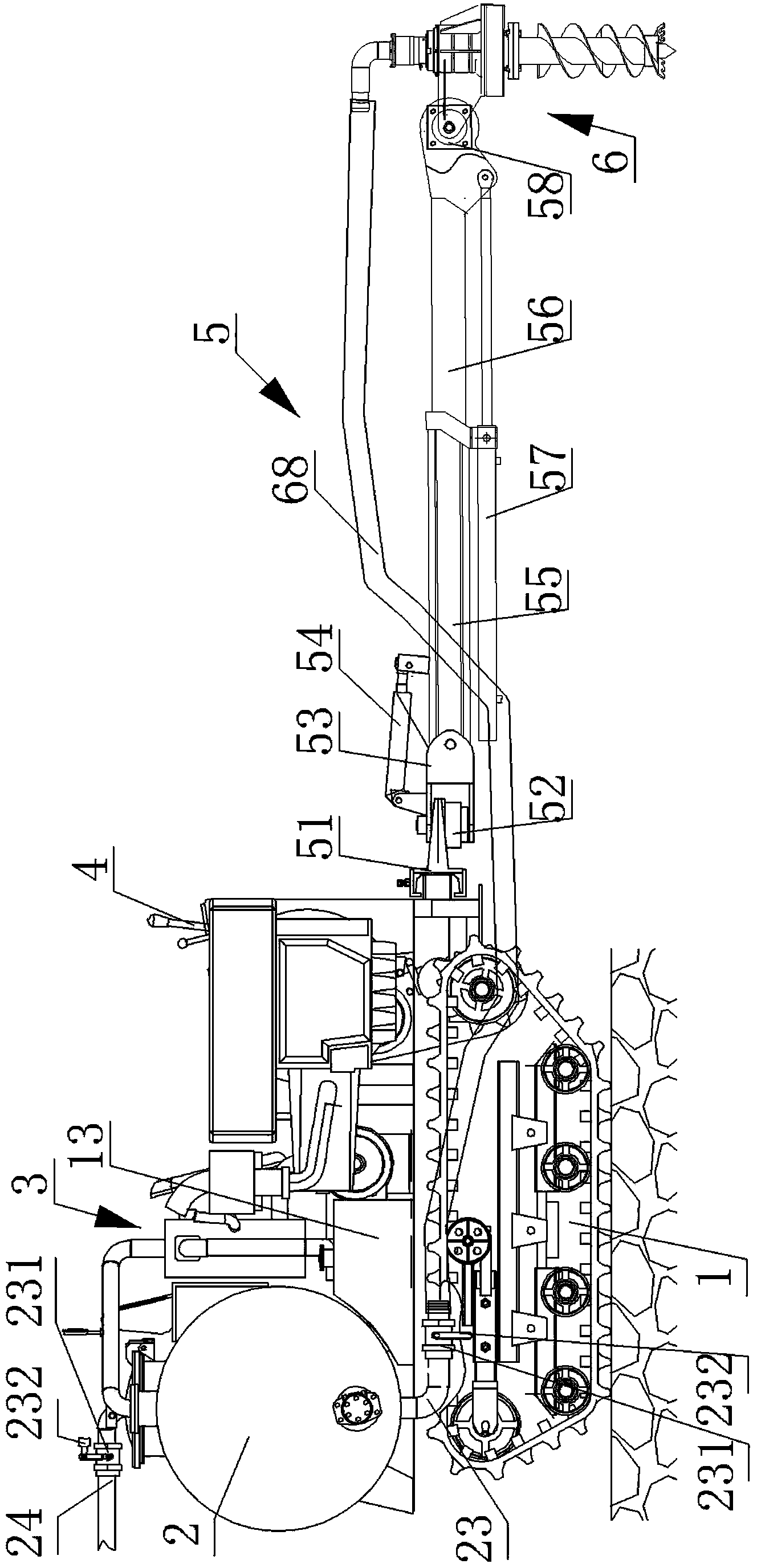

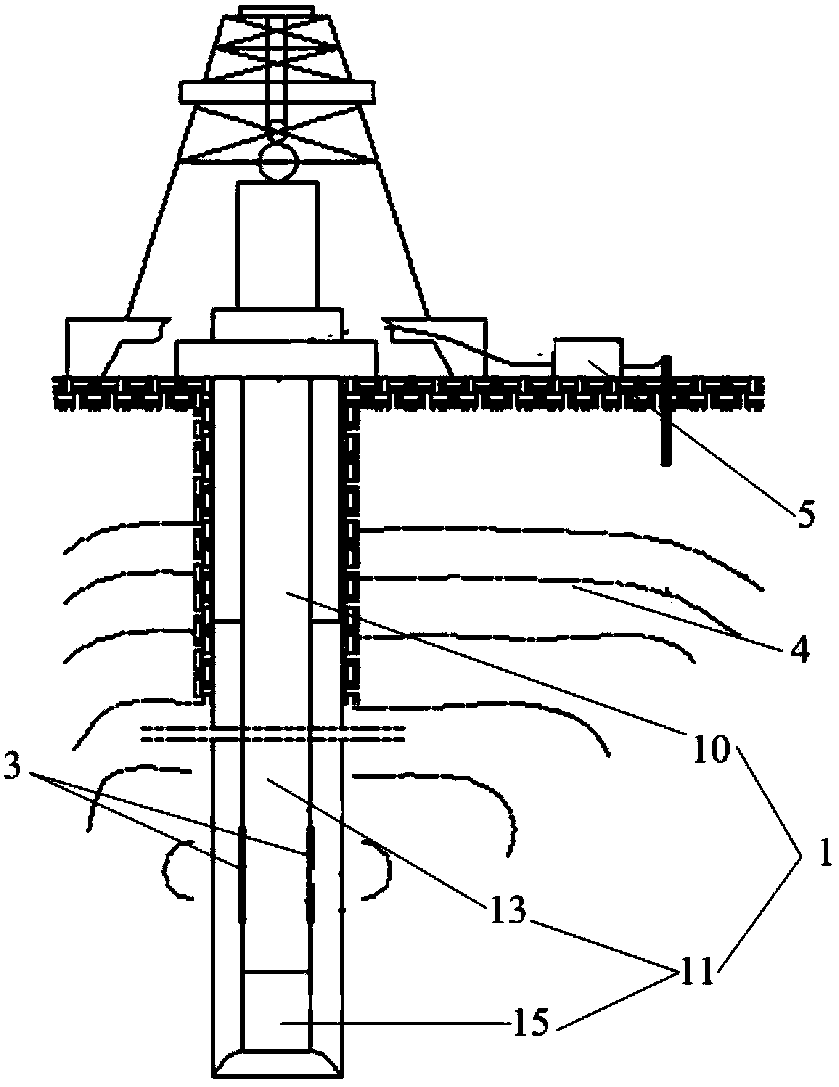

Hydraulic high-speed drill

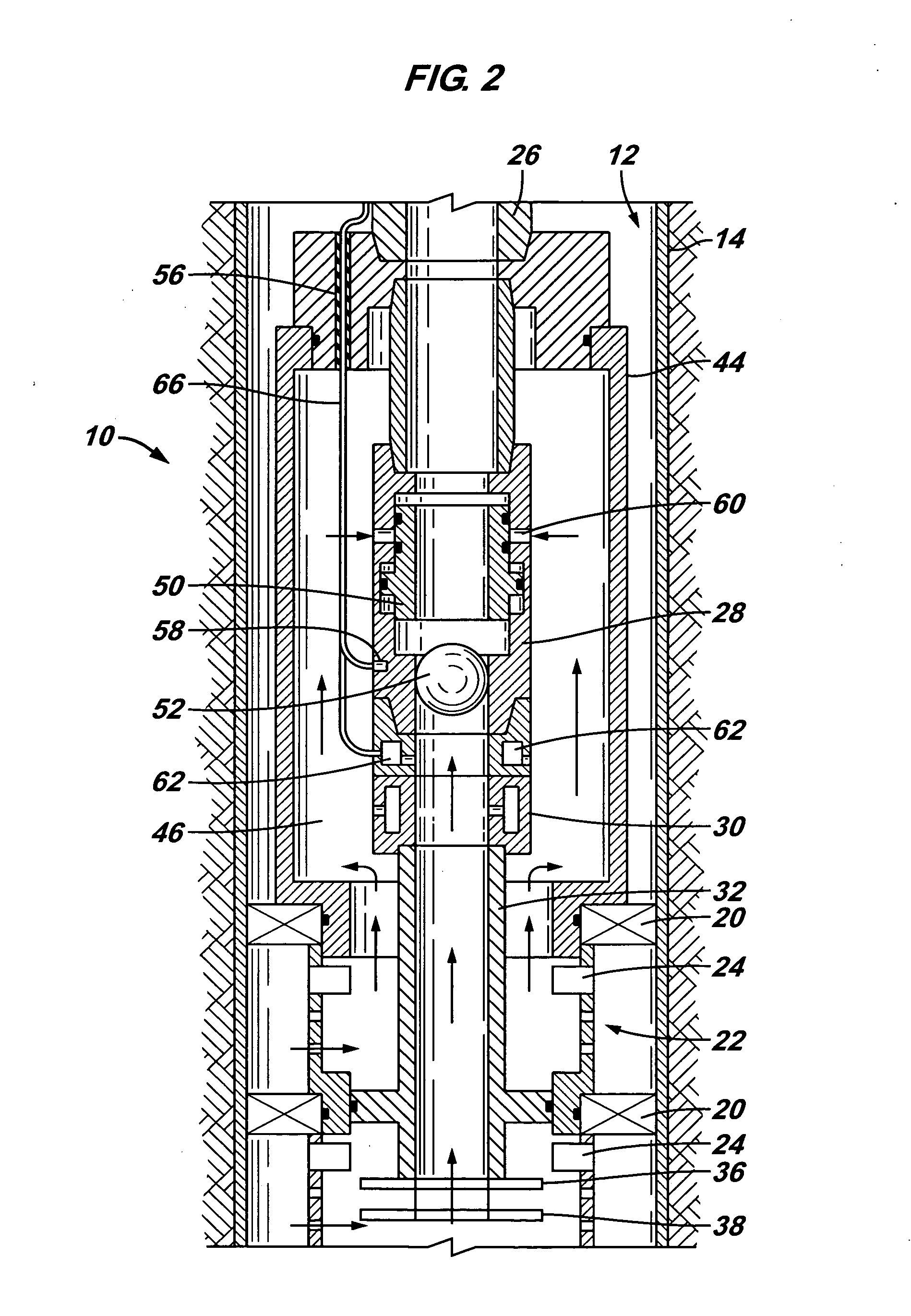

InactiveCN101575943AReduce labor intensityGood synchronizationDrilling rodsDerricks/mastsCouplingEngineering

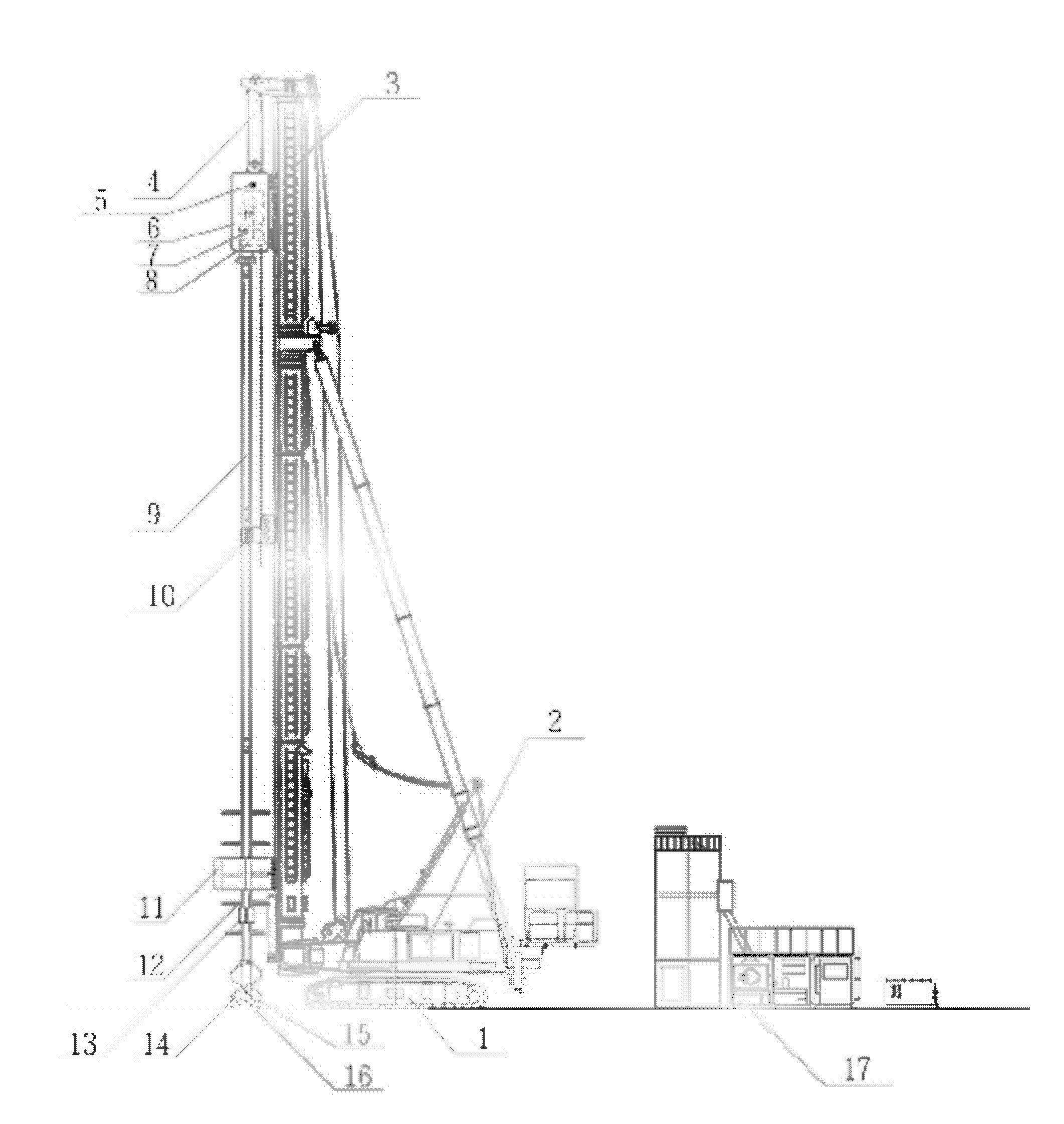

The invention discloses a hydraulic high-speed drill. The front end of the body of an excavator is hinged with the lower end of a drillrig seat through a movable arm; the drillrig seat is fixed in the middle part of the drillrig; a power head is arranged on the drillrig through a skateboard; the output shaft of the power head is connected with the upper end of a drill stem through a coupler; the lower end of the drill stem penetrates a movable locating frame and a fixed locating frame in sequence; the upper end of the drill stem is provided with a first fixed pulley; the lower end of the drillrig is provided with a second fixed pulley; the lower part of the drillrig is provided with a towing jack; two movable pulleys which are arranged up and down are arranged on a piston rod of the towing jack through a bracket; two chains and two steel ropes are arranged between the fixed pulleys and the movable pulleys; the power head and the drillrig can be pulled to move up and down through the fit between the chains and the pulleys, while the movable locating frame can be pulled to move up and down through the fit between the steel ropes and the pulleys. The hydraulic high-speed drill has the advantages of simple and compact structure, low cost, easy operation, convenient maintenance, flexible and reliable motion, low working intensity of the workers, high working efficiency and broad applicable range.

Owner:重庆勤牛工程机械有限责任公司

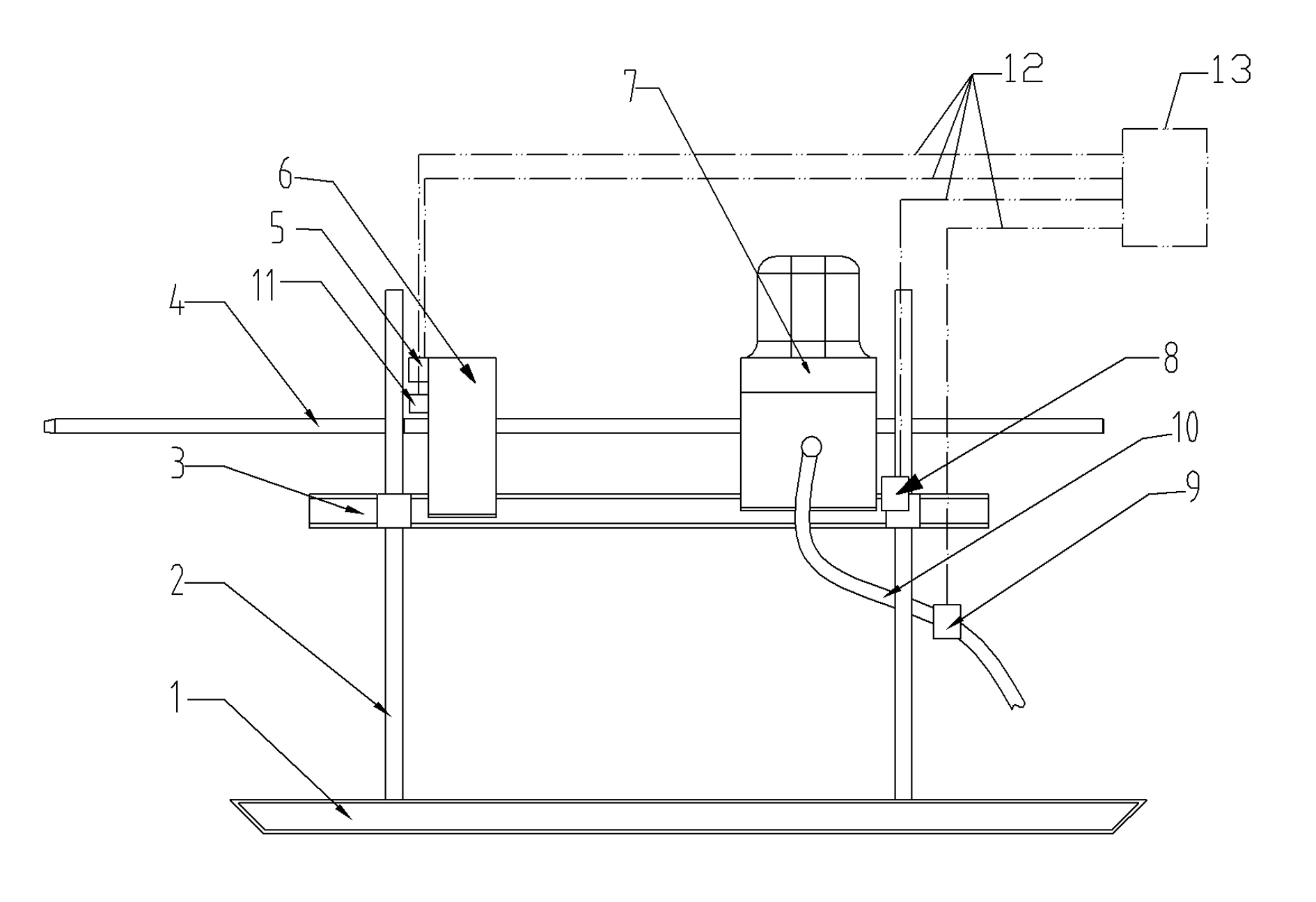

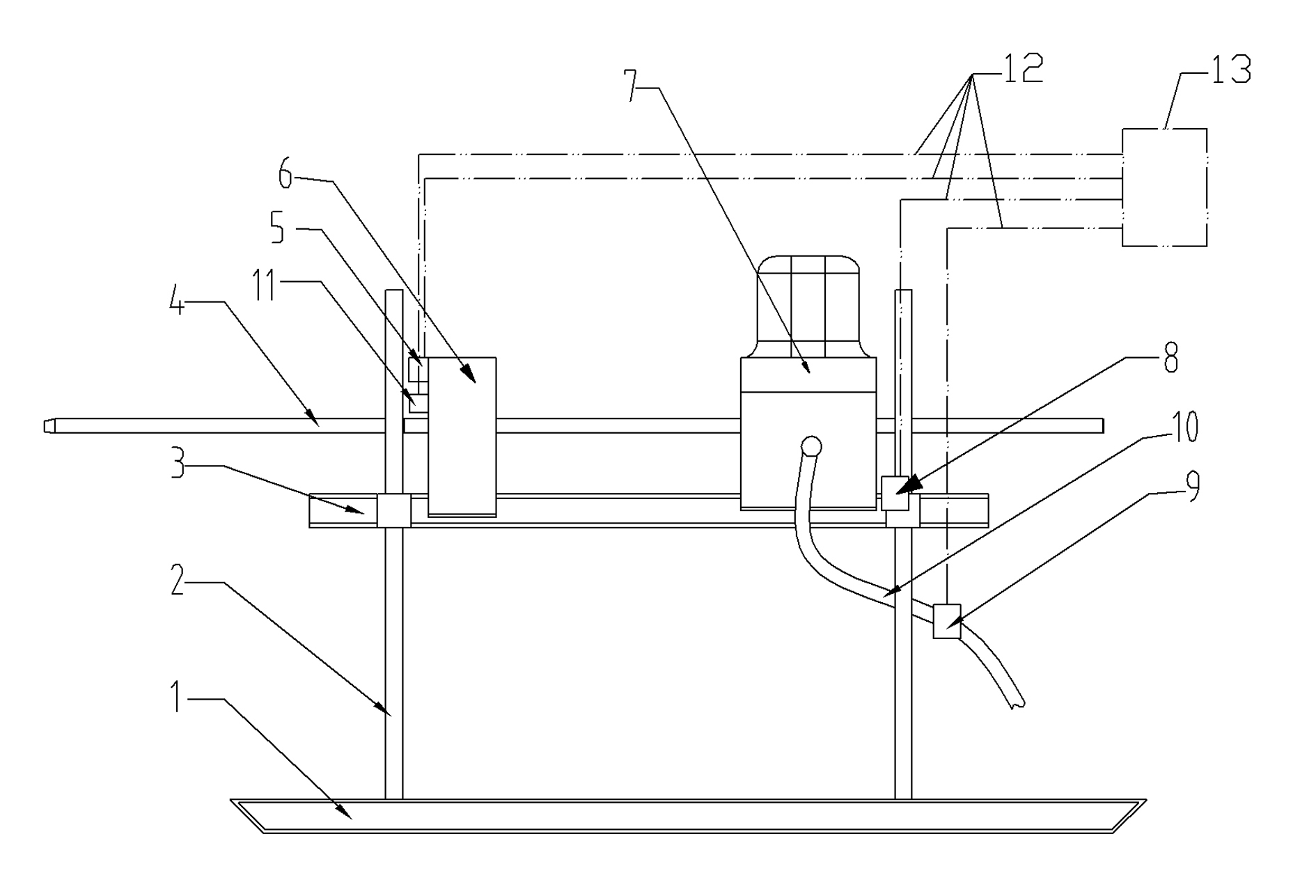

Deepwater drilling condition based marine riser mechanical behavior experiment simulation system and experiment method

Owner:SOUTHWEST PETROLEUM UNIV

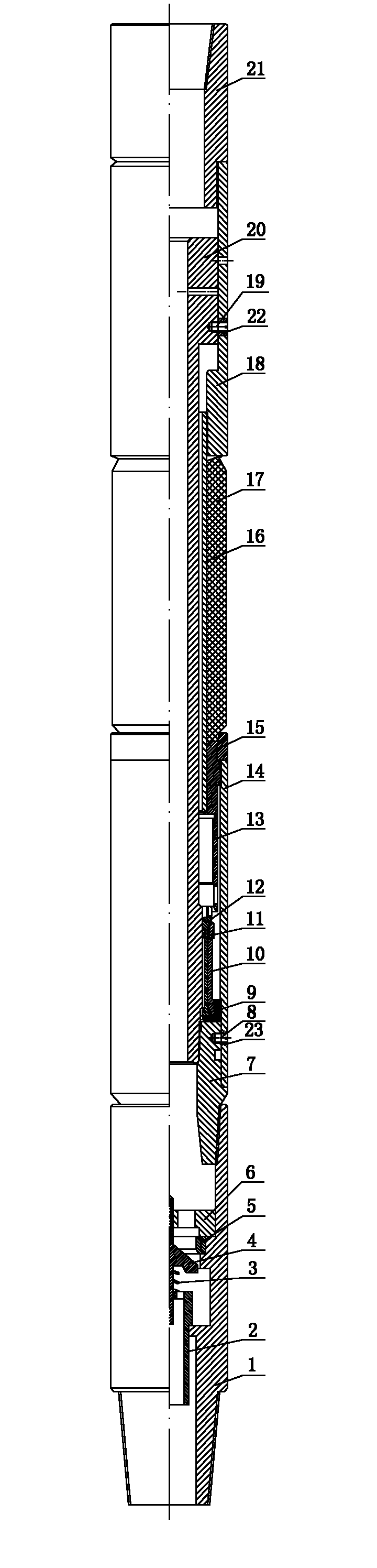

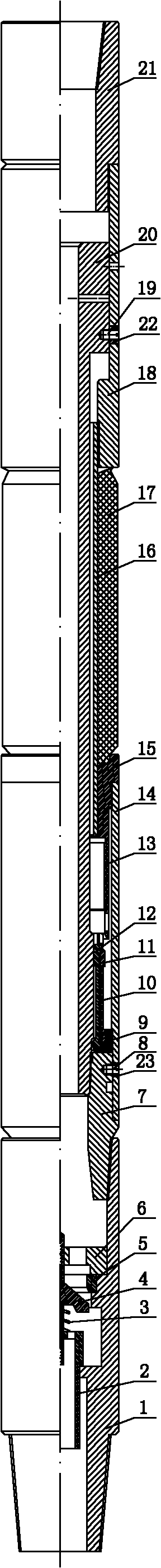

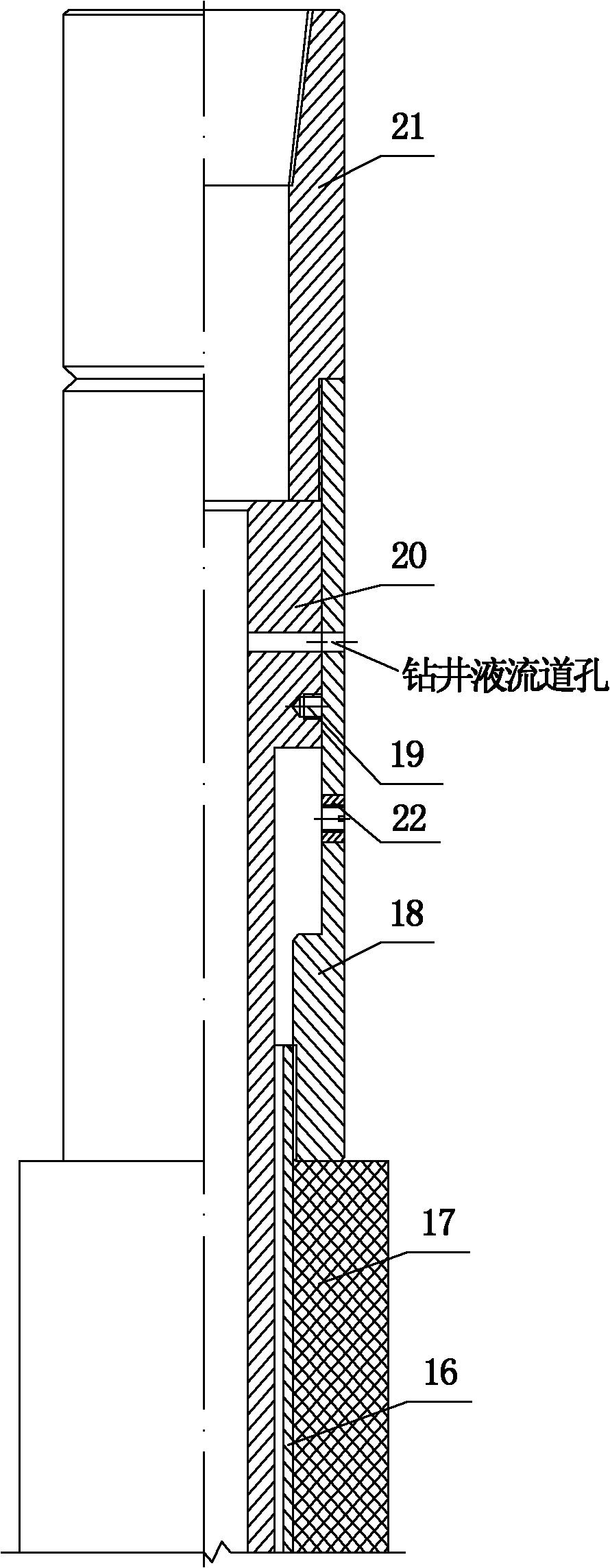

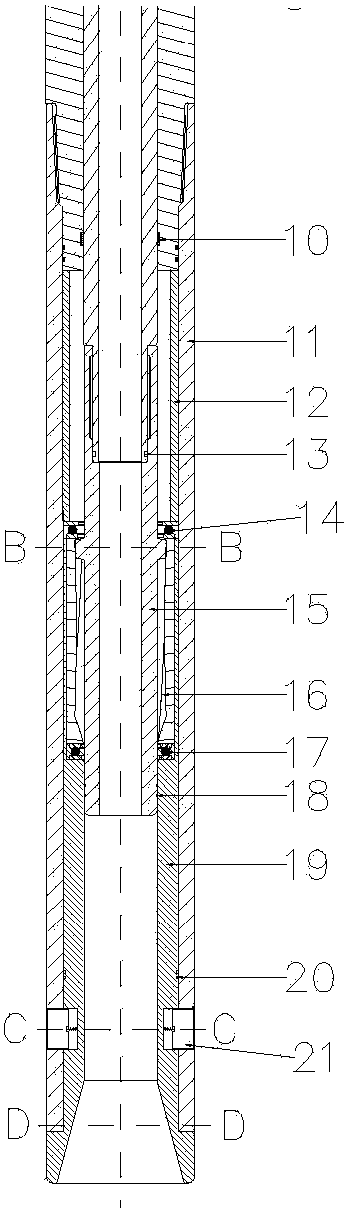

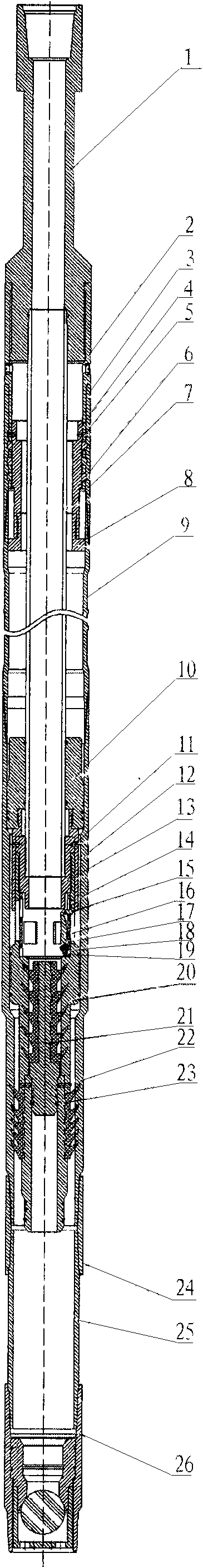

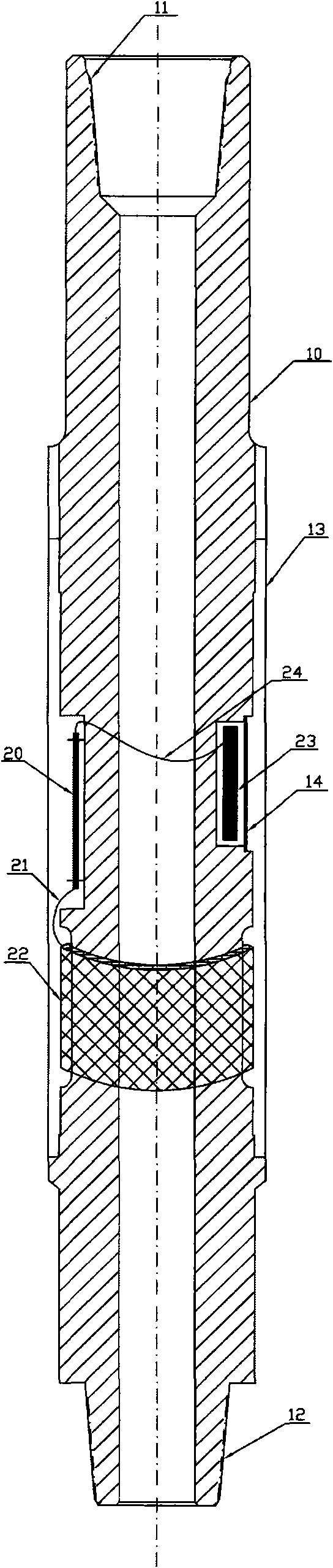

Mechanical underground all-in-one blowout preventer

InactiveCN101812981ASimple structureTo achieve the function of blowout preventionWell/borehole valve arrangementsSealing/packingBlowout preventerCheck valve

The invention relates to a mechanical underground all-in-one blowout preventer, which belongs to the well control equipment. The blowout preventer mainly comprises two parts, an arrow-type check valve and an outer annular packer, wherein the arrow-type check valve adopts the principle of one-way conduction of a valve core to realize annular blowout prevention in a drill stem, and the outer annular packer mainly comprises a plastic cylinder, a set shear pin, an unset shear pin, a locking component and the like. When the set shear pin is cut off, an upper jacket compresses the plastic cylinder downwards to realize sealing under the effect of the gravity of the upper drill stem, and simultaneously drilling fluid circulating runner ports arranged on an inner sleeve and the upper jacket are communicated to realize circulation of the drilling fluid. The invention adopts the fully mechanical operating principle, has the advantages of simple and reliable structure and easy realization, and can realize the sealing of the internal and external annular sealing of the underground drill stem, thereby achieving the function of preventing the blowout, improving the handling efficiency of underground accidents, and reducing the well control risk.

Owner:SOUTHWEST PETROLEUM UNIV

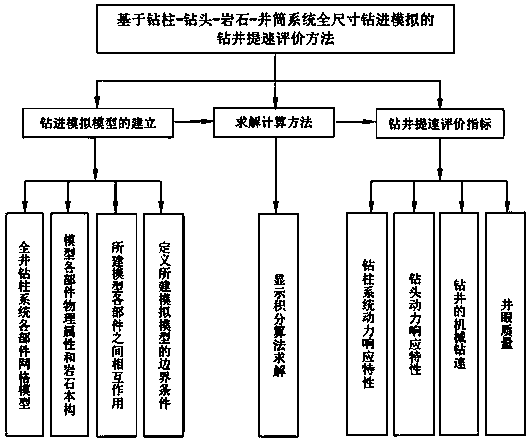

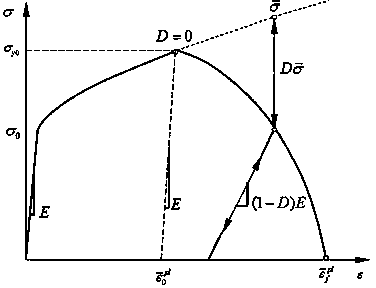

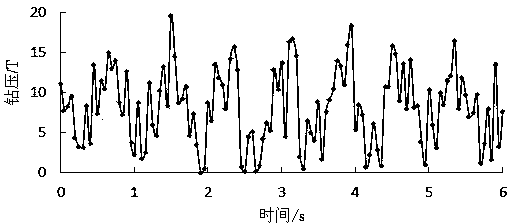

Drilling speed increase evaluation method based on drill stem-drill bit-rock-shaft system full-scale drilling simulation

The invention relates to a drilling speed increase evaluation method based on drill stem-drill bit-rock-shaft system full-scale drilling simulation. According to the technical scheme, the method comprises the following steps: firstly, establishing a finite element model based on drill stem-drill bit-rock-shaft system full-scale drilling simulation, then, analyzing and solving the established model according to the explicit integration algorithm, and finally, evaluating the drilling speed increase according to established evaluation criteria. The process of establishing the finite element model comprises the following steps: establishing a grid model of all components, defining the physical properties of the components and the constitutive relation and breaking failure criteria of rock, establishing a drill tool and well wall random contact and impact model and a drill bit and rock interaction model, and defining boundary conditions. According to the method, the real-time drilling and rock breaking process is simulated with drill bit rock breaking as the boundary conditions of the lower end of the drill stem, and therefore simulation results are closer to the reality, and references are provided for on-site drilling design, drilling parameter optimization, drill bit model selection and drilling speed increase evaluation.

Owner:SOUTHWEST PETROLEUM UNIV

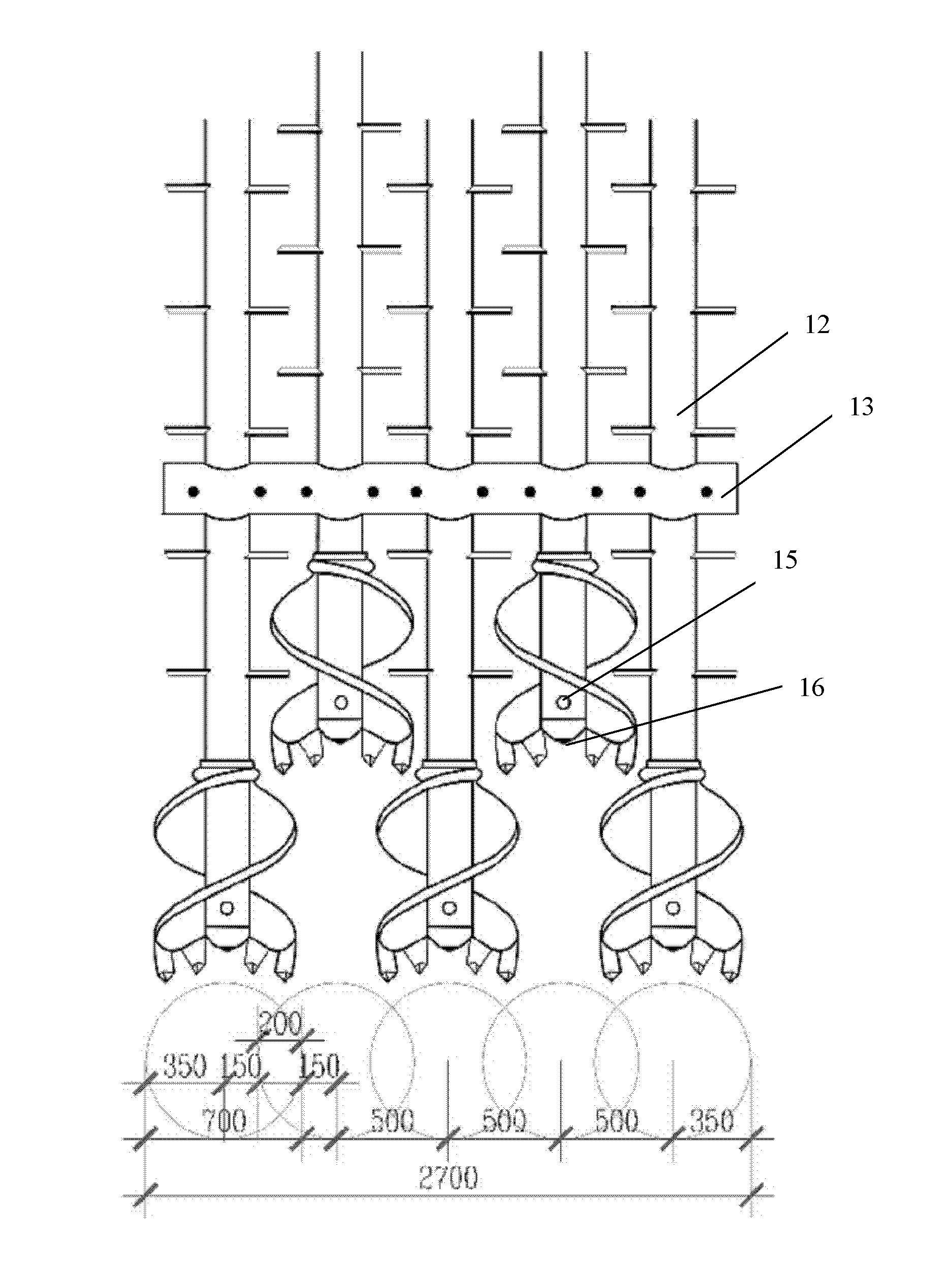

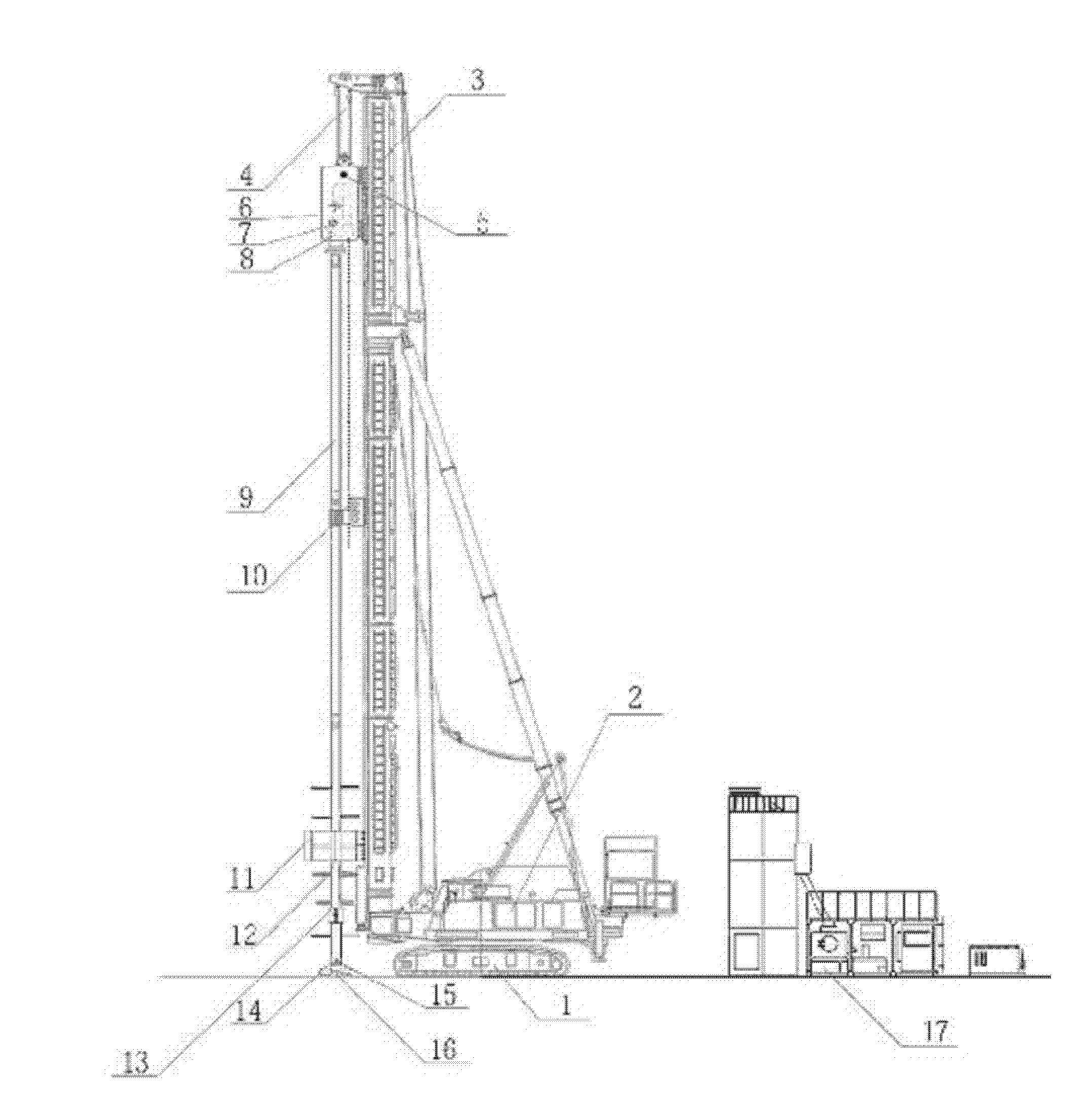

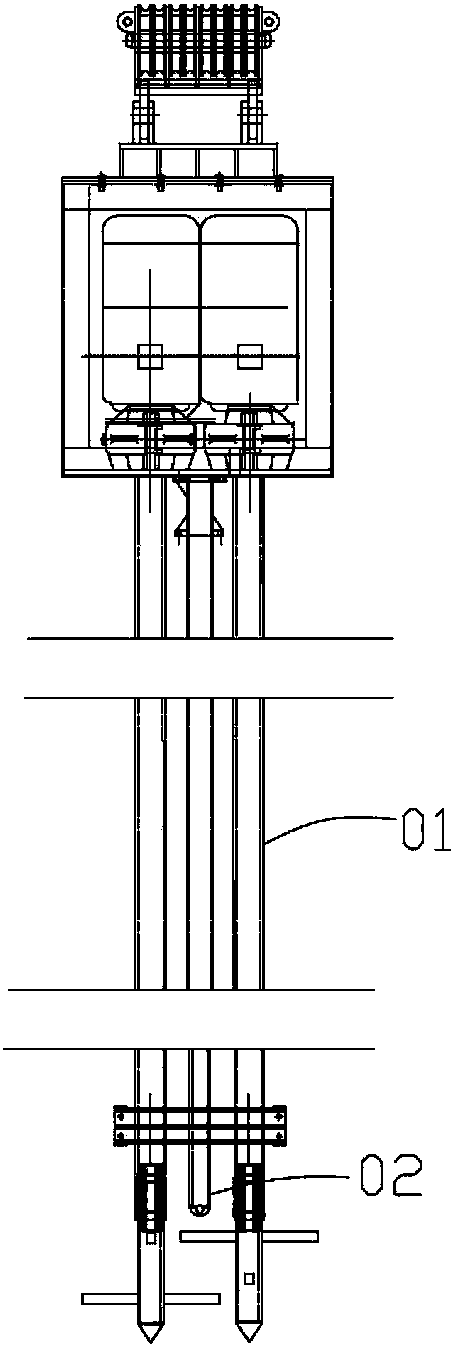

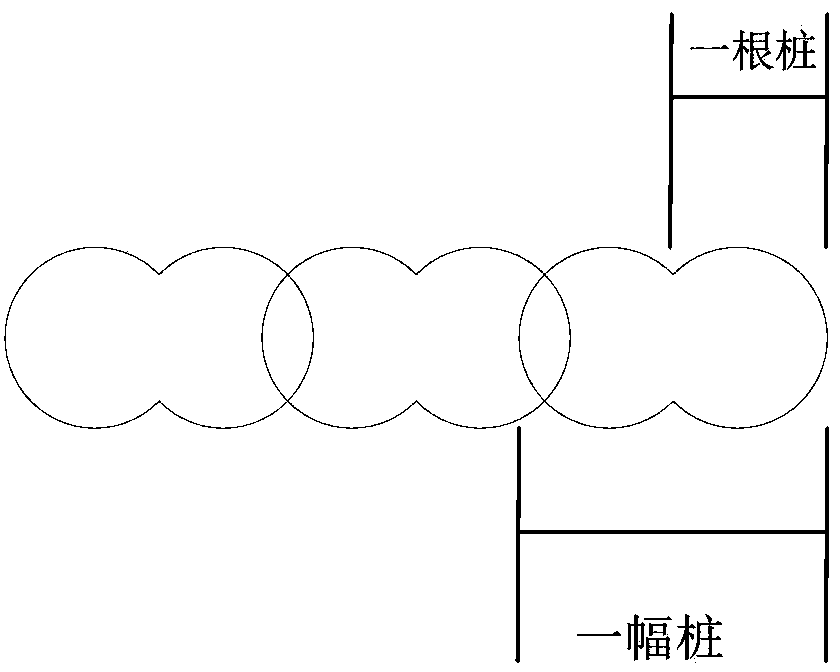

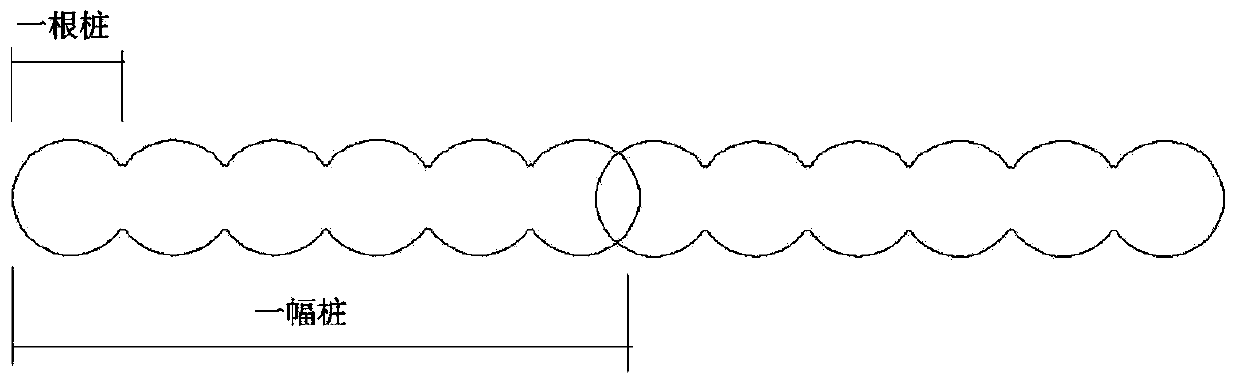

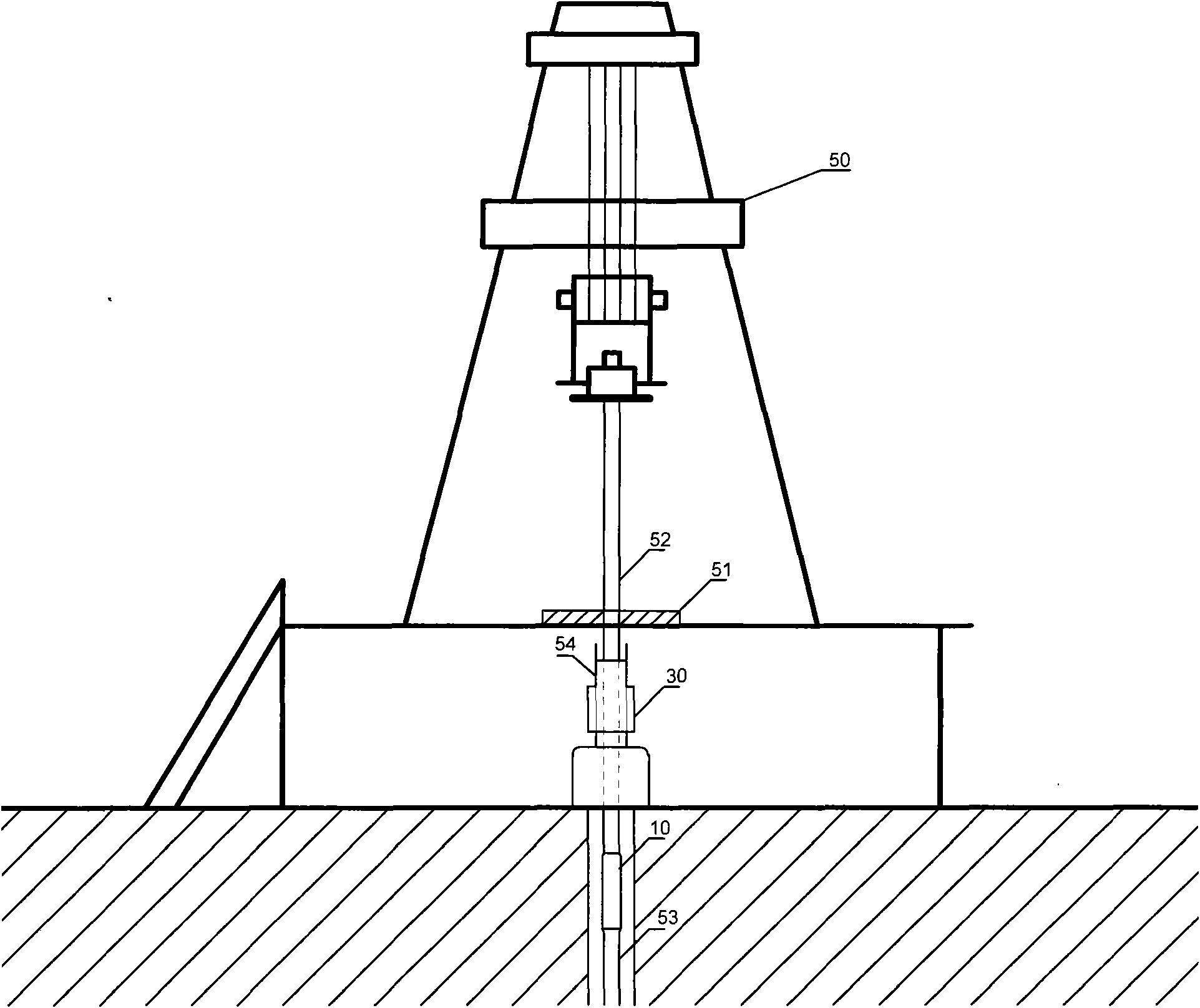

Continuous multi-shaft cement mixing pile device and construction method

InactiveCN102493438AReduce rotational loadImprove securityDrilling rodsExcavationsReducerCement grout

The invention relates to a continuous multi-shaft cement mixing pile device and a construction method; the multi-shaft continuous cement mixing pile device comprises a walking type main machine, a crawler type main machine, a winding engine, a guide rod, a steel wire rope, an air and grout inlet, a power head, a speed changing box, a reduction box, drill stems, middle supporting frames, lower supporting frames, winged drill stems, hoops, drill bits, air injection ports, grout spraying ports and a background cement grout stirring system, wherein the winding engine and the guide rod are fixed on the main machines, the power head is connected with a pulley arranged at the top end of the guide rod through the steel wire rope; the steel wire rope drives the power head to be lifted up and down; the power head is sequentially connected with the multiple drill stems through the speed changing box and the speed reducer; the middle supporting frames are arranged in the middle parts of the multiple drill stems; the lower supporting frames are arranged at the lower parts of the multiple drill stems; the winged drill stems are connected with the lower ends of the drill stems; the hoops are arranged on the winged drill stems; the drill bits are connected with the lower end of the winged drill stems; and the air injection ports and the grout spraying ports are arranged on the drill bits. Compared with the prior art, the continuous multi-shaft cement mixing pile device has the advantages of noiselessness, non vibration, ensured safety and quality, cost reduction, high efficiency, shortened construction period and the like.

Owner:SHANGHAI CHENGDI CONSTR

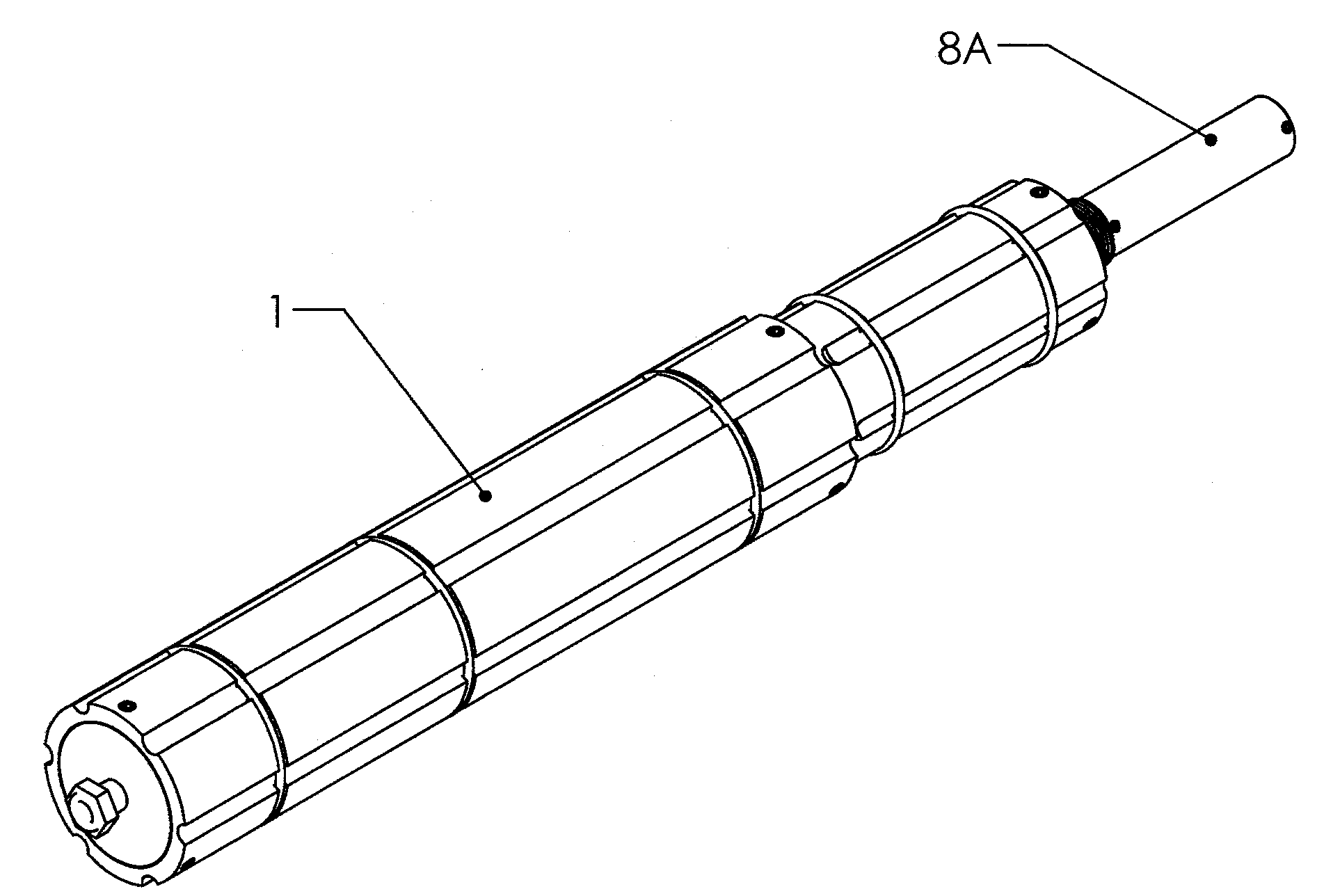

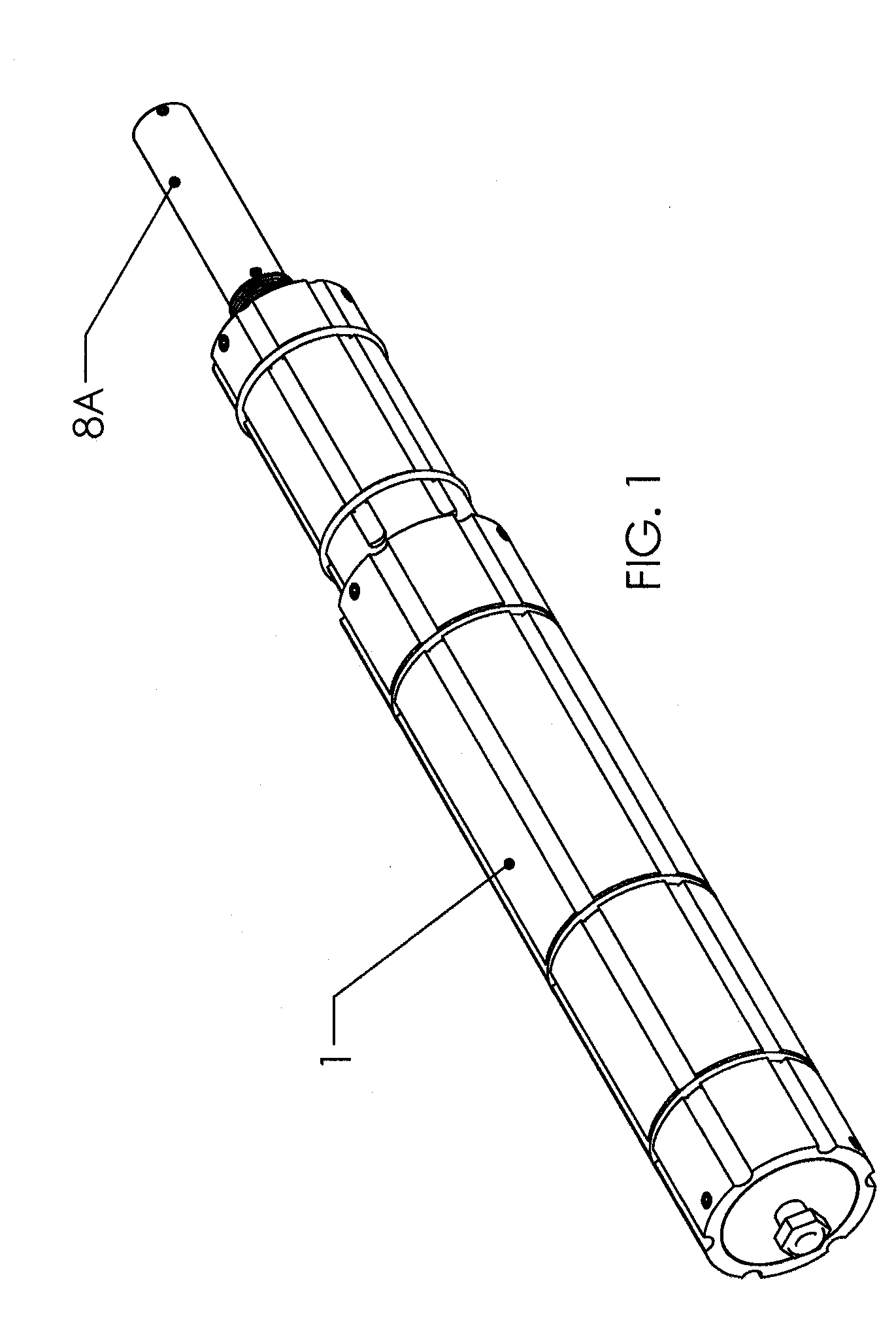

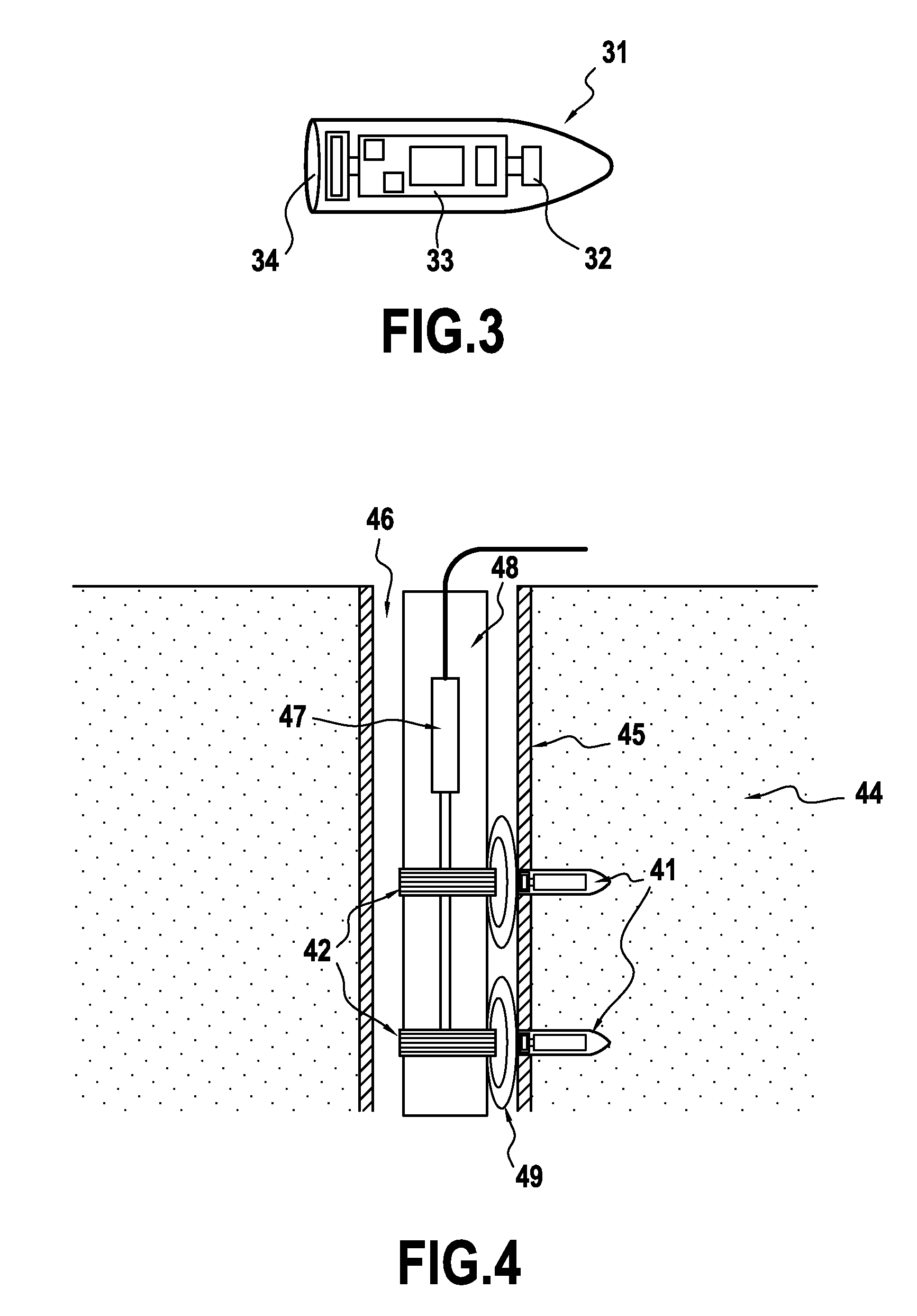

Counterbalance enabled power generator for horizontal directional drilling systems

Owner:WEBB CHARLES T

Counterbalance Enabled Power Generator For Horizontal Directional Drilling Systems

An electrical generating system is used for a horizontal directional drilling system. The drilling system has a generally horizontal drill stem that rotates. A generator has first and second components. The first component rotates with the drill stem, while the second component is able to rotate with respect to the first component. An eccentric mass is rotatably mounted inside of the drill stem and is coupled to the second component, wherein as the drill stem rotates, relative rotational motion is produced between the first and second components and the generator produces electrical power. The eccentric mass is mounted on two spaced apart mounting points inside of the drill stem. The generator provides power to a sonde. The generator is in a housing which has flow channels that allow drilling fluid to flow through the drill stem.

Owner:WEBB CHARLES T

Six-shaft cement mixing pile machine

InactiveCN103362121ASimple structureEasy maintenanceDrilling rodsDrilling casingsWork periodDrill stem test

Owner:SHANGHAI STRONG FOUND ENG

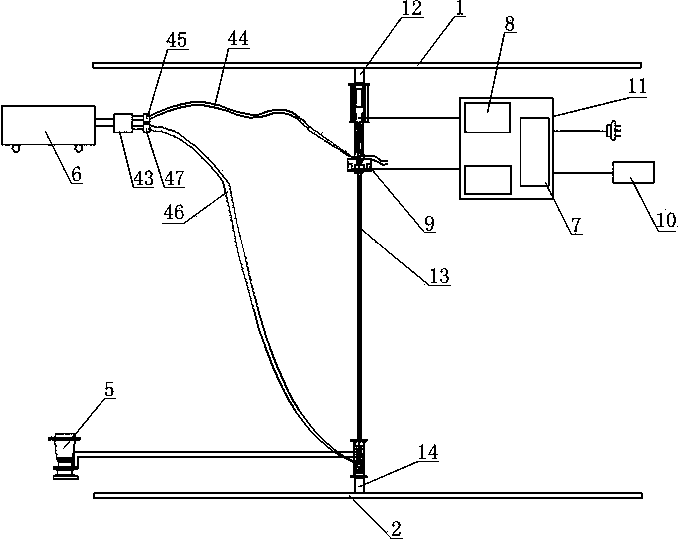

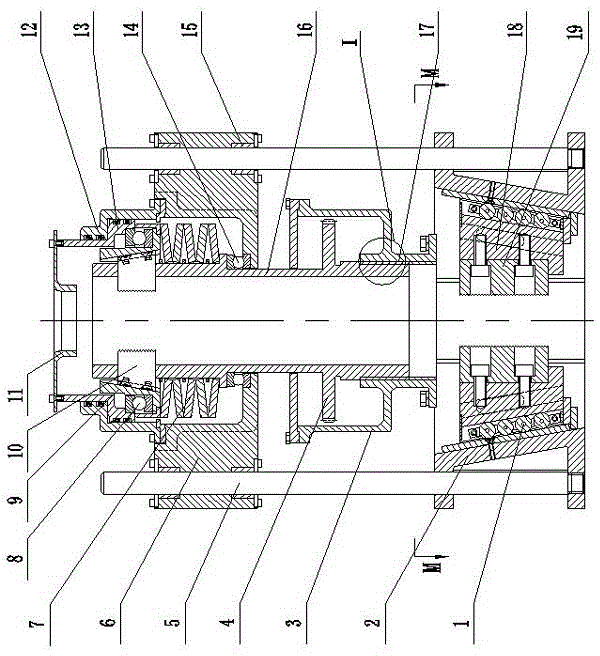

Cone penetration device and cone penetration testing method

ActiveCN102002932ASimple processImprove work efficiencyEarth material testingIn situ soil foundationEngineeringDrilling machines

The invention discloses a cone penetration device. The cone penetration device comprises a cone penetration machine which is provided with a cross beam. The cone penetration device also comprises a protection pipe installing device. The protection pipe installing device contains a protection pipe component, a protection pipe cap, a driving device fixed on the cross beam, a drill stem, wherein the driving device is provided with a rotating part; the lower end of the drill stem is connected with the upper end of the protection pipe component through the protection pipe cap; and the drill stem can be driven by the rotating part to rotate and move downward along the axis of the drill stem. The invention also discloses a cone penetration testing method adopting the cone penetration device. By adopting the method of the invention, the defect that when a deep cone penetration test is performed, the cone penetration machine and a drilling machine used for installing the protection pipe are required to be used alternately, can be solved; and only one device can be used to complete the cone penetration test, thus increasing the efficiency and reducing the equipment cost.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

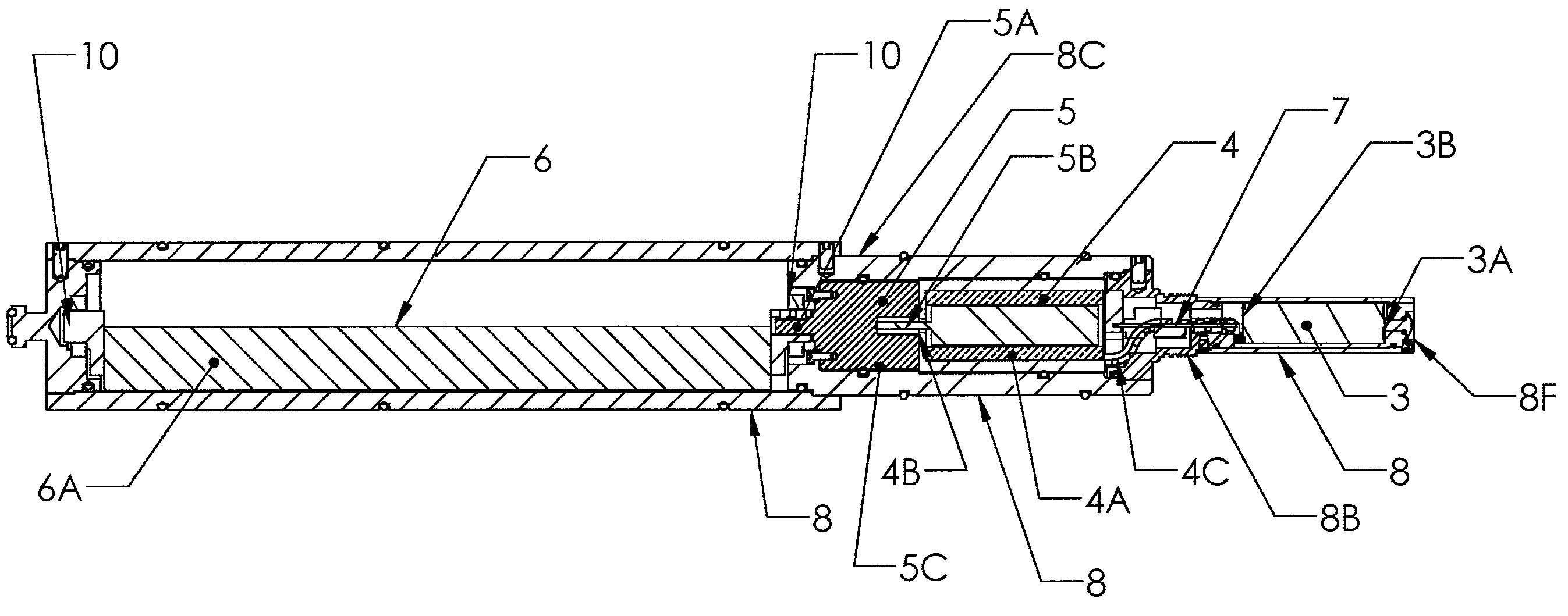

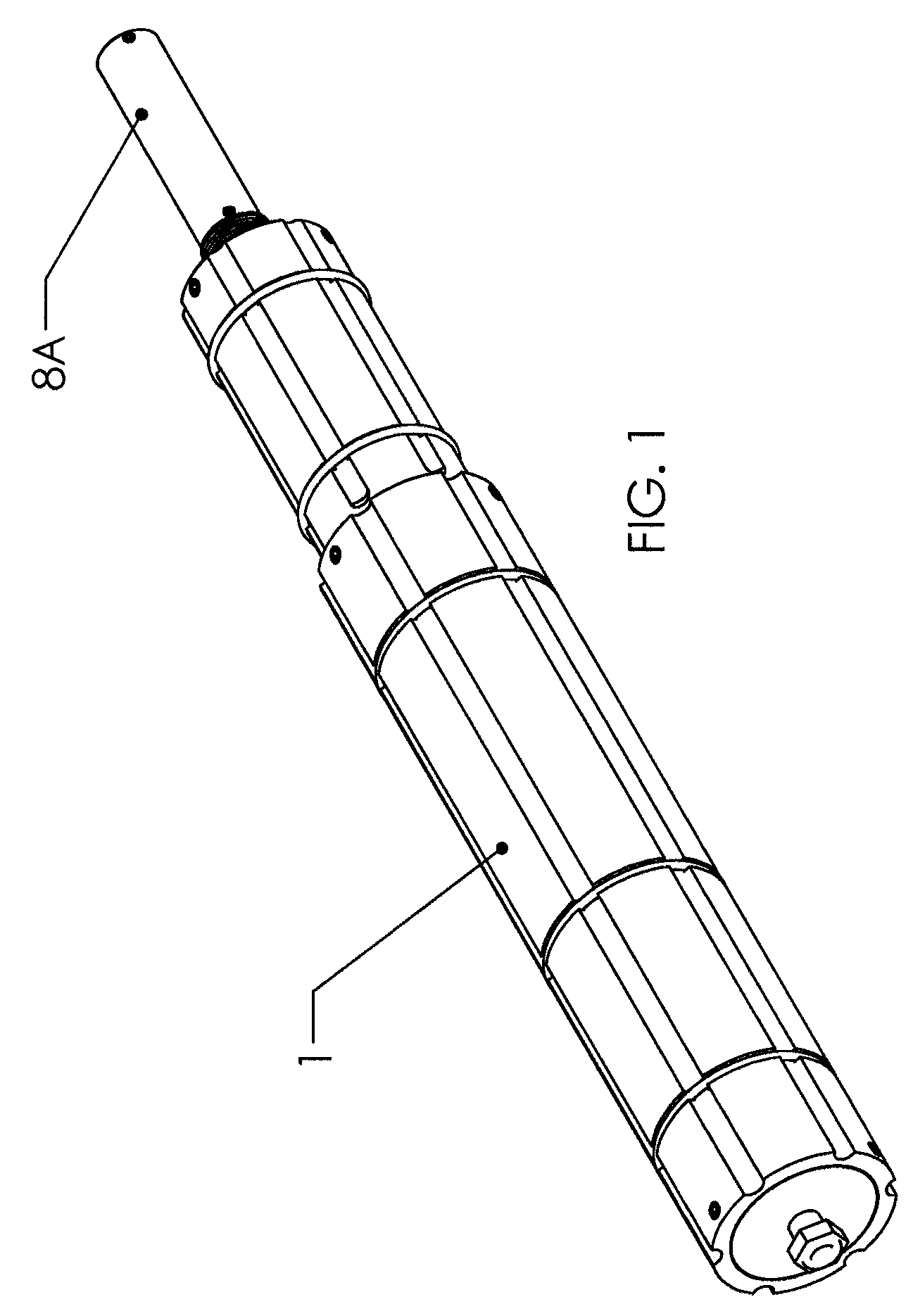

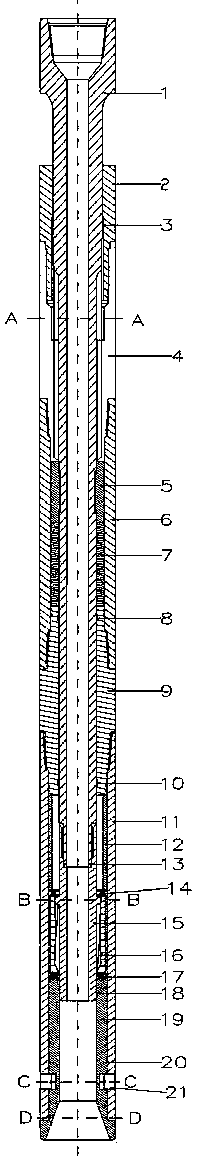

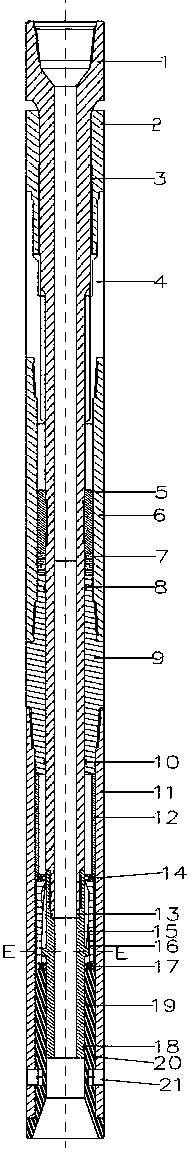

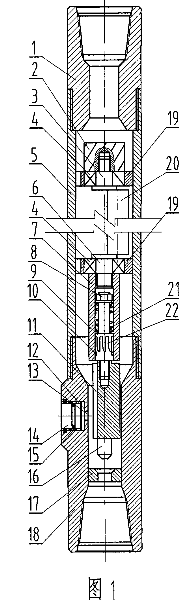

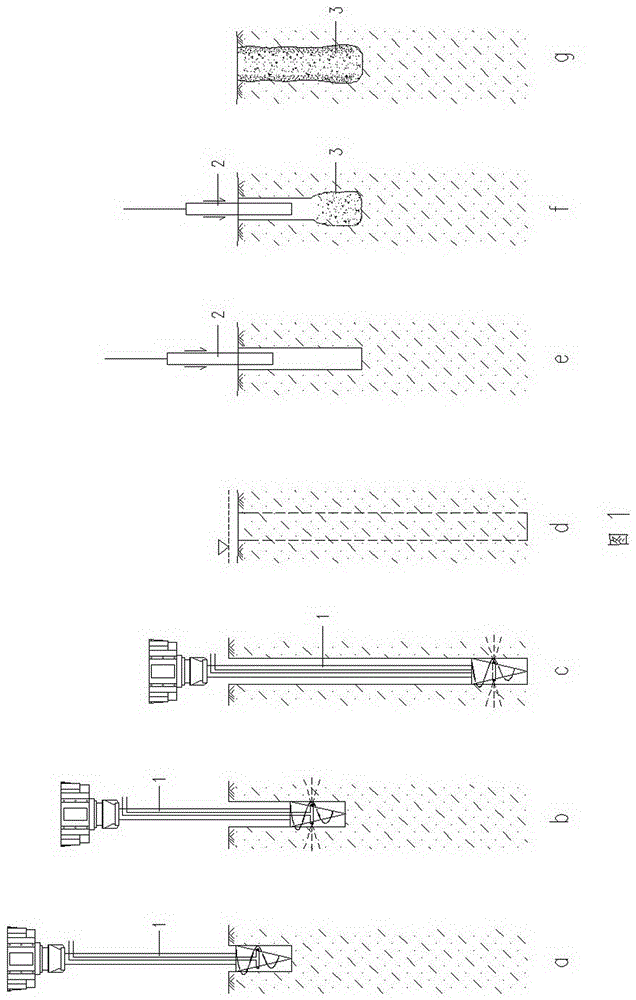

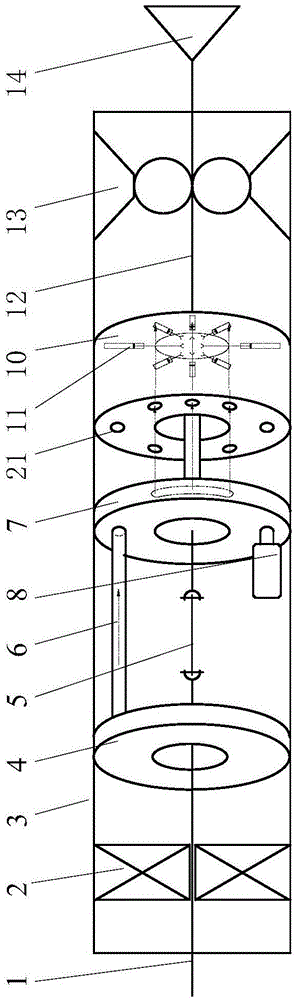

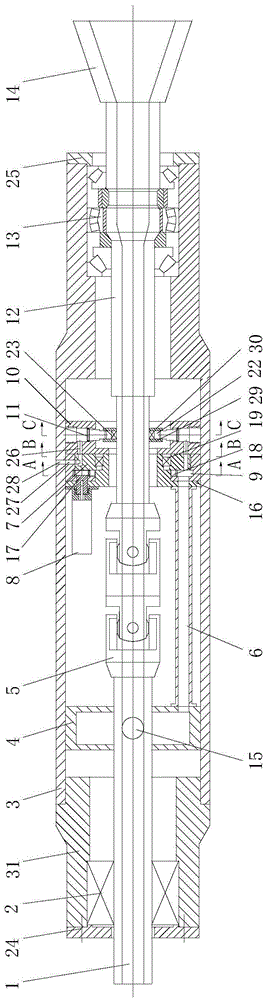

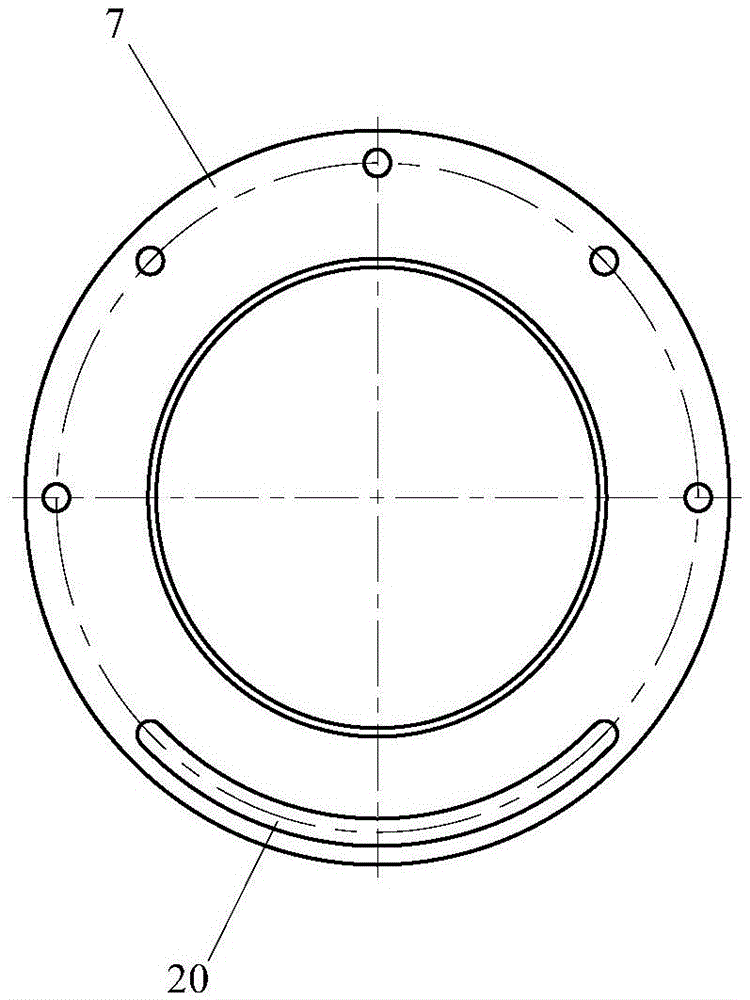

Device for converting longitudinal vibration of drill stem into torsional impact of drill bit

ActiveCN104499941ATorque stability and balanceReduce torsional oscillationsVibration devicesVibration drillingEngineeringLongitudinal vibration

The invention relates to a device for converting the longitudinal vibration of a drill stem into the torsional impact of a drill bit. A longitudinal vibration assembly comprises a vibration transmission shaft which is connected with a limiting sleeve and a spline body, wherein a vibrator is connected to the bottom of the vibration transmission shaft, and an impact lug is arranged on the vibrator; a resetting torsion transmission assembly comprises a spline shell, a spring, a transition joint and an impactor shell; the upper part and the lower part of the spring are respectively in contact with the lower part of the limiting sleeve and the upper part of the transition joint; a torsion generation transmission assembly comprises an impact hammer; the impact hammer is arranged in a drill bit base, a spiral groove is formed in the impact hammer, and the impact lug is matched with the spiral groove; an inner spline is arranged in the spline shell, and the spline body is matched with the inner spline; a shell spline is arranged on the lower end of the impactor shell; a base body spline is arranged at the lower end of the drill bit base; the shell spline is matched with the base body spline. The device disclosed by the invention can be used for converting the harmful longitudinal vibration of the drill stem into circumferential high-frequency torsional impact vibration of the drill bit in the drilling process, so that the mechanical drilling speed is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

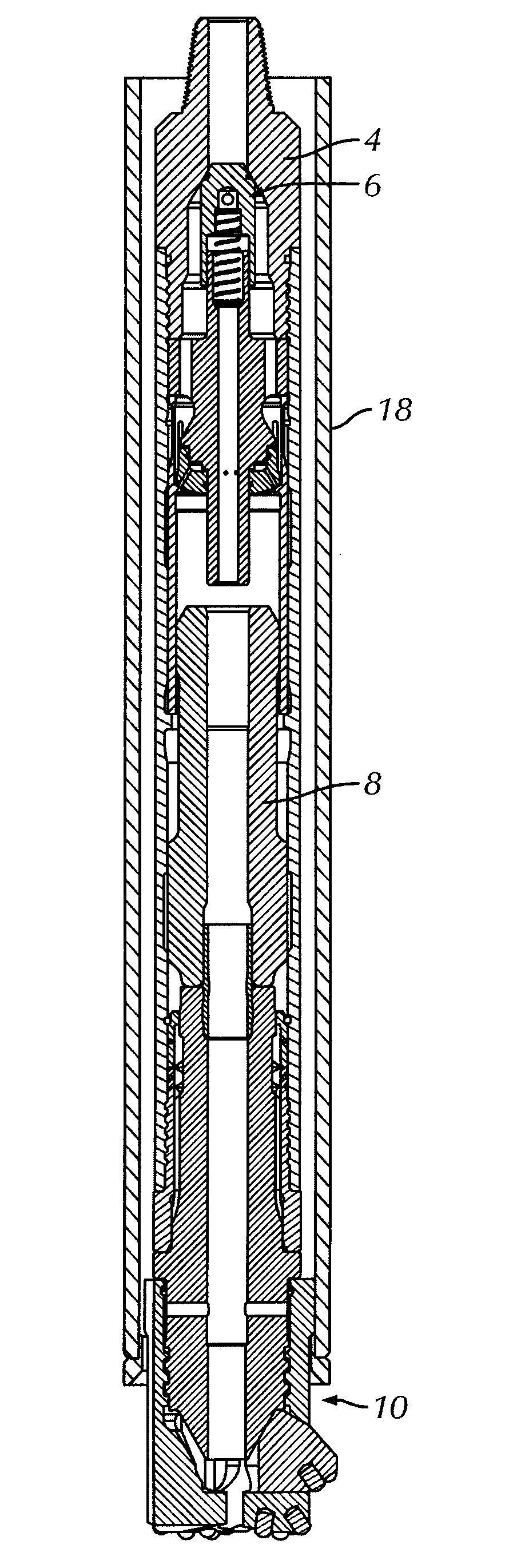

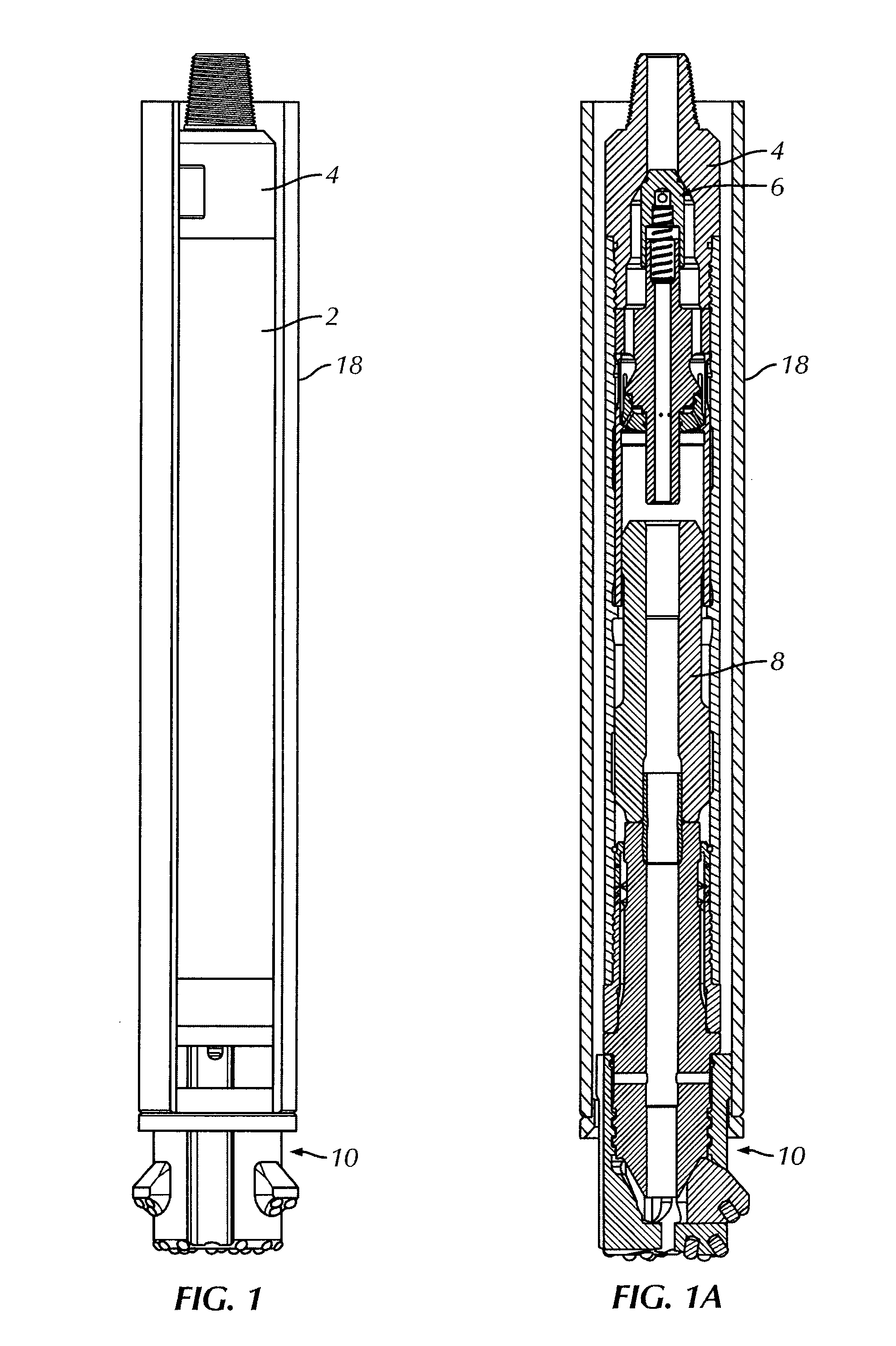

Rotary pushing type guiding drilling tool

ActiveCN101037927AQuality improvementSimple structureDirectional drillingWell drillingPressure difference

Rotary pull-against type guided drilling tool, comprising crossover sub, upper mandrel, bearing, casing, lower mandrel, guiding tubular, guiding shaft, guiding valve, plunger, throttling rod, throttling ring, bit sub and stabilizing block. Principle of the invention is that by using pressure difference formed by circulation of drilling fluid in drill stem inside and outside, the plunger is motivated against borehole wall, periodical side force is applied to the drill head, and the force direction can be adjusted by the guiding valve, borehole deviation and orientation of the borehole is also regulated and controlled. Advantages of the guided drilling tool are that structure is simple, operation is reliable, which has good controllability and adaptability. Drilling efficiency and well body quality can be effectively improved, and production cost is reduced.

Owner:倪红坚

Down-the-hole drill hammer having an extendable drill bit assembly

ActiveUS20110240373A1Cost-effective and reliable under reaming operationSimple and reliable processDrill bitsBorehole drivesPetroleum engineeringDrill hole

A down-the-hole drill hammer assembly includes a casing, a drill stem, a drilling lug segment and a pilot drill bit is provided. The drill stem is housed within the casing and includes an abutment surface. The drilling lug segment is slidably engaged with a distal end of the drill stem and movable between an initial configuration and an extended configuration. The drilling lug segment includes a proximal end engageable with the abutment surface of the drilling lug segment. The drill stem is movable between first and second positions within the pilot drill bit. In moving to the second position, the drill stem slidingly engages the drilling lug segment and moves the drilling lug segment to the extended configuration.

Owner:CENTER ROCK INC

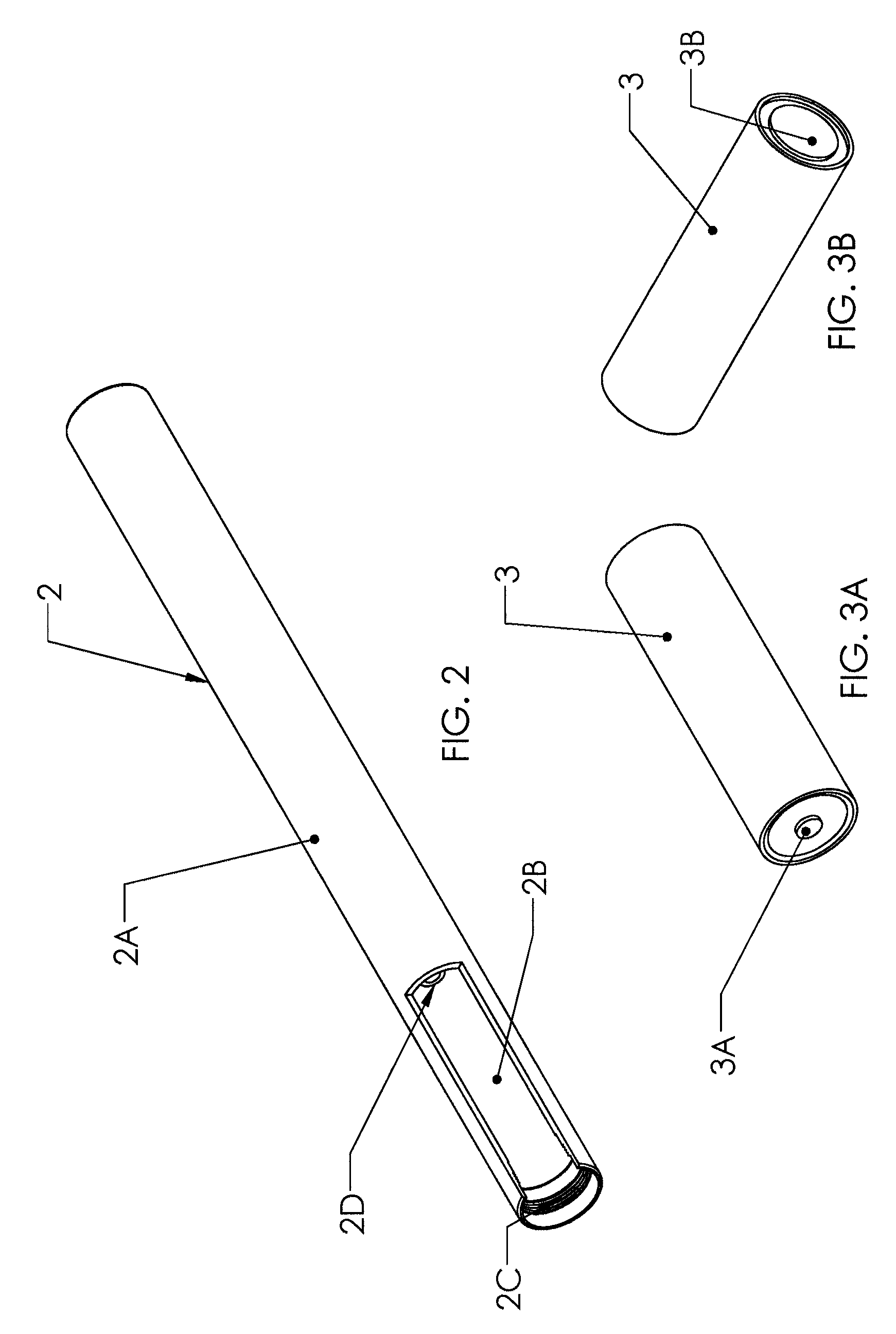

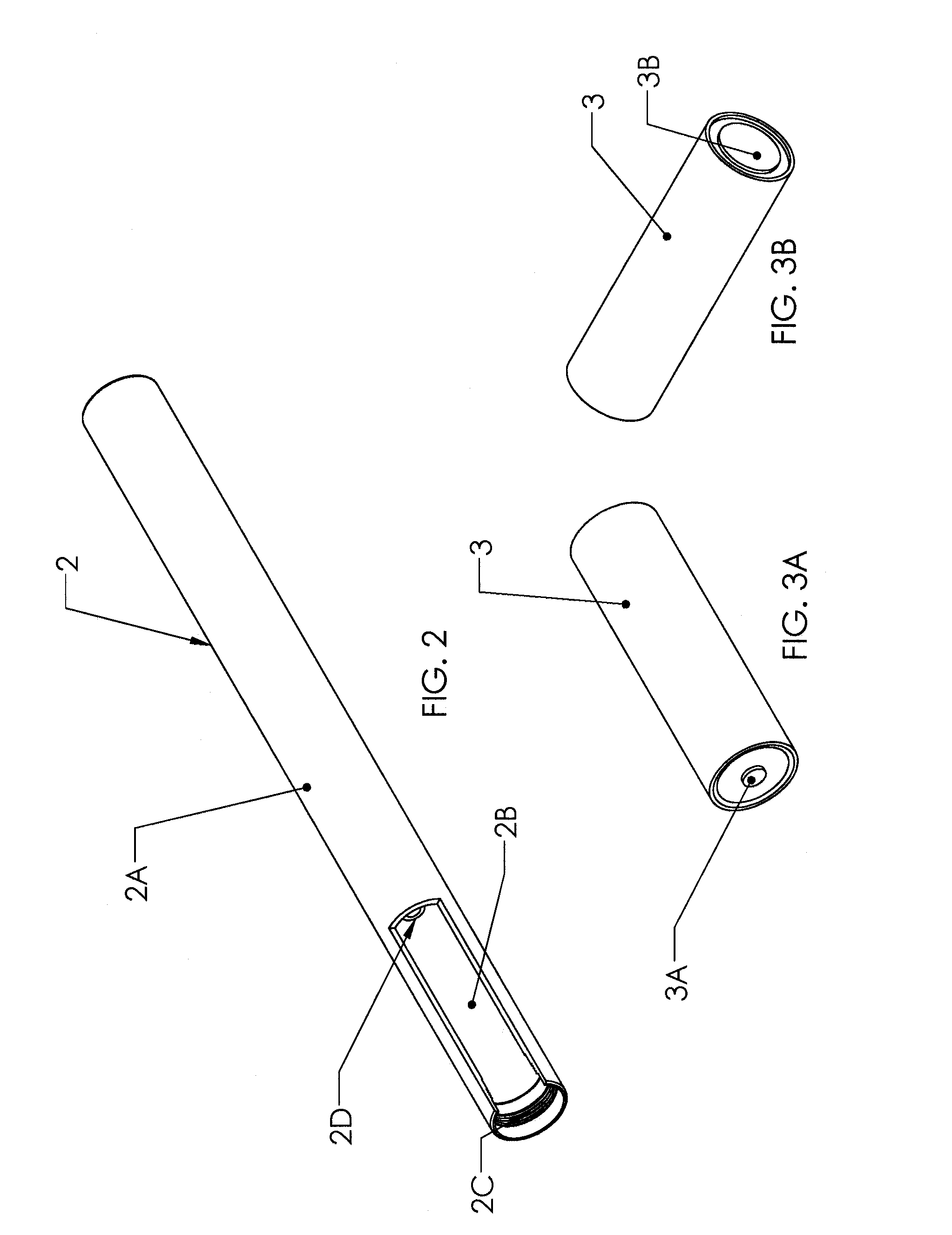

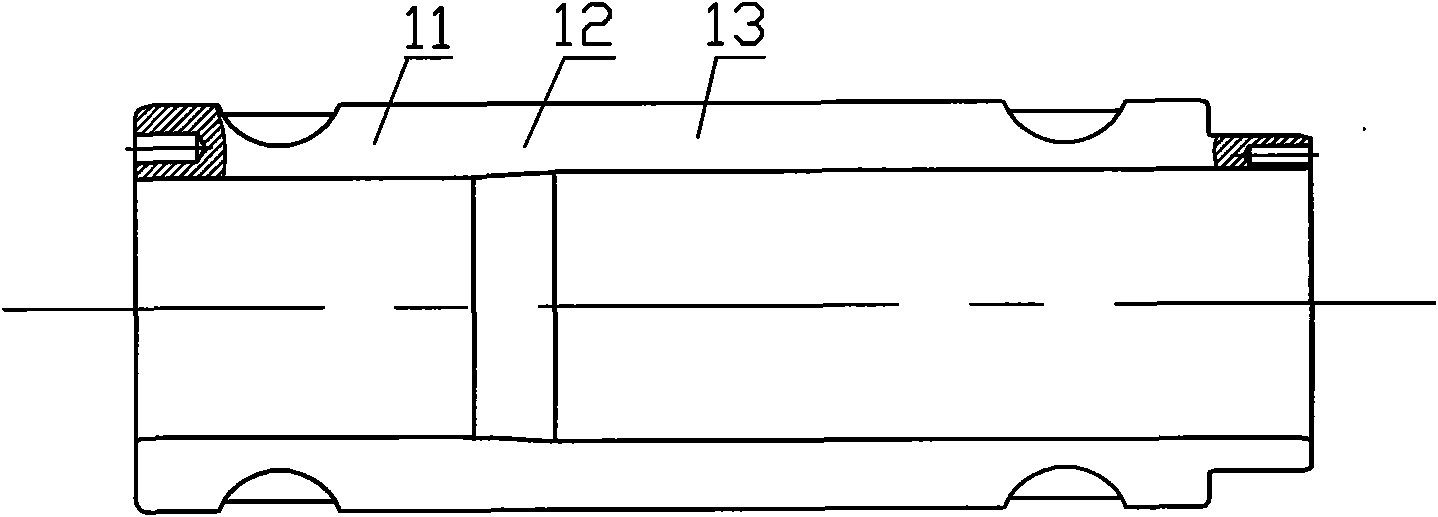

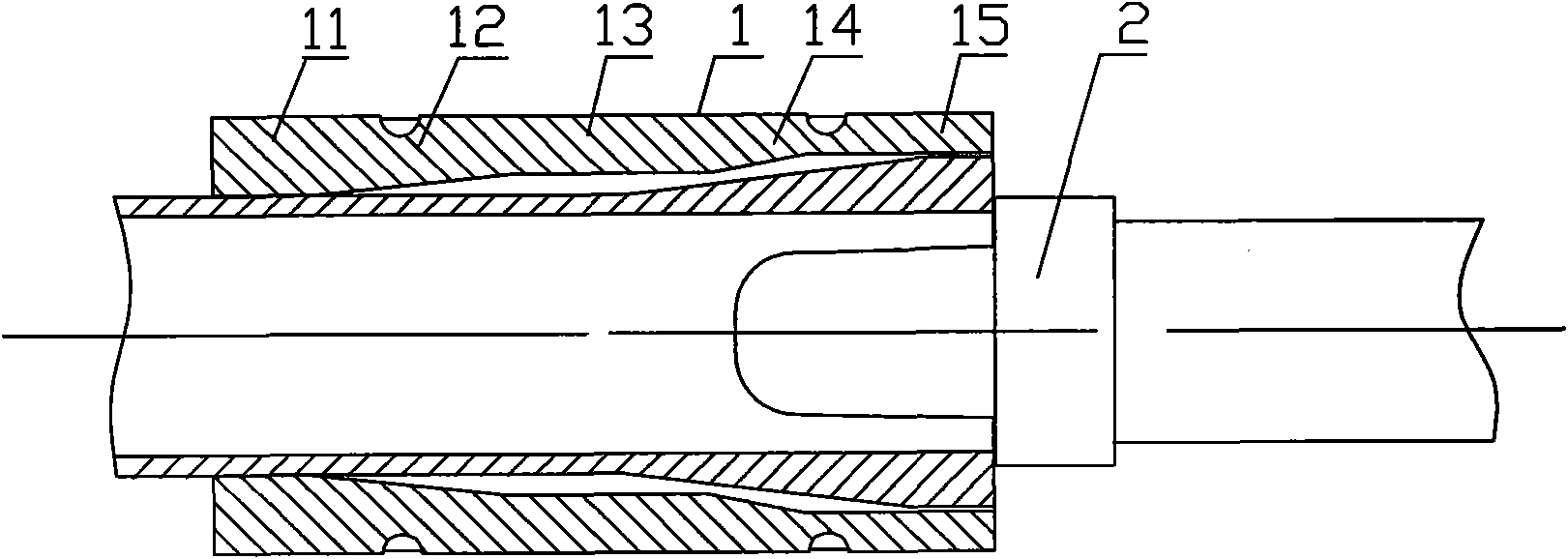

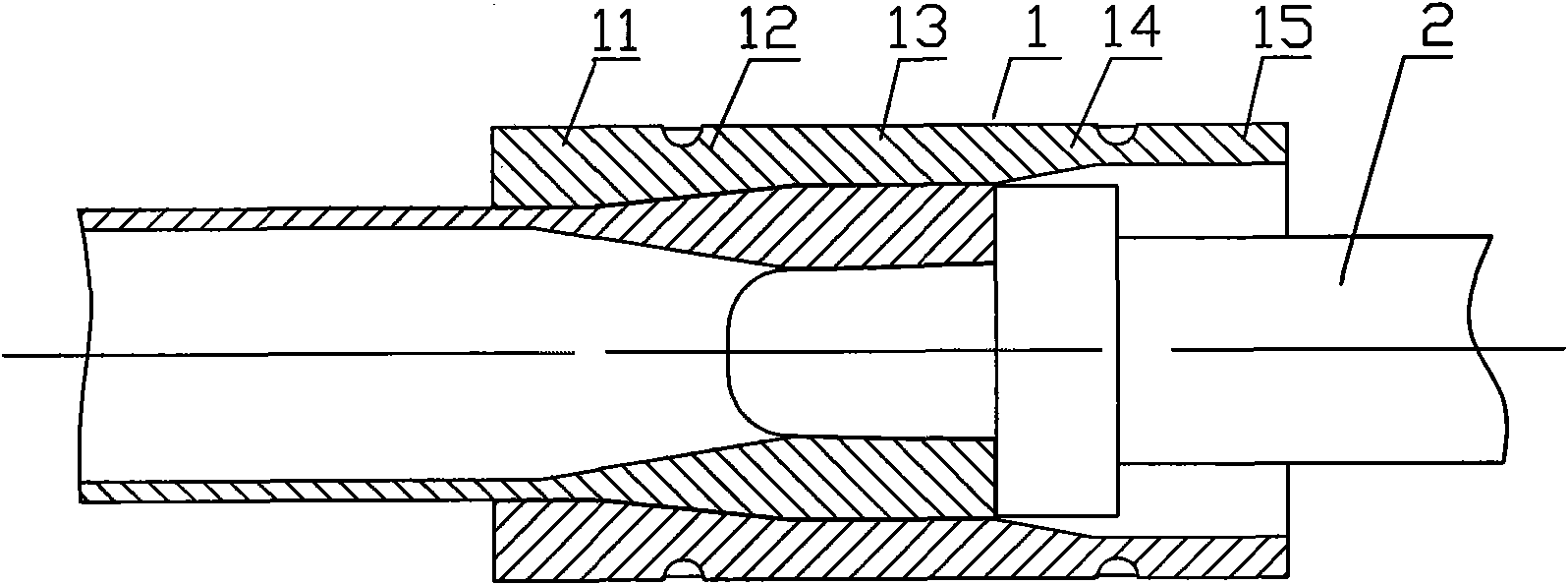

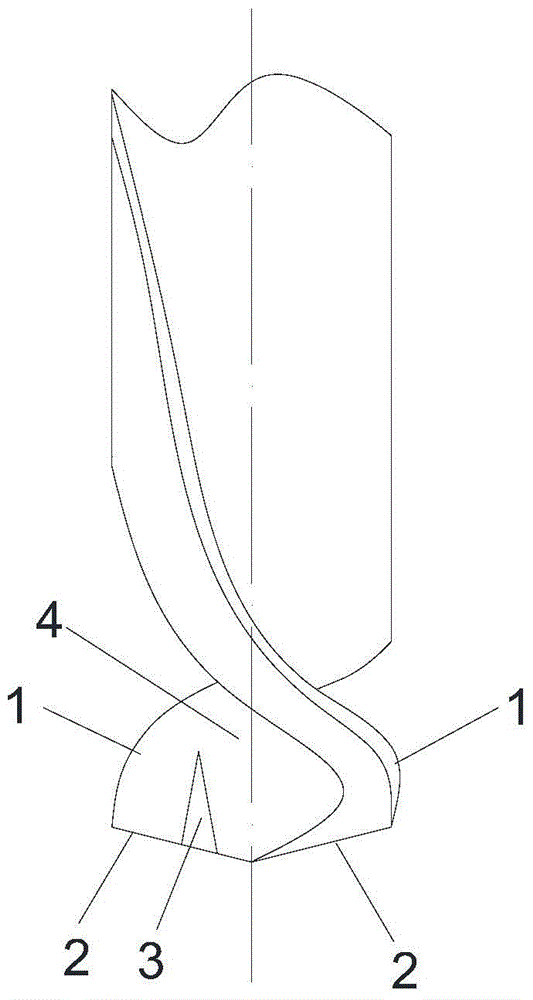

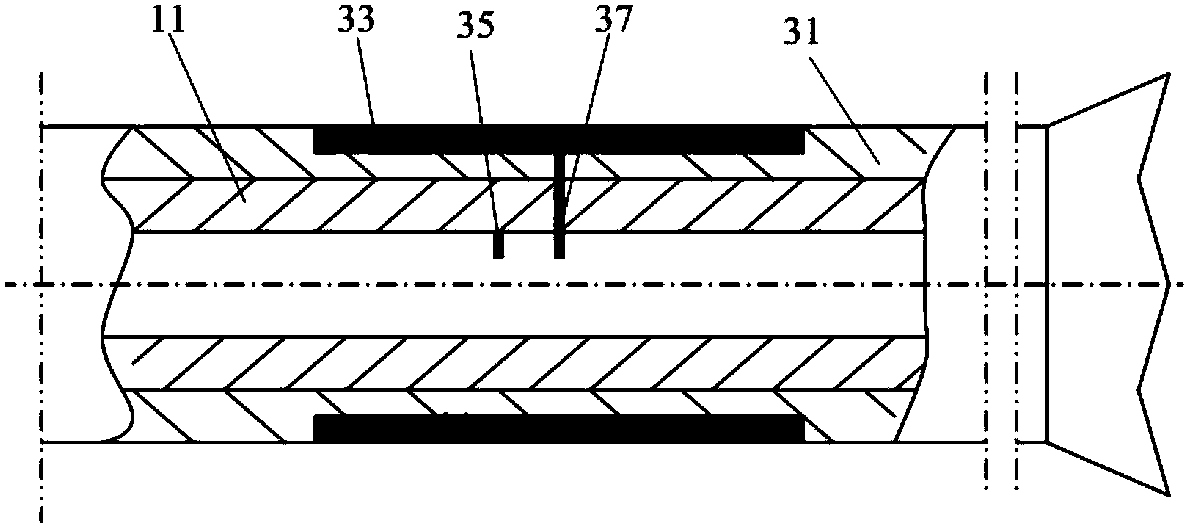

Drill stem thickening process and thickening module

InactiveCN101767173AOvercoming uneven shapeOvercoming processabilityForging/hammering/pressing machinesStress concentrationPunching

The invention relates to a drill stem thickening process and a thickening module. The thickening module comprises a thickening module 1 and a punching module 2. a third time thickening module is a final forming module, namely an inner thickening copying module, which comprises a clamping area 11, a transition belt 12, a thickening area 13, a transformation transition belt 14 and a starting area 15 which are orderly connected with the thickening area 13. The length of the transition belt of the thickening module is prolonged and the transition is performed in the manner of S-shaped smooth transition. The invention overcomes the shortcomings of the prior art that the shape of the transition belt in the drill stem is uneven, lathe work is required, the stress concentration is easily occurred, the service life of the drill stem is short, and the like. Compared with the prior art, the thickening transition belt in the drill stem can naturally smooth transit so the stress concentration in the deformation area and the probability of generating vortex caused by size change during usage are greatly decreased, the stress at the thickened tube joint part is reduced, the inner transition belt of the final products is unnecessary to form, the use life of the drill stem is prolonged and the drill stem quality is ensured.

Owner:HENGYANG VALIN STEEL TUBE +1

Hydraulic expansion type tail pipe hanger

The invention relates to a hydraulic expansion type tail pipe hanger, which comprises that: a drill stem thread at the upper end of a release sub is in threaded connection with a drill string; an internal thread at the lower end of the release sub is in threaded connection with a central pipe; an expansion cone is sleeved outside the central pipe, connected with a shear pin B and a float valve sleeve and freely slides on the central pipe; and the expansion cone and an expansion pipe realize motive seal fitting with the central pipe by a plurality of sealing rubber rings. The hanger is characterized in that a thread at the lower end of the central pipe is in threaded connection with the float valve sleeve; and the float valve sleeve is provided with a hinge mount, a hinge, a shifting fork, a valve cap and a spring. The hanger has the advantages of simple structure, convenient operation, high hanging success rate and good sealing quality. After a tail pipe is hung, the inner drift diameter of a pipe column is large, which is convenient for later drilling work. The hanger has obvious application advantages in ultra deep wells and horizontal wells with large displacement.

Owner:CNPC BOHAI EQUIP MFG

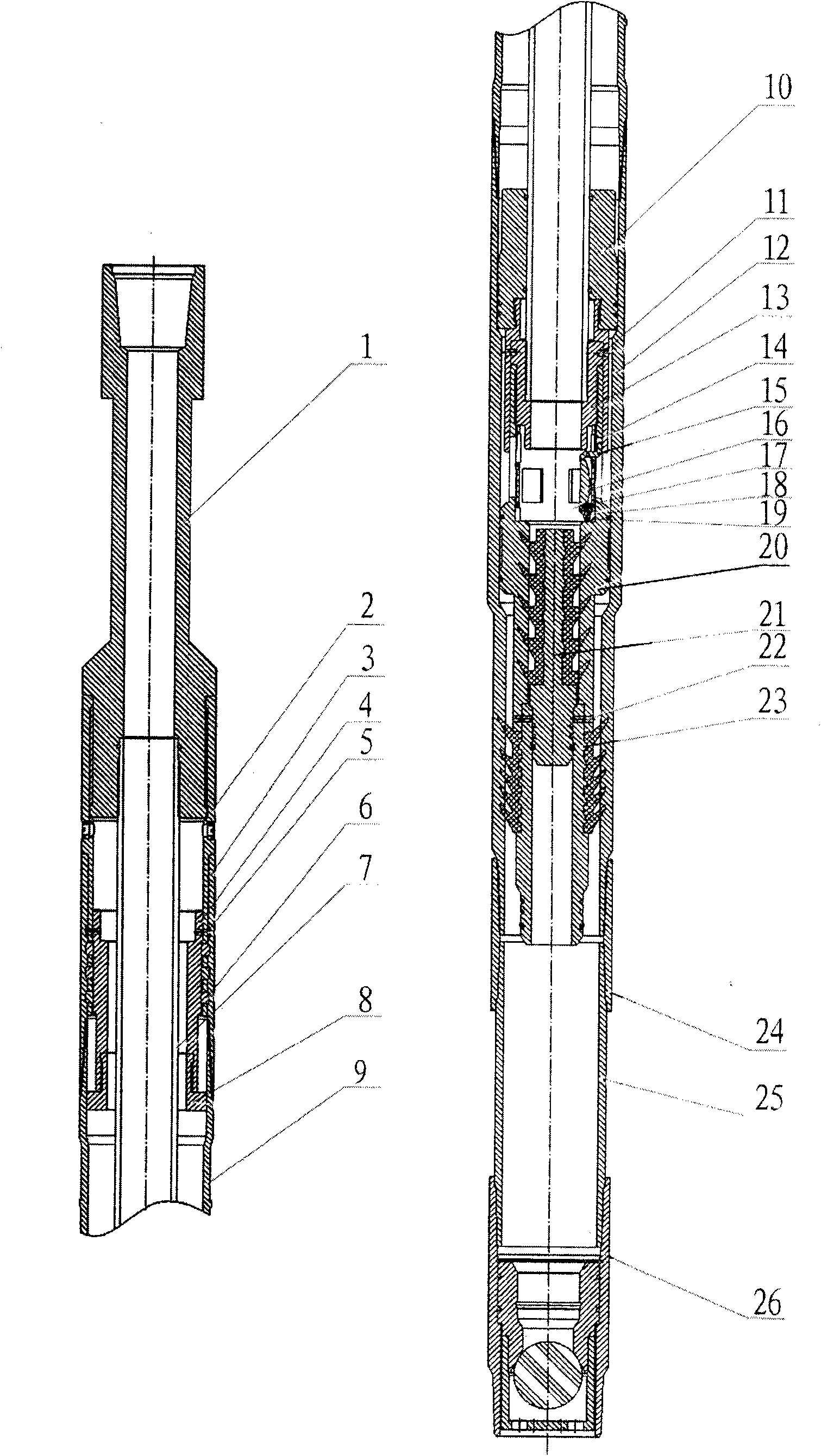

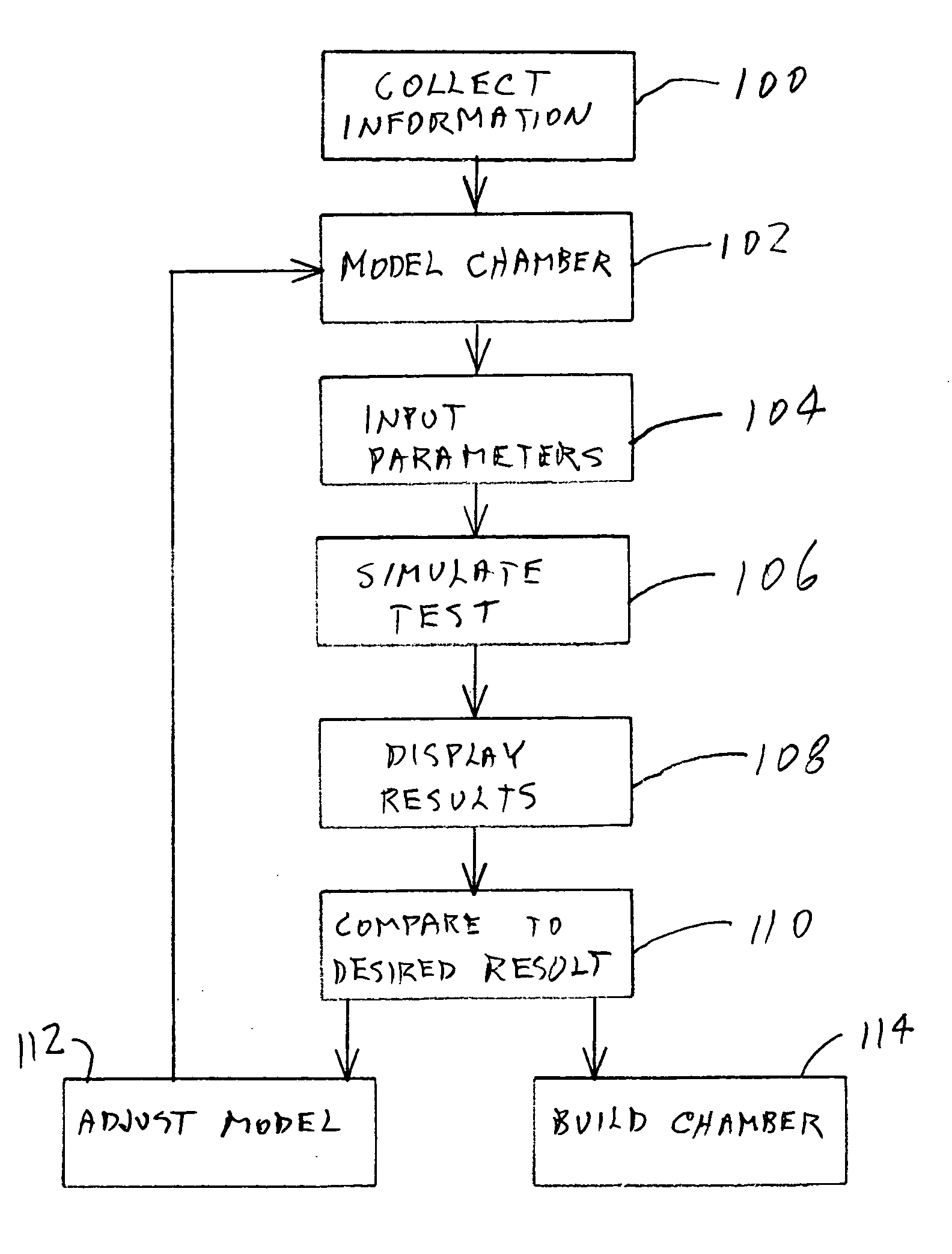

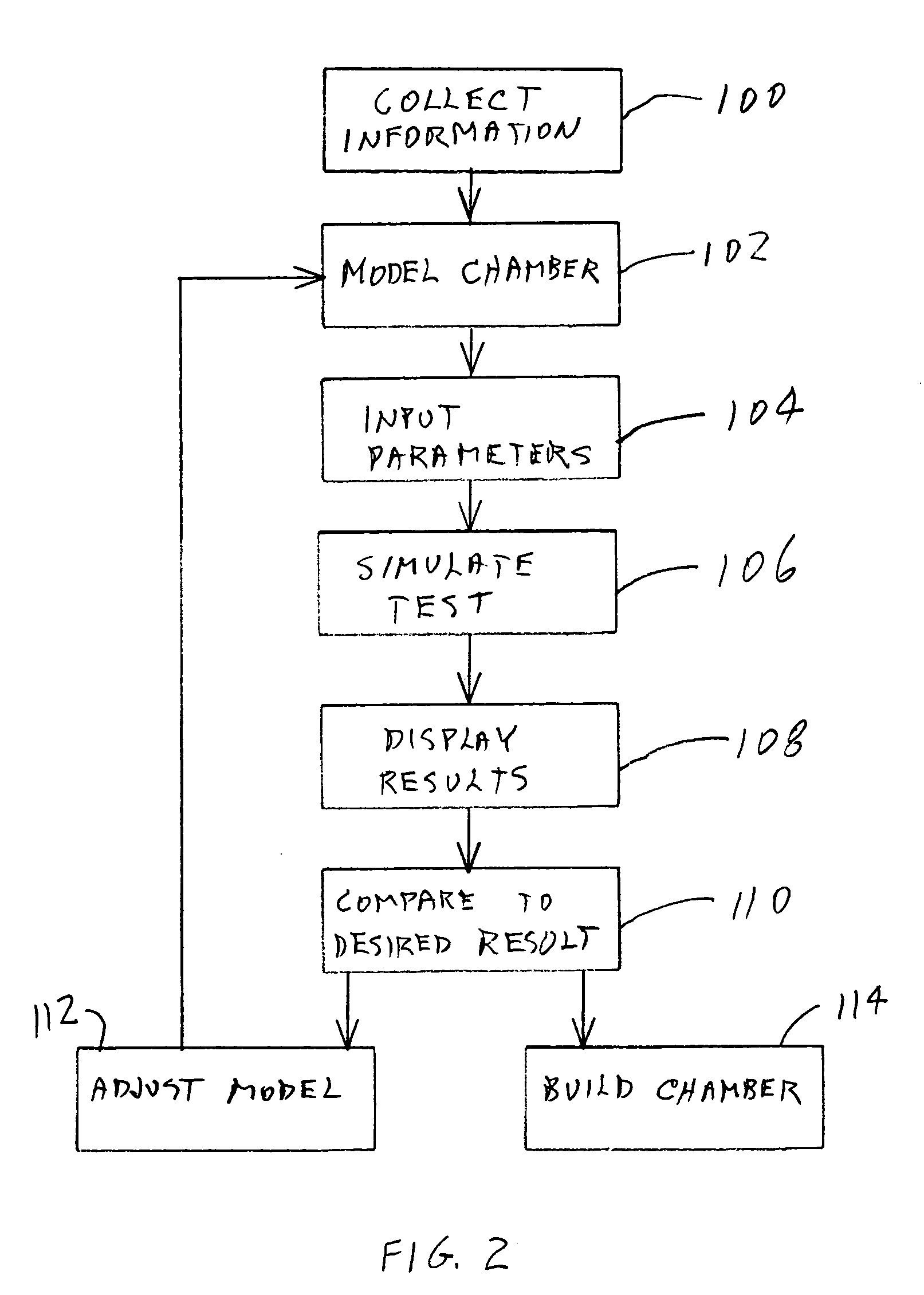

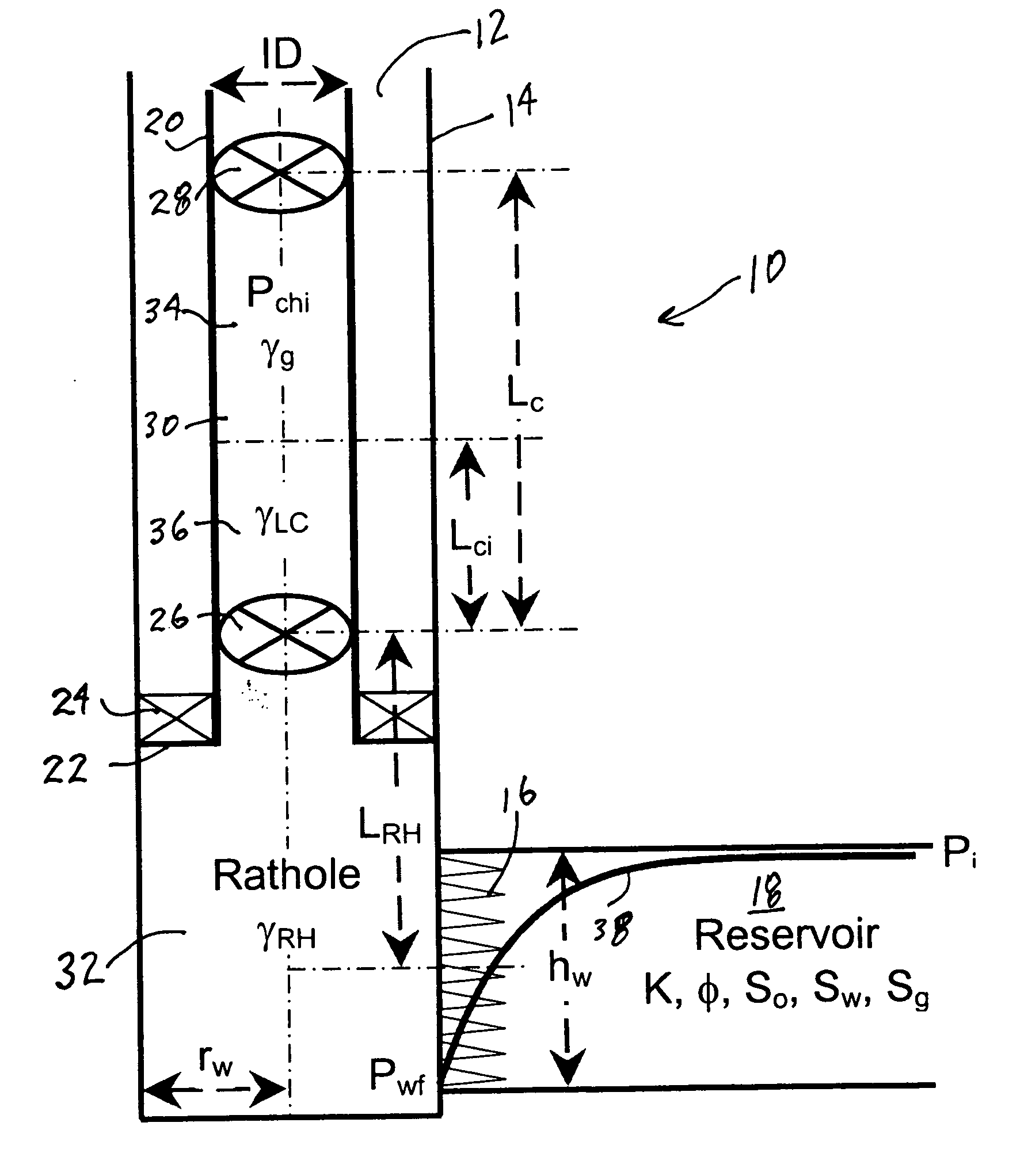

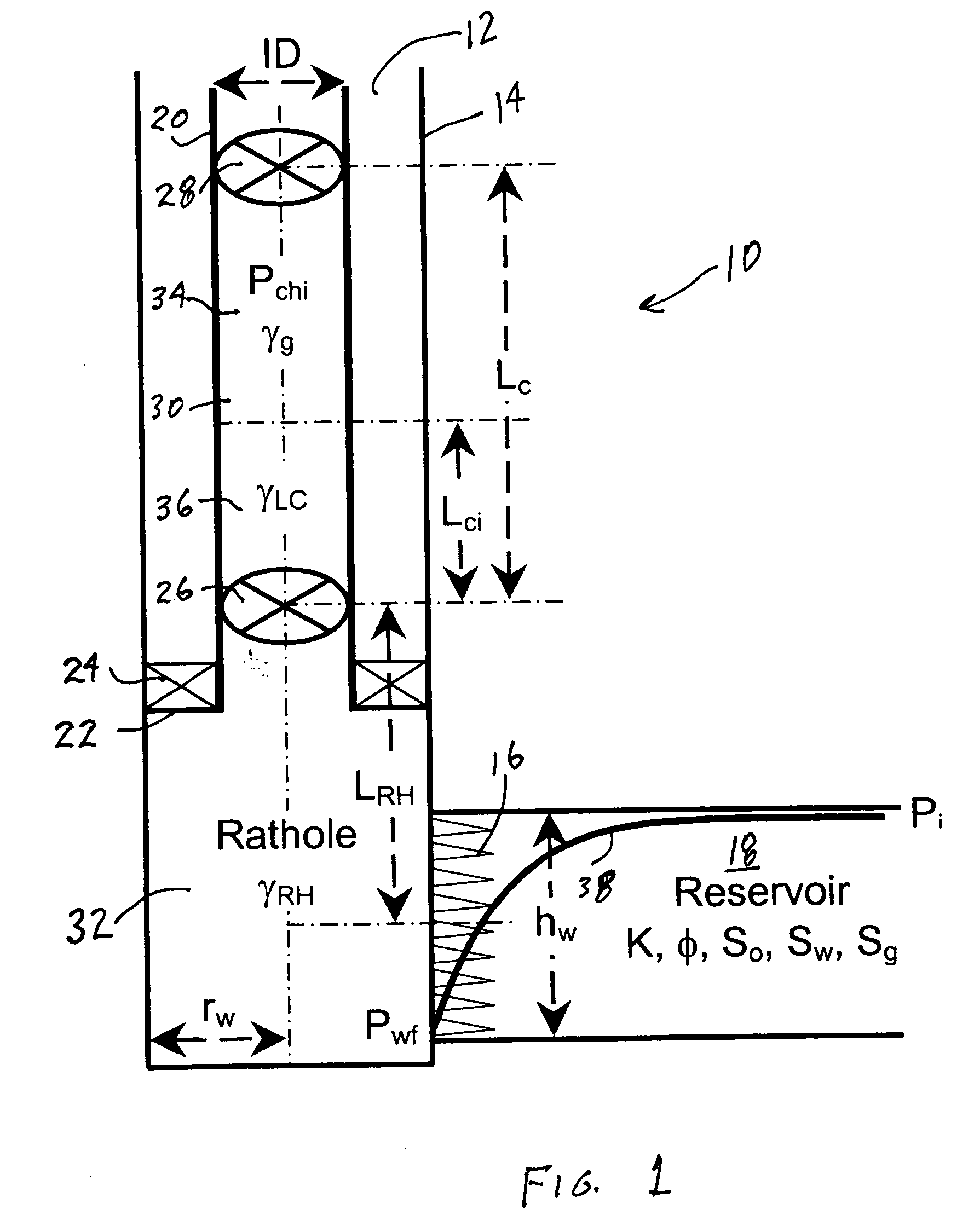

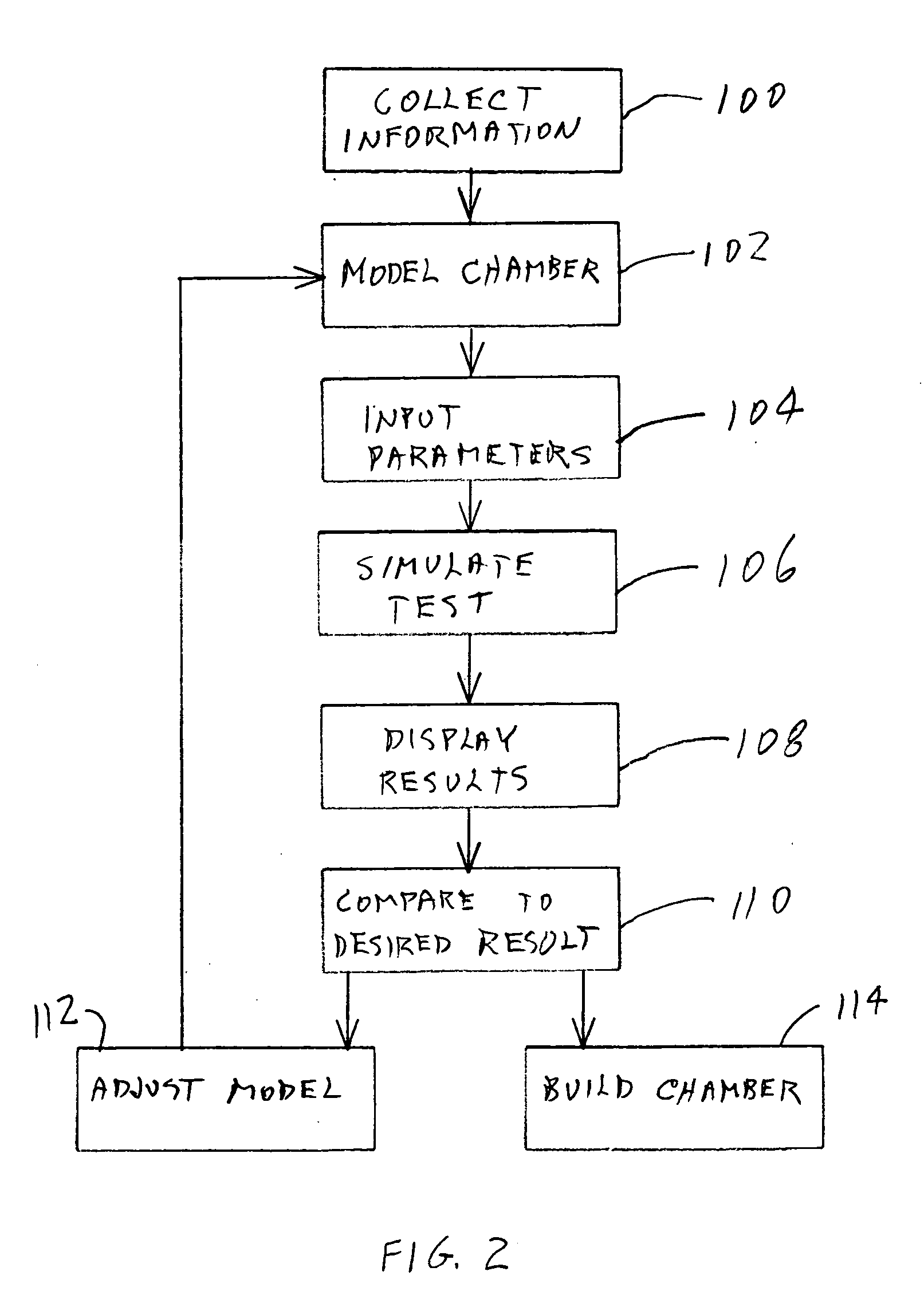

Method for designing formation tester for well

InactiveUS7197398B2Electric/magnetic detection for well-loggingPermeability/surface area analysisClosed chamberEngineering

A method for designing a closed-chamber drillstem test system. Parameters of available equipment and a well to be tested are collected. Initial or proposed chamber size and chamber pressurizing fluids are then selected. A simulation of a test is then performed. The simulation is performed in time increments, with pressure in the well assumed to be static during each time increment. Calculated flow volume from the formation during each increment is used to adjust pressure in the well for the next increment. The process is continued until the test would be considered complete based on an optimization parameter. If the total simulated time to complete the test is not in a desirable range, the initial chamber parameters are changed and the simulation is run again. The process is repeated until the simulated test time reaches a desirable range.

Owner:HALLIBURTON ENERGY SERVICES INC

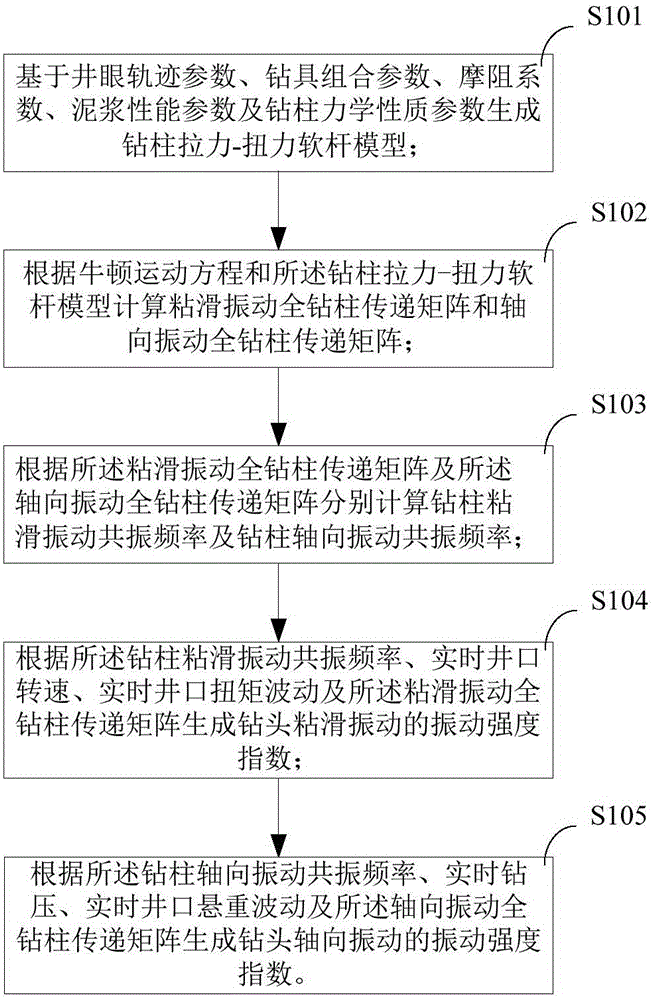

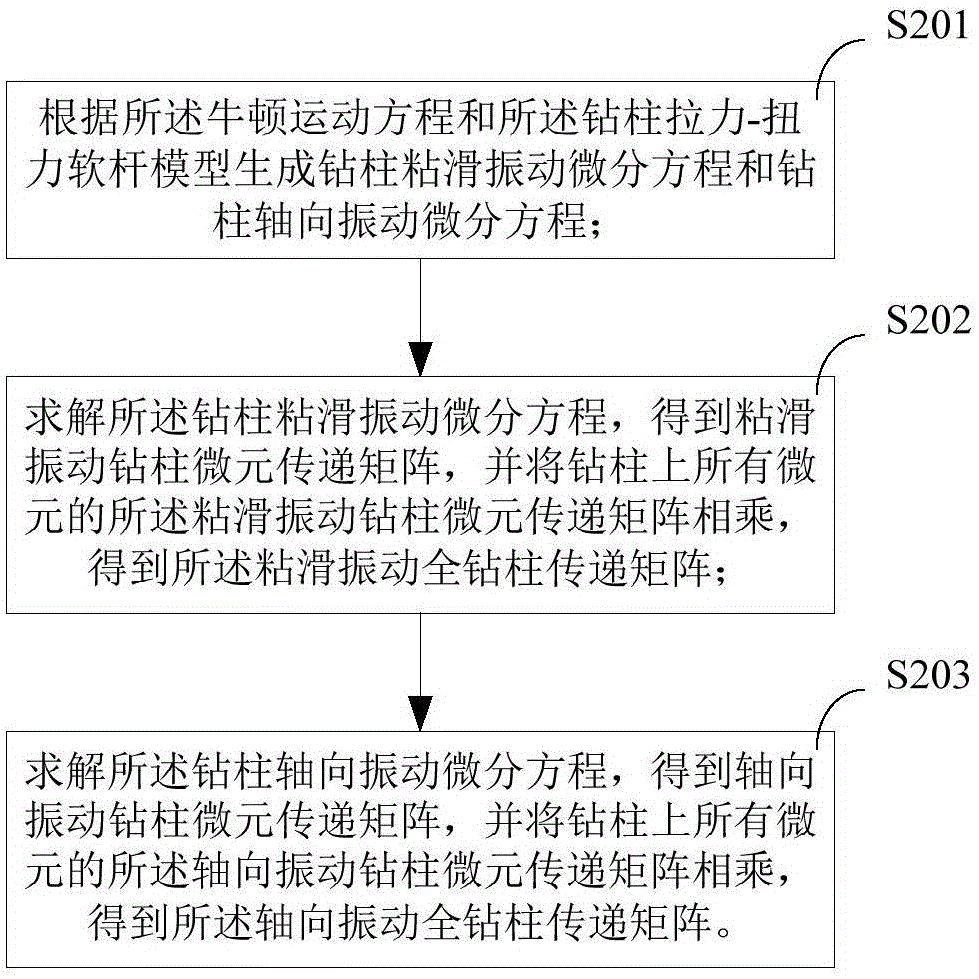

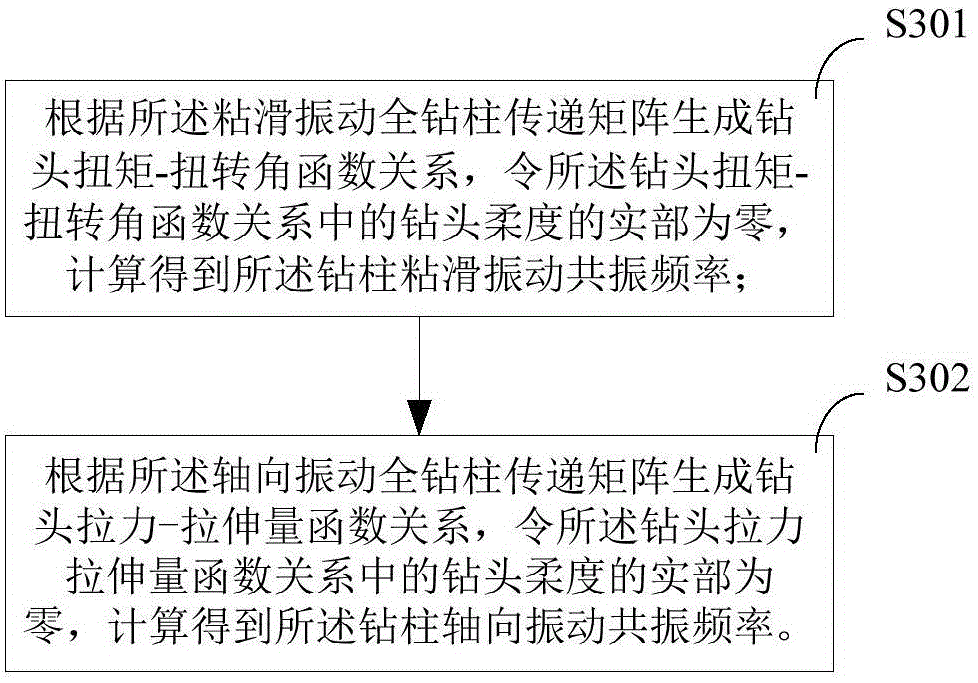

Downhole vibration monitoring method

ActiveCN105986803AAvoid damageImprove rock breaking efficiencyAutomatic control for drillingVibration amplitudeTransfer matrix

The invention provides a downhole vibration monitoring method. The method includes the steps that a drill stem tension-torsion soft-string model is generated on the basic of well track parameters, drilling assembly parameters, coefficients of friction resistance, mud performance parameters and drill stem mechanical property parameters; a stick-slip vibration drill stem transfer matrix and an axial vibration drill stem transfer matrix are calculated according to the Newton motion equation and the drill stem tension-torsion soft-string model; the stick-slip vibration resonant frequency of the drill stem and the axial vibration resonant frequency of the drill stem are calculated according to the stick-slip vibration drill stem transfer matrix and the axial vibration drill stem transfer matrix; the vibration strength index of stick-slip vibration of a drill bit is generated according to the stick-slip vibration resonant frequency of the drill stem, the real-time well mouth rotation speed, the well mouth torque fluctuation and the stick-slip vibration drill stem transfer matrix; and the vibration strength index of axial vibration of the drill bit is generated according to the axial vibration resonant frequency of the drill stem, the real-time drilling pressure, the well mouth hanging load fluctuation and the axial vibration drill stem transfer matrix. By means of the method, the downhole vibration amplitude can be judged visually and quantificationally.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Mine drilling machine

ActiveCN101936127AGuaranteed Effective DepthGuaranteed to proceed normallySurveyConstructionsReciprocating motionEngineering

The invention discloses a mine drilling machine. The machine comprises a bracket, wherein a power driving device for driving standard drill stems with equal lengths is slidably arranged on the bracket and does reciprocating motion on the bracket; and the bracket is also provided with a counter for counting the number of standard drill stems driven by a power device. In the mine drilling machine, the bracket is provided with the counter for counting the number of drill stems drilled into drill holes by the power driving device and the drill stems are standard drill stems with equal lengths, sothat the depth of each drill hole can be obtained by multiplying the measured number of the drill stems by the standard length of the drill stem and the hole depth is measured correctly. The machine has the advantages of realizing detection of the hole depth while drilling, avoiding the effect of collapse of the drill hole or projection of the drill hole on a mine on the detection of the hole depth after drilling and ensuring normal production, along with simple structure, convenience and practicability.

Owner:GL TECH CO LTD

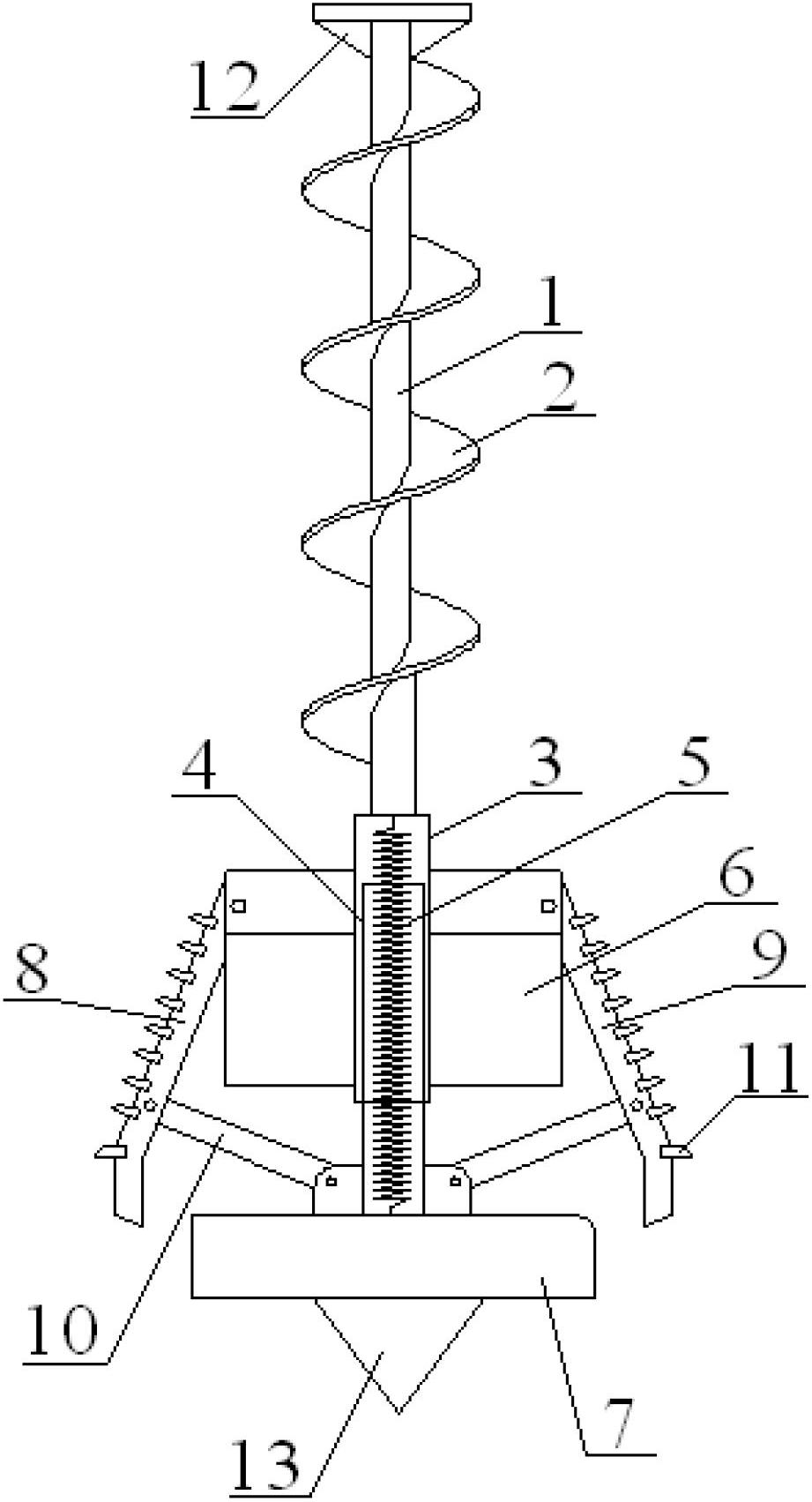

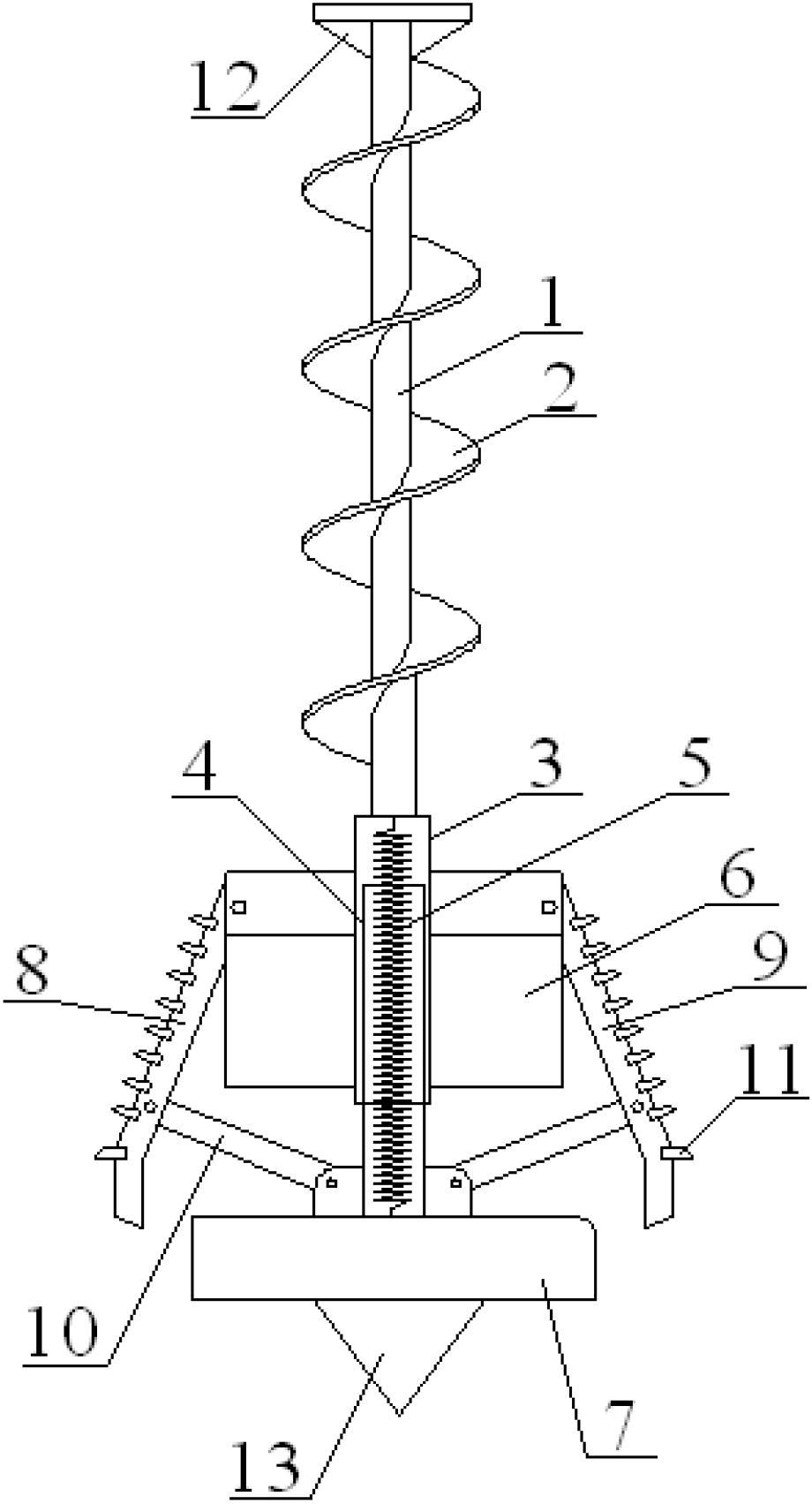

Spirally bottom-expanding integrated drill bit

ActiveCN102678054AImprove work efficiencyImprove vertical compression capacityDrill bitsDrilling rodsDrill bitDrill stem test

The invention discloses a spirally bottom-expanding integrated drill bit. The drill bit comprises a drill stem, a left bottom-expanding arm and a right bottom-expanding arm, wherein the bottom of the drill stem is fixedly connected with an outer sleeve; an inner sleeve is glidingly arranged in the outer sleeve in a matching way; an arm-protecting plate is fixedly arranged outside the outer sleeve; a soil-accommodating disc is fixedly arranged at the bottom end of the inner sleeve; the upper ends of the left bottom-expanding arm and the right bottom-expanding arm are respectively hinged to the two sides of the arm-protecting plate; and the lower ends of the left bottom-expanding arm and the right bottom-expanding arm are respectively hinged to the soil-accommodating disc through connecting rods. The drill bit is simple and reliable in structure and convenient to operate. During bottom-expanding operation, soil is collected through the soil-accommodating disc, and when the drill bit is lifted out of a pile, the soil can be taken out together, so that the time and the labor are saved, and the operation efficiency of the drill bit is greatly improved. In addition, the vertical compression-resistant performance of the pile can be improved, and the drill bit has a wider popularization and application space in the field of buildings.

Owner:FUNAN COUNTY FENJIN MACHINERY MFG

Self Actuating Underreamer

InactiveUS20080251294A1Thorough removalDrill bitsDrilling machines and methodsWell drillingBiomedical engineering

An underreamer for well drilling comprises pivotally extendible roller cutters that extend slightly beyond the diameter of the pilot drill bit but are retained in their retracted position by the casing. Upon encountering an obstruction, the underreamer is pushed out of the casing, allowing the outer edges of the cutters to contact the obstruction. Continued downward pressure of the drill stem causes the roller arms to pivot outward to a fully extended position in which the cutters enlarge the hole to a diameter larger than the casing by rotation of the drilling stem. The advance of the casing relative to the underreamer forces the cutters to retract into the casing.

Owner:MINSHULL RONALD GEORGE

Method and device for telemetering torque moment of drill stem

InactiveCN101603420AGood for long term workReduce consumptionSurveyDrilling rodsEngineeringDiesel engine

The invention provides a method and a device for telemetering the torque moment of a drill stem. The method and the device are characterized in that a lower short circuit is arranged between a square drill stem and the drill stem to collect and transmit data; an upper short circuit is arranged on the position of a mouth of a horn to receive and transmit data; a torque moment signal collected by a parameter collection board in the lower short circuit is transmitted to a sending coil to be converted into an alternating magnetic field; a receiving coil in the upper short circuit converts the induced alternating magnetic field into an alternative electric signal, and transmits the alternative electric signal to a demodulation board to obtain a torque moment signal by demodulating; and the signal is transmitted to a computer or display record equipment through a data cable and a connector. The method and the device have the advantages of directly and effectively completing uploading of measurement on the torque moment of the drill stem in real time with low electric energy consumption and function extension convenience. The method and the device are applicable to a power drill of a diesel engine.

Owner:SOUTHWEST PETROLEUM UNIV

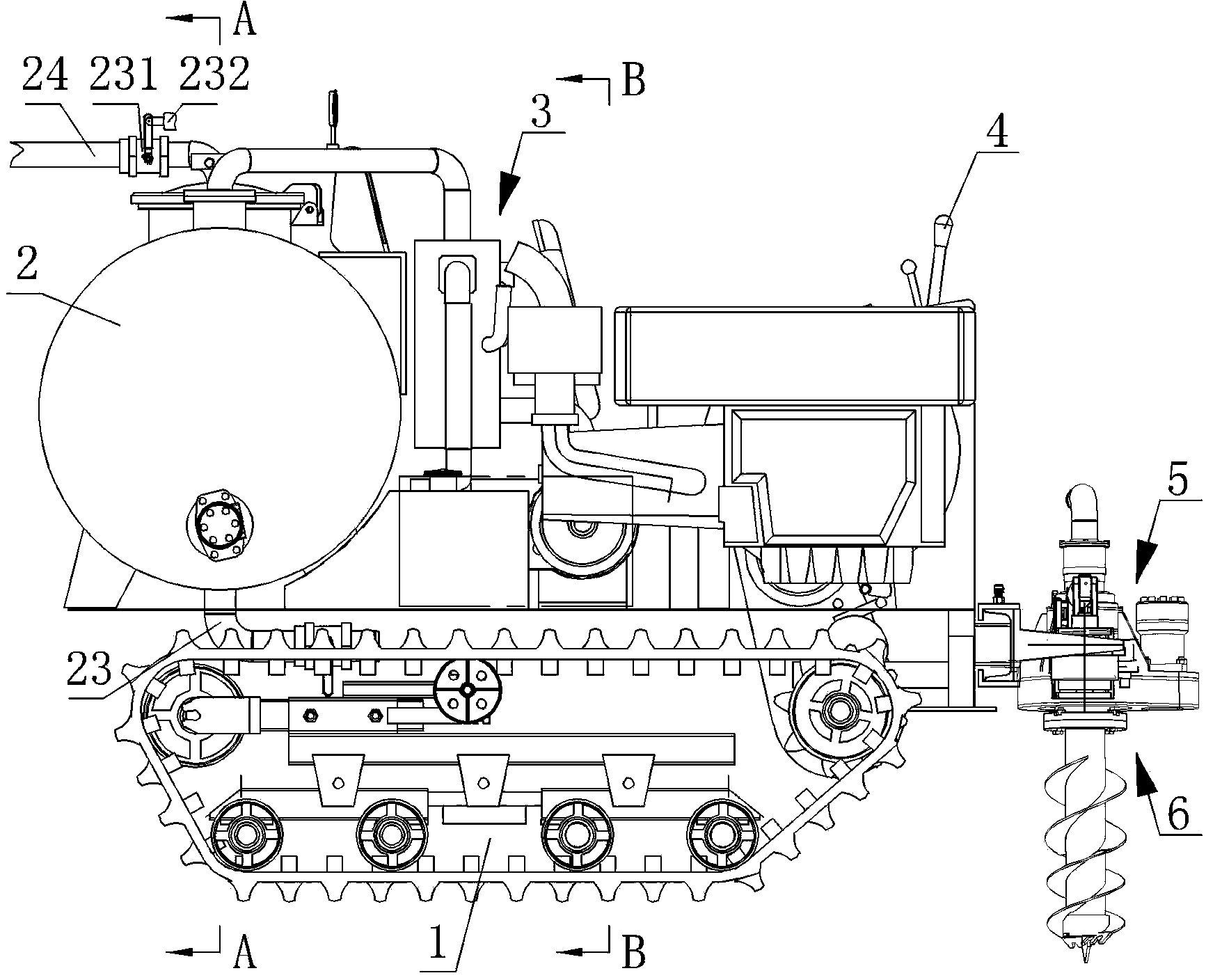

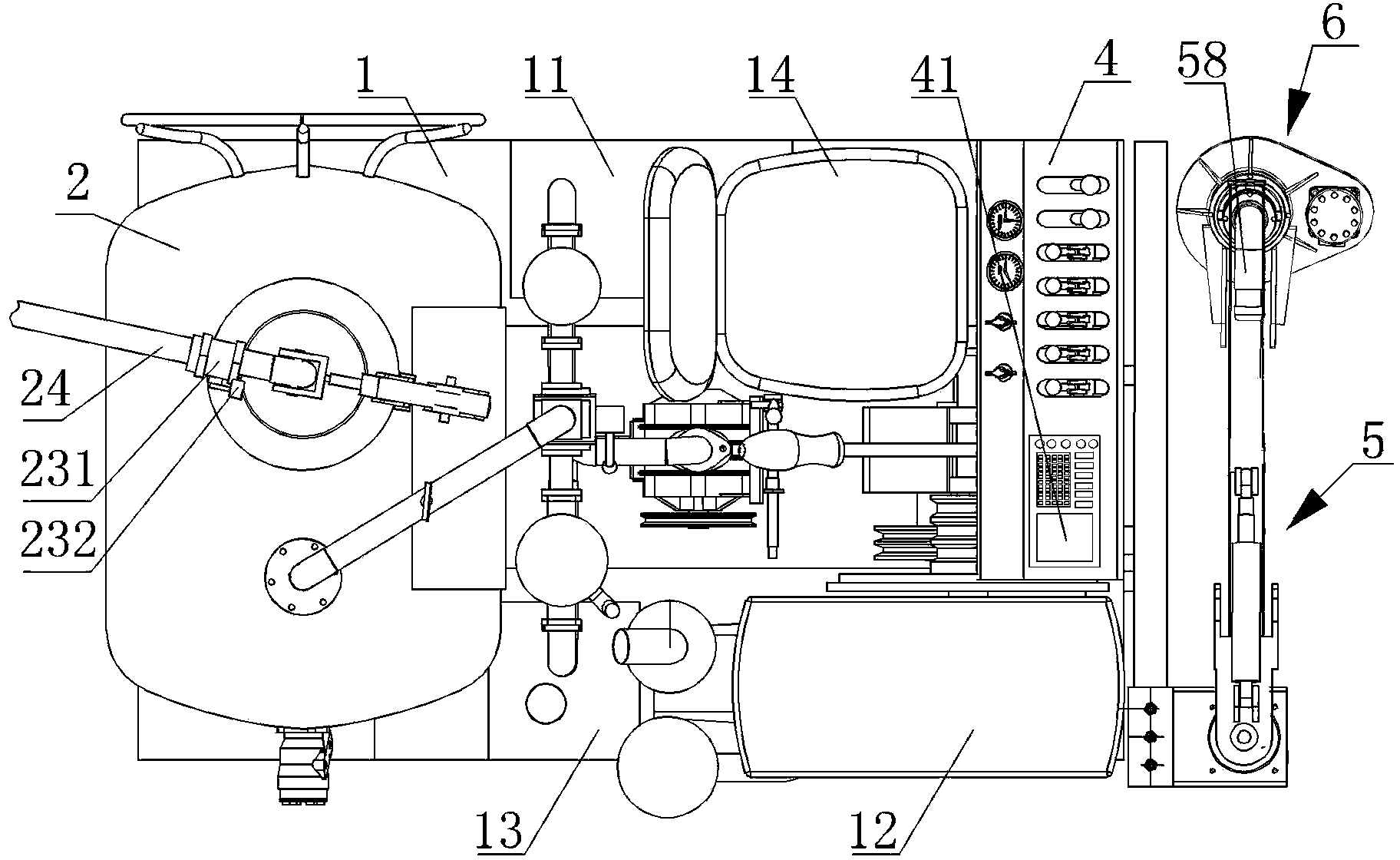

Orchard tumbril

ActiveCN103718719AAvoid contactReduce labor intensityFertiliser distributersAgriculture gas emission reductionVegetationAgricultural engineering

The invention discloses an orchard tumbril which comprises a fertilizer applicator, a chassis with a hydraulic pressure station, an engine and a water tank, and a fertilization tank, a vacuum system, an operating system and a spiral arm system which are arranged on the chassis, wherein a feeding pipe is arranged above the fertilization tank; a discharging pipe is arranged at the bottom of the fertilization tank; the vacuum system is communicated with the fertilization tank and is controlled by the operating system to start so as to drive suction or discharge of the fertilization tank; the spiral arm system is arranged at the front end of the chassis and is controlled to rotate and retract by the operating system; the fertilizer applicator is arranged at the front end of the spiral arm system through a pair of mounting lugs. The orchard tumbril is simple in structure, convenient to operate, high in practicality and low in manufacturing cost, after the drilling and fertilizing actions are finished, a drill stem is retracted, the peripheral soil can automatically cover the fertilizer liquid, the environment is not polluted, the damage to vegetation is small, an odor overflow amount is small, the integration degree is high, and the orchard tumbril is particularly suitable for performing deep point fertilization around the roots of large trees.

Owner:湖南鑫弘科技有限责任公司

Drilling method of thick copper circuit board

InactiveCN104874826AEasy dischargeDischarge in timeTransportation and packagingTrepanning drillsCopper wirePetroleum engineering

The invention discloses a drilling method of a thick copper circuit board and relates to the technical field of circuit board manufacturing. The drilling method uses a drill with the rotation speed of 20-30krmp, tool feeding speed of 20-30mm / s and tool retracting speed of 220-300mm / s to drill holes. The drill comprises a drill stem and a drill bit. The drill bit comprises a cutting blade and a chip groove. The chip groove is axially provided with a groove at the drilling end of the drill bit. The thickness of copper of the inner circuit of the circuit board is not smaller than 3OZ. The method has the advantages that the drill with the groove notch is used, the groove notch in the drilling end of the3 drill bit can cut off a drilling copper wire, the cut-off copper wire can be discharge timely through the groove during drilling, and problems such as hole blocking and drilling copper wire drawing are avoided.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Method for designing formation tester for well

InactiveUS20060212223A1Electric/magnetic detection for well-loggingPermeability/surface area analysisClosed chamberEngineering

A method for designing a closed-chamber drillstem test system. Parameters of available equipment and a well to be tested are collected. Initial or proposed chamber size and chamber pressurizing fluids are then selected. A simulation of a test is then performed. The simulation is performed in time increments, with pressure in the well assumed to be static during each time increment. Calculated flow volume from the formation during each increment is used to adjust pressure in the well for the next increment. The process is continued until the test would be considered complete based on an optimization parameter. If the total simulated time to complete the test is not in a desirable range, the initial chamber parameters are changed and the simulation is run again. The process is repeated until the simulated test time reaches a desirable range.

Owner:HALLIBURTON ENERGY SERVICES INC

Variable-diameter drilling bit mechanism for drill stem

InactiveCN105781424AThe overall structure is simple and reliableTo achieve the effect of variable diameterDrill bitsDrilling rodsDrill bitPetroleum engineering

The invention belongs to the technical field of buildings, and relates to a variable-diameter drilling bit mechanism for a drill stem. The variable-diameter drilling bit mechanism for the drill stem comprises a drill stem component, wherein a diameter varying mechanism capable of moving in a direction close to or far away from an axial line of the drill stem component is movably arranged on the drill stem component, and the diameter varying mechanism can rotate along the circumferential direction of the drill stem component under a dynamic action of the drill stem component, so that the aperture of a drill stem component drilling hole is varied, and a rotation range of the diameter varying mechanism is gradually expanded from the bottom to the top of the drill stem component. The variable-diameter drilling bit mechanism for the drill stem has a simple and reliable structure, and can randomly adjust the aperture in a hole drilling process, so that the variable-diameter effect is achieved and the stress is uniform.

Owner:周兆弟

Collapsible loess treatment method

The invention provides a collapsible loess treatment method. The collapsible loess treatment method comprises the steps that (1) a drill stem with a spiral drill bit and a high-pressure jetting system is rotationally placed downwards; (2) after the drill stem is downwards placed to a certain depth, water is injected at high pressure, the drill stem is rotated simultaneously, and then high-pressure jet is formed and sprayed to soil rotationally, specifically, the water injection amount is no smaller than the water amount required when the layer of collapsible loess reaches the highest saturation degree; (3) the drill stem continues to be placed downwards, and high-pressure water injection and rotary spraying are carried out till the drill stem reaches the set depth; (4) the operations from step (1) to step (3) are carried out repeatedly at set intervals till the high-pressure water injection operation of deep-layer soil is completed in a whole foundation site; (5) the collapsibility subsidence amount of foundation soil is observed and recorded till collapse deformation of the foundation soil is stable; and (6) a shallow soil layer of a foundation is reinforced through a filler compaction method or a dynamic consolidation method.

Owner:王继忠 +2

Pointing Rotary Steering Drilling Tools

InactiveCN104343389BEasy to controlUnaffected by geological formationsDirectional drillingAutomatic control for drillingHydraulic cylinderDrift angle

The invention discloses a directional rotating guide drilling tool. The directional rotating guide drilling tool comprises an outer barrel upper section and an outer barrel, wherein a drill stem and a mandrel are sequentially connected to the outer barrel upper section and the outer barrel from the top to the bottom, the drill stem is connected with the mandrel through a hollow cardan joint, the drill stem is in rotating connection with the outer barrel upper section through a cylindrical roller bearing, a pressure relief cavity positioned in the outer barrel is arranged at the lower end part of the drill stem, the pressure relief cavity is communicated with a draining hole in the drill stem, a biasing mechanism and a knuckle bearing assembly which are positioned in the outer barrel are respectively arranged at the upper end part and the middle of the mandrel, the pressure relief cavity is communicated with the biasing mechanism through a guide pipe, and a drill bit is fixedly connected to the lower end of the mandrel. The biasing of the mandrel is realized by an integrated hydraulic cylinder. The use of the tool is not affected by geological stratification, so that stable and higher drift angle buildup can be obtained. Various work states can be realized without lifting the drill.

Owner:TIANJIN UNIV

Underground measurement information transmission system

InactiveCN103835705AAvoid easy to breakAvoid cable interferenceConstructionsEngineeringGeological exploration

The invention discloses an underground measurement information transmission system and belongs to the field of measurement-while-drilling instruments or non-measurement-while-drilling instruments for petroleum exploration, or mine exploration or geological exploration. The underground measurement information transmission system comprises a drill column, an underground sensor, a ground detecting device and an electrode type transmitting antenna, wherein the drill column comprises a drill stem which is electrically connected with the ground detecting device, a drill collar which is connected with the drill stem, and a drill bit which is connected with the drill collar, the underground sensor is installed on the drill bit, the electrode type transmitting antenna comprises an insulating layer and a metal electrode, the insulating layer is laid on the drill collar, the metal electrode is laid on the insulating layer, a first electrode wire connected with the drill collar and a second electrode wire connected with the metal electrode are led out from the interior of the drill collar, electromagnetic signals are transmitted through the drill collar and the metal electrode, electromagnetic waves are radiated from the electromagnetic signals, and the ground detecting device can obtain data collected by the underground sensor by detecting the electromagnetic waves. The underground measurement information transmission system is higher in universality and can be widely used for transmission of underground measurement information of drilled wells adopting various media as drilling fluid.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

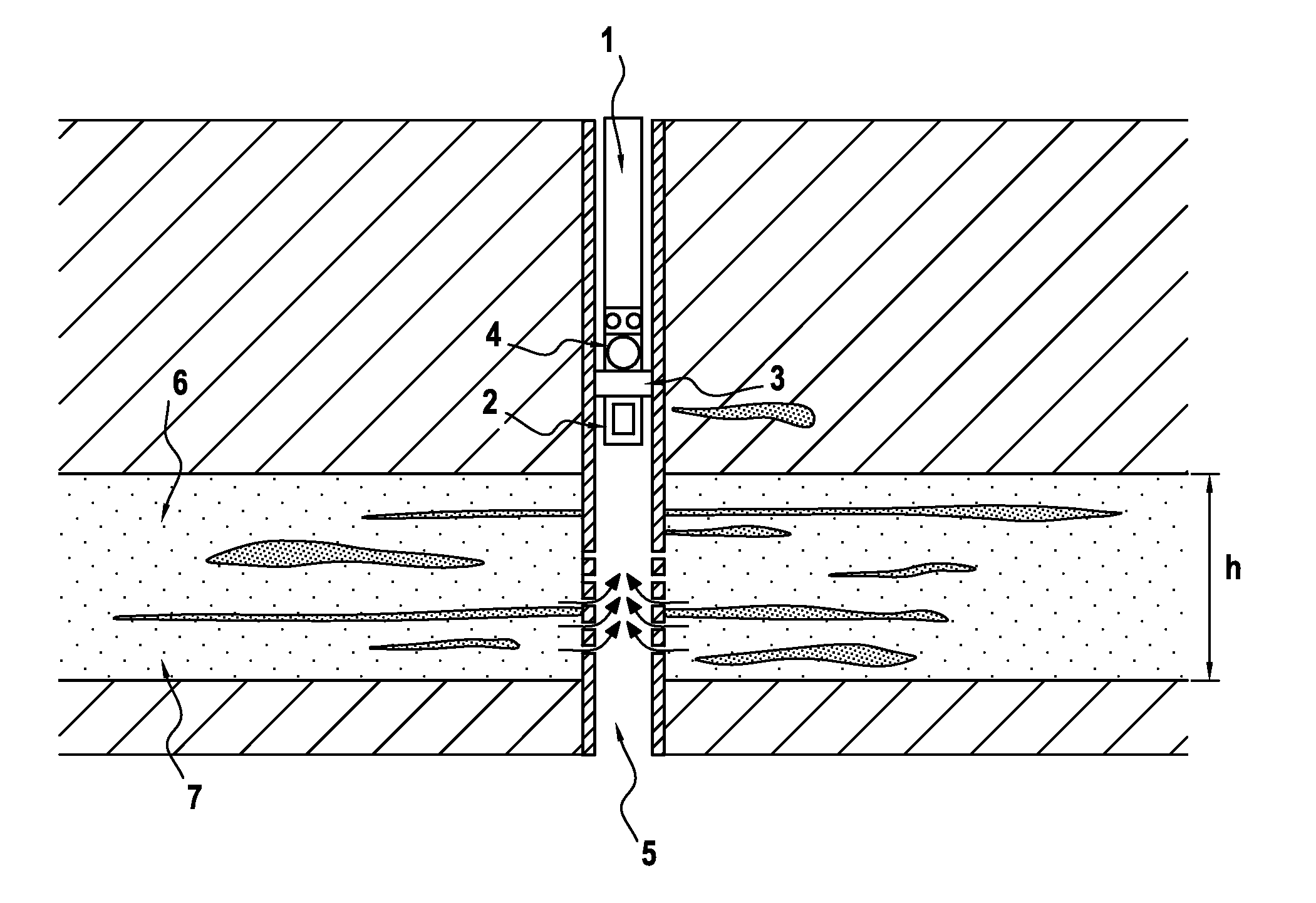

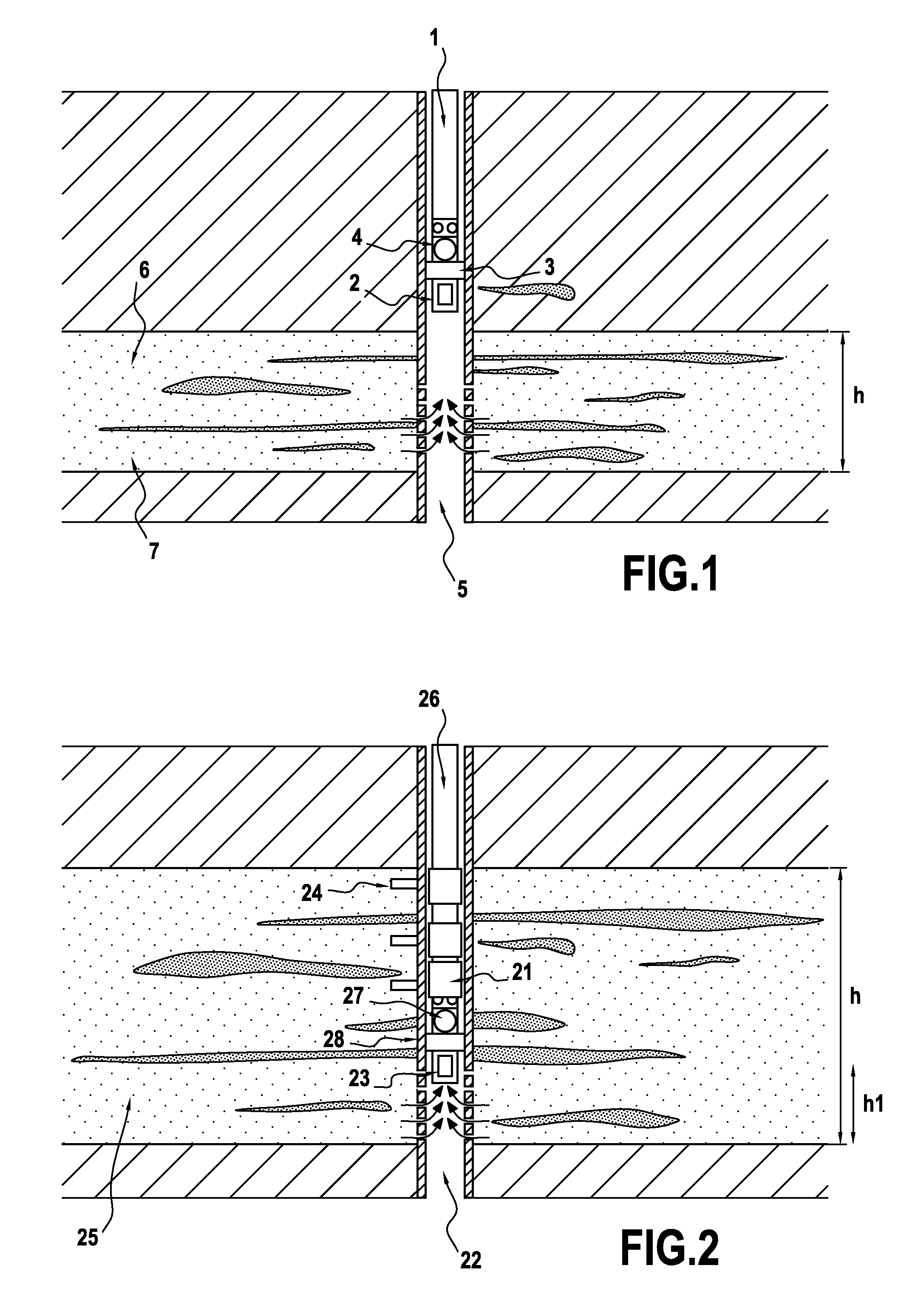

2D Well Testing with Smart Plug Sensor

An apparatus for characterising the permeability of a formation surrounding a wellbore, comprising:a drillstem test (DST) tool comprising, a packer for isolating a zone of the wellbore, a valve for controlling fluid into and out of the zone via the drill string of the tool and, a pressure gauge for detecting the pressure in the zone;wherein the apparatus further comprises an array of at least two antennas arranged on the tool above the packer such that when in use each antenna of the array aligns with a corresponding pressure sensor placed in the formation to obtain pressure measurements and therefore allow horizontal and vertical permeability to be determined.

Owner:SCHLUMBERGER TECH CORP

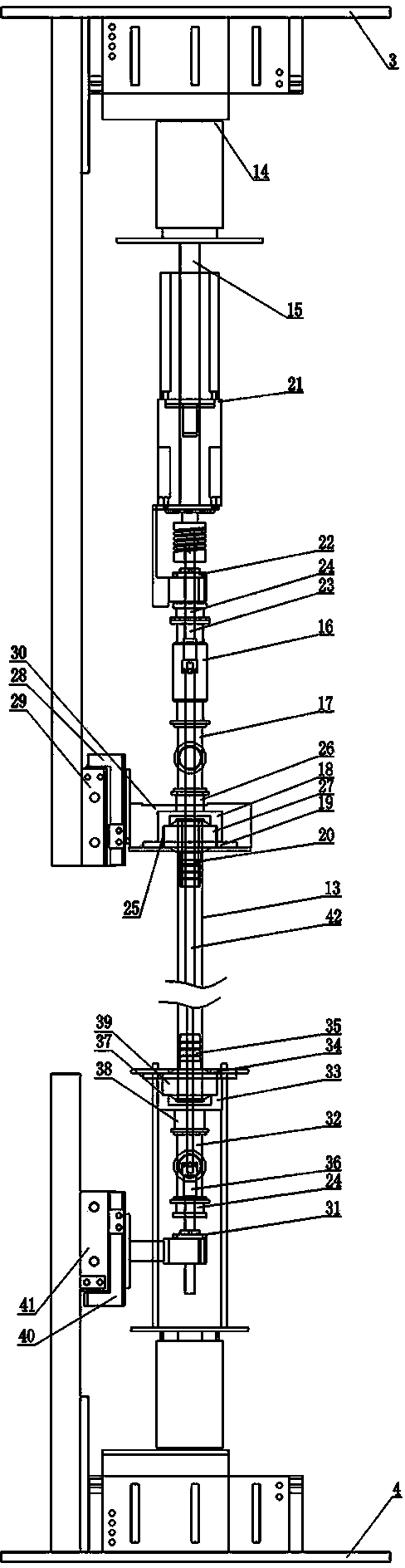

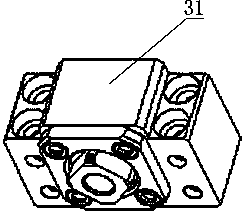

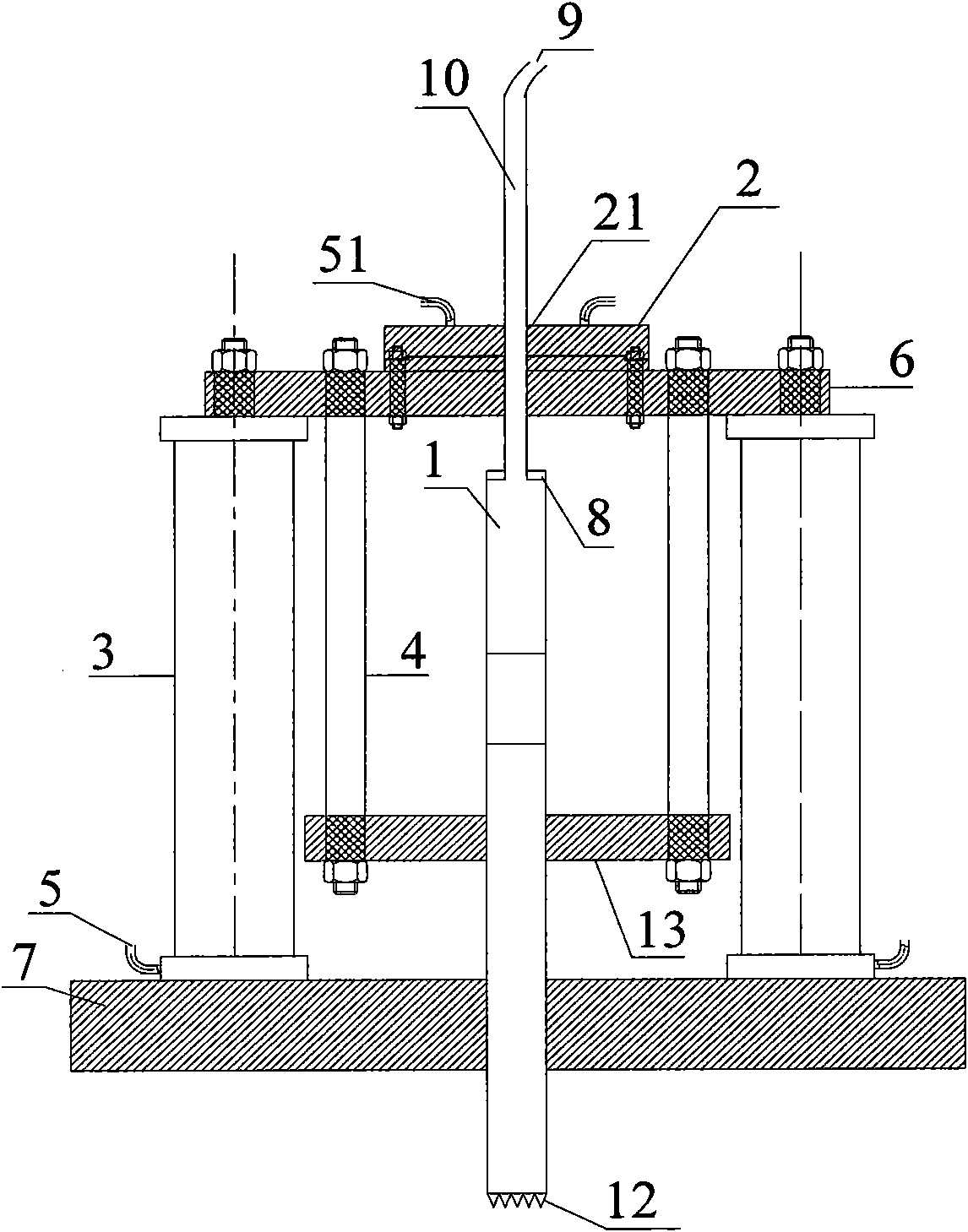

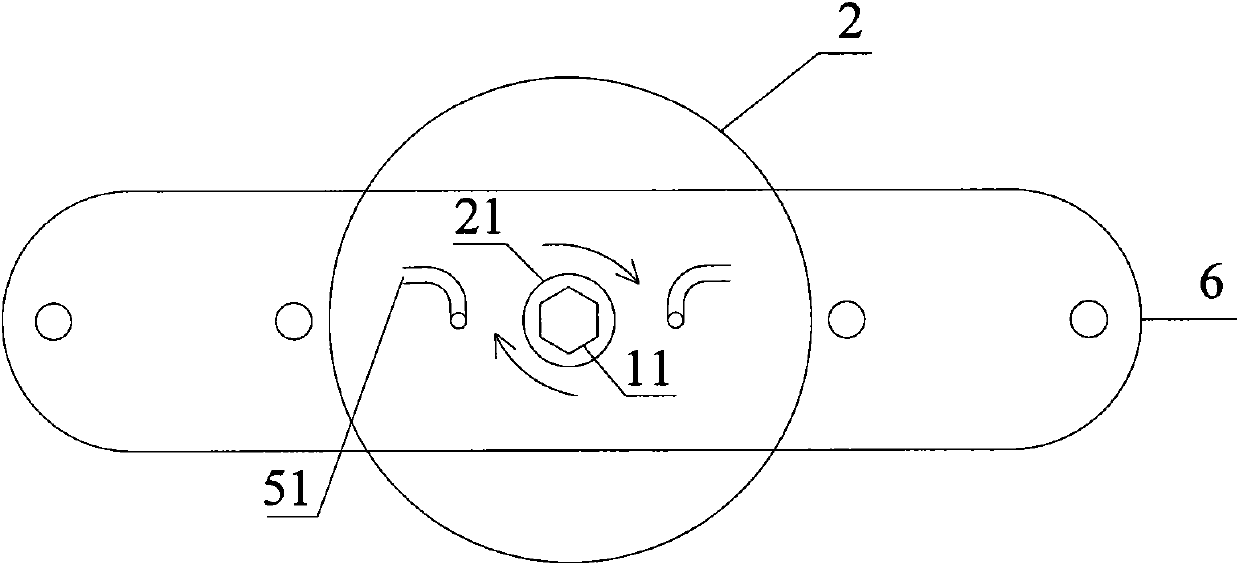

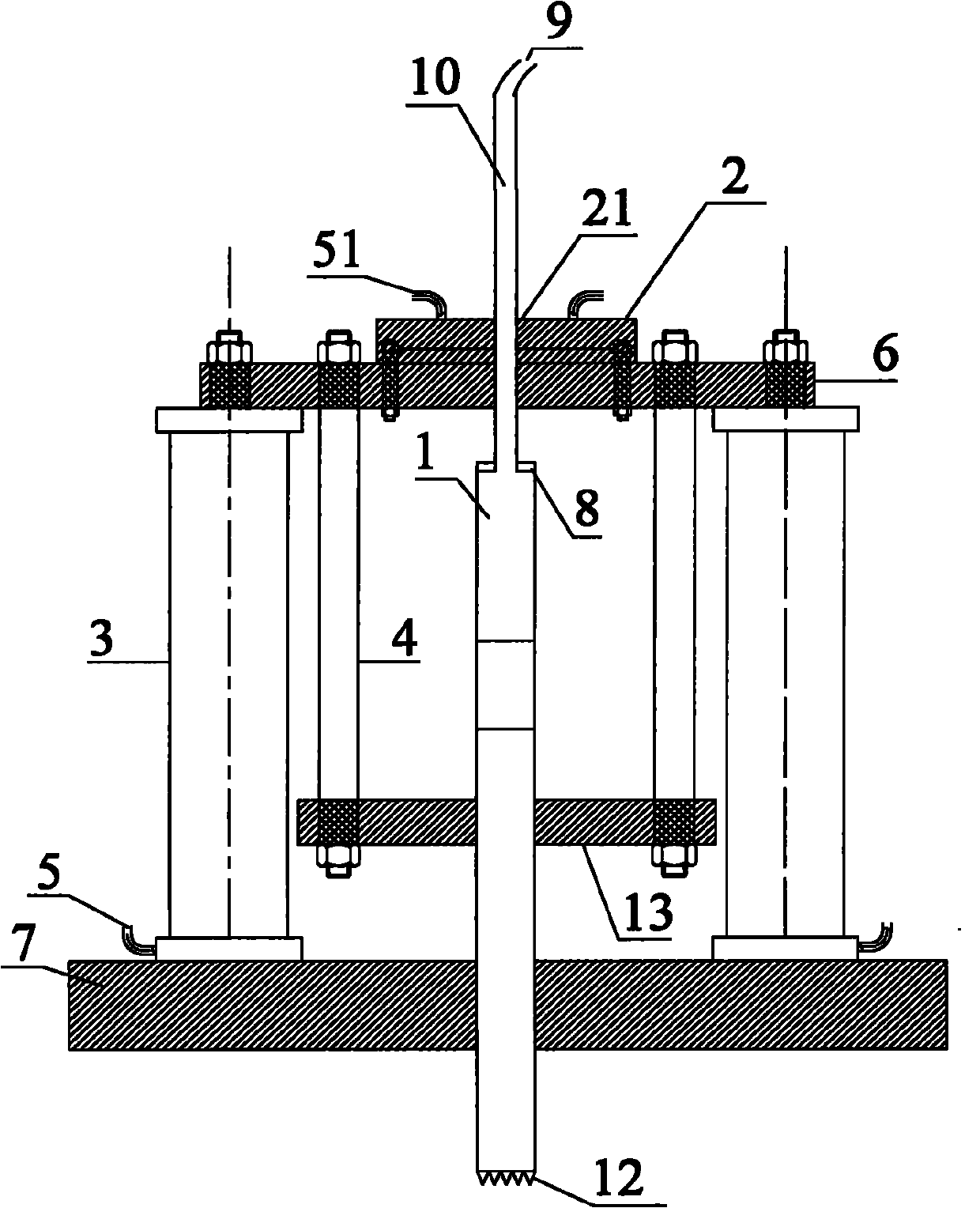

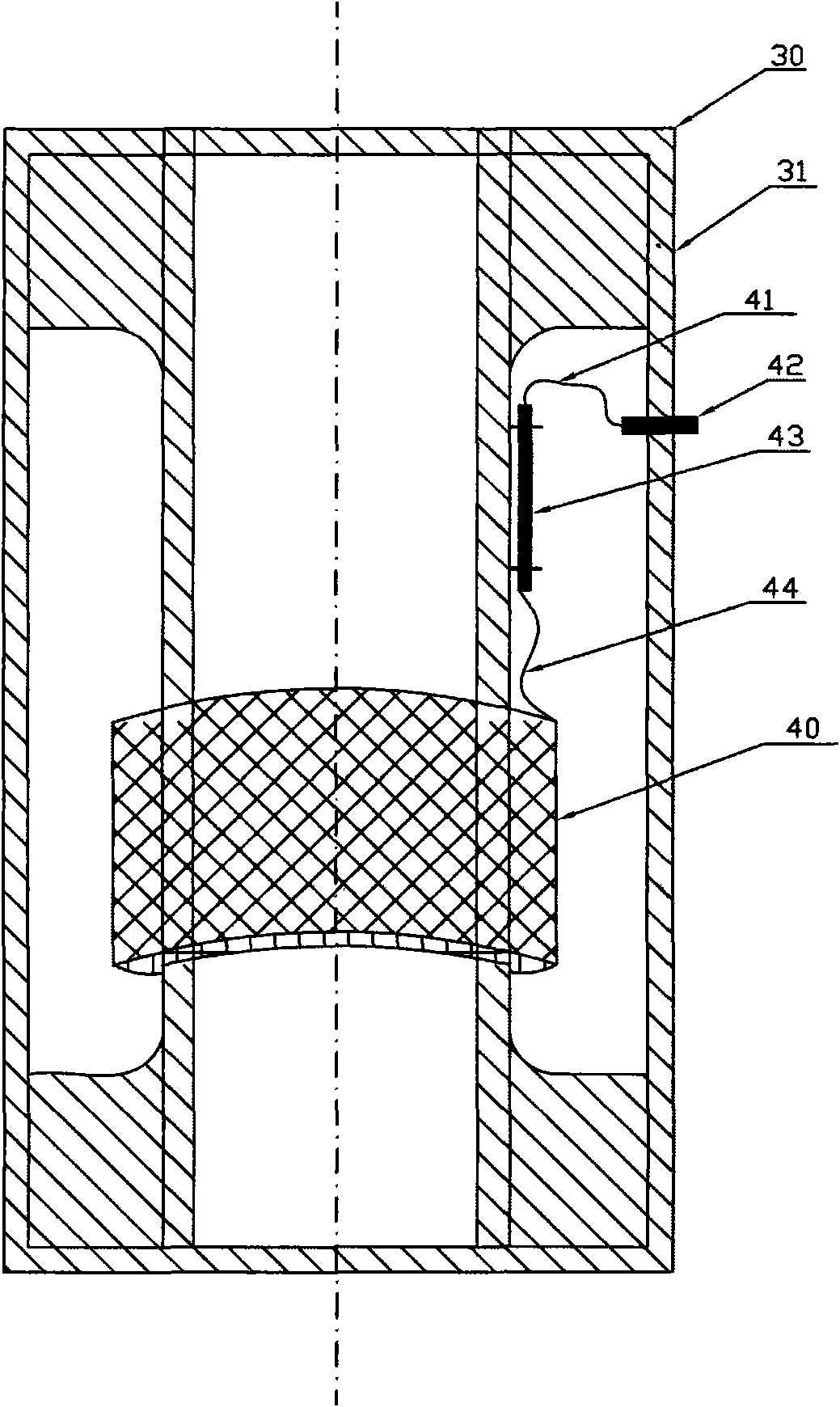

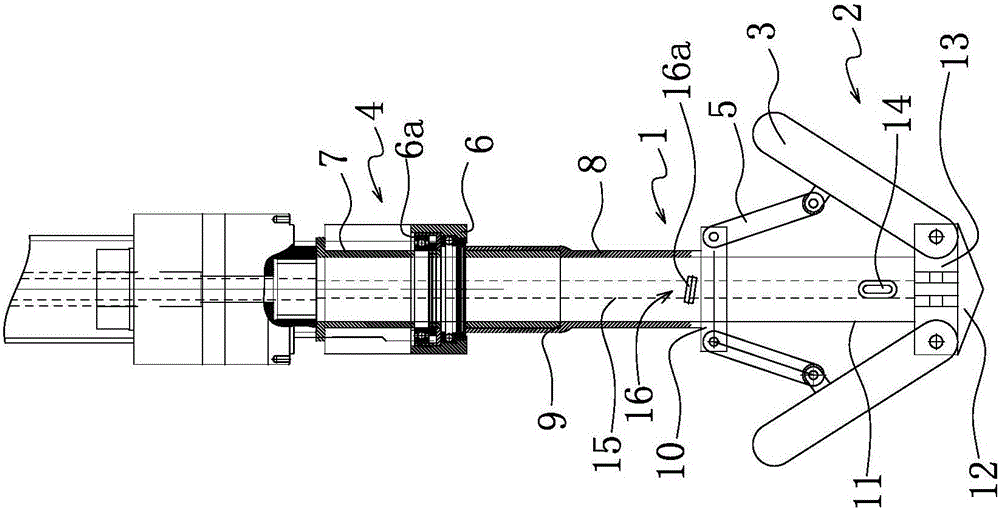

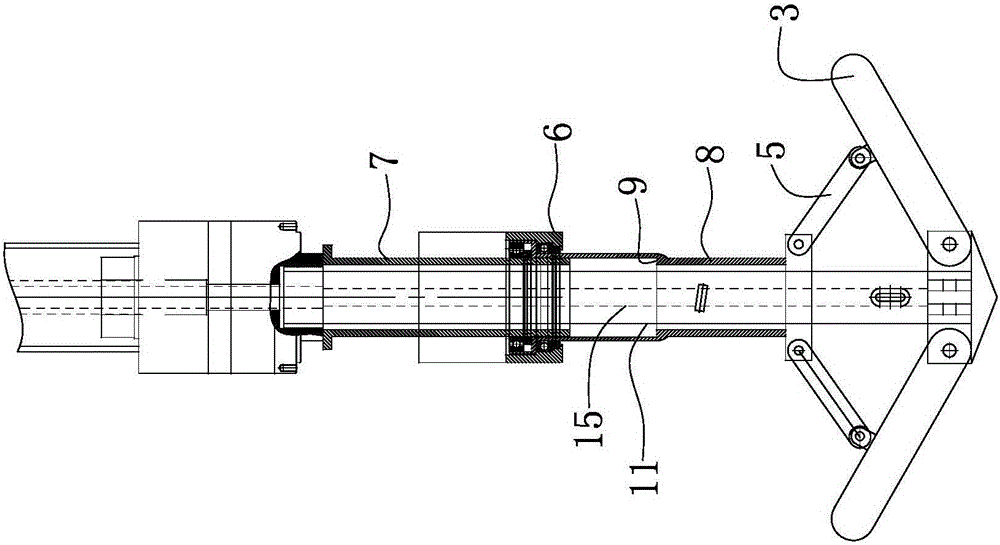

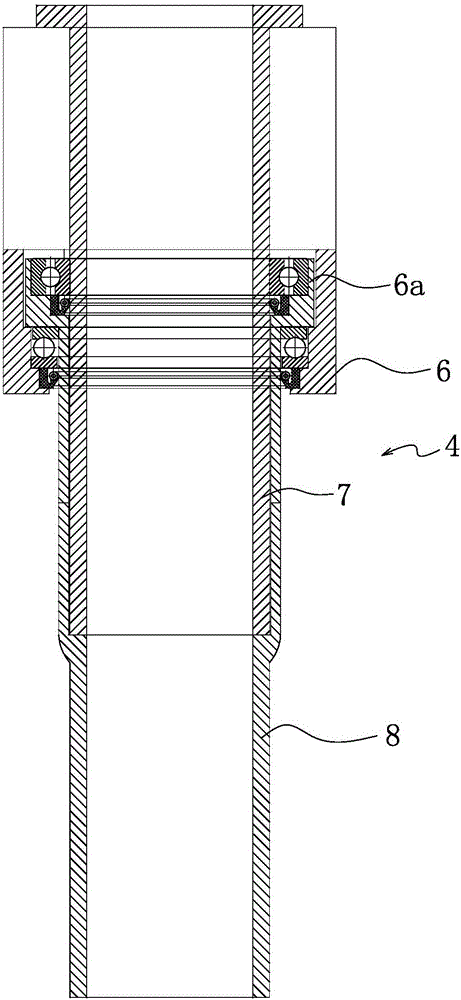

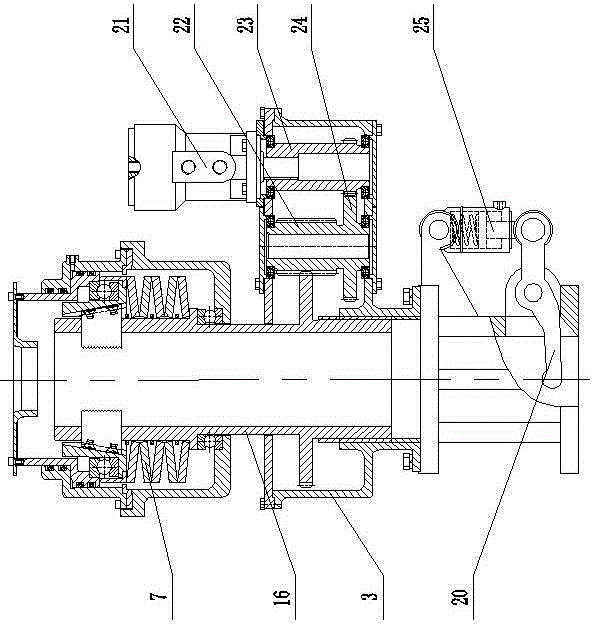

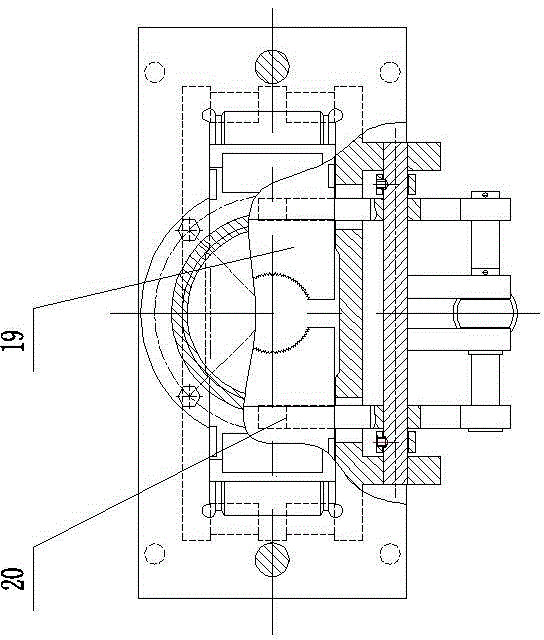

Integrated drill stem clamping and mounting-dismounting device for core drilling machine

ActiveCN104594831ASo as not to damageReduce in quantityDrilling rodsDrilling casingsDrill pipeDrill stem test

The invention discloses an integrated drill stem clamping and mounting-dismounting device for a core drilling machine. The integrated drill stem clamping and mounting-dismounting device is equipped with an upper holder, wherein the upper holder comprises an upper holder housing; a core tube is arranged in the upper holder housing; a lower holder is arranged below the core tube; the lower holder comprises a base, a roller wheel blocking component is arranged inside the base, and a hydraulic oil cylinder is arranged outside the base of the lower holder; the top of the base is upwards equipped with a sleeve which is arranged on the lower part of the core tube in a sleeving mode; a drill stem screw pitch regulating device is arranged outside the core tube between the lower holder and the upper holder. According to the integrated clamping and mounting-dismounting drill stem device, the sleeve and the core tube are in threaded connection, the screw pitch of the threads is same as that of threads of the drill stem, and the drill stem is enabled to relatively move by displacement of one screw pitch in an axial direction of the drill stem every time the drill stem rotates by one circle in the drill stem mounting and dismounting processes, so that the drill stem threads are enabled to be not damaged in the mounting and dismounting processes; the drills tem screw pitch regulating device between the lower holder and the upper holder is utilized, so that the quantity of workers and labor intensity of the workers are reduced, and mechanical control automation is realized.

Owner:H H DRILL TECH DRILLING MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com