2D Well Testing with Smart Plug Sensor

a smart plug and well technology, applied in the direction of survey, wellbore/well accessories, construction, etc., can solve the problems of one dimensional characterization, not homogeneous in quality, and really useful to a reservoir engineer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

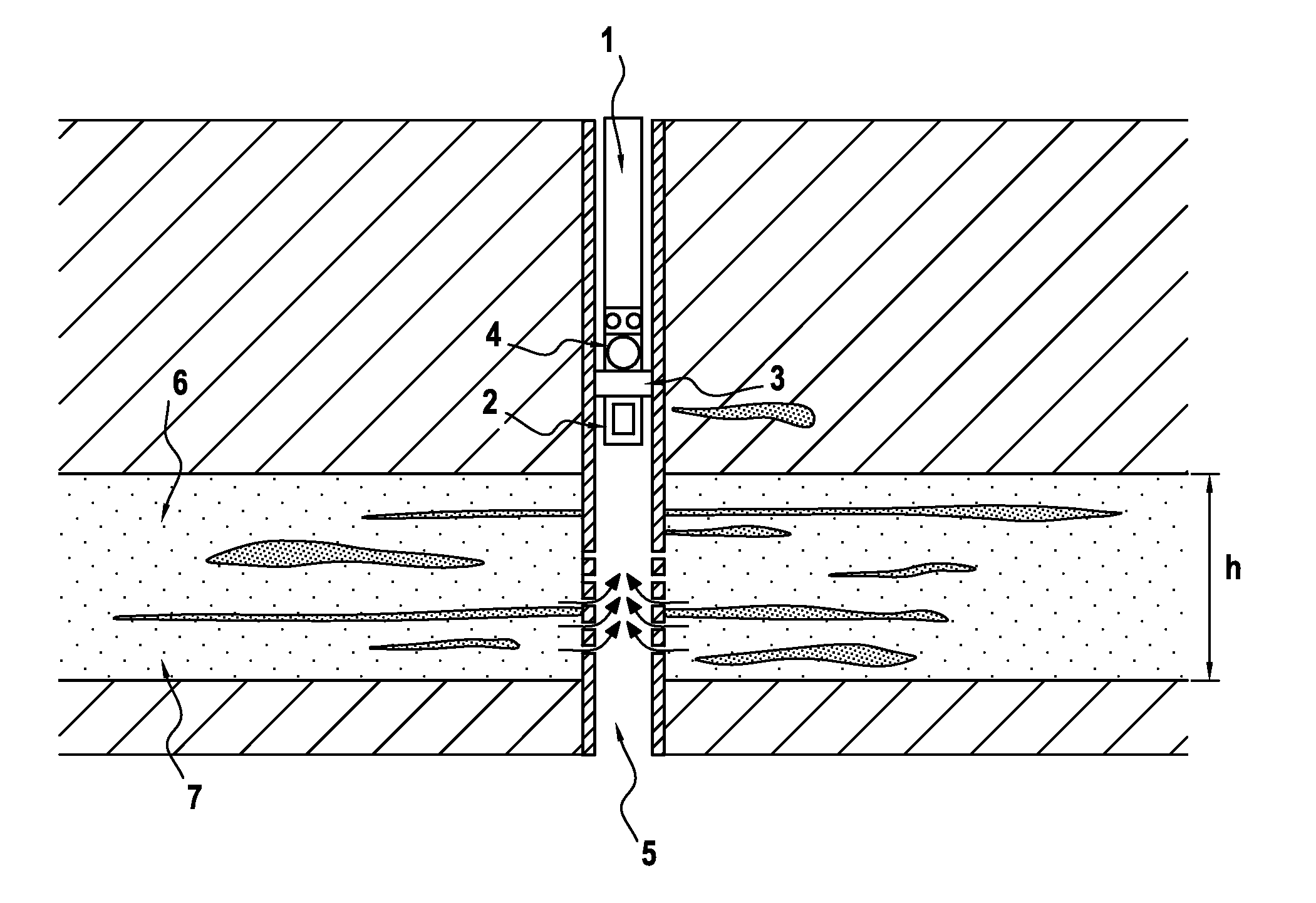

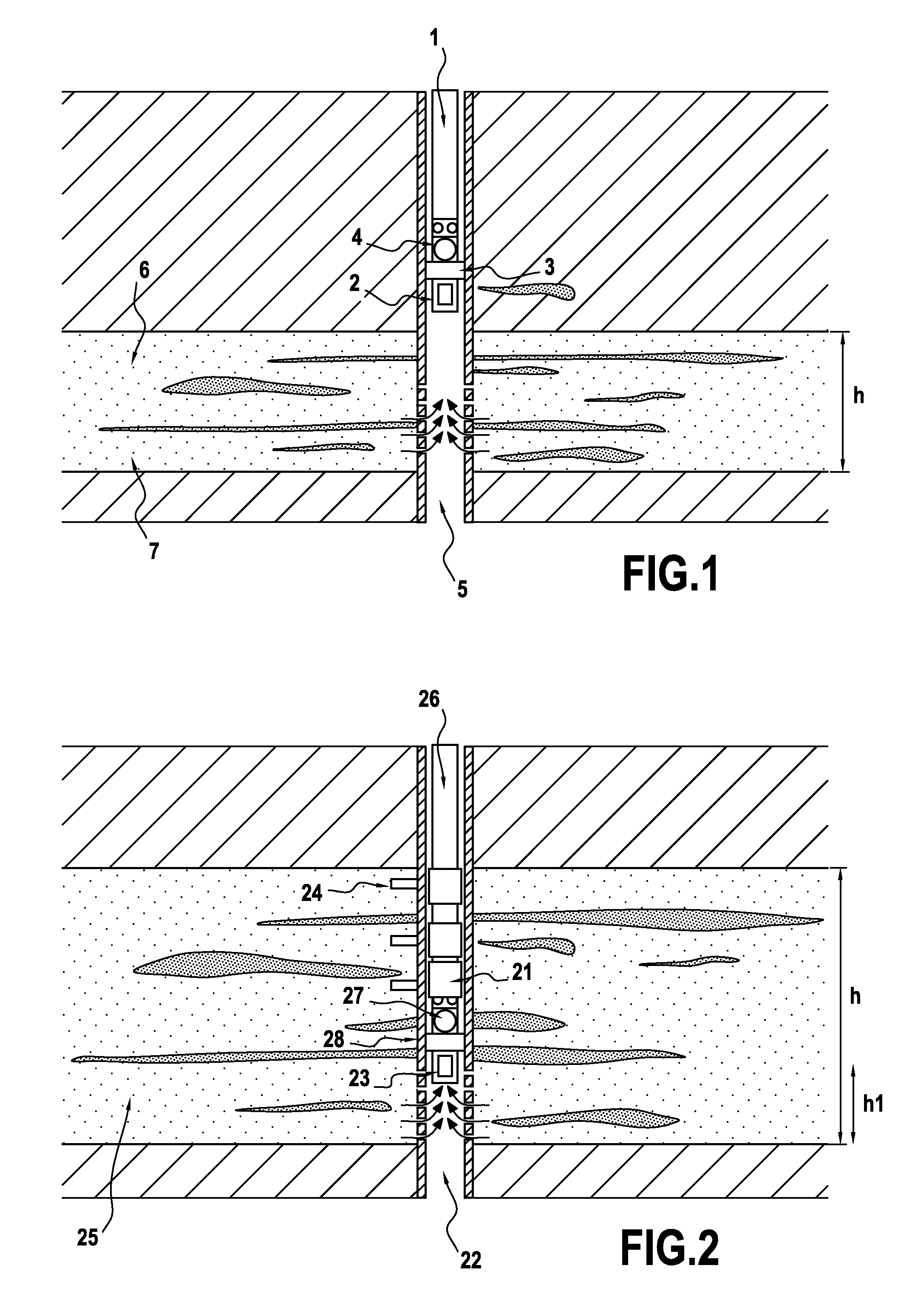

[0042]A vertical test well penetrating a three layer formation as shown in FIG. 5 is constructed and pressure measurements are taken using the apparatus and method of the invention.

[0043]The welltest consists of flowing layer 3 at 2000 bl / d for 24 hours followed by 48 hours of build up. The pressure response is recorded at the wellbore by gauge 53 and within the formation layers 1 and 2 by monitoring gauges 51 and 52 respectively.

[0044]An analytic model is built to have the characteristics shown in Table 1.

TABLE 1Forward model values of test wellLayer #Thickness(ft)kh (mD)kz (mD)Skin1357010—220354—350150200.5

[0045]The model is first run in a forward mode to simulate the pressure responses in the well bore and at the two monitoring gauges. The results are shown in FIG. 6.

[0046]A non-linear regression routine is used to match the pressures transient that are previously established and to recover the individual layer permeabilities along the horizontal and vertical directions (kh, kz)....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com