Integrated drill stem clamping and mounting-dismounting device for core drilling machine

A core drilling rig and an integrated technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of ignoring the relative axial displacement of the drill pipe, increasing the accident rate at the bottom of the drill pipe hole, and damage to the thread of the drill pipe connection, etc., to achieve The effect of reducing the number of workers and labor intensity, good economic benefits, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

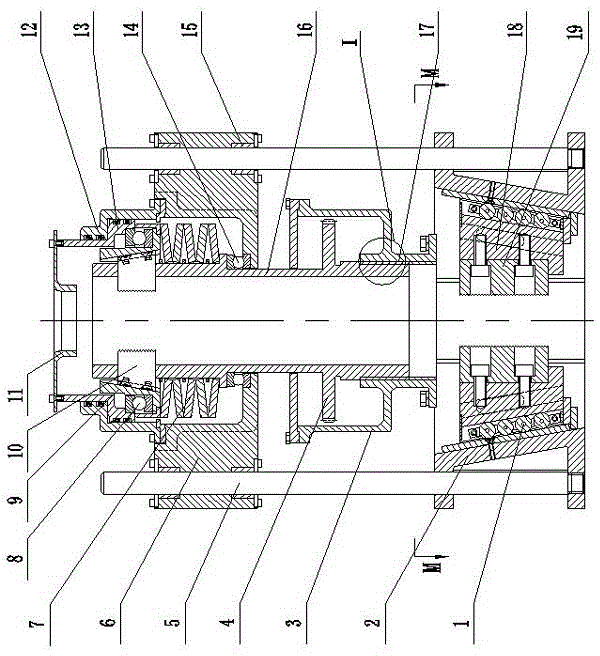

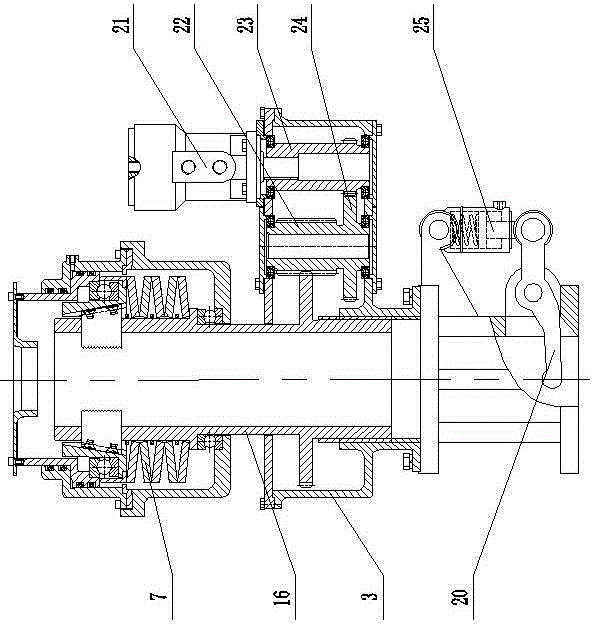

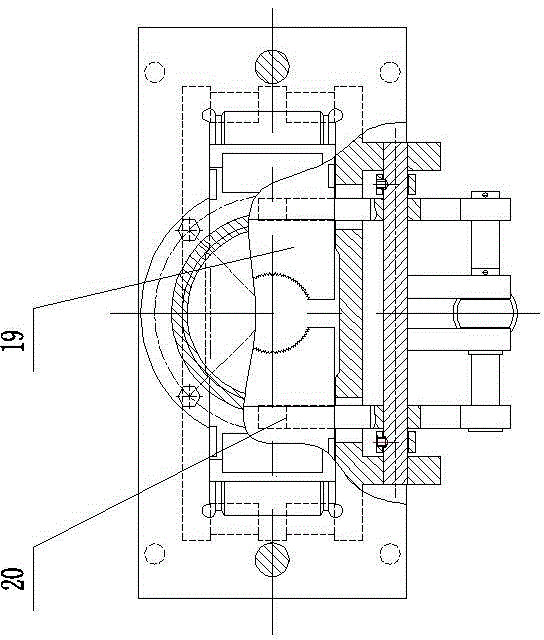

[0014] An integrated device for clamping and unscrewing a drill pipe for a core drilling rig, which is provided with an upper clamper, the upper clamper includes an upper clamper shell 6, and inside the upper clamper shell 6, there is a drill pipe outer jacket The upper core tube 16 is provided with an upper slip clamping assembly between the core tube 16 and the upper clamper housing 6, and a lower clamper is provided below the core tube 16, and the lower clamper includes a base 2, The inner wall of the base 2 is set to a tapered shape with a large top and a small bottom. The inside of the base 2 is provided with a roller slip assembly that moves up and down along the inner wall of the base. The roller slip assembly includes a collar 18, and two are symmetrically installed on the inner wall of the collar. A lower slip 19 for clamping the drill rod, on the outer wall of the collar 18, a roller assembly 1 cooperating with the inner wall of the base is installed, and at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com